Device and method for determining accumulated lead errors of ball screw shaft

A ball screw shaft and error measurement technology, applied in the direction of measuring devices, mechanical measuring devices, transmission devices, etc., can solve the problems of large reproducibility deviation, difficult precision measurement, and measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

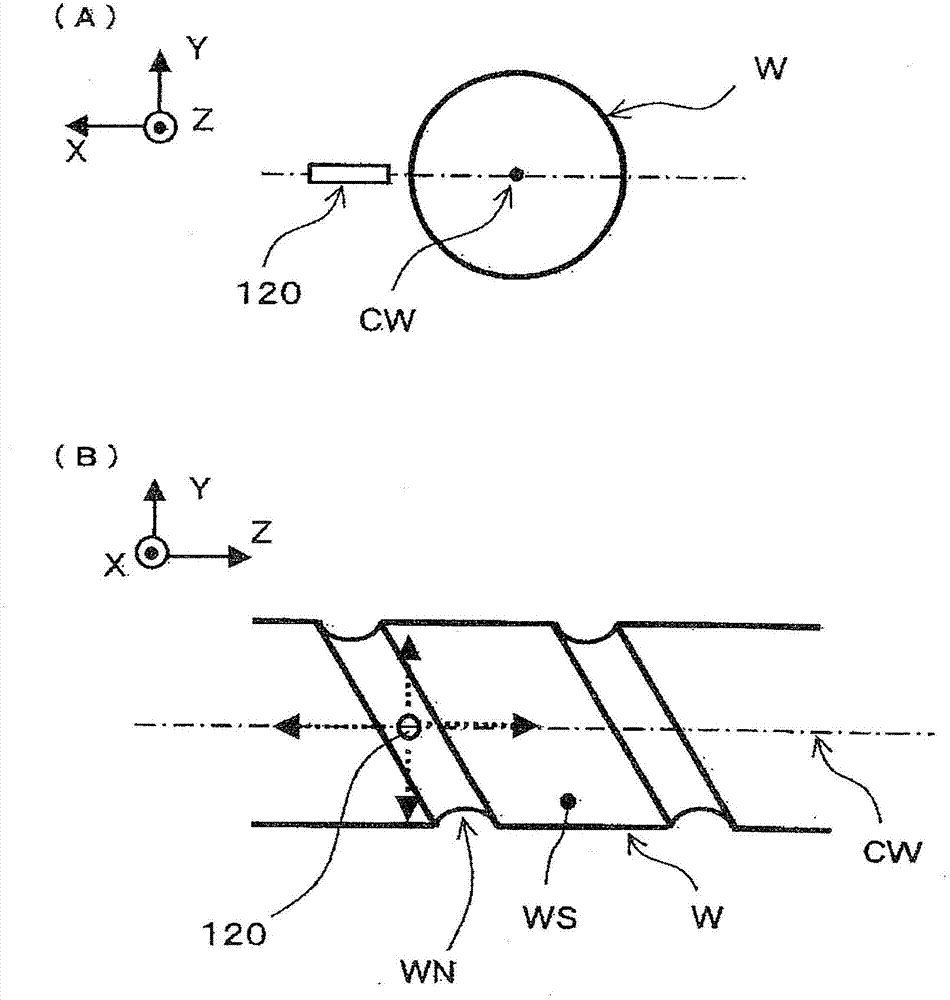

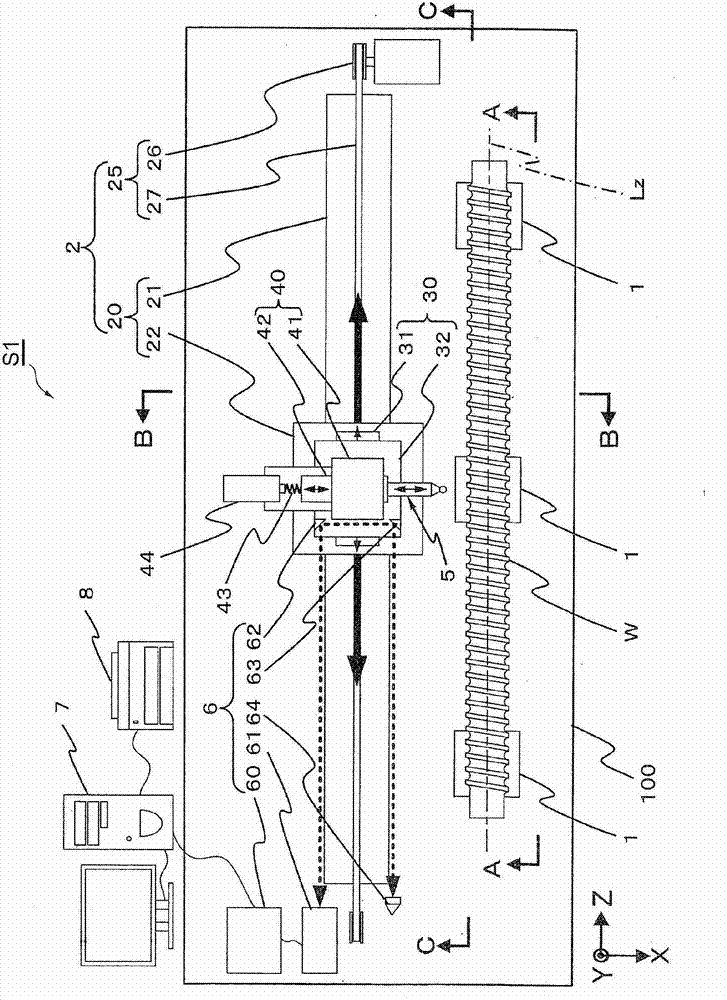

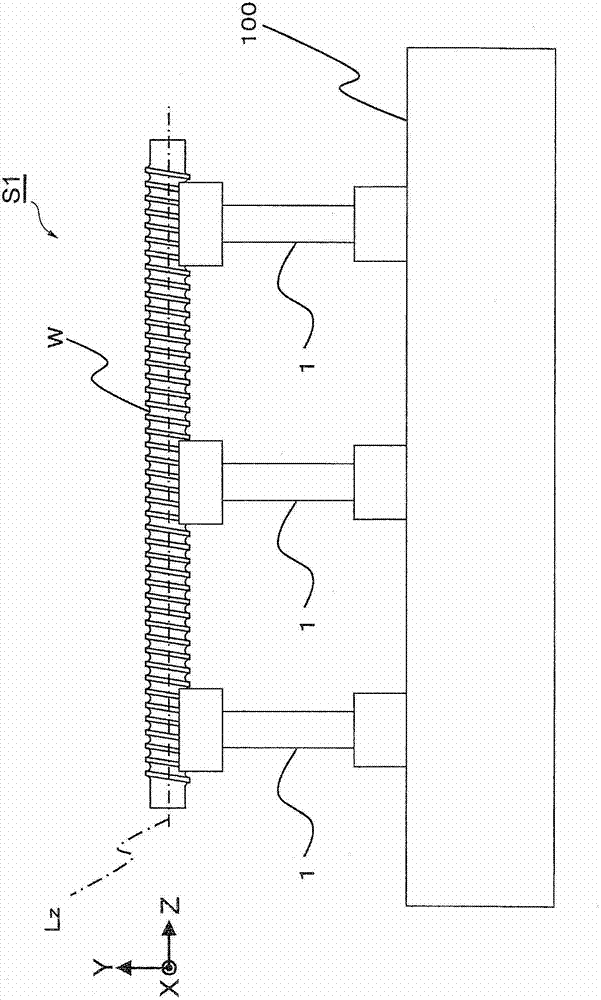

[0026] Hereinafter, a cumulative lead error measuring device for a ball screw shaft and a measuring method using the same according to a first embodiment of the present invention will be described with reference to the drawings. figure 2 It is an explanatory plan view showing the cumulative lead error measuring device of the ball screw shaft according to the first embodiment of the present invention. image 3 is shown from figure 2 An explanatory diagram of the ball screw shaft to be measured and the fixed support base viewed from the A-A arrows. Figure 4 is showing figure 2 An enlarged explanatory diagram of the view from the BB direction of . Figure 5 is showing figure 2 An enlarged explanatory diagram of the view from the direction of C-C. In addition, in Figures 2 to 5 and the following Figure 6 Among them, the X-axis, Y-axis, and Z-axis are orthogonal, and the Z-axis indicates the same direction as the axis center of the measured ball screw shaft, the X-axis...

no. 2 approach )

[0055] Next, a second embodiment of the cumulative lead error measuring device of the ball screw shaft according to the present invention will be described. Figure 6 It is a side explanatory drawing which shows 2nd Embodiment. Since the basic structure and measurement method are the same as those of the first embodiment, description thereof will be omitted.

[0056] This embodiment differs from the first embodiment in that in the first embodiment, the ball contact 5 is brought into contact from the X-axis direction perpendicular to the axis Lz of the ball screw shaft W to be measured, but in the second In the embodiment, the ball contact 5 is brought into contact from the Y-axis direction perpendicular to the axis Lz of the ball screw shaft W. As shown in FIG. Therefore, the measurement device S2 of the second embodiment is as Figure 6 The illustrated configuration is such that the ball contact slide mechanism 4 is mounted on the position detection slide mechanism 3 via an...

Embodiment )

[0066] An example of measurement performed by the cumulative lead error measuring device of the ball screw shaft according to the first embodiment will be described below. In a room where the temperature is adjusted to a room temperature of 20°C ± 0.5°C, the ball screw with a shaft diameter of 40mm, a lead pitch of 10mm, and a total length of 1400mm is equivalent to a standard of C3 in JIS (Japanese Industrial Standards) Shaft (manufactured by THK) measures the cumulative lead error of the ball screw shaft.

[0067] First, the ball screw shaft W to be measured is placed statically on three fixed support stands 1 so that the ball screw shaft W to be measured is parallel to the guide shaft 21 of the aerostatic bearing 20 positioning the reciprocating slide mechanism 2 . And the fixed support table 1 is adjusted so that the height of the axis Lz of the ball screw shaft W to be measured coincides with the center height of the ball 50 of the ball contact 5 within ±1 μm. Then, from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spring constant | aaaaa | aaaaa |

| Spring constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com