Antiskid pile with outer isosceles trapezoid cross section and in unequal interval arrangement

An isosceles trapezoid, anti-sliding pile technology, applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve the problems of high cost and large amount of concrete pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

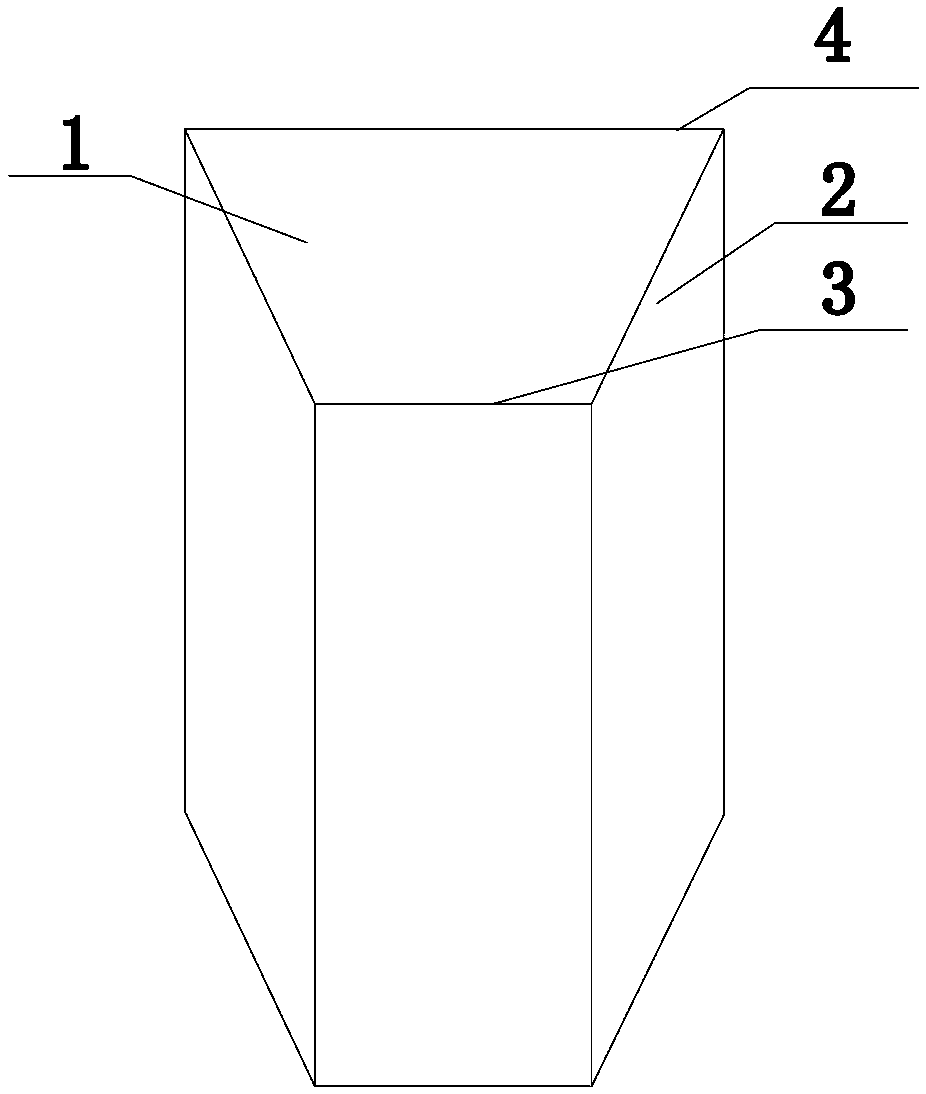

[0029] Embodiment 1: a kind of outer isosceles trapezoidal cross-section anti-sliding pile 9 provided by the present invention, its structure is as follows figure 1 As shown, it is formed by pouring reinforced concrete, and the poured reinforced concrete anti-slide pile has an outer isosceles trapezoidal cross section 1 .

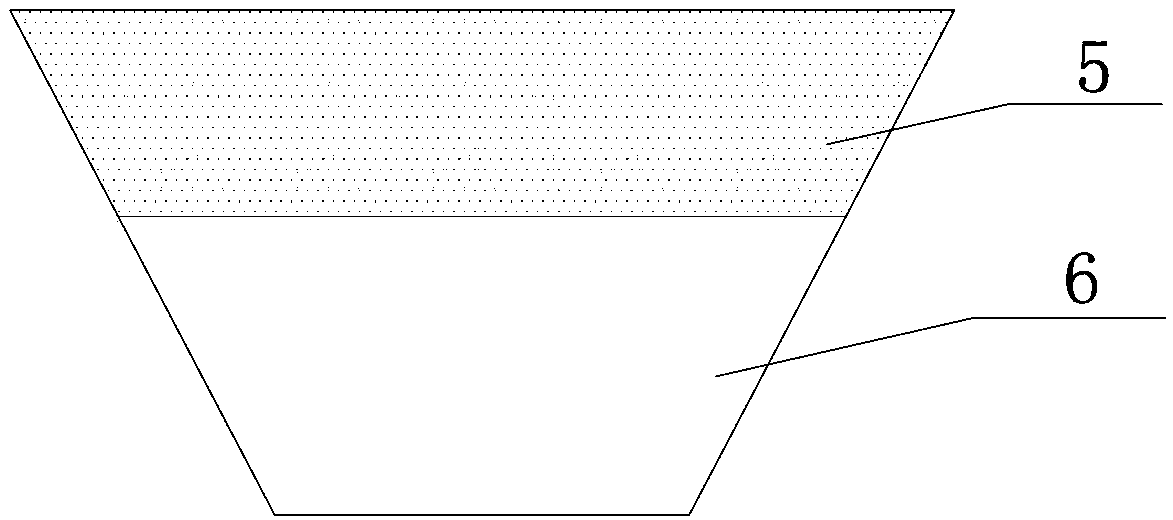

[0030] The stress distribution on the anti-slide pile cross section of the present invention is shown in figure 2 . One side of the longitudinal section of the long base of the outer isosceles trapezoid is used as the pile rear end 4 to bear the landslide thrust 10 , and the force on the pile rear end is tensile stress, which belongs to the tension area 5 . The rear end 4 of the pile is used as the arch foot of the soil arch behind the pile, and the slope body thrust 10 received at both ends is relatively large and complicated. The side of the longitudinal section of the short bottom of the outer isosceles trapezoid is used as the front end 3 of the pile...

Embodiment 2

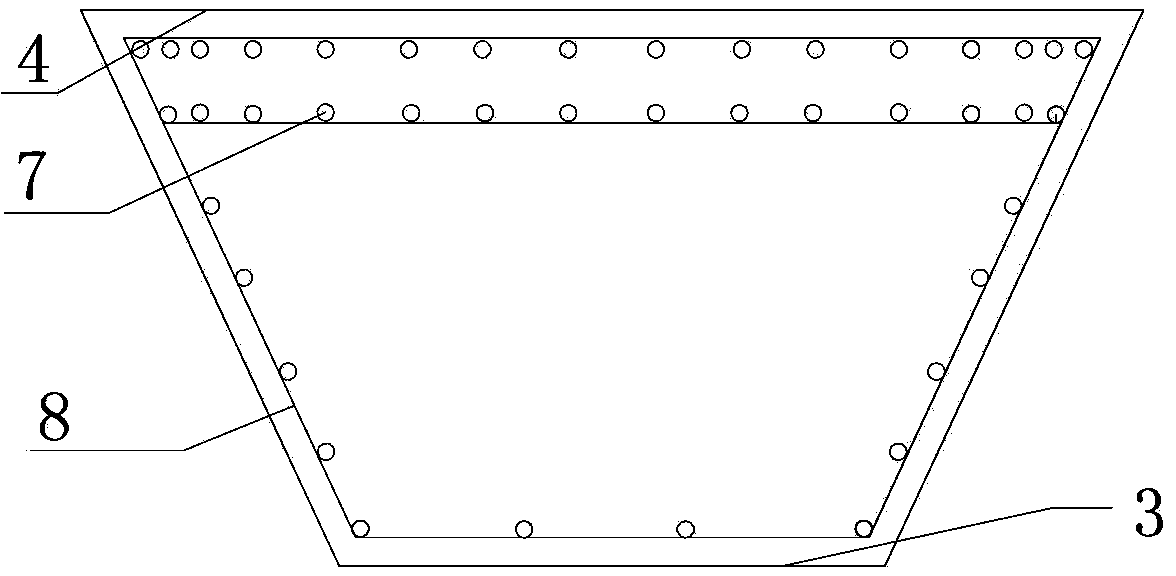

[0034] Embodiment 2: Apply the construction method of laying the anti-sliding piles with outer isosceles trapezoidal cross-section at unequal intervals provided in Embodiment 1 of the present invention. The anti-sliding piles 9 with outer isosceles trapezoidal cross-section of the present invention are poured by reinforced concrete The cross-section of the poured reinforced concrete anti-slide pile is an outer isosceles trapezoid, one side of the longitudinal section of the long base of the outer isosceles trapezoid is used as the rear end of the pile to accept the landslide thrust, and the short base of the outer isosceles trapezoid The longitudinal section of the pile is used as the front end of the pile, and a reinforcement cage is installed in the anti-sliding pile. Relatively dense reinforcement is arranged in the reinforcement cage on the side of the rear end of the pile, and there are few reinforcement bars arranged on the front end of the pile. The amount of work is sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com