Fan, bearing structure and its oil bearing

A bearing and shaft hole technology, which is applied in the directions of bearing elements, shafts and bearings, components of pumping devices for elastic fluids, etc., can solve the problems of shortened service life of oil-impregnated bearings 10, unsmooth overall operation, and limited utility, etc. Achieve the effect of reducing up and down vibration and air hammer, avoiding friction, reducing consumption and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A fan, a bearing structure and an oil-impregnated bearing thereof according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

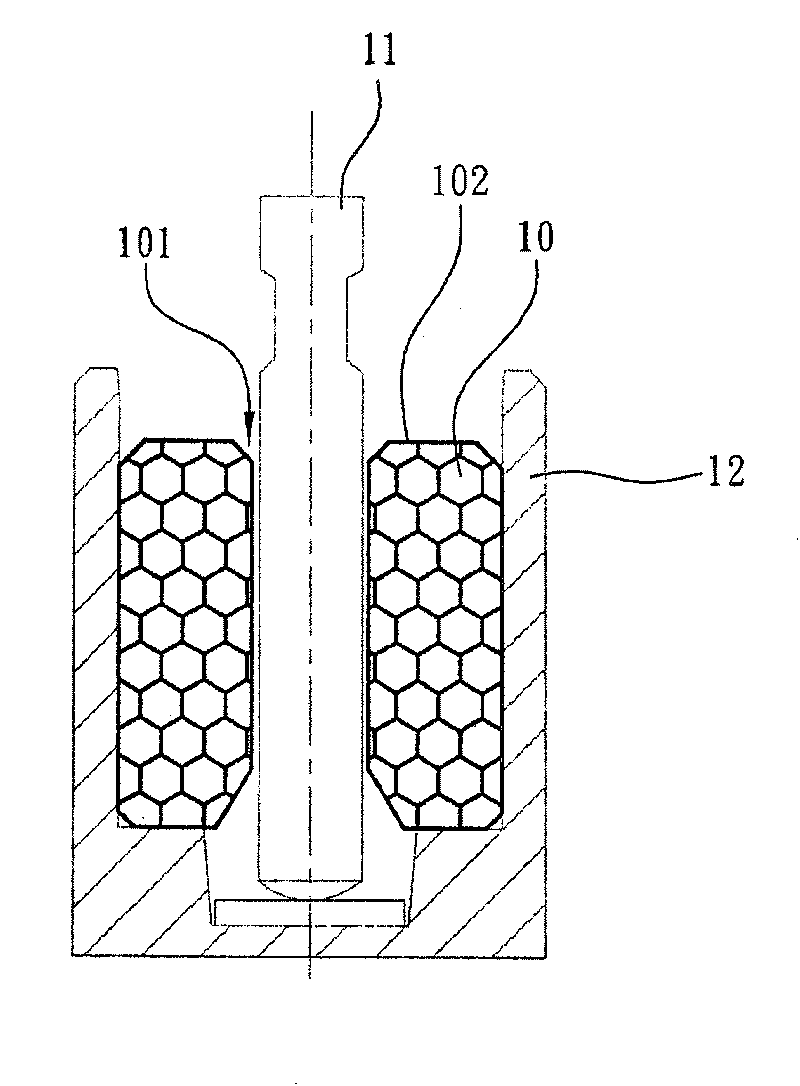

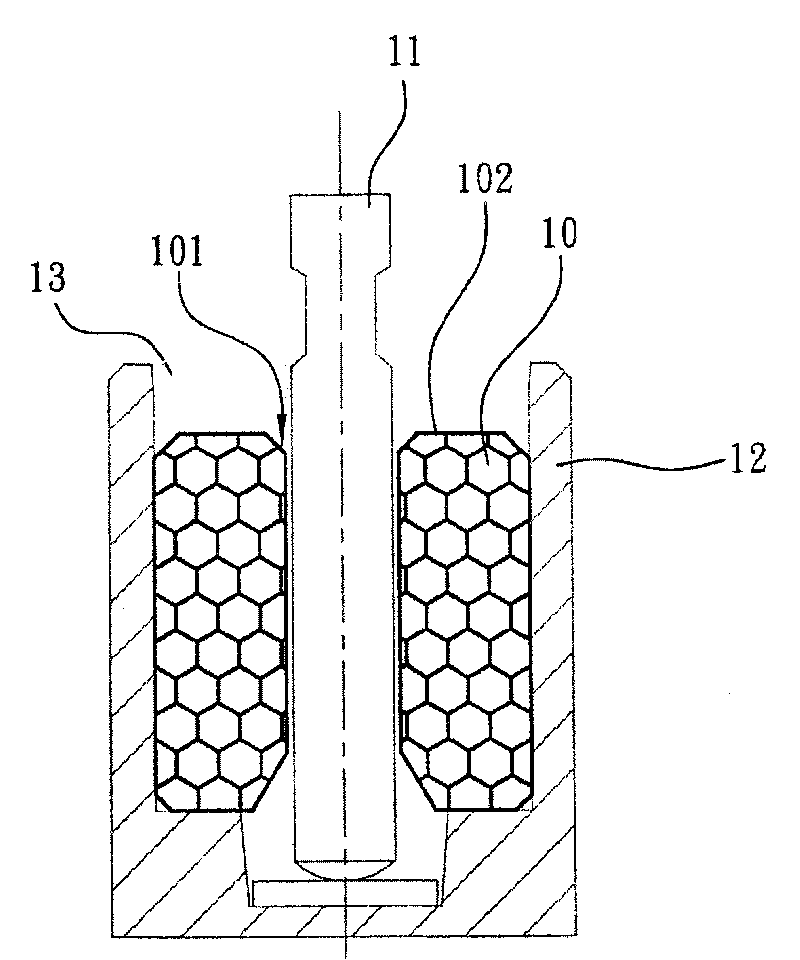

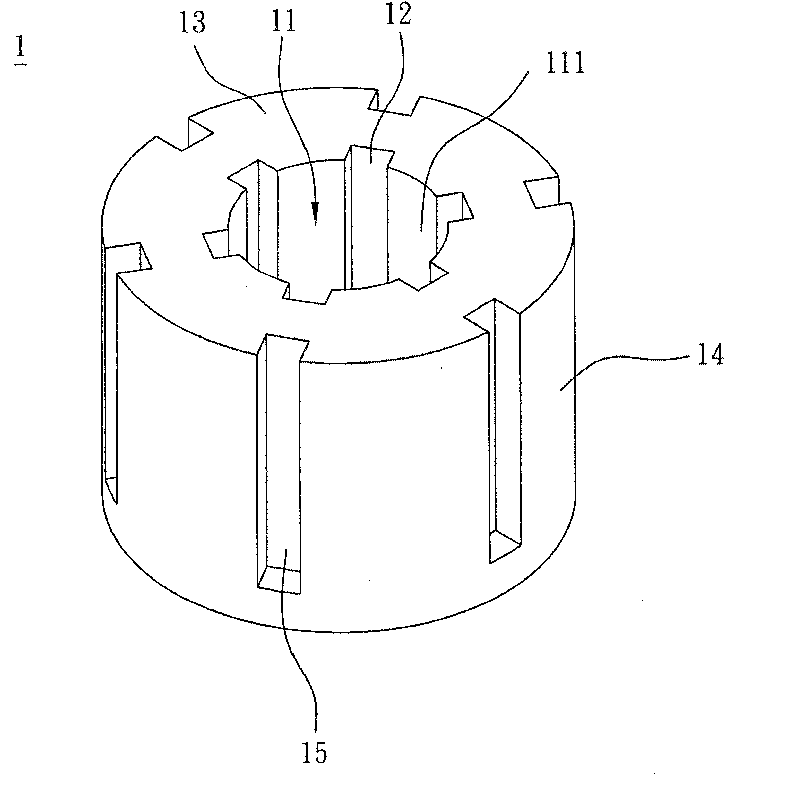

[0040] Please refer to image 3 As shown, an oil-impregnated bearing 1 according to a preferred embodiment of the present invention includes a shaft hole 11 and a plurality of first grooves 12 . In this embodiment, each first groove 12 is disposed on a wall surface 111 of the shaft hole 11 and extends to the top surface 13 of the oil bearing 1 . Each of the first grooves 12 extends parallel to the axial direction of the shaft hole 11 , or extends spirally on the wall surface 111 of the shaft hole 11 (not shown).

[0041] The outer periphery 14 of the oil-impregnated bearing 1 can also form a plurality of second grooves 15, and each second groove 15 can correspond to the first grooves 12, or be formed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com