Patents

Literature

294results about "Aircraft tyres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

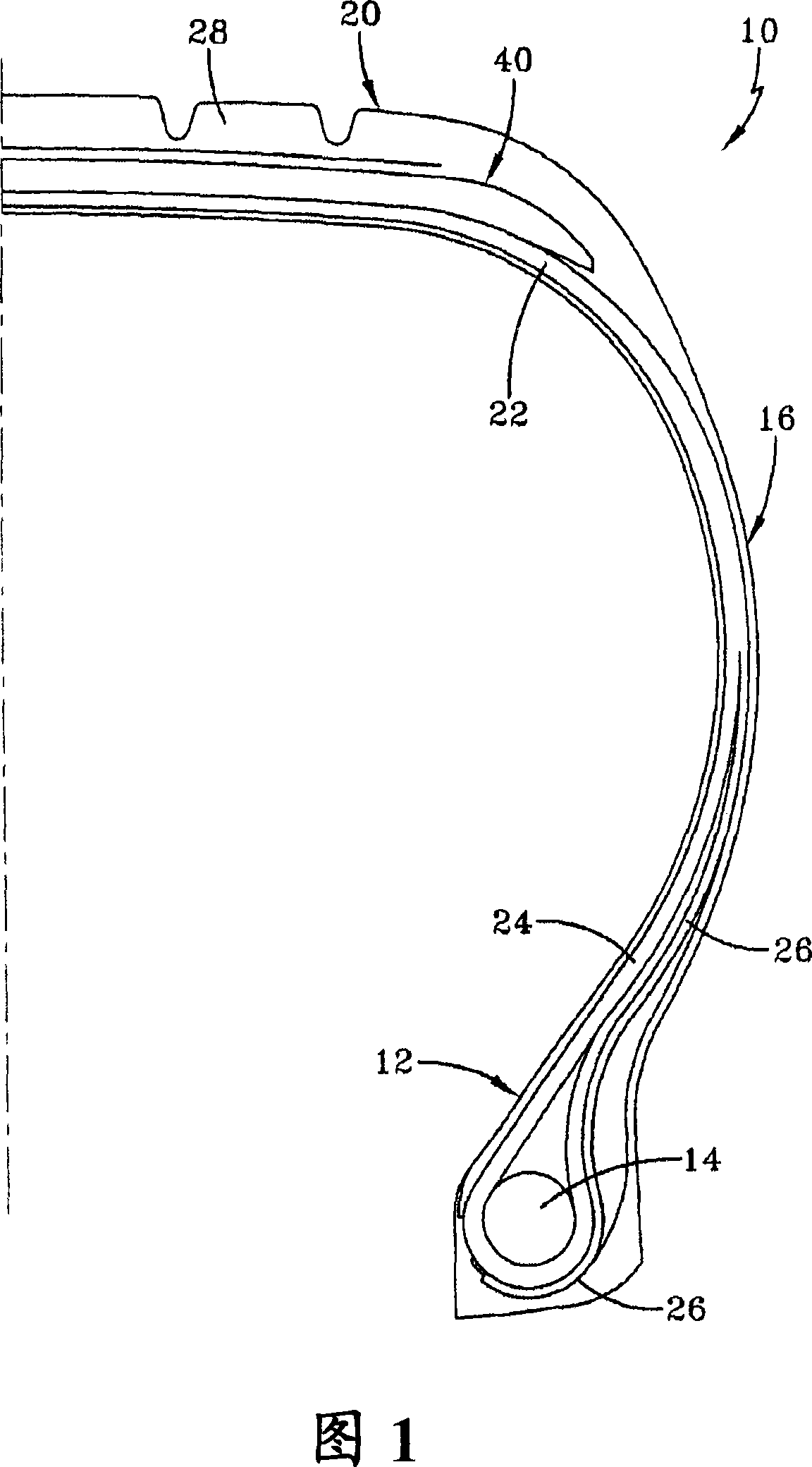

Pneumatic radial tire, and method of producing the same

ActiveUS20050194081A1Weight is lighterLower average tensionTyresPneumatic tyre reinforcementsForeign matterInternal pressure

In the pneumatic radial tire of the present invention, a total strength K0 of a belt layer 20 in a circumferential direction of the tire per unit of width at a tire equator surface position P0 is set greater than a total strength of the belt layer 20 in the circumferential direction of the tire per unit of width at a width position P2 corresponding to ⅔ of a maximum width of the belt layer having the tire equator surface CL as a center. In this way, it is possible to suppress the quantity consume of material in the belt layer 20, and to suppress the amount of expansion of tread rubber in a tread central region in the circumferential direction thereof when a standard internal pressure is charged and when the tire is rotated at high speed, thereby suppressing the growth of tire diameter. Since the expansion amount of the tread rubber in the circumferential direction is suppressed, the tension of the rubber is reduced. Therefore, it is possible to increase the resistance of the tread against the sticking of foreign matter, and even when foreign matter sticks in the tread, it is possible to suppress the growth of the crack.

Owner:BRIDGESTONE CORP

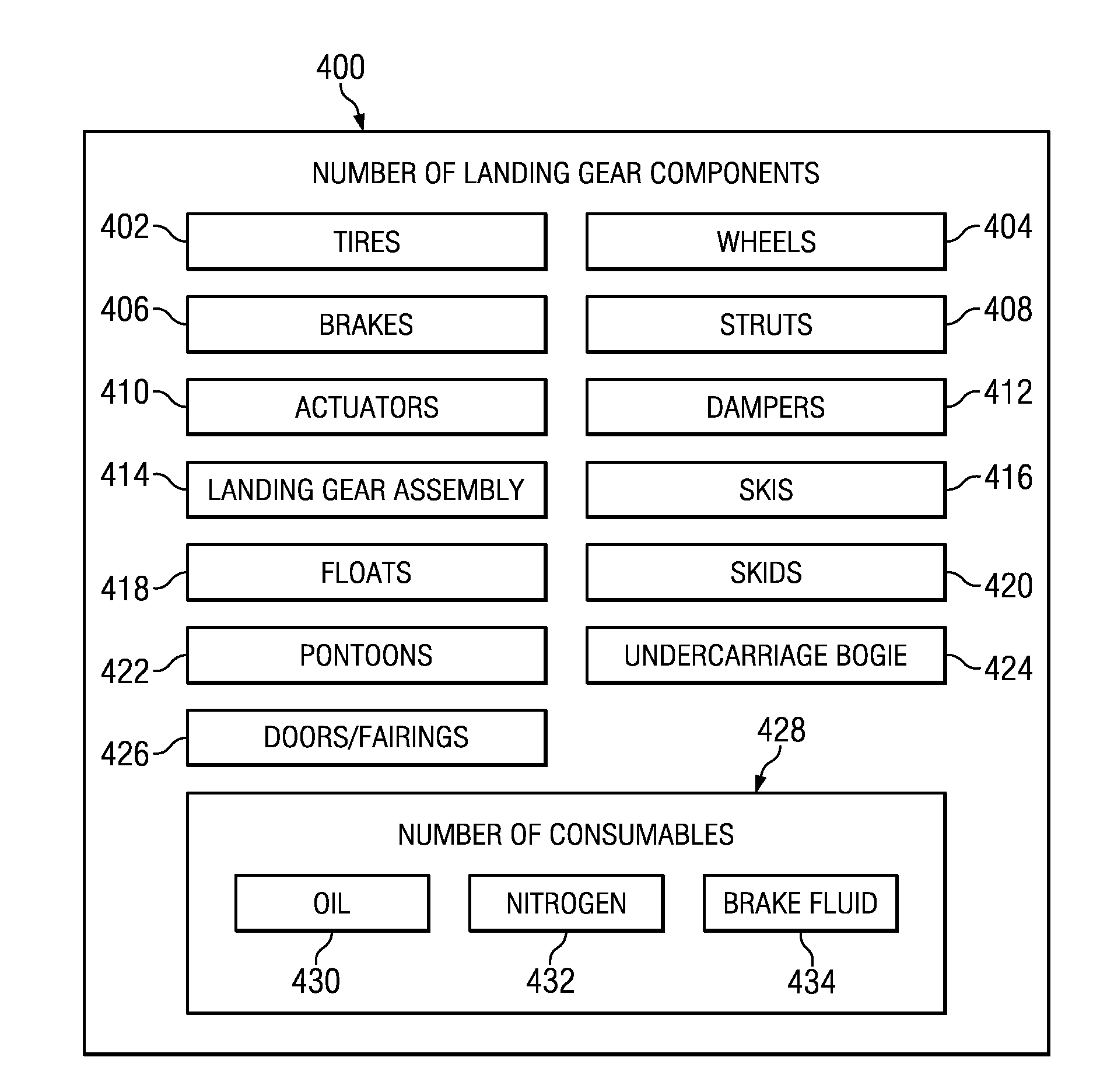

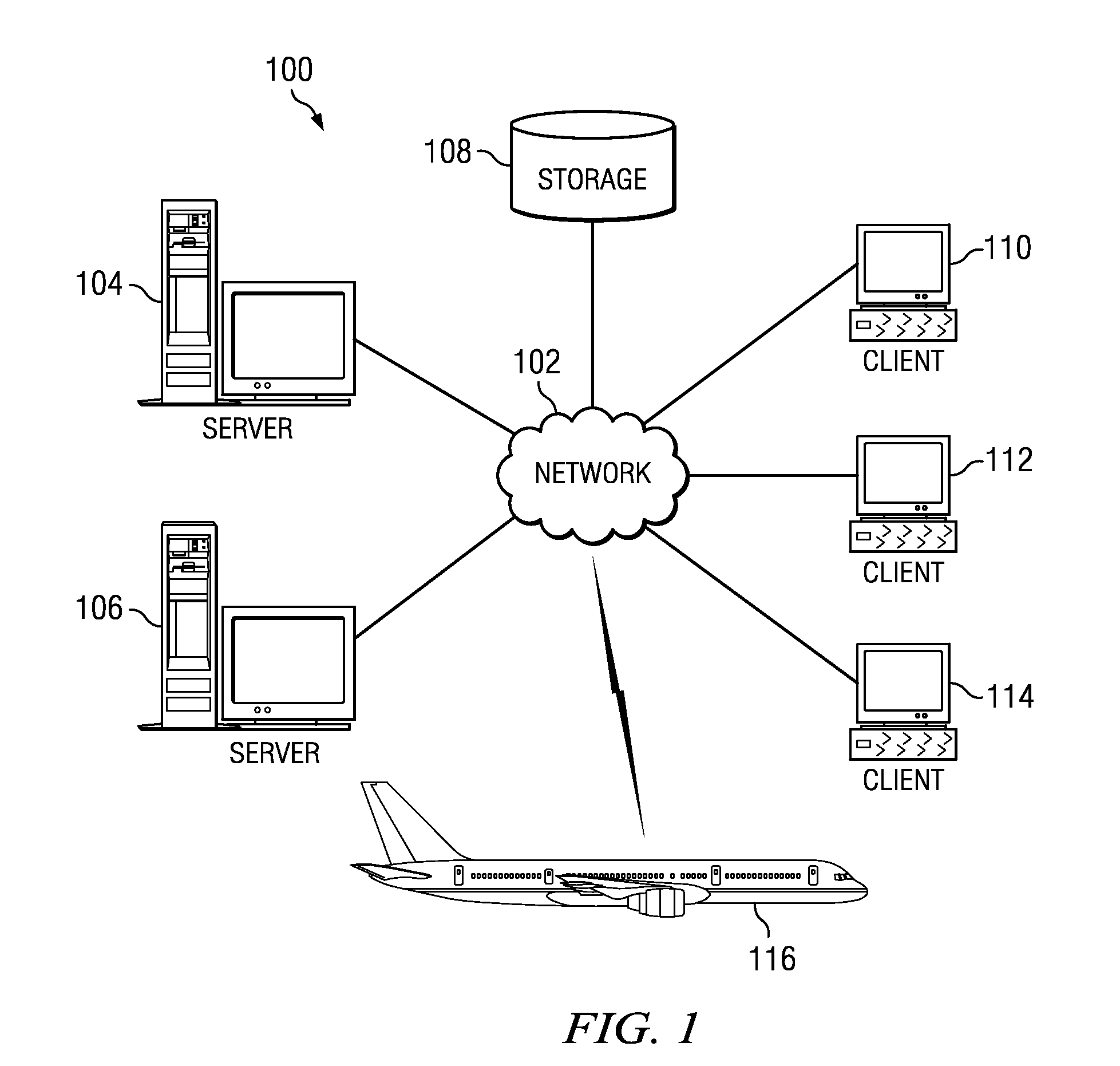

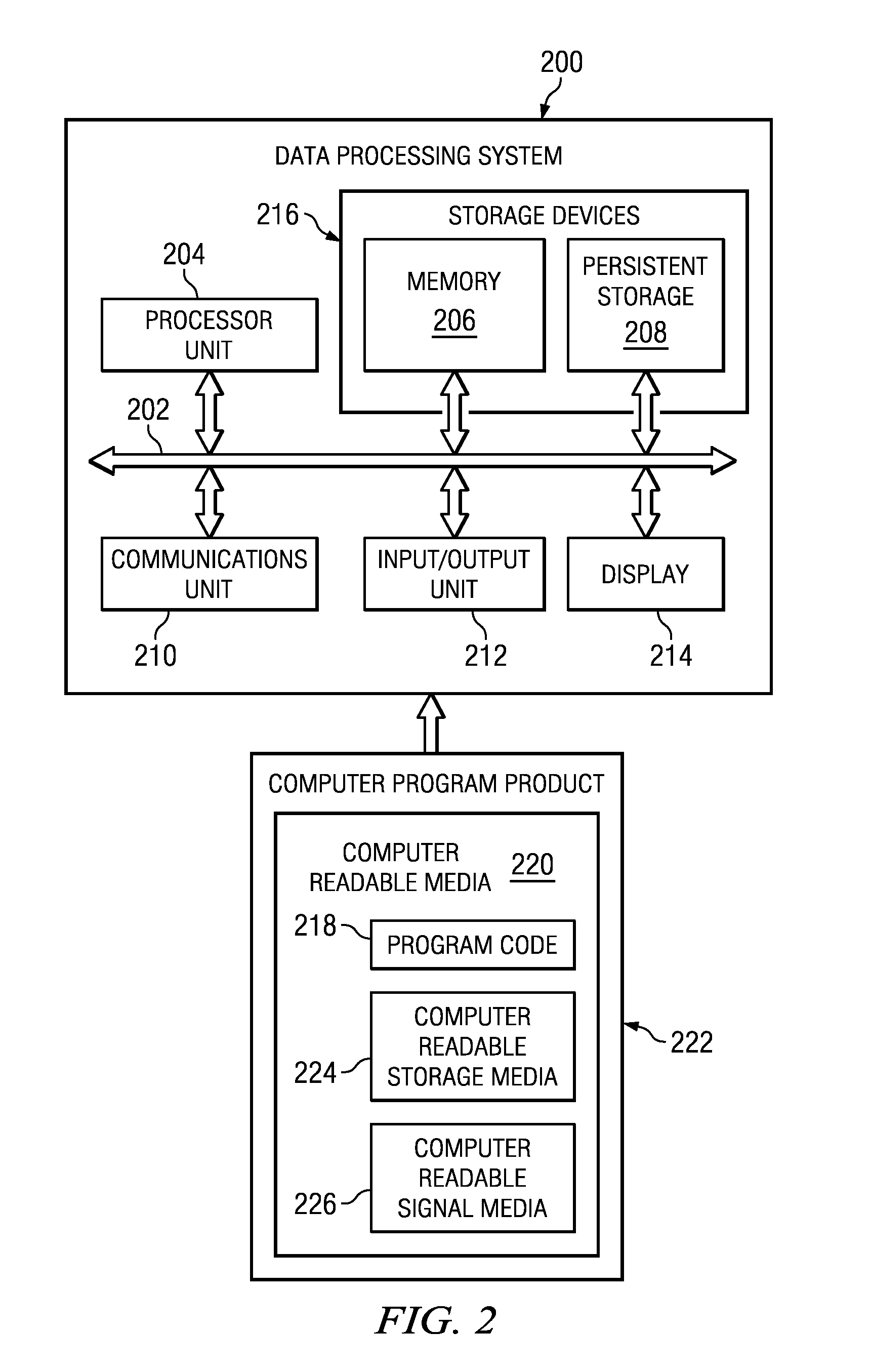

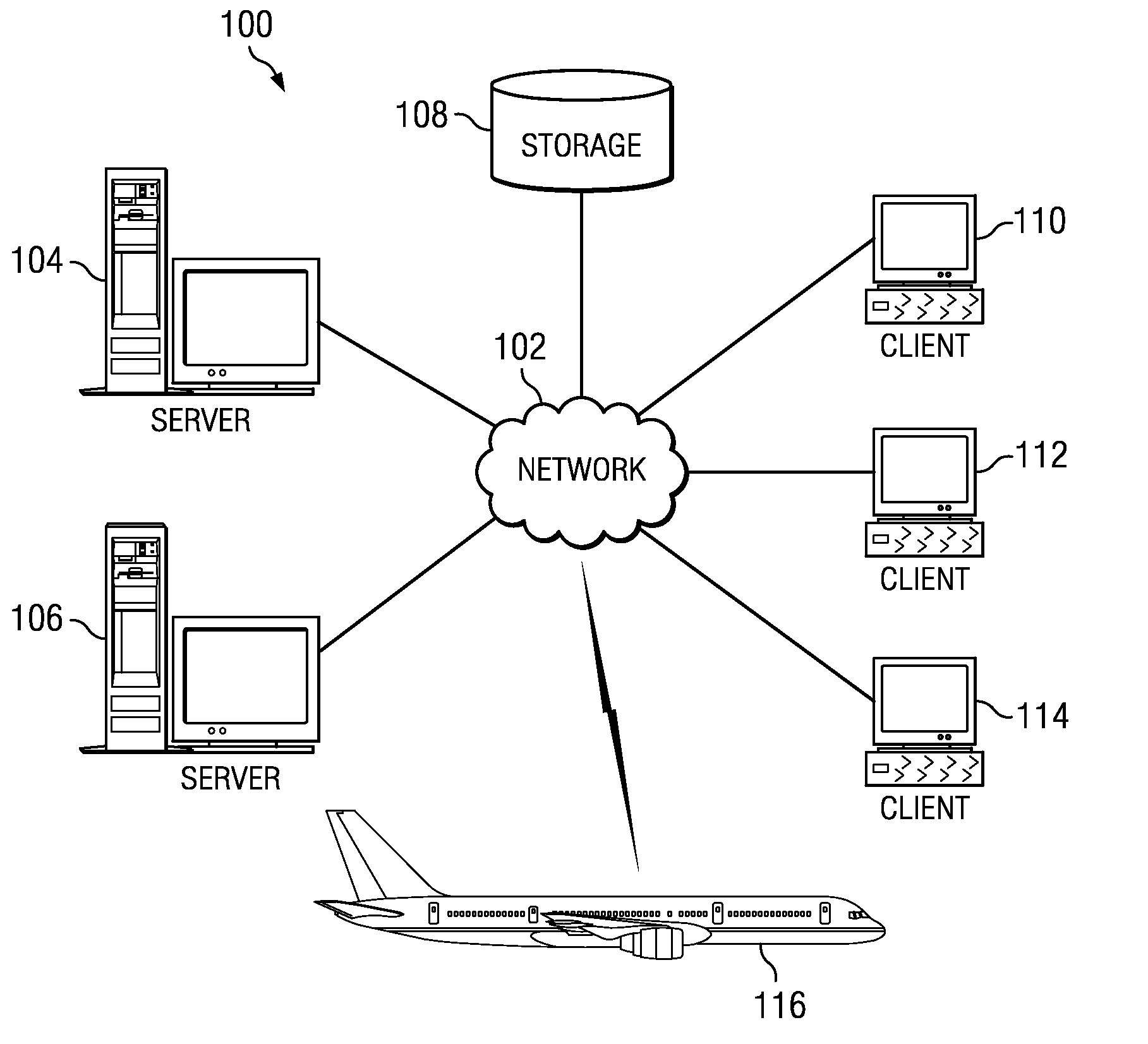

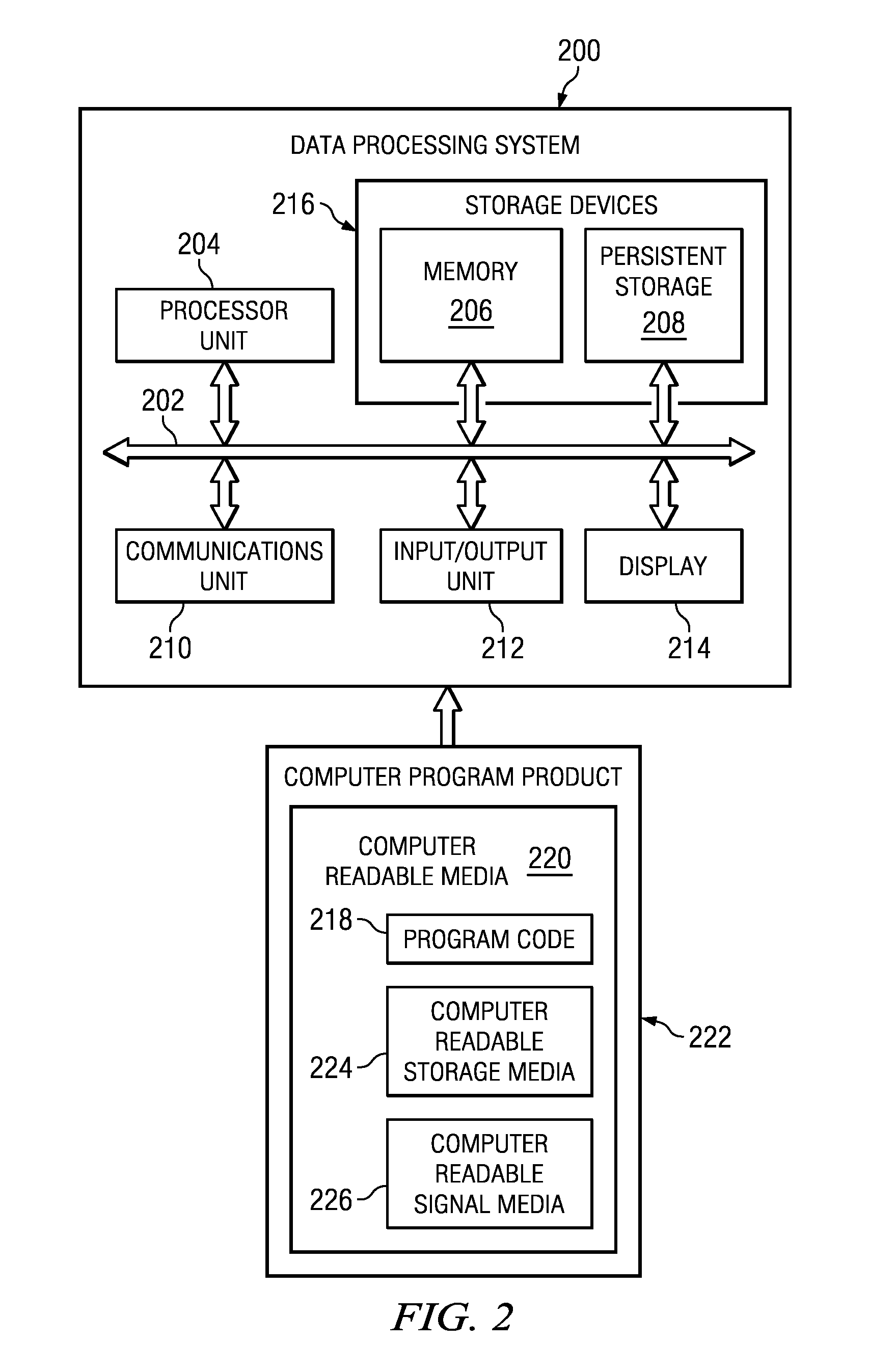

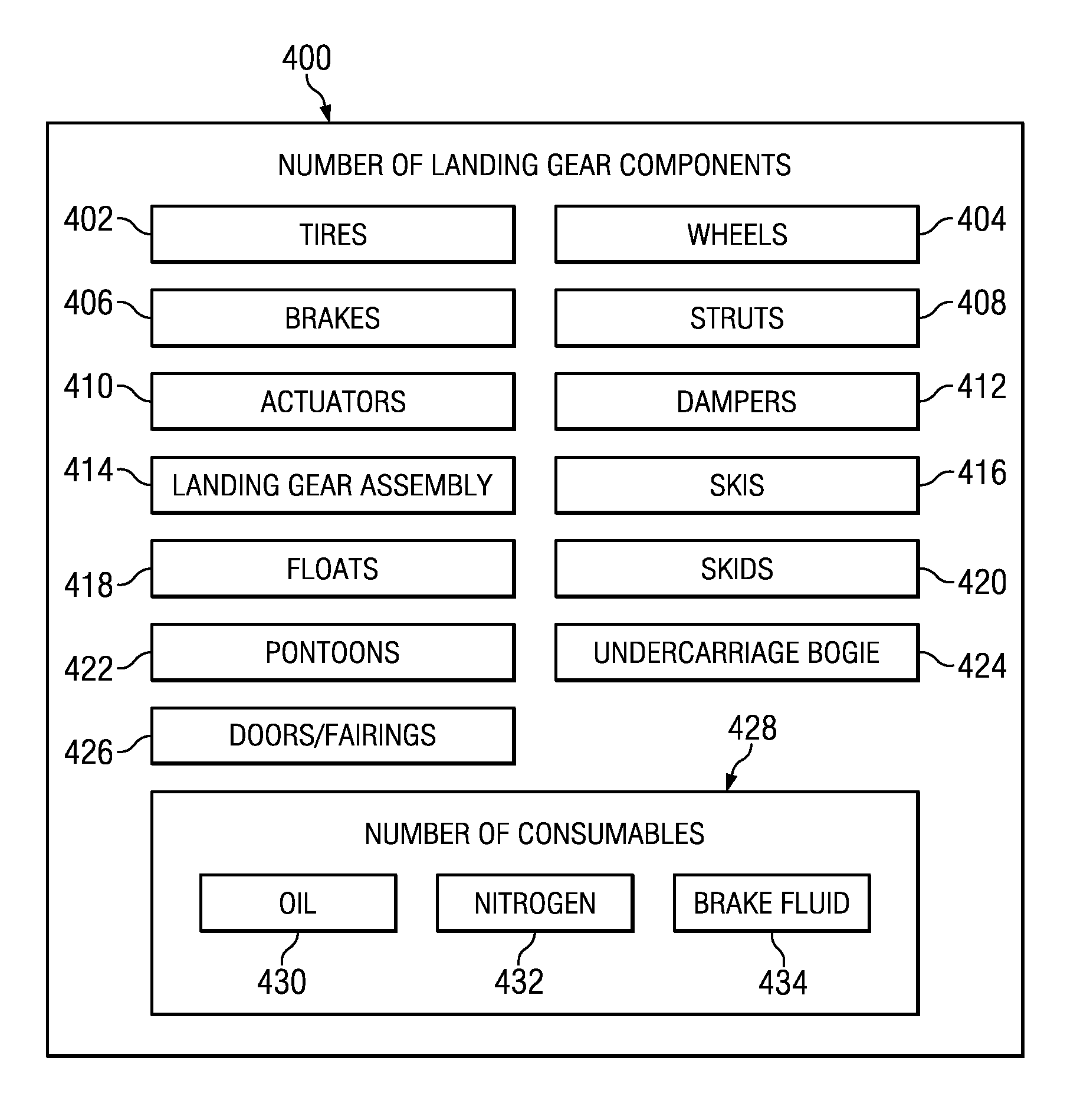

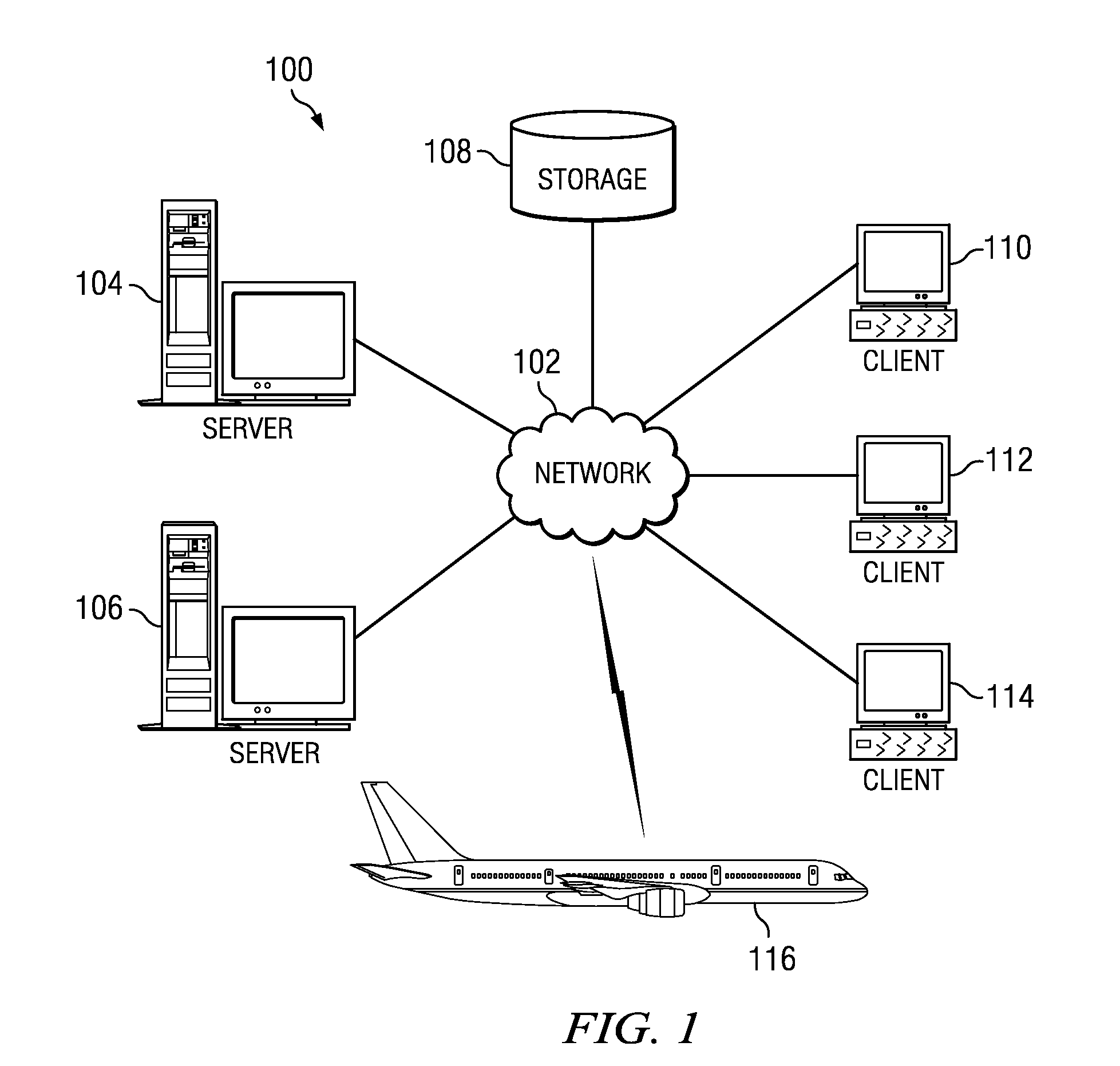

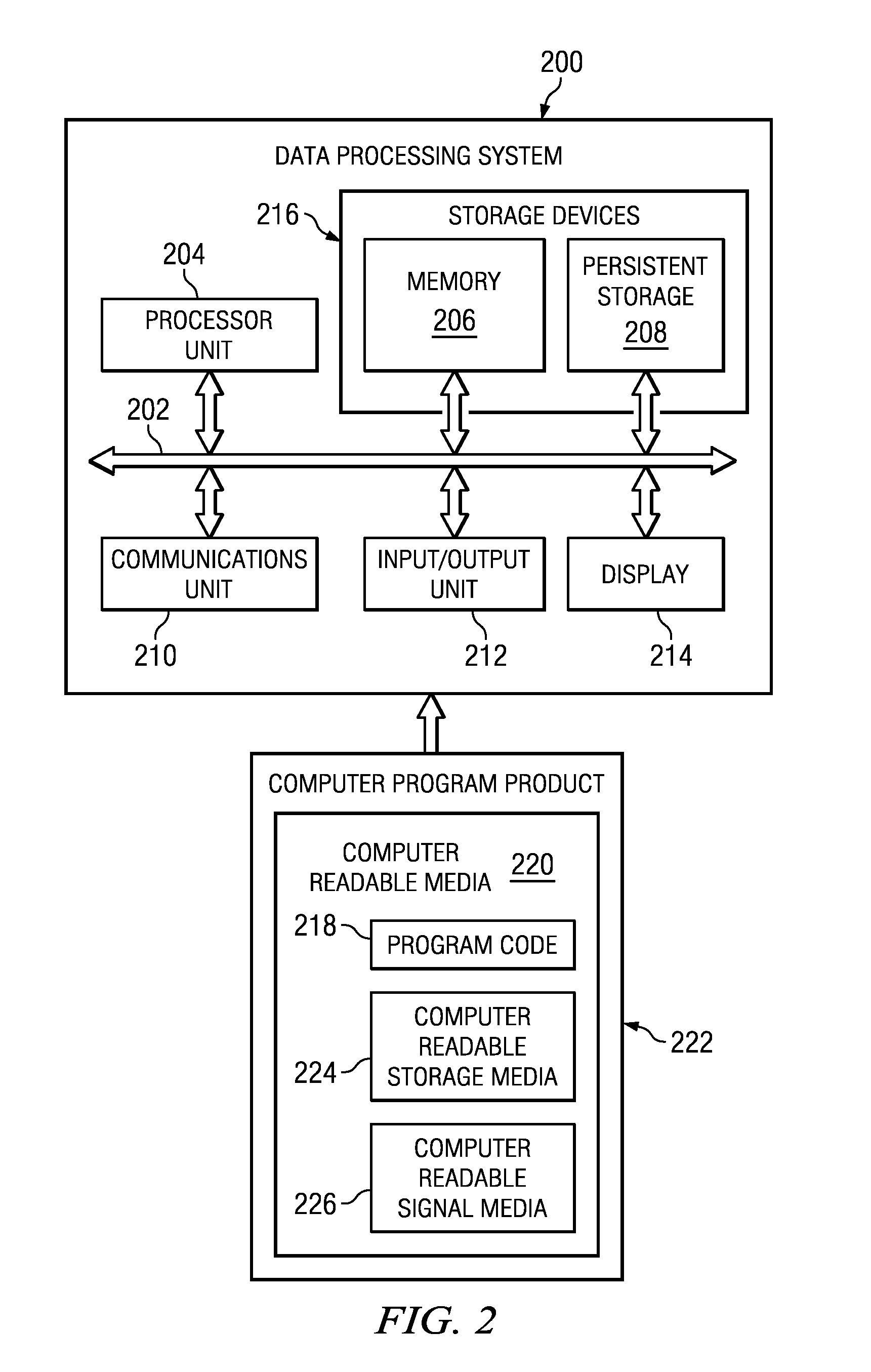

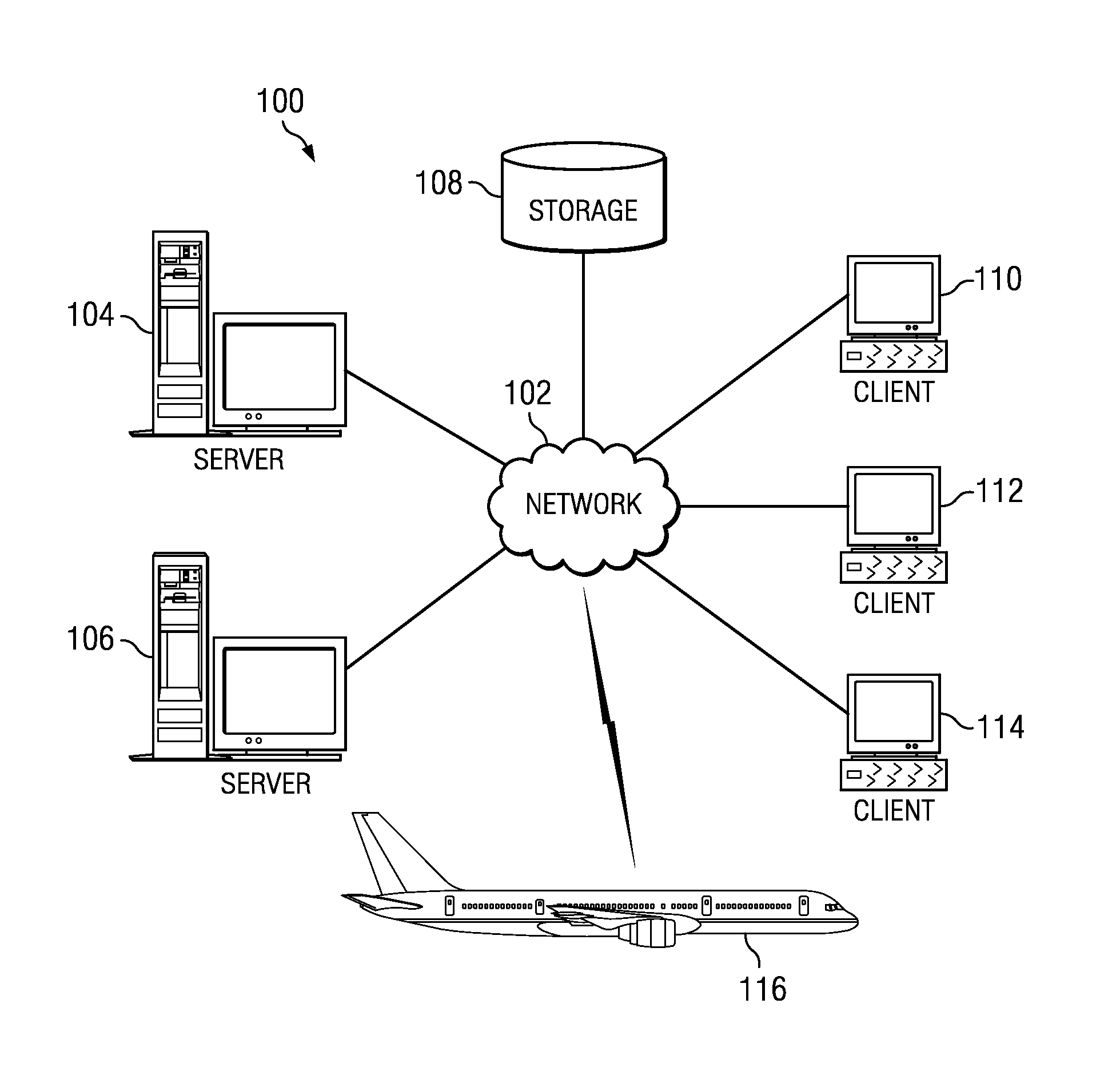

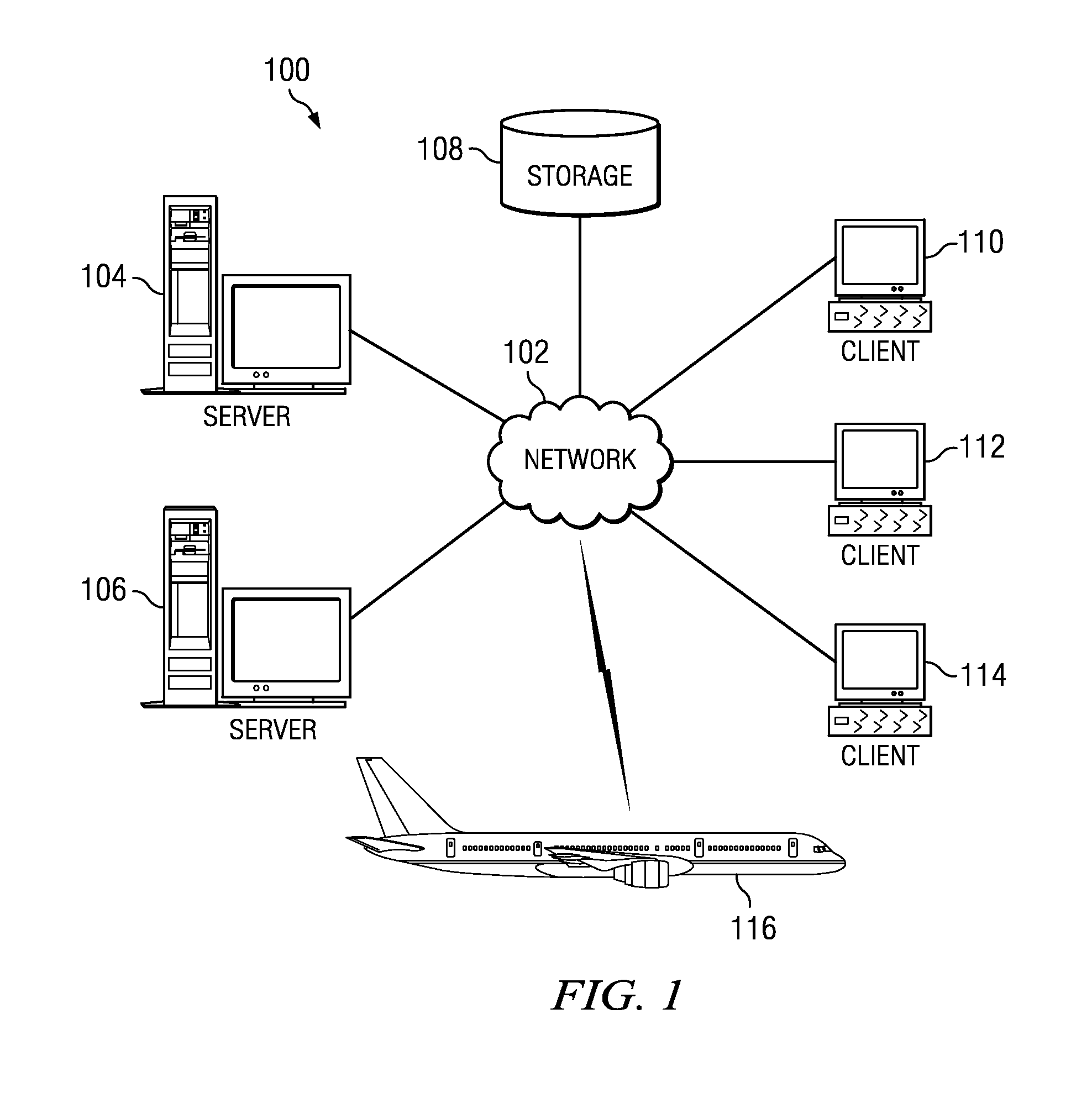

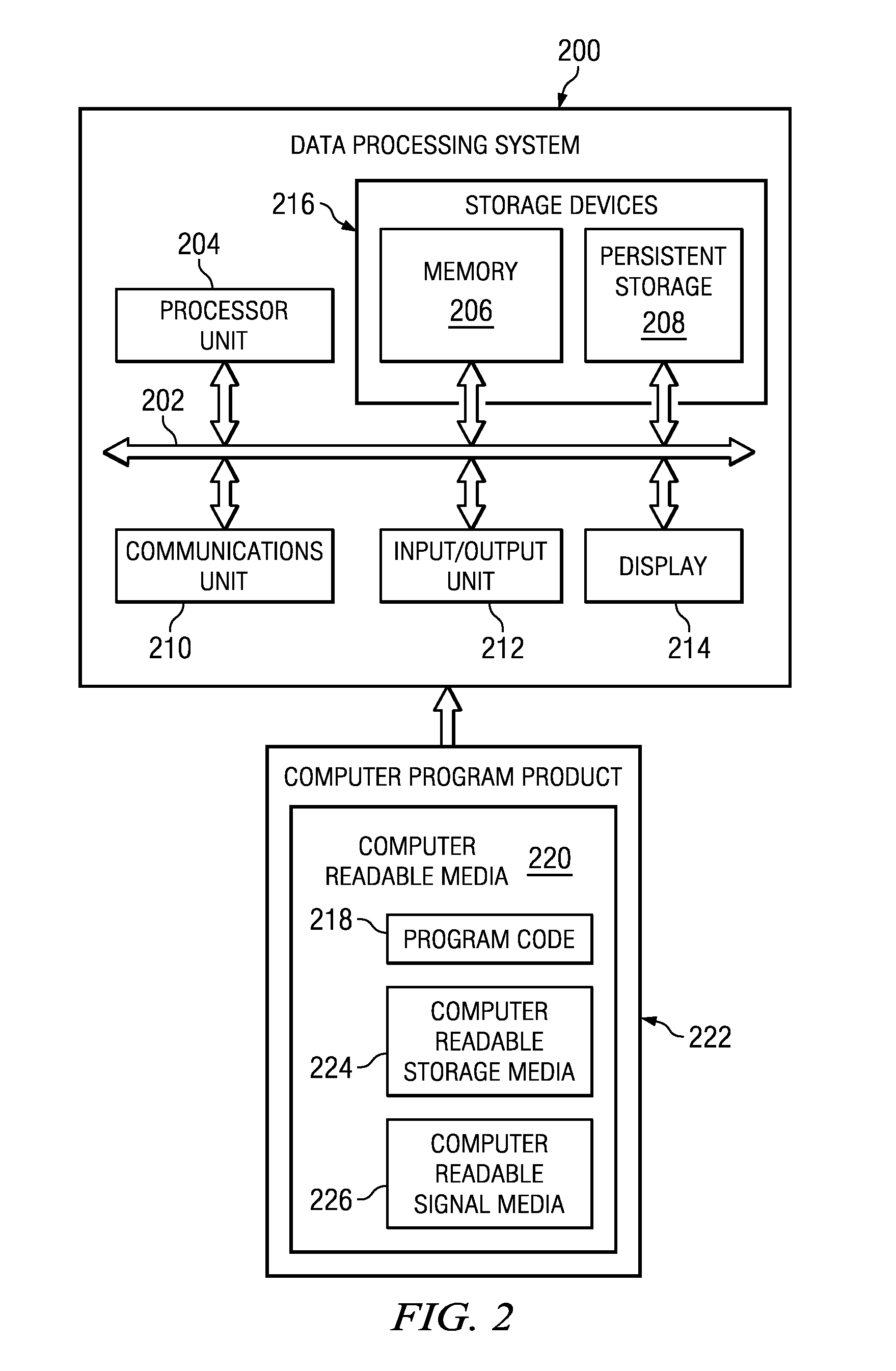

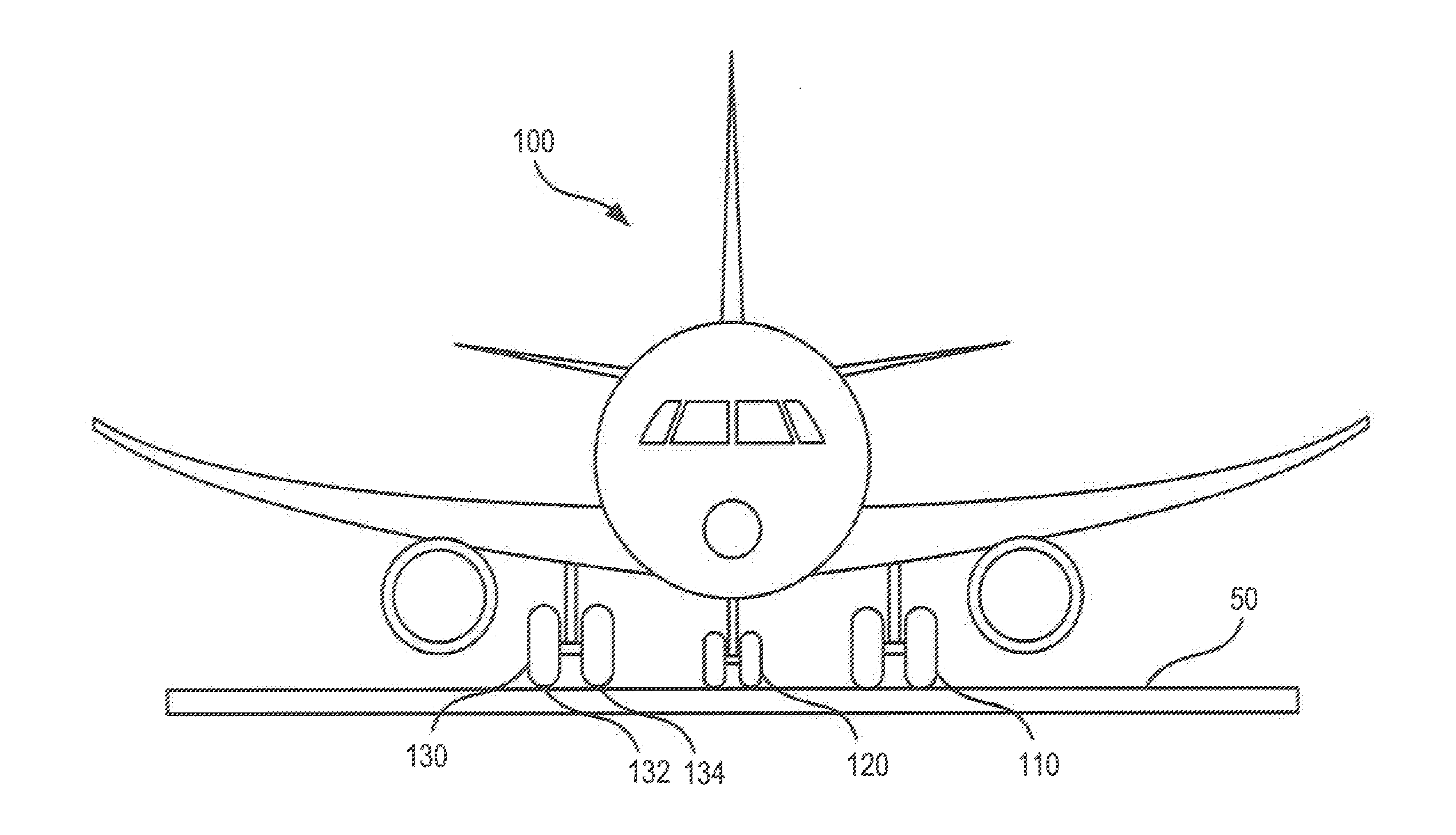

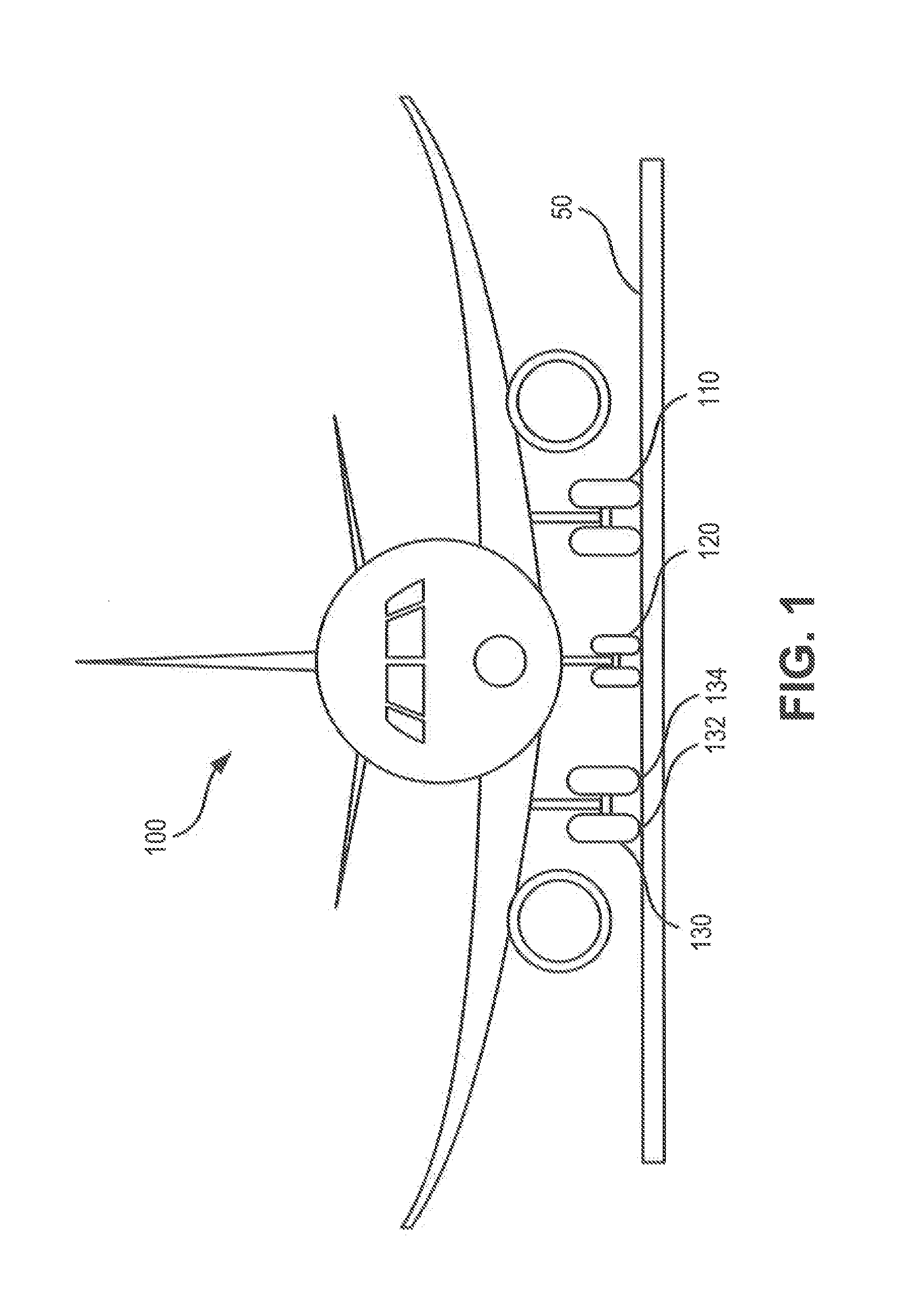

System and Method to Assess and Report the Health of Landing Gear Related Components

ActiveUS20120041639A1Aircraft health monitoring devicesRegistering/indicating working of vehiclesMonitoring dataReliability engineering

The different advantageous embodiments provide an apparatus comprising a number of landing gear components for a vehicle, a number of systems, and a number of processor units. The number of systems is configured to generate data about the number of landing gear components and the vehicle. The number of processor units is configured to monitor the data and manage health of the number of landing gear components.

Owner:THE BOEING CO

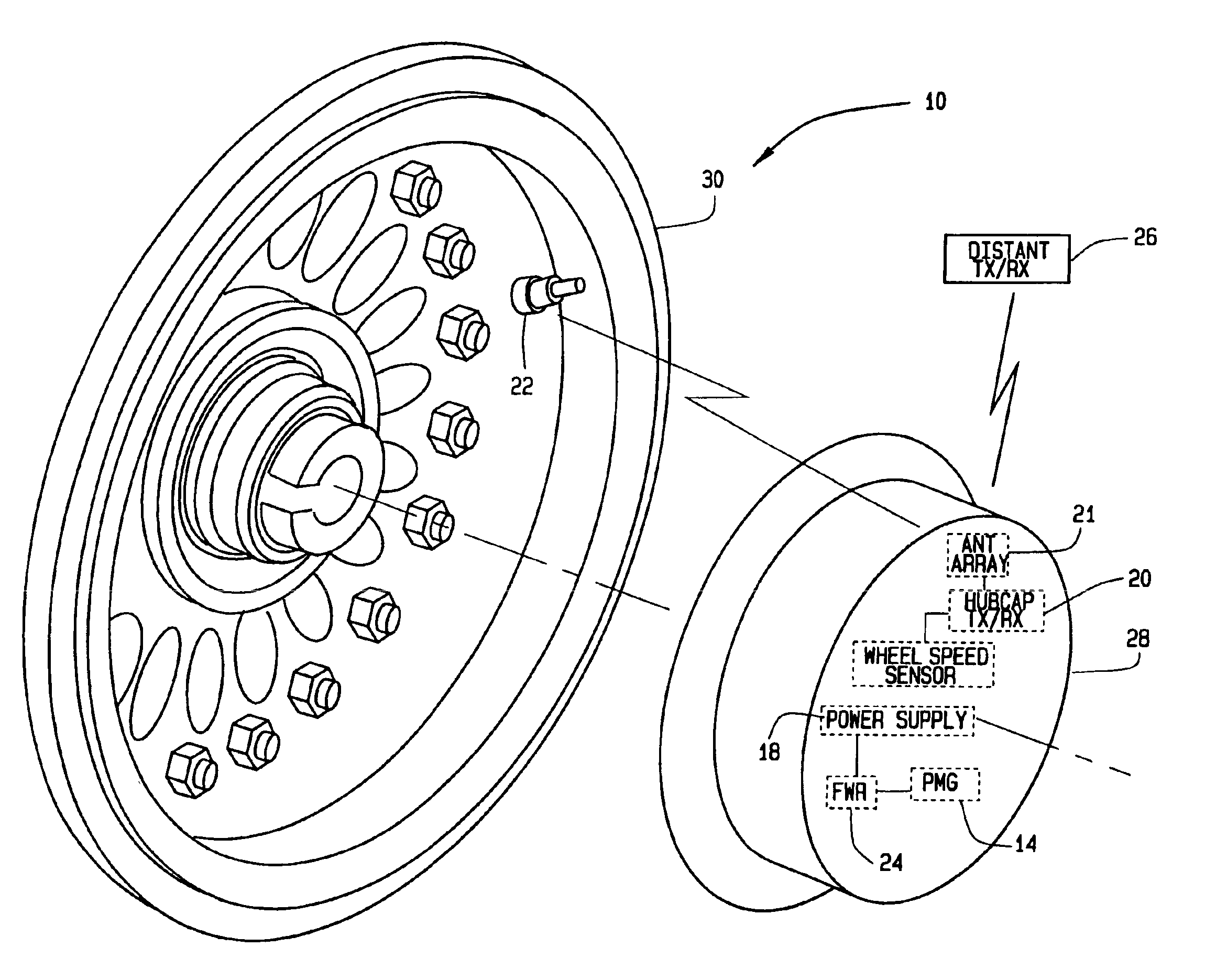

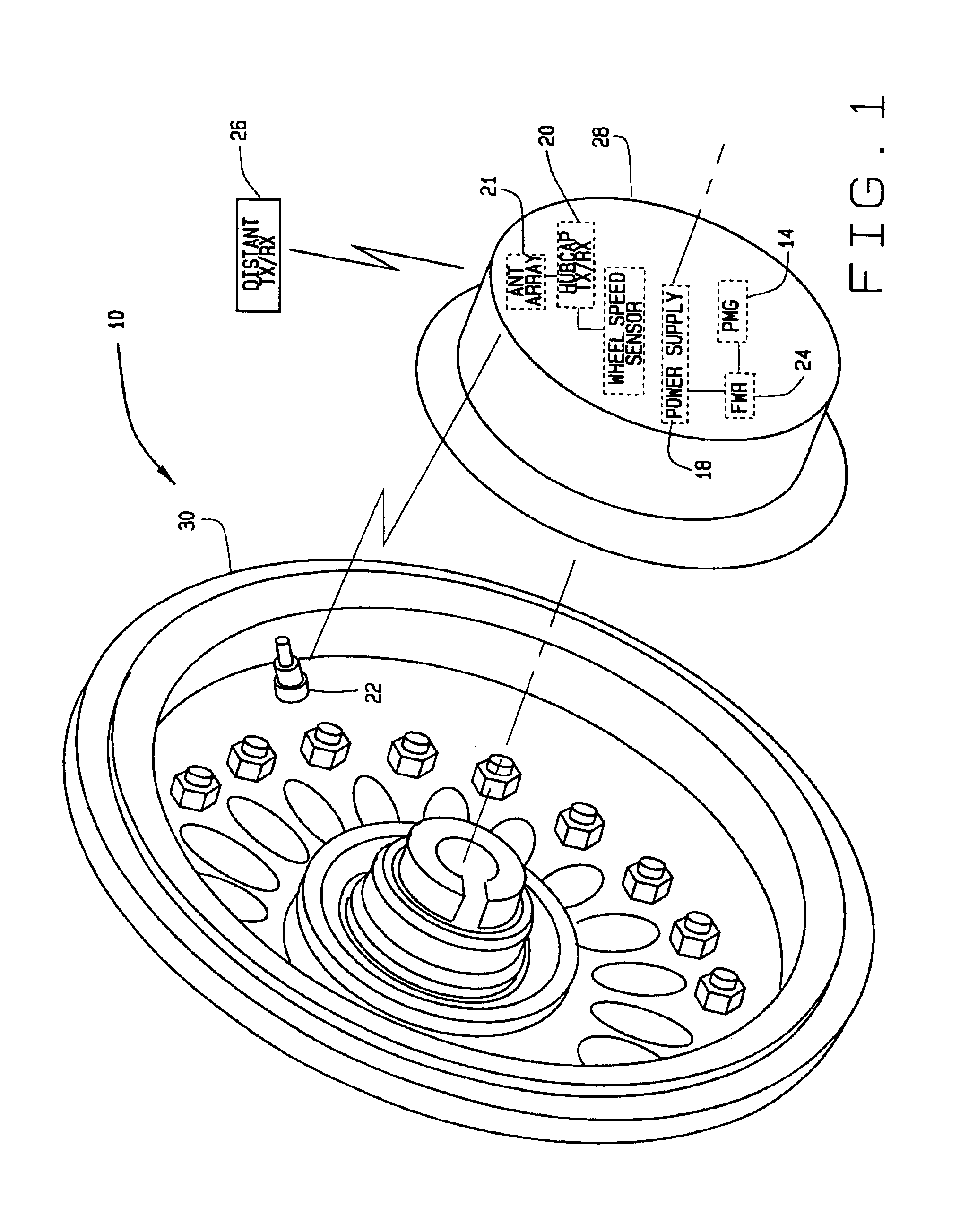

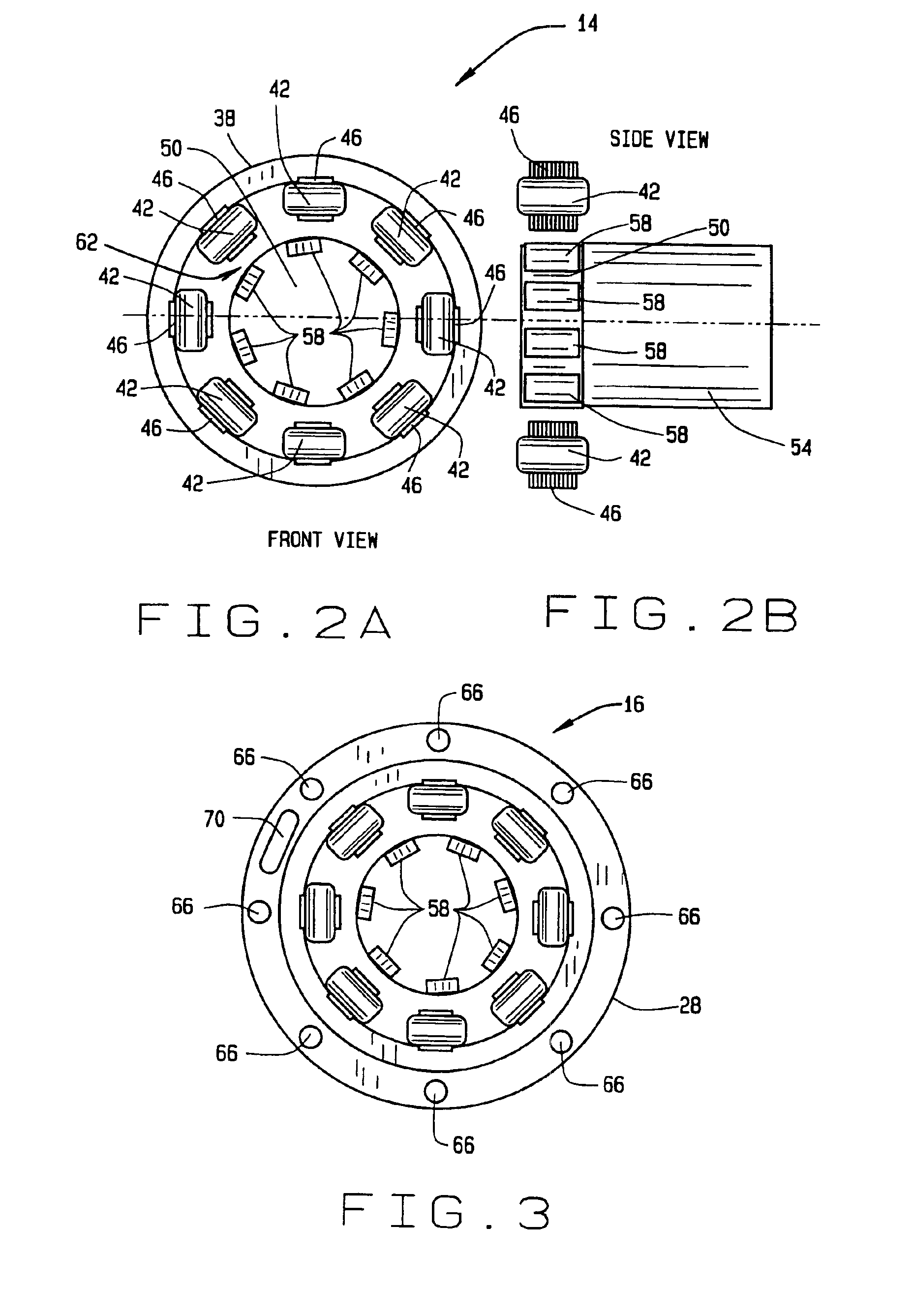

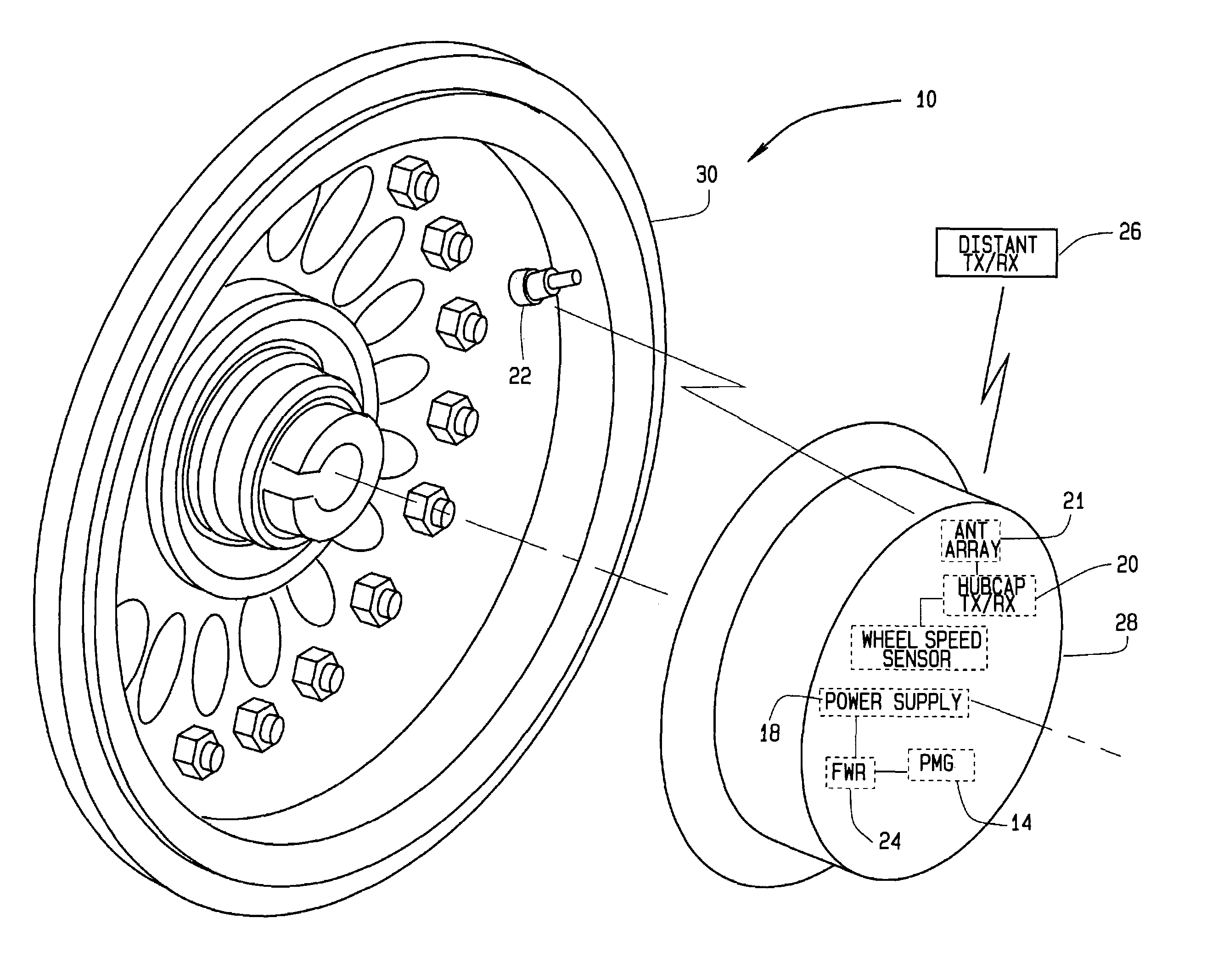

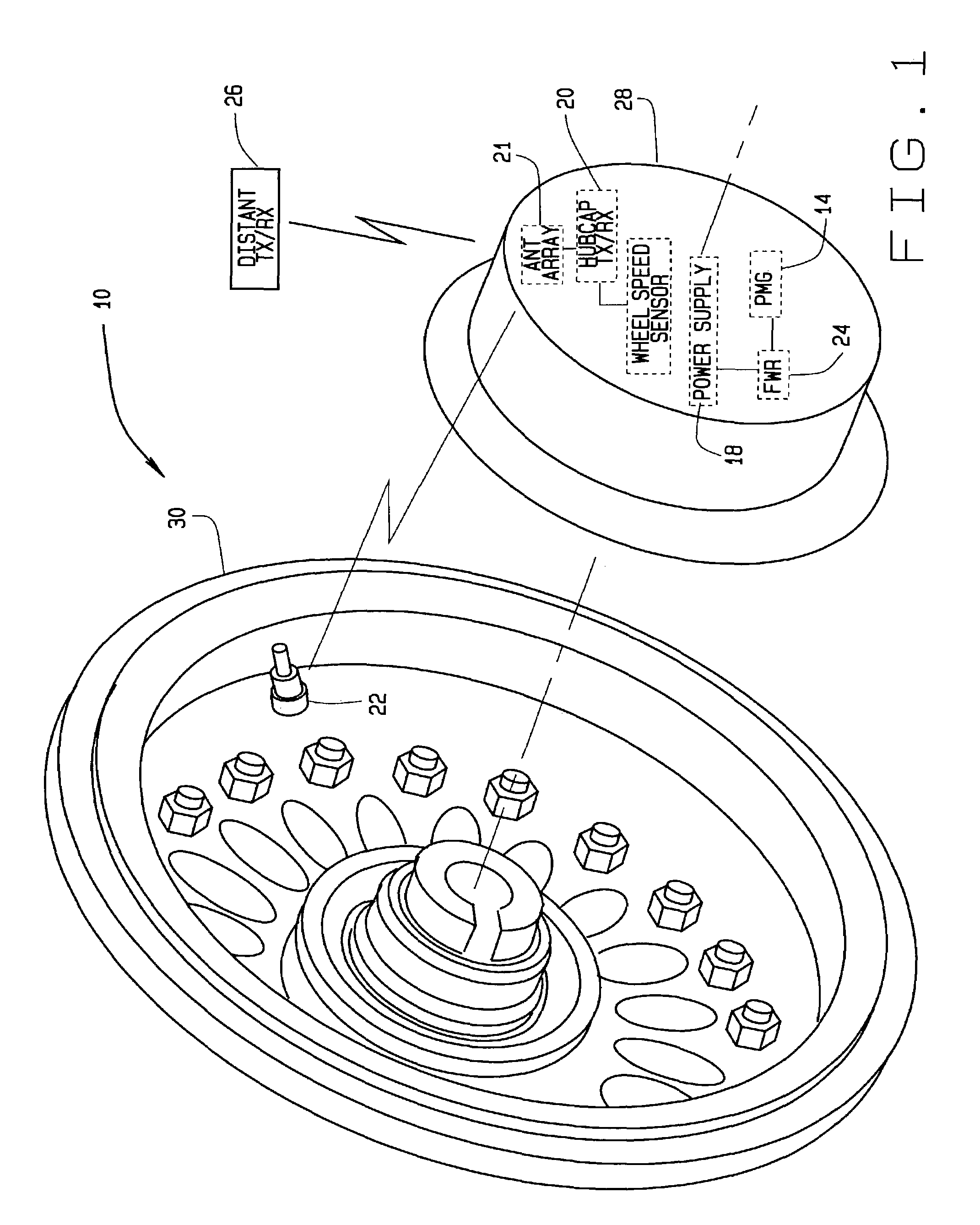

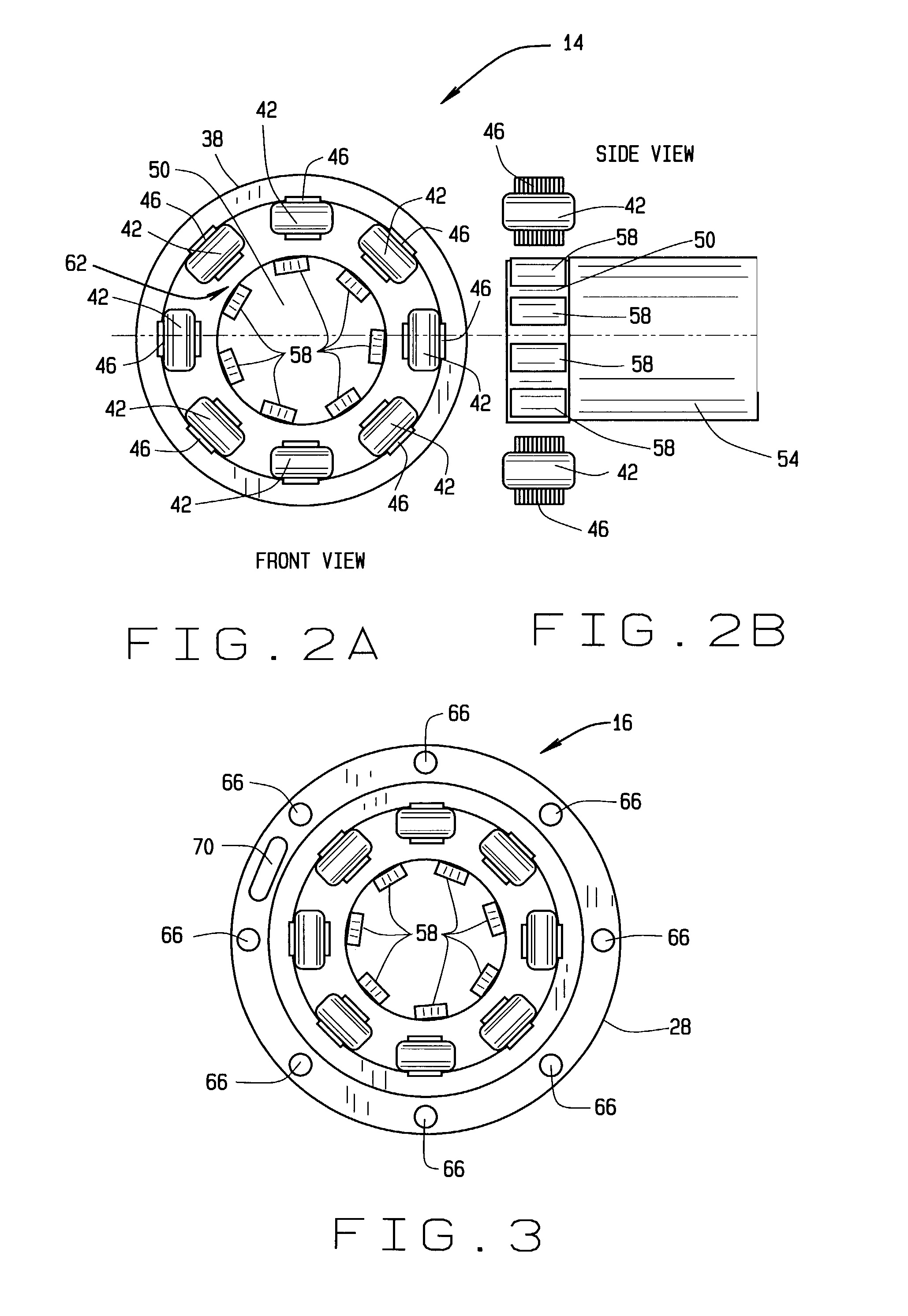

Wireless landing gear monitoring system

A wireless landing gear monitoring system for an aircraft. The monitoring system includes a wireless, e.g. radio frequency (RF), hubcap transceiver powered by a rechargeable battery combined with a super-capacitor, all mounted to an inside surface of a wheel hubcap of the aircraft. Additionally, the system includes a permanent magnet generator (PMG) mounted to the inside surface of the hubcap that charges the battery when the wheel is rotating. The hubcap transceiver communicates with at least one distant, or remote, transceiver inside the aircraft, a tire pressure sensor mounted to a wheel rim, and a Hall-effect wheel speed transducer mounted to the hubcap. The tire pressure sensor uses an extremely low power wireless transmitter to communicate with the hubcap transceiver, which then sends wheel speed and tire pressure data to the distant transceiver.

Owner:THE BOEING CO

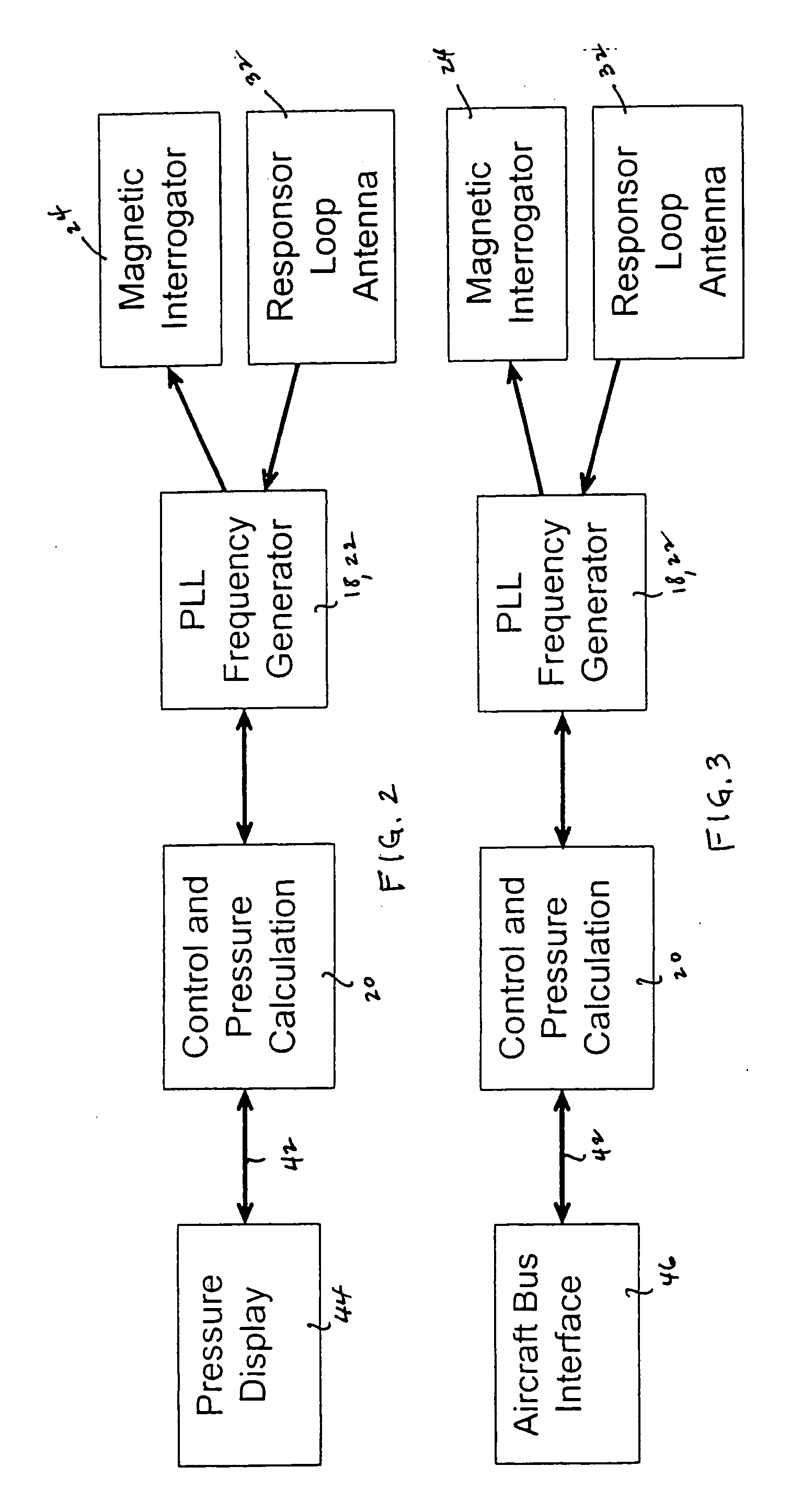

Wireless tire pressure and/or wheel speed sensing system for aircraft

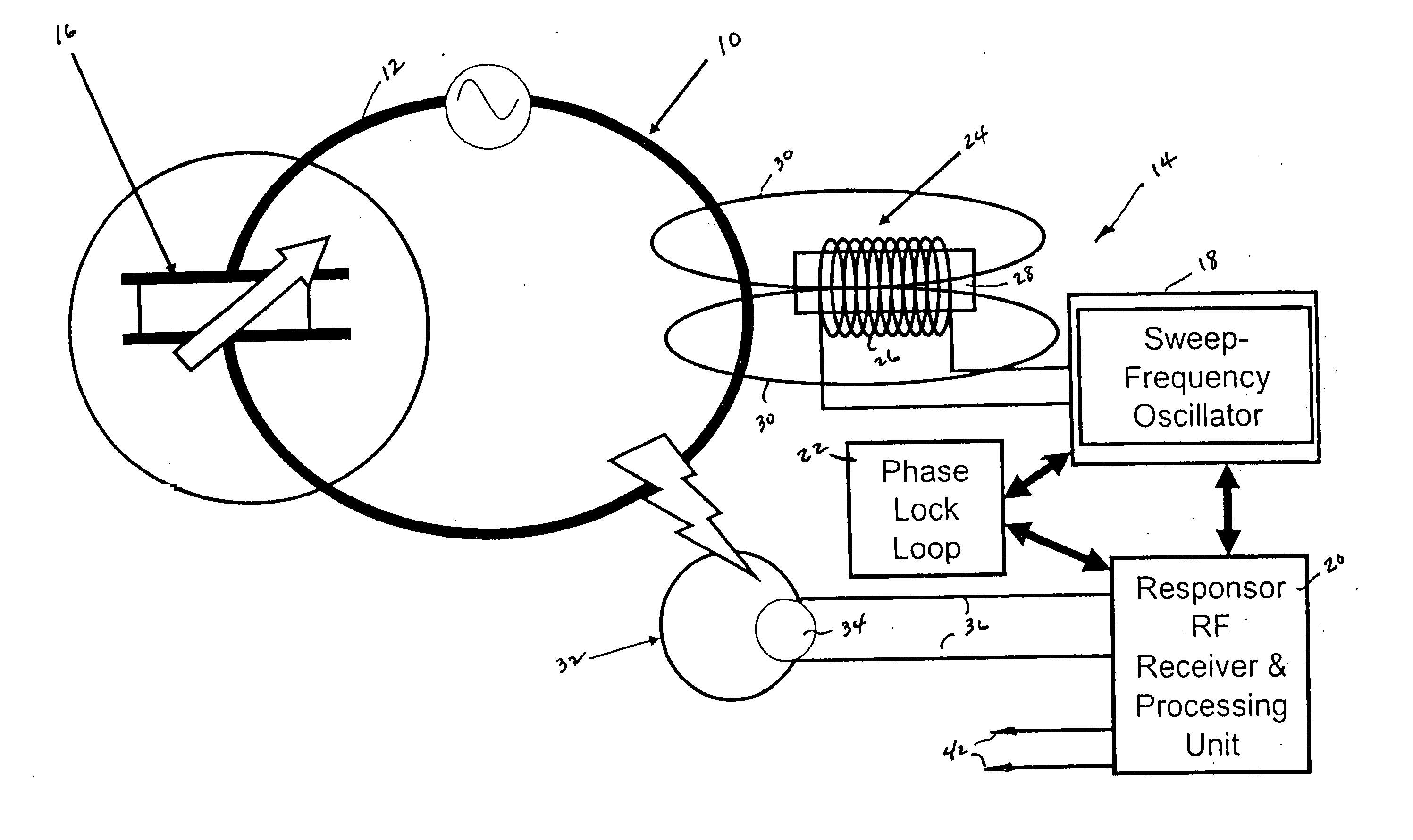

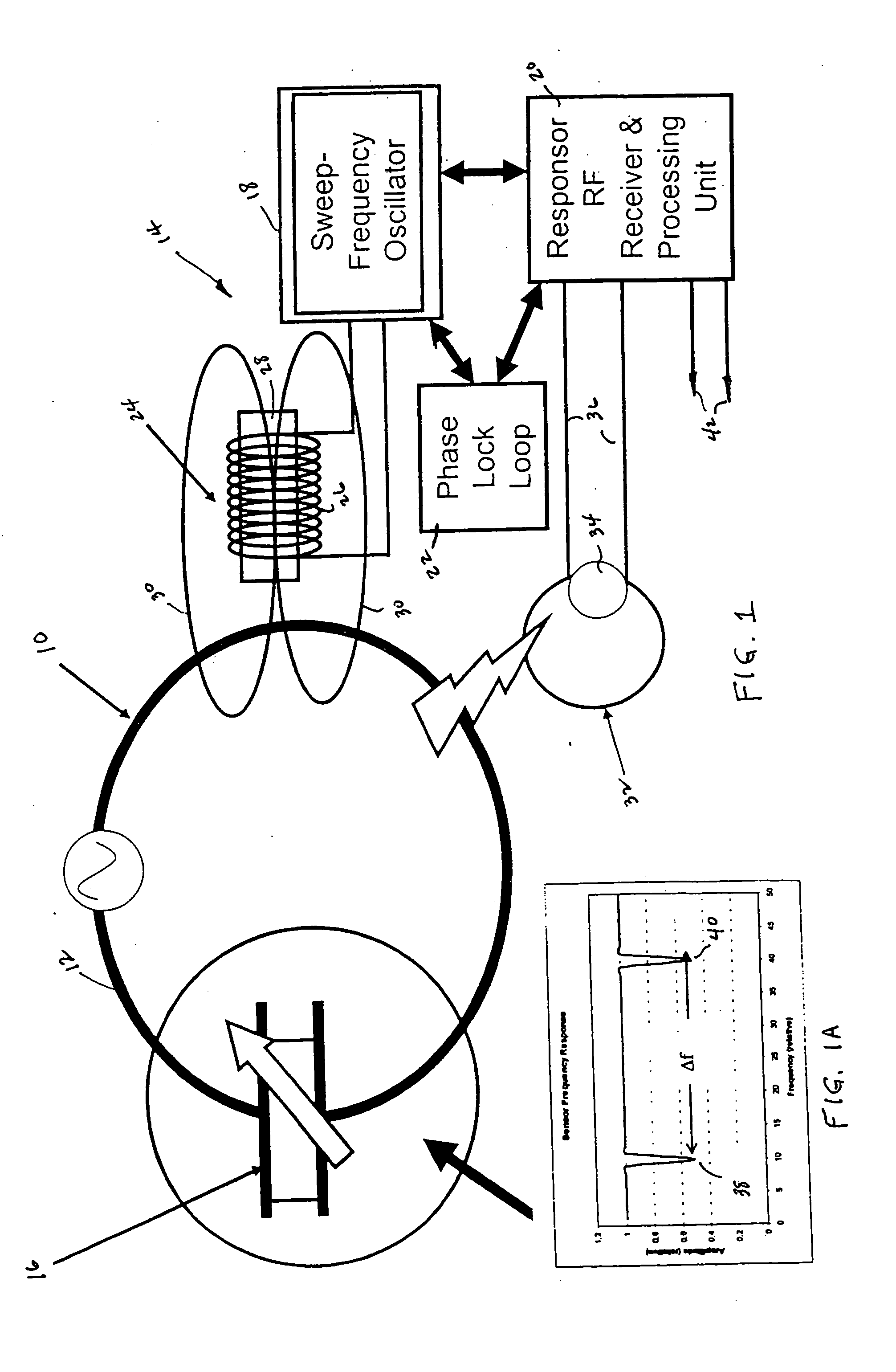

InactiveUS20050264406A1Tyre measurementsDevices using electric/magnetic meansPressure senseEngineering

A wireless tire pressure sensing system for an aircraft comprises: dual resonant circuits mounted to a wheel of the aircraft, each resonant circuit comprising: a variable capacitance sensor and a wire loop of a predetermined inductance coupled thereto, one capacitance sensor for monitoring the pressure of a tire mounted to the wheel, and the other capacitance sensor operative as a reference to the one capacitance sensor; an interrogating circuit magnetically coupleable to the dual resonant circuits and operative to induce magnetically a variable frequency current in the dual resonant circuits, the one resonant circuit responding to the induced current with an E-field signal at a first resonant frequency commensurate with the capacitance of the one sensor, and the other resonant circuit responding to the induced current with an E-field signal at a second resonant frequency commensurate with the capacitance of the other sensor; a receiving circuit E-field coupleable to the dual resonant circuits and operative to receive the E-field signals at the first and second resonant frequencies and to generate first and second signals representative thereof, and a processing circuit coupled to the receiving circuit for processing the first and second signals to generate a compensated pressure reading of the tire. The pressure sensing system may be modified to provide and / or include wheel speed sensing.

Owner:ROSEMOUNT AEROSPACE

Wireless landing gear monitoring system

A wireless landing gear monitoring system for an aircraft. The monitoring system includes a radio frequency (RF) wireless hubcap transceiver powered by a rechargeable battery combined with a super-capacitor, all mounted to an inside surface of a wheel hubcap of the aircraft. Additionally, the system includes a permanent magnet generator (PMG) mounted to the inside surface of the hubcap that charges the battery when the wheel is rotating. The hubcap transceiver communicates with at least one distant, or remote, transceiver inside the aircraft, a tire pressure sensor mounted to a wheel rim, and a Hall-effect wheel speed transducer mounted to the hubcap. The tire pressure sensor uses an extremely low power RF transmitter to communicate with the hubcap transceiver, which then sends wheel speed and tire pressure data to the distant transceiver.

Owner:THE BOEING CO

Reduced weight aircraft tire

Owner:UEYOKO KIYOSHI +3

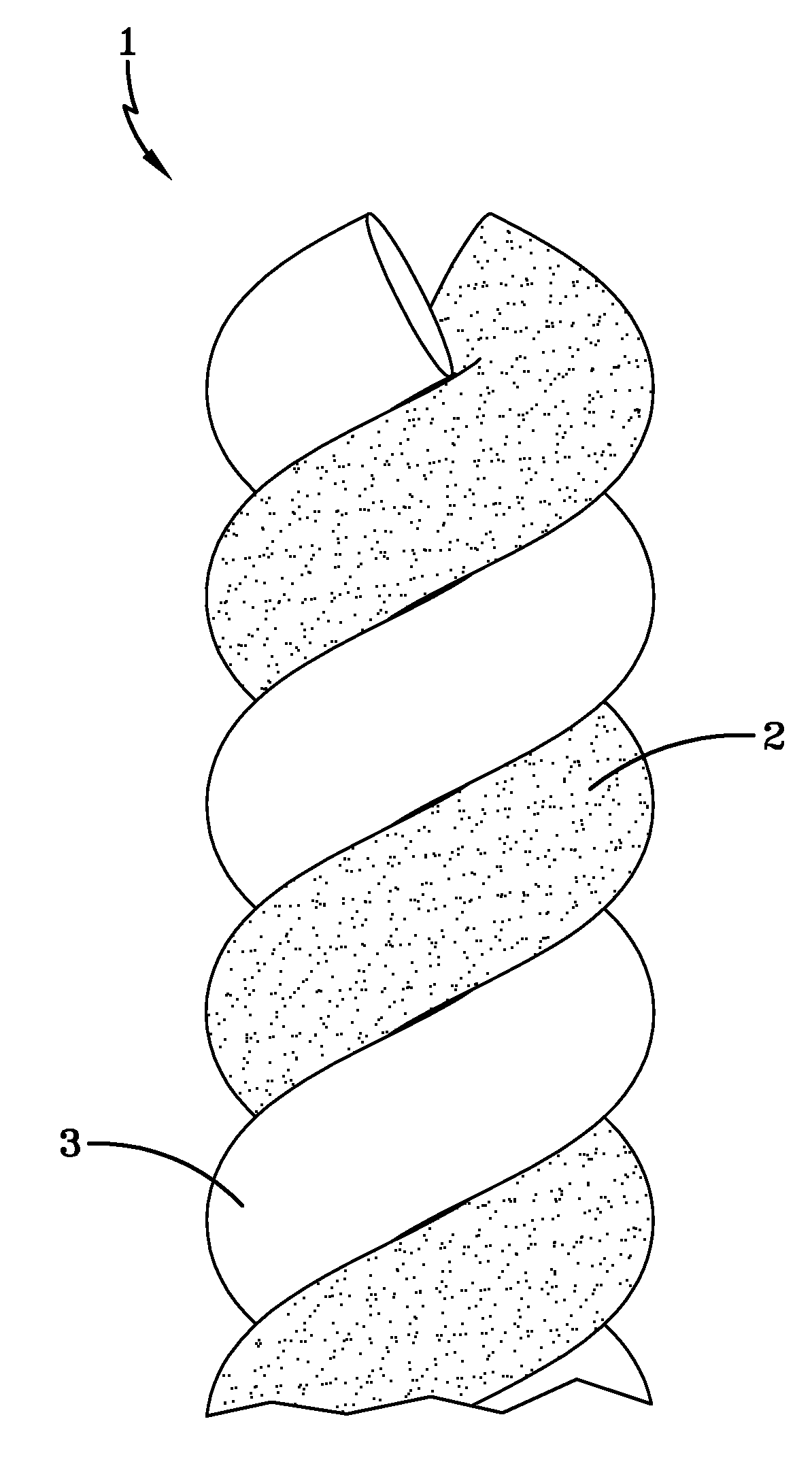

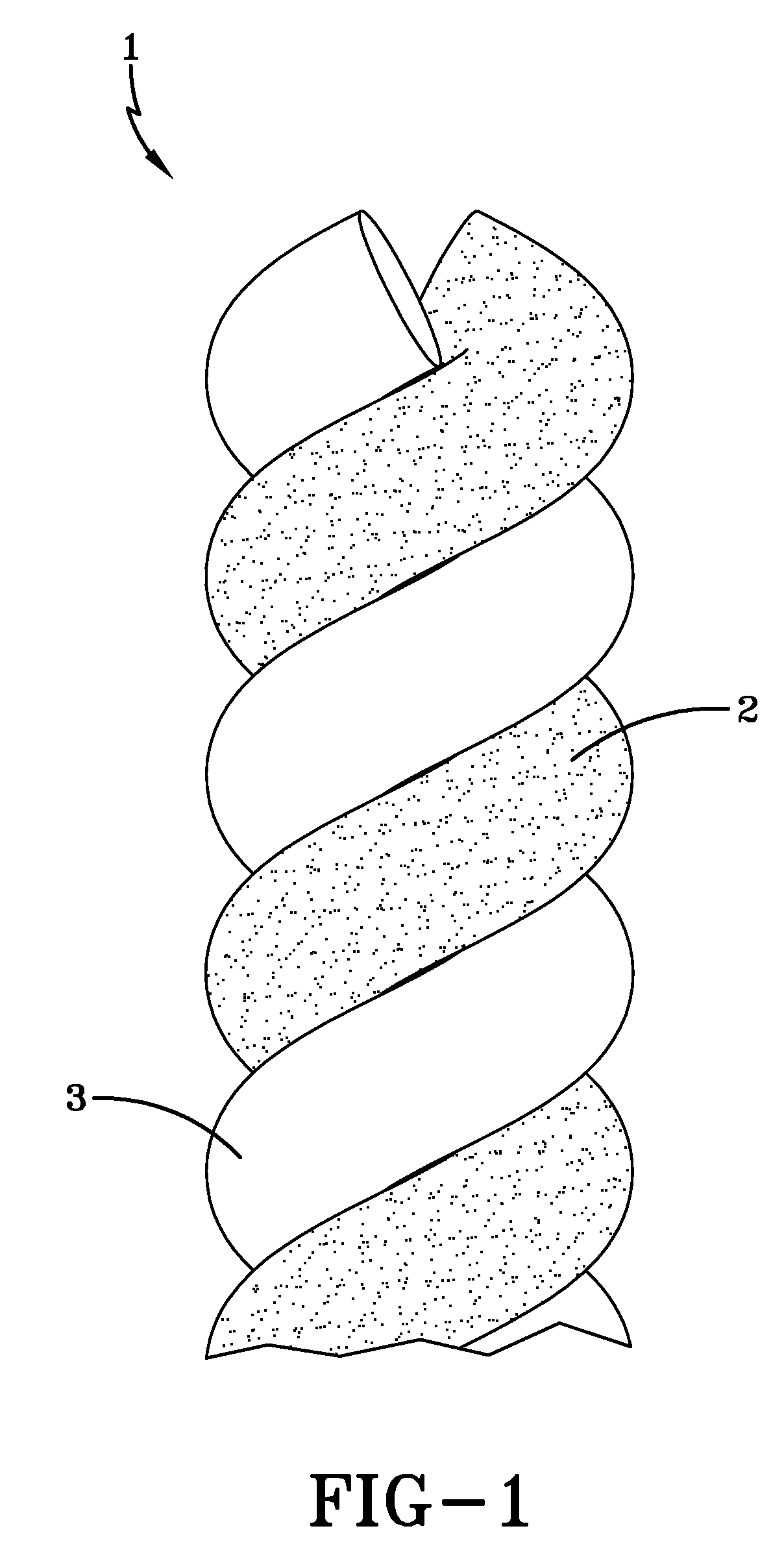

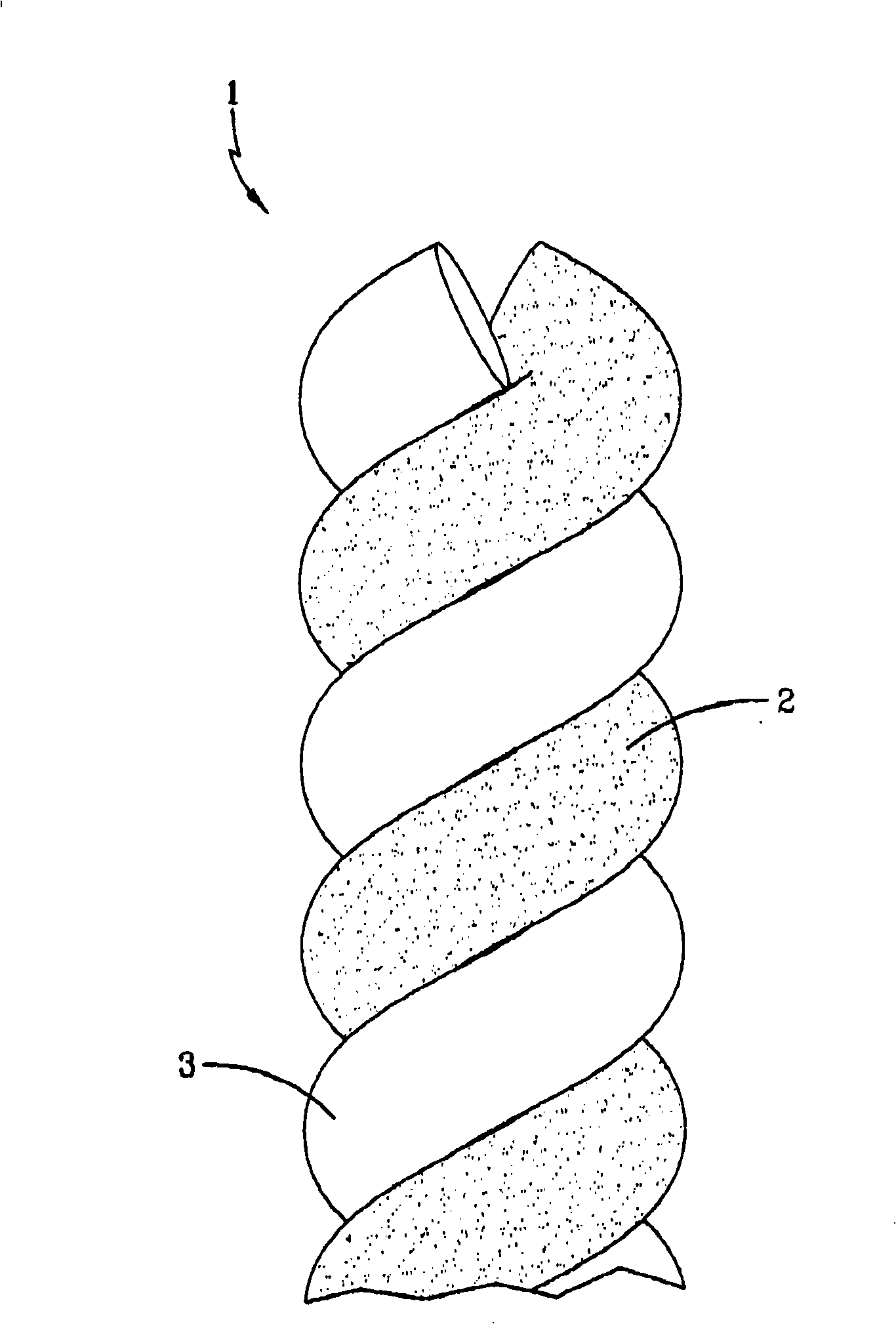

Tire cord reinforcement

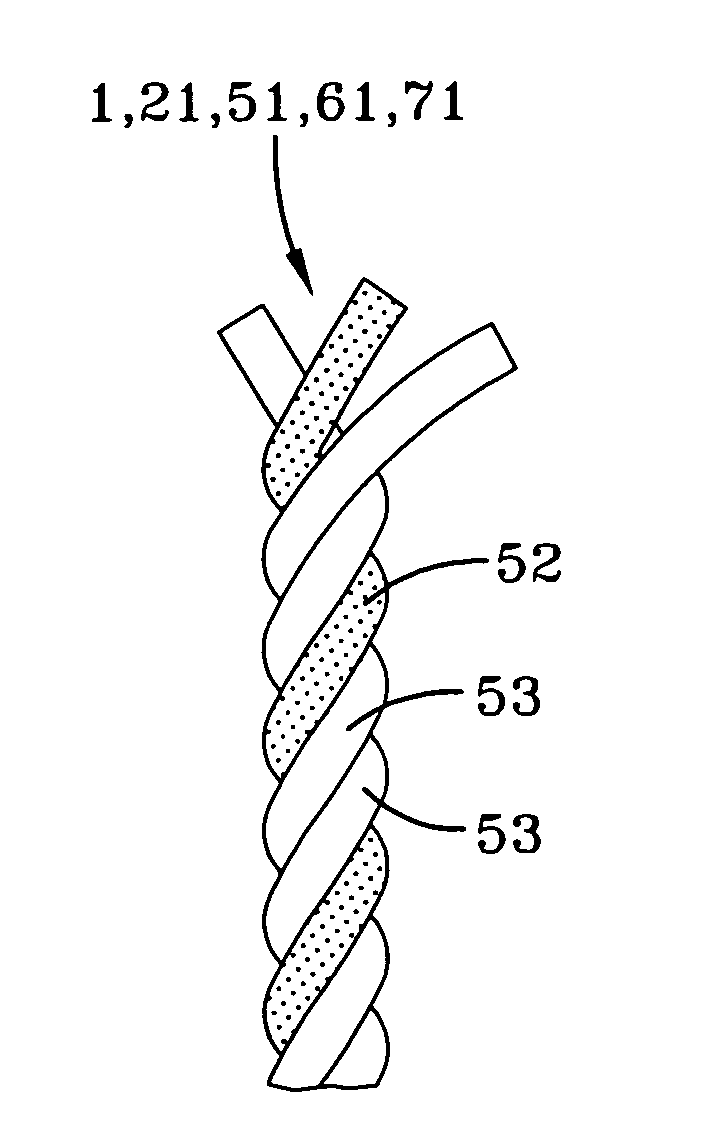

A composite cable is disclosed suitable for use as a reinforcement in an aircraft tire. The cable is formed of an aramid yarn and a nylon yarn cabled together, wherein the aramid yarn has a linear density in the range of about 220 to about 3300 dtex, and the nylon yarn has a linear density in the range of about 220 to about 2100 dtex.

Owner:BALDWIN JR DONALD WILLIAM +2

System and Method to Assess and Report the Health of a Tire

ActiveUS20120038492A1Registering/indicating working of vehiclesOptical signallingComputer scienceHealth states

Owner:THE BOEING CO

Aviation tire

An aviation tire including, a pair of side walls, the side walls having an outer surface, a tread portion spanning a radial outer extremity of the side walls, and a rotating assembly formed on the side wall or the tread portion, the rotating assembly having an increased resistance to wind when located at a lowermost portion of the tire.

Owner:NORDQUIST THOMAS D

Aircraft tire

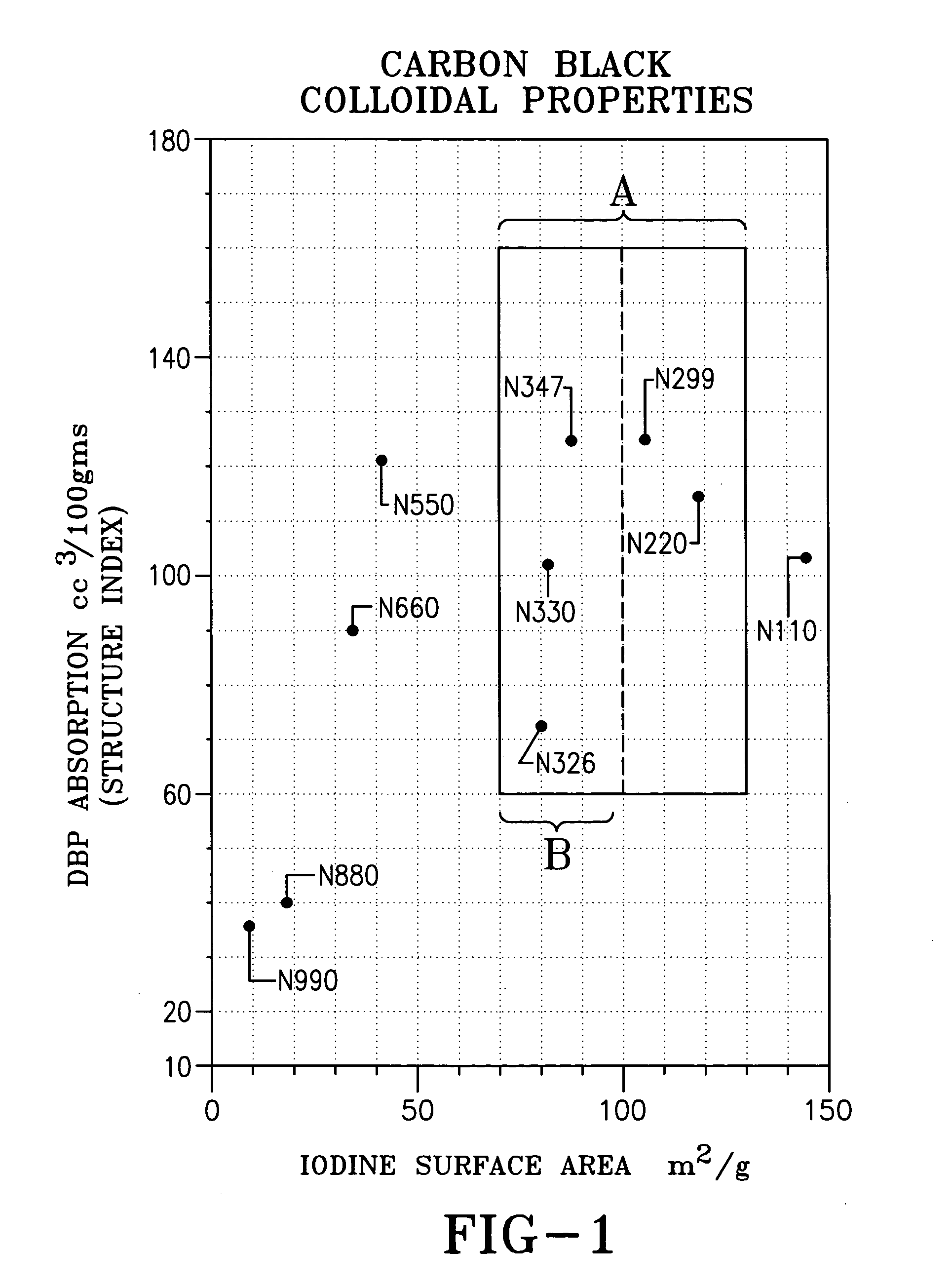

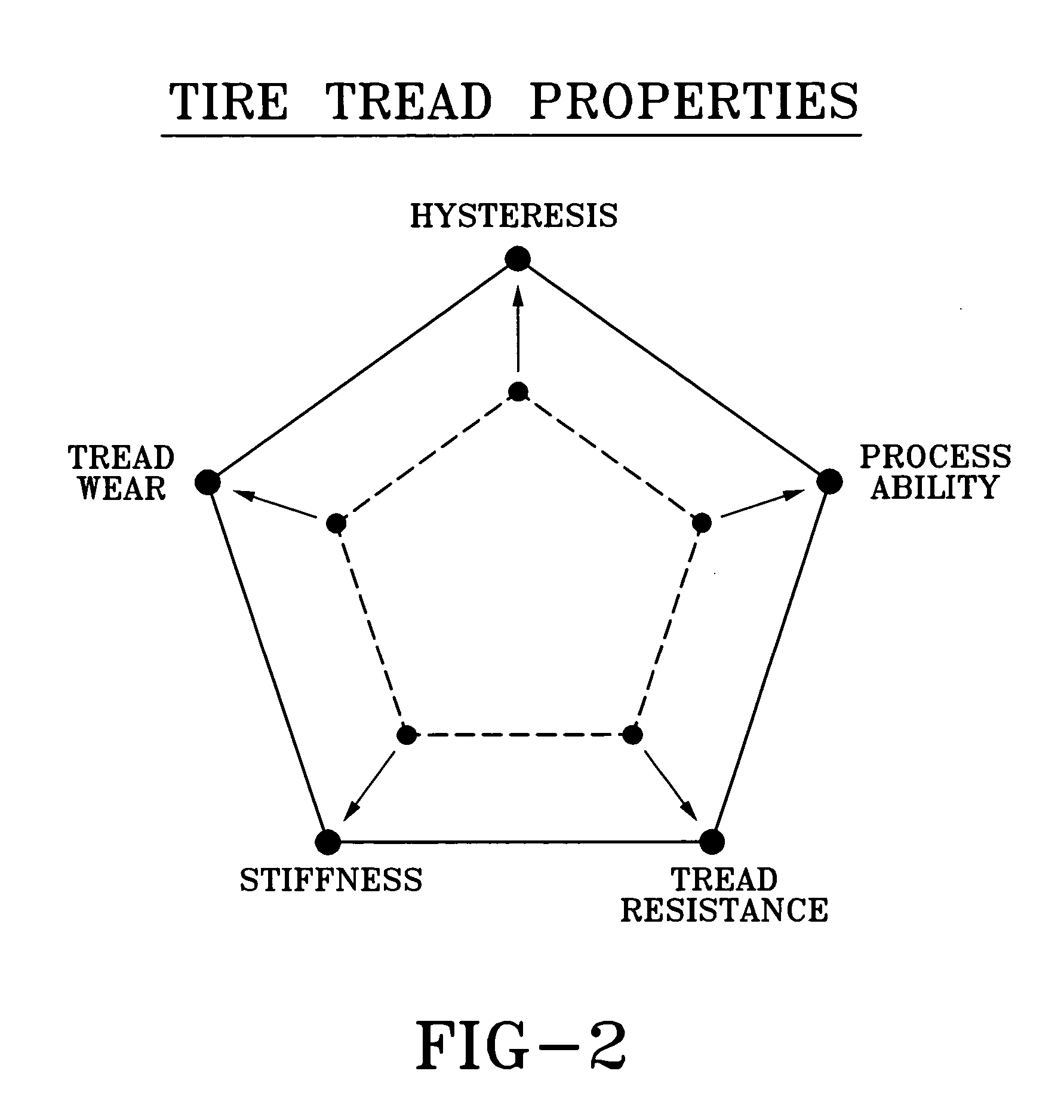

ActiveUS20060063878A1Speed up the processFlat surfaceContainers for annular articlesPneumatic tyre reinforcementsElastomerEngineering

The invention relates to an aircraft tire with a tread having a running surface of a rubber composition which contains elastomers of which a major portion is a specialized cis 1,4-polybutadiene elastomer and a minor portion is cis 1,4-polyisoprene rubber and which contains reinforcement filler comprised of a combination of precipitated silica and defined rubber reinforcing carbon black.

Owner:THE GOODYEAR TIRE & RUBBER CO

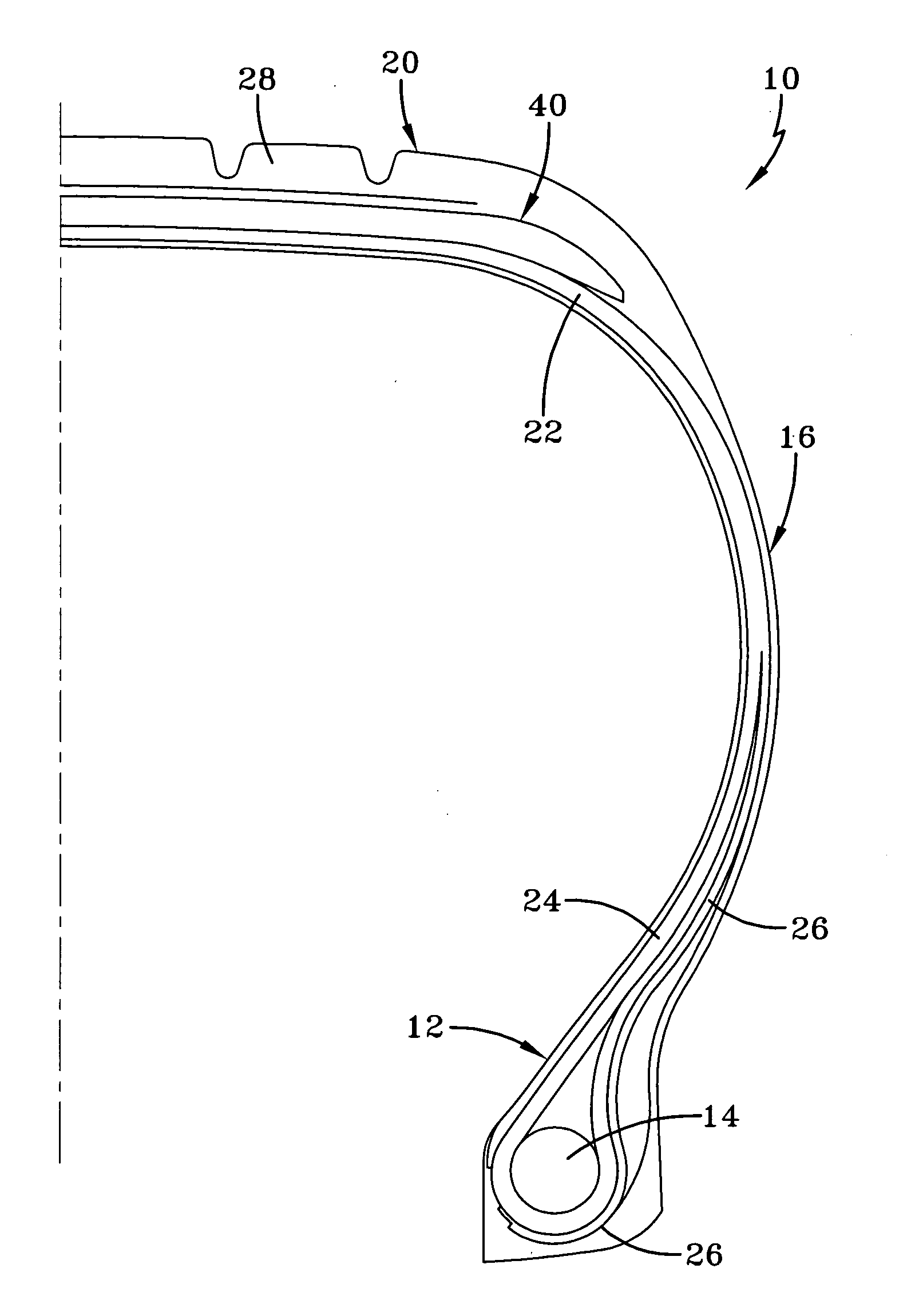

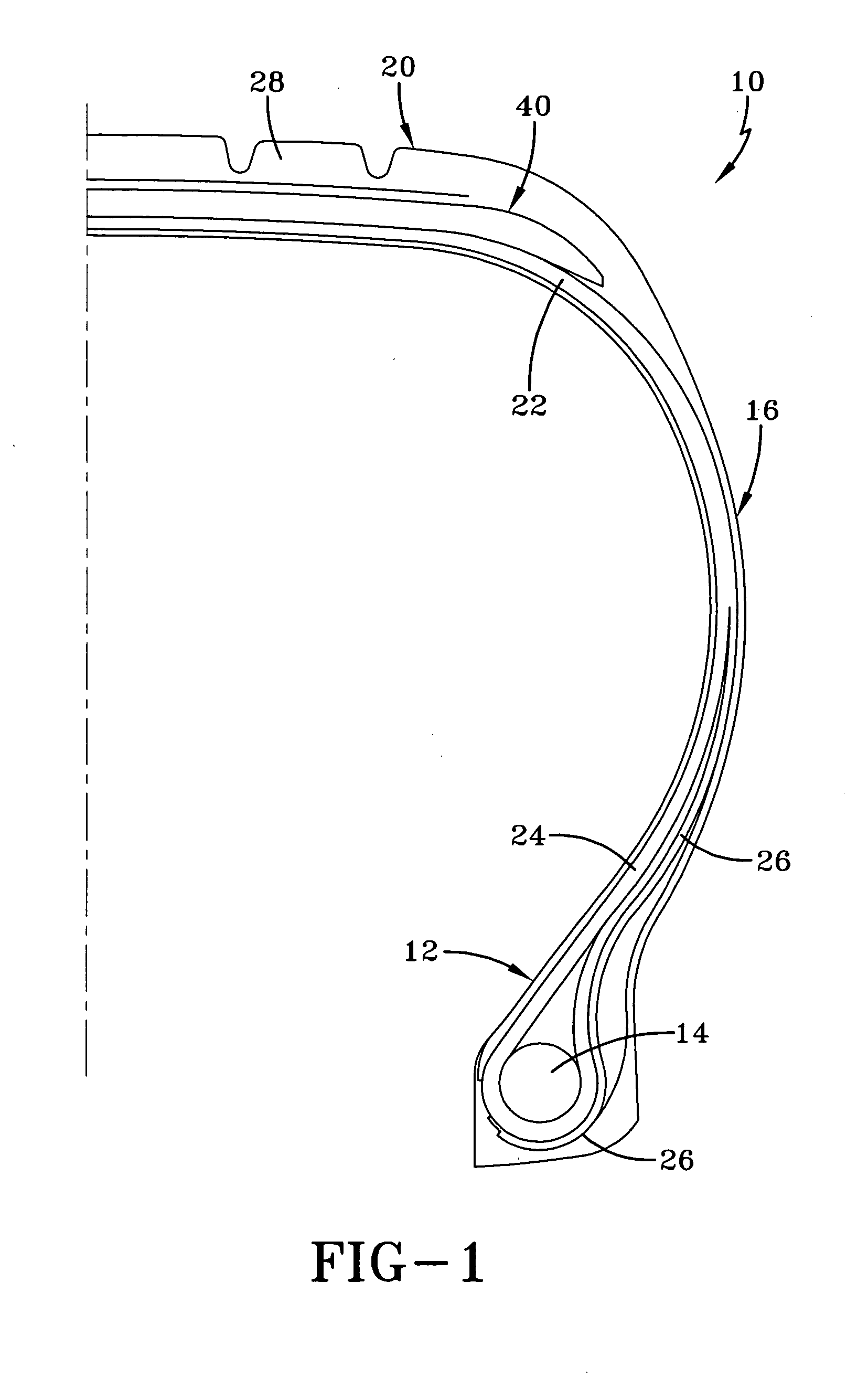

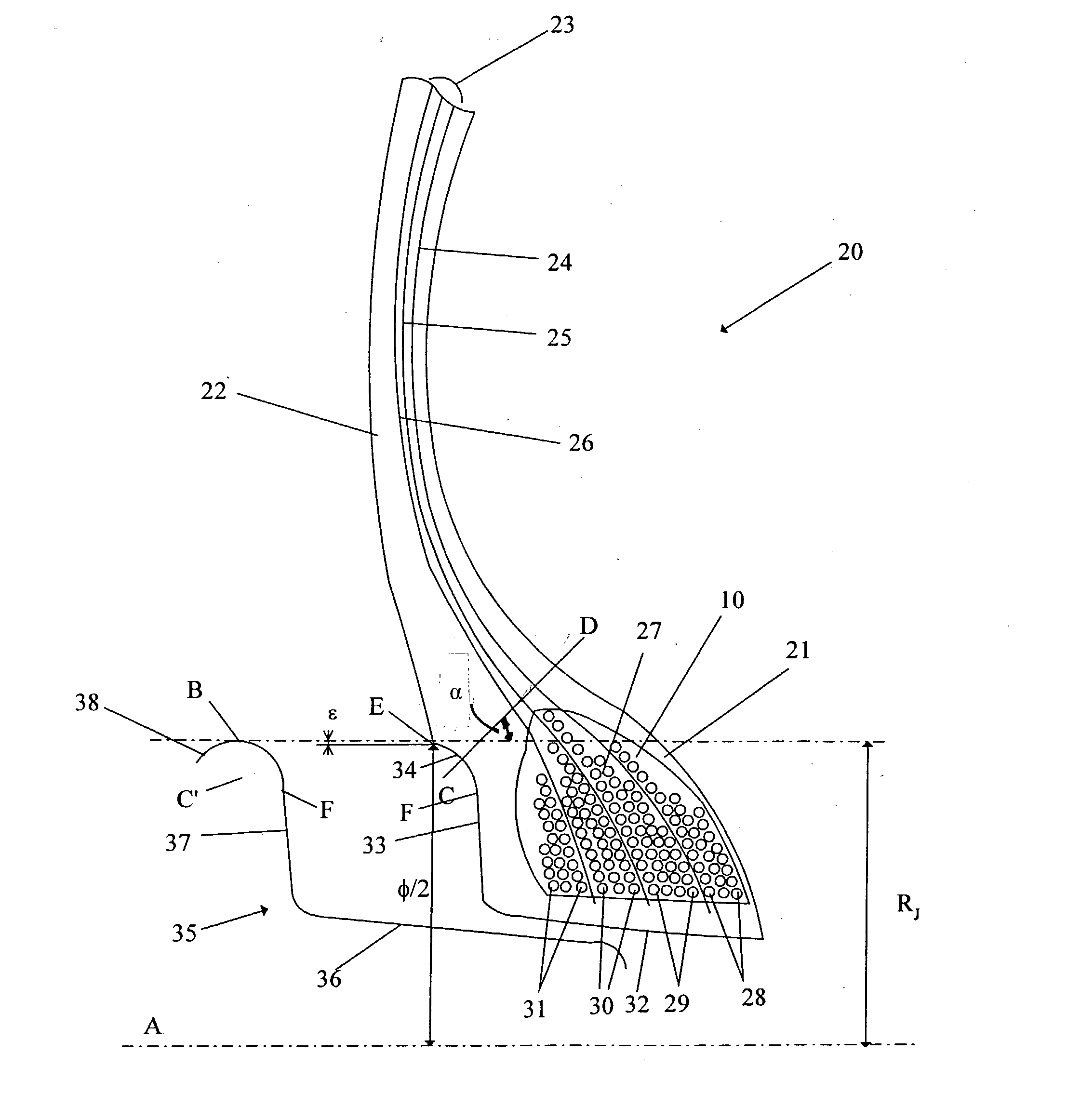

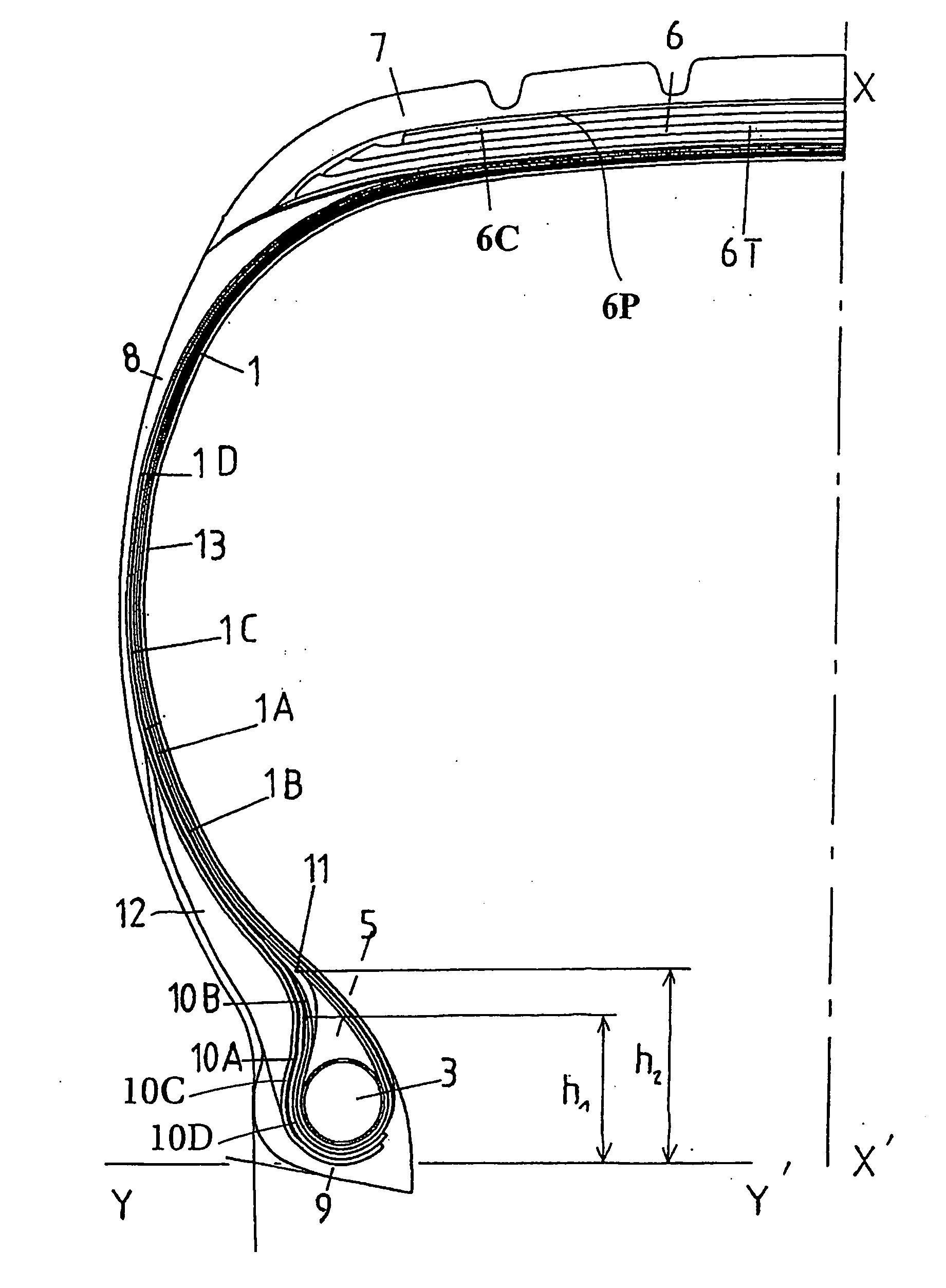

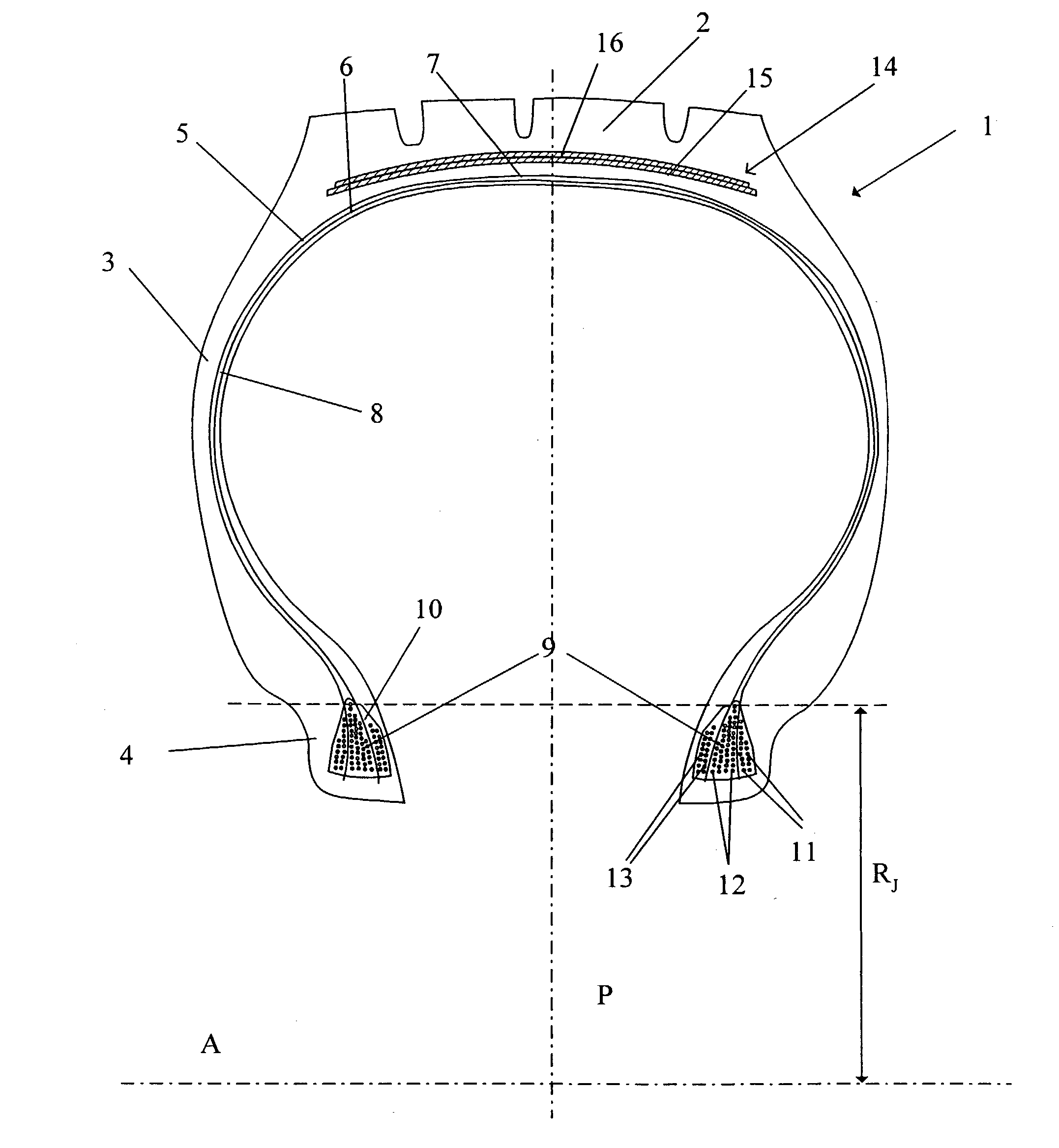

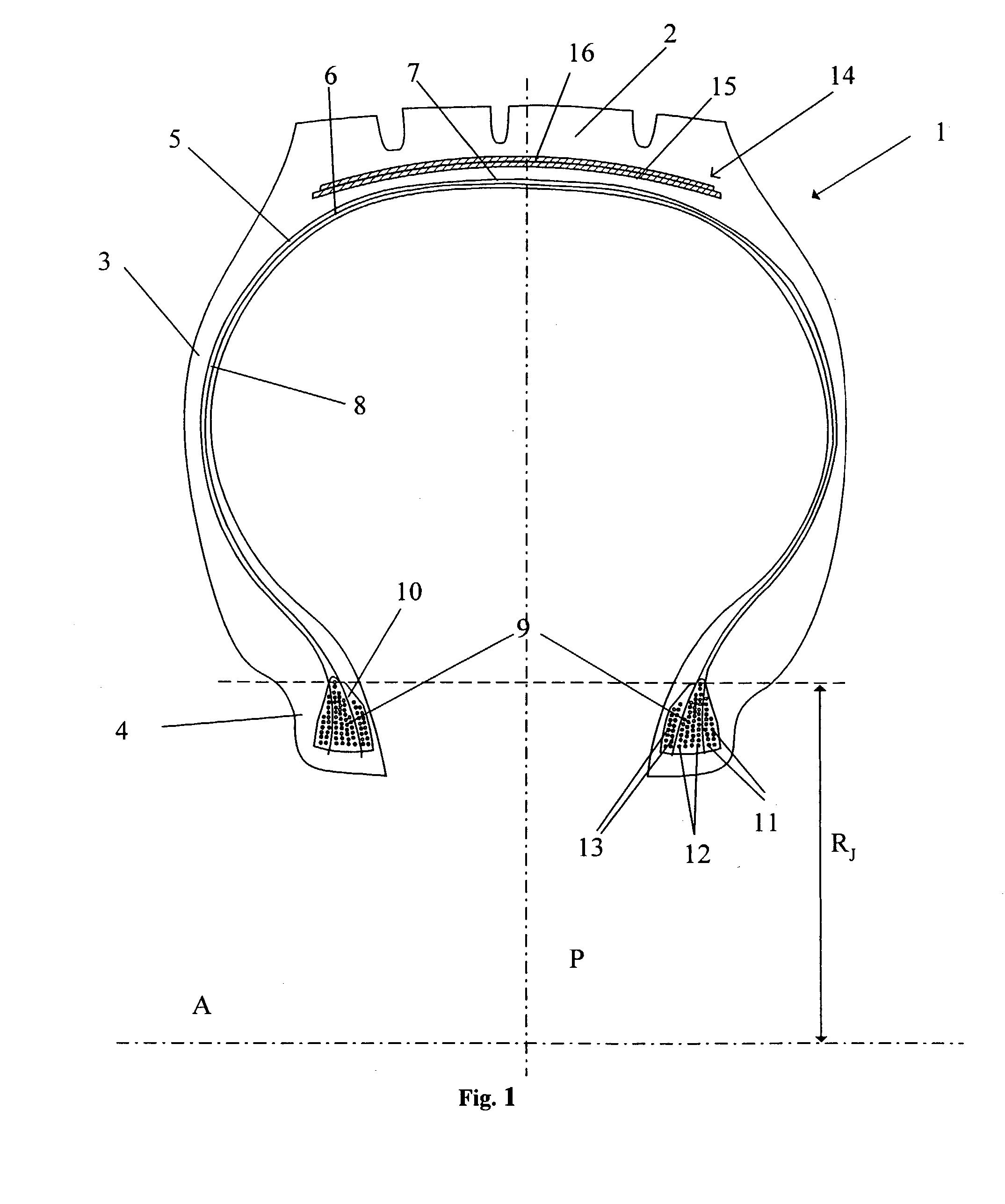

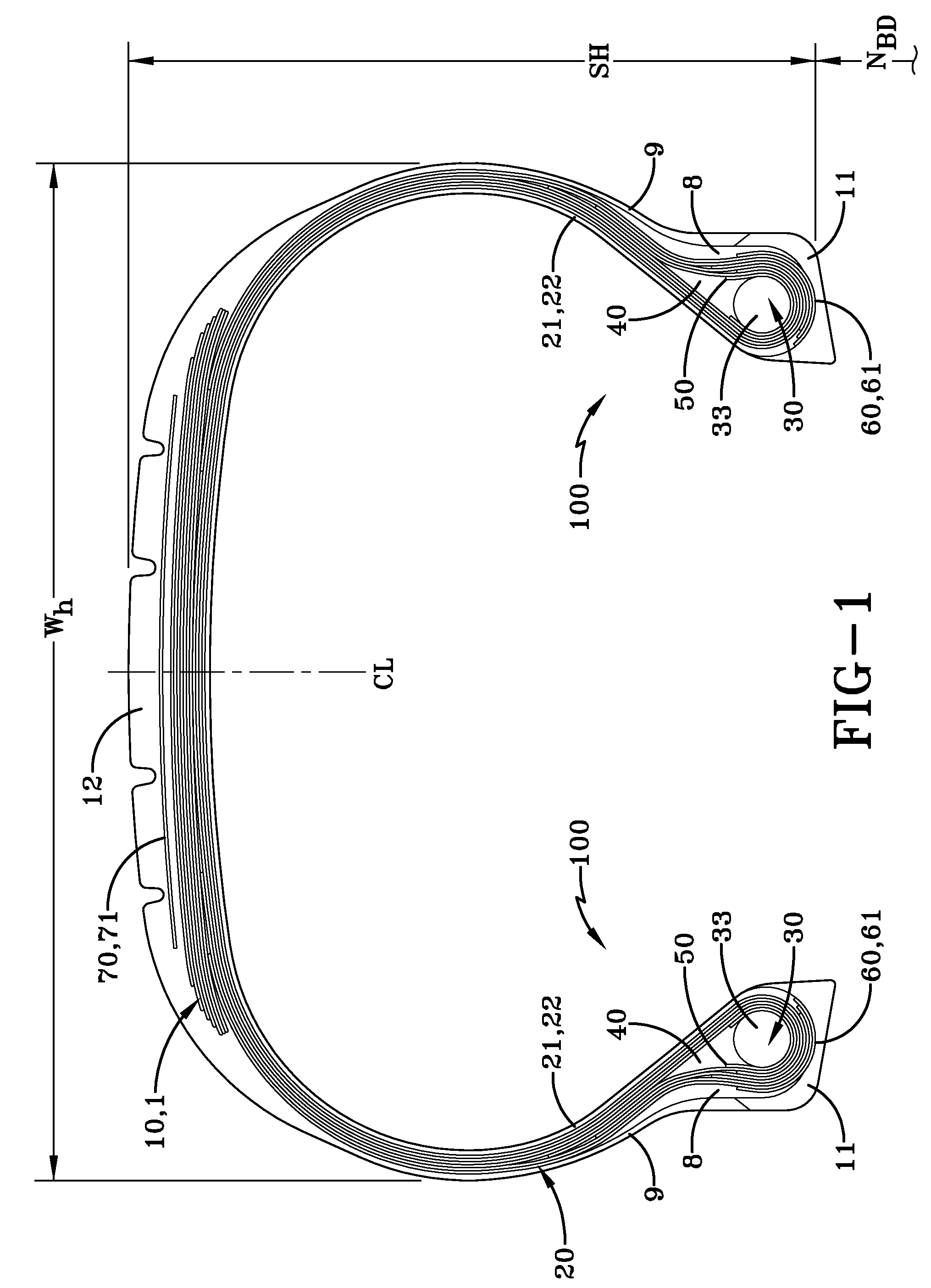

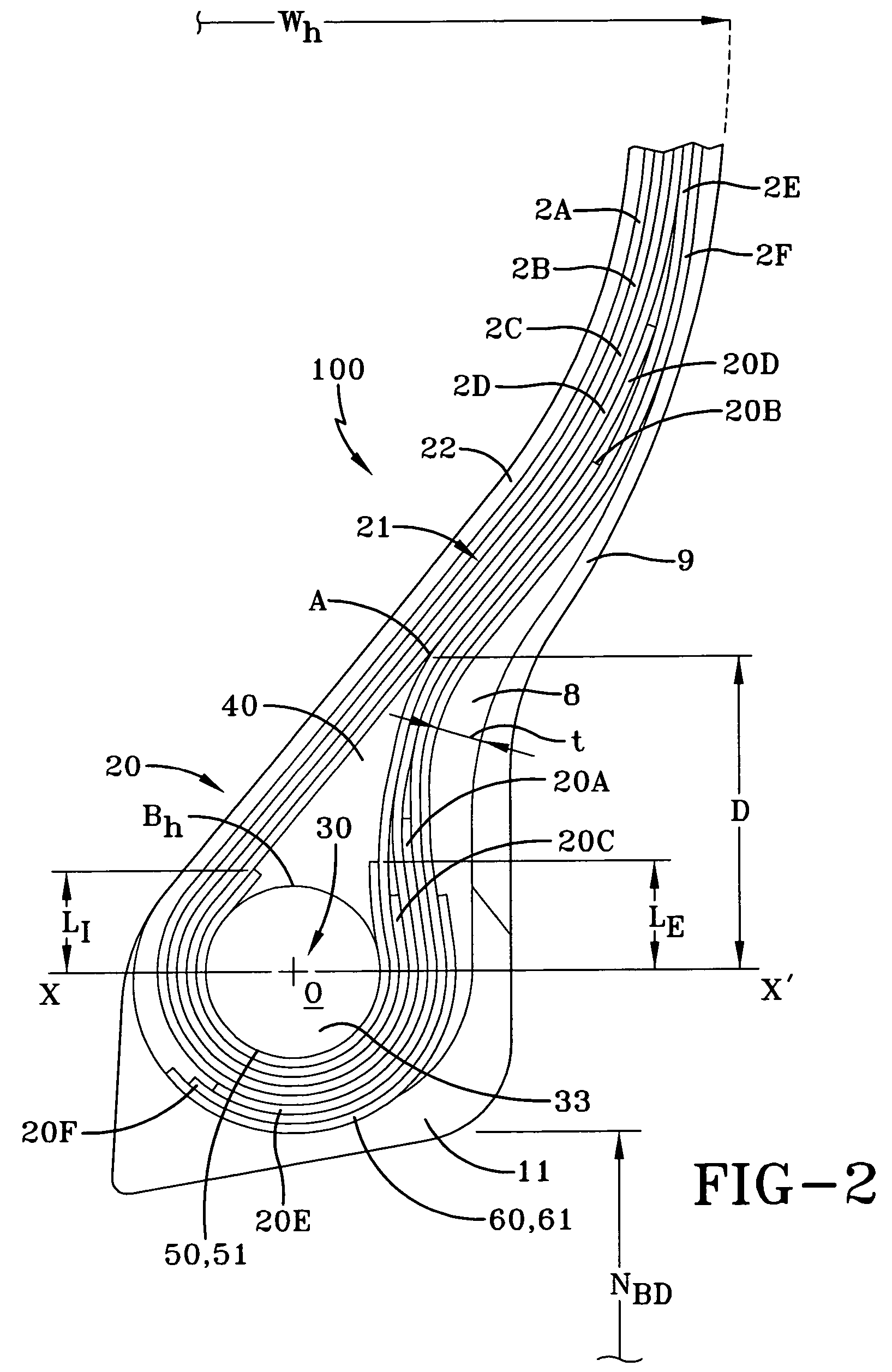

Tire having an improved carcass reinforcement anchoring structure

InactiveUS20030150541A1High densityHigh modulusPneumatic tyre reinforcementsTyre beadsEngineeringResilient modulus

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

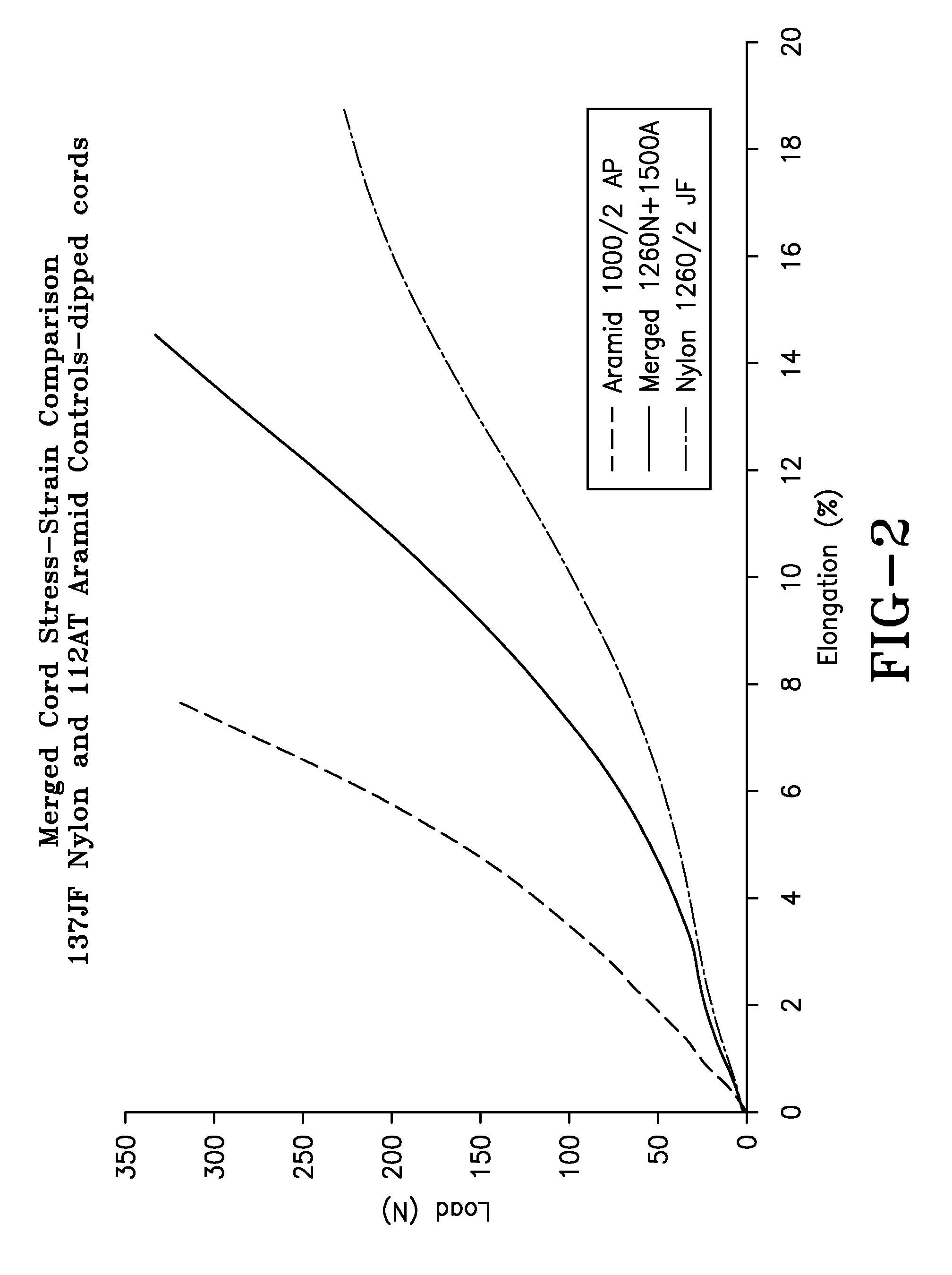

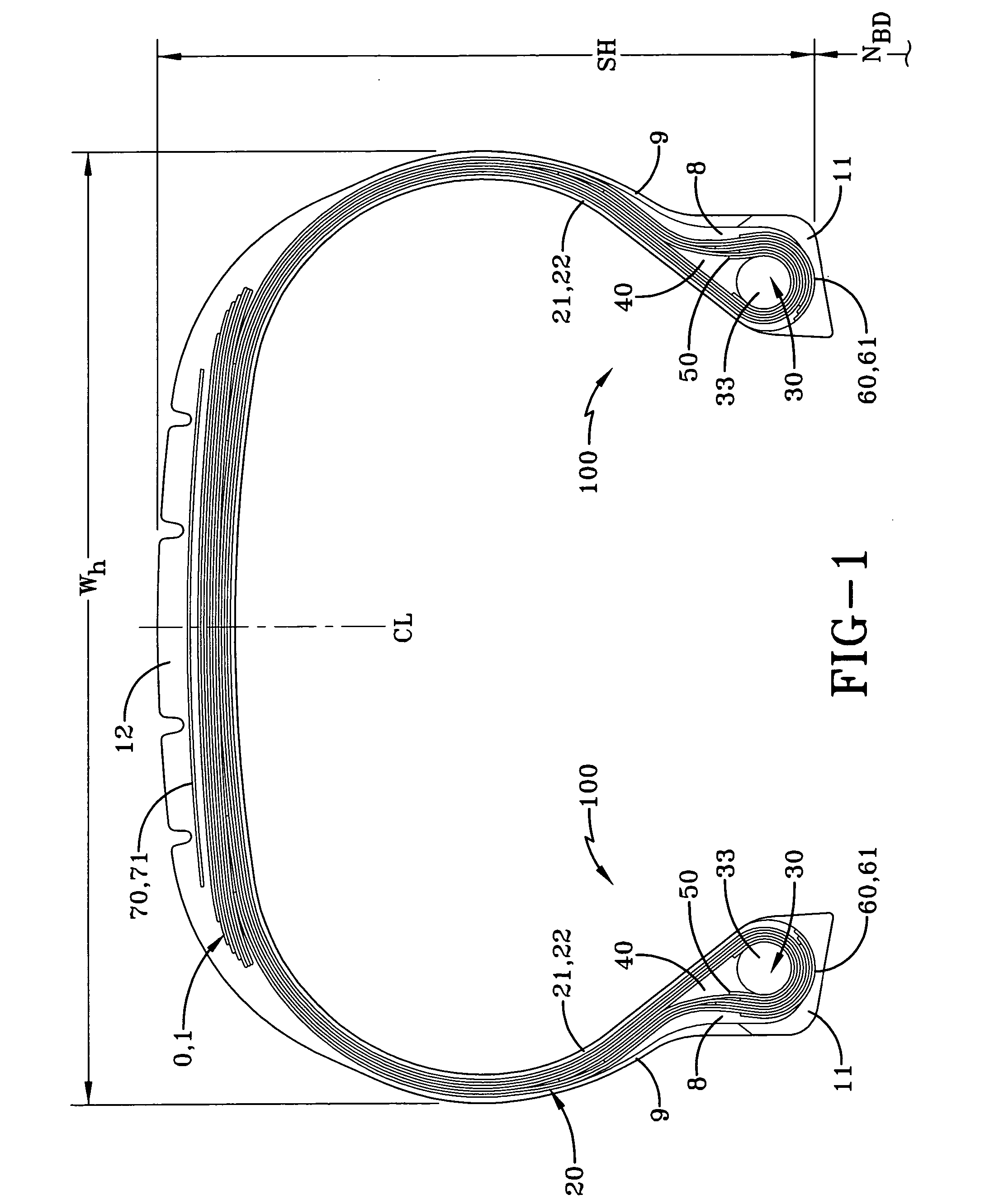

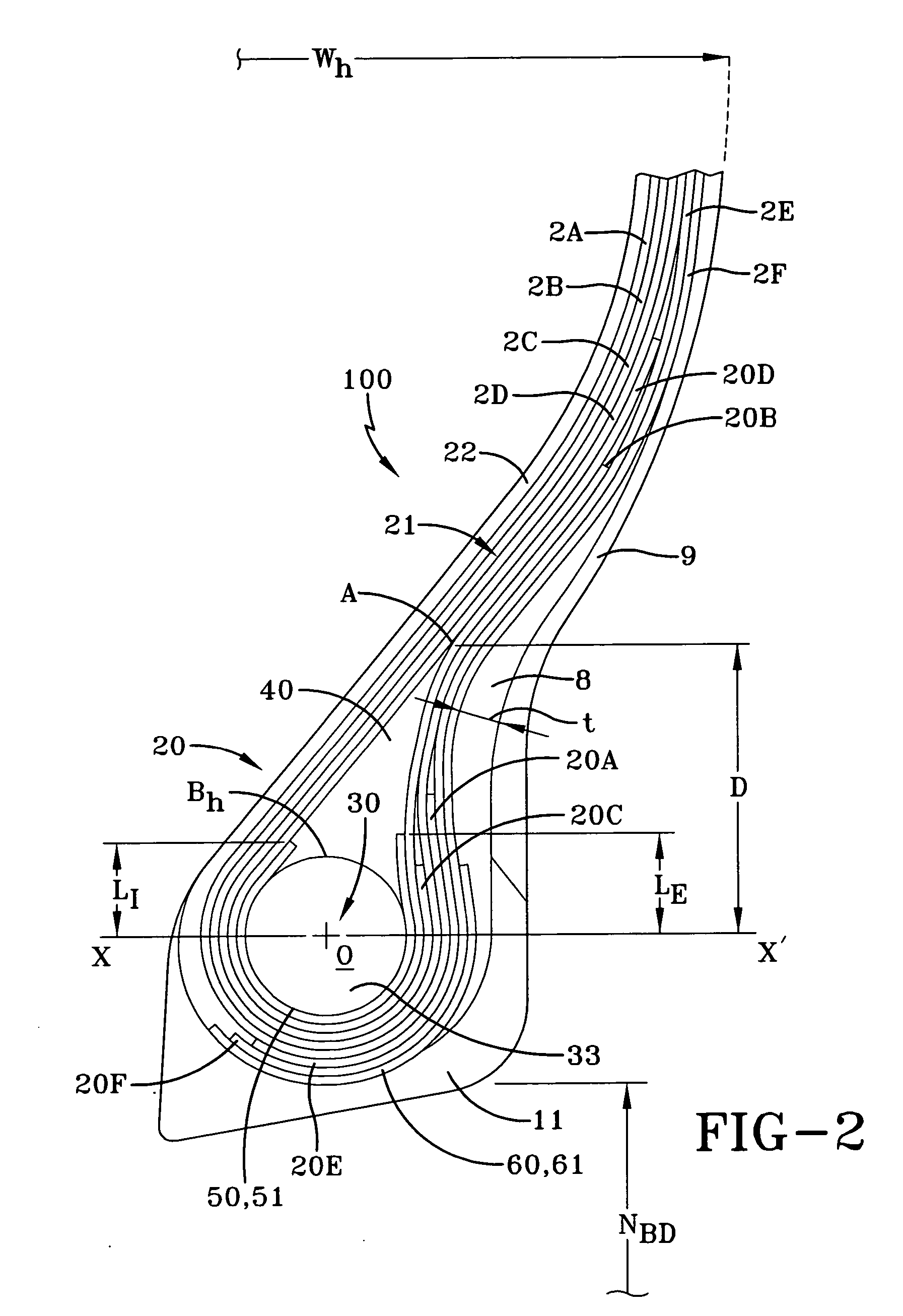

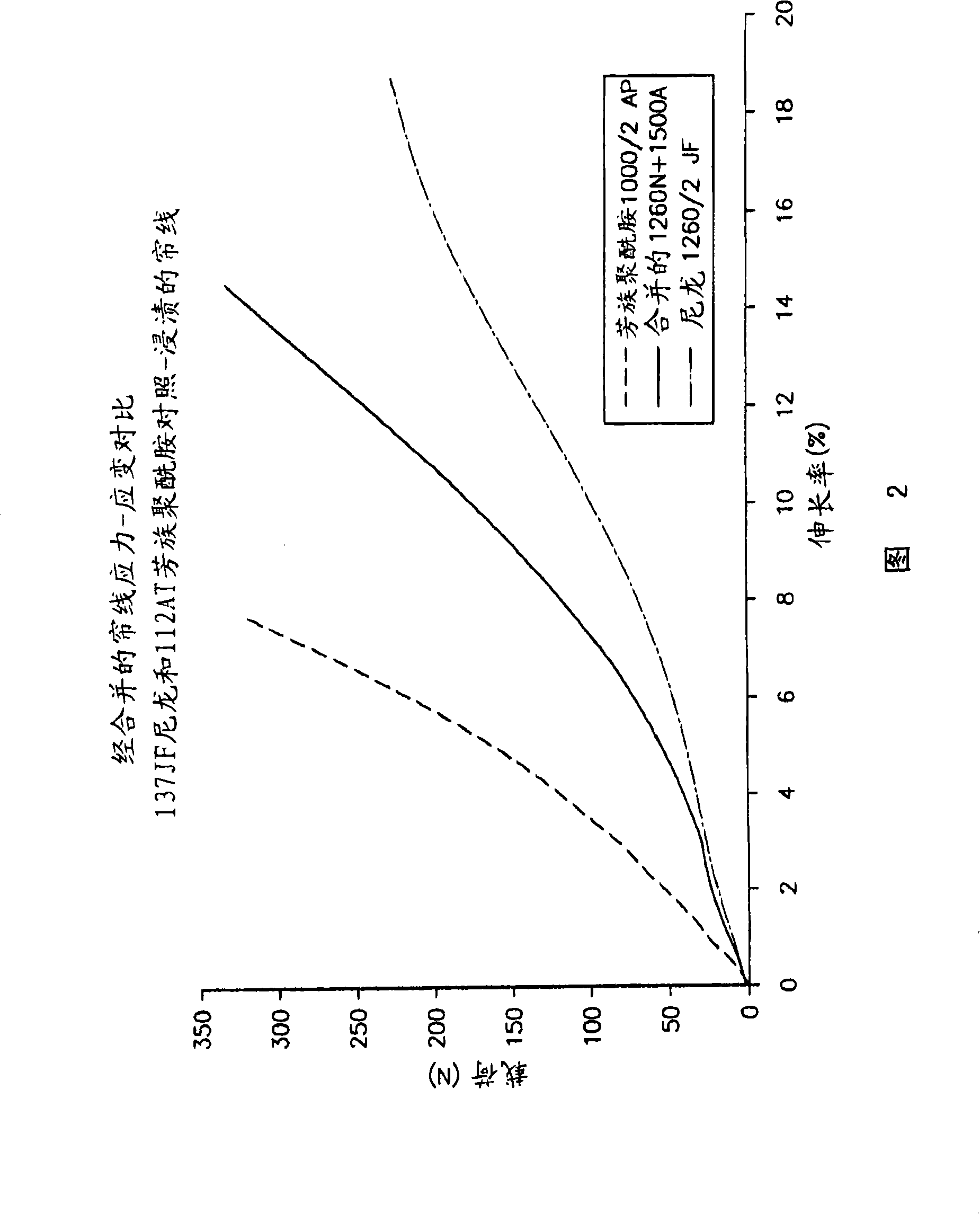

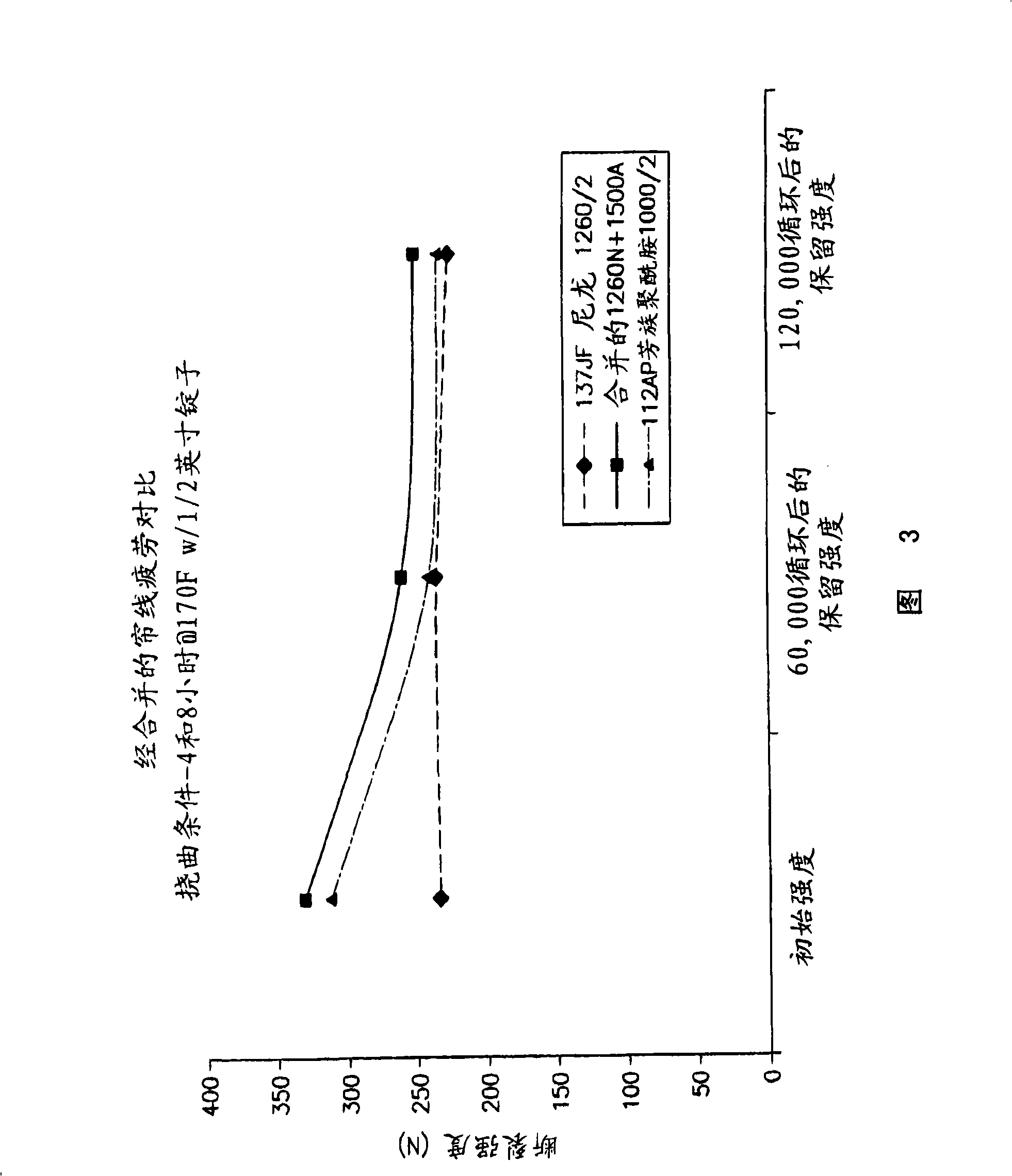

Enhanced radial aircraft tire

This invention disclosed a pneumatic tire for use on aircrafts having a tread, a crown reinforcement, and a radial carcass reinforcement. The carcass reinforcement has at least one axially inner ply of textile cord wound around a pair of bead cores, at least one axially inner ply being wound around the bead core in each bead from inside to the outside forming outside turn-ups and at least one axially outer ply of textile cords extending from bead to bead along the turn-ups of the at least one axially inner ply. Each bead has an elastomeric apex filler. The at least one axially inner ply or at least one axially outer ply has merged cords having a percent elongation at break of 12% to less than 20% and a break strength greater than 1050 N with a linear density of greater than 9,000 dtex. The preferred cord has fibers of polyamide and nylon. The cord fiber of polyamide is an aromatic polyamide 3300 / 2 construction. The cord fiber of nylon is a 1880 / 1 nylon construction. The preferred cord construction is 6.7 (A)+4.5 (N) / 6.7 TPI. The cord reinforcement is preferably used in the ply layers or strips of the crown reinforcement as well.

Owner:THE GOODYEAR TIRE & RUBBER CO

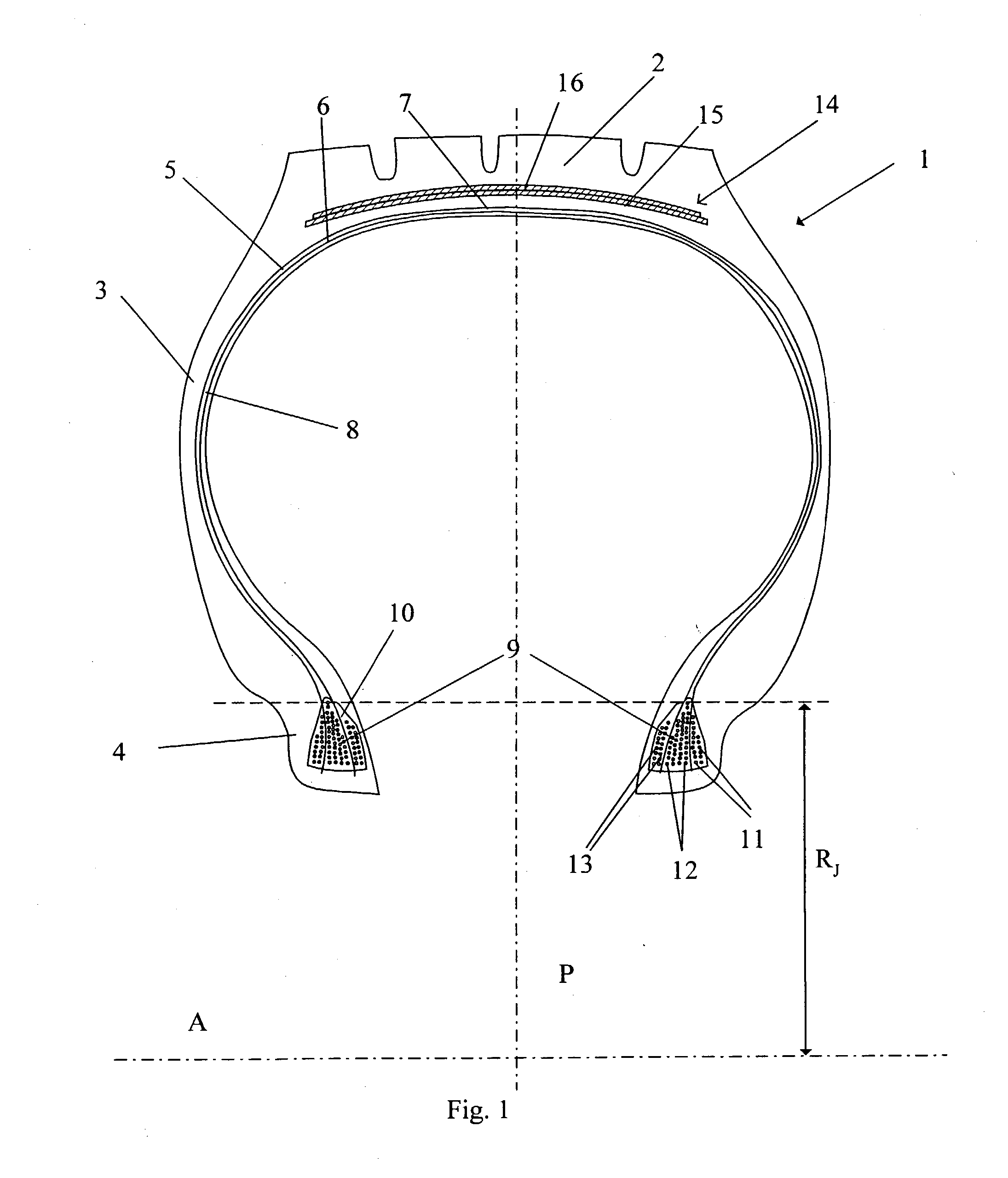

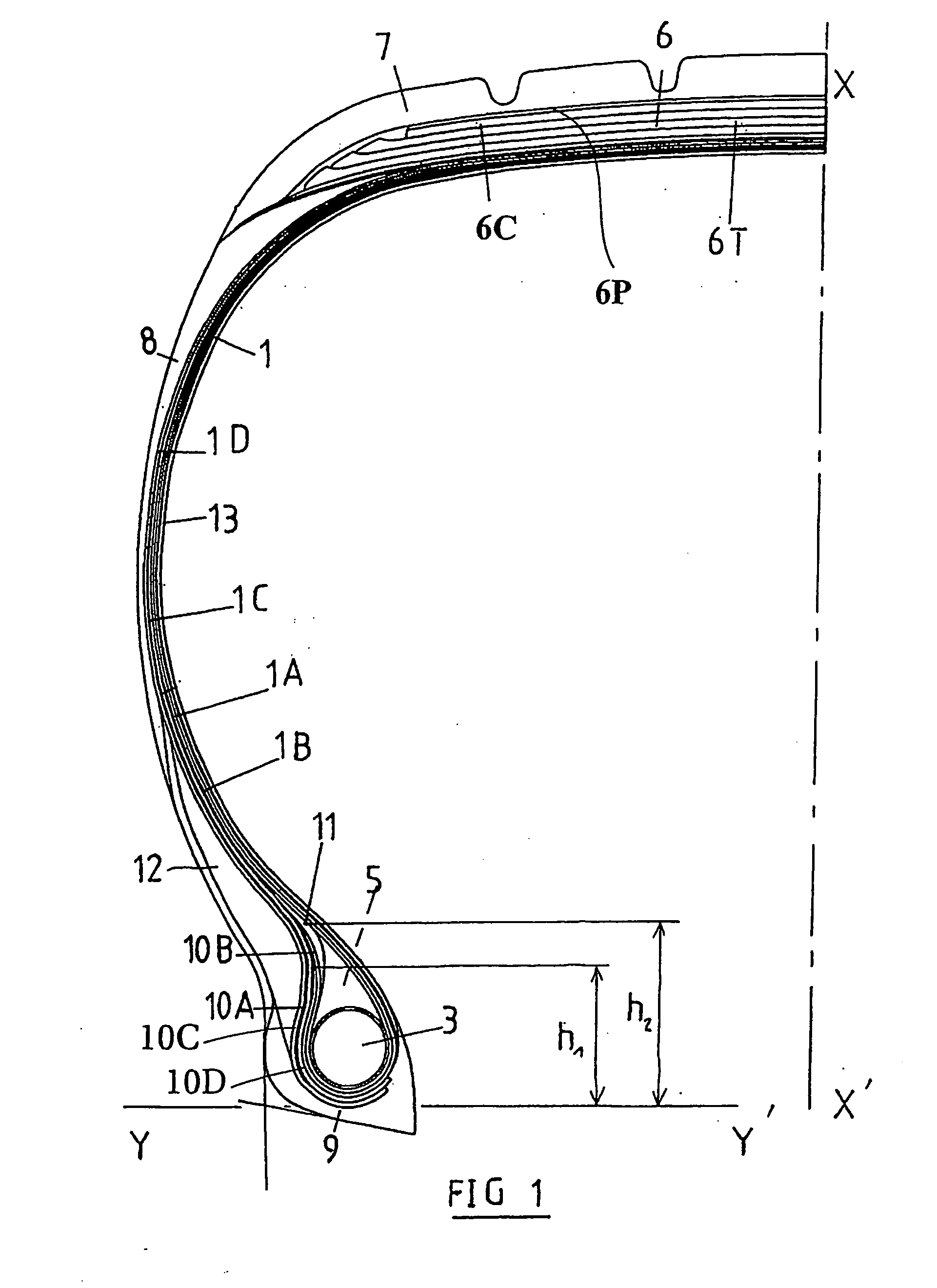

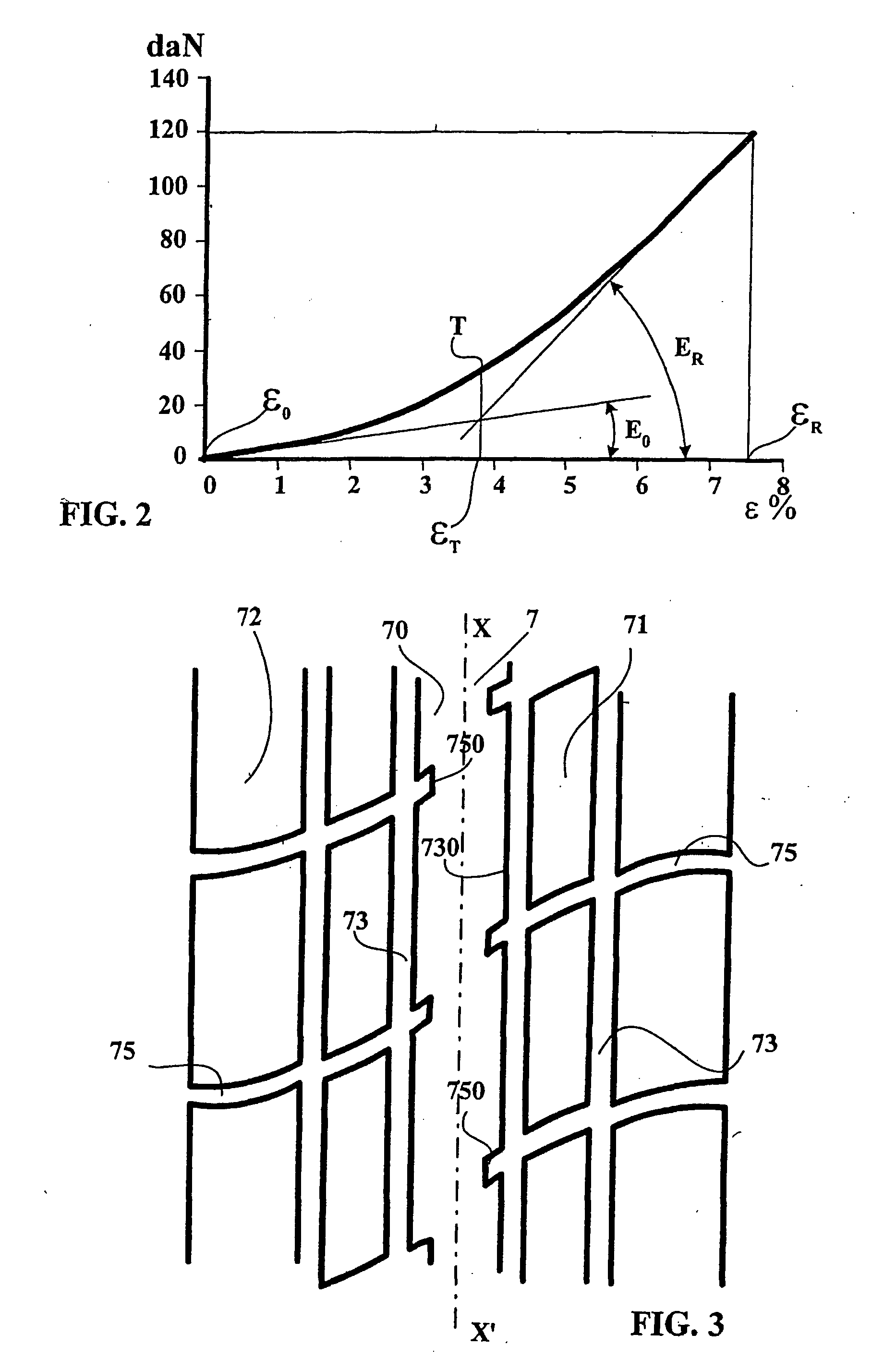

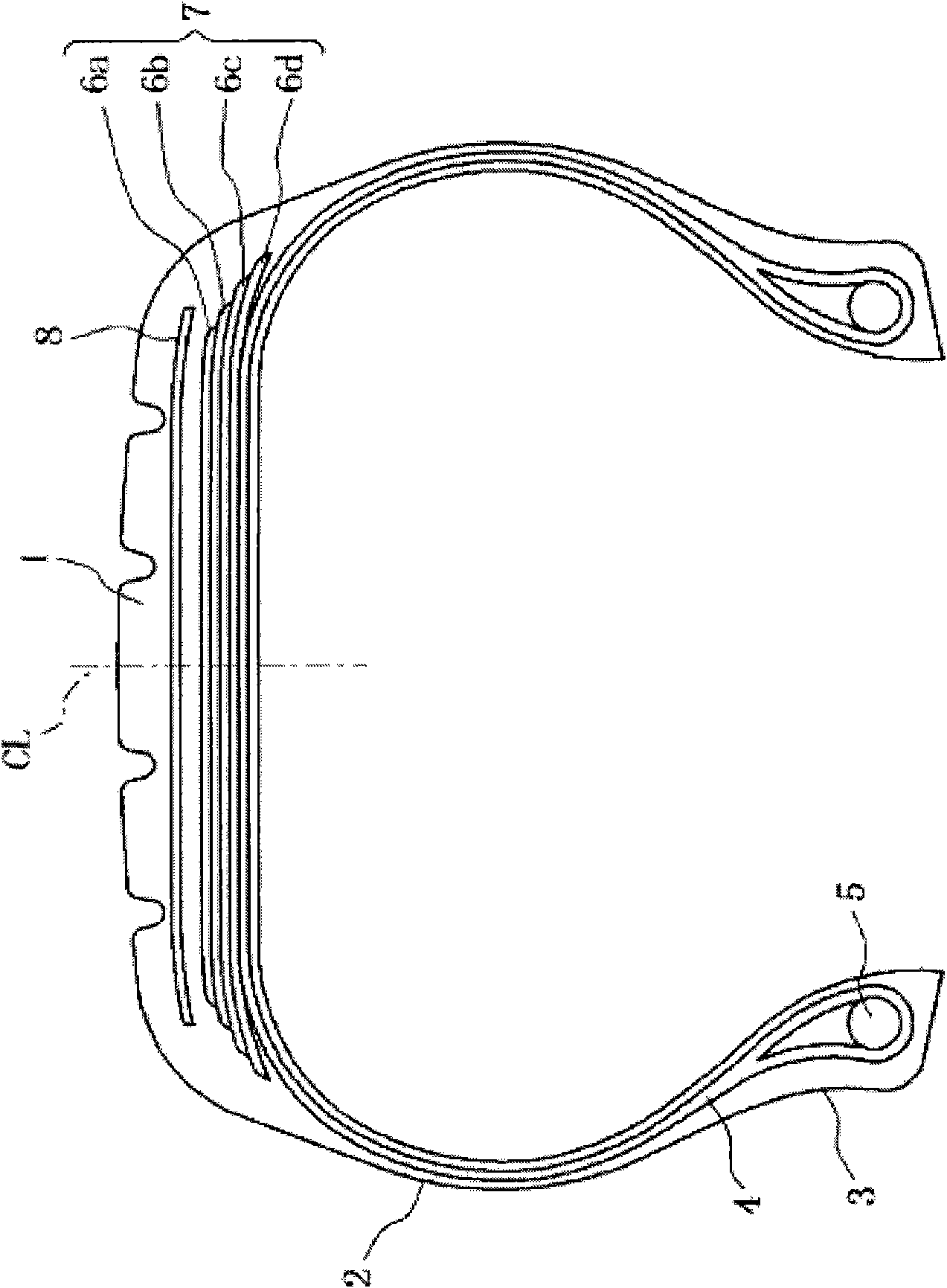

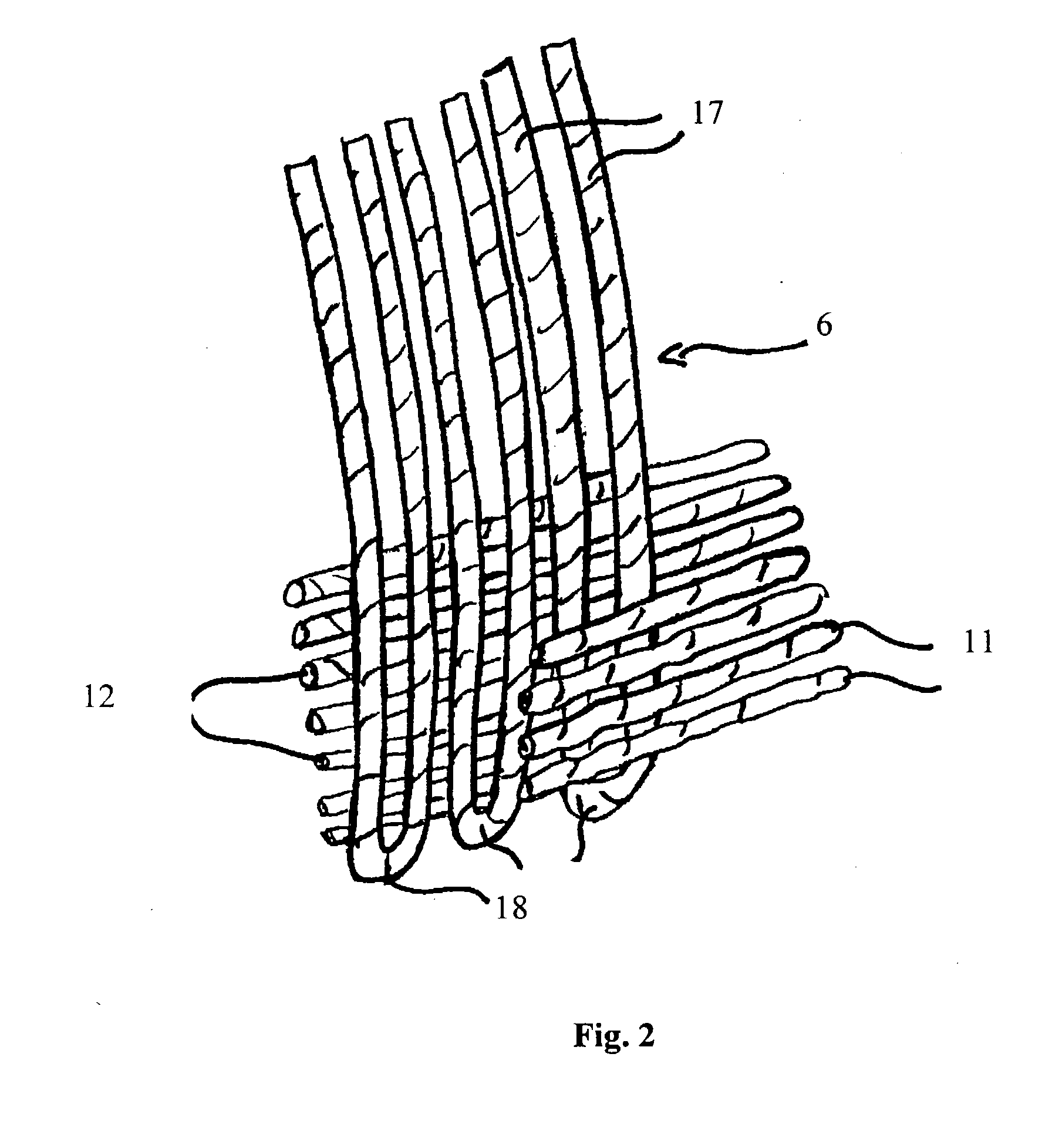

Aircraft tire reinforcements

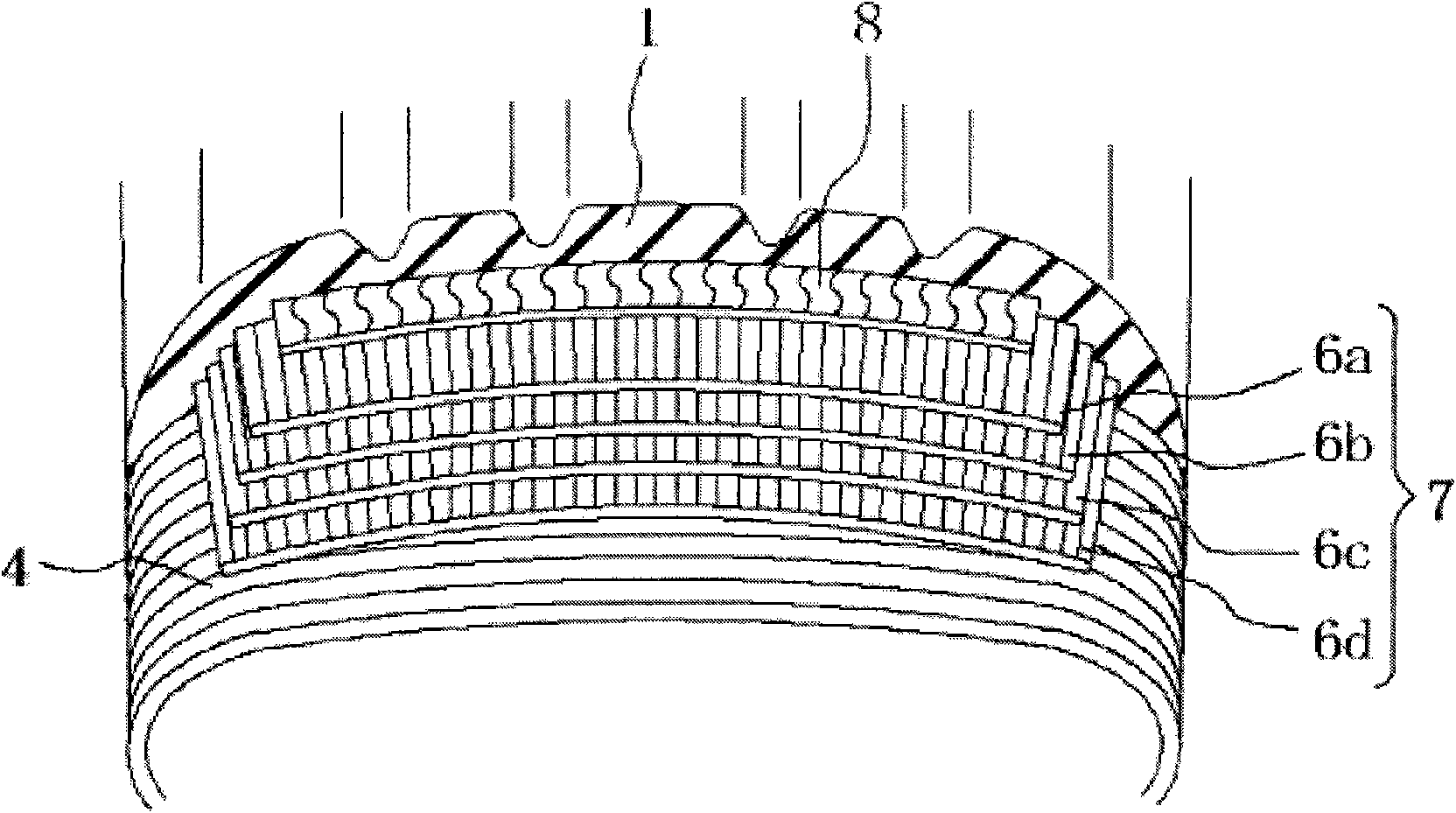

ActiveUS20070235116A1Reduce weightEasy to manufacturePneumatic tyre reinforcementsTyre beadsYarnEngineering

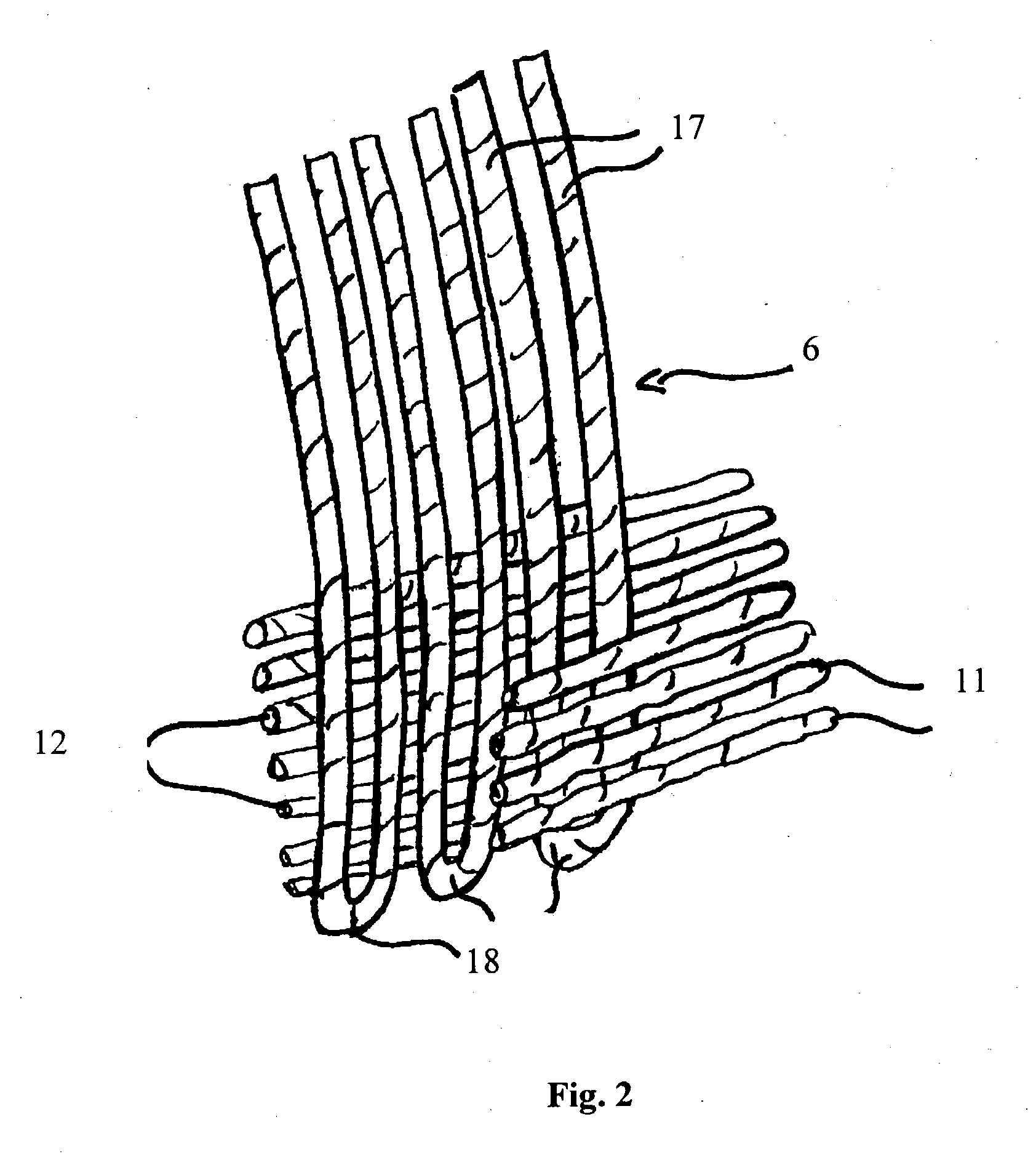

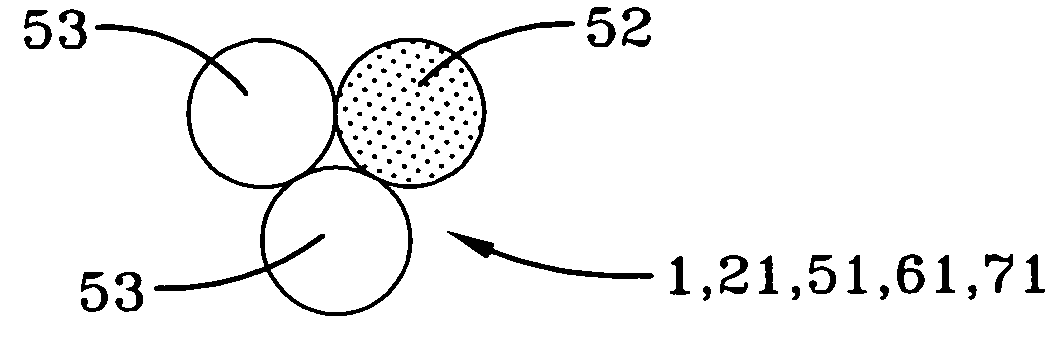

An aircraft tire, inflated to high pressure, with a tread (7), a crown reinforcement (6) and a radial carcass reinforcement (1) comprising at least two axially inner plies (1A and 1B) formed of textile reinforcement elements, said two plies being wound around at least one bead wire (3) within each bead (2) from the inside to the outside, forming upturns (10A and 10B) and at least one axially outer ply (1C, 1D) of textile elements which is superposed radially on the inner plies (1A and 1B) beneath the crown reinforcement (6) to extend along the upturns (10A and 10B) of said inner plies in the beads (2), characterized in that the radial reinforcement elements of all the plies (1A, 1B, 1C, 1D, . . . ) of the carcass reinforcement (1) are cables formed by plying at least one yarn having a modulus of elasticity in tension at least equal to 2000 cN / tex, with a yarn, whether overtwisted or not, having an modulus of elasticity in tension at most equal to 1500 cN / tex, said moduli of elasticity of said yarns being measured for a tensile force equal to 0.1 times the breaking load of a yarn.

Owner:MICHELIN RECH & TECH SA

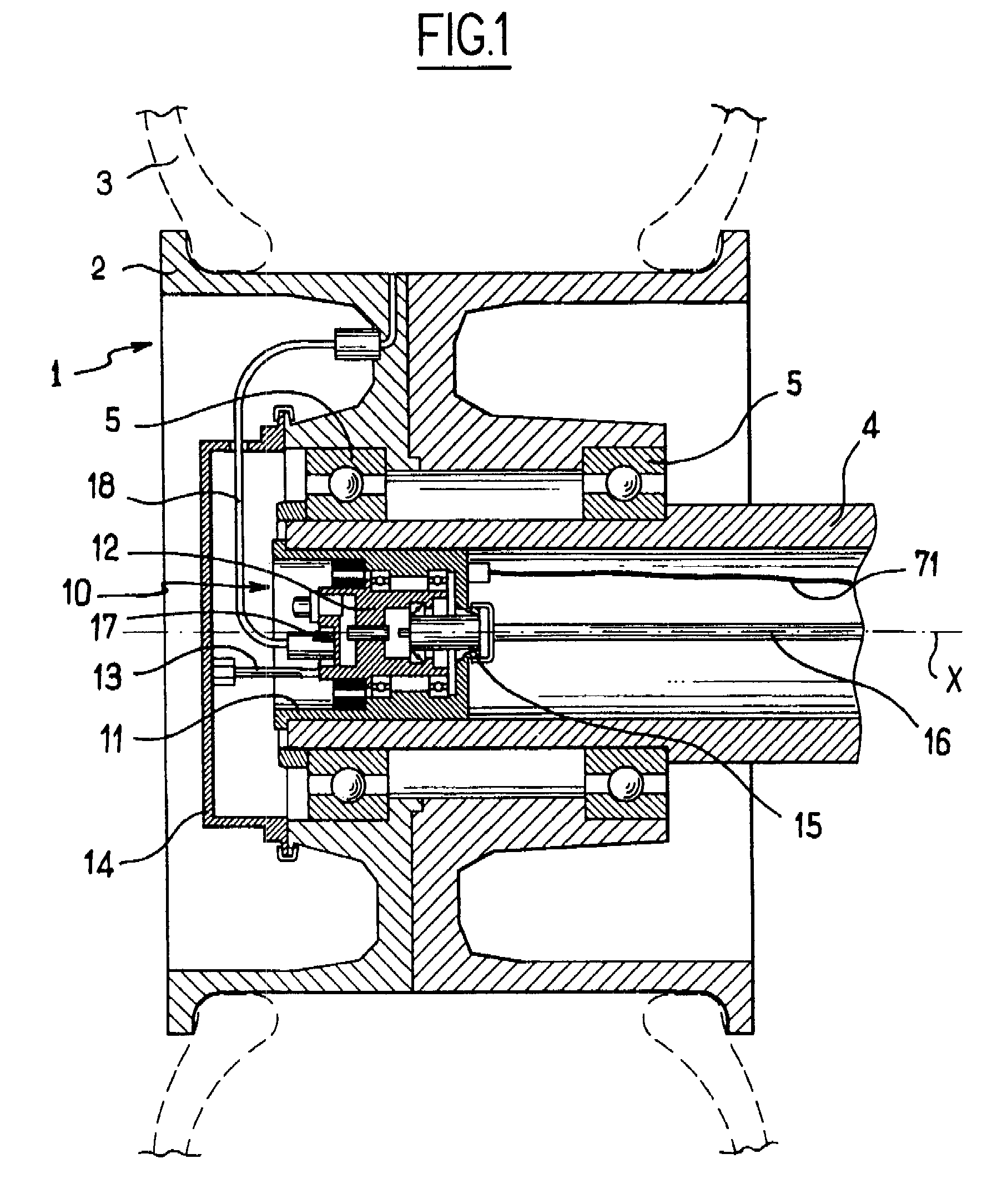

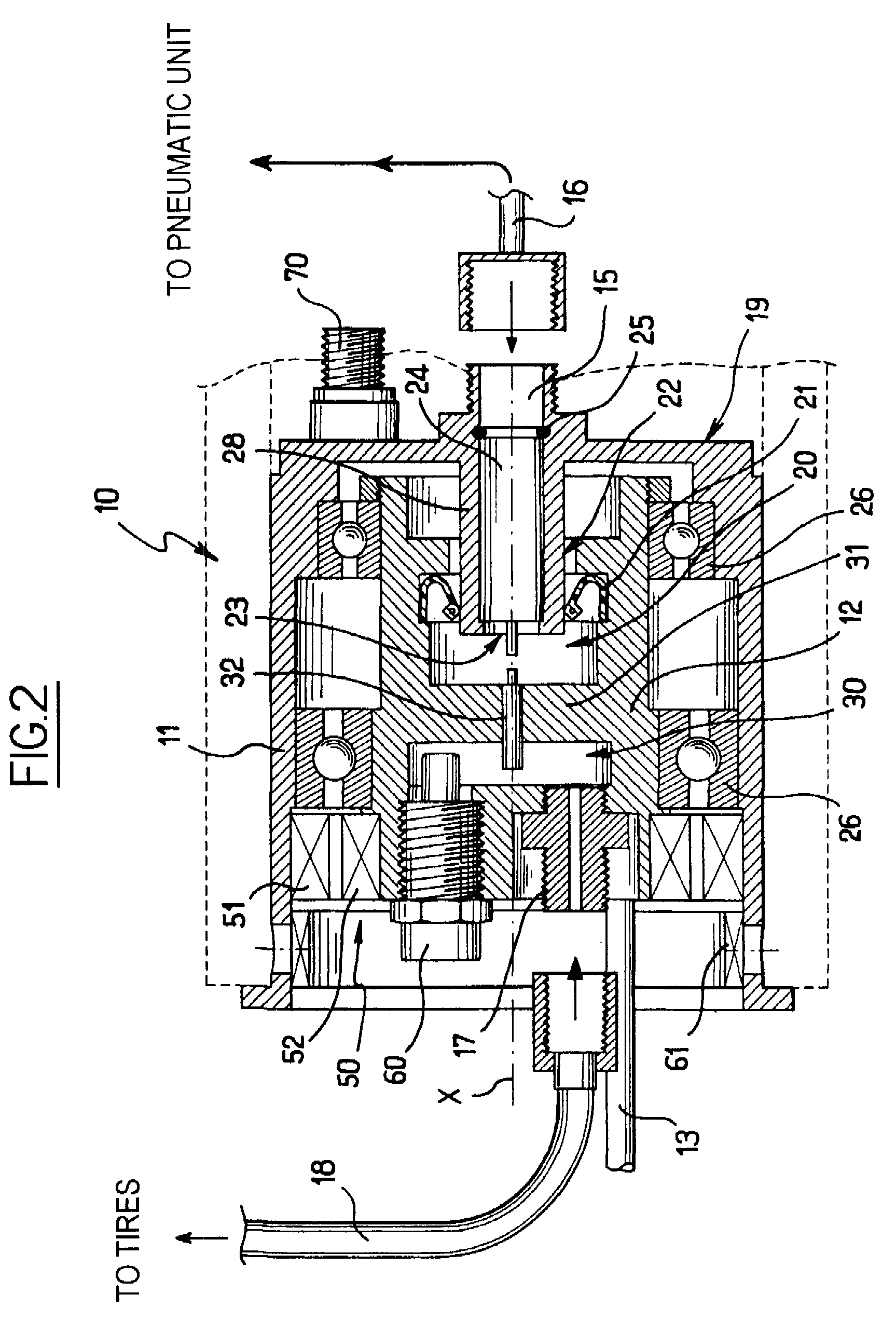

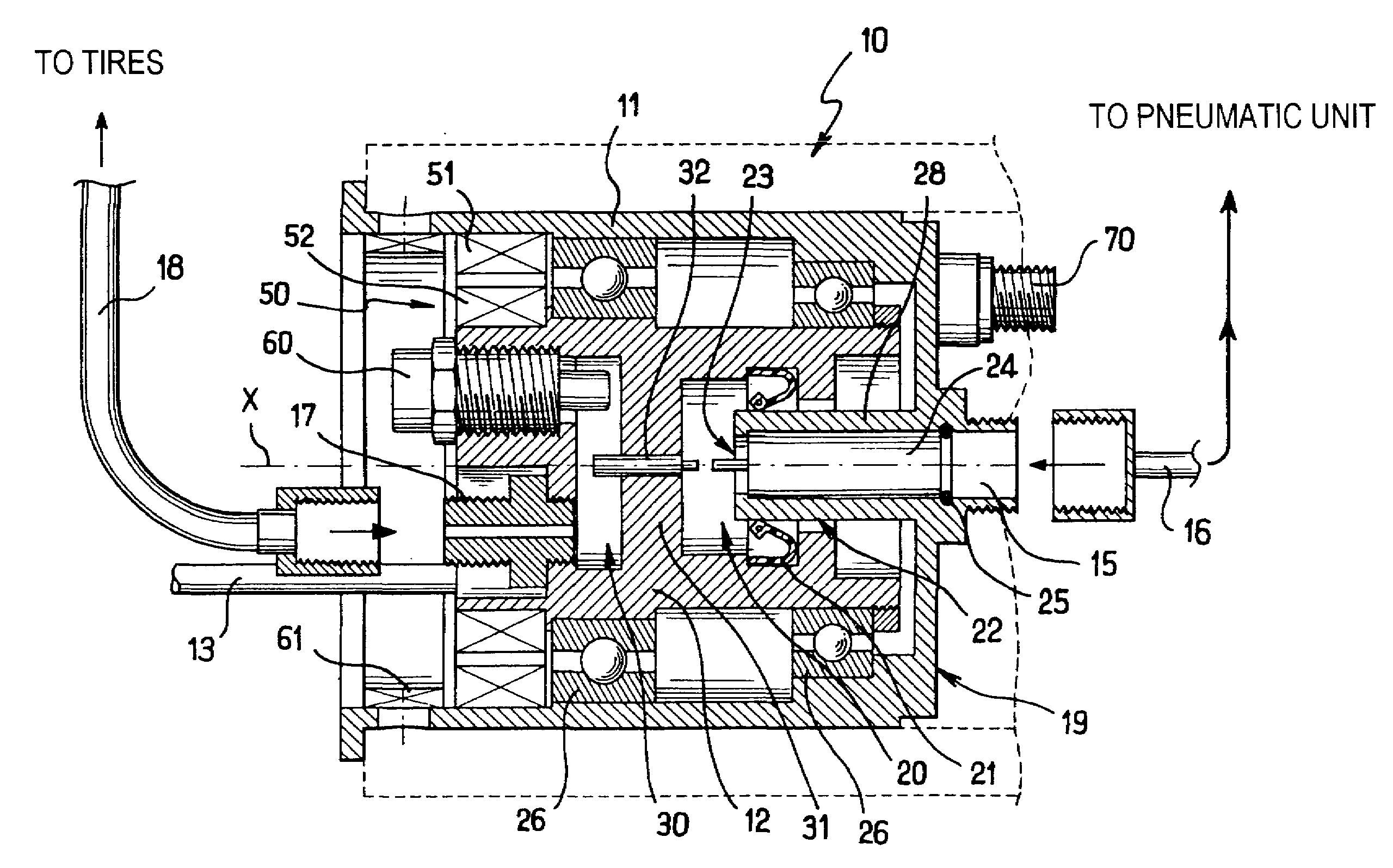

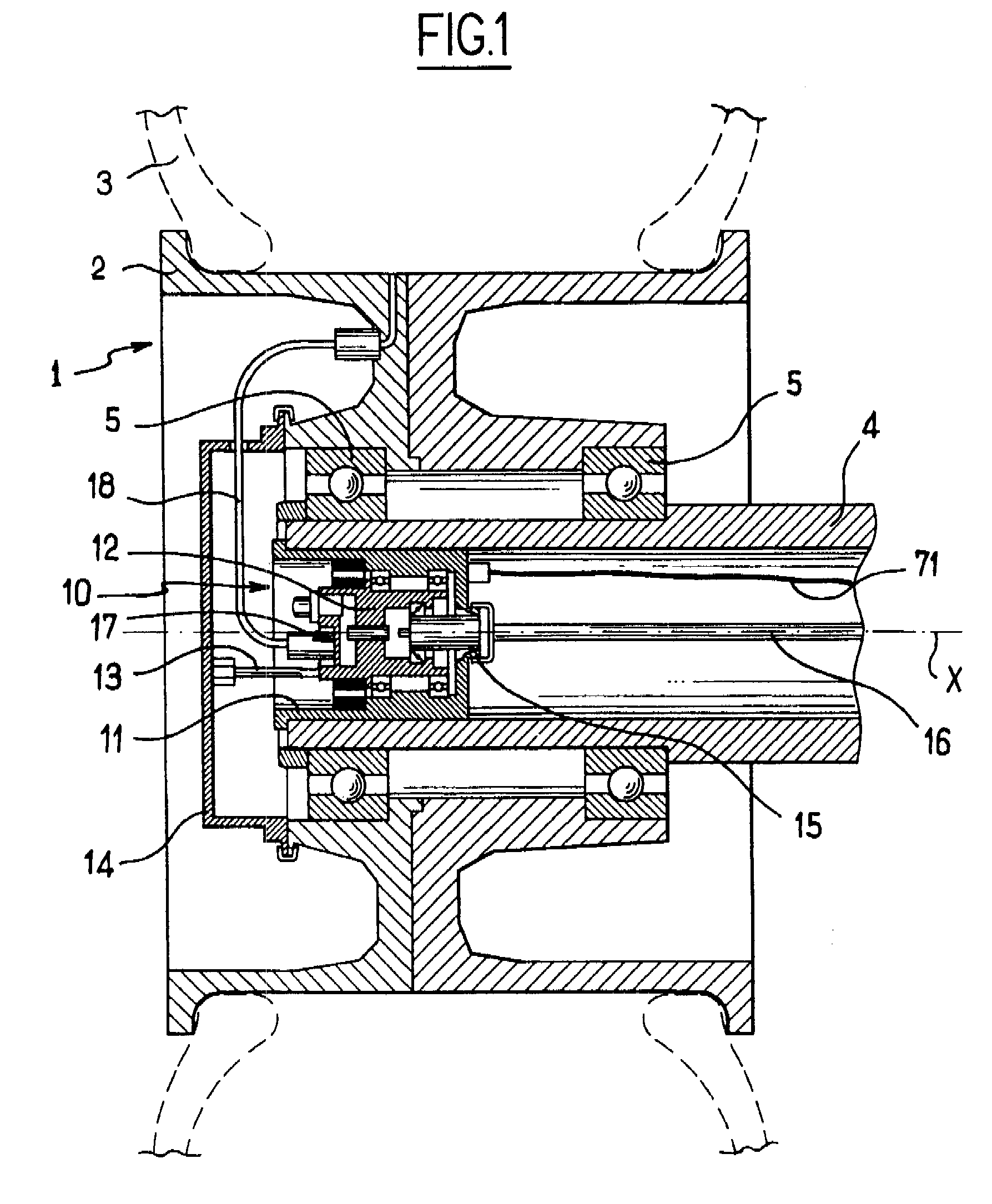

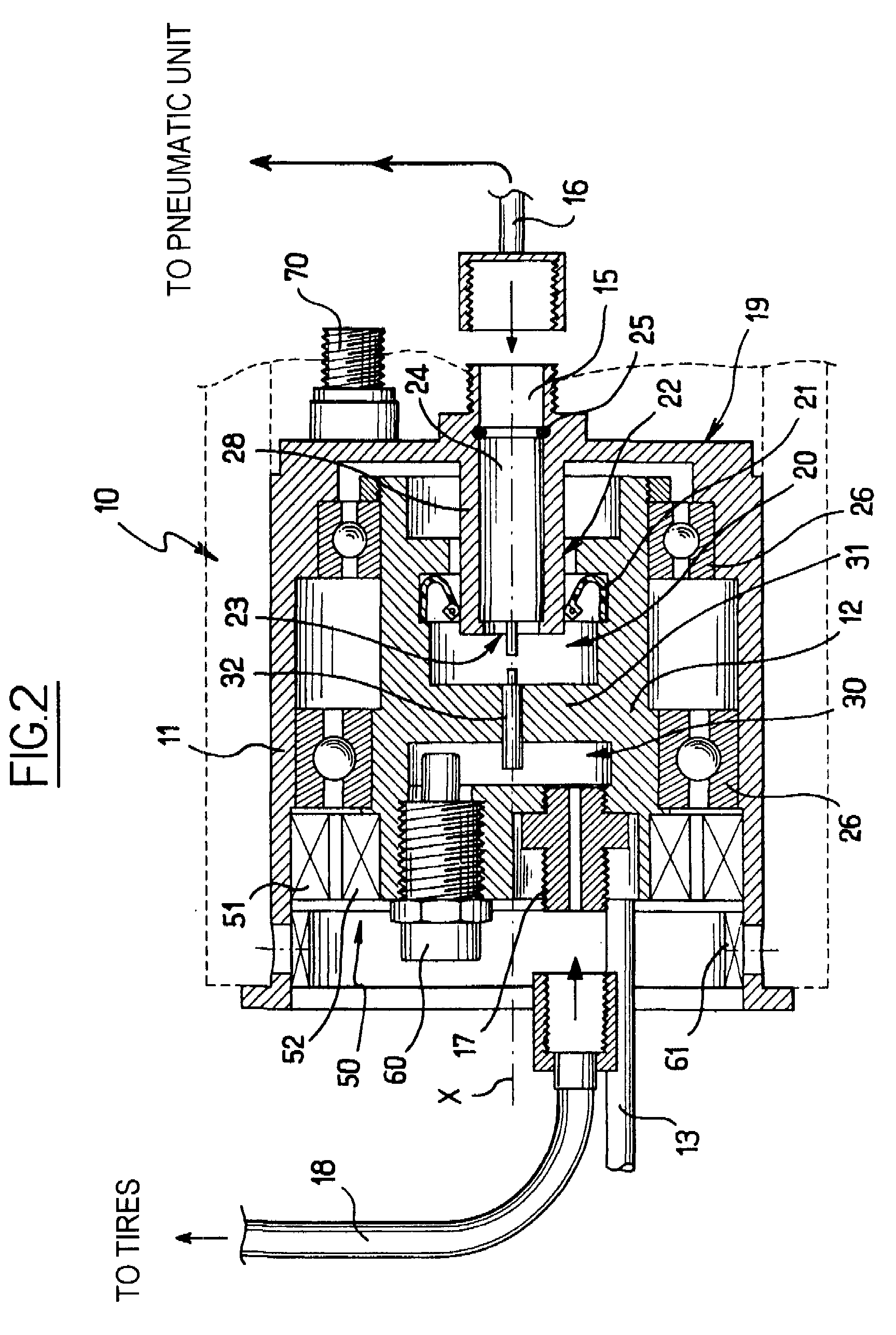

Device for connecting a tire of an aircraft wheel to a pneumatic unit of the aircraft

InactiveUS7992610B2Firmly connectedAvoid shockCheck valvesEqualizing valvesEngineeringMechanical engineering

Owner:SAFRAN LANDING SYSTEMS

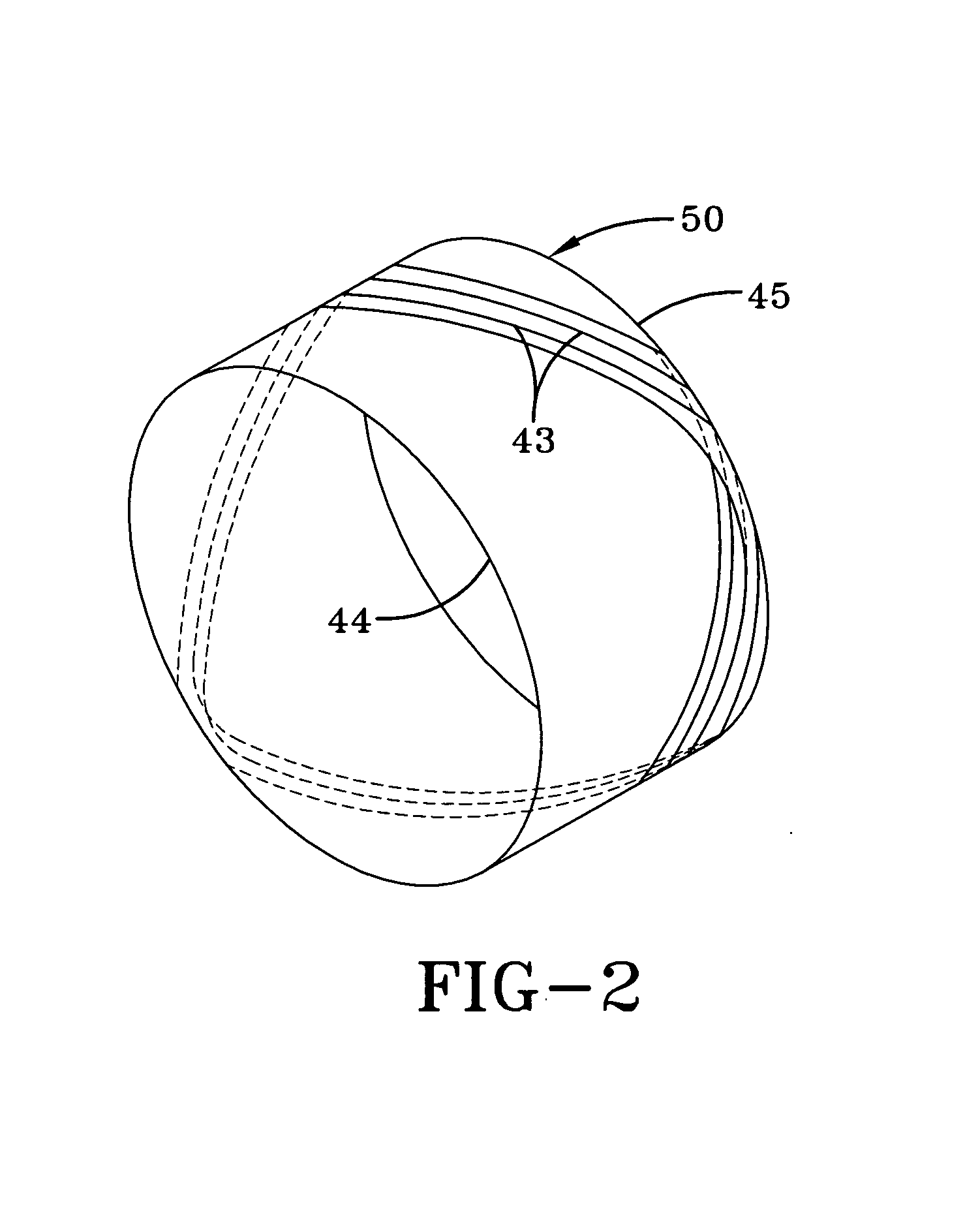

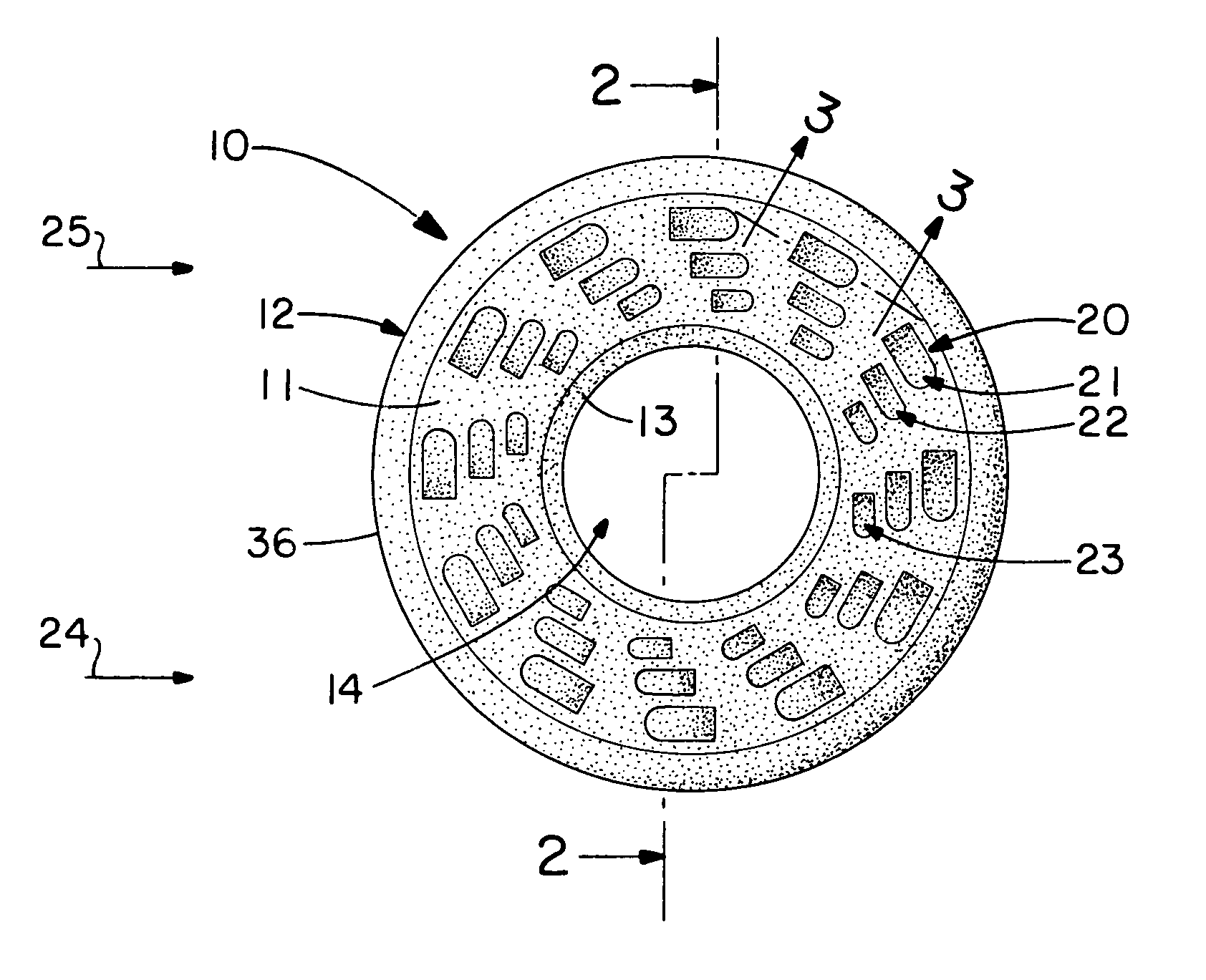

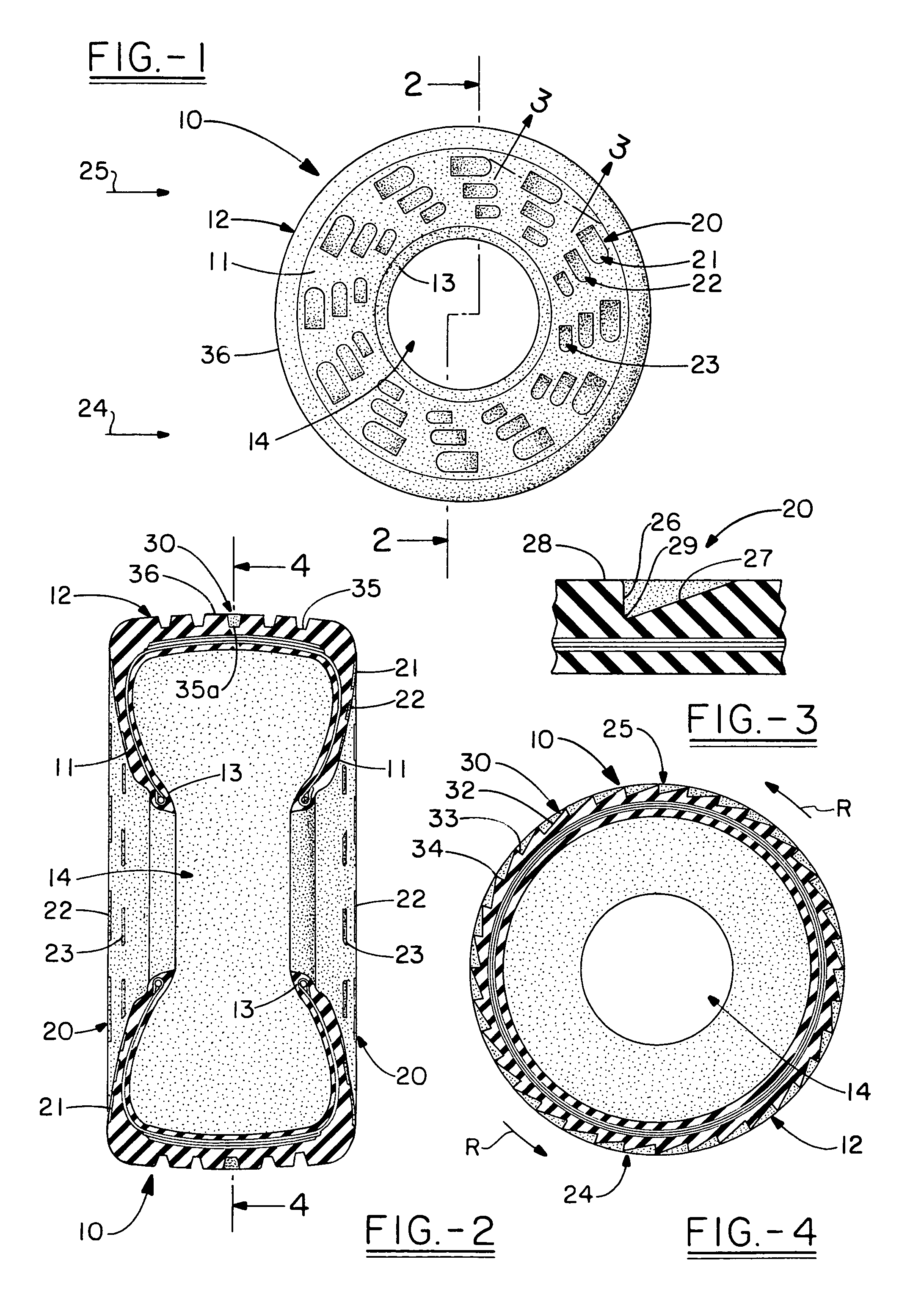

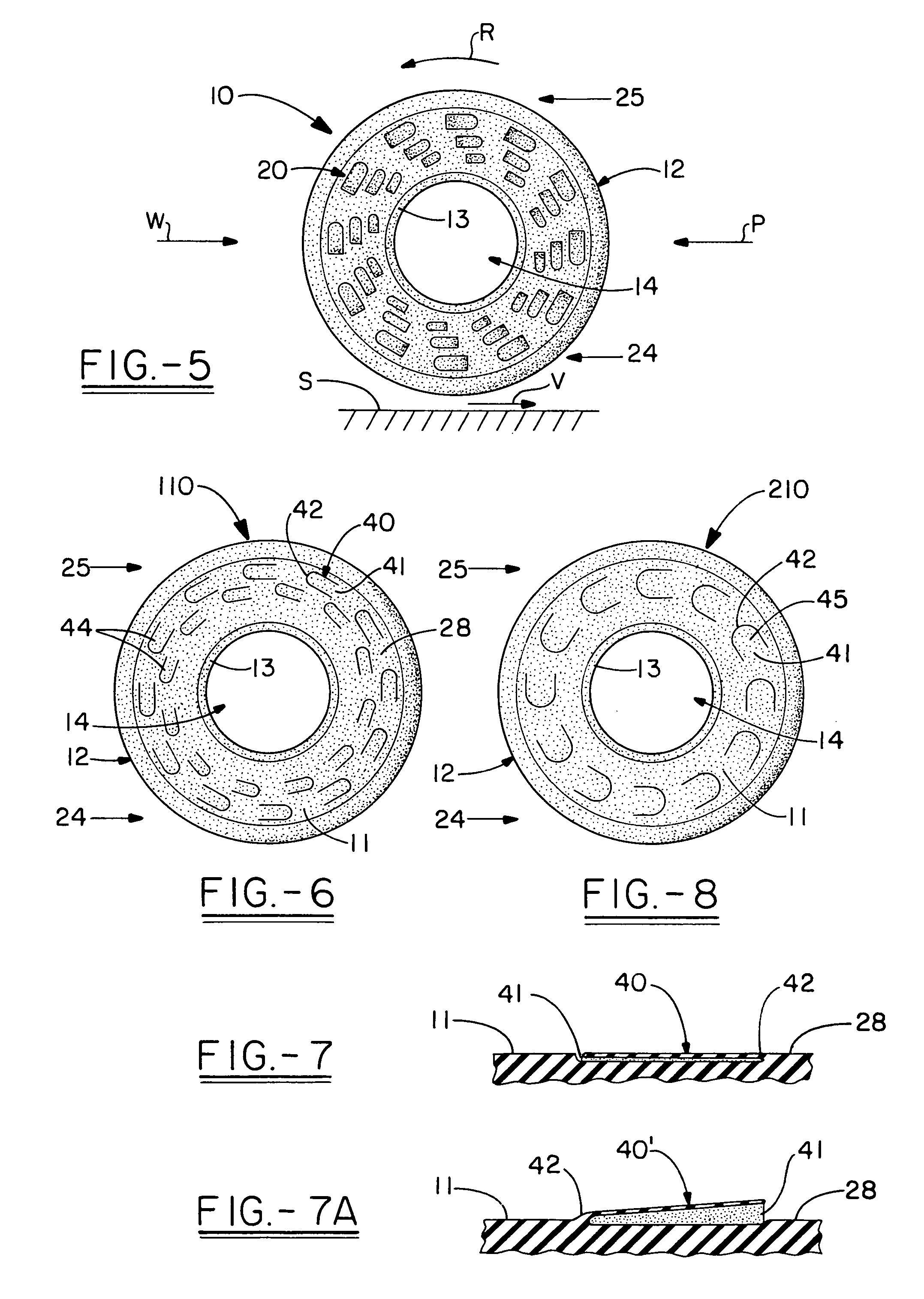

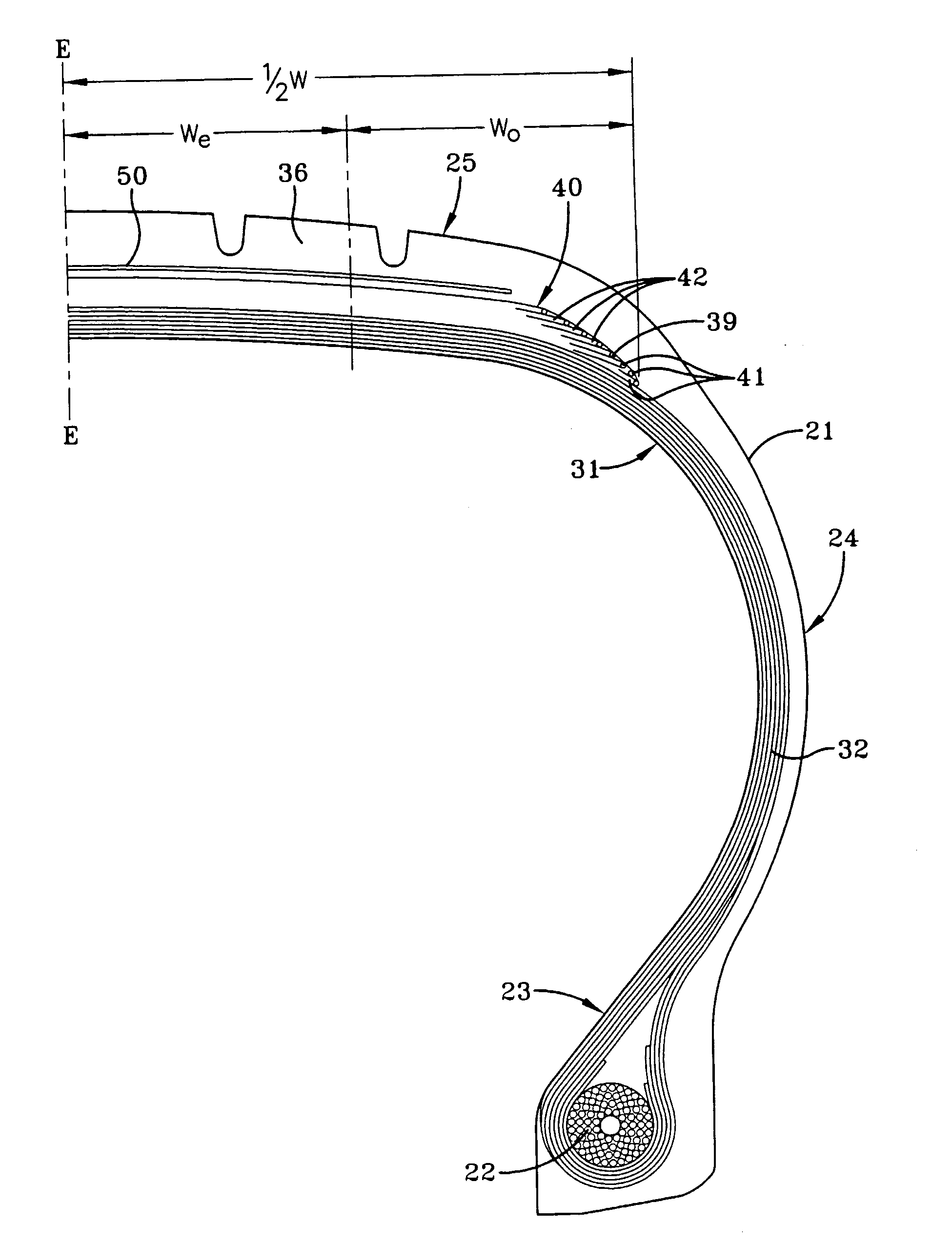

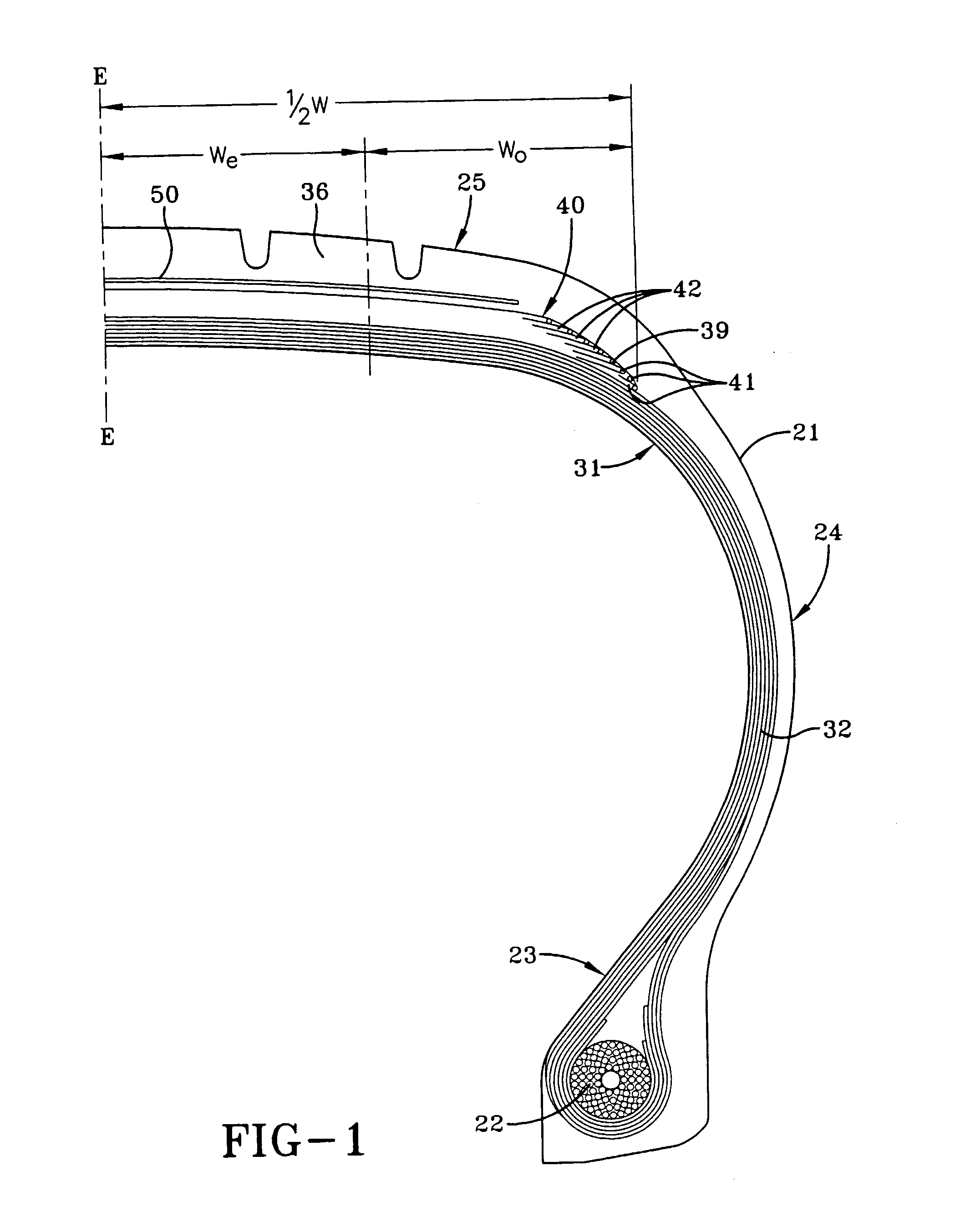

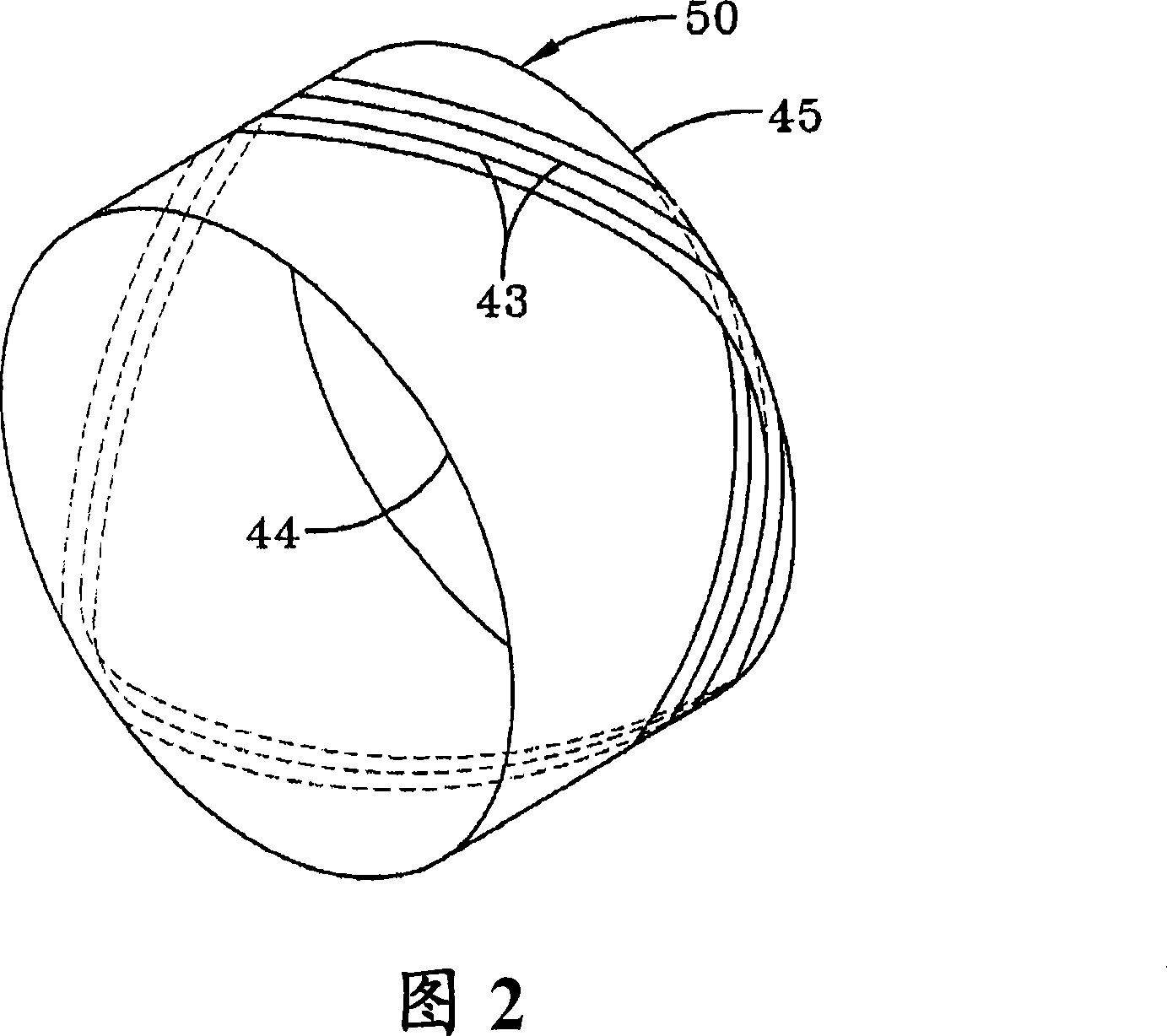

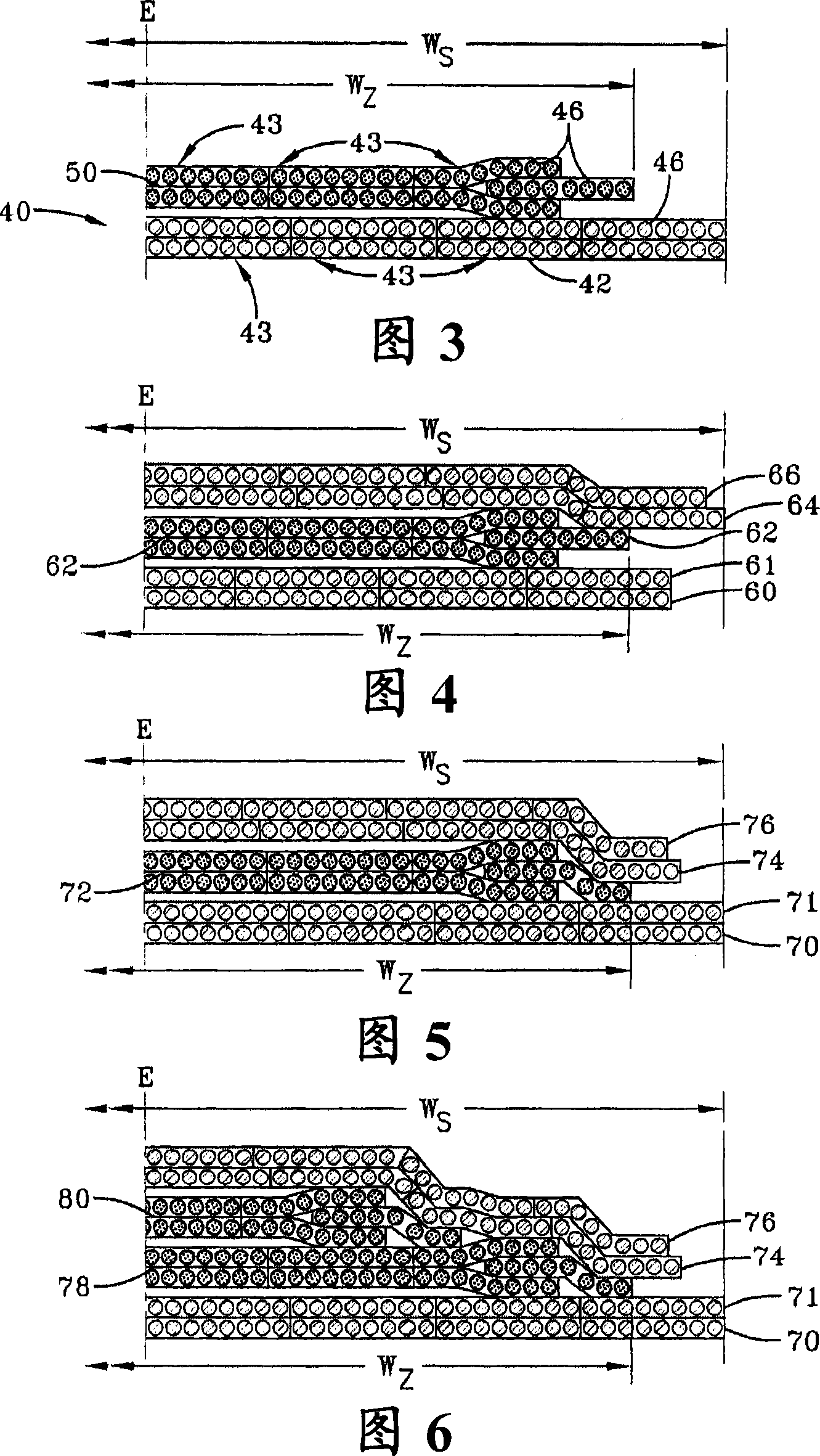

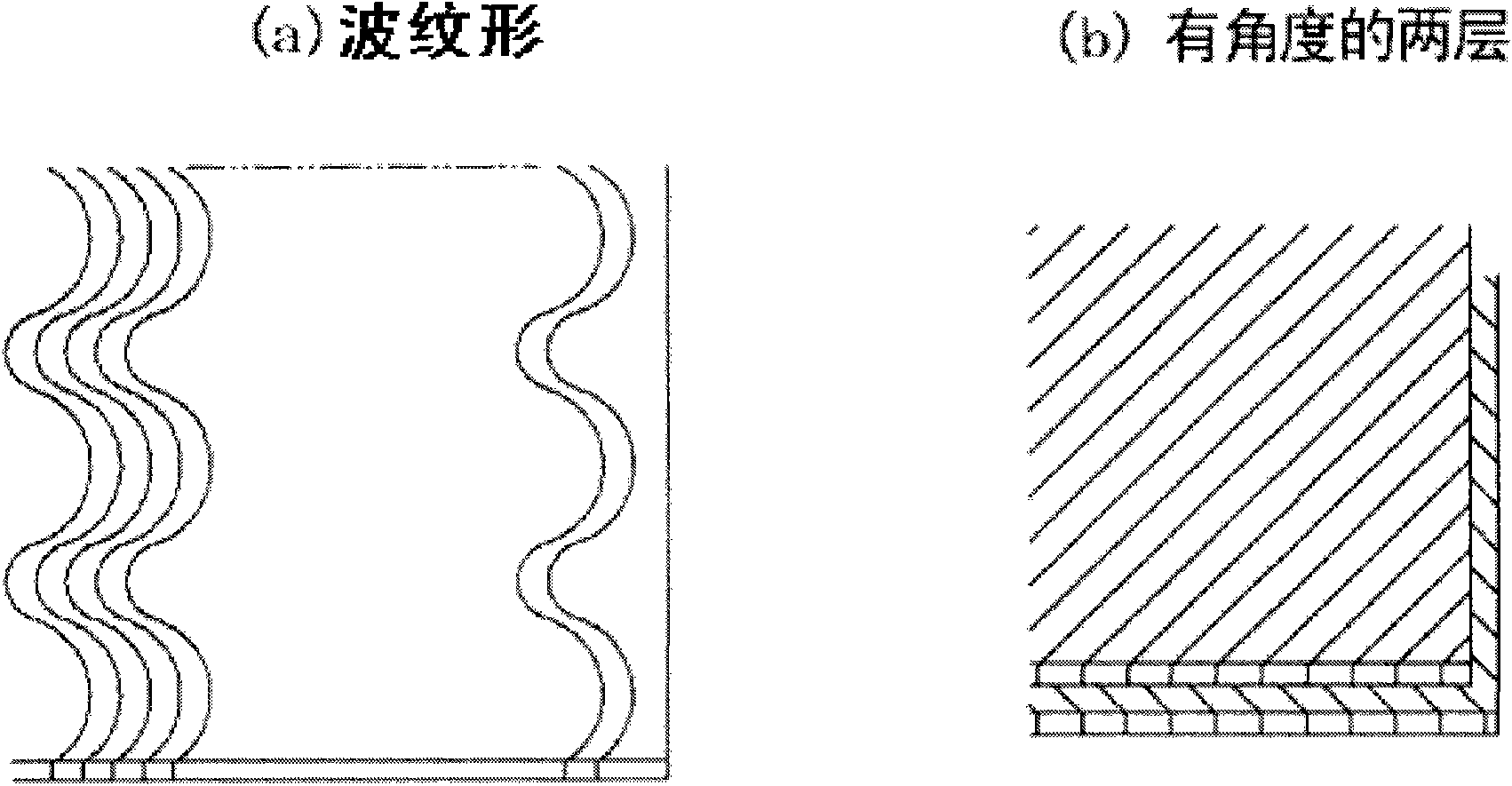

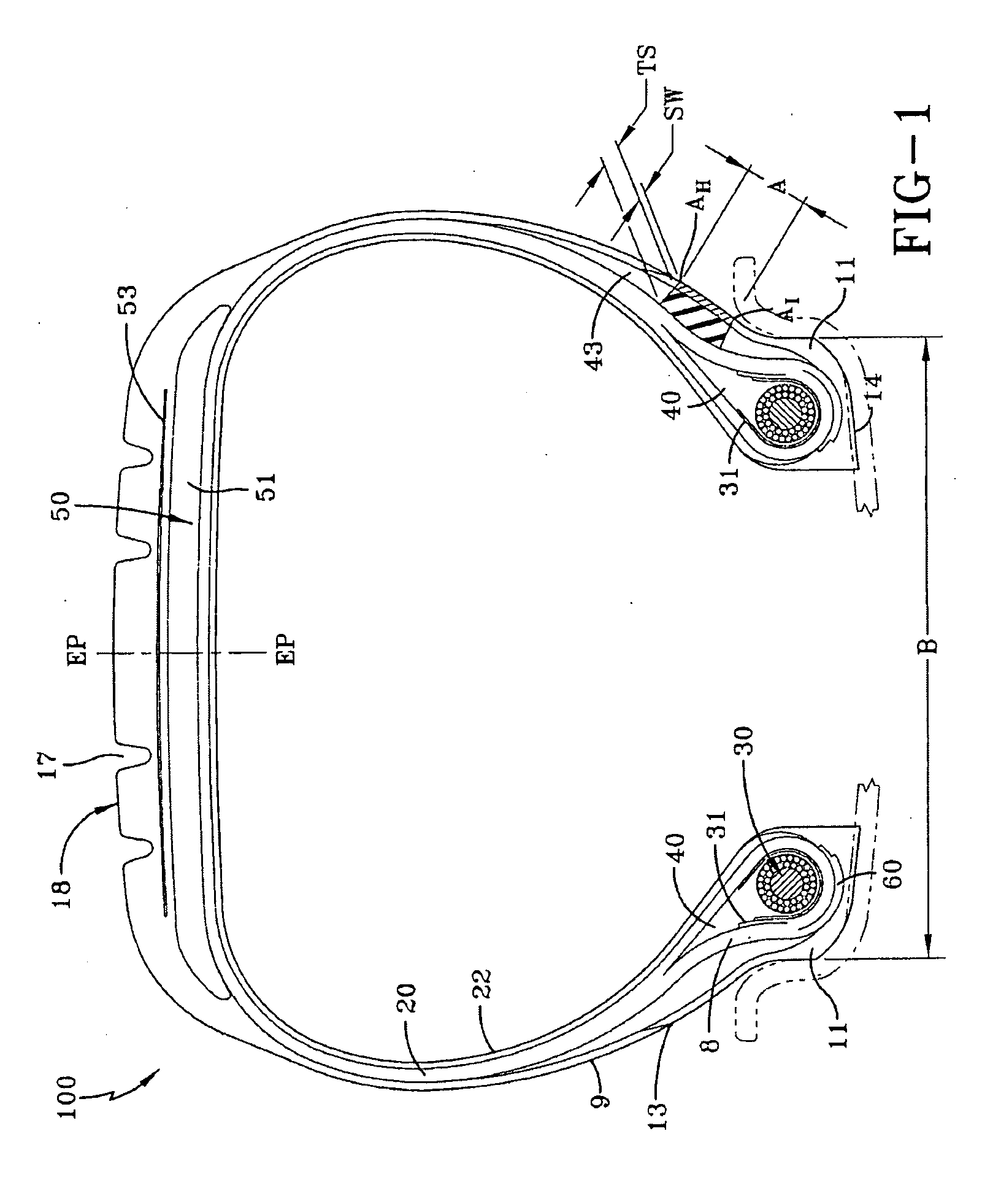

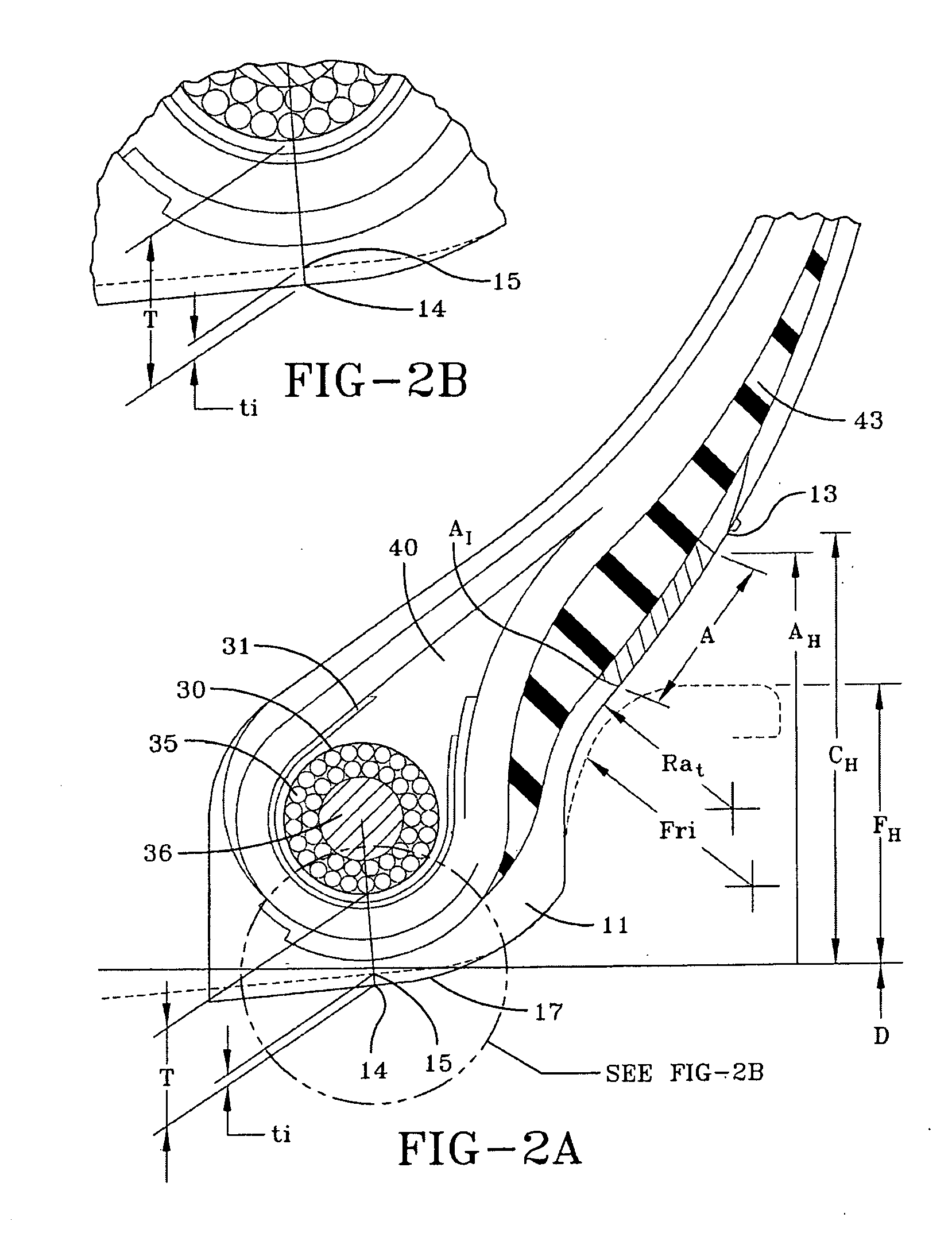

Composite belt structure and a method of manufacturing

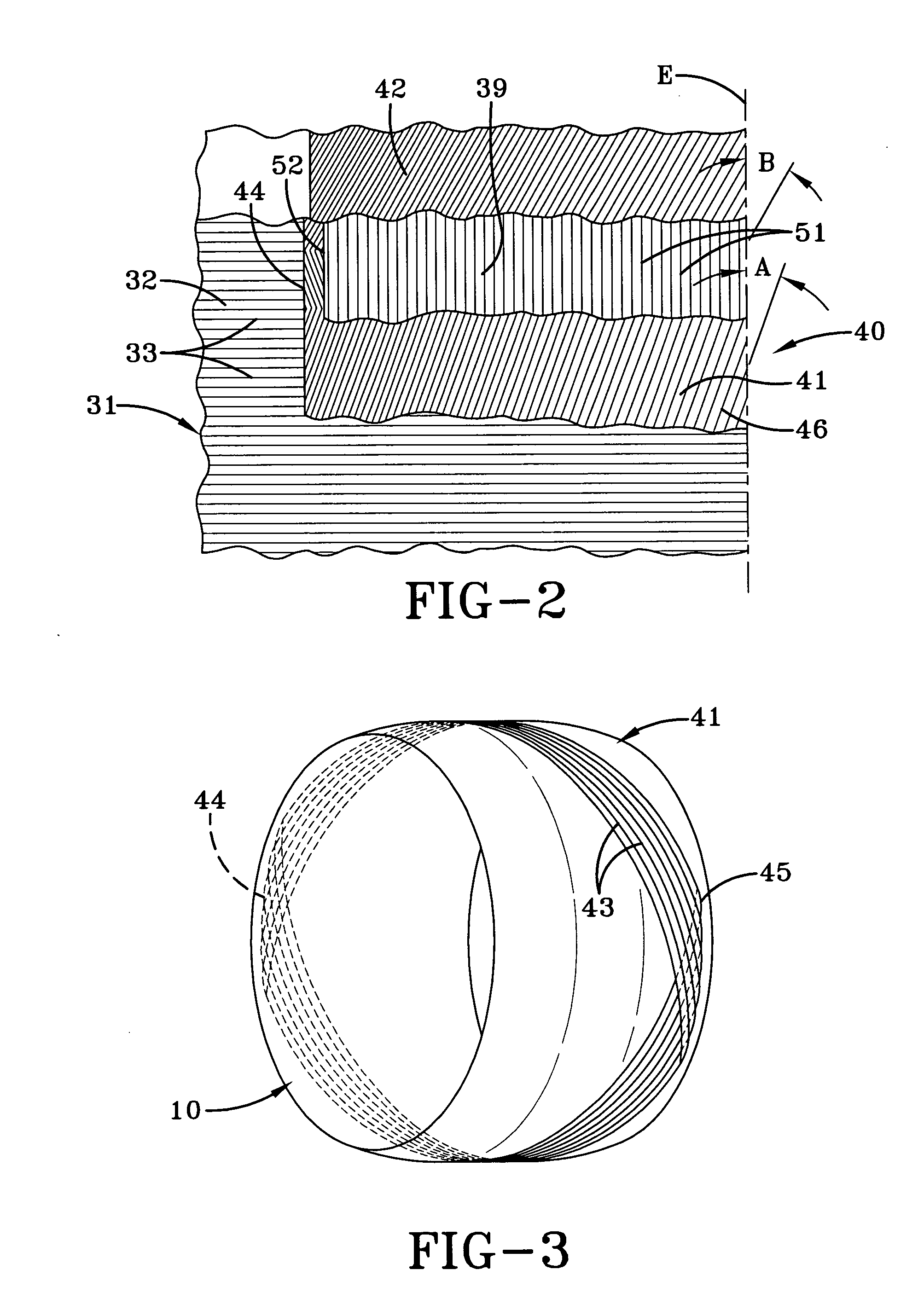

The method of forming a composite belt structure 40 for a tire 21 is disclosed. The method discloses the steps of applying a multicord 46 reinforced strip 43 having a strip width SW onto a rotating crowned building drum, the strips 43 being wound in a zigzag configuration to form at least two zigzag layers 41 wherein the crowned drum has non-overlapping portions of the strips 43 placed in a central portion and extending in alternation to a pair of shoulder portions having portions of the strips 43 overlapping, the central portion having a maximum diameter Do and the shoulder portions have a minimum diameter Di, the adjacent strips 43 being placed apart from 0 to 2 mm in the central portion and the strips 43 are increasingly overlapping in each shoulder portion as the strips 43 extend from the central portion toward lateral ends of the belt structure 40 to form belt layers 39, 40. 42 of a composite belt structure 40 having the cords per inch in the shoulder portion as measured axially inwardly from the axially inner edge of the strip adjacent the lateral ends of the narrowest radially outer belt layer 42 radially inwardly greater than the cords per inch in the central portion as measured centered on the centerplane of the belt structure. The resultant method produces a pneumatic tire 21 having a carcass 31 and a belt reinforcing structure 40, the belt reinforcing structure 40 having a composite belt structure of cord reinforced layers 39,40,41 including at least two radially outer zigzag belt layers 42.

Owner:THE GOODYEAR TIRE & RUBBER CO

Cable for tire cord reinforcement

The present invention relates to a cable for tire cord reinforcement. A composite cable is disclosed suitable for use as a reinforcement in an aircraft tire. The cable is formed of an aramid yarn and a nylon yarn cabled together, wherein the aramid yarn has a linear density in the range of from 220 to 3300 dtex and the nylon yarn has a linear density in the range of from 220 to 2100 dtex.

Owner:THE GOODYEAR TIRE & RUBBER CO

Reduced weight aircraft tire

Owner:THE GOODYEAR TIRE & RUBBER CO

Radial tire for aircraft

InactiveCN101678717ACircumferential rigidity is smallIncreased durabilityPneumatic tyre reinforcementsAircraft tyresFiberForeign matter

This invention provides a radial tire for aircraft comprising a belt composed of a plurality of belt layers, wherein a total strength of the belt T belt ¢N! in a circumferential direction over its full width satisfies T belt / WD 1.510 6 in which D ¢m! is an outer diameter of the tire and W ¢m! is a width of the tire, the belt is composed of at least two belt layers each containing organic fiber cords with an elongation in an extension direction under a load of 3.2 cN / dtex of 2.2-9.3%, a protection belt layer having a circumferential stiffness lower than that of the belt is disposed at an outside of the belt in a radial direction, a ratio of the circumferential stiffness of the protection belt layer to the circumferential stiffness of the belt is less than 0.5, and the protection belt layeris composed of organic fiber cords having a tensile strength at break of not less than 6.3 cN / dtex and a heat shrinkage factor of 0.5-5.0%, whereby a durability of a tread portion can be improved without damaging an excellent durability against foreign matters.

Owner:BRIDGESTONE CORP

Axle end equipment for a vehicle, in particular an aircraft

Owner:SAGEM DEFENSE SECURITE SA

System and method to assess and report the health of landing gear related components

ActiveUS8712634B2Registering/indicating working of vehiclesDigital data processing detailsReliability engineeringMonitoring data

Owner:THE BOEING CO

Aircraft tire having an improved bead

InactiveUS20030150540A1Improve compactnessLow costWithout separate inflatable insertsPneumatic tyre reinforcementsAirplaneElastic modulus

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Radial tire for aircraft with specified merged cords

A pneumatic tire for use on aircraft has a tread, a crown reinforcement, and a radial carcass reinforcement having at least one axially inner ply of textile cords wound around a pair of bead cores, at least one axially inner ply being wound around the bead core in each bead from inside to the outside forming outside turn-ups and at least one axially outer ply of textile cords extending from bead to bead along the turn-ups of the at least one axially inner ply. The at least one axially inner ply or at least one axially outer ply has merged cords having a percent elongation at break of 12% to less than 20% and a break strength greater than 1050 N with a linear density of greater than 9,000 dtex. Merged cord reinforcement is preferably used in the ply layers or strips of the crown reinforcement as well.

Owner:THE GOODYEAR TIRE & RUBBER CO

System and method to assess and report a health of a tire

ActiveUS8599044B2Registering/indicating working of vehiclesOptical signallingState of healthComputer science

Owner:THE BOEING CO

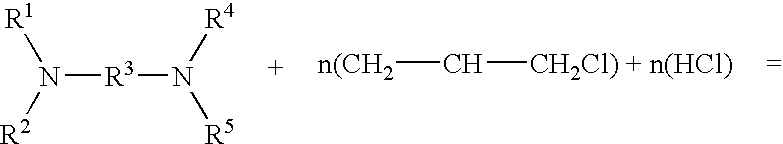

Preparation of nanocomposite of elastomer and exfoliated clay platelets, rubber compositions comprised of said nanocomposite and articles of manufacture, including tires

InactiveUS7342065B2Improve reinforcement efficiencyRolling resistance optimizationAircraft tyresElastomerEmulsion

This invention relates to preparation of nanocomposites comprised of elastomer and a dispersion of an at least partially exfoliated water swellable clay and to rubber compositions containing such nanocomposite and articles of manufacture which contain at least one component thereof. The nanocomposite is prepared by addition of a water suspension of water swellable clay particles to an anionic aqueous emulsion of elastomer particles to form a mixture to which an amine having at least two amine centers is added to intercalate and at least partially exfoliate the water swelled clay particles by an ion exchange within the galleries of the multilayered clay with cation exchangeable ion(s) and to aid in coagulating the elastomer and resultant clay particles to form said nanocomposite.

Owner:THE GOODYEAR TIRE & RUBBER CO

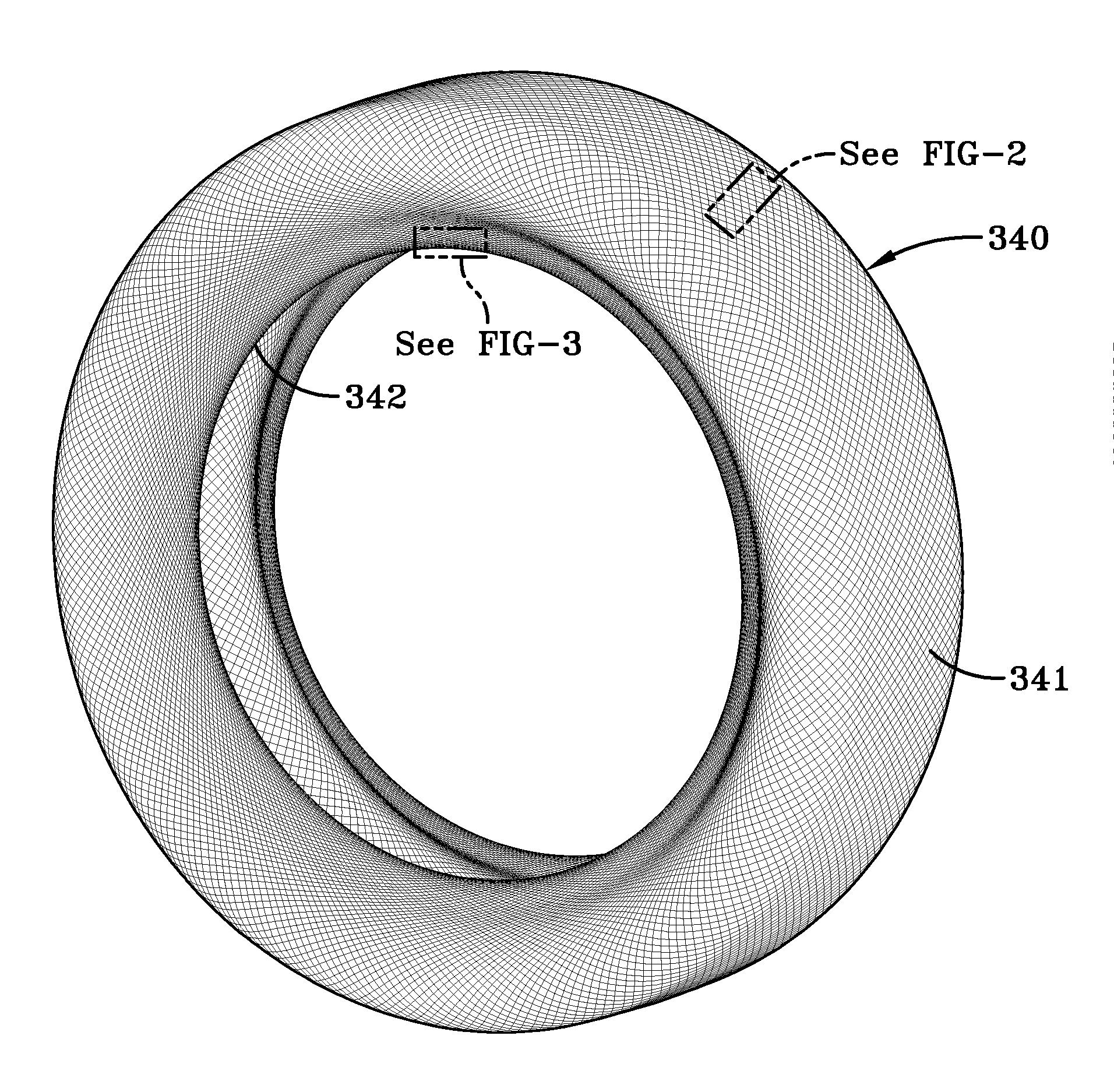

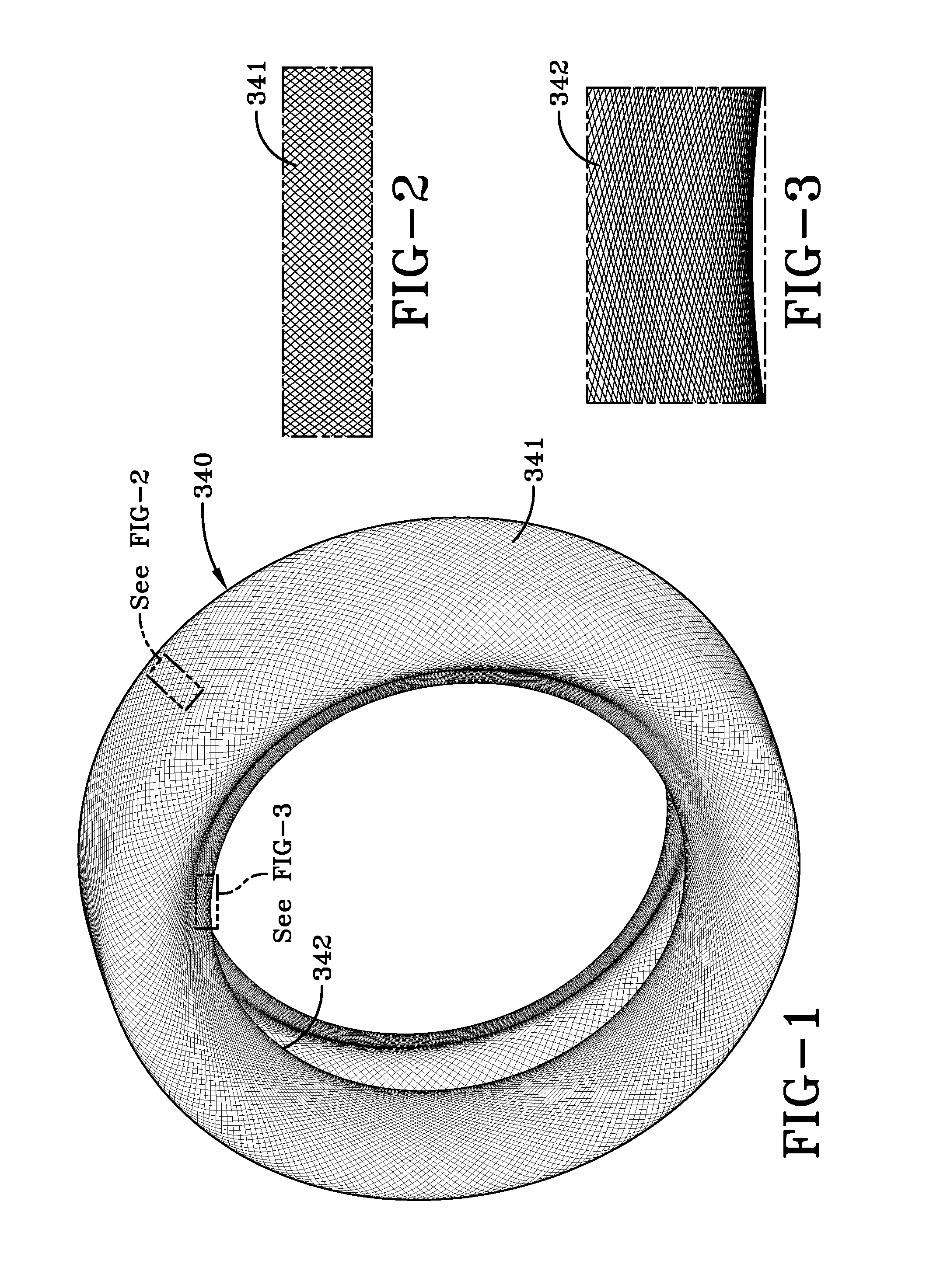

Aircraft tire and method of manufacture

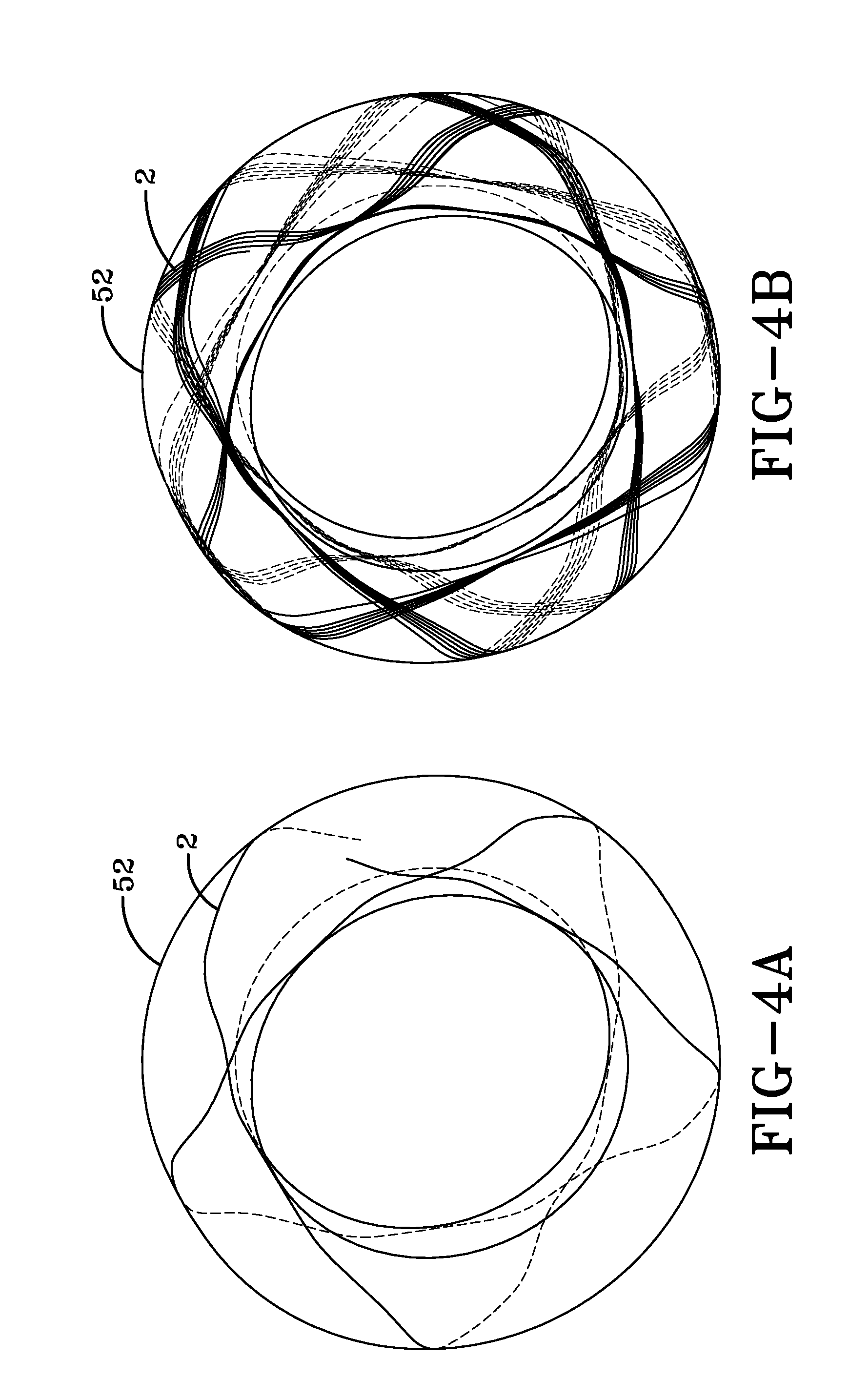

A pneumatic tire comprising a belt structure and a torus shaped carcass having a first inner radius and an outer radius, wherein the carcass is comprised of three or more layers of ply, wherein each layer of ply is formed from a rubberized strip of one or more cords, the strips being wound in an geodesic pattern having the cord extend across the carcass from a first shoulder to a second shoulder in a path that has at least one point tangent to the first inner radius located in the bead area of the tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

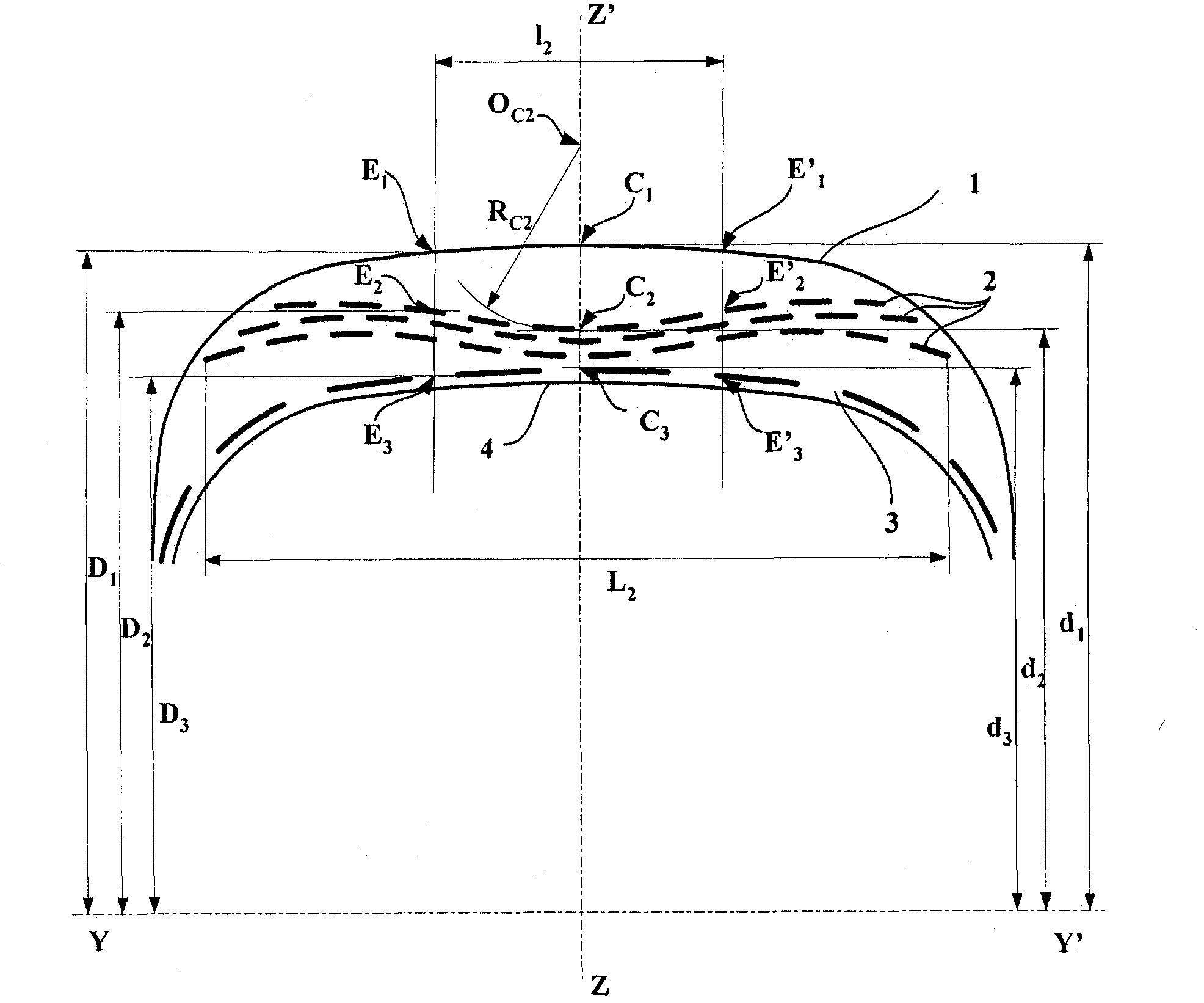

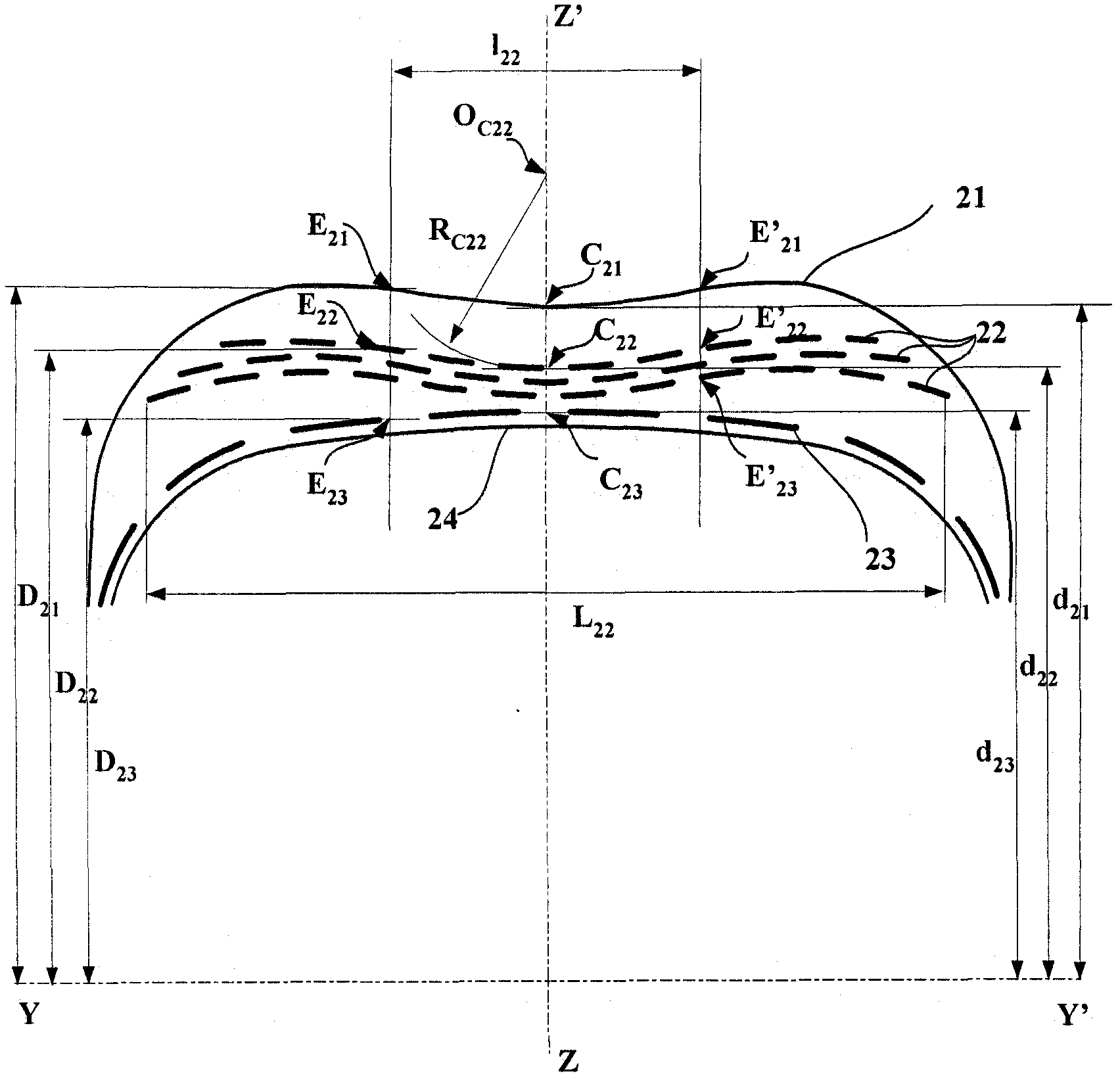

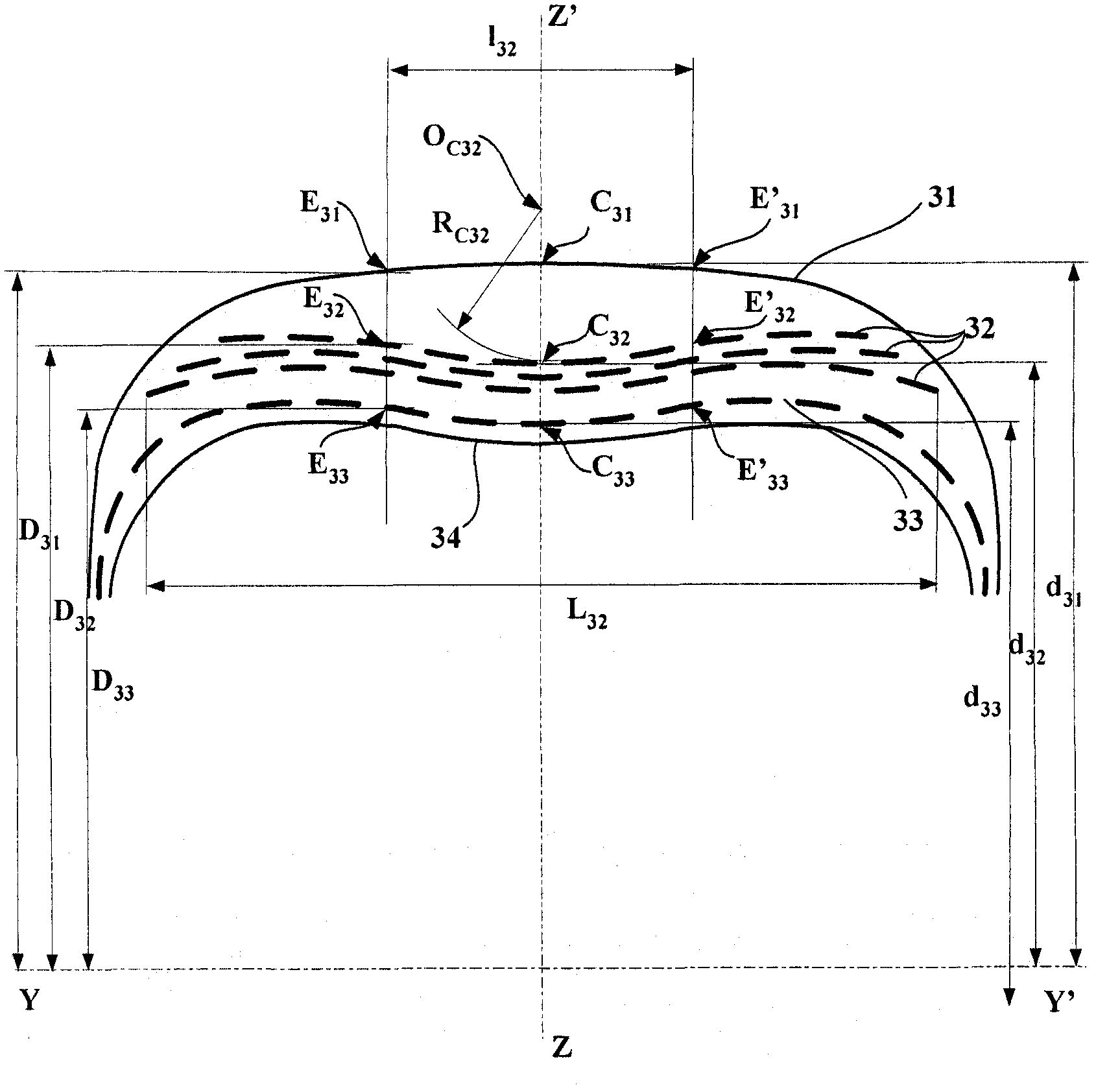

Pneumatic radial tire for airplanes

InactiveUS20070137748A1Uneven resistanceIncreased durabilityPneumatic tyre reinforcementsTyre tread bands/patternsJet aeroplaneInternal pressure

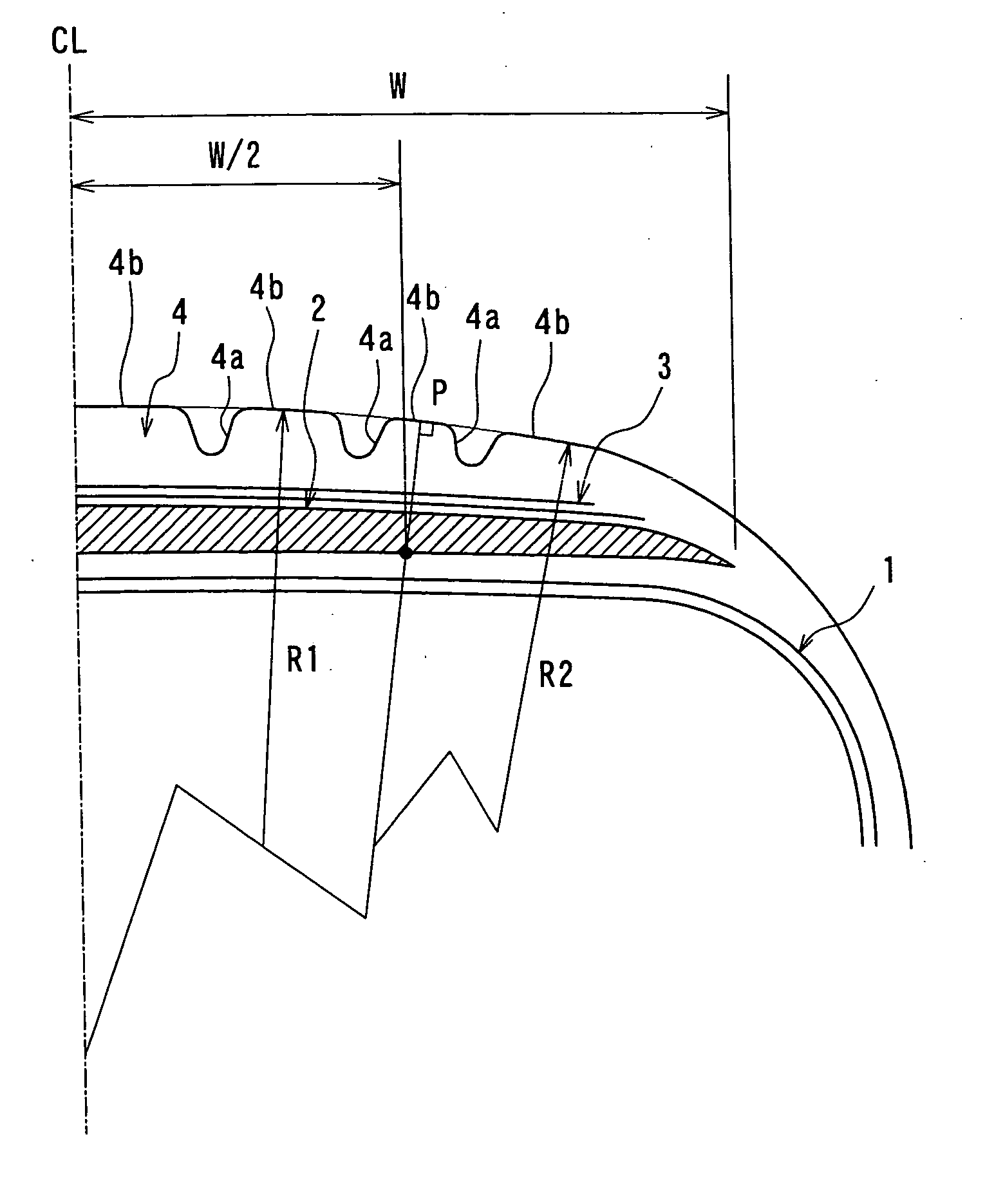

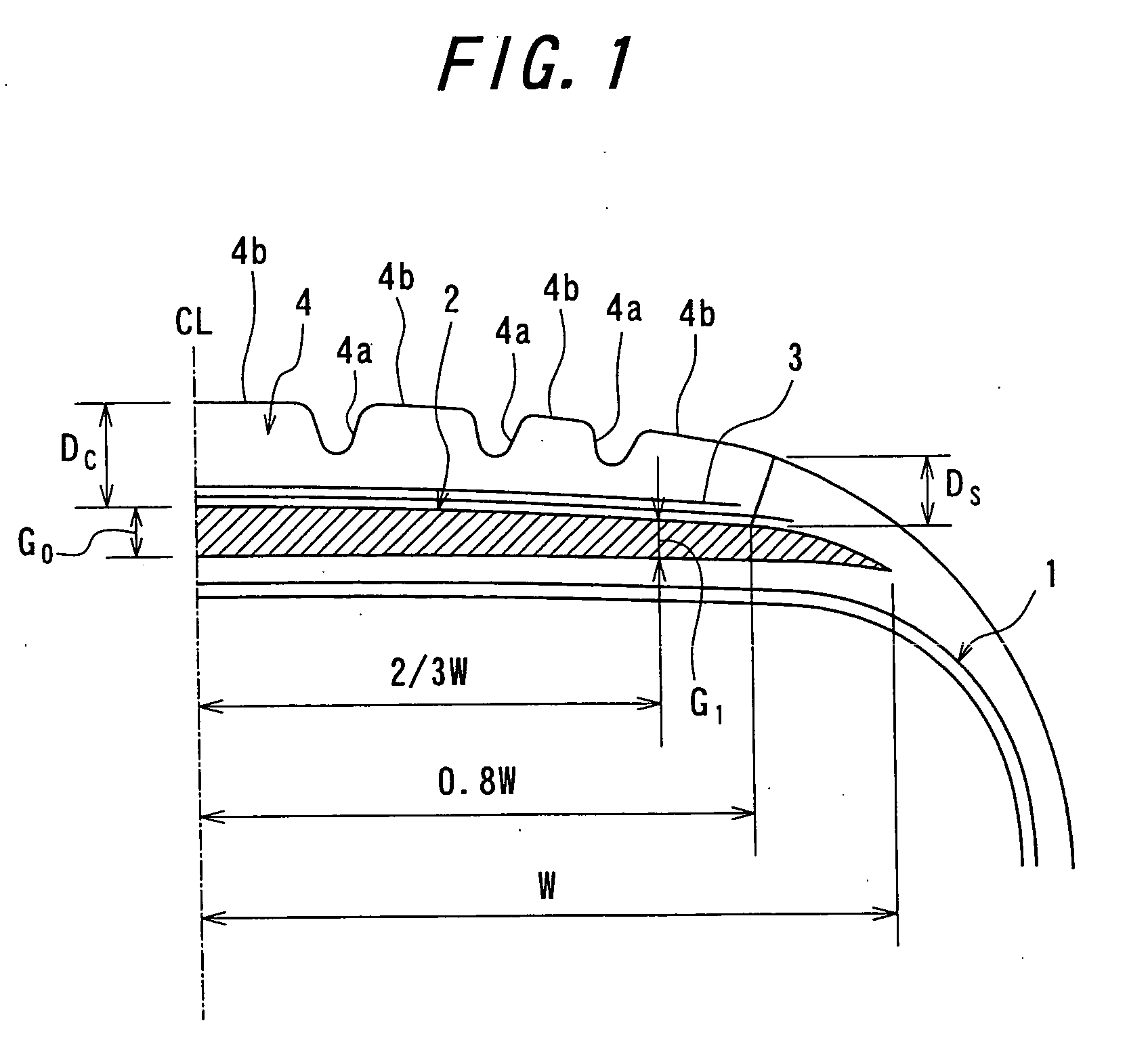

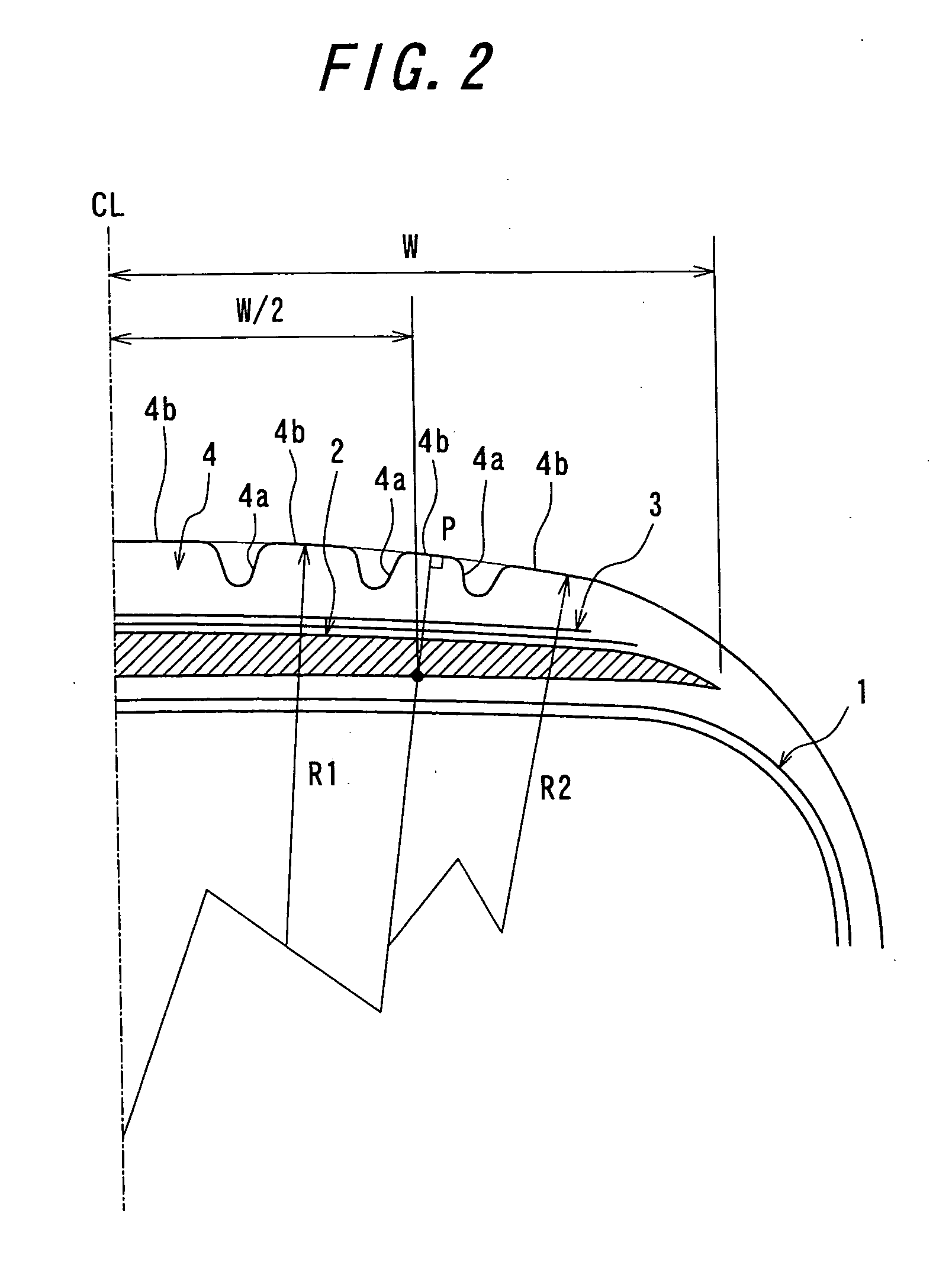

A pneumatic radial tire for an airplane comprises a pair of bead cores, a carcass comprised of at least one carcass ply, a main belt comprised of at least two belt layers, an auxiliary belt comprised of plural layers, and a tread, wherein the main belt has a lamination thickness satisfying 0.2≦G1 / G0≦0.8 as a relation between a lamination thickness at the widthwise center of the tire (G0) and a lamination thickness at a position corresponding to ⅔ of a maximum width (G1), and the tread satisfies 0.85≦DS / DC≦1.1 as a relation between a tread thickness at a widthwise center position of the tire (DC) and a tread thickness at a position of a width corresponding to 80% of a maximum width of the main belt (DS), and has a radius of curvature on an outer surface of the tread formed by filling a normal internal pressure satisfying 0.4≦R2 / R1≦3.0 as a relation between a radius of curvature in a central region including the widthwise center of the tire (R1) and a radius of curvature forming a widthwise side region outward from the central region (R2) being connected to each other at a position corresponding to 40-60% of the maximum width of the main belt.

Owner:BRIDGESTONE CORP

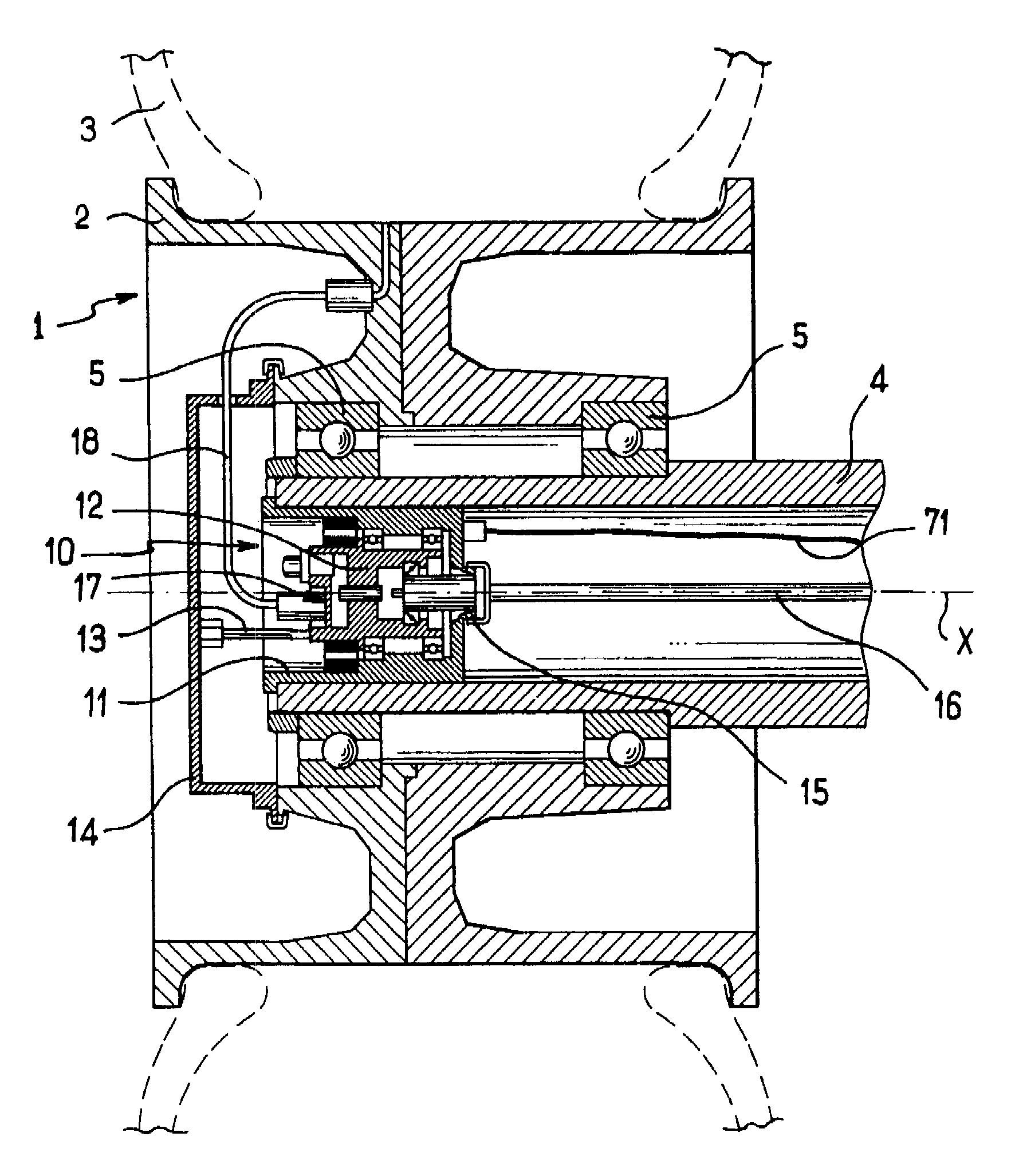

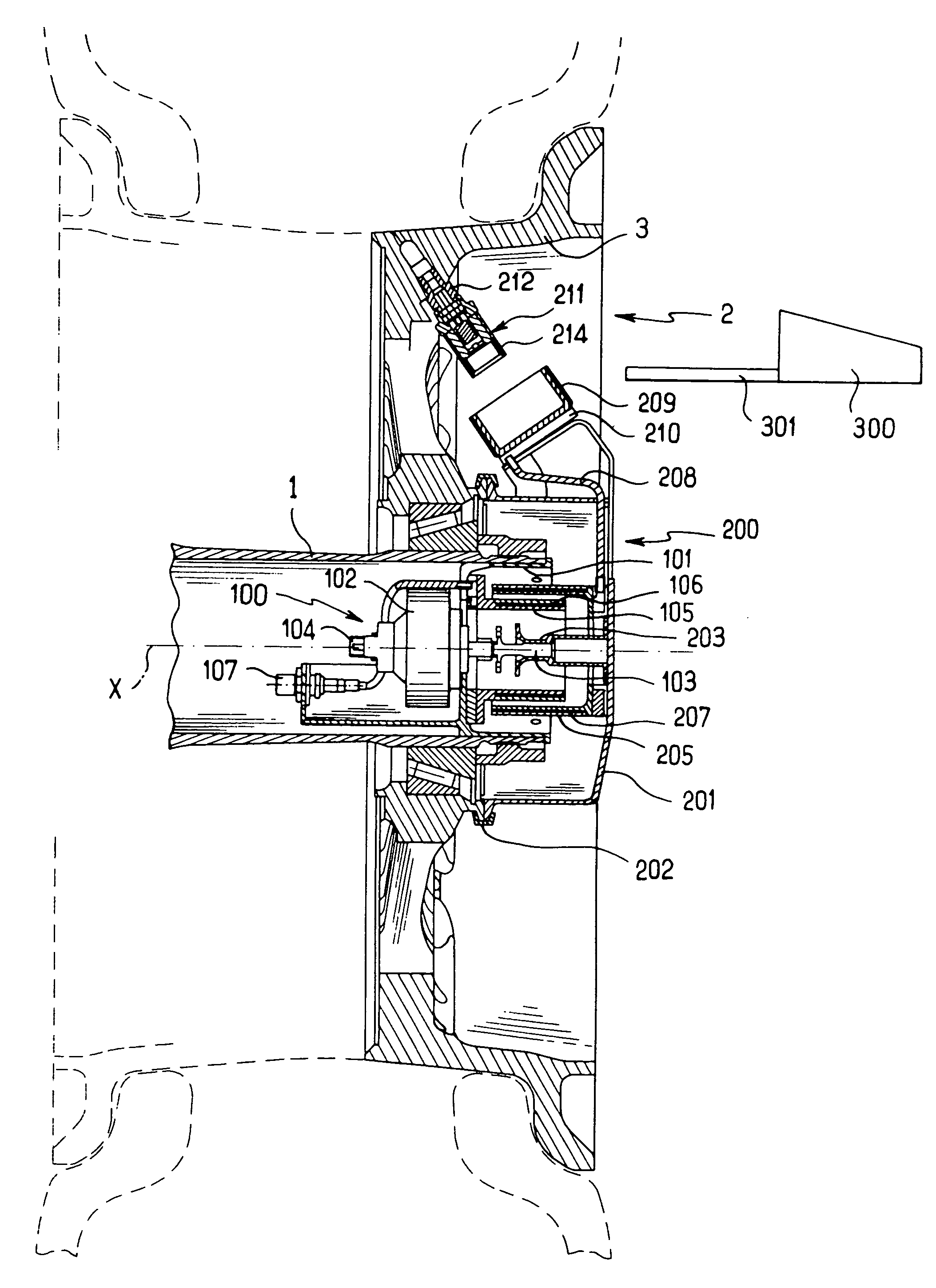

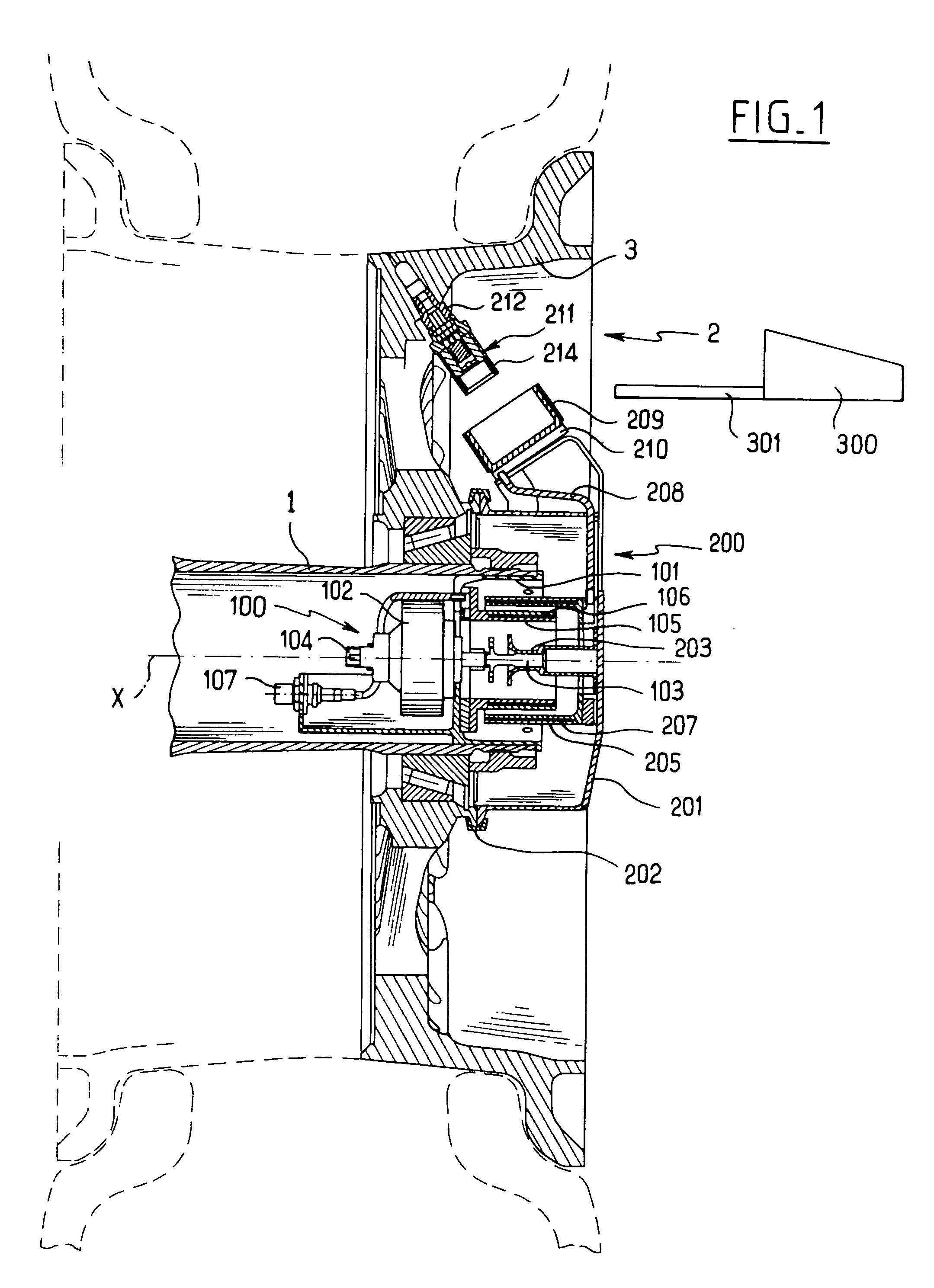

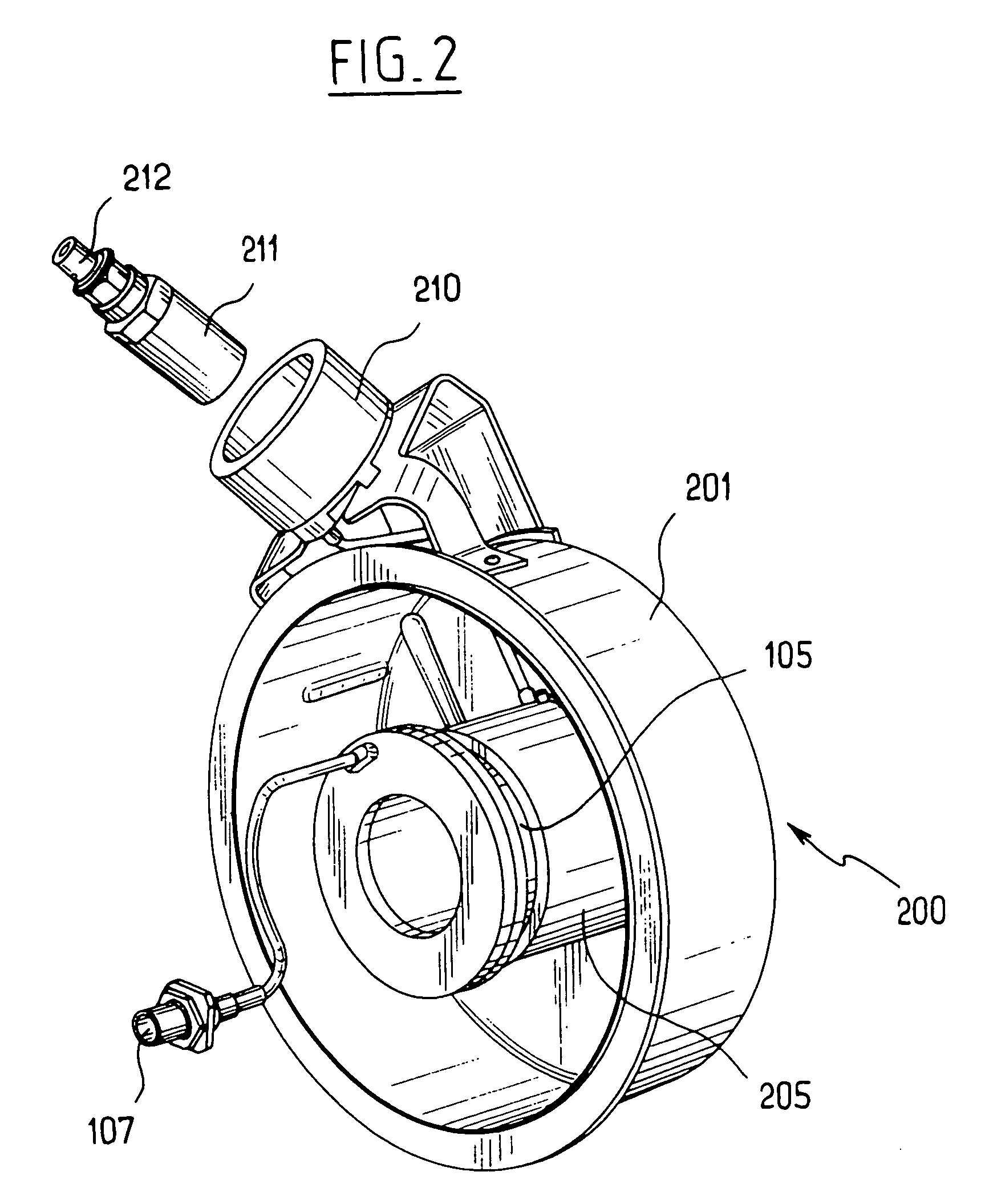

Device for connecting a tire of an aircraft wheel to a pneumatic unit of the aircraft

InactiveUS20090101261A1Firmly connectedAvoid shockCheck valvesEqualizing valvesEngineeringMechanical engineering

The invention relates to a device for selectively connecting a tire to a pneumatic unit of an aircraft, the tire forming part of a wheel mounted to rotate on a hollow axle of the aircraft, the device comprising a stator and a rotor that is mounted to rotate relative to the stator and that includes means enabling it to be rotated by the wheel. According to the invention, the stator is bell-shaped and is designed to be received as a push-fit in the axle, and includes an end wall carrying a first pneumatic port for connection to the pneumatic unit via a tube running along the inside of the axle, the rotor extending substantially inside the stator.

Owner:SAFRAN LANDING SYSTEMS

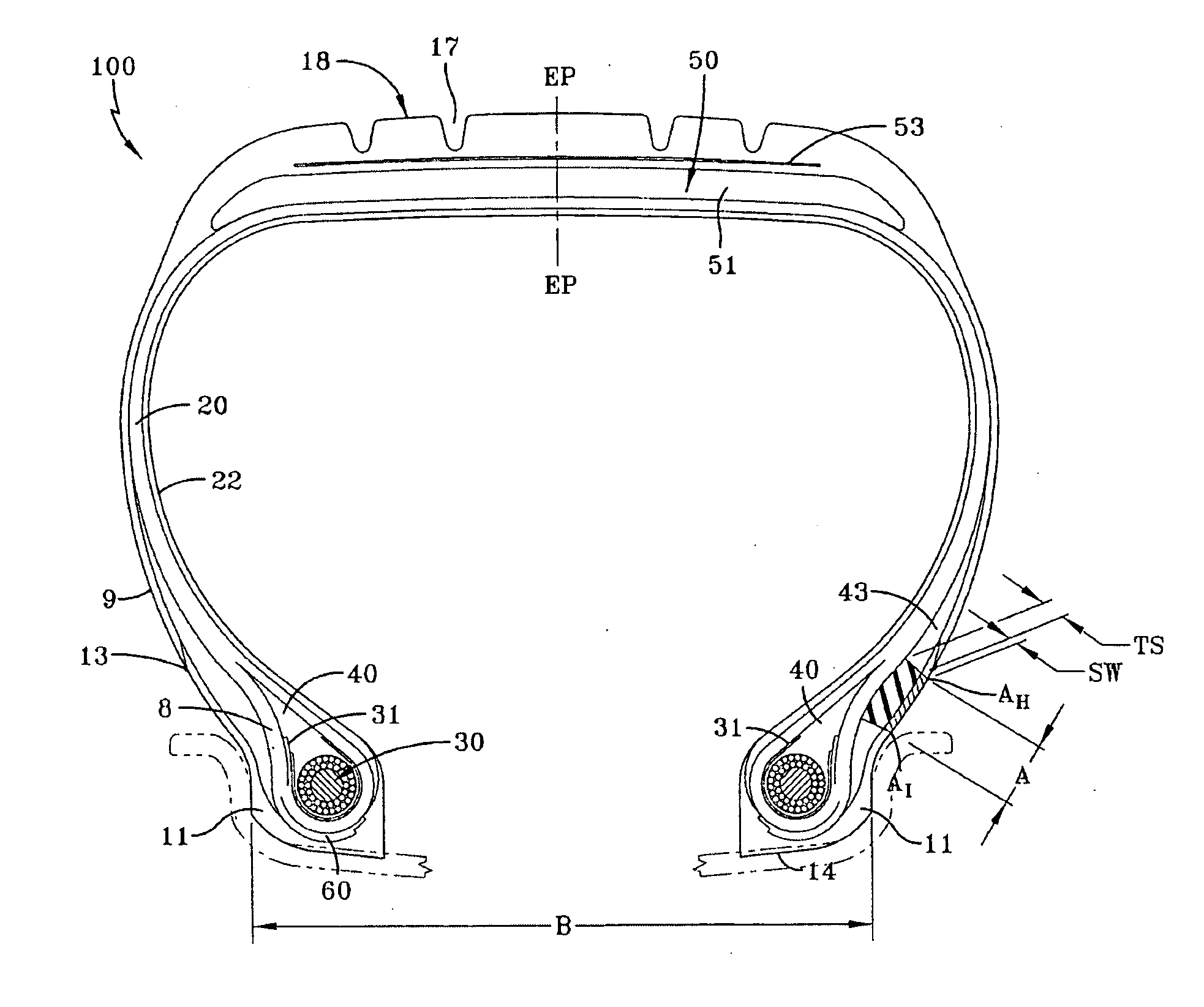

Aircraft radial tire

ActiveUS20100147434A1Tire is sealedWithout separate inflatable insertsPneumatic tyre reinforcementsTire beadMechanical engineering

A pneumatic radial aircraft tire is described having a B / A ranging between 60-70%, wherein B is the width of the tire between the wheel flange, and A is the inflated tire width under rated pressure. The tire may further optionally include a tire bead portion having a Ra / Fr1 relationship which ranges from about 1 to about 2.1, wherein: Ra is the tire heel radius at uninflated and in an new and unused condition, and Fr1 is the wheel flange elliptical radius at the heel section of the tire. The tire may further optionally include a SW / TS ratio which ranges from about 0.1 to about 0.5, wherein SW is the chafer gauge at area A, TS is the total sidewall rubber gauge at area A, wherein A is defined as the region in the sidewall that has a lower radial endpoint defined by the point of contact between the flange and the tire at inflated, unloaded condition, and an upper radial endpoint Ah defined by the tire wheel flange point of contact when the tire is at inflated, and at 100% rated load.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire inflate/deflate indication method and system

Systems and methods for indicating conditions for the appropriate inflation and / or deflation of tires are disclosed. Some systems and methods include measuring a variable affecting the internal gas temperature of a tire, calculating by the processor an estimated internal gas temperature of a tire, and determining whether a tire is appropriate to inflate and / or deflate.

Owner:THE BF GOODRICH CO

Tire crown for an airplane

ActiveCN102076507AExtend your lifeIncrease wear areaPneumatic tyre reinforcementsTyre tread bands/patternsEngineeringTread

The invention relates to an airplane tire, the nominal pressure of which is greater than 9 bars and the sag of which, under a nominal load, is greater than 30%, including a tread having: a rolling surface (41); a crown reinforcement (42), including at least one layer of reinforcing elements; and a carcass reinforcement (43) including at least one layer of reinforcing elements, said rolling surface (41), crown reinforcement (42), and carcass reinforcement (43) being geometrically defined, respectively, by initial meridian profiles. According to the invention, the initial meridian profile of the crown reinforcement (42) is locally concave on a medial portion having an axial width I42 at least equal to 0.25 times the axial width L42 of the crown reinforcement.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com