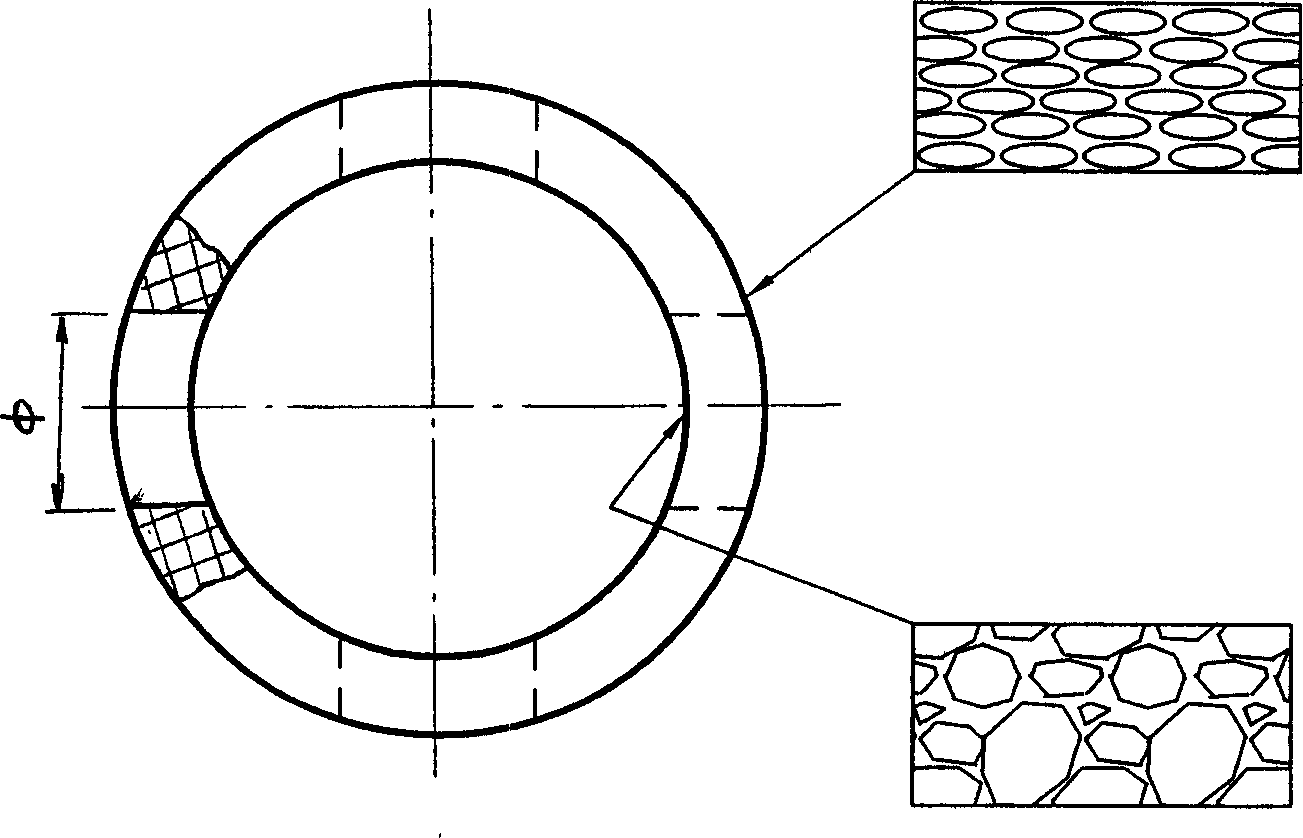

Wood-plastic biological filling and method for making same

A technology of biological fillers and production methods, applied in chemical instruments and methods, biological water/sewage treatment, fixed on/in organic carriers, etc., can solve unfavorable microbial reproduction and survival, unfavorable processing and mass production, biological Complicated packing shape and other problems, to achieve the effect of low cost, simple shape and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The product comprises the following components by weight:

[0033] 1) Waste polyethylene (powder) 100

[0035] 3) Ground calcium carbonate 35

[0036] 4) Ethylene / acrylic acid copolymer 4

[0037] 5) Sodium bicarbonate 1

[0038] Azodicarbonamide 1.5

[0041] Dicumyl peroxide 0.4

[0042] 8) fatty acid 3.5

[0043] Its production steps include:

[0044] (1), prepare materials, prepare the materials of the above-mentioned various components;

[0045] (2), mixing, above-mentioned various component materials are stirred, preliminary mixing;

[0046] (3) Extrusion molding, the above-mentioned various components that are initially mixed are extruded on an extruder to produce biological fillers.

[0047] This embodiment is extruded on an extruder, and the components that are initially mixed are placed in an existing twin-screw extruder for automatic processing, from feeding, mel...

Embodiment 2

[0049] The product comprises the following components by weight:

[0050] 1) Waste polyethylene (waste polyethylene particles are crushed and ground into powder) 100

[0051] 2) Rice husk powder 60

[0052] 3) Ground calcium carbonate 15

[0053] 4) Ethylene / acrylic acid copolymer 3

[0054] 5) Sodium bicarbonate 0.8

[0055] Azodicarbonamide 1

[0057] 7) Zinc stearate 0.5

[0058] Dicumyl peroxide 0.2

[0059] 8) Fatty acid amides 3

[0060] Its preparation steps are identical with the preparation steps of embodiment 1.

Embodiment 3

[0062] The product comprises the following components by weight:

[0063]1) Waste polyethylene 100

[0064] 2) Rice husk powder 150

[0065] 3) Ground calcium carbonate 60

[0066] 4) Ethylene / acrylic acid copolymer 6

[0067] 5) Sodium bicarbonate 1.5

[0068] Azodicarbonamide 1.5

[0069] 6) Zinc oxide 1.5

[0070] 7) Zinc stearate 1.2

[0071] Dicumyl peroxide 0.3

[0072] 8) fatty acid 4

[0073] Its preparation steps are identical with the preparation steps of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com