Patents

Literature

50results about How to "Comply with the force characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

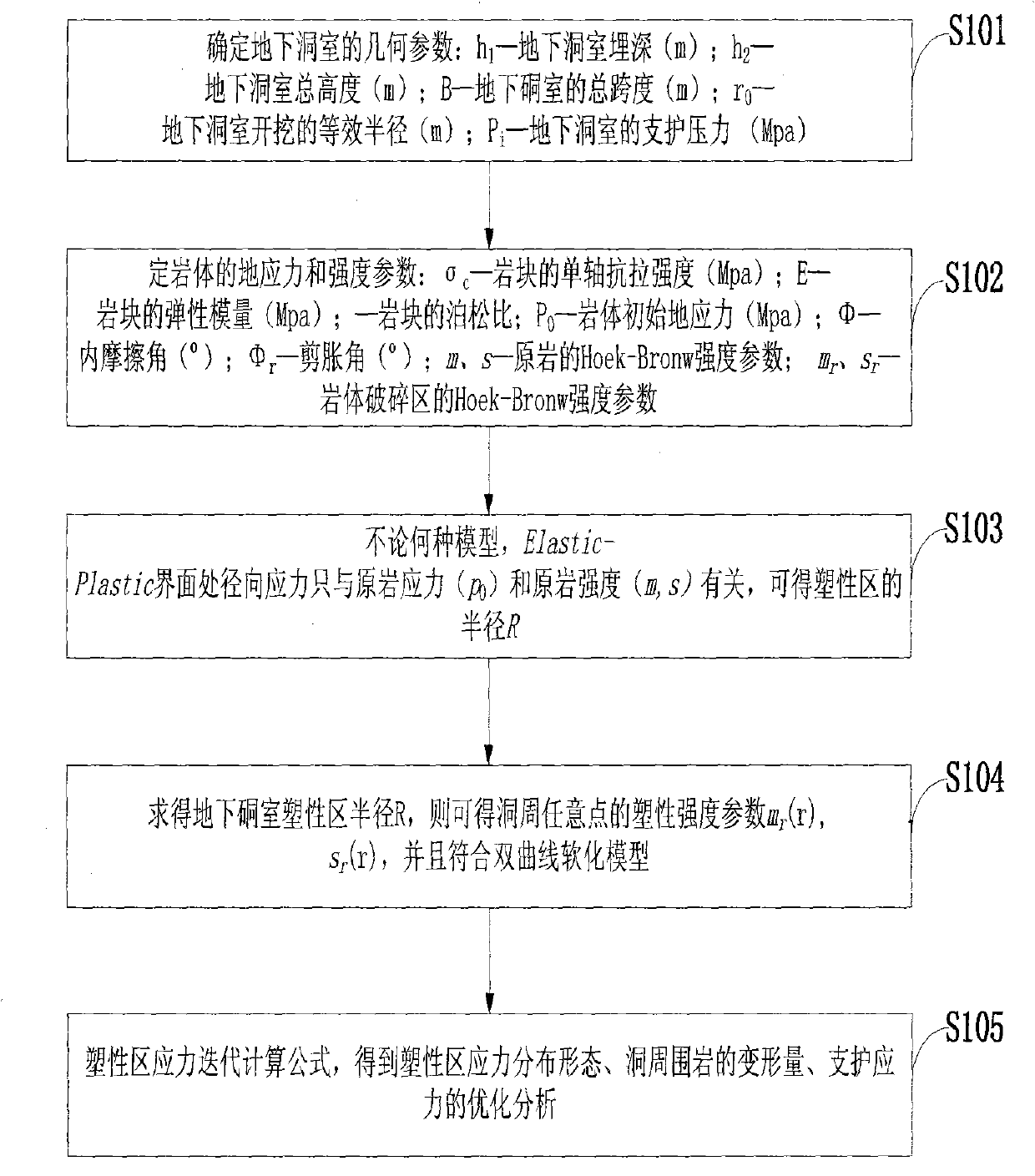

Underground cavity analysis method considering nonlinear softening and dilation characteristics of surrounding rock

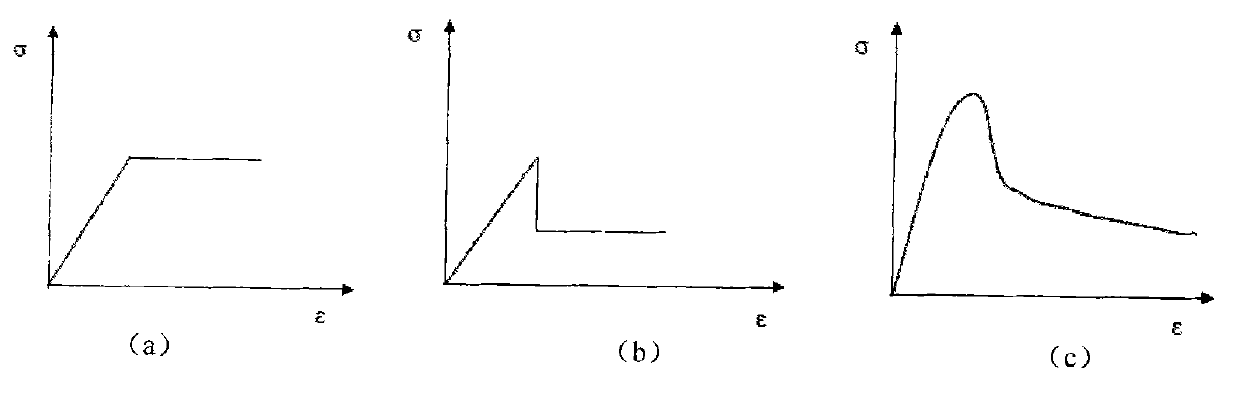

InactiveCN104596837AAvoid complex modeling processFast modelingStrength propertiesStress–strain curveUltimate tensile strength

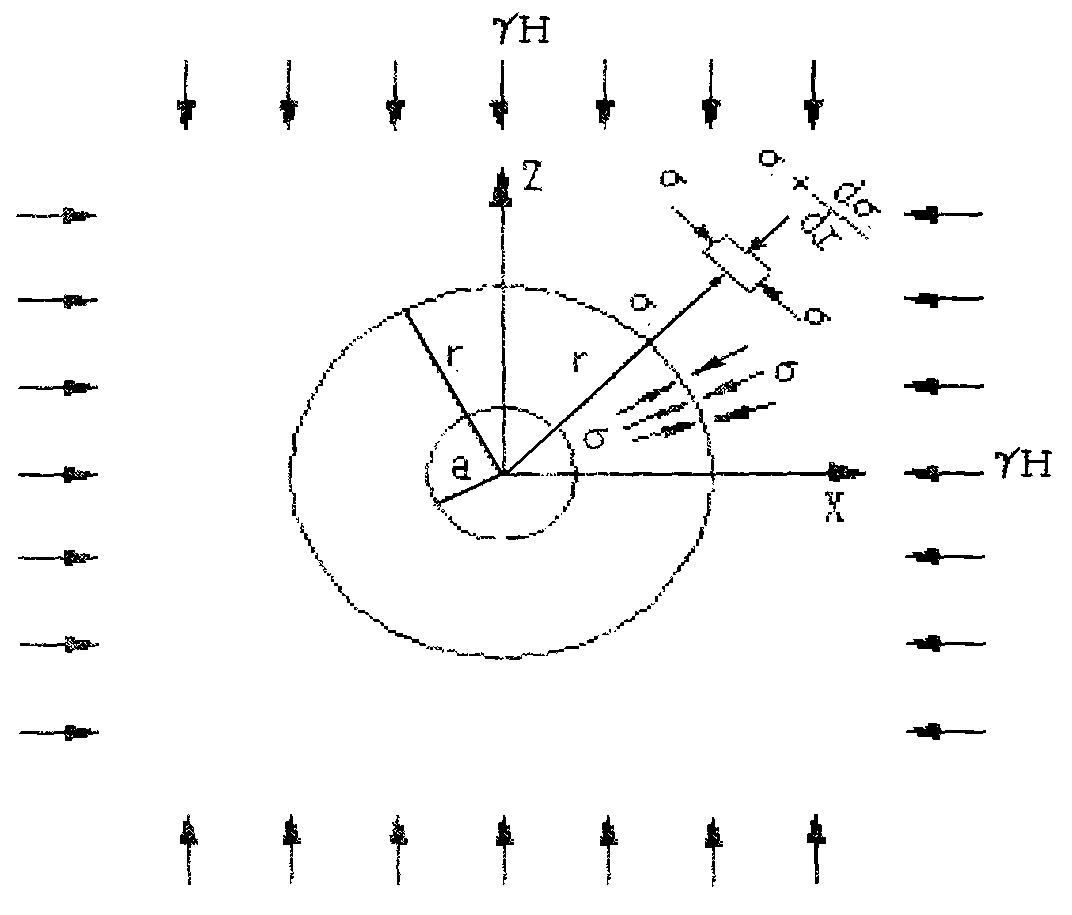

The invention discloses an underground cavity analysis method considering nonlinear softening and dilation characteristics of surrounding rock. According to the method, a hyperbolic softening model based on the characteristics of the Hoek-Brown criterion is established according to the characteristic that the strength parameter of the surrounding rock of a tunnel is weakened with the increasing of the strain of a plastic zone, the model is based on the characteristics of a resultant stress-strain curve of the surrounding rock, and reflects the nonlinear characteristics of the surrounding rock through example verification, the model is applied to analysis for the surrounding rock subjected to strain softening in underground construction, and a new method for an underground cavity analysis is established by considering the nonlinear softening and non-associated flow characteristics as well as a nonlinear failure criterion of a rock mass; the solutions of the stress of the underground cavity, the deformation of the cavity and the radius of the plastic zone are obtained; according to the method disclosed by the invention, the dilation characteristics of the surrounding rock are considered according to a non-associated flow criterion, and with regard to the deformations of the surrounding rock under different plastic models, application example results indicate that the strain dilation of a rock-soil material with dilation and strain softening is considered to be safe.

Owner:张斌伟 +1

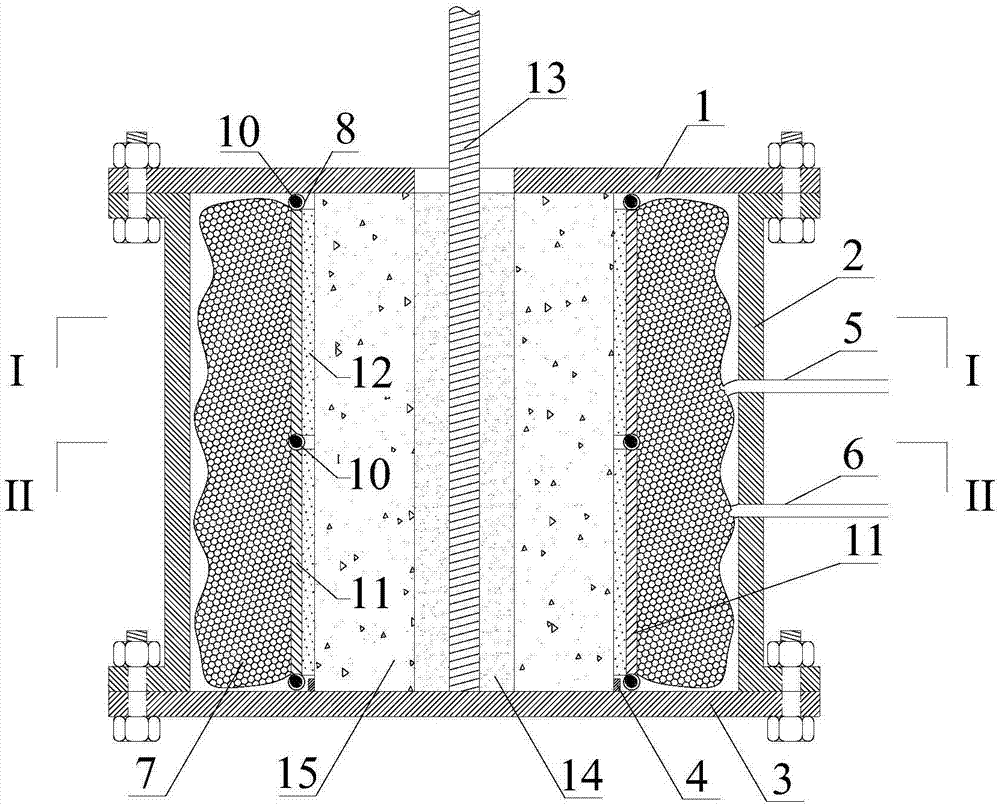

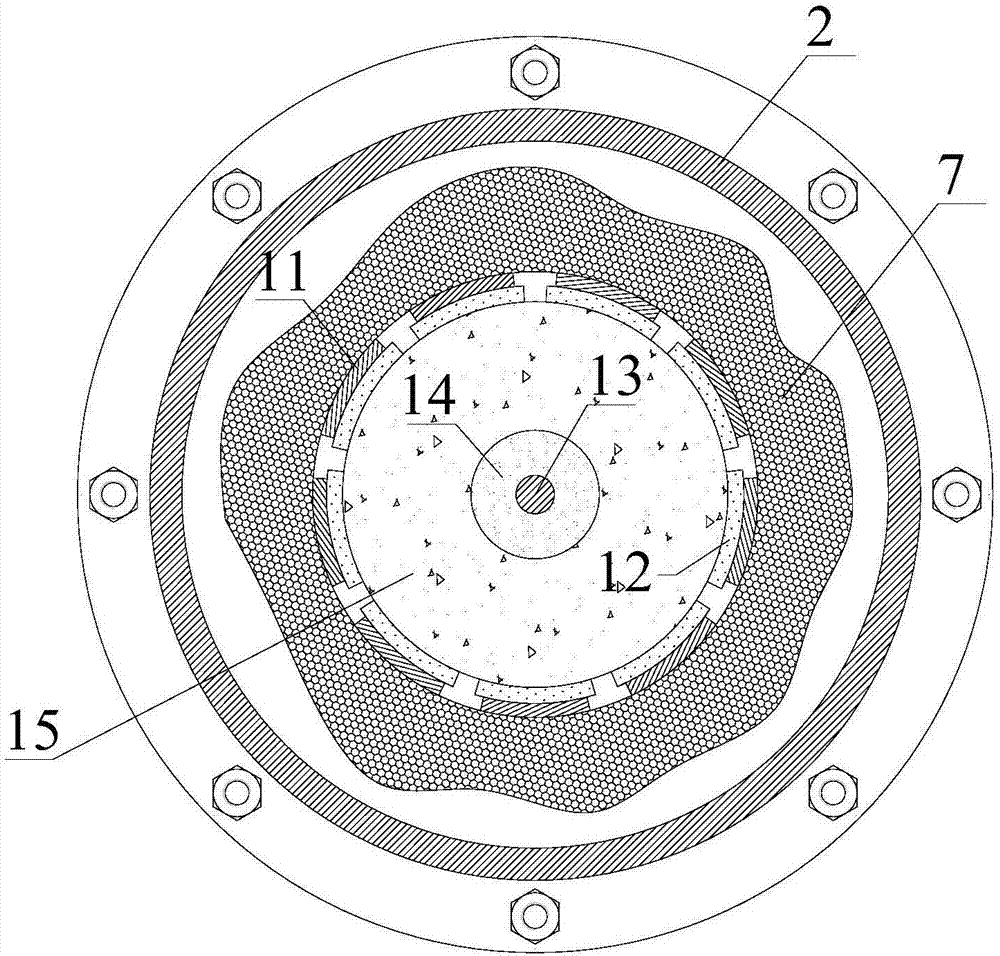

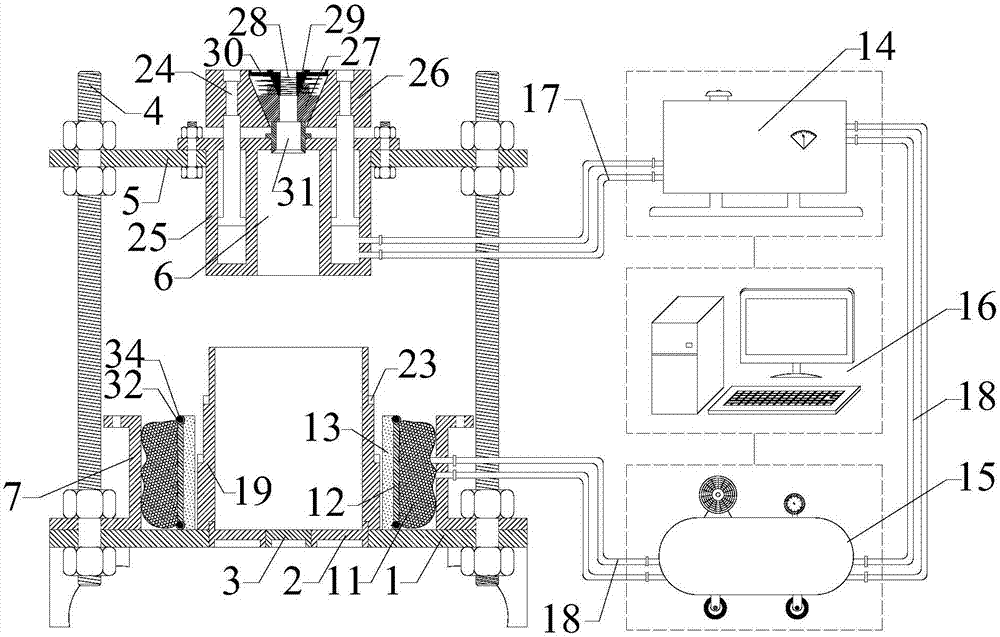

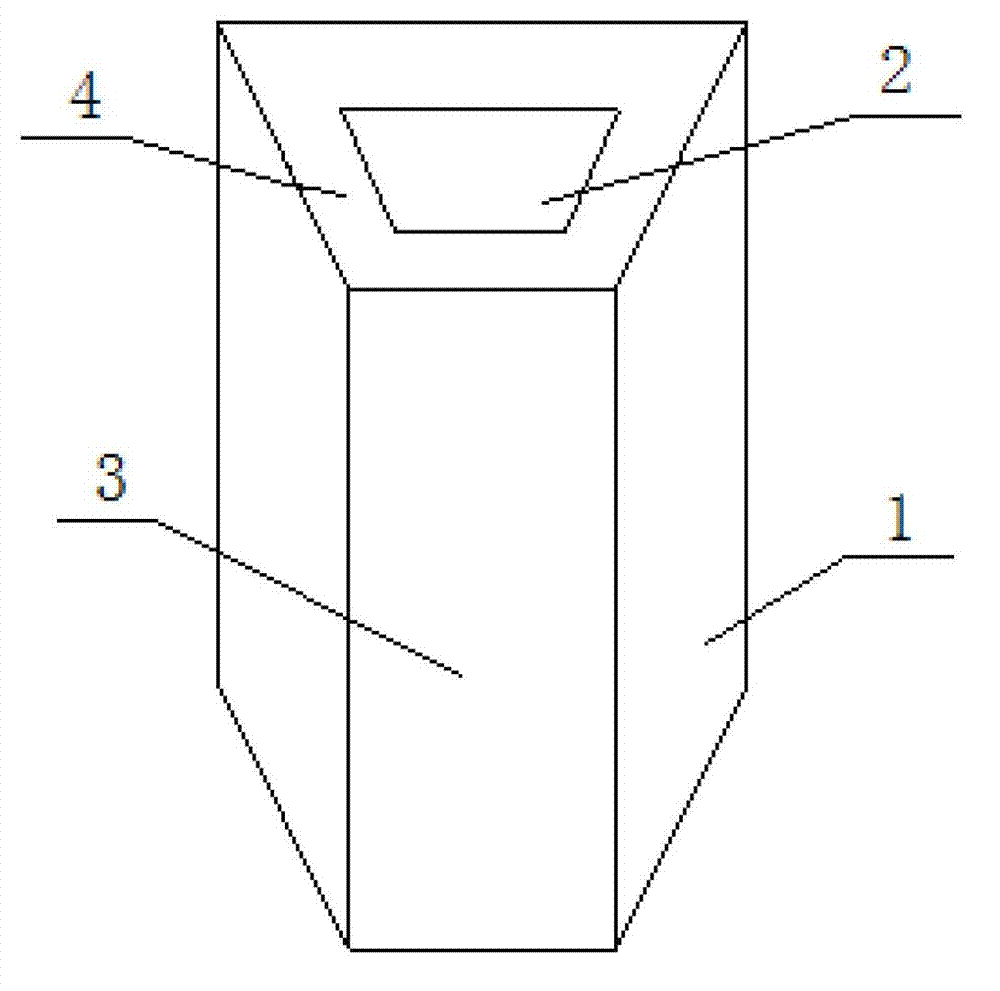

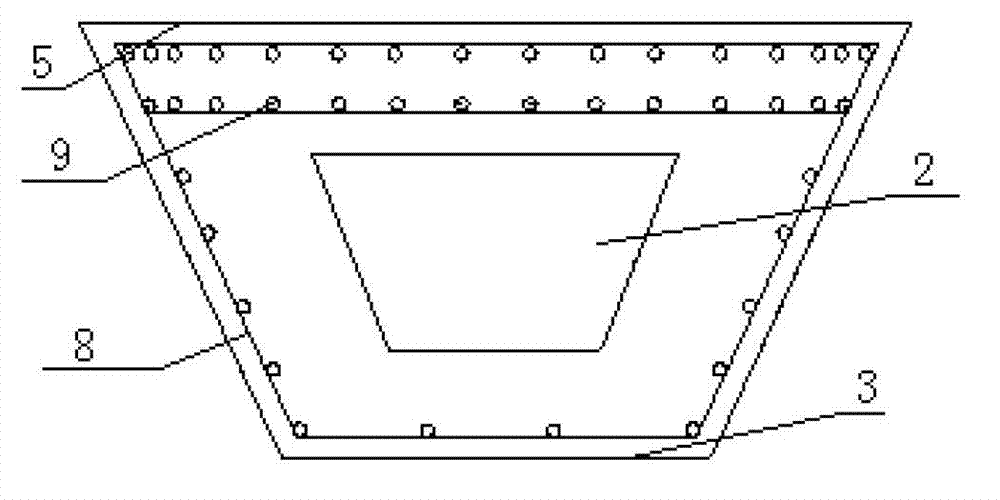

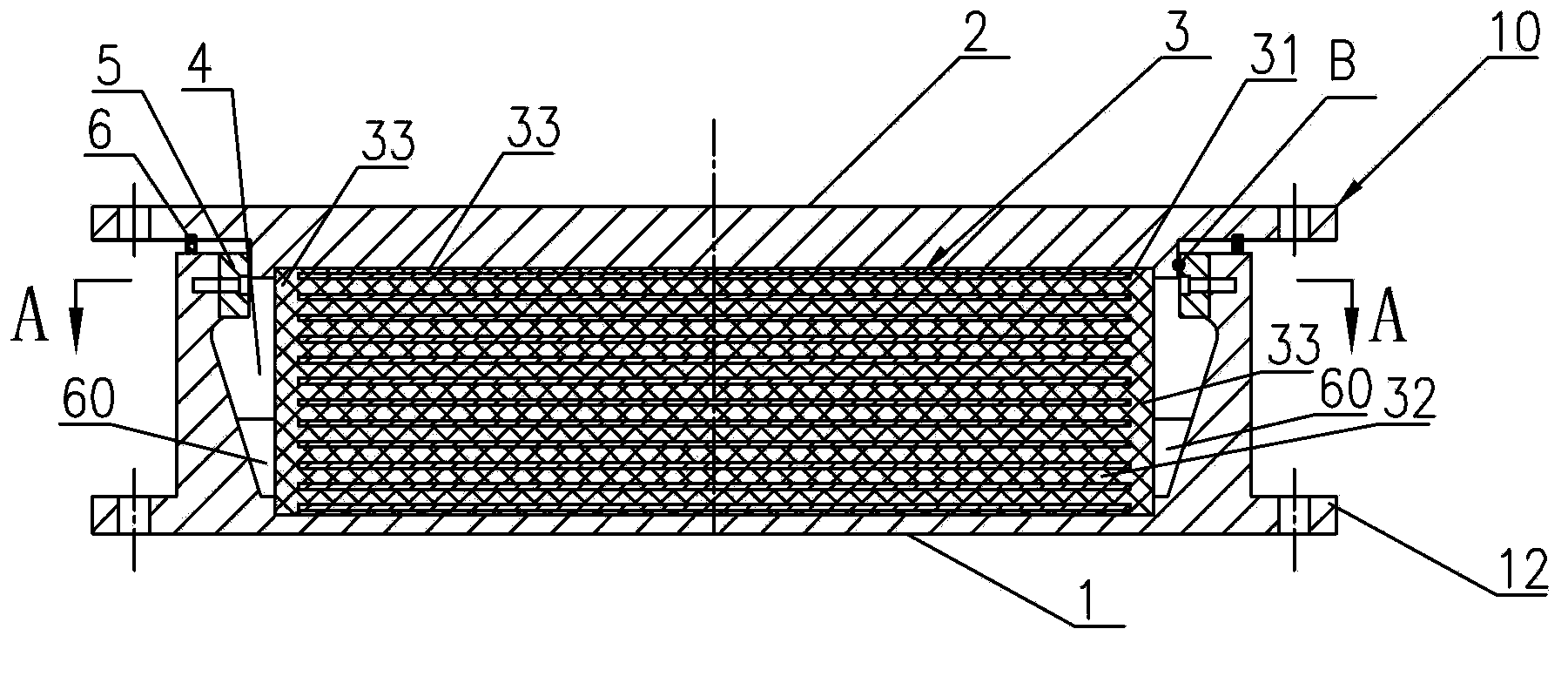

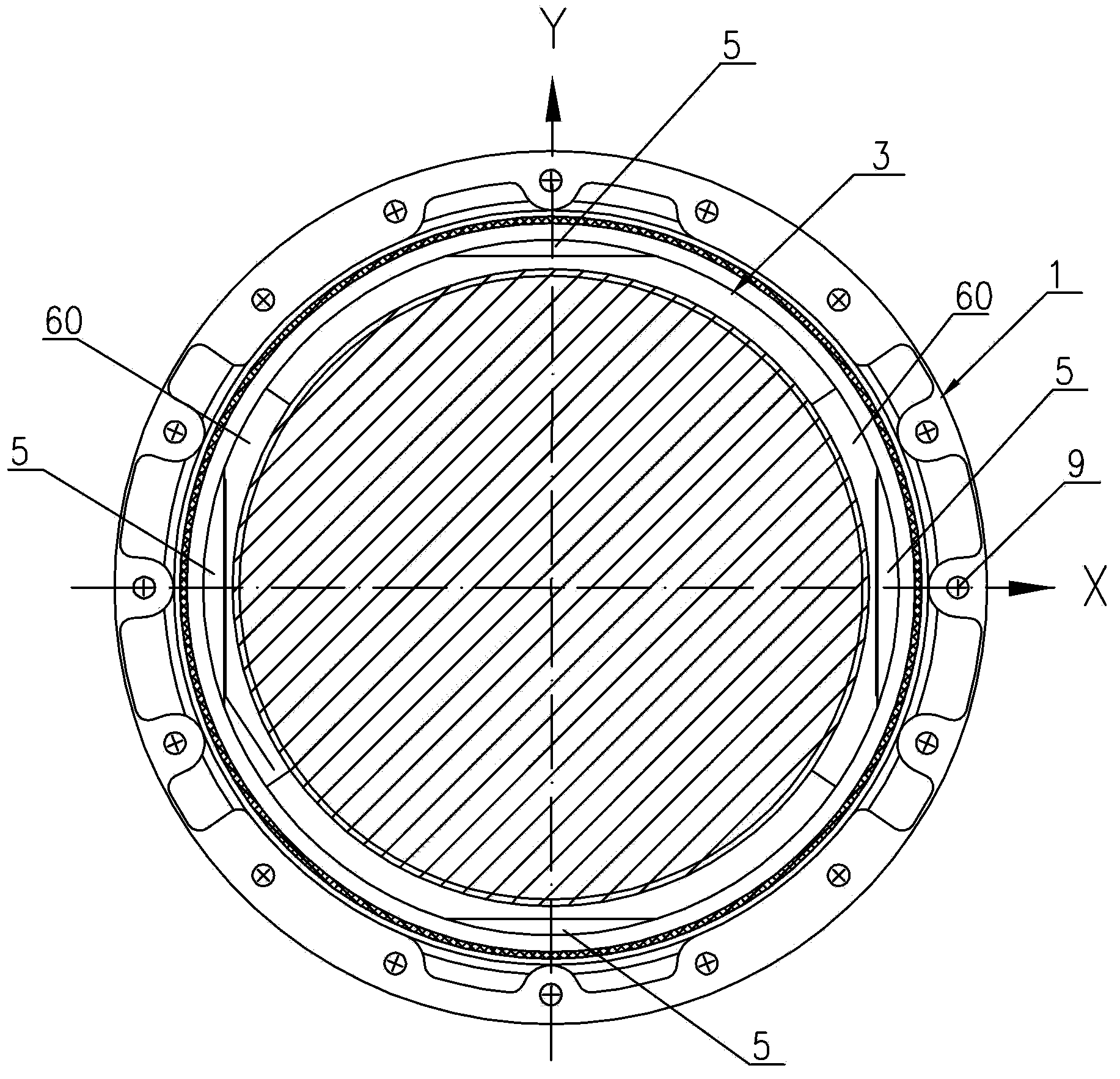

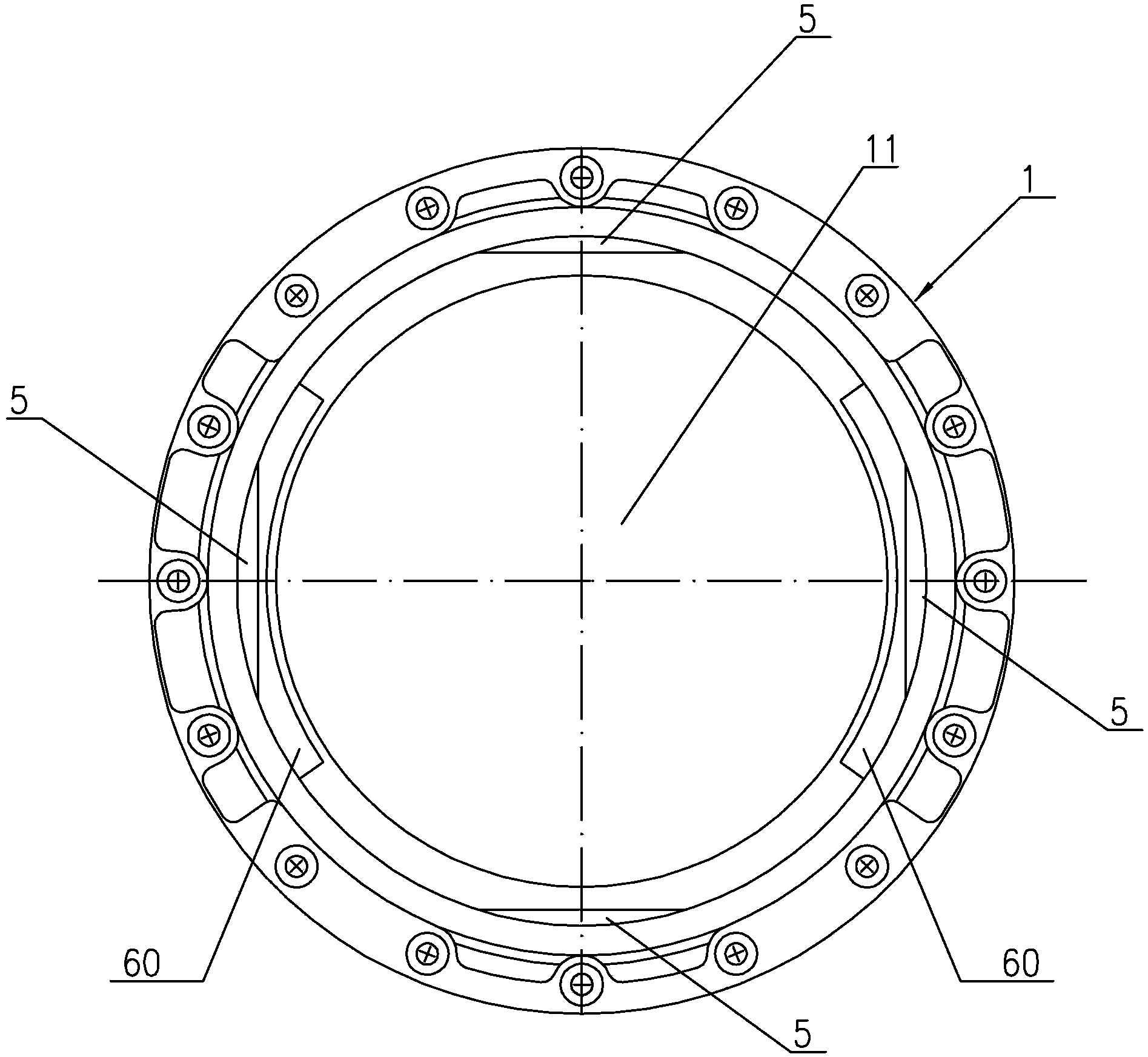

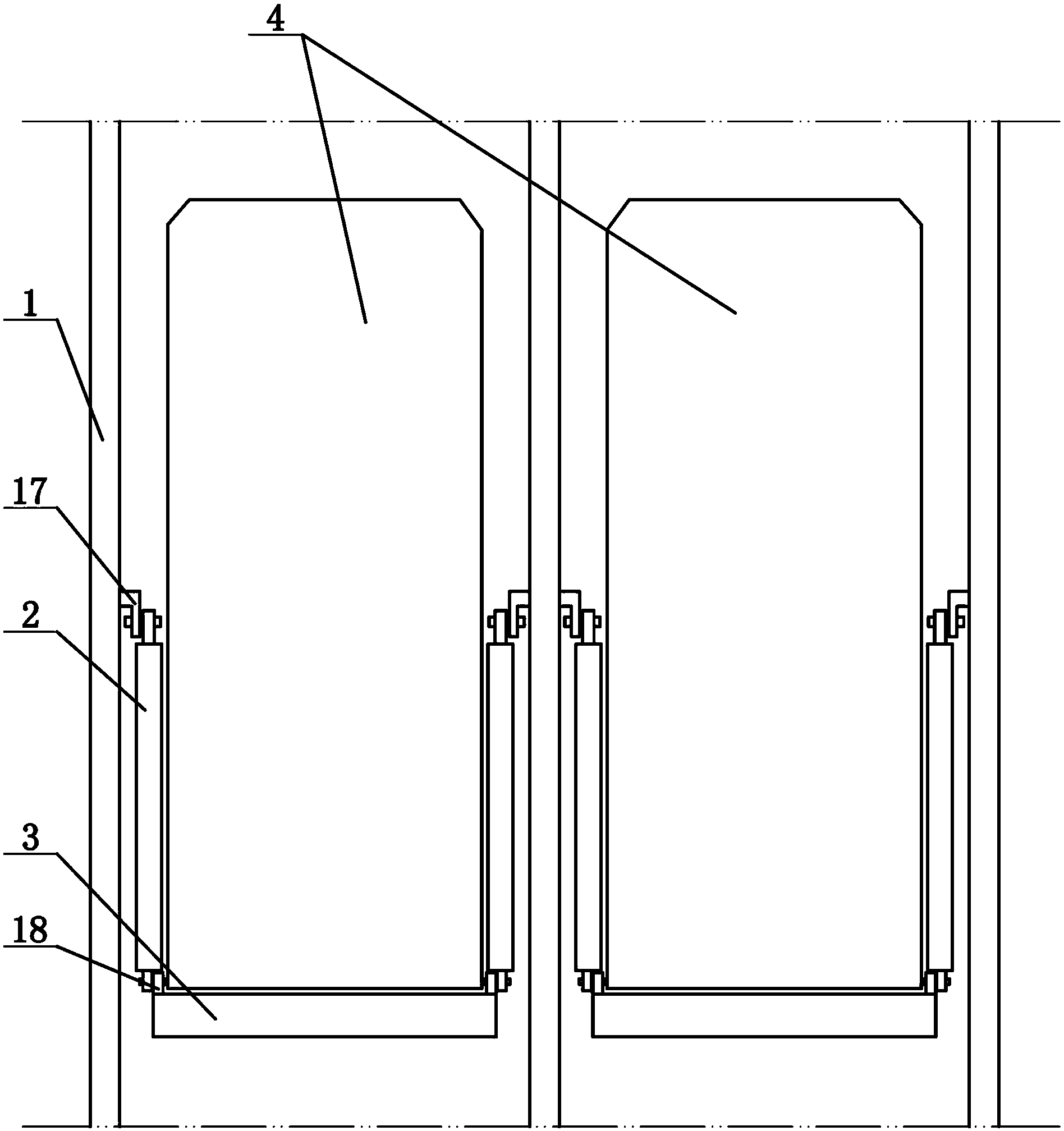

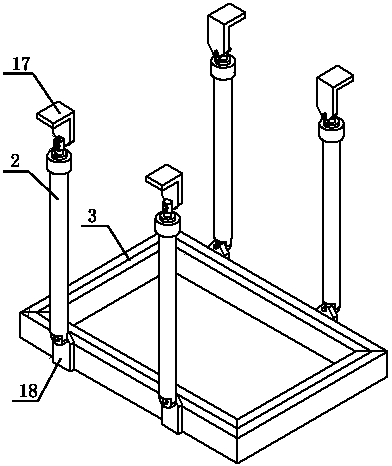

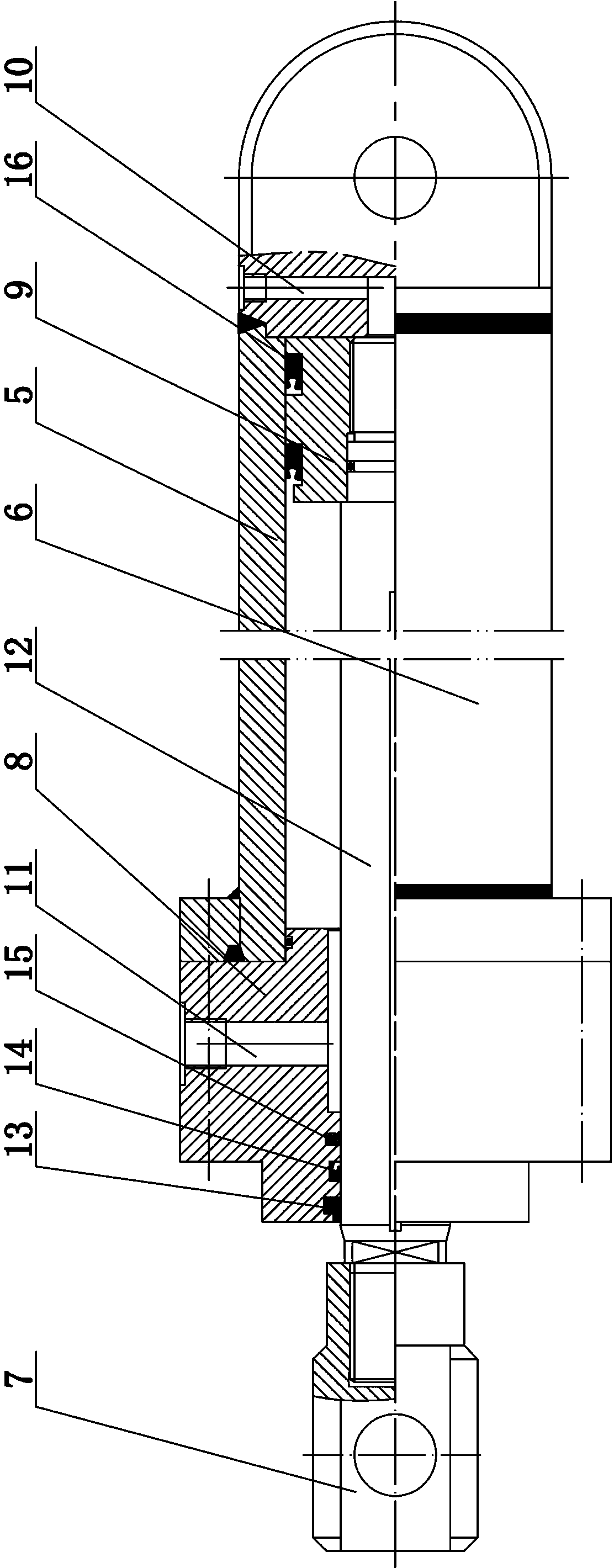

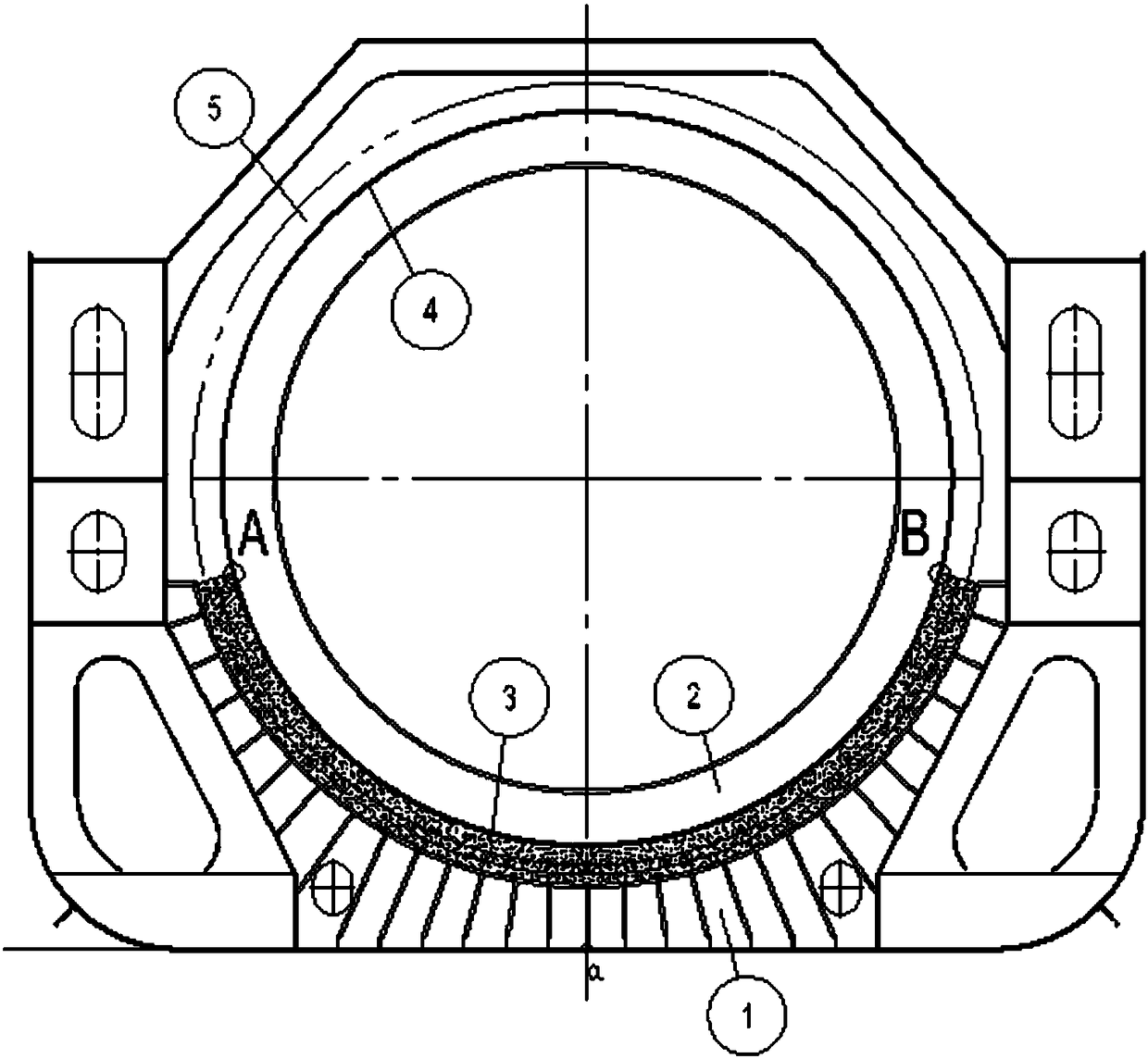

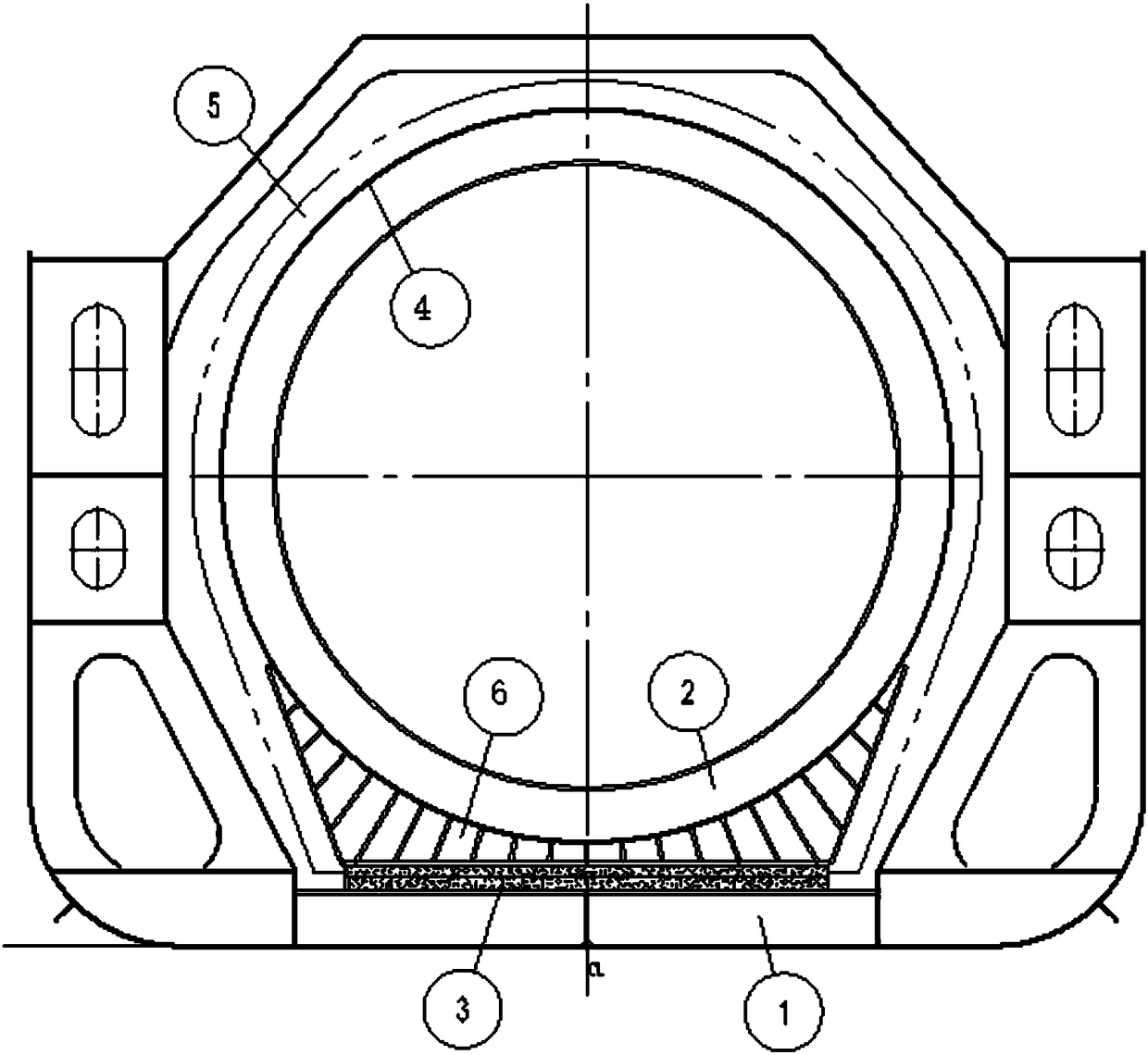

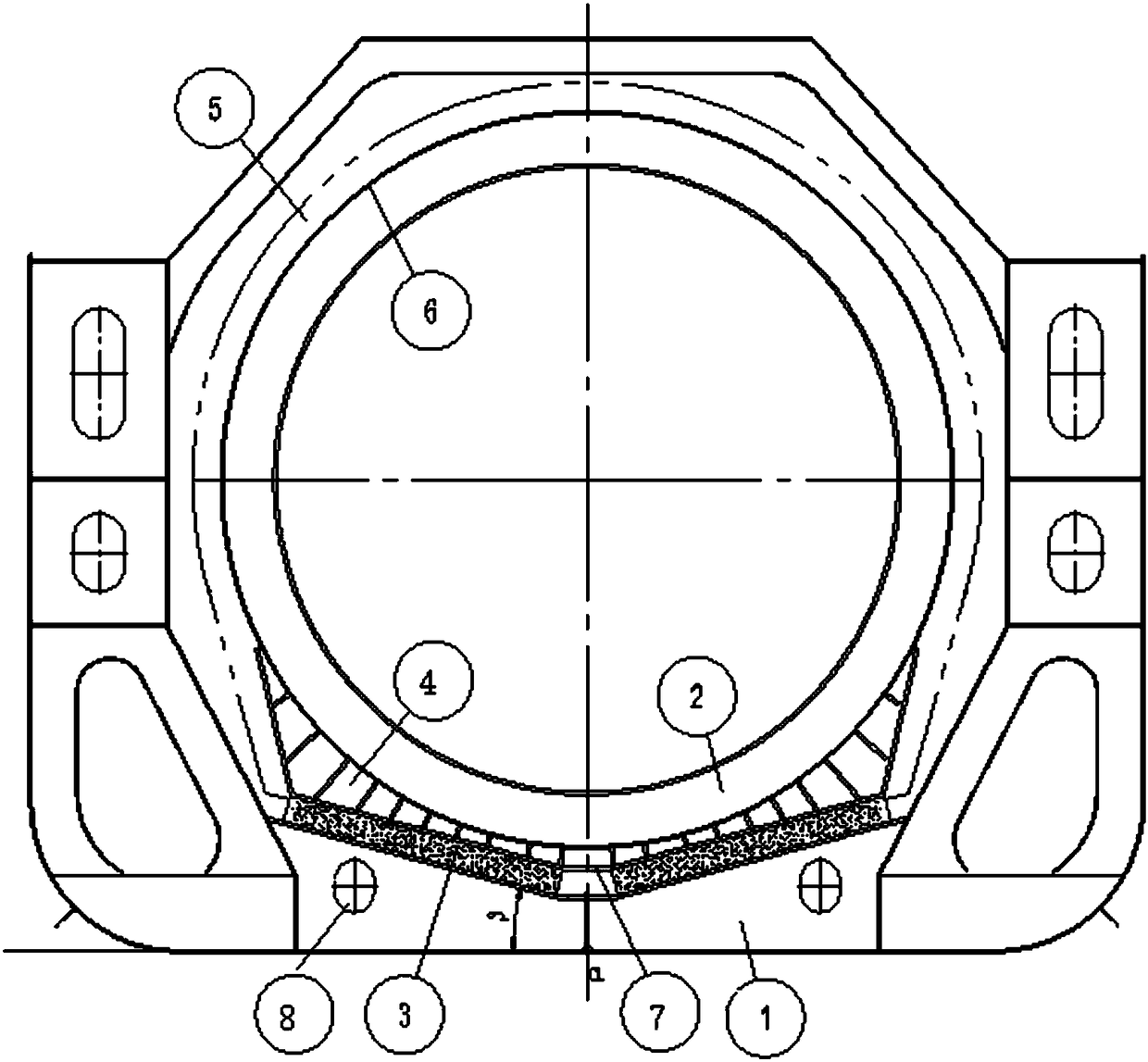

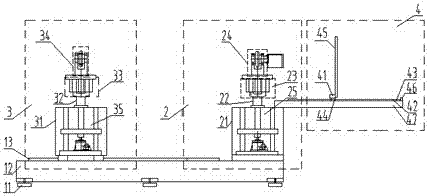

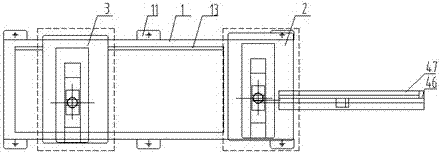

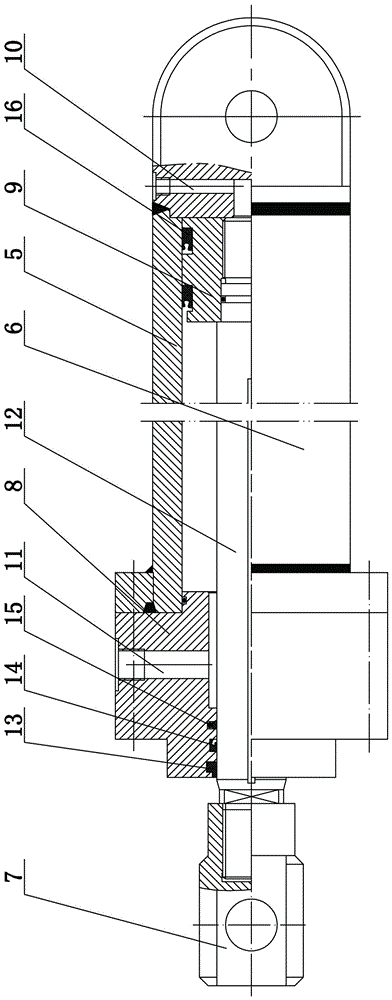

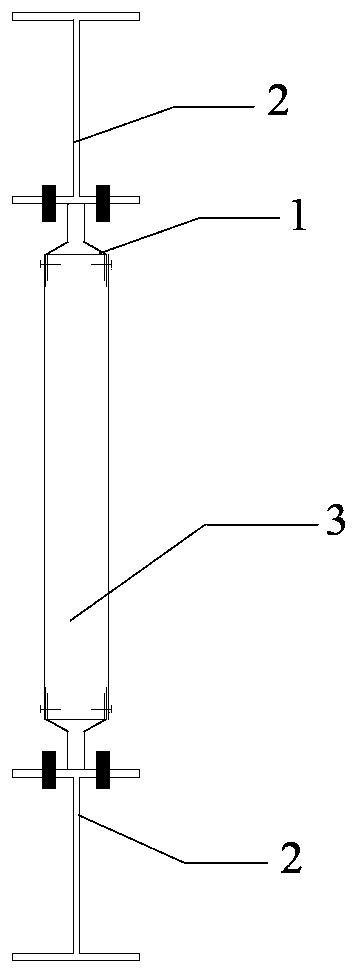

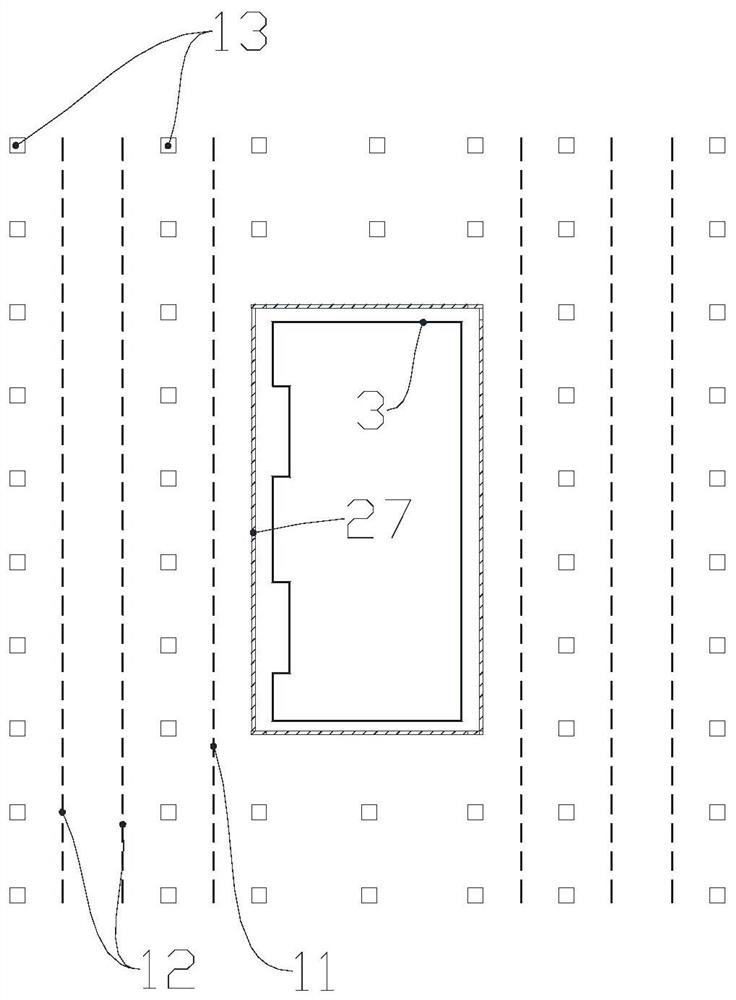

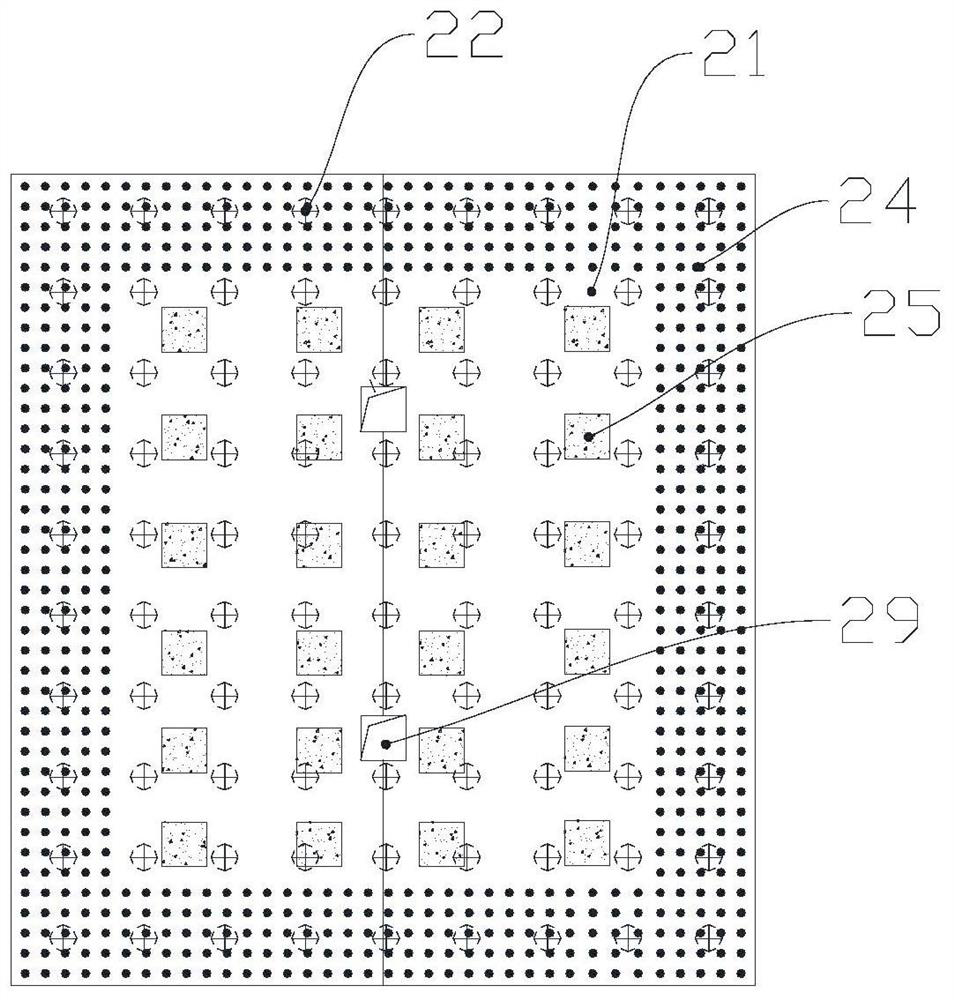

Flexible loading device and method for simulating uniform stress on surface of cylindrical anchorage model

ActiveCN107505205AComply with the force characteristicsThe pull test is real and effectiveMaterial strength using tensile/compressive forcesClimate change adaptationEngineeringMechanical engineering

Owner:SHANDONG JIANZHU UNIV

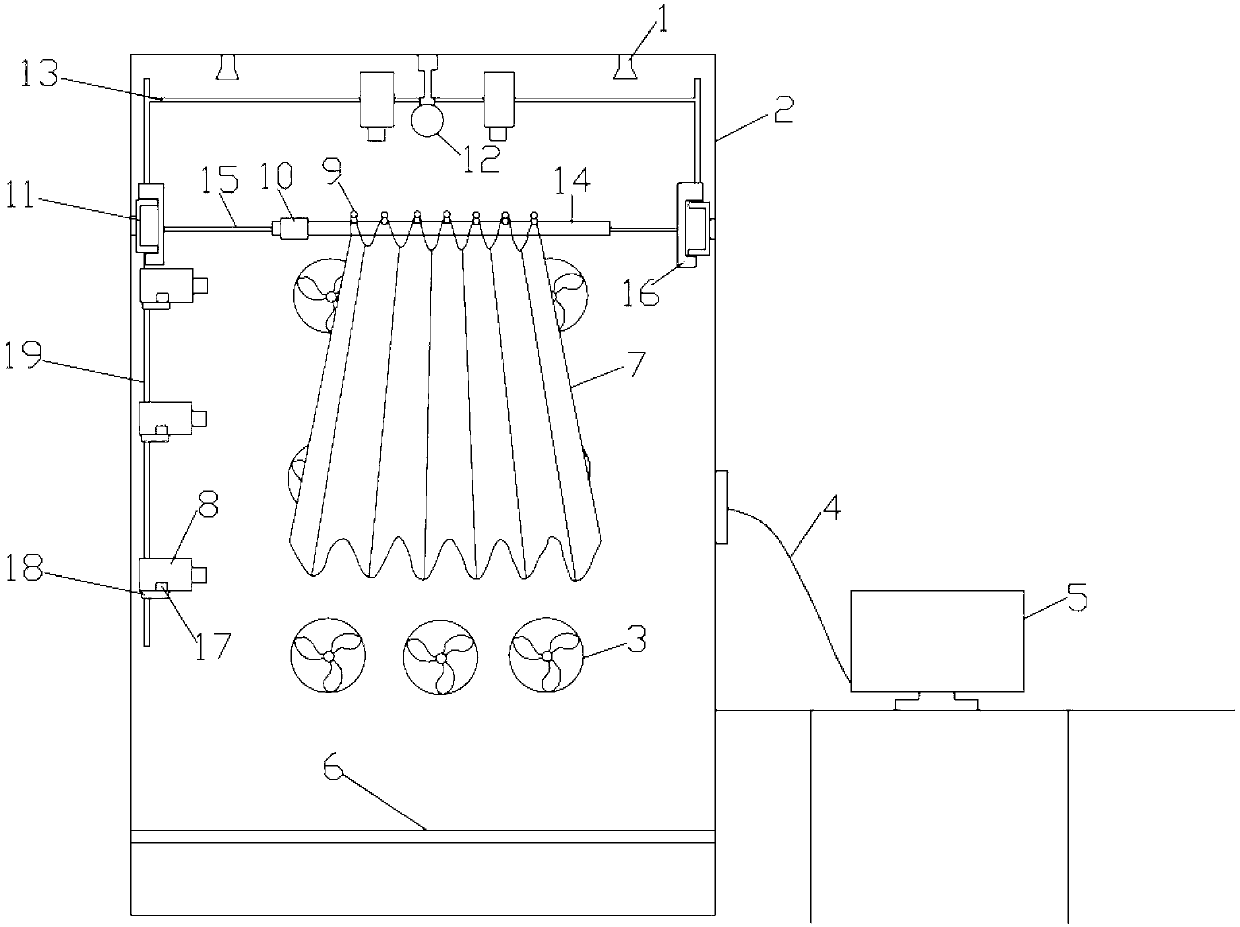

Testing device and method for fabric one-way drape performance

InactiveCN103134799ATest drapabilityVarious evaluation anglesMaterial analysis by optical meansTest fixtureComputer engineering

The invention discloses a device and a method for testing fabric one-way drape performance. The device for testing the fabric one-way drape performance comprises a box body, the box body is a cube in shape, a light source is installed on the inner wall of the top of the box body, a controllable fan is installed on one inner wall of the box body, two longitudinal conducting rods are respectively installed on two side walls which are adjacent with the inner wall, the longitudinal conducting rod is matched with a longitudinal swing support in a sliding mode, the upper portions of longitudinal swing blocks on two sides are respectively connected with a top image capturing device fixing support, the lower portion of one longitudinal swing support is connected with a lateral image capturing device fixing support, guiding rails is connected between the longitudinal swing blocks on the two sides, the guiding rails are matched with fabric fixing rods in a sliding mode, the fabric fixing rods are used for hanging a fabric sample to be tested, and the top image capturing device fixing support and the lateral image capturing device fixing support are respectively fixed with one or a plurality of image capturing devices. The device for testing the fabric one-way drape performance has the technical effects of strong index pertinence and various evaluating angles, and the testing method is close to real stress features of the fabric and the like.

Owner:ZHEJIANG SCI-TECH UNIV

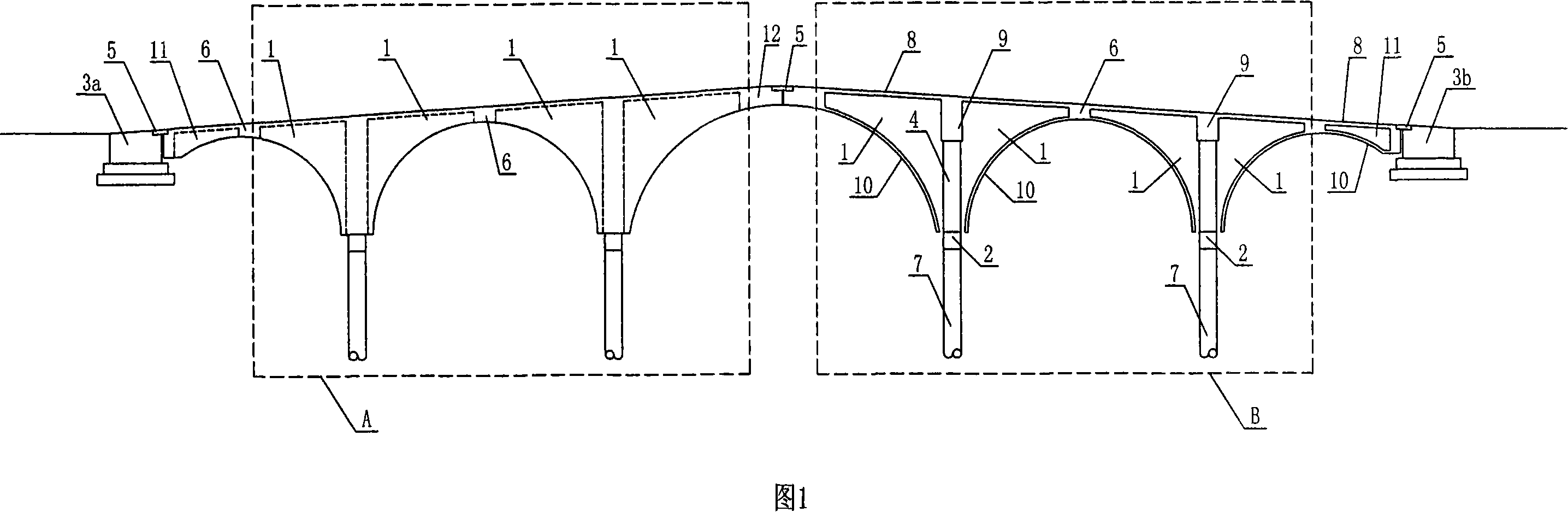

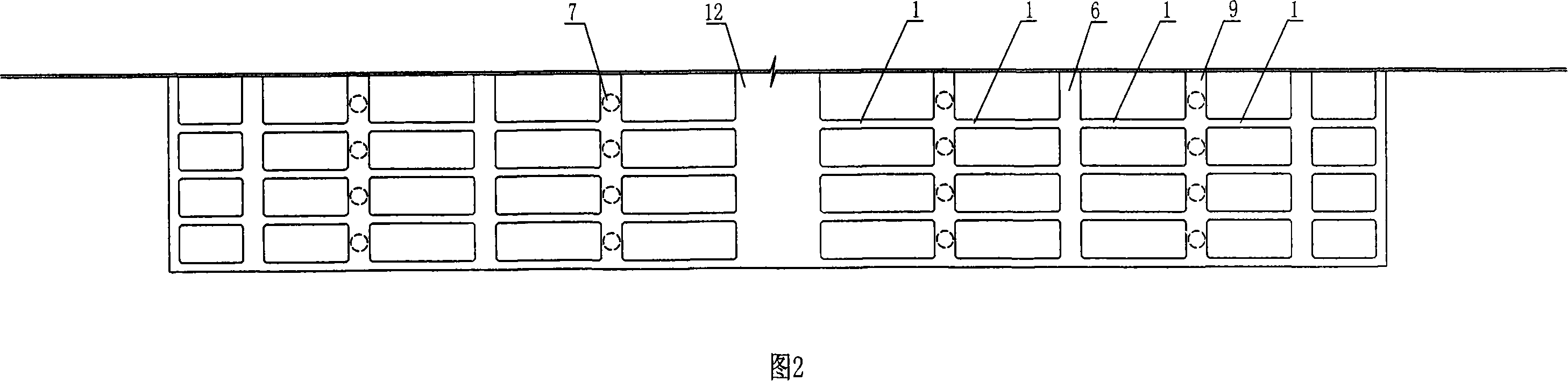

Soft-ground multi-cell twin-cantilever arched bridge structure and its construction method

InactiveCN101130942AComply with the force characteristicsReduce deflectionArch-type bridgeCantileverAbutment

The present invention discloses one kind of multiple-opening double-cantilever arch bridge in soft foundation and its construction process, and belongs to the field of arch bridge building technology. The multiple-opening double-cantilever arch bridge includes two arch bridge abutments, two edge opening cantilever arch beams located between these two arch bridge abutments and several double-cantilever arch beams connected between these edge opening cantilever arch beams. The present invention has the advantages of short construction period, low construction cost and capacity of preventing side shifting or subsidence of the arch bridge abutments.

Owner:CHANGYE CONSTR GROUP

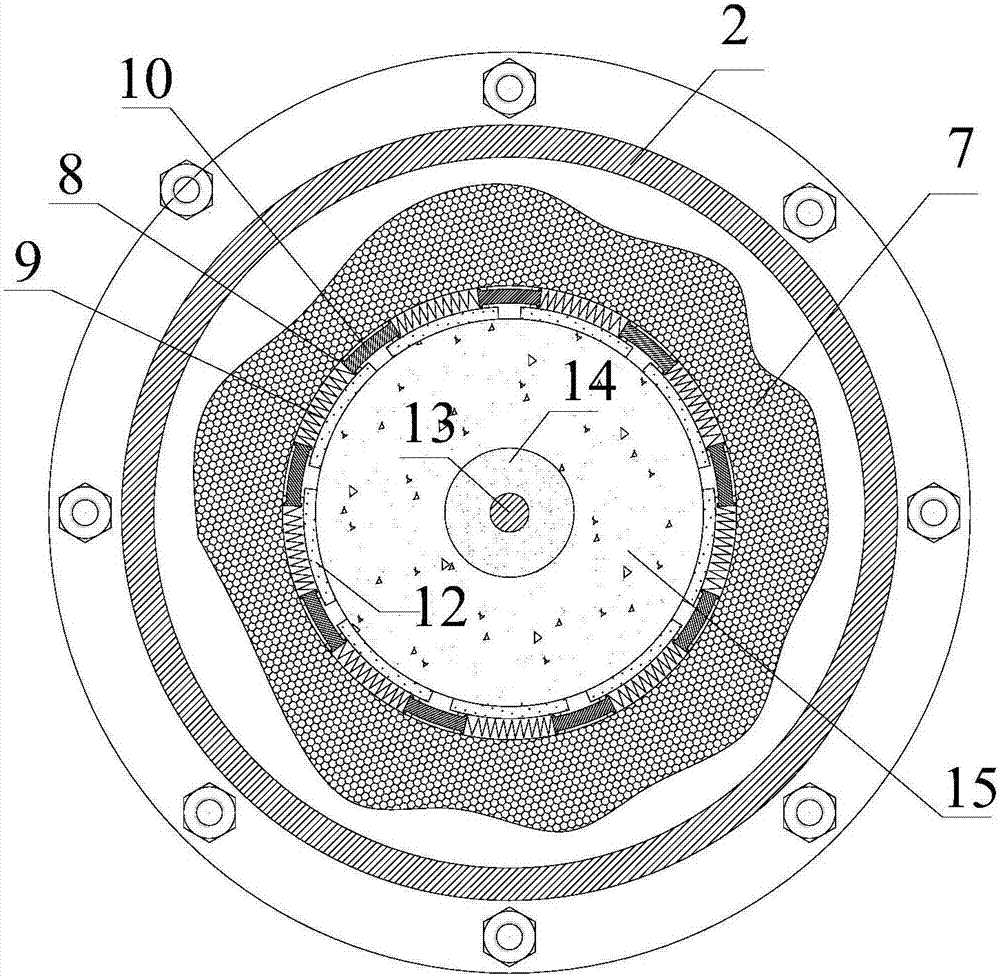

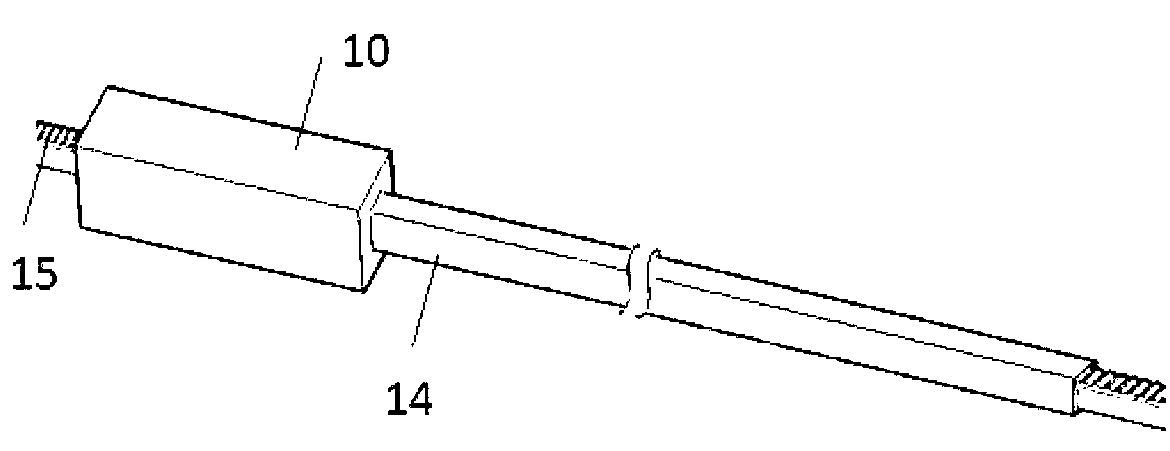

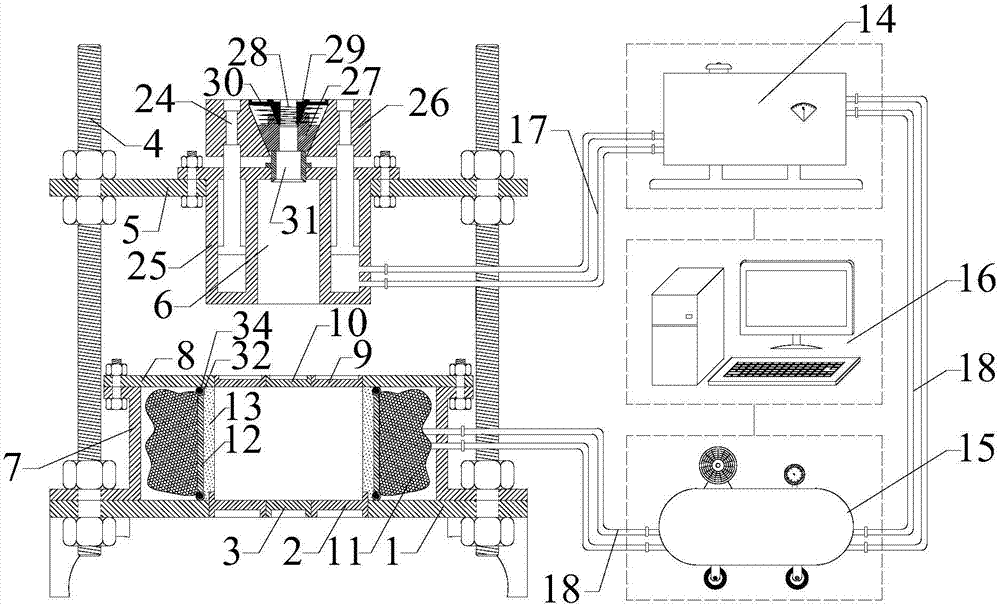

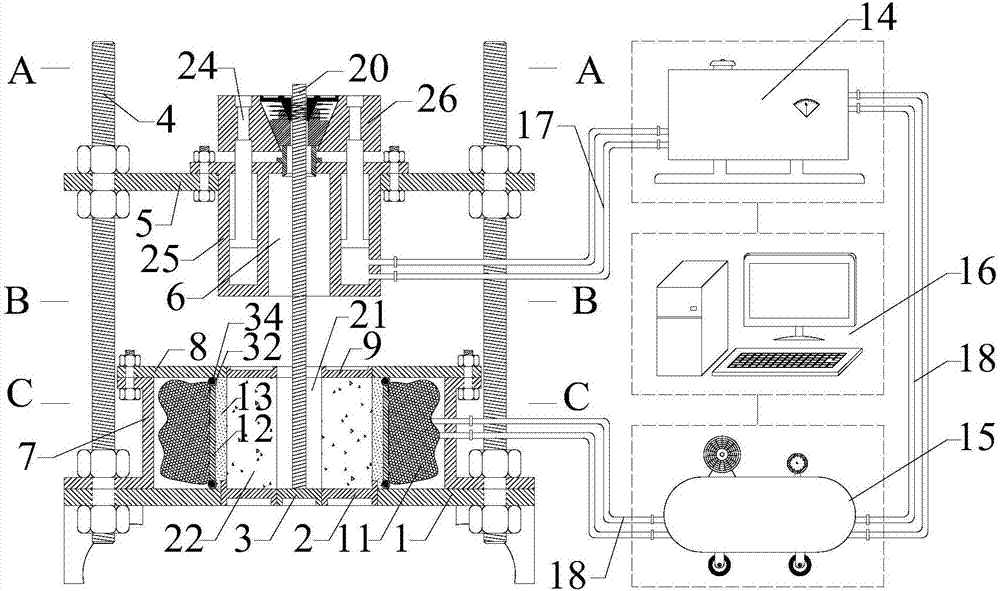

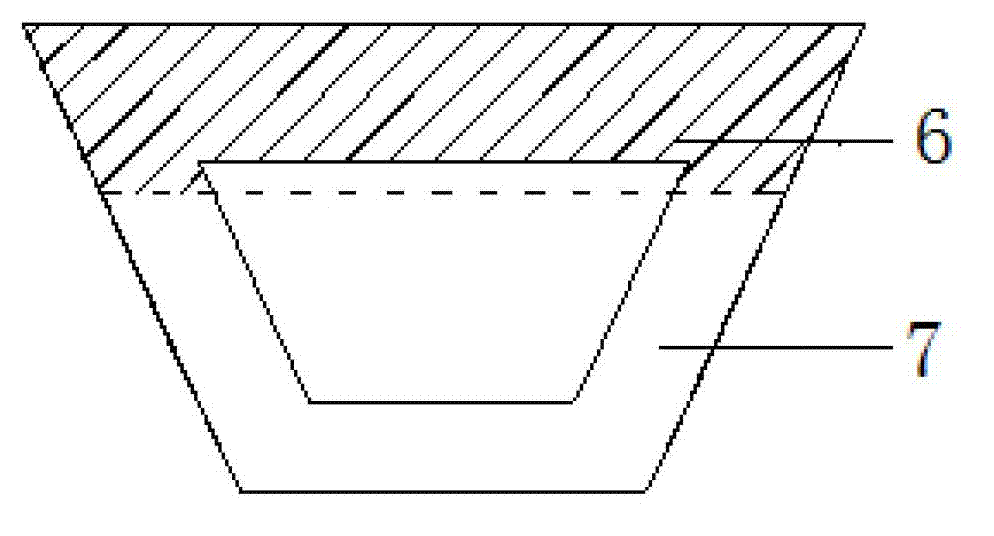

Testing system and method for testing mechanical property of anchor rod or anchor cable anchoring interface in high-stress environment

InactiveCN107268637AComply with the force characteristicsThe pull test is real and effectiveFoundation testingExcavationsClassical mechanicsAir pump

The invention discloses a testing system and method for testing the mechanical property of an anchor rod or anchor cable anchoring interface in a high-stress environment. The testing system comprises an anchor rod or anchor cable clamping mechanism for a test, the anchor rod or anchor cable clamping mechanism is installed at the upper end of a counterforce device, and automatic clamping and loosening of a to-be-tested anchoring body model, namely an anchor rod or an anchor cable can be achieved; and an annular high-pressure loading air bag is of an annular barrel structure, and a flexible constraint hoop is pasted to the inner wall of the annular high-pressure loading air bag, is composed of end arc sleeves, arc pressure springs, arc connection rods and arc force transferring plates and is of a barrel-shaped structure. Under the loading constraint action of the annular high-pressure loading air bag, the flexible constraint hoop can be shrunk inwards automatically, it is guaranteed that in the shrinking process, the cross section is always round, and loading of the stress of surrounding rocks uniformly distributed on the surface of the cylinder-shaped anchoring body model can be achieved. Through cooperation with a pneumatic oil tank pump, a high-pressure air pump and a controller, the mechanical property of the anchor rod or anchor cable anchoring body model interface can be effectively tested in different surrounding rock states and loading manners.

Owner:SHANDONG JIANZHU UNIV

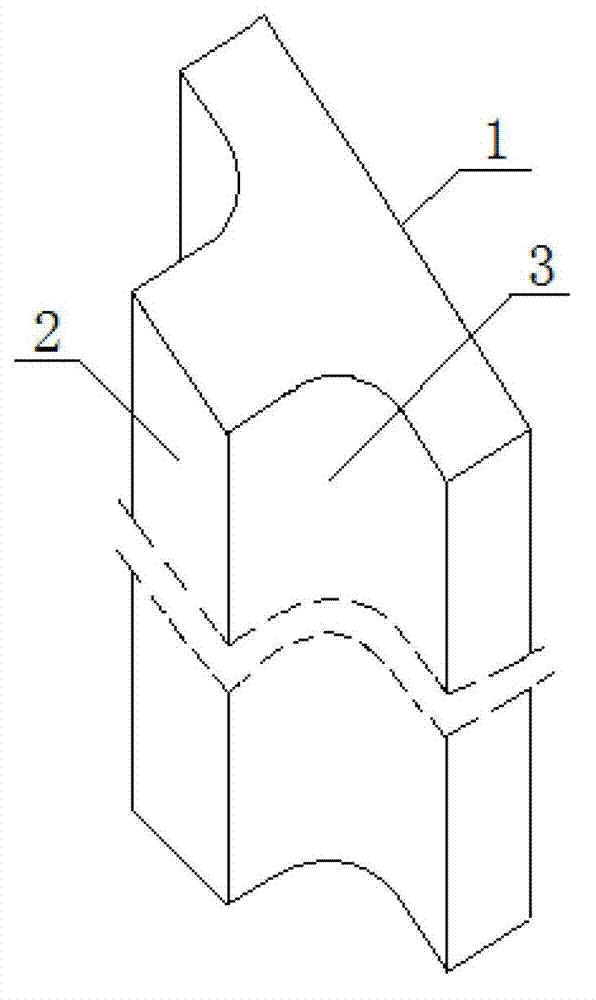

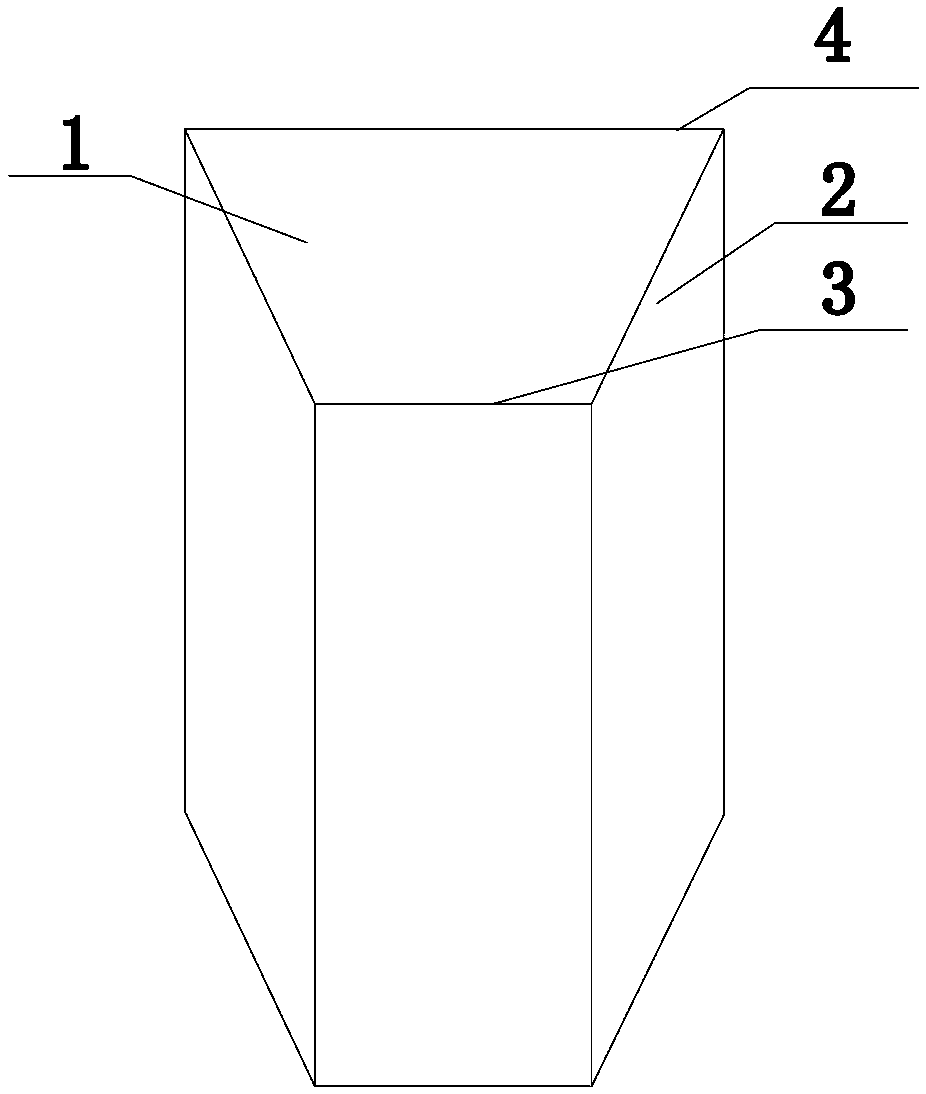

Antiskid pile with hollow outer isosceles trapezoid cross section and in unequal interval arrangement

ActiveCN103046543AGood anti-slip effectReduce in quantityExcavationsBulkheads/pilesRebarReinforced concrete

The invention relates to an antiskid pile with hollow outer isosceles trapezoid cross section and in unequal interval arrangement. The antiskid pile is formed by pouring reinforced concrete, the cross section of the antiskid pile is a hollow outer isosceles trapezoid, the shape of an inner hollow hole of the cross section is identical with that of the cross section, one side of a longitudinal section of a long bottom side of the isosceles trapezoid serves as the rear end of the pile to bear landslide thrust, rebar cages are arranged in the antiskid pile, relatively dense rebars are arranged in the rebar cage on one side of the rear end of the pile, and few rebars are arranged on one side of the front end of the pile. The antiskid pile adopts an unequal interval arrangement method to form pile interval arrangement layout with a dense middle and two sparse sides. Compared with a pile with a rectangular cross section, the antiskid pile can also bear bigger landslide thrust and has excellent anti-bending performance, but the size of the cross section of the antiskid pile is obviously smaller than that of the antiskid pile with the rectangular cross section, so that cubic amount of concrete pouring and rebar using amount can be greatly reduced, and cost is lowered. The antiskid pile with the hollow outer isosceles trapezoid cross section and in unequal interval arrangement is small in construction section, convenient for mechanical construction, safe and simple in construction and wide in popularization and application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

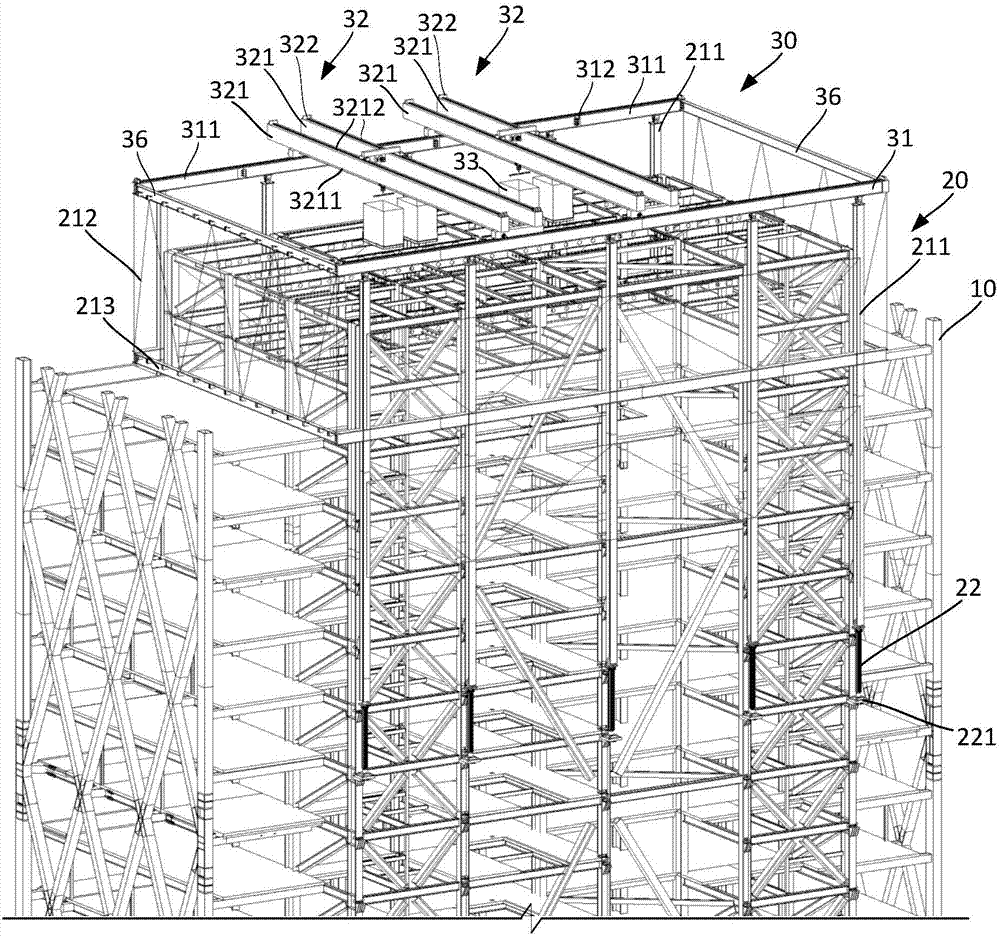

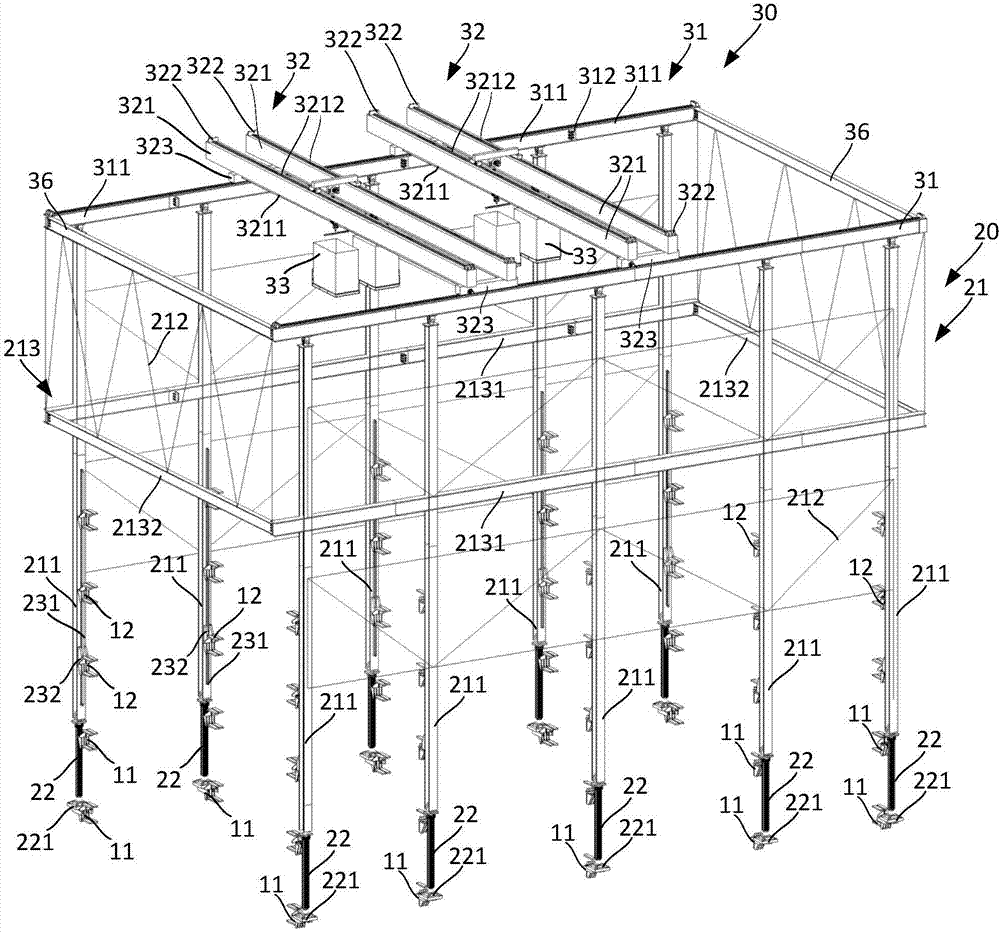

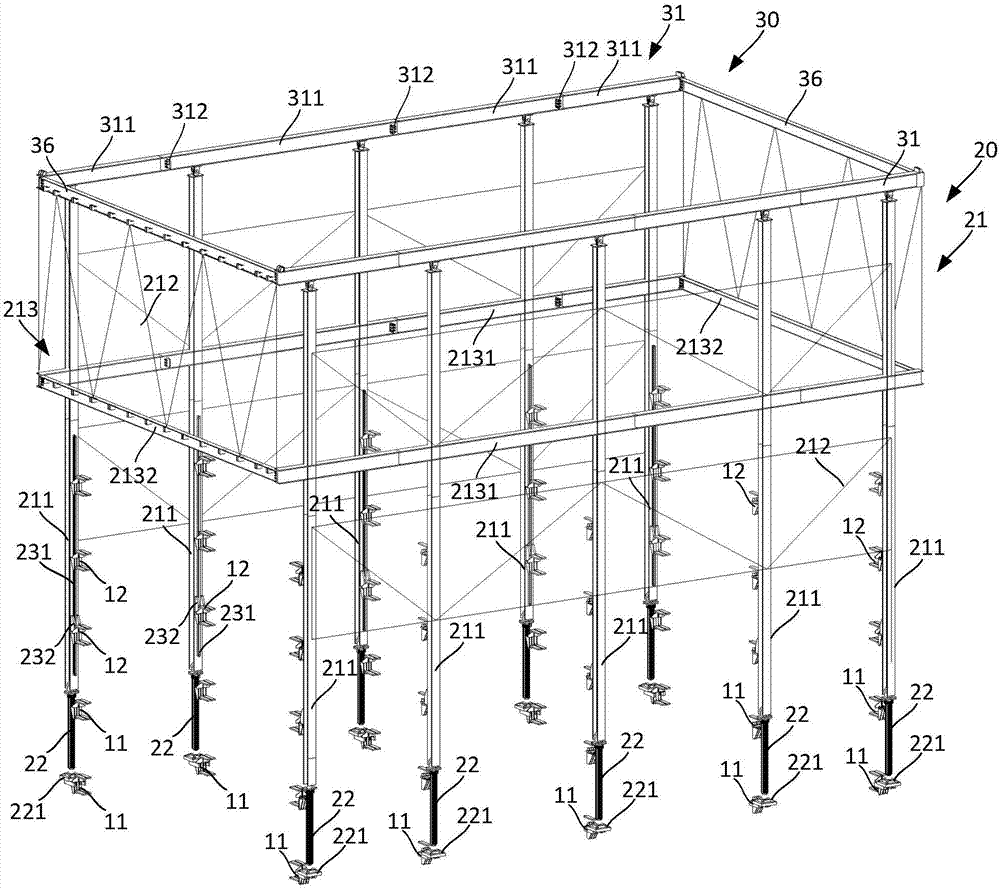

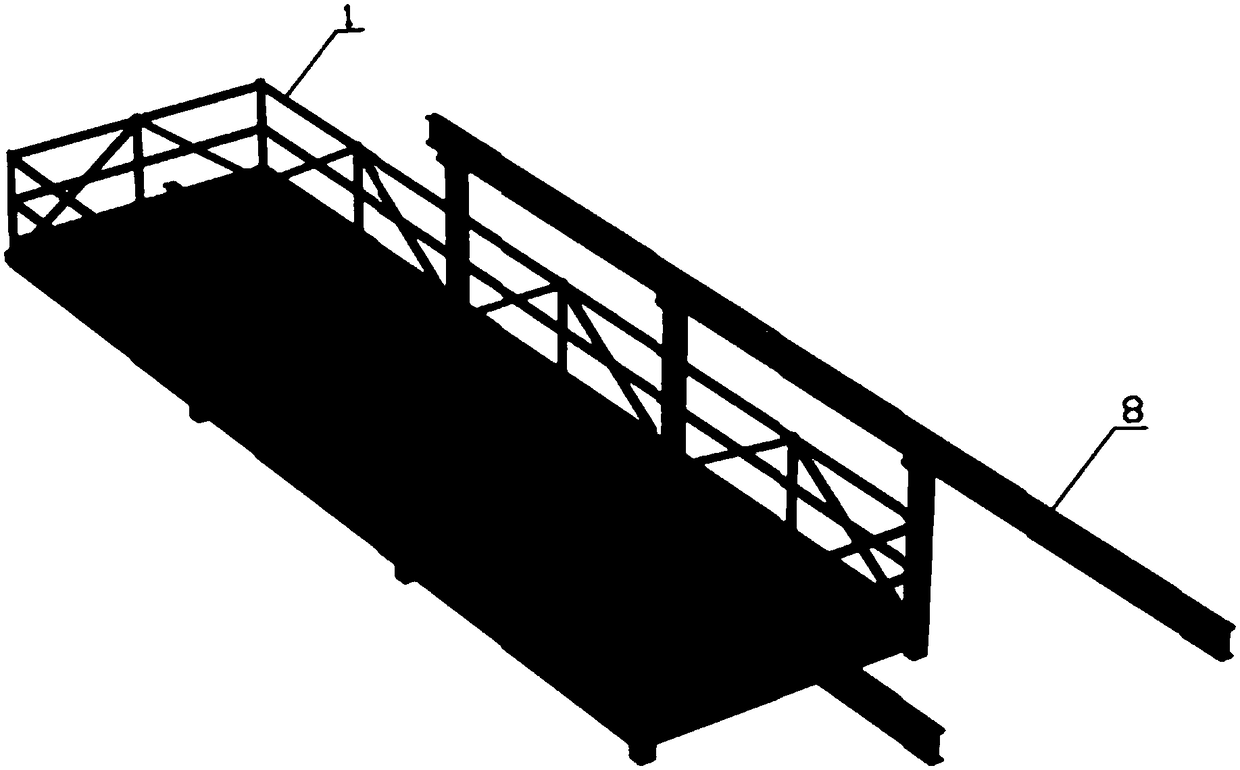

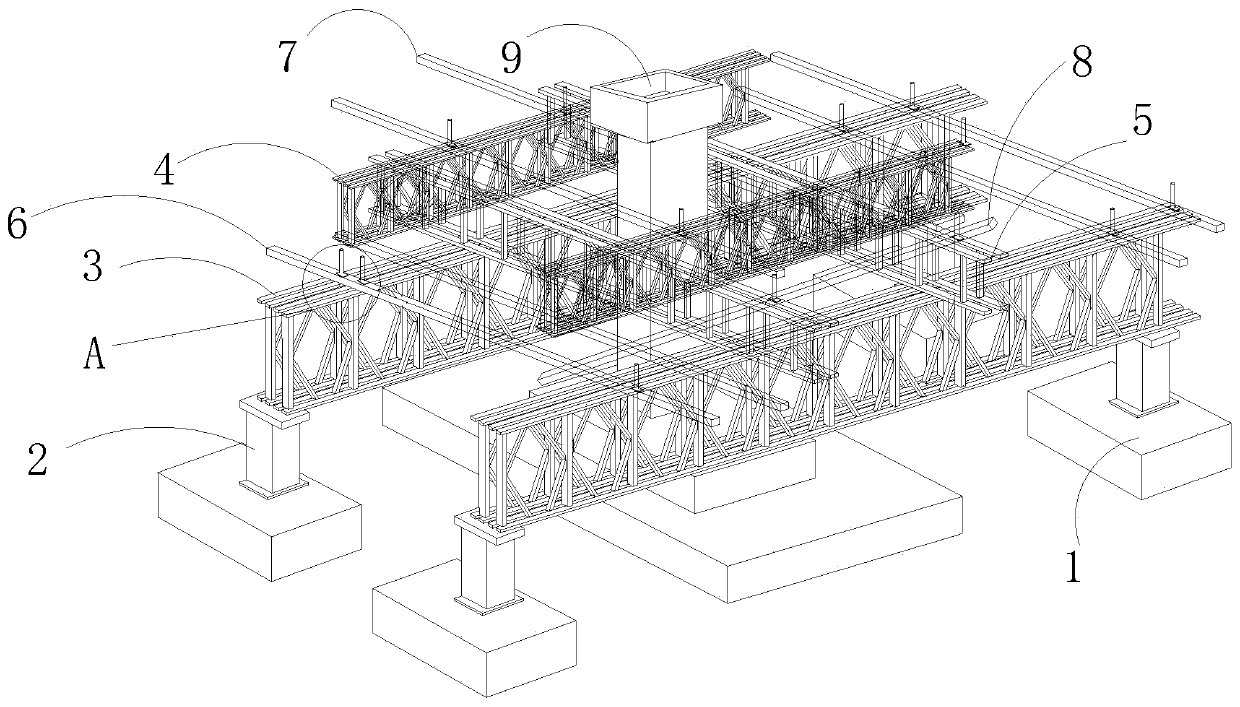

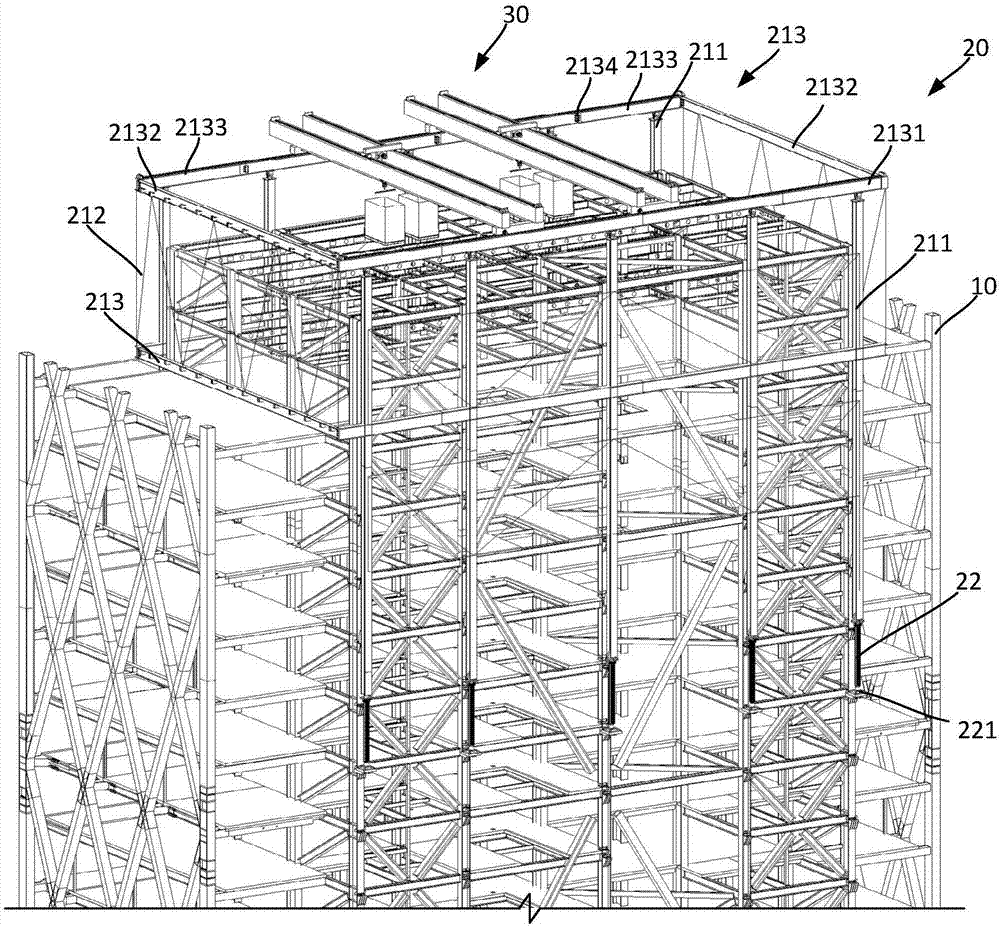

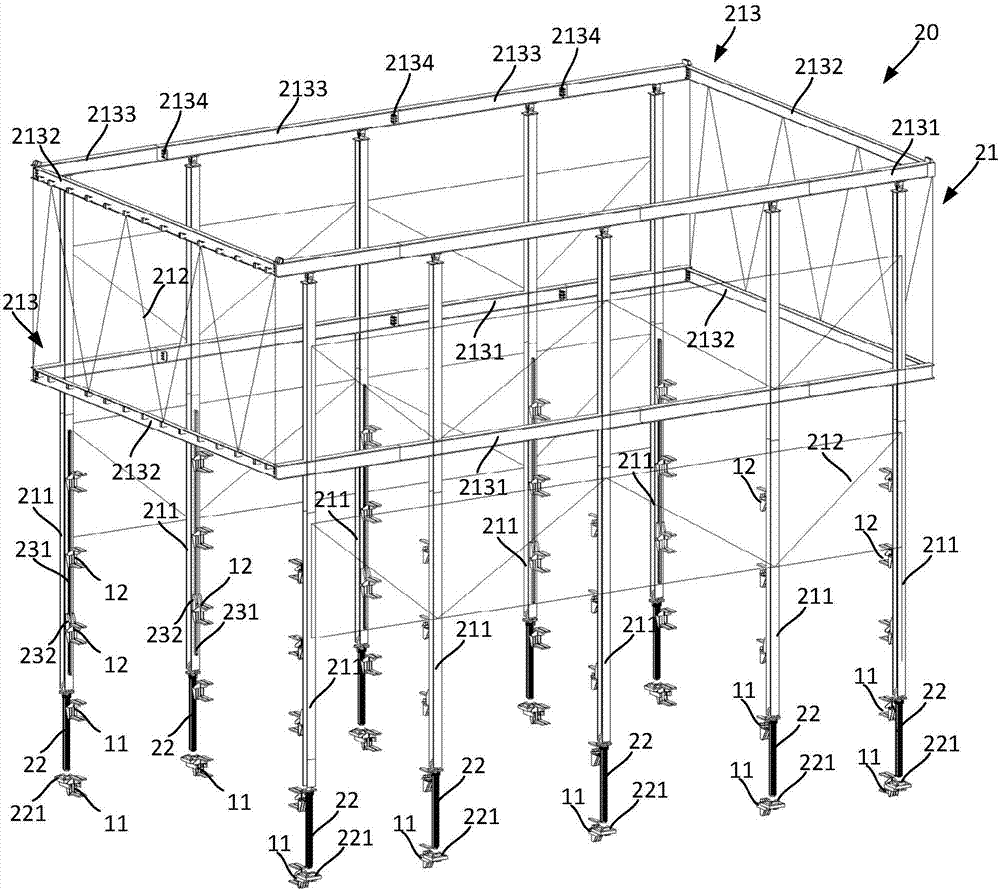

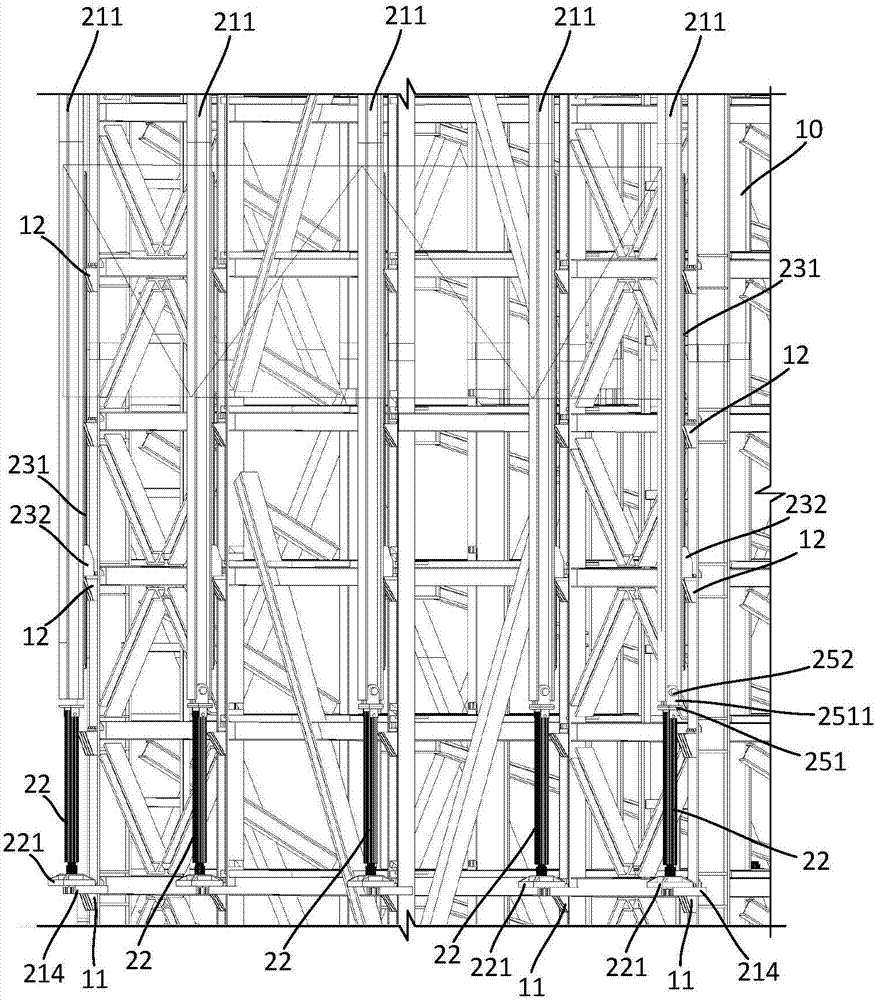

Automatic jacking truss crane system construction operation platform for mounting of steel structure

ActiveCN107355067AHigh degree of automationImprove construction efficiencyBuilding support scaffoldsSystem constructionAutomation

The invention relates to an automatic jacking truss crane system construction operation platform for mounting of a steel structure. The automatic jacking truss crane system construction operation platform comprises a climbing system attached to the steel structure, and a truss crane system mounted on the climbing system. The climbing system comprises a climbing frame structure and a hydraulic jacking mechanism hinged to the bottom of the climbing frame structure, the bottom of the hydraulic jacking mechanism is hinged to the corresponding steel structure, and the climbing frame structure climbs along the steel structure through jacking by the hydraulic jacking mechanism. The truss crane system comprises a pair of sliding rails arranged on the top of the climbing frame structure, rail frame bodies erected on the pair of sliding rails, and a hoisting basket slidably arranged on the rail frame body, and the rail frame bodies are slidably arranged on the corresponding sliding rails. The automatic climbing construction operation platform system can automatically climb along with construction of the steel structure; the operation platform can be provided for constructors, and a steel member also can be directly hoisted; and the automation degree is high, the labor demand is reduced, the construction efficiency and quality are greatly improved, and the cost is saved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

Vibration-isolating and noise-reducing rubber support for buildings

ActiveCN103437445AWill not be damaged by tensionLight weightShock proofingEngineeringMechanical engineering

The invention discloses a vibration-isolating and noise-reducing rubber support for buildings, which comprises a base, a top seat plate and a cylindrical vibration isolator, the base is a block with a sunken mounting cavity, the vibration isolator is arranged in the mounting cavity, the top seat plate covers the top end of the mounting cavity of the base and presses the vibration isolator, the bottom of the mounting cavity is provided with at least one pair of oppositely arranged guide blocks, and the guide blocks are extended along the circumference of the bottom of the inner wall of the mounting cavity and located around the vibration isolator, and hold the lower part of the vibration isolator. Since the lower part of the vibration isolator is held by the guide blocks of the vibration-isolating and noise-reducing rubber support, the guide blocks can be arranged at different positions according to actual requirement to control the horizontal deformation direction and displacement of the vibration isolator, thus ensuring that the concrete members of an upper structure supported by the support cannot be pulled and pressed to be damage due to excessive deformation under the action of the additional stress of vibration.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

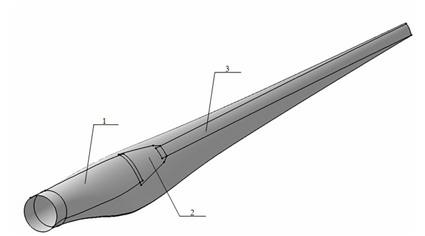

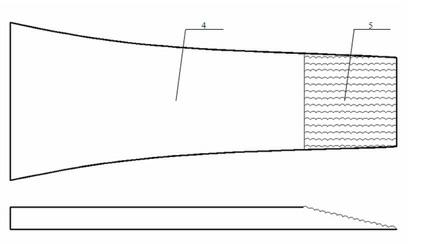

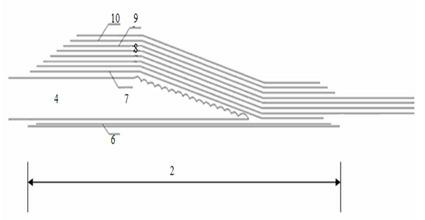

Composite layering type wind turbine blade and manufacturing method thereof

InactiveCN102108946AIncrease leaf strengthIncrease stiffnessFinal product manufactureWind energy generationGlass fiberTurbine blade

The invention discloses a composite layering type wind turbine blade and a manufacturing method thereof. A bamboo laminated timber layering with high specific stiffness is adopted for a girder at a blade root section of the blade; a zero-degree single direction layering with high specific strength is adopted for a girder from a blade middle to a blade tip; a lap joint reinforcing section is arranged between the bamboo laminated timber at the blade root section and the zero-degree single direction layering from the blade middle to the blade tip; the layering design of the lap joint reinforcingsection not only ensures the continuity of the stiffness of the blade and meets the integral strength requirement of the blade, which is favorable for the transmission of loading, but also satisfies the split-level requirement of the technology design; and moreover, the oblique plane of the upper surface of the bamboo laminated timber at the lap joint reinforcing section is subjected to corona treatment, the surface roughness of the bamboo laminated timber is increased, and the interface bonding force between glass fiber cloth and bamboo laminated timber is improved. According to the invention, the layering type of the blade is changed, thus the layering design of the blade is corresponding with the force property of the blade, and the strength of the blade root is improved as well as thestrength requirement of the blade from the blade middle to the blade tip is satisfied; and the bamboo laminated timber layering is adopted for the girder at the blade root of the blade, which is corresponding with the requirement of environment protection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

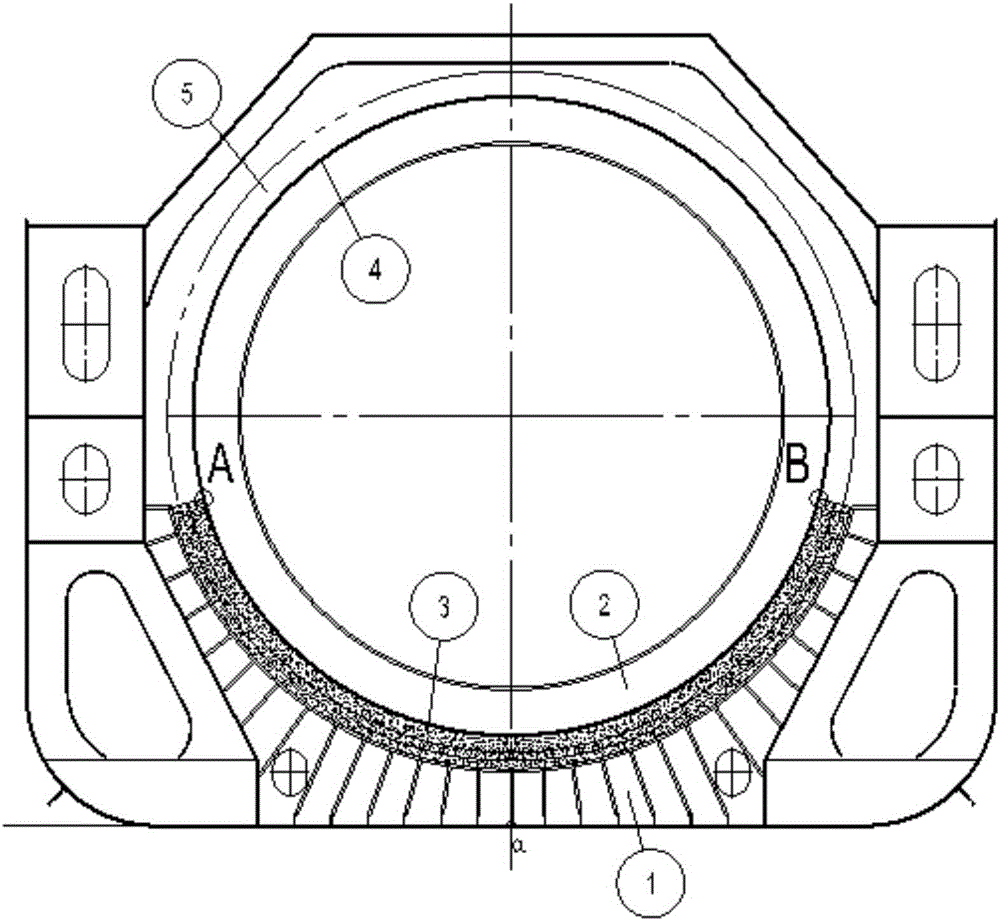

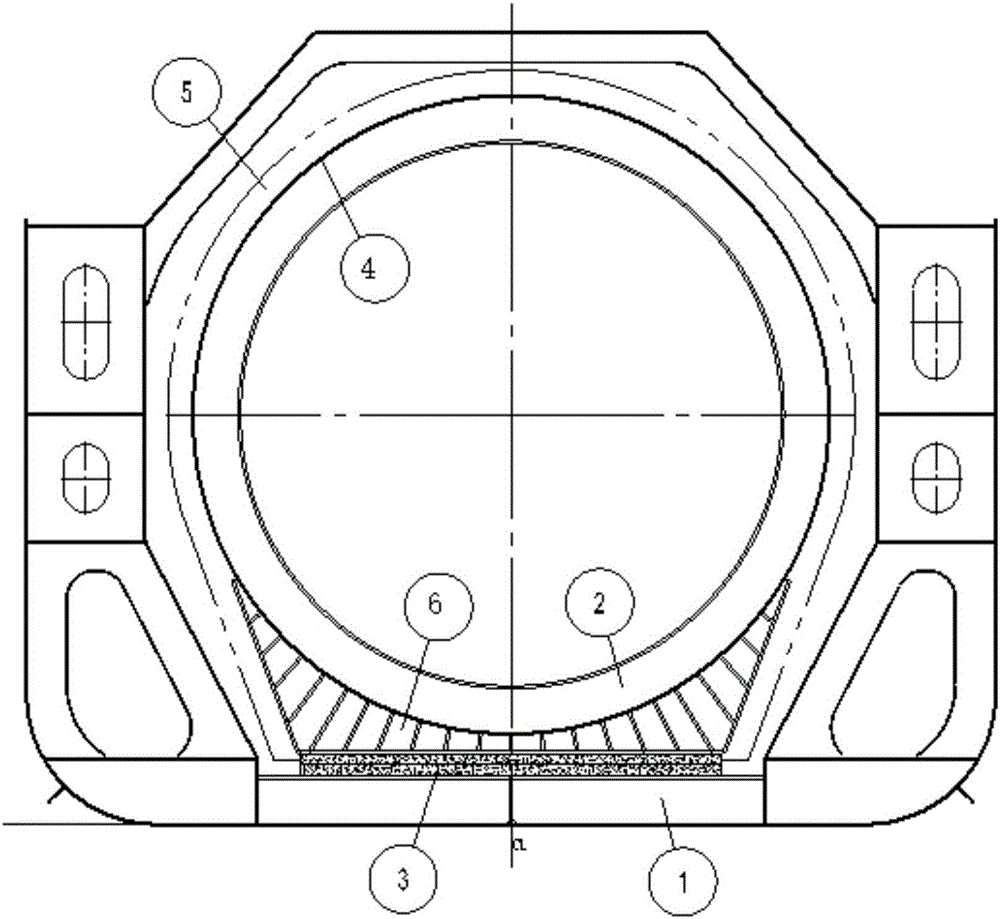

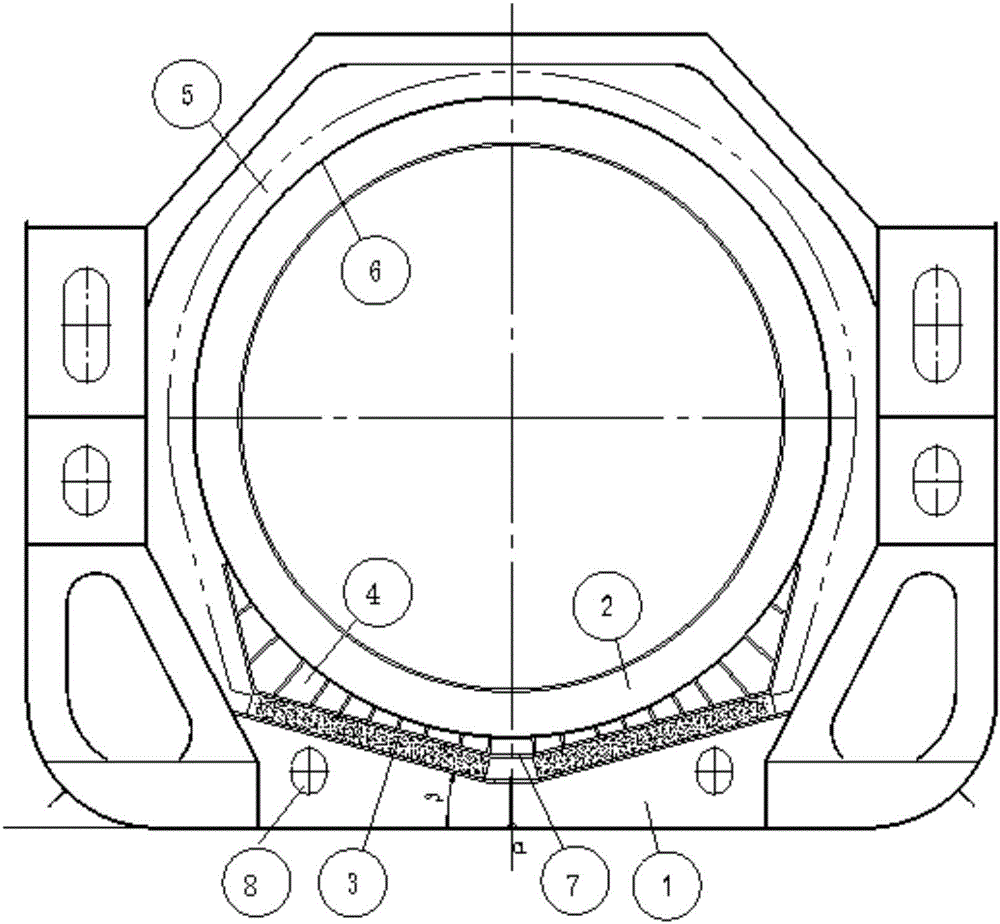

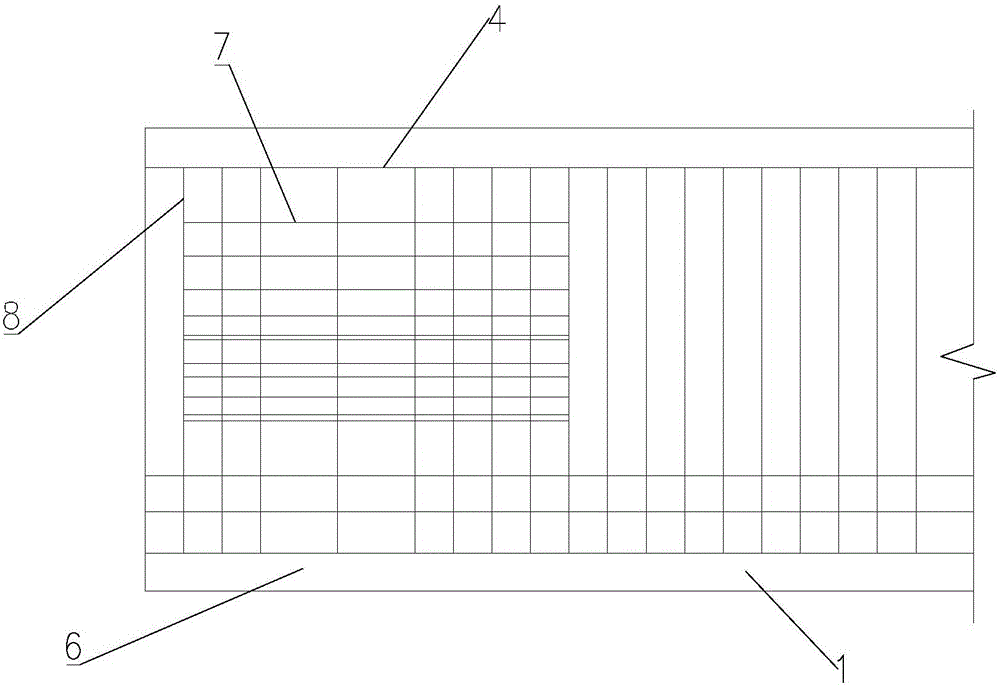

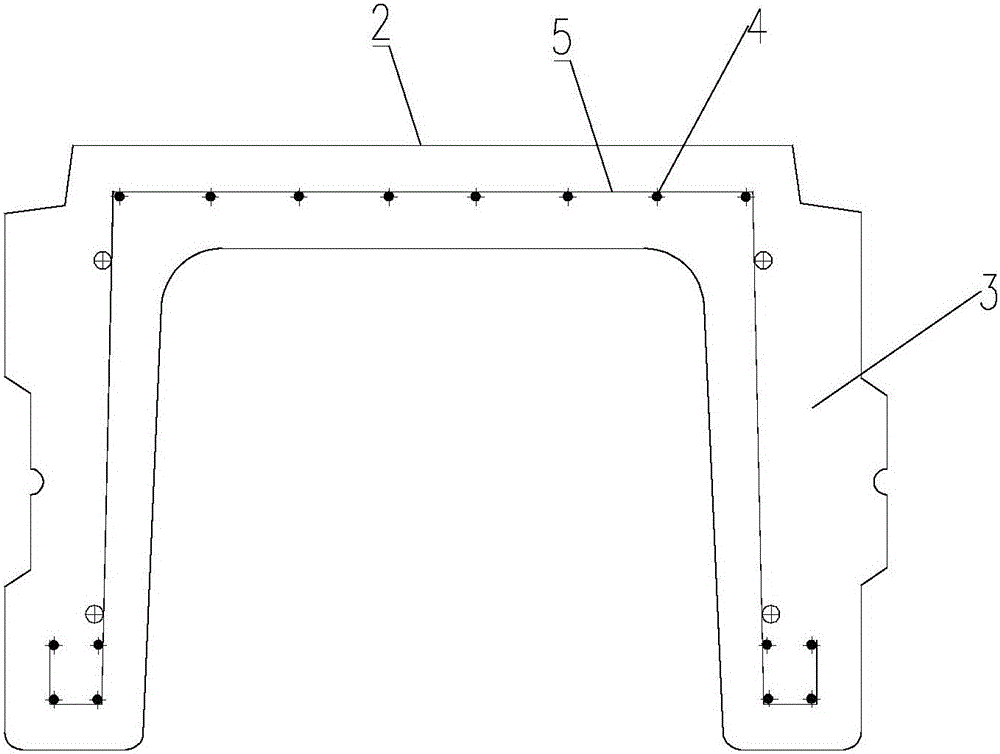

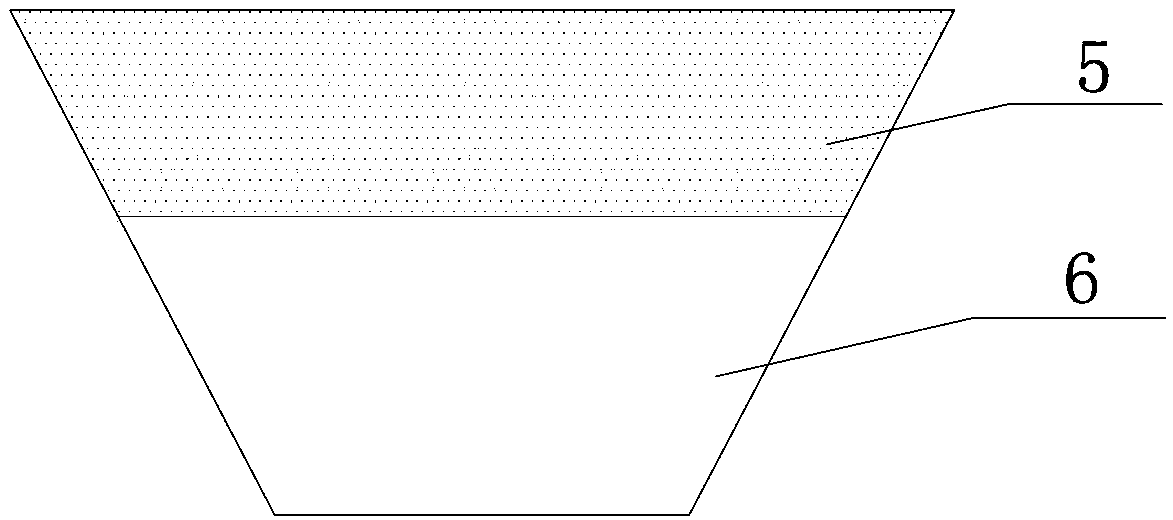

Marine supporting device for independent liquid tank

The invention relates to a marine supporting device for an independent liquid tank. The marine supporting device comprises a hull base (1), a heat insulation cushion block (3) and a liquid tank shell (6). An arc-shaped liquid tank saddle (4) is fixedly connected to the bottom of the liquid tank shell. The upper surface of the arc-shaped liquid tank saddle is fixedly connected with the outer surface of the liquid tank shell. The heat insulation cushion block is placed between the lower surface of the arc-shaped liquid tank saddle and the hull base. The arc-shaped liquid tank saddle is coated with an outer liquid tank heat preservation layer (5) located on the periphery of the liquid tank. The section shape of the upper surface of the hull base is identical to the section shape of the lower surface of the arc-shaped liquid tank saddle, and each section shape is a V shape with the axis of the liquid tank shell as the center line and is symmetric left and right. By the adoption of the marine supporting device, when goods such as LNG with a lower boiling point is loaded and transported, a supporting base can be tightly attached to the independent liquid tank shell all the time, and necessary vertical supporting and transverse supporting are provided.

Owner:上海斯达瑞船舶海洋工程服务有限公司

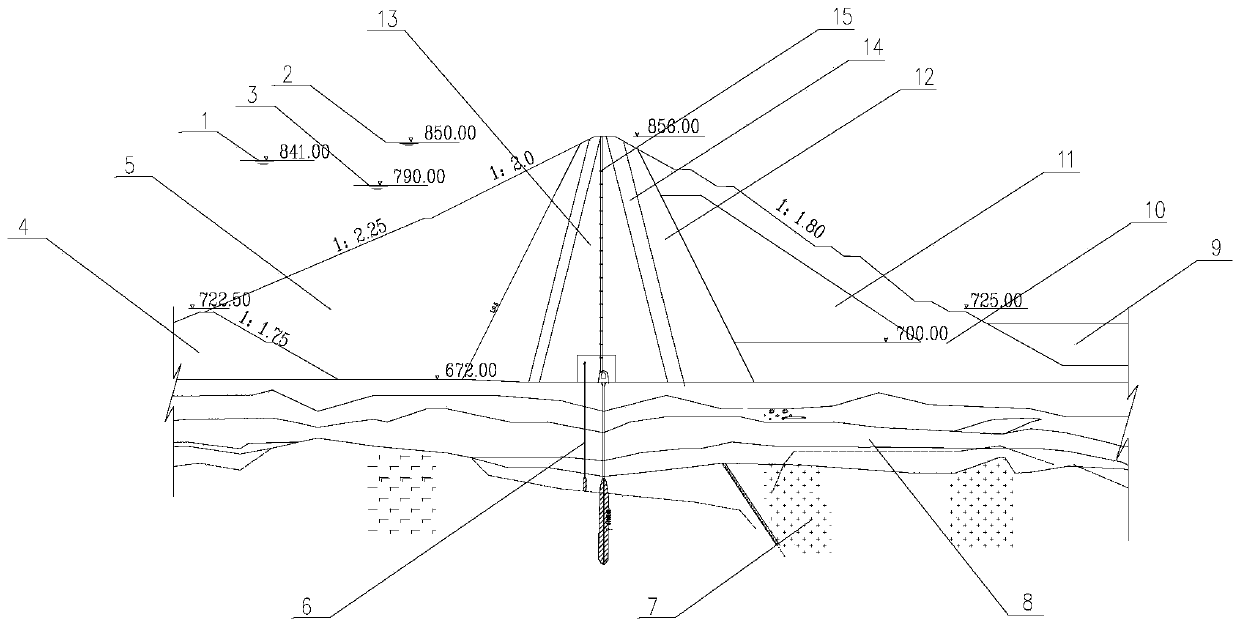

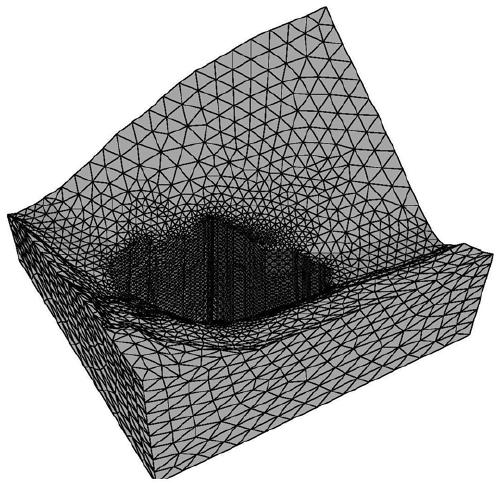

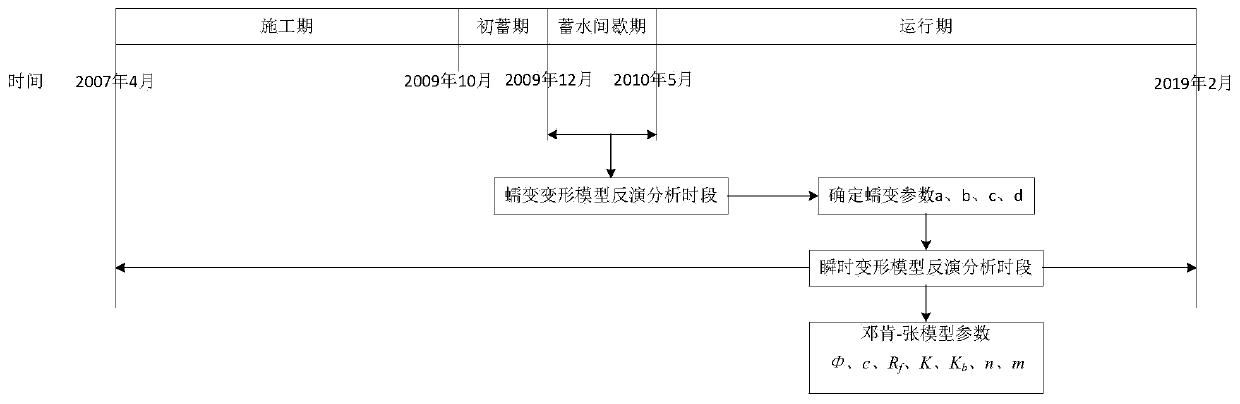

High-core-wall rock-fill dam deformation parameter inversion method

PendingCN111210519AComply with the force characteristicsAvoid issues such as small contributionsImage generation3D modellingClassical mechanicsInversion Time

The invention discloses a high-core-wall rock-fill dam deformation parameter inversion method, and relates to the technical field of high-core-wall rock-fill dam monitoring. A proper inversion time period is selected, a response surface method is adopted to construct a target optimization function, a simulated annealing algorithm is introduced to iteratively optimize the target optimization function. The method can be used for inversion analysis simulation of the deformation parameters of the high-core-wall rock-fill dam, and a technical support is provided for more accurate numerical simulation. The two defects in a traditional high-core-wall rock-fill dam deformation parameter inversion analysis method are overcome: 1, the problem of low inversion efficiency caused by a large number of finite element calculations is solved; and 2, in inversion analysis finite element calculation, creep deformation is not calculated, and instantaneous deformation is taken as total deformation to be compared with a monitoring value for inversion parameter optimization, so that instantaneous deformation parameters obtained by inversion are relatively large.

Owner:SICHUAN UNIV

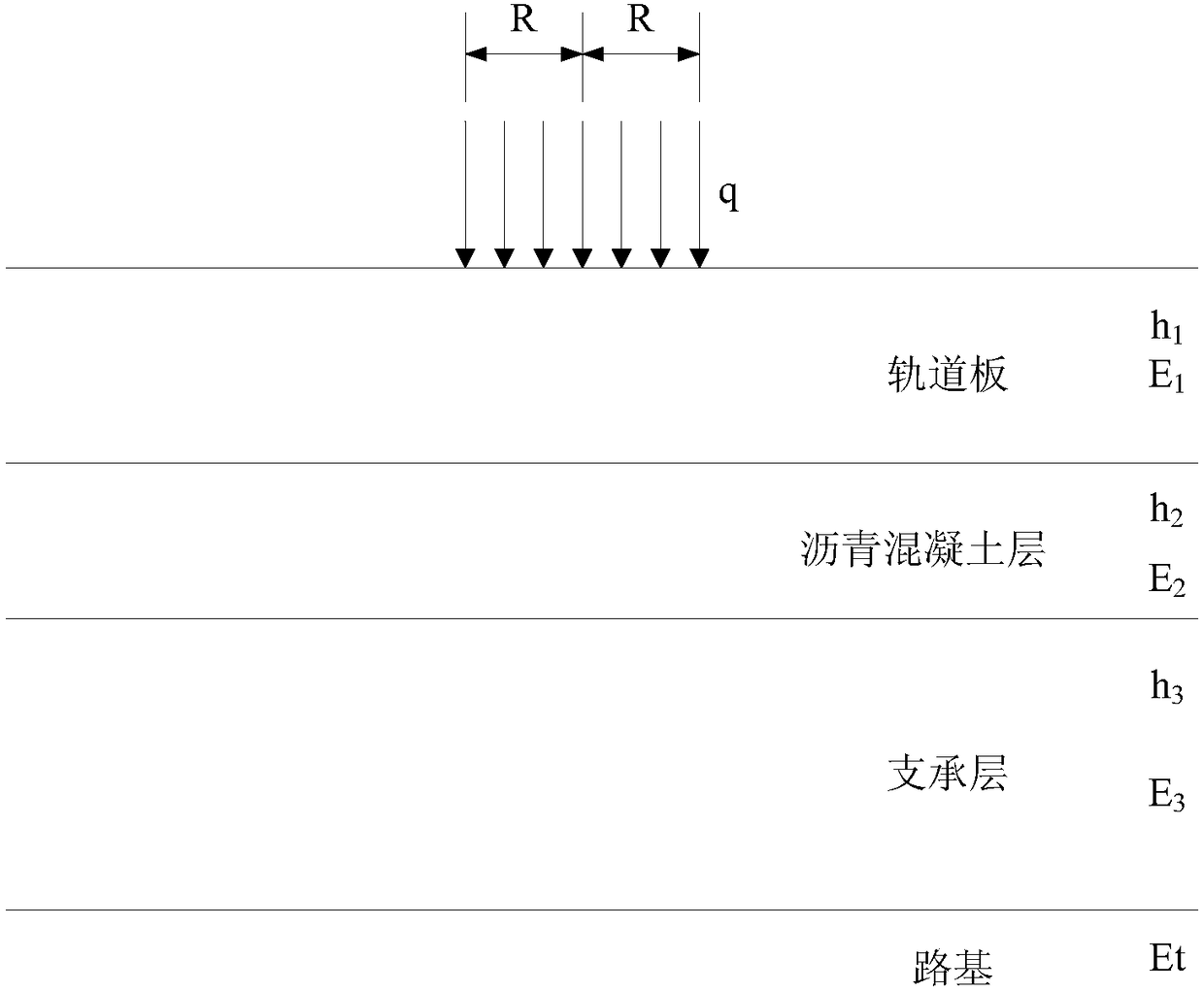

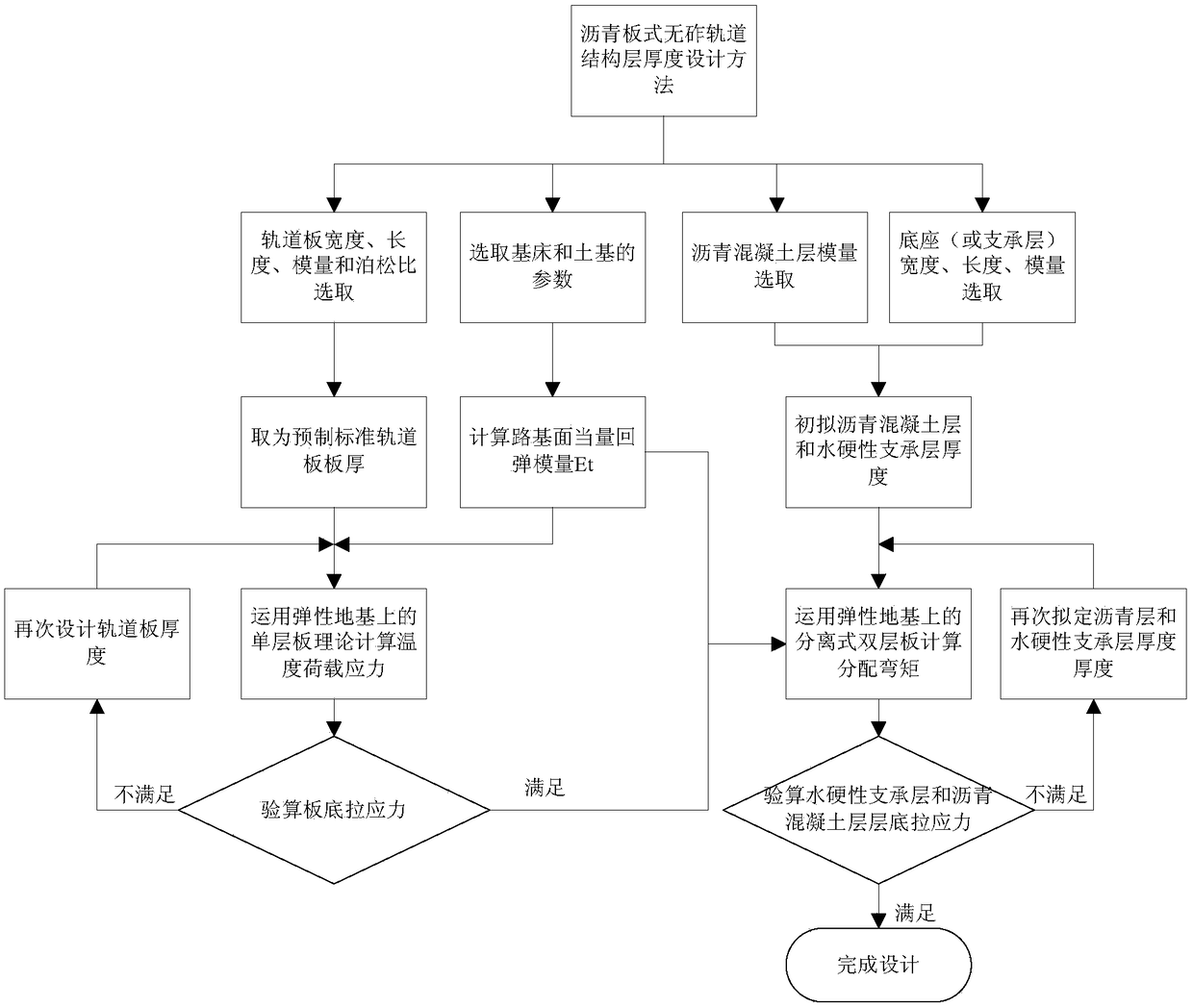

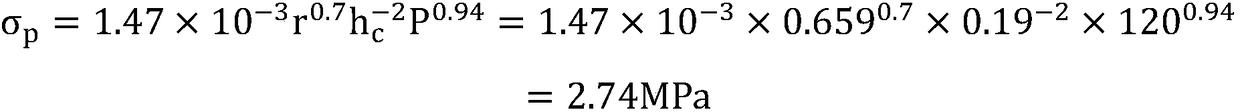

Asphalt slab ballastless track sub-rail foundation structure and quasi-static design method thereof

InactiveCN108399308AIn line with the actual stress situationComply with the force characteristicsRailway tracksDesign optimisation/simulationFatigue damageDesign methods

The invention relates to an asphalt slab ballastless track sub-rail foundation structure and a quasi-static design method thereof. The asphalt slab ballastless track sub-rail foundation structure is positioned above the surface of a ballastless track foundation bed below a steel rail and comprises a three-layer structure of track slab-asphalt concrete layer-hydraulic bearing layer. In order to control fatigue damage, track slab bottom horizontal tensile stress, asphalt concrete layer bottom tensile stress and base (or bearing layer) slab bottom tensile stress control indexes are provided. Compared with the beam-slab theory of elastic foundations where CA (cement asphalt) mortar is considered as a linear spring with no bending moment considered, the asphalt slab ballastless track sub-rail foundation structure and the quasi-static design method thereof have the advantages that the asphalt concrete layer and the hydraulic bearing layer are considered as a double-layer slab for an elasticfoundation, and the bearing characteristics of subgrade slab track structure are better met.

Owner:WUHAN UNIV OF TECH

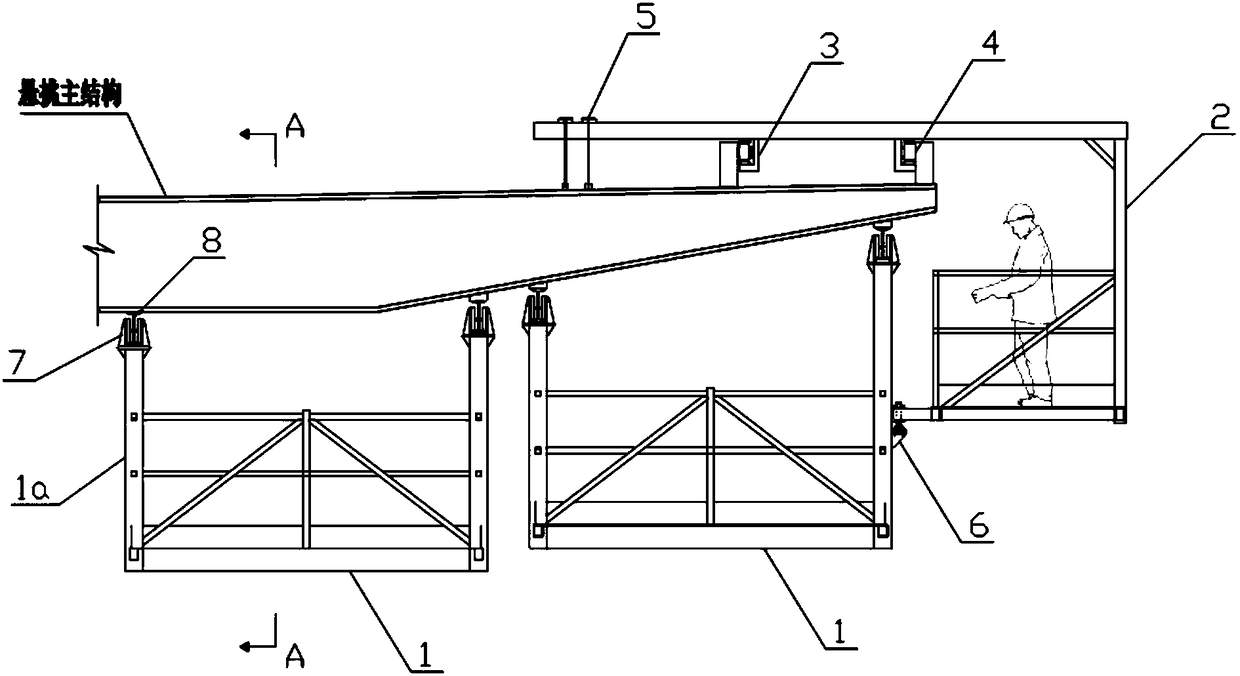

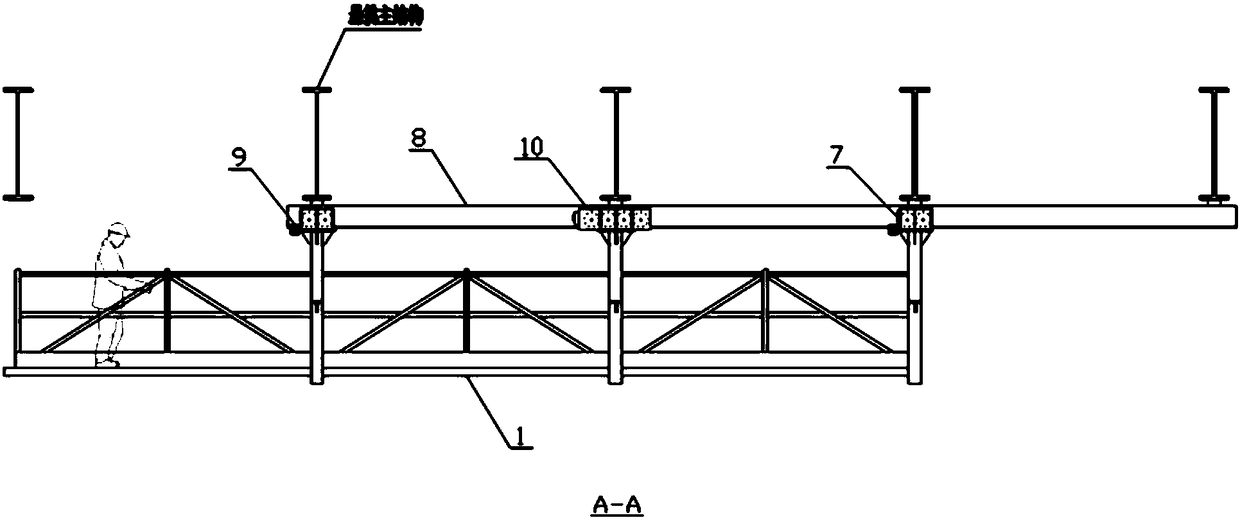

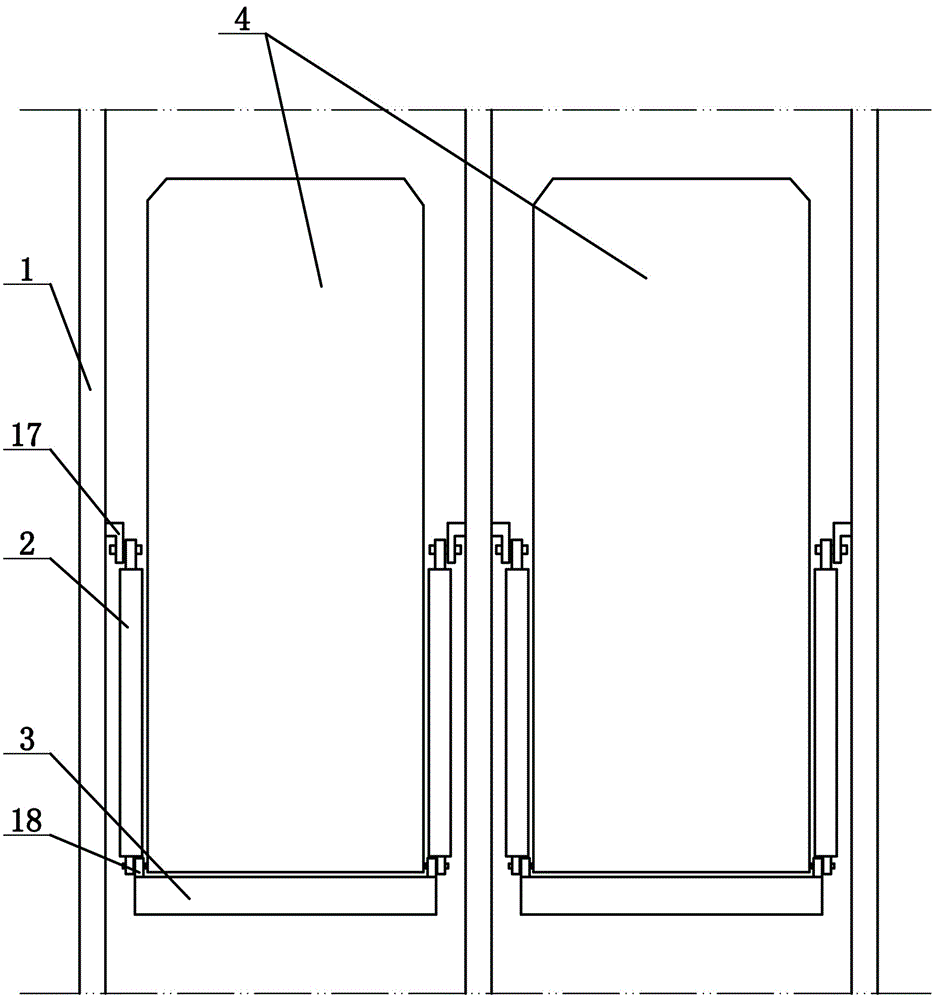

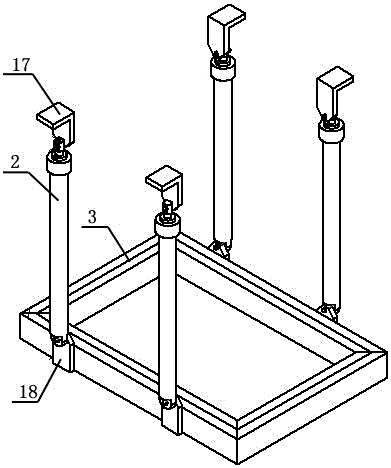

Horizontal-moving type operating platform device applied to construction of creasing curtain wall

PendingCN108277971AMeet construction requirementsConstruction safety and controllableBuilding support scaffoldsHanging basketEngineering

The invention provides a horizontal-moving type operating platform device applied to construction of a creasing curtain wall. The horizontal-moving type operating platform device comprises a modular lower-hanging type platform system and an upper-hanging type overhung platform system, the modular lower-hanging type platform system comprises an operating platform and a hanging system, and the hanging system is composed of a hanging column, a guide rail, a guiding module, a braking device and a power sliding vehicle; the operating platform is assembled through the hanging column and the guidingmodule and is hung on the guide rail, and the operating platform takes the power sliding vehicle as a power source and moves front and back in the direction of the guide rail; and the upper-hanging type overhung platform system comprises an overhung platform body, a guiding module, a guide rail, a rebar hanging ring and a fixing connecting piece, the overhung platform body and the guiding module are assembled into a whole and are buckled on the two sides of an inner edge of the guide rail, the tail end of the overhung platform body is fixed to an overhung main structure by adopting the rebar hanging ring, and the bottom end of the overhung platform body is fixed to a hanging column connecting joint of a lower-hanging type platform by adopting fixing connecting pieces. The horizontal-movingtype operating platform device makes up defects of conventional hanging basket and scaffold construction, and it is ensured that construction is safe and controllable, and the quality and the precision meet design requirements.

Owner:SHANGHAI MECHANIZED CONSTR GRP

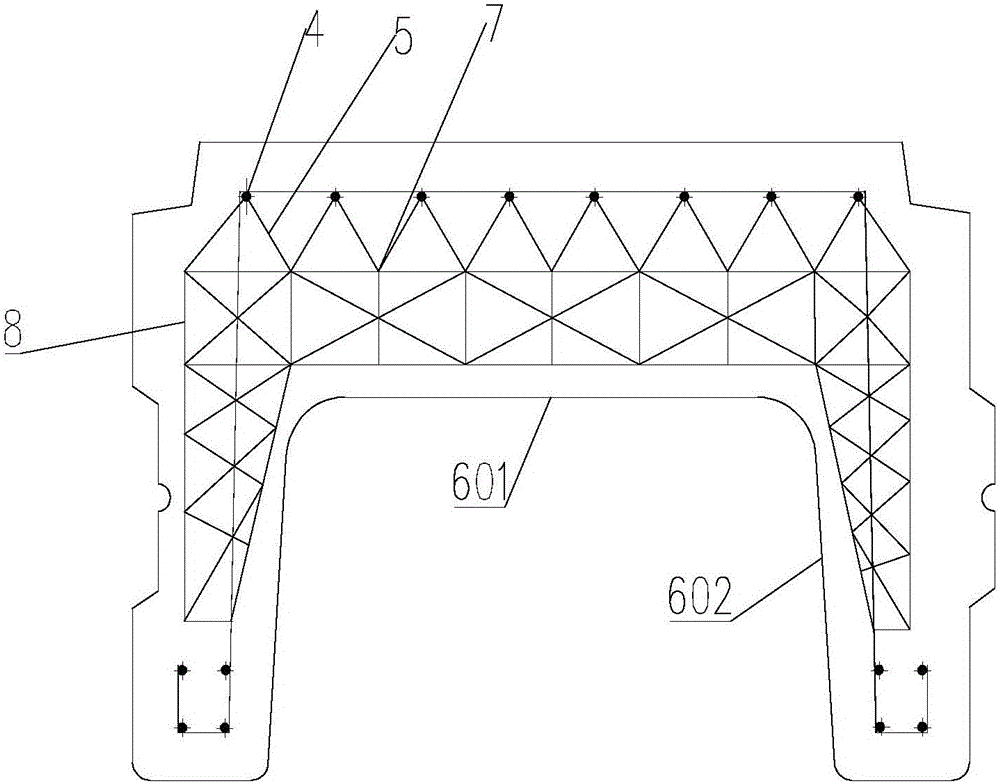

Damping type over discharge buffering device for mine hoisting system

InactiveCN104016206AShort retrofit shutdown cycleReduce security retrofit challengesElevatorsHydraulic cylinderArchitectural engineering

The invention relates to a damping type over discharge buffering device for a mine hoisting system. The damping type over discharge buffering device comprises a steel truss, a damping buffer and a buffering bracket, the steel truss is arranged on the mine wall of the bottom of a mine, one end of the damping buffer is connected with the steel truss, the other end of the damping buffer is connected with the buffering bracket, and a cage of the mine hoisting system falls on the buffering bracket during falling. By means of the damping type over discharge buffering device, a new over discharge prevention device is designed; the damping type over discharge buffering device is installed above over discharge prevention space at the mine bottom of the mine, the steel truss is arranged at the mine bottom, an over discharge prevention buffering device is hung on the steel truss, a damping groove is formed in a piston rod of a hydraulic cylinder, the depth size of the damping groove is changed along with stroke changes, the problem of insufficient over discharge prevention space of old mine transformation is solved, the over discharge prevention device can be additionally arranged in an old mine hoisting system, and security coefficients of mine production can be effectively improved; meanwhile, construction is simple, the construction period is short, the old-mine transformation halt period is short, and the old mine safety transformation problems are decreased as many as possible.

Owner:张纬

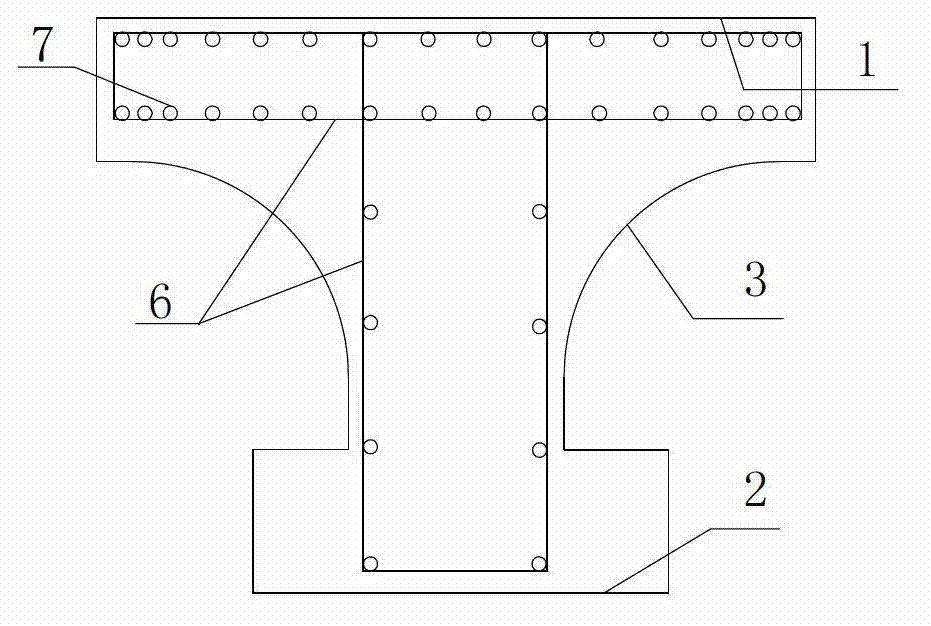

Antiskid pile with T-shaped cross section

InactiveCN103046540AIncrease the pile center distanceReduce in quantityBulkheads/pilesStress concentrationSoil arching

The invention relates to an antiskid pile with a T-shaped cross section. The antiskid pile is formed by pouring reinforced concrete, the cross section of the antiskid pile is in a shape of a T, the top of the T serves as a front end of the pile, the bottom of the T serves as a rear end of the pile, an arc-shaped part is formed between the front end and the rear end of the pile, the design of the arc-shaped part can prevent stress concentration from being generated at a pointed position, rebar cages are mounted in the antiskid pile, dense rebars are arranged in the rebar cage at the rear end of the pile, and few rebars are arranged at the front end and the arc-shaped part. The transverse width of the rear end of the pile is larger than that of the front end of the pile, so that soil arching effect behind the pile can be brought into full play, and during slope treatment, the distance of pile centers between adjacent antiskid piles can be increased while the number of the antiskid piles needed to be arranged is decreased correspondingly; and in addition, the area of the antiskid pile with the T-shaped cross section is evidently smaller than that of an antiskid pile with a rectangular cross section, so that concrete and the rebars can be greatly saved, and cost is lowered. The antiskid pile is small in construction section, convenient for mechanical construction, simple and safe in construction and wide in popularization and application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

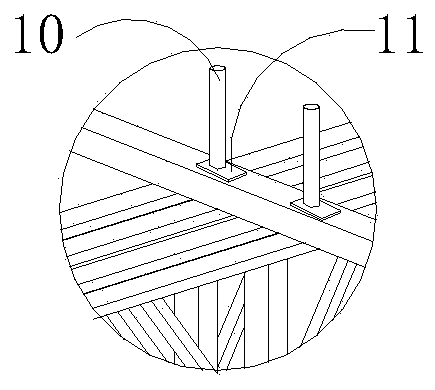

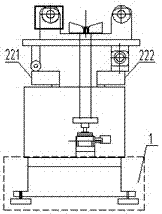

Assembling type large-scale vibrating table test protection device

The invention discloses an assembling type large-scale vibrating table test protection device comprising an anchoring structure and a vibrating table protection frame erected on the anchoring structure. The anchoring structure includes concrete anchor blocks and stand columns anchored on the concrete anchor blocks; the vibrating table protection frame includes steel frames fixedly mounted on the stand columns, the steel frames include Bailey truss girders erected on the stand columns and Bailey truss auxiliary beams fixedly mounted on the girders, the Bailey truss auxiliary beams includes horizontal Bailey truss beams and vertical Bailey truss beams, and the horizontal Bailey truss beams and the vertical Bailey truss beams are erected on the Bailey truss girder to form a double cross shaped structure for placing a vibrating table. The assembling type large-scale vibrating table test protection device has the following advantages: according to the invention, a space-enclosed frame is formed on the neck of a test model, and when the test structure collapses, the safety protection device can clamp a test piece in time; the characteristics of simple assembly and hoisting are achieved;since the shuttle space of the safety protection device is large, a layout platform can be provided for a test sensor, and thus testers can conveniently operate and observe test phenomena.

Owner:SOUTHWEST JIAOTONG UNIV

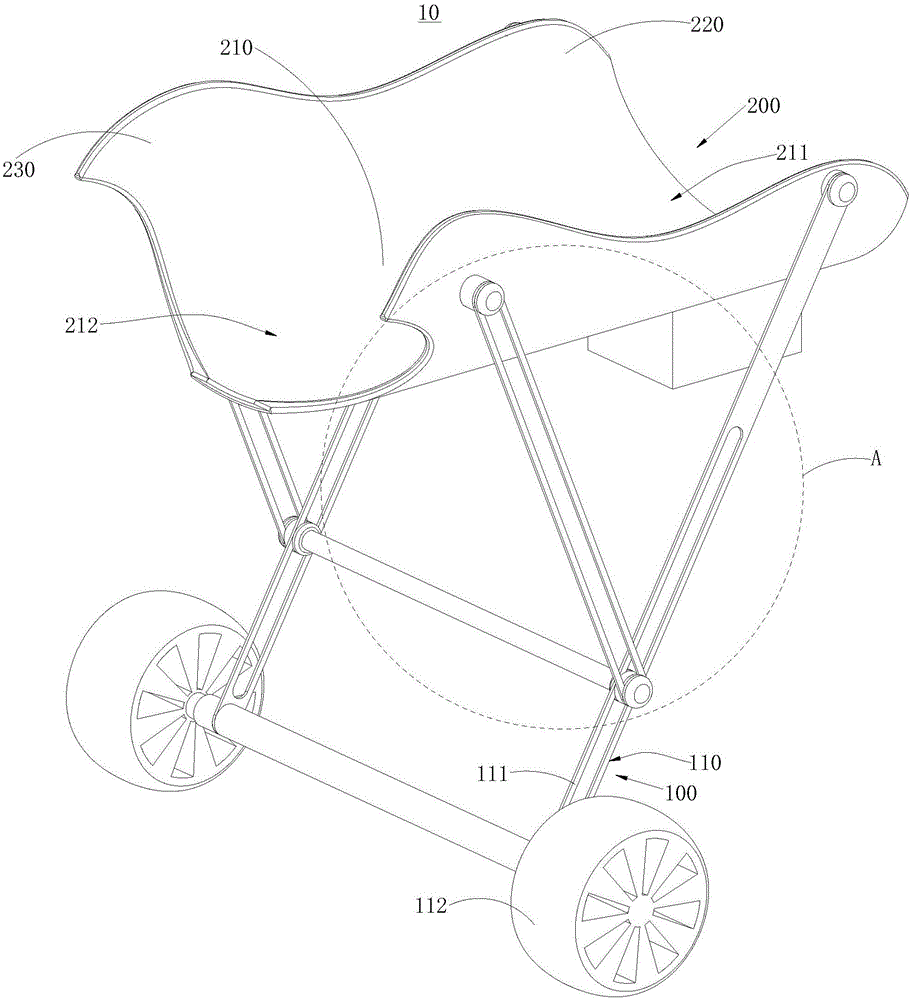

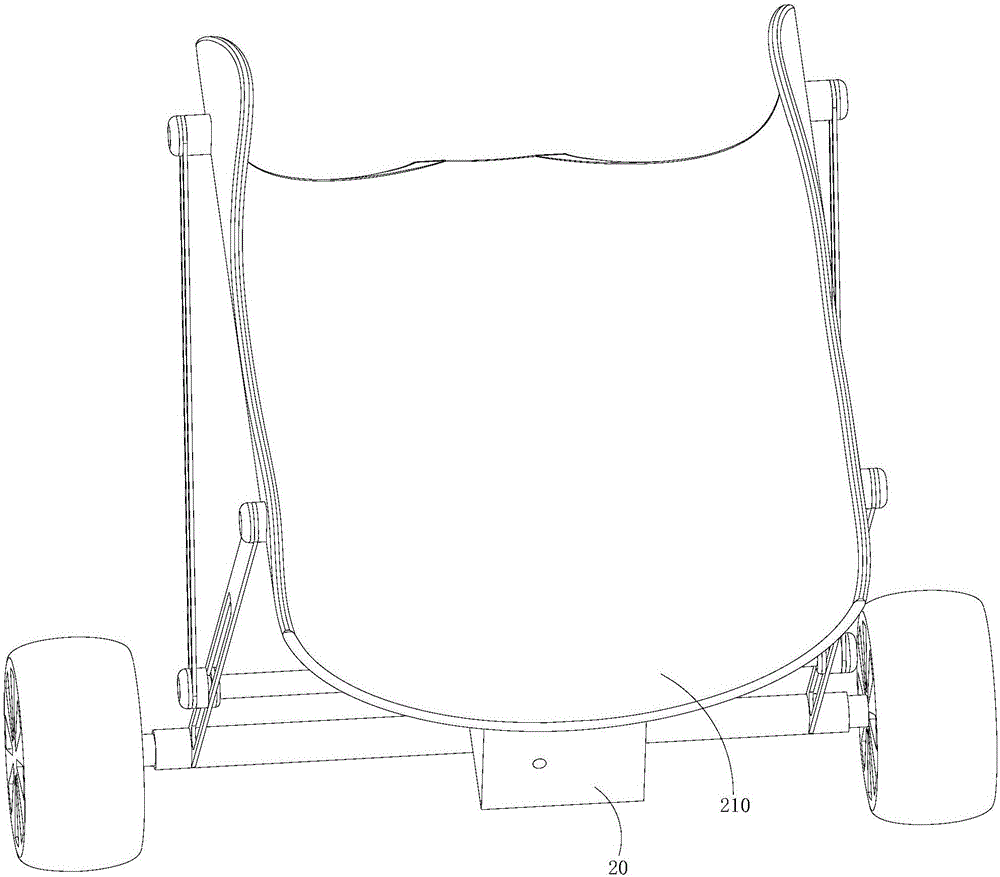

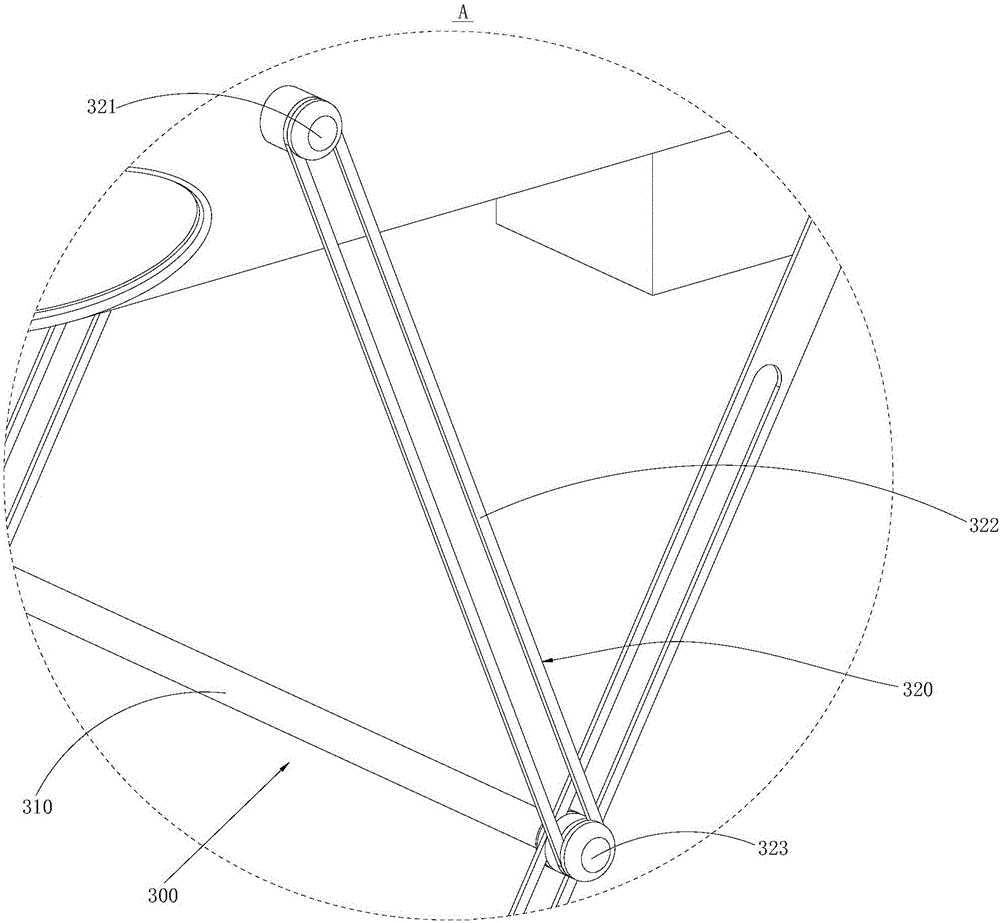

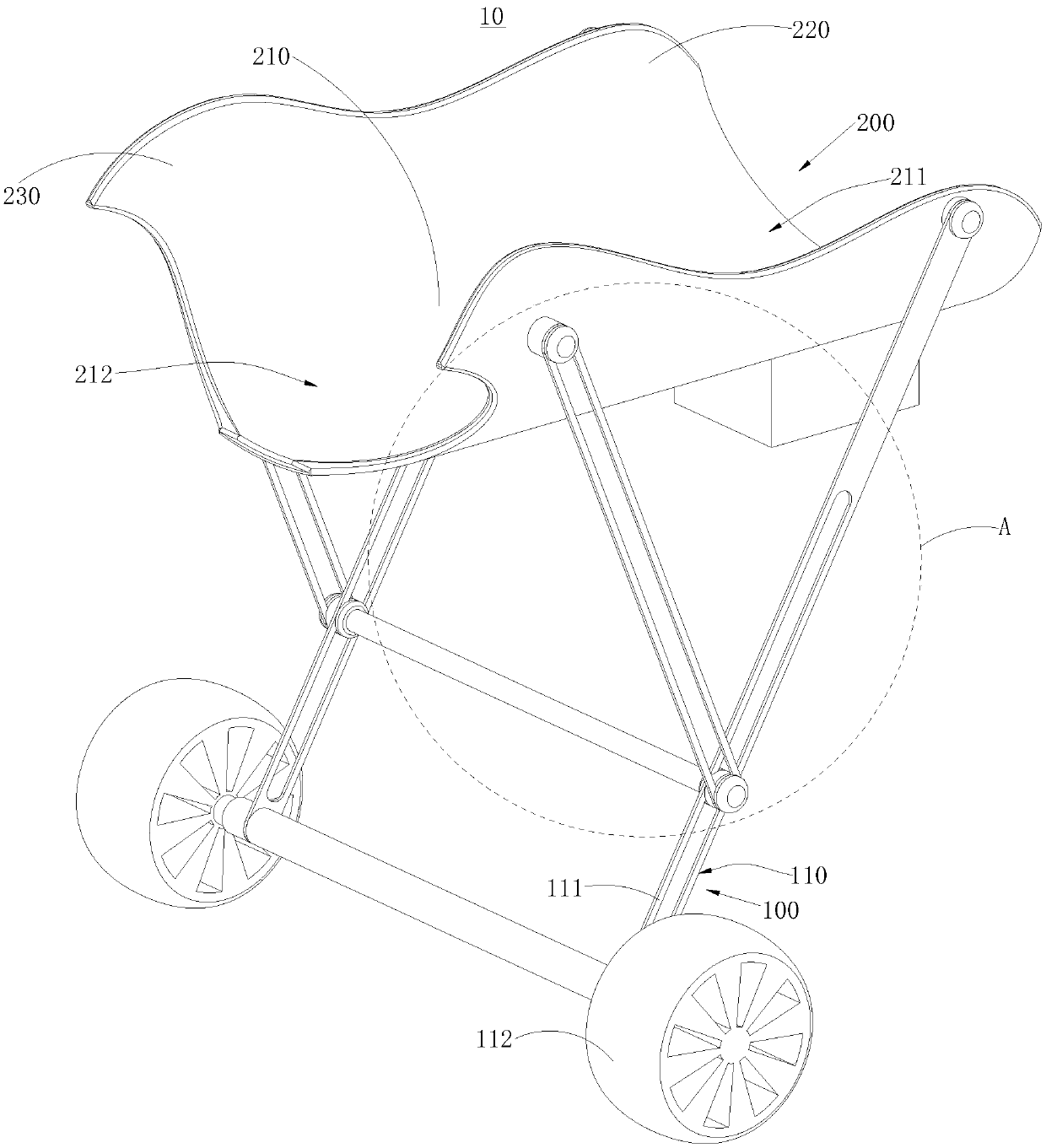

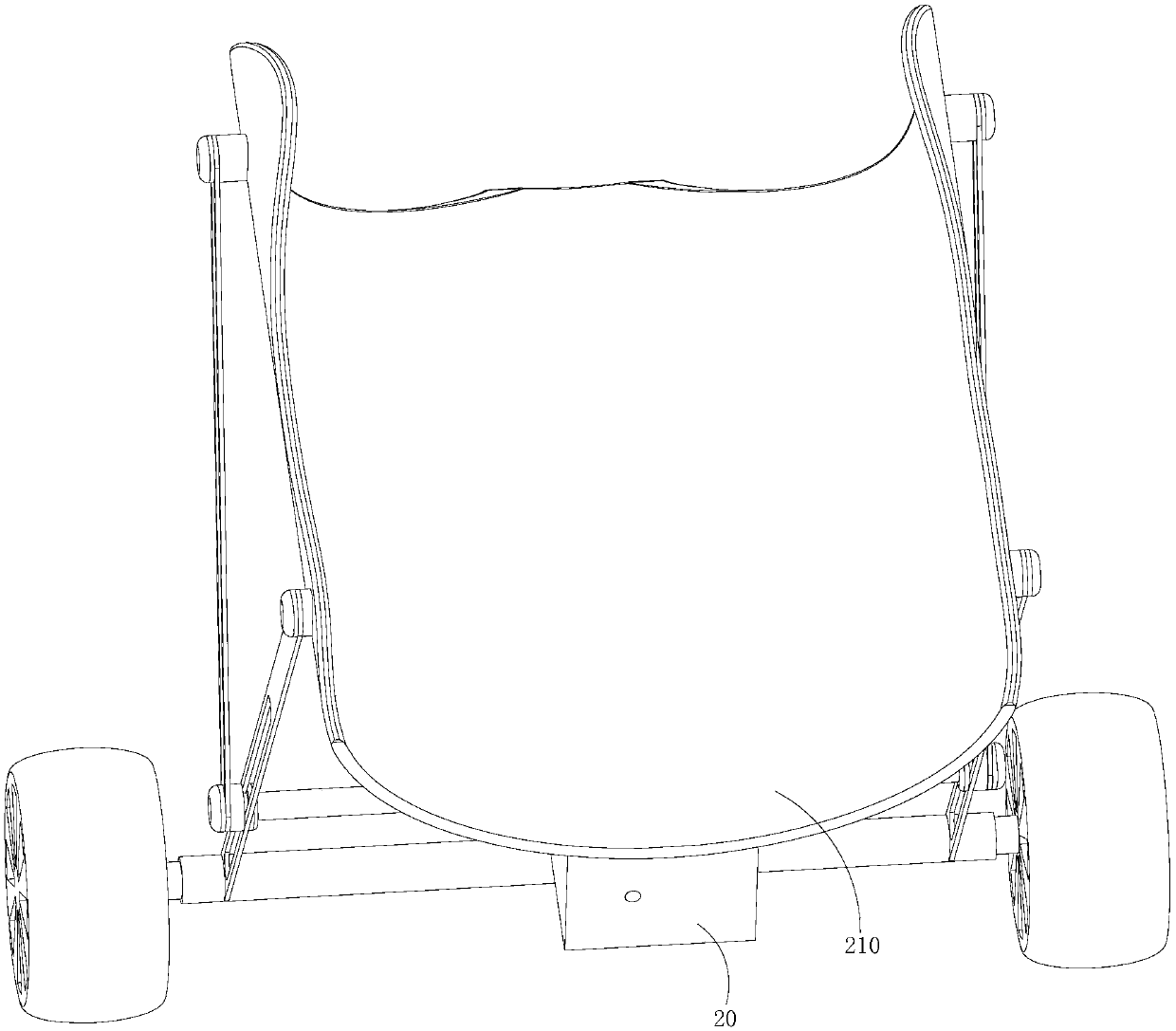

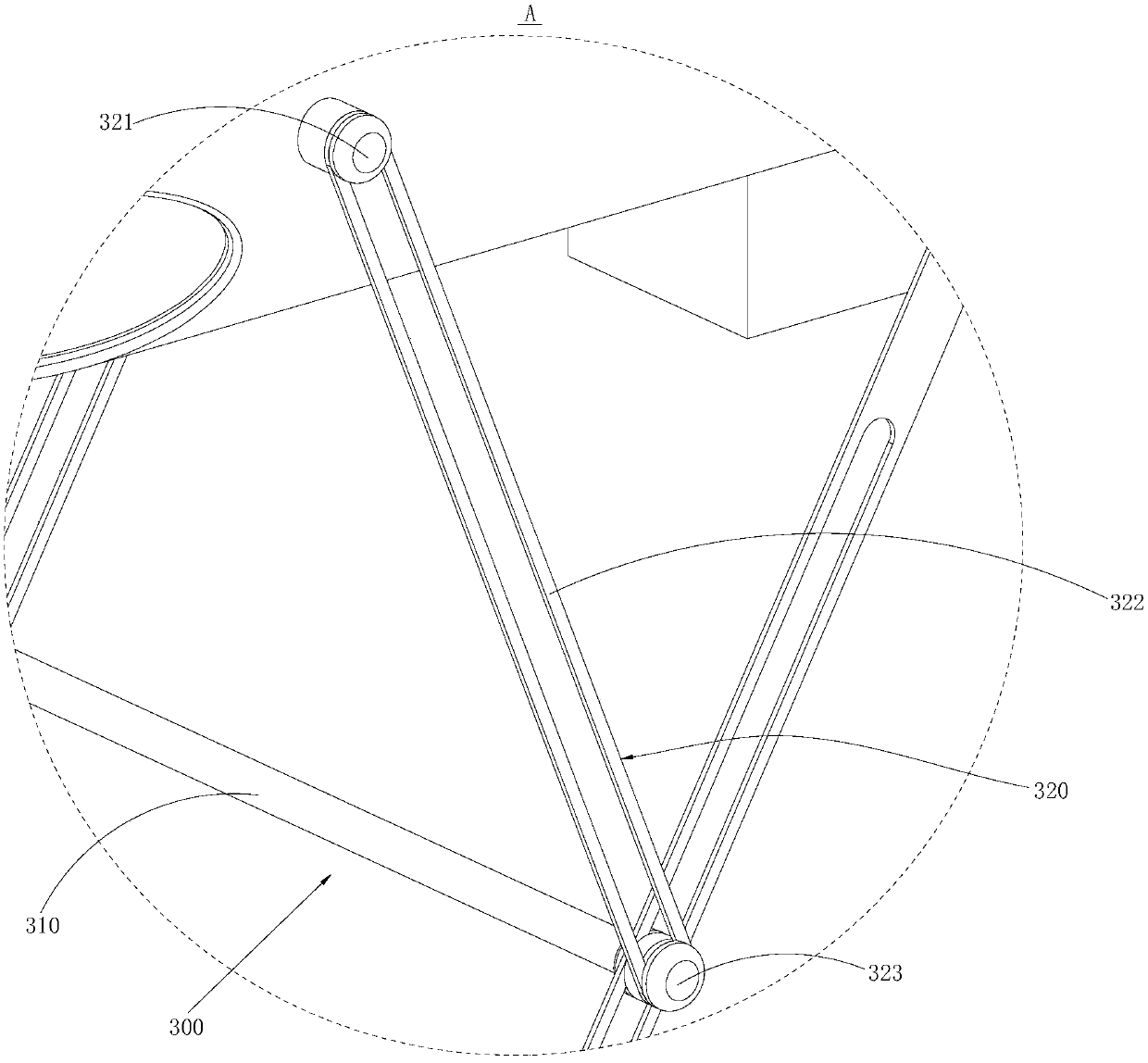

Pet walking device

ActiveCN106806042AAdd supportGood coating effectArtificial legsAgricultural engineeringReflective layer

The invention provides a pet walking device. The device comprises a walking component, a bearing component and a warning component, wherein the walking component comprises two walking modules, each walking module comprises a supporting rod and a walking wheel; the bearing component comprises a bearing part, two mounting parts and two coating parts; each bearing part has a mounting area and a bearing area connected with the mounting area; the two mounting parts are respectively connected with two sides of the mounting area; the two coating parts are respectively connected with two sides of the bearing area, each coating part is connected with one mounting part, and the second end of each supporting rod is connected with one mounting part; and the warning component comprises two warning modules, an embedding groove is formed in each supporting rod, and each warning module is accommodated in each embedding groove correspondingly. The pet walking device has a relatively good effect for bearing and coating a pet dog with disabled legs, and can be used for warning automobiles on a road with dark light since light emitted from automobiles is reflected by a reflective layer, so that the safety of pet dogs can be improved.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Automatic jacking system for steel structure mounting

ActiveCN107190860AComply with the force characteristicsAvoid adverse conditionsBuilding constructionsWind energy generationArchitectural engineeringTower crane

The invention relates to an automatic jacking system for steel structure mounting. The automatic jacking system comprises a frame climbing structure attached to a steel structure and arranged on the outer side of the steel structure, and a hydraulic jacking mechanism mounted at the bottom of the frame climbing structure. The top of the hydraulic jacking mechanism is hinged to the bottom of the frame climbing structure. A spherical hinged force bearing base is mounted at the bottom of the hydraulic jacking mechanism and placed on a corresponding bearing piece on the steel structure. The hydraulic jacking mechanism jacks the frame climbing structure, and accordingly the frame climbing structure climbs along the steel structure. The automatic jacking system can automatically climb along the steel structure. Through automatic climbing of the automatic jacking system, the problems that in existing construction, an operation platform needs to be moved or detached manually and then hoisted through a tower crane, so that construction efficiency is low, the labor force demand is high, and the cost is high are solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

A support device for a marine independent liquid tank

Owner:上海斯达瑞船舶海洋工程服务有限公司

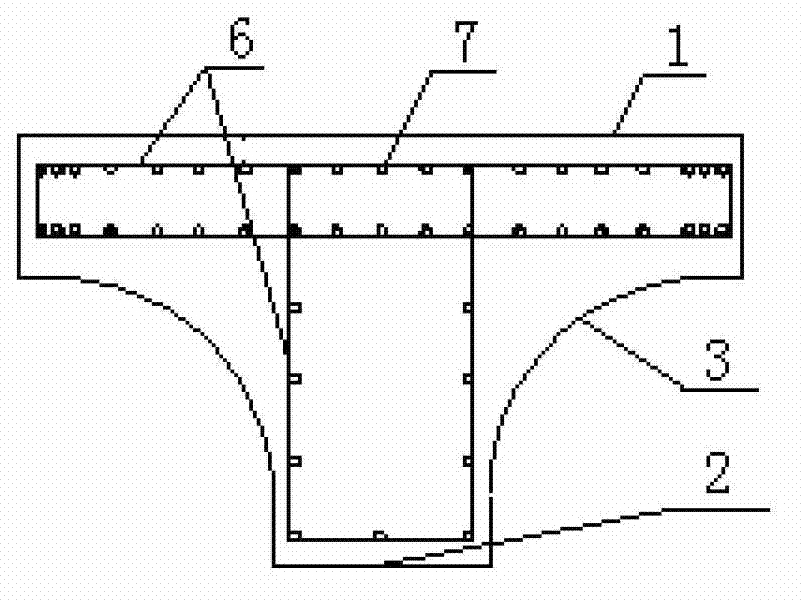

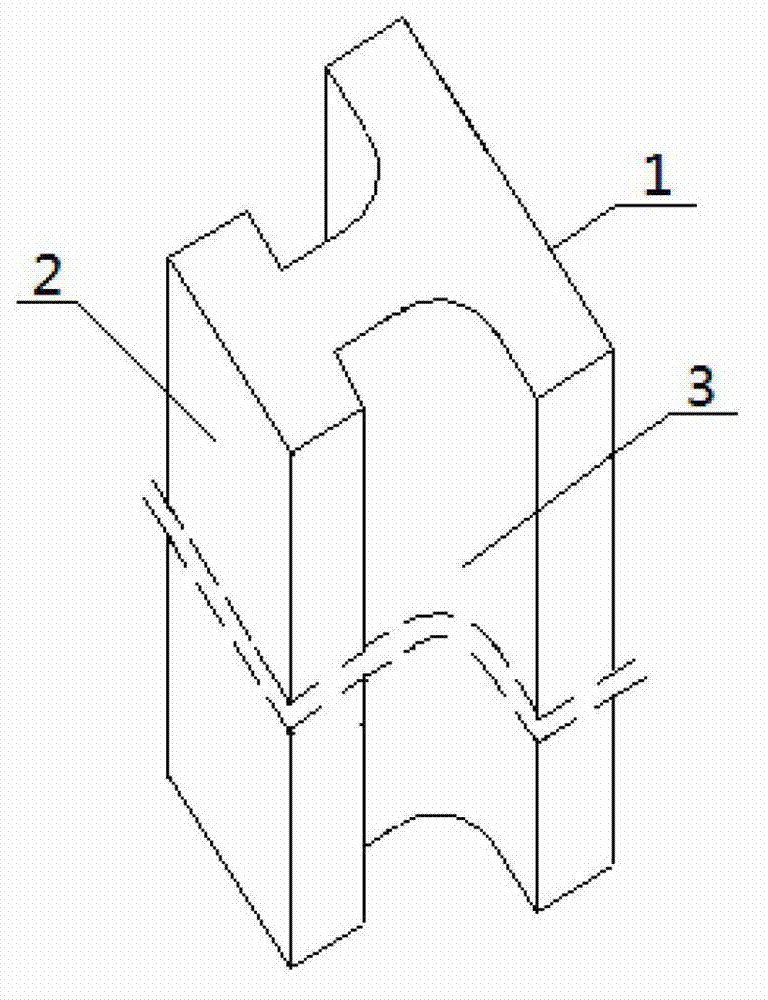

Reinforcing device for prefabricated concrete channel plate pile head

ActiveCN105970963AEffectively withstand uneven stressEasy constructionBulkheads/pilesRebarPrecast concrete

The invention discloses a reinforcing device for a prefabricated concrete channel plate pile head. The reinforcing device comprises a pile body which comprises an upper web and wing plates on the two sides; the upper web is 120 mm in thickness; longitudinal main rebars are laid in the pile body and connected through stirrups; transverse main rebars are arranged in the pile body, and the transverse main rebars and the longitudinal main rebars are fixedly connected through stirrups in the intersecting positions; the pile head is arranged at one end of the pile body, the thickness of a pile head web is 280 mm, a plurality of dense rebars are arranged in the pile head, and the dense rebars and the longitudinal main rebars are arranged in parallel; and the longitudinal main rebars, the stirrups and the dense rebars form rebar grids which are located at the front section of the pile head, three rebar grids are arranged at the intervals of 50 mm, and two rebar grids are arranged at the interval of 100 mm, and five rebar grids are arranged in total. According to the reinforcing device for the prefabricated concrete channel plate pile head, the principles that the dense rebars are small in diameter and are densely arranged are observed, non-uniform stress generated in the vibration pile driving process can be effectively borne, construction is easy to conduct, not only can the pile head be effectively protected, but also a mass of rebars are omitted, and the cost is reduced.

Owner:FUJIAN UNIV OF TECH

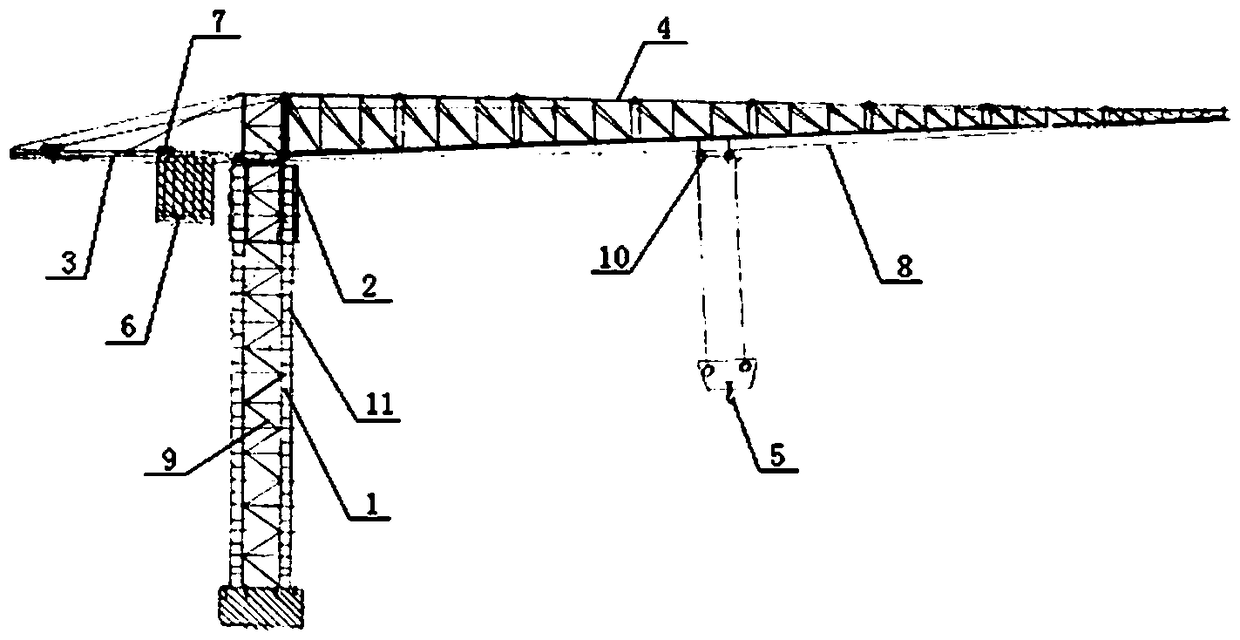

Autobalance tower type crane

The invention discloses an autobalance tower type crane, and belongs to the technical field of cranes. The problems that due to the fact that force borne by a balancing arm and a cargo boom are different, the unbalance situation of an existing tower type crane is serious, and both time and labor are consumable when a stock is lifted up can be solved. The autobalance tower type crane comprises a stock located at the top end of a tower body, a balancing arm and a cargo boom are located at the top end of the stock, and located on the two sides of the stock correspondingly, a jib lubbing mechanismis arranged on each of the balancing arm and the cargo boom, a hook is connected to the cargo boom through a steel wire rope, a balance weight object is located on the balancing arm, the cargo boom becomes slender from the end, close to the stock, to the tail part, the jib lubbing mechanism on the balancing arm comprises a power source, the power source is connected with a motor through a horizontal switch, the output end of the motor is connected with the input end of a gear reducer, the output end of the gear reducer is connected with a coiling block, the coiling block is connected with thebalance weight object through the steel wire rope, a travel switch is arranged at the end, away from the stock, of the balancing arm, and the travel switch is connected with the jib lubbing mechanisms on the balancing arms and the cargo booms in series. The autobalance tower type crane can save both time and labor, and is high in safety performance.

Owner:赵保全

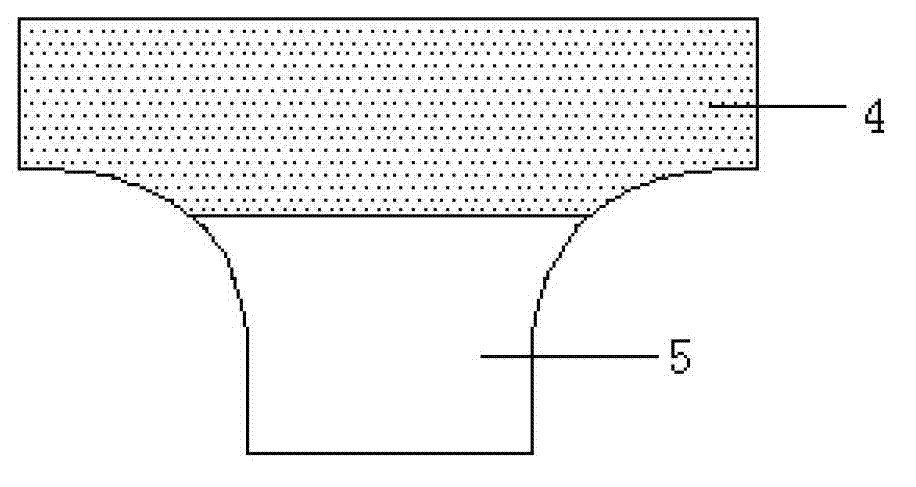

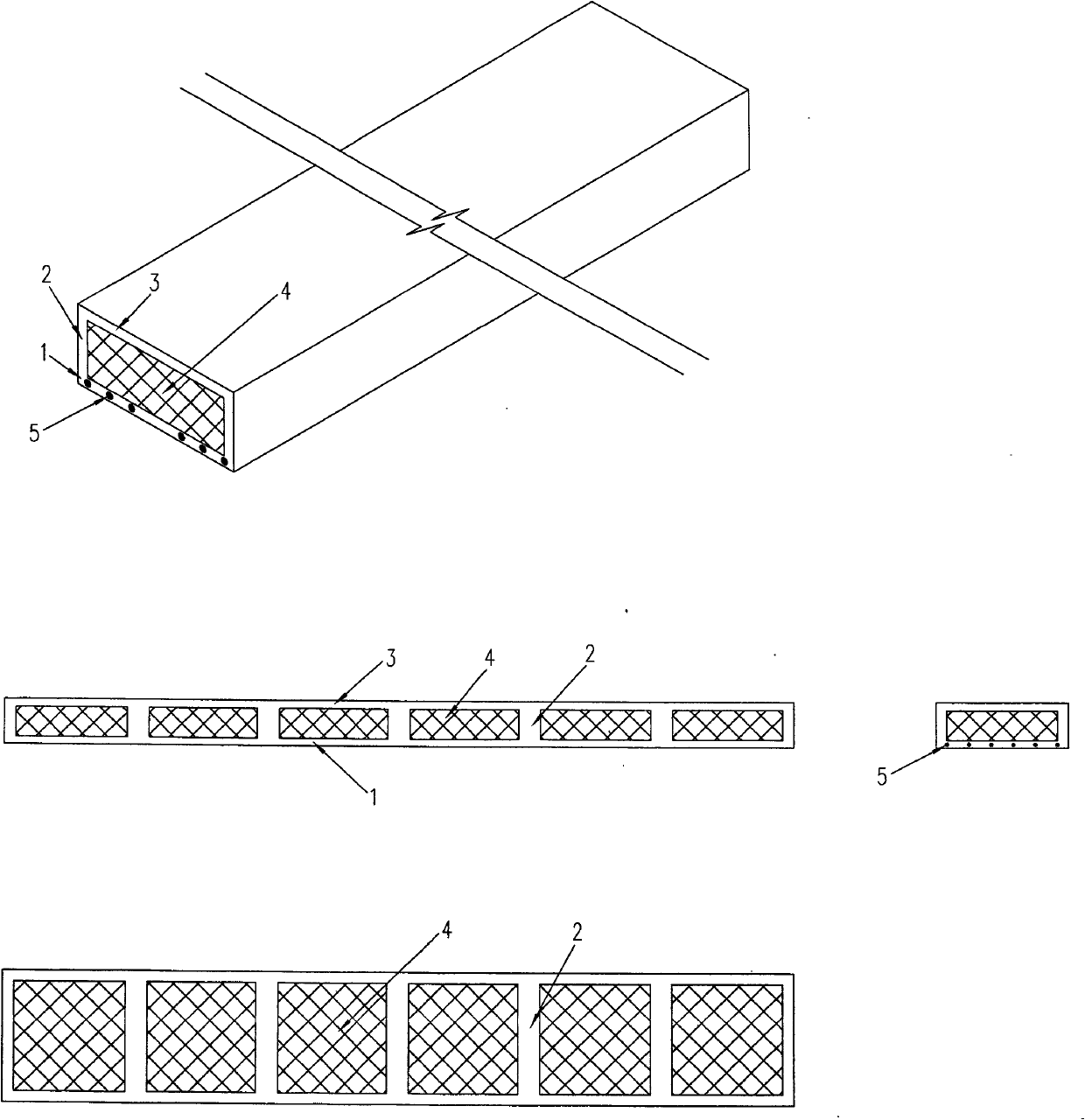

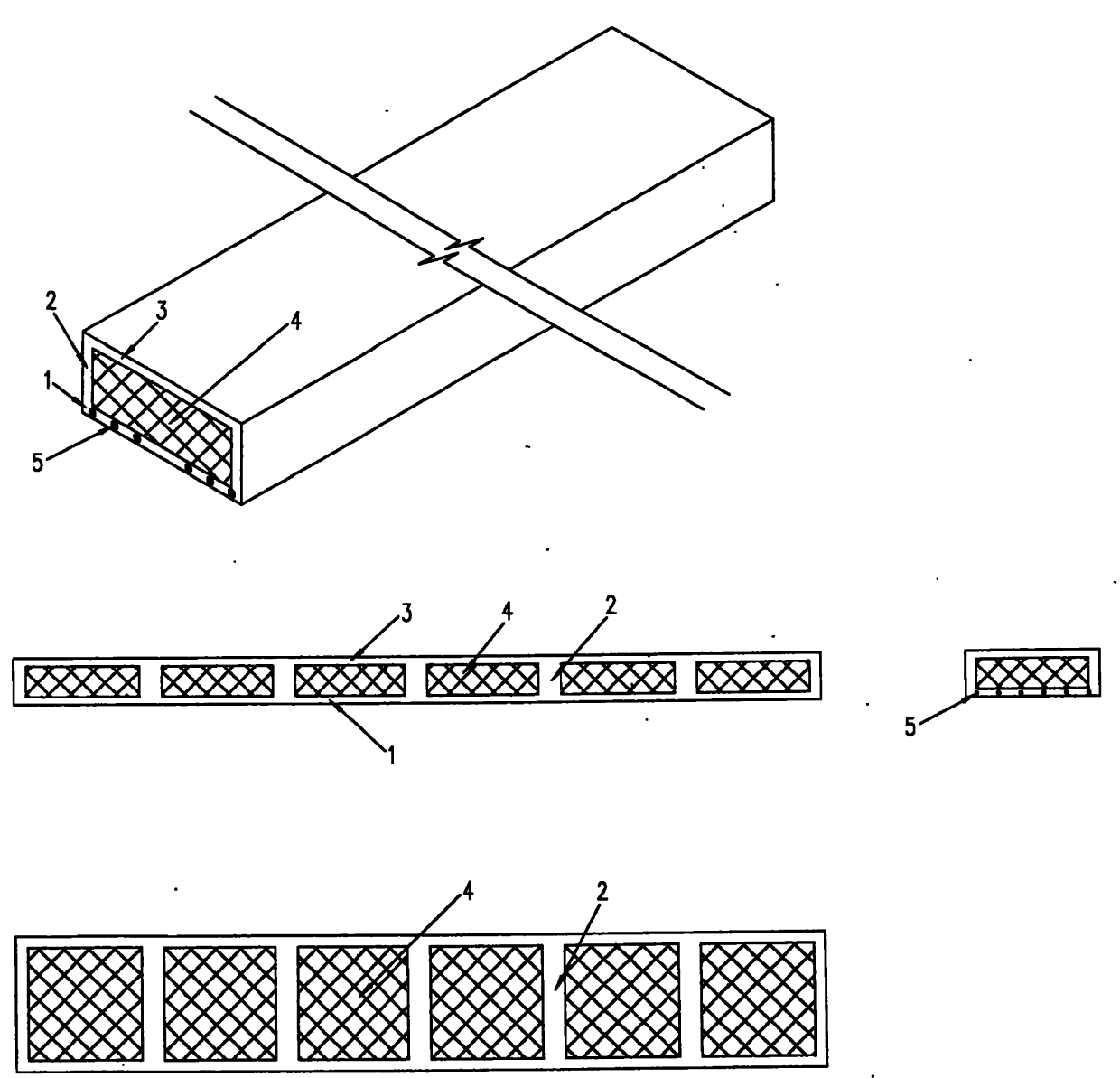

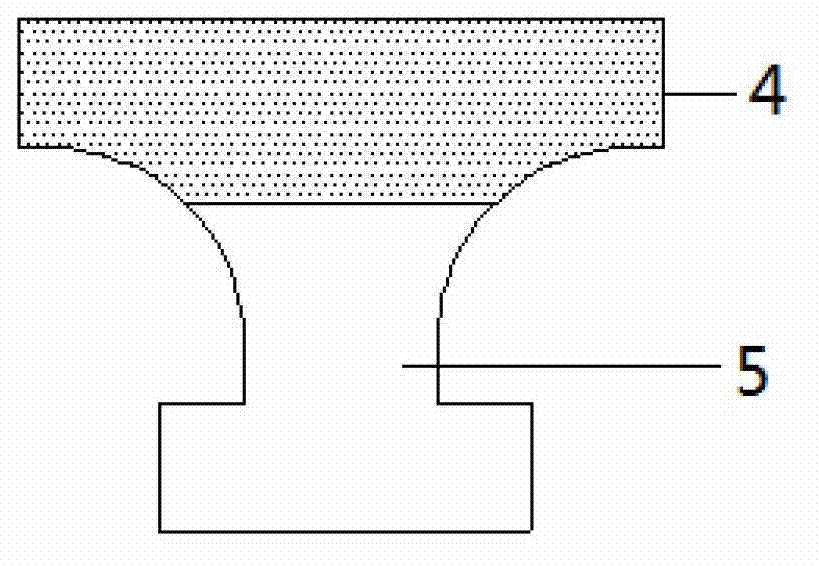

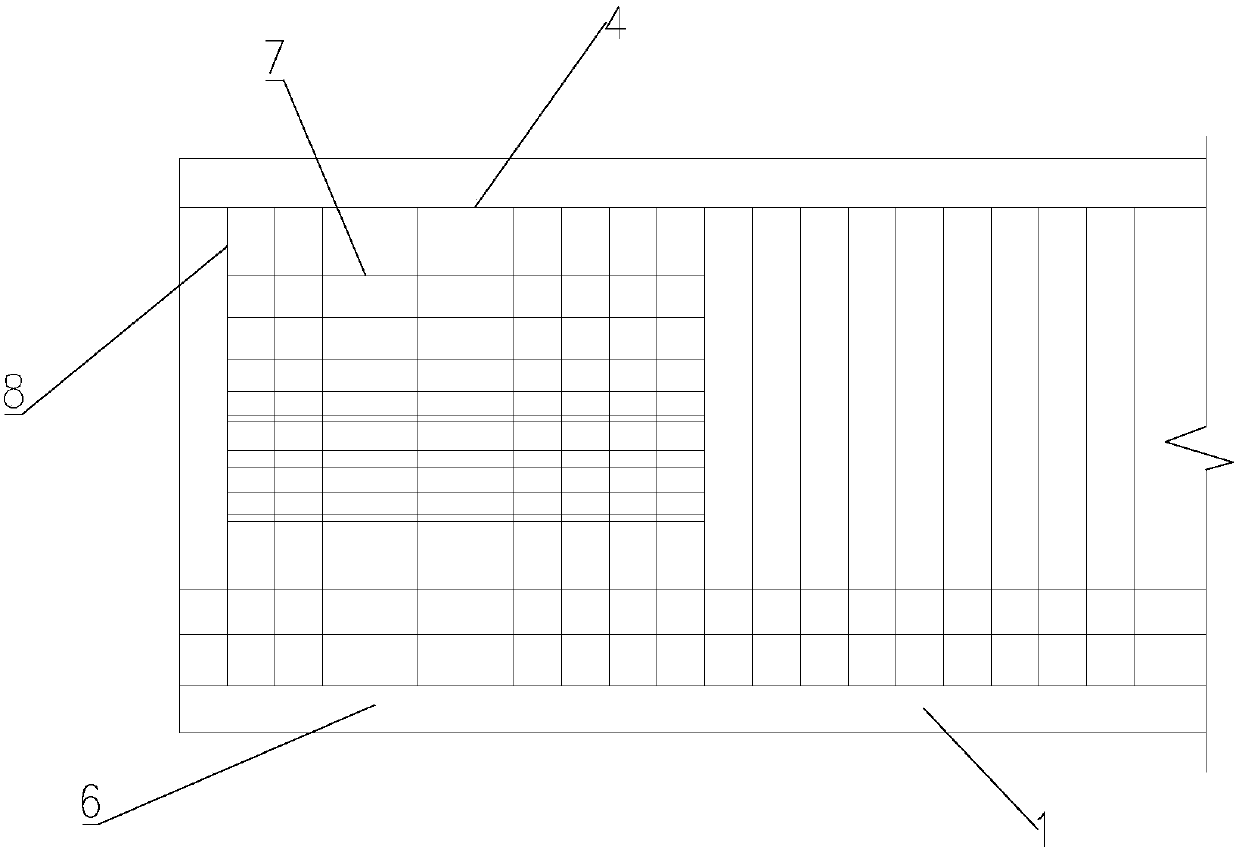

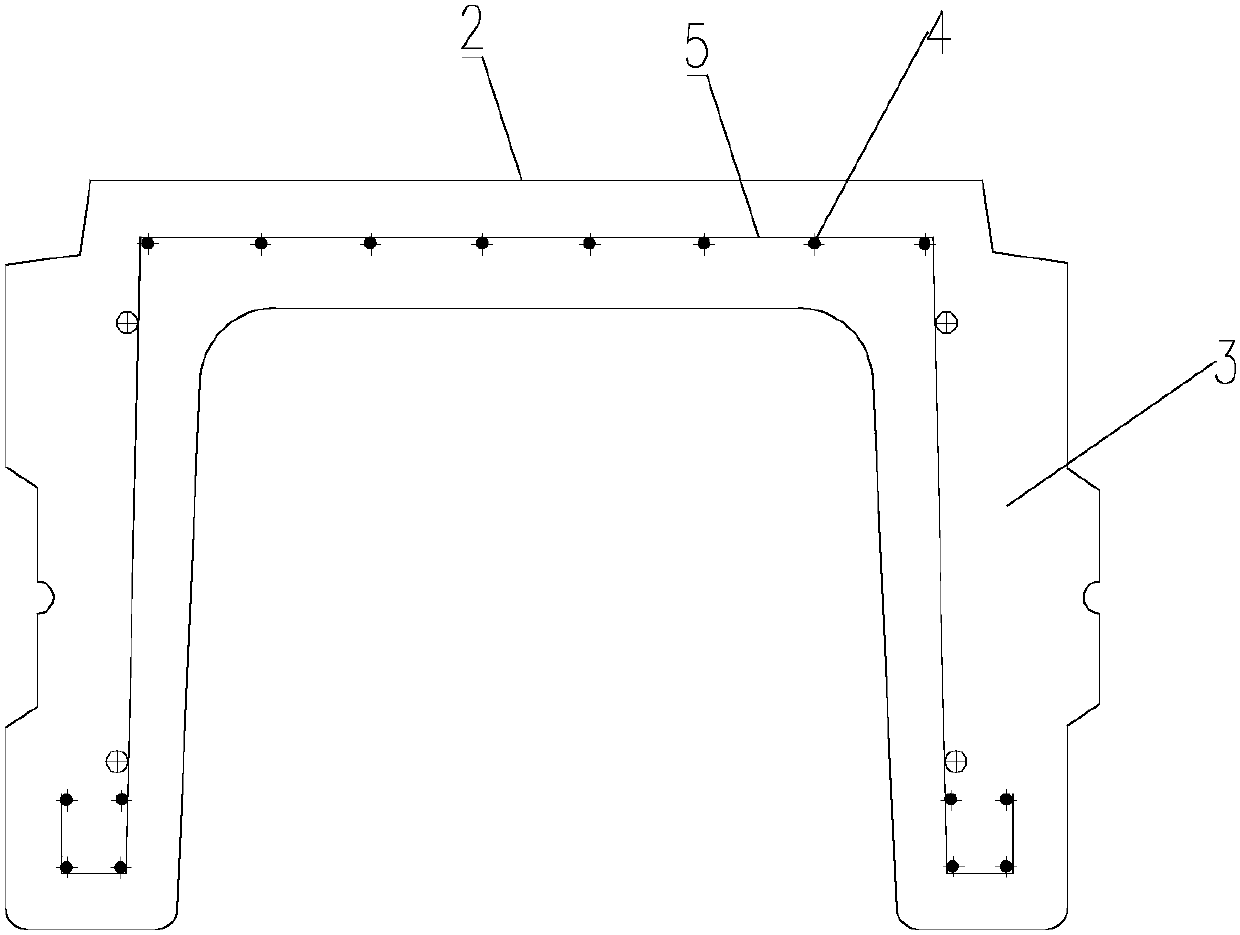

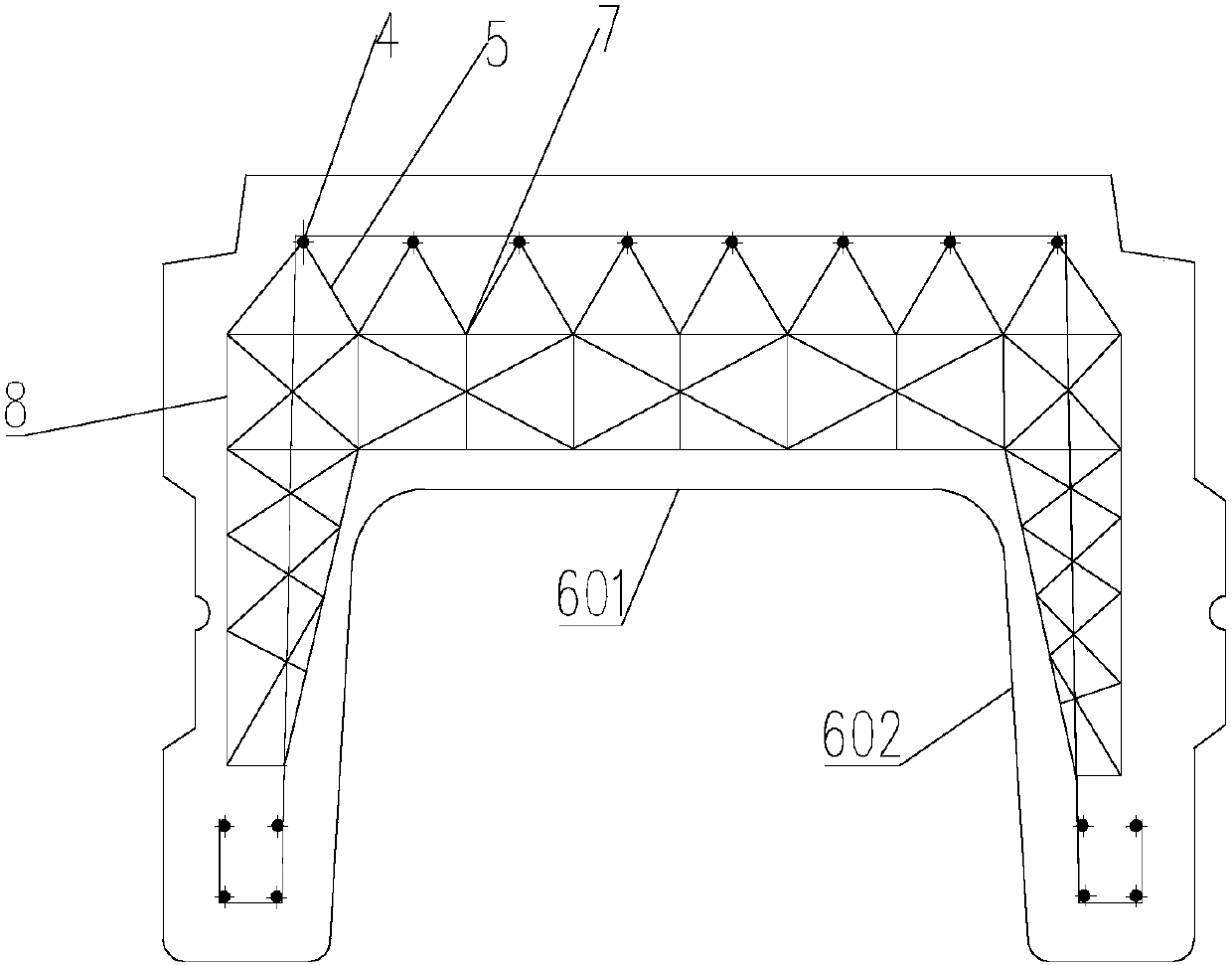

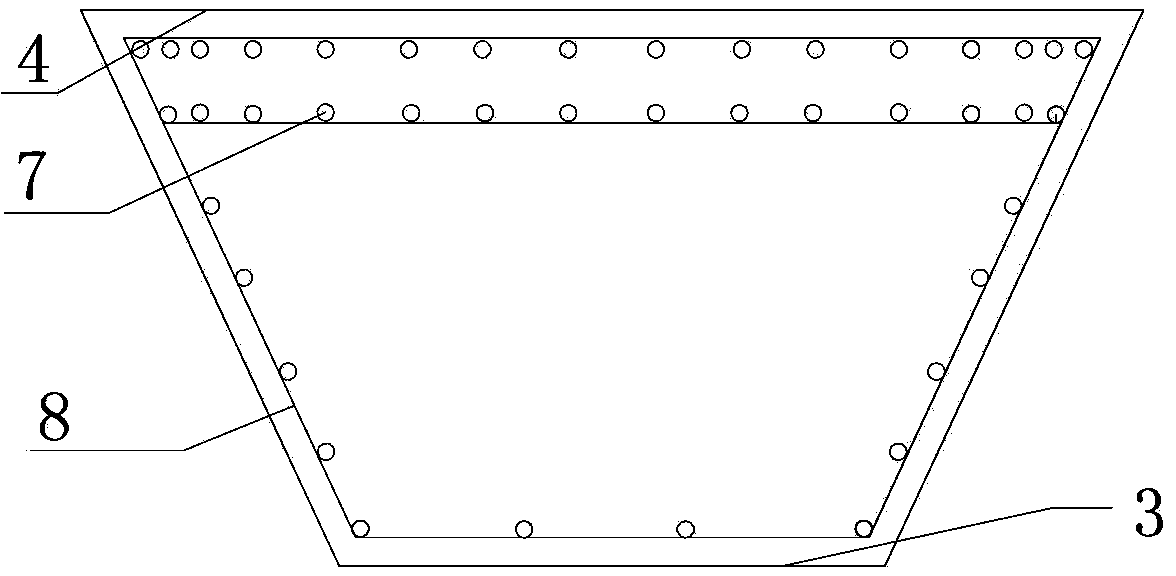

Prestressed reinforced concrete sandwich heat insulating roof-panel

InactiveCN102199940AComply with the force characteristicsLight weightRoof covering using slabs/sheetsReinforced concreteEngineering

The invention discloses a prestressed reinforced concrete sandwich heat insulating roof-panel which is characterized in that the reinforced concrete sandwich warming roof-panel comprises a reinforced bar concrete bottom board 1, a concrete face plate 2, a heat insulating concrete vertical and horizontal rib 3 and light heat insulating sandwich blocks 4 which are embedded in the reinforced bar concrete bottom board 1, the concrete face plate 2 and the heat insulating concrete vertical 3 at interval. The prestressed reinforced concrete sandwich heat insulating roof-panel is also characterized in that reinforced bars in the reinforced bar concrete bottom board 1 are prestressed reinforced bars 5. The heat insulating roof-panel integrates the bearing of the structure and the heat insulation and has the characteristics of light dead-weight, good structural performance, heat insulation and sound insulation, rapid and convenient construction, low cost and the like and is a new green energy-saving roof panel material with excellent cost performance.

Owner:龚友平

Anti-slide pile with I-shaped cross section

InactiveCN103046541AReduce in quantityReduce usageExcavationsBulkheads/pilesStress concentrationReinforced concrete

The invention relates to an anti-slide pile with an I-shaped cross section. The anti-slide pile with the I-shaped cross section is poured by reinforced concrete. Transverse width at the rear end of the anti-slide pile is larger than that of a common anti-slide pile with a rectangular cross section, so that post-pile soil arch effects are brought into full play, pile center distance between two adjacent anti-slide pile can be increased when the anti-slide piles are disposed on a plane, and the amount of the required anti-slide piles is reduced under the same landslide conditions to reduce cost. The rear end and the front end of the anti-slide pile are arc-shaped, stress concentration damaging the anti-slide pile is prevented from being generated at tips. The anti-slide pile can bear large slope pushing force has good bending resistance. The cross section area of the anti-slide pile is remarkably smaller that of the anti-slide pile with the rectangular cross section, so that concrete quantity and rebar quantity needed are reduced greatly, a large amount of concrete and rebar is saved, and cost is lowered. The anti-slide pile is small in construction section and simple and safe in construction, has promising popularization application prospect and facilitates mechanical construction.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A precast concrete grooved sheet pile head reinforcement device

ActiveCN105970963BEffectively withstand uneven stressEasy constructionBulkheads/pilesEngineeringRebar

The invention discloses a reinforcing device for a prefabricated concrete channel plate pile head. The reinforcing device comprises a pile body which comprises an upper web and wing plates on the two sides; the upper web is 120 mm in thickness; longitudinal main rebars are laid in the pile body and connected through stirrups; transverse main rebars are arranged in the pile body, and the transverse main rebars and the longitudinal main rebars are fixedly connected through stirrups in the intersecting positions; the pile head is arranged at one end of the pile body, the thickness of a pile head web is 280 mm, a plurality of dense rebars are arranged in the pile head, and the dense rebars and the longitudinal main rebars are arranged in parallel; and the longitudinal main rebars, the stirrups and the dense rebars form rebar grids which are located at the front section of the pile head, three rebar grids are arranged at the intervals of 50 mm, and two rebar grids are arranged at the interval of 100 mm, and five rebar grids are arranged in total. According to the reinforcing device for the prefabricated concrete channel plate pile head, the principles that the dense rebars are small in diameter and are densely arranged are observed, non-uniform stress generated in the vibration pile driving process can be effectively borne, construction is easy to conduct, not only can the pile head be effectively protected, but also a mass of rebars are omitted, and the cost is reduced.

Owner:FUJIAN UNIV OF TECH

Double-facade rotary mass center eccentricity test device

ActiveCN105092154BReduce processing stepsLow technical requirementsStatic/dynamic balance measurementGratingEngineering

The invention discloses a double-facade rotary mass center eccentricity test device, which comprises a base, a fixed test platform, a mobile test platform, and a grating positioning mechanism. The fixed test platform includes a fixed test box, a fixed sensor, a fixed rotary mechanism, a fixed V-shaped roller frame, fixed lifting mechanism, mobile test bench includes a mobile test box, a mobile sensor, a mobile slewing mechanism, a mobile V-shaped roller frame, and a mobile lifting mechanism. The fixed V-shaped roller frame is fixed on the fixed rotary mechanism, the rotary frame of the fixed rotary mechanism is fixed on the sensor before the fixed sensor is fixed, the fixed rotary leg of the fixed rotary mechanism floats on the sensor after the fixed sensor is fixed, and the V-shaped roller is moved The frame is fixed on the moving slewing mechanism, the moving slewing frame of the moving slewing mechanism is fixed on the sensor before the moving sensor moves, and the moving slewing mechanism moves the slewing foot floating on the sensor after the moving sensor moves.

Owner:南京乾利合科技有限责任公司

Damping type over-discharging buffer device for mine hoisting system

InactiveCN104016206BShort retrofit shutdown cycleReduce security retrofit challengesElevatorsHydraulic cylinderEngineering

The invention relates to a damping type over discharge buffering device for a mine hoisting system. The damping type over discharge buffering device comprises a steel truss, a damping buffer and a buffering bracket, the steel truss is arranged on the mine wall of the bottom of a mine, one end of the damping buffer is connected with the steel truss, the other end of the damping buffer is connected with the buffering bracket, and a cage of the mine hoisting system falls on the buffering bracket during falling. By means of the damping type over discharge buffering device, a new over discharge prevention device is designed; the damping type over discharge buffering device is installed above over discharge prevention space at the mine bottom of the mine, the steel truss is arranged at the mine bottom, an over discharge prevention buffering device is hung on the steel truss, a damping groove is formed in a piston rod of a hydraulic cylinder, the depth size of the damping groove is changed along with stroke changes, the problem of insufficient over discharge prevention space of old mine transformation is solved, the over discharge prevention device can be additionally arranged in an old mine hoisting system, and security coefficients of mine production can be effectively improved; meanwhile, construction is simple, the construction period is short, the old-mine transformation halt period is short, and the old mine safety transformation problems are decreased as many as possible.

Owner:张纬

Disabled vehicle

Owner:FUER INTELLIGENT TECH NANTONG CO LTD

A connector for keel type composite shear wall

The invention relates to connecting pieces for a keel type composite shear wall. Bolt holes are formed in top flanges of the connecting pieces, the connecting pieces are connected with a frame beam through self-tapping screws, lower-end webs of the connecting pieces are connected with an upper guide rail flange of the keel type composite shear wall through self-tapping screws, and the four connecting pieces are symmetrically arranged at the upper end and the lower end of the keel type composite shear wall respectively. Compared with the prior art, the connecting pieces are simple in structure and clear in force transmission, every two connecting pieces are matched to be used, the connecting pieces are symmetrically arranged, horizontal shear force can be transmitted, vertical pressure can be released, and the loading features of the keel type composite shear wall are met.

Owner:SHANGHAI BESTSTEEL STEEL STRUCTURE BUILDING

Antiskid pile with outer isosceles trapezoid cross section and in unequal interval arrangement

ActiveCN103046539BImprove structural strengthComply with the force characteristicsExcavationsBulkheads/pilesIsosceles trapezoidReinforced concrete

The invention relates to an antiskid pile with an outer isosceles trapezoid cross section and in unequal interval arrangement. The antiskid pile is formed by pouring reinforced concrete, the cross section of the antiskid file is an outer isosceles trapezoid, rebar cages are mounted in the antiskid pile, dense rebars are arranged in the rebar cage on one side at the rear end of the pile, and few rebars are arranged on one side at the front end of the pile. The antiskid pile adopts an unequal interval arrangement method to form a pile interval arrangement layout with a dense middle and two sparse sides, namely the antiskid piles arranged close to a main slide section with large landslide thrust are small in pile interval, and the pile interval at sections on two sides of a landslide is gradually increased according to progressive decrease of the landslide thrust. The antiskid pile can bear bigger landslide thrust and has excellent anti-bending performance, and the size of the cross section of the antiskid pile is evidently smaller than that of an antiskid pile with a rectangular cross section, so that cubic amount of concrete pouring and rebar using amount can be greatly reduced, and cost is lowered. The antiskid pile with the outer isosceles trapezoid cross section and in unequal interval arrangement is small in construction section, convenient for mechanical construction, safe and simple in construction and wide in popularization and application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

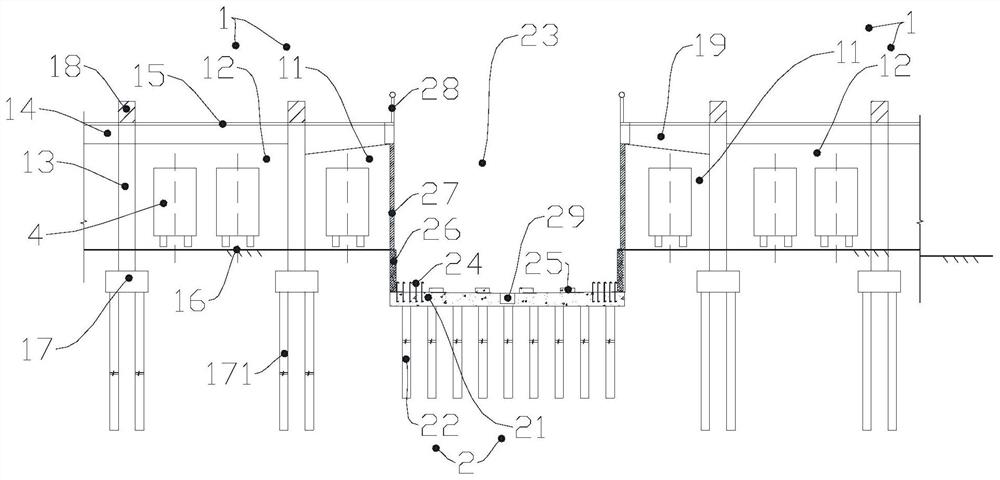

Full-period construction method for flexible reserved floor high-rise building and vehicle depot structure

ActiveCN113802592ASolve the emission problemForce system is clearArtificial islandsUnderwater structuresBrickArchitectural engineering

The invention provides a full-period construction method for a flexible reserved floor high-rise building and vehicle depot structure. The method comprises the following steps of Step 1, constructing a first-stage structure: Step 11, constructing a plurality of building pile foundations and a first-stage raft plate; Step 12, constructing a vehicle depot large garage; Step 13, constructing a retaining wall; and Step 14, building brick partition walls after construction; and Step 2, constructing a second-stage structure: Step 21, constructing a second-stage raft plate and a shear wall of the high-rise building; Step 22, constructing a car garage and the remaining shear walls, and constructing the high-rise building; and Step 23, constructing a second-stage cover plate, performing soil covering, then performing greening till the construction is completed. The full-period construction method of the structure comprises a structure reservation scheme for flexibly adjusting the house type of the floor high-rise building and a construction scheme for the later-stage high-rise building, the house type of the later-stage high-rise building can be flexibly adjusted, and the height of the high-rise building is not limited by a conversion structure.

Owner:GUANGZHOU METRO DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com