Patents

Literature

630results about "Vessel hatches/hatchways" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

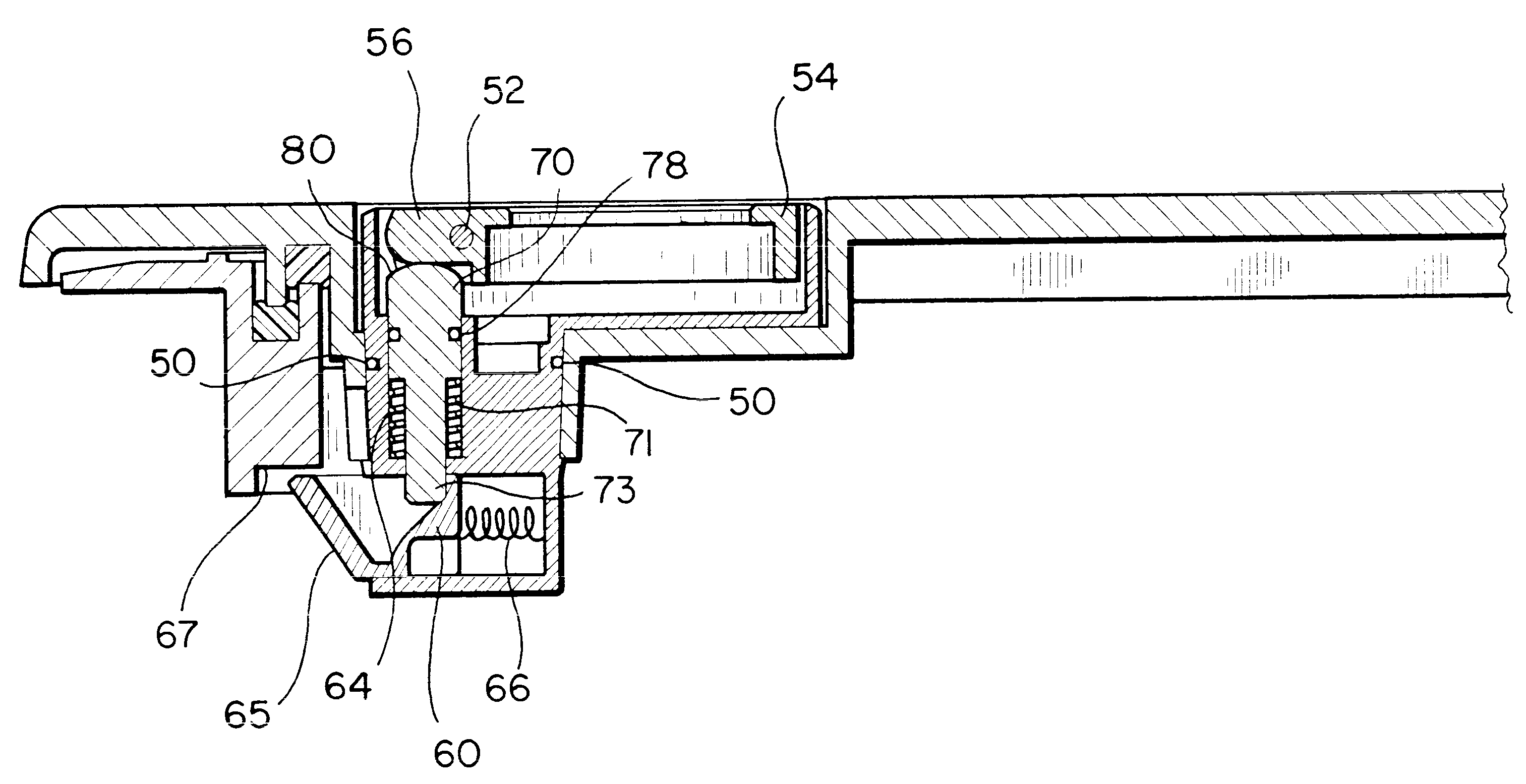

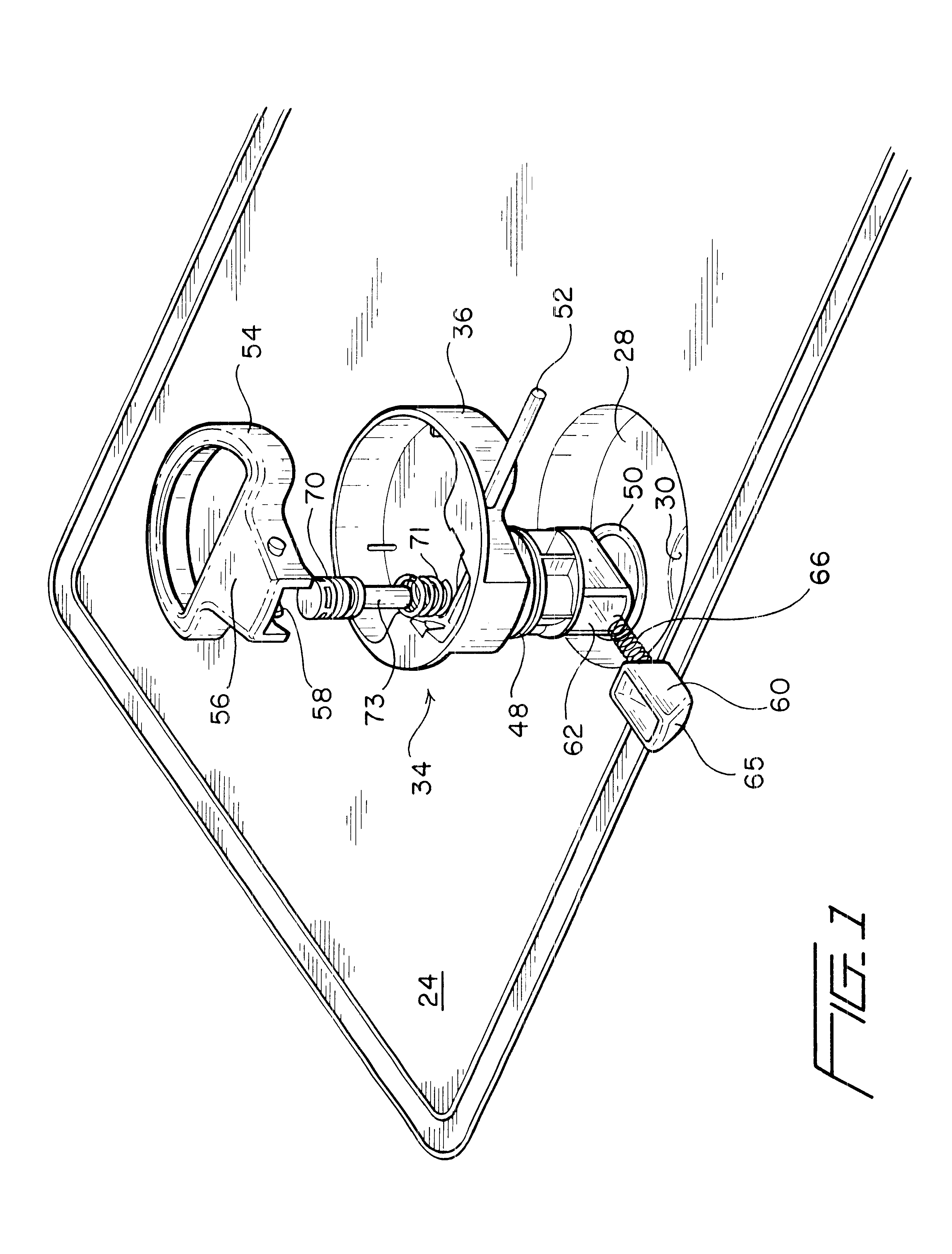

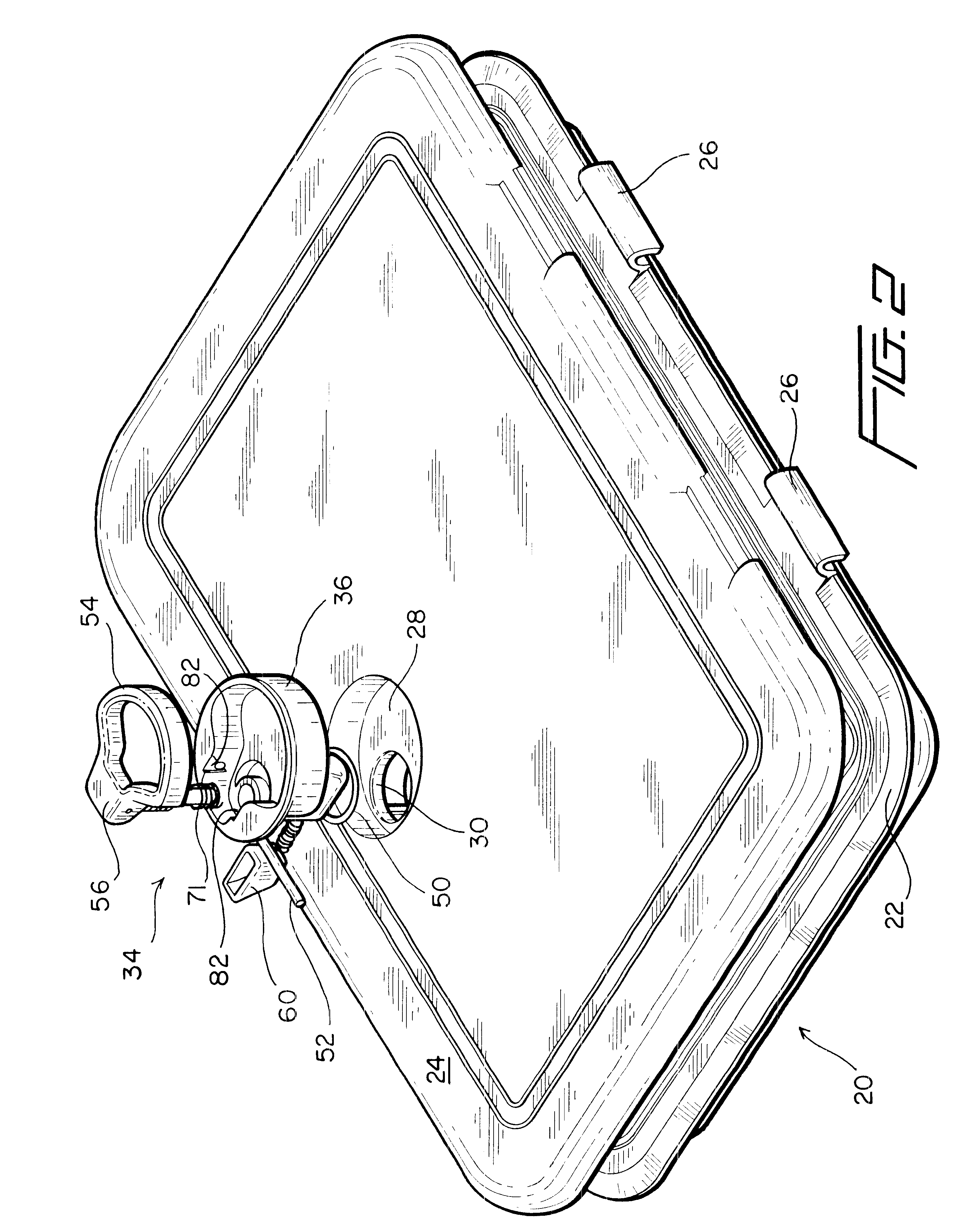

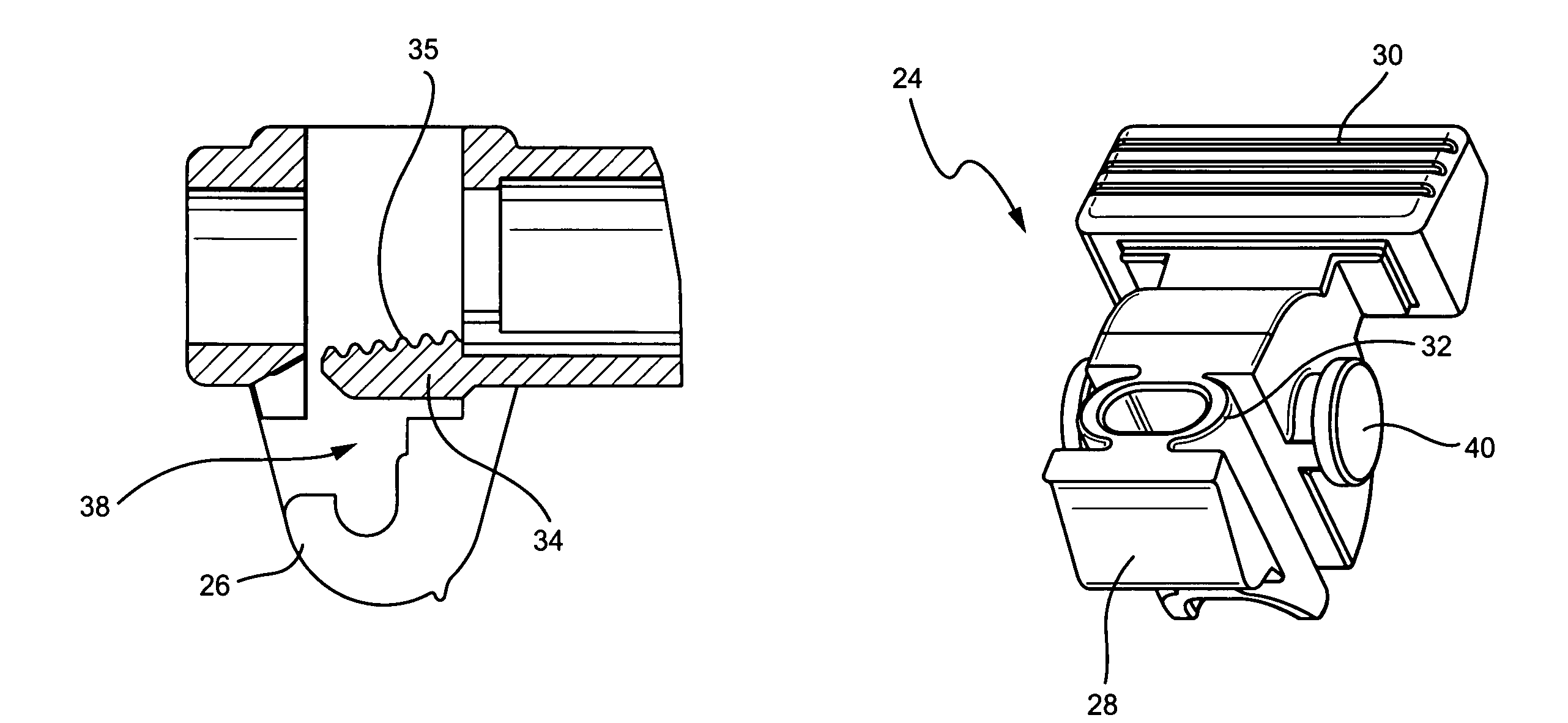

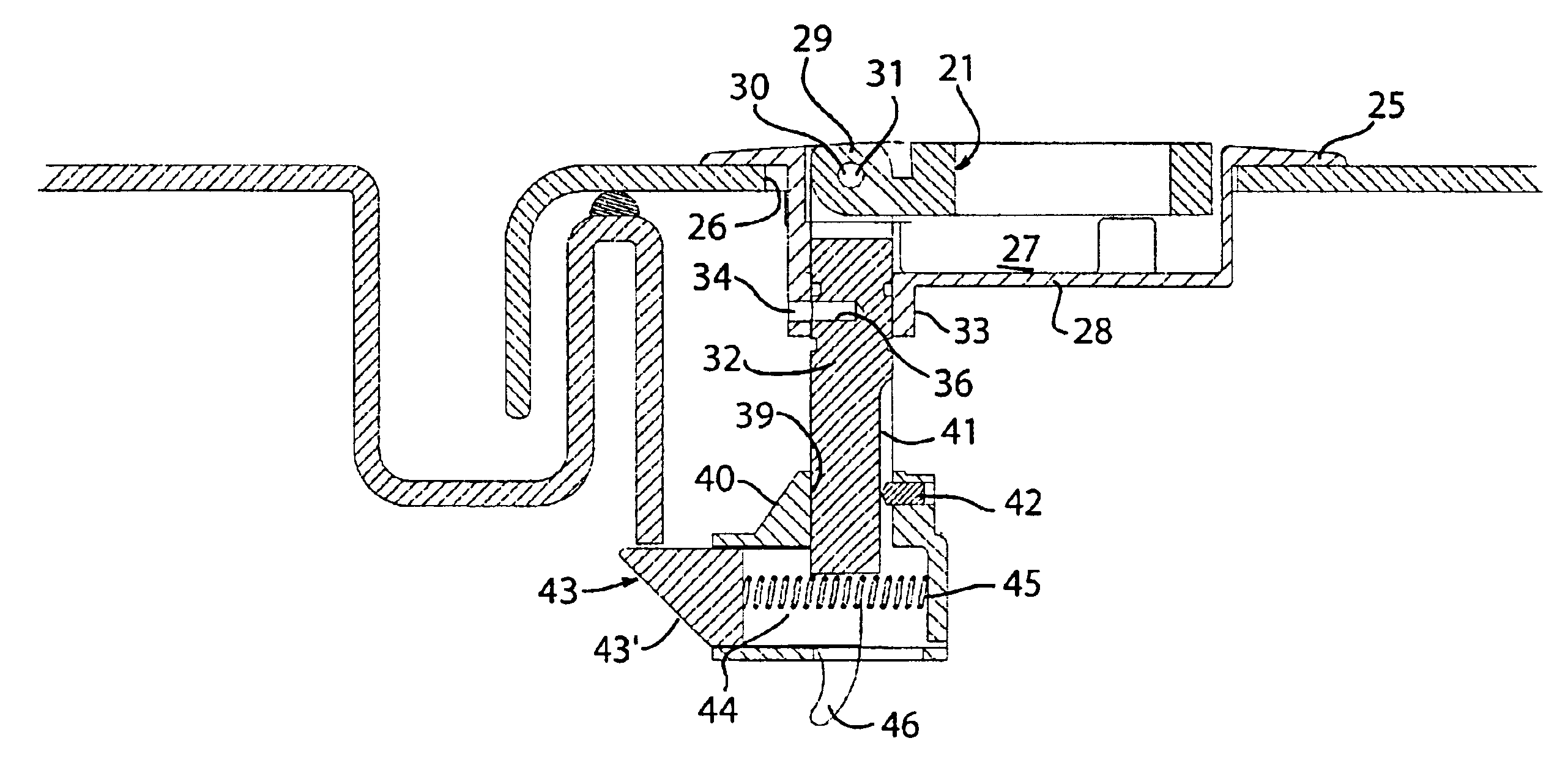

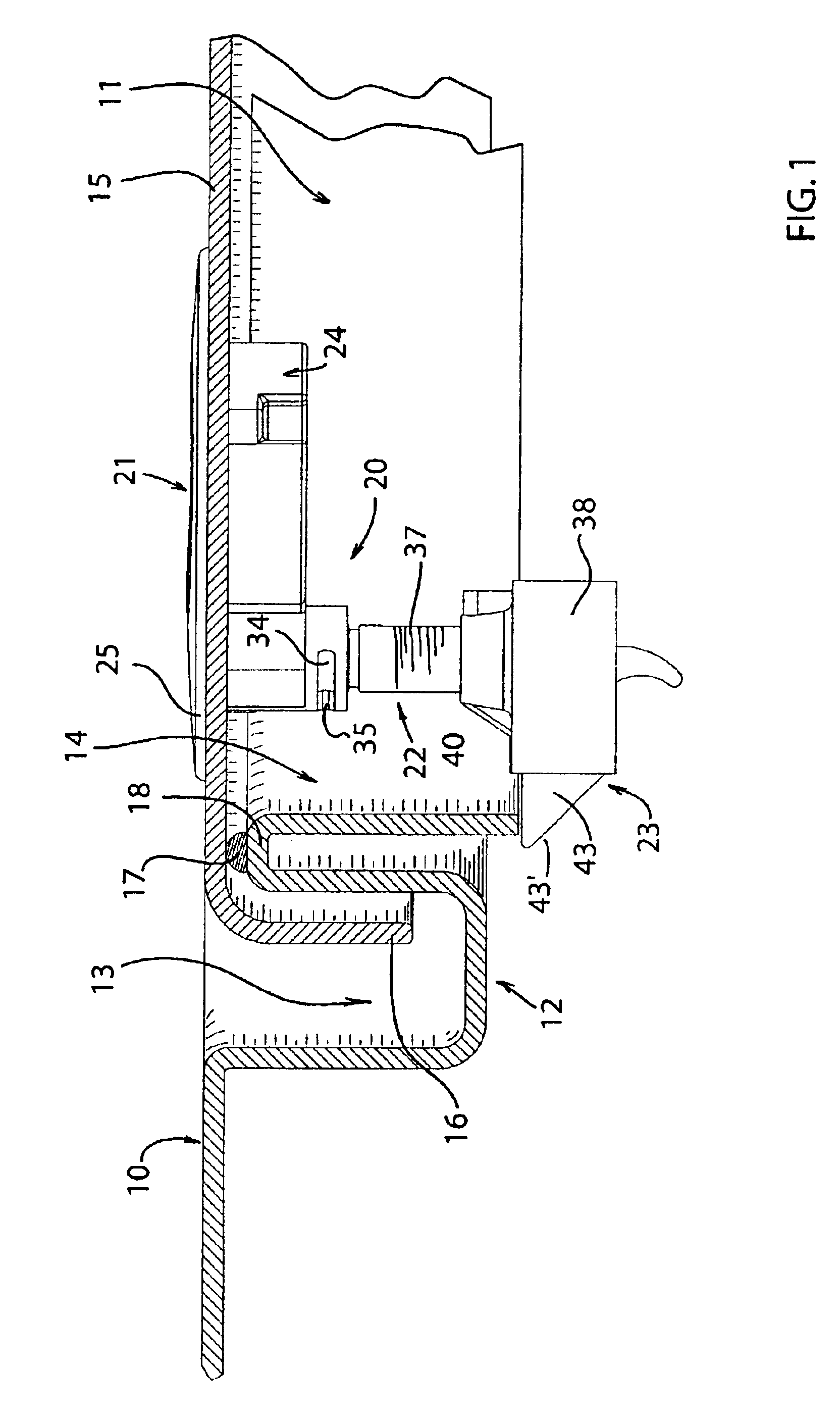

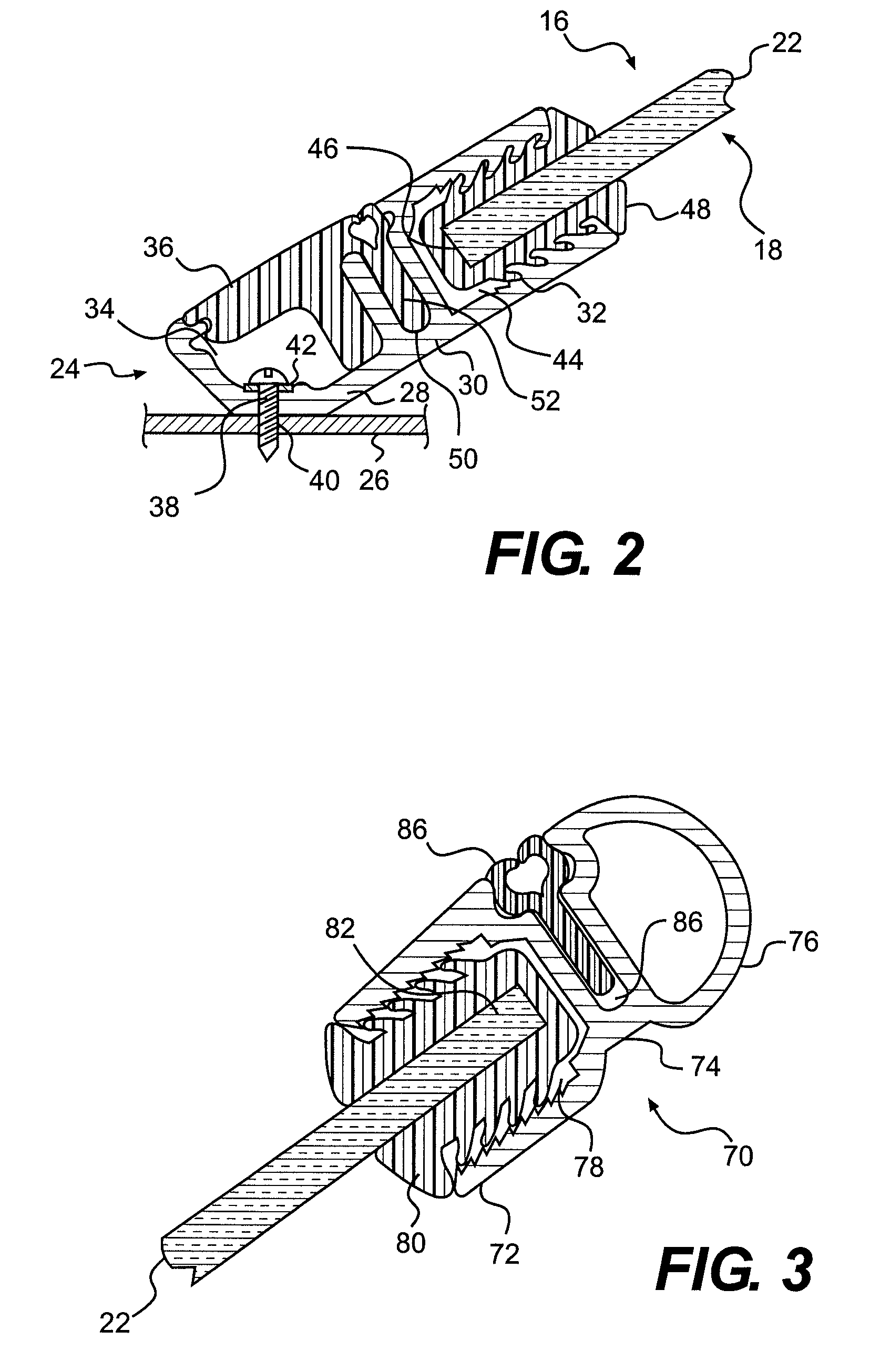

Slam latch and hatch assembly including a slam latch

A hatch assembly for a marine vessel included a slam latch and a frame and a cover having the slam latch disposed therein. The slam latch includes a housing having inner and outer portions and a pivotal handle for rotation between open and closed positions. A reciprocal fastening element including a second cam surface is adapted to engage the frame for retaining the cover against the frame. A spring biases the handle into a closed position and together with the first cam surface maintains the handle in an opened position when the handle is rotated through a predetermined angle. The latch also includes a push rod for converting the rotation of the handle to the reciprocal movement of the fastening element. The latch also includes a pair of seals to prevent water from passing through the latch.

Owner:POMPANETTE

Sliding door for boat cabin companionway

InactiveUS6131340AEliminate re-paintingEliminate re-varnishingWatertight door arrangementsWing arrangementsRotational freedomEngineering

A weatherproof sliding door assembly for opening and closing a boat cabin companionway wherein upper and lower aluminum track C-channel rails are supported to extend generally horizontally above and below the companionway. Each rail has a hollow interior slideway and a longitudinally extending slot opening thereto. A flexible plastic door panel has upper and lower edges respectively juxtaposed to the upper and lower rails and slidably mounted therein by upper and lower slide and cap panel-clamping sub-assemblies respectively that are secured by clamping to the door panel upper and lower edges and that extend the full length thereof. Each sub-assembly has a first leg wall extending therefrom into the associated rail slideway via the rail slot opening and terminating therein in a glide carrier portion. A pair of glides are mounted on each glide carrier portion adjacent its longitudinally opposite ends and bear slidably on the rail slideway for supporting the door panel for sliding motion along the rails. Each said door slide glide has limited rotational freedom around the rail slideway axis so that, if either said slide sub-assembly or rail is twisted during installation or operation, such rotational freedom will compensate for either such twist, thereby enabling the door assembly to be mounted with the rails allowed to twist within certain limits when fastened down to conform to non-parallel or non-level boat hull surfaces to which they are mounted, either as manufactured or as distorted in operation by loading or wave motion causing structural twisting, without thereby inhibiting sliding motion of said door along said rails.

Owner:TECLA

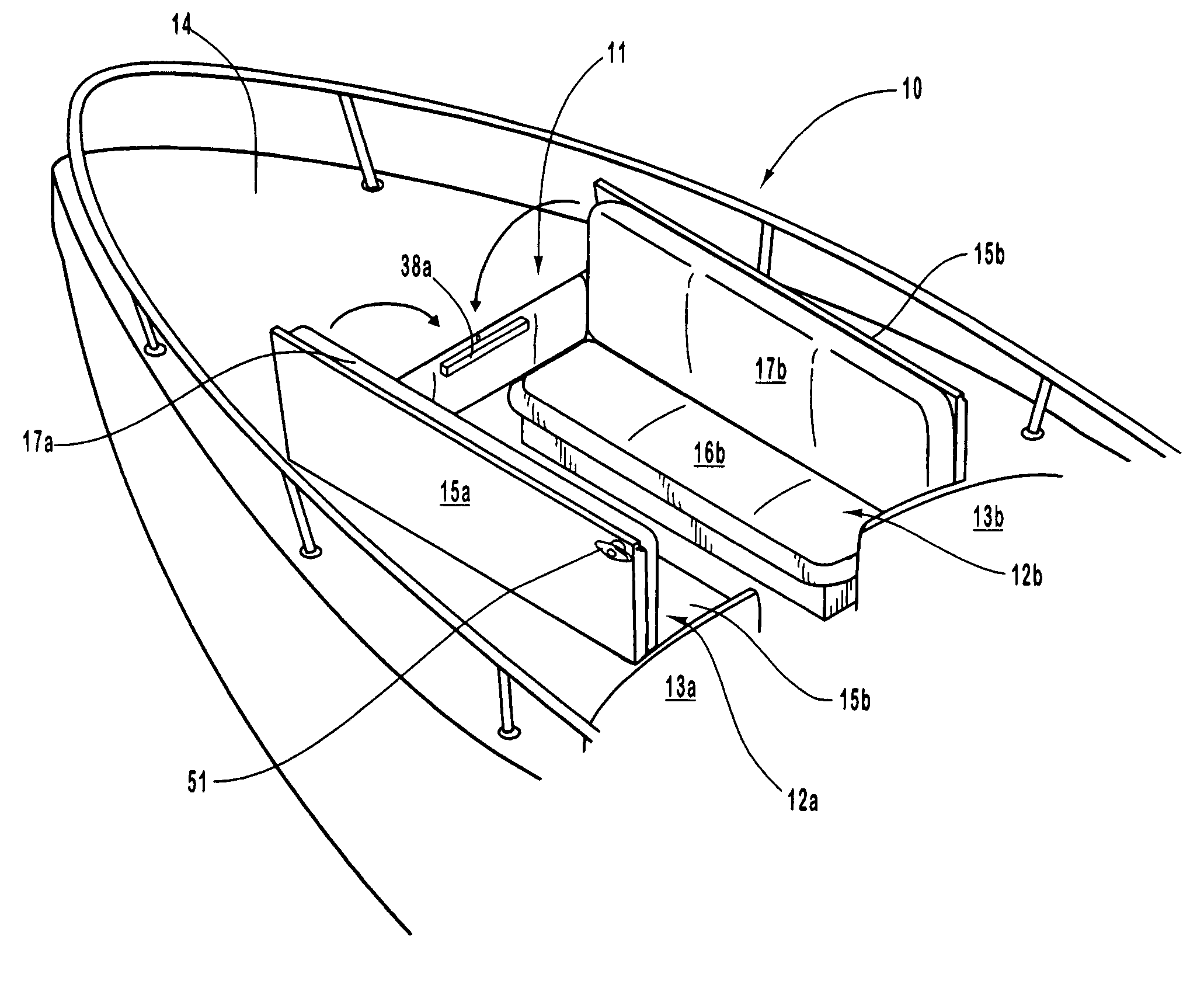

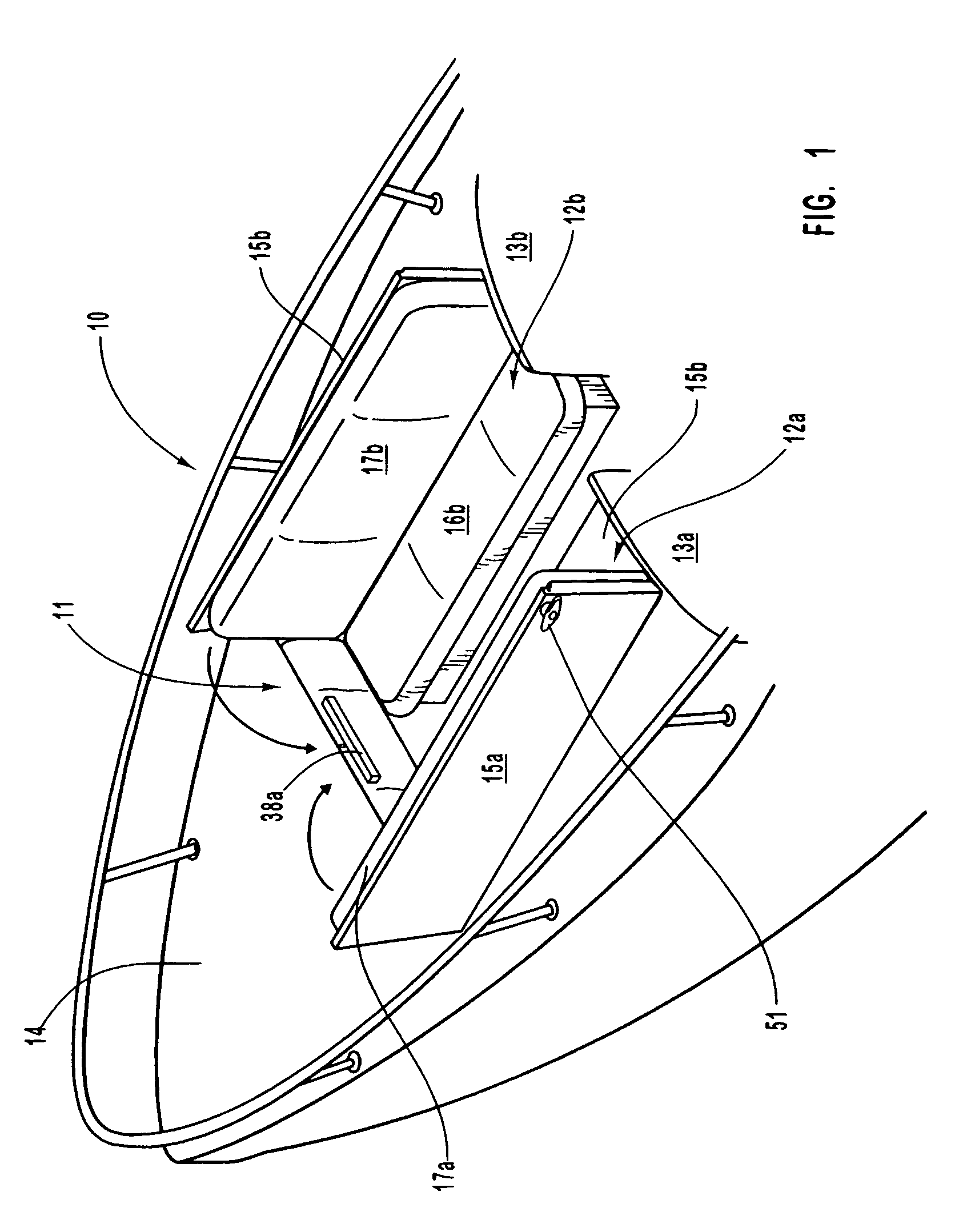

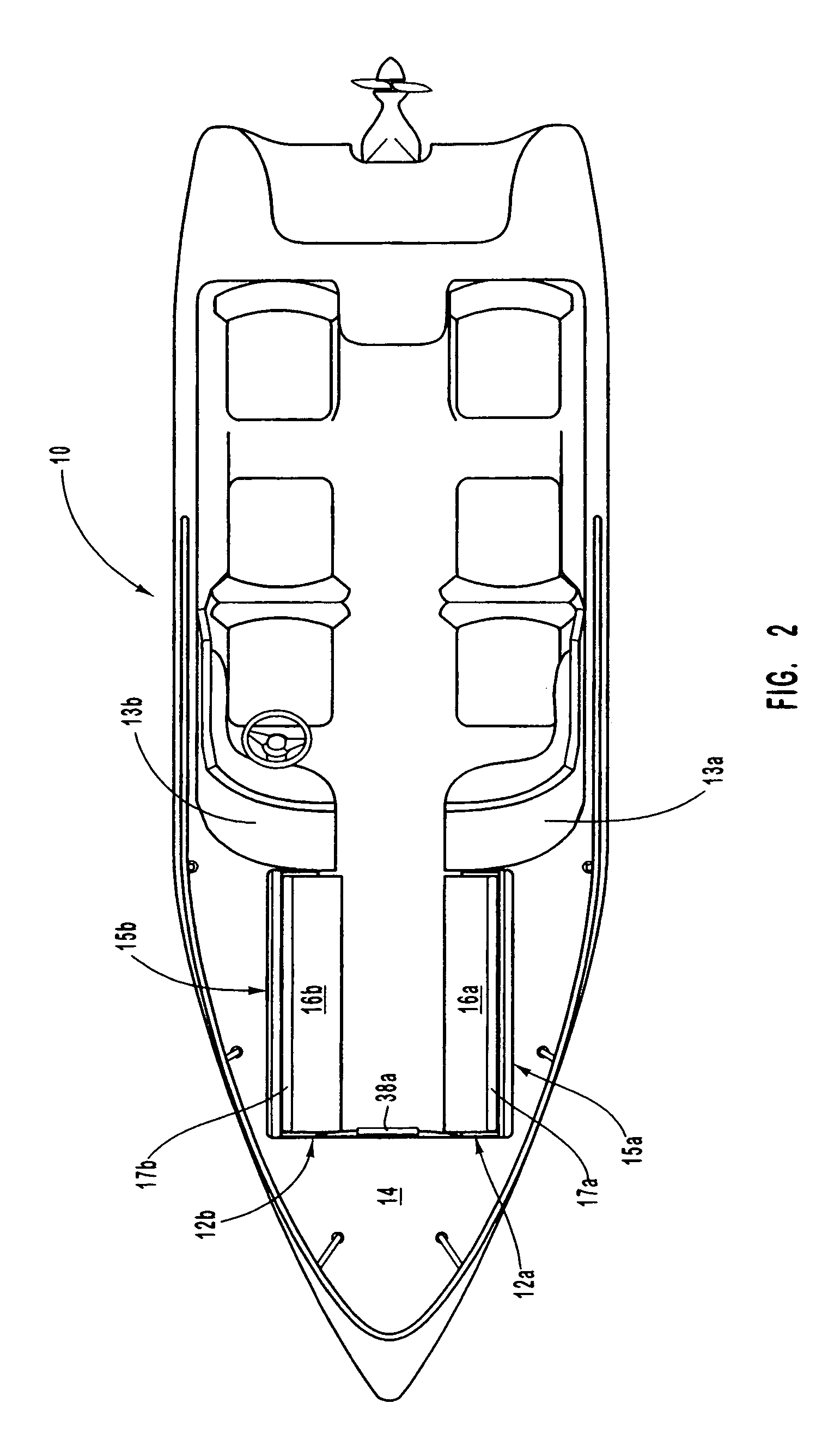

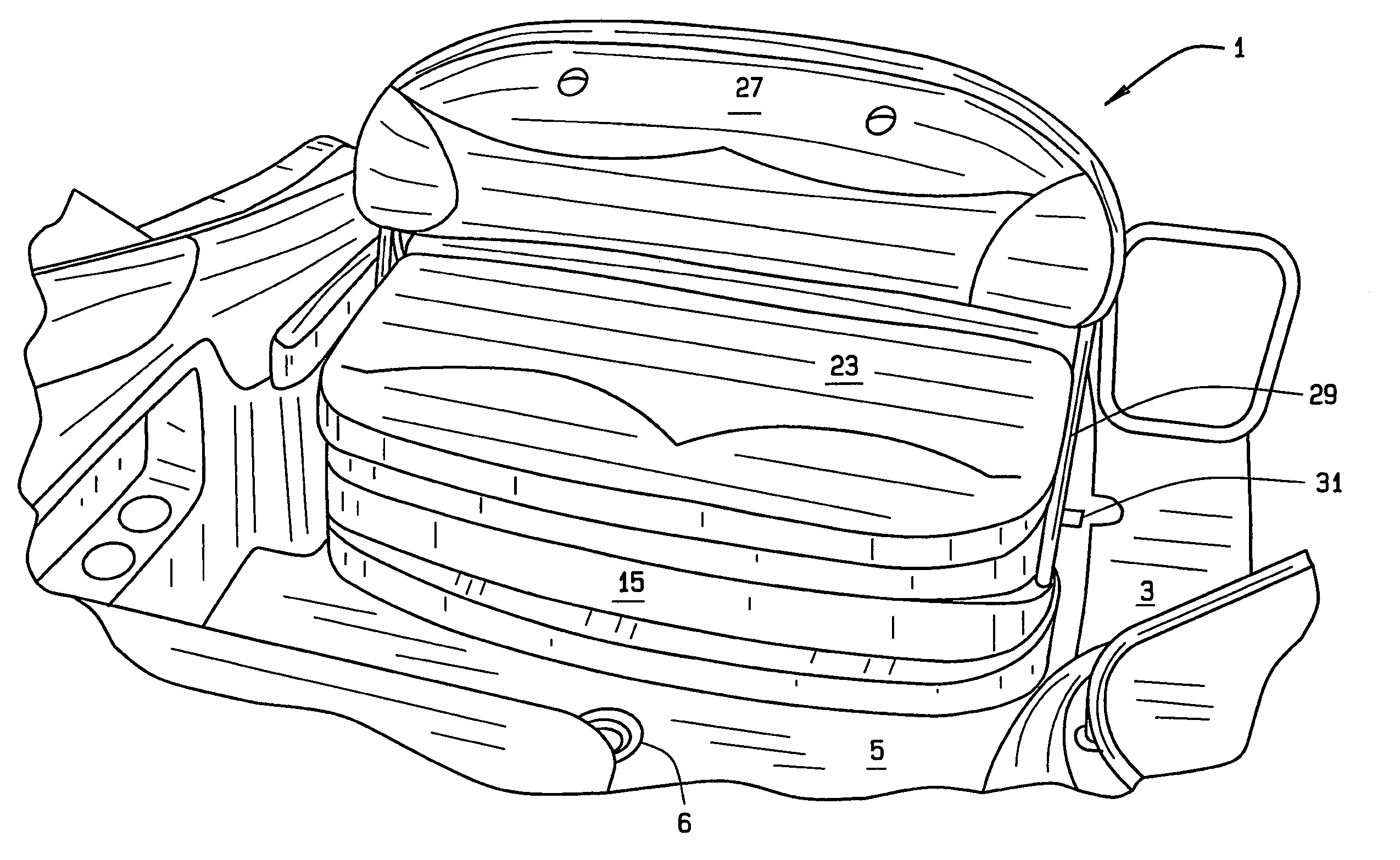

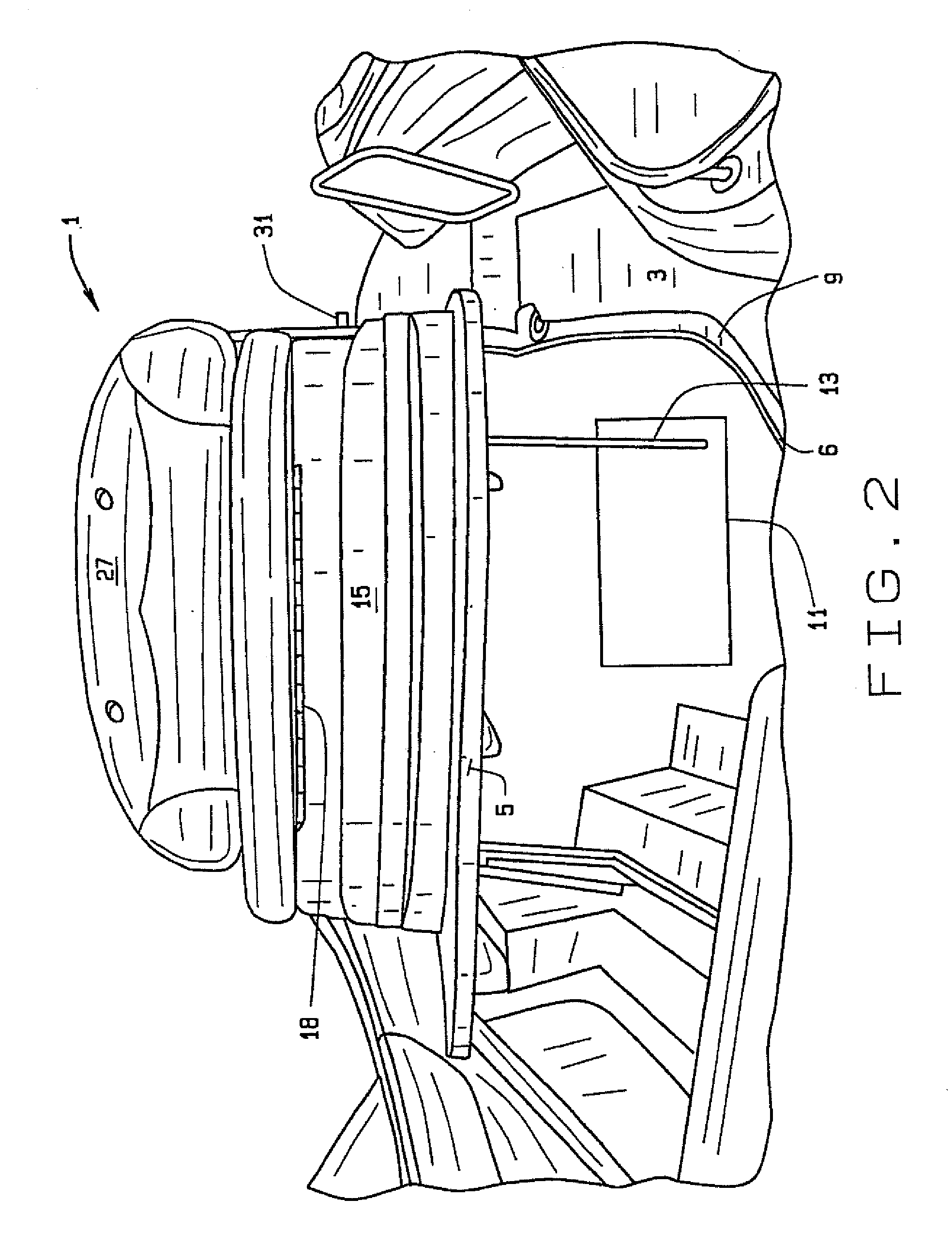

Combination seating and decking for an open bow boat

A seat back system that includes a pair of seat benches for mounting to the floor of an open bow section of a pleasure boat that each include seat backs that are individually mounted to pivot from a vertical, seat back attitude, to a horizontal attitude covering over the open bow section and includes an arrangement for pivoting the seat backs that can be hydraulic, pneumatic or mechanical, that each involve an extending piston between a boat floor and at a location along a brace that is secured to a seat back side, extending at a right angle therefrom, with piston extension to provide seat back travel, providing a load bearing deck.

Owner:FRANDSEN JERRY

Production technology of hatch coaming and hatch cover

InactiveCN101362505AReduce the number of liftingReduce workloadHull decksVessel hatches/hatchwaysManufacturing technologyHydraulic equipment

Owner:江苏熔盛重工有限公司 +1

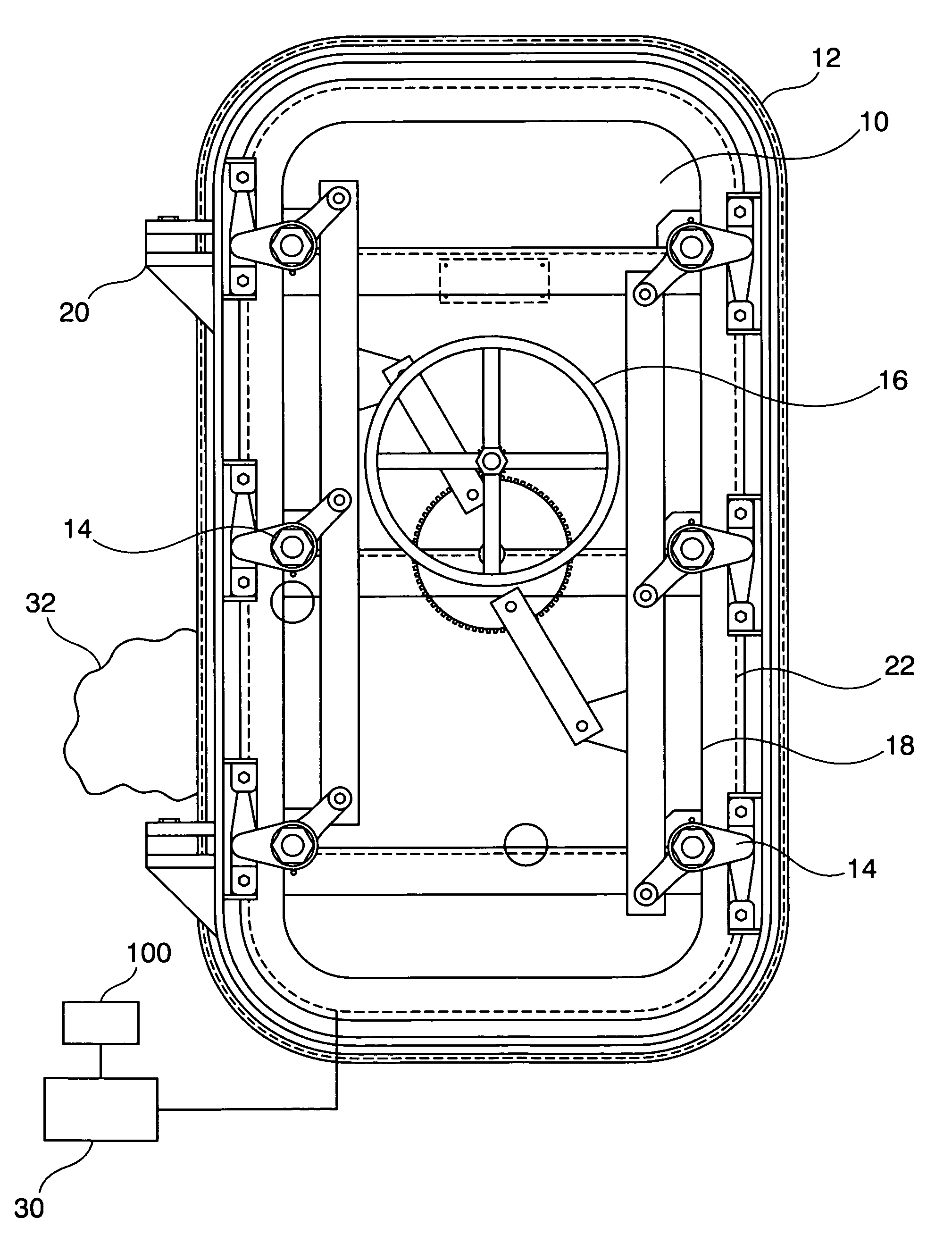

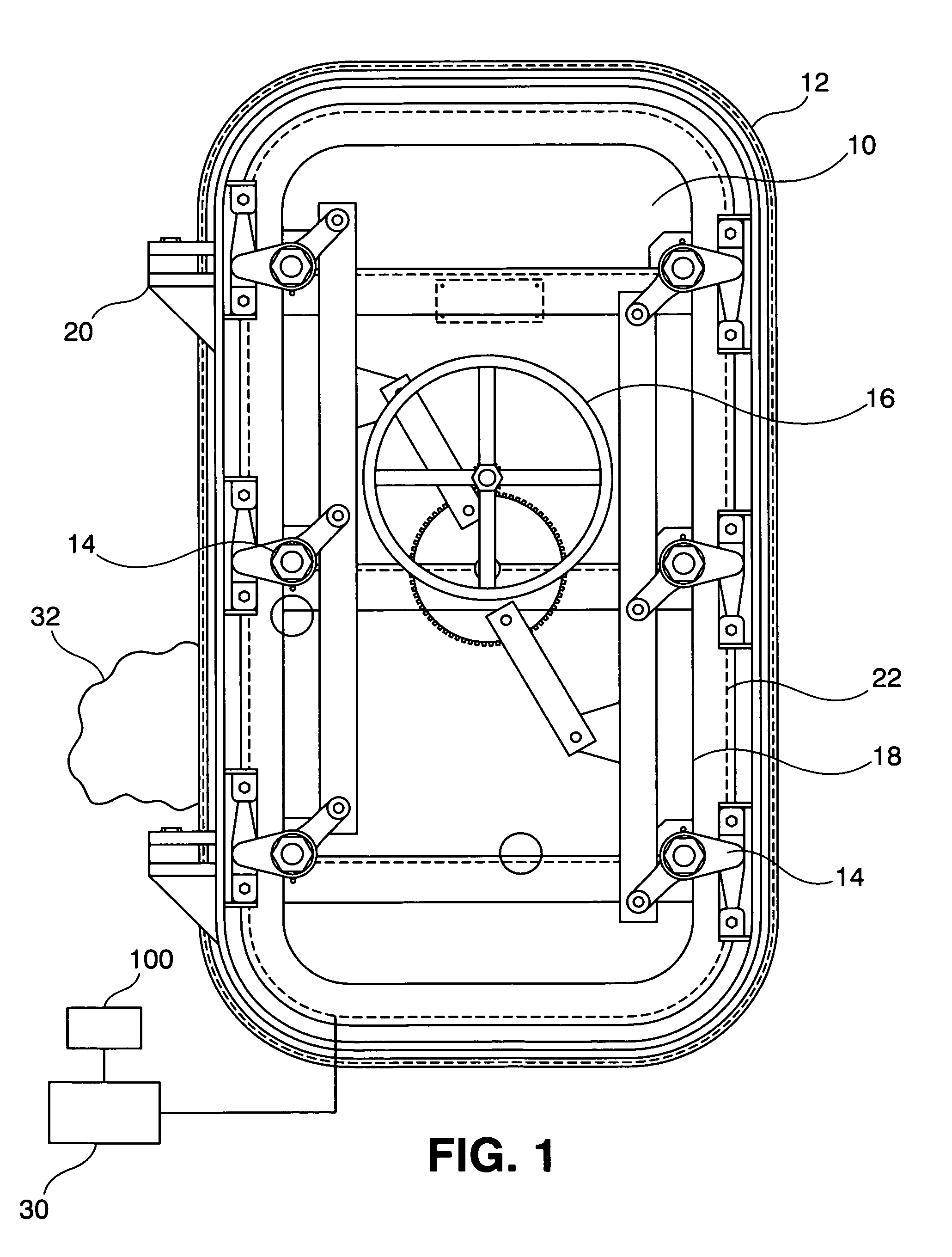

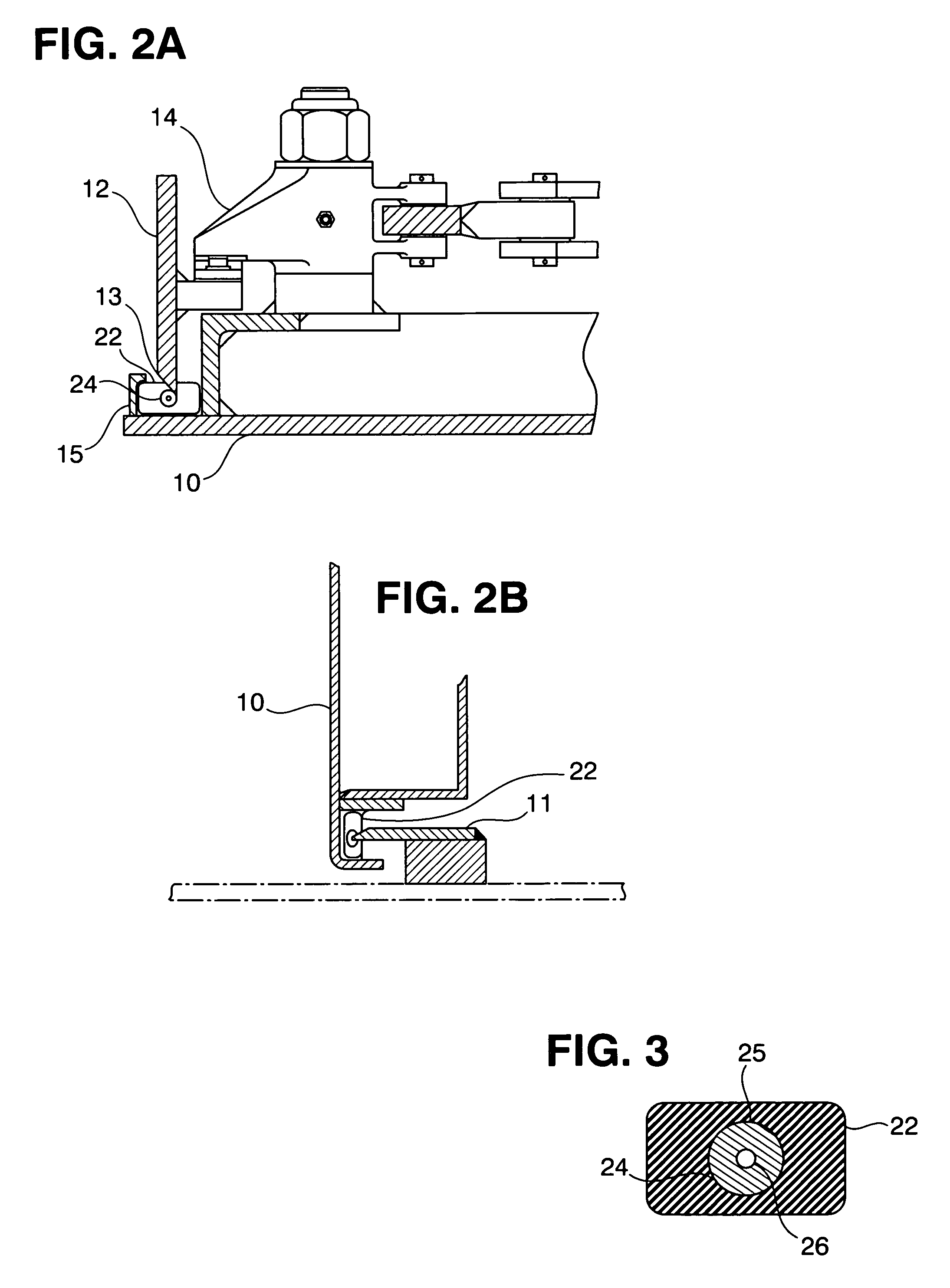

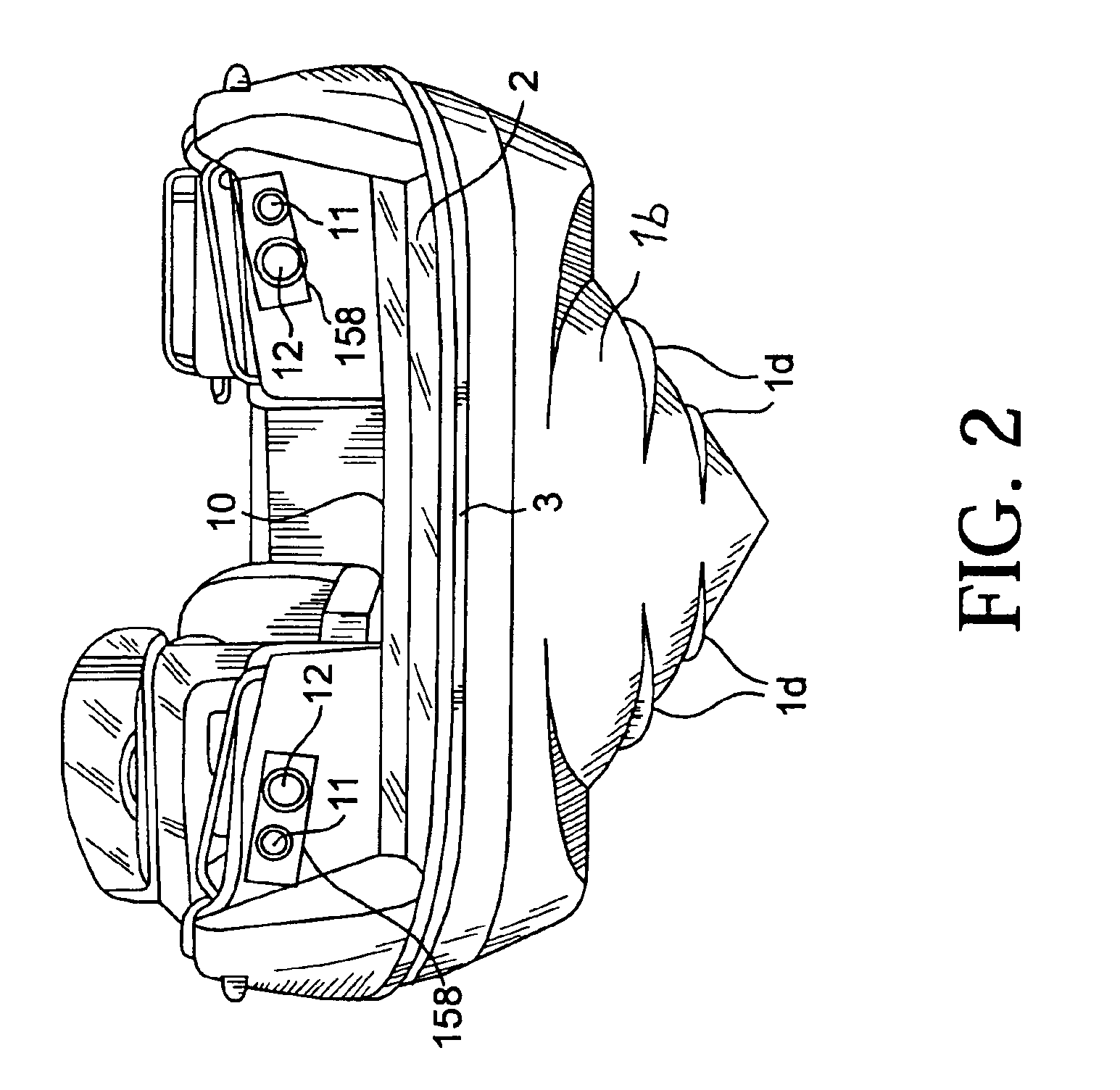

Seal integrity detection system

A seal integrity verification system scans for changes in impedance in a seal with integral coaxial waveguide, twisted pair wires, parallel ribbon wires or parallel wires. The wires are monitored by a TDR to note changes in impedance. The changes indicate the location where the seal is not under proper compression to ensure a tight fit. This is especially useful in verifying that watertight doors on ships or submarines are sealing properly when shut.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

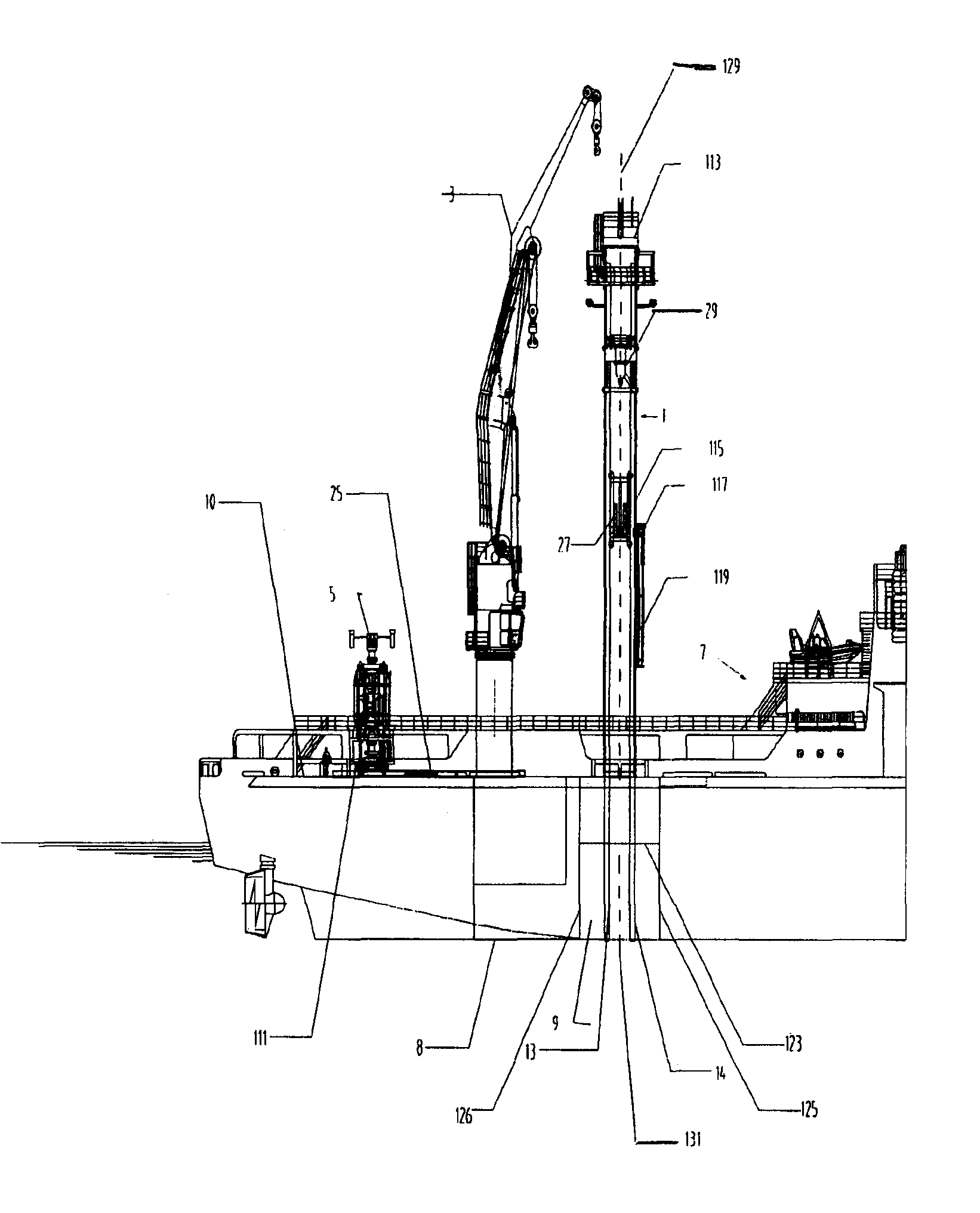

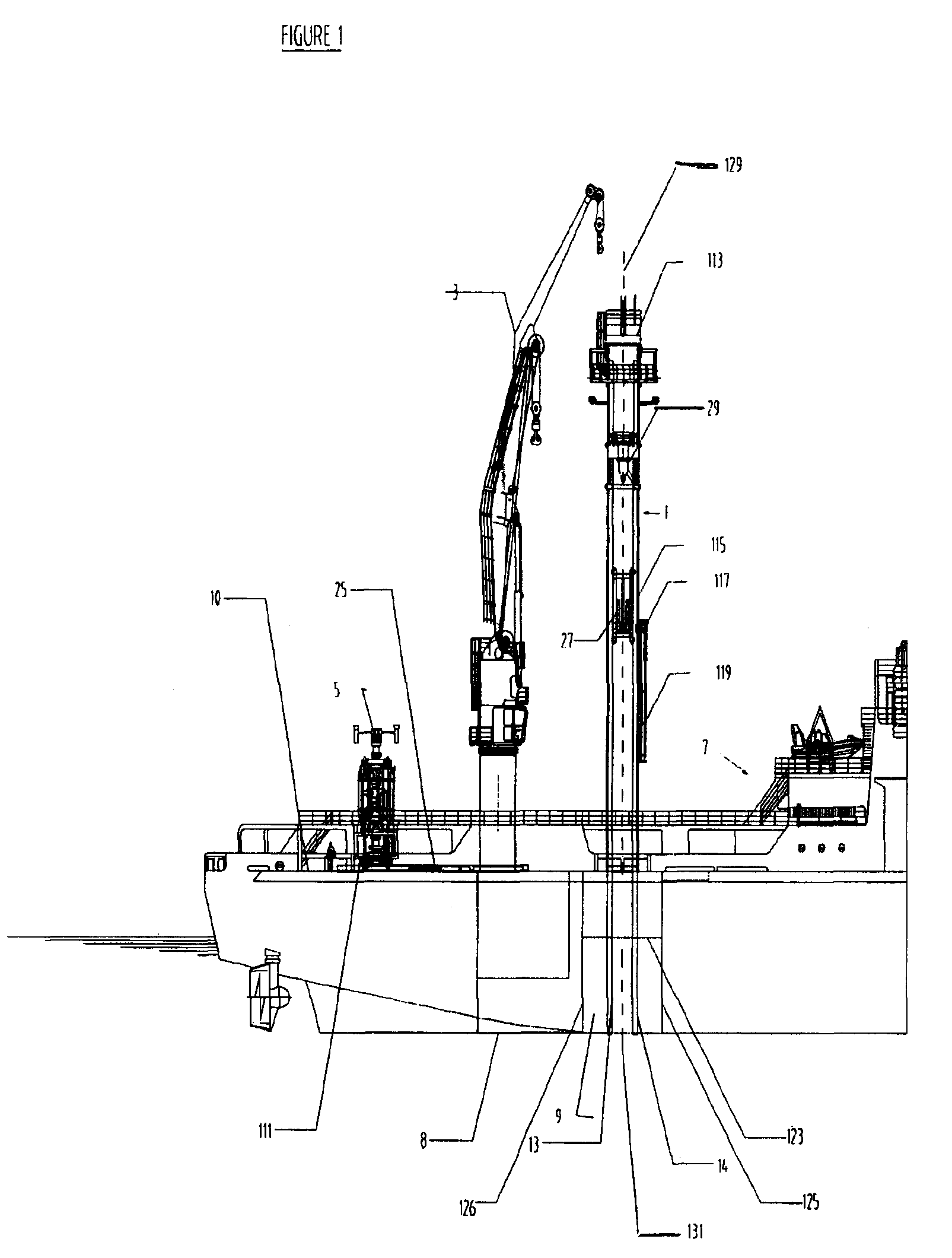

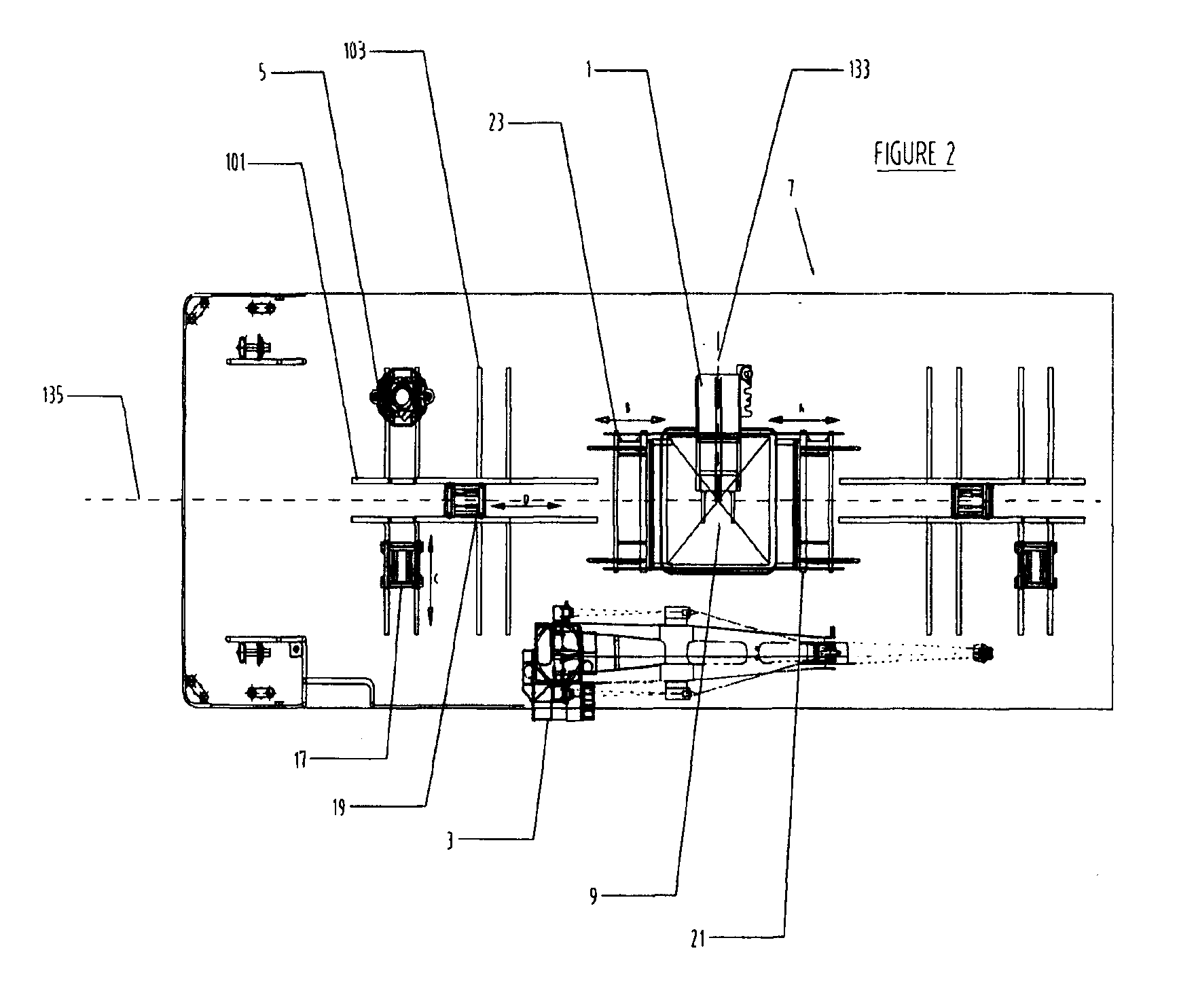

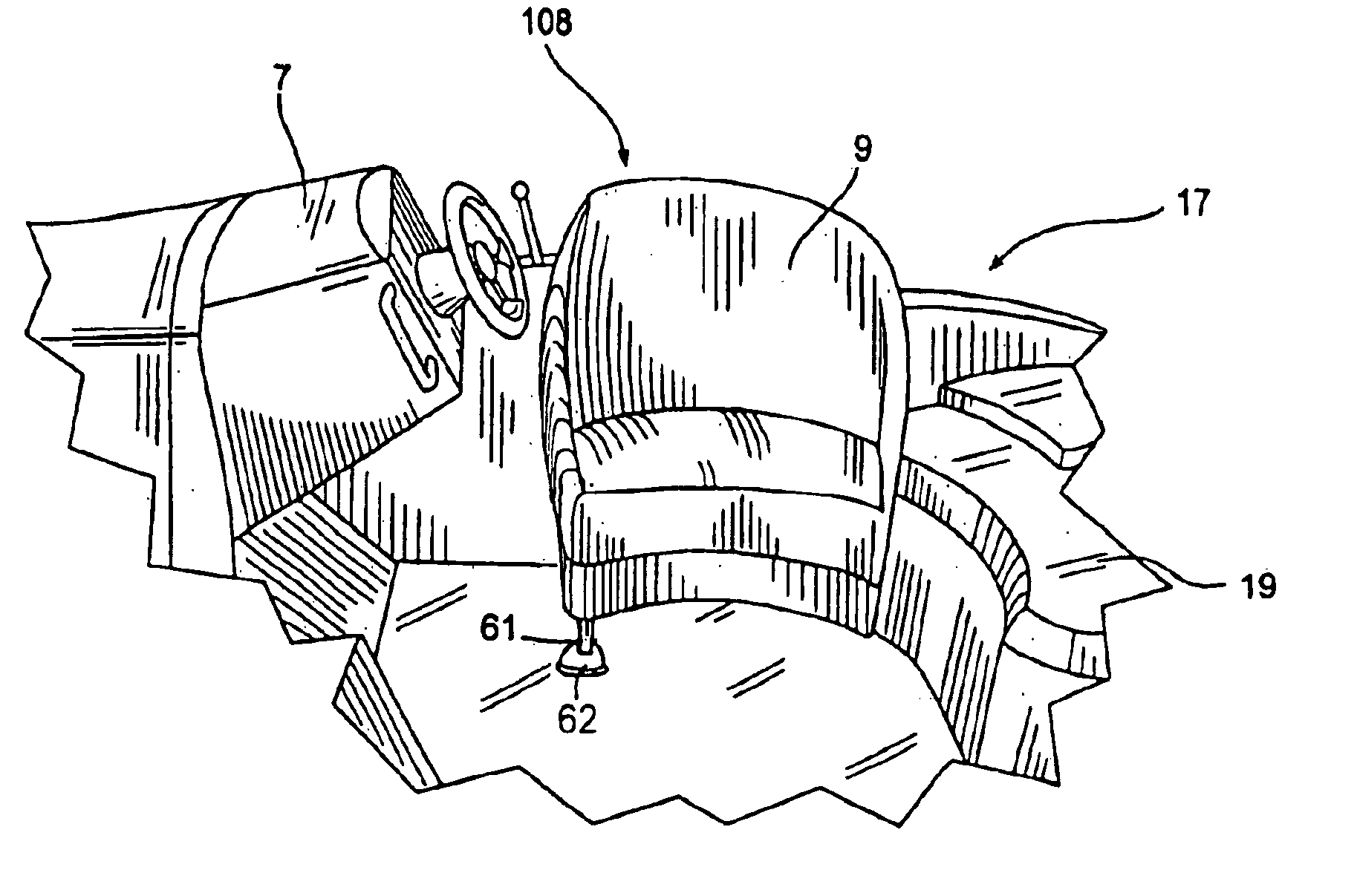

Multipurpose tower for monohull

A vessel with moonpool capable of being used offshore comprising a monohull with moonpool; a multipurpose tower mounted on the vessel; an equipment handling system removably mounted on the vessel; a movable hatch installed on top of the moonpool; and a hoist system installed inside the vessel, as well as an improved multipurpose tower, a moveable hatch and modular features for the tower. The invention is also a moveable hatch and a multipurpose tower.

Owner:ITREC BV

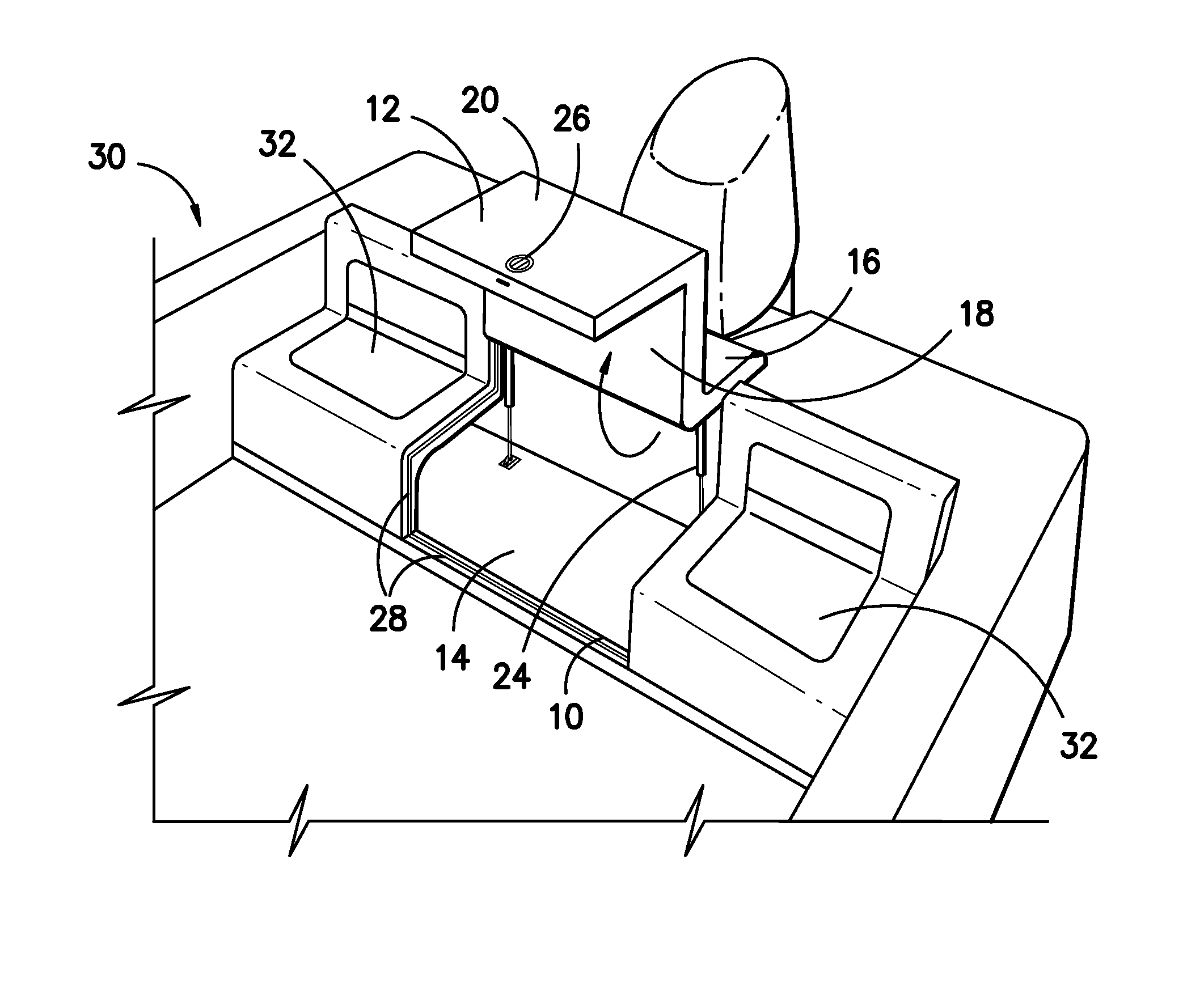

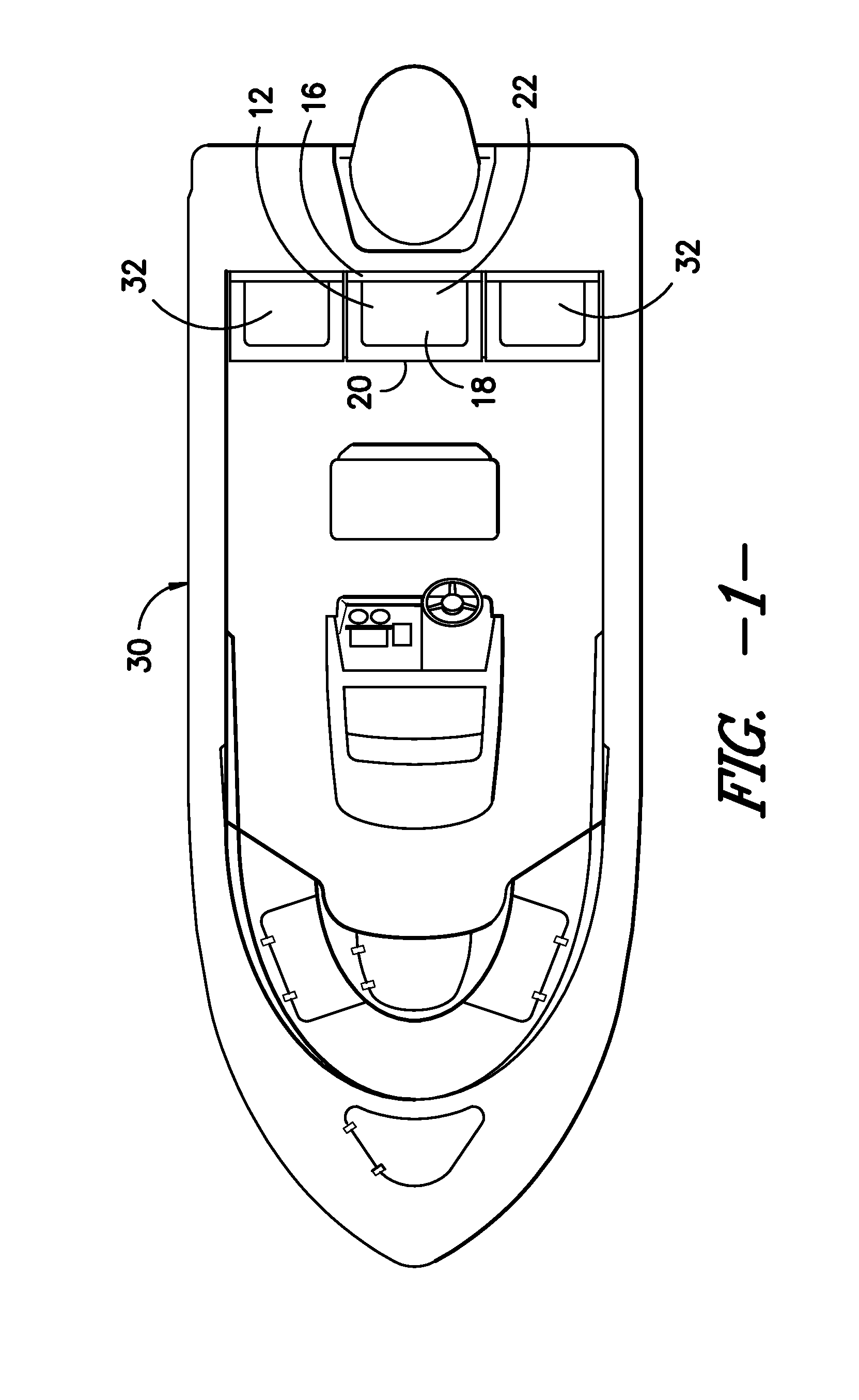

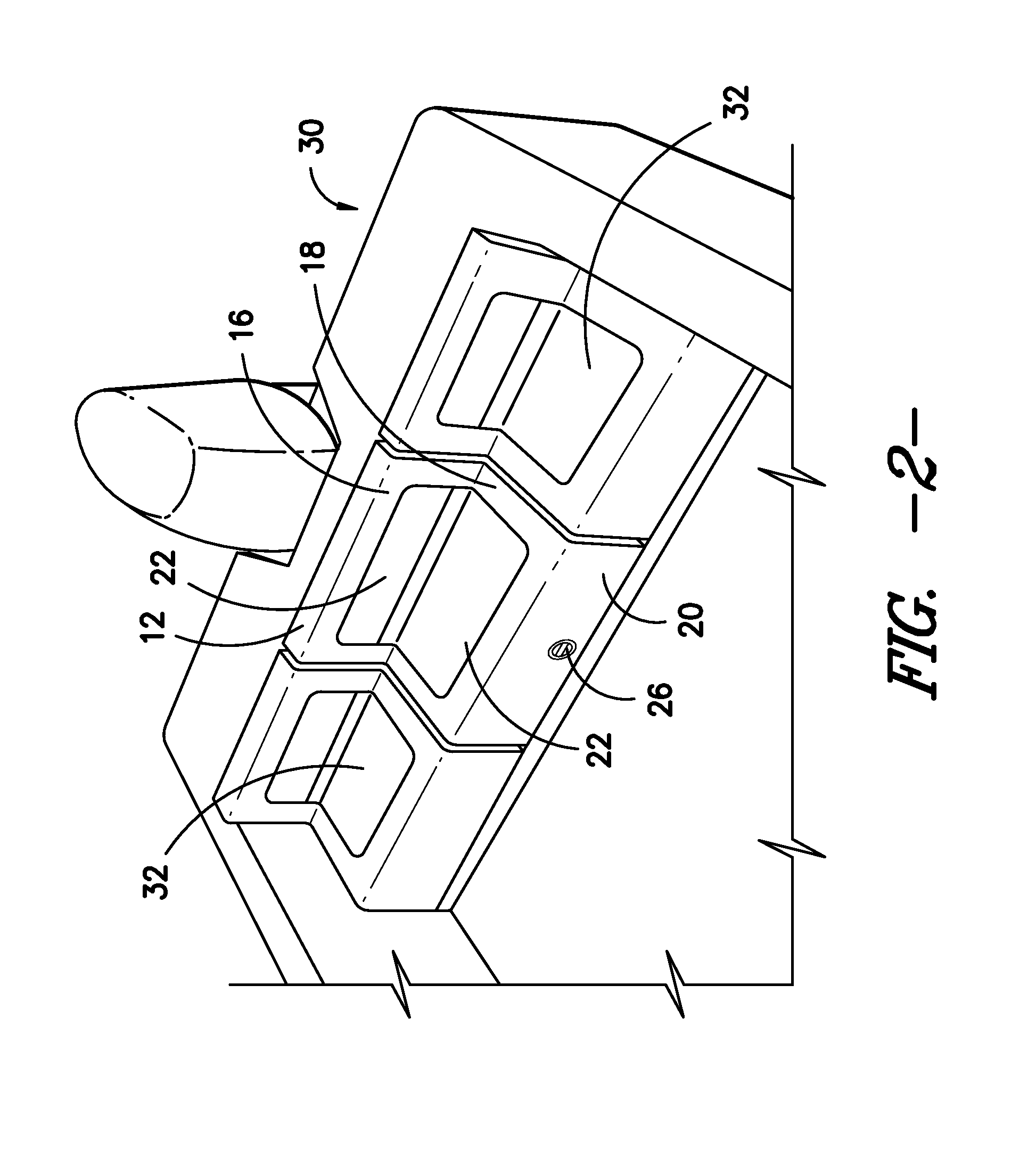

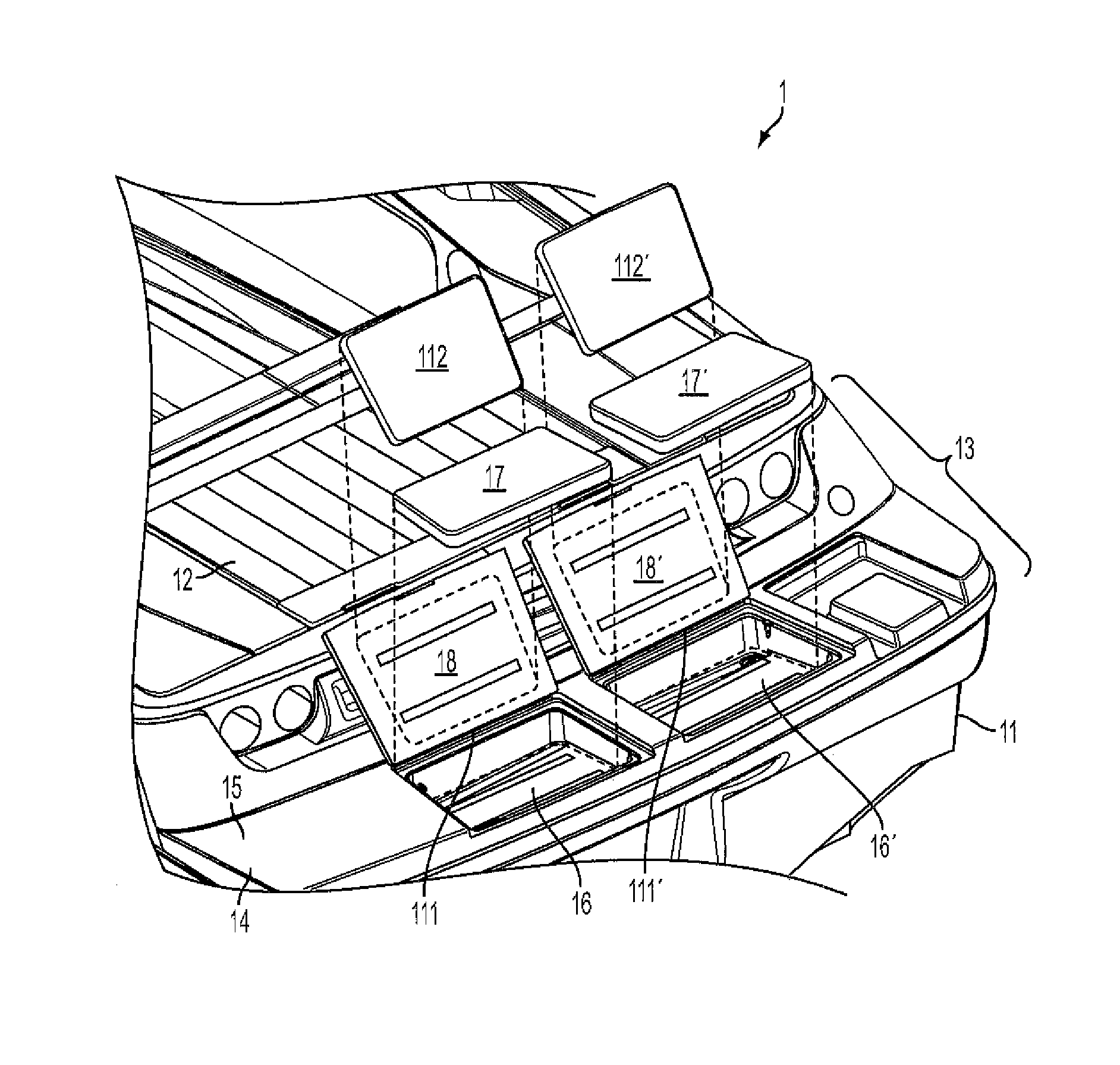

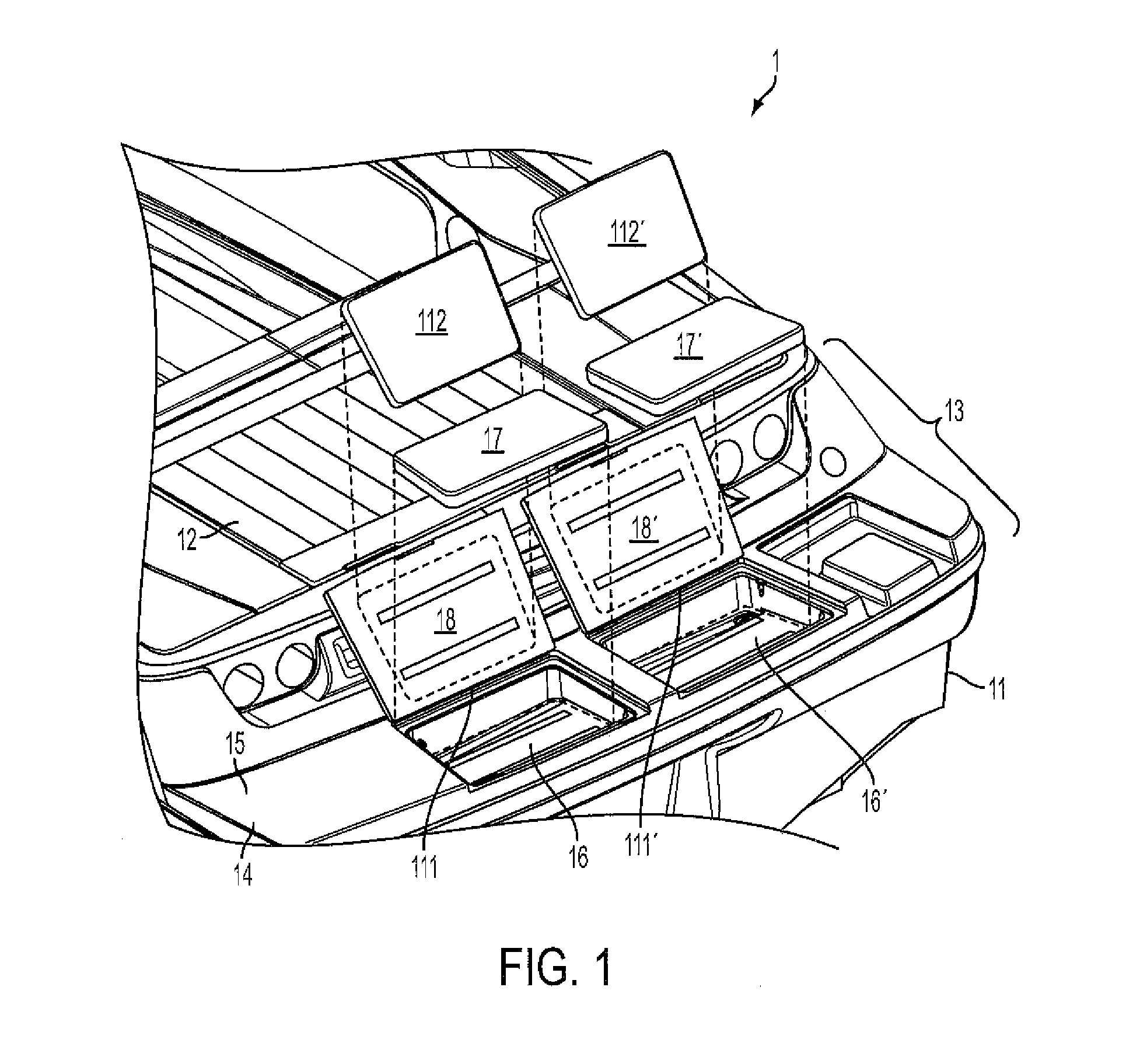

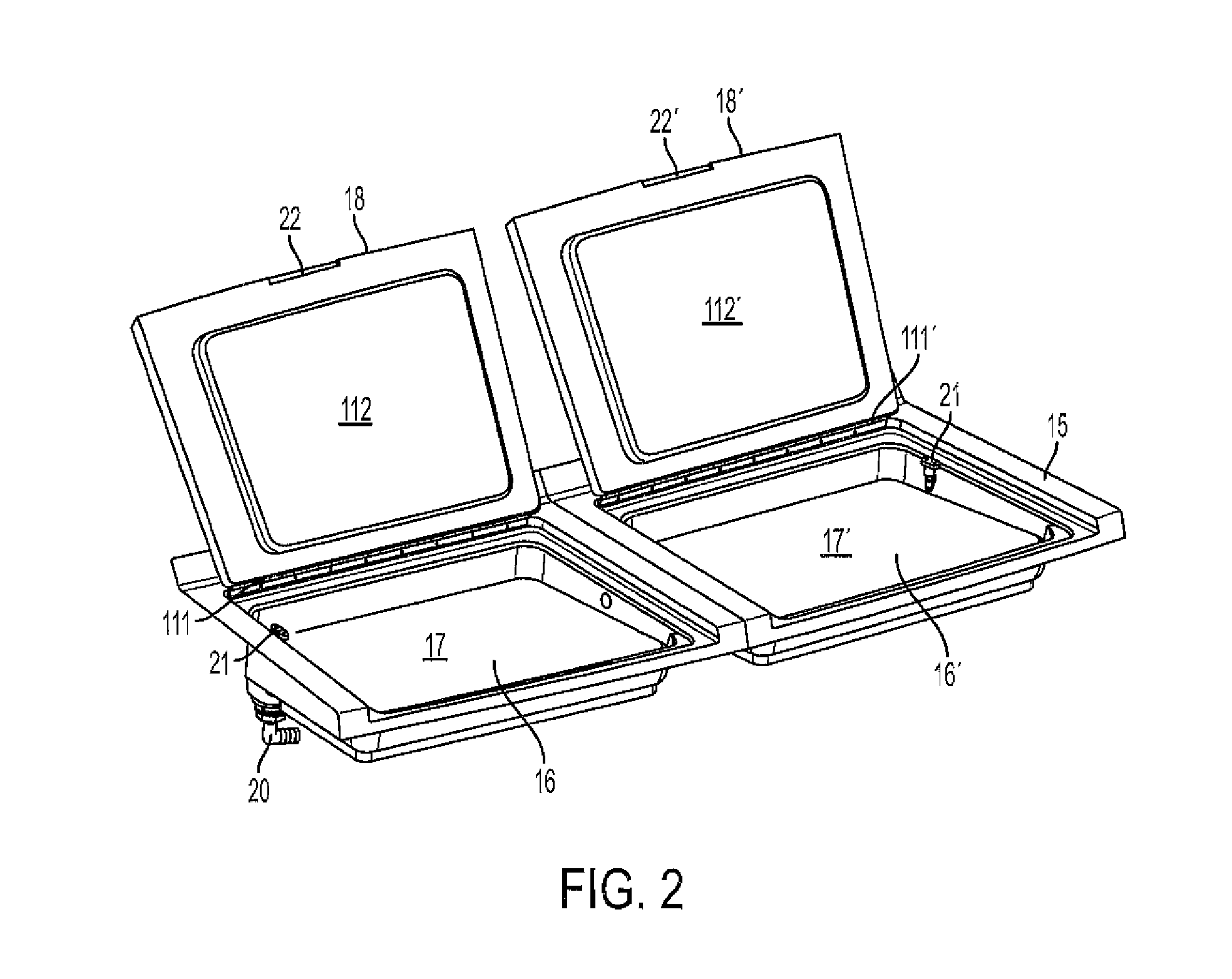

Hatch assembly with seat and storage bin

A hatch assembly for a boat including a base pivotally attached to a boat deck, whereby the base can pivot between an open position and closed position to provide access to an power source within a boat hull. The base defines a storage bin with a compartment for storage. A lid pivotally attaches to the base, whereby the lid can pivot from an open position to a closed position to provide access to the storage bin. A seat attaches to the lid and is supported by the base. A backrest pivotally attaches to the base and pivots between a sitting position and a reclining position.

Owner:LEISURE PROPERTIES

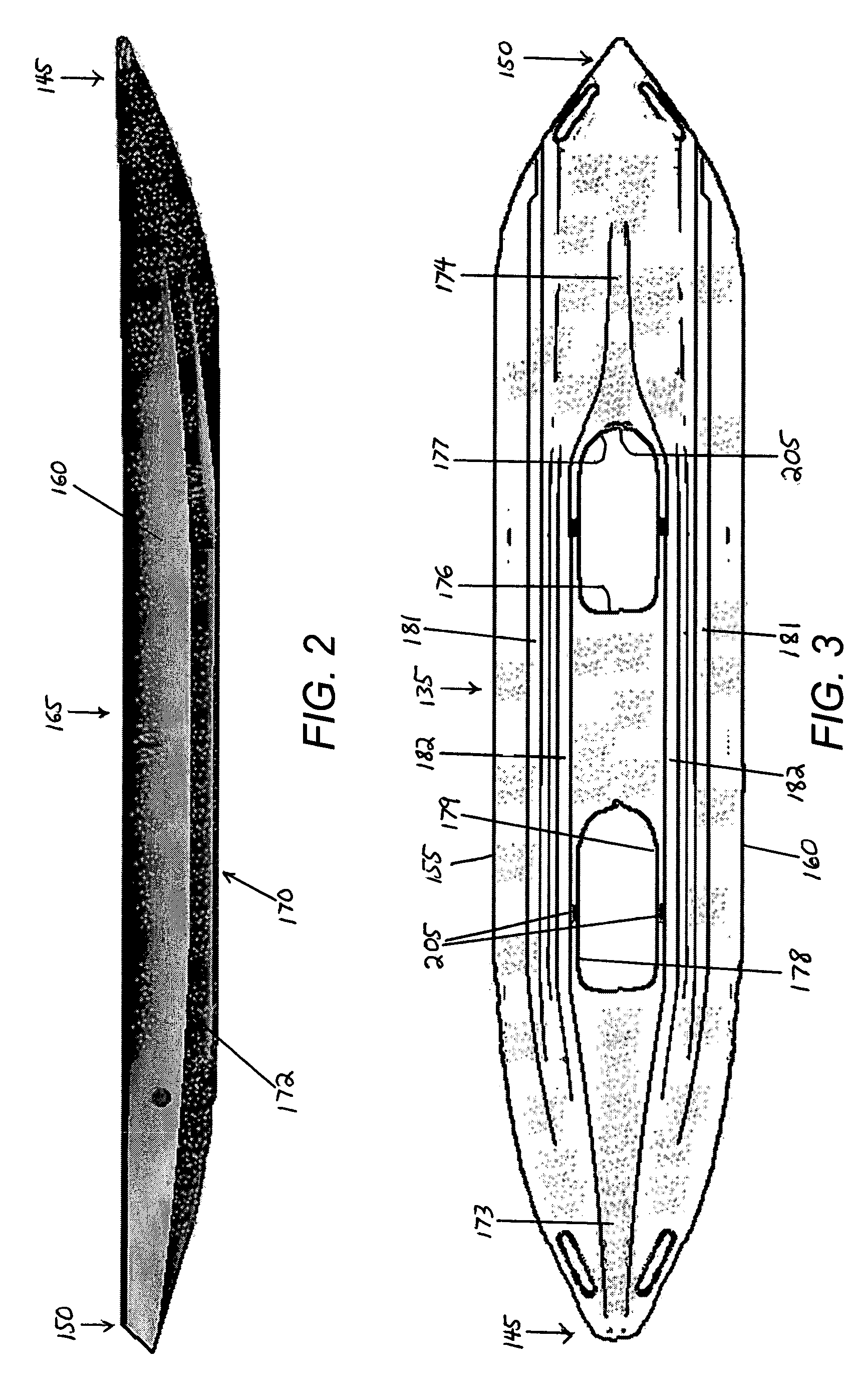

Motorized kayak

The motorized kayak includes foot pedal operated steering, and a selective lever that controls the polarity and speed of an electric motor, which can be retracted when not in use, as can the aft rudder. The kayak preferably has a topside axial enclosure, which may be rendered watertight and used as a bait tank or other liquid container, and typically at least one additional enclosure positioned transversely to the axial enclosure, which may or may not be watertight. These enclosures are preferably configured with the upper surfaces of their covers at a single level, for use collectively as an extended, relatively flat fishing seat.

Owner:CAPLES SEAN G

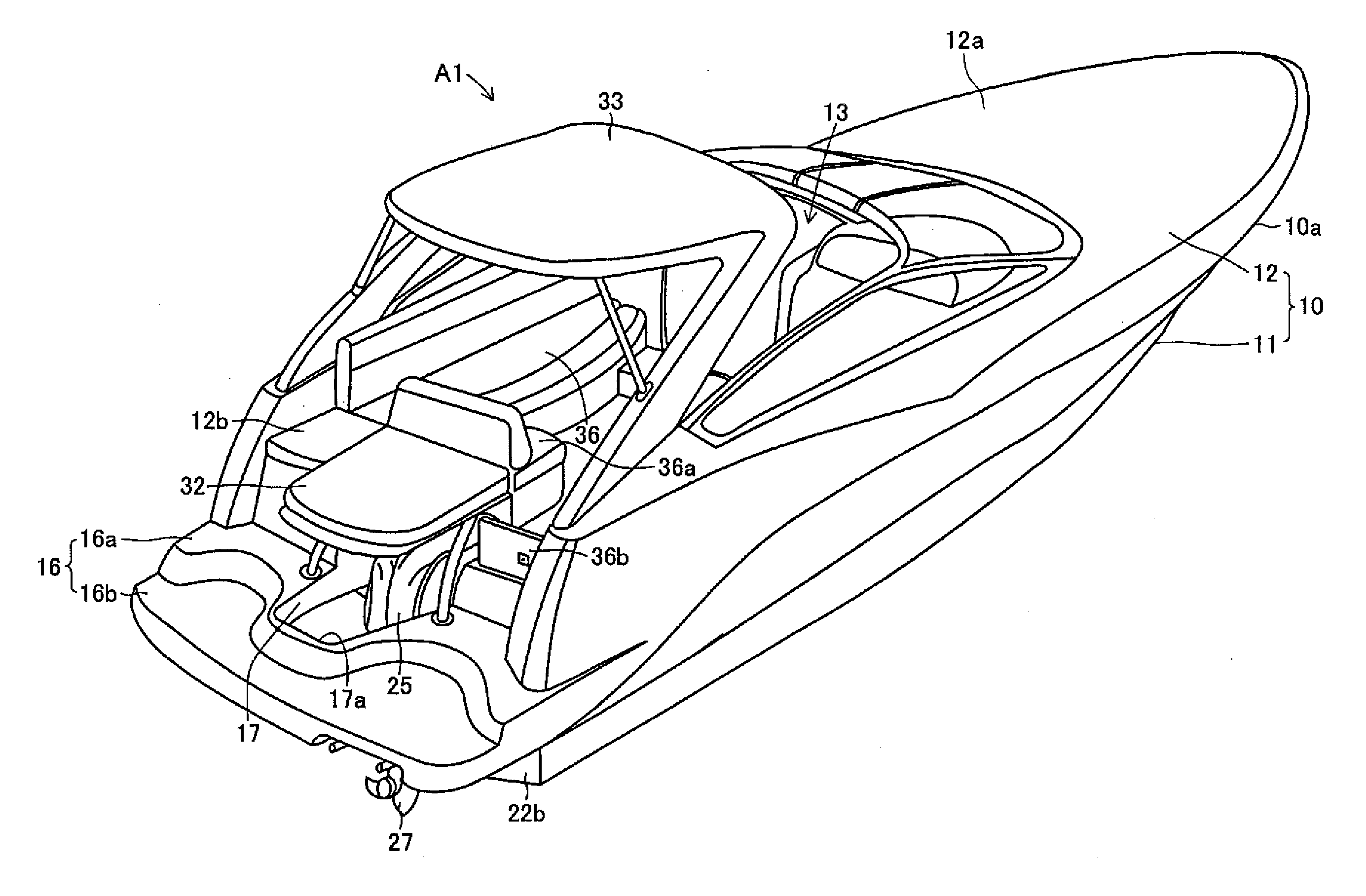

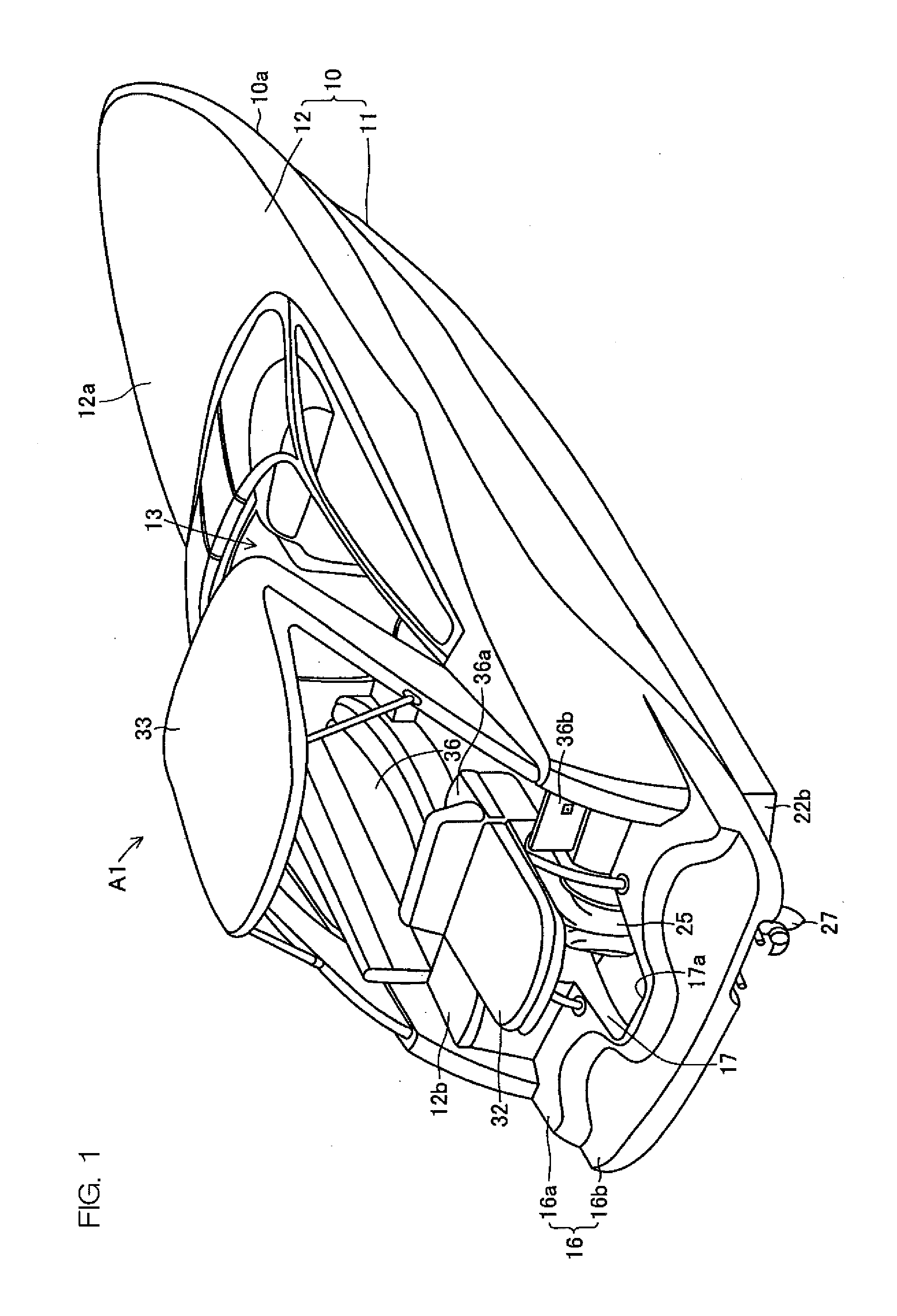

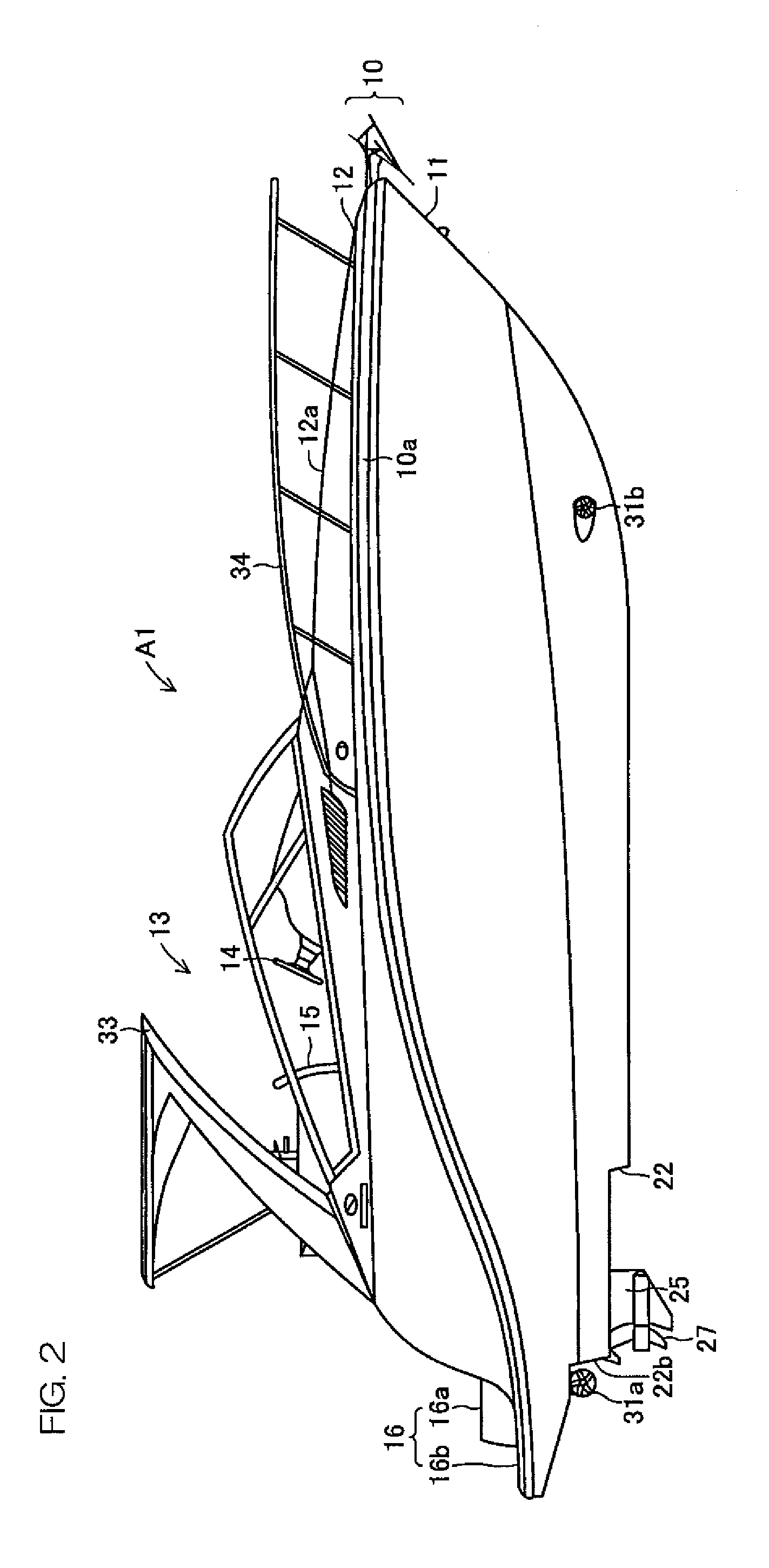

Marine vessel

A marine vessel includes an outboard motor mounting portion provided at a stern of a hull, an outboard motor locating hole provided rearward of the outboard motor mounting portion and near the outboard motor mounting portion and penetrating vertically through the stern, a platform provided rearward of the outboard motor locating hole, and an outboard motor located in the outboard motor locating hole and mounted to the outboard motor mounting portion. This structure enables an occupant of the marine vessel to freely move in a space around the outboard motor on the platform and use the space.

Owner:YAMAHA MOTOR CO LTD

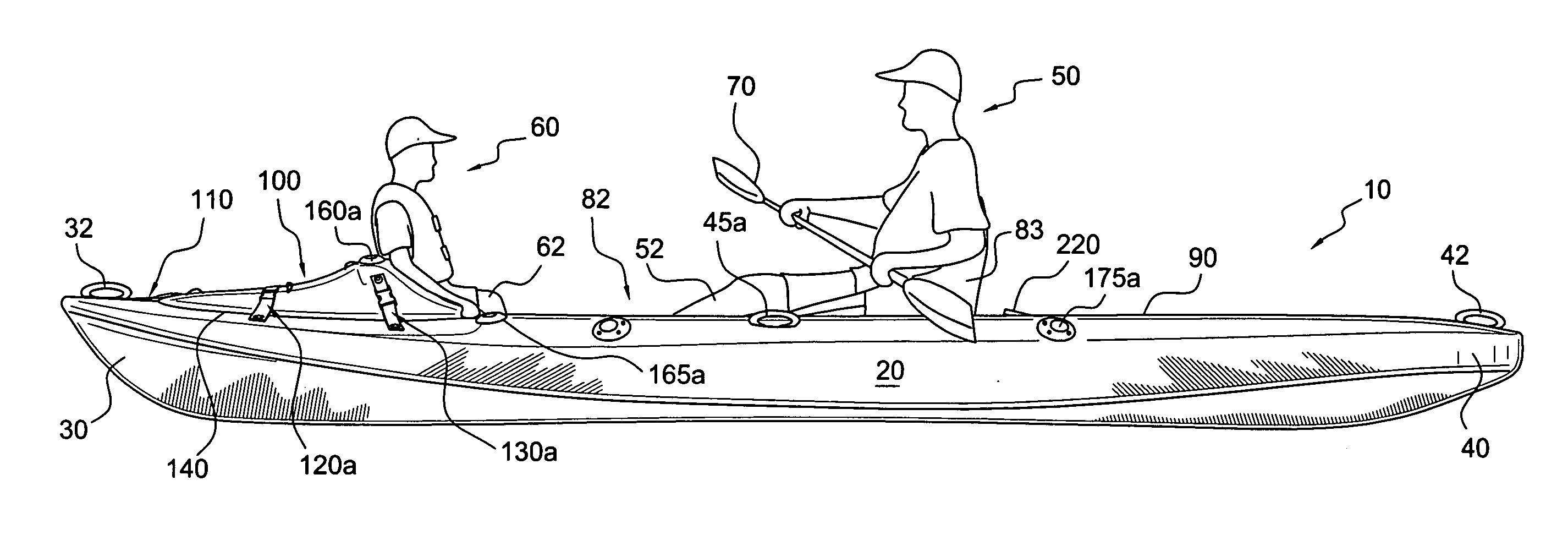

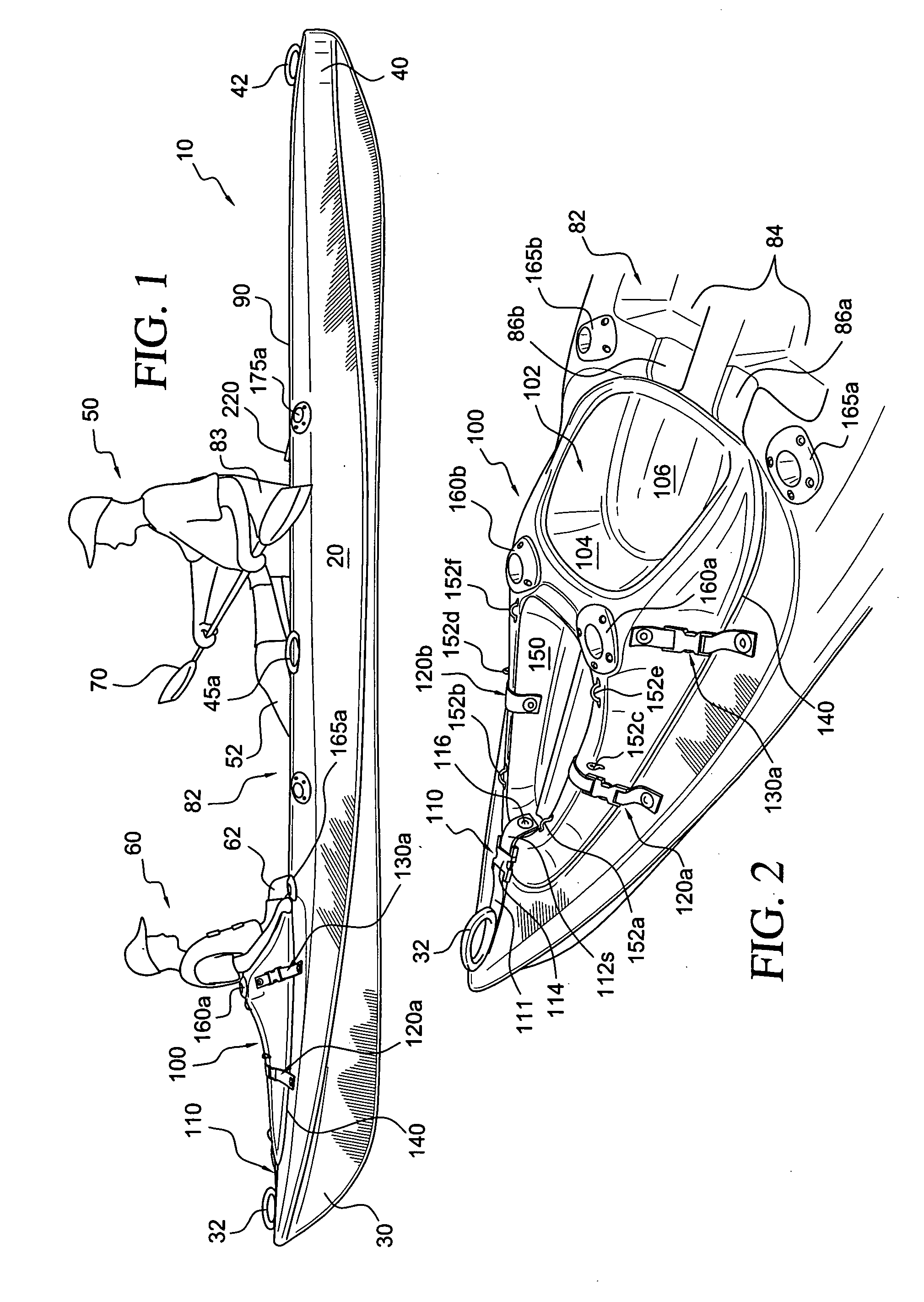

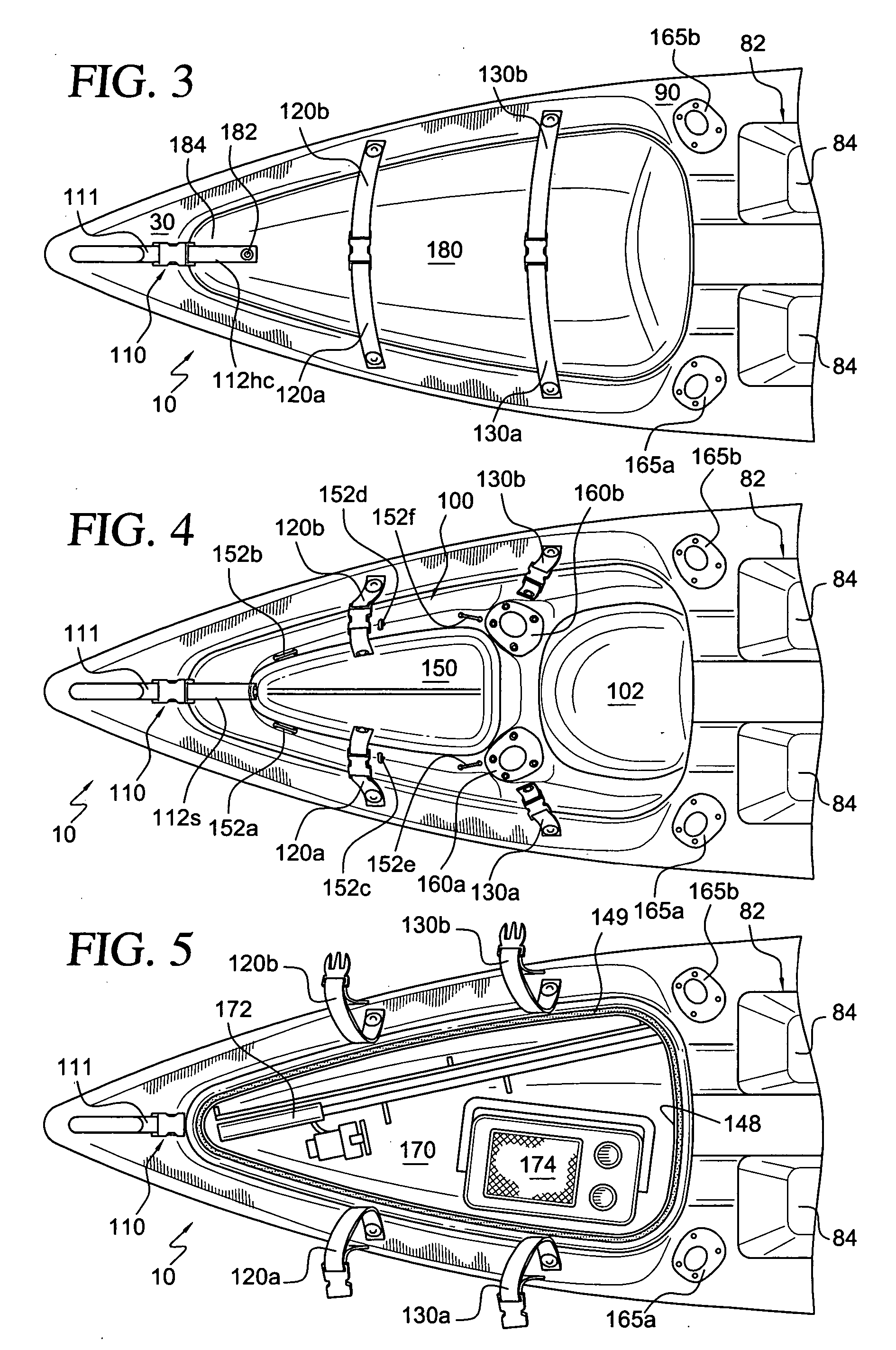

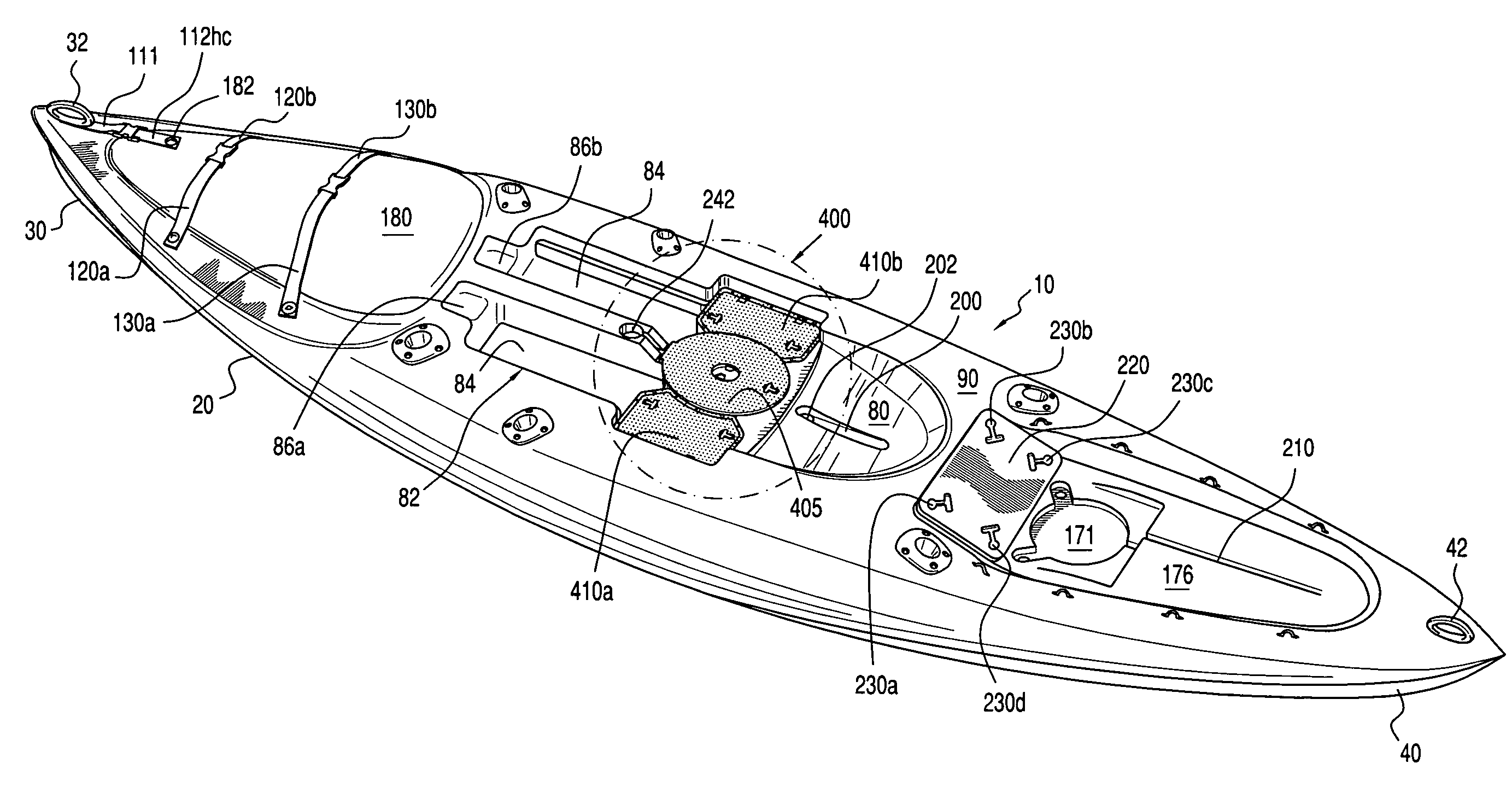

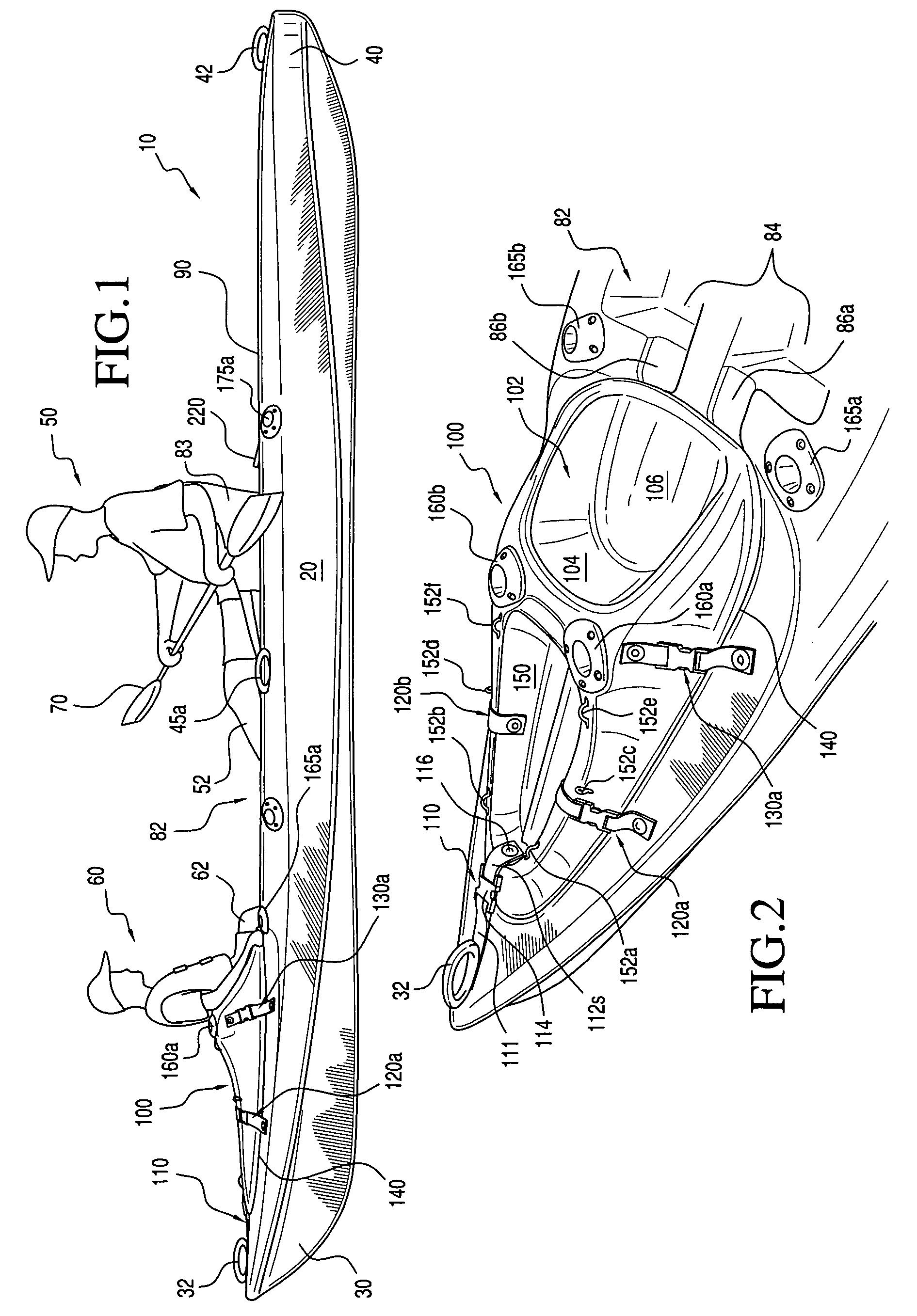

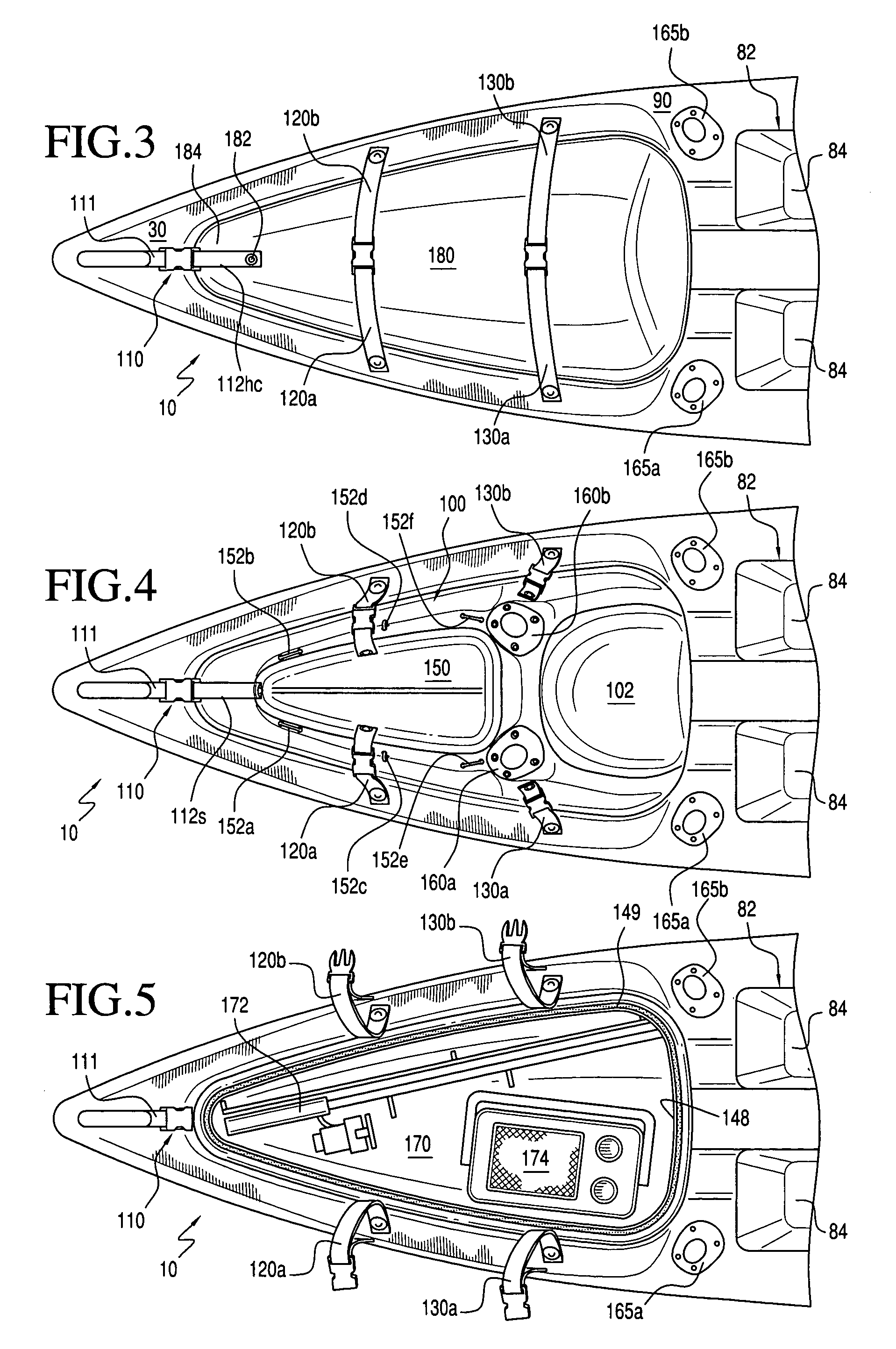

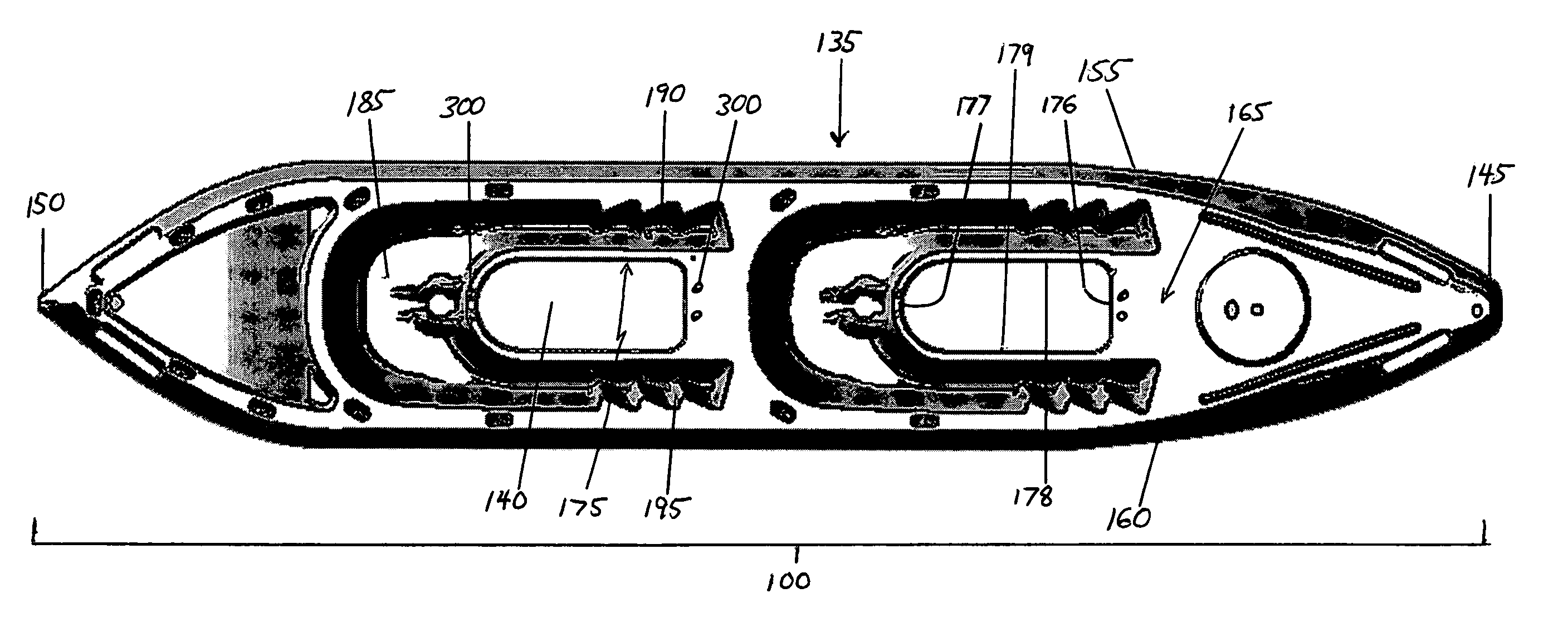

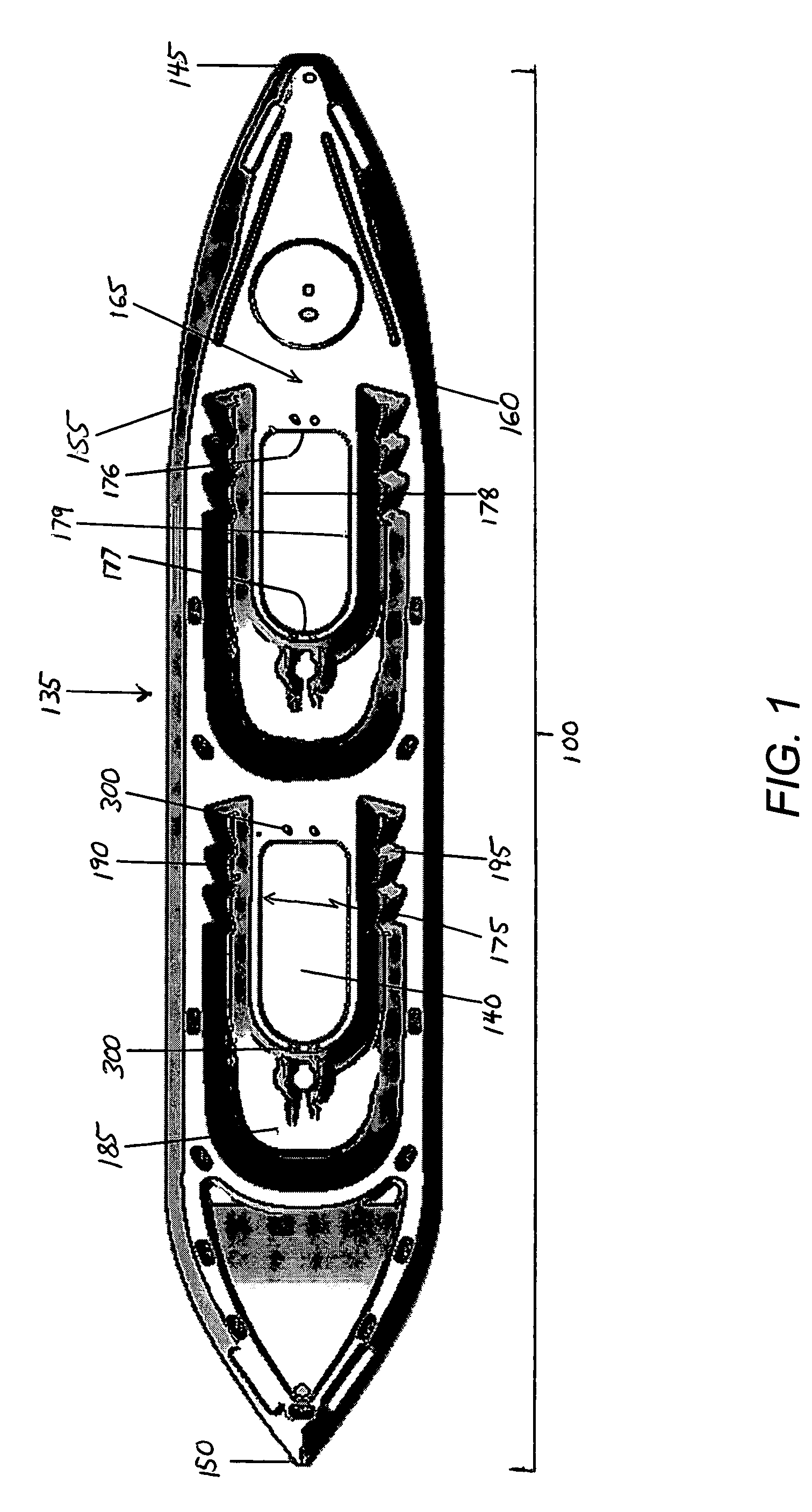

Kayak with a plurality of topside storage enclosures

The kayak has a topside axial enclosure, which may be rendered watertight and used as a bait tank or other liquid container, and at least one additional enclosure positioned transversely to the axial enclosure, which may or may not be watertight. In the preferred embodiment, a second additional enclosure is positioned transversely to the axial enclosure on the opposite side from the first additional enclosure. The enclosures are preferably configured with the upper surfaces of their covers at a single level, so that they may be used collectively as an extended, relatively flat fishing seat. Various access and sealing means are selectively provided for the respective enclosures. For example, a removable transparent access port may be included within the cover of the axial enclosure. In some embodiments, a circulation pump is provided to discharge within the axial enclosure. Likewise, the transversely positioned enclosure(s) may be selectively removable. In some embodiments, those enclosures may, upon removal, expose an opening to the kayak's internal cargo hatch.

Owner:CAPLES SEAN G

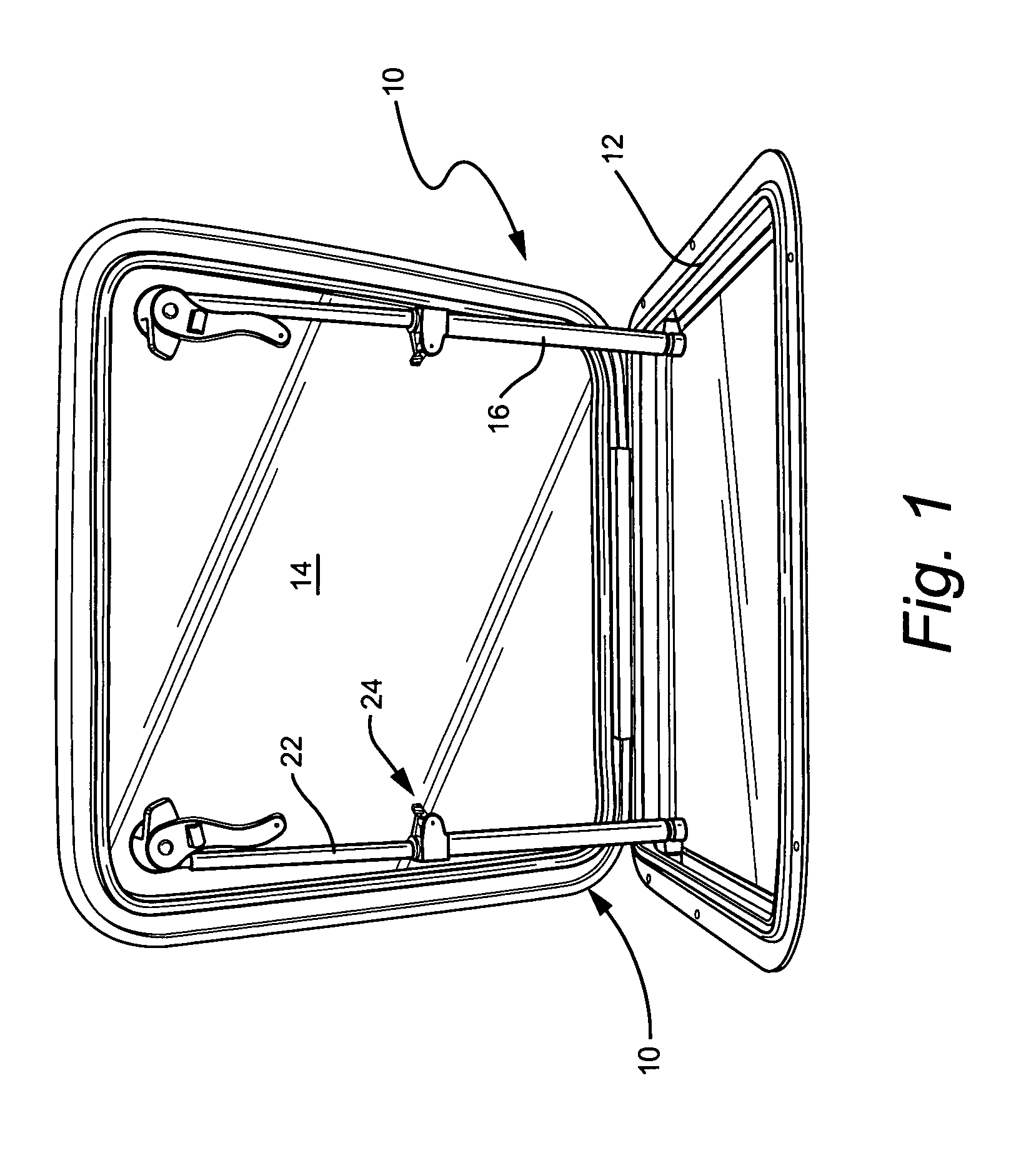

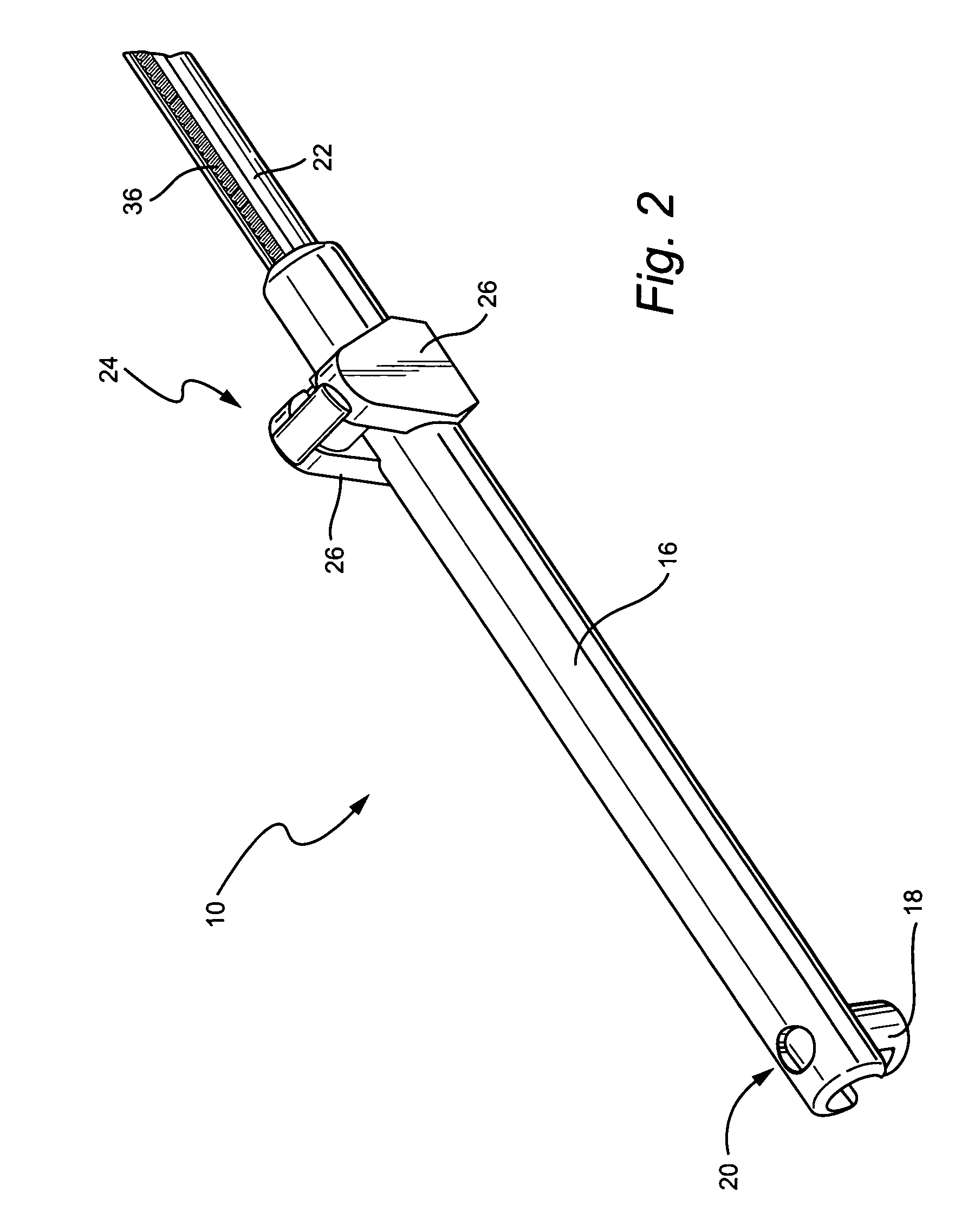

Support bar assembly for deck hatch

Owner:N A TAYLOR CO INC

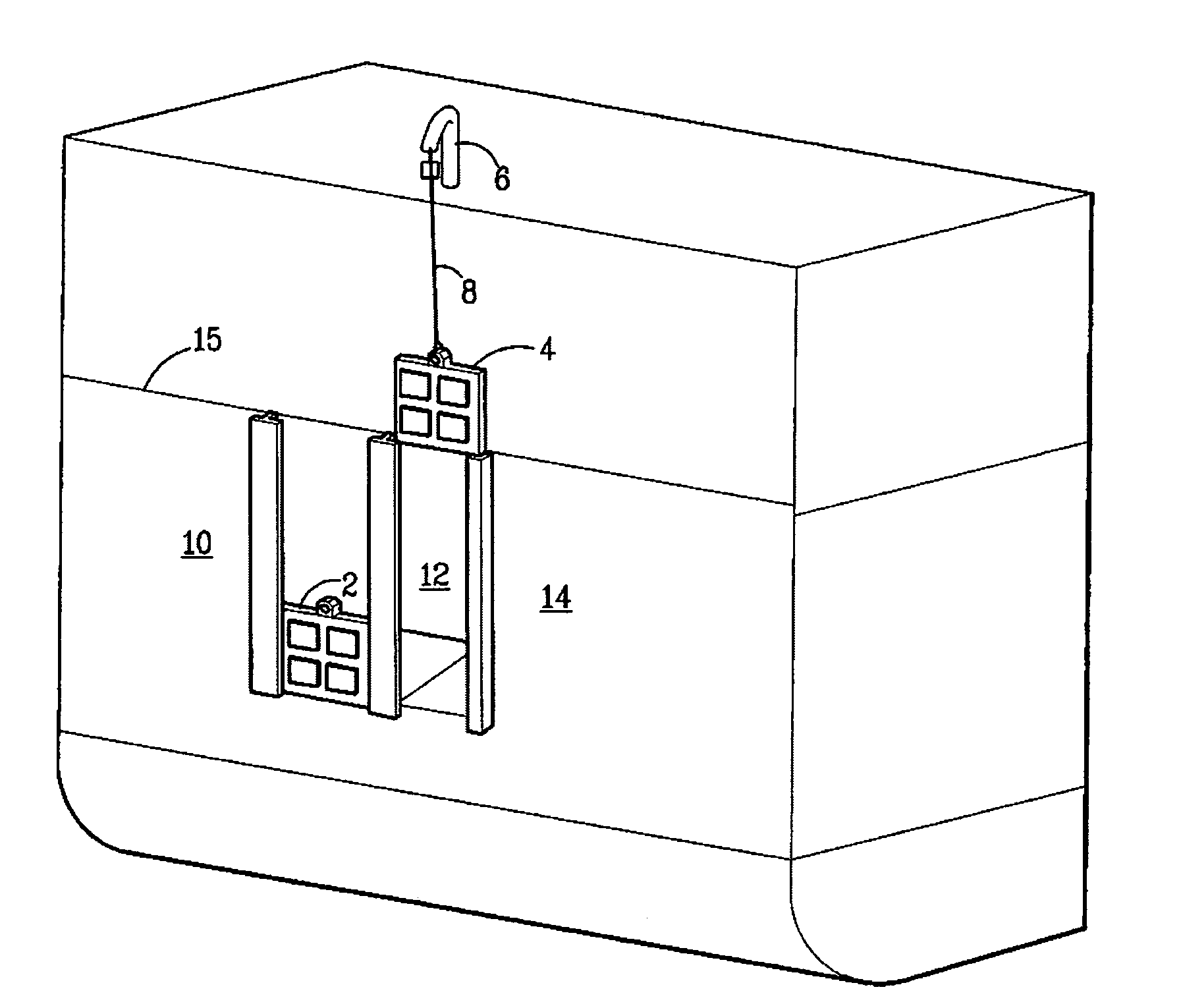

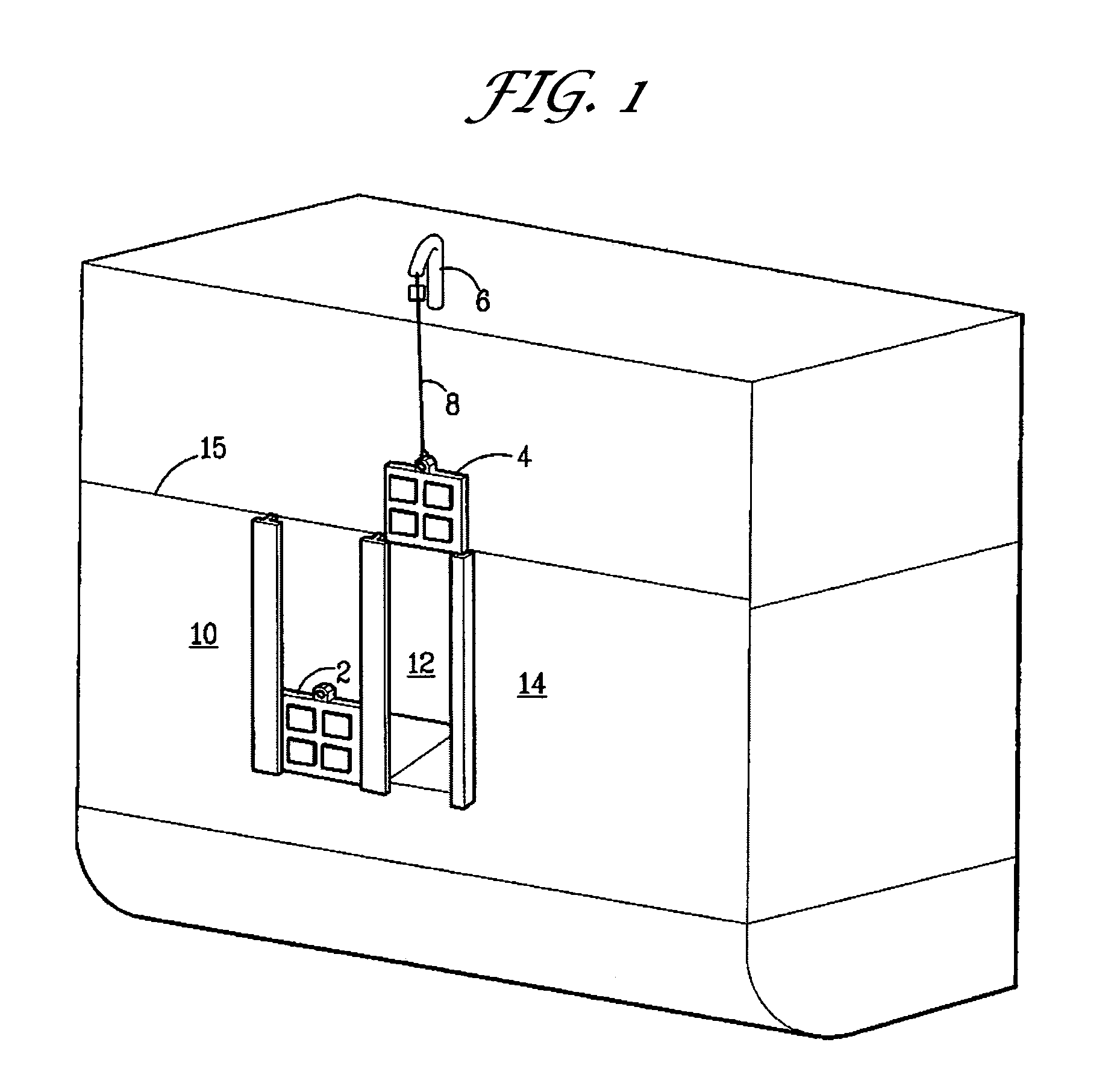

Systems and processes for covering openings of marine vessel hulls

InactiveUS7451717B1Promote repairEasy maintenanceSelf-bailing equipments/scuppersVessel designingGlass fiberMarine engineering

Systems and processes for closing openings in marine vessel hulls are provided. The systems and processes facilitate repairs and maintenance of marine vessels by closing openings in the marine vessel hulls to permit dry access to compartments in communication with the openings. The processes and systems incorporate a cover constructed from a lightweight material such as fiberglass, a viscoelastic material such as polyethylene or polyurethane, and blends thereof. The cover is guided in place to effectuate closure of the opening by a track device that receives at least two of the peripheral edges of the cover and directs the cover to the proper position to close the hull opening. The cover may be lowered into place by use of a hoisting device such as a davit.

Owner:CONOCOPHILLIPS CO

Deck boat

Combined herein are the benefits of a flat deck pontoon boat and the speed and versatility of a jet propelled watercraft. The watercraft is equipped with a propulsion source sufficient to move the watercraft at a substantial speed through the water. The seating layout on the deck provides the amenities of an extremely comfortable watercraft capable of seating multiple passengers while providing sufficient storage space for all necessary items for such a voyage. The watercraft is equipped with a substantially flat deck area with an upper bow deck and a lowered recess area which, when filled with water, provides cooling and amusement for the passengers. The watercraft is equipped with a privacy compartment or toilet, a kitchen area, and a double driver seat, which can be rotated from a relaxing position to a driving position. A rear sundeck can be converted into upright seats. Under the kitchen area an ice chest or some other item can be stowed. The layout of the deck on the boat permits passengers to move easily through the passenger areas.

Owner:BRP US

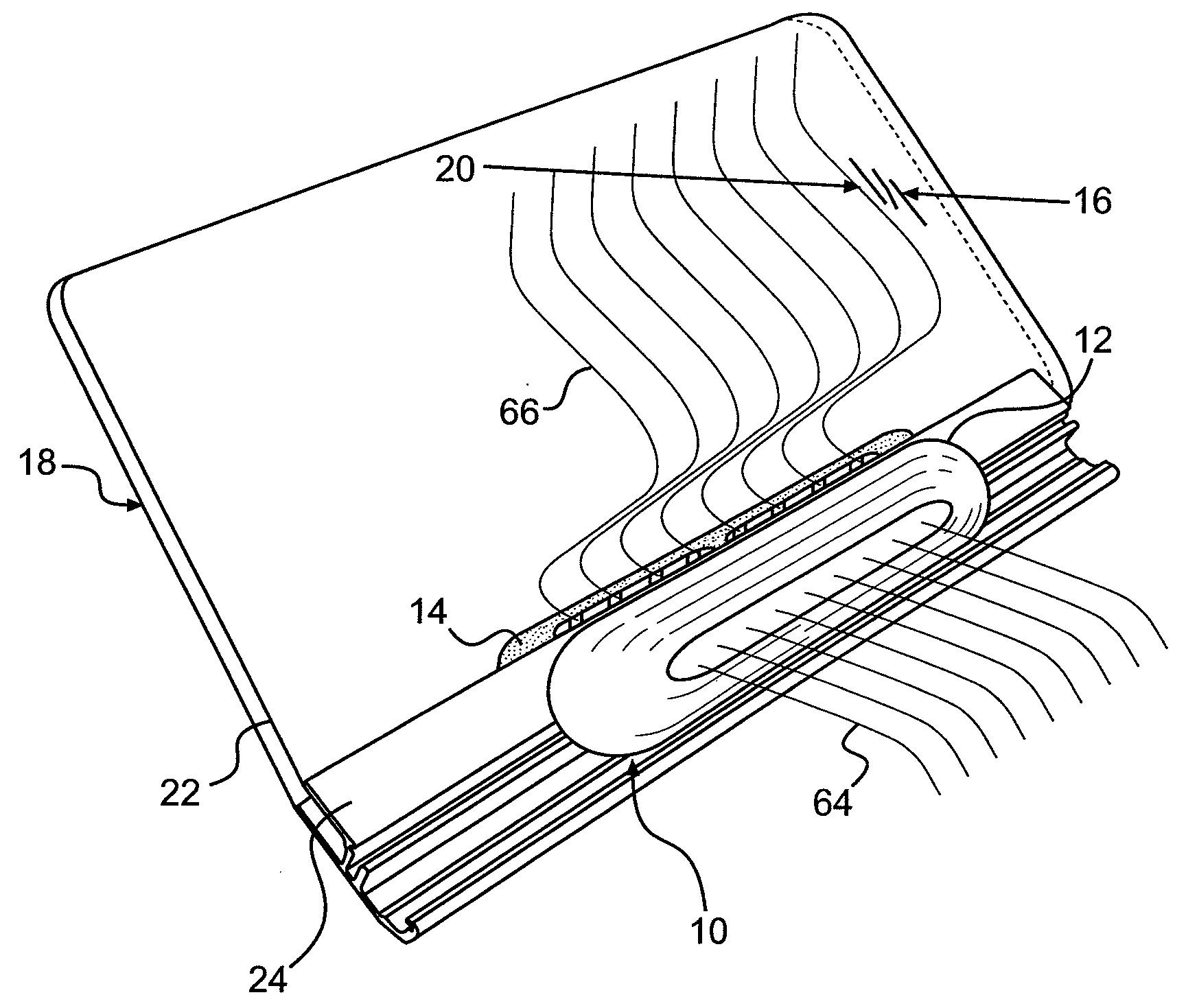

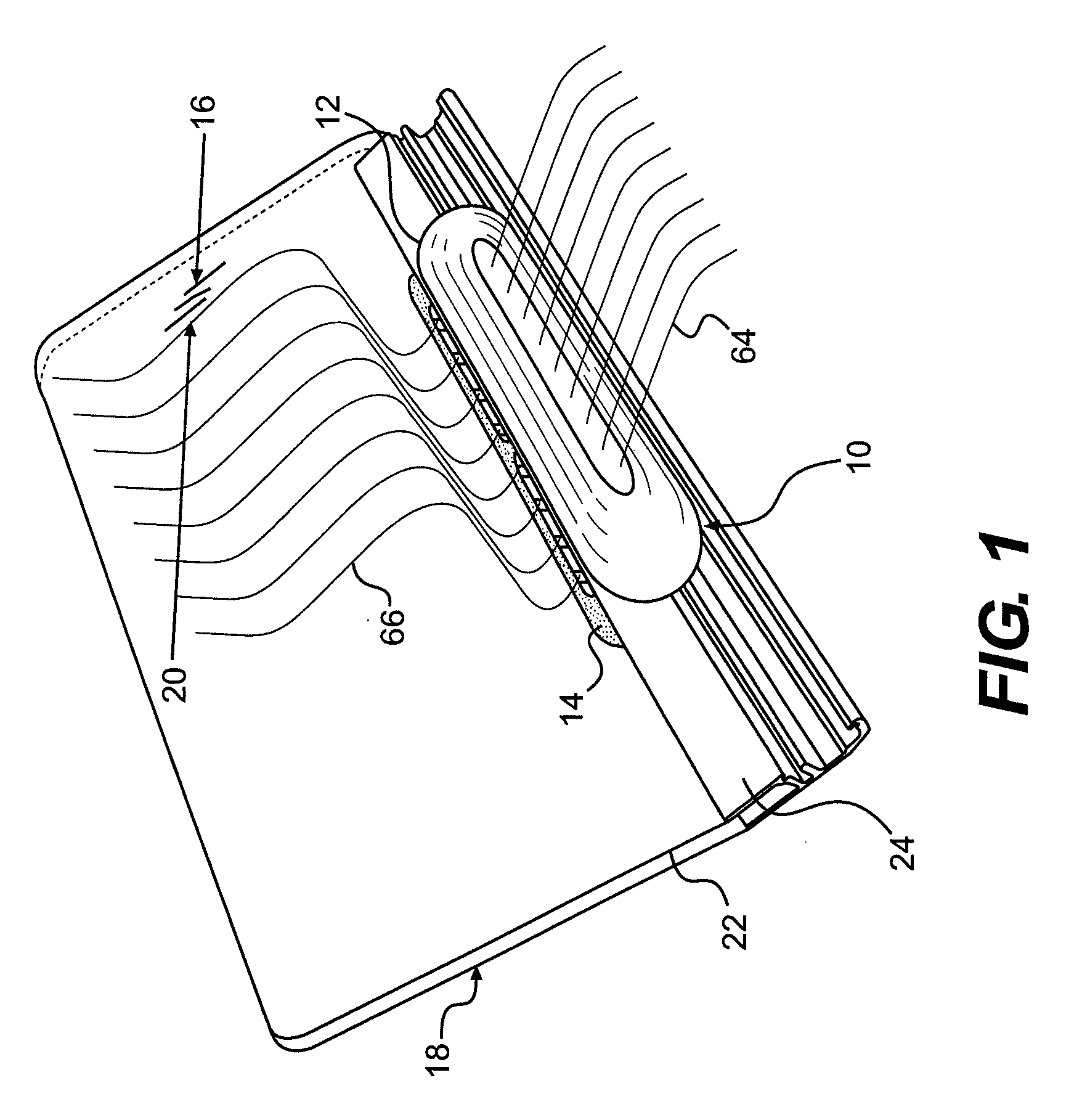

Boat access hatch and seat

ActiveUS8616143B2Prevent water from seeping through the hatchAvoid hard activationOutboard propulsion unitsPropulsive elementsEngineeringFace sheet

Owner:SPORTSMAN BOATS MFG

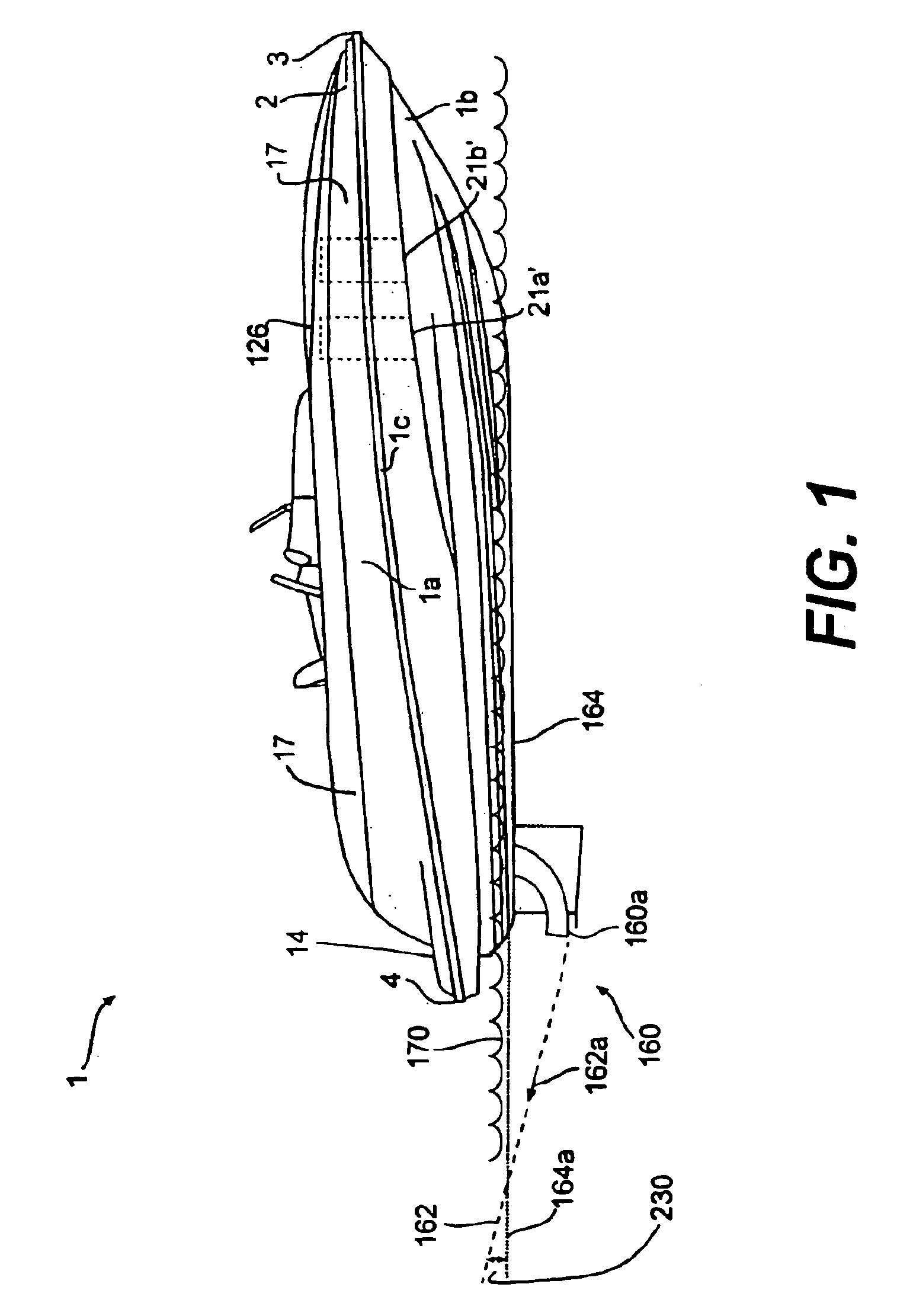

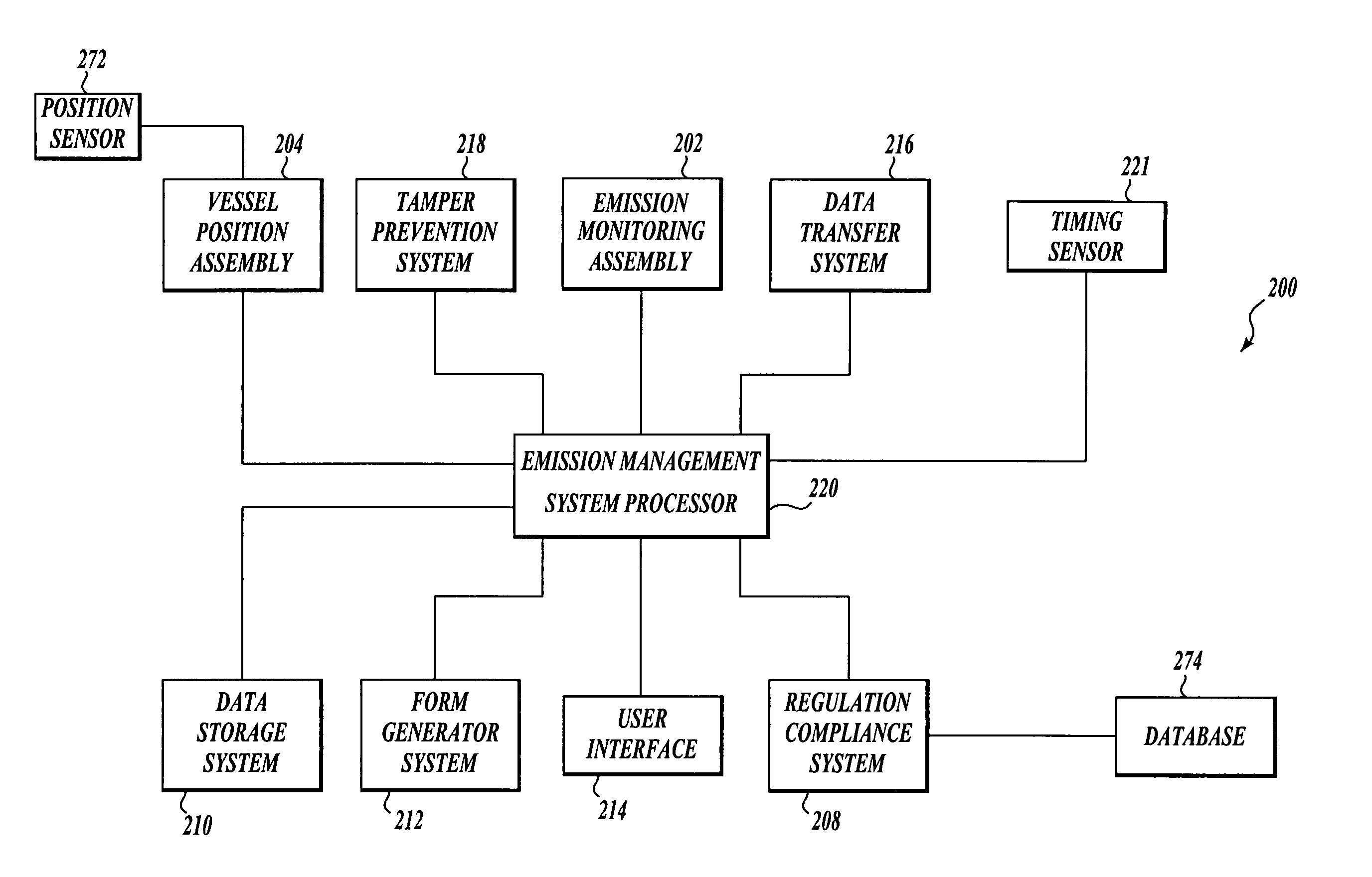

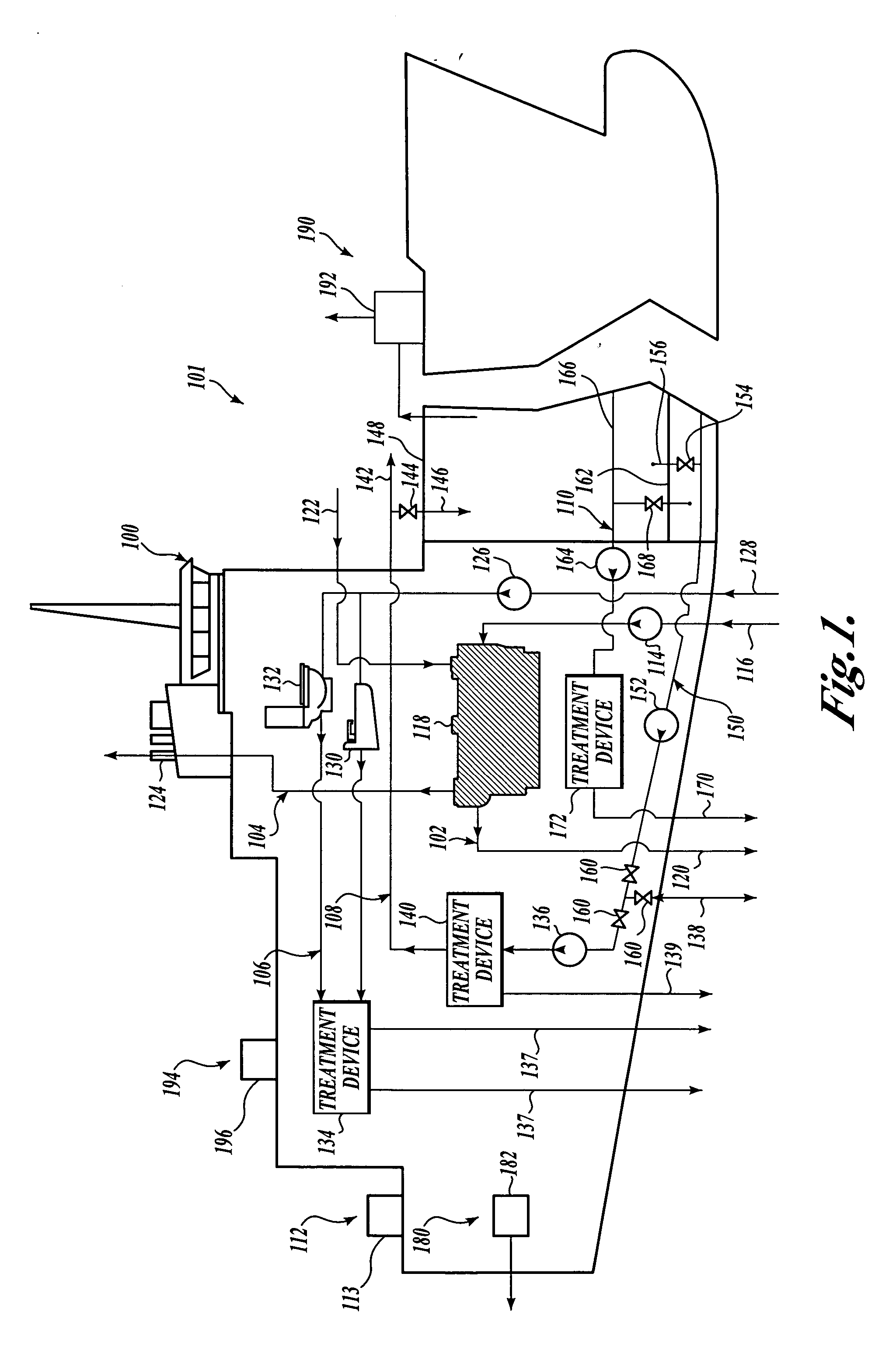

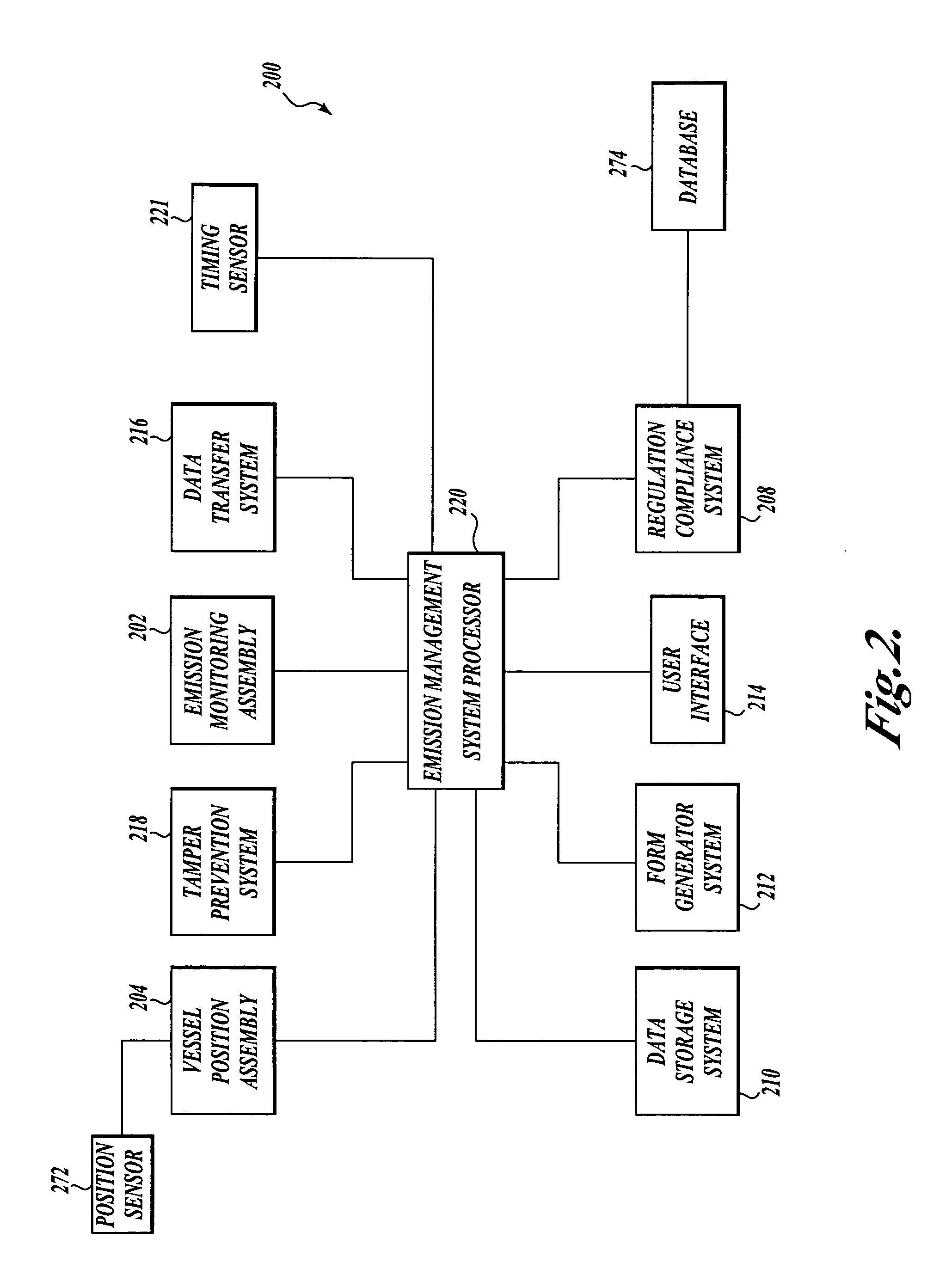

Apparatus and method of vessel emission management

InactiveUS20050165518A1Digital data processing detailsSpecial data processing applicationsData setManagement system

An emission management system (200) for a vessel (100) adapted to travel on water. The emission management system includes a monitoring assembly (202) for monitoring an emission from the vessel. The monitoring assembly is adapted to automatically detect the emission from the vessel and generate a data set representative of a vessel location at a time the emission occurred. The emission management system also includes a data storage system (210) in communication with the monitoring assembly for recording the data set generated by the monitoring assembly.

Owner:GLOSTEN INC

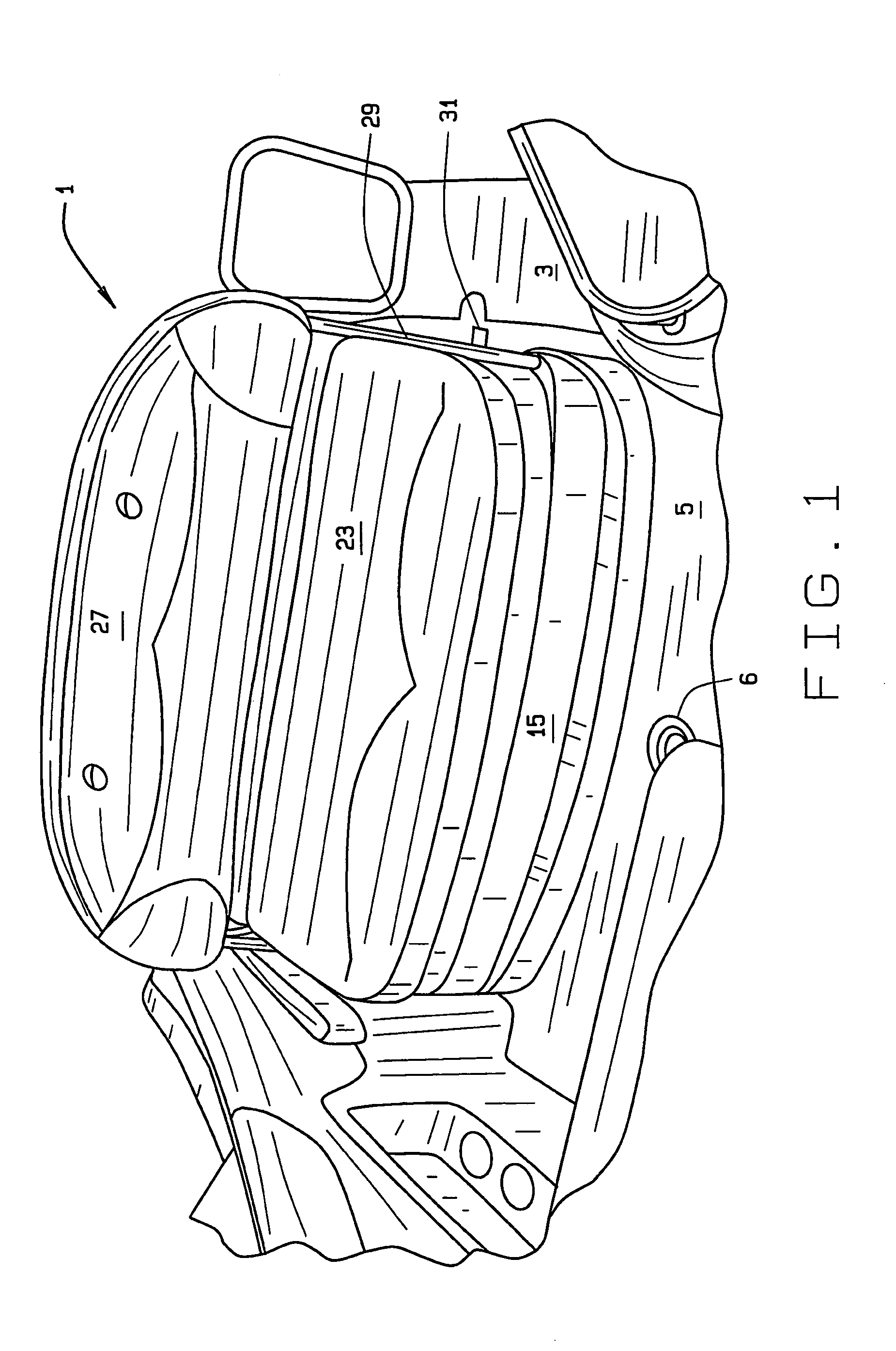

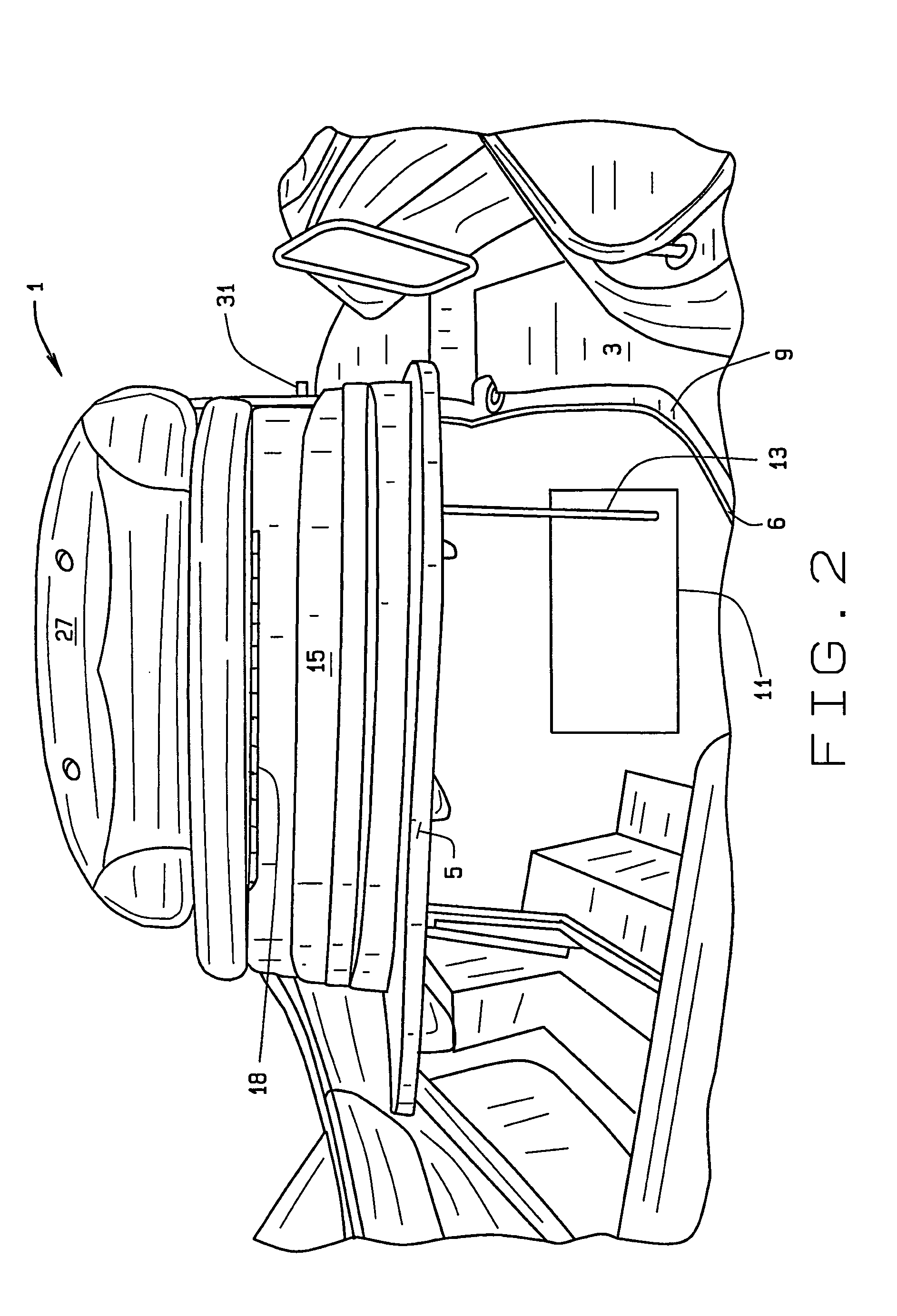

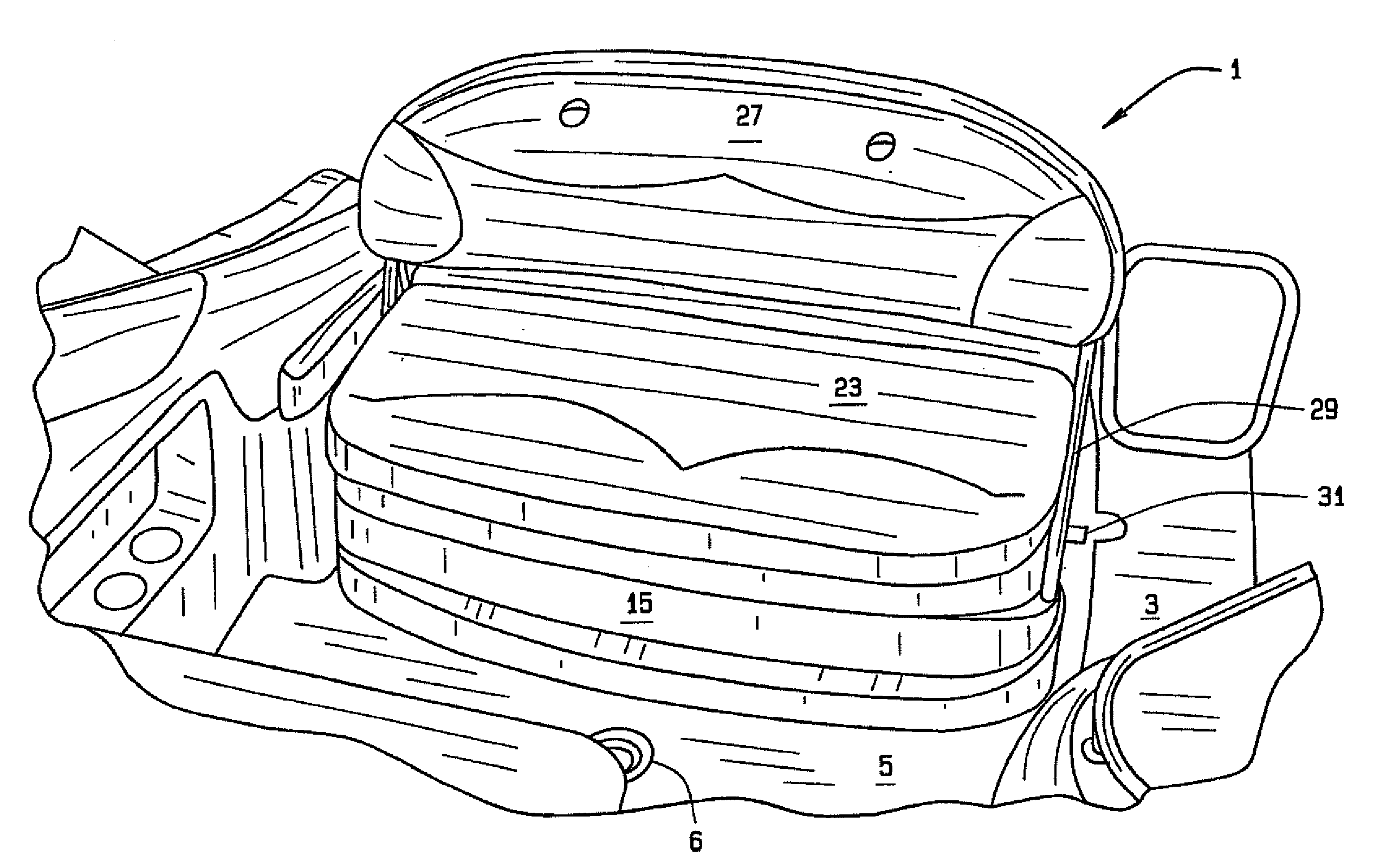

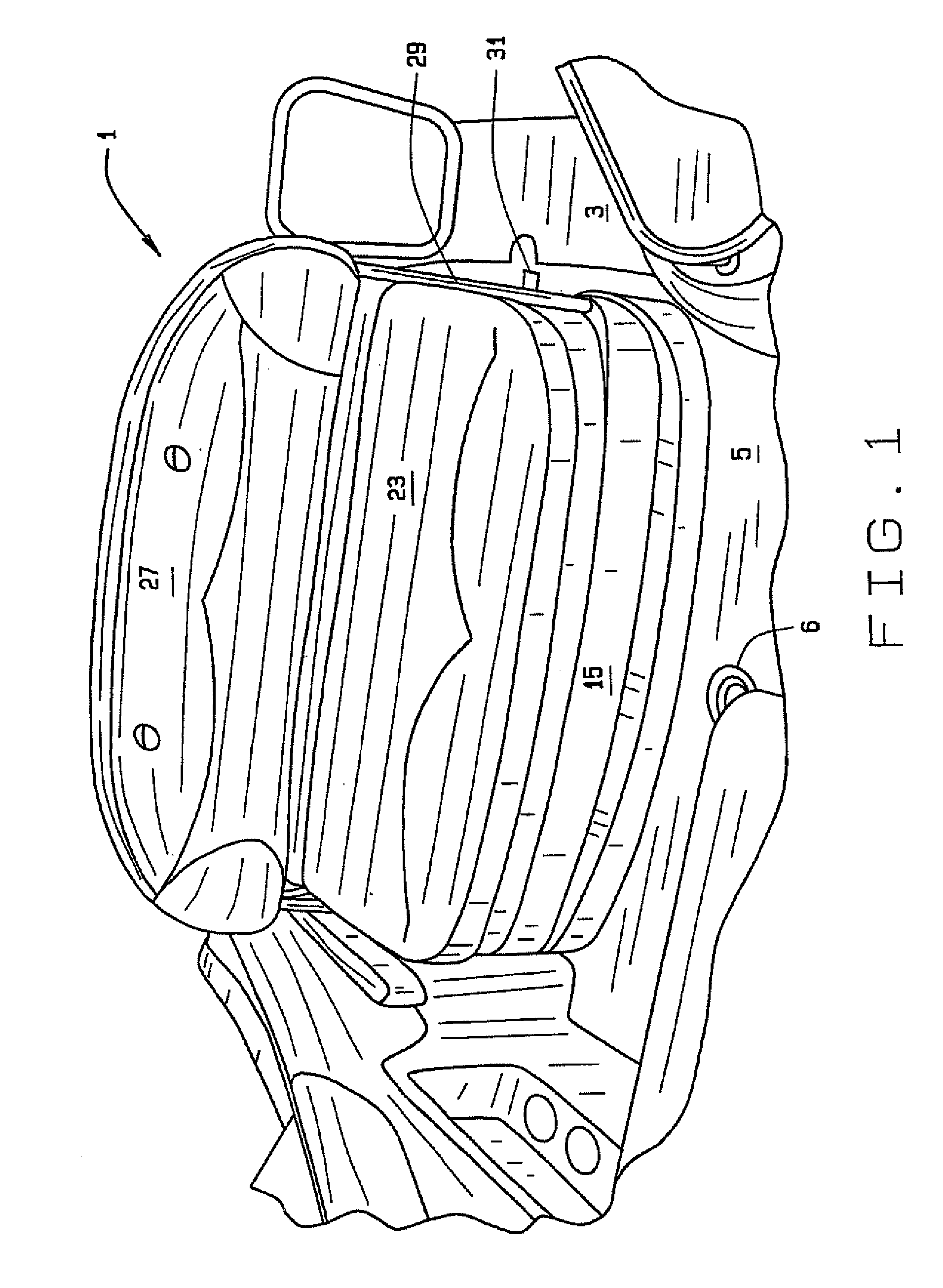

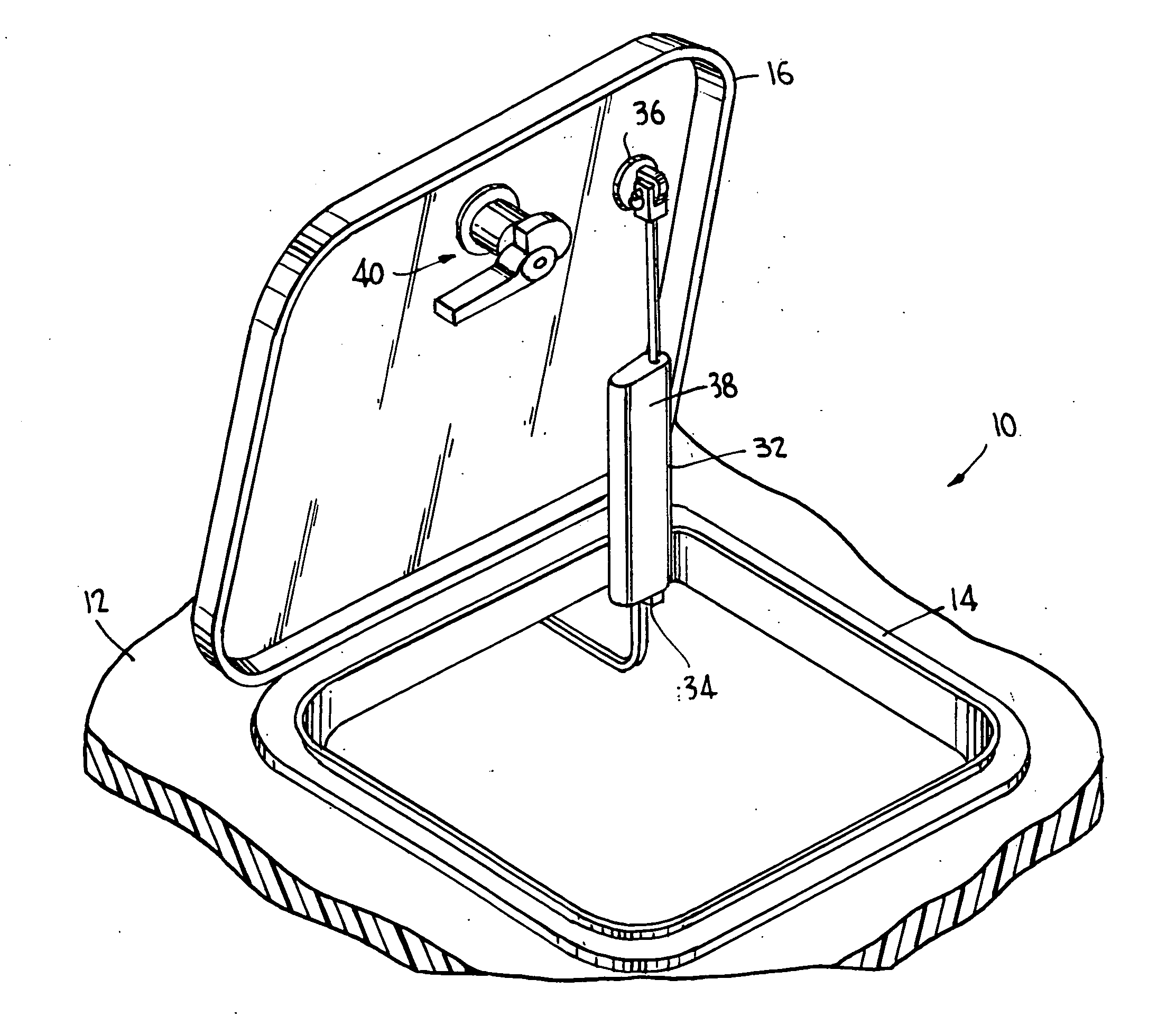

Hatch assembly with seat and storage bin

InactiveUS20080196649A1Cabin furnitureVessel hatches/hatchwaysSitting PositionsMechanical engineering

A hatch assembly for a boat including a base pivotally attached to a boat deck, whereby the base can pivot between an open position and closed position to provide access to a power source within a boat hull. The base defines a storage bin with a compartment for storage. A lid pivotally attaches to the base, whereby the lid can pivot from an open position to a closed position to provide access to the storage bin. A seat attaches to the lid and is supported by the base. A backrest pivotally attaches to the base and pivots between a sitting position and a reclining position.

Owner:KALIL ANTHONY

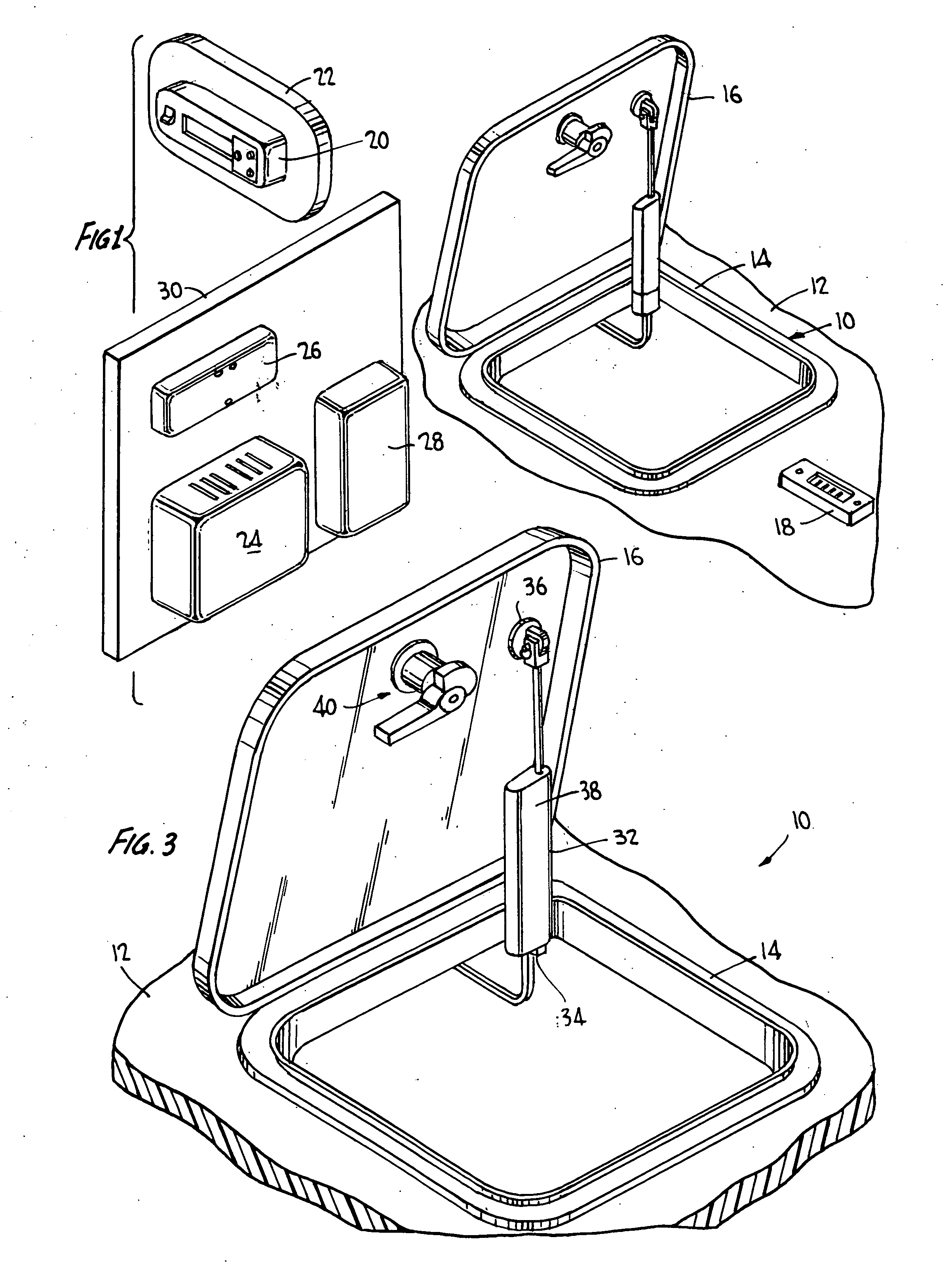

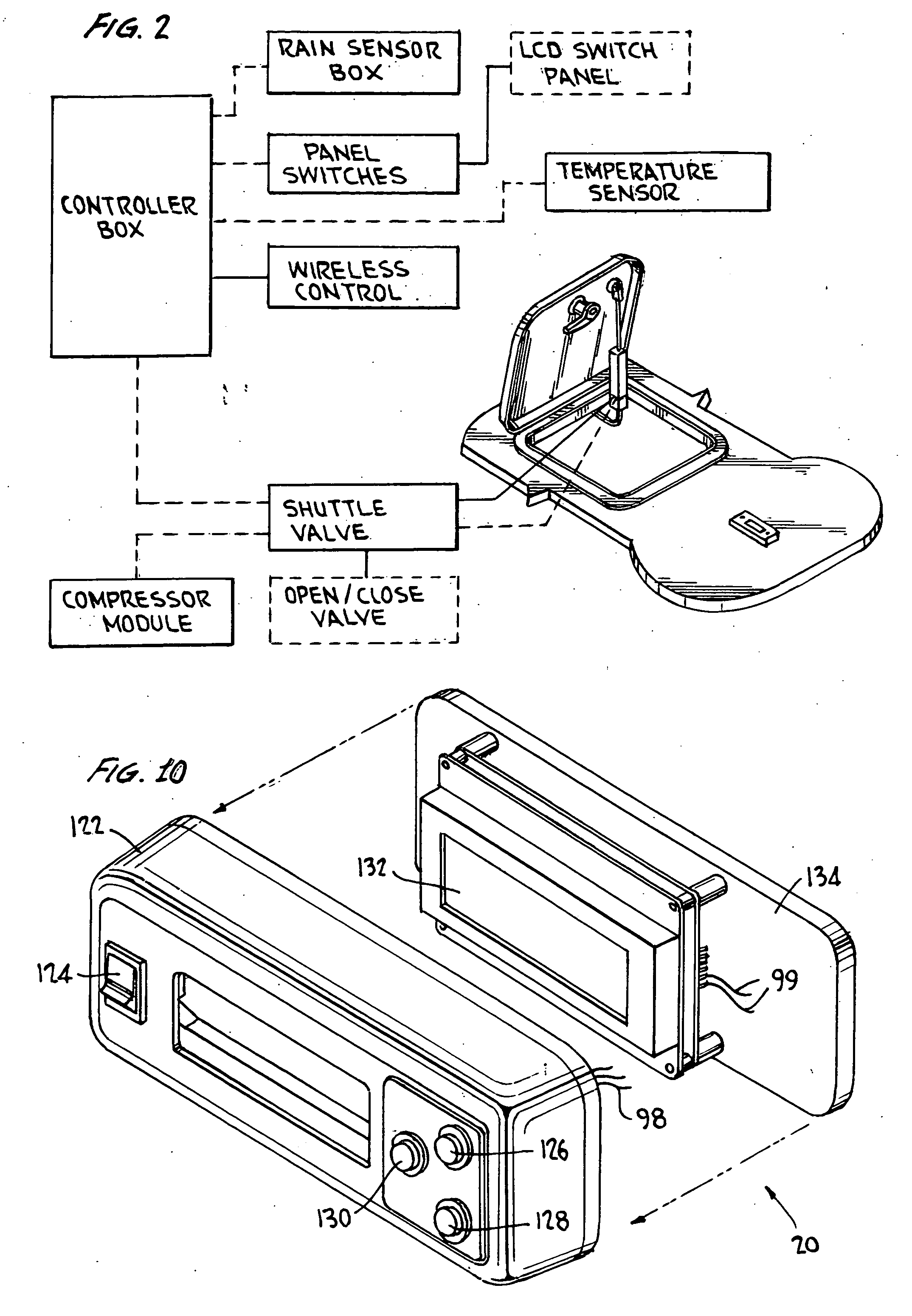

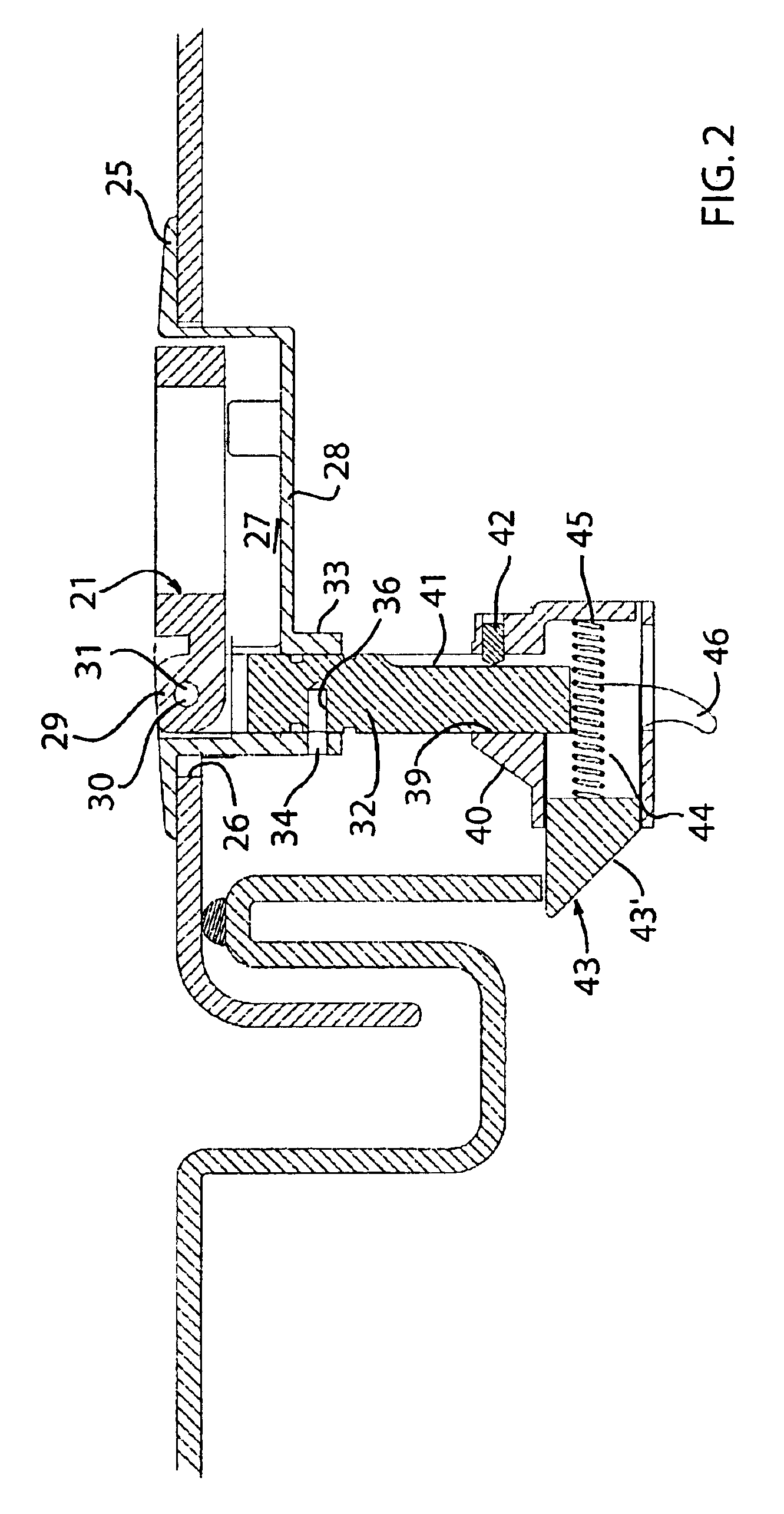

Automatic hatch closer for marine vessels and recreational vehicles

InactiveUS20120072034A1Simple inexpensiveSimple and inexpensive apparatusFlow control using electric meansNon-mechanical controlsMechanical engineeringPneumatic actuator

An automatic hatch system is disclosed. The system includes a hatch frame and a hatch cover connected thereto. A pneumatic actuator assembly is connected to the hatch frame and the hatch cover. The system also includes an automated member for controlling the pneumatic actuator assembly to open, close or adjust the opening of the hatch. The automated member for controlling the pneumatic actuator includes a compressor assembly, a valve assembly, and a controller assembly.

Owner:CATHCART BRUCE C

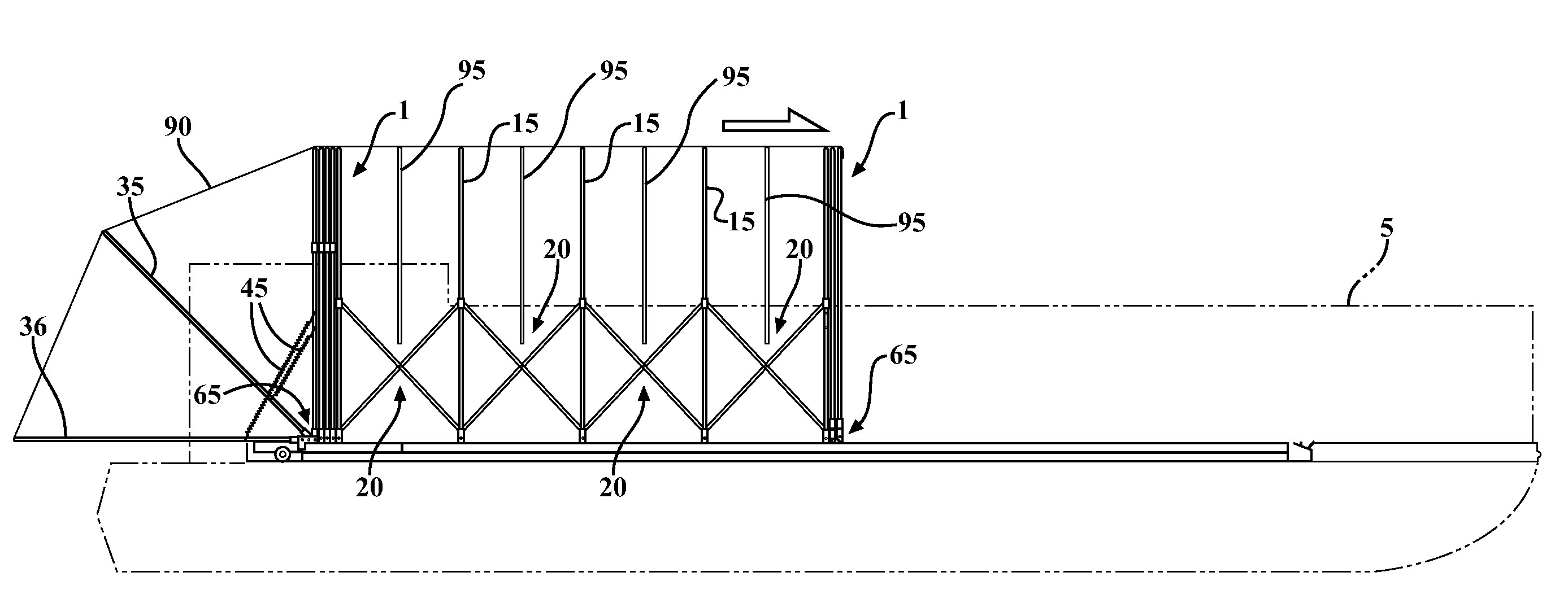

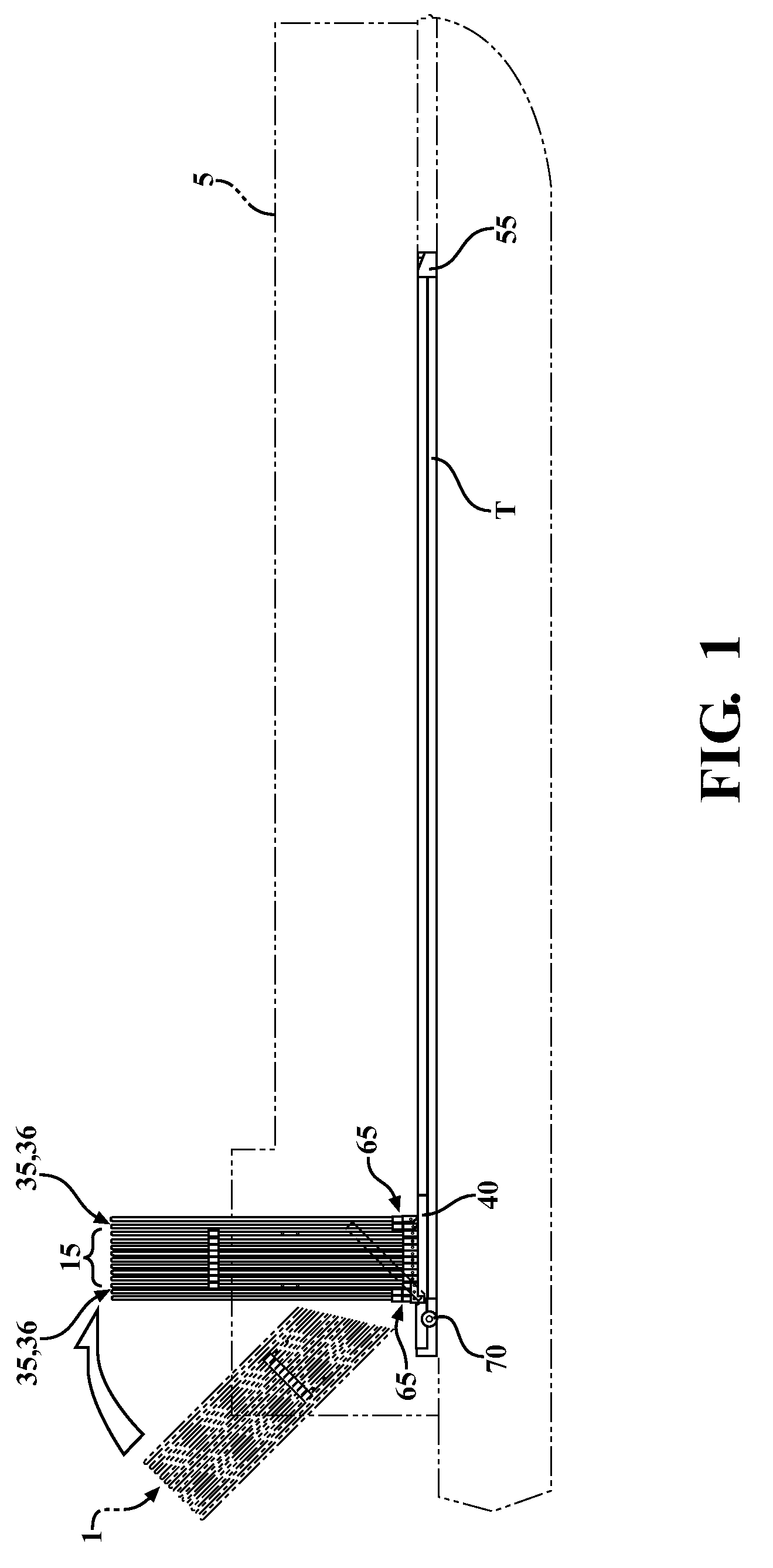

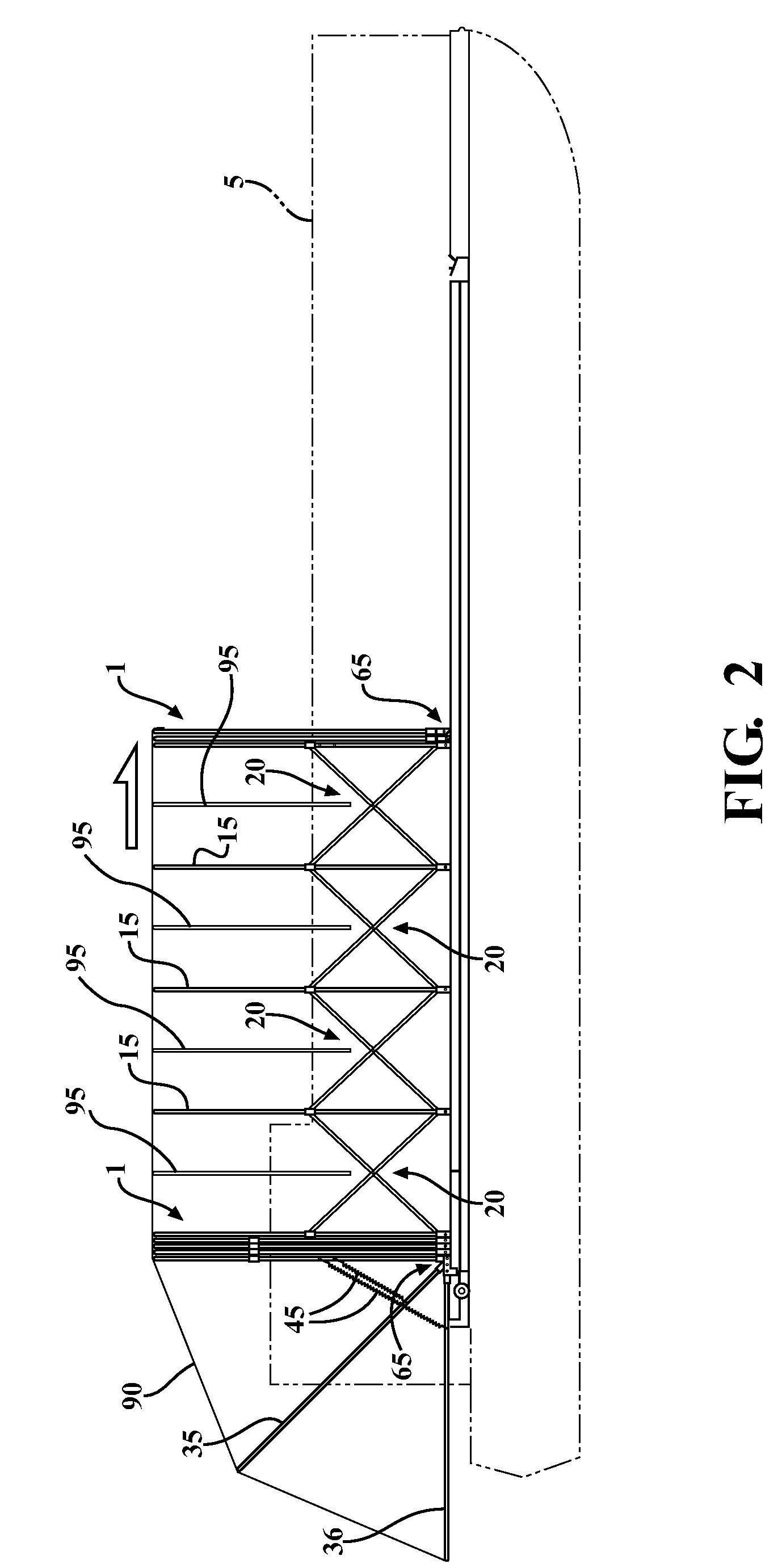

Retractable pontoon boat cover

ActiveUS8359994B1Eliminates unequal side-to-side movementImproved pivot motionFloating buildingsVessel hatches/hatchwaysPontoon bridgeStern

A retractable cover system for a pontoon boat comprising an expanding frame of U-shaped supports sliding in tracks along the sides of the boat, the U-shaped supports interconnected by expanding scissors. The bow and stern ends of the frame are provided with pivoting sections that include horizontal and angled U-shaped supports to define fabric-supporting and fabric-securing structure at the bow and stern of the boat when the frame is fully extended. The retracted frame and fabric cover self-store at the stern of the boat by tilting a pivot station portion of the track rearwardly.

Owner:HIGHFIELD JOHN

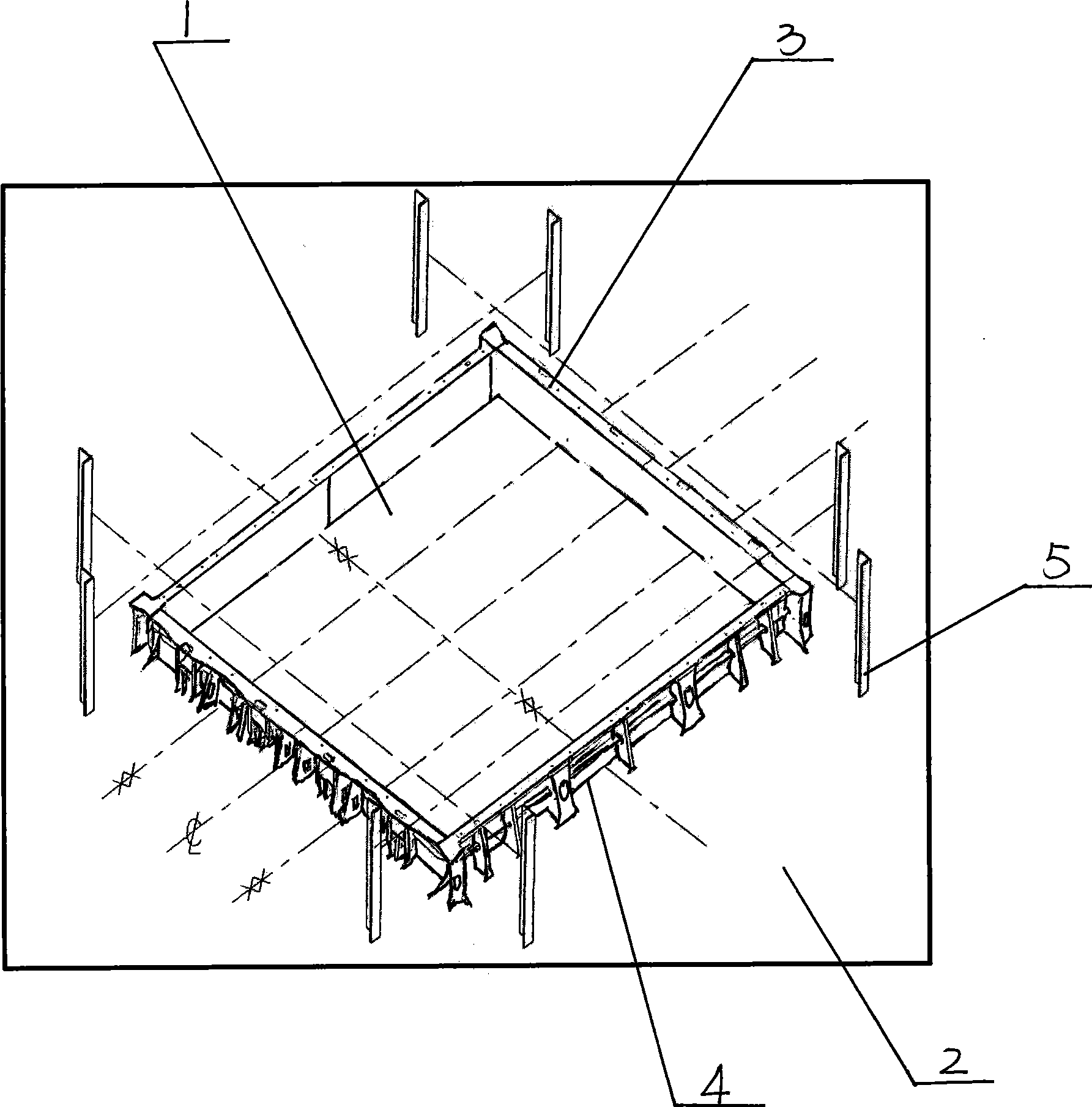

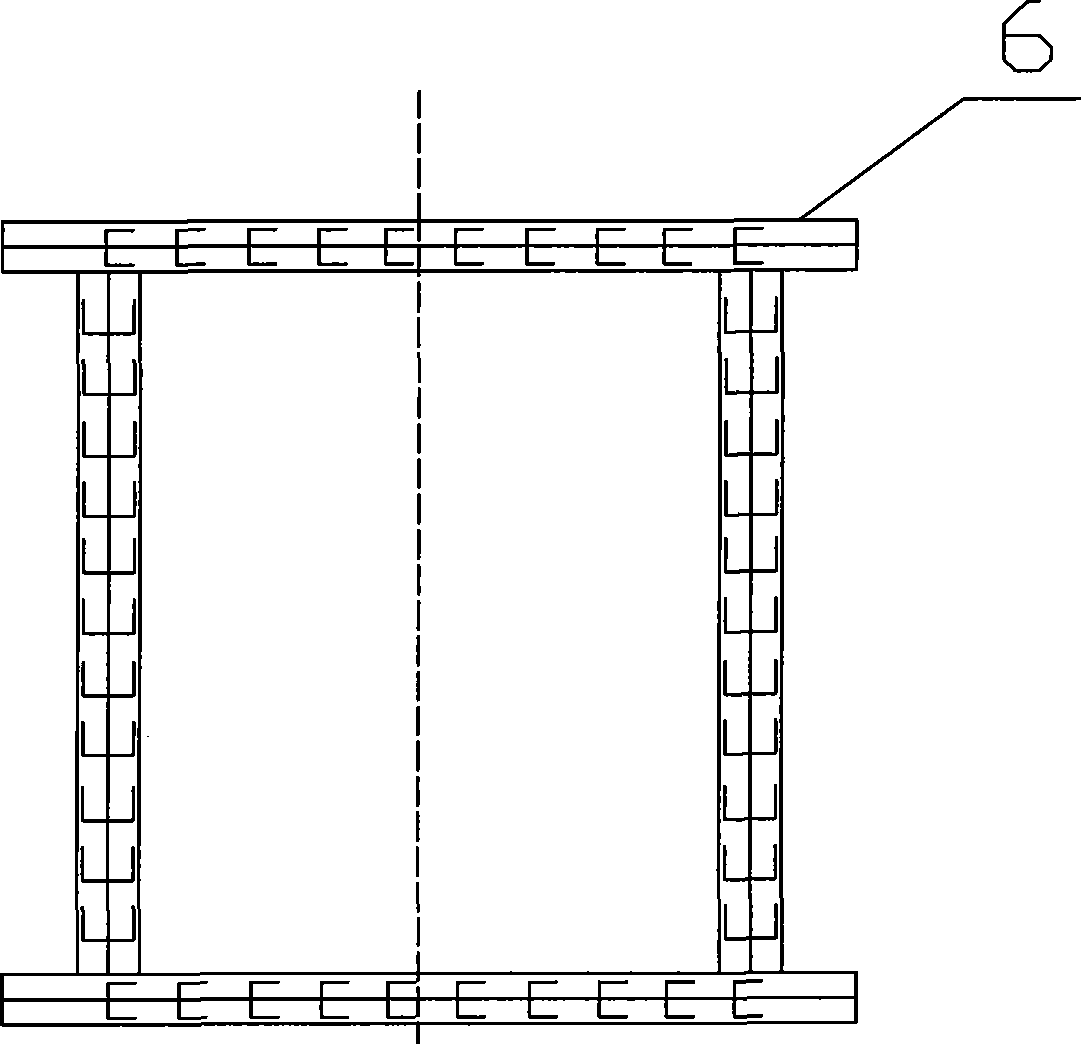

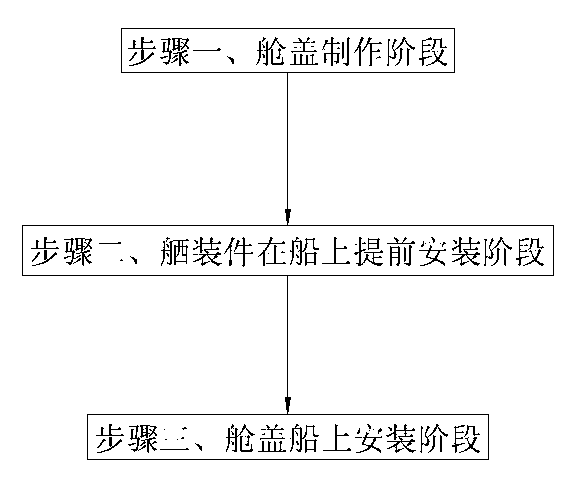

Deck face hatch cover system installing method

ActiveCN104192265AResolve flatness damageReduce repeated liftingVessel hatches/hatchwaysMarine engineeringCovering system

The invention provides a deck face hatch cover system installing method. The method comprises the steps that firstly, hatch covers are manufactured, concretely, longitudinal and transverse center lines and involution lines of the hatch covers are marked; secondly, an outfitting piece is installed on a ship in advance, concretely, longitudinal and transverse center lines and hatch cover theoretical lines of hatch coamings are marked, the positioning size of the outfitting piece is measured, and the outfitting piece is directly assembled and welded before the hatch covers are installed to the ship; thirdly, the hatch covers are installed on the ship, concretely, the hatch covers are hoisted to the ship to correspond to the hatch cover theoretical lines at the front end and the rear end of the upper hatch coaming, separating seams of the port and starboard hatch covers are adjusted to correspond to the longitudinal center line on a hatch coaming panel, and the contact gap between supporting blocks and press depths of rubber strips are adjusted to meet tolerance requirements. By the adoption of the deck face hatch cover system installing method, it can be ensured that the measurement standard needed when the outfitting piece is manufactured and the standard needed when the outfitting piece is preinstalled on the ship are consistent, the period of installing the outfitting piece on the ship is shortened, the percent of pass of installation precision and quality is improved, and hatch cover repeated hoisting and conveying frequency can be reduced.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Process for manufacturing ship hatch cover of ten-thousand-tonnage container ship

ActiveCN102756790AIncrease productivityReduce energy consumptionWatercraft hull designVessel hatches/hatchwaysFillet weldIndustrial engineering

A process for manufacturing a ship hatch cover of a ten-thousand-tonnage container ship belongs to the shipbuilding field and comprises the following steps of: manufacturing an assembly jig; calibrating the levelness of the assembly jig before building and dividing the assembly jig rationally according to the product; lofting and blanking, detailing shrinkage allowance to each part of the hatch cover, and elaborately setting the shrinkage allowance; fabricating parts: dividing the hatch cover into three major assembly areas, requiring that all structures of the part areas are connected through flat fillet weld or butt weld; assembling the structure of the hatch cover, and then checking and meeting various accuracy requirements; mounting a container foot; performing tracking, supervision and measurement by using QC from container seat marking, before welding of the container seats and after welding of the container seats, repairing the unaccepted container seat immediately, and finally performing a container hoisting test to perfectly guarantee the accuracy of the container foot. With the abovementioned process research and improvement, the production efficiency can be improved to a large extent; and compared with the traditional building way, about 8% of energy can be saved for each set and the building period can be shorted by about three weeks.

Owner:浙江扬帆通用机械制造有限公司

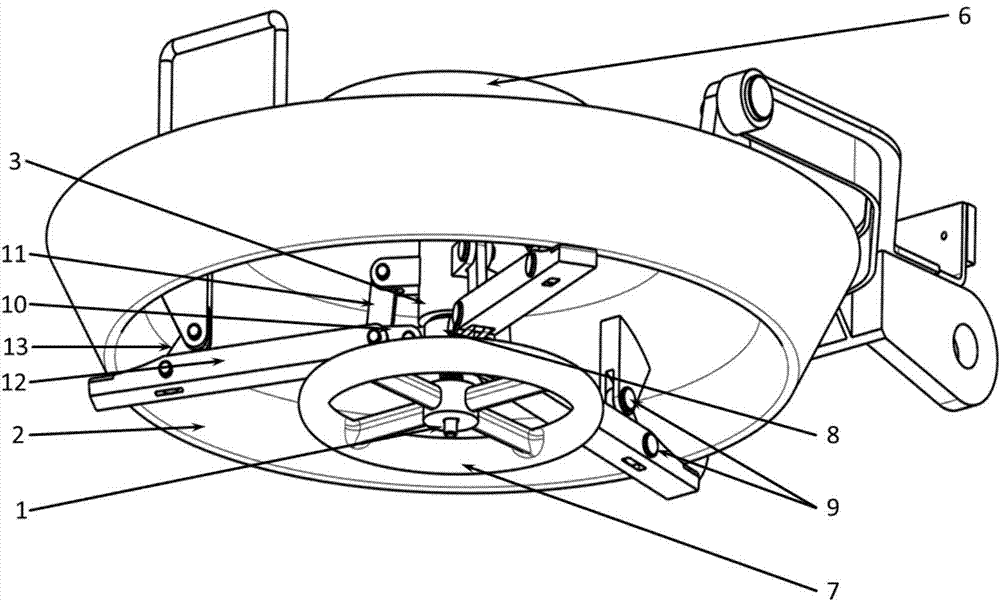

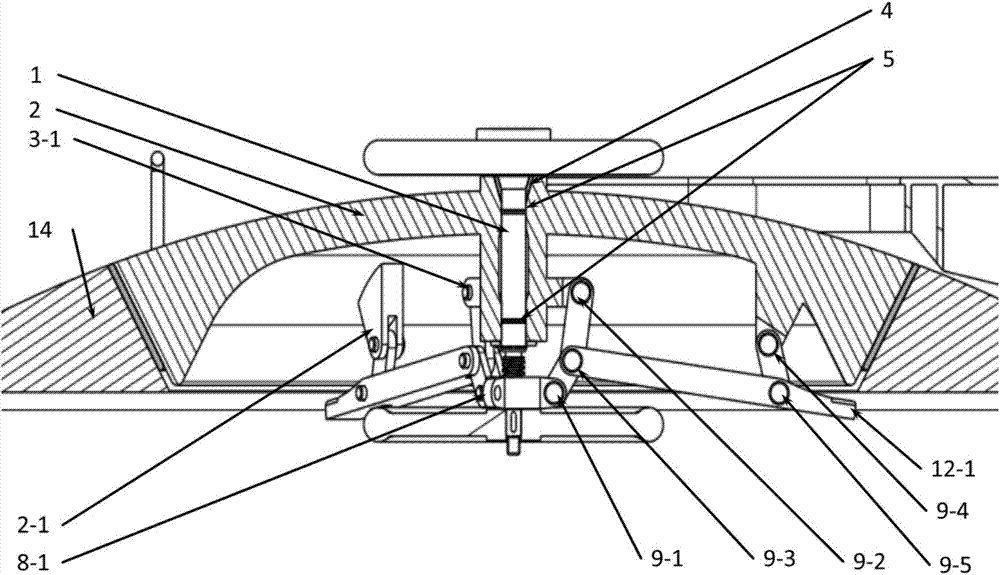

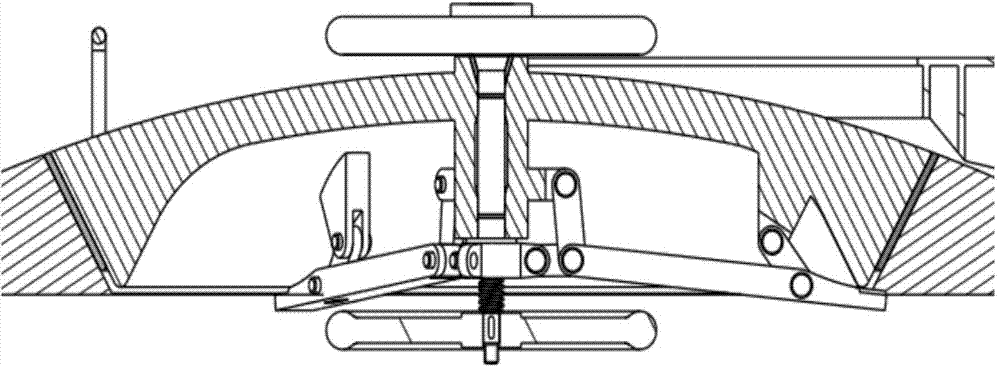

Locking device for deep-sea manned submersible hatch cover

ActiveCN103895817ADoes not destroy the overall strengthReduce difficultyVessel hatches/hatchwaysEngineeringScrew thread

The invention provides a locking device for a deep-sea manned submersible hatch cover. The locking device comprises a rotary shaft penetrating through the hatch cover. A sealing mechanism is arranged among the hatch cover, a shaft sleeve on the hatch cover and the rotary shaft. The two ends of the rotary shaft are provided with an external rotation hand wheel and an internal rotation hand wheel respectively. The rotary shaft is provided with a transmission threaded section, a traction nut is installed on the transmission threaded section, and two to four connecting rod mechanisms are distributed on the traction nut in the equal included angle mode. Each connecting rod mechanism comprises a short traction rod, a long traction rod, a locking rod and a supporting rod, wherein one end of each short traction rod is hinged to the traction nut, one end of each long traction rod is hinged to the shaft sleeve on the hatch cover, the other end of each short traction rod and the other end of the corresponding long traction rod are hinged to the rear end of the corresponding locking rod, the front middle portion of each locking rod is hinged to one end of the corresponding supporting rod, the other end of each supporting rod is hinged to the hatch cover, and the front end of each locking rod is a locking end. According to the locking device, a pressure-resistant shell structure is not damaged, even and reliable pressing force can be provided, and the locking device is used for locking the deep-sea manned submersible hatch cover.

Owner:哈尔滨哈船特装科技发展有限公司

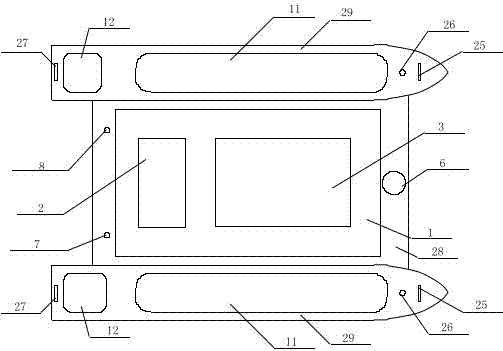

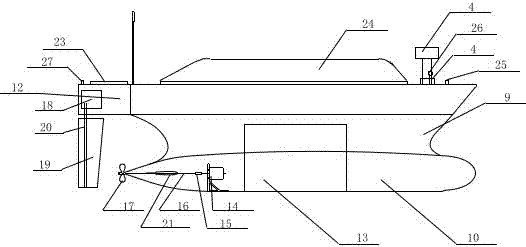

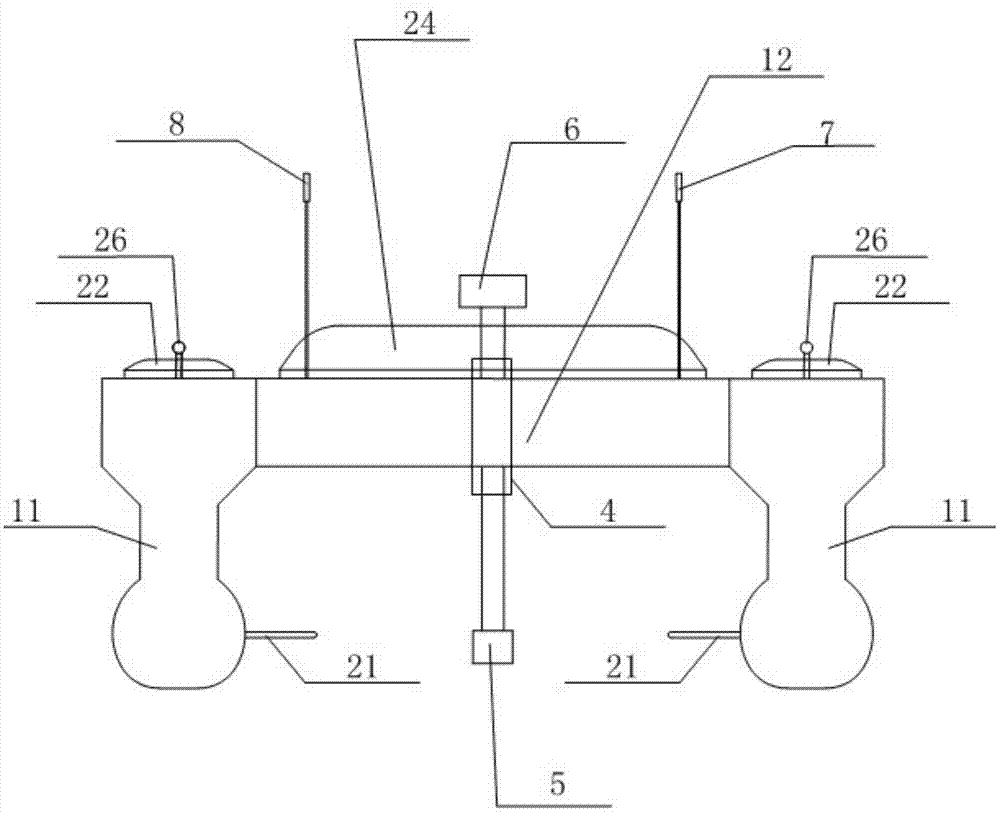

Unmanned intelligent surveying vessel

ActiveCN103661818AReduce swayReduce wave resistanceVessel hatches/hatchwaysHydrodynamic/hydrostatic featuresUnderwater explosionMarine engineering

The invention discloses an unmanned intelligent surveying vessel which comprises a vessel body, a thrusting device installed in the vessel body, a manipulator, a control system, a surveying system and a power-supply device. The vessel body comprises a body and side bodies symmetrically arranged at the two sides of the body. Each side body comprises an over-water portion, a hollow strut penetrating through the water surface and an underwater float bowl from top to bottom. The cross section of each underwater float bowl and the cross section of each strut are respectively of a vase shape with the narrow upper portion and the wide lower portion, the longitudinal section of each strut is of a shape with the thick middle portion and the two sharp ends, the head portion of each float bowl is oval, the tail portion of each float bowl is tapered off gradually and is of a smooth streamline, and the bottom face of each float bowl is parallel to the body. According to the unmanned intelligent surveying vessel, the novel double-body vessel type design is adopted, the underwater portion of each side body and the over-water portion of the side body are connected through the corresponding hollow strut with the thin and long streamline section, so that when surveying is conducted, the navigational speed is higher, the swinging degree of the vessel body is greatly reduced, and the efficiency and the accuracy of surveying are greatly improved.

Owner:南京白鲨测绘科技有限公司

Modular kayak with elevated hull voids

A sit-on-top kayak hull having an elevated void in the area between the normal seated position of a paddlers legs. The elevated void which is formed into the hull of the watercraft and extends there-through to a height above the normal laden waterline generally to a level of the approximate height of the gunwales forms a hole in the craft which is surrounded by walls. Various modules may be inserted into the hull void for varying needs, such as storage modules, clear modules for underwater vision, or flotation modules. The hull void additionally allows for changes in the running surface of the kayak by insertion of rudders, skegs, centerboards or other devices The void may be left open in full or part for egress of scuba hoses, anchors or other marine devices without affecting the structural integrity of the kayak, its buoyancy, or adversely affecting its performance.

Owner:611421 ONTARIO INC

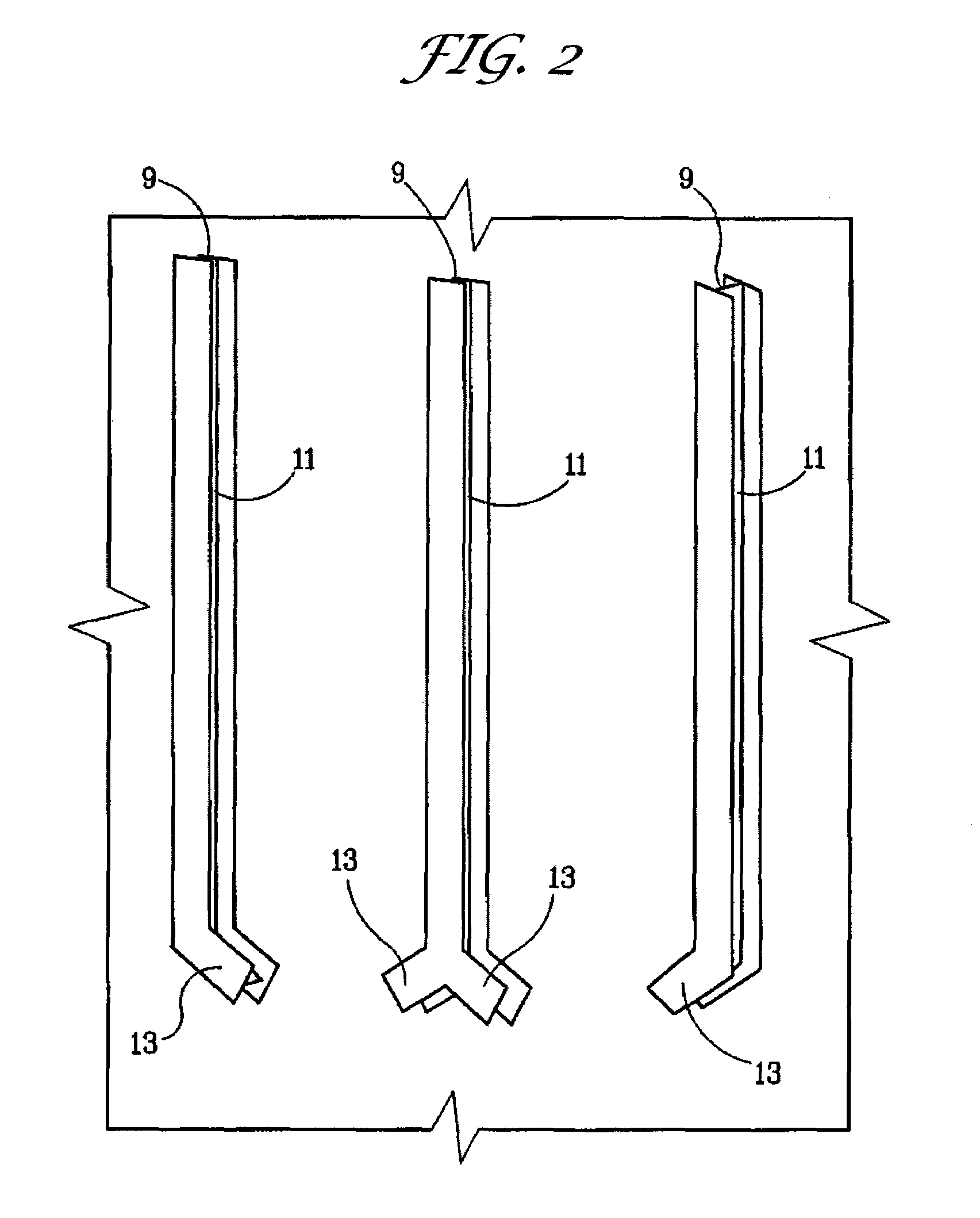

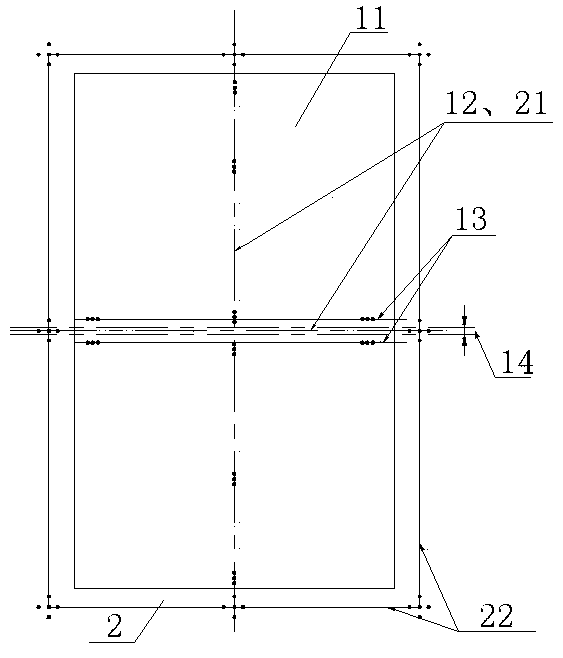

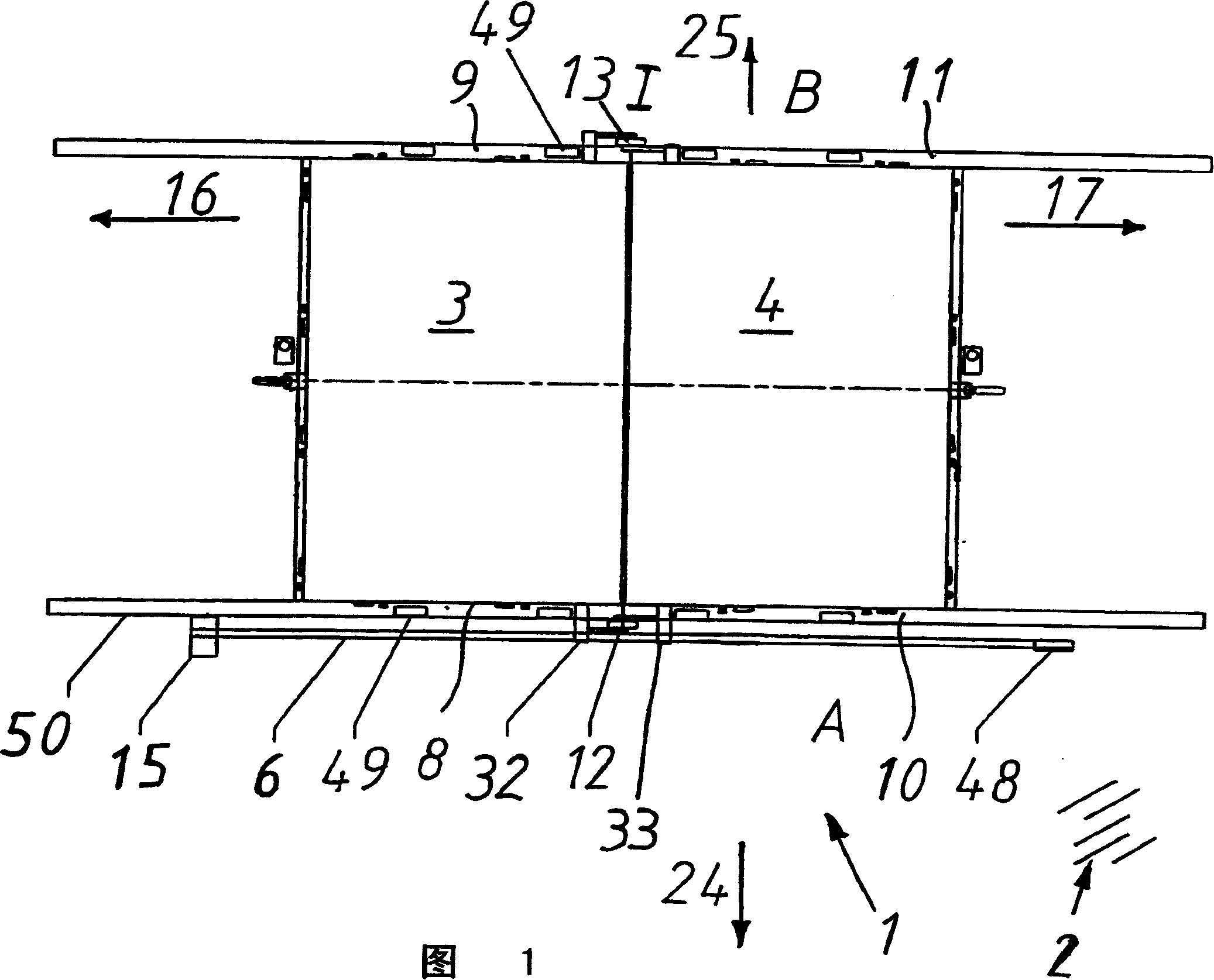

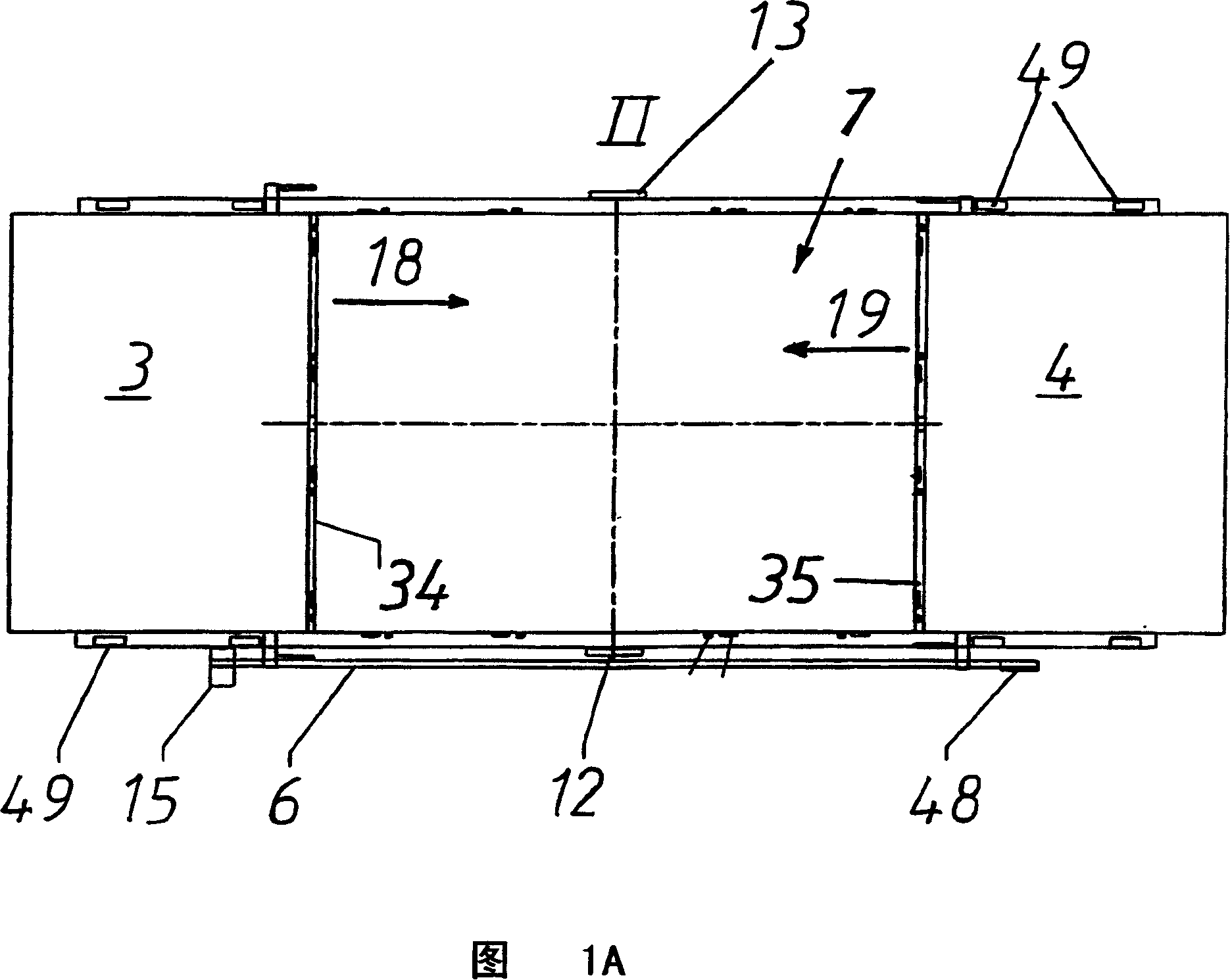

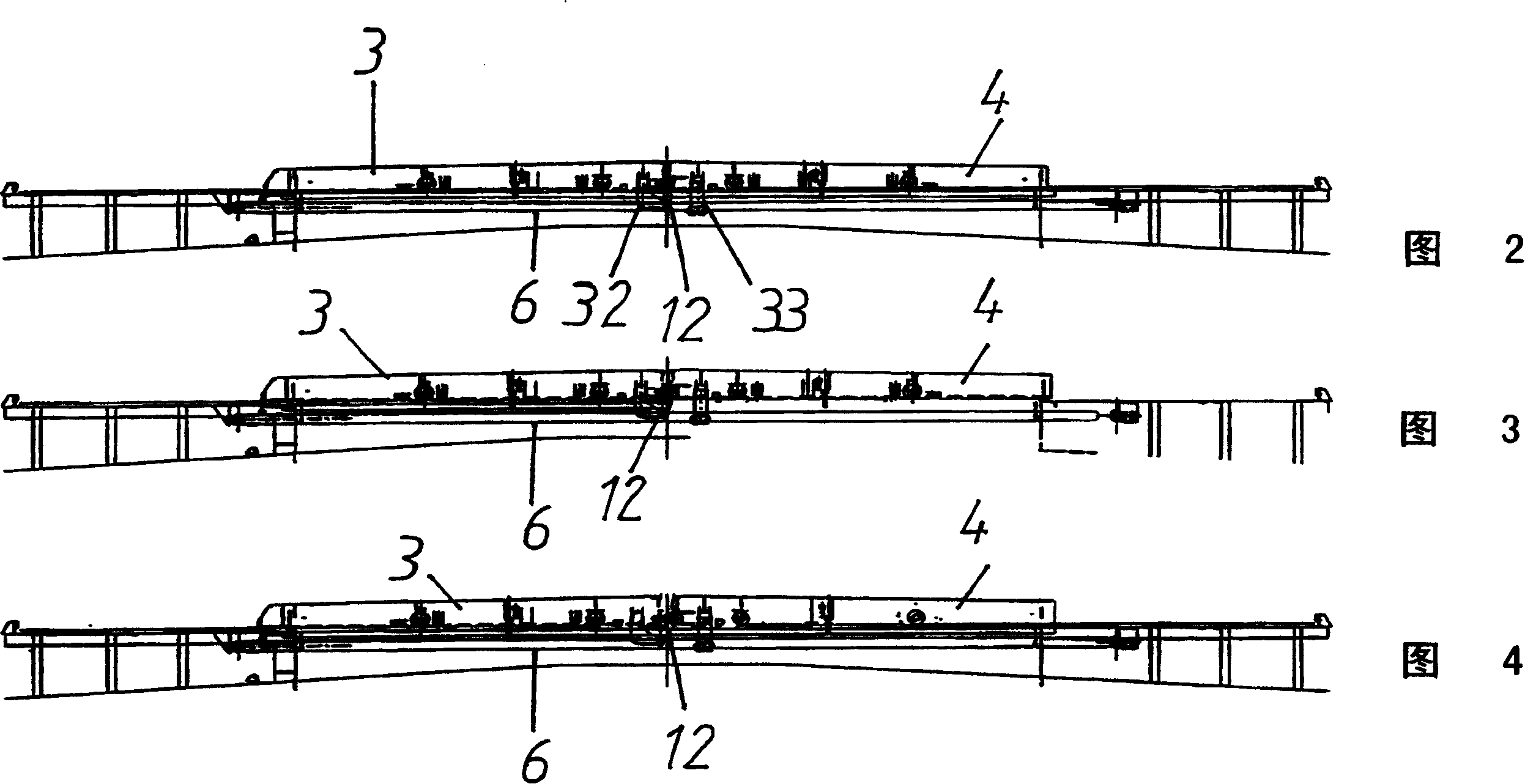

A device at hatch covers

The invention relates to a device (1) at a mechanism in order to effect the operation of displaceably movable hatch covers (3, 4) of ships (2) between a closed (I) and an open (II) position and between an open position (II) and a closed position (I) , respectively, and that comprises actuating means connecting with the respective hatch cover (3, 4). According to the invention, the respective hatch cover (3, 4) is connected to, for instance, a loop- shapedly running, driven pulling rope (6) , as well as that on either side (A, B) of the lateral limiting edge (8, 9 and 10, 11, respectively) of the hatches, there is provided a turnably mounted actuating element (12, 13) , which is detachably inter- connectable with the respective hatch cover (3, 4).

Owner:TTS SHIPS EQUIP AS

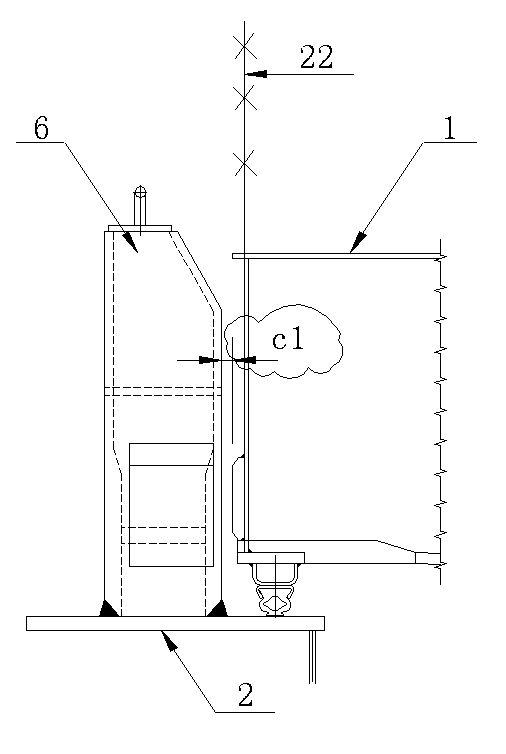

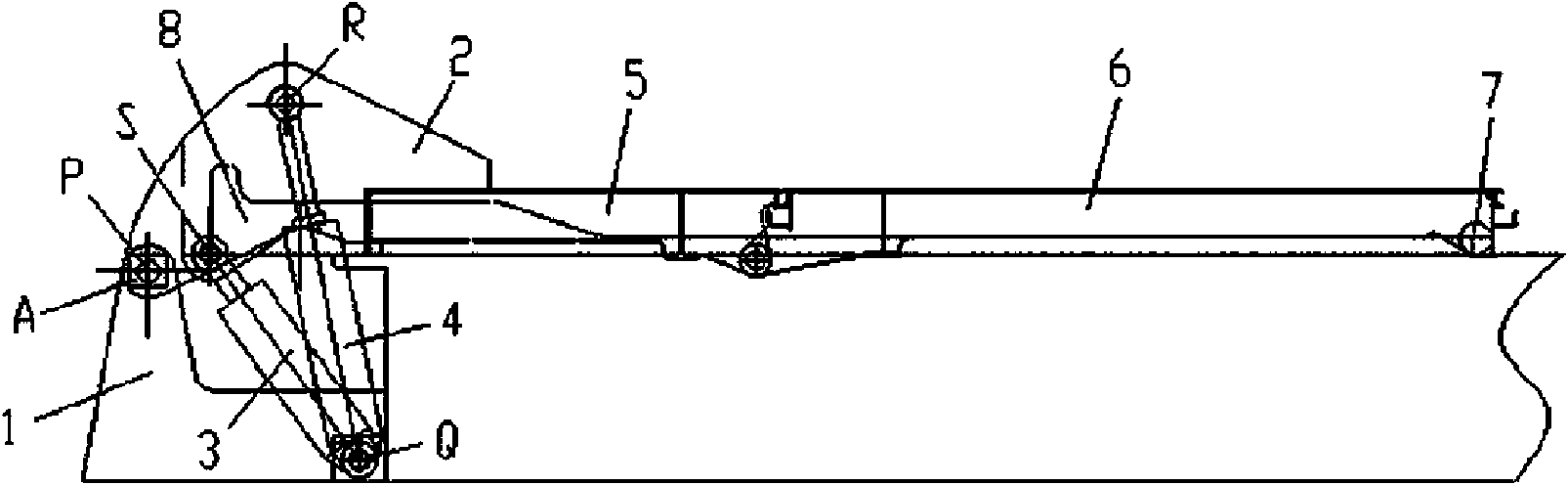

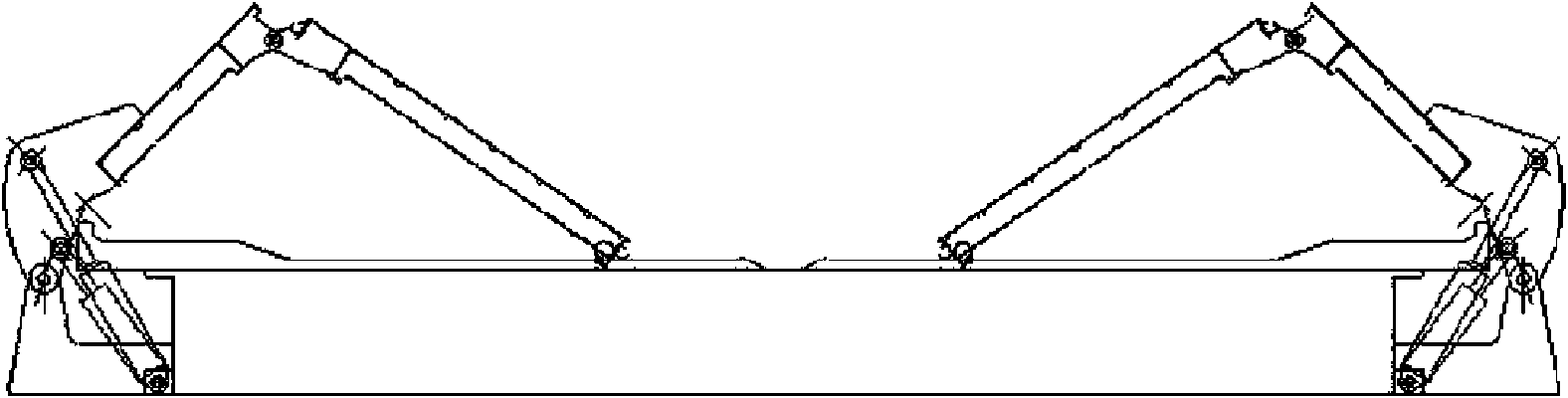

Ship hatchcover opening device

InactiveCN101618754ALower the altitudeWeakening rangeServomotor componentsServomotorsPulp and paper industryIdler-wheel

The invention relates to the technical field of hydraulic drive, in particular to a hydraulic hatchcover opening device applied to a large ship, comprising an active hatchcover, a follower hatchcover and an installation seat arranged at the side of a hatchway, wherein the installation seat is hinged with a turning cover which is fixedly connected with one side end of the active hatchcover, and the other side end of the active hatchcover is hinged with the rear side end of the follower hatchcover; the front side end of the follower hatchcover is provided with a hatchcover idler wheel, and an idler wheel moving rail is correspondingly arranged at the periphery of the hatchway; a first oil cylinder and a second oil cylinder which are provided with oil by a double oil cylinder hydraulic control device are connected between the installation seat and the turning cover; the lower ends of the first oil cylinder and the second oil cylinder are coaxially hinged to the installation seat, and the lower end parts of piston rods of the first oil cylinder and the second oil cylinder are respectively hinged with different connected parts on the turning cover so that the turning cover turns outwards or inwards under the matching action of the double oil cylinders. The device not only lowers the opening height of the hatchcover, but also has little occupation area of the opened hatchcover, compact structure and good use effect.

Owner:陈桂晖

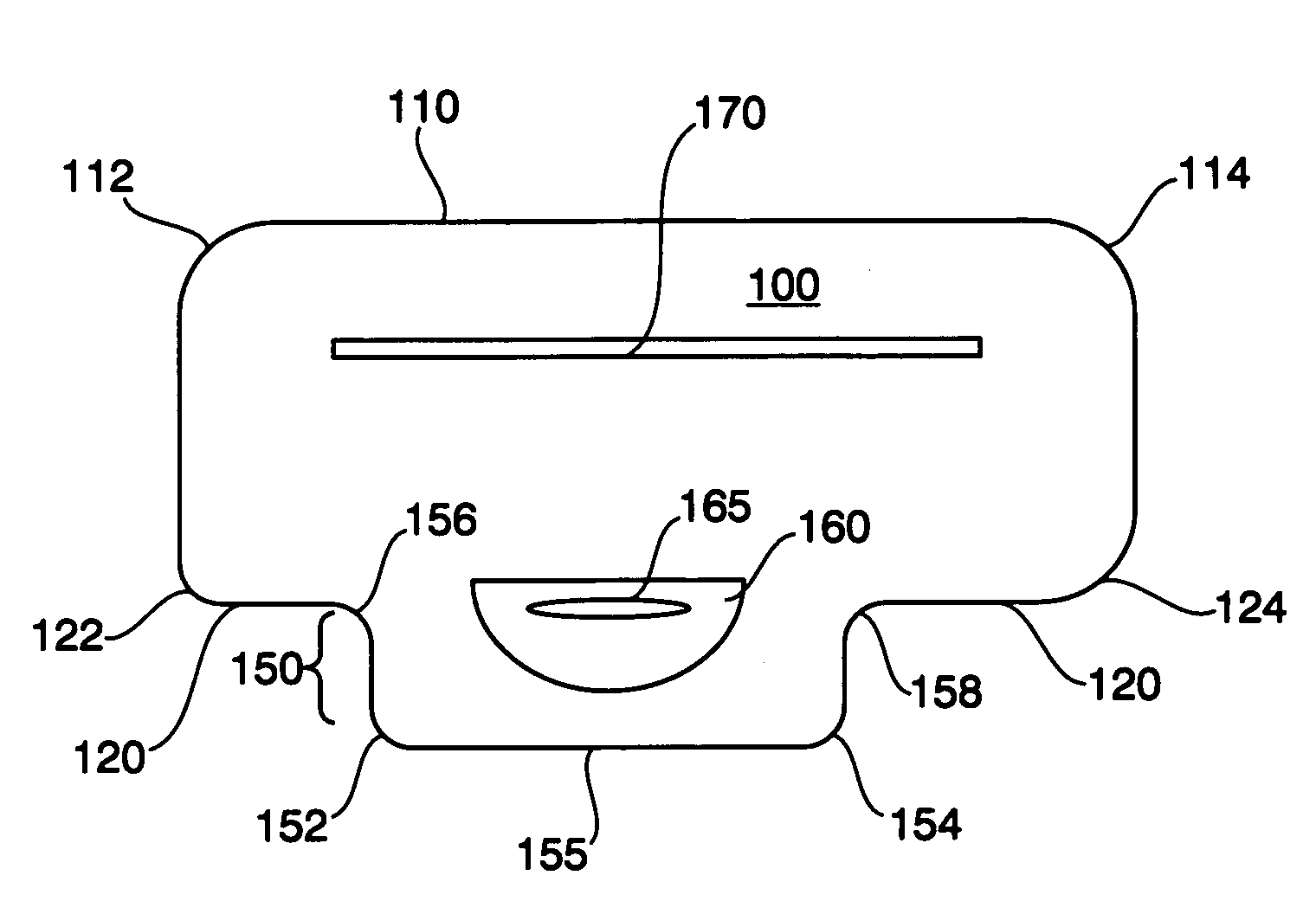

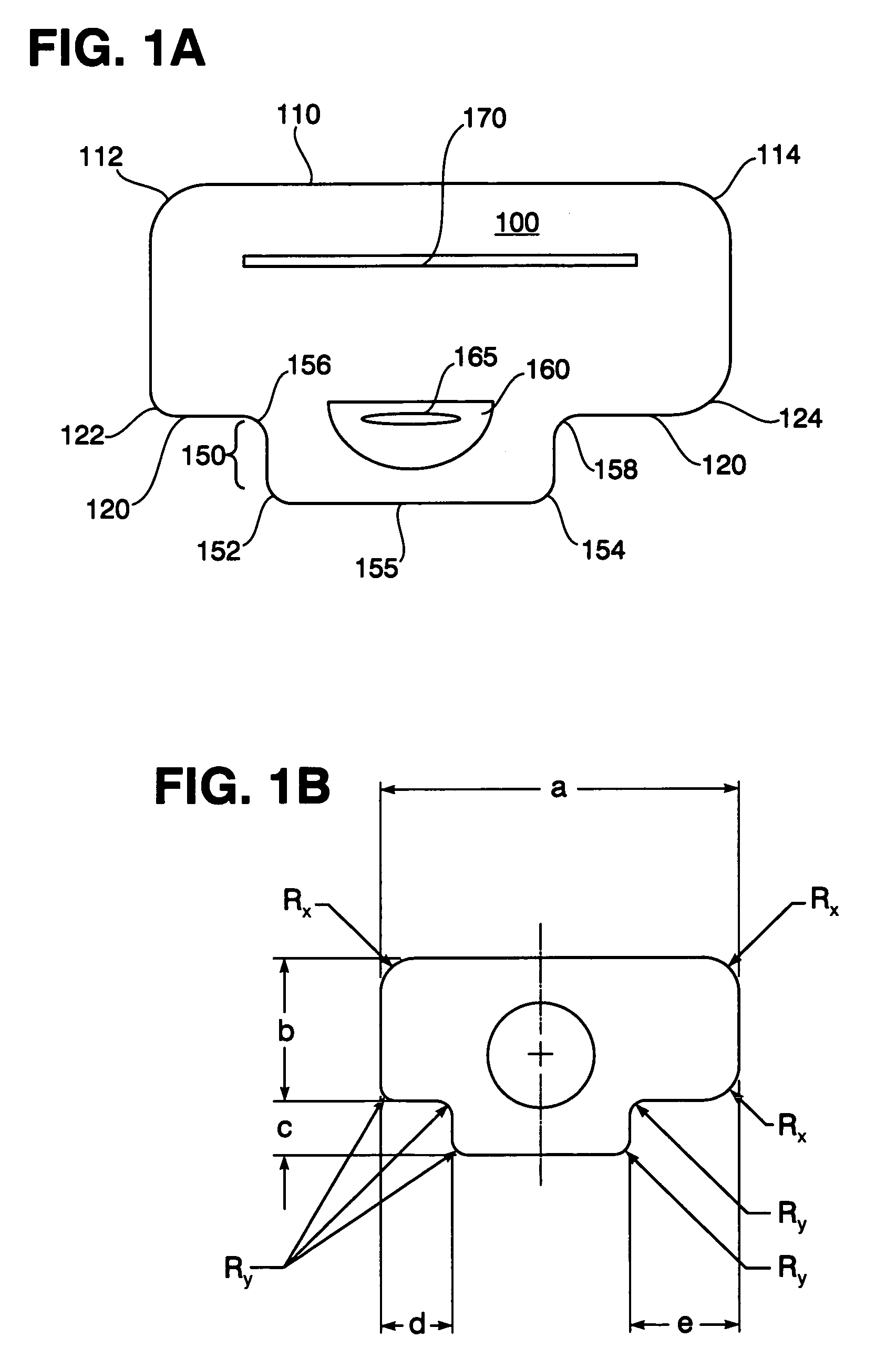

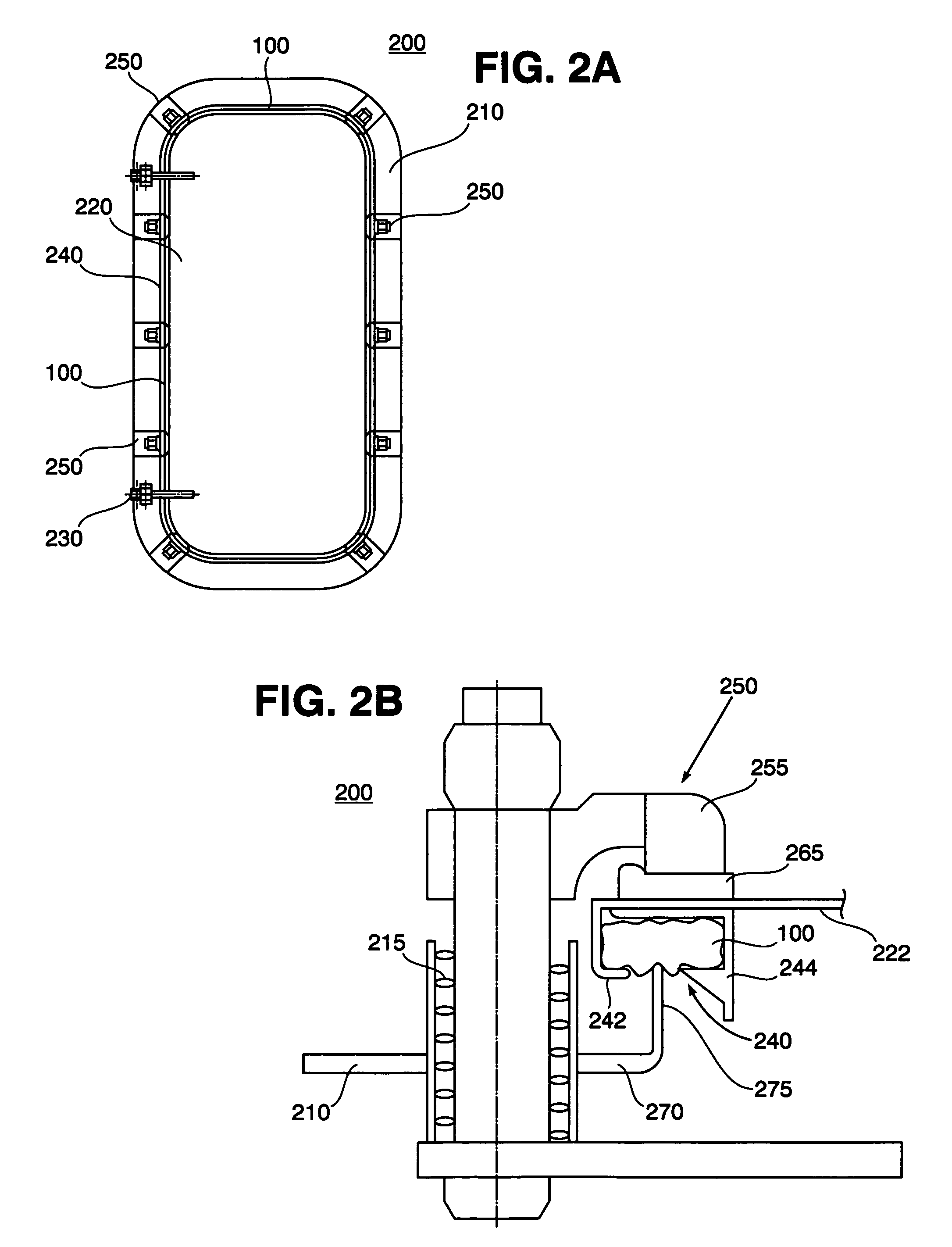

Vessel platform with integrated seating

ActiveUS8899169B1Maximizes usable platform spaceCargo handling apparatusPassenger handling apparatusMechanical engineeringEngineering

A platform for a vessel that includes integrated and stowable seating. The platform comprises a platform surface, at least one seating recess, and at least one seat back panel. The seating recess is disposed below the platform surface. The seat back panel has an inner surface and an opposing outer surface and is pivotably attached to the seating recess to provide a plurality of operative positions, including an open seating position and a closed position. In the closed position, the outer surface of the seat back panel is substantially flush with respect to the platform surface, providing a continuous and unobstructed boarding / swimming platform. The open seating position provides an aftward seating configuration. Both the seating recess and seat back panel can removably receive cushions for added comfort and support of the user. The configuration maximizes usable platform space when the seat back panels are closed.

Owner:BRUNSWICK CORPORATION

All purpose seal

InactiveUS7451714B1Construction fastening devicesSealing arrangementsSilicone rubberElectrical and Electronics engineering

An apparatus for sealing a doorway, more particularly, an all purpose gasket structure capable of sealing a doorway against the entry of water, smoke, and fire. The gasket is primarily an elongated silicone rubber structure having a ridged rectangular cross section for mounting to a gasket retainer. The gasket also includes a crush zone which collapses inwardly when pressure is applied to the gasket surface, resulting in improved sealing and the blockage of water intrusion paths. The gasket may further include an intumescent section within the elongated silicone rubber structure. In the sealing arrangement, the gasket is arranged within a gasket retainer that surrounds the doorway, thereby sealing boundaries between areas of personal egress.

Owner:US SEC THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ATTN CODE OOCIP THE

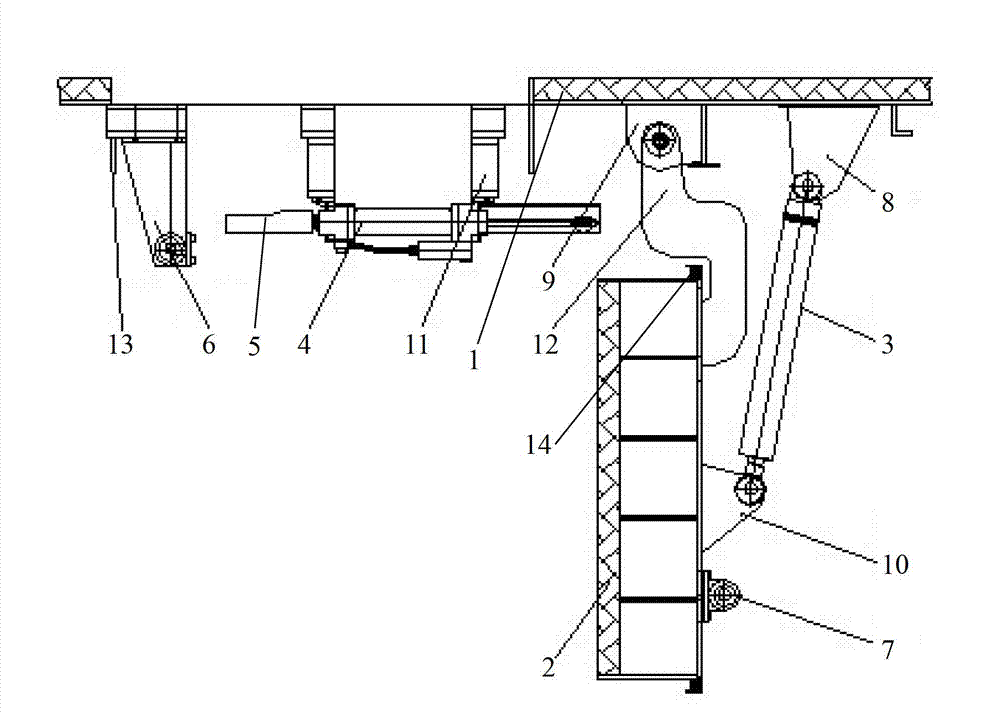

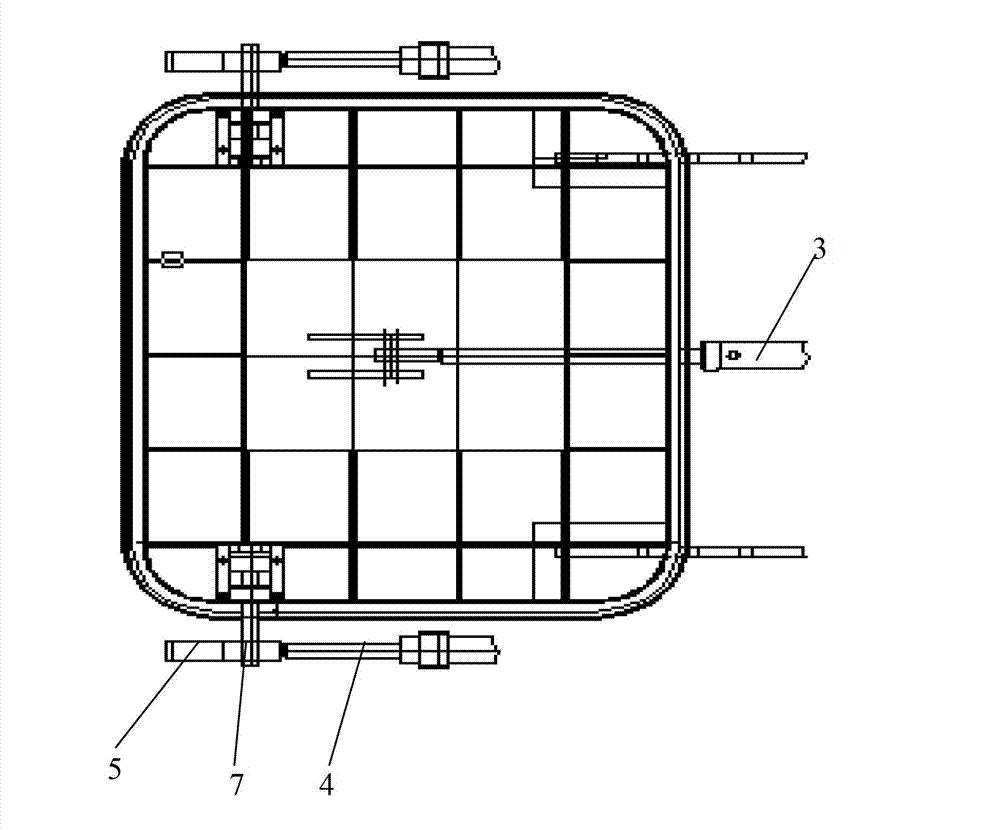

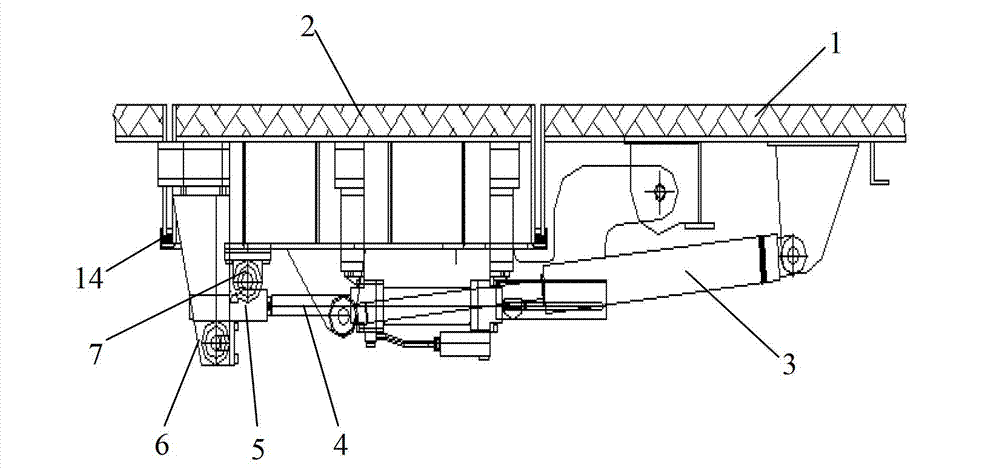

Hydraulic watertight hatch cover device capable of opening and closing automatically

ActiveCN102897285AImprove carrying capacityStable supportVessel hatches/hatchwaysHydraulic cylinderEngineering

The invention relates to a hydraulic watertight hatch cover device capable of opening and closing automatically. The hydraulic watertight hatch cover device comprises a hatch cover (2) and a door opening (13) which is formed in a deck (1), an opening / closing hydraulic cylinder (3), a locking hydraulic cylinder (4) and a wedging mechanism, wherein the hatch cover (2) is hinged to the inner side of the deck (1); the two ends of the opening / closing hydraulic cylinder (3) are respectively hinged to the inner side of the deck (1) and the hatch cover (2); the locking hydraulic cylinder (4) is arranged on the inner side of the deck (1); a sealing ring (14) is arranged on the peripheral wall of the hatch cover (2); and when the hatch cover (2) rotates to be in a closing state, the locking hydraulic cylinder (4) drives the wedging mechanism to act, and the wedging mechanism is supported at the bottom of the hatch cover (2) to press the sealing ring at the lower end of the door opening (13). Compared with the prior art, the hatch cover device has a high degree of automation, is convenient to operate and high in bearing capacity, and is safe and reliable.

Owner:CHINA SHIP DEV & DESIGN CENT

Locking device

A locking device includes a handle member, a rotatable member connected to the handle member, and a bolt member connected to the rotatable member so as to follow rotational movements of the handle between a locking position and an unlocking position of the locking device. The bolt member includes a latch bolt spring-loaded towards an extended locking position and operative to yield towards a less extended position when encountering a stationary part of a coaming when positioned in its locking position.

Owner:SOUTHCO

Boat windshield with vent structure

InactiveUS20090211512A1Reduce formationEliminate condensationAir-treating devicesAuxillariesElectrical and Electronics engineeringWindshield

A boat windshield is described including a transparent pane. A rail is disposed adjacent and secured to one of either the bottom or the top edge of the transparent pane. An opening is defined through the rail. An air intake housing is secured to the front surface of the rail. An air intake opening and passageway are defined in the air intake housing. An air discharge housing is secured to the rear surface of the rail. An air discharge opening and passageway are defined in the rear intake housing. The air intake passageway, the opening through the rail, and the air discharge passageway define an air pathway from the front surface to the rear surface of the rail. The air discharge opening is positioned adjacent to the rear surface of the transparent pane to direct air along the rear surface of the transparent pane upon exiting the air discharge housing.

Owner:N A TAYLOR CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com