Patents

Literature

182results about How to "Good seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

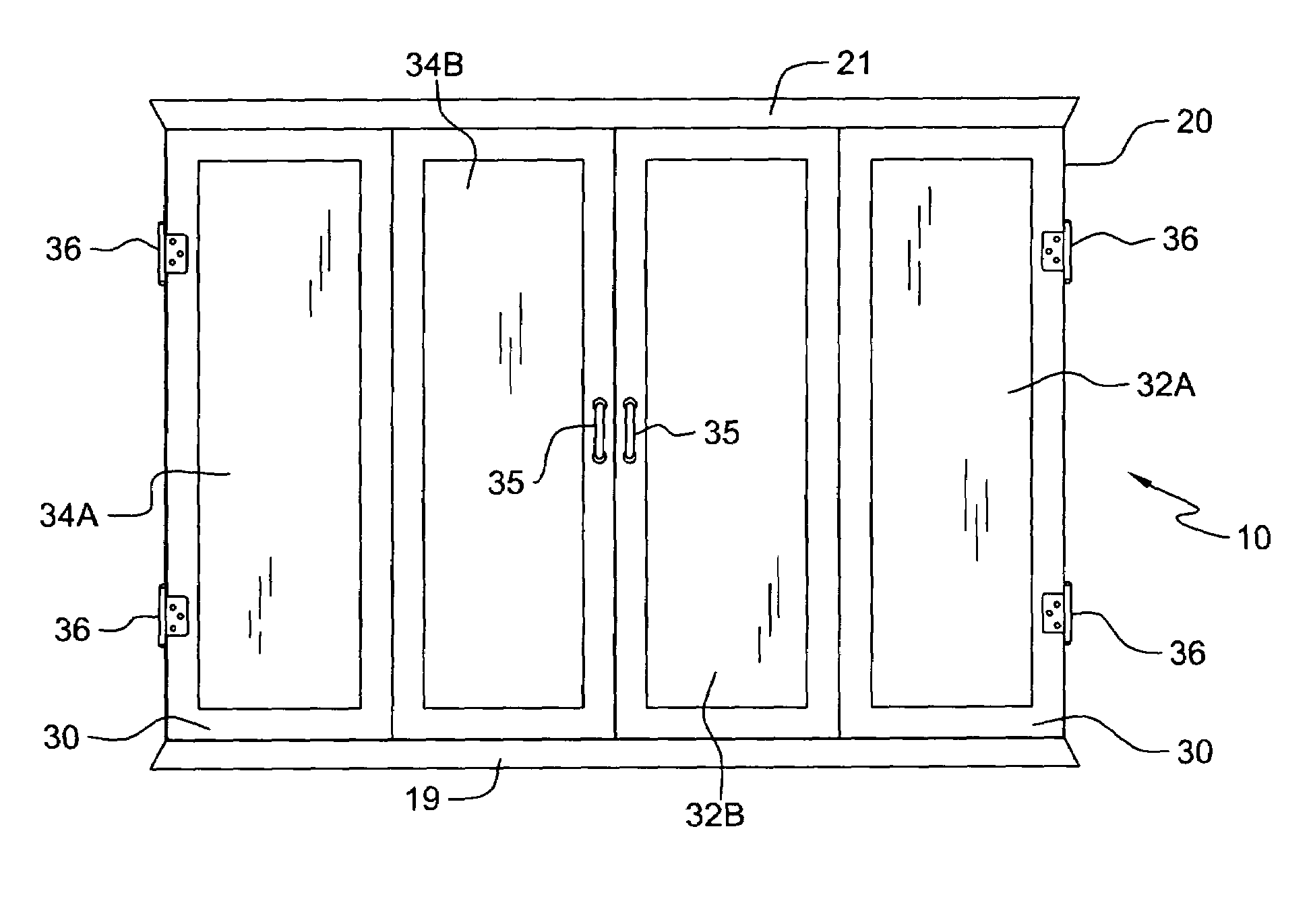

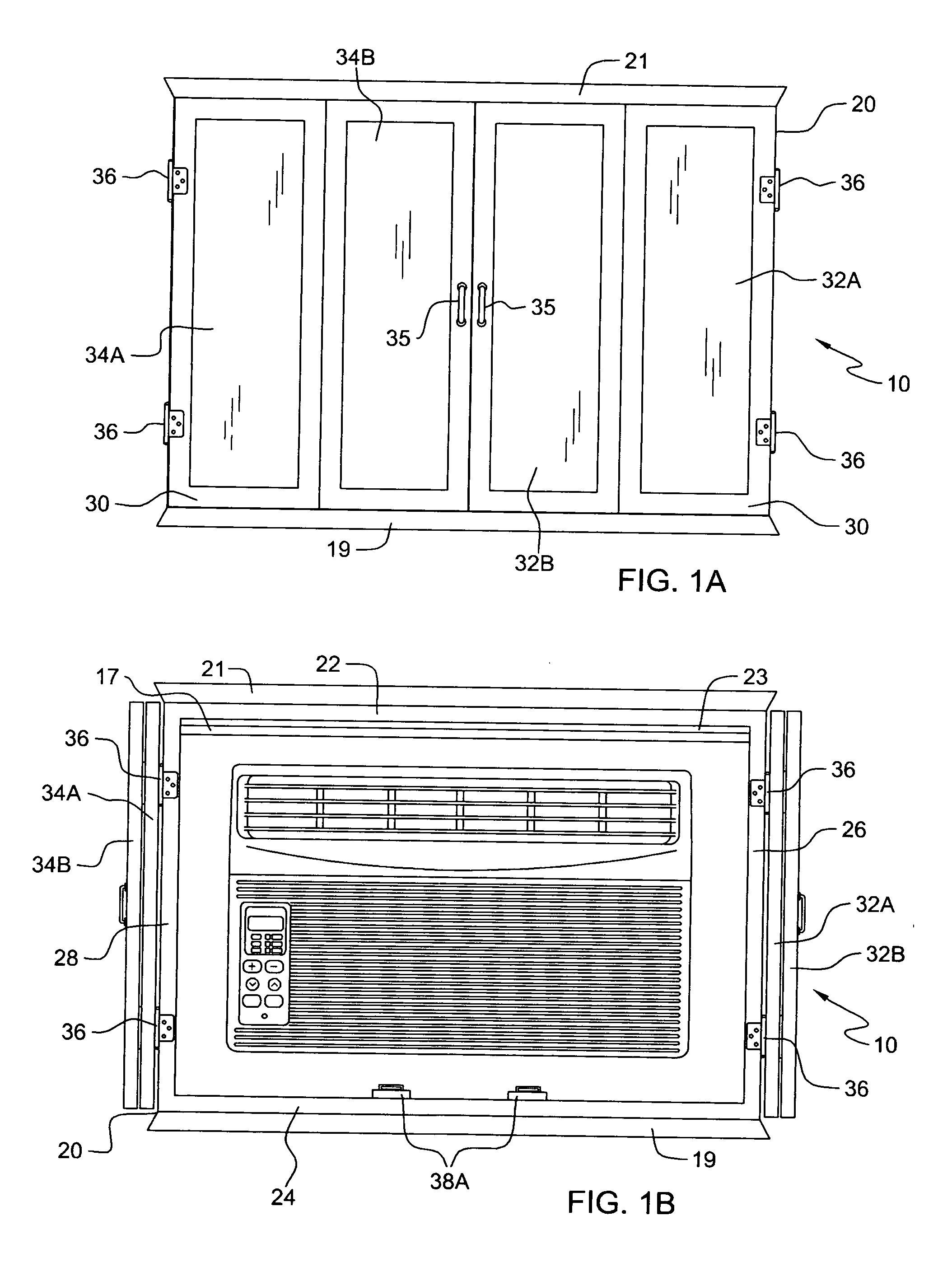

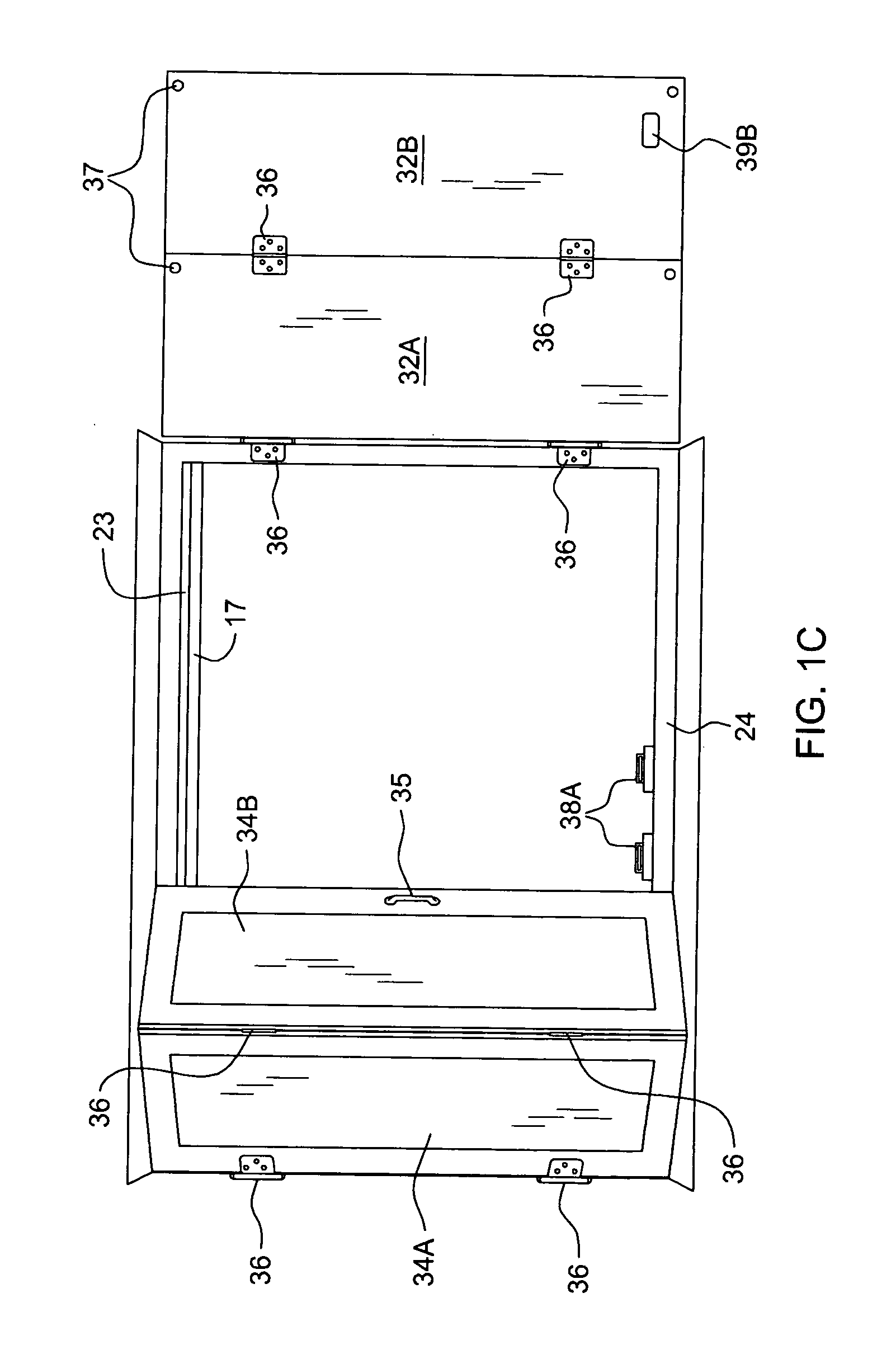

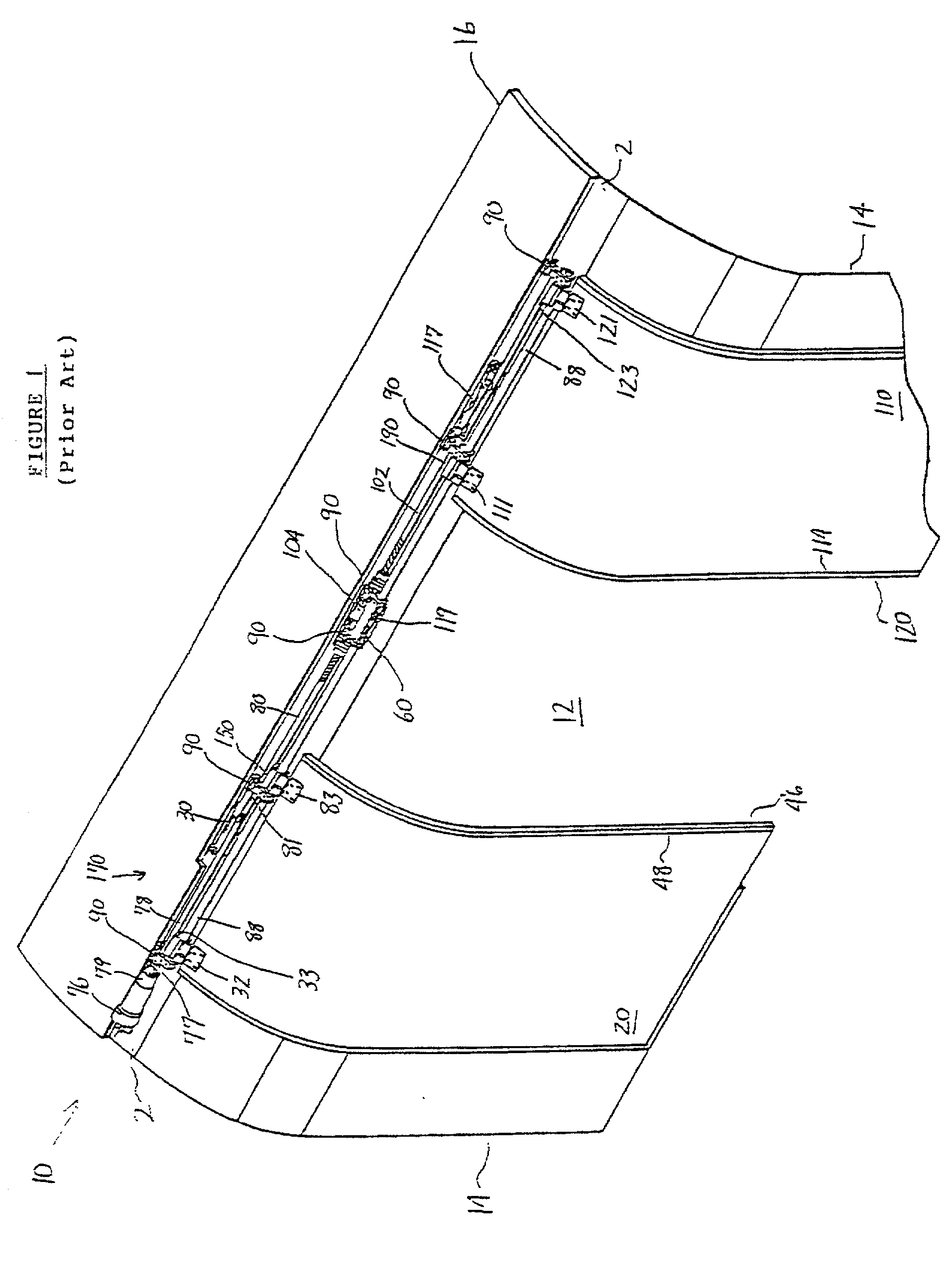

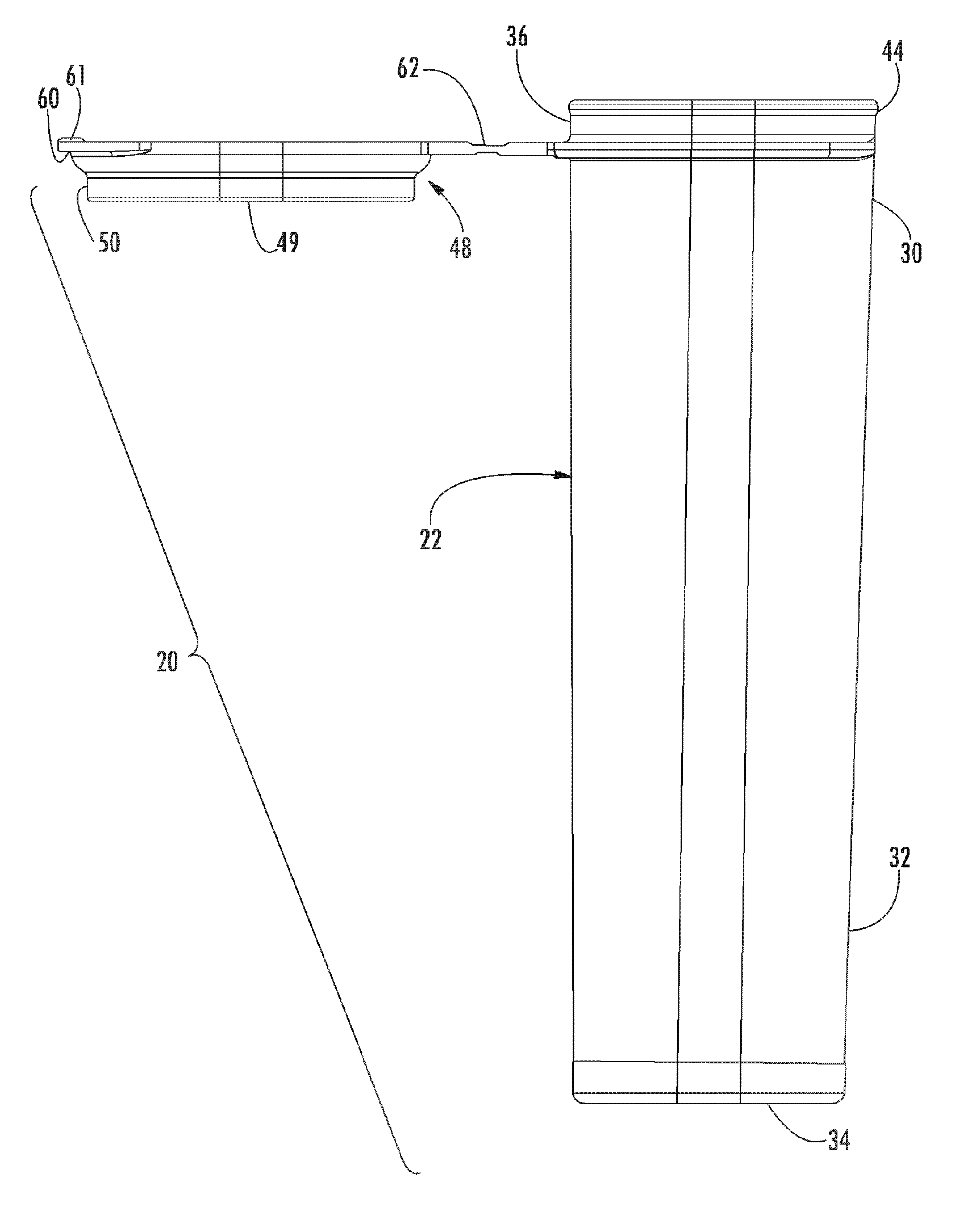

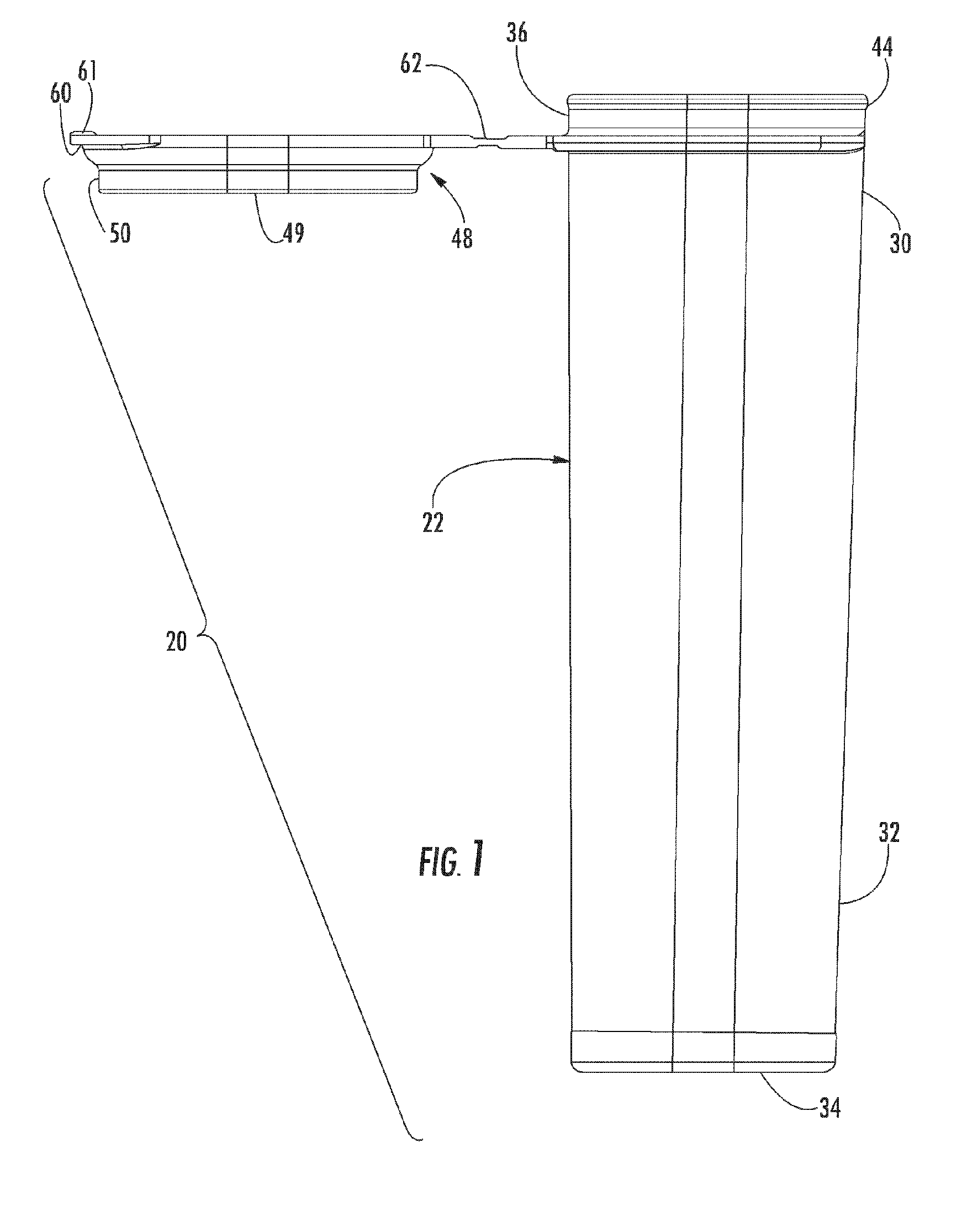

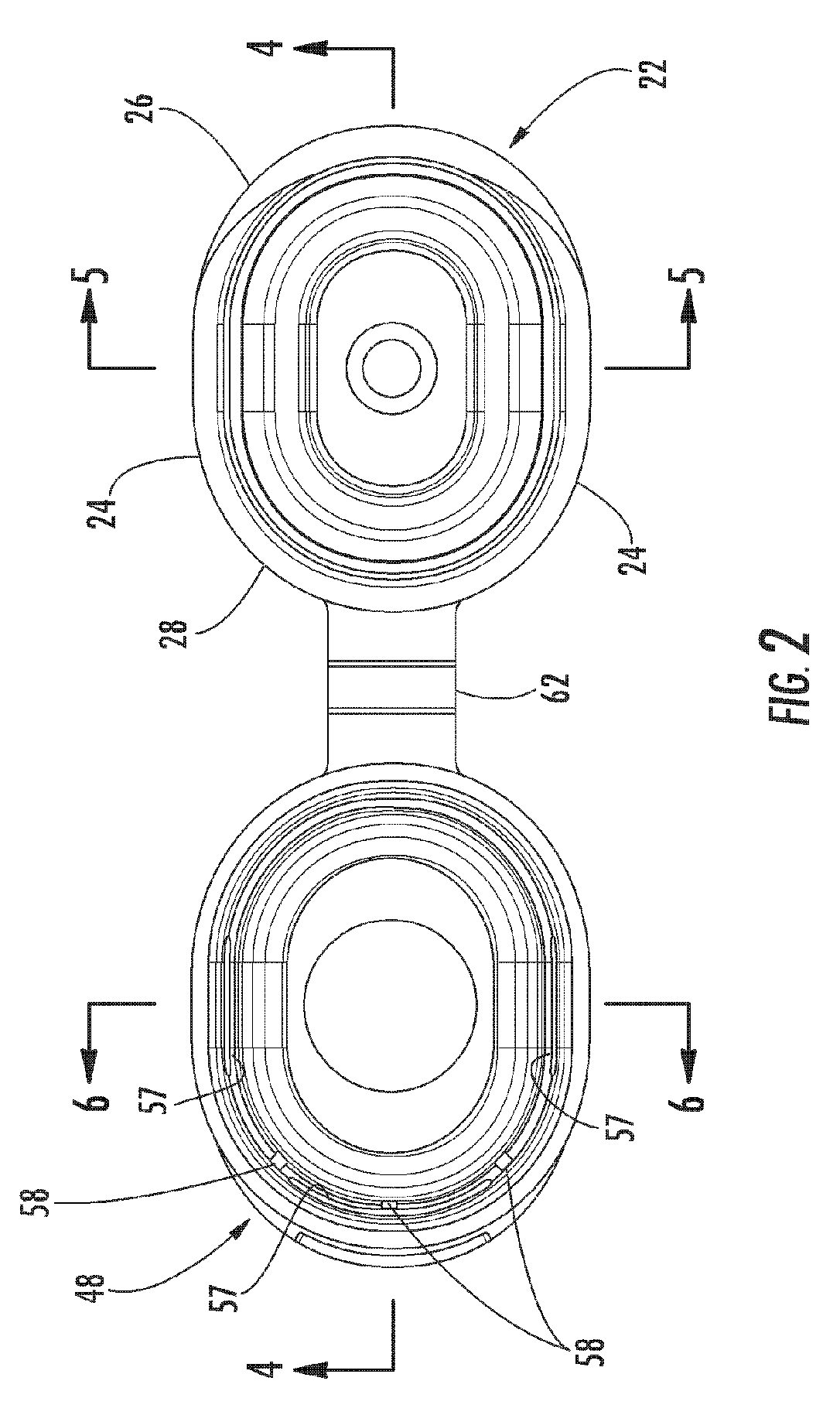

Decorative and functional cabinet for through the wall air conditioners

InactiveUS20100307179A1Prevent communicationGood sealDomestic cooling apparatusLighting and heating apparatusEngineeringWall mount

A cabinet for covering an air conditioner mounted upon and extending through an opening in a wall separating an enclosed inside environment from an outside environment. The cabinet is readily opened to facilitate active air conditioner operation and readily closed to prevent communication of the outside environment with the inside environment when the air conditioner is inactive. The cabinet includes a planar top portion, a planar left side portion a planer bottom portion disposed opposite the planar top portion, a planar right side portion and an outer facing surface interconnected to form the cabinet structure. At least one angled cabinet-mounting member is attached to the planar top portion and configured to meet and cooperate with at least one angled wall-mounting member fixed to the wall, thereby securing the cabinet to the wall. At least one set of doors is attached to the outer facing surface and configured to be opened and closed.

Owner:VIOLETABTAR GOODS

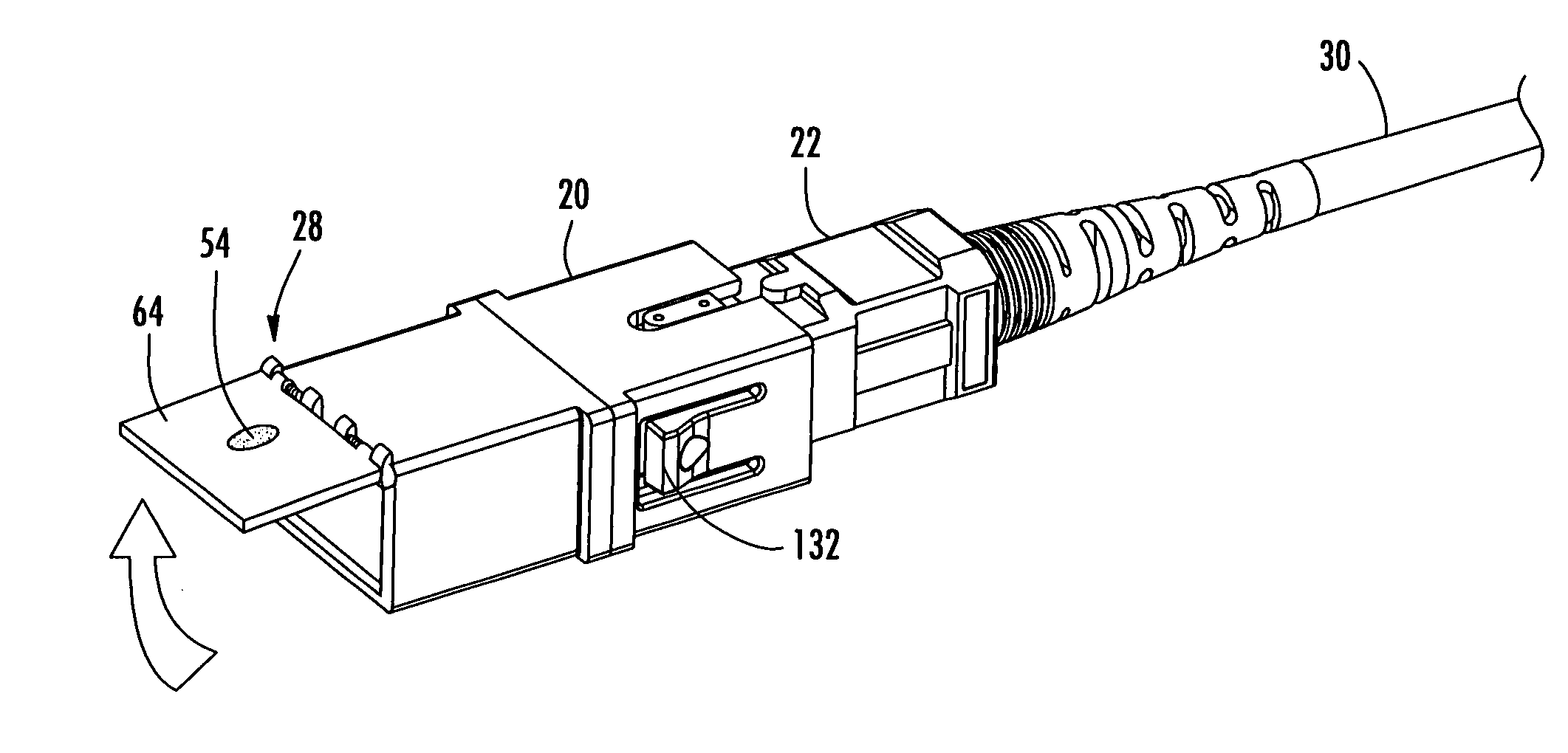

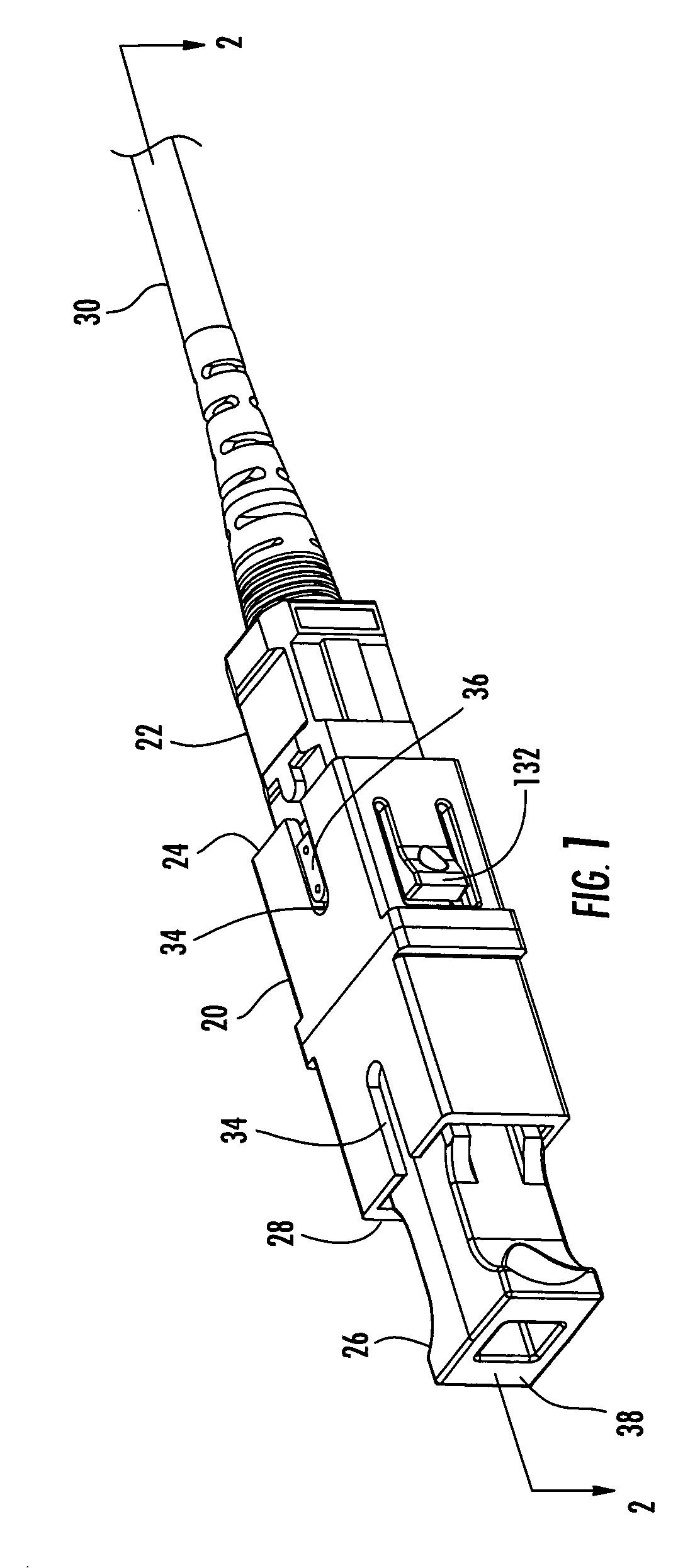

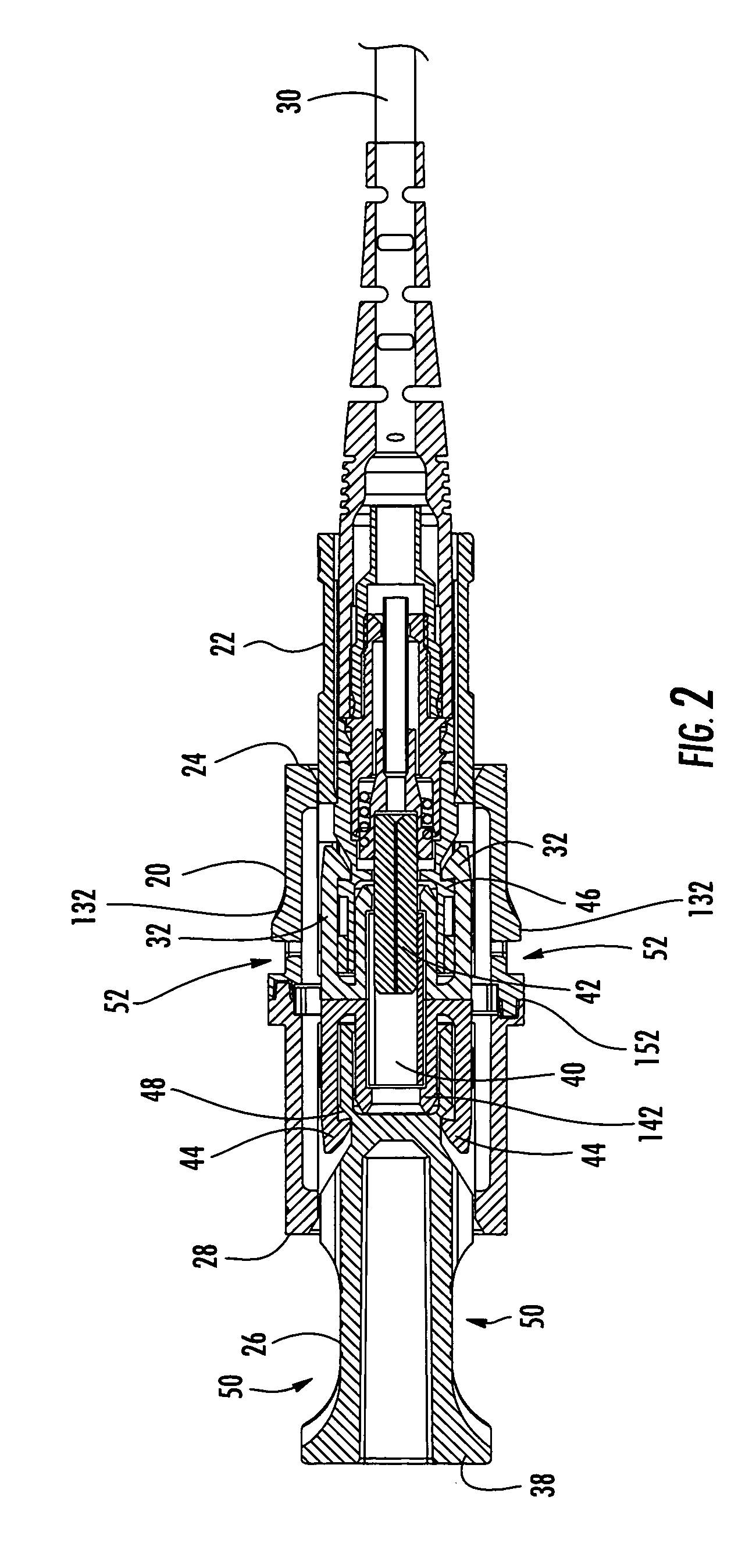

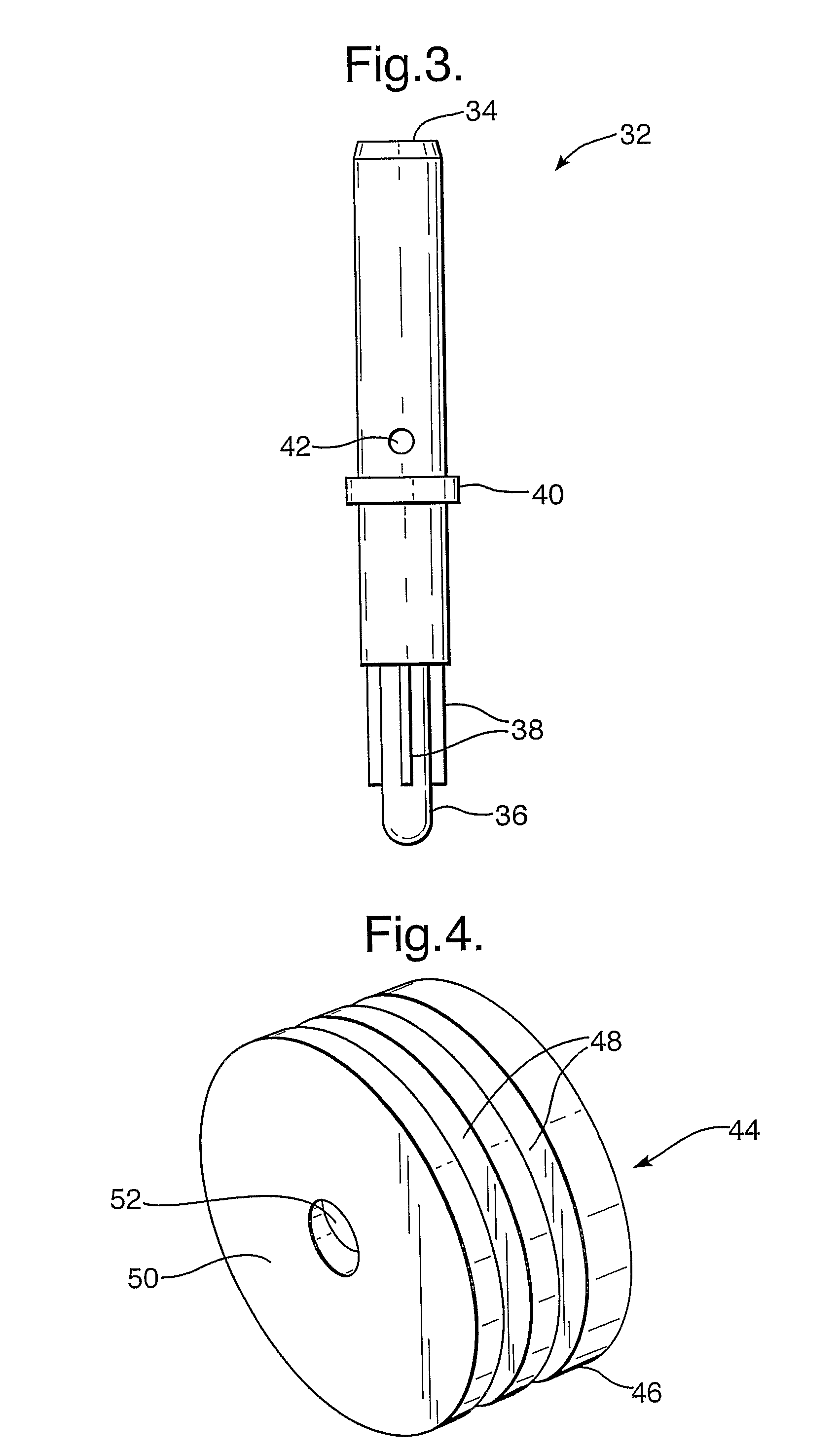

Translucent dust cap for fiber optic adapter

ActiveUS20070217749A1Prevent eye damageGood sealCoupling light guidesOptical fiber connectorEngineering

A translucent dust cap for a fiber optic adapter allows the viewing of visible light emanating from a fiber optic connector coupled to the adapter, without removing the dust cap. A translucent dust cap for a fiber optic adapter that serves to diffuse a visible light source of sufficient power, such as that from a VFL, and lights up to aid in connector identification. A translucent dust cap for a fiber optic adapter that serves to attenuate infrared optical transmission power to prevent eye damage.

Owner:CORNING OPTICAL COMM LLC

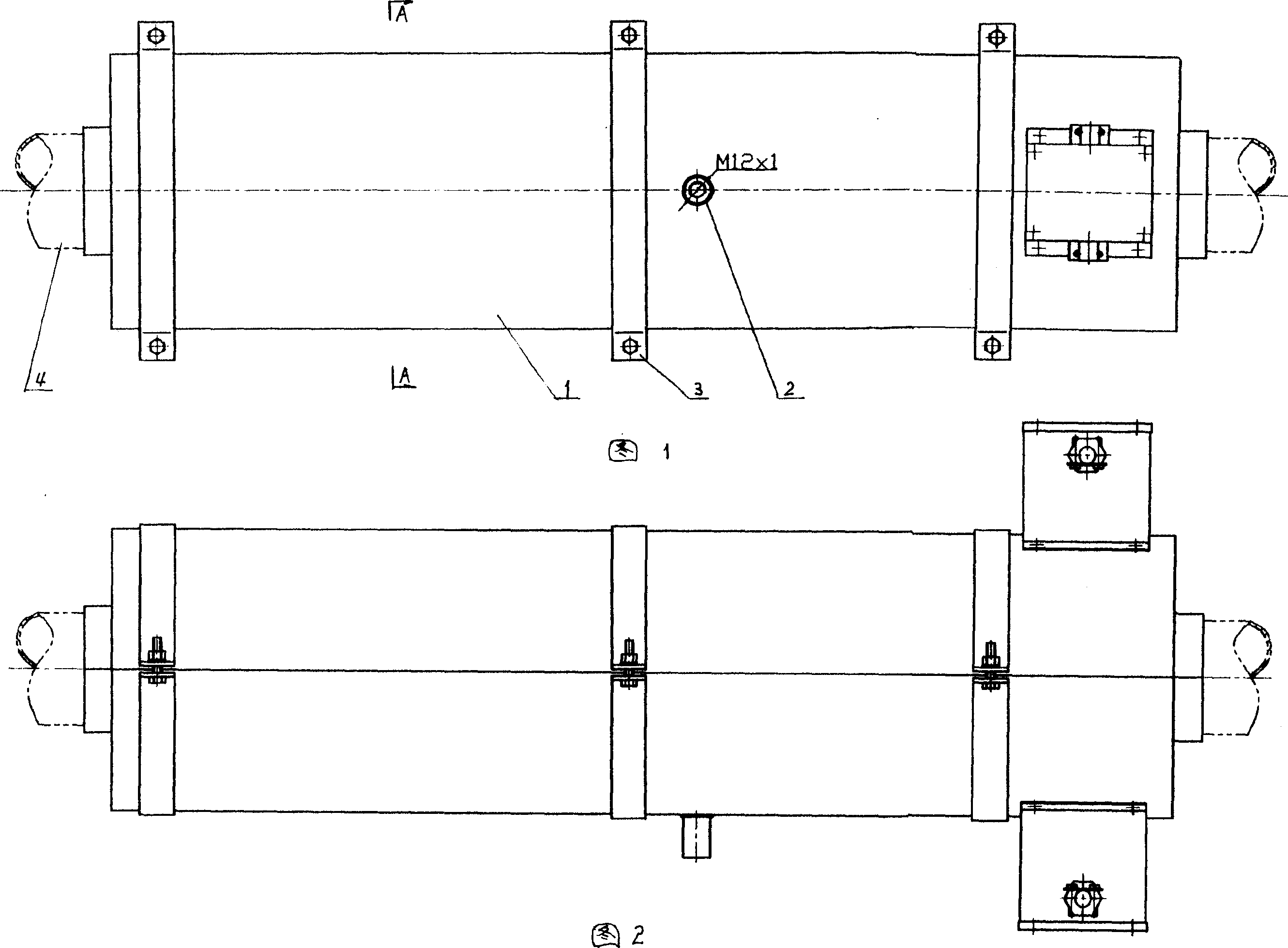

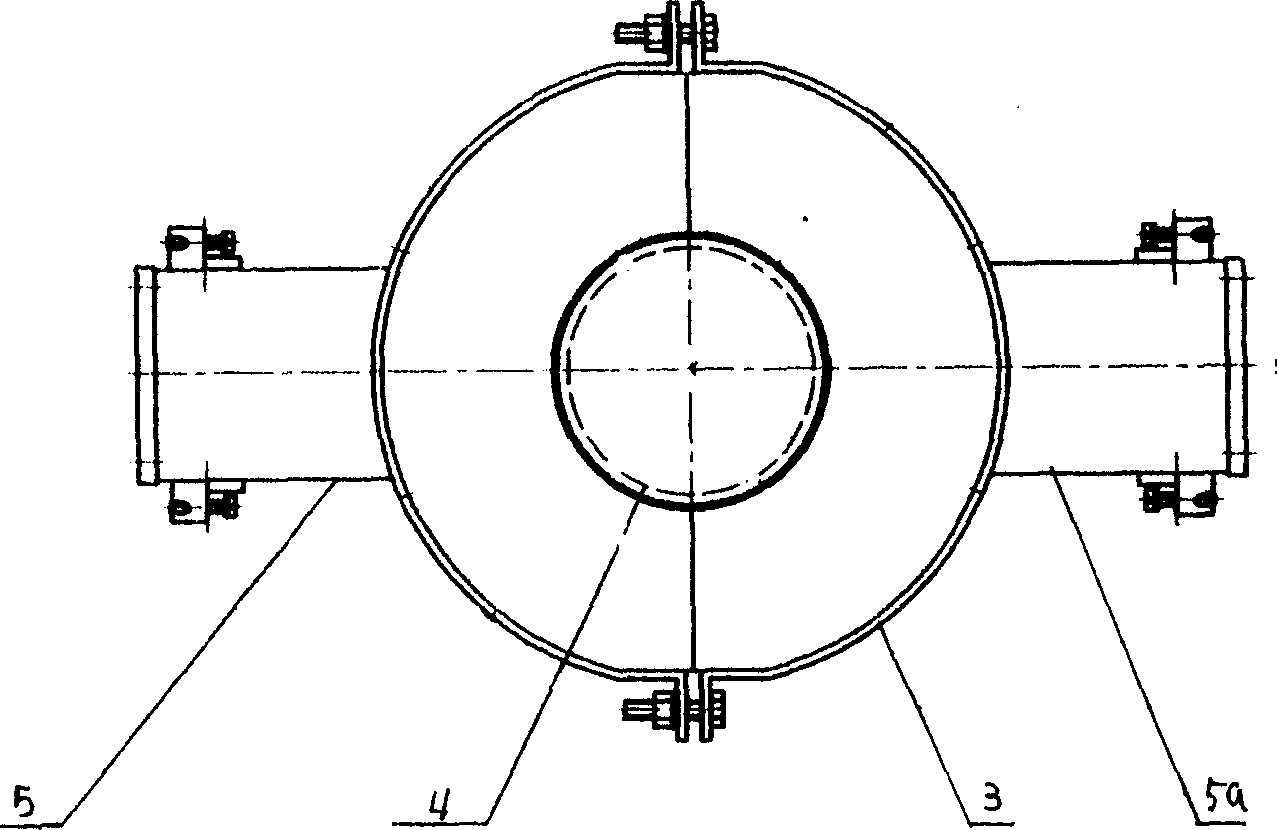

Electric heater for pipeline

InactiveCN1908499AImprove efficiencyIncrease heat conduction areaPipe heating/coolingPipeline systemsElectric heatingEngineering

An electric heater for pipeline is an electric heater used for heating the pipeline or the medium therein. A temperature control unit is composed of a SCM and a temperature sensor, also has two bush-shape metal endoconches. On the inwall side of the two metal endoconches is fixed with an electric heating pipe, also has two bush-shape molding heat-conducting layers made of heat conducting materials used in shrinking on the pipeline. The outerwall side of the molding heat-conducting layers is joint with the inwall side of two metal endoconches. Also provided are two bush-shape molding insulating layers joint with the outerwall side of the two metal endoconches, two bush-shape shell on the external surface of the two molding insulating layers. Also provided are the fixed links joining the heating module on the pipeline. The invention has the advantages of high thermal efficiency, convenient to assemble and disassemble and is widely used in a variety of pipeline heating occasions.

Owner:成都市兴岷江电热电器有限责任公司

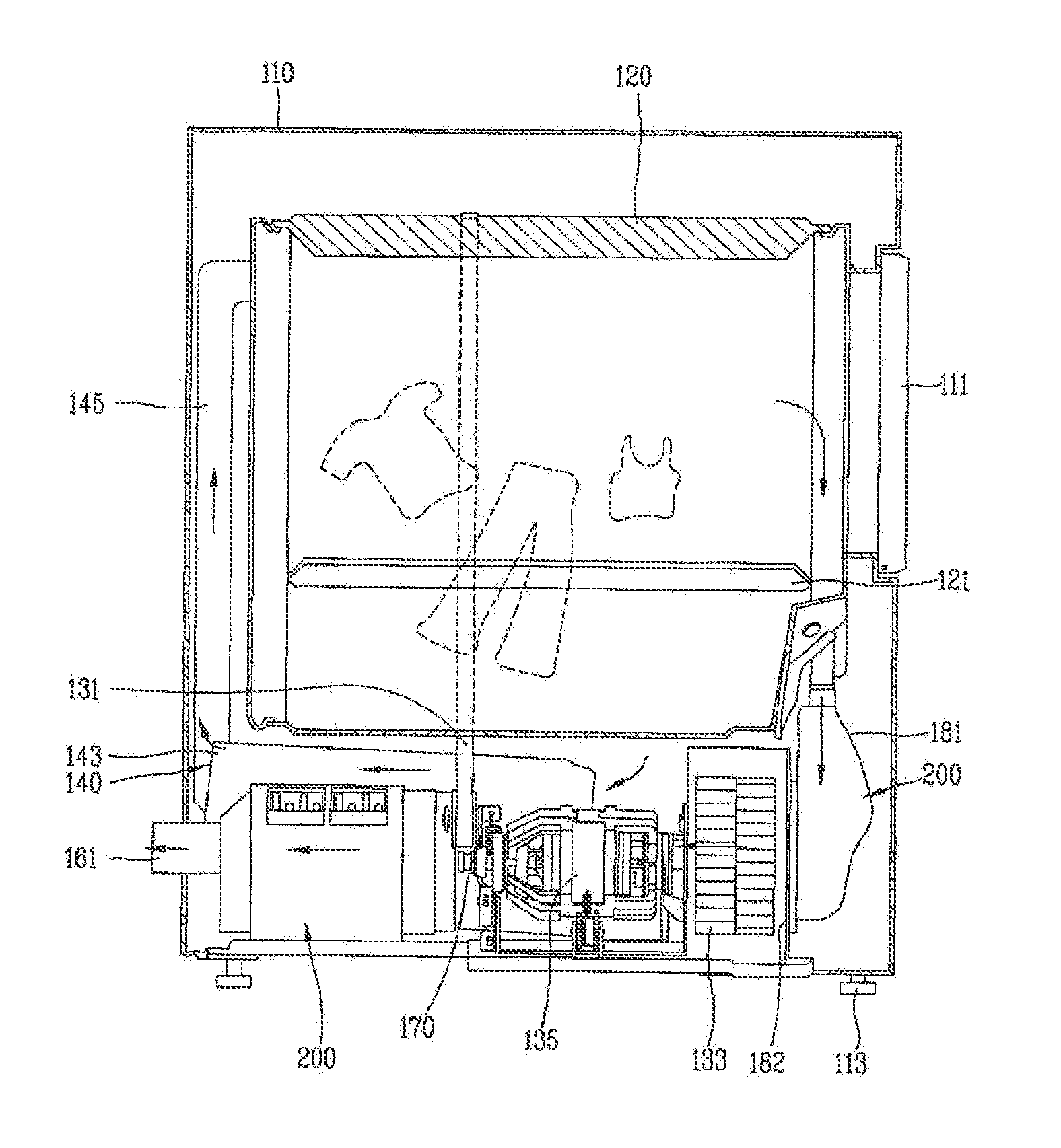

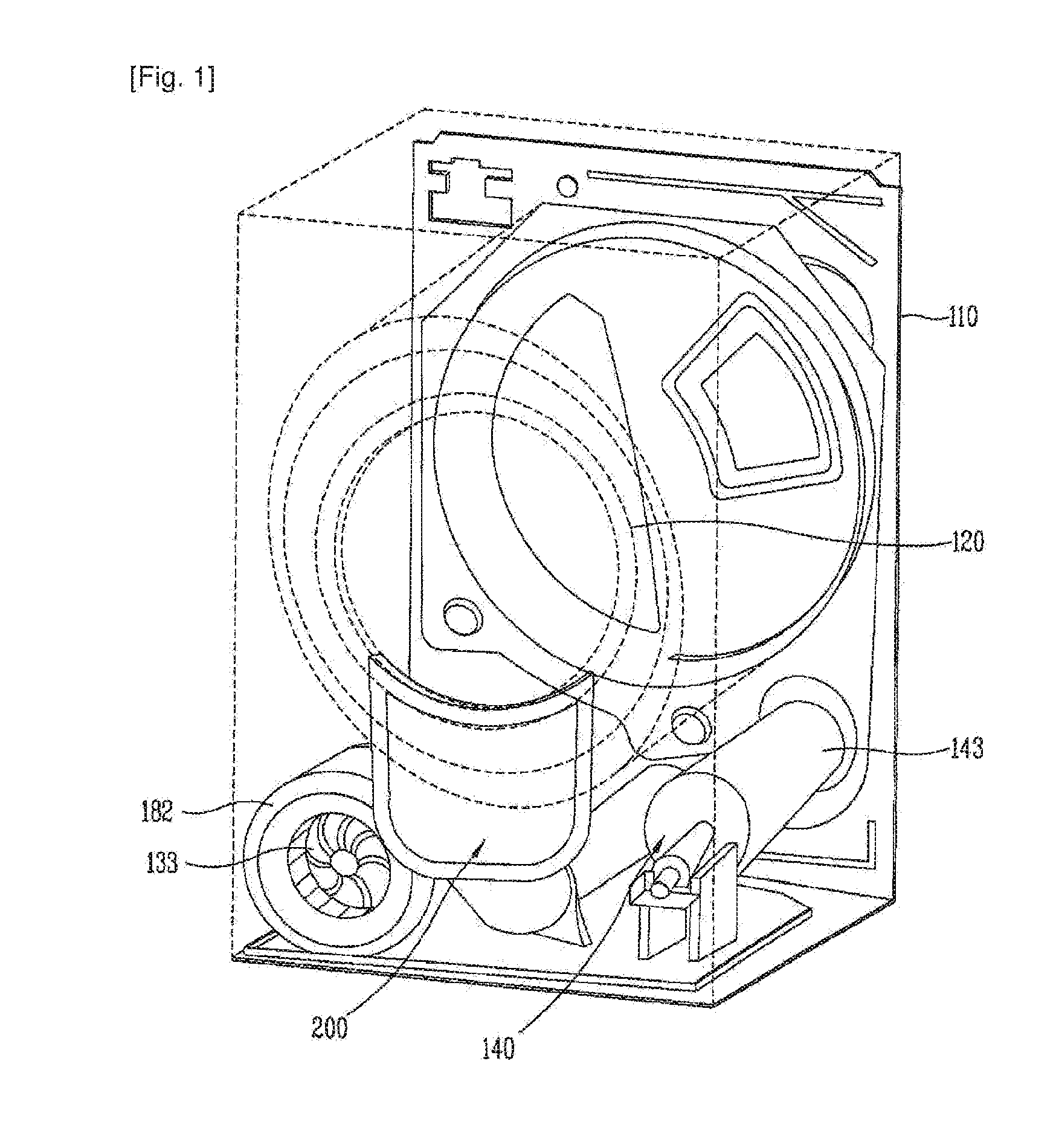

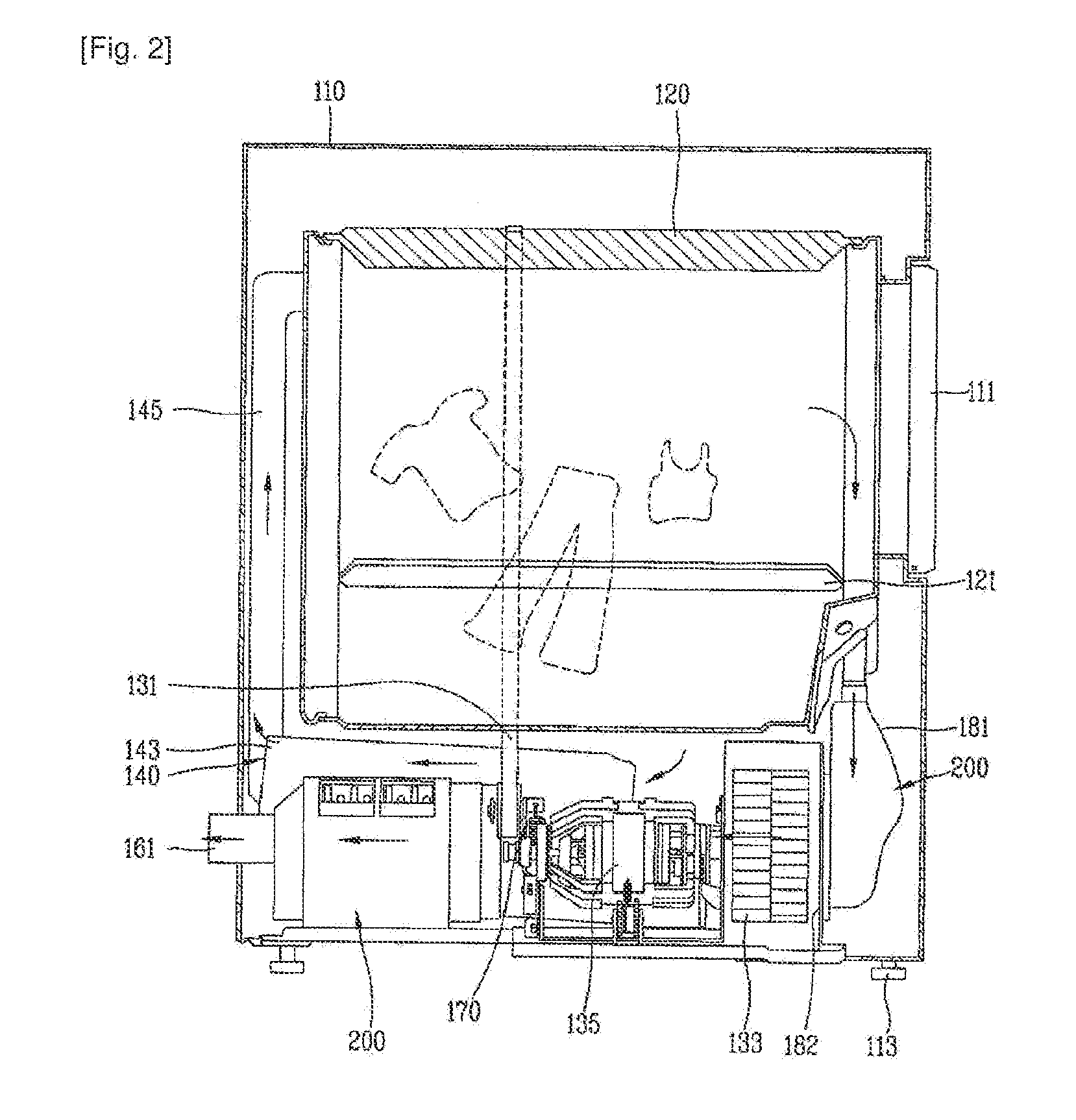

Clothes dryer

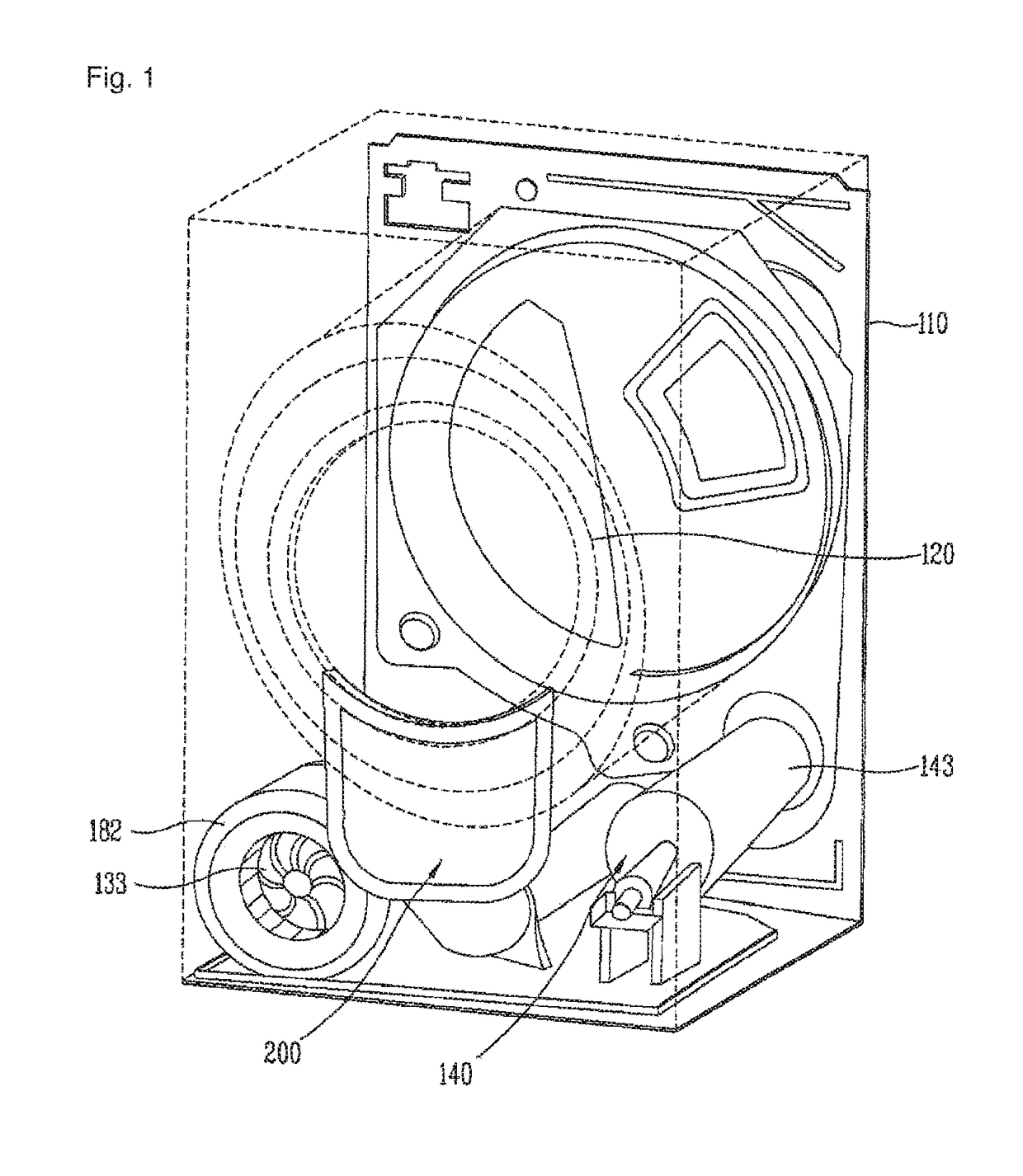

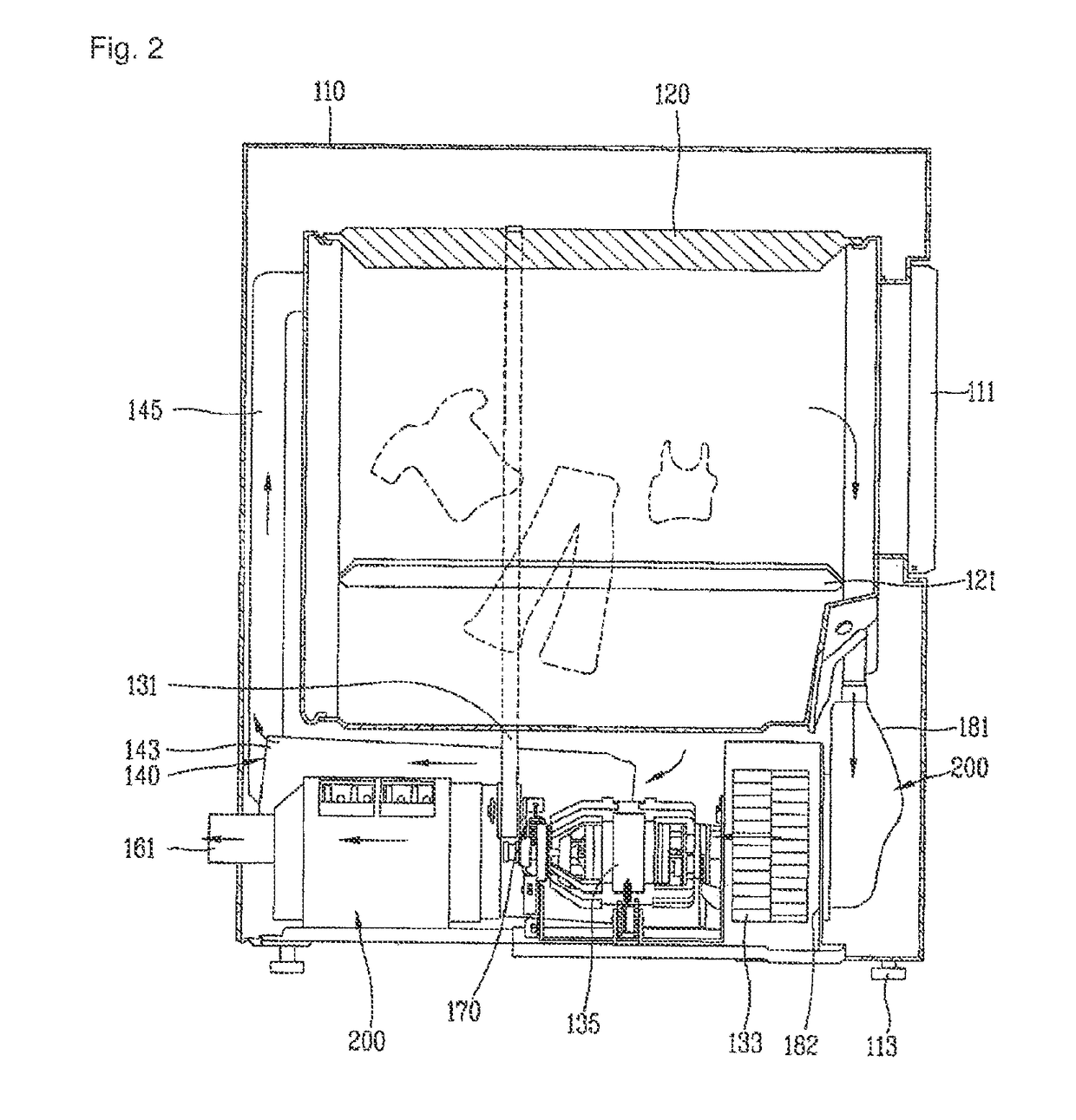

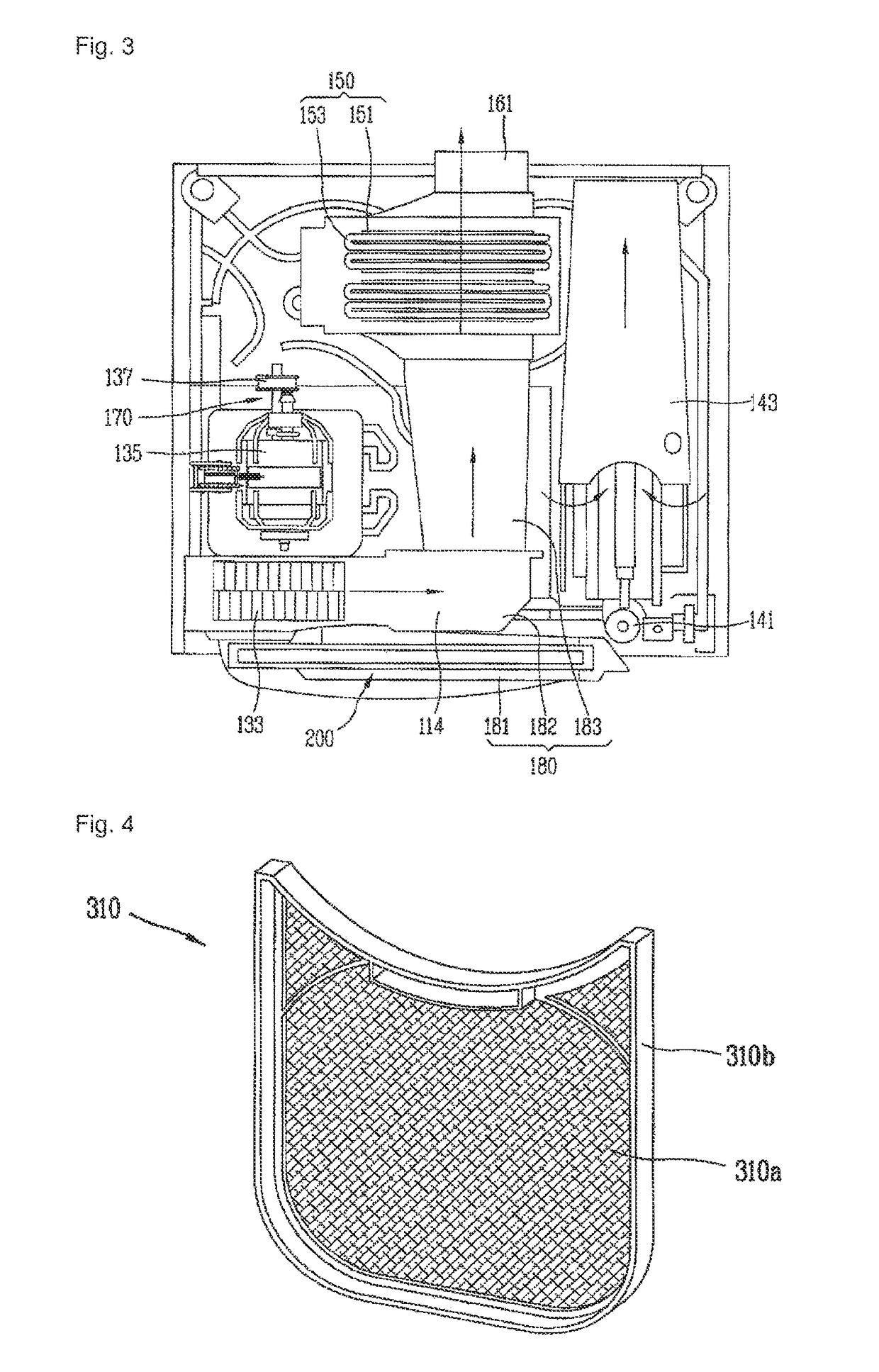

InactiveUS20110016736A1Effectively sealing partEasy to identifyDrying gas arrangementsElectrostatic cleaningReed switchWaste management

Disclosed is a clothes dryer, comprising: a body; a drum rotatably installed at the body; a duct for guiding air exhausted from the drum; and a filter assembly for filtering lint included in the air exhausted from the drum. The filter assembly includes a lint filter and a cover filter, and a lint collector encompassed by the lint filter and the cover filter. The clothes dryer includes sensing means for sensing whether the lint filter has been mounted to a precise position or not. The sensing means consists of a magnet mounted to a mesh frame of the lint filter, and a reed switch mounted to a cover guide.

Owner:LG ELECTRONICS INC

Clothes dryer

InactiveUS8468711B2Preventing lint from leakingGood sealDrying gas arrangementsOther washing machinesReed switchWaste management

Disclosed is a clothes dryer, comprising: a body; a drum rotatably installed at the body; a duct for guiding air exhausted from the drum; and a filter assembly for filtering lint included in the air exhausted from the drum. The filter assembly includes a lint filter and a cover filter, and a lint collector encompassed by the lint filter and the cover filter. The clothes dryer includes sensing means for sensing whether the lint filter has been mounted to a precise position or not. The sensing means consists of a magnet mounted to a mesh frame of the lint filter, and a reed switch mounted to a cover guide.

Owner:LG ELECTRONICS INC

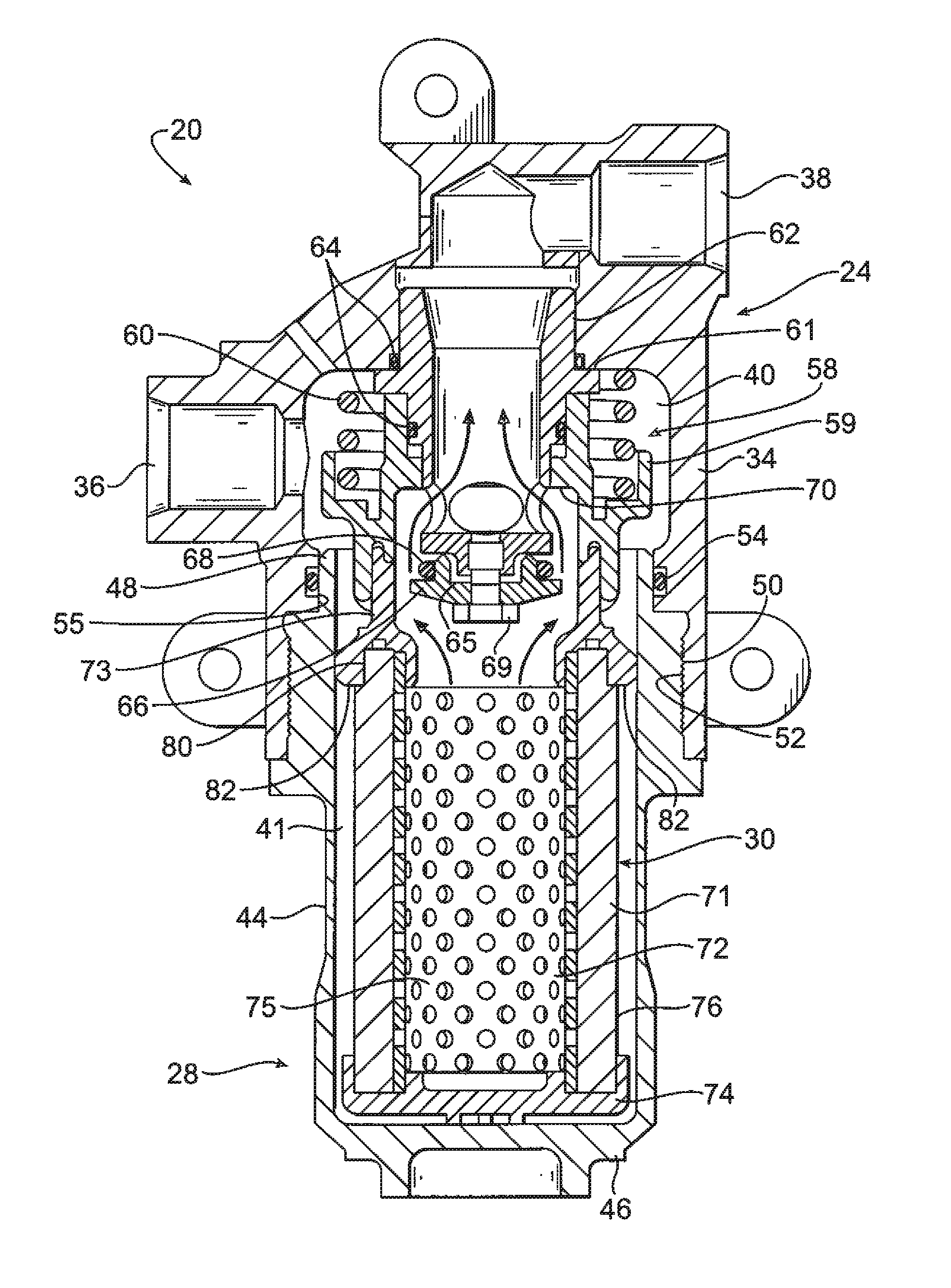

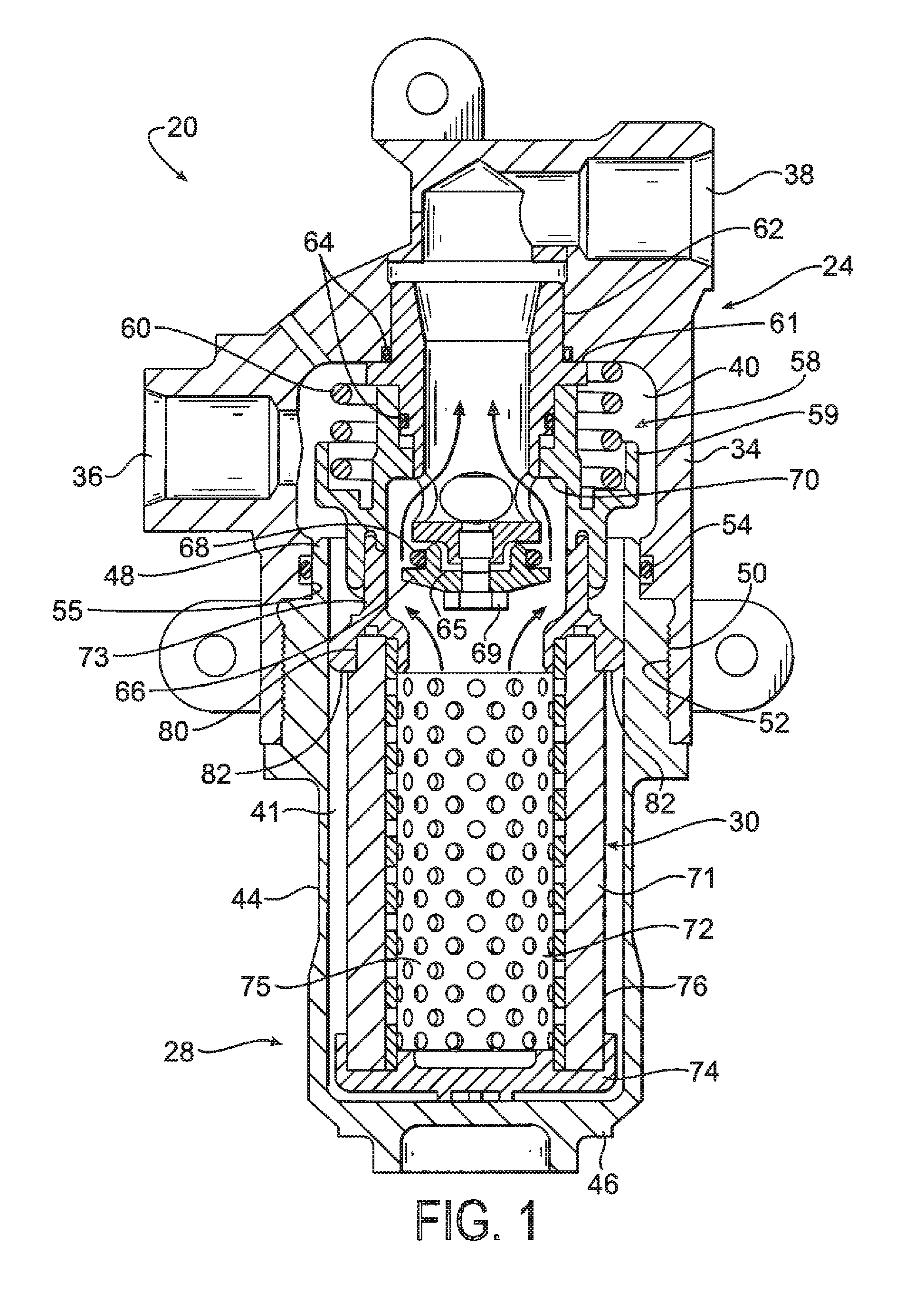

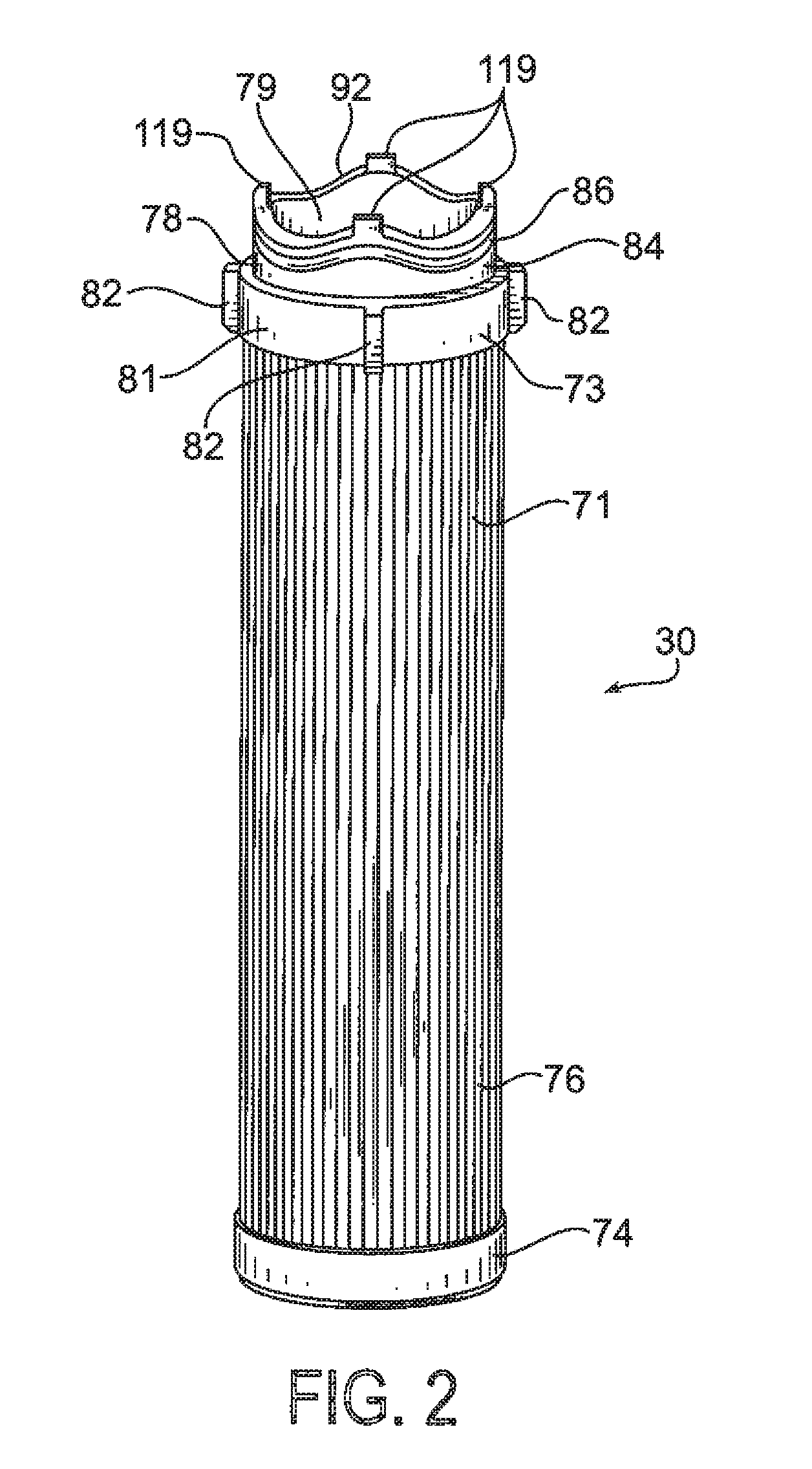

Filter element wave gland seal

ActiveUS20120181224A1Facilitate installationGood sealMembrane filtersCartridge filtersMechanical engineeringFilter element

A filter module includes a filter element with a ring of media and an end cap at one end of the ring. The end cap includes an annular body with a sealing member located around a surface of the body circumscribing a central opening, wherein the sealing member has a repeating, undulating, non-planar geometry. The axial, distal end of the annular body also has an repeating, undulating non-planar geometry, matching the geometry of the sealing member, and can have one or more tabs projecting axially outward from the distal end, positioned at a point of maximum amplitude of the distal end, and which are received in cooperating slots formed in a socket of a diaphragm, to facilitate positioning and installing the element into the module. The socket includes an outer wall having a matching non-planar geometry which receives and seals against the sealing member on the end cap.

Owner:PARKER INTANGIBLES LLC

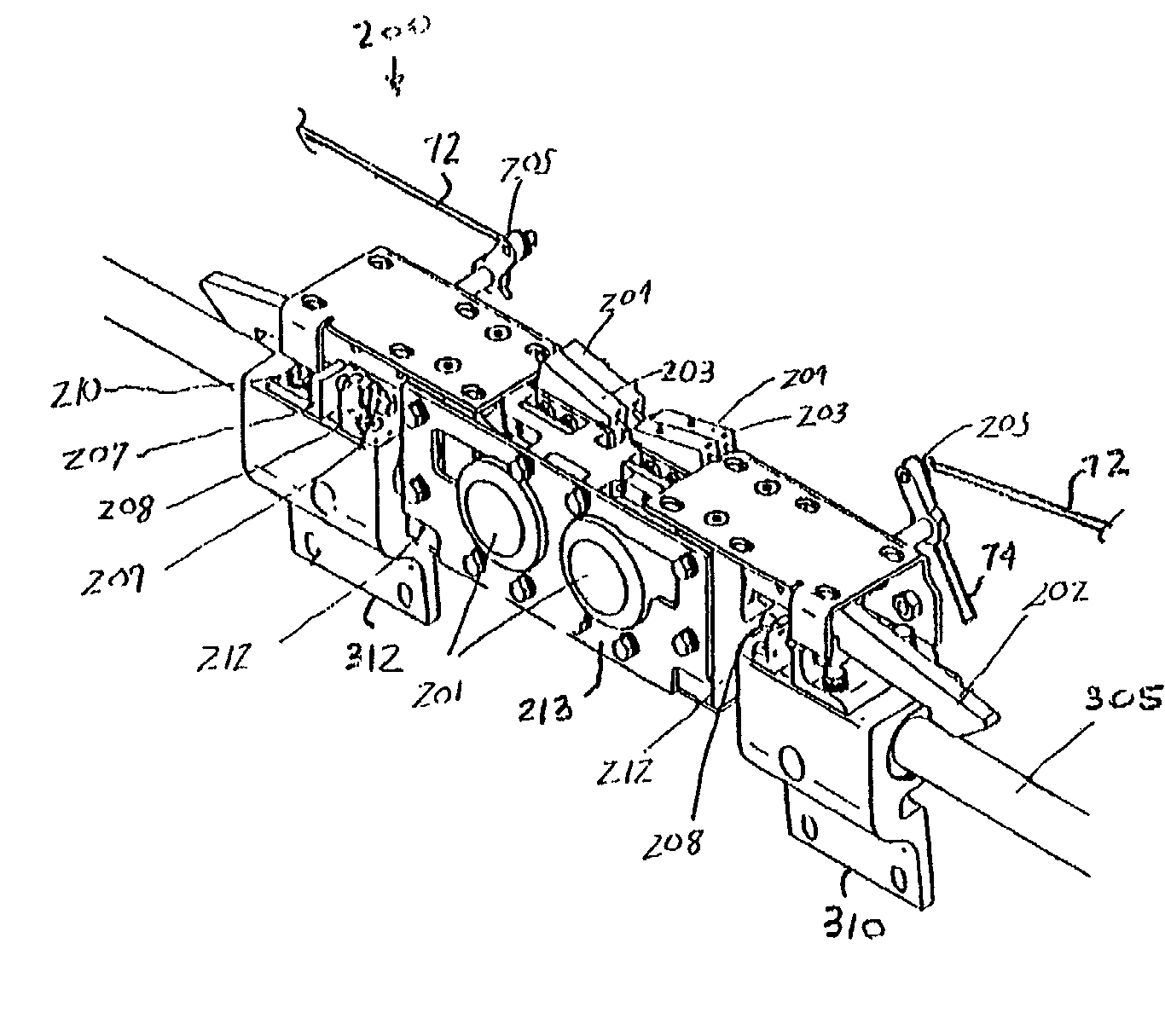

Central lock mechanism

InactiveUS20020194784A1Good sealReliable in operationNon-mechanical controlsWing fastenersEngineeringElectrical and Electronics engineering

A lock mechanism enabling locking of a bi-parting set of right hand and left hand door panels respectively suspended from a right hand and left hand door operators, to be driven by the door operators for covering and uncovering an aperture disposed within a passenger transit vehicle. Such lock mechanism disposed intermediate the door operators. The lock mechanism is capable of operating in a pushback and non pushback arrangement providing a fully-locked state, for each of the two bi-parting doors of a passenger transit vehicle. The integrated design allows the central lock mechanism to be installed and / or maintained over a doorway with only minimal adjustments needed to assure that the door lock assemblies operate in unison. As compared to separate door lock assemblies for each door panel as is typical of prior art designs, the central lock mechanism enables the door panels to be closed and locked more reliably and with better sealing against weather and noise.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

Vial with hinged cap and method of making same

A method of making a dispensing vial from a plastic material. The vial includes a vial body, a vial lid and a living hinge structure connecting the vial lid to the vial body. The dispensing vial is molded and removed from the mold still warm. The living hinge structure is flexed while the plastic is still warm. Thereafter, the sealing surfaces are actively cooled to cause the plastic to fully set, and finally the vial lid is closed shut.

Owner:POLYTOP

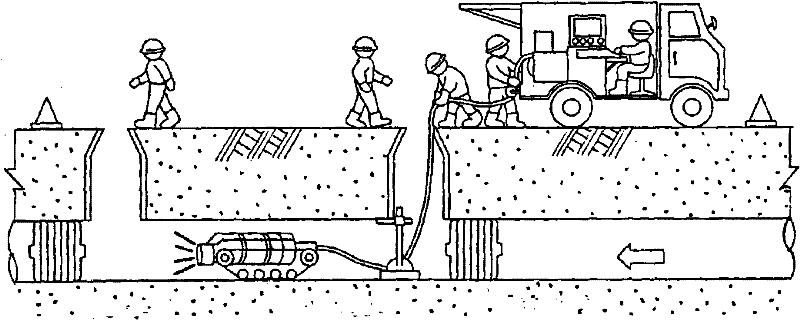

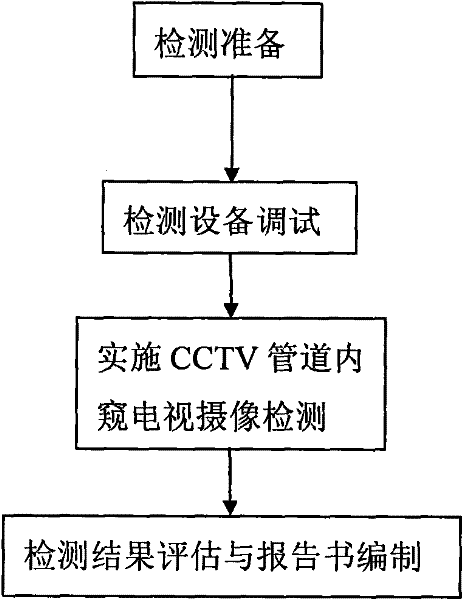

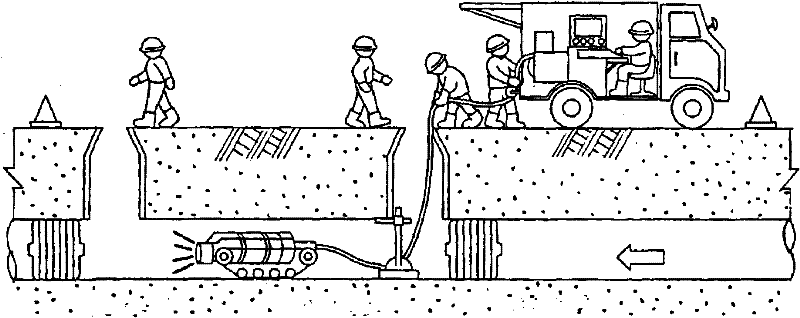

Television detection method for structure condition of pipeline

The invention discloses a closed circuit television (CCTV) shooting detection method. In the detection method, a CCTV pipeline endoscopic television shooting detection system is used for automatically crawling in a pipeline, detecting and shooting the structure condition of the pipeline, displaying and recording in a wired transmission mode, and evaluating according to detection technical regulations. The method comprises the following steps of: 1, preparing detection; 2, debugging detection equipment; 3, performing pipeline endoscopic CCTV shooting detection; and 4, evaluating a detection result and compiling a report. By the television detection method, the internal condition of a drainage pipeline buried underground can be visually known, the safety risk of personnel and detection cost are further reduced, influence on road traffic is reduced, and decision-making bases are accurately provided for the construction, management, operation and maintenance of the drainage pipeline.

Owner:管丽环境技术(上海)有限公司 +1

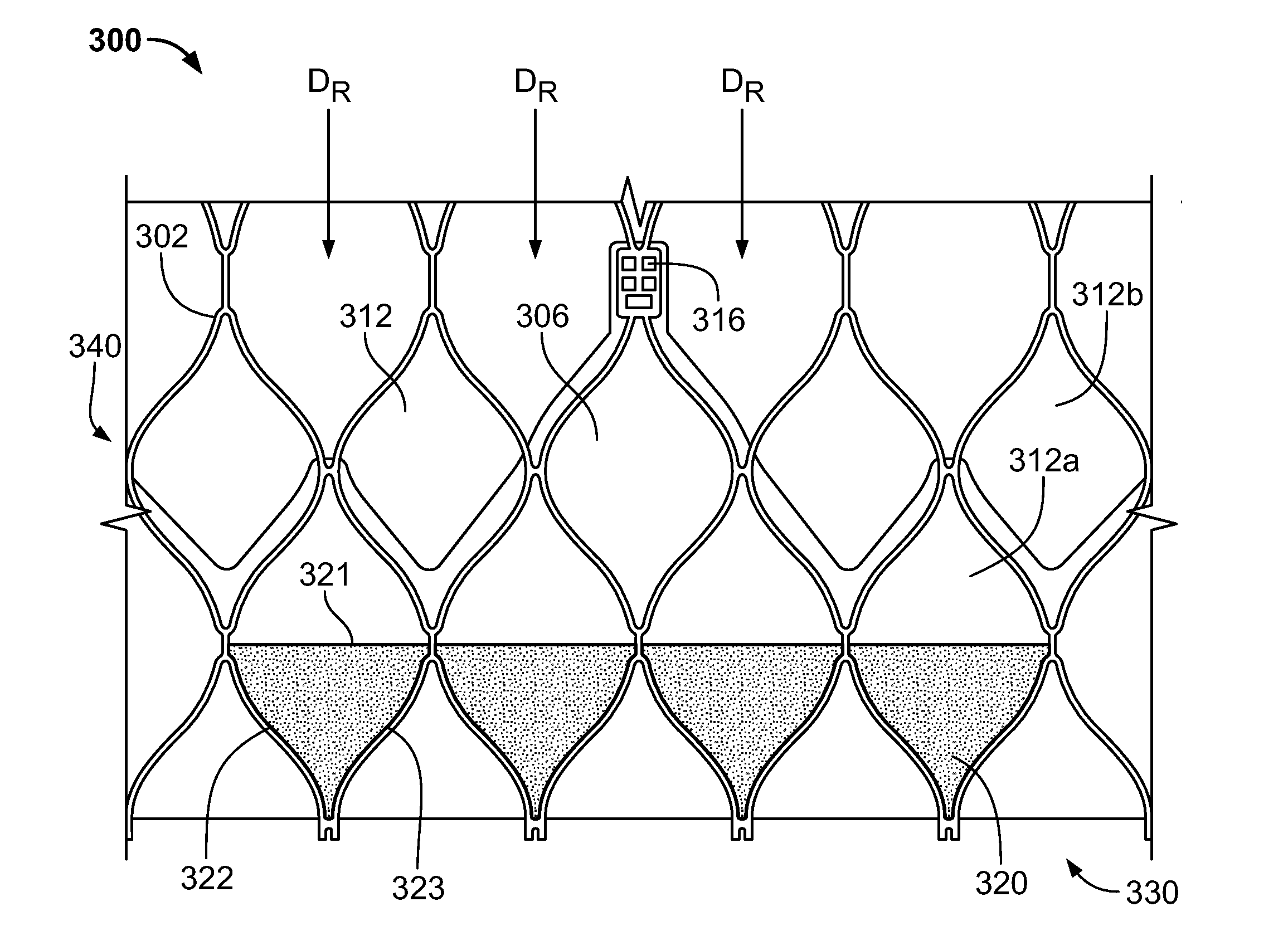

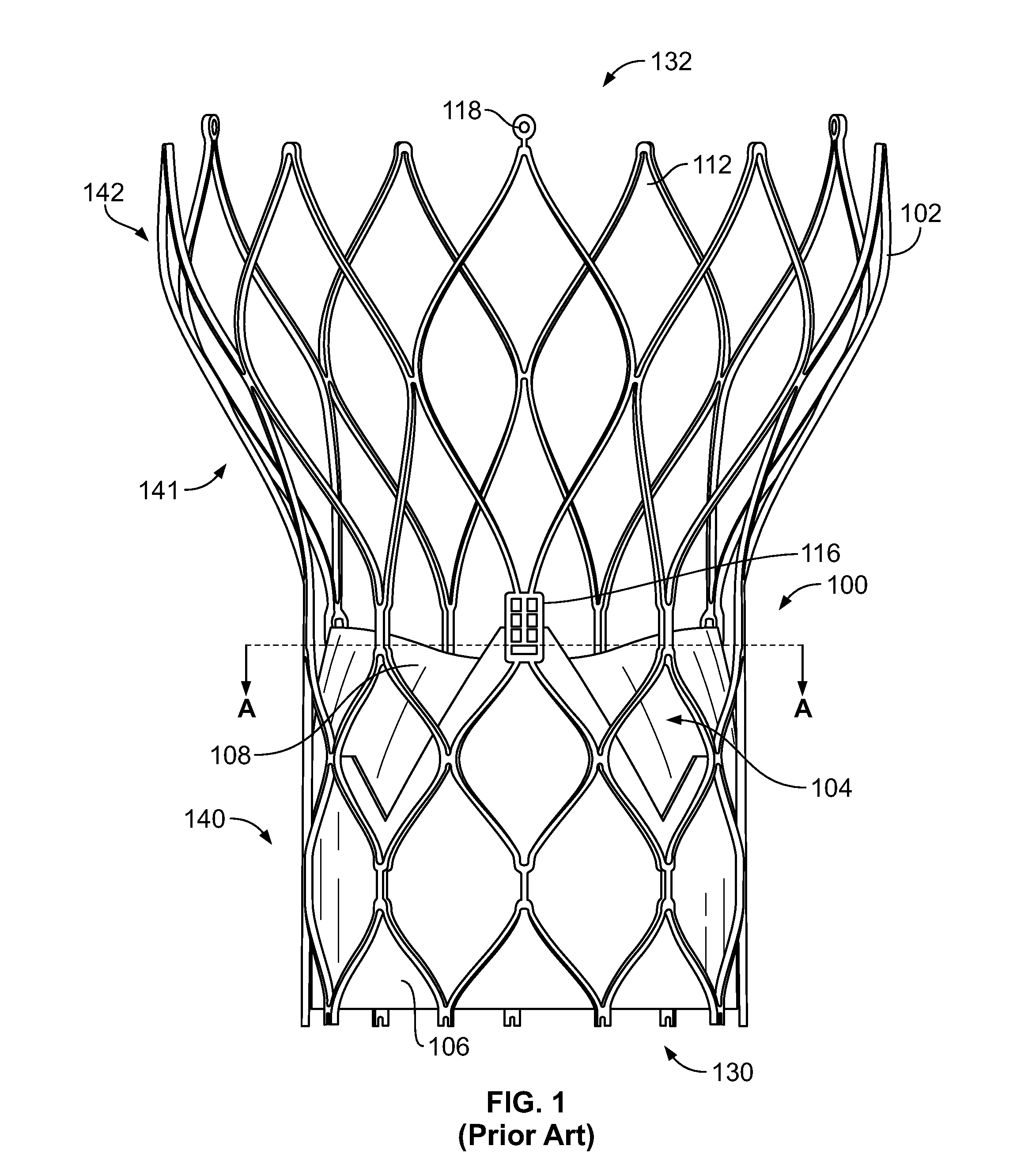

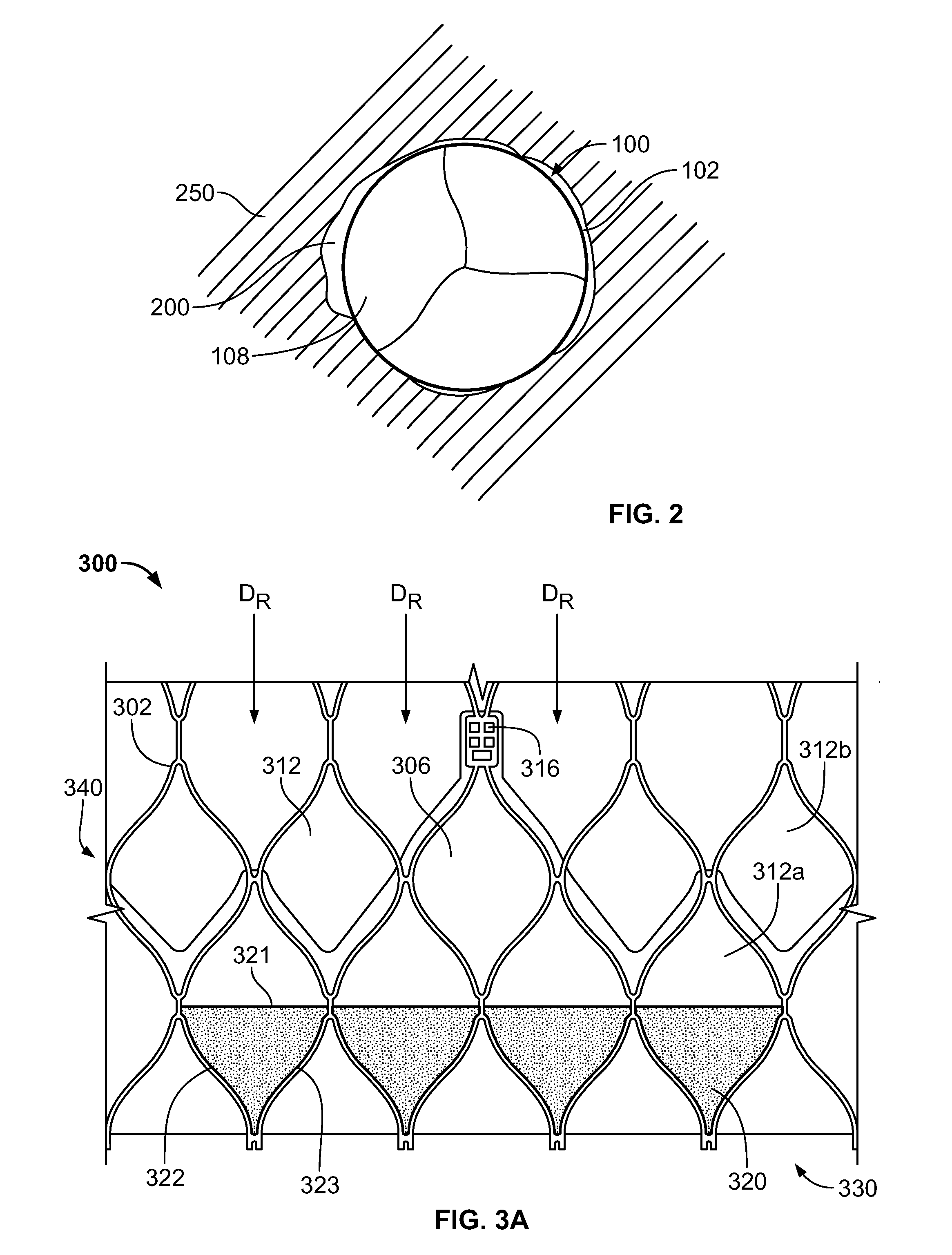

Paravalvular leak sealing mechanism

A prosthetic heart valve includes a stent body with a generally tubular annulus section, which may include one or more circumferential rows of cells. One or more prosthetic valve elements mounted to the stent body operate to allow blood flow in an antegrade direction but to substantially block flow in a retrograde direction. A cuff is attached to the stent body and positioned on a luminal surface of the stent body. At least one sealing member is attached to the cuff. The sealing member may be patch with an open side facing in a first axial direction and a closed side facing in a second axial direction opposite to the first axial direction. Flow of blood in the second axial direction will tend to force blood into the sealing member and cause the sealing member to billow outwardly relative to the stent body.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

Valve for an aerosol device

InactiveUS8464914B2Good sealSimply manufactureRespiratorsLiquid dispensingEngineeringMechanical engineering

Owner:CIPLA LTD

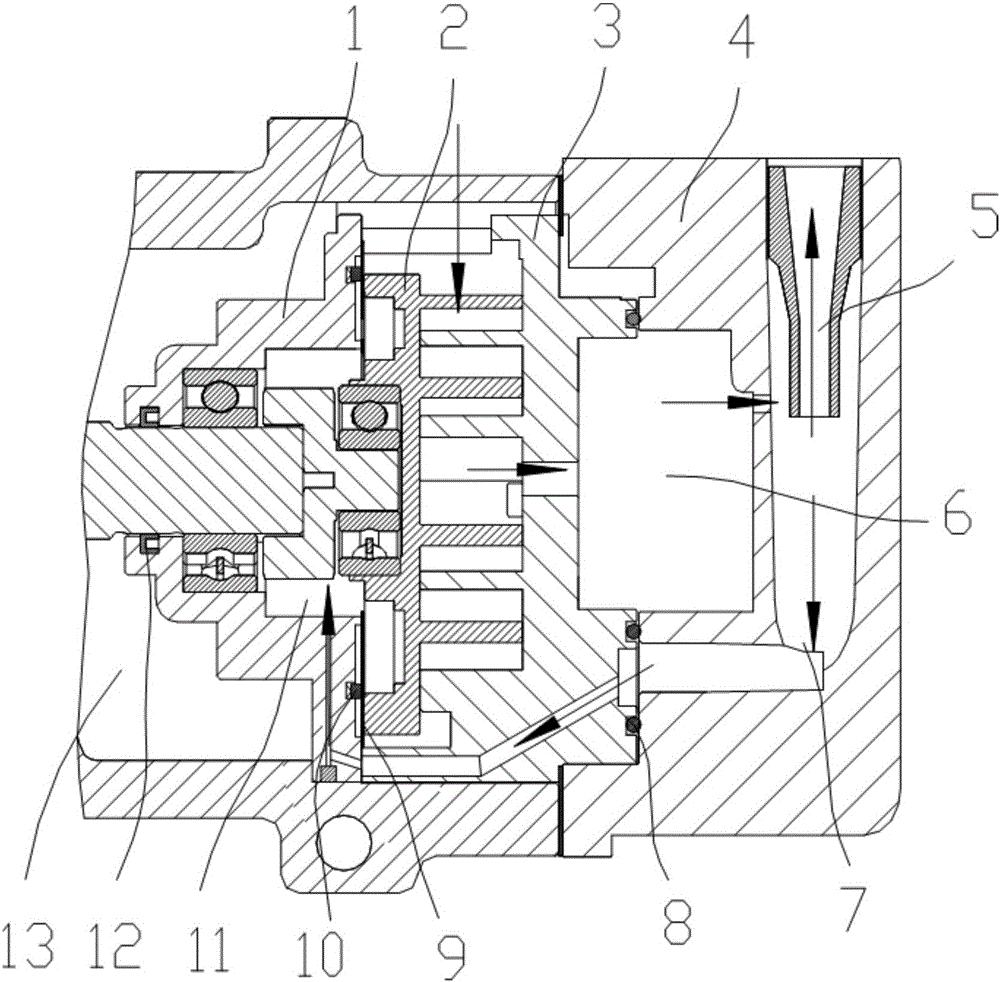

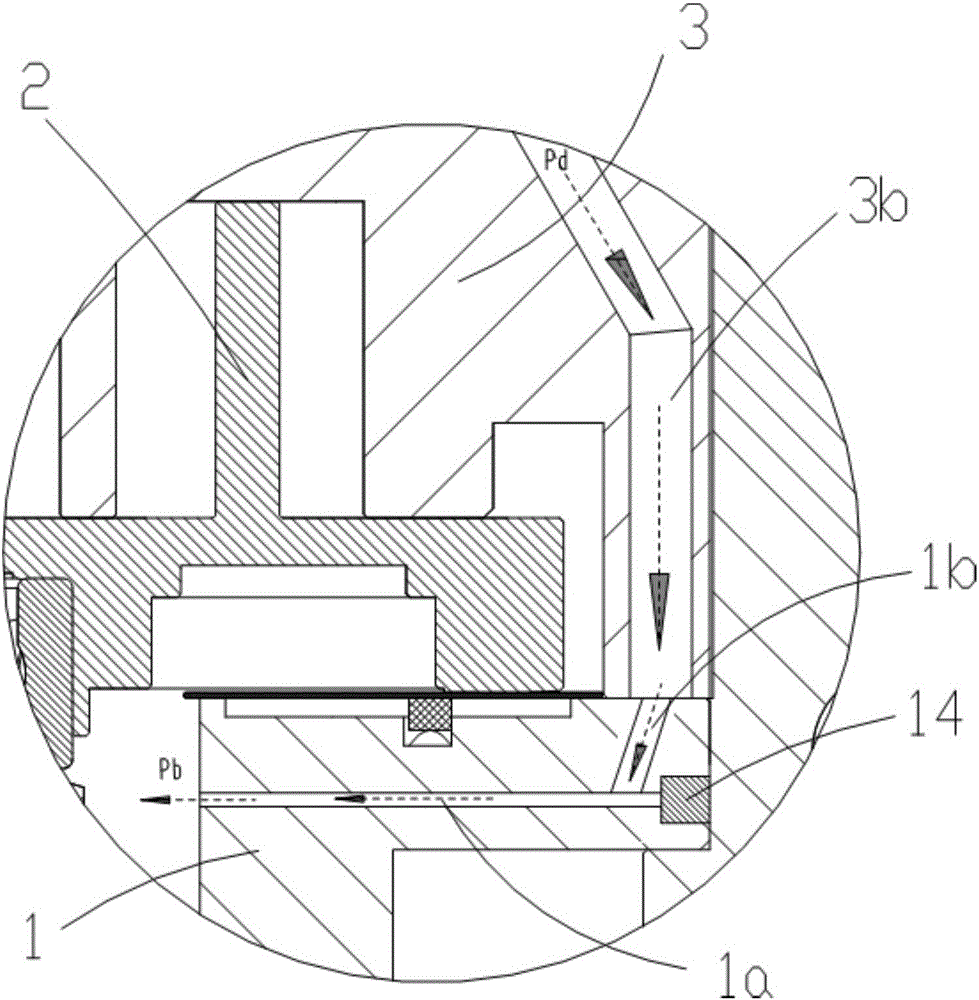

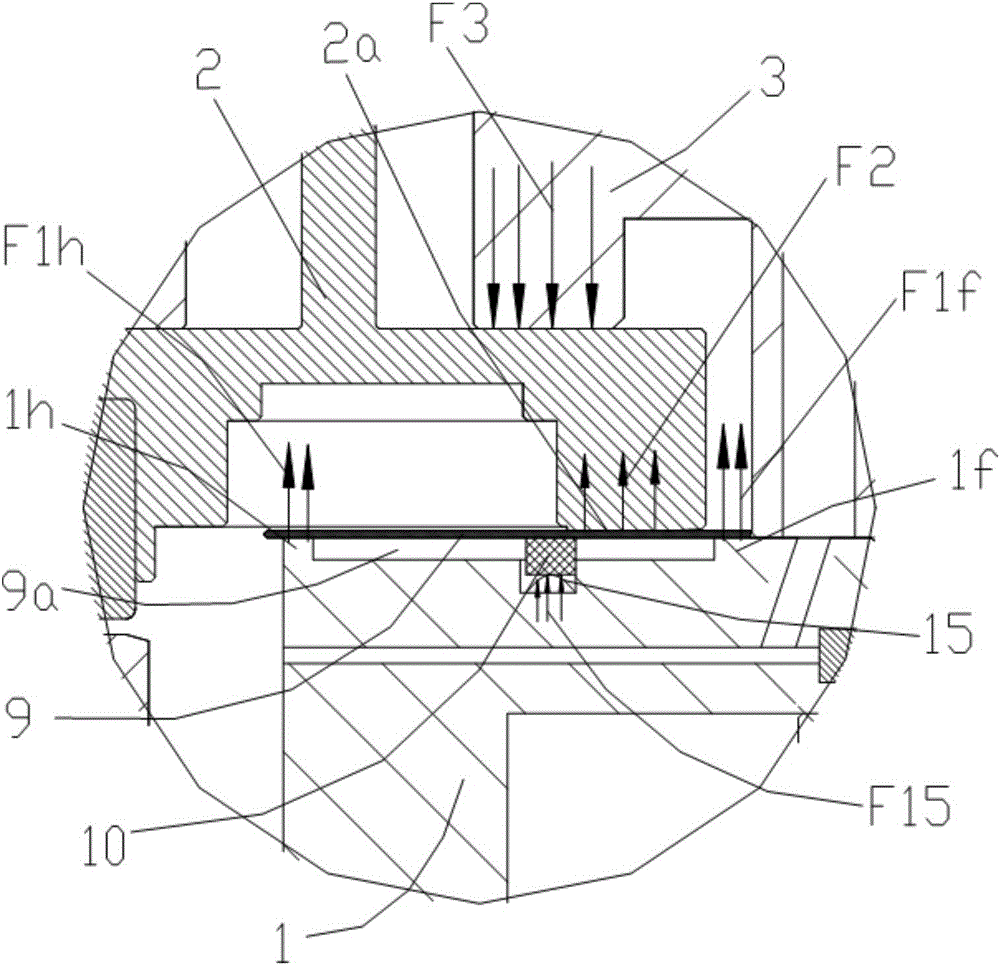

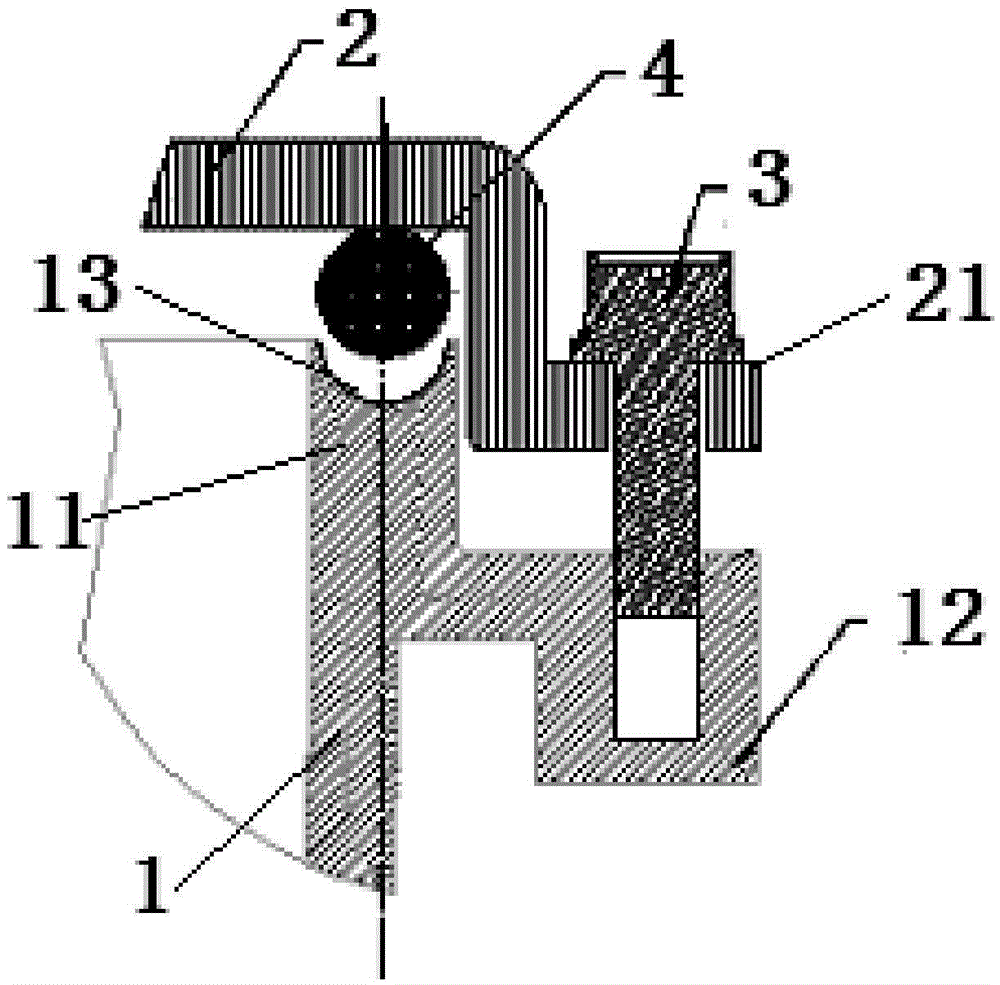

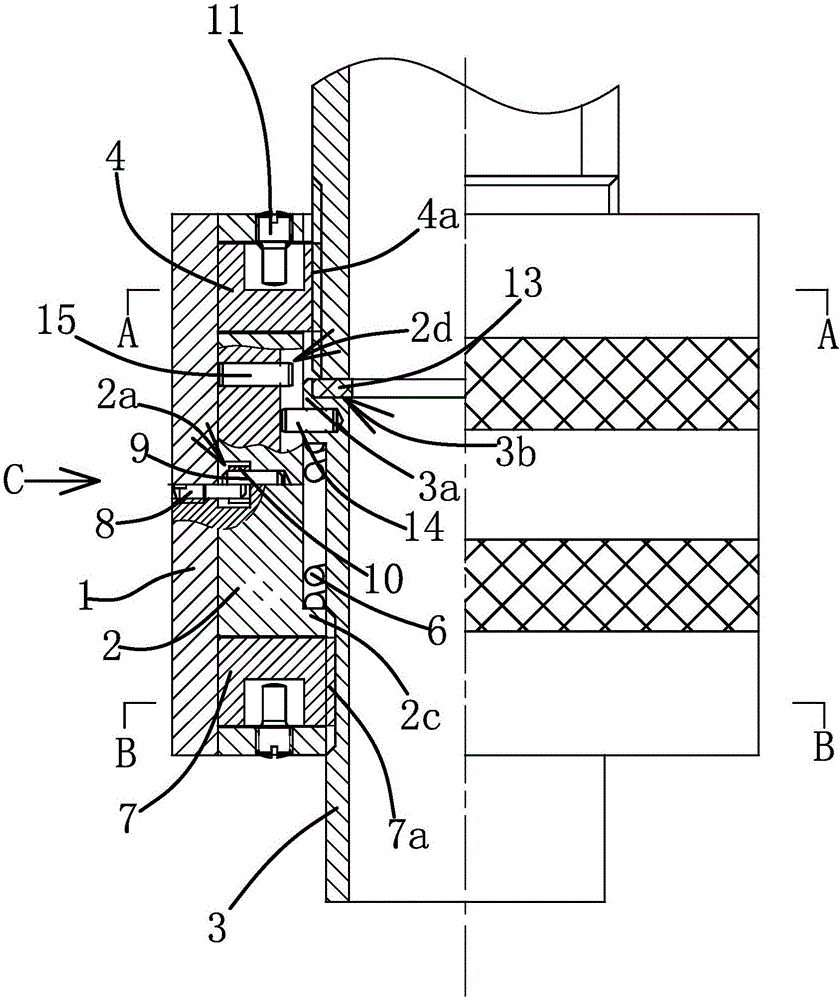

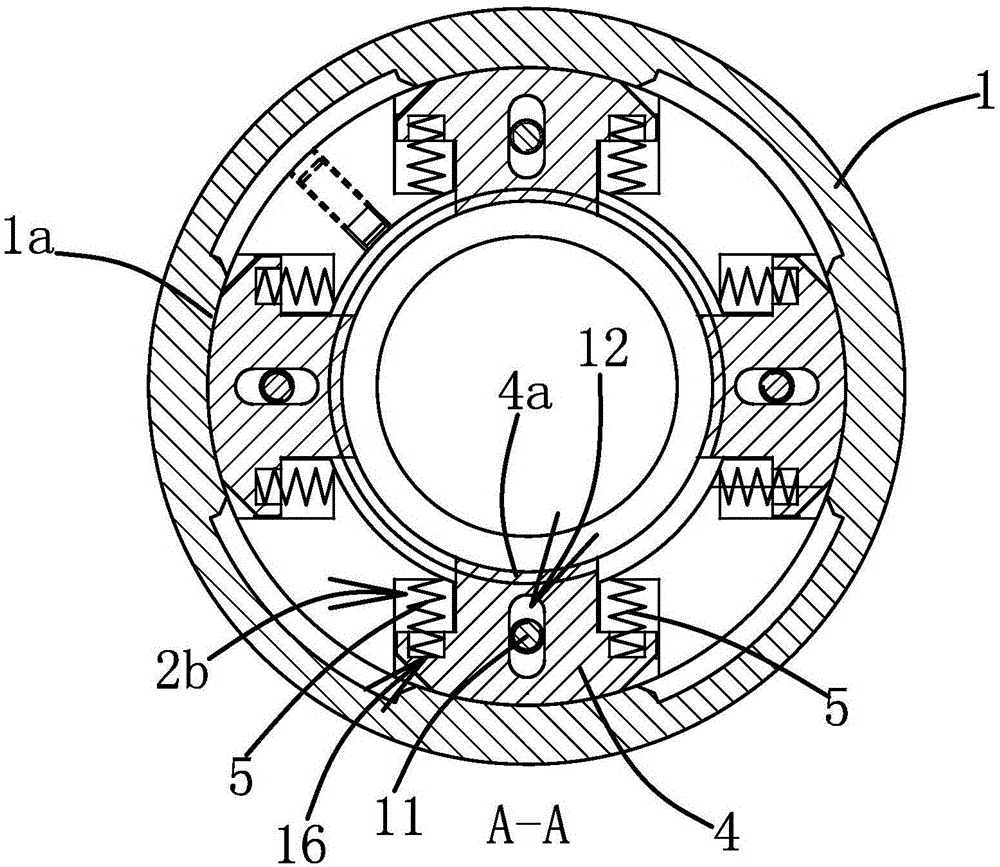

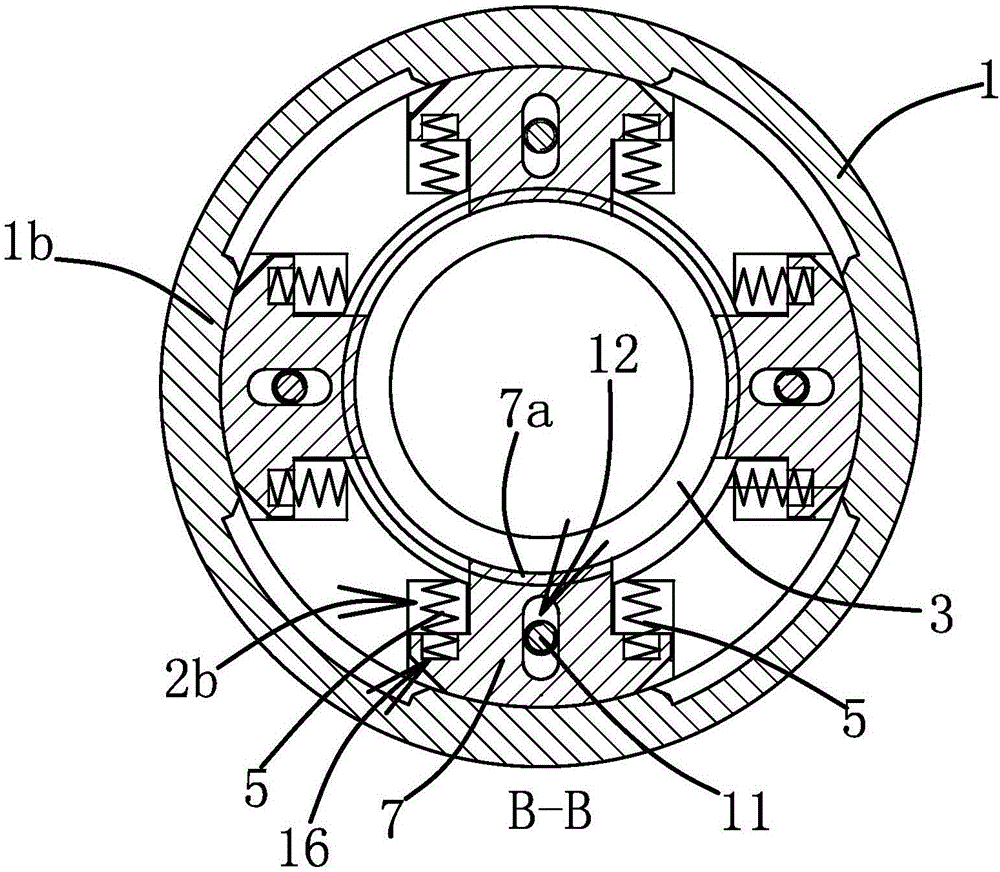

Scroll compressor

ActiveCN105840504AImprove processing strengthIncrease the difficulty of the processRotary piston pumpsRotary piston liquid enginesEngineeringScroll compressor

The invention discloses a scroll compressor. The scroll compressor comprises an upper support and an upper cover, wherein the upper support and the upper cover are connected. A movable scroll plate is arranged in the upper support and in the upper cover. A static scroll plate is coaxially arranged on the side, close to the upper cover, of the movable scroll plate. An elastic circular ring is coaxially arranged on the side, close to the upper support, of the movable scroll plate. The upper support is provided with an inner supporting part and an outer supporting part, wherein the inner supporting part and the outer supporting part are matched with the elastic circular ring. A suspended part is formed between the inner supporting part and the outer supporting part. A back pressure sealing groove is formed in the bottom face of the suspended part. A back pressure sealing ring tightly attached to the elastic circular ring is arranged in the back pressure sealing groove. A back pressure cavity and an air sucking cavity which communicate with the suspended part are formed in the upper support. An exhaust cavity communicating with the back pressure cavity is formed in the upper cover. A compression cavity communicating with the air sucking cavity and the exhaust cavity is formed between the movable scroll plate and the static scroll plate. The scroll compressor is sufficient and reliable in sealing effect, and the technology difficulty of a sealing structure of the scroll compressor is low.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

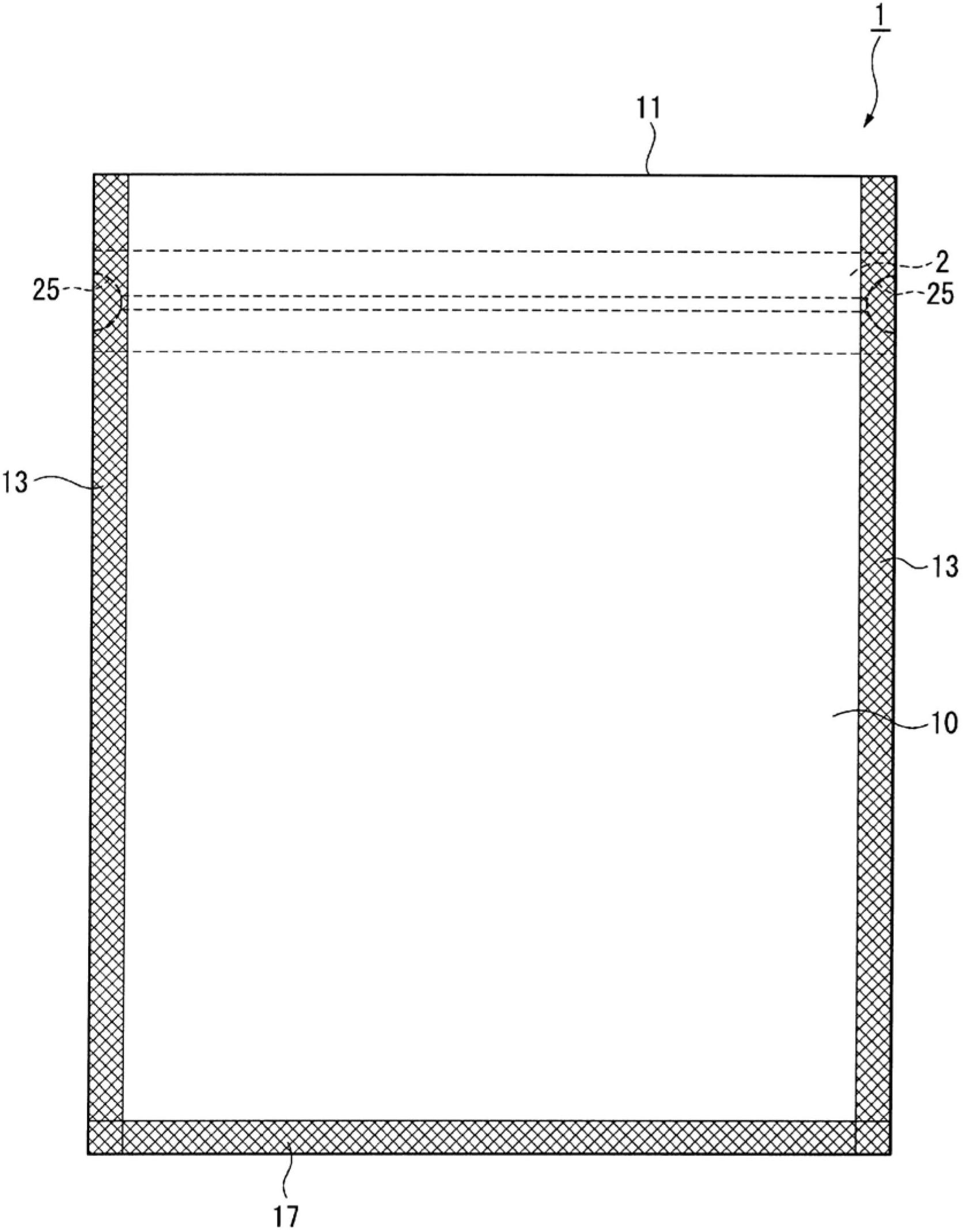

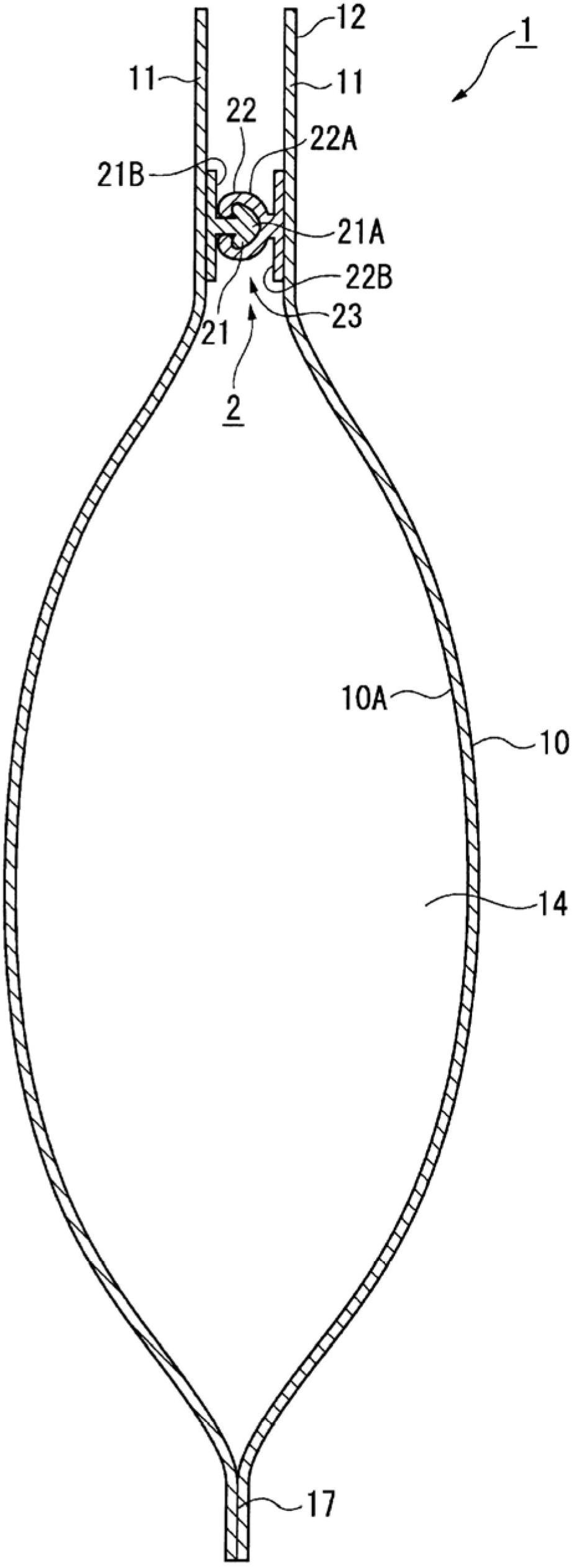

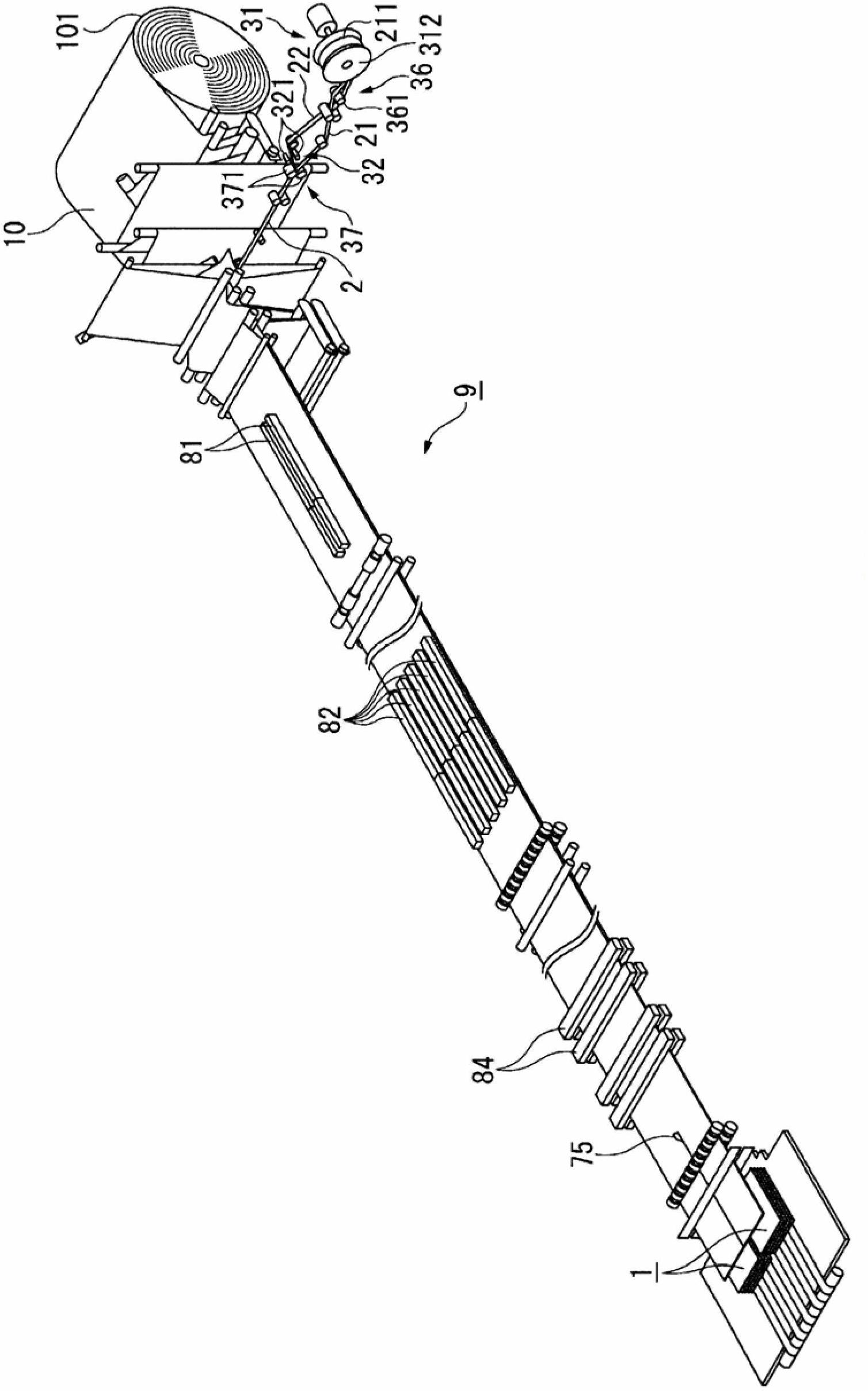

Zipper tape, packaging bag with zipper tape, method for producing packaging bag with zipper tape and production device therefor

InactiveCN102686121AGood sealEasy bag makingEnvelopes/bags making machinerySlide fastenersBand shapeMechanical engineering

The invention provides a zipper tape, a packaging bag with the zipper tape, a method for producing the packaging bag with the zipper tape and a production device therefor. After engagement of a male belt-like member (21) and a female belt-like member (22) are disengaged, a void portion is formed by punching the female belt-like member (22) with a die (321). The female belt-like member (22) having the void portion and the male belt-like member (21) are re-engaged with each other and fed between a folded base material film (10) that is continuously fed. A male belt-like base and a female belt-like base are heat-sealed. A seal bar (82) heat-seals the base material film (10) to form a bottom seal portion. A side seal bar (84) heat-seals the base material film (10) to form side seal portions. The cutter (75) cuts the base material film (10) in the middle of the side seal portions to produce the packaging bag (1) in which three sides of the bottom seal portion and the side seal portions are heat-sealed.

Owner:IDEMITSU UNITECH CO LTD

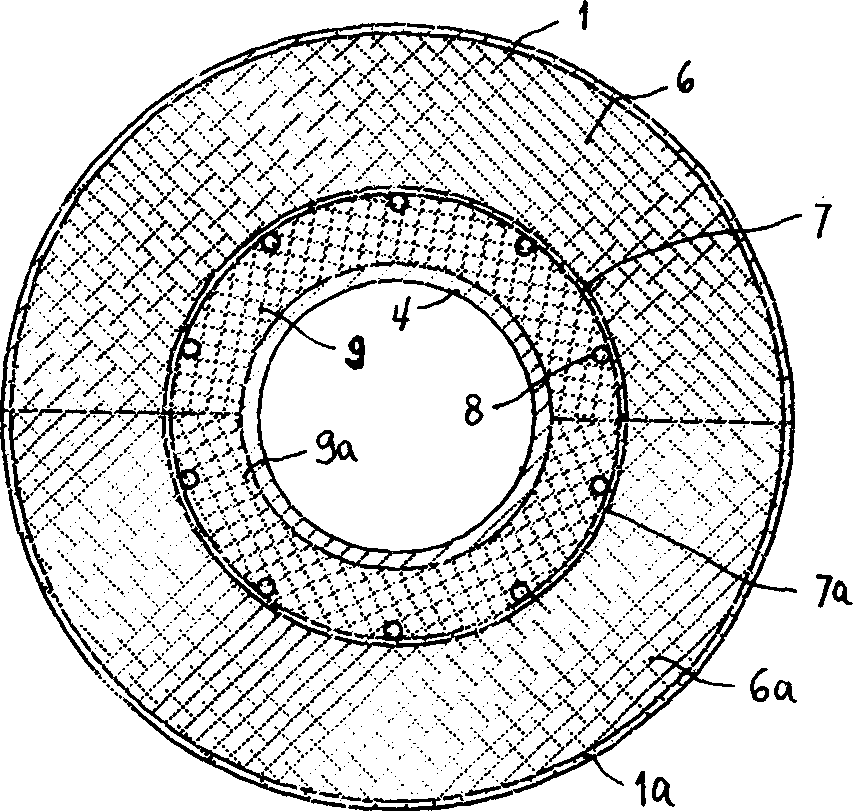

High-lubricating low-friction piston

InactiveCN101178124ARun fastGuaranteed uptimePositive displacement pump componentsPlungersPiston ringEngineering

The invention relates to a high lubrication low friction piston applied to a reciprocating piston internal combustion engine and an air compressor. The technical proposal is that the invention mainly consists of a piston head part, a piston skirt part and a piston cirque trough. The invention is characterized in that the side surface of the external wall of the piston is provided with a plurality of concave troughs which can move along the side surface radian of the external wall of the piston; an interval on the side surface of the external wall of part of the piston preserved between adjacent concave troughs forms a convex ridge; the most convex position of the convex ridge is aligned with the side surface of the external wall of the piston. The invention has the beneficial effects of reinforcing the lubrication performance, reducing the friction resistance, preventing cylinder expansion and locking, reinforcing the sealing performance, improving the exhaust standard and relieving the pollution exhaust, and prolonging the service life of the engine.

Owner:周林

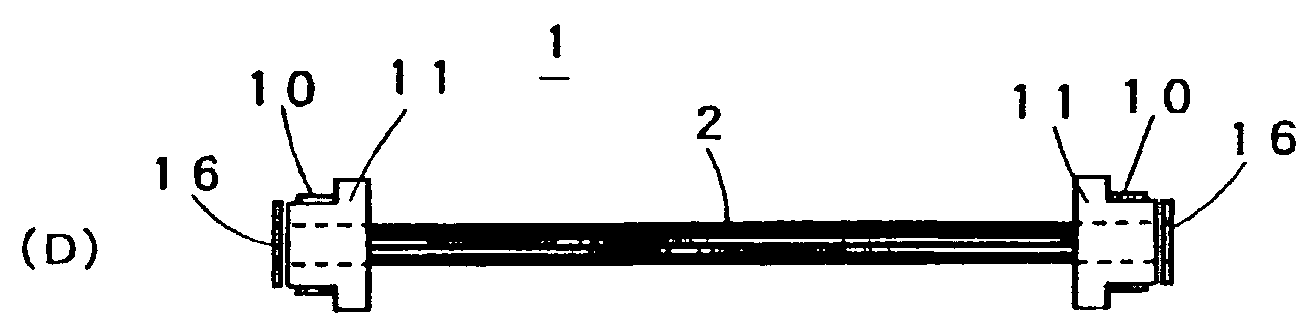

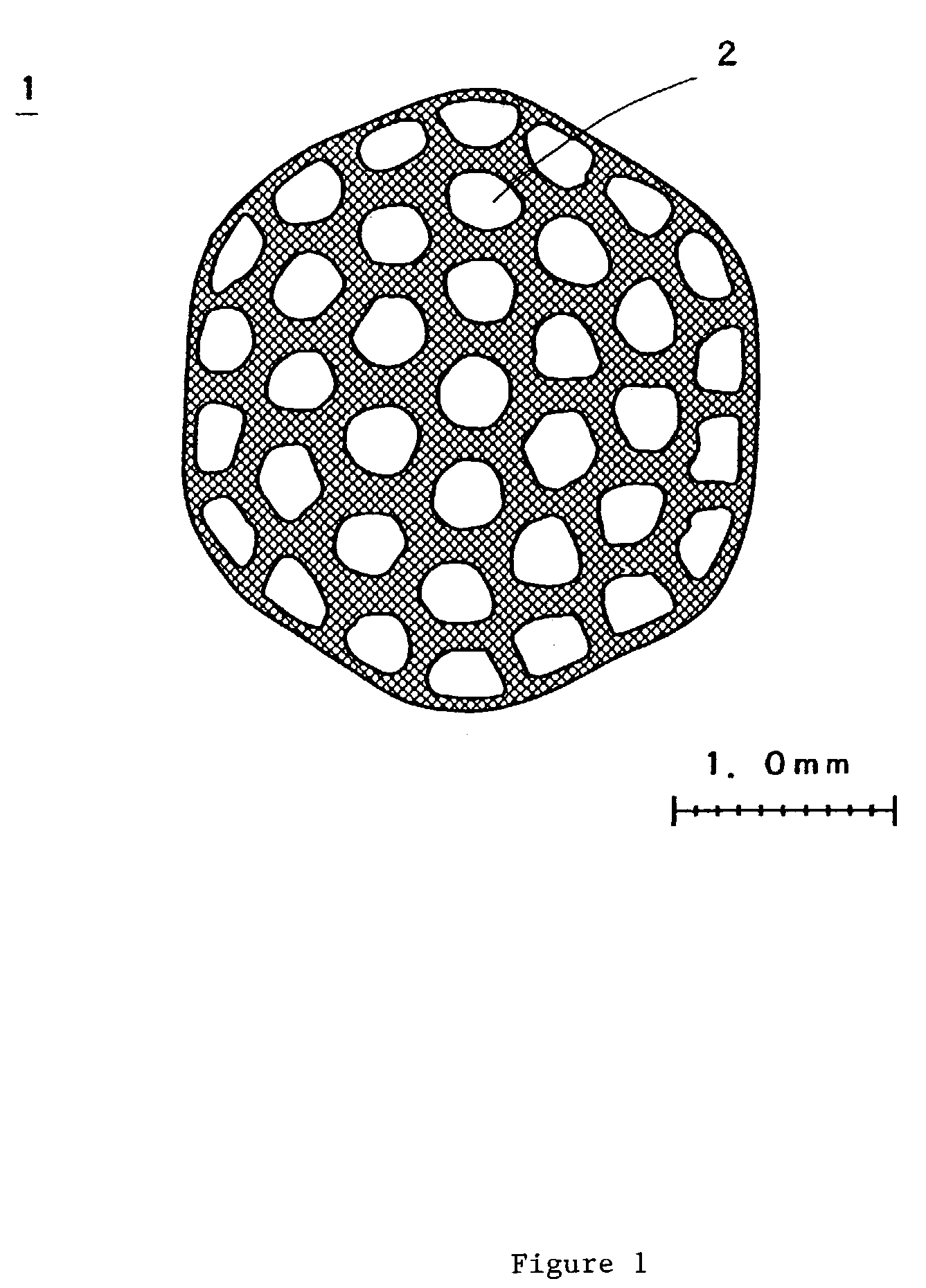

Separation membrane module with hollow fiber and a method of making the same

InactiveUS7291204B2High pack rateGood sealSemi-permeable membranesLiquid degasificationHollow fibreBiomedical engineering

Owner:GORE ENTERPRISE HLDG INC

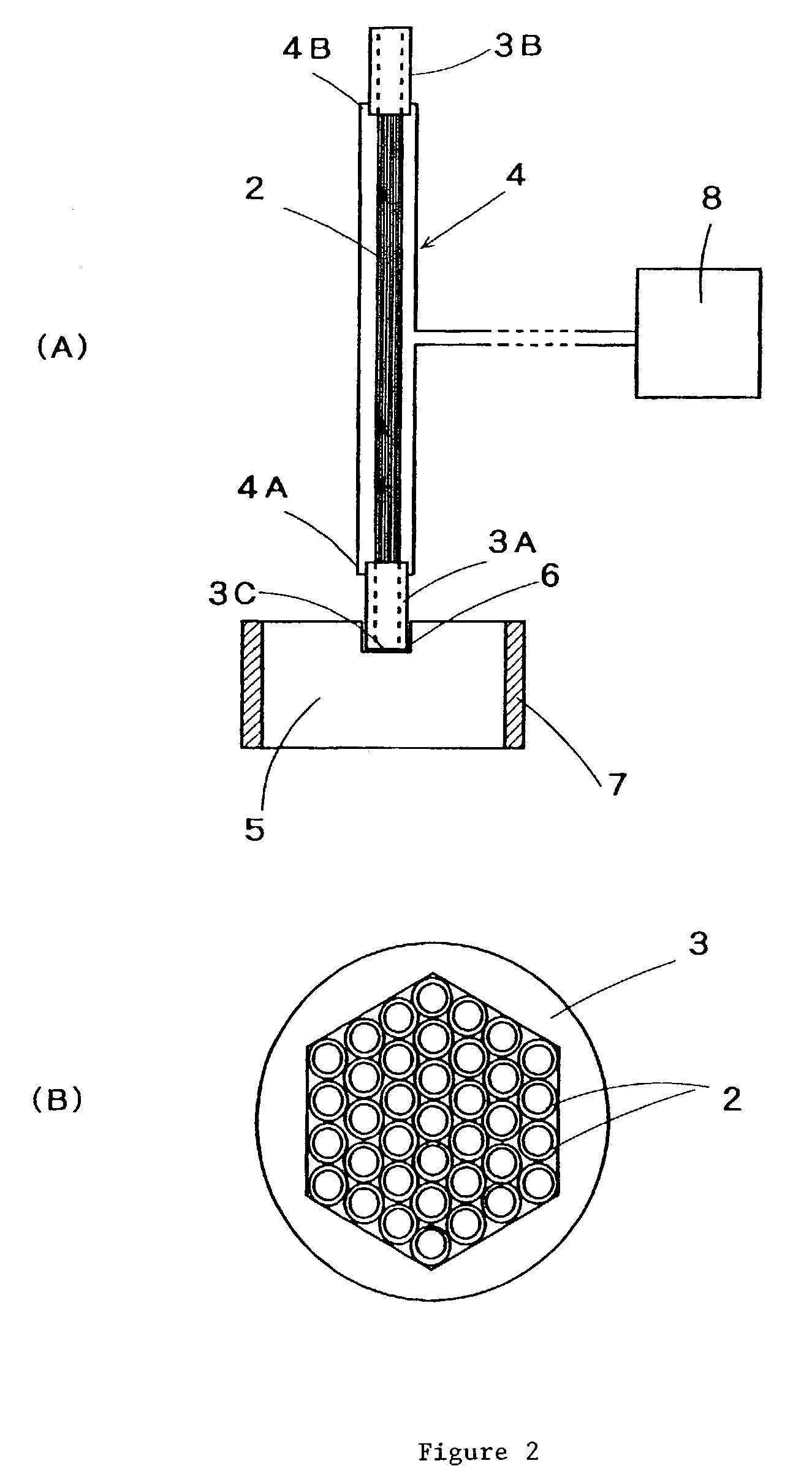

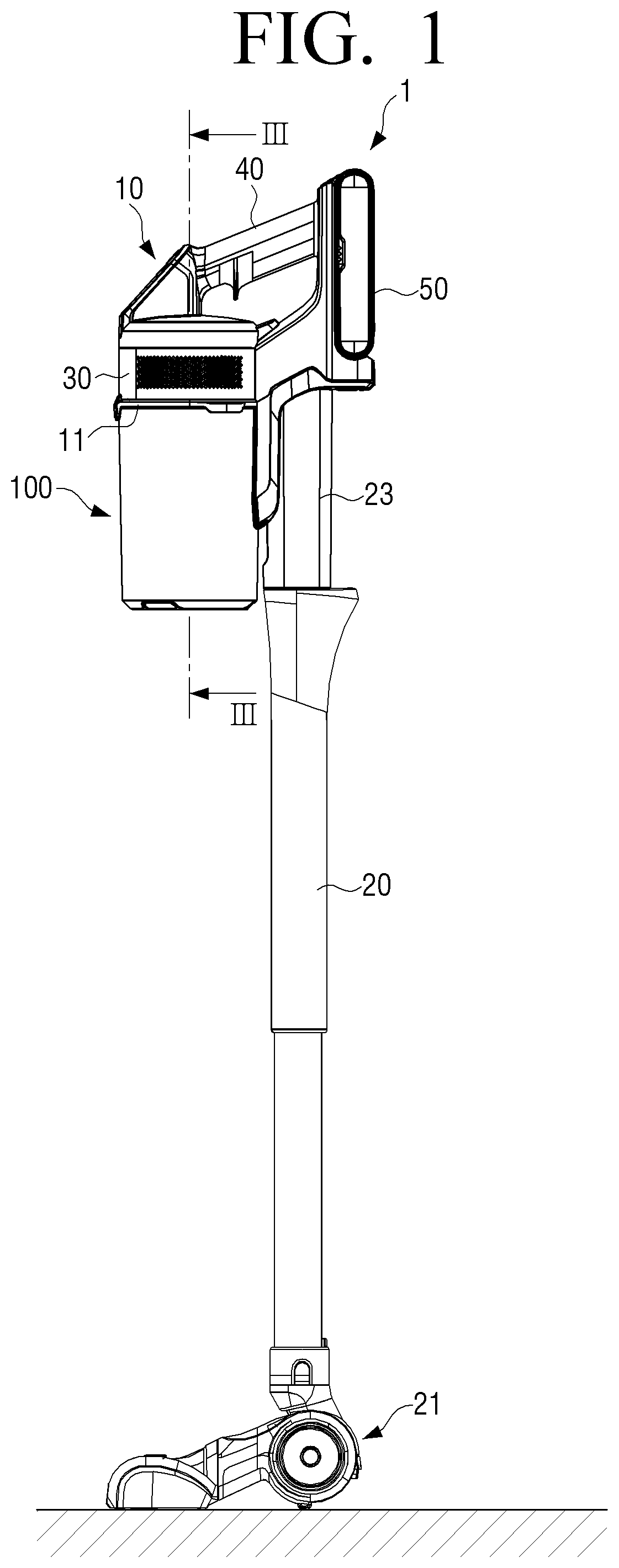

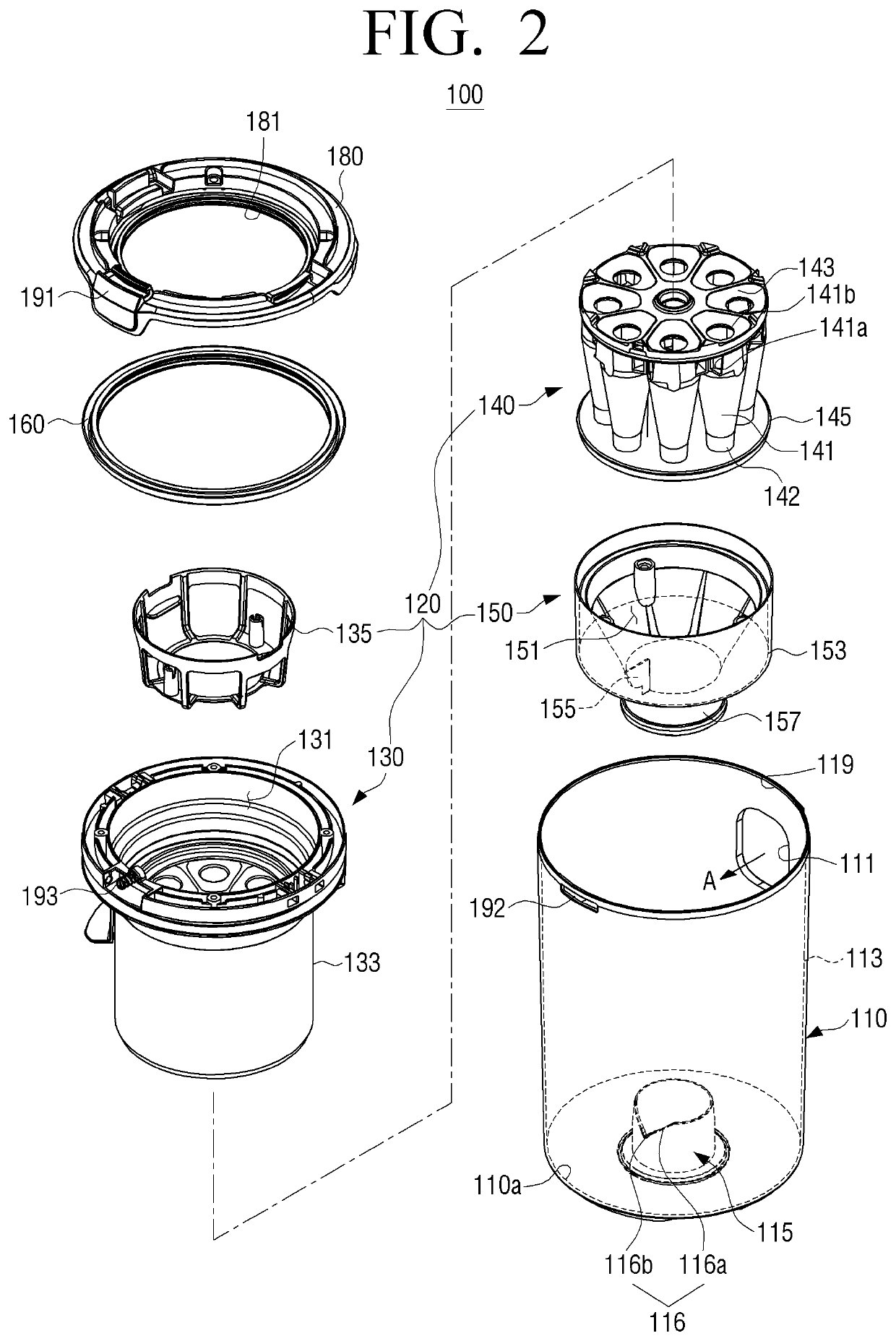

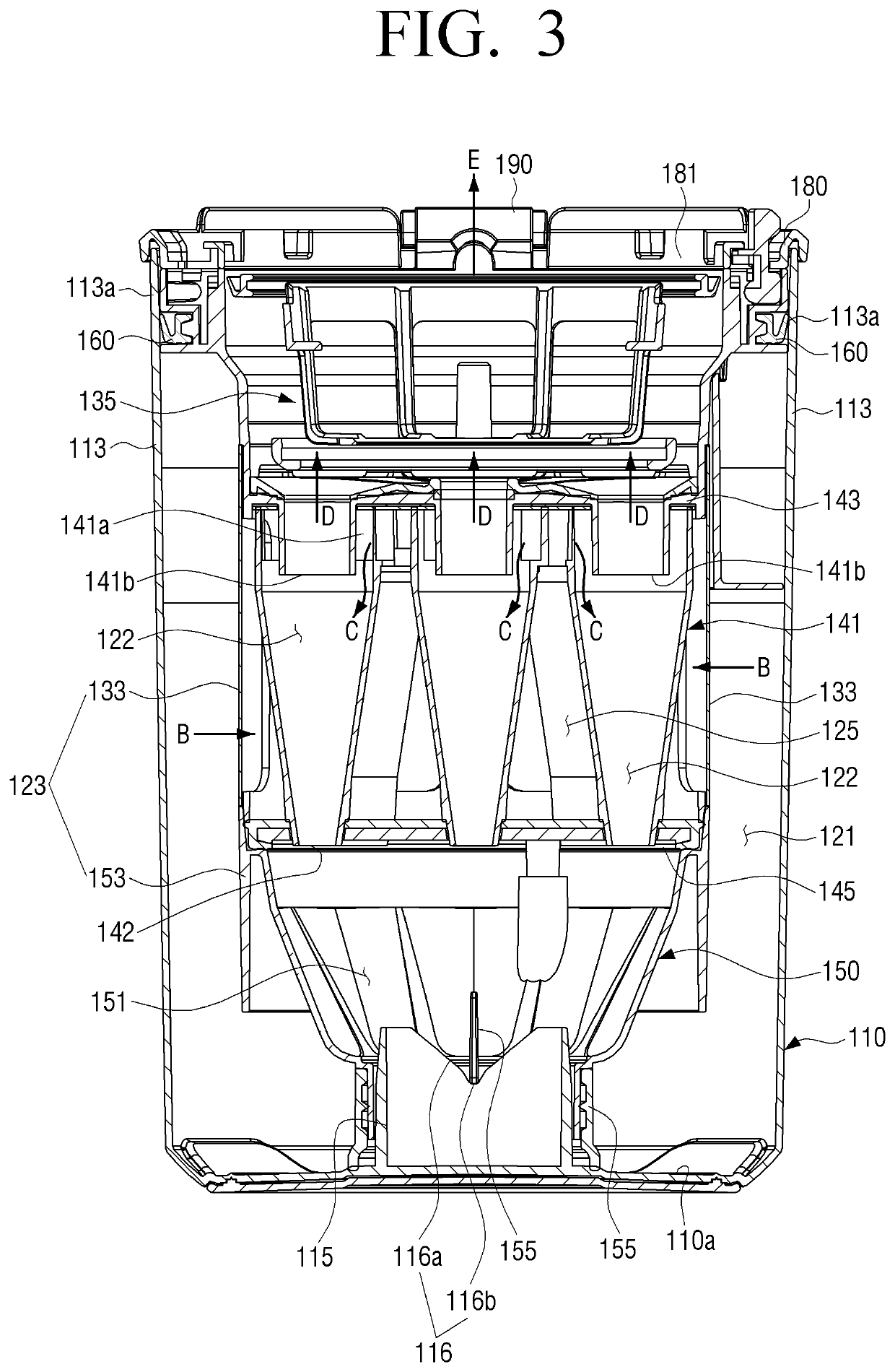

Dust collecting apparatus and cleaner having the same

ActiveUS20200069128A1Improve structureExcellent seal stateGas treatmentSuction filtersEngineeringPhencyclone

A dust collecting apparatus is provided. The dust collecting apparatus according to an embodiment includes a dust collecting case including a dust outlet to discharge collected dust, a cyclone member configured to rotate and move linearly in the dust collecting case to be detachable from and attachable to the dust collecting case, a discharge cover configured to rotate and move linearly together with the cyclone member, and detachable from and attachable to an upper part of the dust collecting case to open and close the dust outlet, and a sealing member having elasticity disposed between the dust collecting case and the discharge cover. The discharge cover rotates along a horizontal direction of the dust collecting case to detach from the upper part of the dust collecting case and form a space between the sealing member and the dust collecting case.

Owner:SAMSUNG ELECTRONICS CO LTD

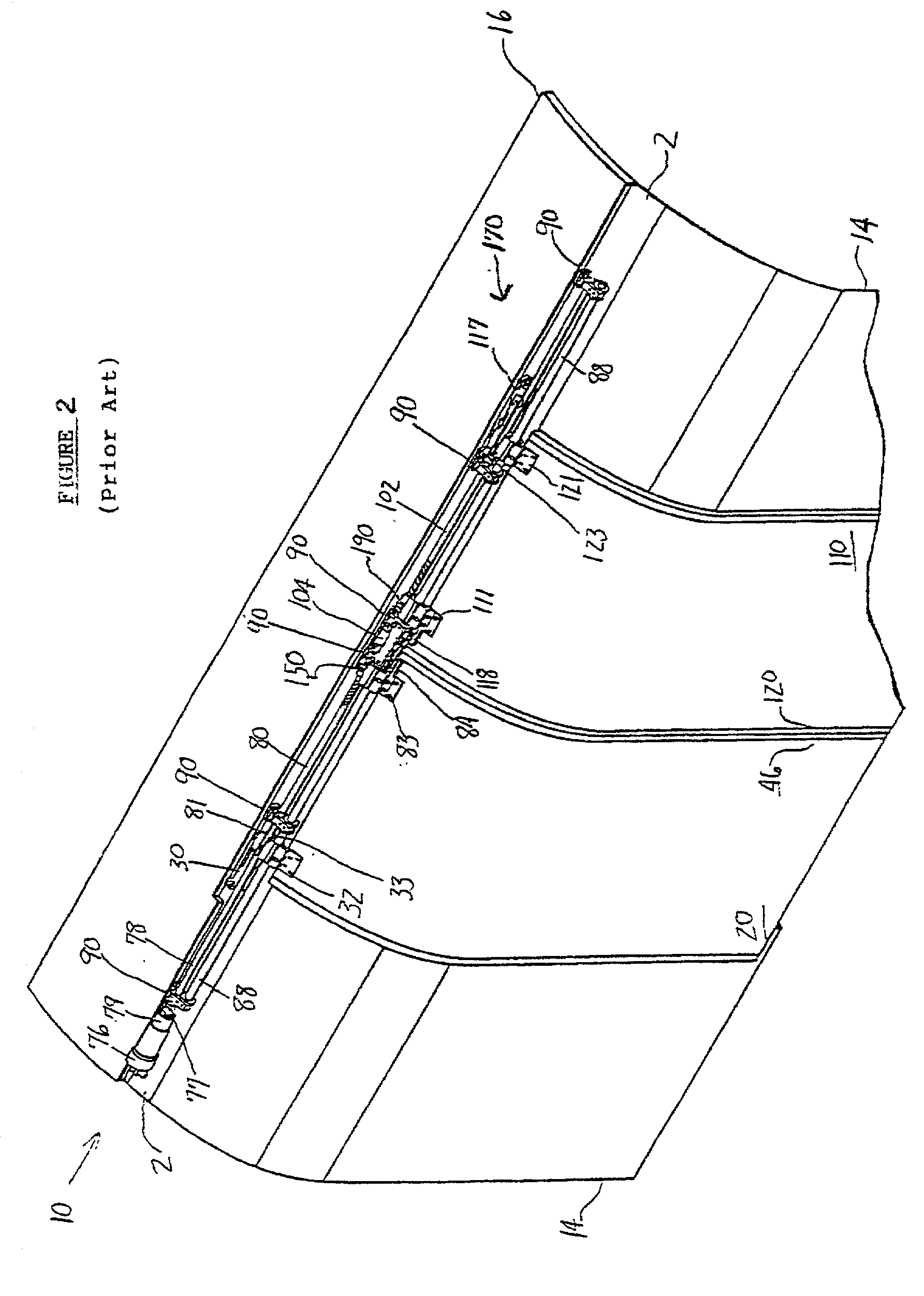

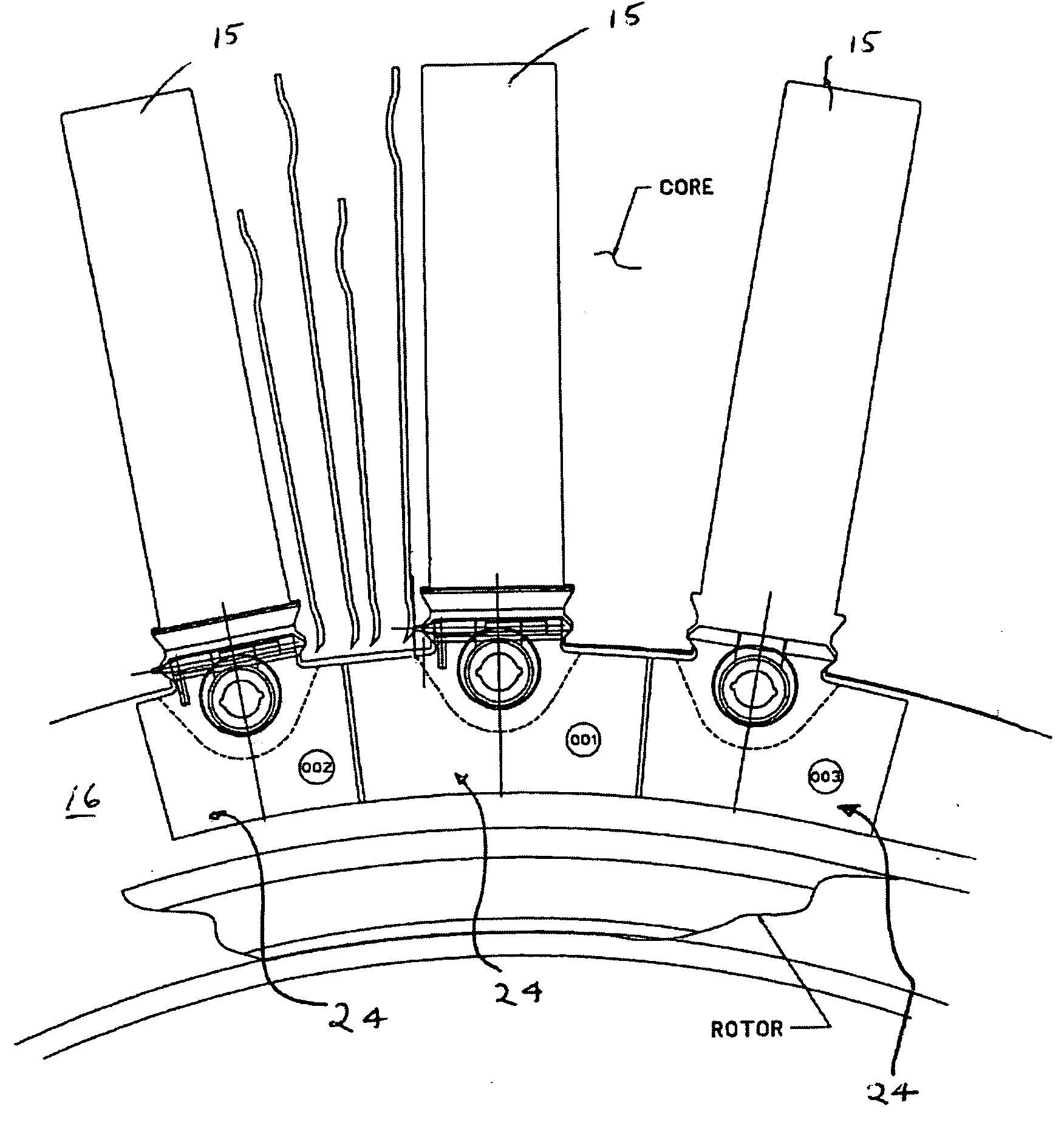

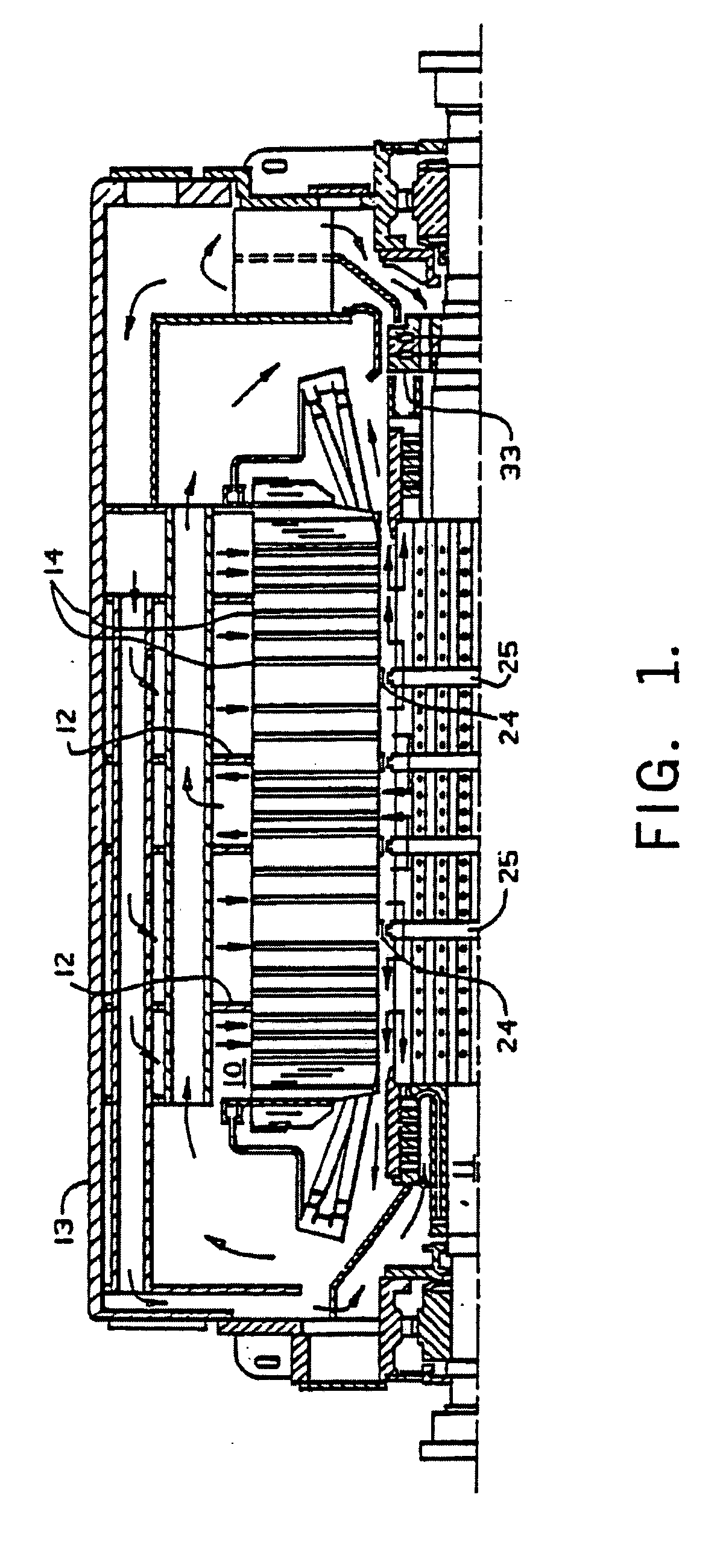

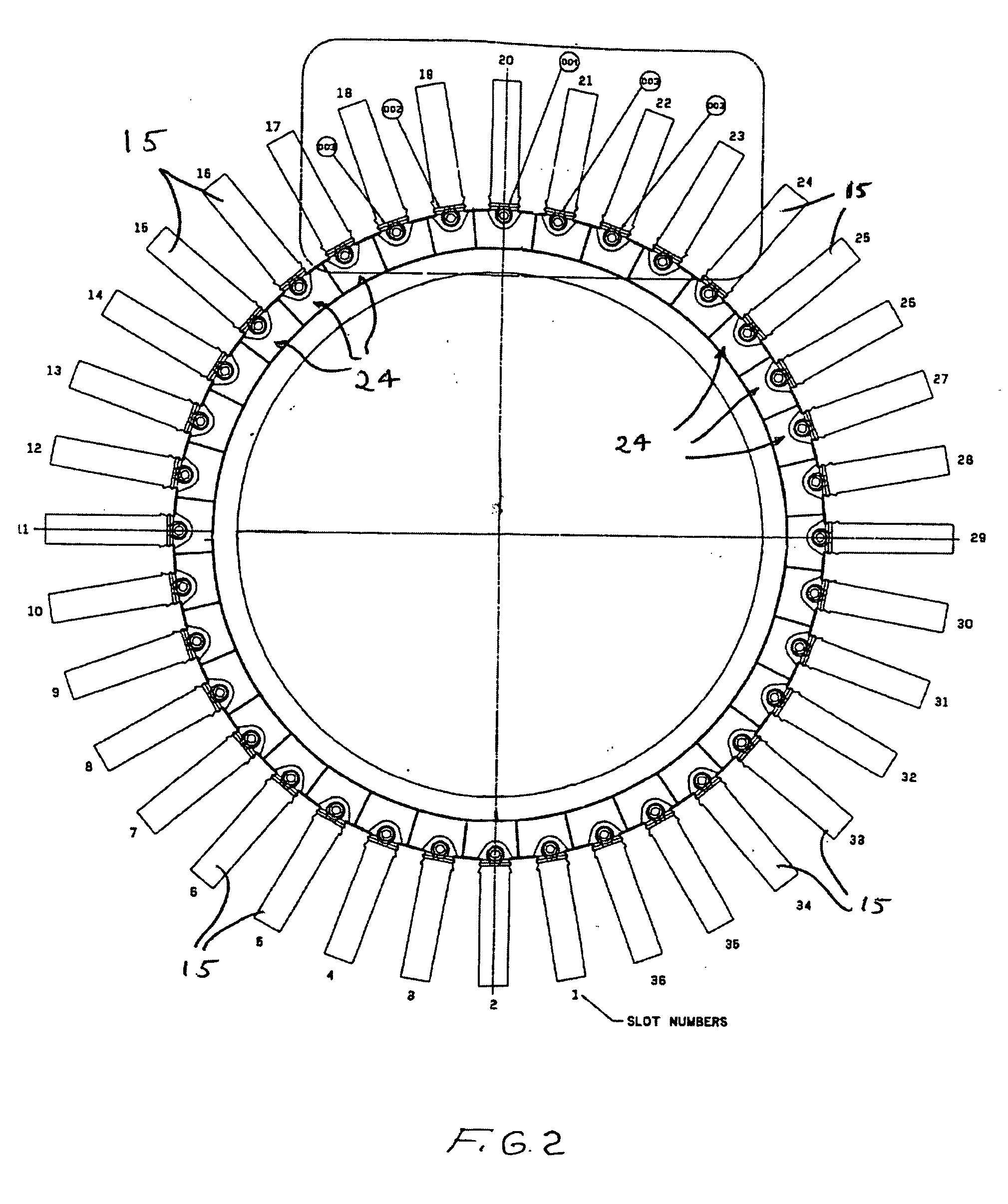

Air gap baffle assembly for gas-cooled turbine generator and method of installing

InactiveUS20050116555A1Repair problem be decreaseGood sealManufacturing stator/rotor bodiesCooling/ventillation arrangementStatorCam

A gas-cooled turbine generator includes a rotor having baffles arranged in rings and defining a plurality of gas cooling zones. A stator core has stator slots in a bore in which the rotor is received. A plurality of air gap baffle assemblies are arranged in segmented baffle rings in the stator slots and cooperate with the zone rings on the rotor. Each of the air gap baffle assemblies includes at least one baffle segment and an individual locking cam cooperating with a respective wedge of the baffle segment to lock the baffle segment relative to a stator slot at which the baffle segment is positioned such that prior baffle “trains” are no longer required.

Owner:SIEMENS ENERGY INC

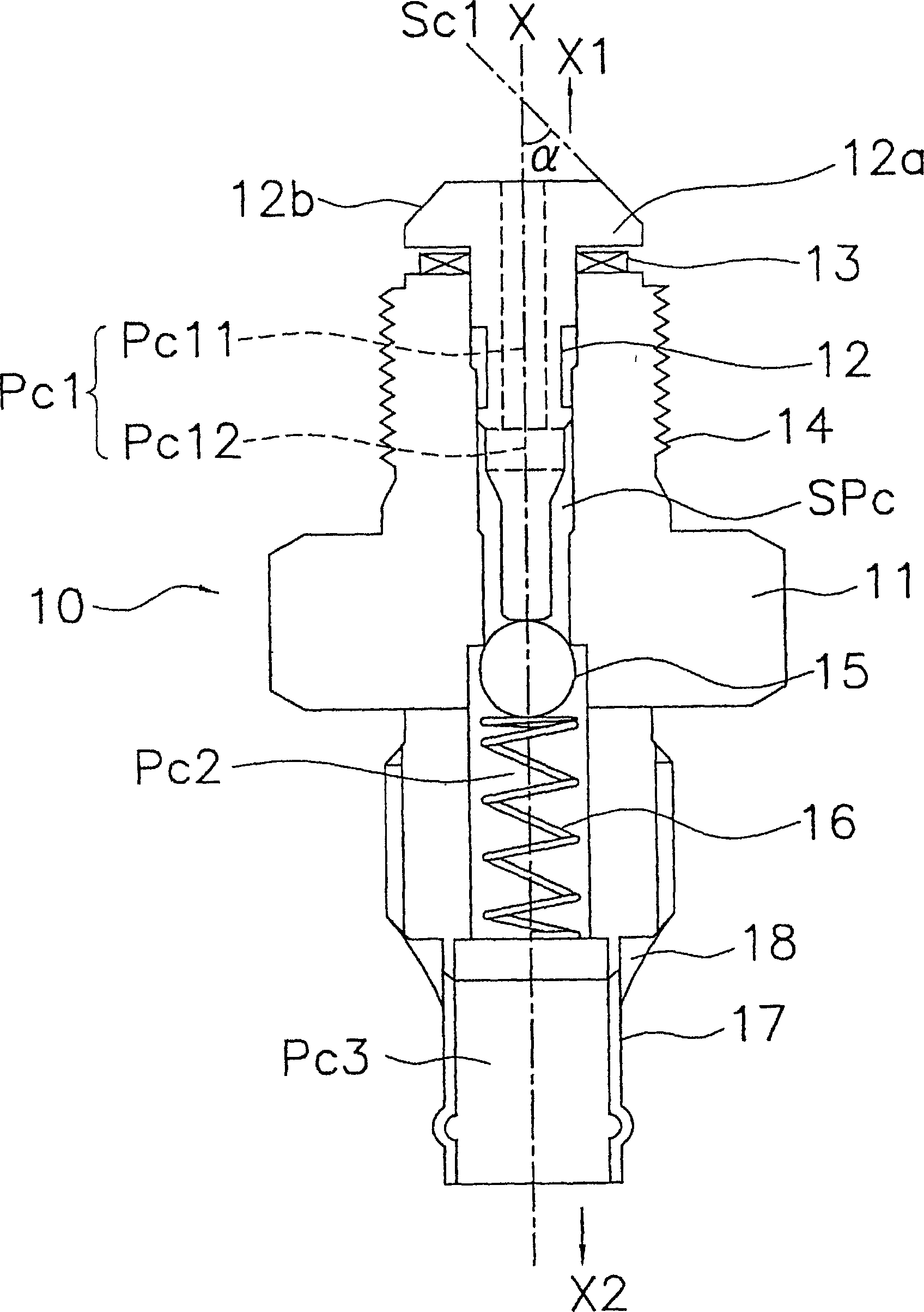

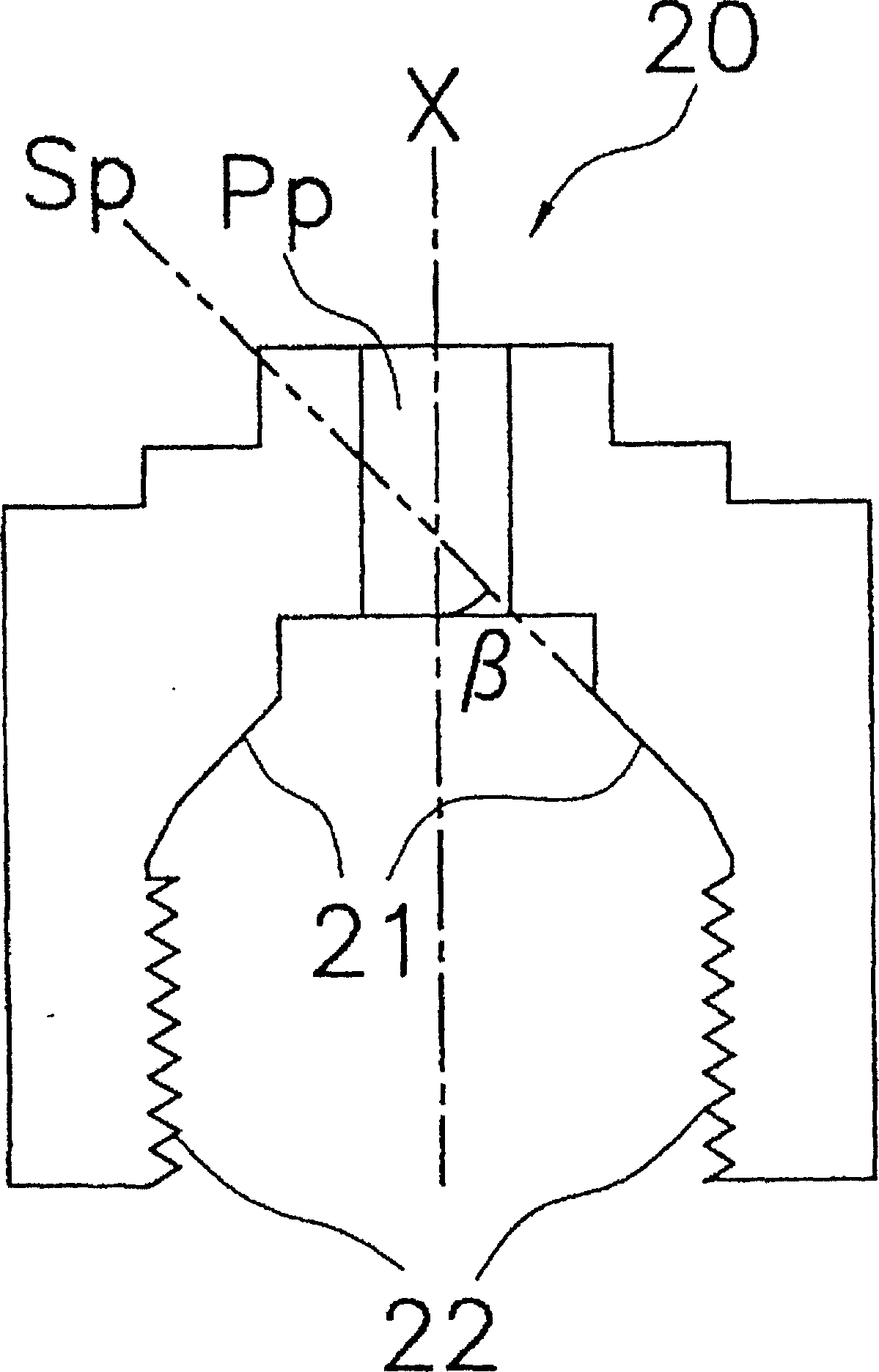

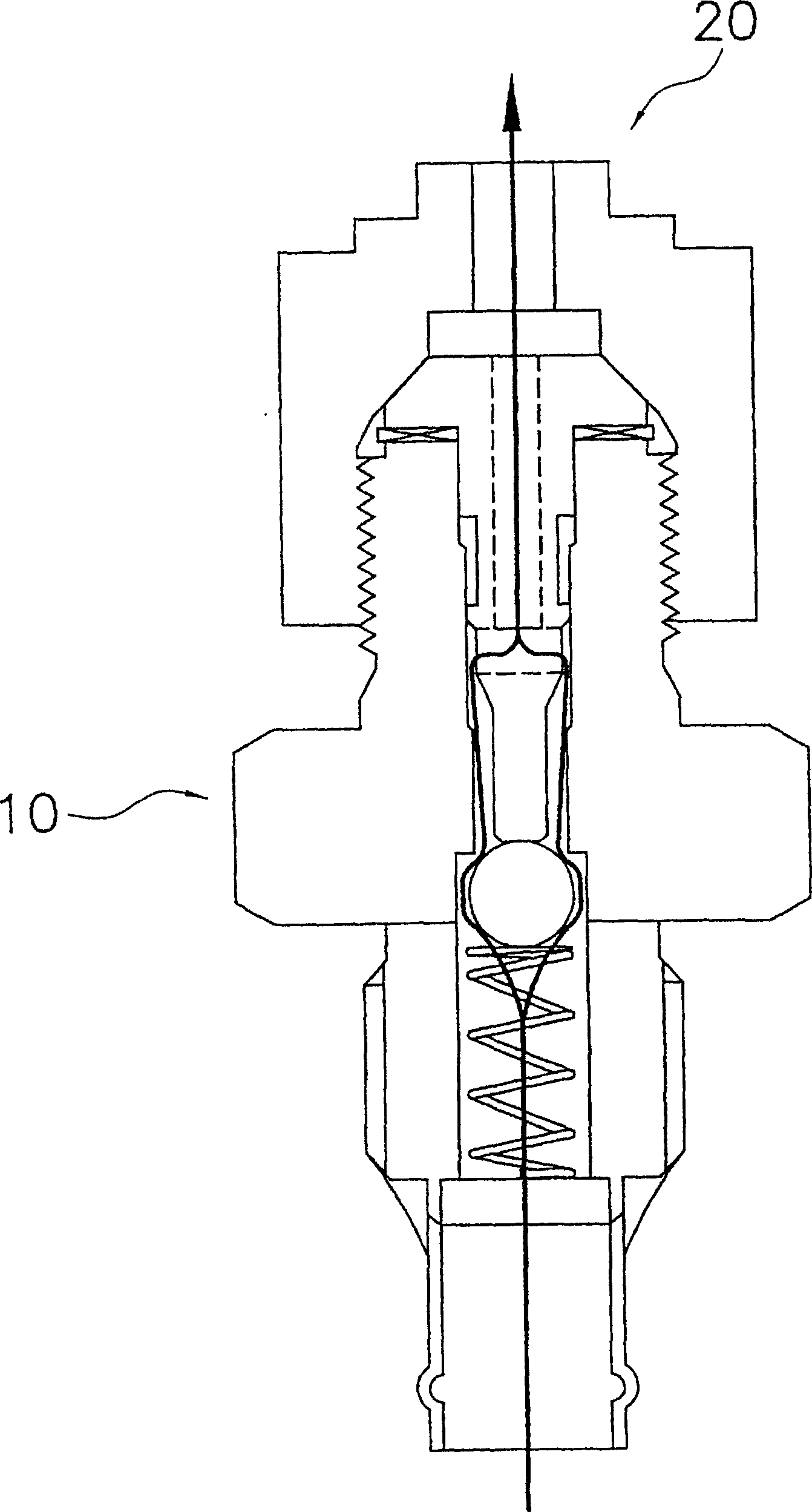

Joint

InactiveCN1839277AAvoid crackingSimple sealing structureJoints with sealing surfacesJoints with fluid cut-off meansEngineeringPressure sensor

A joint where breakage of a pressure sensor connection nut and a flare copper tube connection nut can be prevented. A joint (50) is a joint for communicating a first fluid path and a second fluid path of a nut member (20) having a second fluid path (Pp), a female screw section (22), and a first taper section (21), and the joint has a pushrod (52) and a body (51). The body has a pushrod receiving space (SPi), a communication path (Pi2), a seal structure forming section (53, 163), and a male screw section (54). The pushrod receiving space receives the pushrod such that a portion of the pushrod projects in the pushrod longitudinal direction (X). The communication path is the path communicated with the first fluid path. The seal structure forming section (53, 163) is provided at an end section on the pushrod projection side (X1) so as to surround the outer periphery of the pushrod receiving space and is capable of forming a seal structure when in contact with the first taper section. The male screw section can be screwed into the female screw section in the pushrod longitudinal direction. When the female screw section and the male screw section are screwed to each other, the seal structure forming section is in contact with the first taper section. Further, a part of that portion of the pushrod which projects from the pushrod receiving space comes into contact with a part of the nut member to move the pushrod in the pushrod longitudinal direction to the opposite side (X2) to the pushrod projection side, the pushrod thereby causing the second fluid path and the communication path to communicate.

Owner:DAIKIN IND LTD

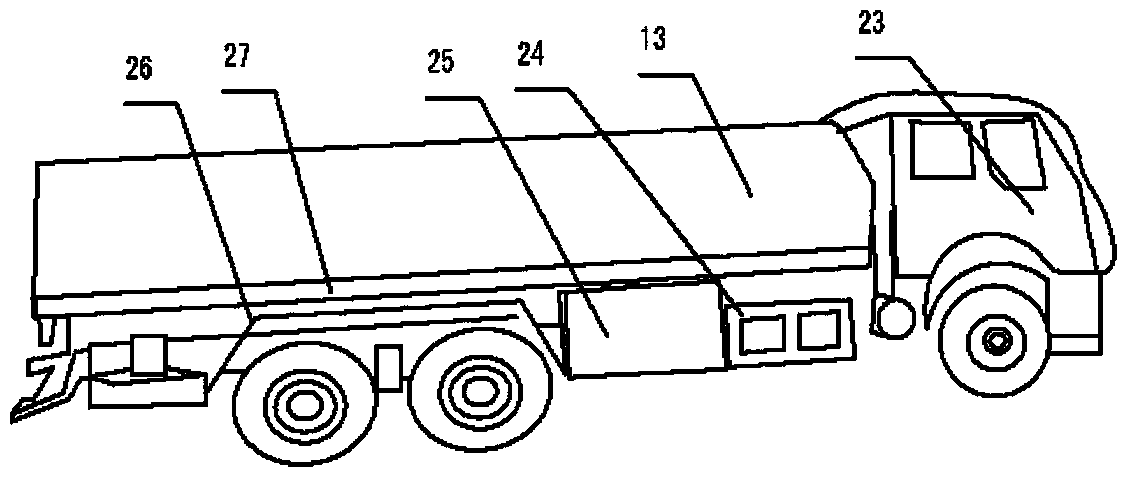

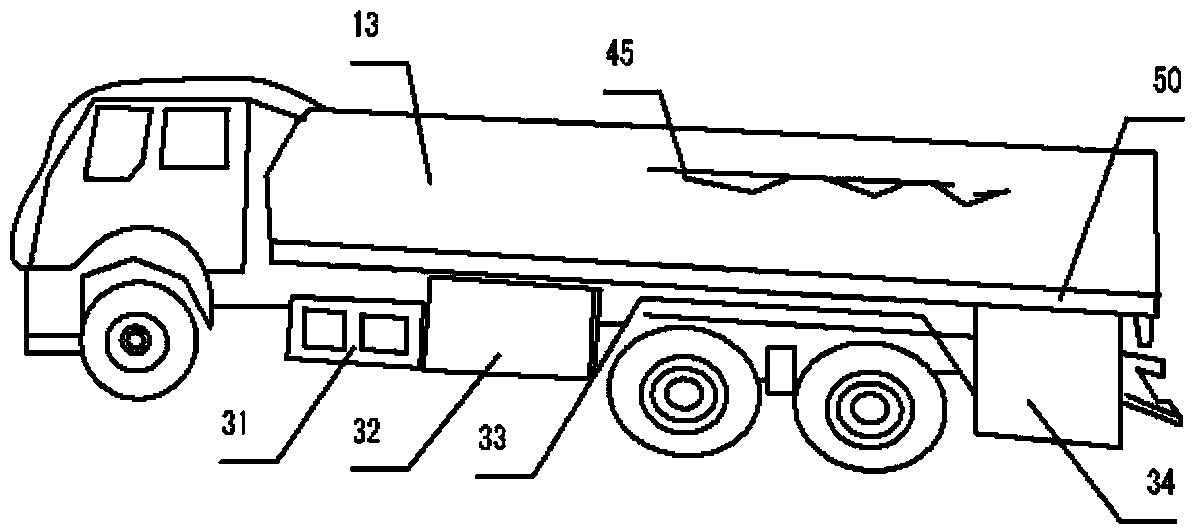

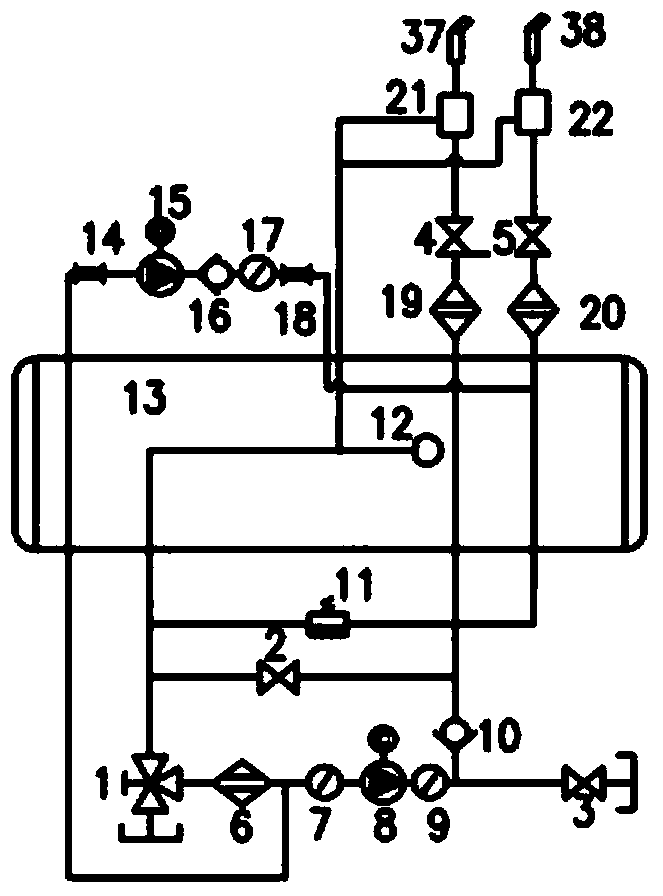

Novel tank type fuel transporting and refueling truck

InactiveCN103539055AEasy to useHigh degree of standardizationTank vehiclesLarge containersControl systemFuel tank

The invention relates to a novel tank type fuel transporting and refueling truck. The novel tank type fuel transporting and refueling truck mainly comprises a vehicle chassis system, a fuel pumping transmission system, a fuel tank system, fuel loading and unloading pipelines, an external 380-volt power supply pump assembly, a control system and a security protection system. The right of the truck body is provided with a control cabinet, and a DN65 (nominal diameter) three-way ball valve, a three-way screen, DN65 straight-through ball valves, a bottom valve air control switch, a CRJ rapid joint anode strip plugging cover, a pipeline pressure meter and a vacuum meter are arranged inside the control cabinet, so that the functions of bottom fuel loading during fuel loading of the truck and automatic-flow fuel unloading, pump discharging and refueling; the left of the truck body is provided with an operating cabinet which is provided with two Censtar refuelers, DN25 straight-through ball valves, a 10-meter one-inch refueling rubber hose refueling gun and the like. The novel tank type fuel transporting and refueling truck replaces a traditional fuel loading manner with the bottom fuel loading manner and performs totally-closed loading, thereby having significant influence on environmental protection and human health ensurance; subsea valves can achieve bottom fuel loading and unloading, so that safety, environmental protection, high efficiency and operative convenience can be obtained.

Owner:BEIJING SANXING AUTOMOBILE

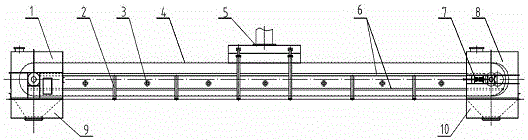

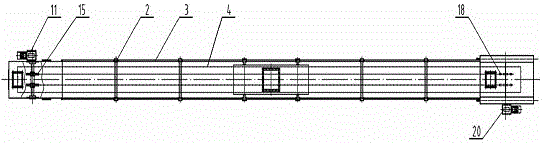

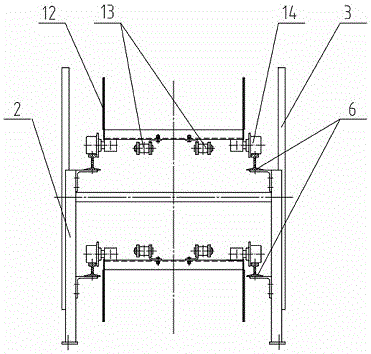

Bidirectional trough type conveyor

The invention relates to a bidirectional trough type conveyor. A head device composed of a drive chain wheel set and a tail device composed of a reversing chain wheel set are arranged at the two ends of a support of the conveyor correspondingly, and a head discharging opening and a tail discharging opening are formed below the head device and the tail device correspondingly. An upper-layer rail and a lower-layer rail are arranged on the support. Troughs are arranged on the rails. Rolling wheels are arranged on the two sides of the bottom of each trough and cooperate with the corresponding rail. Two chains are further arranged at the bottom of each trough and cooperate with a drive chain wheel of the head device and a reversing chain wheel of the tail device. A feeding opening with a dustproof cover is formed in the support, and the feeding opening is located above the troughs. A transmission device is connected to one side of the head device. The bidirectional trough type conveyor operates bidirectionally and can achieve multi-point feeding and two-end discharging.

Owner:SINOMA SHANGRAO MACHINERY LIMITED

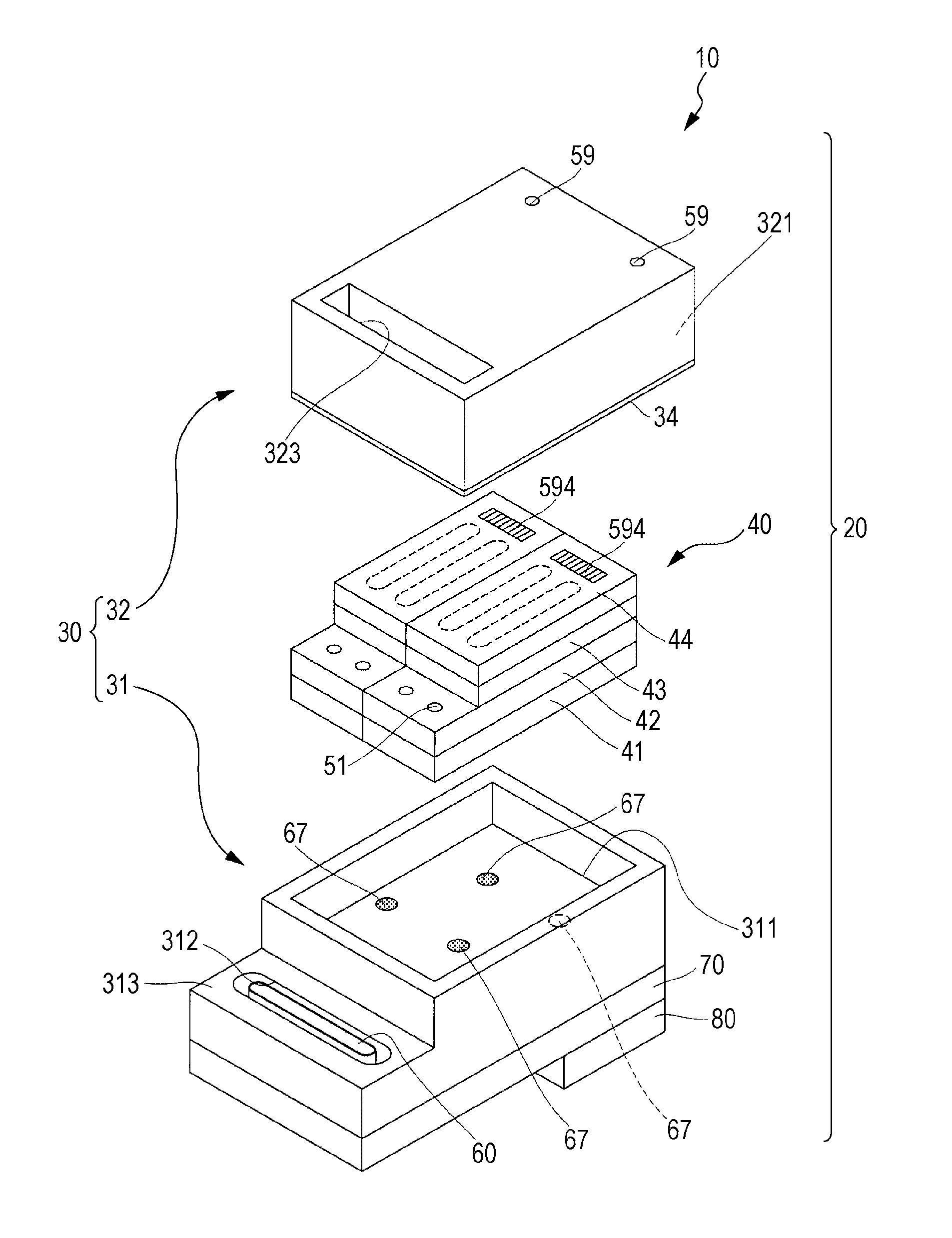

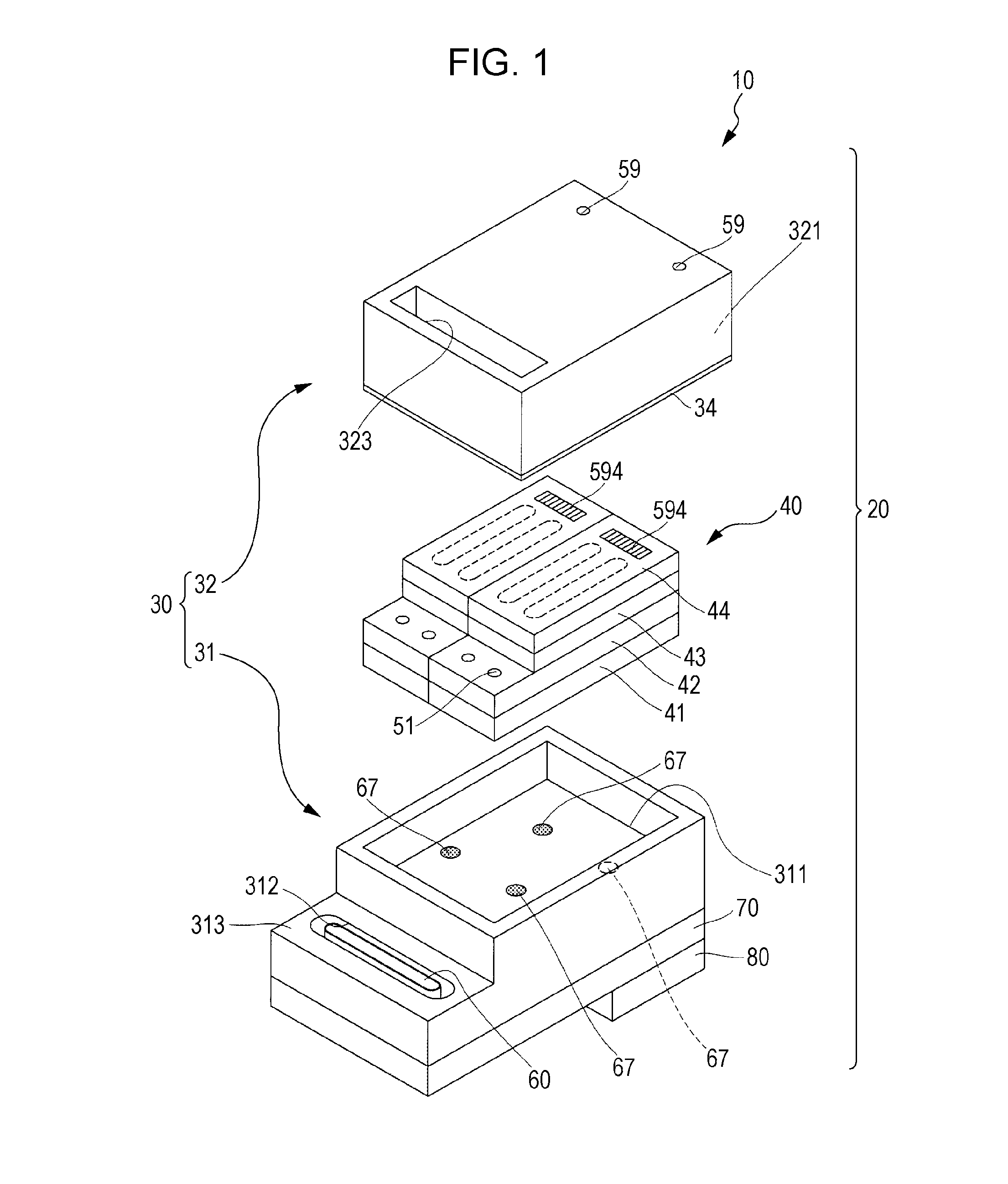

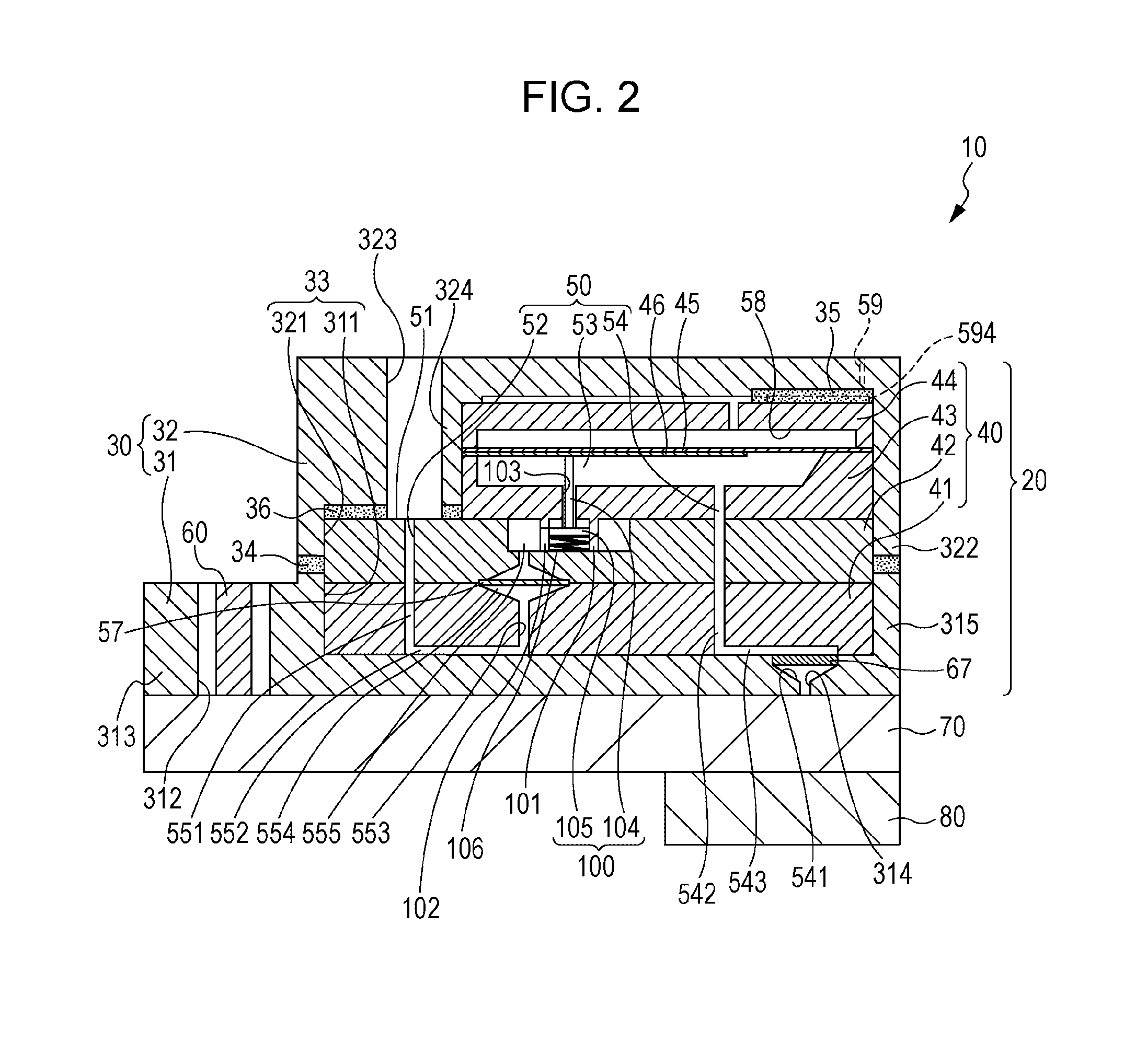

Backpressure control unit, liquid ejecting head, and liquid ejecting apparatus

A backpressure control unit that introduces a liquid from an external liquid holding unit and supplies the liquid to a main head unit for ejecting the liquid via a nozzle opening includes a flow channel member having an introduction channel, a valve member, and a supply channel, and a cover that that combines a base portion and a cover portion and houses the flow channel member therewithin. This provides a backpressure control unit that improves yields by absorbing discrepancies in properties of backpressure control valves to the greatest extent possible while at the same time making it possible to change designs in a flexible manner.

Owner:SEIKO EPSON CORP

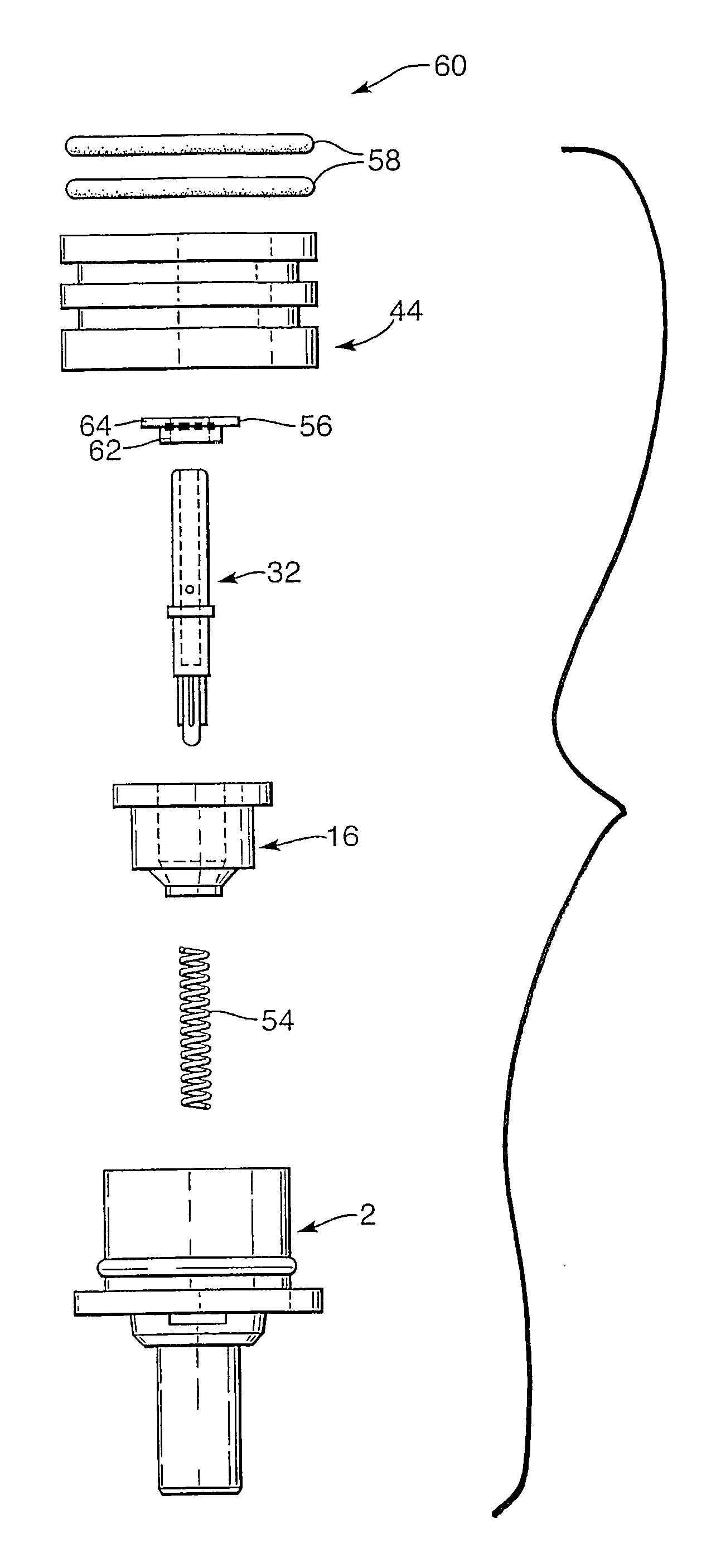

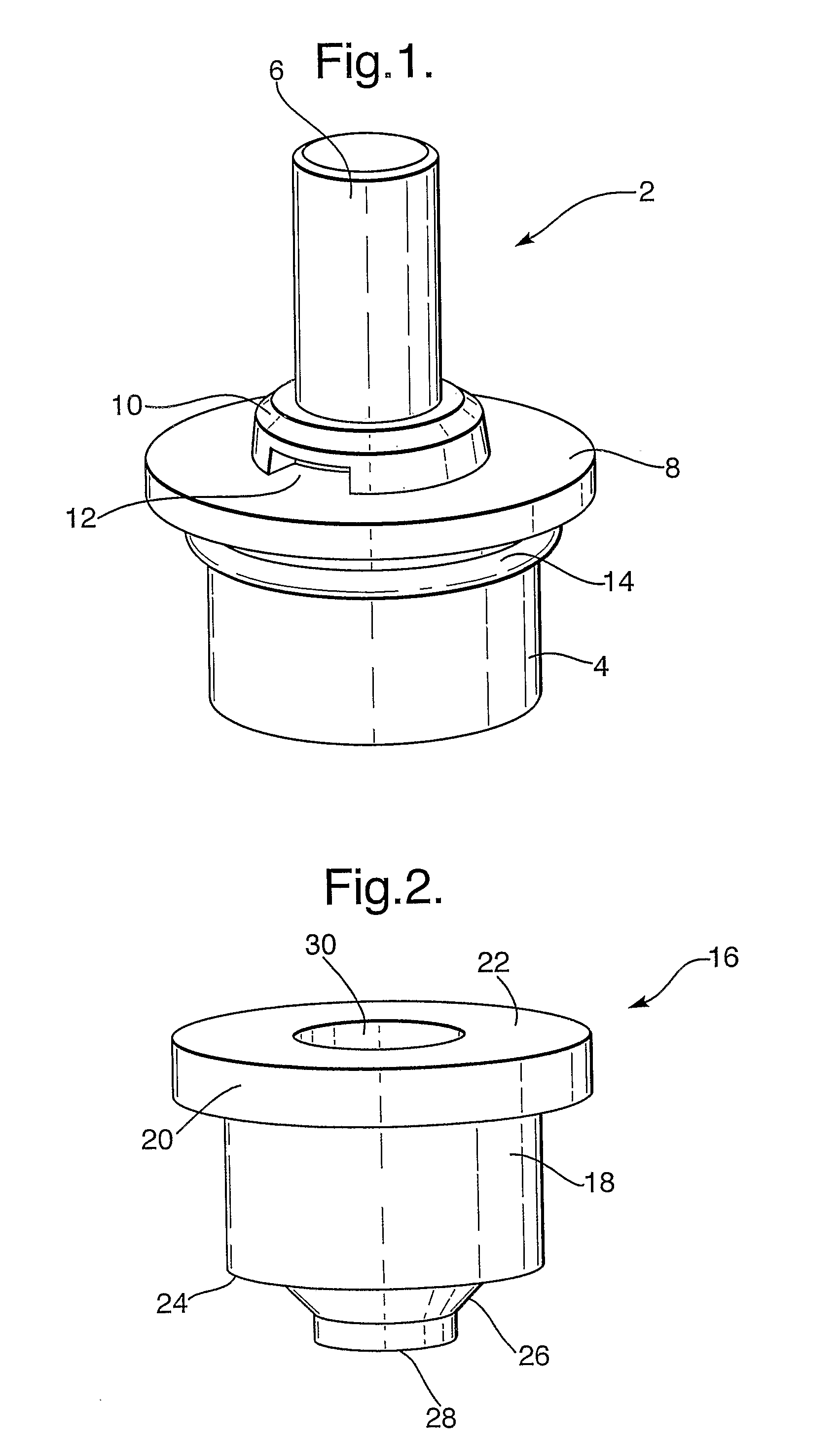

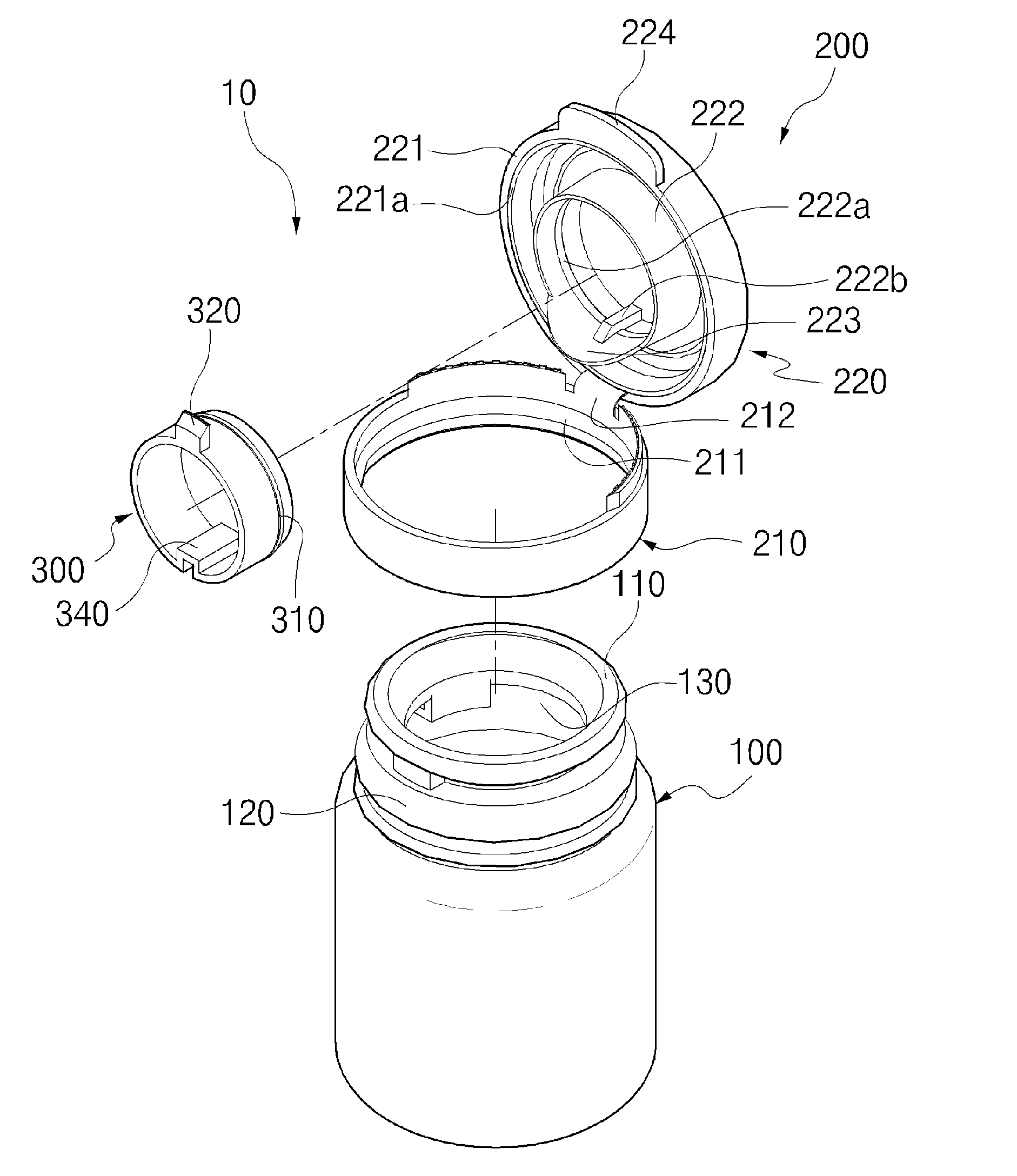

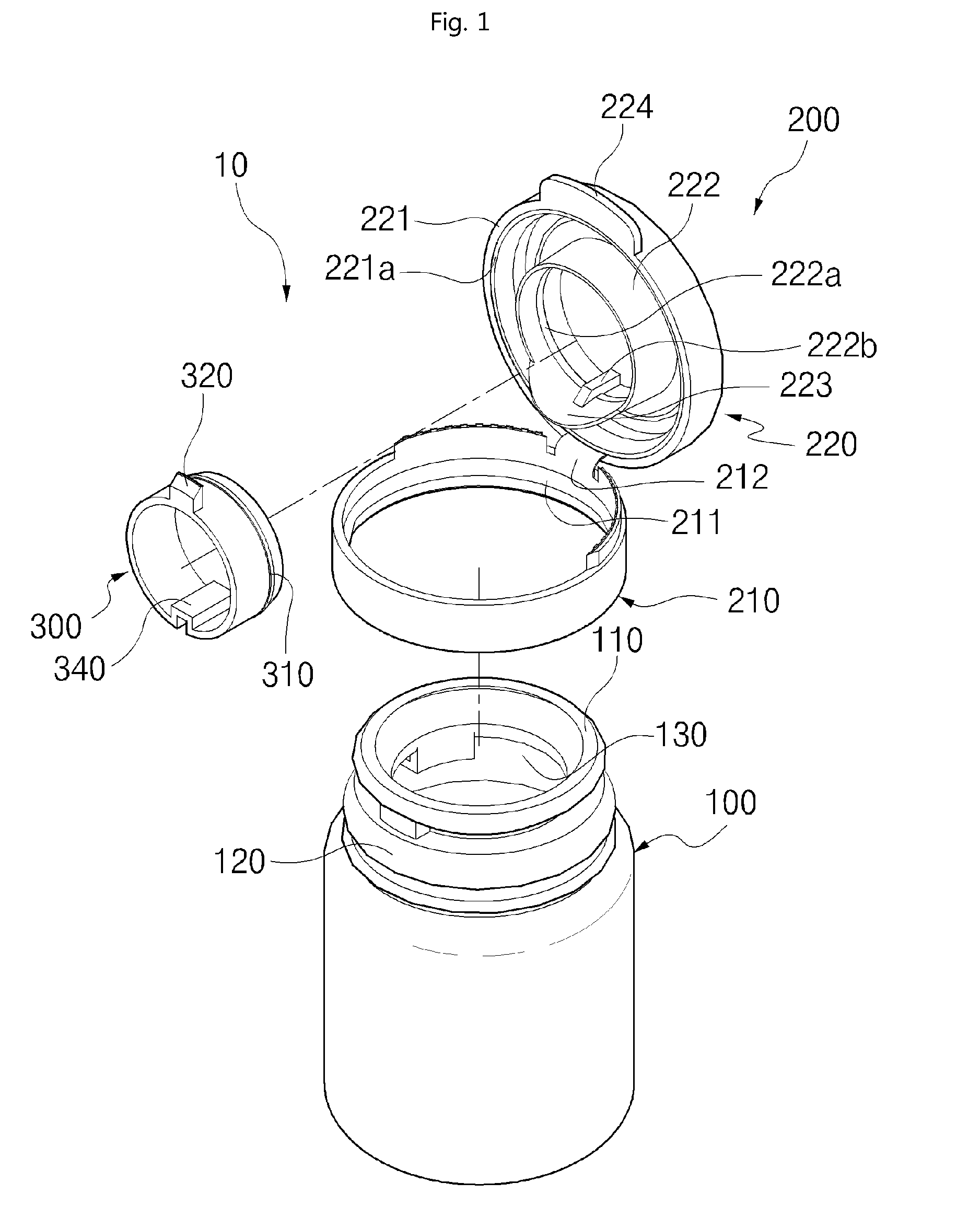

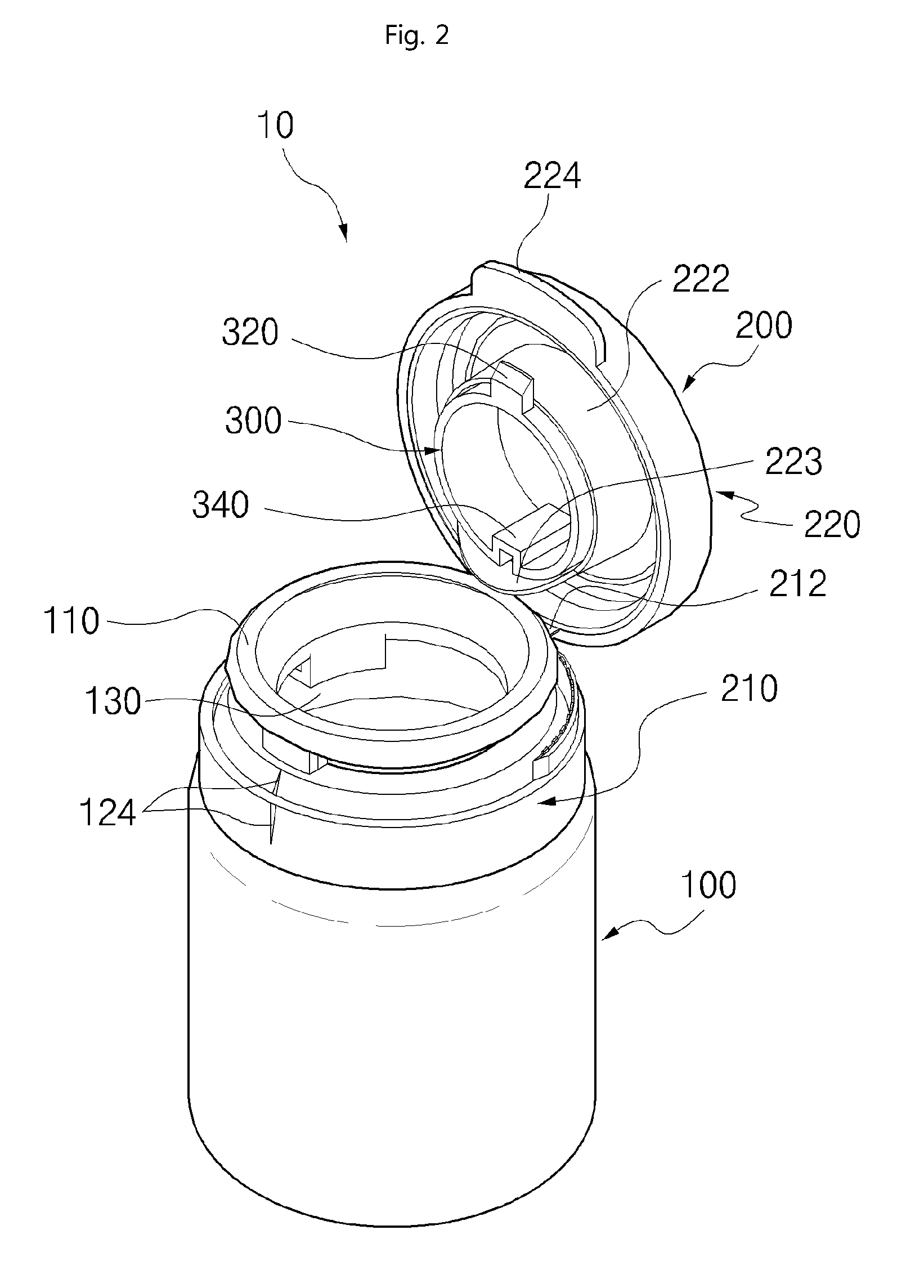

Safety container with safety locking part

InactiveUS8636160B2Improve securitySimple ideaCapsClosure using stoppersEngineeringMechanical engineering

Owner:PARK SUK WOO

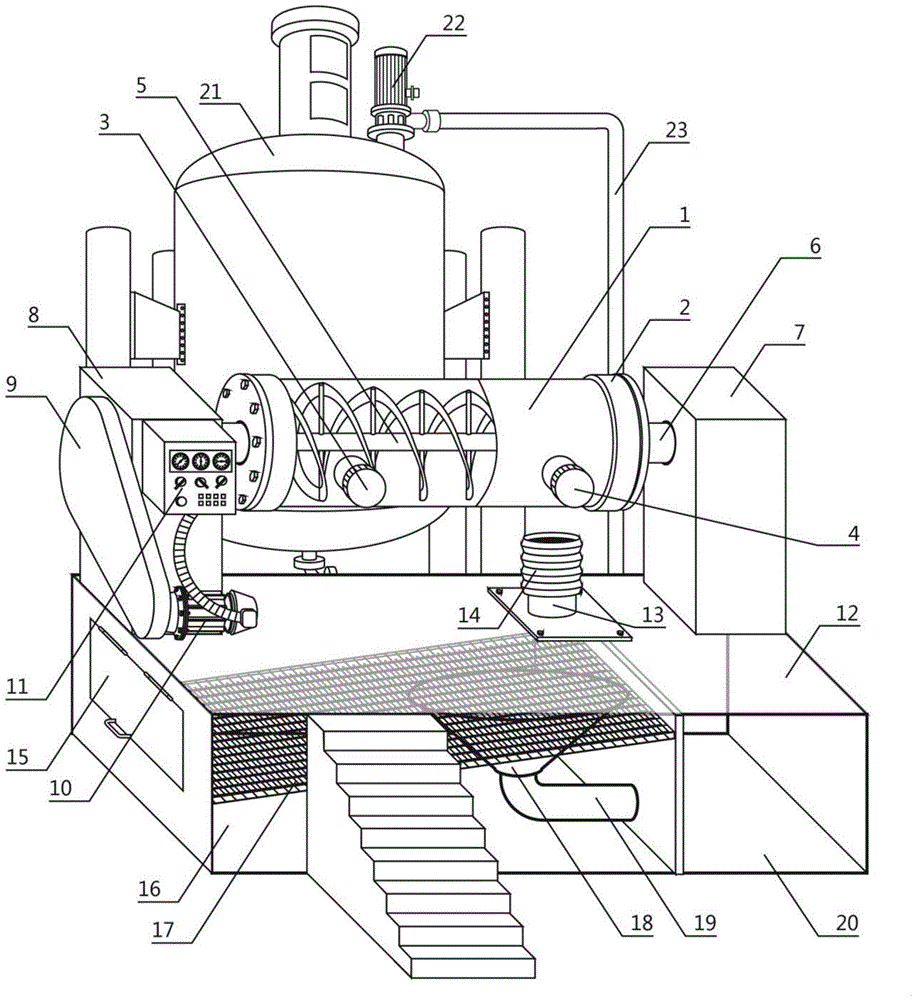

Raw material stirring extraction mechanism with filter apparatus

ActiveCN104971637AReduce high power outputExtended service lifeSievingScreeningHelical bladeImpurity

The present invention aims to provide a raw material stirring extraction mechanism with a filter apparatus. A technical scheme as follows: the mechanism provides an enclosed mixing apparatus for stirring and collecting the chemical raw materials; the mechanism includes a stirring tank, a rotating shaft, a bracing frame, a drive unit, a driving belt, a motor, a control box, a sieving material storage cabin and a storage tank; a stirring rod employs a helical blade stirring device, so the raw materials can be sufficiently stirred and fused within the reactor; an additional power-assisted rotary bearing boosts the stirring rod by virtue of inertia, thus reducing excessive consumption of the motor due to resistance, reducing losses while increasing the life of the motor; the sieving material storage cabin is divided into a sieving cabin and raw material storage cabin, so that the materials before and after filter can be separated; a sieving filter screen in the sieving cabin separate and recover the impurities; and the enclosed stirring mixing mode reduces the negative harm to operation personnel.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

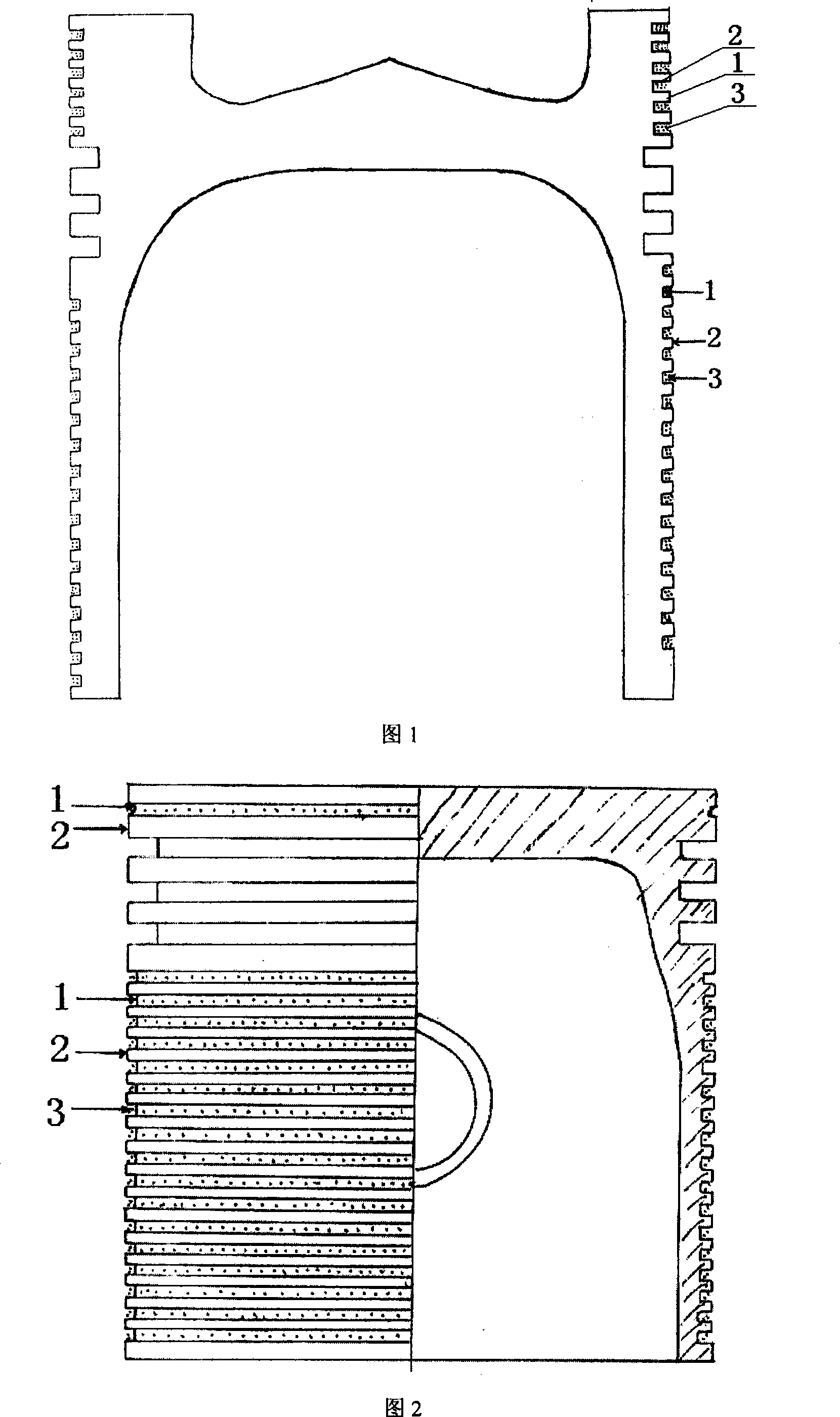

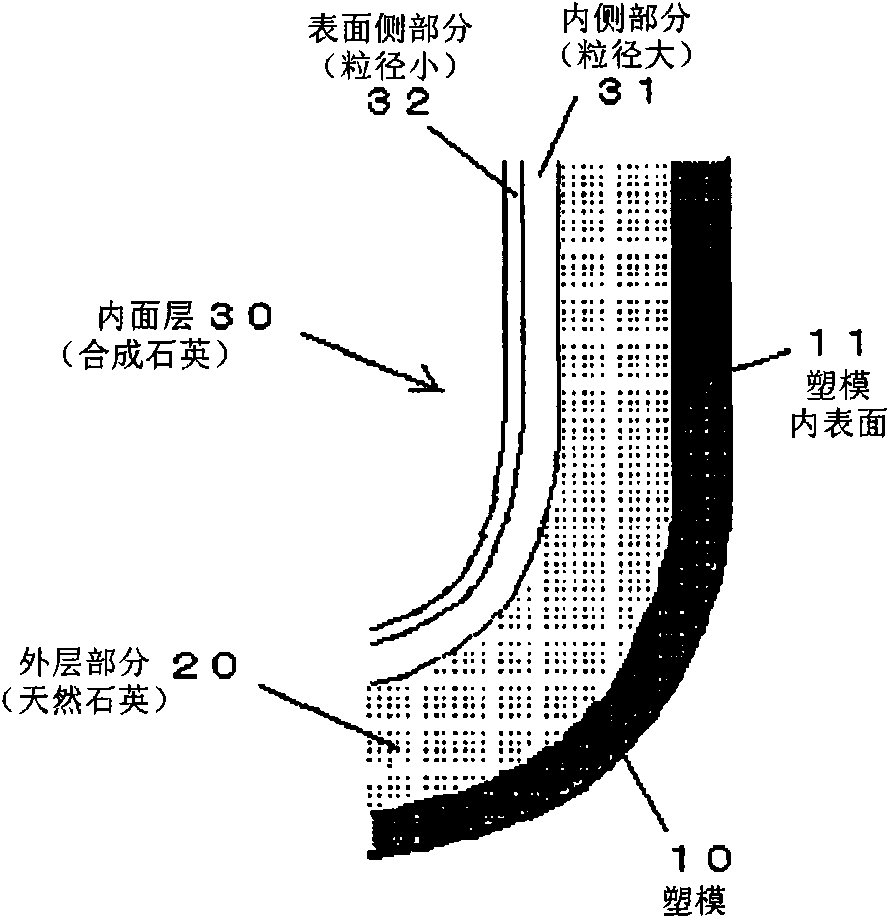

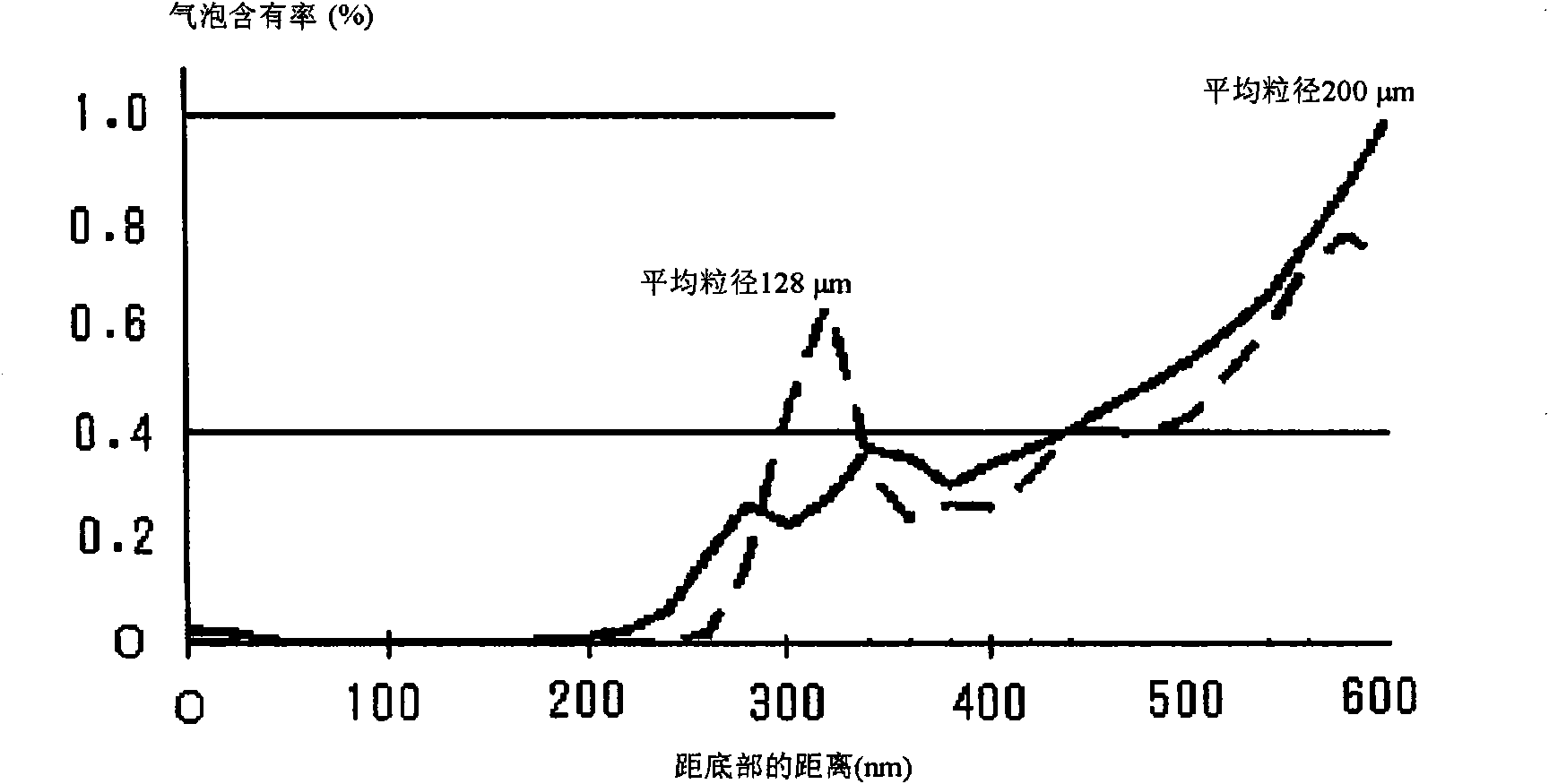

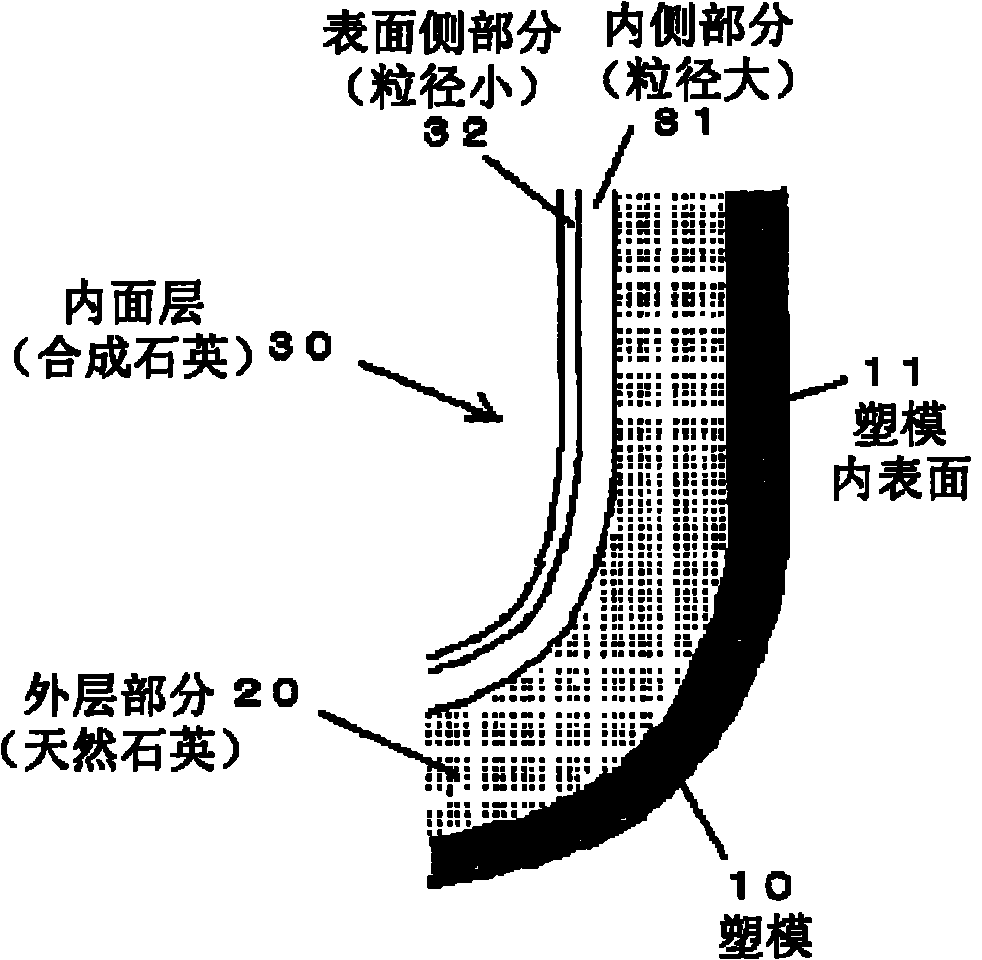

Quartz glass crucible and process for producing the same

InactiveCN101983262AEfficient dischargeEasy to melt evenlyPolycrystalline material growthBy pulling from meltSurface layerCrucible

A quartz glass crucible for use in pulling up a silicon single crystal is provided which has an inner surface layer having excellent homogeneity and a low void content. Also provided is a process for producing the quartz glass crucible. The process for producing a quartz glass crucible for use in pulling up a silicon single crystal comprises forming an inner surface layer (30) from synthetic-quartz powders. In forming the inner surface layer (30), an inner part (31) of the inner surface layer (30) is formed from a first synthetic-quartz powder, and a surface-side part (32) of the inner surface layer (30) is formed from a second synthetic-quartz powder which has a smaller average particle size than the first synthetic-quartz powder. The second synthetic-quartz powder forming the surface-side part (32) of the inner surface layer (30) has an average particle diameter smaller by at least 10 mum than the average particle diameter of the first synthetic-quartz powder forming the inner part (31) of the inner surface layer (30).

Owner:JAPAN SUPER QUARTZ CORP

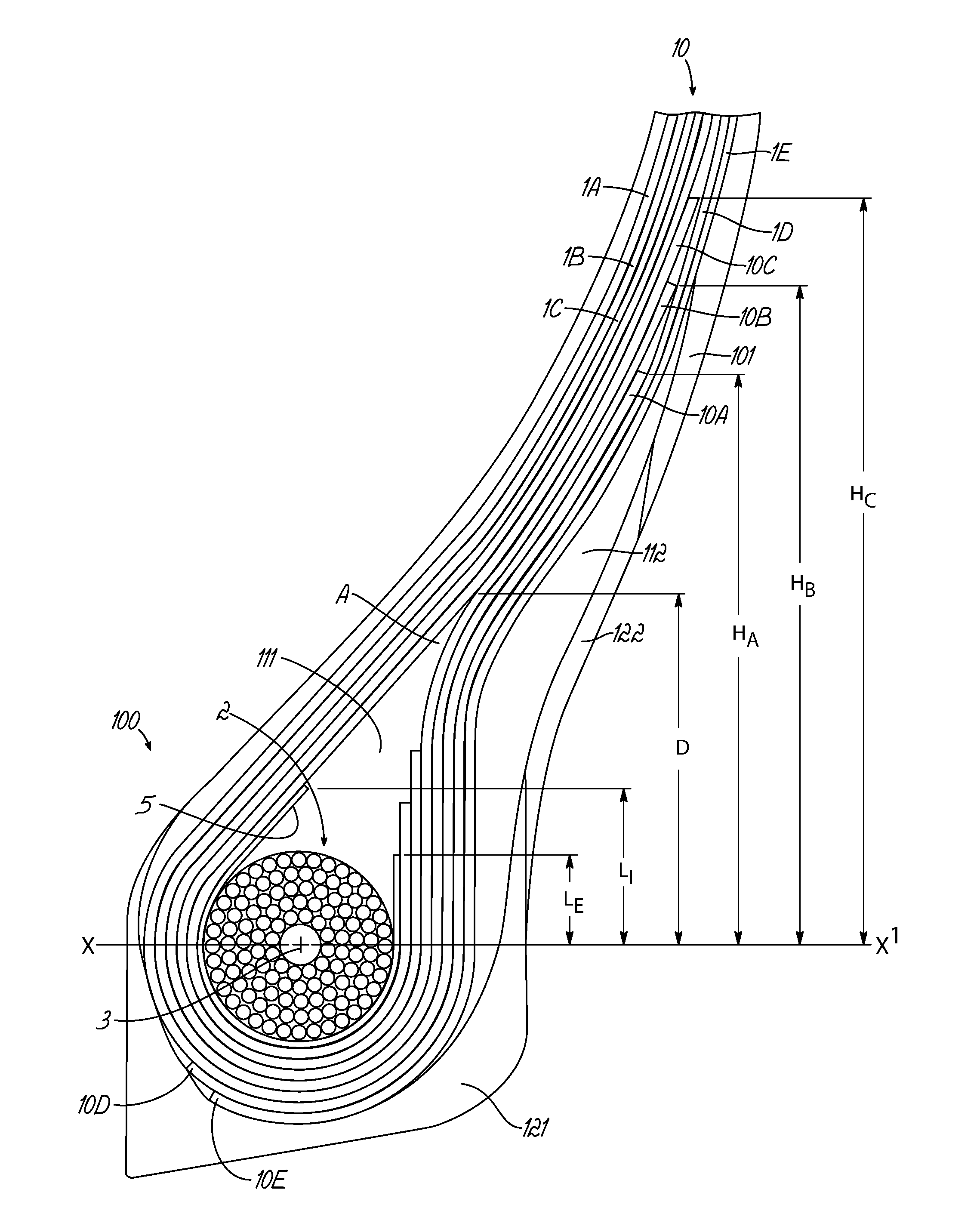

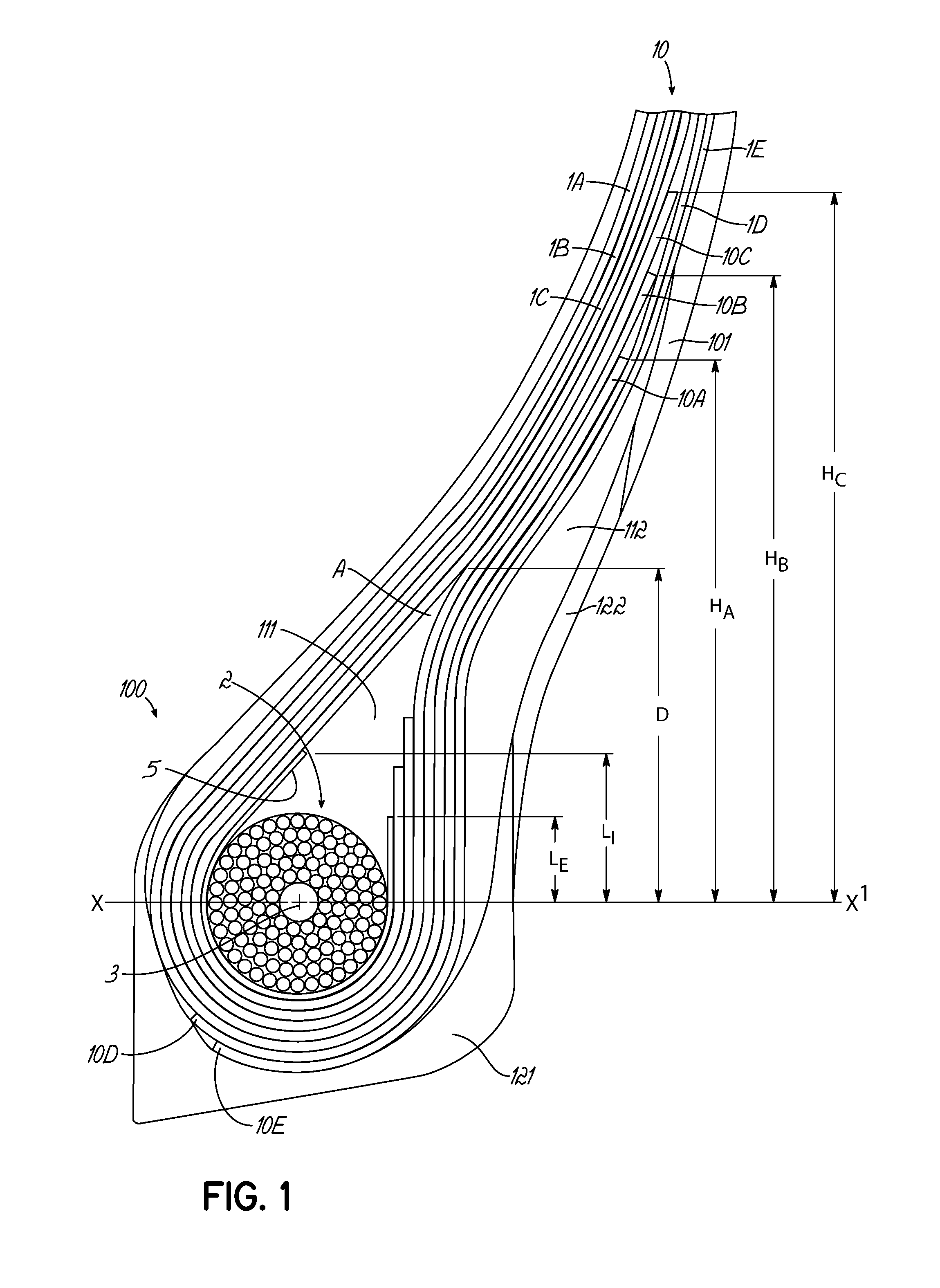

Aircraft tire

A pneumatic tire in accordance with the present invention includes two annular bead portions, a carcass, and a belt reinforcement layer. The carcass extends between the bead portions through sidewall portions and a tread portion. The carcass has at least one carcass ply of parallel cords turned up about the bead portions. The belt reinforcement layer is disposed radially outside the carcass and radially inside the tread portion. Each annular bead portion includes an annular bead core having the carcass ply turned up around the bead core, a first apex disposed adjacent and radially outward of the bead core, a second apex disposed axially outward of the bead core and the carcass ply, a first chafer disposed adjacent the carcass ply and axially outward of the bead core, and a second chafer disposed adjacent and axially outward the second apex and axially inward a sidewall portion. The first apex comprises a material with a 100 percent modulus between 1.0 MPa and 6.0 MPa. The second apex comprises a material with a 100 percent modulus between 1.0 MPa and 6.0 MPa. The first chafer comprises a material with a 100 percent modulus between 2.0 MPa and 4.0 MPa. The second chafer comprises a material with a 100 percent modulus between 1.0 MPa and 6.0 MPa. The sidewall portions comprise a material with a 100 percent modulus between 1.0 MPa and 2.0 MPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

Reciprocating movement type internal pressure compensation sealing piece

ActiveCN102954225AReduce frictionImprove dynamic responsivenessEngine sealsPiston ringsEngineeringInternal pressure

The invention discloses a reciprocating movement type internal pressure compensation sealing piece which comprises a cylinder body and an end cover, wherein a middle piston is arranged between a first piston and a second piston; the edge of the middle piston is provided with an annular sealing piece; the upper and lower ends of the annular sealing piece are provided with raised positioning parts; the outer side of the middle of the annular sealing piece are provided with a raised sealing part which is matched with an inner wall of the cylinder body; grooves matched with the raised sealing part are formed in the first piston and the second piston; and a sealing cavity is formed between the annular sealing piece and the middle piston. According to the reciprocating movement type internal pressure compensation sealing piece, the sealing cavity formed between the sealing piece and the middle piston is utilized and is matched with a one-way valve, and a medium can be filled in and discharged from the cavity according to a gap between the sealing piece and the cylinder body and the working pressure during the operation, so that an optimal sealing state is achieved. A sealing medium with pressure is injected and is matched with a dynamic compensation function of self-elongation of a sealing material, so that a dynamic sealing effect is achieved.

Owner:CHINA THREE GORGES UNIV

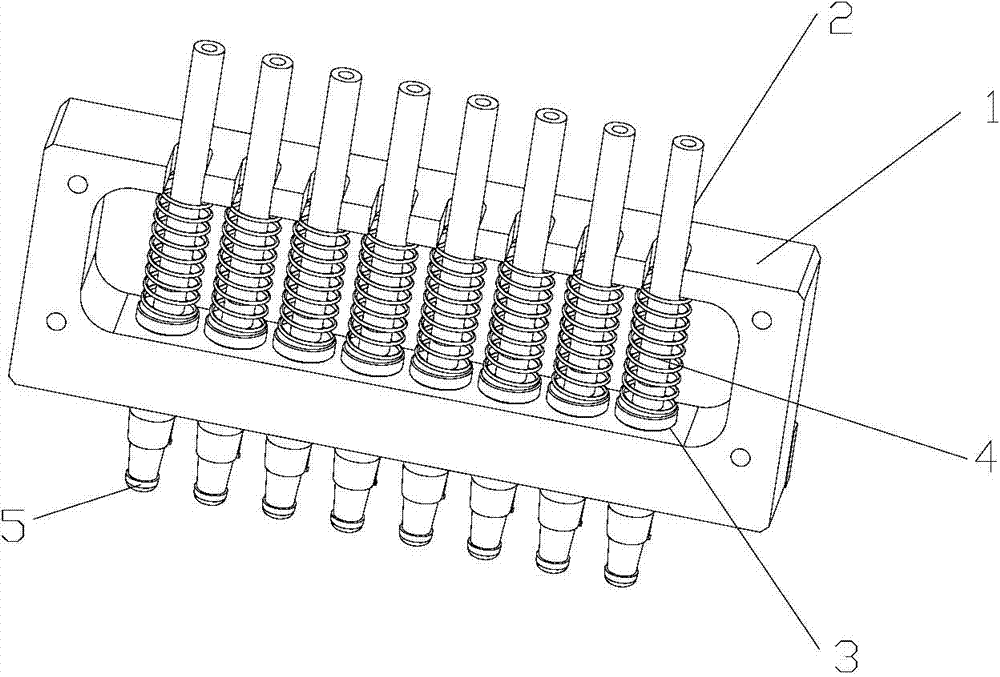

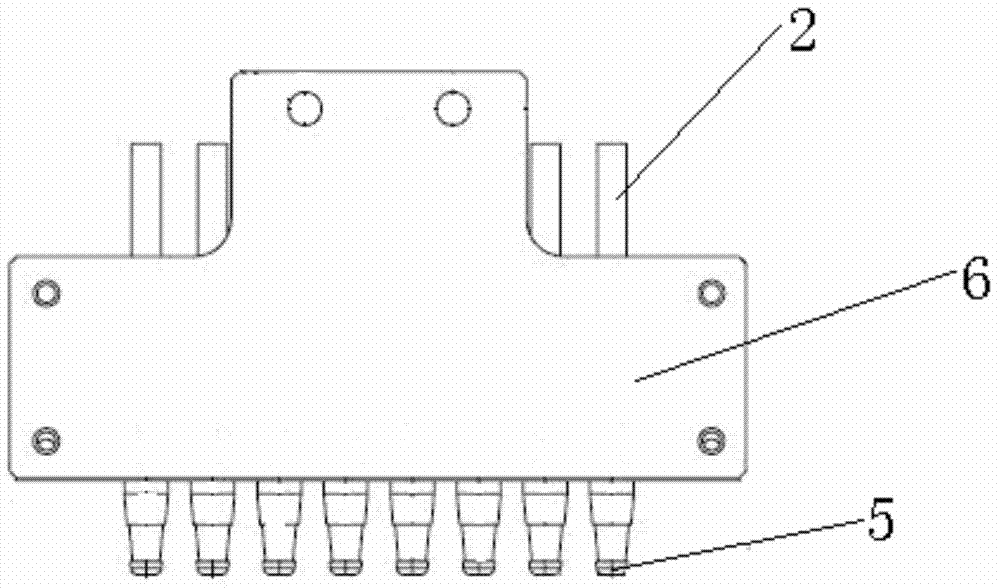

Liquid moving gun inserting device for biologic molecule purification and separation

ActiveCN103897980APrevent gun tip from skewingGood sealBioreactor/fermenter combinationsBiological substance pretreatmentsEngineering

Owner:苏州佰然基因科技有限公司

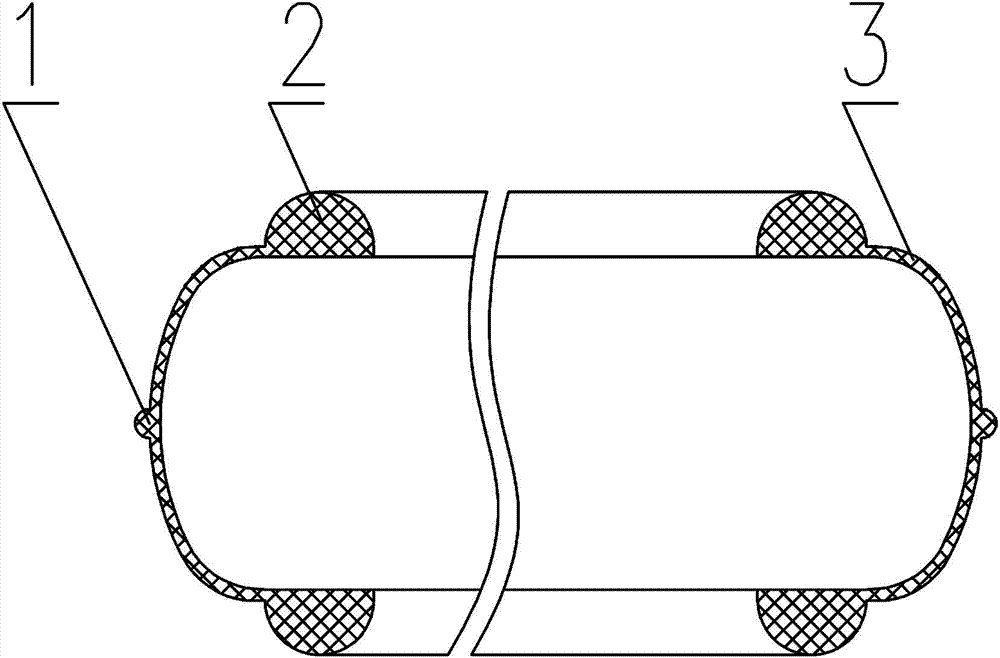

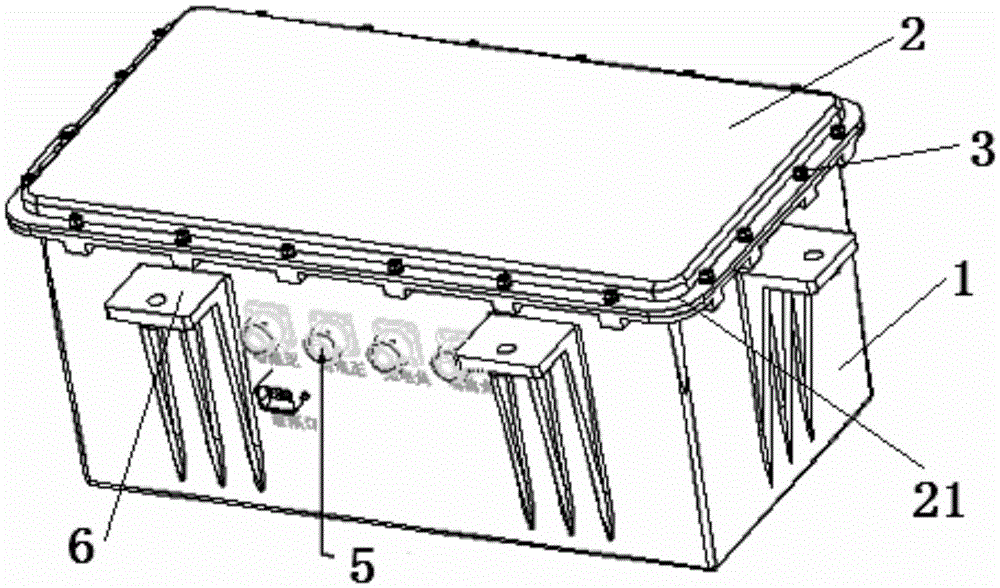

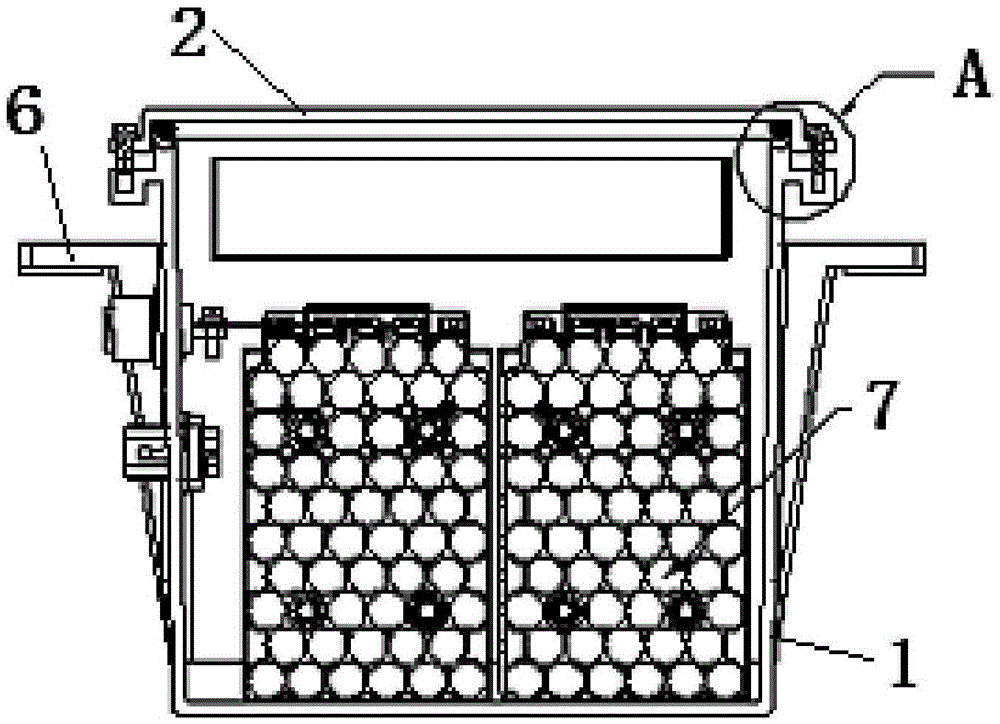

Battery box structure

Owner:DORCEN AUTO CO LTD

Quick-change connector

The invention provides a quick-change connector, and belongs to the technical field of machines. The quick-change connector solves the problems that after an existing quick-change connector is used for a long time, leakage is prone to being generated, and the connecting effect is not ideal. The quick-change connector comprises a barrel-shaped locking sleeve. A barrel-shaped locking framework is inserted and movably connected in the locking sleeve. A connecting pipe is inserted in the locking framework. A plurality of upper locking blocks capable of moving horizontally are arranged at the upper end of the locking framework. A pushing force spring is arranged between each upper locking block and the locking framework. First threaded teeth the same in tooth shape are arranged at the inner ends of the upper locking blocks. A plurality of first convex bodies are arranged on the inner side wall of the upper end of the locking sleeve, and the first convex bodies are located on the outer sides of the upper locking blocks. A first spring is arranged between the connecting pipe and the locking framework. The two ends of the first spring abut against the connecting pipe and the locking framework correspondingly. The quick-change connector has the beneficial effects of being good in sealing effect and connecting effect and long in service life.

Owner:LEO GRP ZHEJIANG PUMP CO LTD

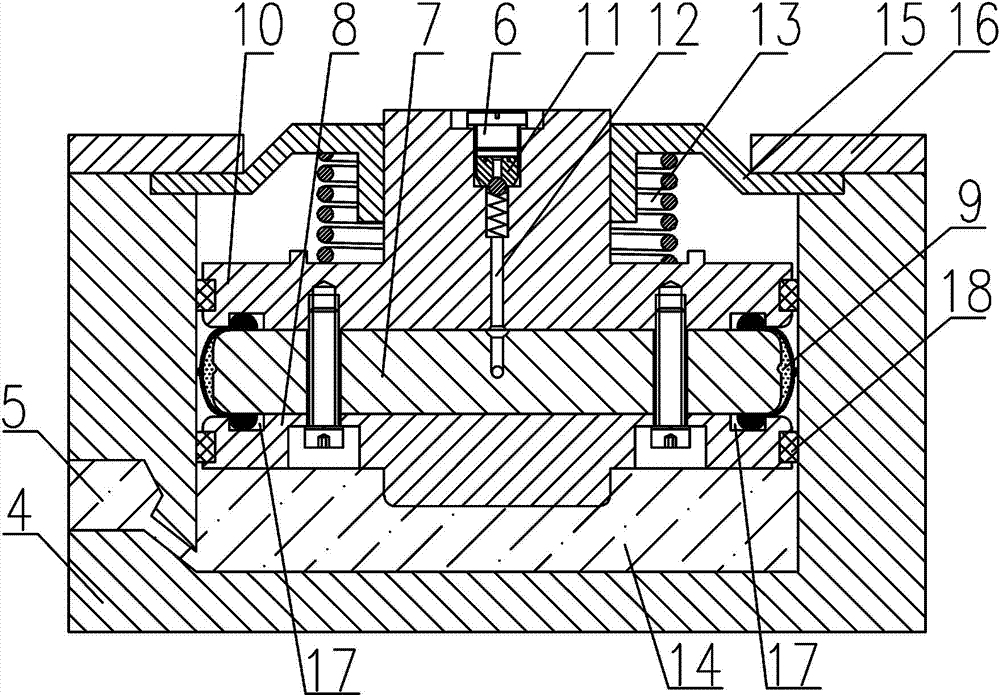

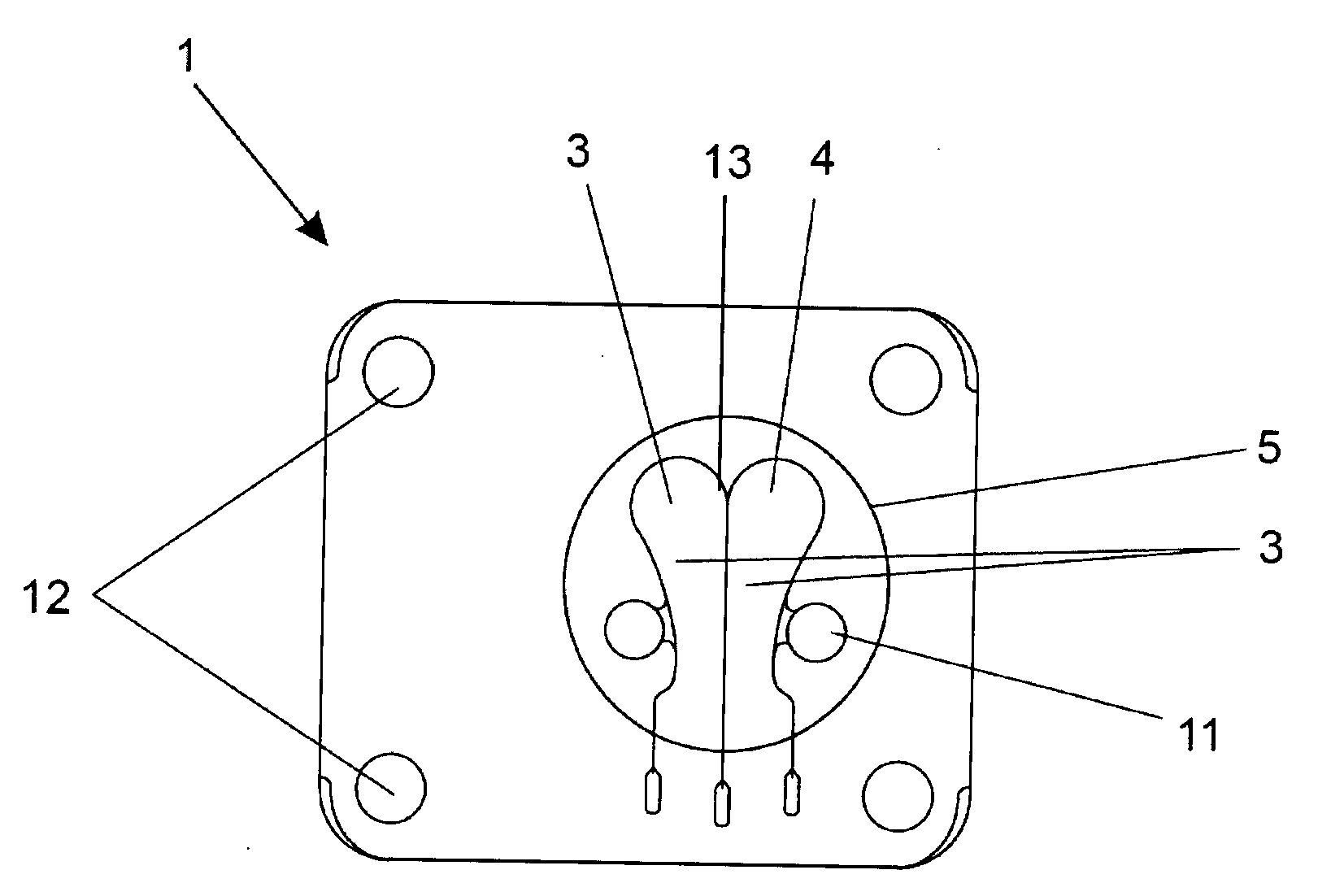

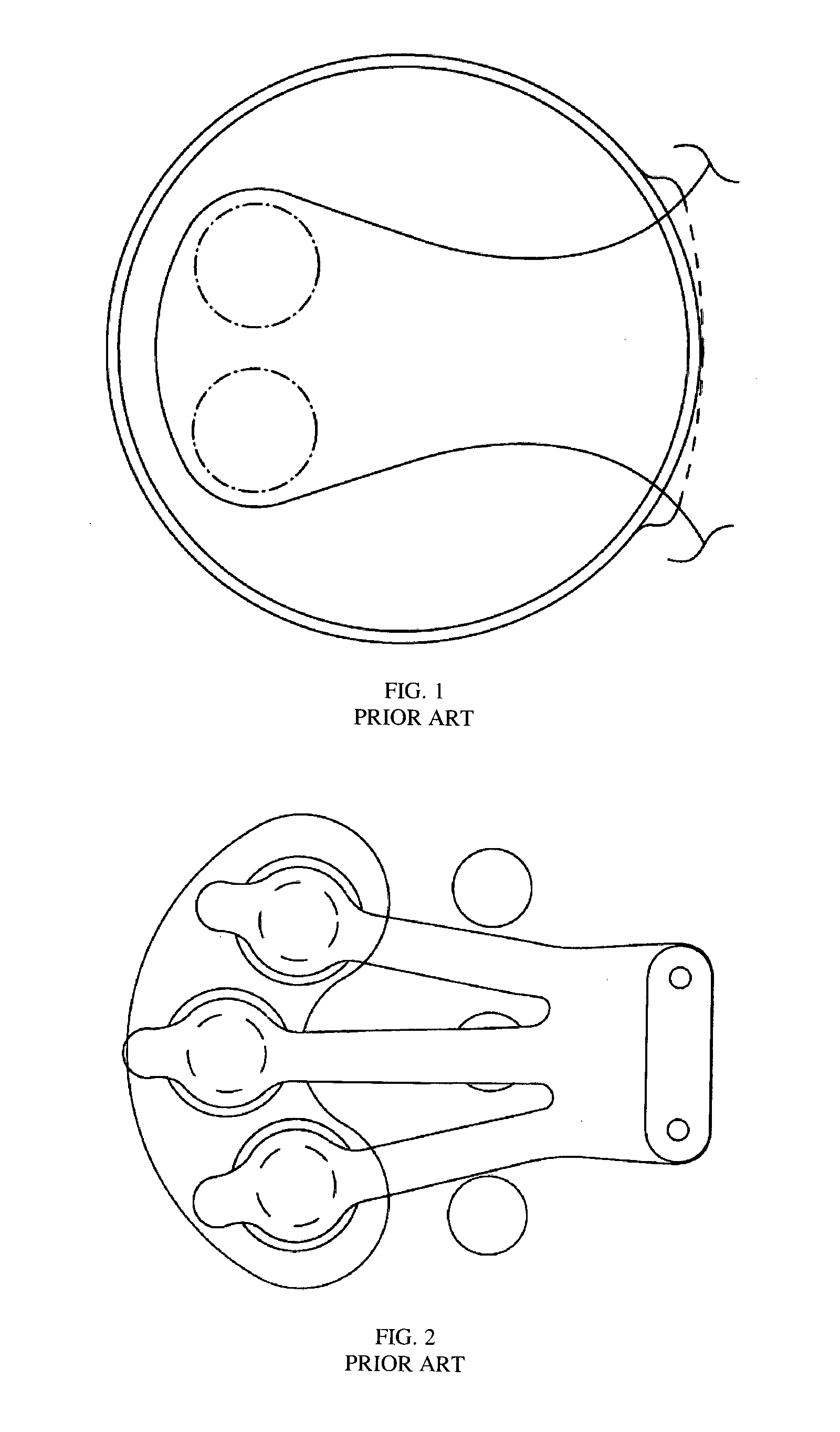

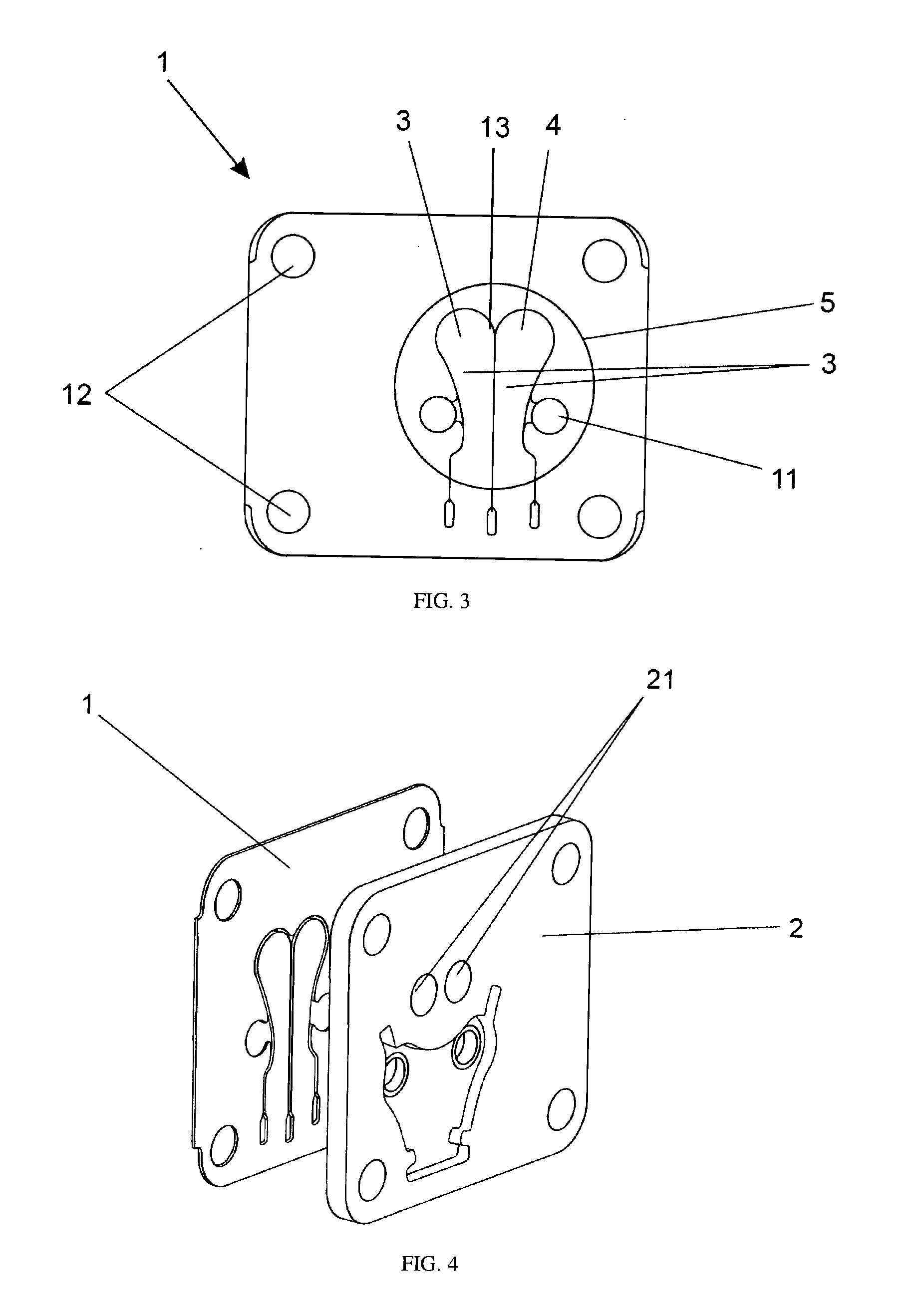

Suction valve assembly for alternative compressor

InactiveUS20140345713A1Less mass and rigidityGood sealPositive displacement pump componentsCheck valvesEngineering

The present invention refers to a suction valve assembly for alternative compressors. Said suction valve assembly comprises at least two suction valves (3) independent from one another and disposed at one same blade (1), wherein each of said suction valves (3) comprises a functional edge (4) intended for a sole suction orifice (21) of the valve plate. Said suction valves (3) are separated from one another by at least one through slit (13).

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com