Oil smoke removing and discharging clean-up machine

A purifier and oil fume technology, applied in the direction of oil fume removal, chemical instruments and methods, household heating, etc., can solve the problems of high resistance of the cyclone separation pipe, affecting the suction force, long suction pipeline, etc., to ensure normal operation , Reduce oily fumes and improve suction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

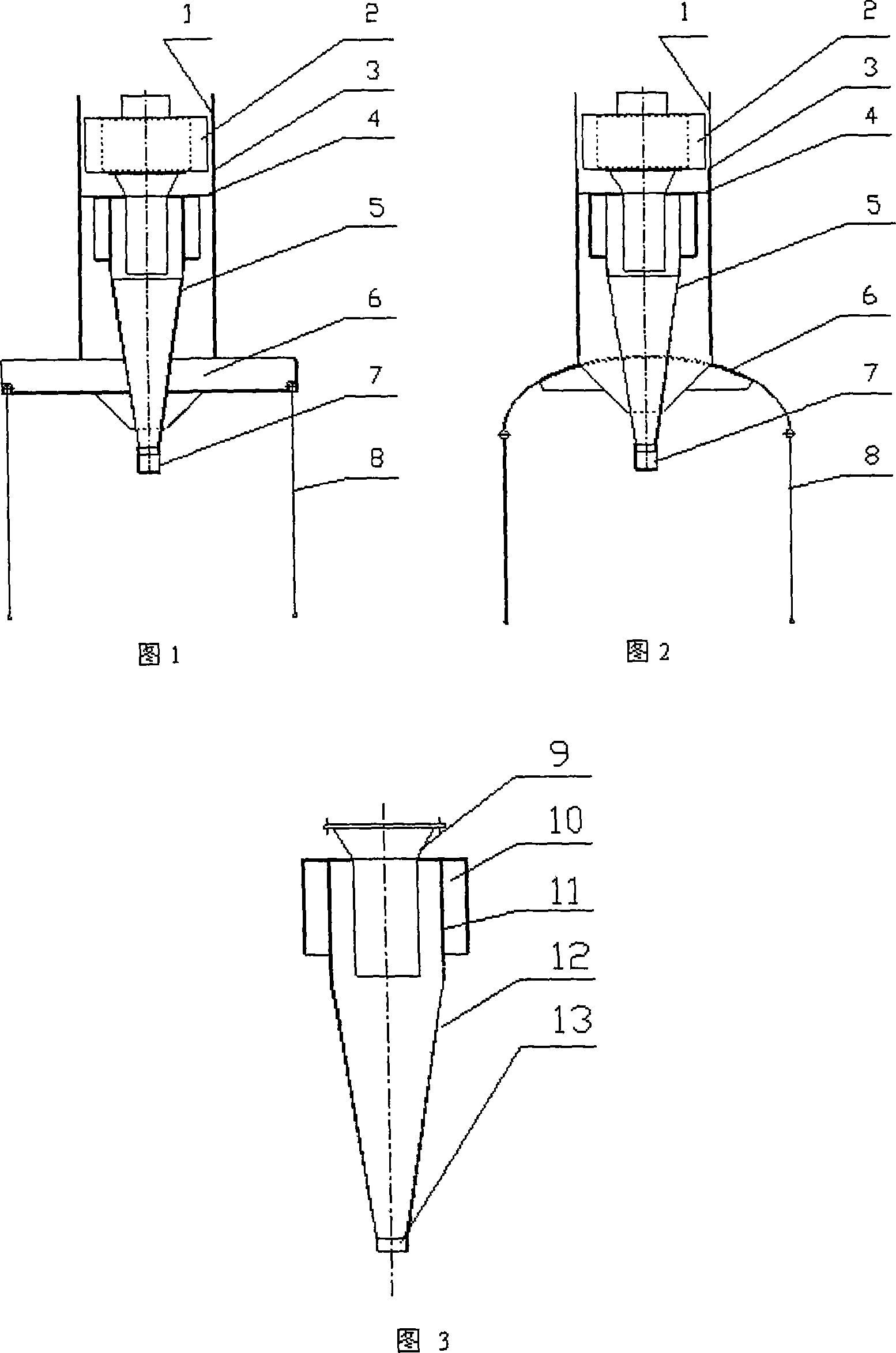

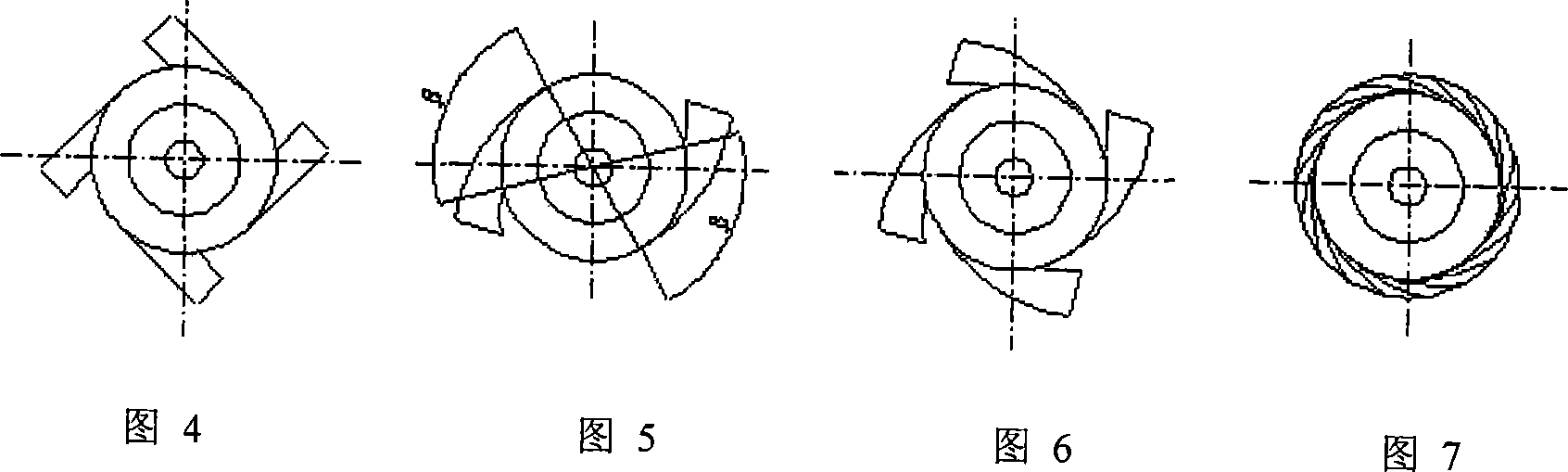

[0029] The composition of the oil fume removal and purification machine given in this embodiment is shown in Figure 1 or Figure 2 . The oil fume removal and purification machine includes an outer cylinder (1), a fan (2), an inner cylinder (3), a partition (4), one or more cyclone separation pipes (5), a fume hood (6), and a collector. The oil cup (7) and the roller shutter (8), wherein the cyclone separation pipe has two or more symmetrical inlets, are vertically installed in the circular inner cylinder. The air outlet (9) of the cyclone separation pipe is connected with the inlet of the fan (2) above; there is a partition (4) on the top of the cyclone separation pipe (5), which is connected with the outer wall of the cyclone separation pipe and the inner cylinder (3) An oil fume annular tornado suction channel is formed; the lower part of the cyclone separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com