Preparation method of spherical nano calcium carbonate

A nano-calcium carbonate and calcium carbonate technology, applied in the field of nanomaterials, can solve the problems of large product particle size, cumbersome synthesis steps, and various reagents, and achieve the effects of uniform size distribution, low cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

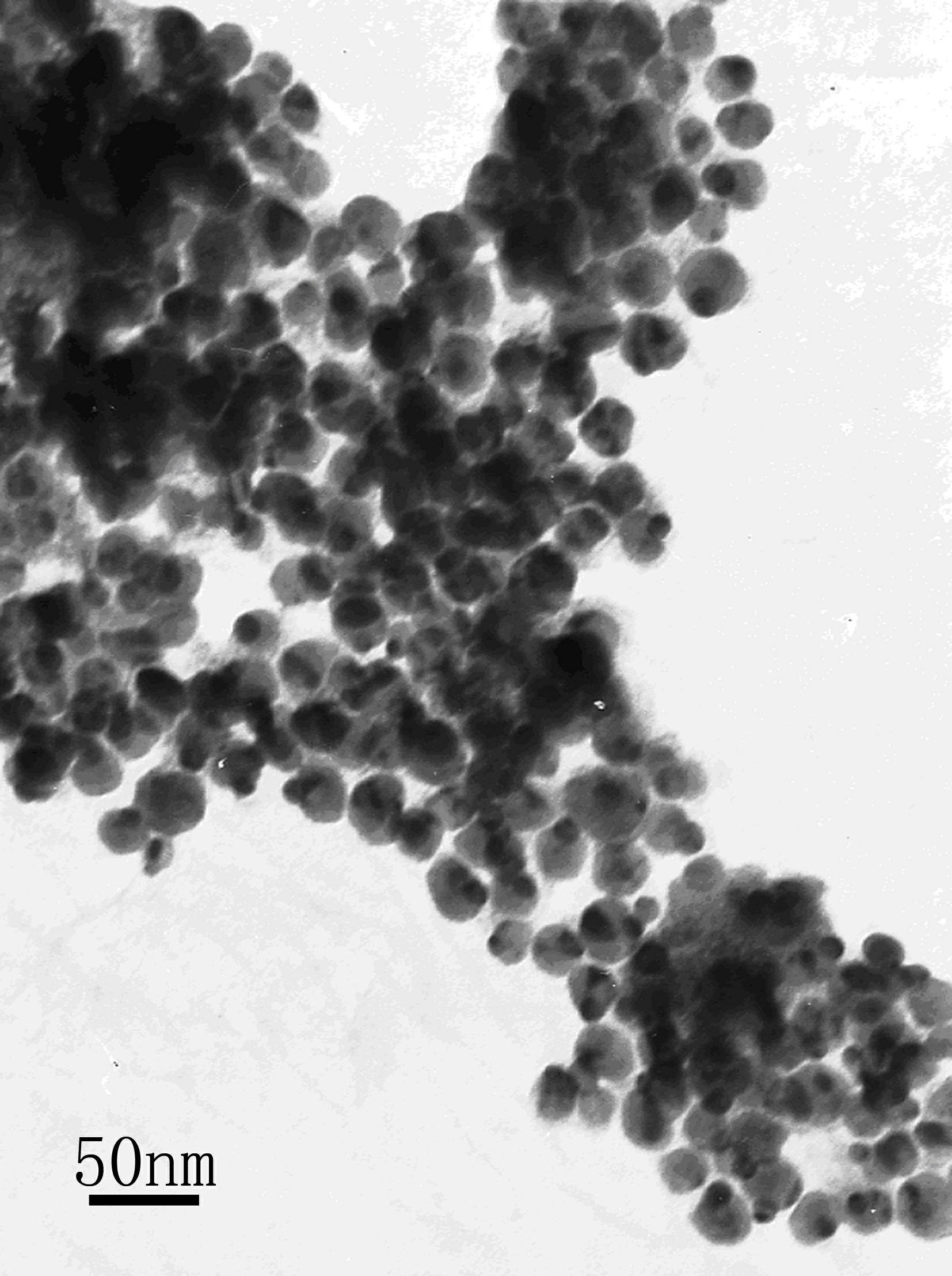

[0027] Weigh 2.65g of sodium carbonate, add water to dissolve, and prepare a 0.1mol / L sodium carbonate solution in a 250ml volumetric flask; weigh 22.2g of anhydrous calcium chloride, add water to dissolve, and prepare a 2mol / L solution in a 100ml volumetric flask Calcium chloride solution; measure 200ml of 0.1mol / L sodium carbonate solution in a 500ml beaker, then add 0.02g of pentaerythritol, the amount is based on 1% of the final product calcium carbonate mass, stir to make it completely dissolve; stirring speed Set to 800r / min, then slowly add 10ml of 2mol / L calcium chloride solution dropwise to the above solution, after the dropwise addition is completed, a nano-calcium carbonate slurry is obtained, and the slurry is continued to be stirred for 30min; the obtained nano-calcium carbonate particle Transmission electron microscope pictures as figure 1 As shown, it can be seen from the figure that the nano-calcium carbonate is spherical in shape, its particle size is about 25...

Embodiment 2

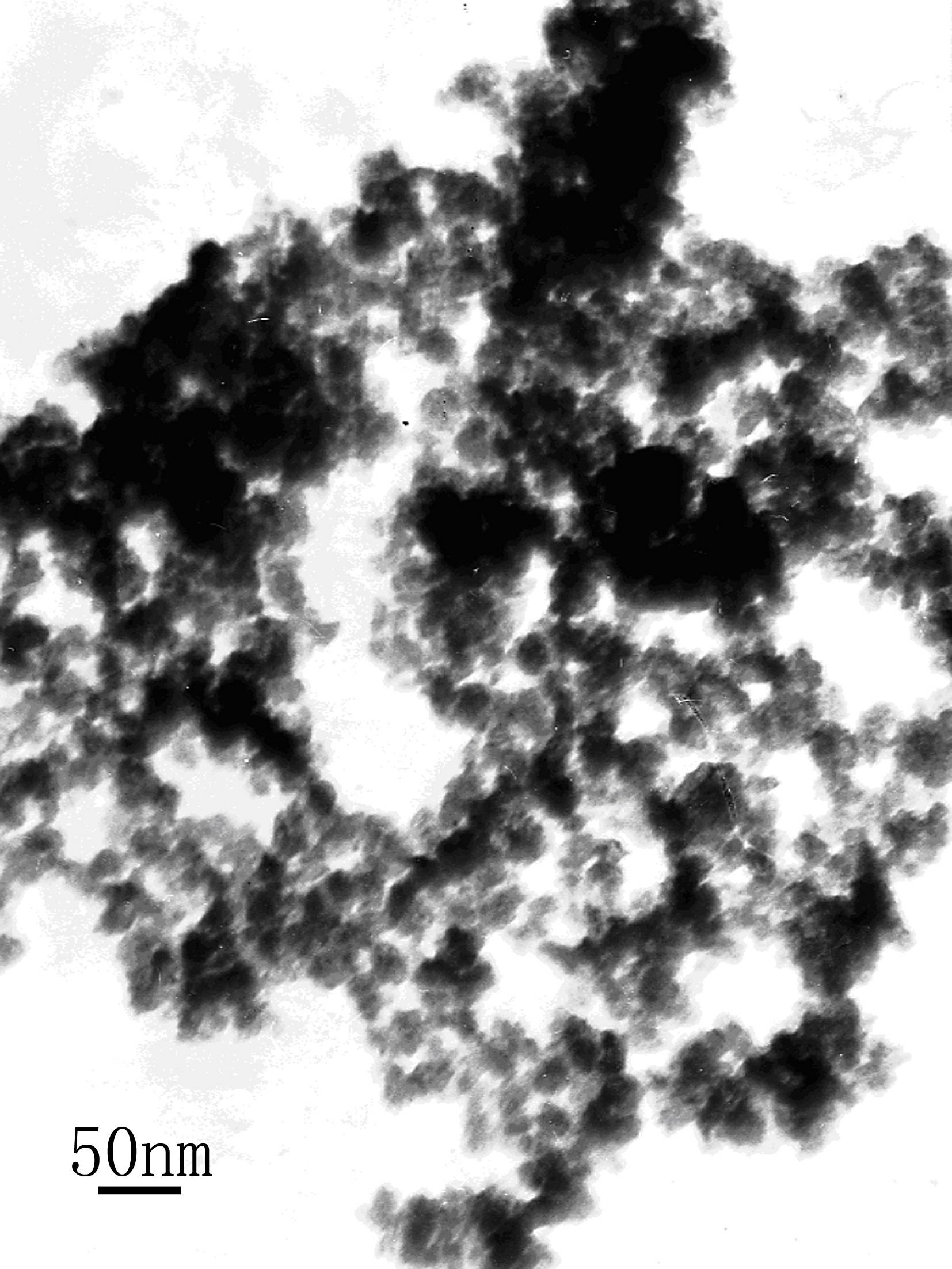

[0029] Weigh 2.65g of sodium carbonate, add water to dissolve, and prepare a 0.1mol / L sodium carbonate solution in a 250ml volumetric flask; weigh 22.2g of anhydrous calcium chloride, add water to dissolve, and prepare a 2mol / L solution in a 100ml volumetric flask Calcium chloride solution; measure 200ml of 0.1mol / L sodium carbonate solution in a 500ml beaker, then add 0.002g of pentaerythritol, the amount is based on 0.1% of the final product calcium carbonate quality, stir to make it completely dissolved; stirring speed Set to 800r / min, then slowly add 10ml of 2mol / L calcium chloride solution dropwise to the above solution, after the dropwise addition is completed, a nano-calcium carbonate slurry is obtained, and the slurry is continued to be stirred for 30min; the obtained nano-calcium carbonate particle Transmission electron microscope pictures as figure 2 As shown, it can be seen from the figure that the nano-calcium carbonate is basically spherical, its particle size is...

Embodiment 3

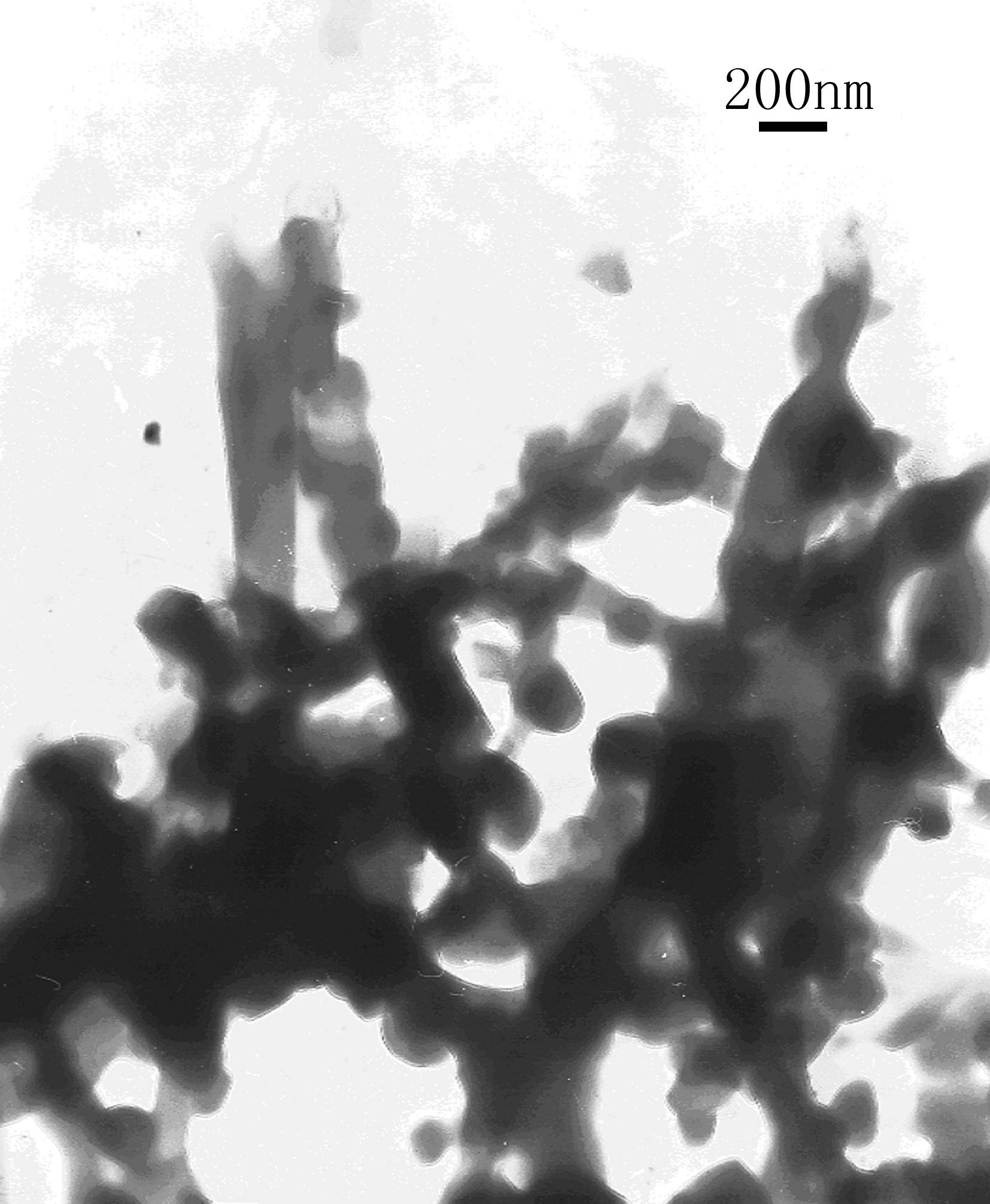

[0031] Weigh 0.1g of sodium stearate (measured by 5% of the mass of calcium carbonate) and stir to dissolve it in 50ml of water at 70°C. After the sodium stearate is completely dissolved, slowly add it to the nanocarbonate prepared in Example 1. In the calcium slurry, after continuing to stir for 30min evenly, obtain the nano-calcium carbonate particle modified by sodium stearate, and the transmission electron microscope photograph of product is as follows: image 3 As can be seen from the characterization of the transmission electron microscope, the surface of the spherical nano-calcium carbonate is successfully coated with one deck of sodium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com