Reciprocating movement type internal pressure compensation sealing piece

A reciprocating motion and compensating technology, which is applied in the direction of engine seals, engine components, piston rings, etc., can solve problems such as difficult processing, high friction, and personal injury, and achieve high dynamic response, small friction, and convenient Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

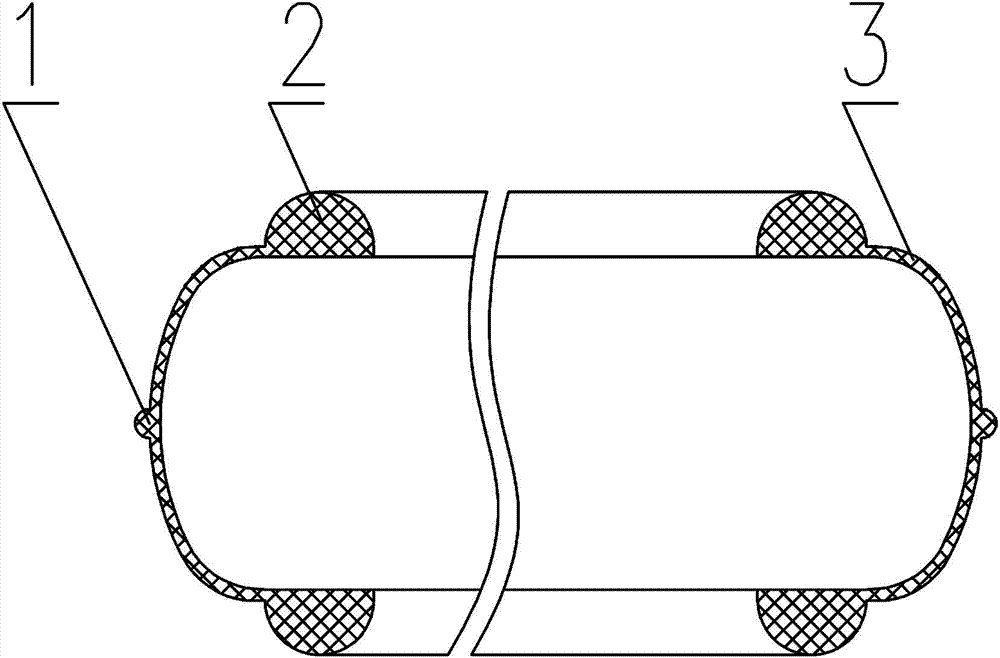

[0022] like figure 1 Among them, a reciprocating internal pressure compensation type seal is provided. The upper and lower ends of the annular seal 3 are provided with raised positioning portions 2 , and the outer side of the middle portion of the annular seal 3 is provided with a raised seal 1 .

[0023] The cross-section of the annular seal 3 is an outwardly convex arc.

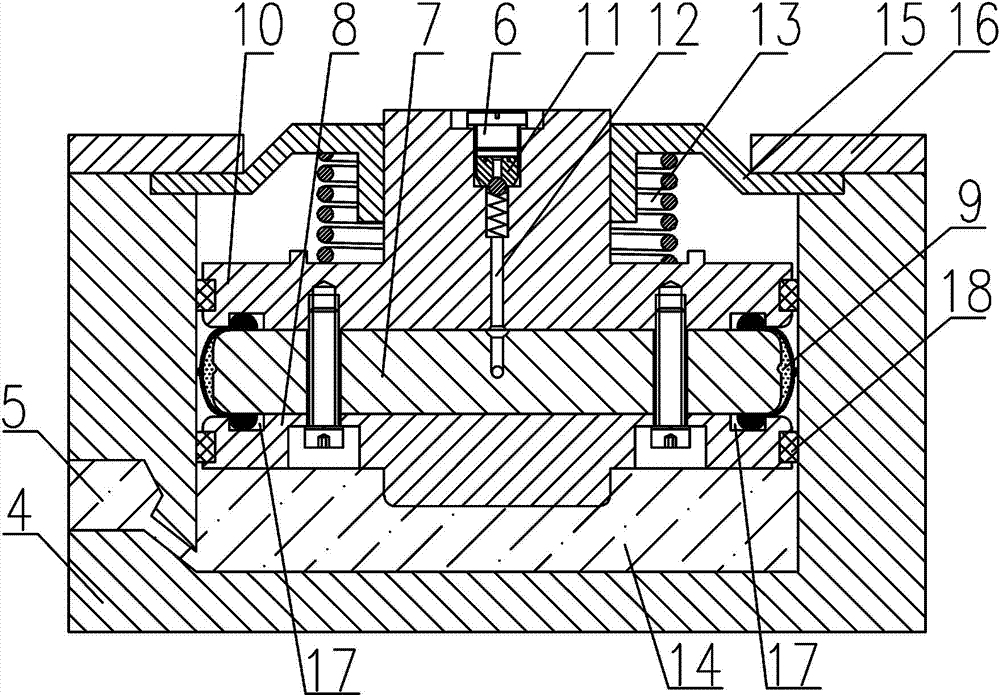

[0024] In order to make the annular seal 3 have good dynamic responsiveness during the working process, the measures adopted are: an annular raised convex sealing part 1 is designed in the middle of the outer wall of the annular seal 3, and its structure is similar to that of the The purpose of the reciprocating "O" type sealing ring is to reduce the contact area between the annular seal 3 and the inner surface of the cylinder 4 as much as possible under the condition of ensuring the sealing, so as to achieve good dynamic response; Good dynamic sealing performance, the closed chamber formed between the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com