Yttrium oxide doping zirconium oxide crucible and producing method thereof by using hot pressing sintering

A technology of hot pressing sintering and yttrium oxide, which is applied in the field of crucibles for vacuum smelting highly active metals and hot pressing sintering crucibles. It can solve the problems of large volume change, difficult shape of yttrium oxide ceramics, and reduce the use temperature of products, and achieve high smoothness. , The shape is simple, the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Manufacture a yttria-doped zirconia crucible capable of melting 0.5Kg titanium Ti alloy

[0037] The target composition of this yttria-doped zirconia crucible is 368 g of yttria Y 2 o 3 Doped with 38g of zirconia.

[0038] The steps of preparing the crucible of the target composition by hot pressing and sintering are as follows:

[0039] The first step: making slurry

[0040] 80% of the Y particles with a particle size of 4.8 μm formulated according to the target composition 2 o 3 , 80% ZrO with a particle size of 5.0 μm 2 Mix with absolute ethanol to prepare a slurry; the amount of absolute ethanol is 0.5L;

[0041] The second step: drying the billet

[0042] Dry the slurry prepared in the first step in a constant temperature drying box to obtain a billet, the drying temperature is 60°C, and the drying time is 15 hours;

[0043] The third step: making crucible by hot pressing and sintering

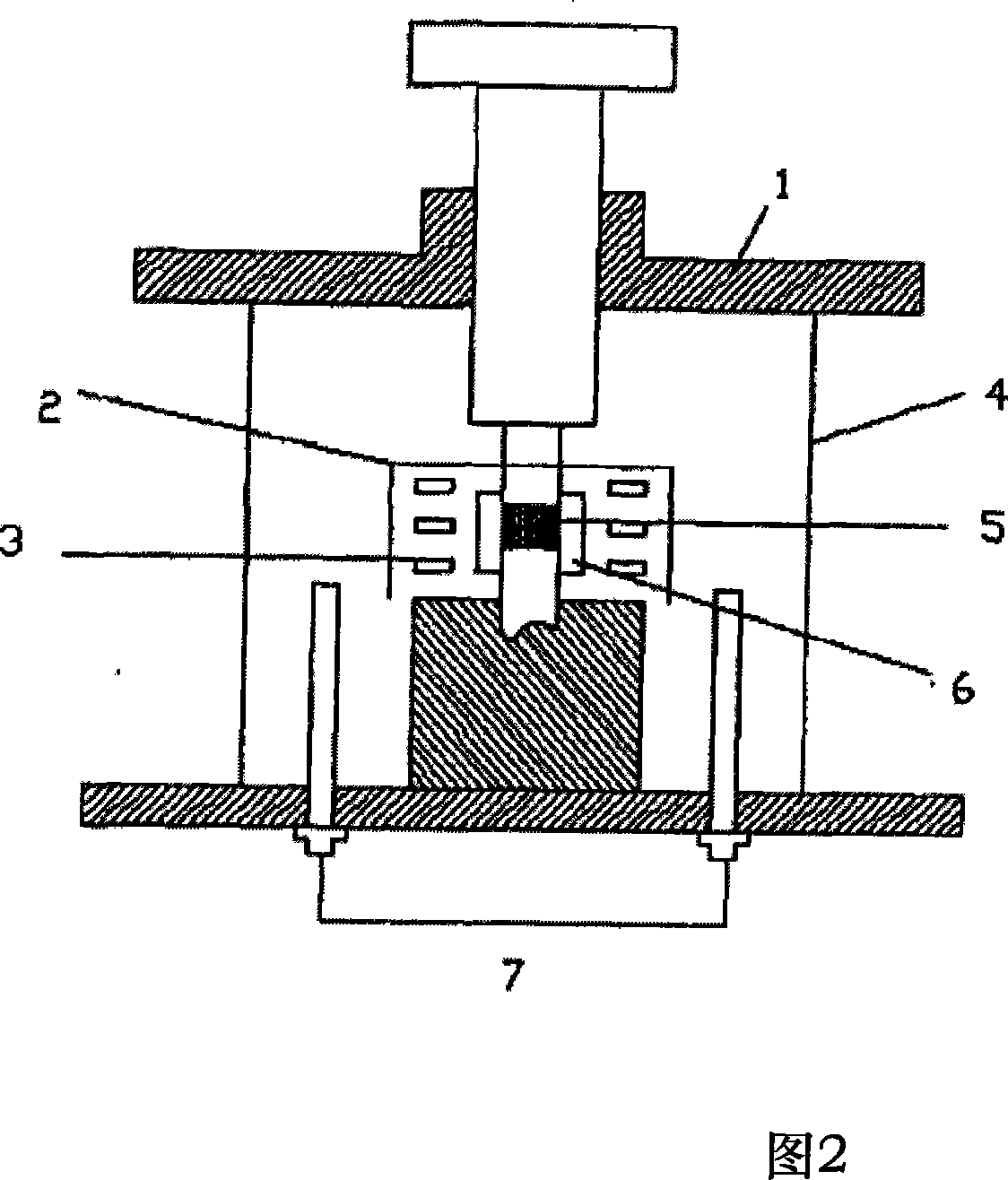

[0044] Put the blank obtained in the second step into the mold cavity...

Embodiment 2

[0048] Manufacture a multi-grade yttrium oxide-doped zirconia crucible capable of melting 0.5Kg titanium Ti alloy

[0049] The target composition of this yttria-doped zirconia crucible is 368 g of yttria Y2 o 3 Doped with 38g of zirconia.

[0050] The steps of preparing the crucible of the target composition by hot pressing and sintering are as follows:

[0051] The first step: making slurry

[0052] Select 0.02μm first grade Y according to the target composition 2 o 3 Fine powder, 1μm second grade Y 2 o 3 Fine powder, 5μm third grade Y 2 o 3 Fine powder, 15μm fourth grade Y 2 o 3 Fine powder, of which, the first grade Y 2 o 3 Fine powder accounted for total Y 2 o 3 5% of the amount of powder, the second grade Y 2 o 3 Fine powder accounted for total Y 2 o 3 20% of the amount of powder, the third grade Y 2 o 3 Fine powder accounted for total Y 2 o 3 30% of the amount of powder, the fourth grade Y 2 o 3 Fine powder accounted for total Y 2 o 3 45% of the ...

Embodiment 3

[0060] Manufacture a yttrium oxide doped zirconia crucible capable of melting 1Kg hafnium Hf alloy

[0061] The target composition of this yttria-doped zirconia crucible is 550 g of yttria Y 2 o 3 Doped with 50g of zirconia.

[0062] The steps of preparing the crucible of the target composition by hot pressing and sintering are as follows:

[0063] The first step: making slurry

[0064] 90% of the Y particles with a particle size of 15 μm formulated according to the target composition 2 o 3 , 80% ZrO with a particle size of 10 μm 2 Mix with absolute ethanol to prepare a slurry; the amount of absolute ethanol is 1L;

[0065] The second step: drying the billet

[0066] Dry the slurry prepared in the first step in a drying oven to obtain a billet at a drying temperature of 80°C and a drying time of 8 hours;

[0067] The third step: making crucible by hot pressing and sintering

[0068] Put the blank obtained in the second step into the mold cavity of the hot pressing equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com