Pantograph device with jet device

A pantograph and device technology, applied in the field of pantograph-catenary system, can solve problems such as discomfort of people in the vehicle, potential safety hazards, aerodynamic noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

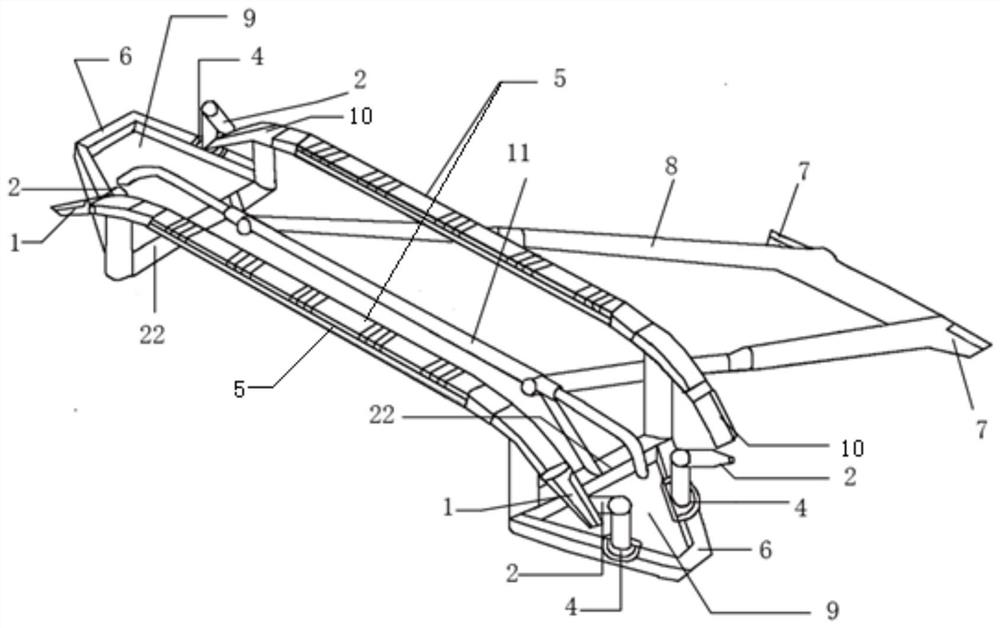

[0040] Such as figure 1 As shown, the present invention provides a pantograph device with a jet device, including a gas jet device 9, a bow bracket 22, an upper frame 8 and an empennage hinge seat 7;

[0041] The gas jet device is arranged on both sides of the bow bracket 22, the front and rear ends of the top of the bow bracket 22 are provided with contact slides 5, and the two sides of the contact slide 5 are provided with bow angles, and the bow bracket 22 is connected to the empennage hinge seat 7 through the upper frame 8 .

[0042] In the embodiment of the present invention, such as figure 1 As shown, the plane formed by the fixed connection of the two tripod brackets is 0-60° to the plane fixed by the bow head bracket;

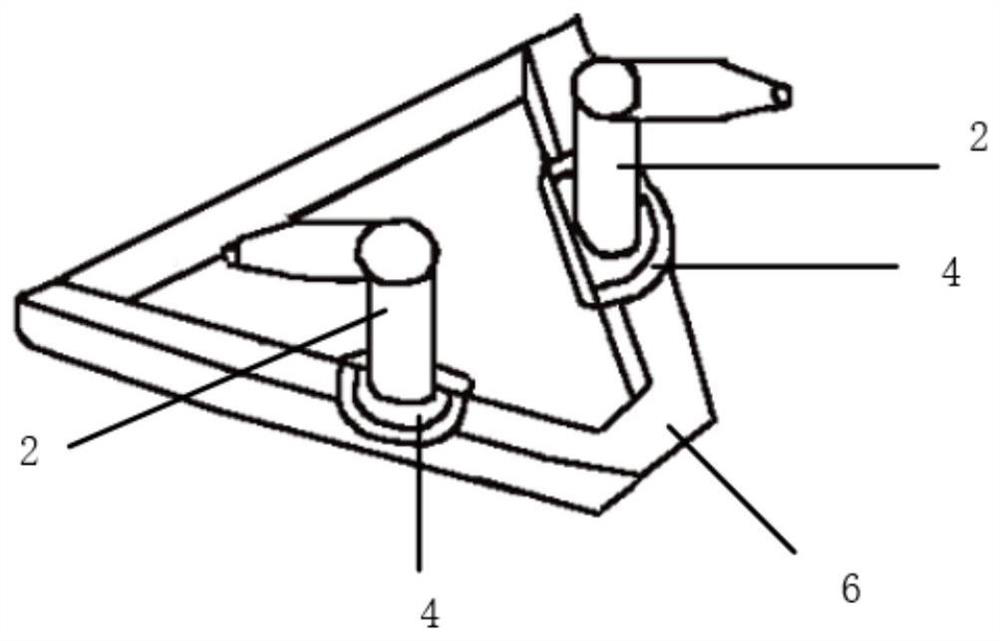

[0043] In the embodiment of the present invention, such as figure 2 As shown, the gas jet device includes a bow bracket 22, a tripod bracket 6, a gas jet generator 2 and a vertically rotating stepper motor 4;

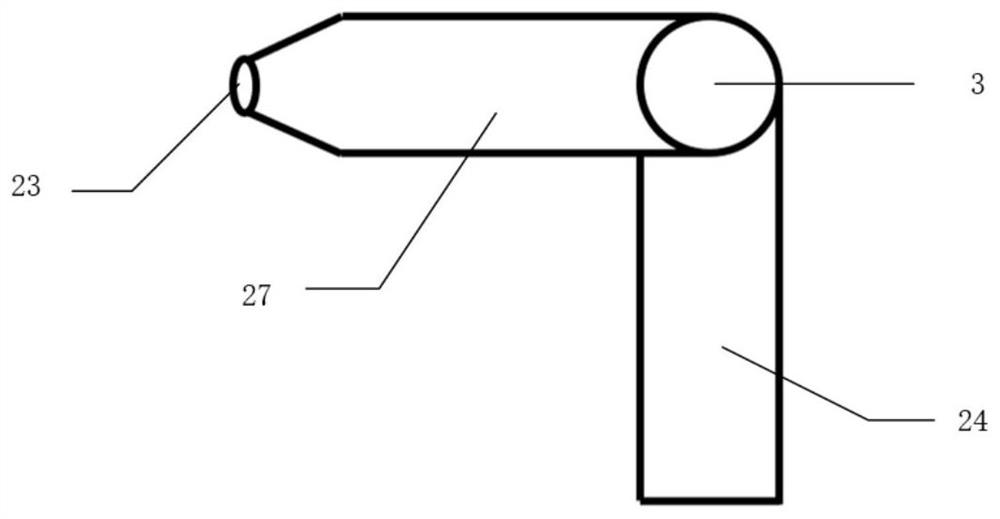

[0044] In the embodiment of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com