Radial tire for aircraft

A technology for radial tires and aircraft, applied to aircraft tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve problems such as improving vulcanization pressure or rubber flow, and achieve the effect of improving durability and maintaining durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

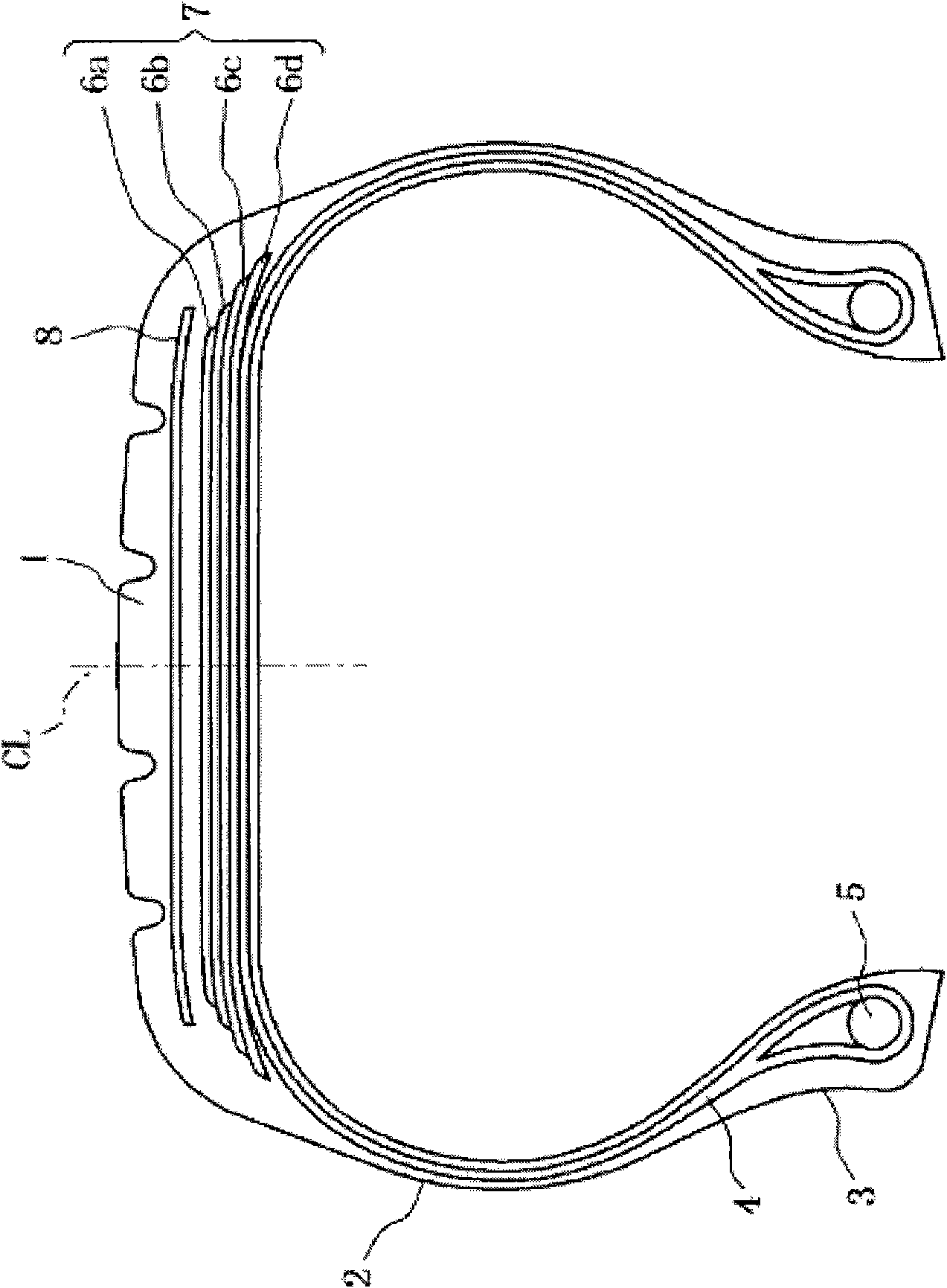

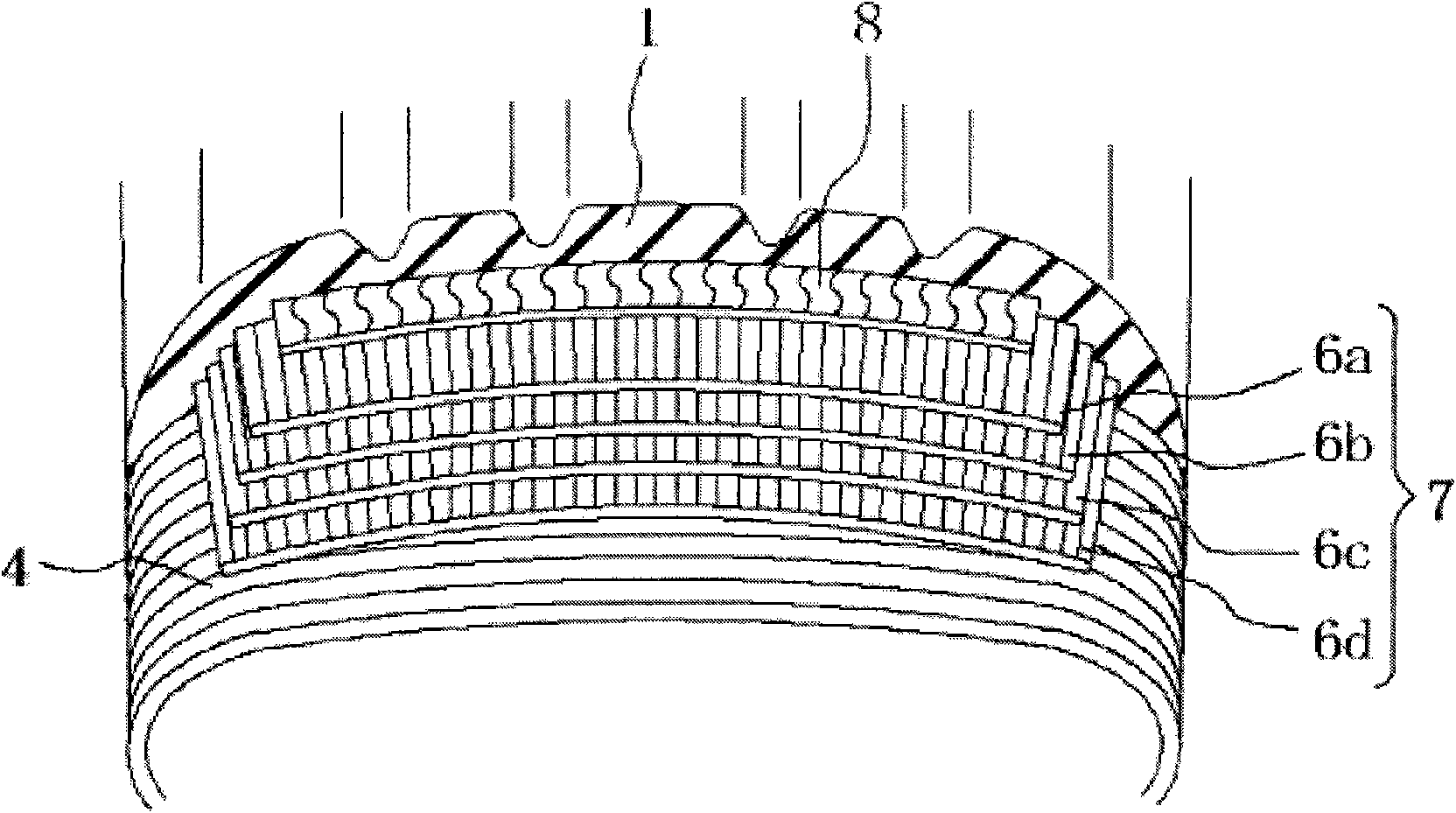

[0017] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. figure 1 is a schematic cross-sectional view of a radial tire for aircraft according to the present invention. exist figure 1 Among them, reference numeral 1 is a tread portion, reference numeral 2 is a pair of sidewall portions each continuously extending radially inward from the side portion of the tread portion 1, and reference numeral 3 is the inner circumference of each sidewall portion 2. Continuously arranged bead portions.

[0018] Further, a radial tire carcass 4 composed of at least one carcass ply extends annularly between two bead portions 3 . The radial tire carcass 4 reinforcing these portions 1 , 2 , 3 is configured by winding each side portion around an annular bead core 5 embedded in each bead portion 3 from the inside to the outside.

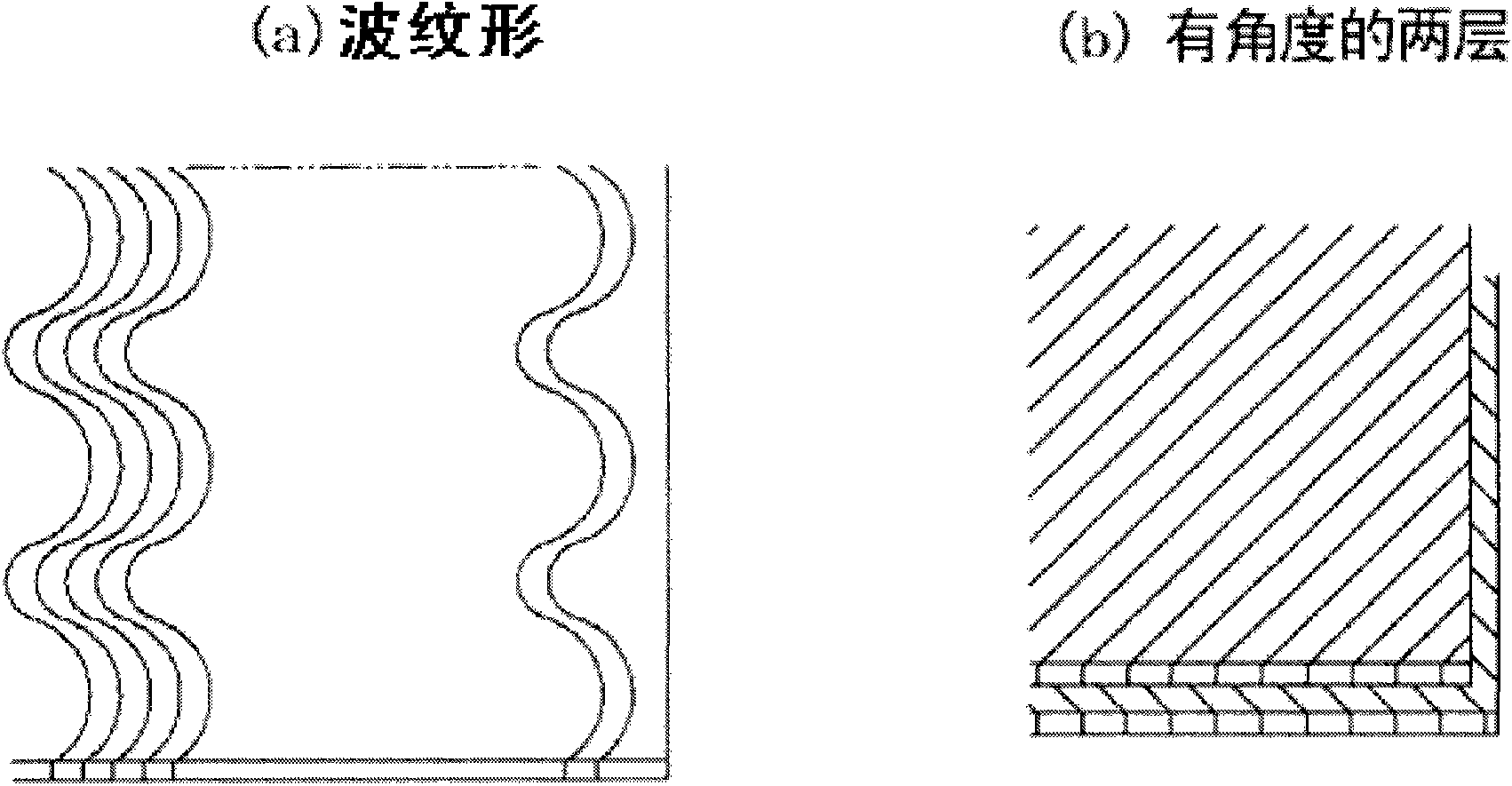

[0019] On the outer periphery of the crown region of this radial tire carcass 4, a belt portion 7 composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com