Anti-slide pile with I-shaped cross section

A technology of anti-sliding piles and cross-sections, which is applied in sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of large concrete pouring volume and high cost, and achieve the effects of construction safety, small construction section and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

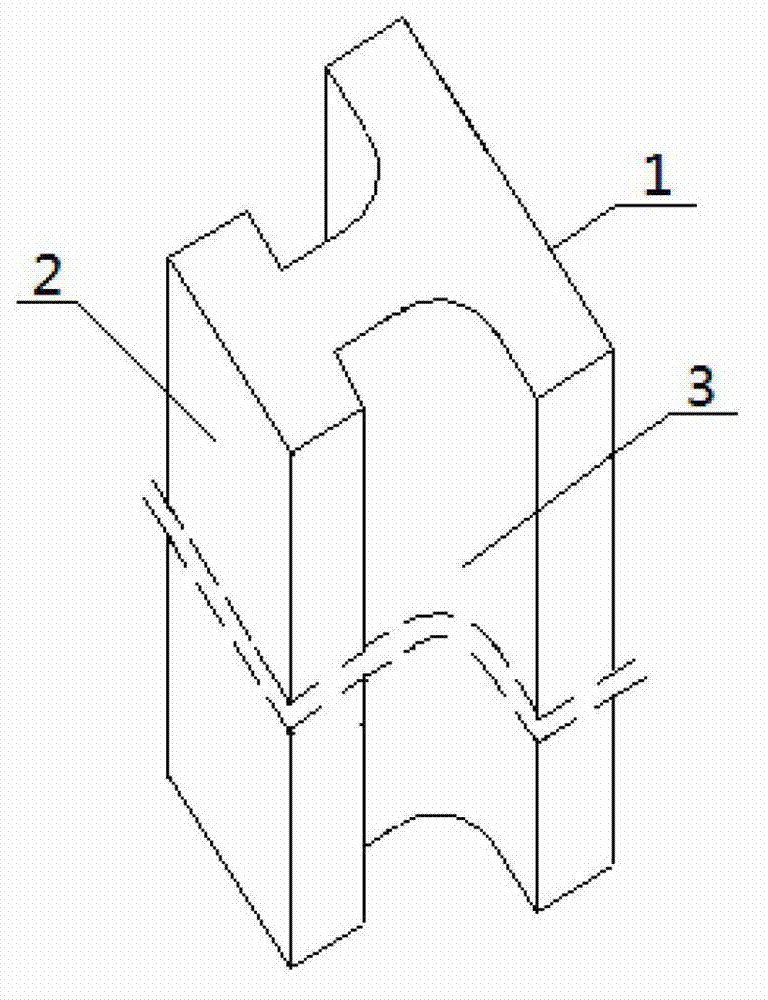

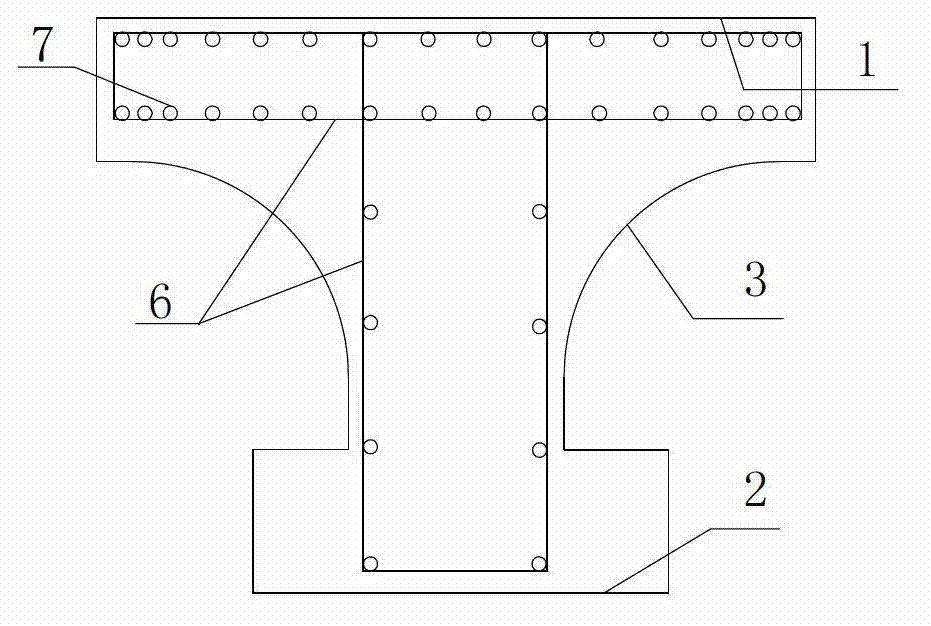

[0024] Embodiment 1: the anti-sliding pile 8 of a kind of I-shaped cross section provided by the present invention, its structure is as follows figure 1 As shown, it is formed by pouring reinforced concrete. The cross-section of the poured reinforced concrete anti-slide pile is I-shaped, the upper end of the I-shaped is the pile rear end 1, the lower end of the I-shaped is the pile front end 2, and the pile rear end 1 The lateral width is longer than that of the pile front end 2, and an arc-shaped body part 3 is formed between the pile rear end 1 and the pile front end 2.

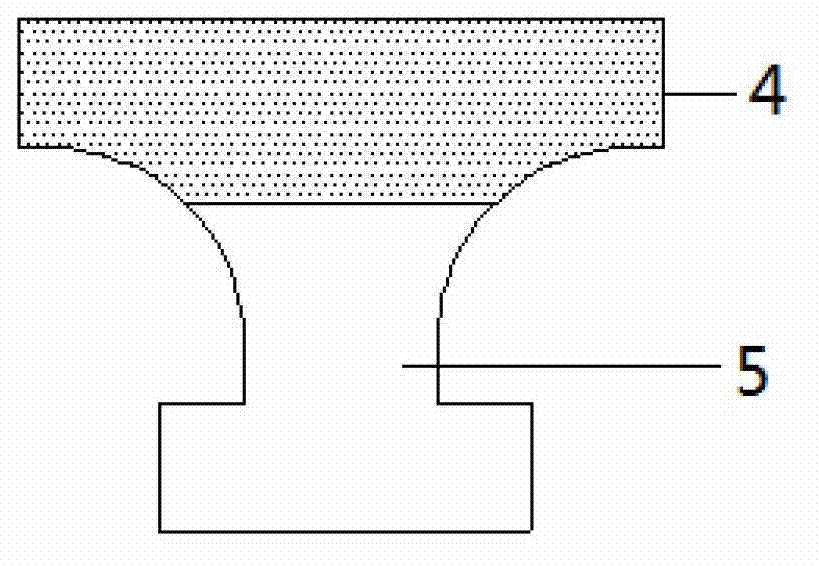

[0025] The stress distribution on the anti-slide pile cross section of the present invention is as follows: figure 2 As shown, the force on the rear end 1 of the anti-sliding pile is tensile stress, which belongs to the tension zone 4, and the force on the front end 2 of the pile and the front part of the arc body part 3 is mostly compressive stress, which belongs to the compression zone 5. In the reinfor...

Embodiment 2

[0029] Embodiment 2: Apply the anti-slide pile 8 of a kind of I-shaped cross-section that the embodiment of the present invention 1 provides to carry out construction, in the construction process of this anti-slide pile, because the engineering quantity of each pile is not big, the landslide body in construction little impact on stability. The construction section of the anti-slide pile is small, and the construction can be carried out by means of mechanical construction. The specific construction steps are as follows:

[0030] (1) Level the site, and measure and locate the center point of the anti-slide pile according to the design drawings. The distance between the centers of adjacent anti-slide piles is slightly larger than that of conventional rectangular anti-slide piles.

[0031] (2) Equipment in place, including digging equipment such as excavators, bulldozers, rock drills, safety equipment such as helmets, seat belts, and software, wall protection equipment such as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com