High-energy density permanent magnet motor water cooling system

A high energy density, permanent magnet motor technology, applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, the shape/style/structure of the winding conductor, etc., can solve uneven heat dissipation, increased flow resistance, etc. problem, to achieve the effect of improving heat dissipation efficiency, reducing water pressure of water pump, and increasing torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

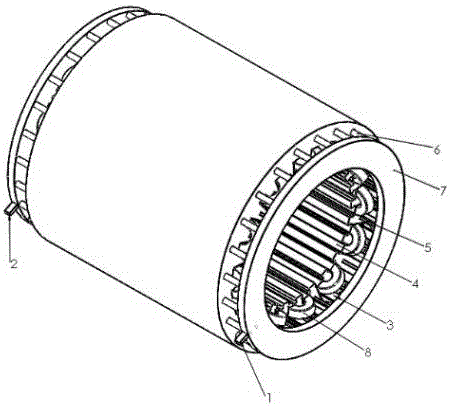

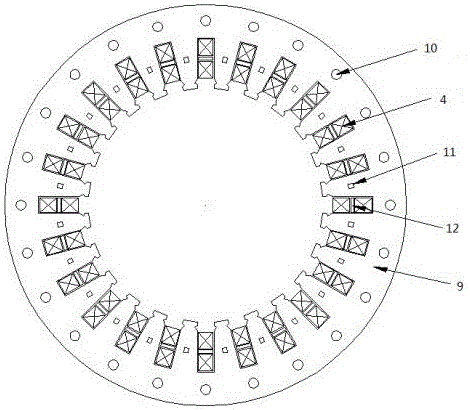

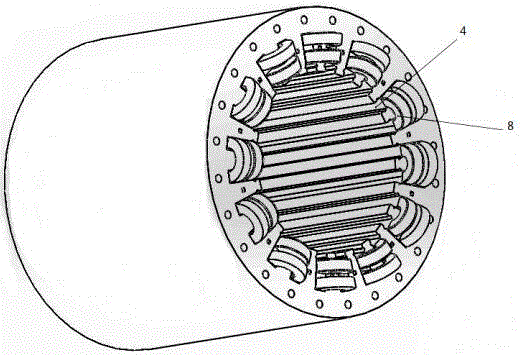

[0019] Embodiment A high energy density permanent magnet motor water cooling system, including a stator, stator windings, cooling water pipes and disc pipes, the cooling water pipes are specifically the cooling water pipes of the stator yoke, the cooling water pipes in the stator slots and the stator teeth. Cooling water pipe, the cooling water pipe is installed axially in the groove of the motor stator, the teeth and the yoke, the disc pipe is located at the end of the motor, the two ends of the cooling water pipe are respectively connected to the two ends of the stator end The disk pipes are connected, and the number of the disk pipes is two; the windings in the stator slot are arranged in upper and lower layers, and a centralized winding with a single tooth winding is adopted; each of the disk pipes There is an interface, which is respectively used as the water inlet and water outlet of the cooling water; the insulating resin whose thermal conductivity is greater than that o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com