Patents

Literature

43 results about "Total strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

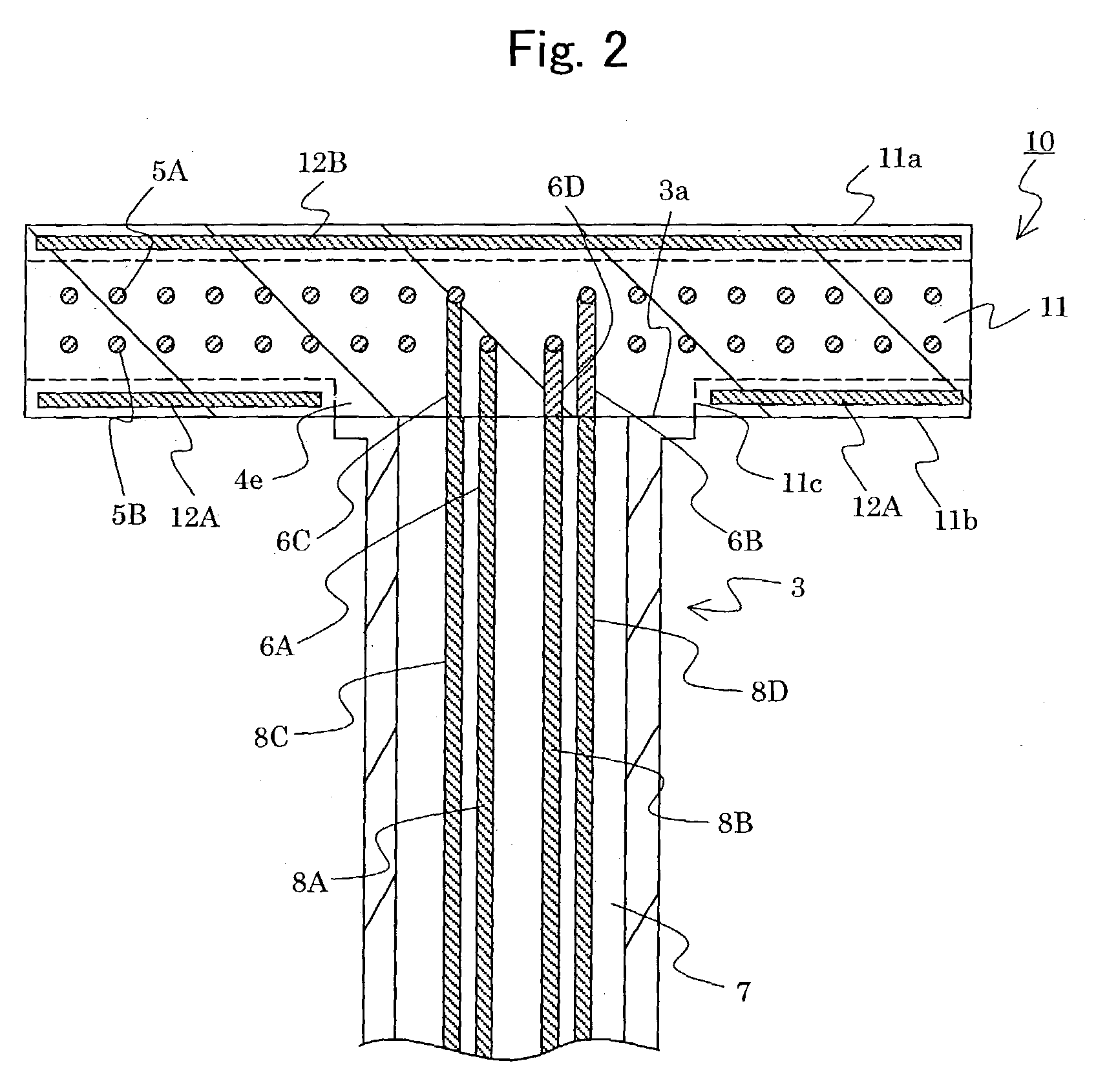

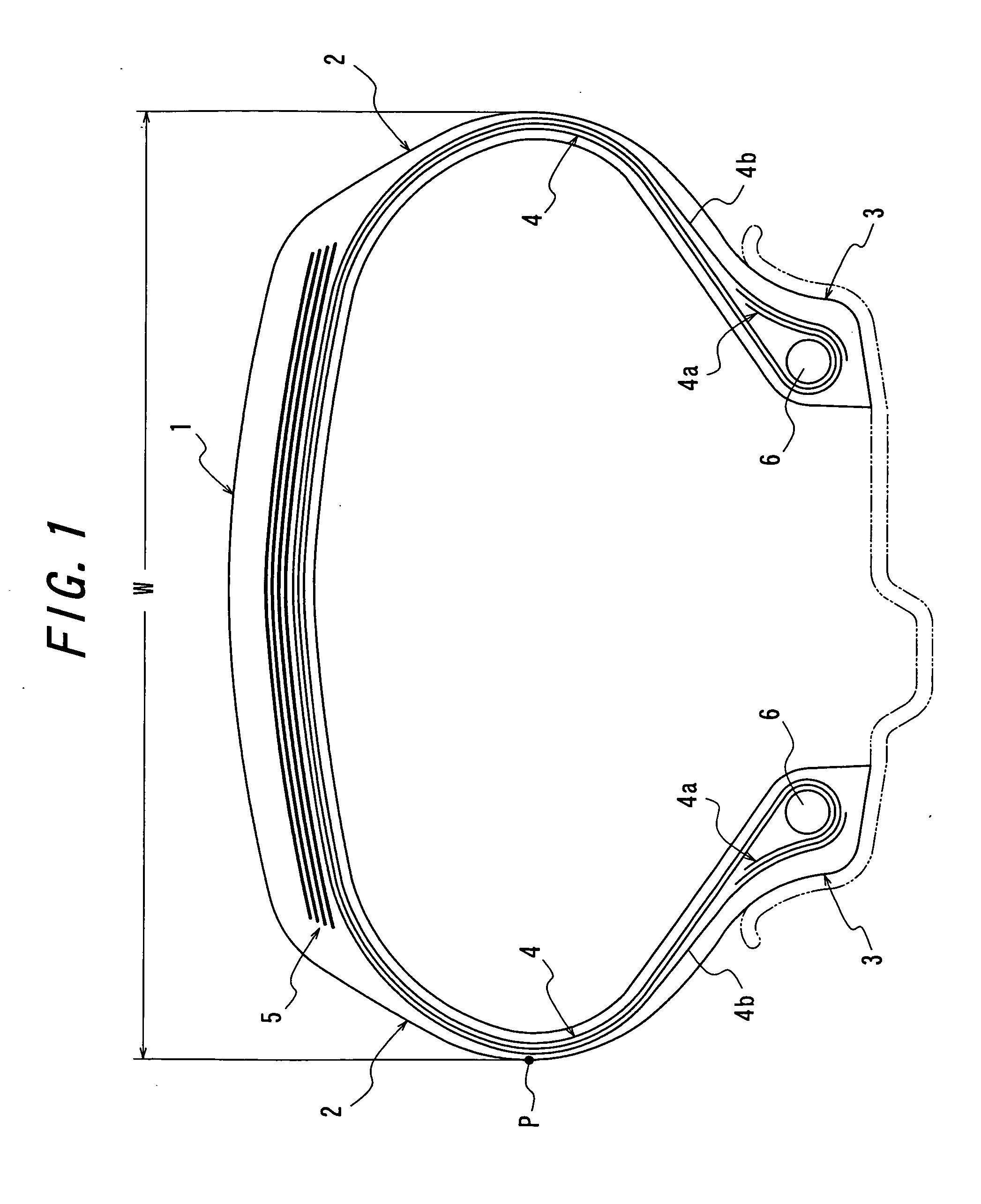

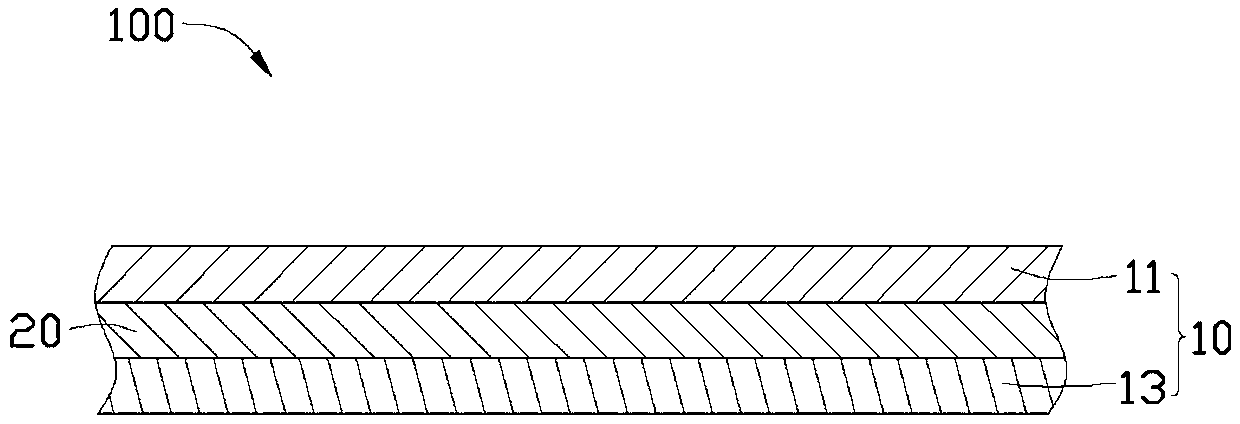

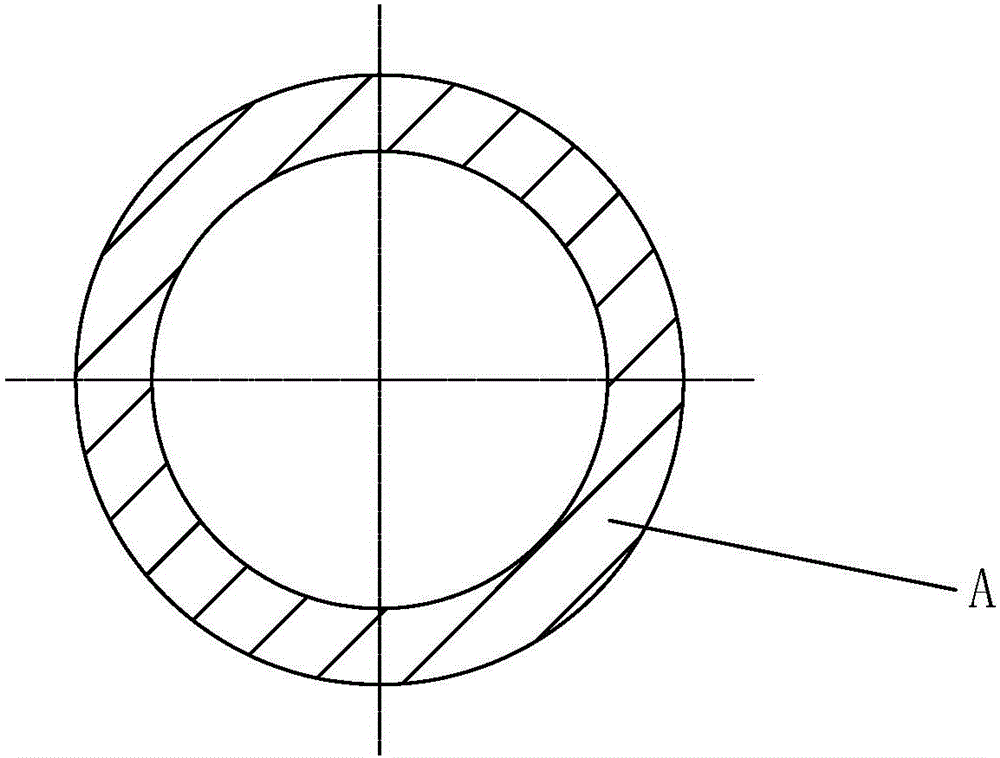

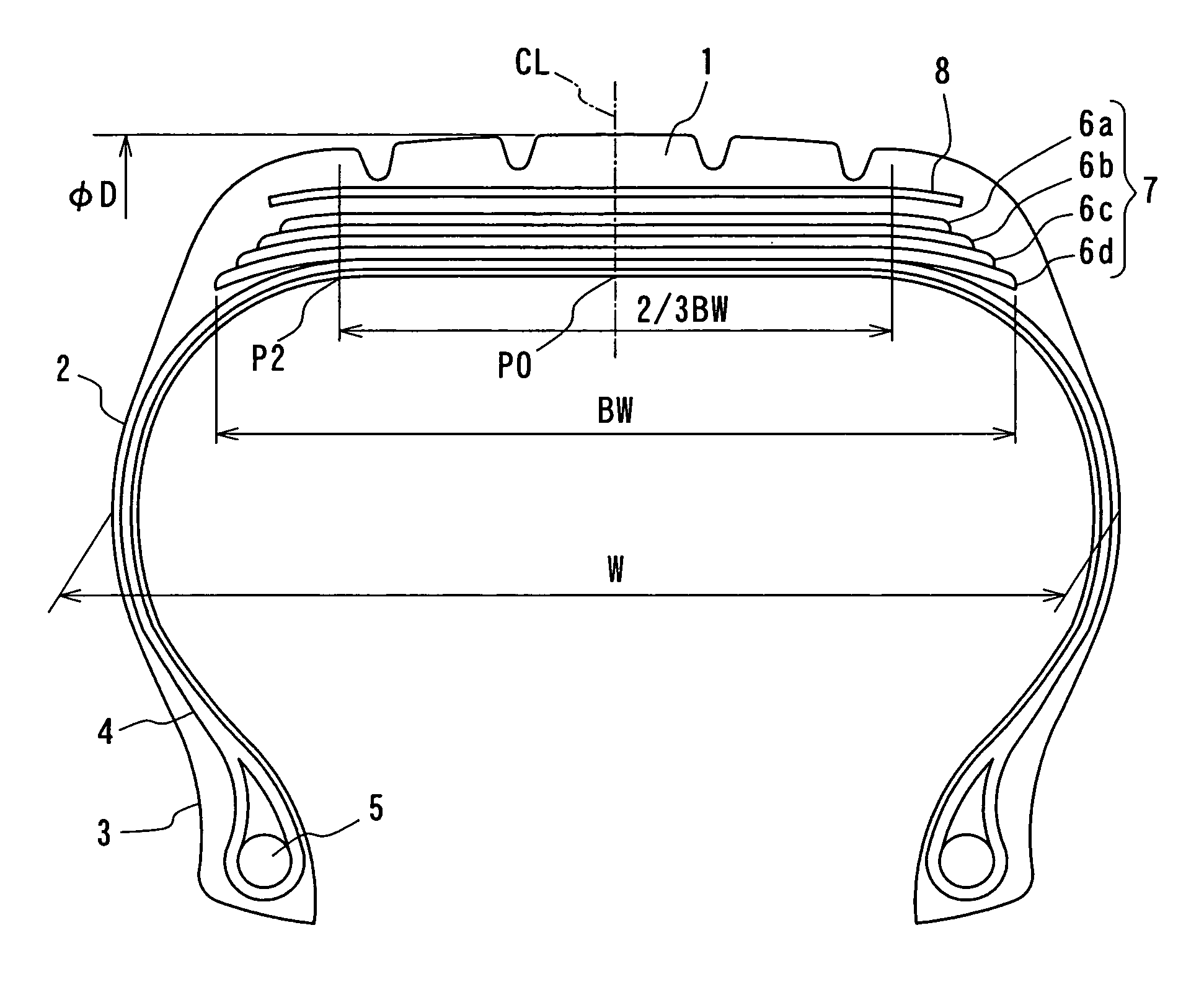

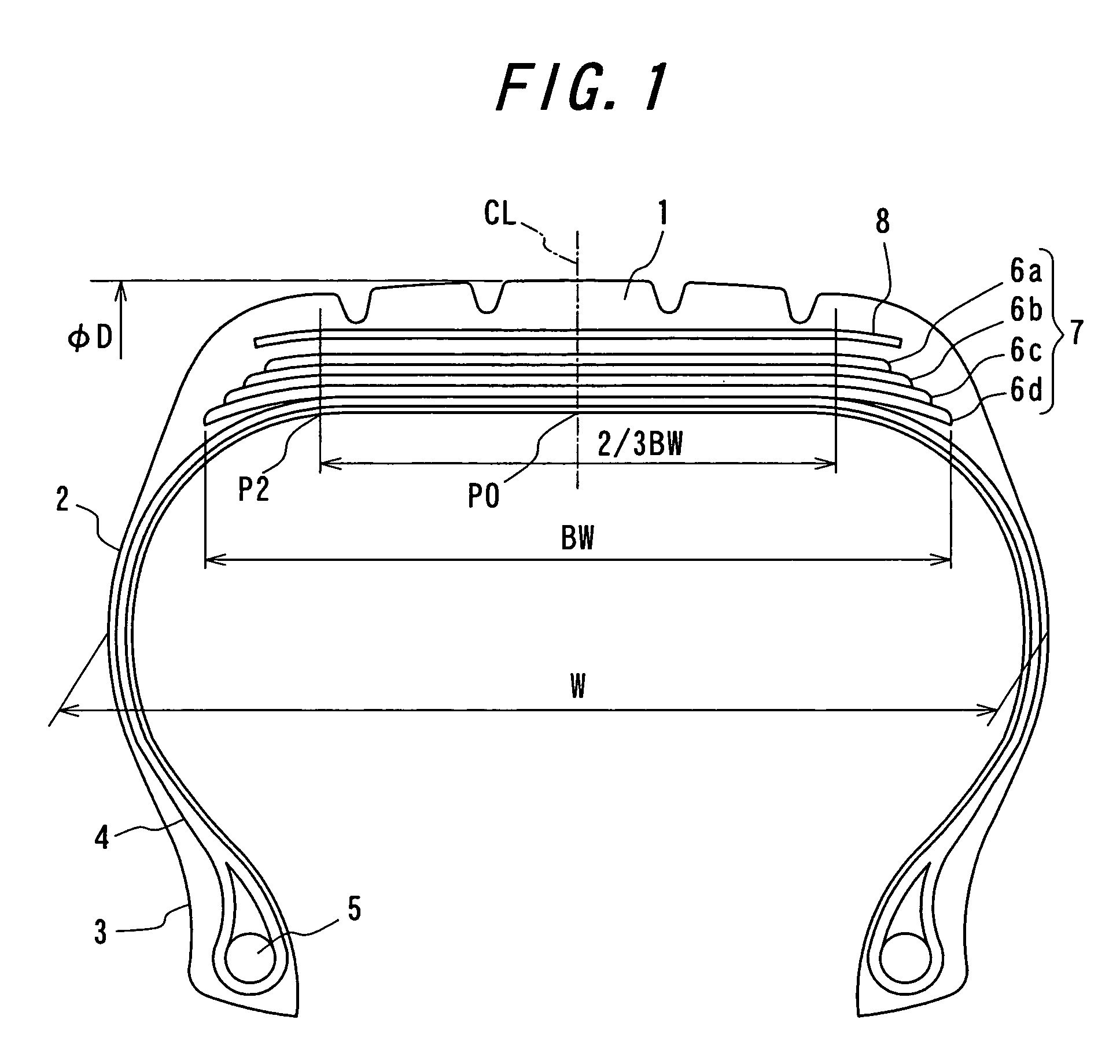

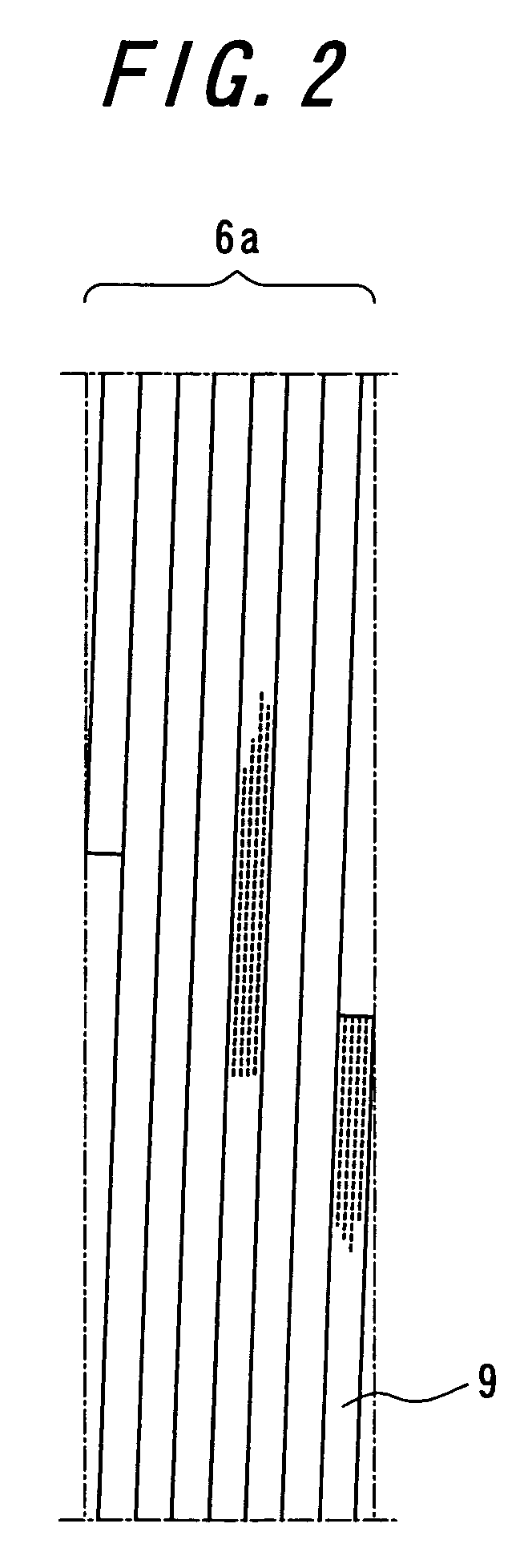

Pneumatic radial tire, and method of producing the same

ActiveUS20050194081A1Weight is lighterLower average tensionTyresPneumatic tyre reinforcementsForeign matterInternal pressure

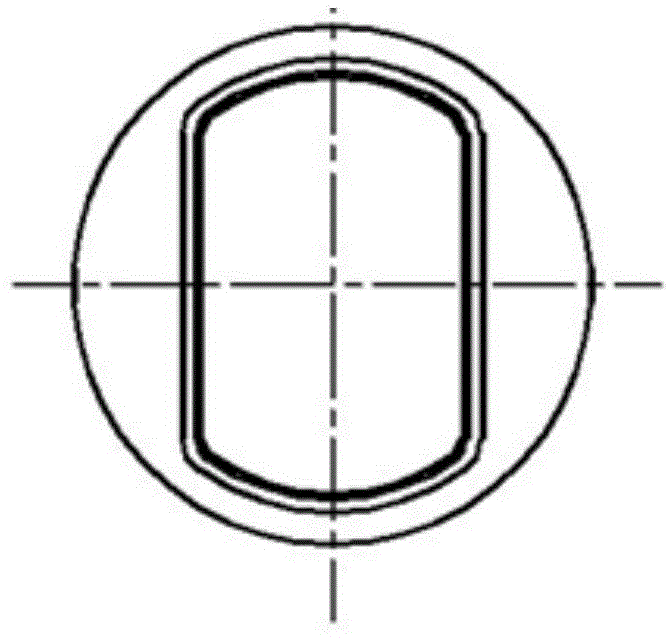

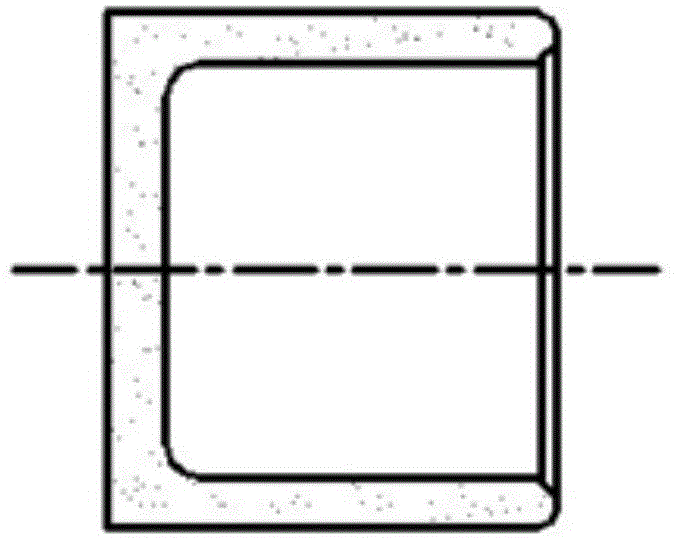

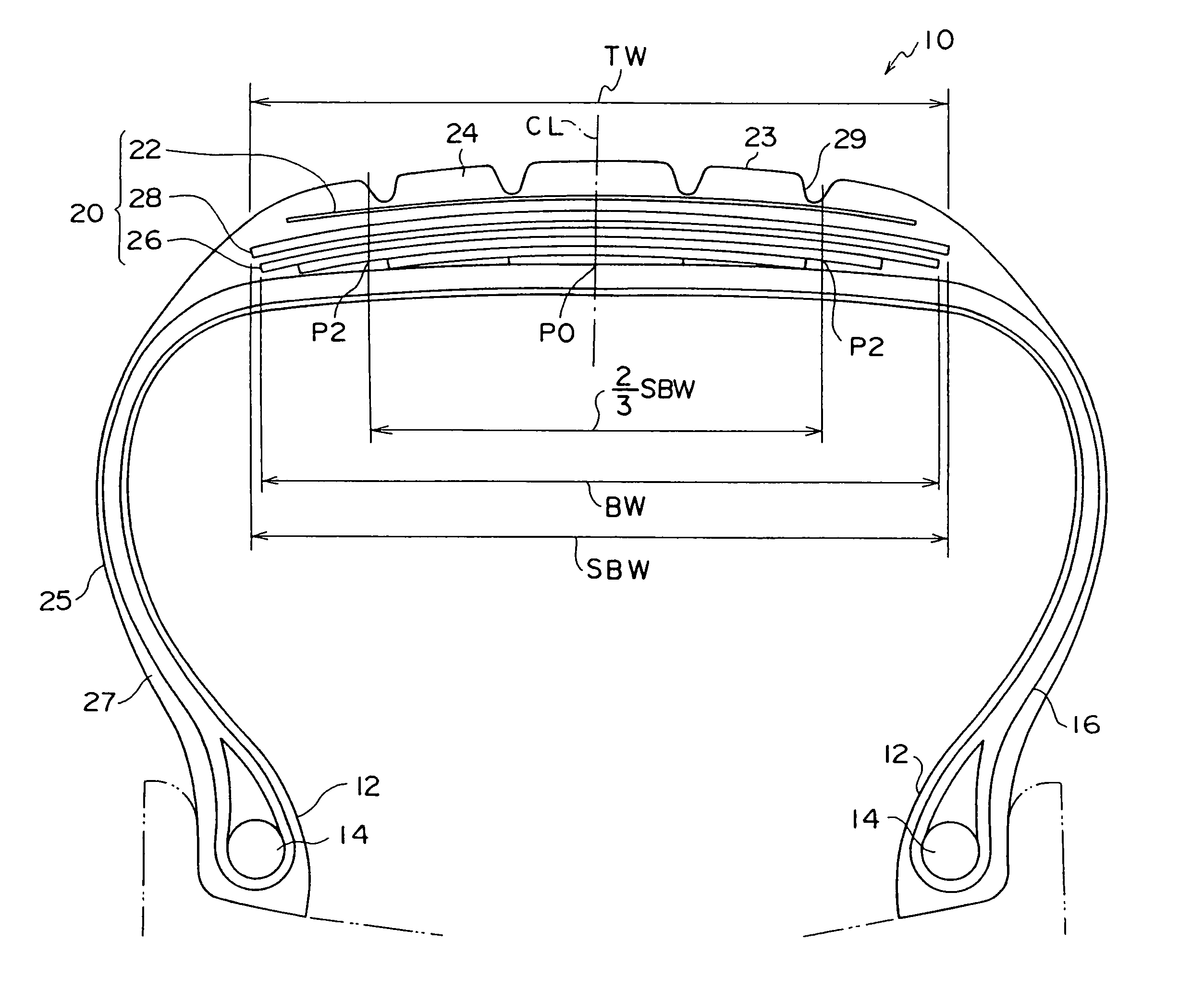

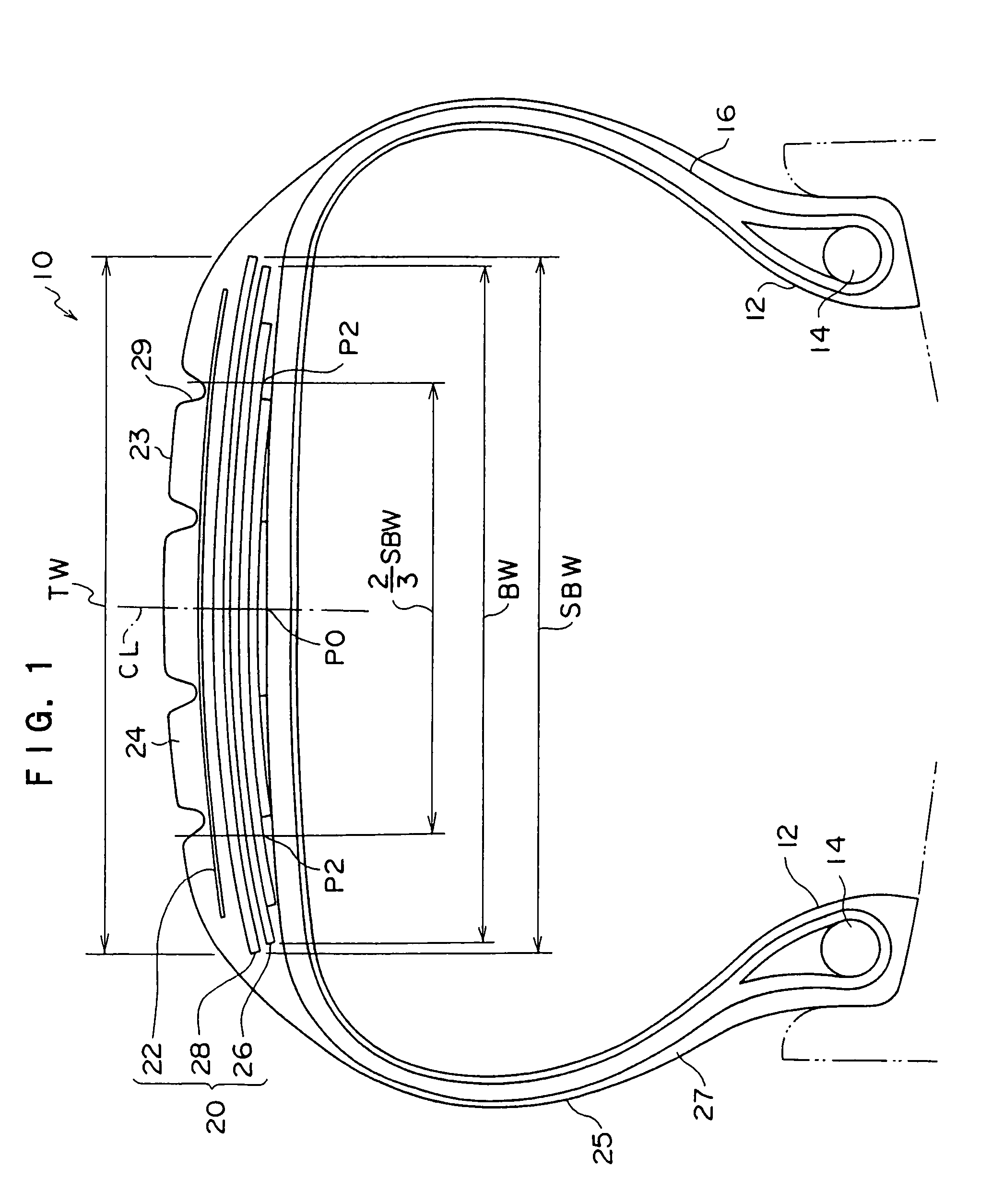

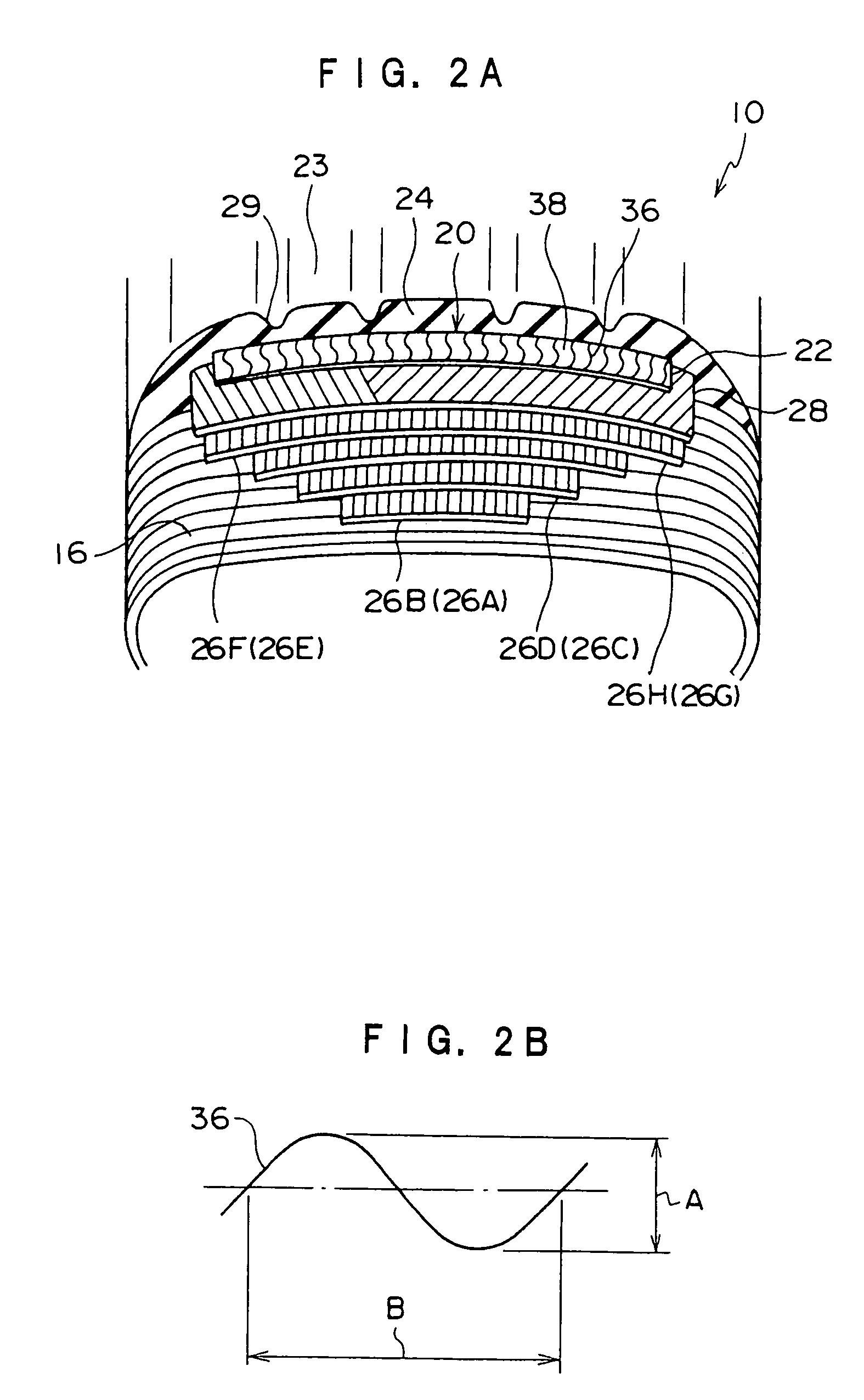

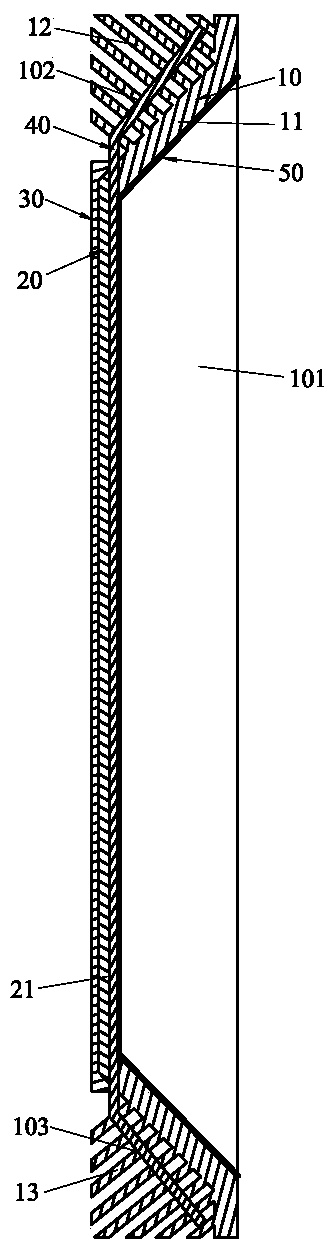

In the pneumatic radial tire of the present invention, a total strength K0 of a belt layer 20 in a circumferential direction of the tire per unit of width at a tire equator surface position P0 is set greater than a total strength of the belt layer 20 in the circumferential direction of the tire per unit of width at a width position P2 corresponding to ⅔ of a maximum width of the belt layer having the tire equator surface CL as a center. In this way, it is possible to suppress the quantity consume of material in the belt layer 20, and to suppress the amount of expansion of tread rubber in a tread central region in the circumferential direction thereof when a standard internal pressure is charged and when the tire is rotated at high speed, thereby suppressing the growth of tire diameter. Since the expansion amount of the tread rubber in the circumferential direction is suppressed, the tension of the rubber is reduced. Therefore, it is possible to increase the resistance of the tread against the sticking of foreign matter, and even when foreign matter sticks in the tread, it is possible to suppress the growth of the crack.

Owner:BRIDGESTONE CORP

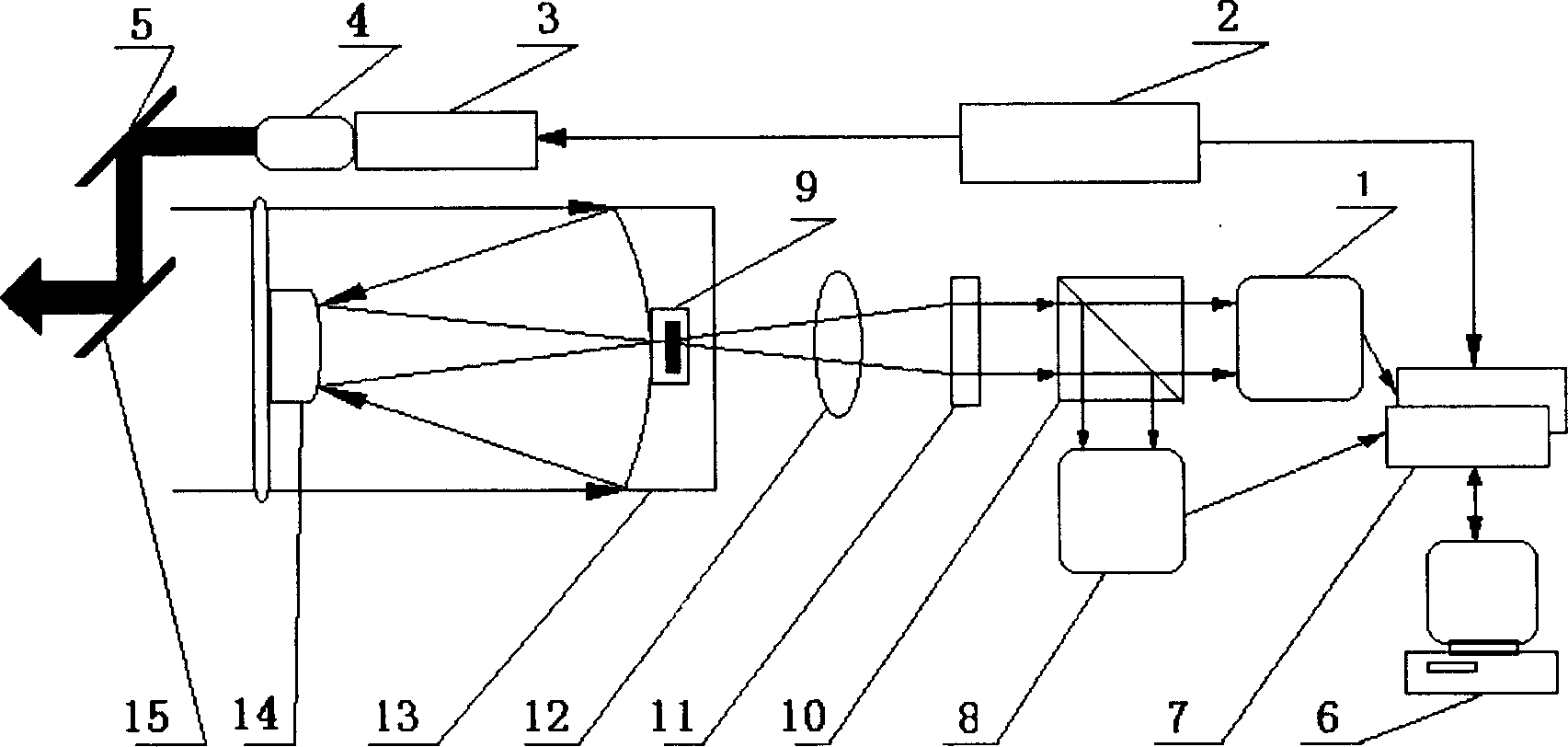

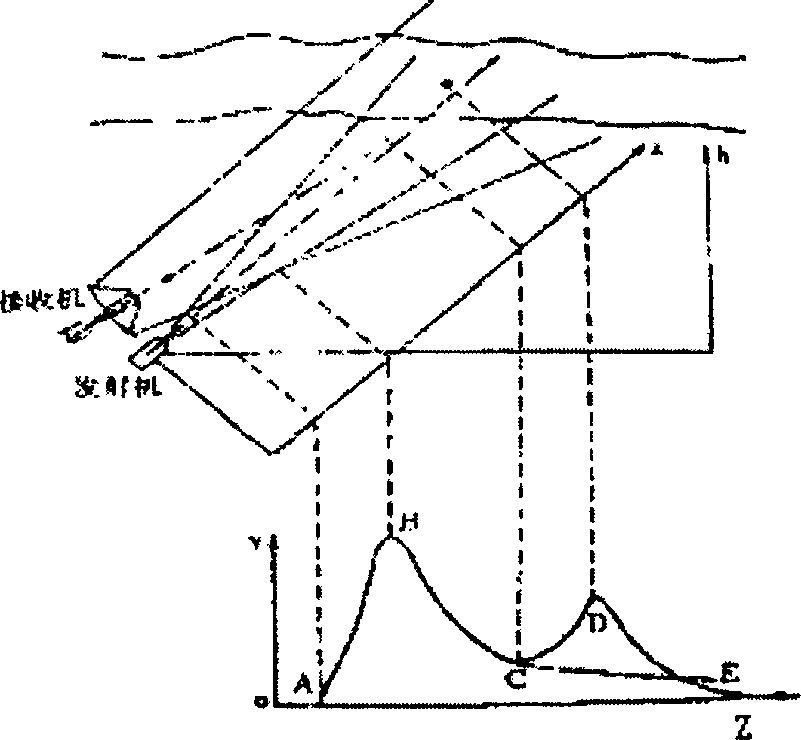

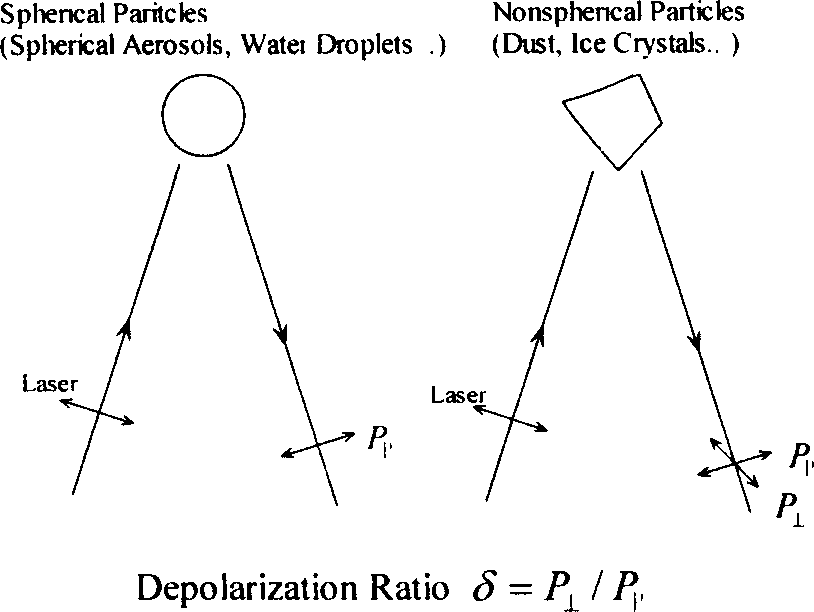

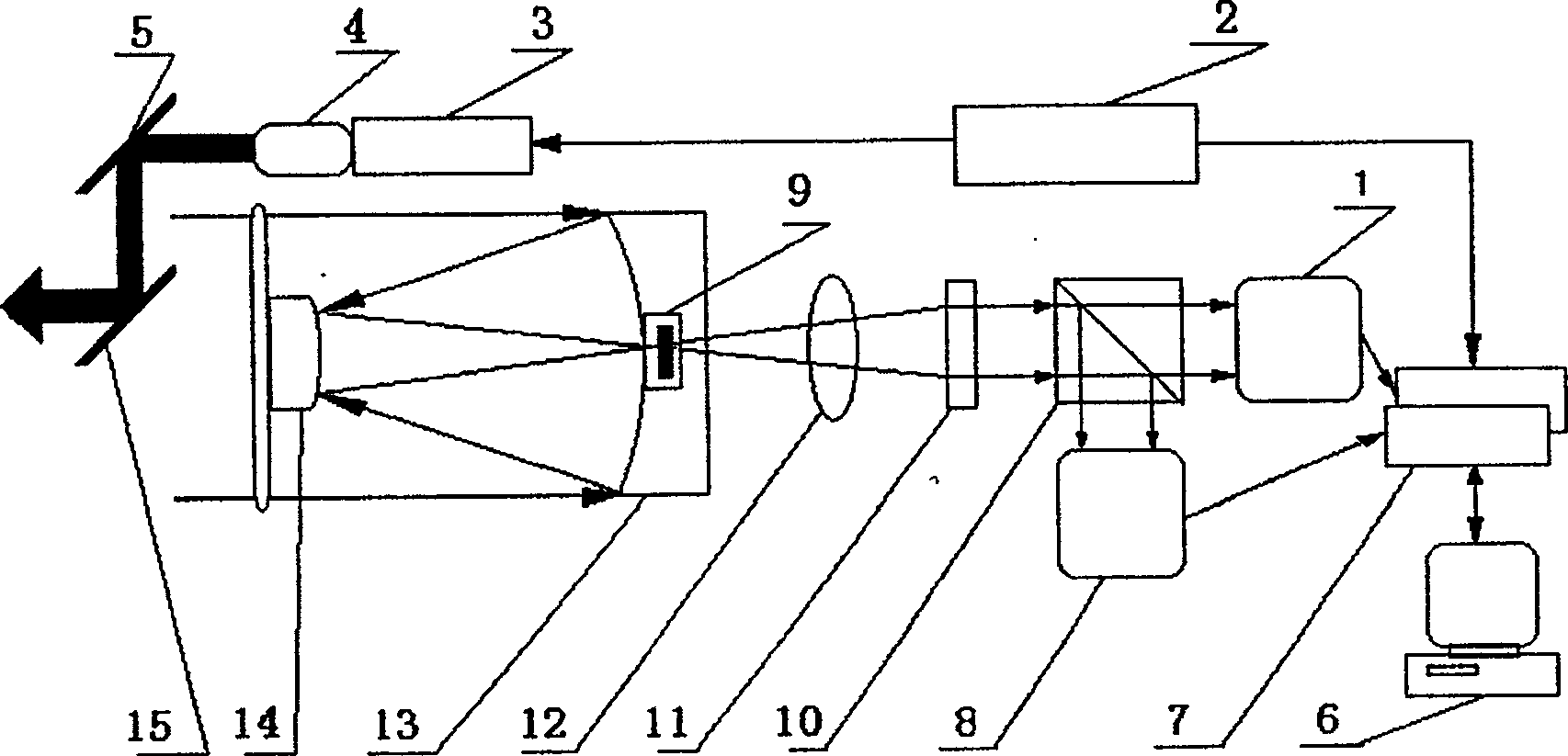

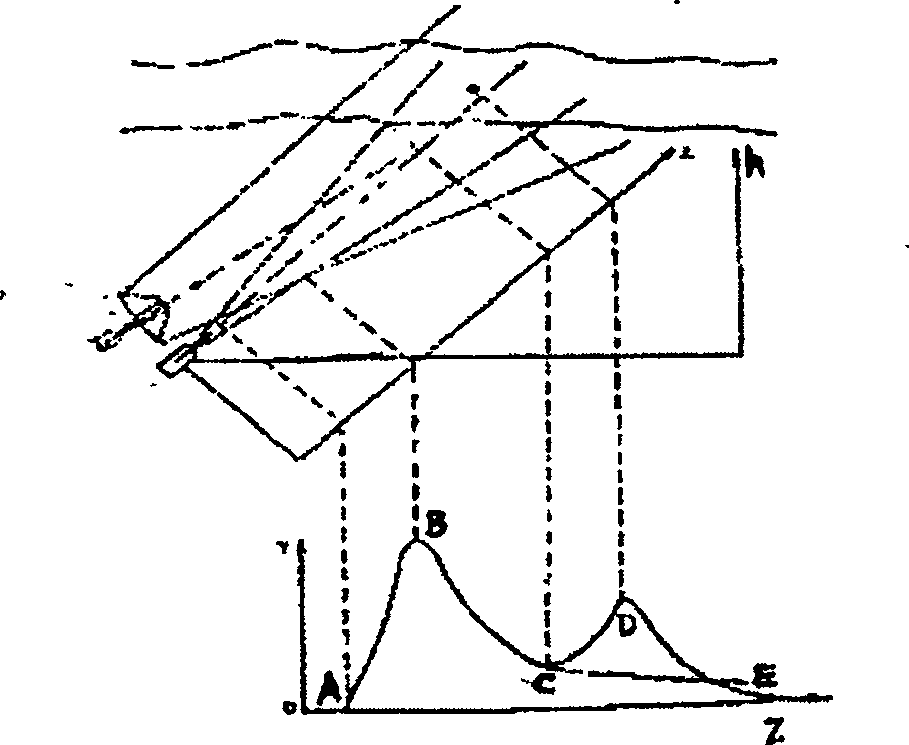

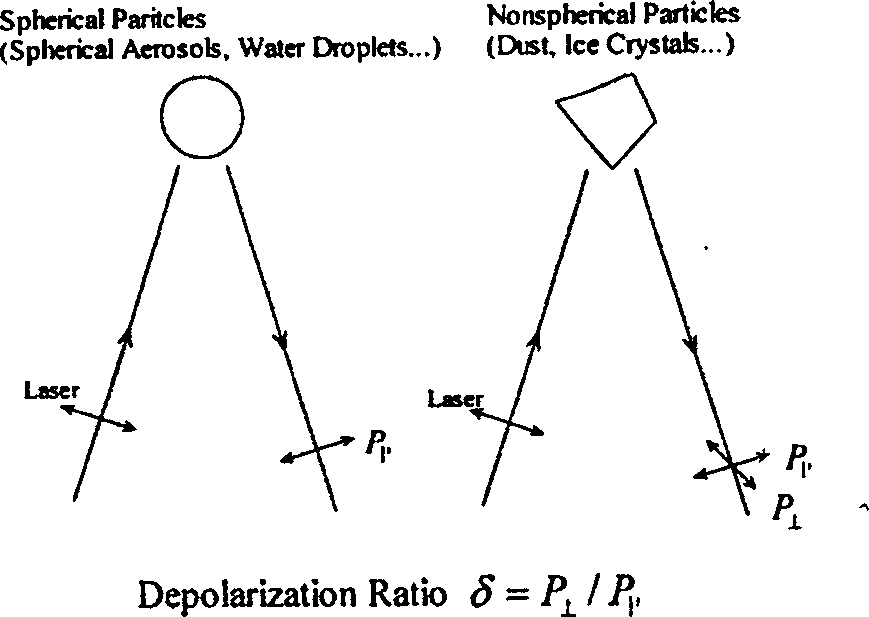

Metre scattering polarization micro-pulse laser radar control method and device

ActiveCN1641339AScattering properties measurementsSpecial data processing applicationsPrismData memory

The invention discloses a dispersive polarized micropulse laser light radar control method and device, inputting polarized laser light emitted by a small-scale semiconductor pumping YAG frequency doubling polarizing laser as working into a beam expander for expanding, then sending the laser to the sky, where the laser is dispersed by aerosol in the atmosphere, the backward dispersed light of spherical particles in the aerosol will not change the polarizing direction of the laser light and that of nonspherical particles will change the polarizing direction of the laser light to form a component vertical to the polarizing direction of the original laser light (i.e. depolarized). The backward dispersive echo signals coming from the spherical and nonspherical particles are received by an optical telescope and two lights of different polarizing directions are separated by a light separating prism and sent to two detectors, respectively; a photon counter card makes contraposition counting and accumulation processing in the time sequence of photoelectric pulse signal returning from the space, and the processed result is stored into corresponding data memory cells; two signals collected are calculated by XJ-PMPL software to obtain echo depolarization degree, thus obtaining space distribution outline of nonspherical particles. Besides, it can also combine the two signals to obtain the total strength distribution of backward dispersed light, therefore the polarized micropulse laser light radar can also complete the functions of a general micropulse radar.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

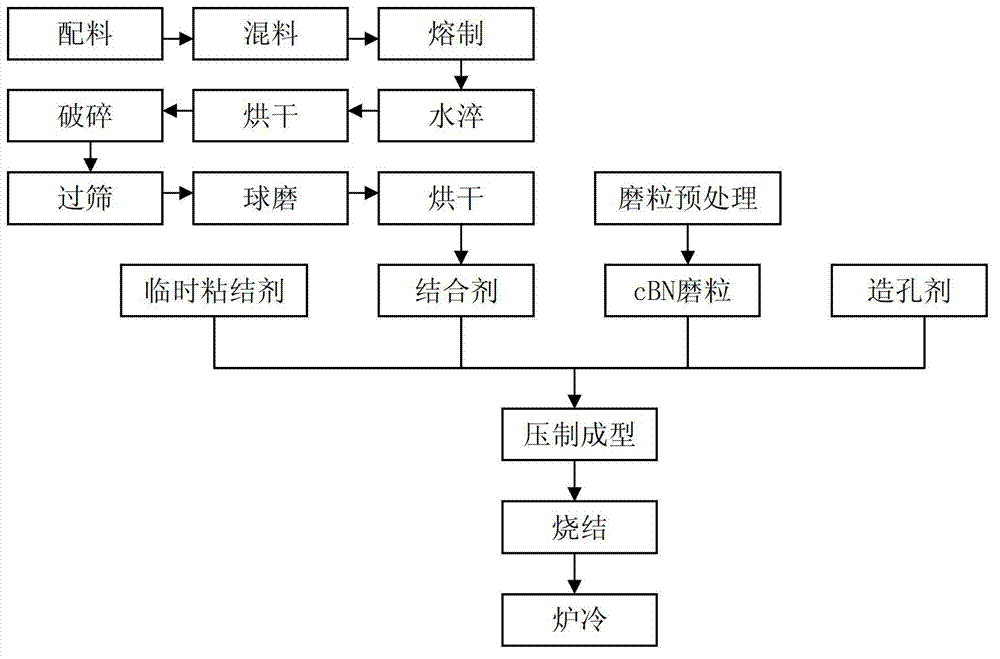

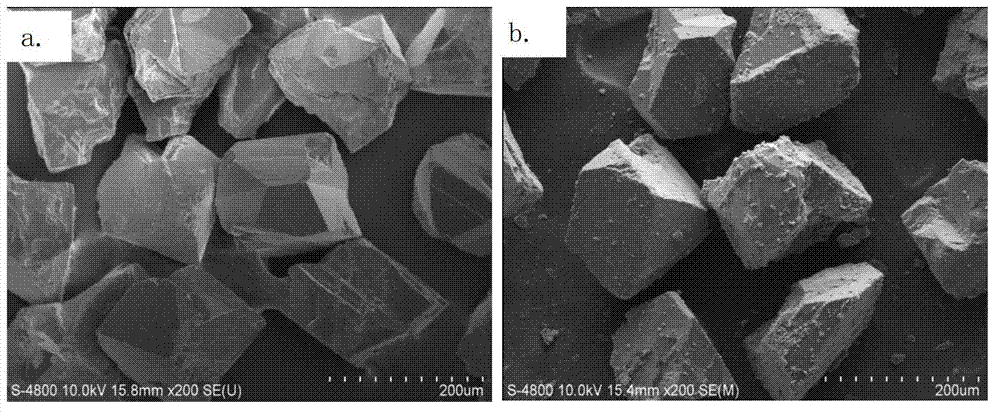

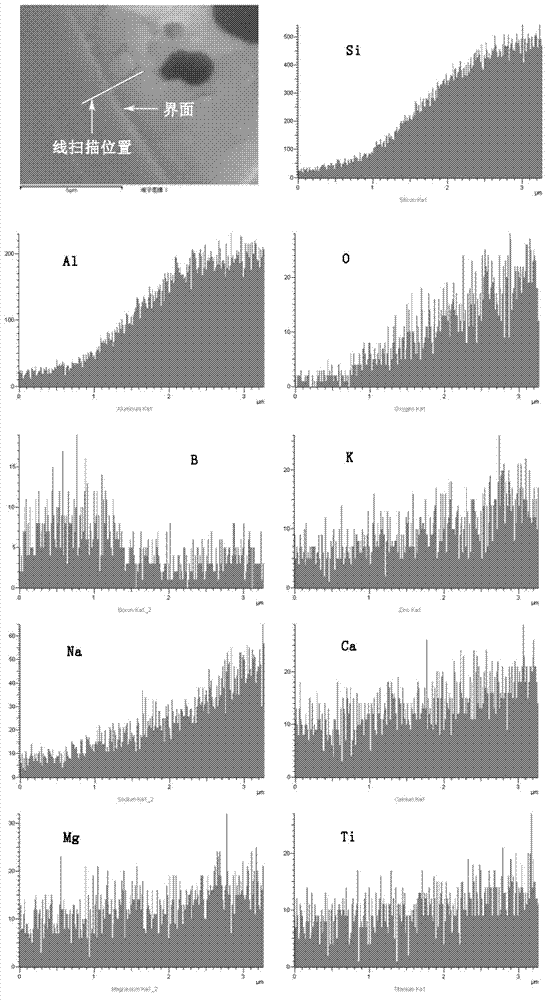

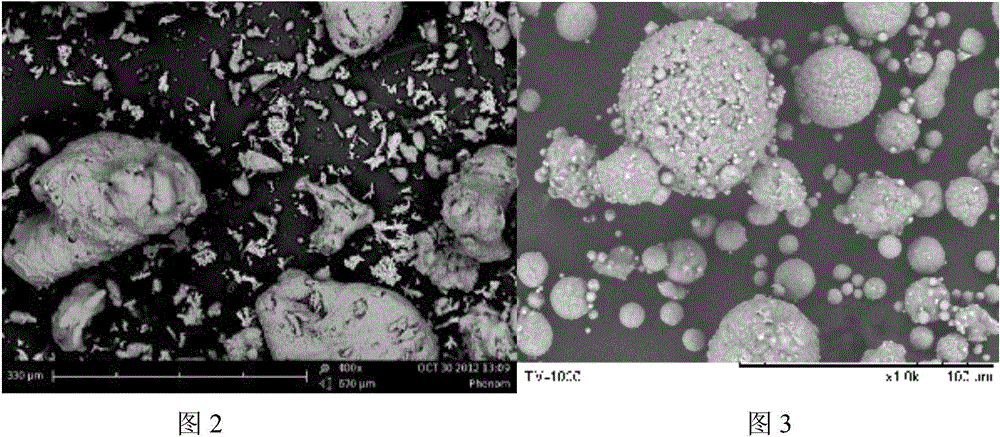

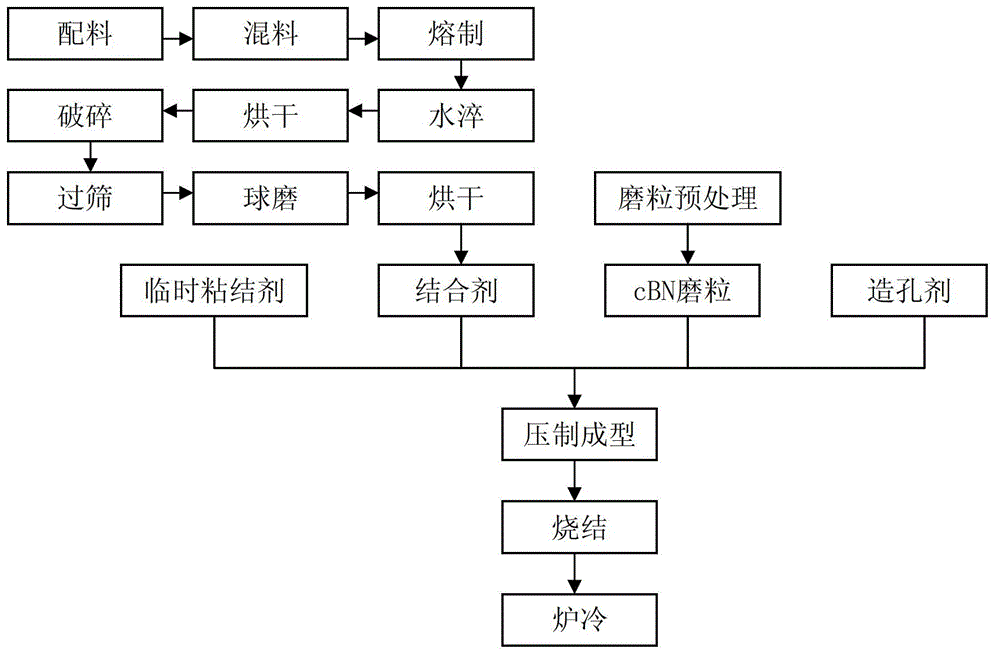

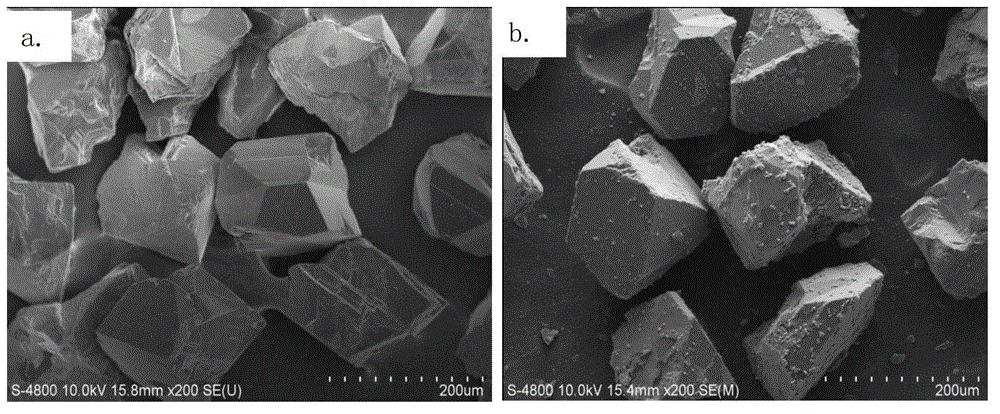

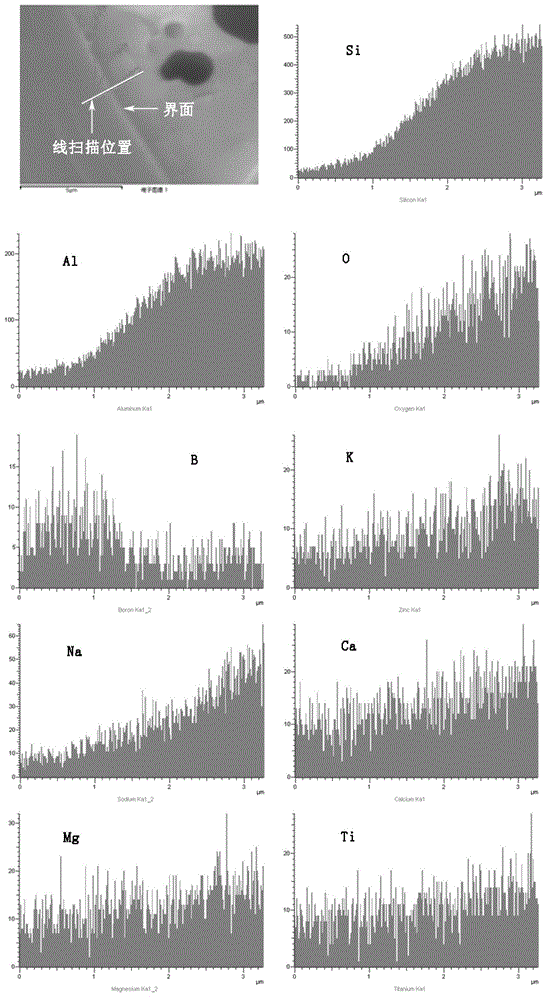

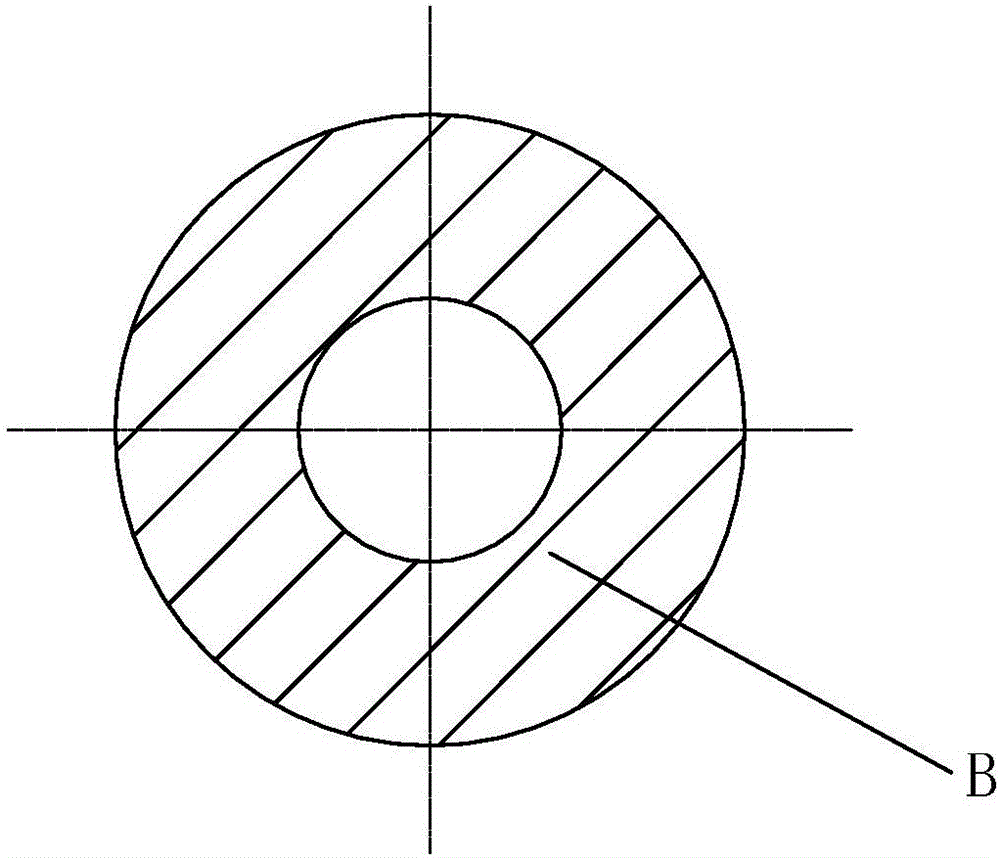

Ceramic bond cubic boron nitride abrasive tool and manufacturing method thereof

The invention discloses a ceramic bond cubic boron nitride abrasive tool and a manufacturing method of the ceramic bond cubic boron nitride abrasive tool. The method comprises preparing materials and mixing, placing mixed materials in an electric furnace for melting, conducting water quenching to prepare ceramic bond blocks, conducting smashing, ball-milling, sieving and drying on the ceramic bond blocks to prepare ceramic bond powder, conducting surface oxidation modified pretreatment on cubic boron nitride (cBN) grains, evenly mixing the ceramic bond powder, the cubic boron nitride (cBN) grains and a pore-forming agent NH4HCO3, obtaining a mixture, adding temporary binding agent polyethylene glycol in the mixture, evenly mixing to obtain abrasive tool raw materials, placing the abrasive tool raw materials in a die, conducting pressing shaping on a pressure machine to prepare an abrasive tool green body, placing the abrasive tool green body in a sintering furnace for sinter molding, and preparing the ceramic bond cubic boron nitride abrasive tool along with cooling of the furnace. The ceramic bond cubic boron nitride abrasive tool improves total strength of the abrasive tool, enables the abrasive tool to be not easy to break in using process, improves using safety of the abrasive tool, and prolongs service life of the abrasive tool.

Owner:XI AN JIAOTONG UNIV

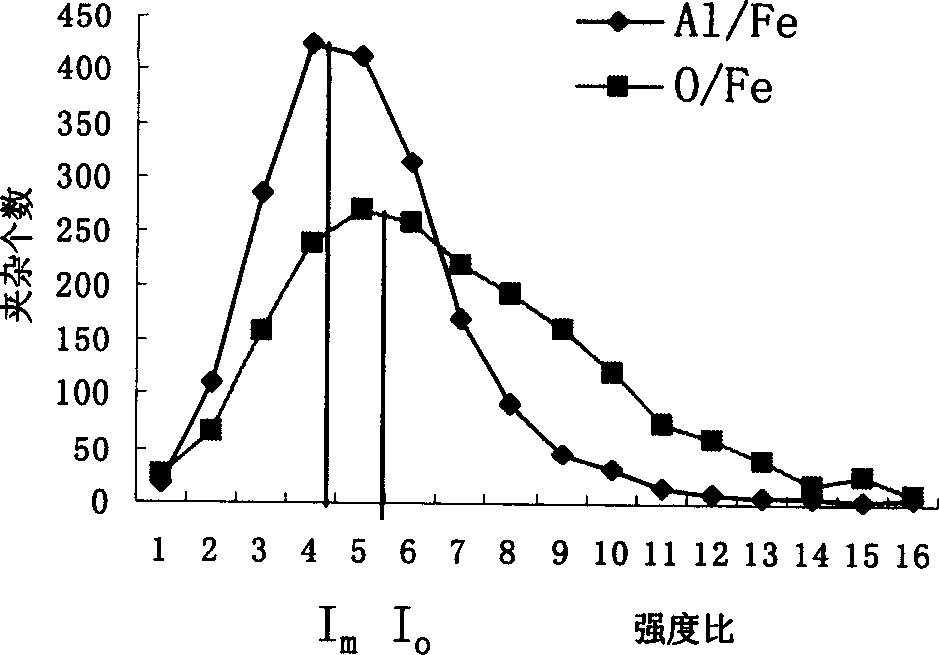

Ceramic heaters, a method for producing the same and articles having metal members

InactiveUS7126090B2Reduce generationEfficient combinationSemiconductor/solid-state device manufacturingHot plates heating arrangementsCeramic sinteringElectrical resistance and conductance

A ceramic heater is provided including a ceramic sintered body and a heat resistor embedded in the substrate, wherein a change in the temperature uniformity on the heating face is reduced. The heat resistor contains a metal comprising one or more metal elements selected from the group consisting of Group IVa, Group Va and Group VIa elements of the Periodic Table and a carbide of the metal. A ratio (Ic / Im) of a total strength (Ic) of main peak of the metal carbide to a total strength (Im) of main peak strength of the metal is not larger than 0.2. Alternatively, the ratio (Rb−Ra) / Ra is not larger than 30 percent, where “Ra” is the resistance of the heat resistor before sintering and “Rb” is the resistance of the heat resistor after sintering.

Owner:NGK INSULATORS LTD

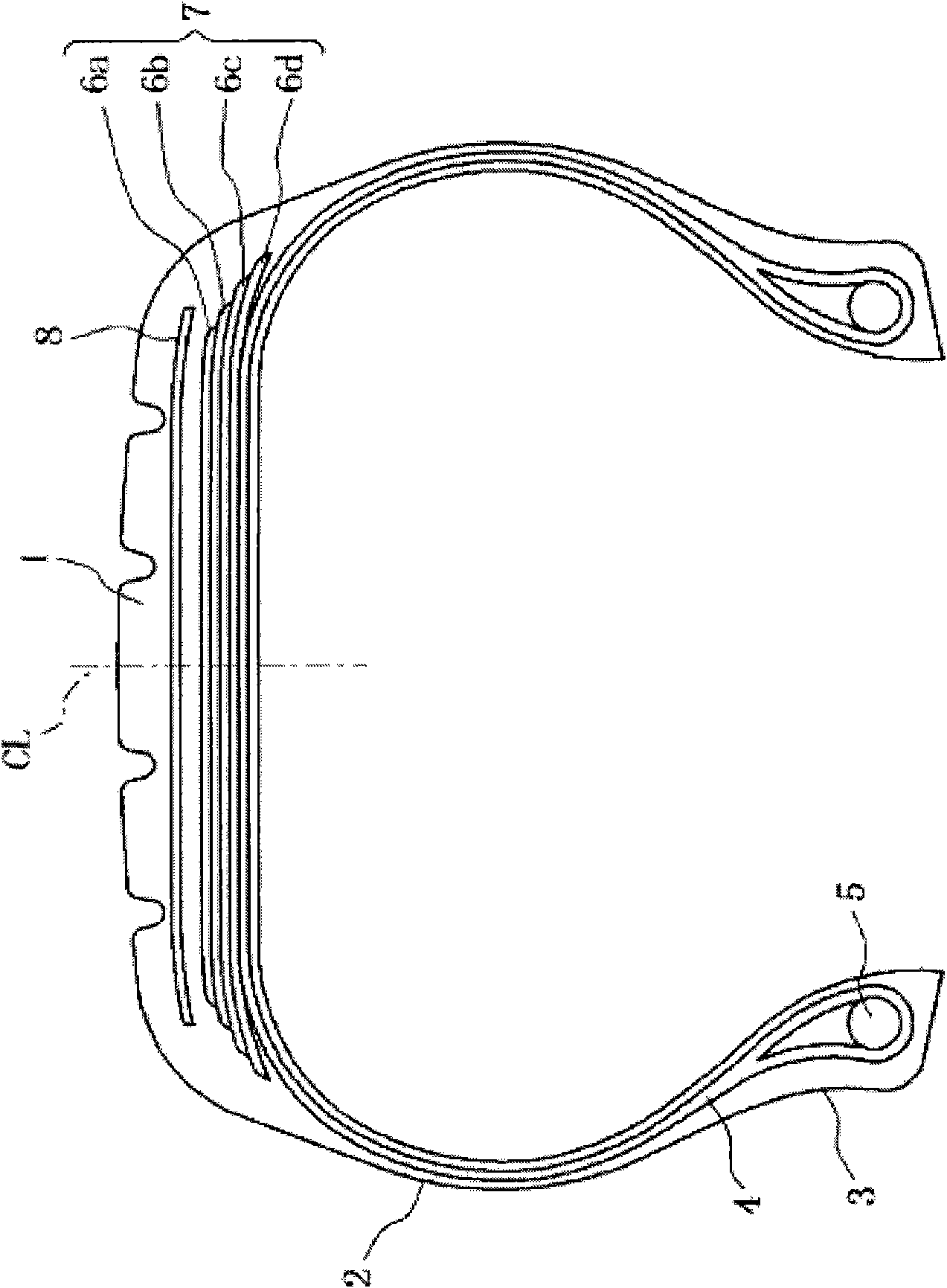

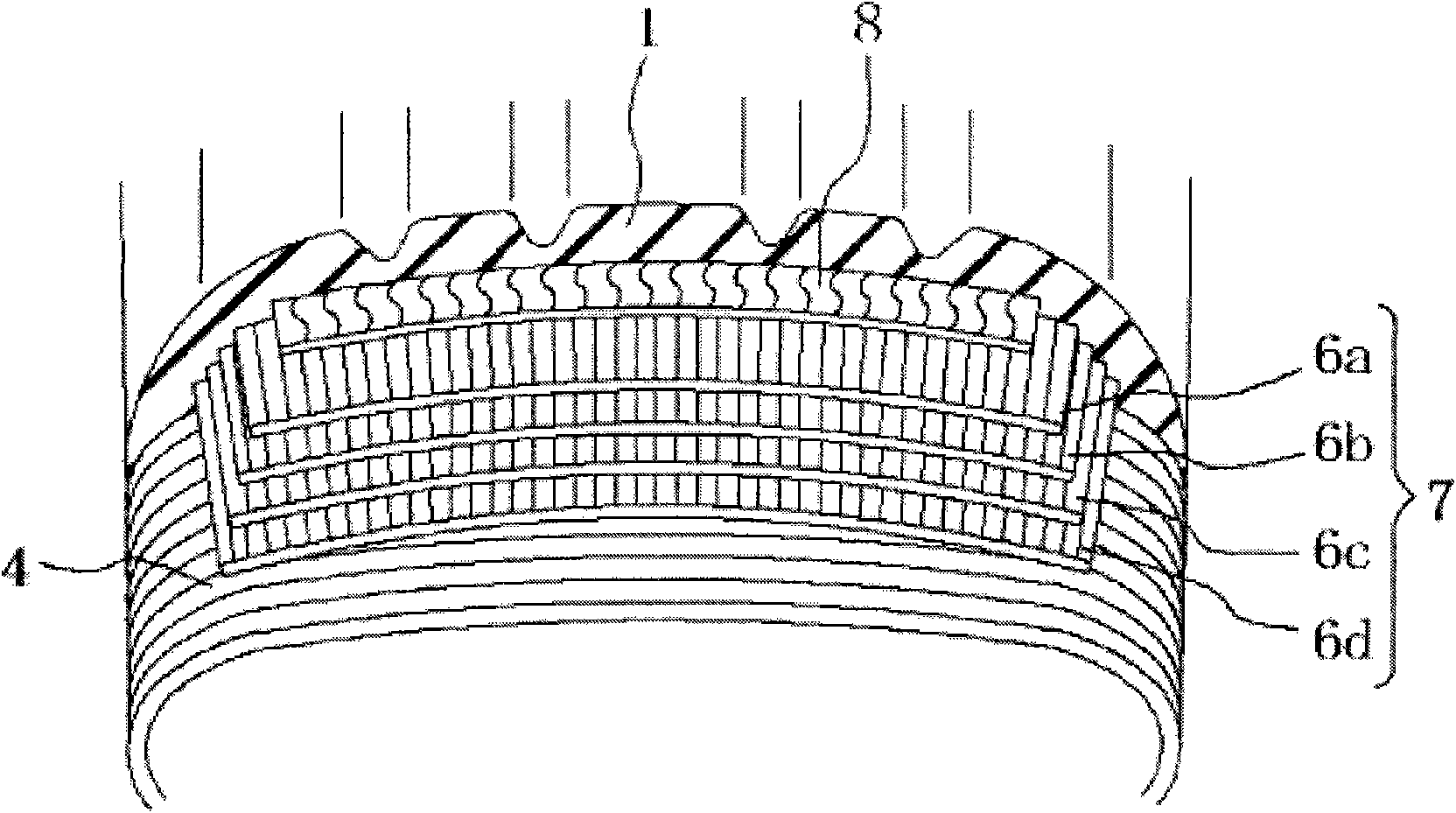

Radial tire for aircraft

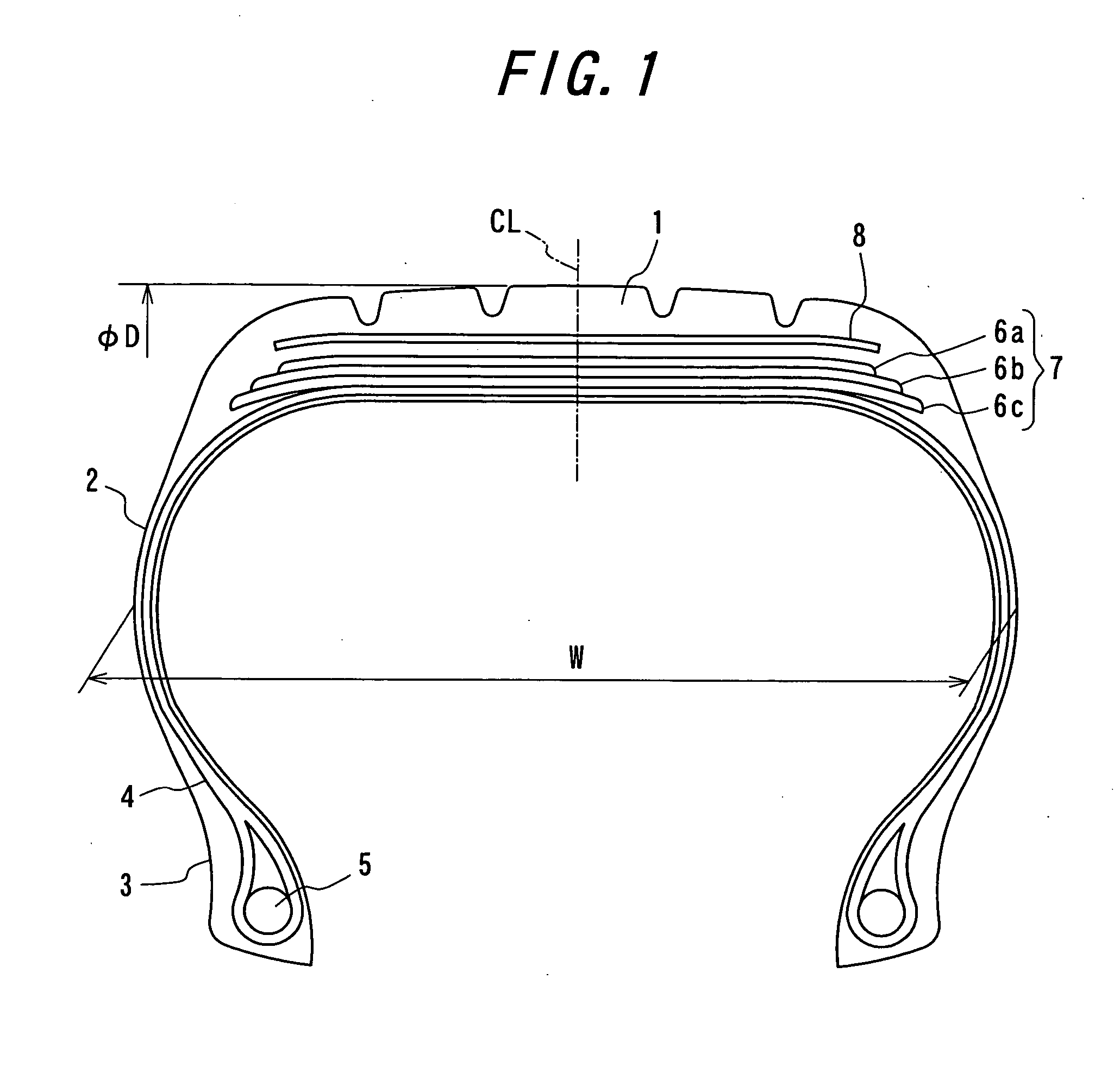

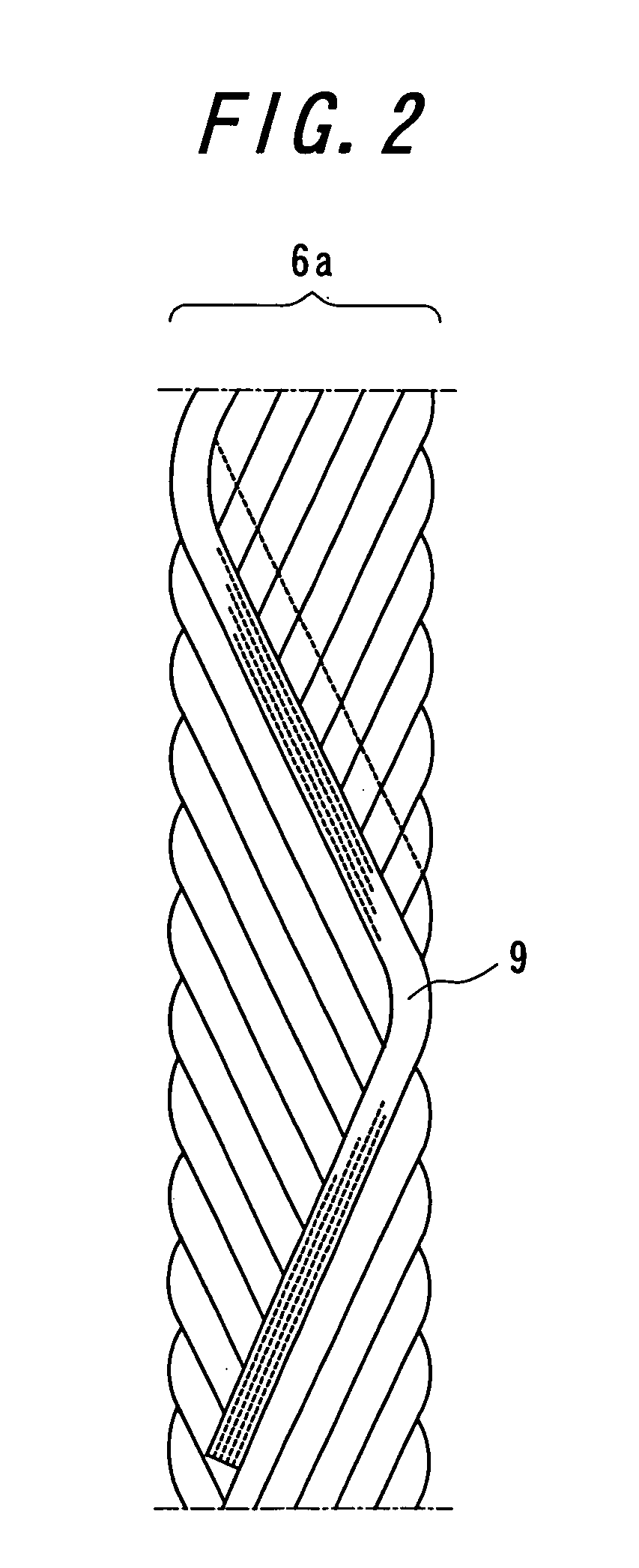

InactiveCN101678717ACircumferential rigidity is smallIncreased durabilityPneumatic tyre reinforcementsAircraft tyresFiberForeign matter

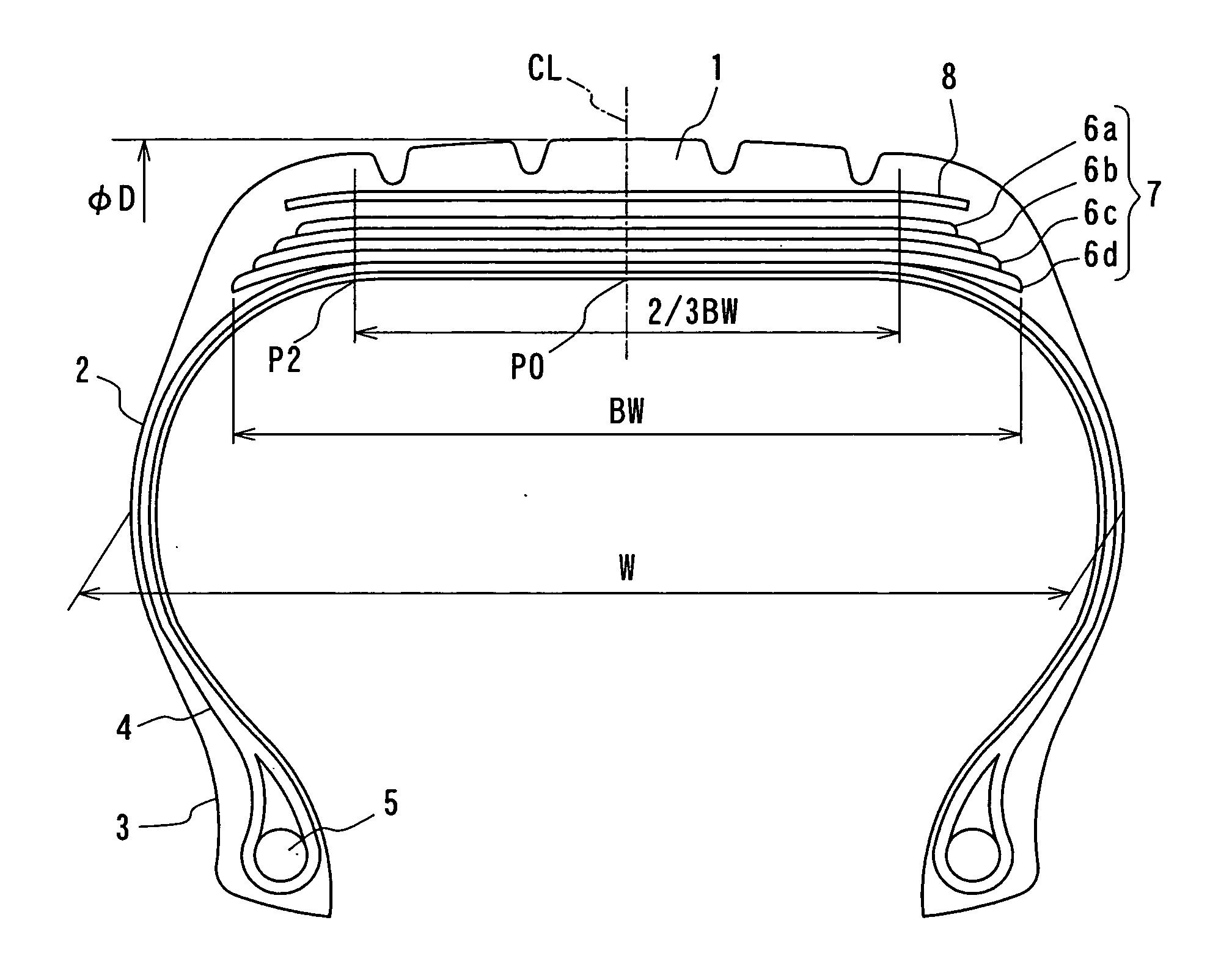

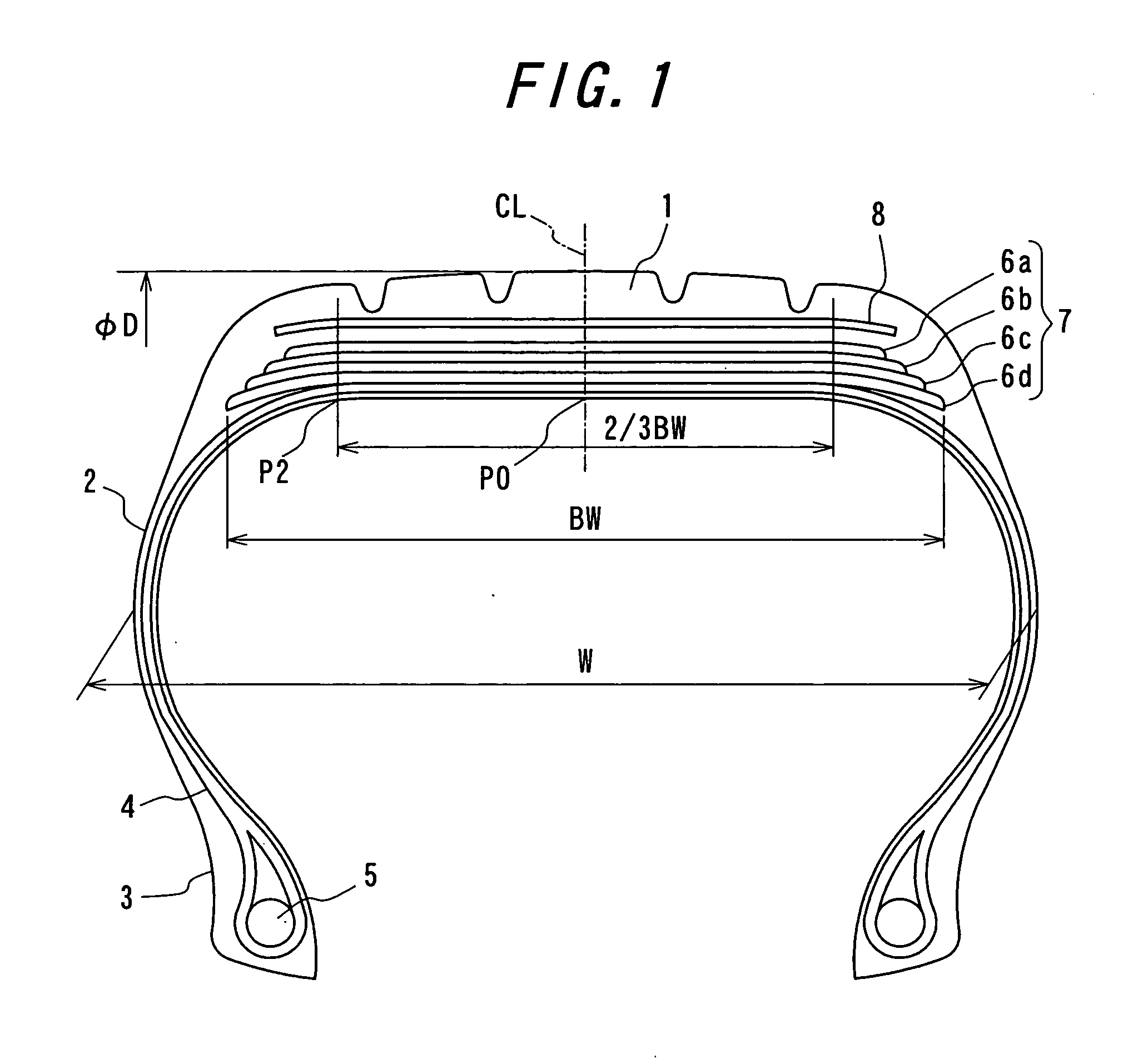

This invention provides a radial tire for aircraft comprising a belt composed of a plurality of belt layers, wherein a total strength of the belt T belt ¢N! in a circumferential direction over its full width satisfies T belt / WD 1.510 6 in which D ¢m! is an outer diameter of the tire and W ¢m! is a width of the tire, the belt is composed of at least two belt layers each containing organic fiber cords with an elongation in an extension direction under a load of 3.2 cN / dtex of 2.2-9.3%, a protection belt layer having a circumferential stiffness lower than that of the belt is disposed at an outside of the belt in a radial direction, a ratio of the circumferential stiffness of the protection belt layer to the circumferential stiffness of the belt is less than 0.5, and the protection belt layeris composed of organic fiber cords having a tensile strength at break of not less than 6.3 cN / dtex and a heat shrinkage factor of 0.5-5.0%, whereby a durability of a tread portion can be improved without damaging an excellent durability against foreign matters.

Owner:BRIDGESTONE CORP

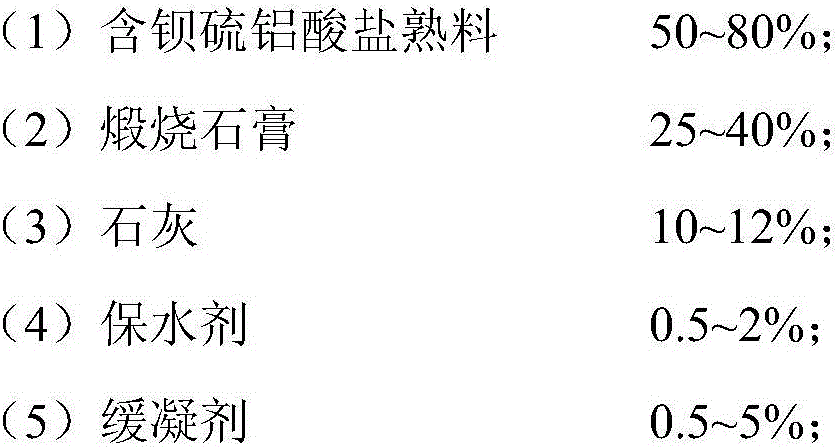

Barium-containing sulphoaluminate soft soil curing agent and preparation method thereof

InactiveCN103275730AFast curingHigh strengthBuilding constructionsOrganic fertilisersAdditive ingredientPortland cement

The invention relates to the field of a soft soil curing agent, and particularly provides a barium-containing sulphoaluminate soft soil curing agent and a preparation method thereof. The sulphoaluminate soft soil curing agent comprises components in percentage by weight as follows: (1), 50%-80% of sulfoaluminateclinker containing barium; (2), 25%-40% of calcined gypsum; (3), 10%-12% of lime; (4), 0.5%-2% of a water-retaining agent; and (5), 0.5%-5% of a retarder. The preparation technique process comprises the steps of calcinating natural gypsum, preparing ingredients, mixing and grinding. The soft soil curing agent has the characteristics of quick condensation, high strength and no shrinkage of curing soil volume, total strength can be formed after the curing for 1-3 days, and the soft soil curing agent is particularly suitable for quick maintenance and reinforcement of road foundations; and besides, under the same additive amount, the unconfined compressive strength of compacted soil adopting the soft soil curing agent is apparently higher than that of compacted soil adopting P.C 32.5 ordinary Portland cement, and the reinforcement effect is remarkable.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Production method of powder metallurgy high-silicon aluminum alloy compressor piston

ActiveCN105522156AThe proportion of material composition is scientific and reasonableSimple preparation processTurbinesOther manufacturing equipments/toolsImpurityPiston

The invention relates to a production method of a powder metallurgy high-silicon aluminum alloy compressor piston. Materials comprise 14-32% of silicon, 0-5.0% of copper, 0.8-2.0% of magnesium, iron not more than 0.3%, other impurities not more than 2.0% and the balance of aluminum; according to alloy components of the piston, pure aluminum powder and aluminum alloy powder are taken for batching; 0.8-2.0% of organic wax bonding agent or lubricating agent is added for mixing; and then, the piston is machined through a series of steps of formation, dewaxing, sintering, heat treatment, shaping, machining, burr brushing, vacuum resin dipping, cleaning, curing and oxidation. The production method is simple in preparation process and reasonable in batching, has the characteristics of low machining quantity and high material utilization, is reasonable in material component ratio of the piston, reduces the production cost, and improves the production efficiency; primary silicons in a microscope structure of the molded piston are fine particles uniformly distributed; and the total strength and the frictional wear performance of the piston can be effectively improved.

Owner:NBTM NEW MATERIALS GRP

Pneumatic radial tire with specified belt layer

ActiveUS7712499B2Weight is lighter.Lower average tensionTyresPneumatic tyre reinforcementsEngineeringUltimate tensile strength

Owner:BRIDGESTONE CORP

Radial tire for airplane

InactiveUS20070221307A1Suitable for productionMethod be limitedPneumatic tyre reinforcementsWheelsFiberJet aeroplane

A radial tire for airplane comprises a pair of bead cores, a radial carcass, and a belt disposed on an outer periphery of a crown portion of the radial carcass and comprised of plural belt layers each containing organic fiber cords, in which a total strength in a circumferential direction over a full width of the belt Tbelt(N) satisfies Tbelt / WD≧1.5×106 when an outer diameter of the tire is D (m) and a width of the tire is W (m), and at least one layer of the belt layers is constituted with an organic fiber cord spirally winding at an angle of approximately 0° with respect an equatorial plane of the tire and satisfying the following equations (I) and (II): σ≧−0.01E+1.2 (I) σ≧0.02 (II) (wherein σ is a heat shrinkage stress at 177° C. (cN / dtex) and E is an elastic modulus at 25° C. under a load of 49 N (cN / dtex)).

Owner:BRIDGESTONE CORP

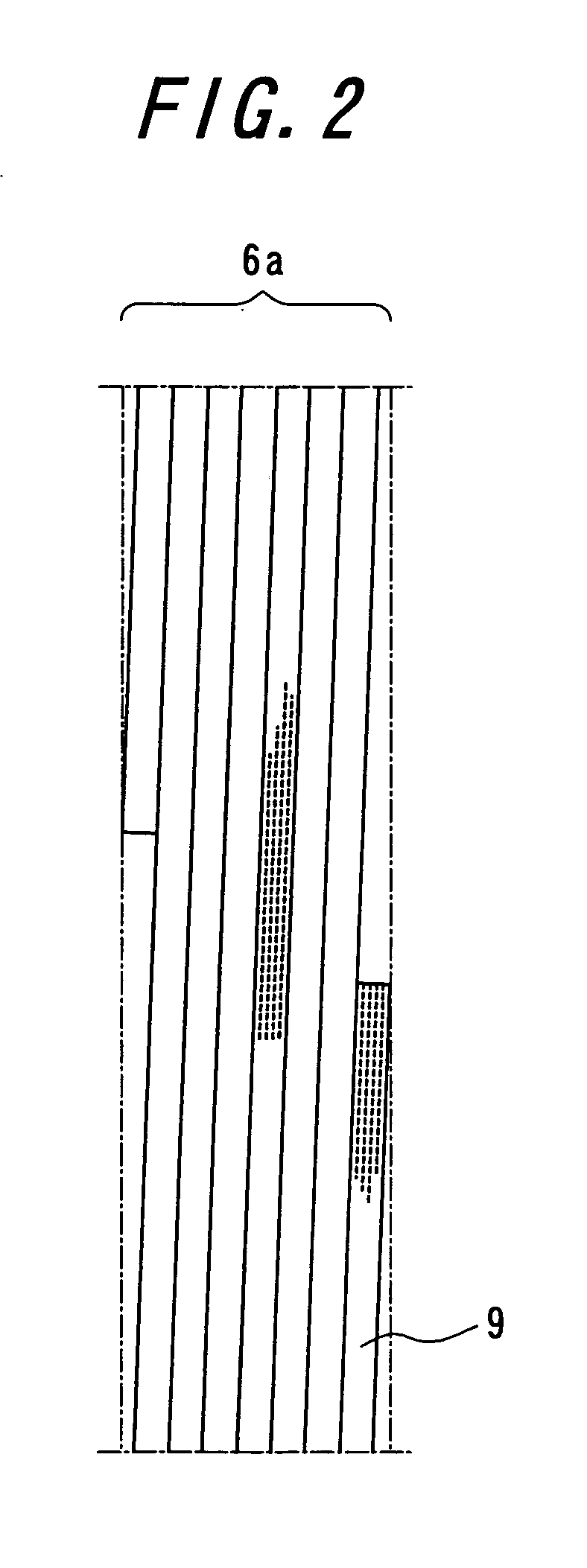

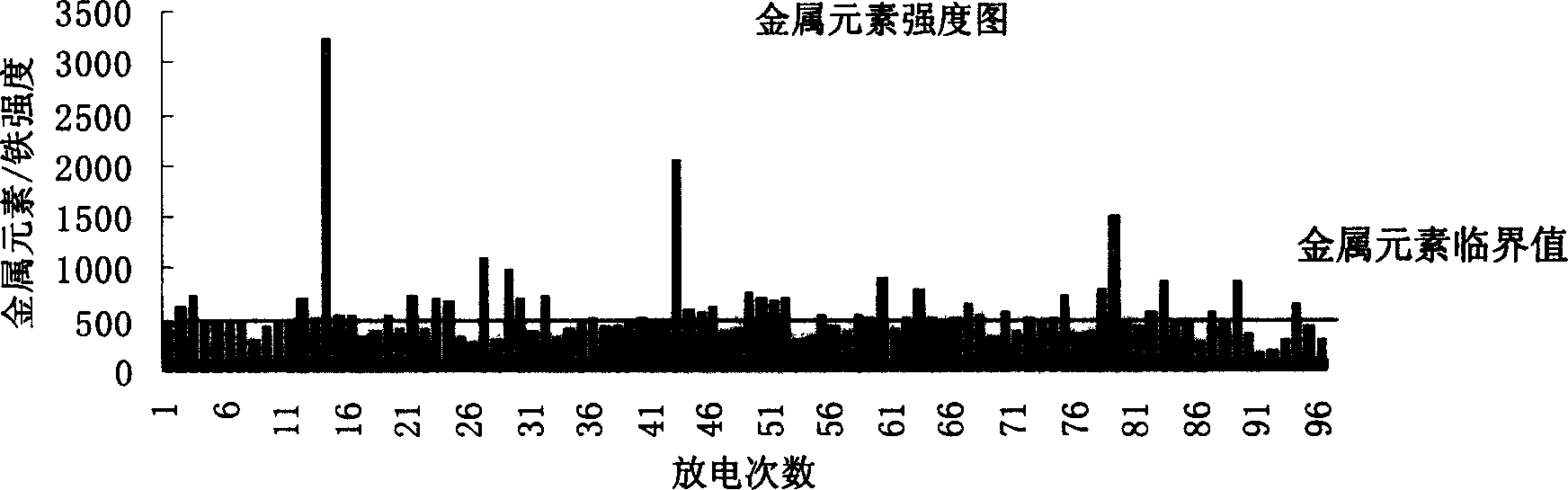

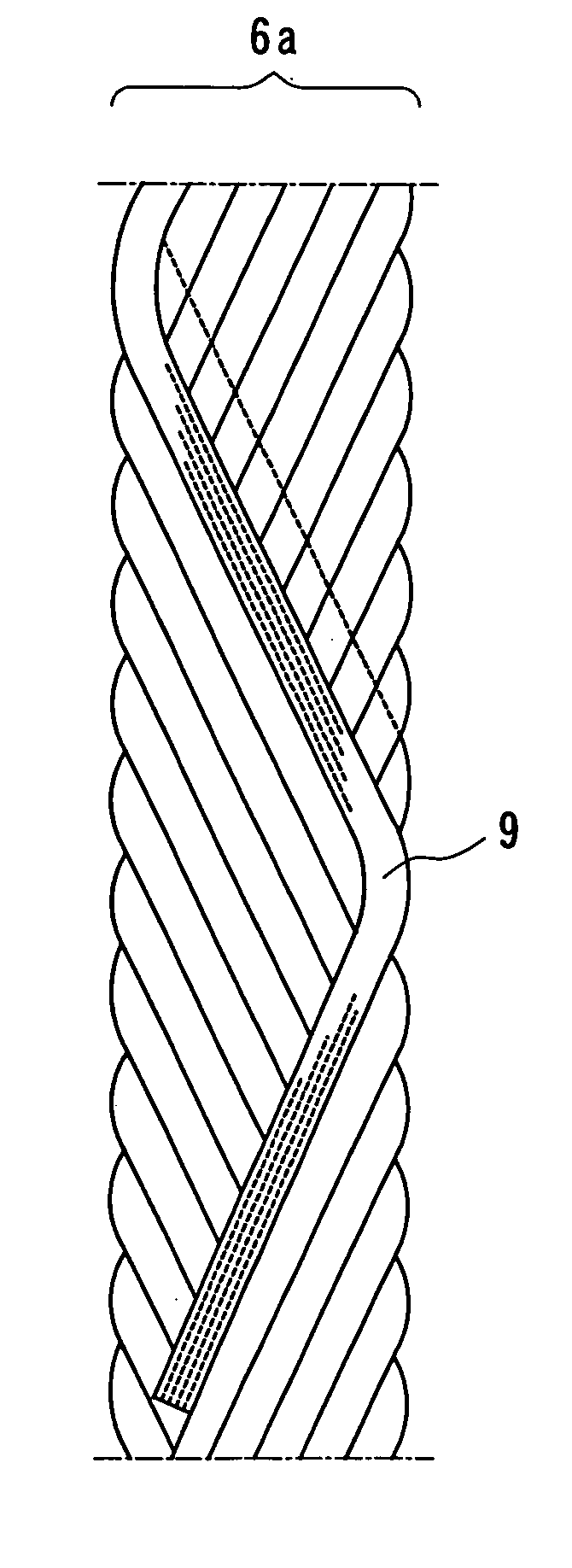

Spectral analysis method for online detecting size distribution of inclusions in steel

InactiveCN1525159AInspection is accurateImprove detection accuracyAnalysis by electrical excitationNitrogenData treatment

The invention provides a spectrum analyzing method of on-line detecting the particle size distribution of inclusions in the steel. On the nitrogen condition, make predischarge and formal spark discharge between the metal sample and electrode pair, make light split analysis on metal element and inclusion-monitor oxygen element, use data processor to make programming and calculating processing on the spectrum data to calculate the total strength of the inclusions, calculate out the contain of the inclusions in the sample according to the preset inclusion strength-content correcting curve, calculate out the particle size distribution of the inclusions according to the weight difference of the sample excited before and after, according to 10 measured results of the particle size distribution and by extremum statistical method, calculate the maximum particle size of the inclusions. It controls refining course according to the detecting result, thus remarkably reducing the rejection quantity caused by the inclusions and enhancing the steel quality. It is applied to analysis on the particle size distribution of the inclusions in the steel such as Al2O3, SiO2, MnO, CaO and MnS.

Owner:ANGANG STEEL CO LTD

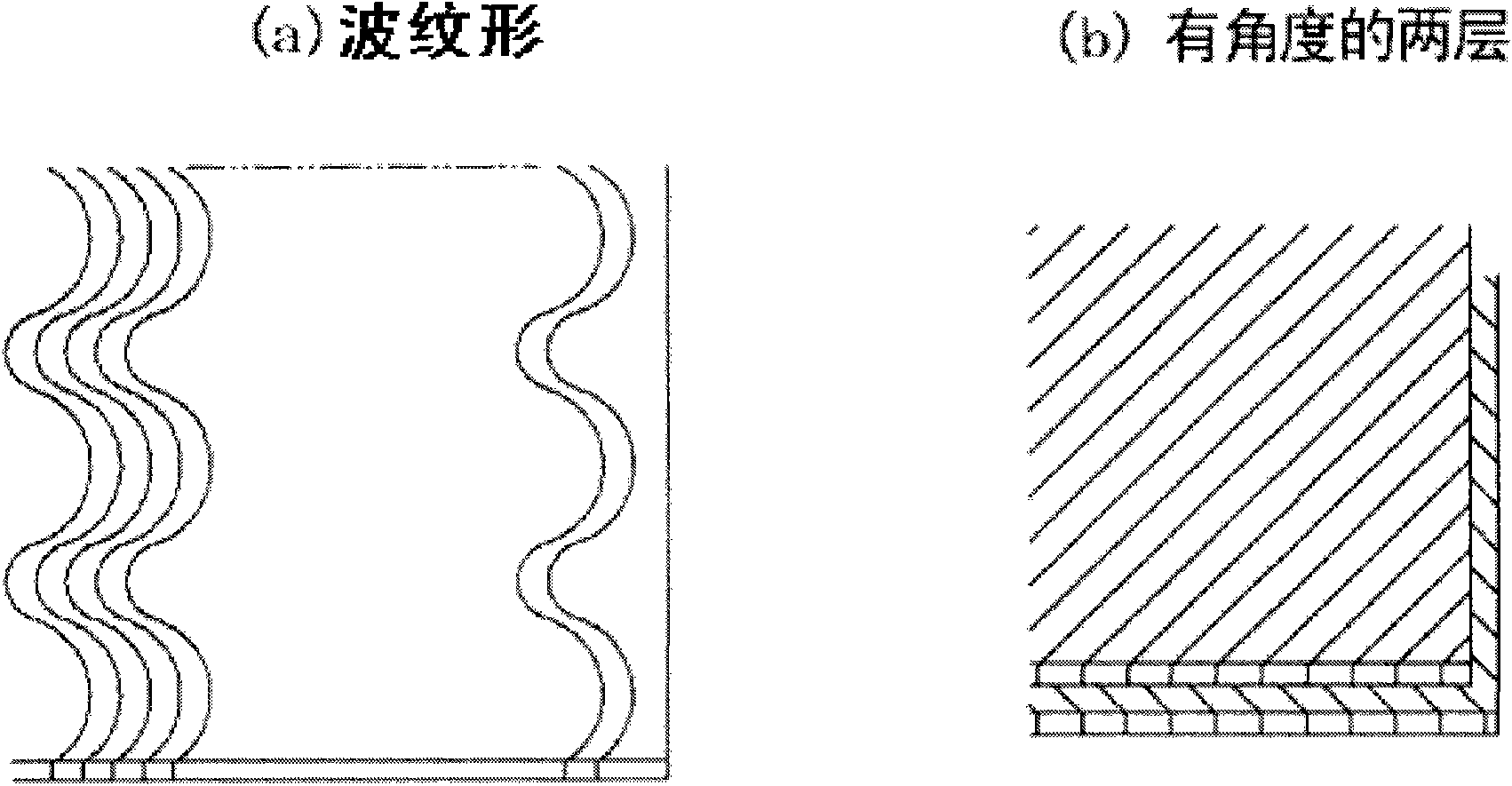

Radial tire for airplane

InactiveUS20070221308A1Suitable for productionMethod be limitedSynthetic resin layered productsPneumatic tyre reinforcementsFiberJet aeroplane

A radial tire for airplane comprises a pair of bead cores, a radial carcass, and a belt disposed on an outer periphery of a crown portion of the radial carcass and comprised of plural belt layers each containing organic fiber cords, in which a total strength in a circumferential direction over a full width of the belt Tbelt(N) satisfies Tbelt / WD≧1.5×106 when an outer diameter of the tire is D (m) and a width of the tire is W (m), and at least one layer of the belt layers is constituted with an organic fiber cord extending zigzag in the circumferential direction and satisfying the following equations (I) and (II): σ≧−0.01E+1.2 (I) σ≧0.02 (II) (wherein σ is a heat shrinkage stress at 177° C. (cN / dtex) and E is an elastic modulus at 25° C. under a load of 49 N (cN / dtex)).

Owner:BRIDGESTONE CORP

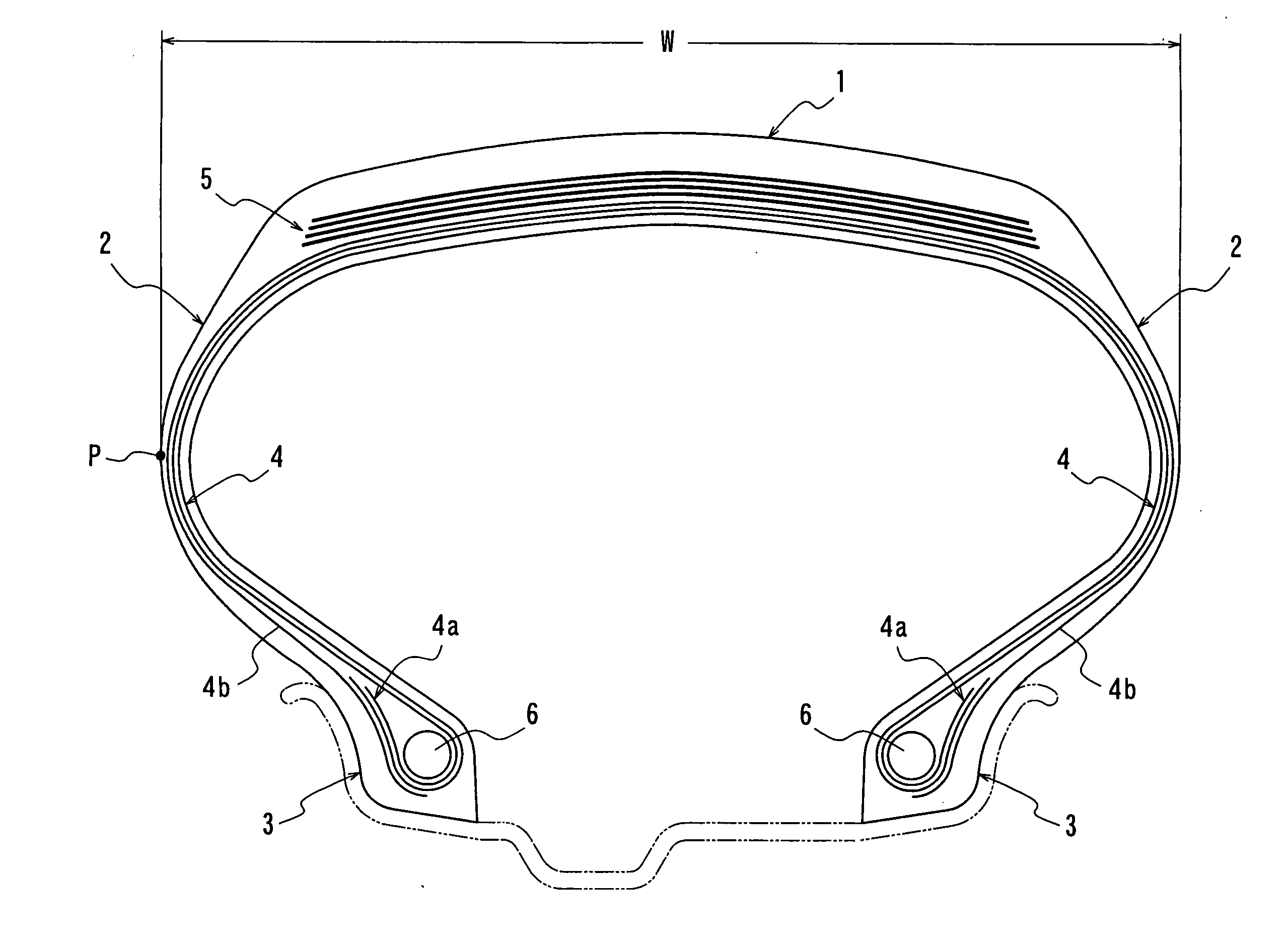

Pneumatic radial tire for airplane

A pneumatic radial tire for airplane comprises a pair of bead cores, a radial carcass comprised of at least two carcass plies, in which the radial carcass is comprised of at least one turnup ply having a main body portion and a turnup portion and at least one down ply, wherein a radially total strength Tply (N) of the organic fiber cords constituting the main body portion of the turnup ply and the down ply at a position corresponding to a maximum width of the tire, a maximum tire width W (m) and a tire outer diameter D (m) satisfies the following equation (I):Tply / WD≧4.0×106 (I)and the organic fiber cord constituting at least one ply of the at least two carcass plies is a polyketone fiber cord satisfying the following equations (II) and (III):σ≧−0.01E+1.2 (II)σ≧0.02 (III)(wherein σ is a heat shrinkage stress at 177° C. (cN / dtex) and E is an elastic modulus at 25° C. under a load of 49 N (cN / dtex)).

Owner:BRIDGESTONE CORP

Clone, expression and biological activity of stingray caudal spine cyclophilin A gene

InactiveCN1428348AGood application prospectHigh industrial development valueSugar derivativesMicrobiological testing/measurementCDNA libraryEscherichia coli

The present invention utilizes the construction of dasytis akajei caudal spine cDNA library and DNA sequencing and designs the primer according to the obtained (CyP) EST 3' end and carrier nucleotide sequence, and uses PCR method to screen the dasytis akajei caudal spine cDNA library and clone the cyclophilin A total strength gene. The tength of new gene is 656 bp for coding mature peptide of 167 amino acids, the isoelectric point of the expressed protein is 8.34, and the molecular weight is 18,021 Dalton. The dasytis akajei caudal spine cyclophilin A gene is cloned in the uxA gene 3' tail end of thioredoxing gene fusion expression vector pTRX and the fusion gene meeting reading frame is construcled, said fusion protein is existed in colibacillus, its expression amount can be up to 60 mg / L.

Owner:北京博奥环宇生物技术有限公司

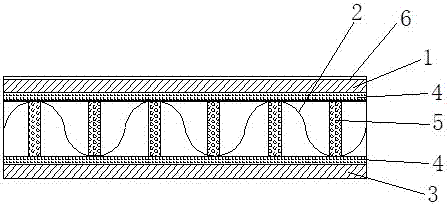

High-strength corrugated paperboard used as package material

InactiveCN107160804AHigh strengthImprove toughnessFlexible coversWrappersPuncture resistancePaperboard

The invention discloses a high-strength corrugated cardboard for packaging materials, which includes face paper, core paper and inner paper. The core paper is arranged between the face paper and the inner paper, and also includes a grid fiber layer and reinforcing ribs. The mesh fiber layers are respectively arranged on the inner side of the surface paper and the inner paper on both sides of the core paper, the cross section of the core paper is in a wave structure, and the reinforcing ribs are respectively vertically arranged on the flute of the core paper. Shaped protruding part and is connected with described face paper or inner paper. Through the above method, the high-strength corrugated cardboard used for packaging materials of the present invention improves the toughness of the corrugated cardboard, has the characteristics of strong tear resistance and good puncture resistance, strengthens the overall strength of the corrugated cardboard, and makes it difficult to deform. It is conducive to the handling of goods, and at the same time has the characteristics of waterproof and is not easy to be scrapped.

Owner:SUZHOU YONGCHUANGDA ELECTRONICS

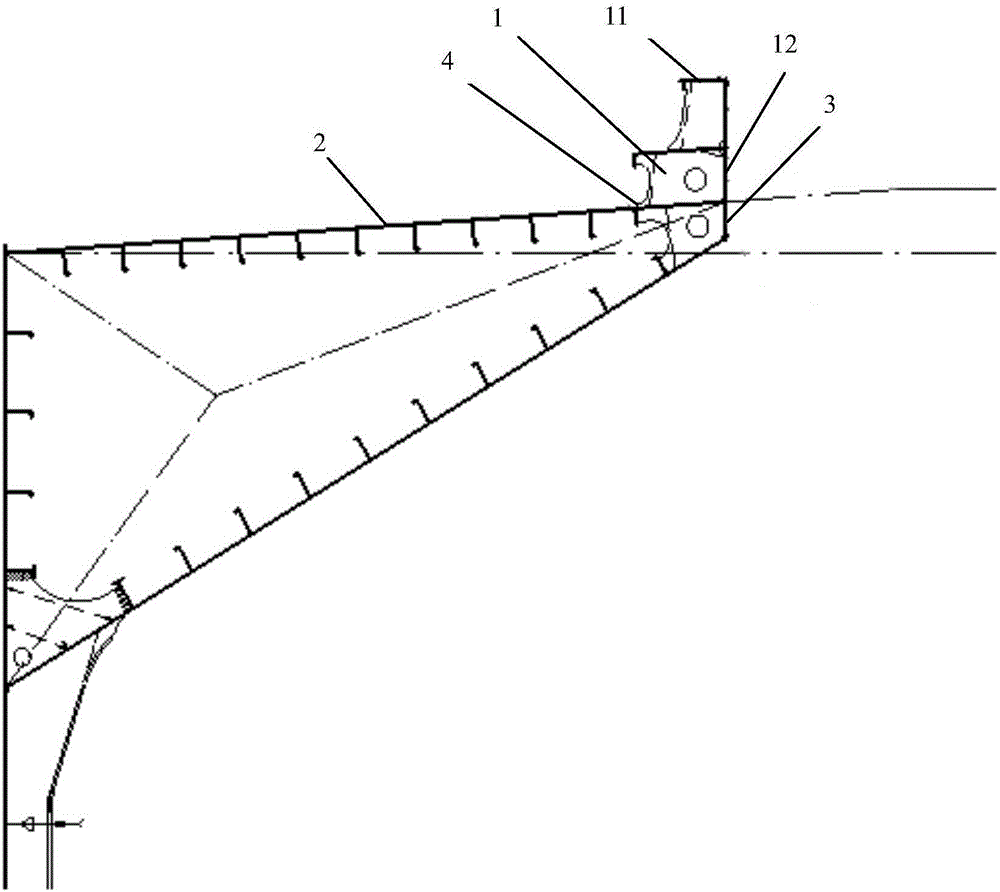

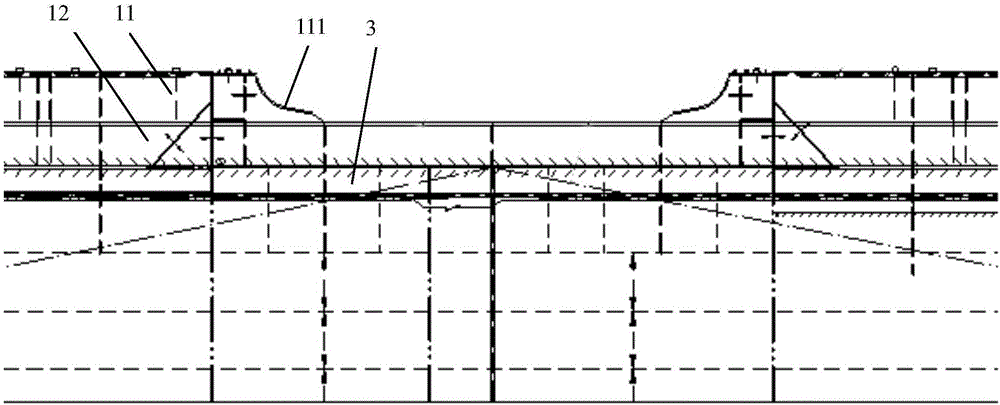

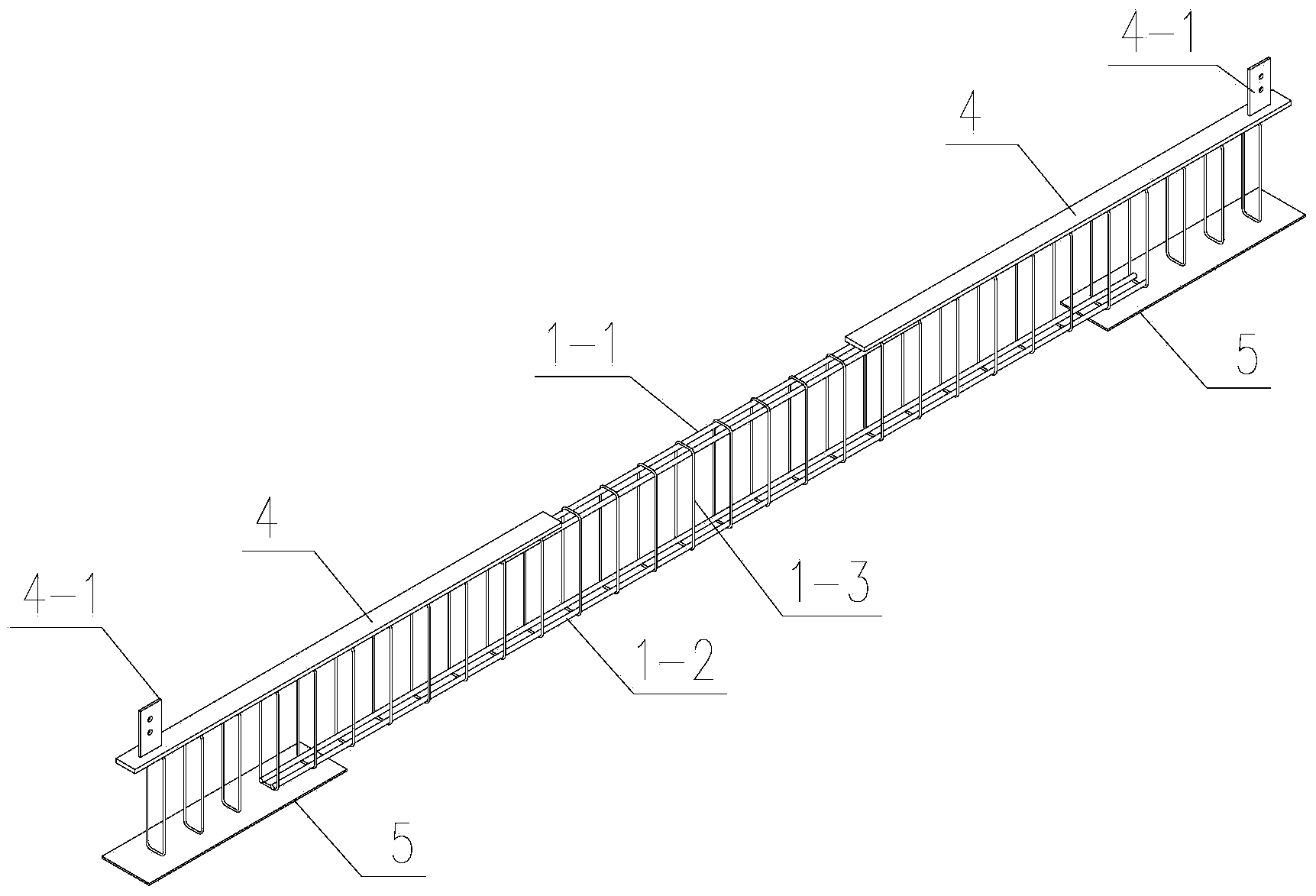

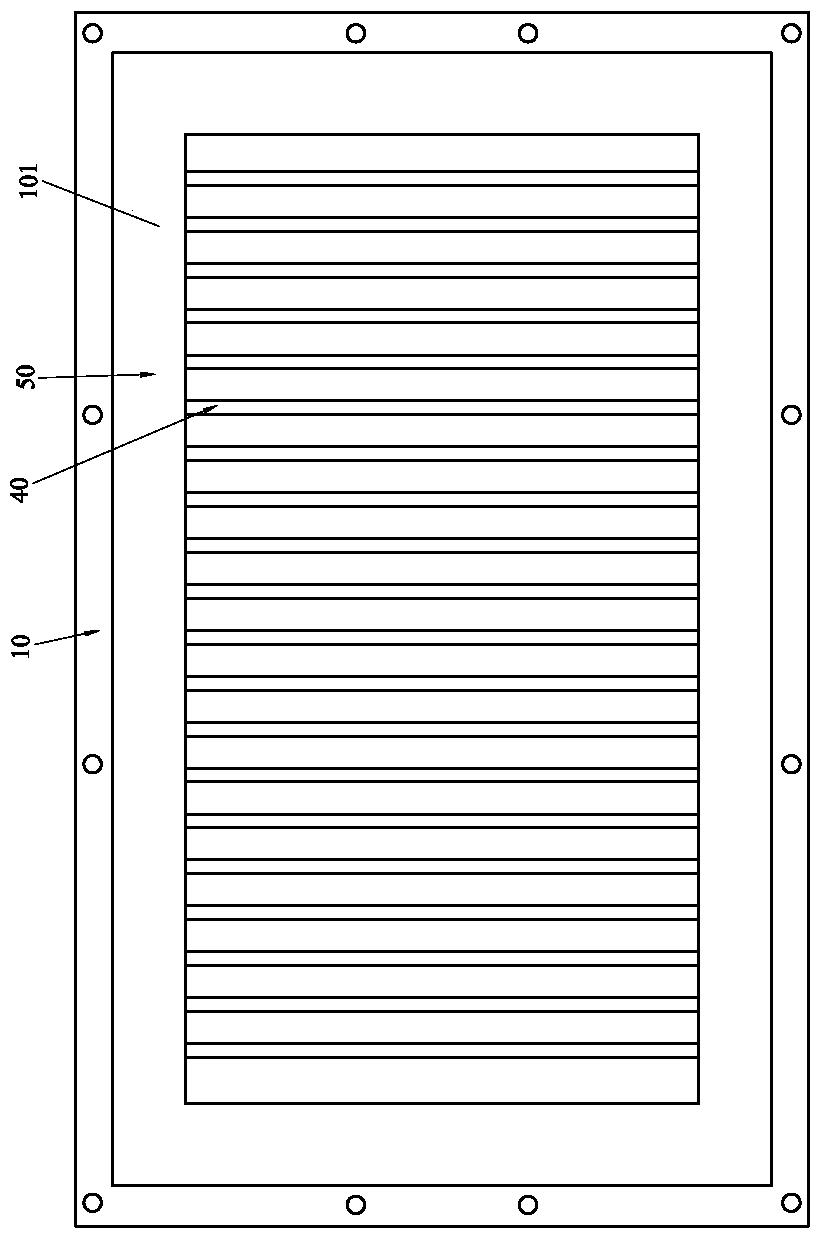

Hatch coaming partially numbered in total strength and hatchway stringer for bulk cargo ship

ActiveCN106476985AImprove structural rigidityIncrease volumeHull partsVessel hatches/hatchwaysEngineeringUltimate tensile strength

The invention discloses a hatch coaming partially numbered in total strength and a hatchway stringer for a bulk cargo ship. The hatch coaming partially numbered in the total strength and the hatchway stringer for the bulk cargo ship comprise a longitudinal hatch coaming and a hatch stringer, wherein the longitudinal hatch coaming comprises an upper coaming and a lower coaming; the upper coaming and the lower coaming are of a detachable structure; the lower end surface of the upper coaming is fixedly connected with the upper end surface of the lower coaming; the lower coaming is continuous in a ship-length direction; the upper coaming is broken at a transverse bulkhead; the material elastic yield limit of the longitudinal hatch coaming is increased by 10% relative to that of a main deck; the height of the lower coaming is 600 mm or below; the height of the hatch stringer is less than that of a conventional hatch stringer. The hatch coaming partially numbered in the total strength and the hatchway stringer for the bulk cargo ship can promote the structural stiffness of a ship-body beam, improves the fatigue life of a hatch corner, and increases the cubage of a cargo hold; moreover, the structural weight of a longitudinal component in a cargo-hold area is averagely decreased by 2.5% or above.

Owner:708TH RES INST OF CSSC

Household paper

ActiveCN103300778AHigh strengthGood flexibilityPaper/cardboard layered productsDomestic applicationsSurface layerPulp and paper industry

The invention discloses a type of household paper, which comprises surface layer paper and core layer paper, wherein the surface layer paper comprises upper surface layer paper and lower surface layer paper; the core layer paper is arranged between the upper surface layer paper and the lower surface layer paper; the core layer paper has a single-layer or multi-layer structure; the total strength of the surface layer paper is higher than that of the core layer paper; the transverse strength of the surface layer paper is 3.0-6.0N.m / g; the longitudinal strength of the surface layer paper is 2.0-4.5N.m / g; the transverse strength of the core layer paper is 2.0-3.0N.m / g; and the longitudinal strength of the core layer paper is 1.2-1.8N.m / g. According to the household paper disclosed by the invention, the characteristics of the surface layer paper and the core layer paper are utilized reasonably, so that the household paper has certain strength and high softness, is prevented from being broken easily in a rewinding process, can meet the requirement of handfeel, is clean on the surface, is prevented from falling paper scraps, and is easy to mold by folding and print.

Owner:海南金红叶纸业有限公司 +1

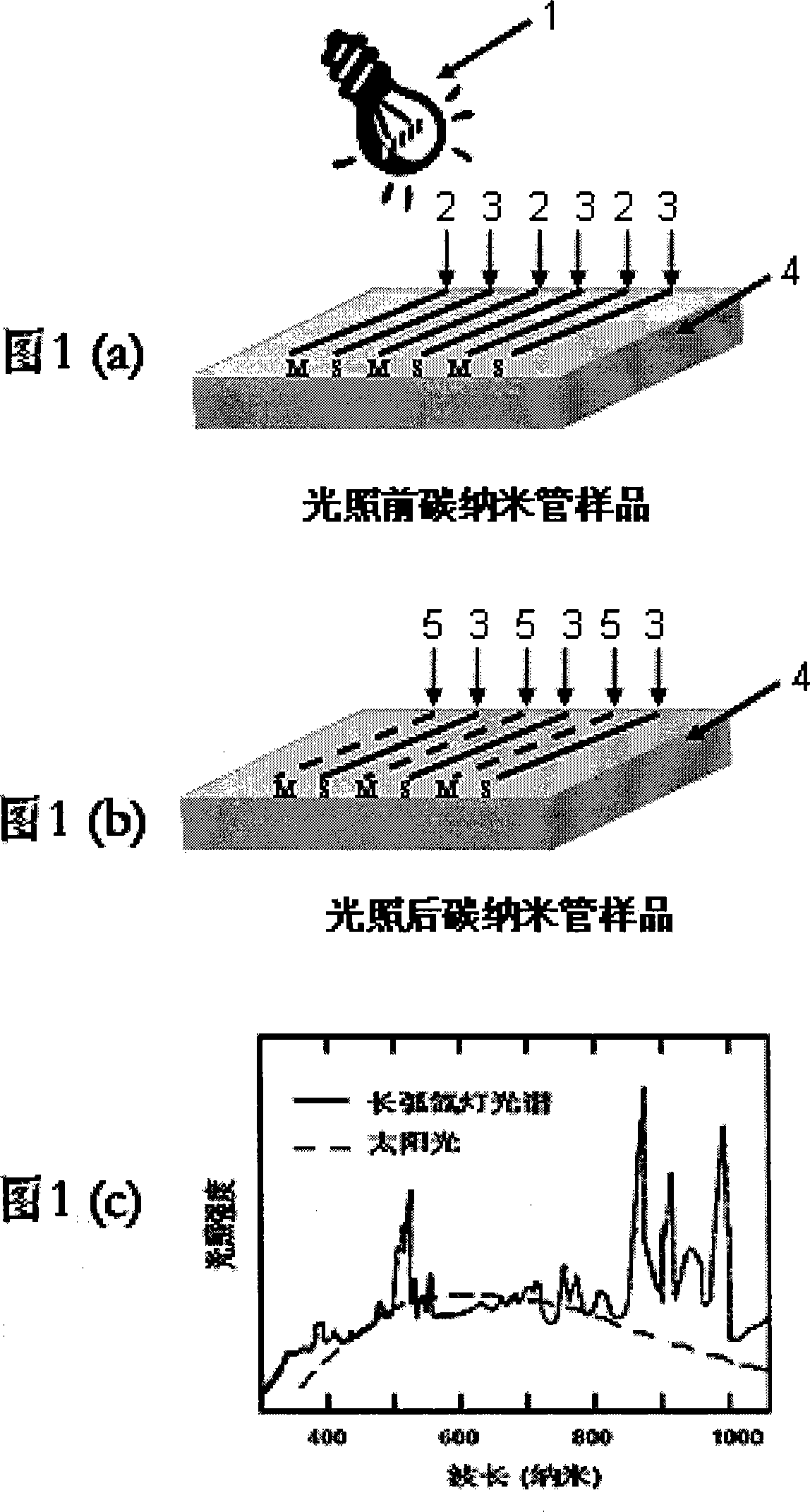

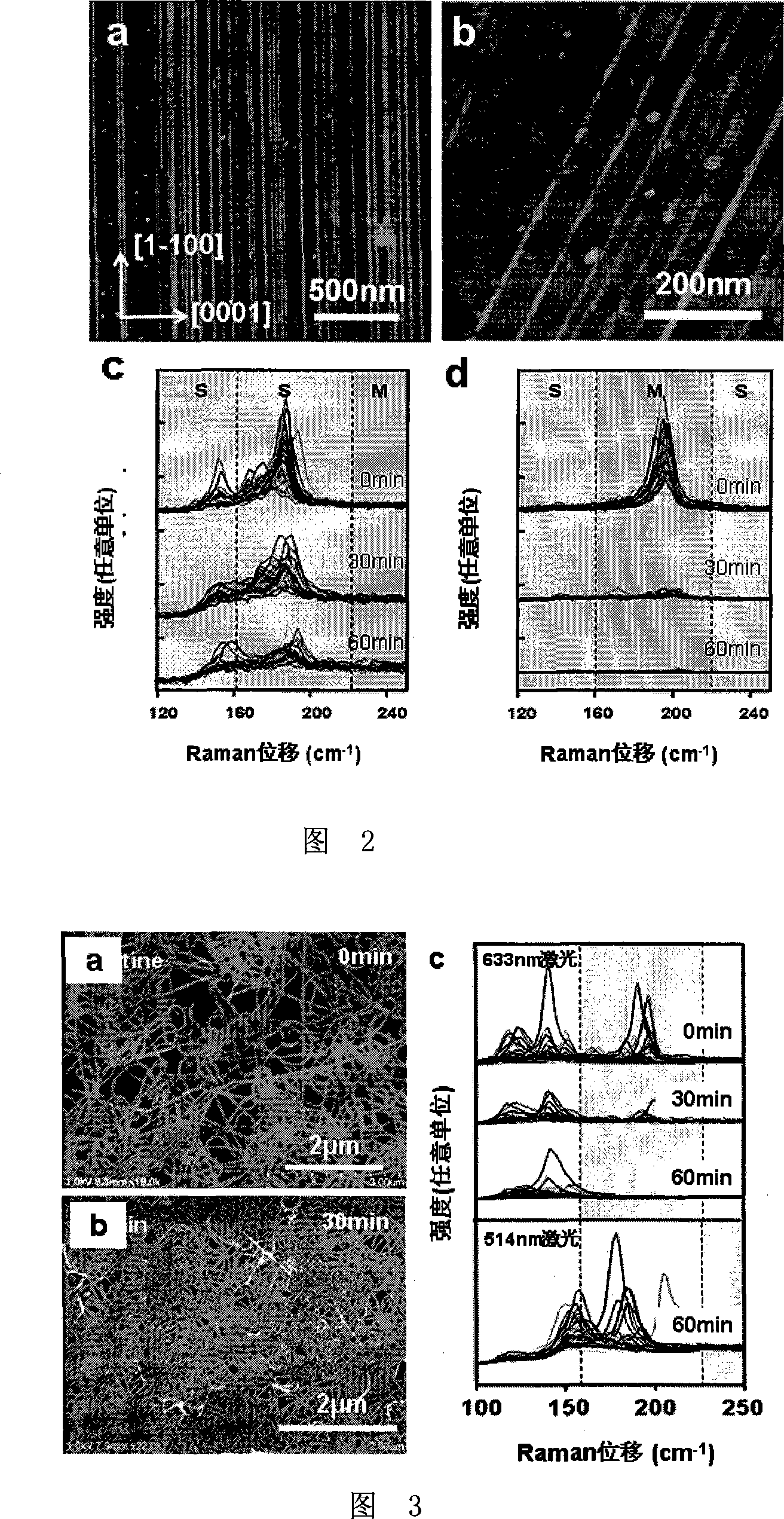

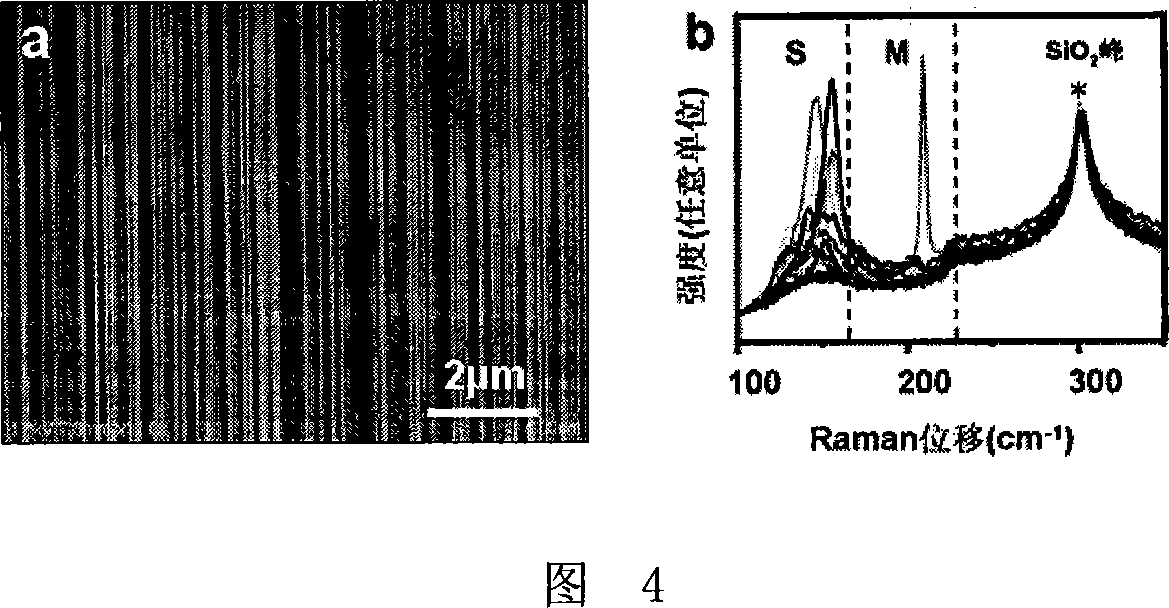

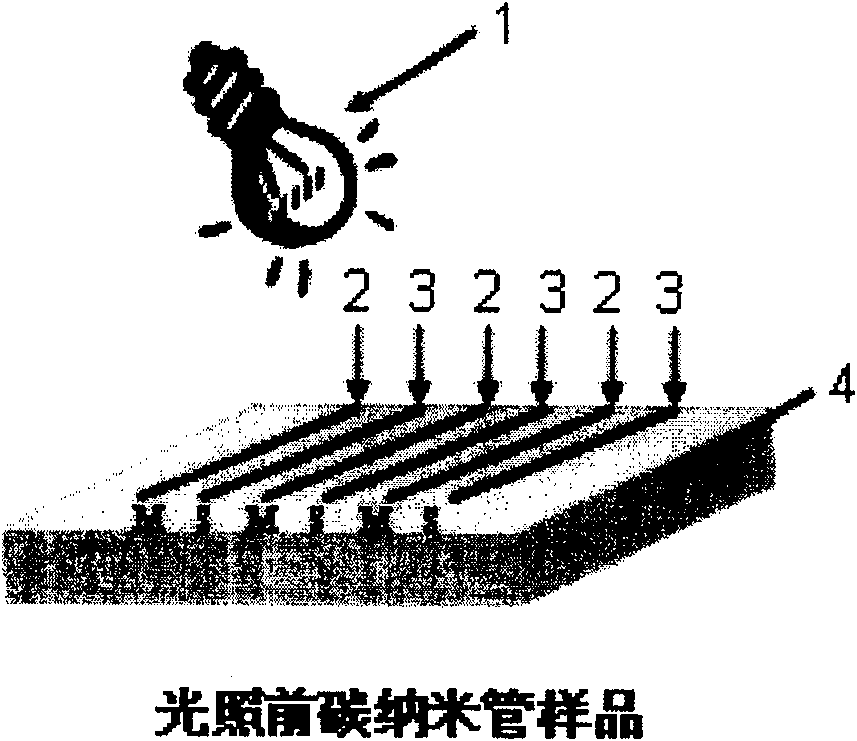

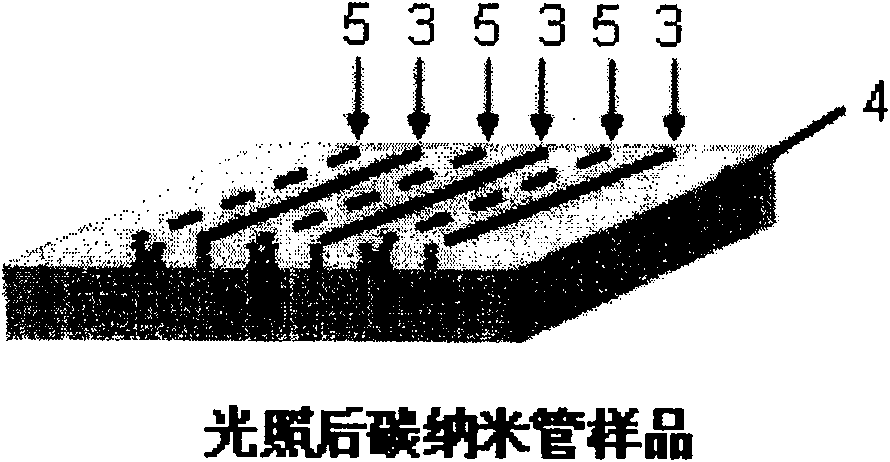

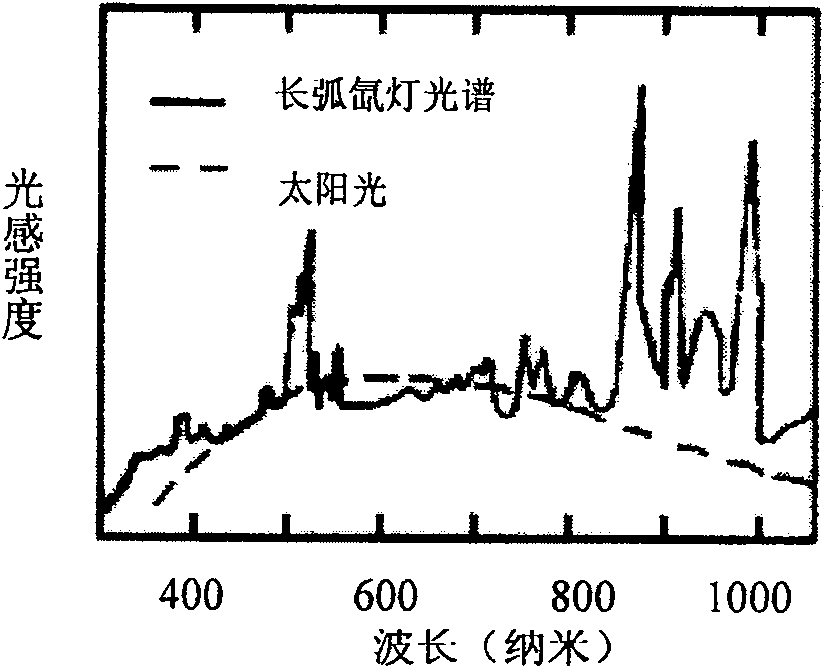

Method for preparing semi-conductive single-walled carbon nanotubes

InactiveCN101200291AEfficient removalWide applicabilityMaterial nanotechnologyNanostructure manufactureWavelengthUltimate tensile strength

The invention discloses a method of preparing semi-conductor single-wall carbon nanometer tube by removing the metallic single-wall carbon nanometer tube in the single-wall carbon nanometer tube, the single-wall carbon nanometer tube is irradiated under a certain strength light so as to remove the metallic single-wall carbon nanometer tube, thereby obtaining the semi-conductor single-wall carbon nanometer tube, wherein total strength of the light that is irradiated on the surface of the carbon nanometer tube sample and has wave length range of 180nm-11um is 30mW per square centimeter to 300mW per square centimeter, compared with the prior art, the invention has the advantages of simple and controllable operation, environmental protection, good effect for removing metallic single-wall carbon nanometer tube, wide adaptability, low cost, and keeping the original look of carbon tube. The utility model has strong practicality and wide application prospect.

Owner:PEKING UNIV

Low-compression-ratio ultrathick EH36 ship plate steel and preparation method thereof

The invention relates to low-compression-ratio ultrathick EH36 ship plate steel and a preparation method thereof; and a finished product structure of a steel plate is a tempered bainite structure. Chemical components of the steel plate adopt the classification society rule and the standard component system staged by GB 712; a continuous casting blank TMCP control rolling process is adopted; after rolling of the steel plate is offline, the steel plate is quickly cooled after normalizing, and is tempered to obtain the steel plate with the tempered bainite structure; the NAC temperature is 880-920 DEG C; the heating insulation time is 2.0-2.3 min / mm; the final cooling temperature of water cooling is 200-500 DEG C; the tempering temperature is 620-660 DEG C; and the tempering insulation time is 2.5-4.0 min / mm. The obtained ultrathick EH36 ship plate steel is higher in impact toughness, in particular, is higher in Akv value in 1 / 2 thickness place, is high in total strength, and is fine and uniform in microscope structure. The method is simple, and totally satisfies stable large-batch enterprise production.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

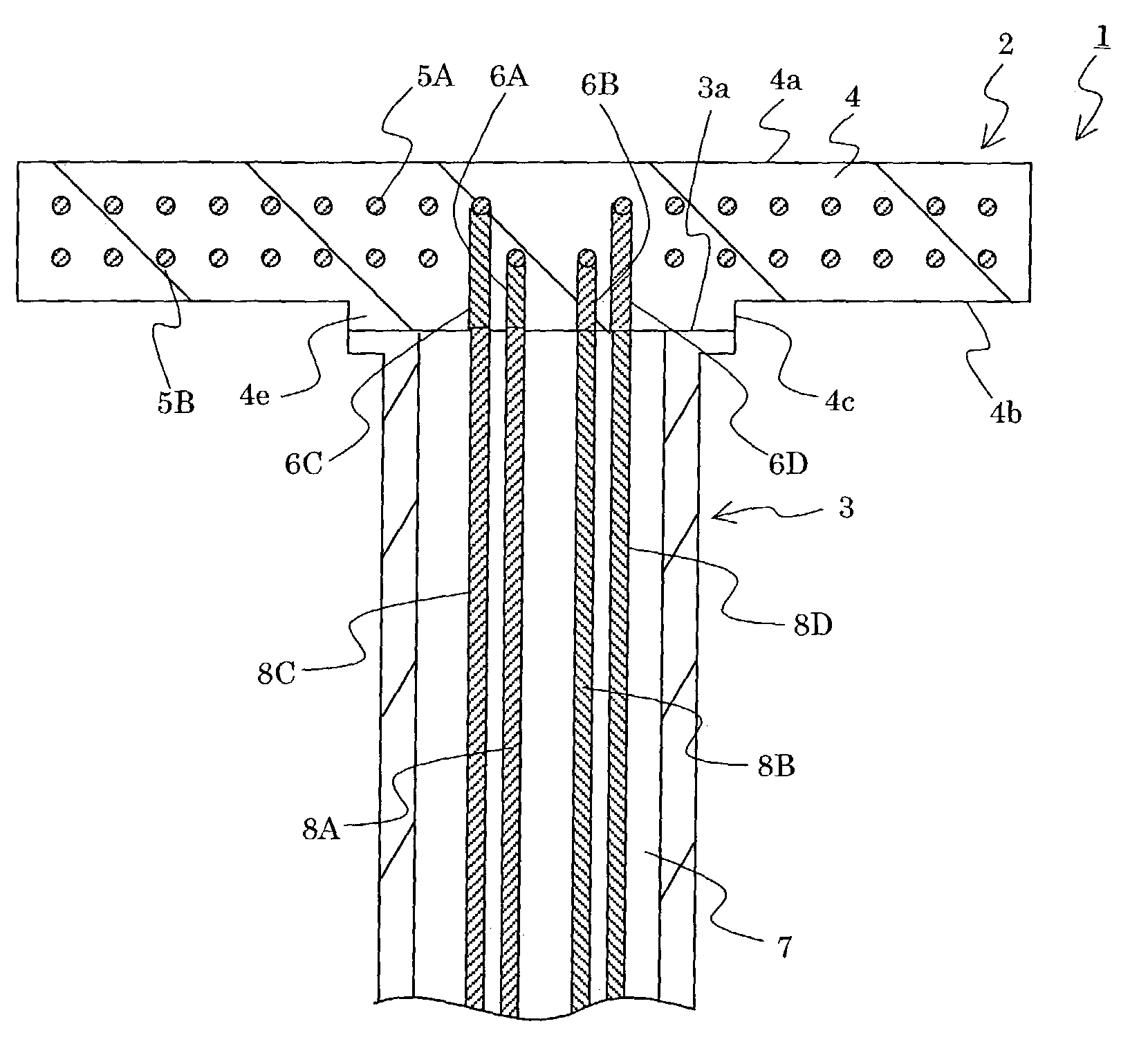

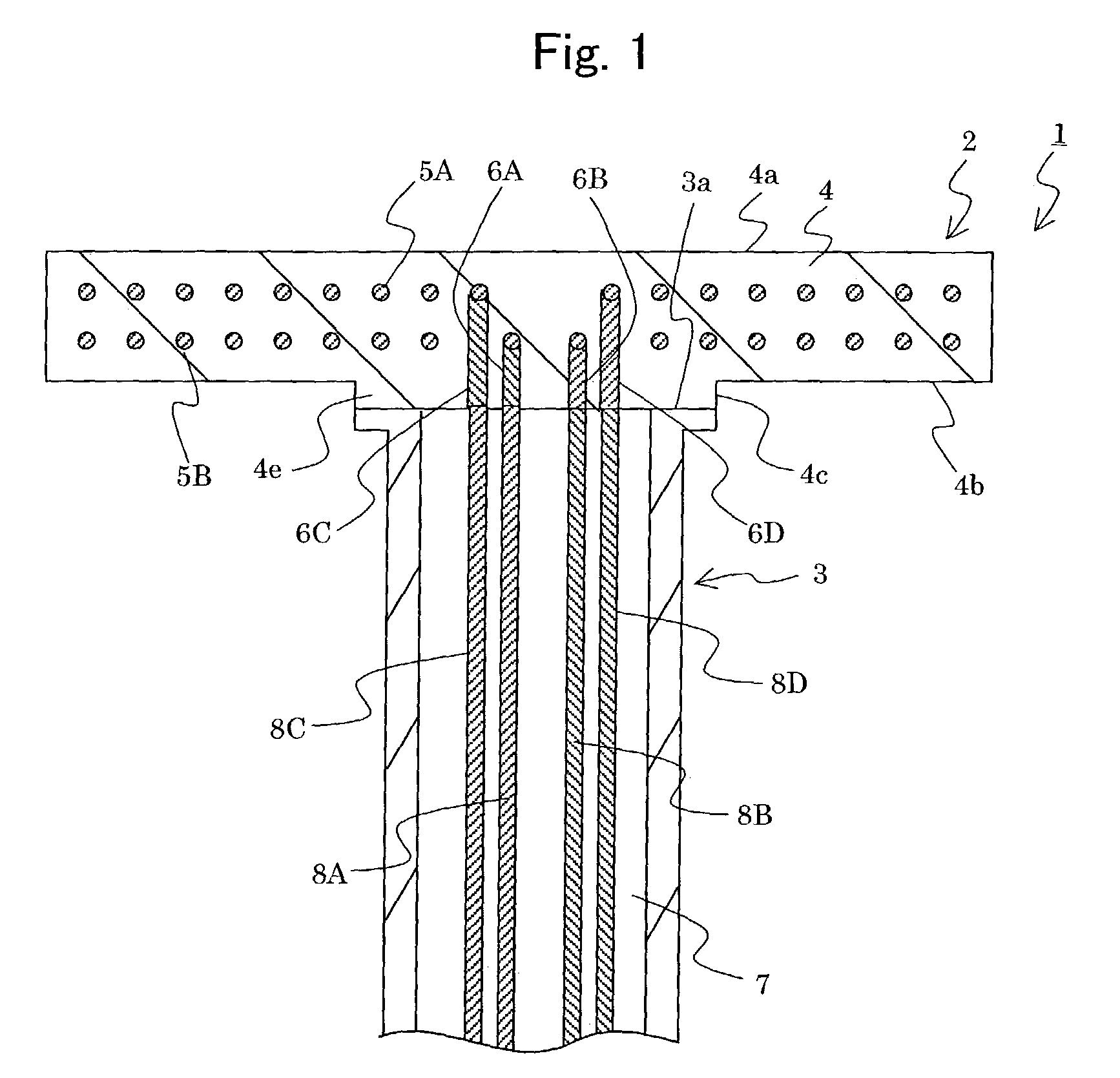

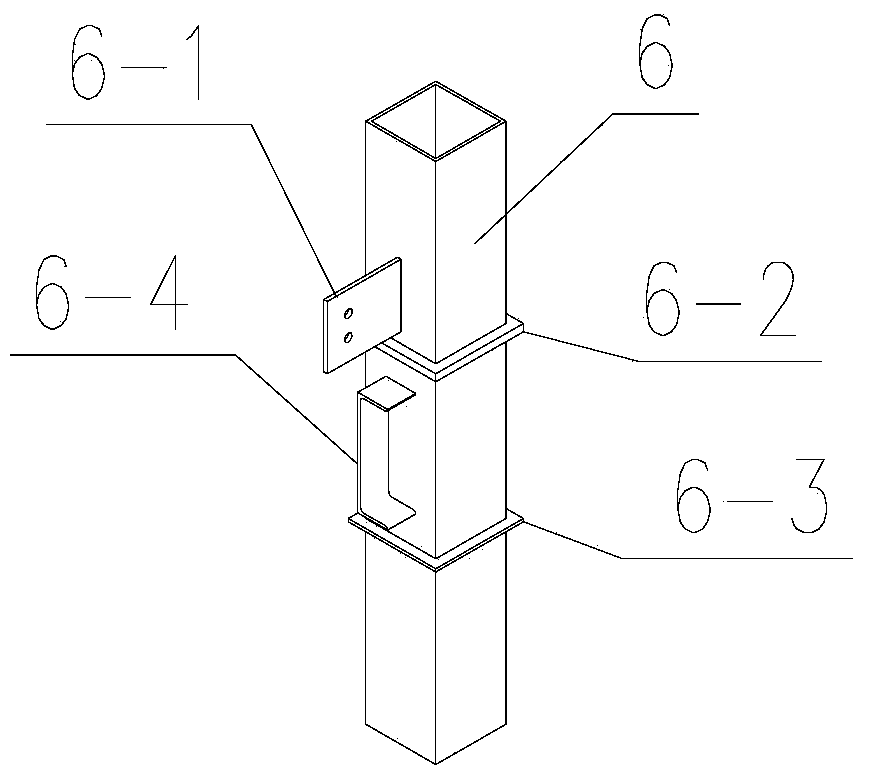

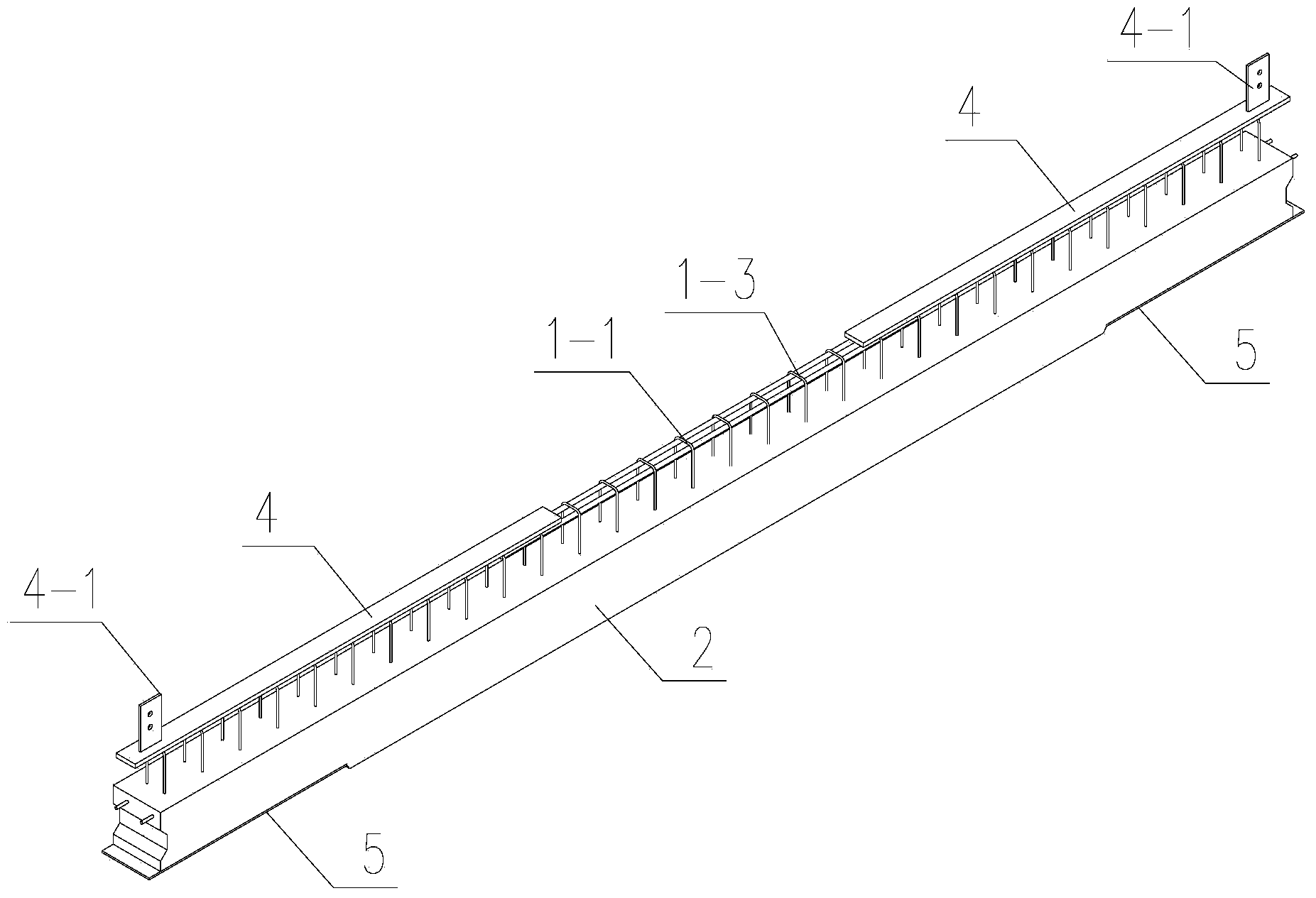

Safe and convenient connection structure for precast reinforced concrete beam and steel pipe column

InactiveCN104294917ASafe and convenient connectionComply with the force characteristicsBuilding constructionsReinforced concreteLap joint

The invention discloses a safe and convenient connection structure for a precast reinforced concrete beam and a steel pipe column and belongs to the field of building structures. The safe and convenient structure comprises the precast reinforced concrete beam and the steel pipe column, and a positioning plate, an upper partition and a lower partition are arranged at the positions of nodes of the steel pipe column; upper node steel plates and lower node steel plates are respectively in lap joint at two ends of an upper horizontal steel bar and a lower horizontal steel bar of the precast reinforced concrete beam, and positioning connecting plates are arranged at ends of the upper node steel plate; the strength of the upper and lower node steel plates is identical to total strength, replaced at the corresponding position, of longitudinal steel bars; positioning connecting plates at two ends of the precast reinforced concrete beam are connecting with the positioning plates of the steel pipe column, the upper and lower node steel plates are respectively correspondingly connected with the upper and lower partitions of the steel pipe columns, and the precast reinforced concrete beam and the steel pipe column are molded in casting in situ and integrally connected. The safe and convenient connection structure is concise, the upper and lower node steel plates are in lap joint with the longitudinal steel bars at the set positions, requirements on equal strength are met, mechanics characteristics of the beam are met, and the beam and the nodes are guaranteed in safety and reliability.

Owner:HUBEI HONGYI STEEL CONSTR ENG

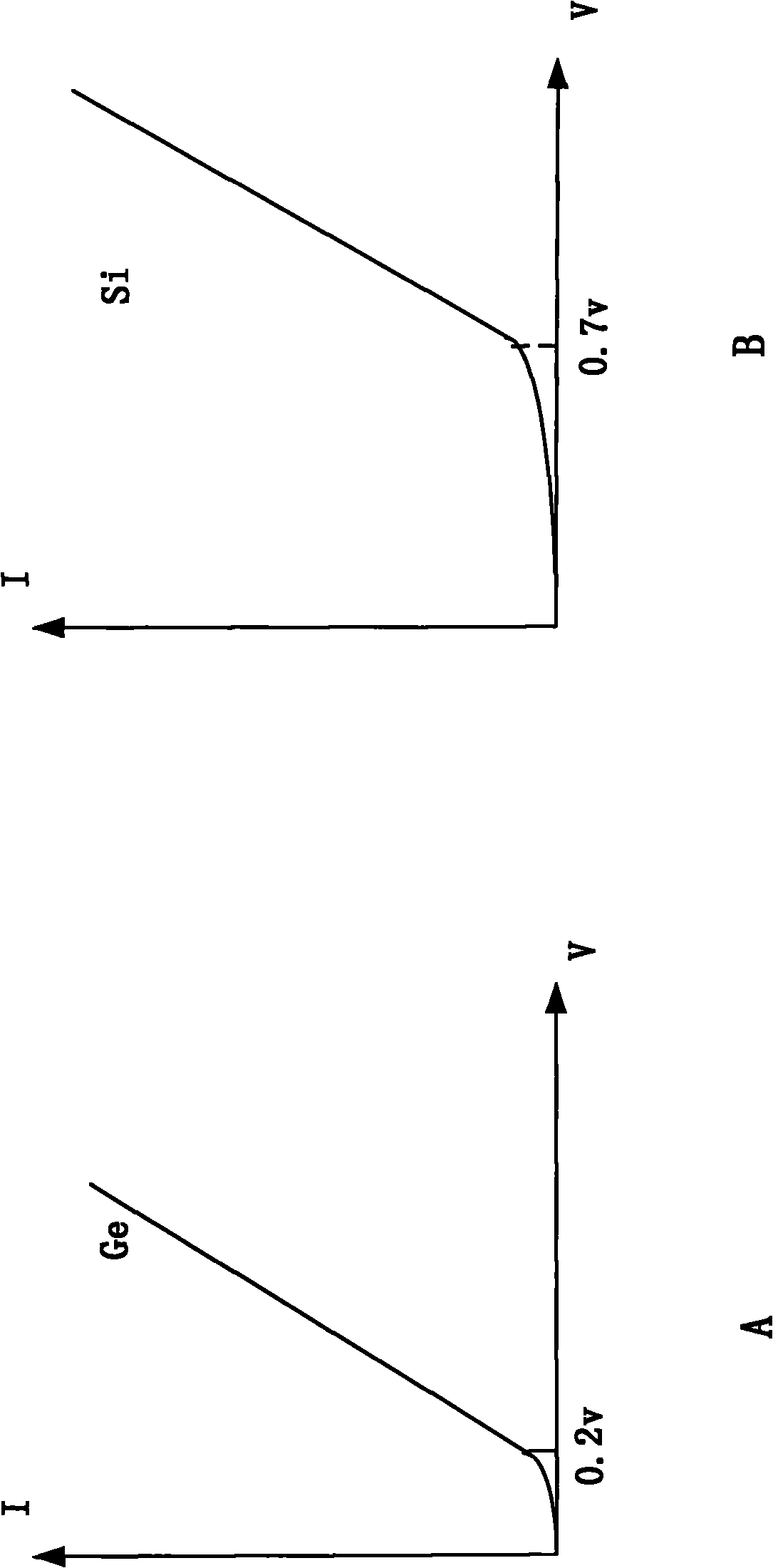

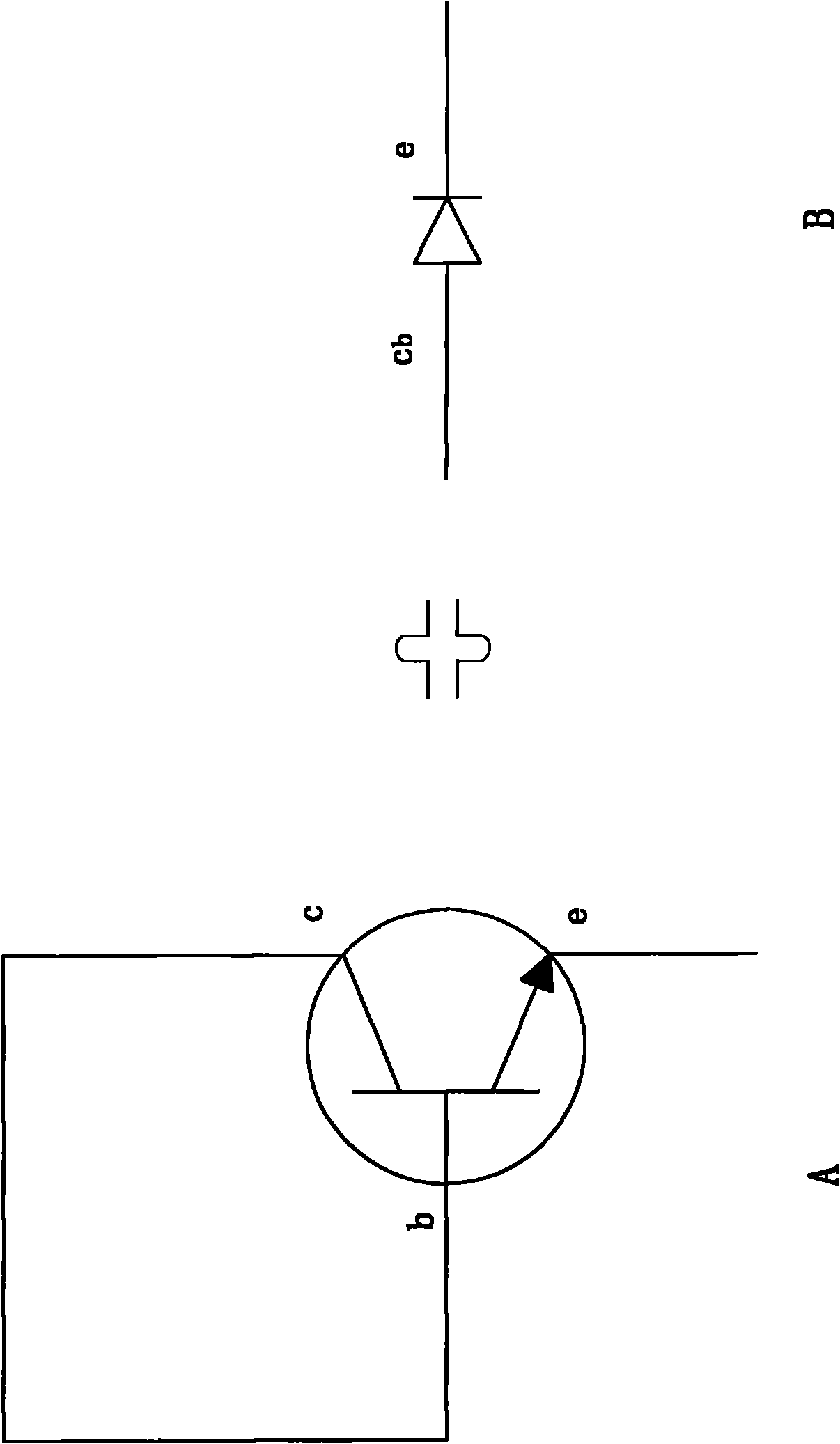

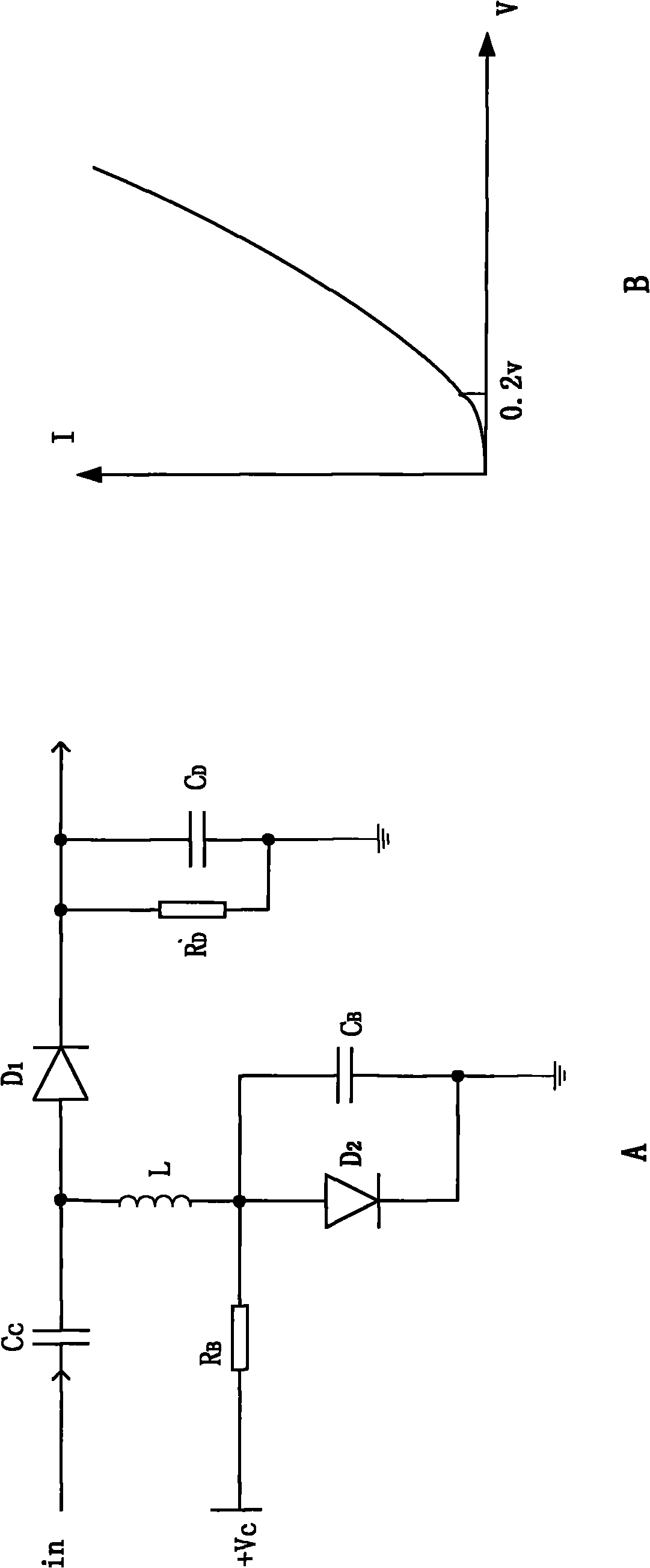

Temperature compensation voltage-multiplying diode detector for ultra high frequency range

InactiveCN101807881ALower the detection thresholdImprove frequency characteristicsAmplitude demodulation by non-linear multiple-pole elementsAmplitude demodulation detailsDouble differenceLinearity

The invention relates to a temperature compensation voltage-multiplying diode detector for an ultra high frequency range. An ultra high frequency silicon crystal audion is adopted to enable a node C and a node B to form a short circuit, and an EB node of the short circuit is utilized to form an ultra high frequency diode. Four CB nodes of the four audions separately form short circuits to form four diodes formed by the EB nodes, and every two of the four diodes are connected in series to form a double EB node voltage-multiplying detector of double-difference geminate transistors. The invention has the advantages of high upper frequency limit reaching 300 MHz or higher, low temperature drifting, good detection linearity, large dynamic range, high output detection voltage and low detection threshold value, thereby having low requirement on the output level of the system before detection and greatly widening the dynamic range of radio astronomy total strength amplitude receiving equipment.

Owner:南京紫淮矿用电子高科技有限公司 +2

Ceramic bond cubic boron nitride abrasive tool and manufacturing method thereof

InactiveCN102826854BImprove bindingHigh strengthAbrasion apparatusElectric arc furnaceSurface oxidation

The invention discloses a ceramic bond cubic boron nitride abrasive tool and a manufacturing method of the ceramic bond cubic boron nitride abrasive tool. The method comprises preparing materials and mixing, placing mixed materials in an electric furnace for melting, conducting water quenching to prepare ceramic bond blocks, conducting smashing, ball-milling, sieving and drying on the ceramic bond blocks to prepare ceramic bond powder, conducting surface oxidation modified pretreatment on cubic boron nitride (cBN) grains, evenly mixing the ceramic bond powder, the cubic boron nitride (cBN) grains and a pore-forming agent NH4HCO3, obtaining a mixture, adding temporary binding agent polyethylene glycol in the mixture, evenly mixing to obtain abrasive tool raw materials, placing the abrasive tool raw materials in a die, conducting pressing shaping on a pressure machine to prepare an abrasive tool green body, placing the abrasive tool green body in a sintering furnace for sinter molding, and preparing the ceramic bond cubic boron nitride abrasive tool along with cooling of the furnace. The ceramic bond cubic boron nitride abrasive tool improves total strength of the abrasive tool, enables the abrasive tool to be not easy to break in using process, improves using safety of the abrasive tool, and prolongs service life of the abrasive tool.

Owner:XI AN JIAOTONG UNIV

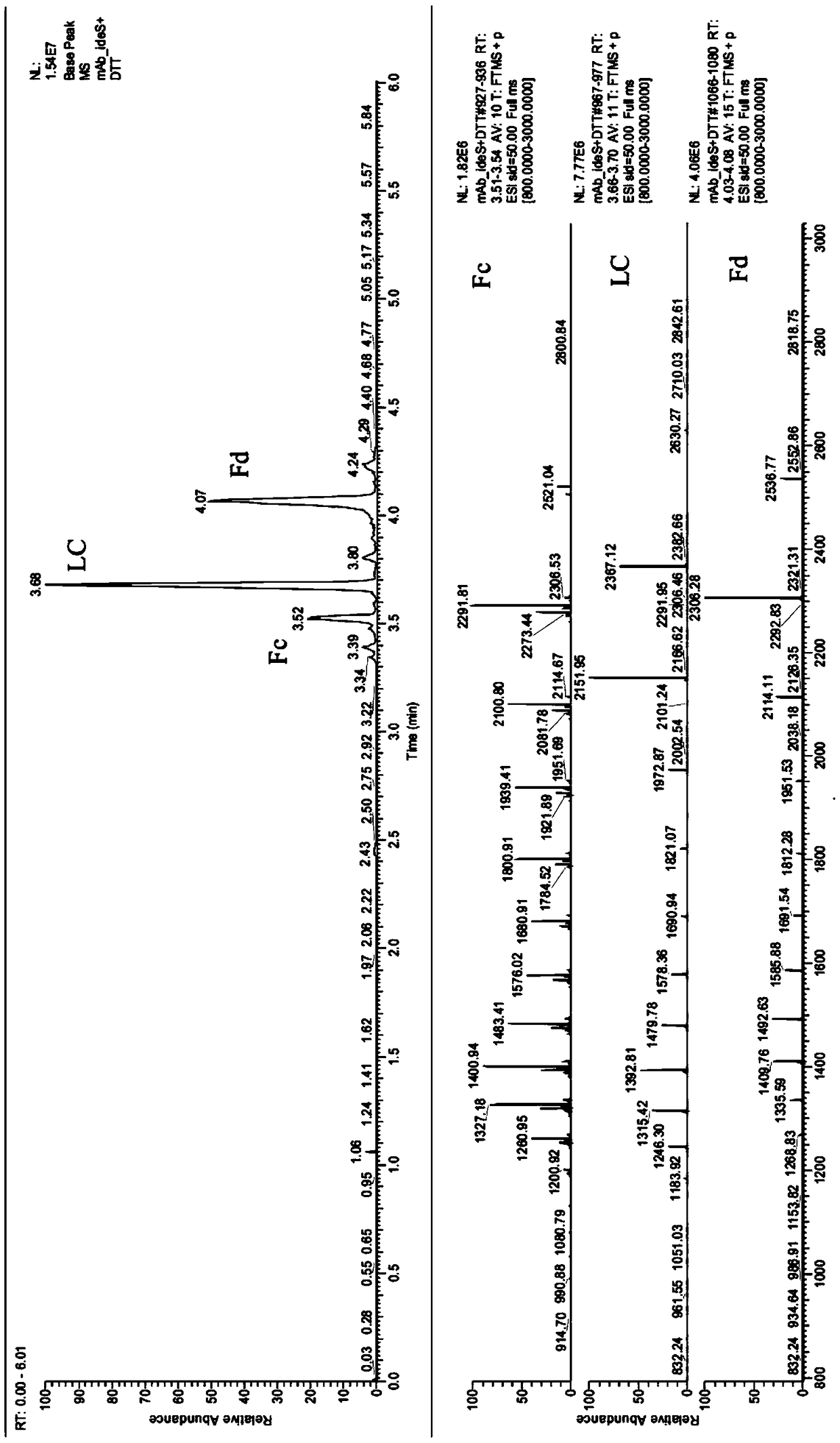

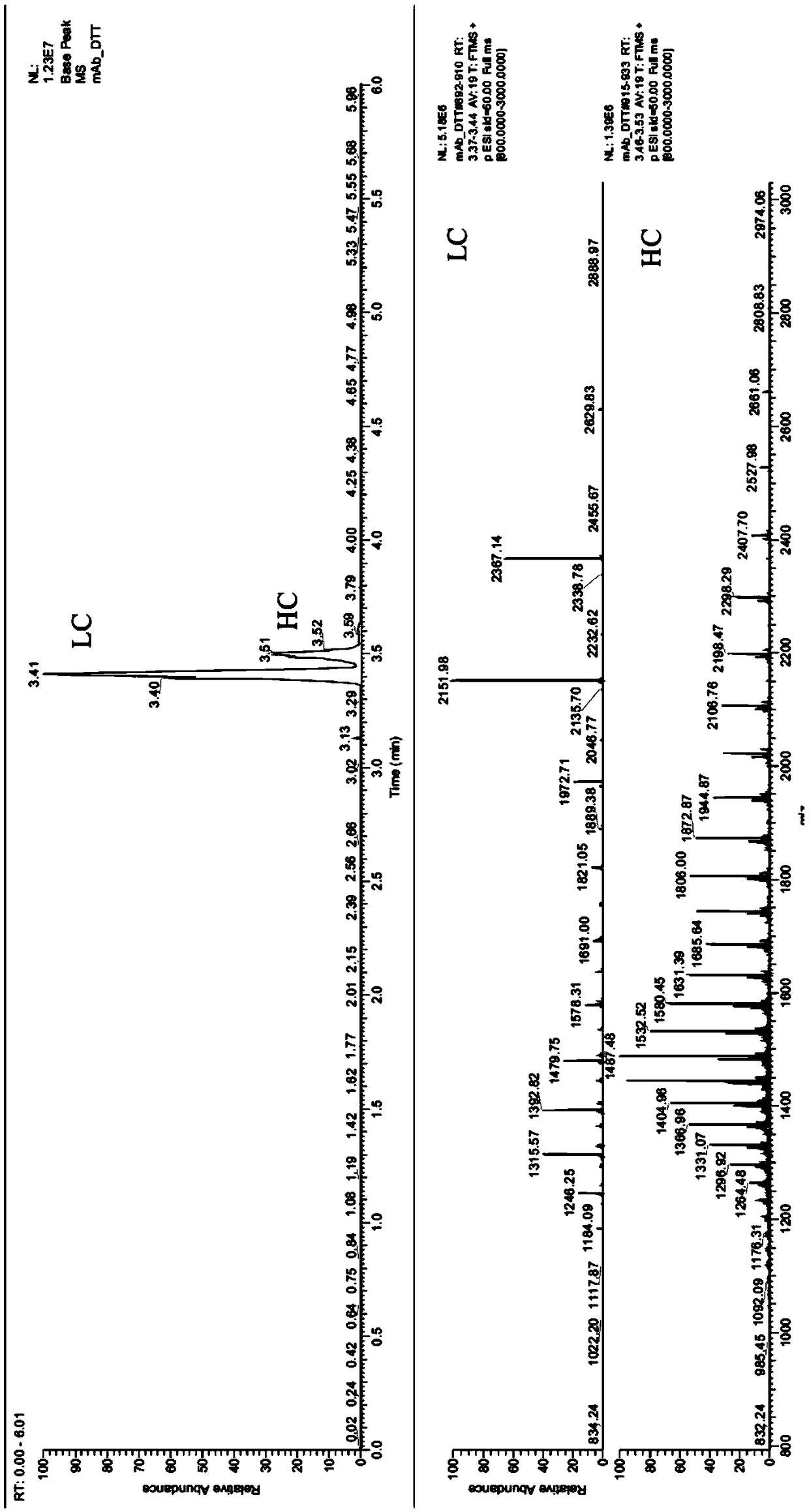

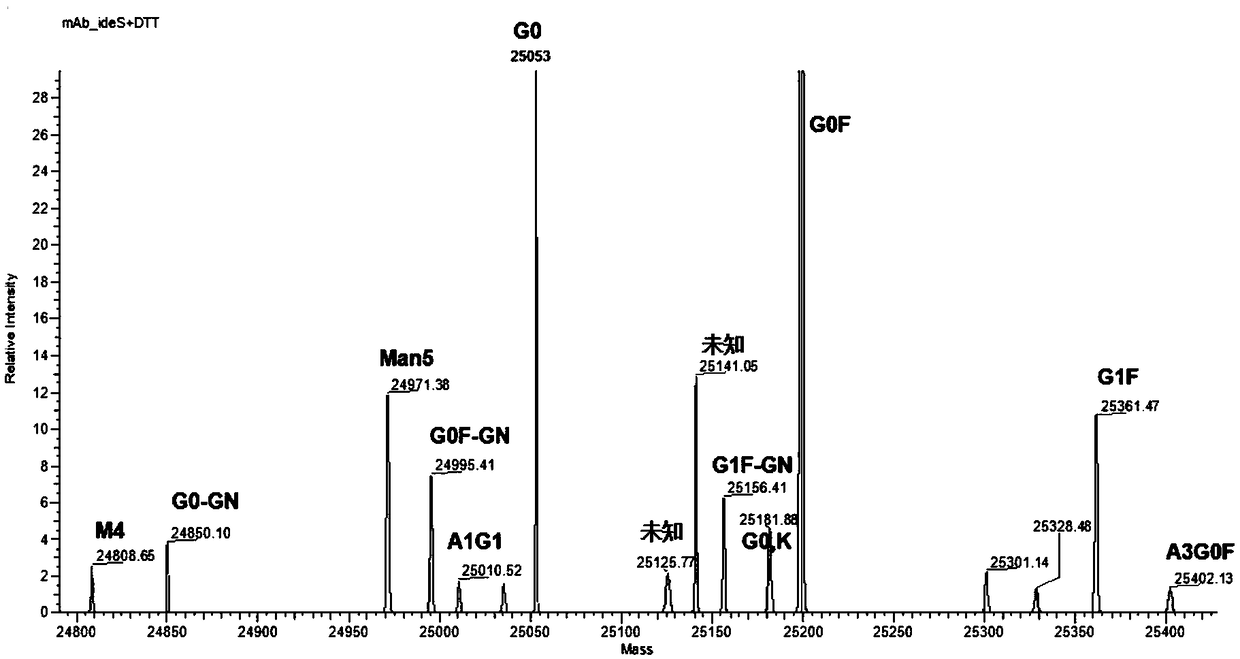

Rapid analysis method for monoclonal antibody N sugar glycoform

ActiveCN109358131AHigh sensitivitySimplified processing requirementsComponent separationDigestionOrganism

The invention provides a rapid analysis method for monoclonal antibody N sugar glycoform. The analysis method comprises the following steps: after centrifuging a to-be-tested cell culture, taking thesupernatant, diluting, adding an IdeS enzyme and a reducing agent to perform enzymatic hydrolysis reaction and reduction reaction, centrifuging, and taking the supernatant; detecting an antibody digestion and a reducing subunit solution by using capillary electrophoresis mass spectrometry to obtain the intensity and molecular weight of different glycoform molecules Ai in the antibody digestion andthe reduction subunit solution; determining the glycoforms corresponding to the molecular weights of the different glycoform molecules Ai by querying a database containing molecular weights of various glycoform molecules, and taking the ratio of the total strength of the subunits to which the intensity of each glycoform molecule Ai belongs as its glycoform ratio. Compared with the traditional polysaccharide labeling method, the rapid analysis method for the monoclonal antibody N sugar glycoform has advantages of rapid, high efficiency and sensitivity, provides strong support for the development of cell strains in the biopharmaceutical industry, and will greatly assist in speeding up the development progress of cell strain screening.

Owner:HJB HANGZHOU CO LTD

Barium-containing sulfoaluminate soft soil curing agent and preparation method thereof

InactiveCN103275730BFast curingHigh strengthBuilding constructionsOrganic fertilisersPortland cementSoft clay

The invention relates to the field of a soft soil curing agent, and particularly provides a barium-containing sulphoaluminate soft soil curing agent and a preparation method thereof. The sulphoaluminate soft soil curing agent comprises components in percentage by weight as follows: (1), 50%-80% of sulfoaluminateclinker containing barium; (2), 25%-40% of calcined gypsum; (3), 10%-12% of lime; (4), 0.5%-2% of a water-retaining agent; and (5), 0.5%-5% of a retarder. The preparation technique process comprises the steps of calcinating natural gypsum, preparing ingredients, mixing and grinding. The soft soil curing agent has the characteristics of quick condensation, high strength and no shrinkage of curing soil volume, total strength can be formed after the curing for 1-3 days, and the soft soil curing agent is particularly suitable for quick maintenance and reinforcement of road foundations; and besides, under the same additive amount, the unconfined compressive strength of compacted soil adopting the soft soil curing agent is apparently higher than that of compacted soil adopting P.C 32.5 ordinary Portland cement, and the reinforcement effect is remarkable.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

High-strength heat radiation type hardware backboard and production technology thereof

InactiveCN109951997AImprove stabilityImprove reliabilityCooling/ventilation/heating modificationsEngineeringHigh intensity

The invention discloses a high-strength heat radiation type hardware backboard and production technology thereof. The hardware backboard comprises a heat radiation frame, a heat radiation cover plate,a reinforcing cover plate and heat conduction tubes; and the heat radiation frame comprises a body frame of a hollow frustum shape and with a frustum-shaped accommodating space, an upper radiating fin group is extended out of the top inclined plane of the body frame in an integrated way, upper jacks arranged horizontally are formed in the upper radiating fin group, and a lower radiating fin groupis extended out of the bottom inclined plane of the body frame. The upper and lower radiating fin groups are extended from the top and bottom inclined planes of the body frame respectively, the spaceis utilized fully, the heat radiation cover plate and the heat conduction tubes are arranged cooperatively, so that the backboard has a good heat radiation effect, and the operational stability and reliability of display equipment are improved; and the reinforcing cover plate is arranged, so that the total strength of the backboard is improved, the backboard is unlikely to deformation and damage,and the service life is longer.

Owner:东莞市鑫米电子科技有限公司

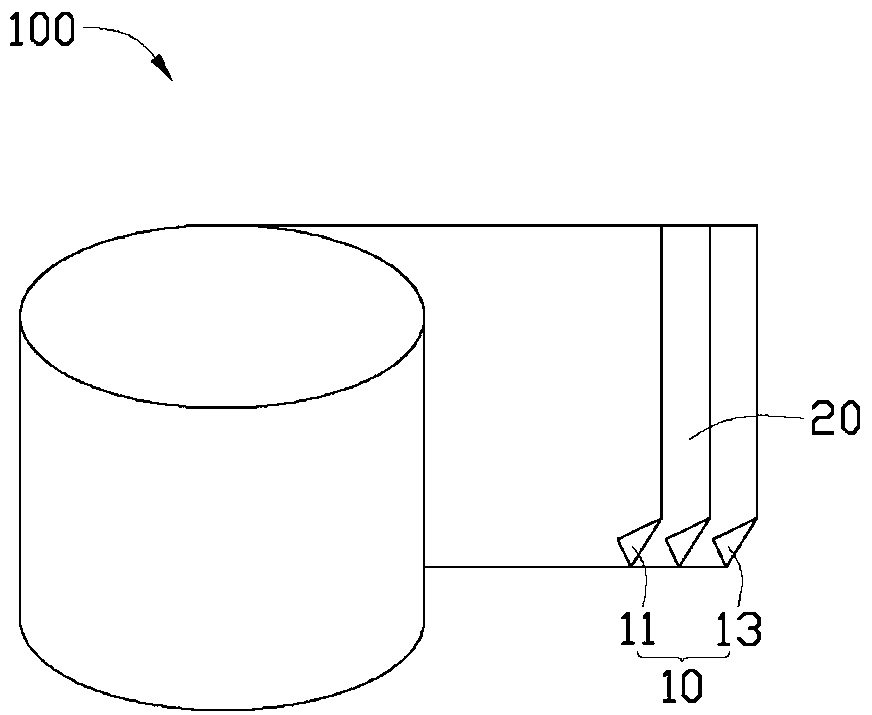

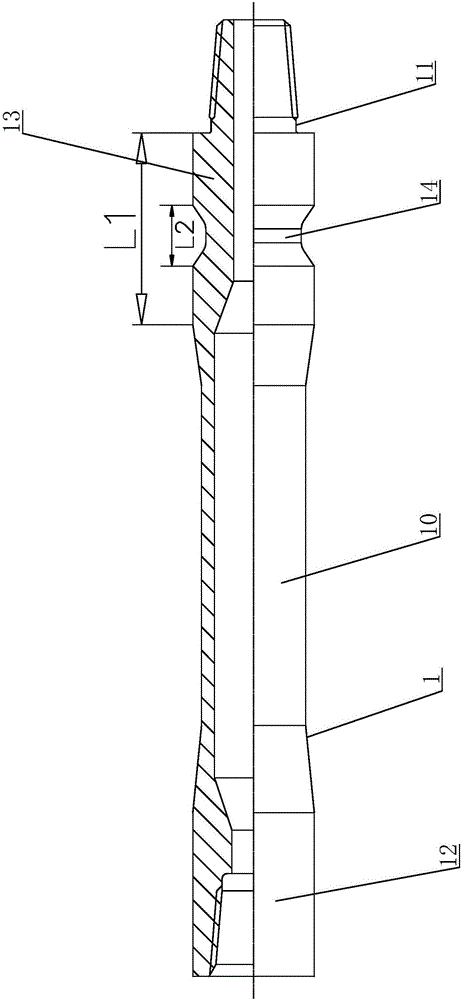

High-toughness non-excavated oriented drill rod

InactiveCN106437543ASmall bending radiusGuaranteed effective areaDrilling rodsDrilling casingsBend radiusUltimate tensile strength

The invention discloses a high-toughness non-excavated oriented drill rod which comprises a drill rod body. The drill rod body comprises a tube body, wherein a male fastener and a female fastener are arranged at two ends of the tube body respectively. The high-toughness non-excavated oriented drill rod is characterized in that a thickened section is arranged on the male fastener, a groove is formed in the thickened section, and the width of the groove is 1 / 3 of the length of the thickened section. The thickened section of the high-toughness non-excavated oriented drill rod adopts a groove design, the bending radius of the drill rod under large curvature is increased, meanwhile the effective area of a cross section is ensured, the total strength is far greater than that of a non-thickened zone, the overall performance in use is ensured, the guiding flexibility of the drill rod is improved, the construction cost can be reduced, and the construction benefits are improved.

Owner:WUXI DOUBLE HORSE DRILLING TOOLS

Mie scattering polarization micro-pulse laser radar control method and device

ActiveCN100495069CScattering properties measurementsElectromagnetic wave reradiationPrismData memory

The invention discloses a dispersive polarized micropulse laser light radar control method and device, inputting polarized laser light emitted by a small-scale semiconductor pumping YAG frequency doubling polarizing laser as working into a beam expander for expanding, then sending the laser to the sky, where the laser is dispersed by aerosol in the atmosphere, the backward dispersed light of spherical particles in the aerosol will not change the polarizing direction of the laser light and that of nonspherical particles will change the polarizing direction of the laser light to form a component vertical to the polarizing direction of the original laser light (i.e. depolarized). The backward dispersive echo signals coming from the spherical and nonspherical particles are received by an optical telescope and two lights of different polarizing directions are separated by a light separating prism and sent to two detectors, respectively; a photon counter card makes contraposition counting and accumulation processing in the time sequence of photoelectric pulse signal returning from the space, and the processed result is stored into corresponding data memory cells; two signals collected are calculated by XJ-PMPL software to obtain echo depolarization degree, thus obtaining space distribution outline of nonspherical particles. Besides, it can also combine the two signals to obtain the total strength distribution of backward dispersed light, therefore the polarized micropulse laser light radar can also complete the functions of a general micropulse radar.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Radial tire for airplane

A radial tire for airplane comprises a pair of bead cores, a radial carcass, and a belt disposed on an outer periphery of a crown portion of the radial carcass and comprised of plural belt layers each containing organic fiber cords, in which a total strength in a circumferential direction over a full width of the belt Tbelt(N) satisfies Tbelt / WD≧1.5×106 when an outer diameter of the tire is D (m) and a width of the tire is W (m), and at least one layer of the belt layers is constituted with an organic fiber cord spirally winding at an angle of approximately 0° with respect an equatorial plane of the tire and satisfying the following equations (I) and (II):σ≧−0.01E+1.2 (I)σ≧0.02 (II)(wherein σ is a heat shrinkage stress at 177° C. (cN / dtex) and E is an elastic modulus at 25° C. under a load of 49 N (cN / dtex)).

Owner:BRIDGESTONE CORP

High-strength composite material used for special cable and preparation method thereof

The invention provides a high-strength composite material used for special cables and a preparation method thereof. In the invention, high-performance engineering-use polyether ether ketone, polyethylene and polyimide are employed as basic polymer materials. Hyperbranched polyurethane is used for modifying molybdenum trioxide and magnesium oxide filling materials and an ethylene-vinyl acetate copolymer is used for modifying silicon nitride and zirconium oxide crystal whiskers, thereby improving binding force between inorganic filling materials and organic substrates. Meanwhile, the hyperbranched polymer penetrates the organic substrate network, thereby improving total strength. The composite material ensures high-temperature resistance, fire-proofing performance and the like and reduces defect generation rate between organic and inorganic interfaces. Compared with special cable materials with non-modified filling materials, the composite material improves strength by more than 33%, thereby effectively improving the durability and reliability of the special cables in use.

Owner:武汉市钢电电线制造有限公司

Method for preparing semi-conductive single-walled carbon nanotubes

InactiveCN100569637CEfficient removalWide applicabilityMaterial nanotechnologyNanostructure manufactureWavelengthUltimate tensile strength

The invention discloses a method of preparing semi-conductor single-wall carbon nanometer tube by removing the metallic single-wall carbon nanometer tube in the single-wall carbon nanometer tube, the single-wall carbon nanometer tube is irradiated under a certain strength light so as to remove the metallic single-wall carbon nanometer tube, thereby obtaining the semi-conductor single-wall carbon nanometer tube, wherein total strength of the light that is irradiated on the surface of the carbon nanometer tube sample and has wave length range of 180nm-11um is 30mW per square centimeter to 300mW per square centimeter, compared with the prior art, the invention has the advantages of simple and controllable operation, environmental protection, good effect for removing metallic single-wall carbon nanometer tube, wide adaptability, low cost, and keeping the original look of carbon tube. The utility model has strong practicality and wide application prospect.

Owner:PEKING UNIV

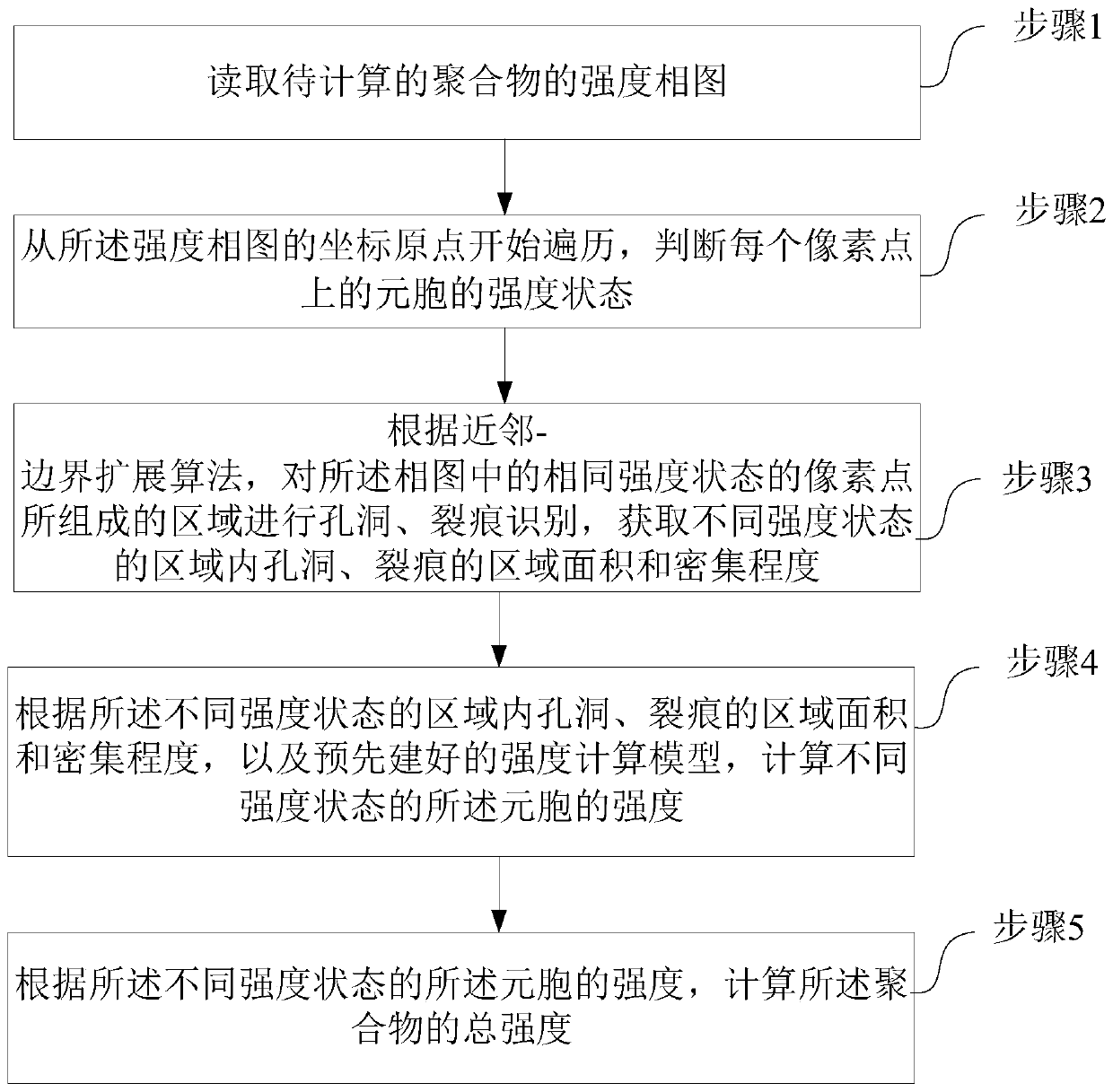

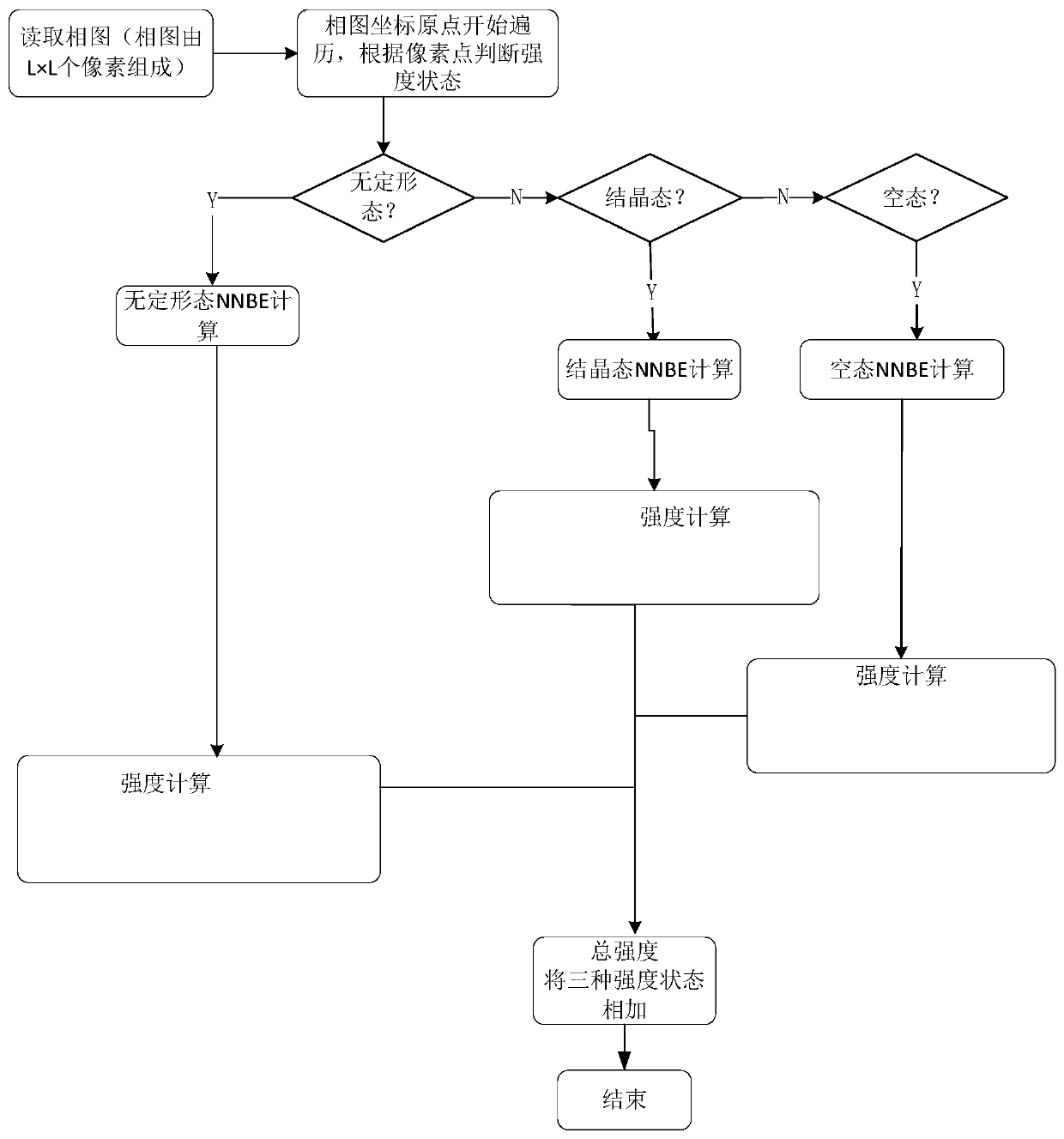

Method and device for calculating polymer degradation strength based on strength phase diagram

ActiveCN110334414ACalculation method is simpleDesign optimisation/simulationSpecial data processing applicationsUltimate tensile strengthPolymer degradation

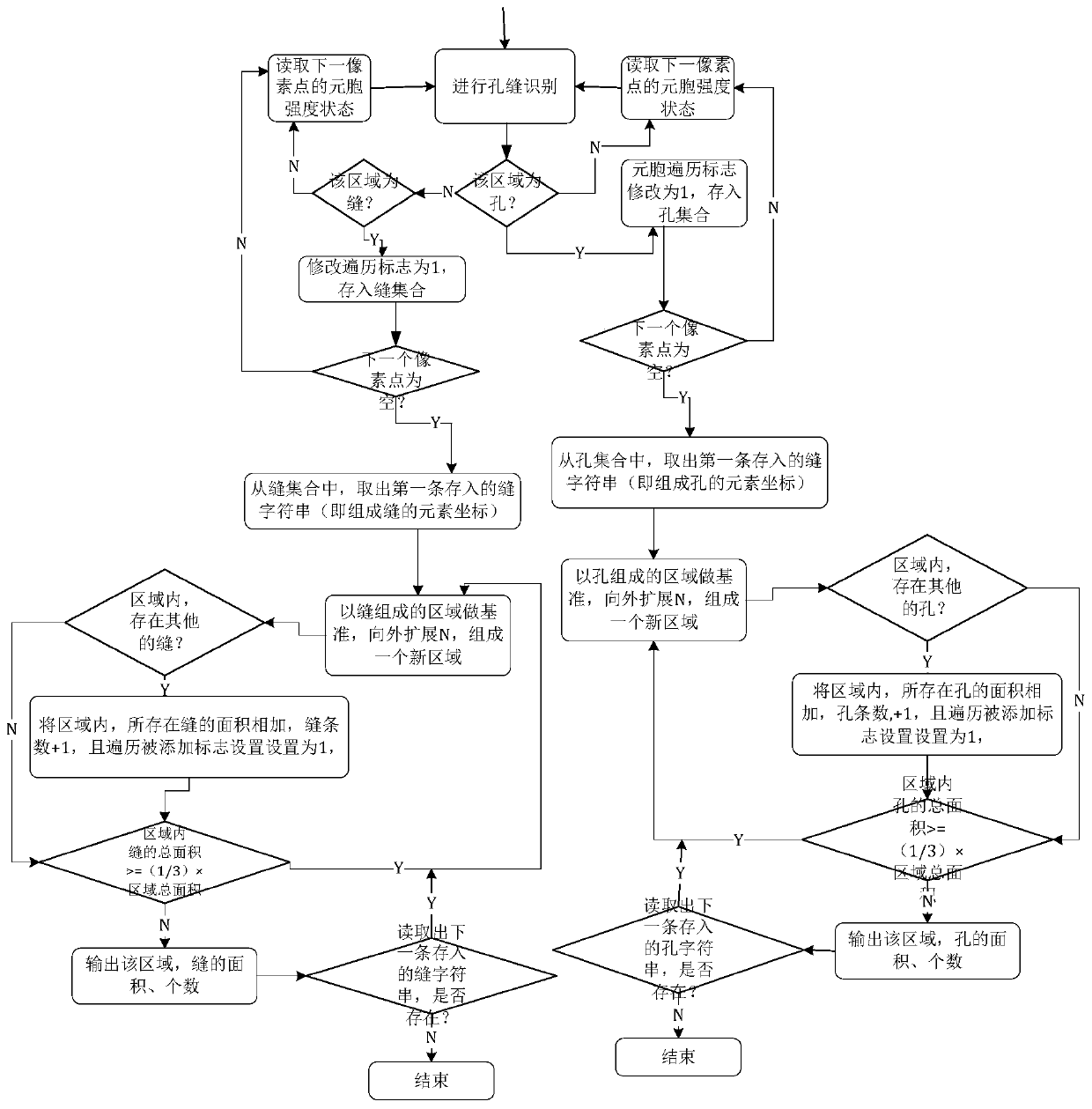

The embodiment of the invention discloses a method and device for calculating polymer degradation strength based on an intensity phase diagram. The method comprises the following steps: step 1, reading an intensity phase diagram of a polymer to be calculated; step 2, starting to traverse from the origin of coordinates of the intensity phase diagram, and judging the intensity state of a cell on each pixel point; step 3, according to a neighbor-boundary expansion algorithm, carrying out hole and crack identification on an area formed by the pixel points in the same intensity state in the phase diagram, and obtaining area and density of holes and cracks in the areas in different intensity states; step 4, calculating the strength of the cells in different strength states according to the areaand the density of the holes and the cracks in the areas in different strength states and a pre-established strength calculation model; and step 5, calculating the total strength of the polymer according to the strength of the cells in different strength states.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com