Spray head cleaning device of 3D printing device

A cleaning device, 3D printing technology, applied in coating devices, 3D object support structures, manufacturing converters, etc., can solve the problems of wasting time and printing materials, damage to the machine, nozzle blockage, etc., and achieve the effect of efficient and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The following is attached Figure 1-8 The present invention is described in further detail.

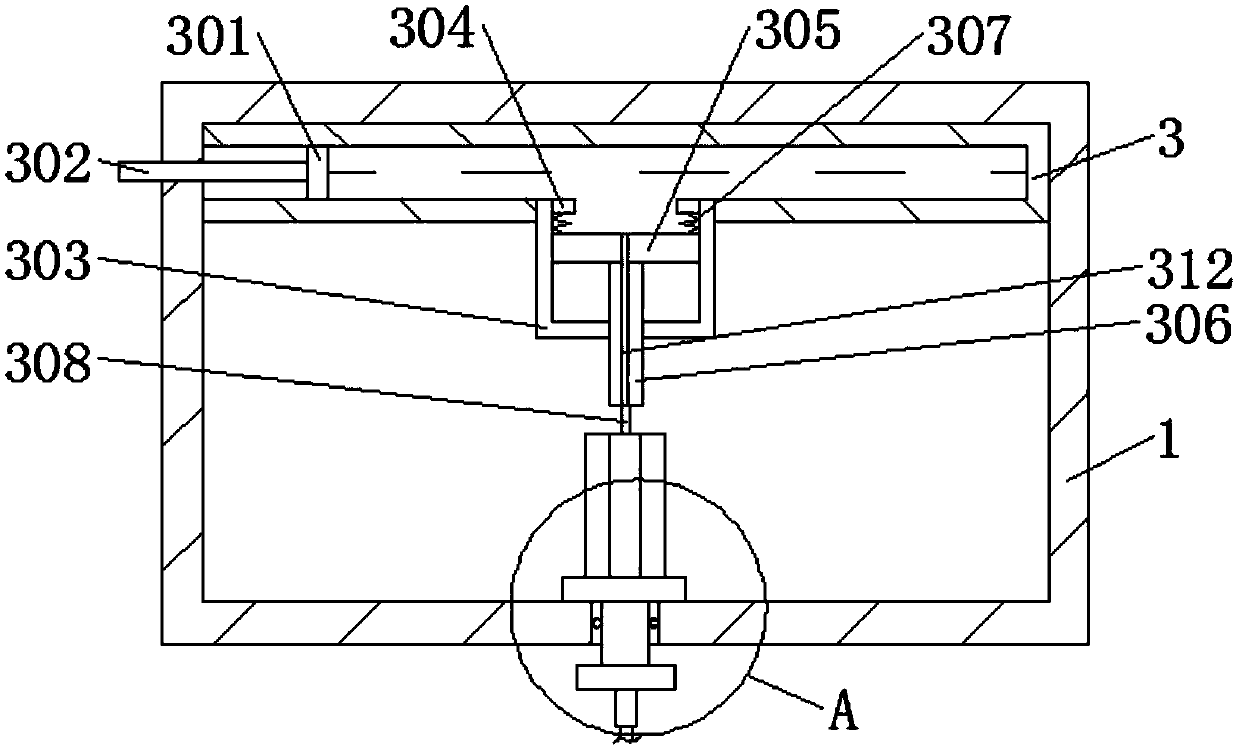

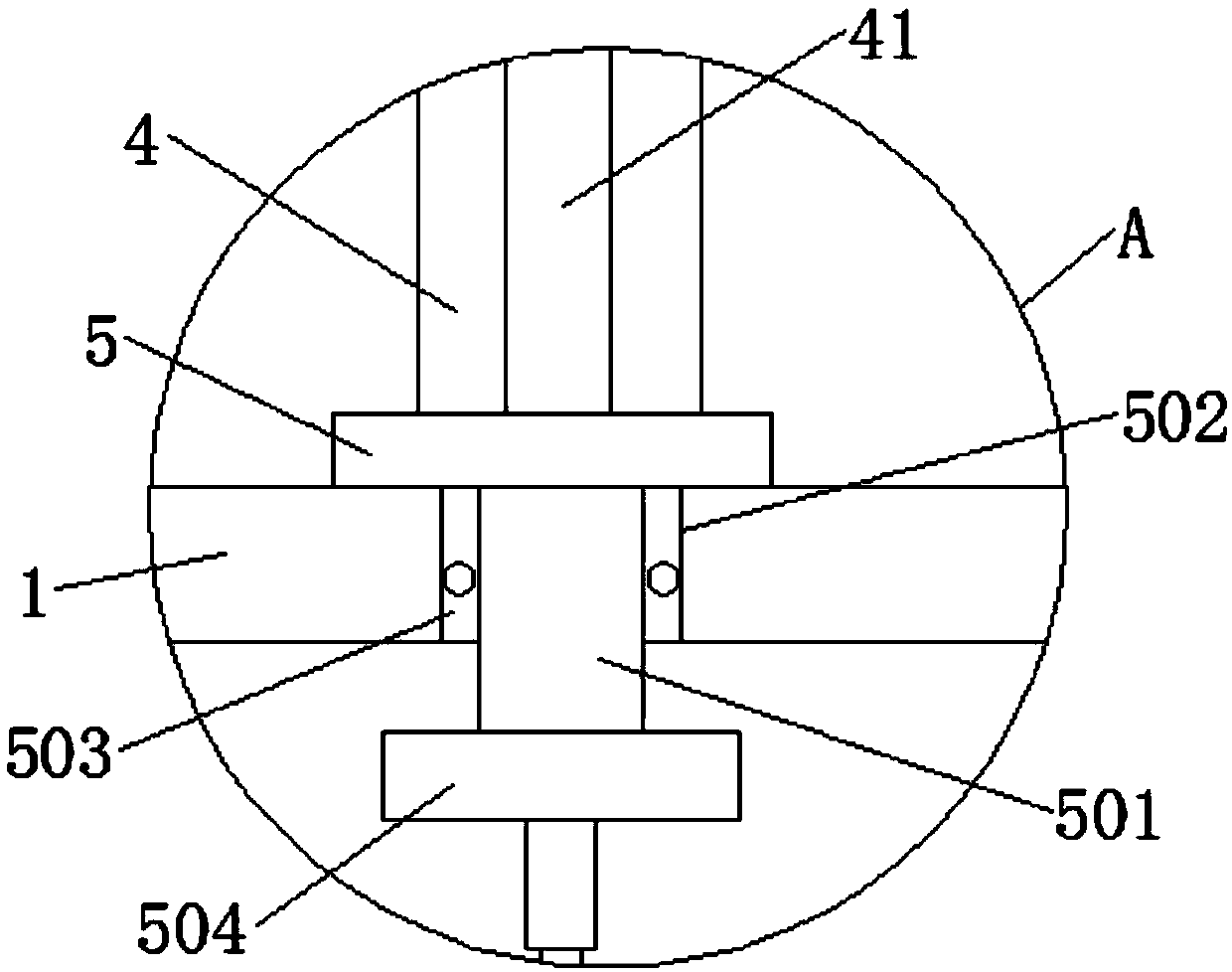

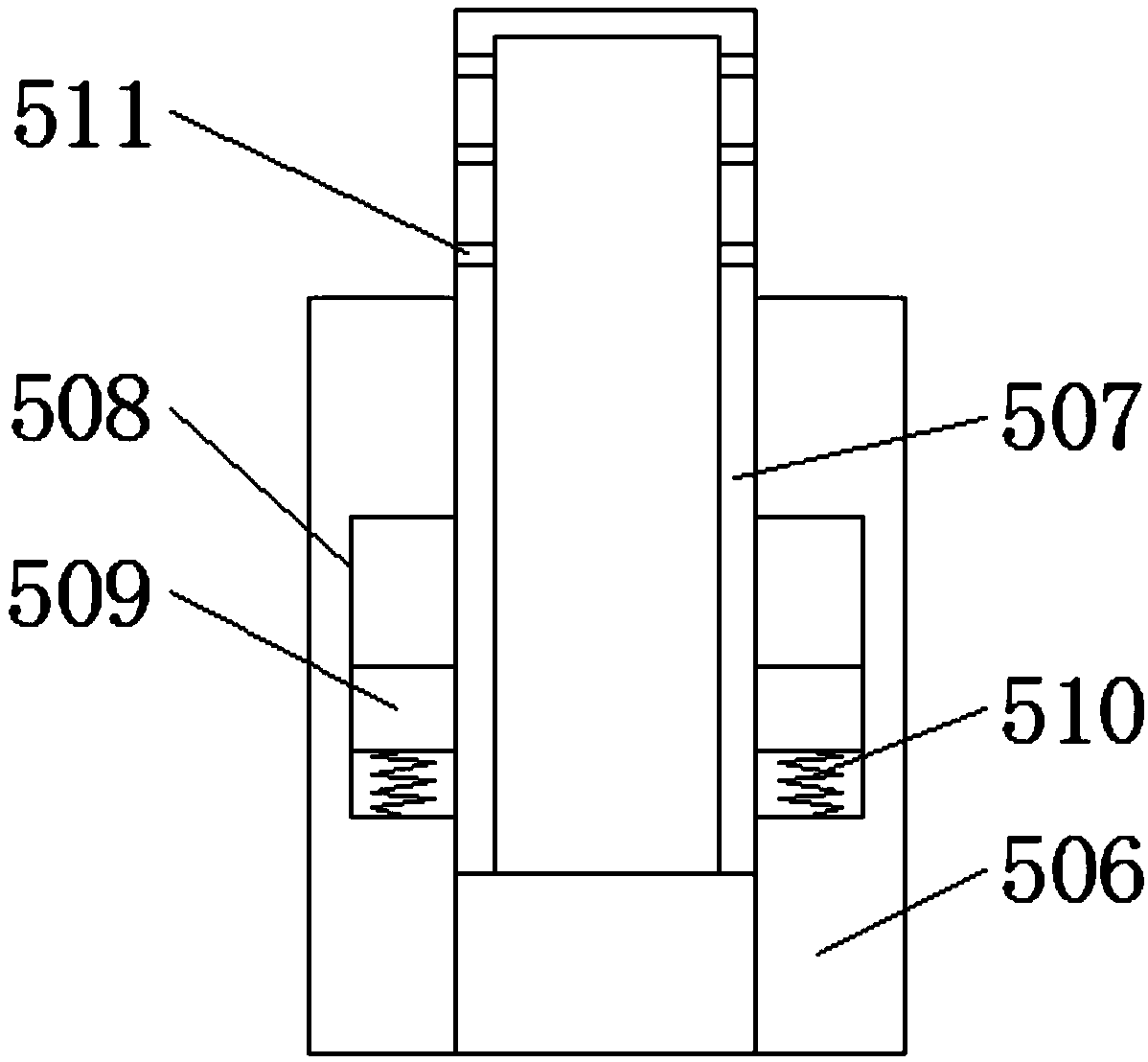

[0031] A 3D printing device nozzle cleaning device, such as Figure 1-8 As shown, it includes a cleaning box 1, the cleaning box 1 is hinged with a cleaning box door 2, and the inside of the cleaning box 1 is provided with a cleaning device.

[0032] The cleaning device comprises a fuel tank 3, which is fixedly connected with the inner top wall of the cleaning tank 1, the inner wall of the fuel tank 3 is slidingly connected with a first piston 301, and one end of the first piston 301 is fixedly connected with a first piston rod 302, and the first piston rod One end of 302 runs through the inner wall of cleaning tank 1 and extends to the outer end of cleaning tank 1. The lower end of fuel tank 3 is fixedly connected with auxiliary fuel tank 303, and the inner walls of both sides of auxiliary fuel tank 303 are fixedly connected with fixed blocks 304. The second piston 305 has a...

Embodiment 1

[0042] A 3D printing device nozzle cleaning device, such as Figure 1-8 As shown, it includes a cleaning box 1, the cleaning box 1 is hinged with a cleaning box door 2, and the inside of the cleaning box 1 is provided with a cleaning device.

[0043] The cleaning device comprises a fuel tank 3, which is fixedly connected with the inner top wall of the cleaning tank 1, the inner wall of the fuel tank 3 is slidingly connected with a first piston 301, and one end of the first piston 301 is fixedly connected with a first piston rod 302, and the first piston rod One end of 302 runs through the inner wall of cleaning tank 1 and extends to the outer end of cleaning tank 1. The lower end of fuel tank 3 is fixedly connected with auxiliary fuel tank 303, and the inner walls of both sides of auxiliary fuel tank 303 are fixedly connected with fixed blocks 304. The second piston 305 has a second piston rod 306 fixedly connected to its lower end, and one end of the second piston rod 306 pen...

Embodiment 2

[0053] A 3D printing device nozzle cleaning device, such as Figure 1-8 As shown, it includes a cleaning box 1, the cleaning box 1 is hinged with a cleaning box door 2, and the inside of the cleaning box 1 is provided with a cleaning device.

[0054] The cleaning device comprises a fuel tank 3, which is fixedly connected with the inner top wall of the cleaning tank 1, the inner wall of the fuel tank 3 is slidingly connected with a first piston 301, and one end of the first piston 301 is fixedly connected with a first piston rod 302, and the first piston rod One end of 302 runs through the inner wall of cleaning tank 1 and extends to the outer end of cleaning tank 1. The lower end of fuel tank 3 is fixedly connected with auxiliary fuel tank 303, and the inner walls of both sides of auxiliary fuel tank 303 are fixedly connected with fixed blocks 304. The second piston 305 has a second piston rod 306 fixedly connected to its lower end, and one end of the second piston rod 306 pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com