Composite multilevel Y2O3 powder crucible and method for producing the same with isostatic pressing technique

A crucible and process technology, applied in the field of metal smelting equipment, can solve the problems of difficult modeling of yttrium oxide ceramics, large volume change, lowering the use temperature of products, etc., and achieve the effects of simple modeling, high smoothness, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

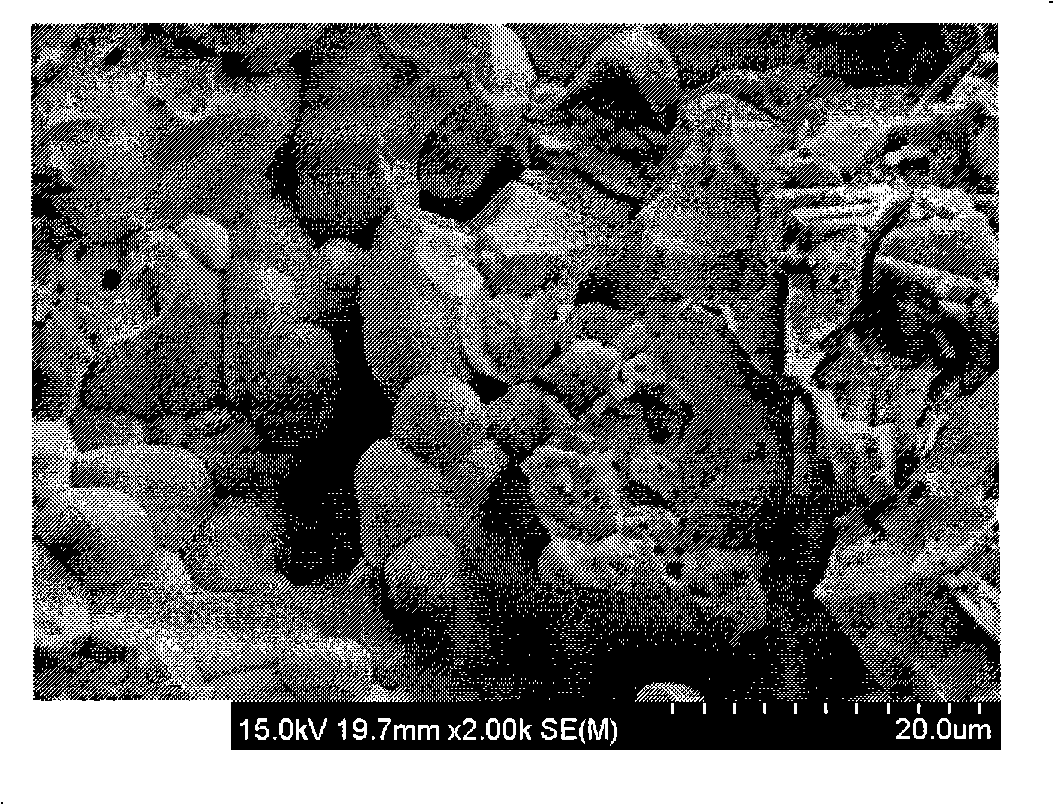

[0047] Example 1: Manufacture a composite multi-stage Y alloy capable of melting 3Kg of Nb-16Si-17Cr 2 o 3 Powder crucible (the weight of the crucible is 2Kg)

[0048] Composite multi-stage Y 2 o 3 The size of the powder crucible: the inner diameter of the crucible is 12cm, and the height of the crucible is 17cm.

[0049] The binder is a polyvinyl alcohol solution with a mass percent concentration of 10%.

[0050] In this example, composite multi-stage Y was prepared by isostatic pressing process. 2 o 3 The steps of powder crucible are:

[0051] Step 1: Prepare crucible raw materials

[0052] Weigh 30g of the first stage Y according to the target composition of the crucible's self-weight 2Kg 2 o 3 Powder, 70g of the second grade Y 2 o 3 Powder material, 500g third grade Y 2 o 3 Powder material, 600g fourth grade Y 2 o 3 Powder, 800g fifth grade Y 2 o 3 The powder is mechanically stirred to obtain a compound multi-stage Y 2 o 3 Powder material; then in the ...

Embodiment 2

[0066] Example 2: Manufacture a composite multi-stage Y that can melt 2.5Kg of Ti-6Al-4V alloy 2 o 3 Powder crucible (the weight of the crucible is 2Kg)

[0067] Composite multi-stage Y 2 o 3 The size of the powder crucible: the inner diameter of the crucible is 12cm, and the height of the crucible is 17cm.

[0068] The binder is: silica sol.

[0069] In this example, composite multi-stage Y was prepared by isostatic pressing process. 2 o 3 The steps of powder crucible are:

[0070] Step 1: Prepare crucible raw materials

[0071] Weigh 40g of the first stage Y according to the target composition of the crucible's self-weight 2Kg 2 o 3 Powder, 60g of the second grade Y 2 o3 Powder material, 450g third grade Y 2 o 3 Powder material, 700g fourth grade Y 2 o 3 Powder, 750g fifth grade Y 2 o 3 The powder is mechanically stirred to obtain a compound multi-stage Y 2 o 3 Powder material; then in the composite multi-stage Y 2 o 3 Add 80ml of binder to the powder m...

Embodiment 3

[0082] Example 3: Manufacture a composite multi-stage Y alloy capable of melting 8Kg Ti-47Al alloy 2 o 3 Powder crucible (the weight of the crucible is 4Kg)

[0083] Composite multi-stage Y 2 o 3 The size of the powder crucible: the inner diameter of the crucible is 12cm, and the height of the crucible is 50cm.

[0084] The binder is (group A binder): 130ml of polyvinyl alcohol solution with a concentration of 10% by mass and 30ml of absolute ethanol.

[0085] In this example, composite multi-stage Y was prepared by isostatic pressing process. 2 o 3 The steps of powder crucible are:

[0086] Step 1: Prepare crucible raw materials

[0087] Weigh 80g of the first stage Y according to the target composition of the crucible's self-weight 4Kg 2 o 3 Powder material, 120g of the second grade Y 2 o 3 Powder material, 1000g third grade Y 2 o 3 Powder, 1000g fourth grade Y 2 o 3 Powder material, fifth grade Y of 1800g 2 o 3 The powder is mechanically stirred to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com