Combined numerical control milling machine

A technology of CNC milling machine and machine tool, applied in the field of machining, can solve the problem of low machining efficiency of machine tool, and achieve the effects of improving efficiency, reducing cutting heat, and reducing machine tool vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better illustrate the purpose and advantages of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

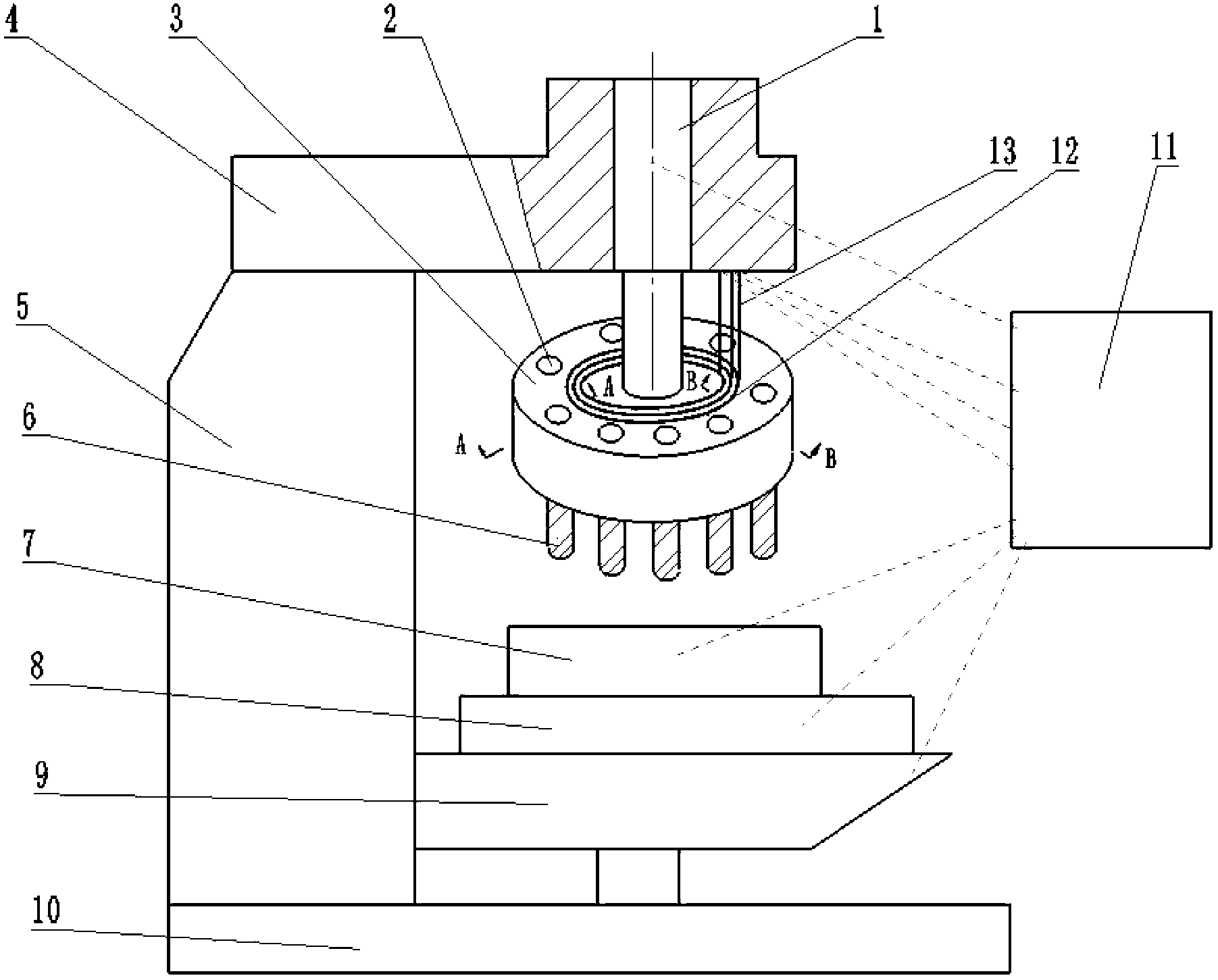

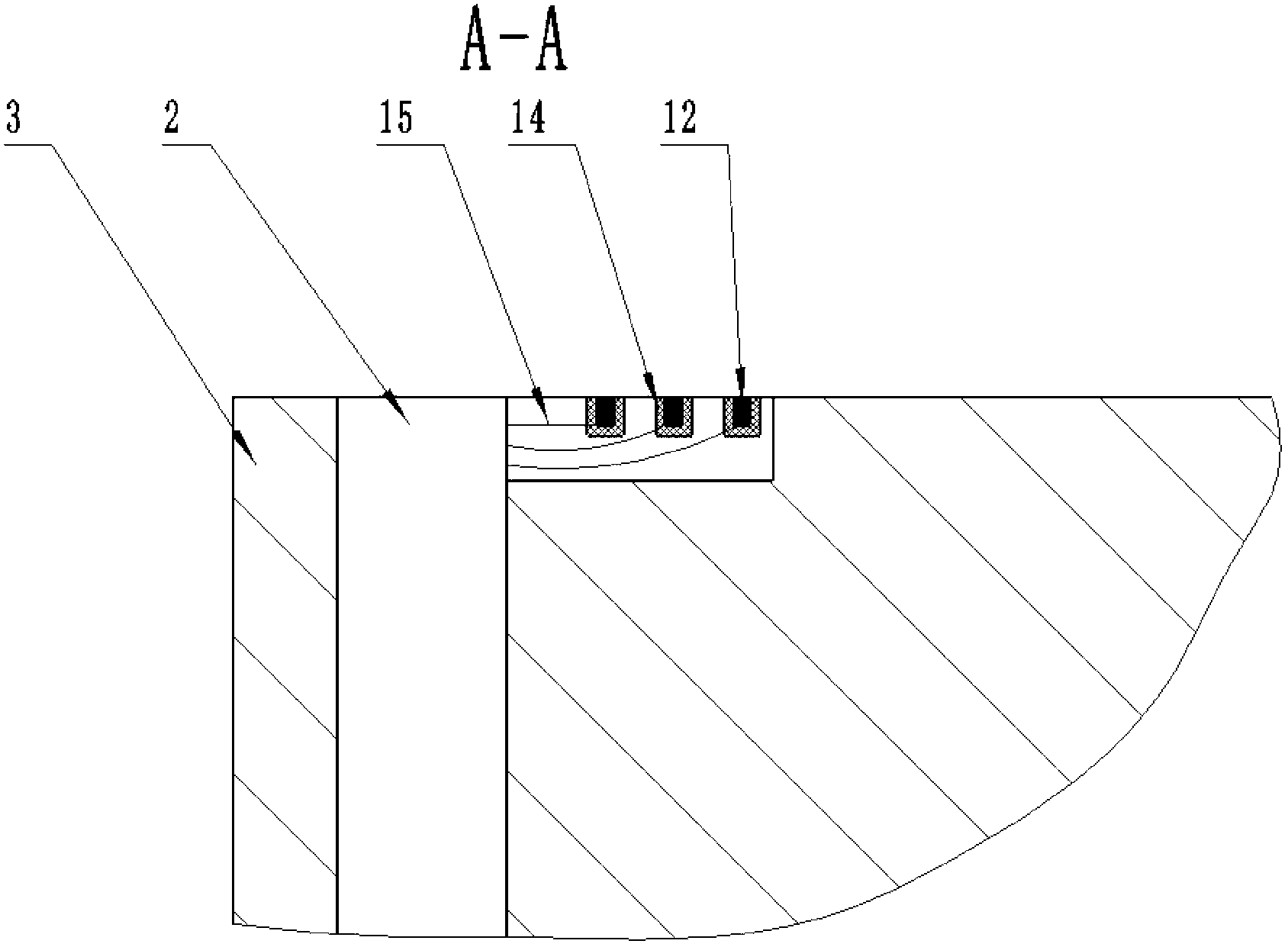

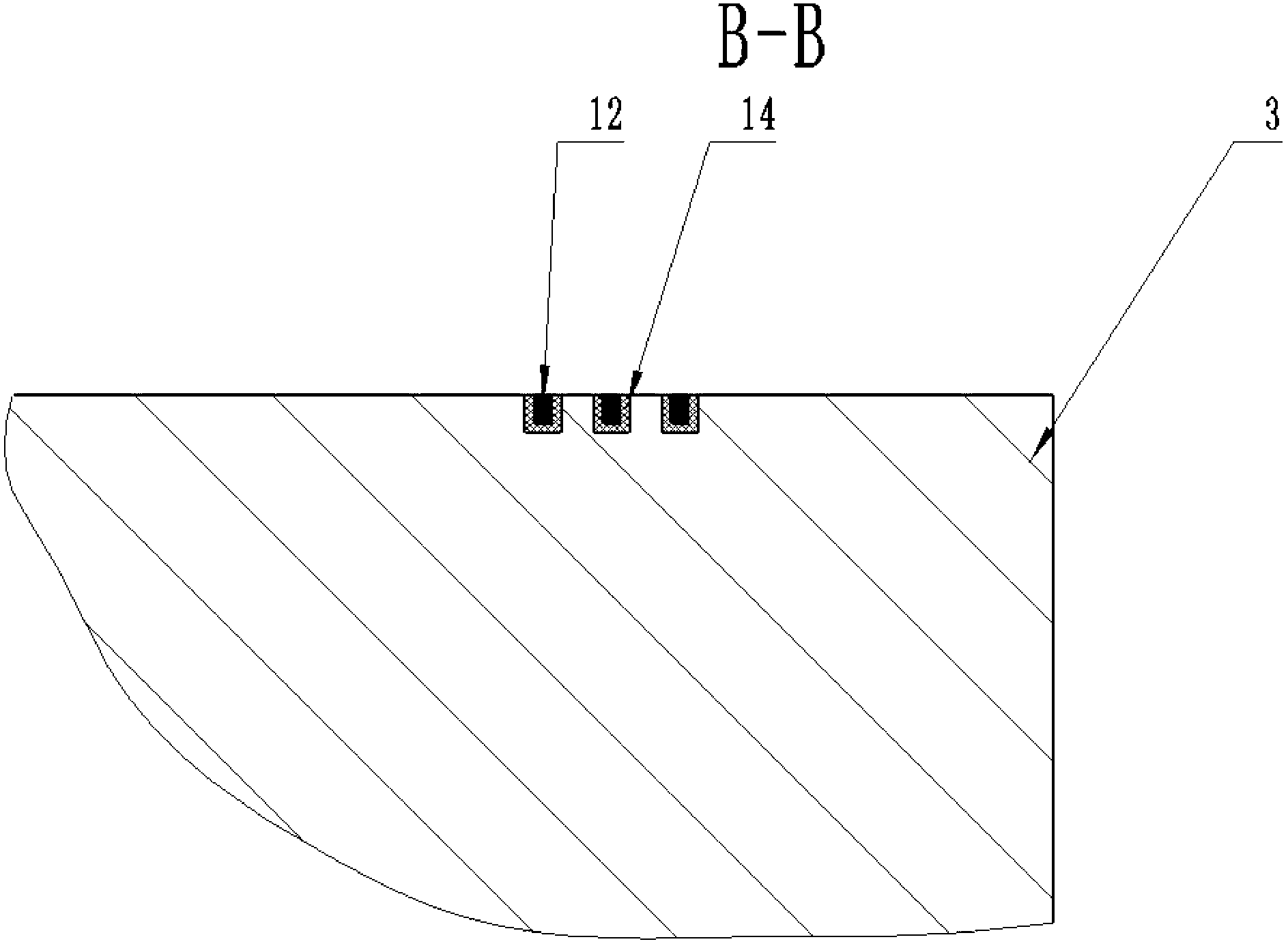

[0019] A compound CNC milling machine such as figure 1 , figure 2 and image 3 As shown, it includes machine tool electric spindle 1, end mill electric spindle 2, milling cutter head 3, ram type beam 4, bed 5, spiral edge end mill 6, transverse feed table 7, and longitudinal feed table 8. Lifting platform 9, base 10, control system 11, moving contact slip ring 12, moving contact 13, insulating ring 14 and wire 15.

[0020] The control system such as Figure 4 As shown, it includes command analysis module, machine tool electric spindle control module, end mill electric spindle control module, trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com