Gas turbine blade/guiding blade

A technology of steam turbine blades and guide vanes, which is applied in the direction of machines/engines, blade support components, mechanical equipment, etc., can solve the problems of compressor mass flow loss, limitation, and increase in design power of gas turbines, and achieve the goal of reducing losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

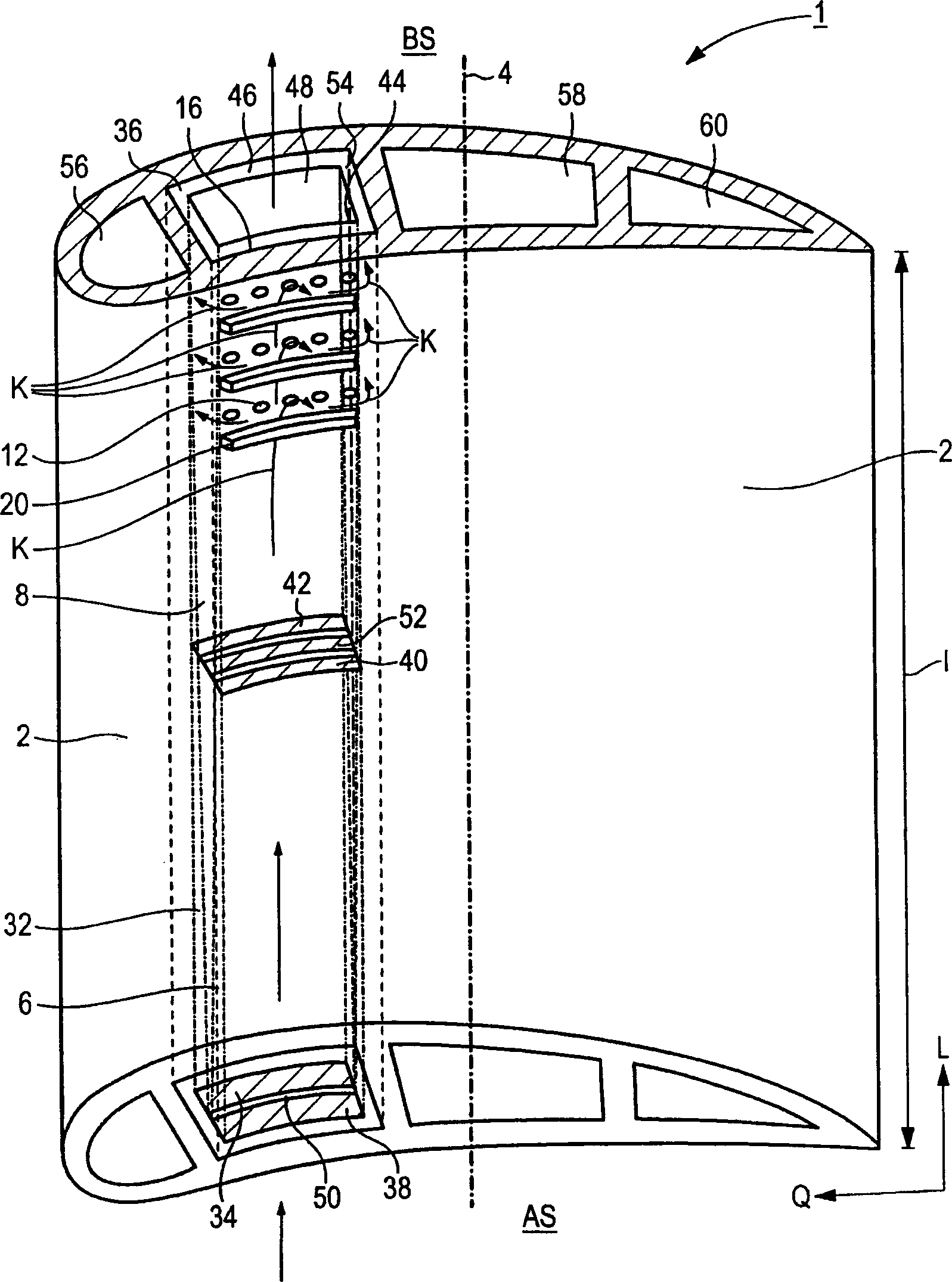

[0027] The same components are provided with the same reference numerals in all figures.

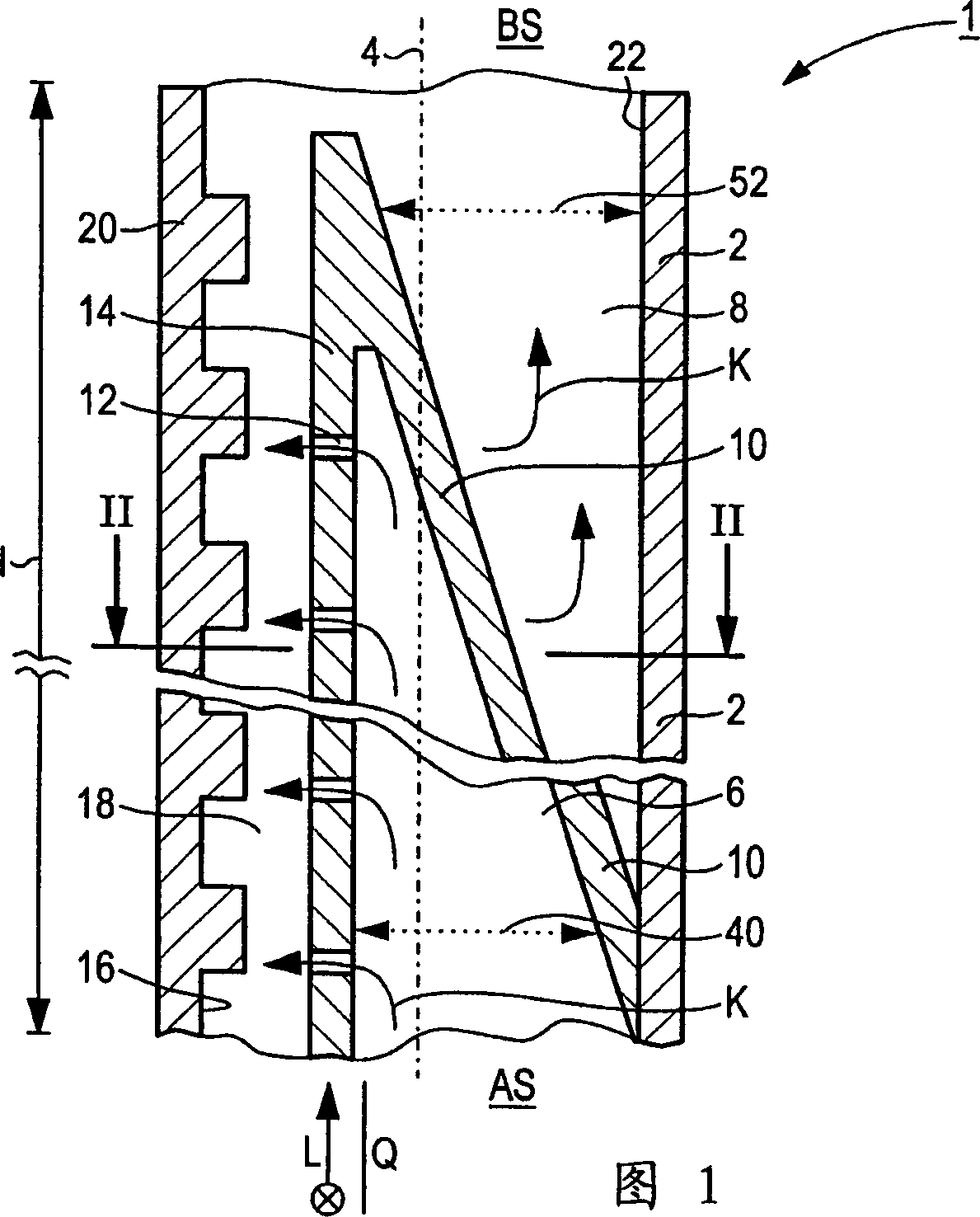

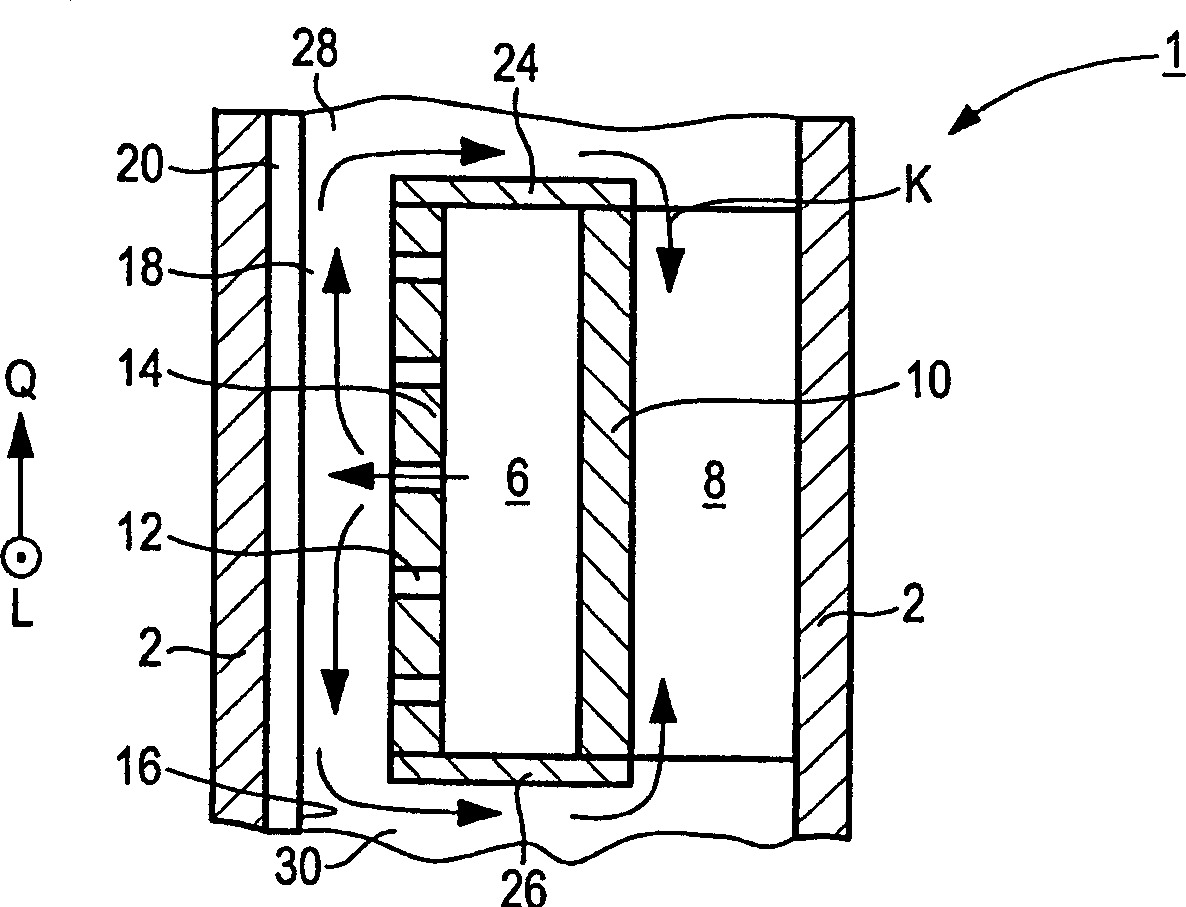

[0028] The steam turbine blade / guide vane shown in FIG. 1 has a blade / guide vane profile 2 extending along a blade / guide vane axis 4 . In order to properly influence the working fluid flowing in the associated turbine unit, the blade / guide vane profile 2 is hemispherical and / or curved.

[0029] The steam turbine blade / guide vane 1 is designed as a guide blade for a gas turbine (not shown in detail here) and in the manner of a closed cooling system as a steam turbine blade / cooling blade that can use air as a cooling medium. For this purpose, the cooling medium K can flow through the blade / guide vane airfoil 2 mainly in the longitudinal direction of the blade / guide vane airfoil 2, the cooling medium enters the blade / guide vane airfoil 2 from the cooling medium inflow port AS, and flows between the cooling medium The outflow end BS again emerges from the blade / guide vane airfoil.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com