Quick-change connector

A technology of connecting pipes and movable connections, applied in the field of machinery, can solve the problems of easy leakage connection effect and unsatisfactory connection, and achieve the effect of wide range of use, fast connection and good connection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

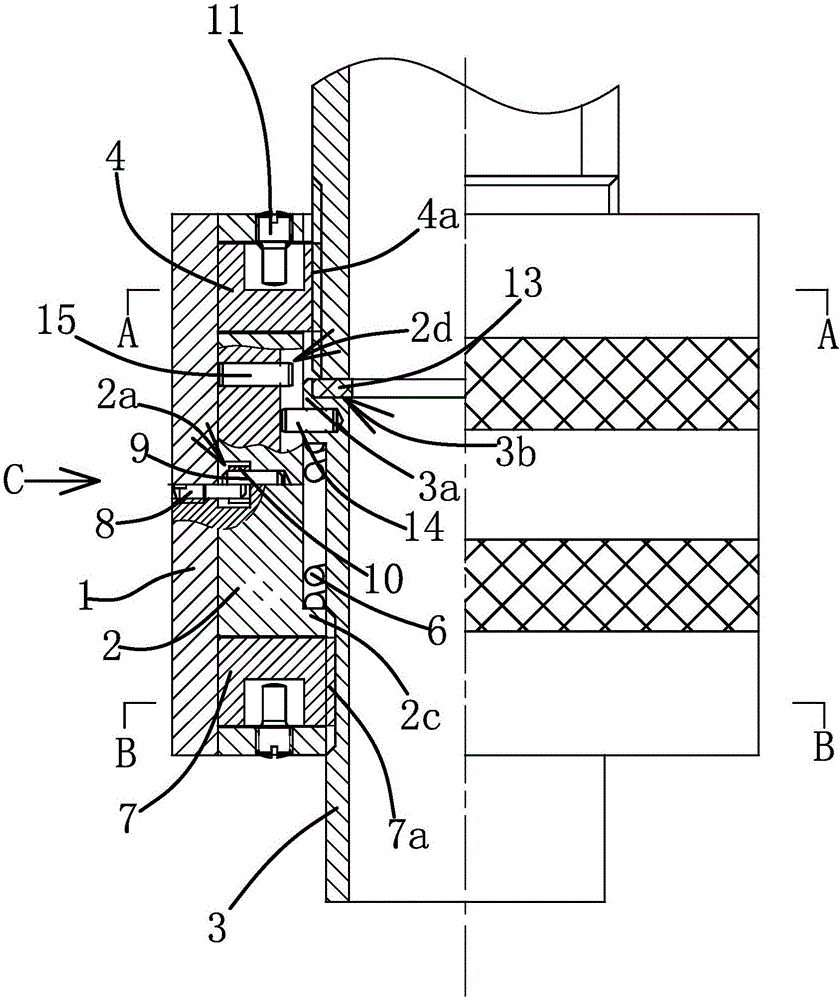

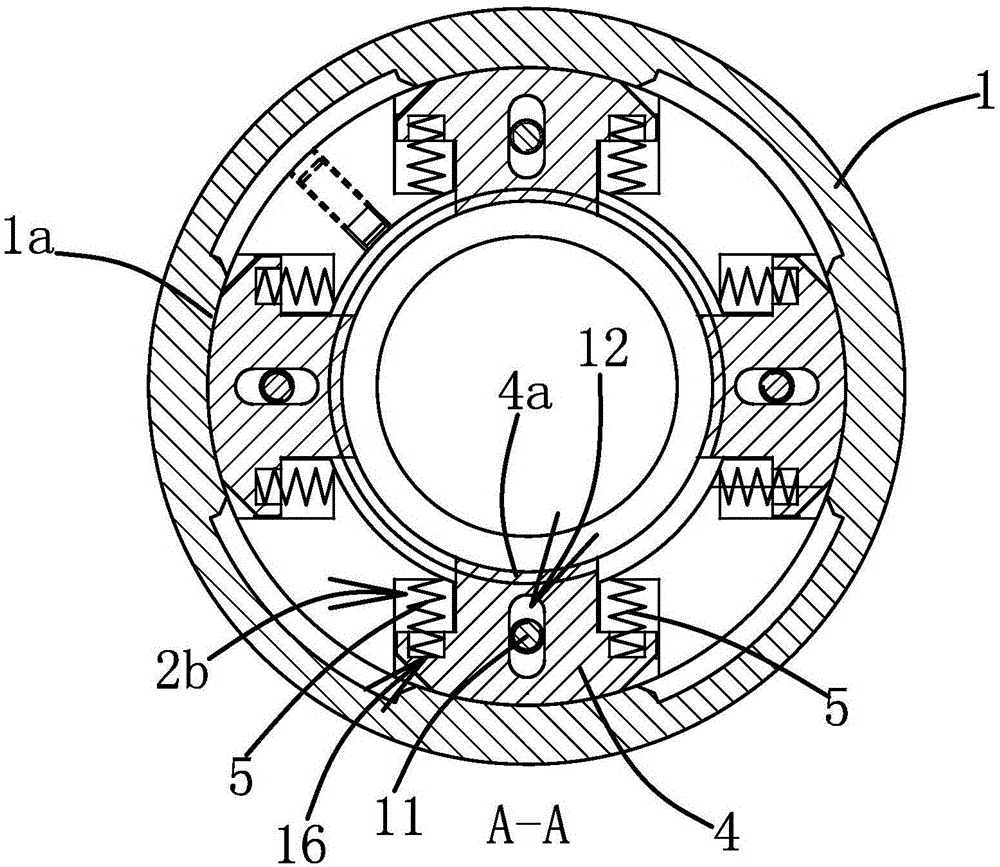

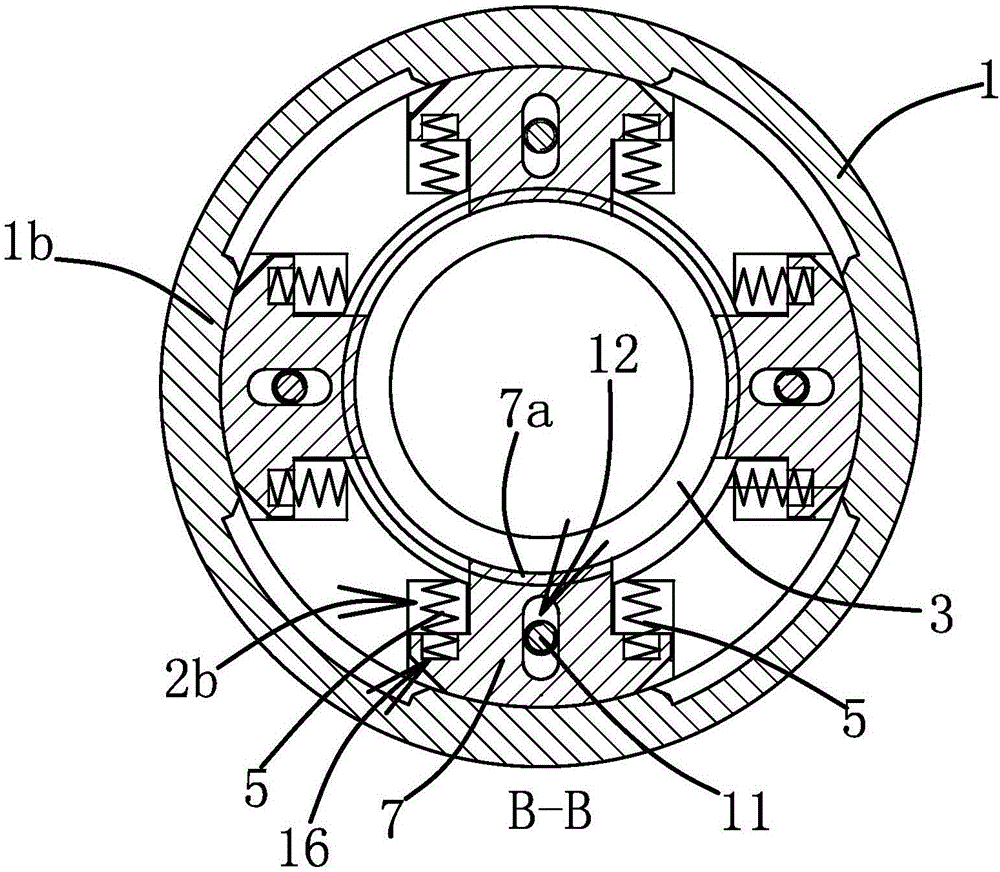

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0028] Such as Figures 1 to 4As shown, the quick-change joint includes a cylindrical locking sleeve 1. A cylindrical locking frame 2 is inserted and movably connected in the locking sleeve 1. A connecting pipe 3 is inserted in the locking frame 2. The lock The side part of the upper end of the tight frame 2 is provided with several through mounting holes 2b, the upper locking block 4 is inserted in the mounting hole 2b, the upper end of the locking frame 2 is vertically threaded to the limit screw 8, and the upper locking block 4 A strip-shaped groove 12 is provided horizontally on the end surface, and the limit screw 8 is embedded in the strip-shaped groove 12 . Between the upper locking block 4 and the locking frame 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com