Carriage for conveying and loading packing materials

A technology of packaging materials and trolleys, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc. It can solve the problems of increasing the complexity and cost of the trolley structure, increasing the maintenance cost and difficulty of the trolley, and slow lifting speed of the hydraulic mechanism. , to achieve the effect of low price, ease of parallelism error, simple and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

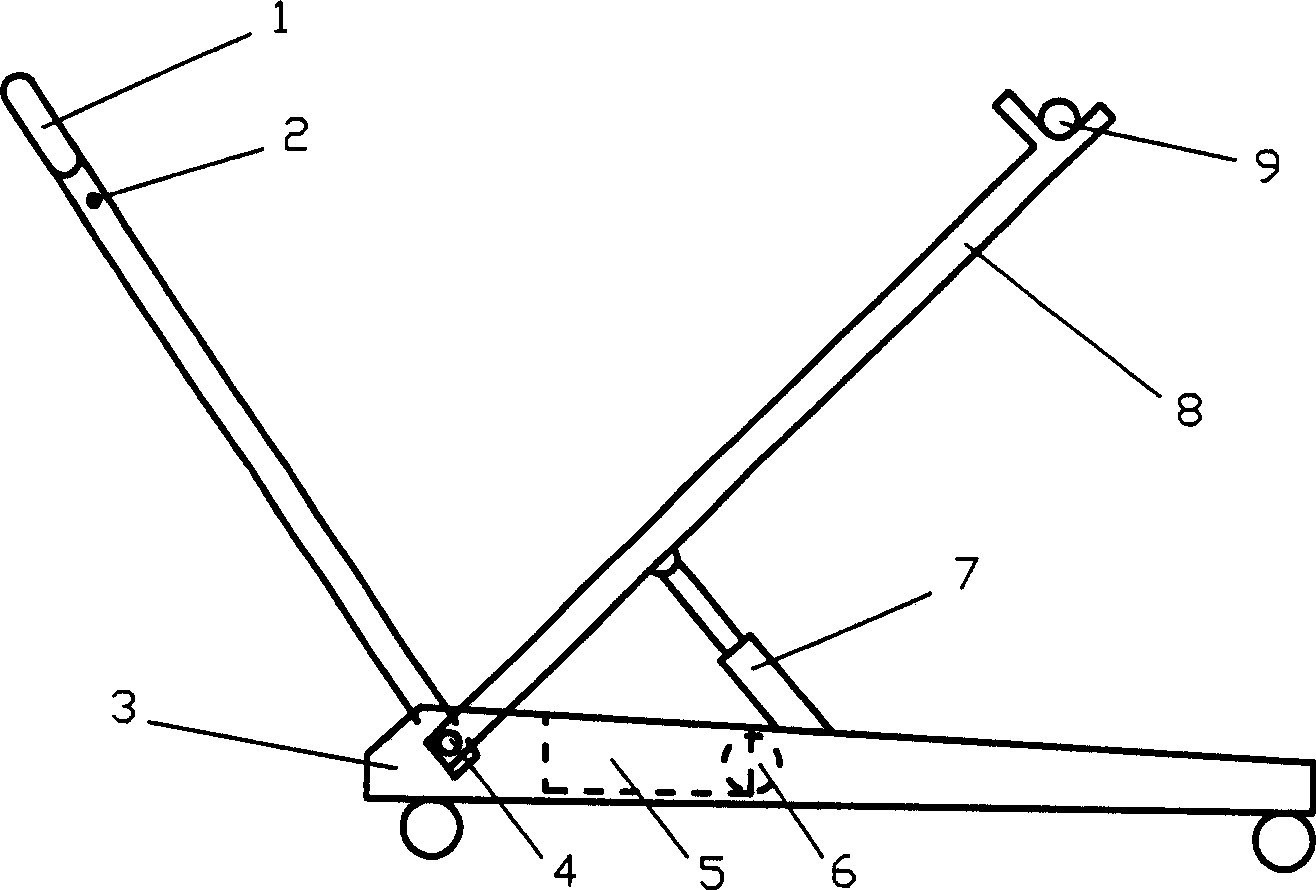

[0012] Such as figure 1 , figure 2 As shown, the present invention includes: a pull rod 1, a motor switch 2, a car body 3, a rotating shaft 4, a storage battery 5, a motor 6, a worm gear system 7, a support beam 8 and a paper shaft 9,

[0013] The tie rod 1 and the support beam 8 are connected to the car body 3 through the rotating shaft 4, one end of the worm gear system 7 is connected to the car body 3, the other end of the worm gear system 7 is connected to the support beam 8, and the motor 6 and the battery 5 are arranged on the car body 3 Above, the motor switch 2 is located at the end of the pull rod 1, the lower end of the support beam 8 is connected to the rotating shaft 4, the upper end supports the paper shaft 9, the storage battery 5 and the motor 6 are arranged on the car body 3, and the motor switch 2 is located on the handle at the end of the pull rod 1.

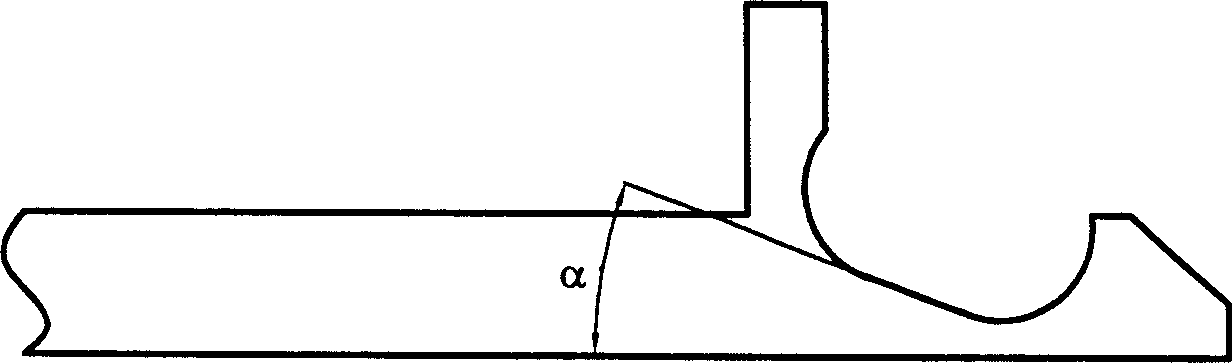

[0014] The upper end of the support beam 8 is arc-shaped. The paper shaft 9 is free to rotate on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com