A connector for keel type composite shear wall

A technology of connectors and shear walls, applied in the direction of walls, building components, buildings, etc., can solve the problems of limited vertical bearing capacity, and achieve the effect of simple structure and clear force transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

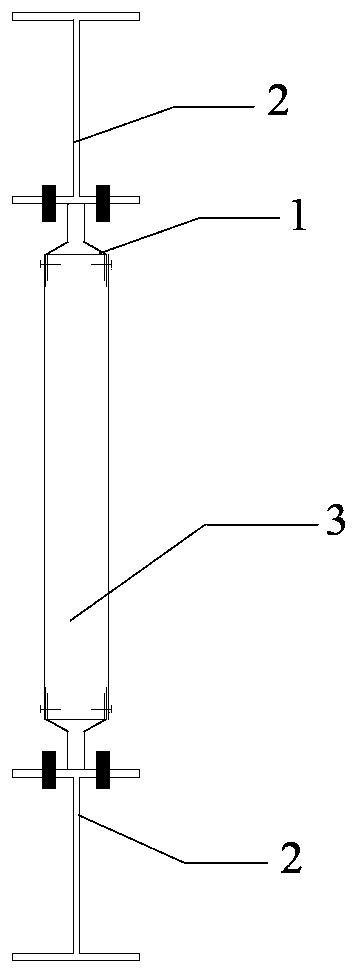

[0013] A connecting piece for keel type composite shear wall, its installation schematic diagram is as follows figure 1 As shown, bolt holes are opened on the upper flange of the connector 1, and the frame beam 2 is connected by self-tapping screws, and the lower end web of the connector 1 is connected to the keel-type composite shear wall 3 by self-tapping screws, specifically connected in On the flange of the upper guide rail of the keel type composite shear wall 3.

[0014] The frame beam 2 is an I-shaped frame beam, which is connected to the keel-type composite shear wall 3 through the connector 1. When in use, there are four connectors 1, which are symmetrically arranged on the upper and lower ends of the keel-type composite shear wall 3 respectively. department. This connection is called "7-shaped connection". It is used in conjunction with each other and arranged symmetrically. It can transmit horizontal shear force but release vertical pressure, which is in line with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com