Patents

Literature

44results about How to "Will not sputter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

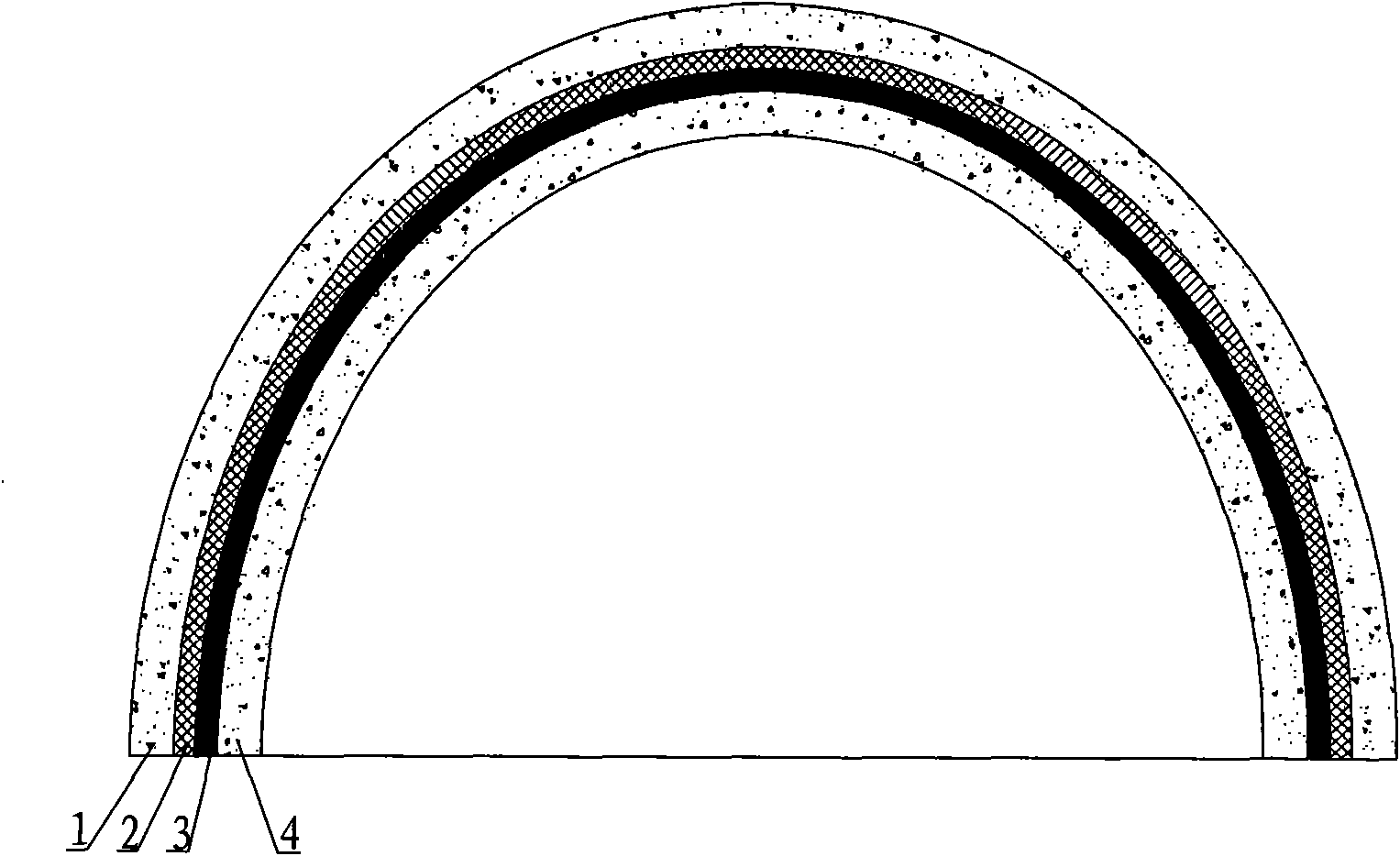

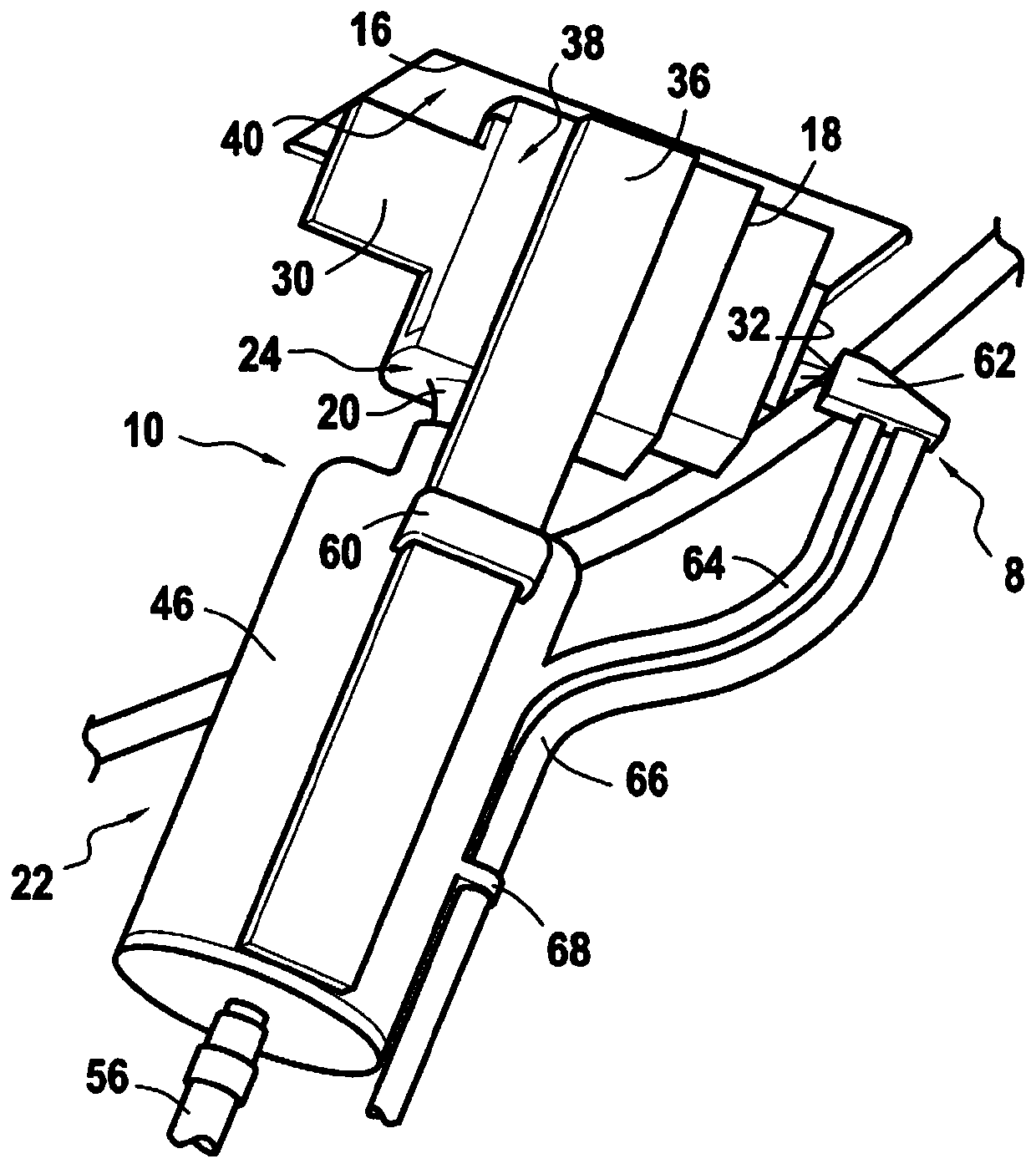

Construction method of tunnel waterproof and water drainage system

InactiveCN101614129AWill not harmWill not sputterUnderground chambersDrainageStructural deformationGeomorphology

The invention discloses a construction method of a tunnel waterproof and water drainage system, comprising the following steps: (1) preparing raw materials on a drainage layer; (2) injecting the drainage layer; (3) injecting a waterproof layer. The drainage layer and the waterproof layer of the invention all adopt the construction technology of injection. On the basis of water conductivity function, the drainage layer also has the functions of leveling and adapting to structural deformation, the waterproof layer adopts the construction mode of instantaneous film forming by ultraspeed curing and injecting, and the formed film is an integral structure, thus realizing that the integral structure is seamless and waterproof, the injection surface is free of flow, the film surface is smooth without bubbles and the construction produces no volatile organic compounds, simultaneously greatly improving the construction efficiency and reducing the labor intensity of workers.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

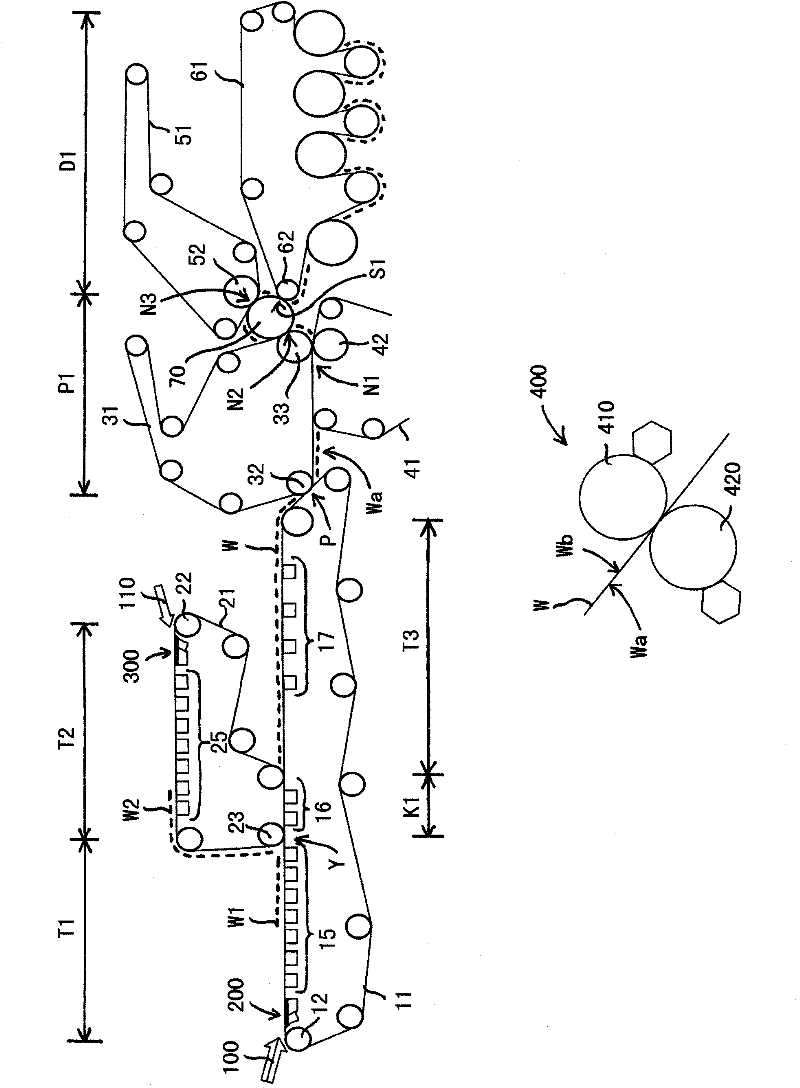

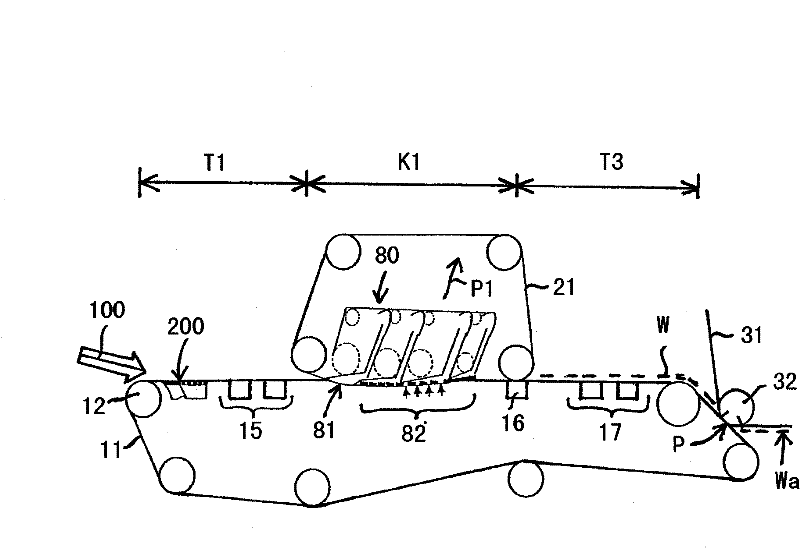

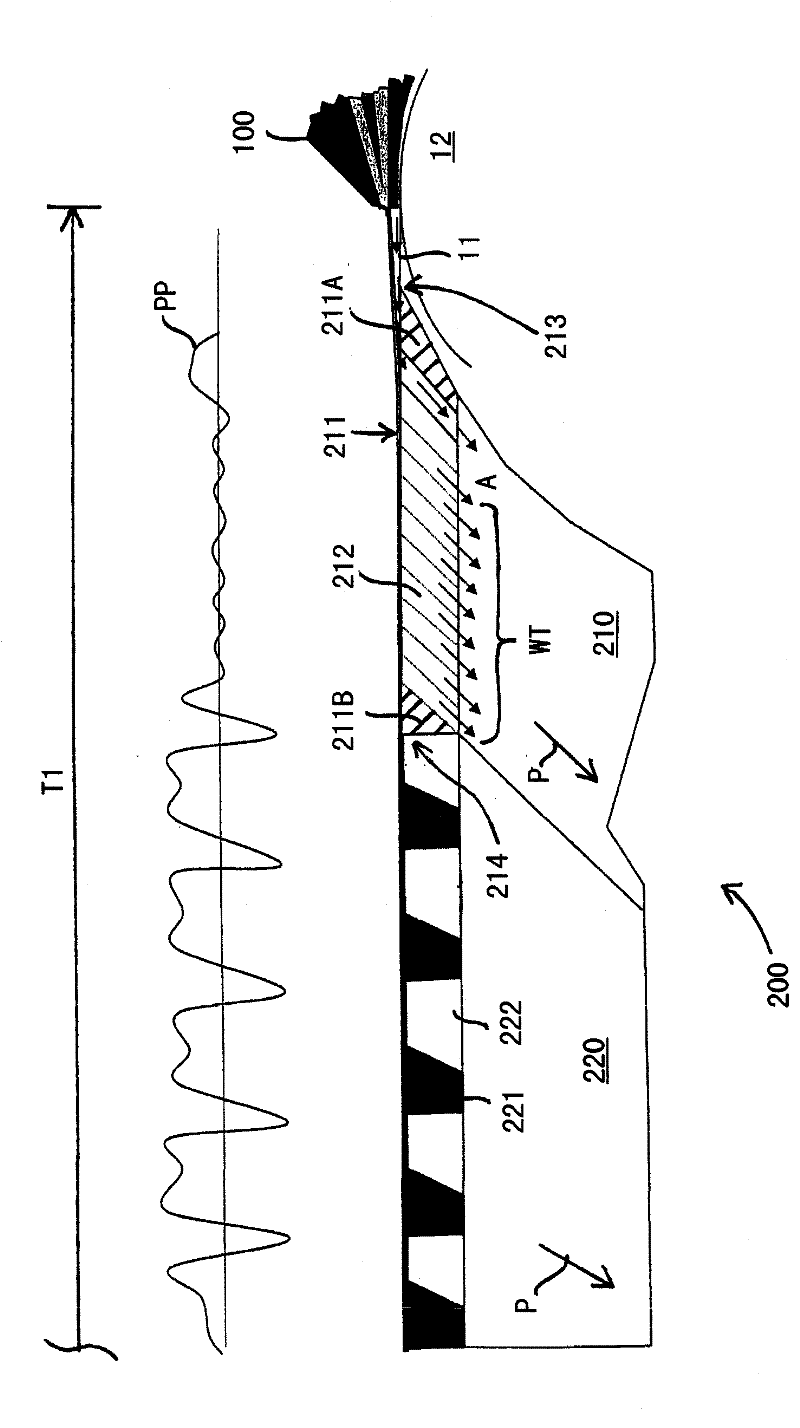

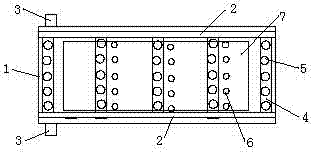

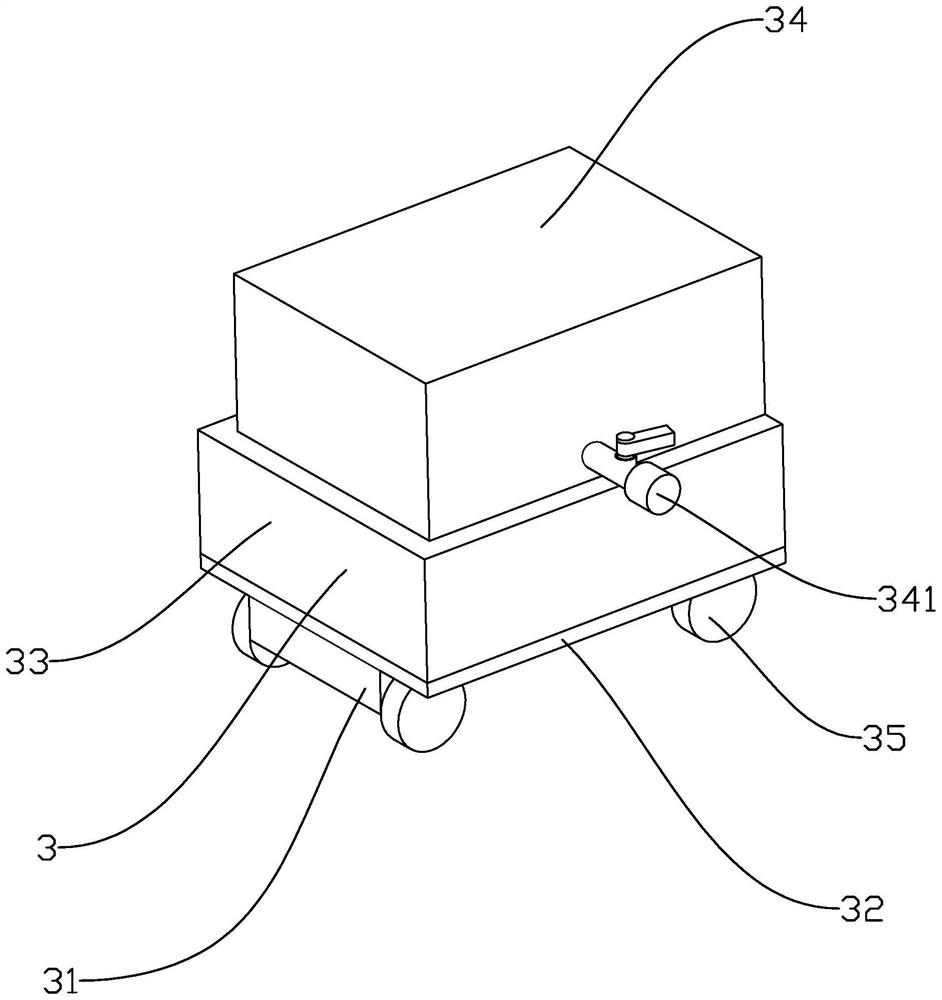

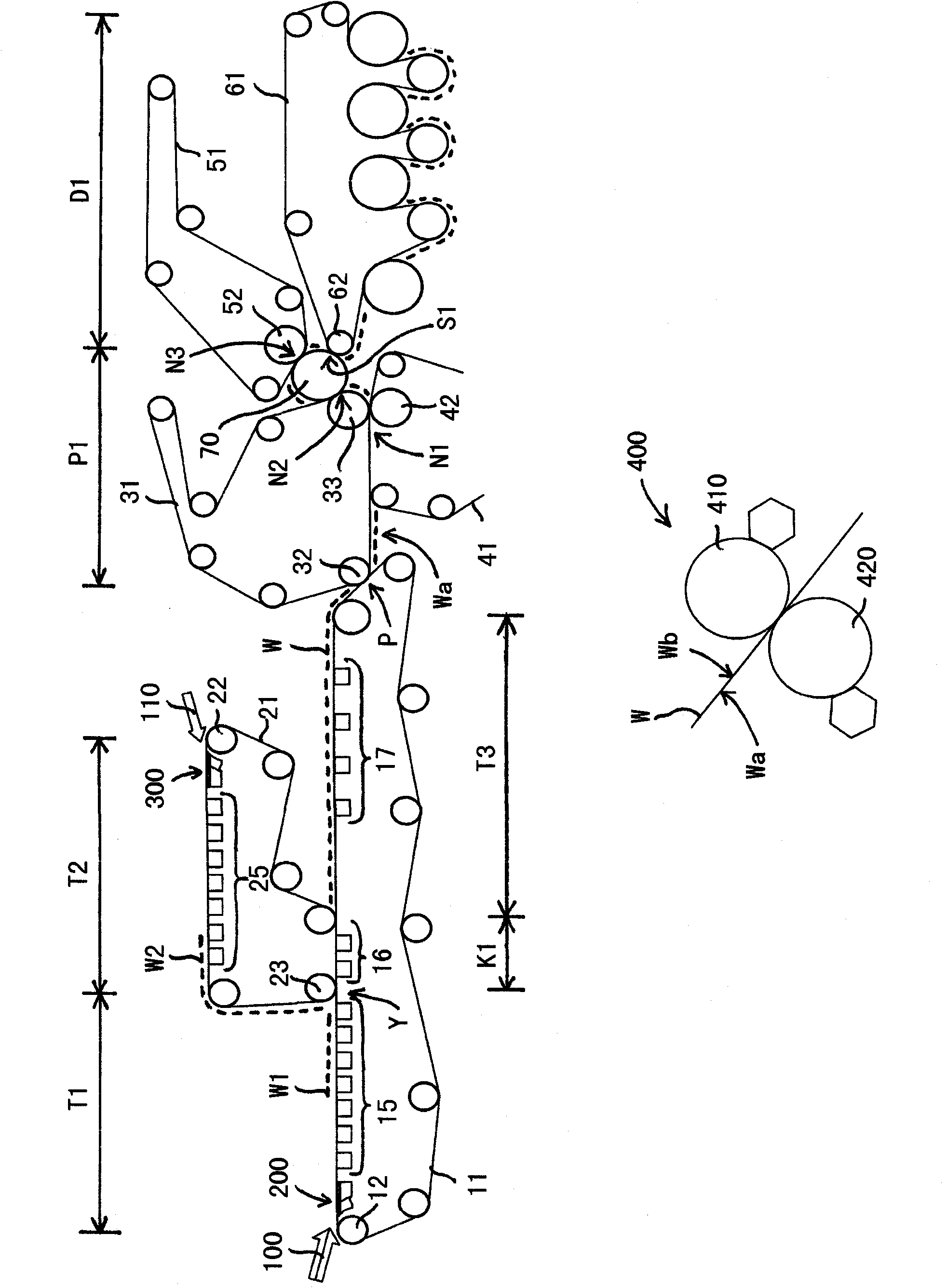

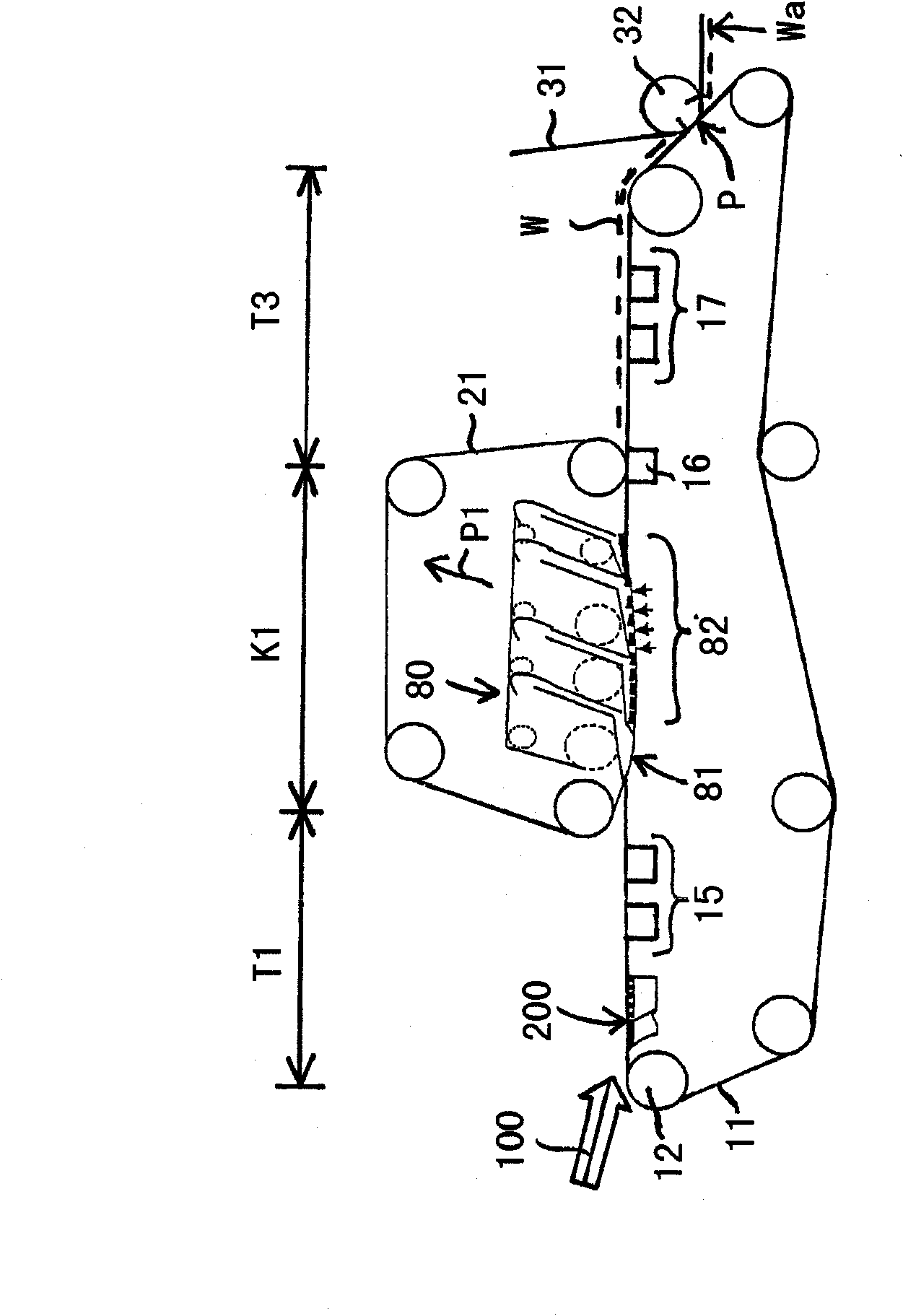

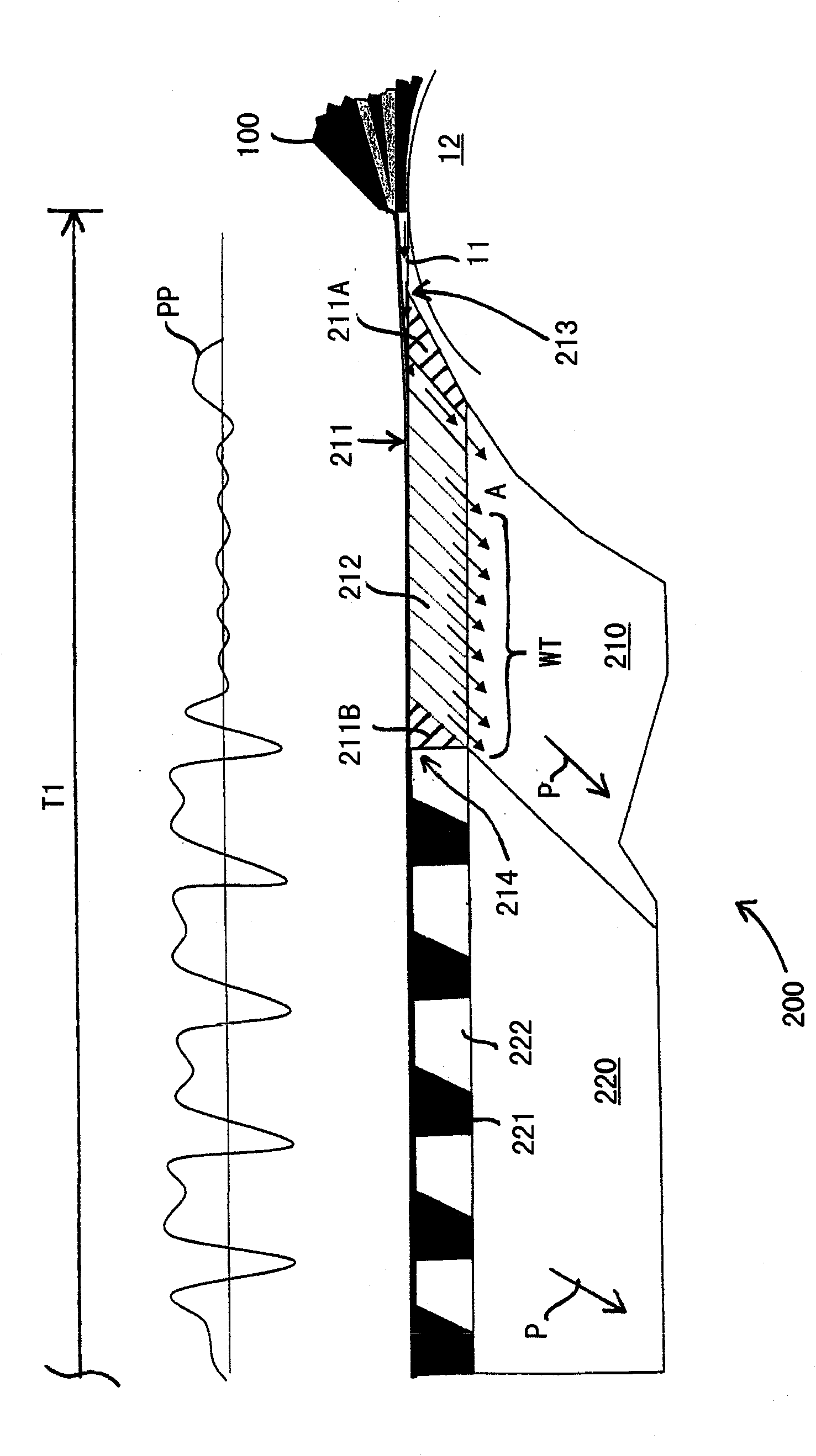

Board machine

InactiveCN102131981ADoes not affect layered purityAvoid deformationMachine wet endEngineeringCoating

A board machine comprises a forming section where a lower wire loop (11) forms a fourdrinier-wire section (Tl) at the beginning of which is located a forming board (200) which consists of at least one stationary, non-pulsating forming shoe (210). In the forming shoe (210), there is a cover (211) provided with thorough holes (212), setting against the inner surface of the lower wire loop (11). A first headbox (100), which is a multi-layer headbox, feeds a pulp suspension jet onto the forming shoe (210). The board machine further comprises a press section (Pl) where a surface (Wa) of the web (W) having been against the lower wire loop (11) is pressed against a smooth surface, a dryer section (Dl) where the web (W) is dried with at least one cylinder-dryer group and a coating section (400) where at least the surface (Wa) of the web (W) having been against the lower wire (11) is coated.

Owner:METSO PAPER INC

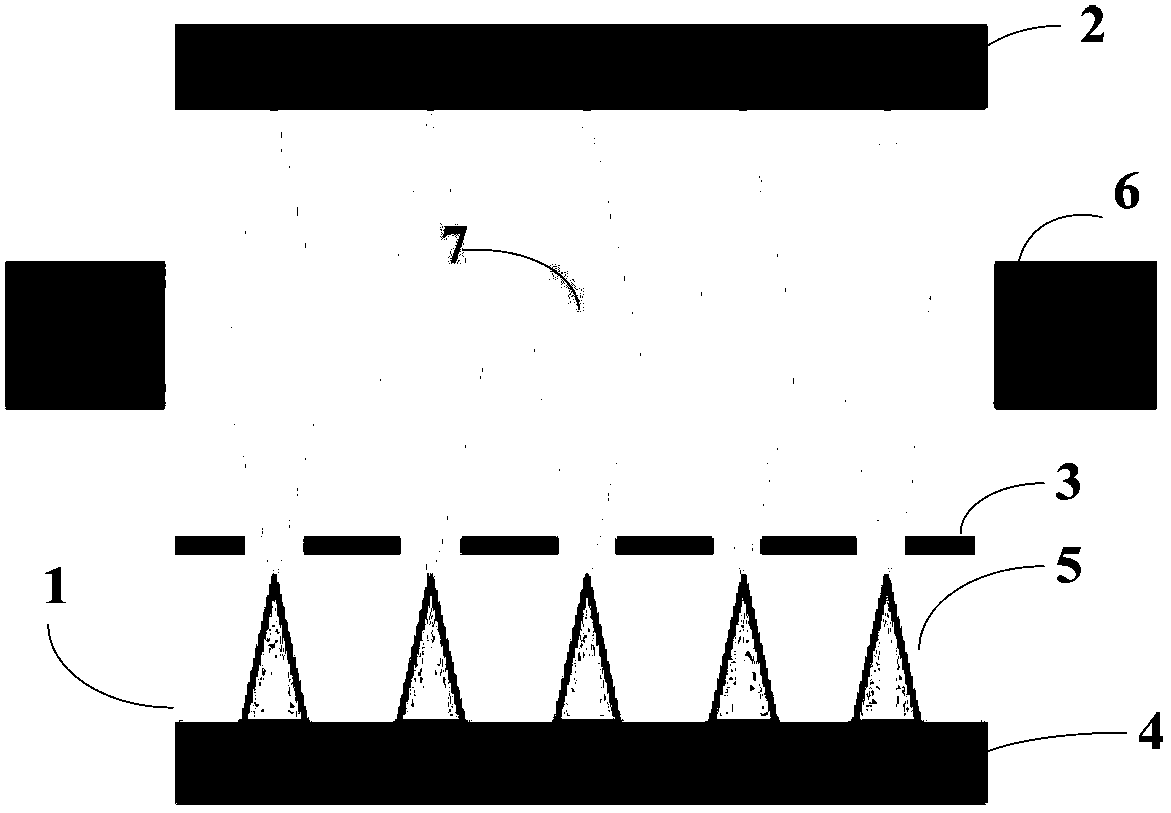

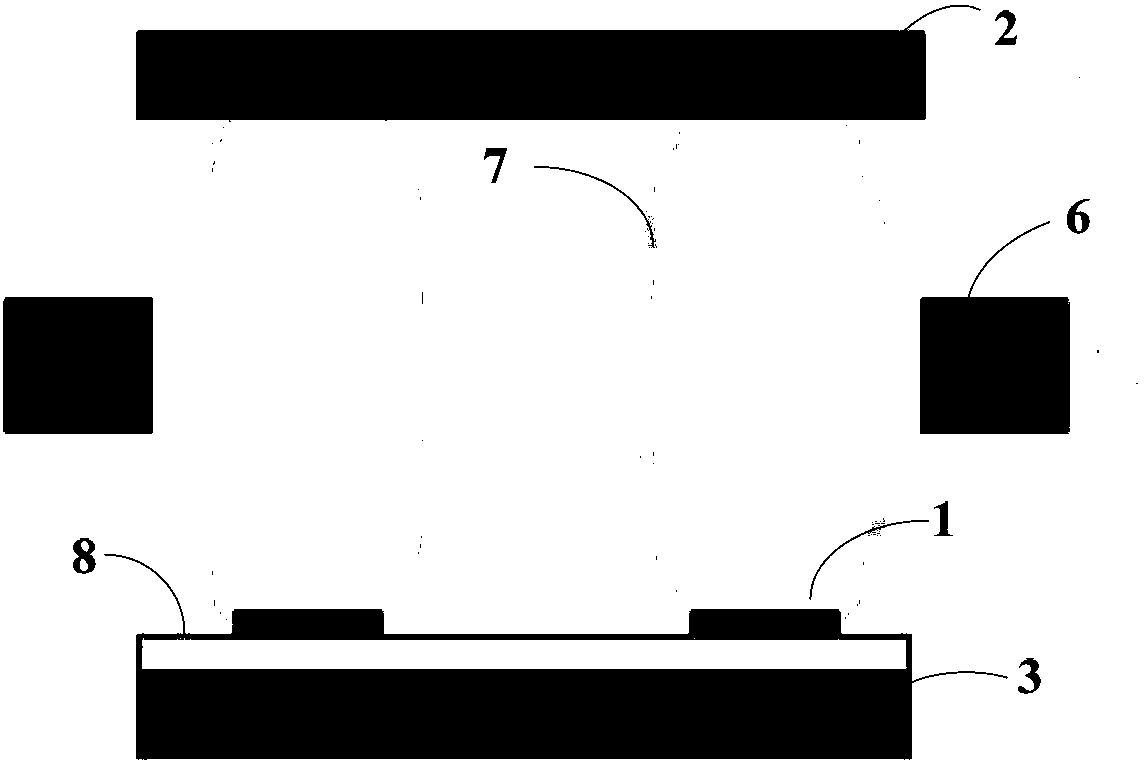

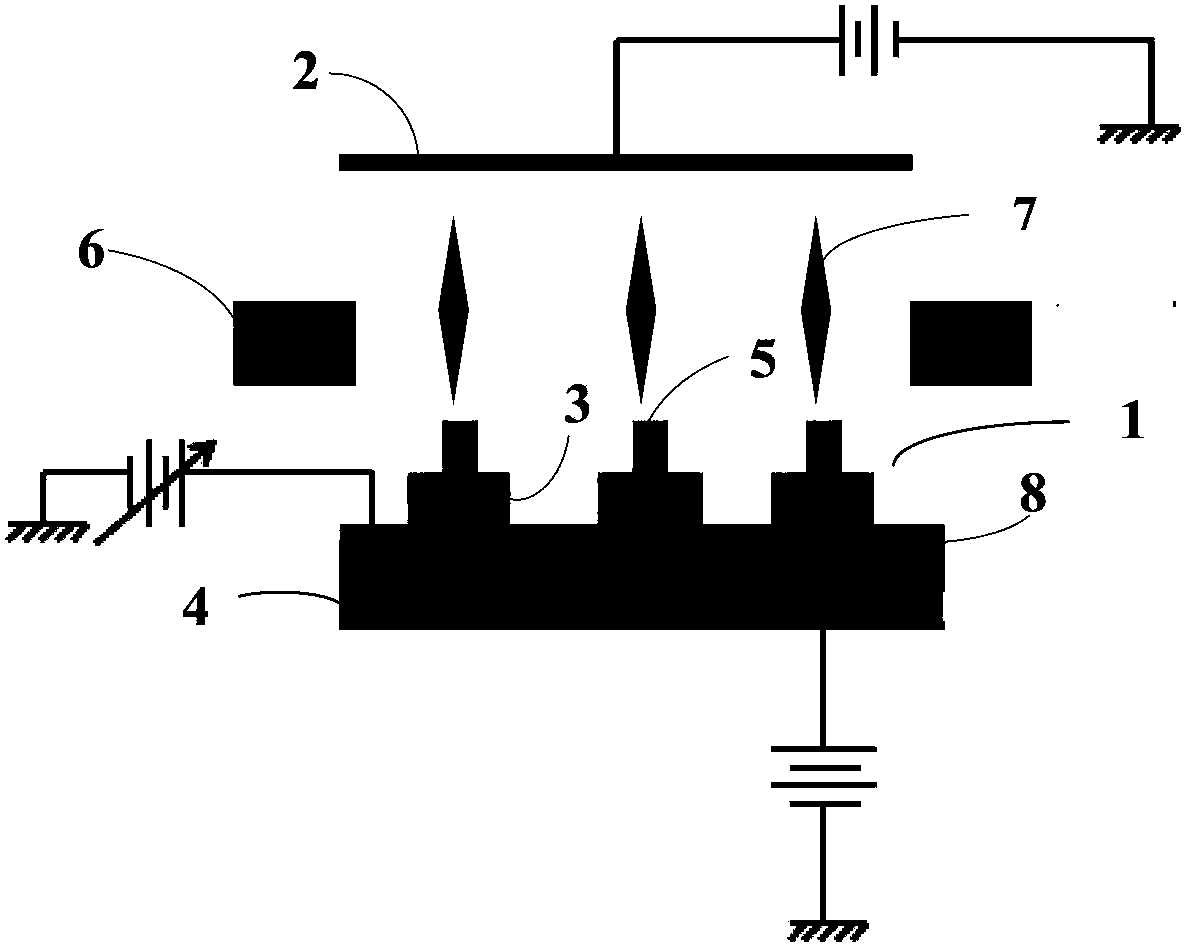

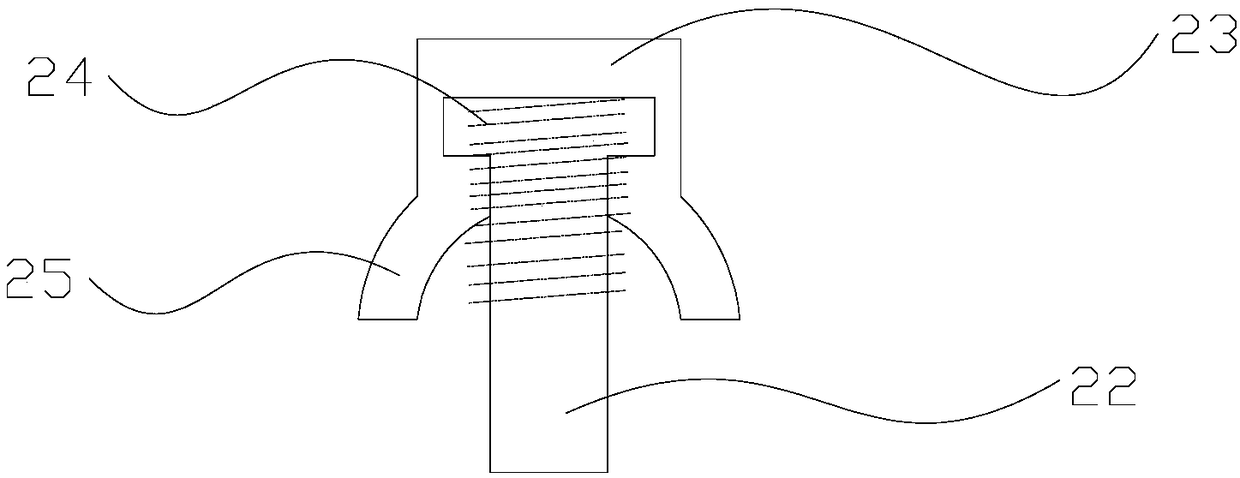

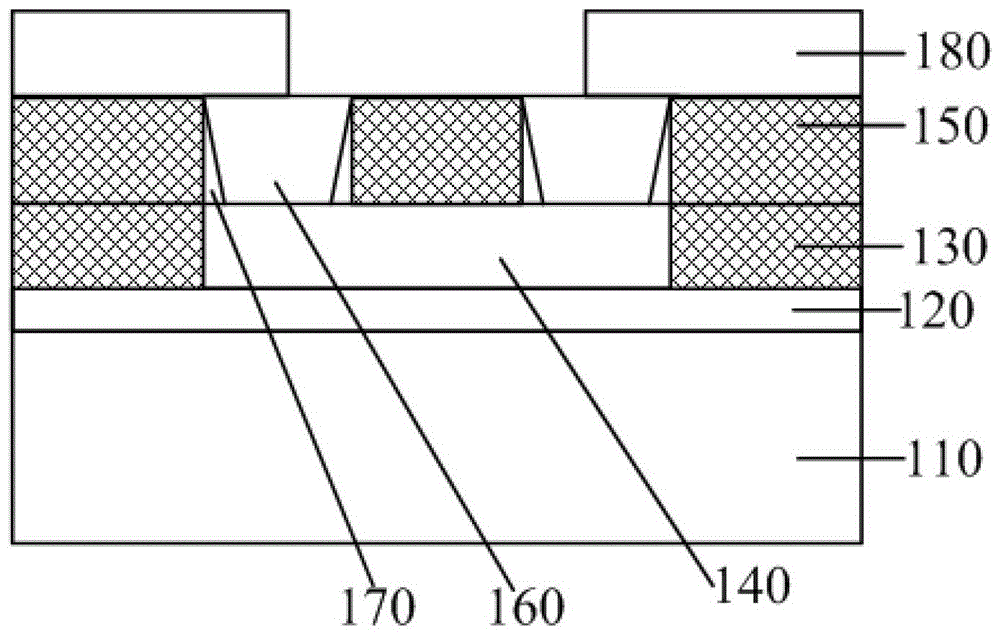

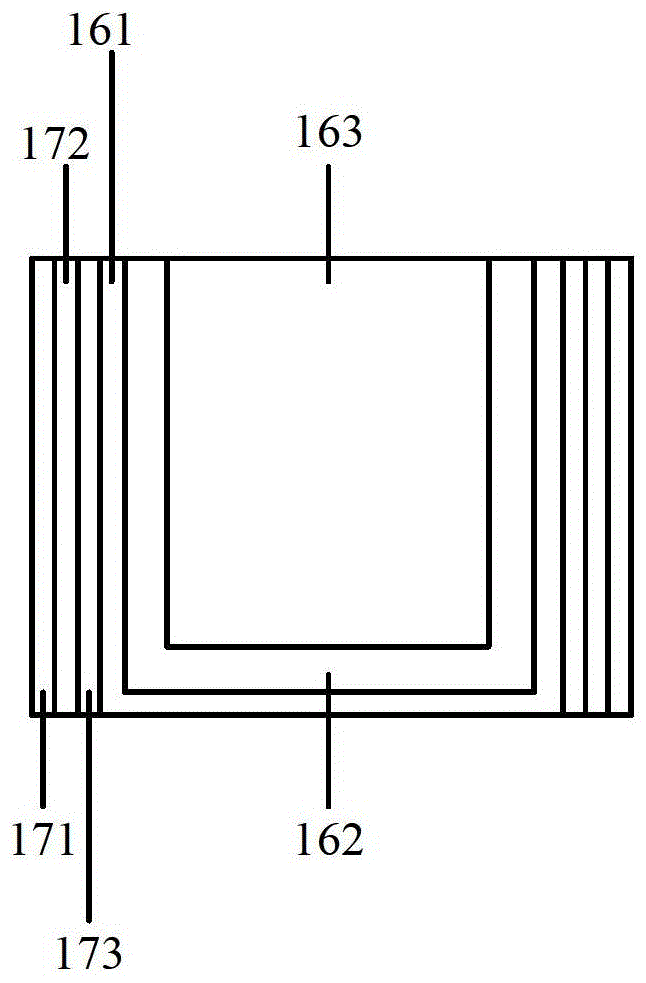

Field emission electron source and preparation method thereof

ActiveCN104078293AExtended service lifeControllable aspect ratioDischarge tube/lamp detailsCold cathode manufactureEmissivityElectron source

The invention provides a field emission electron source which comprises a cathode, a grid electrode, an insulating layer and an anode opposite to the cathode, wherein the cathode comprises a cathode base and a cathode emitter array etched on the cathode base; and the grid electrode is arranged on the upper surface of the cathode base and on the side surface of any cathode emitter in the cathode emitter array by intervals of the insulating layer. The invention further provides a preparation method of the field emission electron source. The preparation method comprises the steps of etching to obtain the cathode emitter array on the surface of the cathode base, depositing the insulating layer on the surface of the patterned cathode, depositing the grid electrode on the surface of the insulating layer, etching on the surface of the grid electrode and on the insulating layer around the cathode emitters, exposing the cathode emitters, and obtaining the field emission electron source. The field emission electron source can improve the grid electron emissivity; the service life of the field emission electron source is prolonged; and the field emission electron source is simple in preparation technology, and is applicable to a cold cathode of an electron device.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

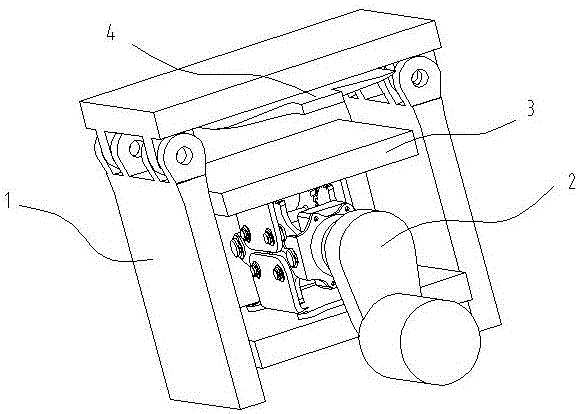

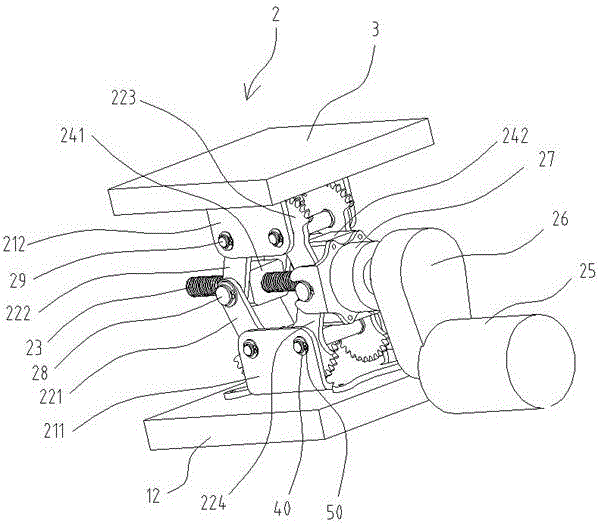

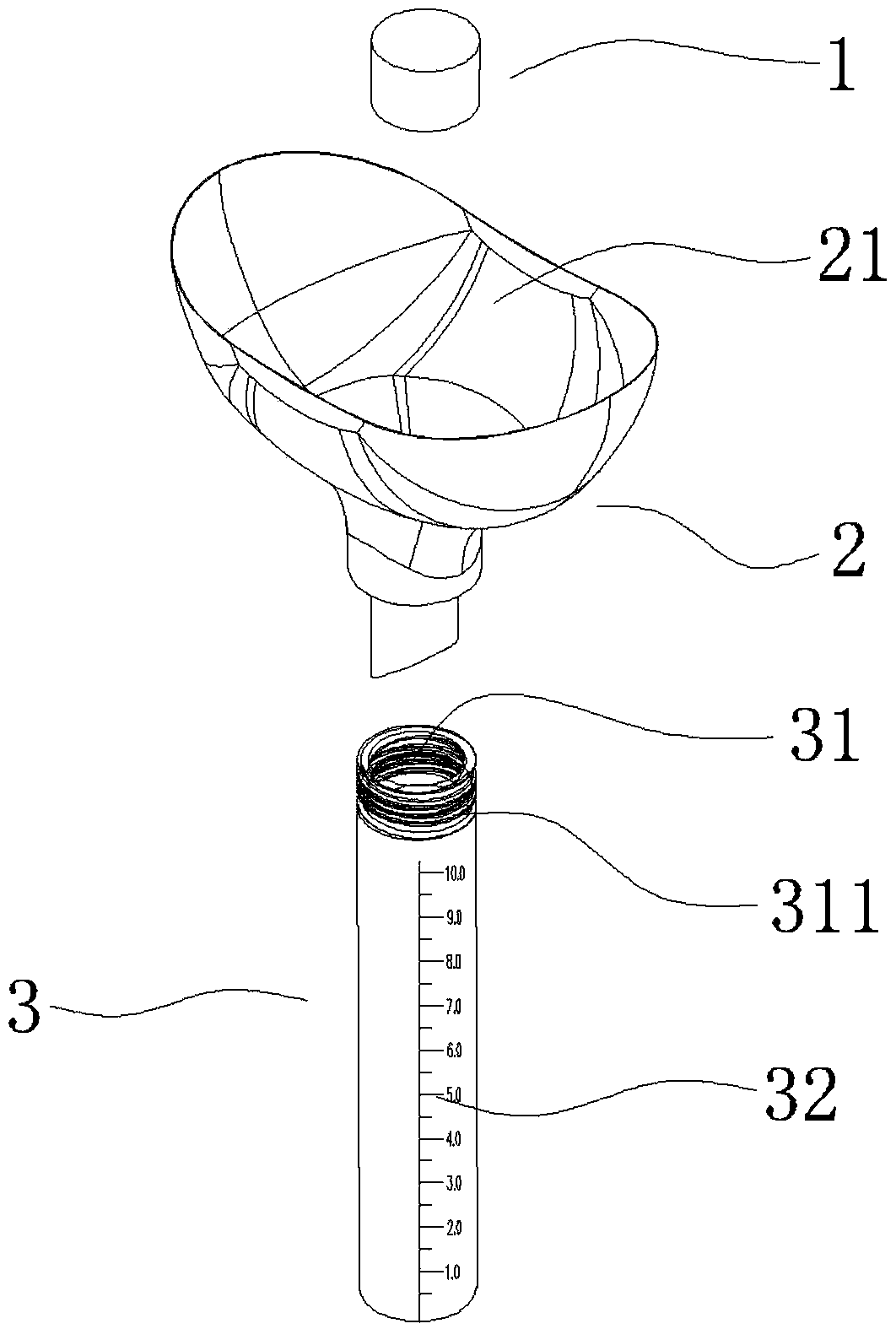

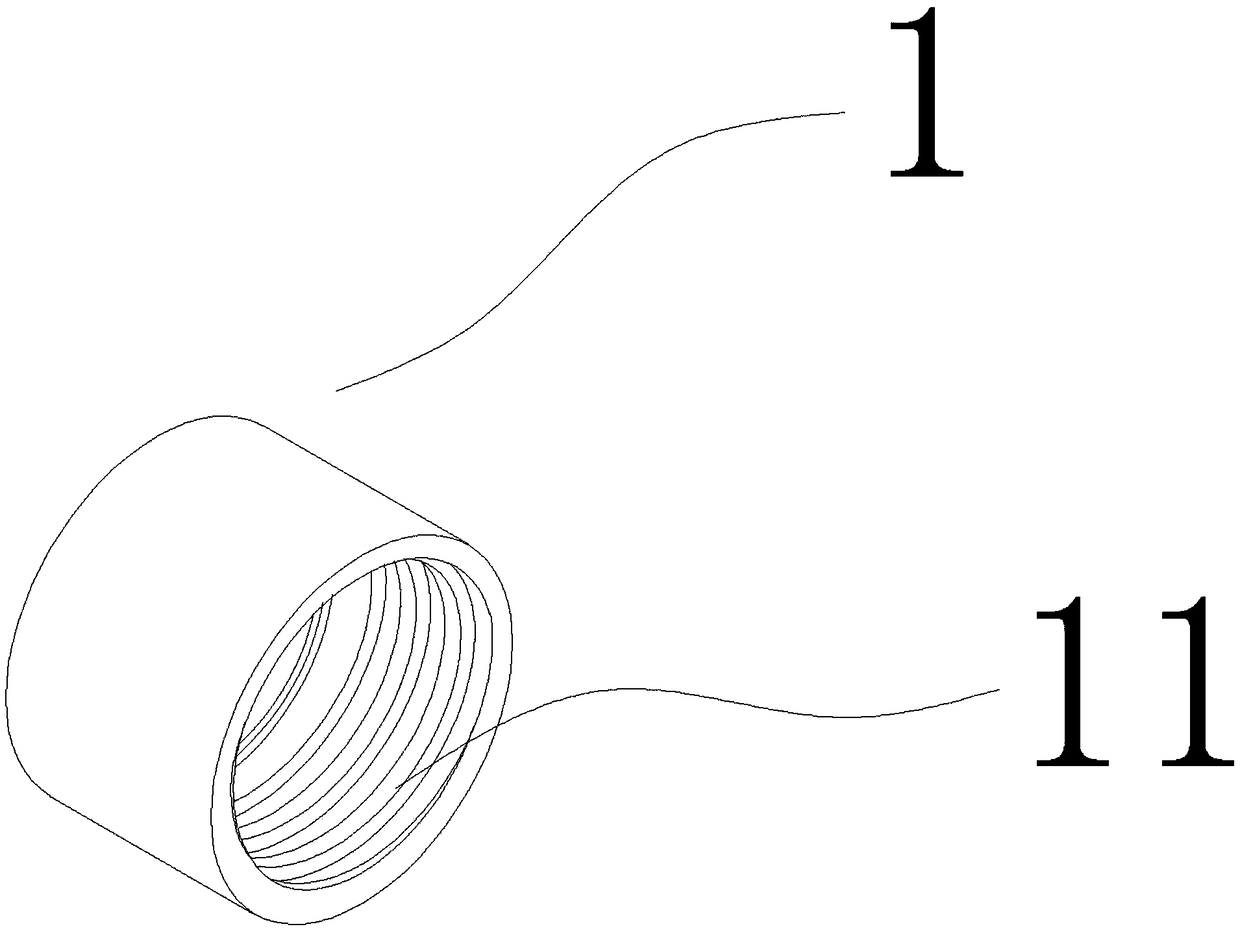

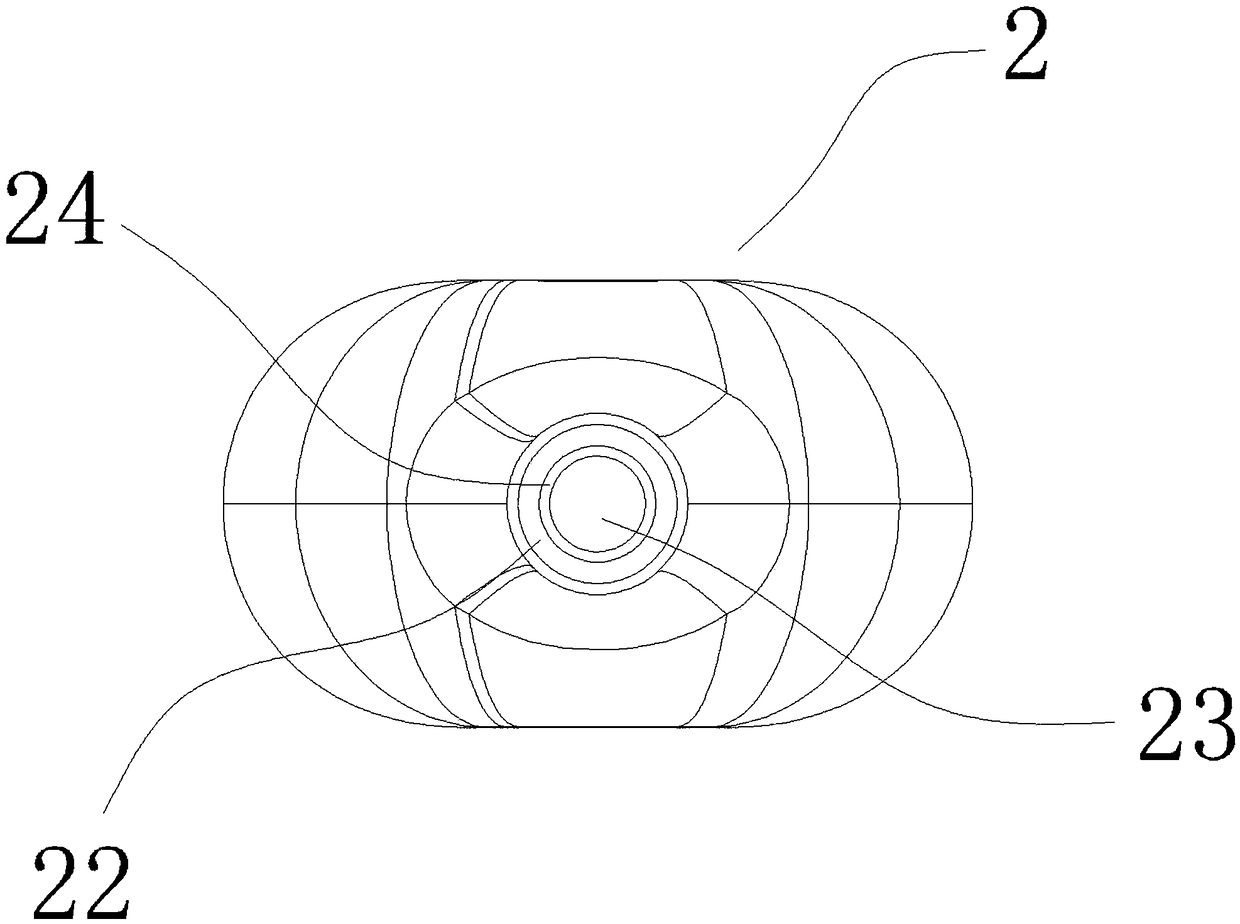

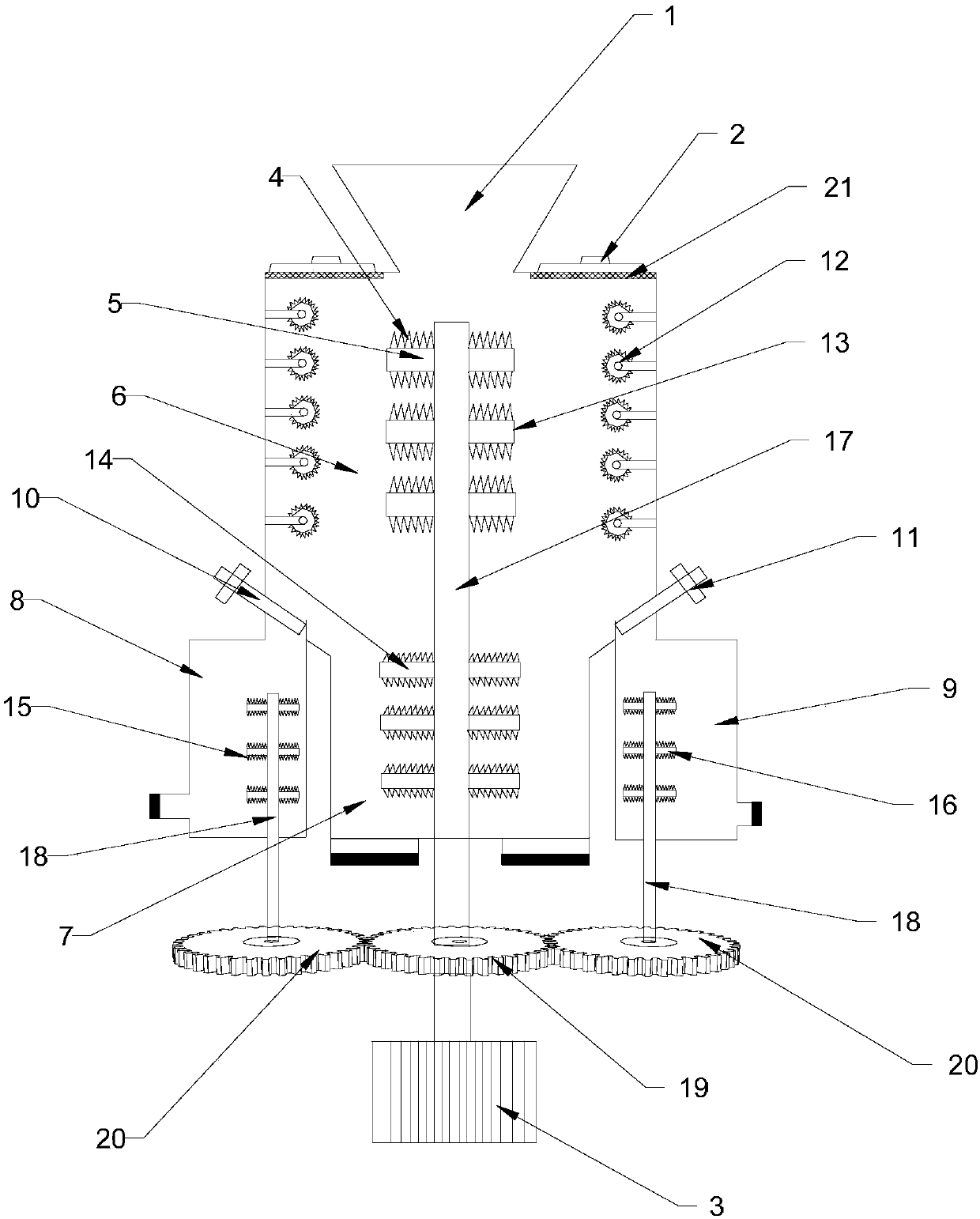

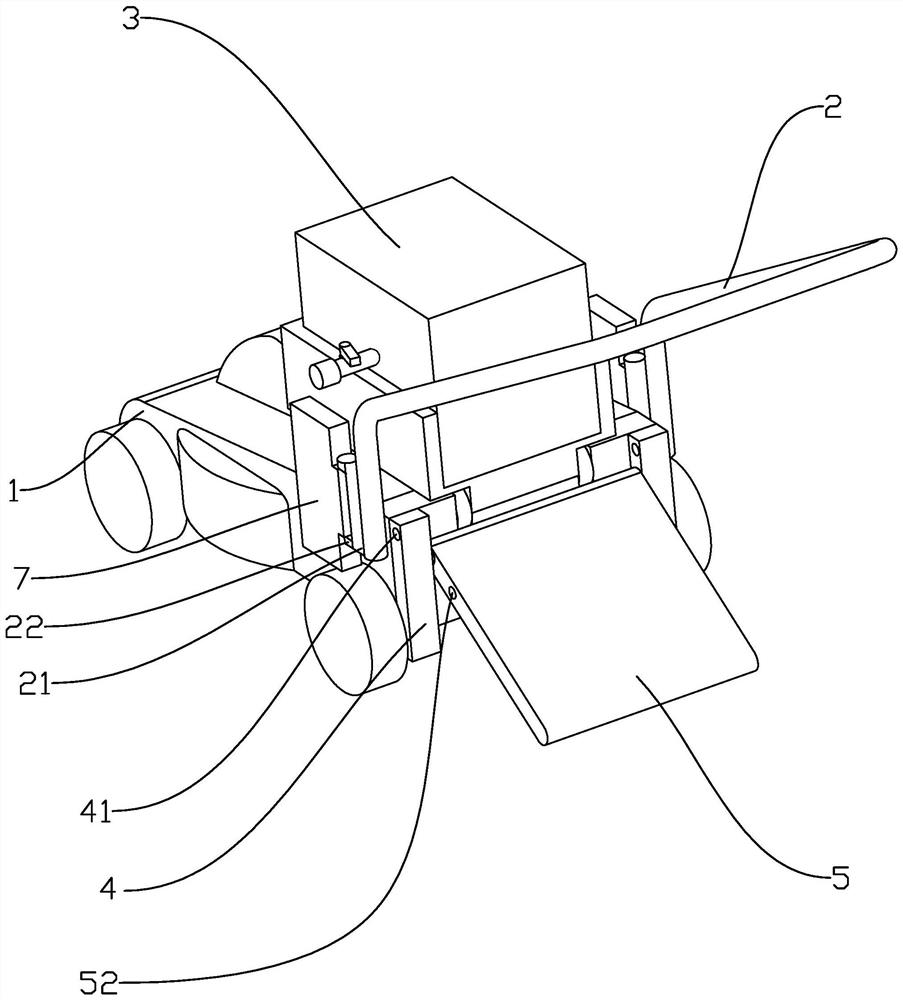

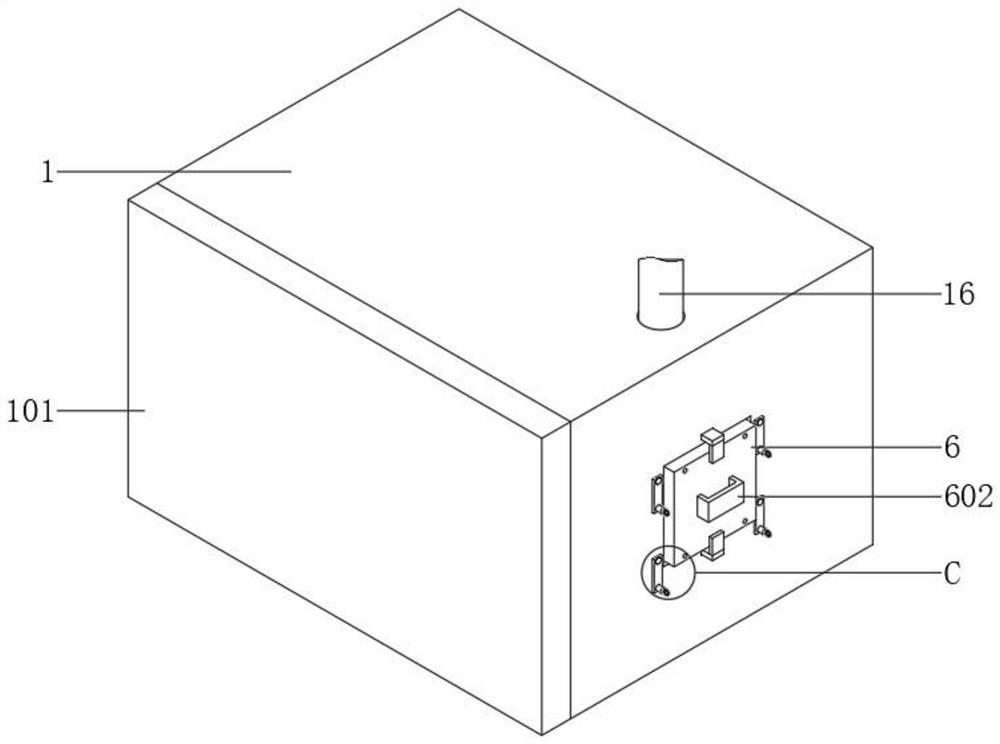

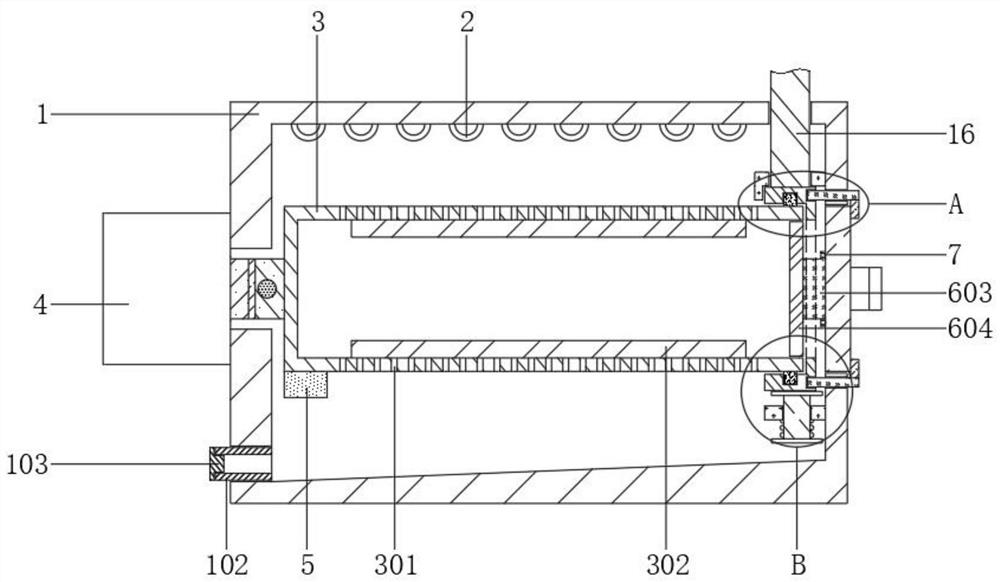

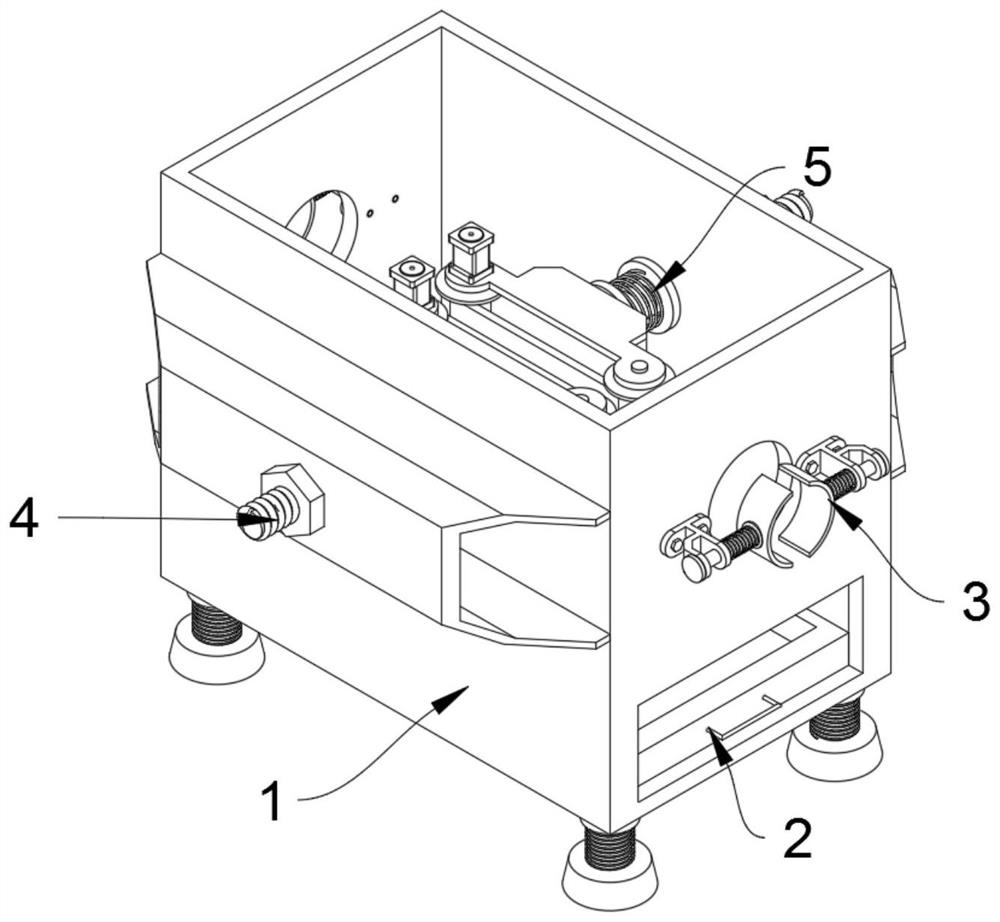

Juice squeezer

The invention provides a juice squeezer, and belongs to the technical field of juice squeezing. The juice squeezer comprises a frame body, an actuator and a capsule bag, wherein the actuator also comprises a fixed piece, a movable piece, a driving rod, an acting block and a driver; according to the juice squeezer, a mounting surface is arranged in the frame body, and a surface which is opposite to the mounting surface is arranged as a fixed surface; the actuator is arranged on the mounting surface; a propelling plate is arranged on one side, far away from the mounting surface, of the actuator; the actuator drives the propelling plate to perform reciprocating rectilinear movement along the mounting surface to the fixed surface, so as to extrude a food raw material which is stored between the propelling plate and the fixed surface; therefore, the work of squeezing juice is finished, and the noise is low; the juice squeezer is driven by a motor, and is provided with a speed changing device, so that the thrust of the actuator is greater, the squeezing is more thorough, and the efficiency is higher; by adopting the coordinated movement of a screw and the acting block, the reciprocating property is high, and the working time is effectively prolonged; the capsule bag is arranged between the actuator and the fixed surface, so that squeezed juice cannot be sputtered on components, and the purpose of avoiding cleaning is achieved.

Owner:SHANGHAI AIWEI ELECTRONICS TECH CO LTD

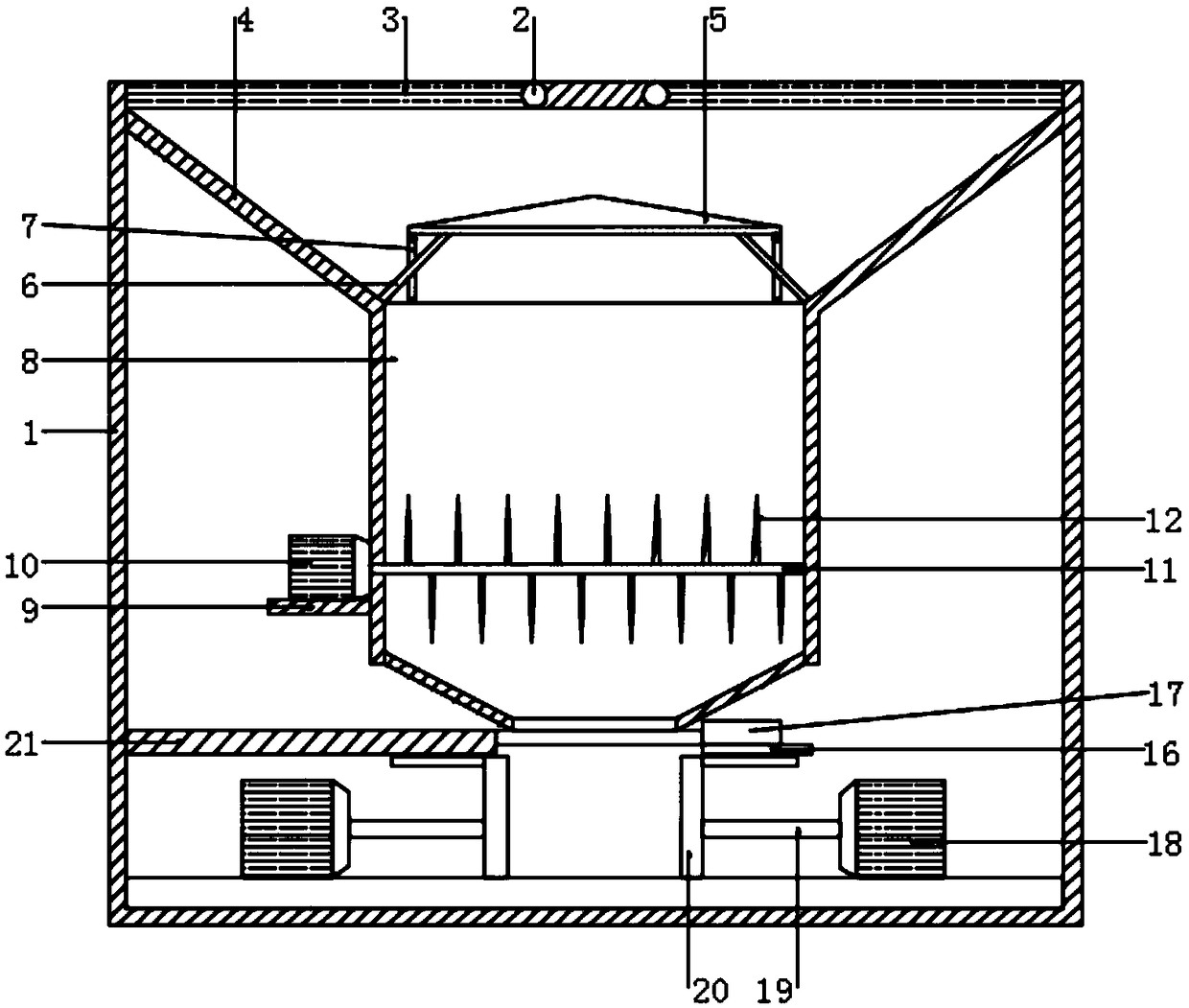

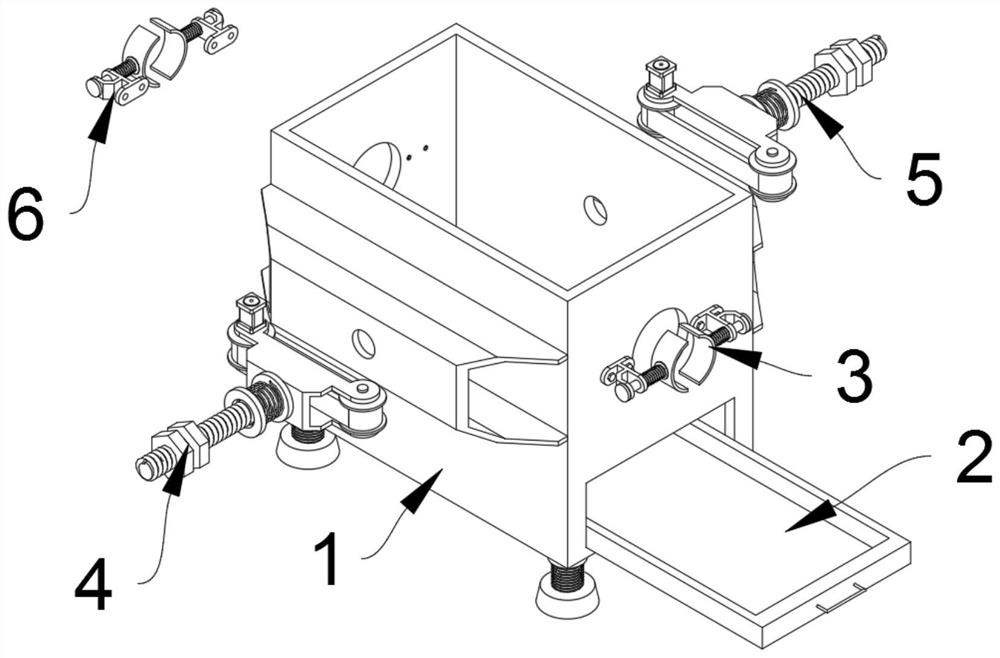

Vegetable garbage treatment device

ActiveCN109382182AWill not sputterGood for stacking and collectingGrain treatmentsEngineeringExtrusion

The invention discloses a vegetable garbage treatment device comprising a box body, an installation seat, a cover plate, a feeding hopper, an anti-sputtering device, a crushing chamber, a crushing device, a second supporting plate, an automatic valve, extrusion devices, a third supporting plate, a storage hopper, a material pushing device, a controller and a cover plate; the cover plate is arranged on the installation seat at the upper end of the box body; the feeding hopper is arranged below the cover plate; the anti-sputtering device is arranged at the lower end of the feeding hopper, and the crushing chamber is connected at the lower end of the feeding hopper; the crushing device is arranged in the crushing chamber; the automatic valve is arranged at the lower end of the crushing chamber; the automatic valve is arranged on the second supporting plate; the third supporting plate is arranged at the left side of the lower end of the crushing chamber; the controller is arranged on the third supporting plate; the extrusion devices are arranged below the second supporting plate and the third supporting plate; the material pushing device is arranged at the rear side of the lower end ofthe crushing chamber. Vegetable garbage cannot be splashed out to the outside when crushing, and the vegetable garbage treatment work can be carried out automatically. The crushed vegetable garbage is compressed to be beneficial to stacking and collection.

Owner:日照佳天下食品有限公司

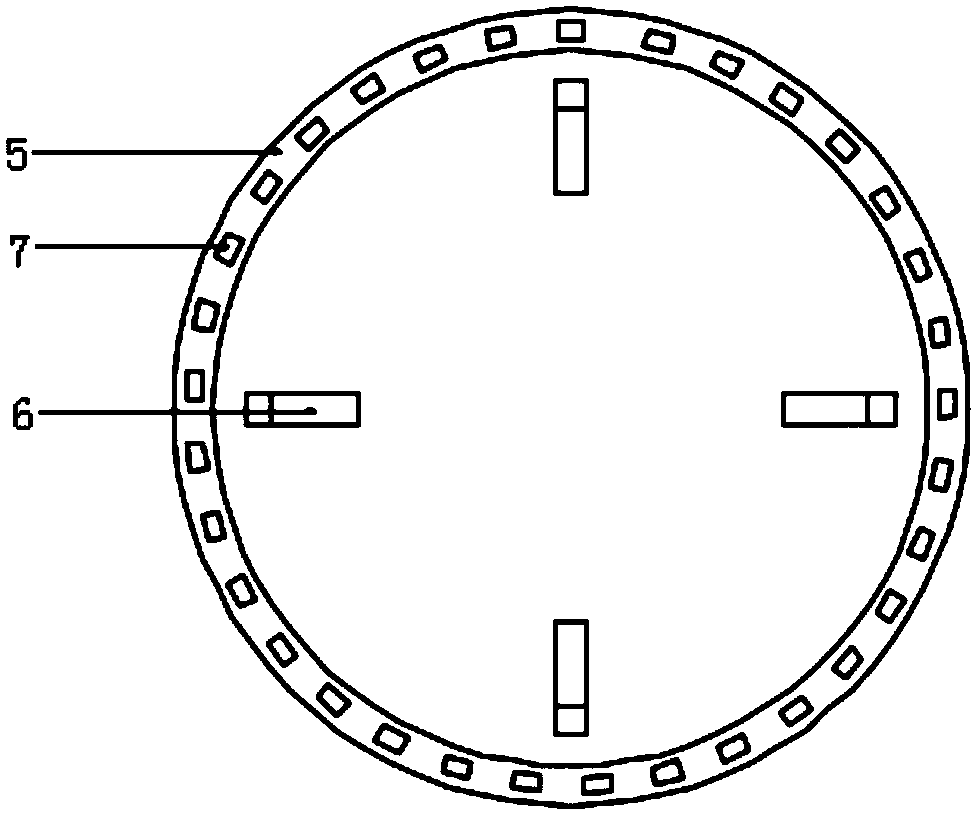

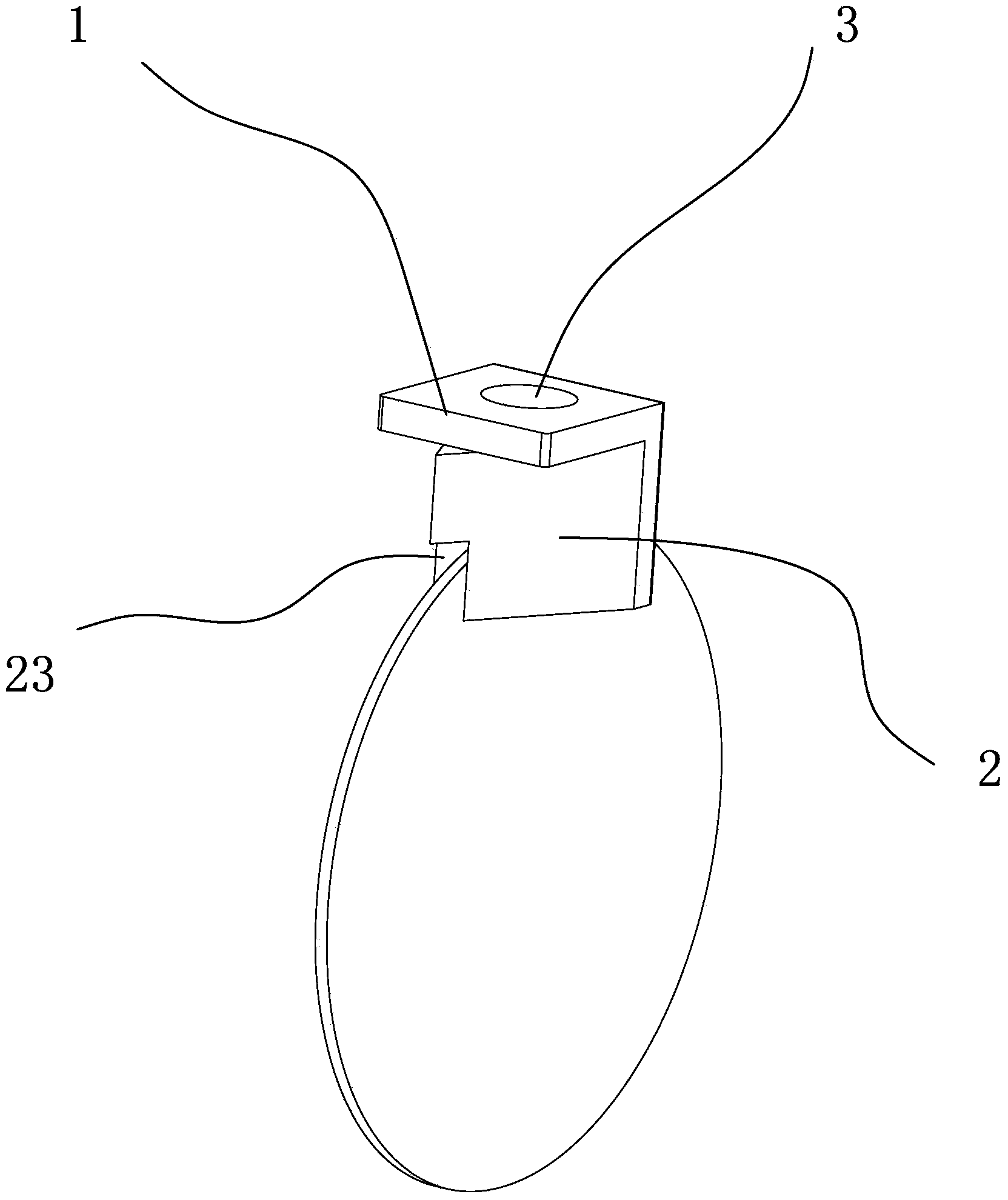

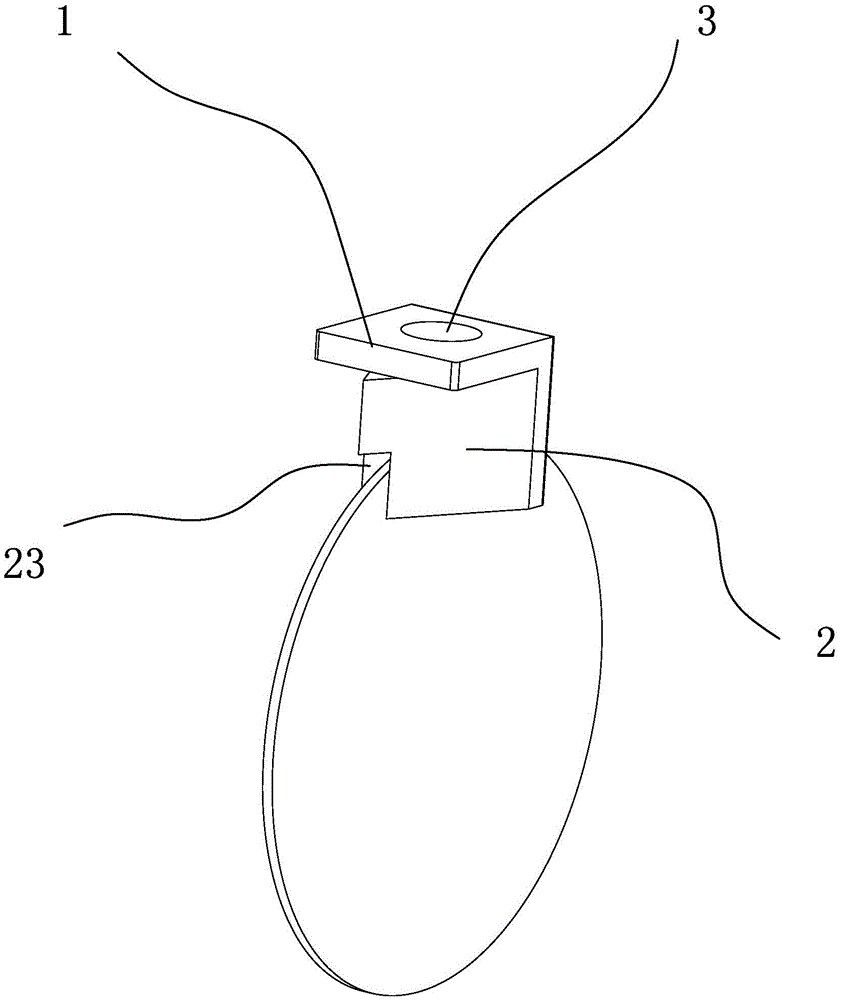

Disposable urine analysis container and use method

InactiveCN109009238AEasy to collectNot easy to polluteSurgeryVaccination/ovulation diagnosticsForeign matterEngineering

The invention discloses a disposable urine analysis container. The container comprises a container cover, a hopper and a container body. The container is a concave hollow body. An inner connection structure is arranged on the inner wall of the container cover. A liquid inlet is arranged in the top of the hopper. An inwards recessed circular groove is arranged in the bottom of the hopper. An innerconnection structure is arranged on the inner wall of the circular groove. The container body is a hollow cylinder. A container opening is arranged in the top end of the container body. An external connection structure is arranged on the outer wall of the container opening. When the hopper is connected with the container body, the inner connection structure on the inner wall of the circular grooveand the outer connection structure on the outer wall of the container opening are connected together. When the container cover is connected with the container body, the inner connection structure onthe inner wall of the container cover and the outer connection structure on the outer wall of the container opening are connected together. According to the invention, it is convenient for a patient to acquire urine samples; it is convenient and clean to storage and convey the urine; the urine will not be splashed out or spill out; and the urine samples are not likely to be polluted by external foreign matters and bacteria.

Owner:太仓合翔包装材料有限公司

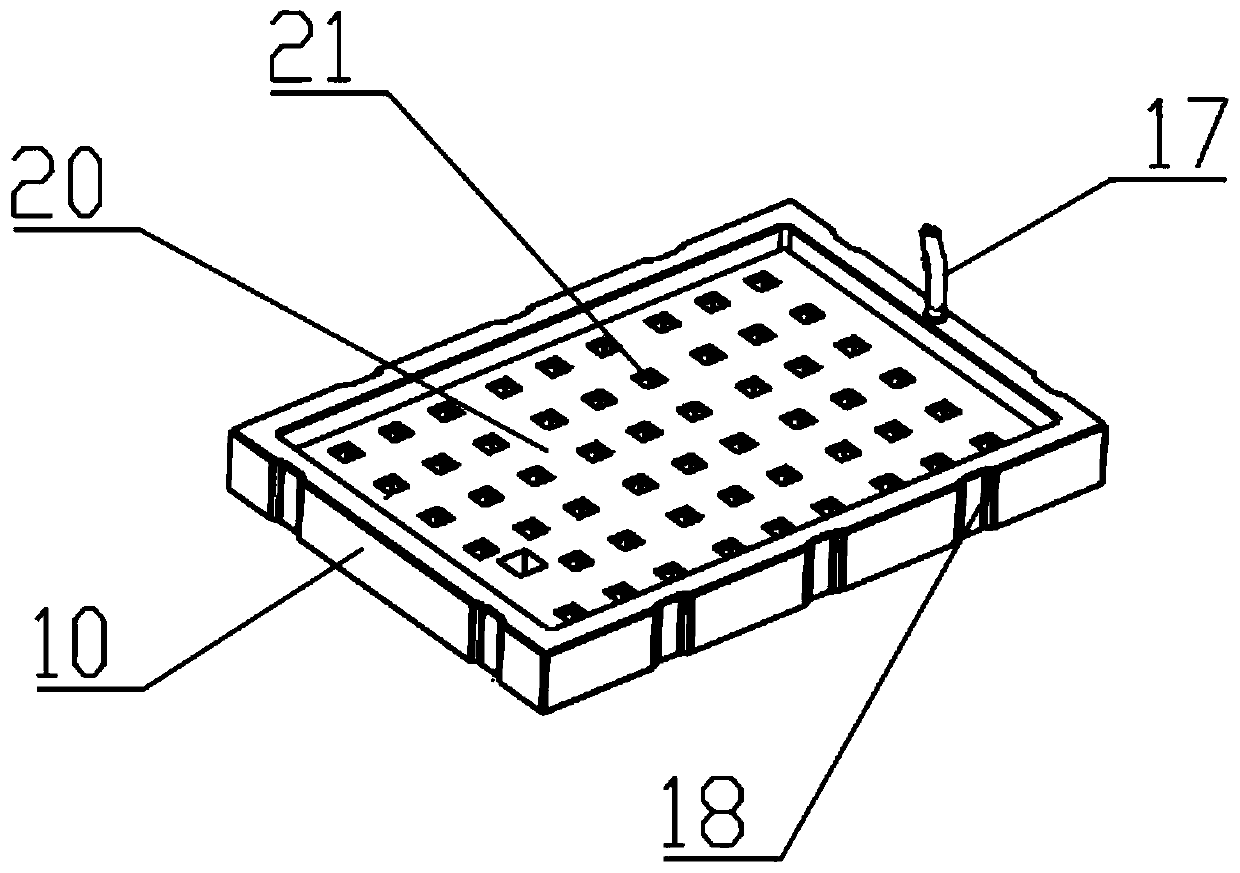

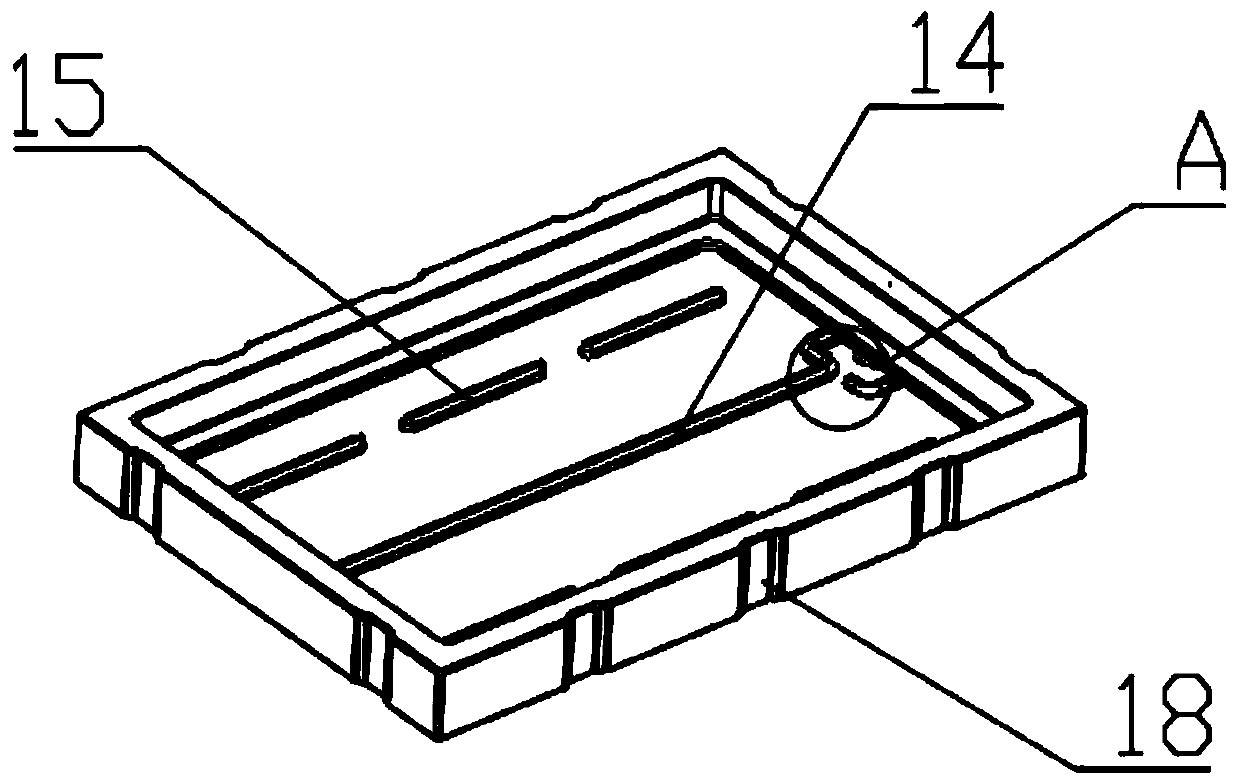

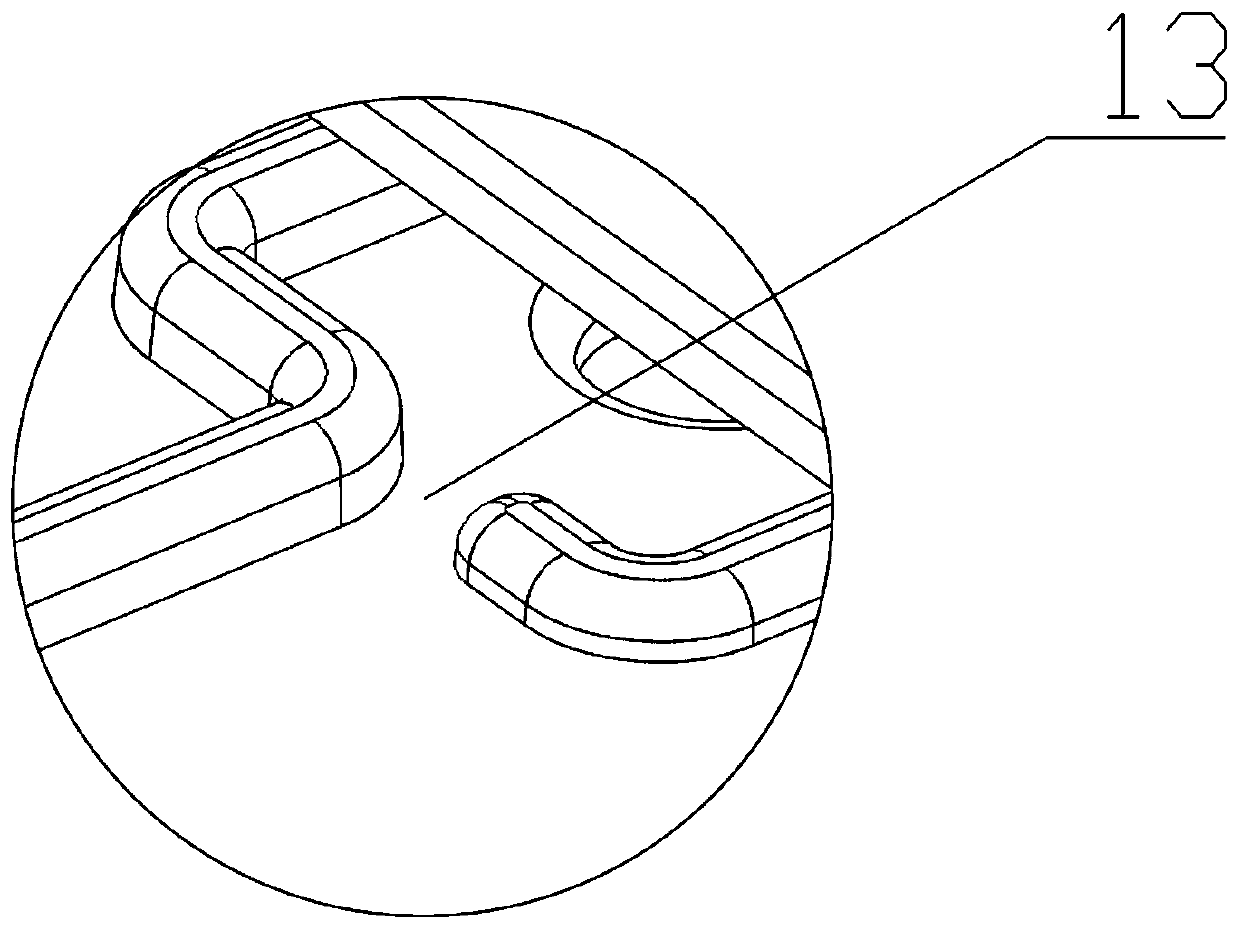

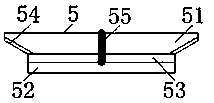

Planter and cultivation module applicable to ships

PendingCN111528079AHas water storage capacityIncrease water flowAgriculture gas emission reductionCultivating equipmentsWater storageWater flow

The invention relates to the field of plant-cultivating equipment and discloses a planter applicable to ships. The planter includes a field planting board and a cultivating tank. The cultivating tankis arranged with a water inlet and a water outlet. The cultivating tank includes a base plate and lateral plates surrounding and enclosing the base plate. The top of each of the lateral plates bends inward and extends to form a supporting platform. Water-storing space is formed between the supporting platform and one of the lateral plates. A water flow channel is formed between the supporting platform and the base plate. The water-storing space is communicated with the cultivating tank through the water flow channel. The field planting board is arranged on the supporting platform. The invention also discloses a cultivation module applicable to the ships. The plant-cultivating equipment provided by the invention can ensure that nutrient solution does not spill and plants can grow normally in a moving or shaking environment of conducting scientific investigation and moving equipment in places like oceangoing vessels, long-distance transport vehicles and remote and insecure regions.

Owner:FUJIAN SANAN SINO SCI PHOTOBIOTECH CO LTD

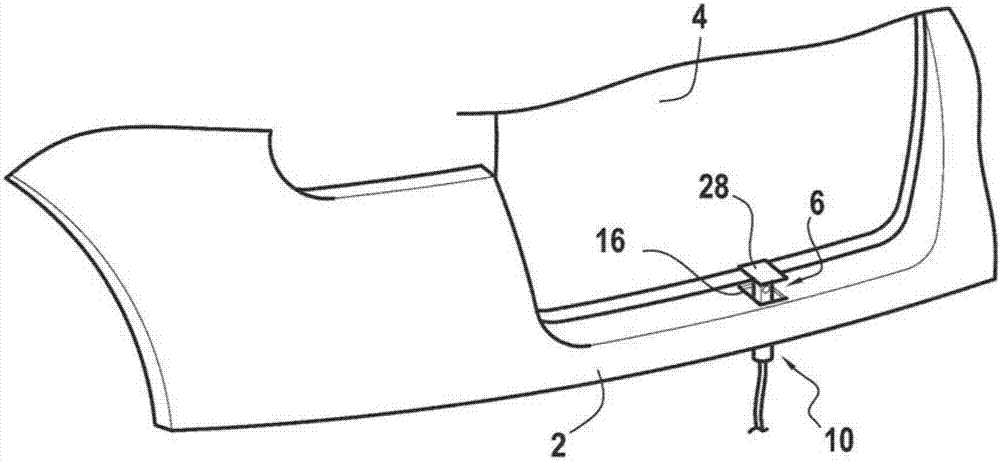

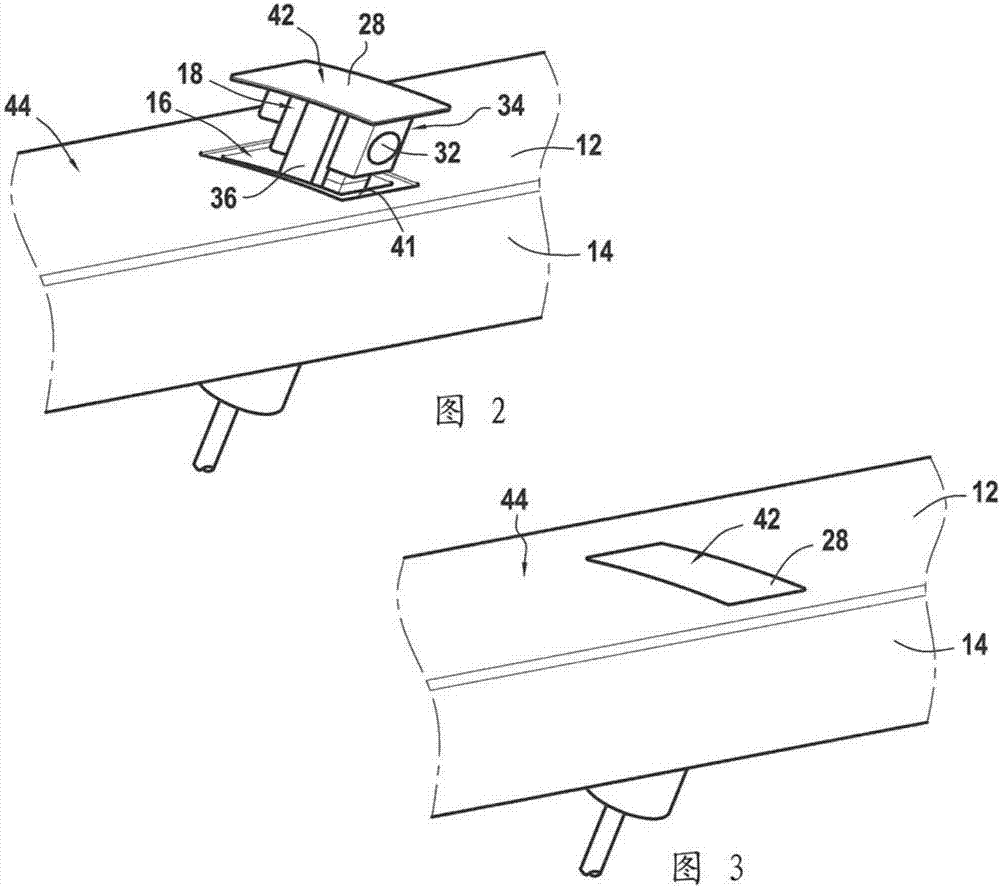

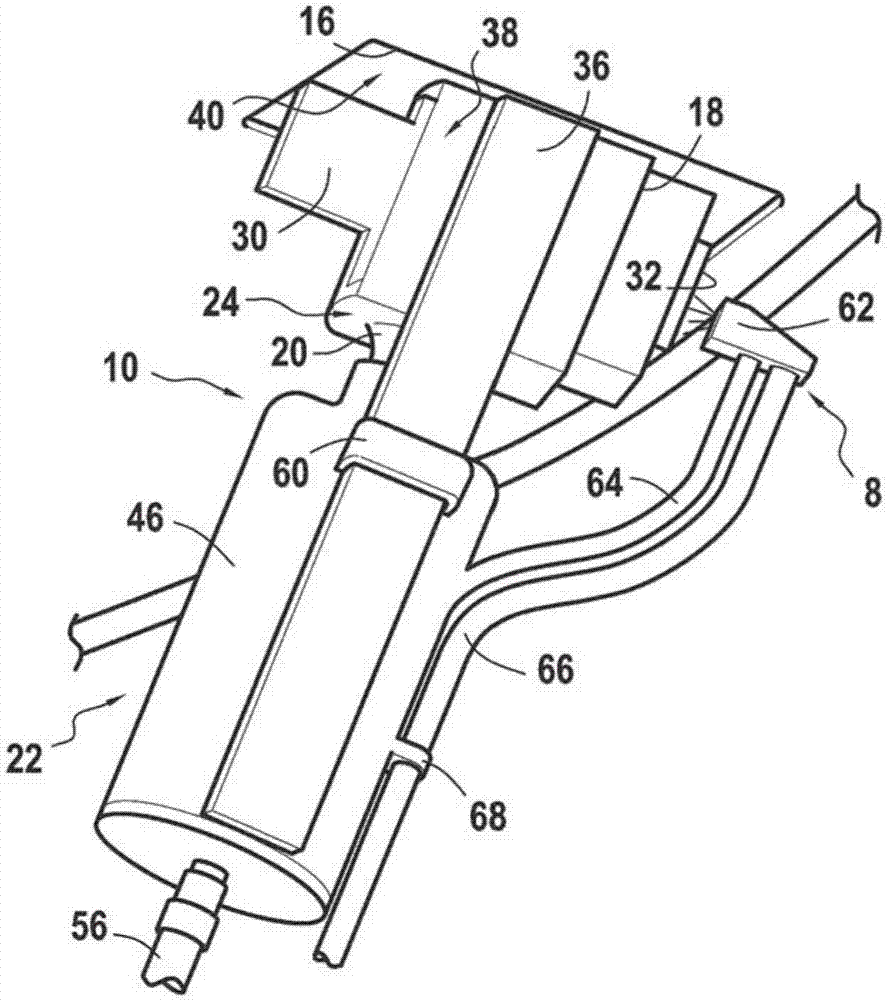

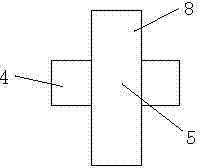

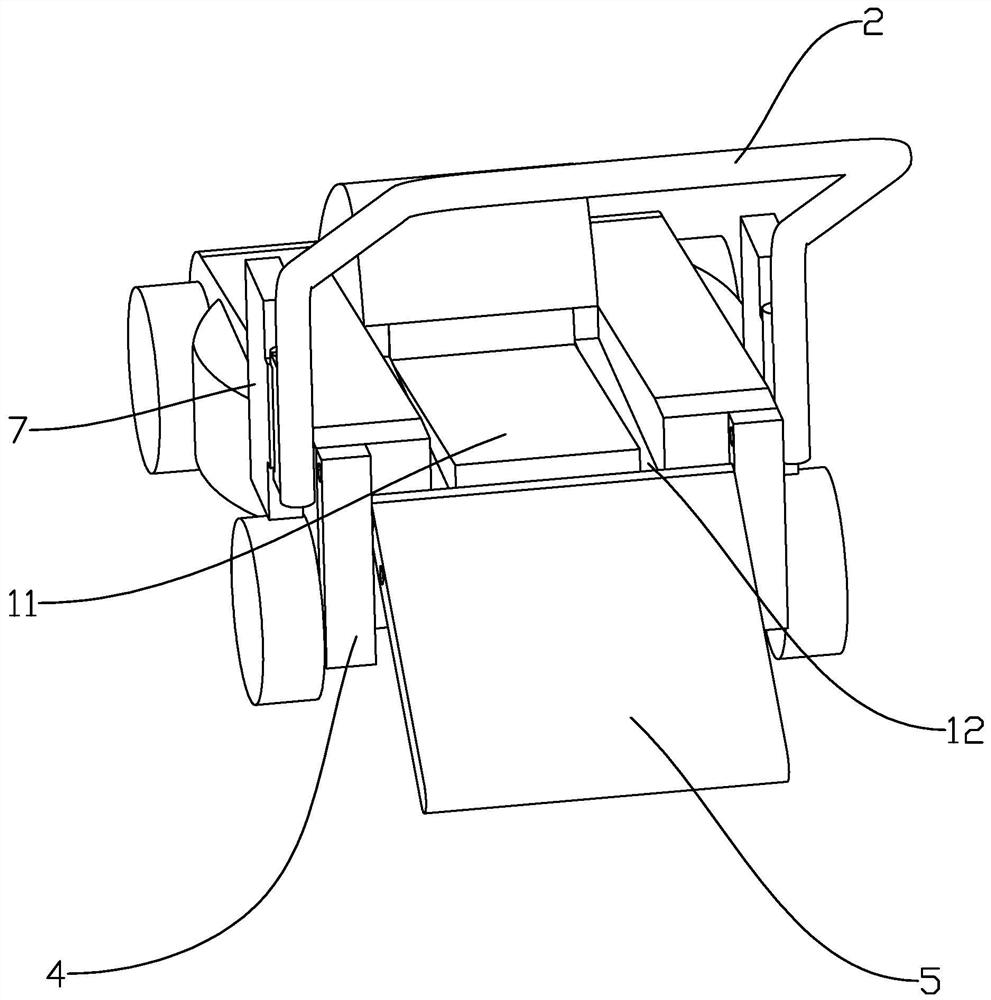

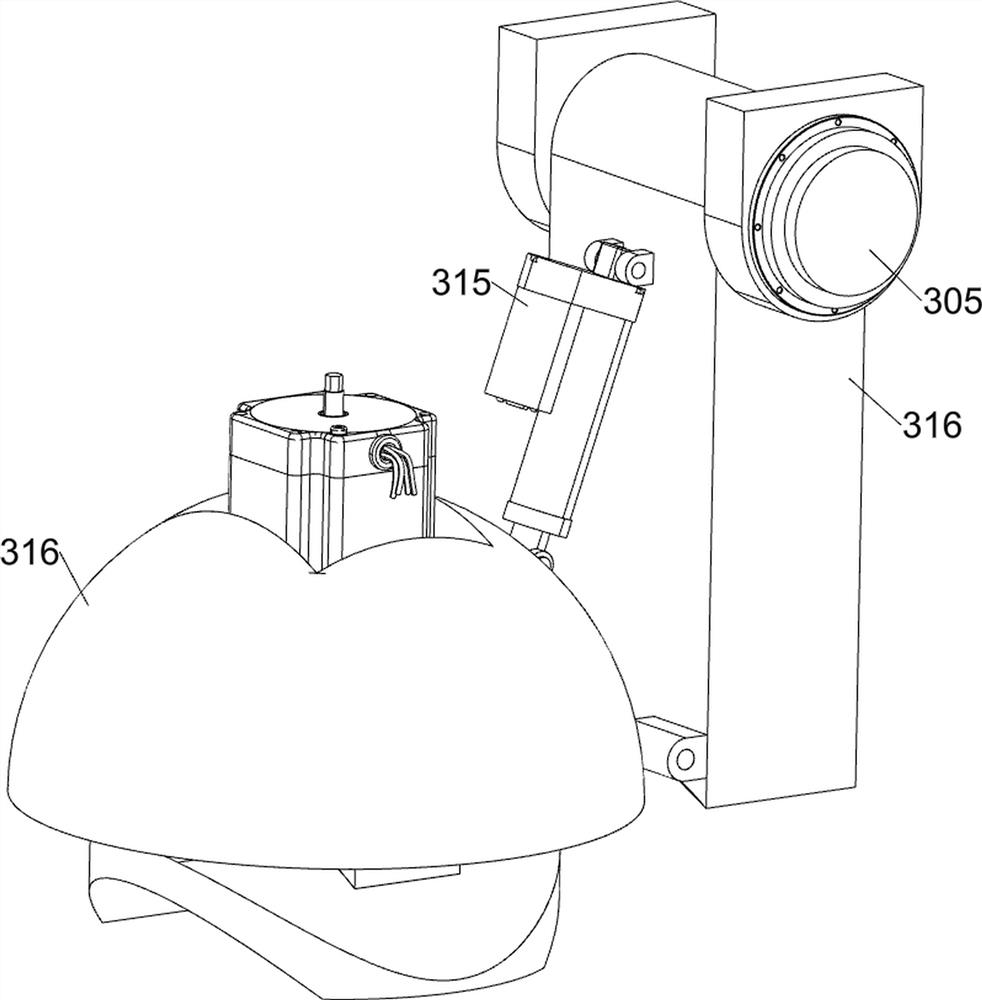

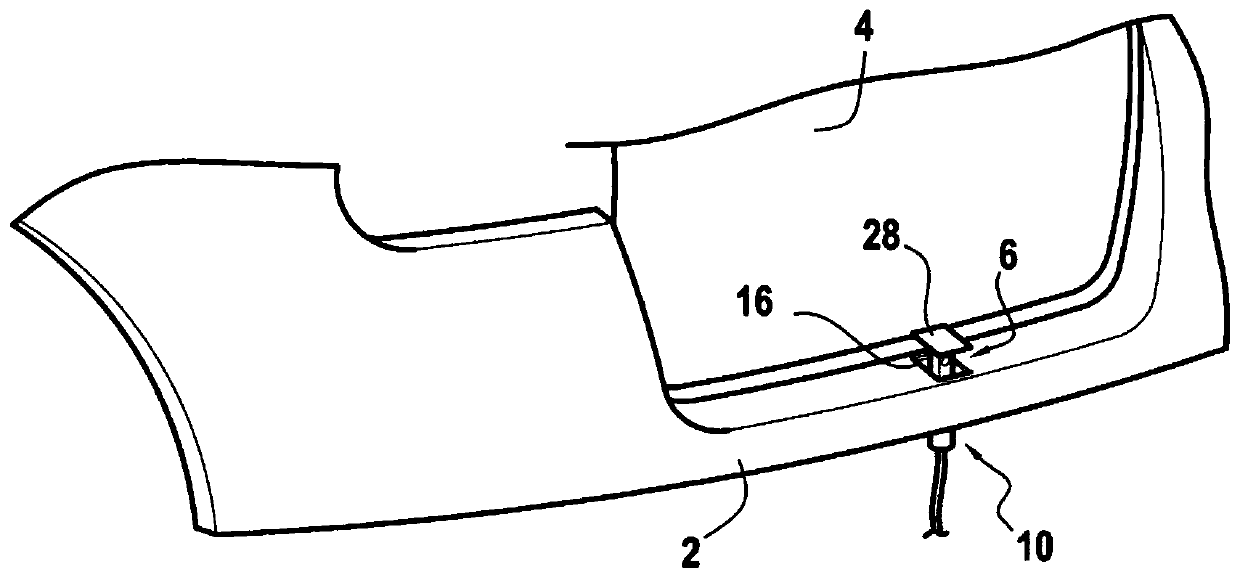

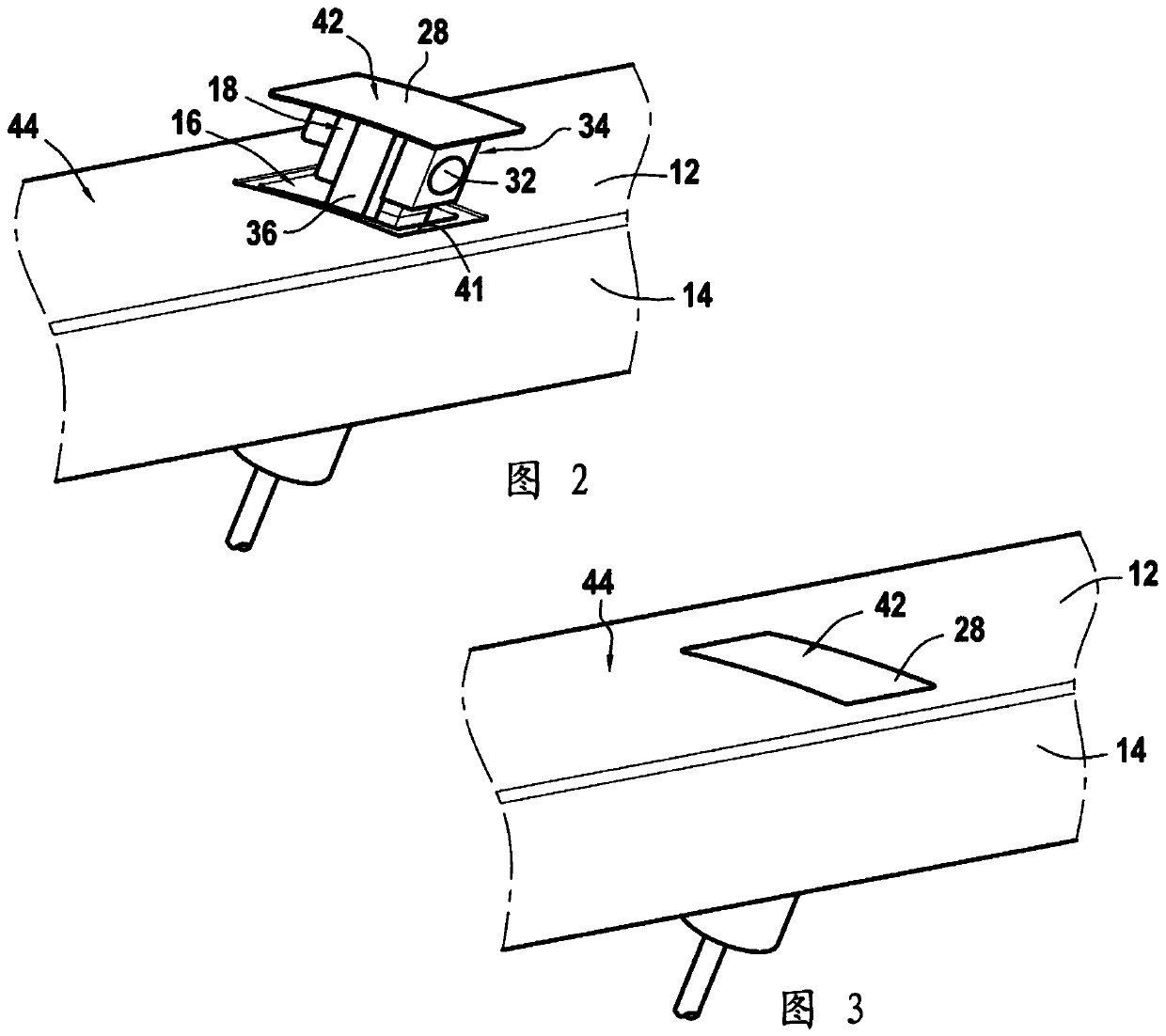

Device for cleaning a driver assistance camera of a motor vehicle

A device for cleaning a camera lens (6), by means of a cleaning head, comprises a fixed cleaning head and a camera that is made mobile by means of drive means (10), the head being accommodated in a structural element (2) of the vehicle. The drive means are suitable for generating a relative movement of the camera in relation to the cleaning head, between a passive image capture position in which the camera is disposed accommodated in said structural element of the vehicle facing the cleaning head, and an active position in which the camera is deployed at a distance from the structural element of the vehicle to allow image capture. The device is particularly effective when applied to the cleaning of a reversing camera implanted in motor vehicles.

Owner:VALEO SYST DESSUYAGE

Built-in pneumatic guide heating multi-cleaning and multipurpose tank for fasteners

InactiveCN107433267AEasy to cleanLiquid splashDrying machines with progressive movementsCleaning using liquidsEngineeringAir compressor

The invention provides a built-in pneumatic guide heating multi-cleaning and multipurpose tank for fasteners. The built-in pneumatic guide heating multi-cleaning and multipurpose tank for the fasteners comprises a shell and a conveying belt, wherein the two ends of the shell are open, and the conveying belt is arranged in the shell. The shell is sequentially provided with a first cleaning tank, a second cleaning tank, a third cleaning tank and a drying tank, single-screw blade rolling racks and air compressors connected with the rolling racks are arranged in the three cleaning tanks correspondingly, water inlets are formed in the tops of the three cleaning tanks correspondingly, and water outlets provided with long electrical heating tubes are formed in the bottoms of the cleaning tanks correspondingly; a heating device is arranged on the drying tank, openings for allowing the conveying belt to pass are sequentially formed between every two tank bodies of the first cleaning tank, the second cleaning tank, the third cleaning tank and the drying tank, and air seal mechanisms are arranged at the openings of the three cleaning tanks correspondingly; and the horizontally arranged conveying belt passes through the shell, penetrates through the openings of the two ends of the shell and extends out of the shell, and the pneumatic rollers are arranged at the two ends of the conveying belt correspondingly. According to the built-in pneumatic guide heating multi-cleaning and multipurpose tank for the fasteners, the functions are diversified, cleaning automation is achieved, the cleaning effect is good, the cleaning amount at a time is large, and the cleaning efficiency is improved.

Owner:NINGBO CITY YINZHOU FENGMING IND PROD DESIGN

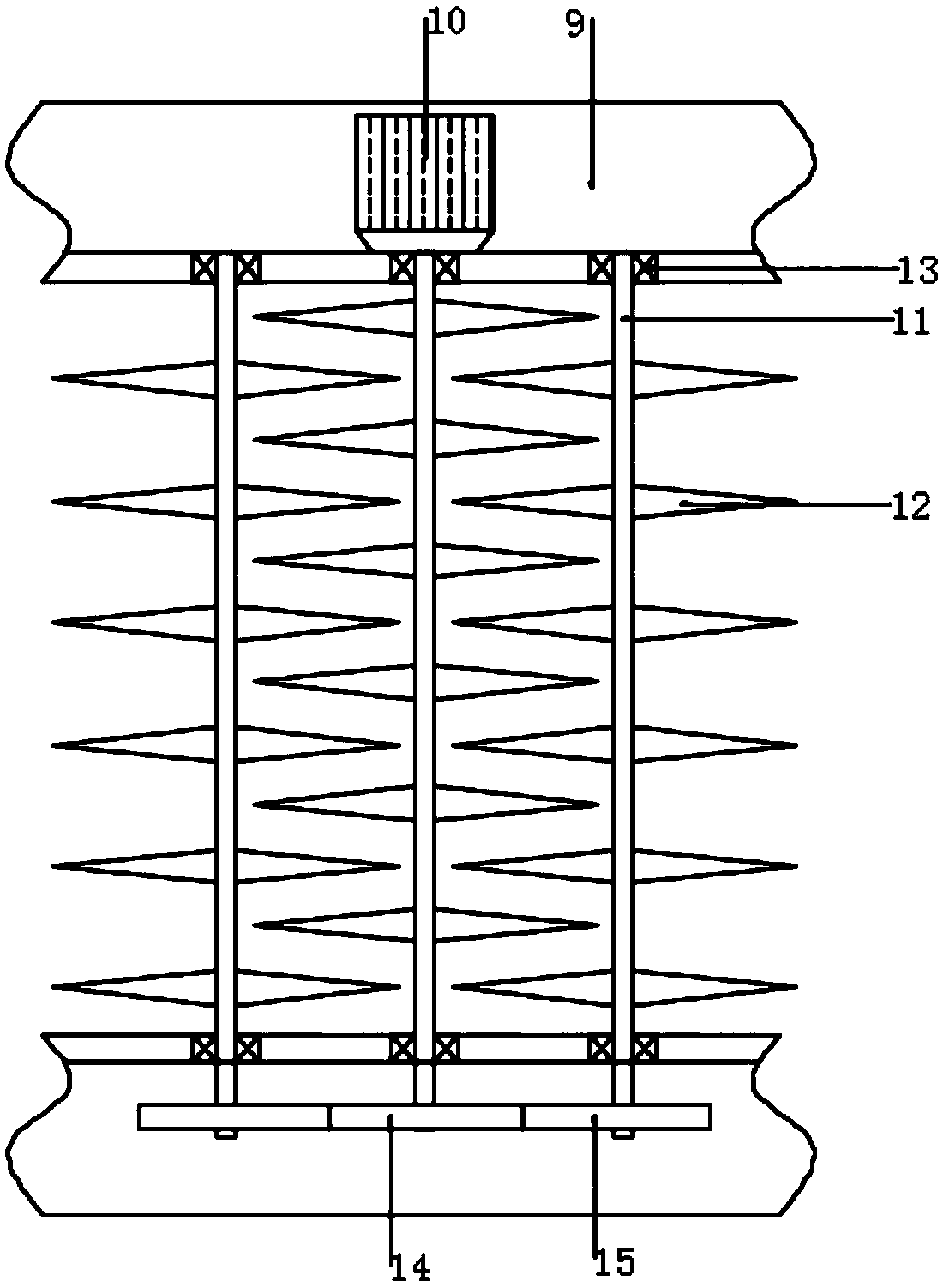

Washing device for bulbs

InactiveCN103480612AEasy and efficient cleaningClean upHollow article cleaningCleaning using liquidsWater collectionElectrical and Electronics engineering

The invention belongs to the technical field of bulb appliances, and particularly relates to a washing device for bulbs. The washing device comprises a frame, two opposite transmission chains are arranged on the frame, the transmission chains are connected with stepping motors through gears, a plurality of connection plates are arranged between the two opposite transmission chains, the connection plates move circularly under the act of the transmission chains, a plurality of lampholes are arranged on the connection plates, water injectors are arranged on the frame below the connection plates, the water injectors and the lampholes are correspondingly arranged, and water collection tanks are arranged below the water injectors. By the aid of the washing device, mechanization operation of washing of the inner walls of the bulbs is achieved, the washing of the bulbs becomes simpler, more convenient and more efficient, and the bulbs are also more cleanly.

Owner:DEQING SHENGXING LIGHTING APPLIANCE

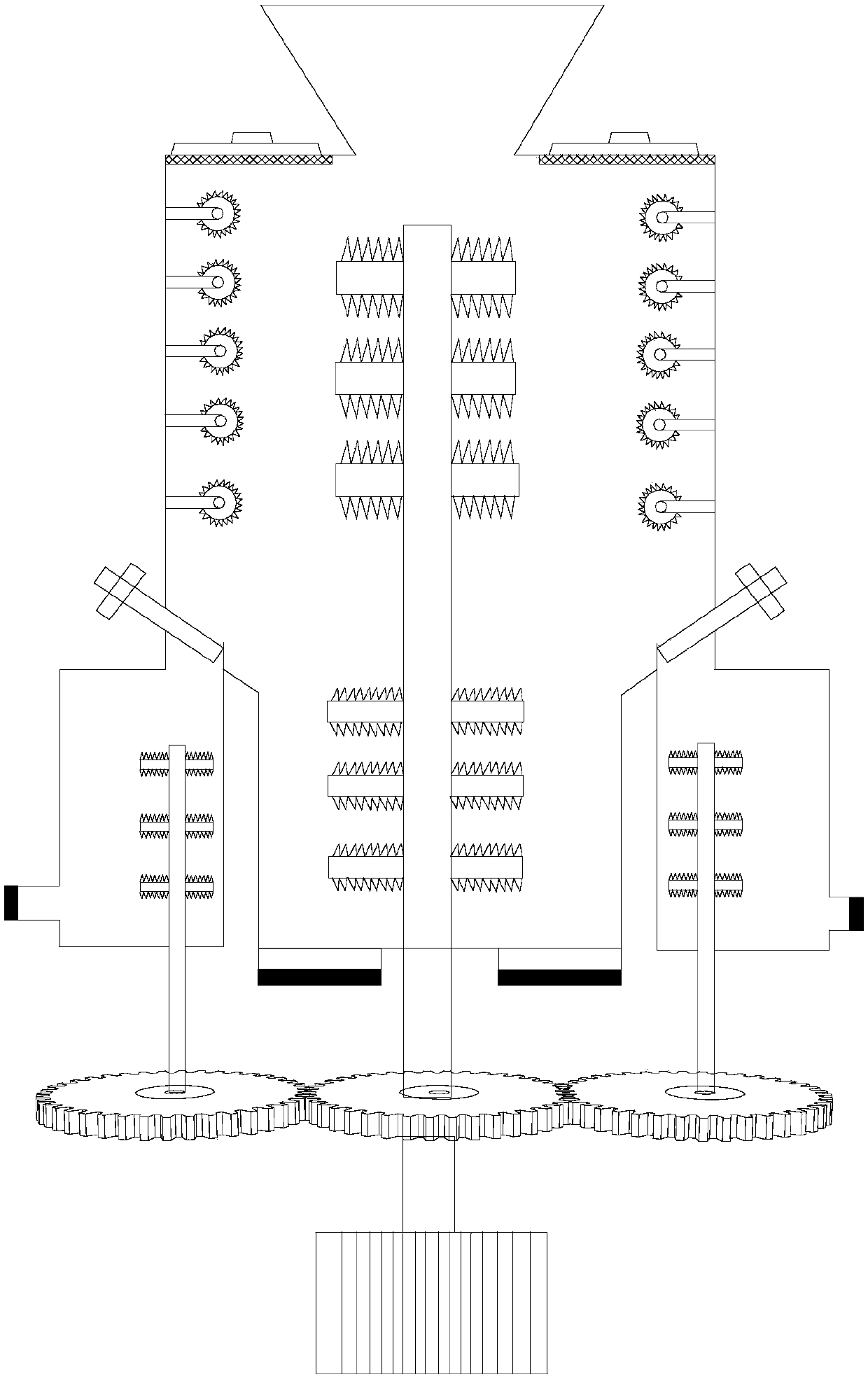

Wear-resisting vertical crusher

The invention discloses a wear-resistant vertical crusher, which relates to the field of aggregate fine crushing, and includes a crushing cavity and a crushing mechanism. The top of the crushing cavity is provided with an aggregate inlet and a cavity cover. The crushing mechanism includes a motor, A crushing rotor is provided on the rotating shaft connected to the rotating shaft, the crushing rotor includes a crushing blade, a connecting rod for installing the crushing blade, the motor is connected to the rotating shaft through a gear; the crushing chamber includes a main crushing chamber, The lower part of the main crushing chamber is divided into the first crushing chamber, the second crushing chamber and the third crushing chamber, a first electromagnetic valve is set between the top of the second crushing chamber and the main crushing chamber, and the third crushing chamber Due to the relatively large volume and weight of the aggregate after the primary crushing of the existing vertical crusher, it will generate a large impact force on the inner wall of the crusher, and this impact force will cause damage to the inner wall, and The traditional vertical crusher cannot obtain aggregates of two particle sizes at the same time after crushing aggregates.

Owner:沈波

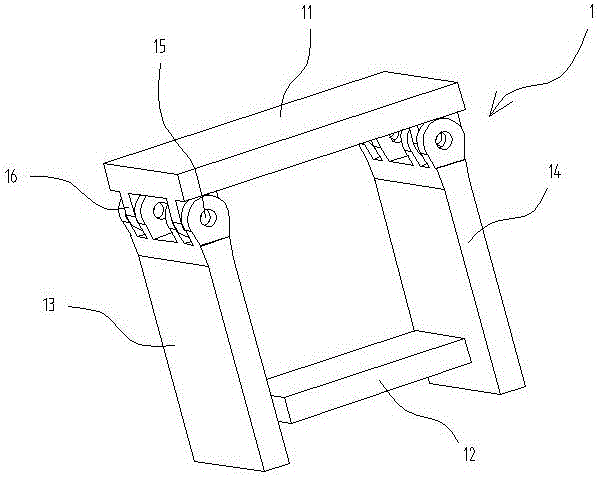

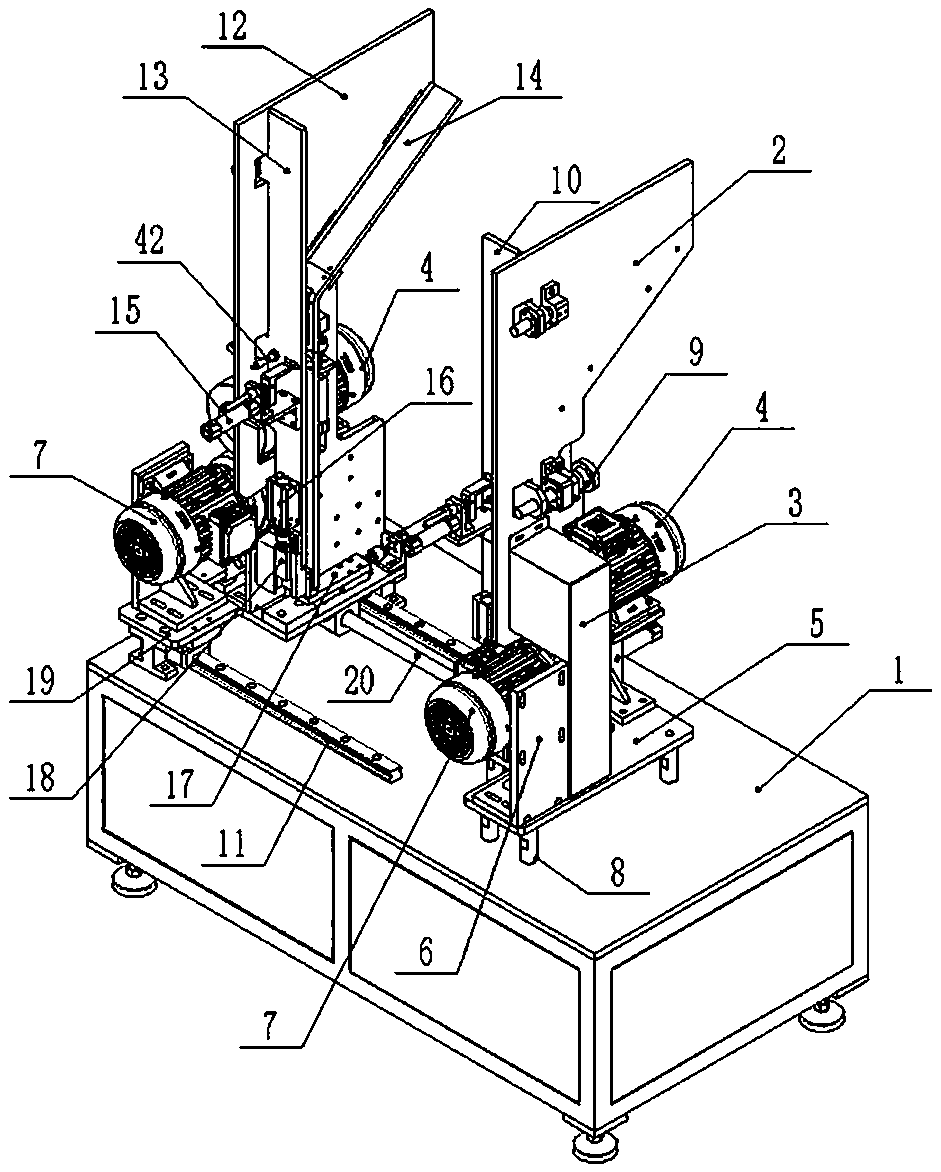

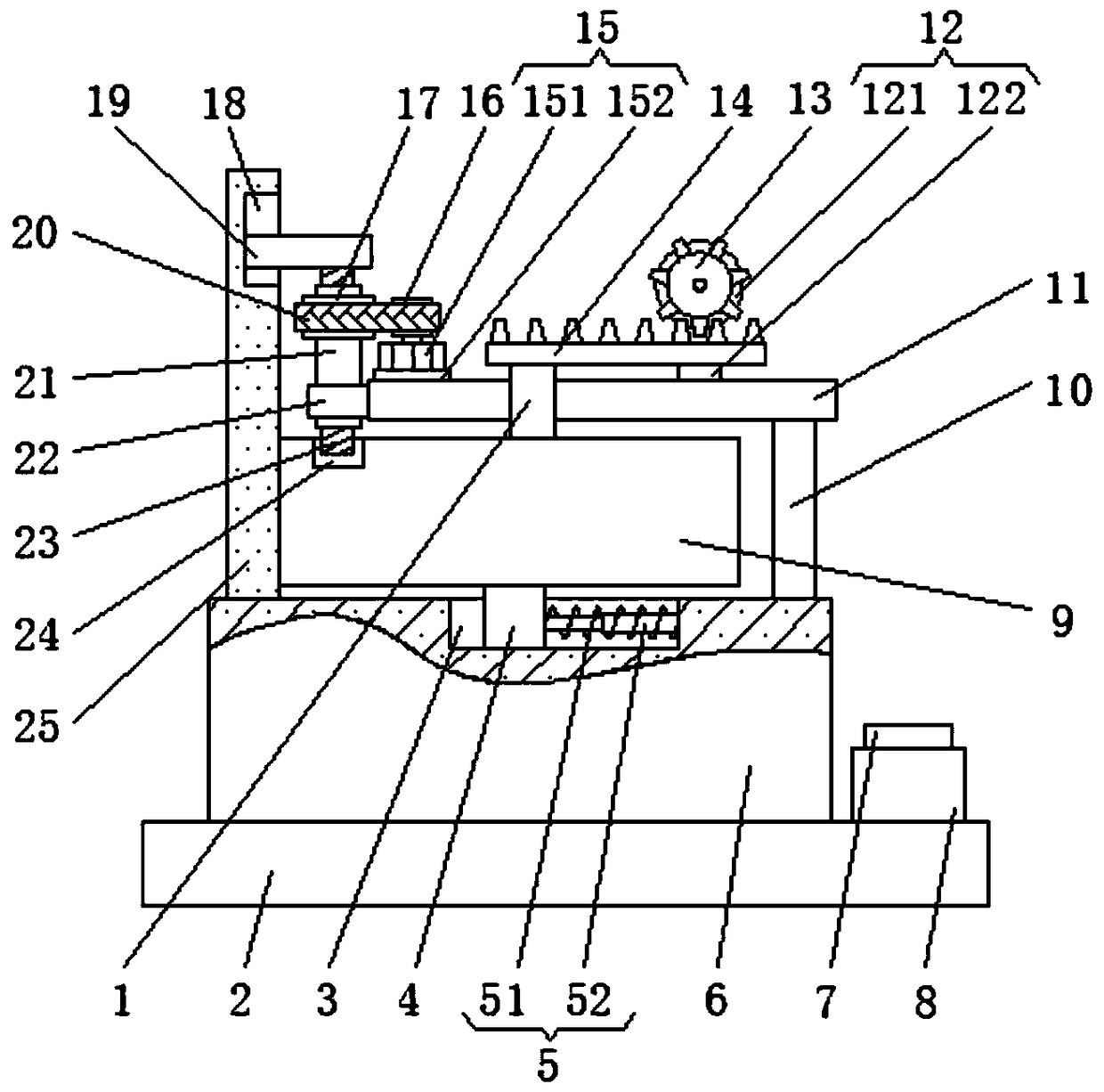

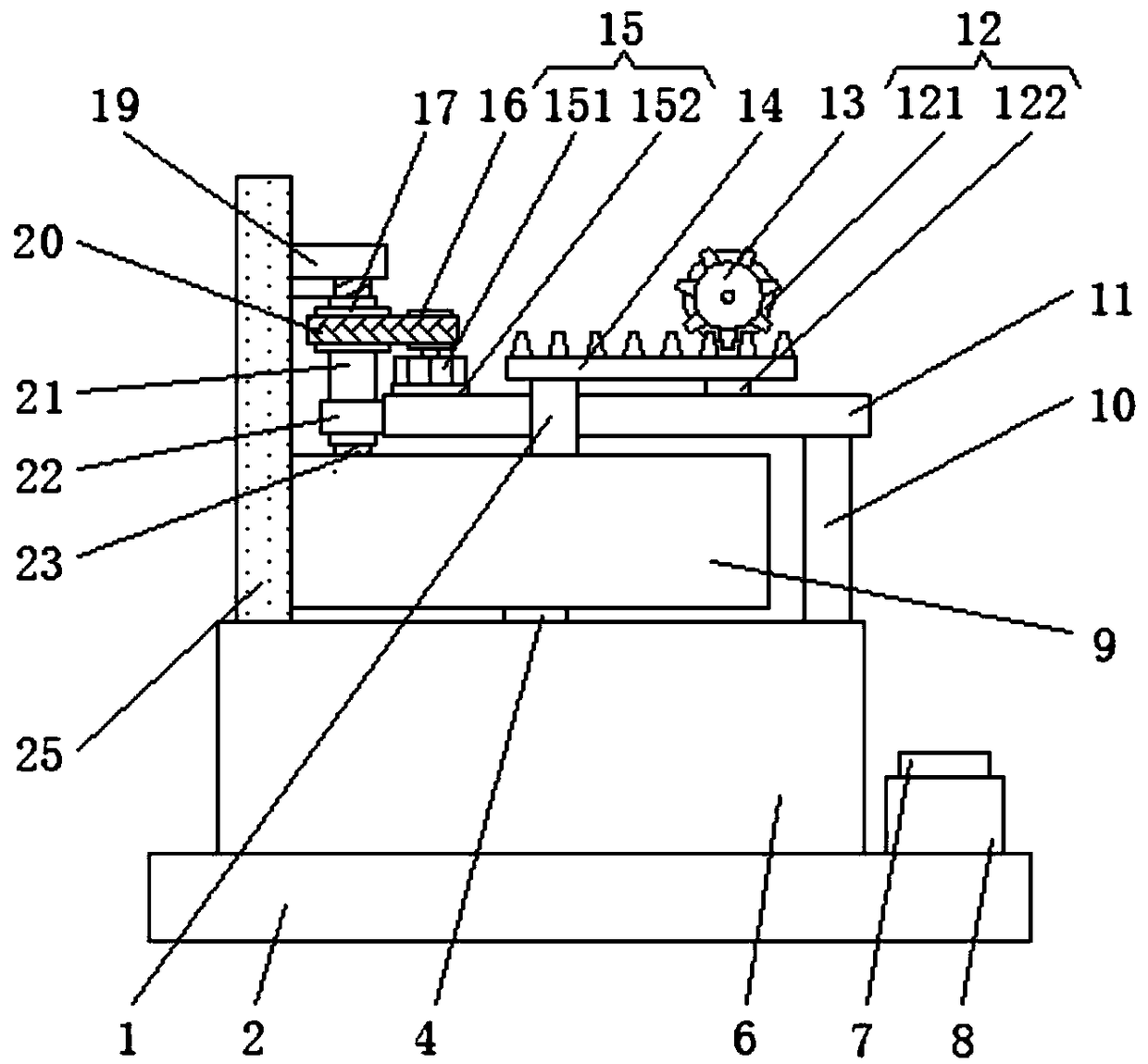

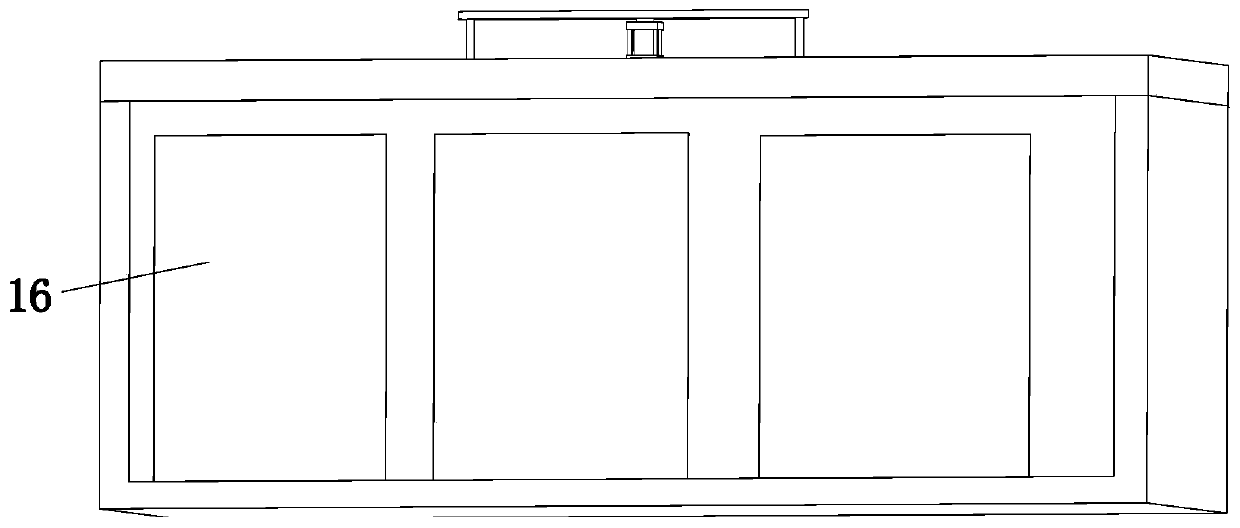

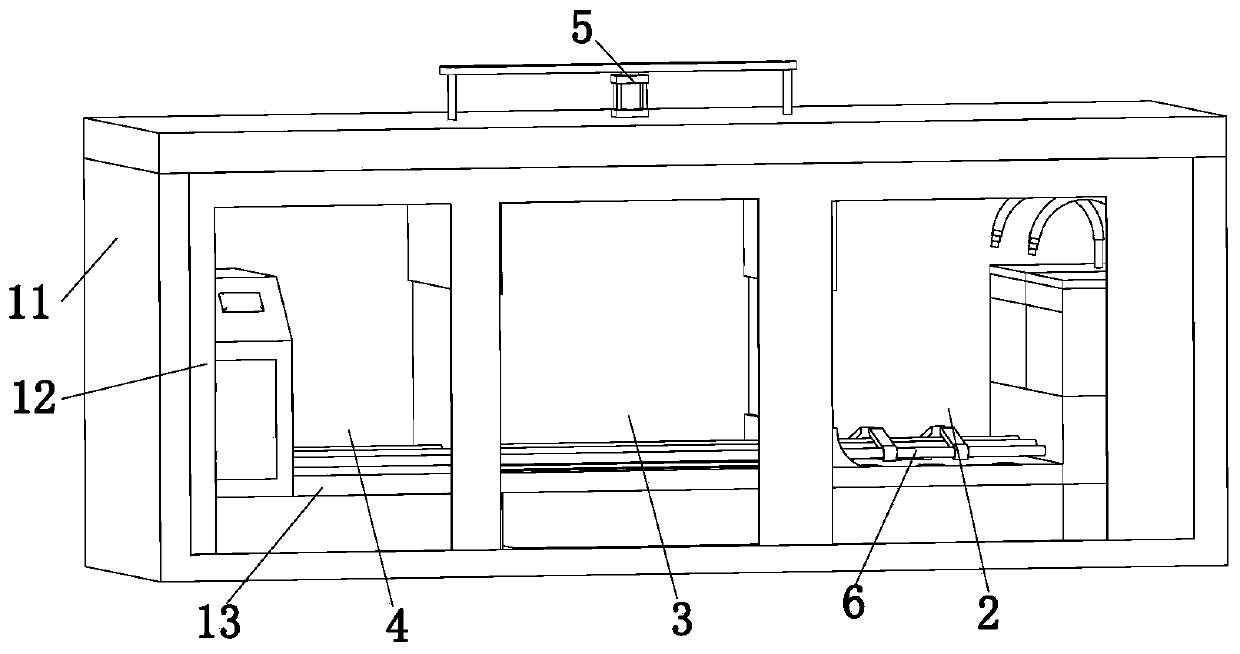

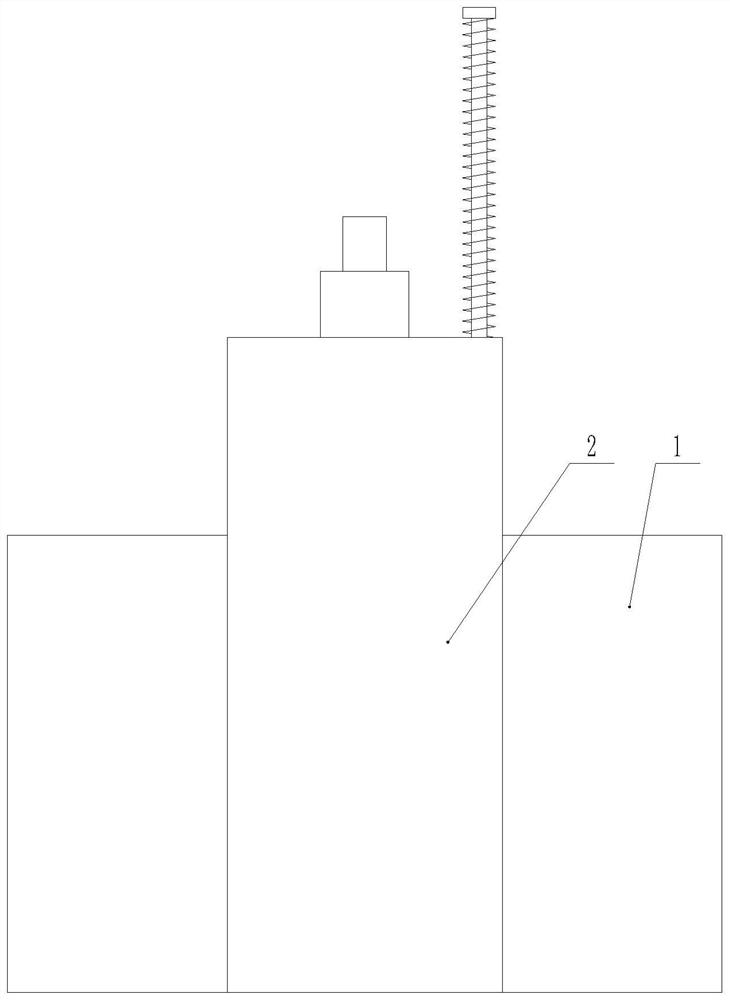

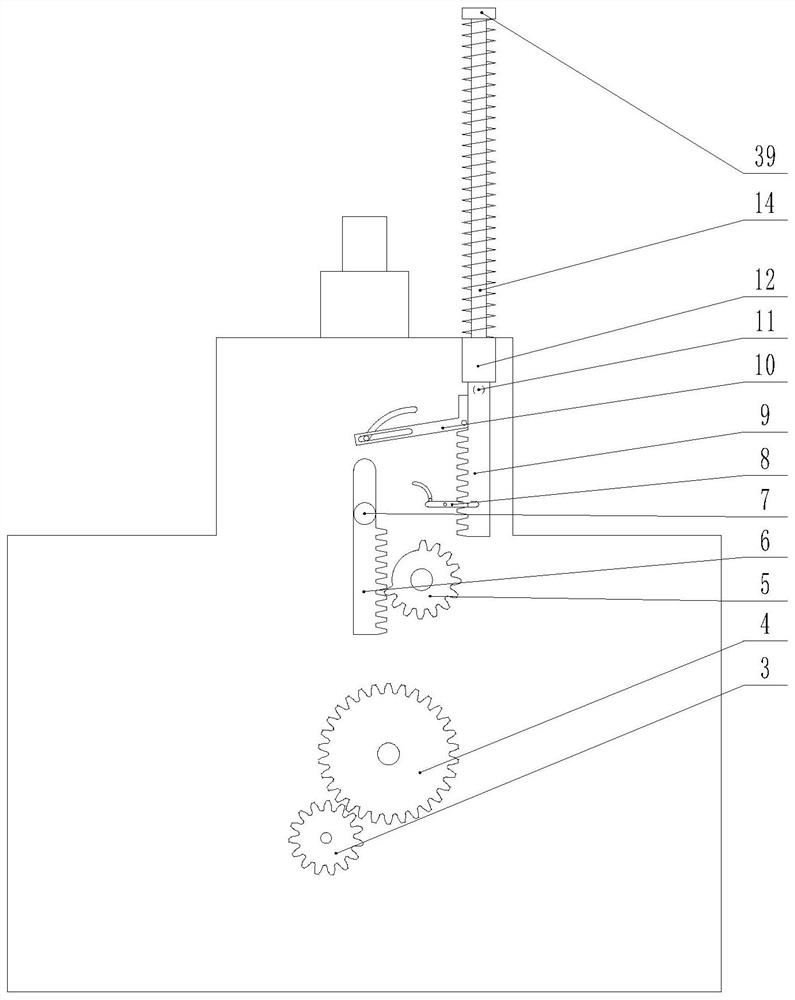

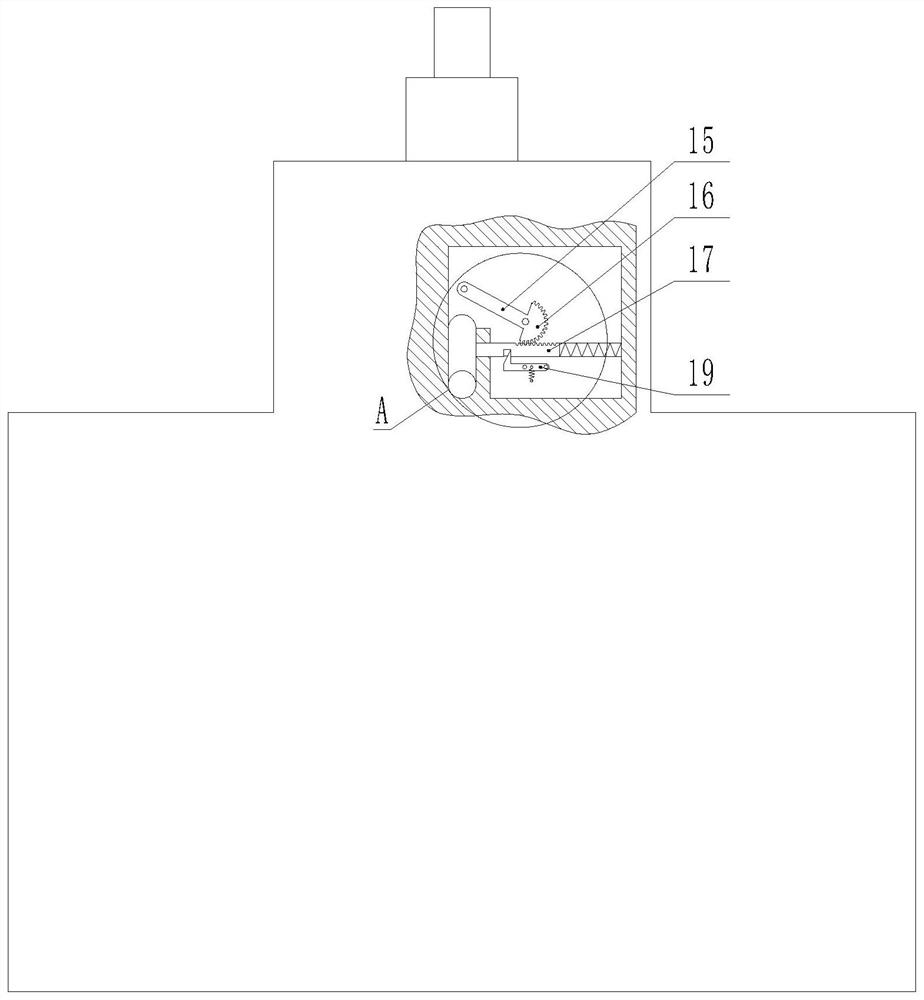

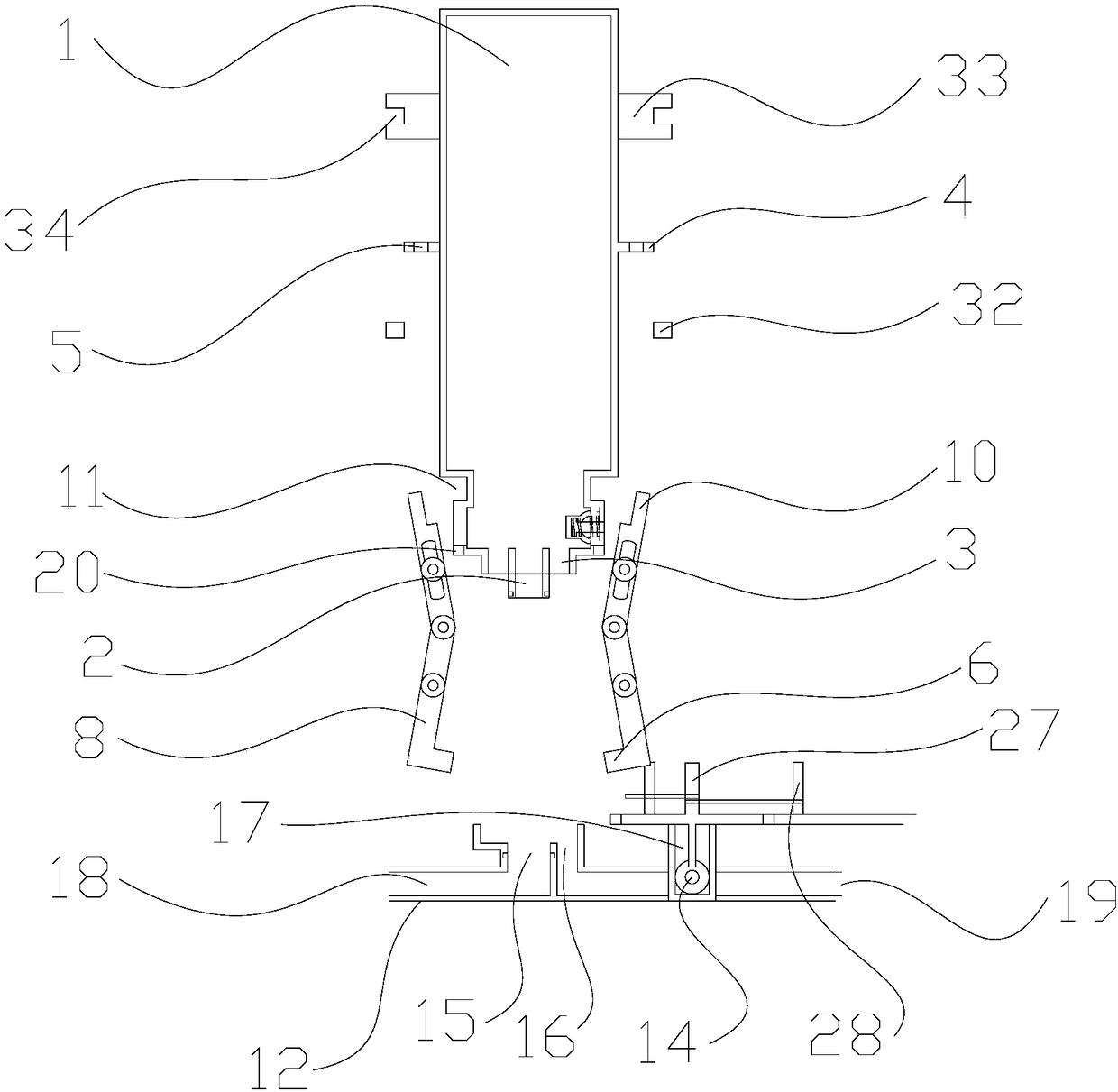

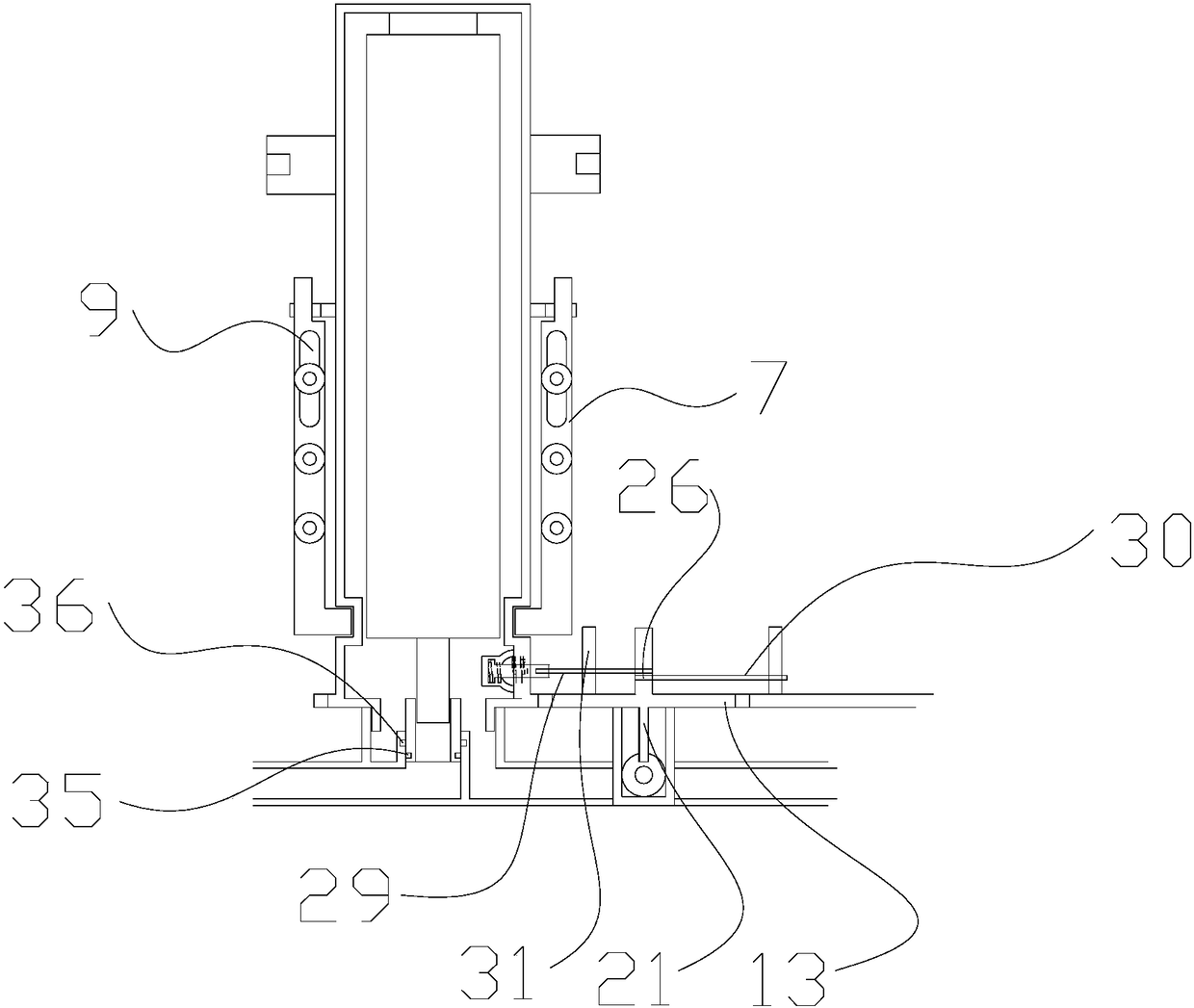

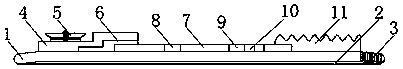

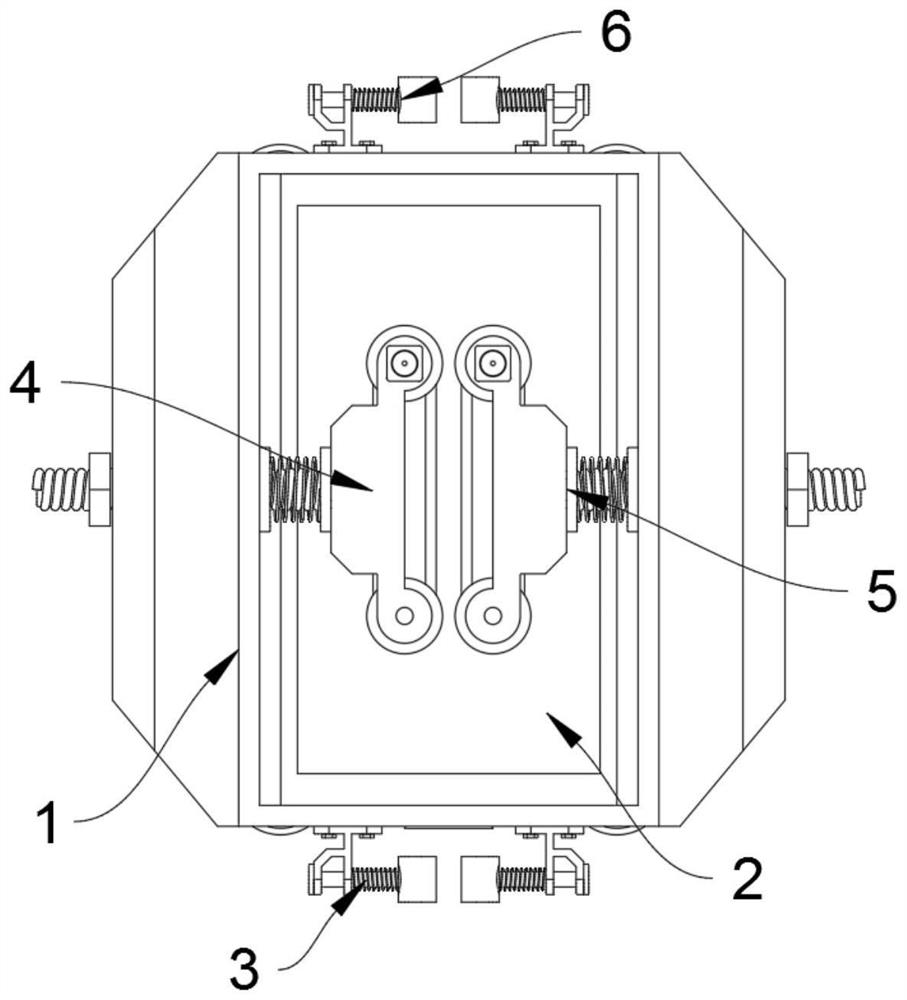

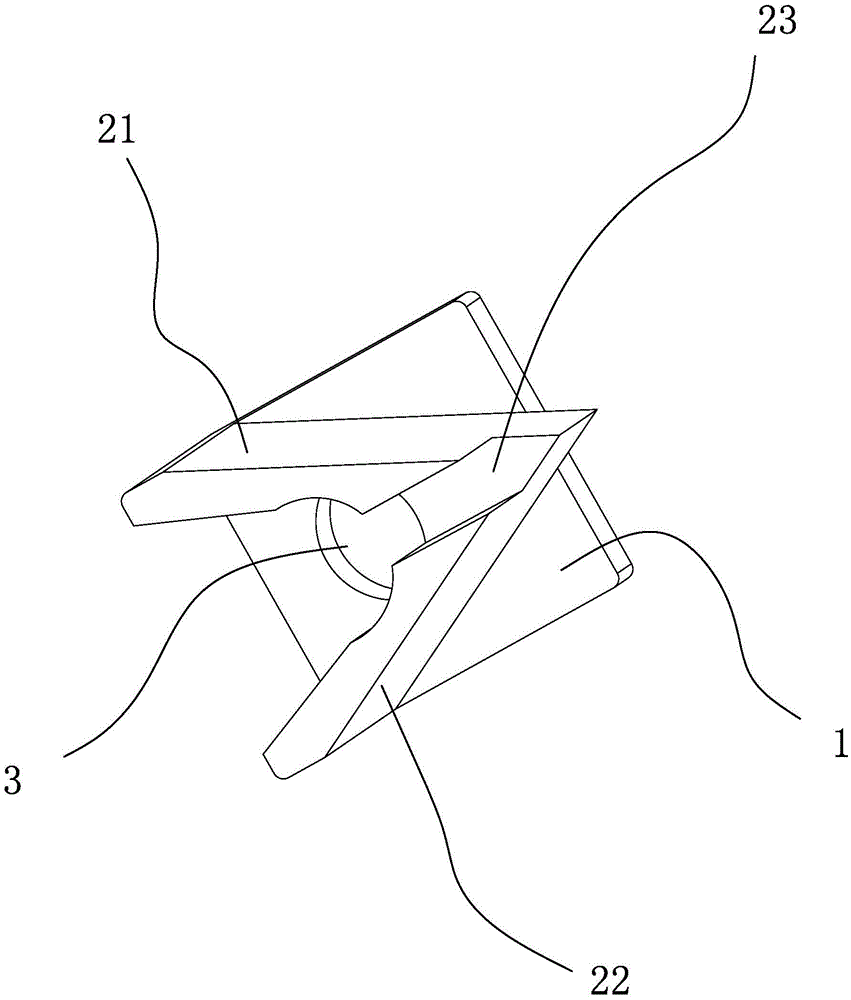

Numerical control pull rod pipe burr removing machine

PendingCN108637822AWill not sputterAdjustable widthEdge grinding machinesGrinding feedersNumerical controlElectric machinery

The invention discloses a numerical control pull rod pipe burr removing machine which comprises a table board, a moving material bin base plate, a fixed material bin base plate, a first motor, a second motor, self-locking devices, material pushing rod devices, pipe adjusting devices and a distance adjuster. Waste discharging openings are formed in the center of the bottom of the moving material bin base plate and the center of the bottom of the fixed material bin base plate. The material pushing rod devices are arranged on the moving material bin base plate and the fixed material bin base plate correspondingly. The self-locking devices are arranged on the rear side of a first width adjusting plate and the rear side of a second width adjusting plate correspondingly. The pipe adjusting devices are arranged on the middle portion of a left side guide blade and the middle portion of a right side guide blade correspondingly. A first air pressure telescoping rod assembly and a first pushing plate are arranged in each pipe adjusting device. The first pushing plate is connected to the upper end of the corresponding first air pressure telescoping rod assembly. According to the machine, energy resources are saved, power does not need to be provided for enabling pipes to enter machining equipment, waste can be collected, the waste generated by a grinding device will not be splashed, and the machine is operable from the performance, and is efficient and safe.

Owner:广州英固特智能装备有限公司

Protecting device for milling machine

InactiveCN109176136AControl displacementSolve the problem of excessive displacementMaintainance and safety accessoriesDrive wheelEngineering

The invention discloses a protecting device for a milling machine. The device comprises a base plate; the upper surface of the base plate is fixedly connected with the lower surface of a milling machine body; a first chute is formed in the upper surface of the milling machine body; a first slide block is arranged in the first chute; the right side surface of the first slide block is fixedly connected with the right side surface of the inner wall of the first chute through an extension device; the upper surface of the first slide block is fixedly connected with the lower surface of a protectingplate; the upper surface of the protecting plate is fixedly connected with the lower surface of a slide sleeve; and the slide sleeve sleeves the outer surface of a slide rod. Through arrangement of the protecting plate, a groove, a thread column, a thread cylinder, the slide sleeve, a first transmission device, a second transmission device, a driving wheel, a driven wheel, the first slide block,a second support plate, an accumulator and a switch, the protecting device for the milling machine cannot enable metal chips from splashing to worker bodies in the cutting process, so that the workerskin cannot be scratched, and the potential safety hazard is reduced.

Owner:章贤德

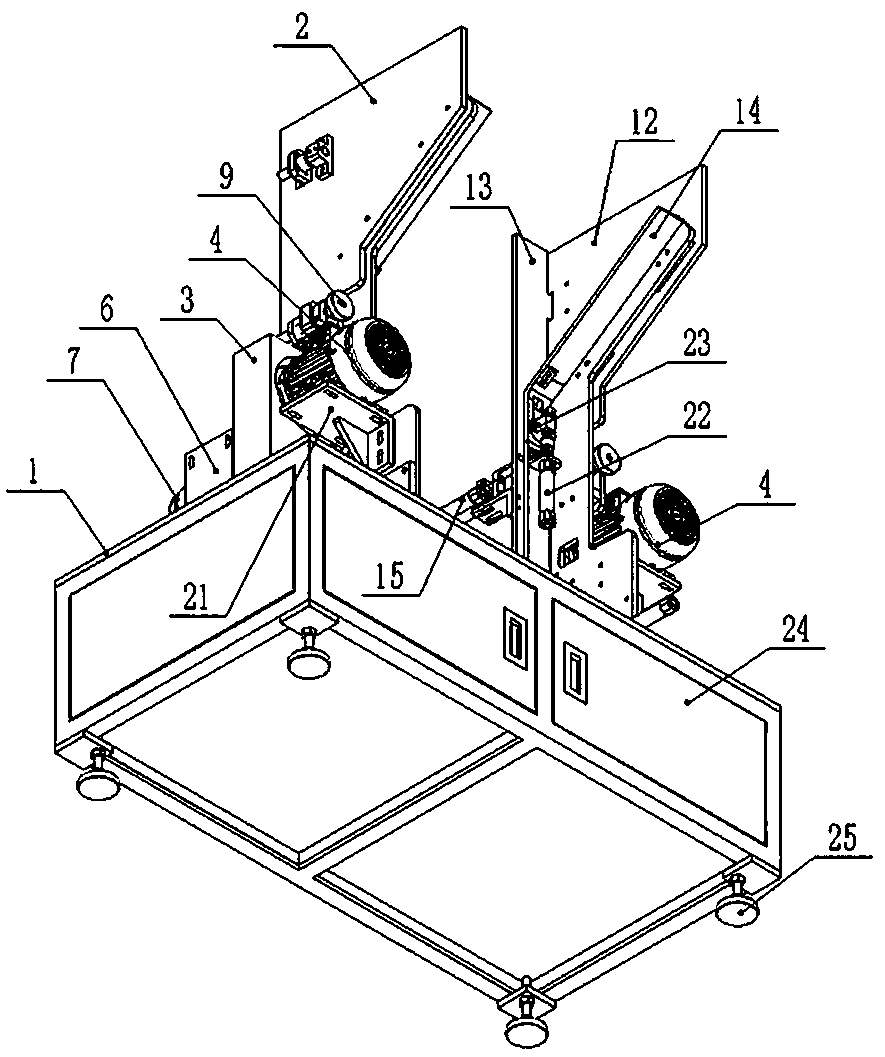

Tire cleaning and rubber spraying integrated machine

InactiveCN111531930AIncrease work rateSolve the dirtTyresDrying chambers/containersAutomotive engineeringAssembly line

The invention relates to the technical field of tire processing, and in particular to a tire cleaning and rubber spraying integrated machine. The tire cleaning and rubber spraying integrated machine comprises a machine case, a washing bin, a drying bin, a rubber spray bin, a closing device and a tire driving device; the machine case is arranged on the ground; the washing bin, the drying bin, the rubber spray bin, the closing device and the tire driving device are arranged inside the machine case; the washing bin, the drying bin and the rubber spray bin are sequentially arranged inside the machine case in the order of the movement direction of a tire; the closing device is connected with the top of the machine case; the tire driving device is arranged inside the machine case after penetrating through the cleaning bin, the drying bin, the rubber spray bin and the tire driving device so as to solve the problems about excessive waste of floor space during actual application of assembly line type tire cleaning and spraying operation as well as dirt on the ground and too much sewage caused by the assembly line type operation that requires frequent manual washing.

Owner:郑云龙

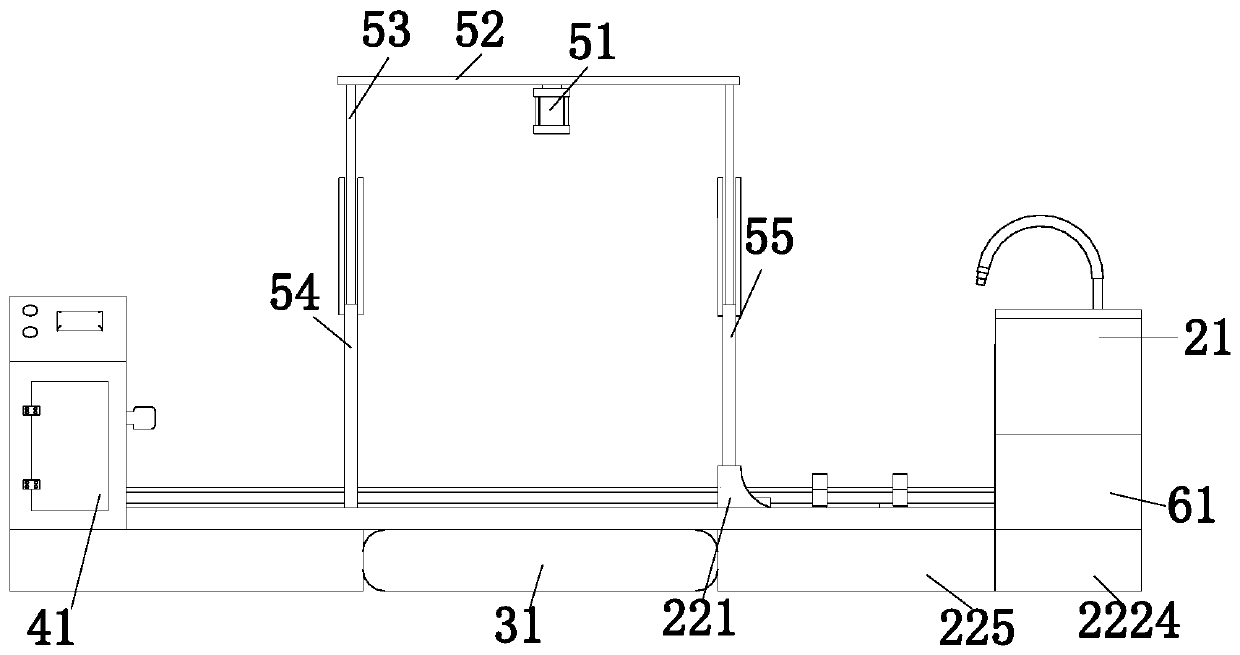

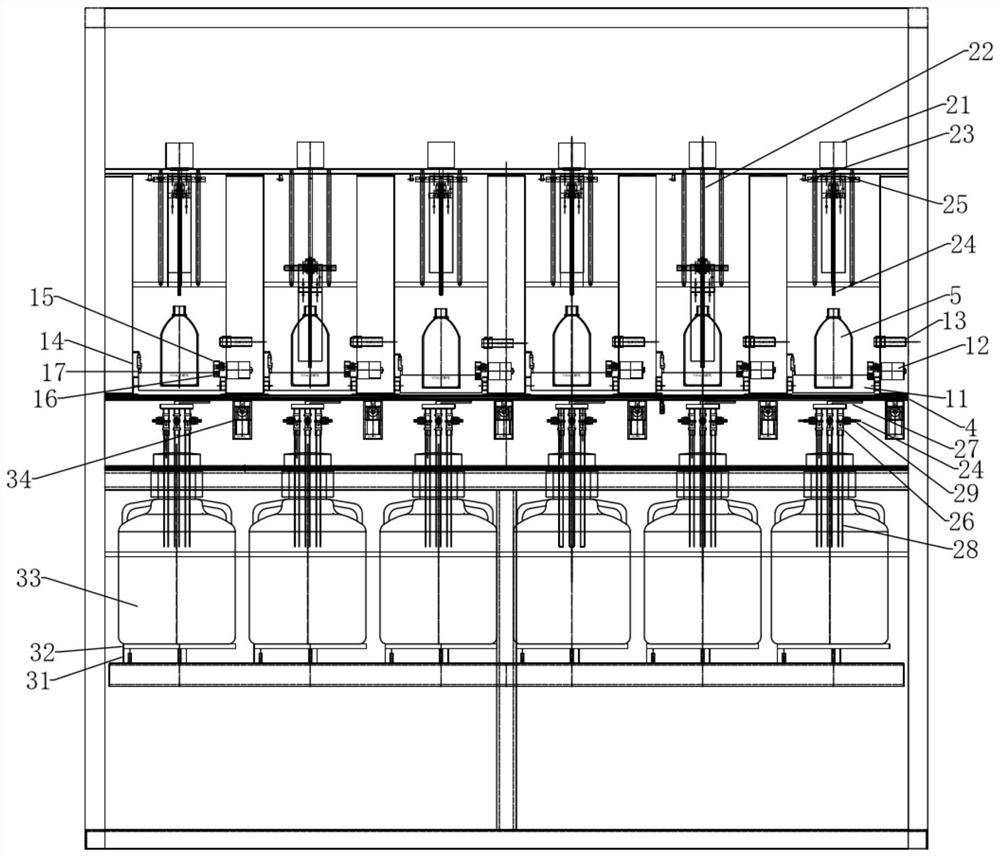

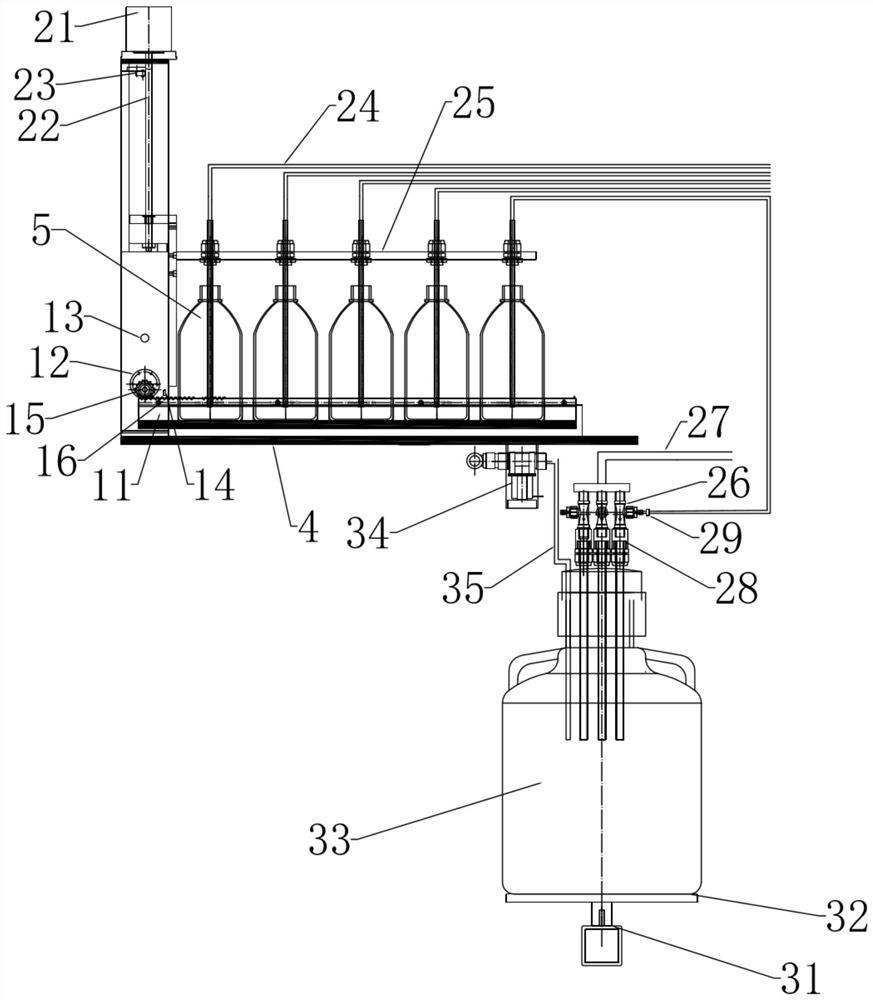

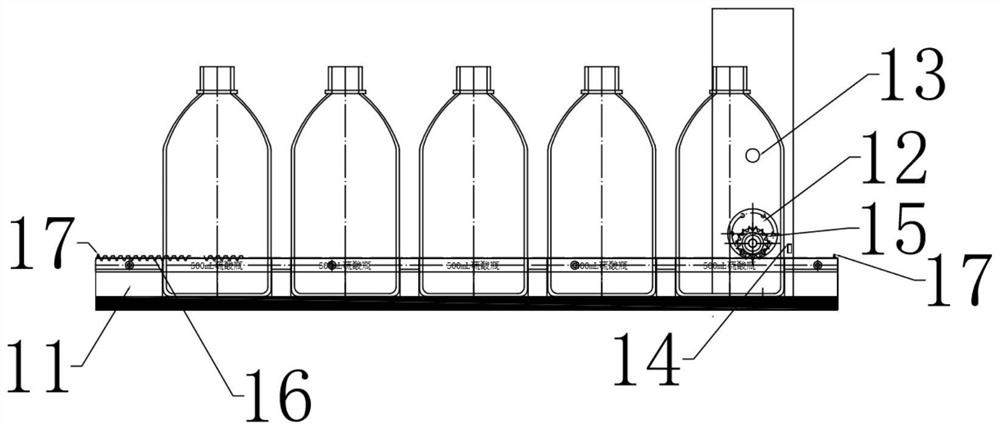

Small automatic acid preparation device and acid preparation method

PendingCN111974300AAchieve transferFully contactedTransportation and packagingMixer accessoriesPhysical chemistryEngineering

The invention discloses a small automatic acid preparation device and an acid preparation method. The device comprises a substrate, a PLC and a plurality of acid preparation units, wherein the PLC isconnected with all the acid preparation units; each acid preparation unit comprises a conveying mechanism, a liquid suction mechanism and a weighing mechanism; the conveying mechanisms are used for conveying liquid containing bottles containing raw acid into the device and conveying empty liquid containing bottles out of the device; the liquid suction mechanisms are used for taking the raw acid out of the liquid containing bottles through a jet flow technology and feeding the raw acid into acid preparation barrels of the weighing mechanisms; the weighing mechanisms are used for detecting the mass of the acid preparation barrels and controlling the water adding amount. The liquid suction mechanisms of the device utilize the jet flow technology to realize acid taking and raw acid atomization; existing liquid-liquid acid preparation is converted into liquid-mist acid preparation, transfer of raw acid is achieved, the raw acid is atomized into small liquid drops, the specific surface areais increased, the raw acid makes more sufficient contact with acid liquid or water, the heat dissipation effect and the heat dissipation efficiency during dilution are greatly improved, and the heat dissipation problem during current acid preparation is ingeniously solved.

Owner:HEBEI UNIV OF TECH +1

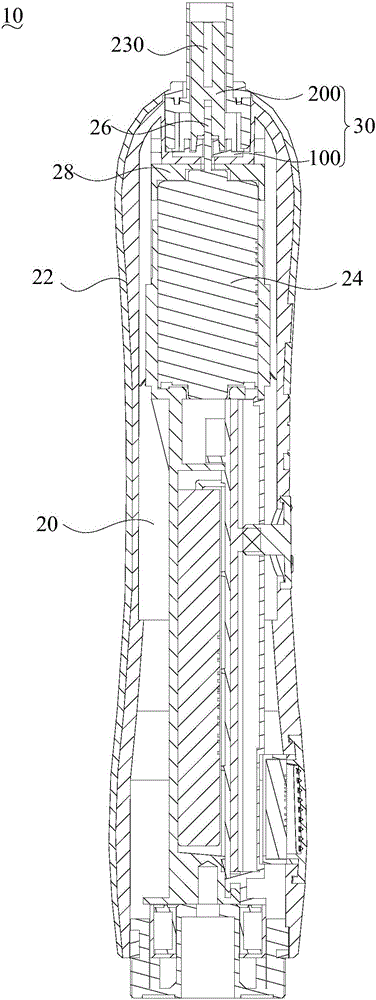

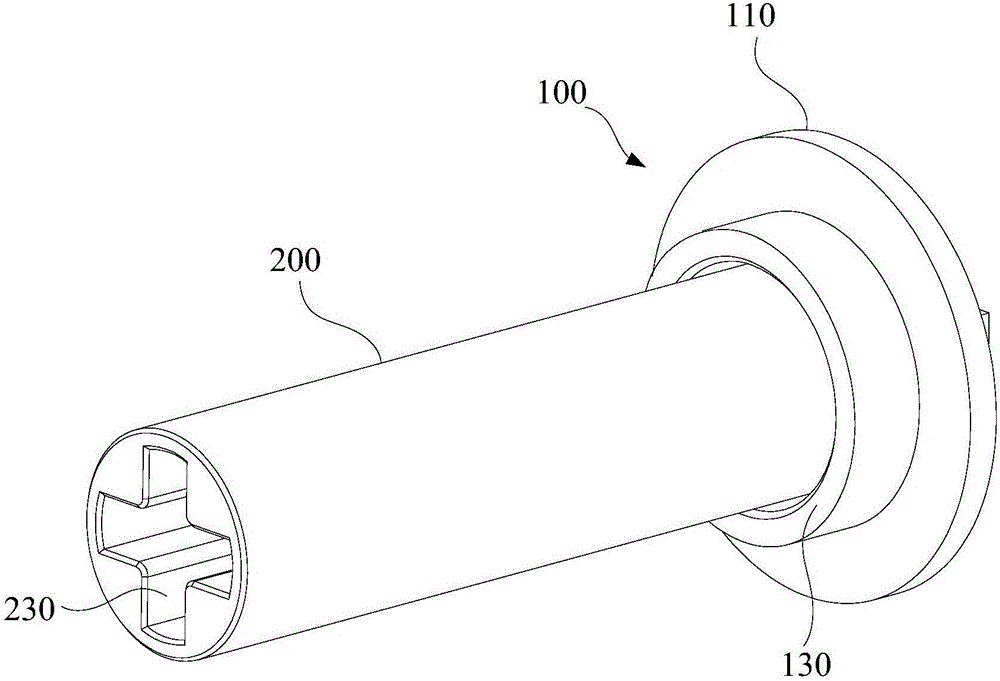

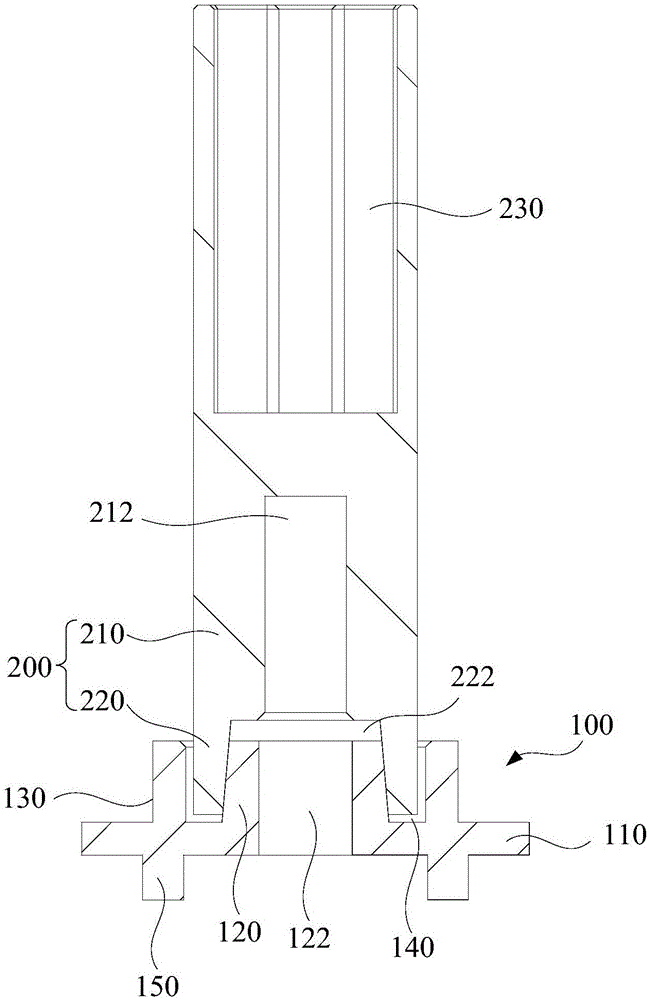

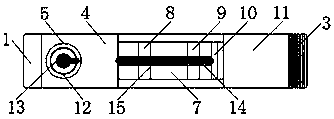

Handheld electronic product and waterproof structure thereof

ActiveCN105899031APrevent leakageWill not sputterHermetically-sealed casingsArchitectural engineeringElectronic component

The invention relates to a handheld electronic product and a waterproof structure thereof. The handheld electronic product comprises a working end, a handheld end and a waterproof structure, wherein the working end sleeves the waterproof structure, the waterproof structure is arranged in the handheld end and sleeves an output shaft of a driving device, the waterproof structure comprises a water insulation disc and a removal sleeve, the water insulation disc comprises a base and a guide post which are connected, the removal sleeve comprises a main body and an extension arm, a second through hole is formed in the middle of the extension arm, the guide post sleeves the second through hole, and the inner side surface of the extension arm is in close contact with the outer side surface of the guide post. In the handheld electronic product and the waterproof structure thereof, the water insulation disc, the removal sleeve, a waterproof medium and the output shaft jointly form a sealing waterproof structure, the waterproof medium can be prevented from being leaked by the contact of the water insulation disc and the removal sleeve and also cannot be sprayed out of the waterproof structure even the output shaft rotates, thus, water cannot be permeated to a product through the waterproof medium, and an electronic component inside the product can be protected by the waterproof structure.

Owner:SHENZHEN JOINTRONIC TECH CO LTD

Mower

InactiveCN112005698AEnsure safety and stabilityNot easy to slideMowersWatering devicesCartLawn mower

The invention provides a mower. The mower comprises a mower body and push rods, the push rods are fixed to the two sides of a mower base of the mower body, the mower body is close to one sides of thepush rods, an open groove is formed in the top of the mower body, two parallelly-formed placement grooves are formed in the bottom of the open groove, a cart is arranged in the open groove and comprises a supporting seat, a bottom plate, three baffles, a water tank and four wheels, every two wheels are arranged on the two sides of the supporting seat, the thickness of the wheels corresponds to thewidth of the placement groove, the bottom plate is fixed to the supporting seat, the three baffles are fixed to the bottom plate, the water tank is placed on the bottom plate, and a water outlet device is fixed to the water tank. By adopting the technical scheme, the cart can be placed on the mower, and the mower has the watering function by arranging the water tank and the water outlet device.

Owner:杭州冀翌科技有限公司

Board machine

InactiveCN102131981BDoes not affect layered purityAvoid deformationMachine wet endMechanical engineeringCoating

A board machine comprises a forming section where a lower wire loop (11) forms a fourdrinier-wire section (Tl) at the beginning of which is located a forming board (200) which consists of at least one stationary, non-pulsating forming shoe (210). In the forming shoe (210), there is a cover (211) provided with thorough holes (212), setting against the inner surface of the lower wire loop (11). A first headbox (100), which is a multi-layer headbox, feeds a pulp suspension jet onto the forming shoe (210). The board machine further comprises a press section (Pl) where a surface (Wa) of the web (W) having been against the lower wire loop (11) is pressed against a smooth surface, a dryer section (Dl) where the web (W) is dried with at least one cylinder-dryer group and a coating section (400) where at least the surface (Wa) of the web (W) having been against the lower wire (11) is coated.

Owner:METSO PAPER INC

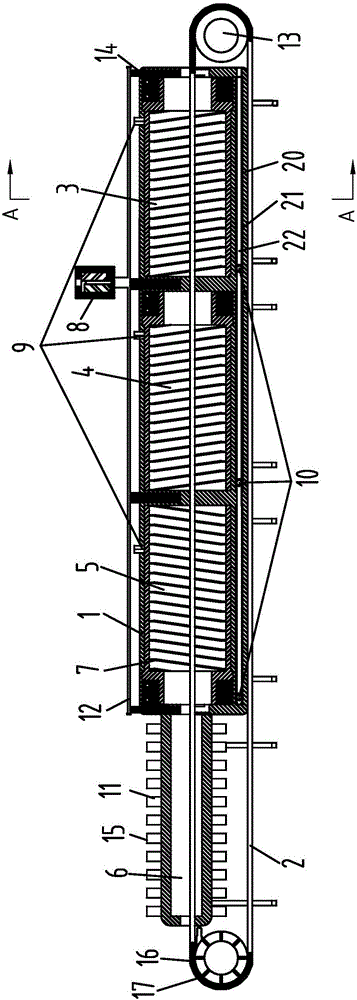

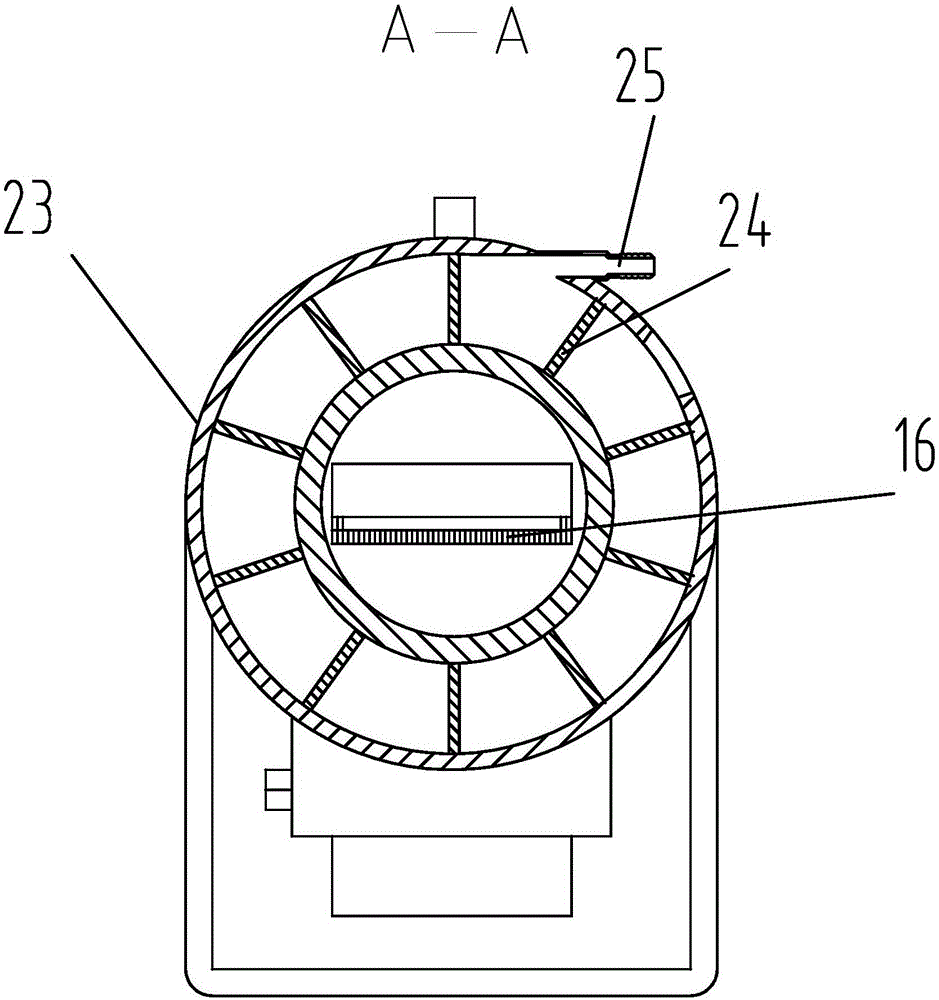

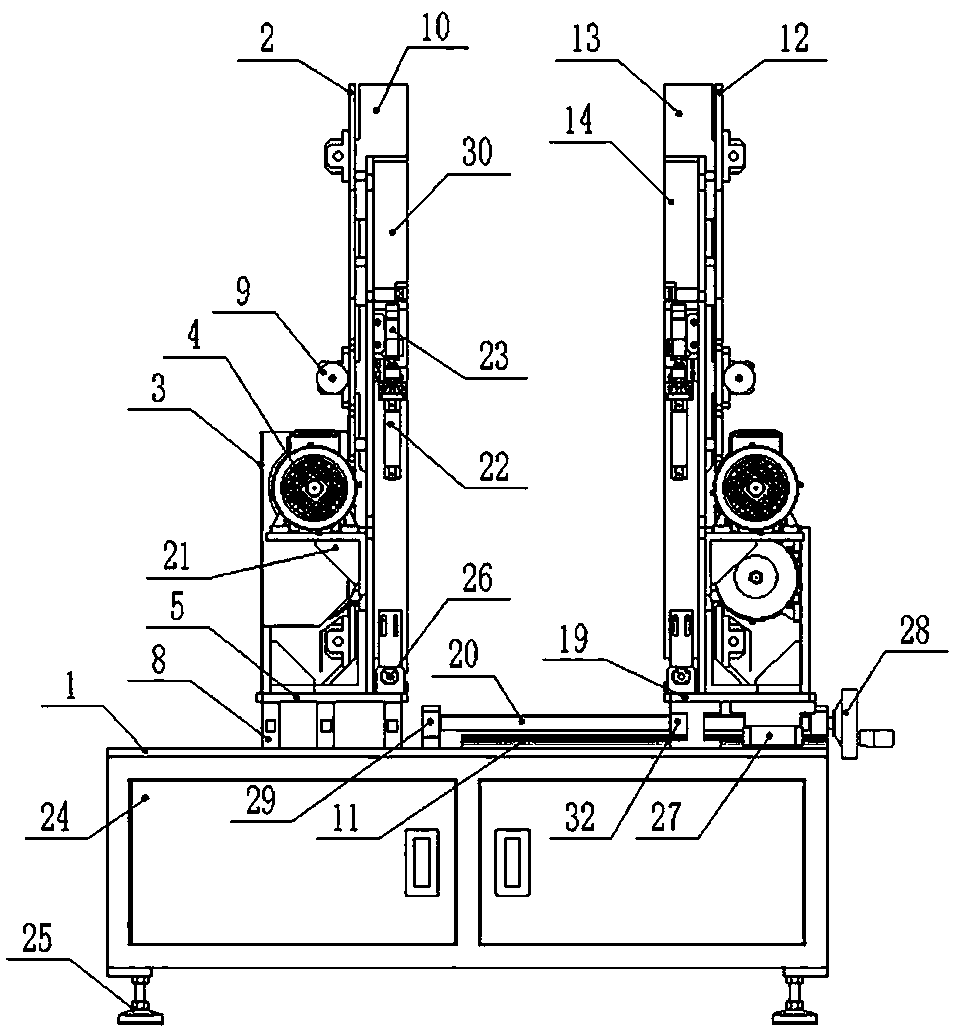

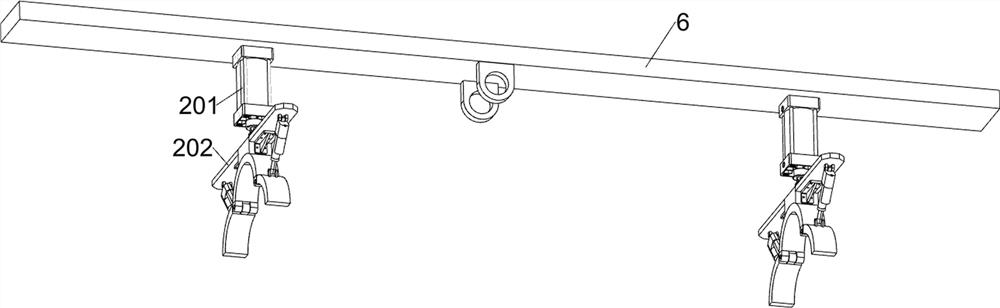

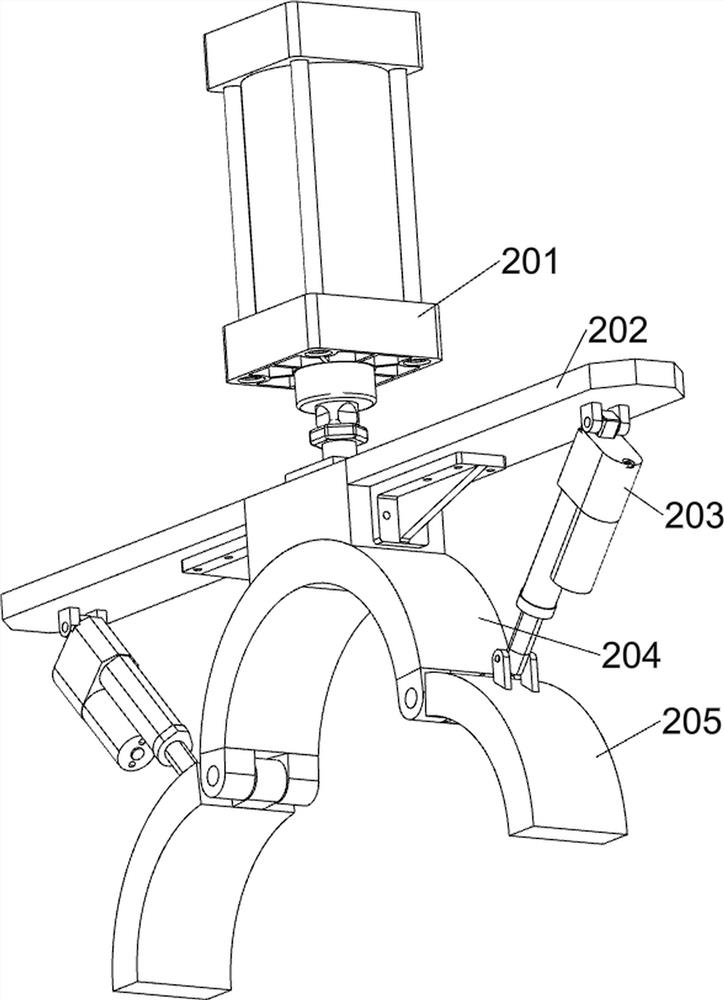

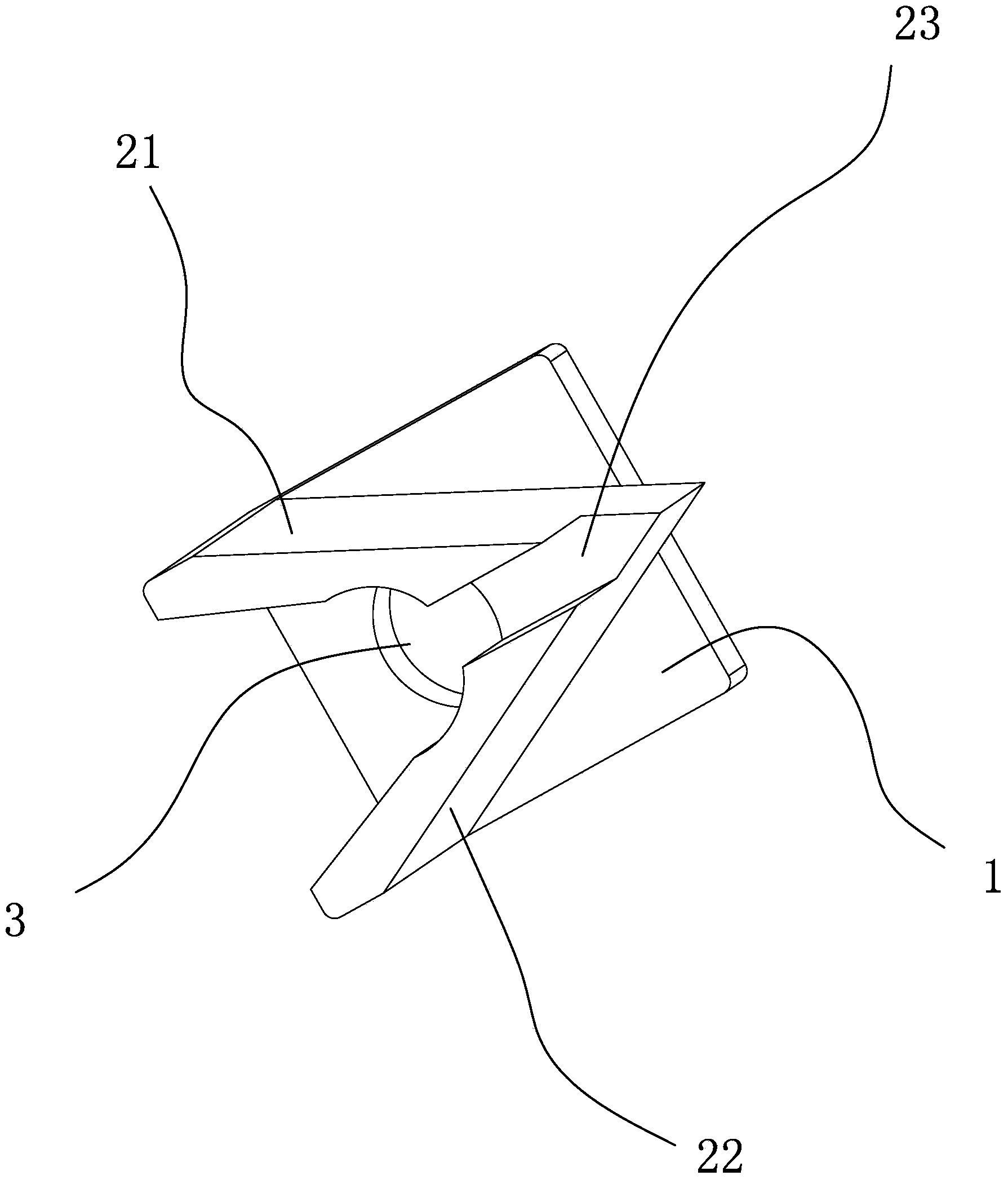

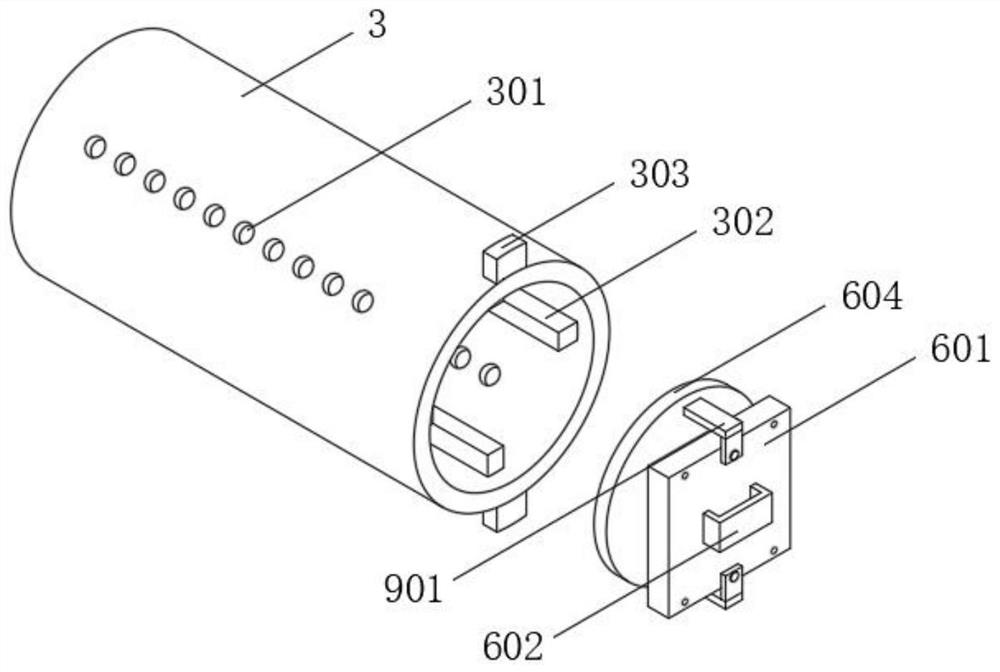

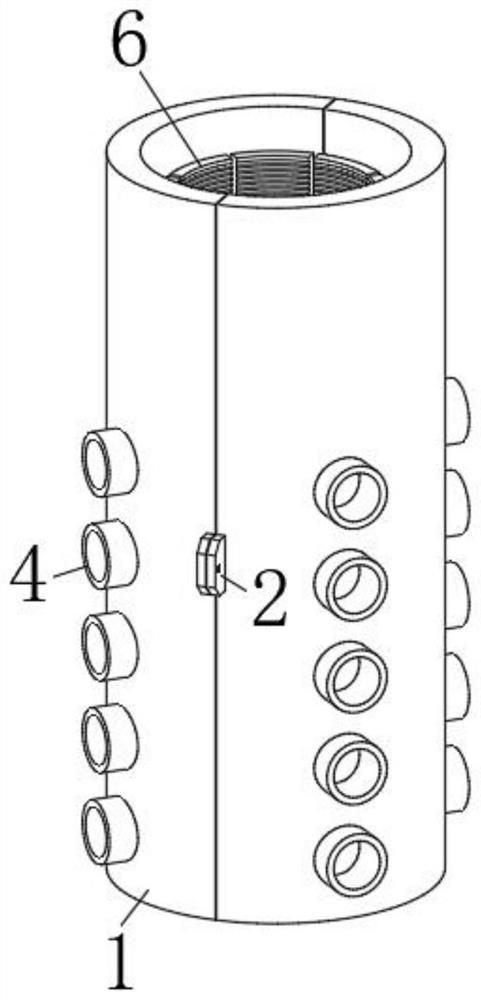

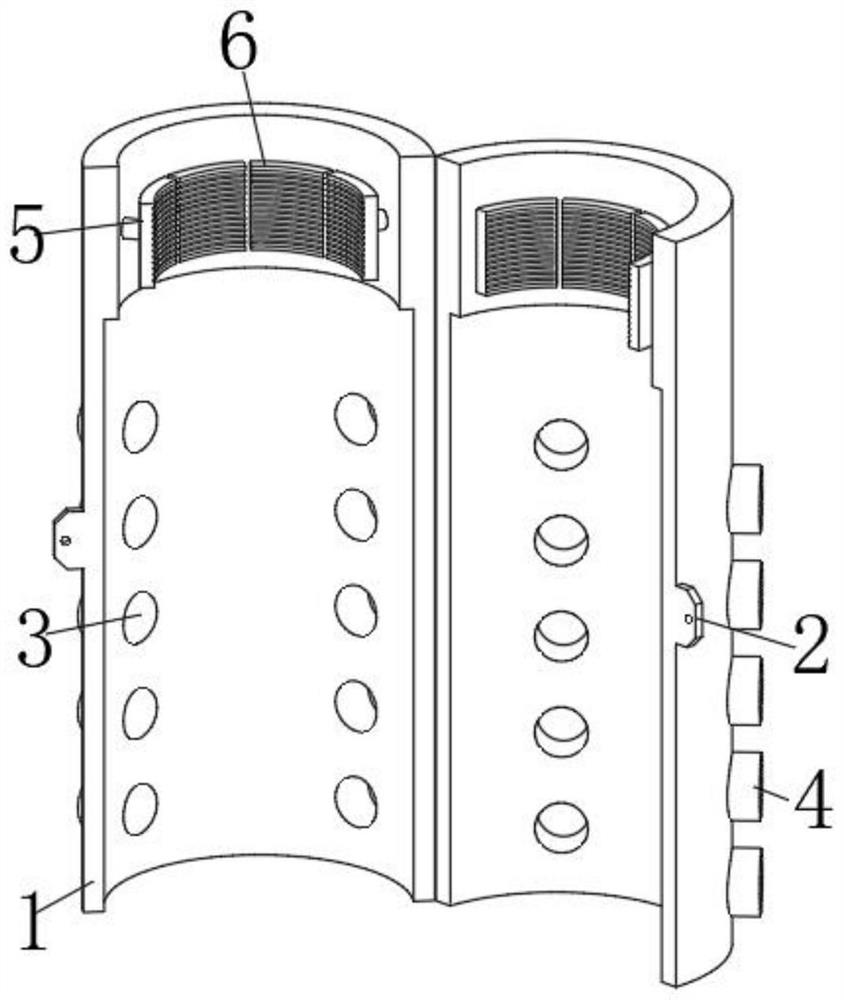

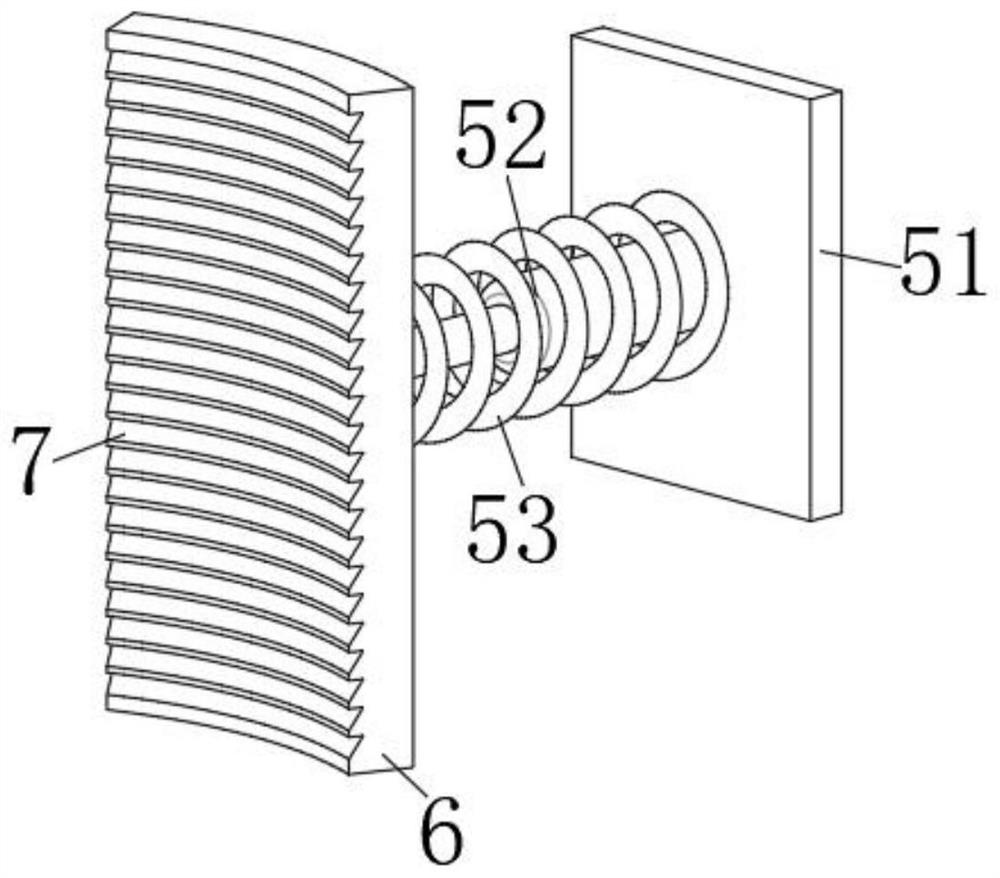

Petroleum pipeline installation lifting appliance capable of achieving closed polishing

PendingCN114030981APrevent deformationAvoid shaking situationsEdge grinding machinesGrinding drivesPhysicsEngineering

The invention relates to the field of petroleum pipeline transportation, in particular to a petroleum pipeline installation lifting appliance capable of achieving closed polishing. The technical problem that when a petroleum pipeline is transferred, the petroleum pipeline is forced to be extruded by a bearing lifting belt, and deformation of the petroleum pipeline is caused is solved. According to the technical scheme, the petroleum pipeline installation lifting appliance capable of achieving closed polishing comprises a lifting ring, a fixing column, a first hanging lug, a lifting rope, a second hanging lug, a supporting beam, a third hanging lug, an anti-bending system, a sealed polishing system and the like; and the fixing column is fixedly connected to the bottom of the lifting ring. According to the invention, the effects that the petroleum pipeline is limited, the bottom of the petroleum pipeline is wrapped, and the situation that the petroleum pipeline is forced to be extruded and deformed is avoided are achieved.

Owner:廖寿佳

A leak-proof liquid dispensing device

The invention discloses a leakproof liquid dividing device, and belongs to the technical field of liquid subpackaging devices. The leakproof liquid dividing device comprises a shell, a liquid inlet assembly and bottle change assemblies, and the liquid inlet assembly and the bottle change assemblies are arranged in the shell. The liquid inlet assembly comprises a liquid inlet pipe, a liquid guide pipe and a subpackaging bottle. The lower end of the liquid inlet pipe penetrates through a through hole in the upper end of the shell, and the liquid guide pipe comprises a sleeve and a liquid outletpipe. The upper end of the liquid outlet pipe penetrates through a through hole in the lower end wall of the sleeve and stretches into a cavity. The sleeve is connected with the upper end wall of a main cavity through a compression spring. The lower end of the liquid outlet pipe penetrates through a through hole of a supporting plate to be inserted into a bucket opening of the subpackaging bottle.First guide shafts are arranged at the two ends of the supporting plates correspondingly. The bottle change assemblies are arranged on the front inner side and the rear inner side of the shell correspondingly. Compared with the prior art, the leakproof liquid dividing device has the characteristics of preventing leakage, reducing loss and reducing cost.

Owner:RIZHAO HOSPITAL OF TCM

Filtering core assembly for filtering water

PendingCN109107260AWill not sputterRealize the effect of automatic water on and offFiltration separationEngineering

The invention relates to a filtering core assembly for filtering water. The filtering core assembly is characterized in that a water inlet and a water outlet are arranged on the lower portion of a filtering core body, two arc-shaped snapping edges are symmetrically arranged on the side wall of the filtering core body, and are provided with arc-shaped snapping ports, the side wall of the filteringcore body is provided with concave rings, two filtering core pin assemblies are fixed on a water machine, the filtering core pin assembly comprises a position limiting rod and a snapping rod, the middle portion of the position limiting rod is provided with a sliding rail, the sliding rail is hinged on the water machine, the position limiting rod can slide along the sliding rail, the lower end of the position limiting rod is hinged to the snapping rod, the middle portion of the snapping rod is hinged on the water machine, the upper end of the position limiting rod is provided with an annular projection, the lower end of the snapping rod is provided with a projection toward the inner side, the projection can be snapped in the concave groove, and the annular projection can be snapped in the arc-shaped snapping port. According to the present invention, with the filtering core assembly, the state of the filtering core can be determined through the rotating position of the filtering core andthe extending block, and whether the filtering core can perform the water purification can be automatically monitored through the dirt in the filtering core.

Owner:FUJIAN OSPRING TECH & DEV

Device for cleaning a driver assistance camera of a motor vehicle

A device for cleaning a camera lens (6) by means of a cleaning head (8), comprising a fixed cleaning head and a camera moved by drive means (10), the head being accommodated in a structural element (2) of a vehicle. The drive means are adapted to produce a relative movement of the camera relative to the cleaning head between a passive image position, in which the camera is arranged facing the cleaning head housed in said structural element of the vehicle, and an active position, in which , the cameras are deployed at a distance from structural elements of the vehicle to allow images to be captured. The device is particularly effective when applied to the cleaning of reversing cameras embedded in motor vehicles.

Owner:VALEO SYST DESSUYAGE

Sawing spray valve block

ActiveCN104107952AImprove working environmentCoolant splashMetal sawing accessoriesInjection portAcute angle

The invention discloses a sawing spray valve block. The sawing spray valve block comprises a plate-shaped base, two stop blocks and an injection port, the stop blocks include a left stop block and a right stop block, lower end faces of the stop blocks are fixed on the same plane of the base, the left stop block and the right stop block are intersected by an acute angle, the injection port runs through the base and intersects with the left stop block and the right stop block, and a cutter groove is formed downwards from the upper end of the intersection of the left stop block and the right stop block. The sawing spray valve block is mounted on the upper portion of a saw blade which is positioned in the cutter groove between the stop blocks, when the saw blade works, air curtains generated by the saw blade is crushed by the stop blocks when passing through the stop blocks, and cooling liquid sprayed from the injection port is enabled to be sprayed on blades directly and is driven to be recycled along the blades by high-speed recycling of the blades, so that the cooling liquid is brought from the upper portion of the saw blade to the lower portion of a sawing work portion to cool the saw blade.

Owner:佛山市南海万格士机械设备有限公司

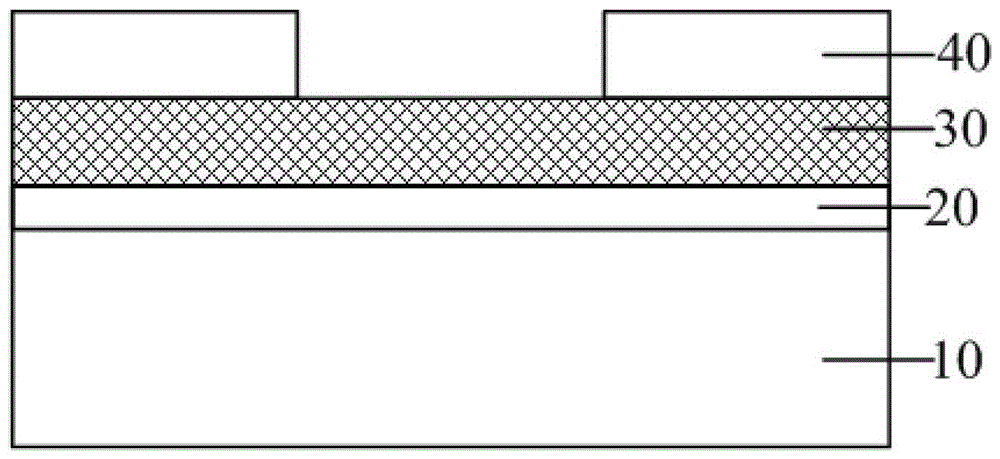

Test device and manufacturing method thereof, semiconductor device and manufacturing method thereof

ActiveCN102931172BGuaranteed performance and stabilityWon't fall offSemiconductor/solid-state device detailsSolid-state devicesElectricityPower semiconductor device

The invention discloses a test device, a test device manufacturing method, a semiconductor device and a semiconductor device manufacturing method. The test device comprises a semiconductor substrate, a dielectric layer positioned on the semiconductor substrate and an electrical connecting line positioned on the dielectric layer, wherein the dielectric layer is made from silicon oxide formed by adopting TEOS (tetraethyl orthosilicate) as a reaction source; the dielectric layer comprises metal plugs and dummy contacts; the dummy contacts can be made of tungsten; the ratio of the upper surface area of the dummy contacts to the upper surface area of the whole dielectric layer is greater than or equal to 20 percent; and the electrical connecting line can be made of copper, aluminum or copper aluminum alloy. The semiconductor device comprises a plurality of dies and cutting channels positioned between the dies, and the cutting channels comprise the test devices. According to the invention, the adhesive force between the electrical connecting line and the dielectric layer of the test device can be increased and finally the stable performance of the semiconductor device can be ensured.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Garbage treatment equipment with quick drying function

InactiveCN113790587AEvenly heatedShorten drying timeDrying chambers/containersDrying solid materialsStructural engineeringRefuse Disposals

The invention discloses garbage treatment equipment with a rapid drying function. The garbage treatment equipment comprises a fixing box body, a drying roller, a sealing mechanism and a positioning mechanism, one side of the fixing box body is installed on a movable door, a plurality of heating pipes are fixedly installed at the top end inside the fixing box body at equal intervals, the drying roller is installed inside the fixing box body, a plurality of air holes are annularly formed in the outer wall of the drying roller in an equidistant array mode, a plurality of fixing strips are annularly and fixedly connected to the interior of the drying roller in an equidistant array mode, the sealing mechanism is arranged at the joint position of the drying roller and the fixing box body, and the positioning mechanism is arranged at the joint position of a port of the drying roller and the sealing mechanism. The garbage treatment equipment has the beneficial effects that the design of the drying roller is utilized, and the fixing strips inside the drying roller can lift up household garbage, so that the household garbage cannot transfer heat from outside to inside, and the household garbage inside the drying roller can be uniformly heated.

Owner:唐纪会

Method for preparing basic chromium sulfate tanning liquor by using tanning chromium sludge

ActiveCN102965455BWill not sputterMild chemical reactionSludge treatmentTanning treatmentChemical reactionSludge

The invention discloses a method for preparing basic chromium sulfate tanning liquor by using tanning chromium sludge, and solves problems in existing method for preparing tanning liquor by using tanning chromium sludge, such as violent reaction, high operation risk coefficient, incomplete organic compound hydrolysis, poor infiltration of the obtained tanning liquor and complex preparation process and steps. The method comprises the following steps: (1) homogenization; (2) leaching; (3) filter pressing; (4) pressure reduction; and (5) cooling and depressurization. The invention has beneficial effects of mild chemical reaction, easily controlled reaction, capability of completely reducing hexavalent chromium to trivalent chromium, low production cost, no introduction of new impurity, simple processing steps, high purity of the finally obtained chrome tanning liquor, high reduction rate of hexavalent chromium, small consumption amount of ethanol or industrial alcohol, deep hydrolysis of organic small molecules, further enhancement of purity and tanning property of the finally obtained tanning liquor.

Owner:ZHEJIANG TELI RECYCLING RESOURCES

A kind of florfenicol rapid detection test strip

Owner:重庆天安生物科技有限公司

Energy-saving and environment-friendly metal product surface rust removal device

The invention provides an energy-saving and environment-friendly metal product surface rust removal device, relates to the technical field of rust removal equipment, and solves the problems that an existing device cannot conduct rust removal and fixation on metal products with different sizes, rust slag cannot be gathered and collected after rust removal, and the surrounding environment is influenced. The energy-saving and environment-friendly metal product surface rust removal device comprises a collecting device, a front clamping device, a first grinding mechanism, a second grinding mechanism and a rear clamping device, wherein the collecting device is located at the lower position in a box mechanism. The metal product is inserted through an insertion hole in the front end of a frame box, the other end of the metal product extends out of an insertion hole in the rear end of the frame box, the front end of the metal product is fixedly clamped through a left clamp A and a right clamp A, the rear end of the metal product is fixedly clamped through cooperation of the left clamp B and the right clamp B, and the metal product is fixed at the moment.

Owner:广州智乾环保科技有限公司

Sawing spray valve block

ActiveCN104107952BImprove working environmentCoolant splashMetal sawing accessoriesInjection portAcute angle

The invention discloses a sawing spray valve block. The sawing spray valve block comprises a plate-shaped base, two stop blocks and an injection port, the stop blocks include a left stop block and a right stop block, lower end faces of the stop blocks are fixed on the same plane of the base, the left stop block and the right stop block are intersected by an acute angle, the injection port runs through the base and intersects with the left stop block and the right stop block, and a cutter groove is formed downwards from the upper end of the intersection of the left stop block and the right stop block. The sawing spray valve block is mounted on the upper portion of a saw blade which is positioned in the cutter groove between the stop blocks, when the saw blade works, air curtains generated by the saw blade is crushed by the stop blocks when passing through the stop blocks, and cooling liquid sprayed from the injection port is enabled to be sprayed on blades directly and is driven to be recycled along the blades by high-speed recycling of the blades, so that the cooling liquid is brought from the upper portion of the saw blade to the lower portion of a sawing work portion to cool the saw blade.

Owner:佛山市南海万格士机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com