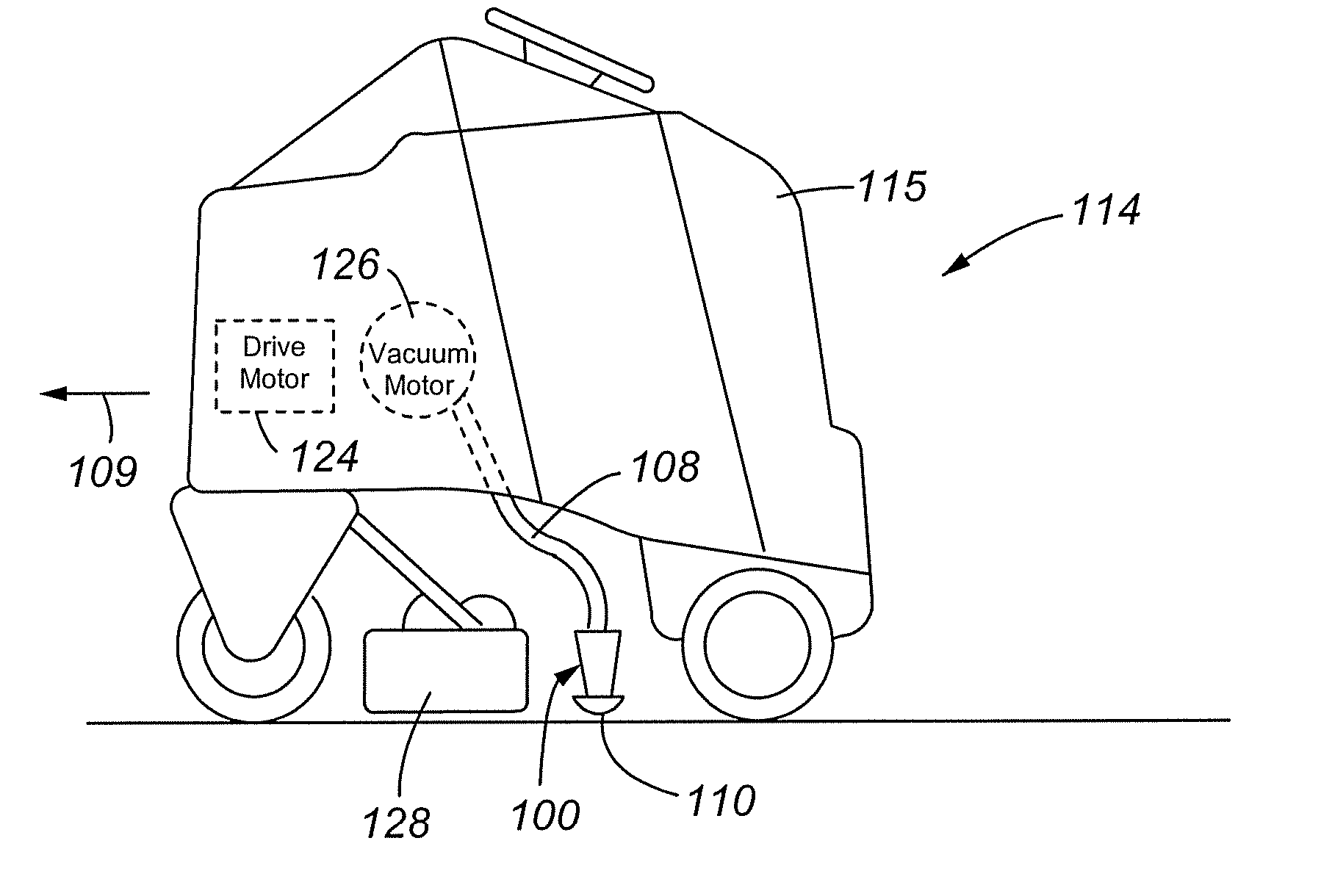

Flexible pickup lips for use with fixed vacuum shoes on self-contained and propelled carpet cleaning equipment

a technology of fixed vacuum shoes and pickup lips, which is applied in the direction of carpet cleaners, cleaning equipment, road cleaning, etc., can solve the problems of limiting the ability of the machine to maneuver, limiting the doorway that the machine can pass through, and affecting the cleaning effect of the surface, so as to increase the efficiency of suction and speed up the drying time , the effect of increasing the battery li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

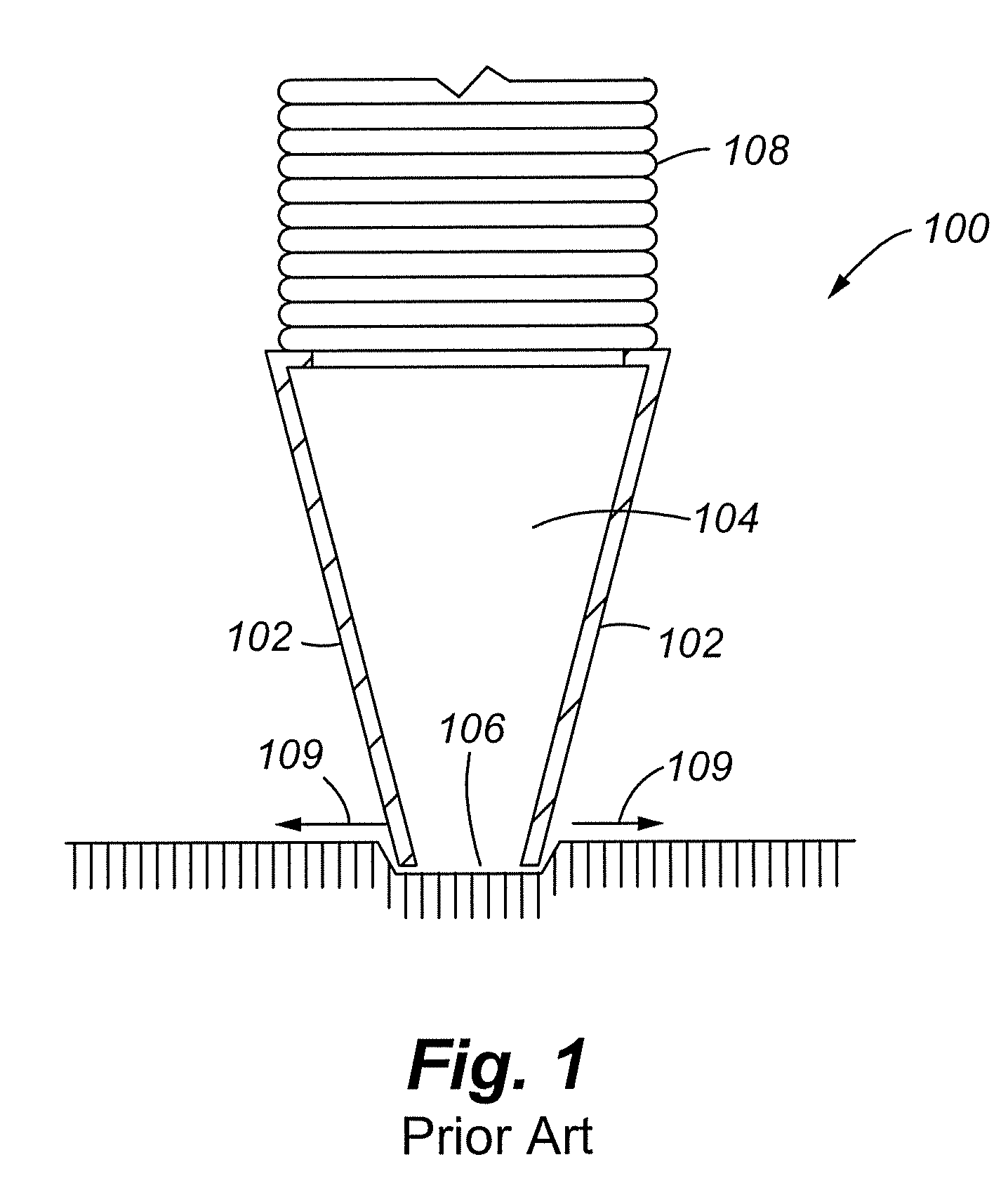

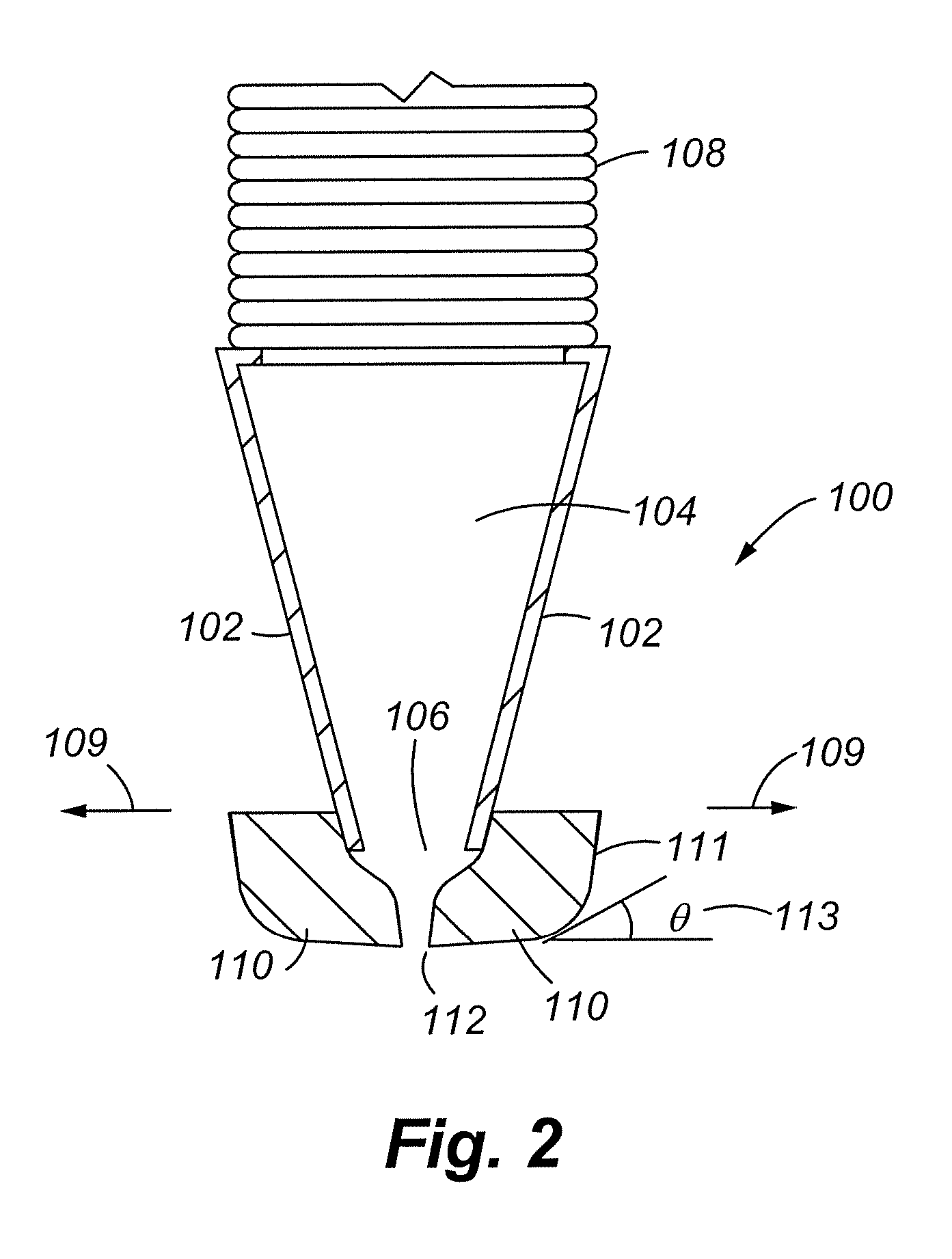

[0026] Referring initially to FIG. 2, an exemplary vacuum shoe 100 will be described in accordance with at least some embodiments of the present invention. The vacuum shoe comprises a shoe housing 102 with a vacuum chamber 104 defined by the shoe housing 102. The shoe housing 102 at a first end has an opening 106 where debris and other material, including fluids, can be received. The other end of the vacuum shoe housing 102 is adapted to be connected with a hose 108 or another type of vacuum source (e.g., a vacuum motor connected to the cleaning machine). The opening 106 of the shoe housing 102 is further adapted to be interconnected to a glide member 110 or set of glide members 110. The glide members 110 may be an integral part of the housing 102 or may be selectively attached and detached from the shoe housing 102. The glide members 110 generally have a space or an opening that defines an inlet of the glide member(s) 110. This opening 112 is typically smaller than the opening 106 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com