Zipper tape, packaging bag with zipper tape, method for producing packaging bag with zipper tape and production device therefor

A manufacturing method and manufacturing device technology, applied in the direction of envelope/bag manufacturing machinery, packaging, closing devices, etc., can solve the problems of pinholes in the film, dislocation of the removal position, damage to the appearance, etc., to achieve a reliable occlusal state, easy bag making, The effect of a good seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

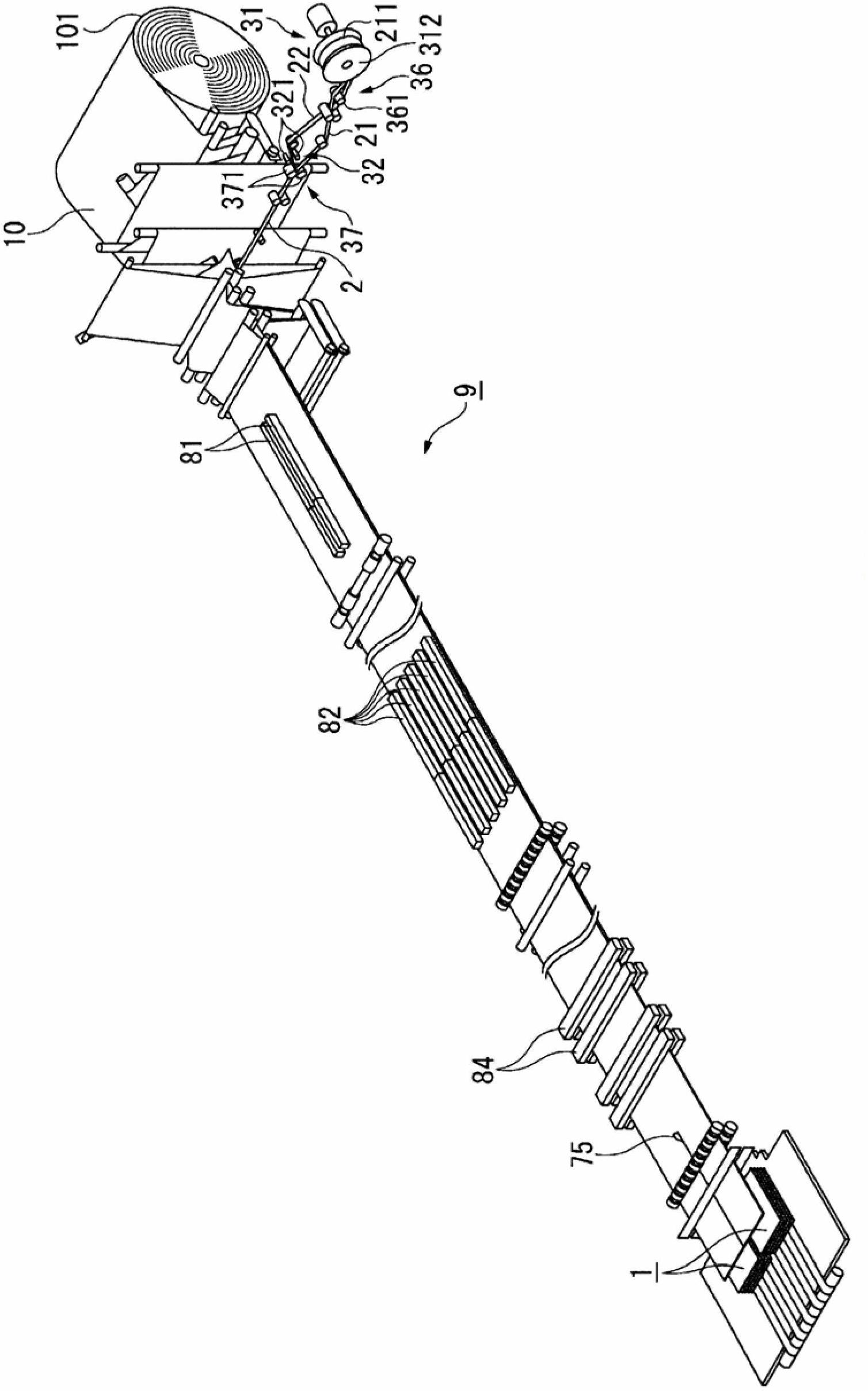

Method used

Image

Examples

Embodiment Construction

[0048] [First Embodiment]

[0049] Next, a first embodiment of the present invention will be described with reference to the drawings.

[0050]In the first embodiment, as a packaging bag with a zipper tape (hereinafter abbreviated as "packaging bag"), a packaging bag for packaging various items such as food, medicine, medical products, and miscellaneous goods is taken as an example. .

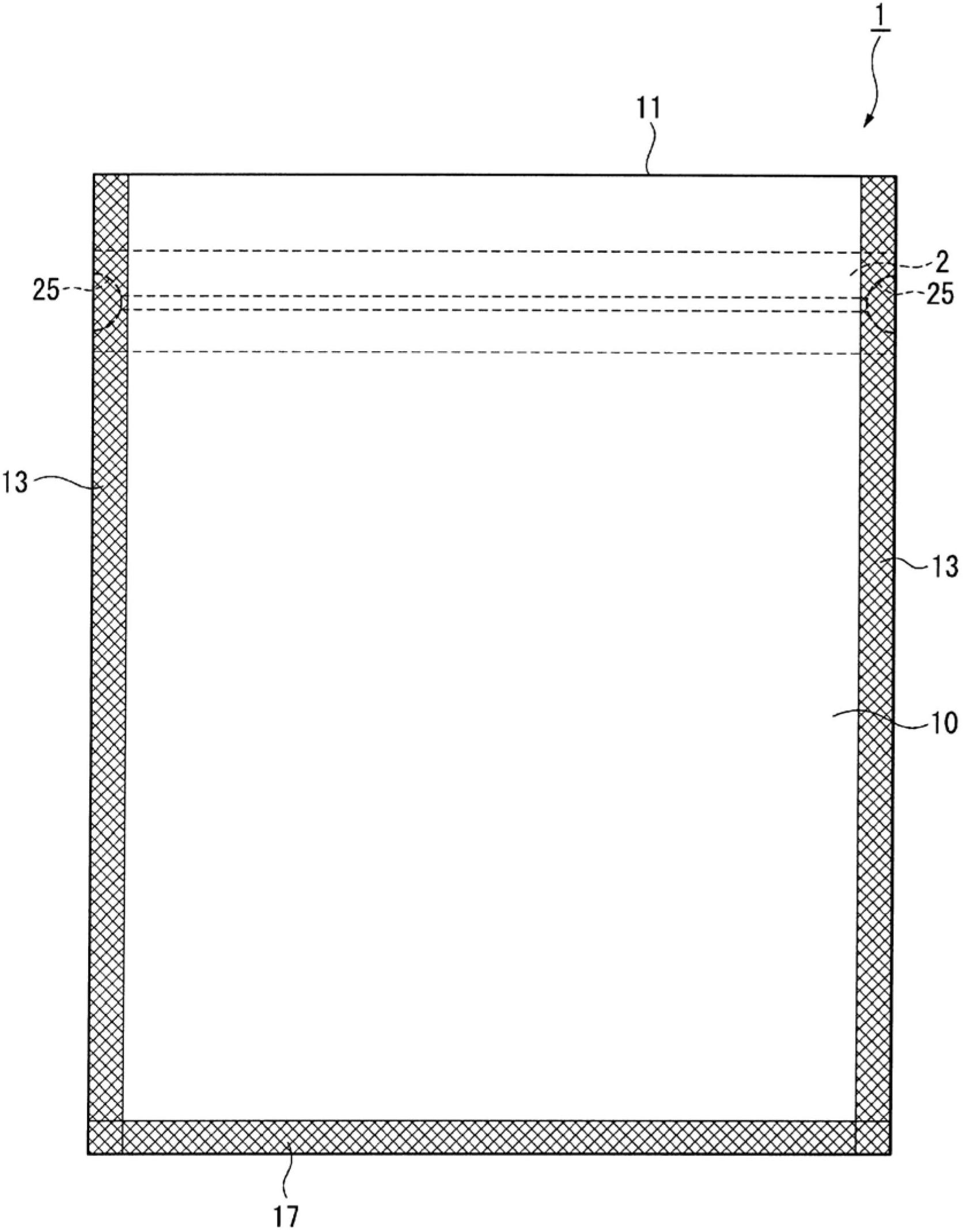

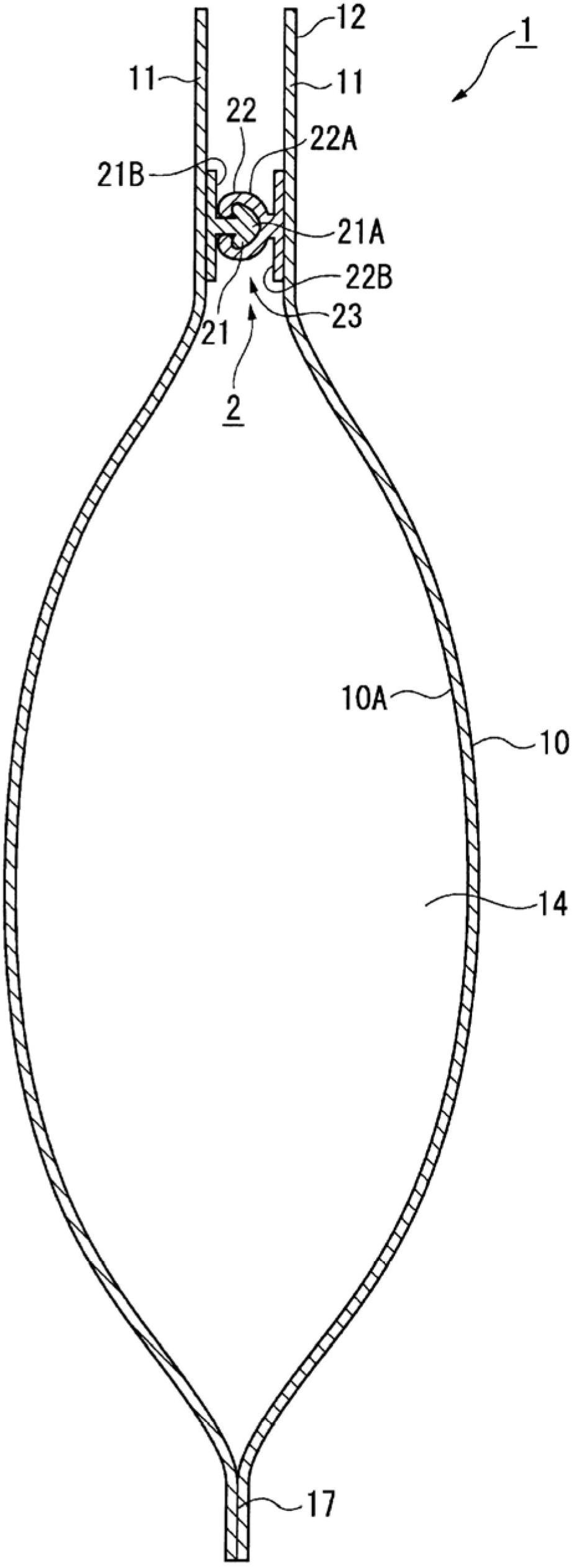

[0051] figure 1 It is a plan view which shows the packaging bag of 1st Embodiment. figure 2 It is a cross-sectional view of the packaging bag of the first embodiment.

[0052] (Structure of packaging bag)

[0053] Such as figure 1 , 2 As shown, the packaging bag 1 is bonded with a male side belt member 21 as a male side tape provided with a male side seaming portion 21A and a female side seaming portion provided with a film for the packaging bag, that is, a sheet of base film 10. 22A is a female-side belt member 22 as a female-side belt. The male-side engaging portion 21A and the femal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com