Patents

Literature

277 results about "Contact slide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

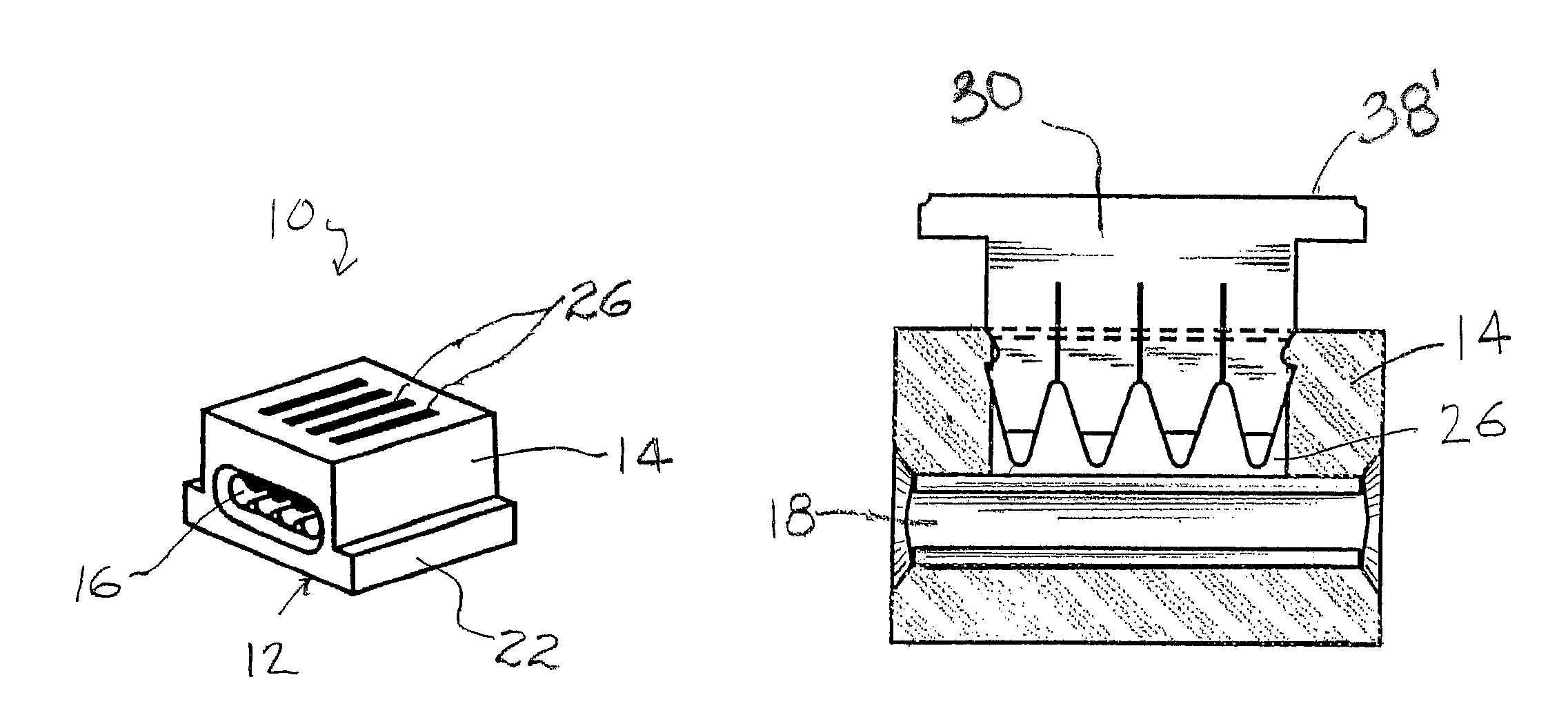

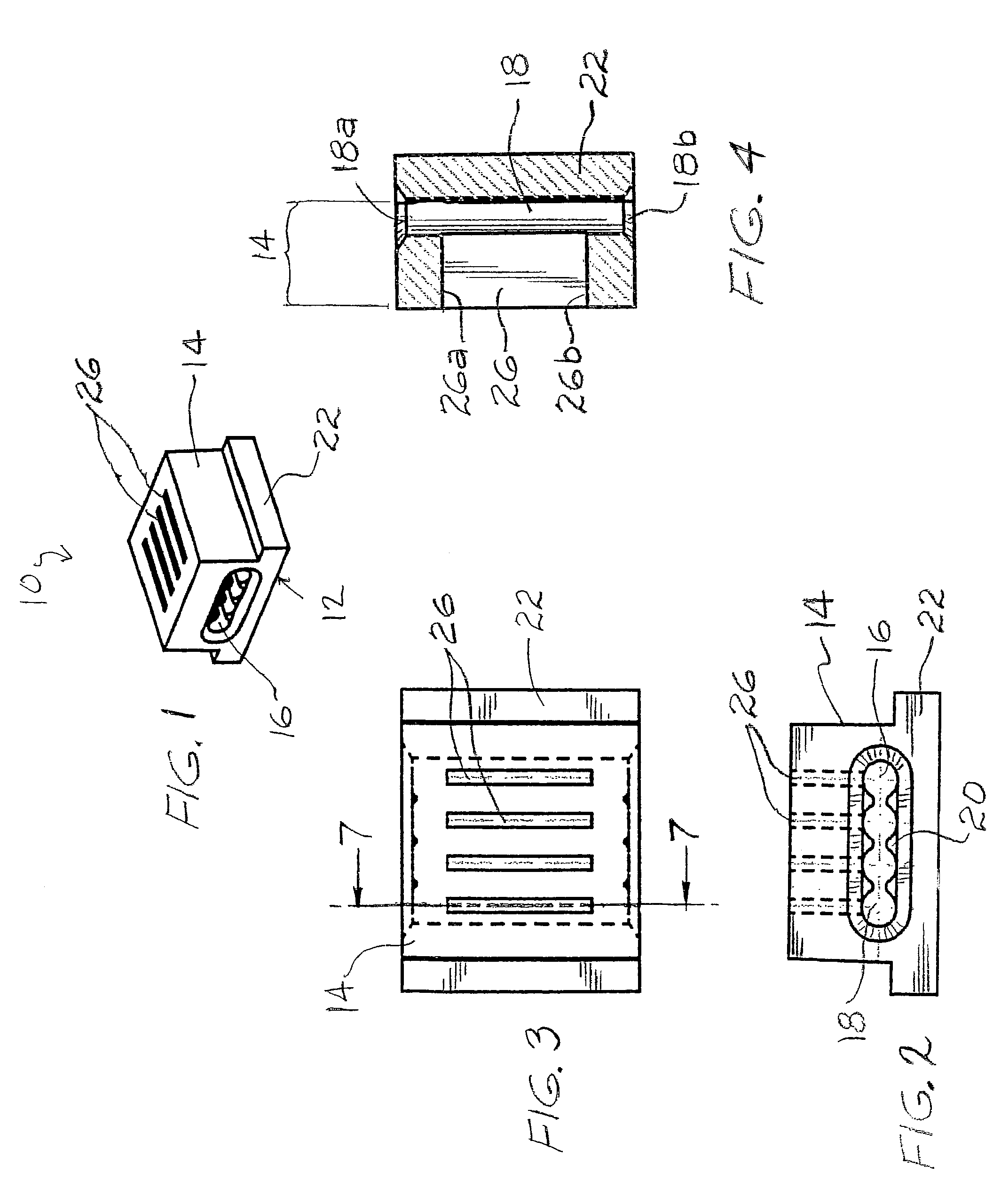

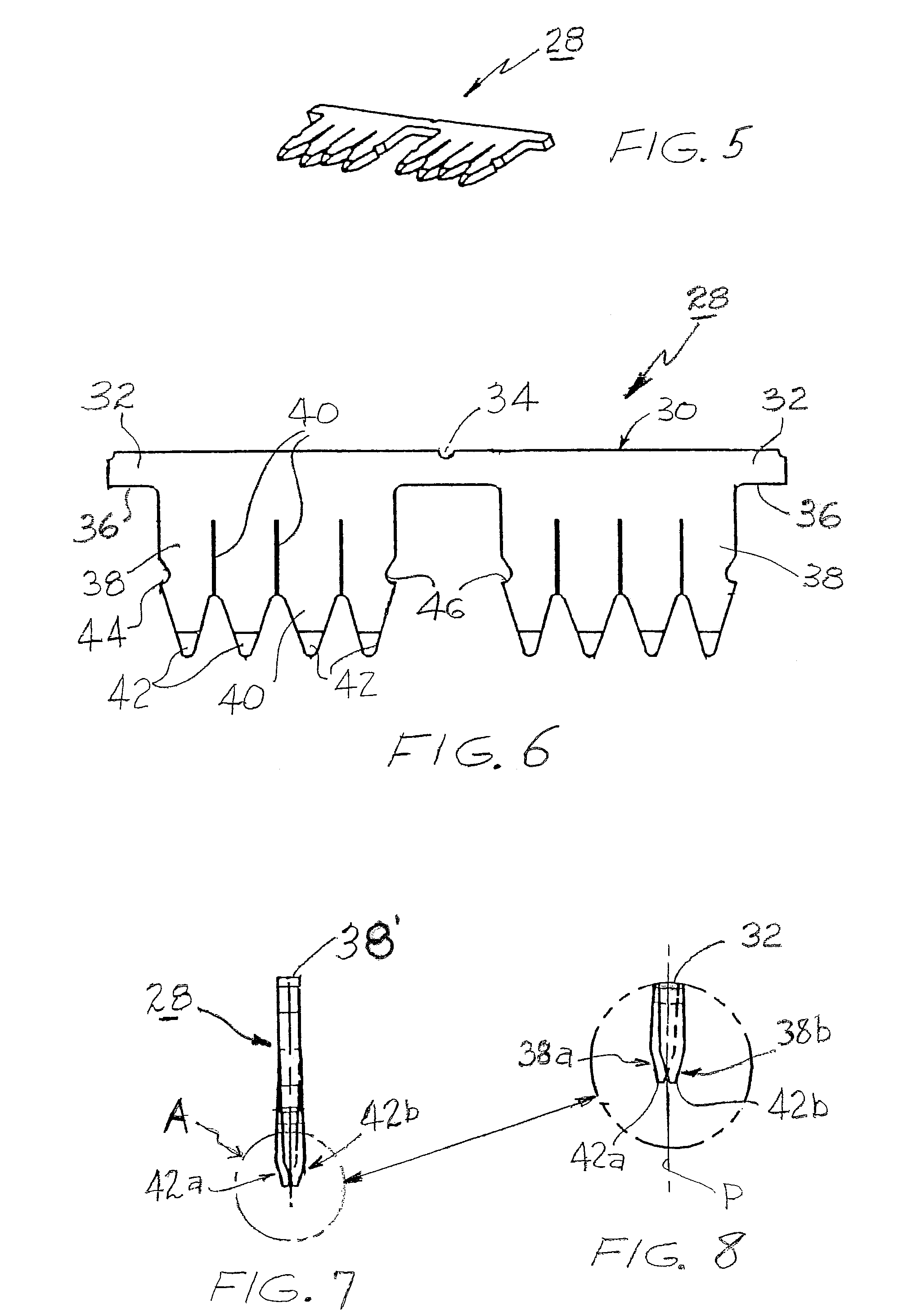

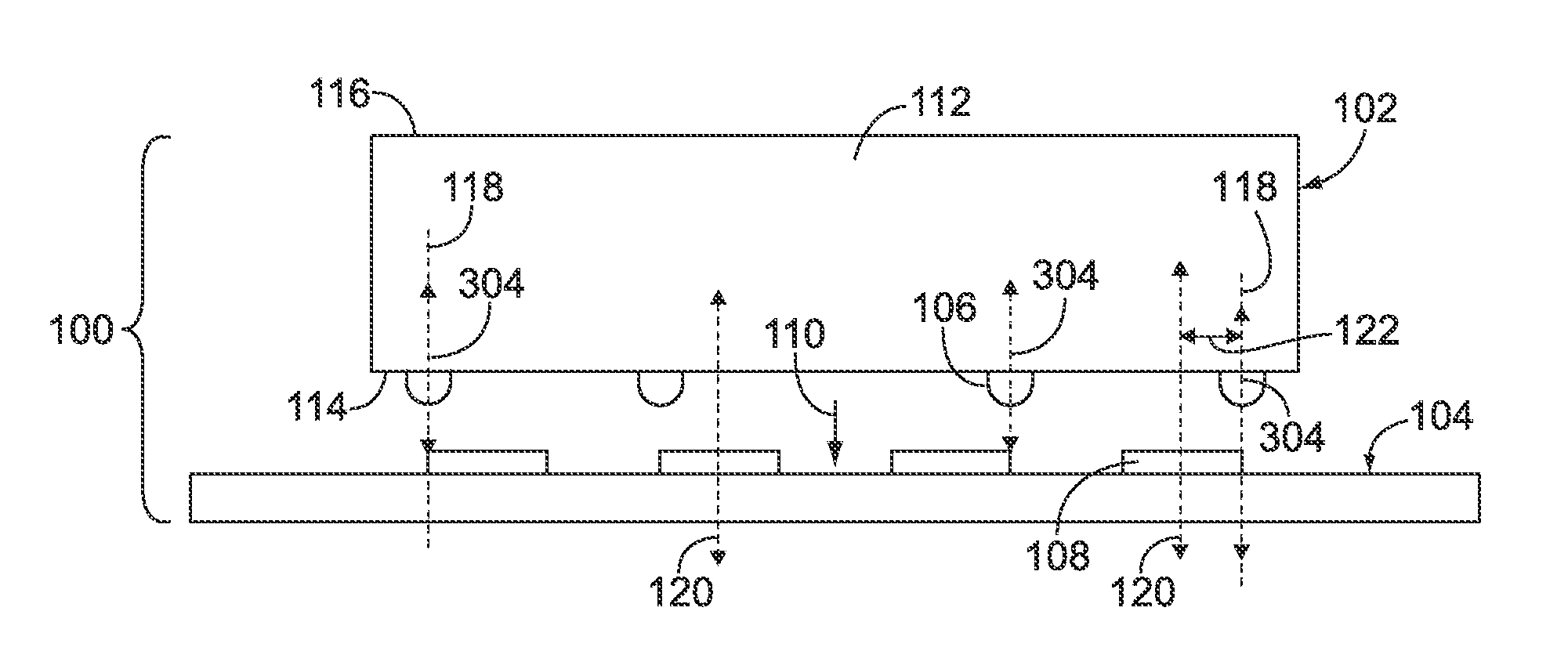

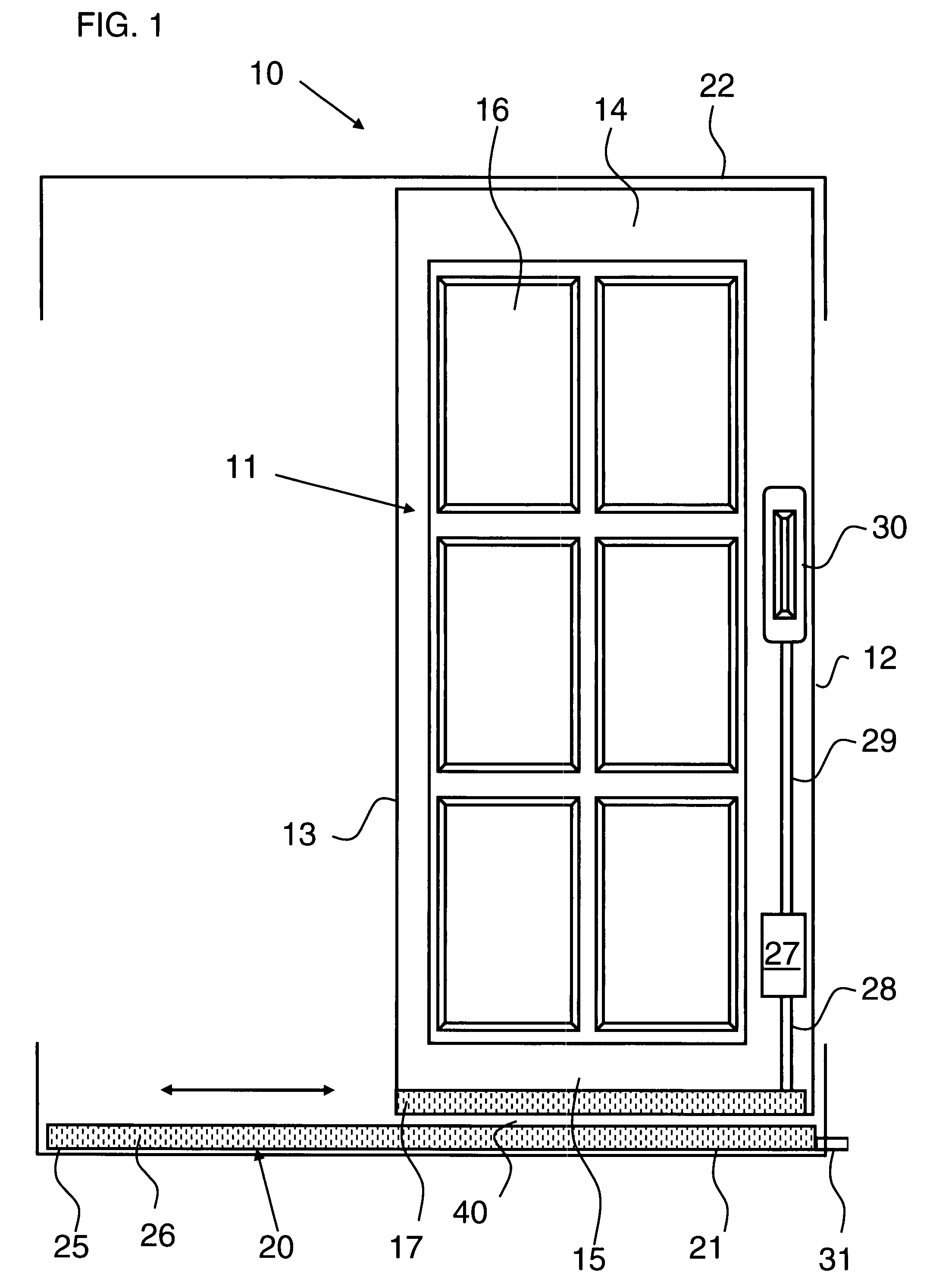

Insulation displacement connector assembly and system adapted for surface mounting on printed circuit board and method of using same

ActiveUS7320616B1Small sizeSmall footprintCoupling device detailsContact members penetrating/cutting insulation/cable strandsSurface mountingEngineering

There is provided an insulation displacement connector (IDC) assembly having a main body defining at least one wire channel. The main body has at least one substantially flat surface to which a vacuum nozzle can be affixed in order to pickup the IDC assembly. The IDC assembly has at least one contact member with a piercing, cutting or slicing end that is slideably disposed within the main body, and a mounting end that extends from the main body. The mounting end of the contact is attached to a printed circuit board. An insulated conductor, such as wire, cable, and / or ribbon, can be quickly and easily inserted in the channel without being pierced by the piercing end of the contact. When a user pushes down on the IDC, the contact slides into the channel and pierces the insulated conductor.

Owner:ZIERICK MFG

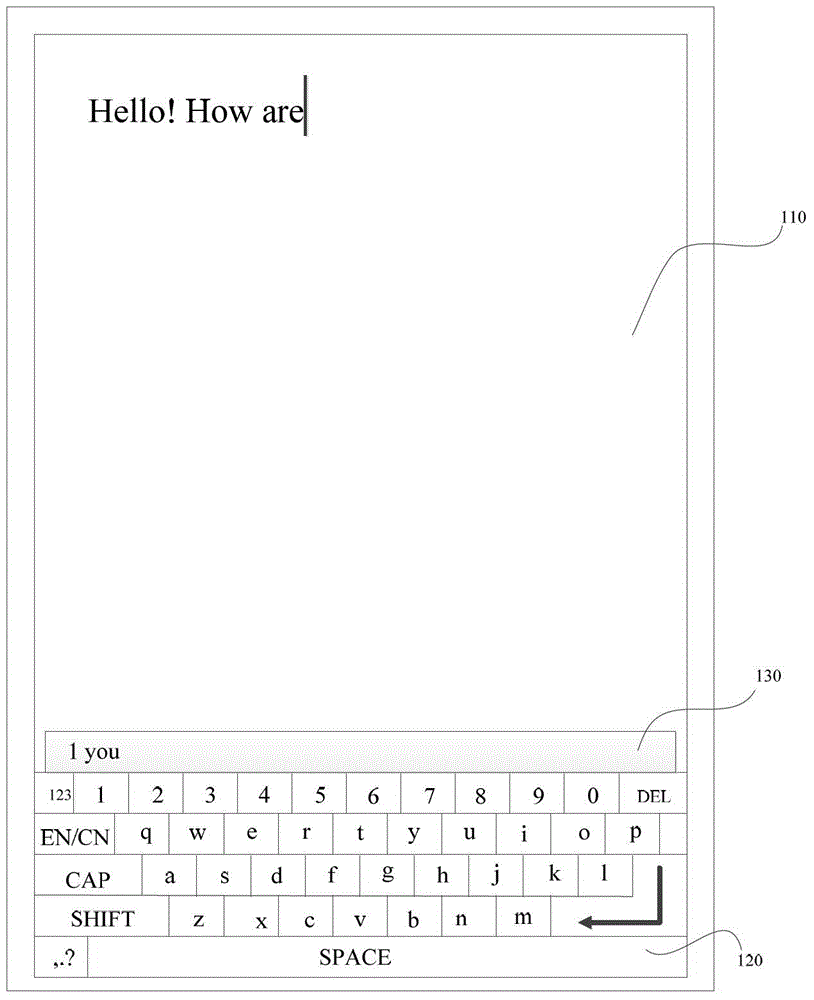

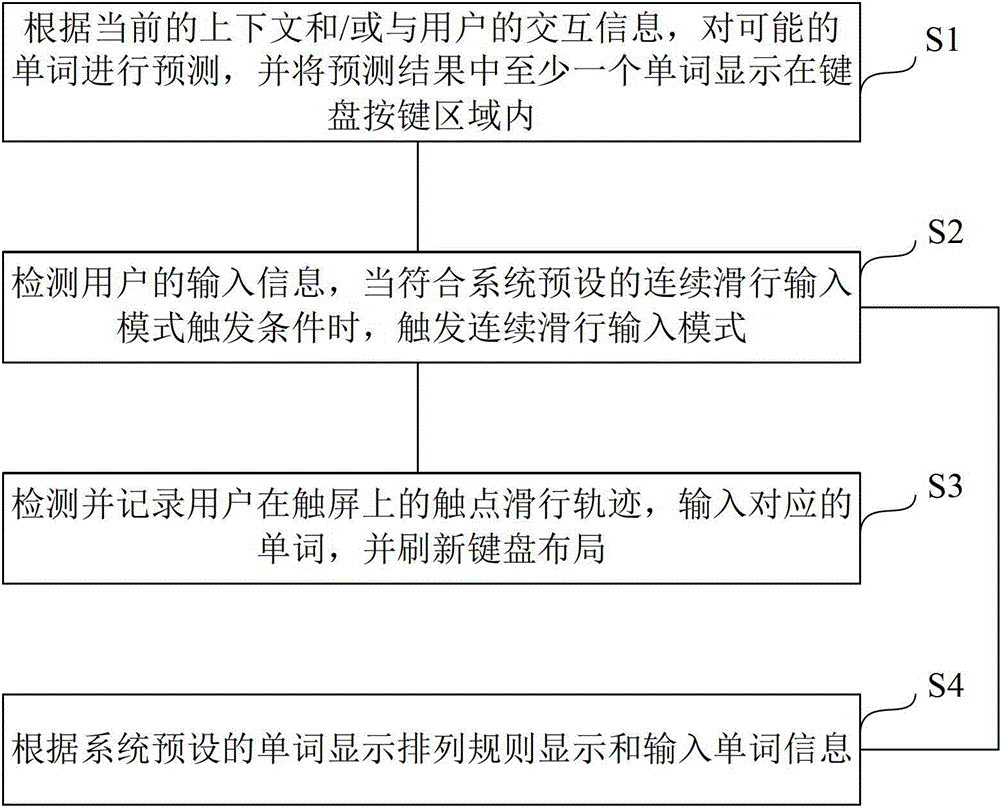

Method for continuously inputting texts by sliding, system and equipment

ActiveCN104007832AImplement inputImprove input efficiencyInput/output processes for data processingUser inputComputer science

The invention relates to a method for inputting text by consecutive slide, and the method includes: detecting whether the consecutive slide input model is triggered according to the user input; detecting and recording the user contact slide track on the touch screen and inputting the corresponding words; and predicting the possible words according to the context and the user input and refreshing the keyboard layout according to at least one of the predicting results. The invention also relates to a system and a corresponding device to realize the method for inputting text by consecutive slide. The method, system and device for inputting text by consecutive slide improve the efficiency of input and realize the intelligent prediction and intelligent arrangement of the candidate words in the keyboard area.

Owner:SHANGHAI CHULE (COOTEK) INFORMATION TECH CO LTD

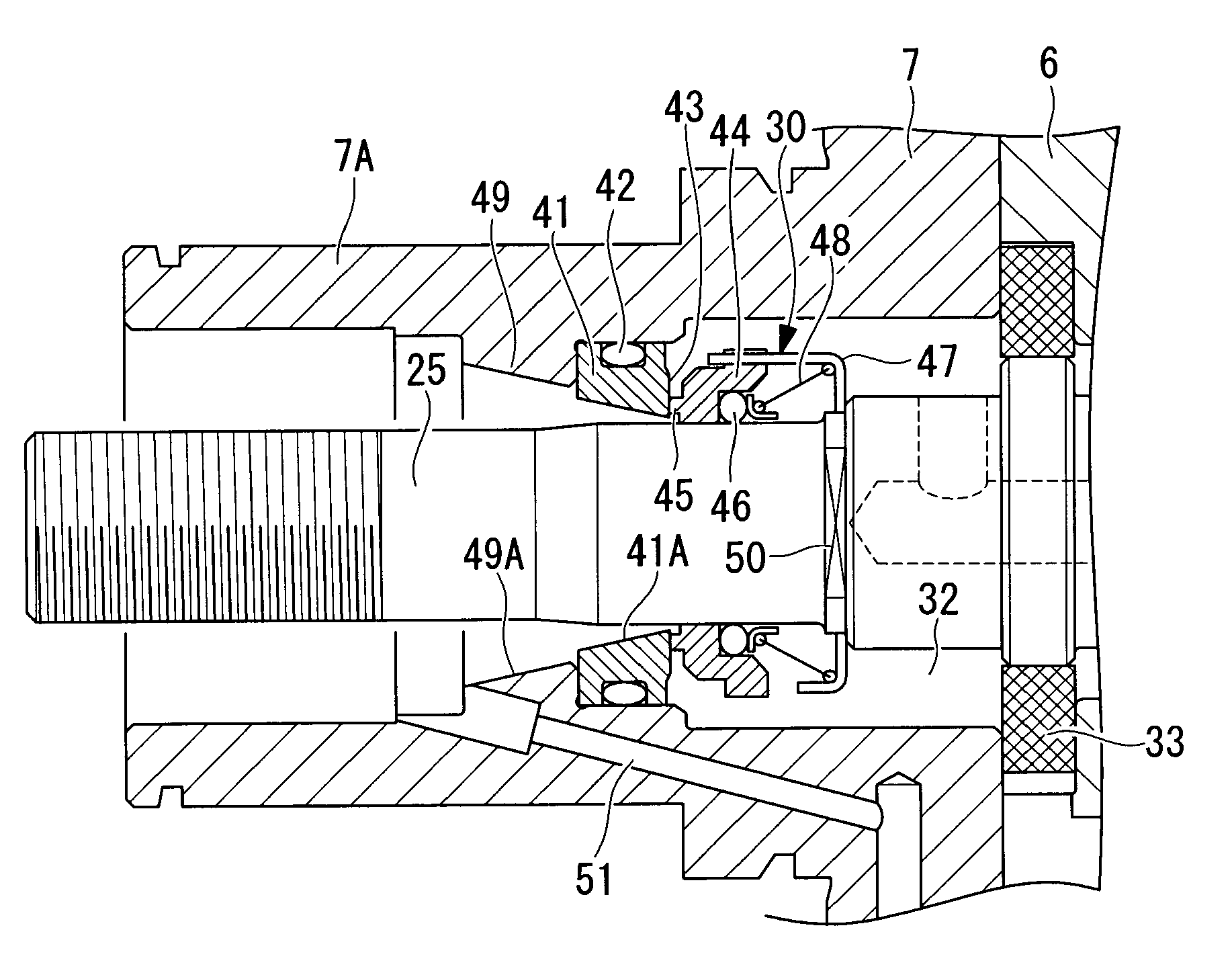

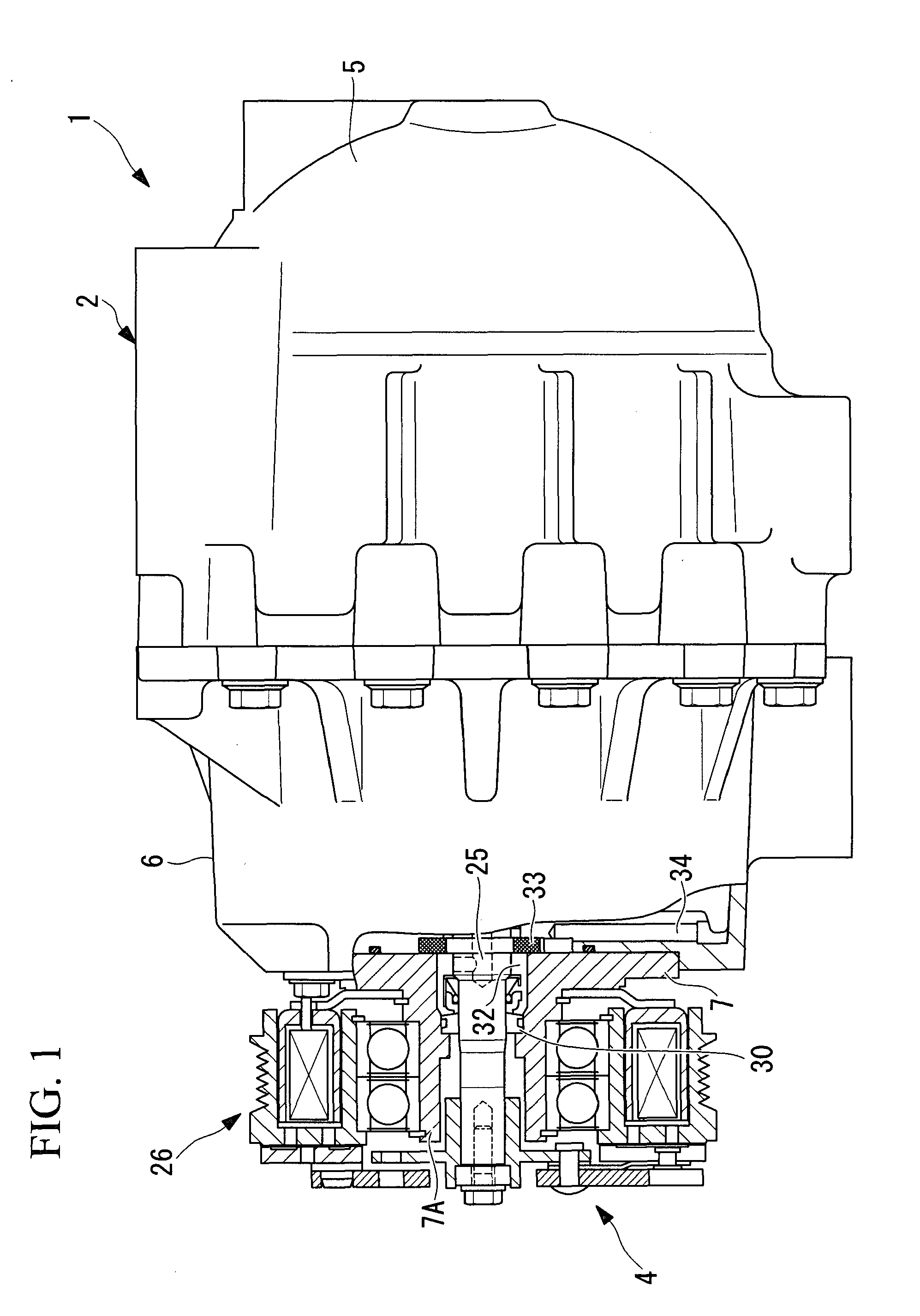

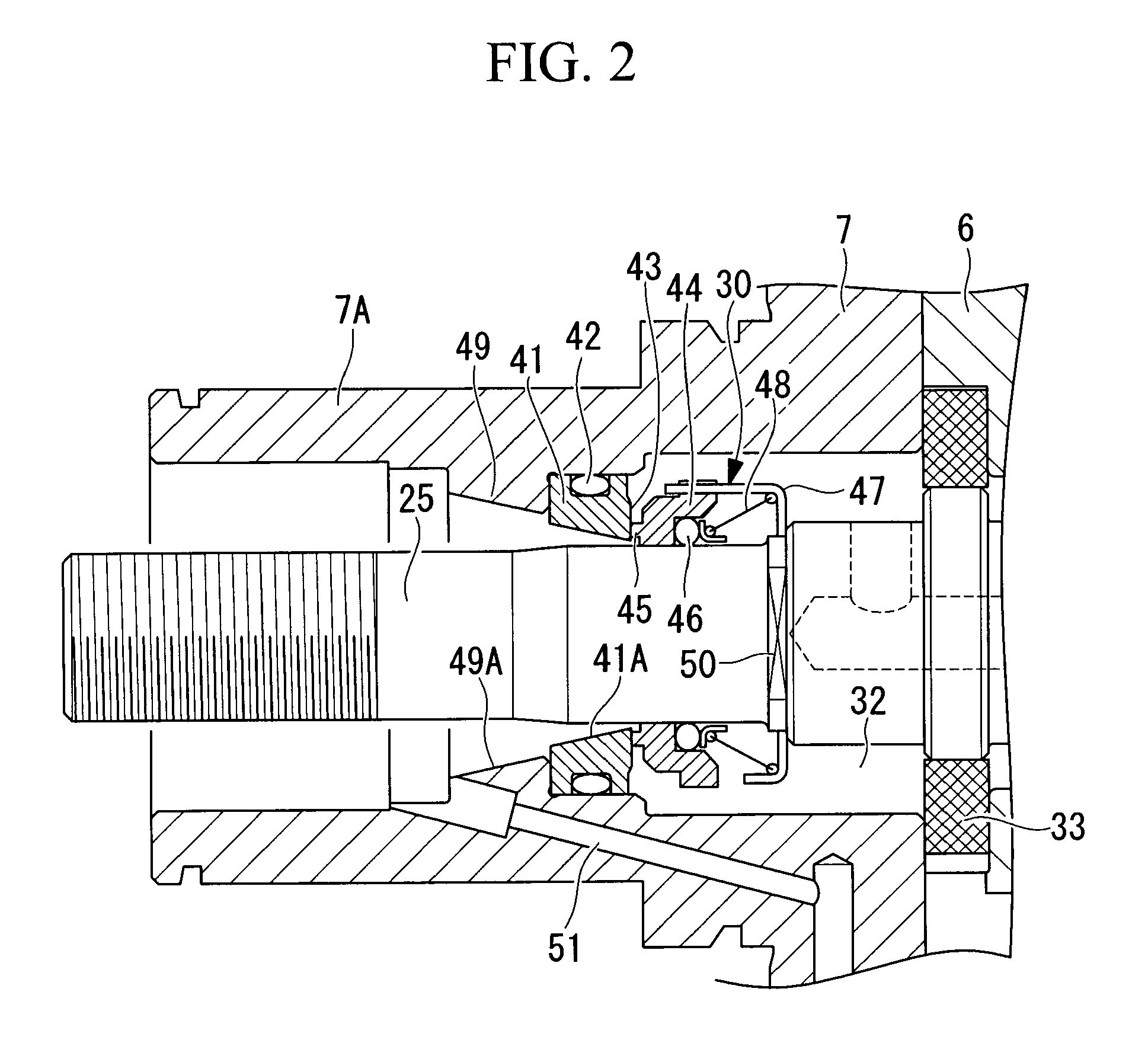

Refrigerant compressor

A refrigerant compressor is provided that can be assembled easily and can quickly discharge lubricating oil that leaks from contact sliding parts of its mechanical seal so as to prevent the oil from turning into sludge around the stationary ring. In a refrigerant compressor in which a mechanical seal which shaft seals the inner side and the outer side of a housing is installed at a portion of the housing through which a rotating shaft penetrates, a mechanical seal comprises a stationary ring securely fastened to the inner circumferential surface of a boss portion, a rotary ring securely fastened to the outer circumferential surface of the rotating shaft to the inside of the stationary ring so as to face the stationary ring, whereby sliding contact is formed between sides of the stationary ring and the rotary ring. The inner circumferential surface of the boss portion to the outside of the stationary ring is provided with an inclined portion over the entire circumference or at least the gravitationally lower portion of the inner circumferential surface, which enlarges from the stationary ring side toward an oil discharge hole to the outside of the stationary ring.

Owner:MITSUBISHI HEAVY IND LTD

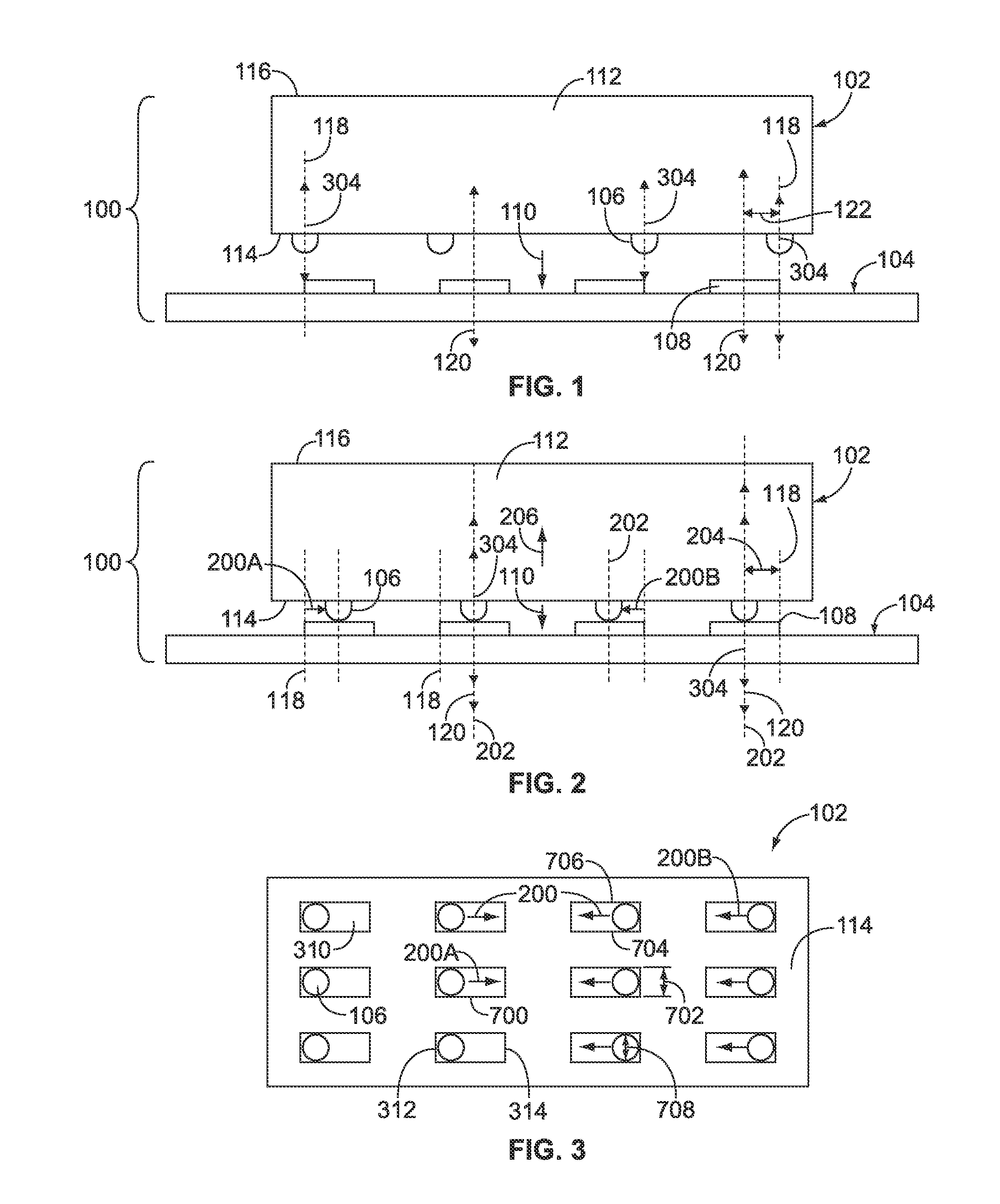

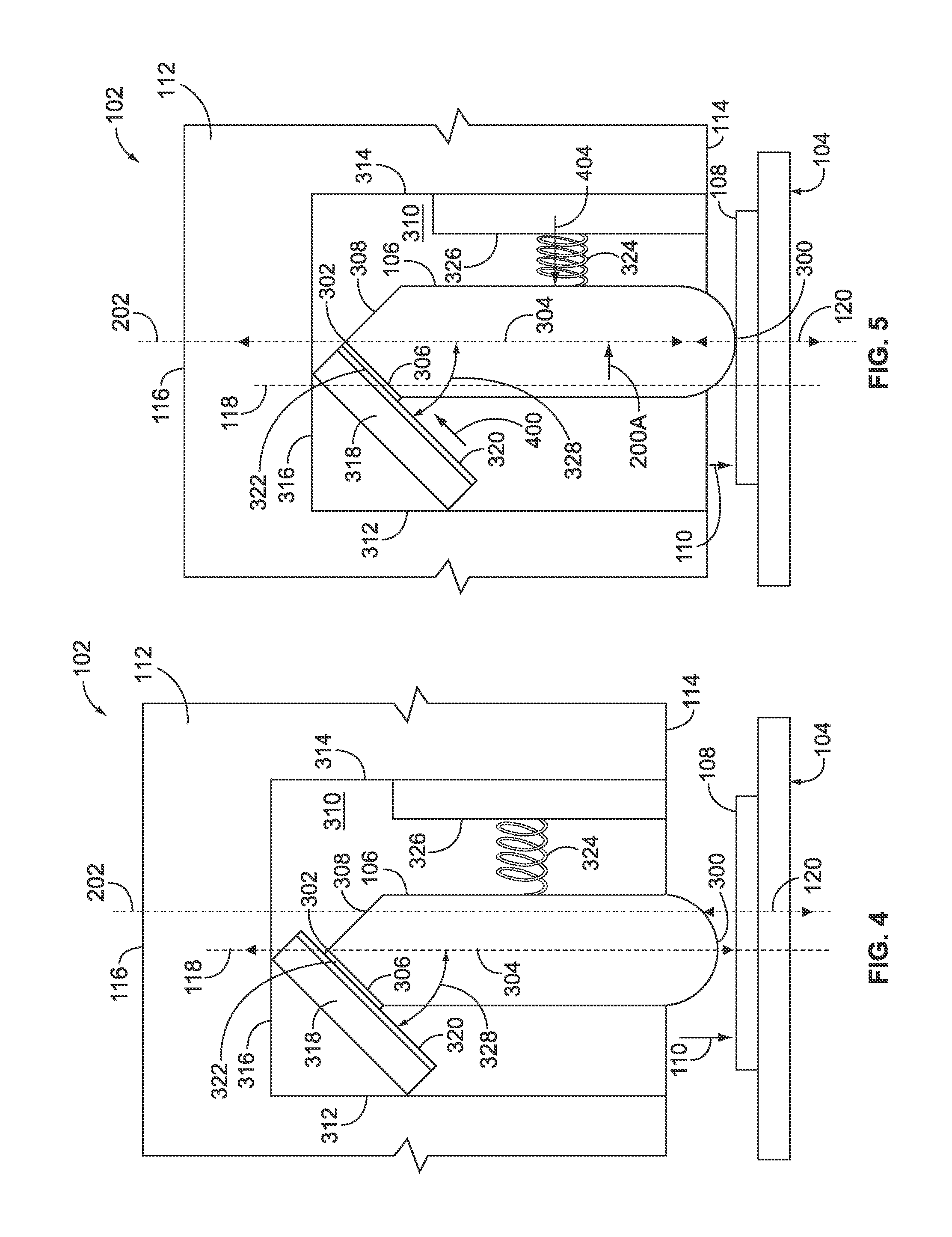

Connector with a laterally moving contact

InactiveUS20110306251A1Securing/insulating coupling contact membersCoupling contact membersOblique angleContact slide

A connector includes a housing, a contact, an angled interface, and a resilient member. The contact is disposed in the housing and includes a mating end and an interface end. The angled interface includes a sliding surface that is oriented at an oblique angle with respect to the longitudinal axis. The resilient member is coupled with the contact and the housing and is configured to apply a force to the contact in a direction that is angled with respect to the longitudinal axis. The mating end of the contact engages a conductive element of a mating connector and the interface end of the contact slides along the sliding surface of the angled interface when the contact is moved in a mating direction toward the conductive element. The angled interface translates movement of the contact in the mating direction into lateral movement across the conductive element.

Owner:TE CONNECTIVITY CORP

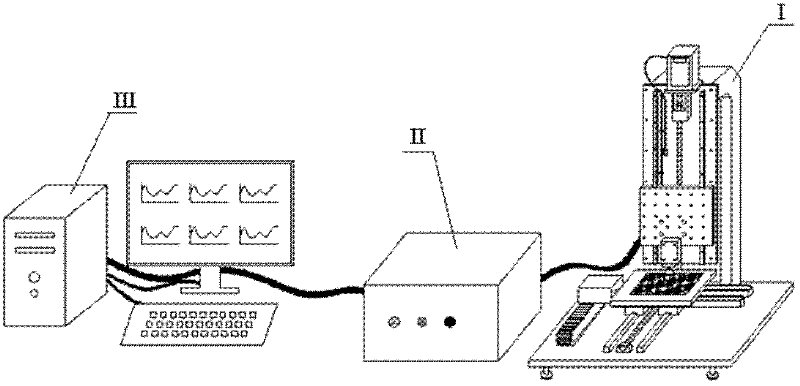

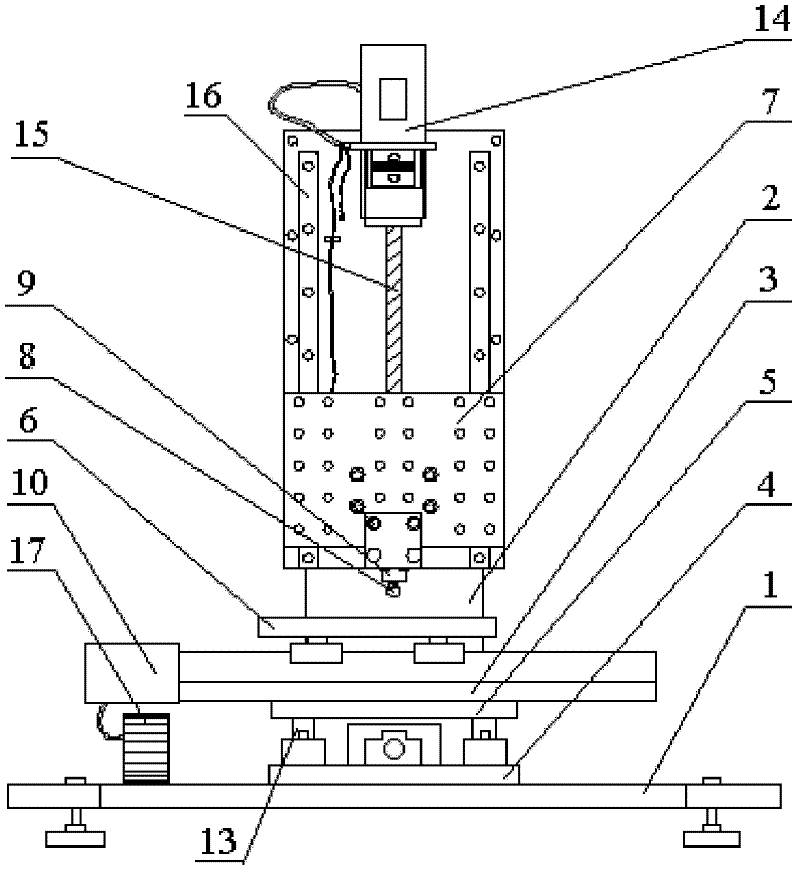

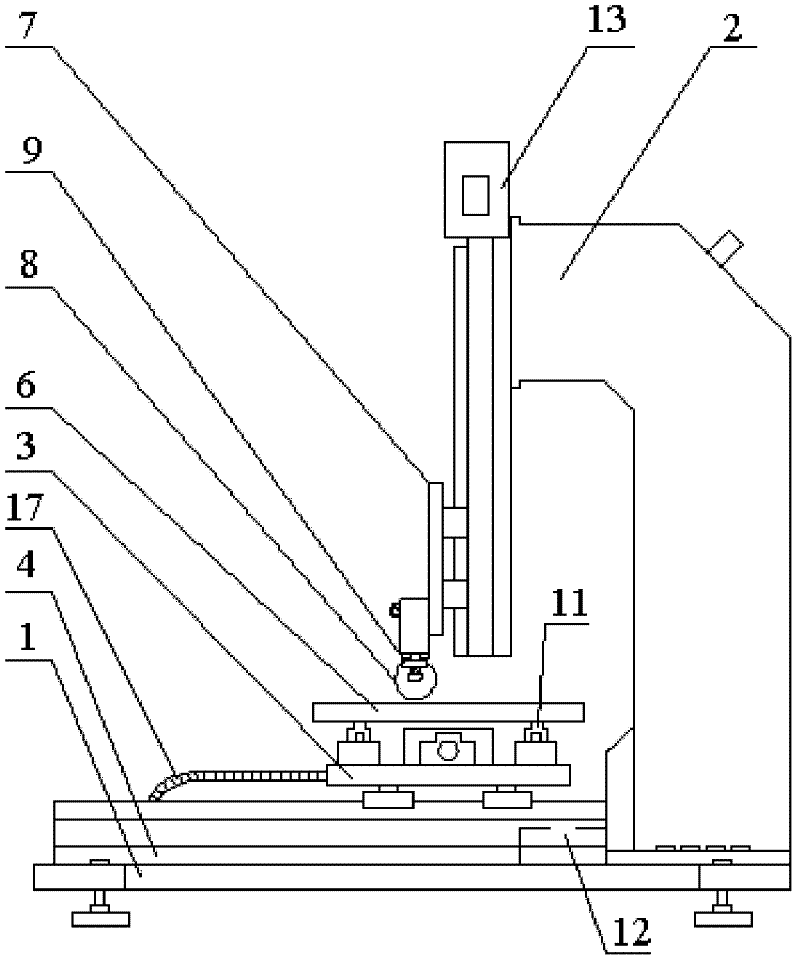

Skin/textile biologic friction dynamic measurement device

InactiveCN102590077AImprove test accuracySmall rangeUsing mechanical meansMaterial analysisData processing systemMeasurement device

The invention relates to a skin / textile biologic friction dynamic measurement device, which comprises a measurement base, wherein a vertical seat is fixed at the rear part of the measurement base; a first sliding way and a second sliding way are installed at the front part of the measurement base; the first sliding way is installed on a movable panel of the second sliding way; a measurement panel is also installed on the first sliding way; an installation panel which can move up and down is arranged at the front side of the vertical seat; a measurement contact is fixed on the installation panel and is positioned above the measurement panel; a multi-axial force / torque transducer is installed between the measurement contact and the installation panel; the multi-axial force / torque transducer is connected with a data processing system of a personal computer through a power supply box; the first sliding way can make the measurement panel move left and right; the second sliding way can make the movable panel move back and forth; and the installation panel can move up and down. The device not only can measure the frictional force, pressure and torque functions during the contact sliding process in real time, but also can truly reflect the skin / textile multidirectional contact friction movement process under different sliding speeds and initial pressures.

Owner:DONGHUA UNIV

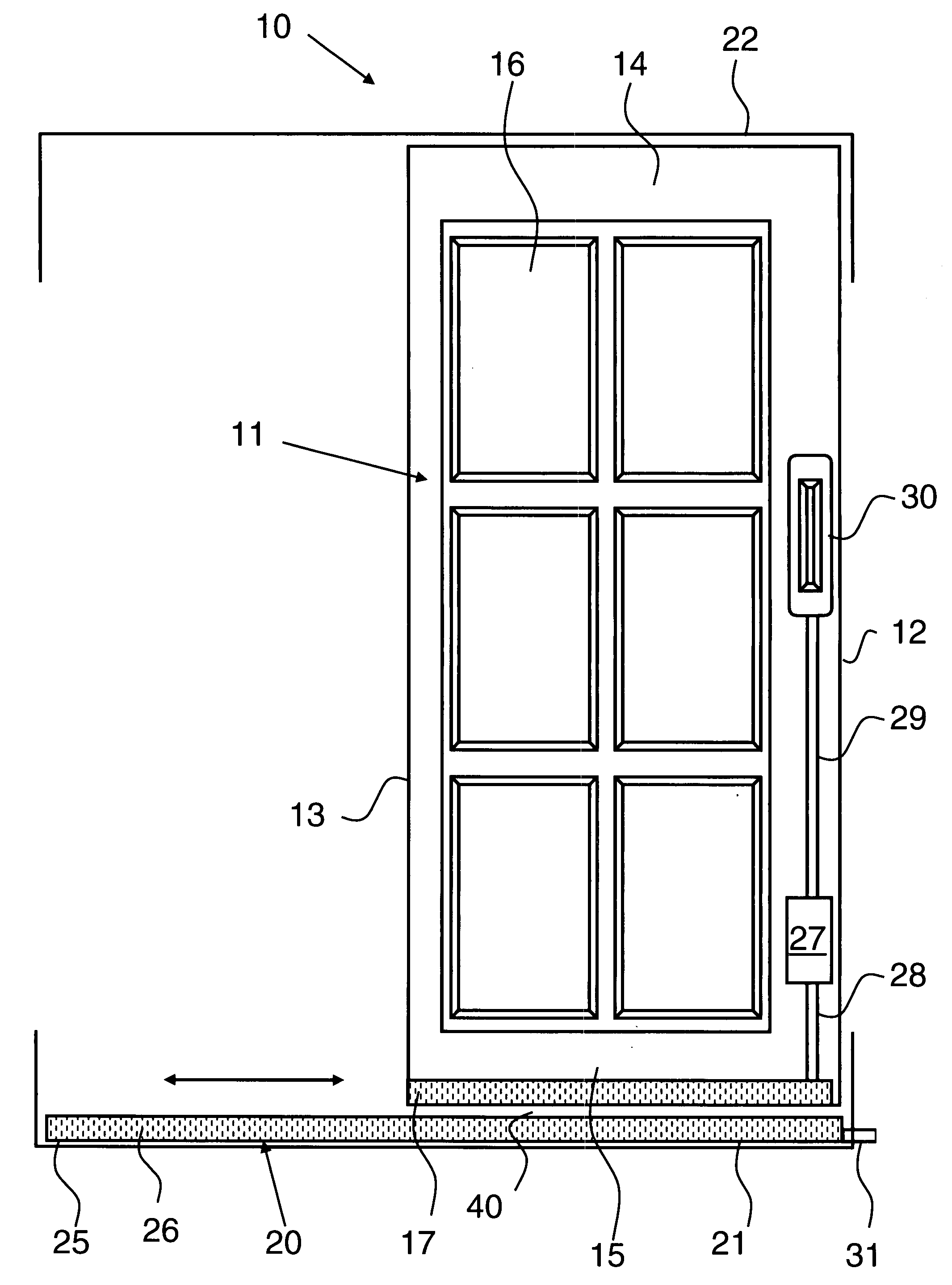

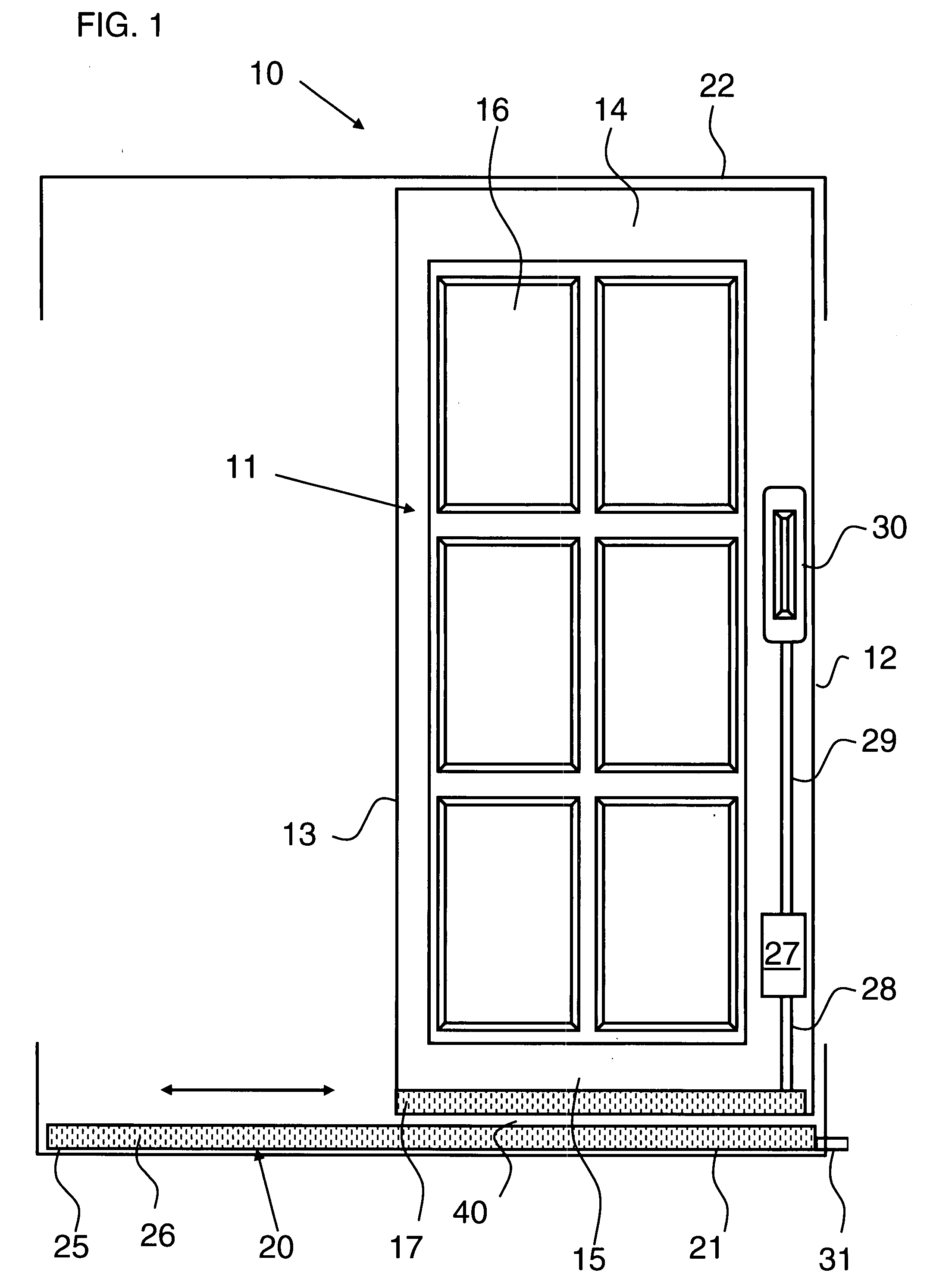

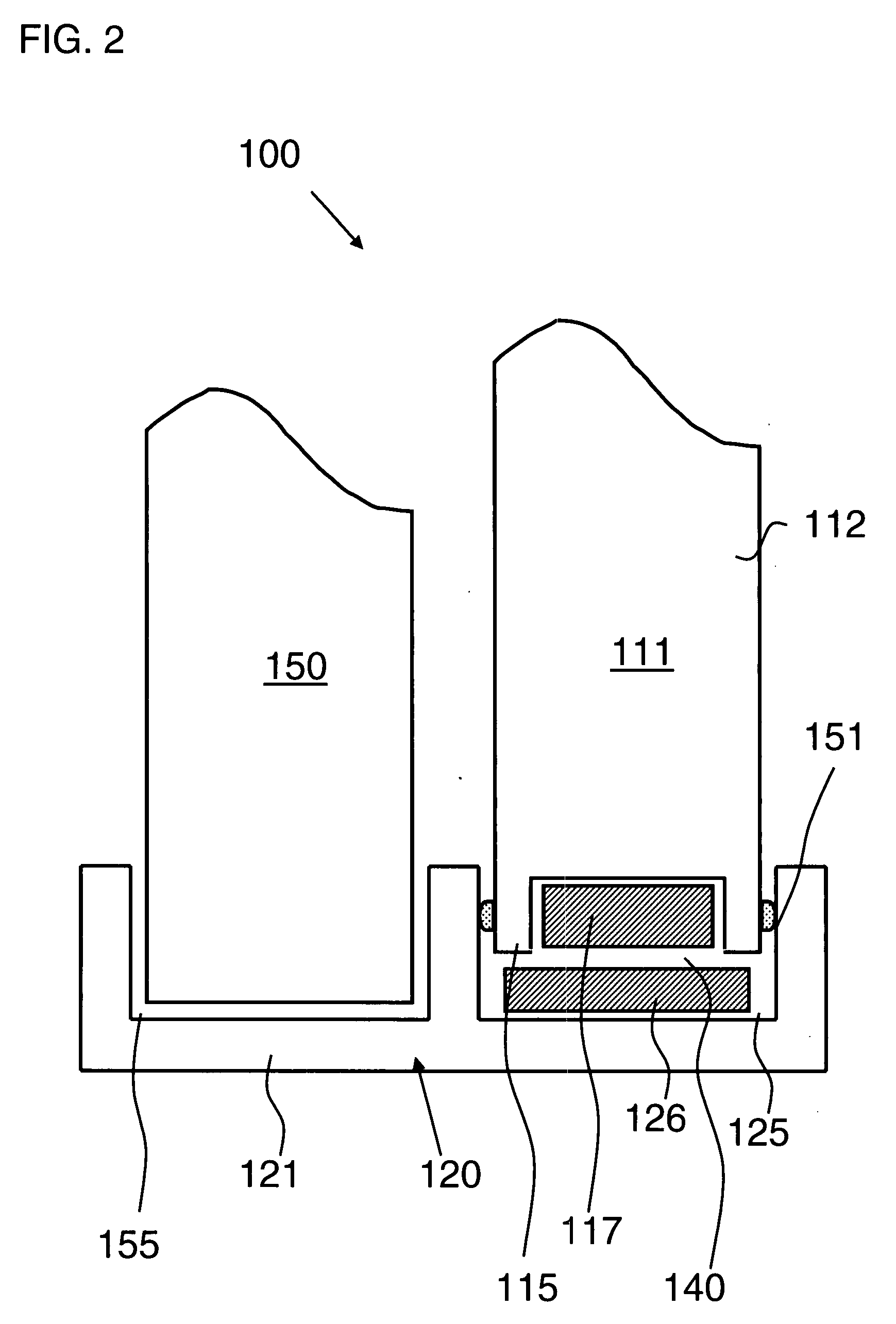

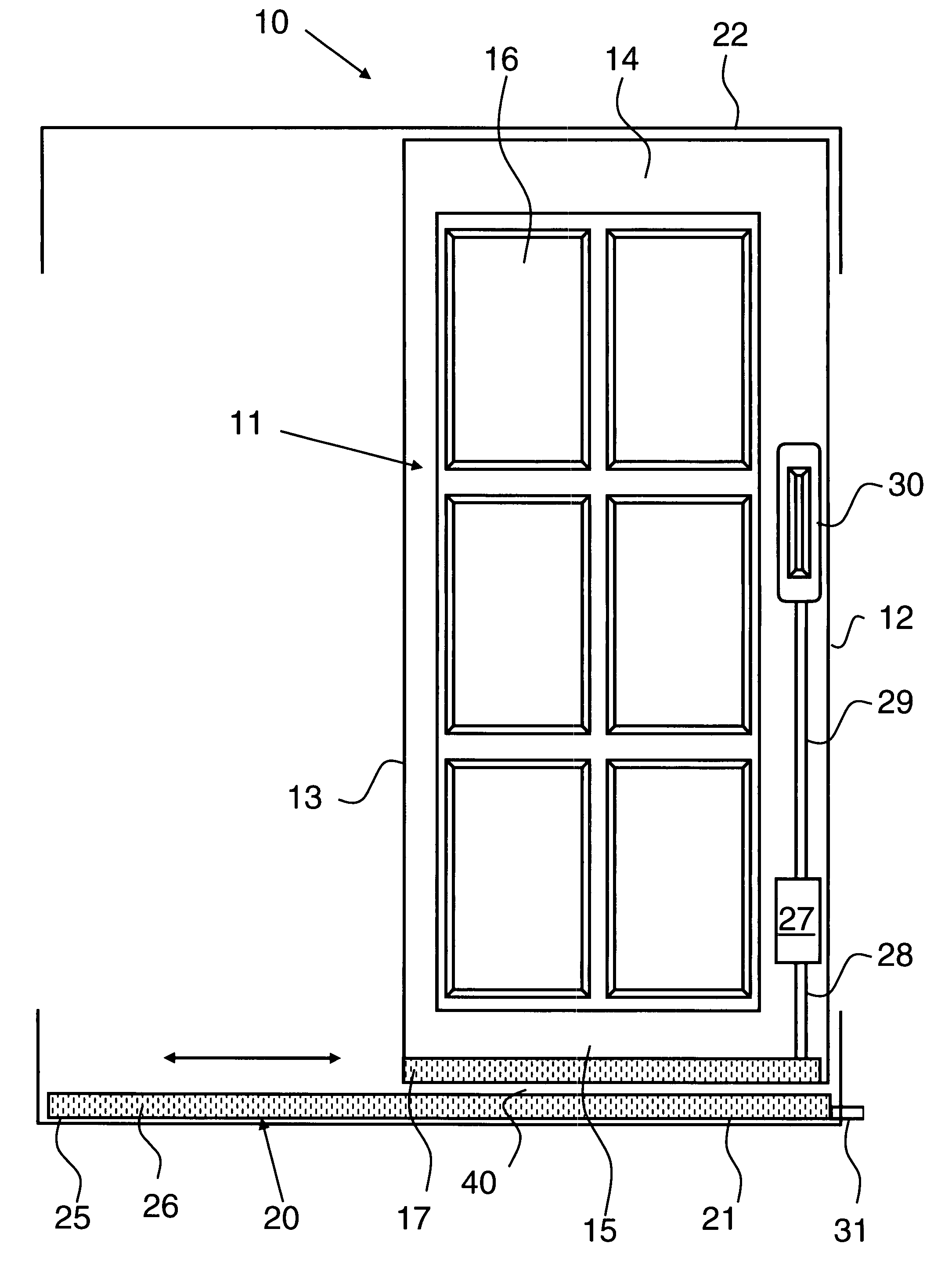

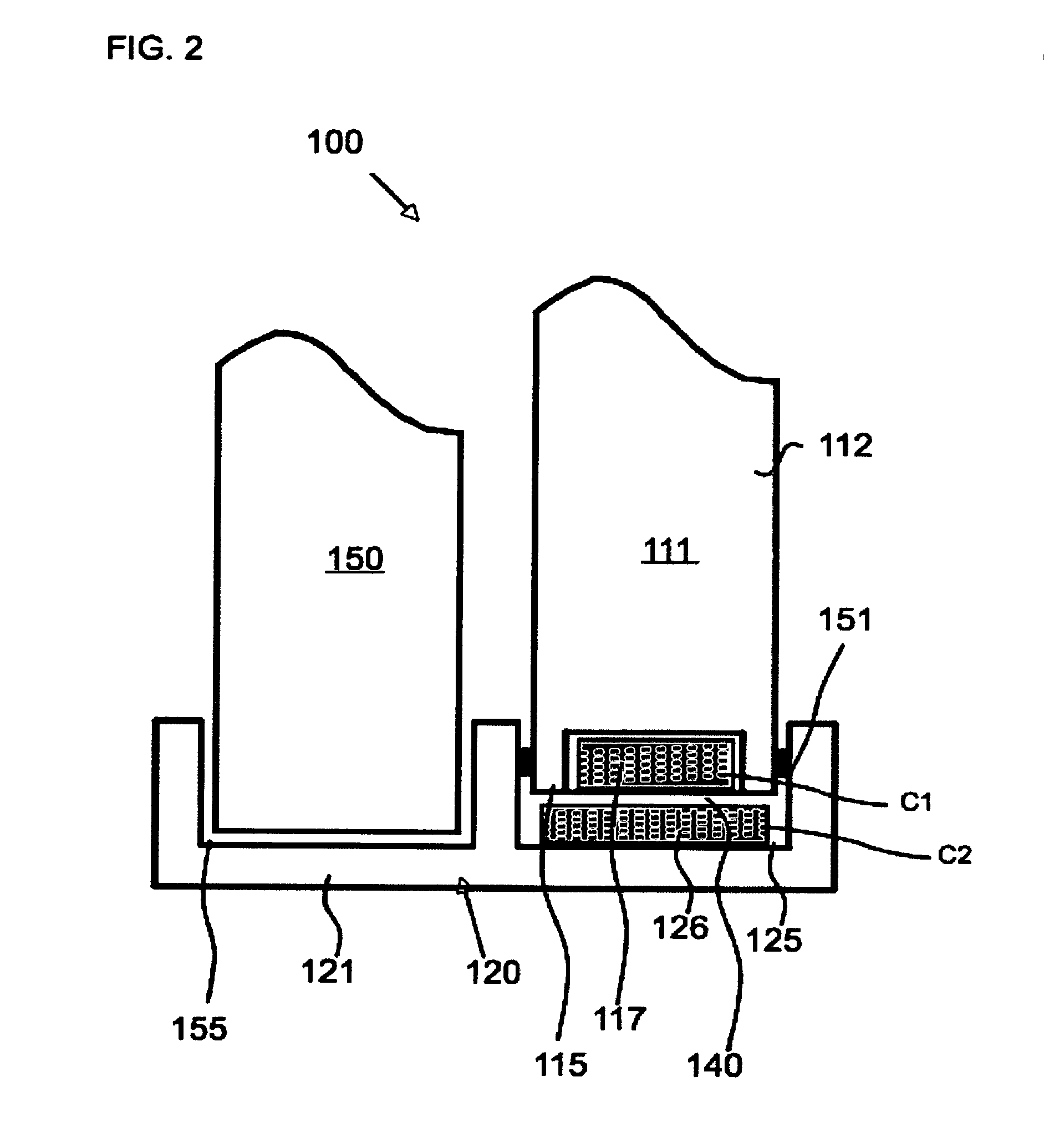

Magnetically supported sliding track system

InactiveUS20090044916A1Large resistancePrevent back movementDoor/window protective devicesMan-operated mechanismSupporting systemFixed frame

A sliding door or window supporting system has a stationary frame with a bottom track and a sliding portion that slides from a closed position to an open position. The bottom portion of the sliding portion and the upper surface of stationary frame track are provided with one or more magnets having identical magnetic polarity, thereby creating repulsion between the bottom of the sliding portion and the stationary track. Forces produced by magnetic repulsion lift the weight of the sliding portion, creating an air gap. A smooth, low friction sliding and door gliding movement results, which is immune to dirt and debris. The front to back movement of the sliding portion is supported by low friction polymeric knobs attached to a stationary frame and contacting sliding portion.

Owner:SINGISER JOSEPH +1

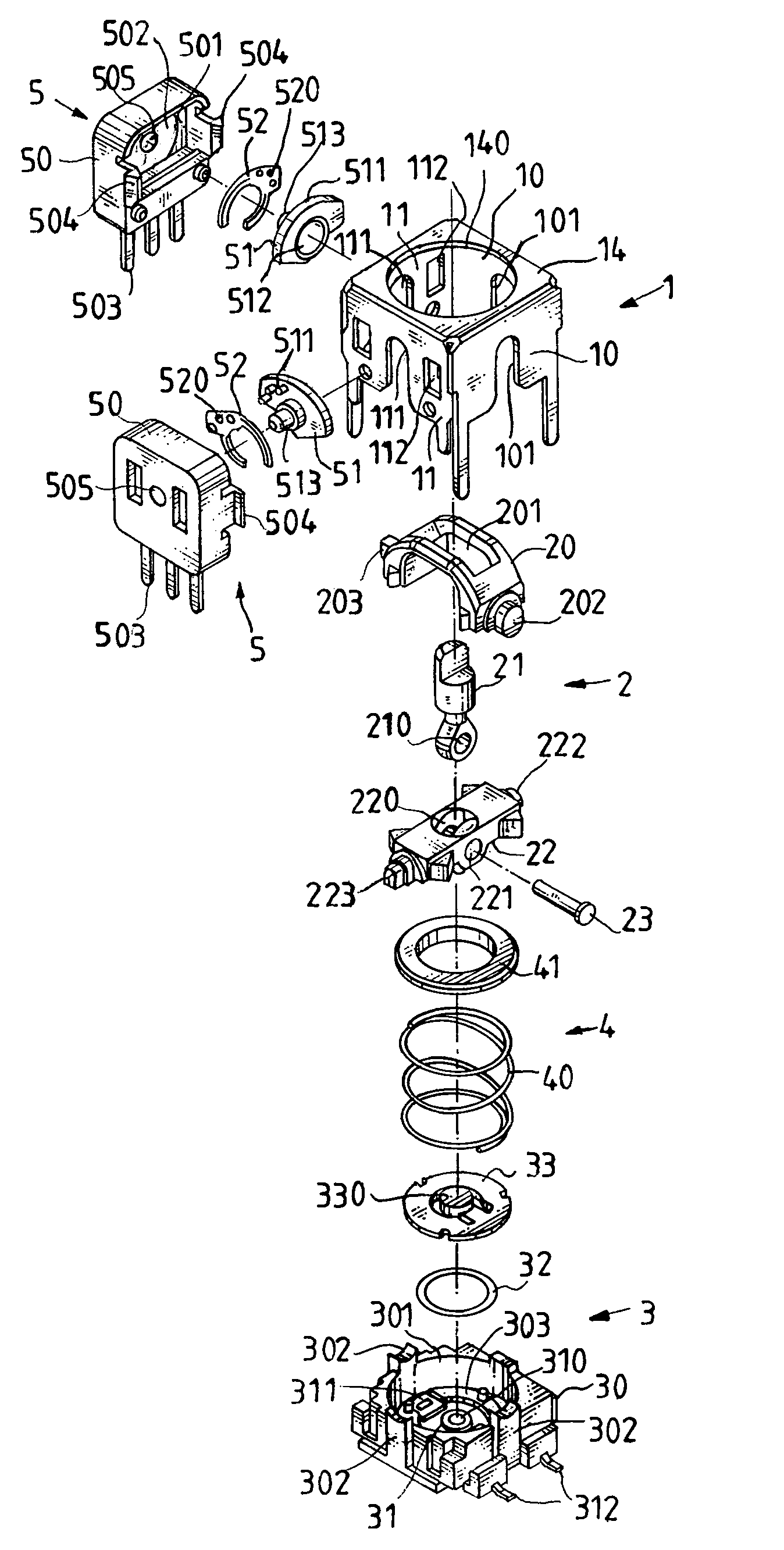

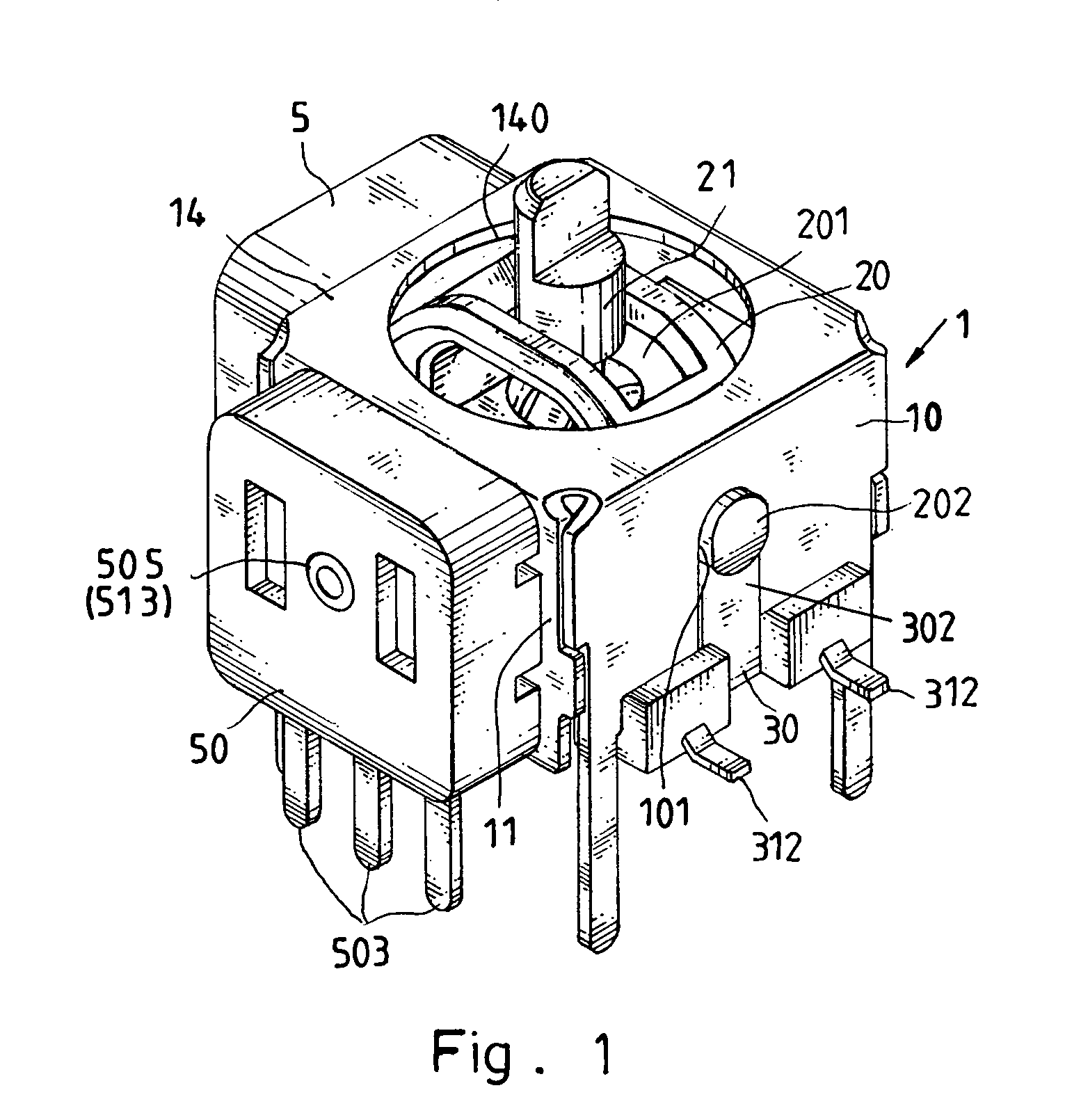

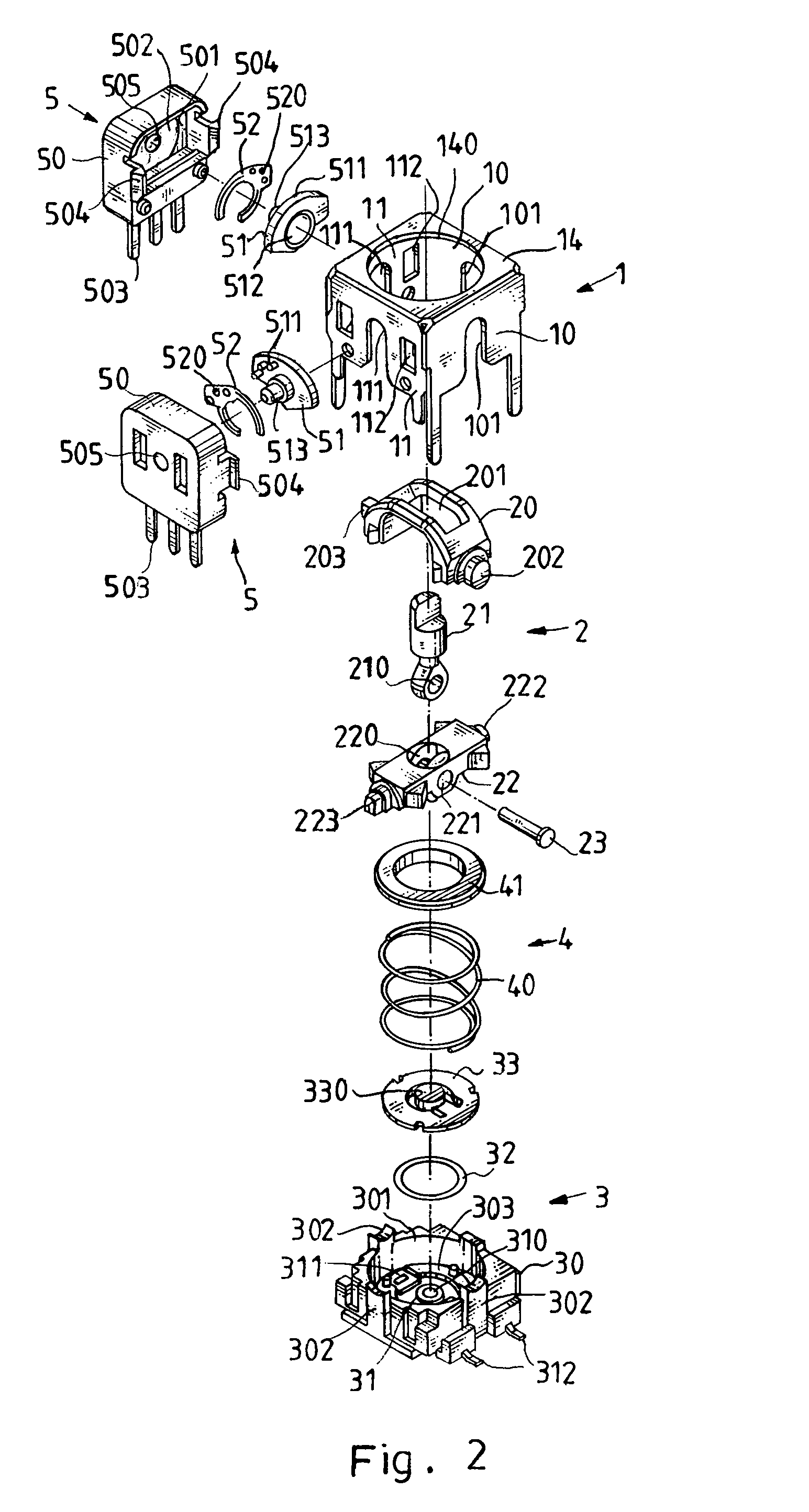

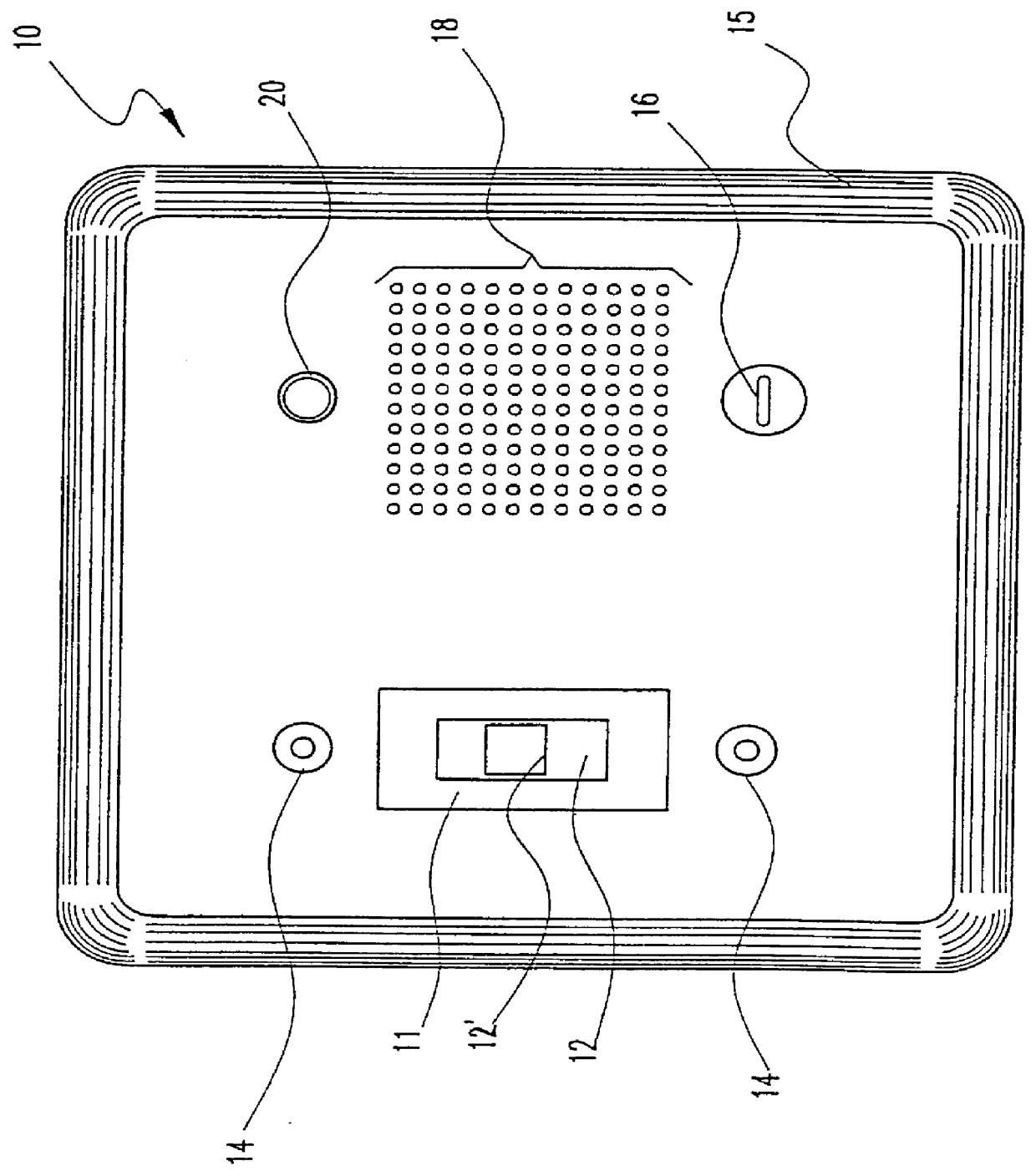

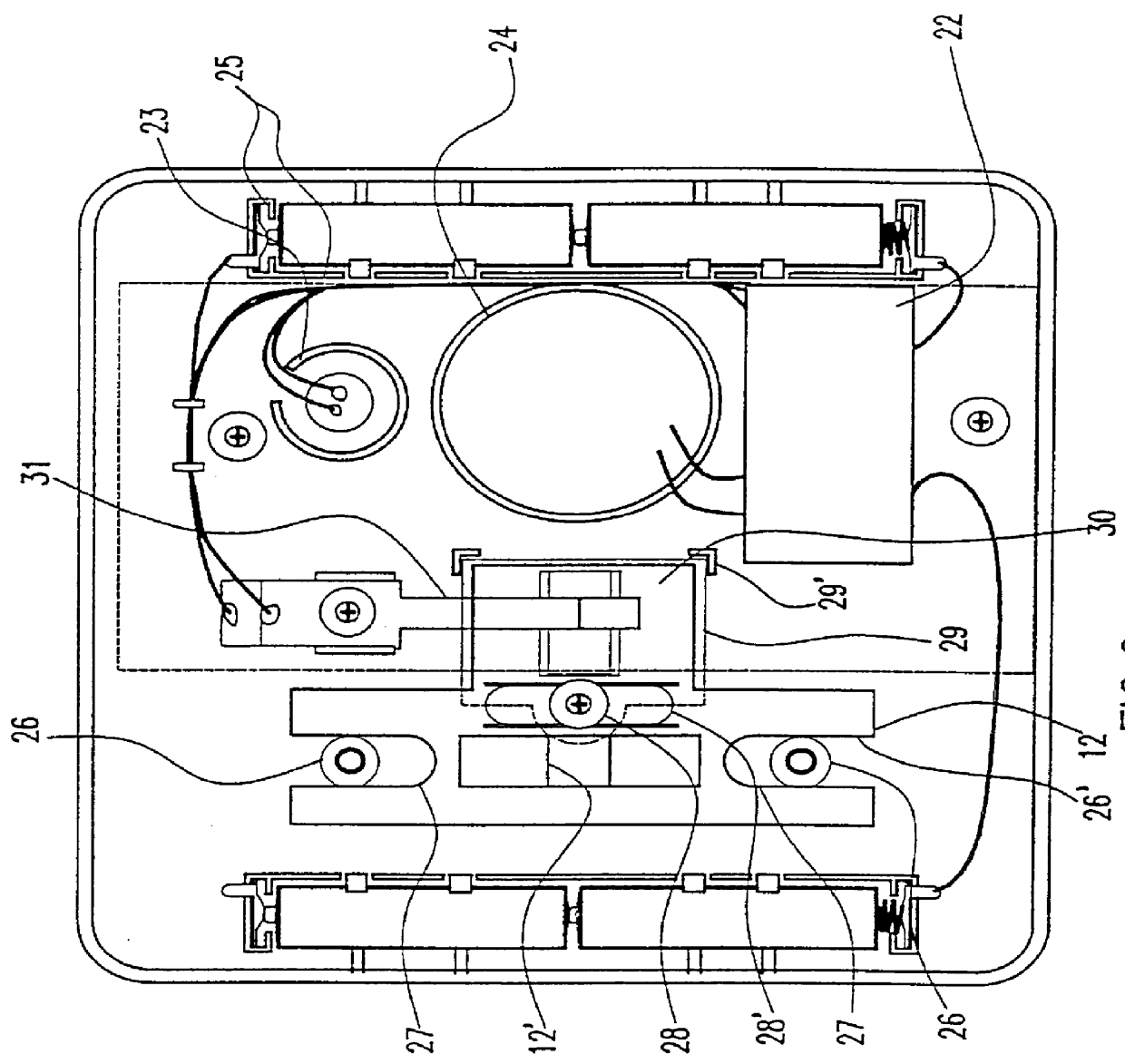

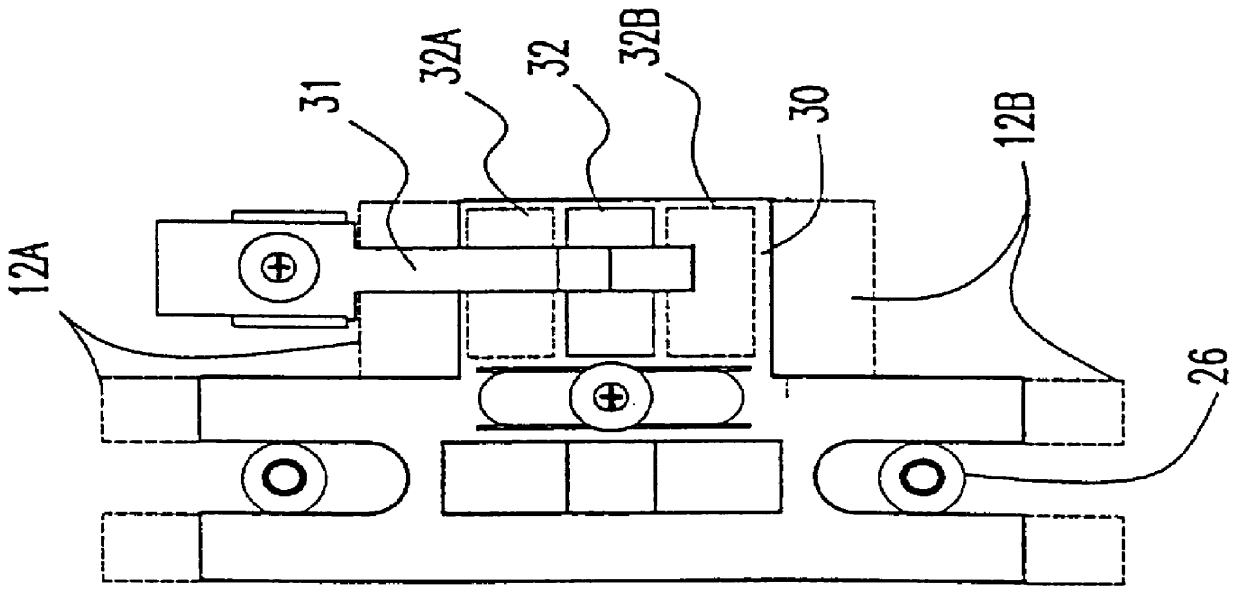

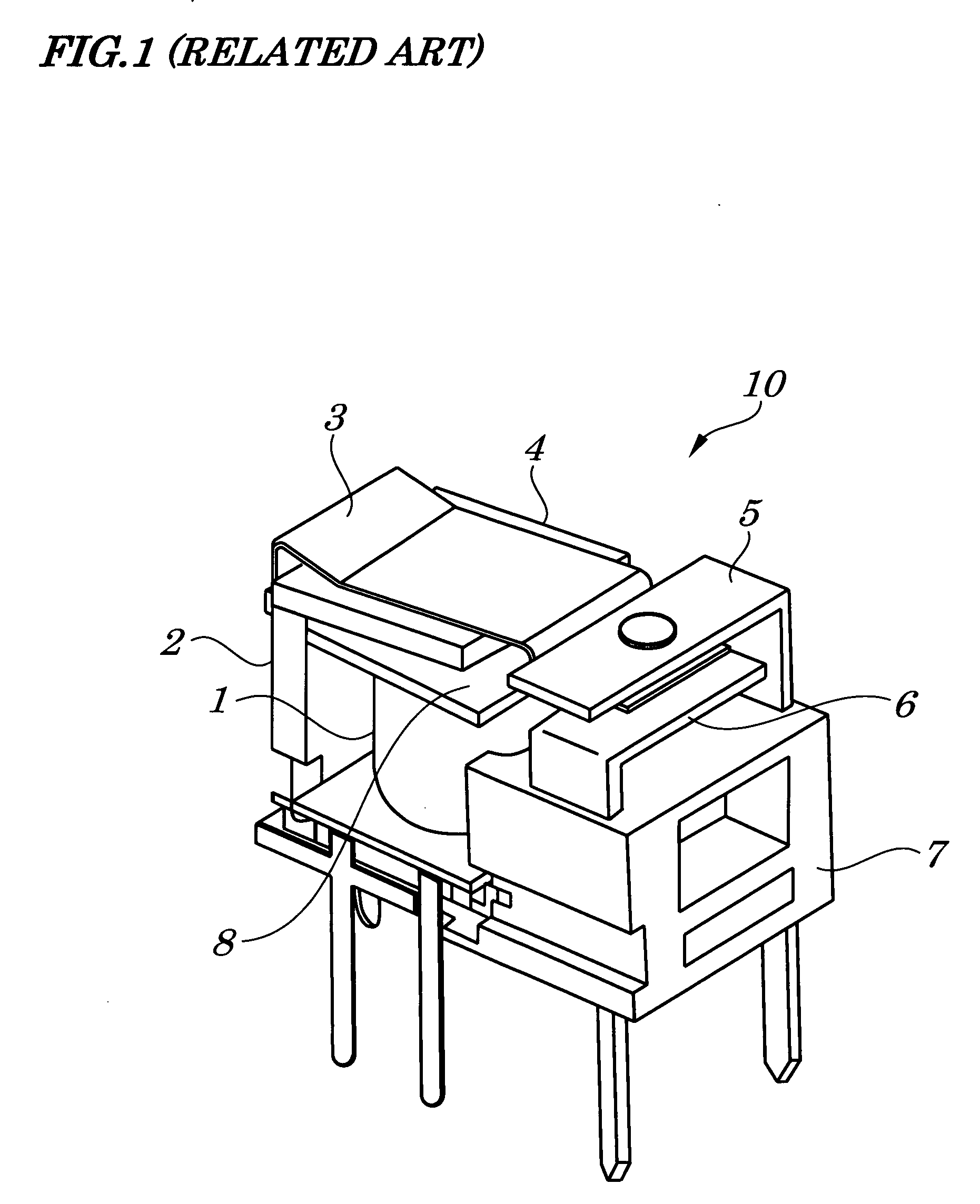

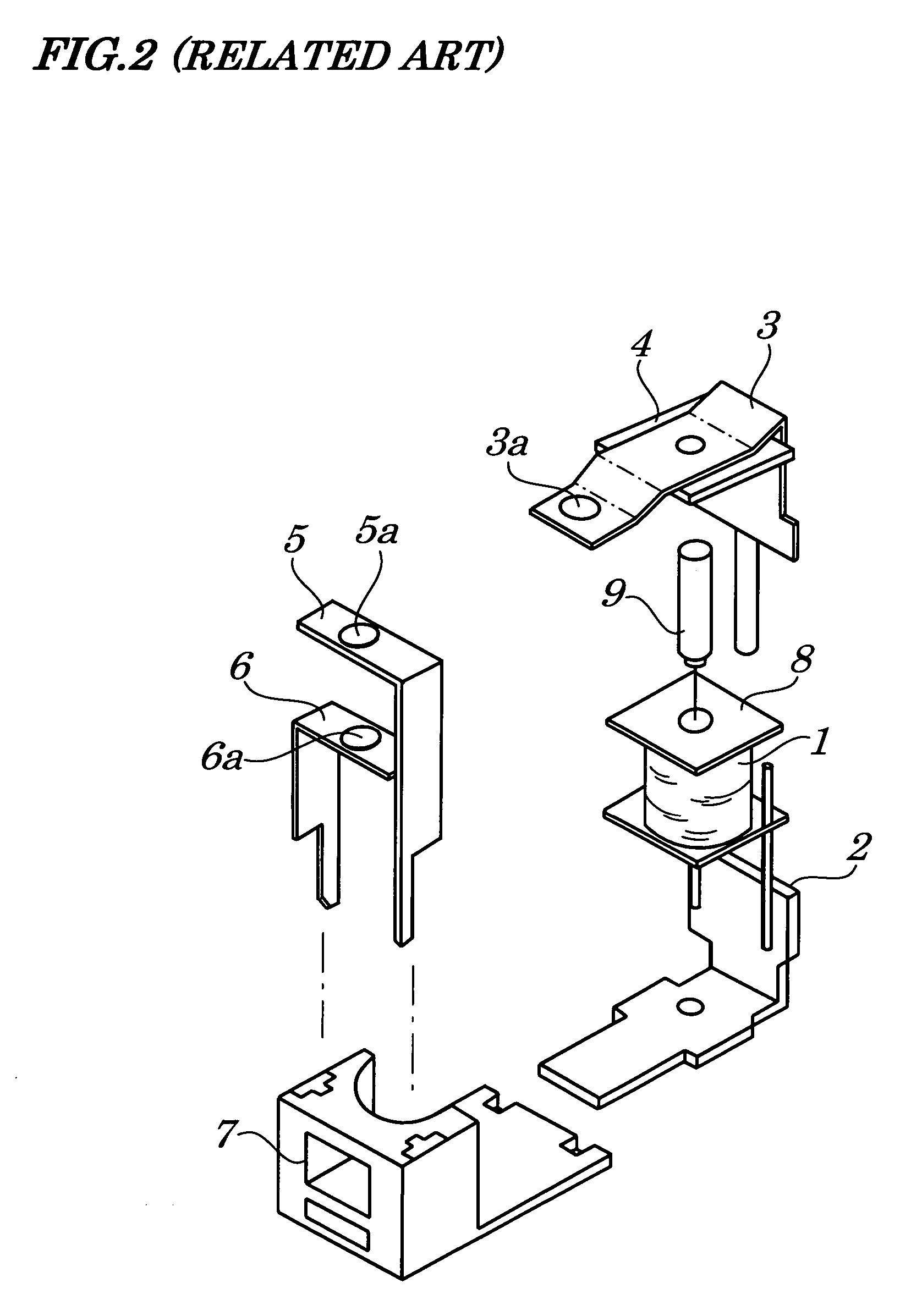

Rocker lever assembly

InactiveUS6989497B1Increase in sizeHigh sensitivityManual control with multiple controlled membersResisitors with sliding contactJoystickEngineering

A rocker lever assembly includes a housing, an operation device, a switch device, a restoring device, and two sensing variable resistors. The operation device includes a first pivot seat, a second pivot seat, and a control lever. The switch device includes a base, a contact terminal, a contact plate, and a cover plate. The control lever is depressed to cause the under surface of the second pivot seat to depress the cover plate. Thus, the switch device is hidden in the housing, thereby reducing the volume of the rocker lever assembly. In addition, the contact slide is moved on the resistance plate of the casing by guidance of the drive member, thereby greatly enhancing the sensitivity of each of the two sensing variable resistors.

Owner:TAIWAN PWL CORP

Miniature momentary contact sliding switch

Owner:BP HLDG

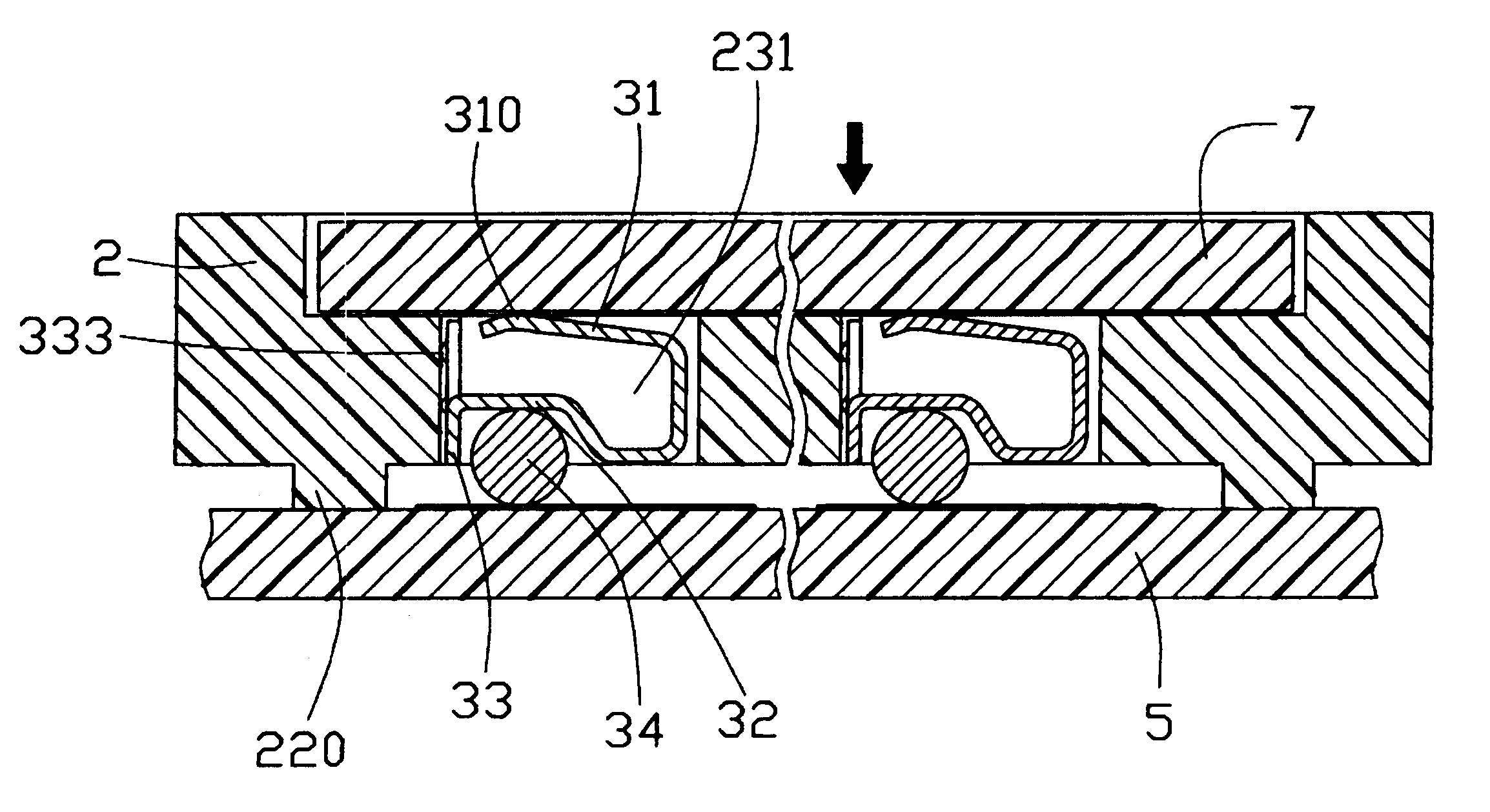

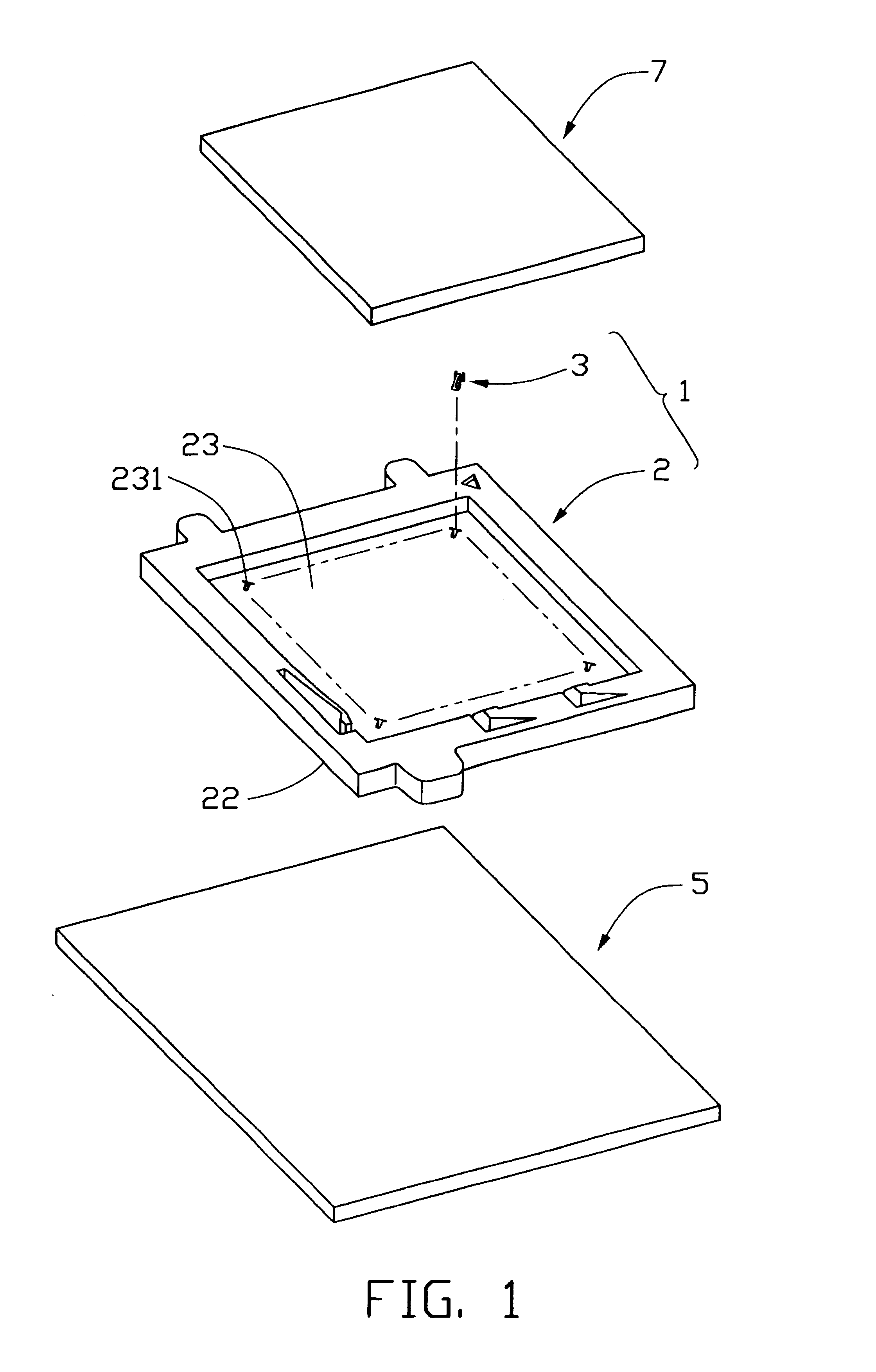

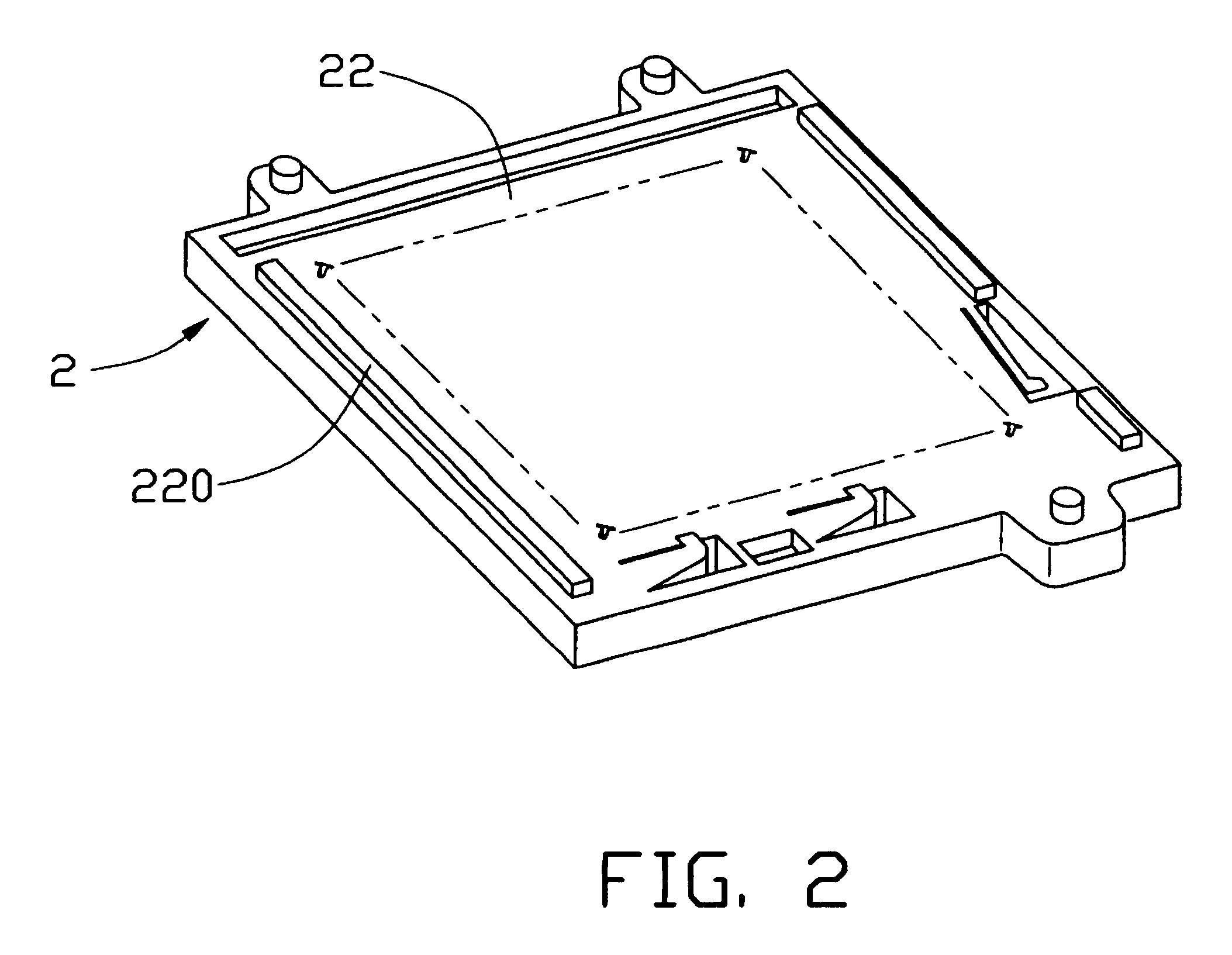

Land grid array connector having movable engagement of electrical contacts thereinto

InactiveUS6731516B1Risk minimizationRack/frame constructionComponent plug-in assemblagesEngineeringLand grid array

An LGA connector (1) includes a housing (2), and a number of contacts (3) received in the housing. The housing defines a cavity (23) in a middle thereof for receiving a CPU (7) and a multiplicity of passageways (231) in a portion thereof under the cavity, and has a number of stand-offs (220) at a bottom surface thereof. Each passageway includes a slot (2312). Each contact comprises an engaging portion (33) movably engaging in the corresponding slot, a long arm (31) accommodated within the passageway, and a solder portion (32) engaging a PCB (5). In use, the CPU is pressed downwardly to press the housing downwardly. The engaging portion of each contact slides upwardly in the slot. The stand-offs of the housing attach on the PCB, and the long arm of each contact deforms elastically to contact the CPU. The LGA connector thus electrically connects the CPU with the PCB.

Owner:HON HAI PRECISION IND CO LTD

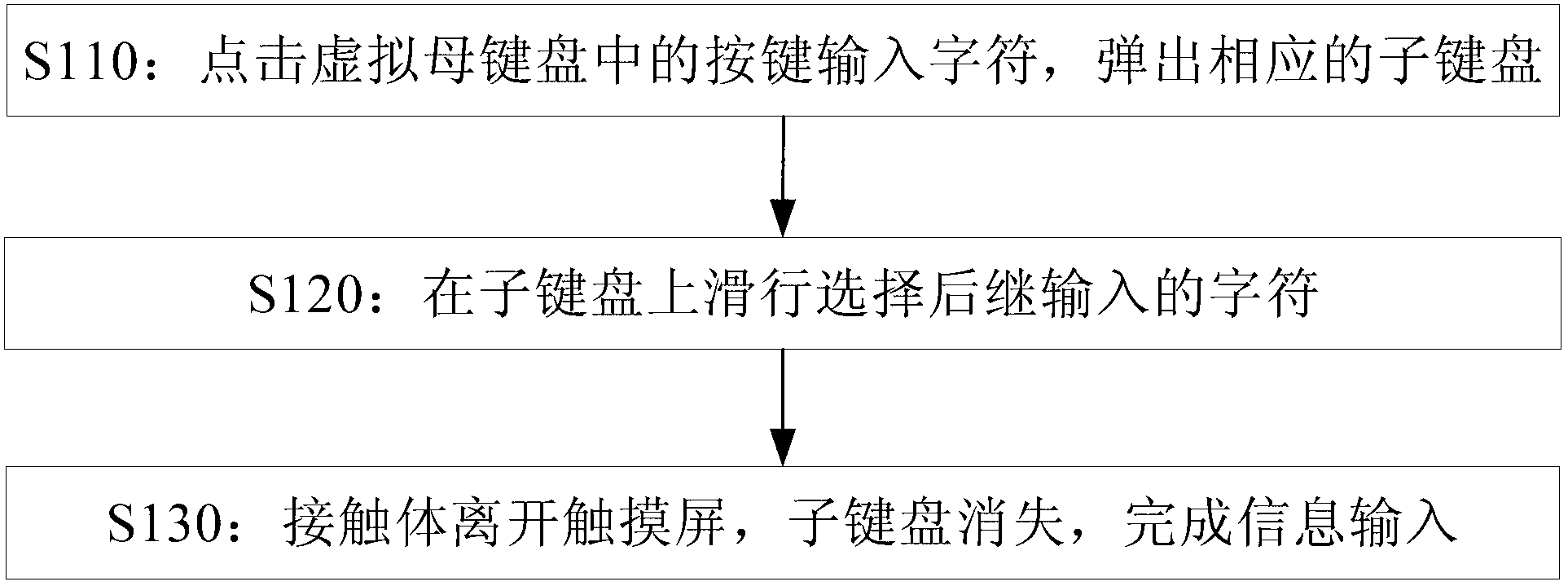

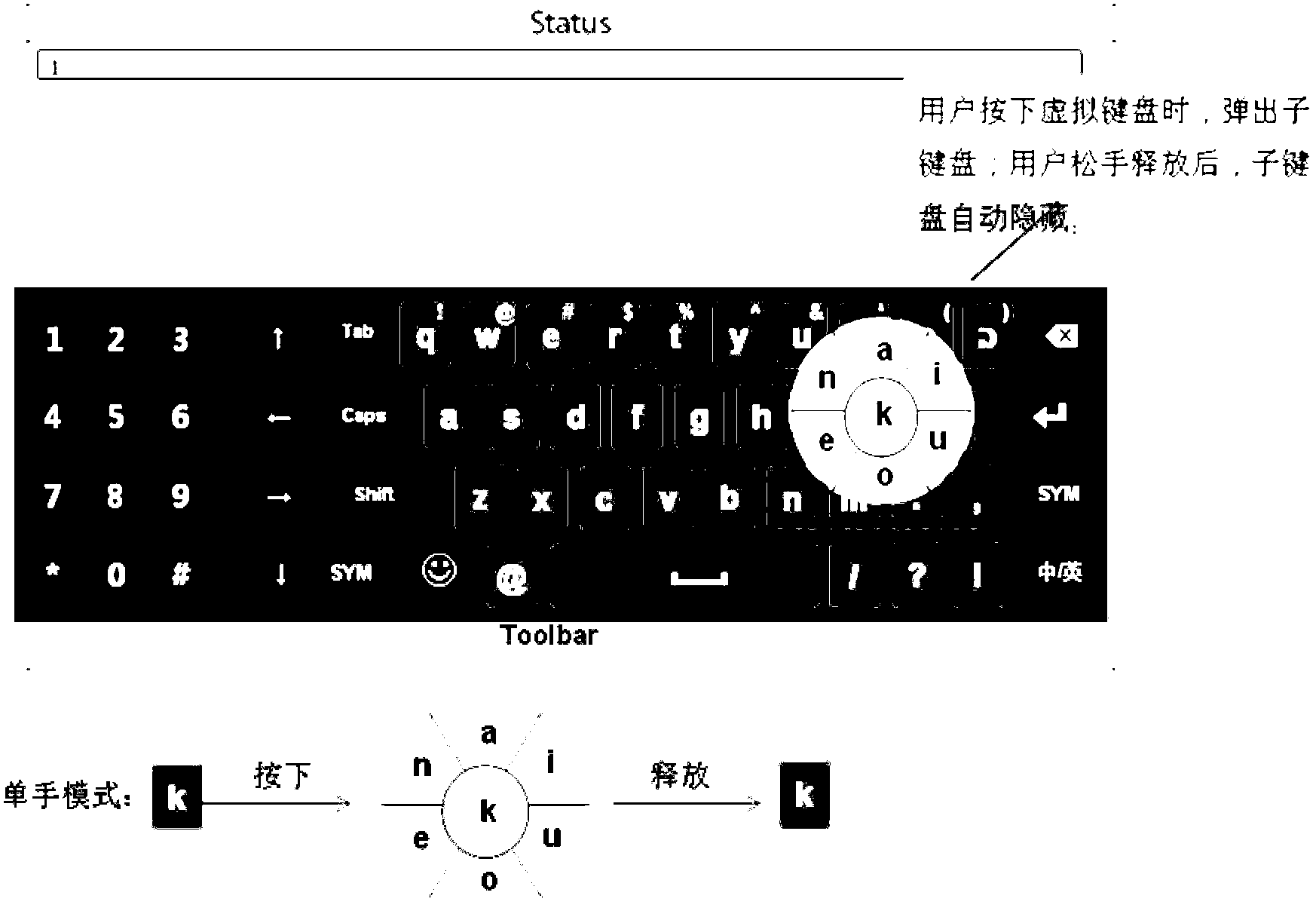

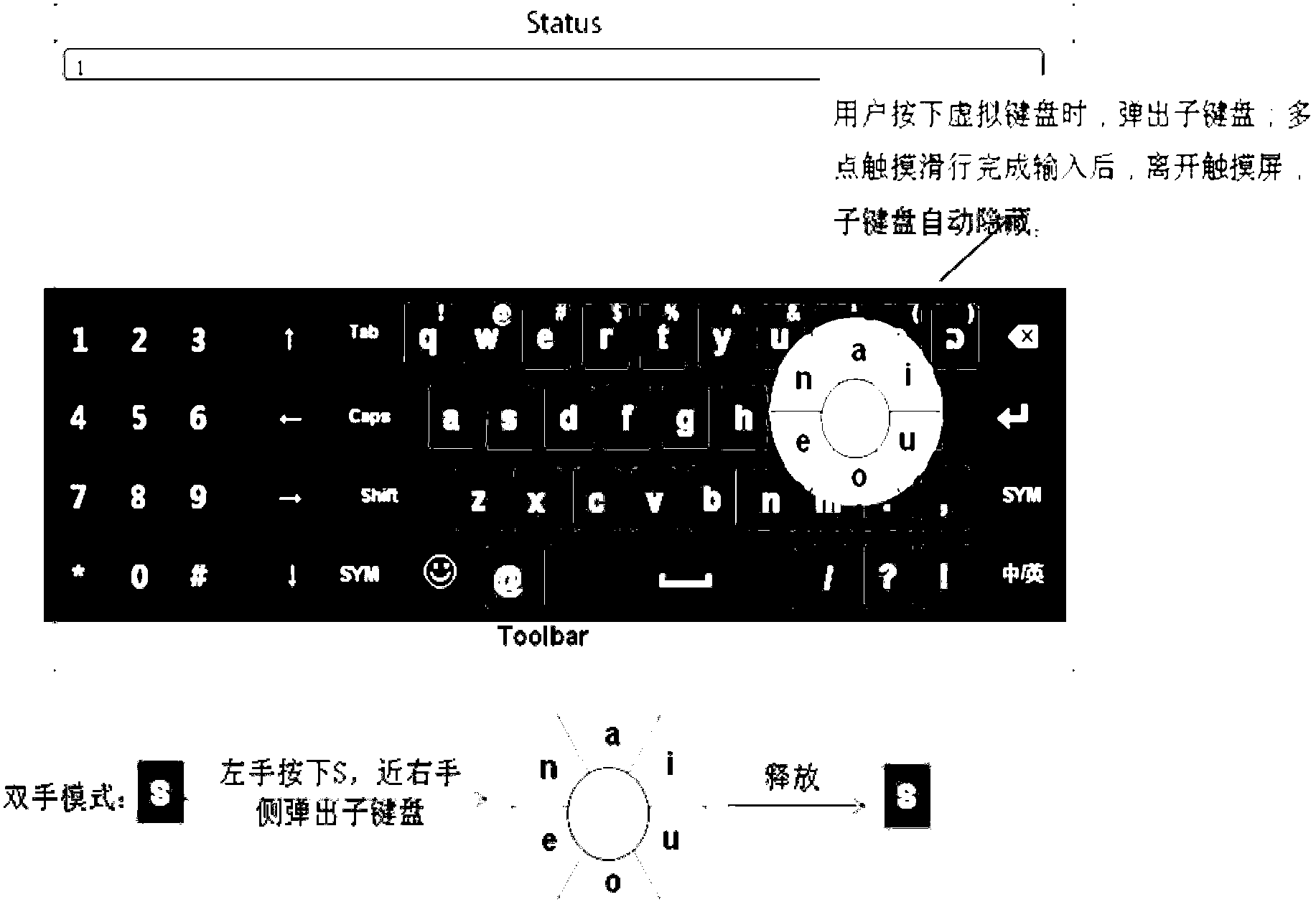

Input method and keyboard of terminal

InactiveCN102999288AEasy to operateIncrease typing speedInput/output processes for data processingKey pressingUser input

The embodiment of the invention provides an input method of a terminal, comprising the steps that a contact clicks a push-button input character in a virtual mother keyboard of a touch screen; the screen pops up a sub-keyboard corresponding to a push-button; and the contact slides on the sub-keyboard and selects a subsequently input character, wherein if the contact departs from the touch screen, the sub-keyboard disappears and the screen outputs a character string or a word corresponding to the character string input by a user. The invention further provides a terminal keyboard and a mobile terminal including the keyboard. According to the scheme provided by the invention, through providing the push-button which is popped up to possibly input in the next step based on a context for the user to slide, select and input, during one whole input process, the contact does not need to depart from the touch screen to effectively input the desired character. By adopting the technical scheme provided by the invention, the user can reduce the clicking times and shorten the sliding distance during inputting, at the same time can effectively reduce the probability of error input according to the prompting of the popped sub-keyboard, therefore the user operation is convenient and the inputting speed and accuracy of the user can be increased obviously.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

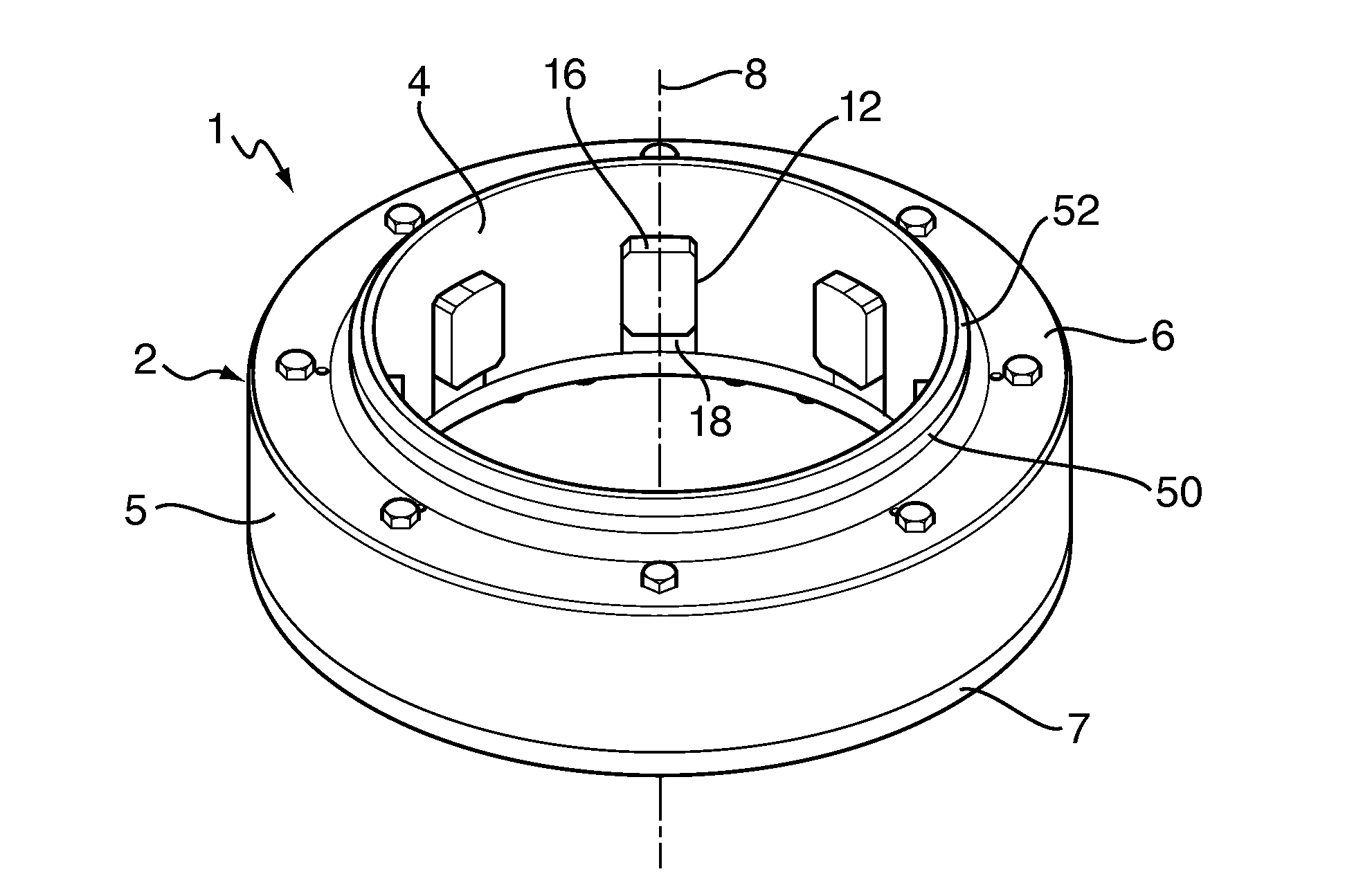

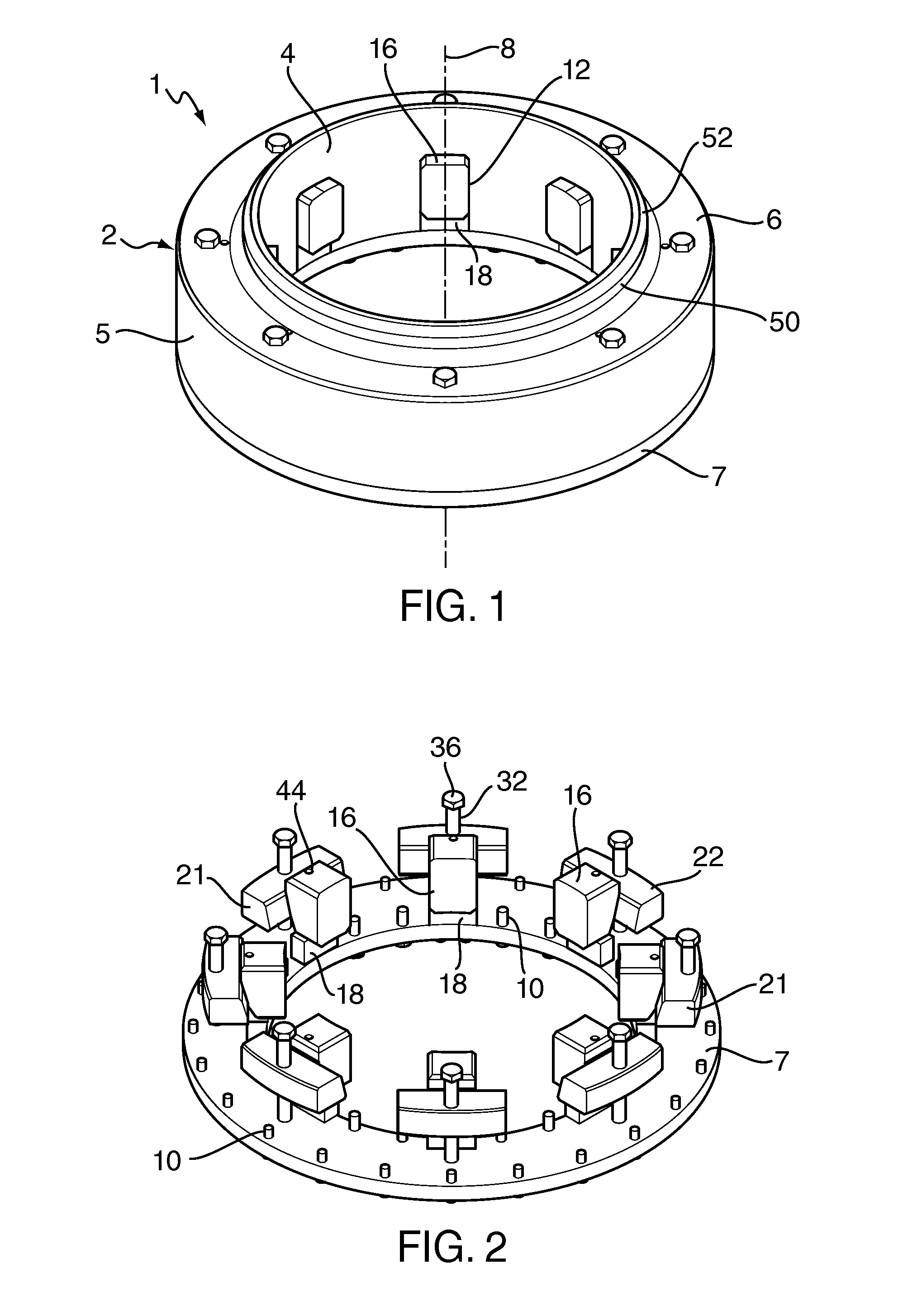

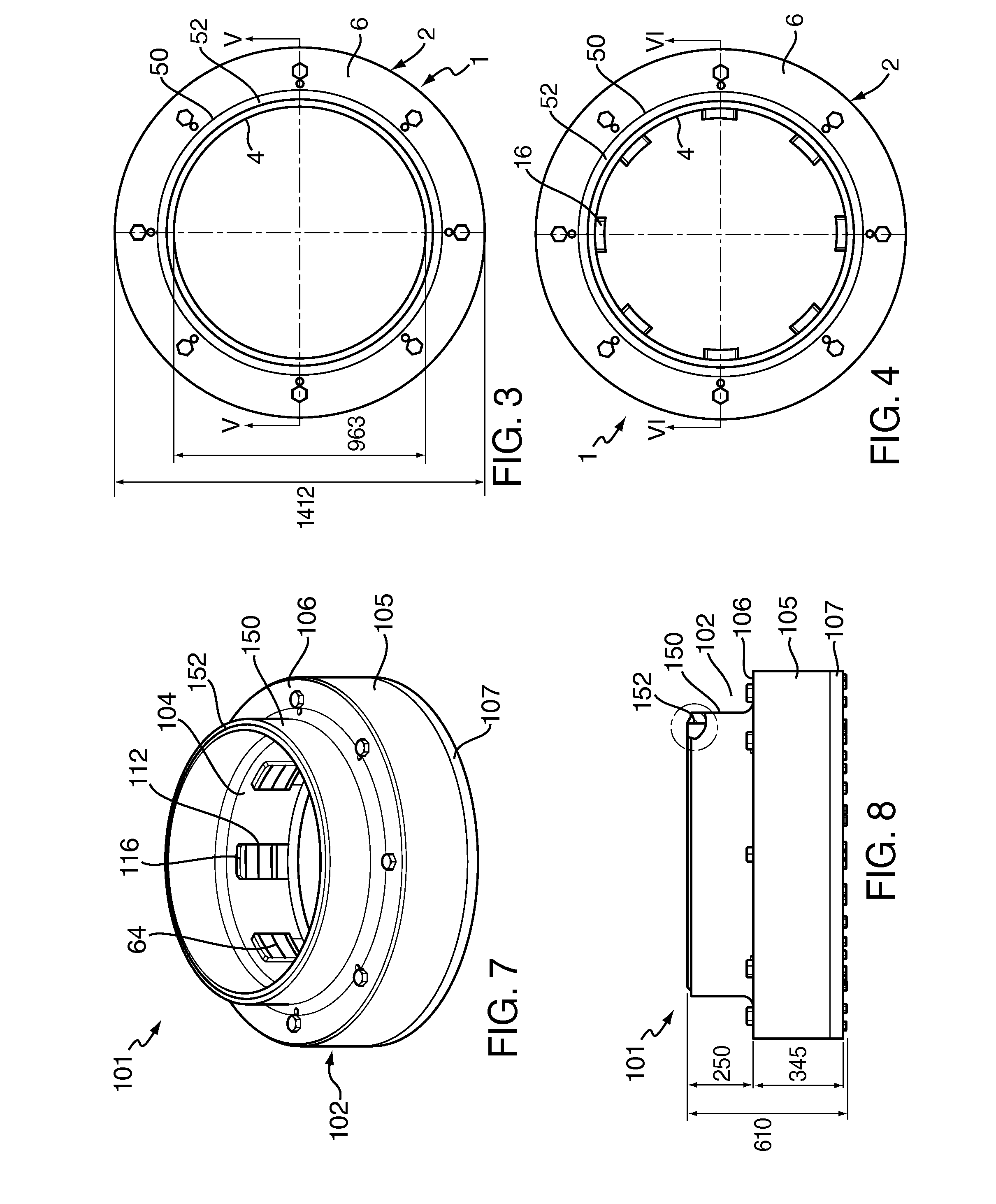

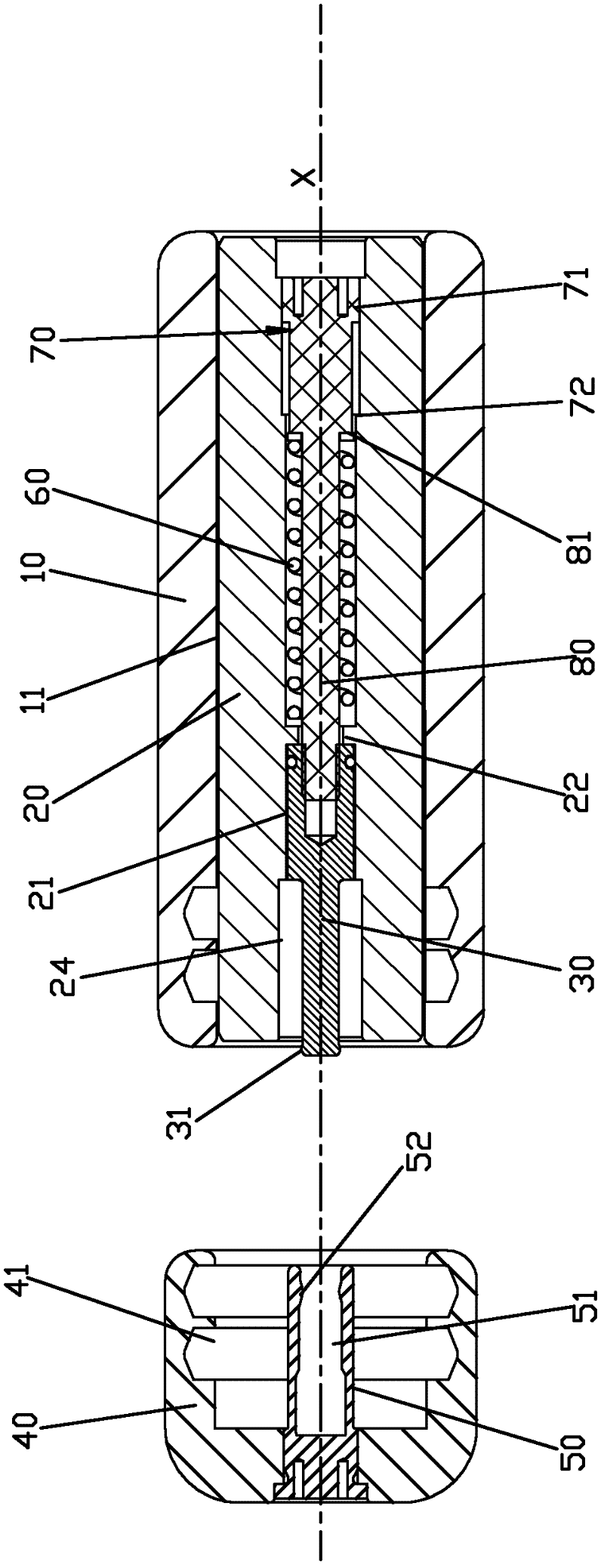

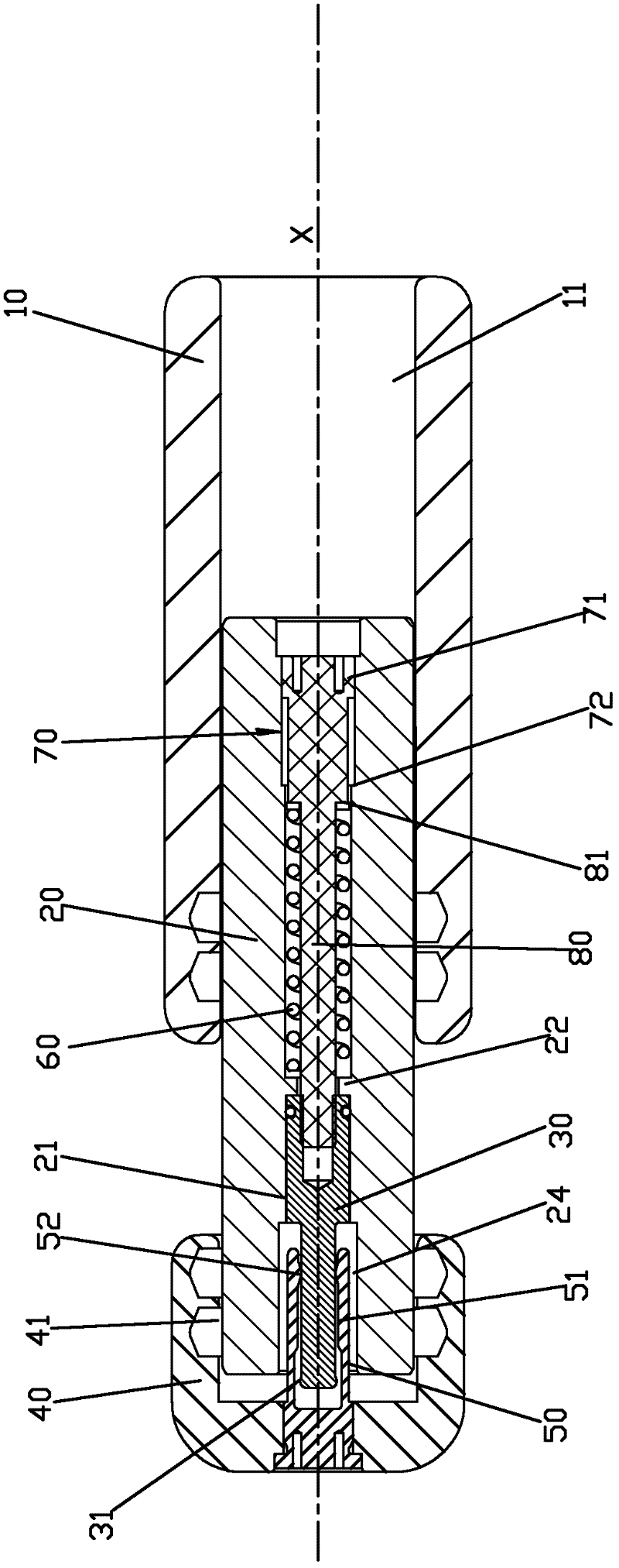

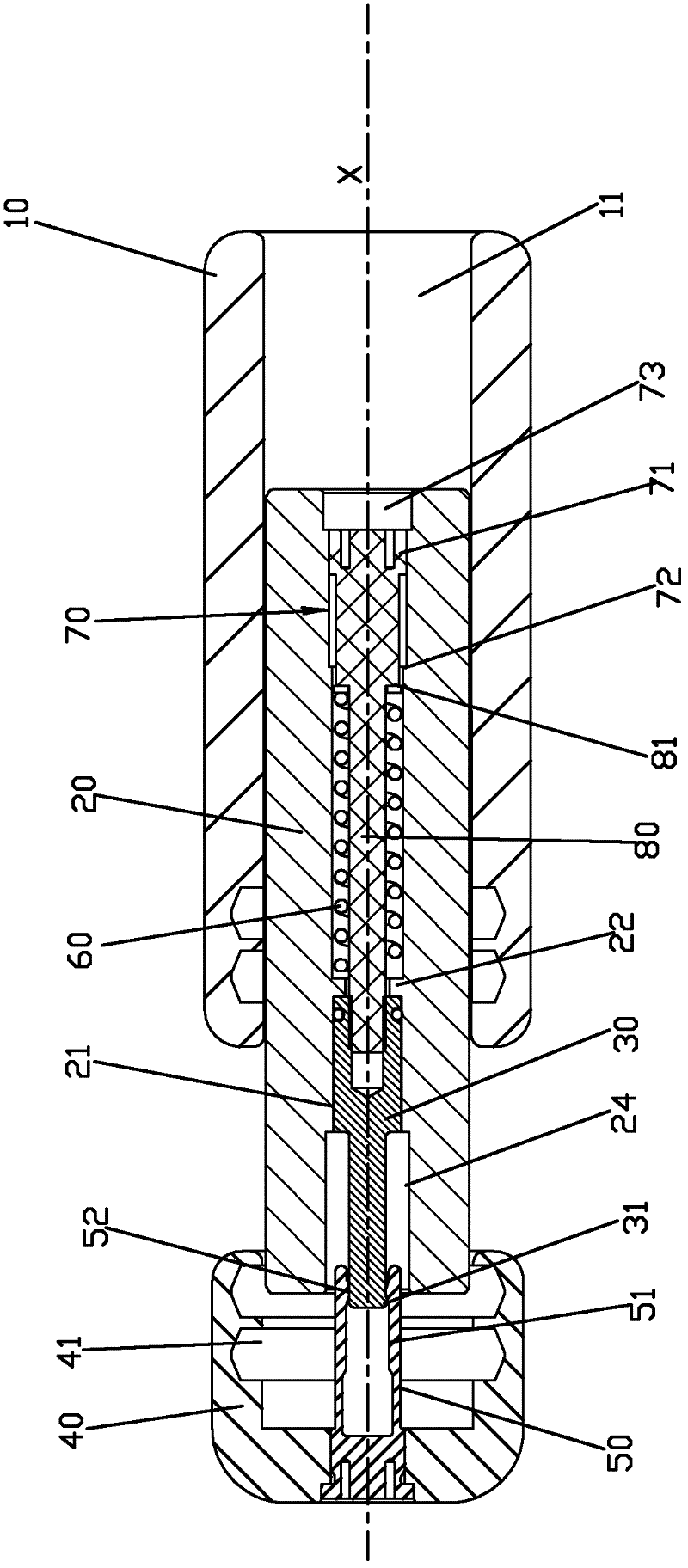

Tubular connector

InactiveUS20120096700A1Large in ovalityLarge in pipe diameterSleeve/socket jointsArtificial islandsEngineeringCanis lupus familiaris

The invention relates to a connector (1) for clamping a component around a tubular member (30) and to a method of using such a connector. The clamping connector (1) comprises a collar (2), a plurality of movable dogs (16) mounted in the collar and actuation means for driving the movement of the dogs. The collar (2) has an inner wall (4) and an outer wall 5, the inner wall being adapted to surround the tubular member (30) with a gap (56) between an outer surface of the inner wall (4) and an outer surface (28) of the tubular member. The inner wall (4) has a plurality of apertures (12) each aperture leading to a passage (14) through the inner wall. Each of the dogs (16) is slidably seated in one of the passages (14) for movement in a radial direction with respect to the tubular member (30). Around each passage (14) the inner wall (4) is spaced apart from an inner surface (25) of the outer wall (5). The actuation means includes a movable block (22) within the space (20) between the inner and outer walls (4, 5) and movement means (32) for moving the block in an axial direction with respect to the tubular member. Each block (22) has a radially outer surface (23) in sliding contact with the inner surface (25) of the outer wall (5) when each block is moved in the axial direction. Each block also has a radially inner surface (24) and each dog has a corresponding radially outer surface (26) that are in sliding contact with each other. At least one pair (24, 26) of these contacting sliding surfaces are oppositely inclined with respect to each other so that the relative axial movement of the block (22) and the dog (16) causes the dog to be driven in a radially inwardly direction across the gap (56) to grip the tubular member (30).

Owner:CLAXTON ENG SERVICES

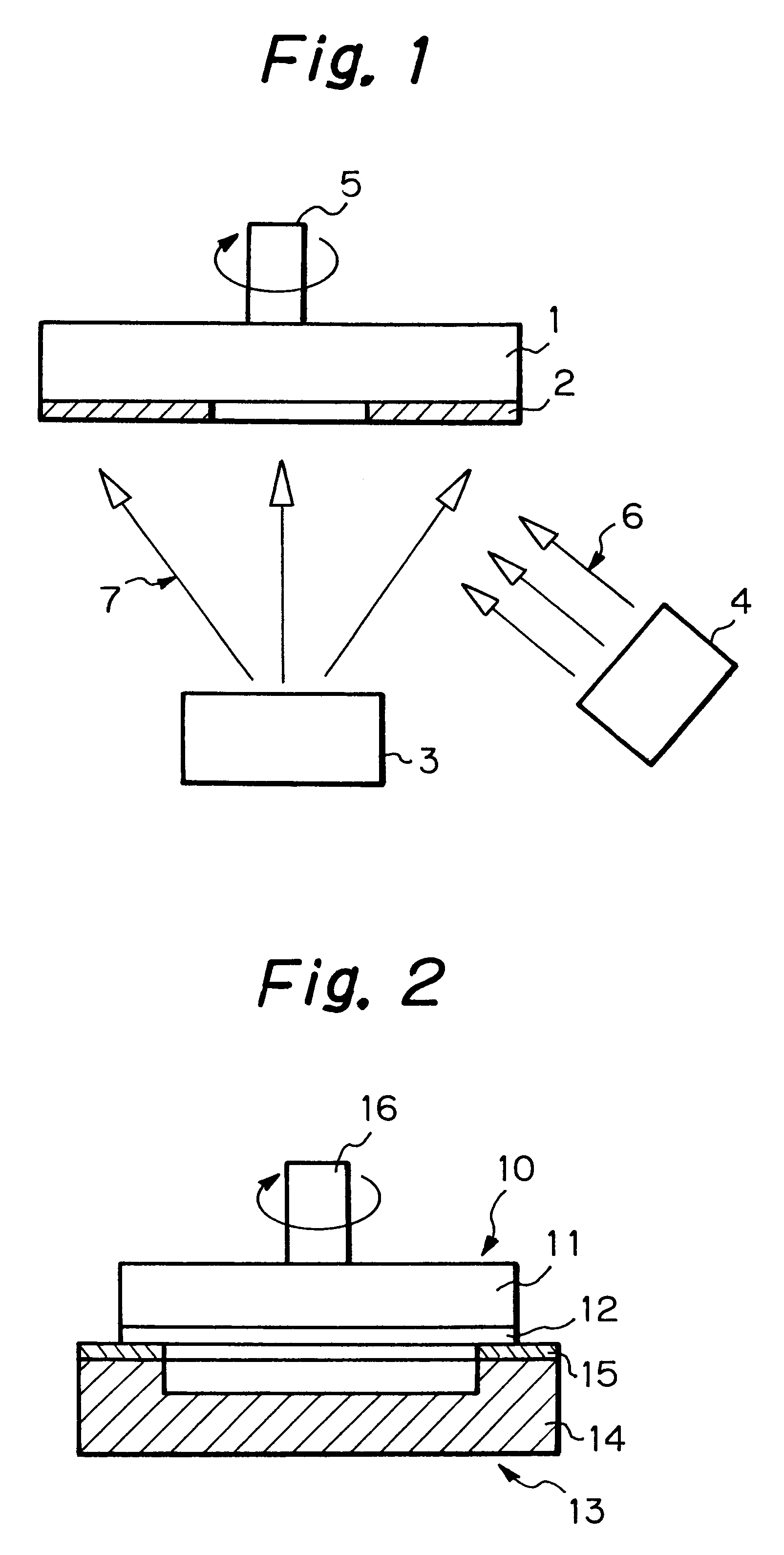

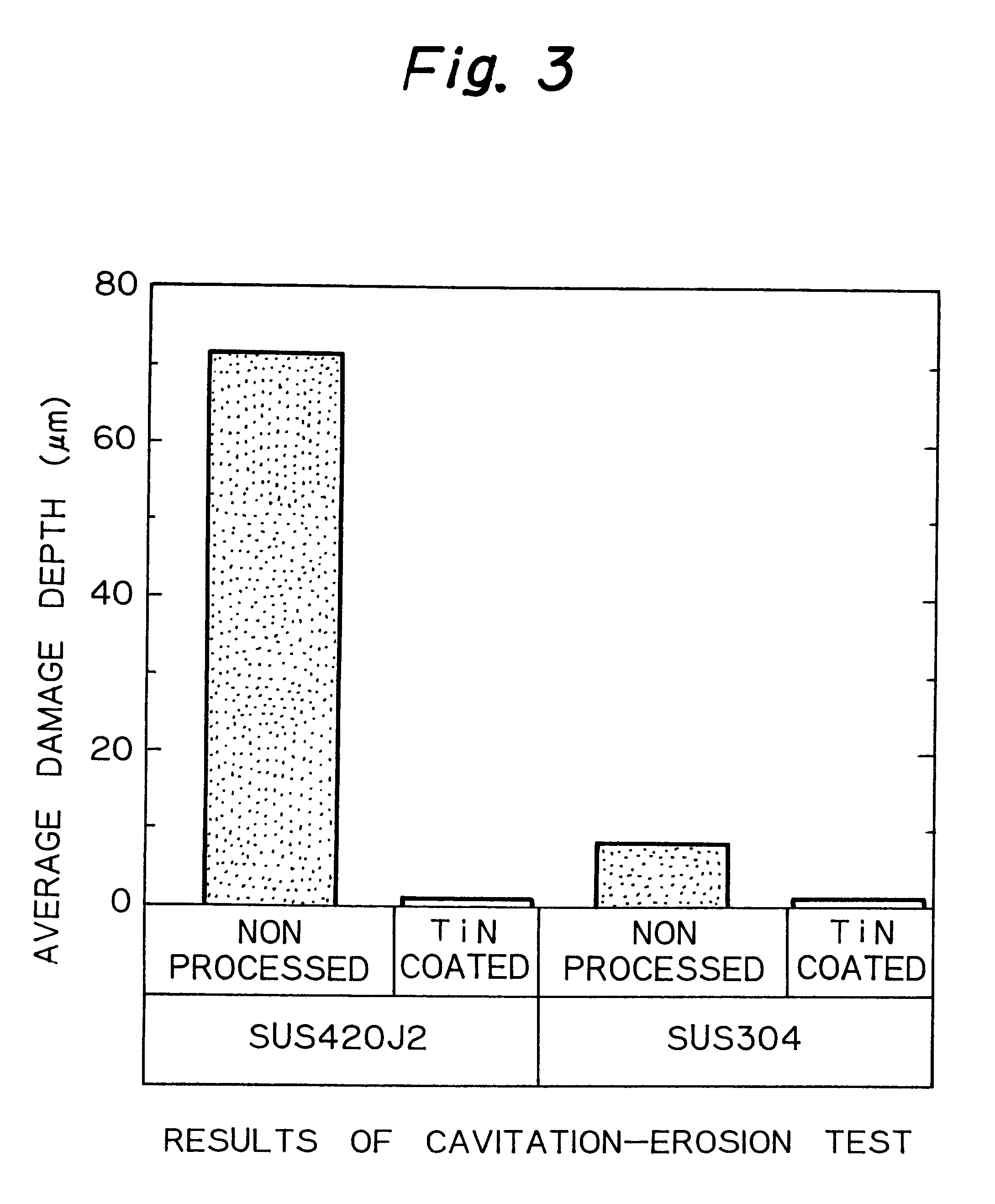

Water lubricated machine component having contacting sliding surfaces

InactiveUS6176619B1Excellent anti-heat shock and anti-mechanical shock propertiesMaintain good propertiesShaftsVacuum evaporation coatingMetallic materialsTitanium nitride

A water lubricated bearing or water lubricated seal using water as a lubricant. The bearing or seal has: a rotary member secured directly or indirectly to a rotary side, and a stationary member secured directly or indirectly to a stationary side and facing the rotary member for making sliding contact therewith. A substrate of either one of the rotary member and the stationary member is a metallic material and a thin titanium nitride film is formed on the sliding surface thereof. The other member is made of a non-brittle material or a film of hard material is formed on the sliding surface thereof. Thereby, a coefficient of friction of the bearing or seal is reduced and a wear resistance of the same is improved.

Owner:EBARA CORP

Magnetically supported sliding track system

InactiveUS8020346B2Large resistancePrevent back movementDoor/window protective devicesMan-operated mechanismSupporting systemEngineering

A sliding door or window supporting system has a stationary frame with a bottom track and a sliding portion that slides from a closed position to an open position. The bottom portion of the sliding portion and the upper surface of stationary frame track are provided with one or more magnets having identical magnetic polarity, thereby creating repulsion between the bottom of the sliding portion and the stationary track. Forces produced by magnetic repulsion lift the weight of the sliding portion, creating an air gap. A smooth, low friction sliding and door gliding movement results, which is immune to dirt and debris. The front to back movement of the sliding portion is supported by low friction polymeric knobs attached to a stationary frame and contacting sliding portion.

Owner:SINGISER JOSEPH +1

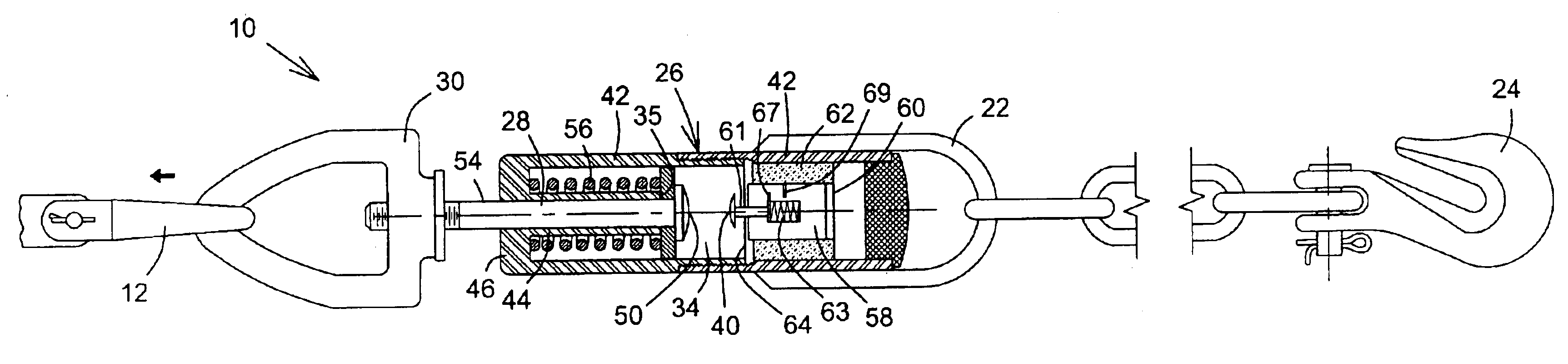

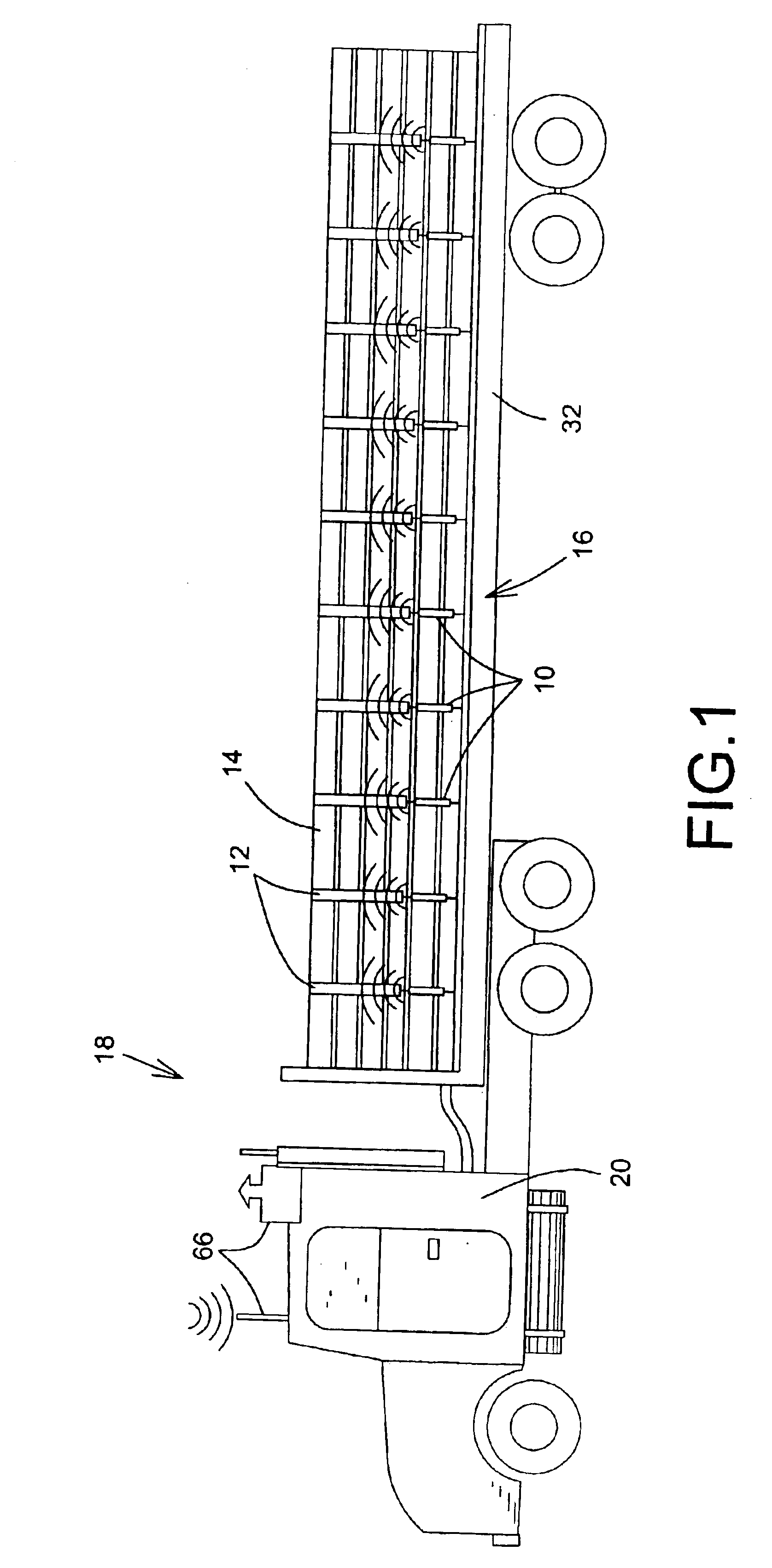

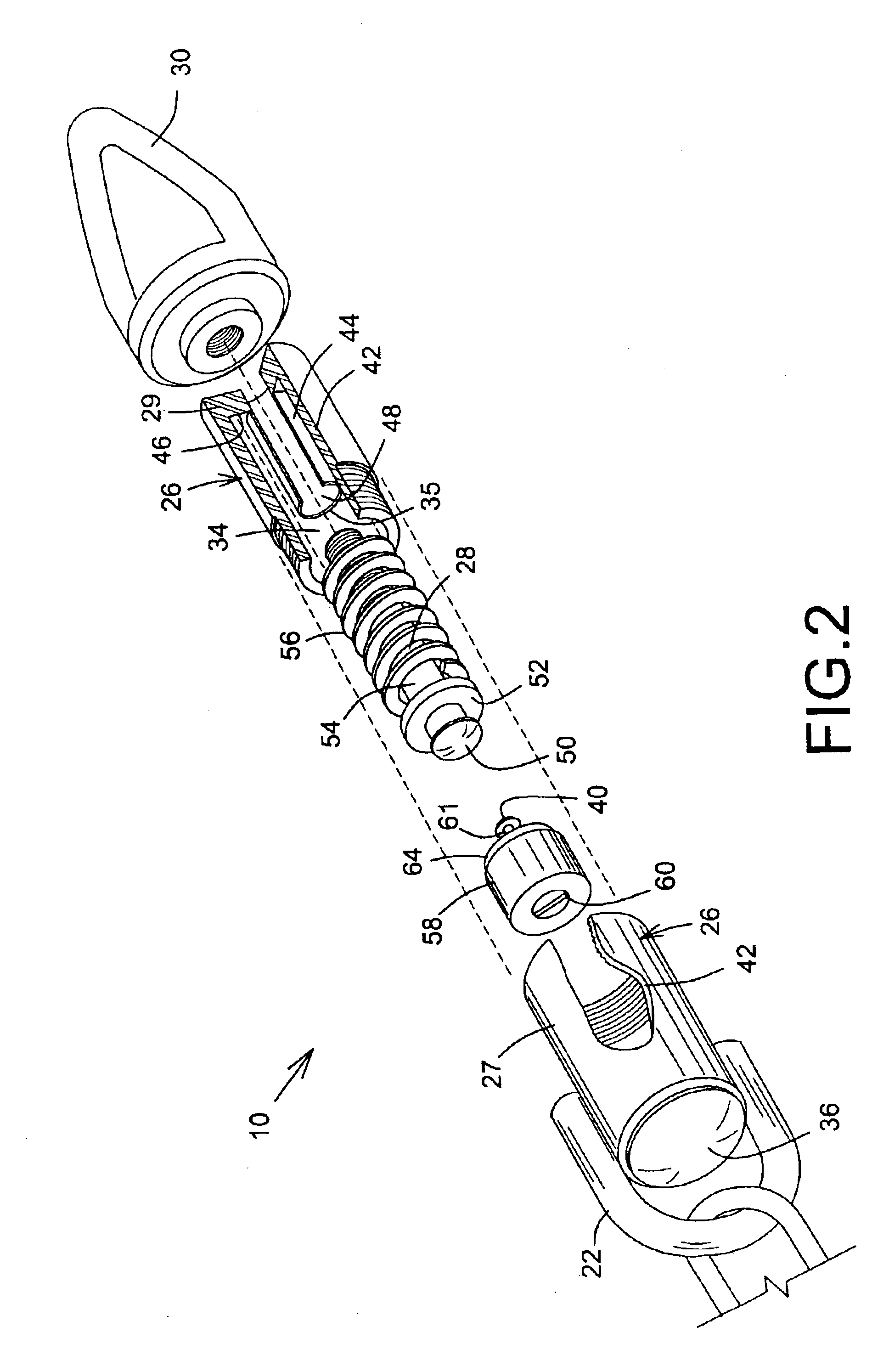

Load tension alert device

InactiveUS6847290B2Reduce difficultyReduce disadvantagesAnti-theft devicesOptical signallingEngineeringSignal generator

Tension alert device is used with a load secured to a vehicle load bed, which has a securing belt having a connector portion and an attachment link. The device includes a connector sleeve, with an axial bore and a sleeve end portion, which is connected to the link. A first contacter connects to an inner end portion of the sleeve and faces into the axial bore. A second contacter slides in the bore along a restricted path of travel and has a second load bed connector. The second contacter faces the first contacter and is urged away from it when the belt has a first tension threshold value. The first contacter has an electrical signal generator for producing an electrical signal, which is activated when the second contacter is biased against it when the belt attains a second threshold tension value.

Owner:TARDIF MAURICE

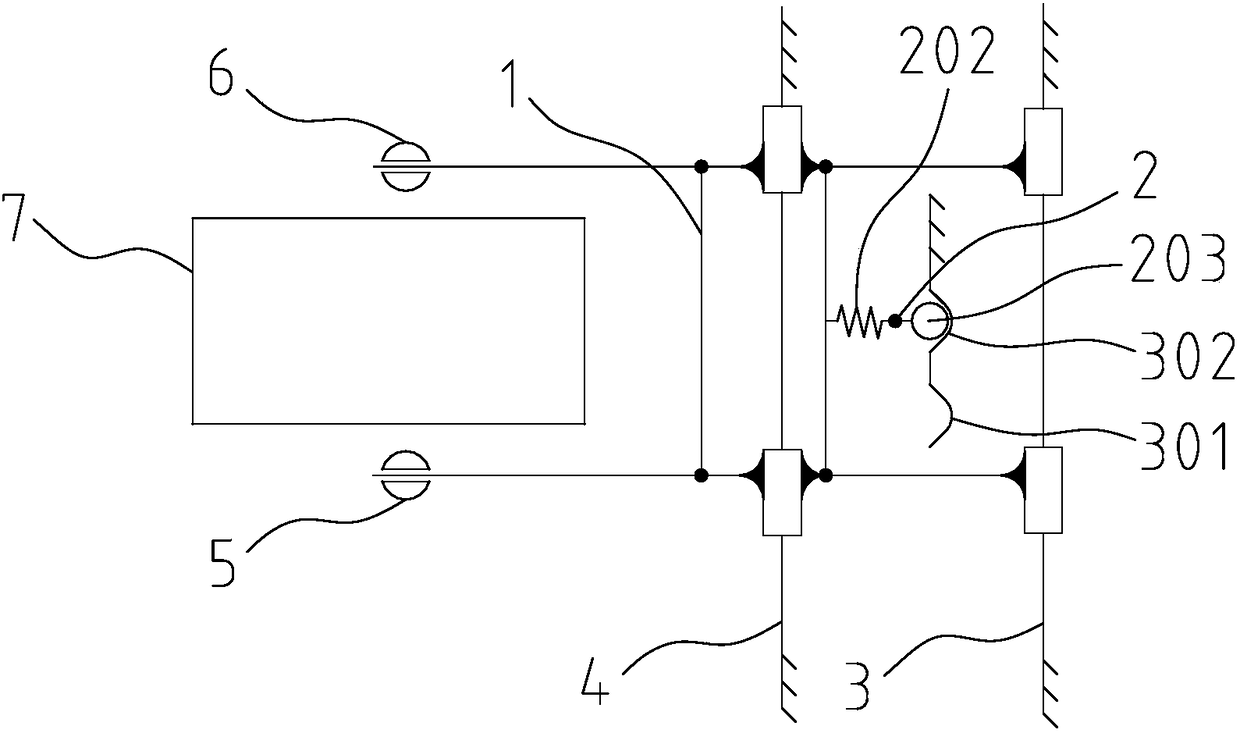

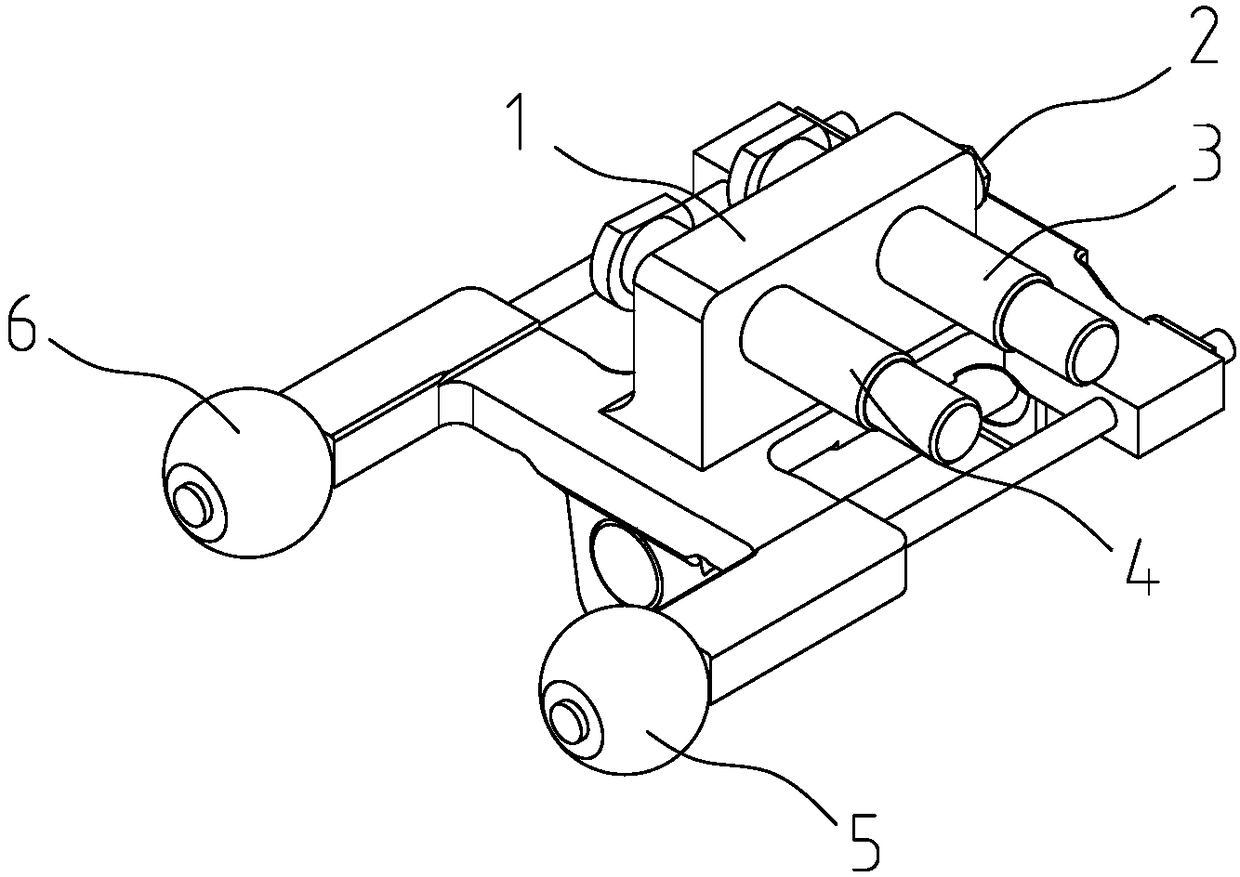

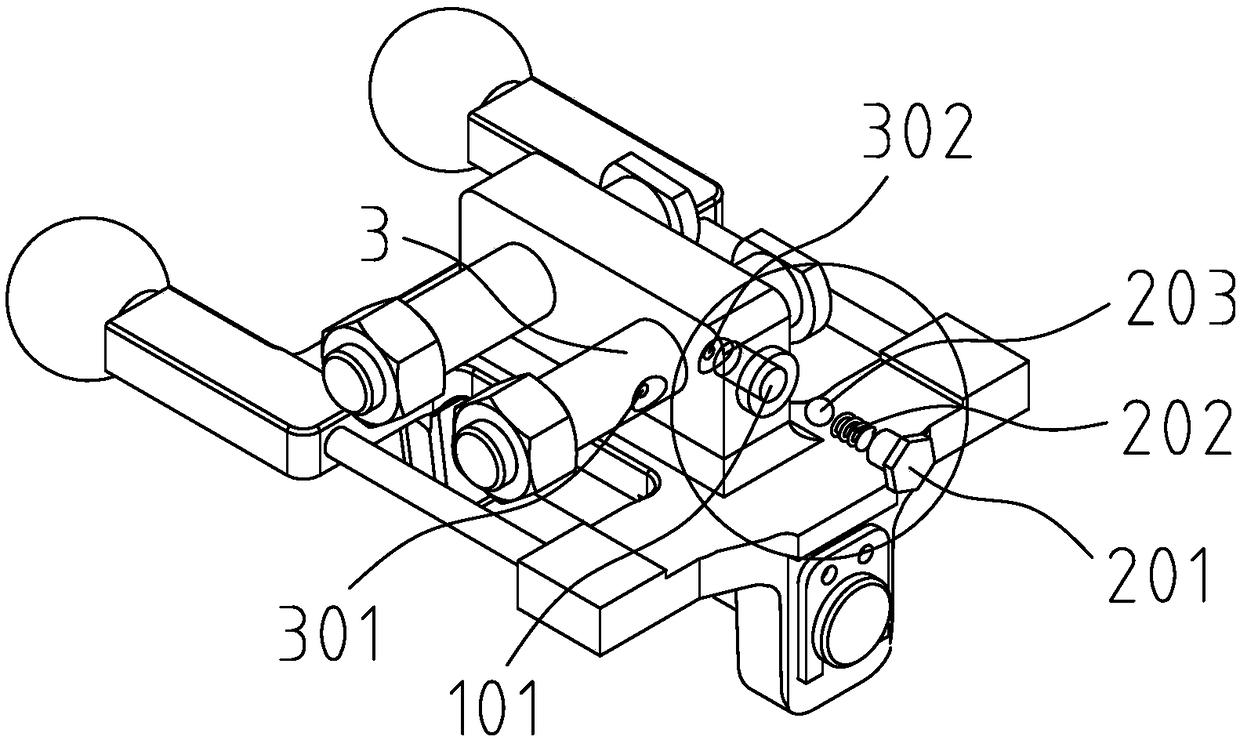

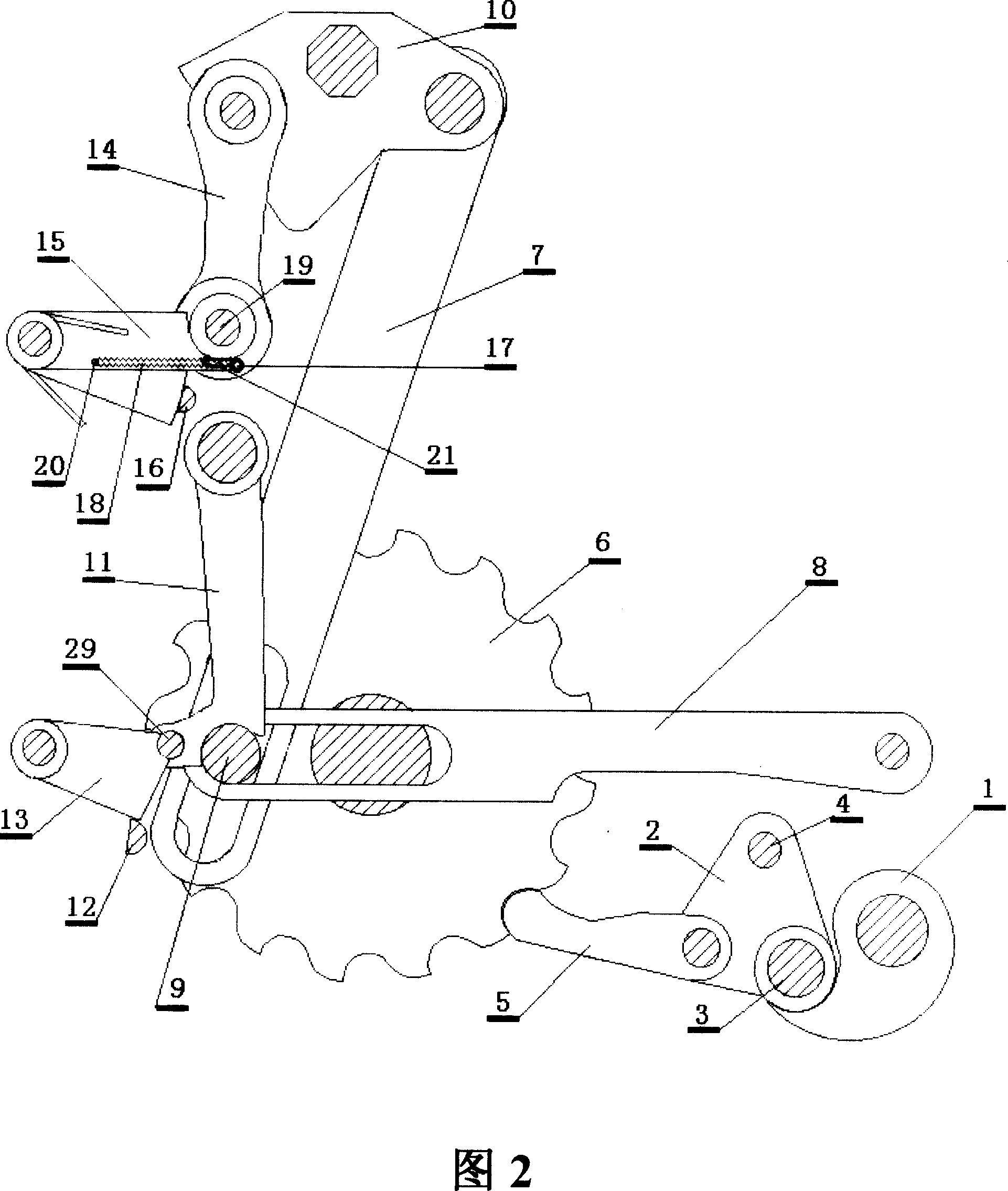

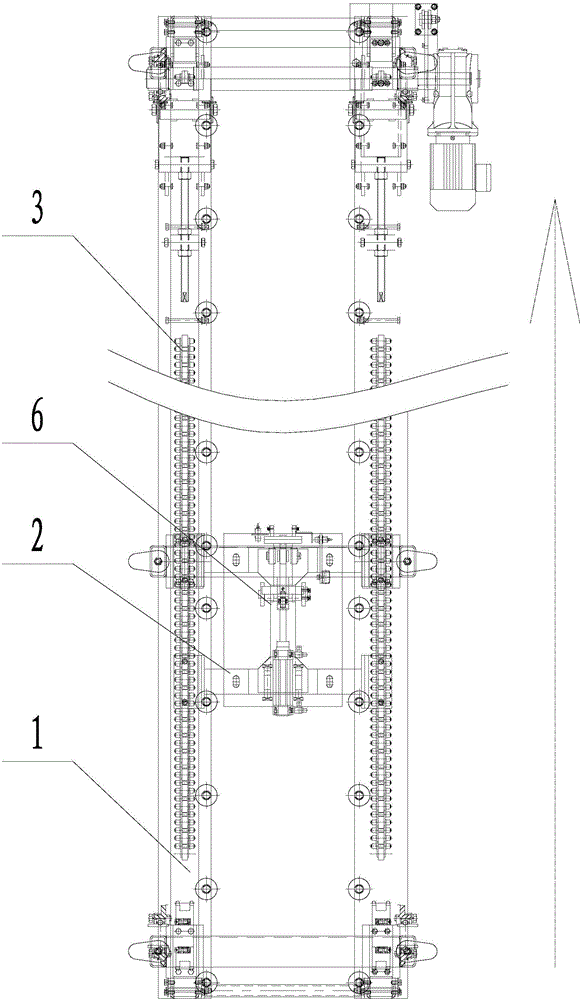

Rigid following mechanism and brake clamp unit for variable-gauge bogie

ActiveCN108482415ASimple structureIncrease flexibilityBogiesBrake arrangement with pressed braking surfaceBogieEngineering

The invention relates to a rigid following mechanism and a brake clamp unit for a variable-gauge bogie. The rigid following mechanism comprises a following connecting part, a positioning device and atleast two fixed parts, wherein the positioning device is mounted on the following connecting part; and the fixed parts are parallel to each other. The following connecting part and the fixed parts are installed in a sliding fit mode. The positioning device is connected with a first fixed part in a contact mode. Contact sliding parts are separately installed on two supporting arms of the followingconnecting part. The brake clamp unit comprises a mounting bracket and a brake actuator and a rigid follower mechanism, wherein the brake actuator is mounted on the mounting bracket. The following connecting part and the brake actuator are installed in a fit mode. The positioning device is tightly attached to the mounting bracket, and the fixed parts are fixedly installed on the mounting bracket.The rigid following mechanism and the brake clamp unit for the variable-gauge bogie can change the position along with wheels, the position on a target gauge position is automatically found, and thechange of the position is achieved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

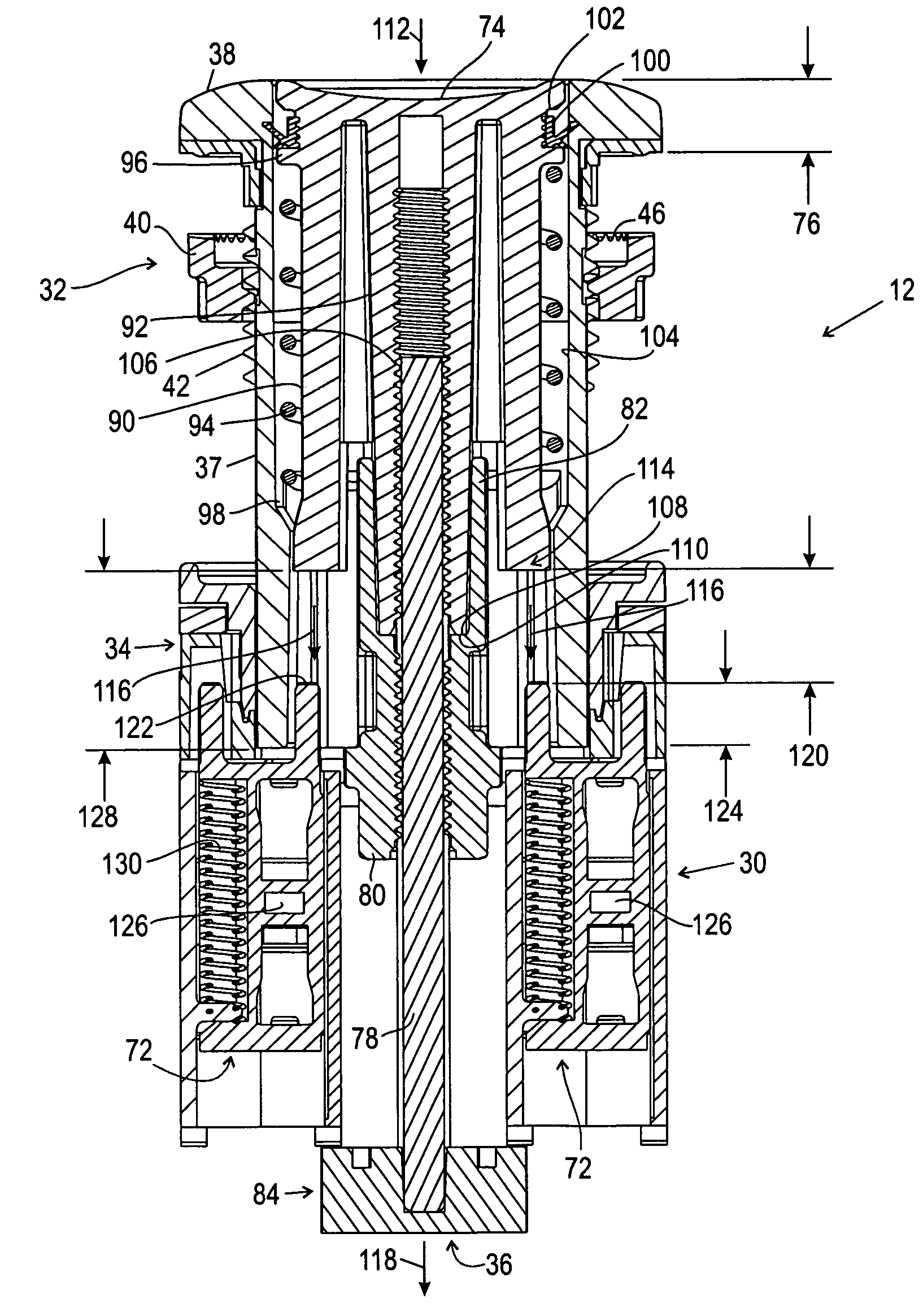

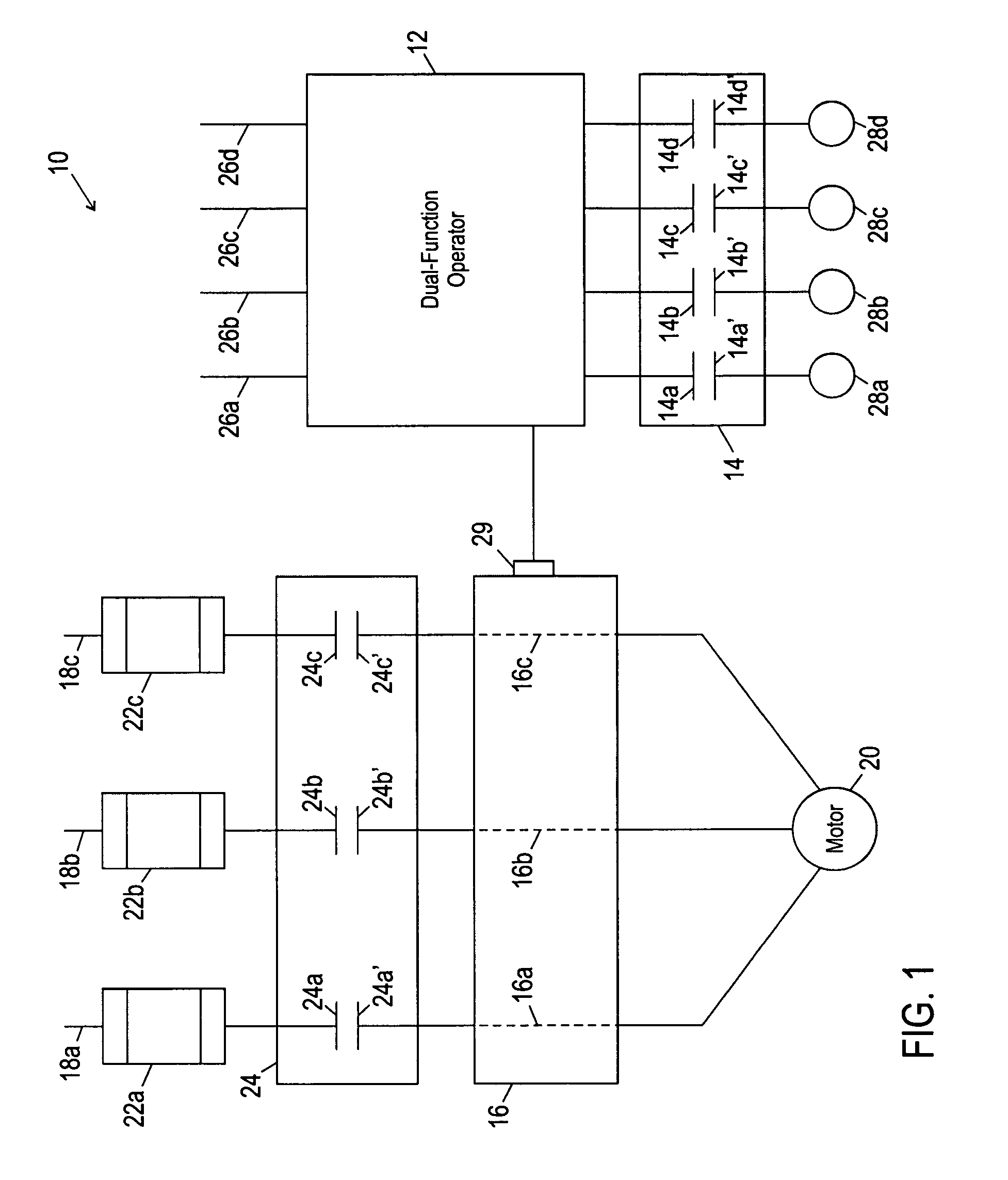

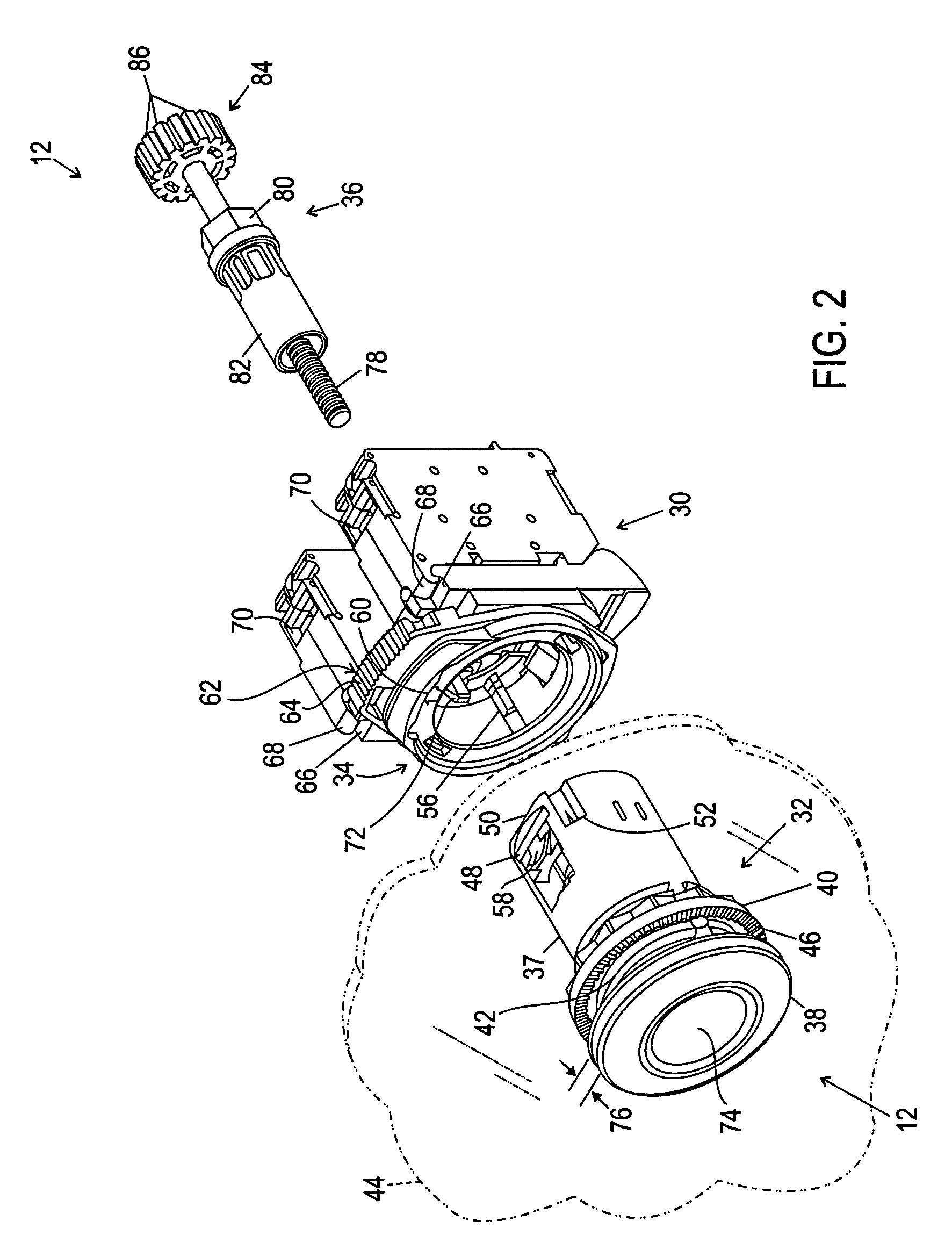

Dual function reset operator for an electrical device

Owner:ROCKWELL AUTOMATION TECH

Combined numerical control milling machine

InactiveCN103056428AExtend your lifeReduce vibrationAutomatic control devicesMilling machinesNumerical controlControl system

The invention relates to a combined numerical control milling machine, which belongs to the technical field of mechanical machining. The combined numerical control milling machine comprises an electric spindle of a machine tool, electric spindles of end mills, a mill disc, a ram-type beam, a machine body, the helical-edge end mills, a transverse feeding working table, a vertical feeding working table, a lifting table, a base, a control system, a movable contact sliding ring, a movable contact contactor, an insulating ring and a lead wire, wherein the control system controls the electric spindle of the machine tool and the electric spindles of the end mills to rotate; the electric spindle of the machine tool drives the mill disc fixedly connected with the electric spindle of the machine tool to rotate; and the control system simultaneously controls the transverse feeding working table, the vertical feeding working table and the lifting table to move, so that the planes of workpieces on the transverse feeding working table are machined. According to the numerical control milling machine provided by the invention, the plane milling efficiency can be effectively improved, the cutting force and the cutting head are reduced, the service life of the mills is prolonged, and the vibration of the tool machine can be alleviated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

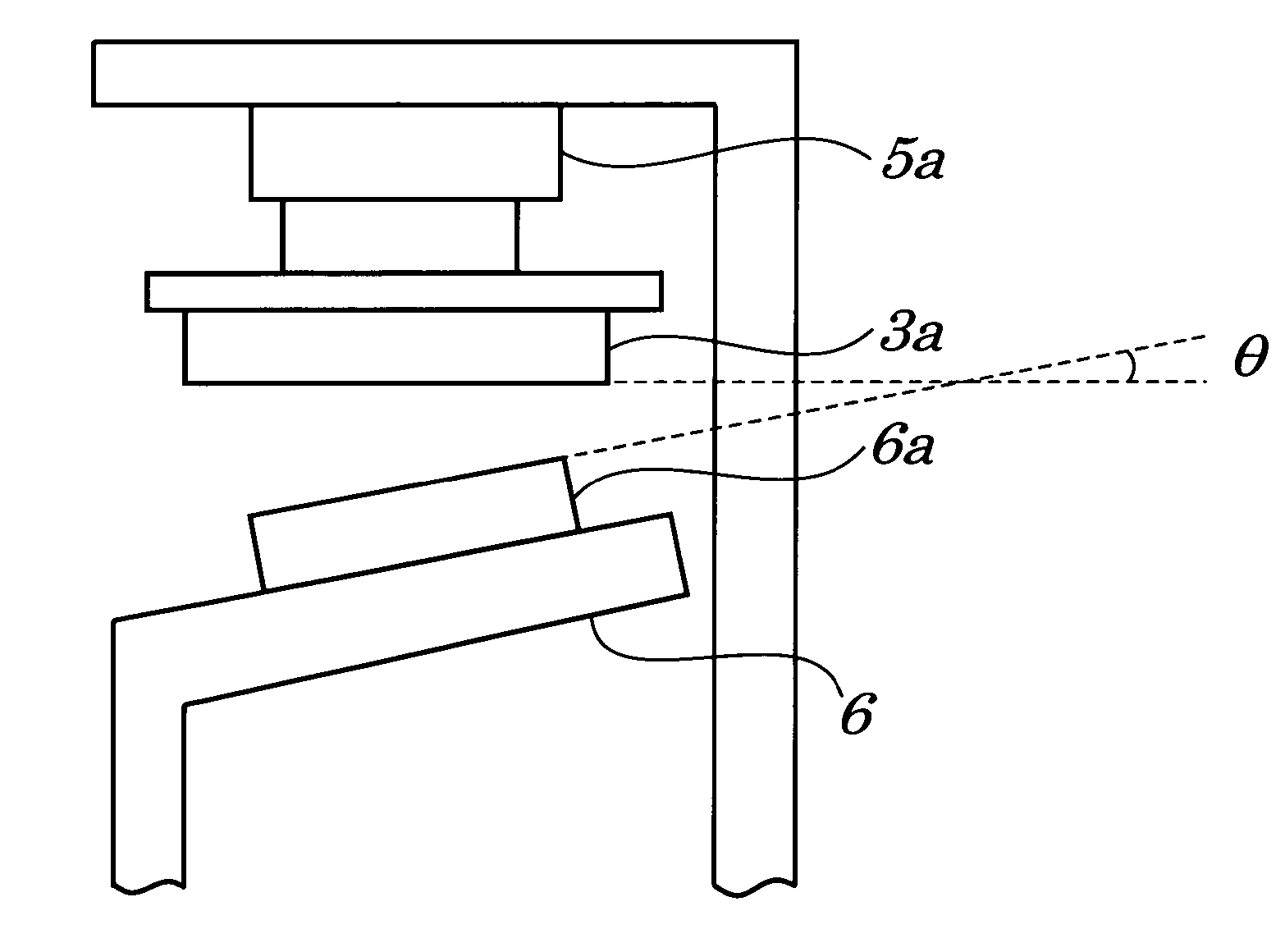

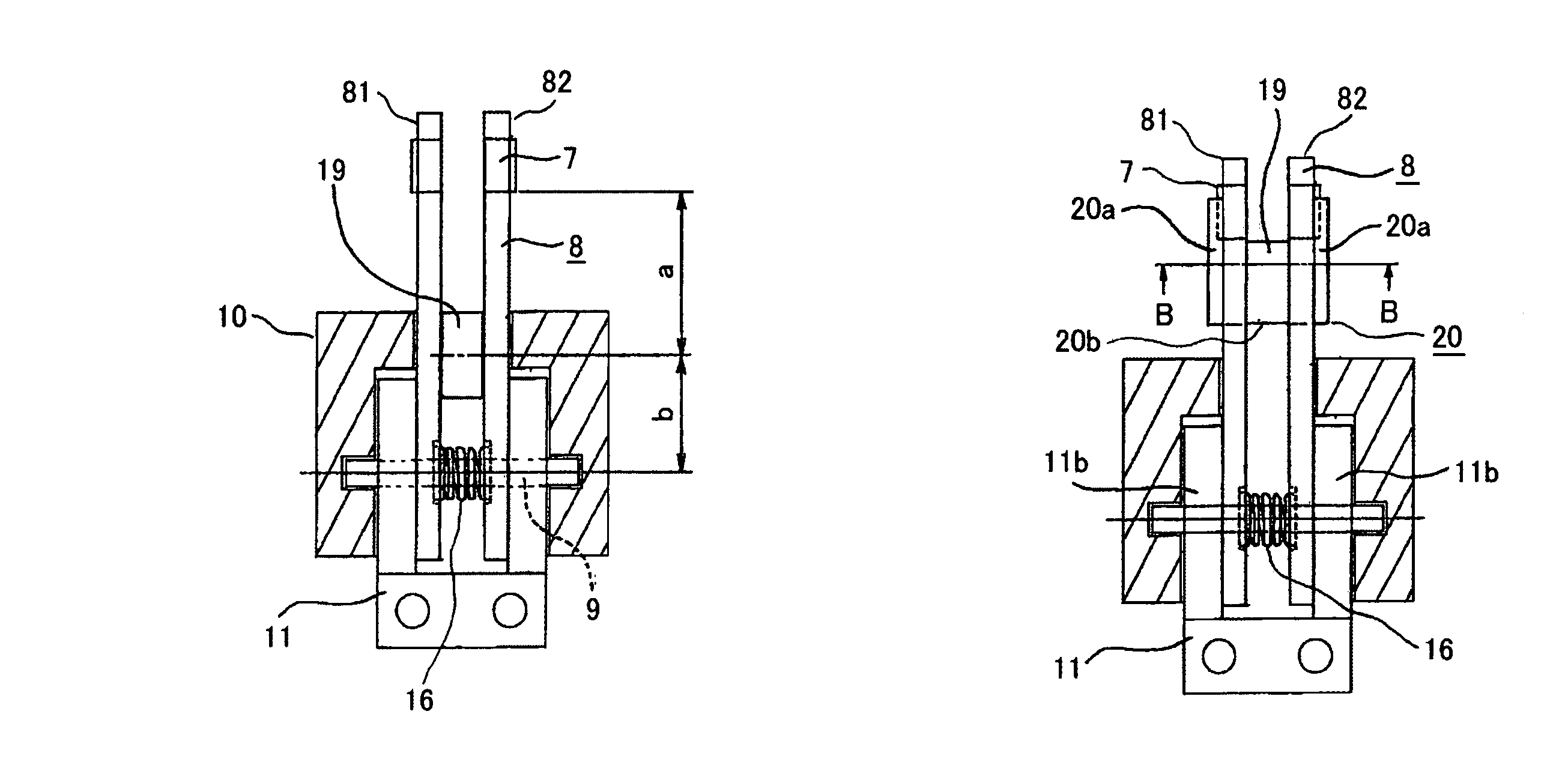

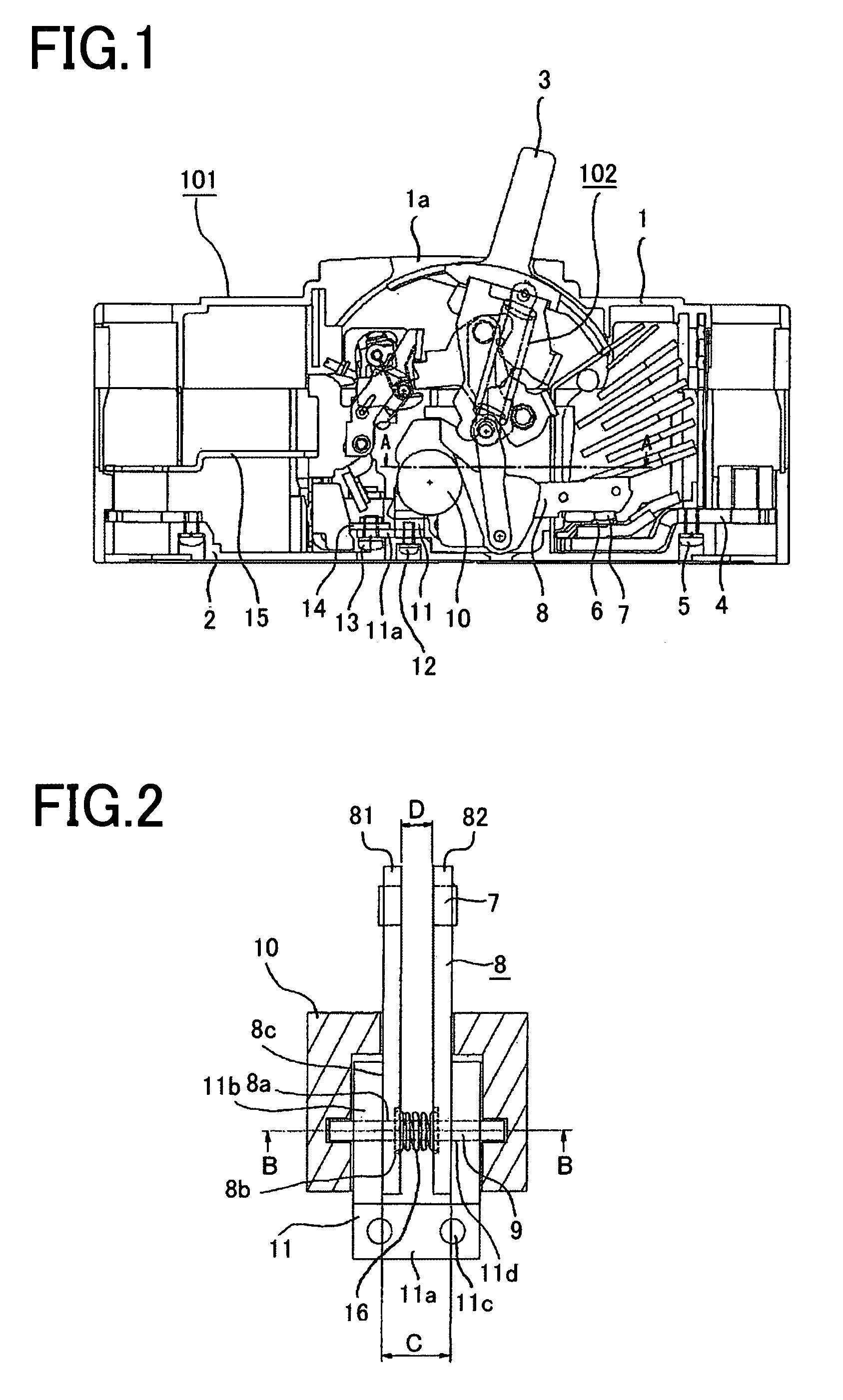

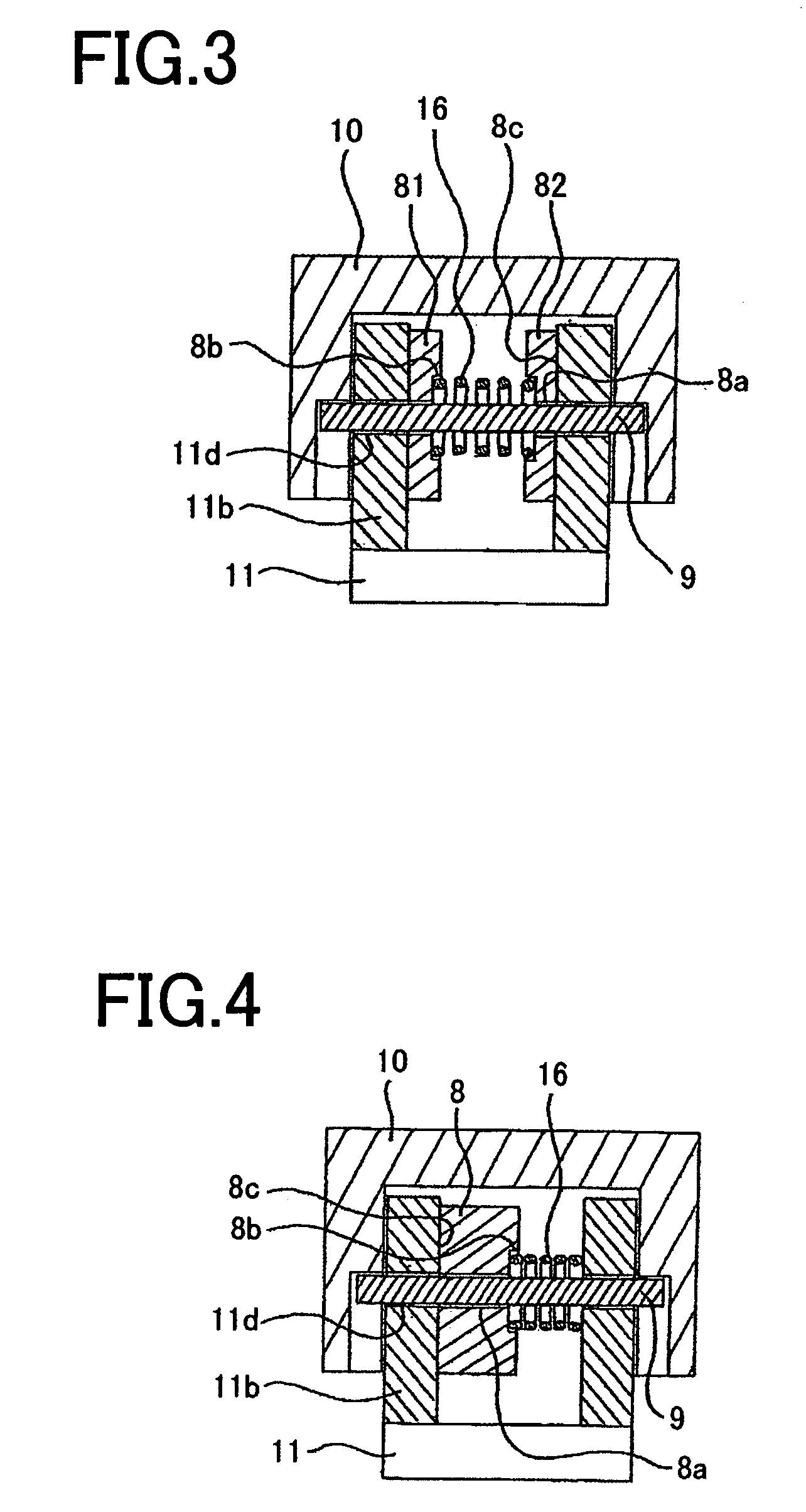

Electromagnetic relay

ActiveUS20060226935A1Reduce contact bounceLower capability requirementsElectromagnetic relay detailsSelector switchesEngineeringContact slide

An electromagnetic relay is provided which is capable of reducing a contact bounce at time of closing a contact. The electromagnetic relay is so configured that an opposed angle θ is 0°<θ<45°, when viewed from a direction to which a normally open fixed contact and a movable contact slide before the normally open fixed contact comes into surface-contact with the movable contact spring.

Owner:EM DEVICES CORP

Quickly-separated disconnecting switch

ActiveCN102368443AIncrease the opening speedIncrease the number ofSwitch power arrangementsContact engagementsEngineeringExtreme position

The invention discloses a quickly-separated disconnecting switch, comprising an outer seat, a moving contact, a moving arcing contact, a fixed contact, a fixed arcing contact, an elastic body and a limiting mechanism, wherein the moving arcing contact can slide relative to the moving contact; the elastic body can store energies when the moving contact slides away from the moving arcing contact; the limiting mechanism is used for arranging the relative sliding extreme positions between the moving contact and the moving arcing contact; an outer ring at the tail end of the outer wall of the moving arcing contact is provided with a male buckle in a raised mode; an inner ring at a port of the inner wall of a second conductive slot of the fixed arcing contact is provided with a female buckle; the moving contact is far away from the fixed contact in the process of separating brake; the male buckle is coordinated with the female buckle to connect the moving arcing contact with the fixed arcing contact, the moving contact slides away from the moving arcing contact oppositely, and the elastic body stores the energies; and after the moving contact slides away from the moving arcing contact oppositely to the extreme position, the moving arcing contact is separated from the fixed arcing contact under the action of the limiting mechanism, and the energies stored by the elastic body are released to quickly separate the moving arcing contact from the fixed arcing contact.

Owner:XIAMEN HUADIAN SWITCHGEAR

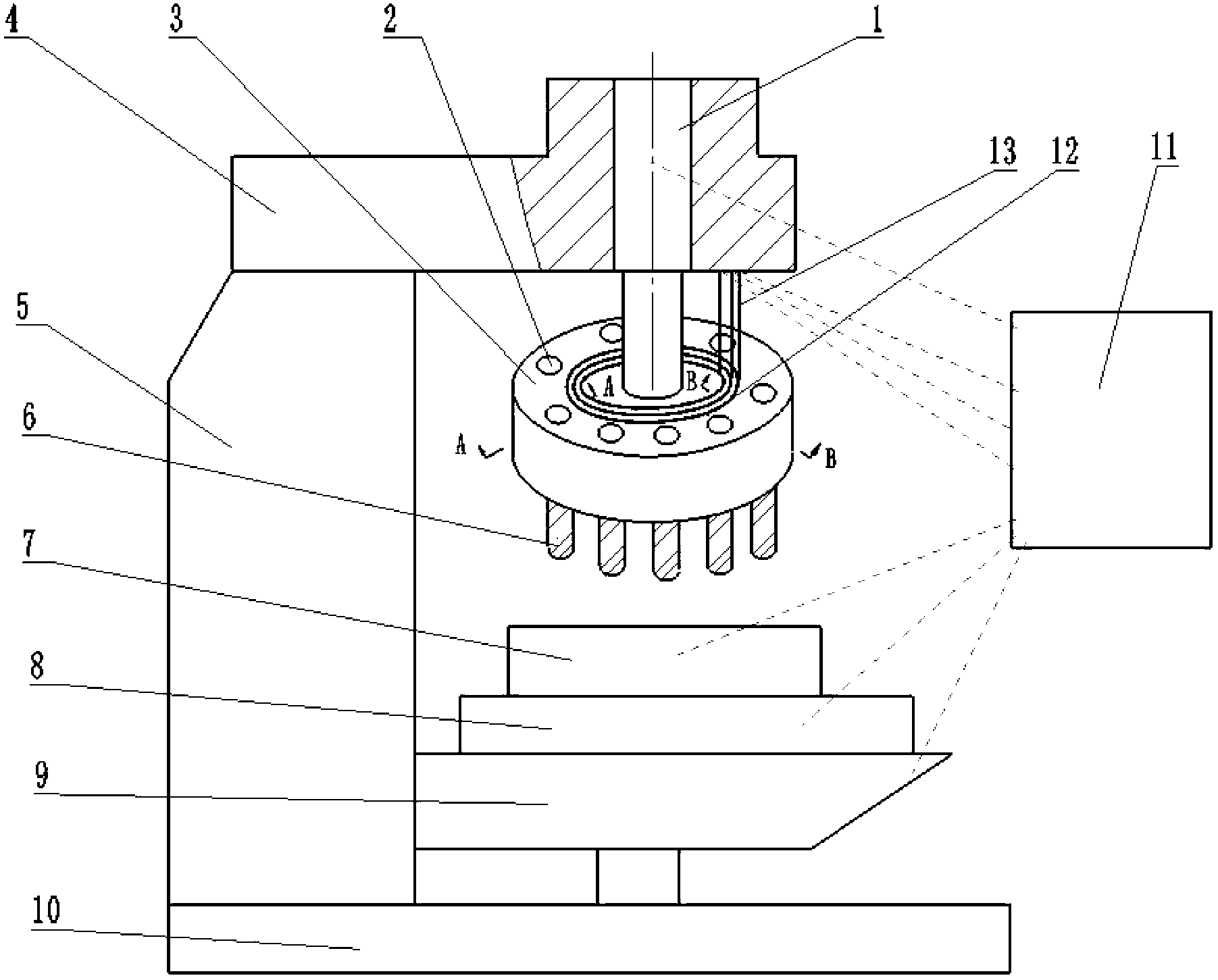

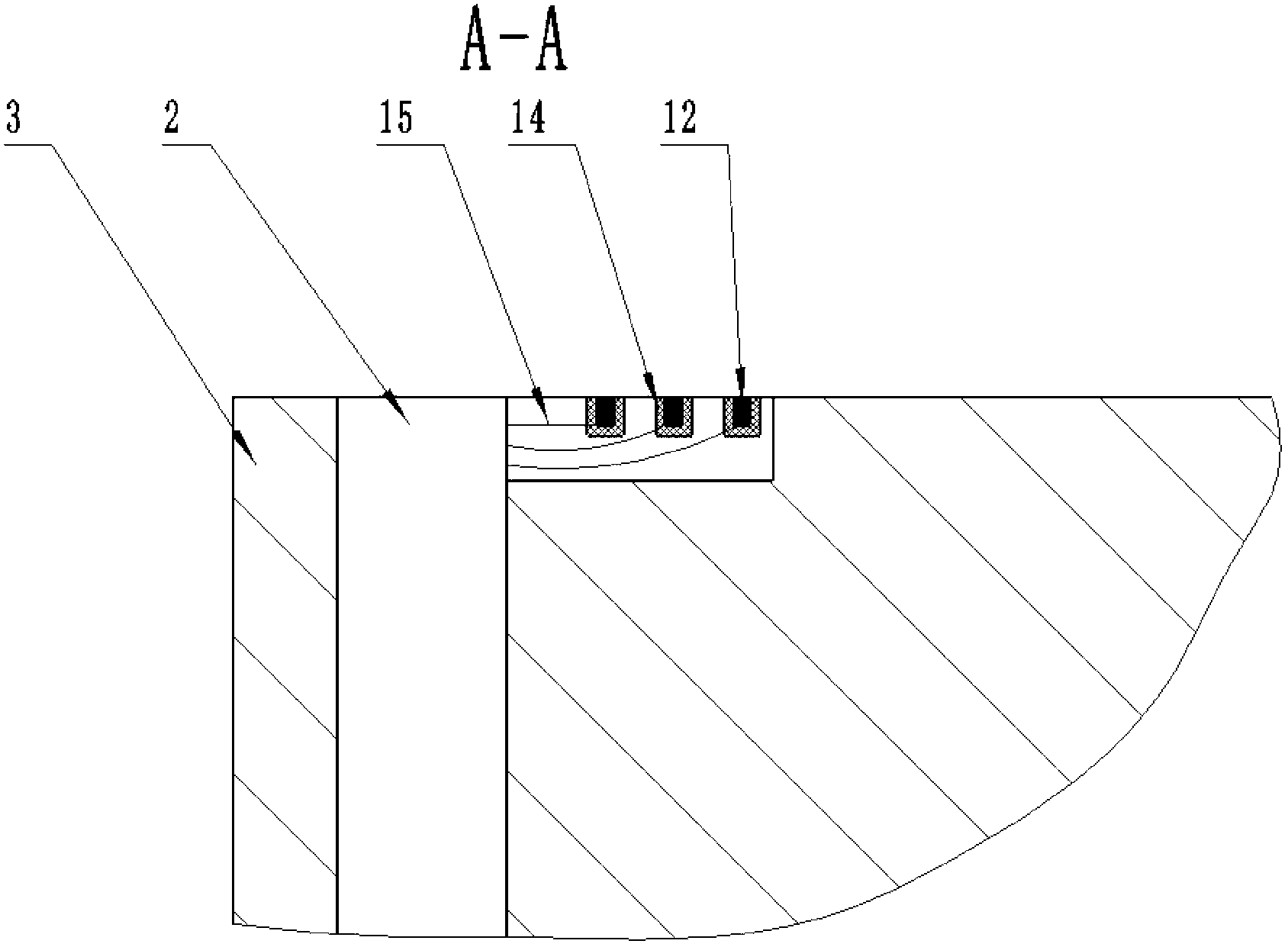

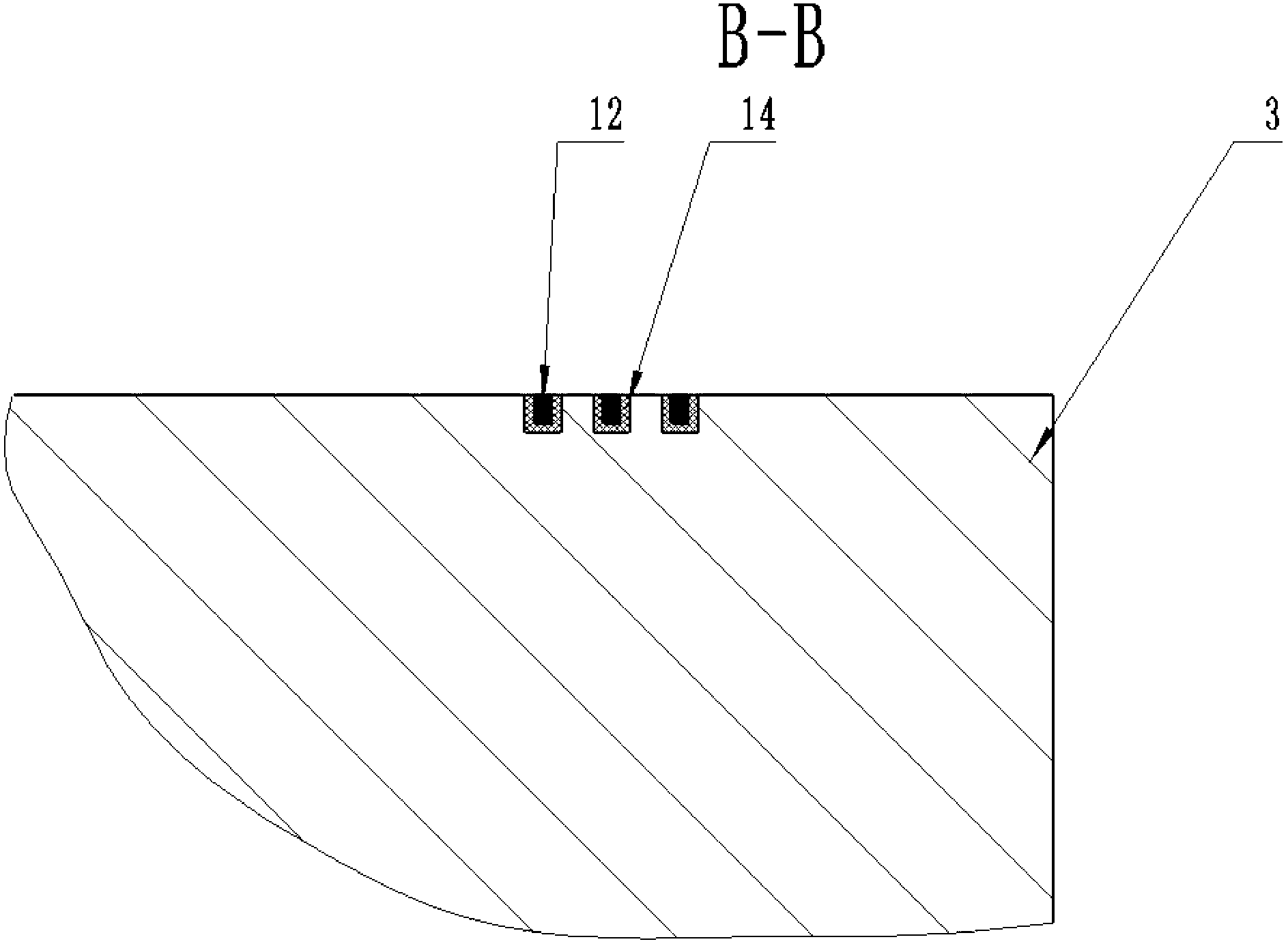

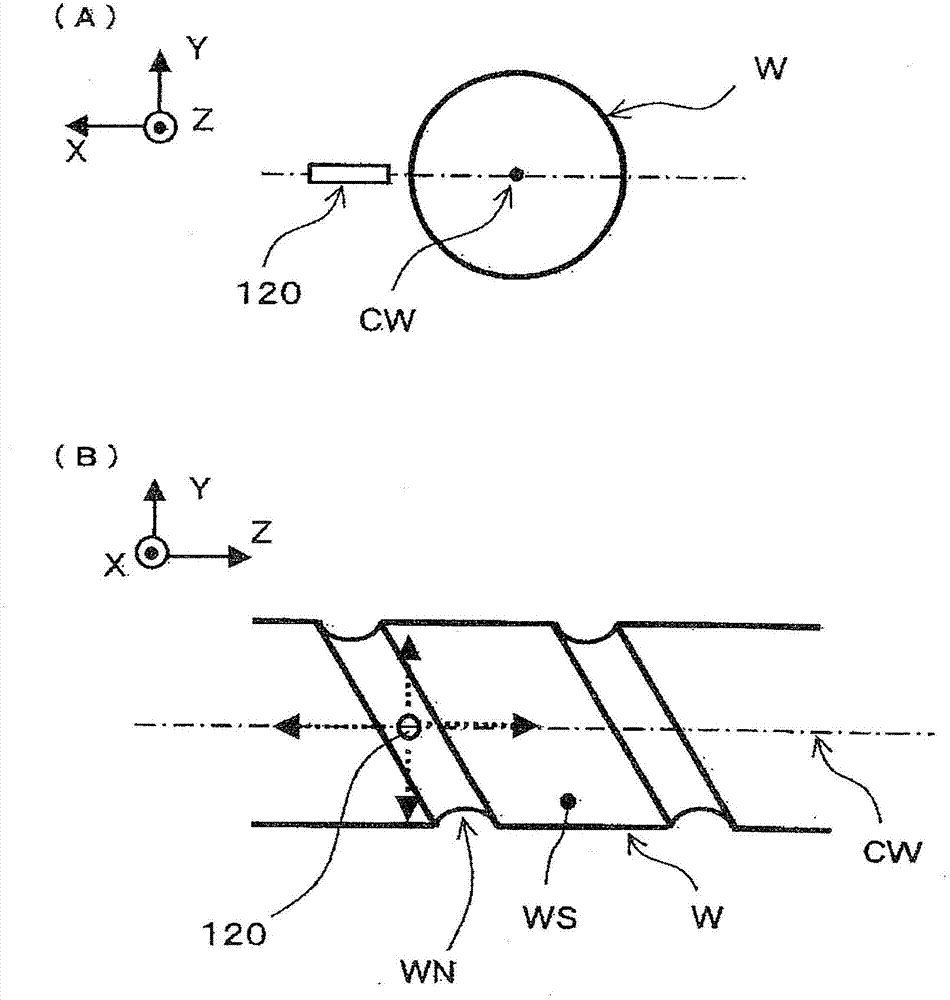

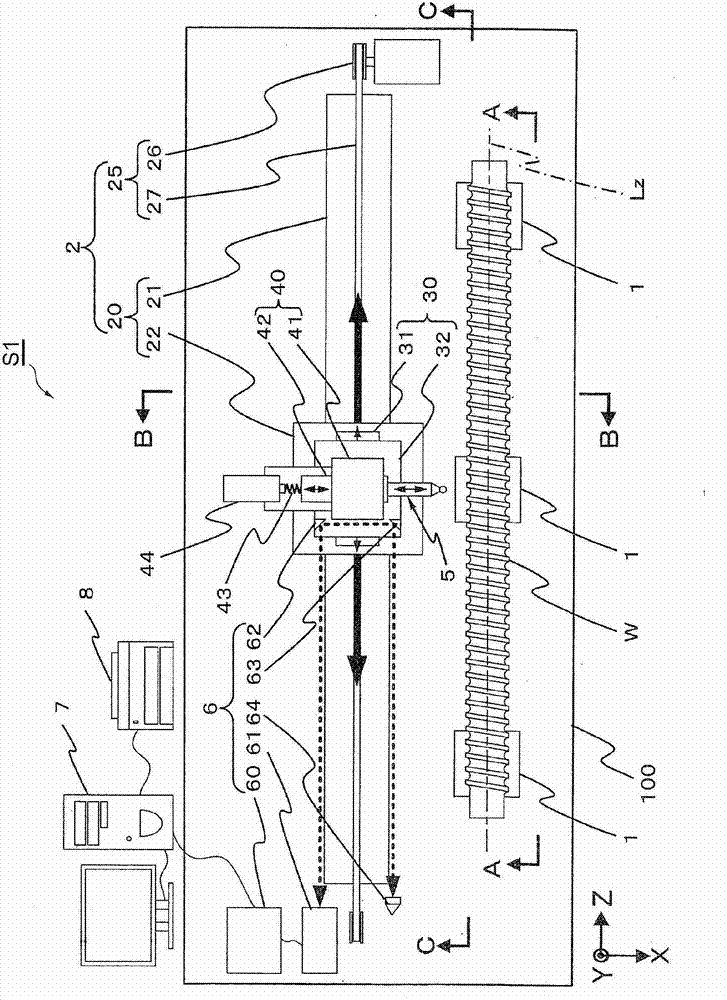

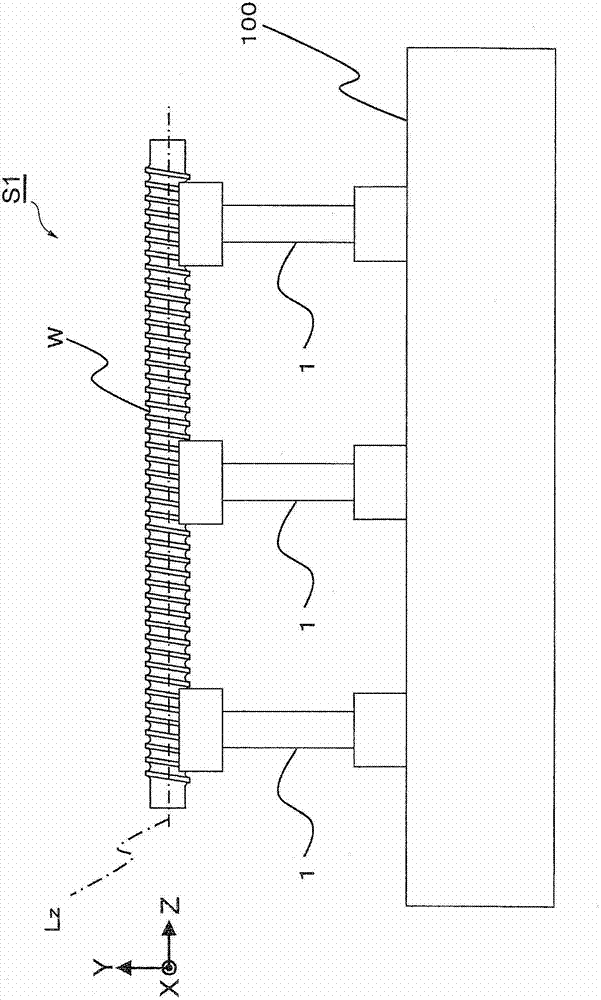

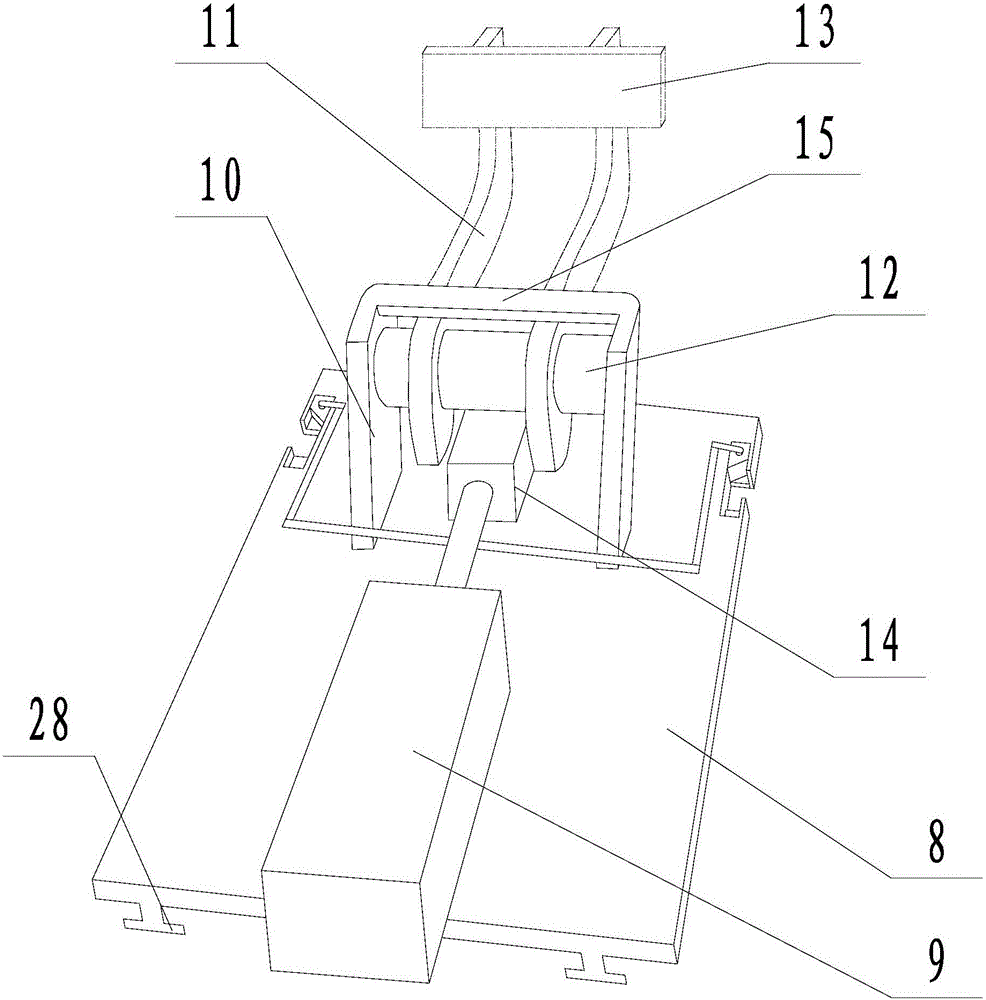

Device and method for determining accumulated lead errors of ball screw shaft

ActiveCN102809350AEasy accessHigh precisionMachine part testingMechanical counters/curvatures measurementsLocation detectionReciprocating motion

The invention relates to a device and a method for determining accumulated lead errors of a ball screw shaft. The device (S1) for determining accumulated lead errors of a ball screw shaft comprises a fixing supporting platform (1) by which the ball screw shaft (W) to be determined is fixed and cannot rotate, a ball contact (5) which abuts against a thread groove of the ball screw shaft to be determined, a ball contact sliding mechanism (4) which enables the ball contact to perform reciprocating motion along the direction orthogonal to a shaft center of the ball screw shaft to be determined and to abuts against the thread groove under the effect of a specified pressing force, a position detection sliding mechanism (3) which enables the ball contact sliding mechanism to perform reciprocating motion horizontally in parallelism with the shaft center, a positioning reciprocating sliding mechanism which enables the position detection sliding mechanism to perform reciprocating motion in the thread part of the ball screw shaft to be determined, and a lead position determining mechanism (6) which detects he position of the ball contact in the direction of the shaft center.

Owner:SINTOKOGIO LTD

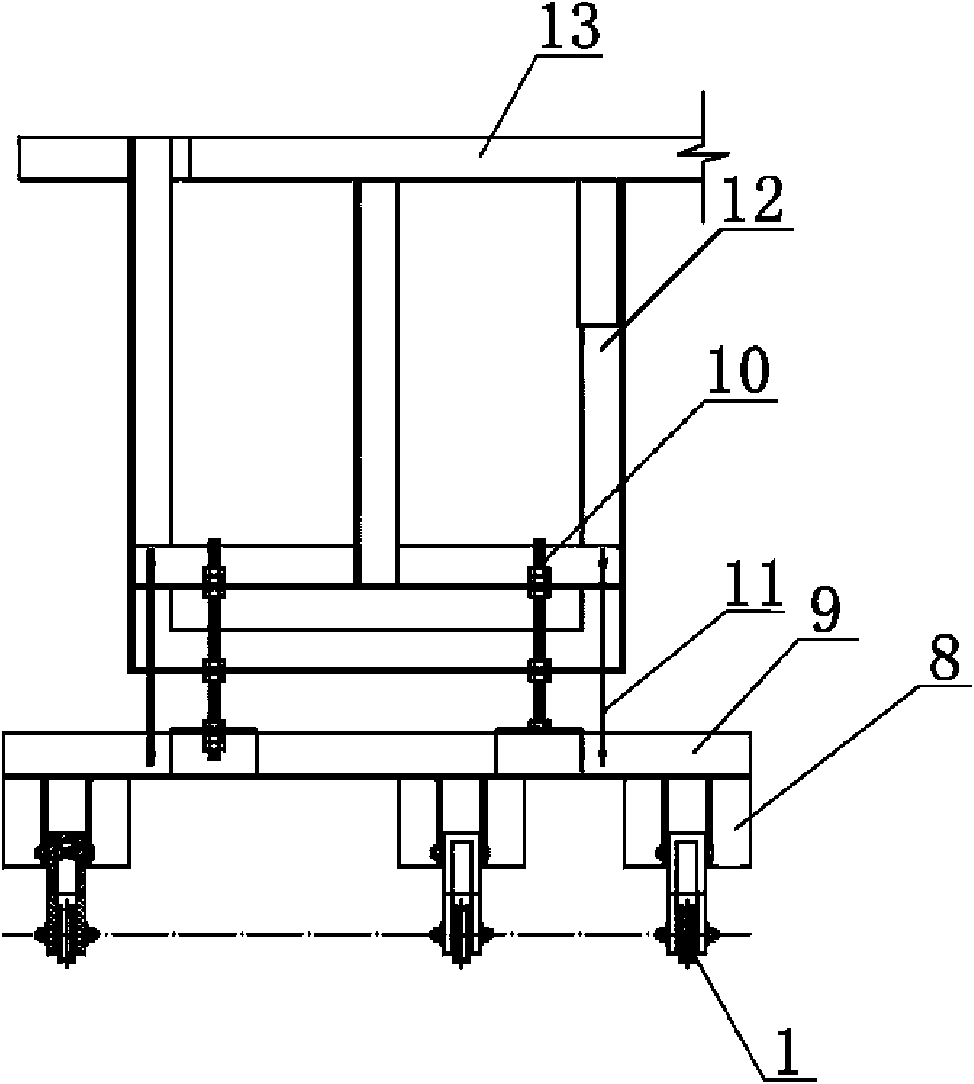

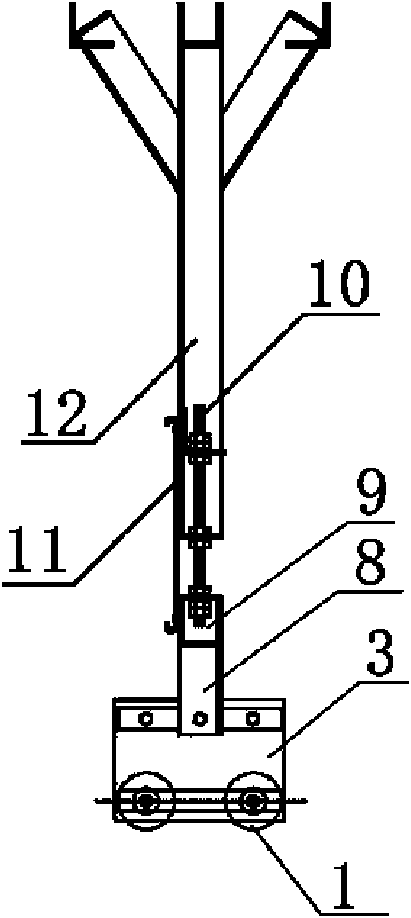

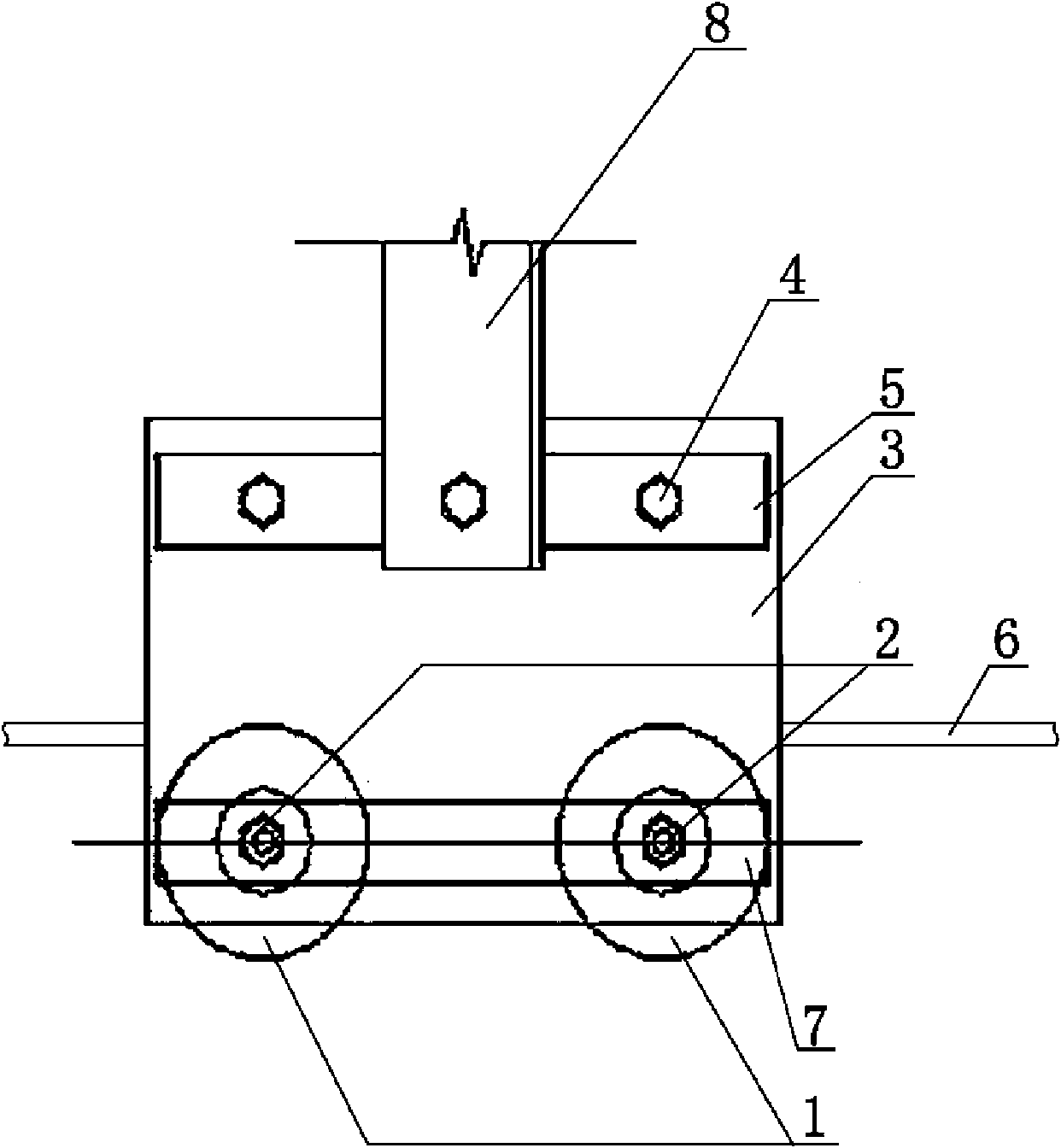

Gantry crane sliding contact line mobile power supply device

The invention relates to a 50T gantry crane sliding contact line mobile power supply device. A sliding contact line is suspended and fixed by sliding contact units and connected to a power supply line of a gantry crane, each sliding contact unit comprises three parts, namely, a contact sliding block, a connecting part and a suspension frame, two sliding contact rolling wheels with grooves at the wheel rims are arranged at the lower part of the contact sliding blocks, the sliding contact line is erected in the grooves of the two sliding contact rolling wheels, a wheel shaft of the two sliding contact rolling wheels is connected between glass steel insulating plates on the two sides, and the outer surfaces of the upper parts of the glass steel insulating plates are connected with an upper flat iron by bolts. A set of sliding contact power supply system consists of three contact sliding blocks which are transversely arranged and connected with the suspension frame by the connecting part, and the suspension frame is connected with a support on the gantry crane. The sliding contact line mobile power supply device can meet the power supply demand of the gantry crane during the operation, has the advantages of low cost, low failure rate, simple and convenient installation and operation and the like, and can be used in a beam yard gantry crane power supply system.

Owner:中国建筑土木建设有限公司

Process for lubricating a refrigerator containing sliding parts made of an engineering plastic material

InactiveUS20100252772A1Low viscosityImprove sealingChemical industryHeat-exchange elementsEtherEngineering plastic

Owner:IDEMITSU KOSAN CO LTD

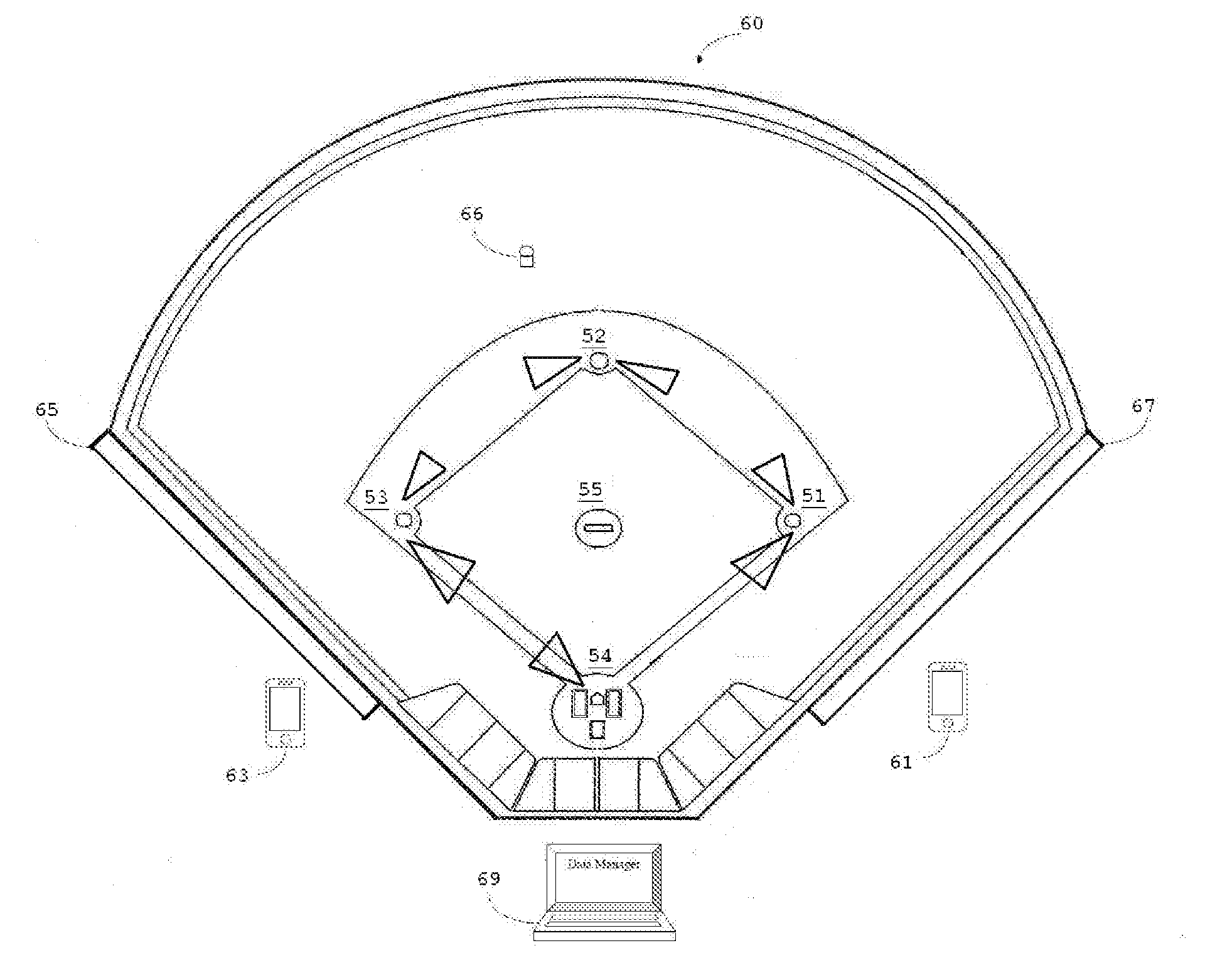

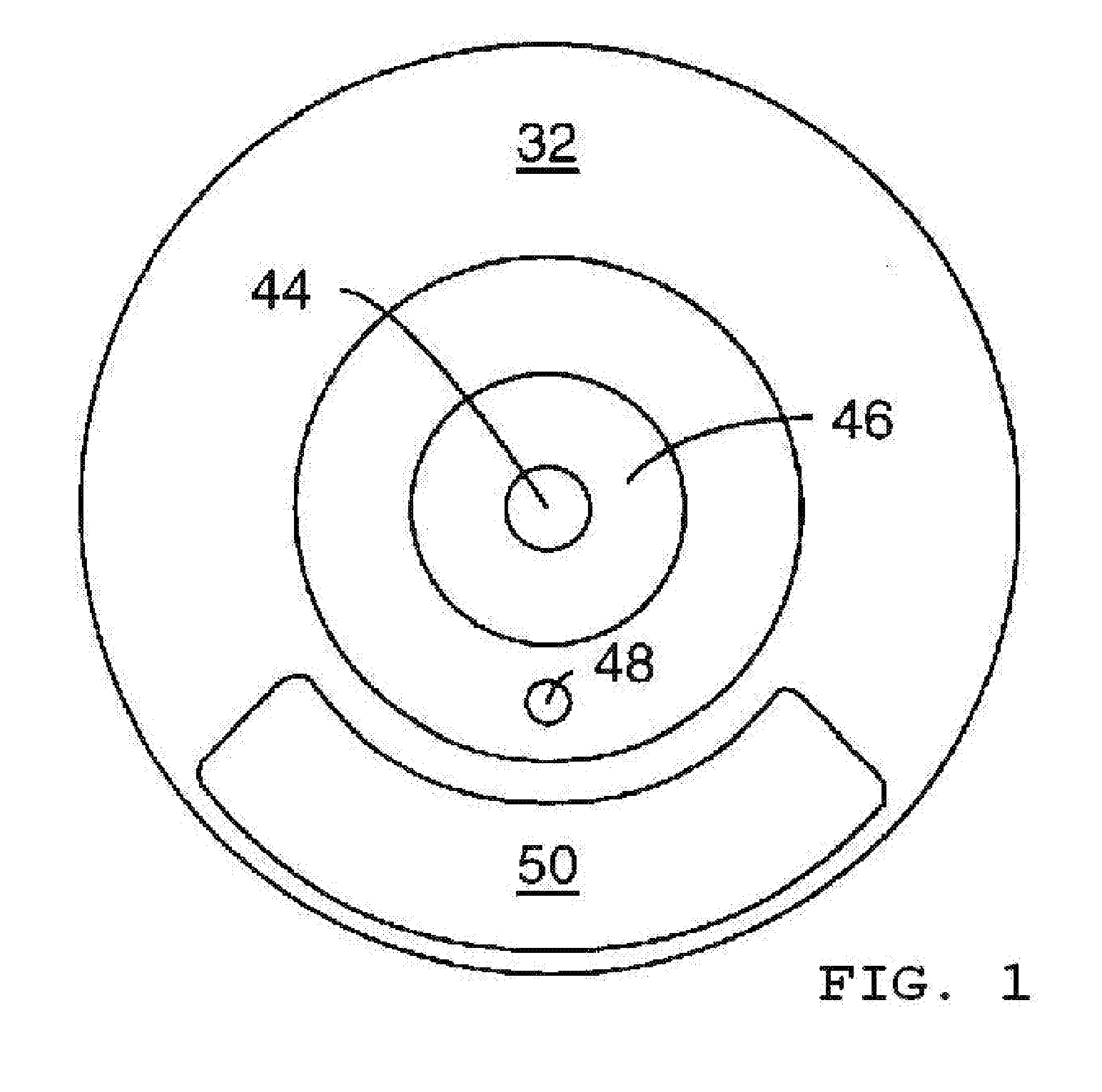

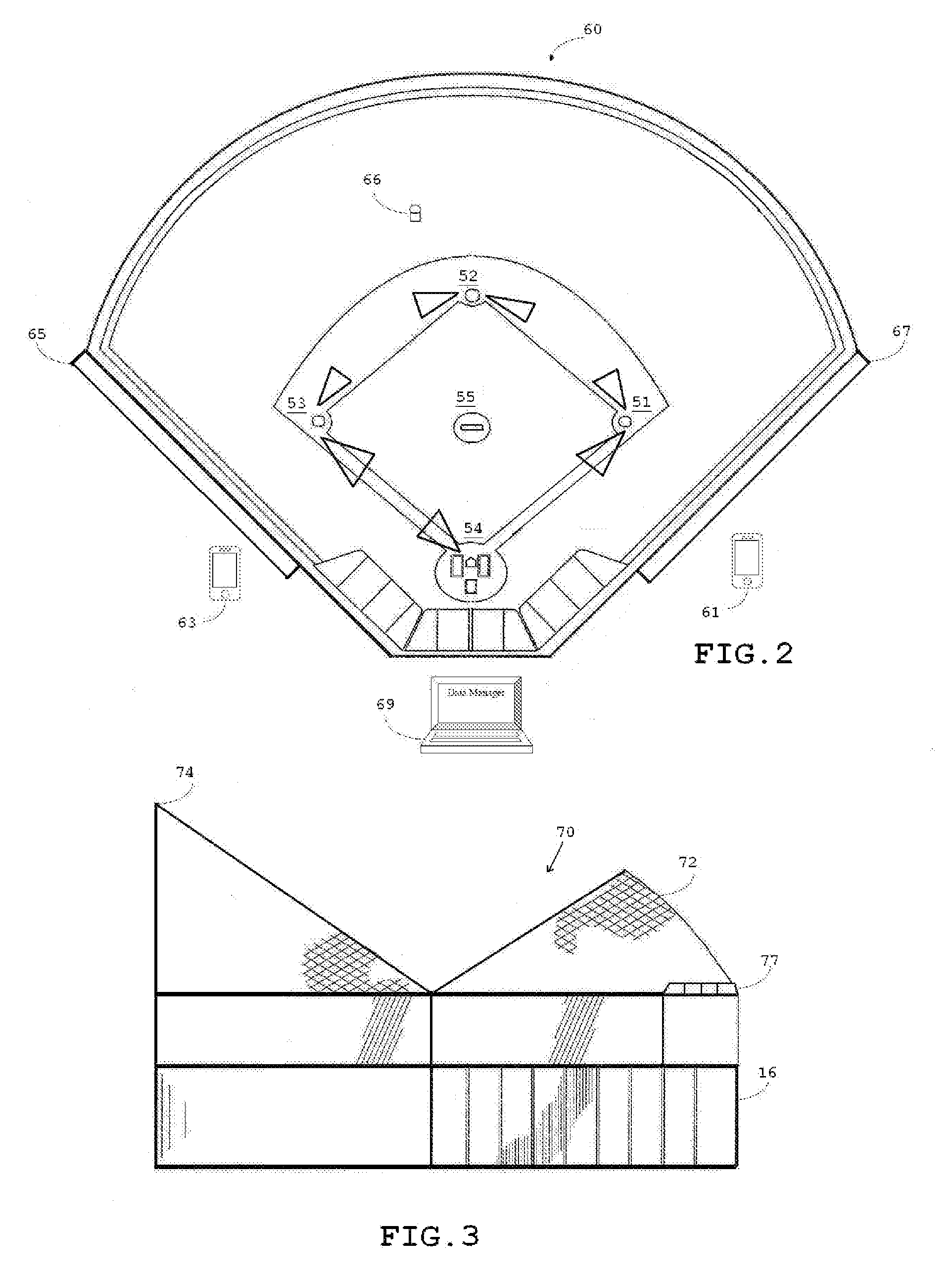

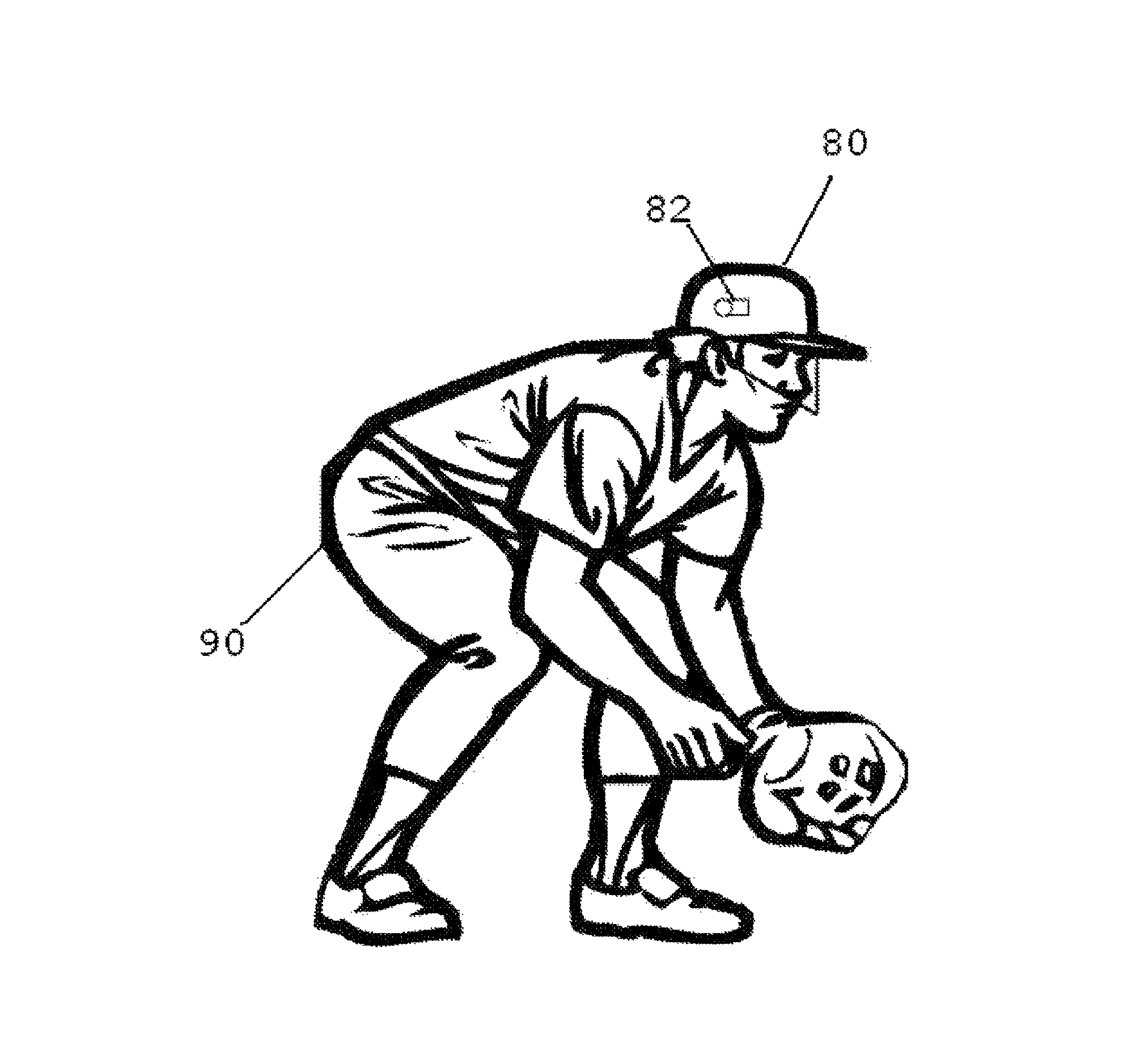

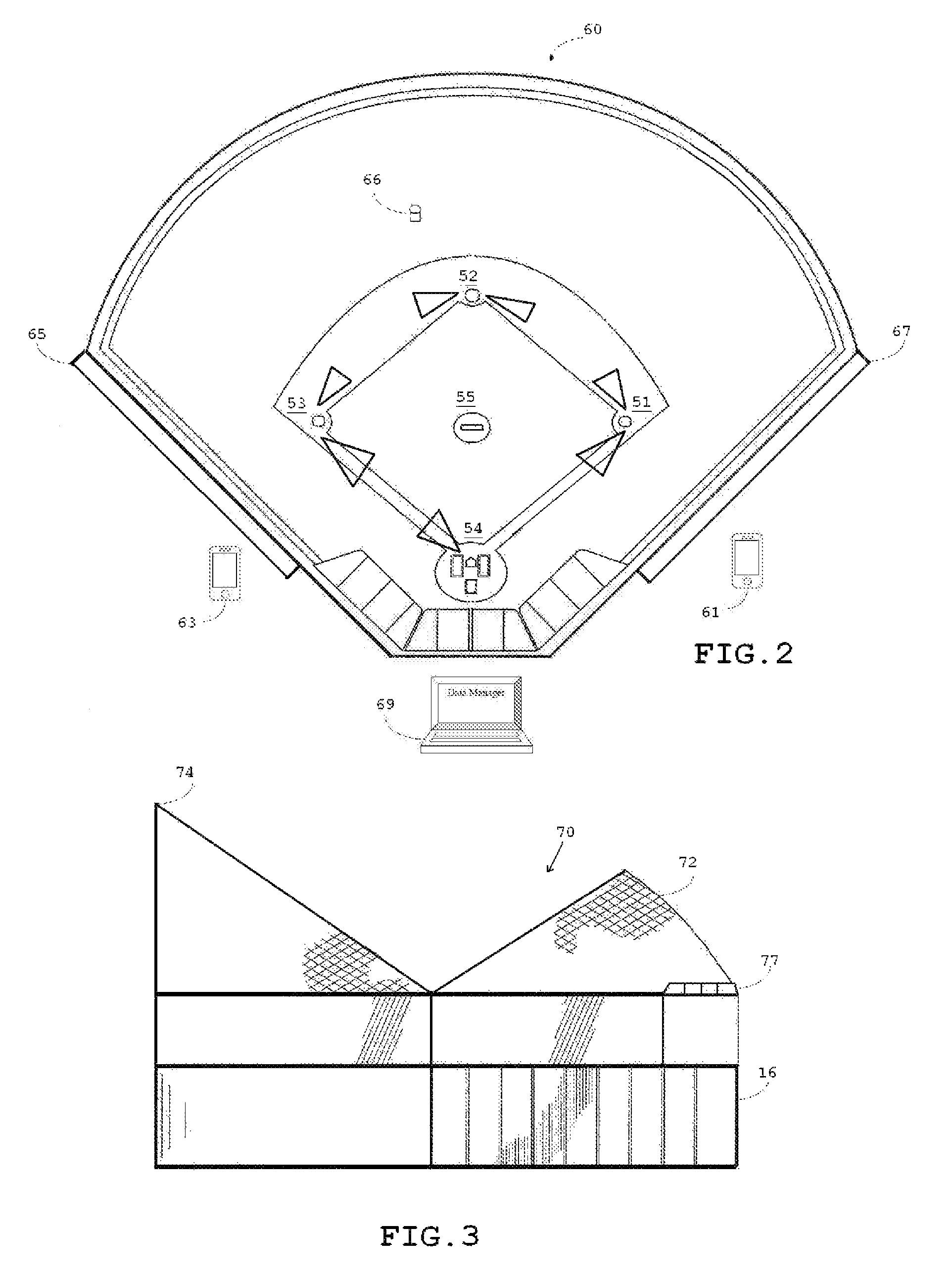

Arena baseball game system

Arena Baseball Game system method of play includes base excessive force, no collision contact slide zones and describes a protective helmet apparatus for use by baseball fielders. The protective sport television or radio audio device means of communication equipped with display, GPS, infrared scan and sensors to monitor performance and physiological parameters. In operation one or more infrared sensor sits against skin of a user to measure his or her heart rate. In response to oscillation translation and / or rotation of the electronic sport device, portions of forces induced by the mass are transferred to the piezoelectric elements. Electrical energy output by these piezoelectric elements is received in a power controller and can be applied to the battery as self charging.

Owner:JENNINGS JAMES EDWARD

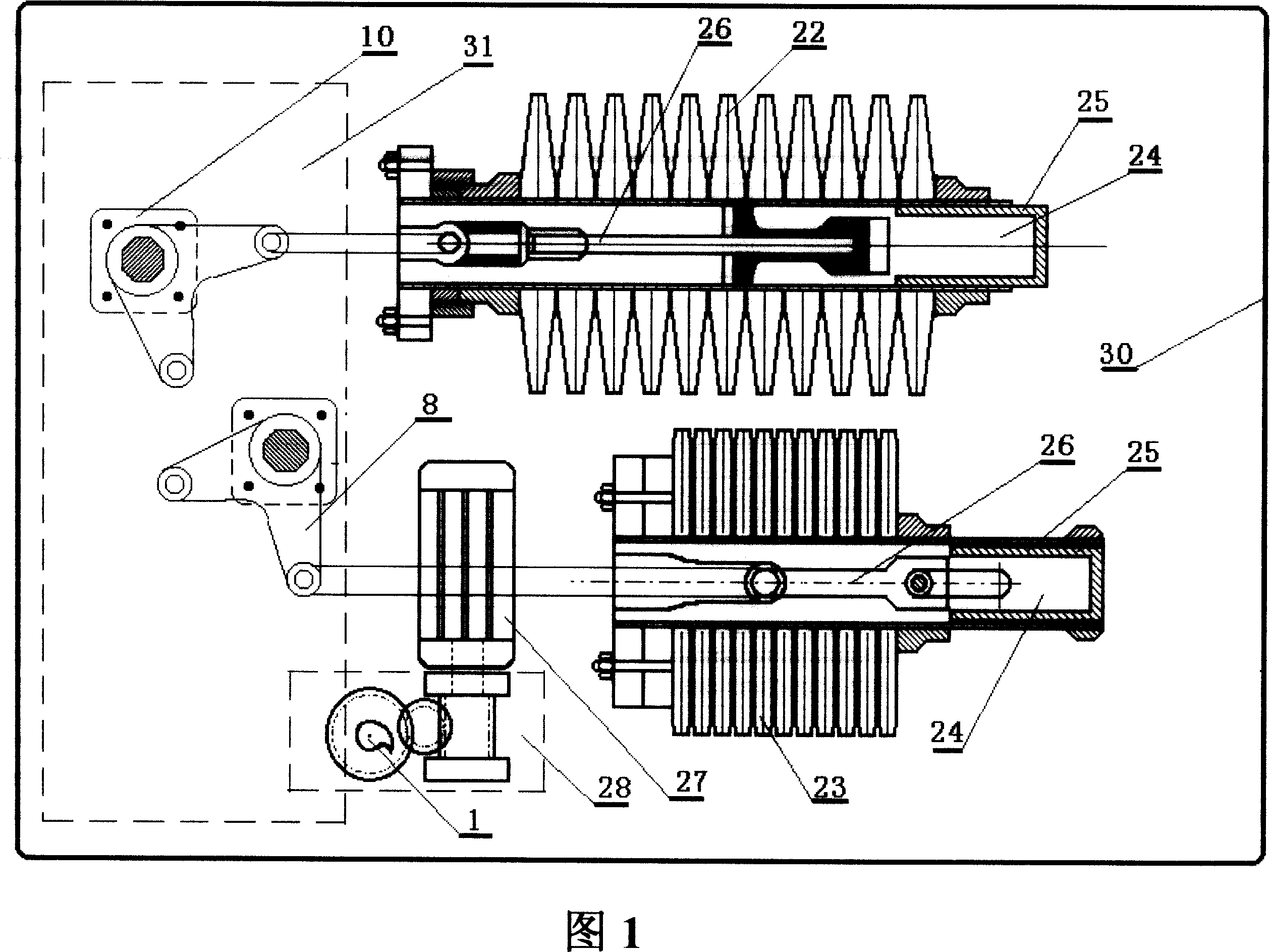

Face contact sliding four-pole drive disk spring energy storage operation machine

InactiveCN101086931AReduce wear and tearReduce impactSwitch power arrangementsHigh-tension/heavy-dress switchesDecreased energyHigh energy

The surface-contacted sliding four-bar linkage disc-reed storing energy operation mechanism includes motor, derailleur, drive gearing device, open, close disc-reed storing energy component, cam is mounted on output axes of motor and derailleur, and contacts with column-type idler wheel which is mounted on fan-shaped arm, the other end of the fan-shaped arm possesses drive claw, needle of claw is half-round, tooth of driver is also half-round, and joggled with each other to be surface contacting. The driver possesses column-type pin roll which is at middle groove-type gap of open and close gate connecting rod and close connecting board, sliding four-bar linkage on-off structure is composed, structure of the invention is novel, original and scientific, design is reasonable, the invention adopts surface-contacted arthrosis-type high load storing energy system and sliding four-bar linkage drive on-off structure technique and disc-reed with high energy density as storing energy component, it can obtain 9000 joule operation work, fits for 252KV to 363KV high voltage breaker. It adopts gate with pin axes to decrease energy loss and wallop.

Owner:杨士玉

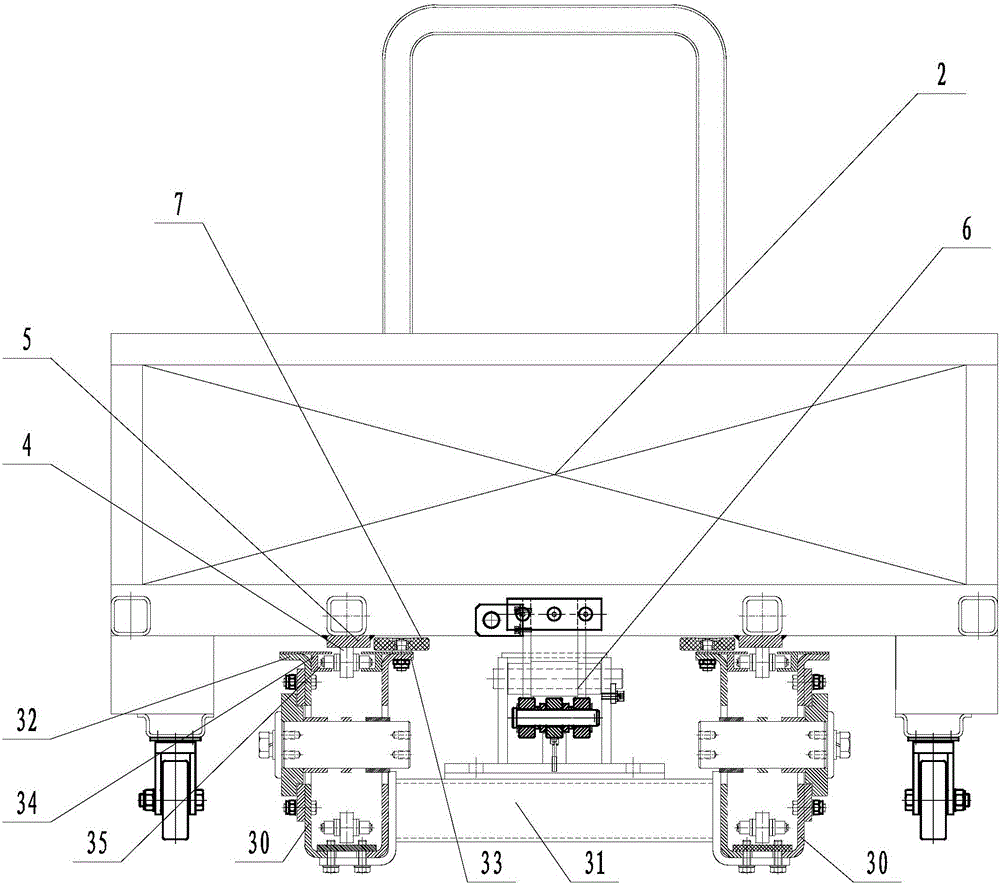

Material conveyor line

ActiveCN105858099AImprove buffering effectGuaranteed uptimeMechanical conveyorsFailure rateContact slide

The invention discloses a material conveyor line. The material conveyor line aims at overcoming the defects that conveying trolleys on a material conveyor line cannot be stacked and cannot be conveyed freely, the conveyor line needs to be stopped if one station fails, the whole line is affected, normal operation of other stations is affected, the great line stop loss is caused, and the collision failure rate is high in the trolley conveying process. The material conveyor line comprises a sliding track and multiple sliding trolleys. Conveying chains are mounted on the two sides of the sliding track. Multiple rollers are arranged on each conveying chain at equal intervals. Multiple assembly stations are arranged on the sliding track. Two contact sliding strips corresponding to the two conveying chains are arranged on the lower surface of each sliding trolley. Every two contact sliding strips are supported on the corresponding rollers of the two conveying chains. A stopper used for braking the sliding trolleys is mounted on each assembly station on the sliding track. A rotatable limiting guide wheel is mounted on the inner side of each contact sliding strip on the sliding track, the axis of each limiting guide wheel is vertically arranged, and the upper surfaces of the limiting guide wheels are arranged above the lower surfaces of the contact sliding strips.

Owner:NINGBO YUANJING AUTO PARTS +1

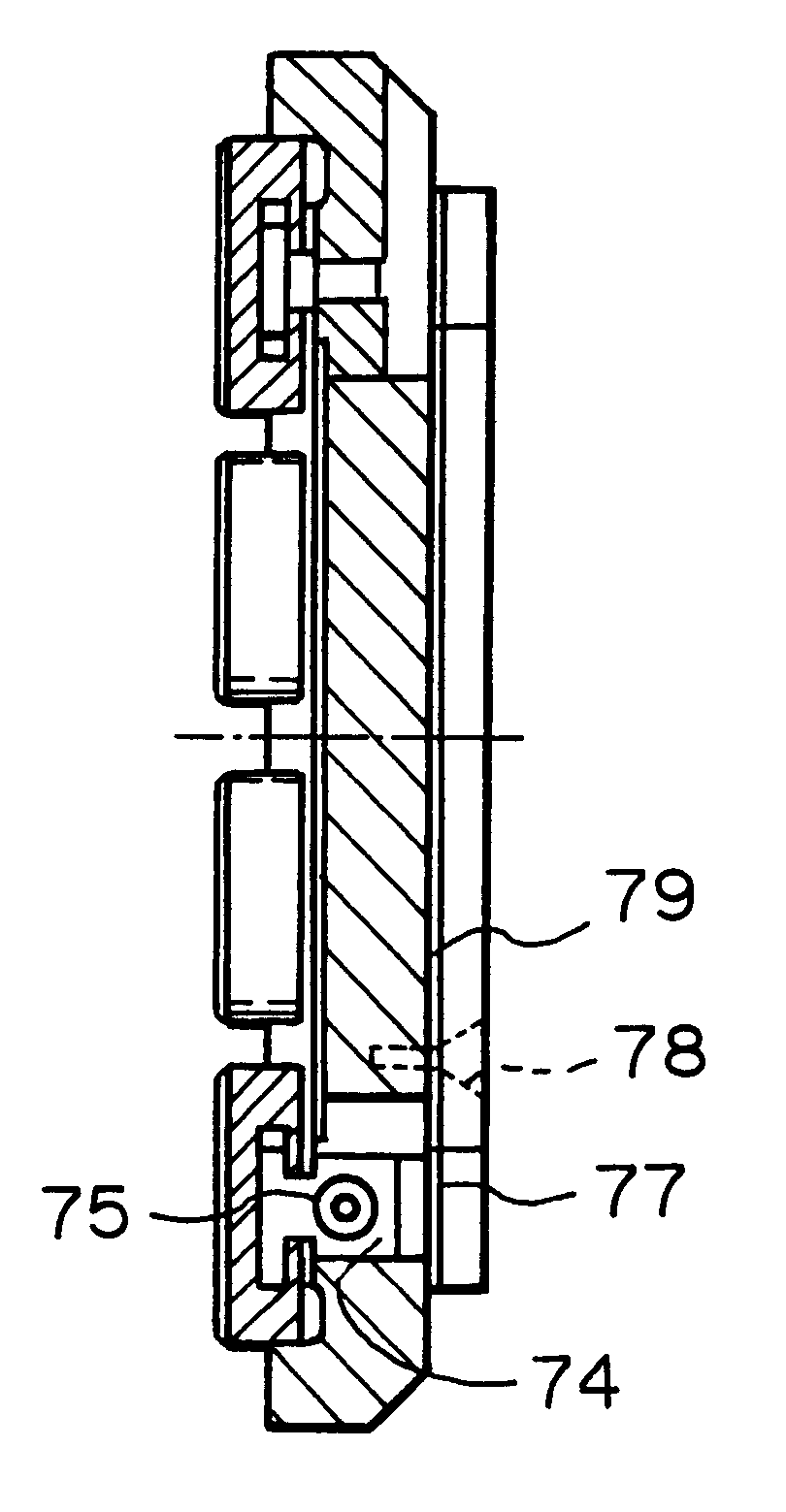

Circuit breaker

InactiveUS7777601B2Improve current carrying capacityProtective switch detailsContact surface shape/structureEngineeringContact resistance

A movable contacting device in a circuit breaker comprises: a crossbar linked with the opening / closing mechanism and carried so as to pivot cooperatively with the opening / closing mechanism; a movable contact arm engaged, so as to cooperational with the crossbar, with a shaft fitted into a mutually opposing recesses in the crossbar; and a movable contact arm support fixed to the case accomodating the opening / closing mechanism and having mutually opposing through-holes through which the shaft is passed; and the movable contact being configured so that the movable contact slides between surfaces of movable contact arm support having the mutually opposing through-holes; and the construction of a single-pole portion of the movable contact arm is constituted by arranging in parallel two movable contact arm members each having a movable contact at one end, and in a shaft-supporting portion at the other end, an elastic member is sandwiched between the two movable contact arm members. With this arrangement, circuit breakers provided with a movable contacting device that is small in size and stable in contact resistance can be made available.

Owner:MITSUBISHI ELECTRIC CORP

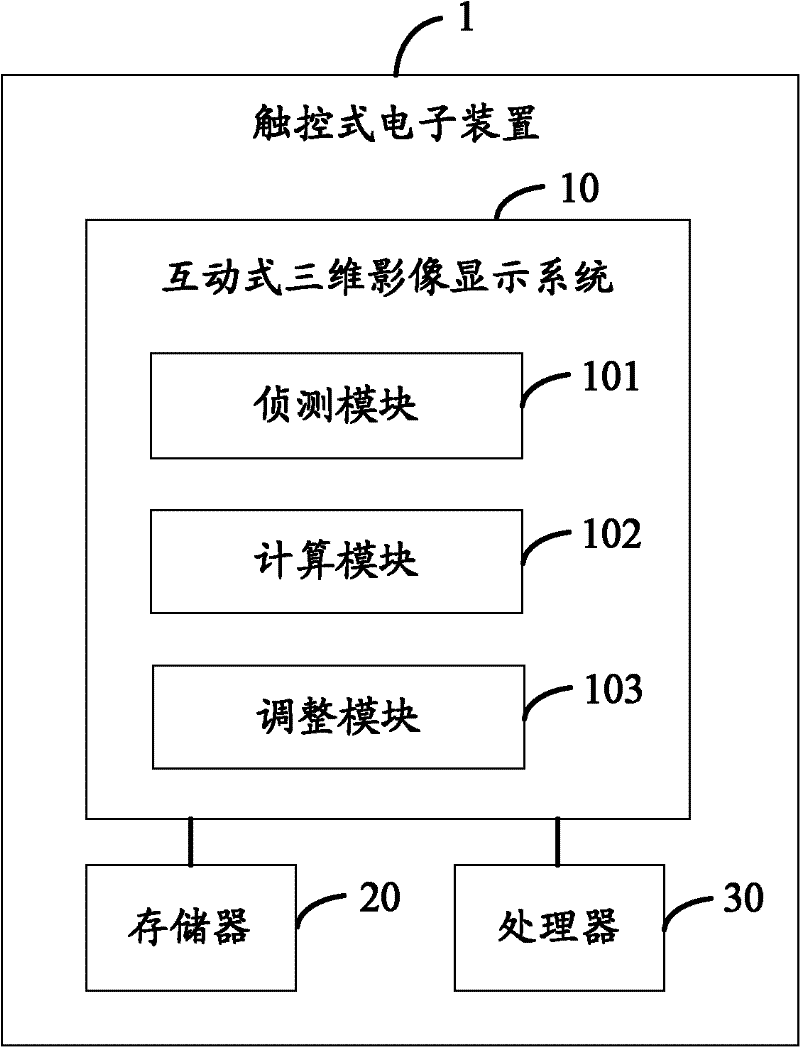

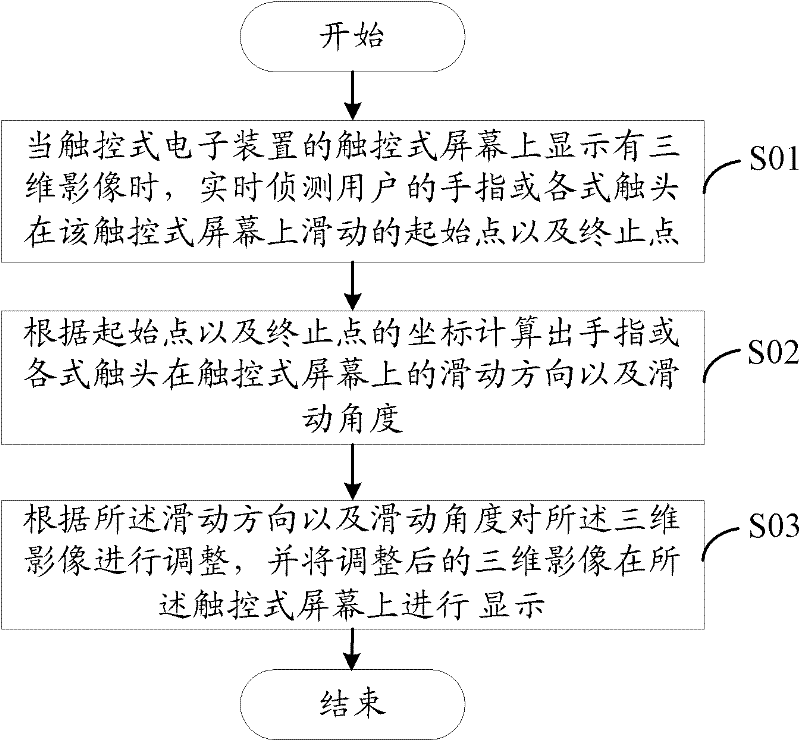

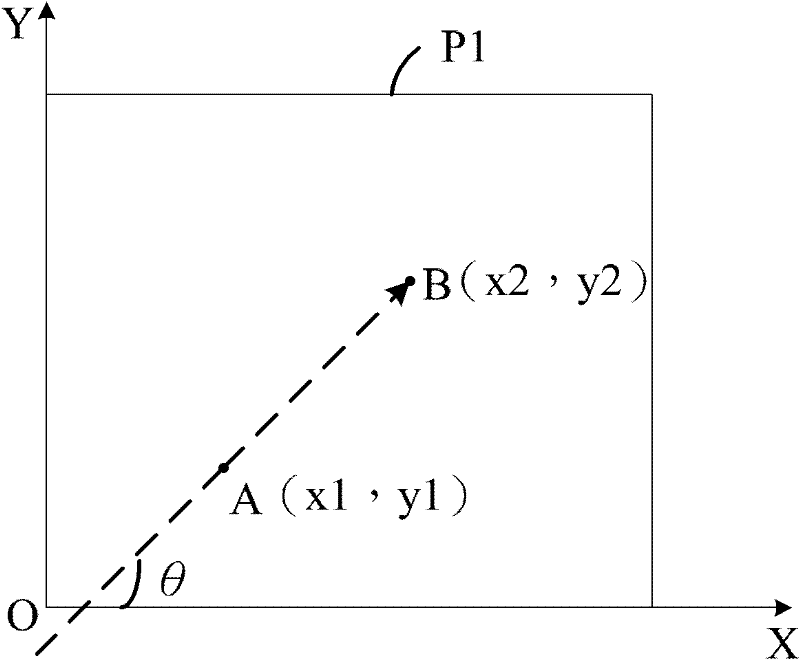

Interactive three-dimensional image display system and method

InactiveCN102236441AImprove visual experienceInput/output processes for data processingComputer moduleHuman–computer interaction

The invention discloses an interactive three-dimensional image display system, which is operated in a touch type electronic device. The system comprises a detection module, a calculating module and an adjusting module, wherein the detection module is used for detecting a starting point and a stop point of a finger of a user or each of various contacts sliding on a touch type screen in real time when a three-dimensional image is displayed on the touch type screen of the touch type electronic device; the calculating module is used for calculating sliding direction and sliding angle of the finger or each of the various contacts on the touch type screen according to coordinate values of the detected starting point and stop point on the touch type screen; and the adjusting module is used for adjusting the three-dimensional image according to the sliding direction and the sliding angle and displaying the adjusted three-dimensional image on the touch type screen. The invention also provides an interactive three-dimensional image display method. According to the system and the method, visual experience of the user is enhanced.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Arena baseball game system

Arena Baseball Game system method of play includes base excessive force, no collision contact slide zones and describes a protective helmet apparatus for use by baseball fielders. The protective sport television or radio audio device means of communication equipped with display, GPS, infrared scan and sensors to monitor performance and physiological parameters. In operation one or more infrared sensor sits against skin of a user to measure his or her heart rate. In response to oscillation translation and / or rotation of the electronic sport device, portions of forces induced by the mass are transferred to the piezoelectric elements. Electrical energy output by these piezoelectric elements is received in a power controller and can be applied to the battery as self charging.

Owner:JENNINGS JAMES EDWARD

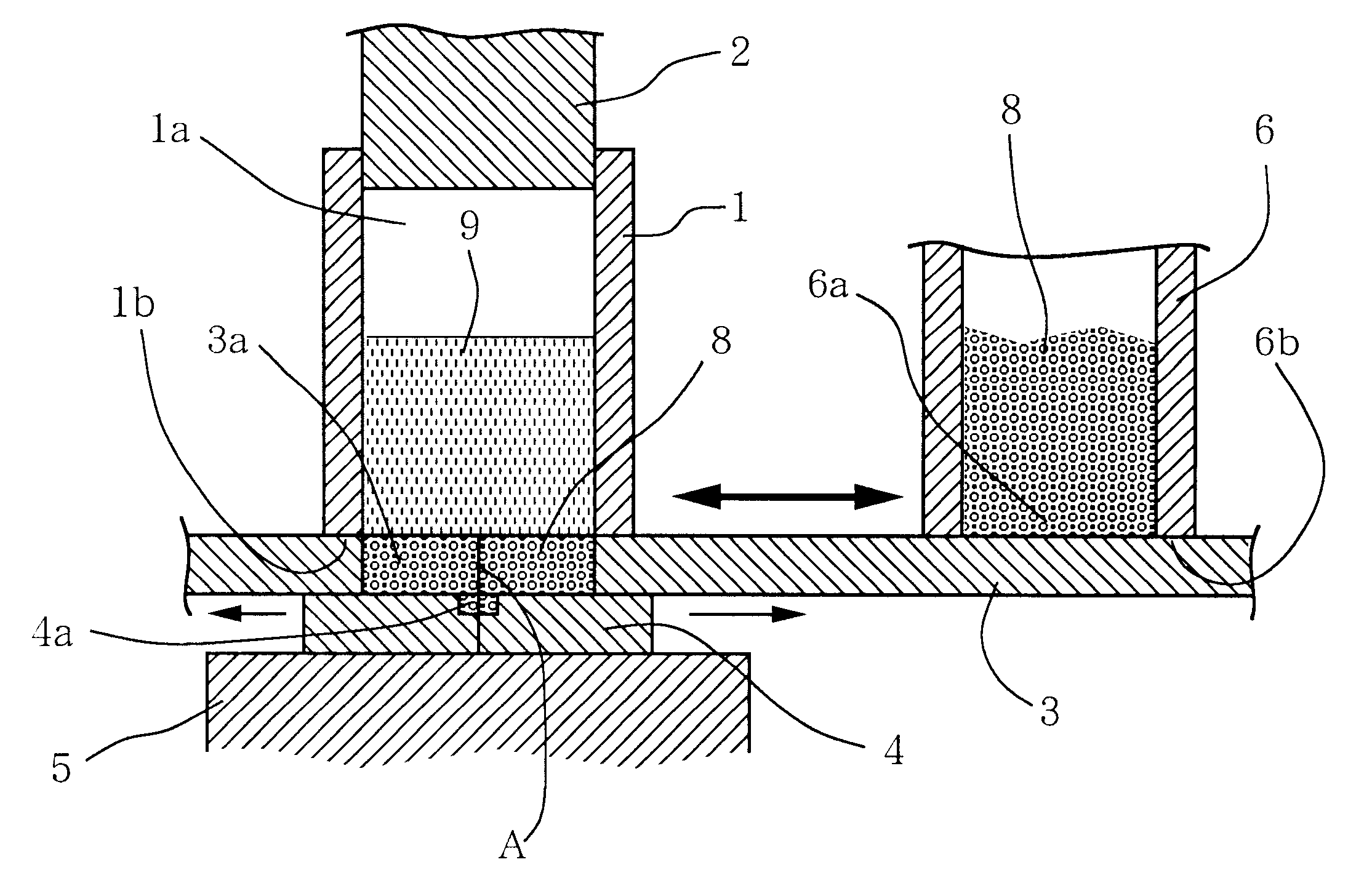

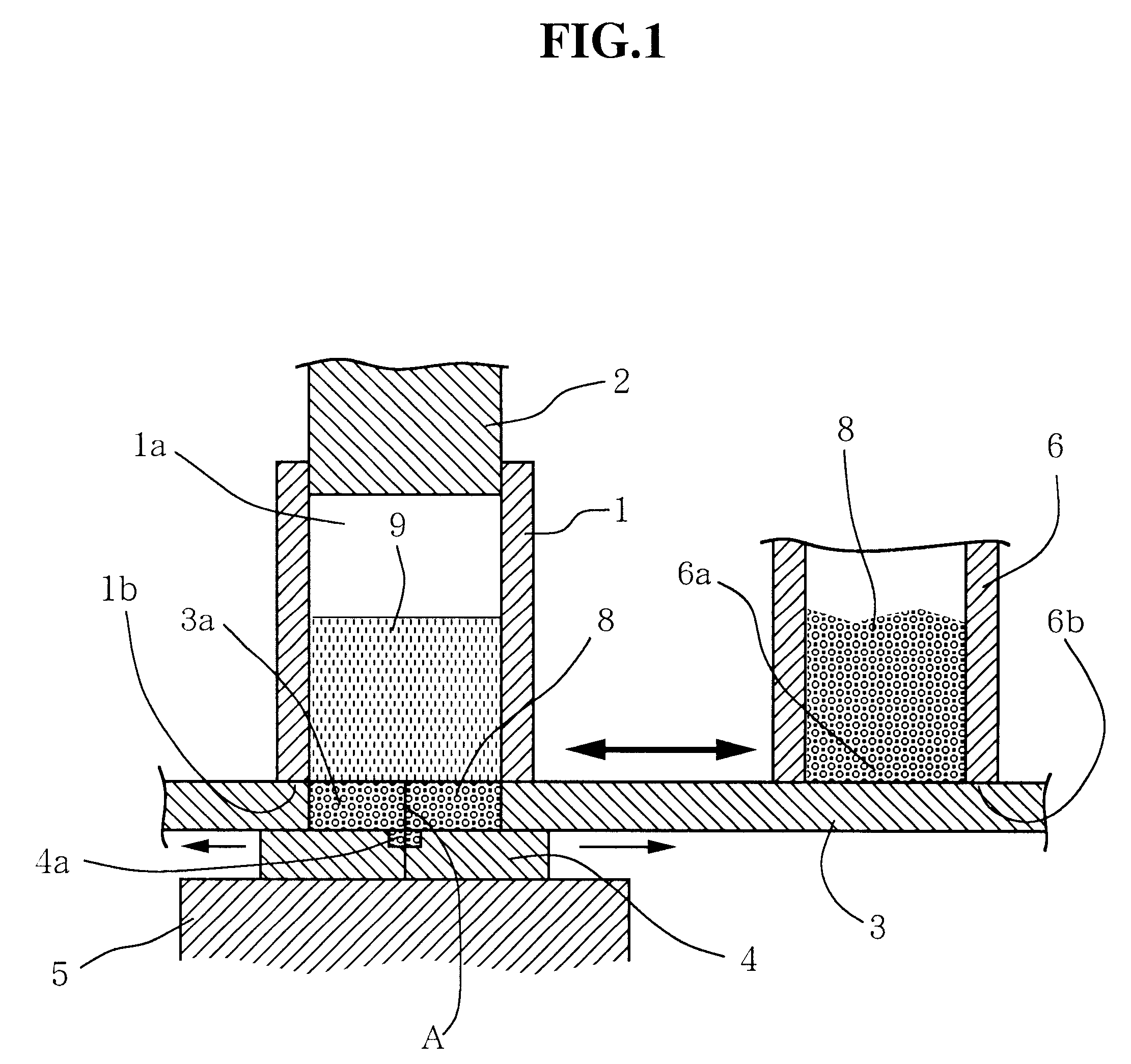

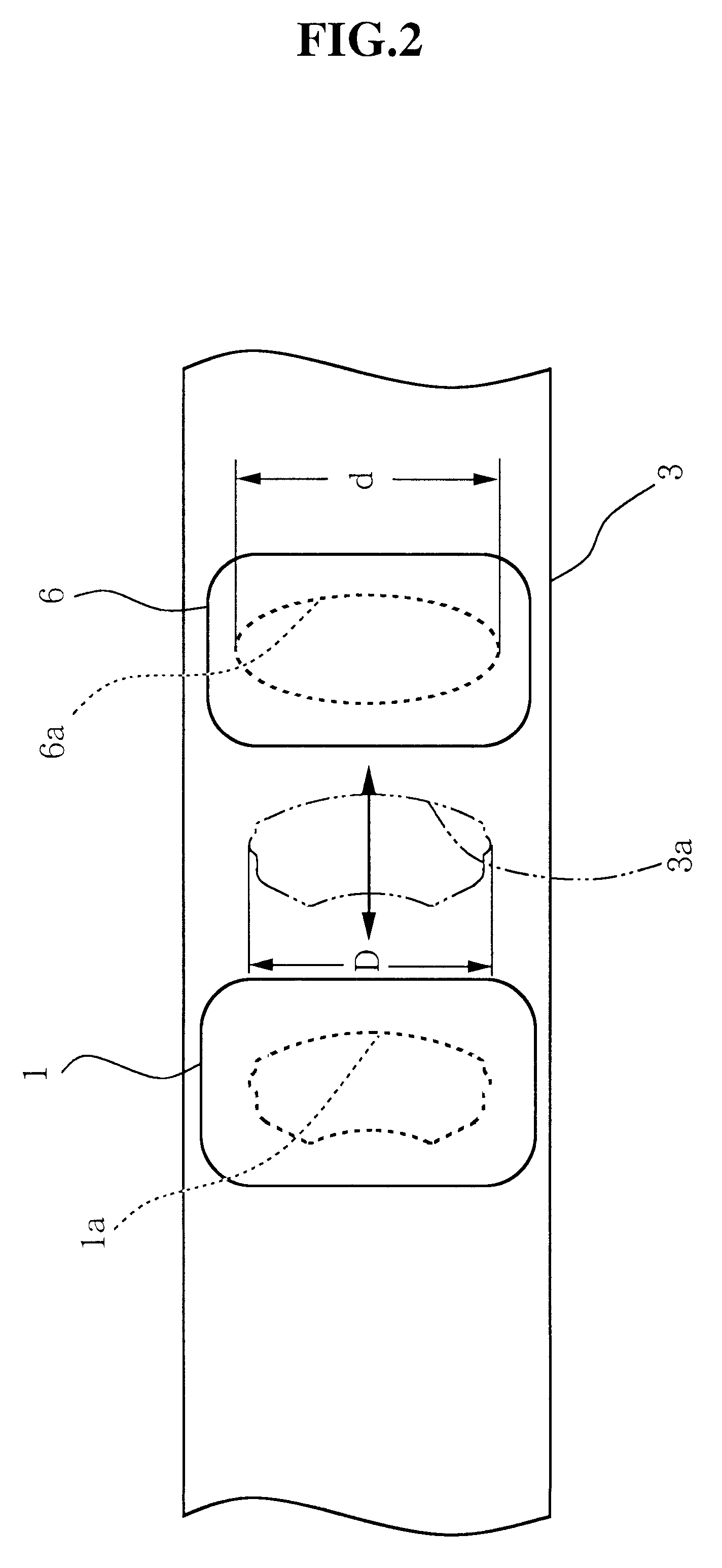

Friction component manufacturing apparatus and method

To provide a friction component of a multilayer structure in which each layer can be formed so as to have a specified thickness, as well as its manufacturing apparatus and method.A side plate 3 having a void 3a of a specified depth formed therein is provided between a plunger 2 and a fixed mold 5 so as to move in the horizontal direction. A hopper 6 for adhesive-layer materials is provided near a molding box 1. An output port 6a in the hopper is located so as to contact slide plate 3. When the side plate 3 is moved in the lateral direction in the figure so that the void 3a is located under the hopper 6, the lower end surface 6b of the hopper acts as a leveling plate to feed an adhesive-layer material 8 into the void. The adhesive-layer material is moved to the lower part of the molding box 1, a specified amount of friction material 9 is fed in such a way that its thickness becomes uniform, and the plunger is then used to pressurize and mold the materials. By placing a plurality of slide plates one on another, a multilayer structure having three or more layers can be obtained.

Owner:NISSHINBO IND INC

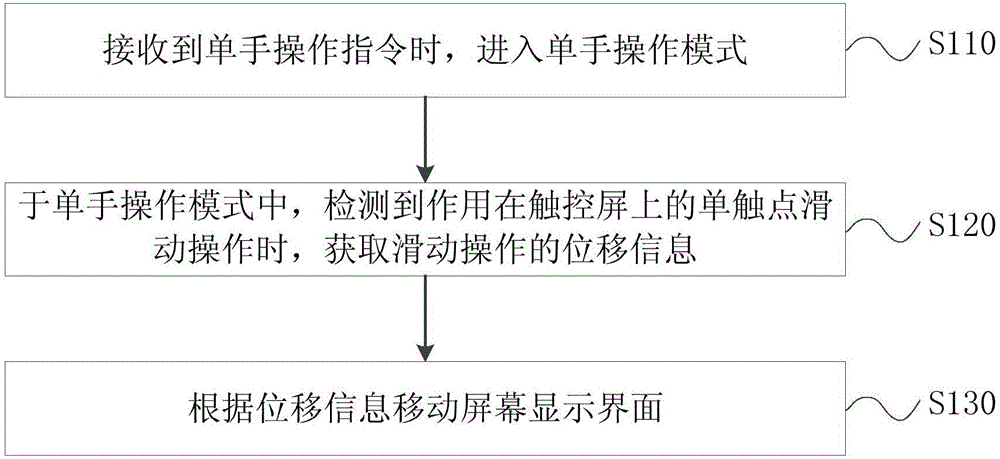

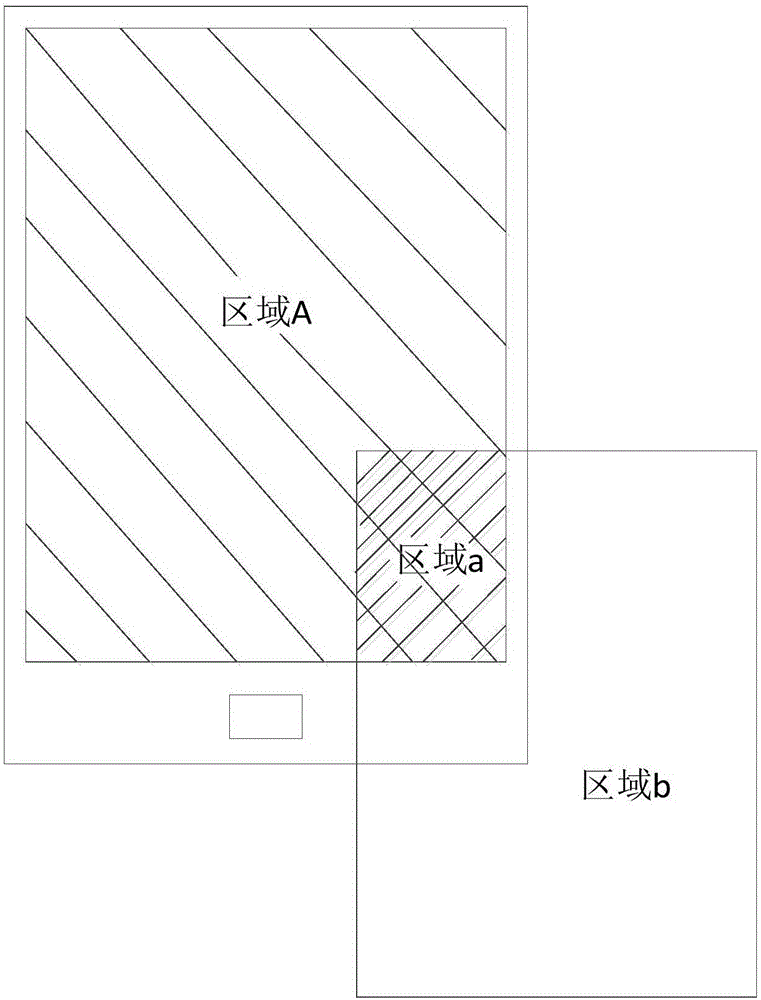

Screen interface display method and device

InactiveCN106527860AImprove experienceInput/output processes for data processingHuman–computer interactionOn-screen display

The embodiment of the invention discloses a screen interface display method and device. The screen interface display method comprises entering a single-hand operation mode when a single-hand operation instruction is received; in the single-hand operation mode, obtaining displacement information of a slide operation when a single-contact slide operation acted on a touch screen is detected; and moving a screen display interface according to the displacement information. According to the embodiment of the method and the device, the problem that a user is poor in visual experience is solved, and a purpose of improving the user experience of the user in the single-hand operation mode is realized.

Owner:SHANGHAI YUDE INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com