Landing craft with fixed and retractable azimuthing drives

a technology of azimuthing drive and landing craft, which is applied in the field of marine vessels, can solve the problems of limited maneuverability of marine vessels, limited cargo capacity of larger marine vessels, and difficulty in transferring, and achieves the effect of high maneuverability of the disclosed marine vessel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

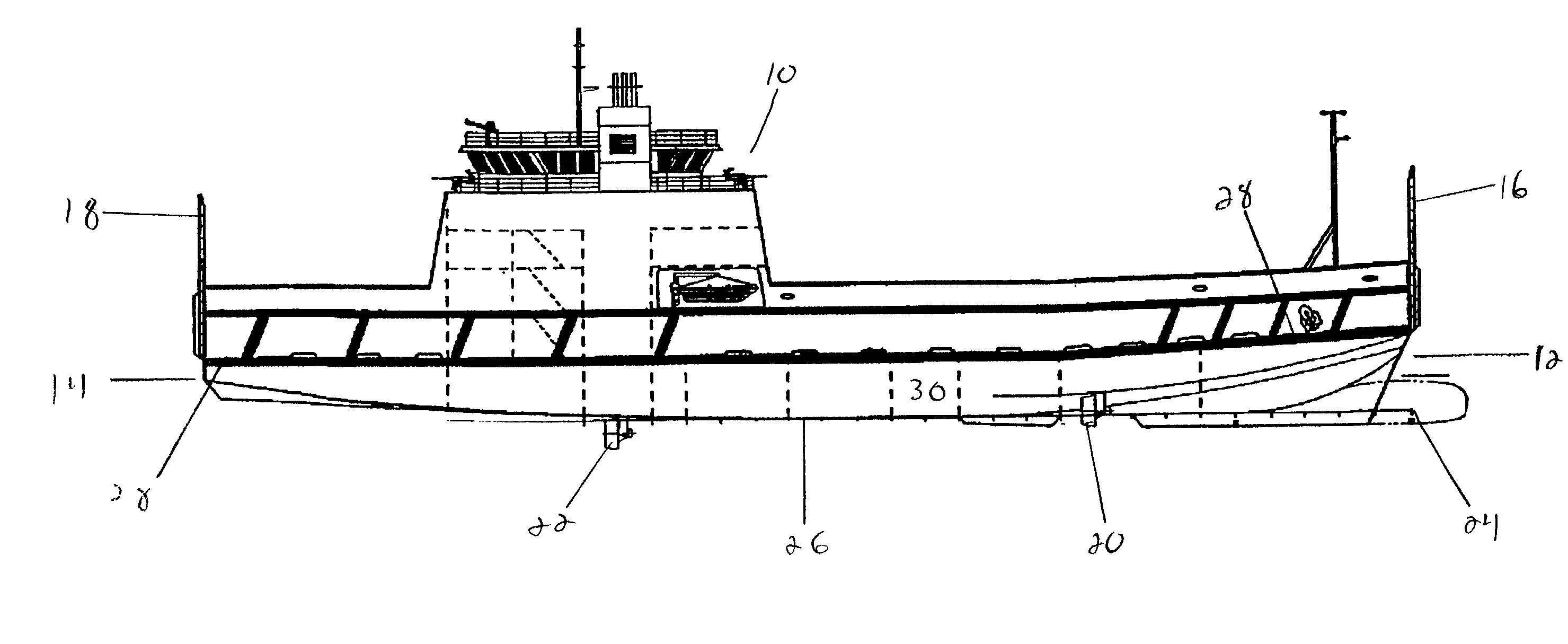

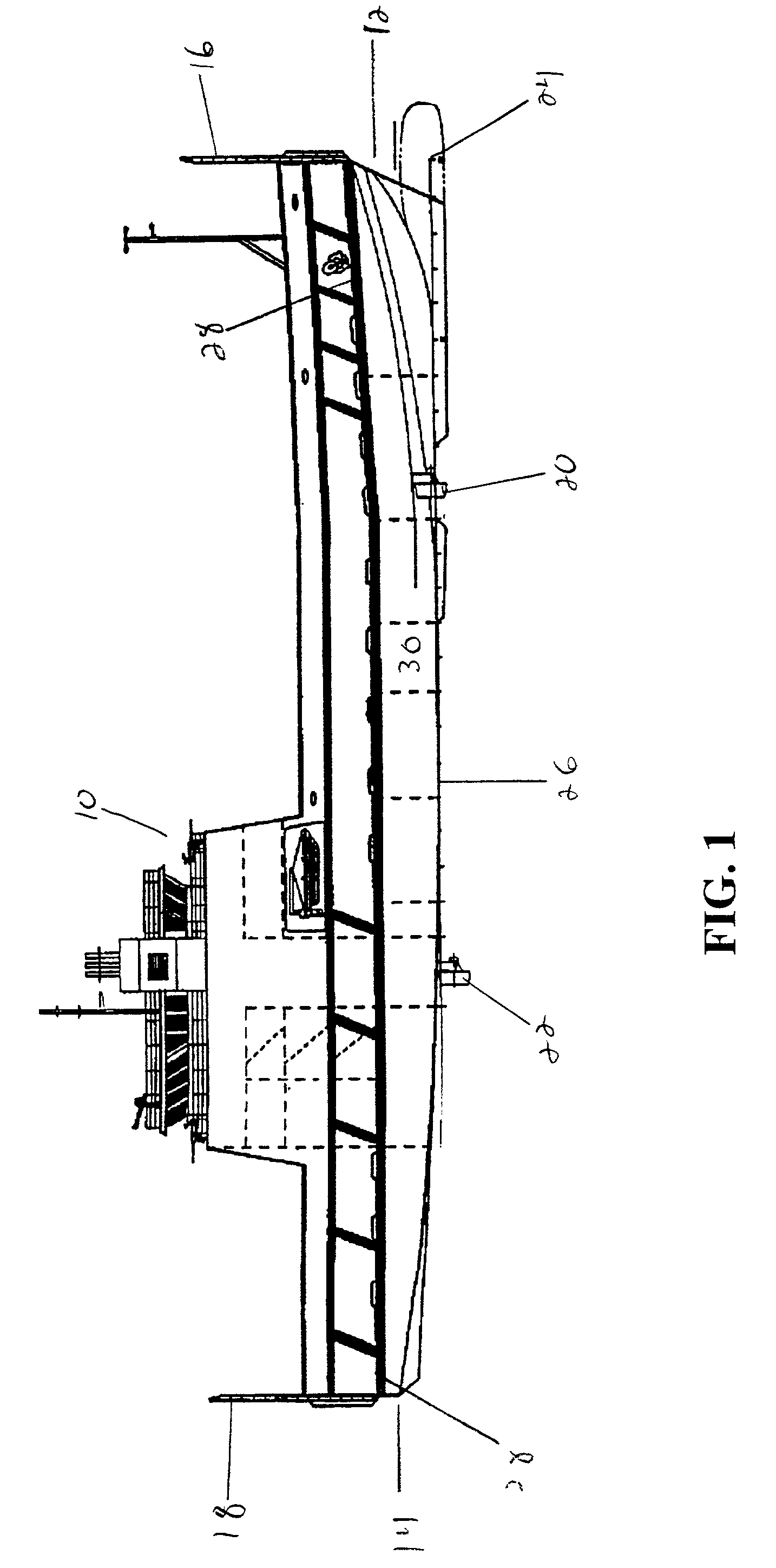

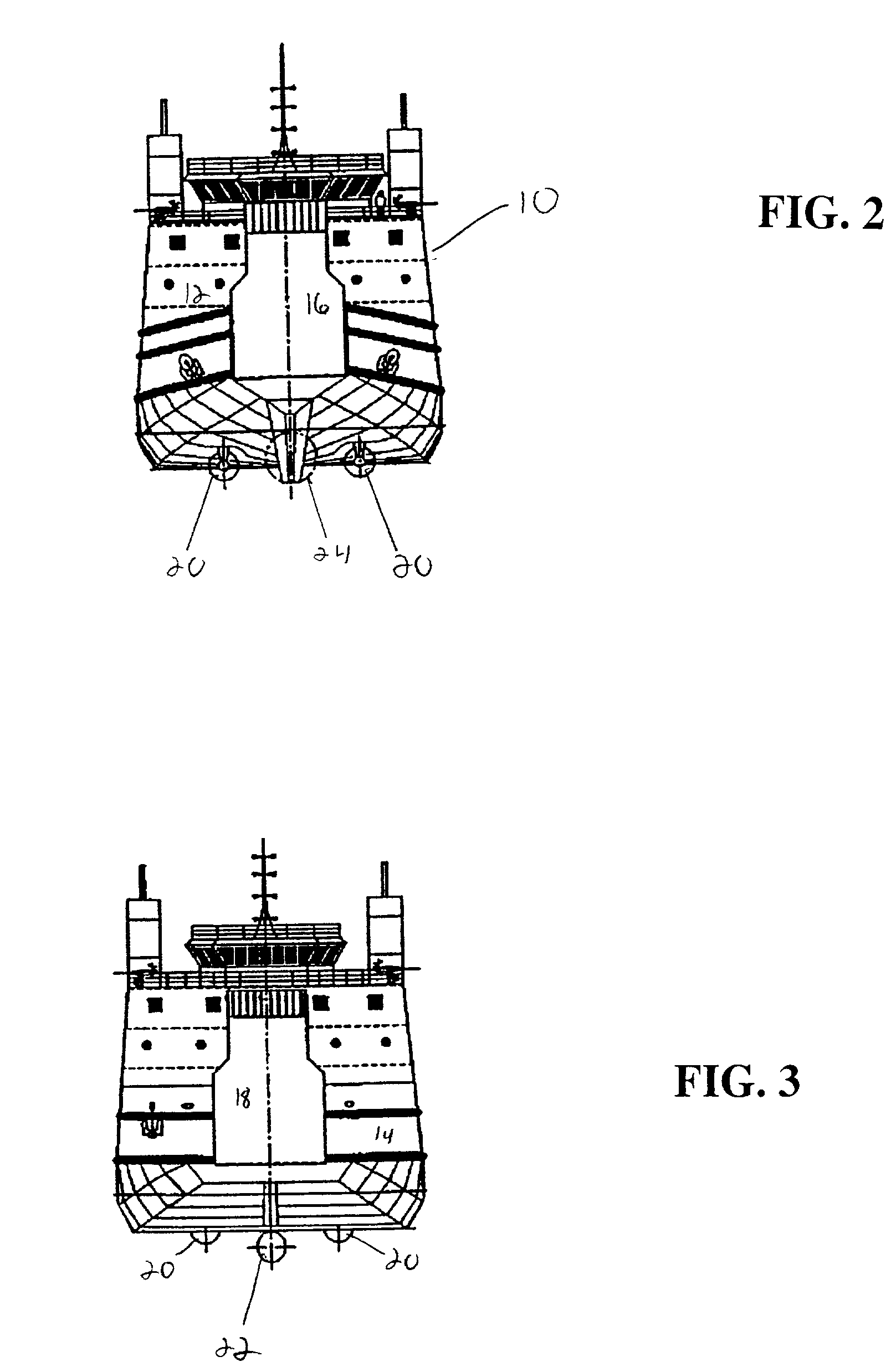

[0029] Referring to FIG. 1, vessel 10 generally contains a boat hull 30 having a bow portion 12, a stem portion 14 and a keel 26. Located at the bow 12 is a bow ramp 16. The bow ramp 16 is generally used to load vehicles or other cargo onto the vessel 10. Located at the stem 14 is a stem ramp 18 that is generally used to offload vehicles or other cargo, particularly during beaching operations. Below the waterline of the vessel 10 are two sets of azimuthing or steerable thruster drives 20 and 22. At least one drive 20 is located on the bow portion 12 of the vessel. Similarly, at least one drive 22 is located on the stem portion 14 of the vessel. In the preferred embodiment of the invention, vessel 10 contains two bow thrusters 20 and two stern thrusters 22. However, as shown in FIGS. 2 and 3, one stem thruster 22 may be used in combination with two bow thrusters 20.

[0030] Referring to FIGS. 1 and 2, the bow portion 12 of the vessel 10 incorporates, to the extent possible, characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com