Preparation method of cadmium tungstate monocrystal nanoribbon

A single crystal nanometer, cadmium tungstate technology, applied in the field of nanomaterials, can solve the problems of difficult process control, high energy consumption, high temperature, and achieve the effects of simple equipment, low energy consumption and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

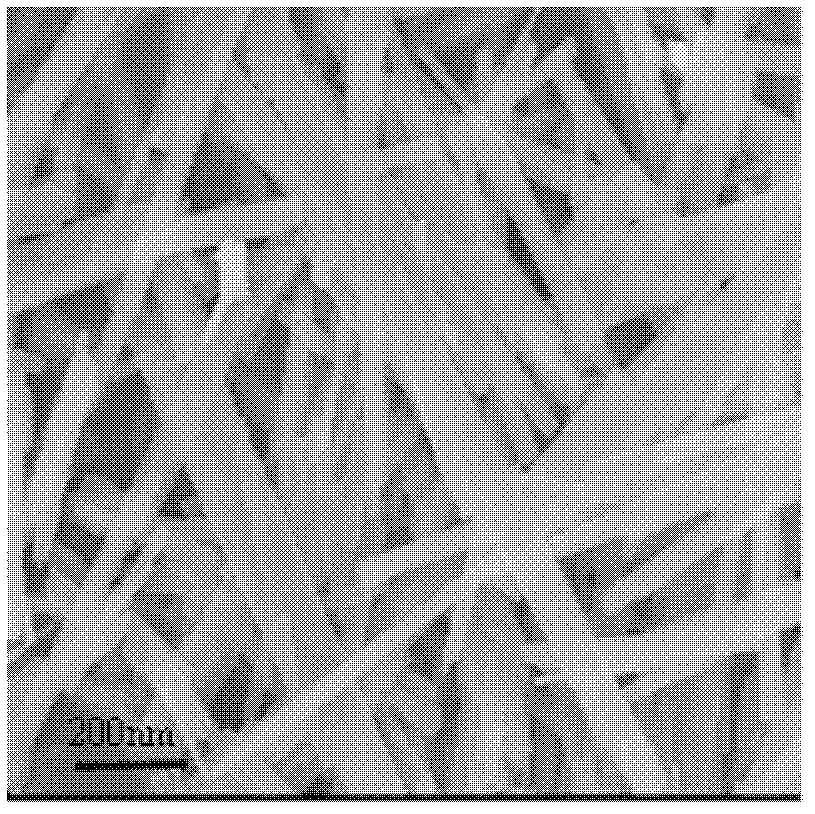

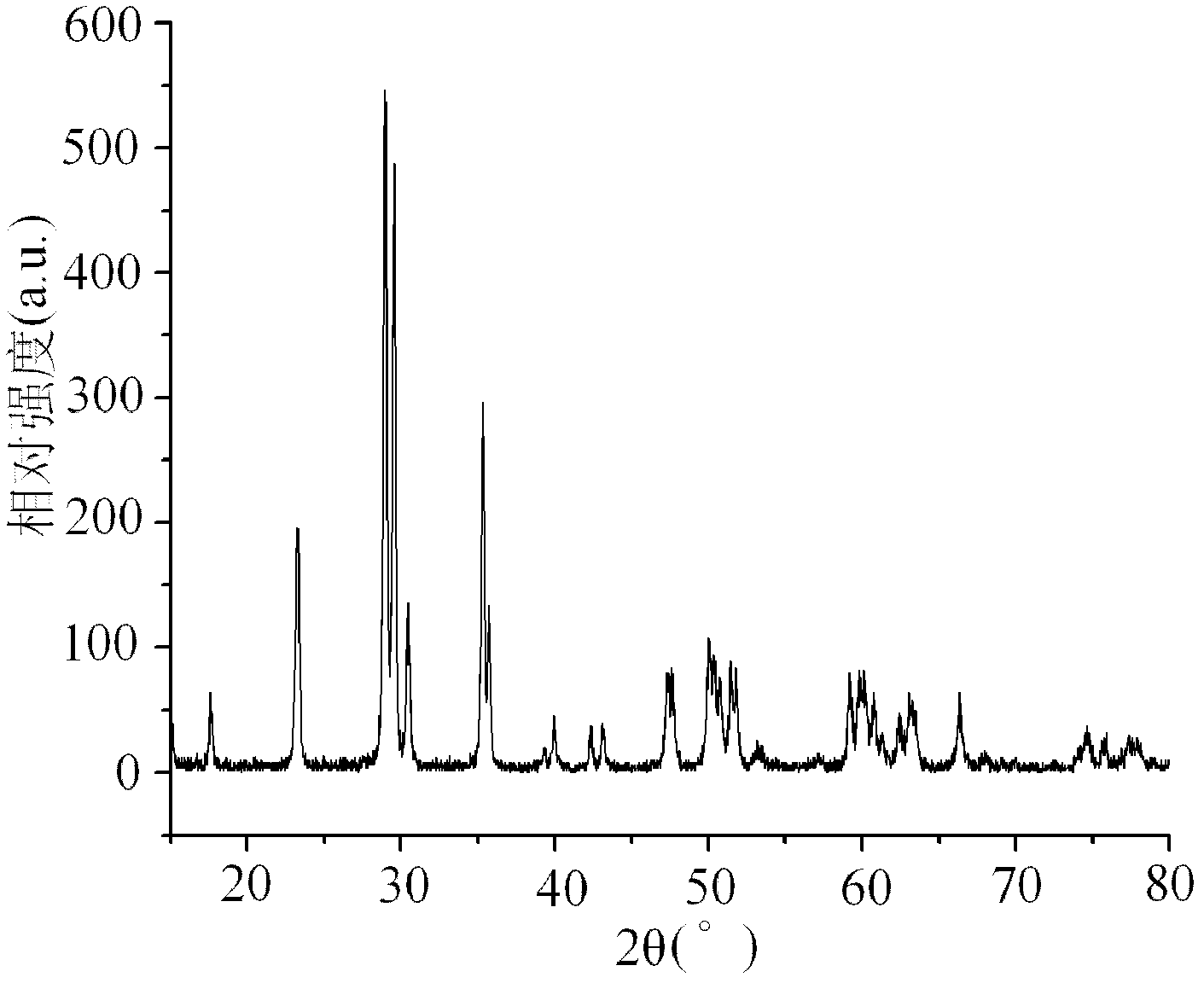

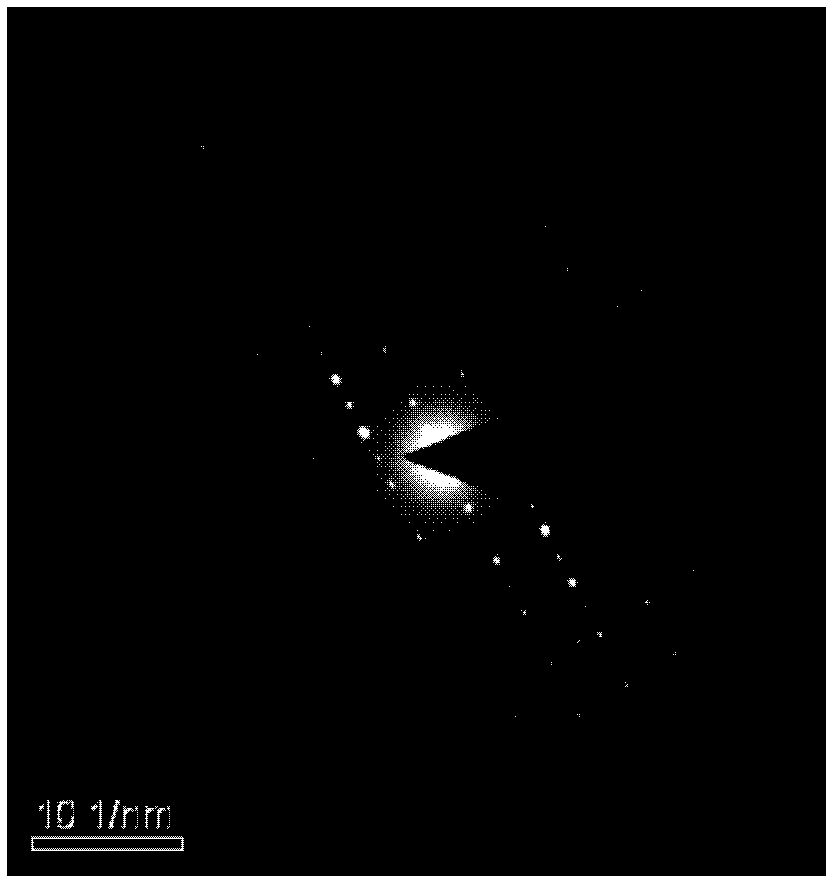

[0020] The preparation method of cadmium tungstate single crystal nanobelt of the present invention adopts soluble cadmium salt as cadmium source, uses water as medium, under the situation that surfactant sodium dodecylbenzenesulfonate (sodium dodecylbenzenesulfonate, SDBS) participates, Sodium tungstate was used as a precipitating agent to obtain a suspension solution at room temperature. Then, through hydrothermal reaction, filtration, washing and drying, single crystal cadmium tungstate nanobelts with wolframite structure can be obtained. Specifically follow the steps below:

[0021] Step 1: Grinding the soluble cadmium salt into finer powder at room temperature, dissolving in deionized water to obtain a molar concentration of 0.1-0.3mol L -1 transparent solution. The soluble cadmium salt is cadmium nitrate or cadmium chloride.

[0022] Step 2: In the case of stirring, add surfactant SDBS to the cadmium salt solution obtained in step 1, and the concentration of SDBS in t...

Embodiment 1

[0030] Dissolve cadmium nitrate in deionized water after grinding to obtain a concentration of 0.1mol L -1 cadmium nitrate transparent solution; in the case of stirring, add surfactant SDBS to the cadmium nitrate solution, the amount of SDBS added, so that the SDBS concentration in the final solution is 0.005mol L -1 ; Set the concentration to 0.4mol L -1Sodium tungstate solution was added to the above solution, the transparent solution turned into an opaque suspension, and continued to stir vigorously for 1h; then, use 1mol L -1 hydrochloric acid solution and sodium hydroxide solution to adjust the pH value of the suspension to 7, and continue stirring for 0.5 h.

[0031] After stirring, move the suspension to a 100ml polytetrafluoroethylene-lined stainless steel reactor, add the suspension to 3 / 4 of the volume of the reactor, tighten the top cover of the reactor, and heat it in an electric furnace until the temperature reaches Predetermined temperature and heat preservatio...

Embodiment 2

[0034] Dissolve cadmium nitrate in deionized water after grinding to obtain a concentration of 0.3mol L -1 cadmium nitrate transparent solution; in the case of stirring, add surfactant SDBS to the cadmium nitrate solution, the amount of SDBS added, so that the SDBS concentration in the final solution is 0.015mol L -1 ; Set the concentration to 0.8mol L -1 Sodium tungstate solution was added to the above solution, the transparent solution turned into an opaque suspension, and the vigorous stirring was continued for 3 hours; then 1mol L -1 hydrochloric acid solution and sodium hydroxide solution to adjust the pH value of the suspension to 9, and continue stirring for 1 h.

[0035] After stirring, move the suspension to a 100ml polytetrafluoroethylene-lined stainless steel reactor, add the suspension to 3 / 4 of the volume of the reactor, tighten the top cover of the reactor, and heat it in an electric furnace until the temperature reaches Predetermined temperature and heat prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com