Face contact sliding four-pole drive disk spring energy storage operation machine

An operating mechanism and four-link technology, applied to the power device inside the switch, high-voltage air circuit breaker, electrical components, etc., can solve the problems of only 3.8 kJ, cannot be used, cannot be operated alone, etc., to achieve Sensitive and reliable opening and closing operation, convenient debugging, avoiding the effect of distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

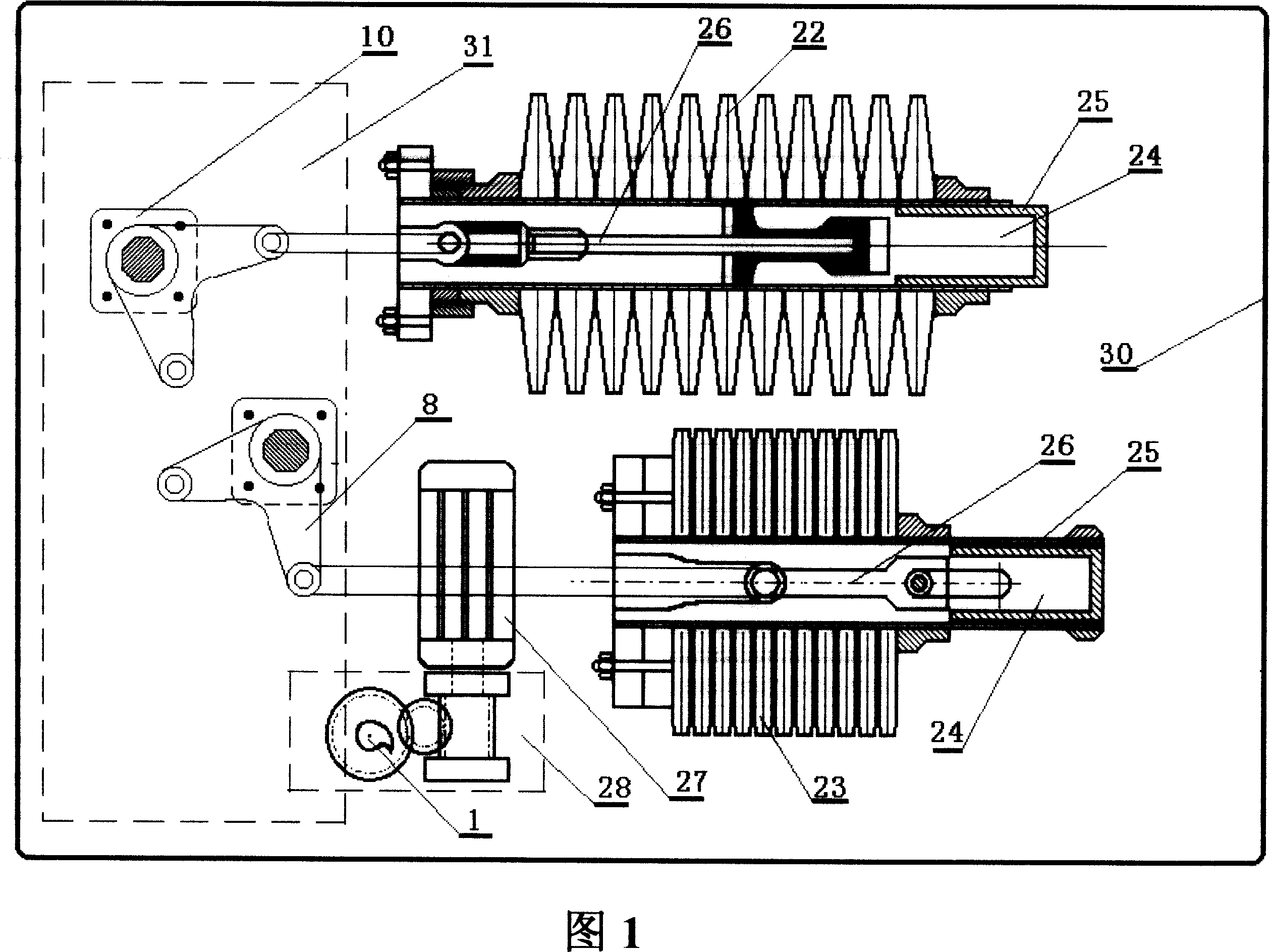

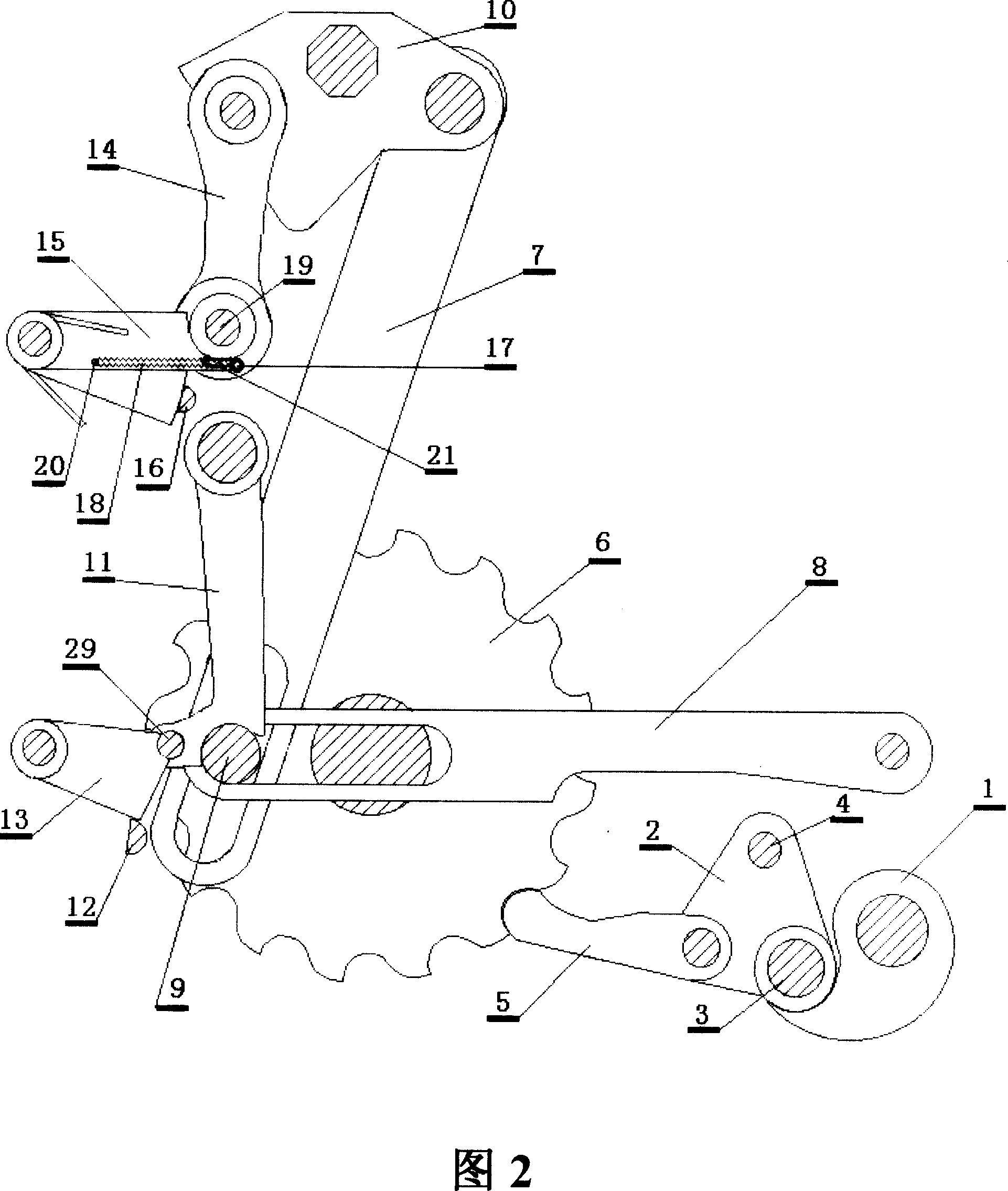

[0024] As shown in Figure 1-2, the disc spring energy storage operating mechanism of the surface-contact sliding four-bar linkage transmission includes a chassis 30 and a motor 27 installed inside, a transmission 28, a power transmission device 31, closing parts, and opening parts. Components, opening and closing disc spring energy storage parts, closing and opening buffers, the cam 1 is installed on the output shaft of the motor 27 and the transmission 28, and the cam 1 is in contact with the cylindrical roller 3 installed at one end of the sector crank arm 2 , the fan-shaped crank arm 2 is positioned by the pin shaft 4, and the other end of the fan-shaped crank arm 2 is equipped with a driving claw 5. The claw tip of the driving claw 5 is made into a semicircular arc shape, and the gear teeth of the driving wheel 6 are also made into a semicircular arc shape, which is just in line with the driving claw 5. The claw tips are engaged, and the driving wheel 6 is equipped with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com