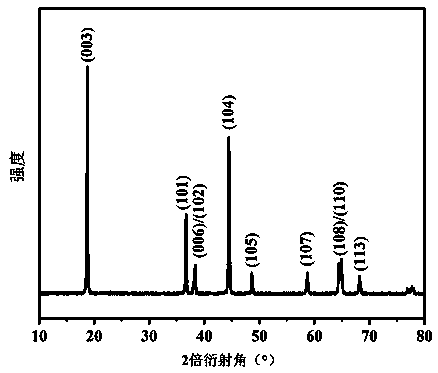

Core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material and preparation method thereof

A core-shell structure and positive electrode material technology, which is applied in the field of lithium battery positive electrode materials and its preparation, can solve the problems that can not reflect the improvement of adding aluminum, complex synthesis process, difficult to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

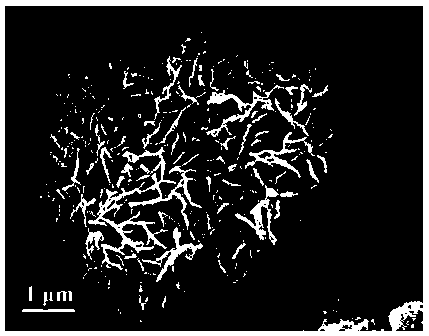

Embodiment 1

[0063] This embodiment includes the following steps:

[0064] (1) Under stirring conditions, 2 L low-nickel solution (a mixed solution of nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate, wherein the molar ratio of Ni, Co, Mn, and Al ions is 7:1:1.4:0.6 , the total molar concentration of Ni, Co, Mn, Al is 2.0 mol / L) with the feed rate of 50mL / h, pump into 2 L high-nickel solution (the mixed solution of nickel sulfate and cobalt sulfate, wherein, Ni, Co ion The molar ratio is 9:1, the total molar concentration of Ni and Co is 2.0 mol / L), at the same time, under stirring conditions, the high-nickel solution that is continuously pumped into the low-nickel solution is fed at a rate of 100 mL / h , continuously pumped into 2 L 2 mol / L ammonia solution to form a reaction system, passed high-purity nitrogen gas to form an inert atmosphere, adjusted the temperature and kept it at 50 ° C, and at the same time adjusted the ammonia concentration of the reaction system...

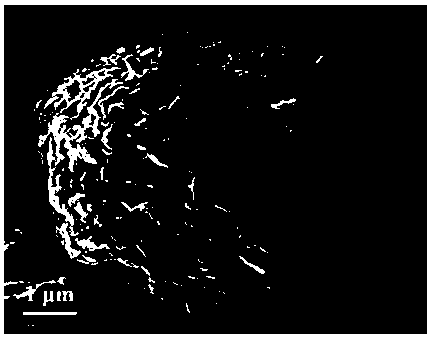

Embodiment 2

[0070] This embodiment includes the following steps:

[0071] (1) Under stirring conditions, 3 L low-nickel solution (a mixed solution of nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate, wherein the molar ratio of Ni, Co, Mn, Al ions is 7:1:1.4:0.6 , the total molar concentration of Ni, Co, Mn, Al is 2.0 mol / L) with the feeding speed of 50mL / h, pump into 2 L high-nickel solution (the mixed solution of nickel sulfate and cobalt sulfate, wherein, Ni, Co ion The molar ratio is 9:1, and the total molar concentration of Ni and Co is 2.0 mol / L), at the same time, under stirring conditions, the high-nickel solution that will be continuously pumped into the low-nickel solution is fed at a rate of 100 mL / h, Continuously pump into 3 L 3 mol / L ammonia solution to form a reaction system, pass high-purity nitrogen gas as an inert atmosphere, adjust the temperature of the reaction system to maintain at 55 °C and continue stirring. At the same time, adjust the ammonia...

Embodiment 3

[0077] This embodiment includes the following steps:

[0078] (1) Under stirring conditions, 4 L of low-nickel solution (a mixed solution of nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate, wherein the molar ratio of Ni, Co, Mn, and Al ions is 7:1:1:1 , the total molar concentration of Ni, Co, Mn, Al is 2.0 mol / L) with the feeding speed of 50 mL / h, pump into 4 L high-nickel solution (the mixed solution of nickel sulfate and cobalt sulfate, wherein, Ni, Co ion The molar ratio of Ni and Co is 9:1, and the total molar concentration of Ni and Co is 2.0 mol / L). At the same time, the high-nickel solution that is continuously pumped into the low-nickel solution is continuously pumped into the 4 L, 4 mol / L ammonia solution to form a reaction system. At the same time, high-purity nitrogen gas was introduced as an inert atmosphere, and the temperature of the reaction system was increased by 60 ° C. At the same time, the ammonia concentration of the reaction system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com