Filtering core assembly for filtering water

A filter element and component technology, applied in the field of filter element components for filtering water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

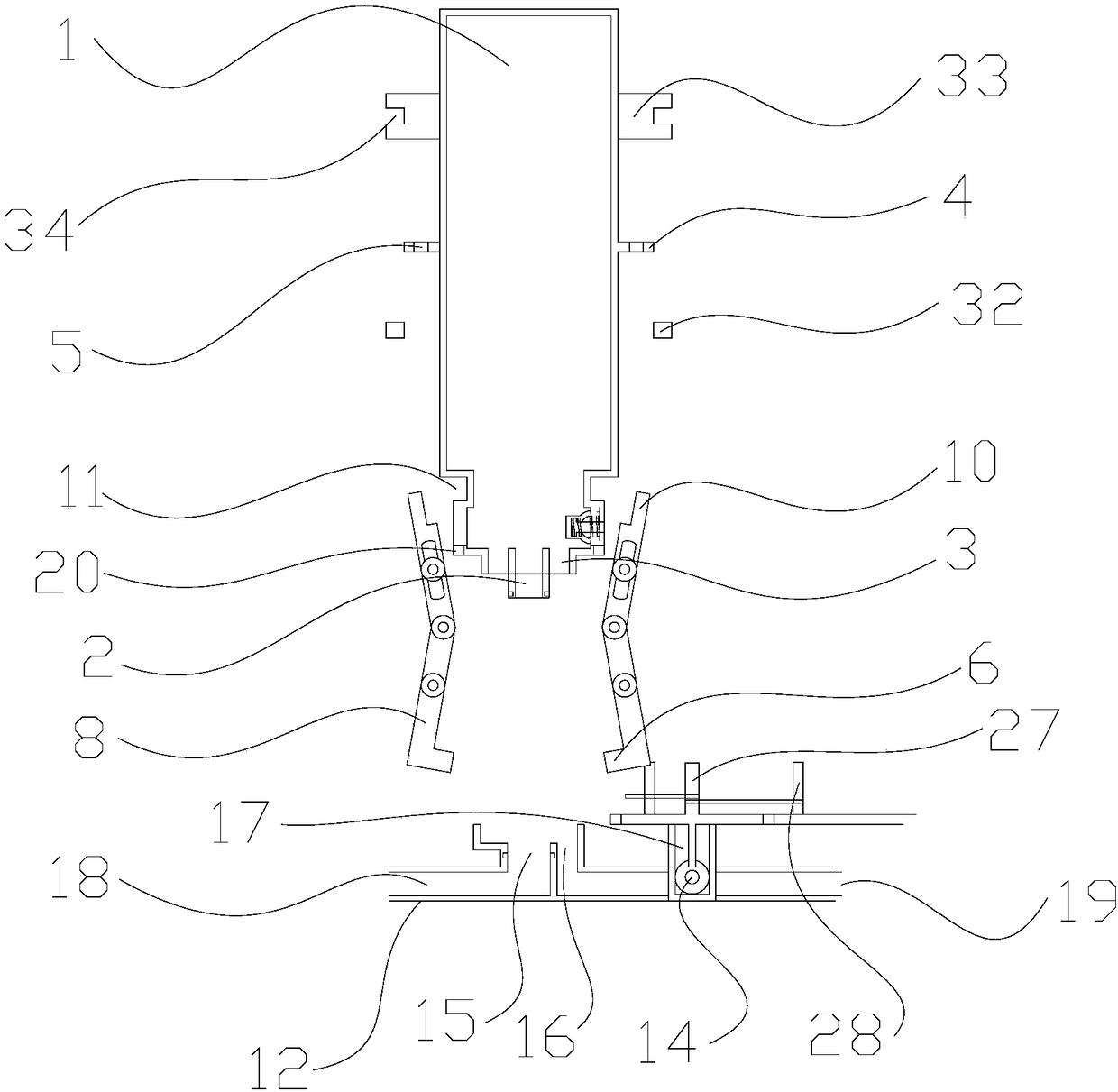

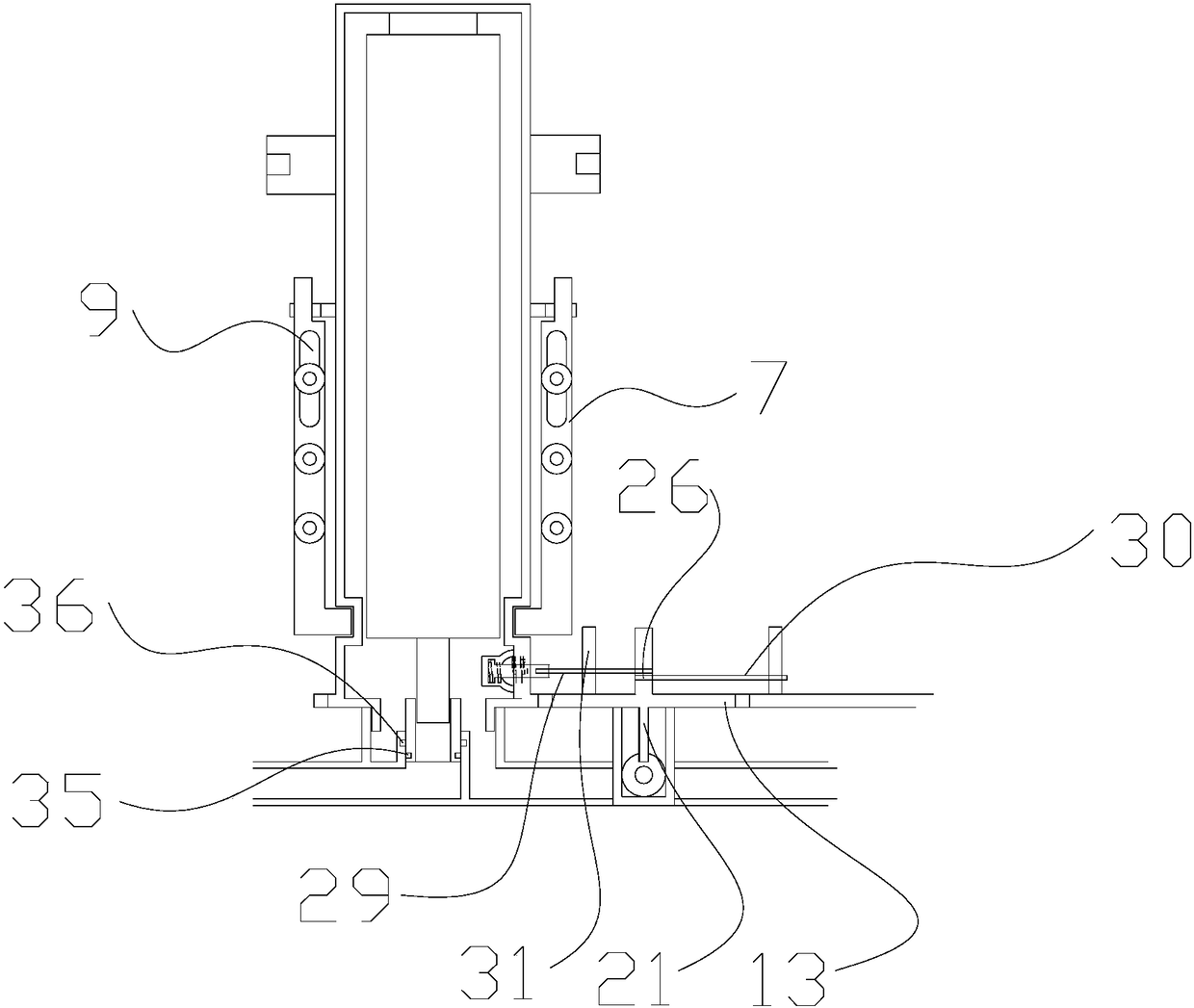

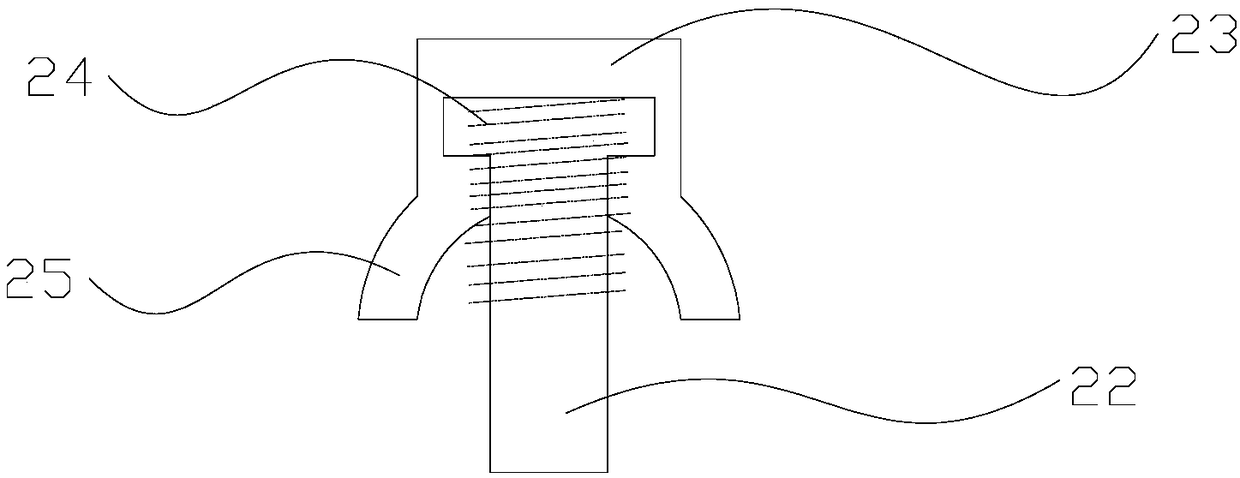

[0026] Such as Figure 1~4 As shown, the present invention provides a filter element assembly for filtering water, comprising: a filter element body 1, the lower part of the filter element body 1 is provided with a water inlet 2 and a water outlet 3, and the side wall of the filter element body 1 is symmetrical with respect to the filter element body 1 Two arc-shaped card edges 4 are provided, and an arc-shaped bayonet 5 is opened on the arc-shaped card edges 4, and a concave ring 11 is arranged on the side wall of the filter element body 1; two filter element pin assemblies, two filter element pin assemblies The assembly is fixed on the water machine, the filter element pin assembly includes a limit rod 7 and a clamping rod 8, the middle part of the limit rod 7 is provided with a slide rail 9, the slide rail 9 is hinged on the water machine and the limit rod 7 can slide along the slide rail 9, The lower end of the limit rod 7 is hinged with the upper end of the clamp rod 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com