Double-facade rotary mass center eccentricity test device

A test device, a rotary technology, applied in the direction of measuring device, machine/structural component test, static/dynamic balance test, etc., can solve the problem of accurate calculation of torque balance formula, high technical requirements, uncertain force points, etc. problems, to achieve the effect of improving test accuracy and repeatability, simplifying the structure of the measuring device, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

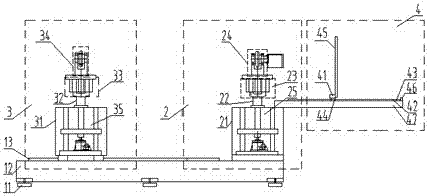

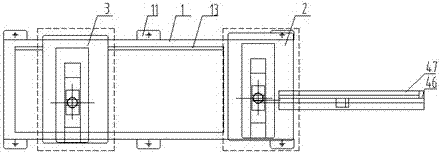

[0034] combine figure 1 , figure 2 , image 3 , Figure 4 , Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, Fig. 10, the double-facade rotary mass center eccentricity testing device of the present invention includes a base 1, a fixed test bench 2, a mobile test bench 3, and a grating positioning mechanism 4.

[0035] The base 1 that realizes the double-facade rotary mass center eccentricity testing device of the present invention includes a level adjustment seat 11, a bottom plate 12 and a guide rail 13, the guide rail 13 is arranged on the bottom plate 12, and the bottom plate 12 is arranged on the level adjustment seat 11 on.

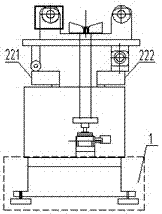

[0036] The fixed test bench 2 that realizes the double-facade rotary mass center eccentricity test device of the present invention includes a fixed test box 21, a fixed sensor 22, a fixed rotary mechanism 23, a fixed V-shaped roller fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com