Patents

Literature

146results about How to "Simple shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

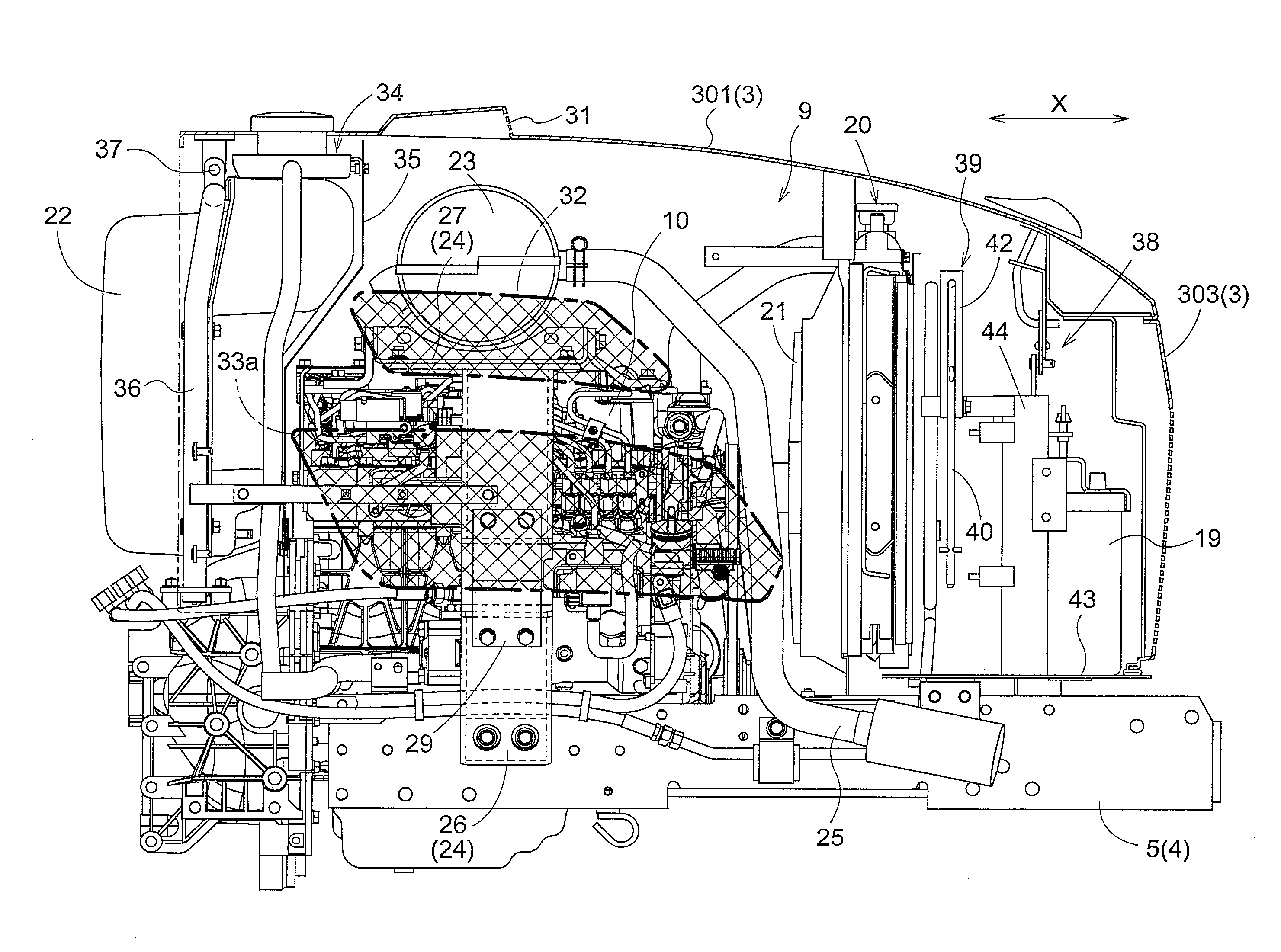

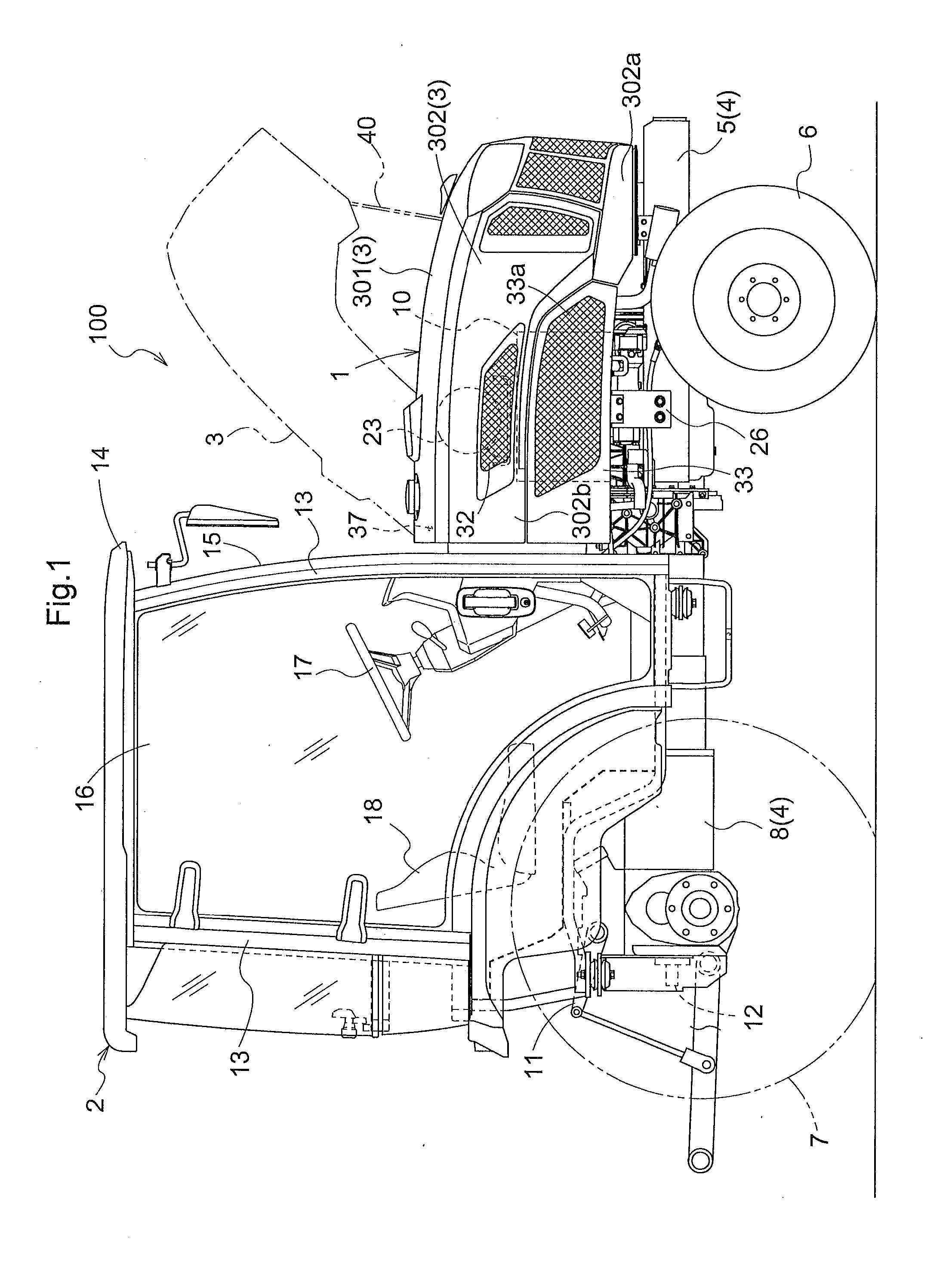

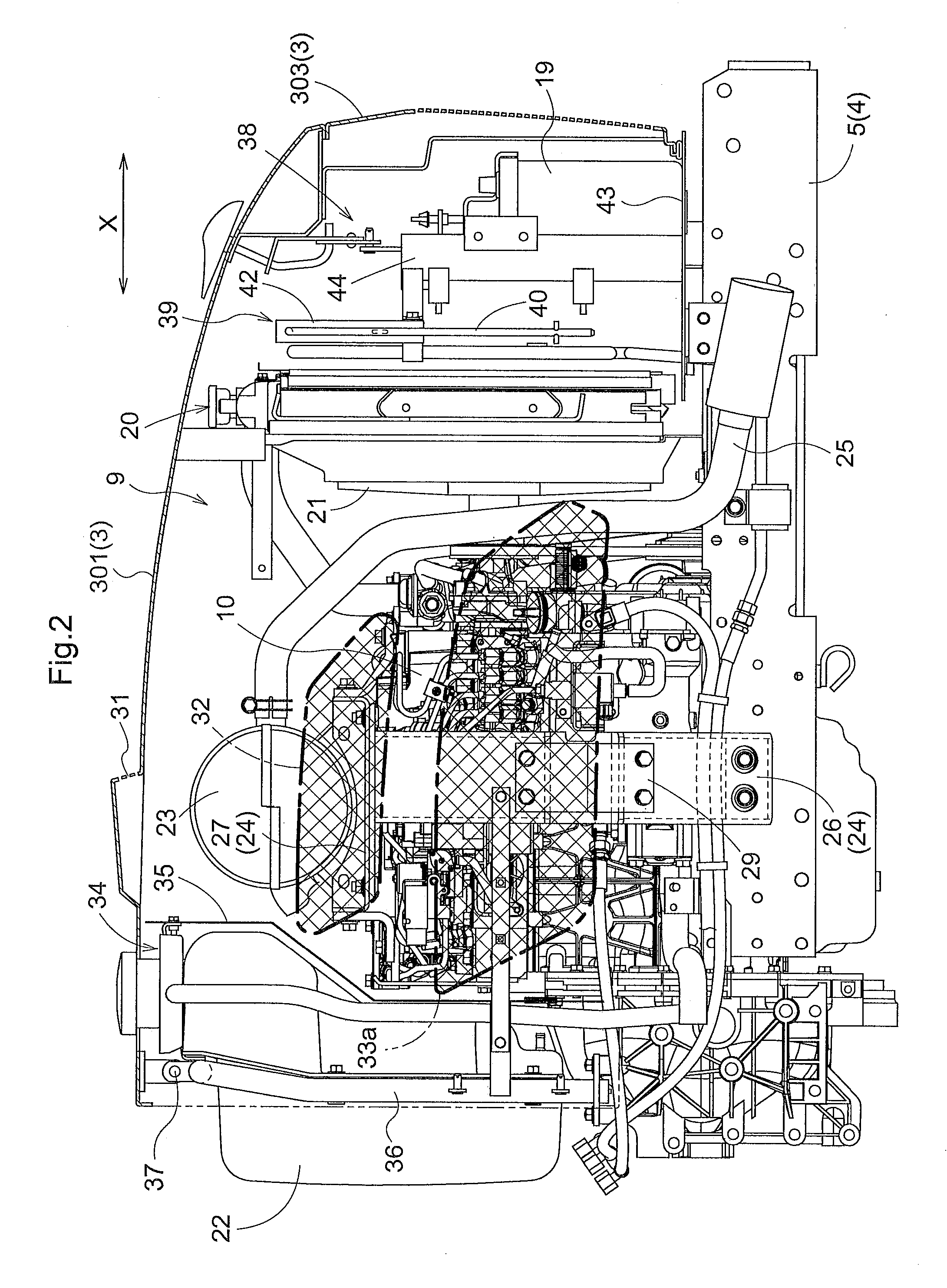

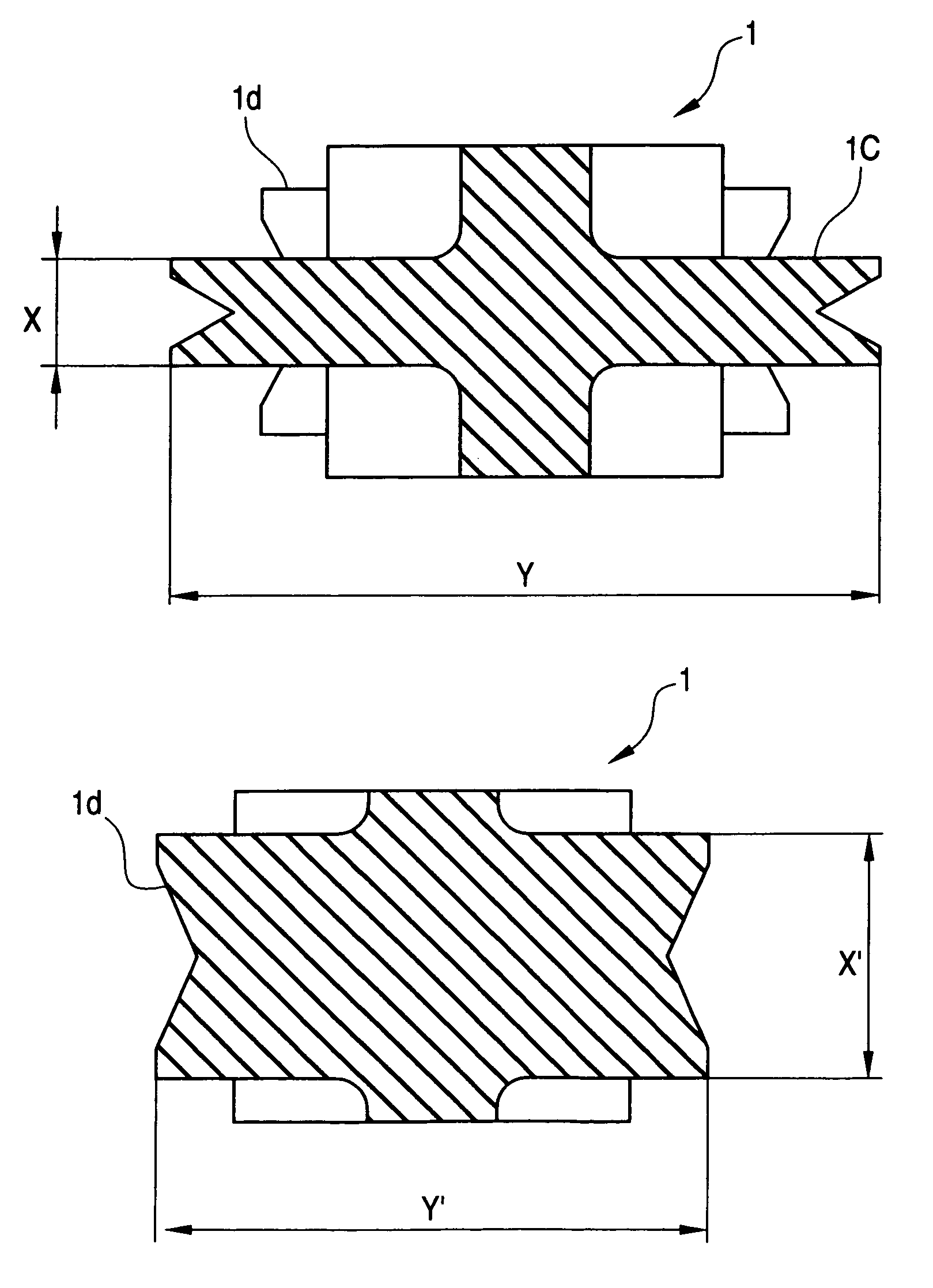

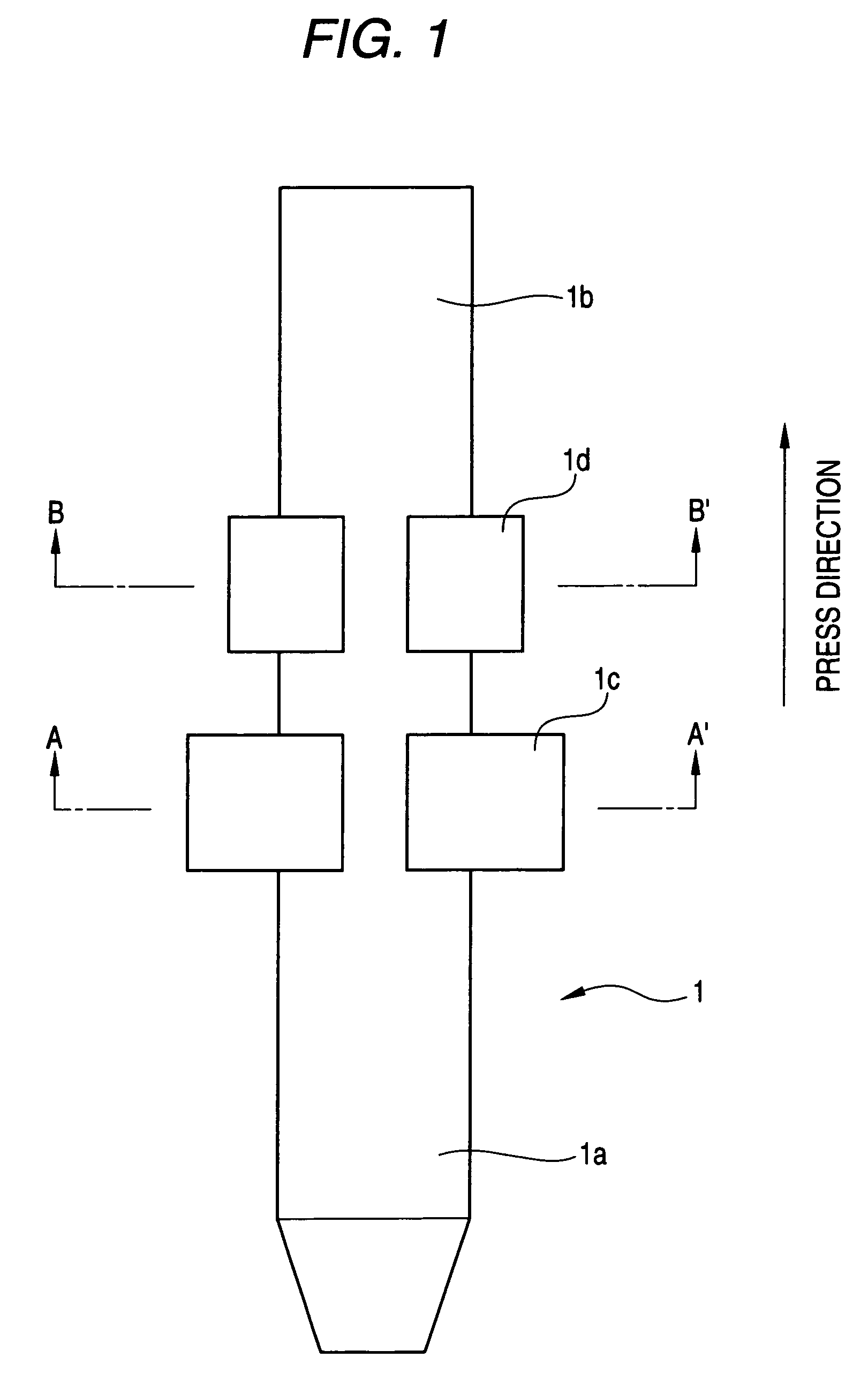

Work Vehicle Having an Exhaust Treatment Apparatus in an Engine Room

ActiveUS20140020972A1Reduce adverse effectsSimple shapeExhaust apparatusSilencing apparatusExhaust gasAutomotive engineering

A board-like division member is provided that extends in a vehicle body transverse direction so as to divide a portion of the engine room into an upper region and a lower region along in an engine room height direction. An engine is mounted downwardly of the division member. An exhaust treatment apparatus is mounted upwardly of the division member for treating exhaust gas from the engine. An air discharge portion is formed in a lateral face region of the hood which corresponds to a position of the division member in the engine room height direction. Air present inside the engine room is discharged to the outside through this air discharge portion.

Owner:KUBOTA LTD

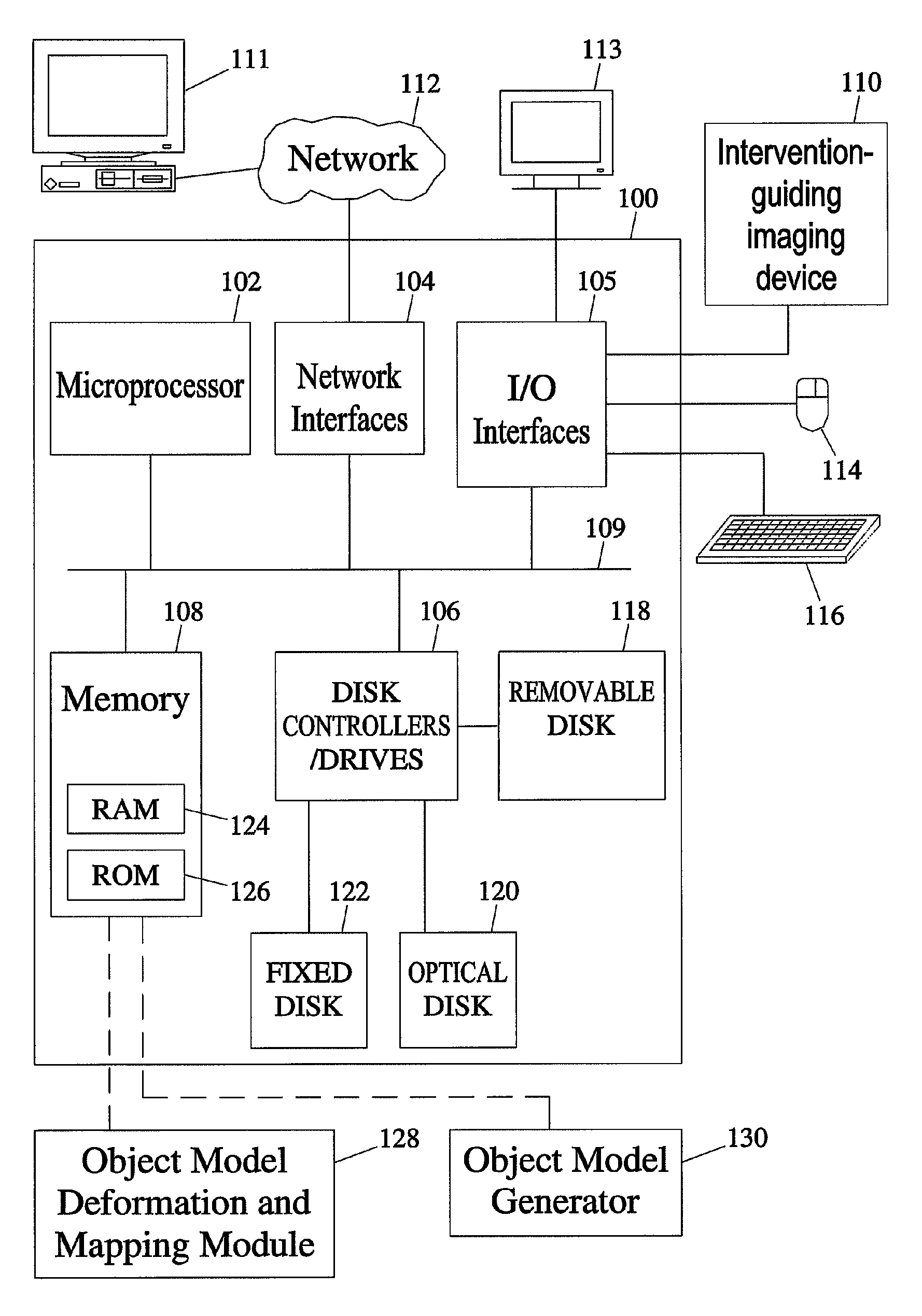

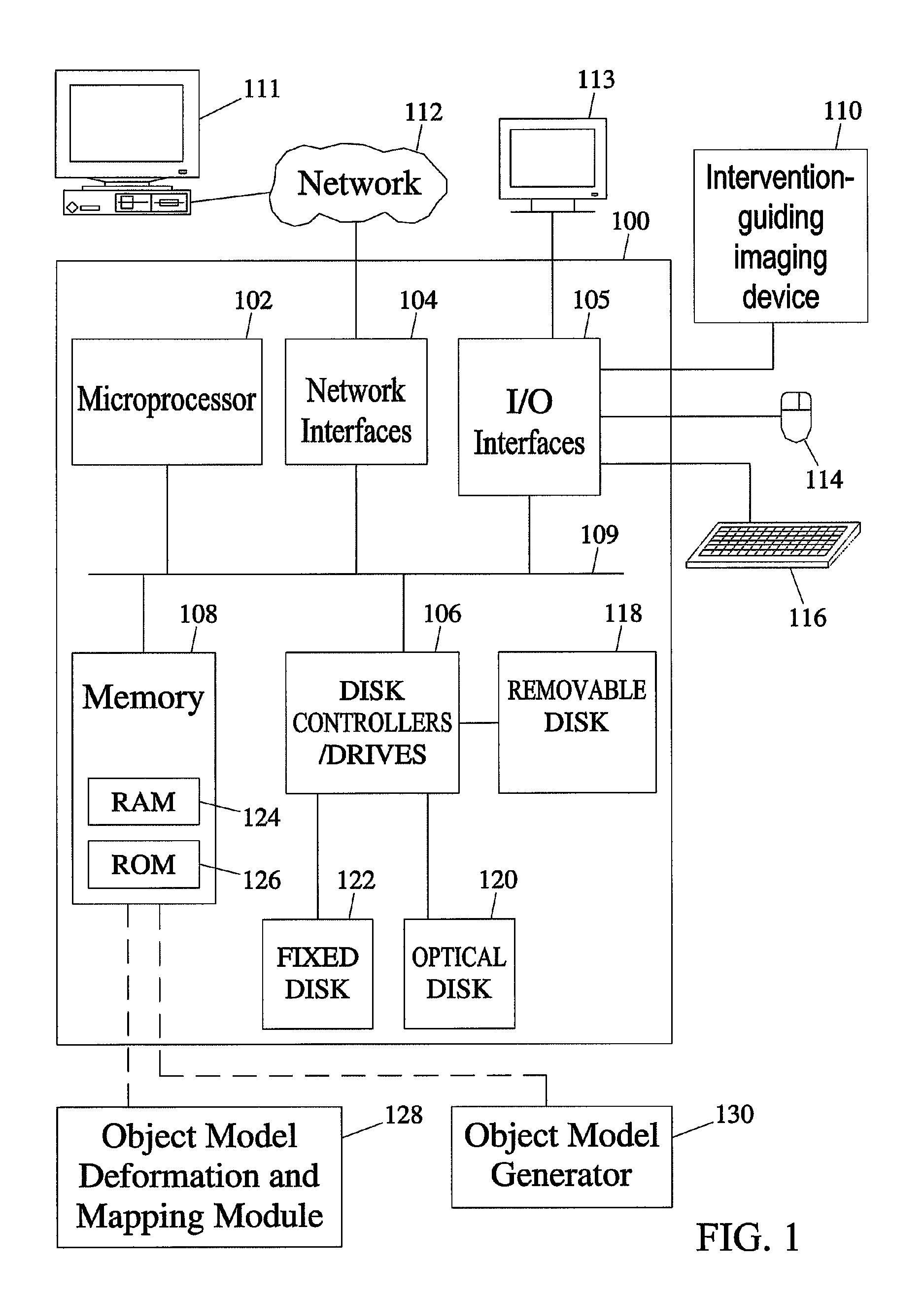

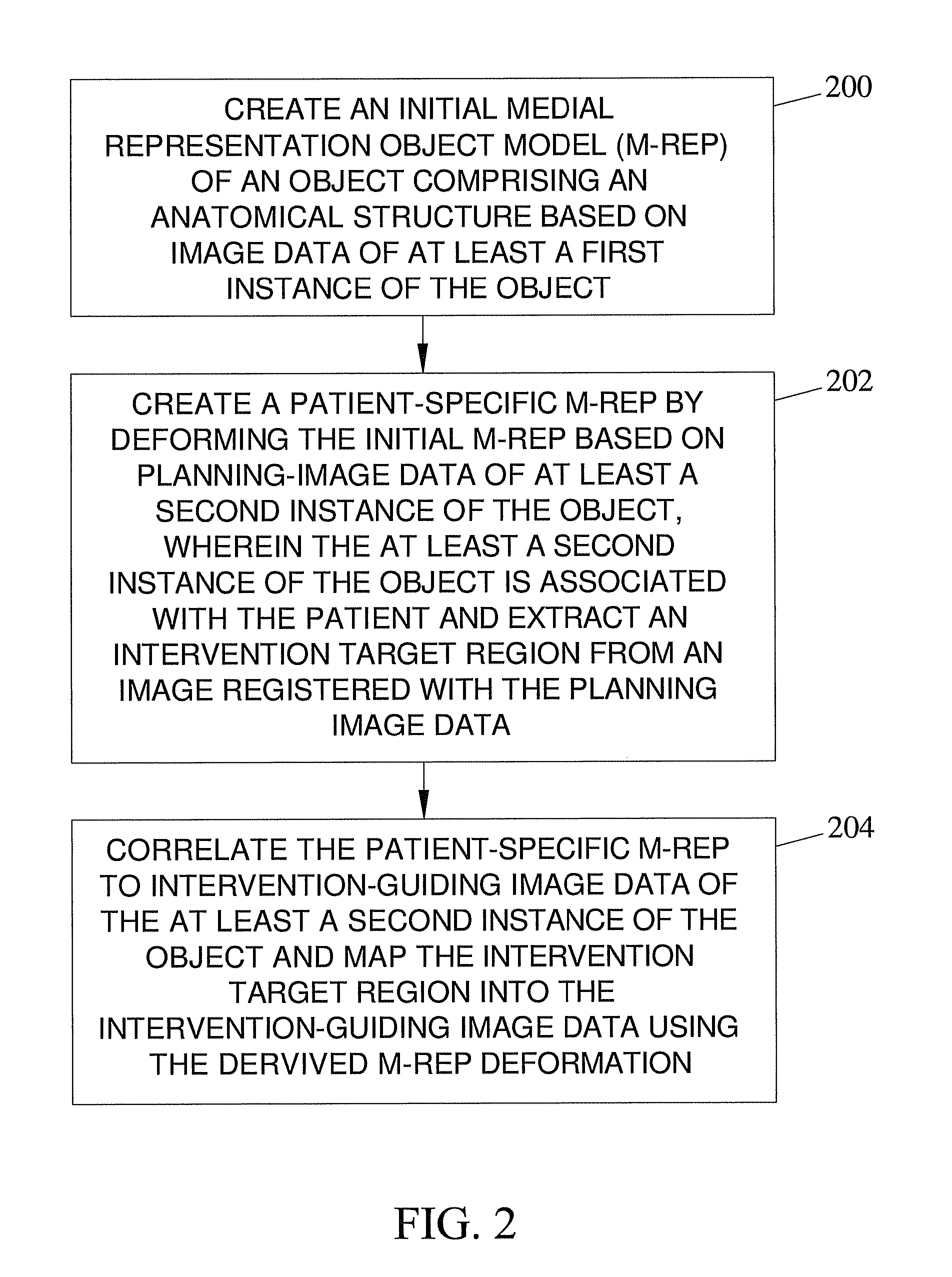

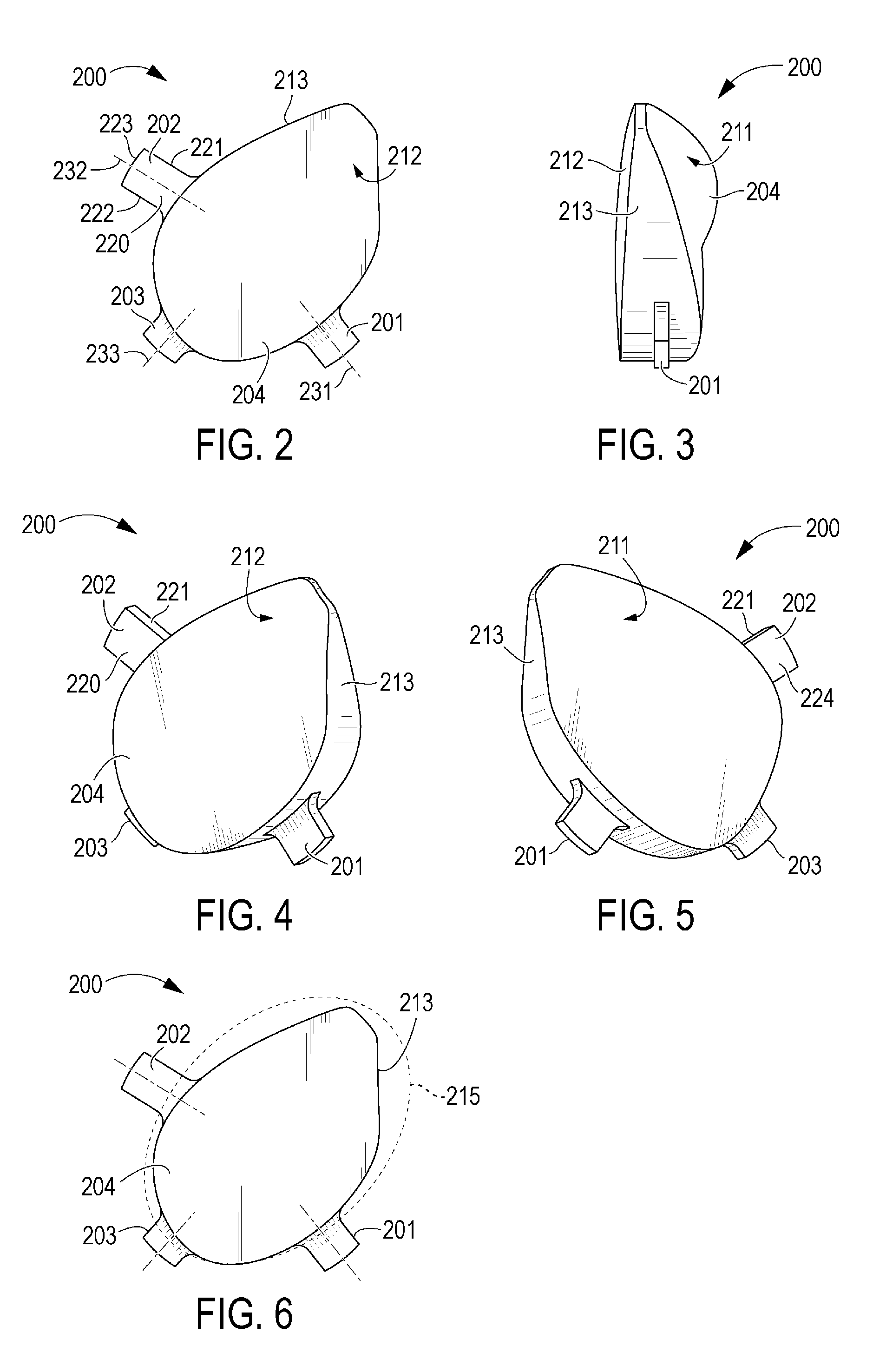

Methods, systems, and computer readable media for mapping regions in a model of an object comprising an anatomical structure from one image data set to images used in a diagnostic or therapeutic intervention

Methods, systems, and computer readable media for mapping a model of an object comprising an anatomical structure in a planning image and an intervention target region within it to intervention-guiding image data are disclosed. According to one method, an initial medial representation object model (m-rep) of an object comprising an anatomical structure is created based on image data of at least a first instance of the object. A patient-specific m-rep is created by deforming the initial m-rep based on planning image data of at least a second instance of the object, wherein the at least second instance of the object is associated with the patient. An intervention target region within the m-rep is identified in an image registered with the planning image. The patient-specific m-rep is correlated to the intervention-guiding image data of the at least second instance of the object, deformed from the planning image. The intervention target region is transferred to the intervention-guiding image according to the transformation between the m-rep in the planning image and the m-rep in the intervention-guiding image.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

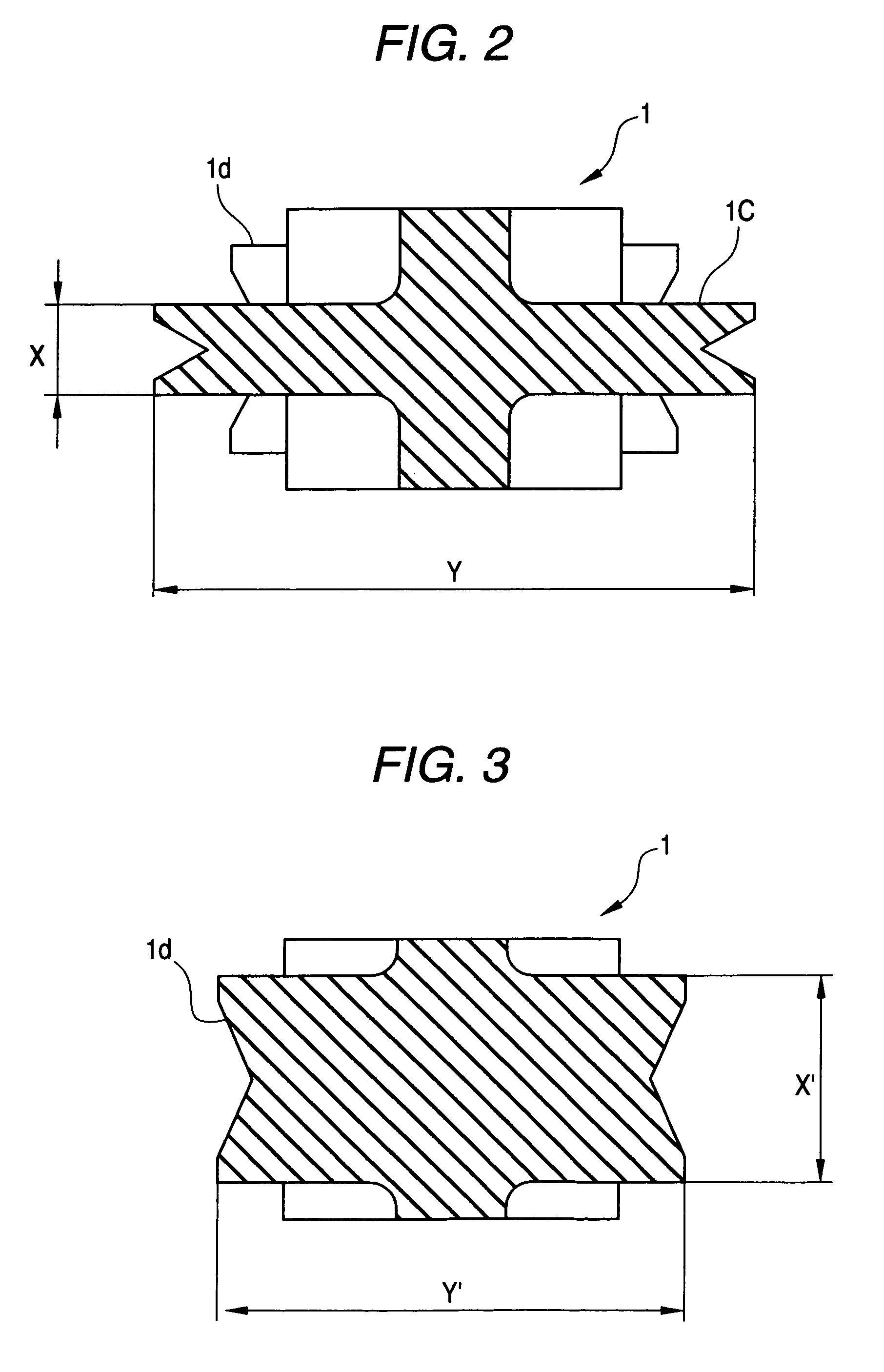

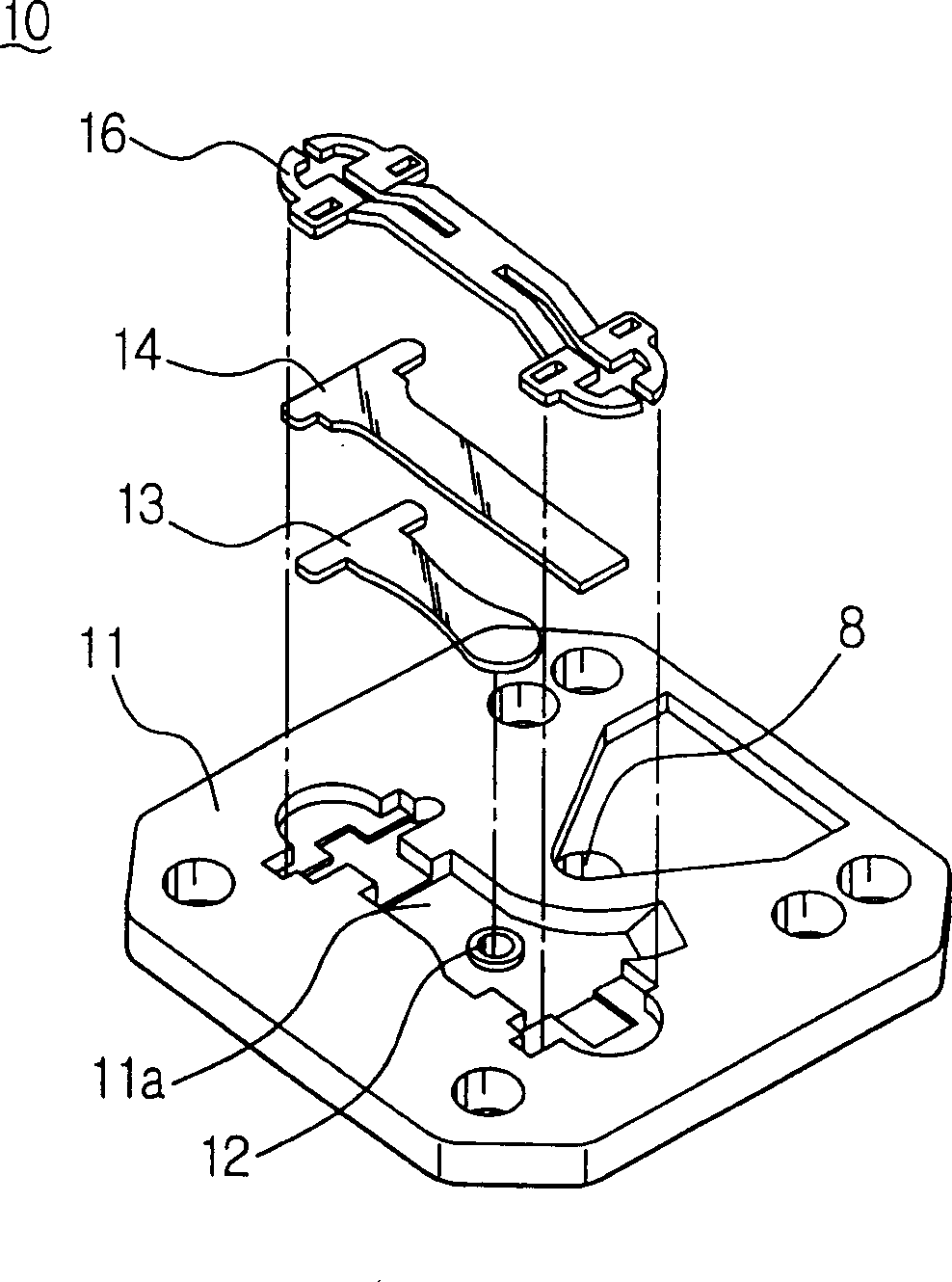

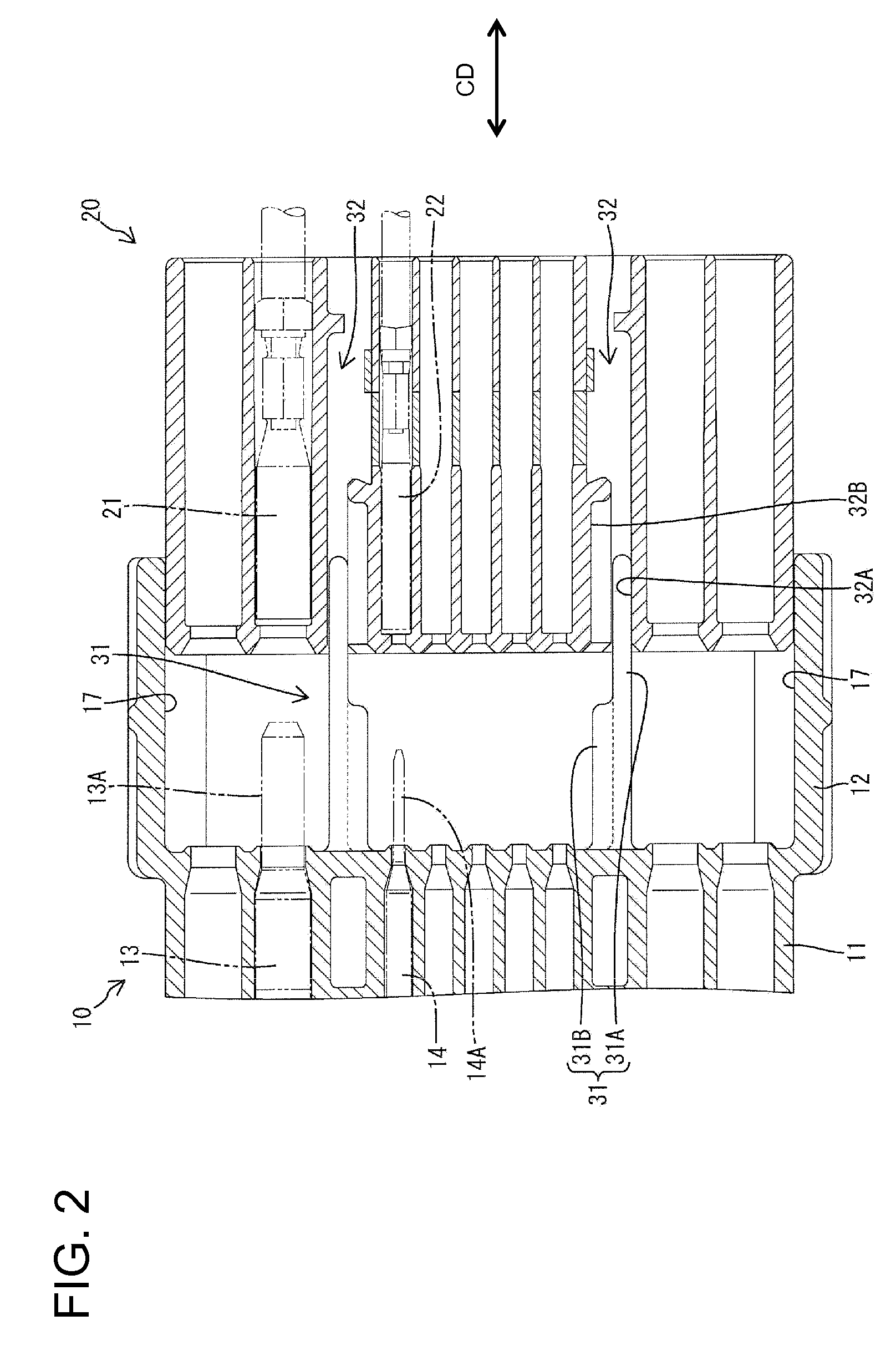

Terminal holding structure of board mounted-type connector

ActiveUS7083478B1Simple shapeEasily form or shapeSecuring/insulating coupling contact membersMechanical engineeringEngineering

Owner:YAZAKI CORP

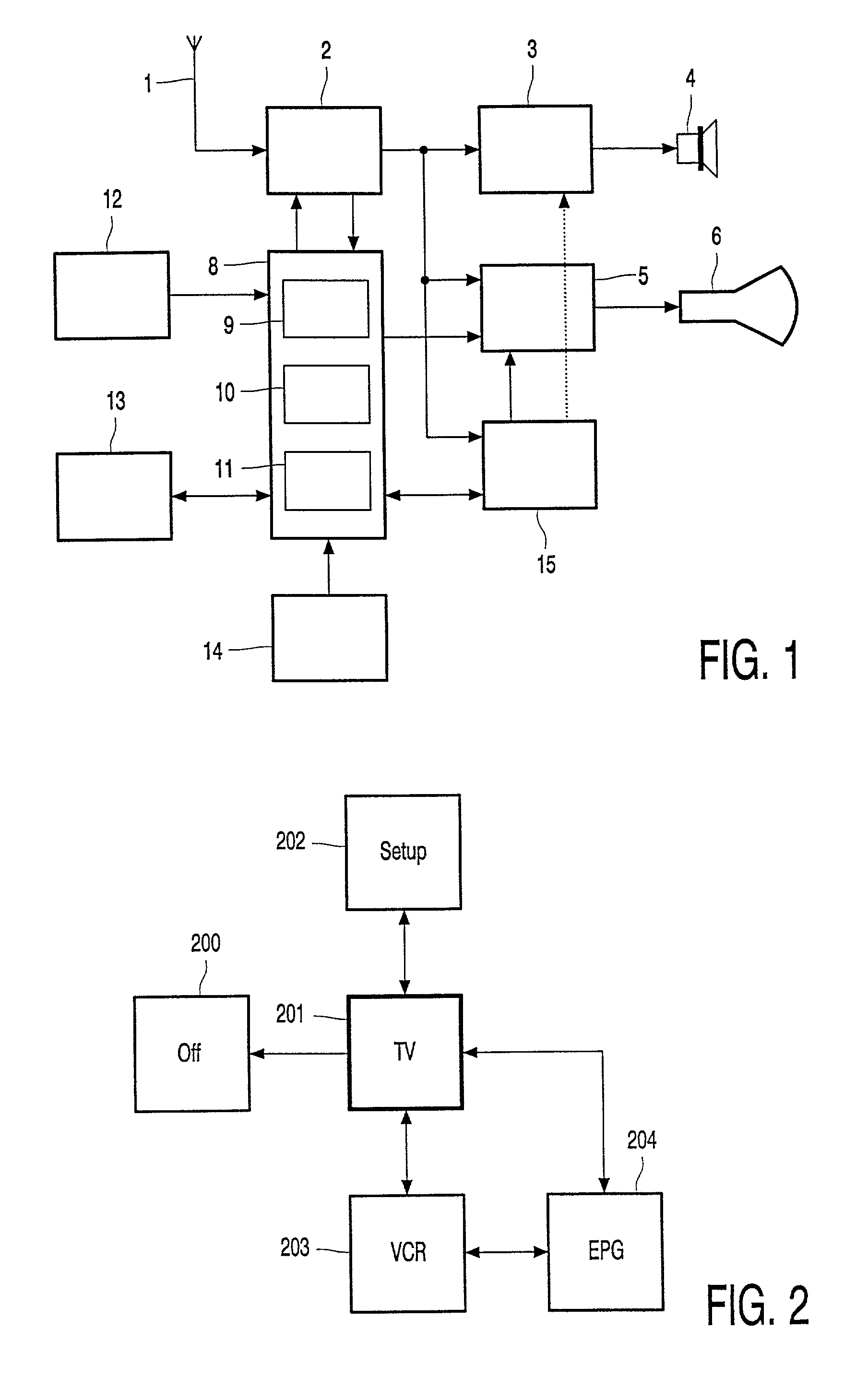

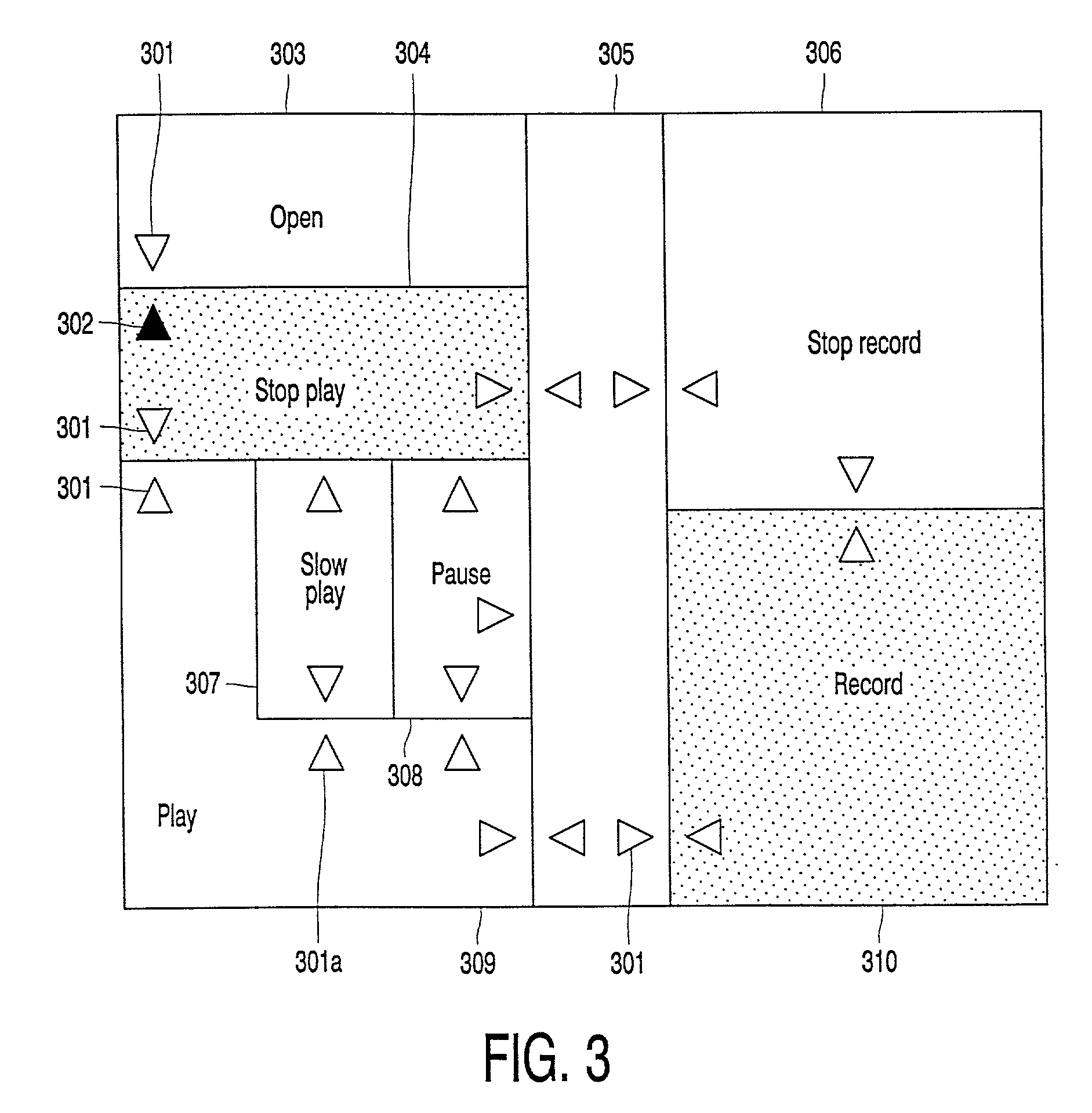

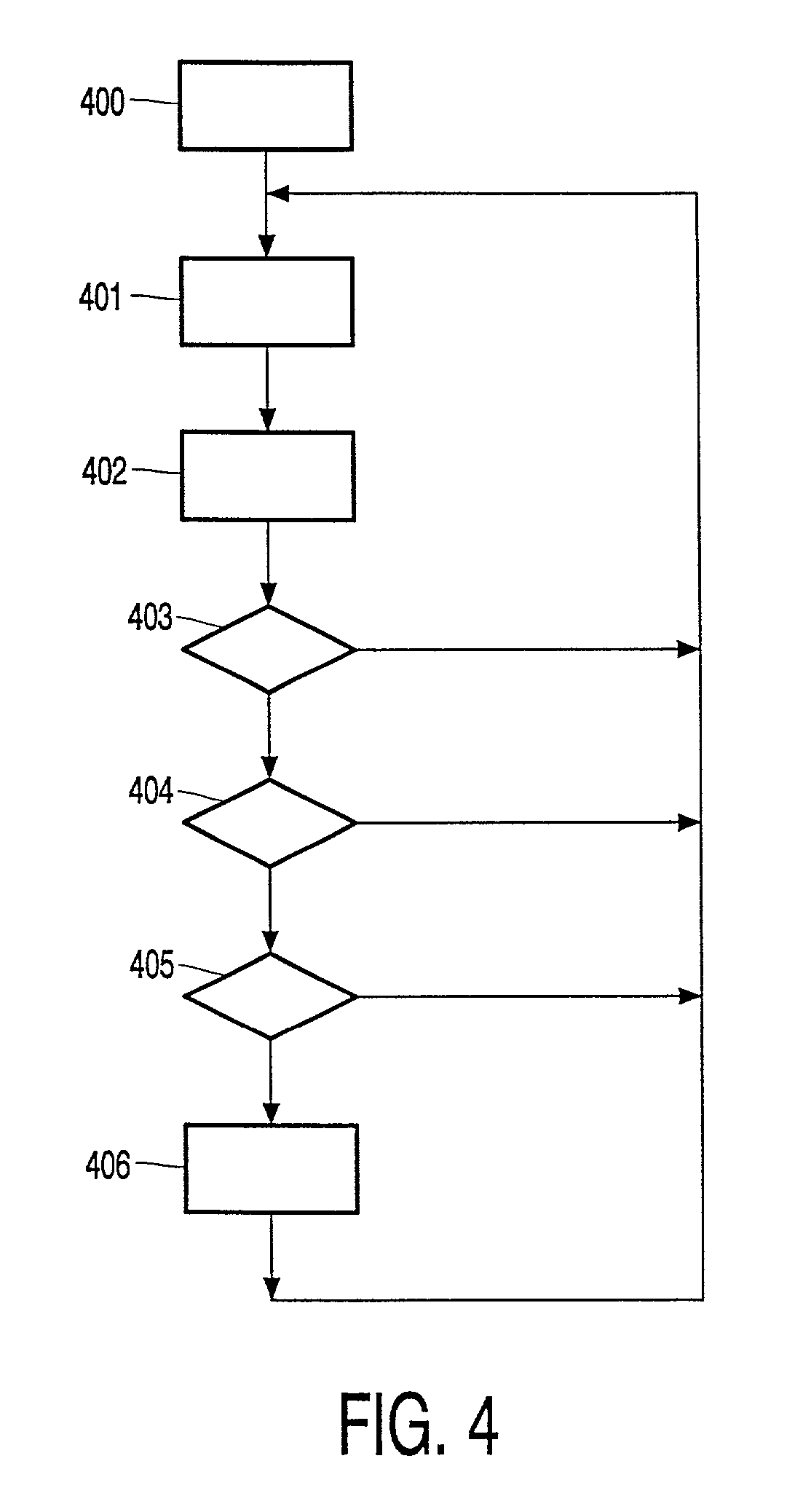

Method of operating an appliance

InactiveUS20010013906A1Easy user interfaceSimple shapeTelevision system detailsColor television detailsMarine navigationState diagram

The invention relates to a method of operating an appliance. The method according to the invention comprises the display of a state diagram on a display screen. The state diagram comprises state symbols representing operative states of the appliance. A state cursor is provided, which indicates a position relative to the state diagram, which state cursor can be relocated in response to user supplied cursor control commands. The appliance can be operated by navigating the state cursor to a state symbol representing a desired state of the appliance, which causes the appliance to adopt the desired state in response to said navigation.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

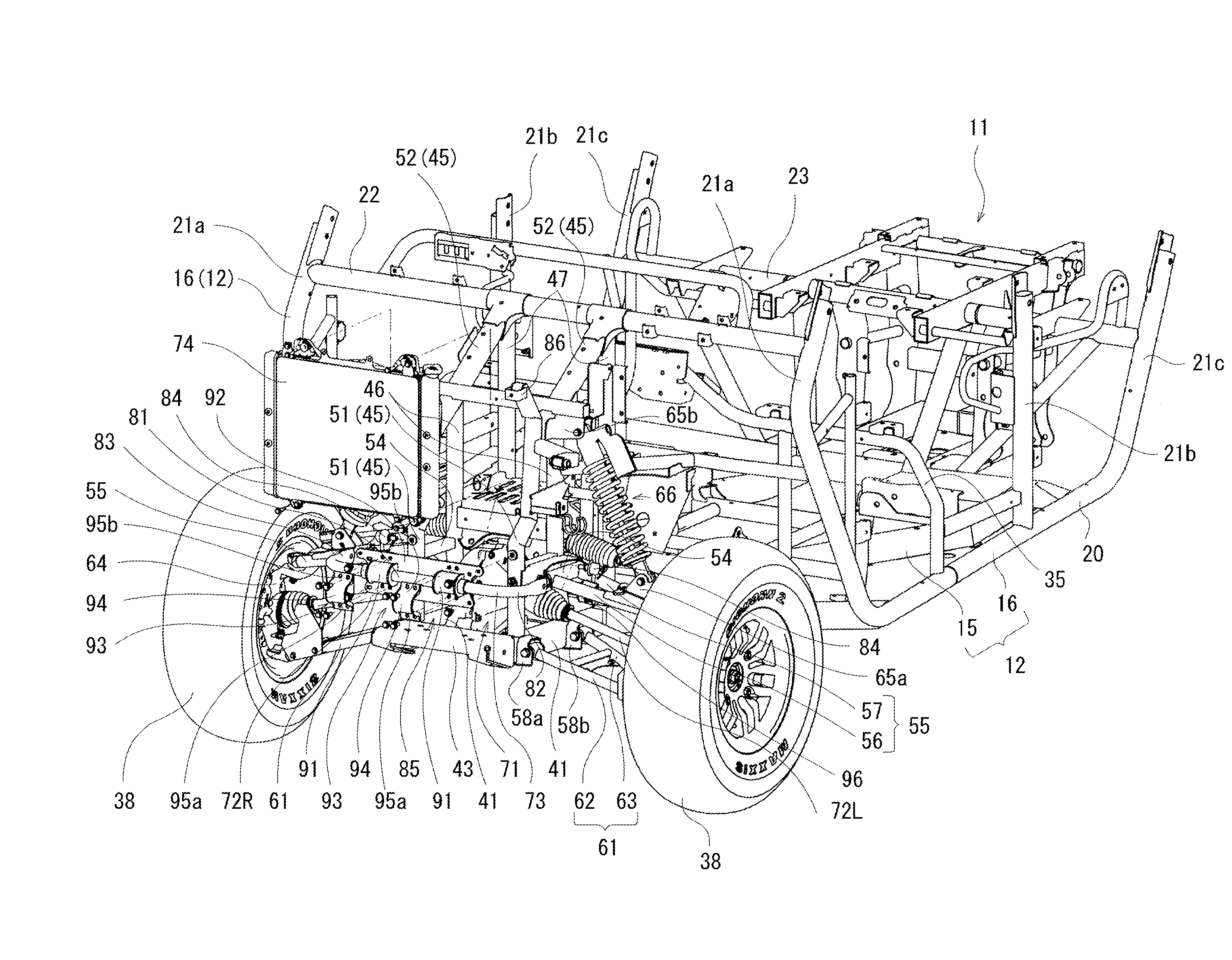

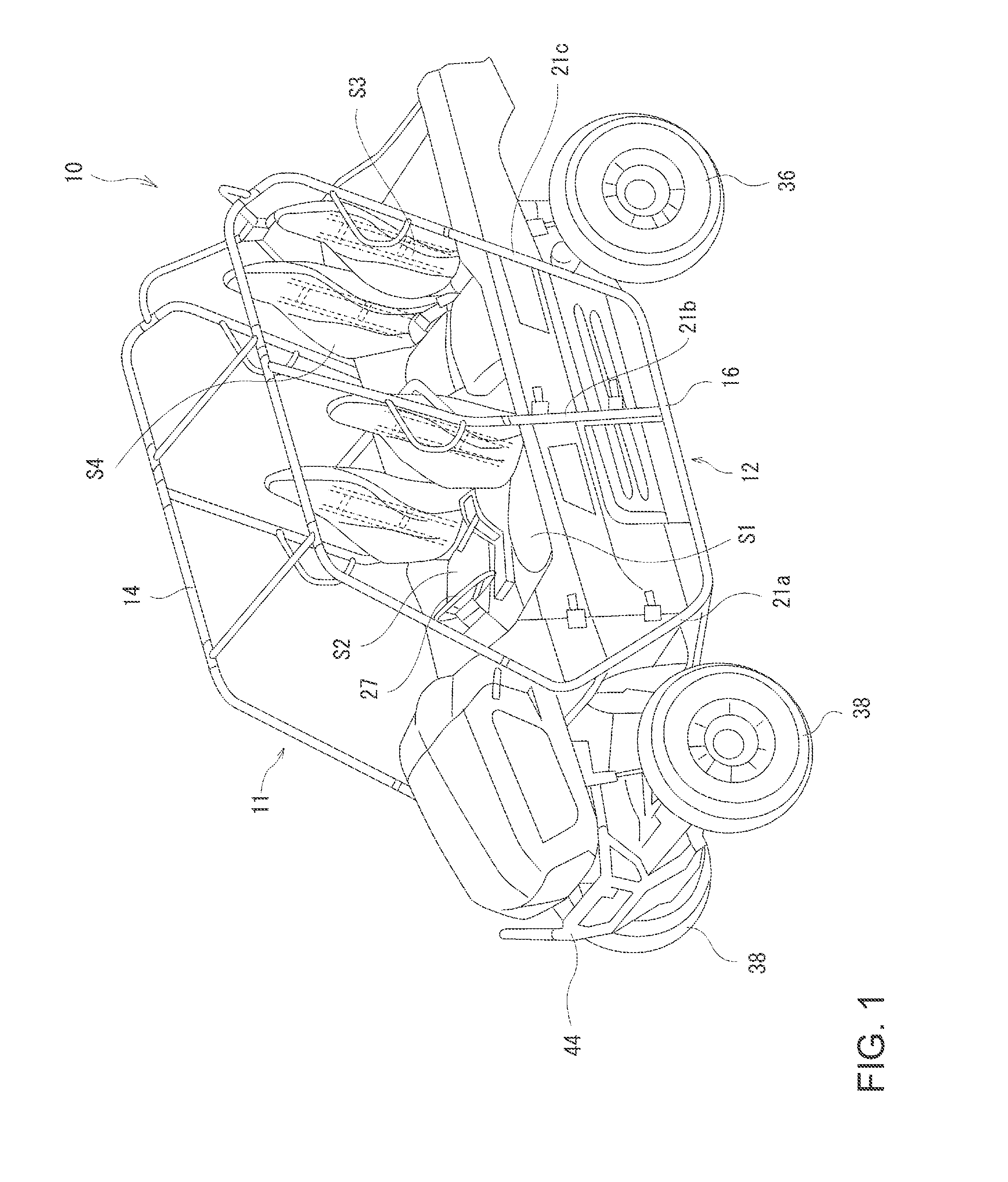

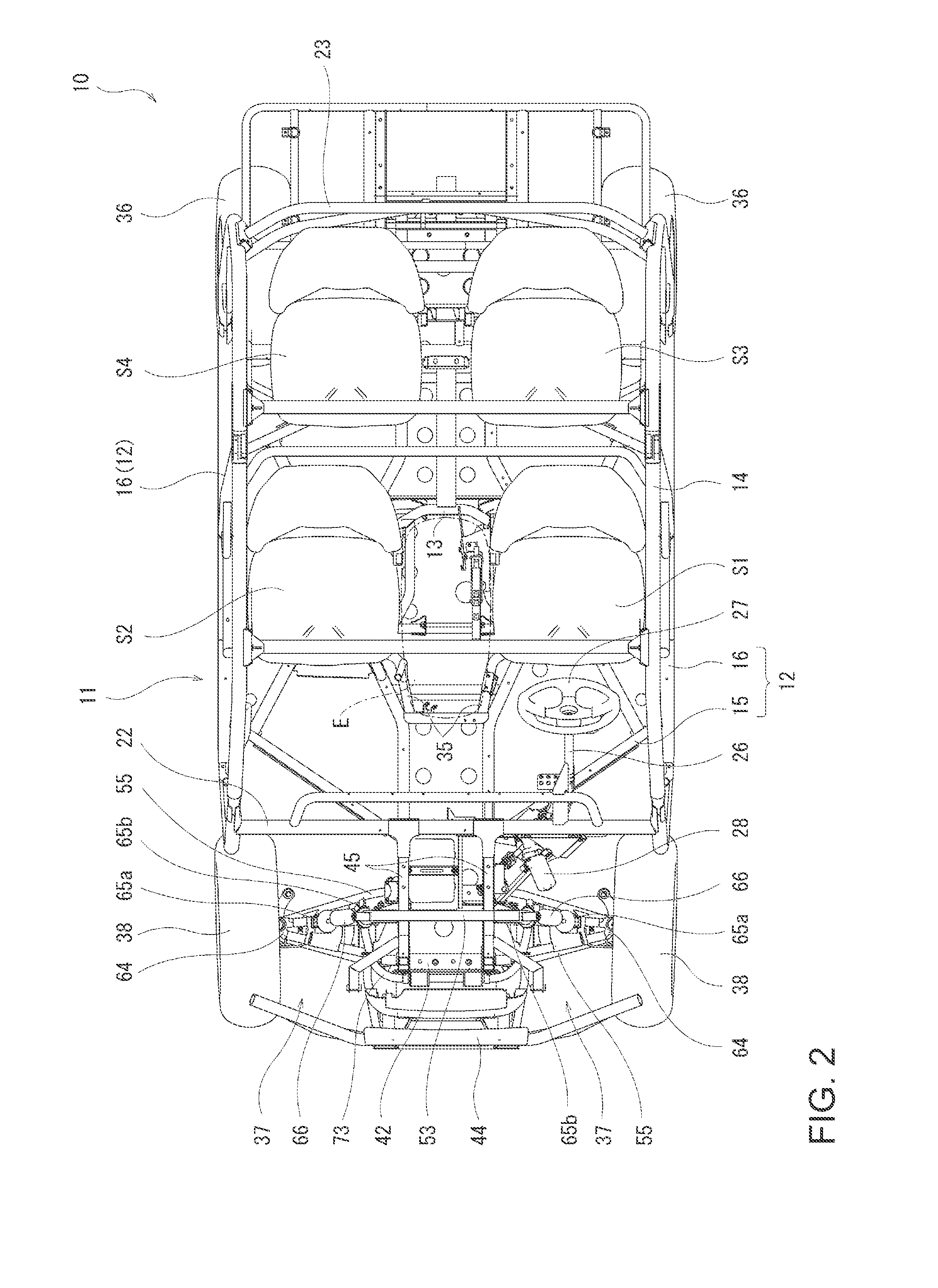

Utility Vehicle

ActiveUS20130087397A1Simple shapeEasy to assembleSteering linkagesUnderstructuresSport utility vehicle

A utility vehicle comprises a vehicle body frame, a first pair of pivot arms provided at right and left sides, respectively, at a front end portion of the vehicle body frame such that the pivot arms extend in a rightward and leftward direction from the front end portion and are vertically pivotable, the first pair of pivot arms being attached to front wheels at tip ends thereof, respectively, and a stabilizer having one end mounted to one of the first pair of pivot arms and an opposite end mounted to the other of the first pair of pivot arms. The stabilizer extends through a front side of the vehicle body frame, outside the vehicle body frame, from the one end thereof to the opposite end thereof, and has an intermediate portion located in front of the vehicle body frame and mounted to the front end portion of the vehicle body.

Owner:KAWASAKI MOTORS LTD

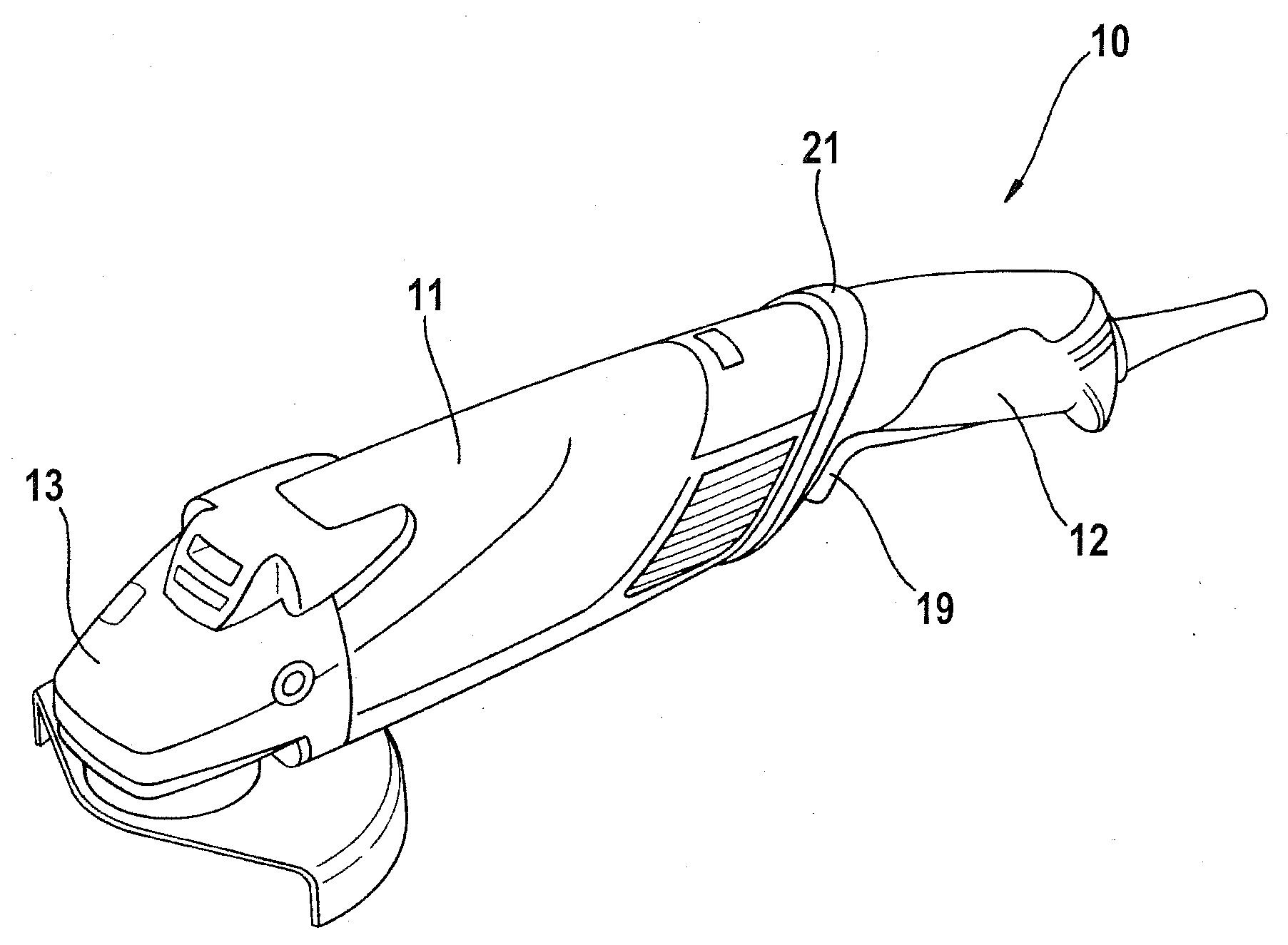

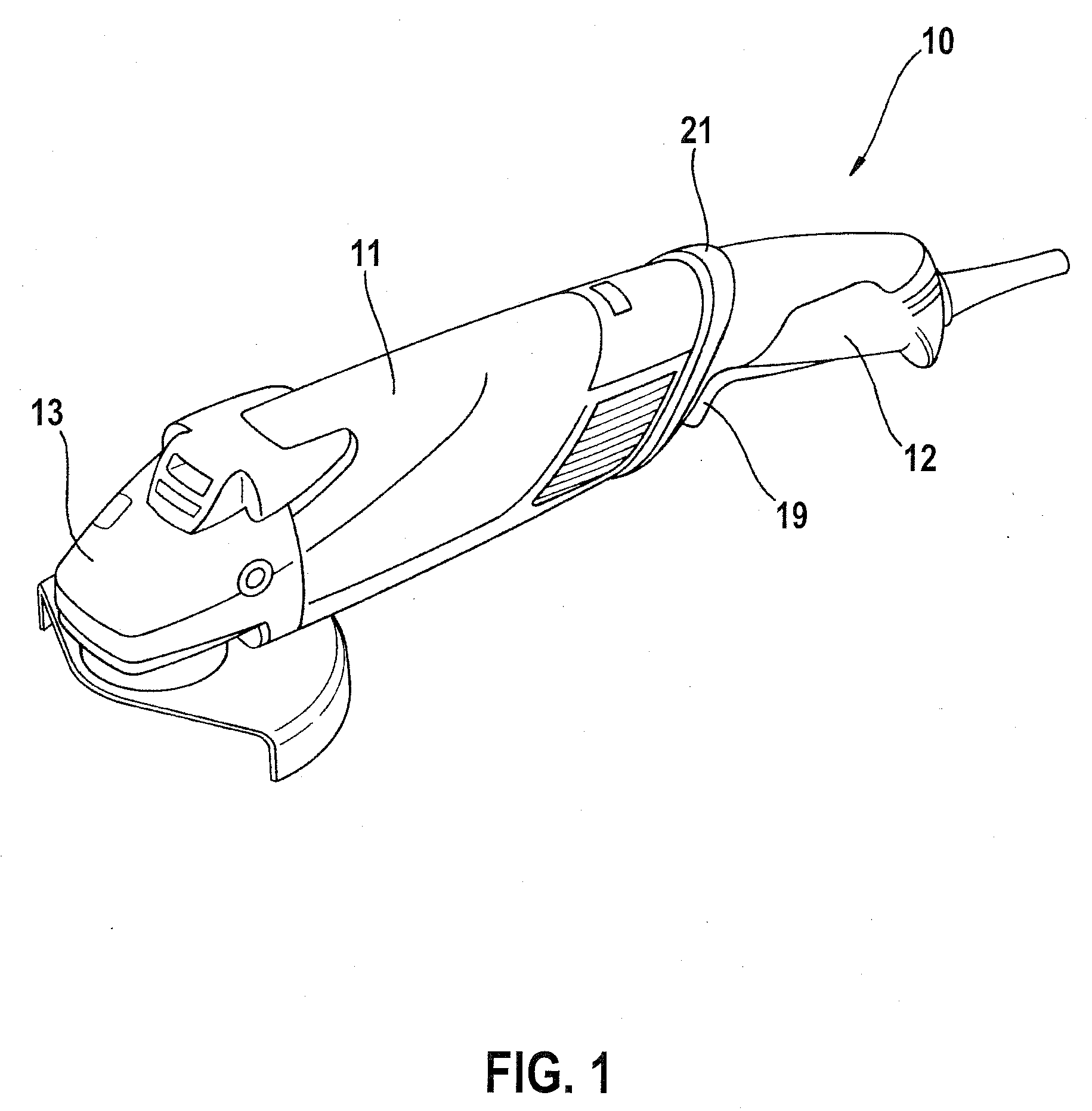

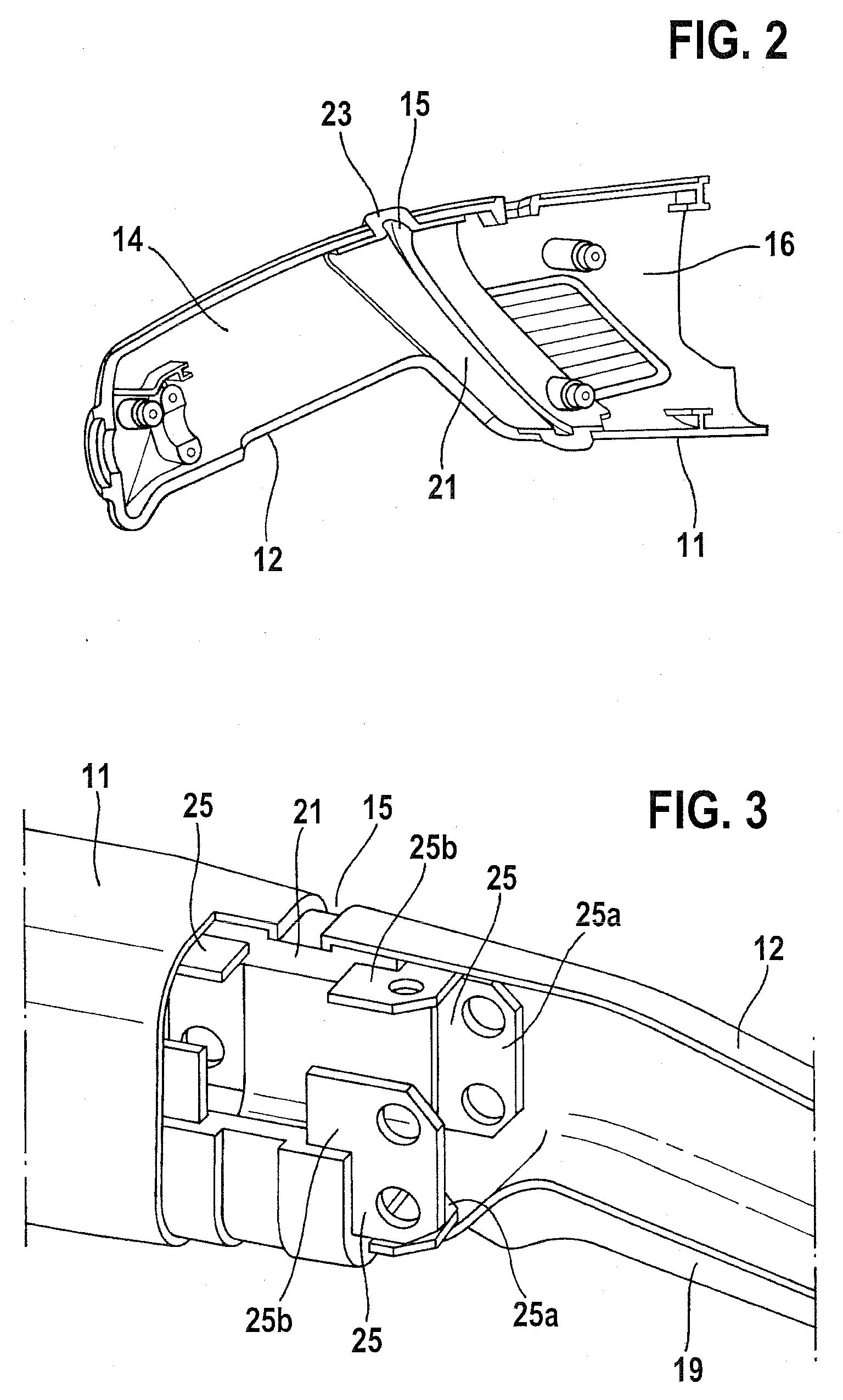

Hand power tool

InactiveUS20070289763A1Enhance user-friendlinessSimple shapePortable percussive toolsPortable grinding machinesPower toolHand held

In a hand power tool, including a first housing part and a second housing part as well as a damping element between the first housing part and the second housing part, the damping element is connectable to the first housing part and the second housing part, wherein the first housing part and the second housing part are spaced apart from one another longitudinally of the hand power tool.

Owner:ROBERT BOSCH GMBH

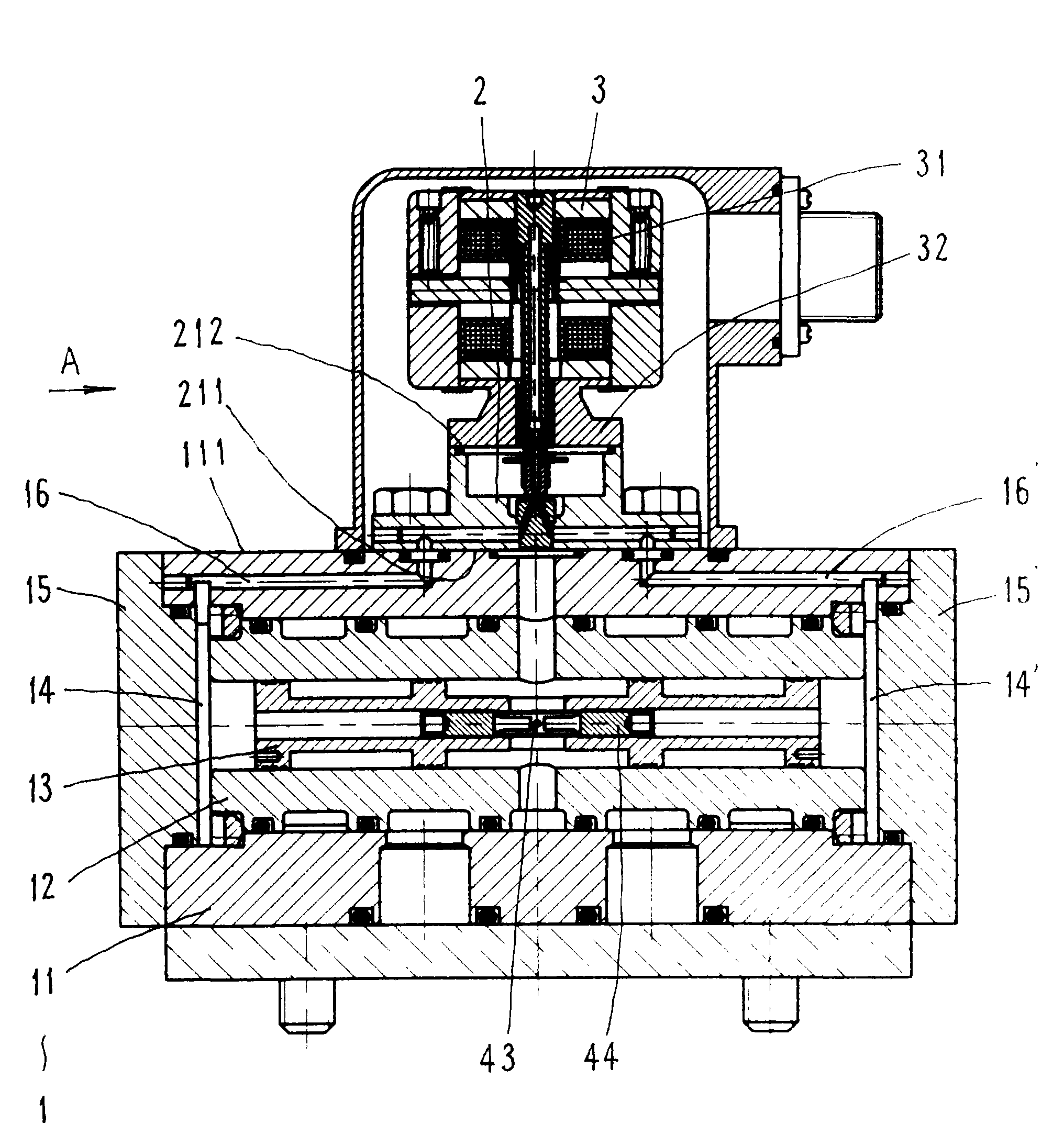

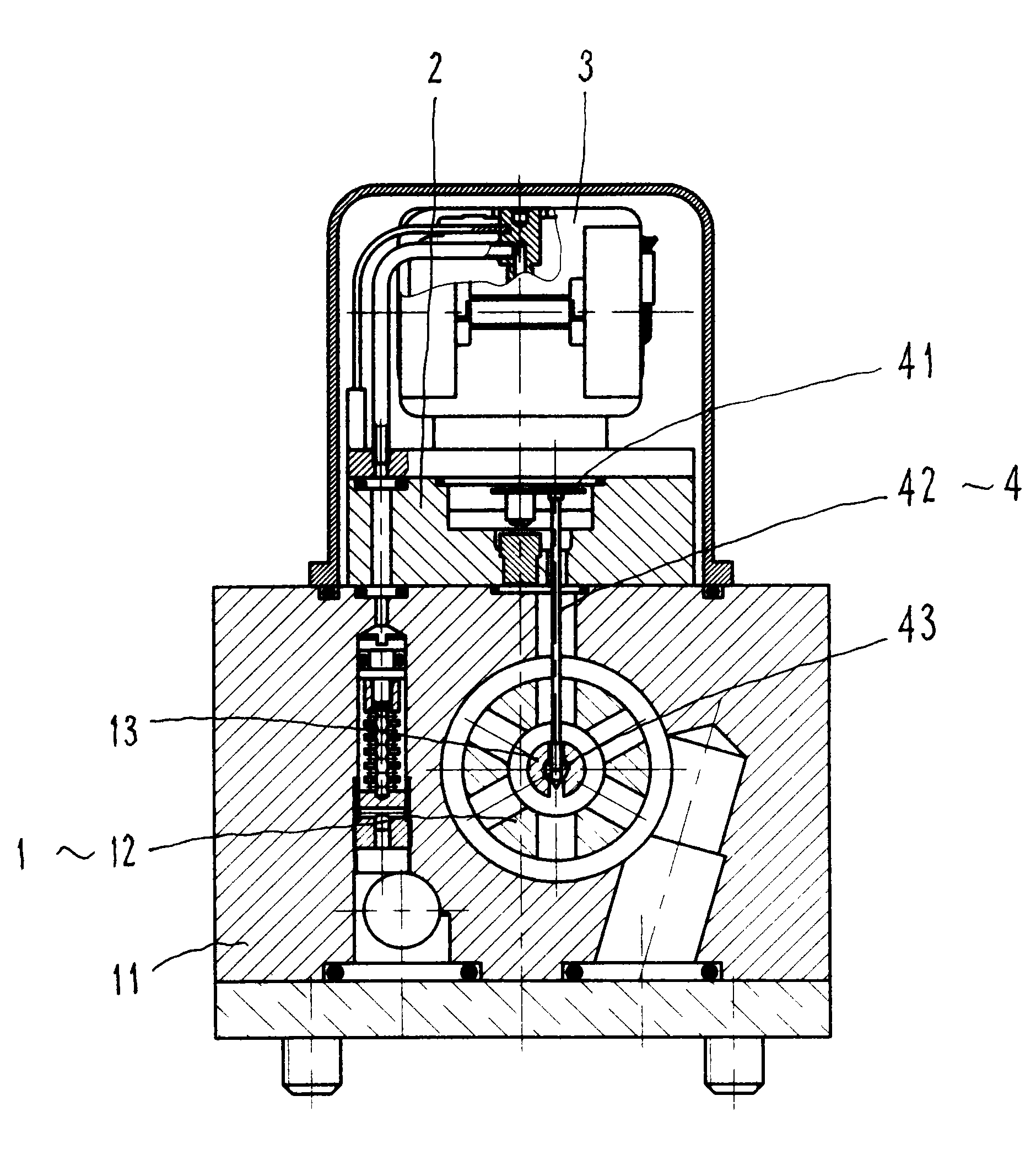

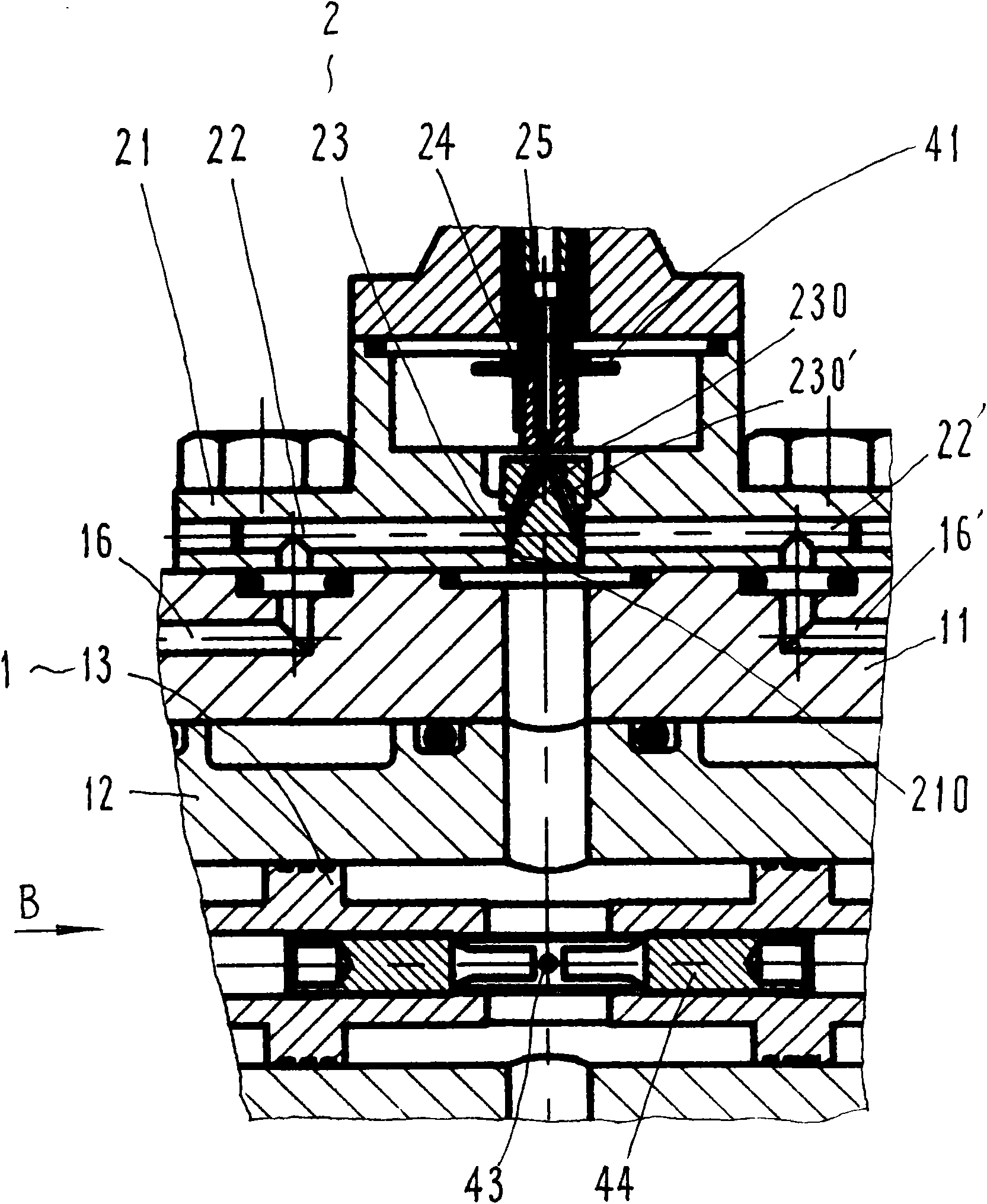

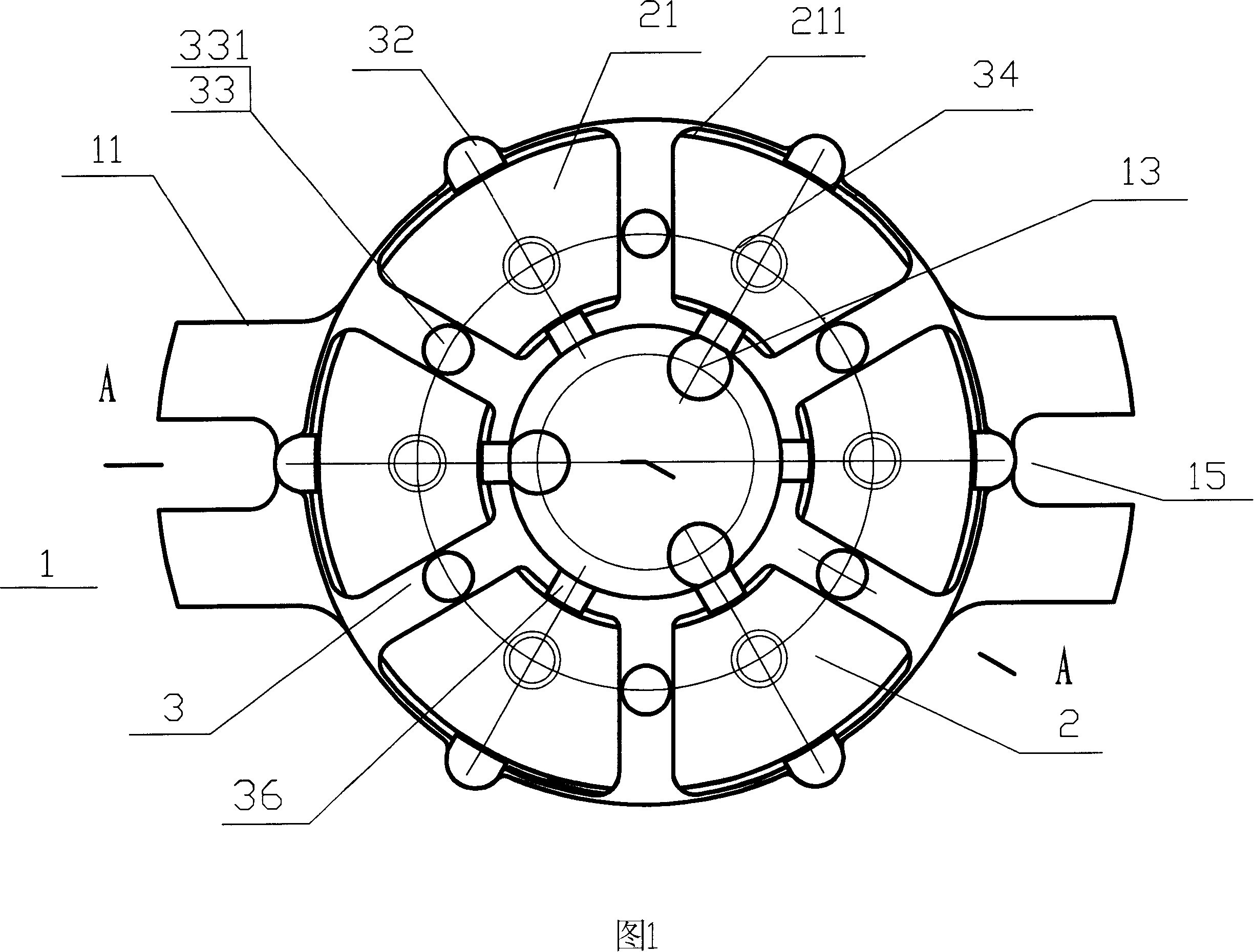

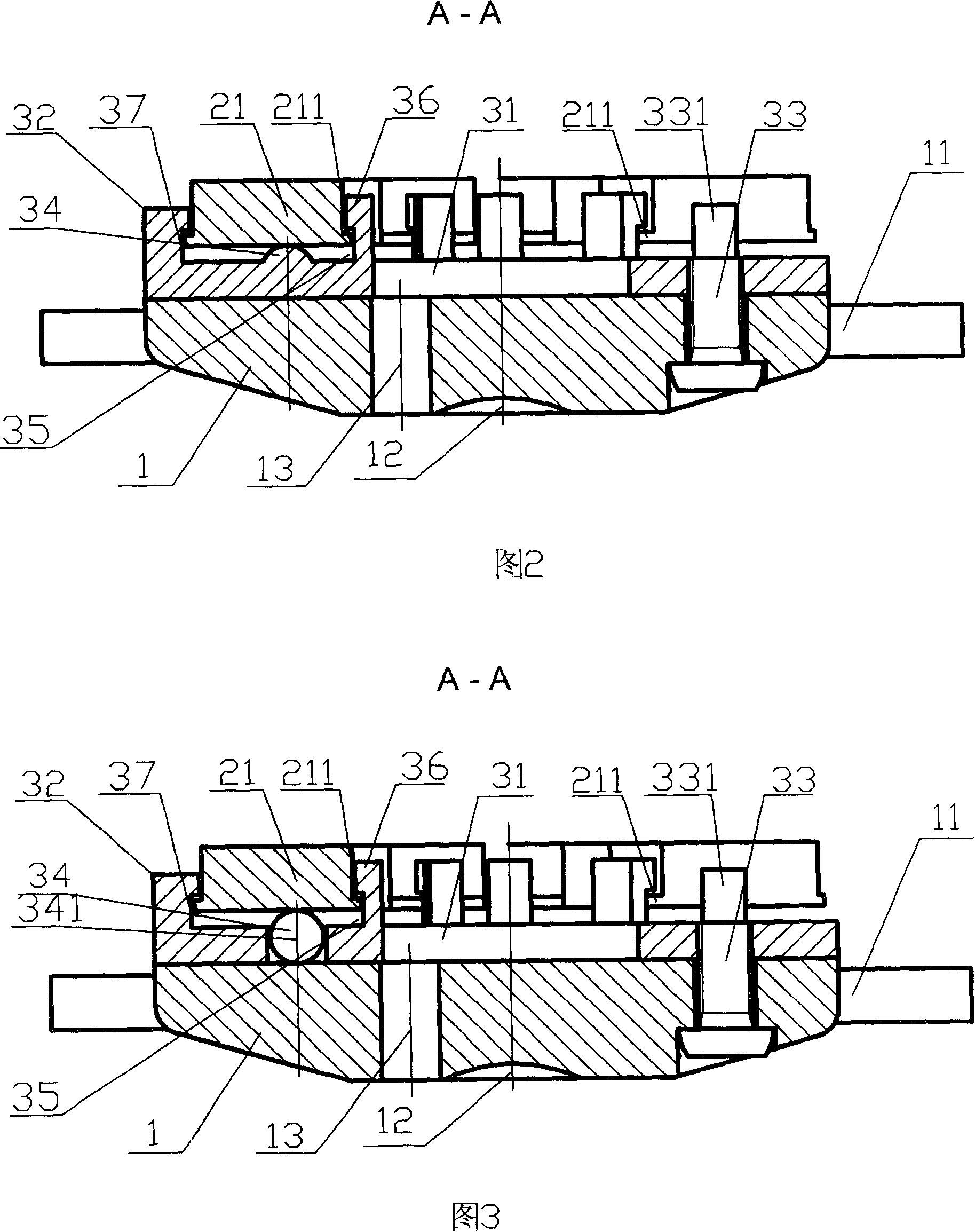

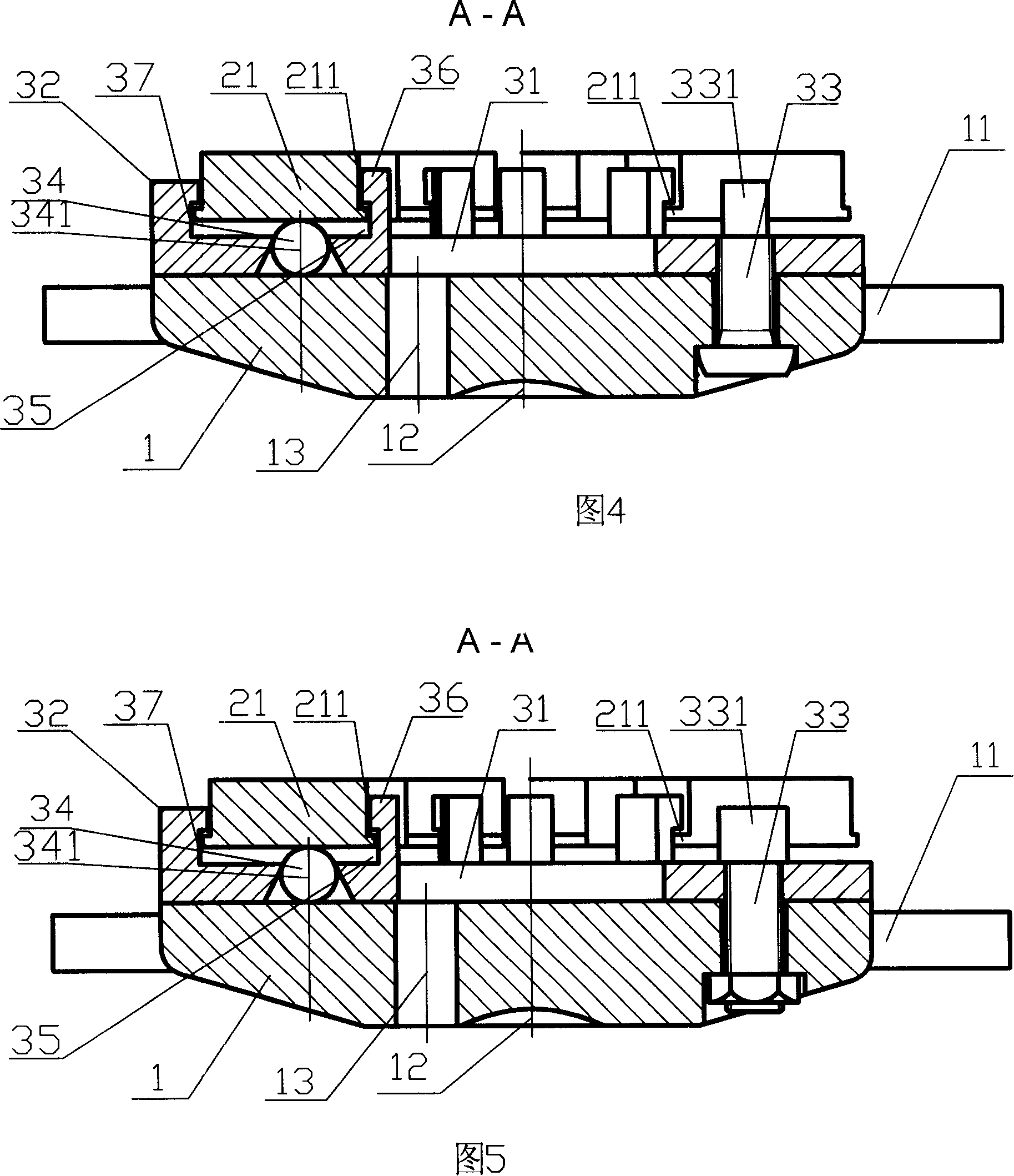

Electro-hydraulic servo valve for prestage independent type jet flow pipe

ActiveCN101614289ASimple shapeImprove machining accuracyOperating means/releasing devices for valvesServomotor componentsElectrohydraulic servo valveElectro hydraulic

The invention relates to an electro-hydraulic servo valve for a prestage independent type jet flow pipe, which mainly solves the technical problems of the improvement of the manufacturability of the electro-hydraulic servo valve, and the like. The electro-hydraulic servo valve adopts the technical scheme that the prestage jet flow pipe is provided with a switching block; the bottom surface of the switching block is connected with a main valve; the top surface of the switching block is connected with a torque motor; a receptor is fixed in an installing hole of the middle part of the switching block; a position adjacent to the bottom surface of the switching block is provided with a left oil hole and a right oil hole; one end of the left oil hole and one end of the right oil hole are connected with a left guide hole and a right hole of the main valve respectively; and the other end of the left oil hole and the other end of the right oil hole are communicated with a left receiving hole and a right receiving hole of the receptor respectively. The electro-hydraulic servo valve for the prestage independent type jet flow pipe is suitable for various electro-hydraulic servo valves for the prestage jet flow pipe.

Owner:SHANGHAI HENGTUO HYDRAULIC CONTROL TECH

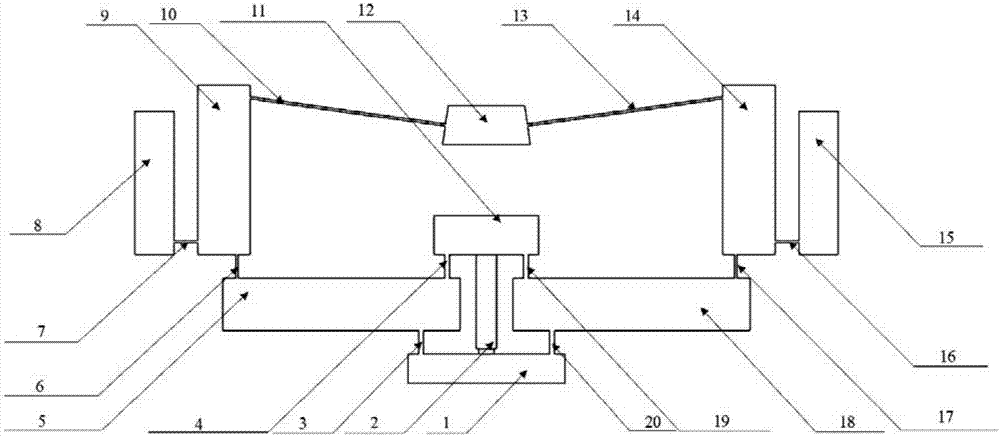

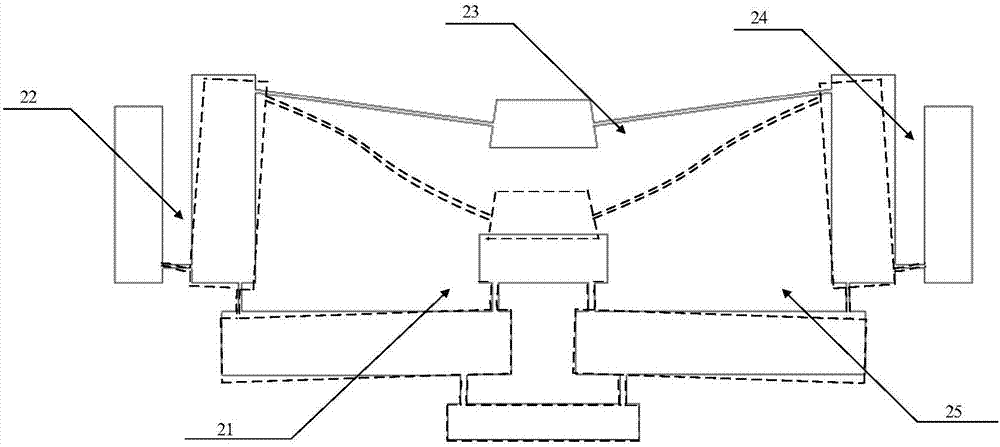

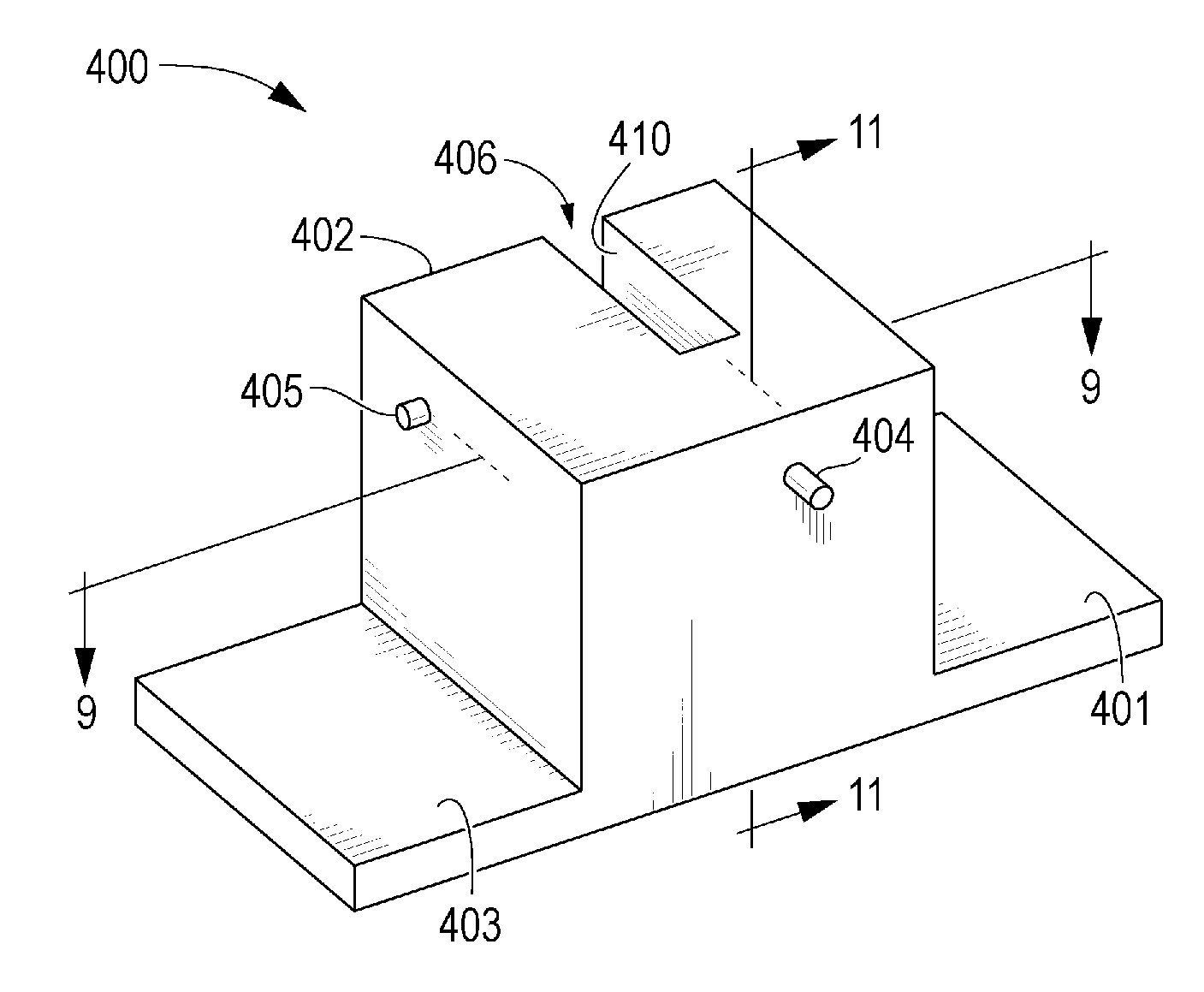

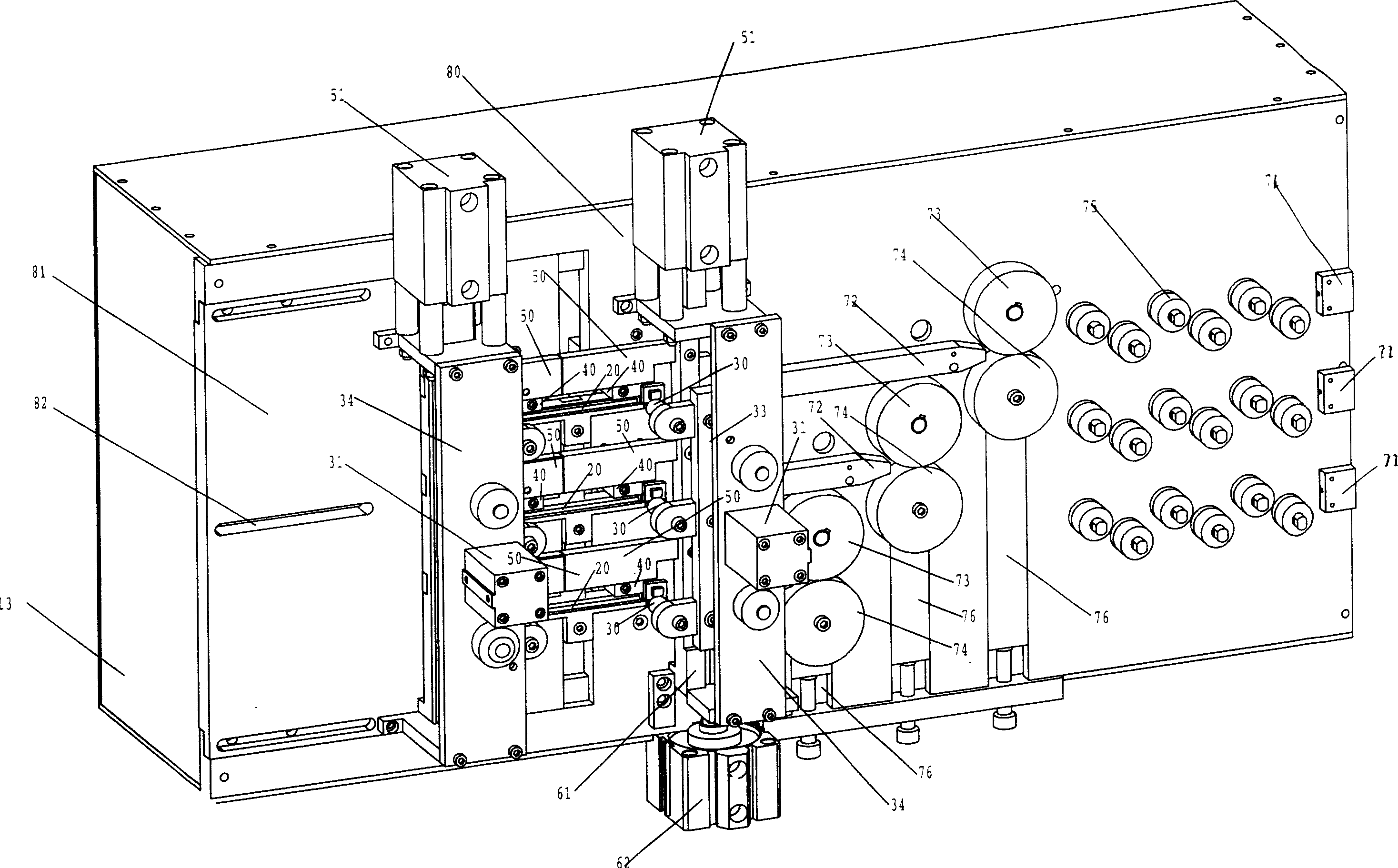

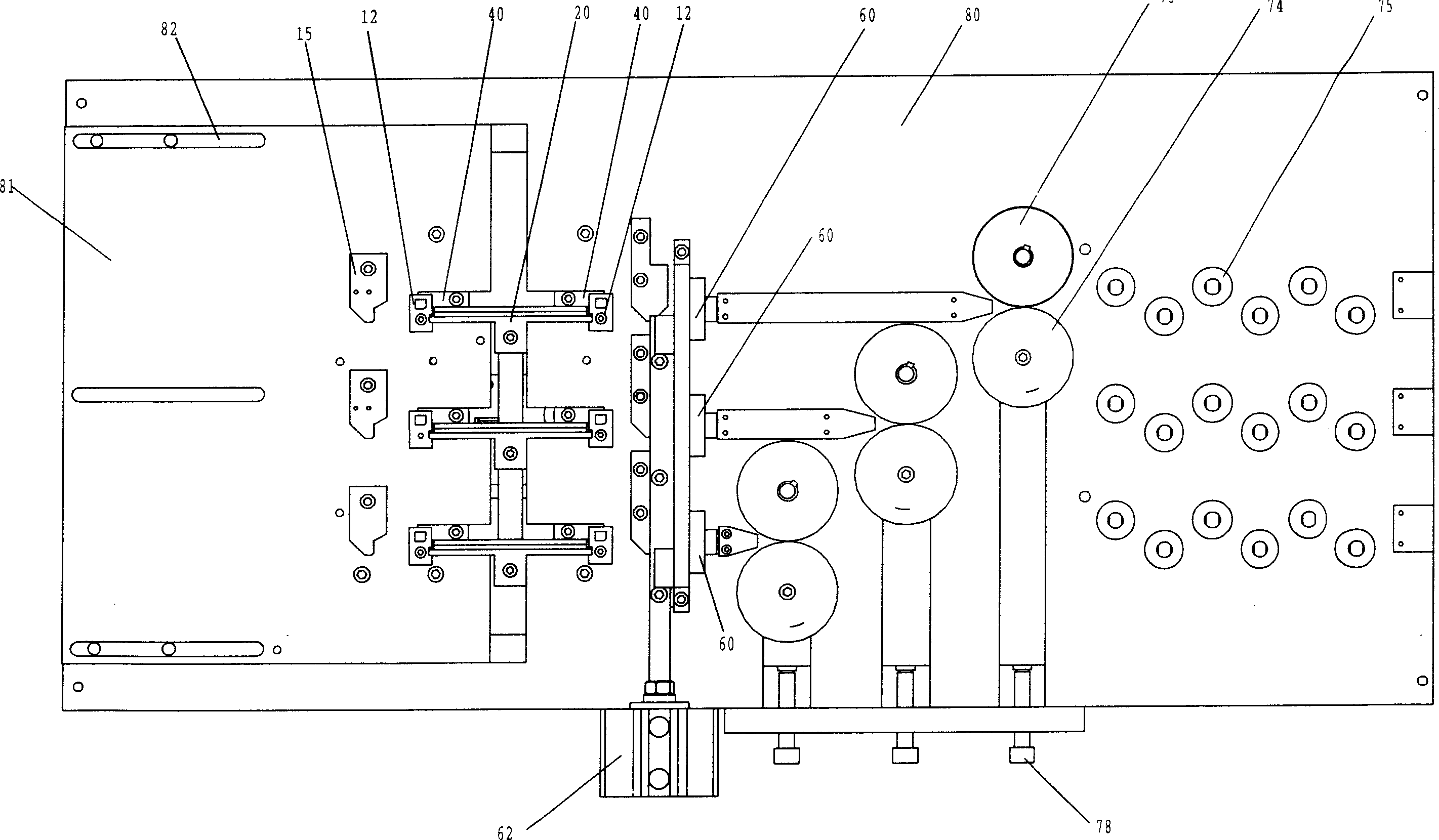

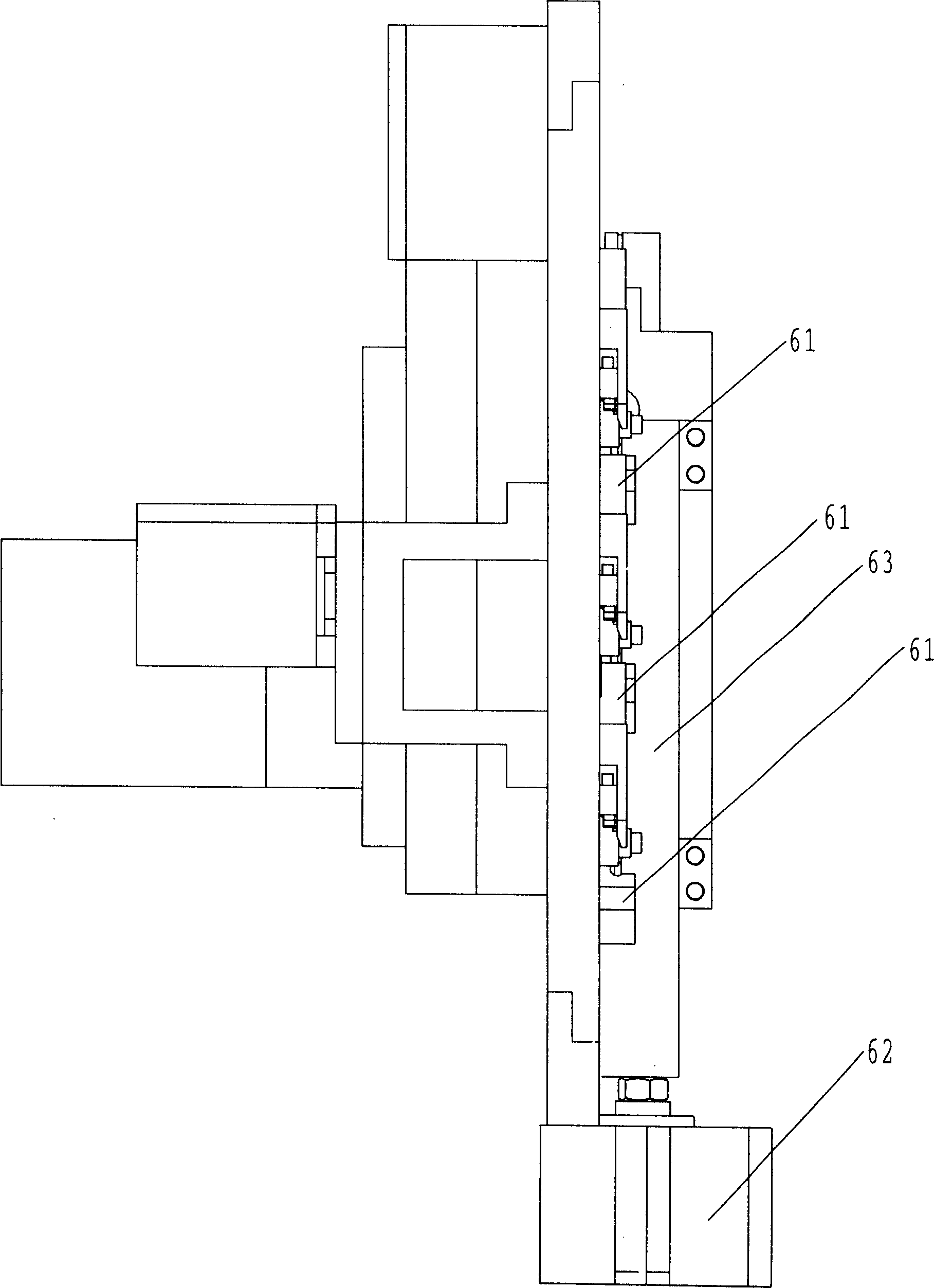

Micro-displacement positioning platform with three-stage amplifying mechanisms

ActiveCN106981316AHigh displacement amplification ratioEffective introductionInstrumental componentsThree stageFixed frame

The invention relates to a micro-displacement positioning platform with three-stage amplifying mechanisms. The micro-displacement positioning platform comprises a fixed frame, a displacement input platform, a motion input mechanism, two sets of first-grade lever mechanisms, two sets of second-grade lever mechanisms and a semi-axle amplifying mechanism; the two sets of first-grade lever mechanisms and the two sets of second-grade lever mechanisms are symmetrical; fulcrums of the first-grade lever mechanisms and the second-grade lever mechanisms are both in transmission connection with the fixed frame; two ends of the motion input mechanism are respectively connected with the fixed frame and the displacement input platform; input ends of the two sets of first-grade lever mechanisms are respectively in transmission connection with the displacement input platform, and output ends are respectively in transmission connection with input ends of the corresponding second-grade lever mechanisms; and the semi-axle amplifying mechanism is connected between the output ends of the two sets of second-grade lever mechanisms. The micro-displacement positioning platform depends on compound serial connection of two stages of lever mechanisms and one stage of bridge mechanisms to solve such problems as low displacement-amplification ratio and parasitic displacement in the prior art so as to realize wide-range precise positioning of a motion platform.

Owner:SHANGHAI UNIV OF ENG SCI

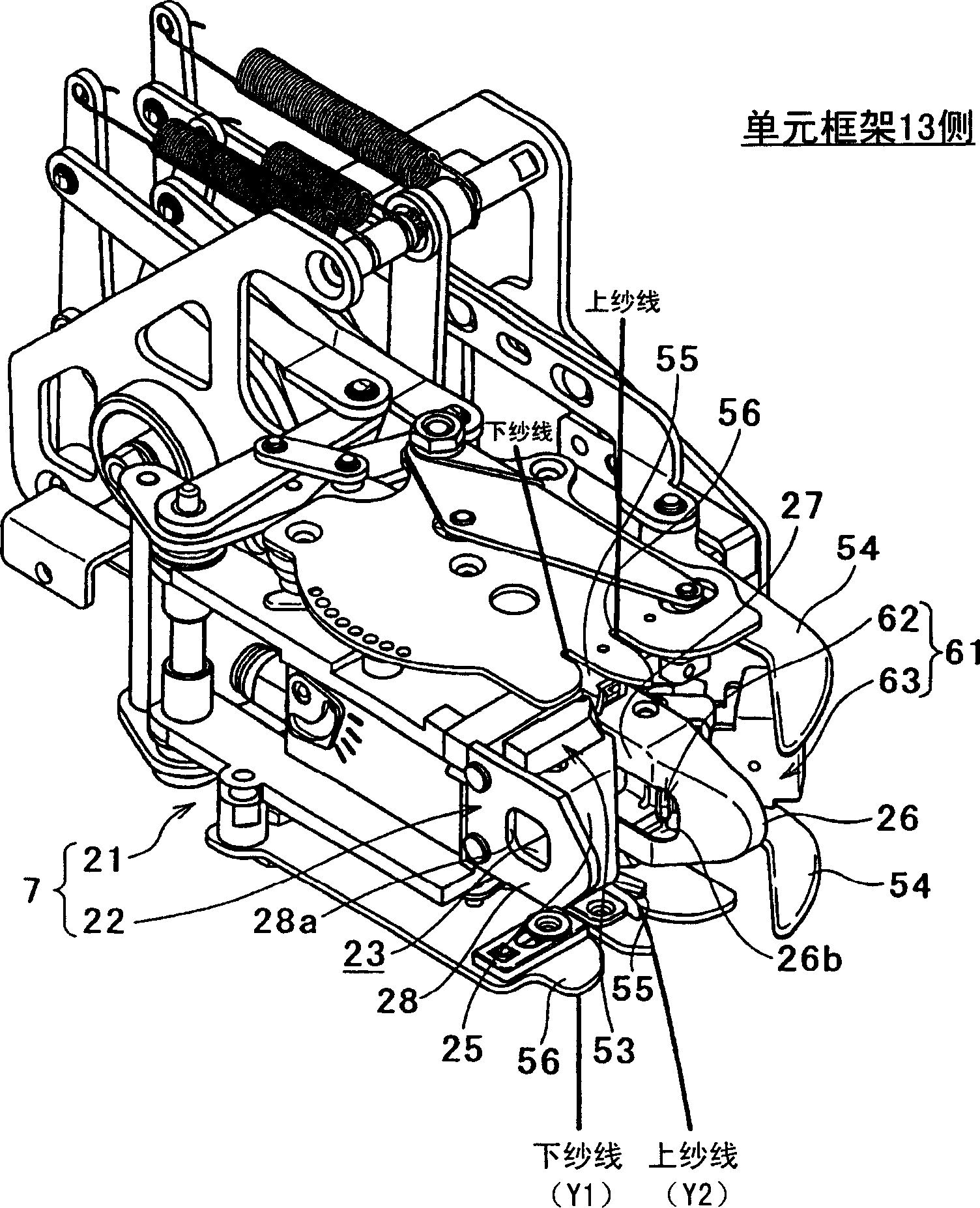

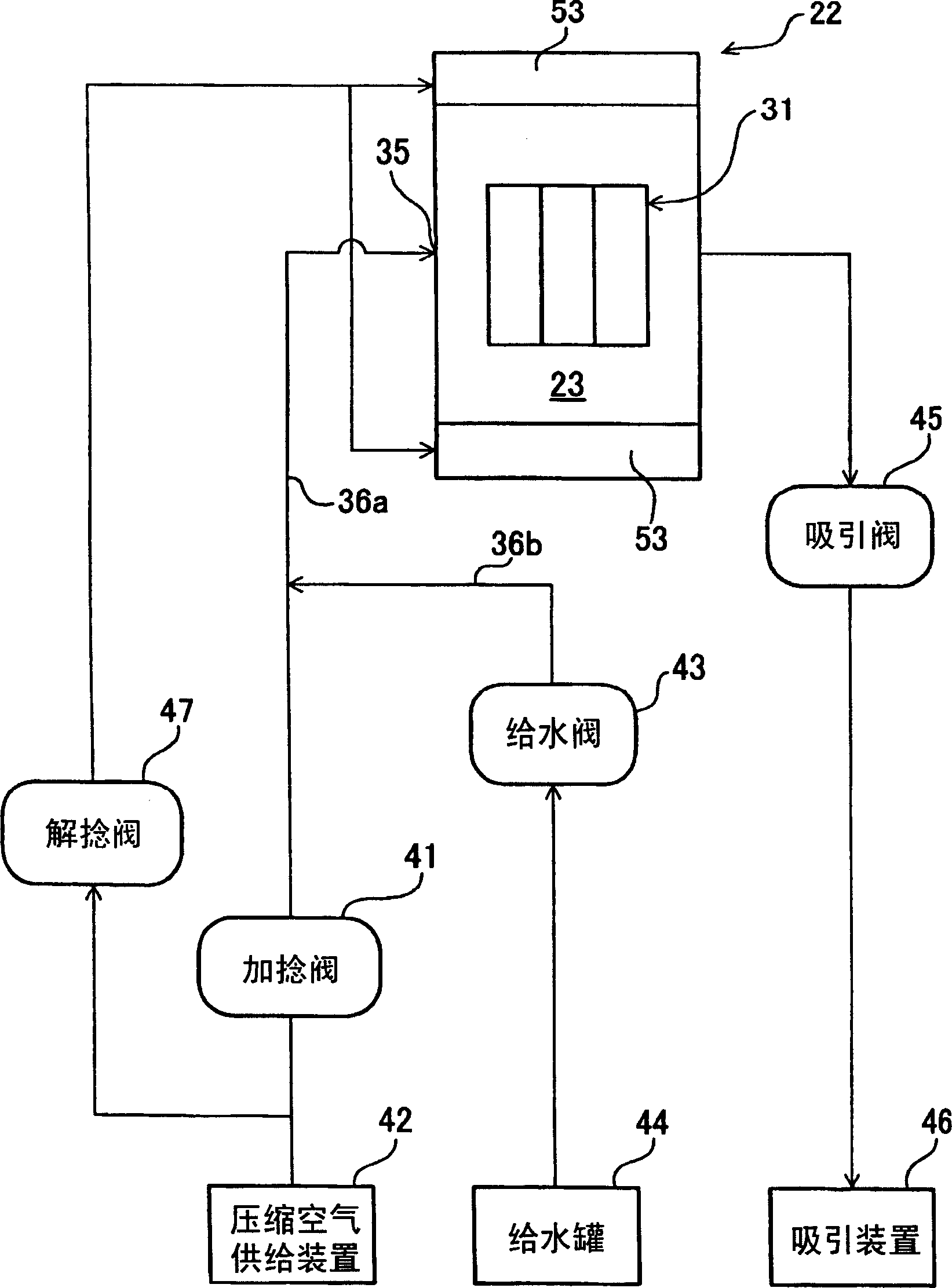

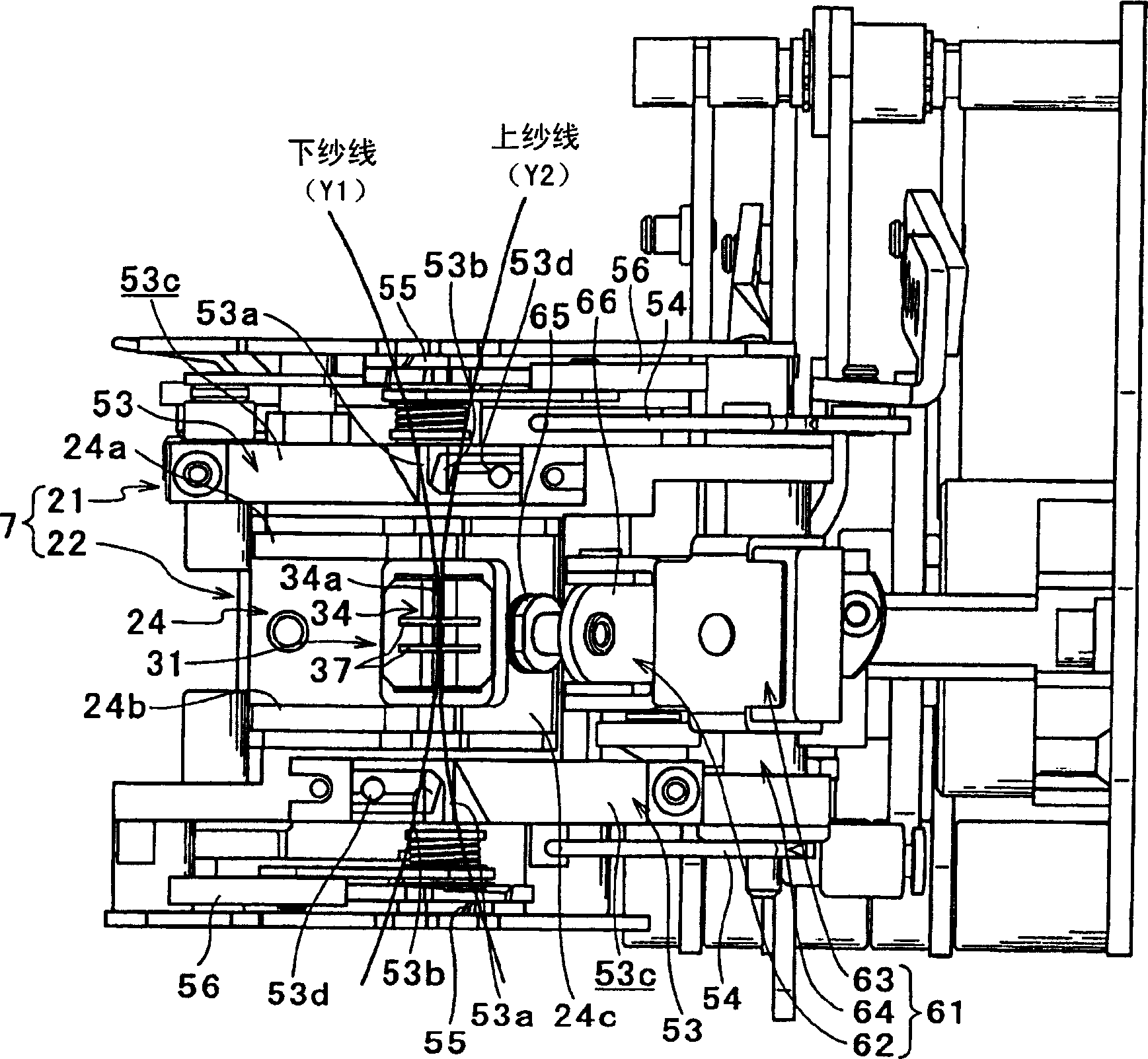

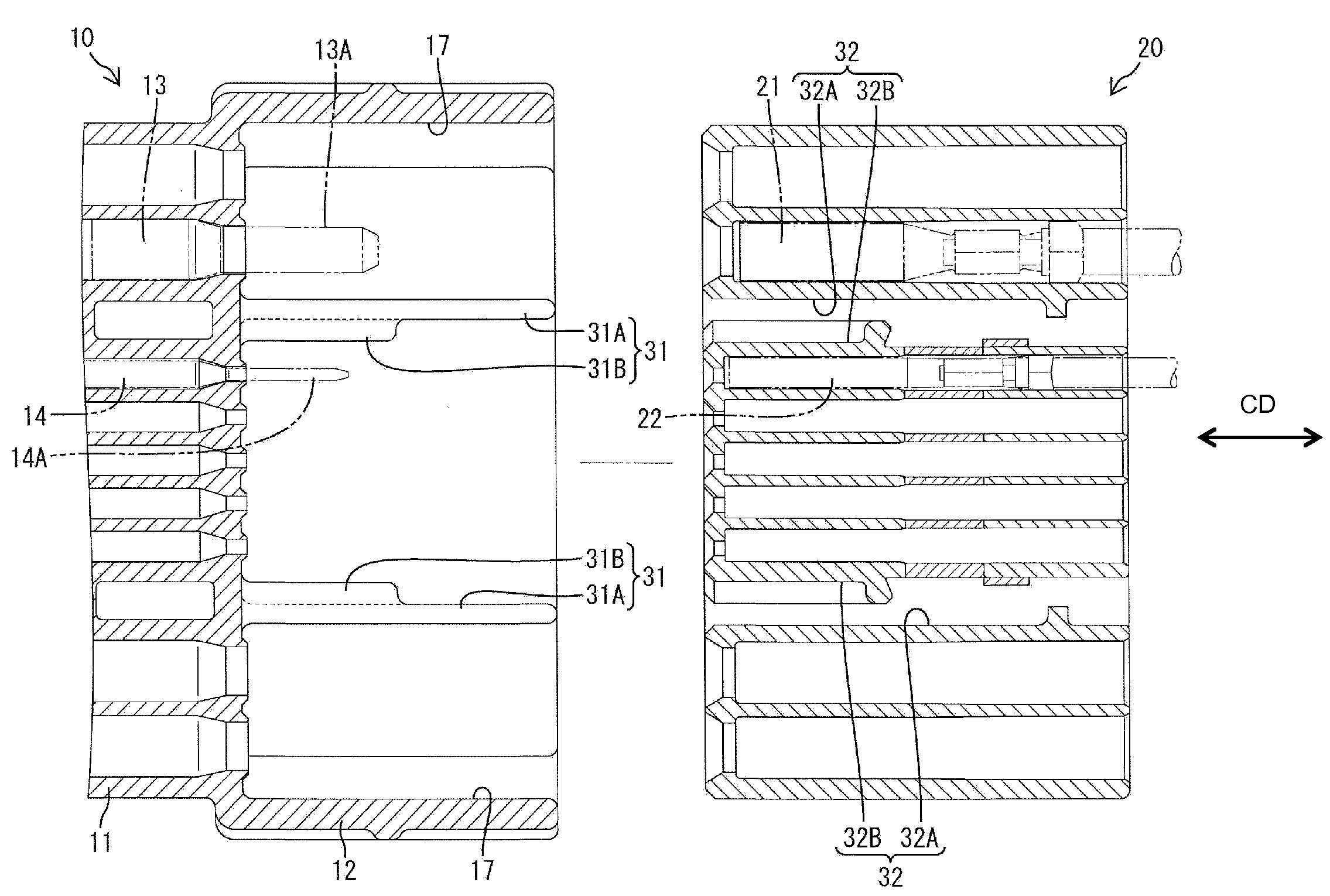

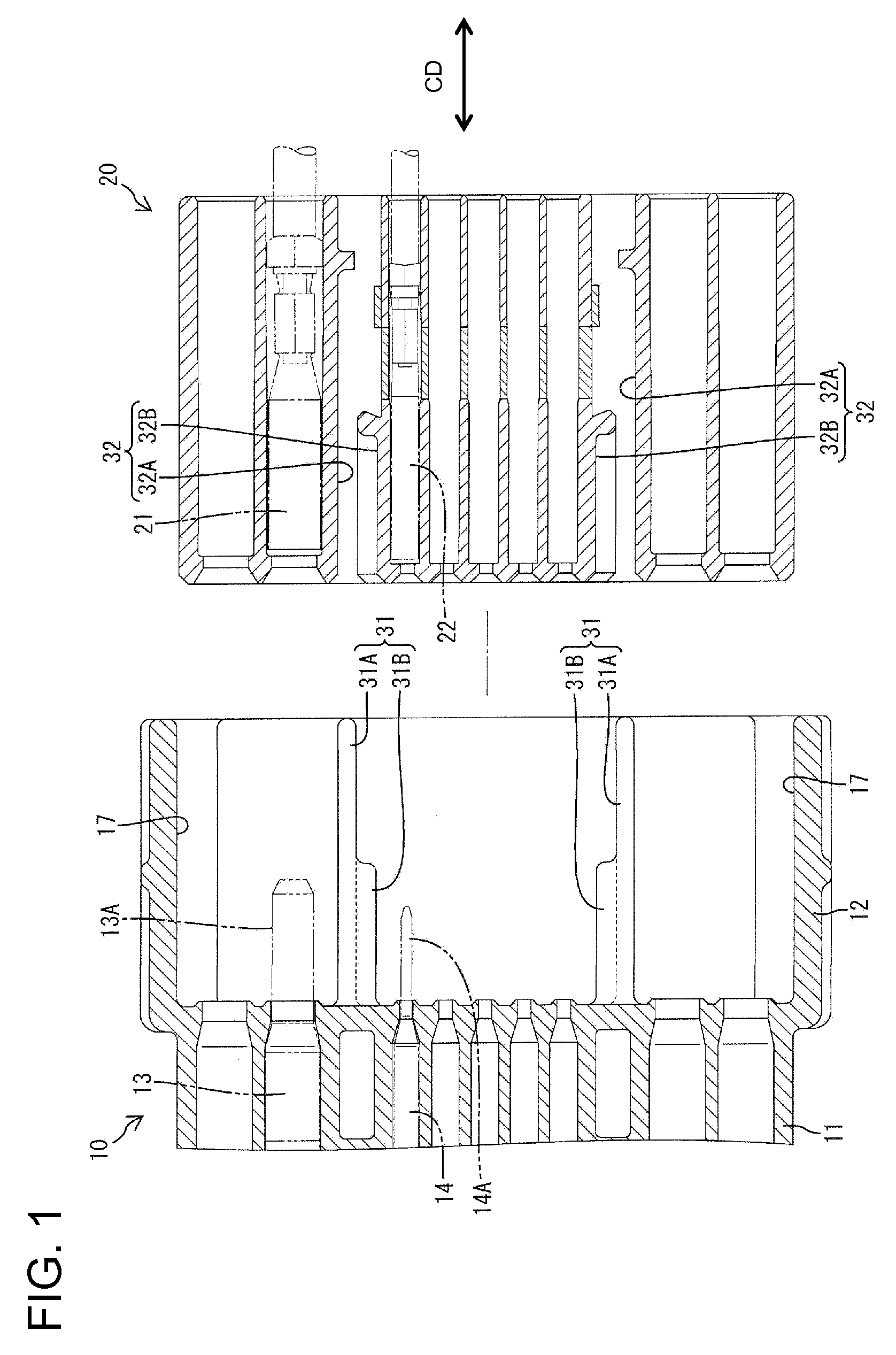

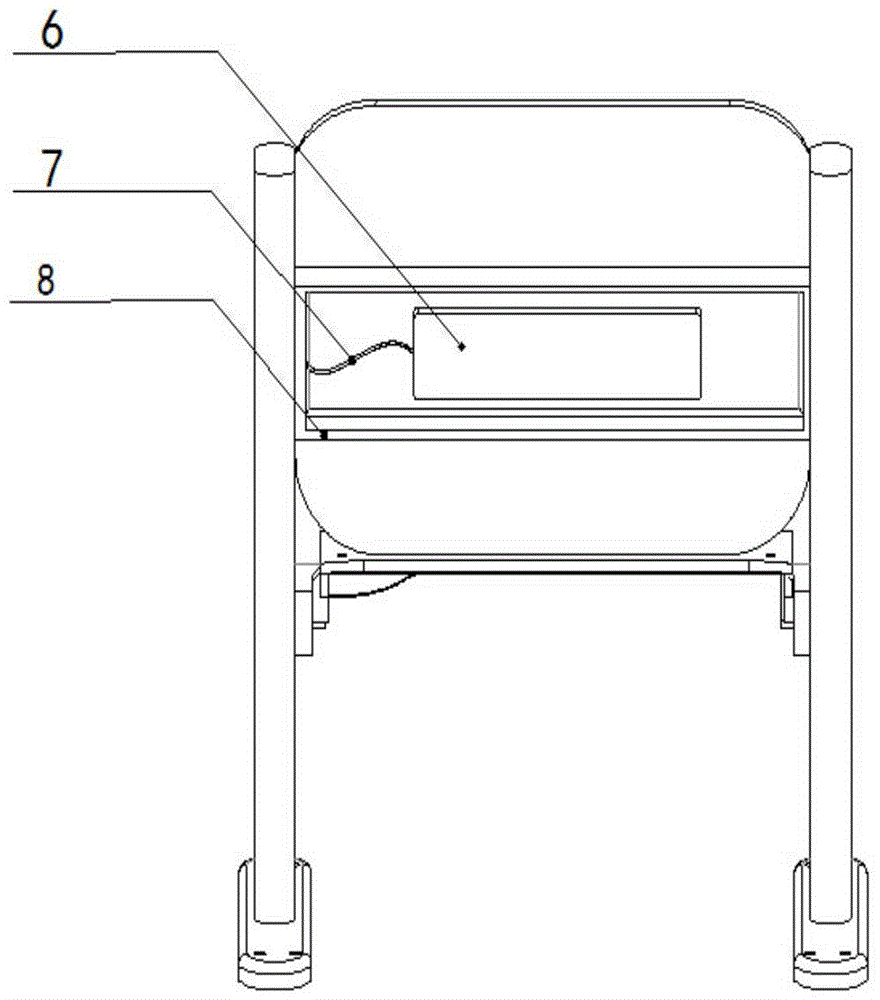

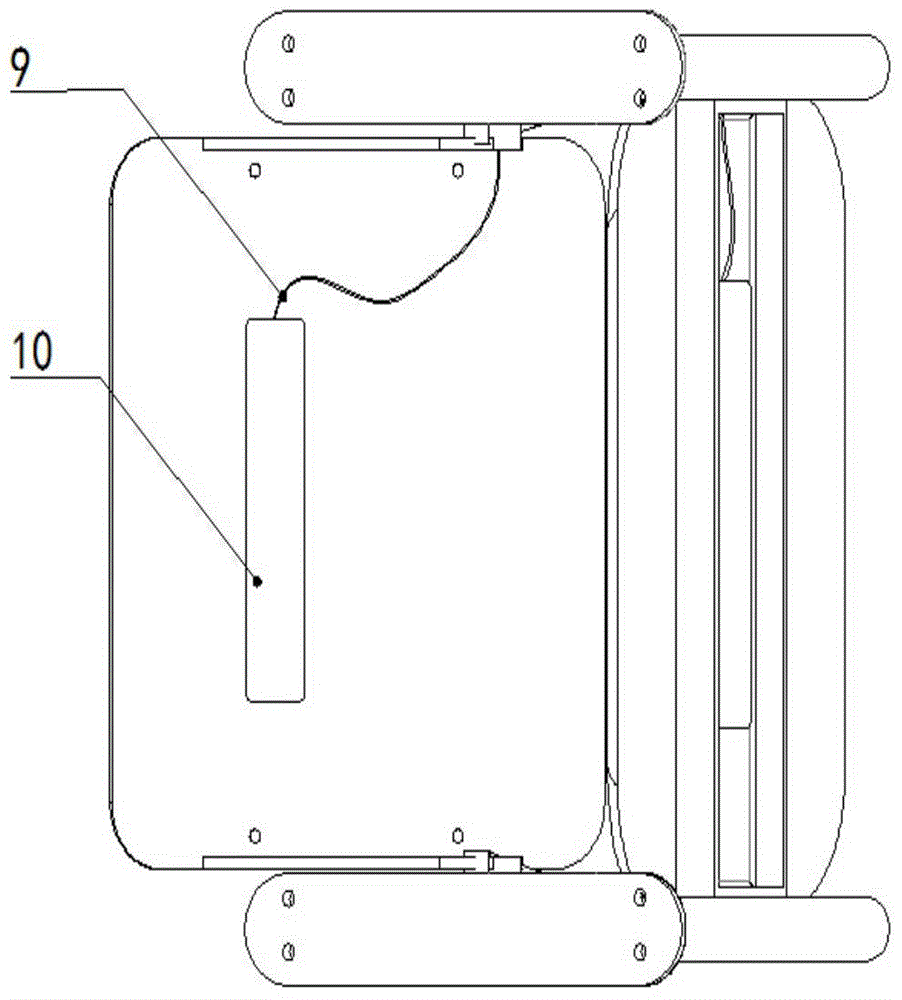

Splicing device, yarn splicing method and joint

InactiveCN1876539ASimple shapeLow manufacturing costFilament handlingPiercing arrangementsYarnGas release

A twisting member (31) of a splicing device includes a yarn splicing hole (34a) in which yarns to be twisted (Y, Y1, Y2) are set, groove portions (37, 37) as gas release portions (37, 37) formed in directions different from a longitudinal direction of the yarn splicing hole (34a), and air paths (34c, 34c) provided in a pair that form air injection ports (34b, 34b), respectively, in the yarn splicing hole (34a) and form whirling flows opposite to each other inside the yarn splicing hole (34a). A plurality of groove portions (37, 37) are formed, and the air injection ports (34b, 34b) formed by the air paths (34c, 34c) in the yarn splicing hole (34a) are positioned further outside than the plurality of groove portions (37, 37).

Owner:MURATA MASCH LTD

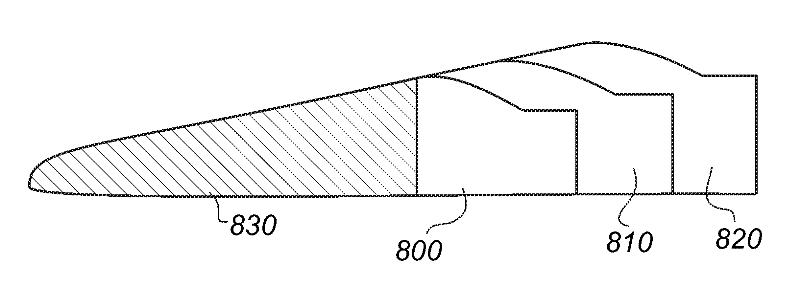

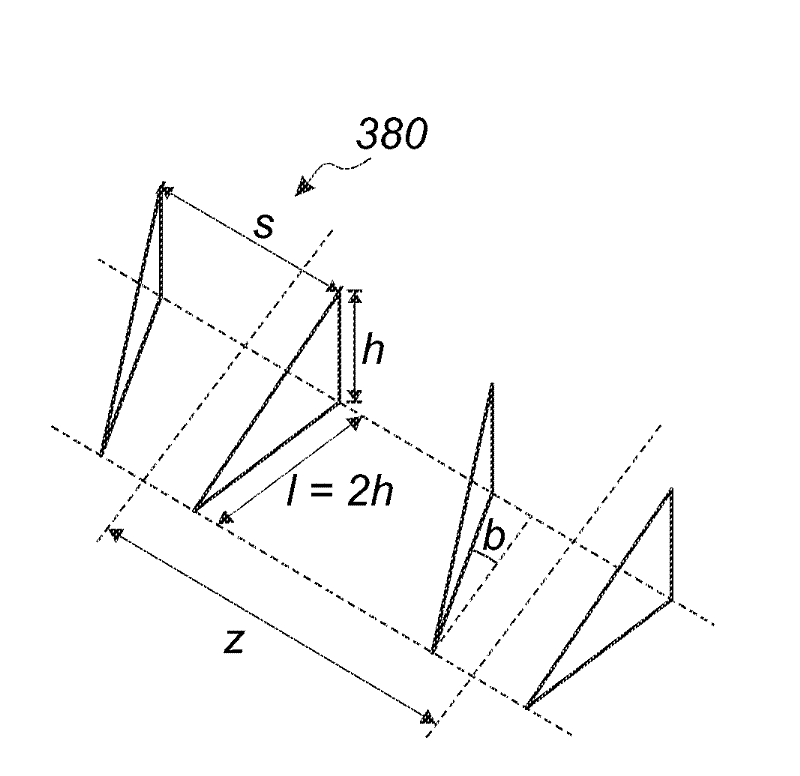

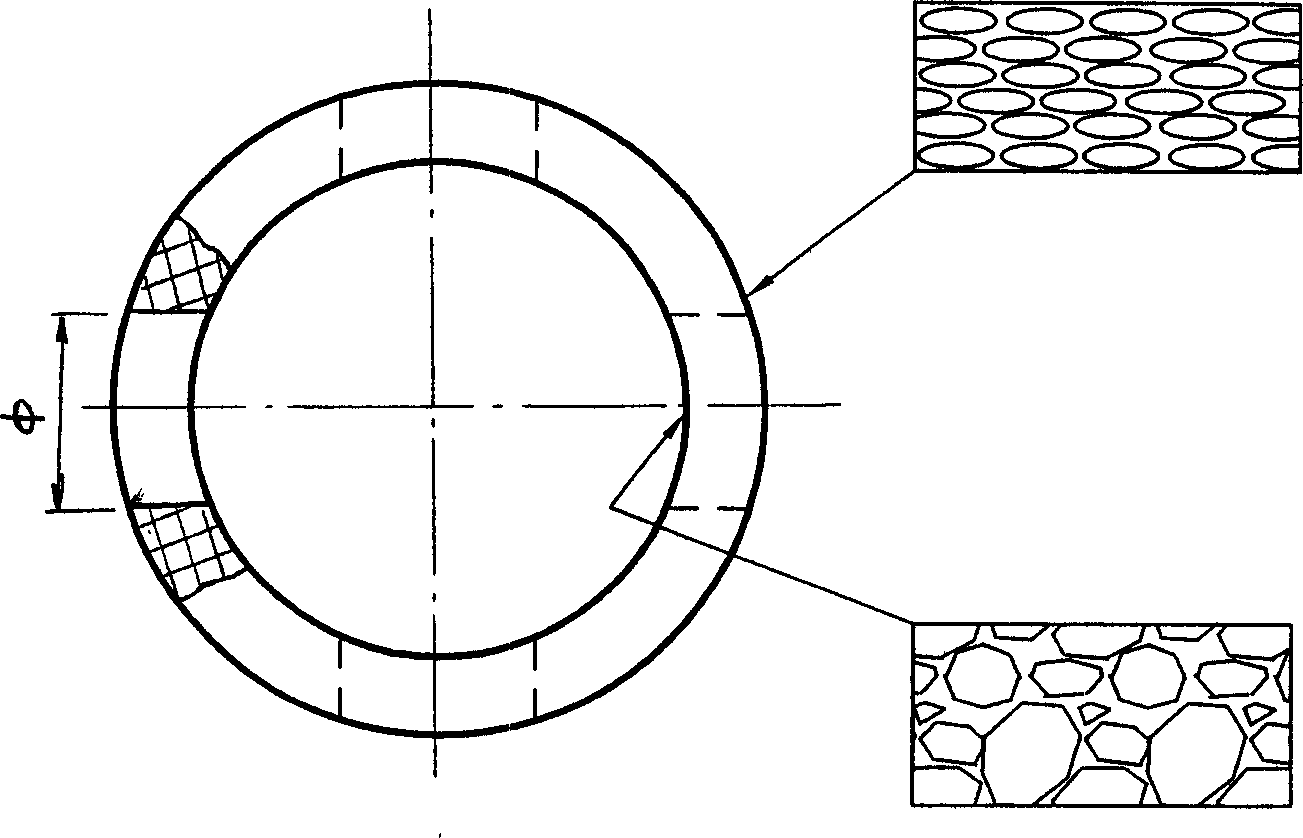

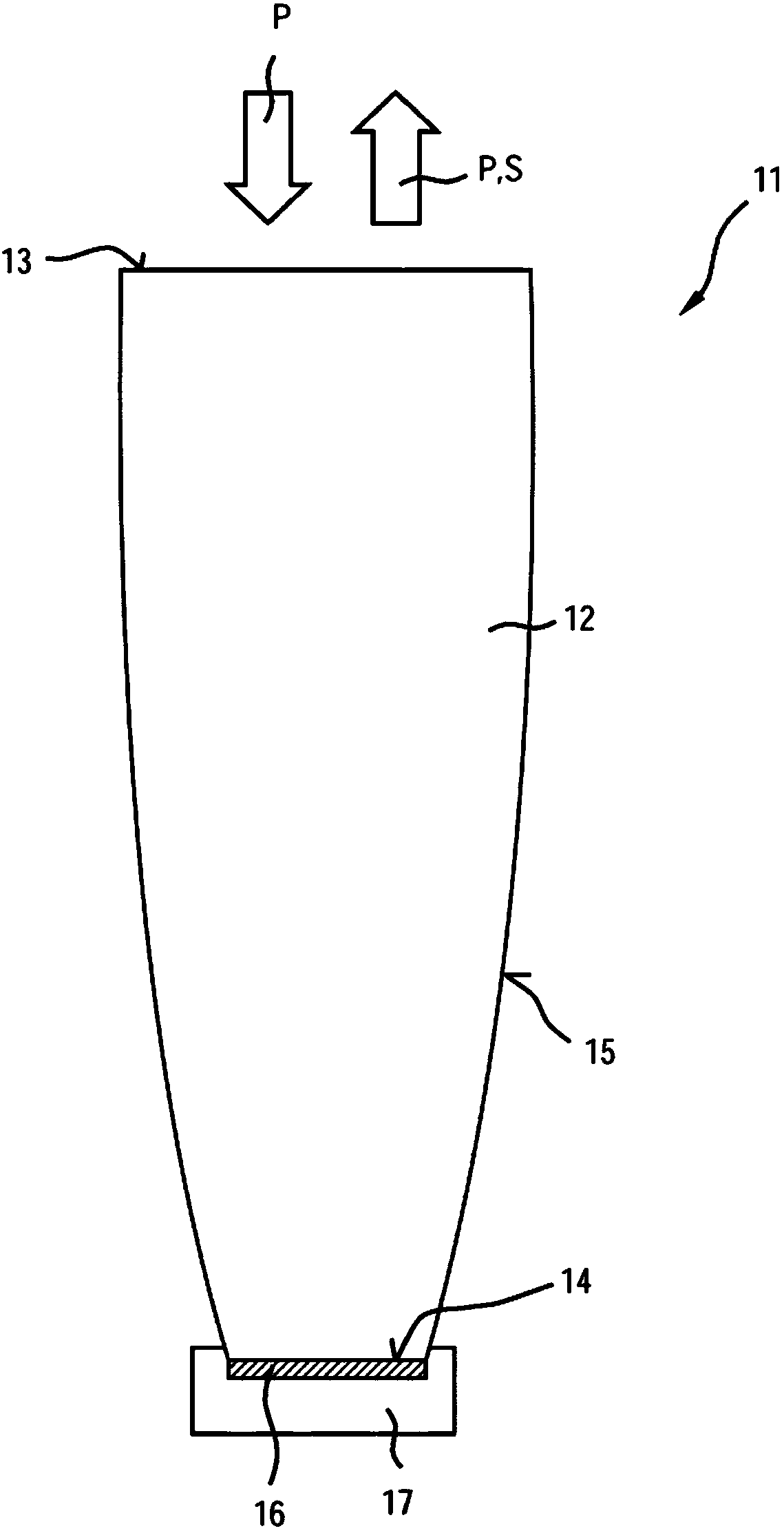

Wind turbine blade

ActiveCN102459881ASimple shapeThe mold part is simpleMachines/enginesEngine componentsTrailing edgeWind force

A blade for a rotor of a wind turbine having a substantially horizontal rotor shaft is described. The rotor comprises a hub, from which the blade extends substantially in a radial direction when mounted to the hub. The blade comprises a profiled contour comprising a pressure side and a suction side as well as a leading edge and a trailing edge with a chord extending between the leading edge and the trailing edge, the profiled contour generating a lift when being impacted by an incident airflow, the profiled contour in the radial direction being divided into a root region with a substantially circular or elliptical profile closest to the hub, an airfoil region with a lift generating profile furthest away from the hub, and preferably a transition region between the root region and the airfoil region, the transition region having a profile gradually changing in the radial direction from the circular or elliptical profile of the root region to the lift generating profile of the airfoil region, wherein the airfoil region comprises at least a first longitudinal segment extending along at least 20% of a longitudinal extent of the airfoil region, the first longitudinal segment comprising a first base part having a leading edge and a trailing edge with a chord extending between the leading edge and the trailing edge. The first base part has an inner dimension that varies linearly in the radial direction of the blade in such a way that an induction factor of the first base part without flow altering devices at a rotor design point deviates from a target induction factor. The first longitudinal segment is provided with a number of first flow altering devices arranged so as to adjust the aerodynamic properties of the first longitudinal segment to substantially meet the target induction factor at the design point.

Owner:LM GLASSFIBER

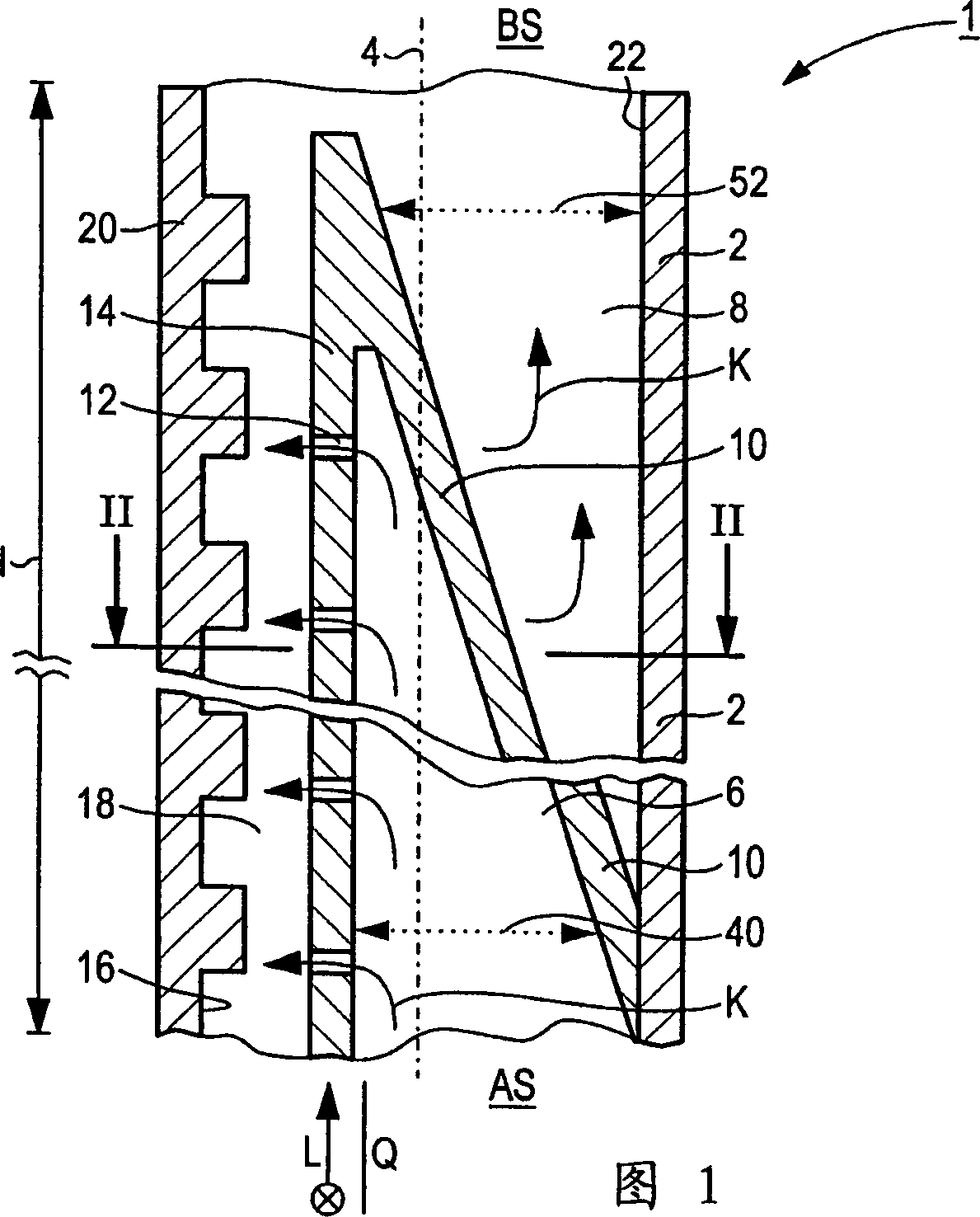

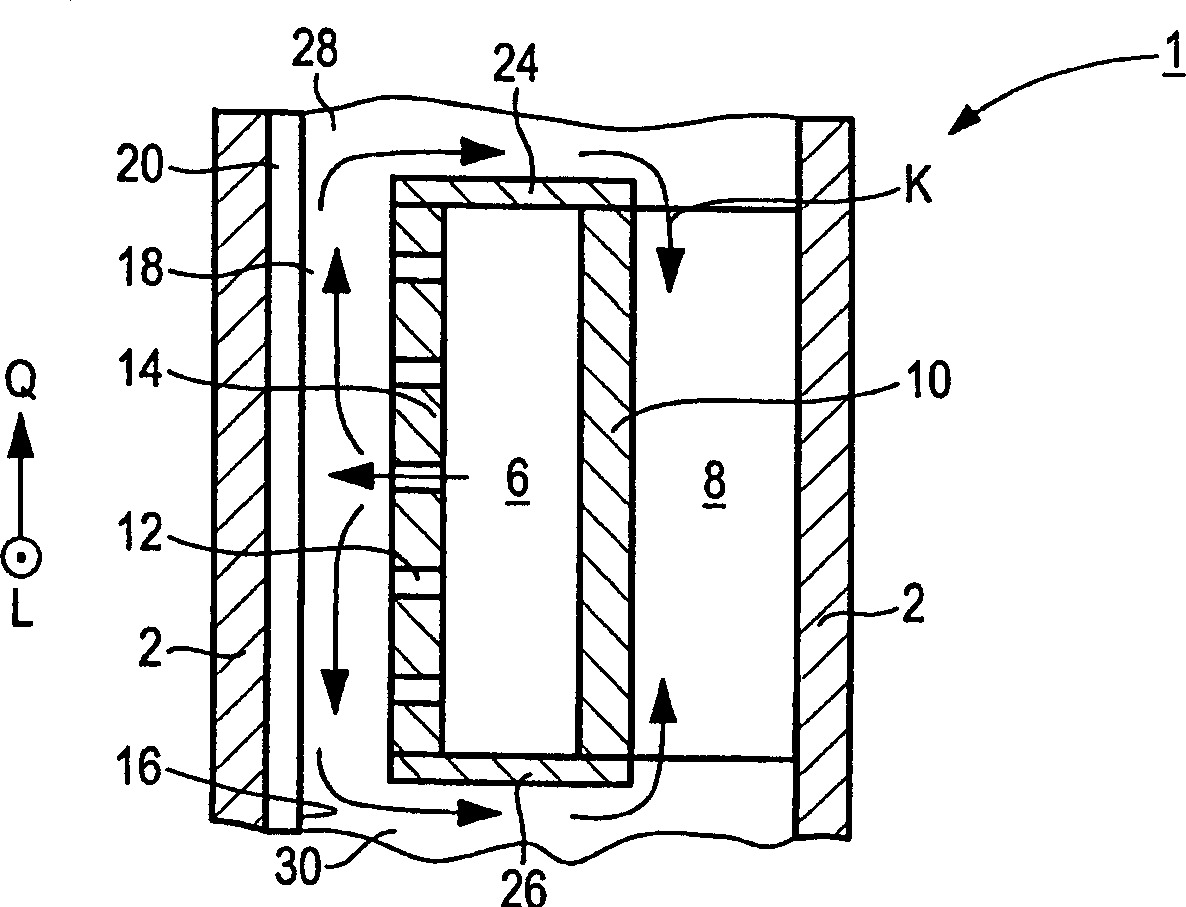

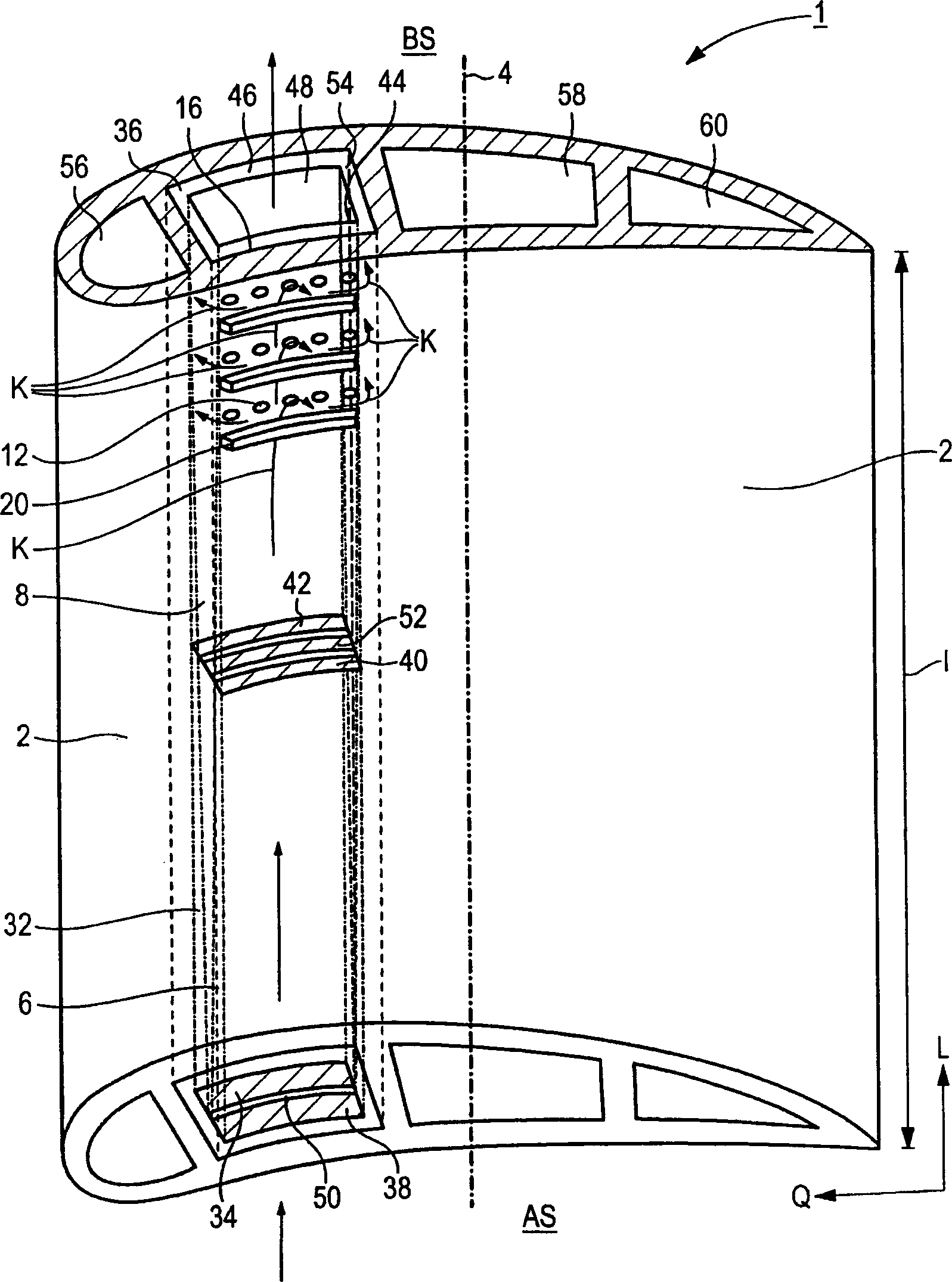

Gas turbine blade/guiding blade

InactiveCN1405431AEfficient removalFree cross section reductionEngine fuctionsBlade accessoriesSteam turbine bladeReturn channel

The turbine blade (1) has a blade section (2) supplied with a cooling medium (K), e.g. air, flowing in the direction of the blade, axis via flow and return channels (6,8) extending over its full length. The flow and return channels are coupled together so that the cooling medium flows between them in a transverse direction across an internal partition wall (16) of the blade section.

Owner:SIEMENS AG

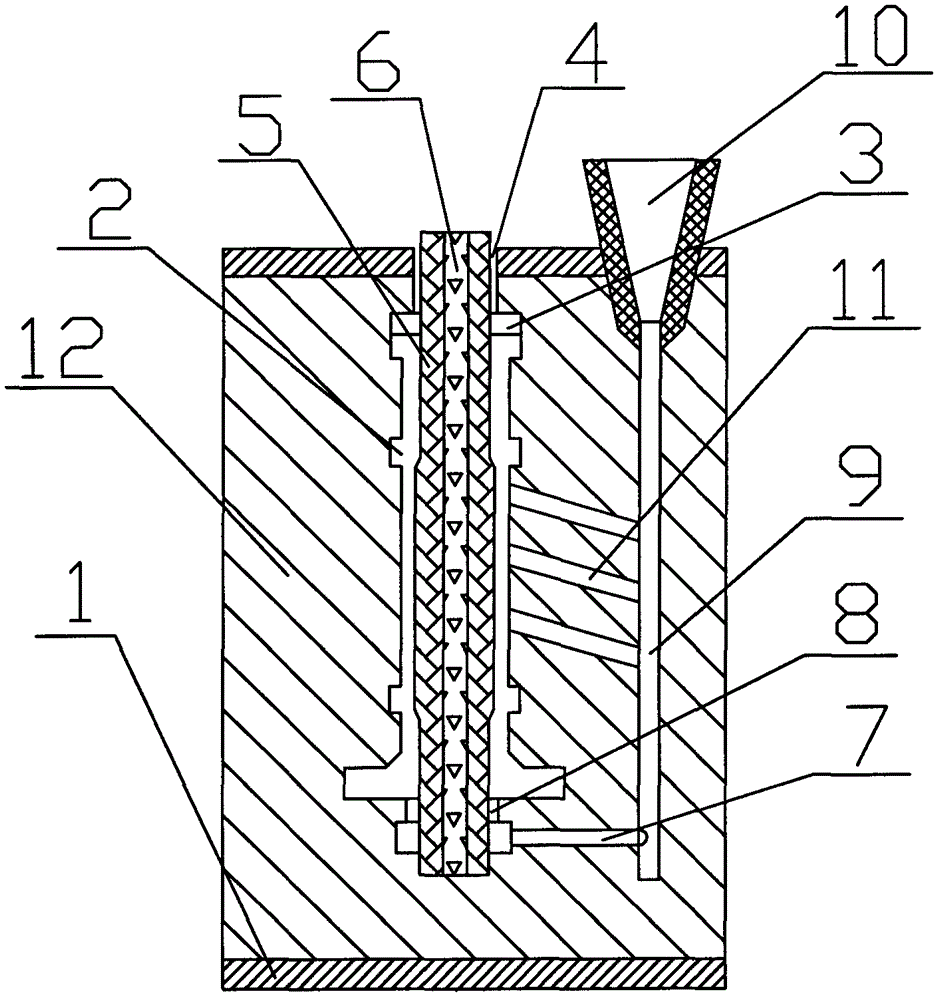

Thrust bearing

ActiveCN101153628AIncreasing the thicknessFlexible activitiesBearing componentsSliding contact bearingsSurface finishCircular disc

The invention discloses an end thrust bearing for submersible motor in well, comprising a disk bearing support with a chucking lug and a concave spherical surface in the center of the bottom, a gap block consisting of a plurality of independent multipart bearing slide blocks, and a bearing disk fixed on the disk bearing support, wherein, the bearing disk is provided with a center hole, a limited post I with a groove I arranged on the inner circle edge, a limited post II with a groove II arranged on the outer circle edge, a positioning stud limiting the position of the multipart bearing slide block, and a spherical crown convex hall; the two surfaces of the multipart bearing slide block are smooth, and the big and small circular arc edges are provided with a flange. When the invention is installed, the big and the small circular arc edges are respectively embedded into the groove II and the groove I and then locked after being limited by the positioning stud, and each slide block is in a flexible and nondeciduous state. Therefore, the shape and the structure as well as the way of installation of the multipart bearing slide block are improved, the thickness of the multipart bearing slide block is greatly increased, the intensity and the surface finish quality are greatly improved, and the full contact of the multipart bearing with a trust disk is guaranteed. With good carrying capacity, abrasive resistance and simple structure, the friction plane is easy to be processed and the manufacturing accuracy is easy to be guaranteed.

Owner:GUANGDONG RUIRONG PUMP IND

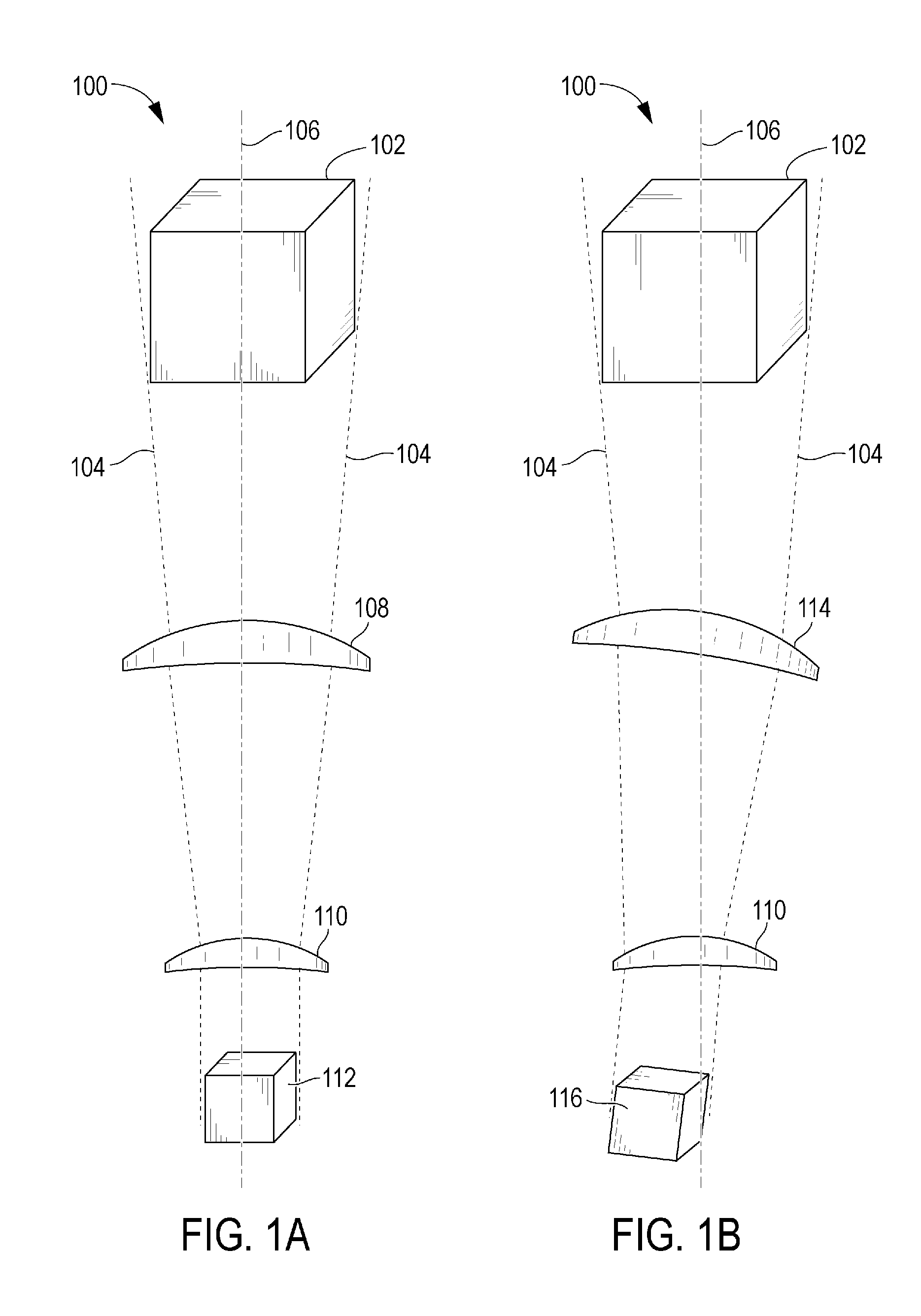

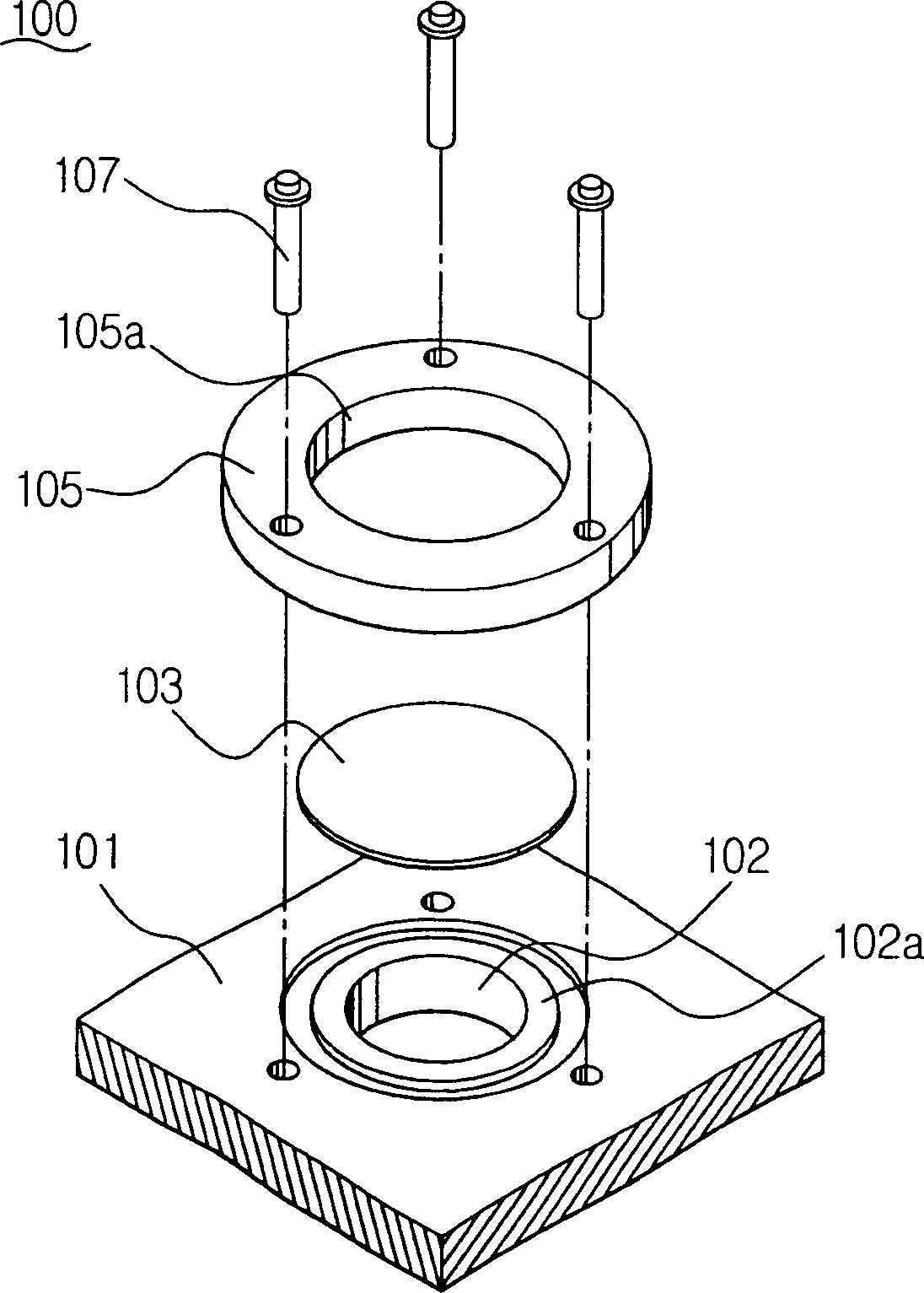

Apparatus and method for making and assembling a multi-lens optical device

A system for aligning a plurality of high-precision lenses in a lens train. Each of the lenses has at least two alignment tabs disposed around the perimeter of the lens. The lenses are aligned by placing the lenses in a jig having a plurality of high-precision alignment blocks. The lenses are attached to a lower-precision shroud, having slots that receive the alignment tabs. A gap-filling adhesive is used to provide a high-precision fit for the lenses in the shroud.

Owner:THALES VISIONIX

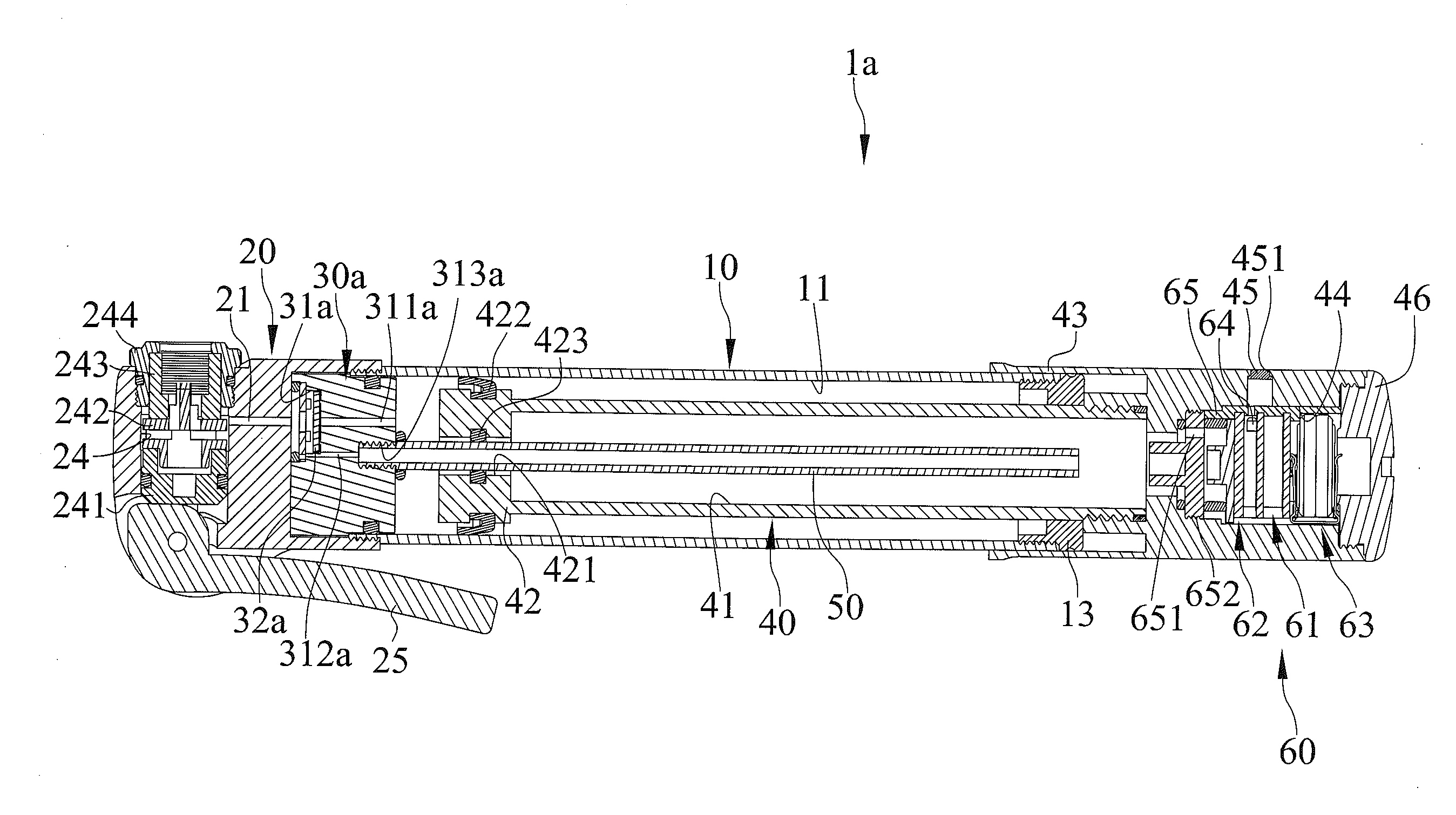

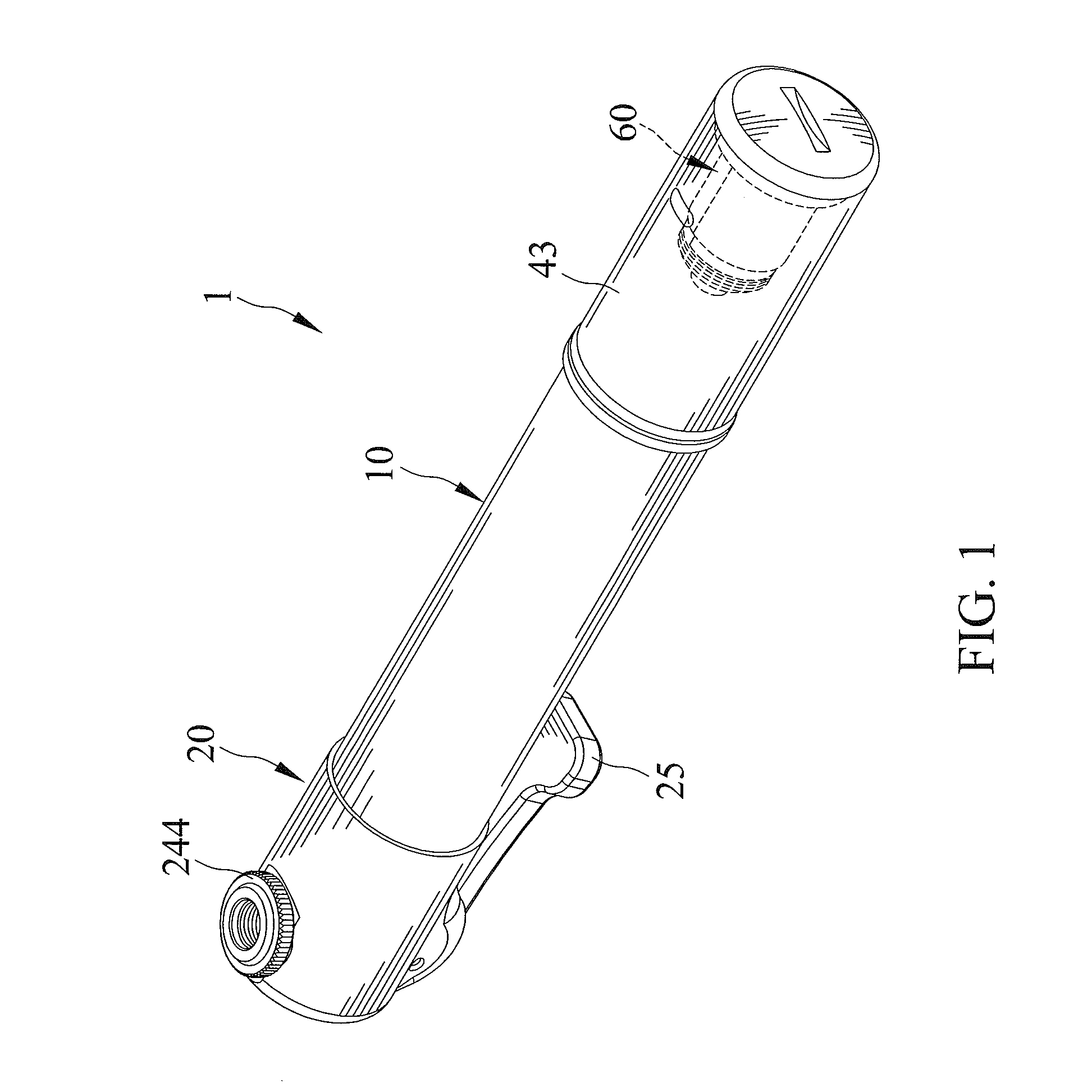

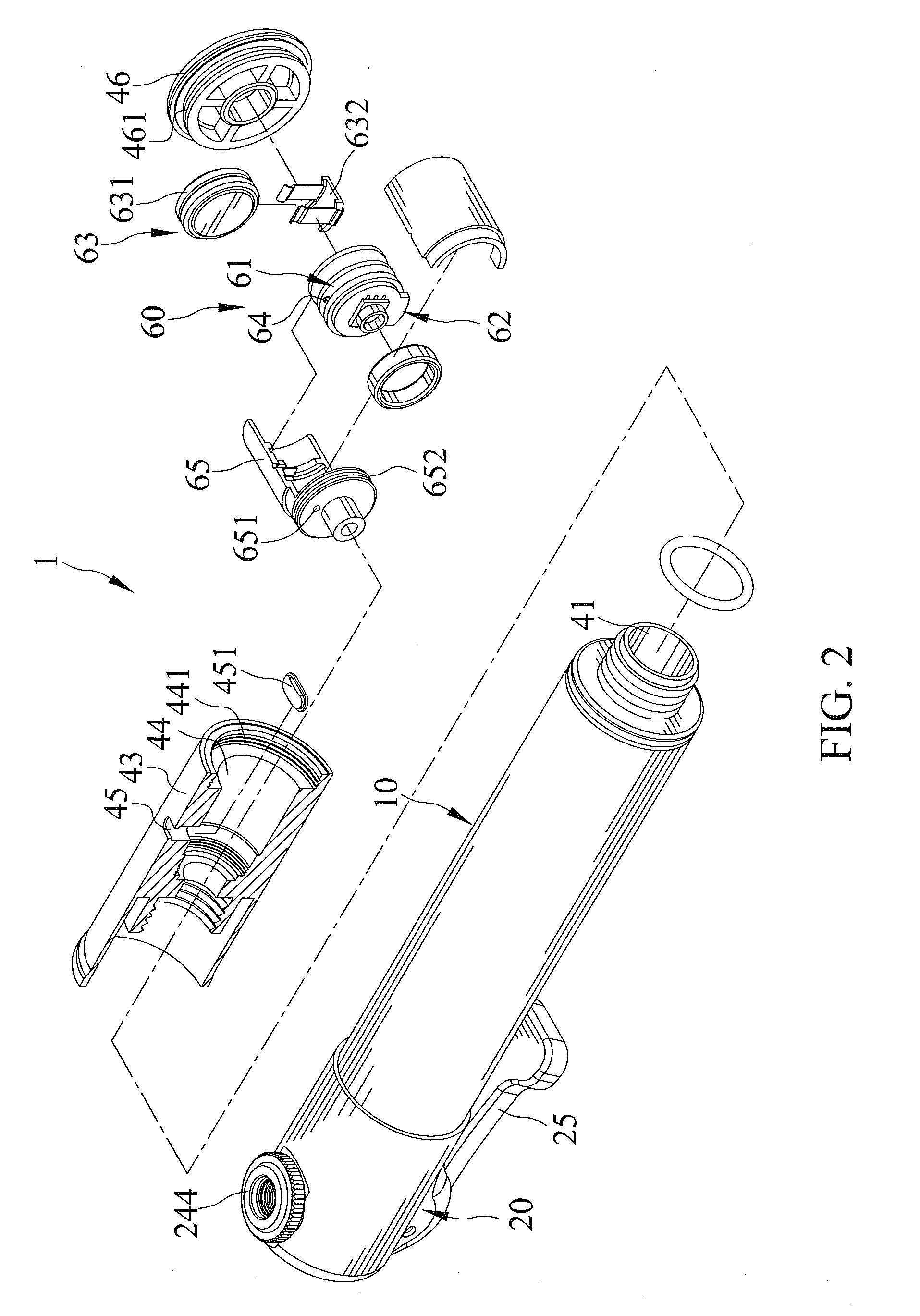

Portable Pump Capable of Transmitting Air Pressure Value Via Wireless Transmission to Mobile Electronic Device for Indication

ActiveUS20150110645A1Simple shapeSmall volumeInflated body pressure measurementPositive displacement pump componentsMobile electronicsEngineering

A portable pump includes a cylinder, a nozzle, a valve, a piston rod, a tube, and a pressure sensing device. The nozzle connects with the cylinder and includes a passage connectable with the inflatable. The valve is mounted between the cylinder and the nozzle. The piston rod has a rod hole and is connected with a piston and a handle. The handle includes a recess. The tube connected with the valve. The pressure sensing device is disposed in the recess. The pressure sensing device can measure the pressure value of the air flowing into the recess and is connectable with a mobile electronic device via wireless transmission for indication.

Owner:WU SCOTT

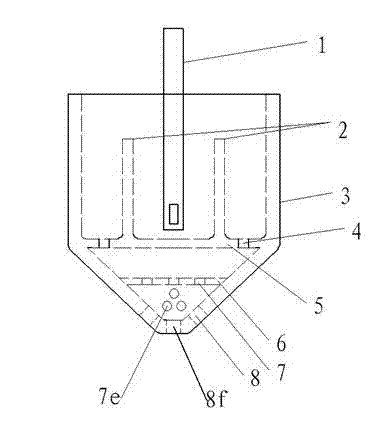

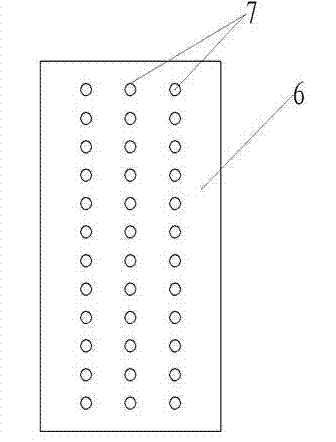

Water turbine sleeve casting mould assembling box

InactiveCN102794412AReasonable structureSimple shapeFoundry mouldsFoundry coresMaterials scienceWater turbine

The invention relates to a water turbine sleeve casting mould assembling box, comprising a sand box. Sand moulds are uniformly arranged in the sand box; a casting part is arranged in the sand box; the upper end of the casting part is provided with an annular casting head; an air outlet hole is arranged between the casting head and the upper end of the sand box; a sand core penetrates through the air outlet hole, the casting head and the casting part; the upper end of the sand core is arranged at the outside of the sand box; the lower end of the sand core passes through the casting part and is arranged in the sand box; a core tube is arranged in the sand core; the lower end of the sand core is provided with a horizontally placed side gate; a first flow gate is arranged between the side gate and the lower end of the casting part; one end of the side gate is provided with a vertically placed sprue gate; the upper end of the sprue gate is connected with a pouring cup penetrating through the sand box; the upper end of the pouring cup is arranged outside the sand box; and a plurality of second flow gates placed obliquely are arranged between the outer wall of the casting part and the sprue gate. The water turbine sleeve casting mould assembling box has the advantages of reasonable structure and convenience for modeling, and guarantees an internal circle machining face of a sleeve without casting flaw.

Owner:张年生

Lightweight spray carving mortar

The invention discloses a lightweight spray carving mortar, and belongs to the field of carving mortars. The mortar is produced from, by mass, 20-40 parts of an inorganic gelling material, 2-10 parts of re-dispersible latex powder, 0.3-1.5 parts of cellulose ether, 1-3 parts of PP fibers, 30-60 parts of quartz sands, 15-25 parts of heavy calcium powder, 10-20 parts of a lightweight filler, 0.5-2 parts of an anti-shrinkage agent and 0-2 parts of a pigment. The lightweight spray carving mortar can realize mechanical spray working, can realize a very large thickness without cracks due to lightweight, and also has the advantages of convenience in molding of the carving mortar, good stacking stability, difficulty in cracking, high durability and weatherability, carving time saving and lifelike effect reaching.

Owner:西卡德高(上海)建材有限公司

Wood-plastic biological filling and method for making same

InactiveCN1827701ASimple shapeProcessing methodOn/in organic carrierBiological water/sewage treatmentVegetable fibersScrap

The disclosed wood-plastic biological filler comprises the following ingredients (by weight portions): plastic 100, vegetable fiber 40-150, stone powder 10-60, expanding agent 2-6, heat absorption / release foaming agent 1-3, foaming activating agent 0.5-1.5, oxidation bond breaking agent 0.5-1.5, and lubricating agent 2.5-4. The biological filler can be prepared from wastes.

Owner:徐凌秀

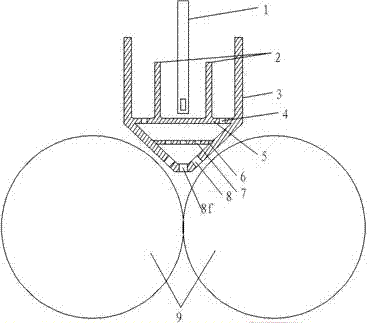

Multi-nozzle flow stabilizing and distributing device for strip continuous casting

The invention discloses a multi-nozzle flow stabilizing and distributing device for strip continuous casting. The device comprises a flow distributor arranged above a molten pool at the front end of a metal initial solidification interface; molten metal is poured into a cavity of the flow distributor through a submerged nozzle at the bottom of a group of tundishes; and after the flow distributionof the flow distributor, the molten metal enters the molten pool at the front end of the metal initial solidification interface. The cavity of the flow distributor is also communicated with a cavity of a flow stabilizer; the cavity of the flow stabilizer is located above the cavity of the flow distributor; the submerged nozzle is submerged in the molten metal in the cavity of the flow stabilizer;and the molten metal is poured into the cavity of the flow stabilizer through the submerged nozzle, and then enters the cavity of the flow distributor after the flow stabilization of the flow stabilizer. The device can improve the flow stability of the molten metal and reduce the influence of the stream impact of the molten metal turbulence on the continuous casting process, so that the temperature distribution of the molten metal is uniform, the casting quality of a metal strip is improved, and the demand for producing relatively wide and thin strip steel is met.

Owner:SHANGHAI UNIV

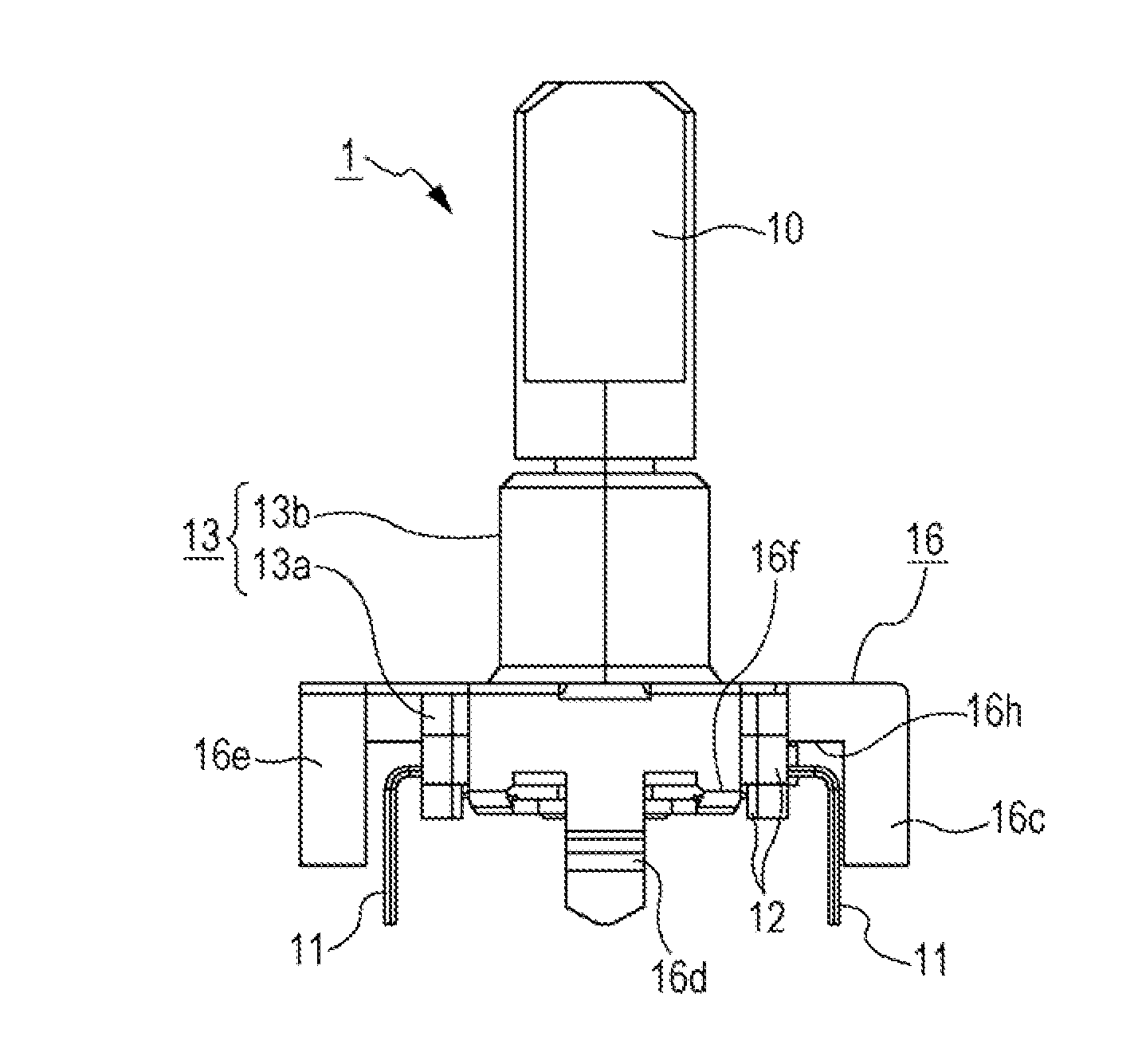

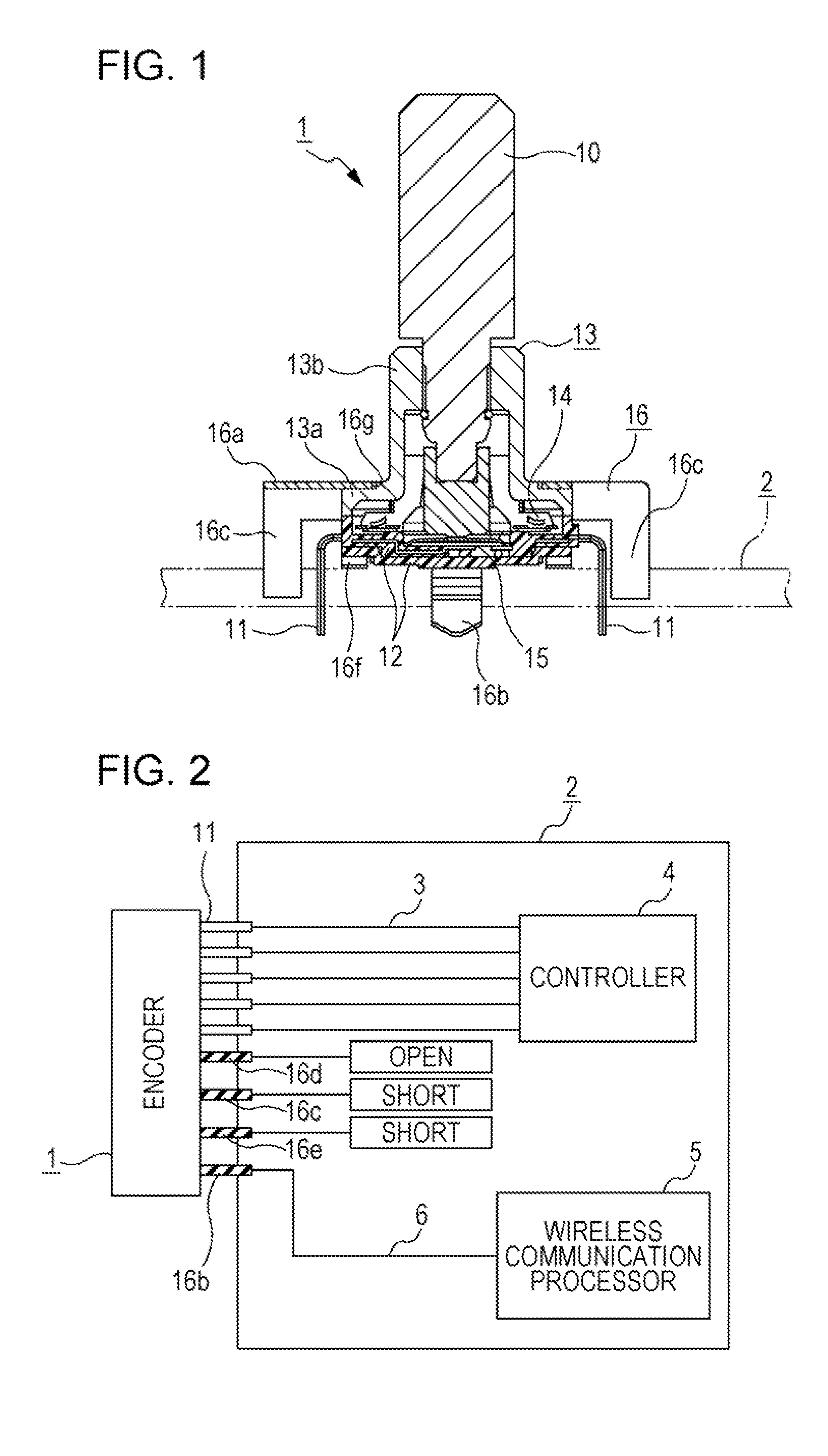

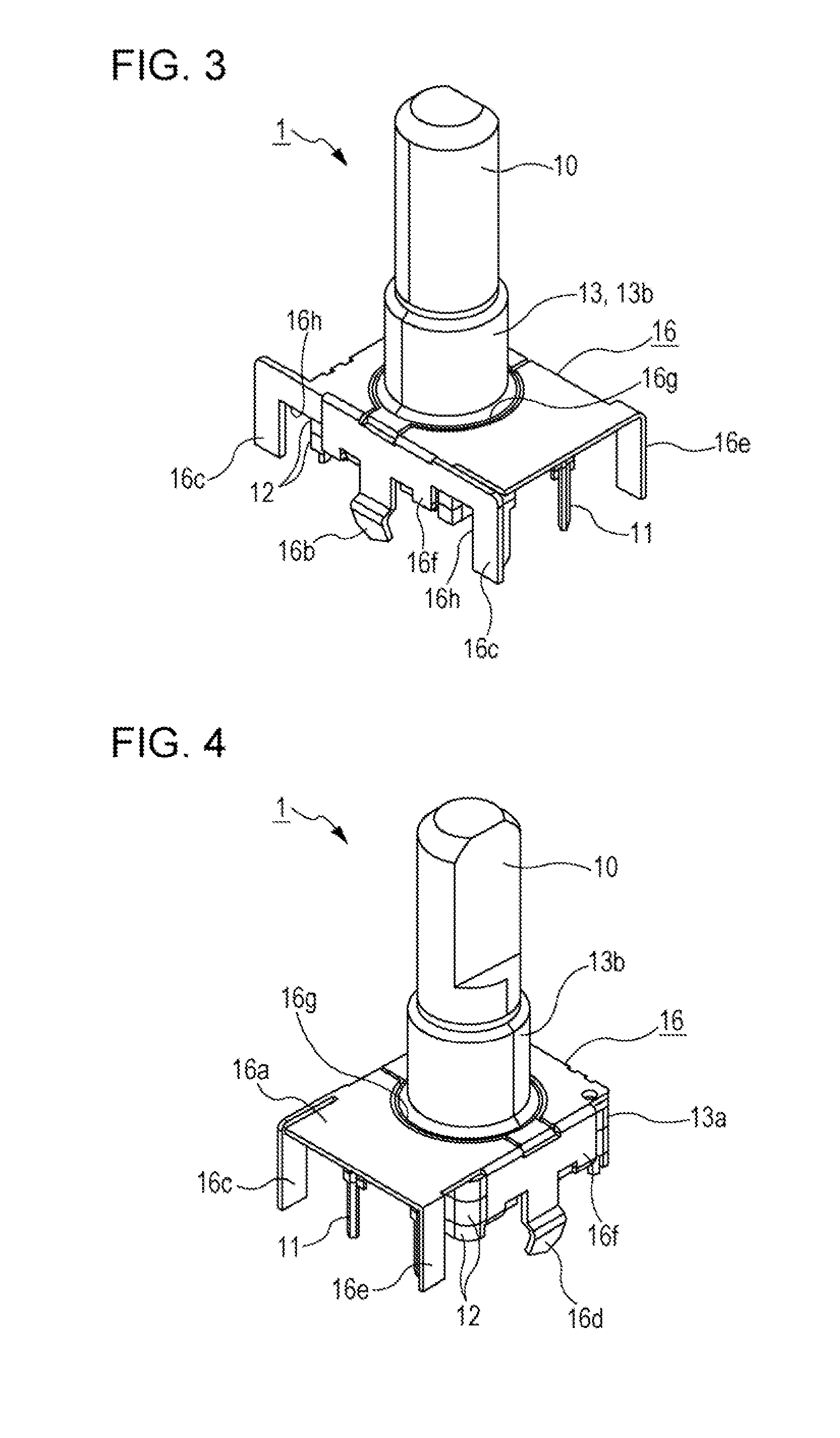

Electronic device

InactiveUS20130189936A1Simple shapeEasy to design and processAntenna supports/mountingsAntenna adaptation in movable bodiesHigh frequencyResonance

An electronic component (encoder) including an operation body is mounted on a circuit board. The electronic component causes a controller to perform processing in accordance with an operation input by the operation body. The mounting board includes a power-feeding leg piece connected to a wireless communication processor so that high frequency communication is allowed, a first short-circuiting leg piece that is adjacent to the power-feeding leg piece via a cut-out portion, and a second short-circuiting leg piece separated from the power-feeding leg piece. The short-circuiting leg pieces are connected to grounded portions. The impedance is adjusted by appropriately selecting the width or the depth of the cut-out portion. The resonance frequency is adjusted by appropriately selecting the size or the position of the short-circuiting leg piece. Thus, the mounting board operates as an inverted-F antenna in which the power-feeding leg piece functions as a power feeding portion.

Owner:ALPS ALPINE CO LTD

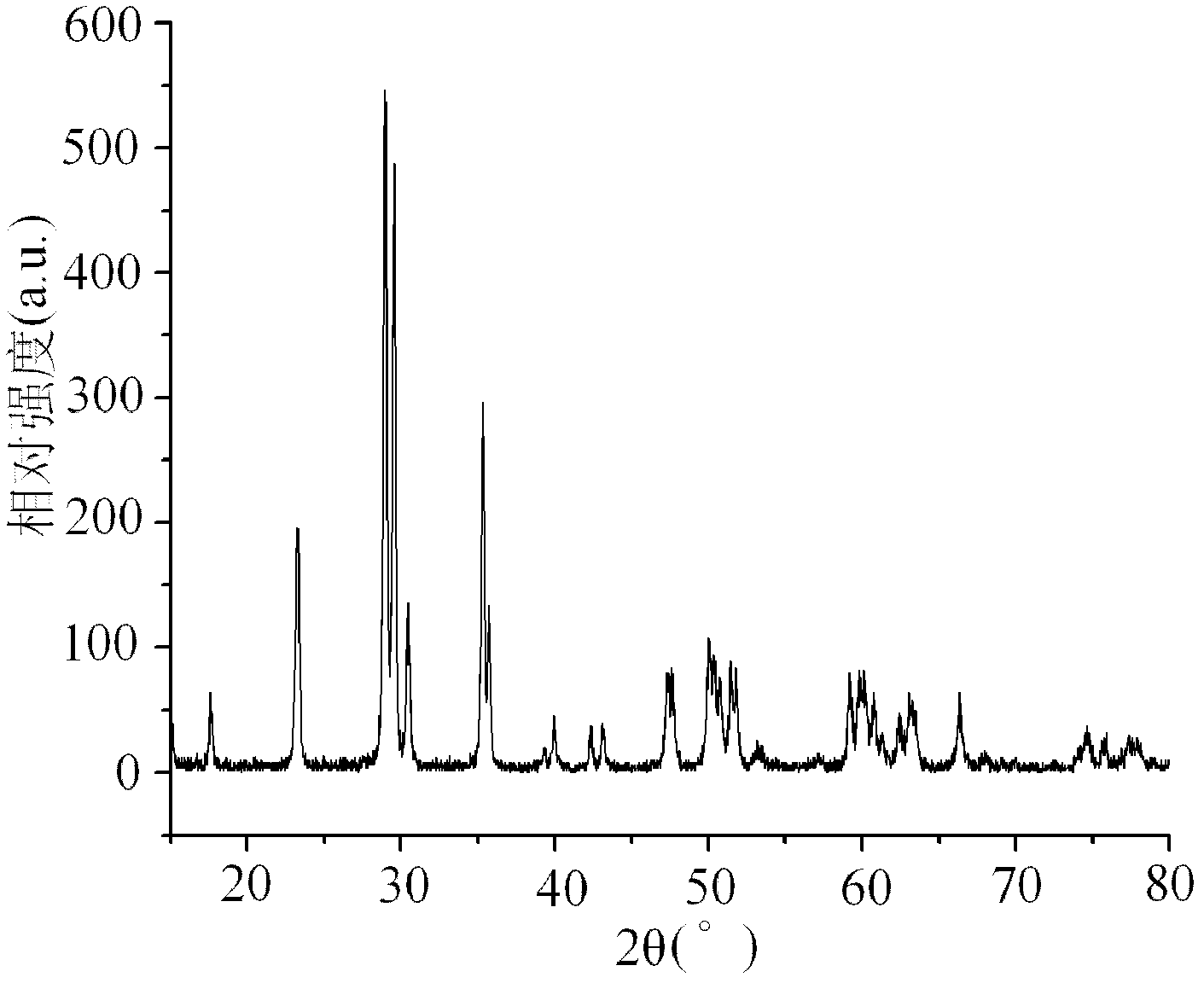

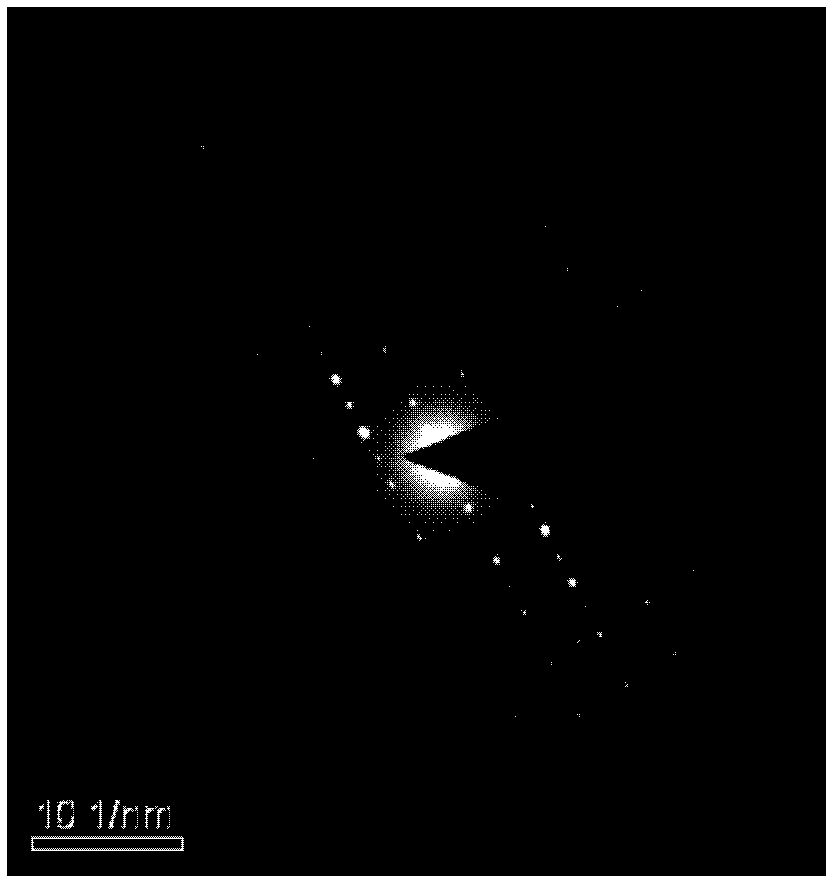

Preparation method of cadmium tungstate monocrystal nanoribbon

InactiveCN102358950AUniform size distributionReduce widthPolycrystalline material growthFrom normal temperature solutionsX-rayReaction temperature

The invention discloses a preparation method of a cadmium tungstate monocrystal nanoribbon, wherein the cadmium tungstate nanoribbon with unique shape and better uniformity in dimensional distribution is prepared by taking a soluble cadmium salt and sodium tungstate as raw materials, a surfactant SDBS (Sodium Dodecyl Benzene Sulfonate) as an additive and water as a medium, and strictly regulating reaction temperature, addition amount of the surfactant SDBS and a solution pH value. The nenoribbon is small in width and good in shape, has a wolframine nomocrystal structure, and is 60-120nm in width, 1.2-2.5mum in length and 20nm in thickness. The preparation method disclosed by the invention has the advantages of easily obtainable raw materials, simple equipment, low energy consumption, short cycle, low preparation cost, high yield, and safety and reliability for operation; the product has the characteristics of unique shape and dimension, good technical repeatability and sable quality, is easy to prepare on a large scale, and can be widely applied to various fields of nanometer-device XCT (X-ray Transcission Computed Tomography) detectors, radioactive nucleus spectrum and radioactivity determining and nuclear medical instruments and the like.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Lacing hole structure of turbine blade and loose lacing wire installation structure of the same turbine blade

InactiveCN103061823ASimple shapeEasy to processBlade accessoriesMachines/enginesImpellerStress level

The utility model discloses a lacing hole structure of turbine blades and a loose lacing wire installation structure of the same turbine blades. The lacing hole structure of turbine blades comprises a straight circular boss structure, the straight circular boss structure is disposed on the turbine blades, the axis of the straight circular boss structure is perpendicular to the normal of the blade-shaped cross section of the turbine blades and is tangentially parallel to the impeller, a pressure side and a suction side of the blades protrude from the straight circular boss structure, a lacing hole is formed in the middle of the straight circular boss structure, the axis of the lacing hole and the axis of the straight circular boss structure are in the same direction, two small boss structures are arranged at the two ends of the lacing hole, the two ends are on one side of the lacing hole near to the top of the blades, and pits are formed on the side of the lacing hole near to the top of the blades. The loose lacing wire and the lacing hole have two contact points, thereby effectively improving the damping capacity of the loose lacing wire structure, shorting the free segment length of the loose lacing wire, reducing the stress level of the loose lacing wire structure, enabling the loose lacing wire to use alloy steels with good damping effect to replace titanium alloys, and being capable of controlling the stress level of the loose lacing wire structure and improving the damping capacity of the loose lacing wire structure at the same time.

Owner:XI AN JIAOTONG UNIV

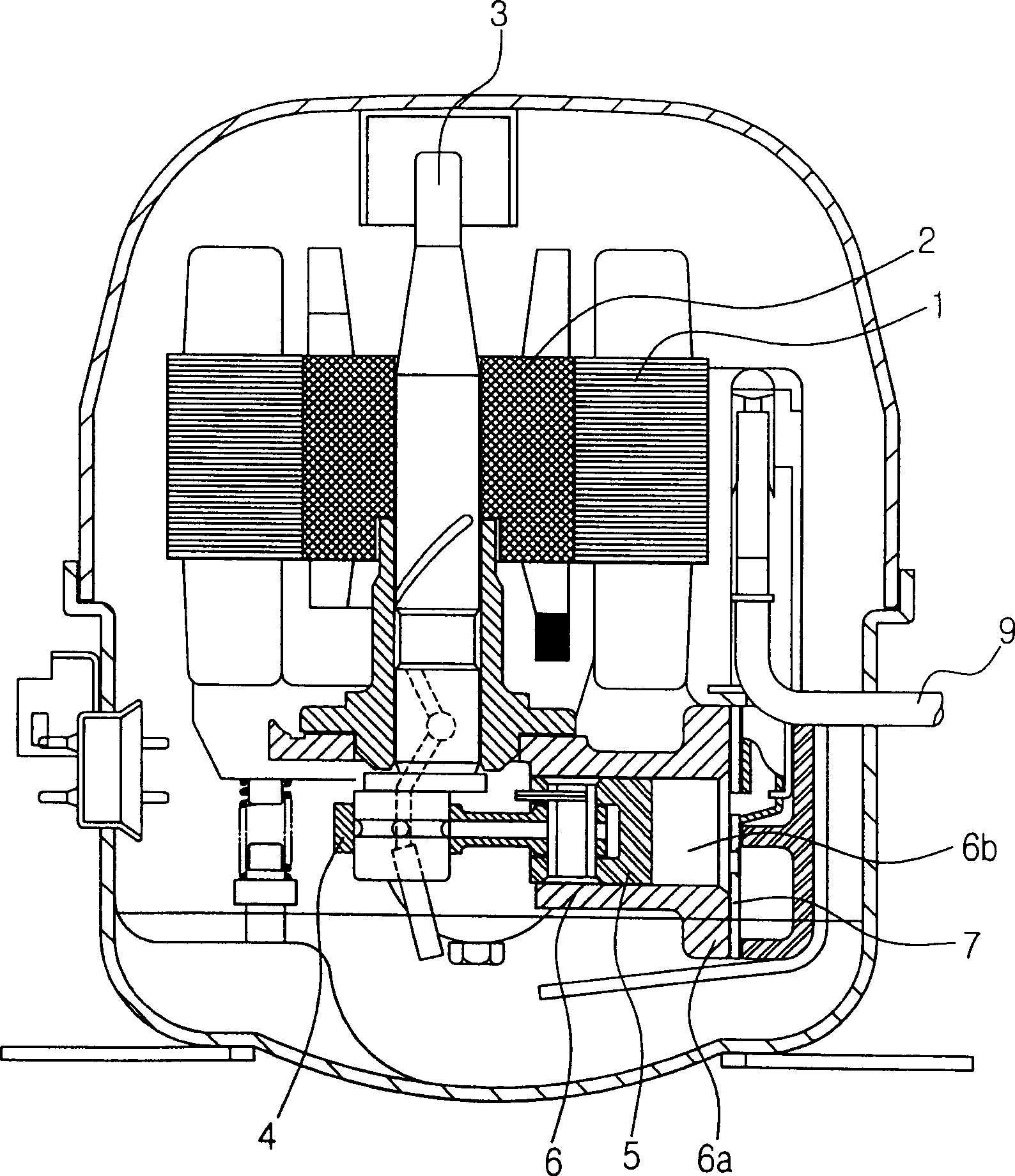

Exhaust valve of sealed compressor

InactiveCN1420274AReduce noiseImprove work efficiencyPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveReciprocating motion

A discharge valve of a hermetic compressor includes a valve plate disposed on a cylinder head that sucks and discharges refrigerant according to reciprocal movement of a piston, and the discharge valve having a discharge hole formed therein through which refrigerant is discharged, a disc valve disposed adjacent the discharge hole of the valve plate, the disc valve being raised or lowered by the reciprocal movement of the piston, and a stopper disposed above the disc valve, for guiding the raising and lowering of the disc valve and also for limiting the height to which the disc valve may be raised. The compressor is not subject to overload or over pressurization that may otherwise result from the elastic force of the valve, and as a result, compression efficiency is increased, while noise is decreased.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Connector

ActiveUS20090149057A1Easy to operateEasy to adjustIncorrect coupling preventionCouplings bases/casesStructural engineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

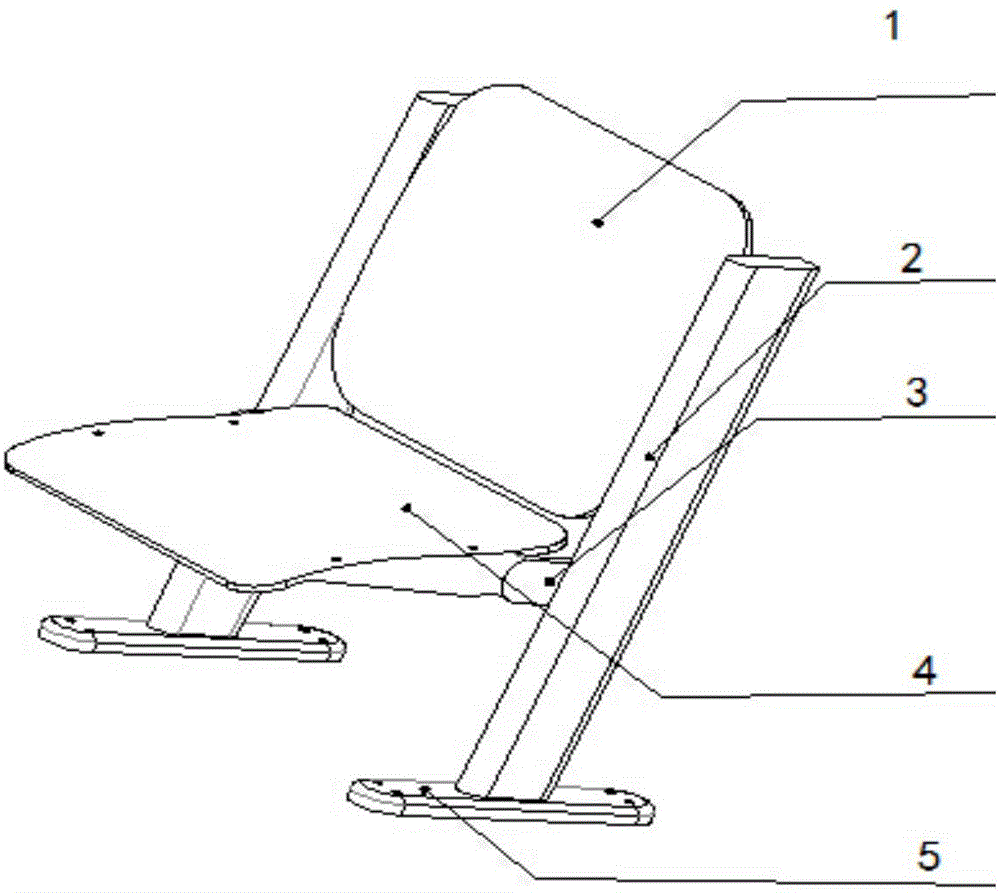

System for controlling electric lamp by seat

InactiveCN104023454ASimple shapeSimple processElectric light circuit arrangementStoolsEngineeringComputer control

The invention discloses a system for controlling an electric lamp by a seat, belonging to the control field of electrical appliances. The system consists of a temperature sensor, a baffle plate temperature sensor, a switch, a bracket, a fixed base, a seat plate, a baffle plate, a seat plate temperature sensor conductor wire, a baffle plate temperature sensor conductor wire, a fixed plate, a computer and an electric lamp; the system is characterized in that the seat plate is in hinged connection with the bracket, wherein the baffle plate is fixed on the bracket; the bracket is fixed on the ground by the fixed base; the baffle plate temperature sensor is embedded in the baffle plate; the seat plate temperature sensor is embedded in the seat plate; when people sit on the seat, the switch is switched on, so that the baffle plate temperature sensor on the baffle plate and the seat plate temperature sensor on the seat plate can detect a signal, and can transmit the signal to a computer processing system by the seat plate temperature sensor conductor wire and the baffle plate temperature sensor conductor wire, and therefore, the computer controls on and off of the electric lamp according to the state whether people sit on the seat or not.

Owner:陈刚

Forming machine for screw thread

InactiveCN1915555ASolve the problem of misalignment sticking outRealize mechanized workWire articlesScrew threadHorizontal and vertical

A machine for manufacturing the fastening wire used as binding part is composed of machine frame, wire bending unit with symmetrically arranged wire bending head and rotation driver, wire guider, fastening unit, primary shaping unit, final shaping unit, and the telescopic cylinder matched with the push press plates used by the last 4 units for bending by 270 degrees and horizontal and vertical 90 degrees.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

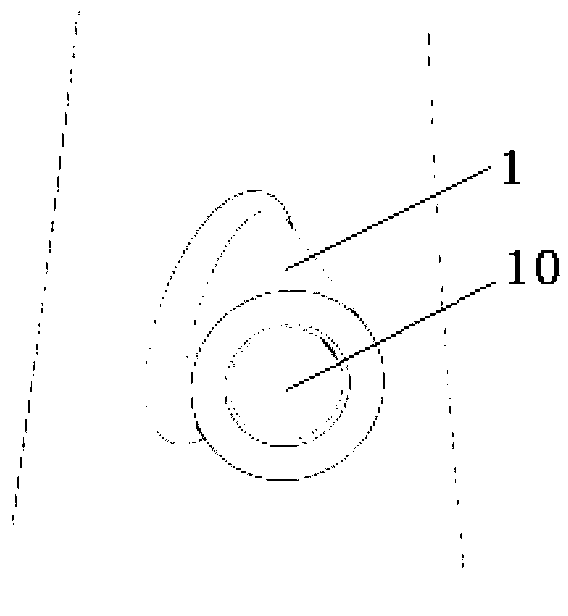

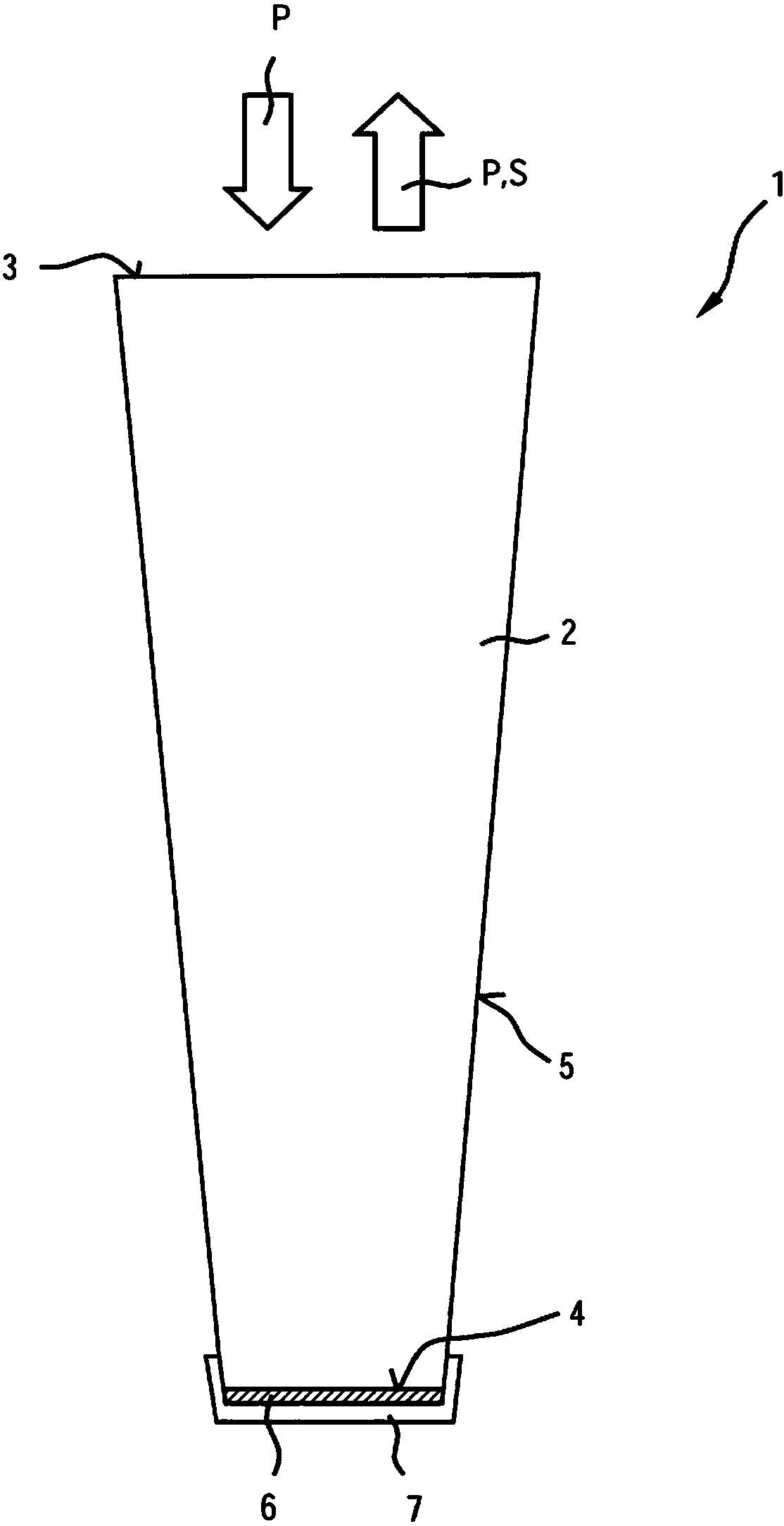

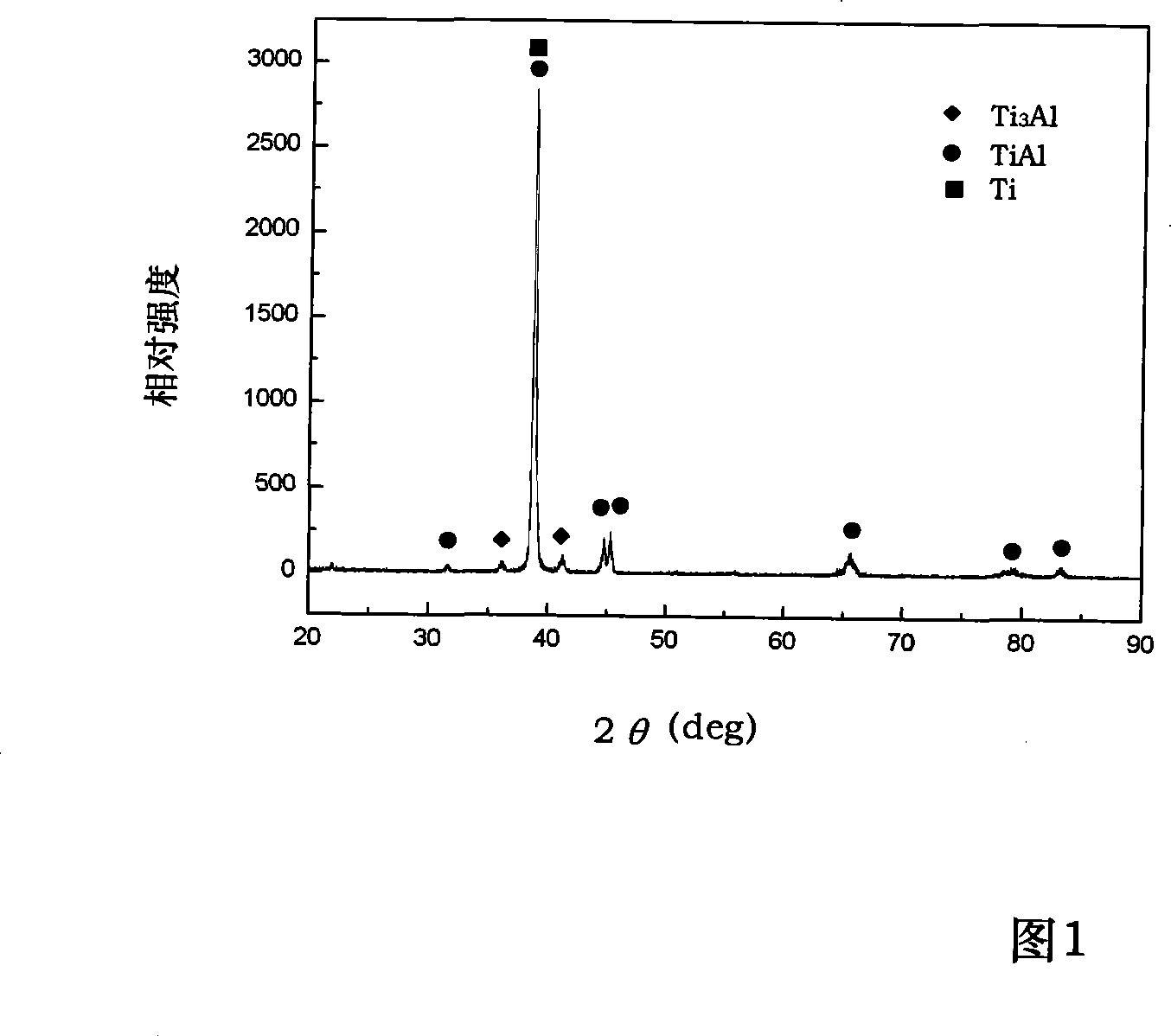

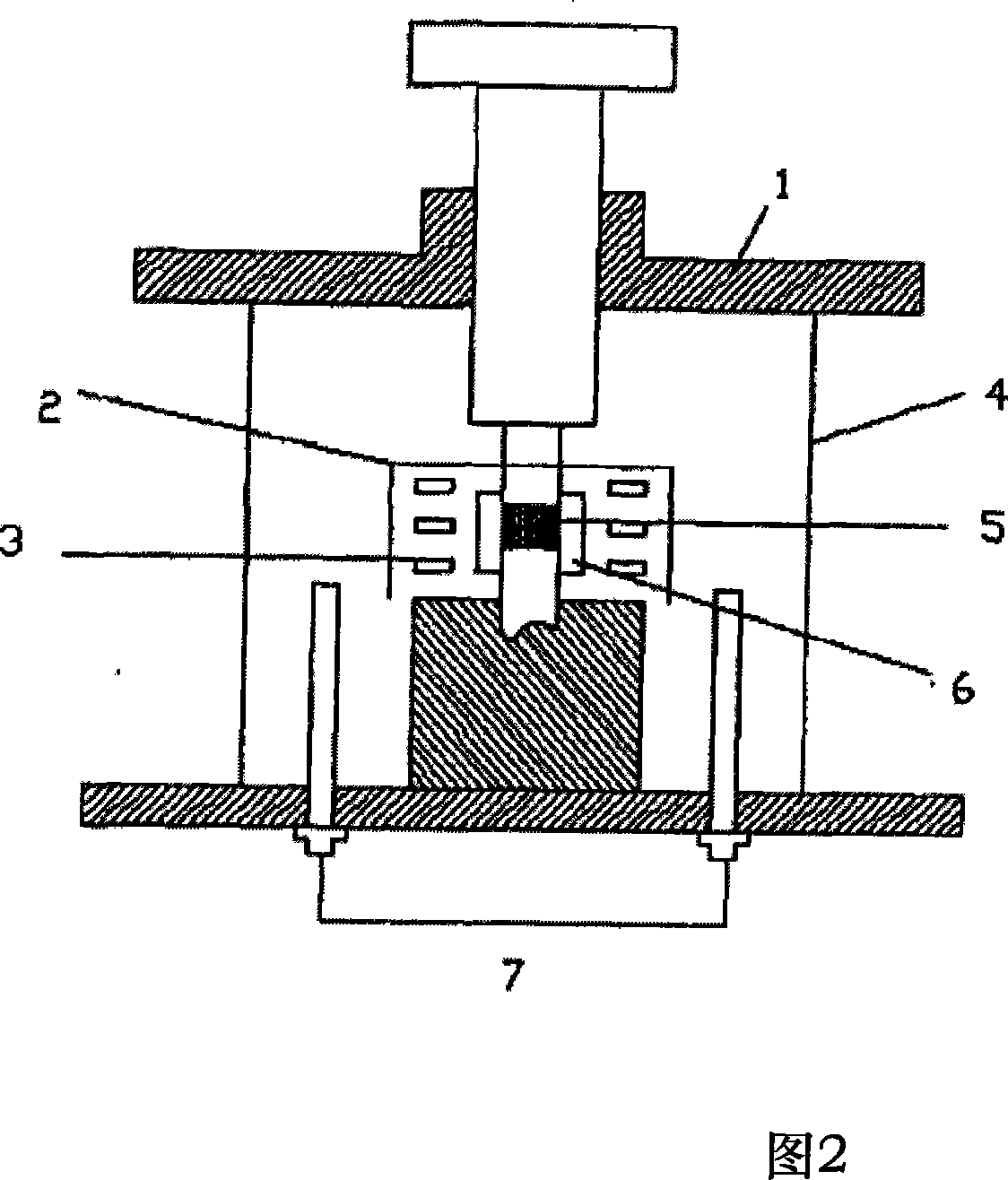

Wavelength conversion body and method for manufacturing same

ActiveCN103733363ASimple compositionSimple shapeSemiconductor/solid-state device manufacturingSpectral modifiersLight guideWavelength conversion

The invention relates to a wavelength conversion body (1) for generating wavelength converted light (S) from primary light (P) radiated into the wavelength conversion body (1), comprising a light guiding body (2) which is transparent for the primary light (P) and for the wavelength converted light (S), and at least one luminescent body (6) containing a luminescent substance, wherein the light guiding body (2) is monolithically connected to the at least one luminescent body (6). The invention further relates to a method for producing a wavelength conversion body (1; 11).

Owner:CORETRONIC

Yttrium oxide doping zirconium oxide crucible and producing method thereof by using hot pressing sintering

The present invention discloses an yttrim oxide doping zirconium oxide crucible and a method adopting the hot pressing sintering crucible, the component of the yttrium oxide doping zirconium crucible is that the zirconium oxide with 0.2-1.5g is doped in each 10g of yttrium oxide Y2O3. The grain diameter of the yttrim oxide Y2O3 for hot pressing sintering is 0.01-20 mu m, and the grain diameter of yttrim oxide ZrO2 is 0.01-20 mu m. The using temperature of the yttrium oxide doping yttrim oxide crucible of the invention is 1600-2000 DEG C, and the crucible is taken as the apparatus of vacuum melting in the temperature surrounding, the inner surface of the crucible does not take part in the reaction of the active metal or alloy thereby increasing the purity of the flux.

Owner:BEIHANG UNIV

Composite multilevel Y2O3 powder crucible and method for producing the same with isostatic pressing technique

The invention discloses a composite multi-level Y2O3 crucible and a method for preparing the same by an isostatic pressing process. The multi-level Y2O3 crucible is prepared from multi-level Y2O3 powder and binder, wherein 20-100 ml of the binder is added to 1,000g of the composite multi-level Y2O3. During the preparation process, Y2O3 powders with different particle diameters are mixed, and small particles enter the voids of large particles during the mixing; therefore, the density of the Y2O3 crucible is increased, and the volume change when sintering at a high temperature is reduced. The prepared Y2O3 crucible can be used for smelting high-melting point active metal or alloy at 1,600-2,000 DEG C.

Owner:BEIHANG UNIV

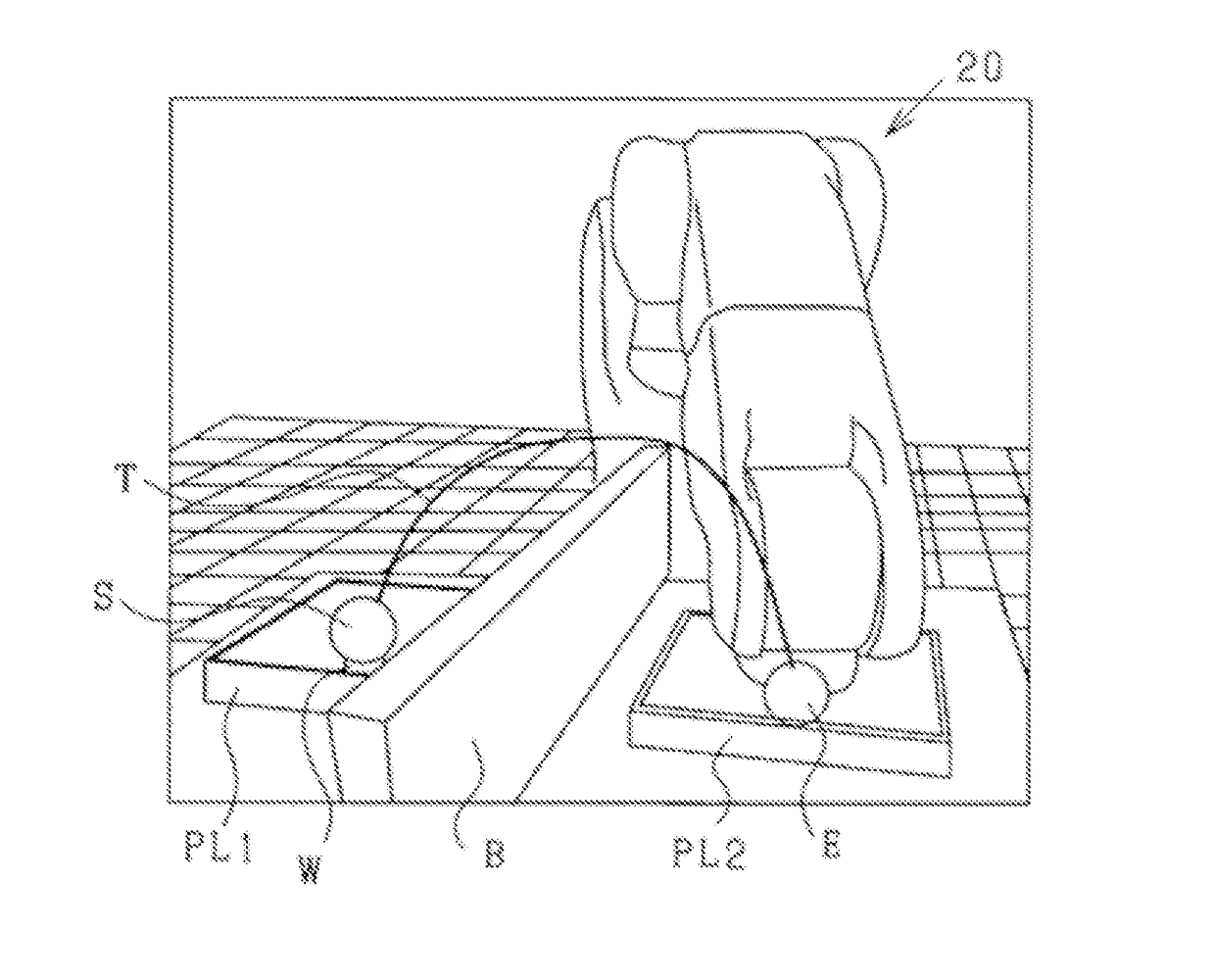

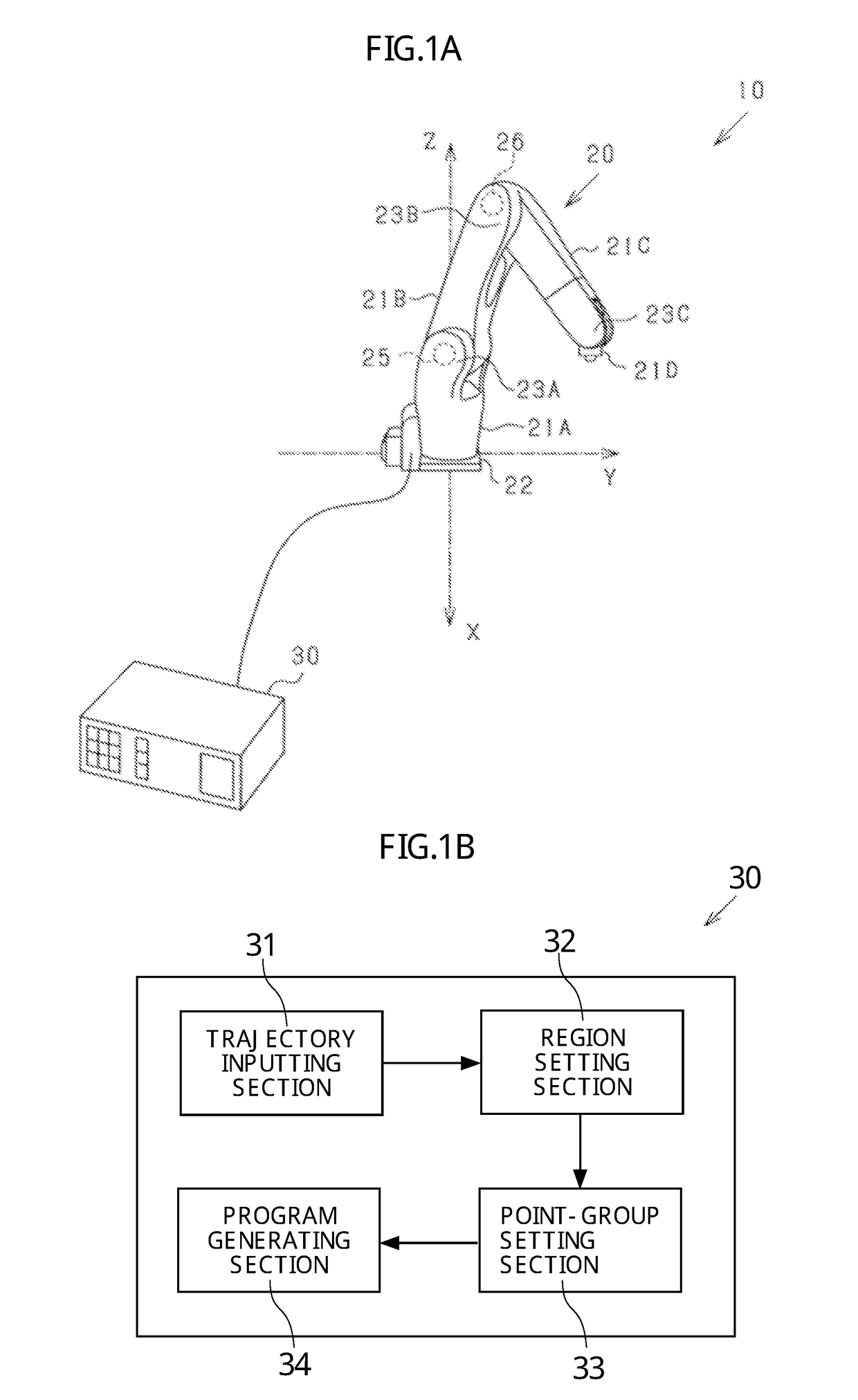

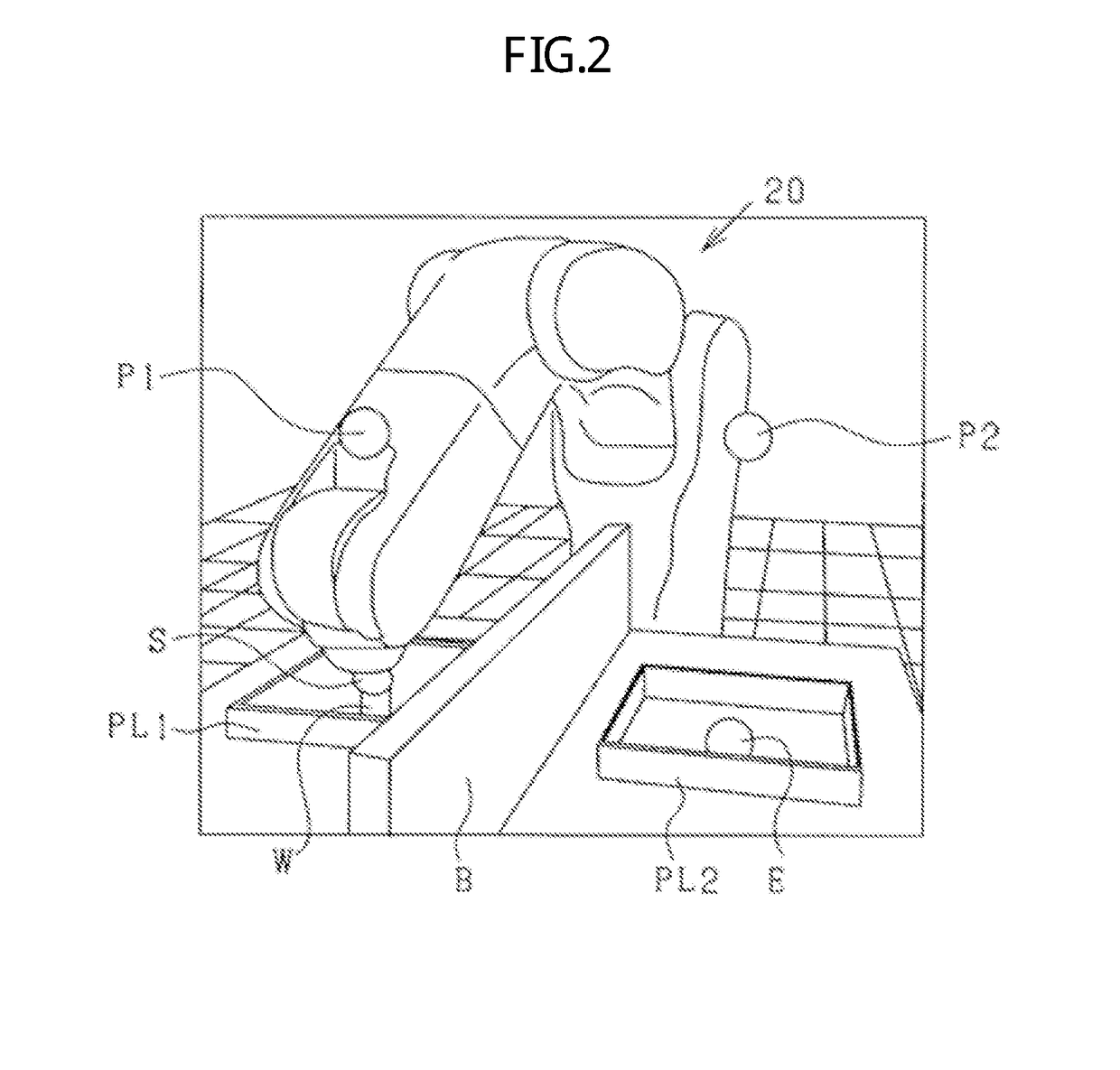

Robot motion program generating apparatus

ActiveUS20180250819A1Simple shapeLarge widthProgramme controlProgramme-controlled manipulatorLine segmentRobot locomotion

A robot motion program generating apparatus generates a motion program for moving a robot, avoiding an obstacle. The apparatus comprises a section inputting a taught trajectory of the robot, a section setting a tolerance region around the trajectory inputted by the trajectory inputting section, a section setting a motion-point group that is a collection of the motion points, by determining motion points of the robot in the tolerance region set by the region setting section, and iterating a task of connecting a source motion point to a subsequent motion point through a line segment, avoiding the obstacle, starting from one end and ending at the other end of the trajectory, and a section generating the motion program, based on the motion-point group set by the point-group setting section.

Owner:DENSO WAVE INC

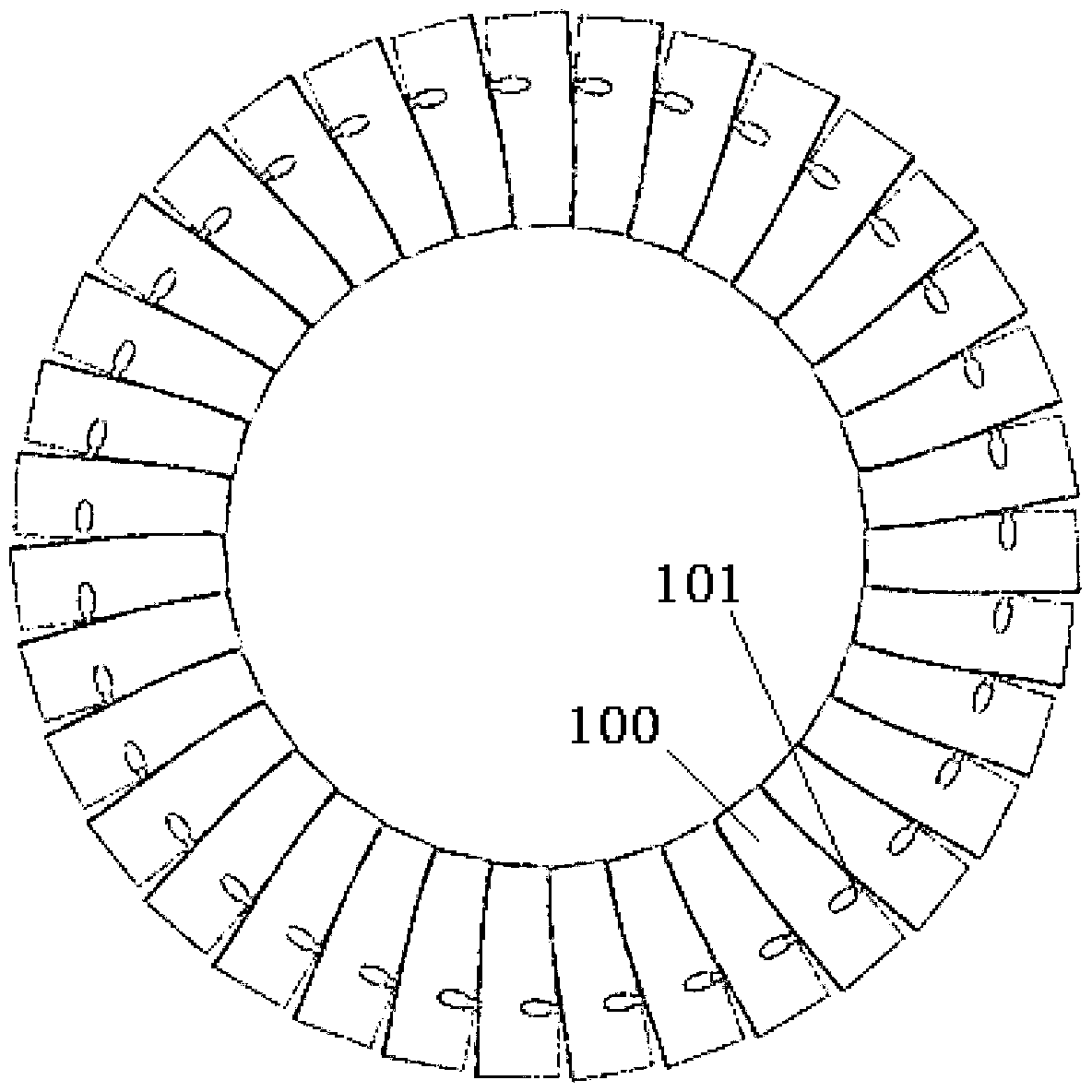

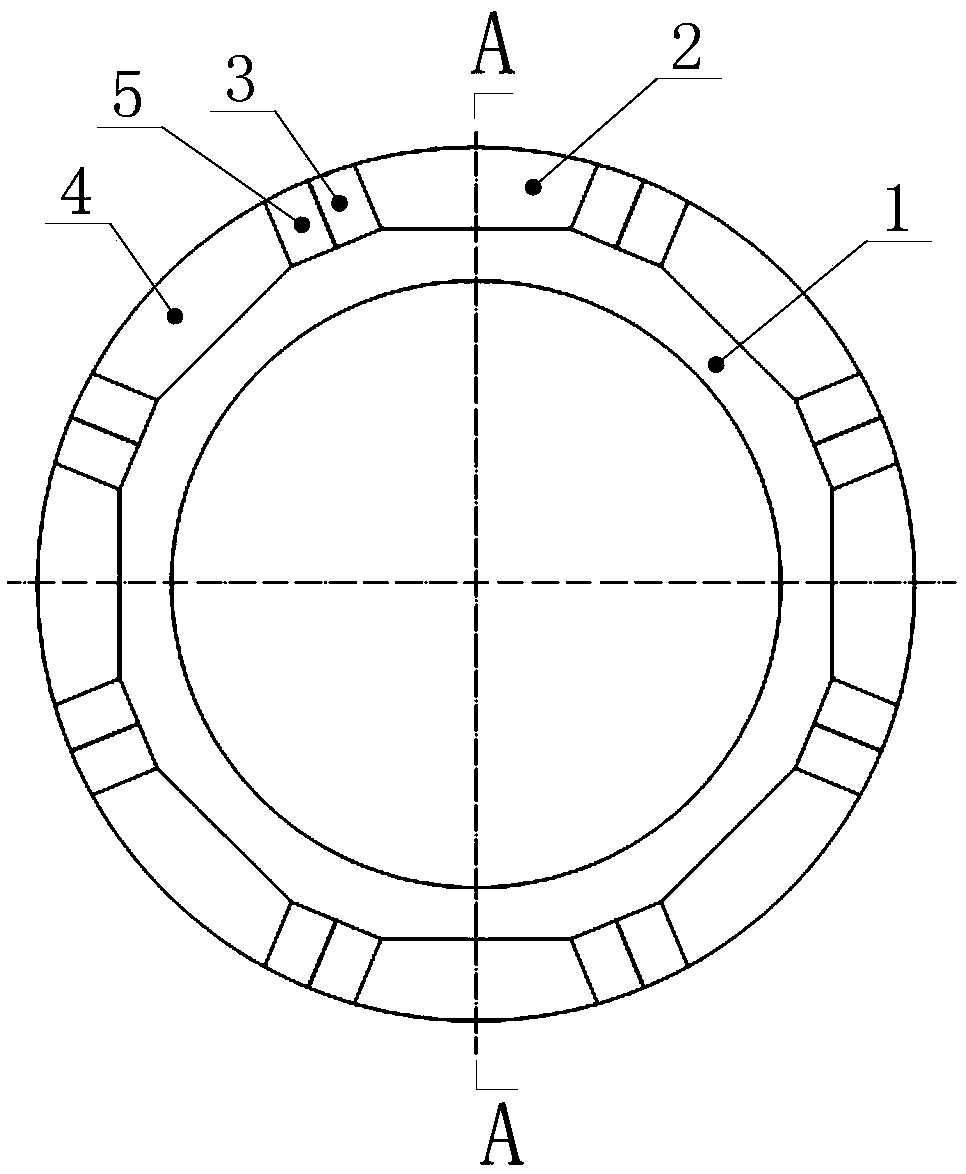

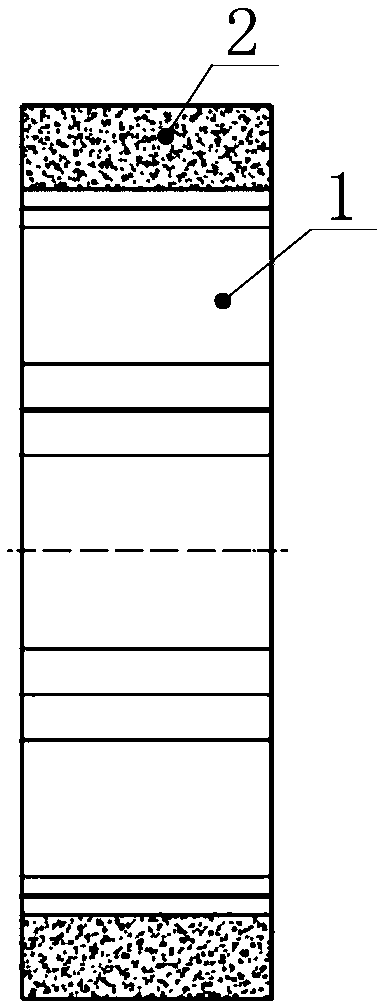

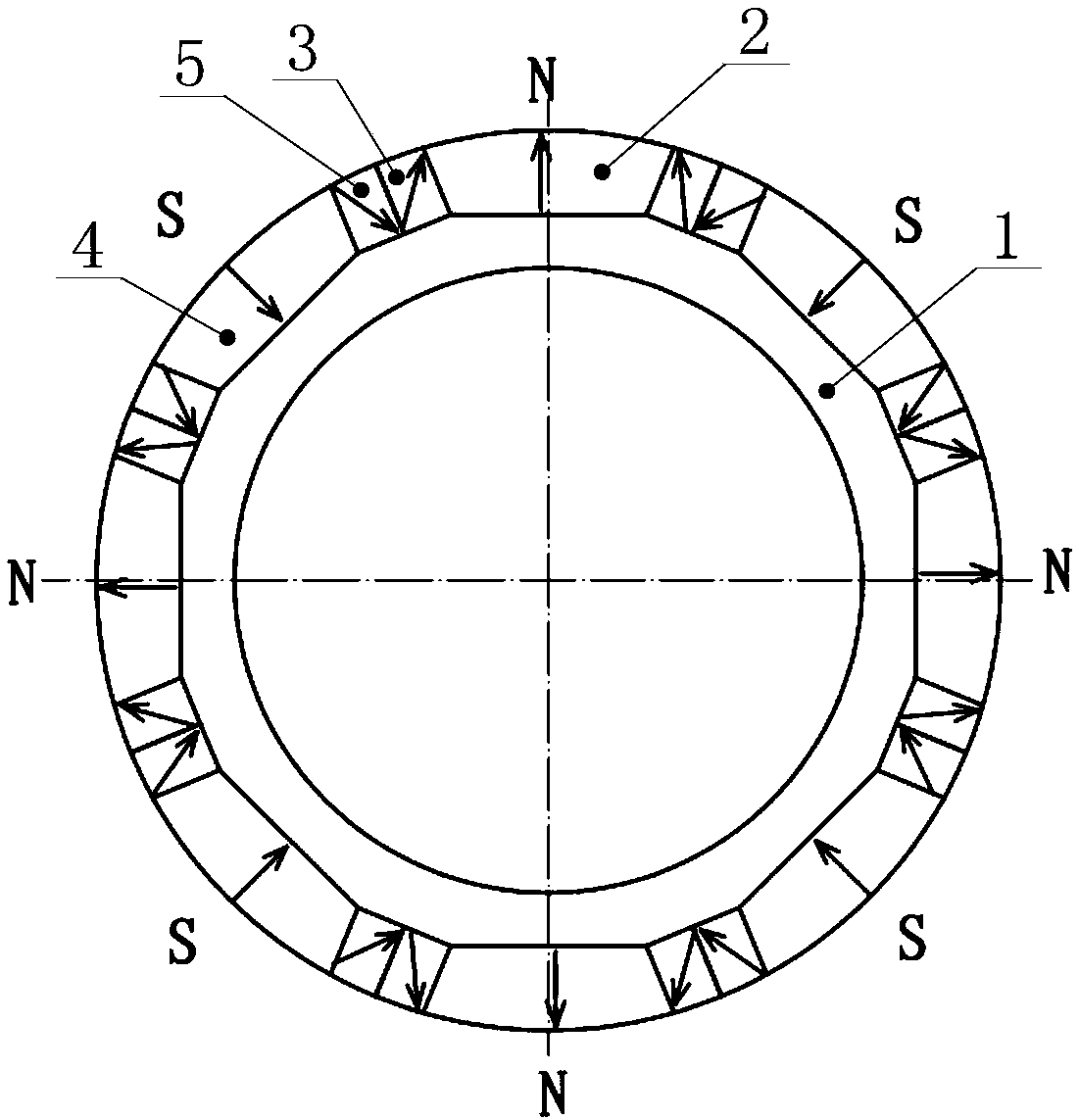

Rotor structure of Halbach motor and manufacturing method thereof

PendingCN108736608ASmall structural errorSimple shapeMagnetic circuit rotating partsManufacturing stator/rotor bodiesForce linesAcute angle

The invention provides a rotor structure of a Halbach motor. The rotor structure comprises N-pole magnetic steel, S-pole magnetic steel and a rotating shaft, wherein the N-pole magnetic steel comprises N-pole large magnetic steel and N-pole small magnetic steel; S-pole magnetic steel comprises S-pole large magnetic steel and S-pole small magnetic steel; and specific limitation is as follows: the magnetic force line inside the N-pole small magnetic steel is parallel to the diagonal line of the radial section of the N-pole small magnetic steel or has an acute angle included angle, and the magnetic force line inside the S-pole small magnetic steel is parallel to the diagonal line of the radial section of the S-pole small magnetic steel or has an acute angle included angle. The invention alsoprovides a manufacturing method of the rotor structure of the Halbach motor. The rotor structure has the advantages that a permanent magnet forming a magnetic group is simple in structural shape and low in processing difficulty; the installation operation is simple and convenient, the motor production efficiency is high, and the homogeneity of product is improved; the structure of the magnetic group is limited, the accumulative error during assembling can be eliminated, and the motor performance is improved; the cross area of the permanent magnet is larger, and a magnetic circuit inside the permanent magnet is longer, so that the demagnetizing resistance of the motor is promoted.

Owner:NO 21 RESERCH INST OF CHINA ELECTRONICS TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com