Material conveyor line

A technology for conveying lines and materials, applied in the directions of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of inability to realize the free transportation of each trolley, line stop loss, and small collision force of trolleys, so as to reduce the number of assembly workers. Bit fault, stable and reliable operation, small loss of line stoppage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

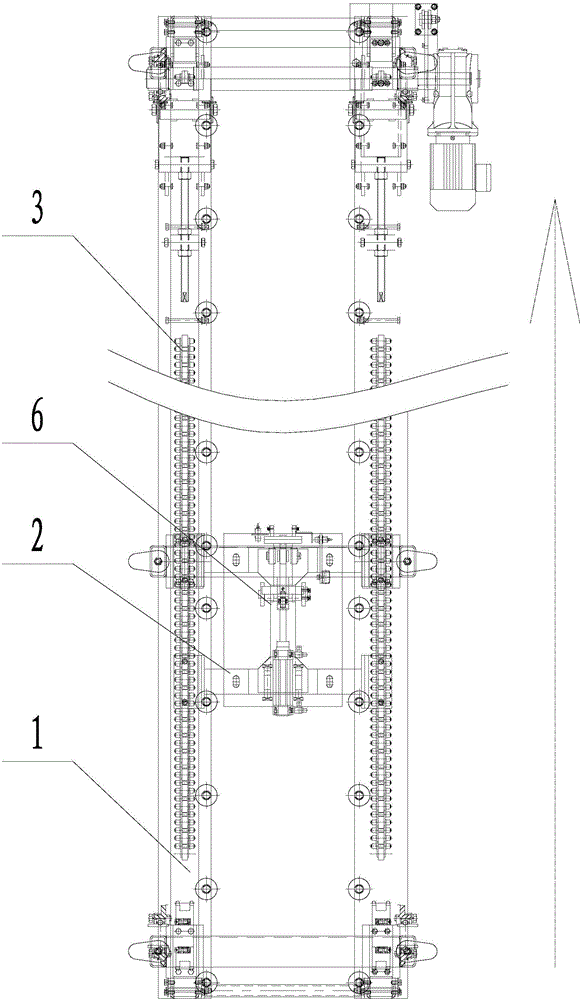

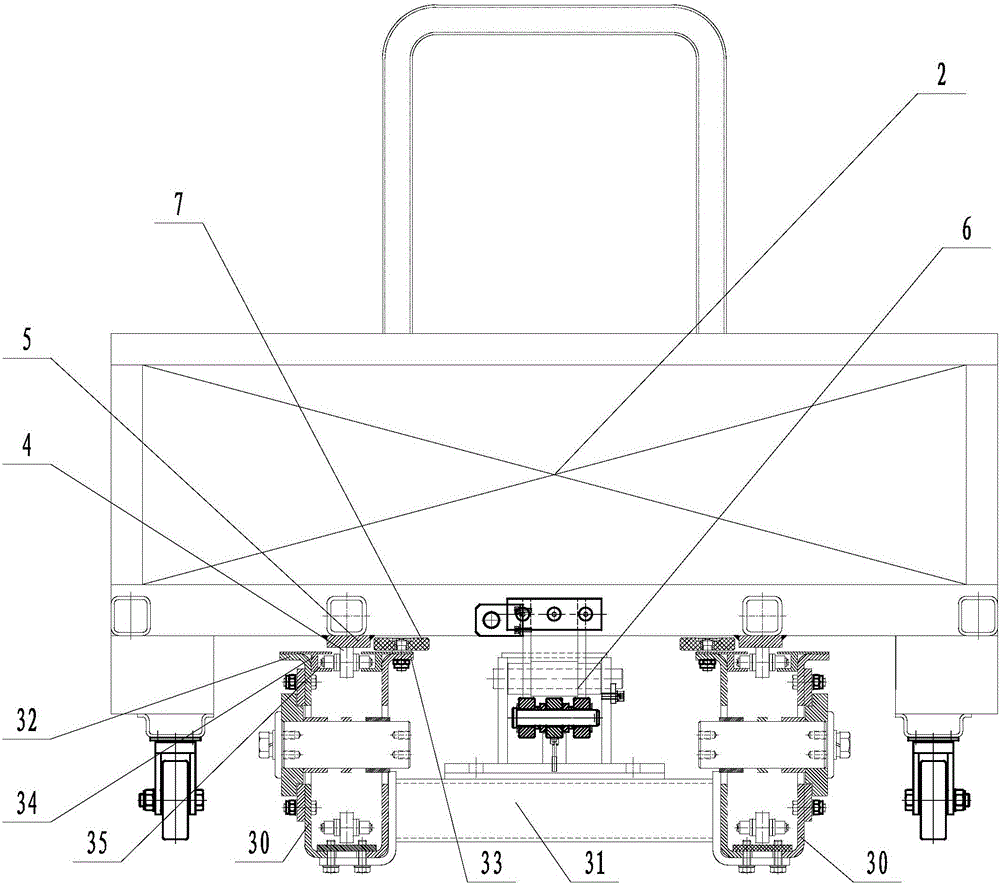

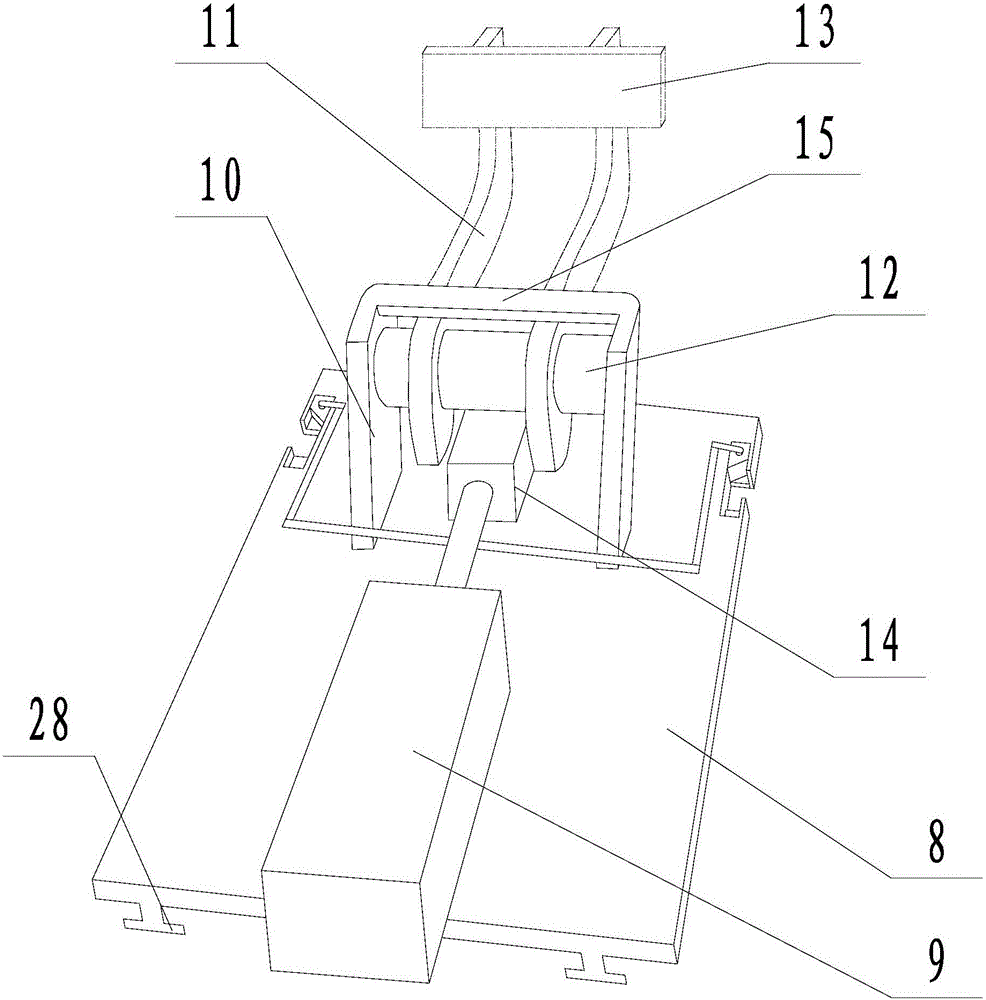

[0022] Embodiment: a kind of material conveying line (see attached Figures 1 to 4), including sliding track 1, several sliding trolleys 2 connected to the sliding track and separated from each other, conveying chains 3 are installed on both sides of the sliding track, and several rotatable rollers 4 are arranged at equal intervals on the conveying chain. The chain is densely arranged, and the sliding track is provided with several assembly stations along the length direction. Two contact slide bars 5 corresponding to the two conveying chains are provided on the lower surface of the sliding trolley, and the contact slide bars protrude from the lower surface of the sliding trolley. The two contact slide bars are respectively supported on the rollers of the two conveying chains. Each assembly station on the sliding track is equipped with a stopper 6 for braking the sliding trolley, and a rotatable limit guide wheel 7 is installed on the inside of the contact slide bar on the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com