High-lubricating low-friction piston

A low-friction, piston technology, applied in the direction of pistons, cylindrical pistons, plungers, etc., can solve the problems of reduced engine efficiency, large frictional resistance, and shortened service life, so as to reduce the possibility of cylinder knocking, enhance lubrication performance, and use The effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

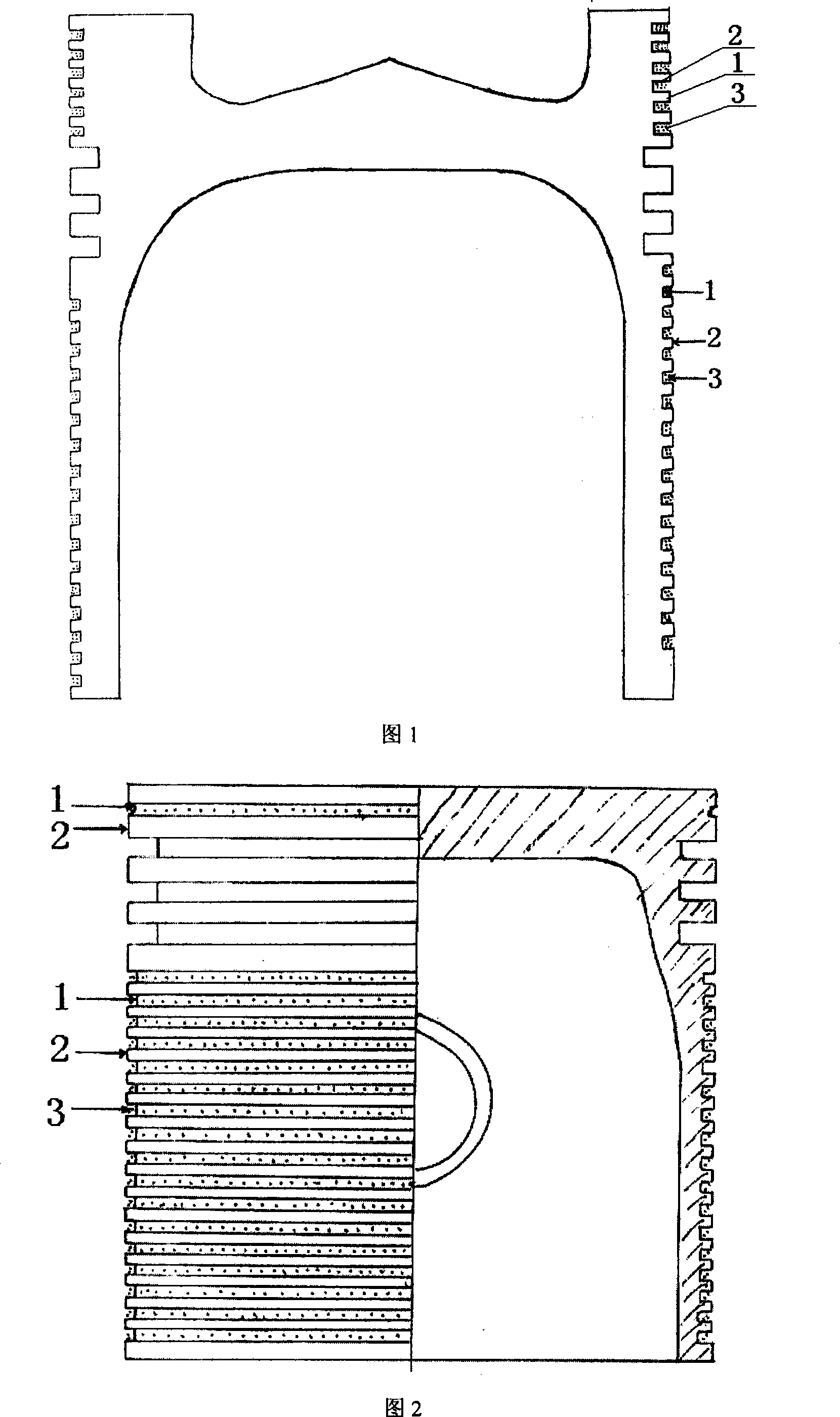

[0022] Embodiment 1: Taking the piston of a certain 135 type diesel engine directly as 135 millimeters as an example, the top of this piston has a common deep pit ω-shaped combustion chamber, and the depth of the deep pit ω-shaped combustion chamber on the top of the piston is 20 millimeters , have completed the opening of all piston ring grooves. This type of piston has a 30 mm high head outer circle. The depth of the head outer circle around the head outer circle surface from the top surface is 3 mm from the top surface of this piston. 3 mm width and 2 mm cross-section is a rectangular annular groove 1, and then the same annular groove 1 is opened every 2 mm, each groove 1 can be continuous or discontinuous, the accompanying drawing Each groove 1 shown can be continuous, and there are 6 grooves in total, so that 7 ring-shaped ridges 2 with a height of 3 millimeters and a width of 2 to 3 millimeters are naturally formed on the outer circle of the head of this type of piston. ...

Embodiment 2

[0026] Embodiment 2 (as accompanying drawing 2): Taking a flat top piston with a diameter of 95 mm as an example, all the piston ring grooves have been opened, and a 1.5 mm deep and 1.5 wide ring groove is opened in the middle of the outer circle of its head. mm, a semicircular annular groove 1 in cross-section, so that the outer surface of the upper and lower heads of the groove 1 naturally forms two ridges 2, and these grooves 1 and ridges 2 are parallel to the piston ring groove. . The ring land excircle of this piston is narrow and small, does not offer annular groove 1 here either. On all the outer surfaces of the piston skirt that can be in contact with the cylinder wall, multiple annular grooves 1 parallel to the piston ring groove are uniformly provided. The interval between adjacent annular grooves 1 is 1 mm, and the width of the annular groove 1 is 1 mm. The depth is 0.8 mm, the cross section of the groove 1 is rectangular, thus forming the annular ridge 2, the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com