Suction valve assembly for alternative compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

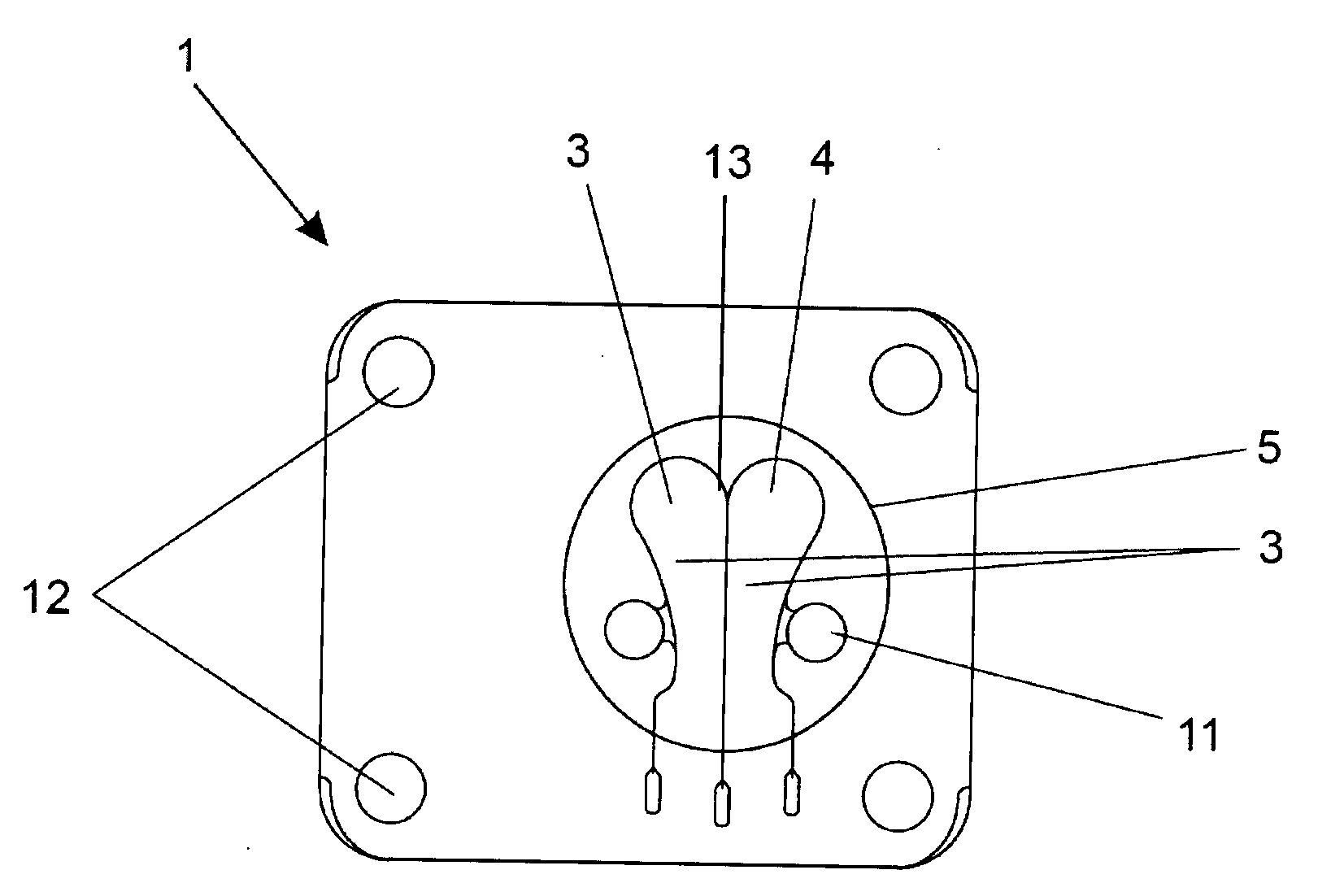

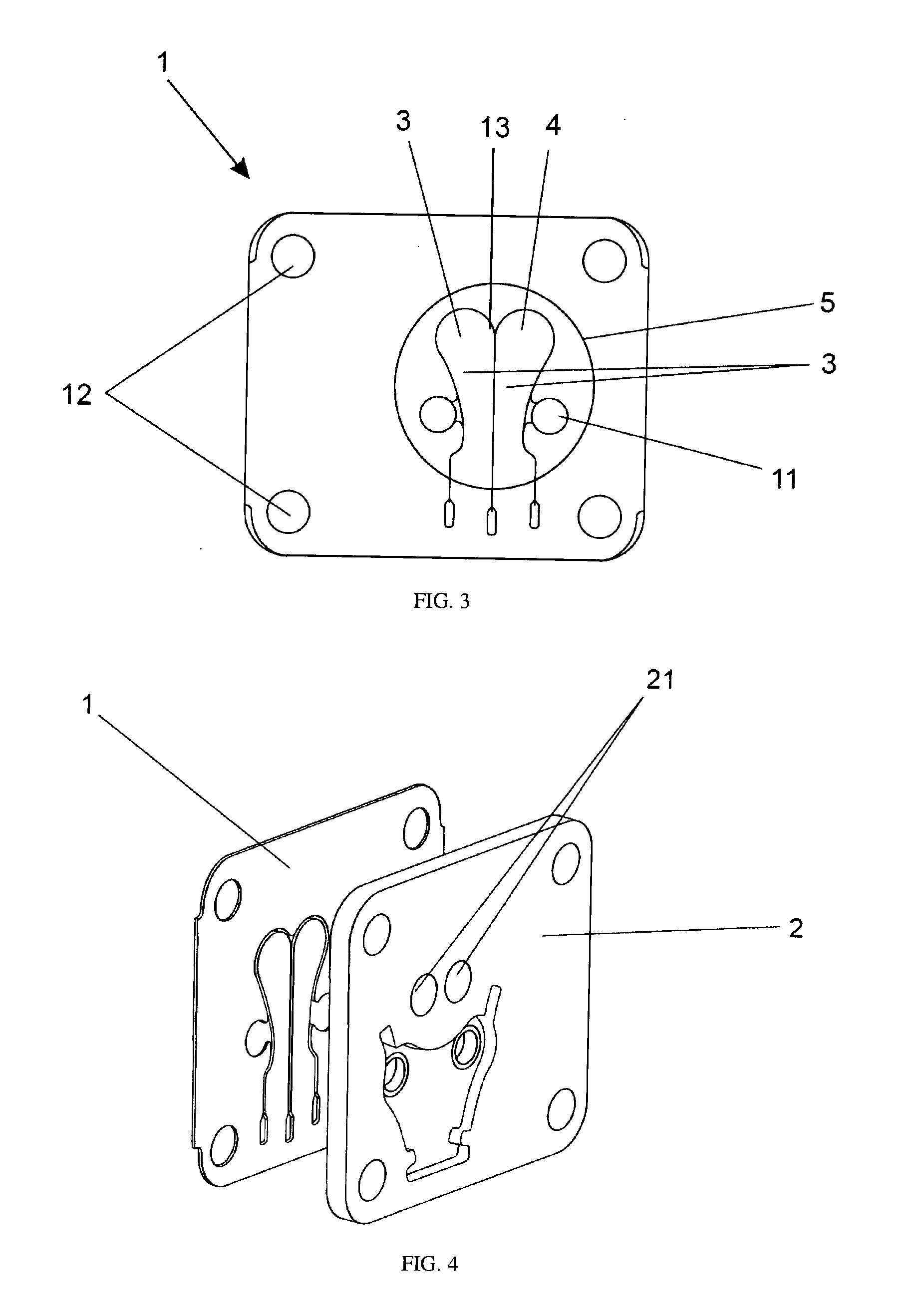

[0026]In accordance with the main objects of the present invention, a new suction valve assembly for alternative compressor, whose arrangement of its members makes it particularly suitable for a single suction chamber (not shown) comprising at least independent suction orifices (not shown), is disclosed.

[0027]Therefore, said suction valve assembly comprises at least two sealing / opening edges for independent suction orifices. Especially, the number of sealing / opening edges of the suction valve assembly is similar to the number of independent suction orifices 21 housed in valve plate 2 of an alternative compressor.

[0028]By this way, and based on such concepts, reference is made to FIGS. 3 and 4 in order to give an detailed description of the preferred embodiment of the present invention. It is herein pointed out that in this description, sealing / opening edges of suction valves are designated “functional edges.”

[0029]According to the preferred embodiment of the present invention, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com