Patents

Literature

90results about How to "Less turns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

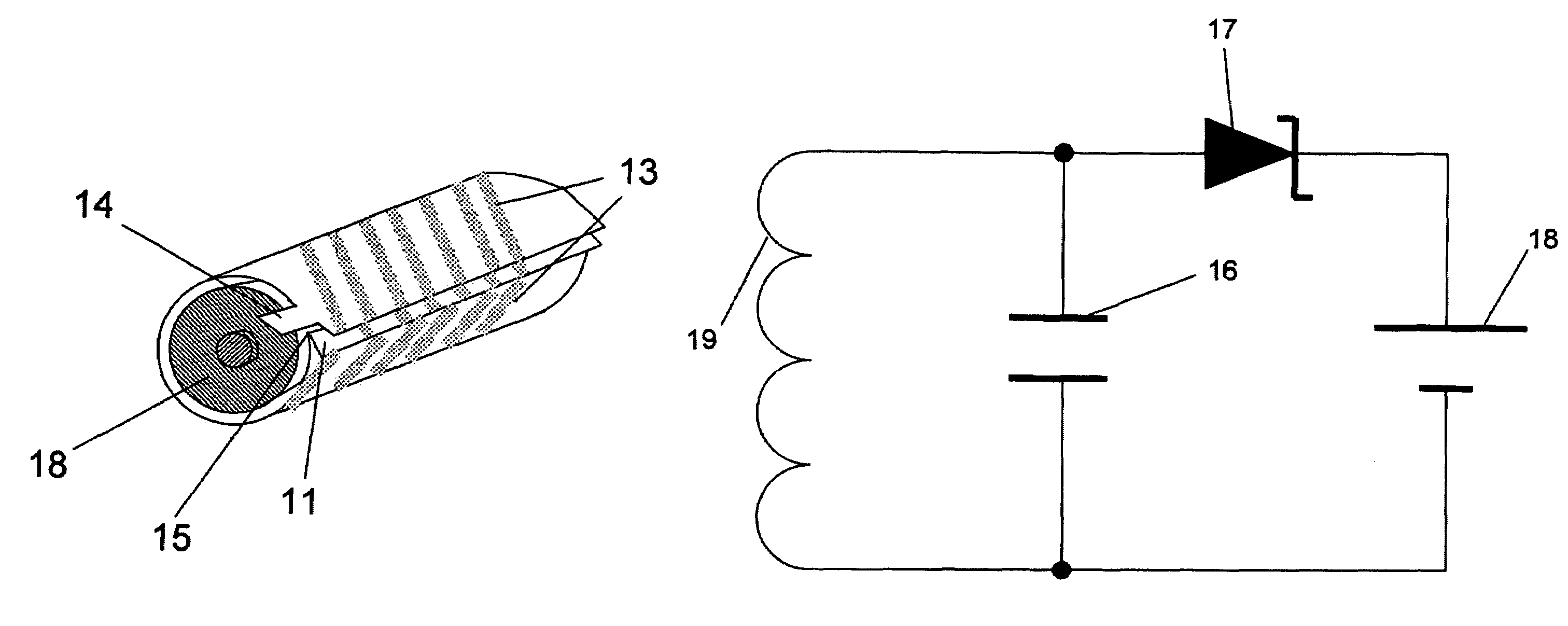

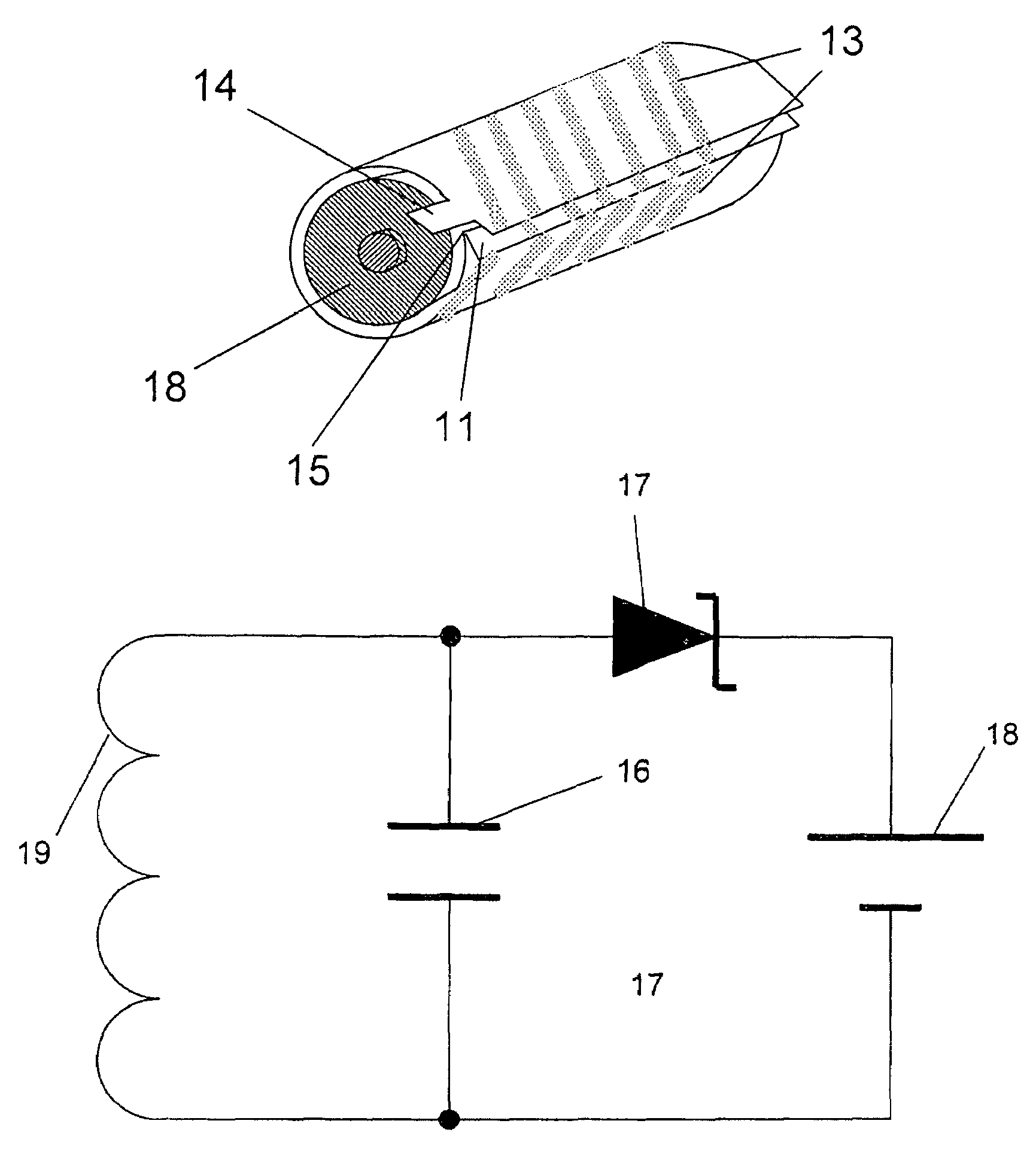

Battery label with wireless battery charging circuit

InactiveUS7511454B1Eliminate requirementsLarge mutual inductanceResonant long antennasBatteries circuit arrangementsElectricityBattery charge

Owner:IBM CORP

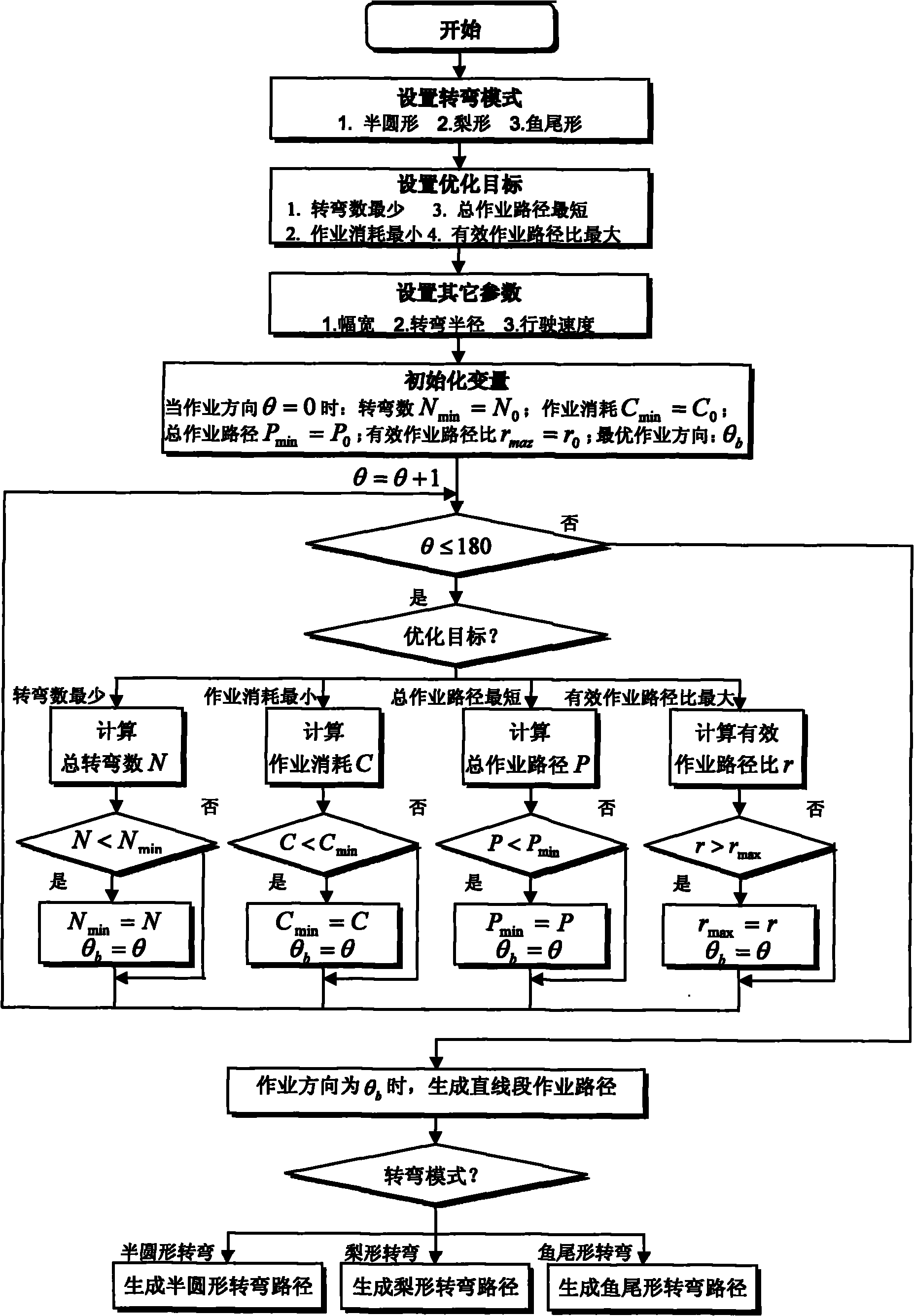

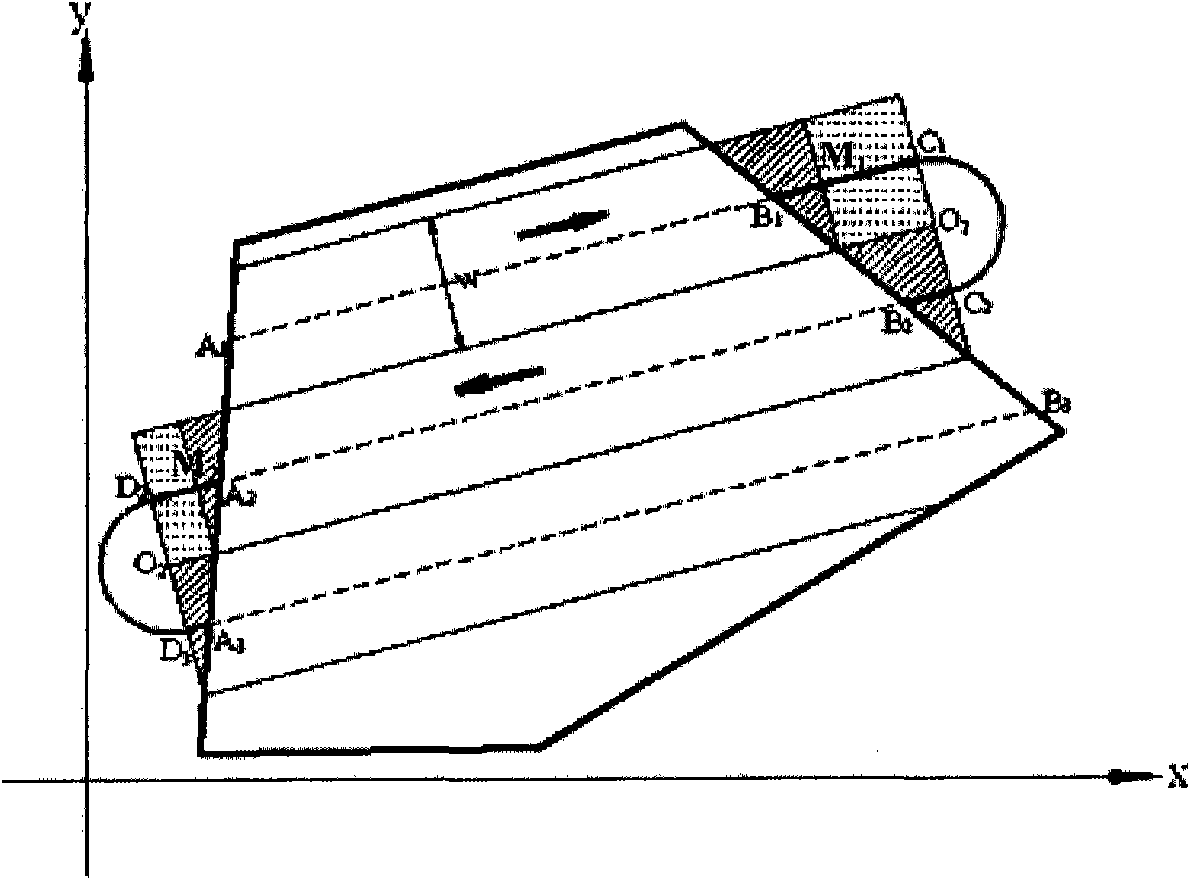

Method and device for generating all-region-covering optimal working path for farmland plot

The invention discloses a method and device for generating an all-region-covering optimal working path for a farmland plot. The method comprises the following steps of: forming headland turning modes such as a semicircular turning mode, a pear-shaped turning mode, a fish-tail-shaped turning mode and the like by considering the working requirements of tractor units of different types and scales inconsistence with the practical requirement of agricultural machinery operating management; putting forward a plurality of working path optimization standards of the tractor units to realize optimization targets such as minimum turning, lowest turning working consumption, a shortest working path, an optimal effective working path ratio and the like; establishing an optimal working direction search method and a working path generating algorithm of the tractor units on the basis of priori information such as a working plot vector, a working unit parameter, a path optimization target and the like to realize all-region-covering of the farmland plot; and integrating embedded hardware devices of functional modules such as a storage module, an input module, an output module, auxiliary equipment and the like to realize planning, calculating, displaying and introducing of the all-region-covering optimal working path for the farmland plot and recording, storing and displaying the practical working path of each tractor unit.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

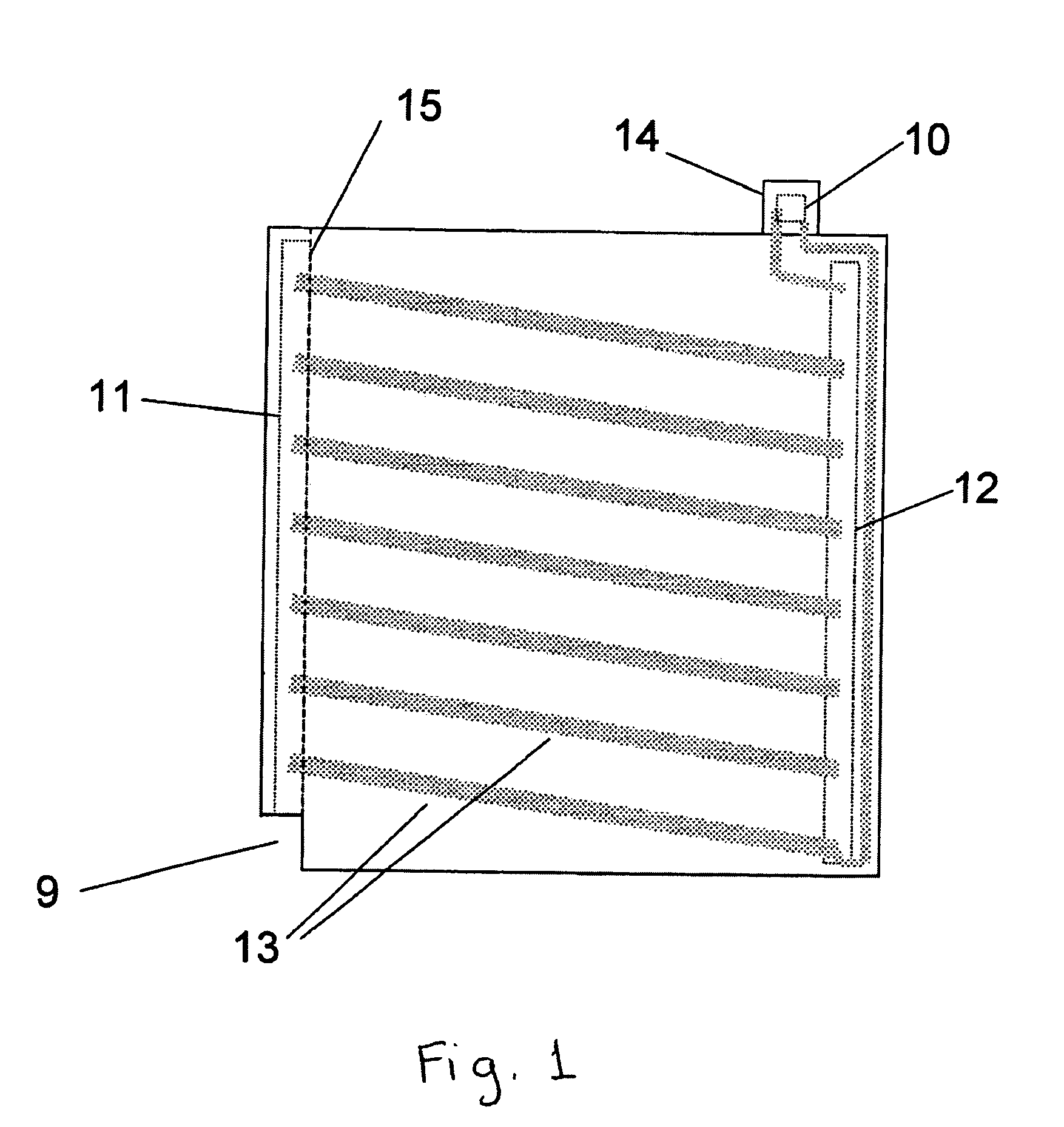

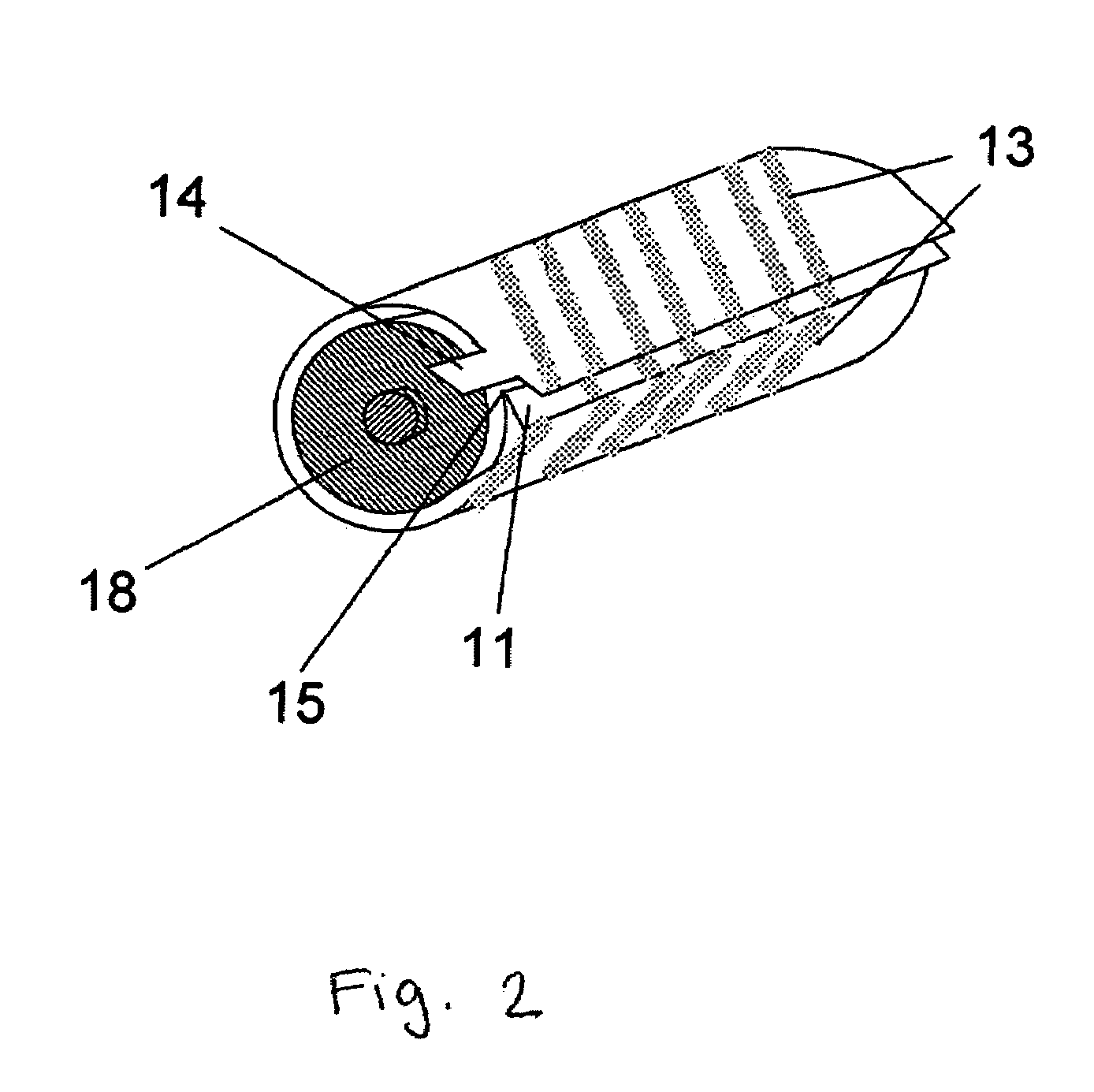

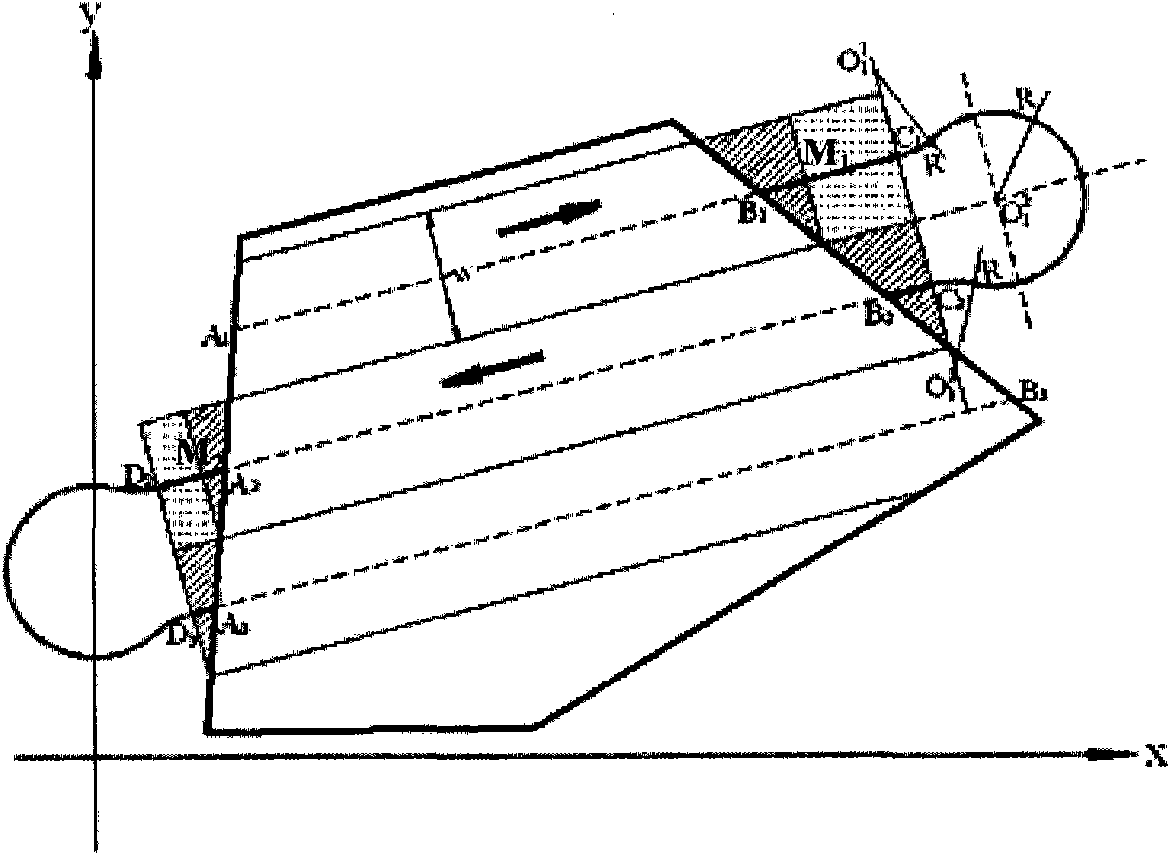

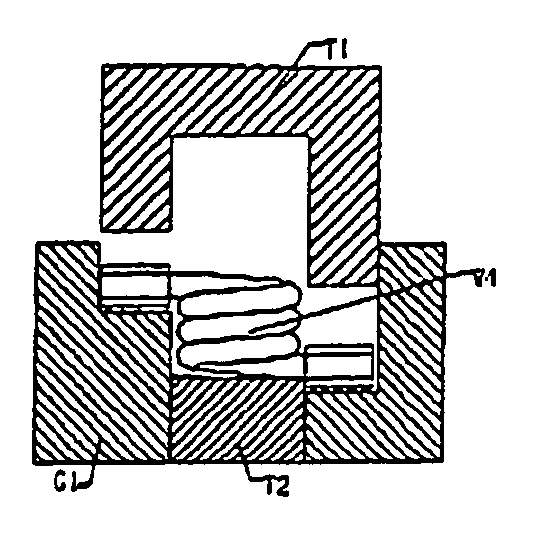

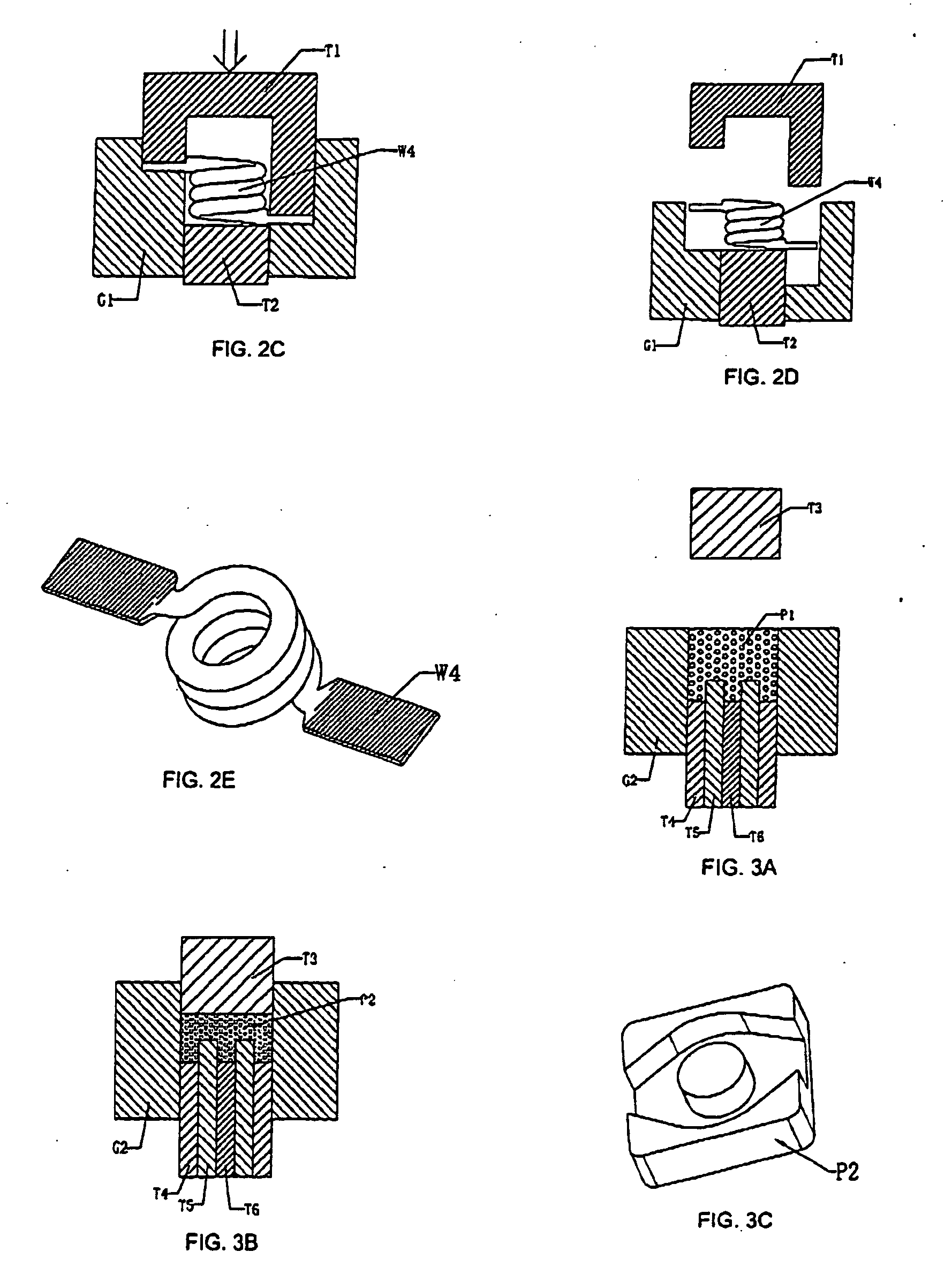

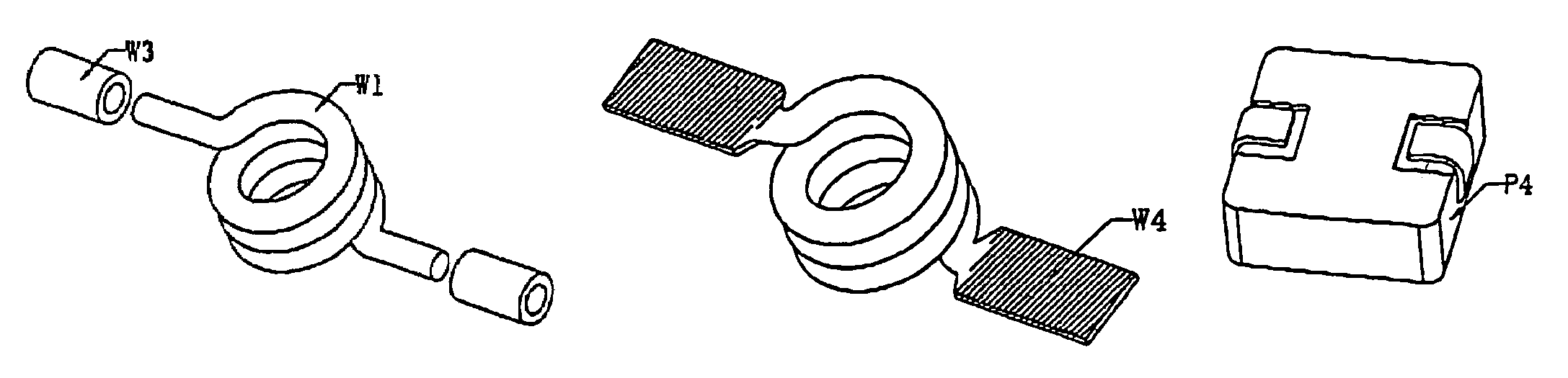

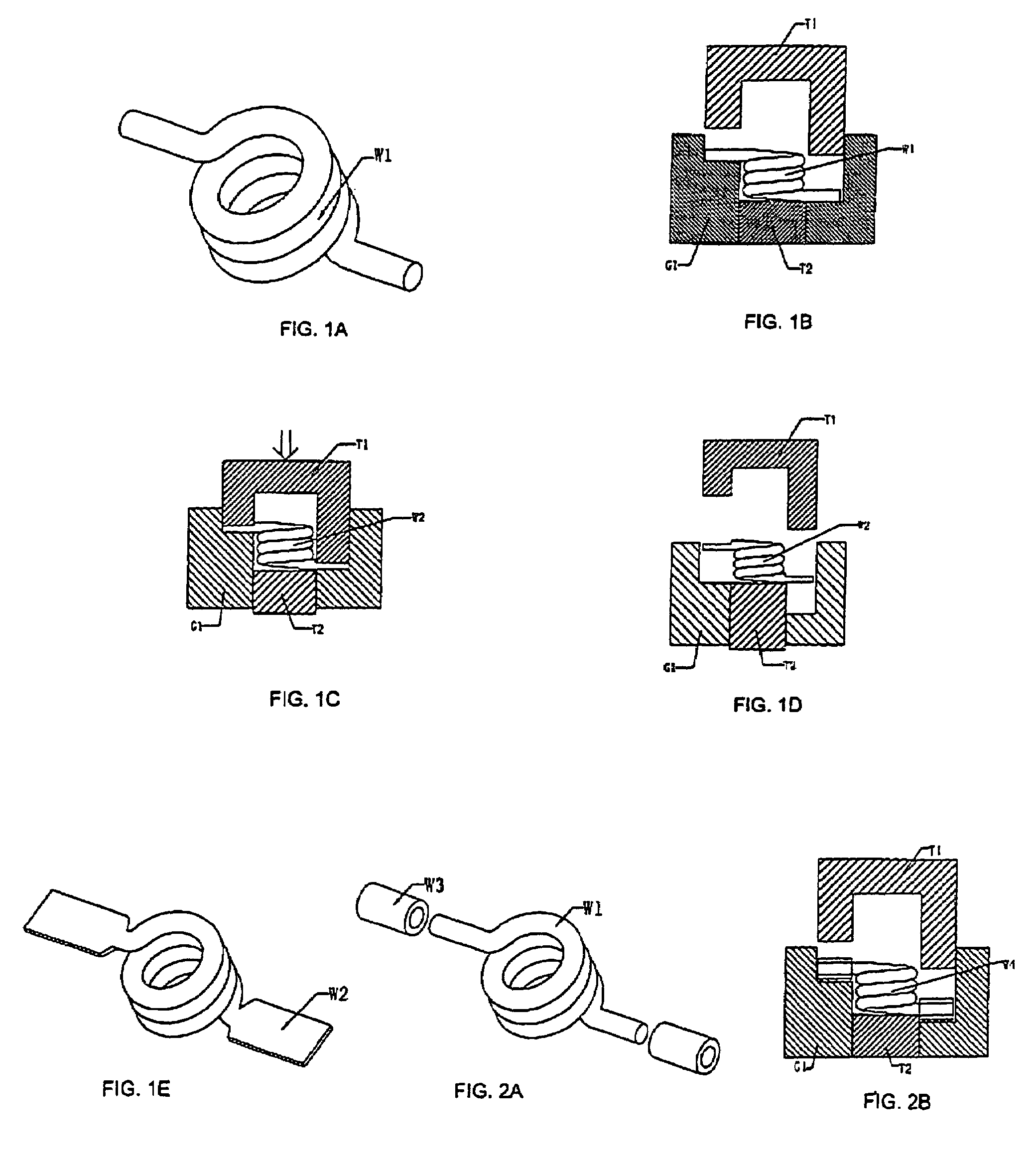

High current inductor and the manufacturing method

InactiveUS20060001517A1Improve featuresCompact structureTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorDie casting

An inductor with the characteristic of resisting high current comprising a conductor coil and a magnet envelope, the magnet envelope tightly wraps the periphery of the conductor coil and forms the main body of the inductor, and the two extending parts of the conductor coil extend to outside of the main body of the inductor, forming terminal electrode. As of the manufacturing method, it includes the part of toroid coil and the extending parts composing the conductor coil. After the toroid coil part is winded into rings, the unwinded wire ends form the extending parts. Through magnet envelope die-casting and wrapping the molded magnet core of the conductor coil to form the main body of the inductor, and the extending parts of the conductor coil extend to outside of the main body to form the terminal electrode.

Owner:CHENG CHANG MAO

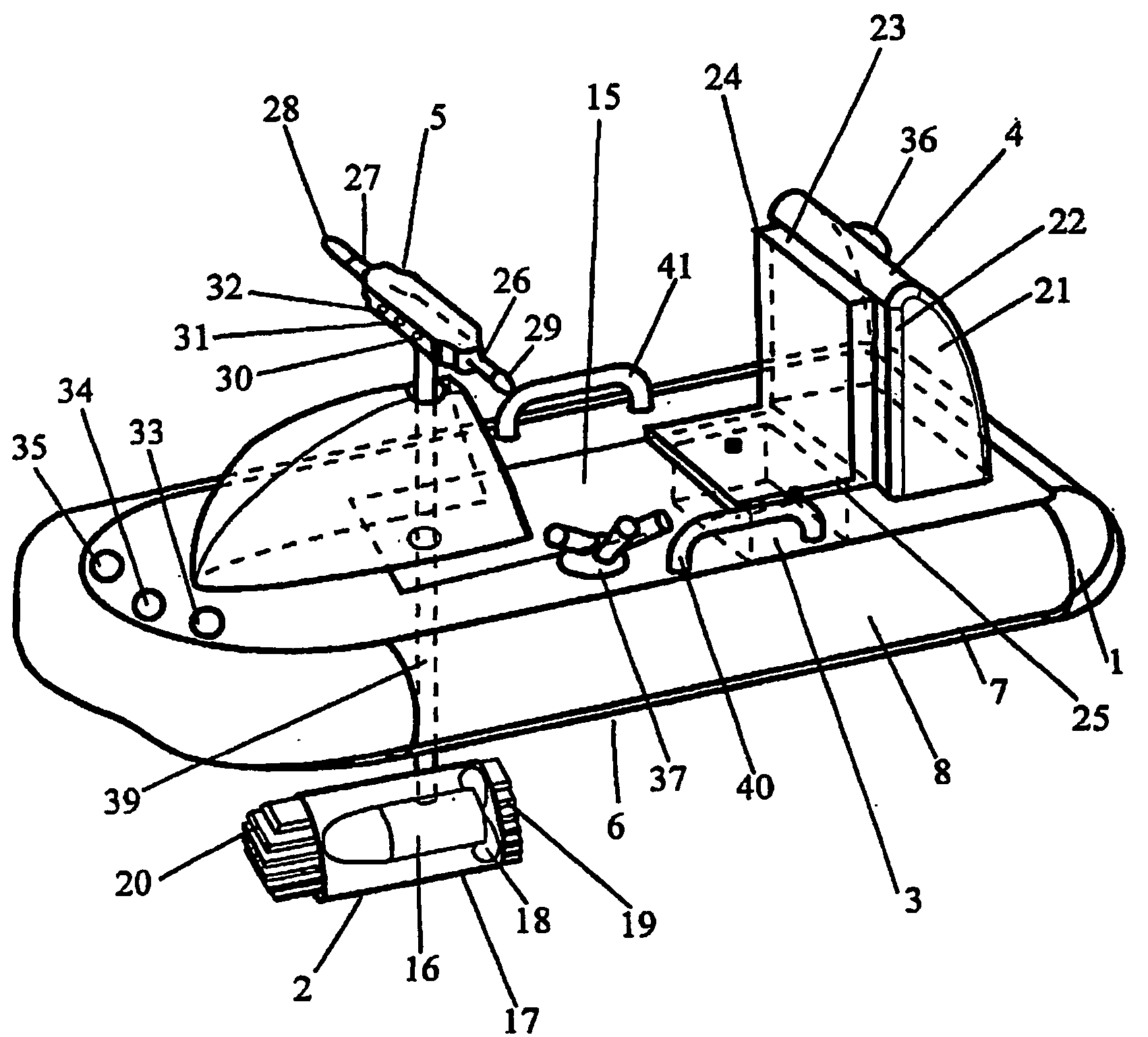

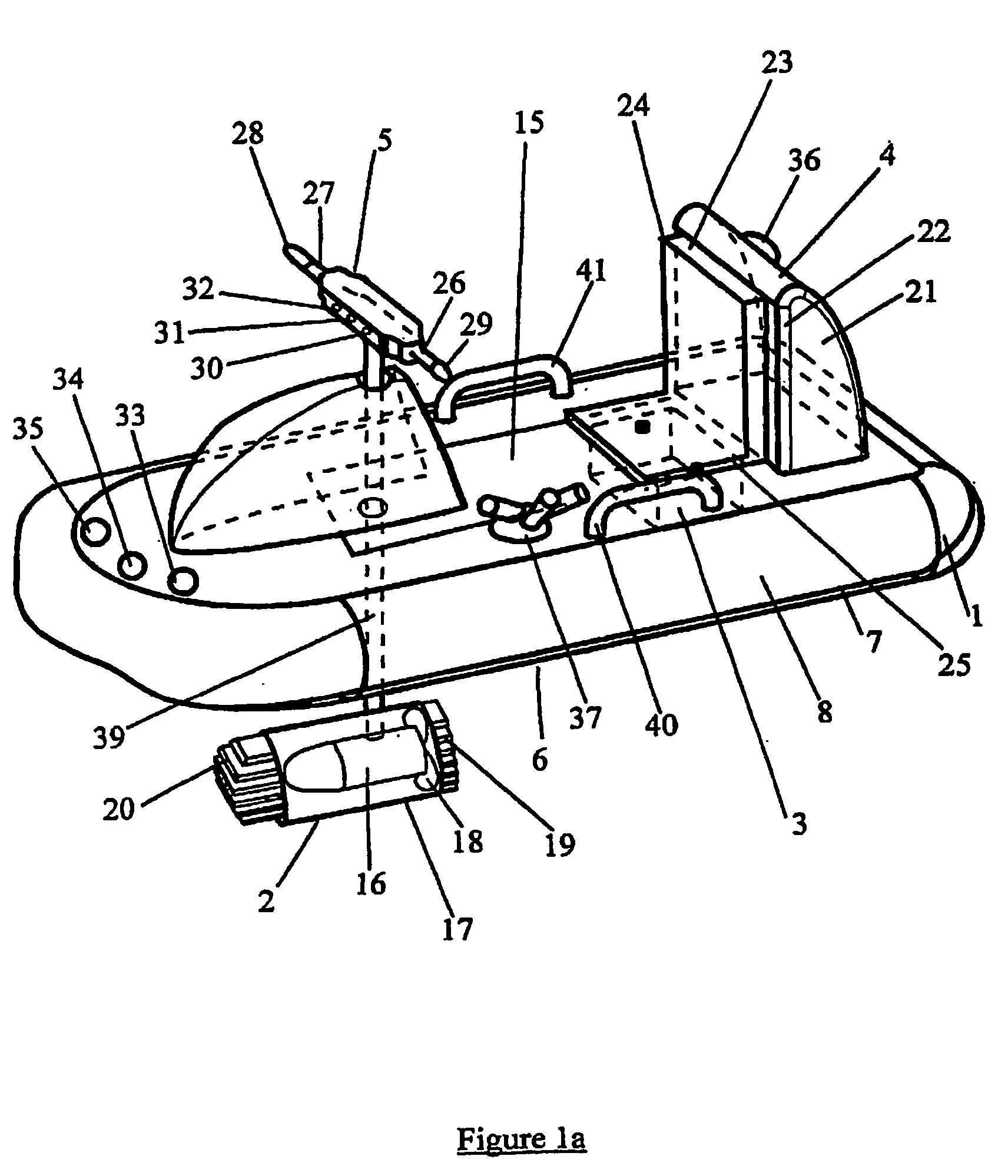

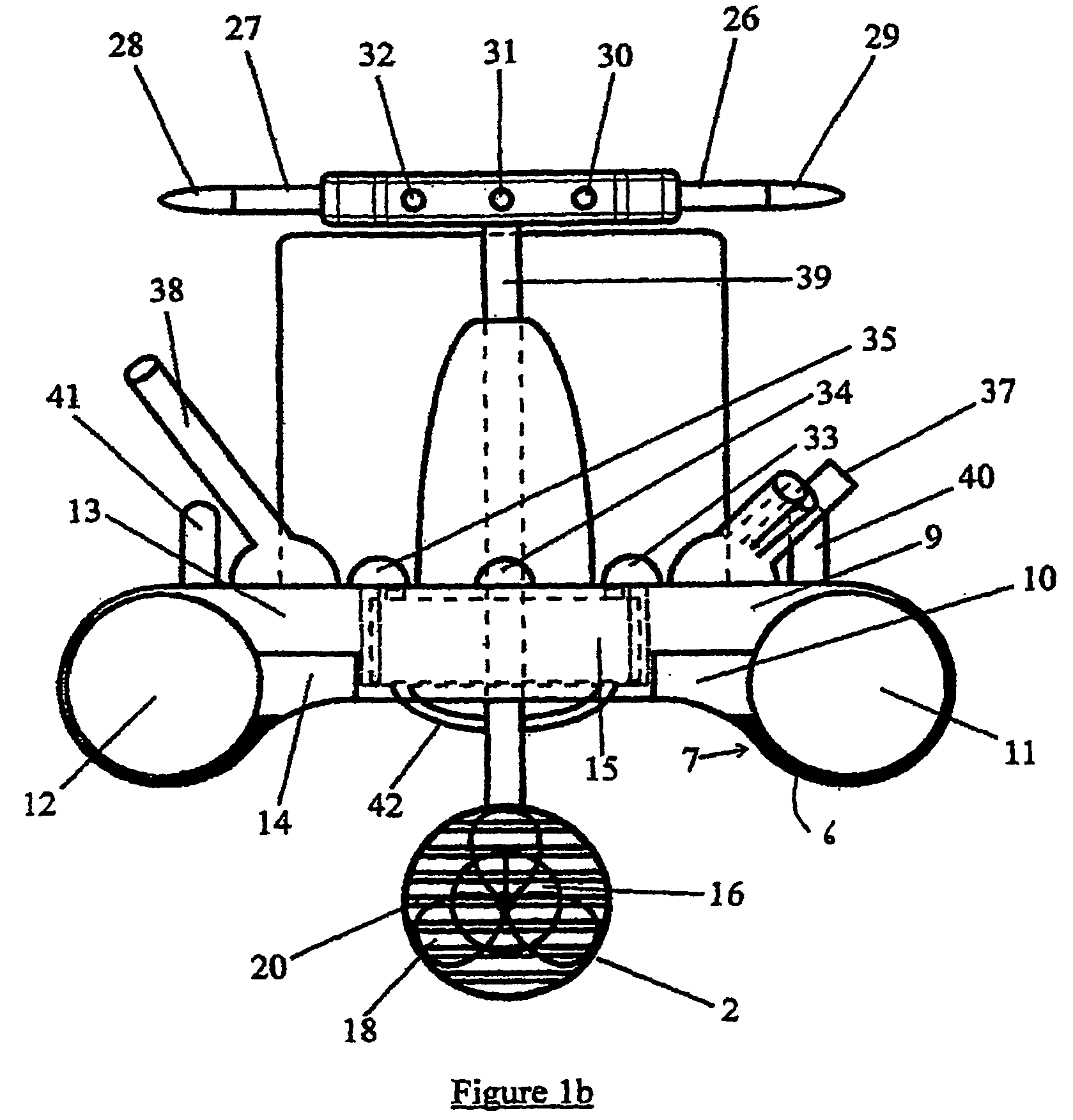

Portable personal watercraft

InactiveUS20050268833A1Improve performanceMaintain securityPropulsion power plantsOutboard propulsion unitsEngineeringWatercraft

A watercraft includes a number of subassemblies, including an inflatable hull, a drive system, a battery, a seat assembly and a steering and thrust control. Each of the subassemblies of may be of one or more particular designs which are detailed herein. A watercraft in accordance with the teaching herein may use one or more of these designs and each such watercraft is within the scope of this disclosure.

Owner:CONRAD WAYNE ERNEST

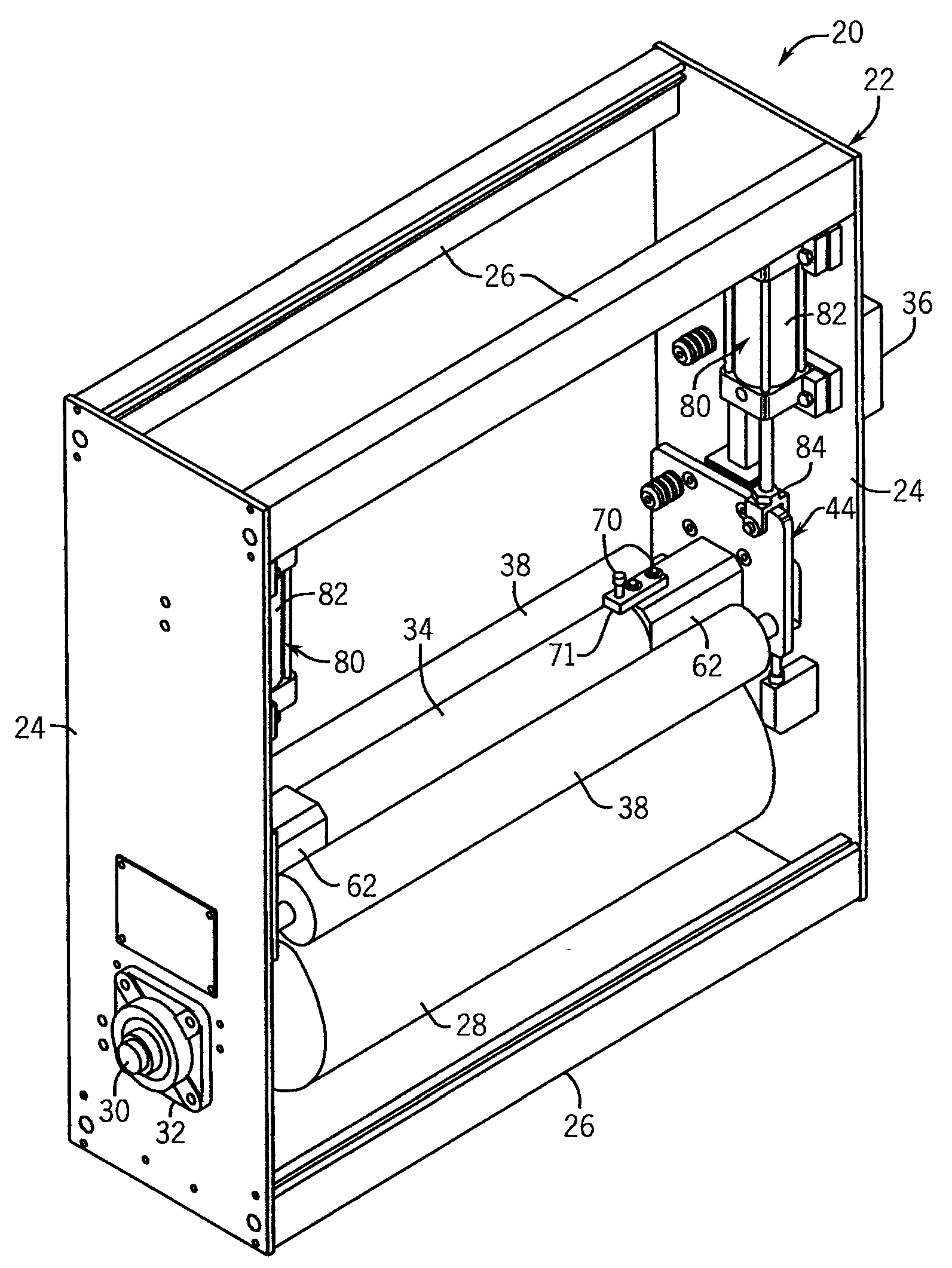

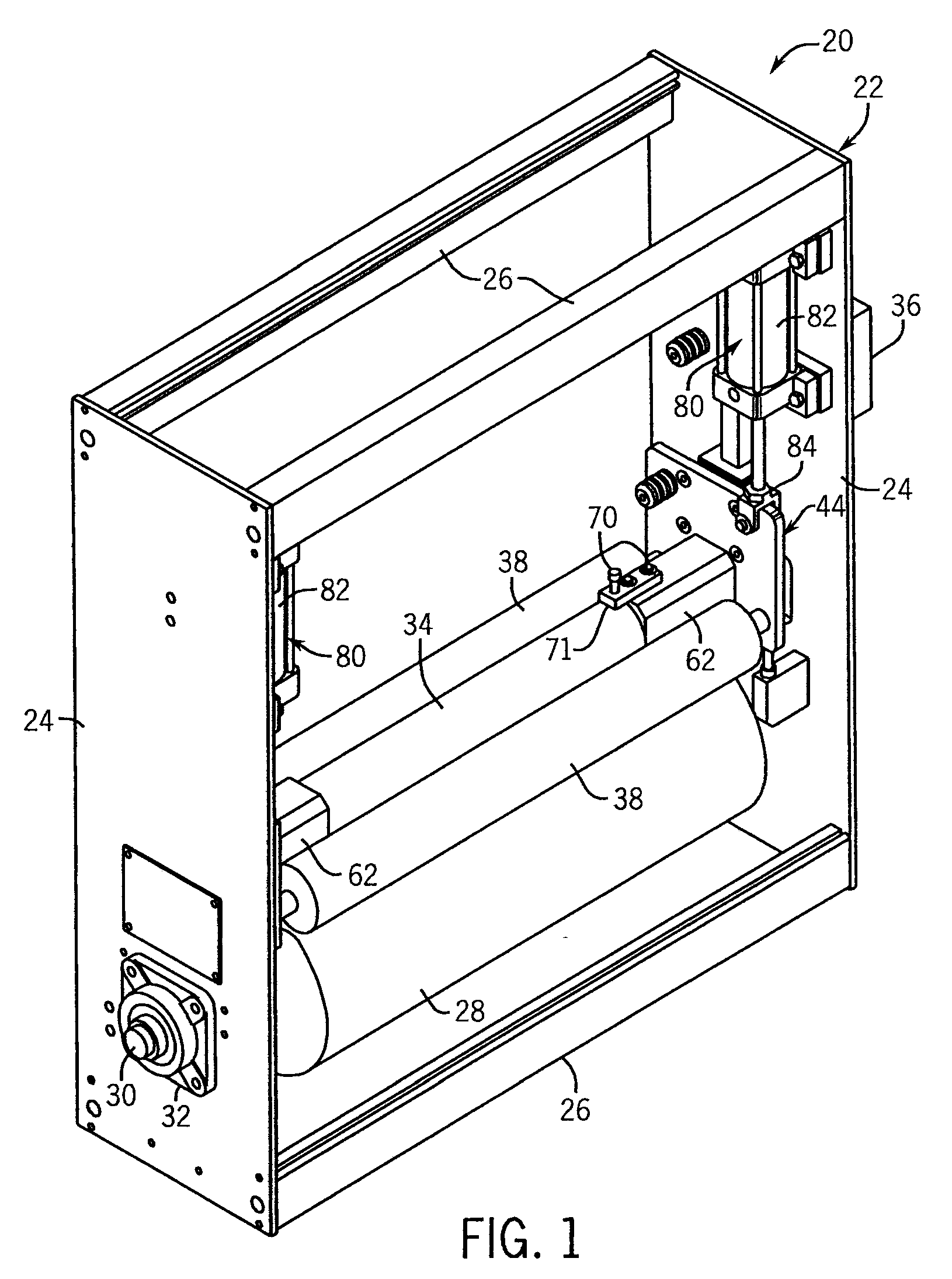

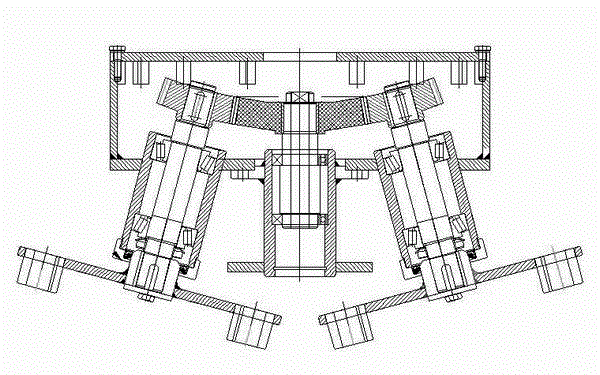

Atmospheric Treater With Roller Confined Discharge Chamber

ActiveUS20090120782A1Good surface treatmentQuality improvementDuplicating/marking methodsPhysical paper treatmentEngineeringAtmospherics

A continuous feed discharge surface treater for treating web materials has a discharge chamber where ionization of a process gas occurs defined and contained by one or more rollers. Enhanced chemical coronas and plasmas are achieved by limiting depletion of the gas chemistry from the discharge chamber and dilution or contamination from mixing with drawn in ambient air. Atmospheric coronas can also be achieved in which minimal or no ozone is exhausted from the treater. Various roller and electrode assemblies, including both fixed and rolling electrodes, can be employed.

Owner:ENERCON INDS

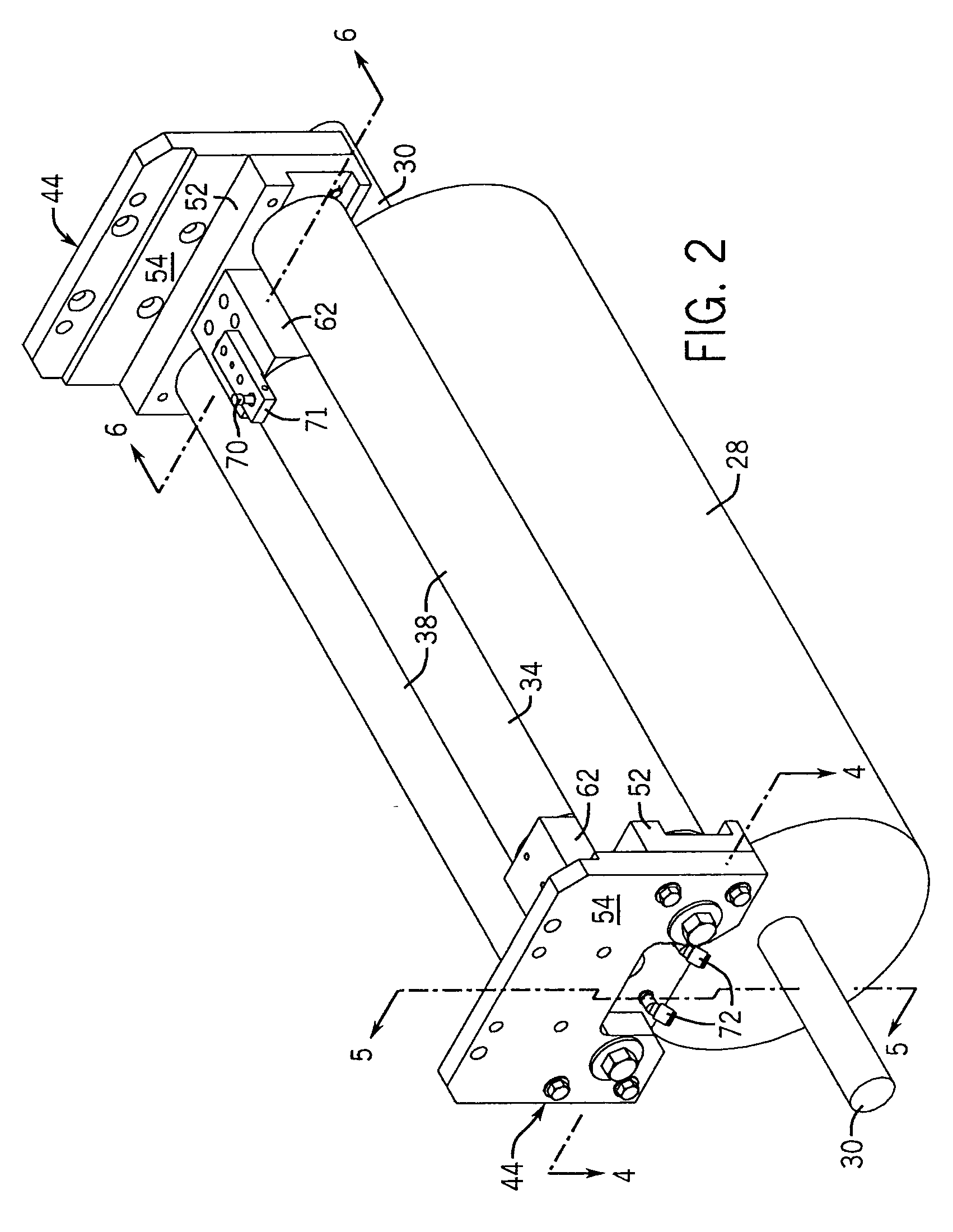

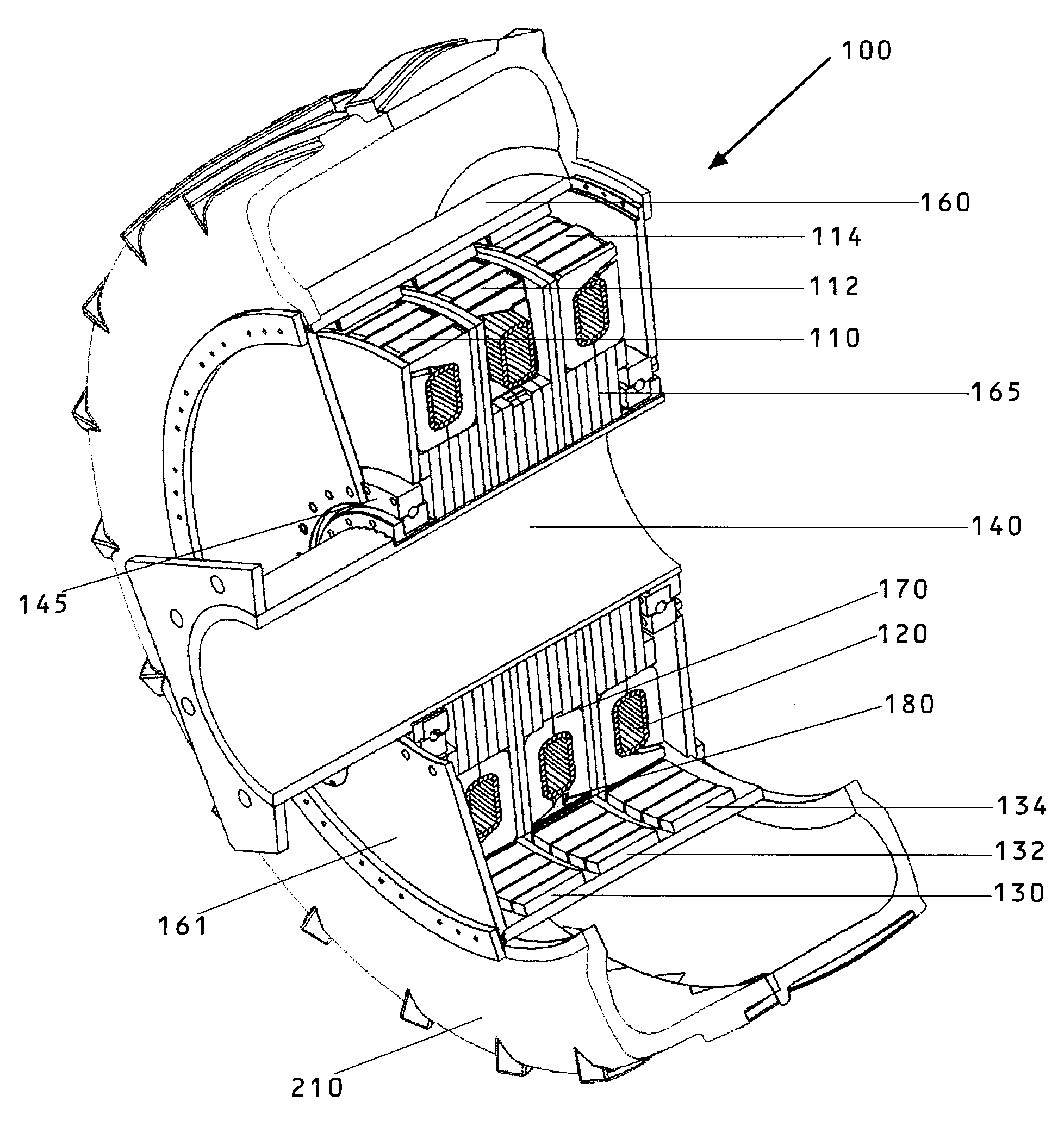

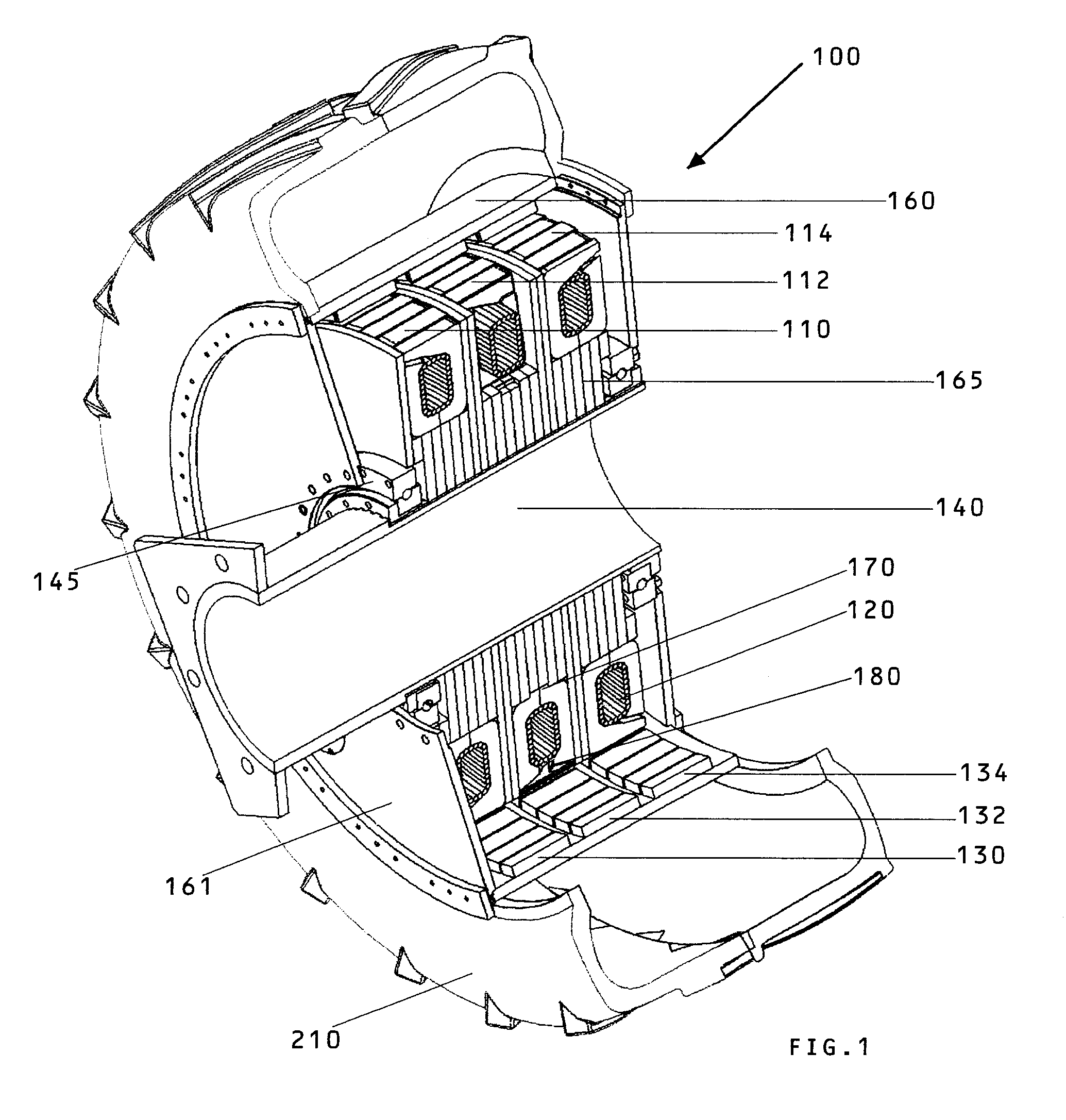

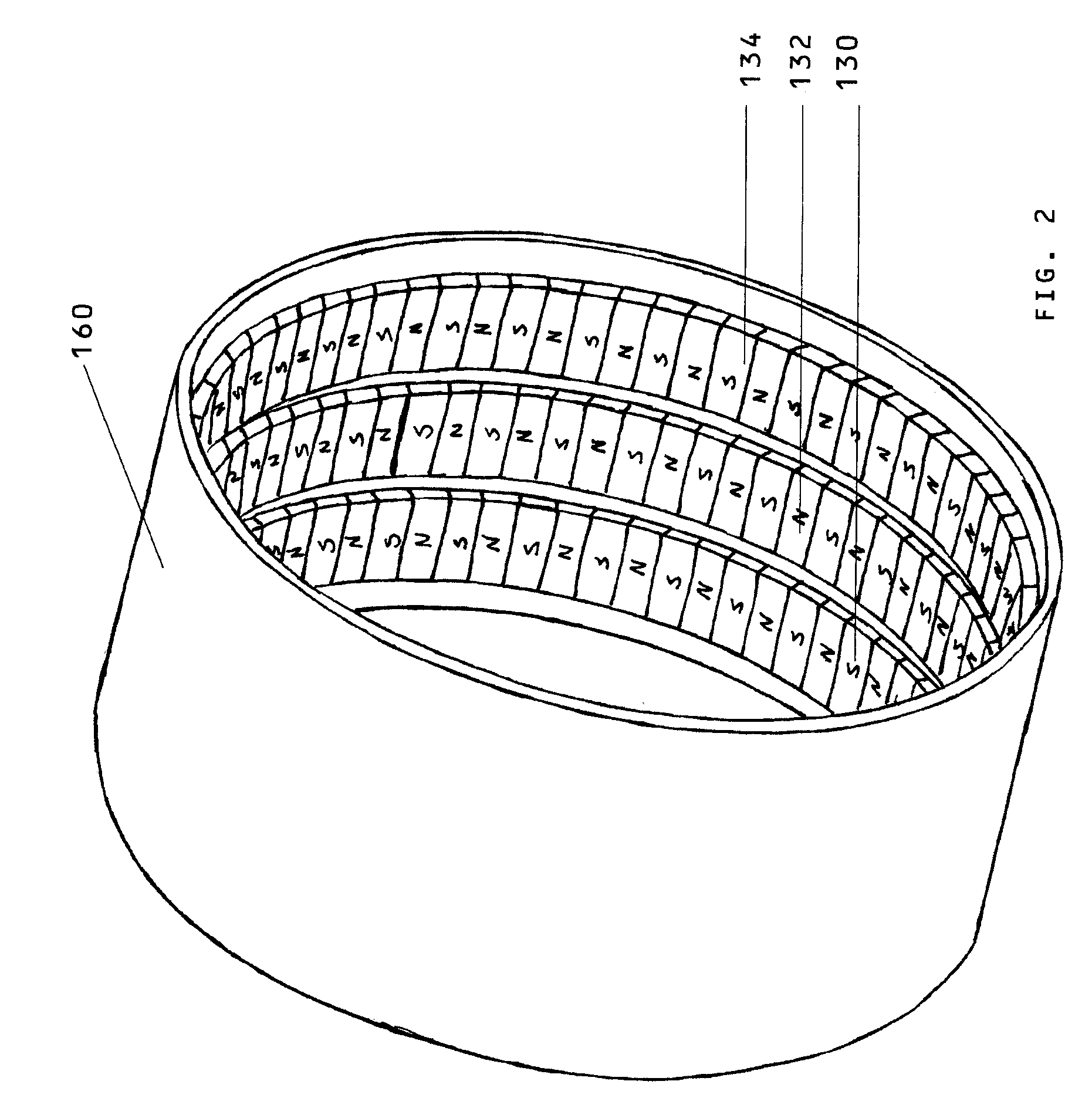

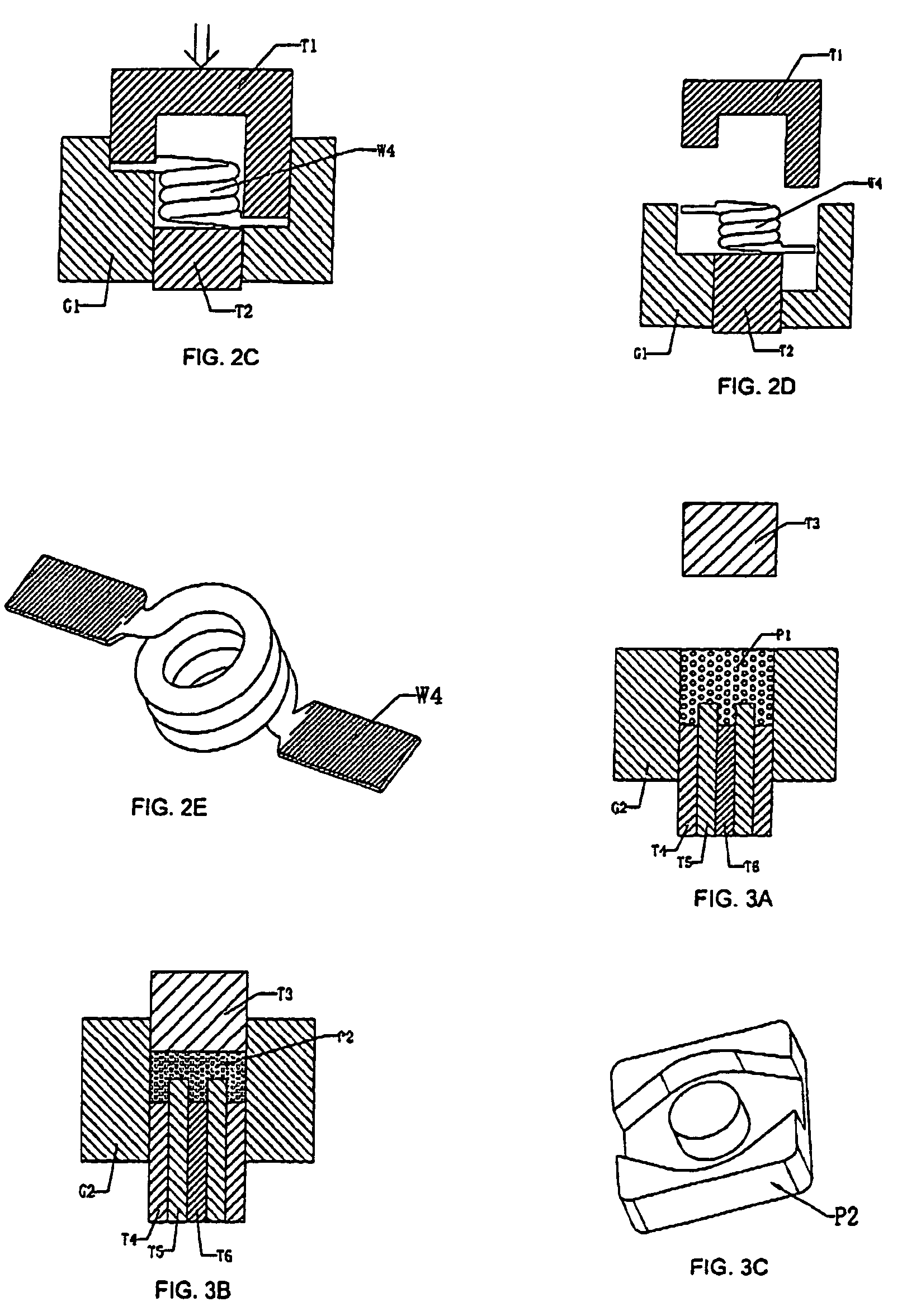

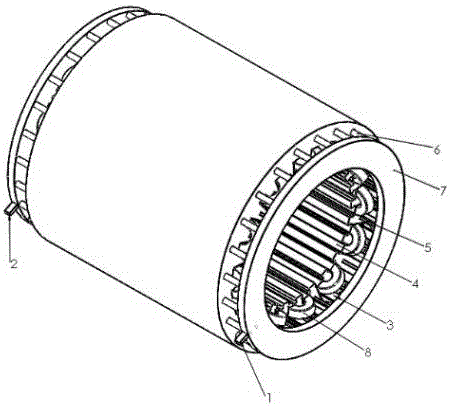

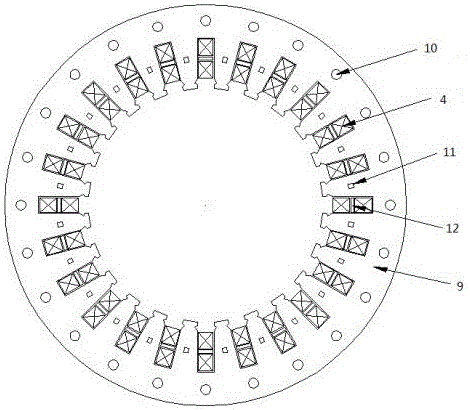

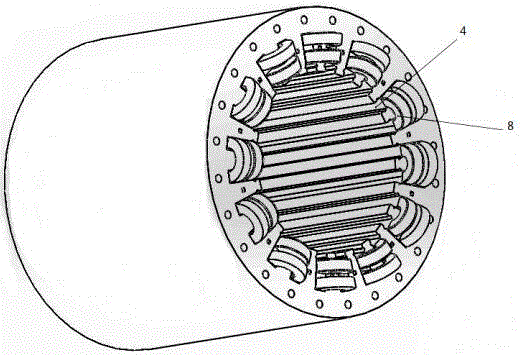

Method of fabricating a magnetic flux channel for a transverse wound motor

InactiveUS7640648B1Improve efficiencyReduce eddy currentSynchronous generatorsAdditive manufacturing apparatusPole pieceConductor Coil

Methods of fabricating a magnetic flux channel for a transverse wound electric motor by forming a ring of plural adjacent molded magnetic flux channel pole pieces and a second ring of opposite pole pieces. The two rings are mated such that each pole piece mates with an opposite pole piece to form magnetic flux channels and a c-shaped recess forms a winding channel for a transverse phase winding. After mating, the rings are bonded together to form a stator assembly of the transversely wound electric motor. The two rings may be approximately identical, or the two rings may be different as long as they mate to form the plural molded magnetic flux channels and the transverse phase winding channel. The molds may be designed to form the outer surface of a stator assembly. Molds of adjacent phases may be combined back-to-back to reduce part count and increase mechanical strength.

Owner:RITTENHOUSE NORMAN

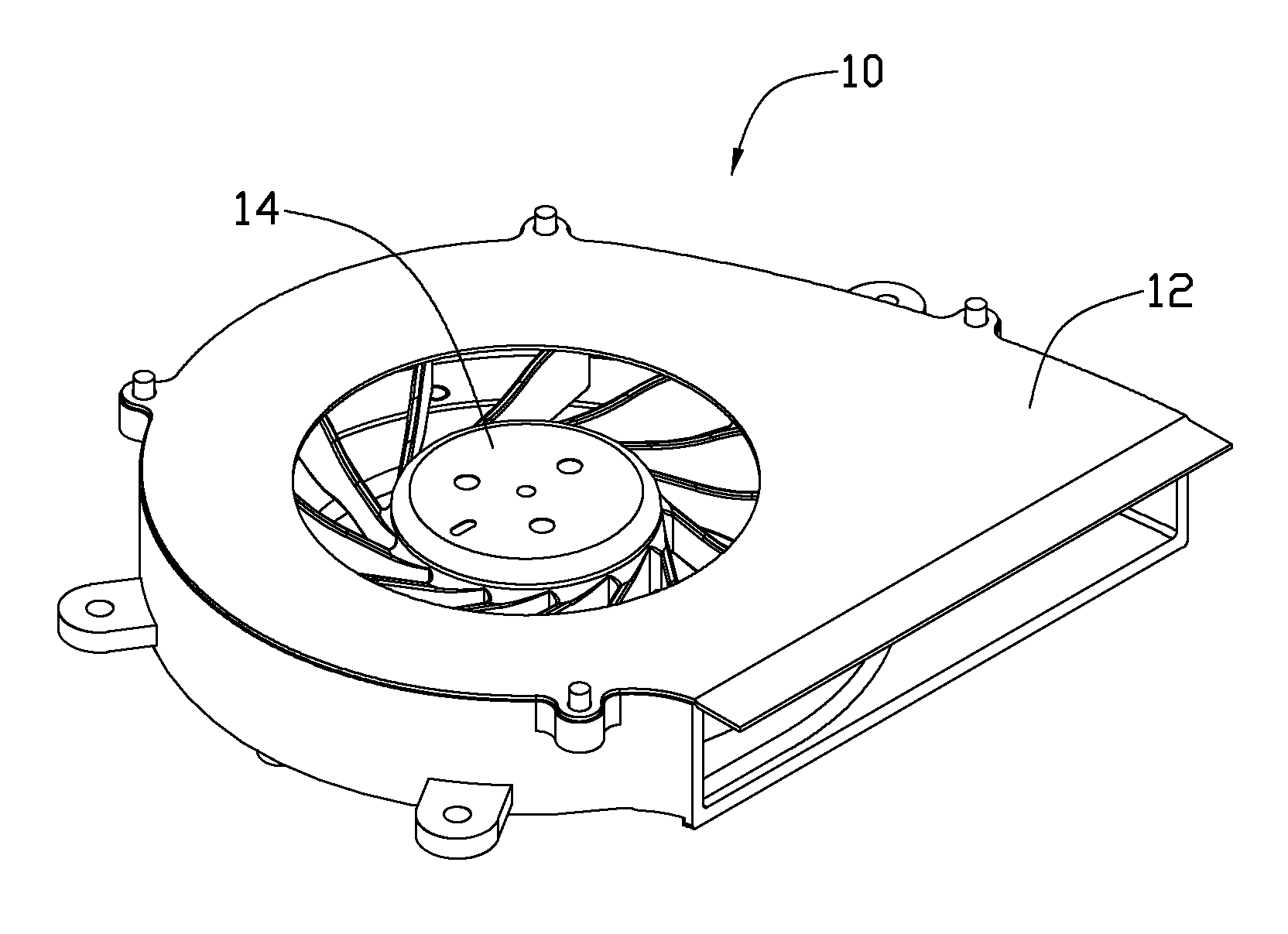

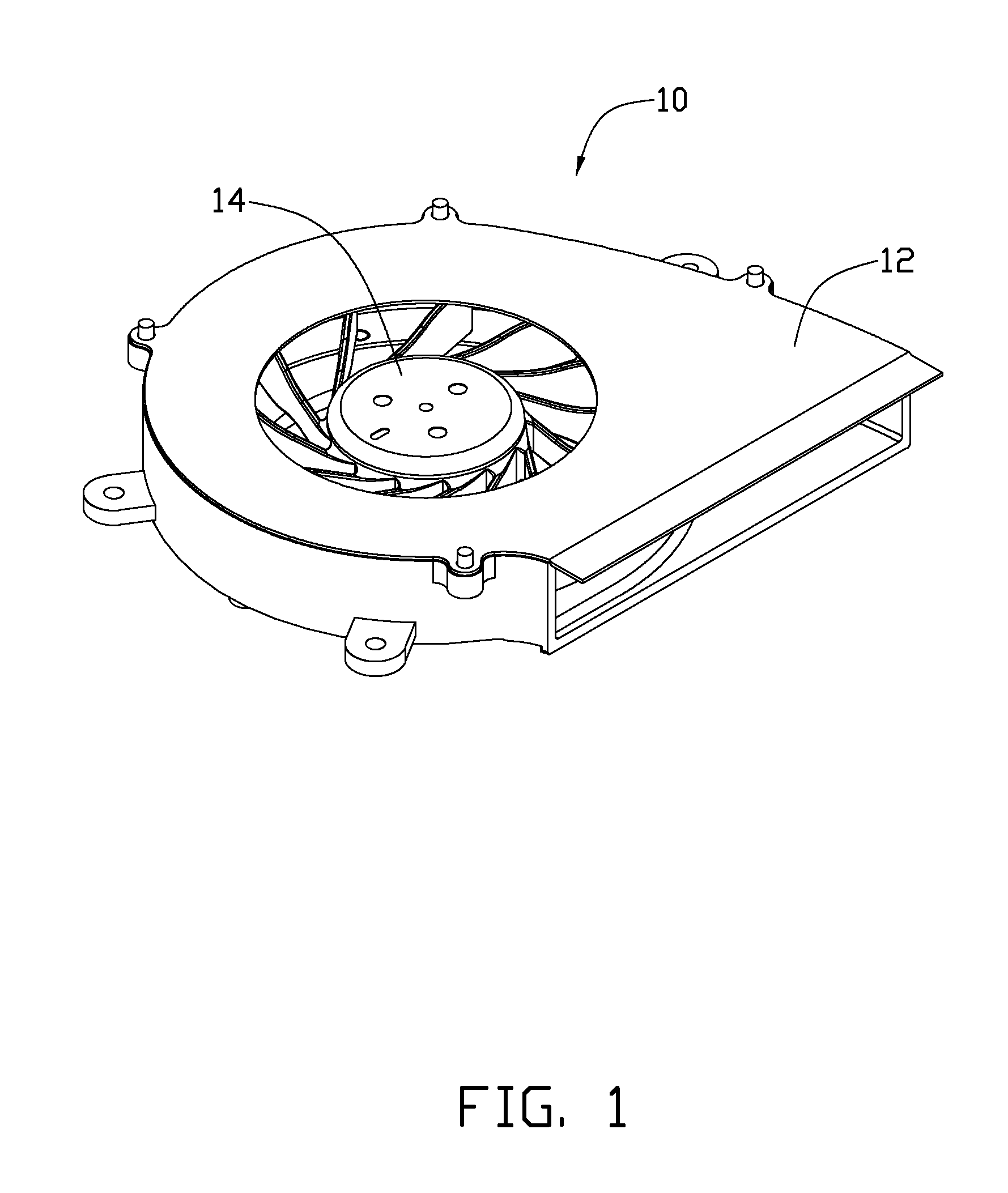

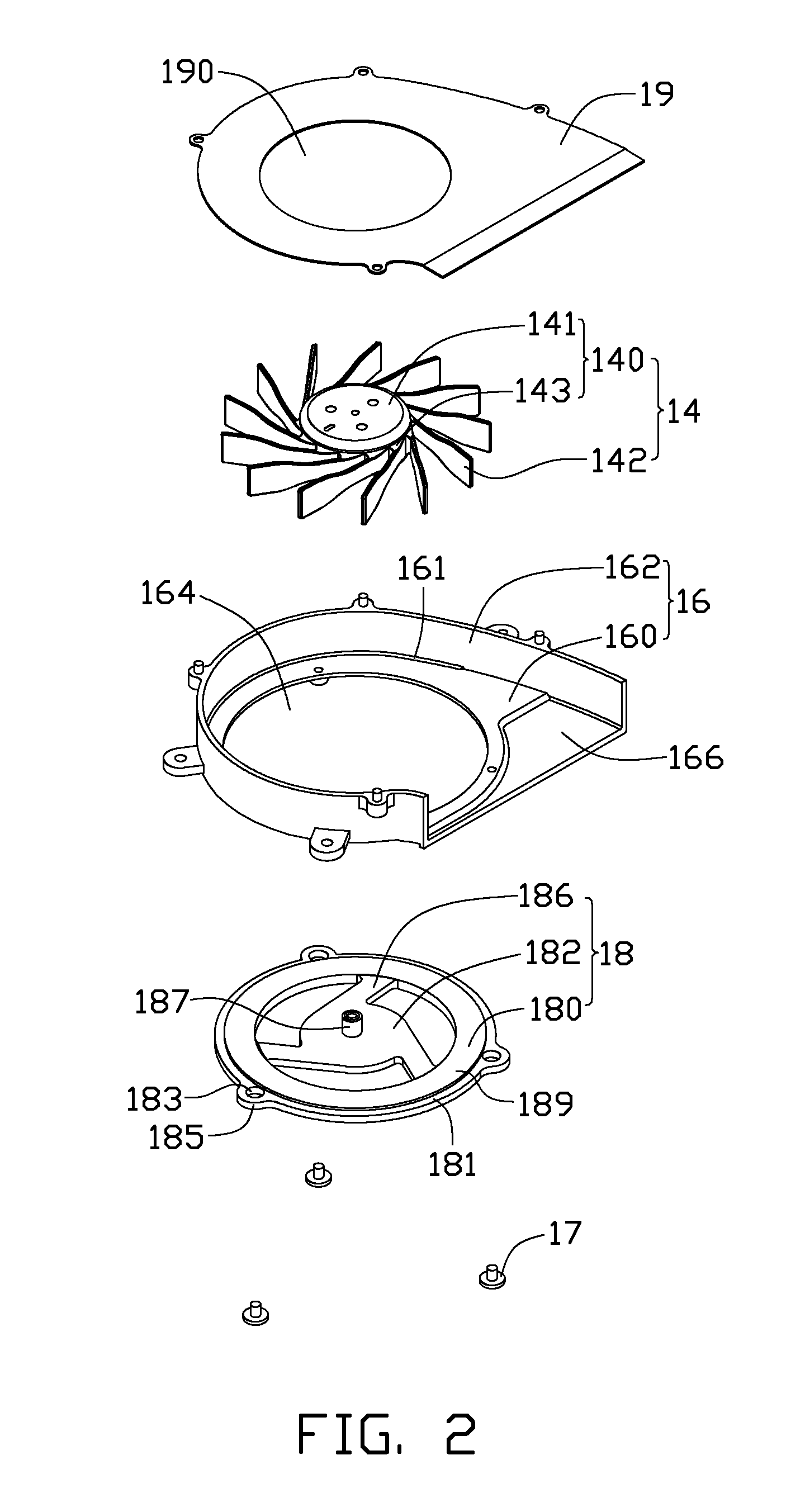

Centrifugal fan

A centrifugal fan includes an impeller and a housing receiving the impeller therein. The impeller includes a hub and blades extending radially from the hub. The housing includes a bottom wall, a sidewall extending upwardly from the bottom wall and a bracket for supporting the impeller thereon. The bottom wall defines an air inlet therein. A plurality of protruding posts extend downwardly from a bottom surface of the bottom wall around the air inlet. Each of the protruding posts defines a screw hole therein. The bracket is located in the air inlet. The bracket defines a plurality of through holes corresponding to the protruding posts respectively. The protruding posts of the bottom wall are respectively inserted into the through holes of the bracket. A plurality of bolts are respectively screwed into the screw holes of the protruding posts to connect the bracket and the bottom wall together.

Owner:HON HAI PRECISION IND CO LTD

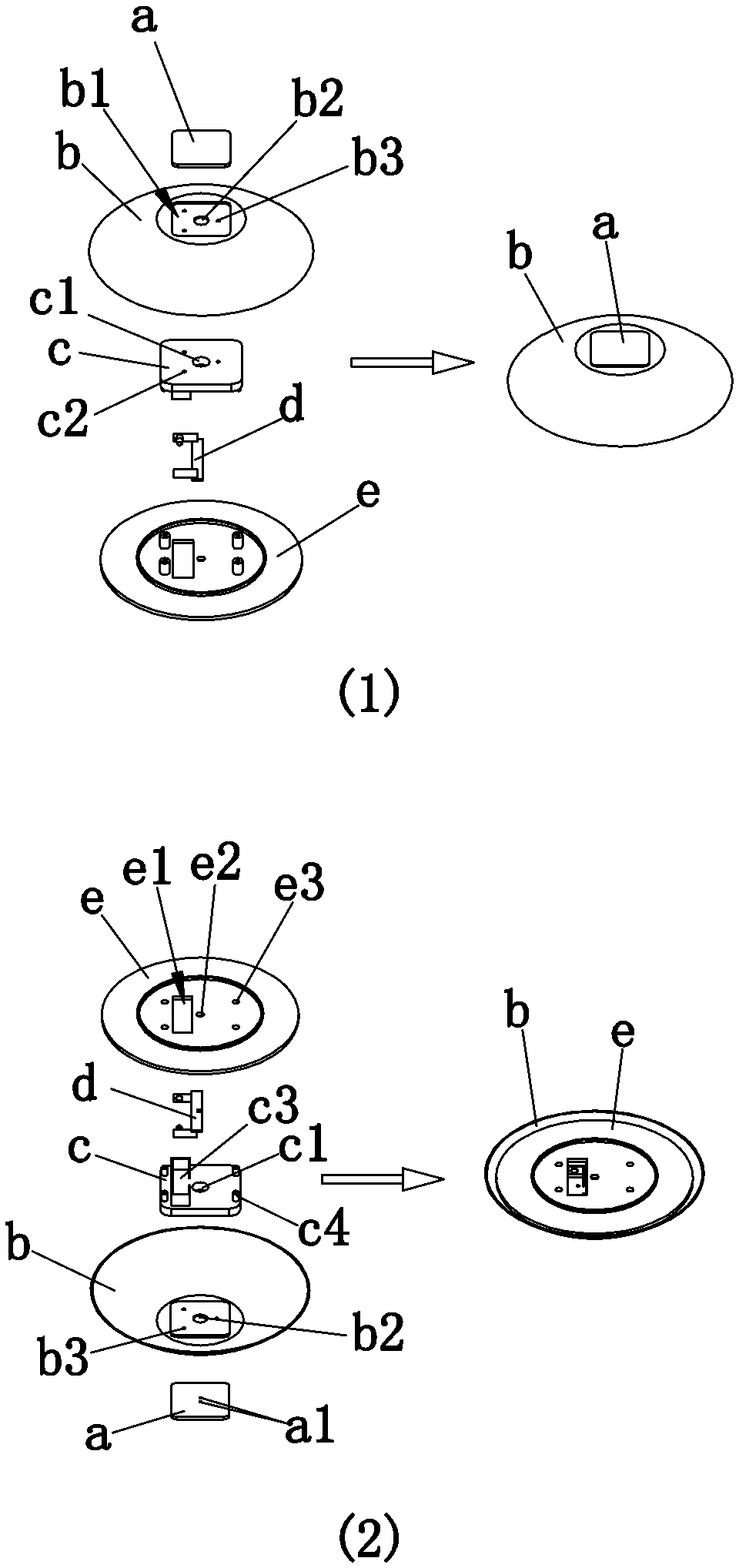

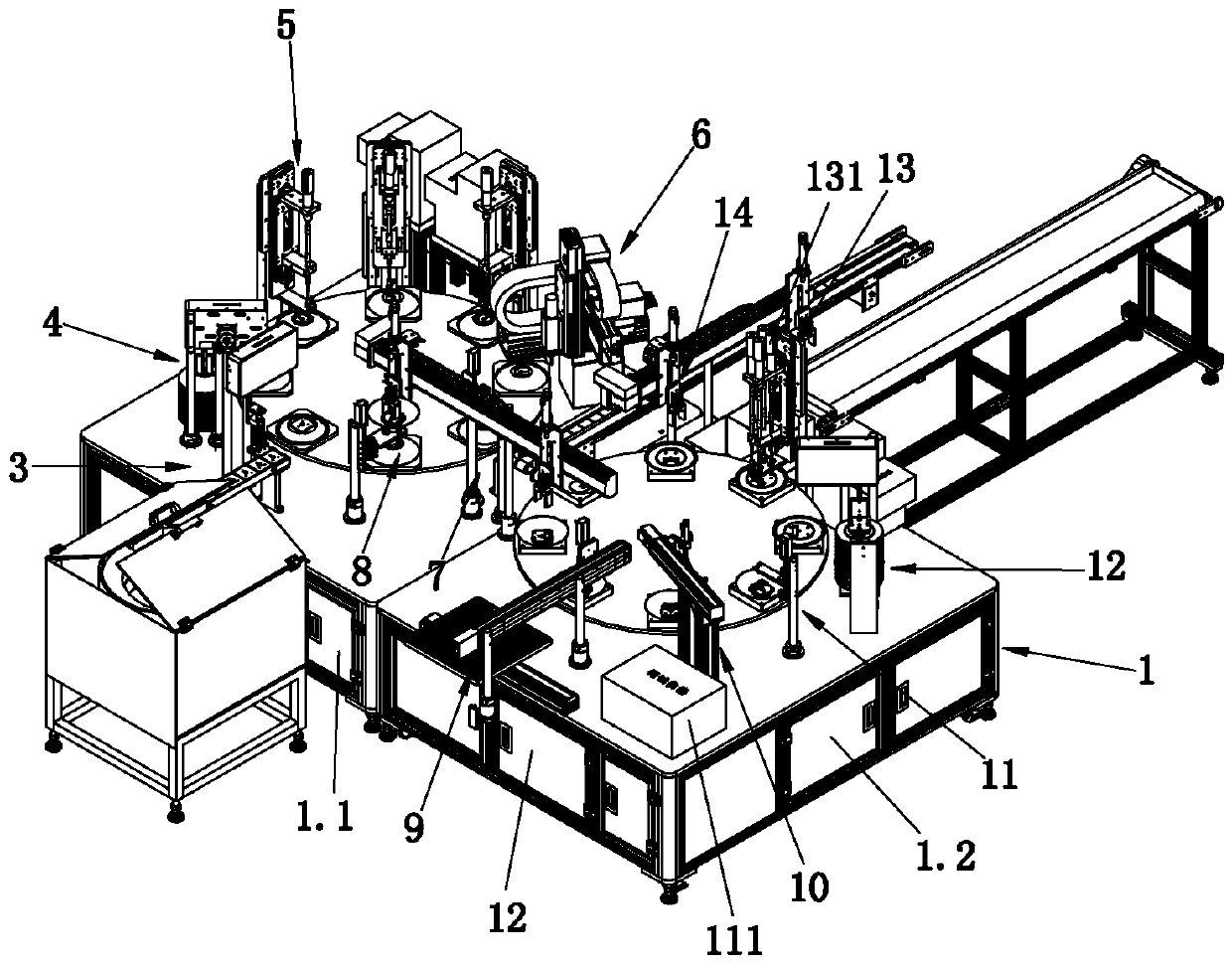

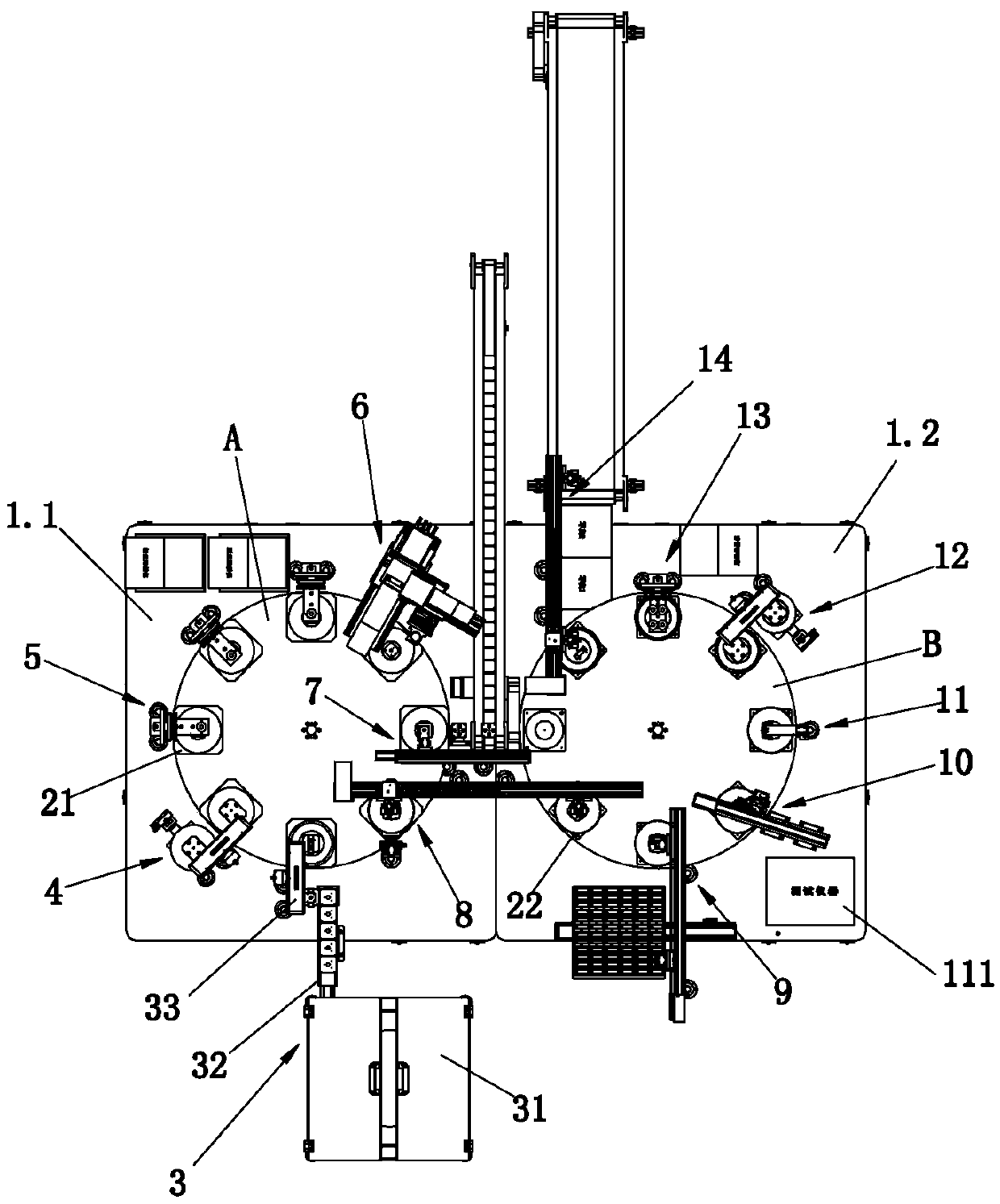

Automatic assembling machine of solar lamp

ActiveCN105499989ALess turningPrevent slidingAssembly machinesMetal working apparatusEngineeringSmall footprint

The invention discloses an automatic assembling machine of a solar lamp, relating to the field of automatic production equipment. The automatic assembling machine of the solar lamp comprises a base (1), wherein the base (1) is provided with a first disc (A) and a second disc (B); the base (1) surrounding the first disc (A) is sequentially provided with a first feeding device (3), a second feeding device (4), at least one automatic screw driving machine (5), a triaxial dispenser (6), a third feeding device (7) and an overturning transferring device (8) at intervals; and the base (1) surrounding the second disc (B) is sequentially provided with a fourth feeding device (9), an automatic welding machine (10), a fifth feeding device (12), an automatic screw driving machine (13), and a discharge device (14) at intervals. The automatic assembling machine of the solar lamp has the beneficial effects that the assembling machine can automatically assemble the solar lamp, and has the advantages of high production efficiency, compact layout, small occupied area, high automation degree and the like.

Owner:FUJIAN JOY SOLAR TECHNOLOGY CORPORATION

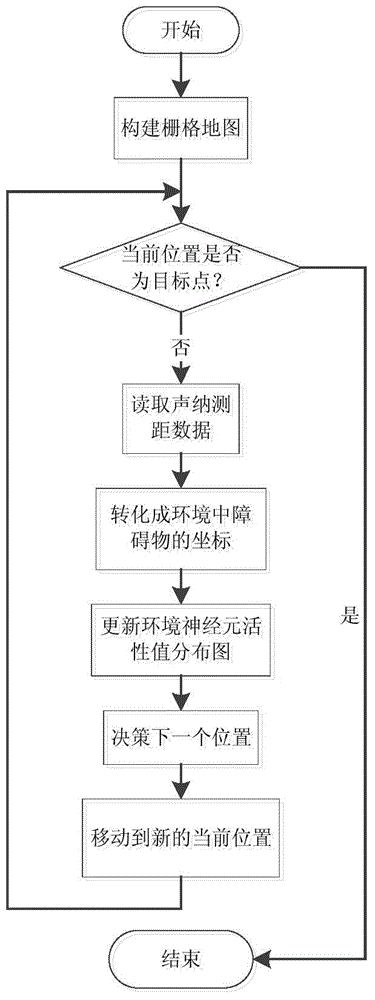

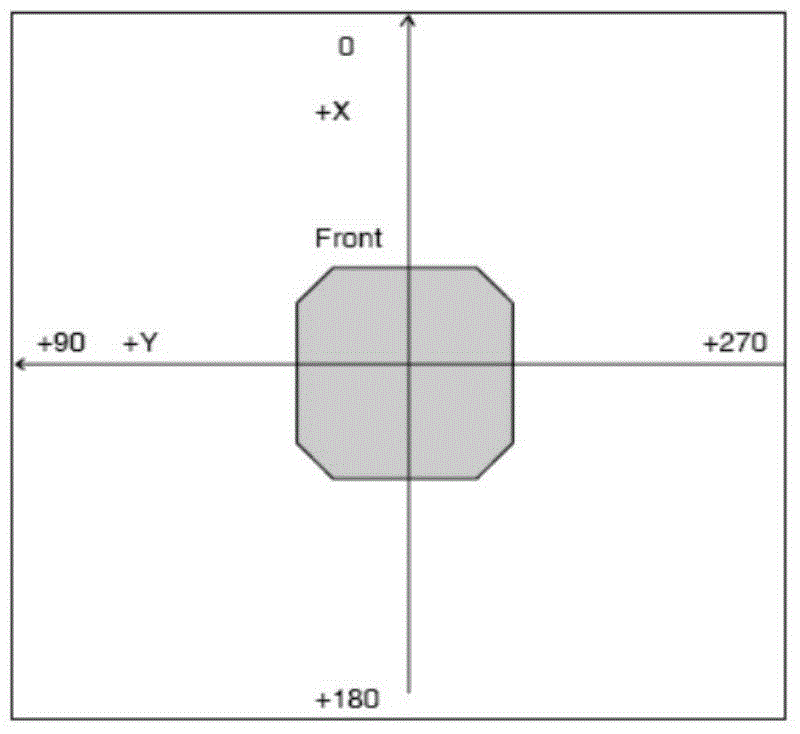

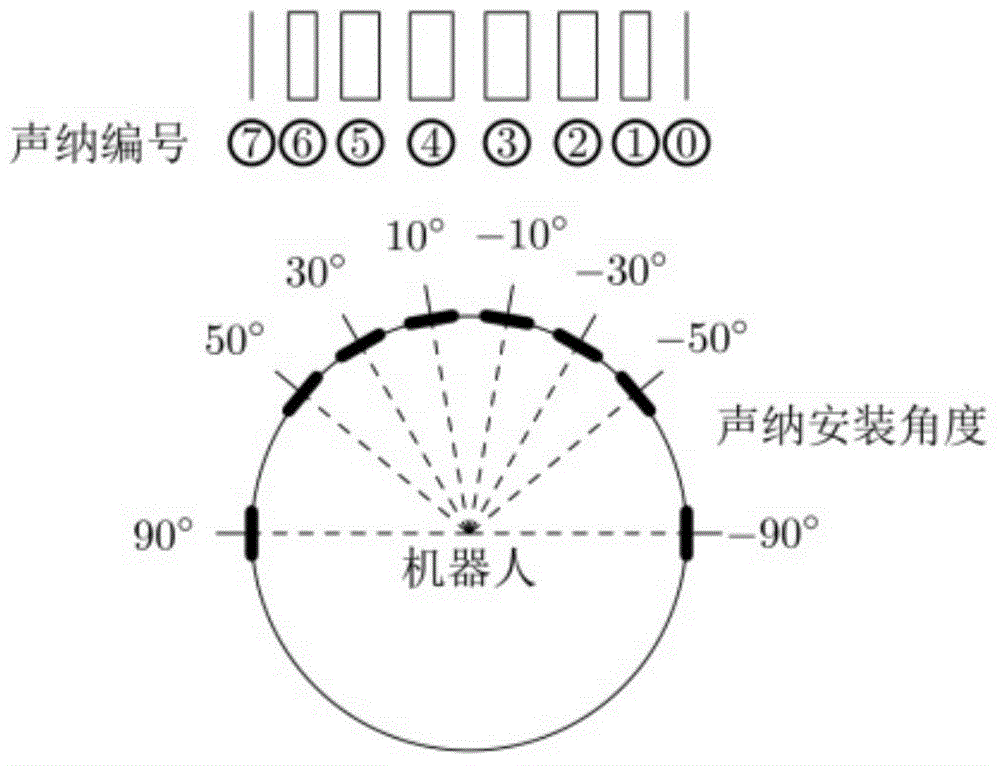

Mobile robot path planning method in unknown dynamic environment

InactiveCN105045260ASolve the problem of misjudgmentShorten the lengthPosition/course control in two dimensionsMobile robots path planningState-space representation

The invention discloses a mobile robot path planning method in an unknown dynamic environment. The method enables each position to be converted into a nerve cell, employs the activity values of nerve cells to represent environment changes, and ingeniously employs a biological motivation nerve network model to simulate a dynamic environment. The biological motivation nerve network model guarantees that the activity values of positive nerve cells can be transmitted outside to affect the whole state space, and the activity values of negative nerve cells just act on a local part. A decision at the next position point comprises a maximum nerve cell activity value and minimum robot corner factor, and an obtained path is the shortest one or about the shortest one. Moreover, the path is smooth, and the number of corners is smaller. The method does not have a problem of local minimum points, is small in calculation amount, is simple in implementation, and is good in adaptability in the unknown dynamic environment.

Owner:HUNAN UNIV

High current inductor and the manufacturing method

InactiveUS7142084B2Improve featuresCompact structureTransformers/inductances coils/windings/connectionsEncapsulation/impregnationElectrical conductorDie casting

An inductor with the characteristic of resisting high current comprising a conductor coil and a magnet envelope, the magnet envelope tightly wraps the periphery of the conductor coil and forms the main body of the inductor, and the two extending parts of the conductor coil extend to outside of the main body of the inductor, forming terminal electrode. As of the manufacturing method, it includes the part of toroid coil and the extending parts composing the conductor coil. After the toroid coil part is winded into rings, the unwinded wire ends form the extending parts. Through magnet envelope die-casting and wrapping the molded magnet core of the conductor coil to form the main body of the inductor, and the extending parts of the conductor coil extend to outside of the main body to form the terminal electrode.

Owner:CHENG CHANG MAO

Battery label with wireless battery charging circuit

ActiveUS7456606B1Eliminate requirementsLarge mutual inductanceResonant long antennasBatteries circuit arrangementsElectricityBattery charge

Owner:IBM CORP

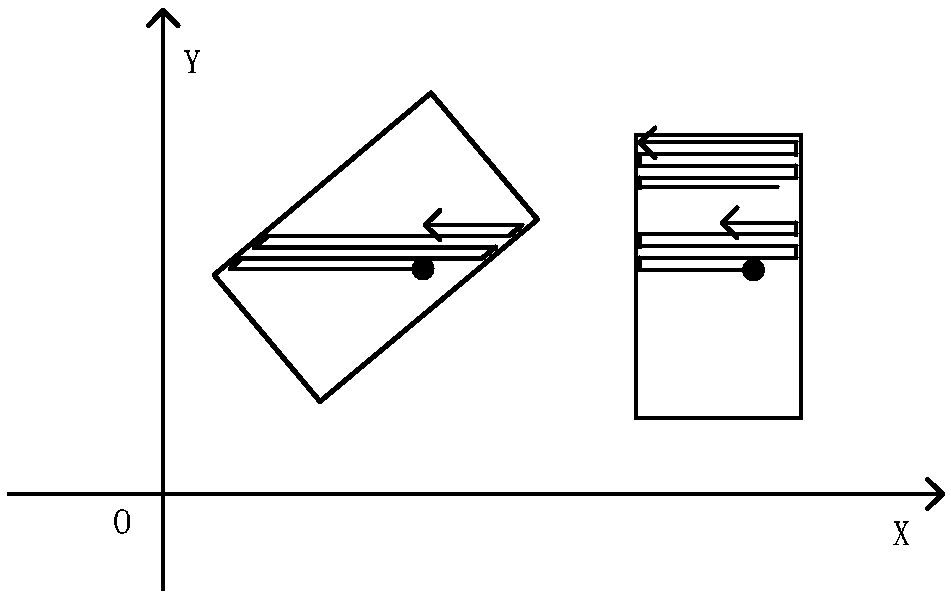

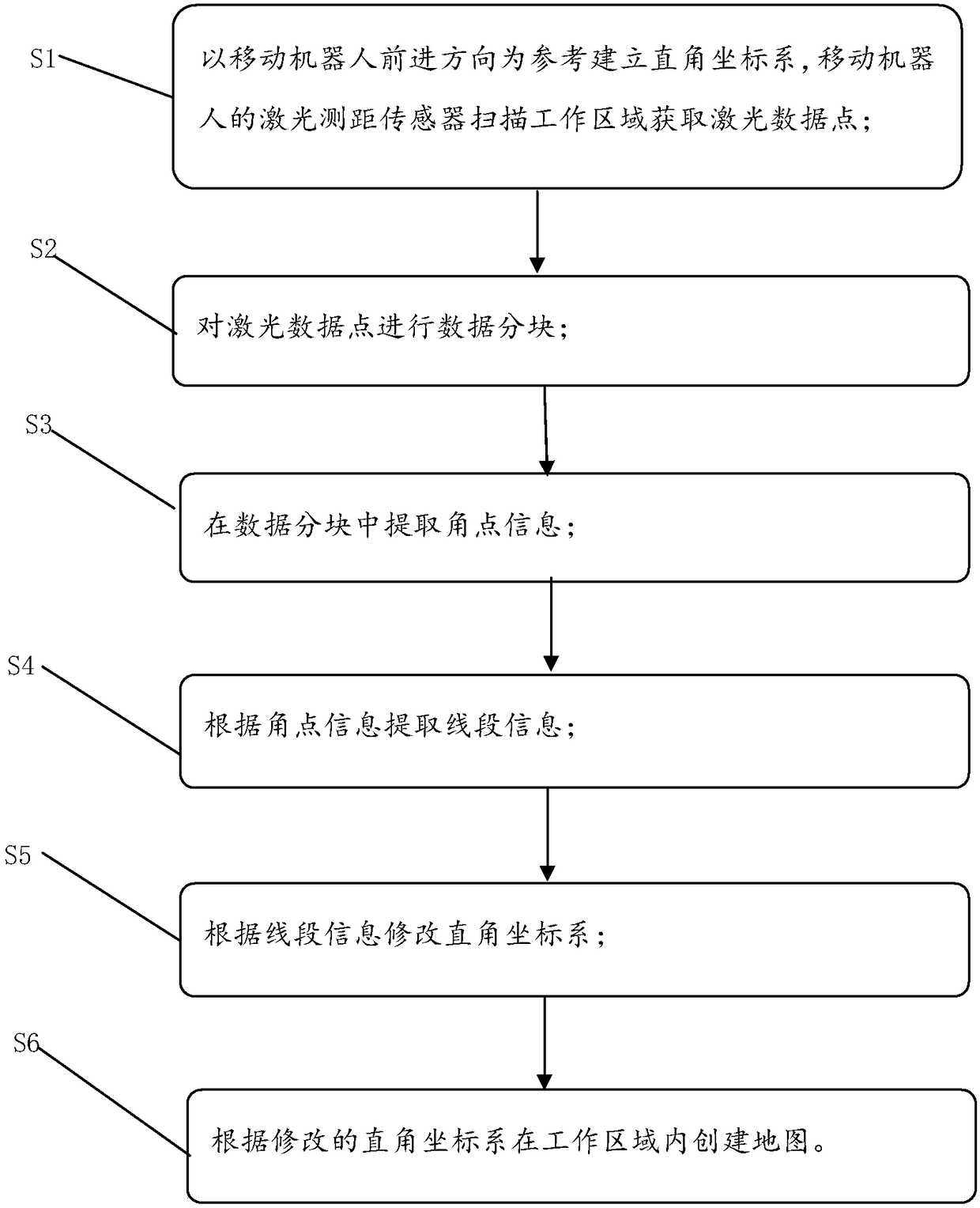

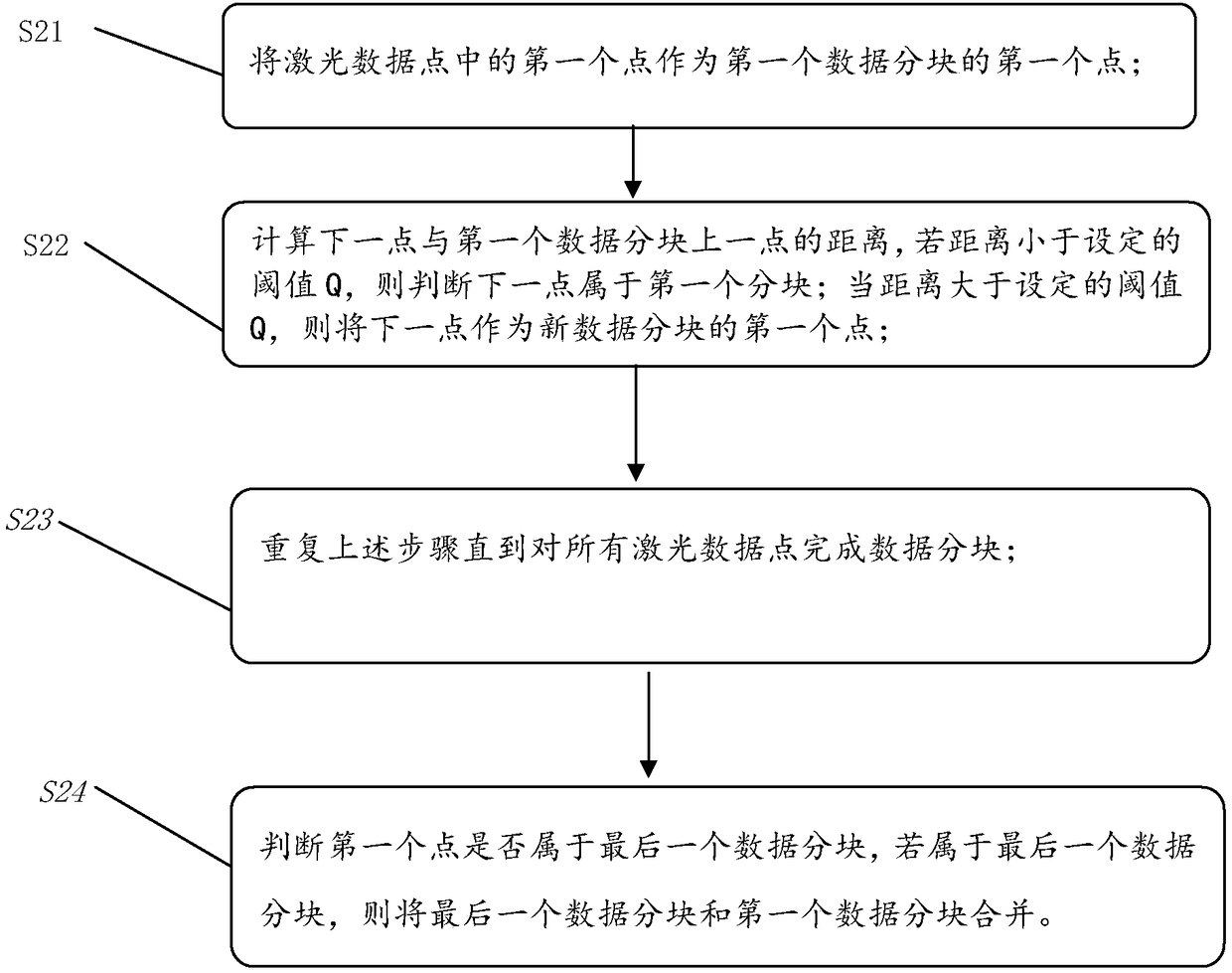

Map building method of mobile robot based on laser ranging sensor

ActiveCN108387234AImprove cleanlinessOptimize cleaning planning processNavigational calculation instrumentsCarpet cleanersLaser rangingRectangular coordinates

The invention provides a map building method of a mobile robot based on a laser ranging sensor. The method comprises the following steps: S1, establishing a Cartesian coordinate system by taking the forwarding direction of the mobile robot as reference, and scanning a working area of the mobile robot by the laser ranging sensor to obtain laser data points; S2, performing data segmentation on the laser data points; S3, extracting corner point information from the segmented data; S4, extracting line segment information according to the corner point information; S5, modifying the Cartesian coordinate system according to the line segment information; and S6, building the map in the working area according to the modified rectangular coordinate system. Compared with the prior art, the method caneffectively optimize a subsequent cleaning planning process, reduce the turning process during cleaning and optimize cleaning in the edgewise process by extracting the corner information and the linesegment information from the laser data, modifying the Cartesian coordinate system according to the line segment information and rotating the map to an angle perpendicular to a wall, so the intelligence and the efficiency of the cleaning process are improved.

Owner:GUANGZHOU COAYU ROBOT CO LTD

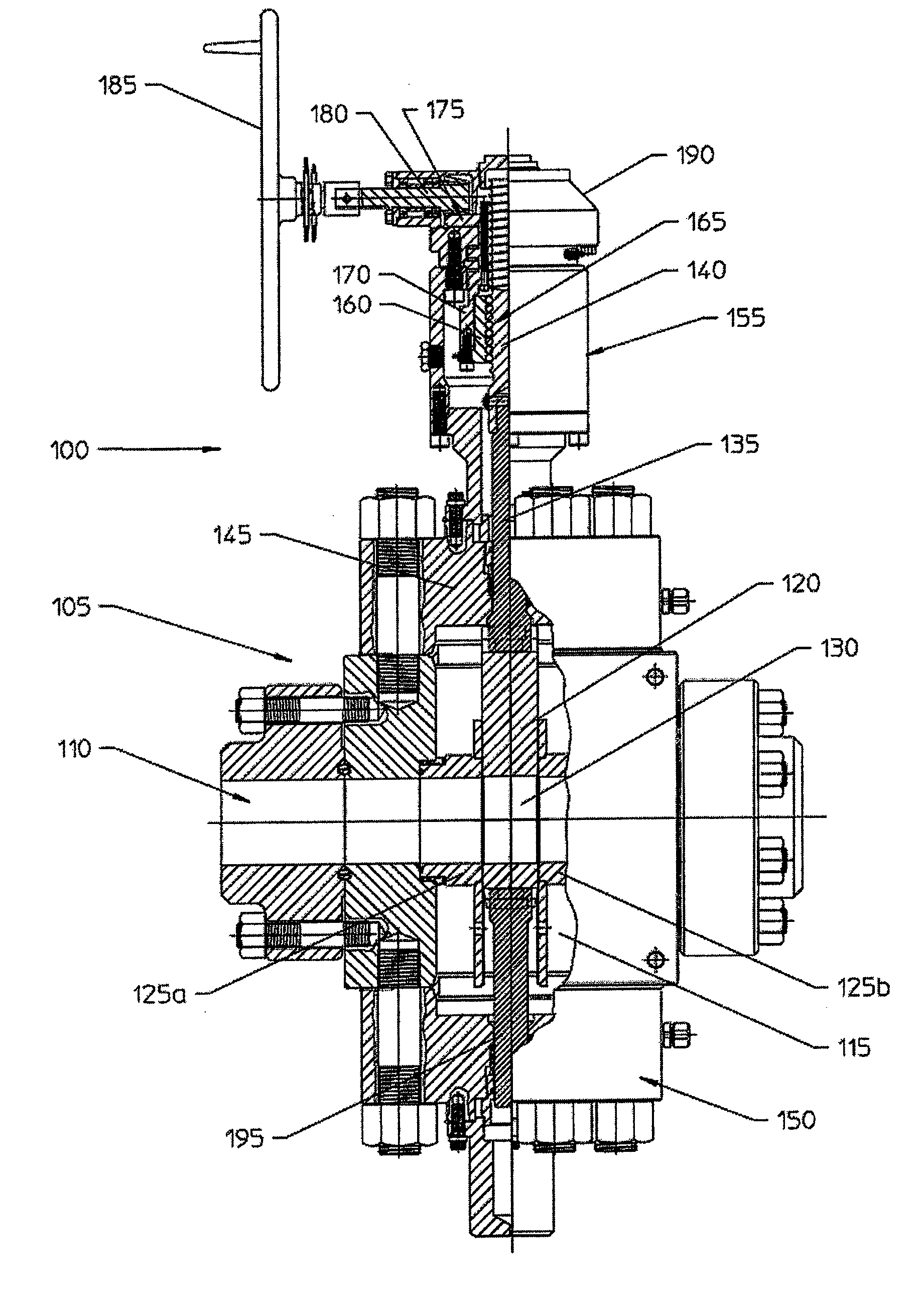

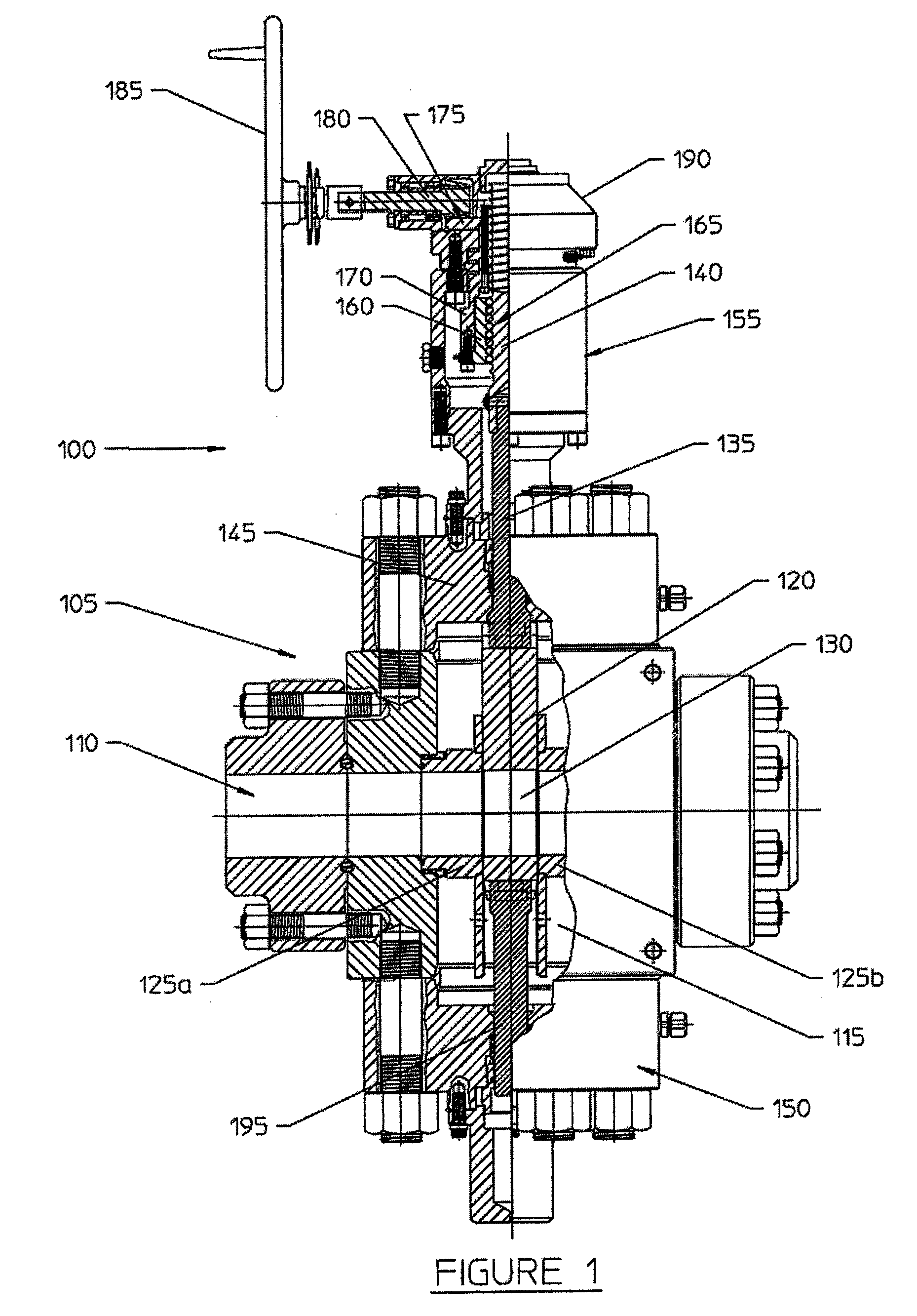

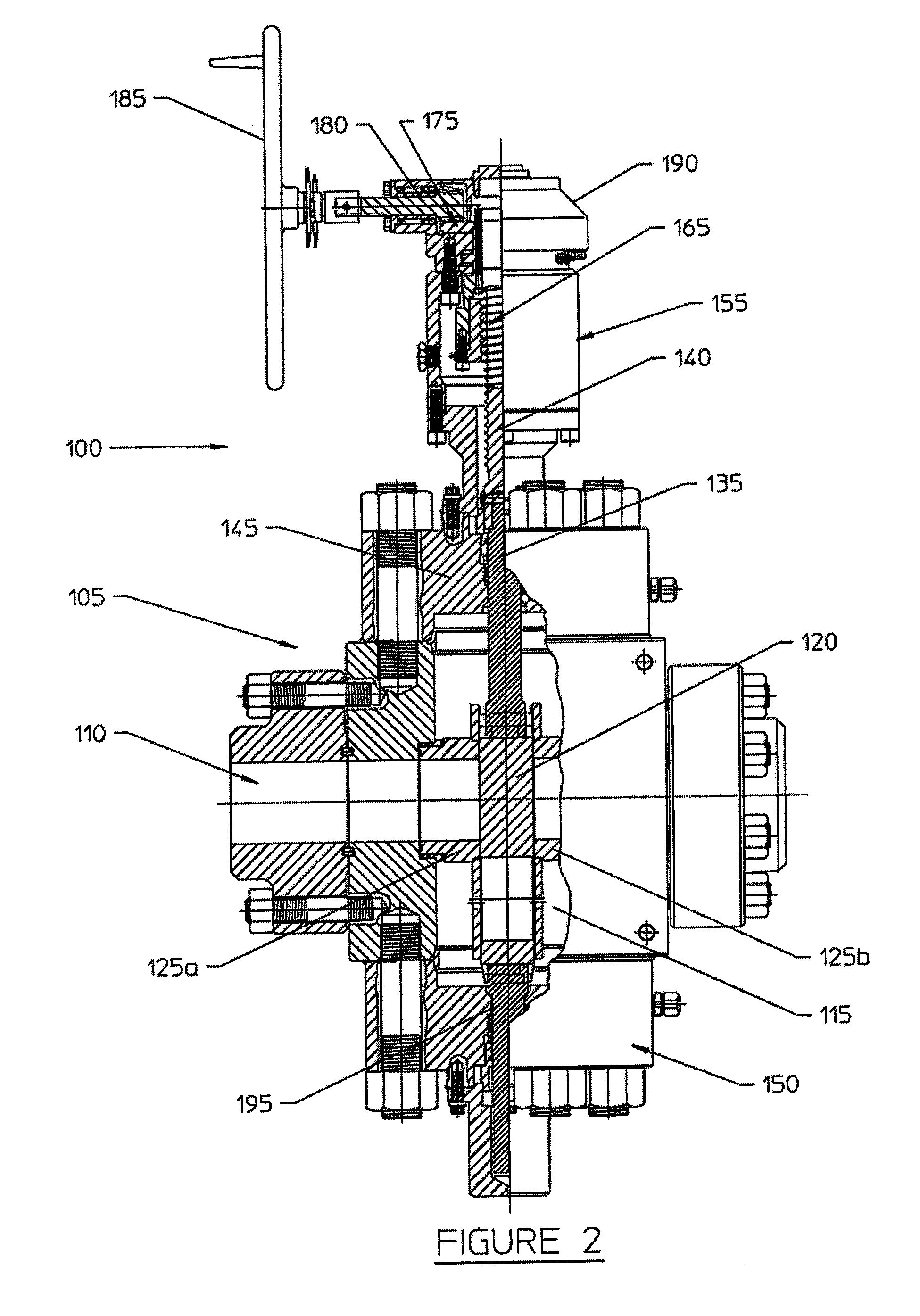

Low Torque Gate Valve Mechanism

InactiveUS20080217569A1Reduce torqueMinimize the numberOperating means/releasing devices for valvesPipeline systemsGear wheelBall screw

A gate valve apparatus provides a manually operated gate valve with an operation mechanism that reduces the force required to actuate the gate valve and minimizes the number of handwheel turns required. Disclosed is a gate valve apparatus including a valve body, a bonnet, a gate, a ball screw arrangement, a gear reducer arrangement and a handwheel. The ball screw arrangement, gear reducer arrangement, and the handwheel are associated with the valve stem and gate such that rotational force applied to the handwheel is converted by the gear reducer arrangement and the ball screw arrangement into linear force applied to the valve stem and then to the gate.

Owner:DRIL QUIP

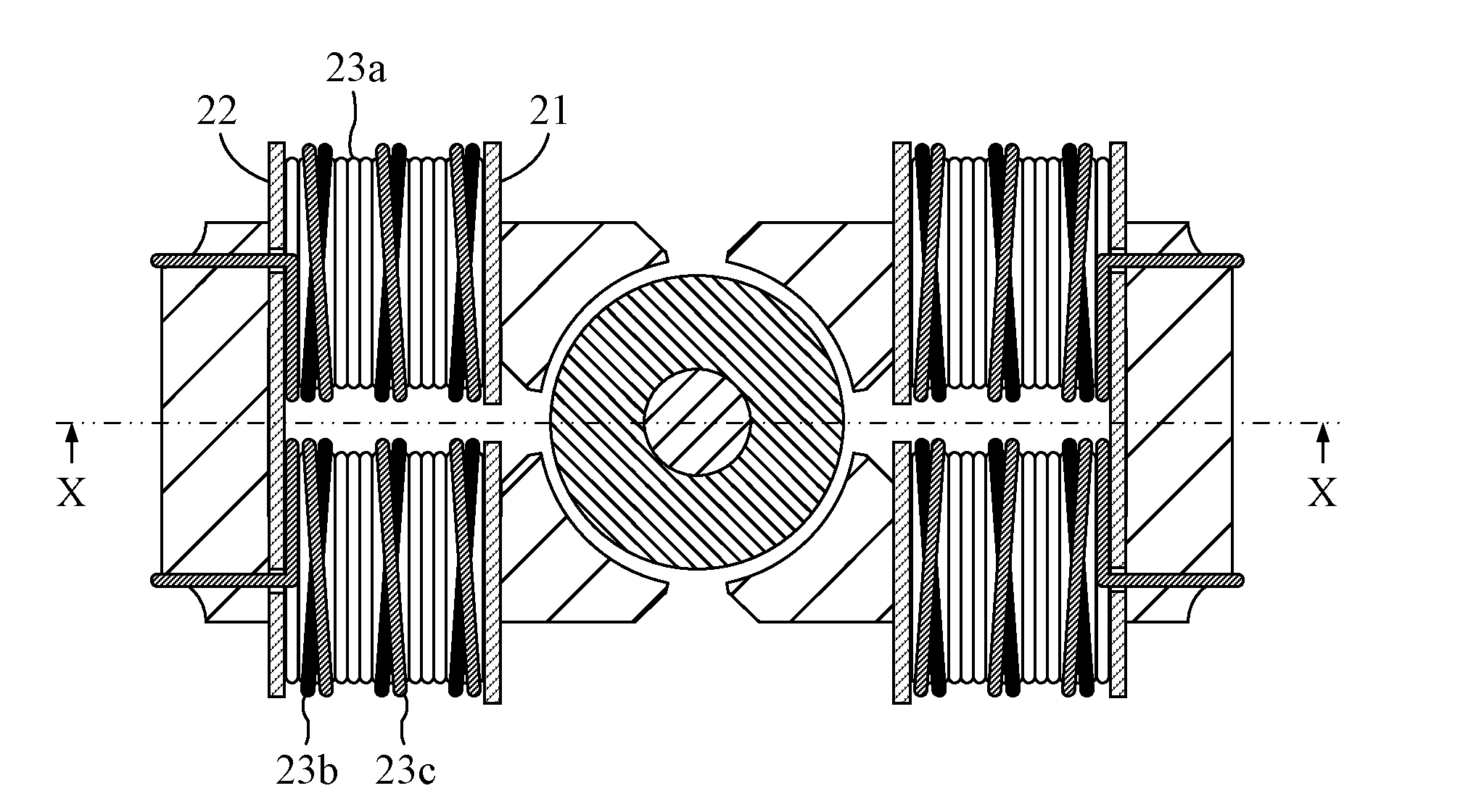

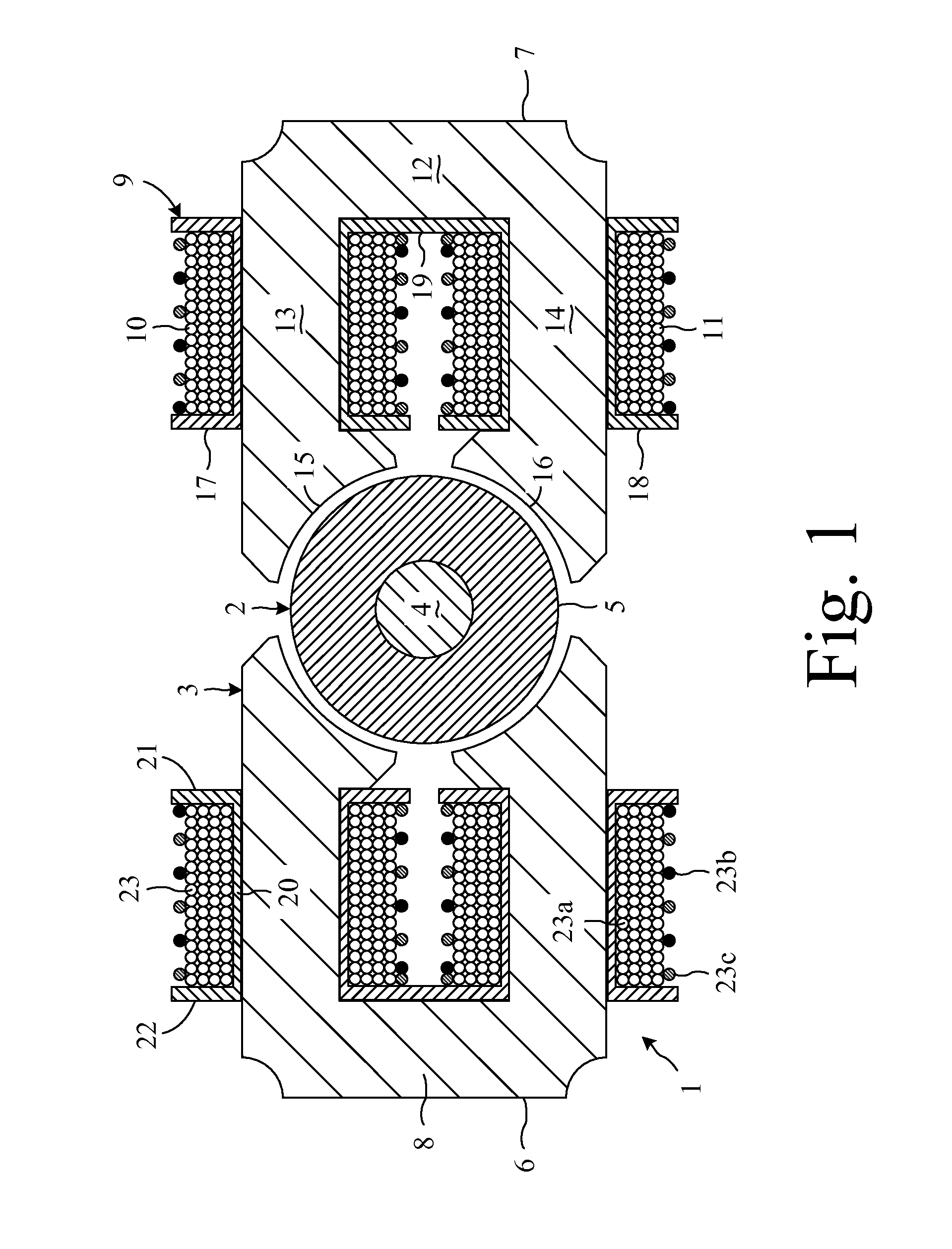

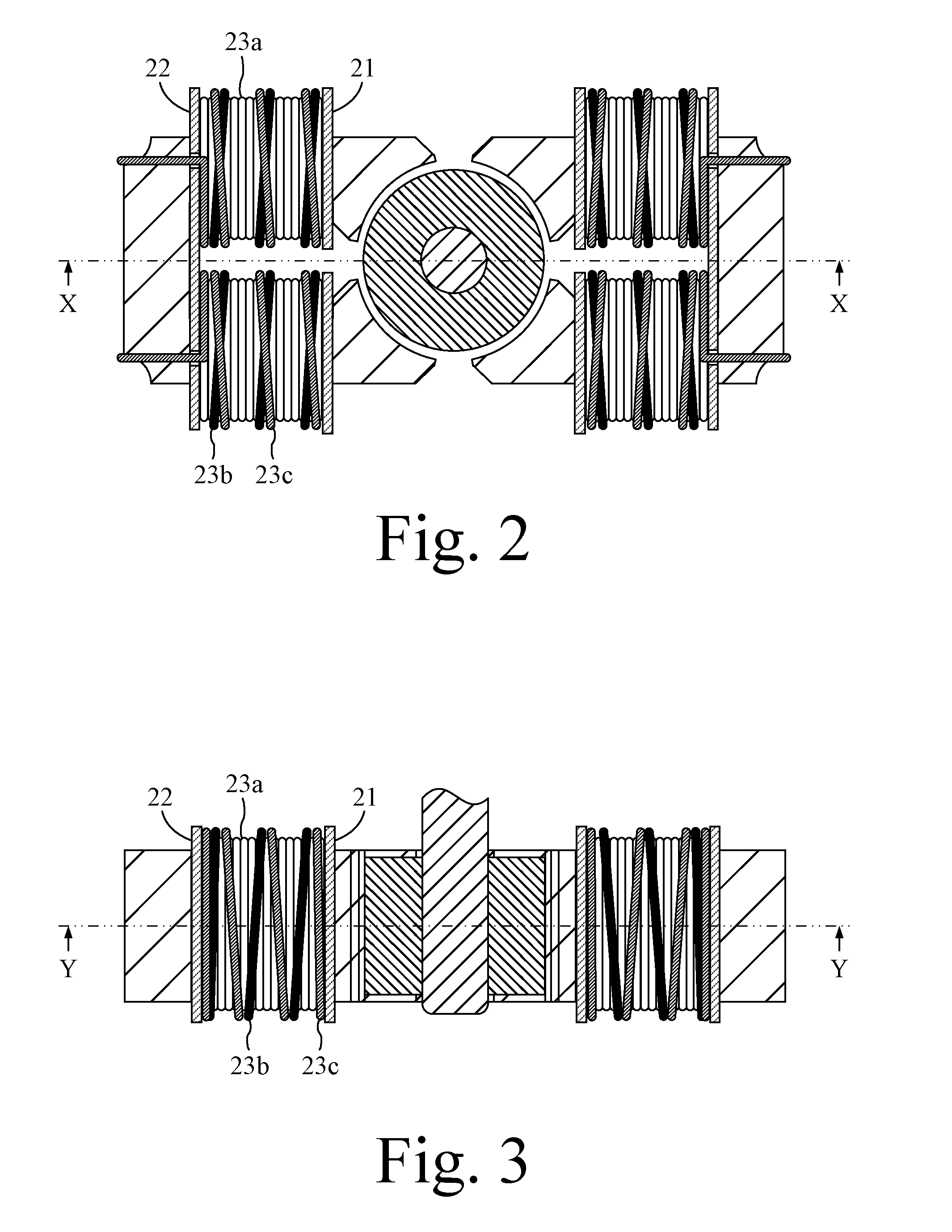

High-energy density permanent magnet motor water cooling system

InactiveCN106208443AReduce uniformityImprove uniformityMagnetic circuit stationary partsWindings conductor shape/form/constructionHigh energyTorque density

The present invention discloses a high-energy density permanent magnet motor water cooling system. The high-energy density permanent magnet motor water cooling system comprises a stator, stator windings, cooling water pipes and disc pipelines. The cooling water pipes specifically comprise cooling water pipes at a stator yoke, cooling water pipes in centers of stator slots, and cooling water pipes at stator teeth. The cooling water pipes are axially mounted in the slots, teeth and yoke of the motor stator. The disc pipelines are at ends of the motor. Two ends of the cooling water pipes are respectively connected with the two disc pipelines at the ends of the stator. The number of the disc pipelines is two. The water cooling system directly cools main heating parts of the motor, that is, the windings and an iron core, so that the heat dissipation efficiency is greatly improved. The cooling water pipes are simple and have fewer turnings, so that the flow resistance of cooling water is reduced sharply, and the water pressure of a water pump is lowered. The temperature of the motor is distributed more uniformly, the heat dissipation capacity is greatly improved, and further, the torque density of the motor is improved.

Owner:伊泽瑞尔(大连)科技有限公司

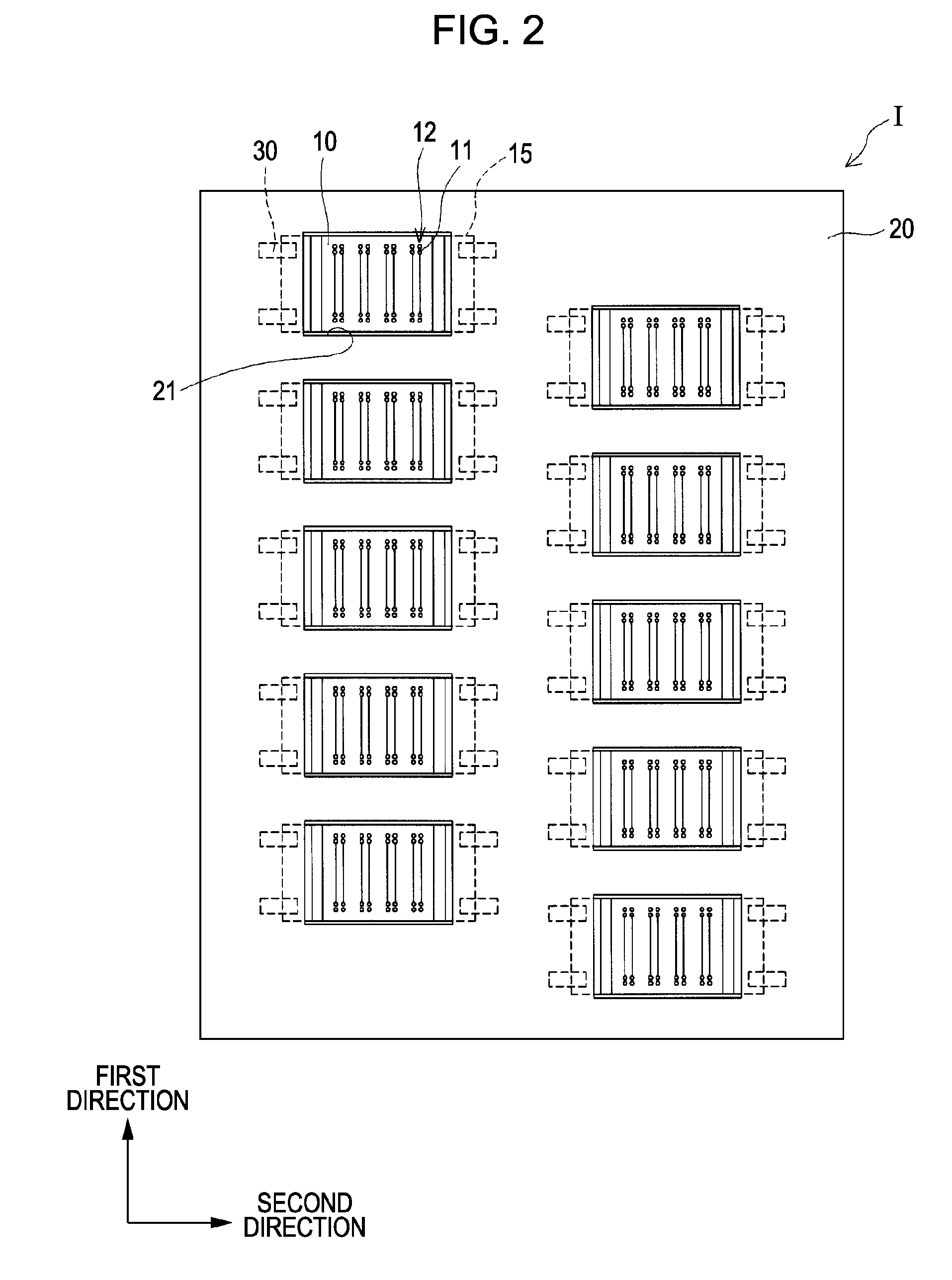

Liquid ejecting head and liquid ejecting apparatus

InactiveUS20100026759A1High positionalImprove printing qualityInking apparatusEngineeringLiquid drop

Owner:SEIKO EPSON CORP

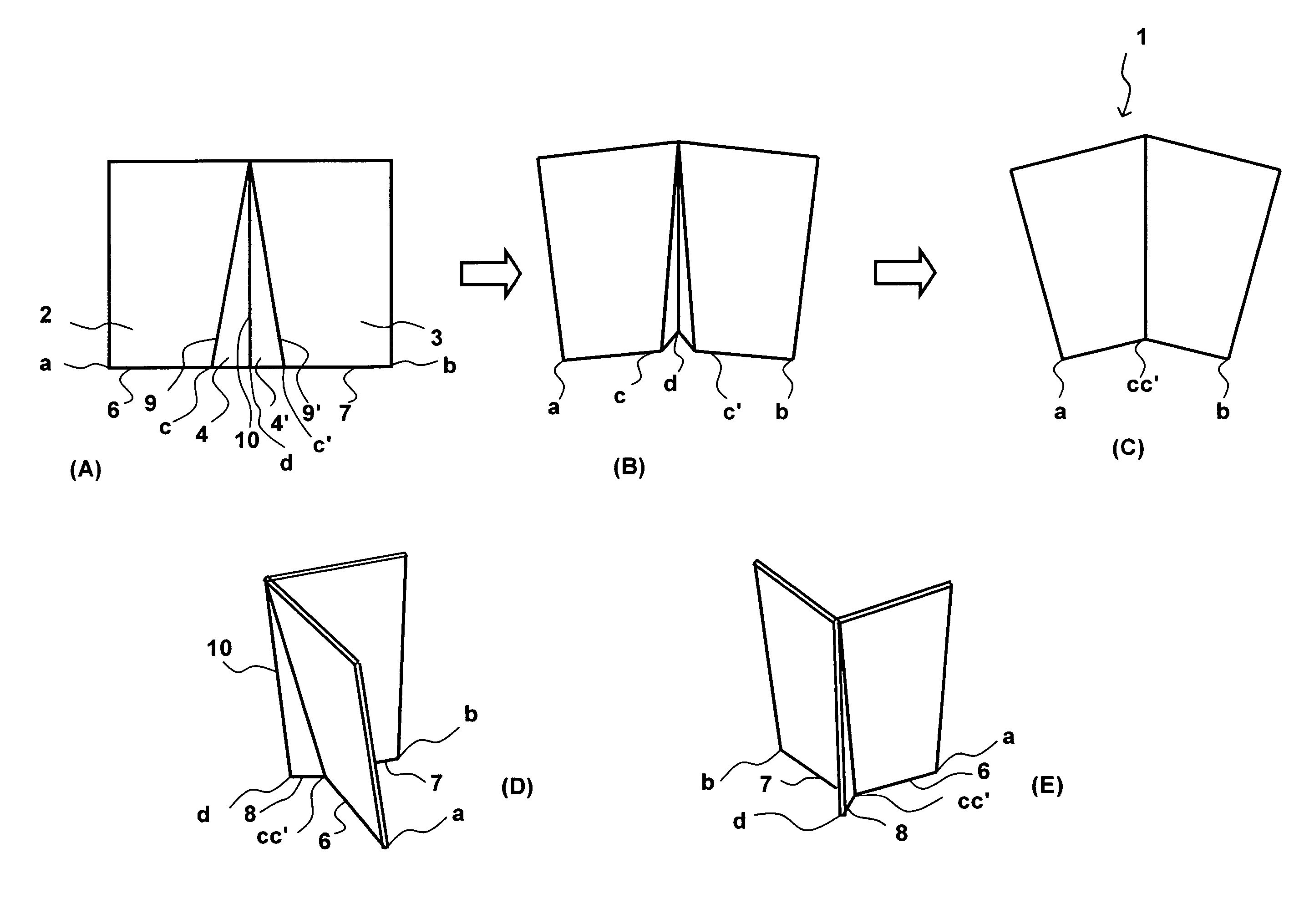

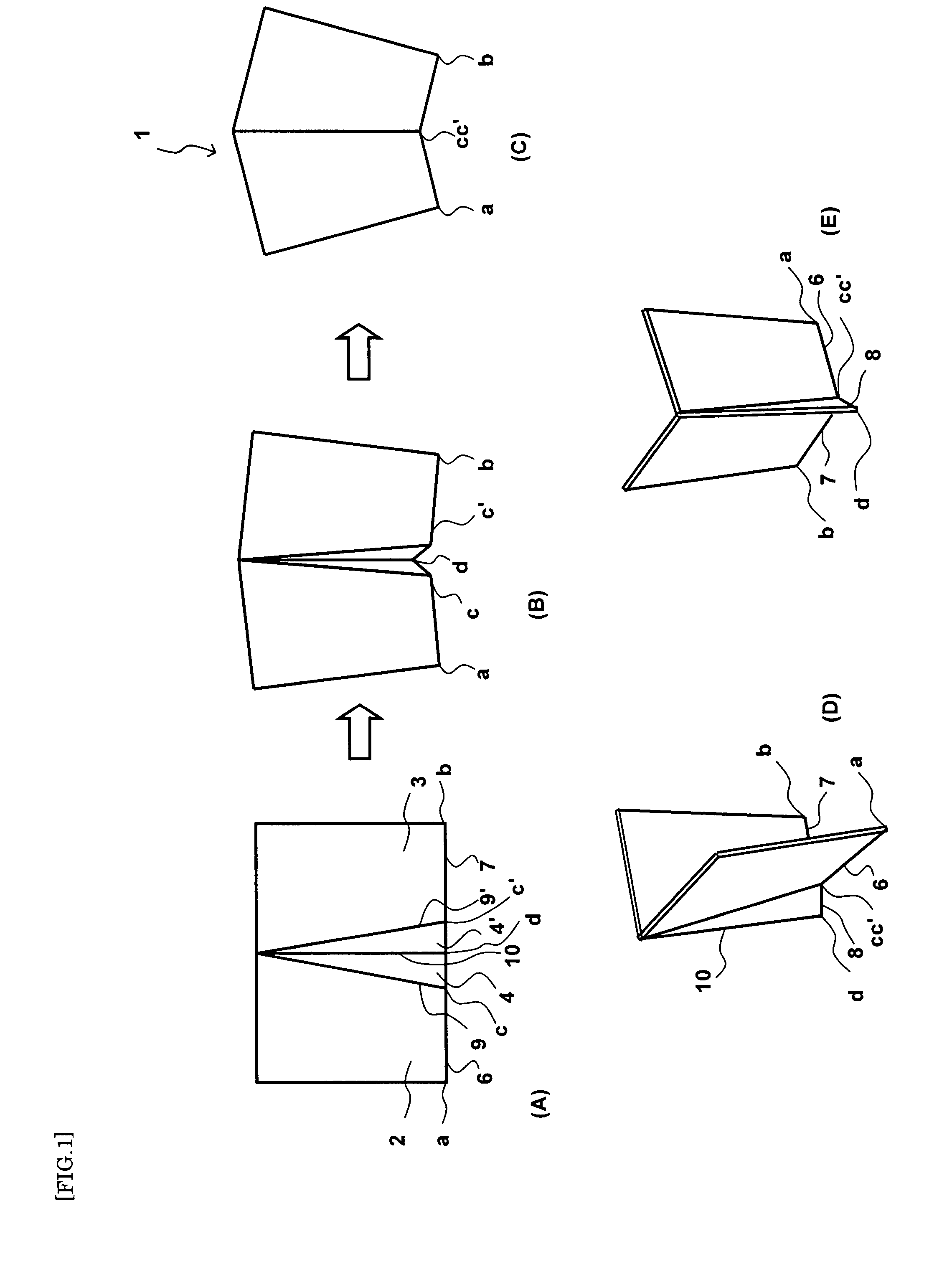

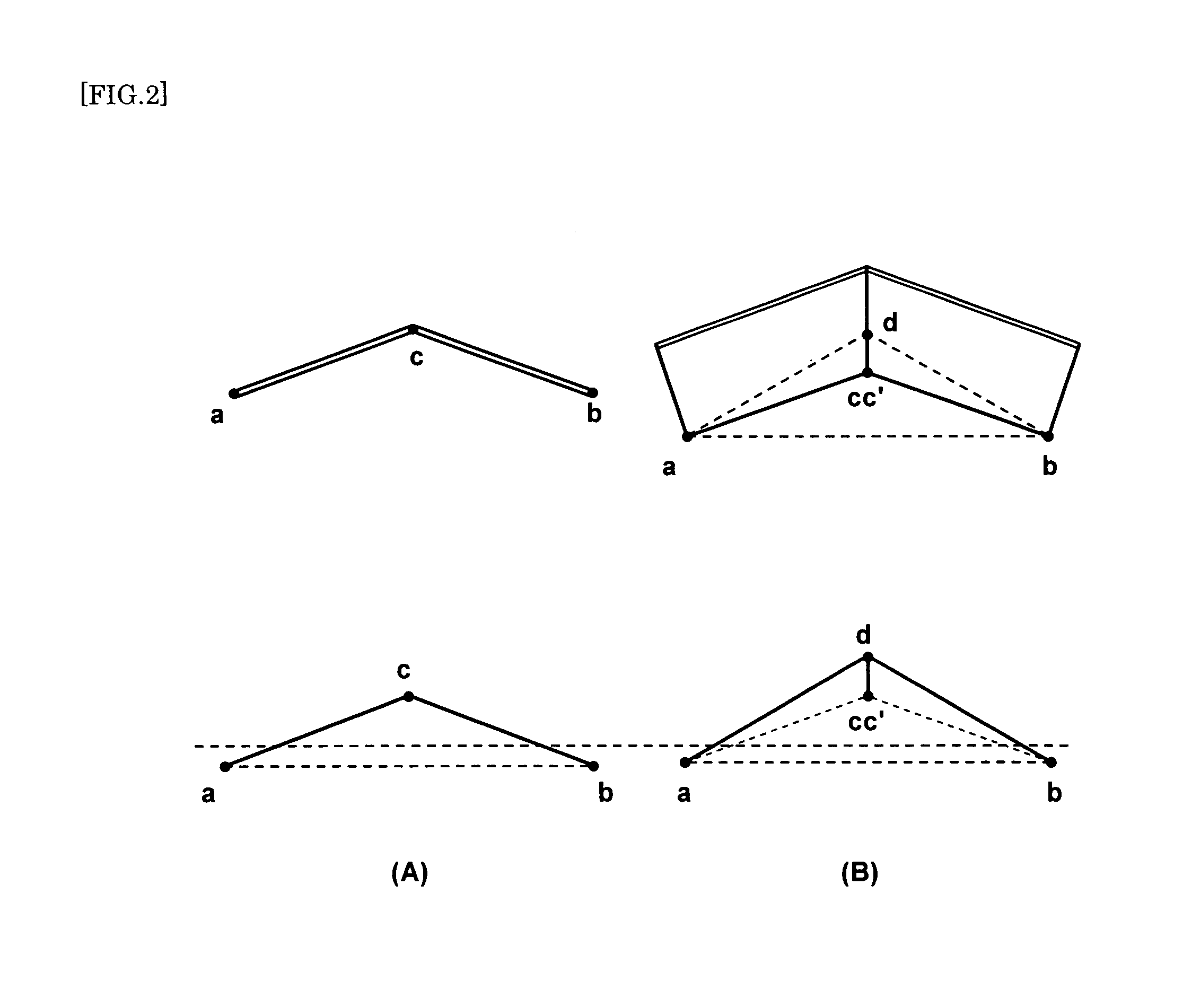

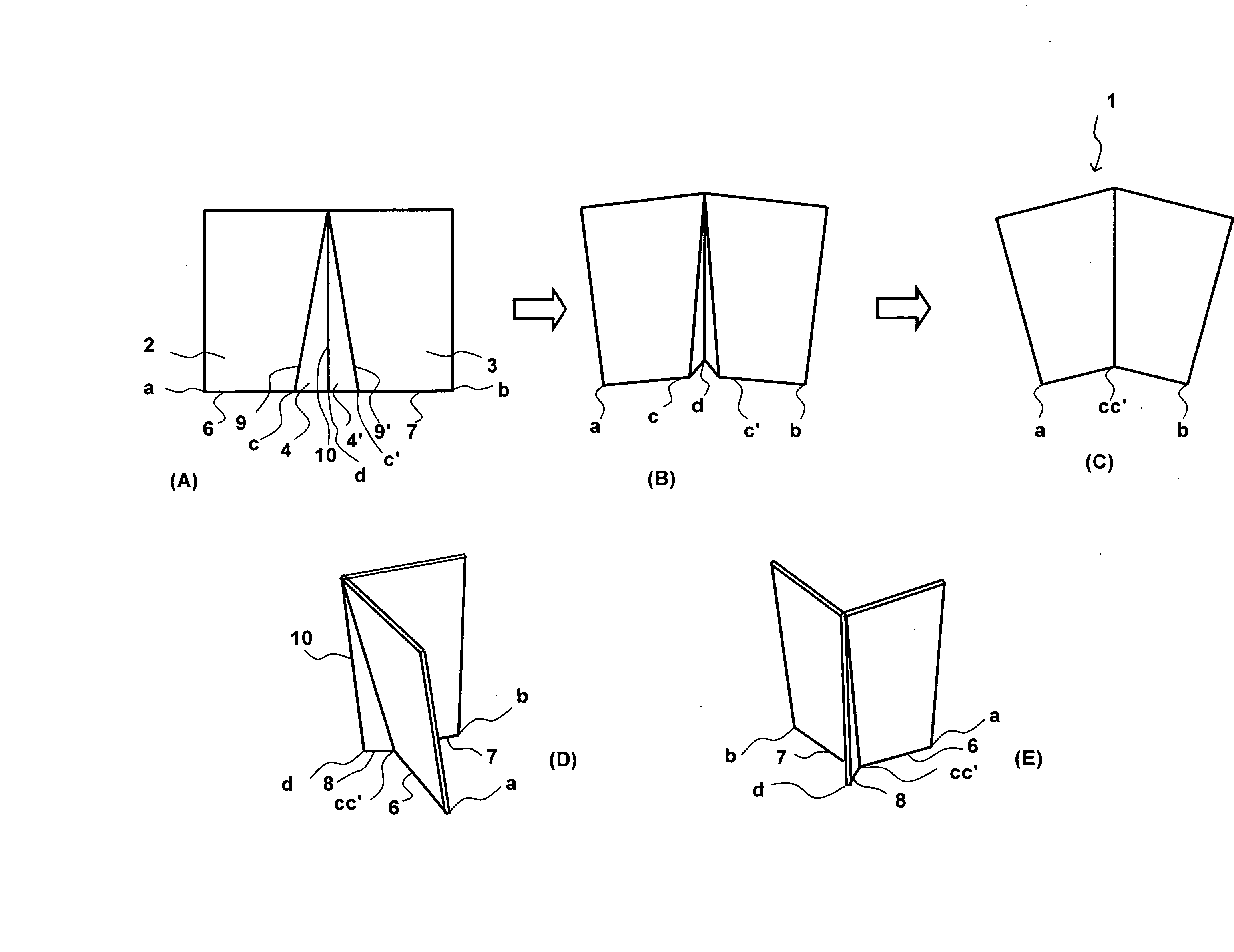

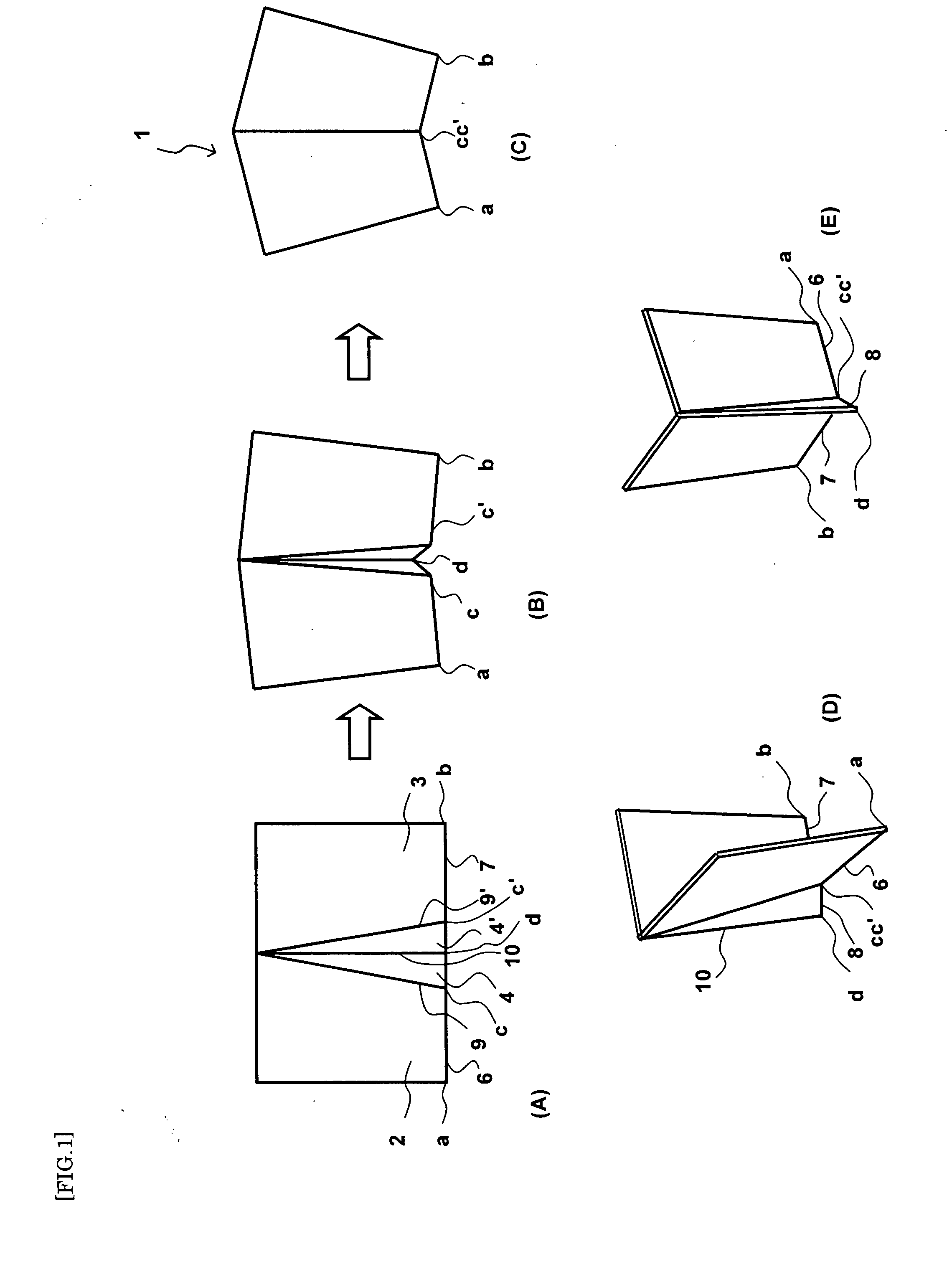

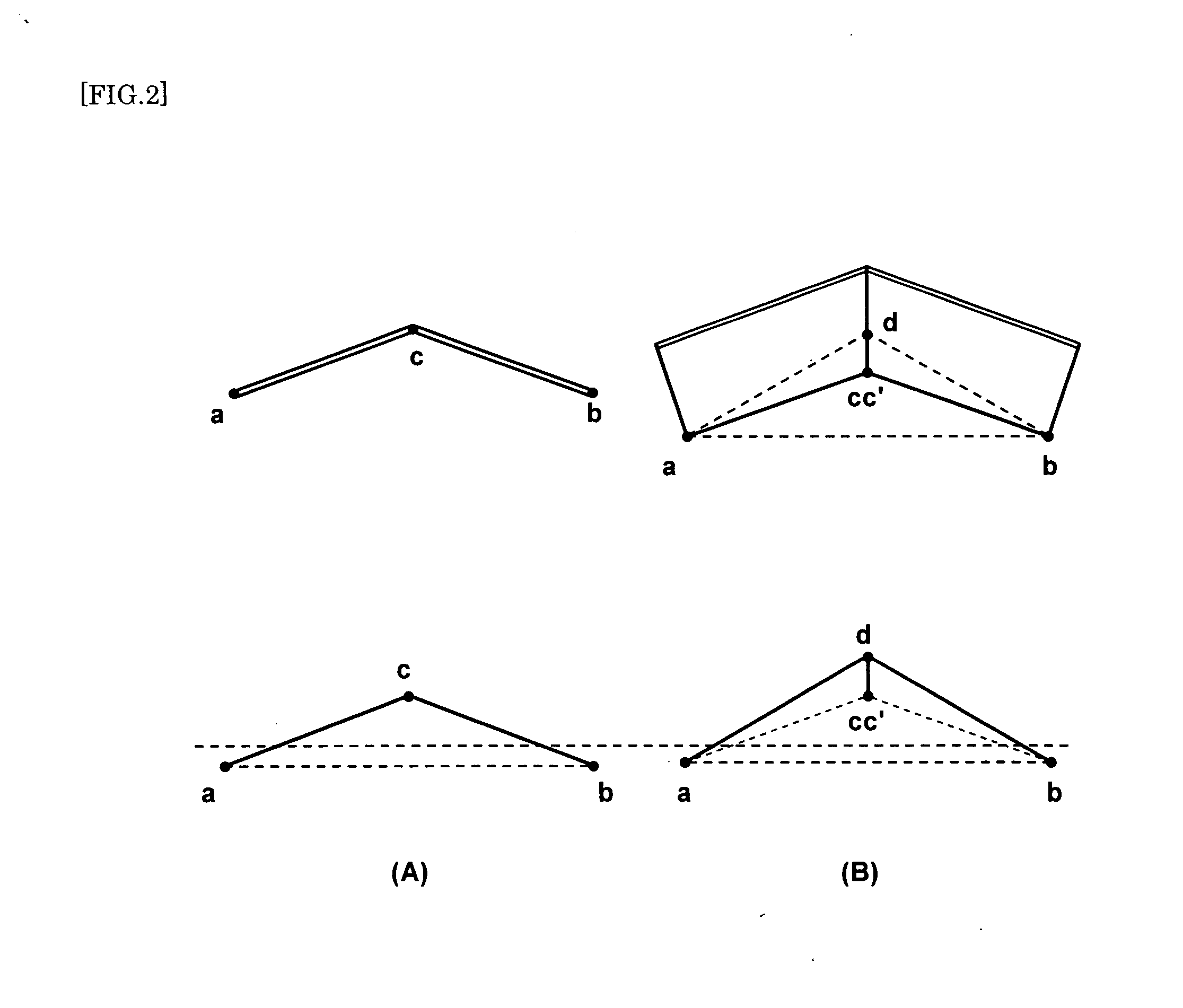

Self-standing flat plate-like article and methods of exhibiting and manufacturing the same

InactiveUS7739816B2Easy to observeLess turnsPicture framesDigital data processing detailsGround contactBorder line

A method for stably and easily exhibiting a flat plate-like article such as a flat exhibited article so as to be easily observed and less turned over and the flat plate-like article stably and simply exhibitable so as to be easily observed and less turned over and manufacturable at low cost. The flat plate-like article comprises two or more flat plate-like members and one or more connection parts. The flat plate-like article is characterized in that (A) any first and second flat plate-like members are connected to each other through the connection part and positioned on the border line of these both members and projected backward from the border line so that they can be double-spread and (B) the flat plate-like article can be self-stood when the first and second flat plate-like members are brought into a double-spread state so that a state that the insides of the first and second flat plate-like members are positioned diagonally upward relative to a ground contact surface when at least a part of the bottom-side of the connection part, at least a part of the bottom-side of the first flat plate-like member, and at least a part of the bottom-side of the second flat plate-like member are used as the ground contact parts.

Owner:FERRIC INC

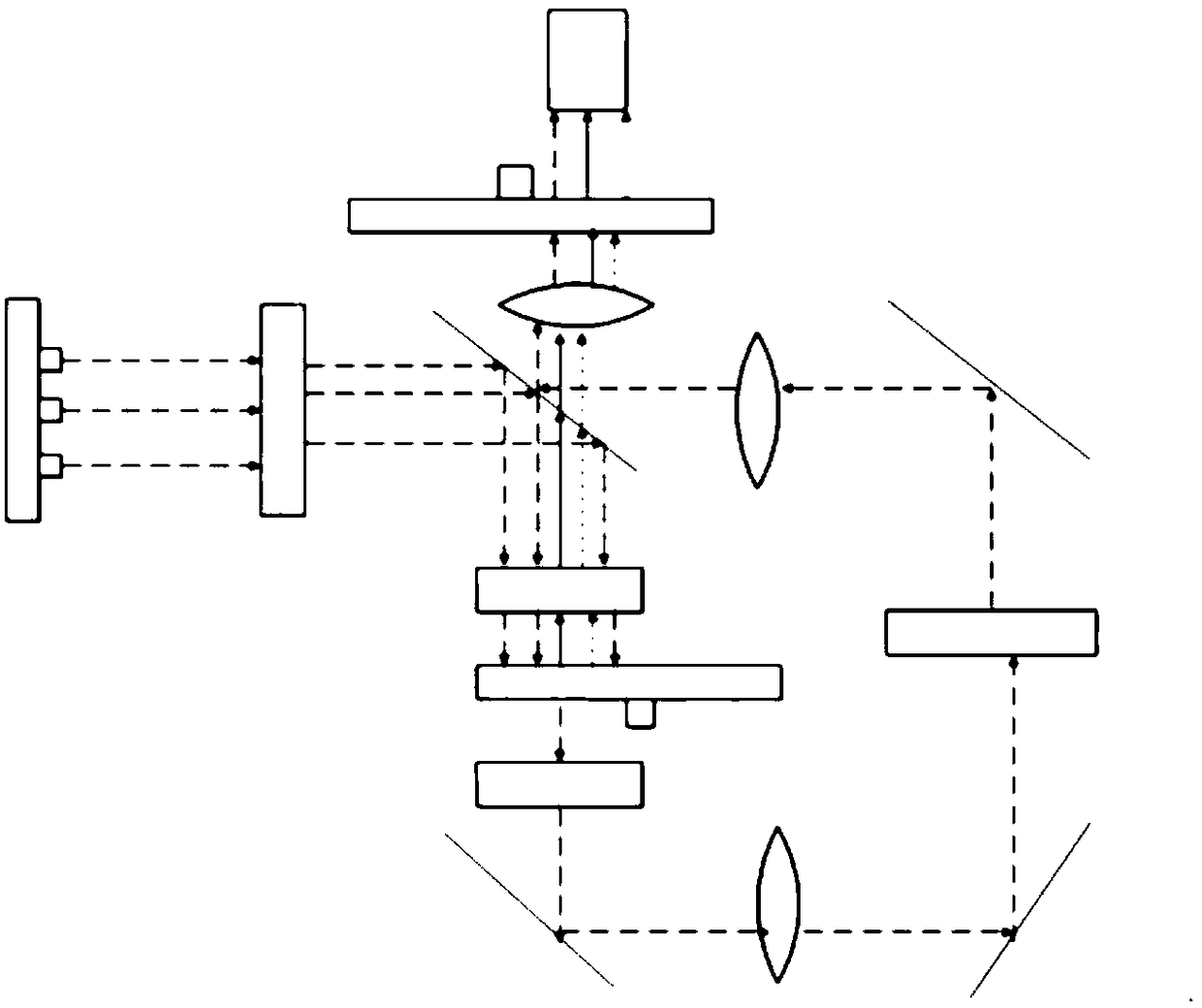

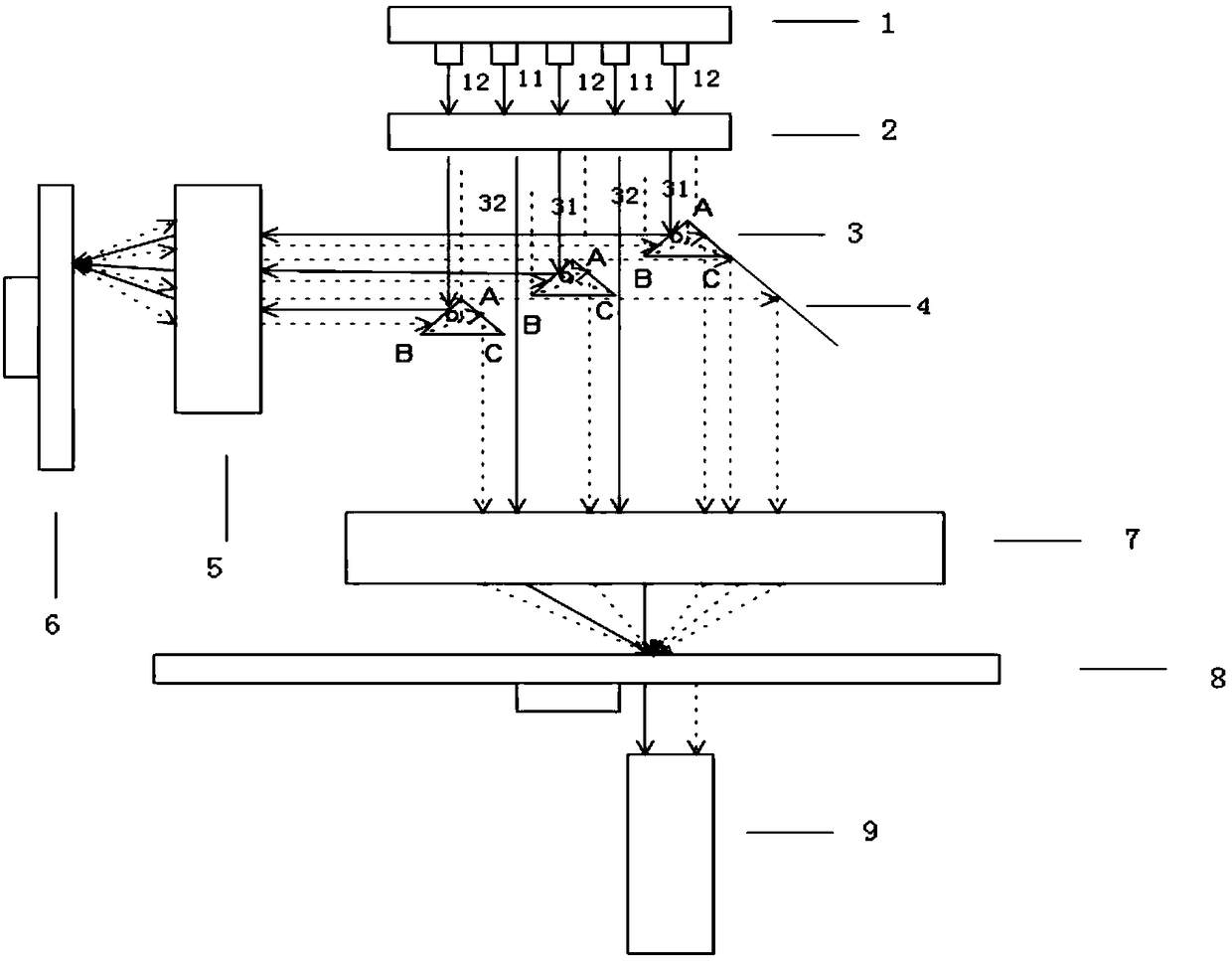

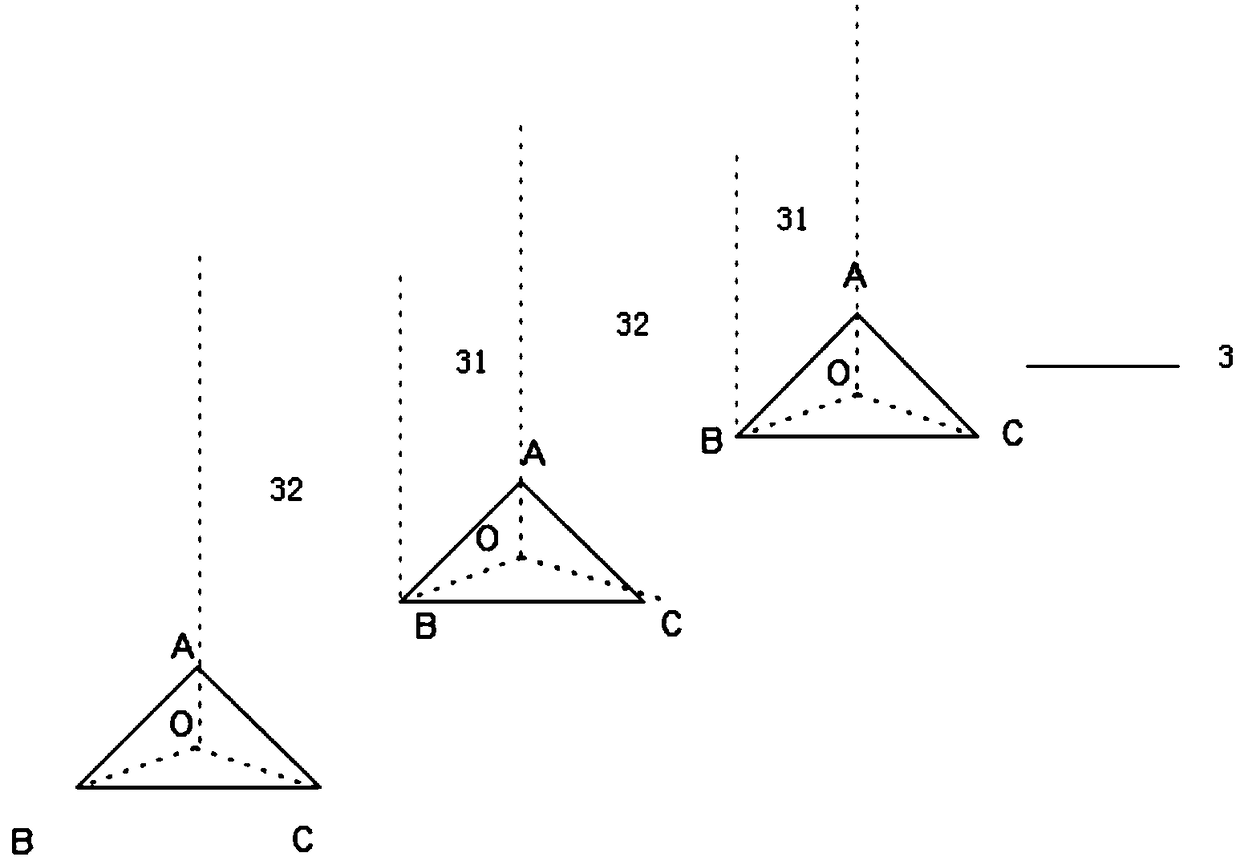

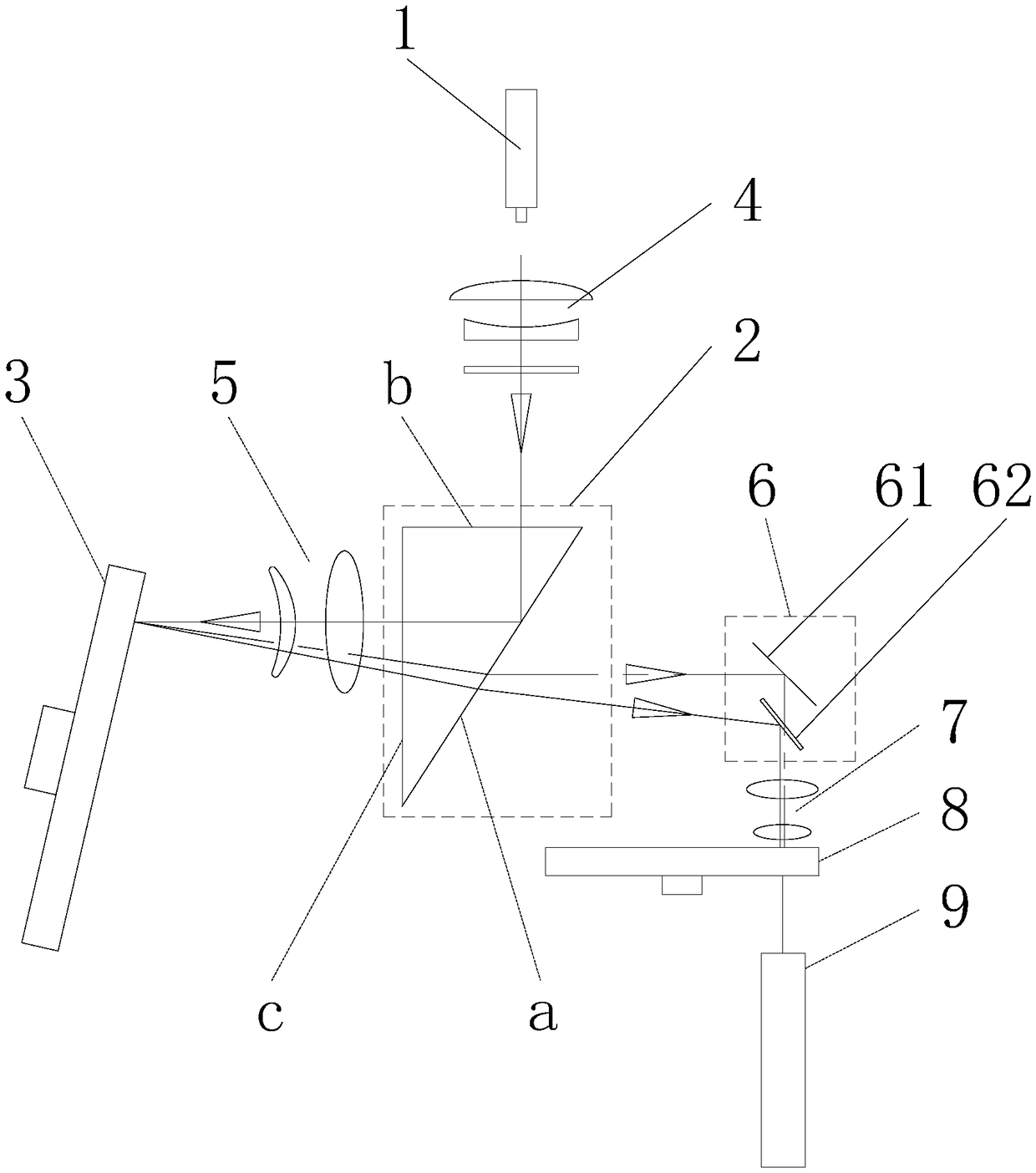

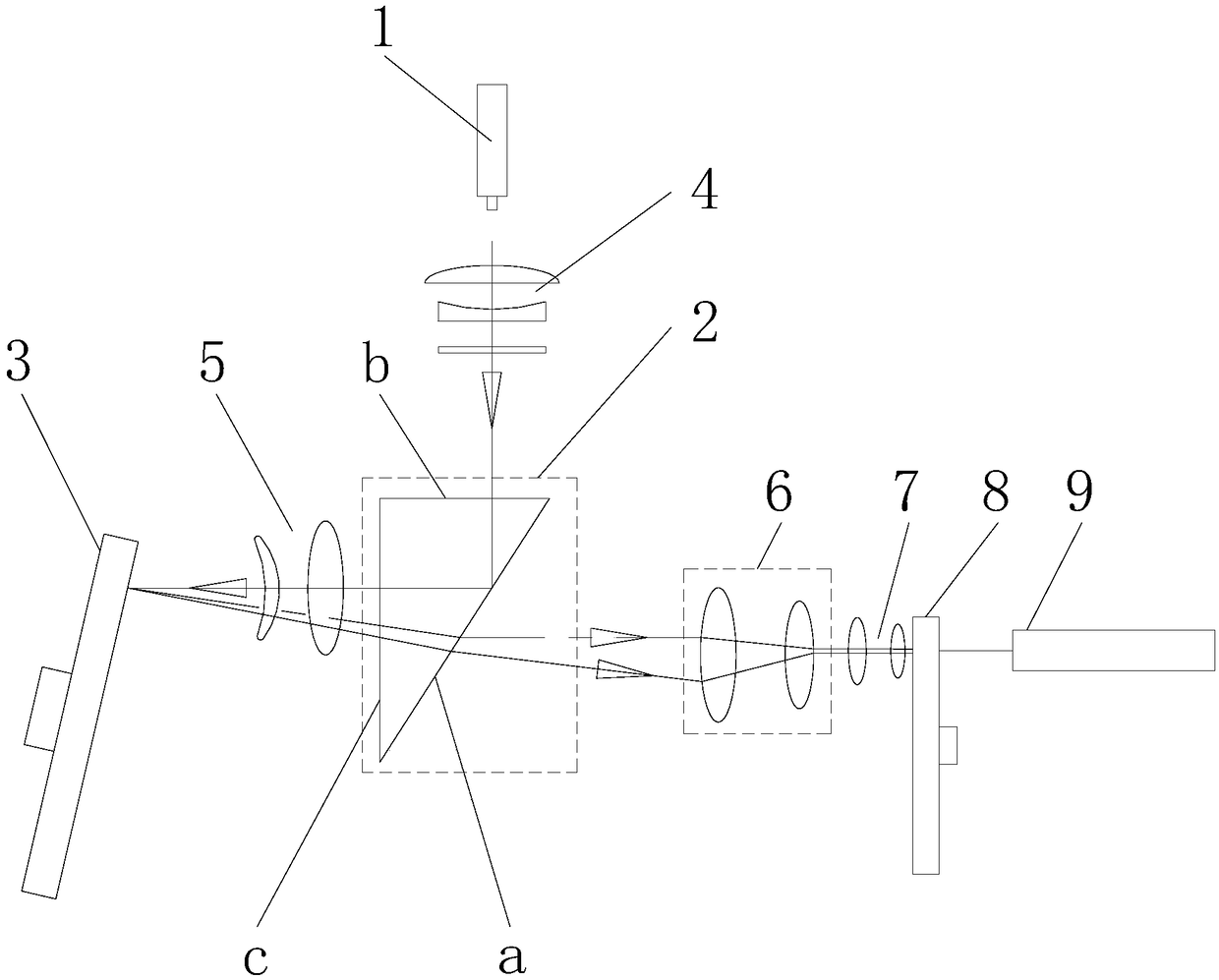

Novel projector light source structure with small size

The invention relates to the technical field of projection light sources, in particular to a novel projector light source structure with a small size. Transmissive regions are disposed on a spectroscopic component to directly transmit a part of the light emitted by a light source, and reflective regions are disposed to reflect a part of the laser light emitted by the light source, and the light isirradiated onto a fluorescent wheel to excite fluorescence. The fluorescence and the laser light are combined into one optical path, the optical path is reduced, the number of optical path lenses isreduced, the size is reduced, and the cost is reduced. In addition, two kinds of blue lasers with different dominant wavelengths can be used to improve the fluorescence excitation efficiency, therebyimproving the light conversion efficiency of the entire light source, outputting high luminous flux, meeting the demand of highlighting, and reducing the stimulation to the human eye. The novel projector light source structure is compatible with various light source schemes such as a monochromatic blue laser, a blue laser and a red laser, and a red, green and blue laser, which is advantageous forsharing molds in mass production and reducing expensive mold costs.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

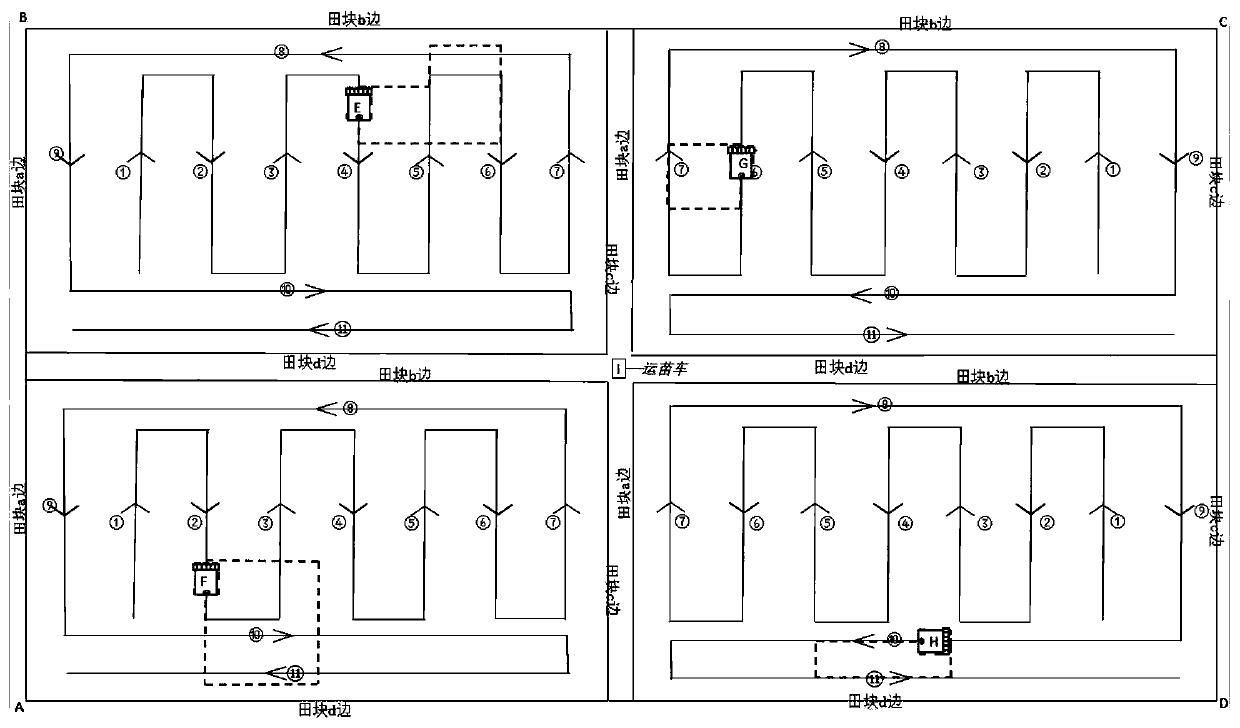

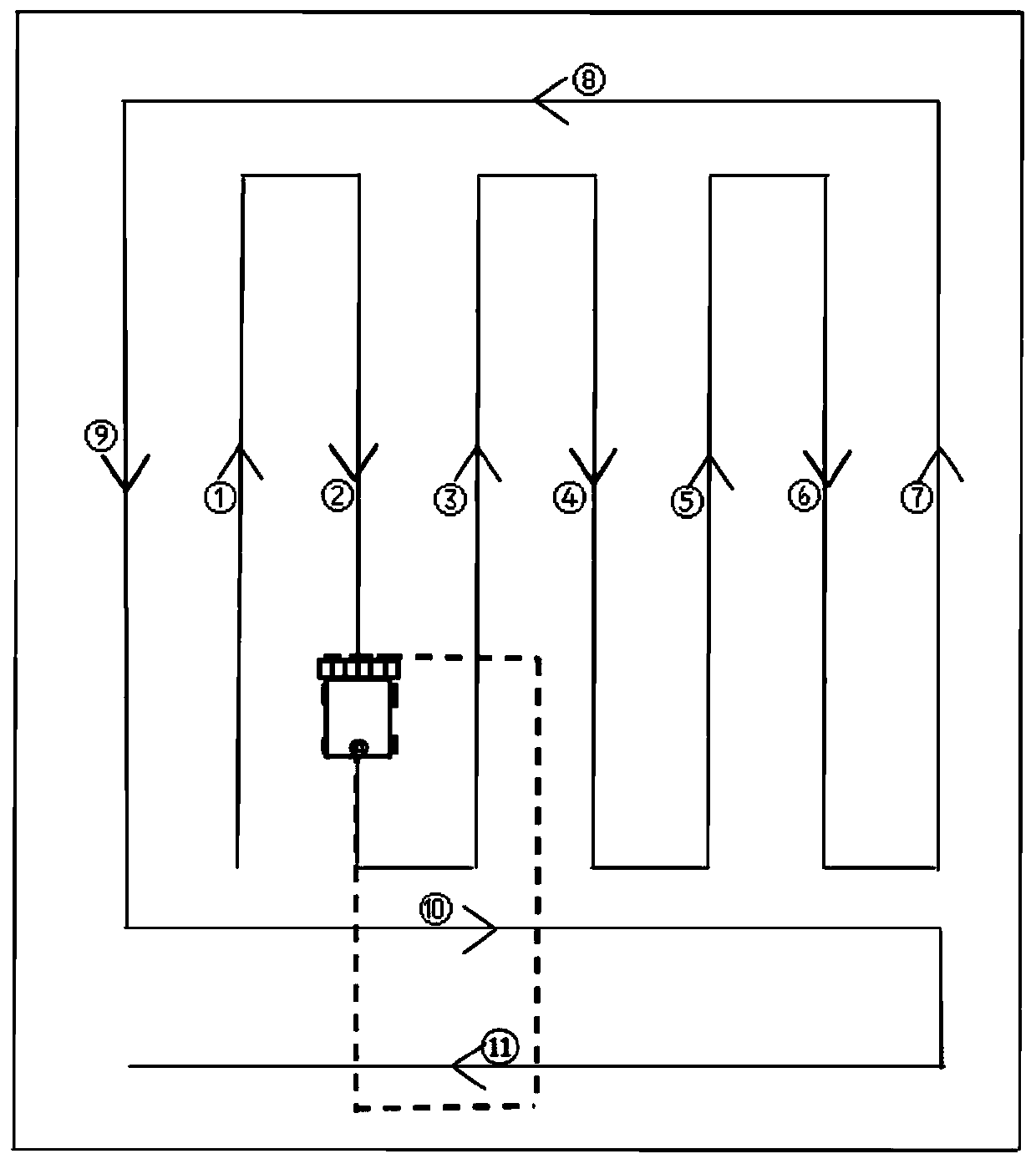

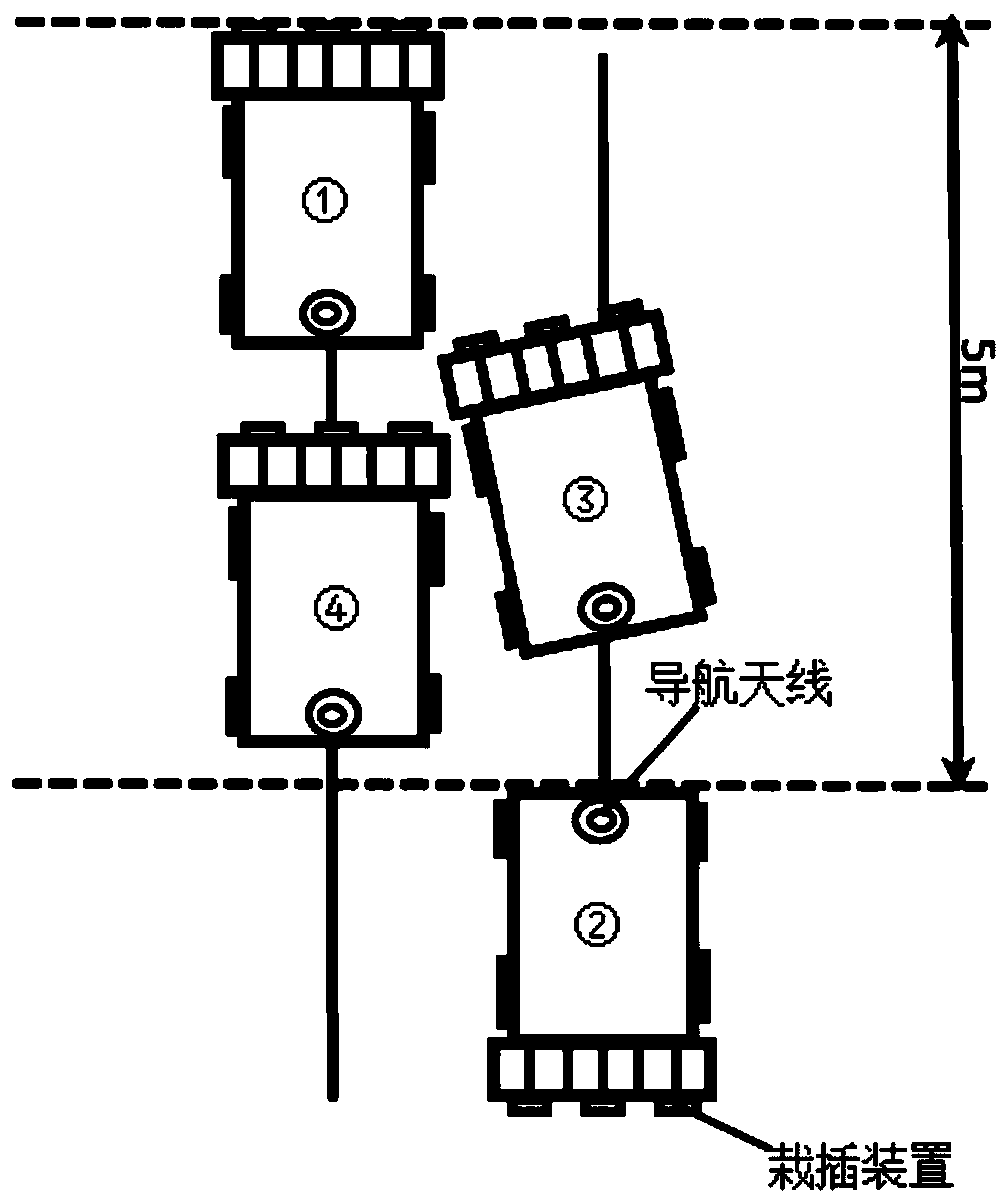

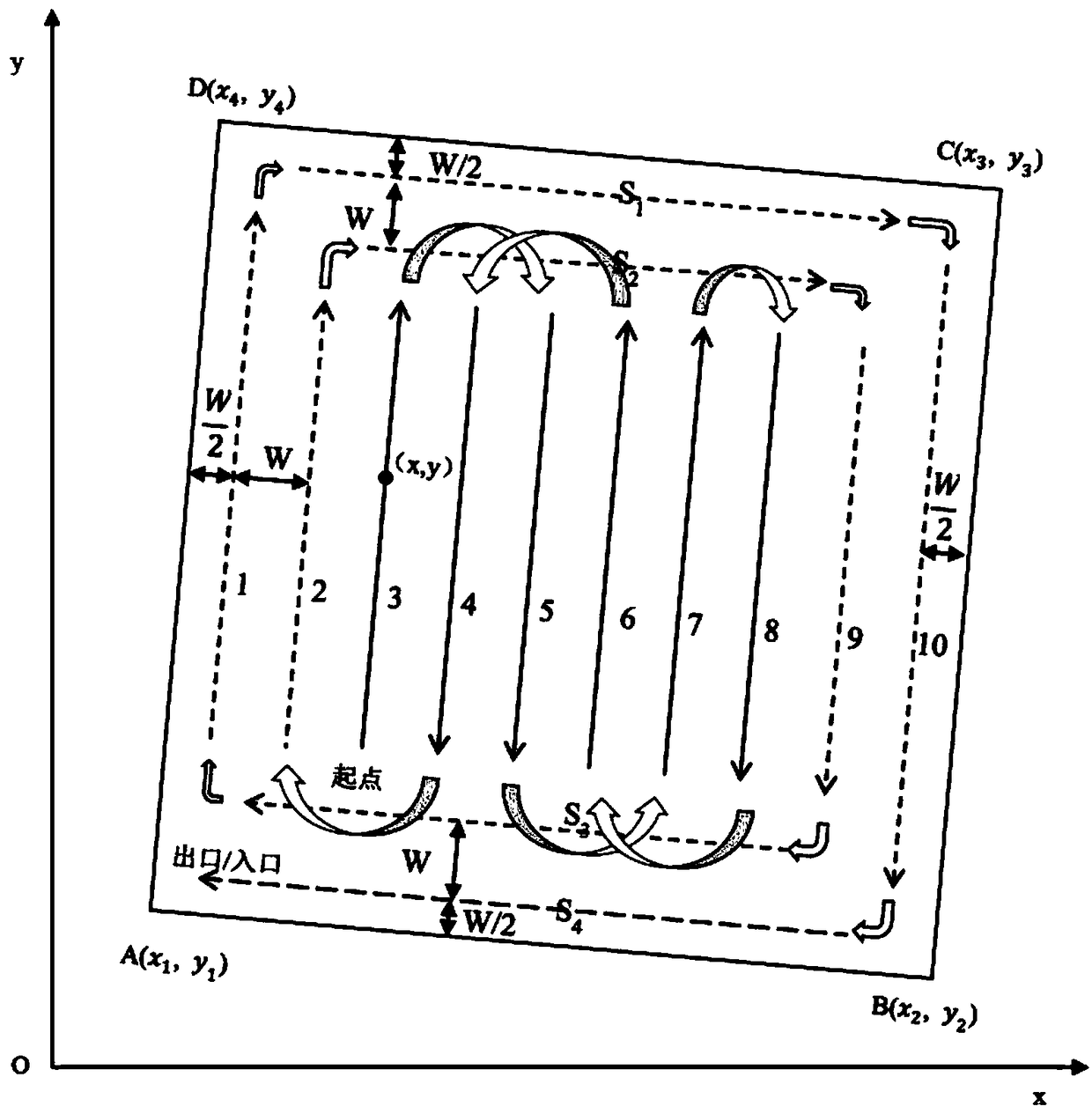

Full path planning and breakpoint endurance method for unmanned rice transplanters

ActiveCN110837252ALess turnsShorten the timeNavigational calculation instrumentsPosition/course control in two dimensionsAgricultural scienceAgricultural engineering

The invention provides a full path planning and breakpoint endurance method for unmanned rice transplanters. According to the method, a vertex coordinate of an operated parcel of rice field is firstlyobtained, widths of the short edges and long edges are calculated, the operated parcel of rice field is divided into four parts and full path planning is carried out on each area; a distance from anoperation rice transplanter to the boundary of each area is calculated according to the boundary of the parcel of rice field of each divided area, a breakpoint endurance mode is started to eliminate the transplanted areas and a path is planned according to the obtained distances of the boundaries so that the rice transplanter can go to the boundary of a nearest parcel of rice field to fill the gaps with seedlings; meanwhile, a real-time distance between a seedling vehicle and the operation rice transplanter in each area and seedling supplementing is carried out on the rice transplanter according to the real-time distance; and finally, the rice transplanter is controlled to turn back to the original operation point according to the path started during the breakpoint endurance. According tothe method, the problem that rice transplanting cannot be carried out at the edges of the fields as the rice transplanters make turns at the edges of the fields is solved, and the conditions of seedling pressing caused by the rice transplanters and missing transplanting in the operation process are decreased, so that the operation efficiency is effectively improved.

Owner:JIANGSU UNIV

Self-Standing Flat Plate-Like Article and Methods of Exhibiting and Manufacturing the Same

InactiveUS20070295677A1Easy to observeLess turnedPicture framesSpecial ornamental structuresGround contactBorder line

A method for stably and easily exhibiting a flat plate-like article such as a flat exhibited article so as to be easily observed and less turned over and the flat plate-like article stably and simply exhibitable so as to be easily observed and less turned over and manufacturable at low cost. The flat plate-like article comprises two or more flat plate-like members and one or more connection parts. The flat plate-like article is characterized in that (A) any first and second flat plate-like members are connected to each other through the connection part and positioned on the border line of these both members and projected backward from the border line so that they can be double-spread and (B) the flat plate-like article can be self-stood when the first and second flat plate-like members are brought into a double-spread state so that a state that the insides of the first and second flat plate-like members are positioned diagonally upward relative to a ground contact surface when at least a part of the bottom-side of the connection part, at least a part of the bottom-side of the first flat plate-like member, and at least a part of the bottom-side of the second flat plate-like member are used as the ground contact parts.

Owner:FERRIC INC

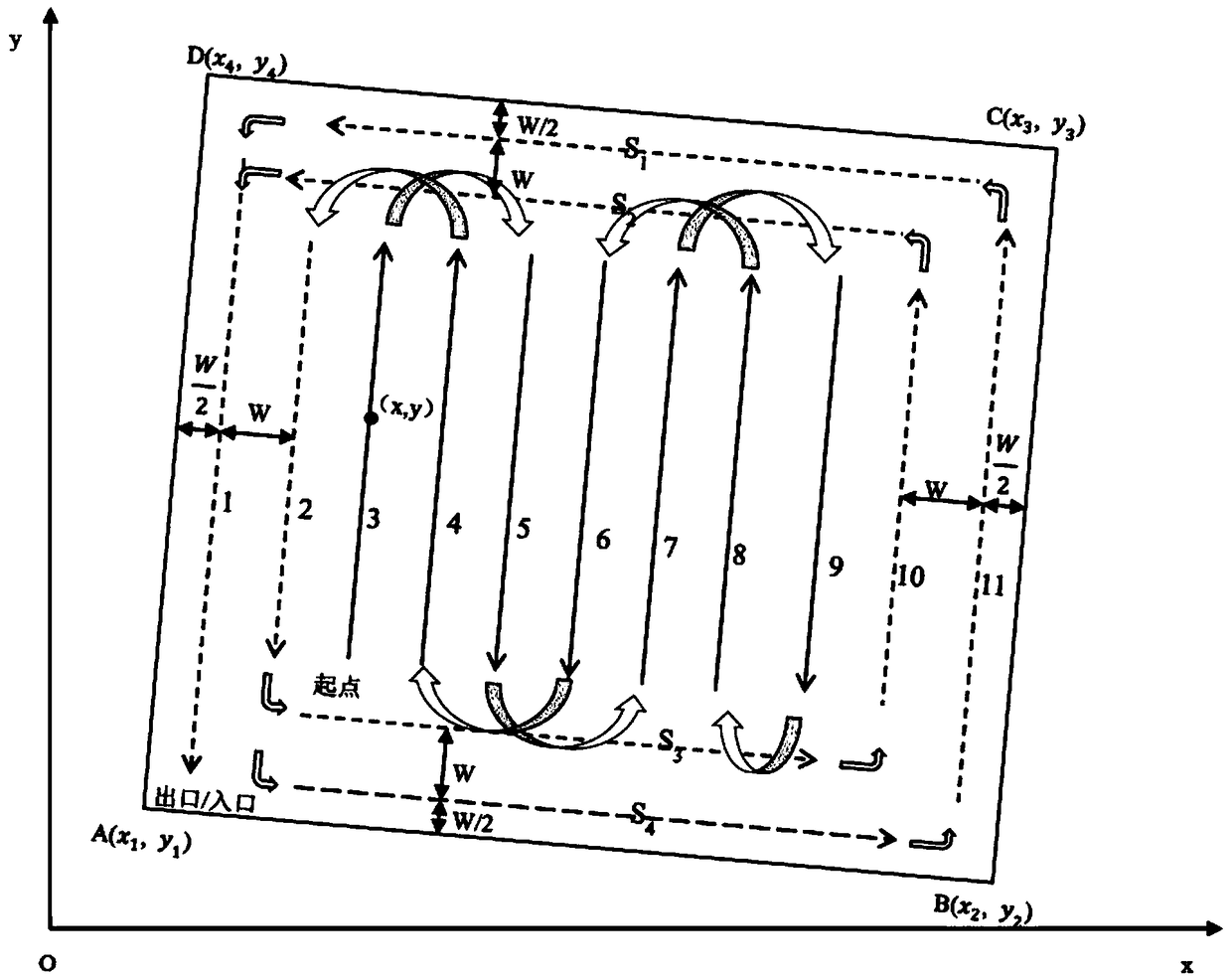

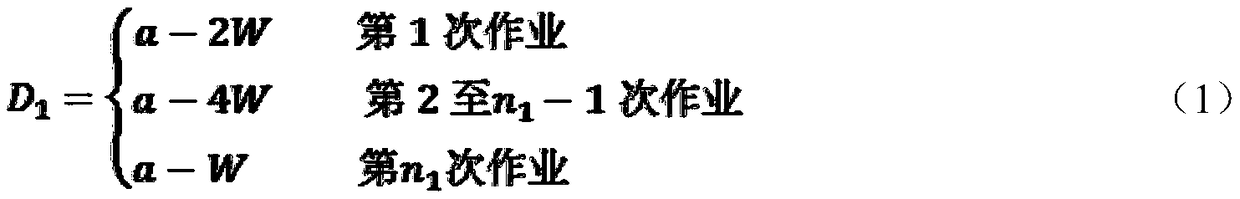

Unmanned transplanter path planning method

InactiveCN108759828ALess turnsReduce difficultyNavigational calculation instrumentsSatellite radio beaconingPlanning methodComputer science

The invention discloses an unmanned transplanter path planning method, which comprises: obtaining the coordinates of the vertexes of a to-be-operated area; calculating the widths of the short edge andthe long edge of the to-be-operated area; obtaining the operating width of a transplanter, and calculating the number of operations; determining the number n2 of operating paths along the short edgeaccording to the obtained operation number n1, and calculating the operating distance along the long edge direction; according to the obtained number n1 and the obtained number n2, calculating the operating distances along the long edge direction and the short edge direction; and carrying out path planning. According to the present invention, by using the cross-row operating method, the difficulties in the turning of the transplanter at the edge of the field and the accurate row aligning can be reduced, and the turning time of the transplanter at the edge of the field and the accurate row aligning time can be shortened, such that the machine planting area of the operating area is greatly improved, and the basis is established for the unmanned driving of the transplanter; and the path planning method can be used for unmanned transplanters, can further be used for unmanned sowing machines, and has characteristics of wide application and simple operation.

Owner:JIANGSU UNIV

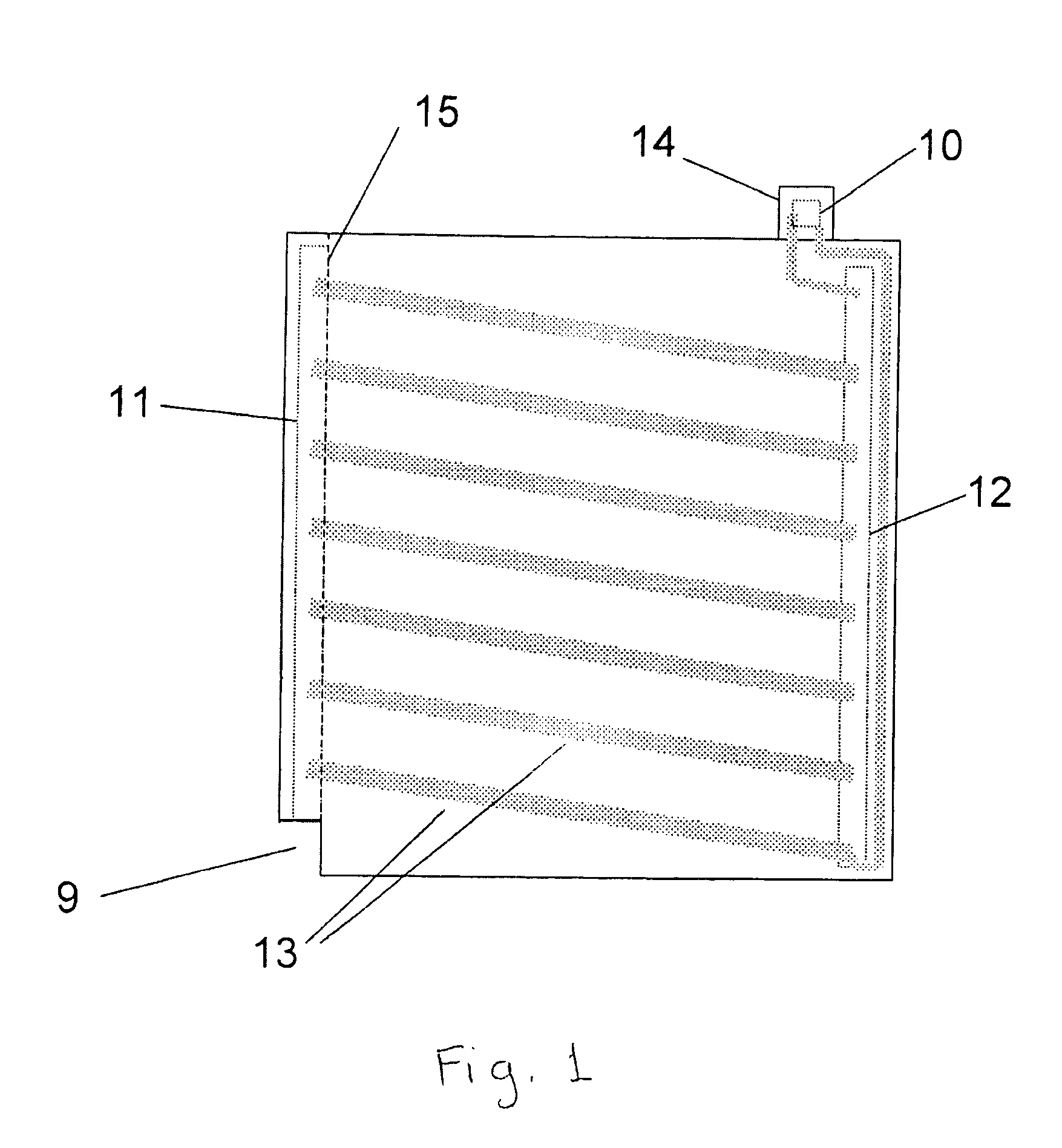

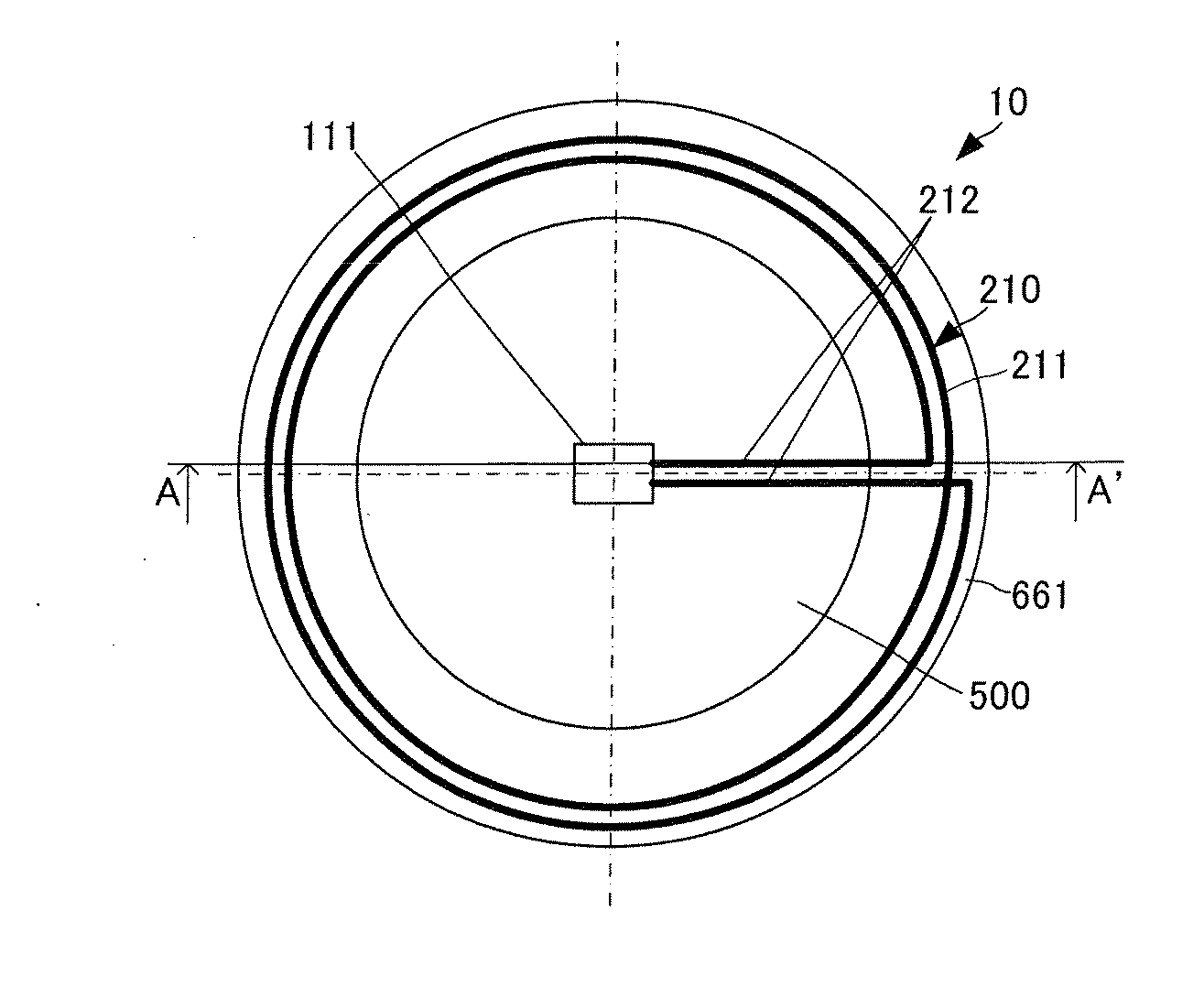

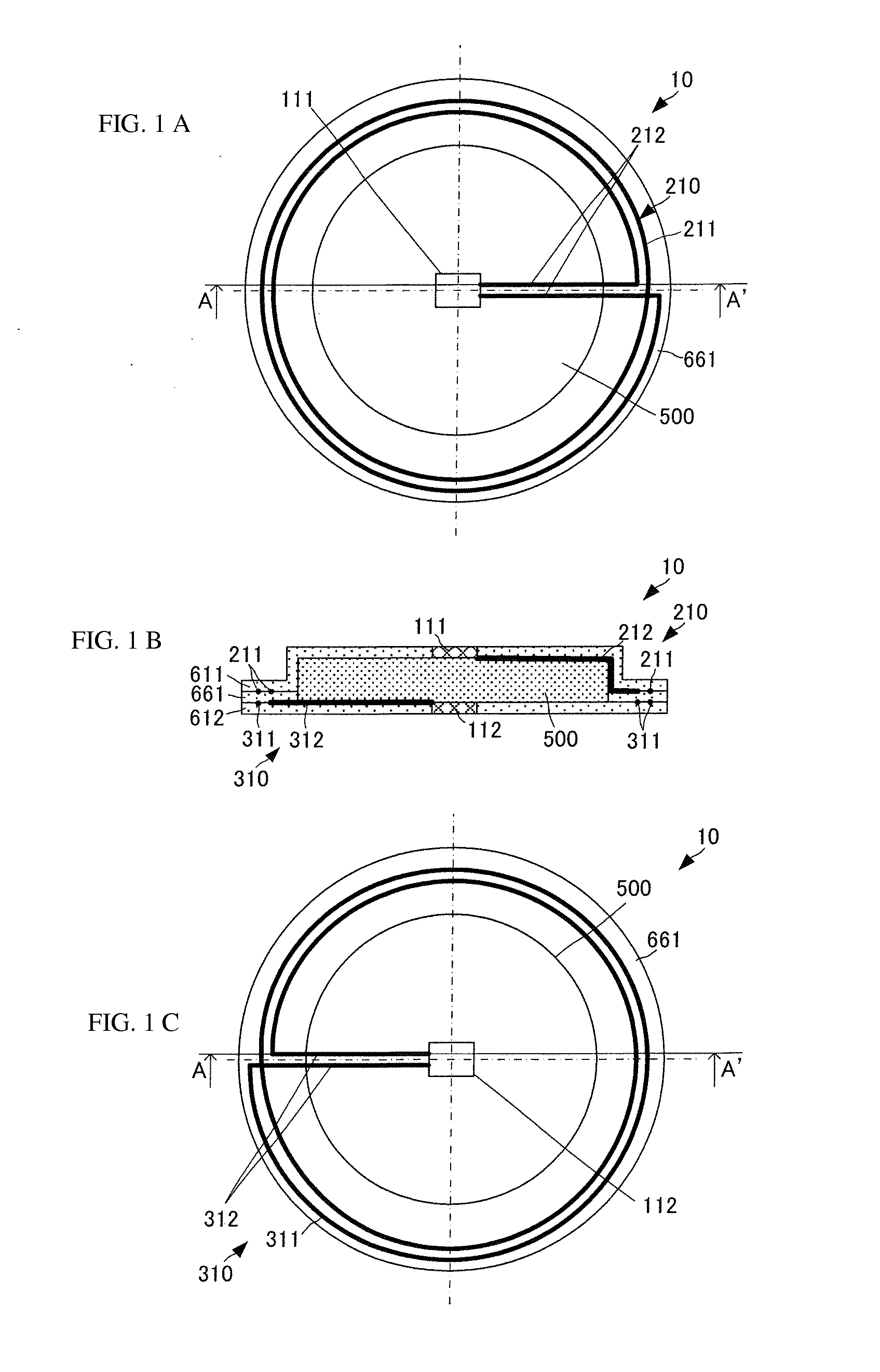

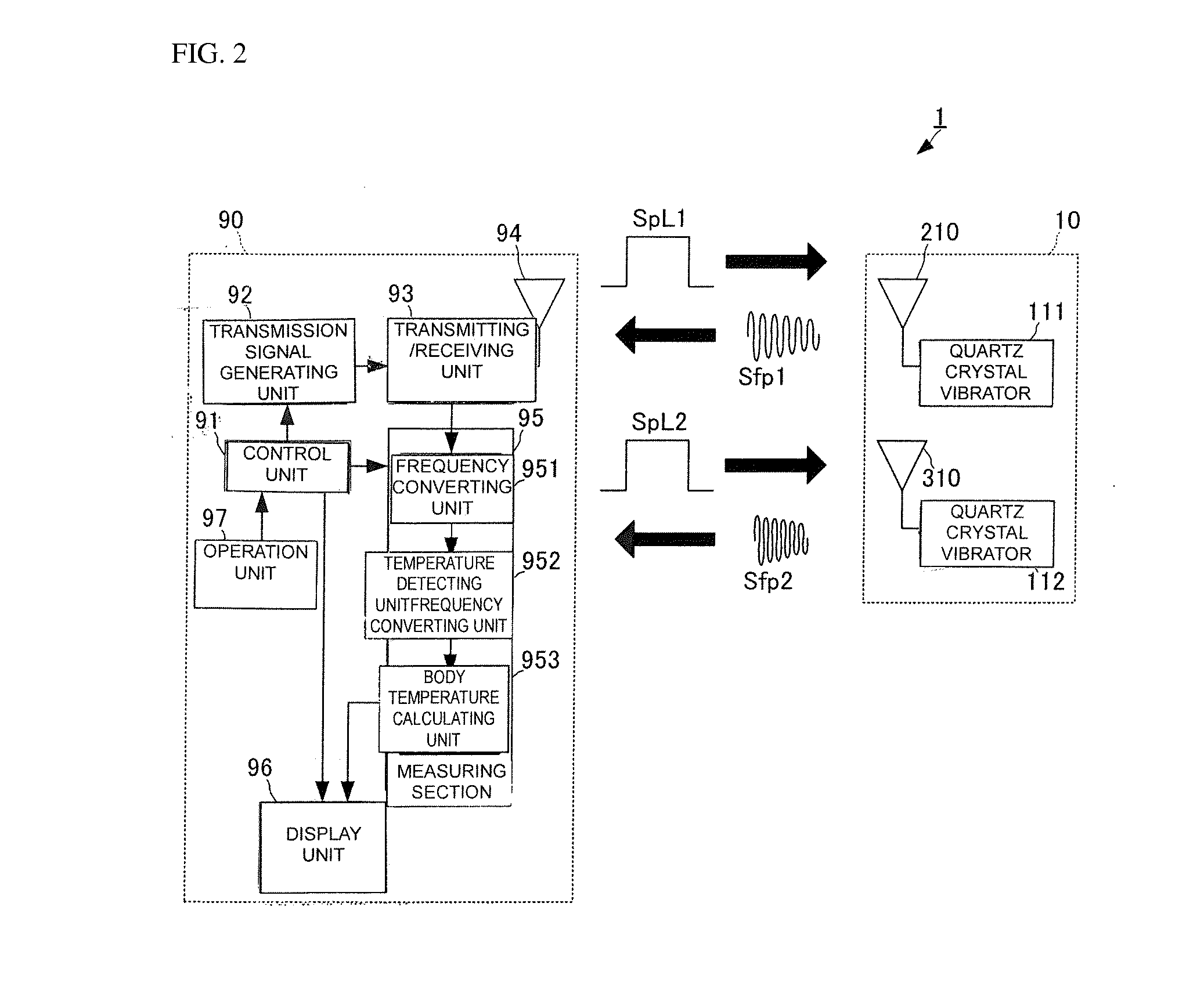

Wireless thermometer

ActiveUS20150010040A1Reduce size of antennaReduce distanceThermometer detailsThermometers using electric/magnetic elementsThermometerEngineering

A wireless thermometer is provided, which measures a deep temperature with high accuracy and has an improved communication distance. A wireless thermometer includes a flat film-like substrate. A quartz crystal vibrator and an antenna are disposed on a principal surface of the substrate. A quartz crystal vibrator and an antenna are disposed on the other principal surface of the substrate. A winding conductor of the antenna is substantially symmetrical with a winding conductor of the antenna with respect to the substrate. A lead conductor of the antenna is connected to the winding conductor at one end and is connected to the quartz crystal vibrator at the other end. A central portion of the lead conductor is bent. By folding the central portion, the quartz crystal vibrator can be positioned opposite the quartz crystal vibrator with a heat insulator interposed there between.

Owner:MURATA MFG CO LTD

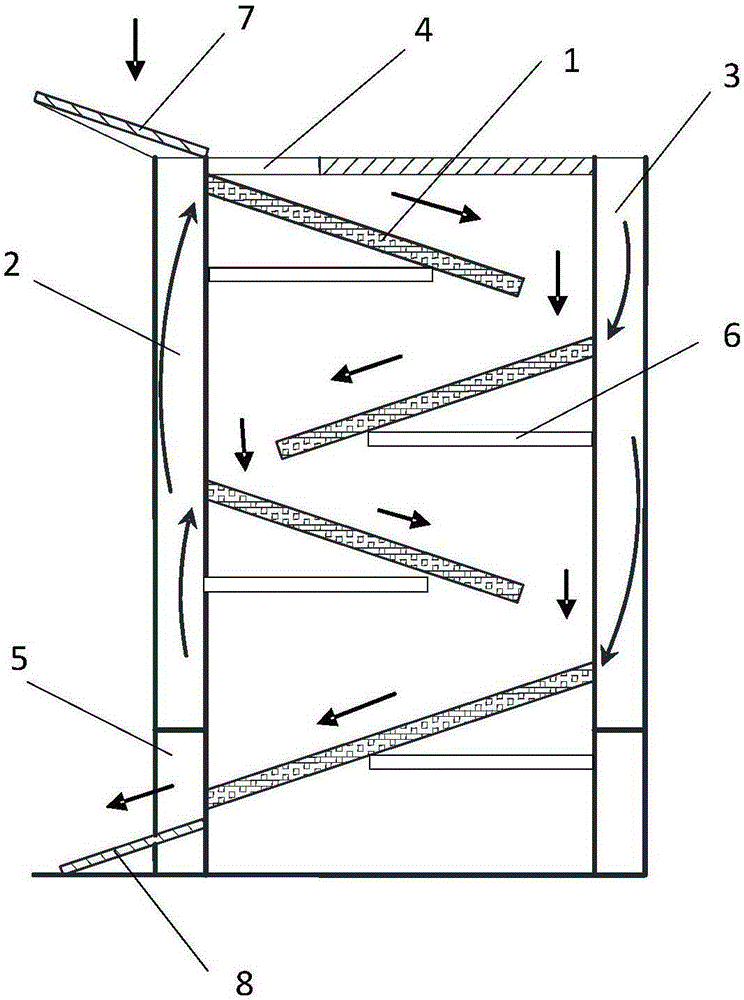

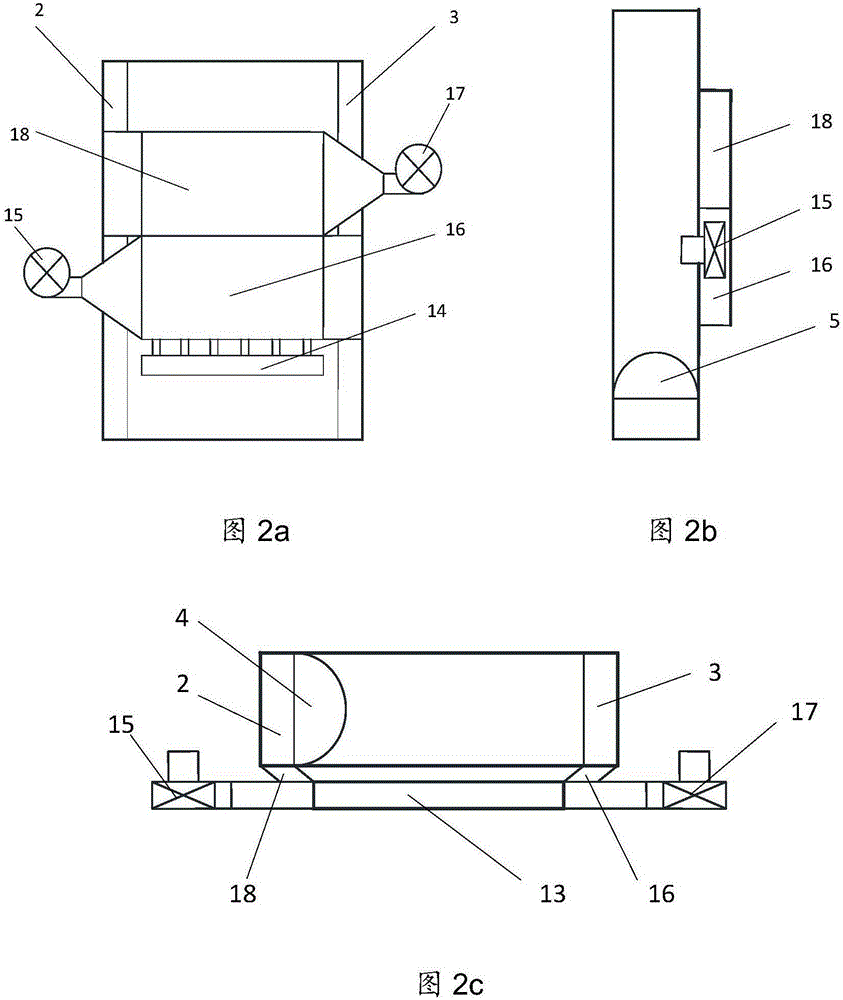

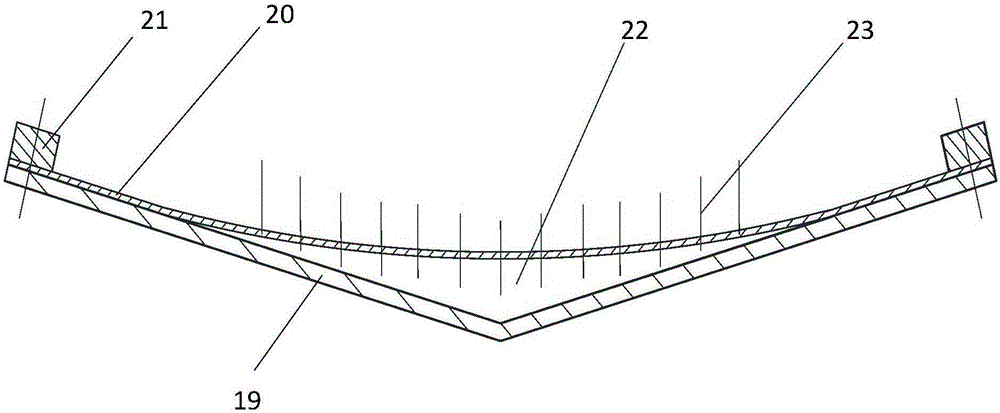

Heat pipe type impinging stream grain dryer

ActiveCN105180626AKeep dryUniform temperature fieldDrying gas arrangementsSeed preservation by dryingPlate heat exchangerEngineering

The invention relates to a heat pipe type impinging stream grain dryer. The heat pipe type impinging stream grain dryer comprises a feed port, a discharge port, sliding ways, an air cavity, a heat pipe heat exchanger, air ducts and draught fans. Each sliding way comprises an internal sliding way cavity and a small hole array at the upper portion of the sliding way cavity. The sliding way cavities are communicated with the air cavity. The air cavity is communicated with the air ducts. Inlets of the air ducts are provided with the draught fans. After to-be-dried grains enter the dryer through the feed port, the grains fall into the sliding ways, slide downwards along the sliding ways, and are discharged from the discharge port; and in the downward sliding process, the heat pipe heat exchanger transfers heat to air in the air ducts, and the heated air is fed into the air cavity through the draught fans, enters the sliding way cavities, and flows out from the small hole arrays at the upper portions of the sliding way cavities to dry the grains. The novel impinging stream drying principle is adopted in the dryer, hot air flows upwards, the grains flow downwards, impinging streams are formed to generate the optimal drying effect on the grains, a temperature field is more uniform and more efficient, mechanical parts are omitted, the structure of the dryer is more compact, and energy consumption is greatly reduced.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

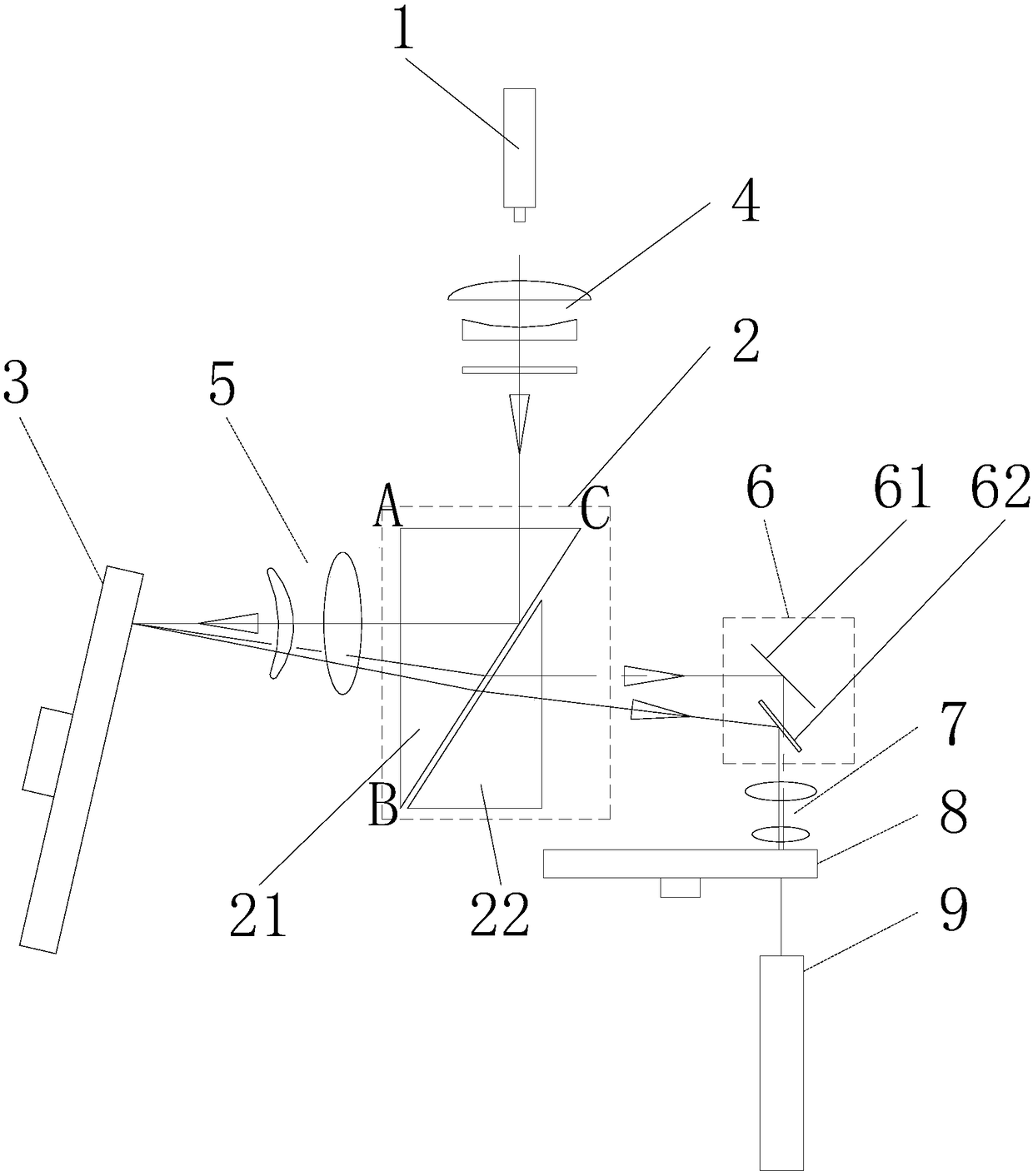

Compact projection light source

The invention discloses a compact projection light source. The light source comprises a light source body, a fluorescent wheel and a prism assembly arranged between the light source and the fluorescent wheel, the prism assembly is provided with a first prism surface, light emitted by the light source is emitted to the first prism surface in an angle greater than the critical angle, a first reflection light is obtained by the full reflection of the first prism surface, the first reflection light is emitted on the fluorescent wheel in the direction oblique to the rotary shaft of the fluorescentwheel, the fluorescent wheel is reflective fluorescent wheel, reflecting areas of a second reflection light obtained by conducting reflection on the first reflection light and a plurality of fluorescent powder areas used for generating irradiation fluorescence of different colors through excitation are distributed along the circumference of the fluorescent wheel, and the second reflection light and the irradiation fluorescence are combined and output by passing through a light combining component after the second reflection light and the irradiation fluorescence are emitted to the first prismsurface in an angle smaller than the critical angle. The light source has the advantages of being simple and compact in structure, less in optical path reflecting times, less in using components, lowin production cost, small in floor occupation area and good in using stability.

Owner:成都九天光学技术有限公司

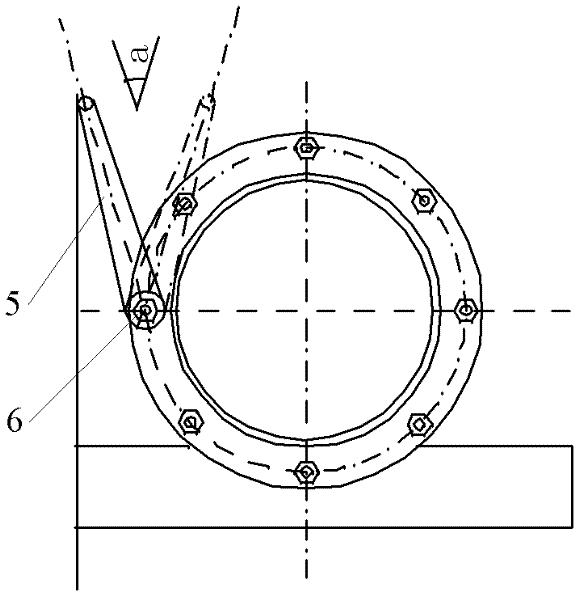

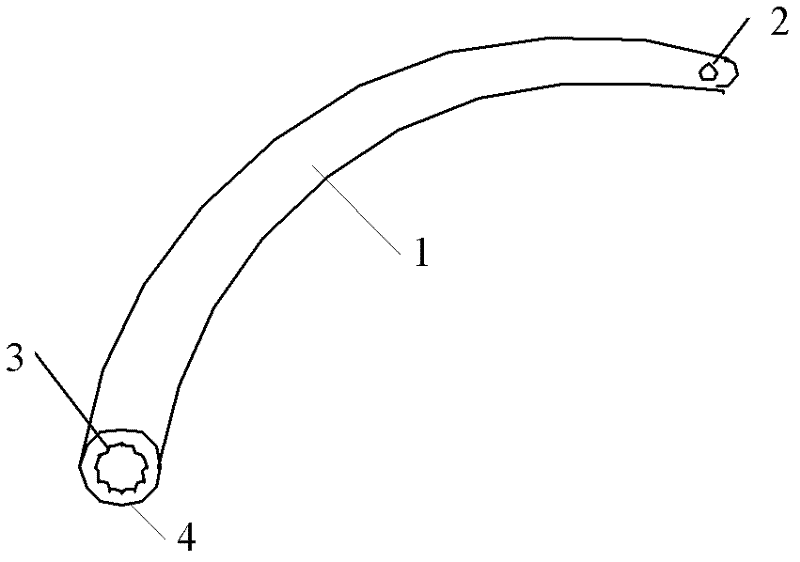

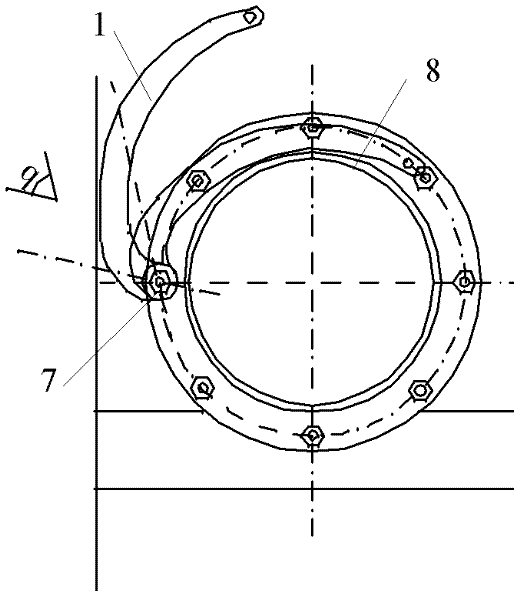

Wrench

The invention provides a wrench which comprises an arc wrench body. The arc wrench body is provided with an operating end and a holding part, wherein the operating end is provided with a regular polygon through hole. The wrench body adopts an arc wrench body, and the arc structure ensures that the holding part of the wrench can be more close to a pipe wall of a pipeline system than a holding part of a common straight handle wrench, so that the angle of the wrench rotating for one time is larger than that of a straight handle wrench in the condition of identical distances from the pipeline system to the side part of a laneway, and the rotating time of the wrench for fastening and disassembling flange bolts is less in same operating condition, and the operating efficiency is improved.

Owner:HUAINAN MINING IND GRP

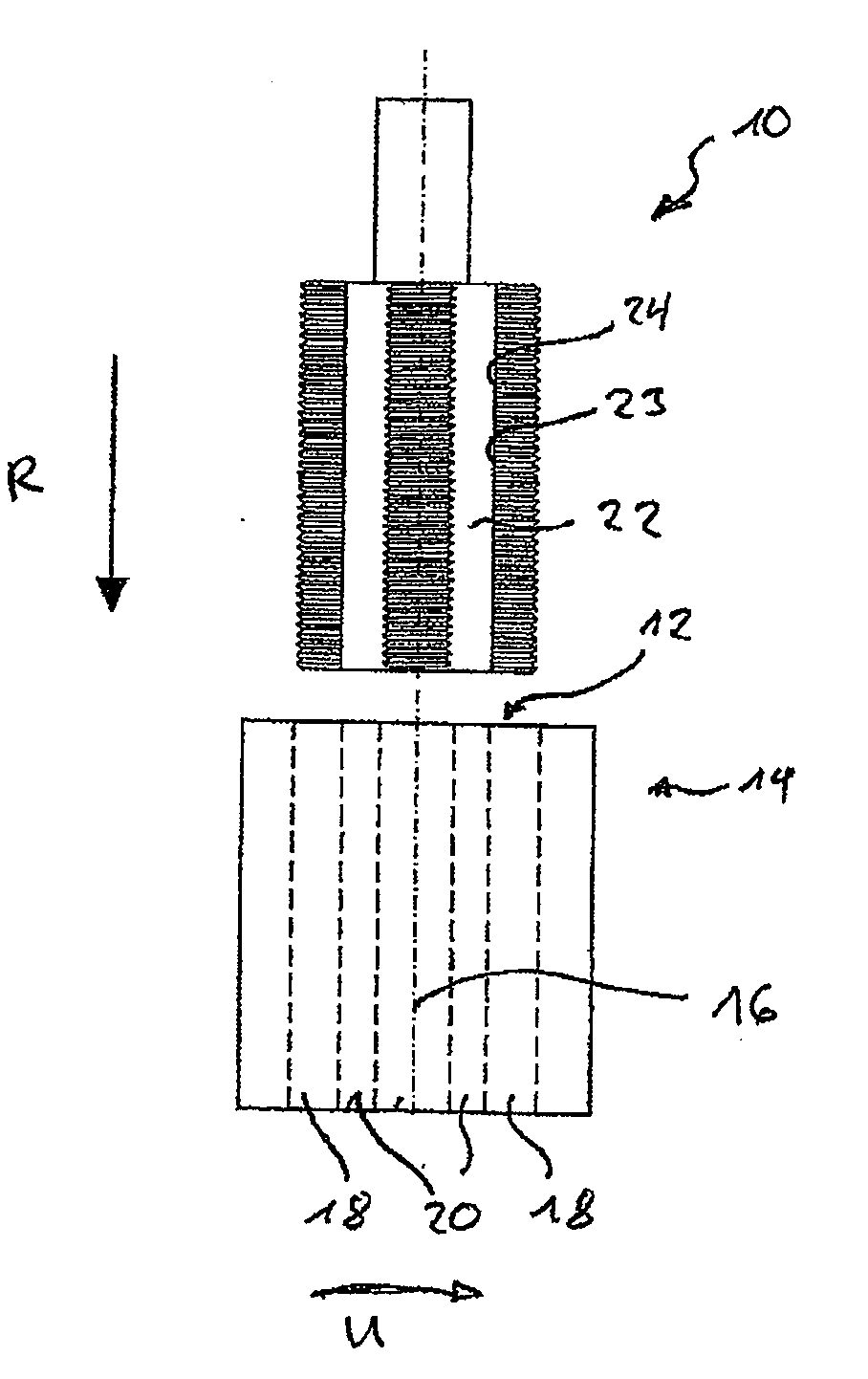

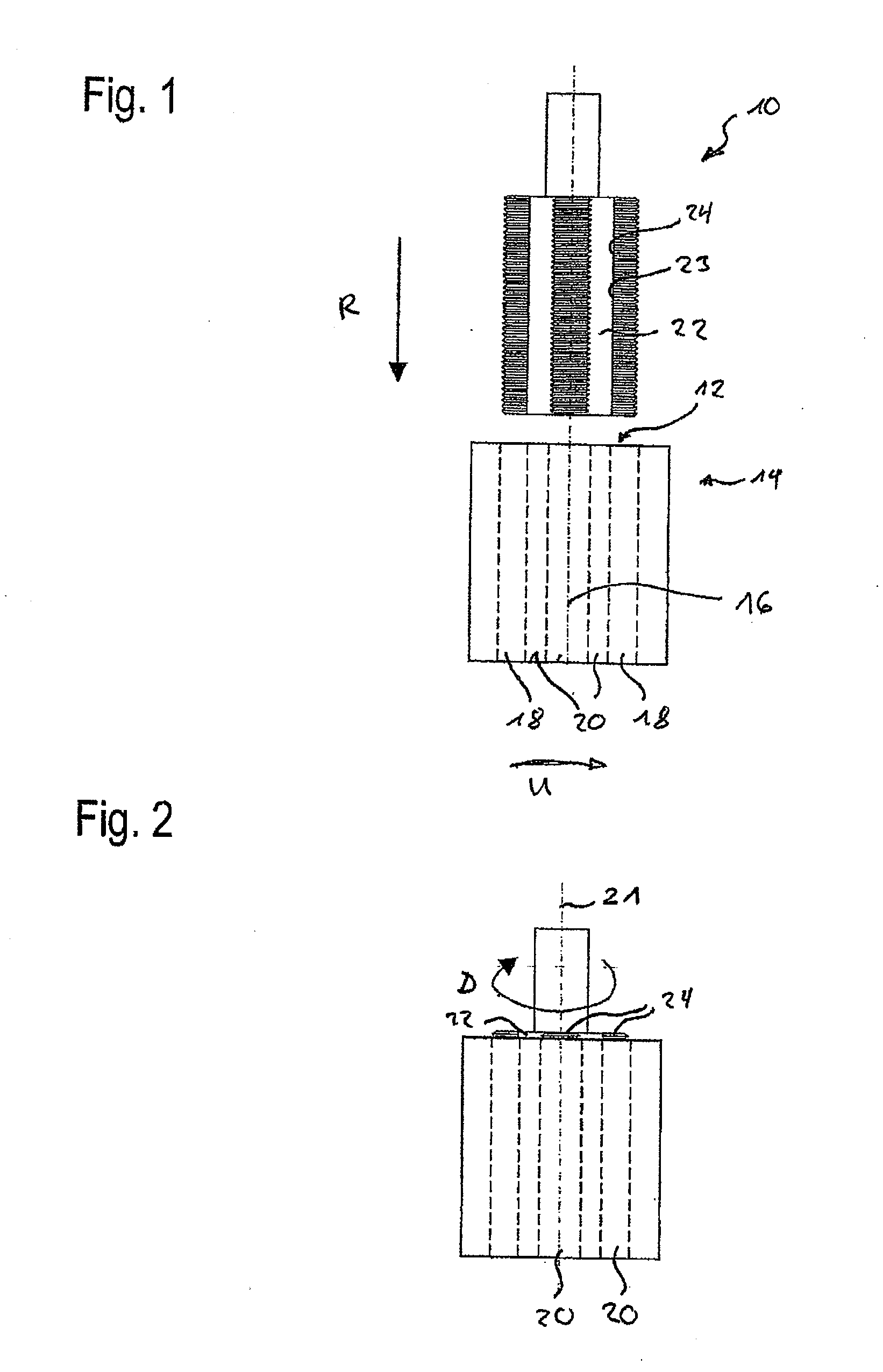

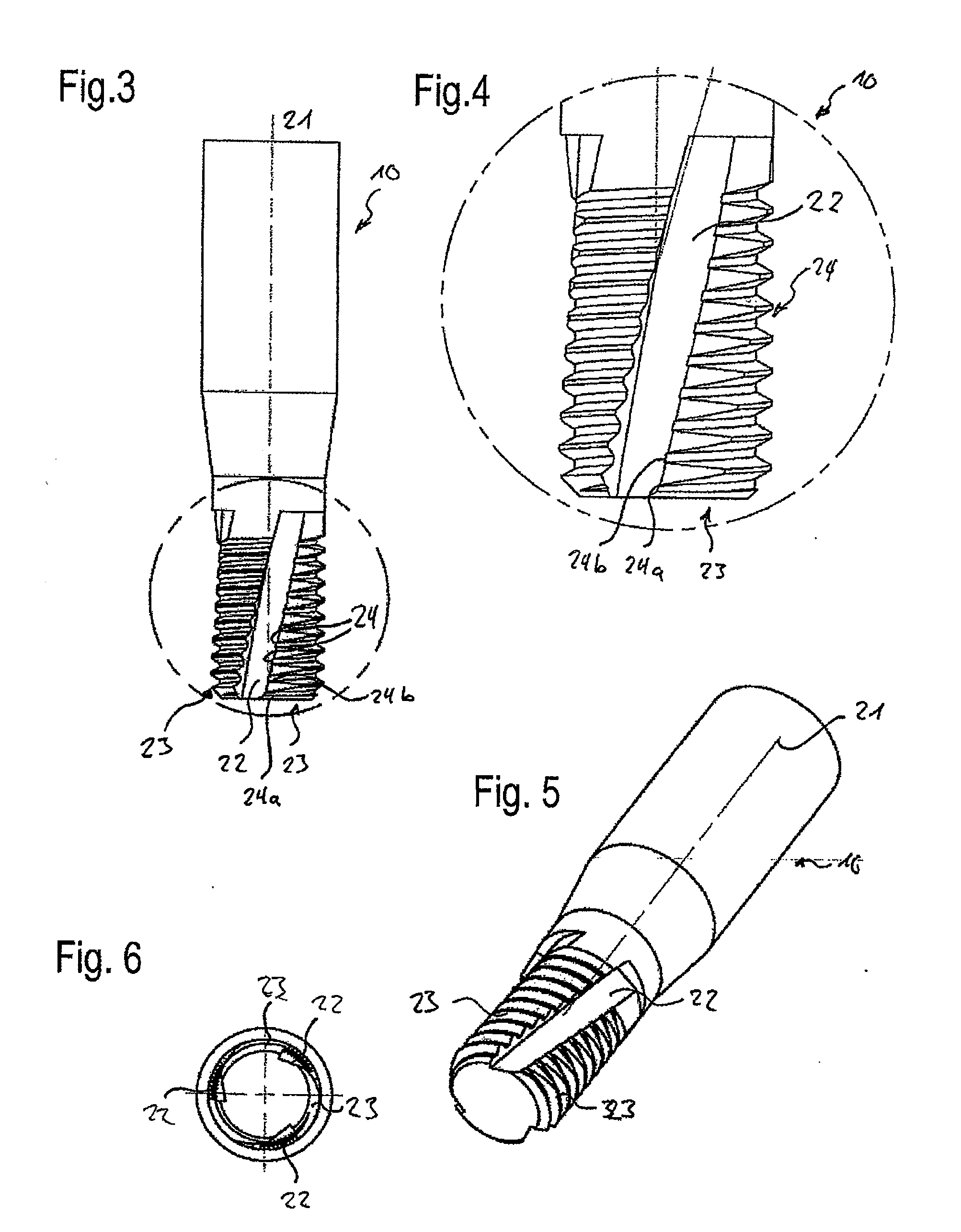

Method for creating an inner thread as well as a combination of a thread cutter and a body having a cutout

ActiveUS20120289350A1Reduce the amount requiredLarge force peaksThread cutting toolsWood turning toolsEngineeringScrew thread

A method for creating an inner thread in an opening of a body, using a thread cutter, including the following steps:a) the thread cutter having an axial lengthwise cutout adjacent to which there are blades that project radially outwards and that have cutting edges, is inserted into the opening, whereby several cutting edges arranged one after the other in the longitudinal direction are provided on the lengthwise cutout, which are offset with respect to each other in the circumferential direction, and which are pushed into the groove when the thread cutter is being inserted,b) the cutting tool is rotated by a maximum of 360° in order to create the entire inner thread in at least one projection next to the groove, whereby the cutting edges penetrate into the projection one after the other as the thread cutter turns, andc) the thread cutter is moved axially out of the opening.

Owner:HILTI AG

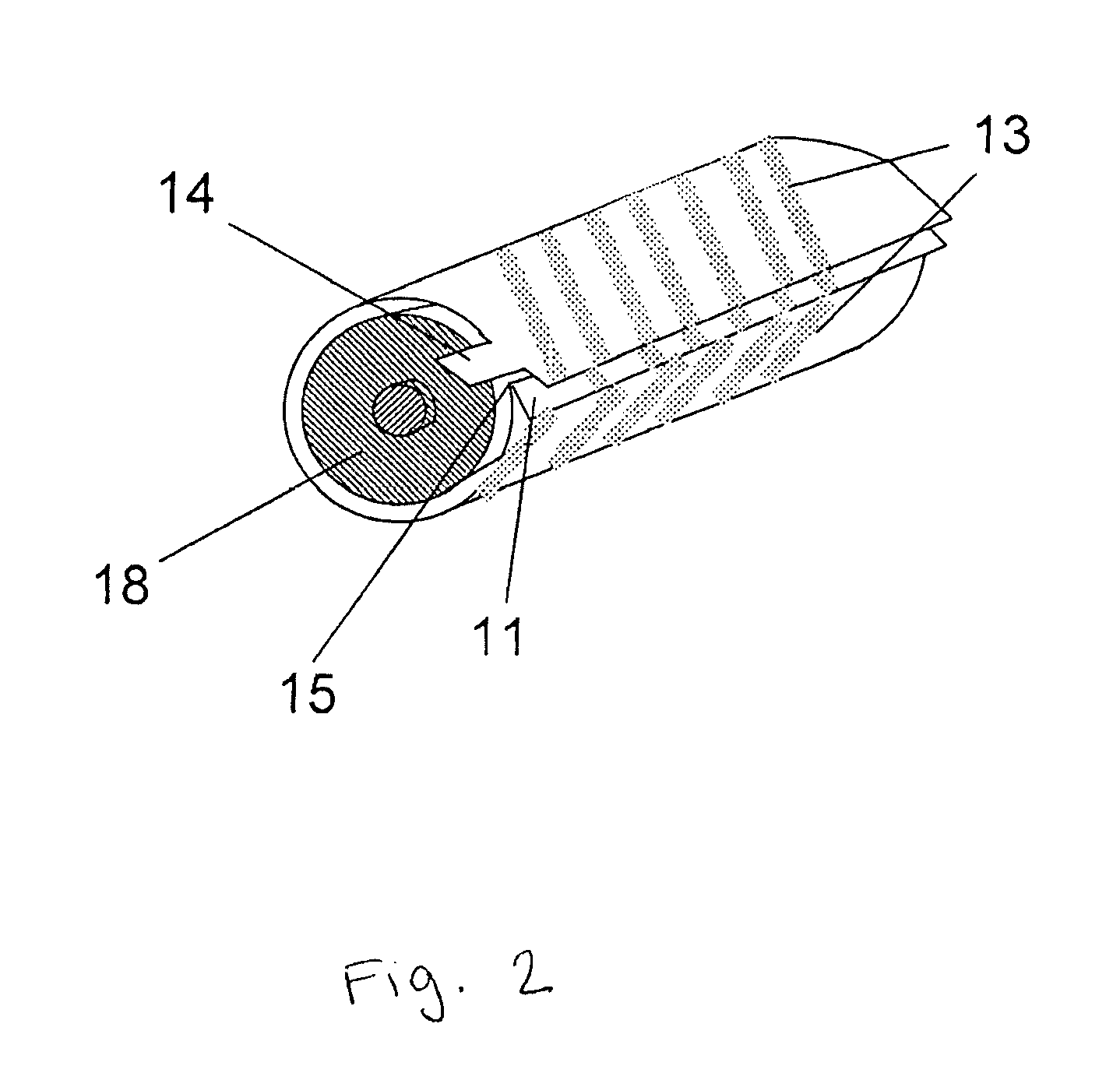

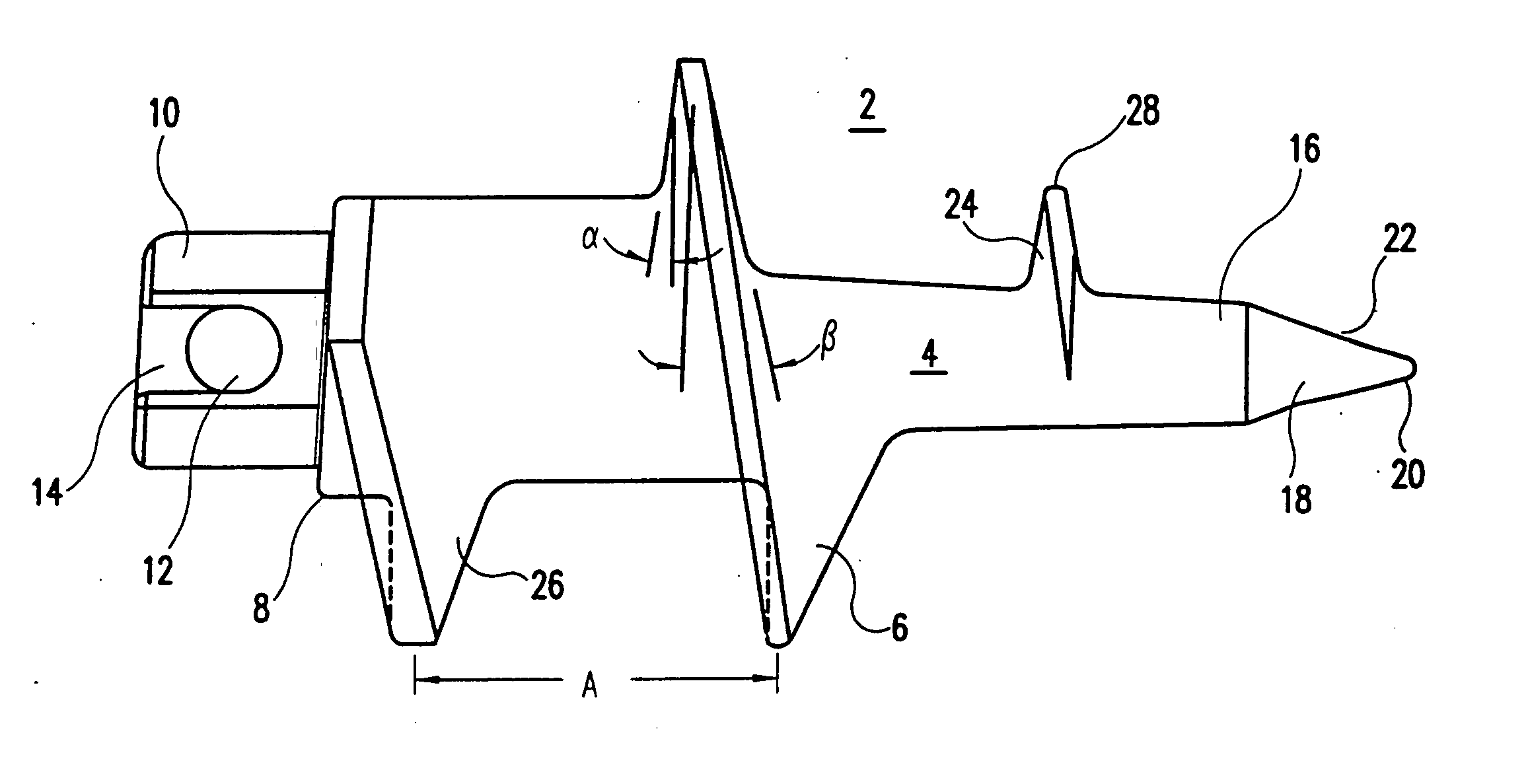

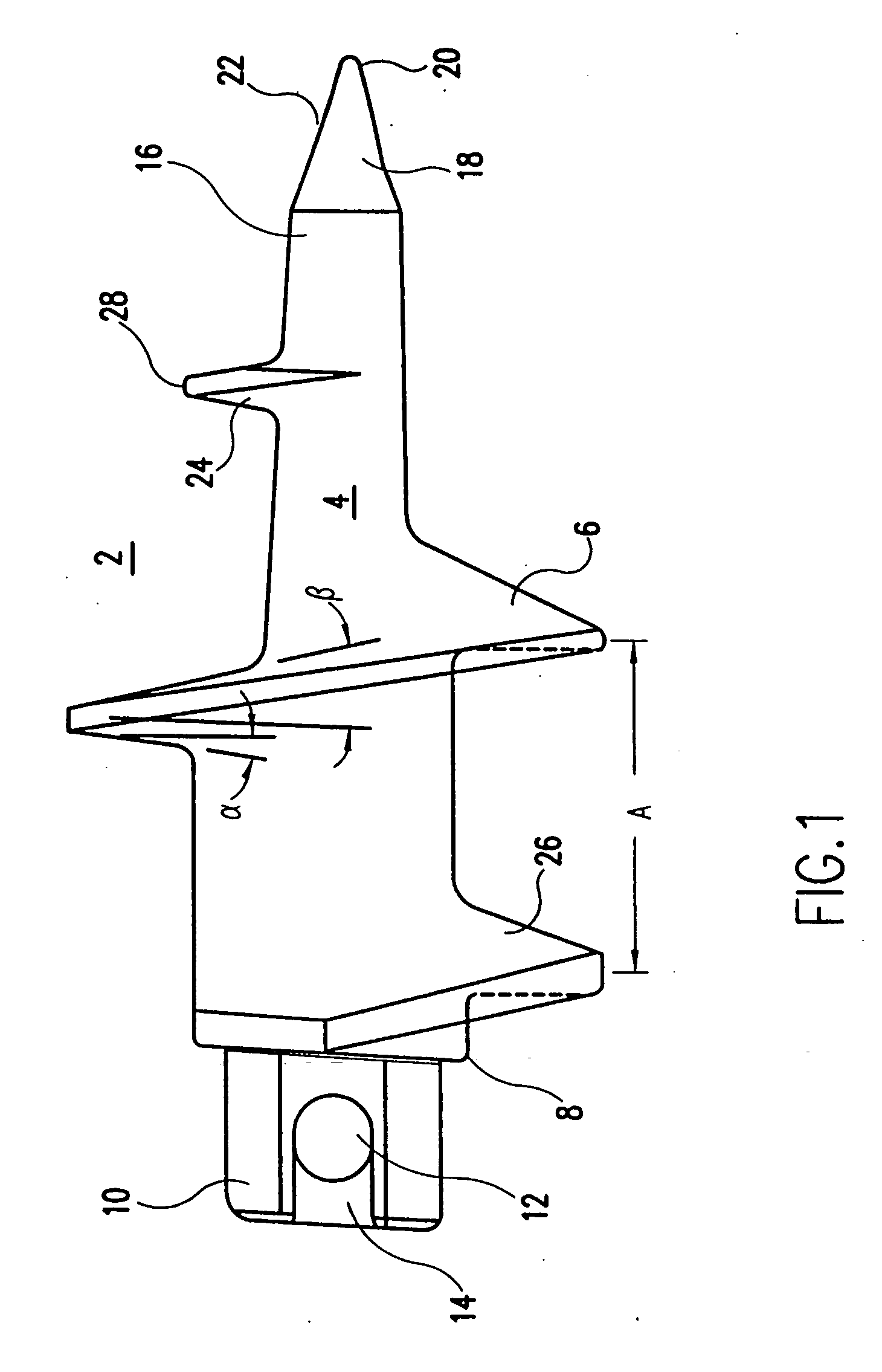

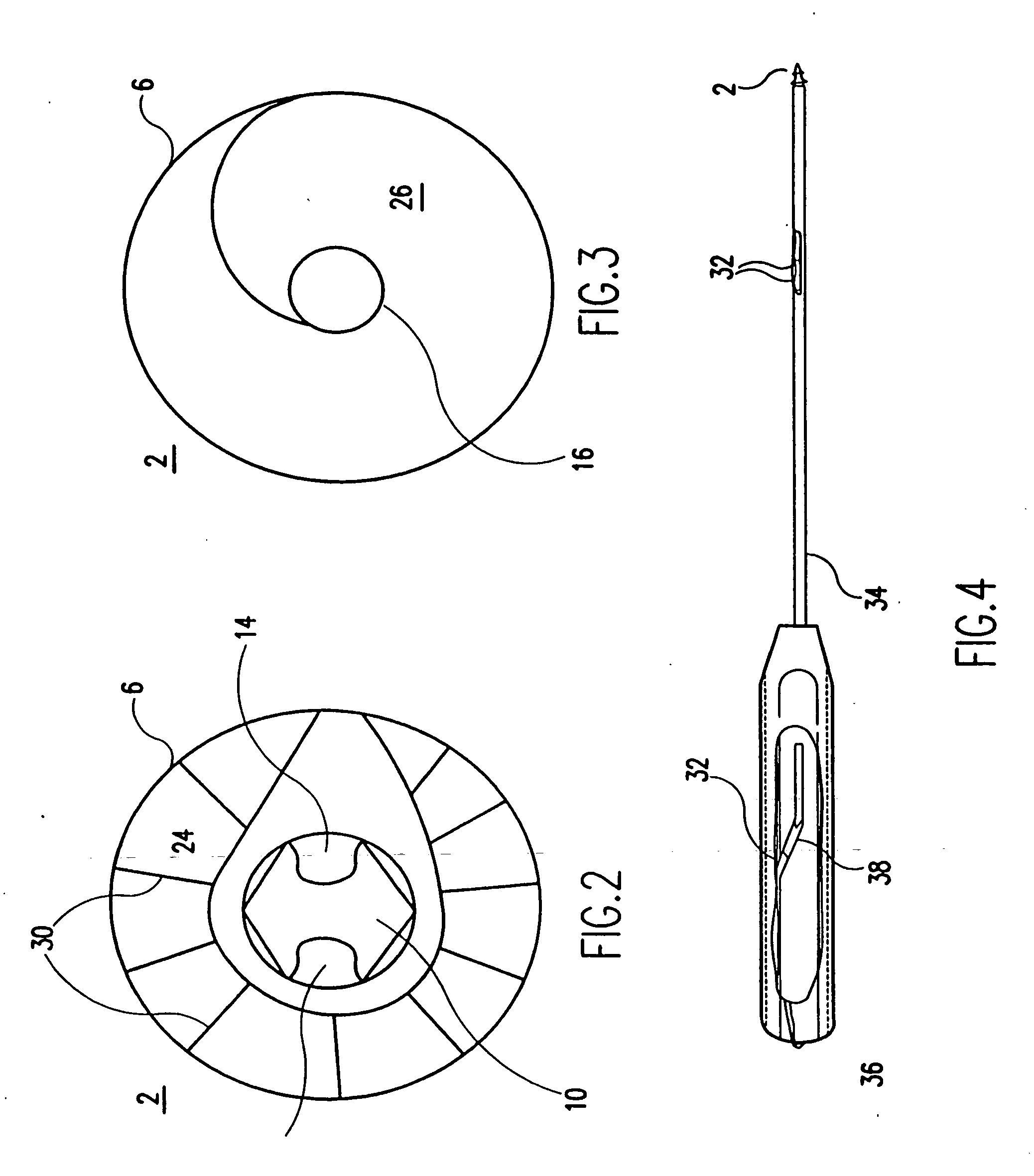

Corkscrew suture anchor

InactiveUS20060004365A1Avoid collisionIncrease surface areaSuture equipmentsLigamentsSuture anchorsSurgery

A corkscrew suture anchor has a continuous thread spiraling around a tapering central core. At the distal end, the suture anchor terminates in a rounded point. At the proximal end of the suture anchor is an eye for receiving suture. The suture anchor has a large thread surface per turn of thread. Anti-backout ridges can be formed on the front and / or back faces of the threads. A driver for the suture anchor is provided, the driver including a shaft having a central axis, a length, a distal end, and a proximal end. The shaft is provided at its distal end with an opening aligned with the central axis of the shaft, for receiving the hexagonal proximal end of the suture anchor. One or more sutures threaded through the suture eye are threaded through the hollow tubular shaft. The suture is pulled into and captured by V-shaped notches on the proximal end of the handle to hold the suture anchor in place on the distal end of the driver under the tension of the captured sutures.

Owner:ARTHREX

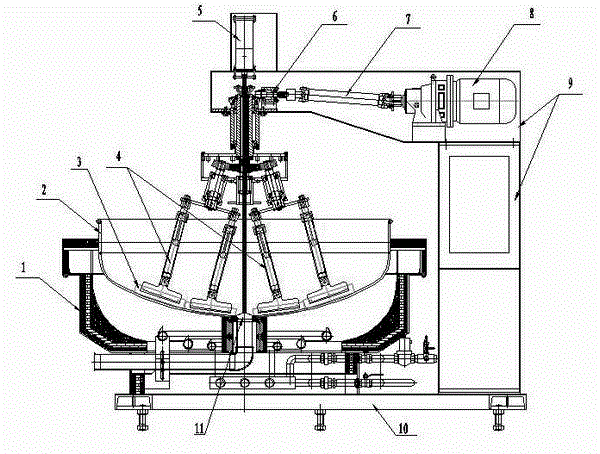

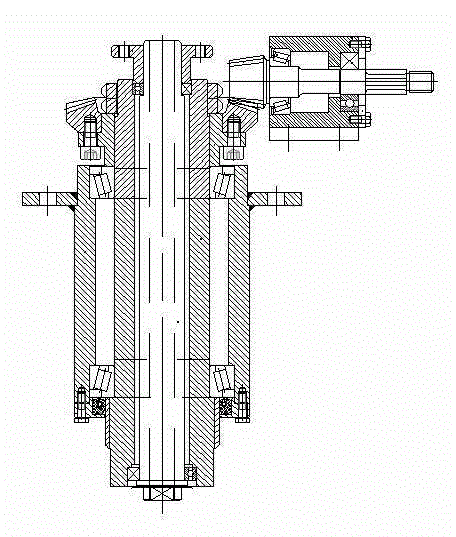

Double-star stirring and bottom discharging frying pan

InactiveCN102907661AStir wellLess turningChemical industryPharmaceutical product form changeFood industryChemical industry

The invention discloses a double-star stirring and bottom discharging frying pan, which mainly comprises outer cylinders (1), a pan body (2), a burner and stirring devices, wherein the pan body is fixedly connected with the upper part of the outer cylinders (1) and is erected on the cylinders (1), a hearth is formed between the cylinders (1) and the pan body (2), the stirring devices are fixed on a bottom frame (10) by a support (9), smoke discharge holes are arranged on the cylinders (1), and the double-star stirring and bottom discharging frying pan is characterized in that the stirring devices are double-star stirring devices (4). The double-star stirring and bottom discharging frying pan is an improved naked flame sauce frying pan; since the double-star revolution stirring device, the pan body and stirring are unnecessarily to turn over, discharging is performed by a discharge pipe at the center of a pan bottom, the original single-star revolution stirring is replaced, and a hydraulic turnover device is reduced. The double-star stirring and bottom discharging frying pan has the advantages of uniform sauce stirring, good pan scraping effect, difficultly in making pan become sticky, good frying quality, high efficiency and simple structure, and the double-star stirring and bottom discharging frying pan is an ideal pan for frying sauce in food industry, and is also suitable for frying of medical and chemical industries.

Owner:HANDAN CITY YUANSHUN MACHINERY EQUIP

Stator for an electrical machine

InactiveUS20140319955A1Magnetic flux leakageReduce Flux LeakageWindings insulation shape/form/constructionSynchronous machinesElectric machineEngineering

A stator comprising a coil wound onto a bobbin. The coil is wound as a plurality of layers, each layer comprising a plurality of turns that extend between opposite ends of the bobbin. The outermost layer has a turn pitch greater than that of a lower layer. Additionally, an electrical machine comprising the stator.

Owner:DYSON TECH LTD

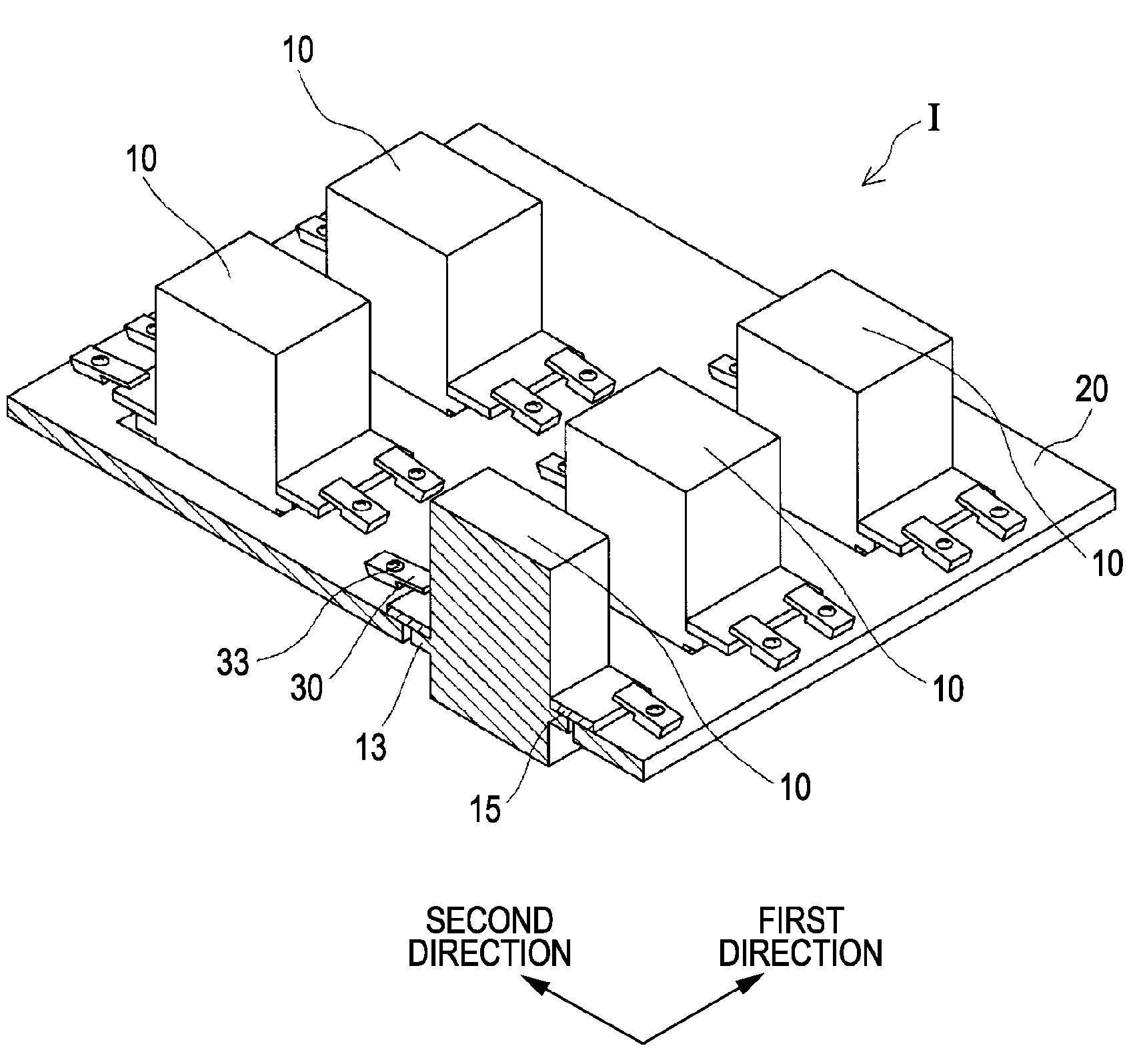

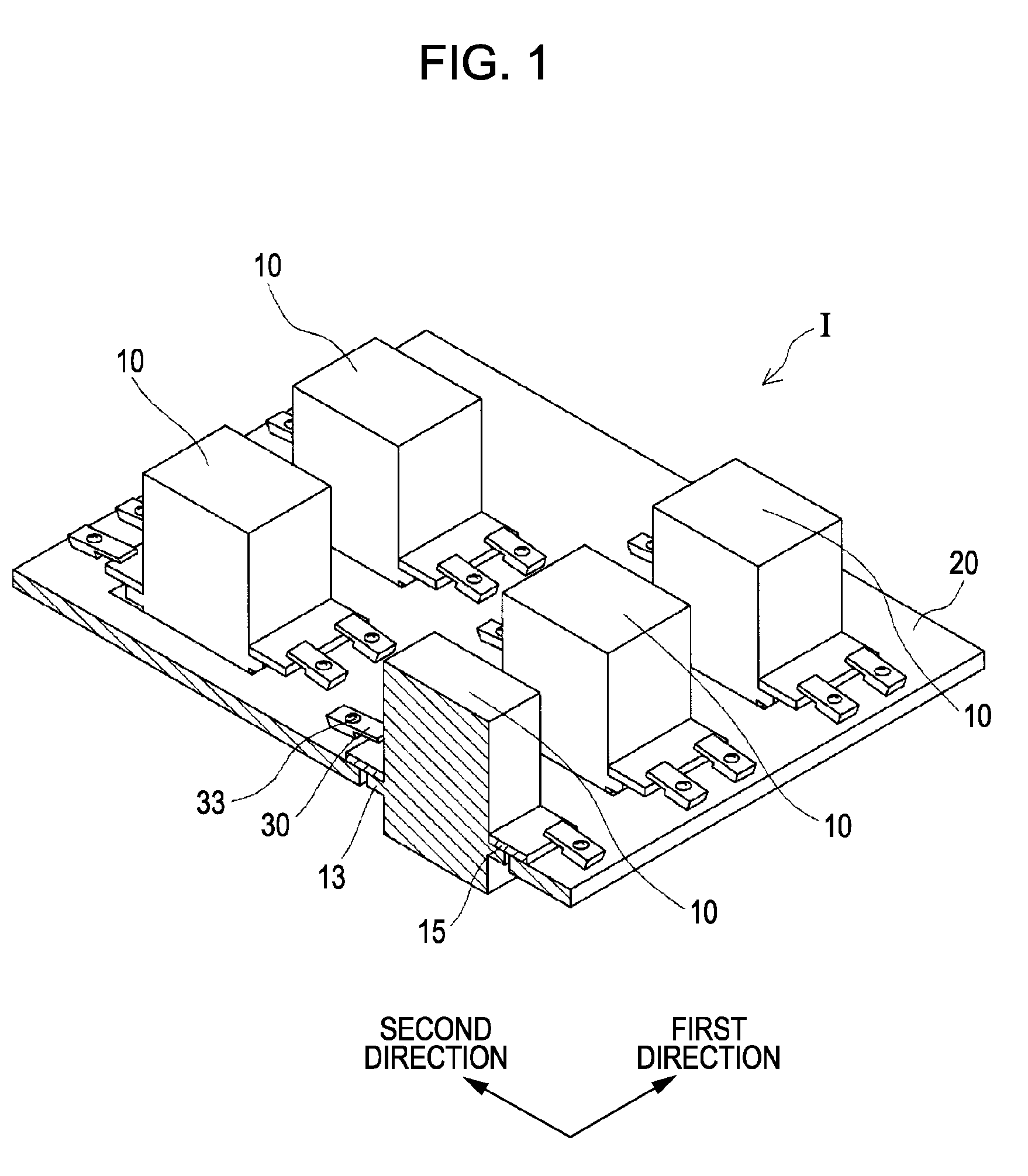

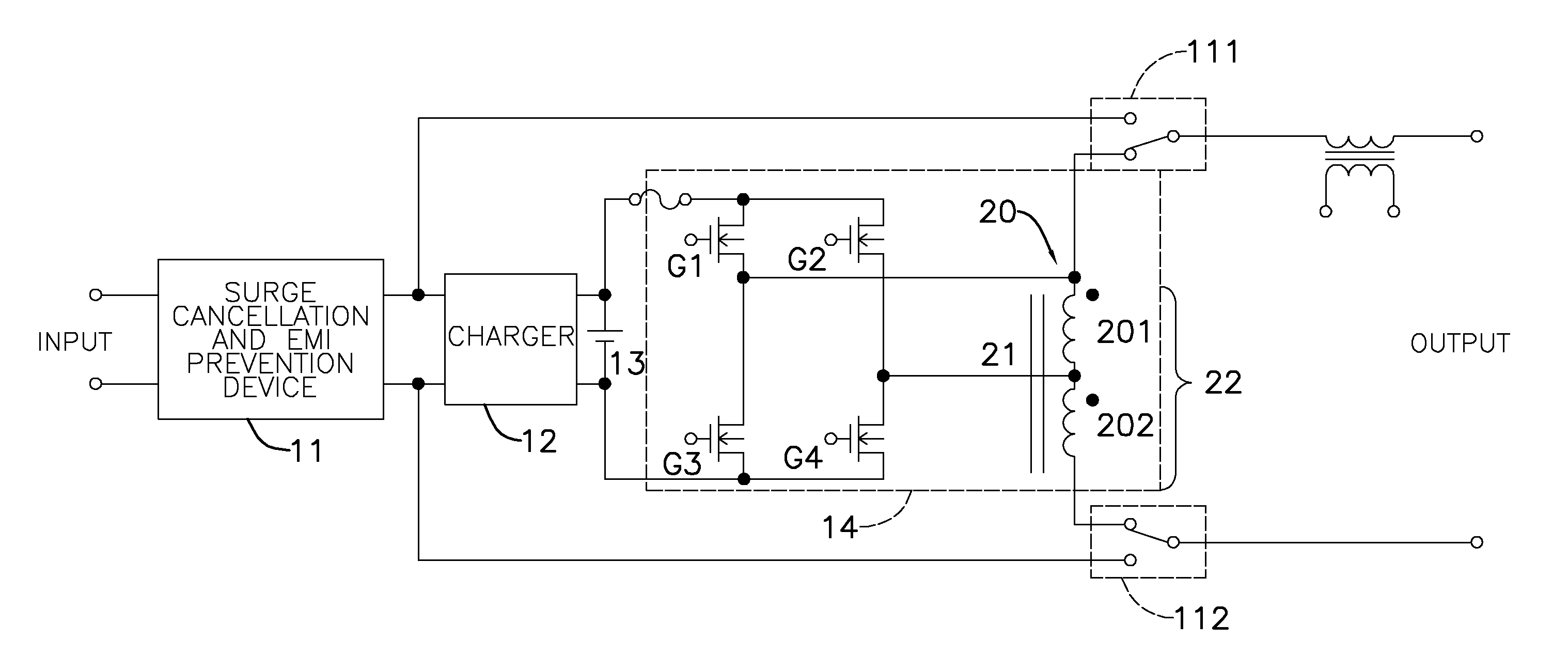

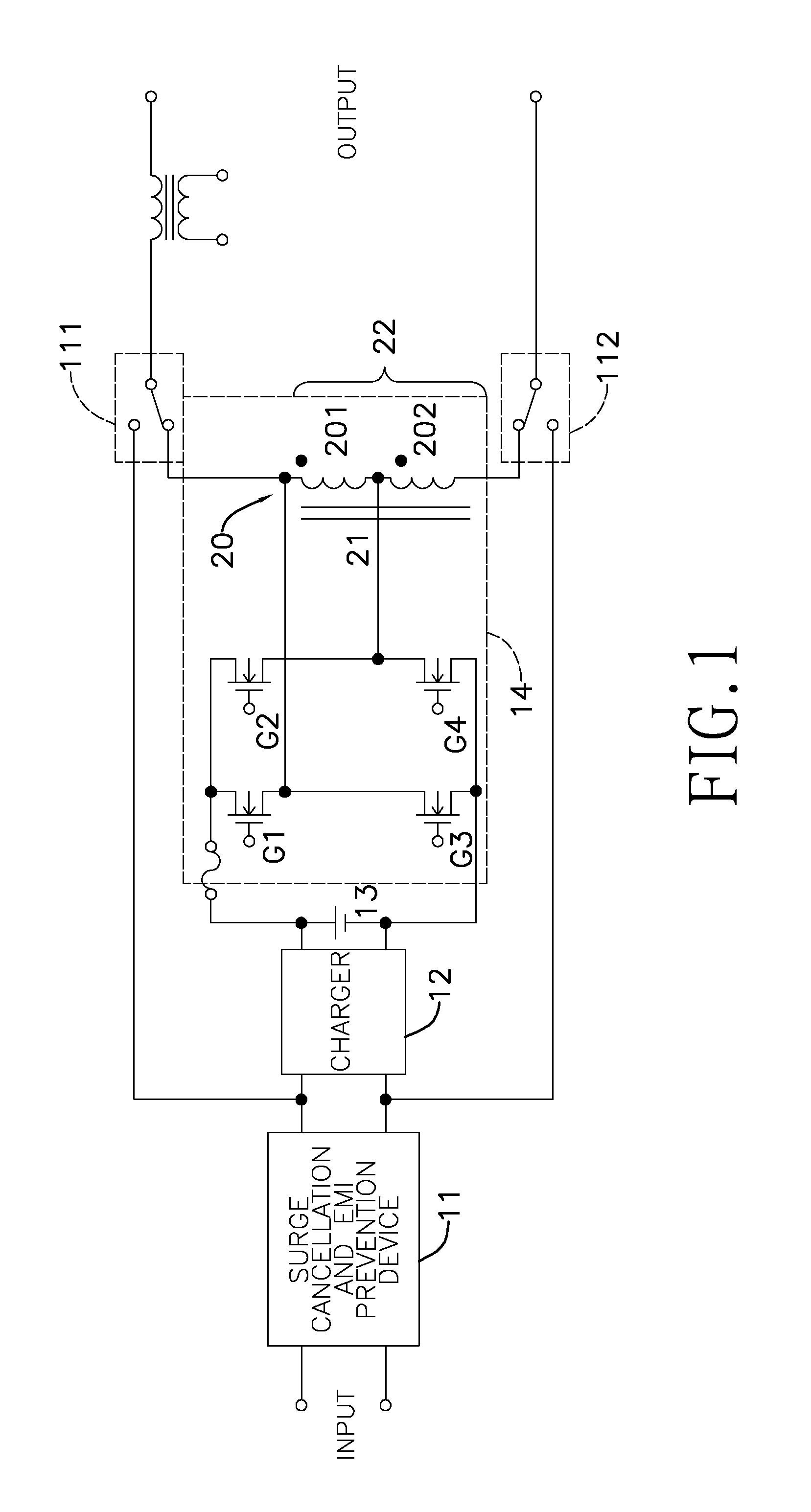

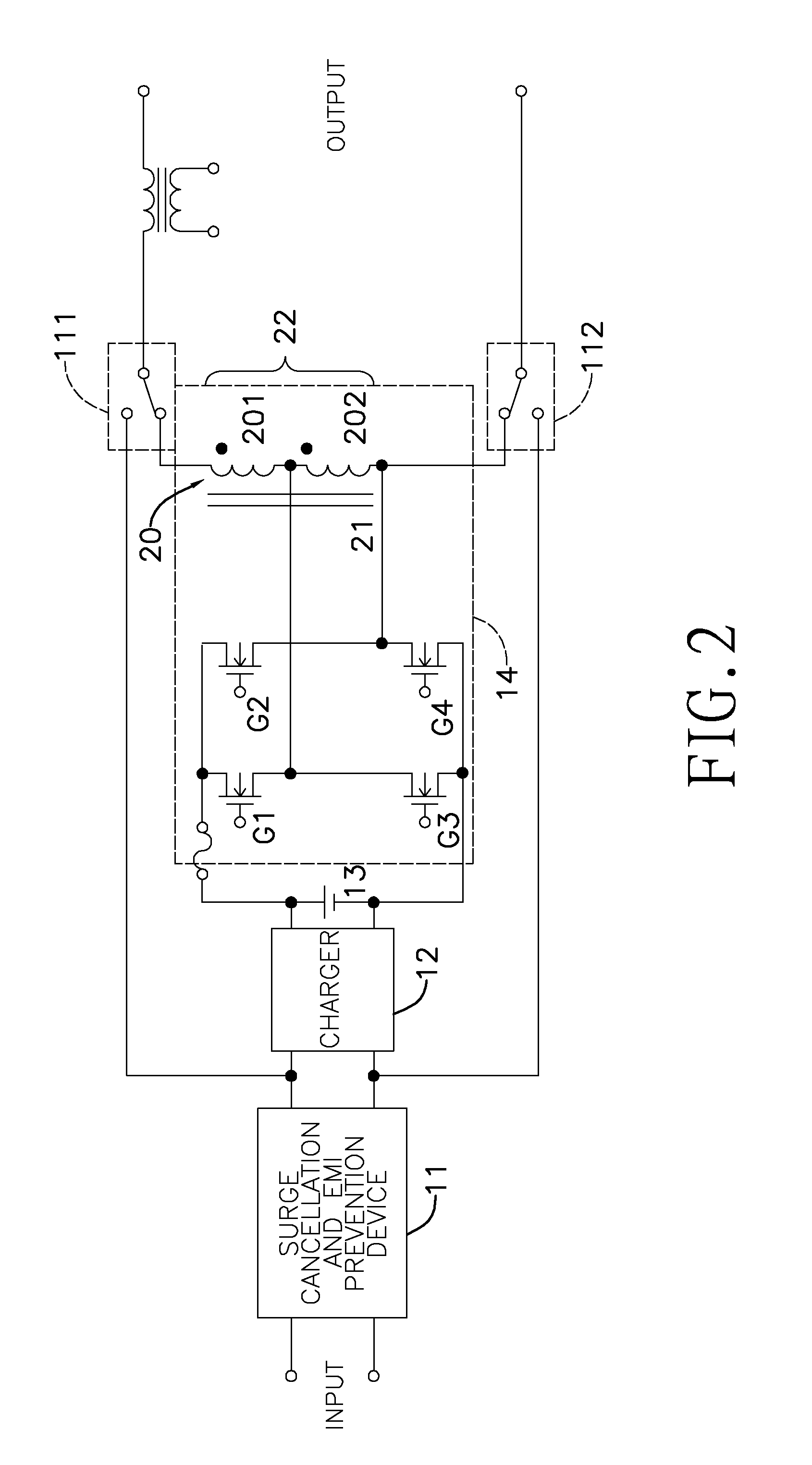

Uninterruptible power supply having an integrated transformer

ActiveUS20130002028A1Less turnsTurns of windings can be decreasedBatteries circuit arrangementsElectric powerElectromagnetic interferenceUninterruptible power supply

An interruptible power supply (UPS) has a surge cancellation and electromagnetic interference (EMI) prevention device, a charger, a battery set and a power converter. The power converter has multiple power switches, an integrated transformer and a controller. An input terminal of the surge cancellation and EMI prevention device is connected with the AC mains, and an output terminal is connected with the integrated transformer. The charger is connected with the battery set. The battery set is connected with the power switches. The integrated transformer has a primary side having a first winding and a second winding serially connected. The first and second windings respectively have multiple sub-windings. The first winding is connected with the power switches. The second winding is connected with a power output terminal and shares a part of the first winding, thereby decreasing turns of the windings and reducing the size and cost of the UPS.

Owner:CYBER POWER SYST

Universal sweeping robot sweeping path planning method

InactiveCN110377014AReduce energy consumptionLess turnsPosition/course control in two dimensionsSimulationClosed loop

The invention relates to a universal sweeping robot sweeping path planning method comprising the following steps: (1) starting, pose control based on a closed loop of a robot; (2) finding objects witha laser reflection property; (3) extracting an area between the laser reflection substances and partitioning the area; (4) carrying out cleaning on each partition in sequence; (5) checking whether all the partitions are cleaned or not, entering the next step if yes, otherwise returning to the step (2); and (6) returning a charging point. The method in the invention has the beneficial effects thatin the solution of the invention, a mode of executing a cleaning task while collecting environment information is adopted in comparison with the mode of some sweeping robot products on the market that a target environment is traversed in advance so as to collect the environment information and then the cleaning task is executed.

Owner:SHANGHAI XPARTNER ROBOTICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com