Vertical take off plane

a vertical take off and plane technology, applied in the field of can solve the problems of complicated control system for developing vertical take off aircraft, difficulty in launching a plane from a runway or via manual throw, and increased weight and cost of aircraft utilizing extra thrusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fourth embodiment

[0041]In a fourth embodiment aircraft 400, illustrated in FIGS. 7a through 7e, the aircraft 400 includes an airframe 402 that is has an aft section 404 and a bow section 406. The aft section 404 includes a tail section 407, which has horizontal stabilizers 408 and a vertical stabilizer 410. The aft section 404 also includes a cockpit 412 and a pair of wings 414 extending outwardly from a front portion 416 of the aft section 404. The front portion 416 of the aft section 404 also includes an opening 418 sized to receive a means to propel 405 the aircraft. The propelling means 405 is in this embodiment in the bow section 406 of the aircraft. The opening 418 also includes a pair of diametrically opposed pins 420 that are received into apertures 422 on the bow section 406. When assembled the propelling means 405 is freely pivotally attached to the front portion 416 of the aft section 404. The propelling means 405 includes a propeller 424 that will create horizontal thrust when the propel...

sixth embodiment

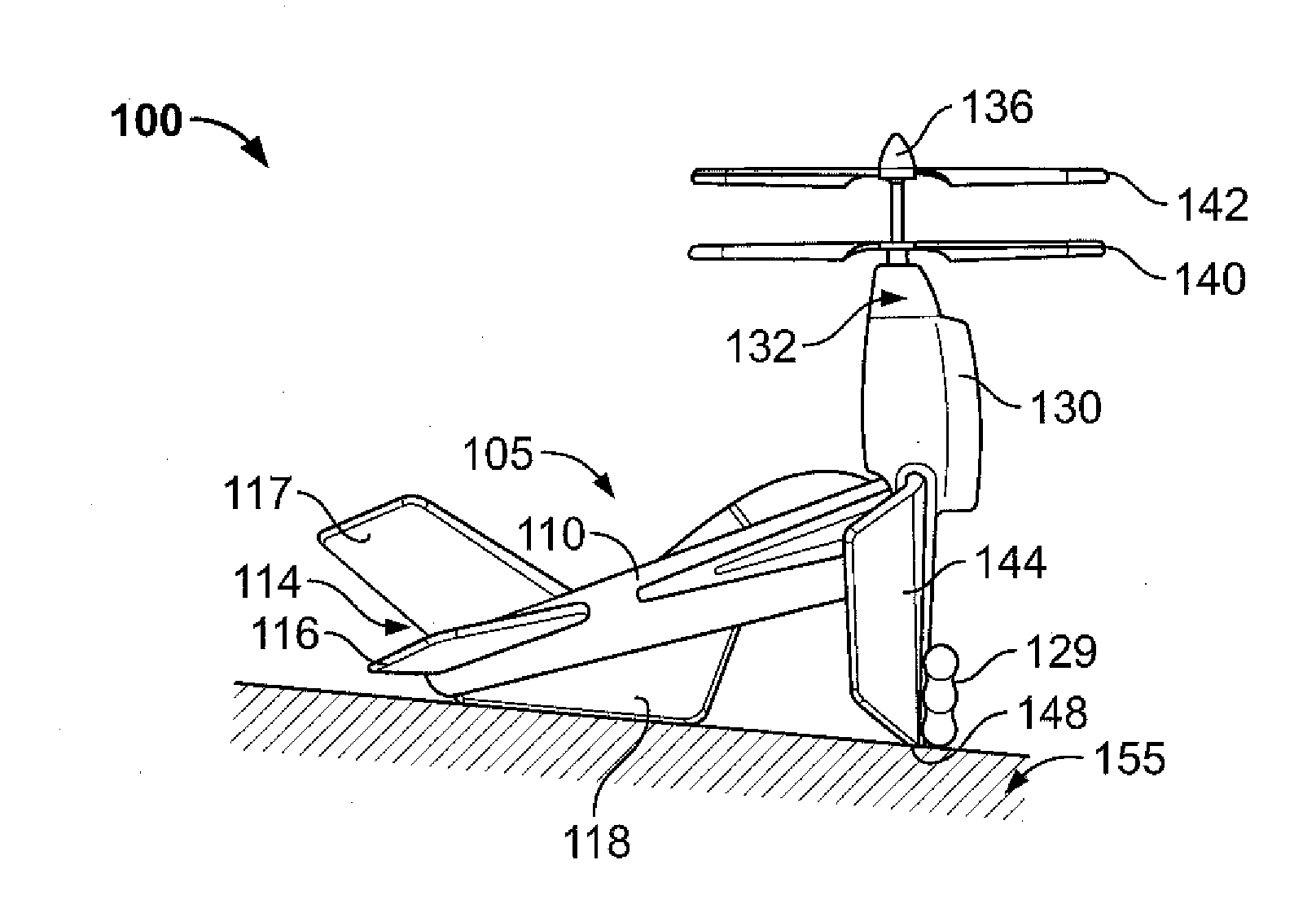

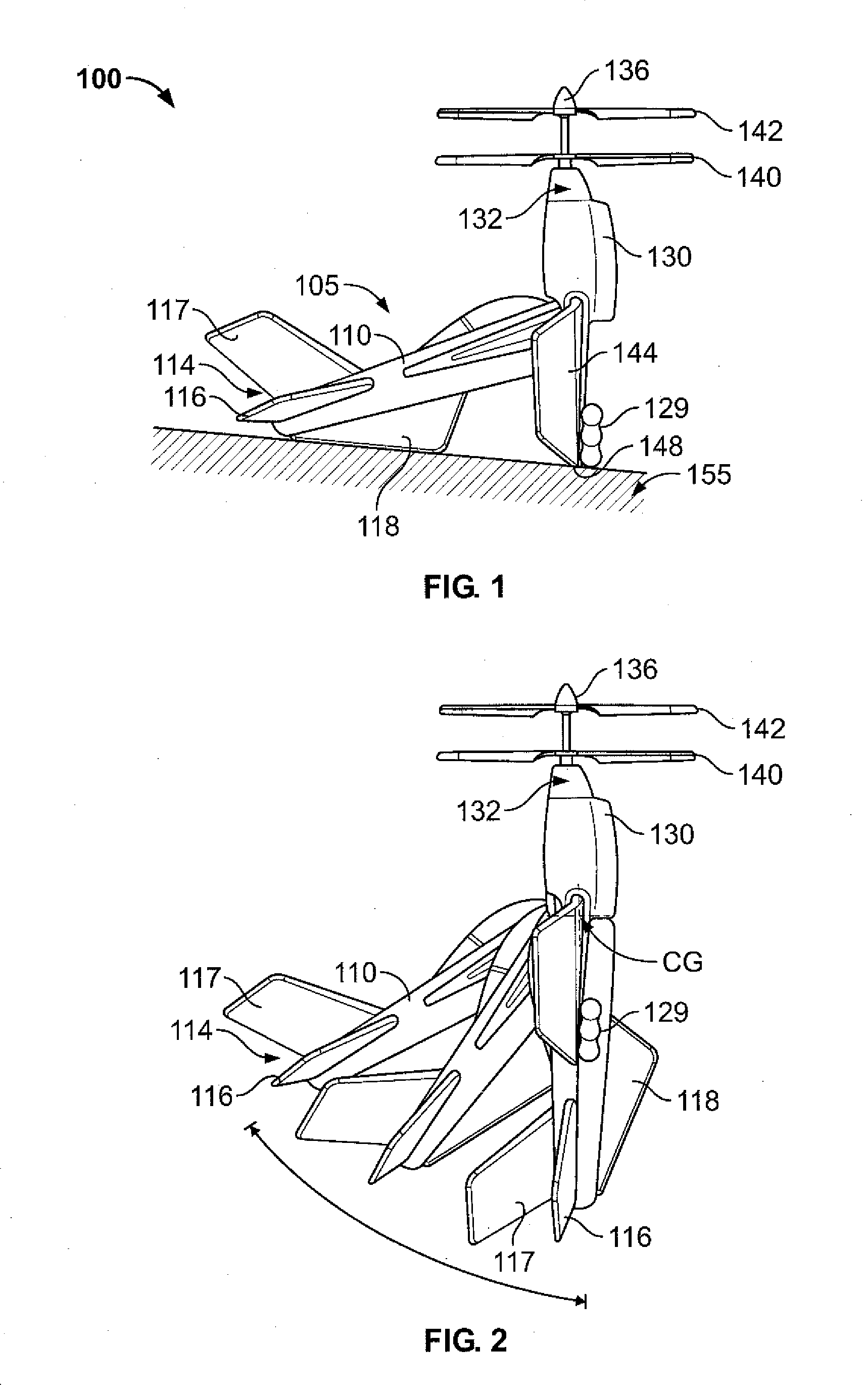

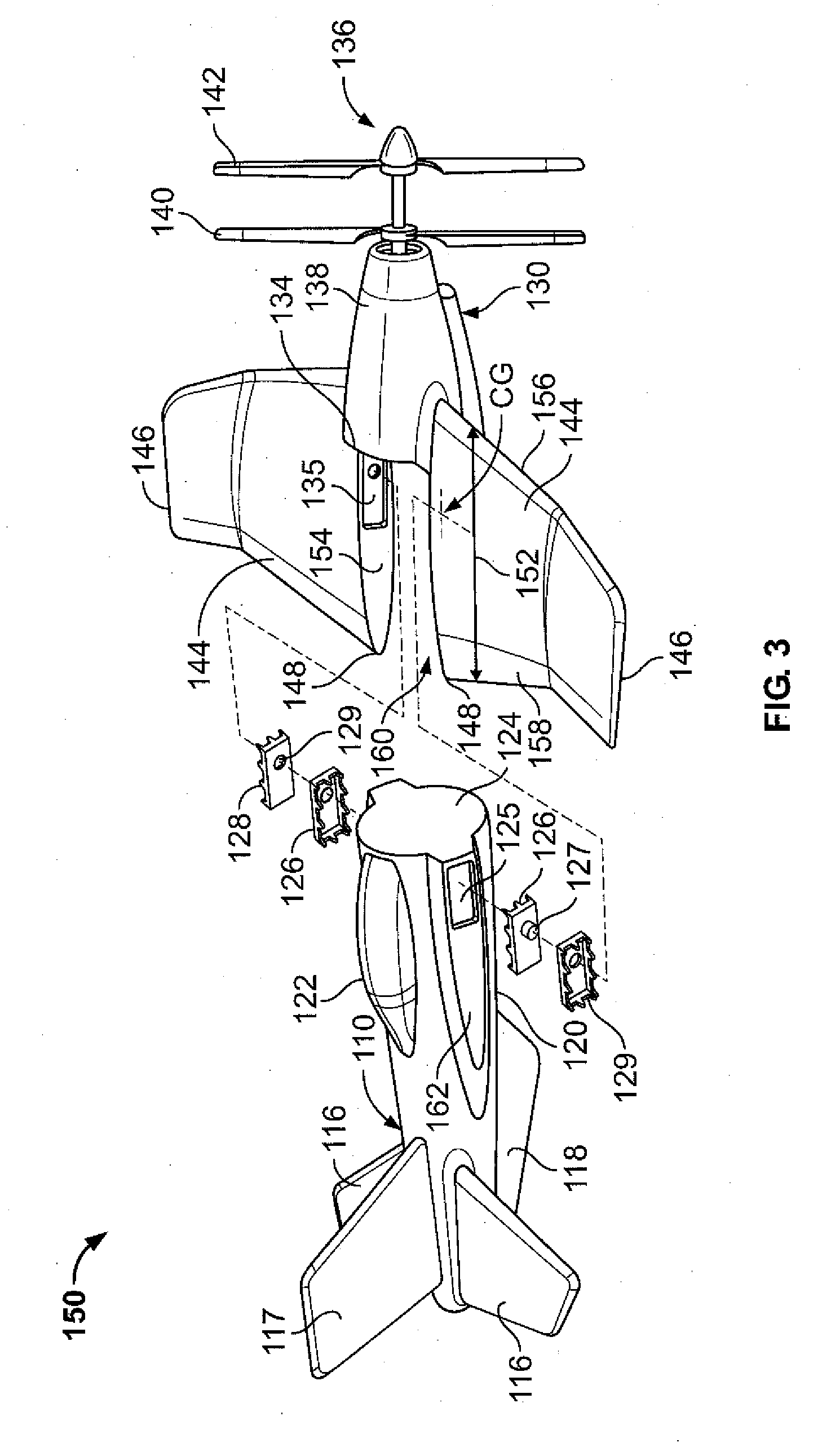

[0044]Referring now to FIGS. 9a and 9b, a sixth embodiment aircraft 600 is illustrated and includes an airframe 602. The airframe 602 includes a pair of wings 604 extending therefrom and a tail section 606. Pivotally attached to each wing 604 is a means for propelling the aircraft 606. The propelling means 606 is freely pivotally attached to each wing 604, by having an opening 608 in each wing. Each opening 608 includes a pair of diametrically opposed pins 610 that fit into apertures 612 on either side of the propelling means 606. During operation, the propelling means 606 are pivoted such that the base 614 of each propelling means 606 is on a surface. The propelling means 606 when activated will vertically lift the aircraft 600 off of the surface and the airframe 602 will pivot such that it becomes aligned with the propelling means 606 in substantially the same plane. After which, the wind currents over the wings and stabilizers will cause the aircraft 600 to tilt into a more horiz...

seventh embodiment

[0045]Referring now to FIGS. 10a and 10b, an aircraft in accordance with the invention is referenced as 700. The aircraft 700 includes a means for propelling 702 the aircraft both vertically off of the ground and horizontally. As illustrated, the propelling means 702 may include a counter-rotating propeller system 703. Unlike the previous embodiments, the aircraft 700 does not include a pivotal connection. The aircraft 700 includes a tail section 704 with stabilizers 705 and an end knob 706 and wings 712. On the belly 708 of the aircraft 700, the aircraft 700 includes a protruding column 710. The column 710 may be a single column, or as illustrated, a broken column. During takeoff the aircraft 700 is positioned on a launch pad 750. The launch pad 750 includes a concave bowl 752 sized to receive the knob 706 of the aircraft 700. The launch pad 750 further includes a rod 756 projecting upwardly from the base 754 of the launch pad 750. The rod 756 is sized to slide through the column 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com