Wavelength conversion body and method for manufacturing same

A wavelength conversion and ontology technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor devices of light-emitting elements, etc., can solve the problems of color wheel consumption, low-efficiency wavelength conversion, etc., and achieve the effect of simple shape and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

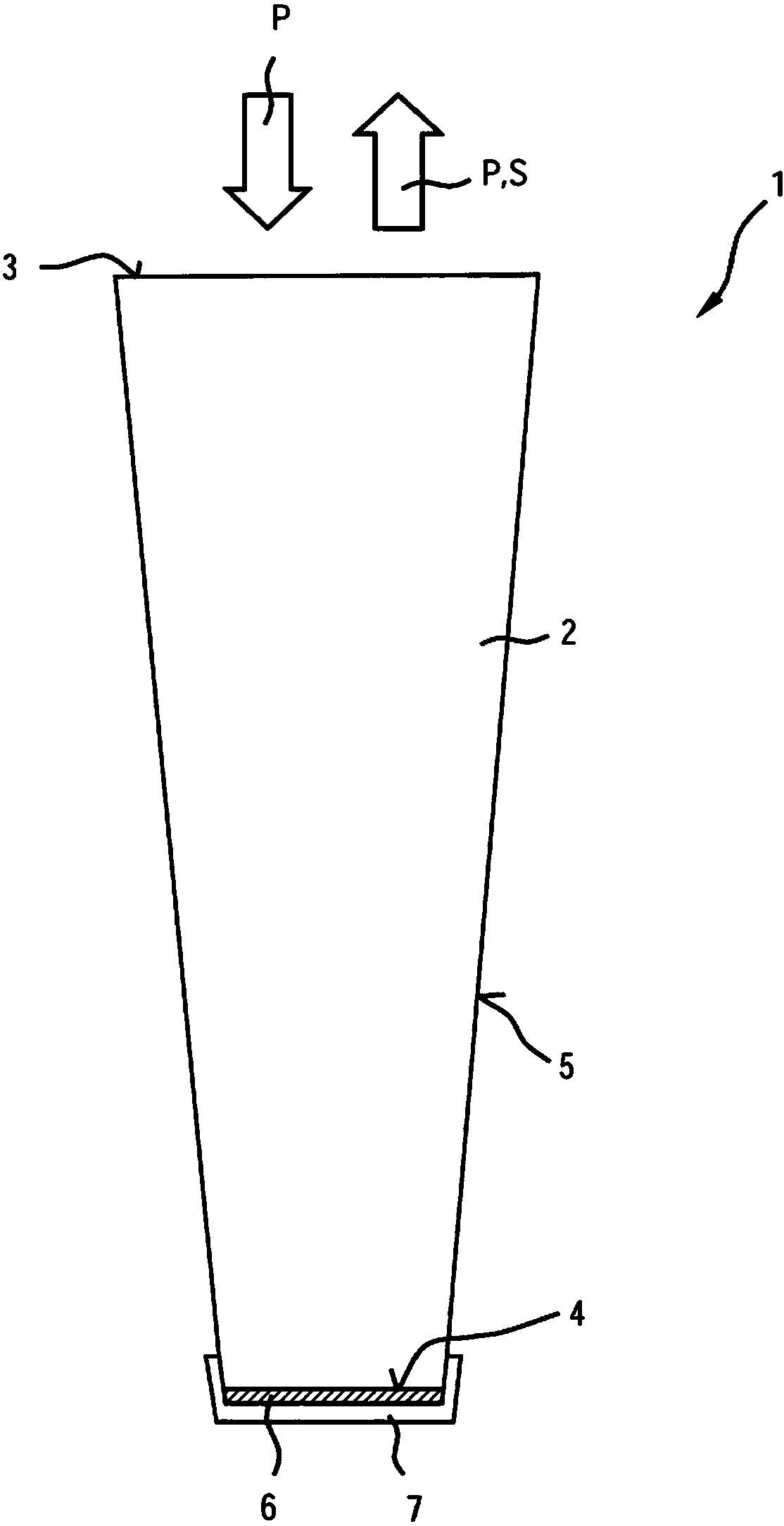

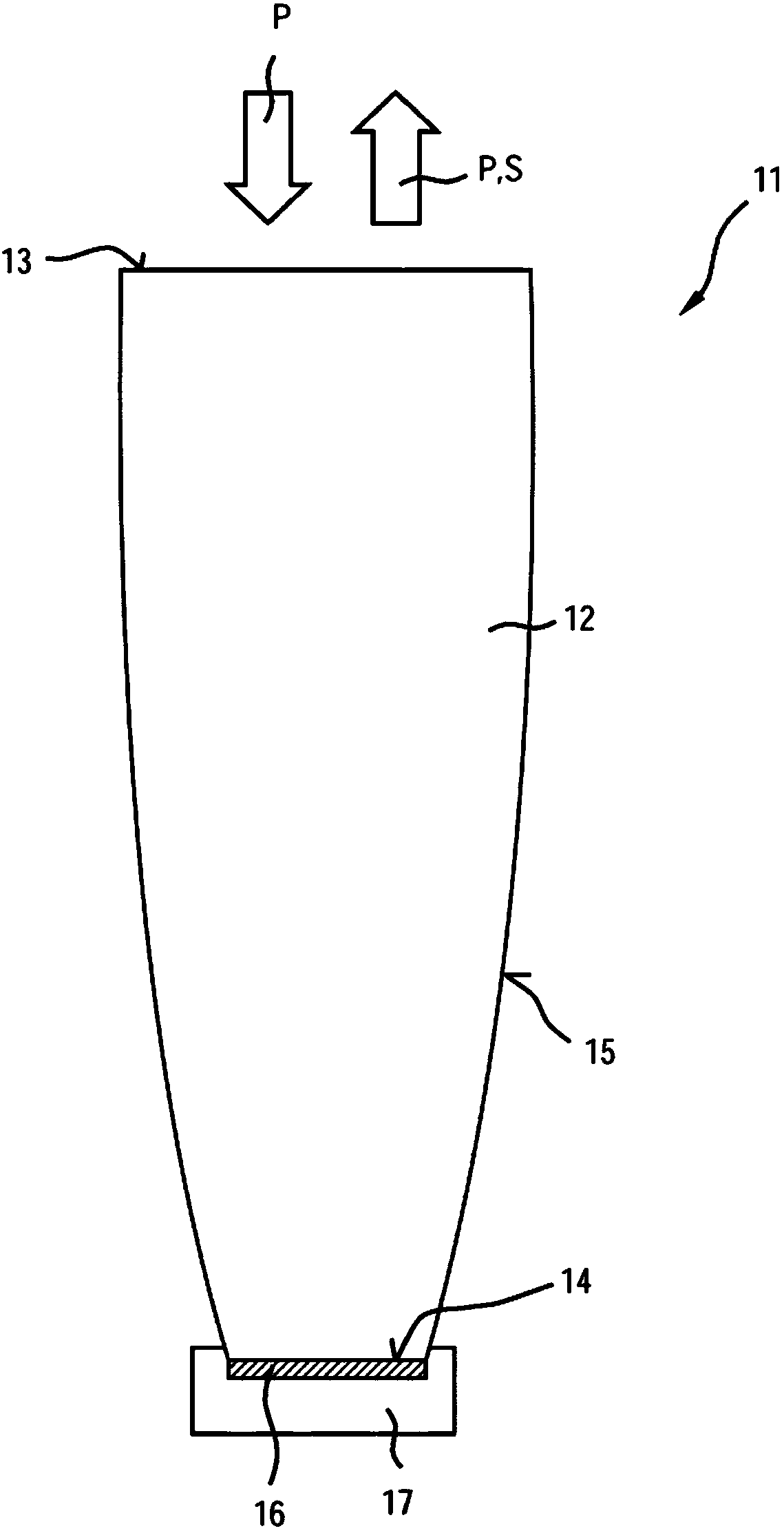

[0045] figure 1 A side view of the wavelength conversion body 1 according to the first exemplary embodiment is shown in section. The wavelength conversion body 1 is used to generate wavelength-converted light from primary light P incident into the wavelength conversion body 1 . The primary light P can be, for example, laser light generated by a laser or narrow-bandwidth light generated by a light-emitting diode. However, the type of light source generating the primary light P is in principle not limited and may also include, for example, light sources of broadband radiation with or without filters arranged downstream, or wavelength emissions with linear emission or broadened pressure. range of discharge lamps. Particle beam irradiators (eg electron beam or ion beam) can also be used.

[0046] The wavelength converter 1 has a light guide 2 which is transparent to primary light P, in particular transparent. The light guide 2 here has the shape of a truncated cone with a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com