Patents

Literature

367 results about "Prow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The prow is the forward-most part of a ship's bow that cuts through the water. The prow is the part of the bow above the waterline. The terms prow and bow are often used interchangeably to describe the most forward part of a ship and its surrounding parts. In old naval parlance, the prow was the battery of guns placed in the fore gun-deck.

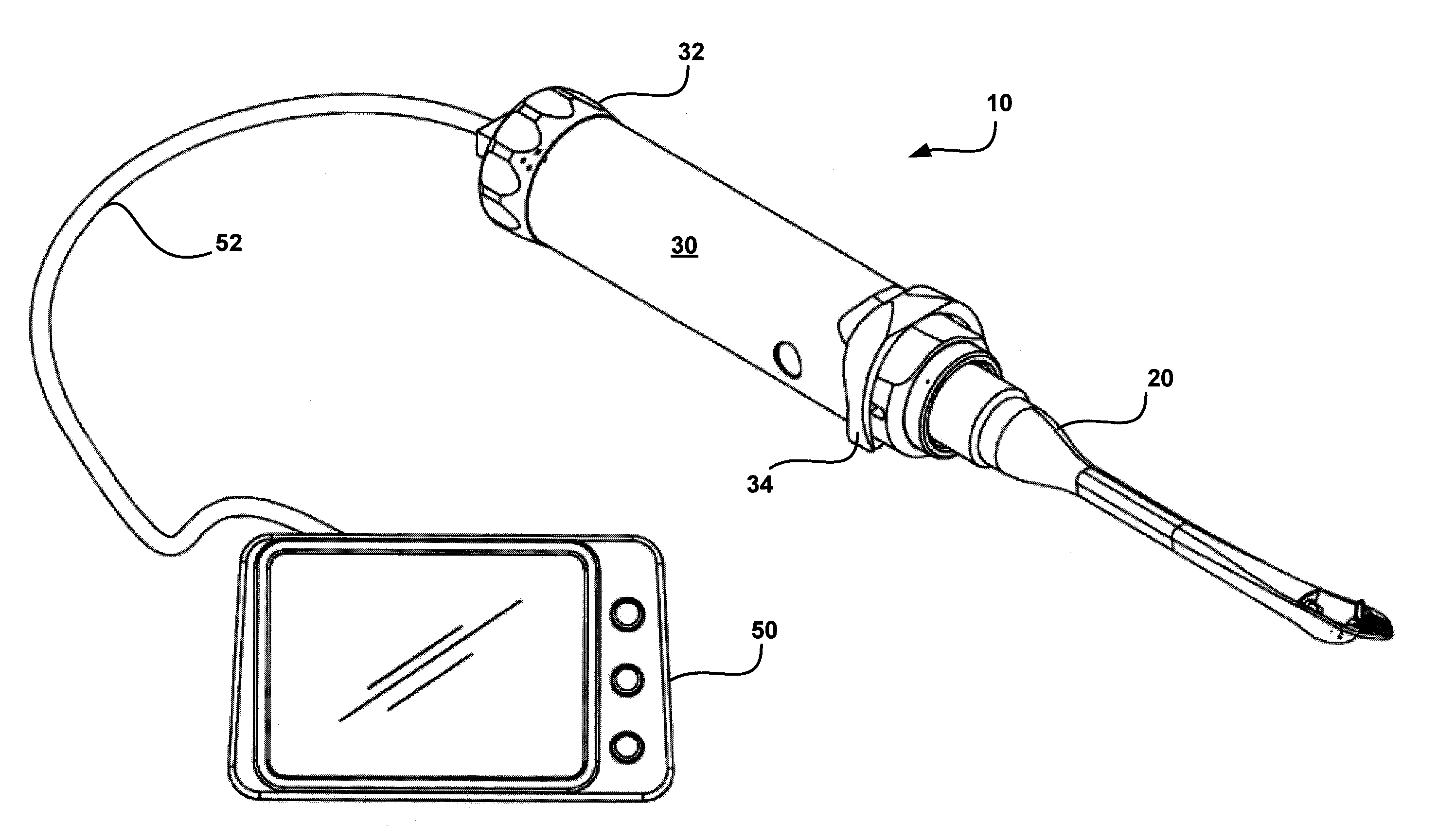

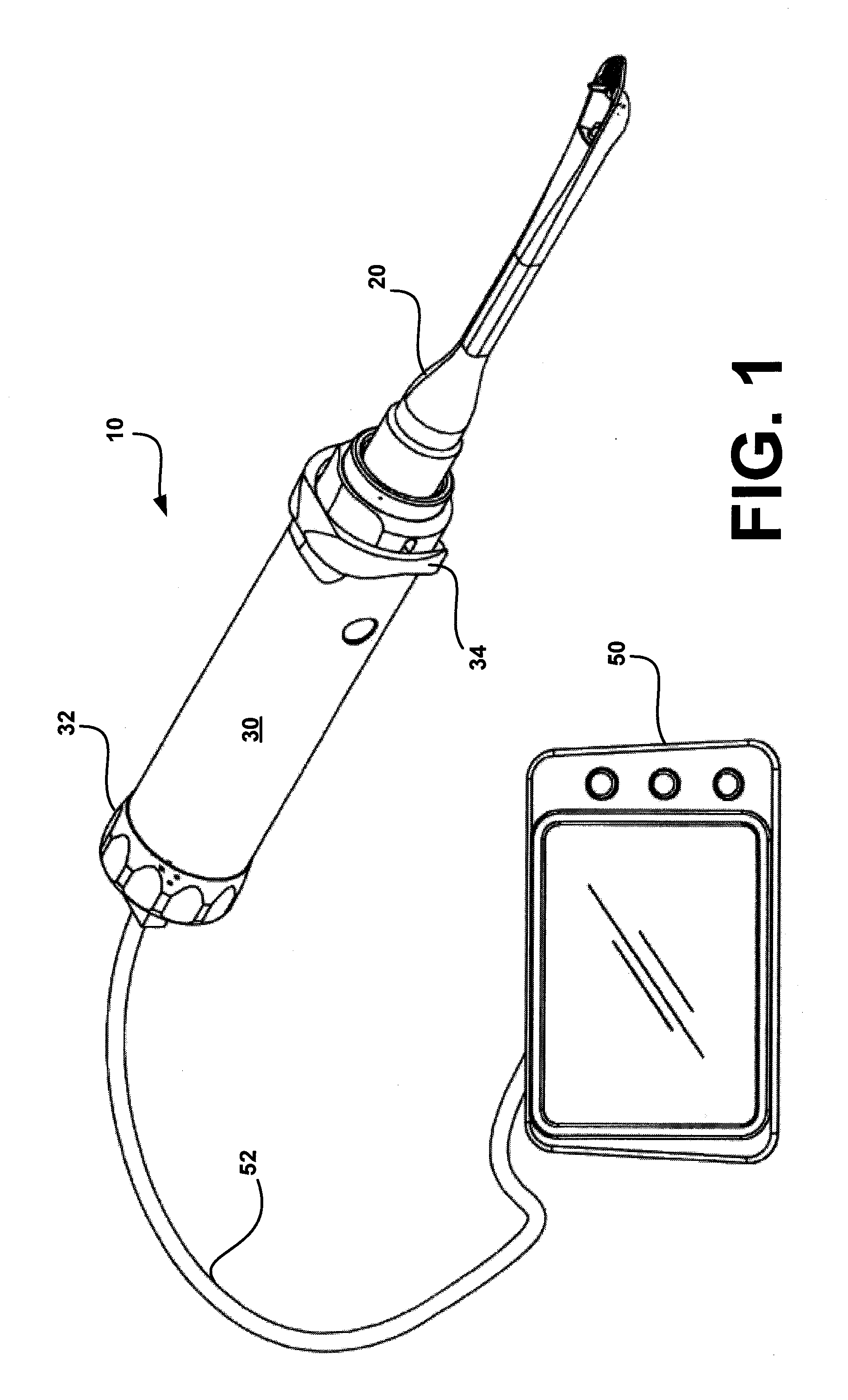

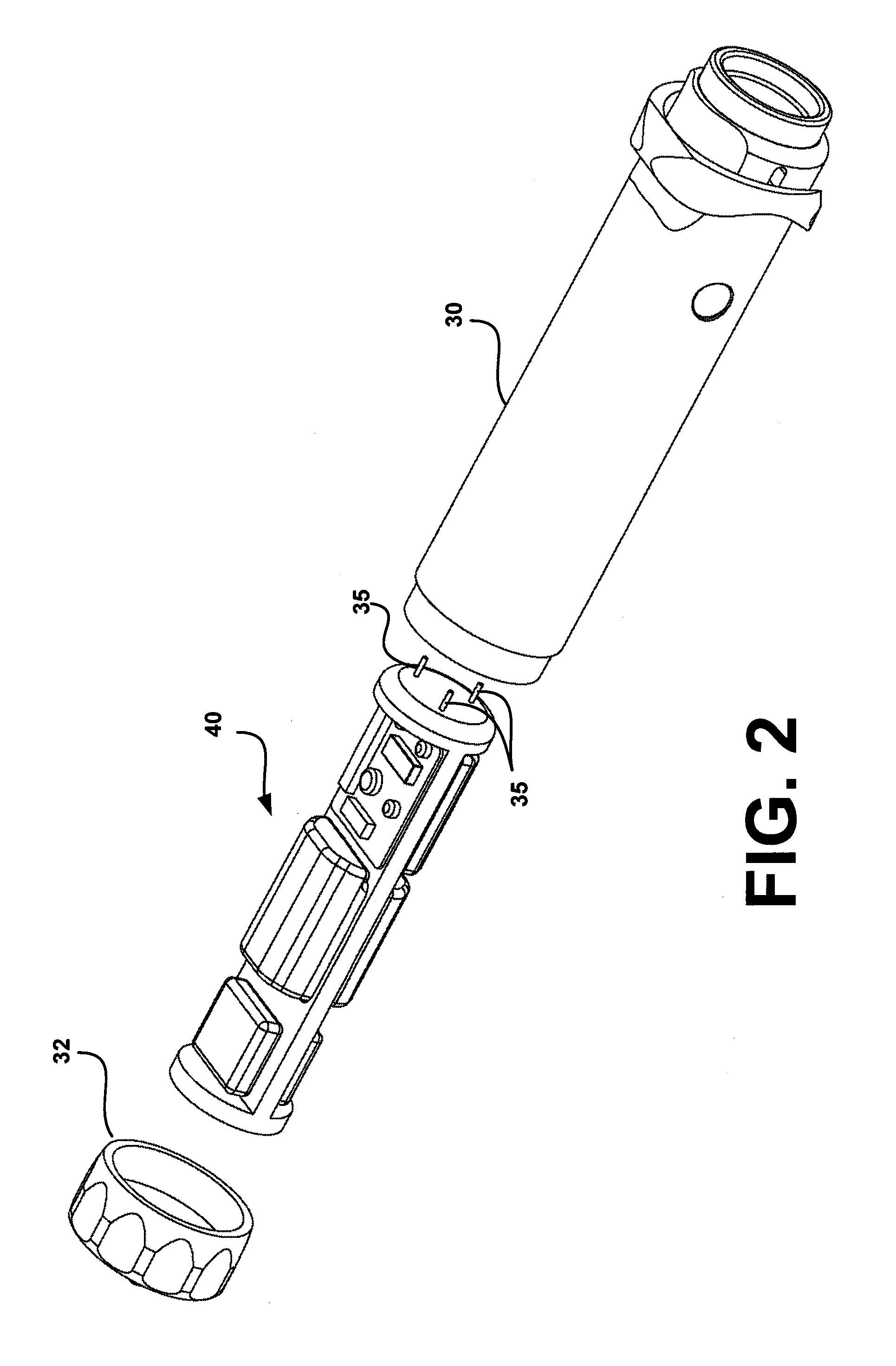

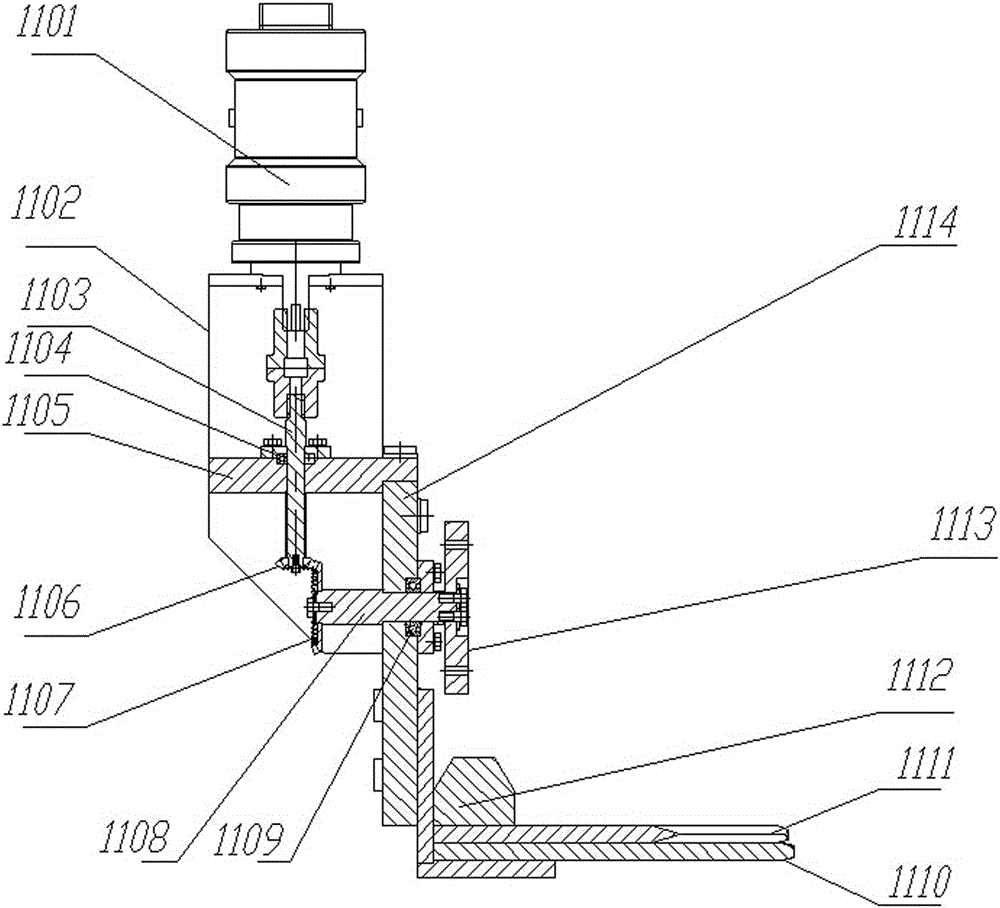

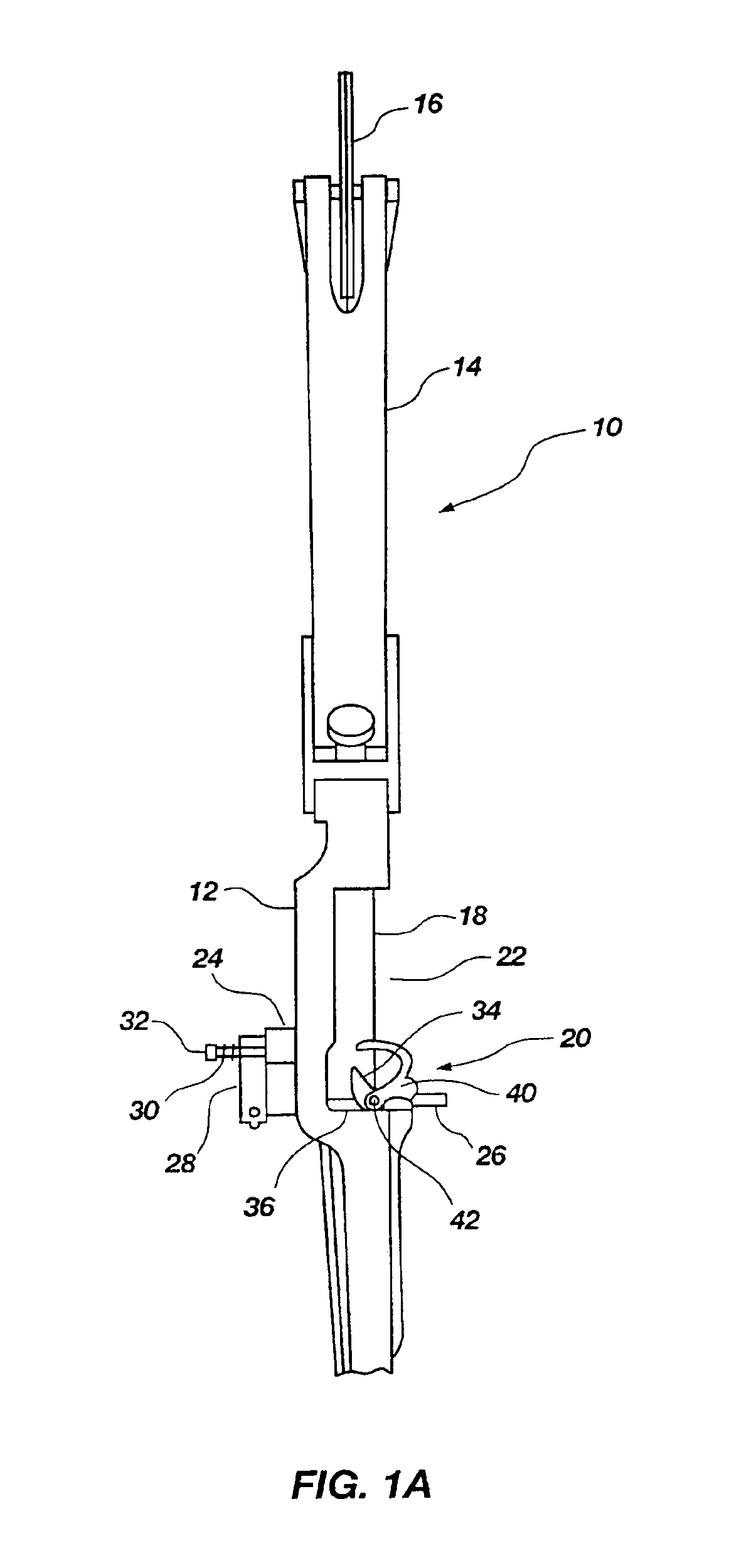

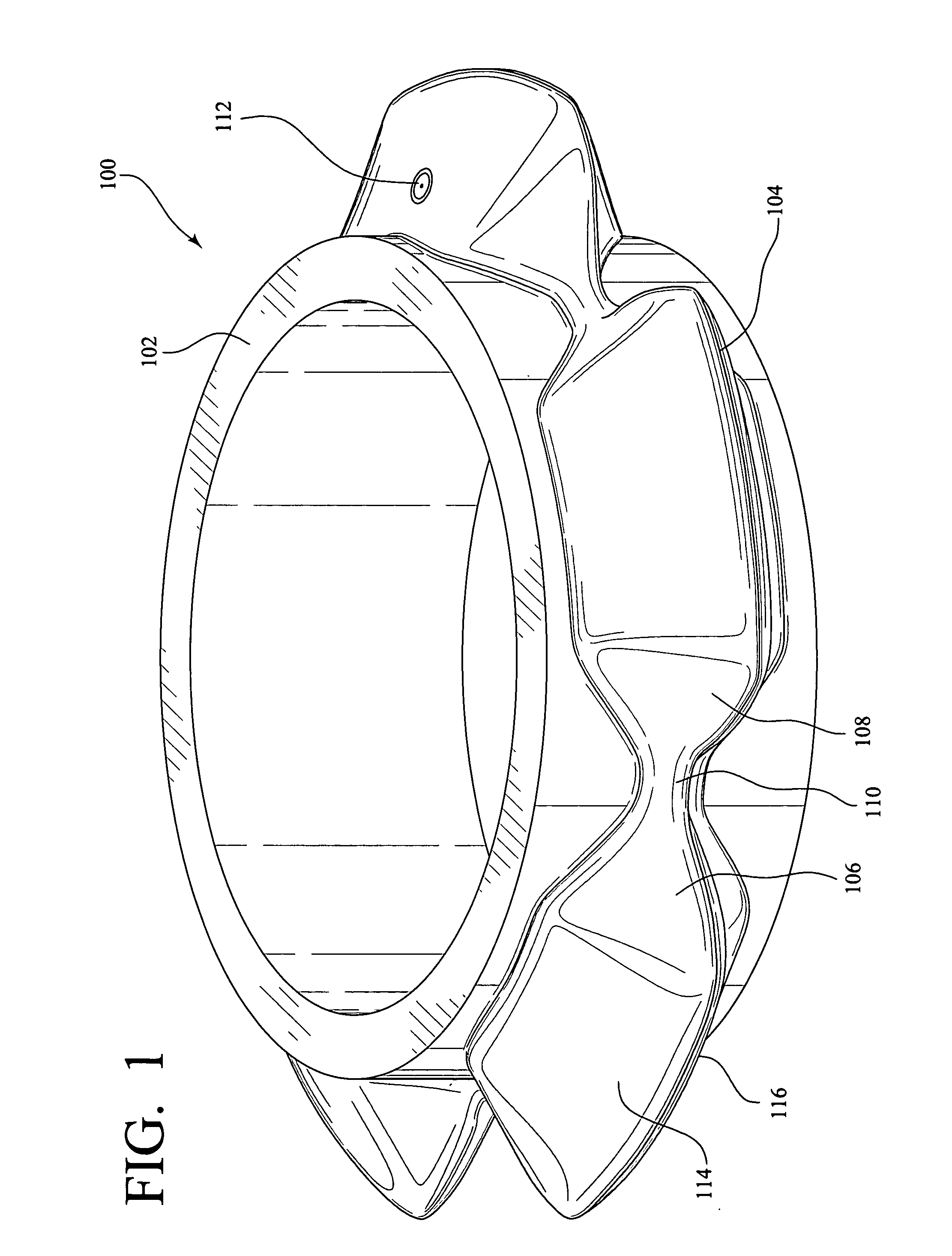

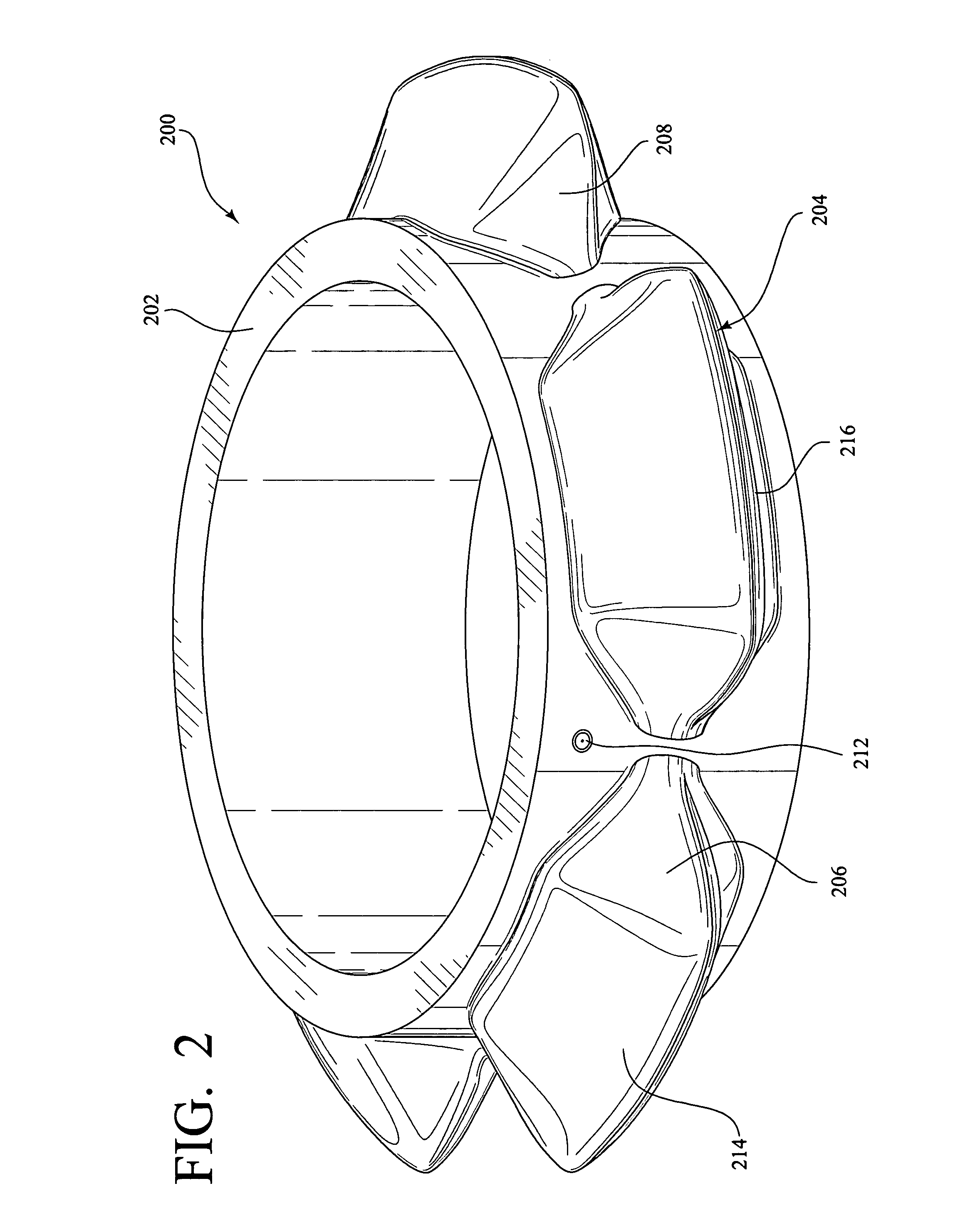

Endo-surgical device and method

ActiveUS20080195128A1Overcome disadvantagesIncision instrumentsCannulasEngineeringEndoscopic surgery

An endo-surgical device, system and method are provided. The endo-surgical device includes a flared prow that limits the displacement and rotation of the cannula to keep the knife away from tissues that are not intended to be cut. The endo-surgical tool can be utilized as part of a system for performing an endo-surgical procedure

Owner:SKELETAL DYNAMICS INC

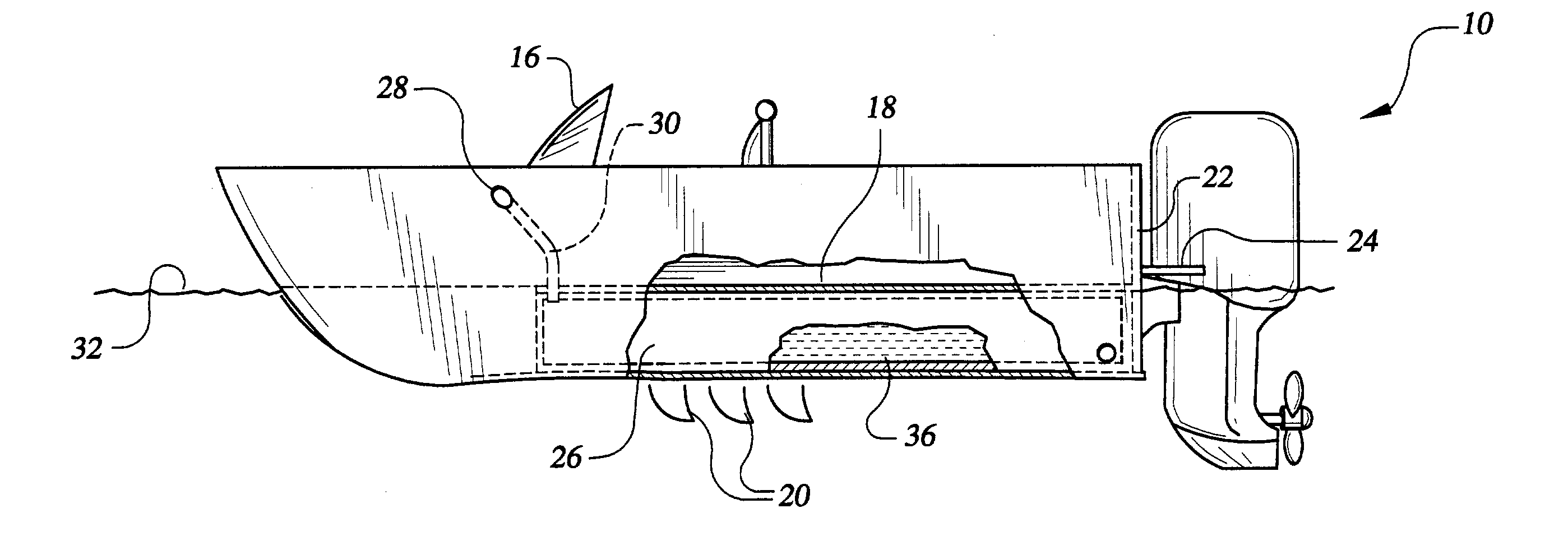

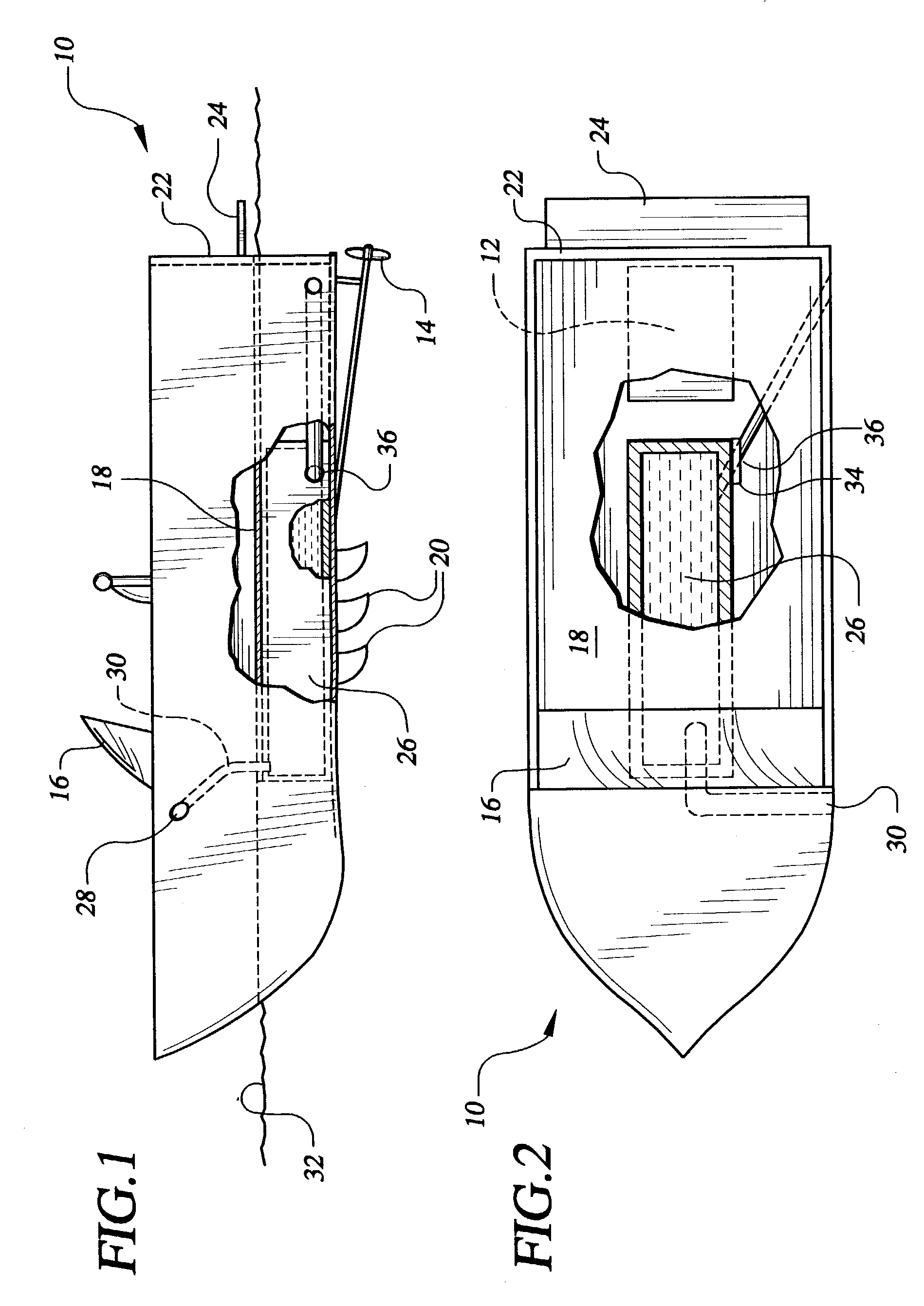

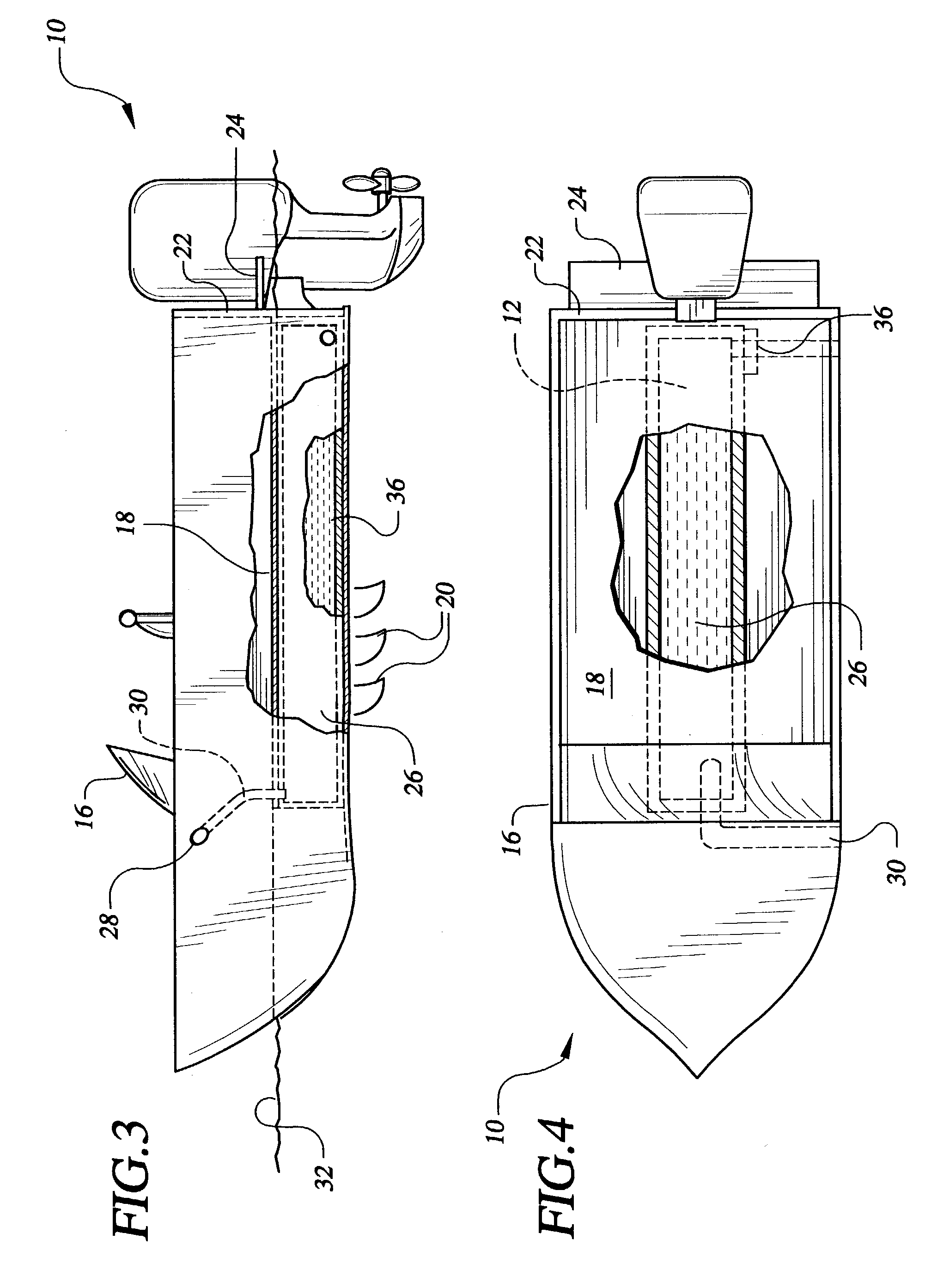

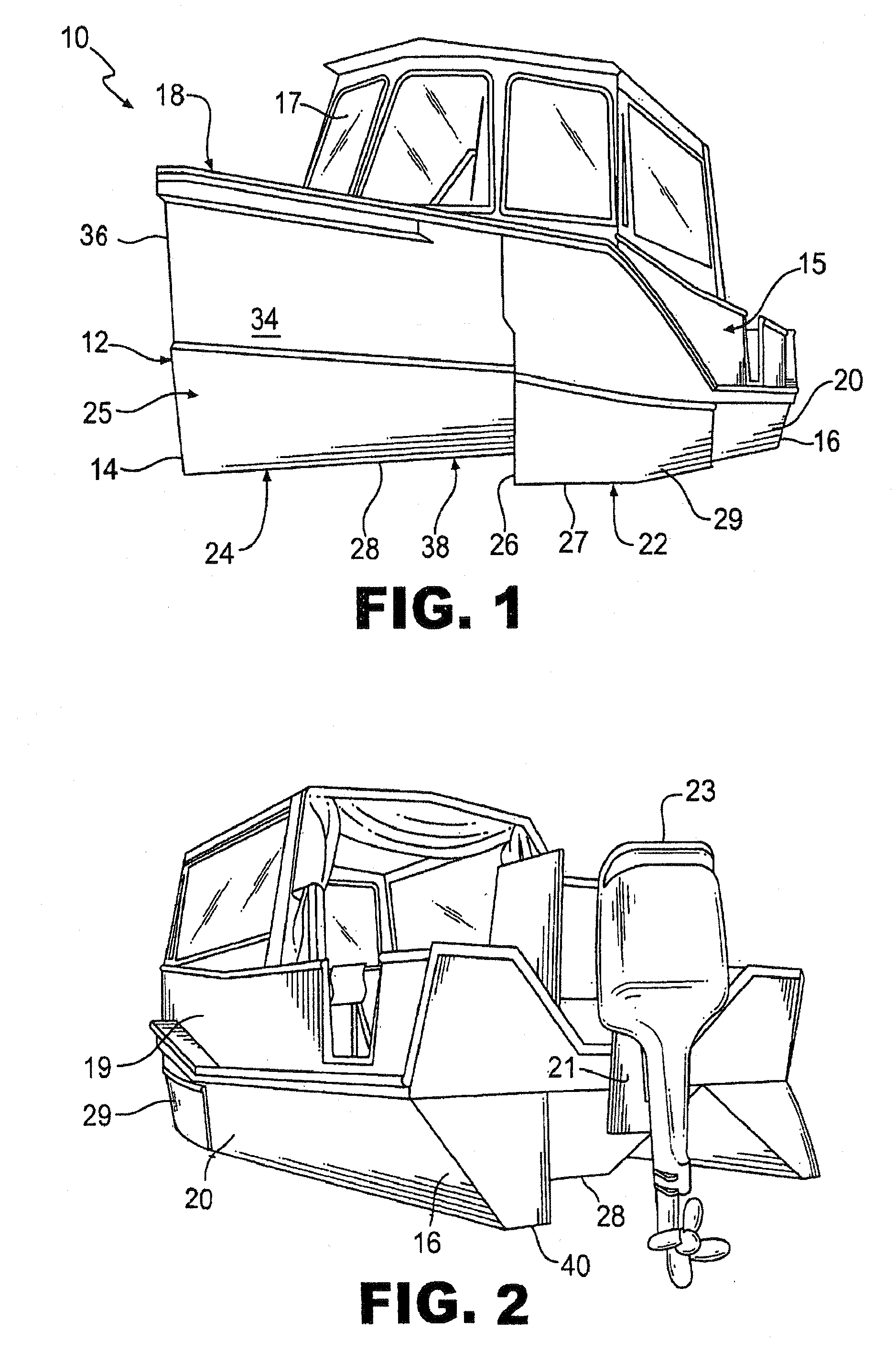

Boat wake system

InactiveUS6953002B2Enhance wake sizeIncrease speedWatercraft hull designVessel partsKeelLiquid water

A water craft having a bow and a stern including an engine of sufficient thrust to create an enlarged wake at the stern of the boat as the boat moves along the surface of a body of water.The water tight compartment is positioned to carry water below the water line and essentially astride the centerline or keel of the boat. The compartment is adapted to contain liquid water in an amount sufficient to enhance or equalize the size of the boat wake.The compartment extends from a point forward of the transom and engine, and extends to a point forward of the midpoint between the bow and the stern, and terminates short of the bow while serving to exert downward force on the bow against the water when the water craft is underway and the compartment carries water.

Owner:MIKE MURPHYS ENTERPRISES

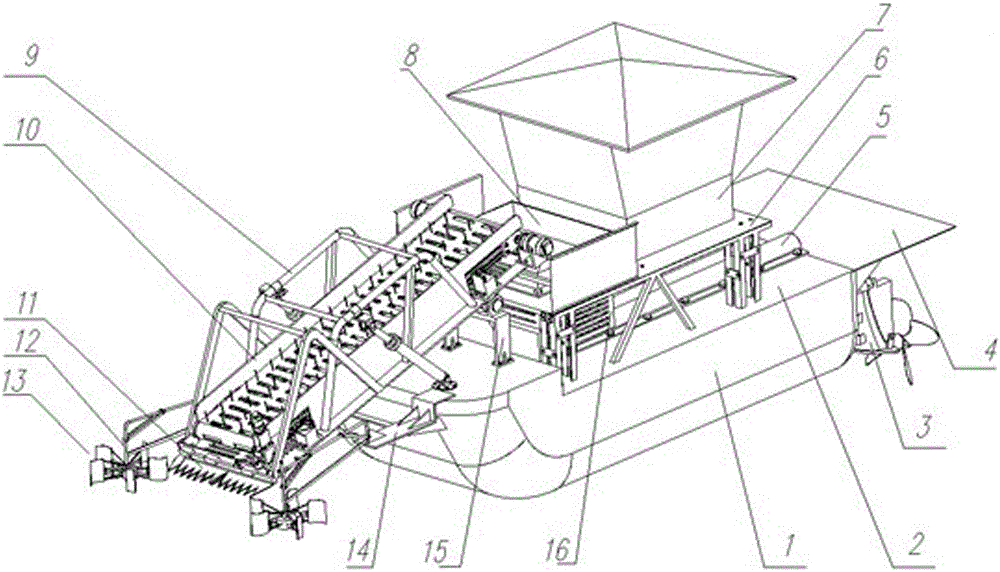

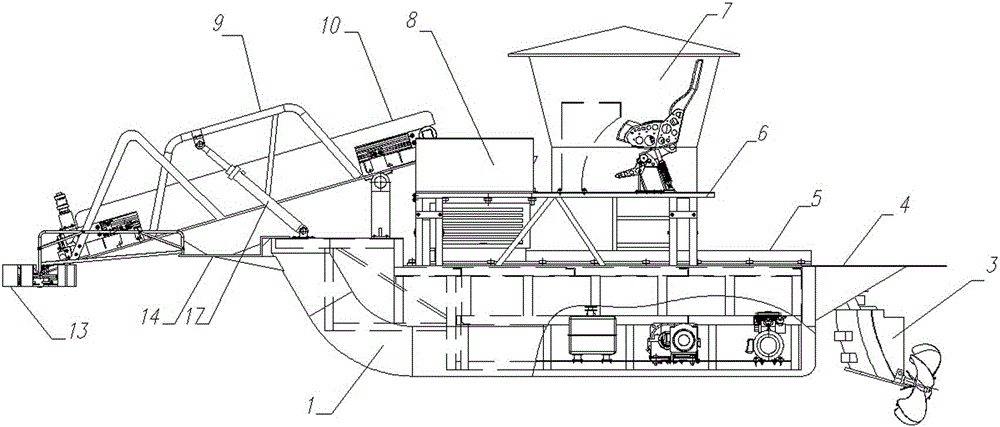

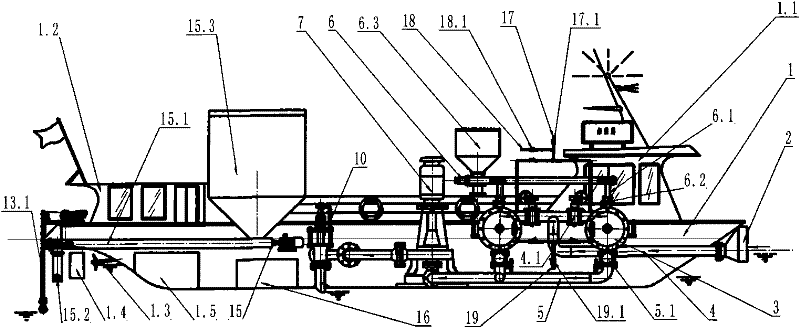

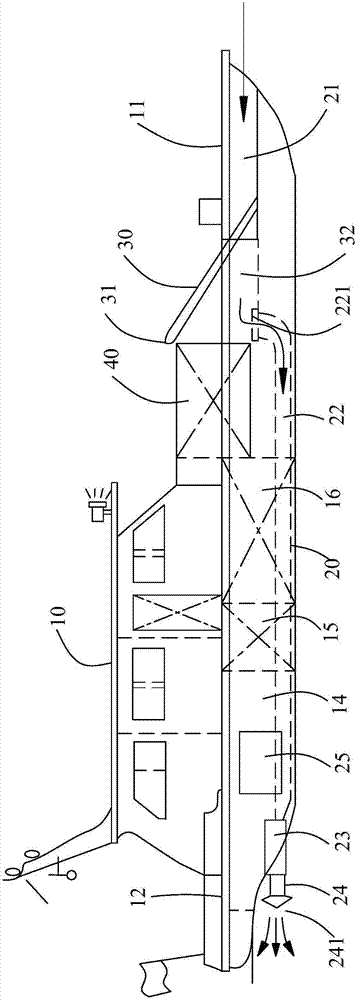

Water plant reaping and harvesting ship

The invention provides a water plant reaping and harvesting ship which comprises a hull, a water plant cutting device, a water plant conveying device, a water plant collecting device, auxiliary collecting devices and a power device. The water plant conveying device is arranged on an installing frame of the bow in an inclined mode, the lowest end of the water plant conveying device is connected with the water plant cutting device, and the water plant collecting device is arranged at one side of the highest end. The water plant cutting device comprises a bevel gear drive mechanism, a slider-crank mechanism and a cutter reciprocating mechanism. The water plant conveying device comprises a chain plate, a chain wheel, a chain, and a water plant leakage preventing mechanism arranged on the chain plate. The water plant collecting device comprises a collecting hopper, a collecting box, a guide rail, and a collecting platform arranged on the stern. The auxiliary collecting devices are profiling variable wing eccentric collecting wheels or collecting plates arranged on the bow. The water plant reaping and harvesting ship integrates water plant cutting, conveying and collecting, all the devices are convenient to combine, and easy to disassemble, replace and maintain, connection in the whole harvesting process is close, the mechanical degree is high, and the reaping efficiency is far higher than that of manual salvage.

Owner:LUOYANG INST OF SCI & TECH

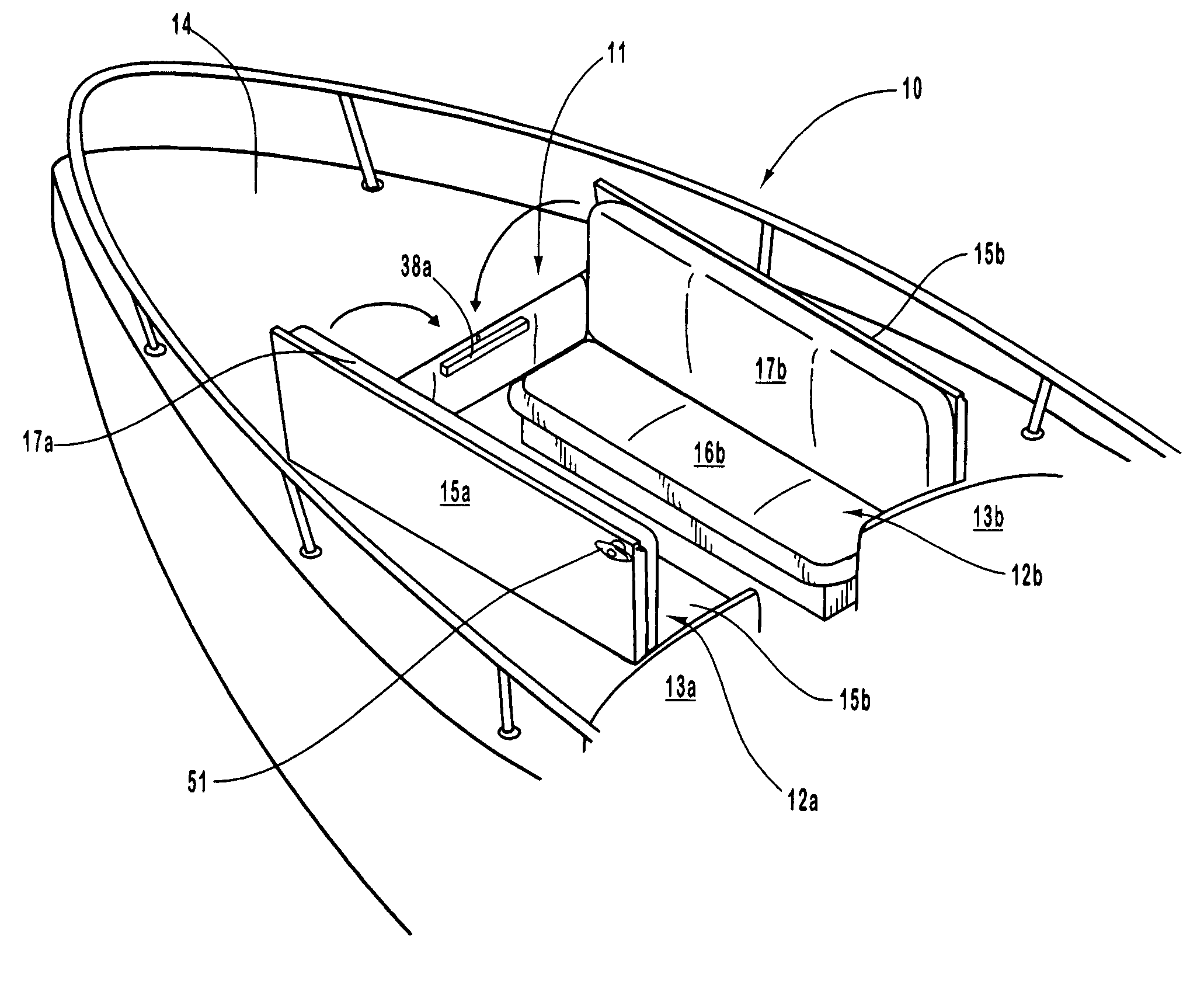

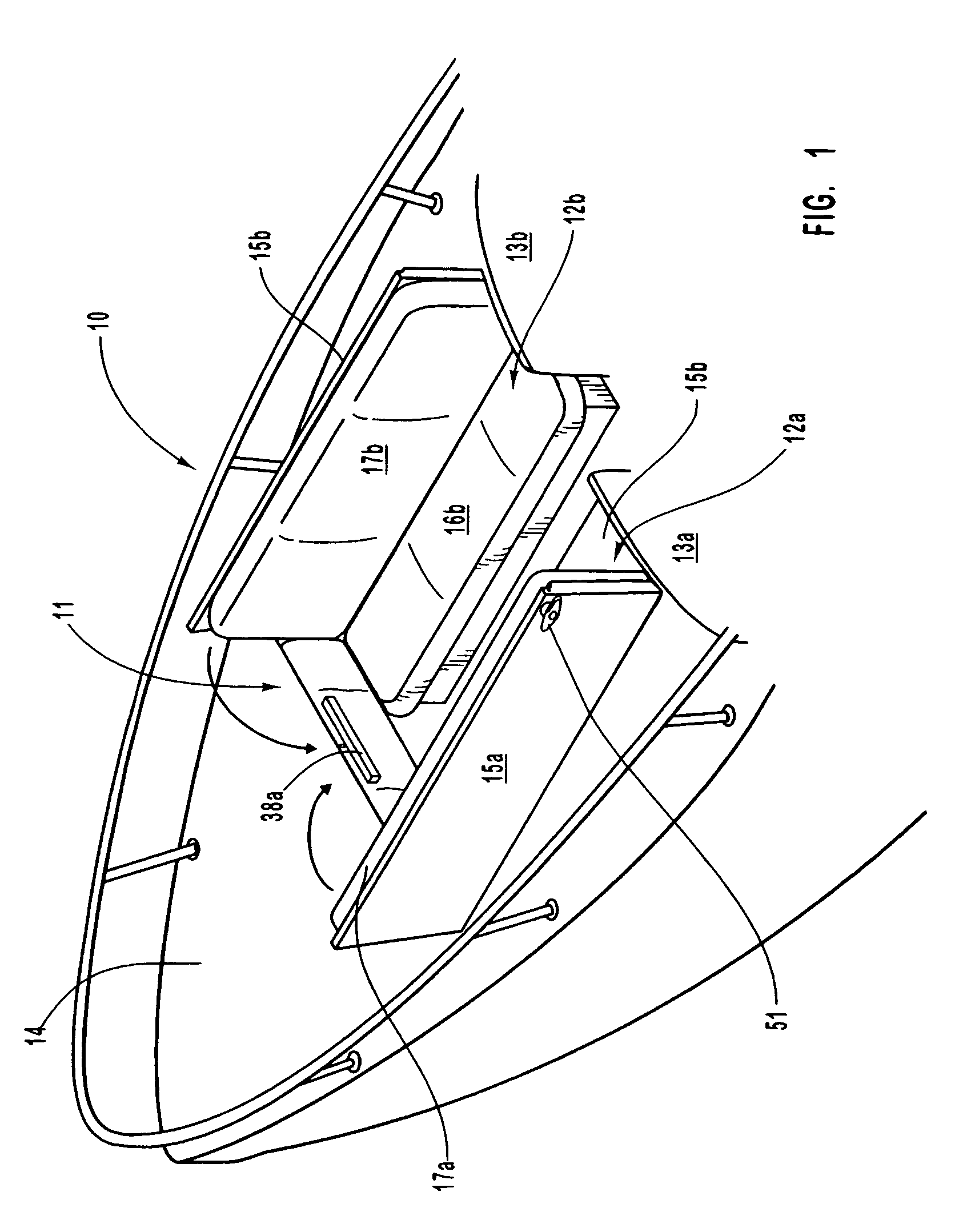

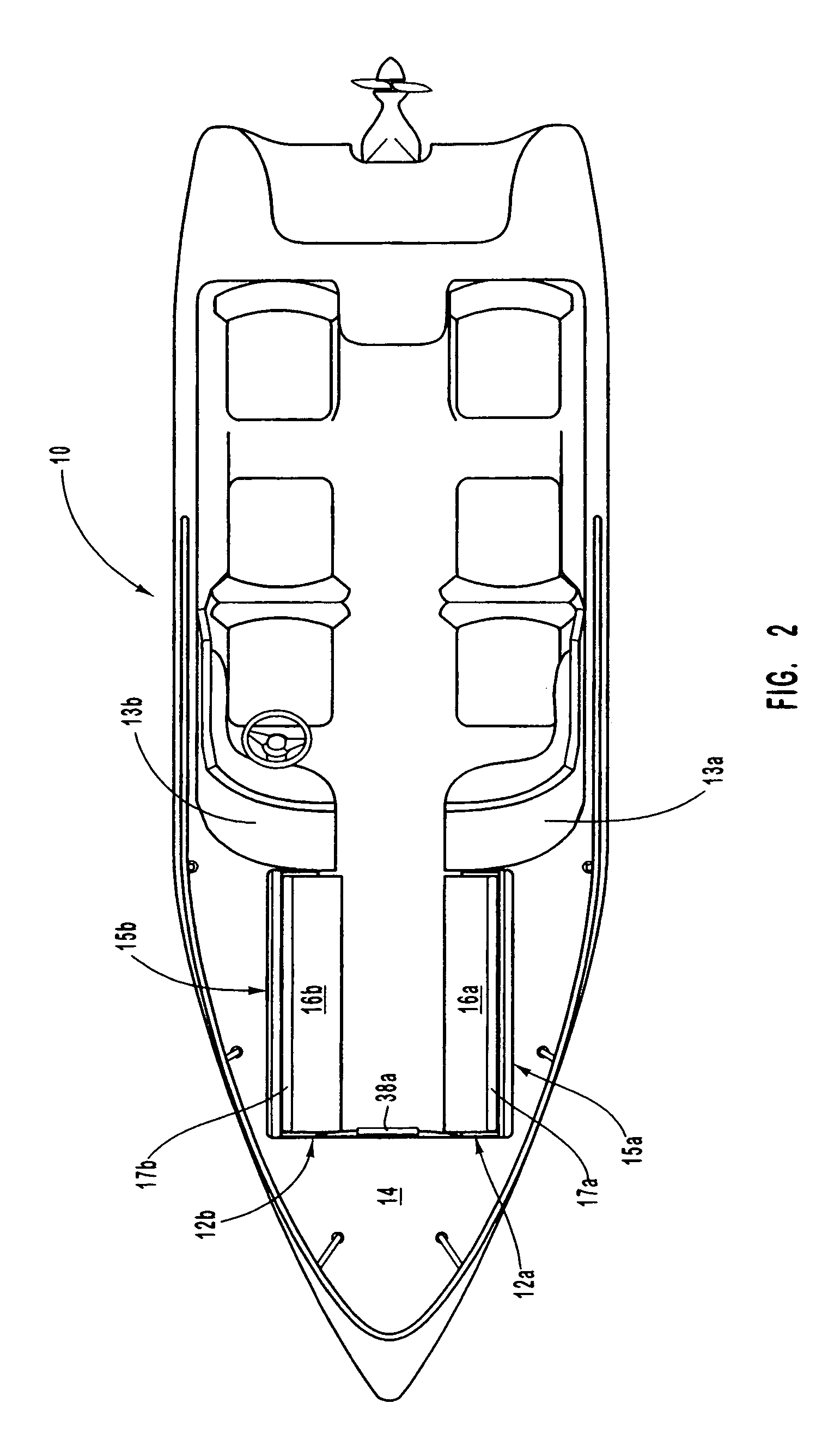

Combination seating and decking for an open bow boat

A seat back system that includes a pair of seat benches for mounting to the floor of an open bow section of a pleasure boat that each include seat backs that are individually mounted to pivot from a vertical, seat back attitude, to a horizontal attitude covering over the open bow section and includes an arrangement for pivoting the seat backs that can be hydraulic, pneumatic or mechanical, that each involve an extending piston between a boat floor and at a location along a brace that is secured to a seat back side, extending at a right angle therefrom, with piston extension to provide seat back travel, providing a load bearing deck.

Owner:FRANDSEN JERRY

Low drag ship hull

ActiveUS20050126464A1Reduce resistanceReduce hull dragWatercraft hull designVessel movement reduction by foilsSternAir cavity

A low drag ship hull generally includes a side air cavity initiated by wetted bow section, bottom air cavity initiated by wetted bottom nosepiece, wetted stem section that closes a lower portion of the side cavity, wetted bottom tailpiece that closes the bottom cavity, stabilizing fin, and propulsor. The bottom of a catamaran hull cross structure includes bow impact alleviator. Optional flaps in the stabilizing fins, together with optional all-movable canard fins are used for control. Different wetted bow sections and retractable means are used for starting side cavities. A low drag hull may utilize multiple air cavities. A new low drag hull includes a new upper bottom air cavity that is initiated by an upper bottom wetted nosepiece, and closed by an upper bottom tailpiece. Alternative designs include a shortened forward hull spaced ahead of a shortened aft hull, and a hydrofoil-supported trimaran with low drag hulls.

Owner:LANG THOMAS G +1

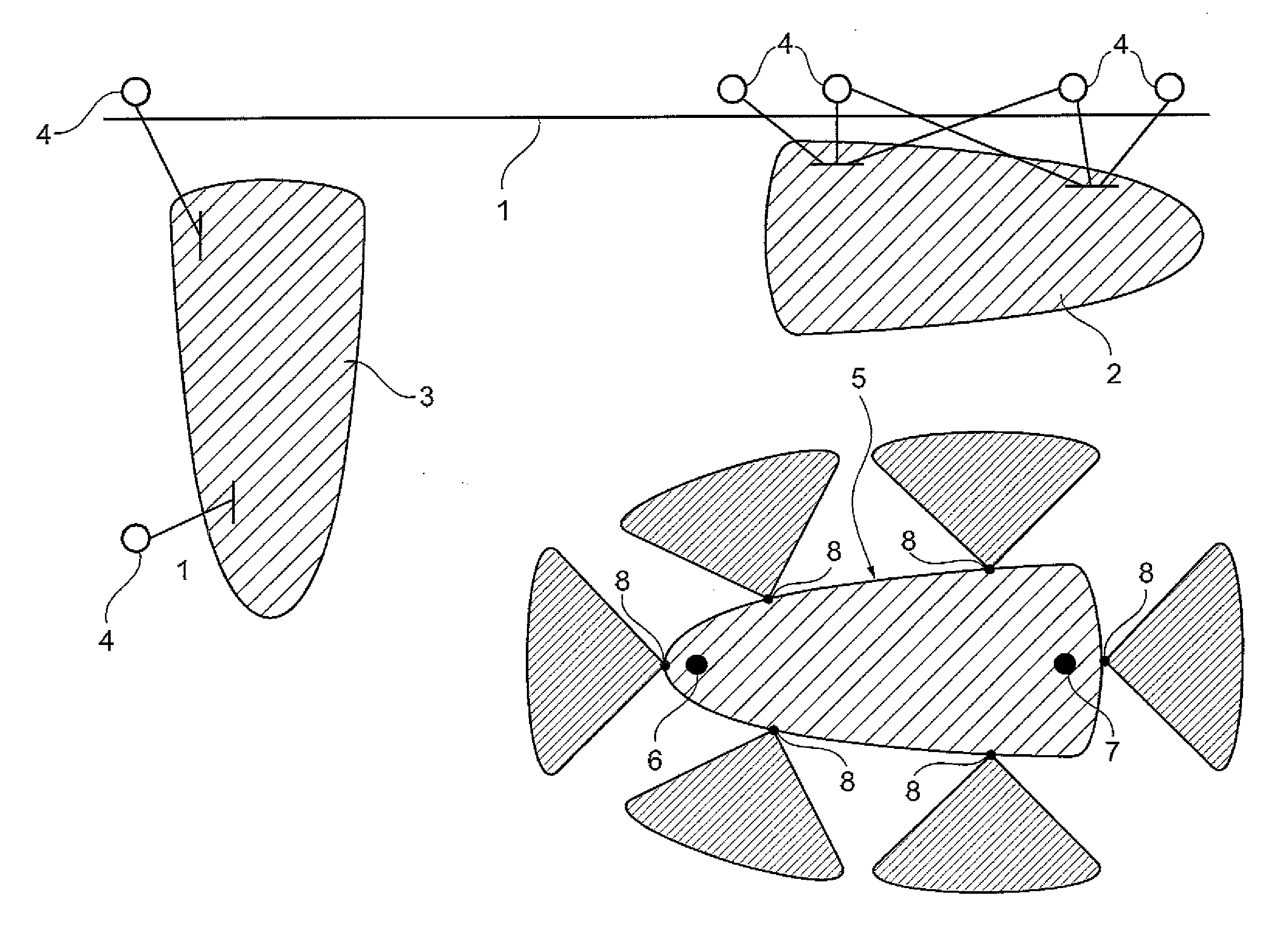

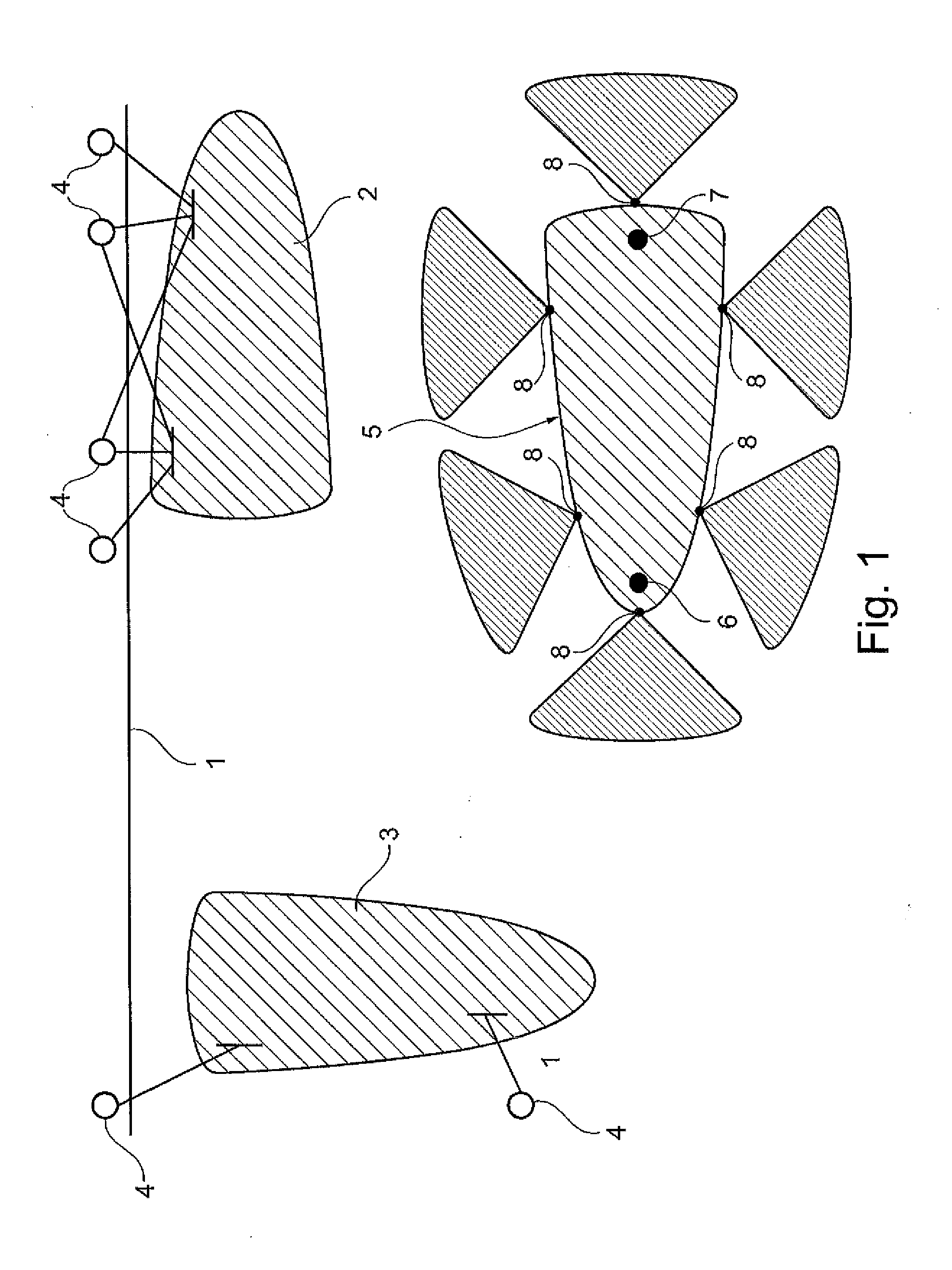

Method for the computer-supported control of a ship

InactiveUS20120072059A1Accurate mappingHigh precisionDigital data processing detailsAnti-collision systemsProwStern

The positions and motions of a bow and a stern of the ship are detected using redundant devices and evaluated to automatically perform difficult maneuvers in ports or to generate recommendations for controlling the ship

Owner:GLAESER PHILIPP

Boat hull design

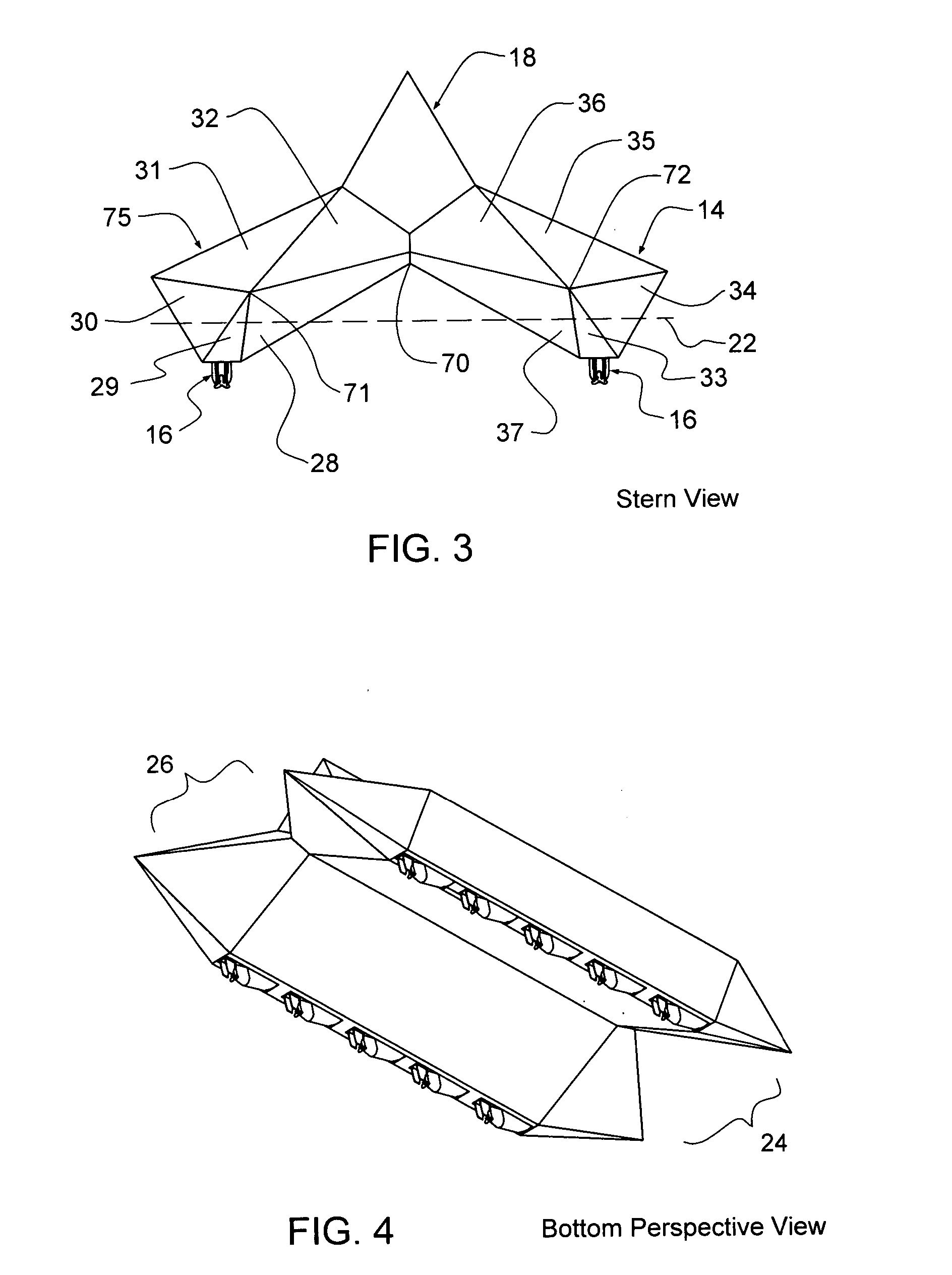

InactiveUS20050000400A1Improve stabilityEasy to adjustPropulsion power plantsPropulsive elementsSternAngle of attack

A multi-hull design suitable for various size boats ranging from racing craft to the large military ships. The apparatus is a polygonal boat hull apparatus having a bow and stern wave penetrating feature. The hull is made from triangular-shaped essentially flat panels which provides for substantially stability and strength. The hull can be made in various configurations ranging from catamarans, triamarans to multiple hull designs in accordance with the projected use of the vessel. The invention includes a drive pod system having a plurality of propulsion units. The invention also provides at least one hydropneumatic cylinder that adjusts the angle of attack of the propulsion unit. The hull may also be rigged as a multi-masted sailing vessel.

Owner:KINGSBURY ROBERT P

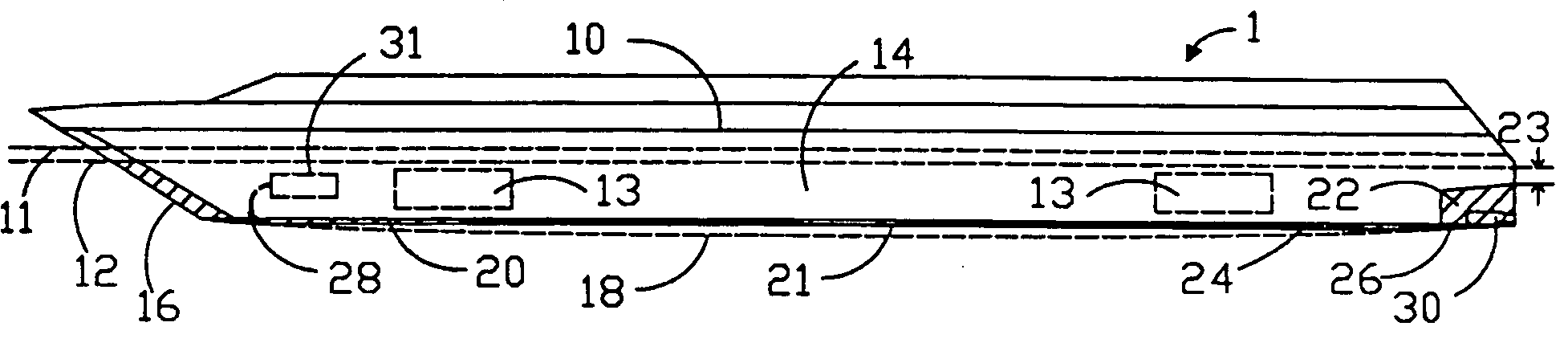

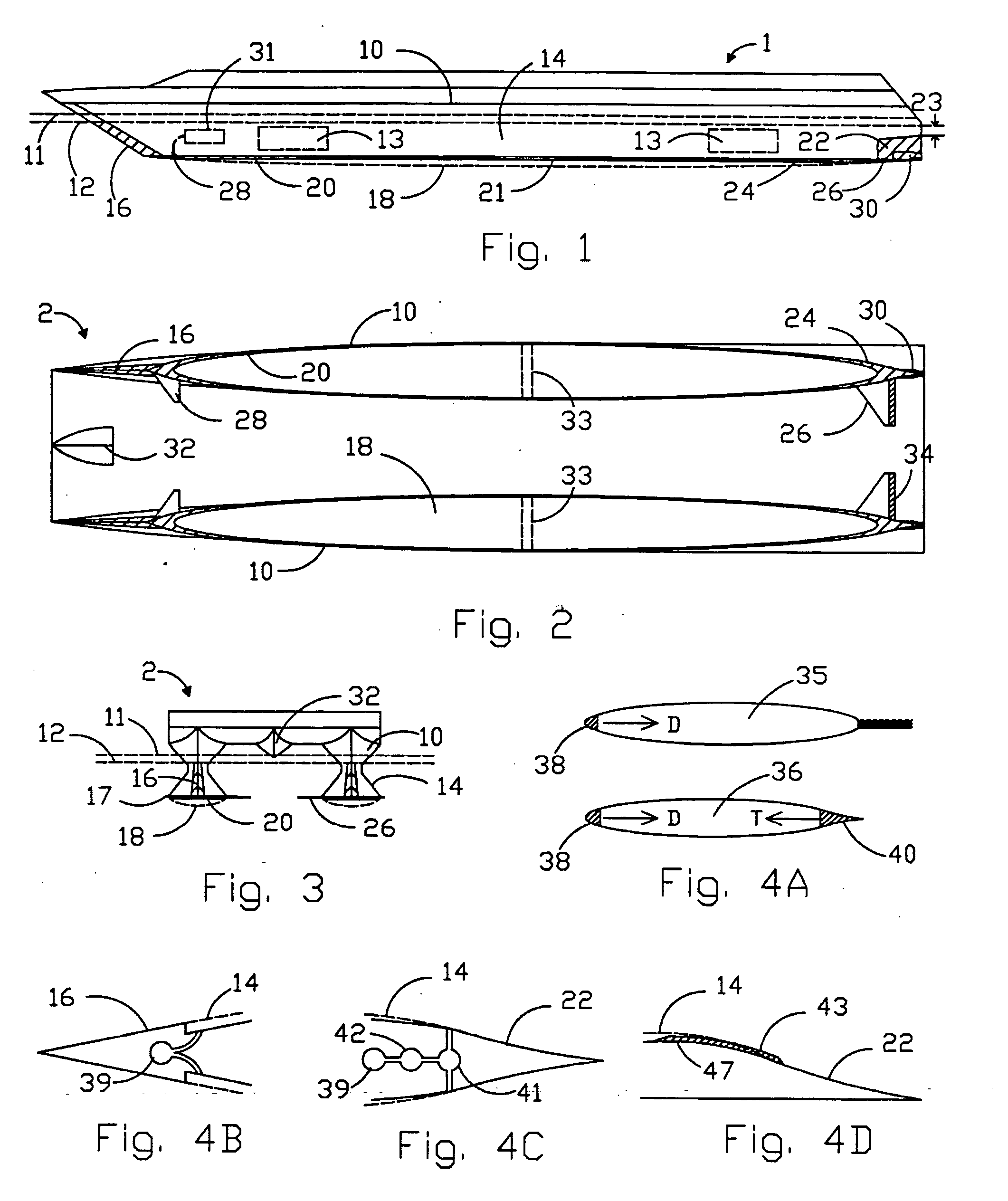

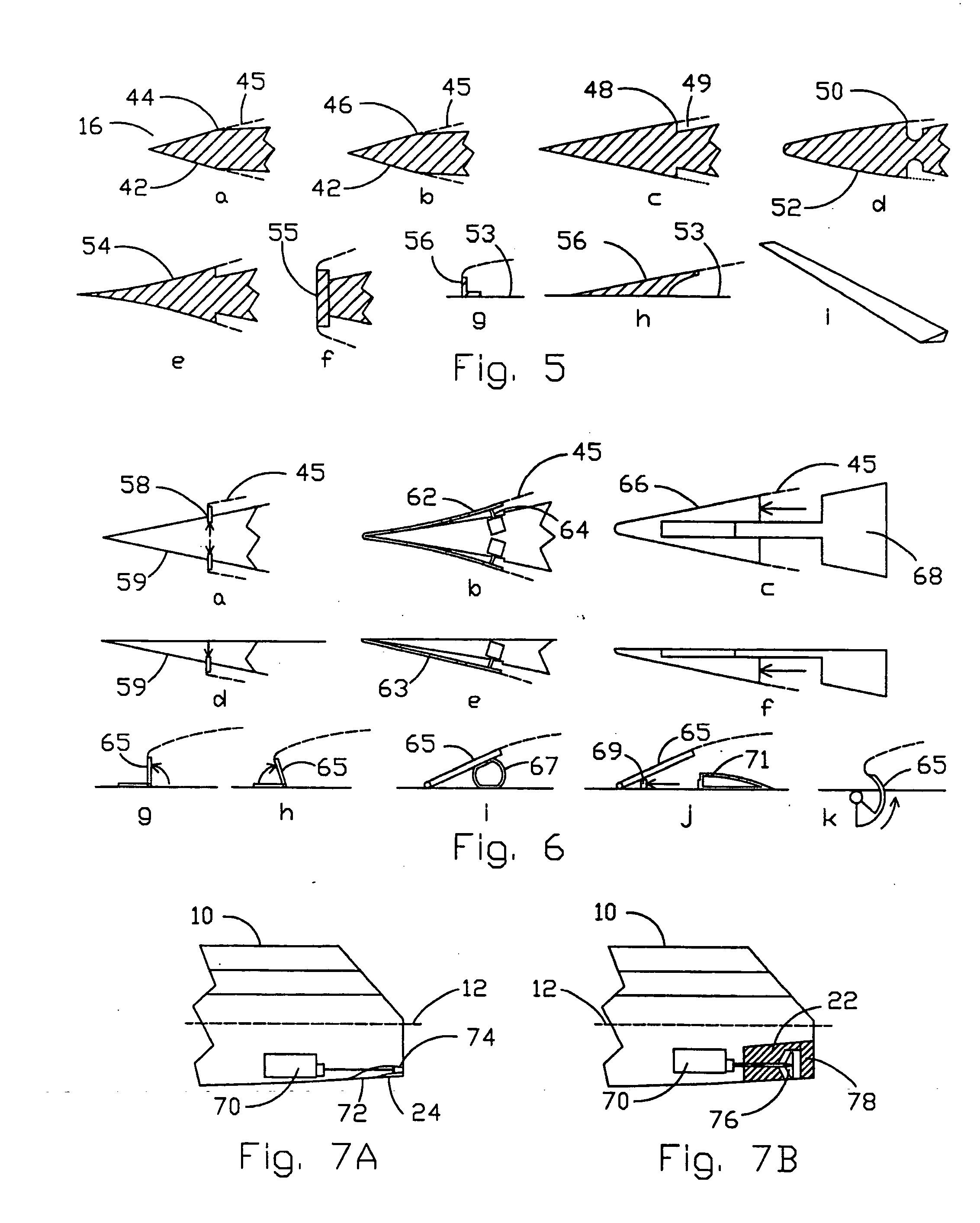

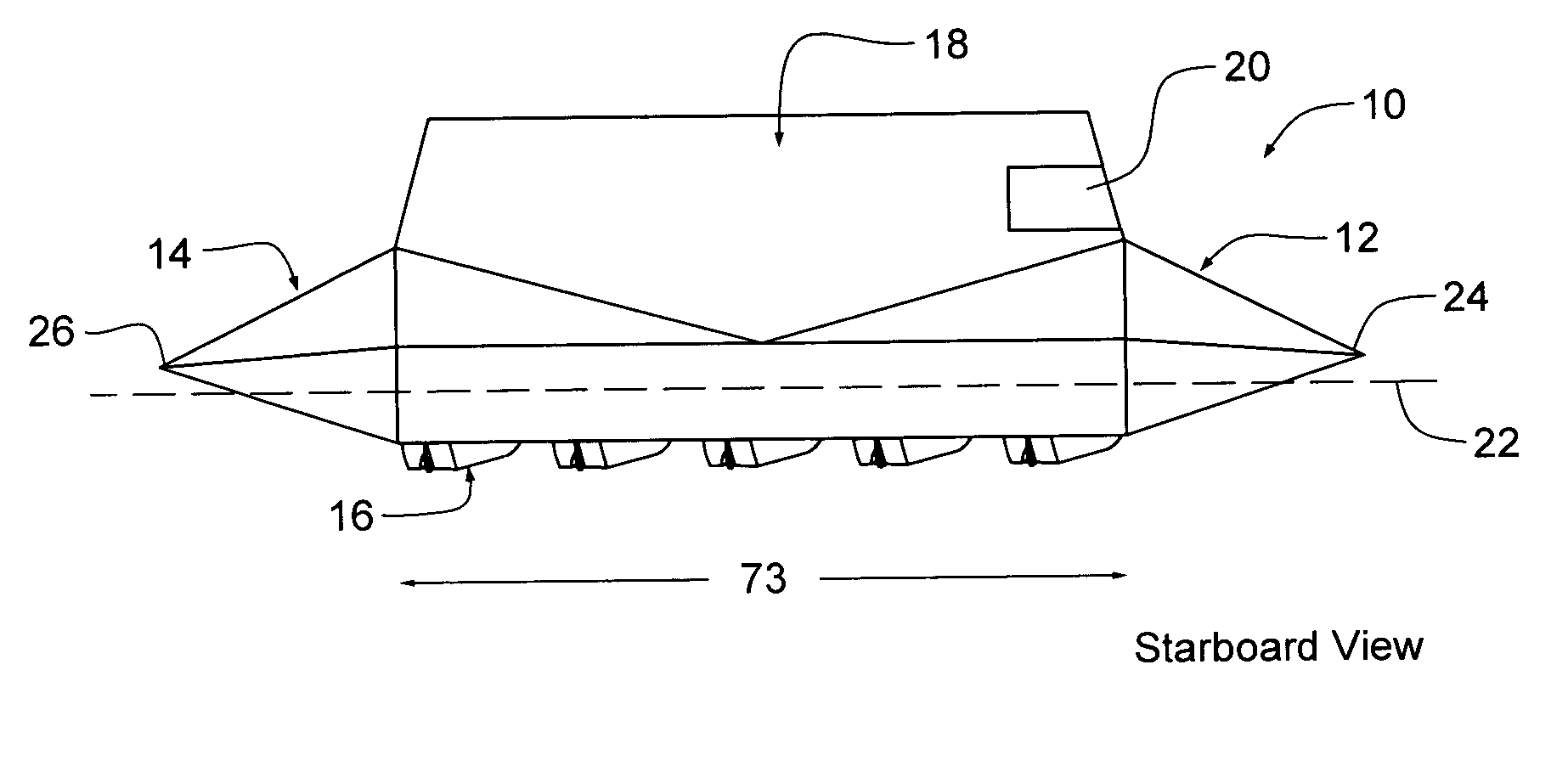

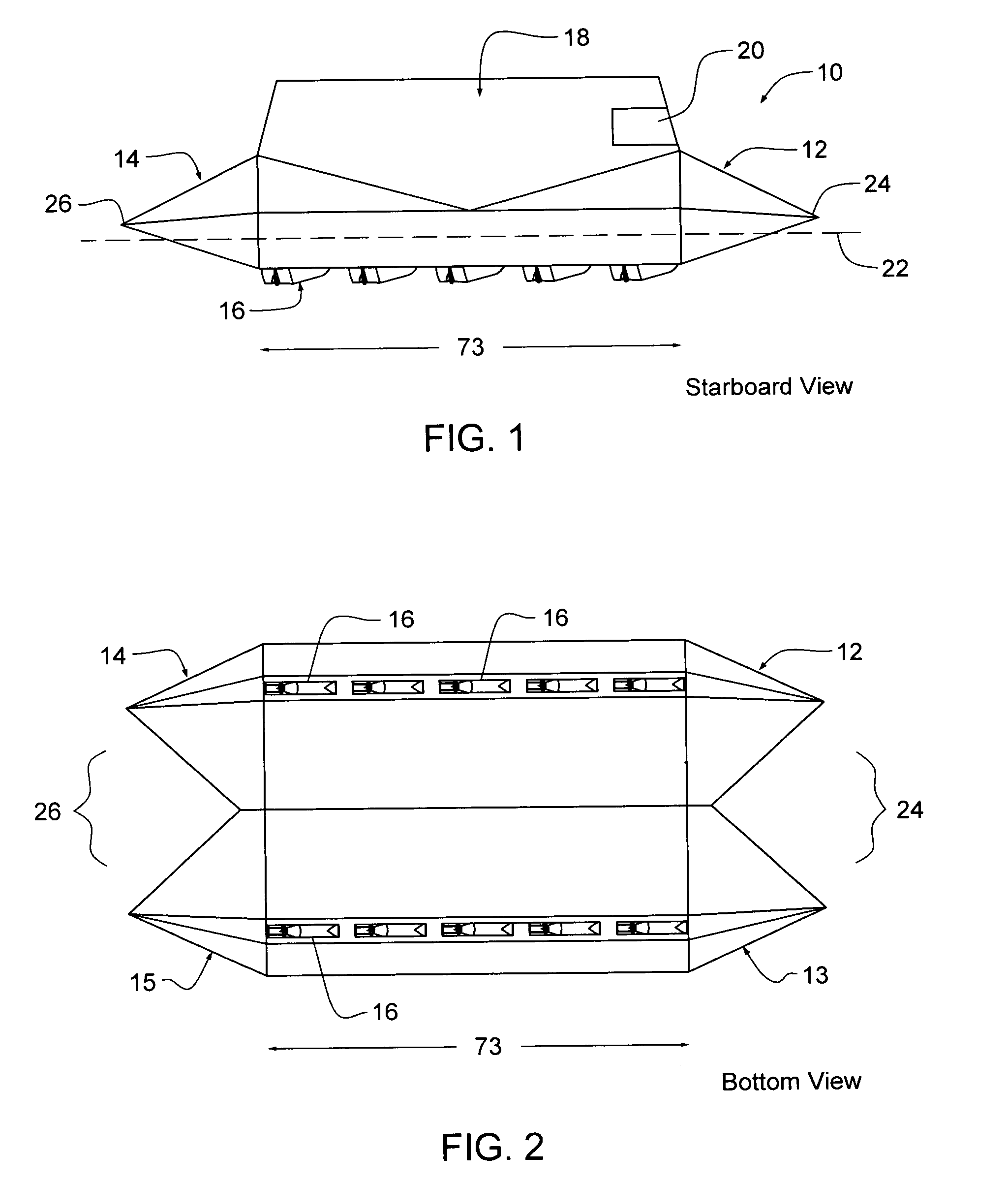

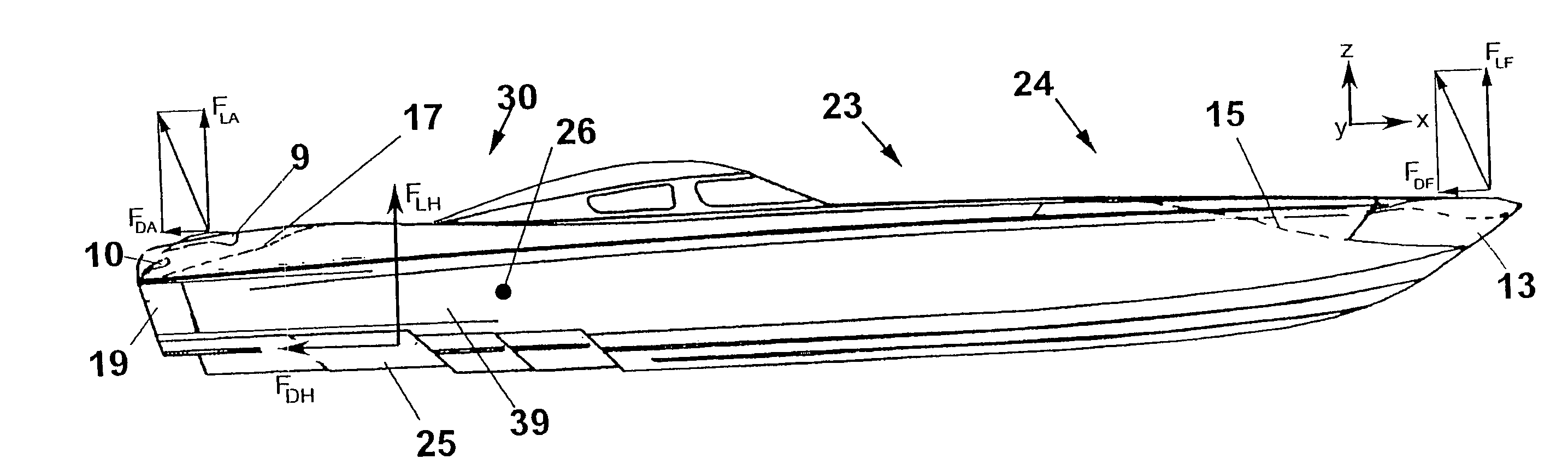

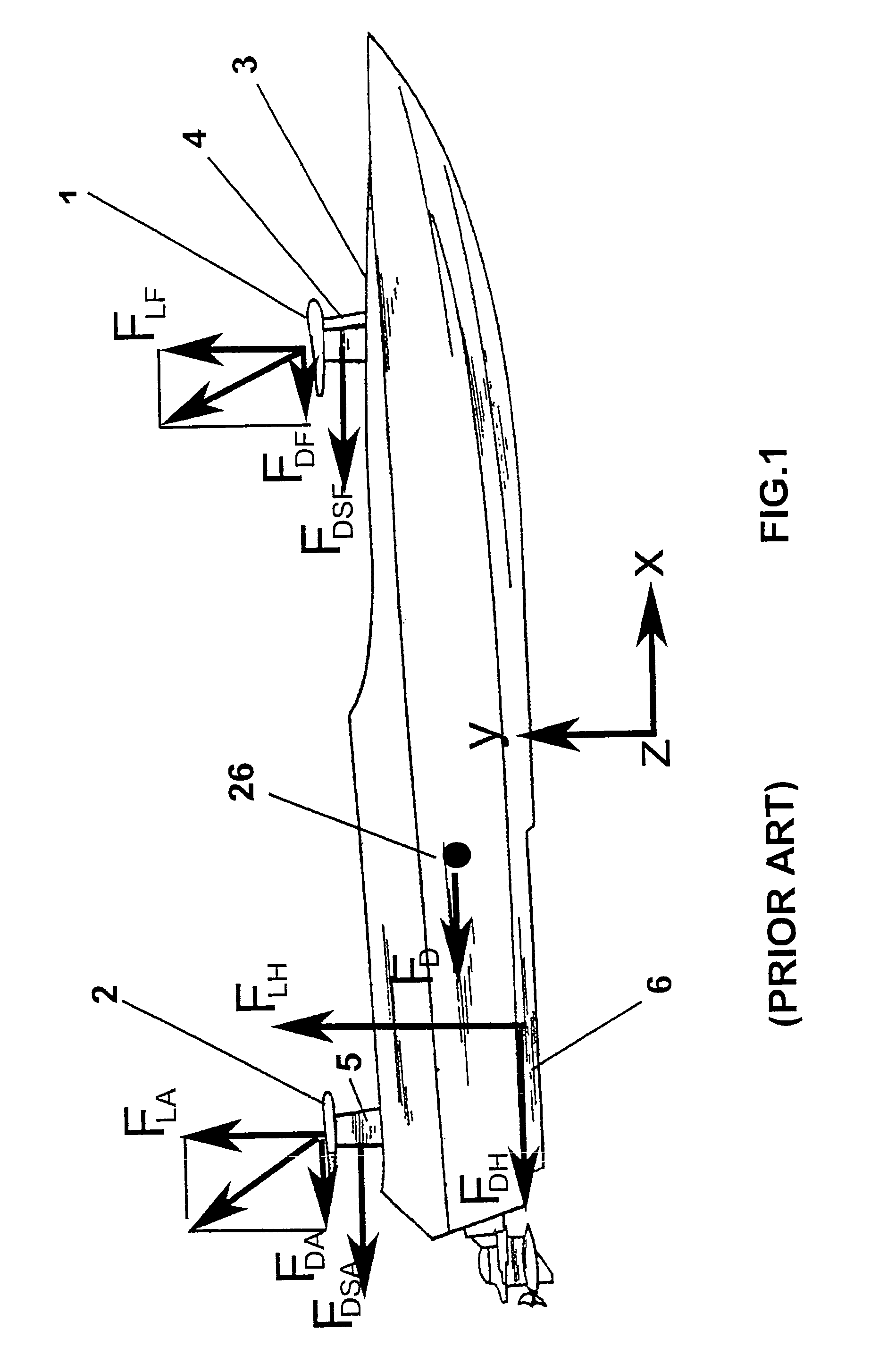

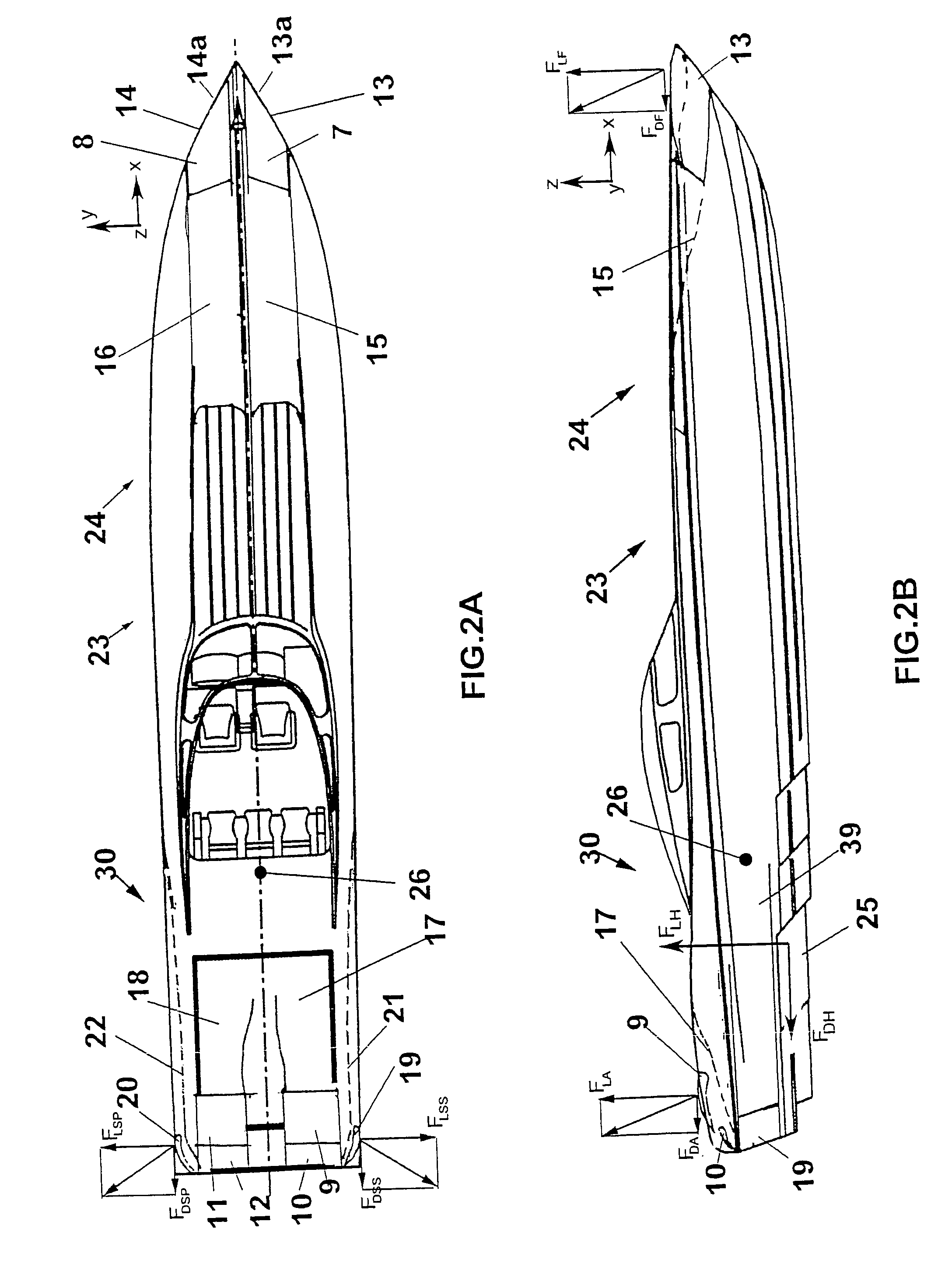

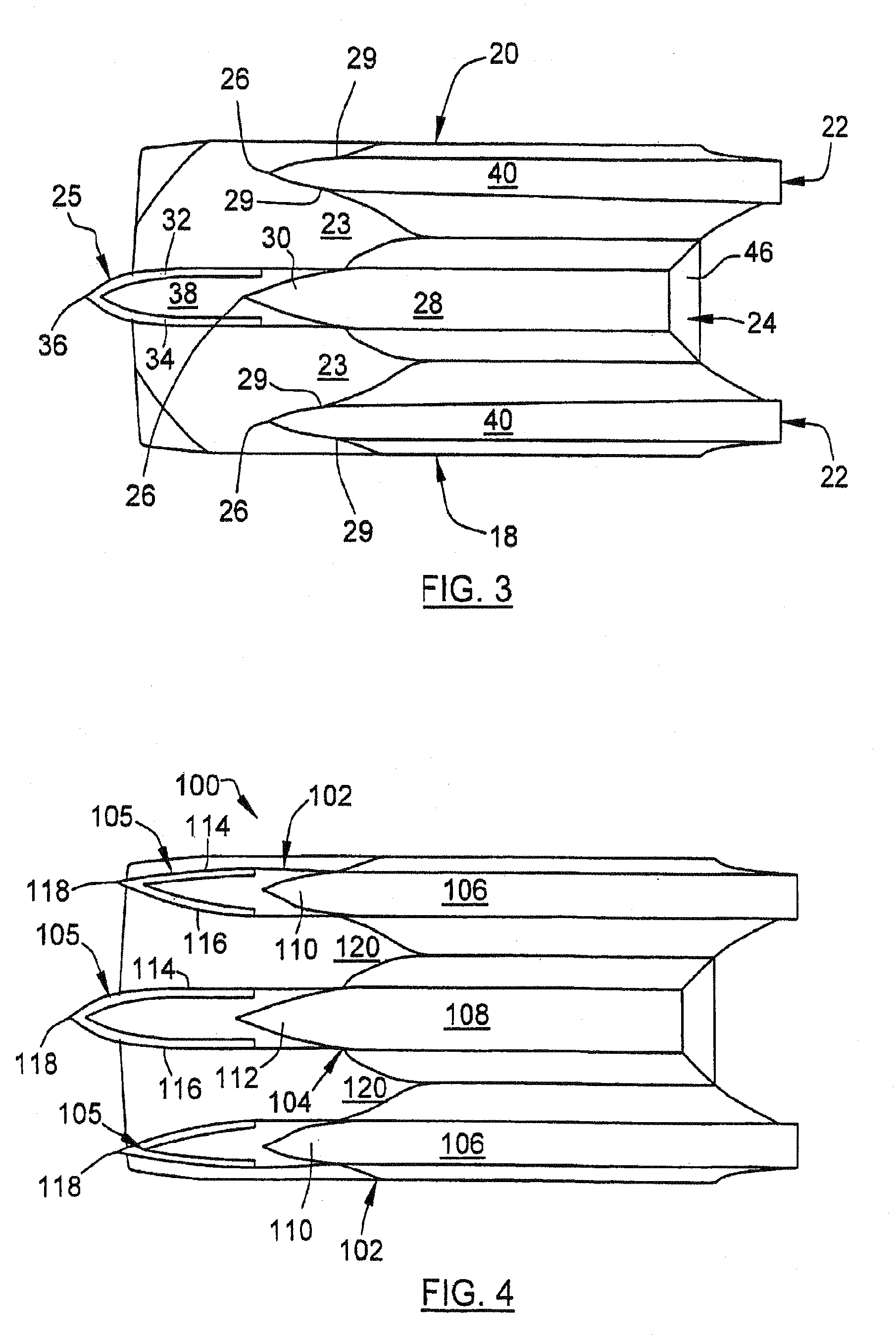

Methods and apparatus for aerodynamic and hydrodynamic drag reduction and attitude control for high speed boats

InactiveUS7543544B2Without increasing aerodynamic cross sectionReducing hydrodynamic and aerodynamic dragWatercraft hull designVessel movement reduction by gyroscopesLeading edgeAerodynamic drag

The present invention provides methods and apparatus for reducing sinkage and wetted surface, and thus hydrodynamic drag of a high-speed boat through the generation of aerodynamic lift while decreasing overall aerodynamic drag. At least one lift-generating front wing proximate a bow section of the boat with at least one corresponding front air channel may be provided. At least one lift-generating rear wing proximate a transom section of the boat with at least one corresponding rear air channel may also be provided. At least one of the wings may be adjustable to generate aerodynamic lift with one of: (1) a neutral; (2) a transom-lifting; and (3) a bow-lifting pitching moment about a center of inertia of the boat. At least one wing proximate the leading edge of the tunnel of a multi-hull boat may be provided to increase the operational envelope.

Owner:FLOW WORKS

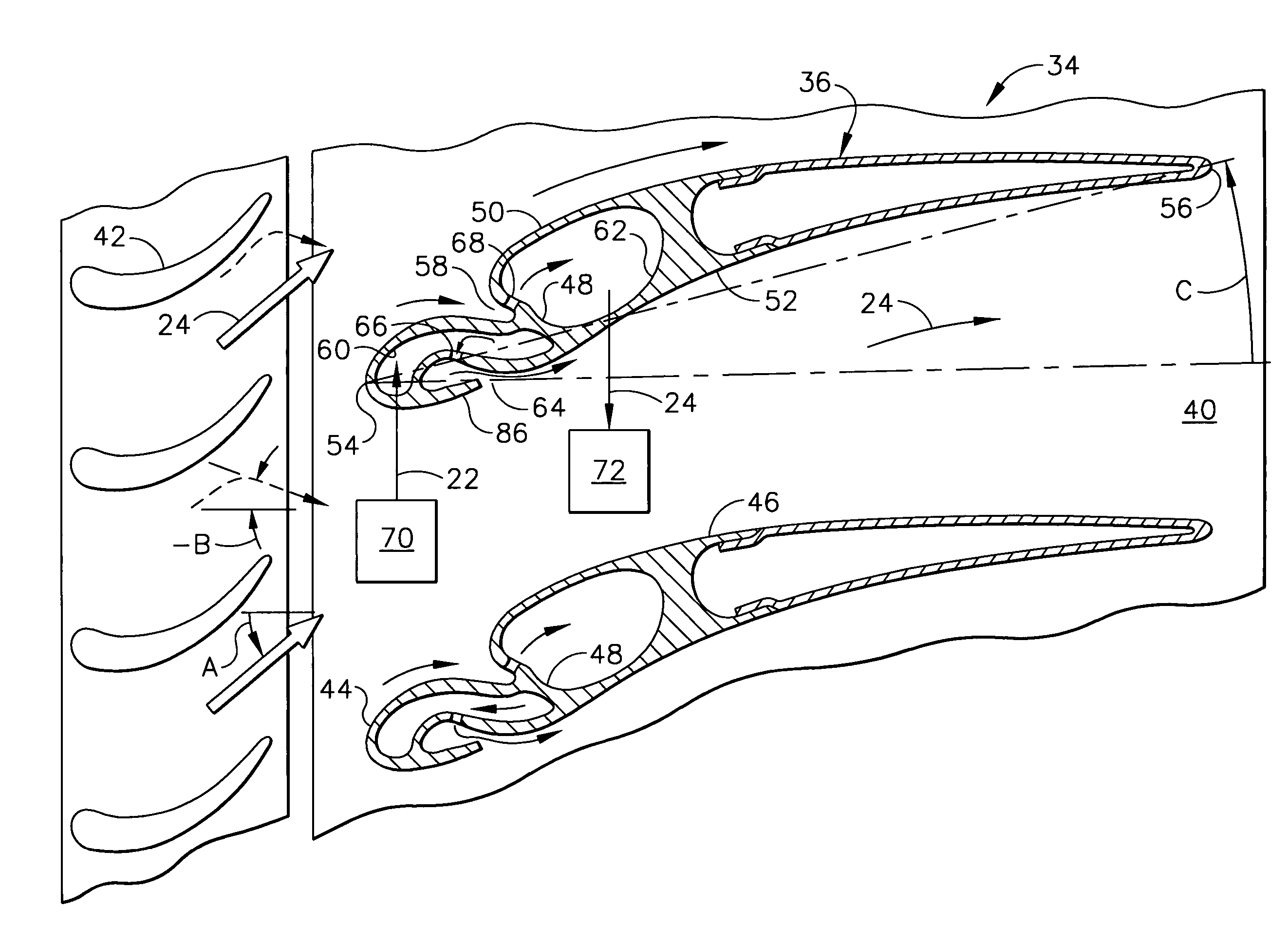

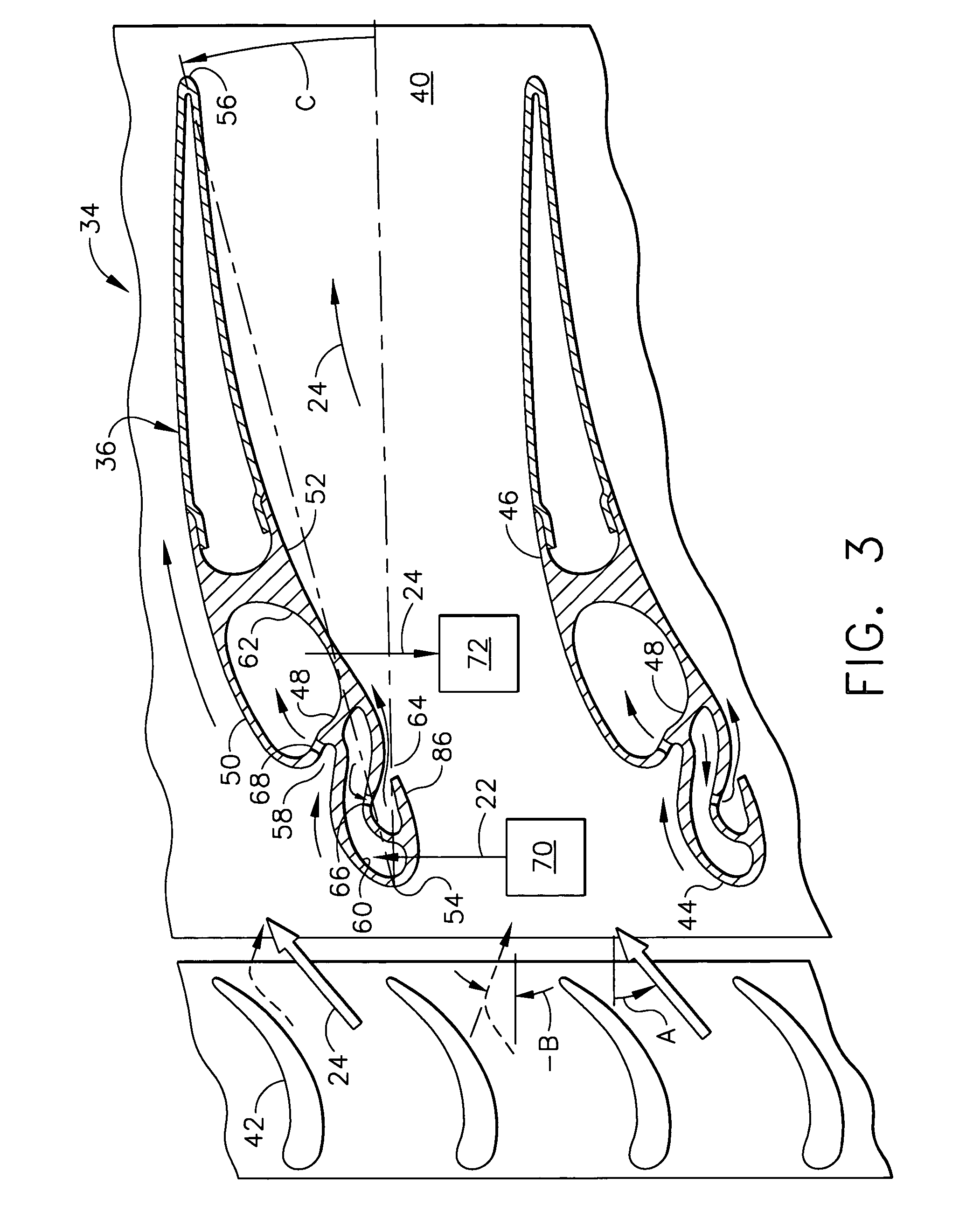

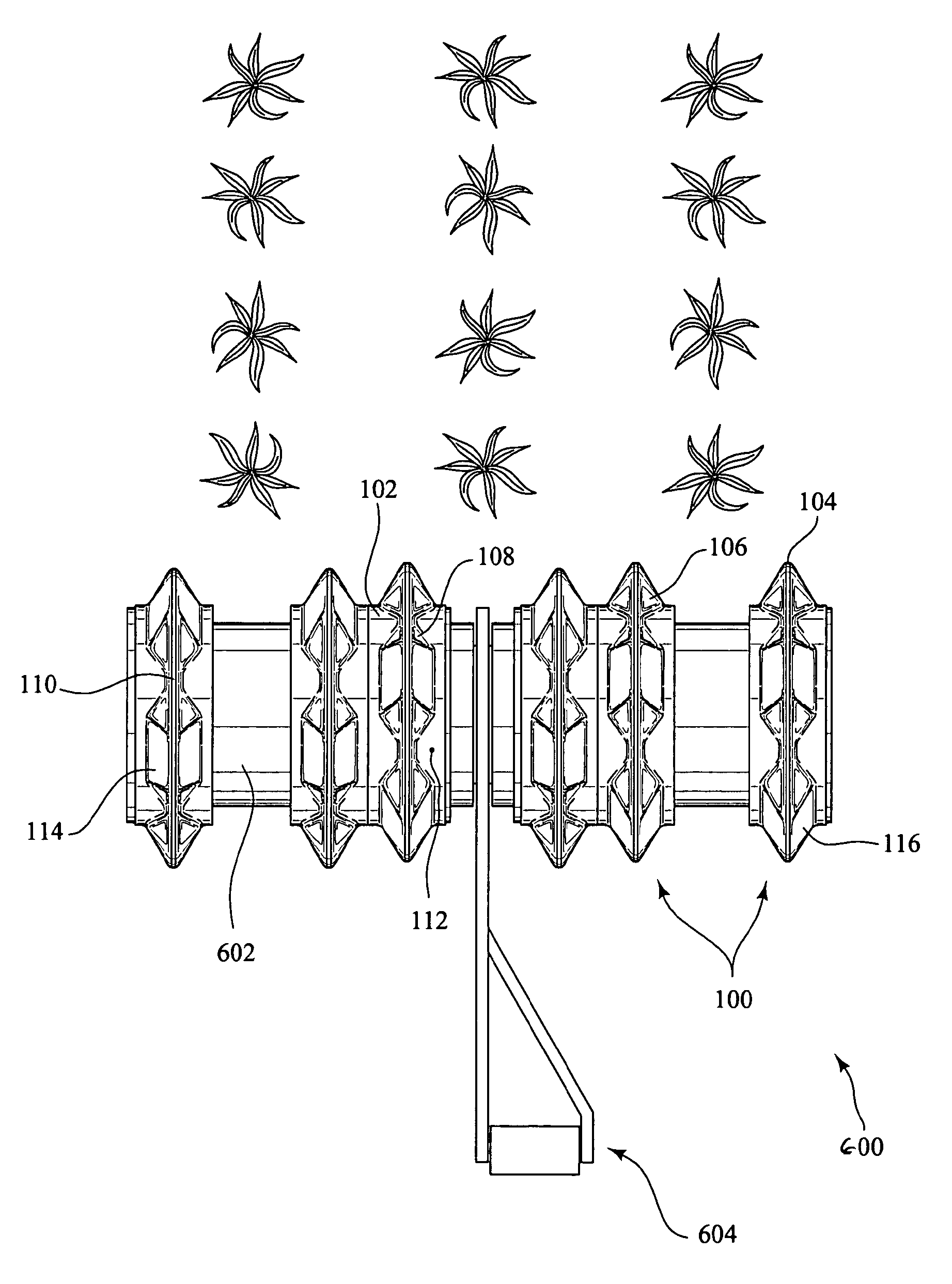

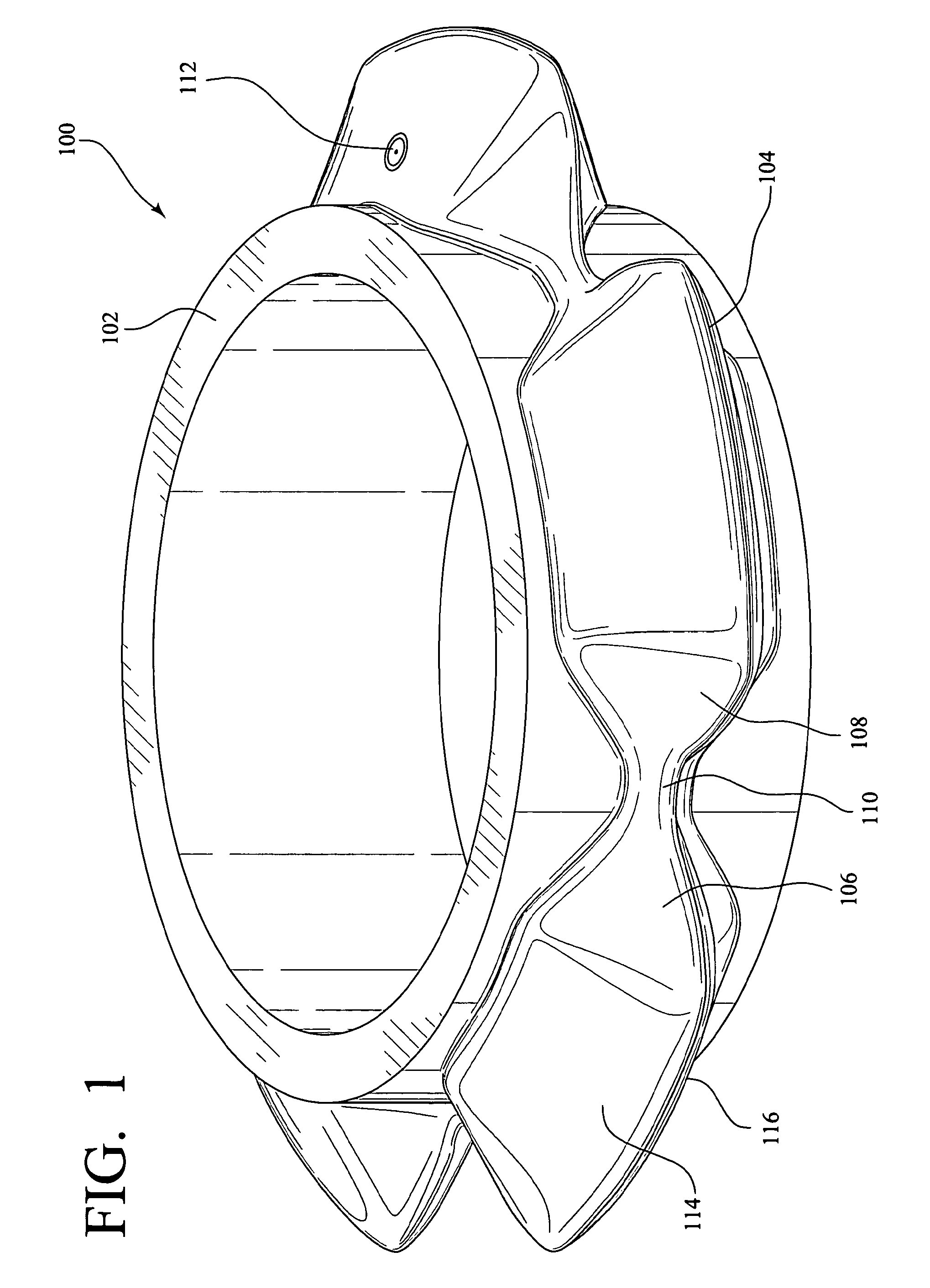

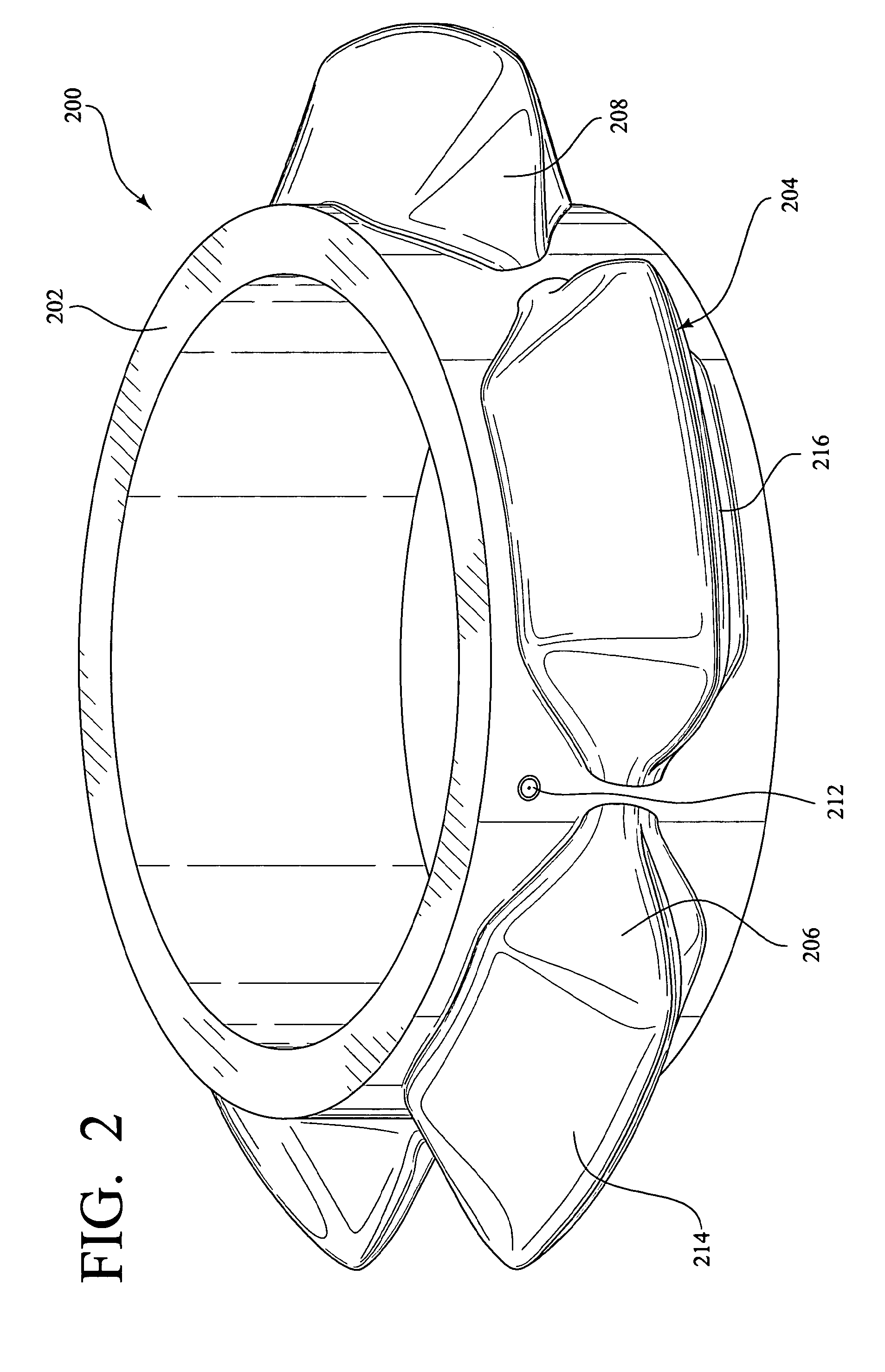

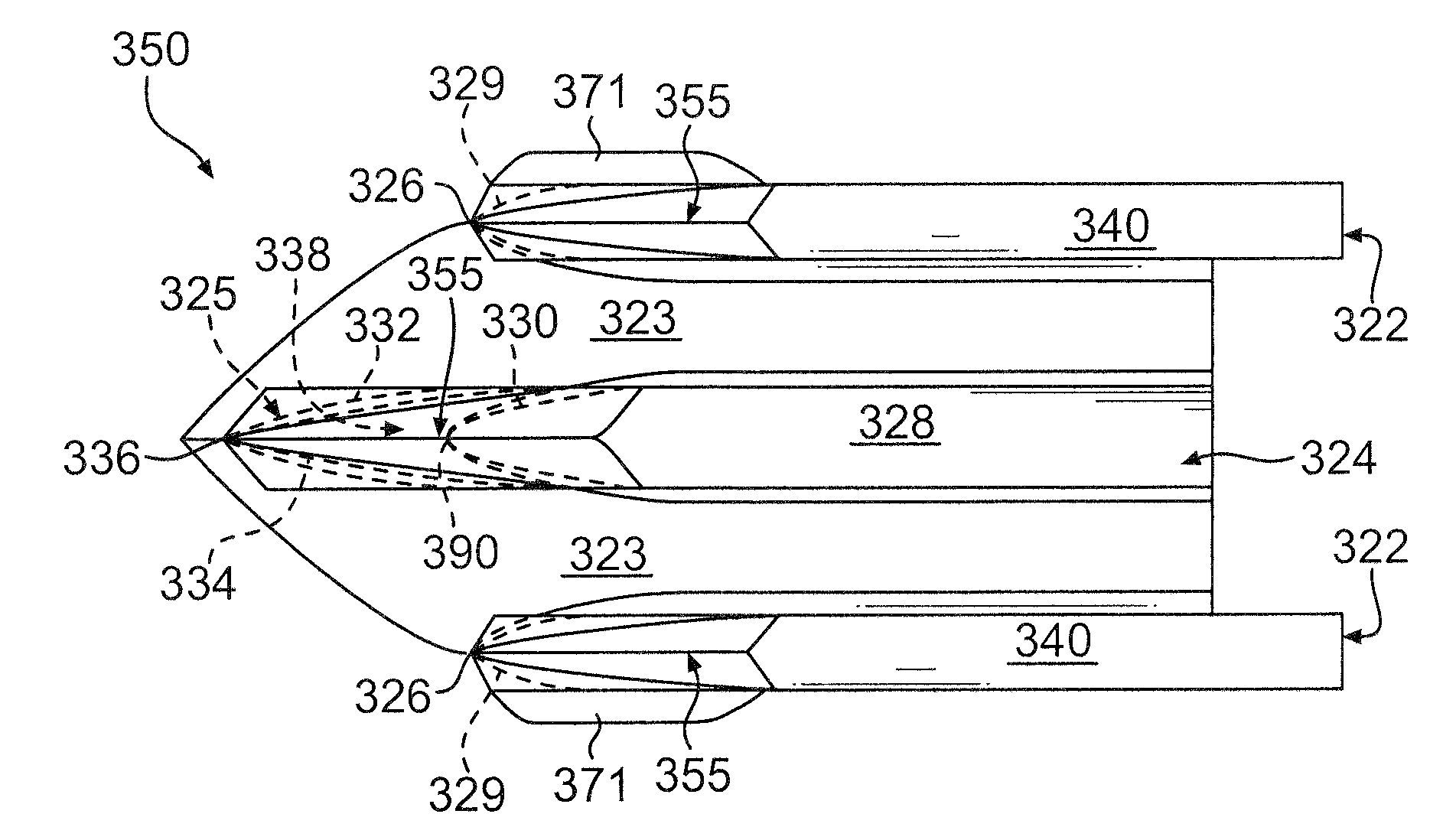

Bifurcated outlet guide vanes

A turbine rear frame includes a row of outlet guide vanes extending between outer and inner bands. Each of the vanes is bifurcated into a forward prow integrally joined to an aft stern by a septum therebetween. The prow and stern collectively define the aerodynamic profile of each vane which is locally interrupted at the septum.

Owner:NAVY DEPT OF THE

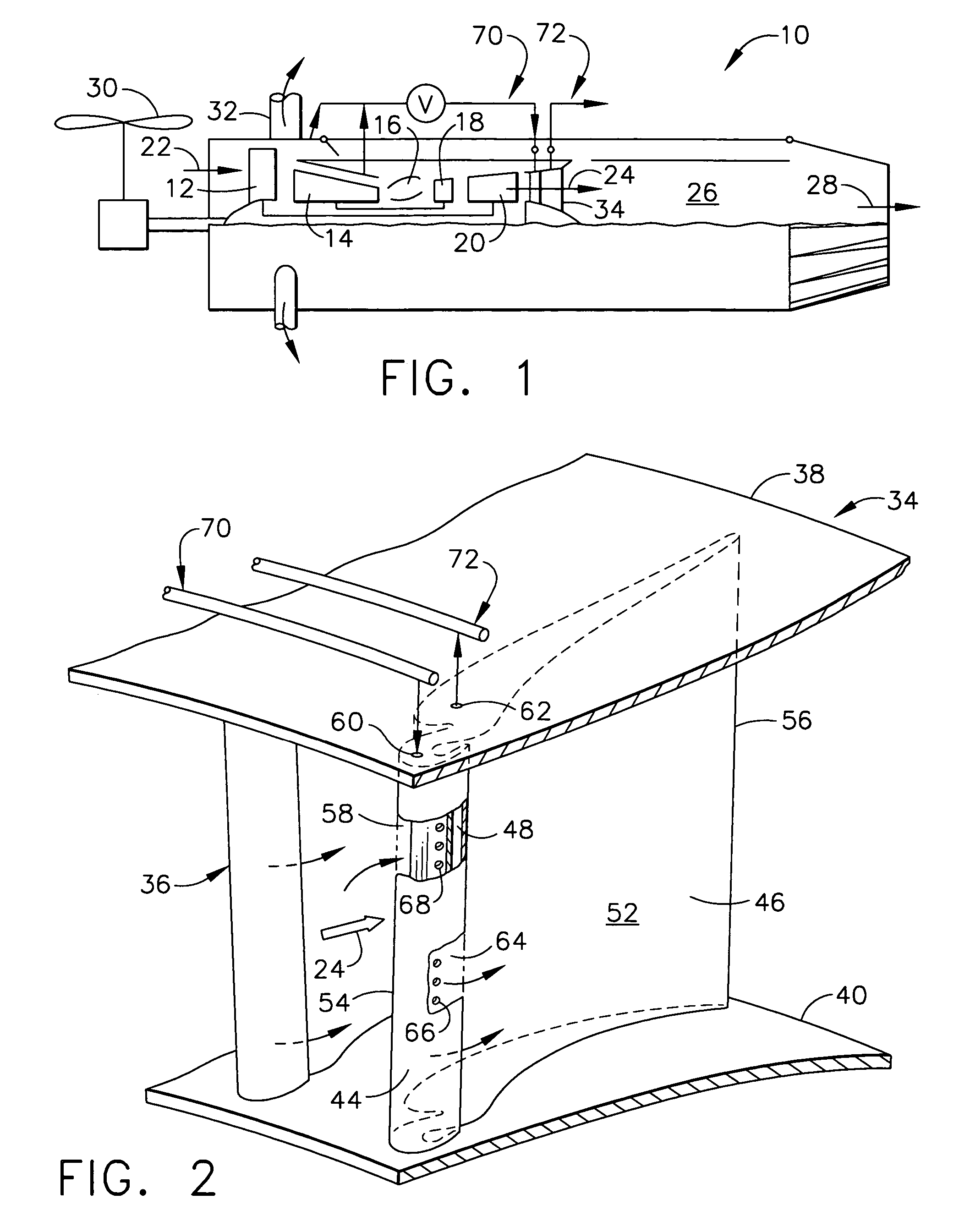

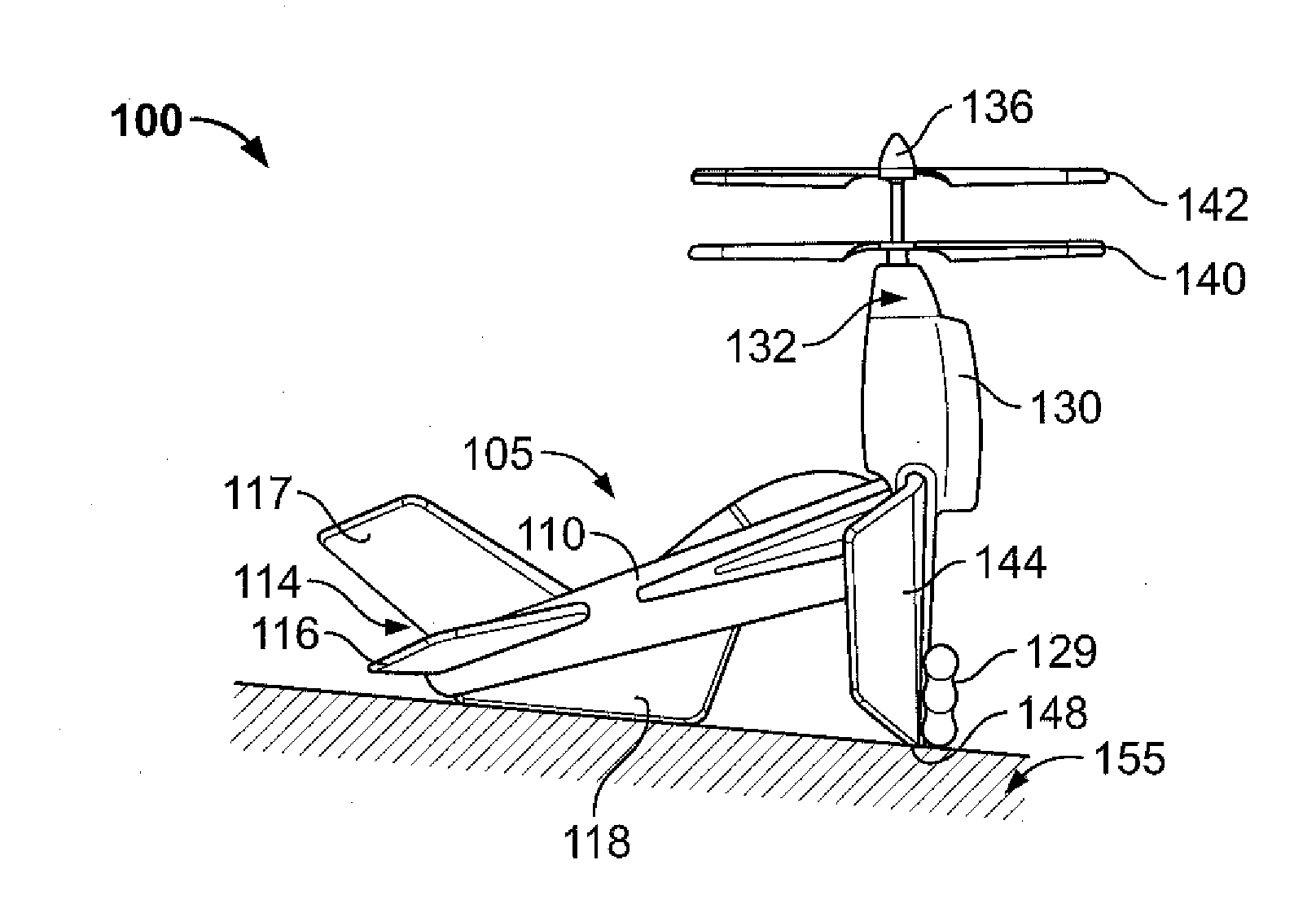

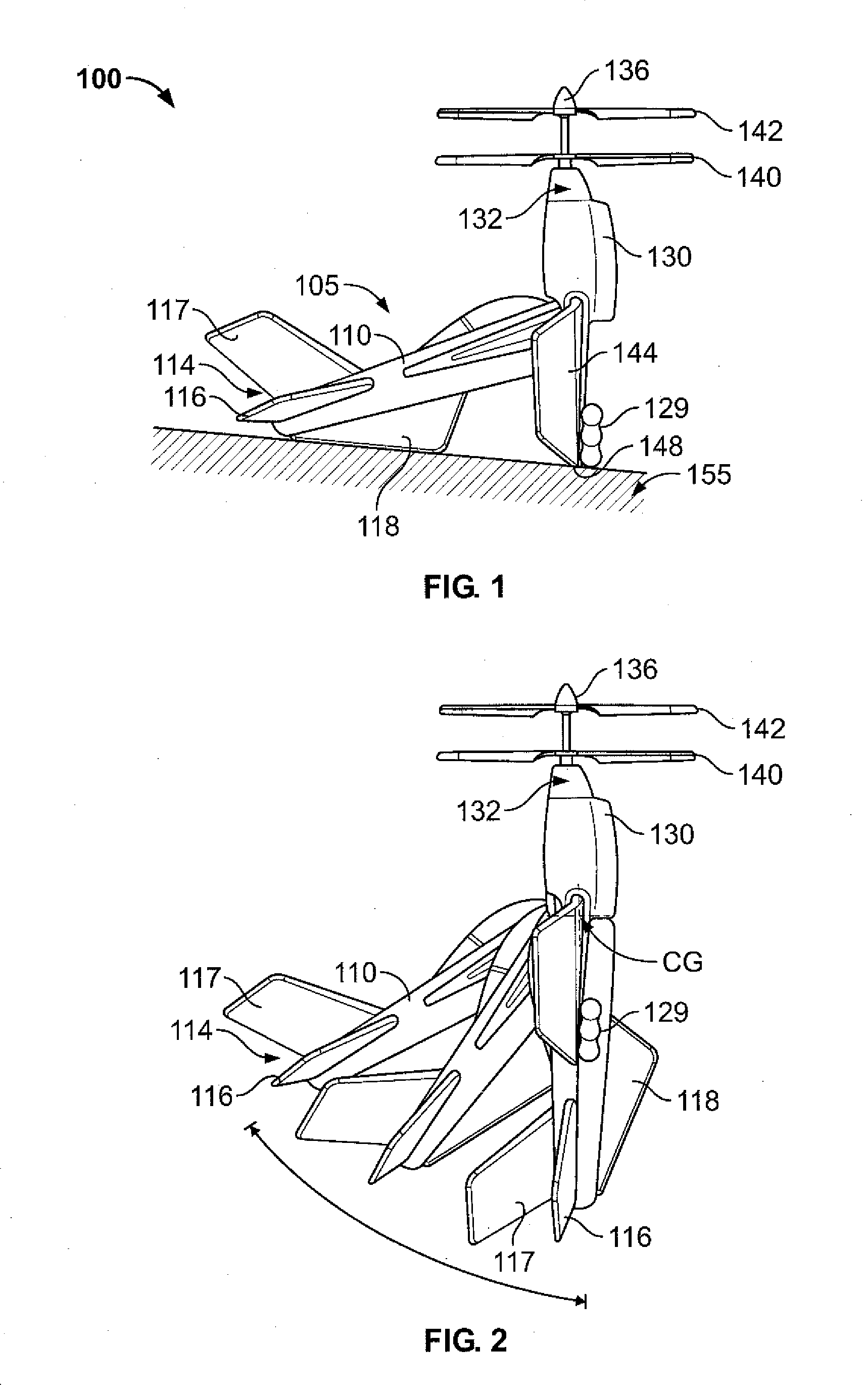

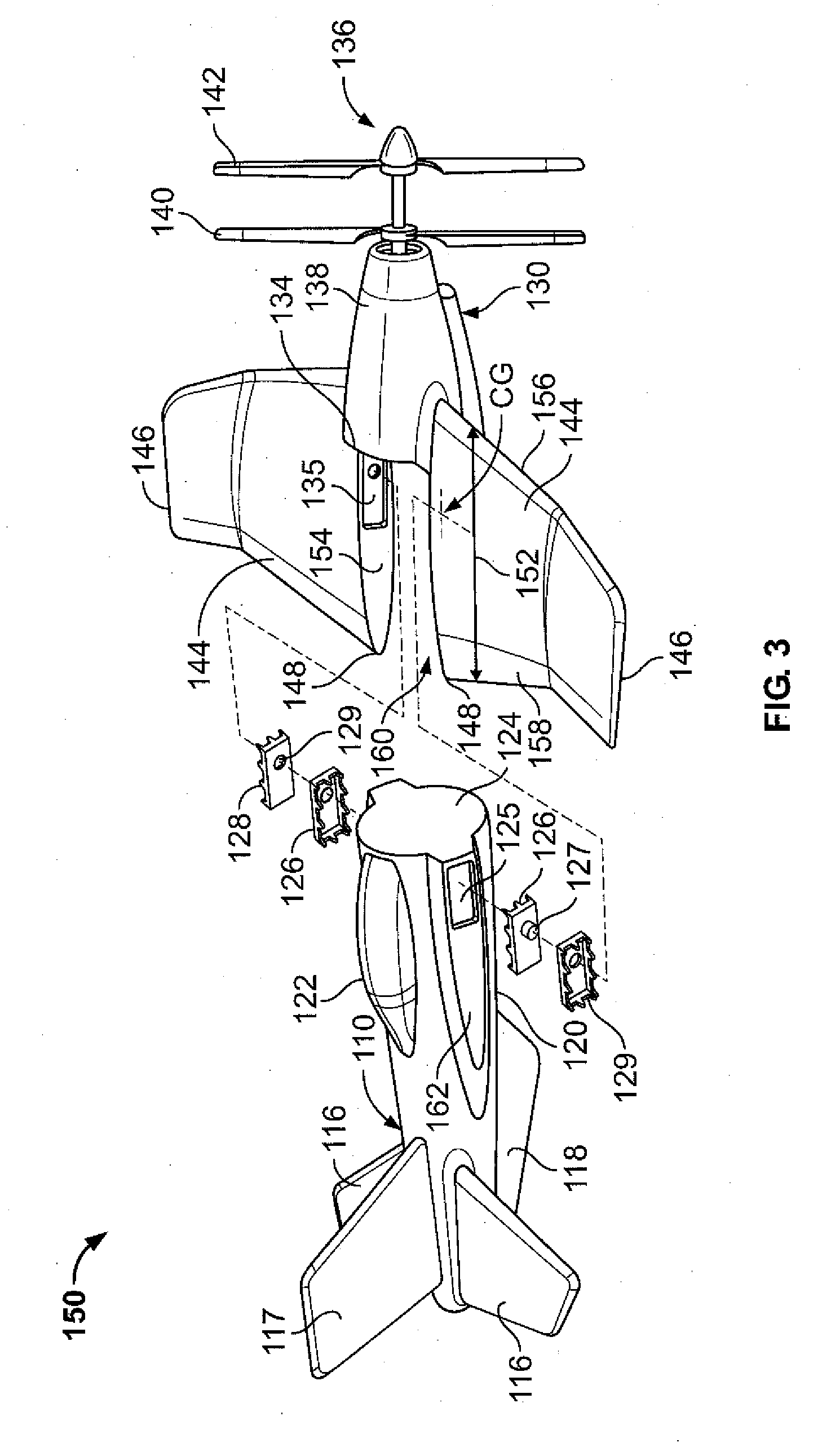

Vertical take off plane

In one embodiment of the present invention, a vertical take off aircraft is provided with an airframe having an aft section freely pivotally connected to the bow section. The airframe is substantially planar when the aft section is pivotally aligned with the bow section. A propeller system and a pair of wings are secured to the bow section of the airframe. When the bow section is pivoted to a vertical position and the aircraft is placed on a surface, the propeller system when activated will vertically lift the aircraft off of the surface. Furthermore, when the aircraft vertically lifts off of the surface, the aft section freely pivots to form the substantially planar airframe which creates larger lift forces in a horizontal direction than in a vertical direction causing the aircraft to fly in a more horizontal direction, whereby the aircraft automatically switches from a vertical take off to horizontal flight.

Owner:REHCO LLC

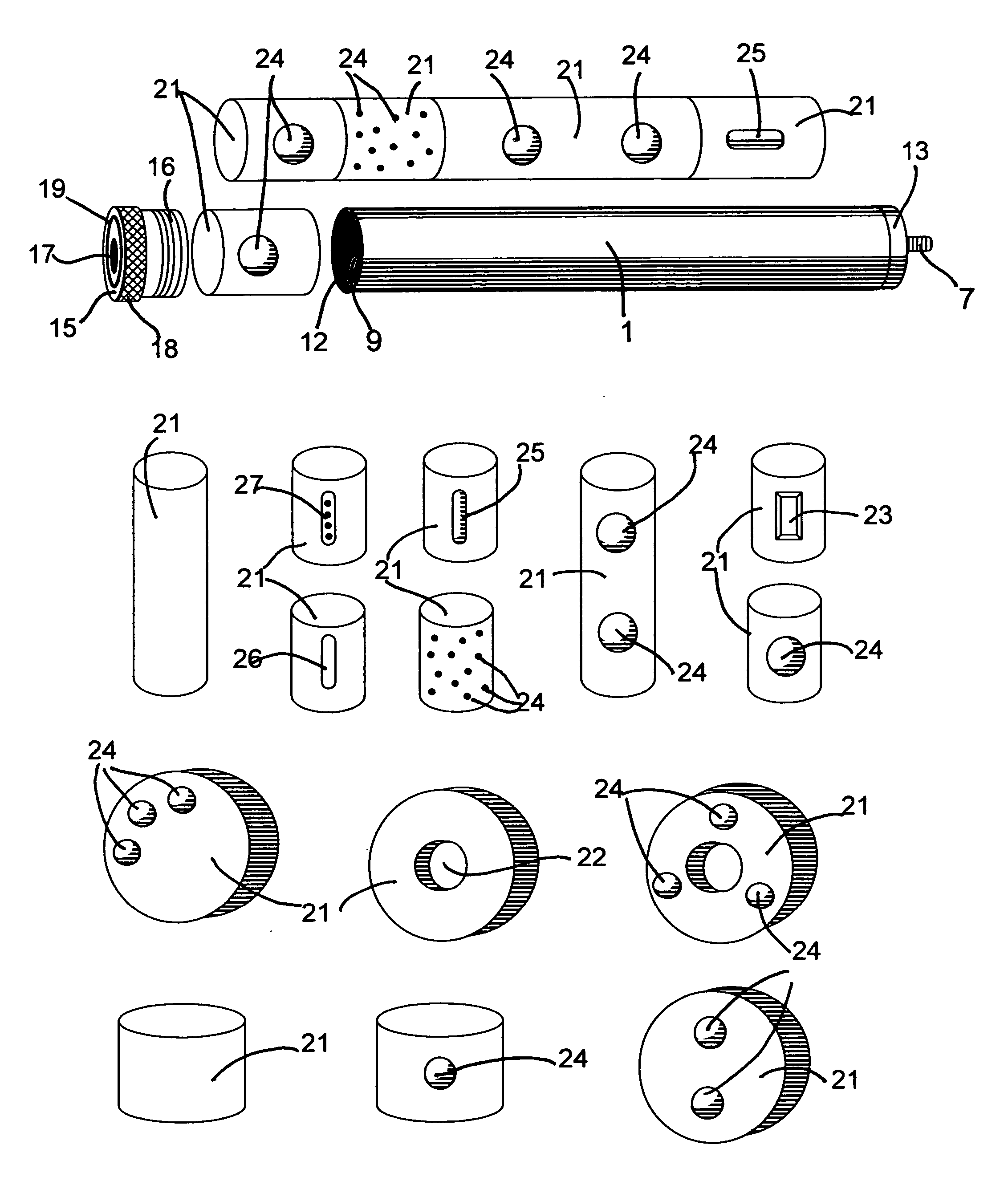

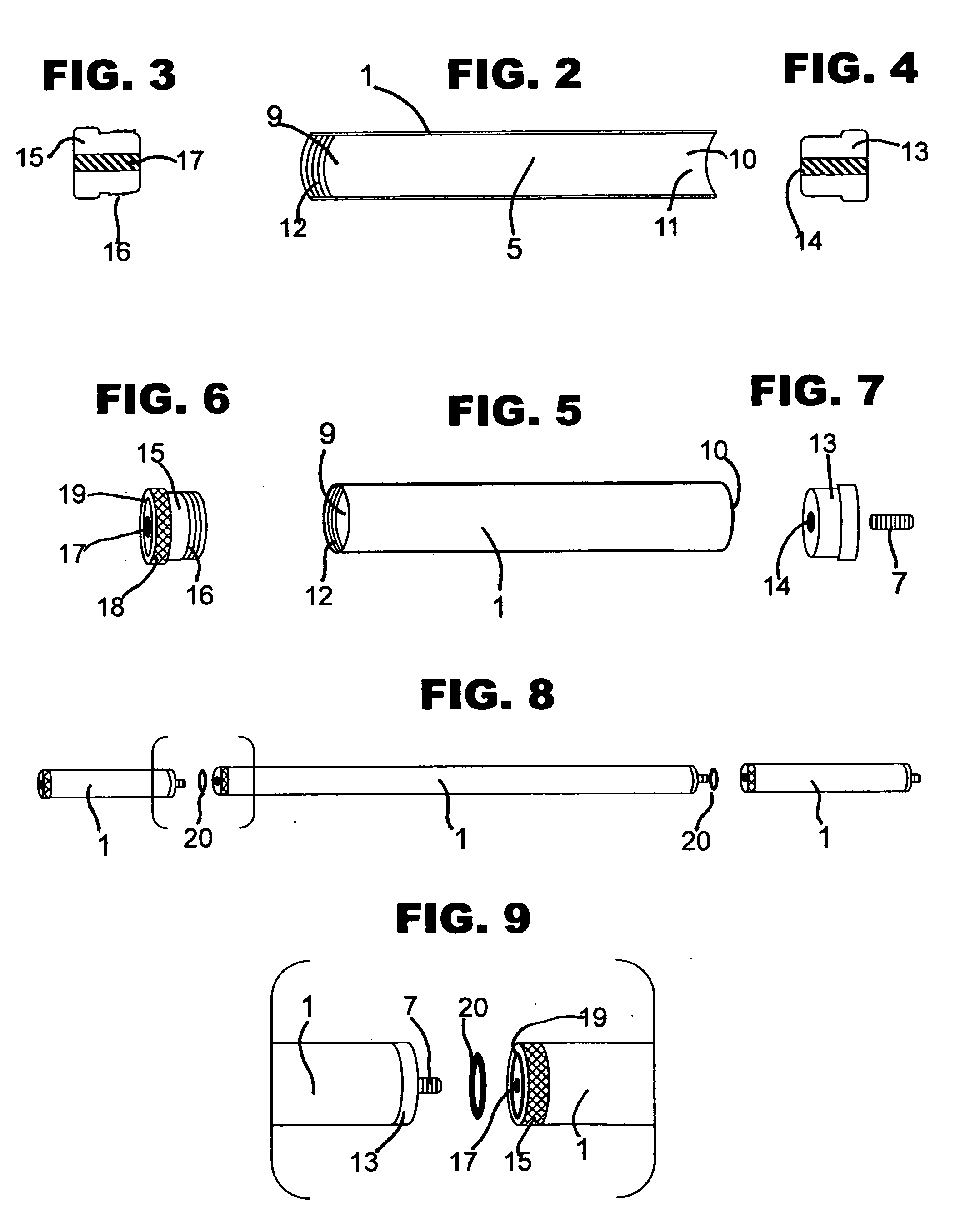

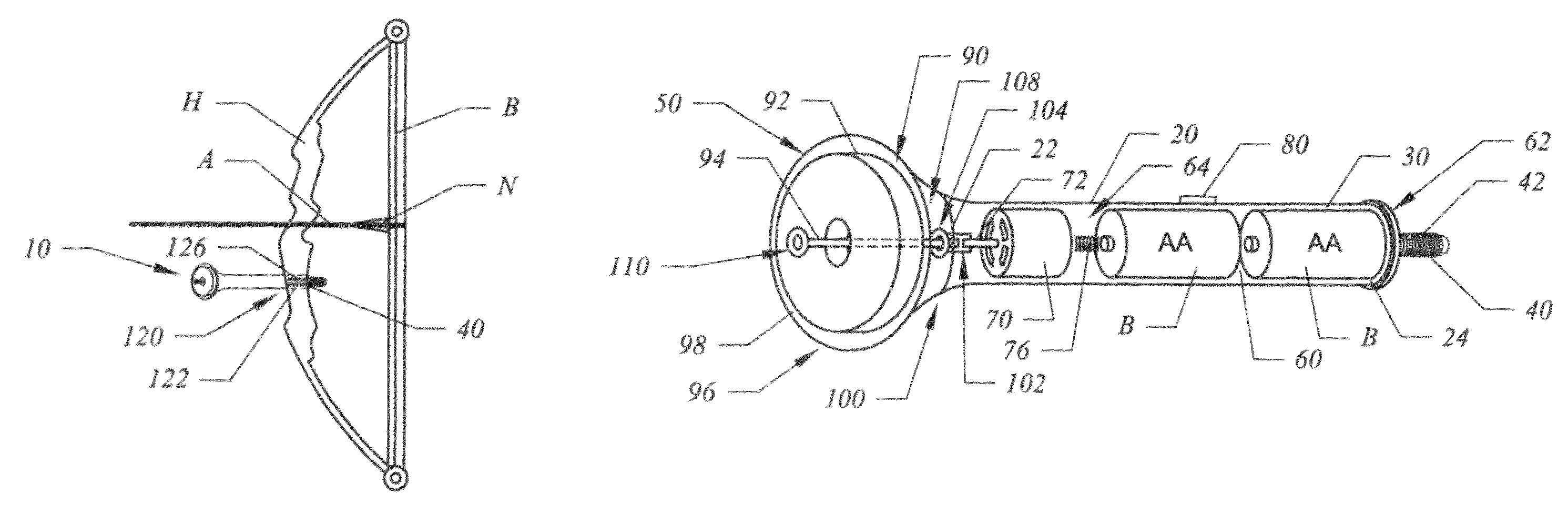

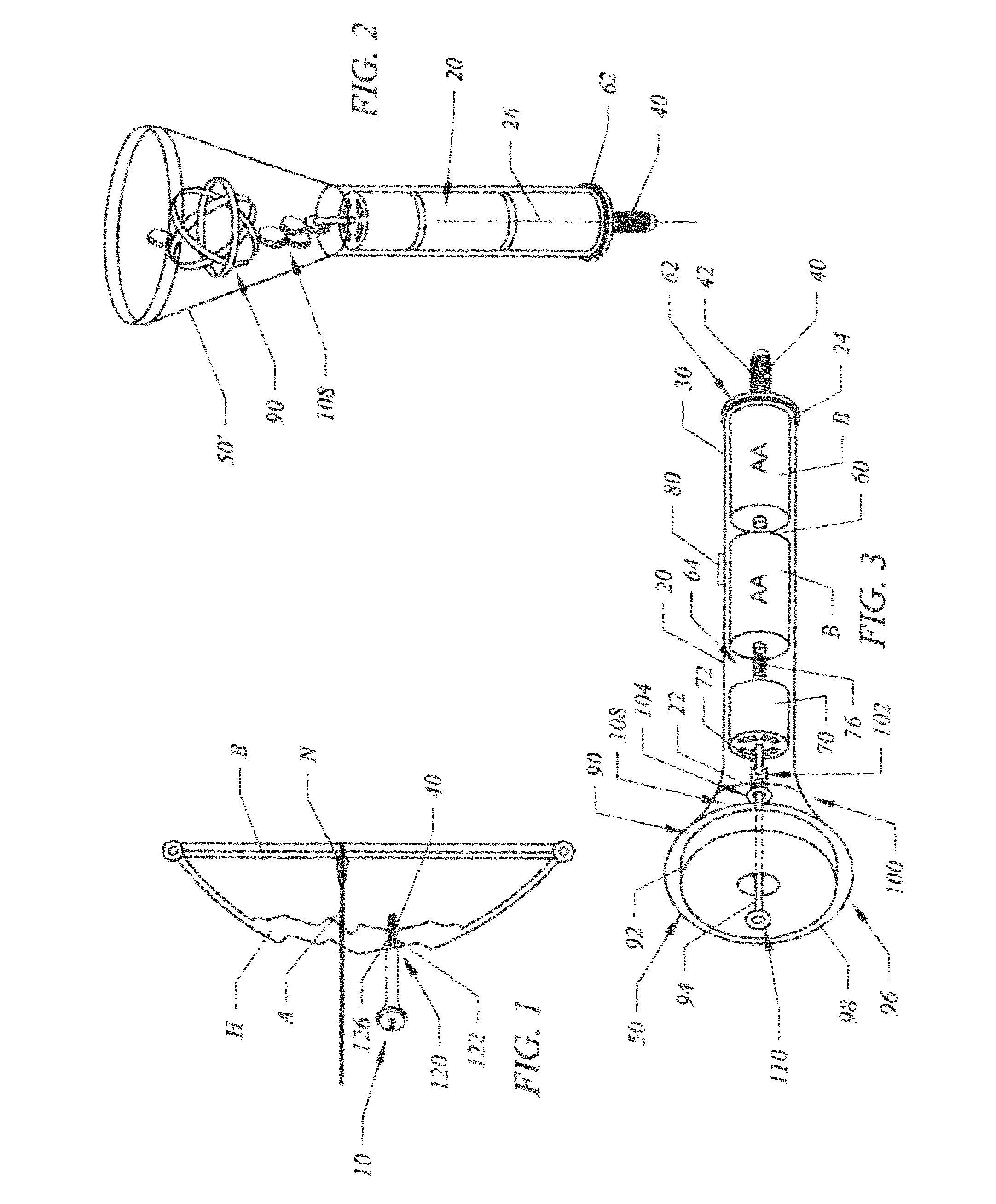

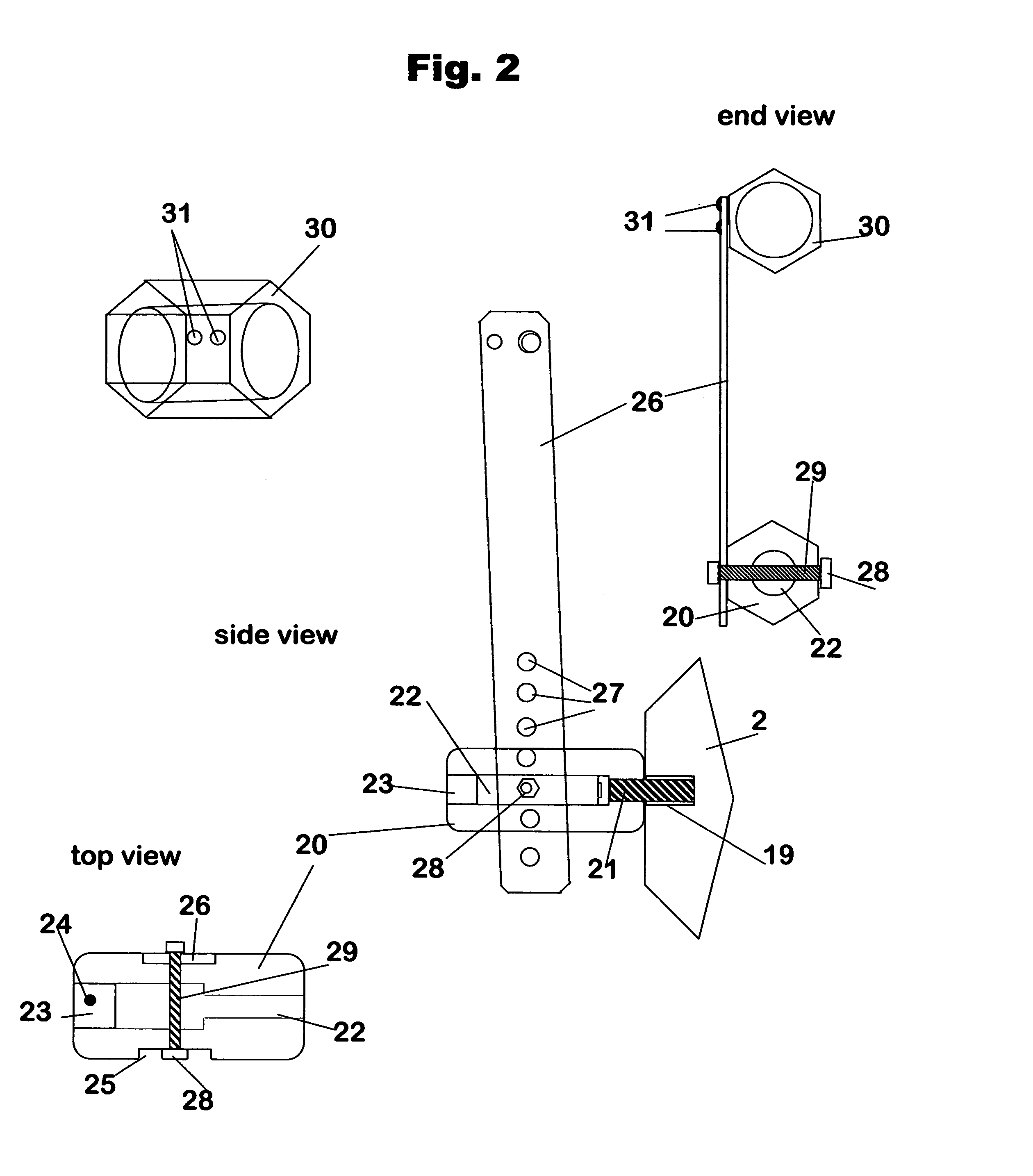

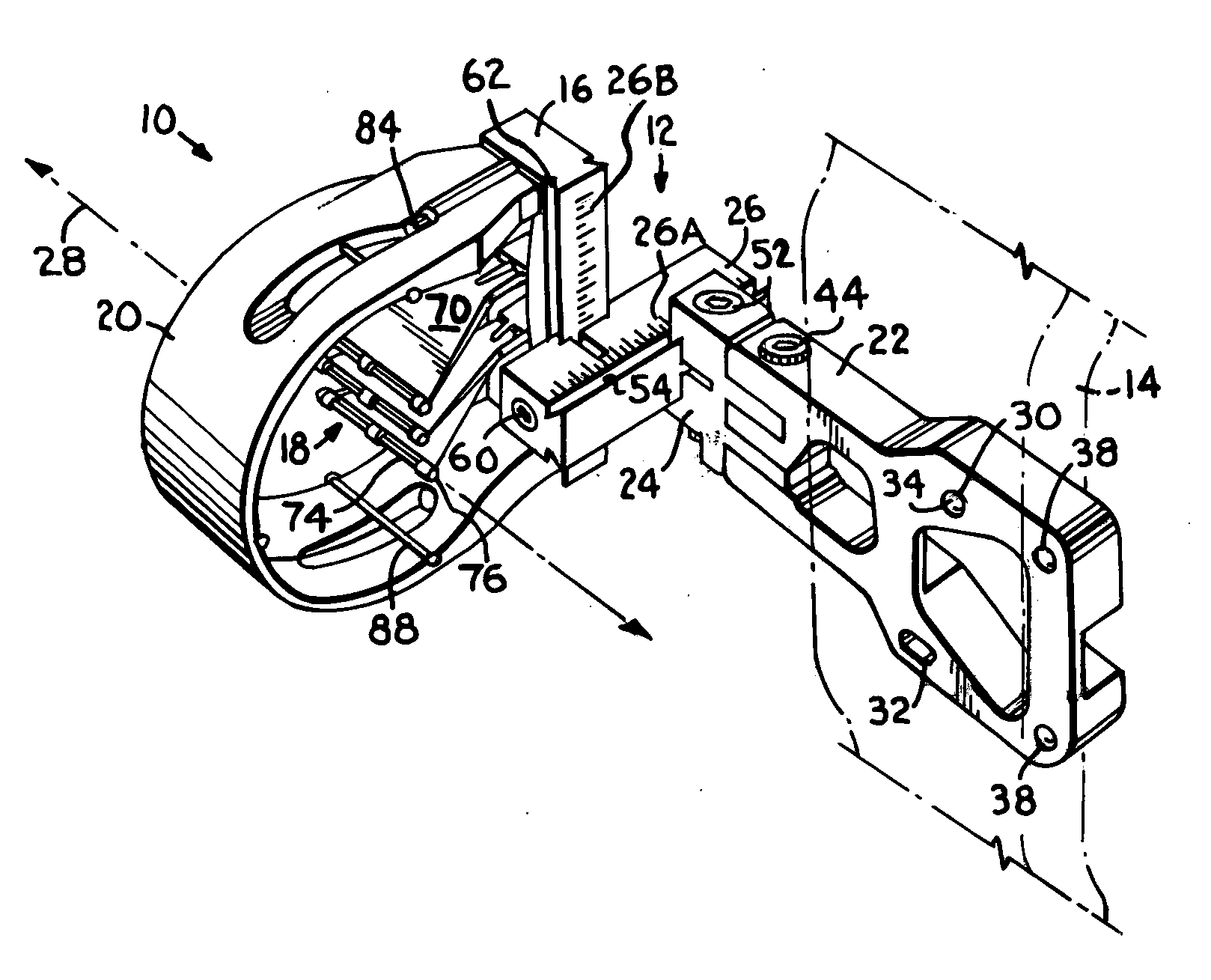

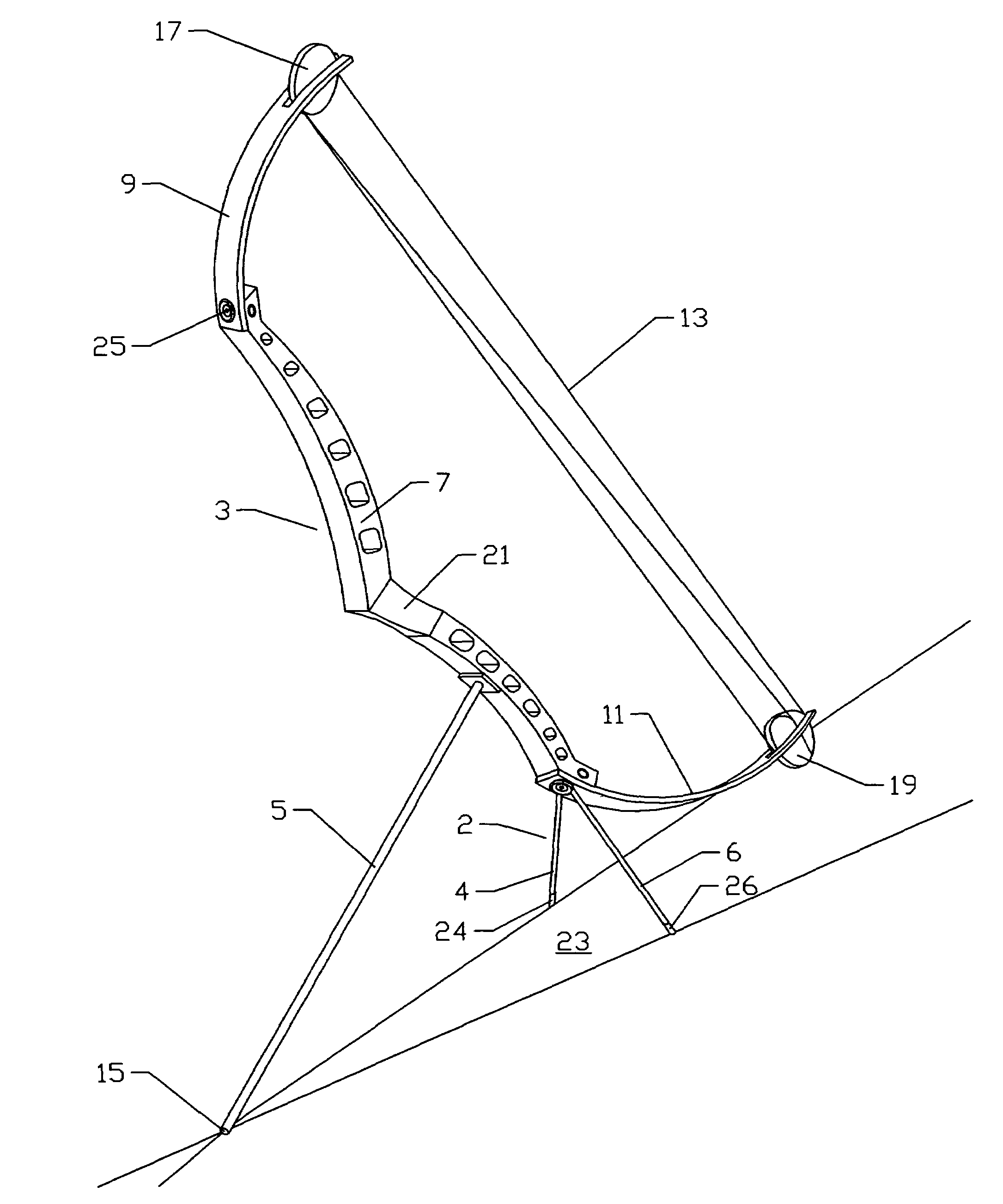

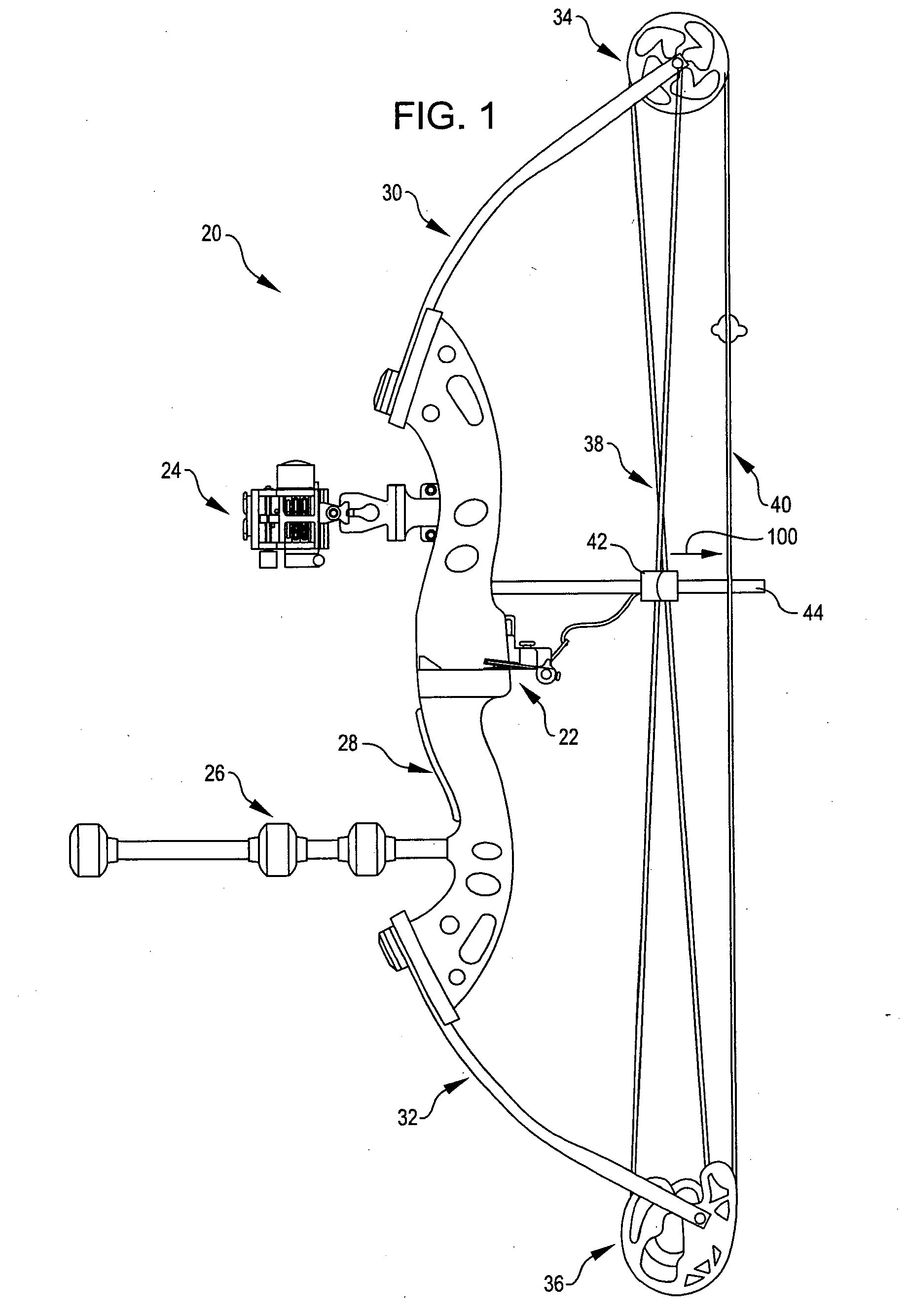

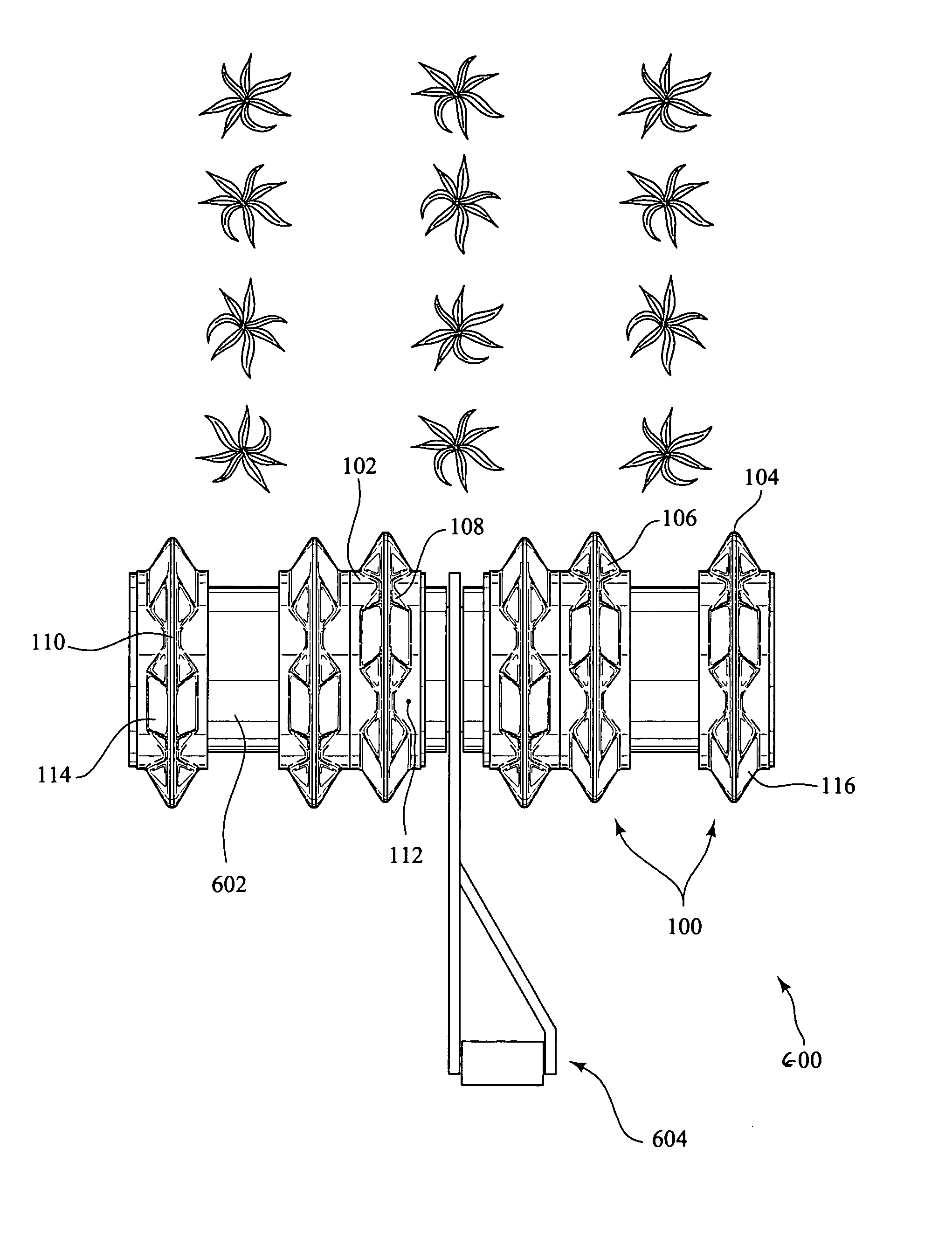

Stabilizer and vibration/noise dampening device that attaches to an archery bow

The contents of stabilizers for archery bows in the past have been a non-removable material that is permanently sealed inside the stabilizer housing unit by the manufacturer. Most stabilizers are made from tubular aluminum or other lightweight materials. The inside contents of the tubular stabilizers vary, such as fluid, granular steel, granular rubber, lead or solid elastomer, none of which can be moved around, altered or removed or added to by the archer. A unique feature of this device is that the housing of the stabilizer can be easily opened and re-closed securely by the archer, enabling the archer to remove, replace, adjust, change, add to or subtract from the contents, in order to get the exact desired weight, balance and / or vibration and sound dampening effect. An additional unique feature of this design is that the contents can consist of weighted material inside removable soft elastomer modular units of various sizes and / or mass weights. The weighted material can be made of steel or lead shot, ball bearings, weight rods, capsules filled with fluid, or fluid plus weighted pellets, or any combination of these weighted materials. Any or all of these can be suspended and / or sealed or molded inside the soft elastomer modules. This weighted material and / or fluid suspended in the elastomer absorbs vibration and sound, and the vibration and sound then is dissipated and absorbed further by the elastomer, then by the stabilizer housing itself. The archer can use different sized and / or weighted sections or internal modules, packets, that fit and / or stack snugly inside the housing of the stabilizer. The archer can change them easily, at will, to get the desired weight, balance and / or amount of vibration and sound dampening. The size and weight of these removable internal vibration dampening modules are only limited by the inside volume of the hollow chamber of the stabilizer housing that attaches to the bow. Another unique feature of this design is that two or more stabilizer housing of the same or varying sizes and shapes can be joined together, with or without an O-ring compressed between the stabilizer housings, to make one longer modular stabilizer with adjustable internal variable weight components. Also, a system of offset brackets and / or V-bars can be used to secure one or more of these stabilizer units in a position not normally available because of the limitations and configuration of a particular archery bow handle / riser.

Owner:PELLERITE BERNARD M

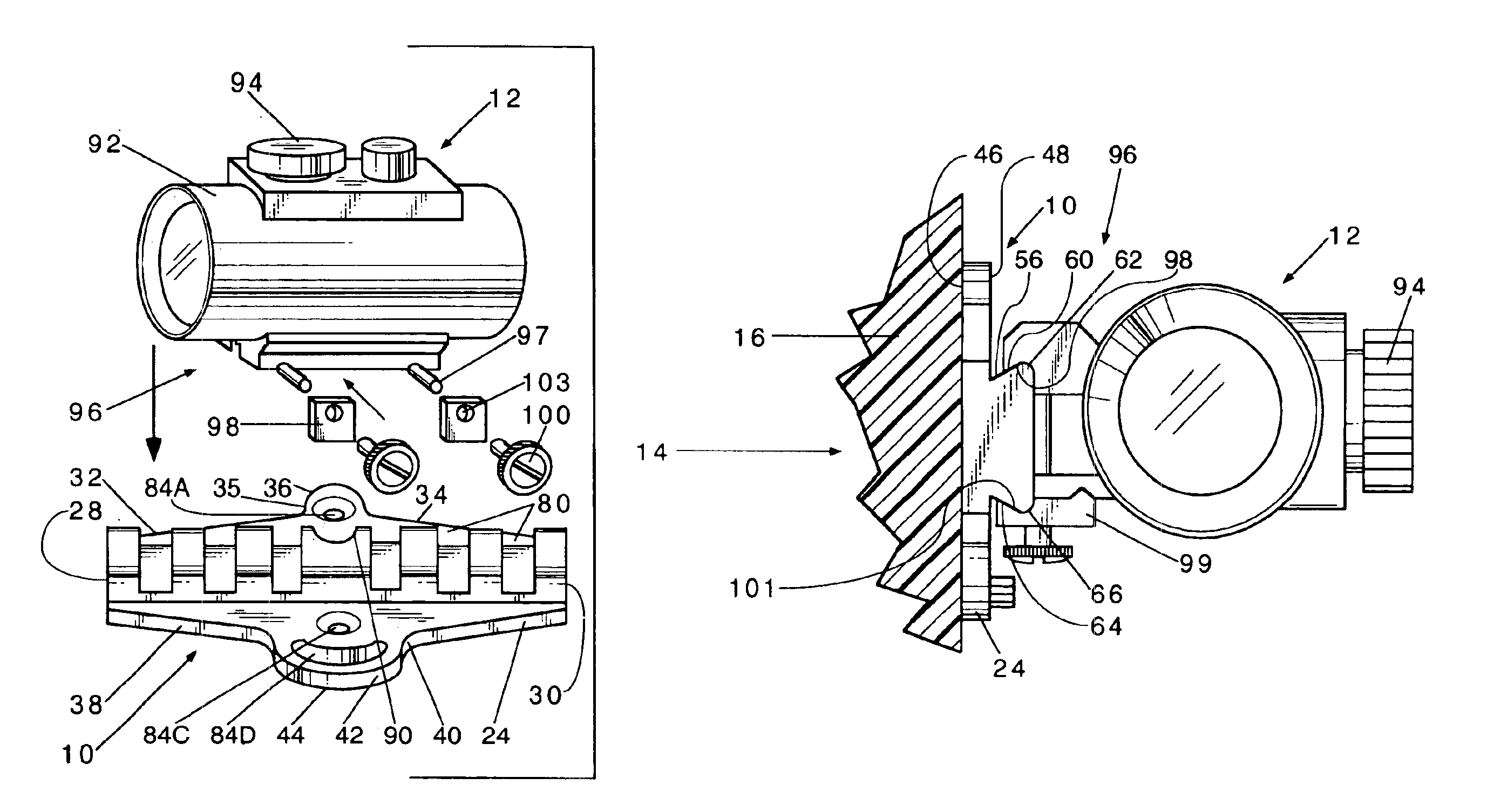

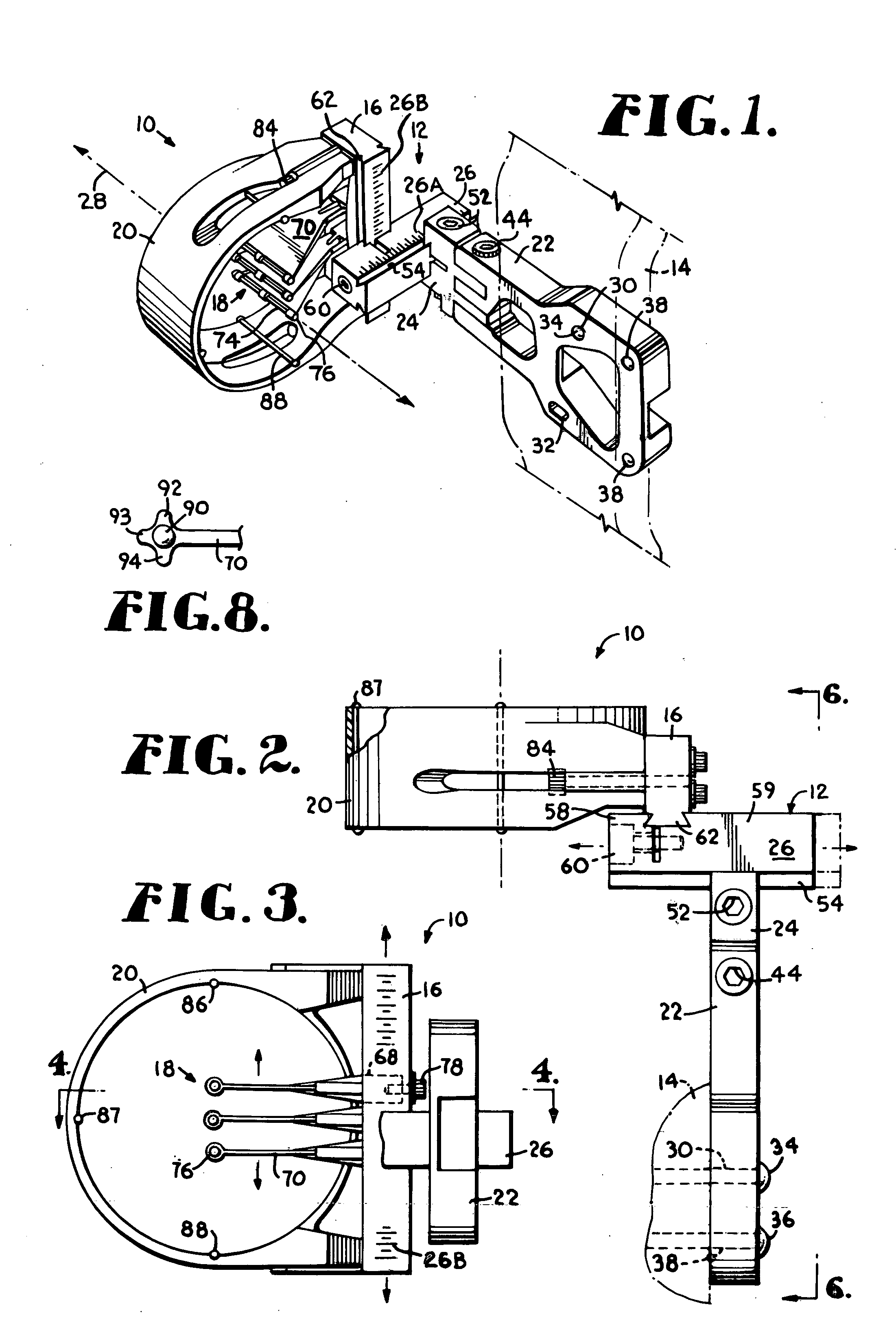

Archery scope mount

InactiveUS6895676B1Easy slide installationBows/crossbowsSighting devicesShortest distanceEngineering

This invention relates to a one-piece lightweight, compact, low profile adjustable scope mount for mounting a sighting scope on a lateral side surface of an archery bow. The mount includes a dovetail sight mounting rail which projects perpendicular away from the bow and includes a plurality of spaced apart scope receiving channels therein. The mount is detachably swingably mounted on the bow and allows the user to adjust the adjustable mounting plate either vertically and / or horizontally. The adjustable scope mount is unitary in construction and extends a very short distance away from the inside riser of the bow whereby making it virtually impossible to inadvertently move the plate. The adjustment of fasteners is all that is required to make vertical and / or horizontal adjustments.

Owner:MENDYK PATRICK

Archery bow stabilizer

Owner:MOGGO WILLIAM R

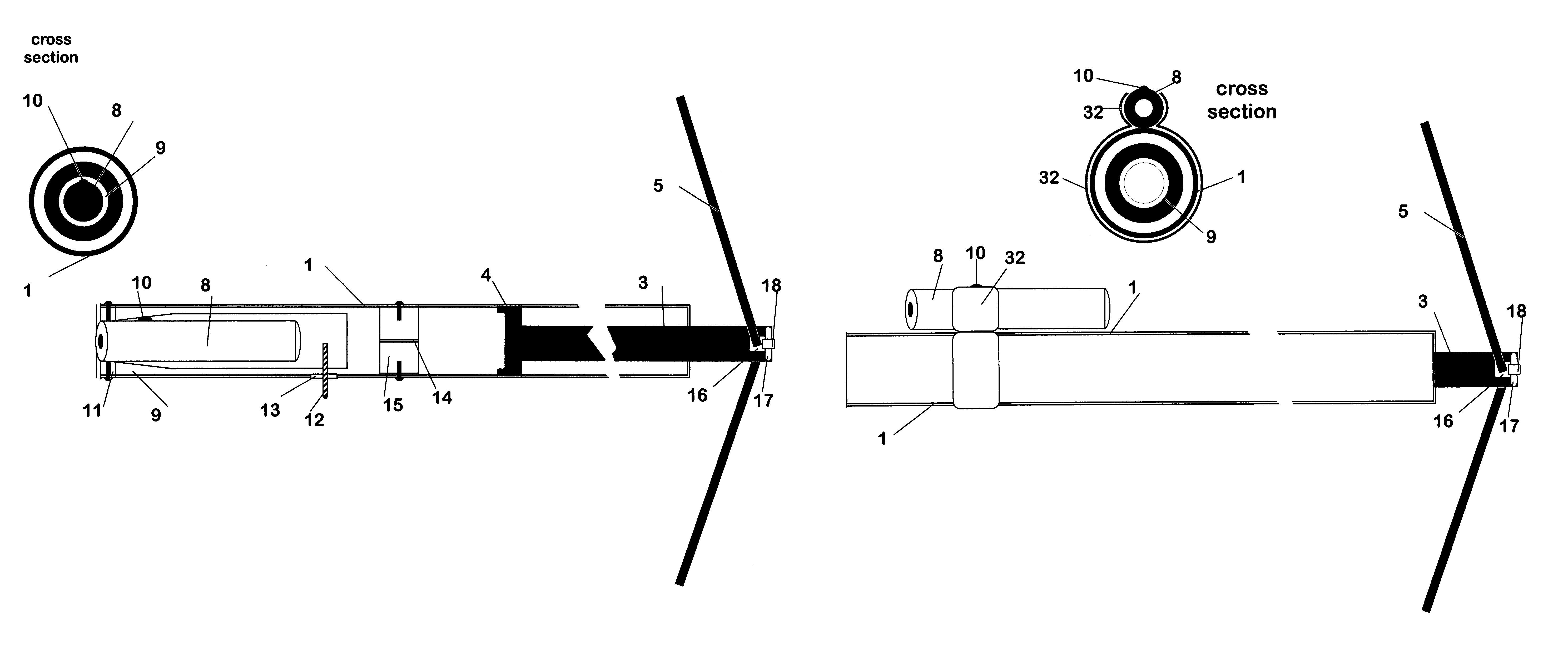

Laser-equipped pneumatic training aid for safe drawing of the bowstring

InactiveUS7216643B2Quickly and safely attachedEasy to separateBows/crossbowsSighting devicesAerodynamic dragLaser light

A pneumatic tube that is secured to the bow and bowstring with an arrow and piston inside for safe drawing and firing of an archery bow. When the archer looses the string and it drives the arrow forward, the piston creates pneumatic air resistance like a hand operated bicycle pump. This resistance is sufficient to prevent damage to the bow and / or its components from loosing the string without an actual arrow on the string. Normal loosing the string without an arrow on it is called “dry-firing” and would damage the bow and / or its components. This tube is attached to a bracket that is affixed to a mounting block that can be fastened to the front of the bow at the standard stabilizer mounting hole. There is also a laser mounted in the end of the tube, which can be turned on by the archer and projects a laser light on the target. This light is automatically turned off as the bow is fired, thus showing the archer exactly where an actual arrow would have hit. This device can be used without removing or disabling the arrow rest and is used in practice and to identify and then rectify any release flaws and other shooting maladies.

Owner:PELLERITE BERNARD M

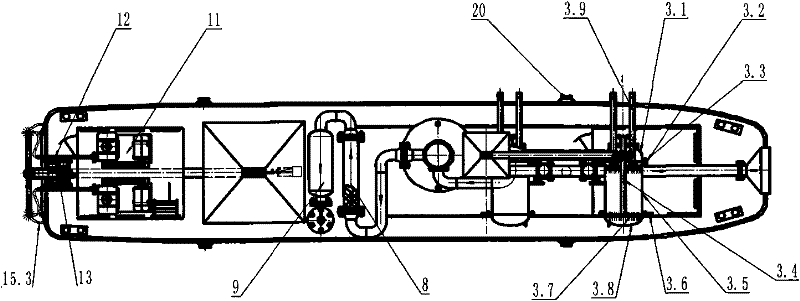

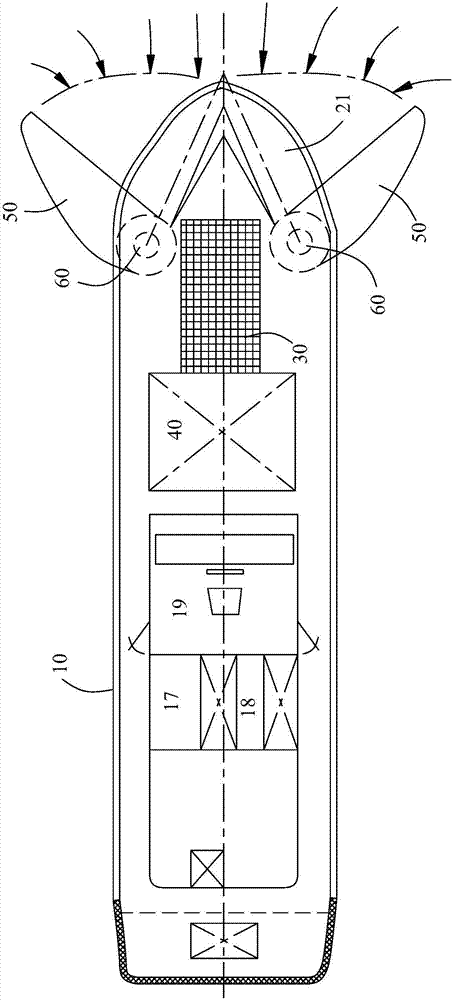

Water-scavenger multifunctional environmental-friendly ship equipment and method thereof

InactiveCN101746488ASimple structureRun smoothlyWater cleaningWaterborne vesselsScavengerWater quality

The invention discloses a water-scavenger multifunctional environmental-friendly ship equipment and a method thereof, relating to a water-scavenger multifunctional environmental-friendly ship. The invention breaks fake vacuoles of blue-green algae cells by pressure so that blue-green algae loses necessary buoyancy so as to fast remove water-level blue-green algae and absorb the blue-green algae in kieselguhr organisms to be subsided to a lake bottom and absorbs nitrogen, phosphorus and organics contained in a lake to be automatically subsided to the lake bottom by a kieselguhr high-efficiency flocculant, so the purposes of fast lake water cleaning, denitrification and dephosphorization are achieved. The water-scavenger multifunctional environmental-friendly ship equipment has simple and compact structure, stable operation and high efficiency of blue-green removing at prows and denitrification and dephosphorization at sterns; the blue-green algae on a processed water body surface is obviously reduced; a water quality detection result shows that the invention can be used as an emergency measure when the blue-green algae is spread in large area; and in addition, a town lake water body repairing technology applying kieselguhr is a cheapest and most effective and efficient technology which has the best effect, fastest repair and effectiveness.

Owner:程中和

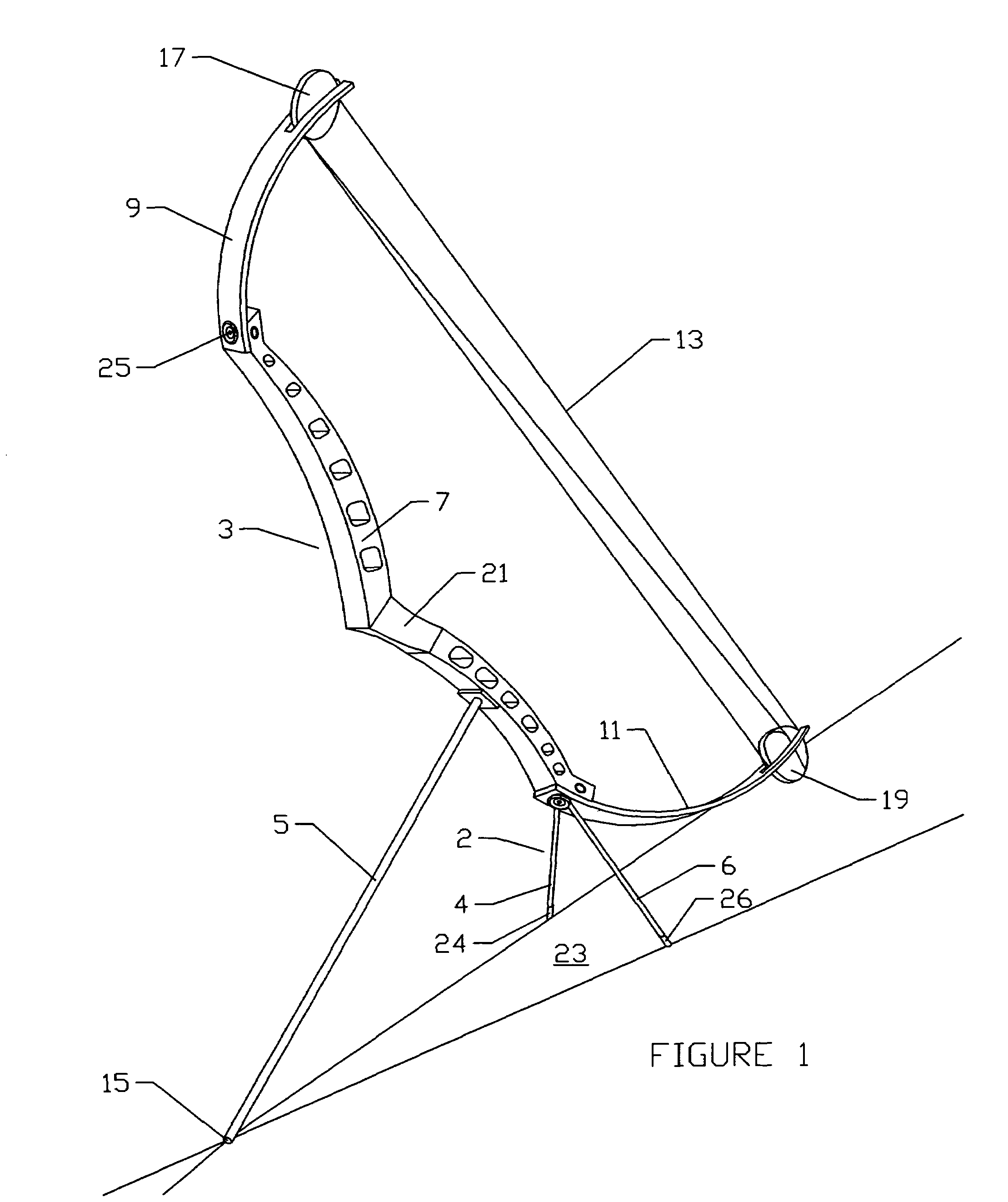

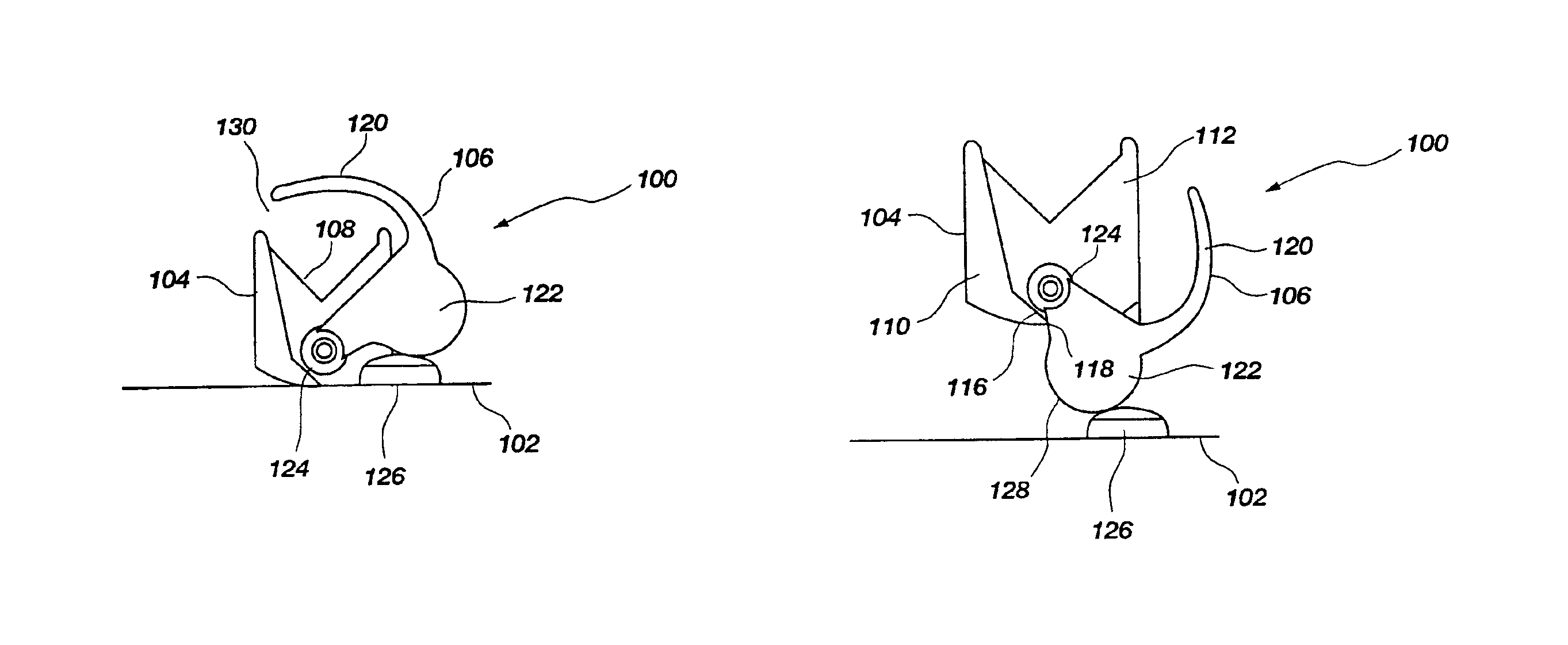

Soil conditioning device

InactiveUS7730961B2Increase aeration and water retention and infiltrationImprove breathabilitySpadesSoil-working equipmentsEngineeringSoil surface

A soil conditioning device having a series of peripheral ridge members having a leading and trailing prow shaped surface circumscribing a disc, wheel or drum. Optionally the prow shaped peripheral ridge members are joined by sub-ridge members forming a single ridge of varying heights circumscribing the disc, wheel or drum. The invention is also of a method for creating a permeable soil surface using the apparatus herein.

Owner:TERRACON TECH LLC

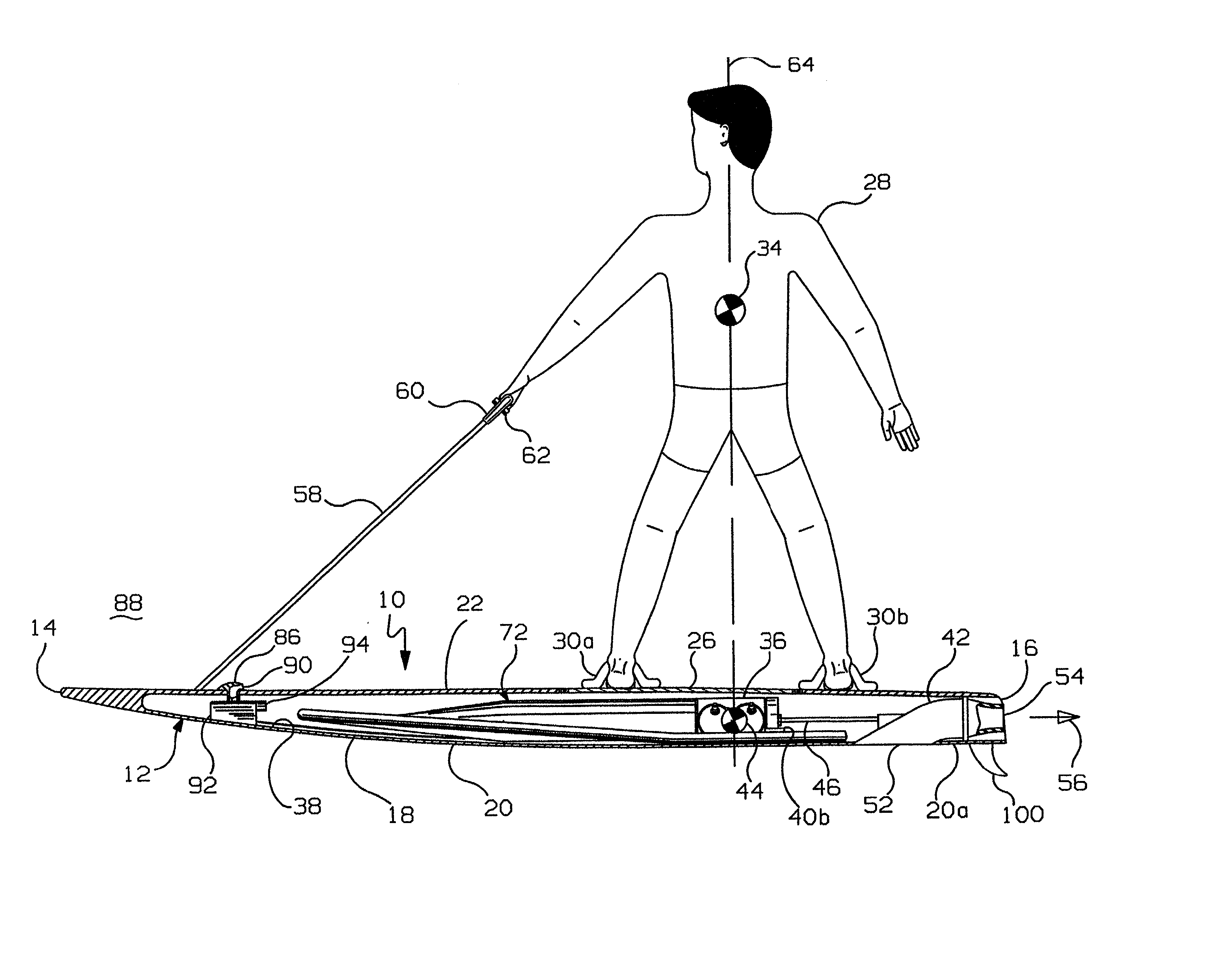

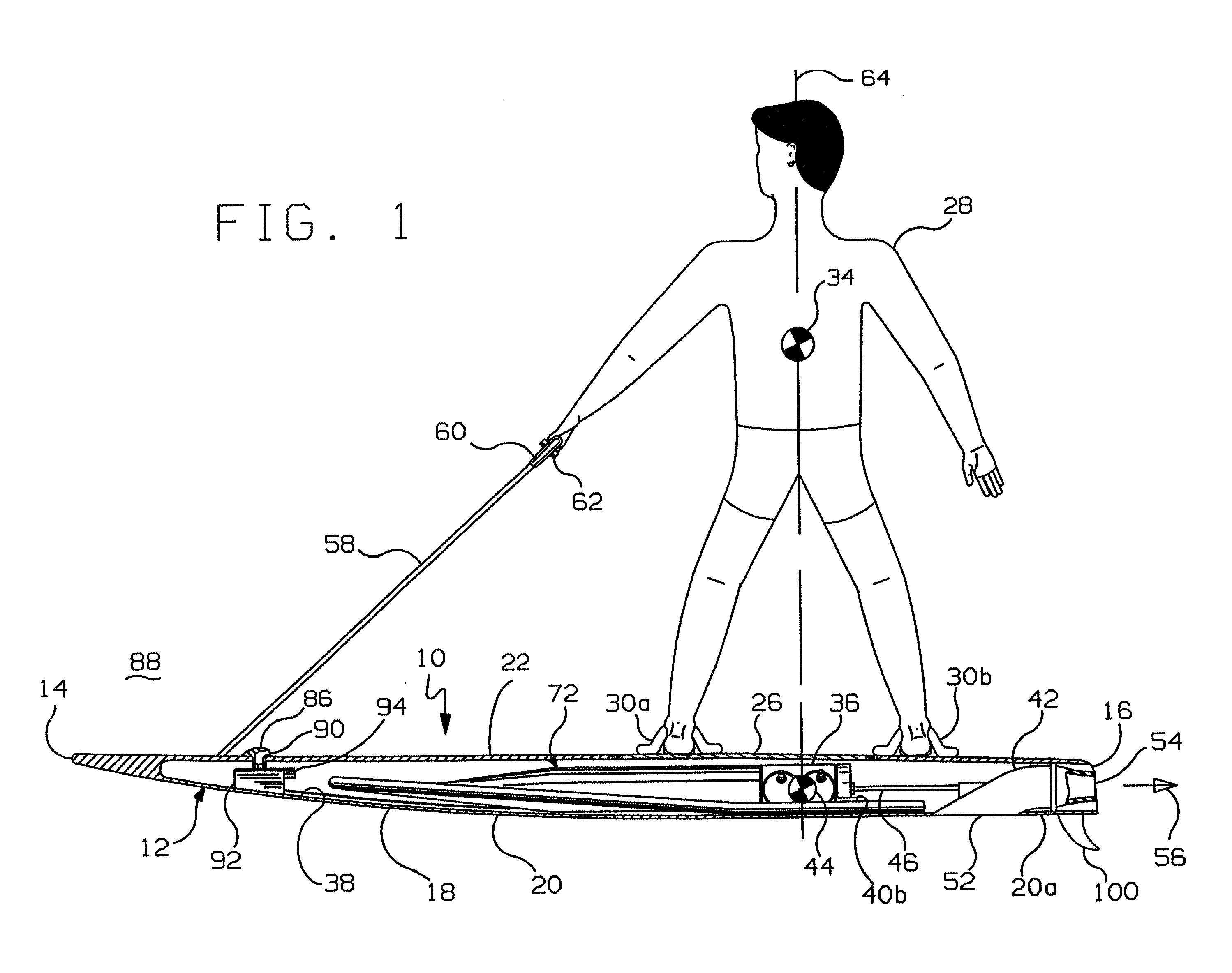

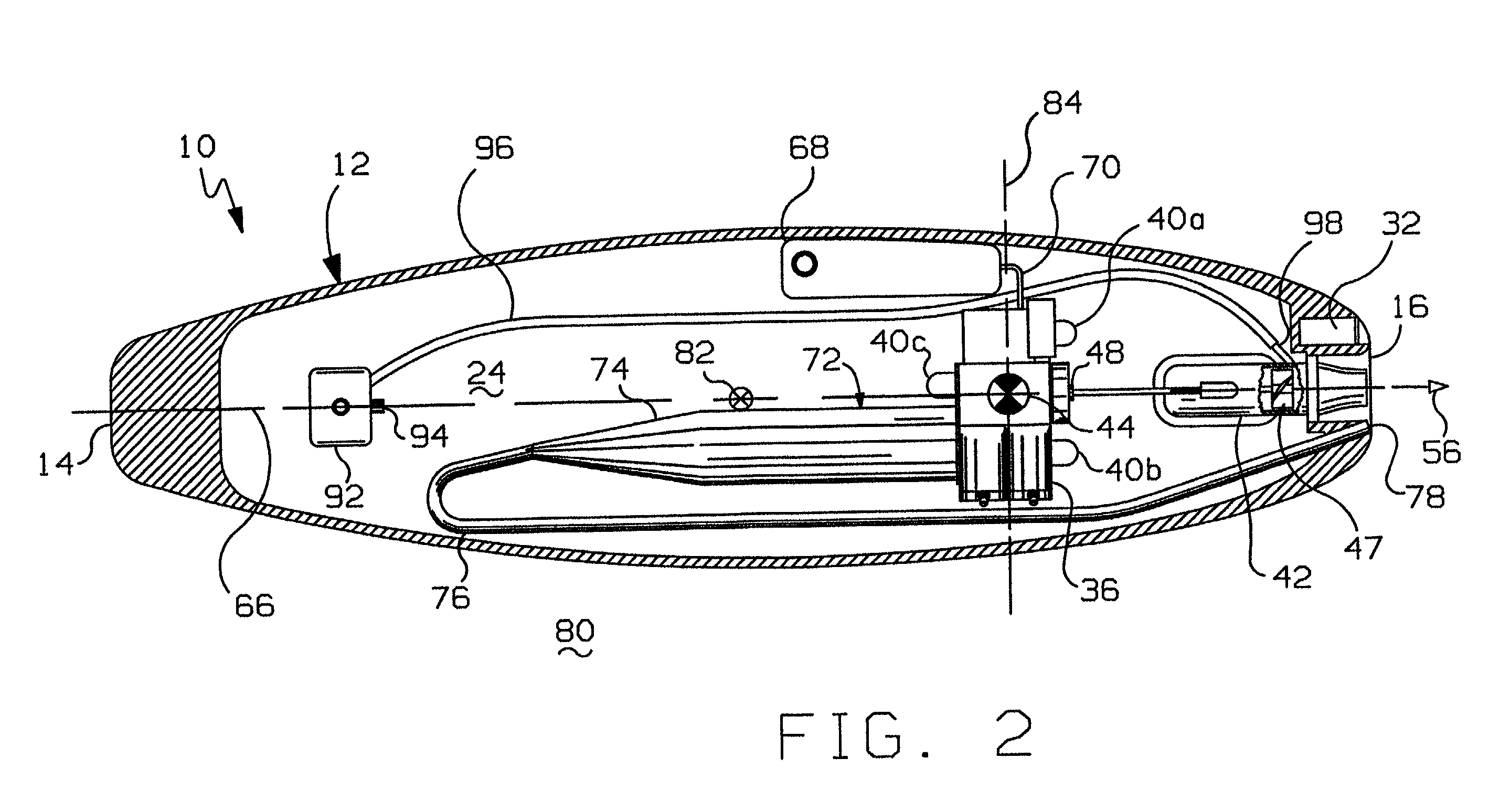

Motorized wakeboard

A wakeboard assembly transports a rider across a body of water. The rider defines a rider center of gravity. The wakeboard assembly includes a hull that extends between a stem and a stern. The hull defines an interior compartment and a deck for receiving the rider thereon during operation of said wakeboard assembly. An engine is mounted to the hull within the interior compartment. The engine is mounted to the hull at a position between the stem and the stern below the deck. The engine is mounted such that the engine extends through the center of gravity of the rider.

Owner:DEC ANDRZEJ +1

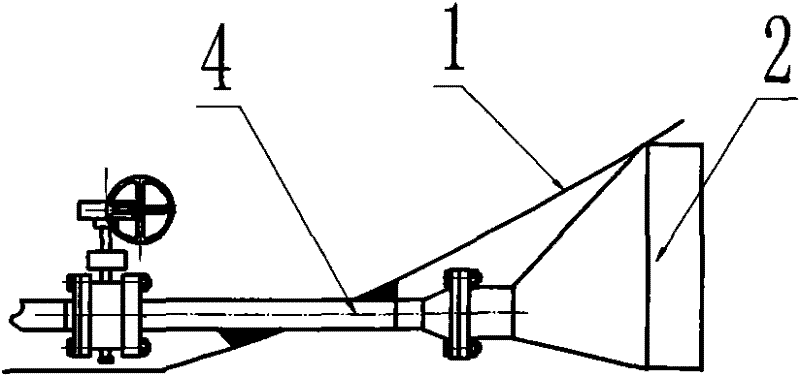

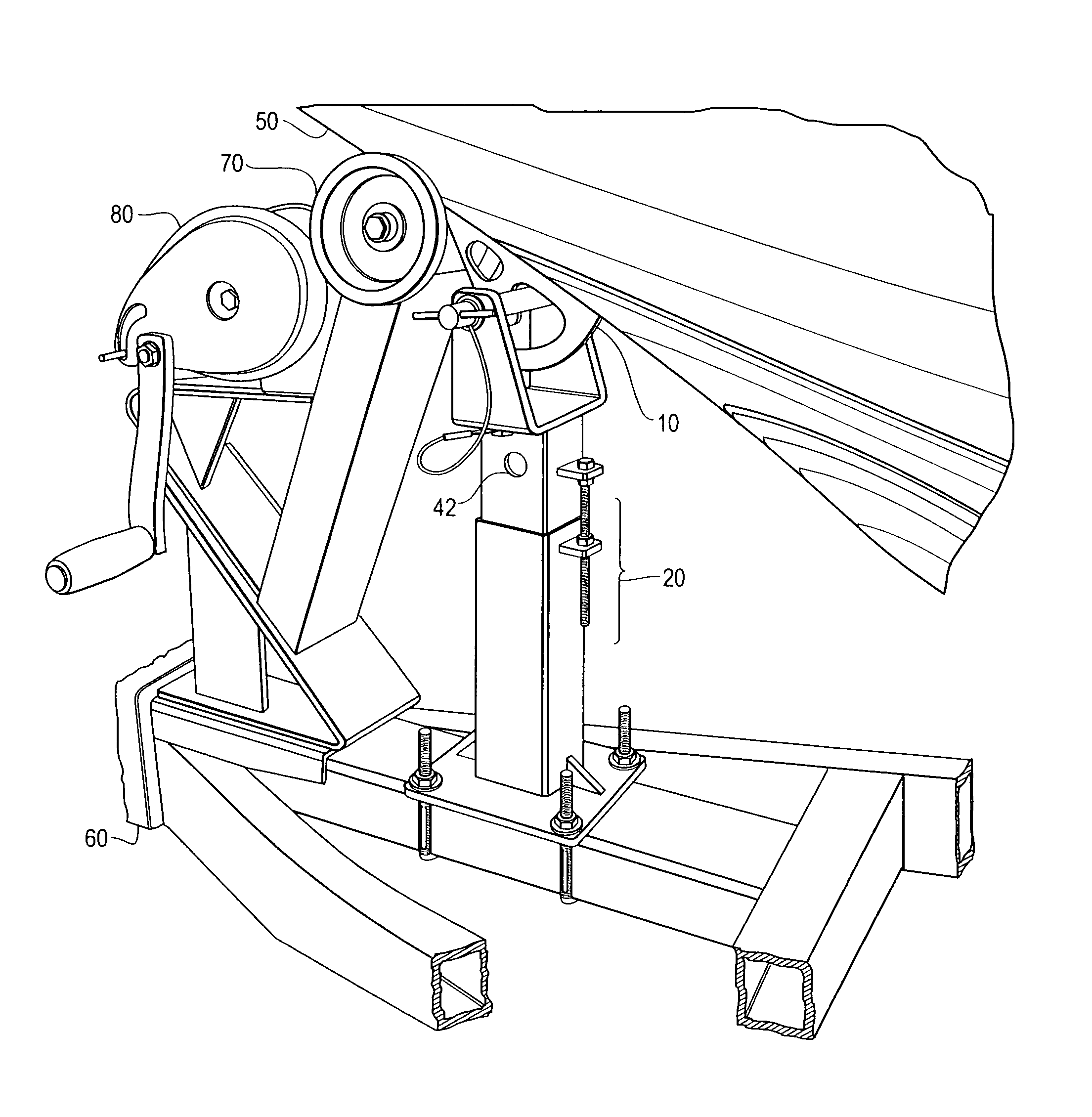

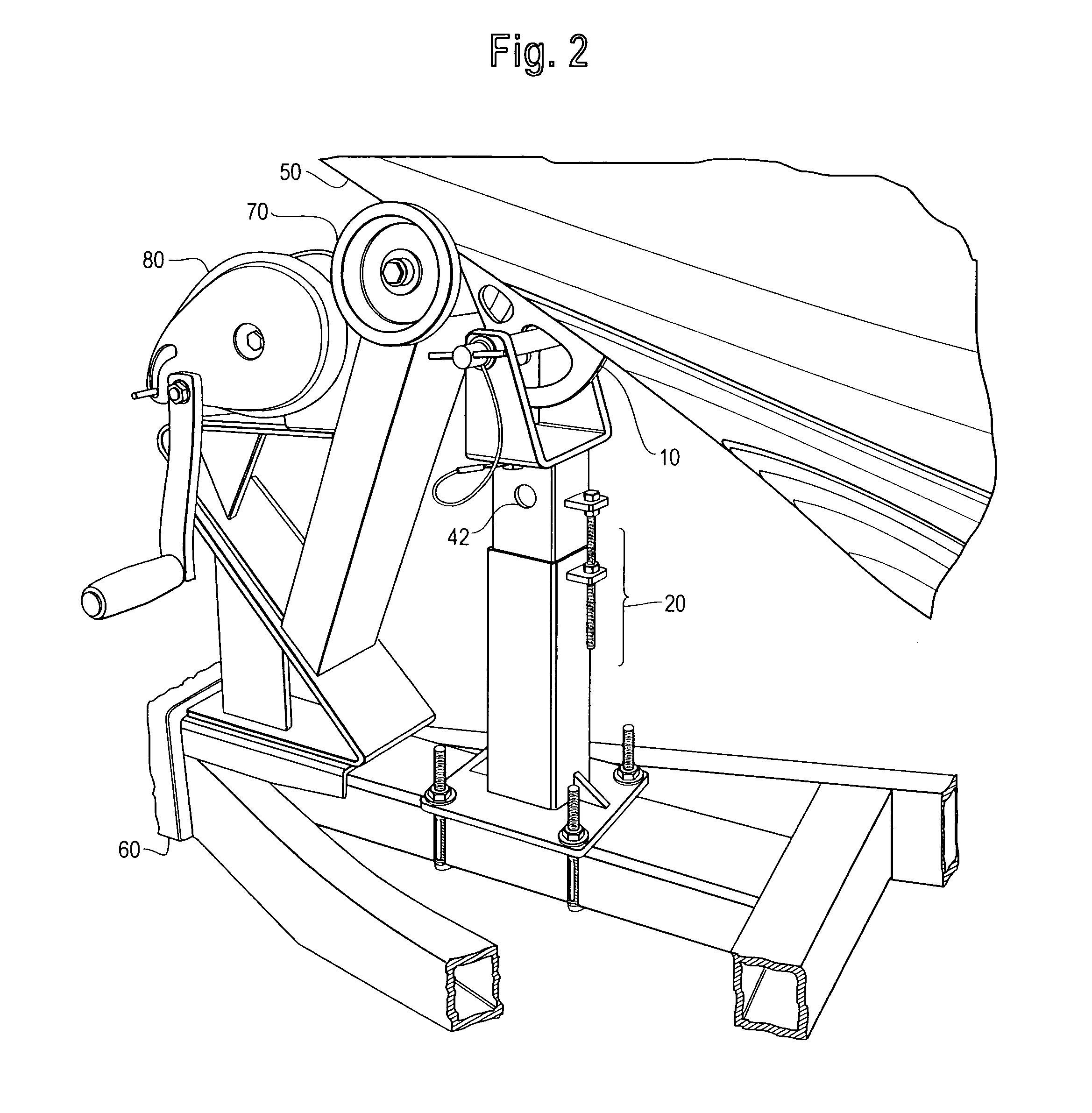

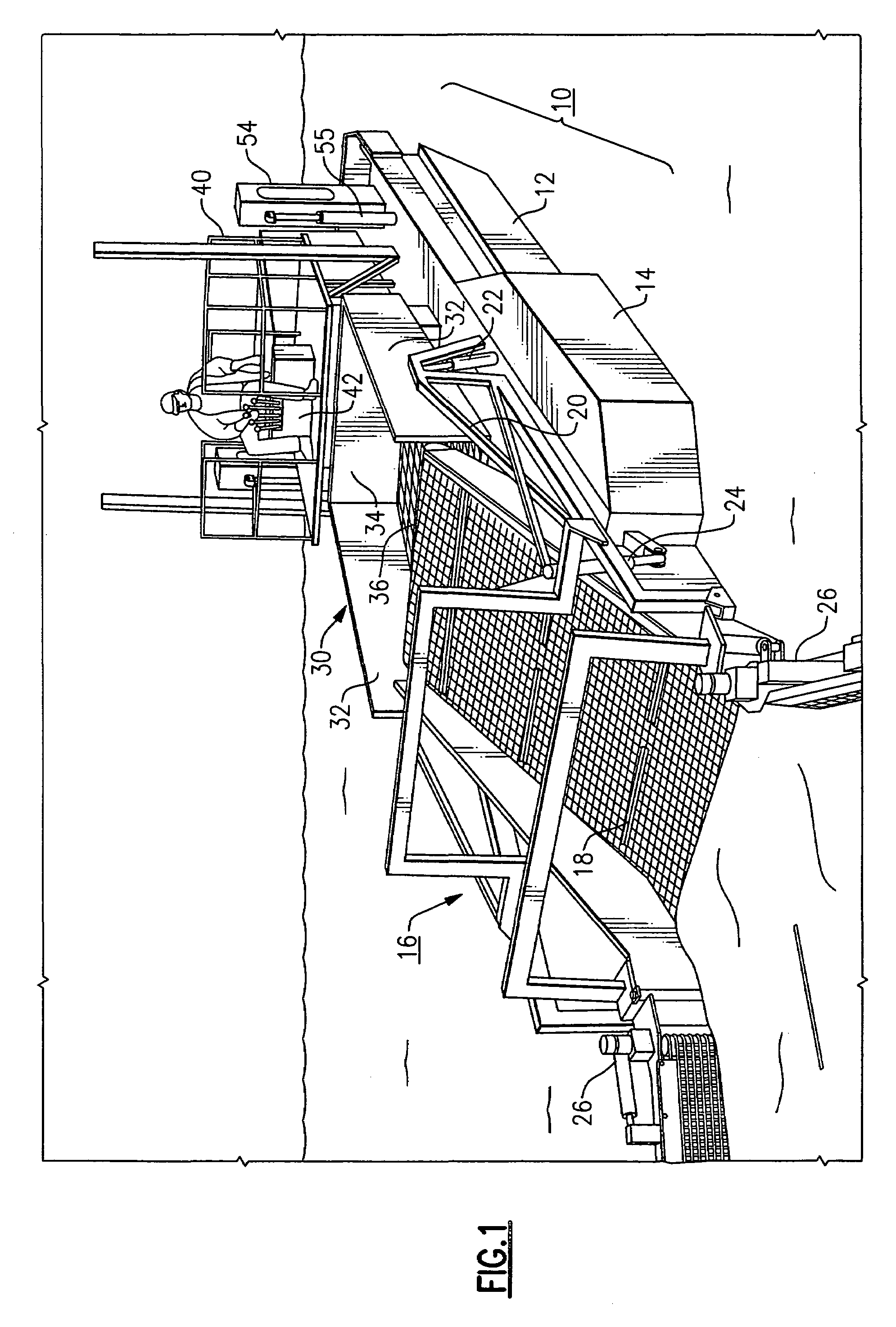

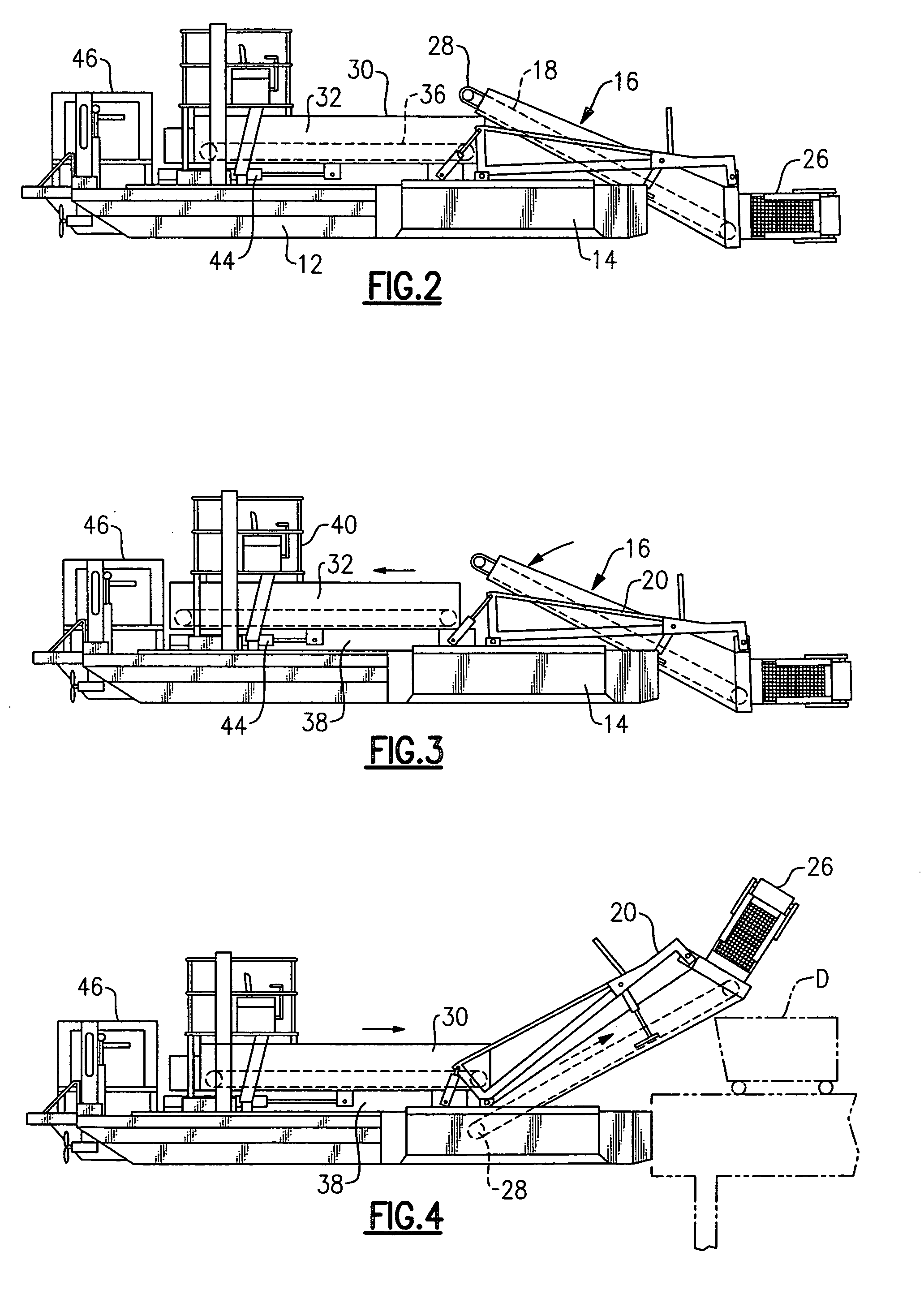

Boat loading system

A system enables a boat to be loaded from water onto a trailer that is partially submerged on a ramp at the edge of the water. One part of the system is a connector that is mounted on the keel of the bow. Another part of the system is a transversely mounted removable pin that is positioned on the trailer.

Owner:NORBITS G THEODORE

Sight and sight pins for archery bow

A device used to facilitate the accurate shooting of an archery bow. The device includes horizontally and vertically adjustable support structure for attaching the device to a bow. Moreover, the device includes a base, a guard and sight pins. The base includes arcuate channels sized for receipt of sight pins and arched to ensure that the sight pins are aimed at the archer's eye regardless of vertical spacing. The sight pins include an offset-Y-shaped fiber support and a light-gathering fiber. The light-gathering fiber comprises a length of fiber optic material with a sighting point on each distal end thereof. The offset-Y-shaped fiber support is an offset-Y-shaped member whose offset allows for placement in either of two spaced arcuate channels while maintaining the targeting axis position of the sighting points. The guard, which encircles the sight pins, includes three fiber optic fibers spaced about its diameter to allow for low-light alignment.

Owner:BLACK GOLD ARCHERY LLC

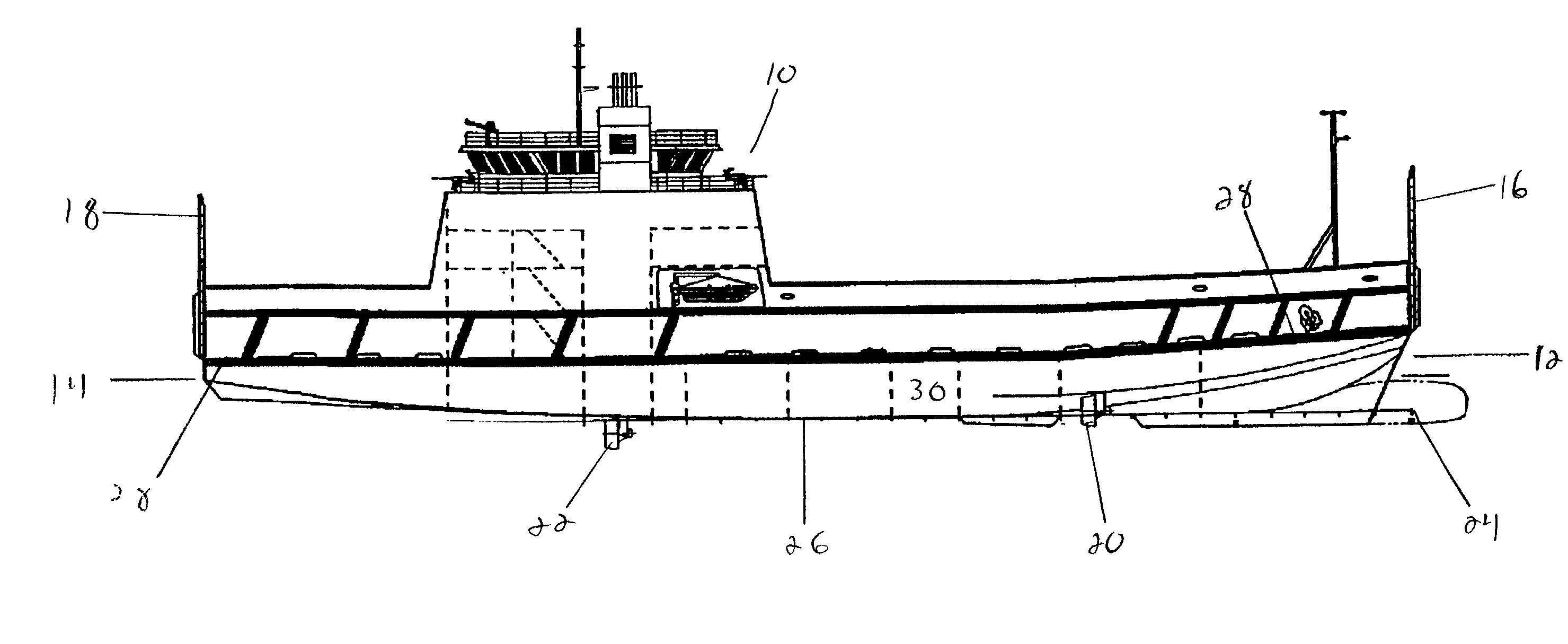

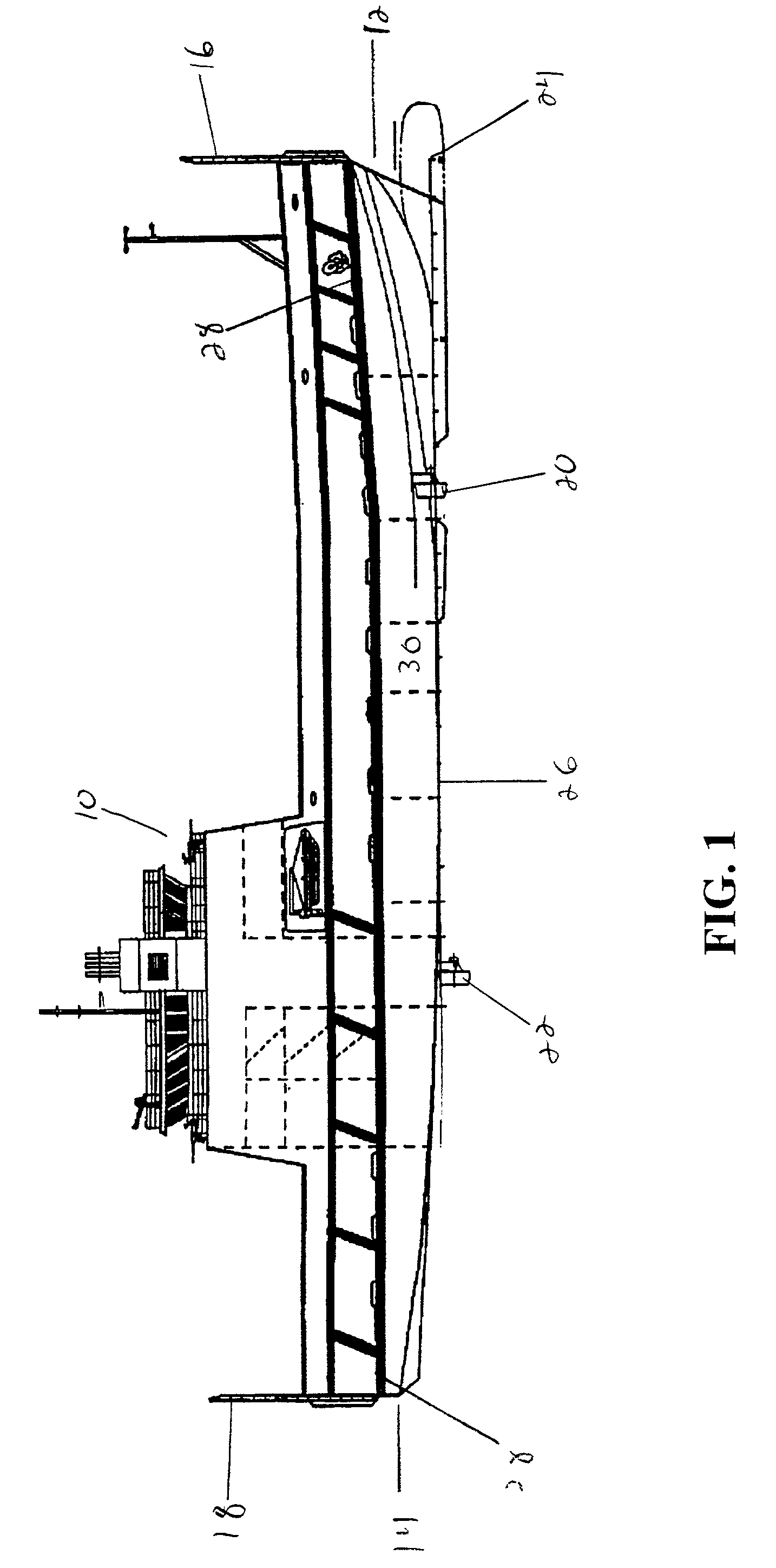

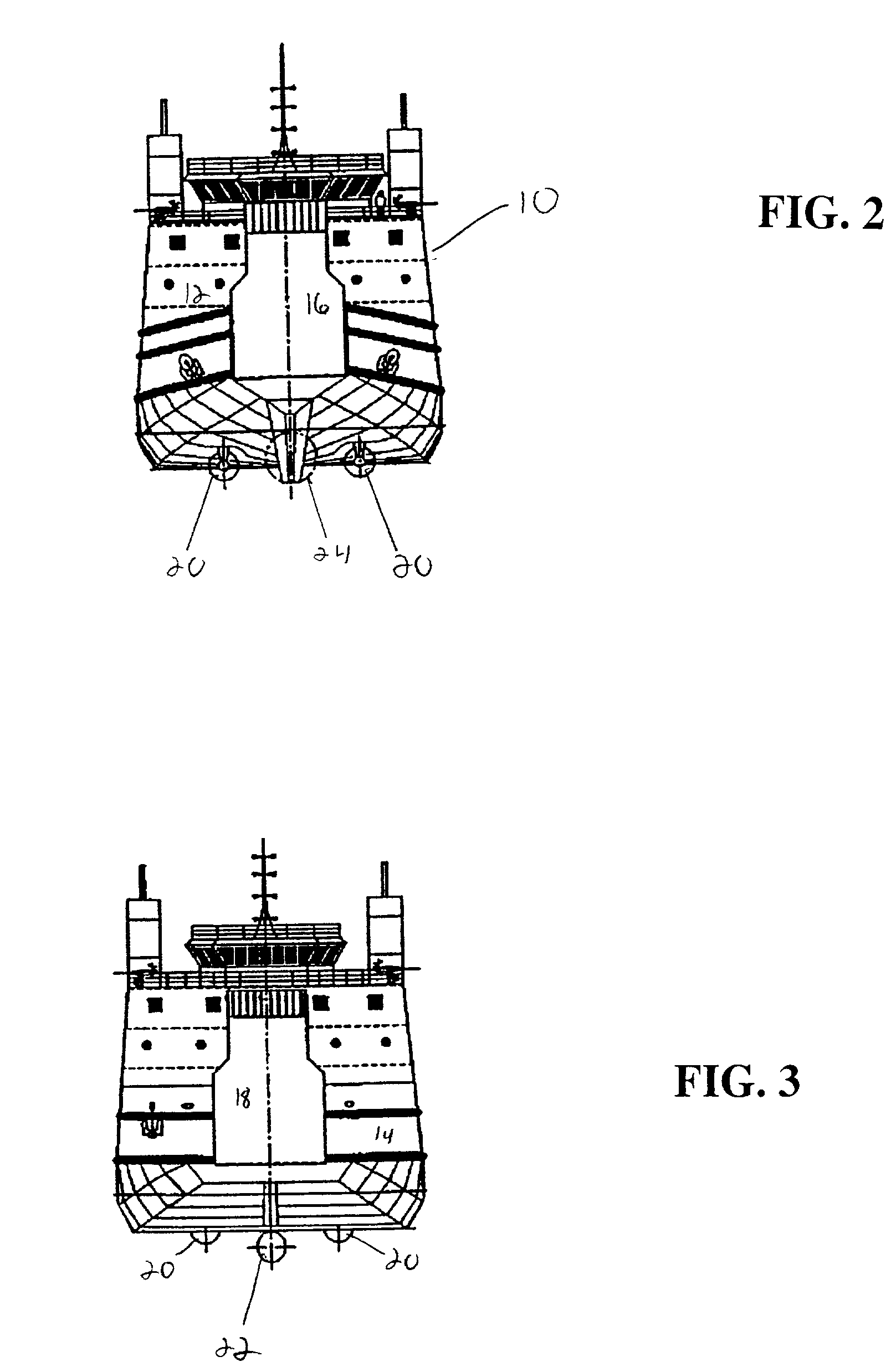

Landing craft with fixed and retractable azimuthing drives

InactiveUS20020134290A1Improve mobilityImprove airworthinessCargo handling apparatusFerriesSeakeepingProw

A marine vessel used for loading and offloading vehicles and cargo that has both excellent seakeeping and beaching properties. The vessel is provided with azimuthing or steerable thrusters below the waterline at the bow and stern of the ship, with the stern end thrusters being retractable into the hull during beaching operations. Because the vessel is beached "stern first" the bow may be designed with better wave breaking and seakeeping features than are on prior landing craft designs.

Owner:KVAERNER MASA MARINE

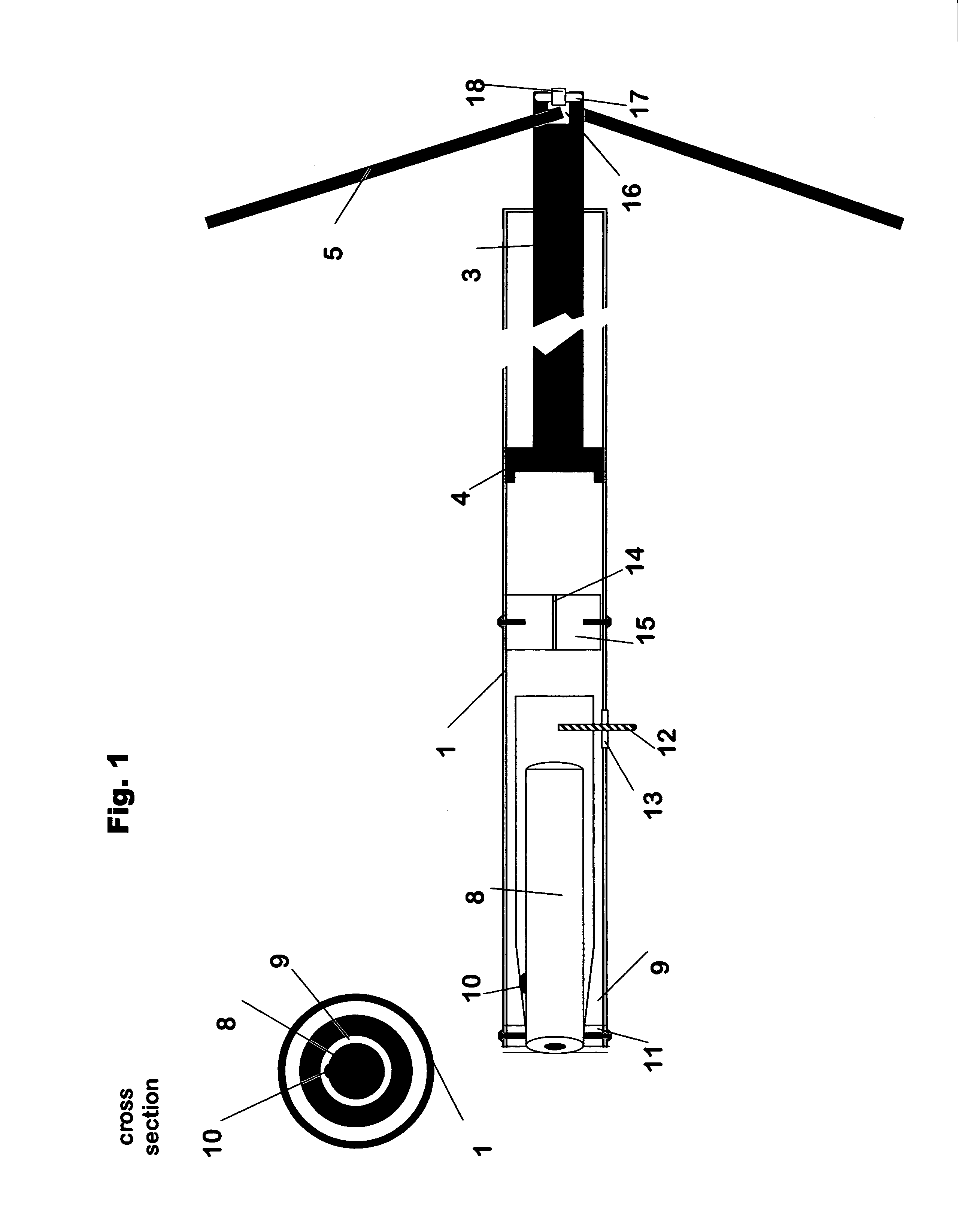

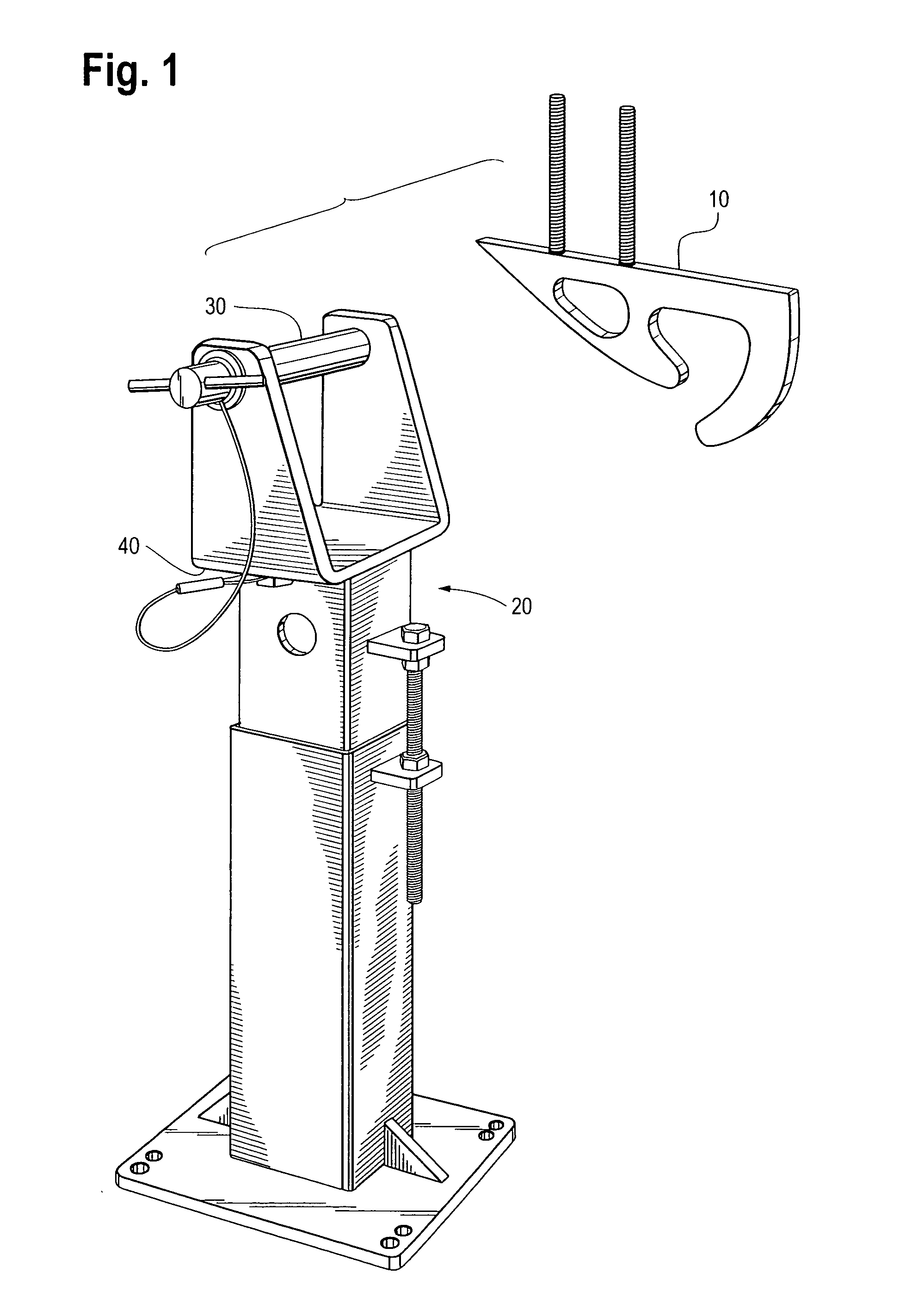

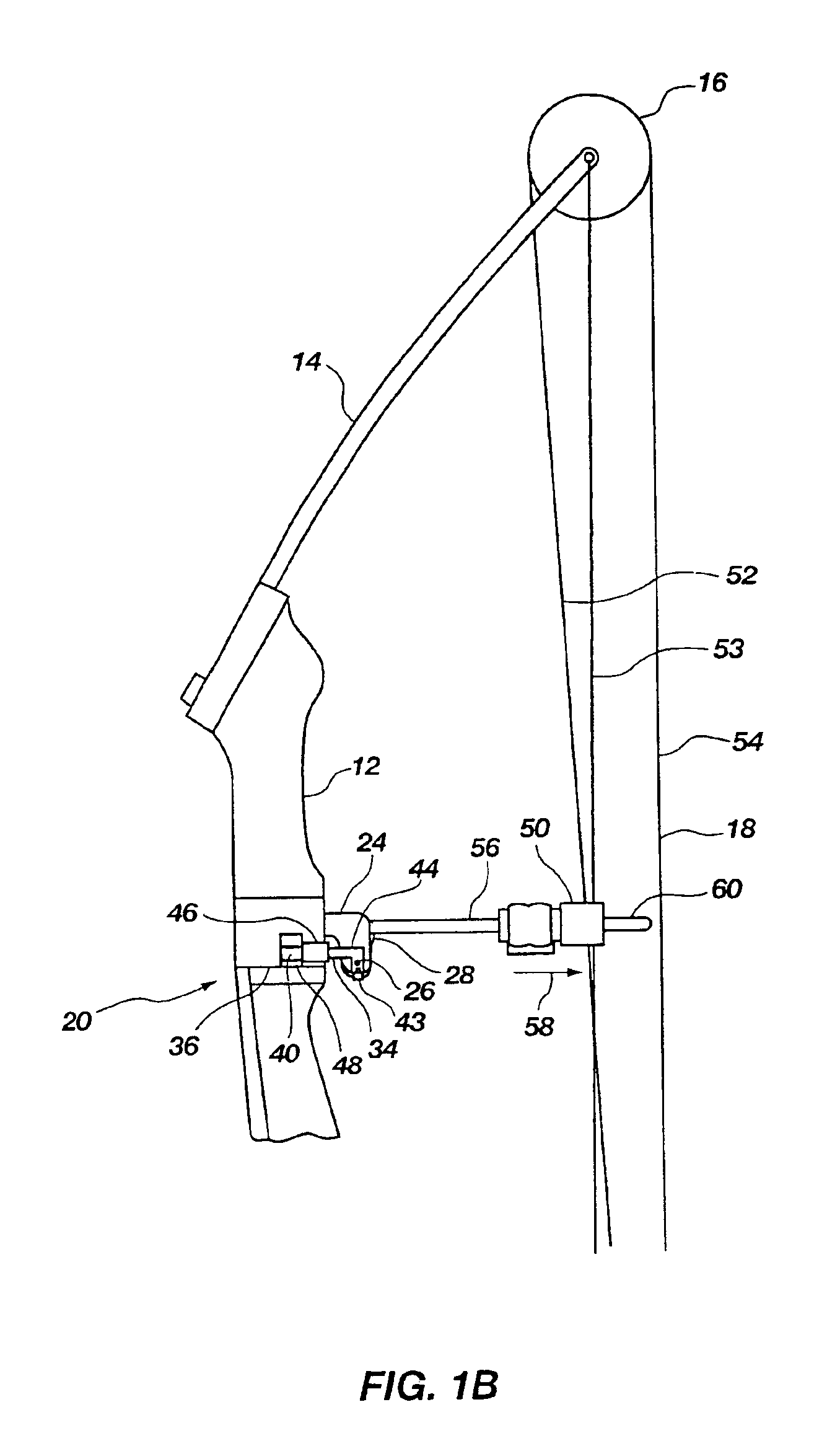

Archery bow stand

InactiveUS7036497B2Quickly and easily removed and reattachedBows/crossbowsStands/trestlesVertical tubeEngineering

A bow stand attachment for an archery bow has a base which mounts to the riser of the bow. The base has a pair of legs extending downward from it. The legs are slid onto stubs which extend away and downward from the outer rim of the base. The ends of the legs and the end of a stabilizer mounted to the bow can cooperate to provide a supporting tripod for the bow. When no stabilizer is attached to the bow, the bow stand and lower pulley act as a tripod to support the bow. Performance of the bow is not affected by presence of the attachment because of its low mass and symmetry on the riser of the bow.

Owner:HORN EDWARD

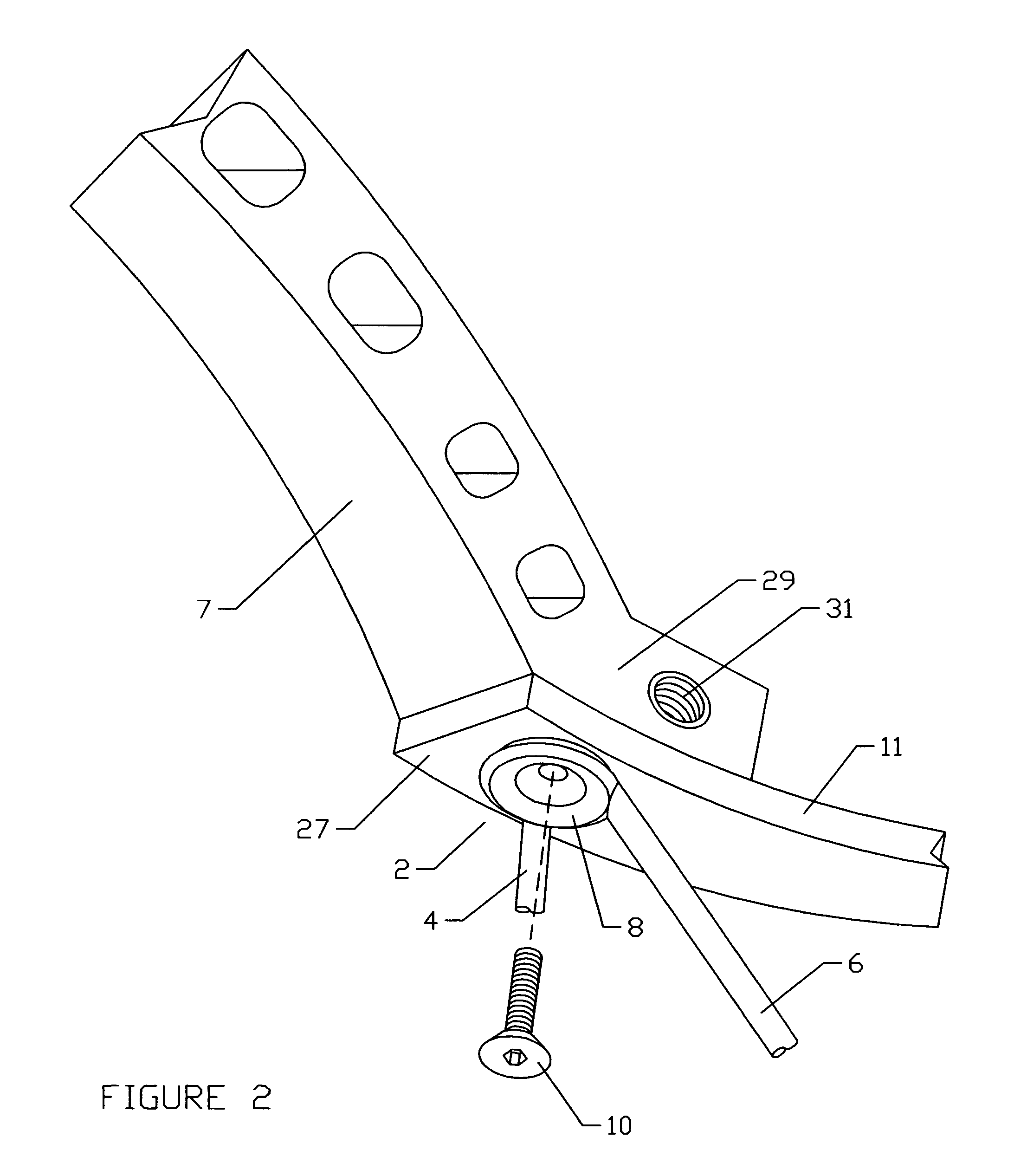

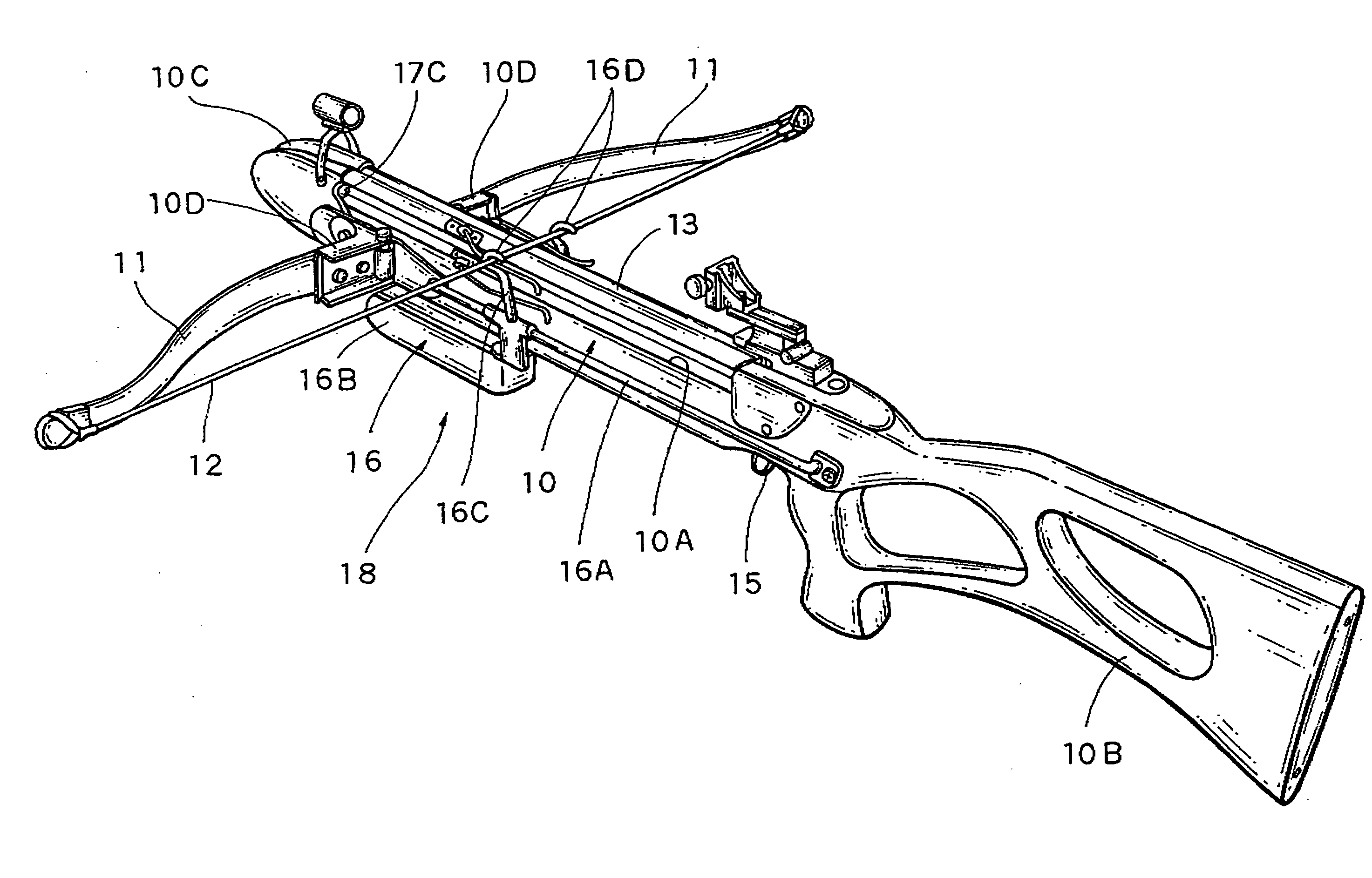

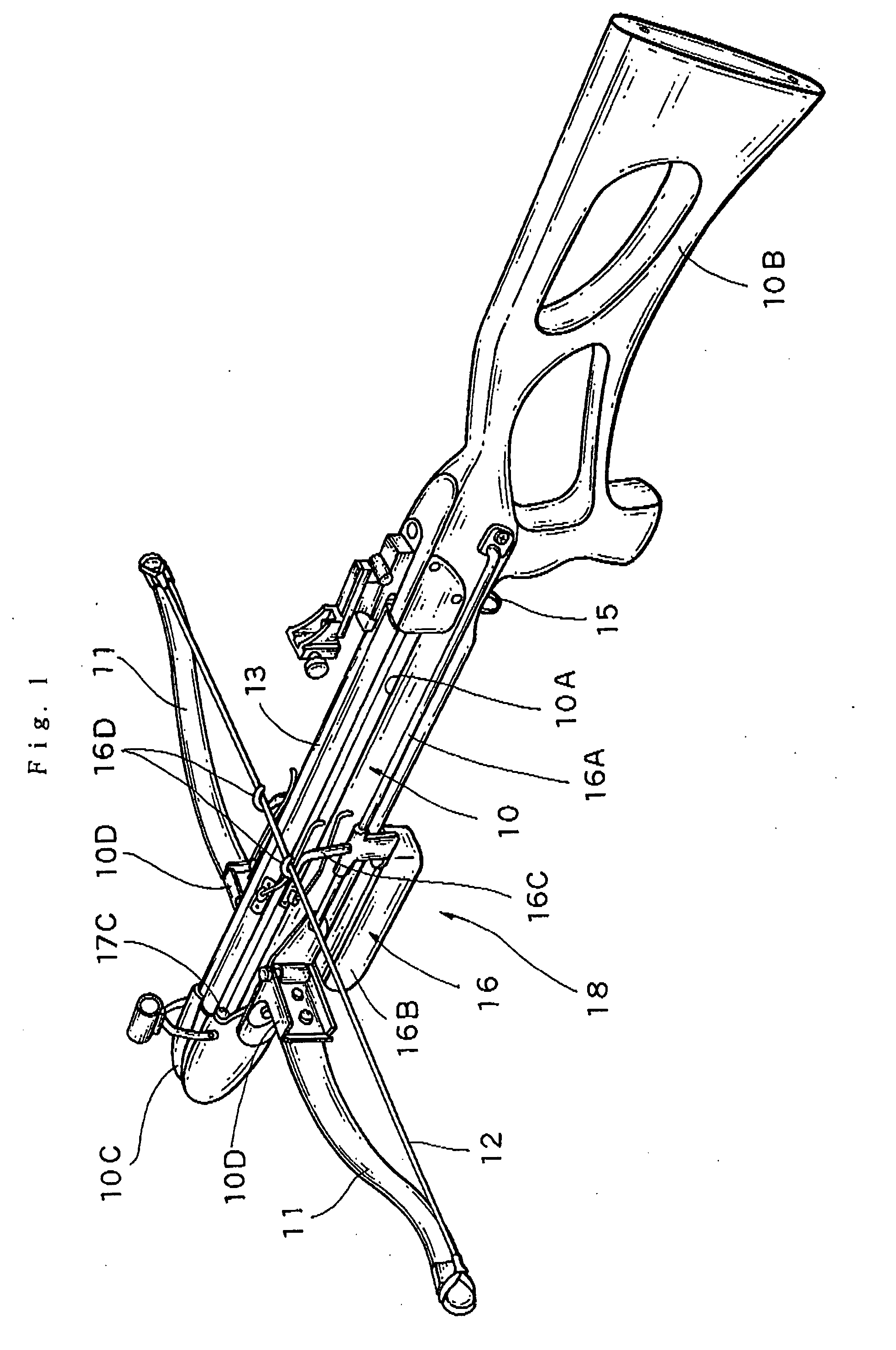

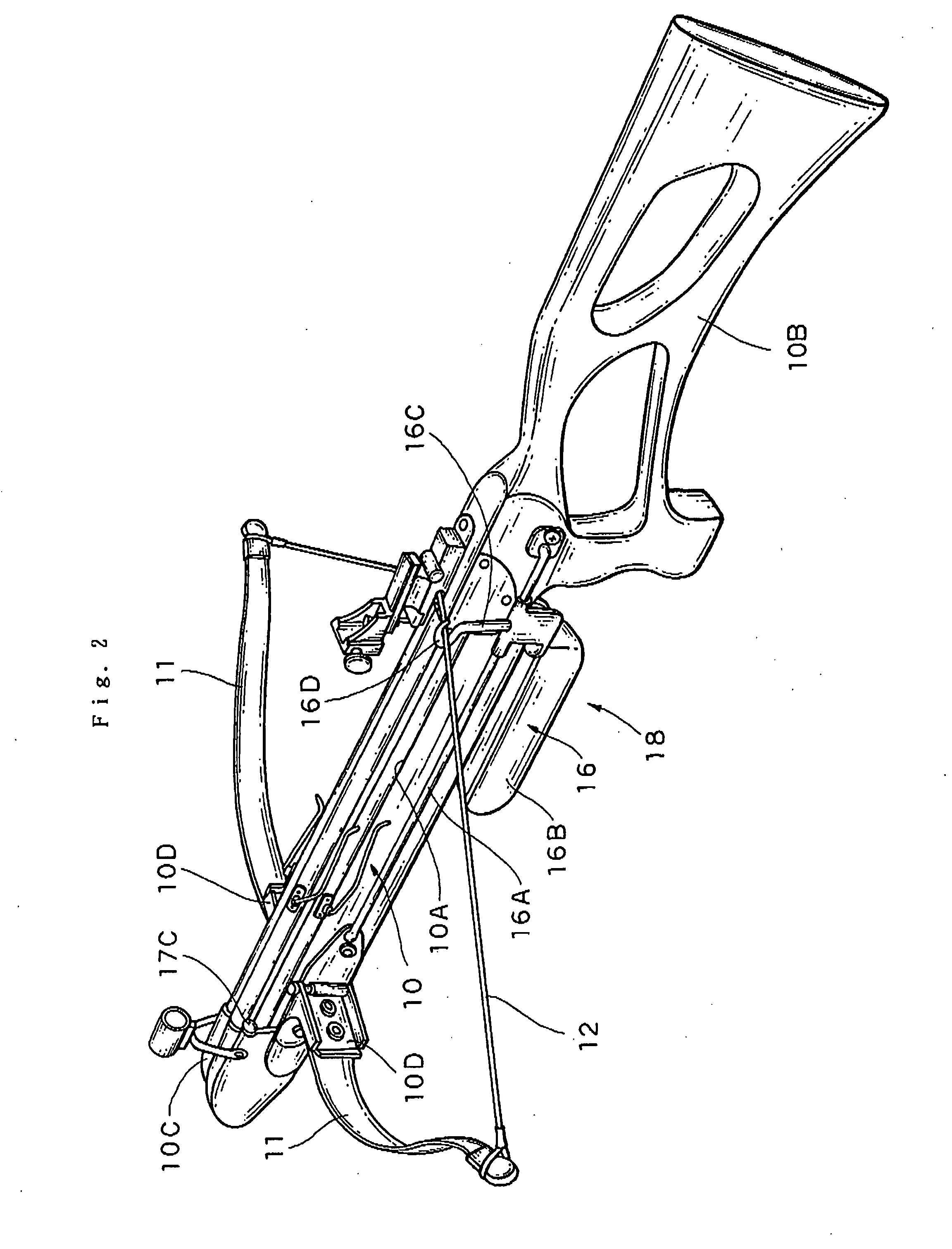

Crossbow

A crossbow that enables arrows to be shot with simple operation is provided. The crossbow includes a bow stock that has a fitting recess for a cylinder formed between a front end and a rear end thereof, a bow that is attached to the front end of the bow stock thereacross, and has a string tensioned between both ends thereof, a wire catch that is rockably provided at the rear end of the bow stock to hook the tensioned string, a trigger that is provided at the rear end of the bow stock to cock the wire catch that has hooked the string and to release the cocking of the wire catch by triggering, thereby shooting an arrow, a cylinder that is rotatably fitted in the fitting recess of the bow stock, and has a plurality of arrow grooves formed at predetermined angular intervals in an outer peripheral surface thereof so as to extend in a longitudinal direction, and has arrows slidably inserted in the plurality of arrow grooves, respectively, and a rotation operating mechanism that rotates the cylinder at every predetermined angle, and locates one arrow groove in front of the wire catch.

Owner:OGAWA TSUYOSHI

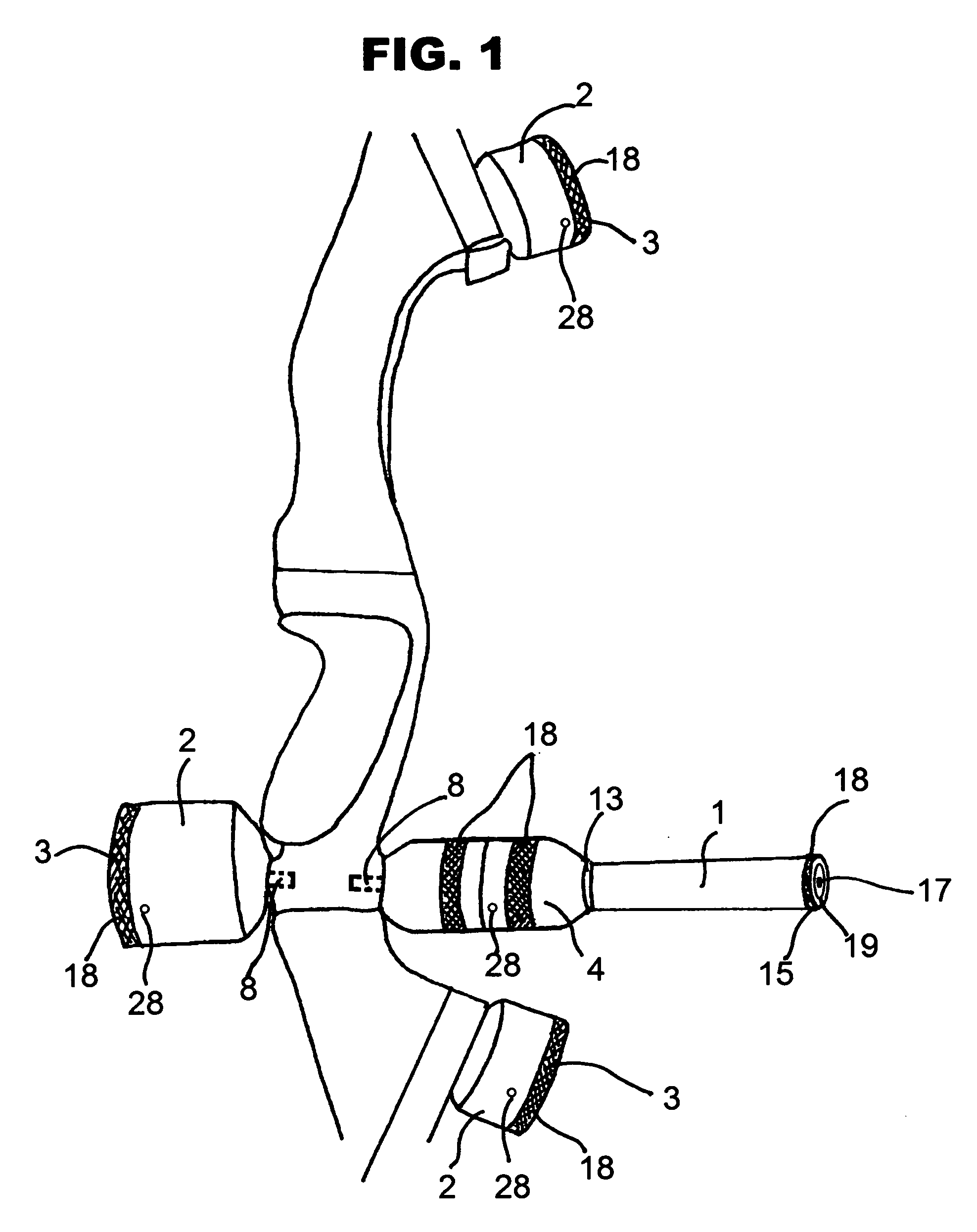

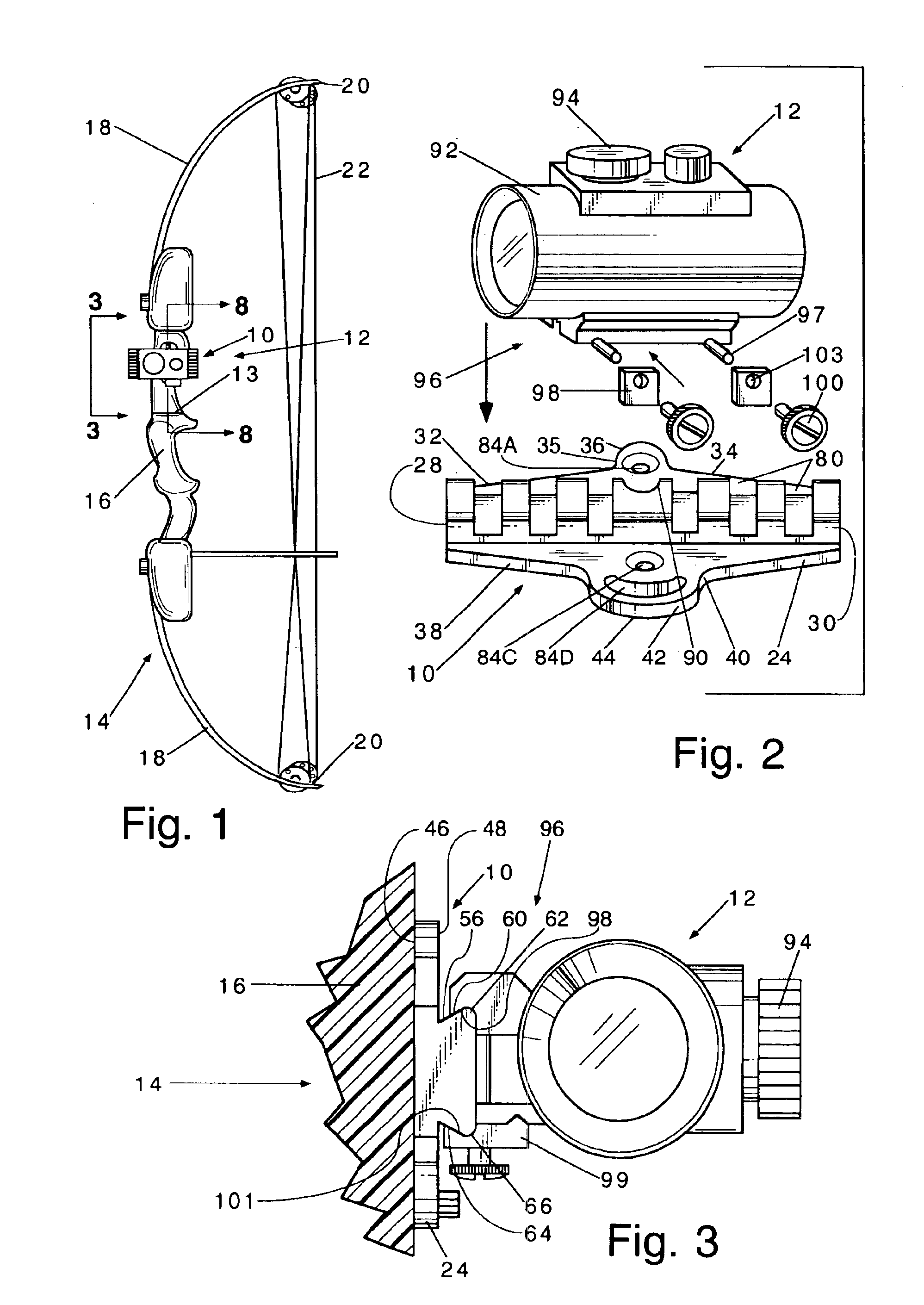

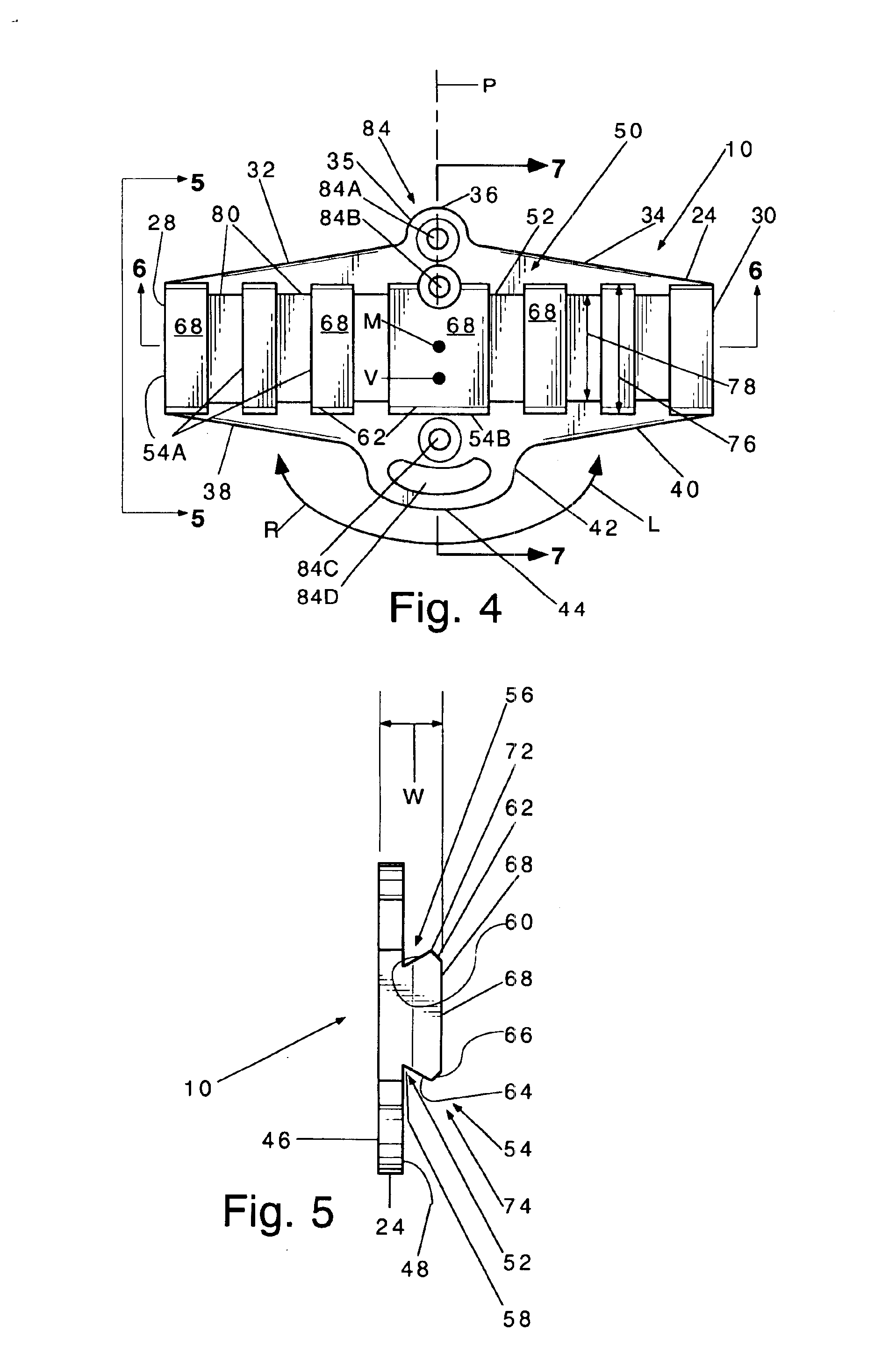

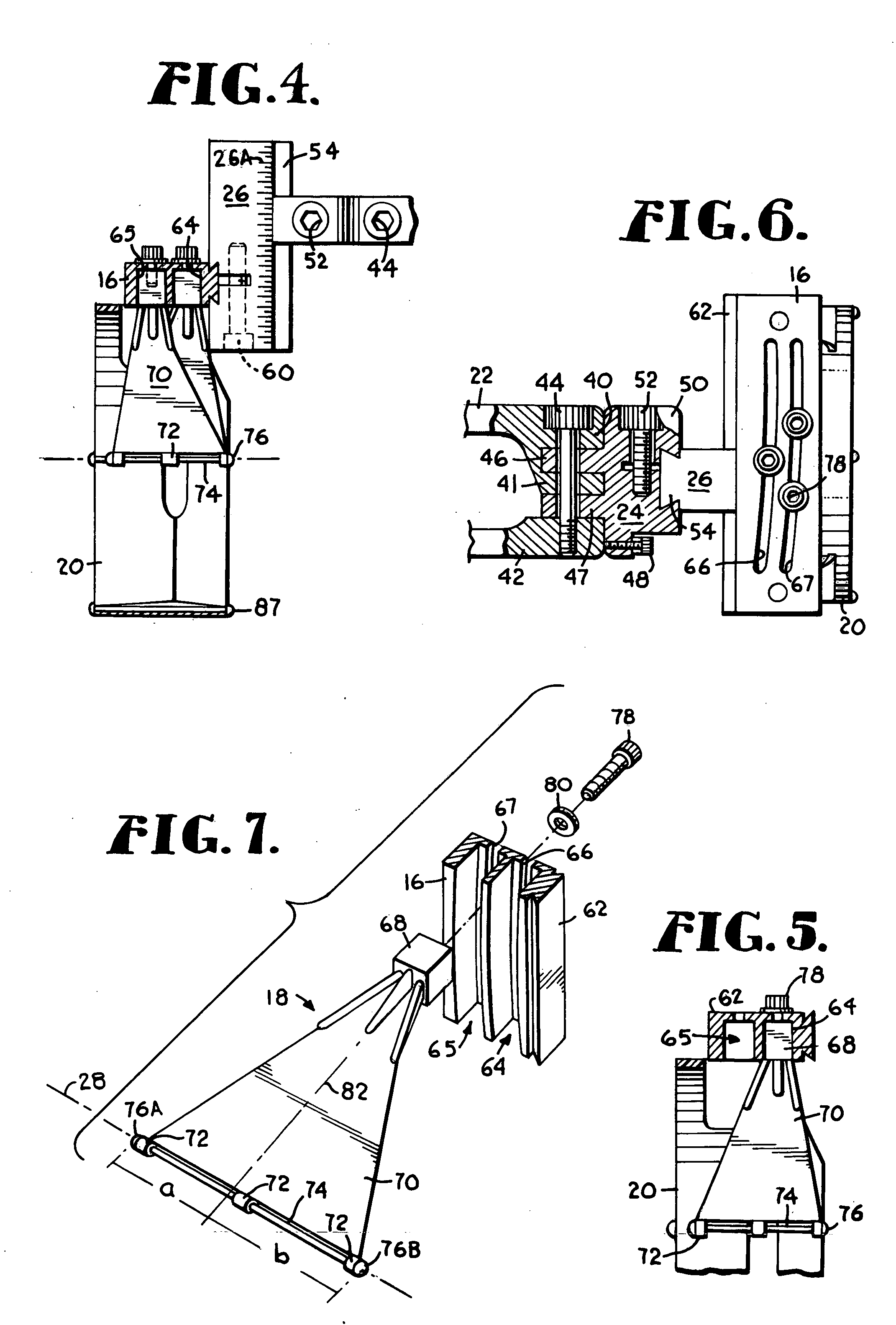

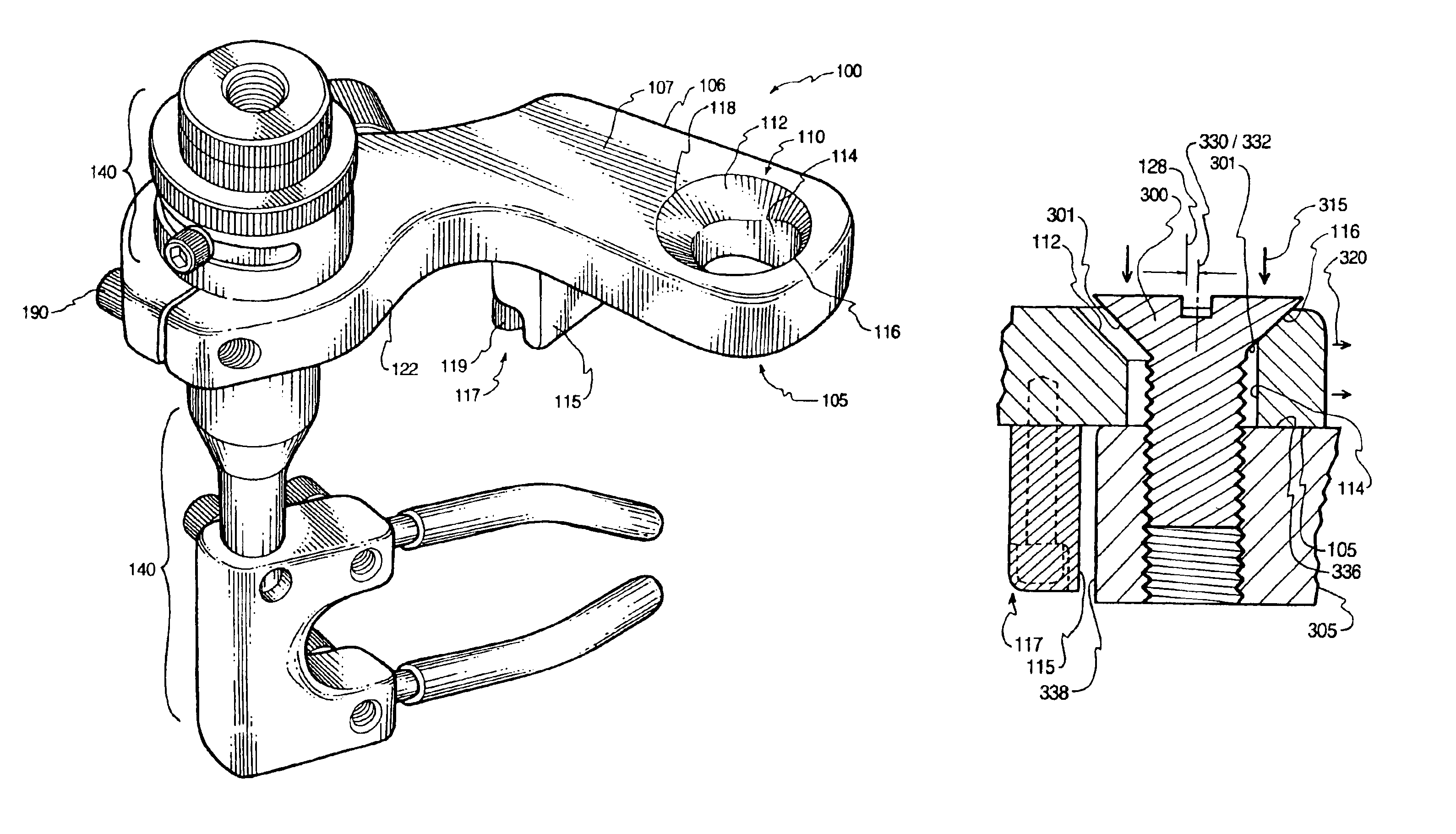

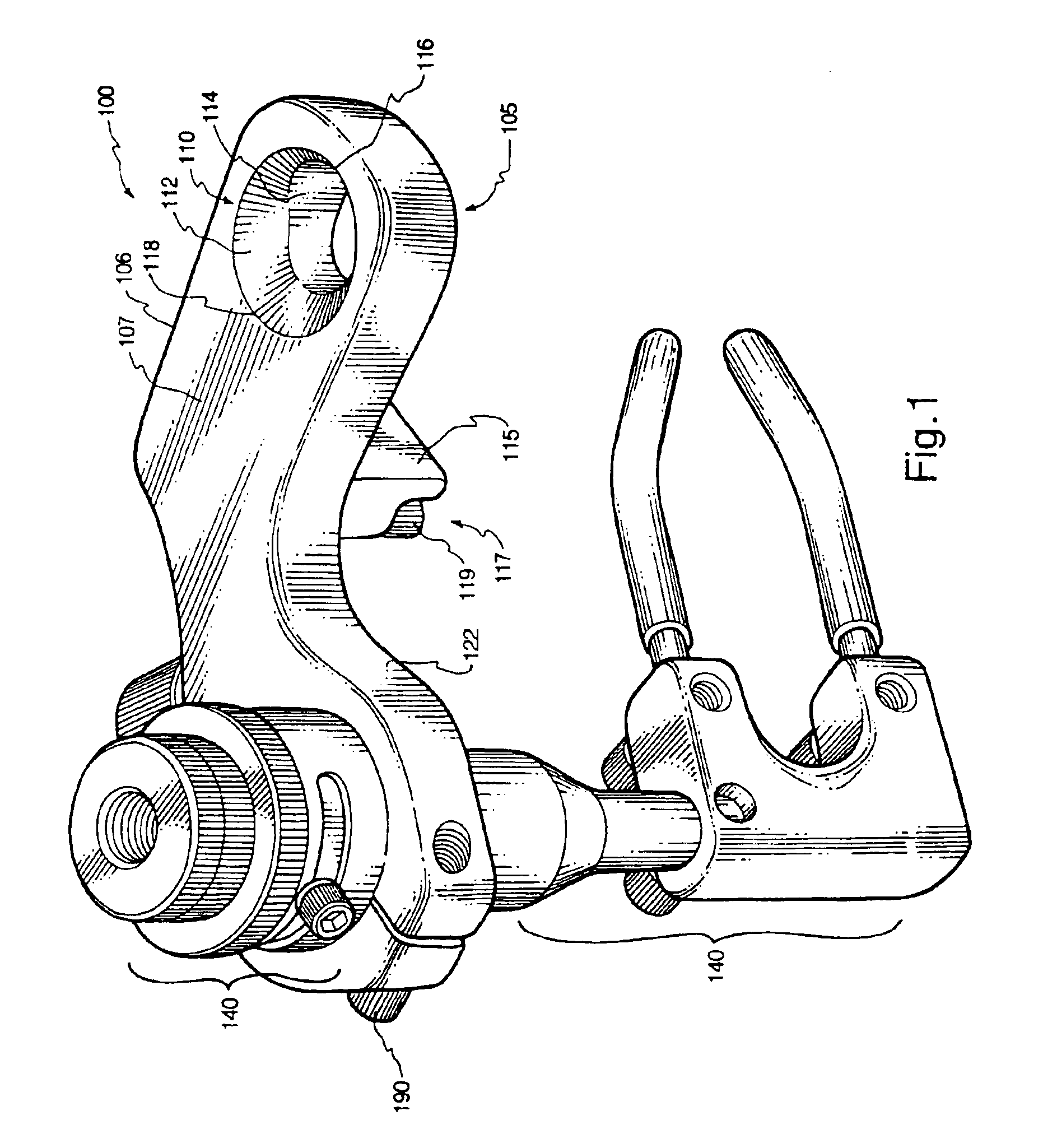

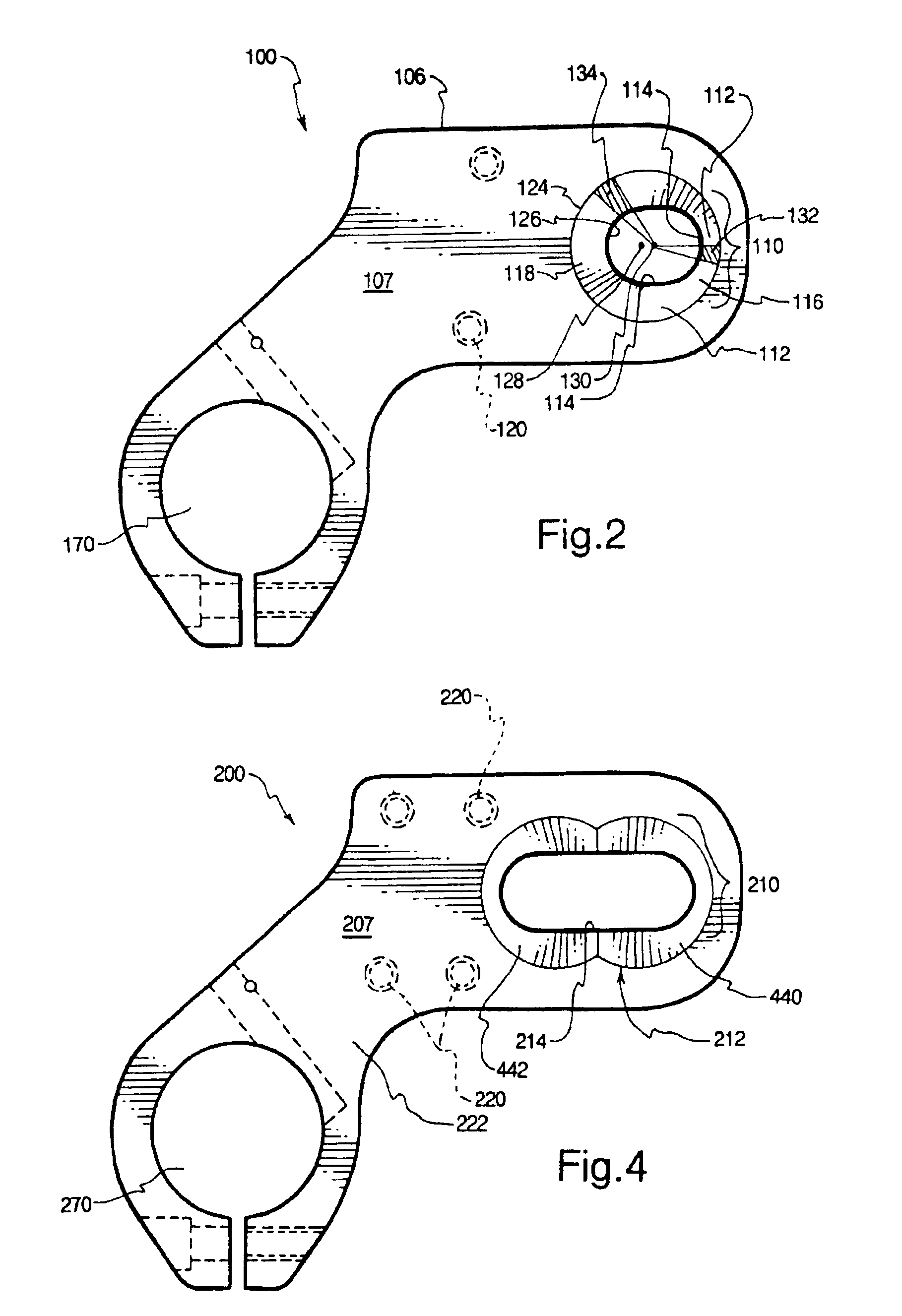

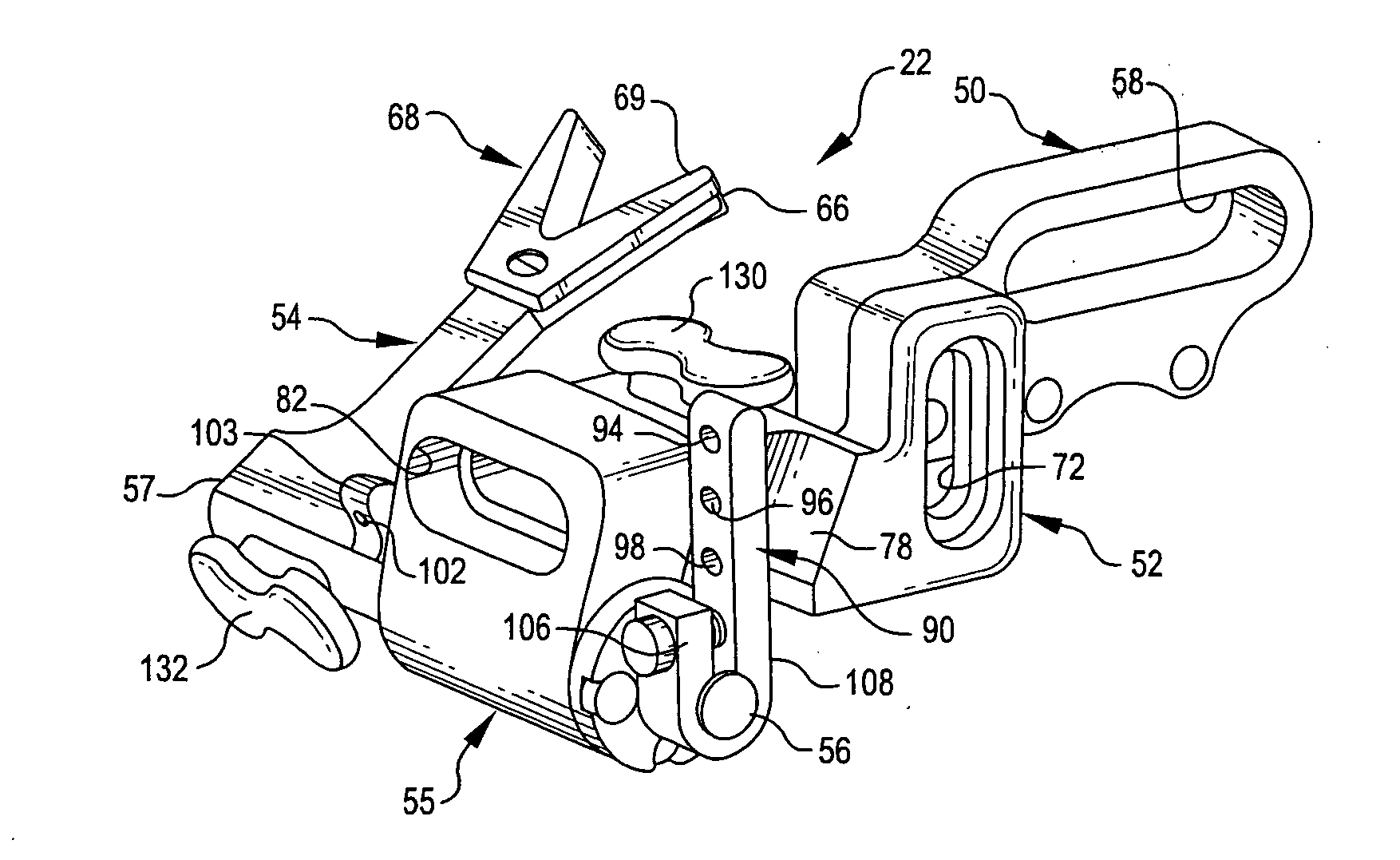

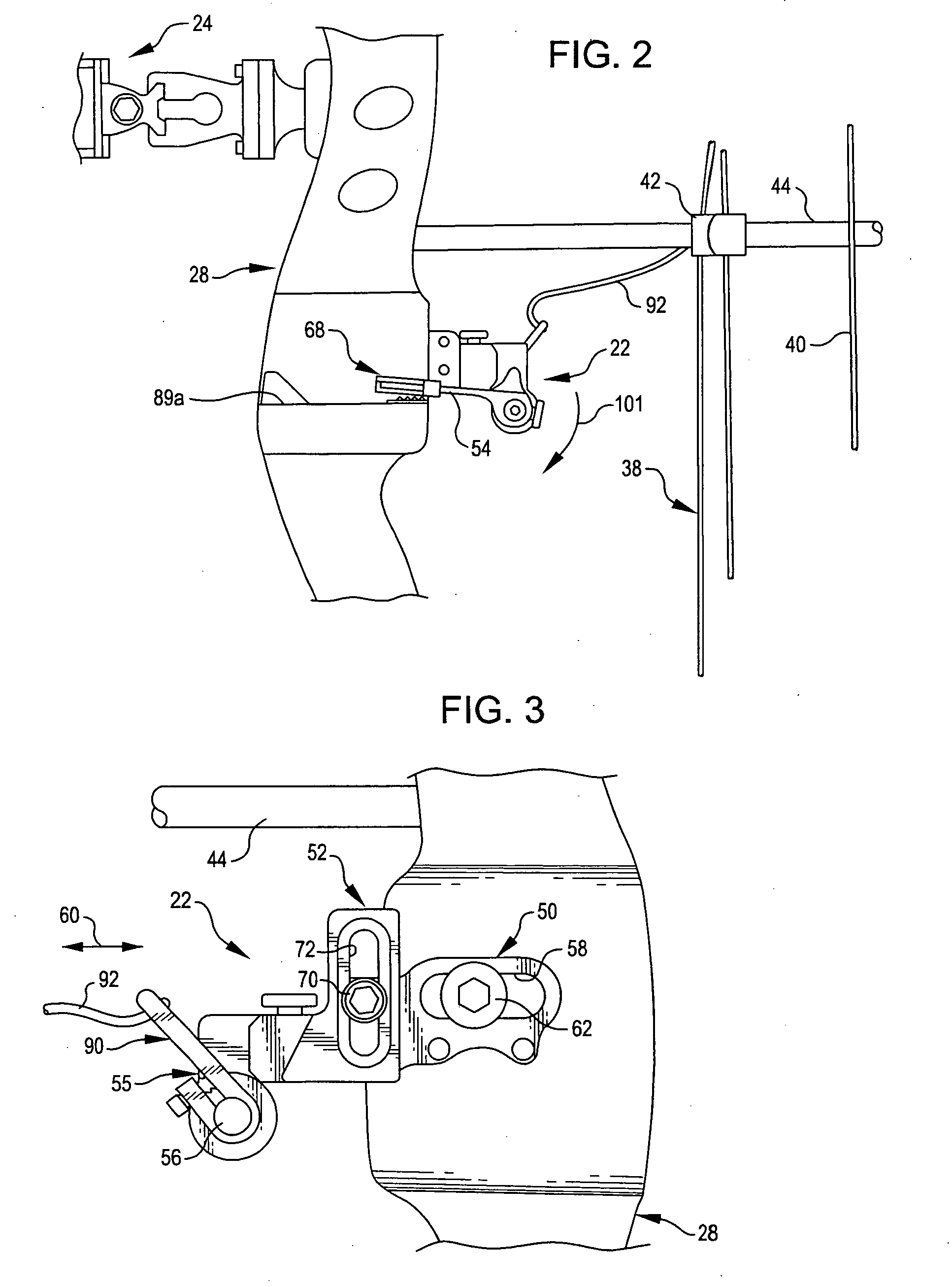

Archery bow accessory mounting system and method

A method and apparatus for mounting accessories onto a bow. Accessories are mounted onto a bow in a precise, repeatable manner so that an archer need only to position and calibrate or adjust a particular accessory for a particular bow once. Therefore, when the calibrated accessory is removed from the bow it can later be reattached to the archery bow in the precise previous location thereby eliminating the need for the archer to recalibrate the accessory. Likewise, the present invention requires only one mounting hole in the handle riser to minimize the negative structural ramifications of drilling multiple holes.

Owner:HOYT ARCHERY

Shaft clamping arrow rest

Owner:AFSHARI ABBAS BEN

Fall-away arrow rest

InactiveUS20080236556A1Convenient heightEasy to adjustSpring gunsBows/crossbowsCoil springEngineering

Fall away arrow rests for archery bows. The rests have an arm with an arrow-supporting feature and an arm-associated axle which pivots the arm to displace the arrow-supporting feature between a first, arrow-loading position and a second, more elevated, arrow-launching position. The arrow support arm can be adjusted vertically, laterally, and in fore-and-aft directions relative to a riser or other rigid bow component on which the rest is mounted. Radial arms rotatable with the axle and connectable to a buss cable or cable slide by a flexible link rotate the arm to elevate the arrow-supporting feature to its arrow-launching when the bow is drawn and offer further adjustment of the arrow rest operation. A coil spring installed in an axle housing returns the arrow-supporting feature to its first, loading position concomitantly with arrow launch, moving the support out of the path the arrow travels as it leaves the bow. Axle-associated stops automatically stop the arm-associated axle as the arrow-supporting feature respectively reaches its arrow-launching and arrow-loading positions. One or more dampers can be advantageously attached to arrow rest structural members to reduce shock and vibrations, including noise, as the arrow support arm displaces the arrow-supporting feature between its first and second positions, especially as an arrow is launched from the bow. Noise reduction can be furthered by a installing a Teflon or comparable component on the arrow-supporting feature of the arm and / or by installing an elastomeric pad on the rigid bow component in the path followed by the arrow-supporting feature as that feature approaches its arrow-loading position.

Owner:SIMS STEVEN C +4

Watercraft with wave deflecting hull

InactiveUS20080190348A1Easily reach planeStimulate displacementVessel movement reduction by foilsFloating buildingsCruise speedWatercraft

The invention is directed to a watercraft hull design that comprises a hull having a bow, stern, top, and bottom. A wedge-shaped wave spreading system is located at a forward portion of the craft. The wave-contacting surface planes of the wave spreading system are positioned substantially perpendicular to the plane of smooth water. The bottom edge of the wave spreading system is positioned near the level of smooth water when the watercraft is at cruising speed. The wave spreading system has a forward apex which forms a substantially perpendicular or vertical leading wedge to the plane of water. Since the apex and planes of the wave spreader are substantially perpendicular to the water, oncoming waves encountered by the wave spreader will tend to be deflected horizontally. Accordingly, the watercraft will more easily “cut through” waves instead of riding over them. Located rearwardly of the wave spreader, an internal hull prow is spaced from the wave spreading system, creating an air space therebetween. The air space extends from the rearward surface of the wave spreader to the front of internal hull prow, creating a buffer zone or dampening space to further minimize any wave action not detected by the spreading system.

Owner:BAKER ELBERT H

Soil conditioning device

InactiveUS7478684B2Promote infiltrationImprove retentionSoil-working equipmentsHarrowsEngineeringProw

A soil conditioning device having a series of peripheral ridge members having a leading and trailing prow shaped surface circumscribing a disc, wheel or drum and a method of use. Optionally the prow shaped peripheral ridge members are joined by sub-ridge members forming a single ridge of varying heights circumscribing the disc, wheel or drum.

Owner:TERRACON TECH LLC

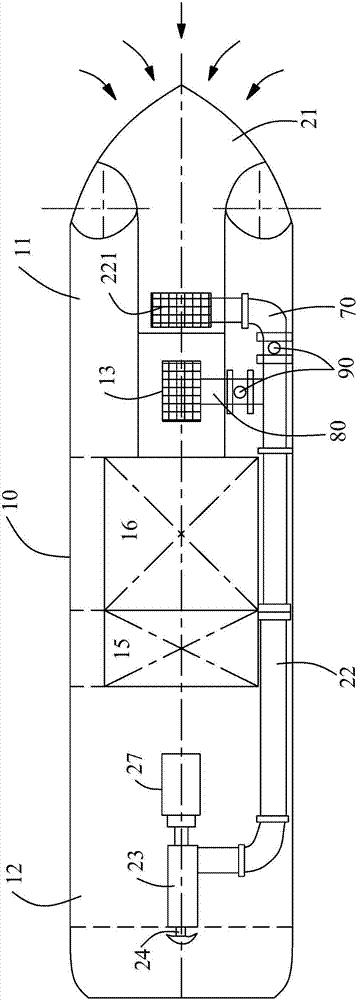

Water jet propulsion water surface clean-keeping ship

PendingCN107128448AImprove the salvage effectPlay a diversionWater cleaningPropulsive elementsProwFishing

The invention provides a water jet propulsion water surface clean-keeping ship. The water jet propulsion water surface clean-keeping ship comprises a hull with a prow and a stern, a water jet propulsion device, a fishing device installed on the prow and a fished article collecting bin on the hull; the water jet propulsion device comprises a main water sucking opening, a water jet propulsion water sucking pipeline, a water jet propulsion pump and a water jet pipe which are sequentially communicated front and back, the main water sucking opening penetrates through the prow in the length direction of the hull, the lower end of the fishing device is located in the main water sucking opening and stretches across the main water sucking opening in the width direction of the hull, the fishing device comprises a fished article outlet located in a fished article inlet of the fished article collecting bin, a water outlet located on the lower side of the fishing device, a water jet propulsion opening of the front end of the water jet propulsion water sucking pipeline is communicated with a water outlet, and a water jet opening is formed in the rear end of the water jet pipe. The water jet propulsion device has the effects of water jet propulsion, flow guide and flow drainage, garbage floating on the water surface automatically flows into the main water sucking opening, the garbage fishing effect is good, and the fishing image can be improved.

Owner:上海水域环境发展有限公司

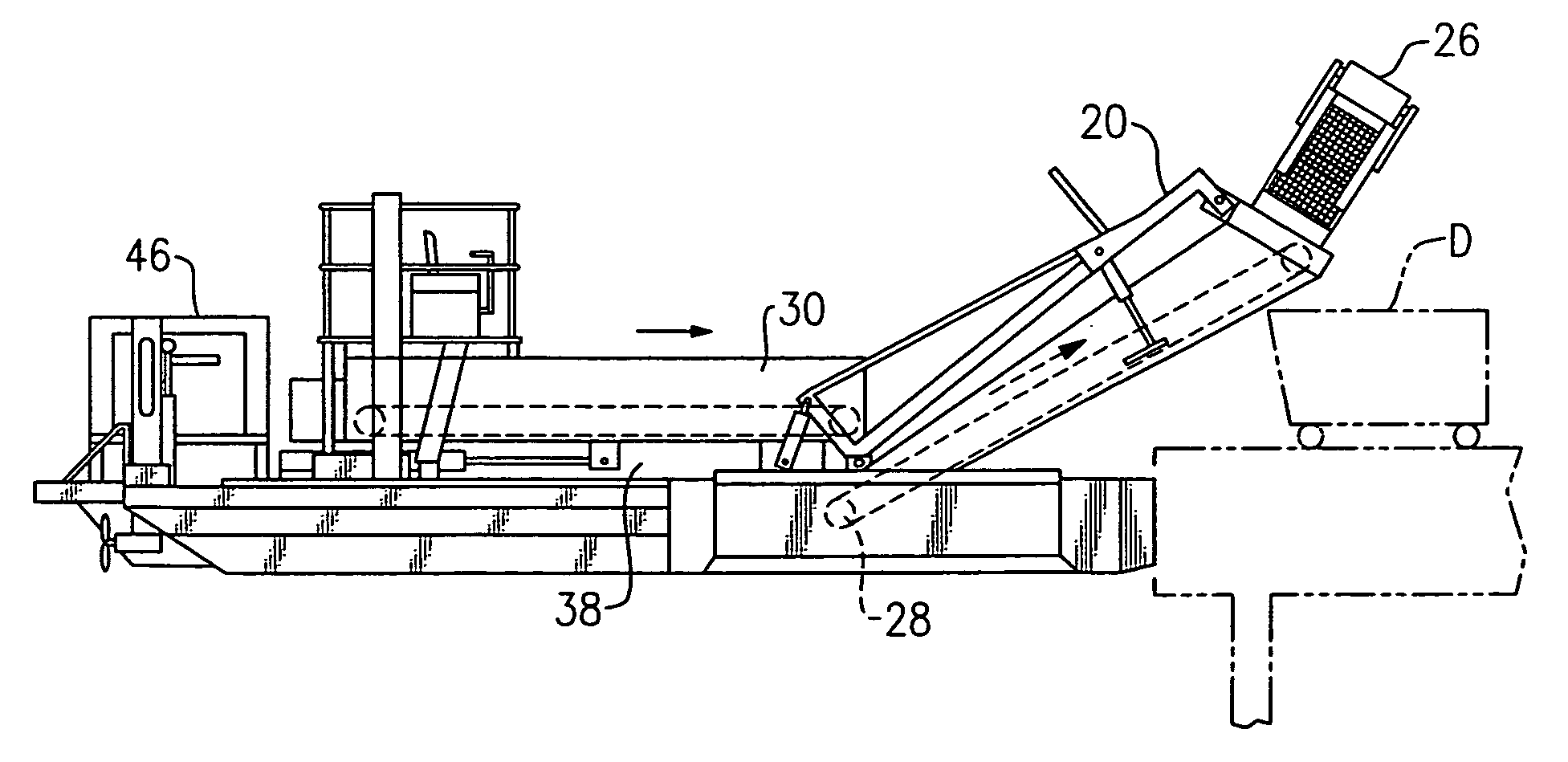

Trash collection skimmer boat

ActiveUS7045058B2Efficient and effectiveAvoid disadvantagesFatty/oily/floating substances removal devicesWater cleaningRefuse collectionLitter

A trash skimmer work boat collects and discharges debris from the front or bow. A storage conveyor positioned approximately amidships and along the center line, and is mounted to the hull on a slide or track arrangement that permits fore and aft motion. A collection and discharge conveyor is mounted at the bow portion of the hull. The forward conveyor can be oriented in a trash collection position or in a trash discharge position. The storage conveyor is brought sternward so that there is clearance for the proximal end of the forward conveyor to be raised or lowered, and then is brought back forward so that the storage conveyor is in position to receive debris or to discharge it. Auxiliary floats at the sides of the boat hull provide additional buoyant support for the front conveyor, and are detachable so they can be removed for road transport of the boat.

Owner:BARBER WELDING

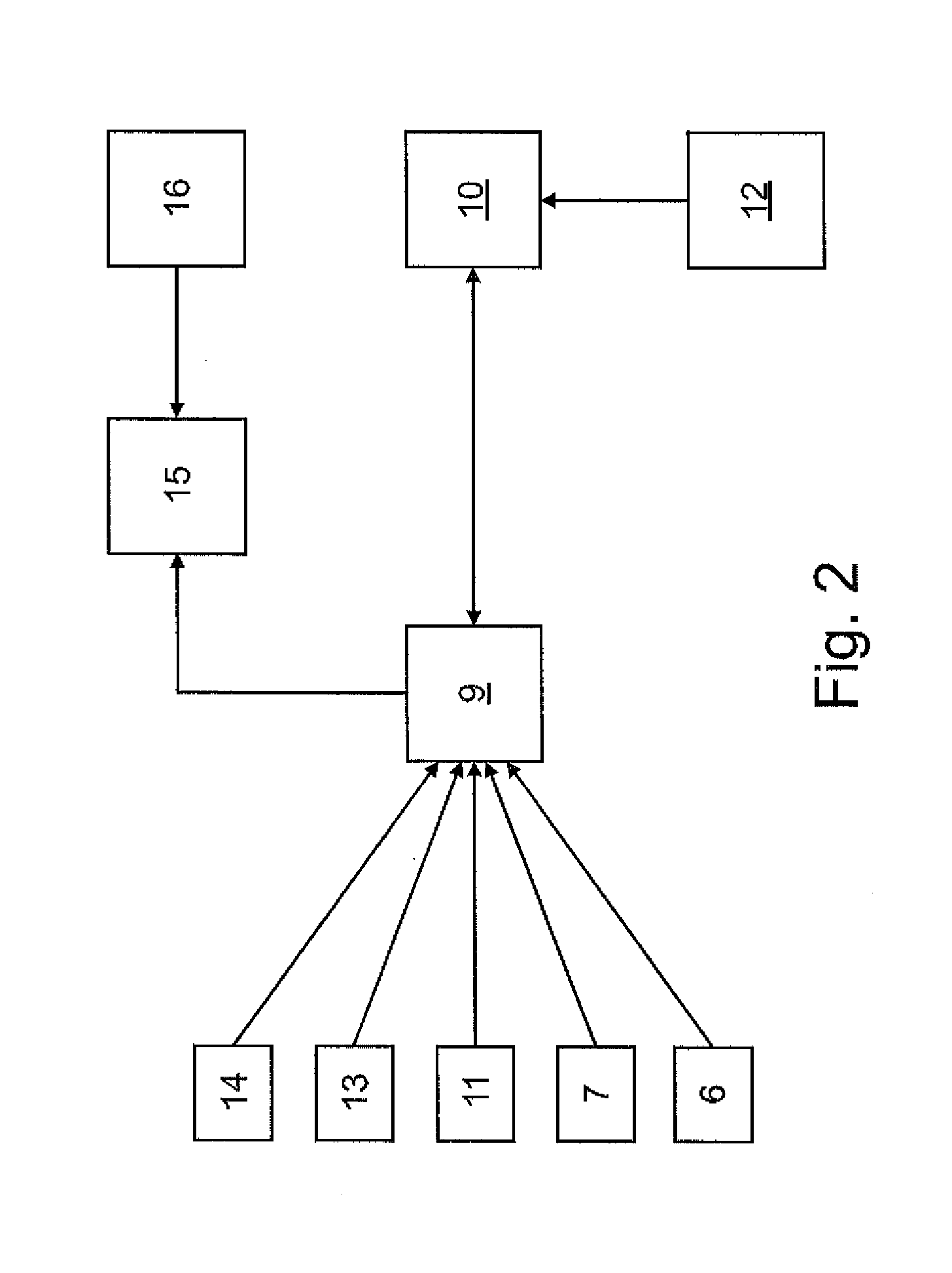

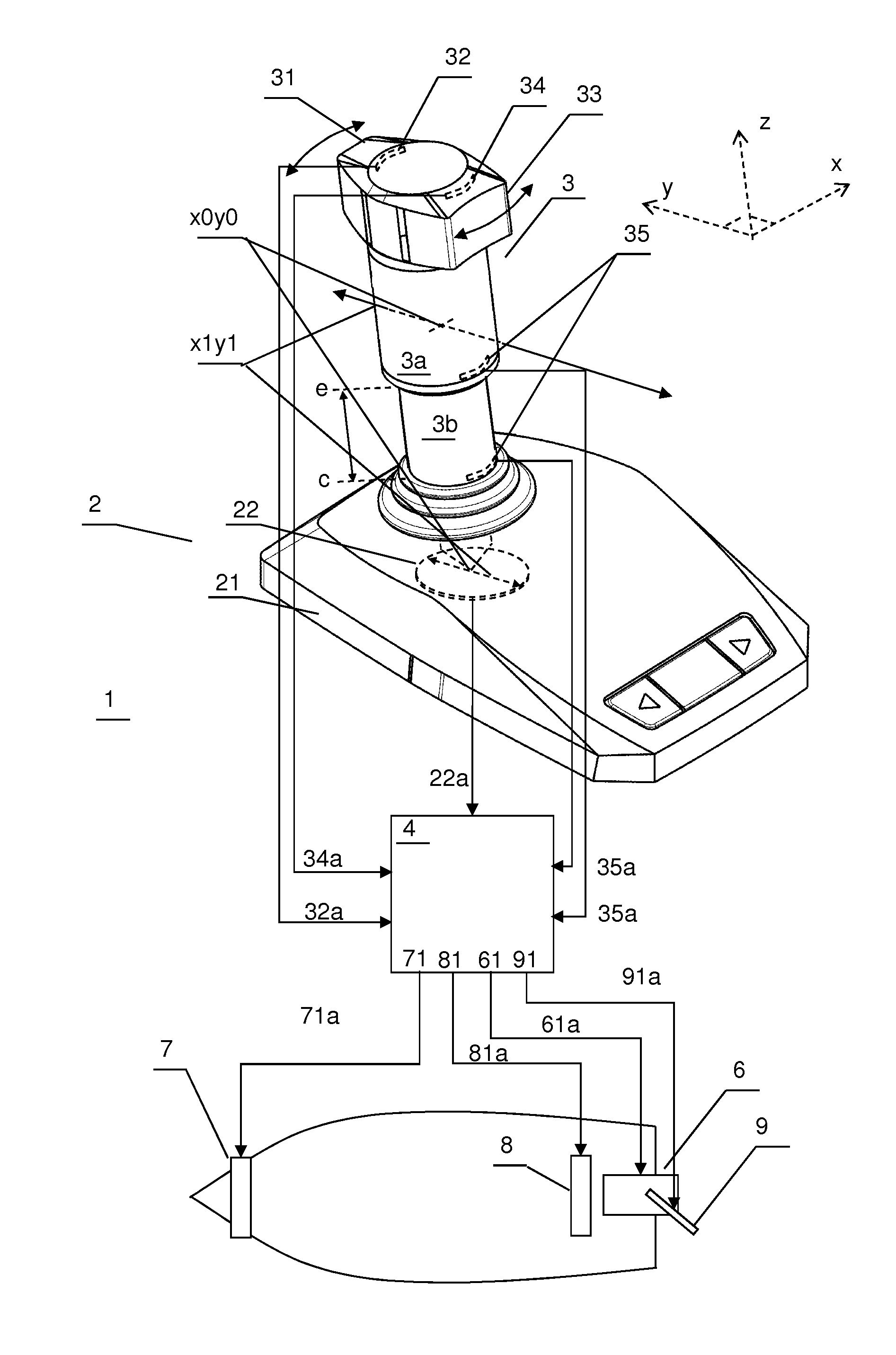

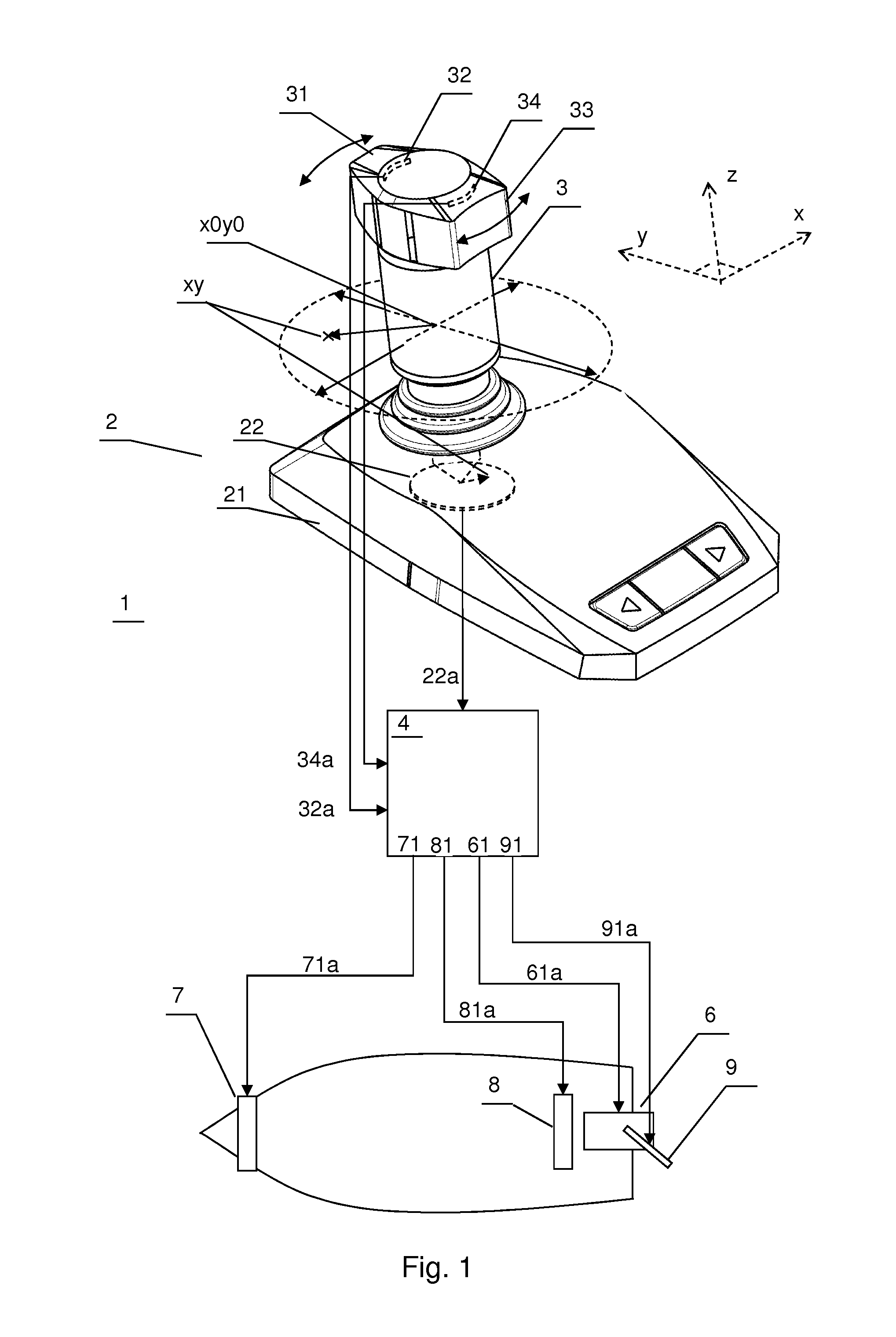

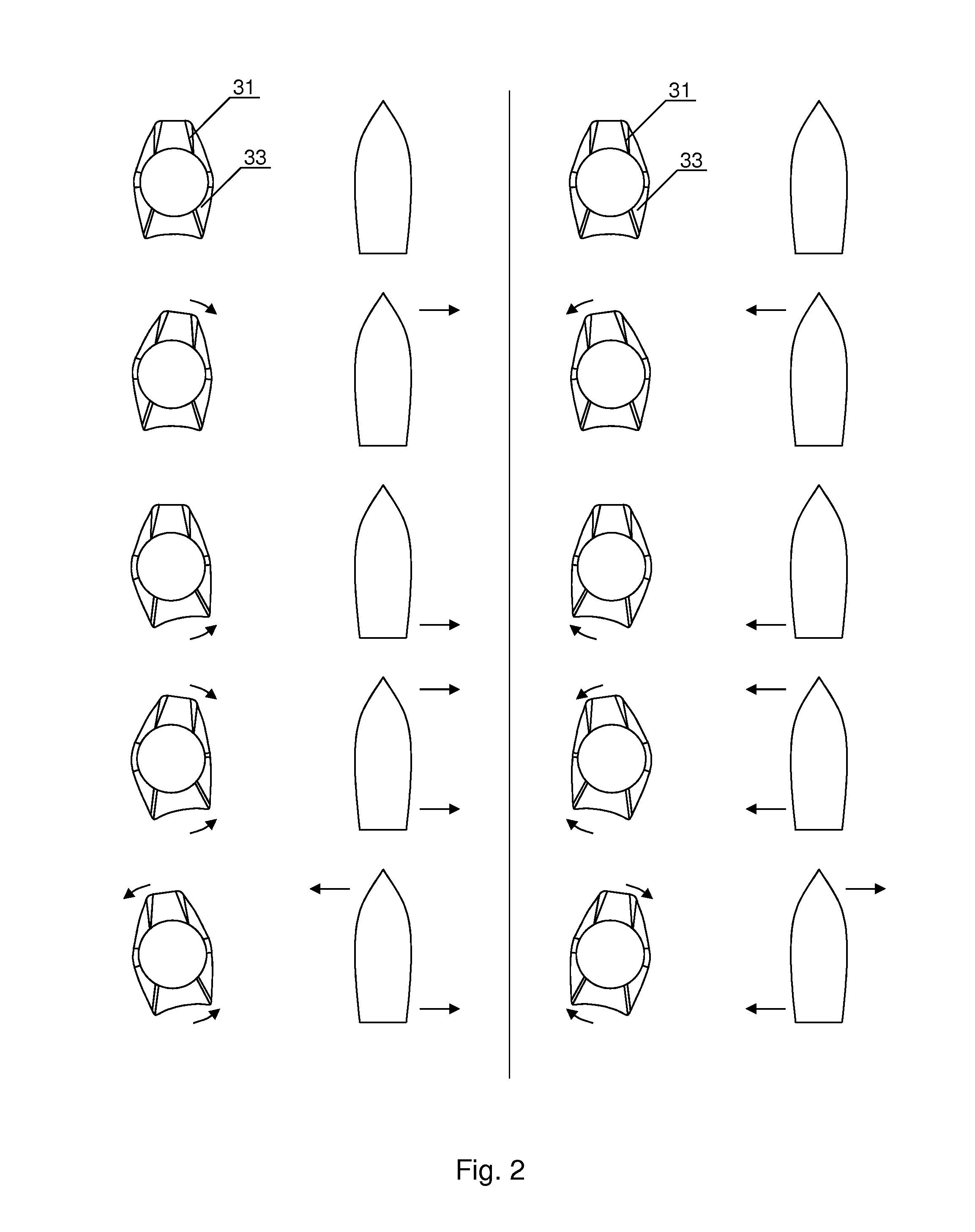

Joystick, system and method for manouvering a boat

ActiveUS9387916B2Ensure correct executionCompensation driftManual control with multiple controlled membersPropulsion power plantsJoystickDual mode

A boat maneuvering joystick, system and method for maneuvering a boat. The joystick has a base with sensors arranged for detecting a position of the maneuvering stick. The maneuvering stick comprises a first bidirectional control knob and a second bidirectional control knob, arranged movably relative each other. The joystick comprises first control sensors detecting a first position of the first bidirectional control knob and second control sensors detecting a second position of the stern control knob. The system comprises a maneuvering control unit comprising a bow thruster output terminal and a propulsion output terminal. The maneuvering control unit is arranged for receiving position, first and second control signals and calculating a bow thruster signal and a propulsion signal. A dual mode joystick is also shown.

Owner:SLEIPNER MOTOR AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com