Patents

Literature

112results about How to "Easy and efficient cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

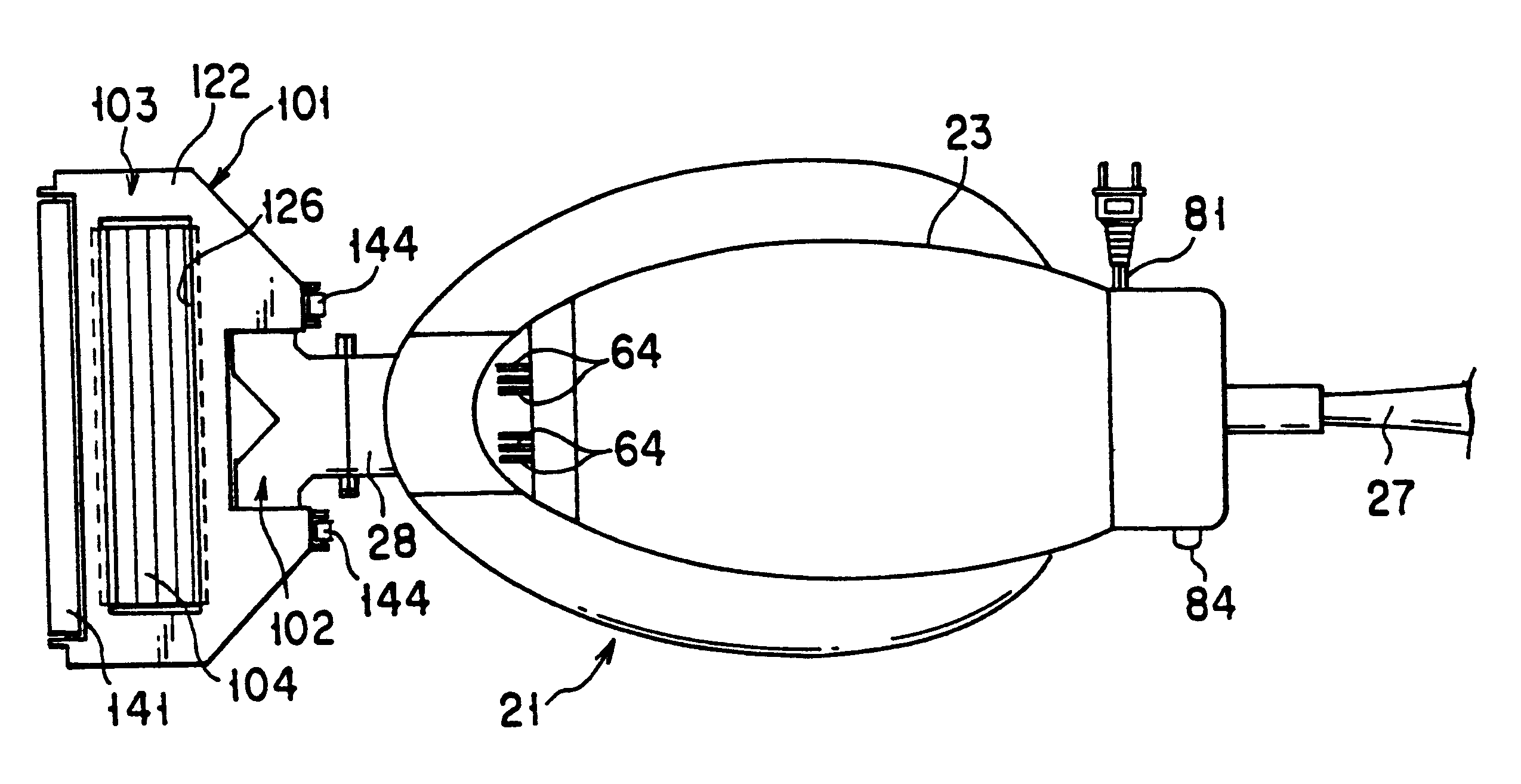

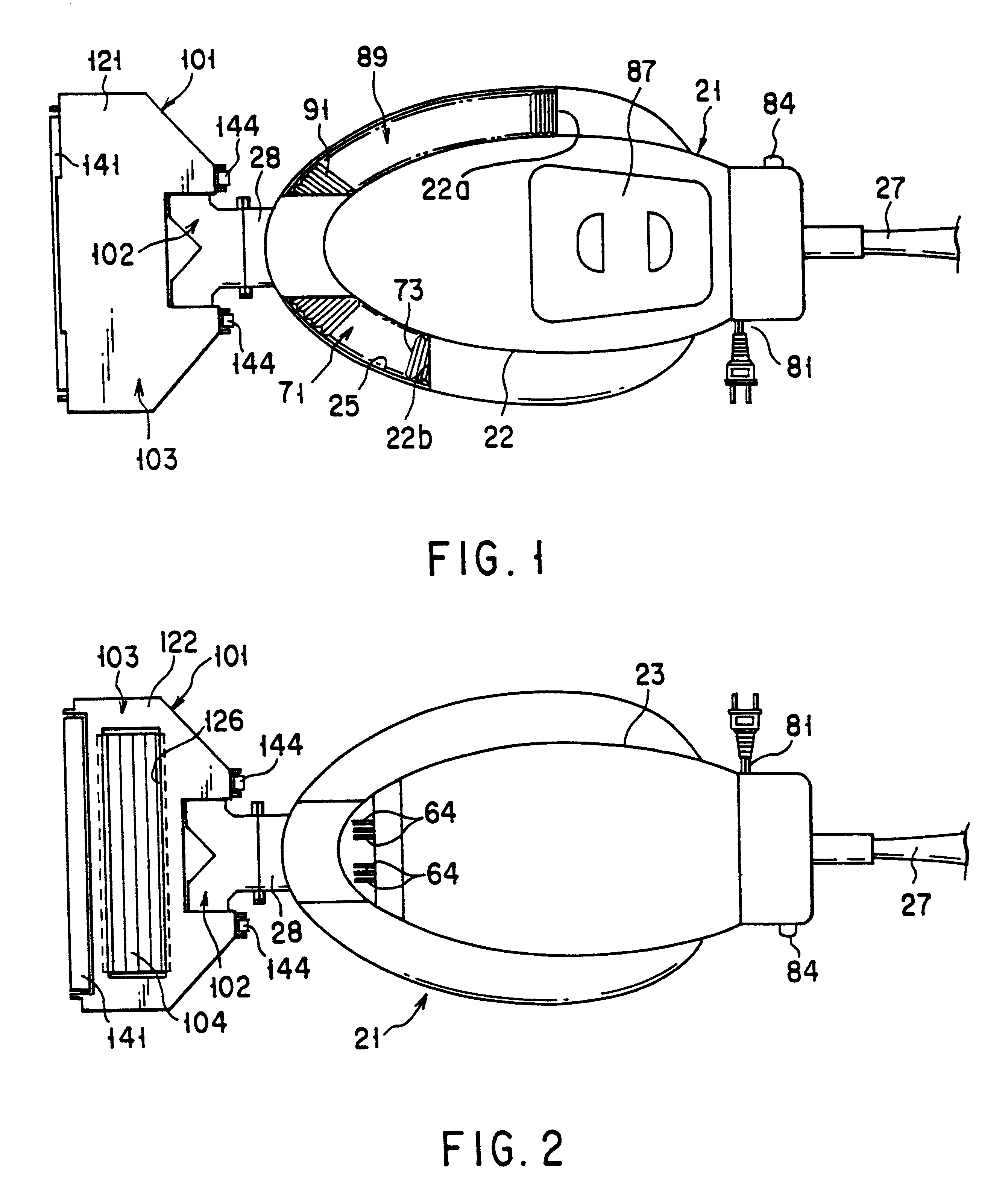

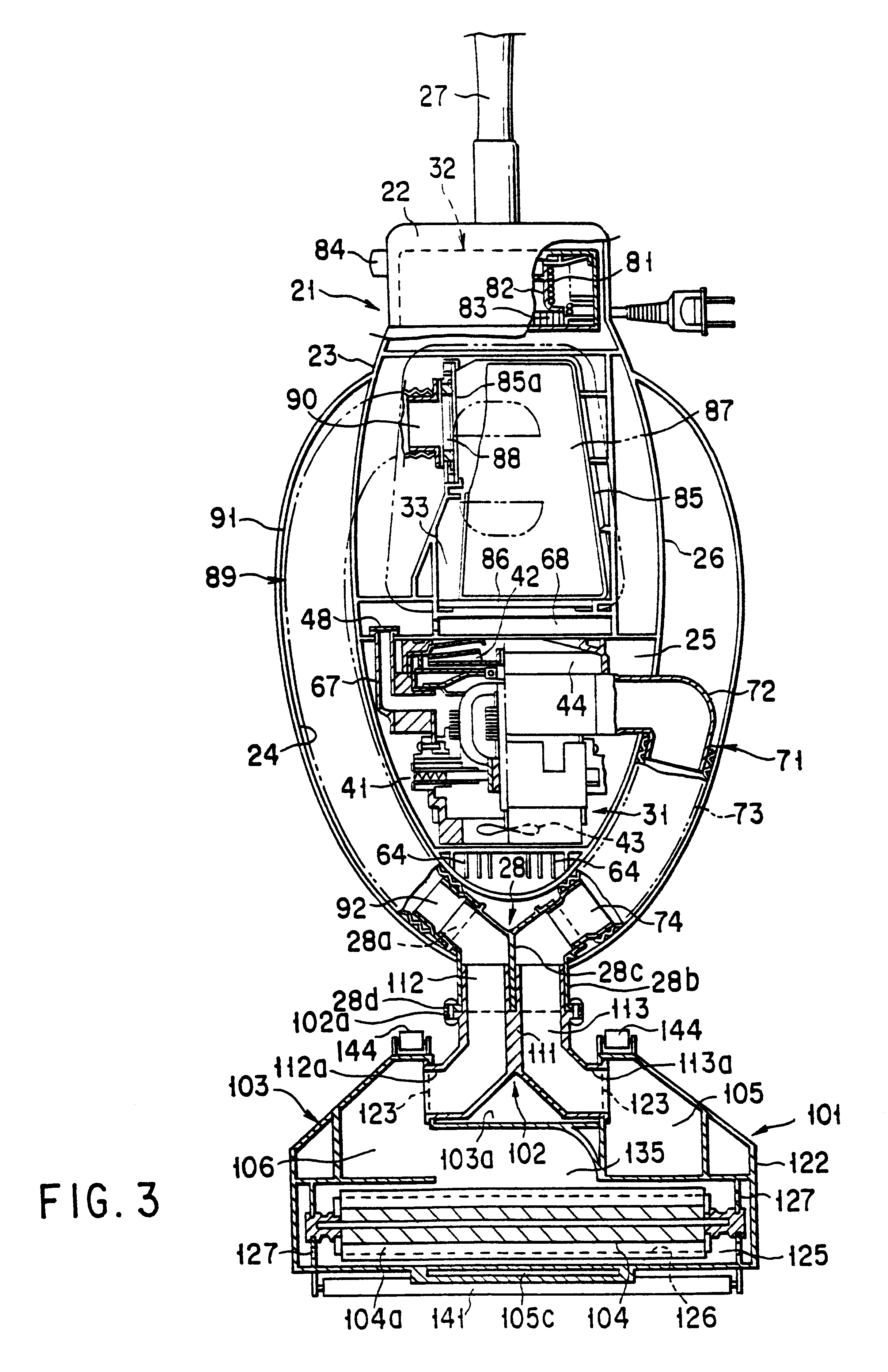

Suction port body for vacuum-cleaner and vacuum-cleaner having the same

A suction nozzle for a vacuum cleaner is designed so that exhaust from a motor blower in the body of the vacuum cleaner is provided into a suction port of the suction nozzle. The exhaust provided into the suction nozzle is prevented from being discharged to the atmosphere at the point where the suction nozzle meets the to-be-cleaned surface.

Owner:TOSHIBA TEC KK

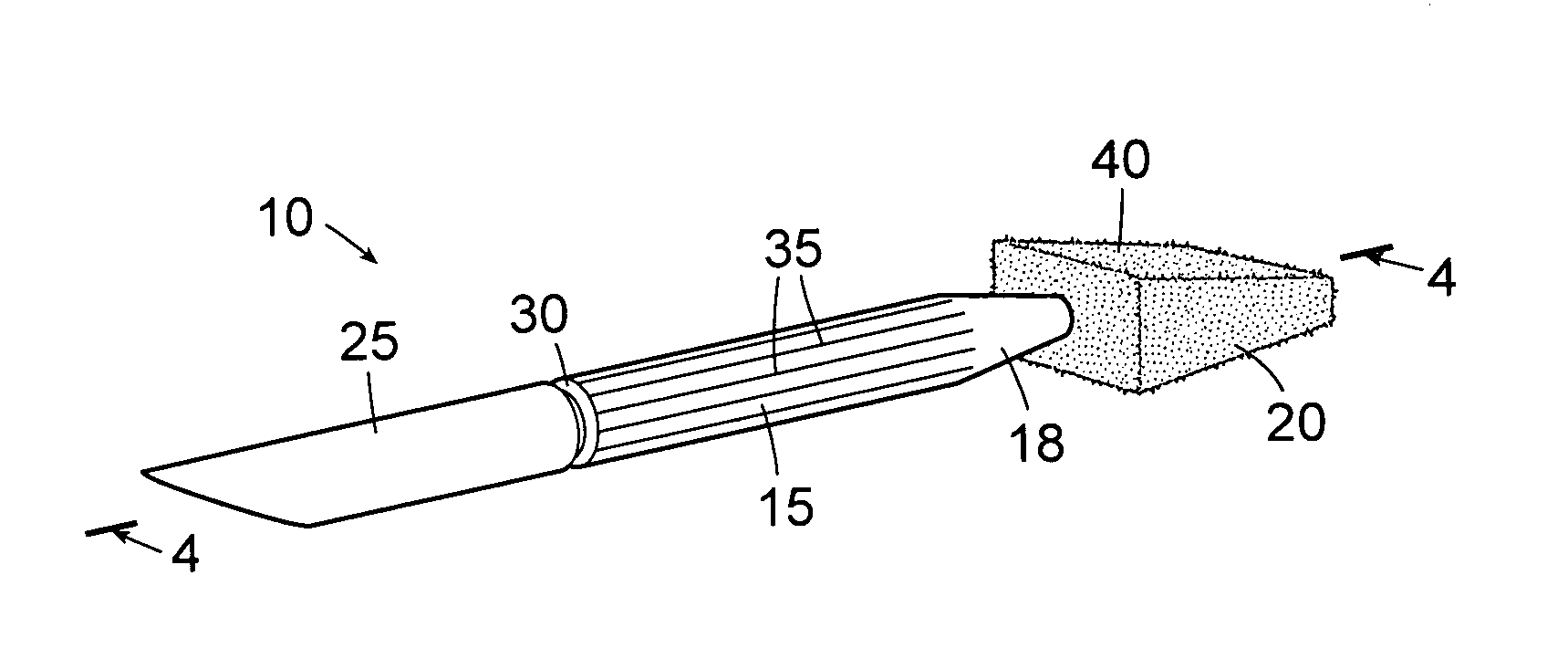

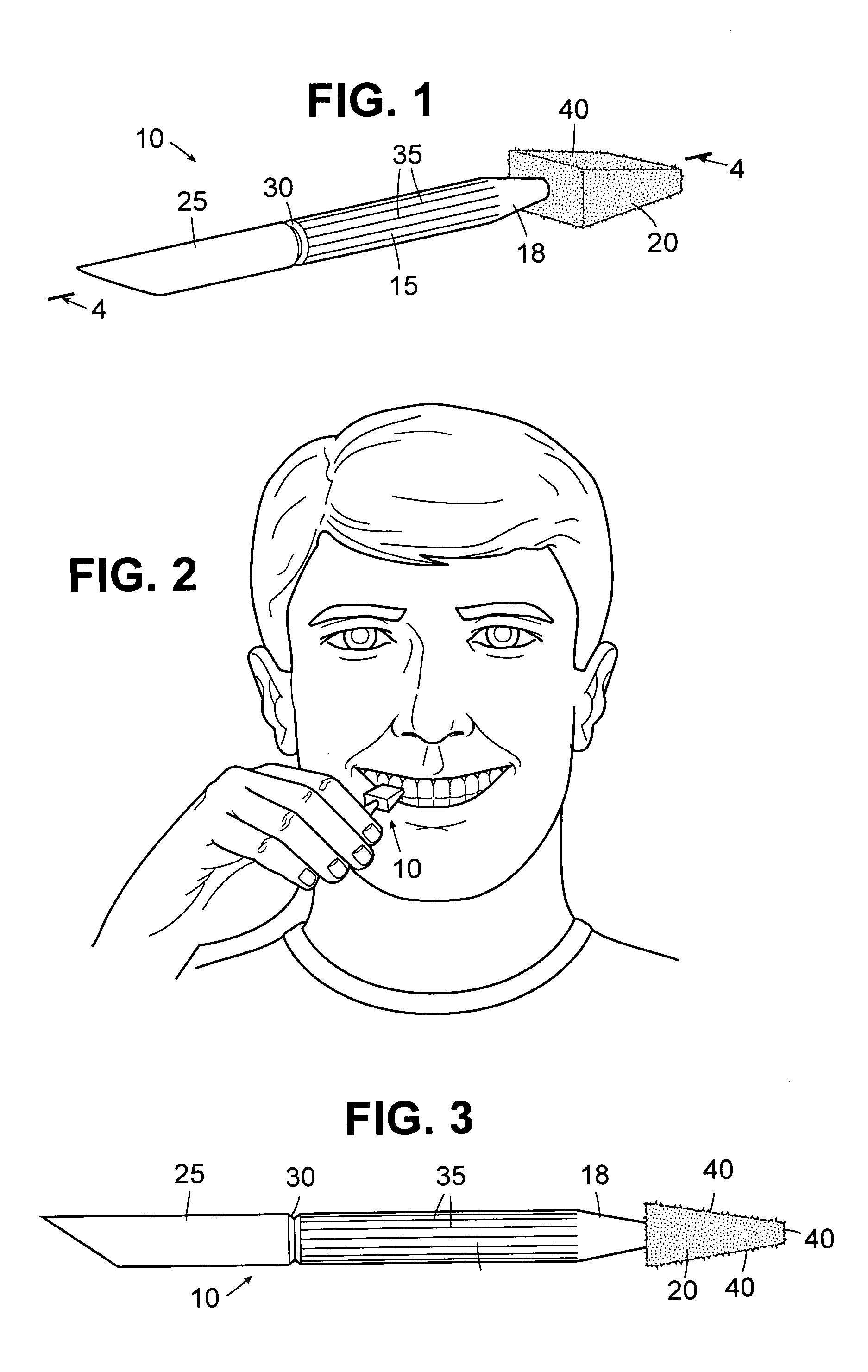

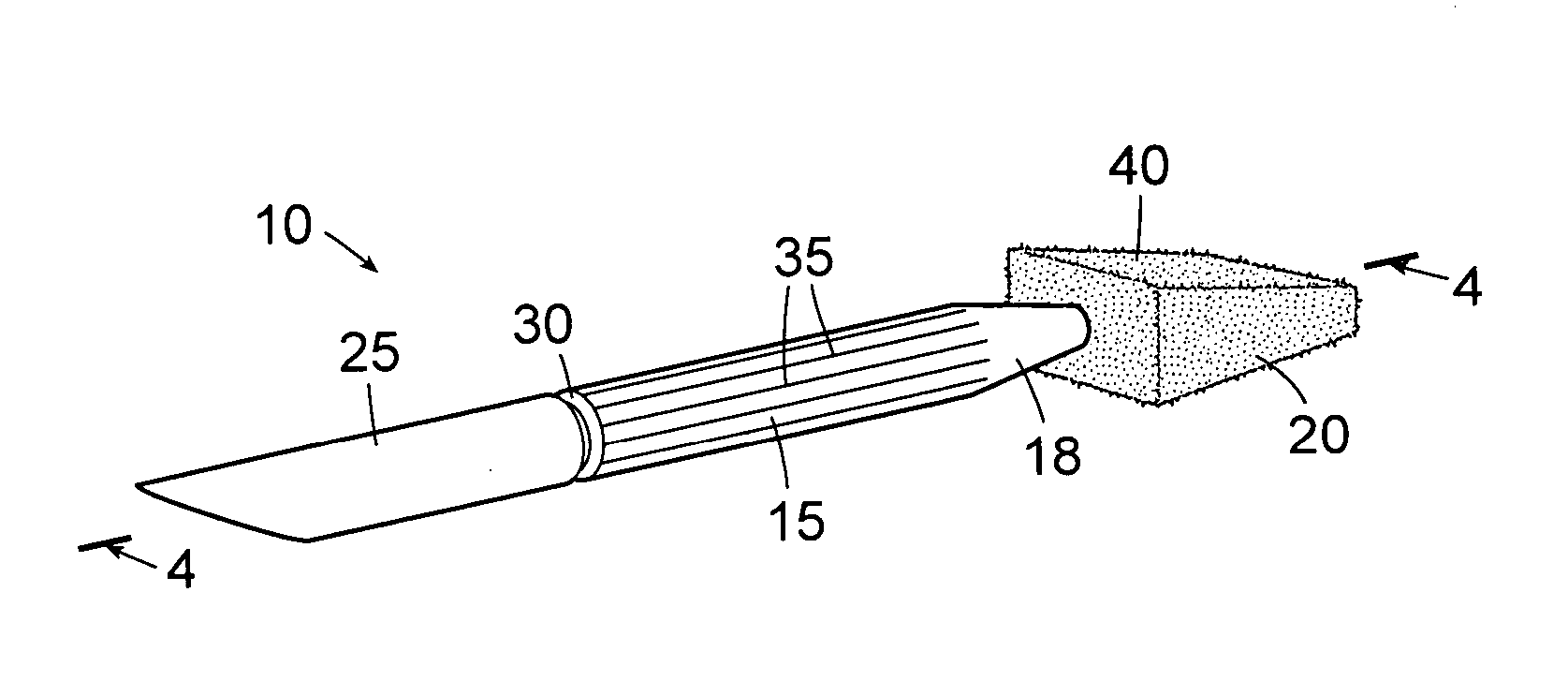

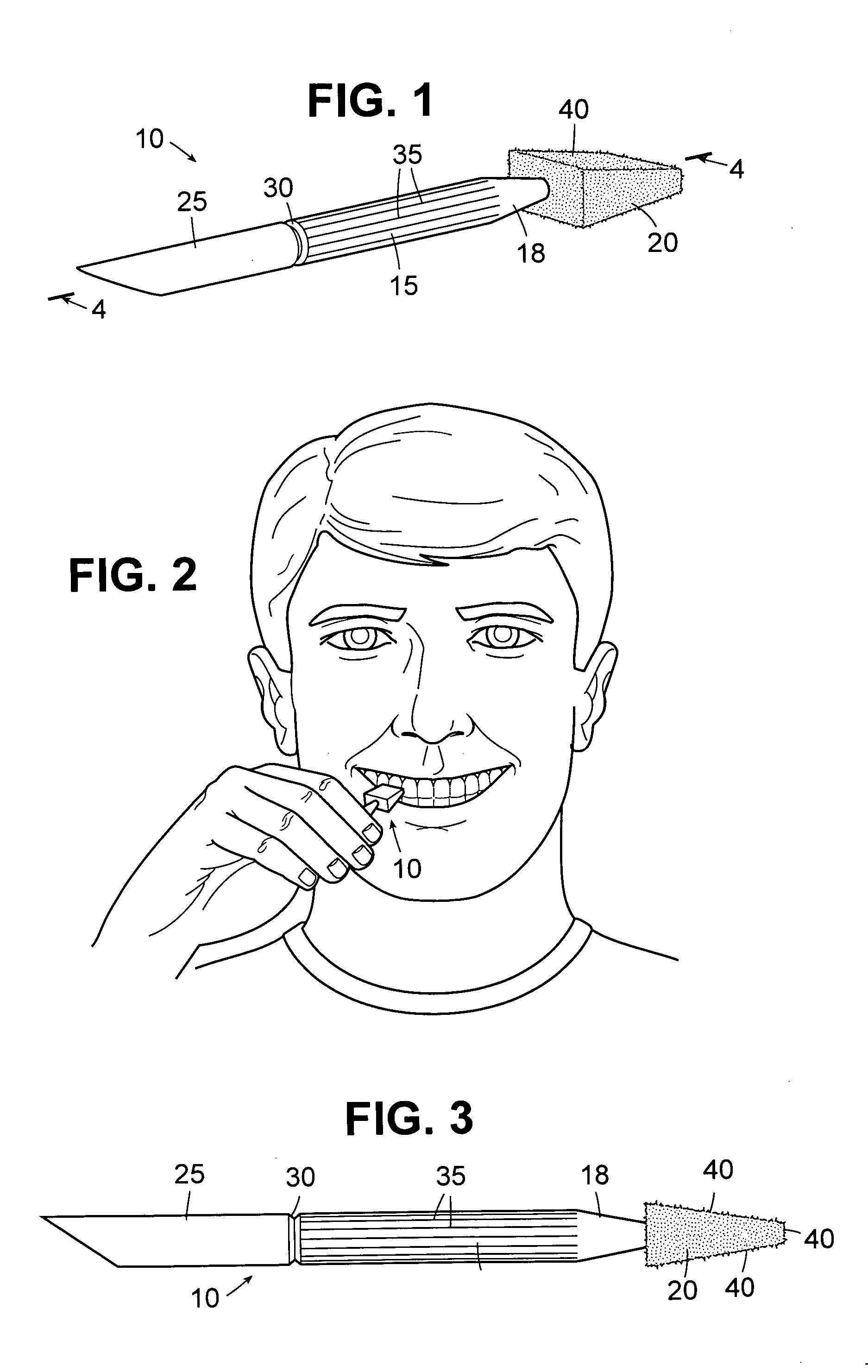

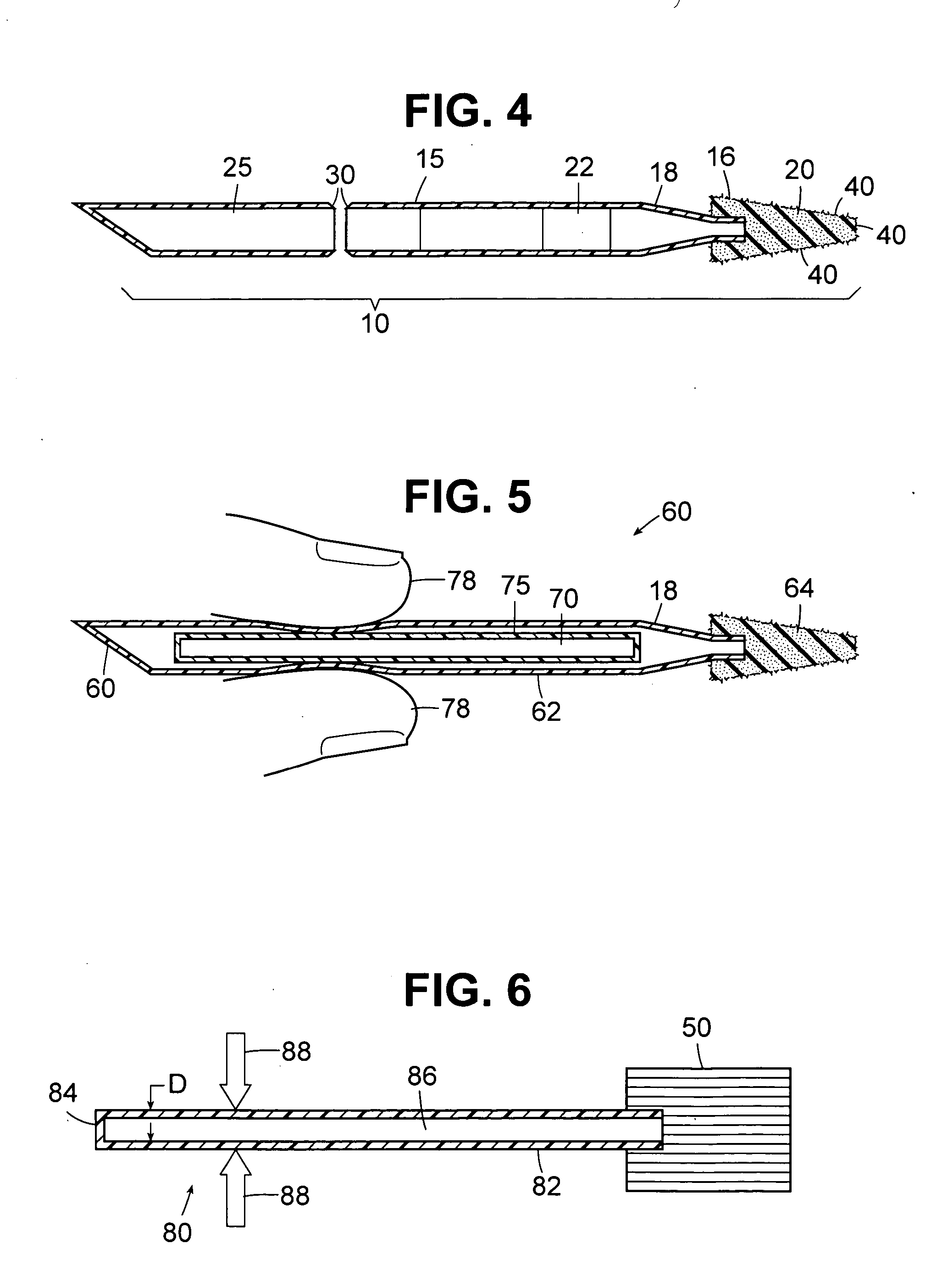

Applicator for cleaning teeth

InactiveUS7044671B2Easy and efficient cleaningGum massageCarpet cleanersTeeth cleaningCleaning teeth

A disposable teeth cleaning applicator device. An elongated tubular shaft member has an applicator tip member at one end and a toothpick device at the other end. A liquid dental material is positioned inside the tubular shaft member and, once released, is squeezed or allowed to flow into the applicator tip member and used to clean a person's teeth.

Owner:MCNEIL PPC INC

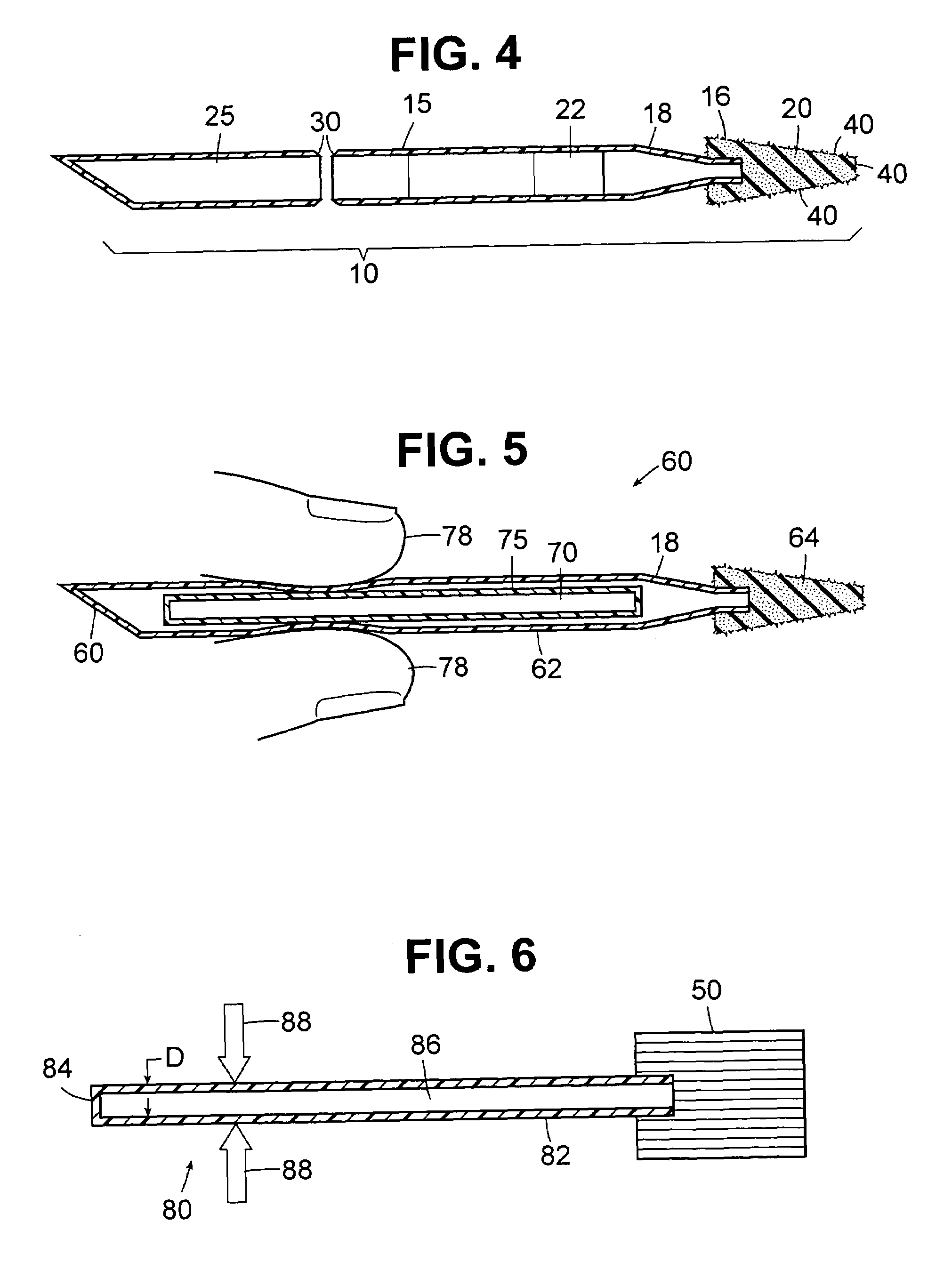

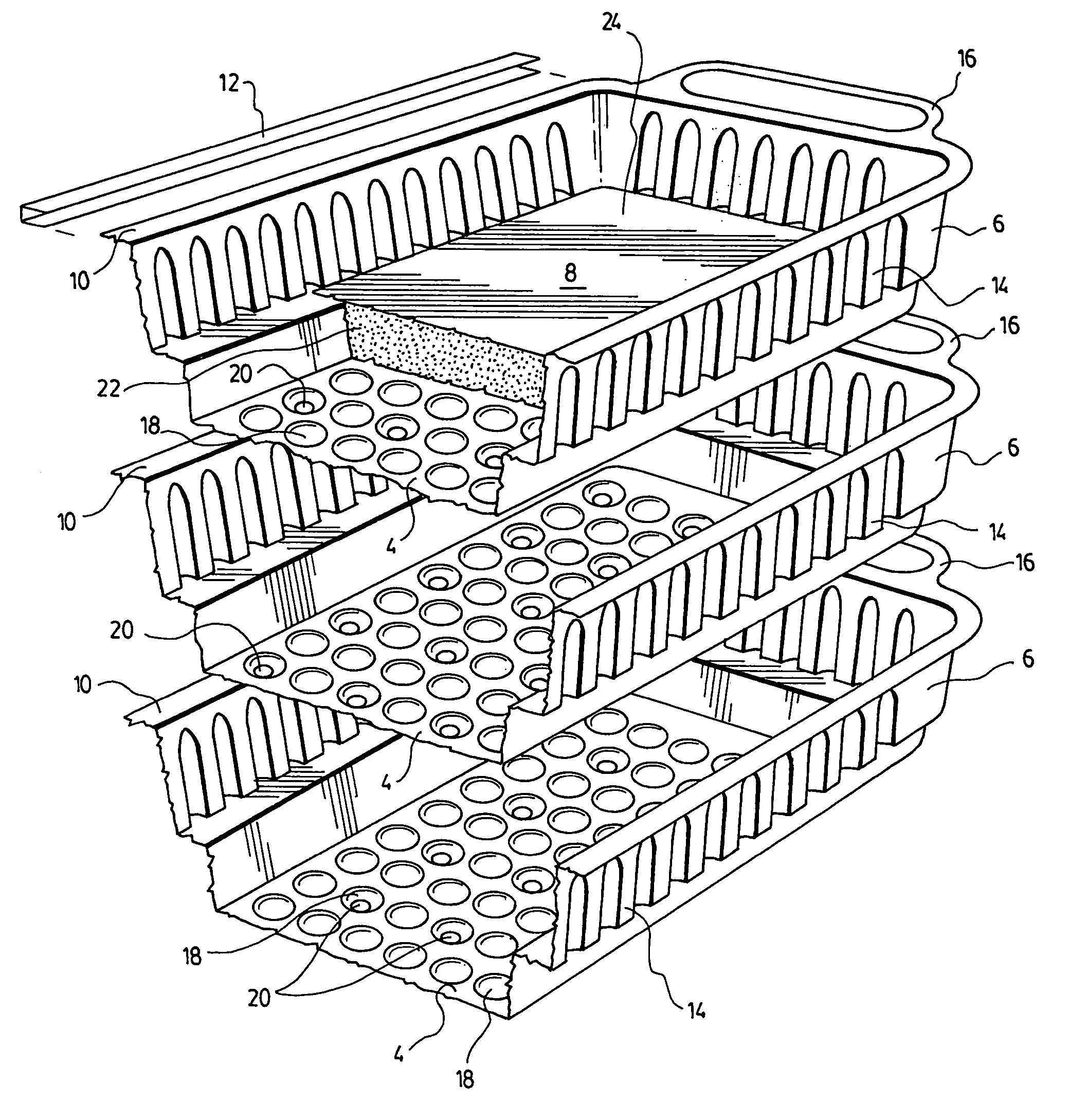

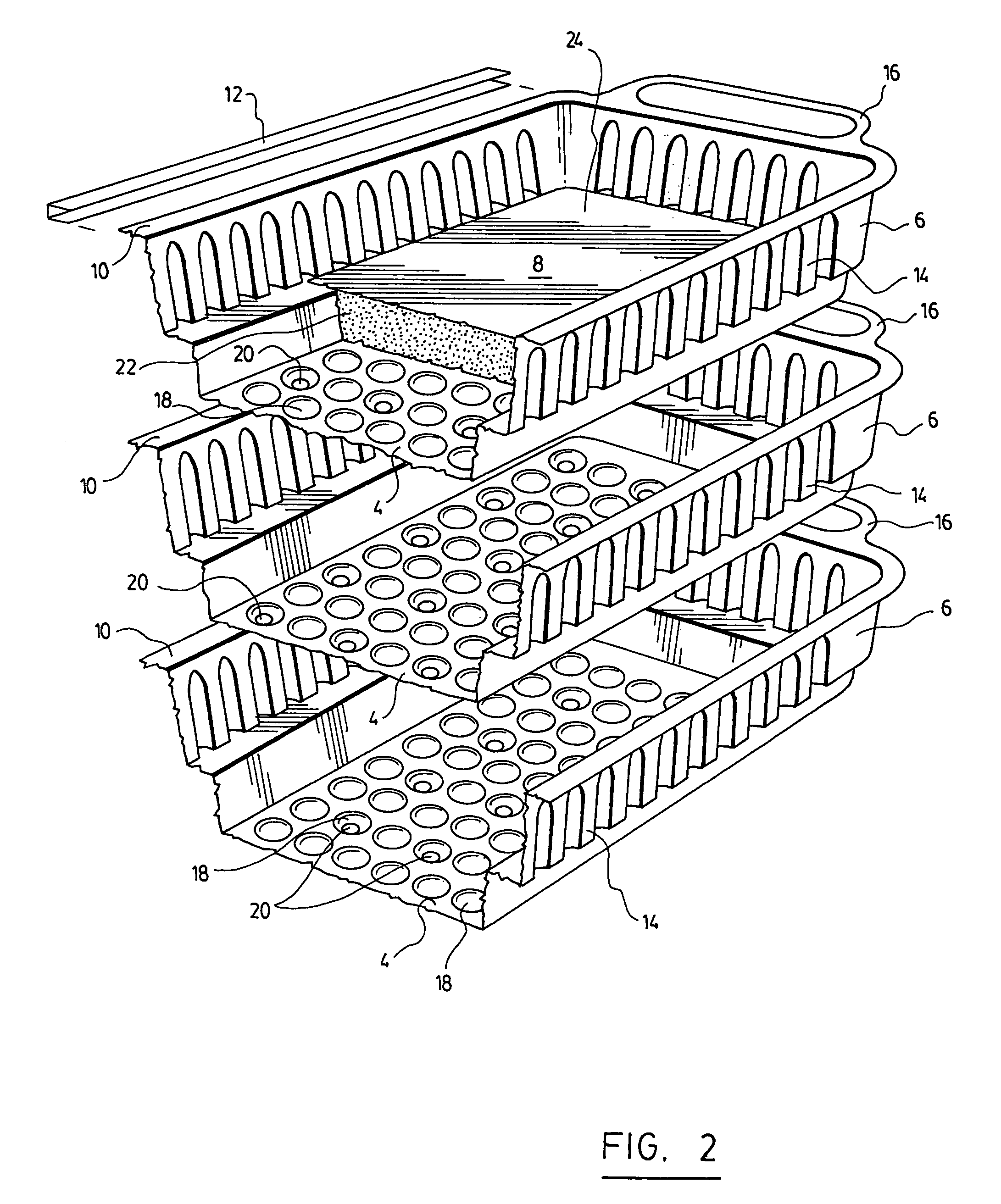

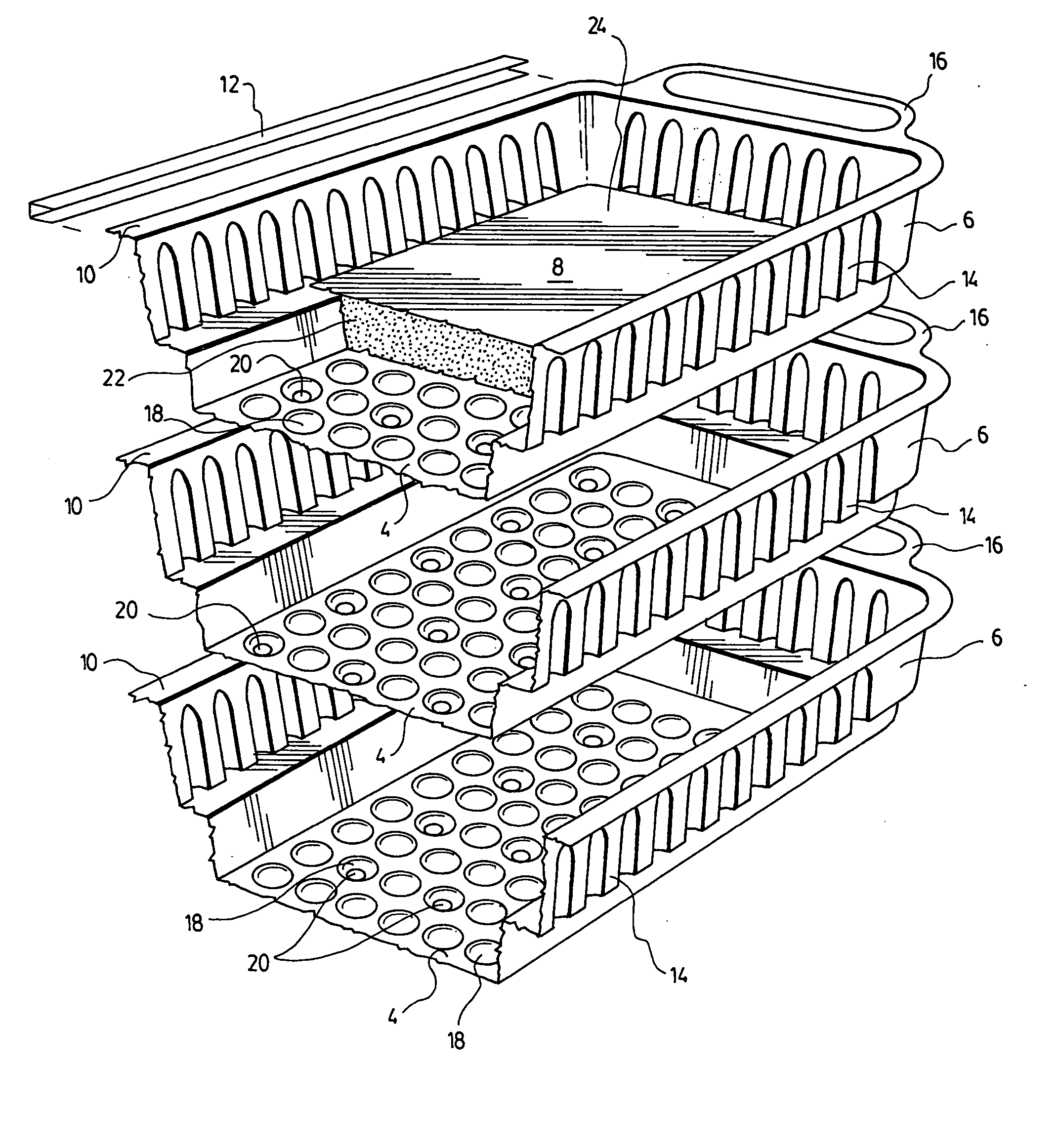

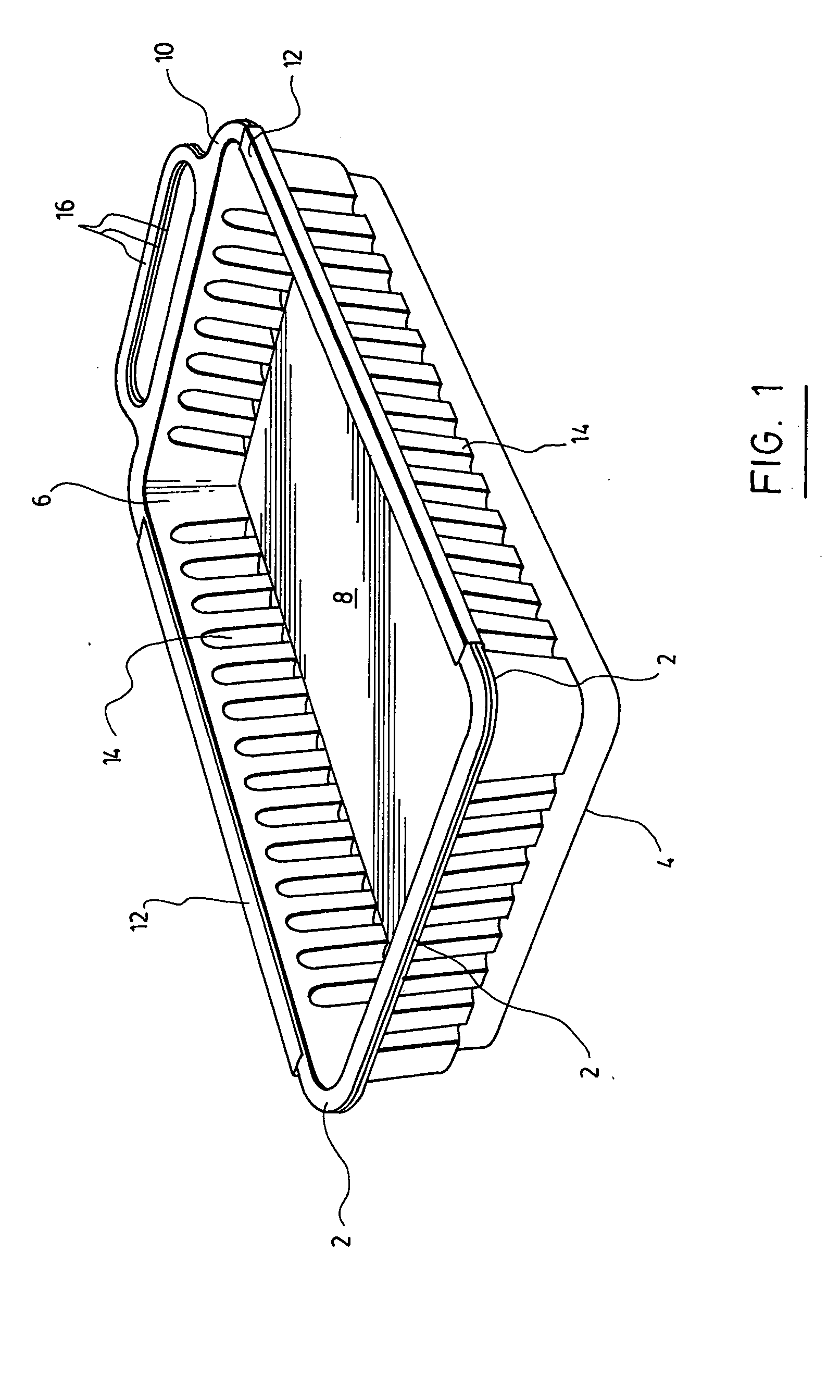

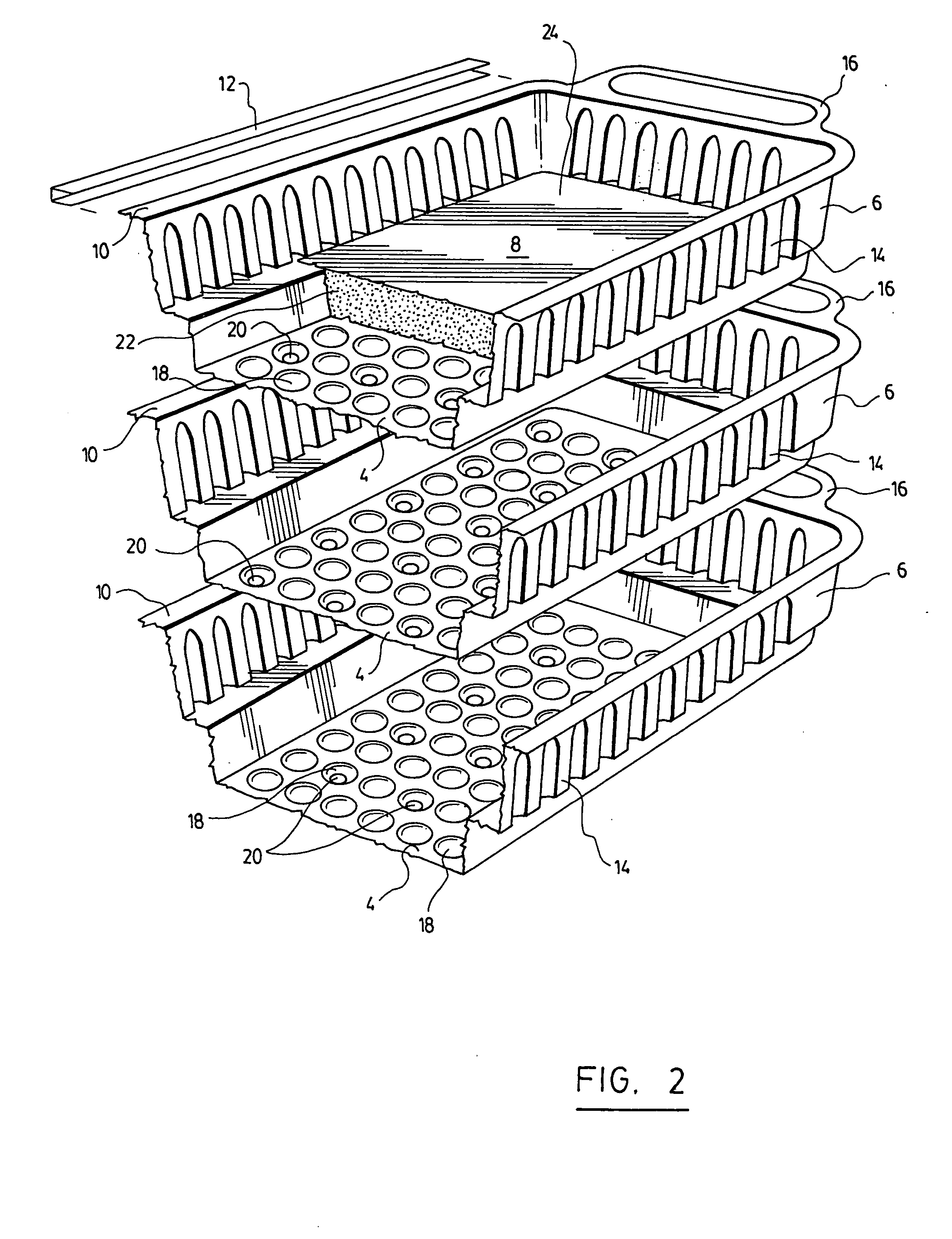

Litter box made of several perforated pans for cats or other domestic animals

A litter box for cats or other domestic animals, which comprises three pans insertable into each other to form a stack. The position of the pans is interchangeable and each pan has openings in its inferior part for filtration of an absorbing material used to solidify and absorb the organic wastes. The openings of each pan are located at positions different from the openings of the other pans in such a manner that the openings of each pair of adjacent pans be vertically out of line. One advantage of this litter box is that it is not necessary to use a shovel to pick up and dispose of the organic wastes.

Owner:SCOTTO DANIELO RENE

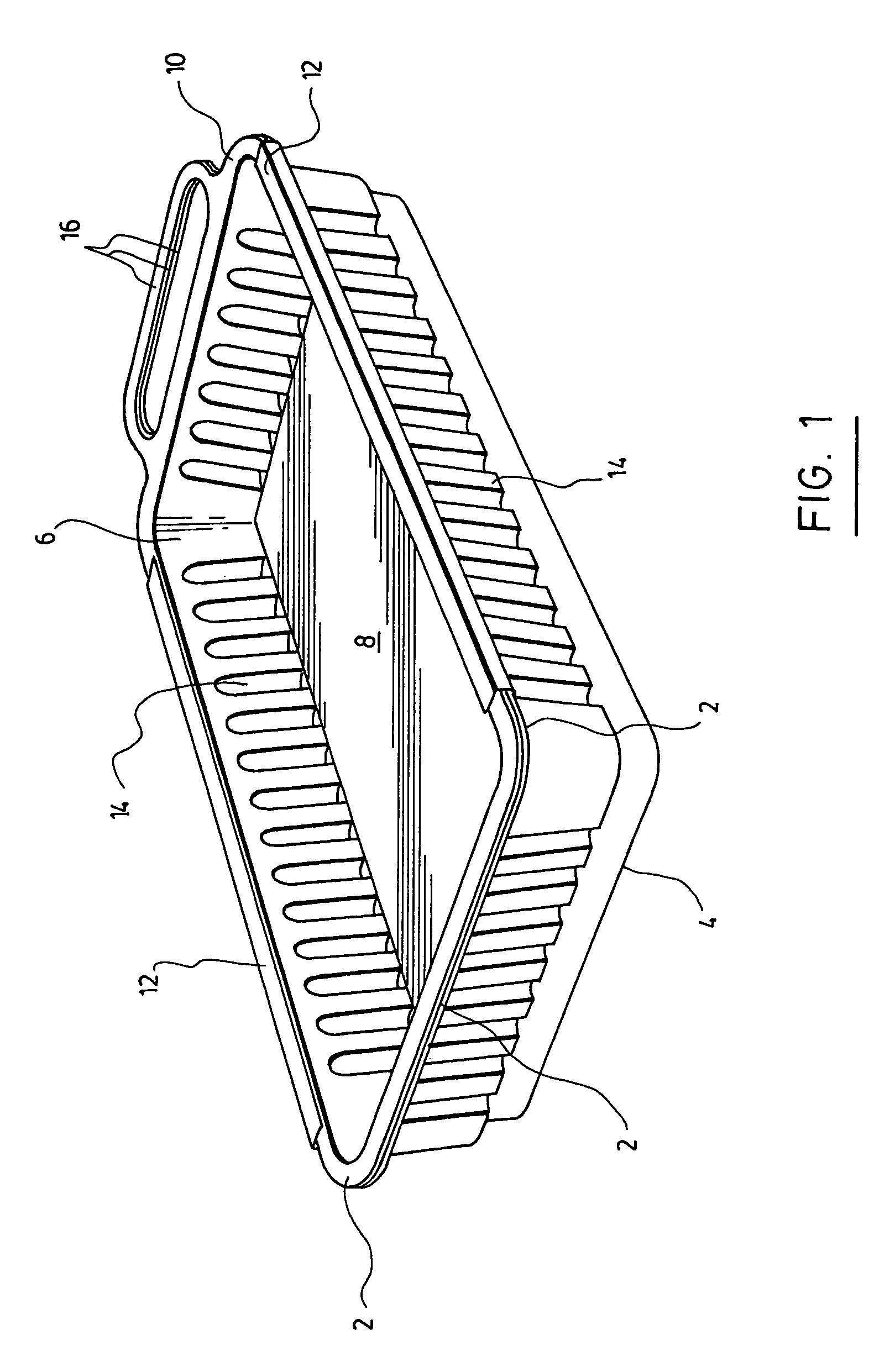

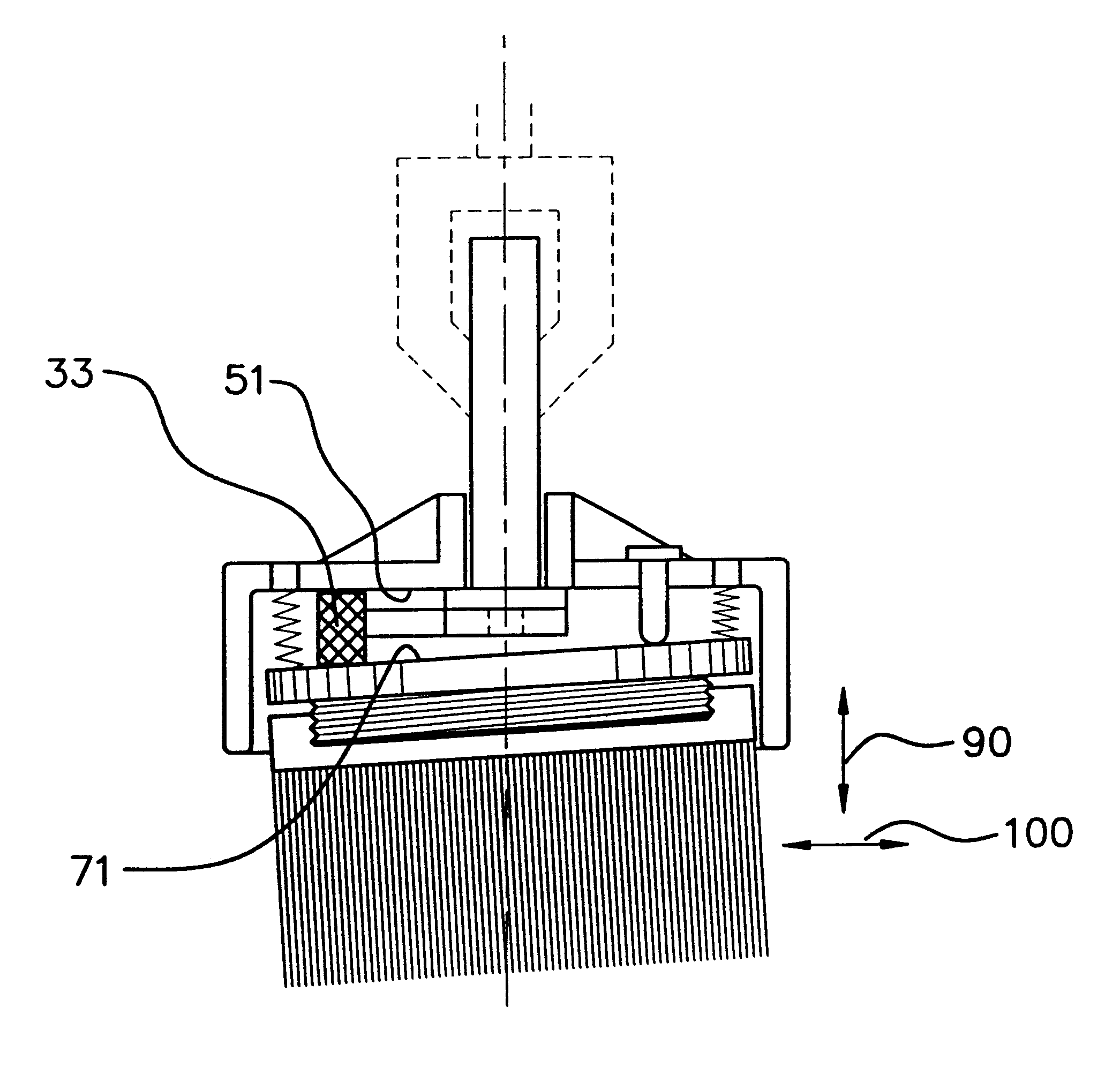

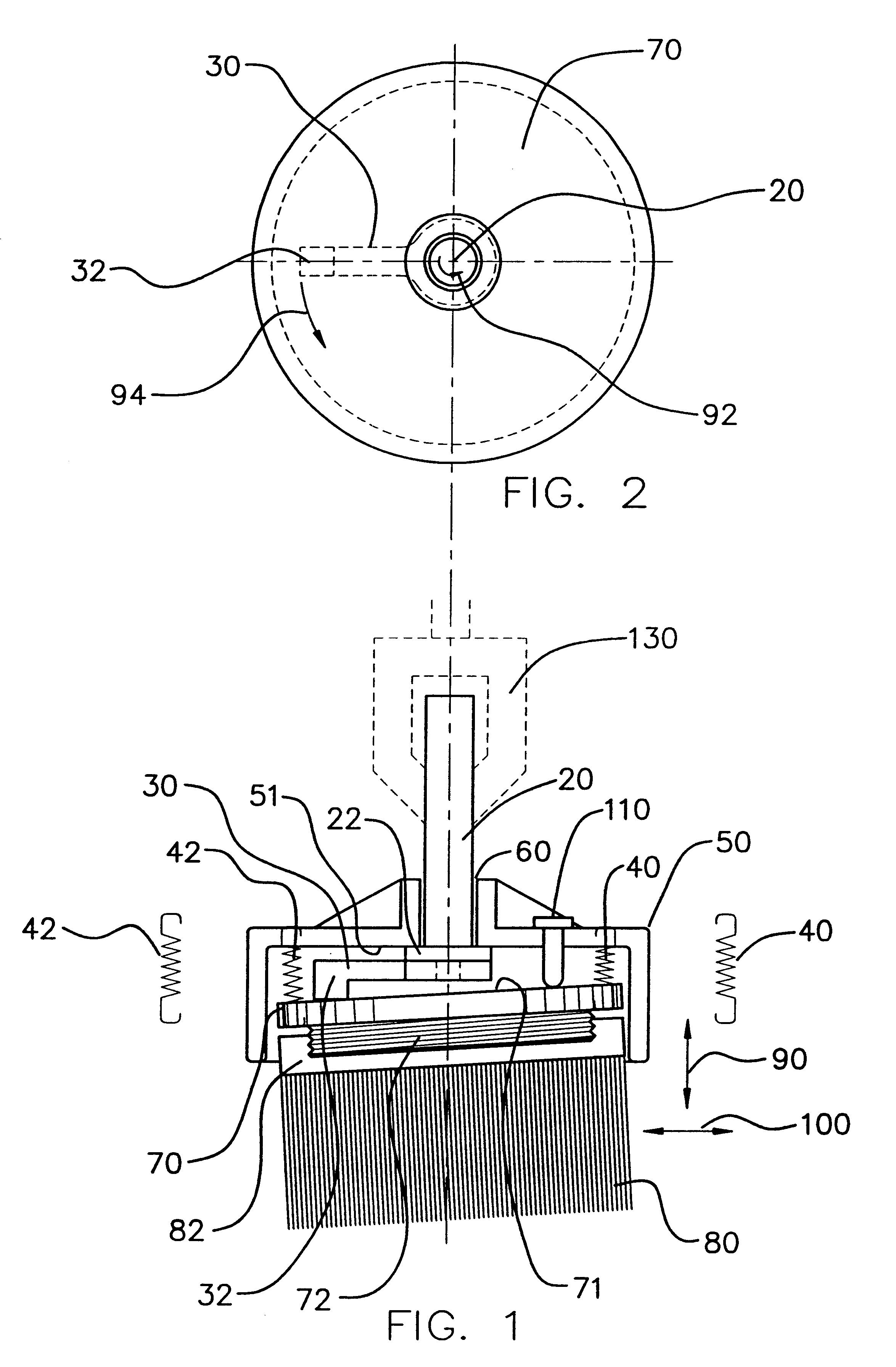

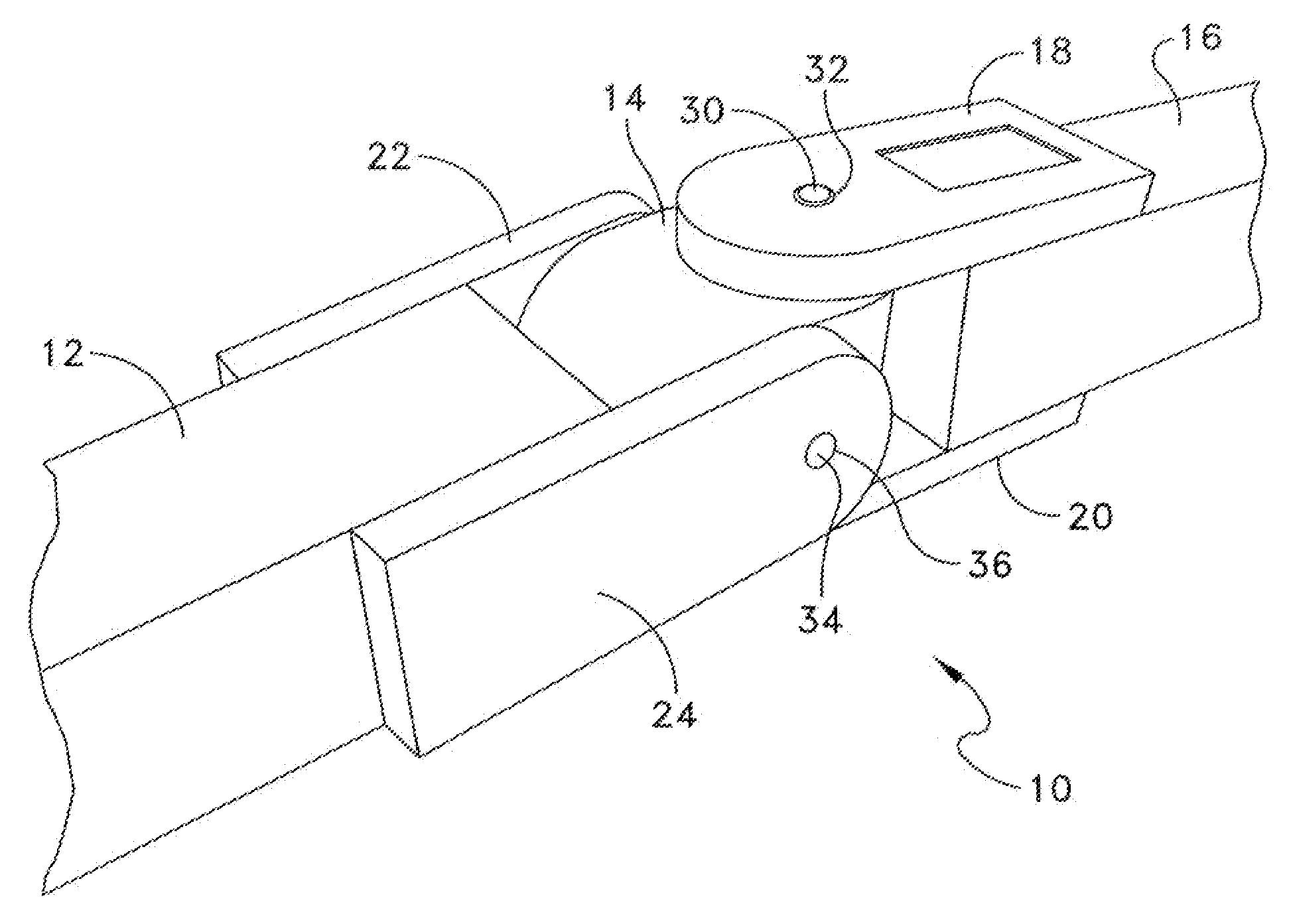

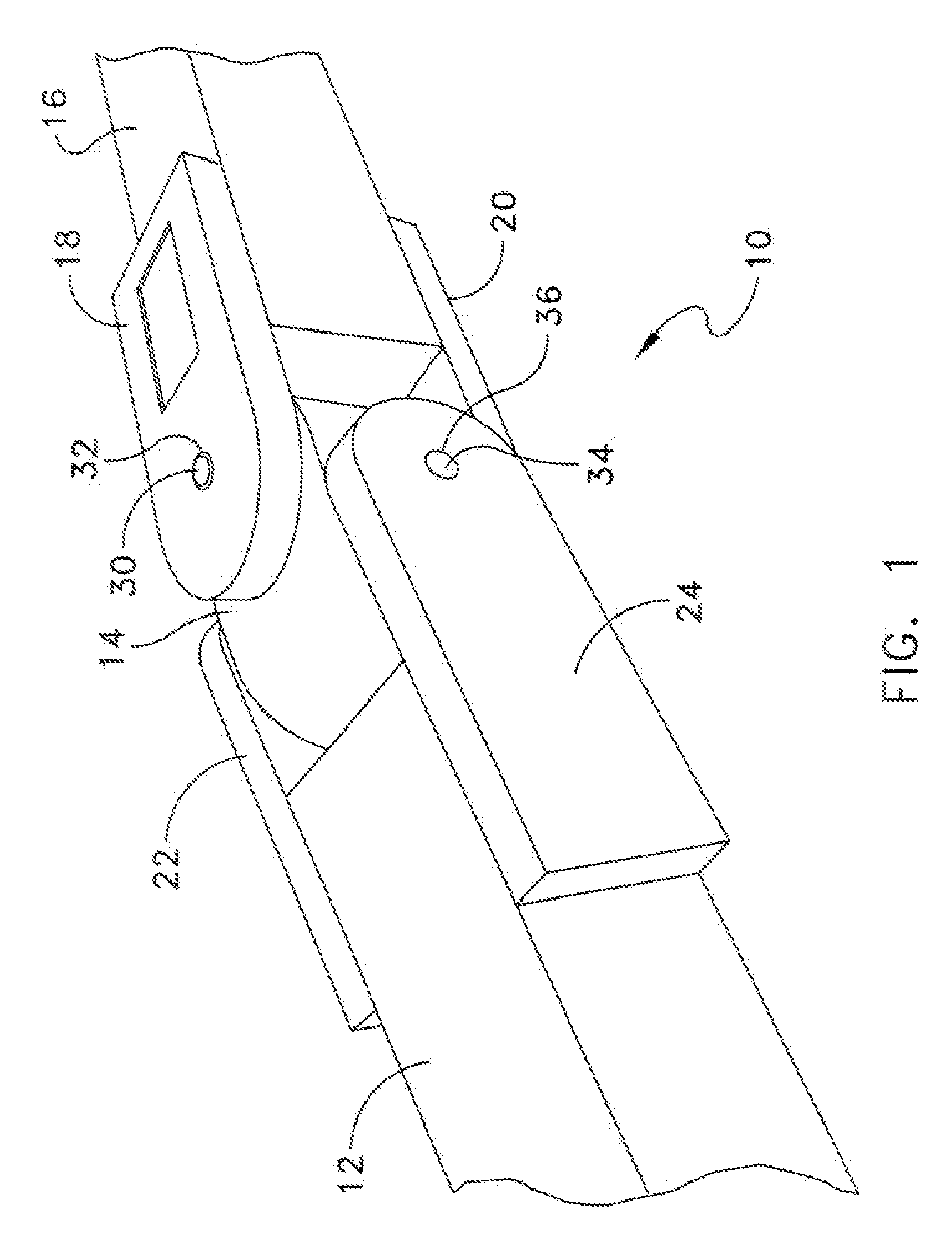

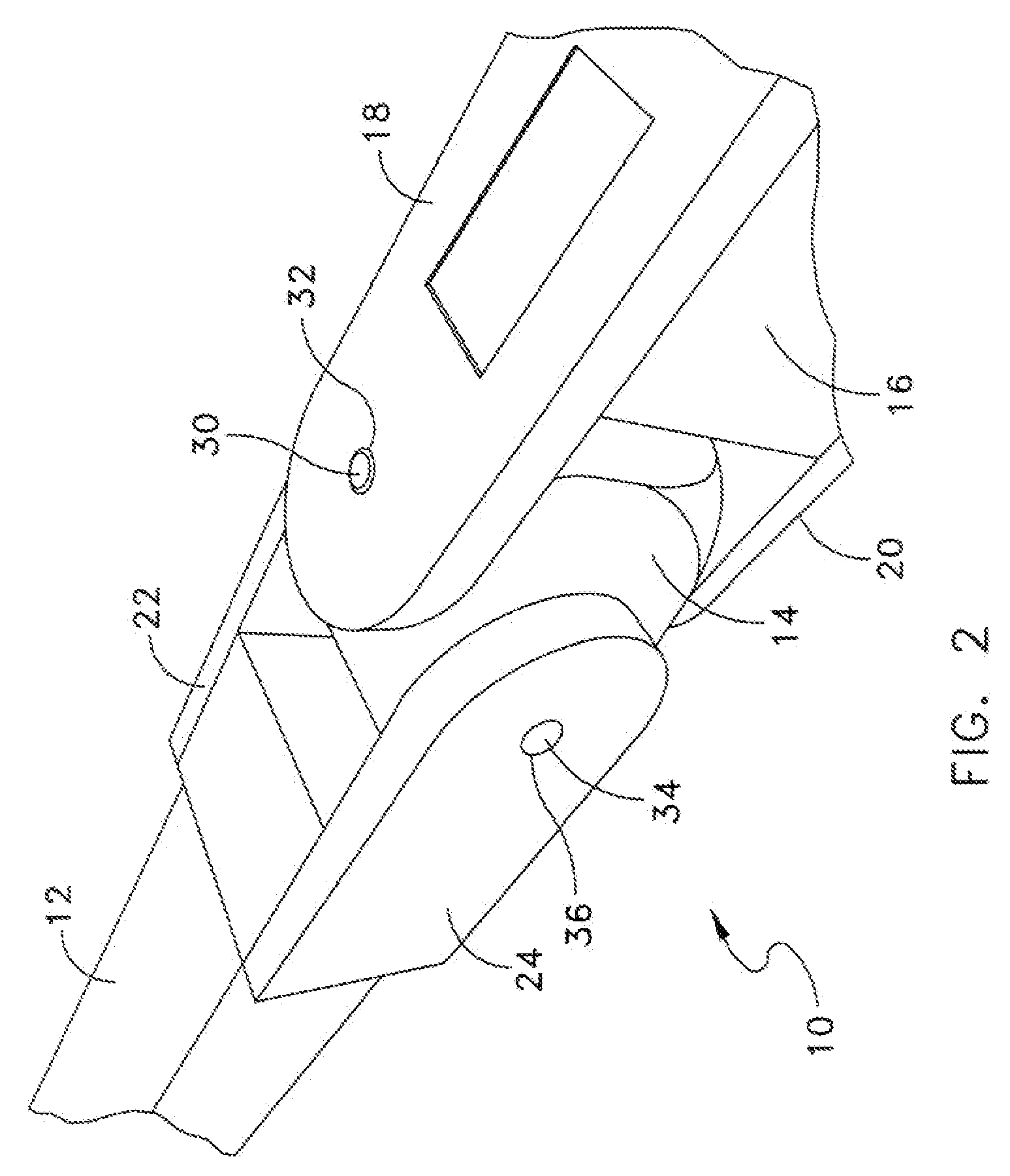

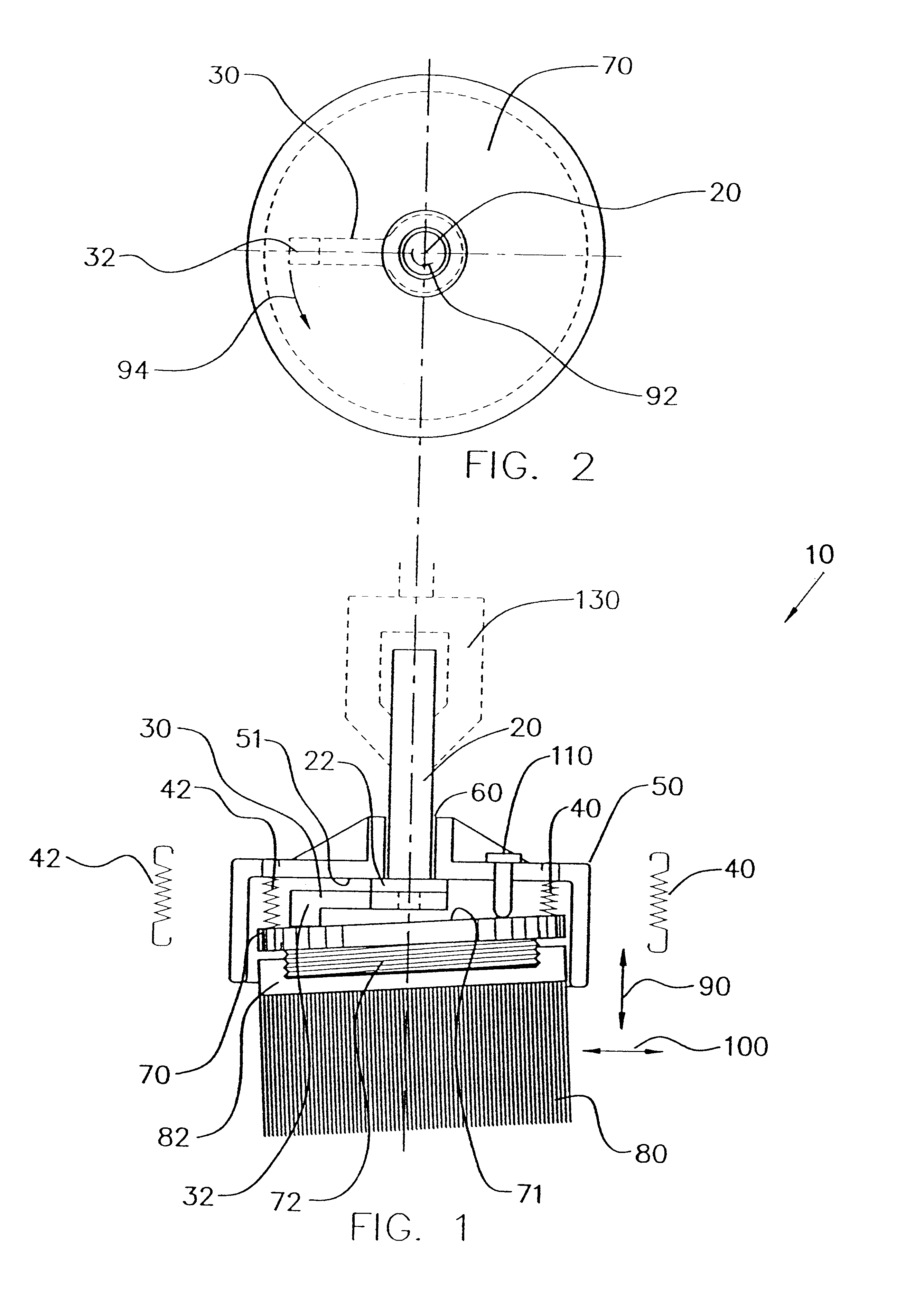

Wobble brush apparatus

InactiveUS6449792B1Easy and efficient cleaningReduce riskBowling gamesCarpet cleanersConfined spaceEngineering

Disclosed is an apparatus imparting a wobbling motion to a planar surface. In one embodiment the wobbling motion is imparted to a brush which can be used to clean uneven surfaces efficiently and easily. In another embodiment the wobbling motion is imparted to a brush which can be used to clean surfaces in confined spaces and reducing the risk of scratching or marring areas in the confined spaces. In another embodiment a method of cleaning a surface using a wobbling apparatus is disclosed.

Owner:MYERS HAROLD R

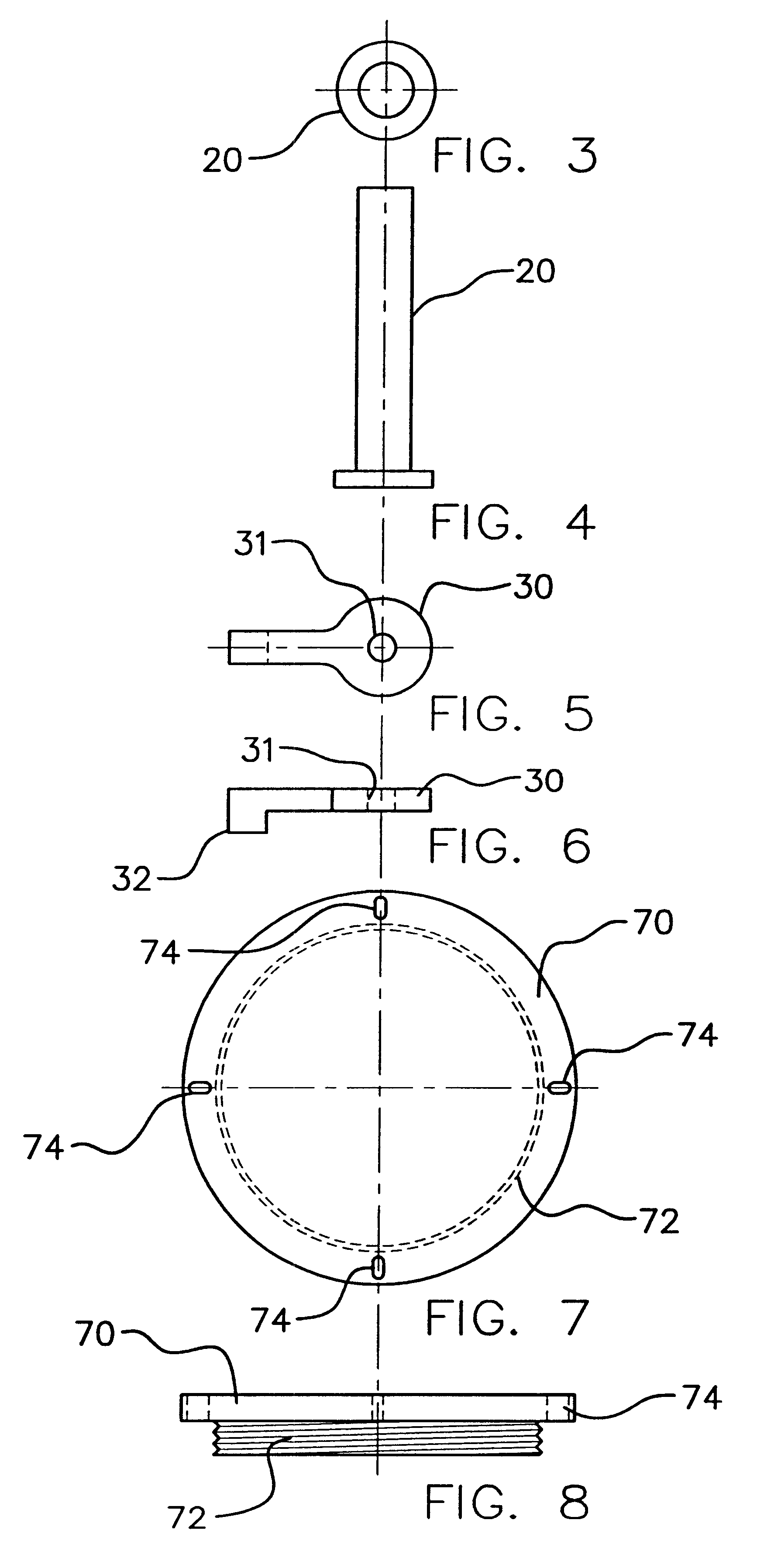

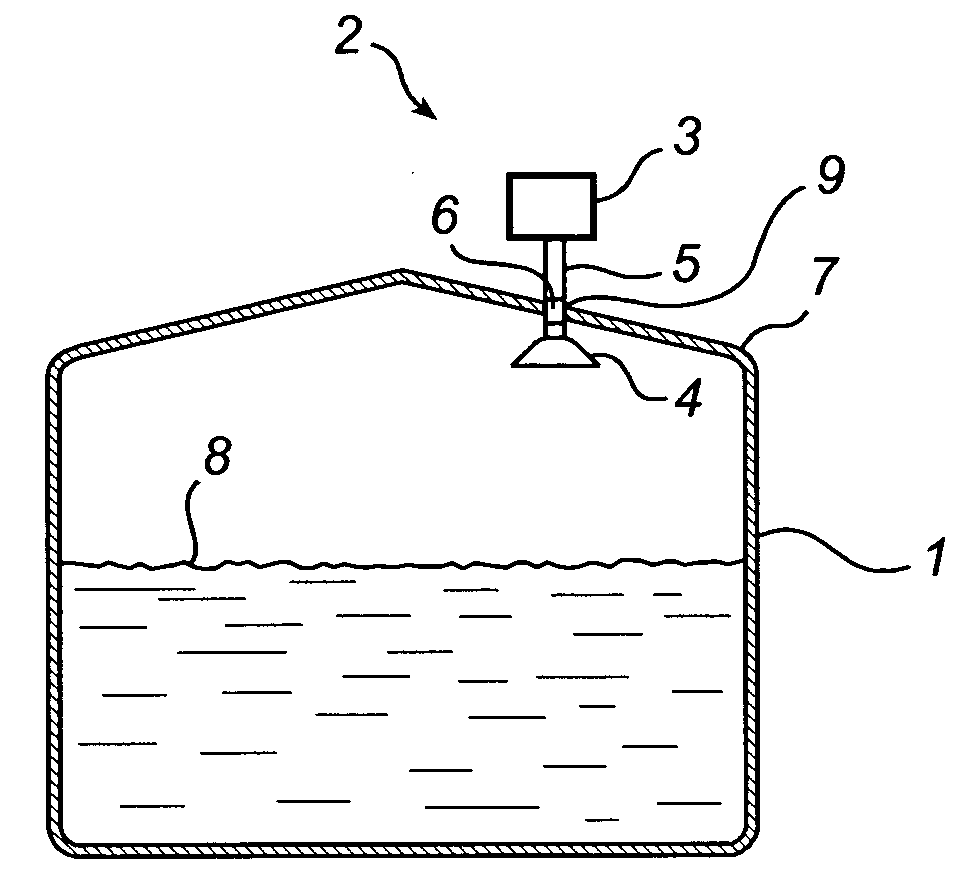

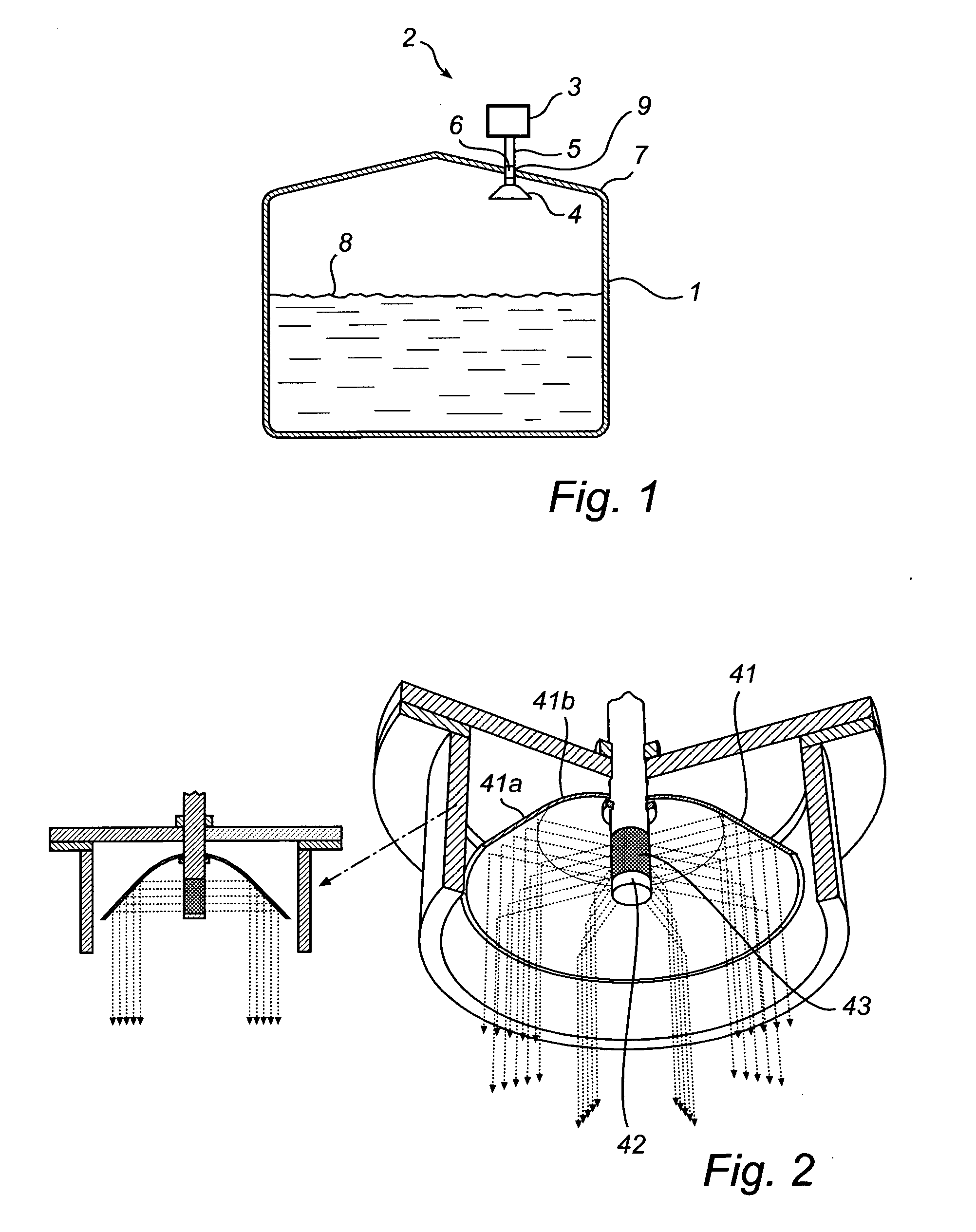

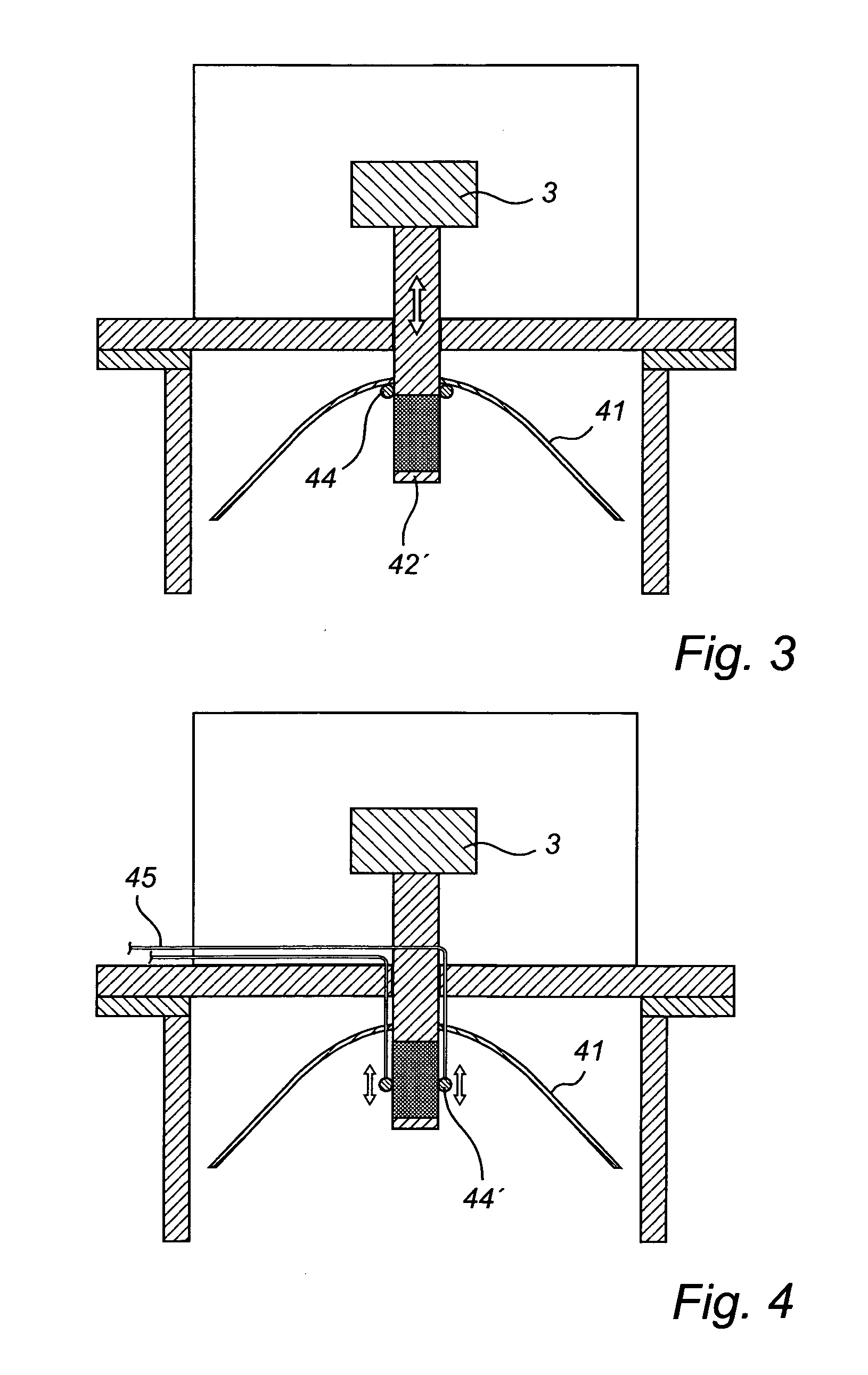

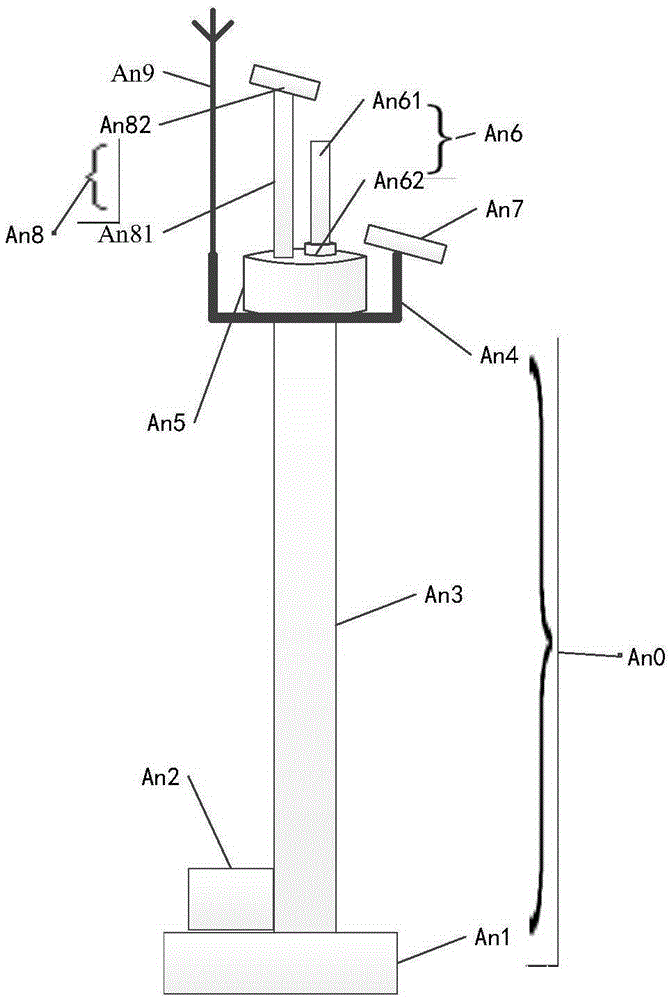

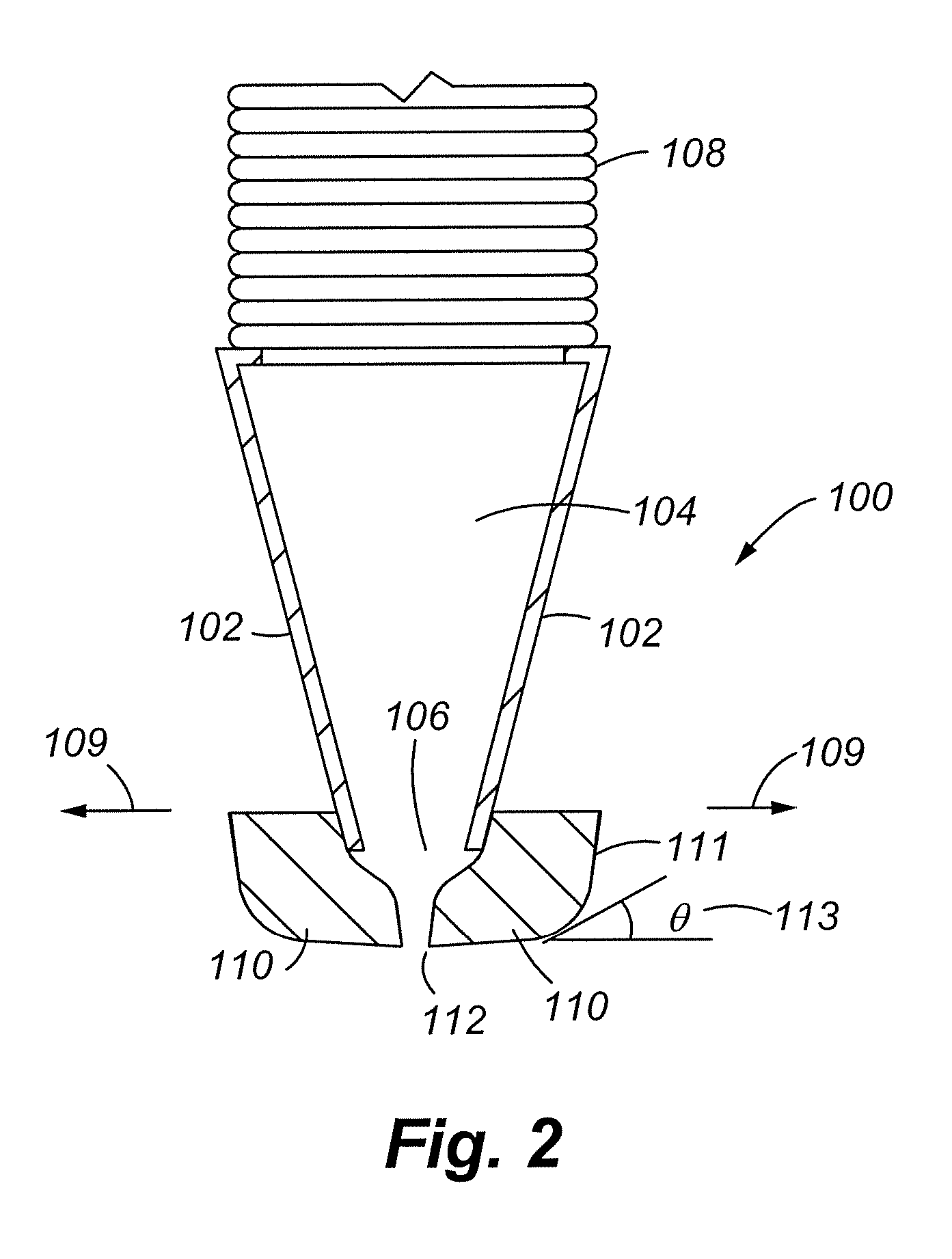

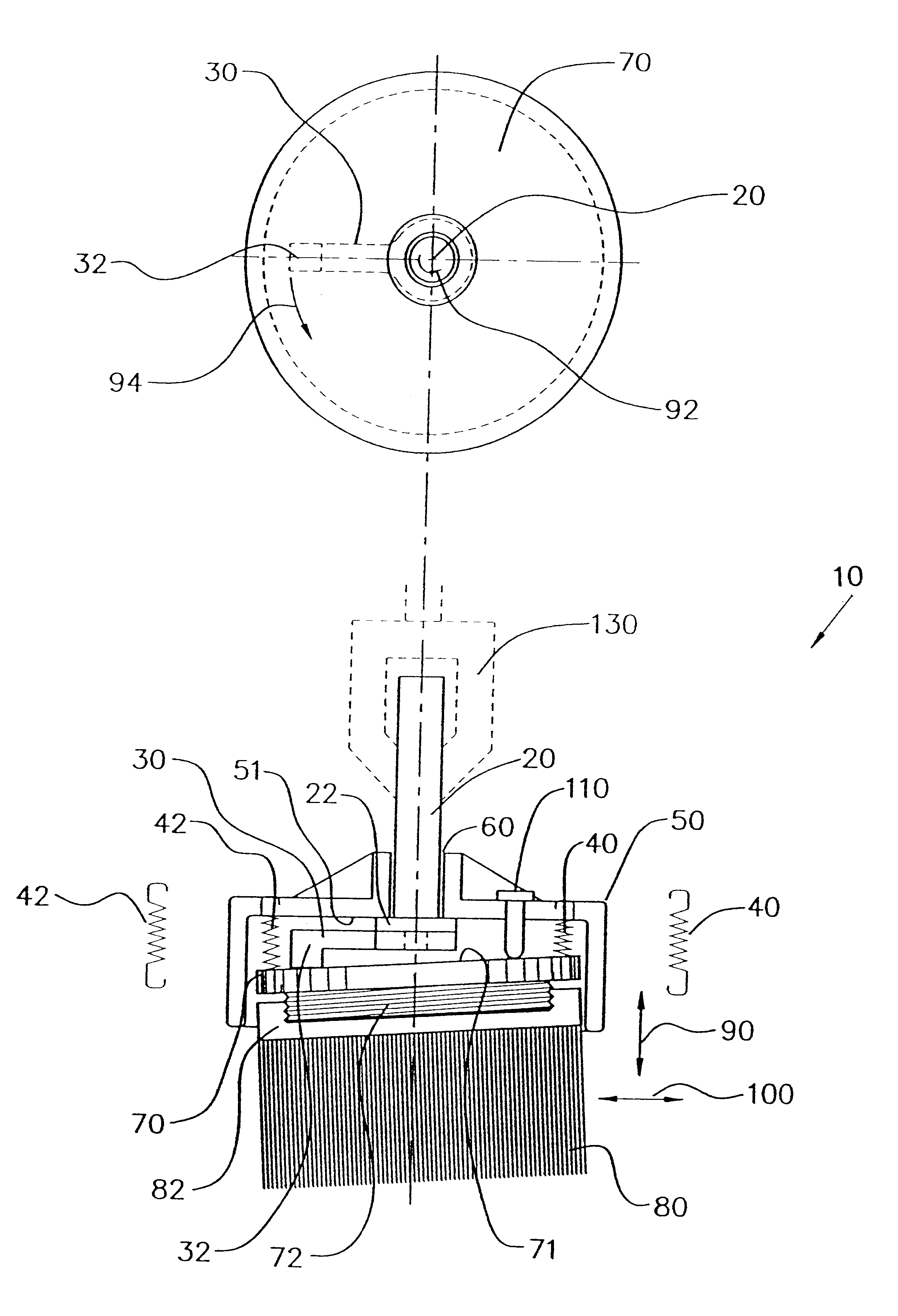

Antenna for a radar level gauge

InactiveUS20080100501A1Improve anti-pollution performanceEasy and efficient cleaning methodVolume meteringLevel indicatorsFilling materialsEngineering

An antenna for a radar-based level gauge useable for determining a filling level of a filling material contained in a container is disclosed. The antenna comprises a reflector, which is symmetric around a symmetry axis; and a feeder for feeding microwave signals to and from the reflector. The feeder is of an elongate, essentially cylindrical shape, with a longitudinal axis of said feeder essentially coinciding with said symmetry axis of the reflector, wherein said feeder comprises a ring-shaped radiation feeding area for transmitting electromagnetic radiation towards the reflector and for receiving reflected electromagnetic radiation. In a preferred embodiment, an abutment ring is arranged around the feeder, wherein at least one of the feeder and the abutment ring are movable in relation to each other in the axial direction of said feeder, whereby simple and effective cleaning of the feeder is rendered possible. A method for cleaning an antenna is also disclosed.

Owner:ROSEMOUNT TANK RADAR

Applicator for cleaning teeth

InactiveUS20050069373A1Easy and efficient cleaningGum massageCarpet cleanersTeeth cleaningCleaning teeth

A disposable teeth cleaning applicator device. An elongated tubular shaft member has an applicator tip member at one end and a toothpick device at the other end. A liquid dental material is positioned inside the tubular shaft member and, once released, is squeezed or allowed to flow into the applicator tip member and used to clean a person's teeth.

Owner:MCNEIL PPC INC

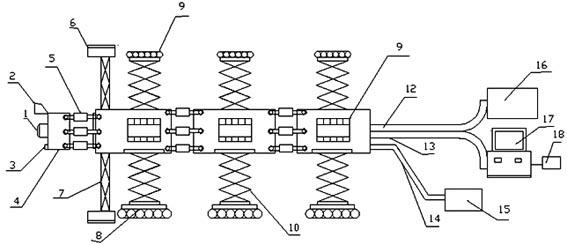

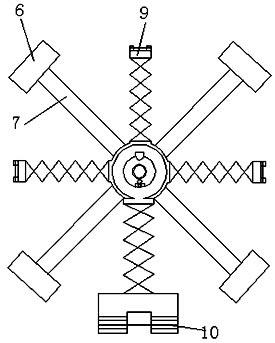

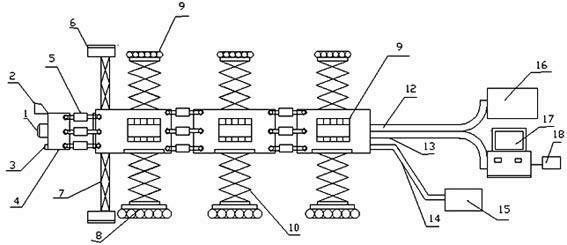

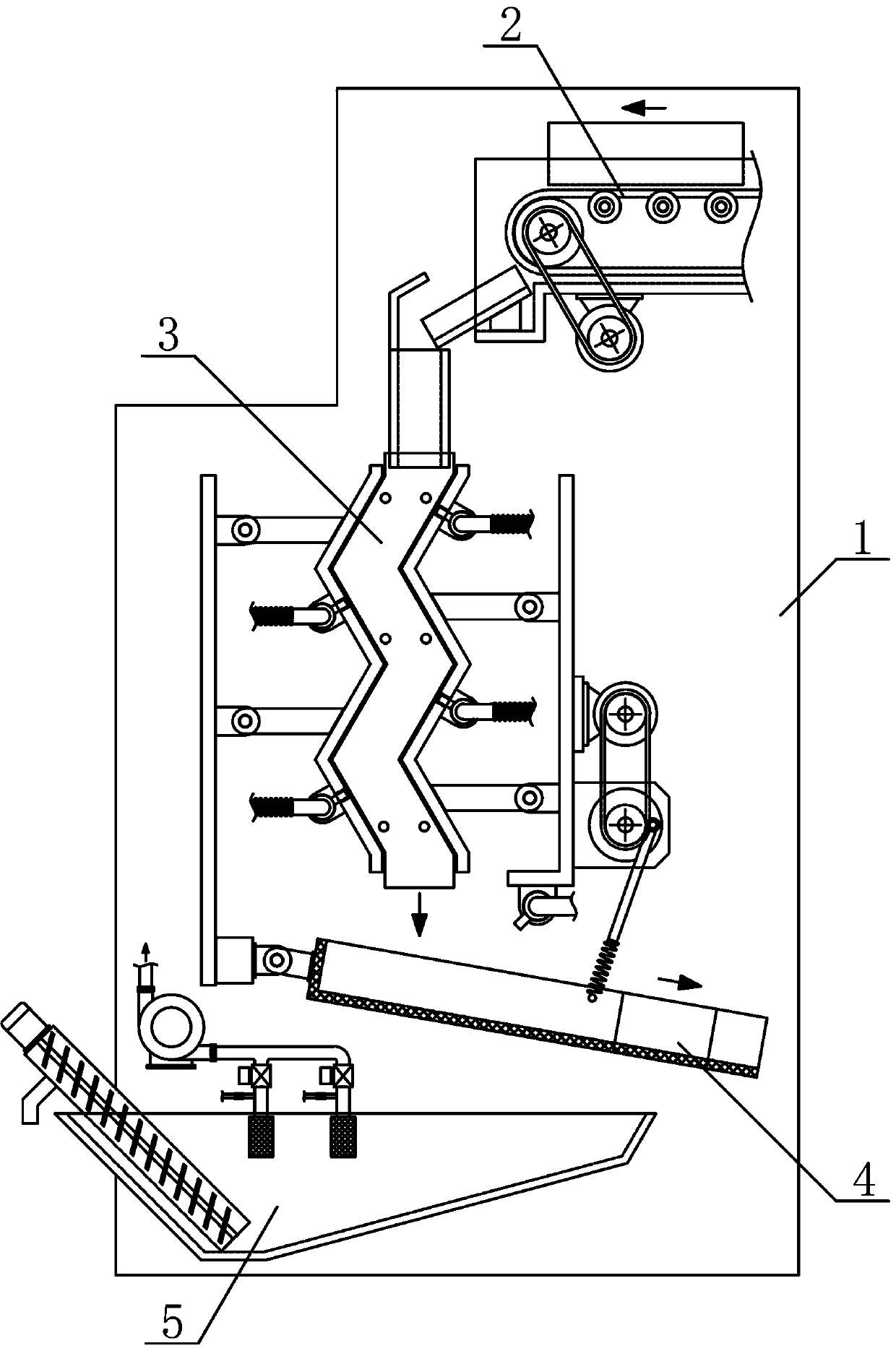

Coal-fired power station boiler air duct and air-conditioning ventilation duct wormlike cleaning robot

InactiveCN102489481AFlexible movementComprehensive air duct cleaningHollow article cleaningVehiclesVentilation ductCentral air conditioning

The invention relates to a coal-fired power station boiler air duct and an air-conditioning ventilation duct wormlike cleaning robot. The air-conditioning ventilation duct wormlike cleaning robot comprises a peristaltic vehicle body, a controller, a vision system, an ultrasonic obstacle avoidance device and the like. The peristaltic vehicle body comprises a head and a vehicle body. The head is connected with the vehicle body through a skeleton type hydraulic connection turning device, and parts of the vehicle body are also connected through skeleton type hydraulic connection turning devices. The left, the right and the top of each section of the vehicle body are respectively provided with a non-power fixed traveling platform through a foldable telescopic device, and the bottom of each section of the vehicle body is respectively provided with a power traveling platform through a foldable telescopic device. The vision system and the ultrasonic obstacle avoidance device are installed at the front end of the head. A surrounding type cleaning device is disposed on a first section of the vehicle body, a second section of the vehicle body is connected with the controller, and a dust collection device is arranged on a third section of the vehicle body. The air-conditioning ventilation duct wormlike cleaning robot is capable of cleaning a primary-air air duct, a secondary-air air duct and a central air-conditioning air duct of a coal-fired power station boiler, and has the advantages of being flexible and accurate in motion, capable of cleaning air ducts in all-round manner, reliable in performance, reasonable in price and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

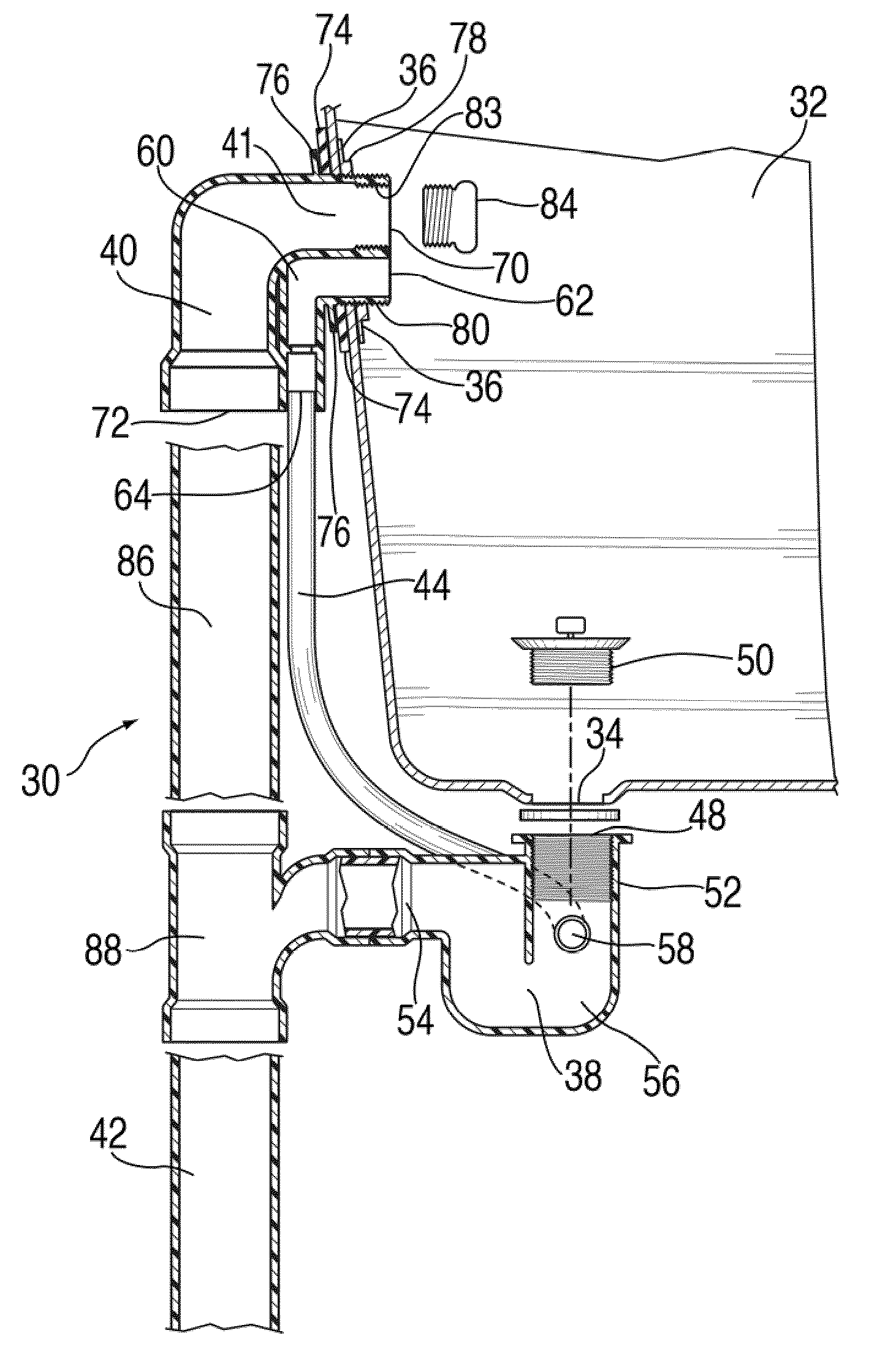

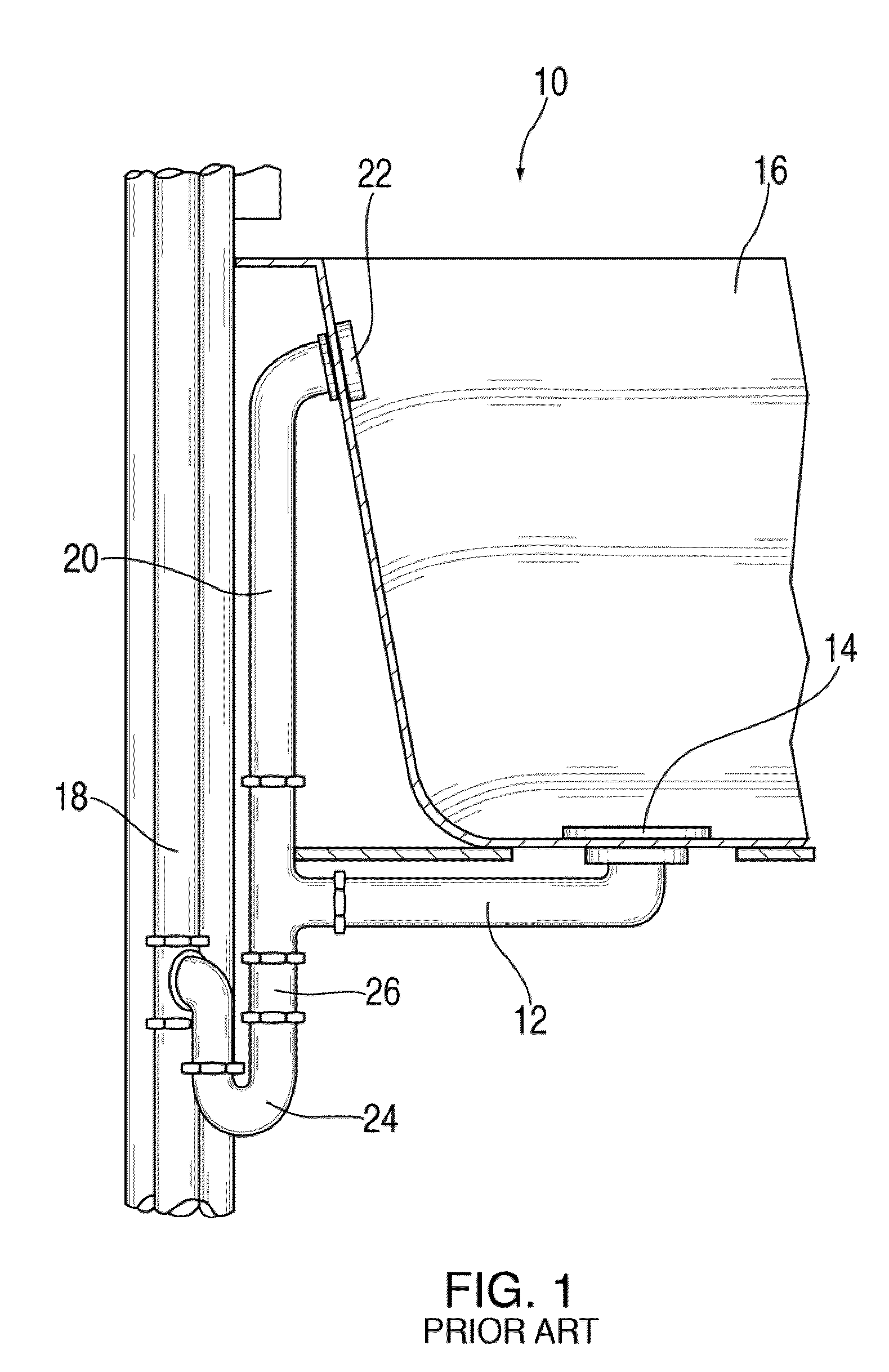

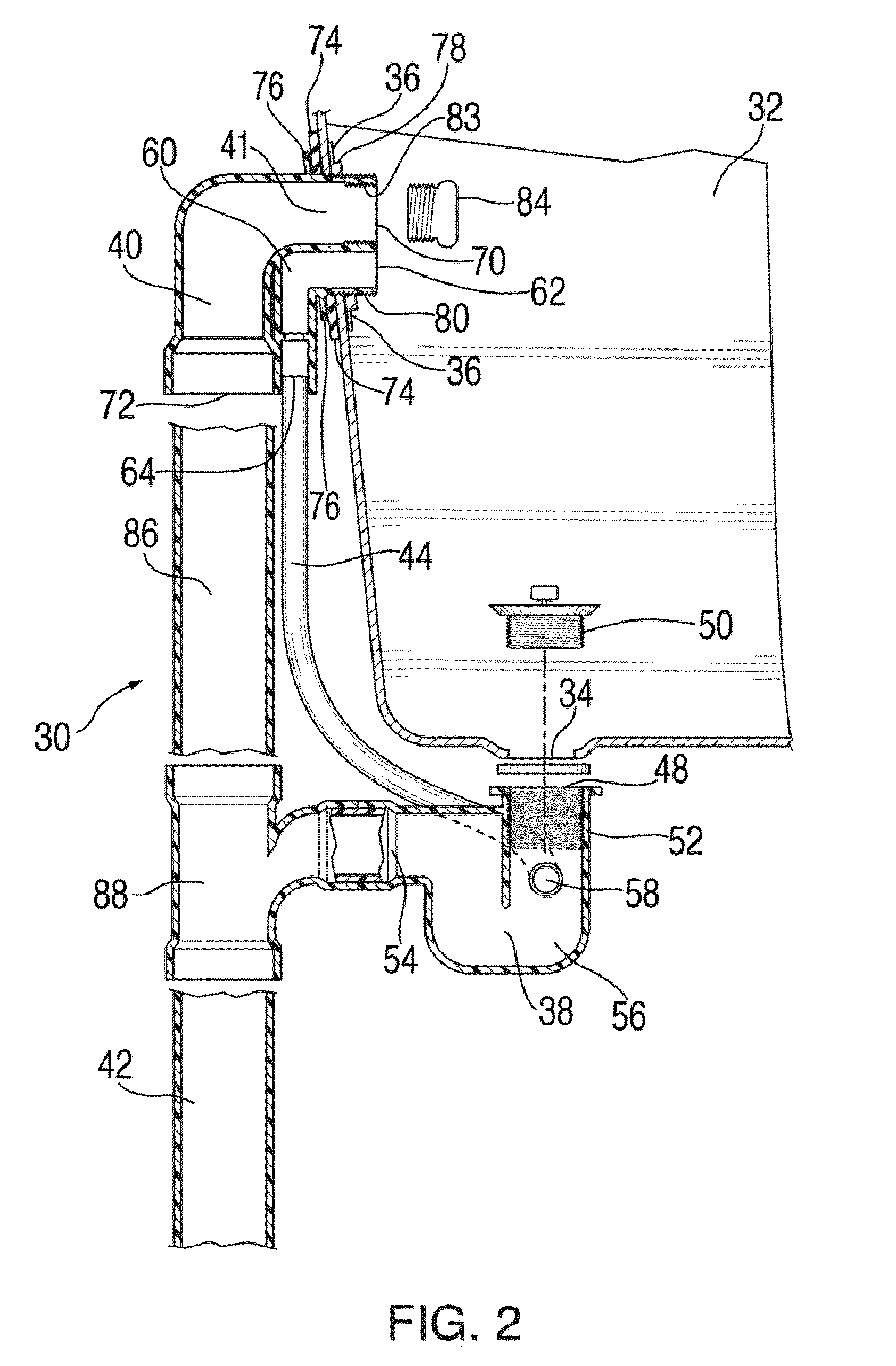

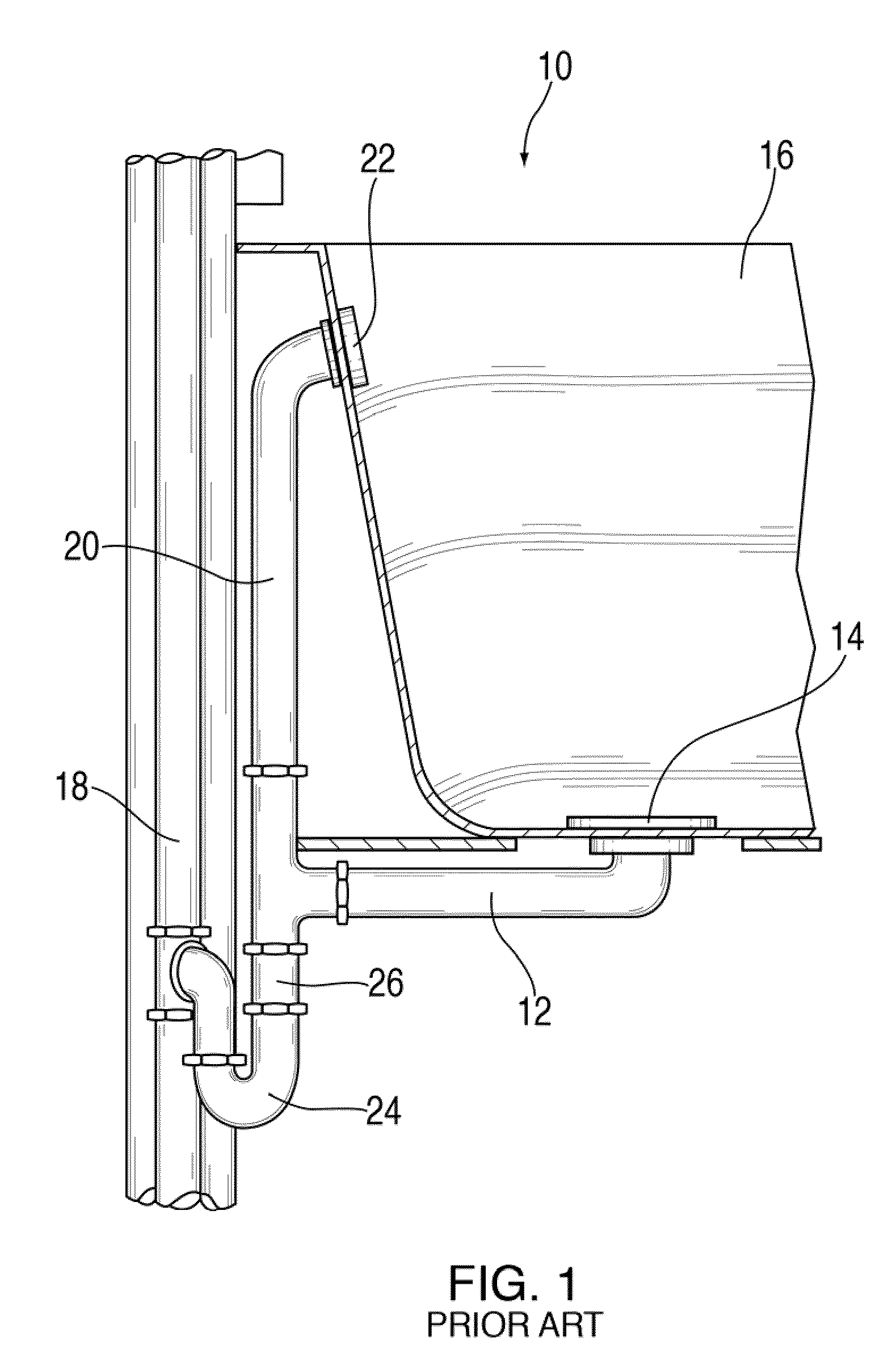

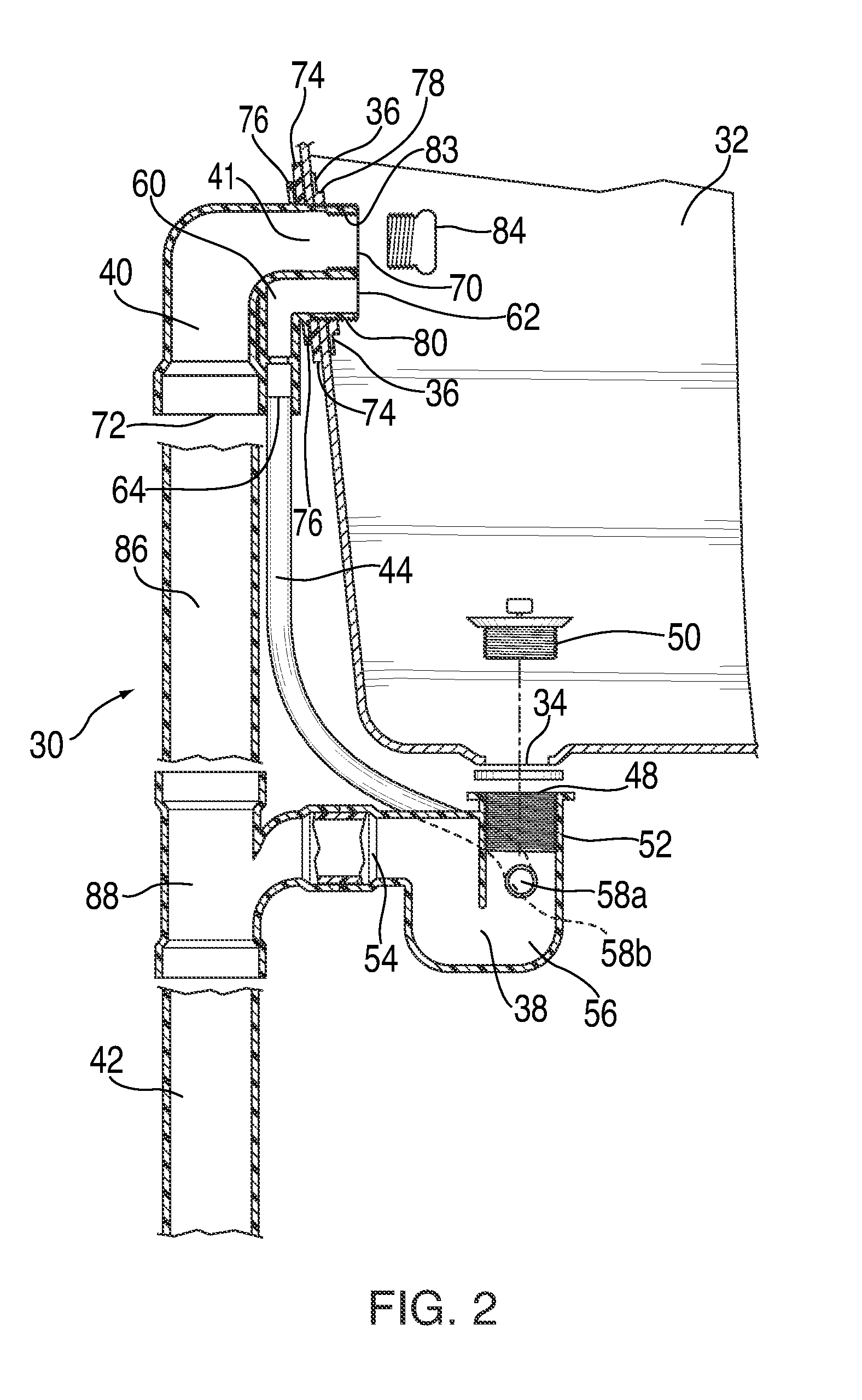

Tub drain and overflow assembly

The invention provides a drain and overflow assembly for a tub having a drain opening and a overflow opening, including a main drainage pipe, a drain fitting having a drain inlet end configured to be connected to the drain opening and a drain outlet end configured to be connected to the main drainage pipe, a trap, an overflow receiving hub disposed between the trap and the drain inlet end, and a multi-purpose fitting including an overflow path having an overflow inlet end configured to be connected to the multi-purpose opening and an overflow outlet end configured to be connected to the overflow receiving hub, the multi-purpose fitting further including a cleanout path having a cleanout inlet end configured to be connected to the multi-purpose opening and a cleanout pipe end configured to be connected to the main drainage pipe.

Owner:SHOOP DOUGLAS M

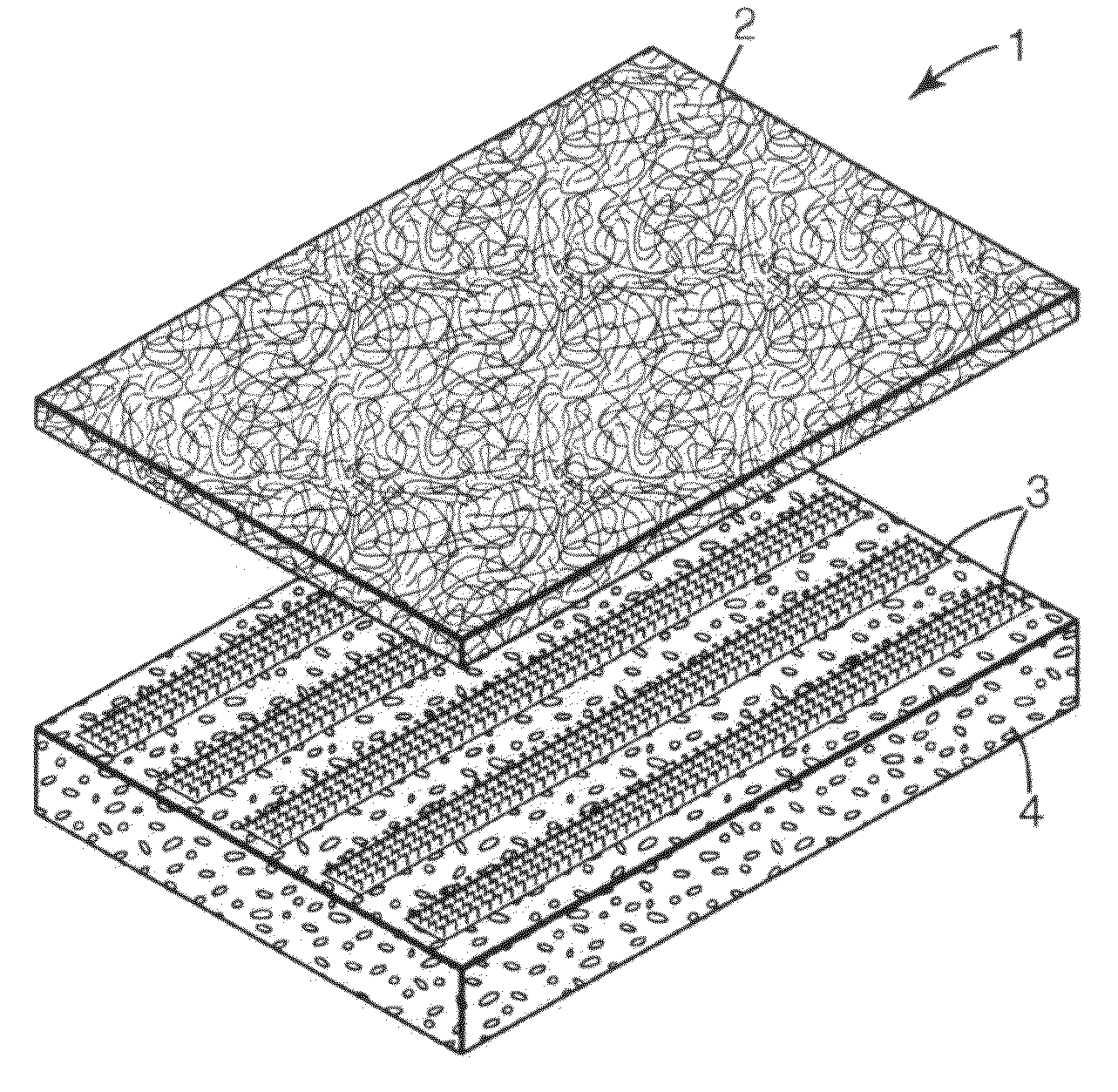

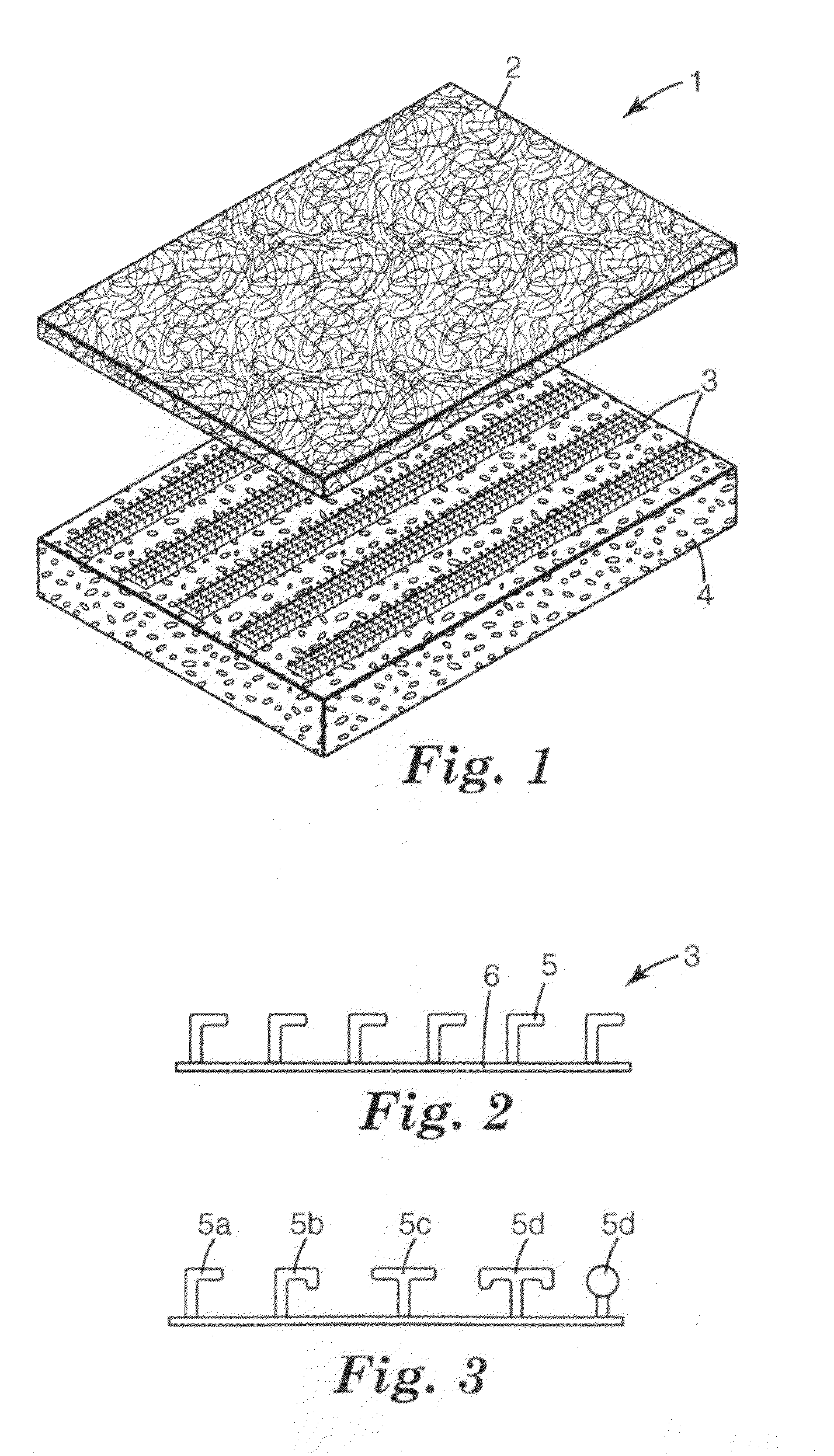

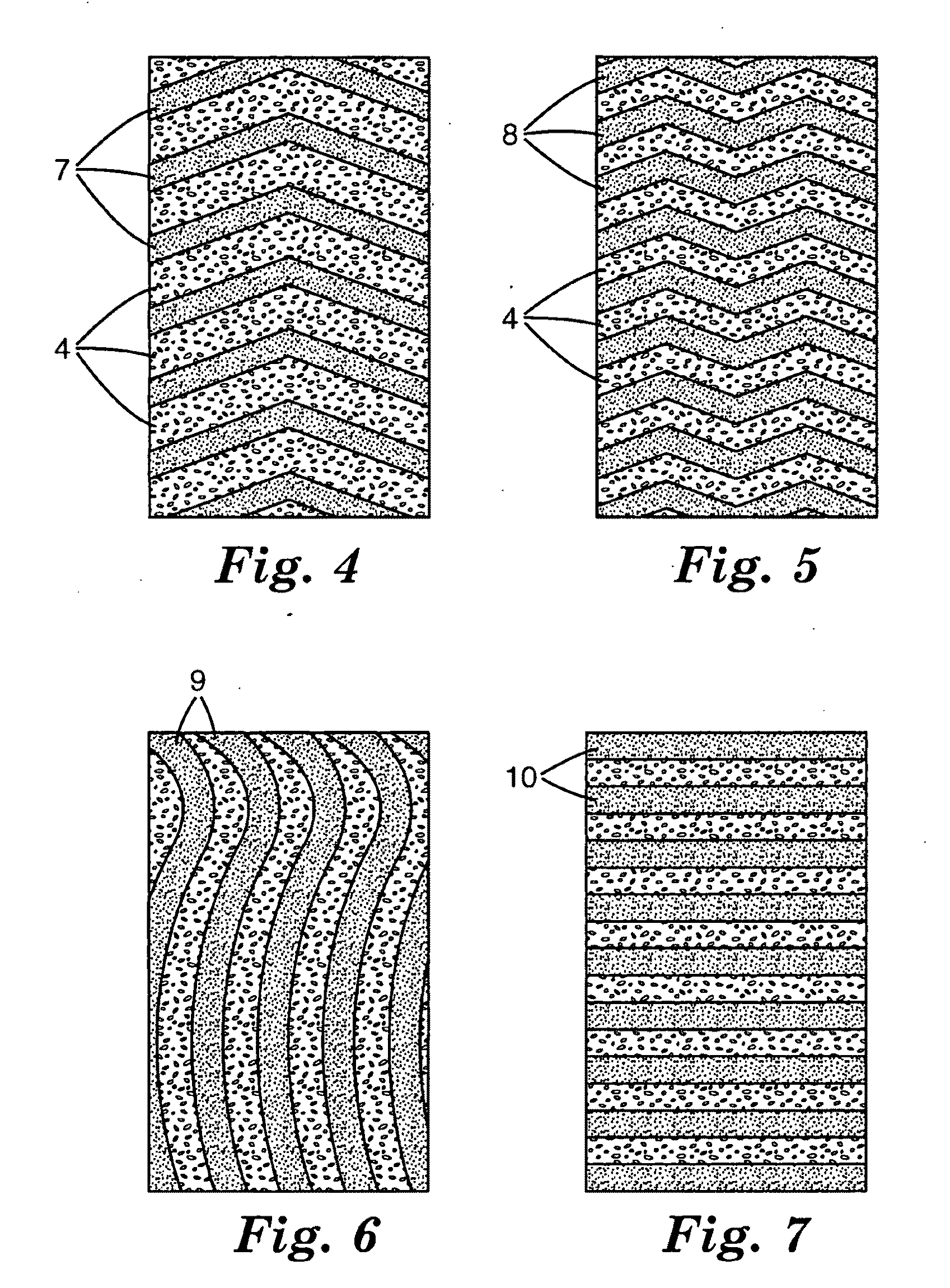

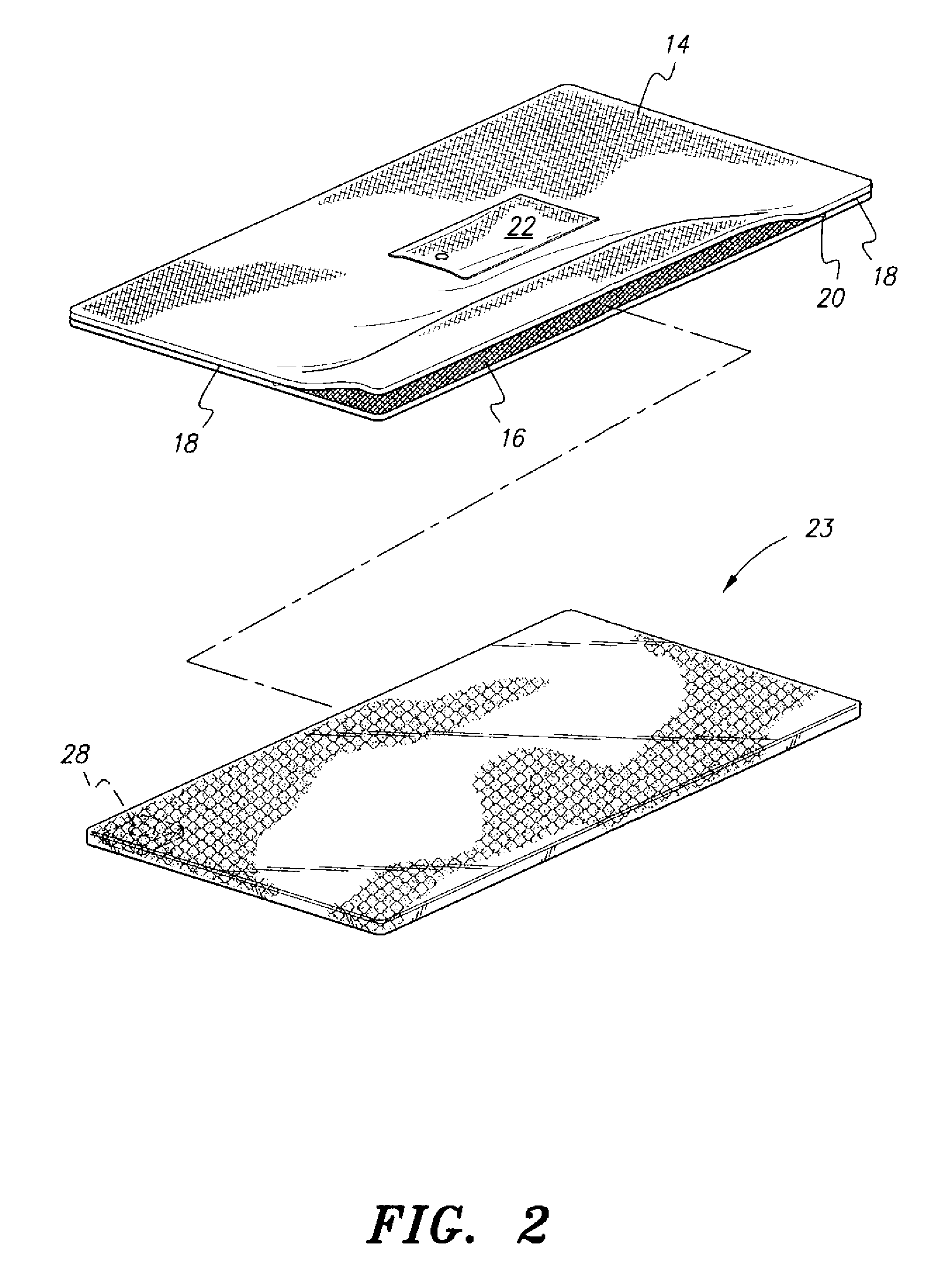

Flexible cleaning article

InactiveUS20100162508A1Easy and efficient cleaningEasy to adaptCarpet cleanersKitchenware cleanersPliabilityEngineering

The invention refers to a flexible and permeable cleaning article, more specifically the invention relates to a foam having a mechanical fastener for attaching scouring webs composed of hook-like projections, wherein said webs can be replaced depending on the type of cleaning needed, for example, heavy duty cleaning, delicate cleaning, surface polishing, etc. Flexibility and permeability are two important characteristics exhibited by the object of the present invention; said flexible article easily conforms to substrates and their particularities, such as corners and grooves, thus rendering the cleaning process easier and more efficient. Permeability allows water and chemical cleaning compositions (e.g., detergents, soaps, etc.) to pass through it, thereby forming suds.

Owner:3M INNOVATIVE PROPERTIES CO

Litter made of several perforated pans for cats or other domestic animals

Disclosed is a litter for cats or other domestic animals, which comprises three pans insertable into each other to form a stack. The position of the pans is interchangeable and each pan has openings in its inferior part for filtration of an absorbing material used to solidify and absorb the organic wastes. The openings of each pan are located at positions different from the openings of the other pans in such a manner that the openings of each pair of adjacent pans be vertically out of line. One advantage of this litter is that it is not necessary to use a shovel to pick up and dispose of the organic wastes.

Owner:SCOTTO DANIELO RENE

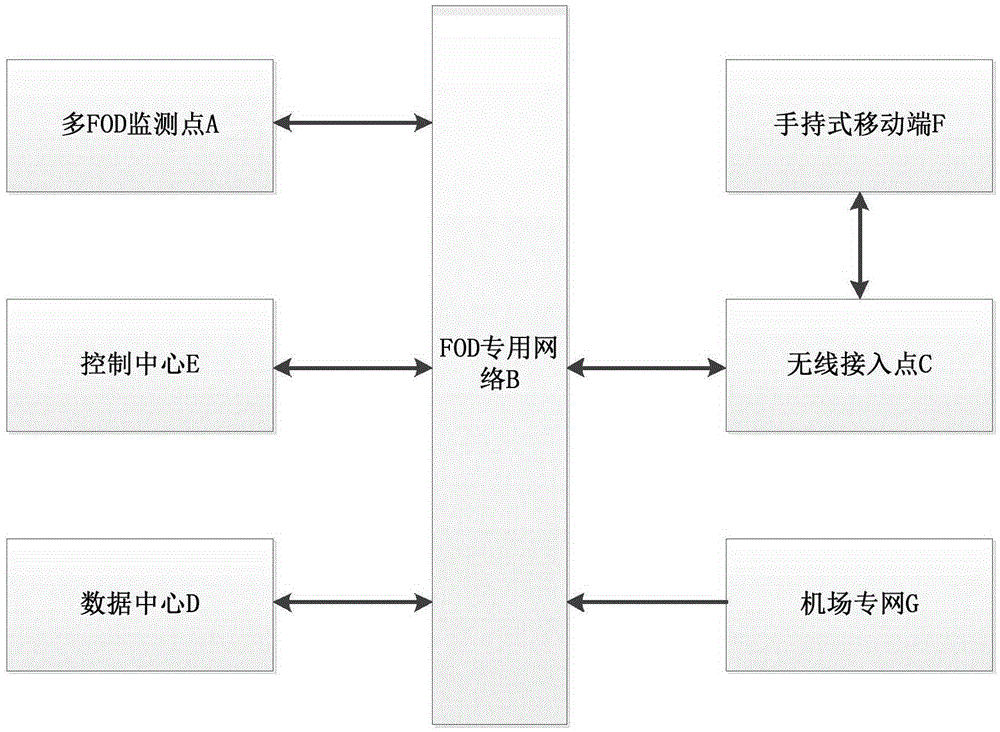

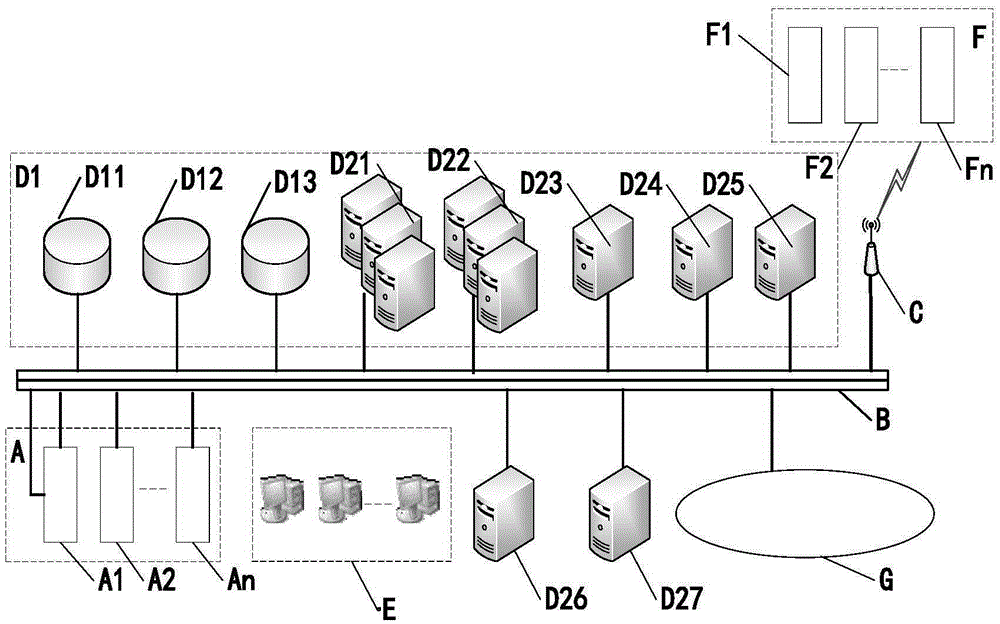

Airport runway foreign body monitoring system and method

ActiveCN105389921AEasy and efficient cleaningReduce the likelihood of interactionBurglar alarmAircraft traffic controlForeign matterData center

The invention relates to an airport runway foreign body monitoring system and method. The system includes an FOD private network which is connected with a plurality of FOD monitoring points, a wireless access point, a data center, a control center an airport private network; the wireless access point is connected with a handheld mobile terminal to obtain feedback, access and foreign body information and send foreign body cleaning instructions; the FOD private network obtains flight plans, foreign body confirmation instructions, monitoring point control instructions, database operation instructions, monitoring point control instructions, data fusion results and video splicing signals, and obtains monitoring point returned information, foreign body information, feedback information, access information and the state information of the control center; the data center obtains the FOD monitoring point control instructions, the database operation instructions, the returned information, the feedback information, the access information, the state information of the control center and the wireless access point; the control center obtains the flight plans, the data fusion results and the video splicing signals; and the FOD monitoring points obtain the foreign body confirmation instructions to confirm foreign body information. With the airport runway foreign matter monitoring system and method of the invention adopted, false alarm can be effectively reduced, and the reliability of a system can be improved.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

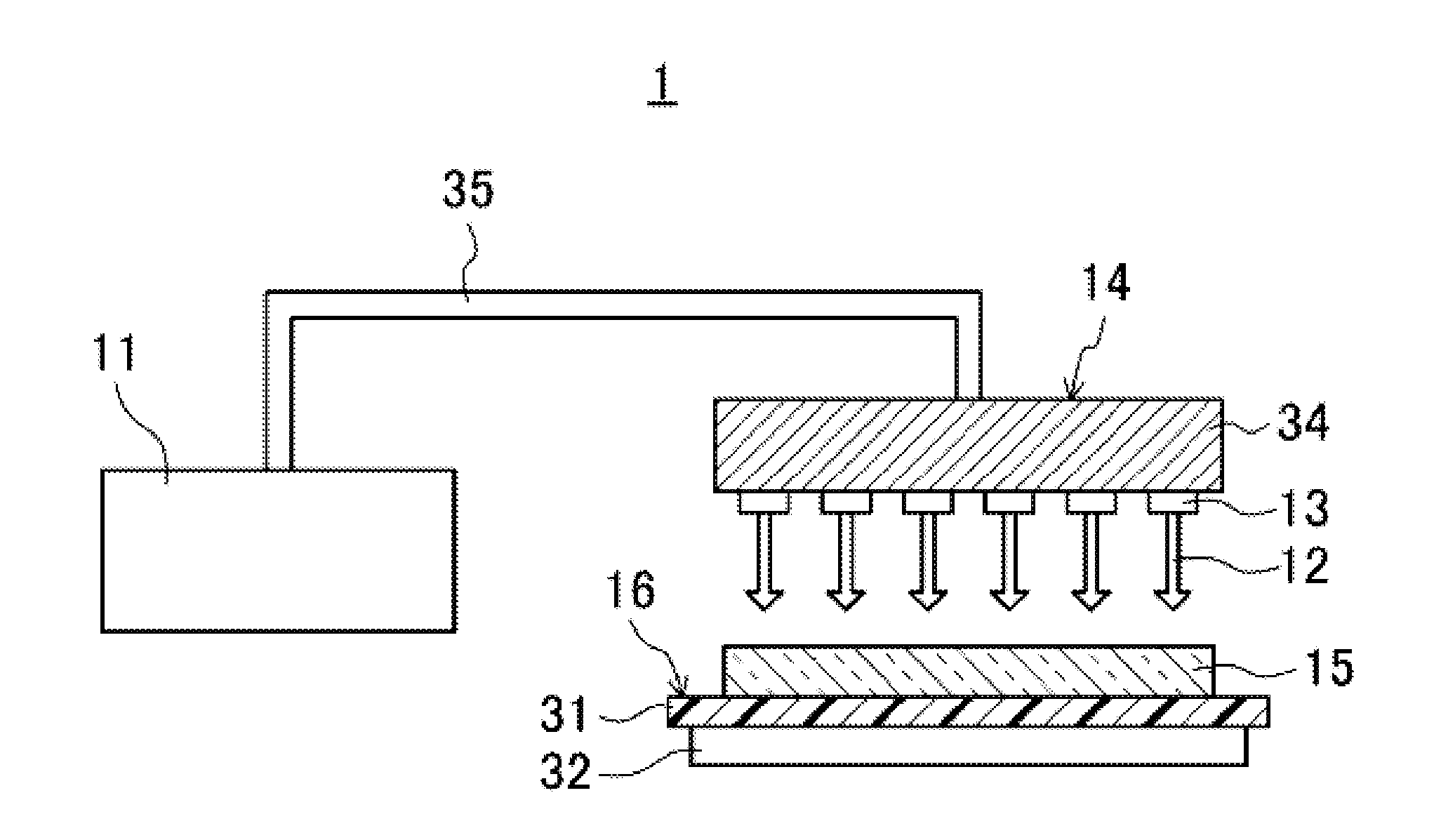

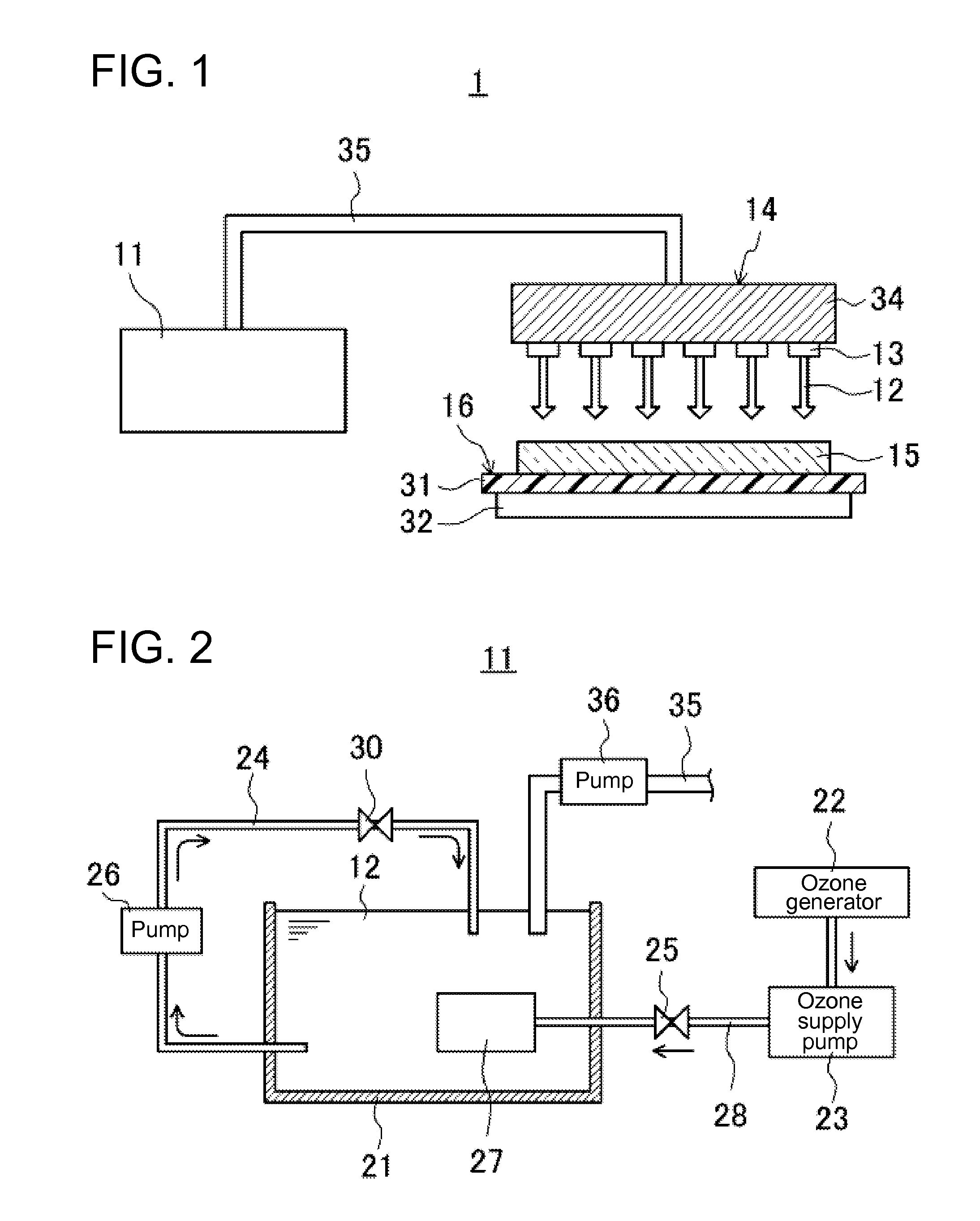

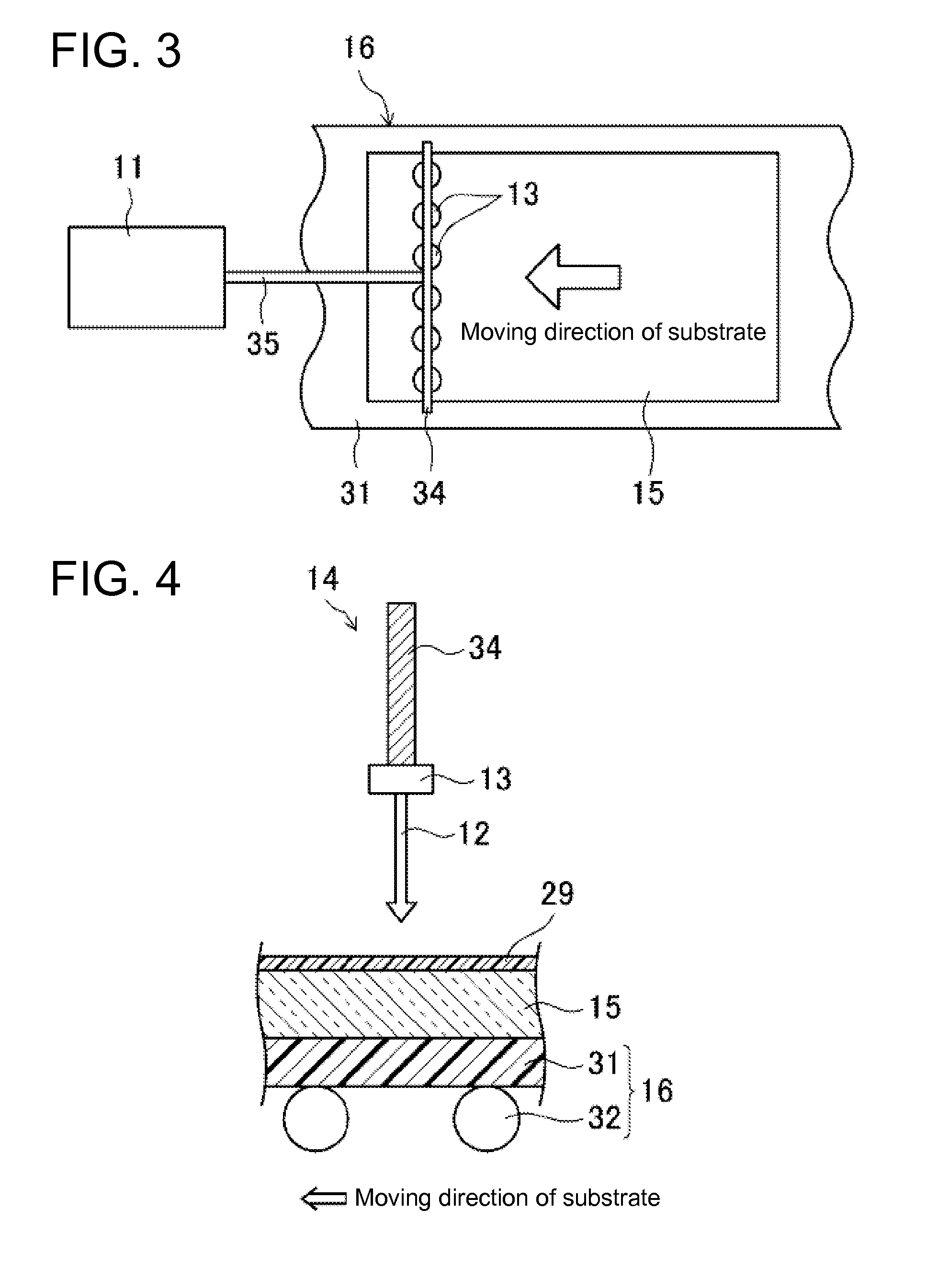

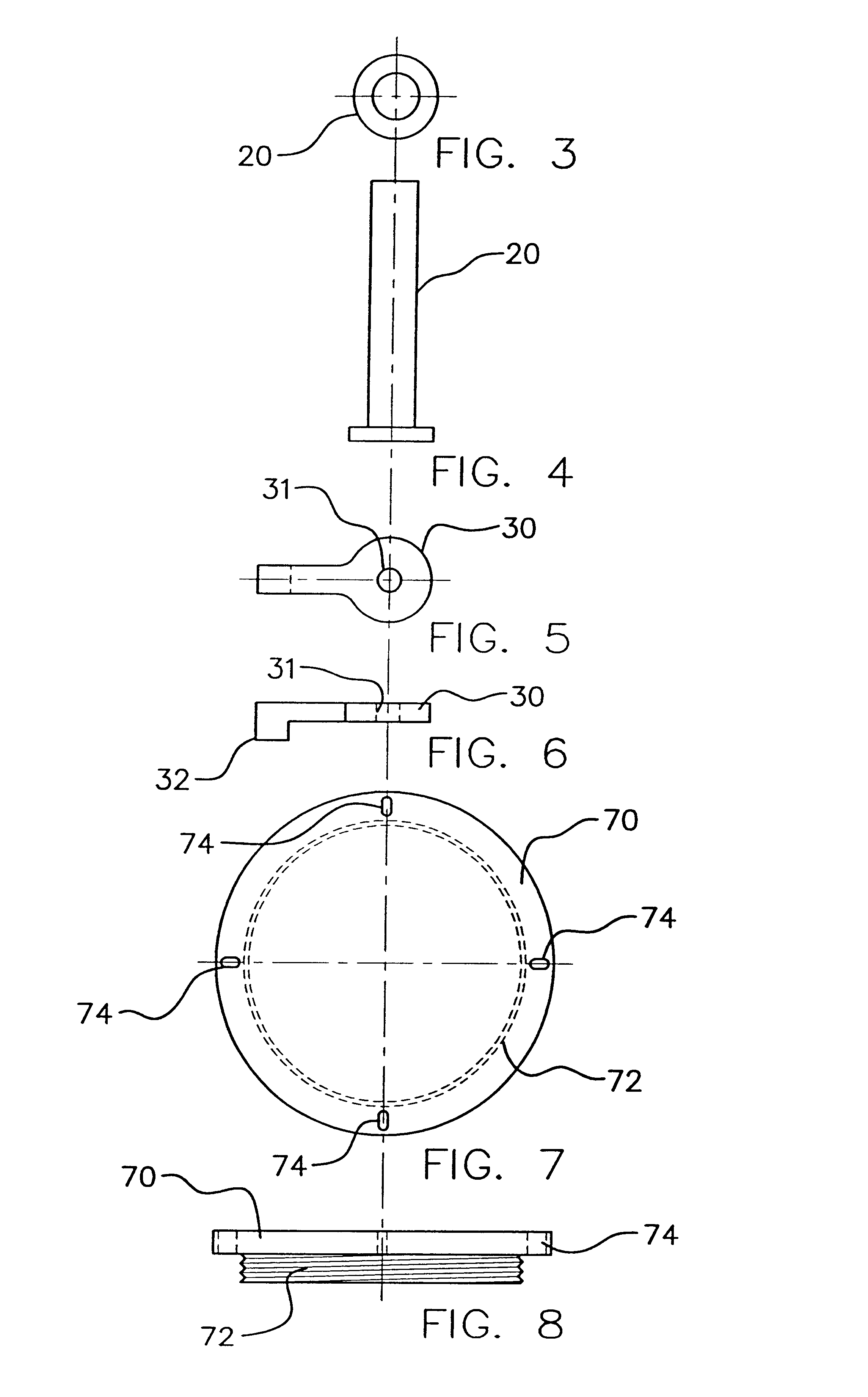

Substrate cleaning device and substrate cleaning method

InactiveUS20120216828A1Increase flexibilitySimple structureSolid-state devicesPhotomechanical apparatusSpray nozzleEnvironmental engineering

Disclosed is a substrate cleaning device provided with: a generation unit that generates ozone micro-nanobubble water; a nozzle header unit provided with a plurality of spray nozzles that spray the ozone micro-nanobubble water; and a substrate support unit that supports a substrate to be treated. The surface of the substrate supported by the substrate support unit is cleaned by spraying the ozone micro-nanobubble water from the plurality of spray nozzles onto the substrate.

Owner:SHARP KK

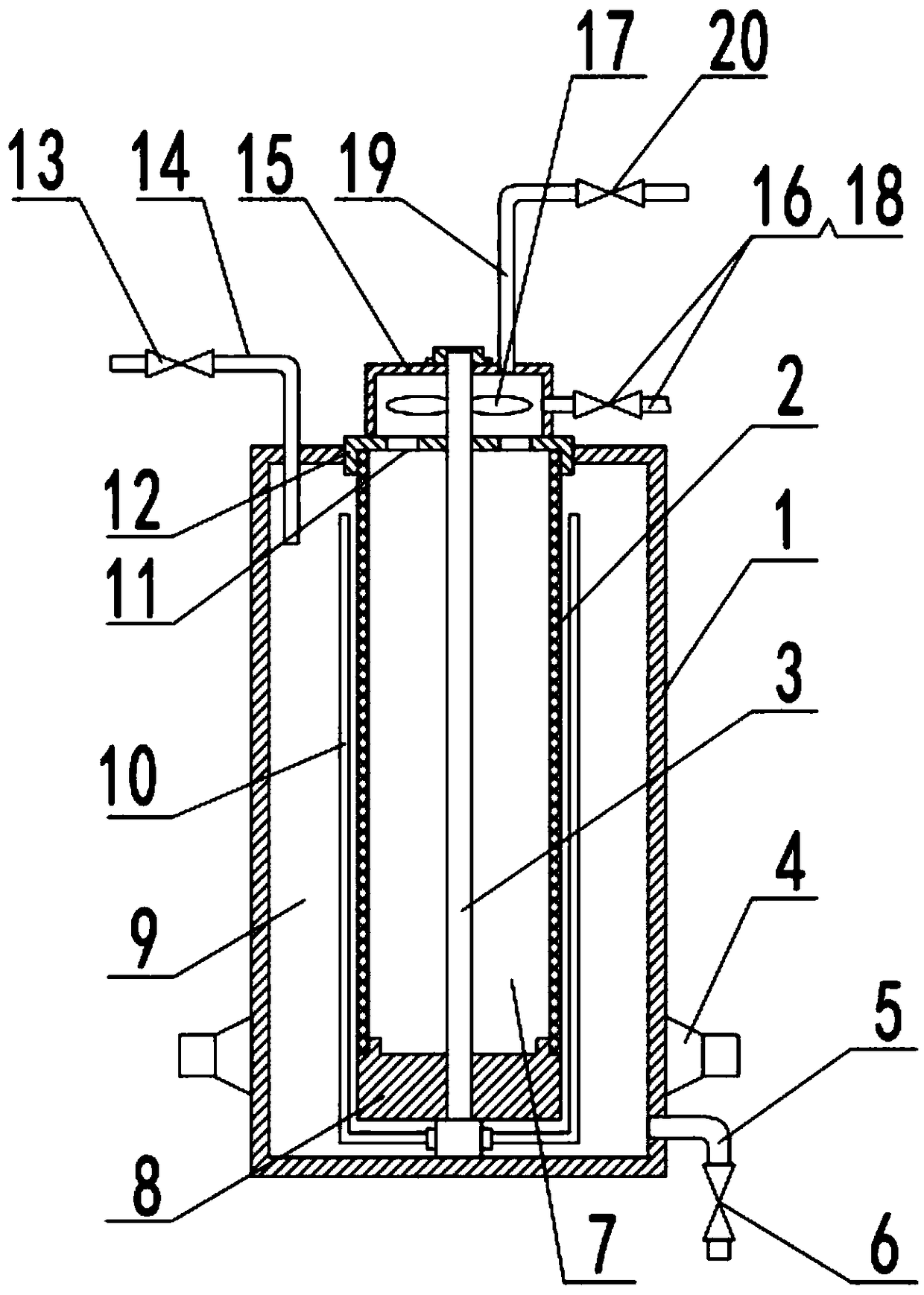

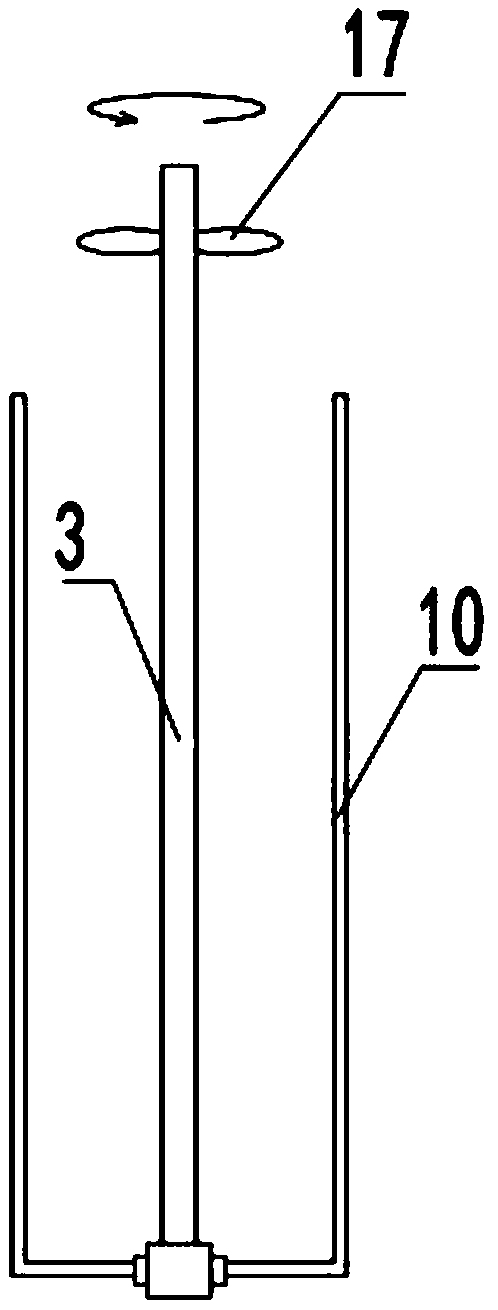

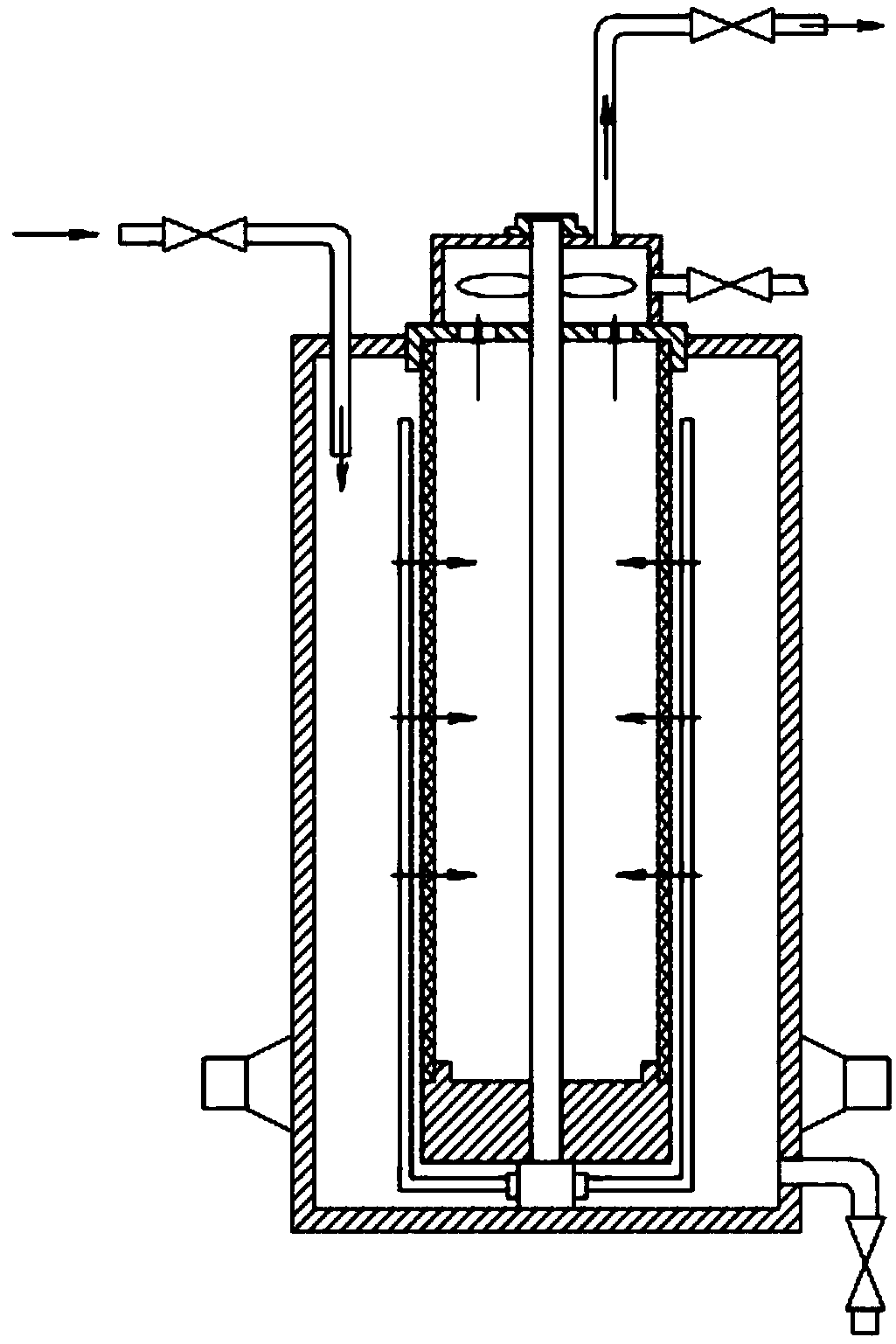

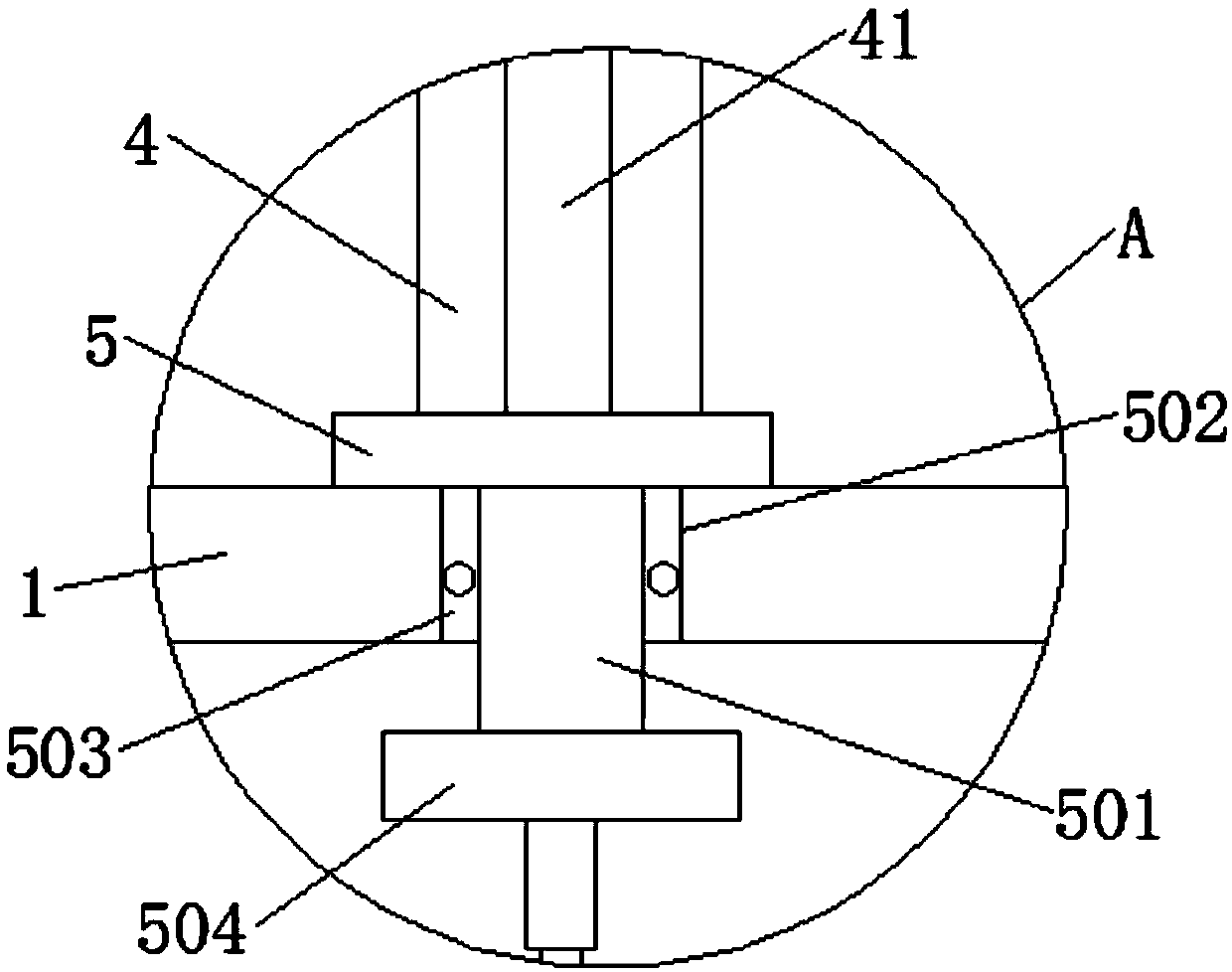

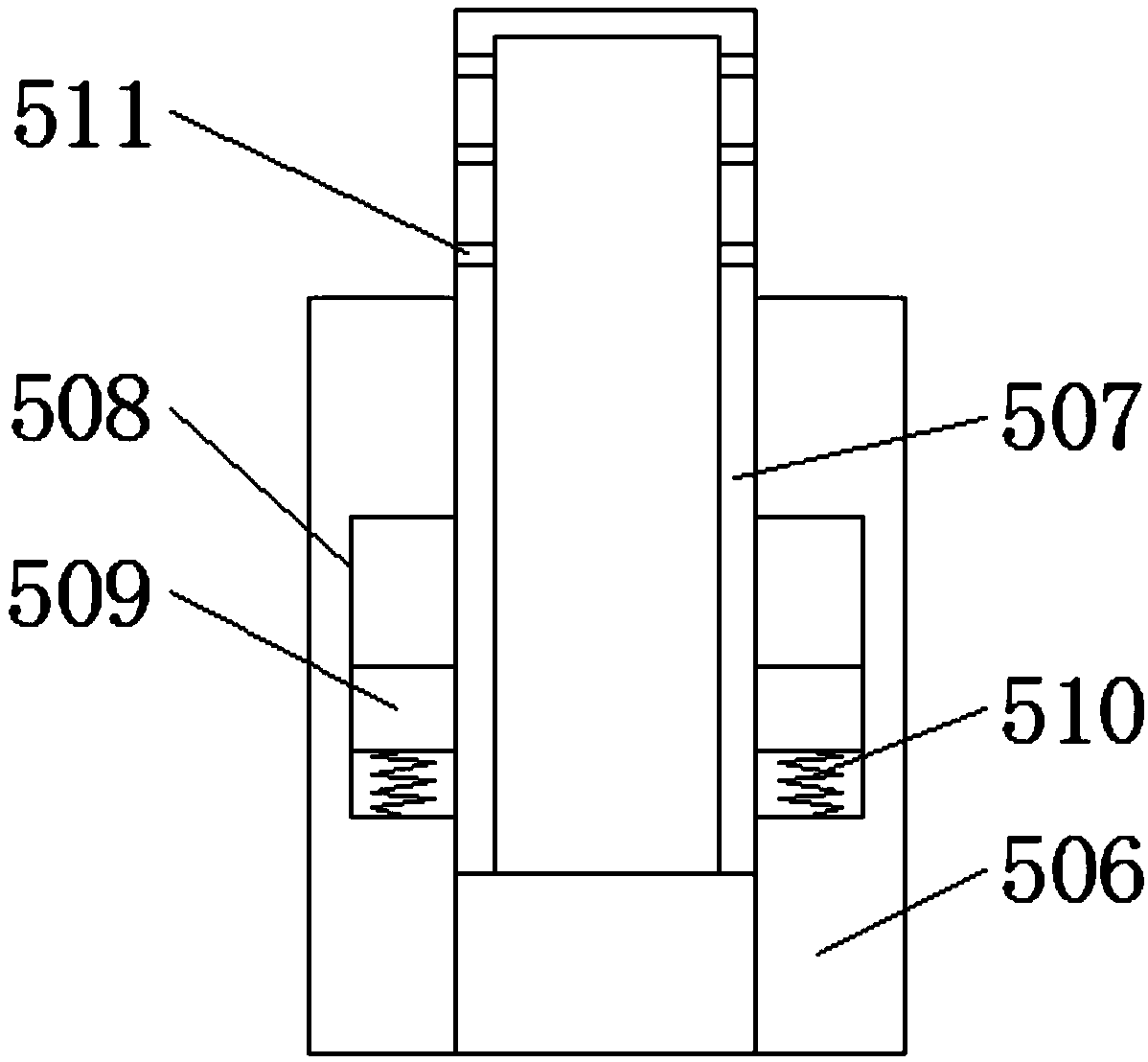

Ultrasonic backwashing filter device for sewage treatment

InactiveCN108771893AEasy and efficient cleaningAchieve cleaningWater/sewage treatment by irradiationSpecific water treatment objectivesWater pipeSewage

The invention discloses an ultrasonic backwashing filter device for sewage treatment. The device comprises a filter barrel, a filter element, an ultrasonic oscillator, a water outlet, a top cover, a water inlet pipe, an outer cover and a water outlet pipe, wherein the filter element is installed in the filter barrel in a coaxial way; a base is installed at the bottom of the filter element, and thetop of the filter element is installed in the filter barrel by means of the top cover; the filter barrel is divided into two parts by means of the filter element, and the two parts comprise a sewagecavity positioned between the filter element and the filter barrel, and a clean water cavity positioned in the filter element; the filter barrel is connected with the water inlet pipe used for inputting sewage into the filter barrel; the water inlet pipe is provided with an electromagnetic valve of the water inlet pipe; a residue discharge pipe is connected with the bottom position of the filter barrel. The ultrasonic backwashing filter device has the beneficial effects that the ultrasonic oscillator works so as to send ultrasonic waves into the filter barrel, and the high-frequency vibrationcauses the impurities to fall off from the outer surface of the filter element; furthermore, when the flushing water is input, the rotation of a cleaning rod can be driven, so that the filter elementcan be cleaned by means of bristles; due to the cooperation of the cleaning rod and the bristles, the impurities on the surface of the filter element can be conveniently and efficiently cleaned.

Owner:张琛

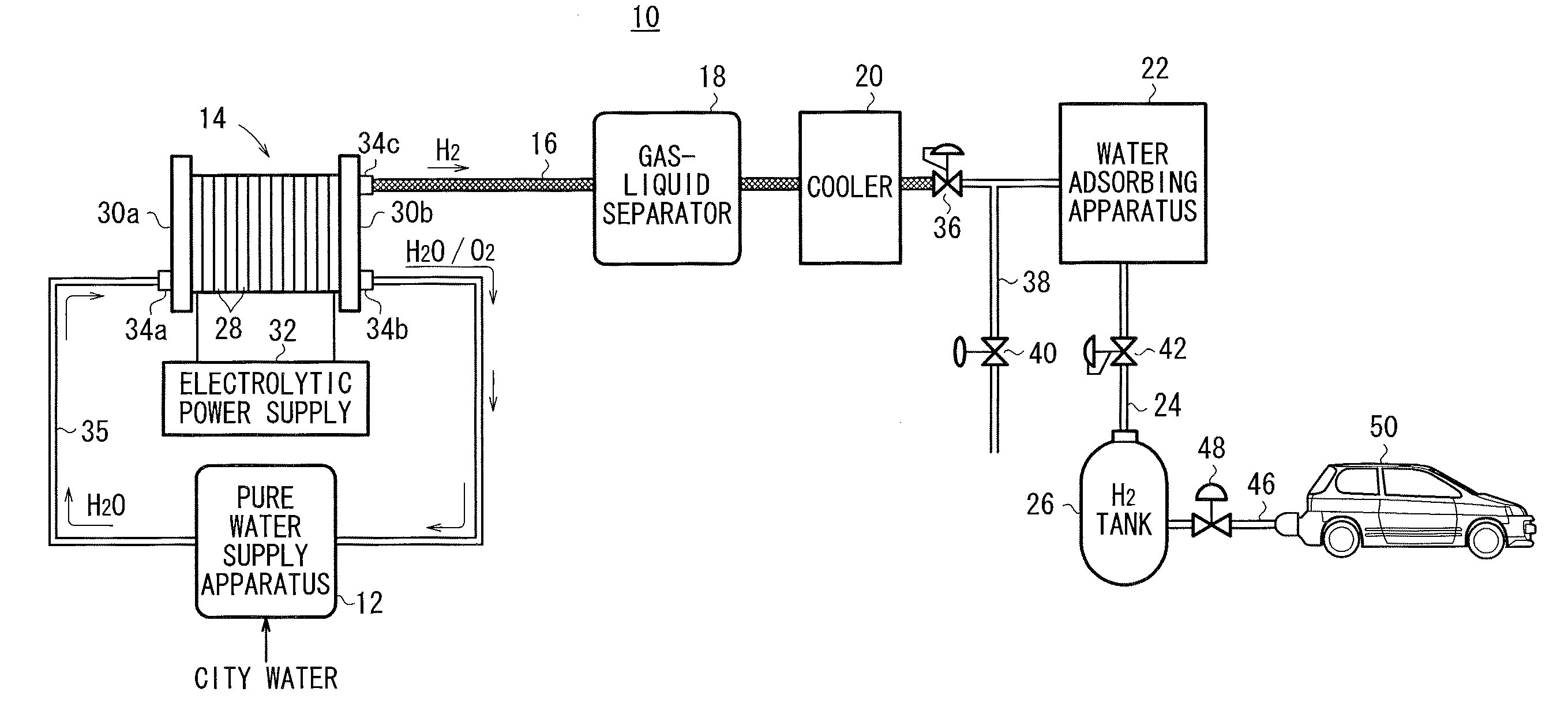

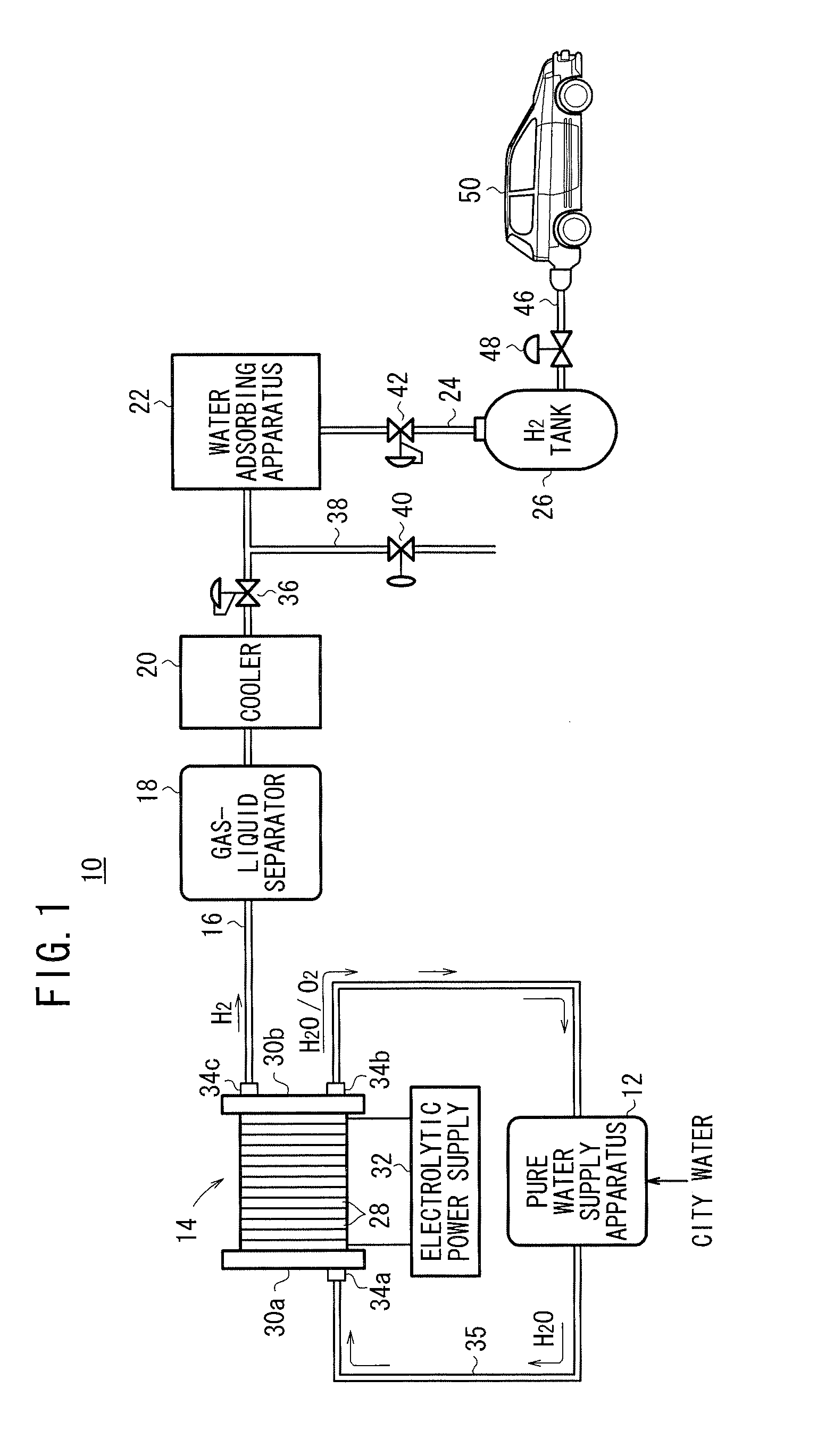

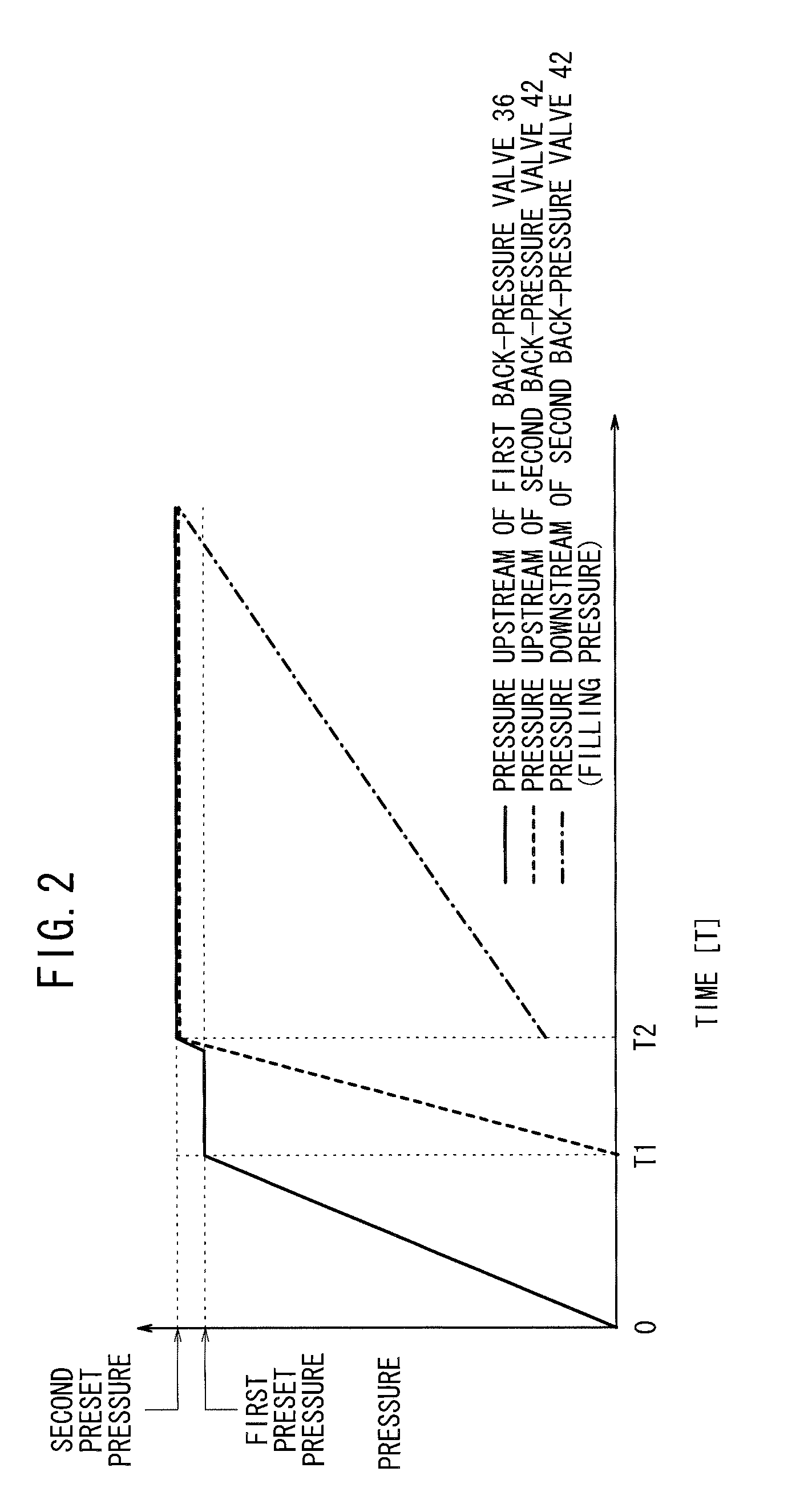

Water electrolysis system

InactiveUS20100219066A1Reliably preventing water contained in hydrogenEfficient supplyCellsFuel cellsVapor–liquid separatorElectrolysis

A water electrolysis system includes a water electrolysis apparatus for electrolyzing pure water supplied from a pure water supply apparatus for manufacturing high-pressure hydrogen. The water electrolysis apparatus has a pipe serving as a hydrogen outlet to which a gas-liquid separator, a cooler, and a water adsorption apparatus are successively connected in this order along the direction in which hydrogen is discharged from the water electrolysis apparatus. A first back-pressure valve is connected between the cooler and the water adsorption apparatus, and a second back-pressure valve is connected downstream of the water adsorption apparatus.

Owner:HONDA MOTOR CO LTD

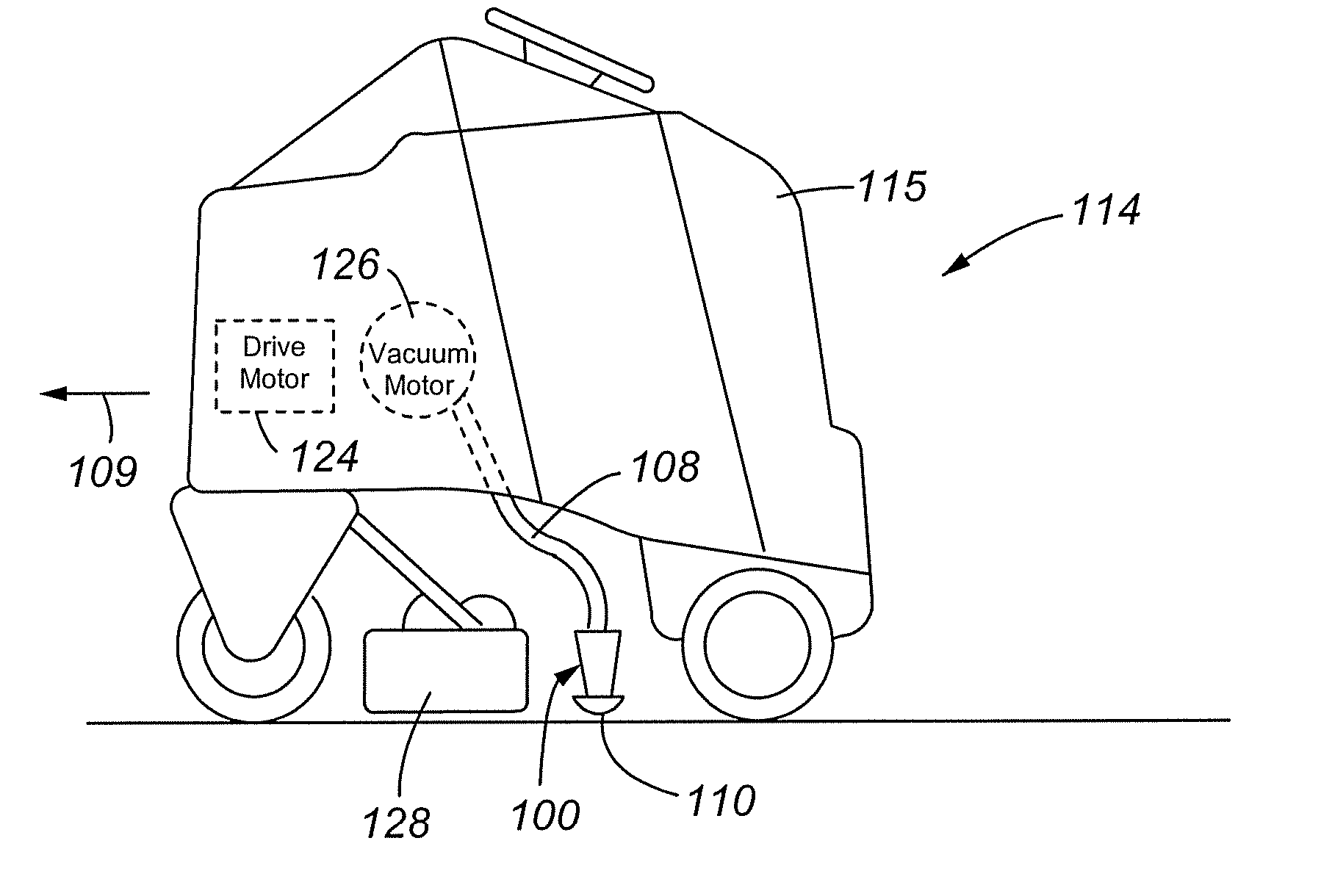

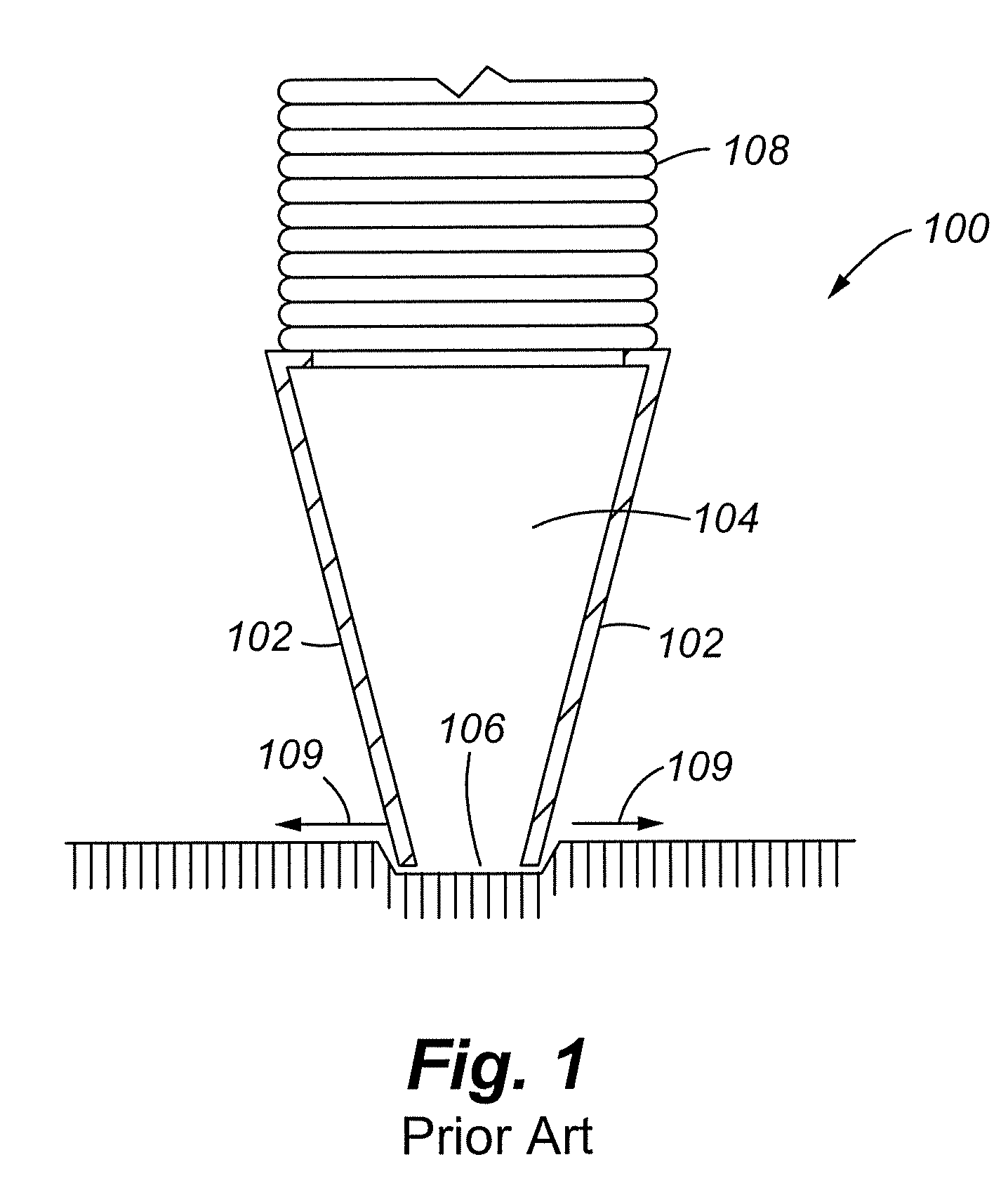

Flexible pickup lips for use with fixed vacuum shoes on self-contained and propelled carpet cleaning equipment

InactiveUS20070240276A1Improve suction efficiencyReduce wearCarpet cleanersFloor cleanersDrag coefficientElectrical and Electronics engineering

An improved vacuum shoe for use on a self-propelled cleaning apparatus is disclosed. Specifically, the vacuum shoe may have a gliding member either integral or connected to the shoe housing. The gliding member is designed to decrease the drag coefficient of the vacuum shoe as it traverses a surface thereby increasing the machine's efficiency and decreasing the amount of required operating power.

Owner:KARCHER NORTH AMERICA INC

System and apparatus for trailer hitch assembly

InactiveUS20080106065A1Improve vehicle stabilityImprove featuresTowing devicesEngineeringMechanical engineering

An improved trailer assembly capable of carrying a load and having improved stability characteristics is disclosed. Specifically, in a preferred embodiment, the trailer hitch assembly has an interconnecting member pivotally connected to a first member and a second member. The interconnecting member has a longitudinal center line, relative to the first member and second member pivots. The first member is pivotally connected at its one end to the interconnecting member, wherein the first member is capable of pivoting in a horizontal direction relative to the longitudinal center line. The center member is pivotally connected at its one end to the interconnecting member, wherein the second member is capable of pivoting in a vertical direction relative to the longitudinal center line. Thus, a towed vehicle operably connected to the trailer hitch assembly, which for example is a trailer or carrier having a narrow width, is substantially restricted from rotating about a longitudinal axis during transit or during a turn, which decreases the risk of tipping and otherwise provides increased stability.

Owner:CUTTS EDMUND A

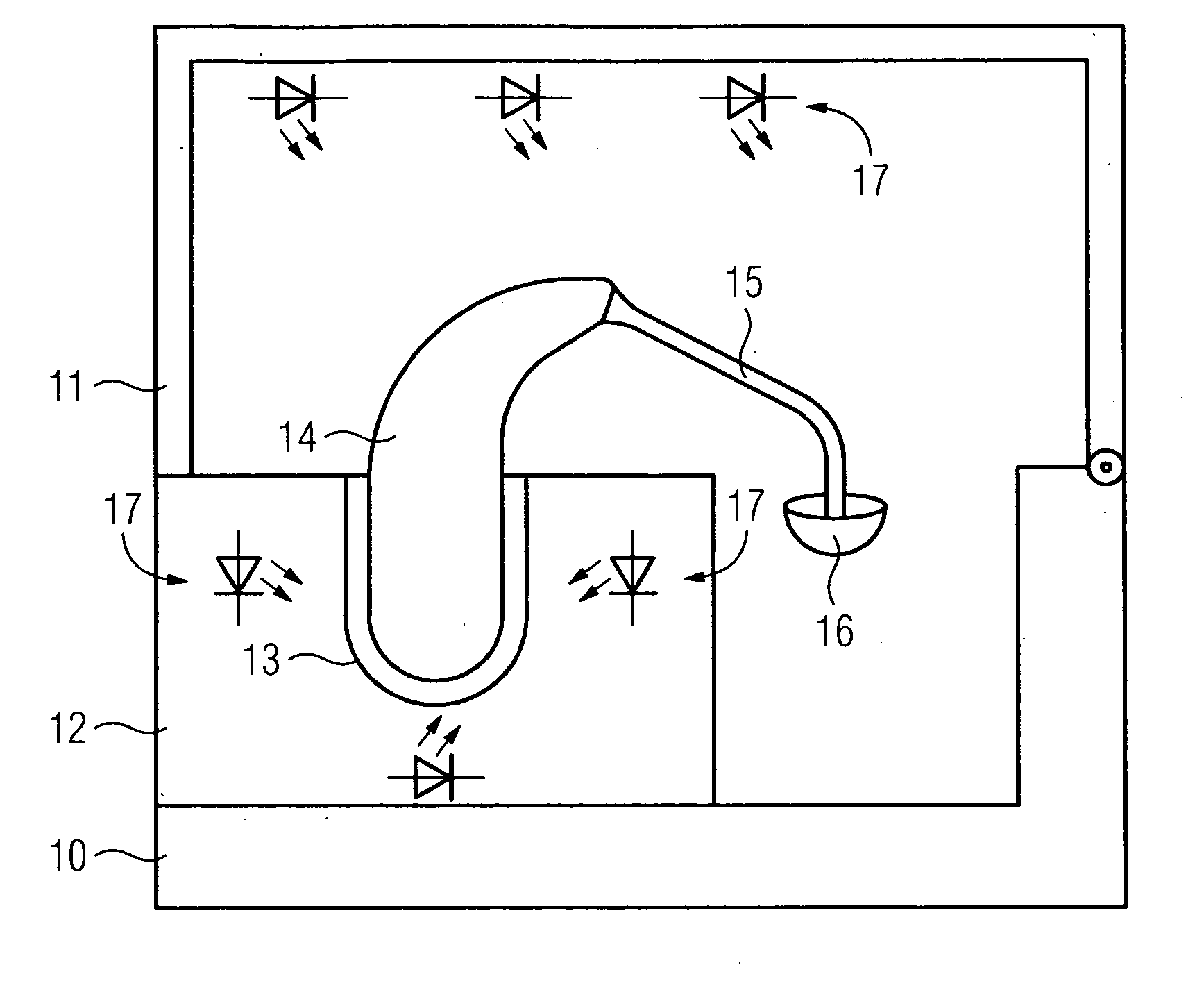

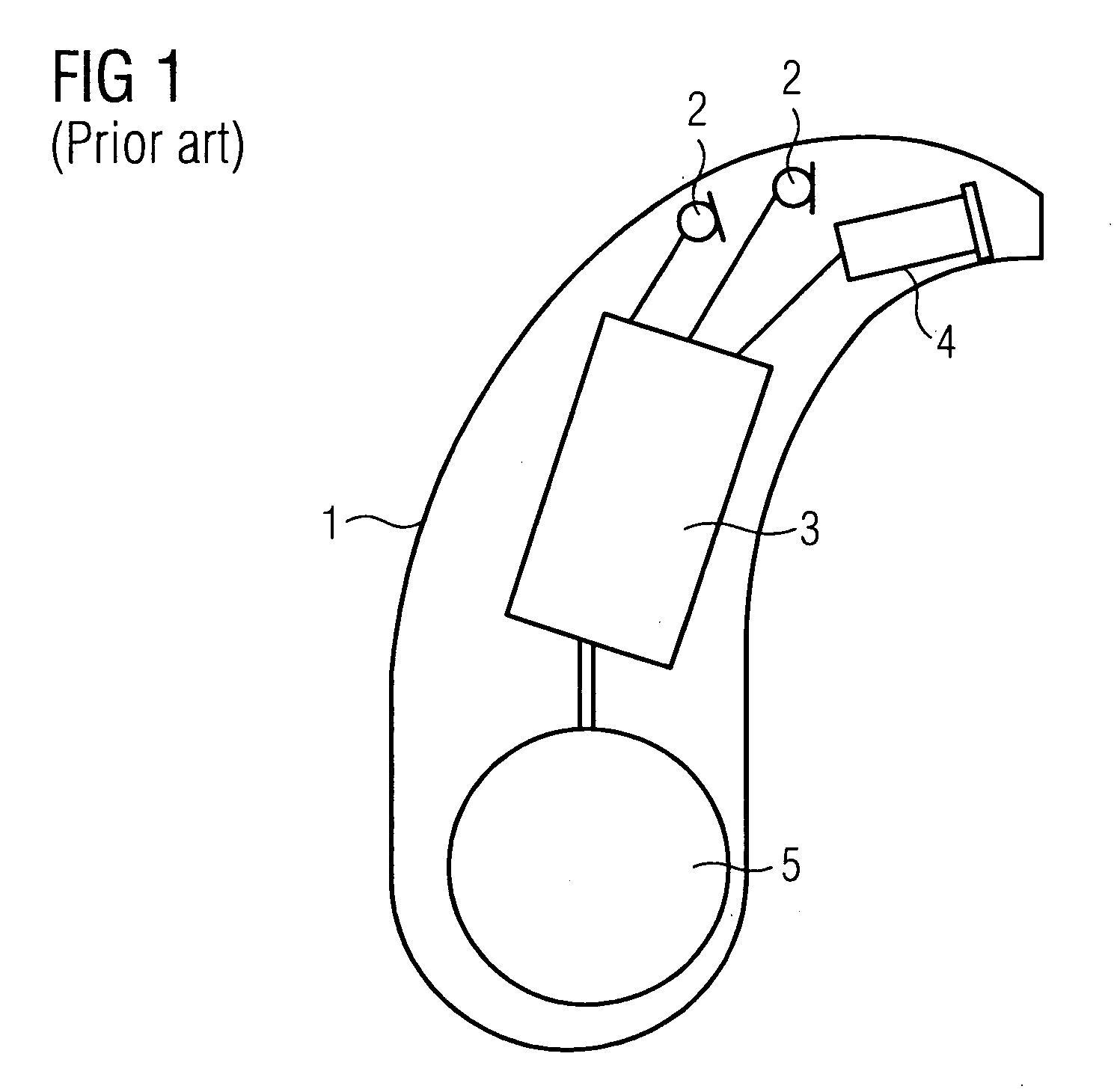

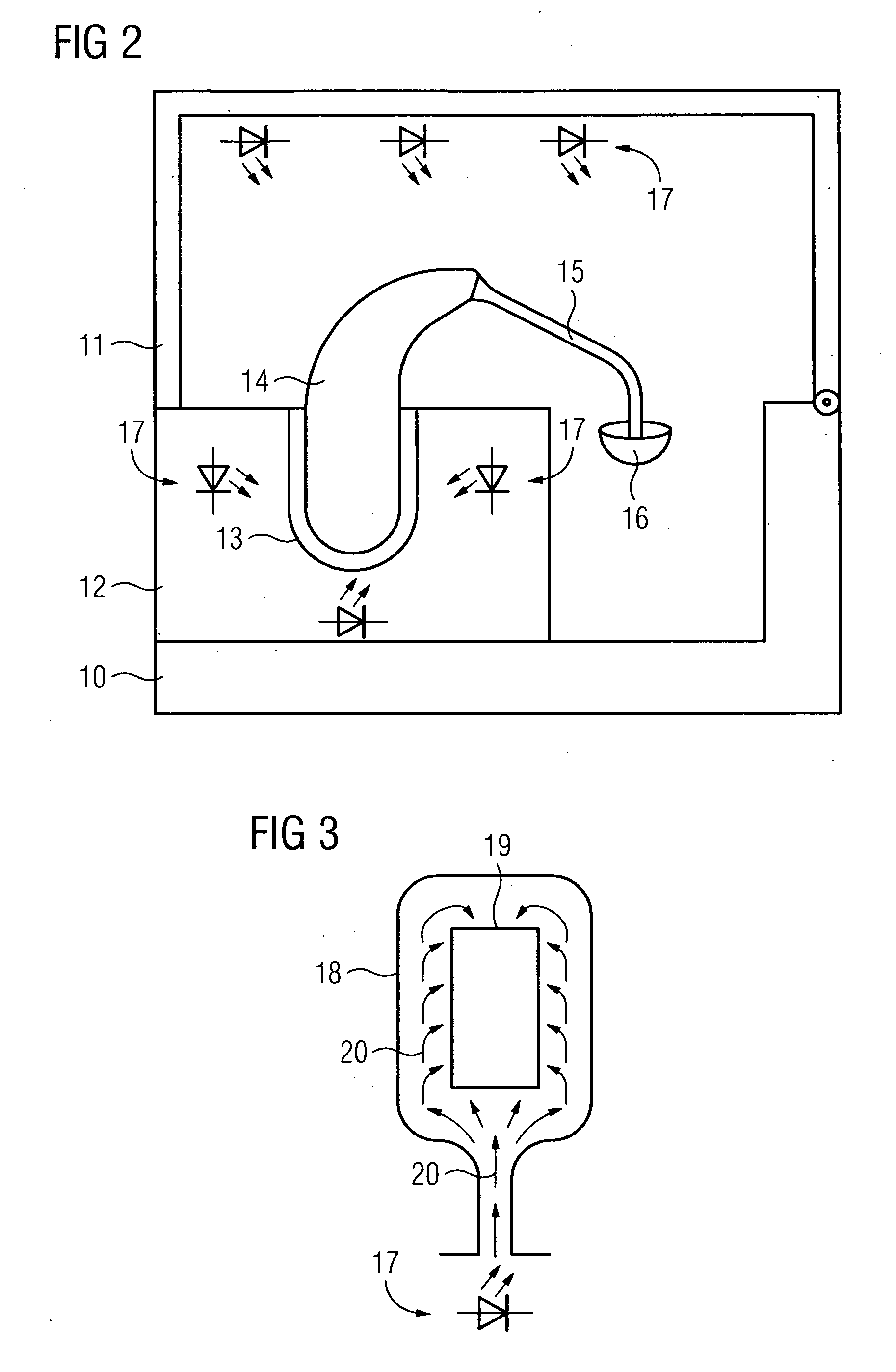

Securing device with light source for a hearing apparatus and corresponding hearing apparatus

InactiveUS20090080679A1Easy and efficient cleaningFacilitate and improve cleaningMouthpiece/earpiece sanitary/hygienic devicesEnergy based chemical/physical/physico-chemical processesHearing apparatusEngineering

A securing device for securing a hearing apparatus is provided which has at least one light source, in particular a UV emitter, for emitting light and for irradiating the hearing apparatus that is to be secured. The securing device can be installed in a charger or a storage box, for example, so that the hearing apparatus can be conveniently cleaned there by means of the light. To improve the cleaning effect, the hearing apparatus can be coated at least partially with a photocatalyst.

Owner:SIEMENS MEDICAL EQUIPMENT

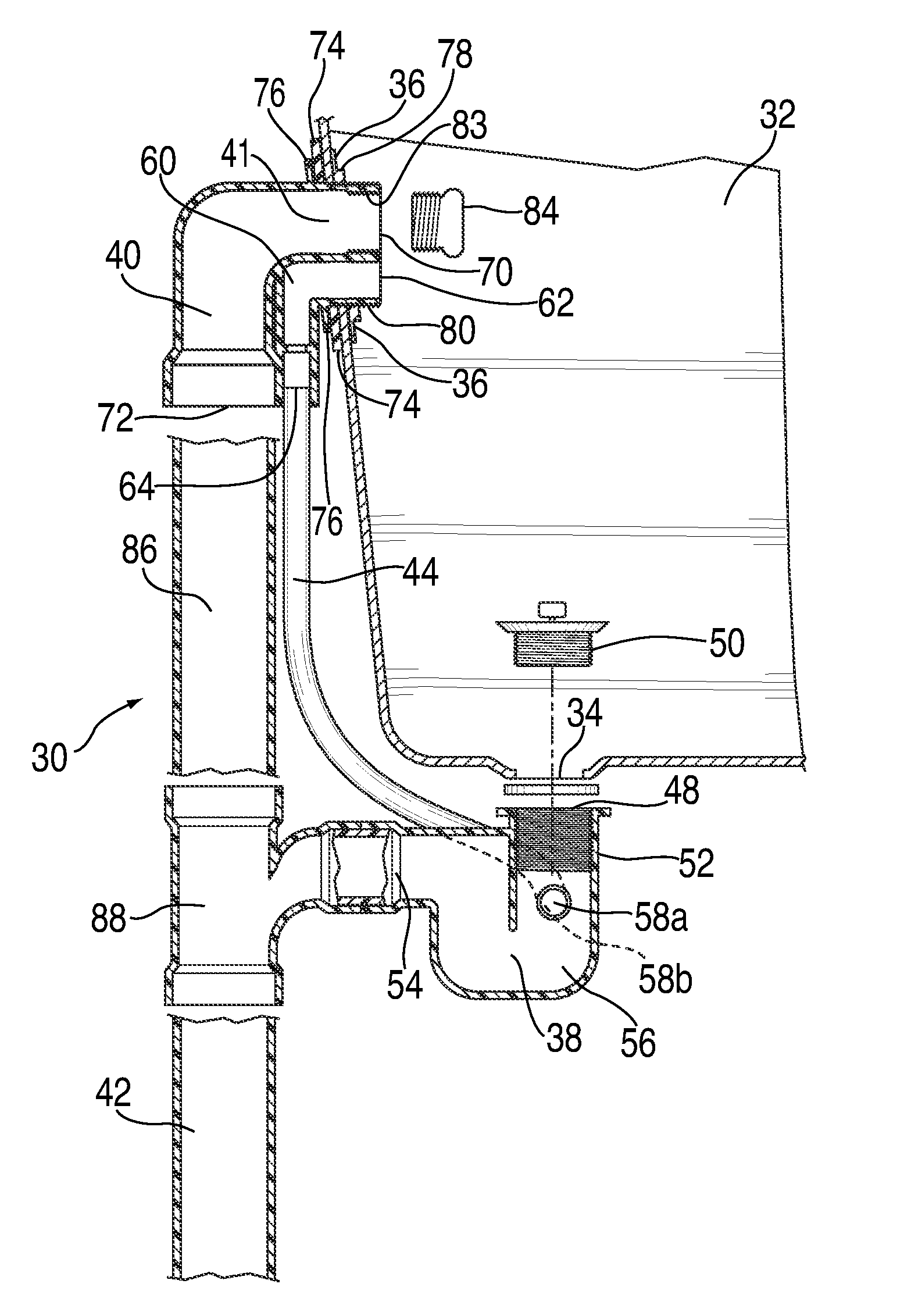

Tub drain and overflow assembly

ActiveUS8782824B2Easy and efficient cleaningBathroom accessoriesDomestic plumbingDraining tubeEngineering

The invention provides a drain and overflow assembly for a tub having a drain opening and a overflow opening, including a main drainage pipe, a drain fitting having a drain inlet end configured to be connected to the drain opening and a drain outlet end configured to be connected to the main drainage pipe, a trap, an overflow receiving hub disposed between the trap and the drain inlet end, and a multi-purpose fitting including an overflow path having an overflow inlet end configured to be connected to the multi-purpose opening and an overflow outlet end configured to be connected to the overflow receiving hub, the multi-purpose fitting further including a cleanout path having a cleanout inlet end configured to be connected to the multi-purpose opening and a cleanout pipe end configured to be connected to the main drainage pipe.

Owner:SHOOP DOUGLAS M

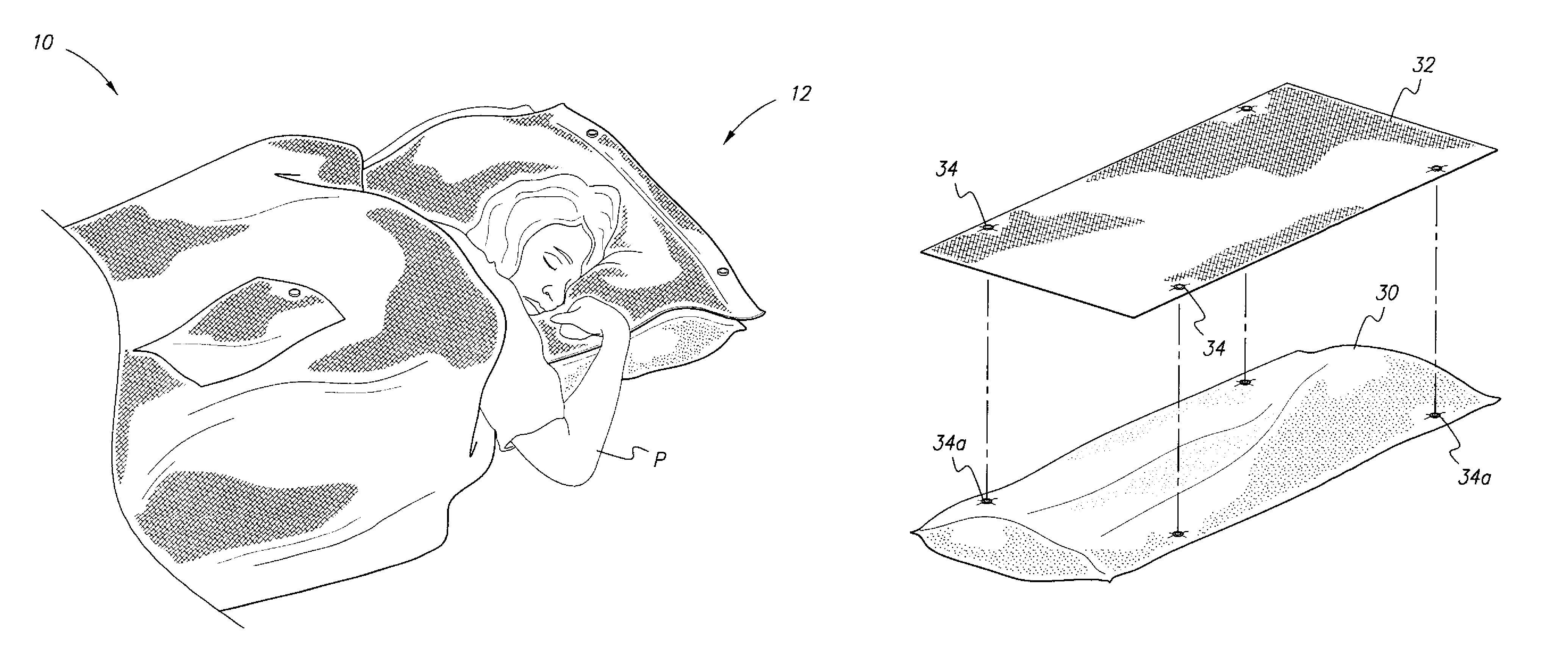

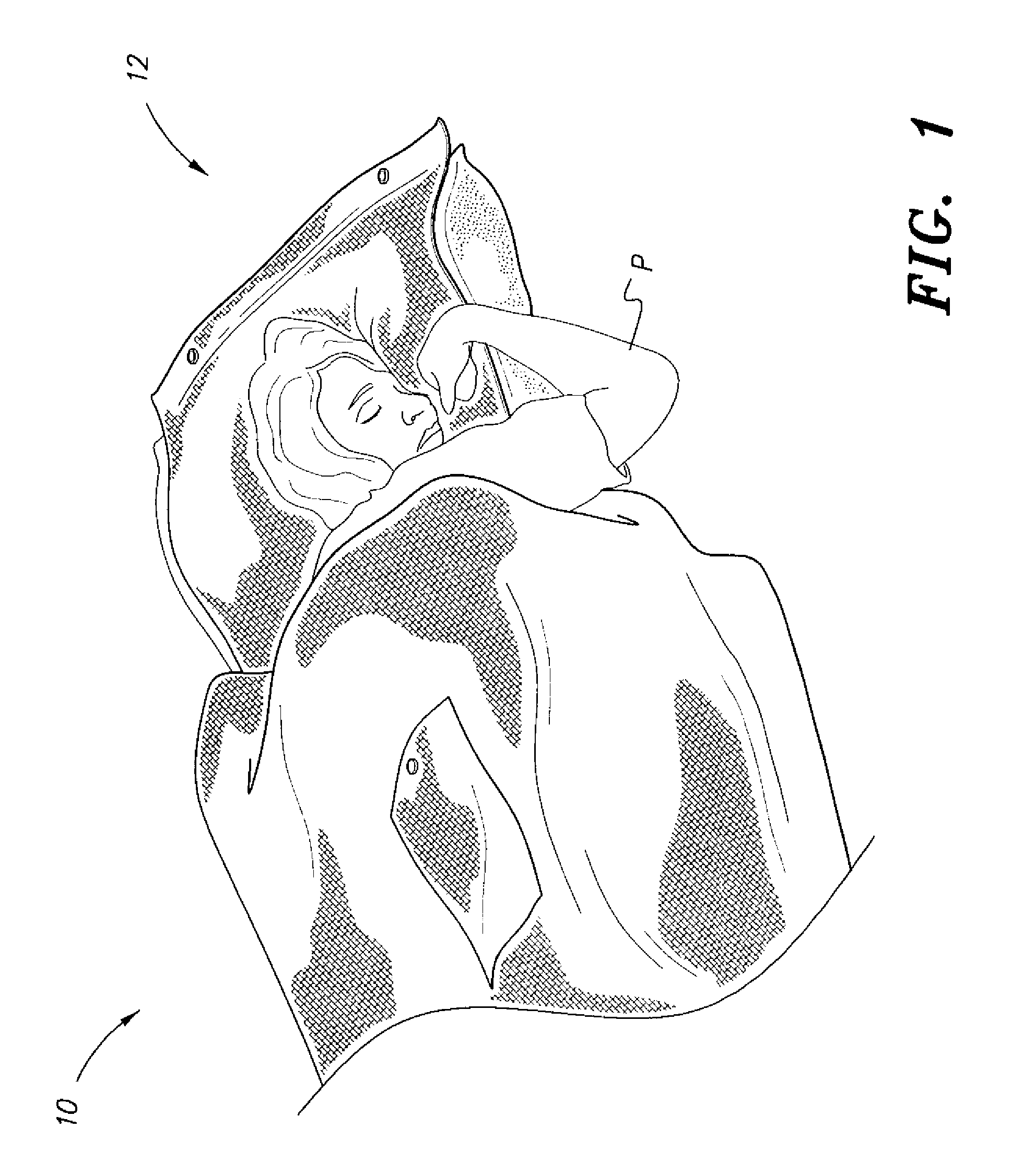

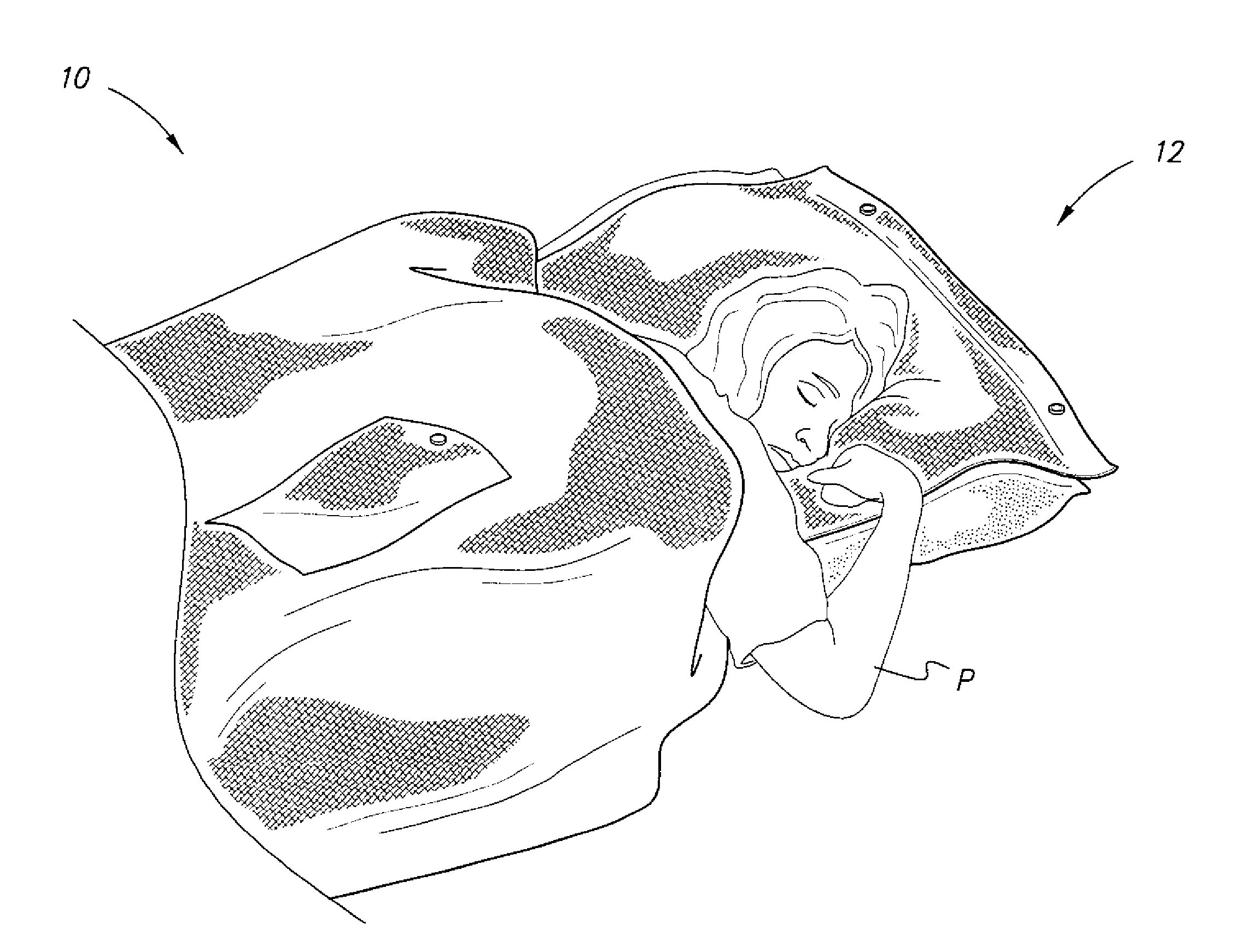

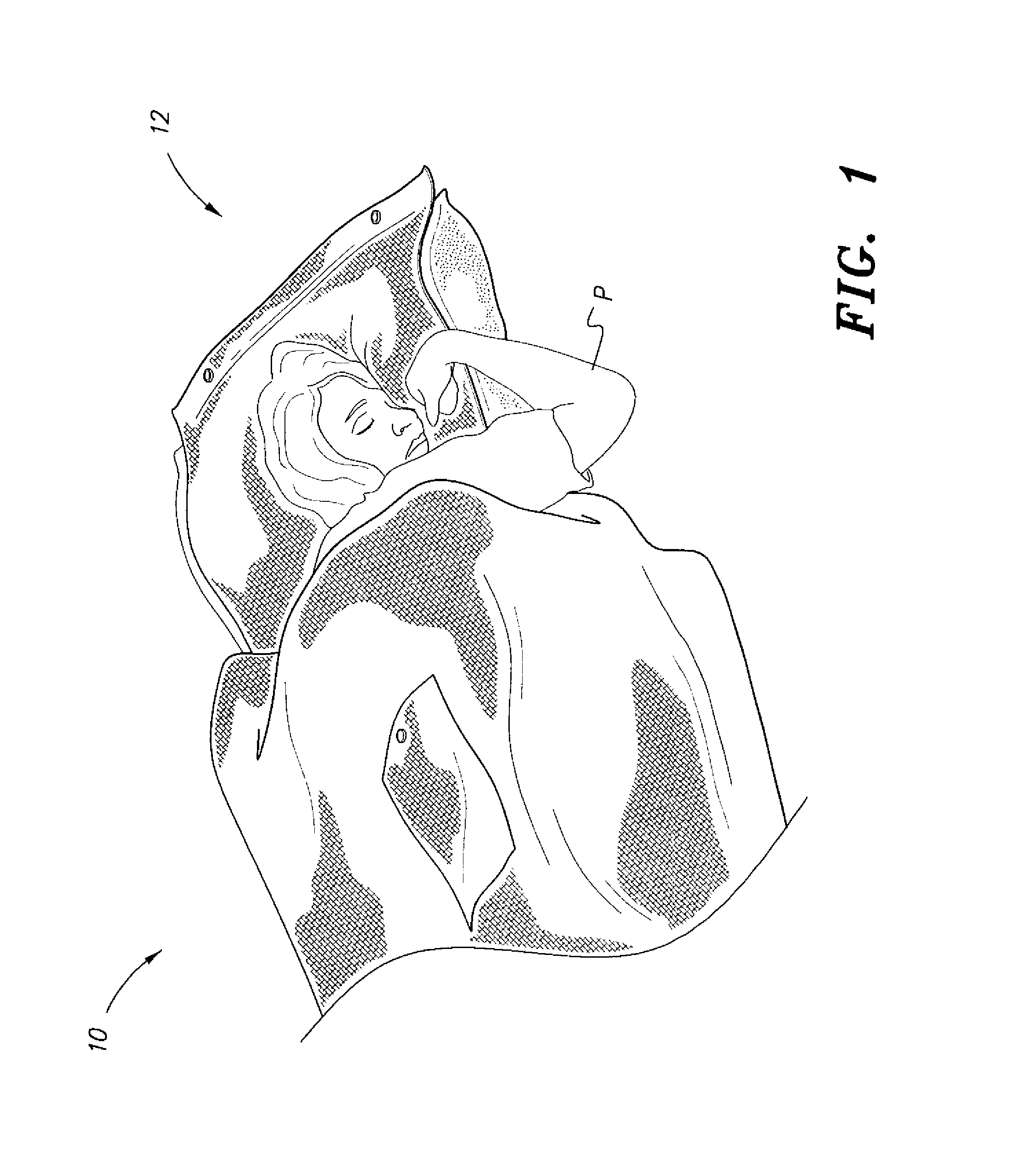

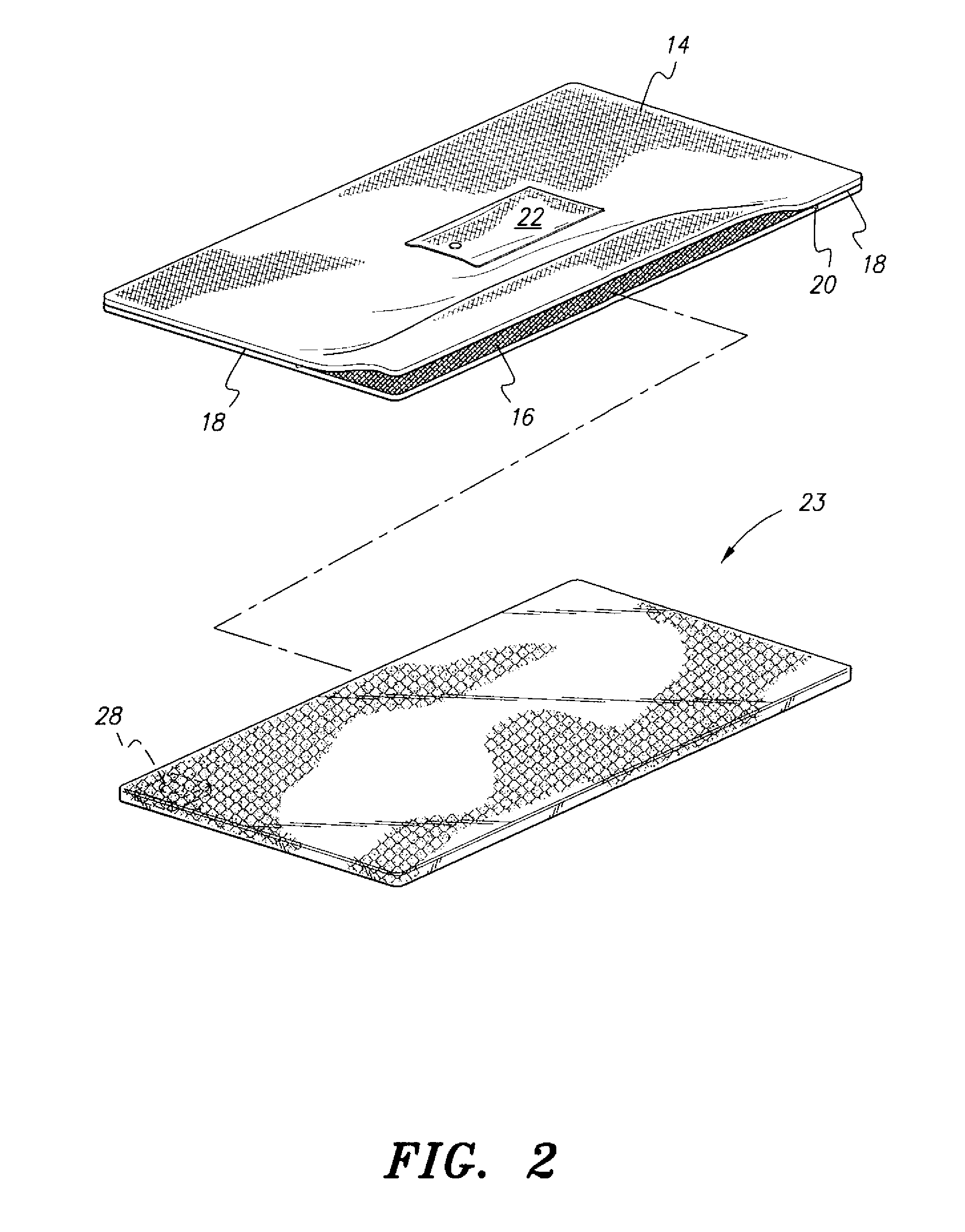

Comfort quilt and pillowcase

InactiveUS8516632B2Easy and efficient cleaningEasy to disassembleSleeping rugTravelling rugEngineeringMechanical engineering

Owner:OGUNDARE BEVERLY L

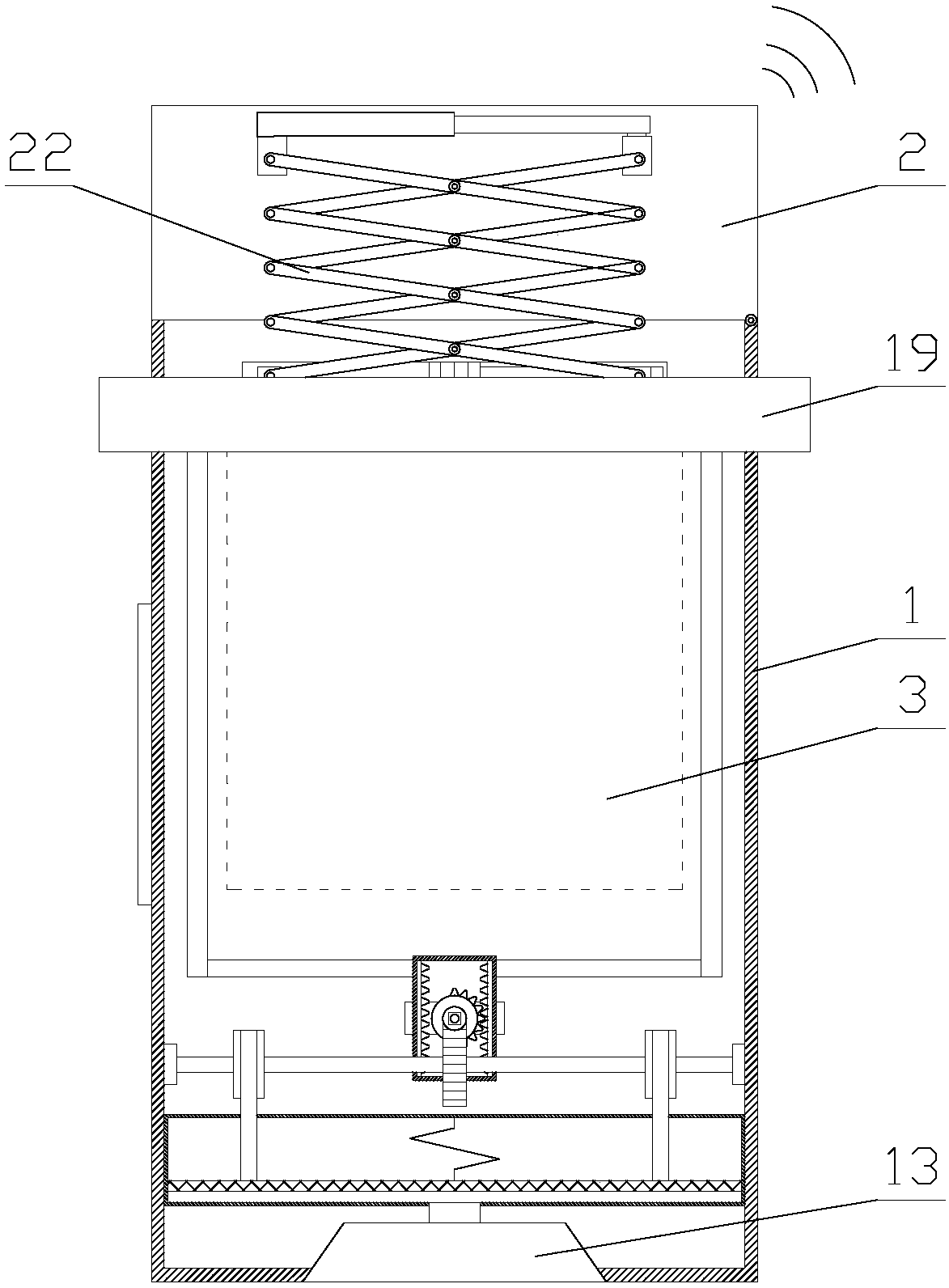

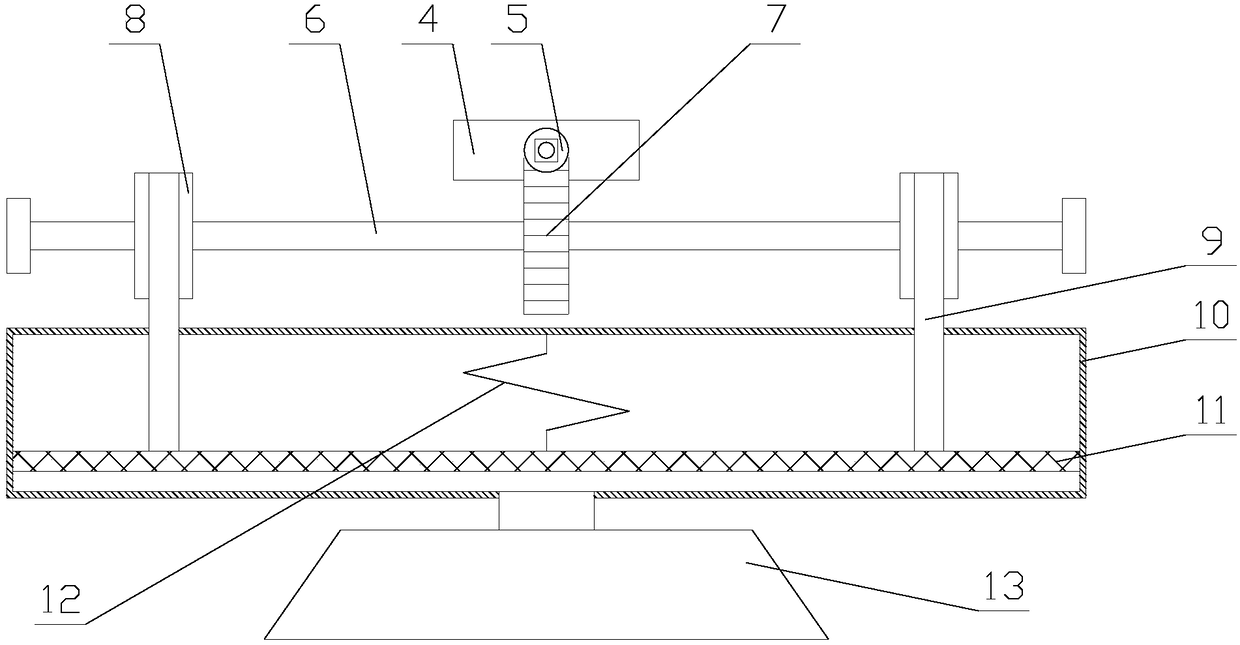

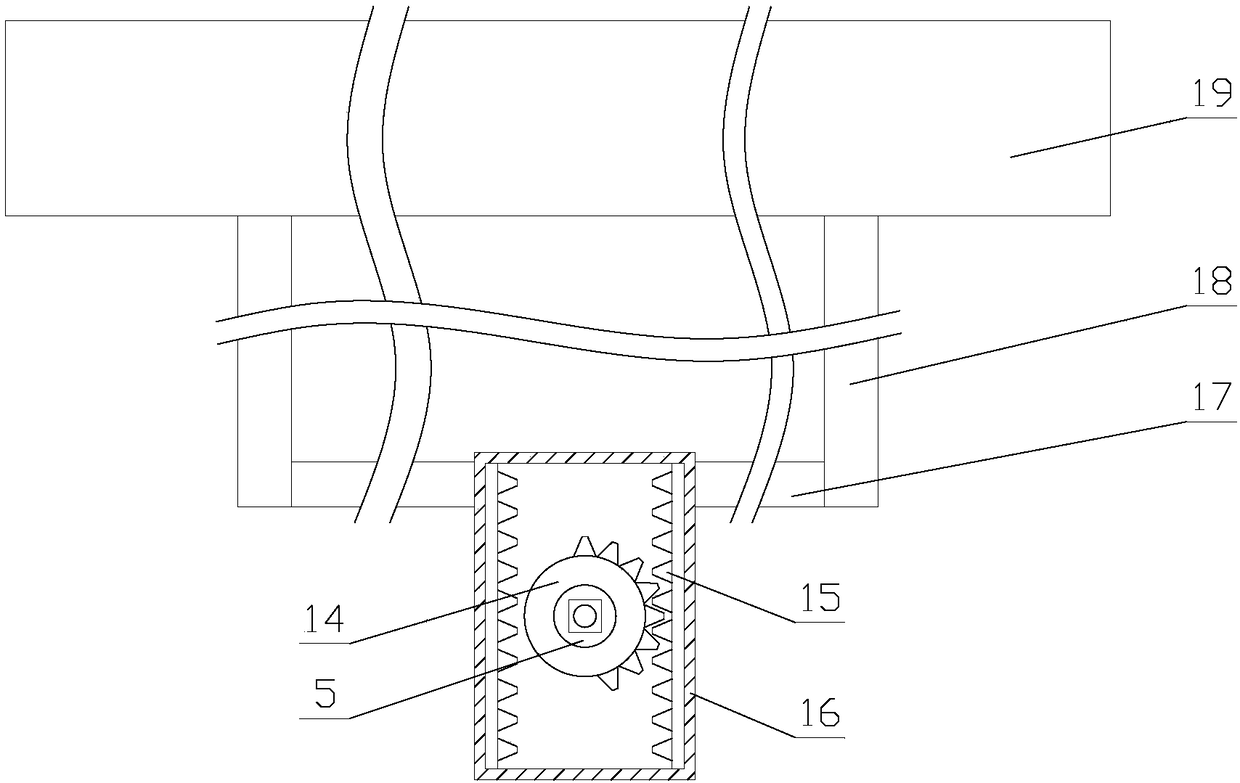

Intelligent water cup with anti-falling and cleaning functions

InactiveCN108402843AImprove practicalityImprove reliabilityTableware washing/rinsing machinesDrinking vesselsEngineering

The invention relates to an intelligent water cup with anti-falling and cleaning functions. The intelligent water cup comprises a body, a cup cover, a lining, a processing mechanism and a cleaning mechanism, the processing mechanism comprises a fixing assembly and a water absorbing assembly, the cleaning mechanism comprises an air cylinder, a moving block, a telescopic frame, a sliding block, a lifting plate, a second motor and a cleaning block. According to the intelligent water cup with the anti-falling and cleaning functions, the cup can be fixed with a desktop and accumulated water on thecup can be removed through the processing mechanism. Compared with existing intelligent water cups, the occurrences of falling over and dropping from high positions of the water cup caused by negligence of people resulting in the damage of the water cup are avoided, an anti-skid effect can also be achieved, and the use of the water cup is more reliable; through the cleaning mechanism, dirt on a the wall of the lining and the bottom of the water cup can be cleaned to improve the drinking quality; compared with the existing intelligent water cups, the cleaning is more convenient and efficient, and the practicability and reliability of the intelligent water cup are greatly improved.

Owner:惠安县冠威机械设备有限公司

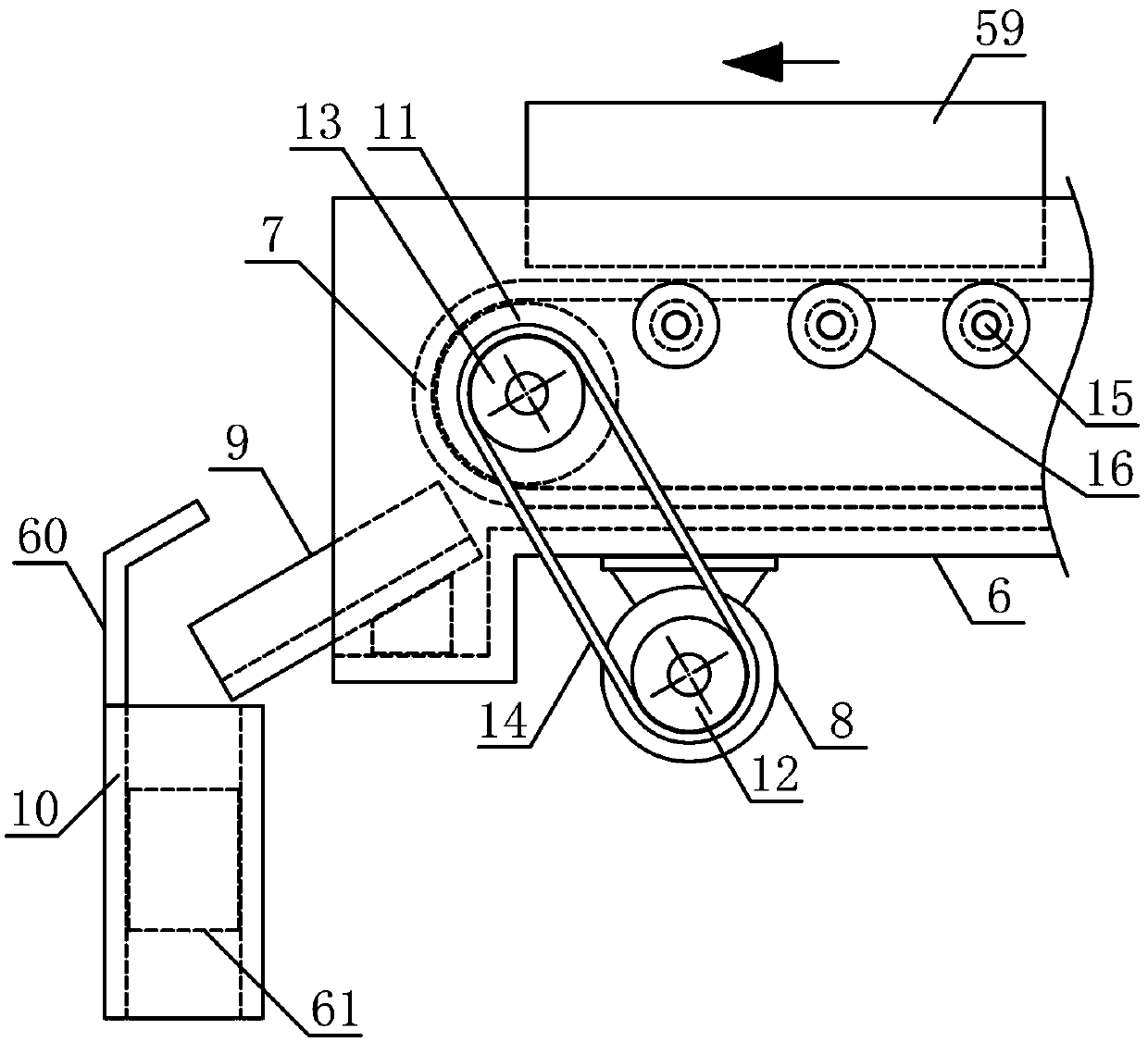

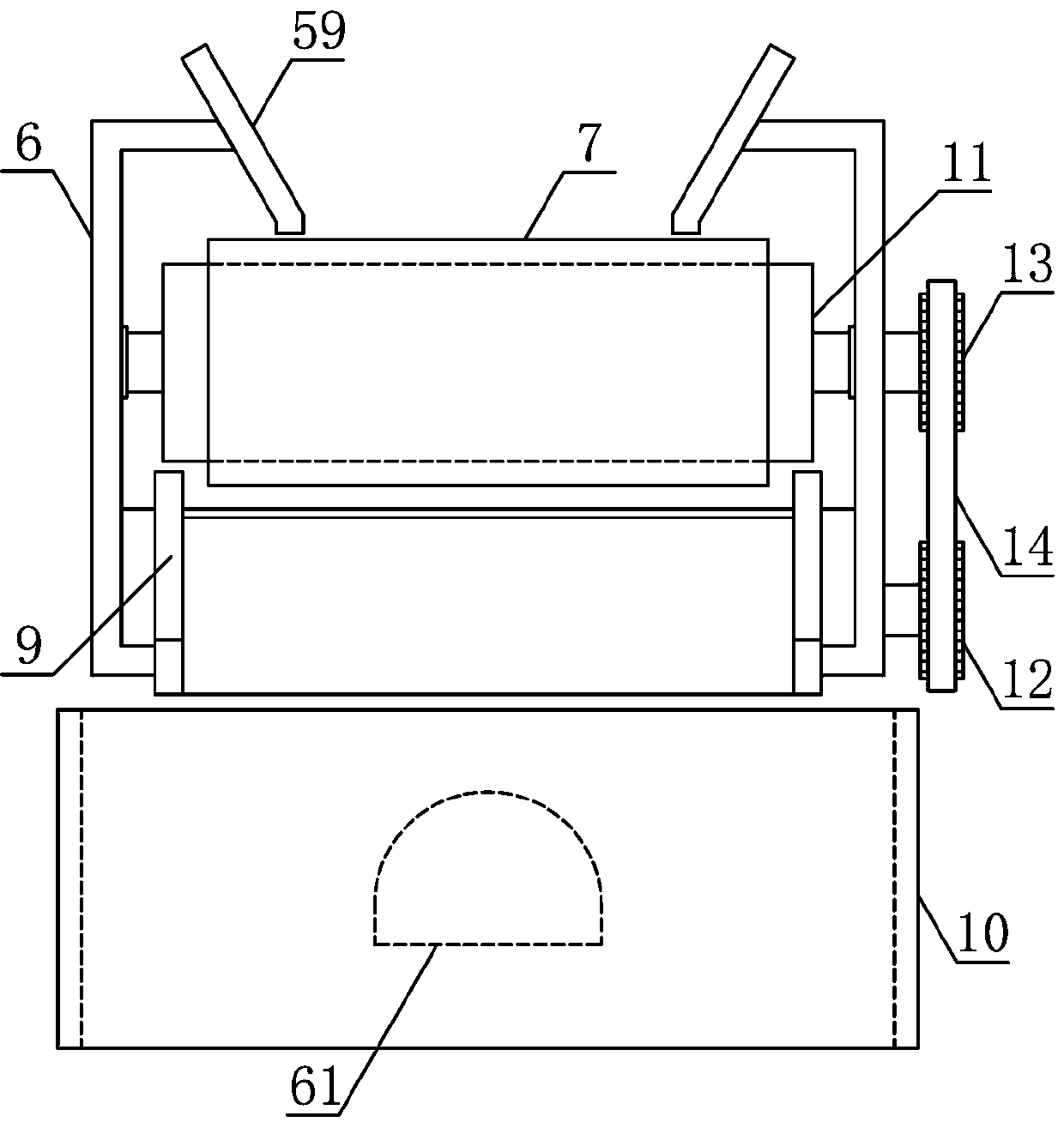

Sand stone washing device used for concrete machining

PendingCN110355152AAchieve vibration sheddingEfficient exclusionCleaning using liquidsMechanical equipmentEngineering

The invention discloses a sand stone washing device used for concrete machining and belongs to the field of building material machining mechanical equipment. A sand stone feeding mechanism, a sand stone falling mechanism, a sand stone washing mechanism and a washing water circulating mechanism are fixedly arranged on one side of a sand stone guiding and conveying support in sequence from top to bottom. A sand stone conveying belt is horizontally connected to a material conveying rotating roller in a winding manner. A sand stone dispersing pipe is vertically and fixedly arranged on the sand stone guiding and conveying support on the lower side of the end portion of a material guide oblique plate. Reciprocating falling plates are vertically arranged on the two sides of fixed falling connecting plates on the two sides below the sand stone dispersing pipe. A washing screen is arranged on the lower side of the falling support obliquely. A fixed washing water pipe is fixedly arranged on thelower side of the falling support on the upper side of the middle portion of the washing screen horizontally. A fixed water collecting groove is horizontally and fixedly formed in the lower side of the washing screen. The sand stone washing device is reasonable in structural design, sand stones used for machining the concrete can be washed rapidly and efficiently in the conveying process, the machining automation degree is high, and the requirement of machining and using is met.

Owner:桐乡市钟大建材有限公司

Comfort quilt and pillowcase

InactiveUS20110265261A1Easy and efficient cleaningEasy to disassembleSleeping rugTravelling rugEngineeringMechanical engineering

Owner:OGUNDARE BEVERLY L

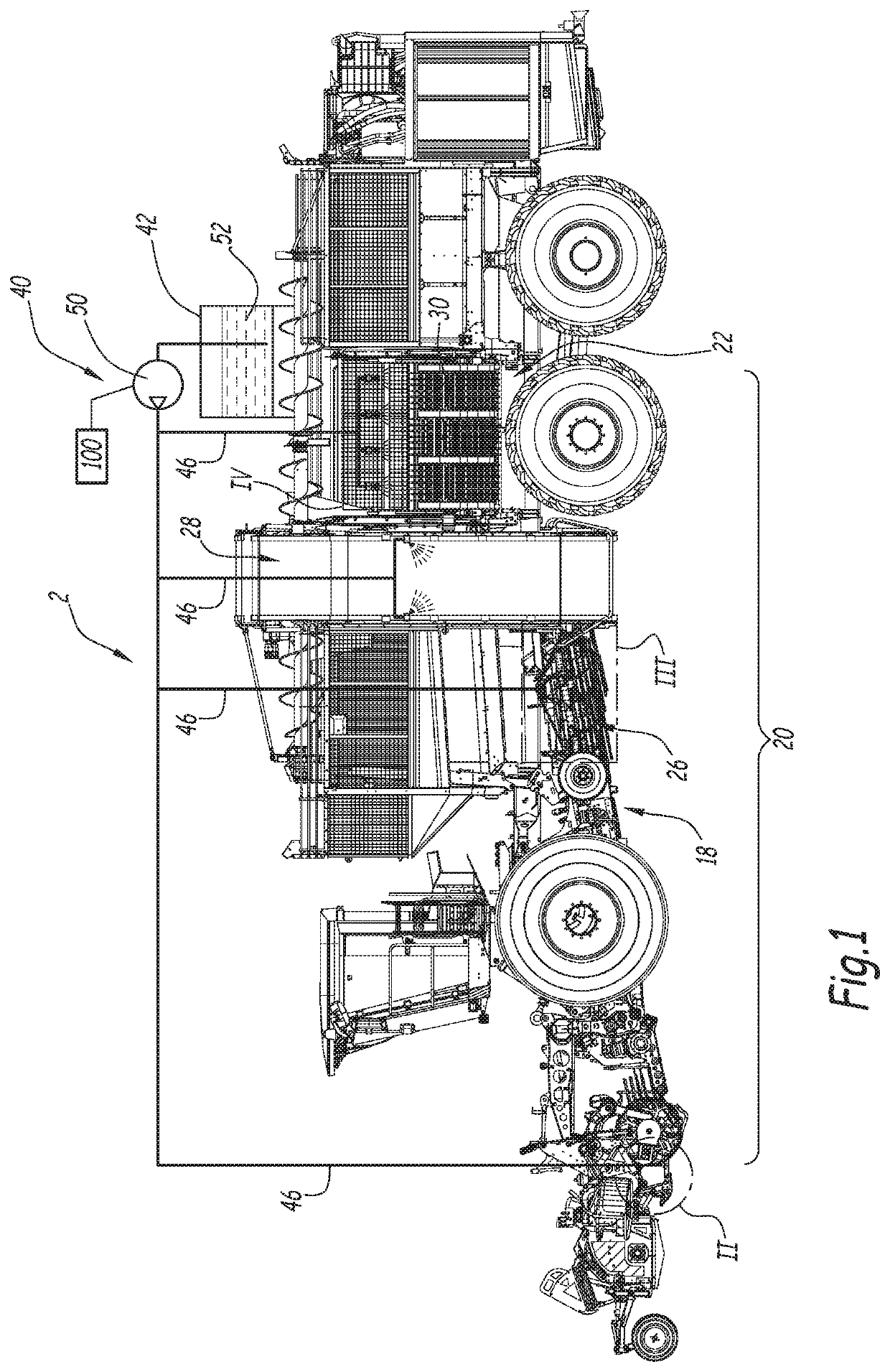

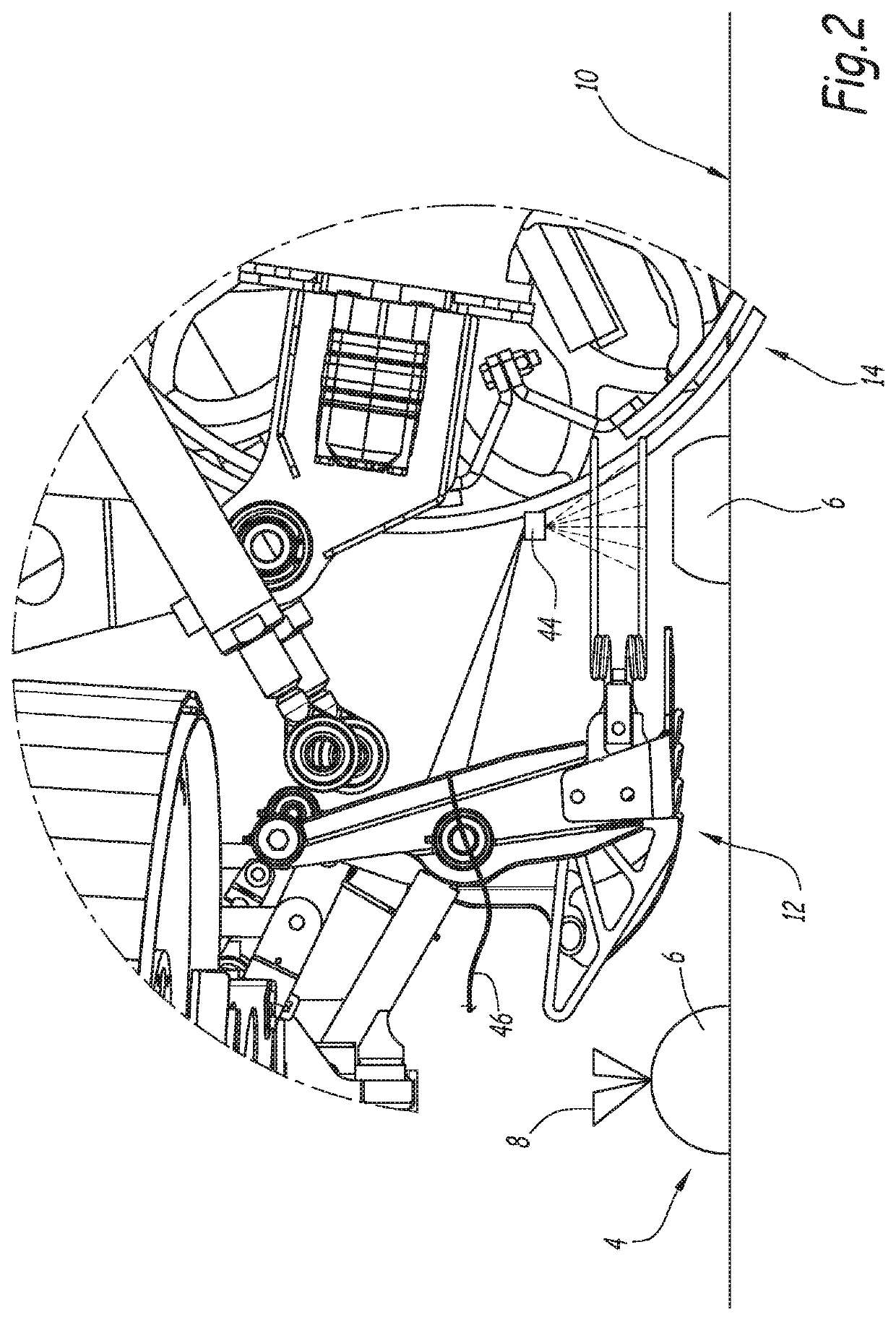

Beet crop harvesting machine, corresponding method and use

ActiveUS10561062B2Reduce lossesEasy and efficient cleaningLiftersTopping machinesBiotechnologyRoot crops

Owner:EXCEL IND INC

Method of using wobbling brush apparatus

InactiveUS6645309B1Easy and efficient cleaningReduce riskCarpet cleanersKitchenware cleanersConfined spaceEngineering

Disclosed is a method of imparting a wobbling motion to a planar surface. In one embodiment the wobbling motion is imparted to a brush which can be used to clean uneven surfaces efficiently and easily. In another embodiment the wobbling motion is imparted to a brush which can be used to clean surfaces in confined spaces and reducing the risk of scratching or marring areas in the confined spaces. In another embodiment a method of cleaning a surface using a wobbling apparatus is disclosed.

Owner:MYERS HAROLD R

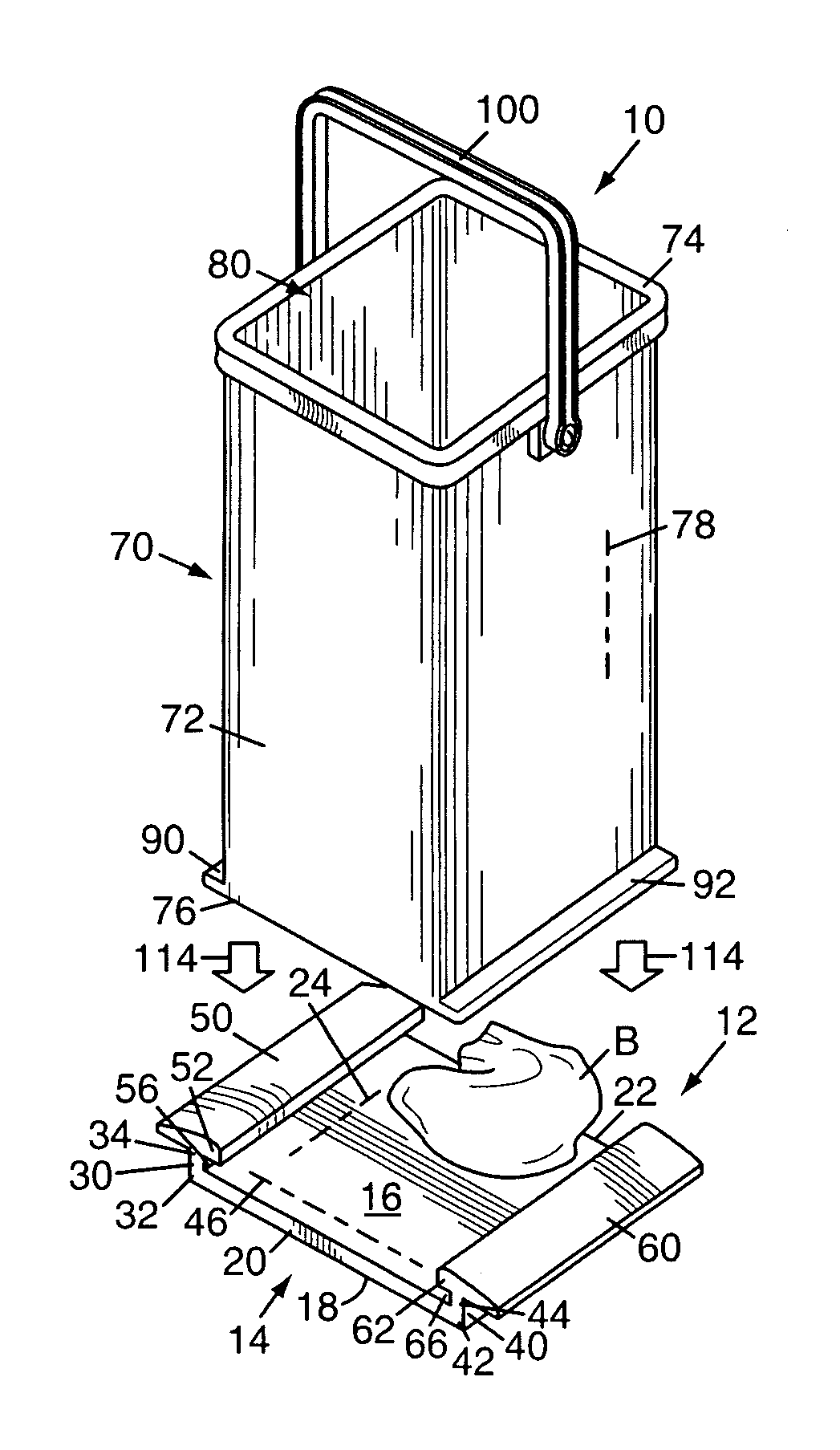

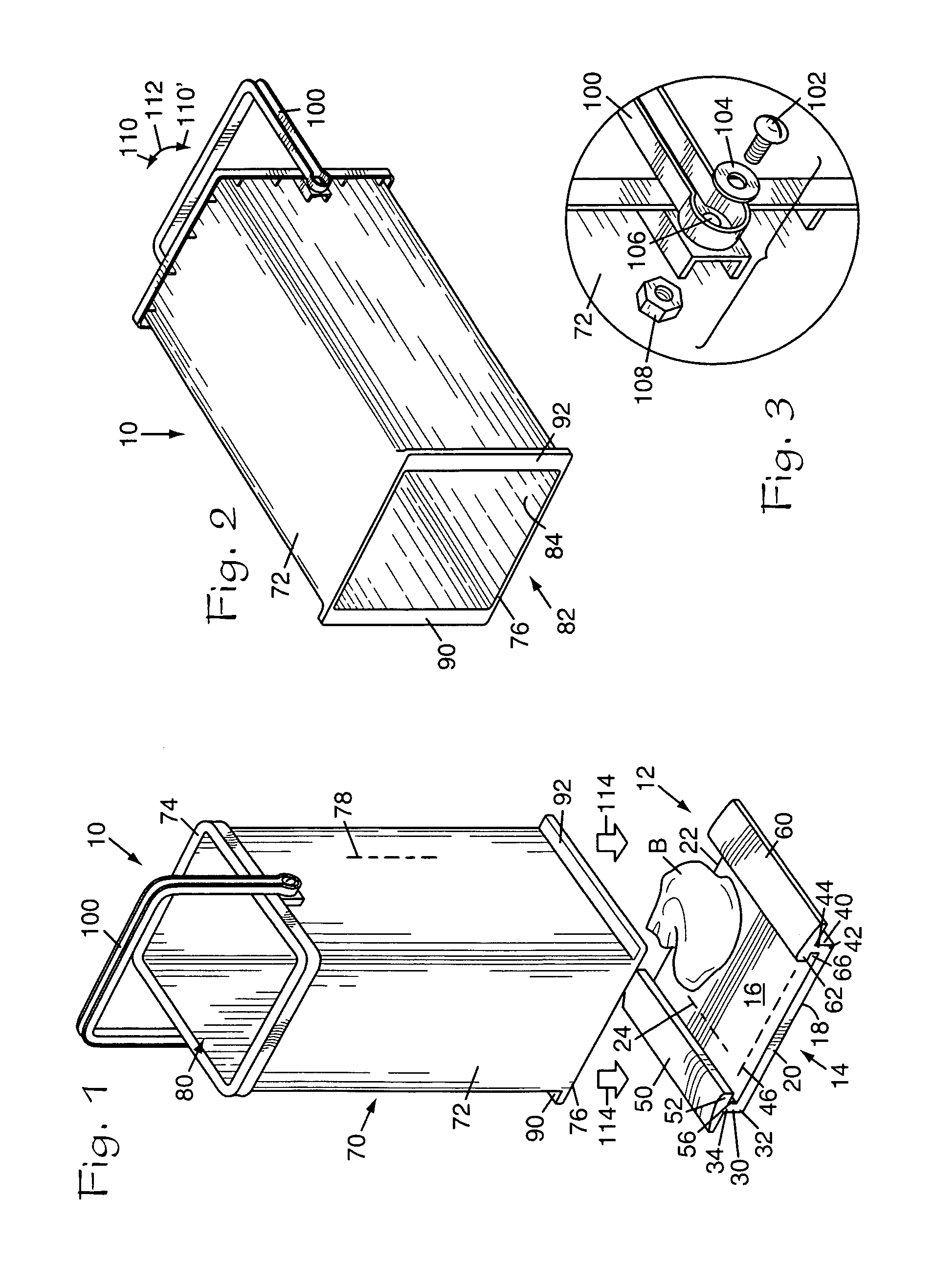

Trash receptacle unit

InactiveUS7108150B1Easily place and removeEasy loading and cleaningInternal framesRemovable lids/coversEngineering

Owner:ROUSE JASON C +1

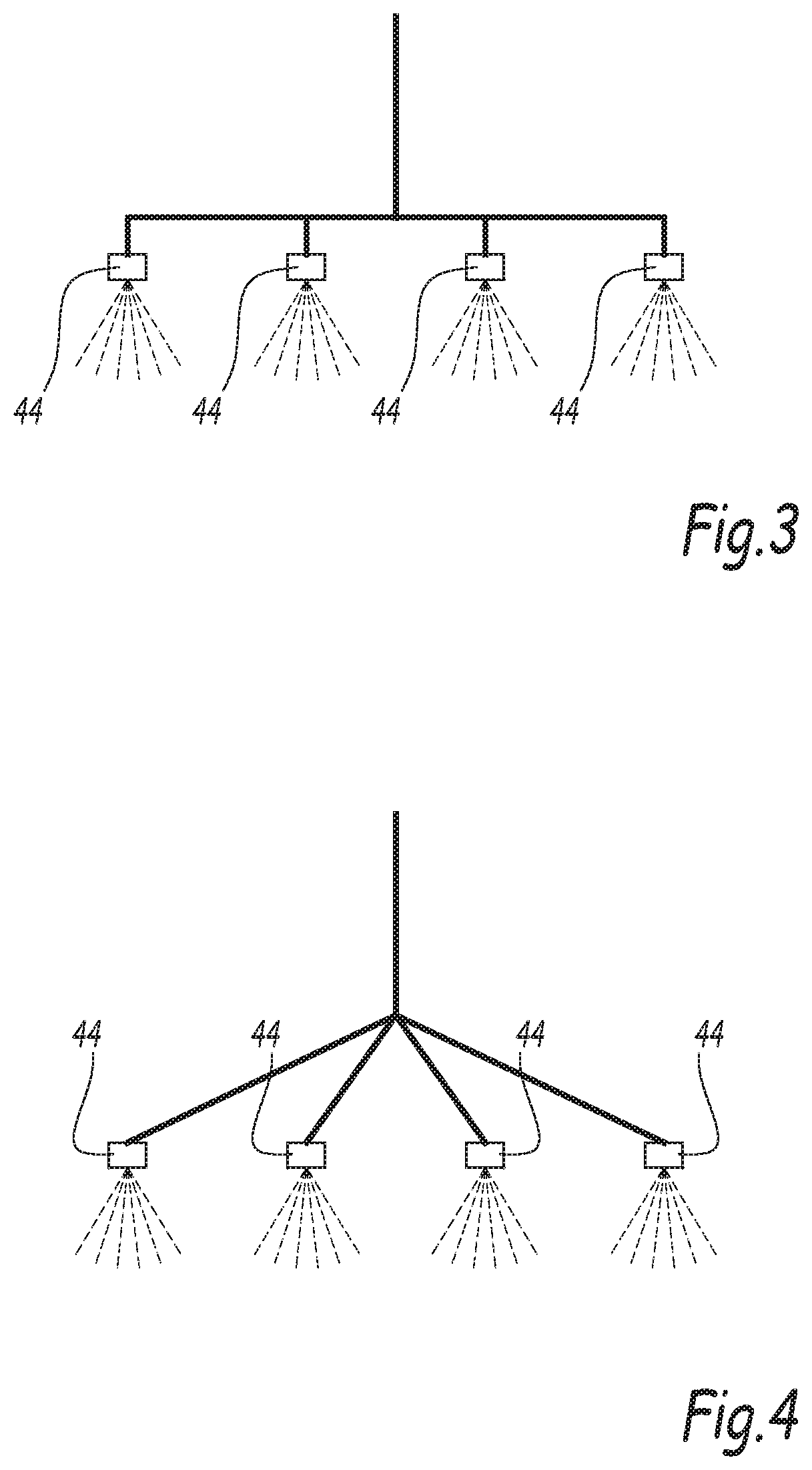

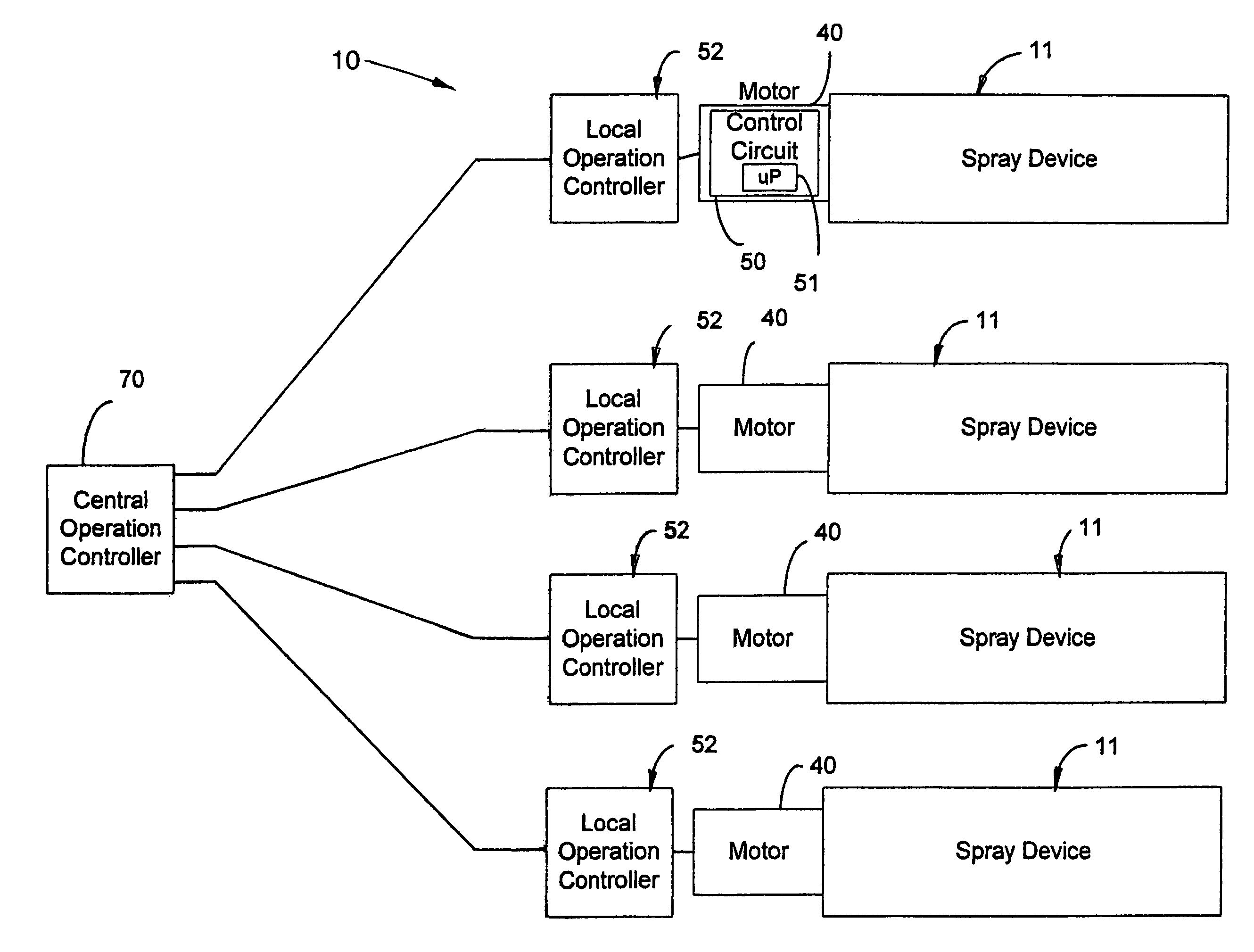

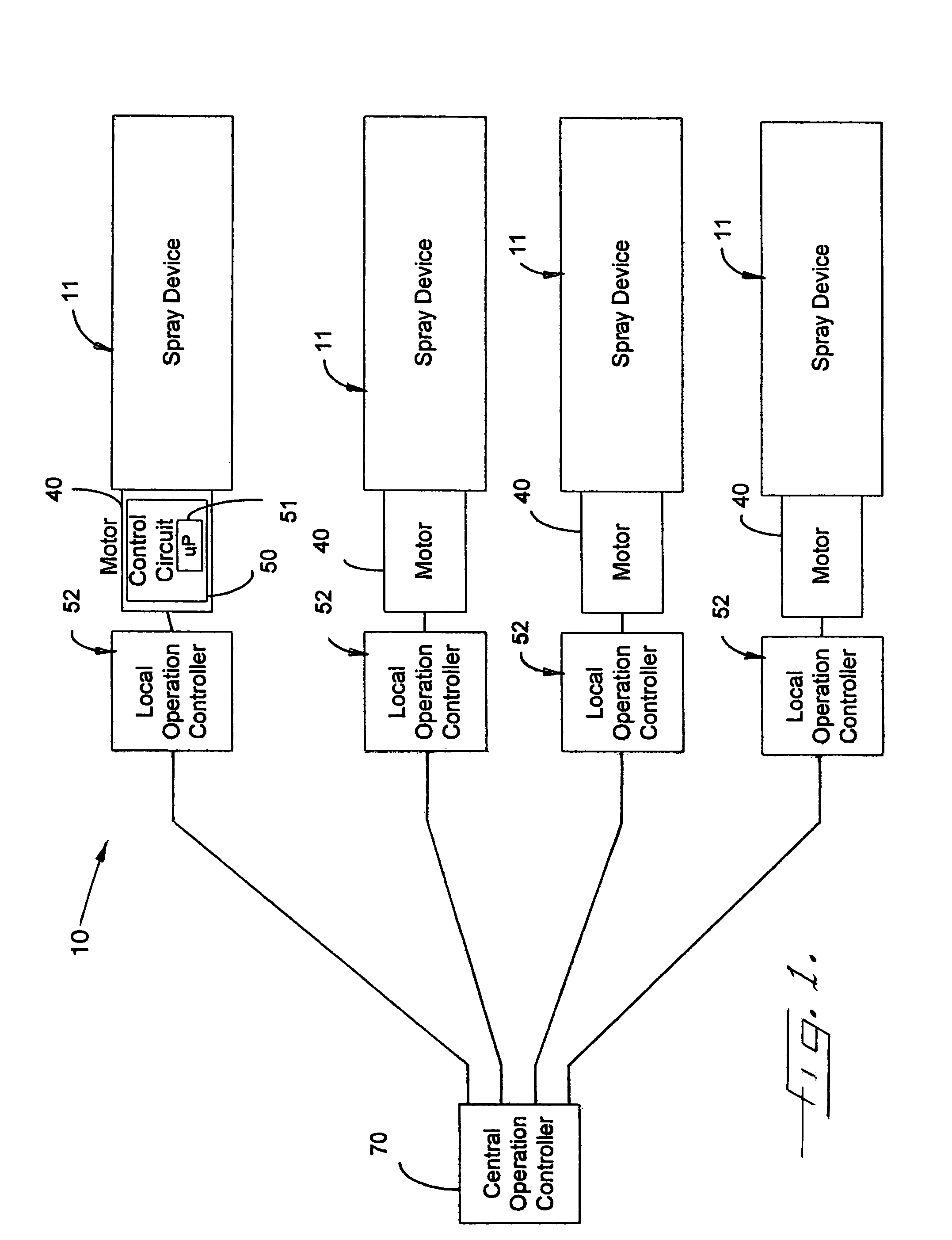

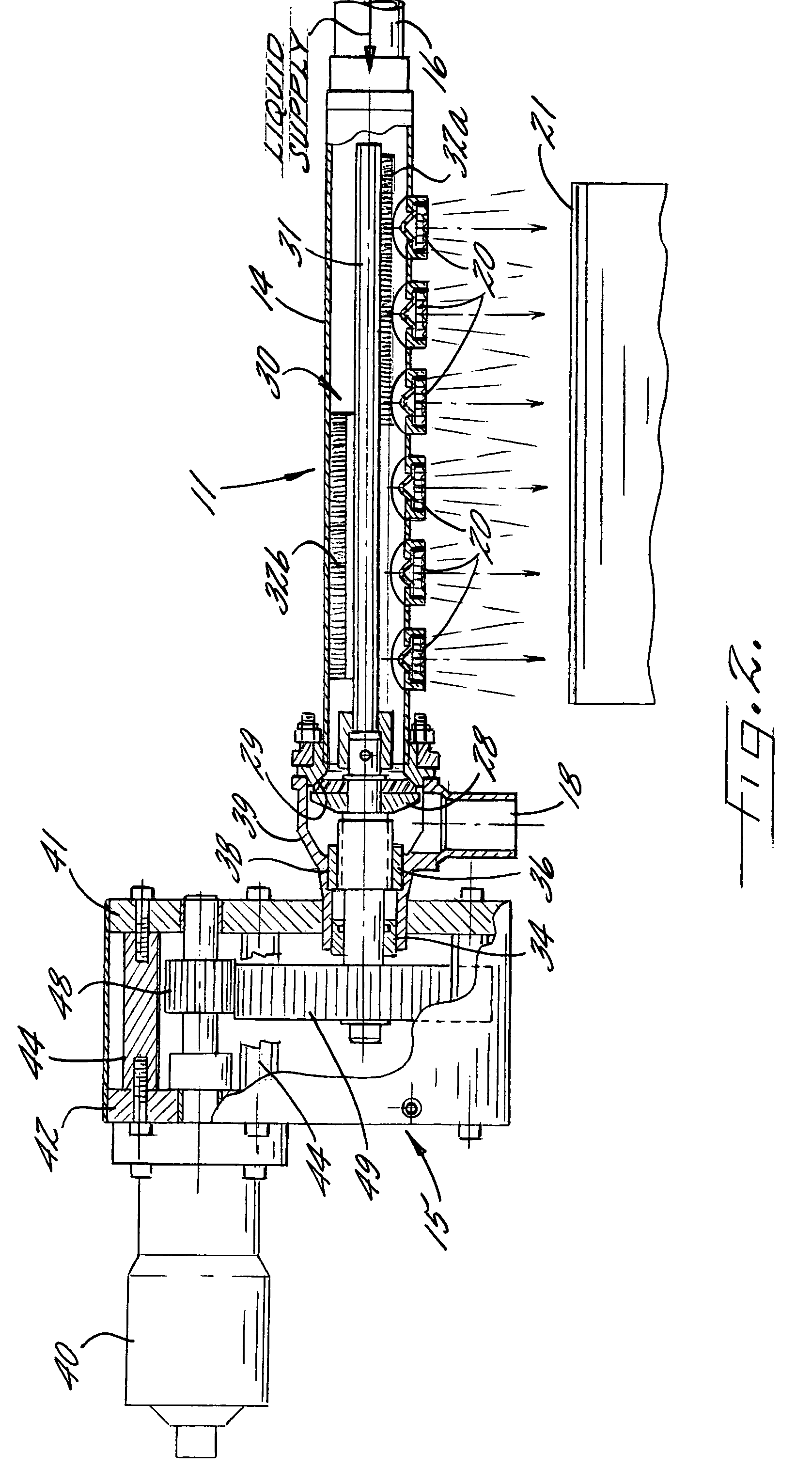

Spraying system with automated nozzle cleaning device

ActiveUS7182273B2Easy and efficient cleaningMinimizeHollow article cleaningSpray nozzlesEngineeringMechanical engineering

A shower header type spray device has a motorized cleaning brush on a rotary shaft mounted therein for cleaning inlet apertures of its spray nozzles. The brush shaft is supported to impart axial movement when it is rotated, and has a sealing valve attached thereon such that when the brush is rotated by the motor in a cleaning operation the valve is opened to allow discharge of liquid with debris brushed off the nozzle inlets. The motor is activated for a cleaning operation from either a local controller or a centralized controller that controls multiple spray devices.

Owner:SPRAYING SYST

Coal conveying side camera dust removal device for high-humidity area power plant

PendingCN112055140AAutomate cleaningSave human effortTelevision system detailsColor television detailsThermodynamicsDust control

The invention discloses a coal conveying side camera dust removal device for a high-humidity area power plant, and relates to the technical field of cameras, the coal conveying side camera dust removal device comprises a bottom plate, a camera is fixedly connected to the top of one side of the bottom plate, a first shell is fixedly connected to the top of the camera, and a fan and an electric heating wire are fixedly connected to the interior of the first shell; an air cavity is formed in the first shell, and a third shell is fixedly connected to the top of the side, away from the camera, of the bottom plate. According to the dustproof camera for pulverized coal conveying, through cooperation of the scraping plate, the fixing rod, the rotating disc, the ejector rod and the first motor, thescraping plate can automatically clean dust on the surface of the camera, manpower is saved, use is convenient, a good dustproof effect is achieved, and through cooperation of a fan, an electric heating wire, an air cavity and an air baffle, wet pulverized coal on the surface of the camera is dried through warm air, a scraper blade can conveniently clean the pulverized coal, dust cleaning is convenient and efficient, and application and popularization are facilitated.

Owner:SHANXI SANHESHENG IND TECH

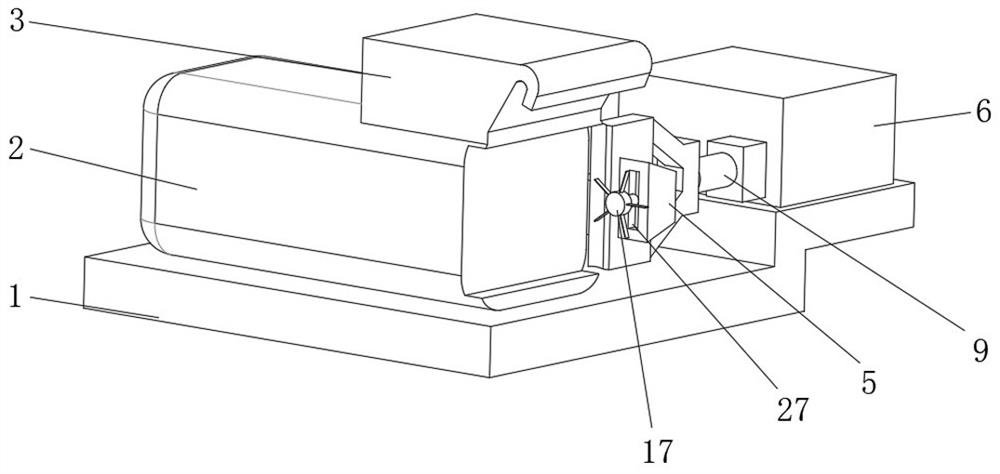

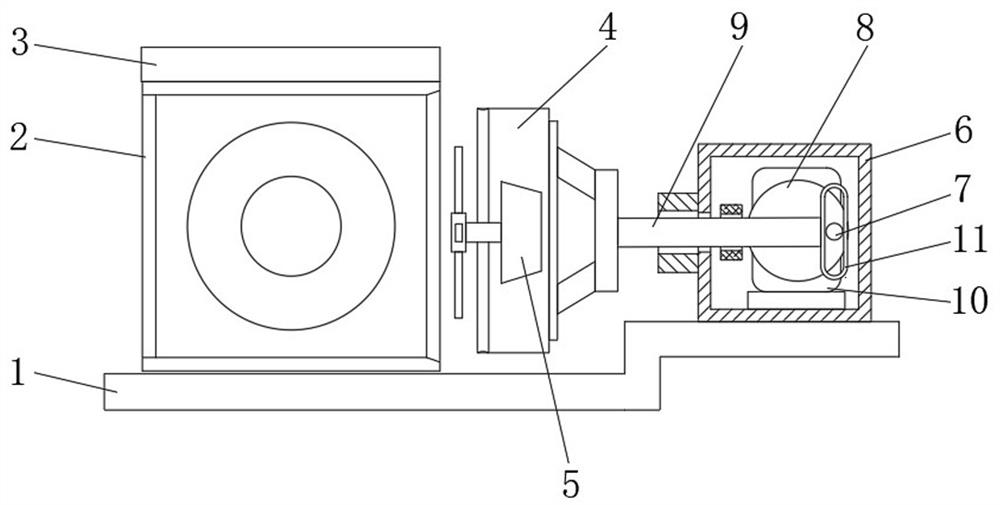

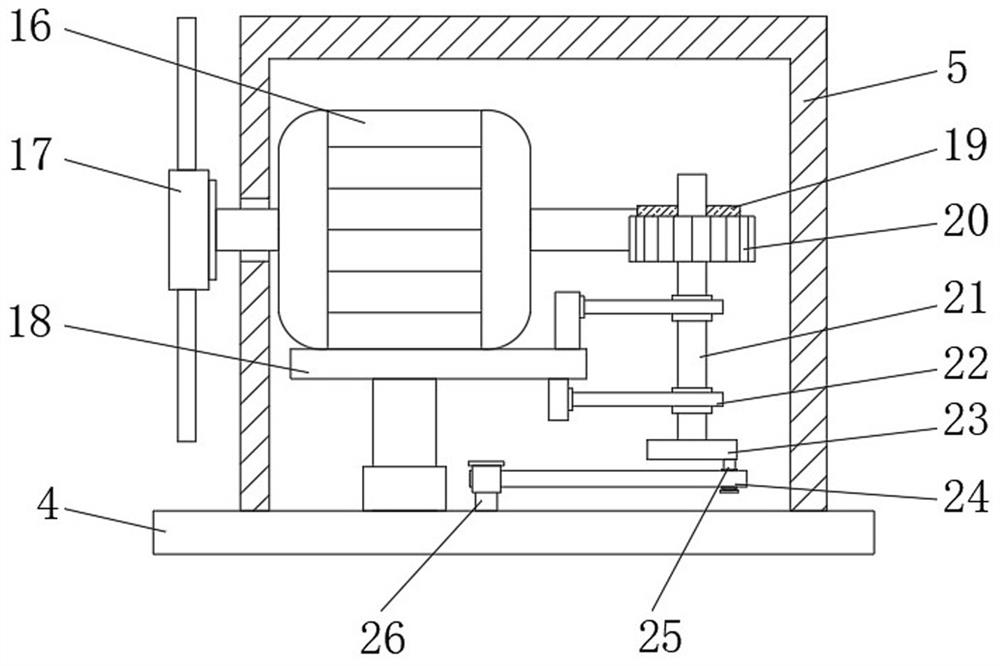

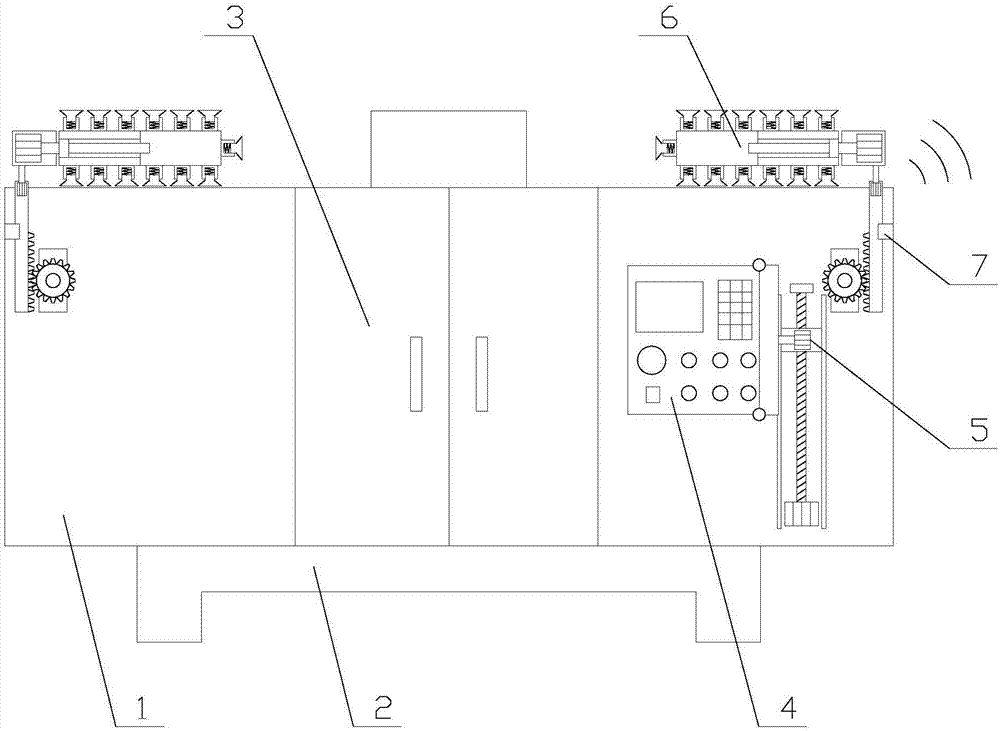

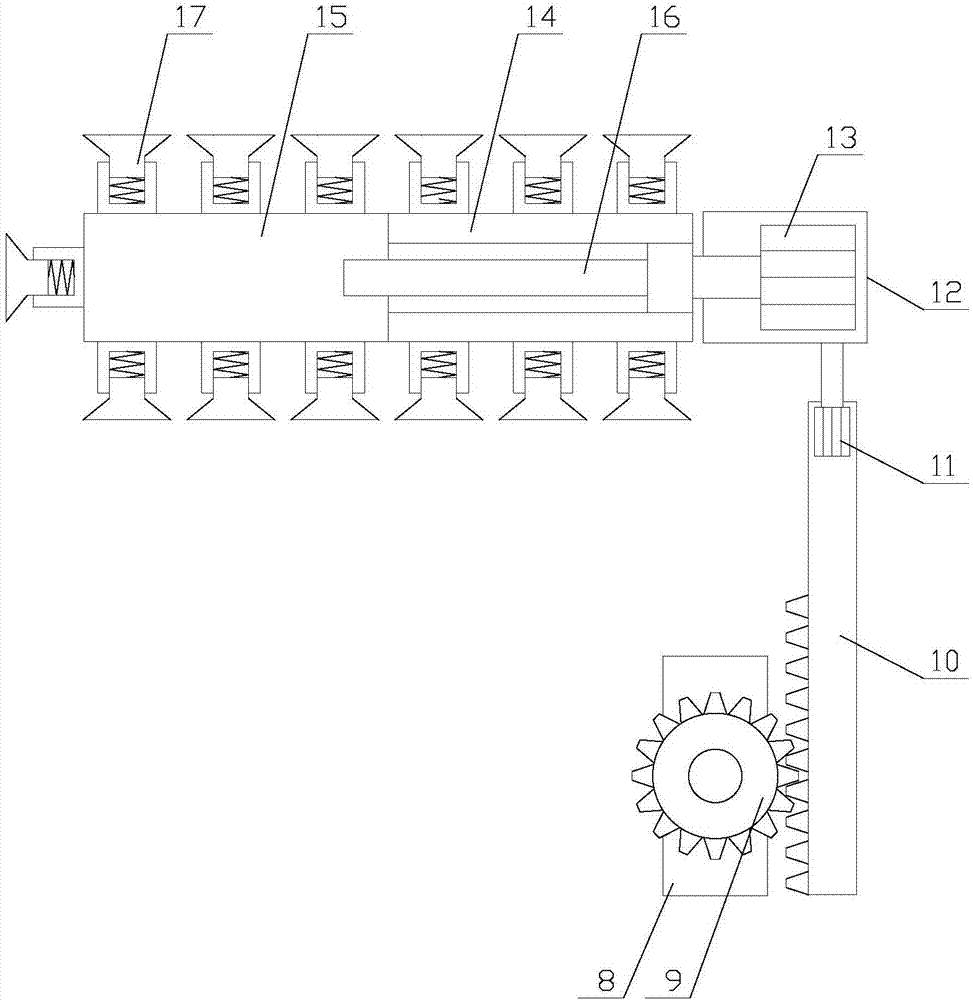

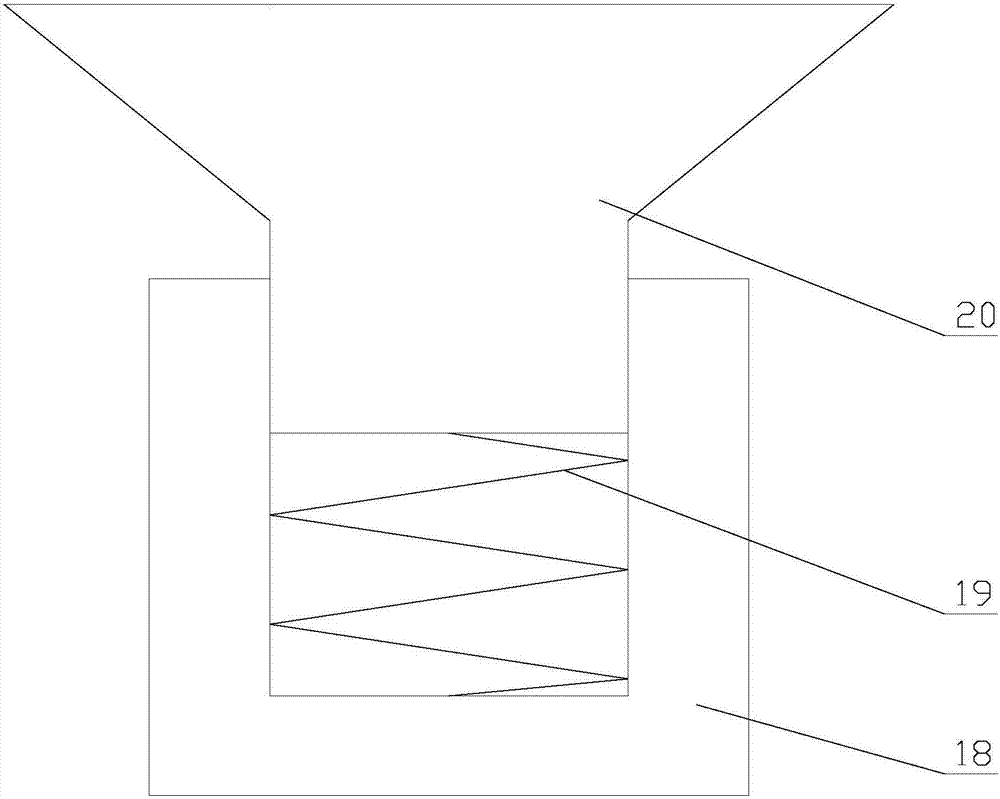

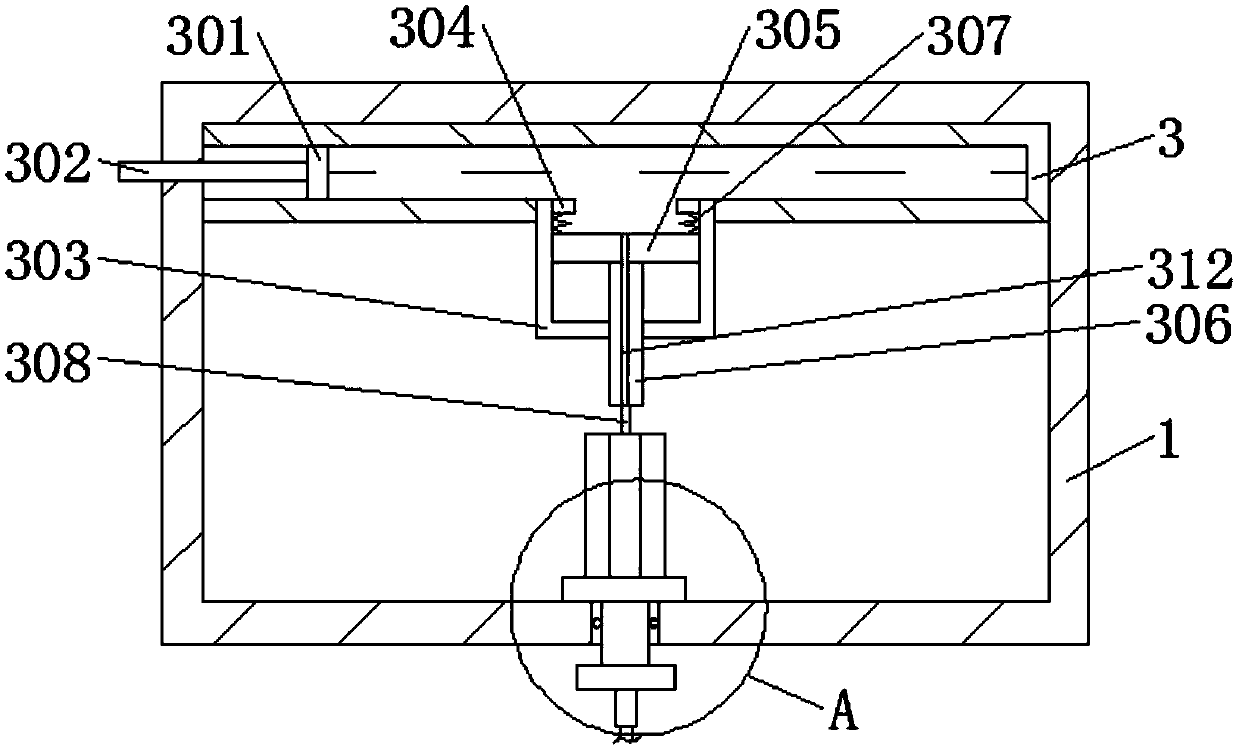

Internet of things based machining center with automatic machine top washing function

ActiveCN107498378AAvoid safety hazardsImprove cleaning efficiencyCleaning using toolsMaintainance and safety accessoriesElectric machineDrive shaft

The invention relates to an Internet of things based machining center with an automatic machine top washing function. The Internet of things based machining center with the automatic machine top washing function comprises a machine body, a base, a door which can be opened or closed, a machining mechanism, a center control mechanism, an adjusting mechanism and two washing mechanisms. Each washing mechanism comprises a moving assembly, a swinging assembly and a rotating assembly. Each rotating assembly comprises a third motor, a third drive shaft, a first roller, a second roller, a linear actuator and a plurality of cleaning units. The adjusting mechanism comprises a lifting assembly and a rotating assembly. The lifting assembly comprises a fourth motor, a lead screw and a lifting plate. The rotating assembly comprises a fifth motor, a fourth drive shaft and a fixing plate. By means of the washing mechanisms, sweeping is more convenient and efficient, and potential safety hazards existing in climbing the machine are avoided; by means of the adjusting mechanism, the position where the center control mechanism is located can be freely and flexibly changed so as to meet the actual working demands of operators; and by means of the mechanisms, the safe practicability and using comfort in machining are greatly improved.

Owner:江苏汉达机械有限公司

Spray head cleaning device of 3D printing device

InactiveCN109624319ANot easy to blockEasy and efficient cleaningManufacturing converters3D object support structuresFuel tankEngineering

The invention discloses a spray head cleaning device of a 3D printing device. The spray head cleaning device of the 3D printing device comprises a cleaning box, a cleaning box door is hinged to the cleaning box, and a cleaning device is arranged in the cleaning box. The cleaning device comprises a fuel tank, the fuel tank is fixedly connected with the inner top wall of the cleaning box, a first piston is slidably connected to the inner wall of the fuel tank, and a first piston rod is fixedly connected to one end of the first piston. One end of the first piston rod penetrates through the innerwall of the cleaning box and extends to the outer end of the cleaning box, an auxiliary fuel tank fixedly communicates with the lower end of the fuel tank, and fixed blocks are fixedly connected to both sides of the inner walls of the auxiliary fuel tank. A second piston is slidably connected to the inner wall of the auxiliary fuel tank, and a second piston rod is fixedly connected to the lower end of the second piston. According to the spray head cleaning device of the 3D printing device, by arranging the cleaning device, a cleaning rod hooks sundries in a spray cavity and pulls back the first piston rod, under the action of a tension spring, a cleaning pipe leaves the spray cavity, the cleaning rod draws up the sundries in the spray cavity, so that the printing spray head is not prone tobeing blocked.

Owner:NANTONG INST OF TECH

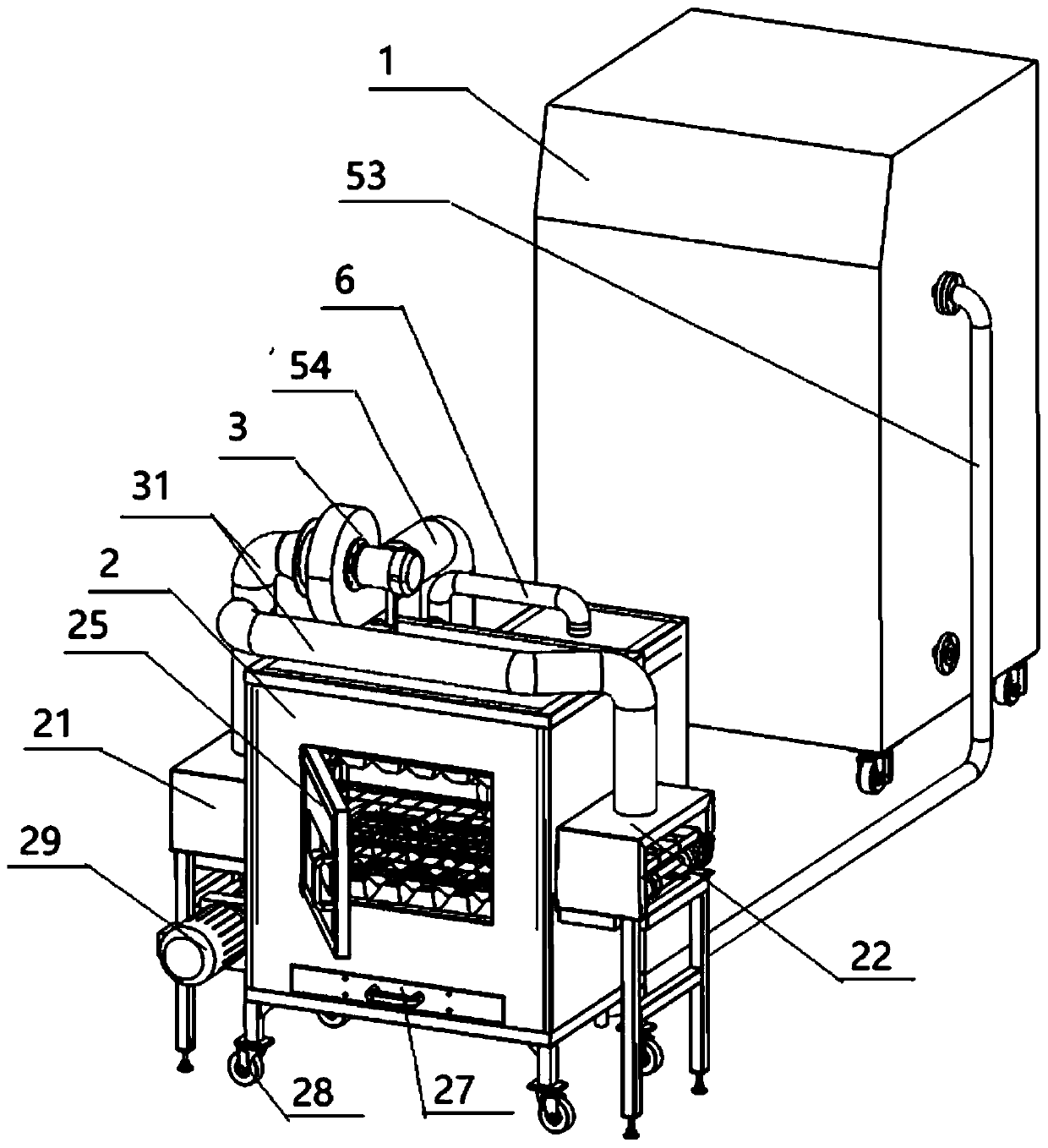

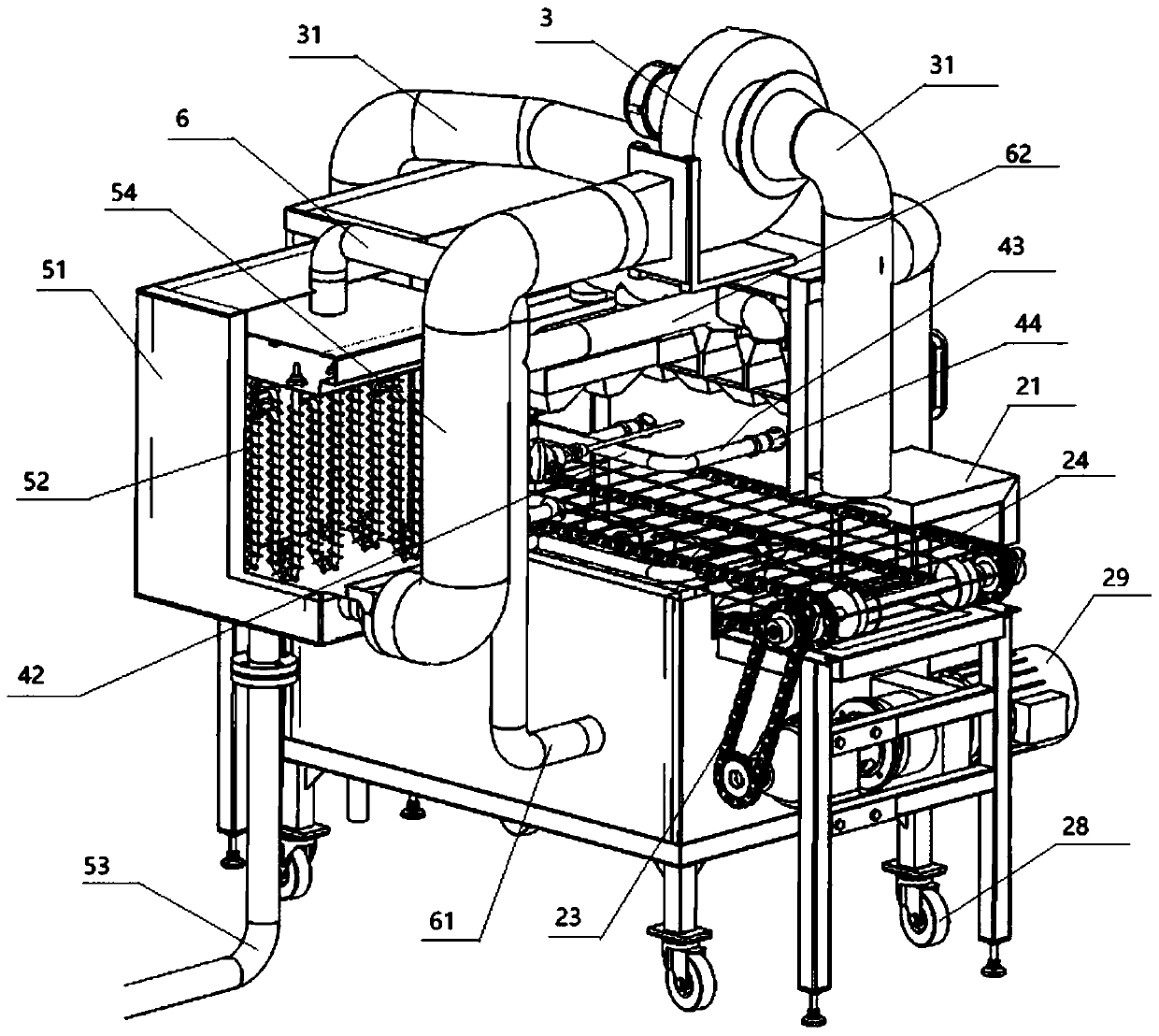

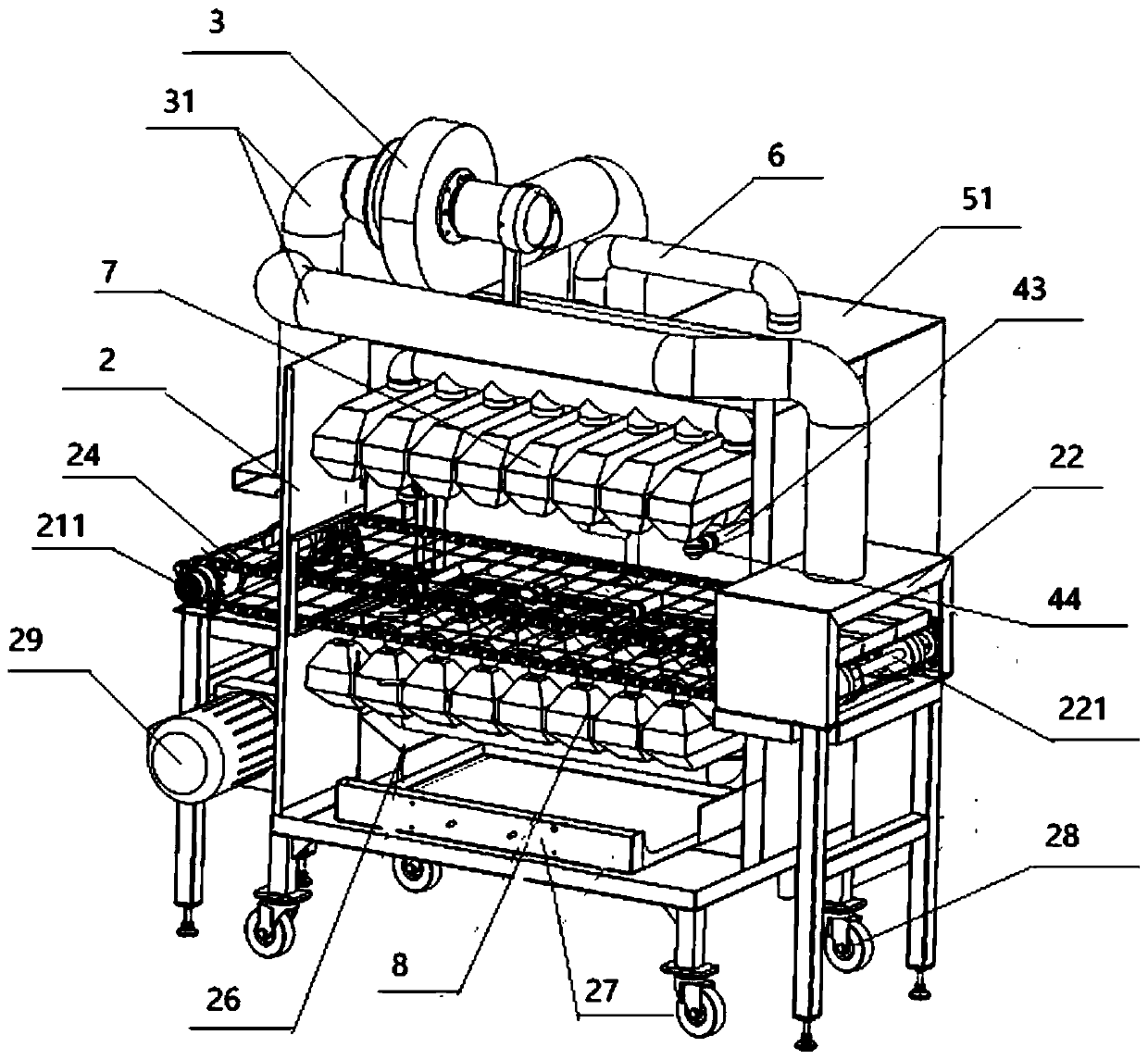

Device for flexibly processing food through superheated steam

The invention discloses a device for flexibly processing food through superheated steam. The device comprises a steam generator, a steaming oven and a cleaning mechanism, wherein the upper portion andthe lower portion of the steaming oven are both communicated with a steam outlet of the steam generator, the middle of the steaming oven is communicated with an air inlet of an exhaust fan, the opposite first side face and second side face of the steaming oven are provided with a feeding port and a discharging port respectively, the cleaning mechanism comprises a water guide pipeline located in the steaming oven, a water inlet pipe for making the water guide pipeline communicated with the outside world, and a high-pressure rotary spraying nozzle rotationally sleeving one end of the water guide pipeline. By arranging the cleaning mechanism capable of rotationally spraying water in the steaming oven, oil stains in the steaming oven can be regularly and automatically cleaned away, and cleaning is convenient and efficient.

Owner:合肥中农科泓智营养健康有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com