Wear-resisting vertical crusher

A crusher, wear-resistant technology, applied in grain processing and other directions, can solve problems such as large volume and weight, inability to obtain two kinds of granular aggregates at the same time, and inner wall damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

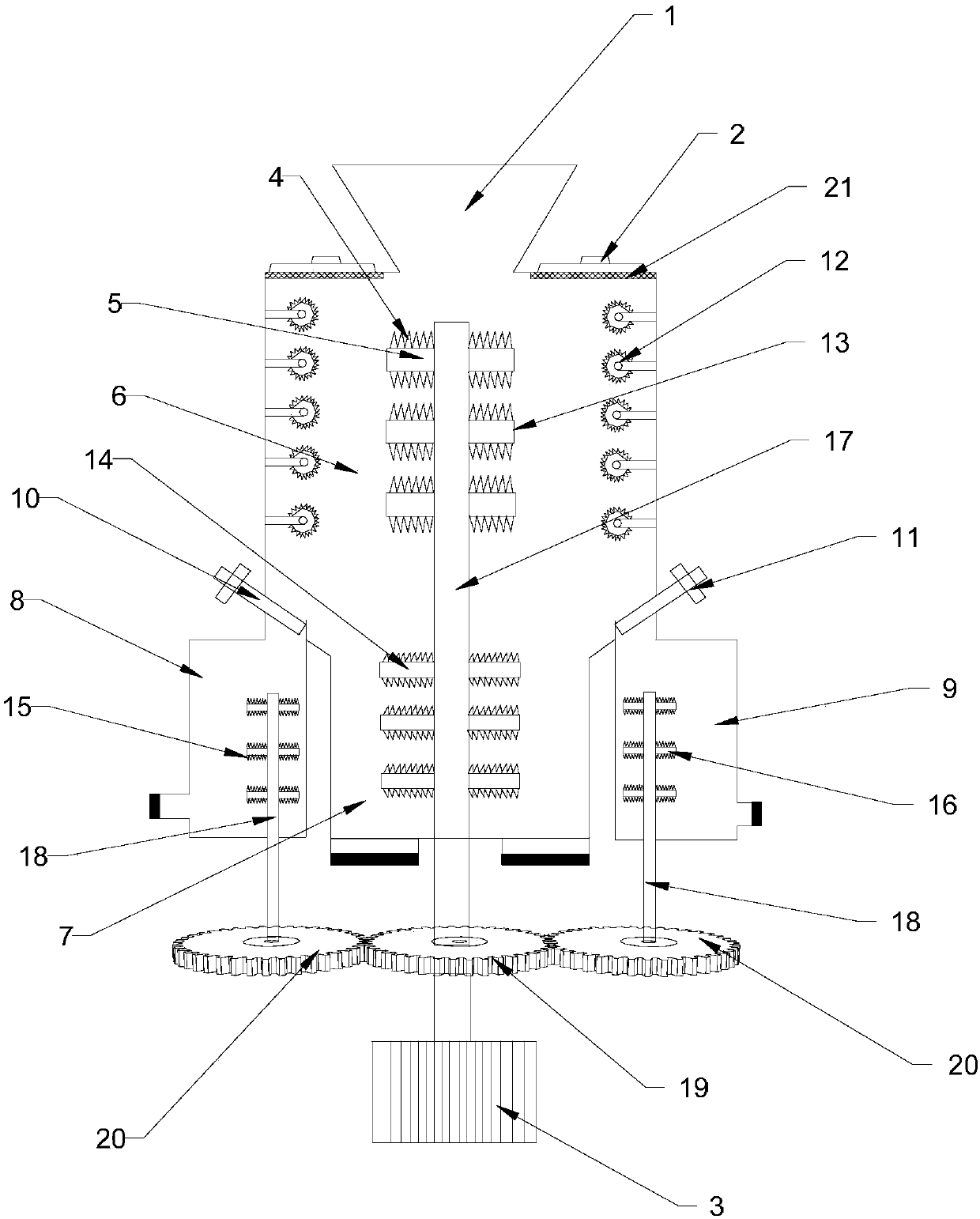

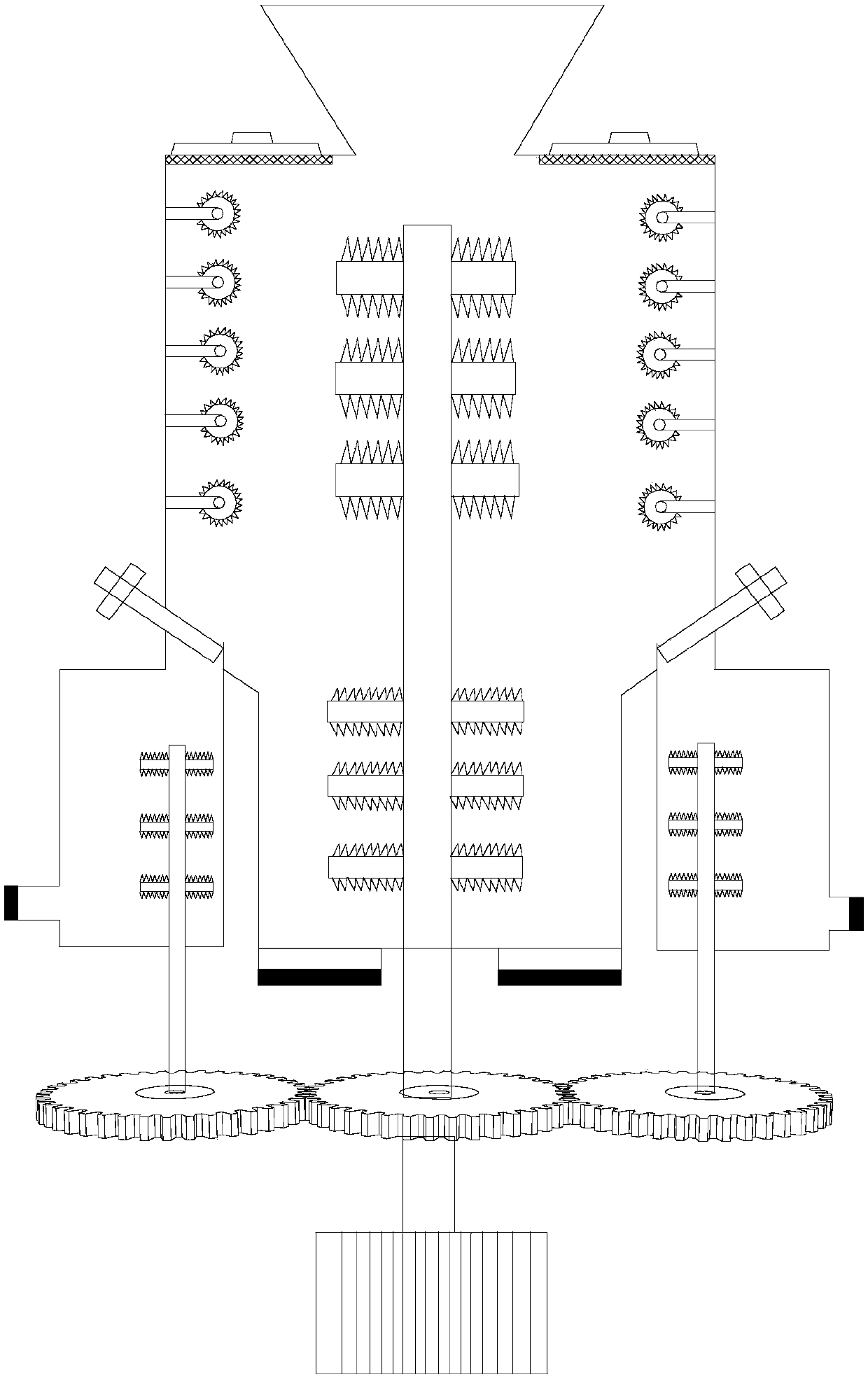

[0019] like figure 1 As shown, a wear-resistant vertical crusher includes a crushing cavity and a crushing mechanism, the top of the crushing cavity is provided with an aggregate inlet 1 and a cavity cover 2, and the crushing mechanism includes a motor 3 and the crushing mechanism. The rotating shaft connected to the motor 3, the rotating shaft is provided with a crushing rotor, the crushing rotor includes a crushing blade 4, a connecting rod 5 for installing the crushing blade 4, the motor 3 is connected to the rotating shaft through a gear; the crushing cavity includes a main The crushing chamber 6, the lower part of the main crushing chamber 6 is divided into the first crushing chamber 7, the second crushing chamber 8 and the third crushing chamber 9, the top of the second crushing chamber 8 and the main crushing chamber 6 A first solenoid valve 10 is provided, a second solenoid valve 11 is provided between the top of the third crushing chamber 9 and the crushing chamber; a...

Embodiment 2

[0022] On the basis of Embodiment 1, a ventilation net 21 is arranged under the lid, and the material of the ventilation net 21 is W18Cr4V. During the crushing process, the inner wall of the crusher will generate heat. If the inside of the crusher is completely closed, the temperature inside will be very high, and the equipment will be ignored. Heat dissipation is carried out inside the machine. In specific implementation, specific ventilation equipment, cooling equipment, etc. can be prevented outside the ventilation net 21.

Embodiment 3

[0024] On the basis of Example 1 or Example 2, the bottom of the first crushing chamber 7 is provided with a first material outlet, the bottom or side of the second crushing chamber 8 is provided with a second material outlet, and the third The bottom of the crushing chamber 9 is provided with a third material outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com