Patents

Literature

30results about How to "High positional" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

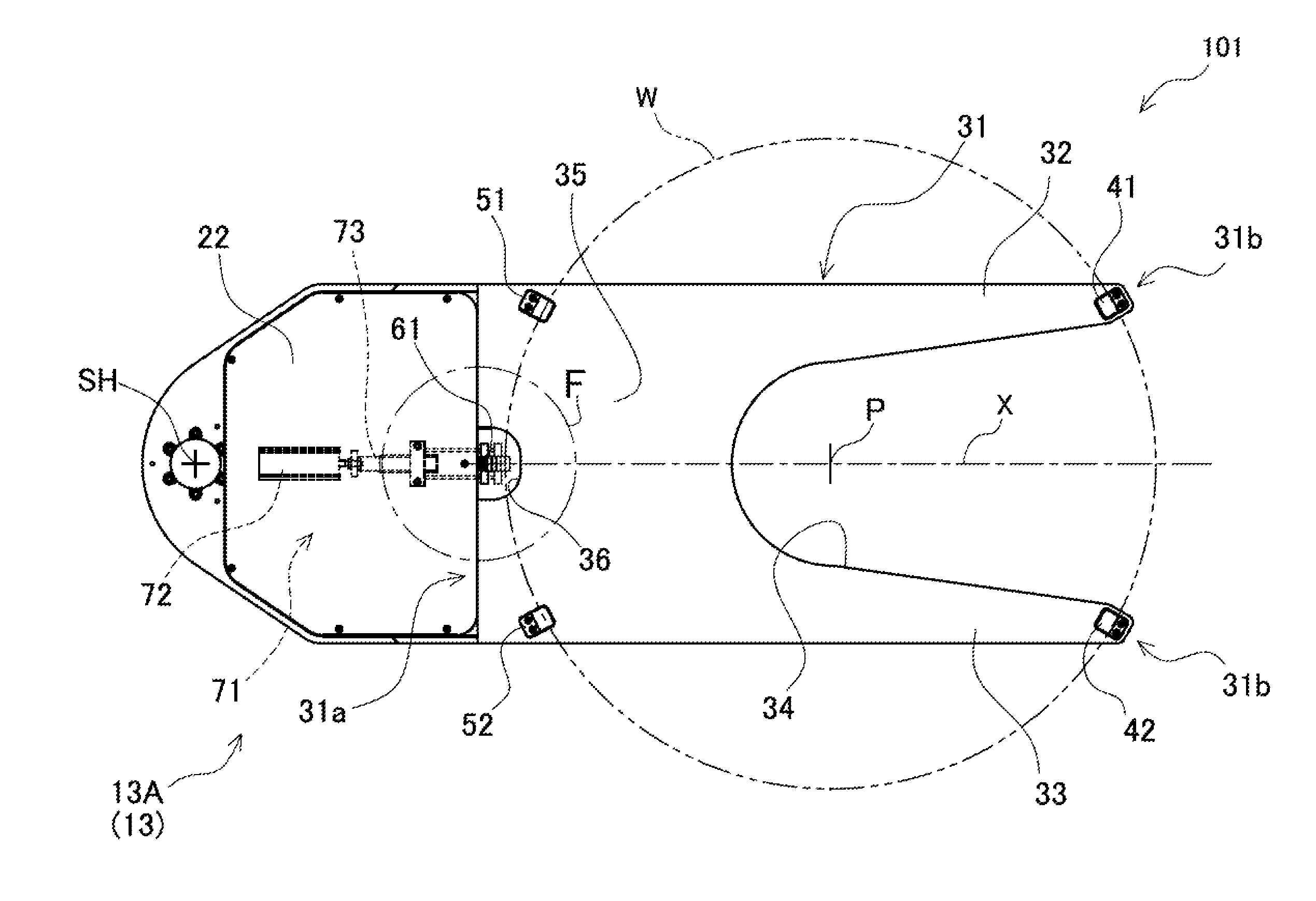

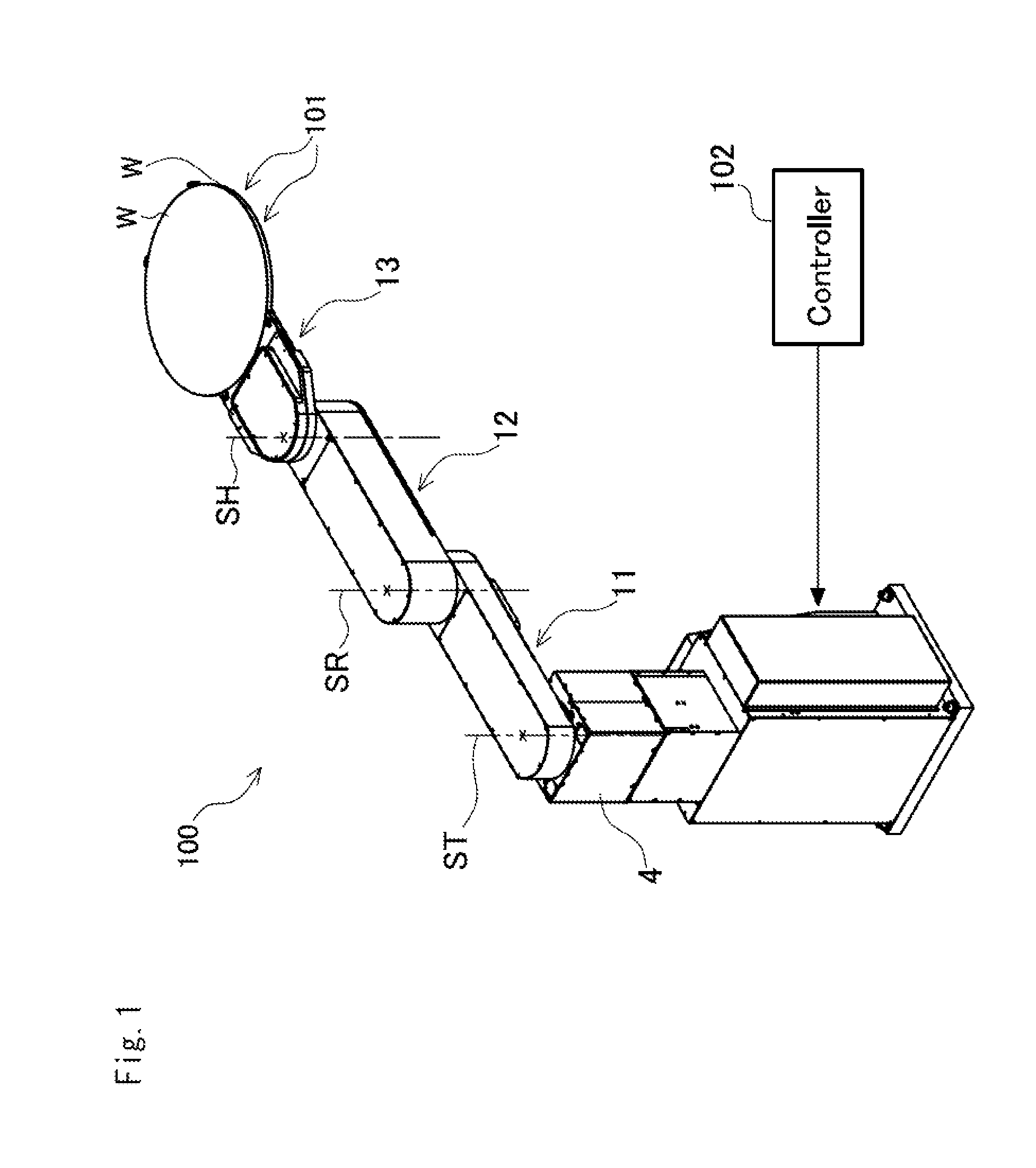

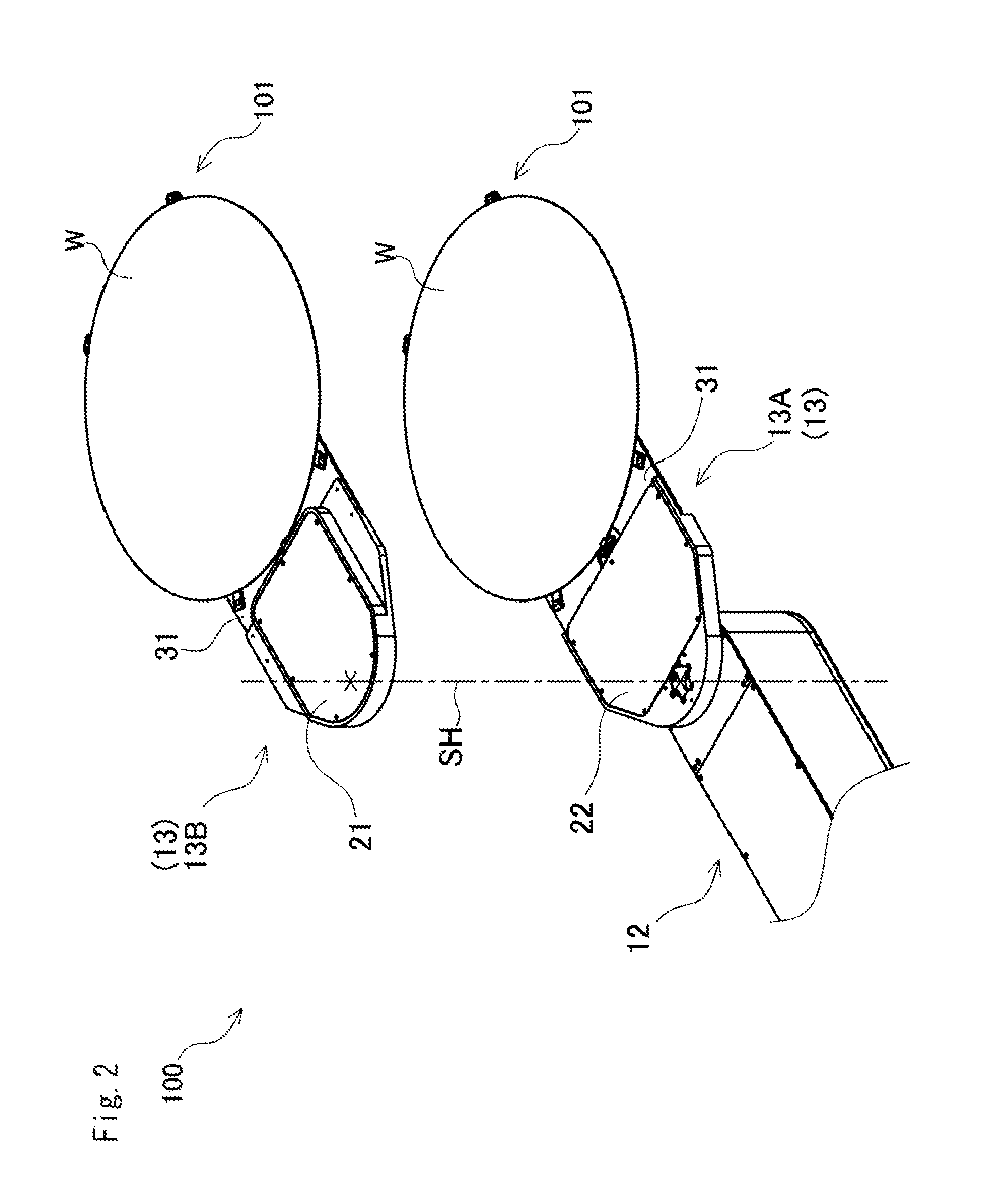

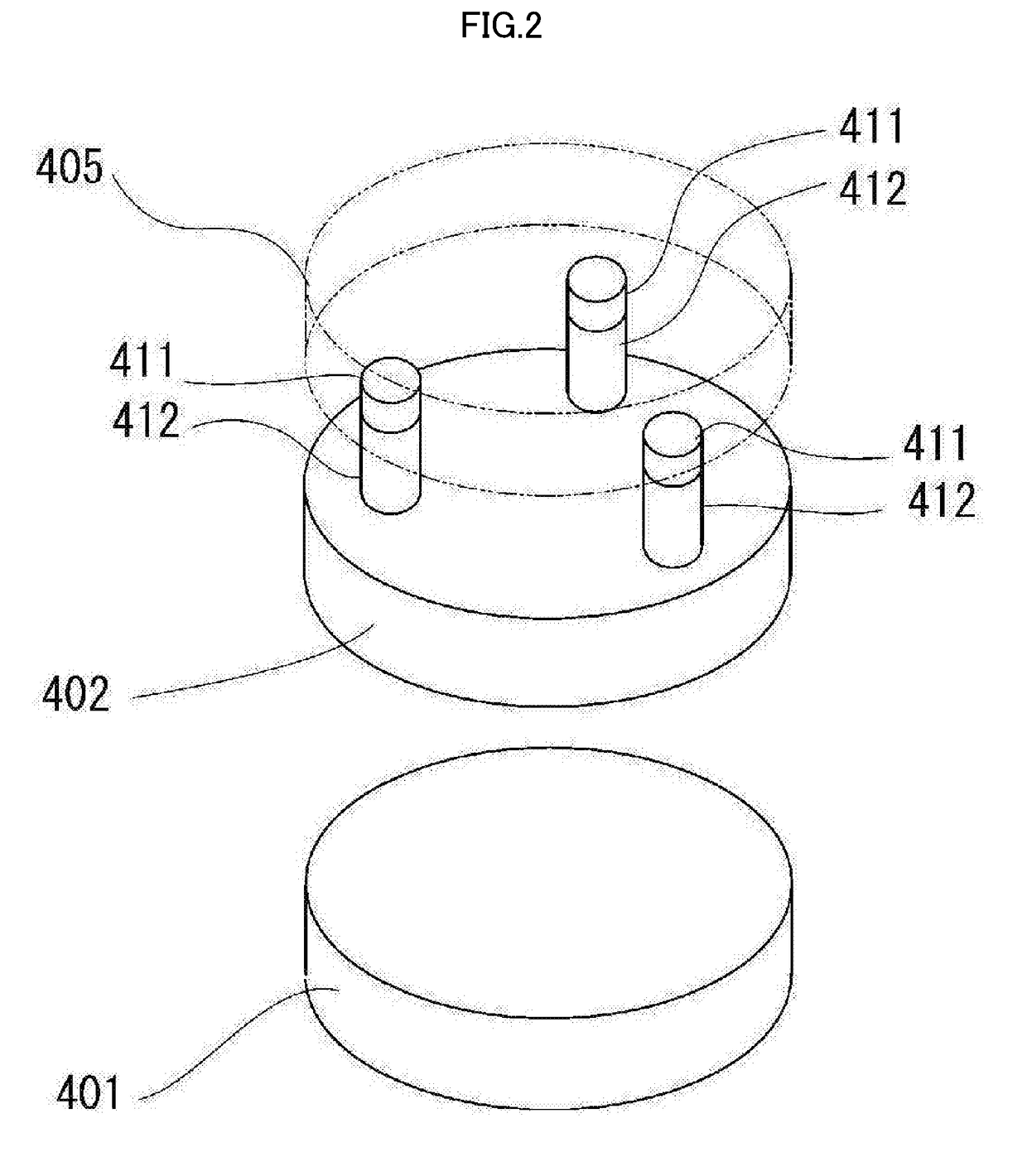

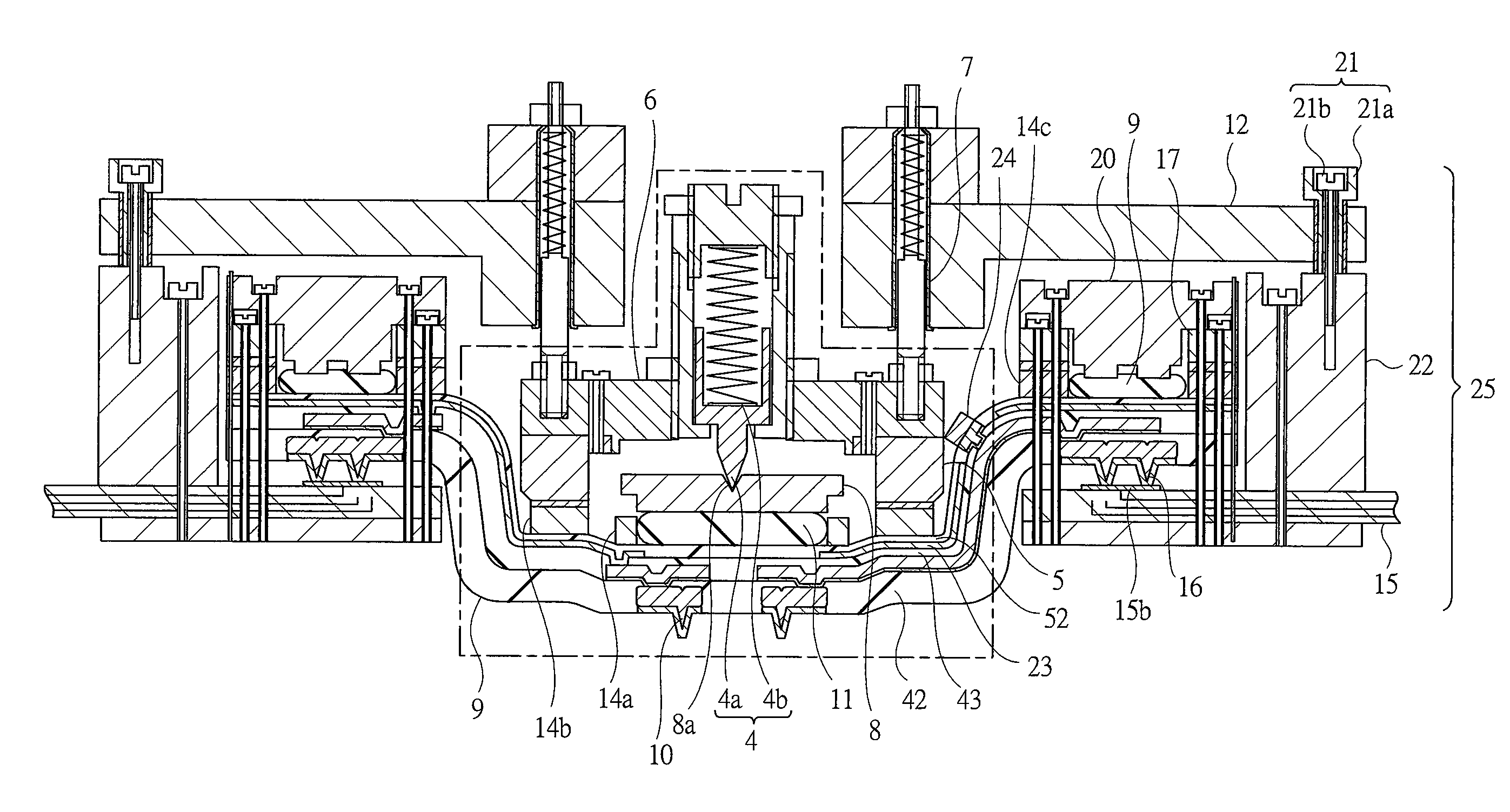

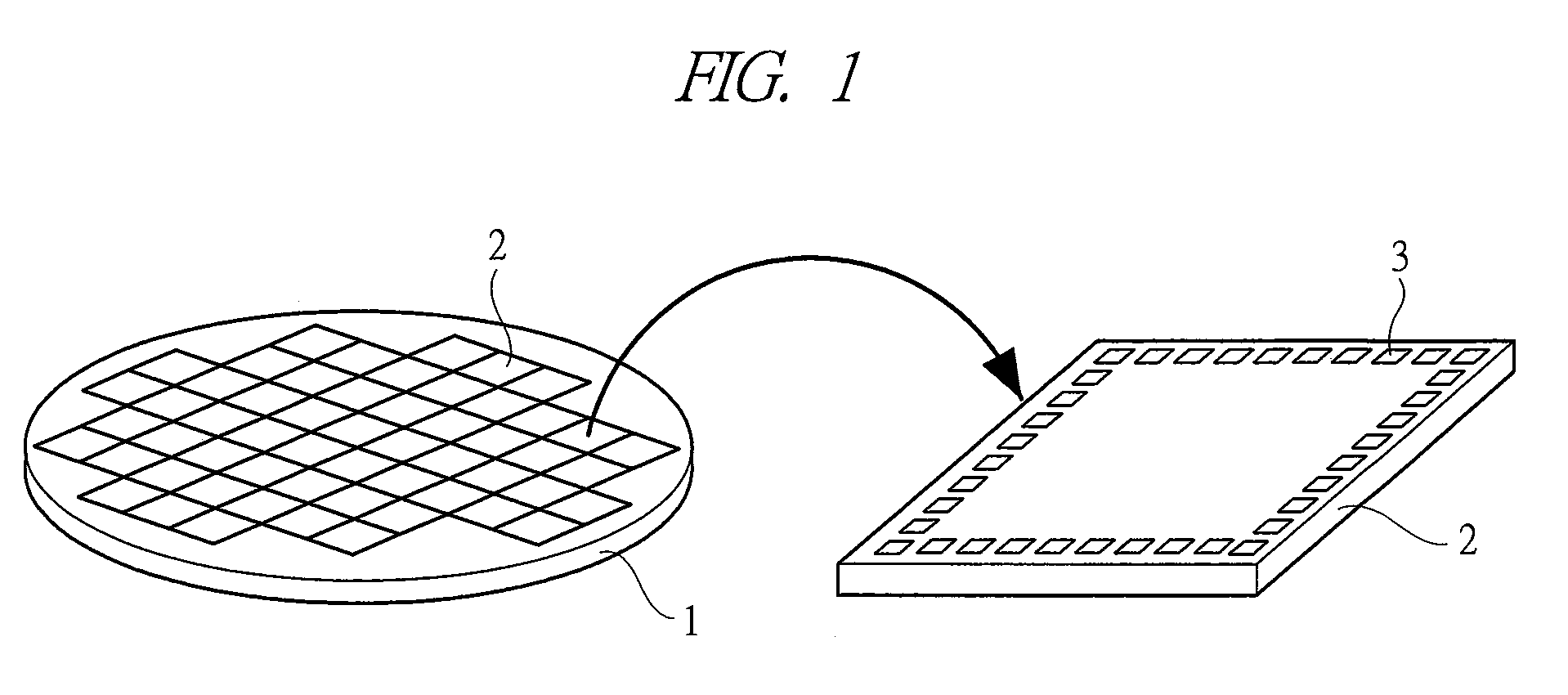

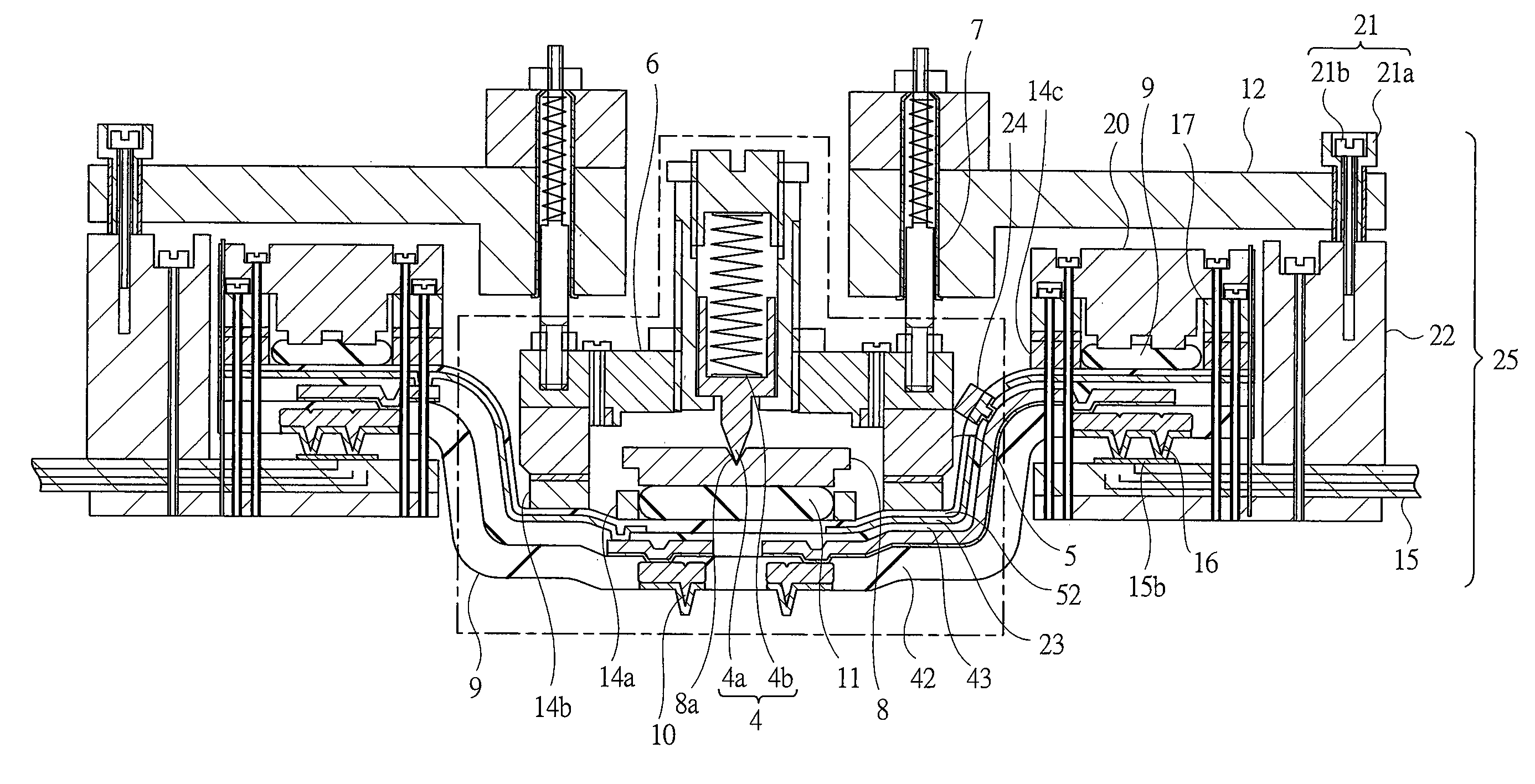

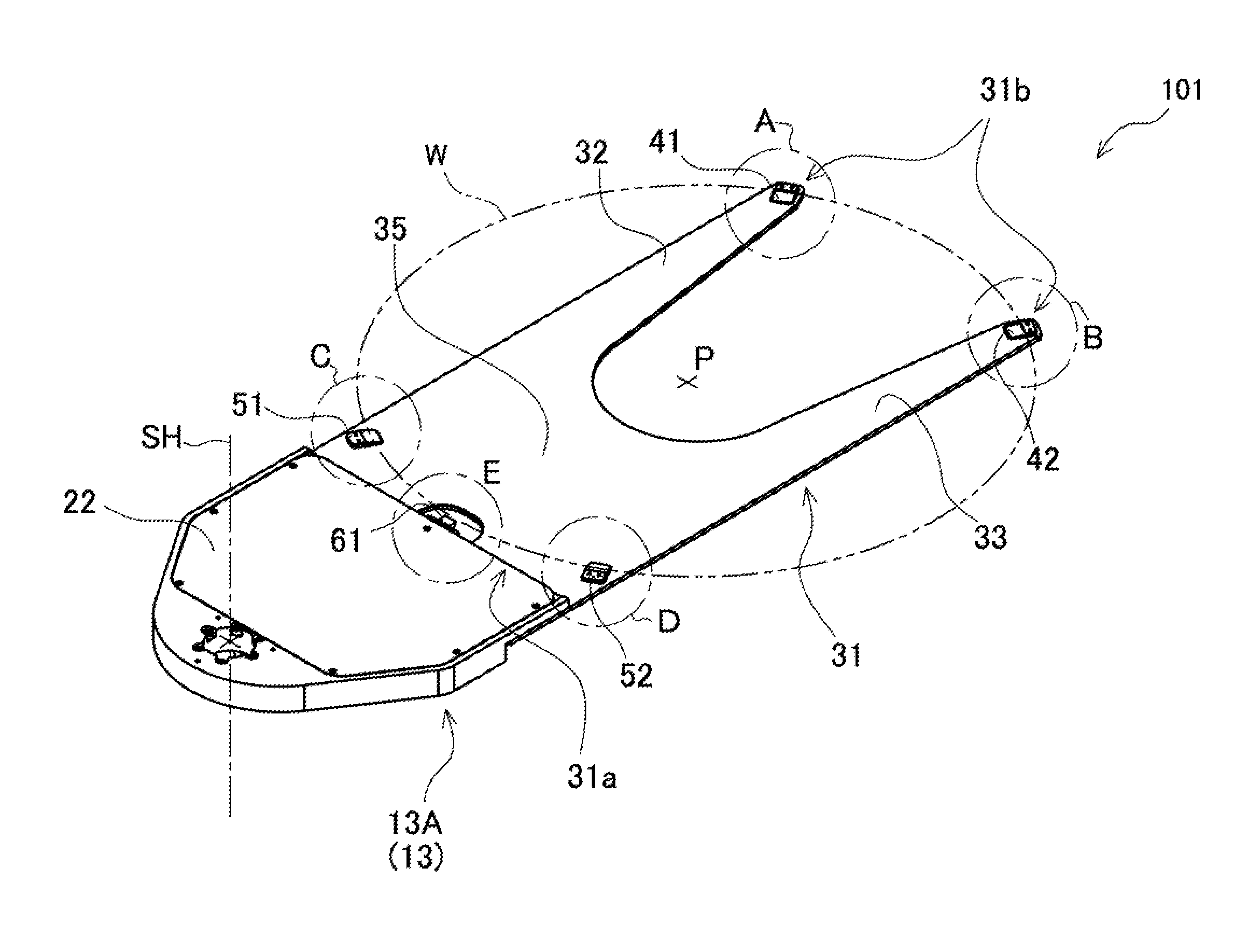

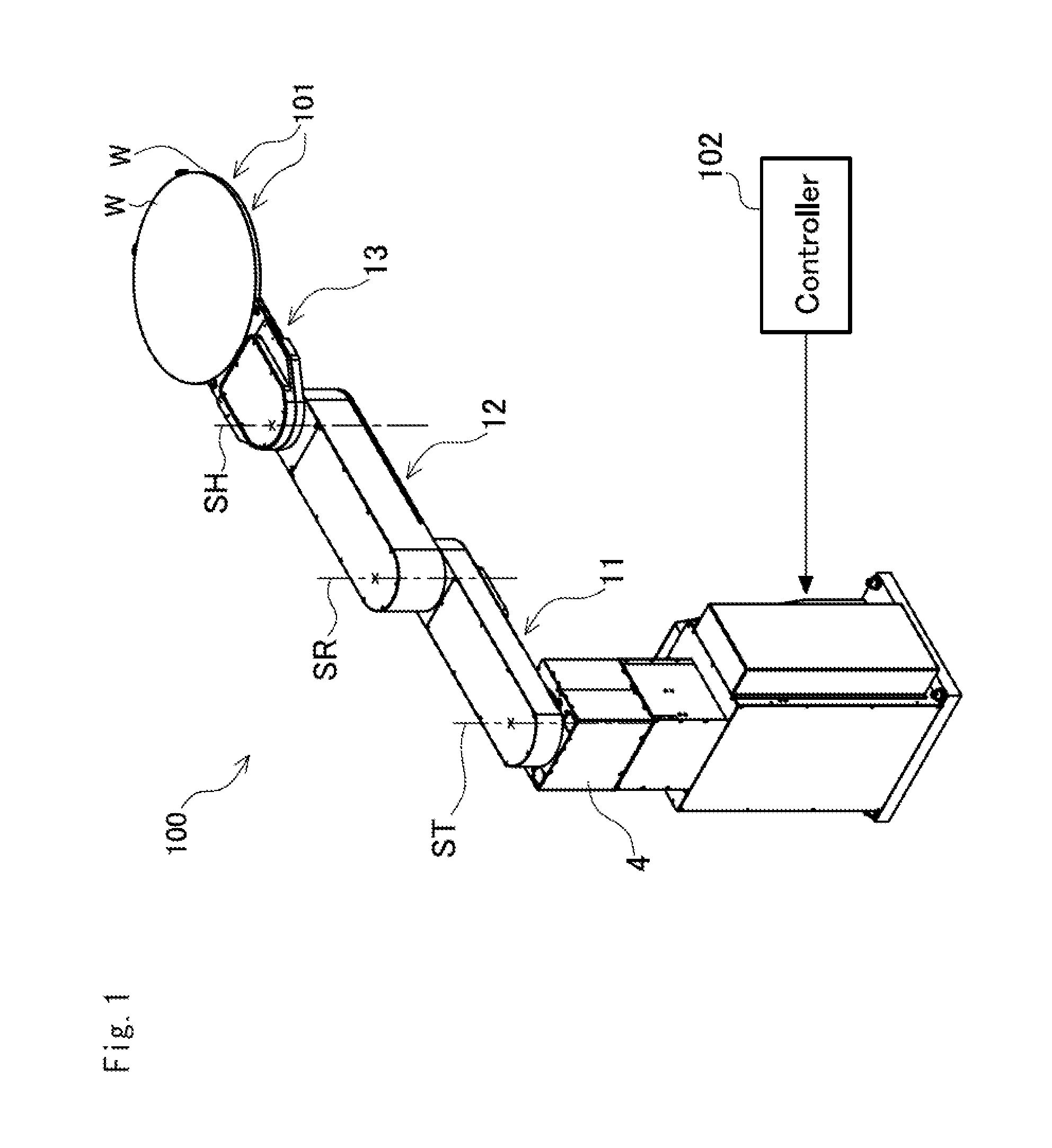

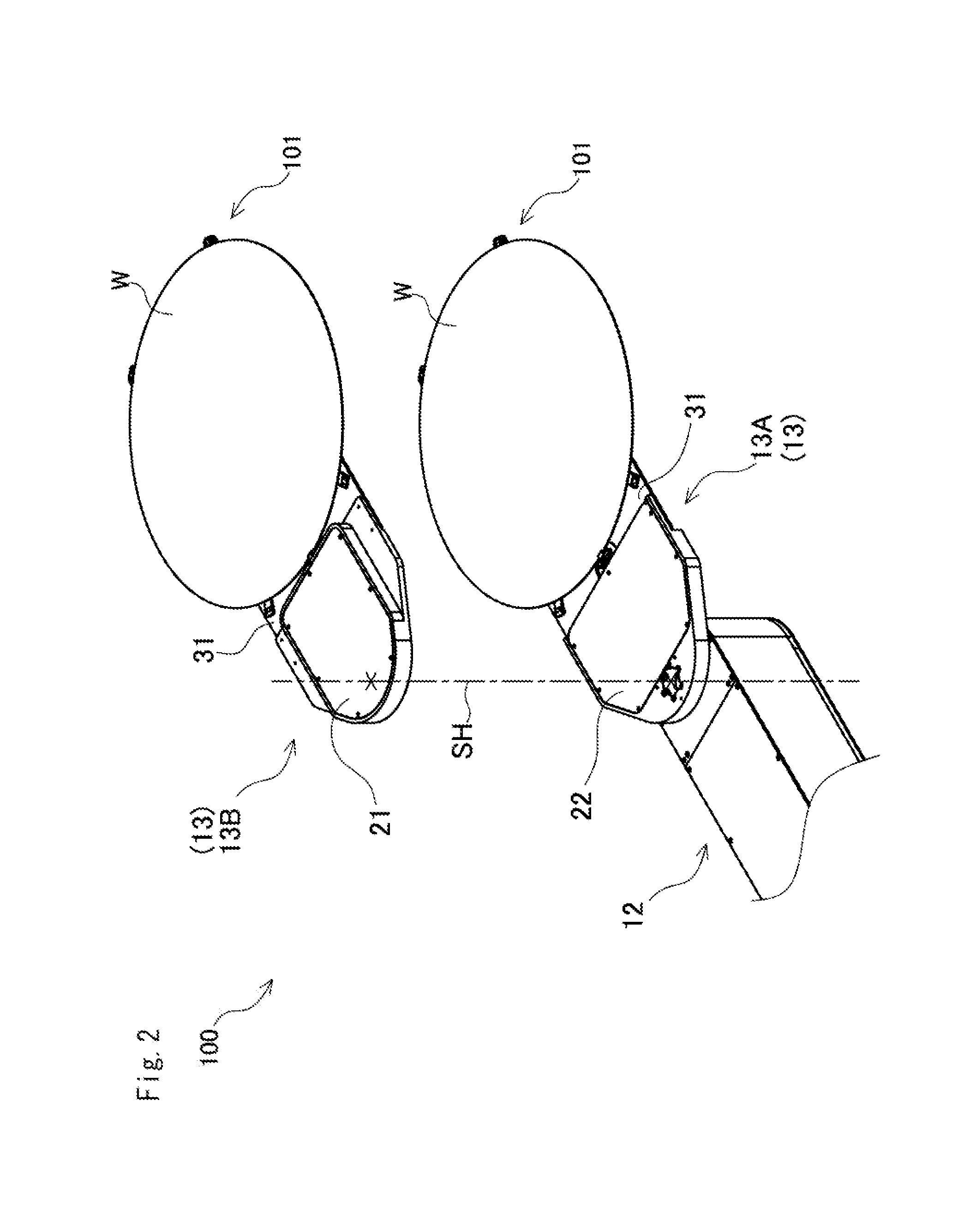

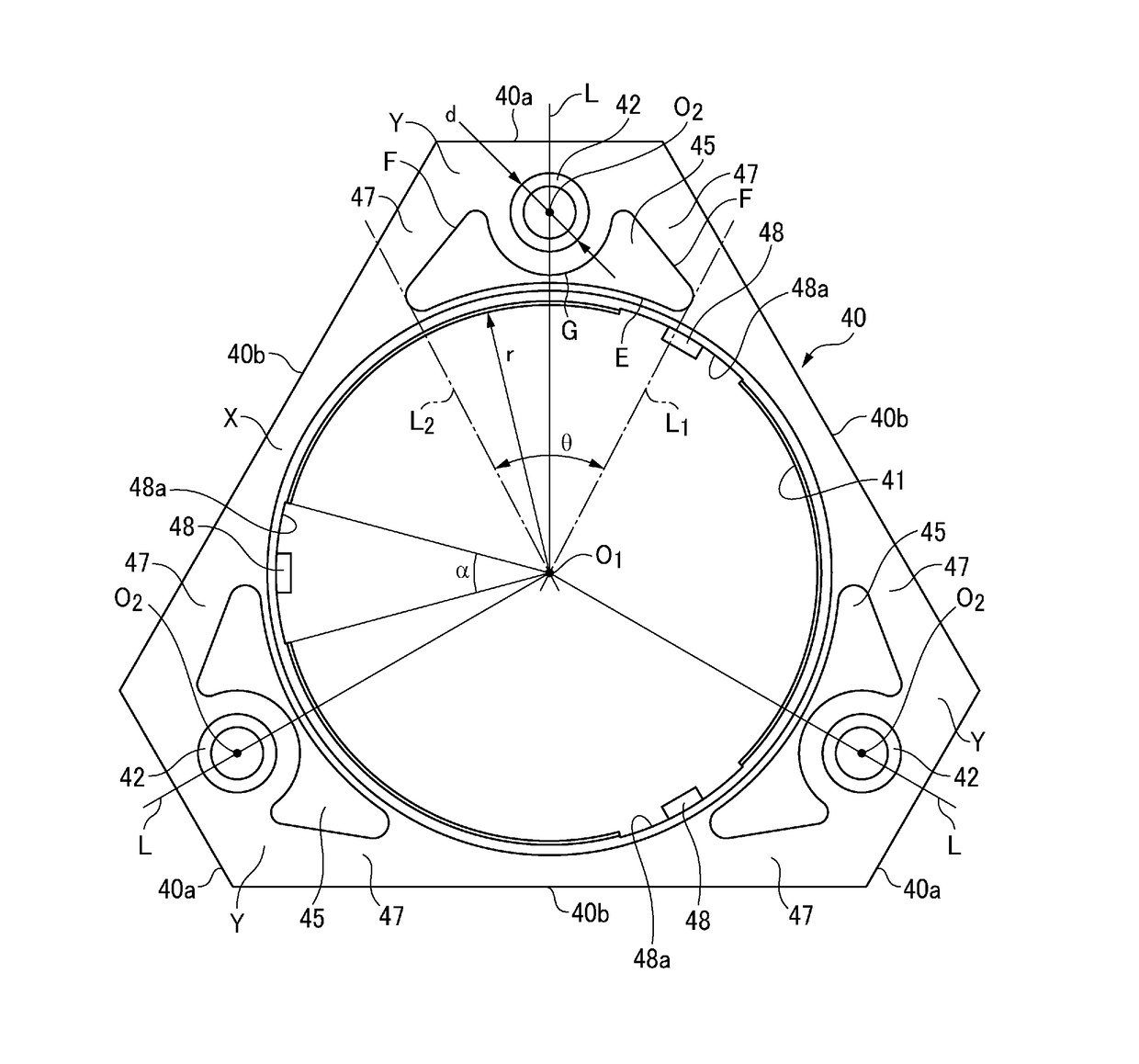

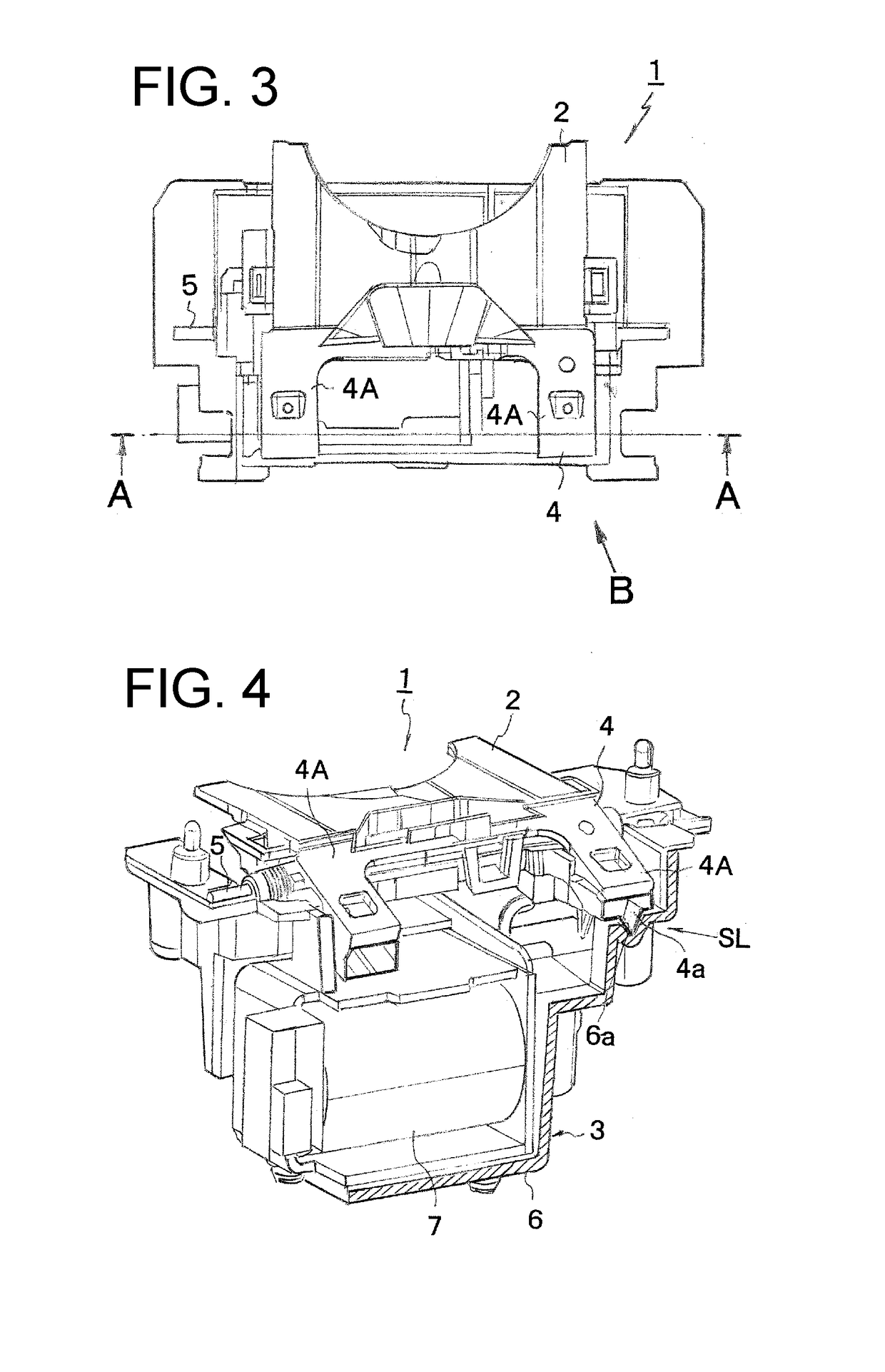

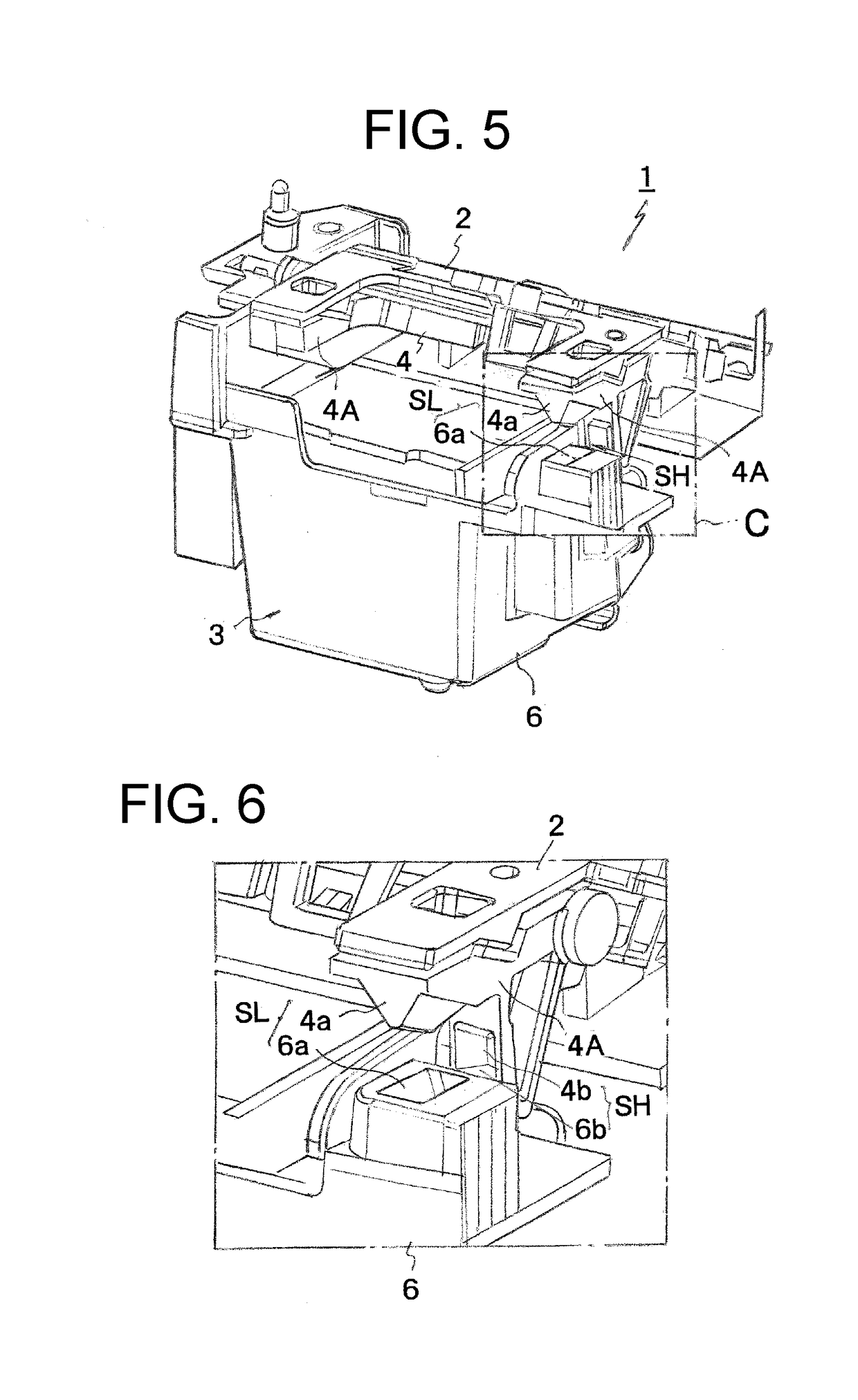

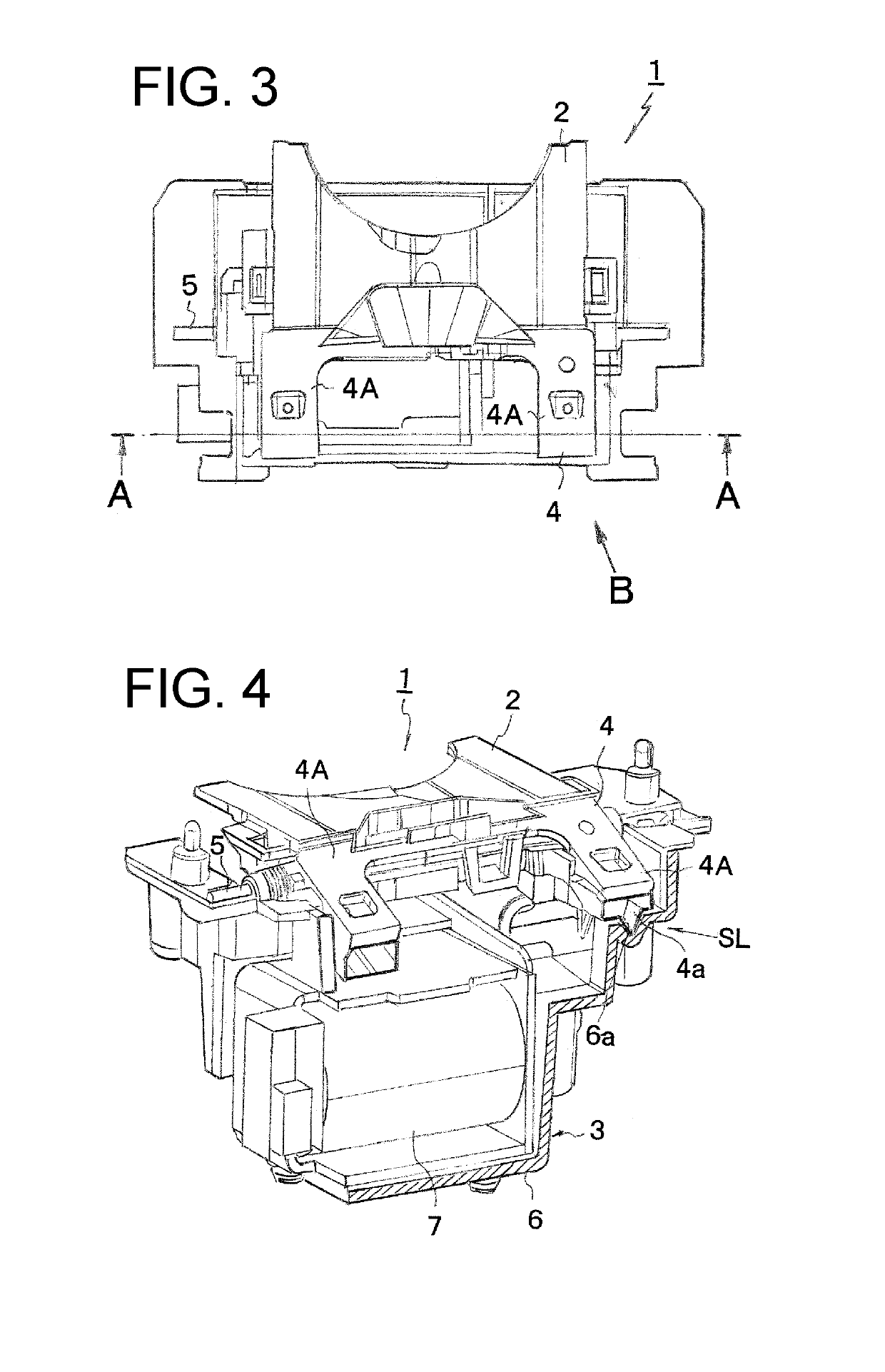

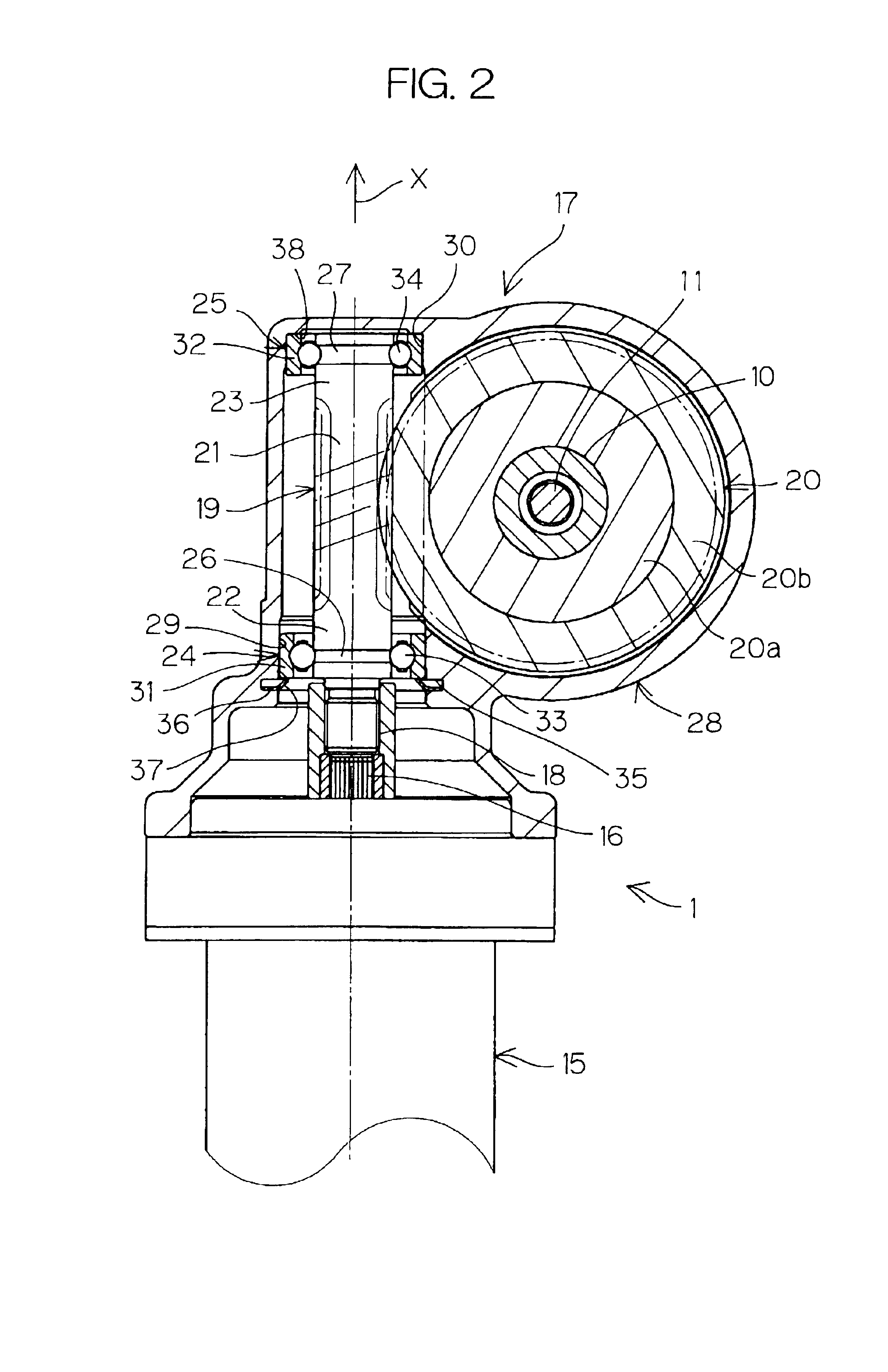

Clamping device and workpiece conveying robot

InactiveUS8764085B2High positionalImprove retentionGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SINFONIA TECHNOLOGY CO LTD

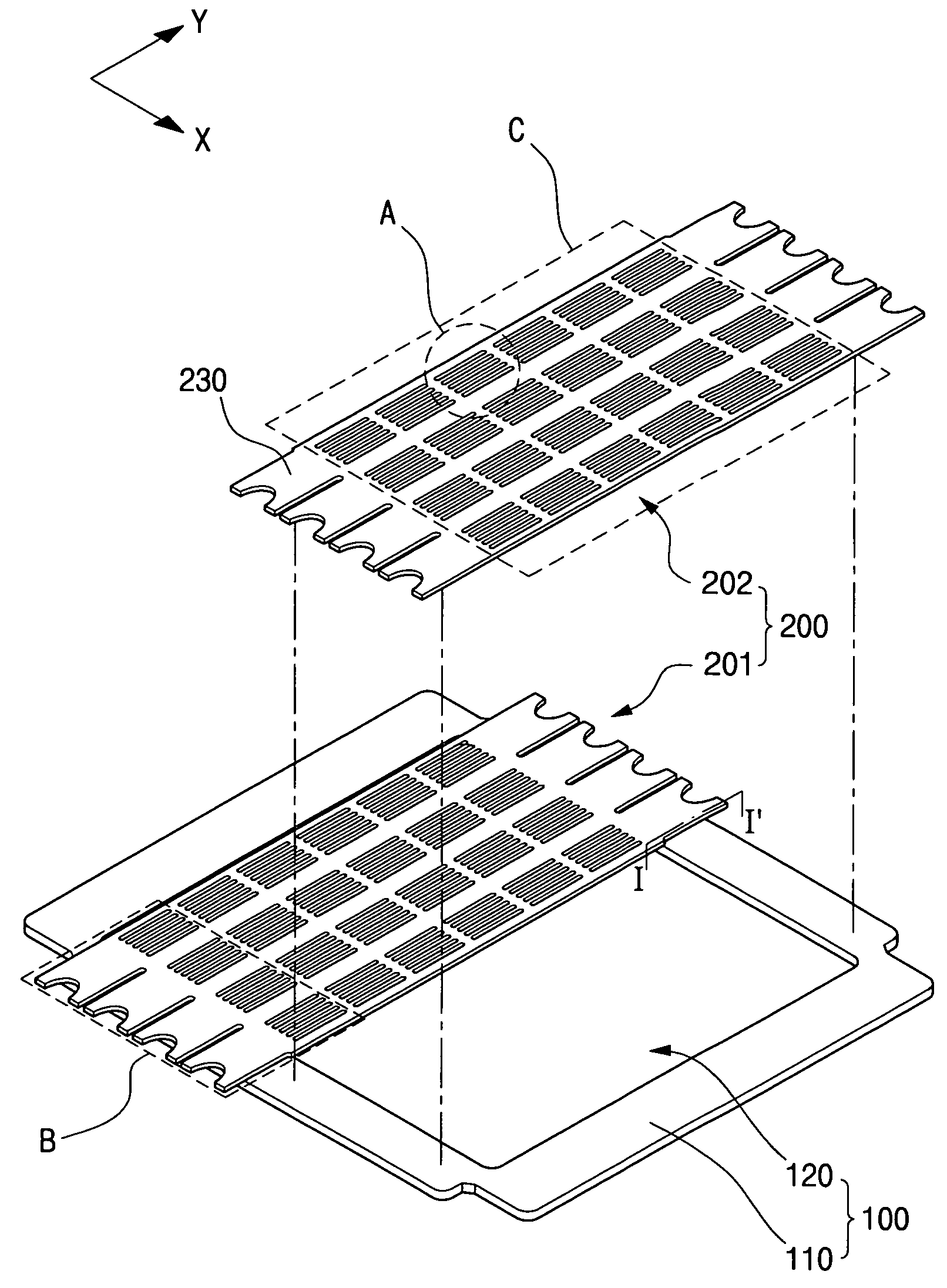

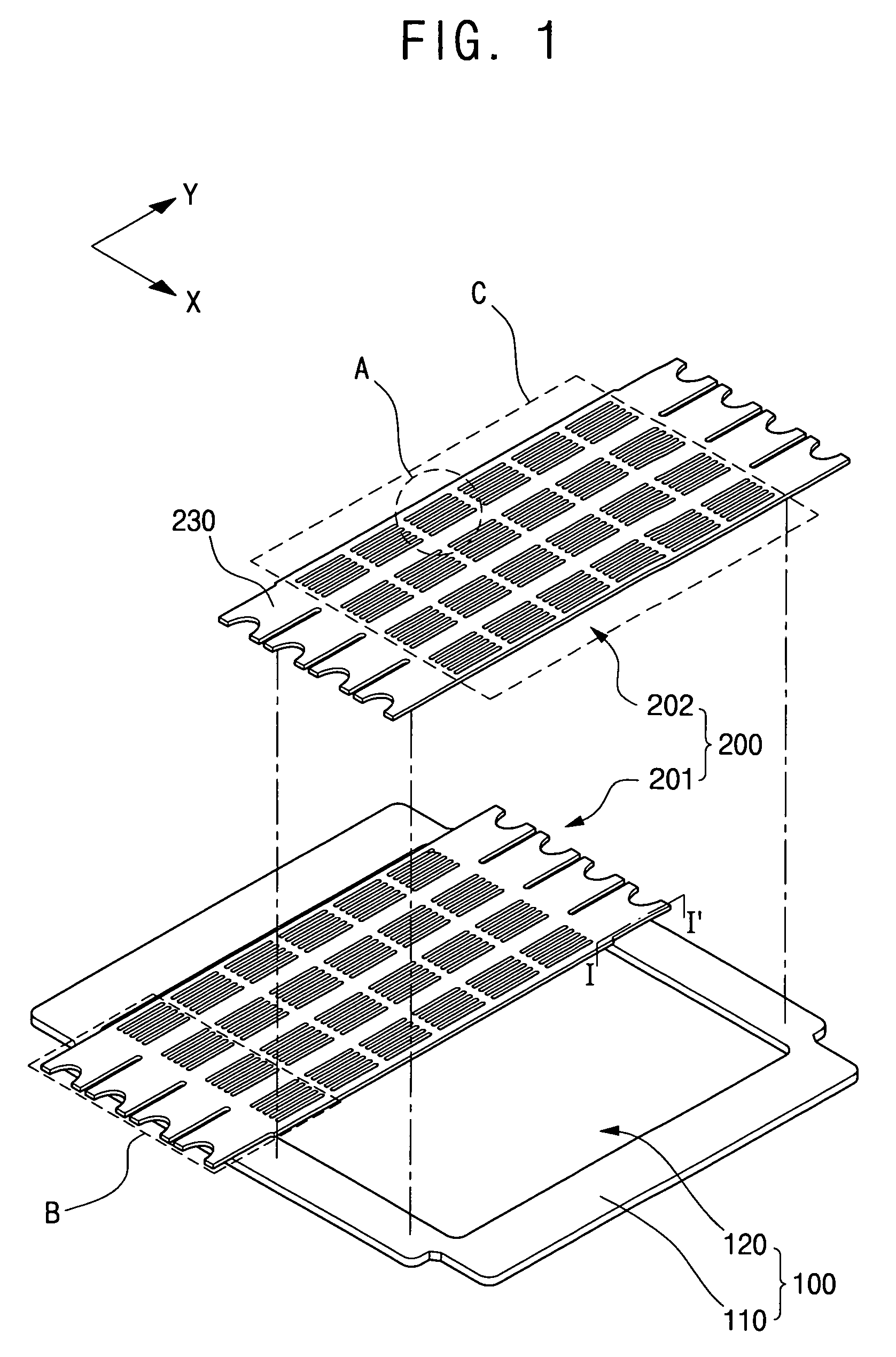

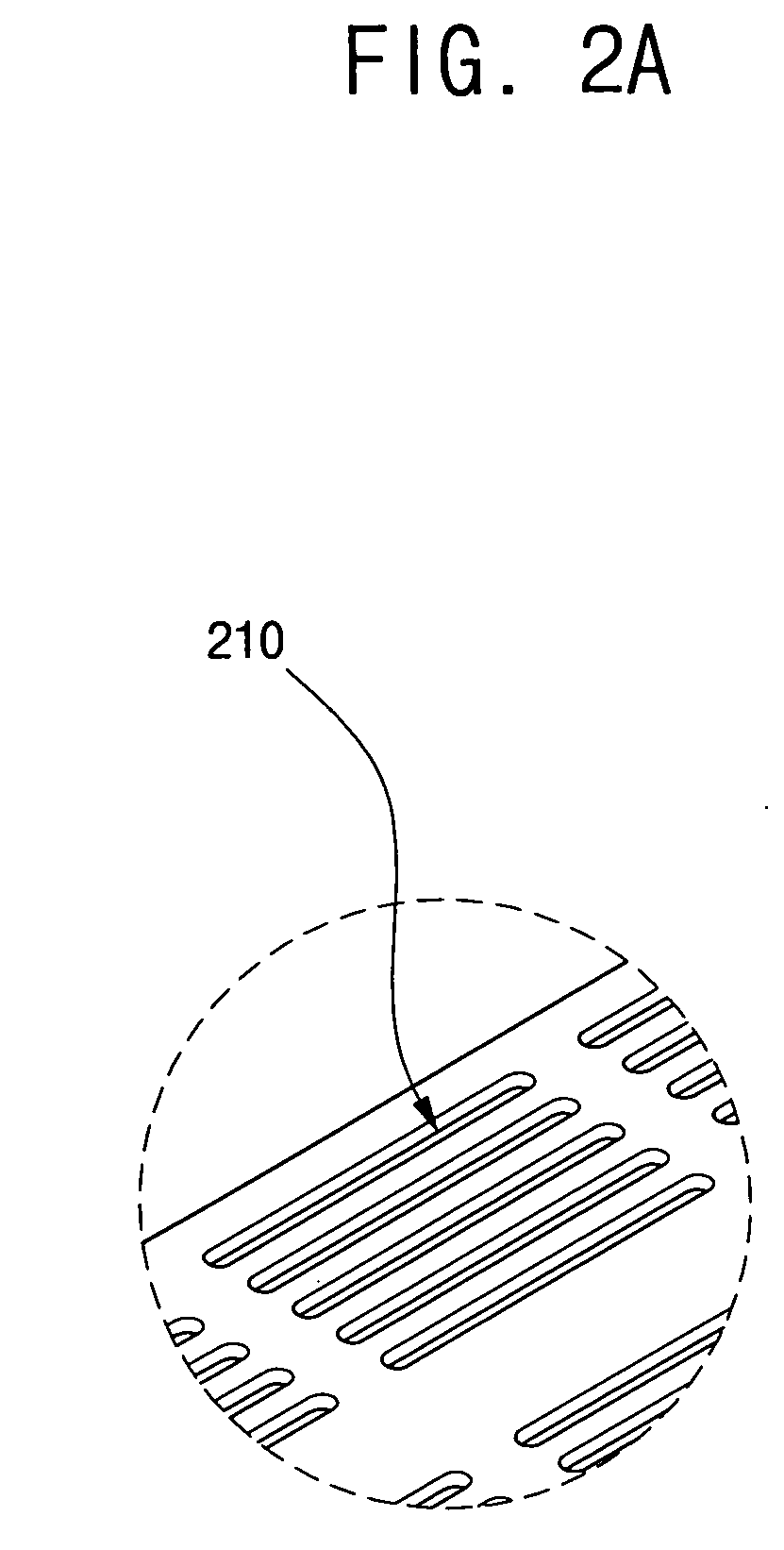

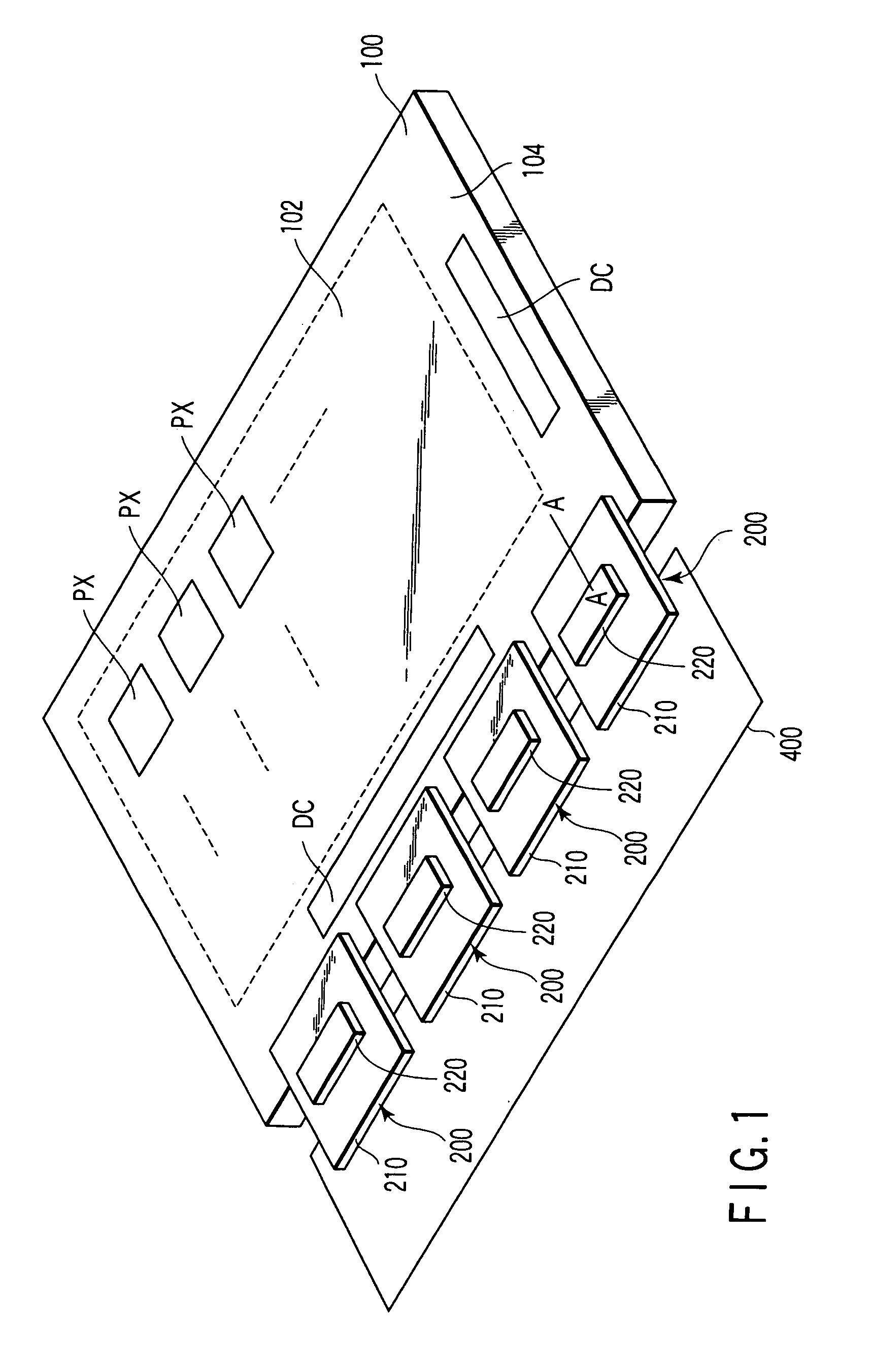

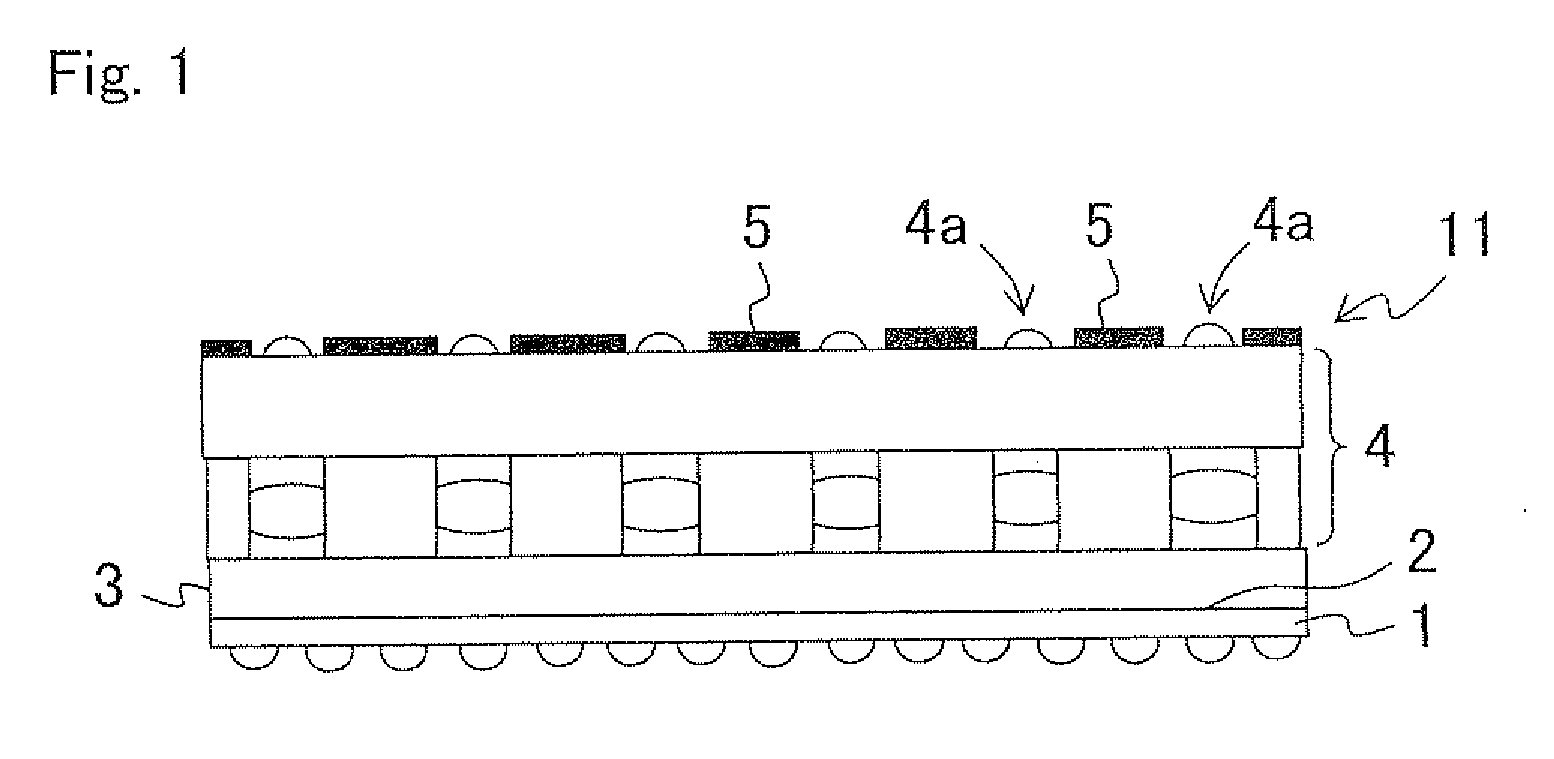

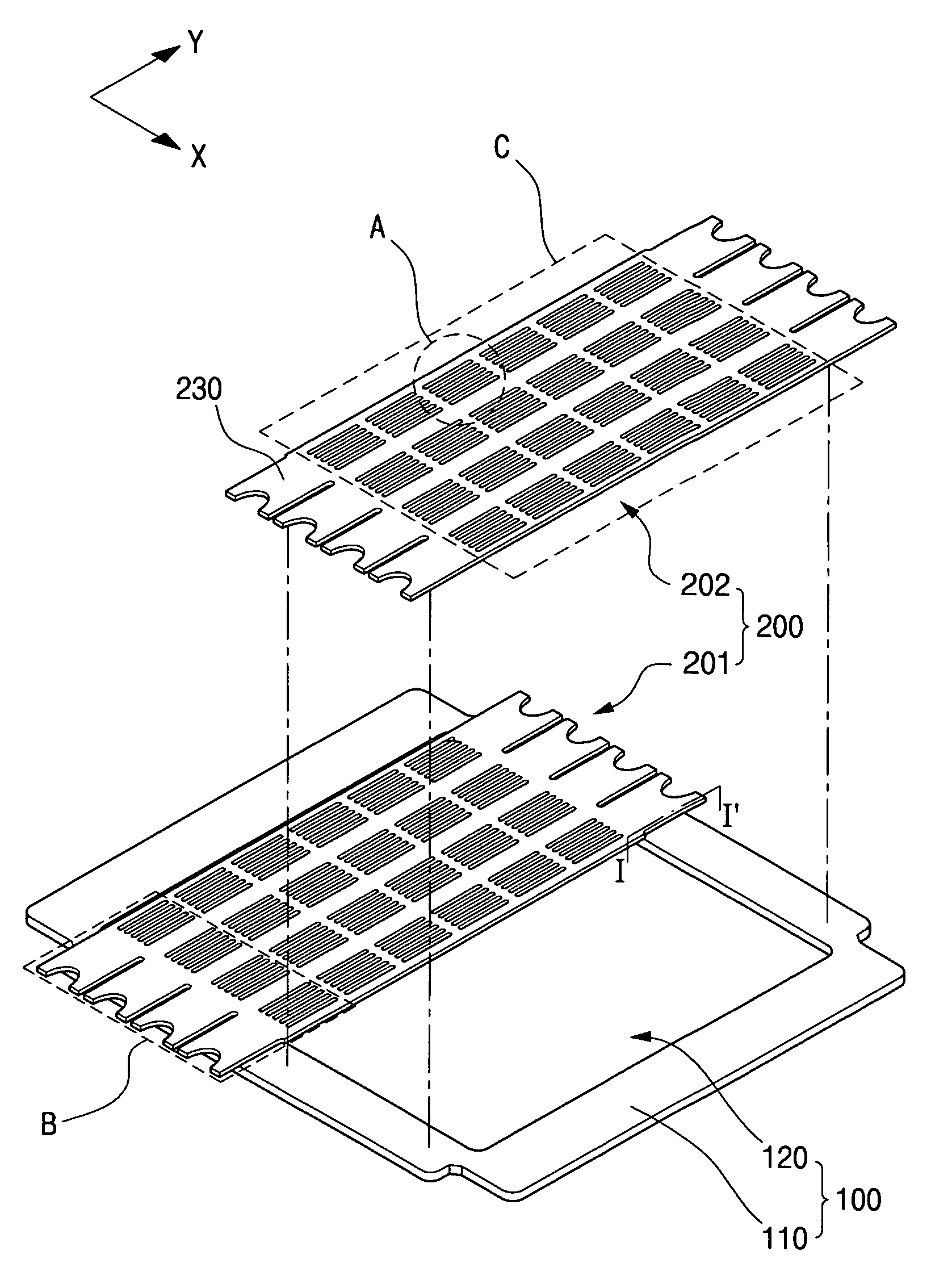

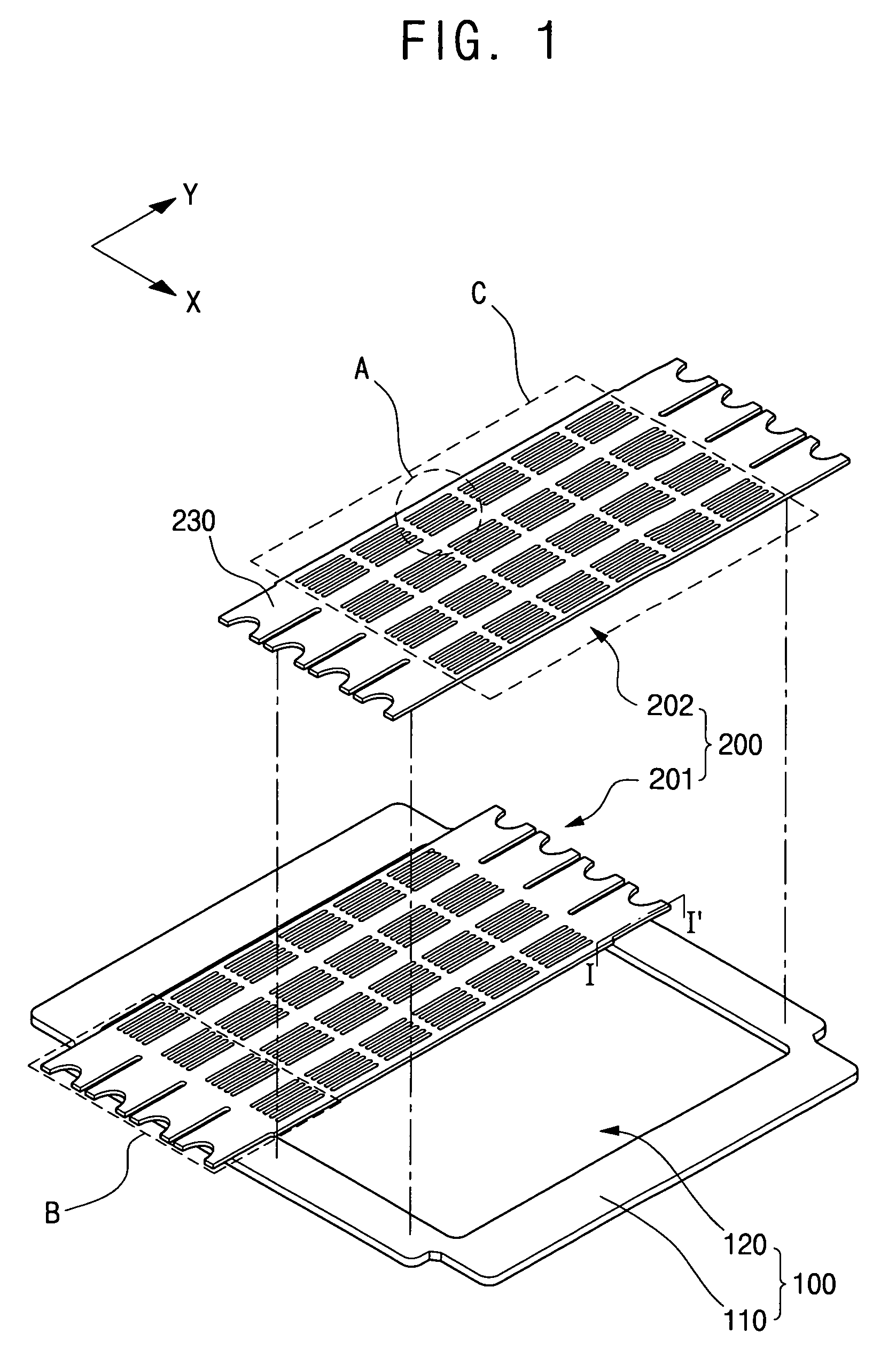

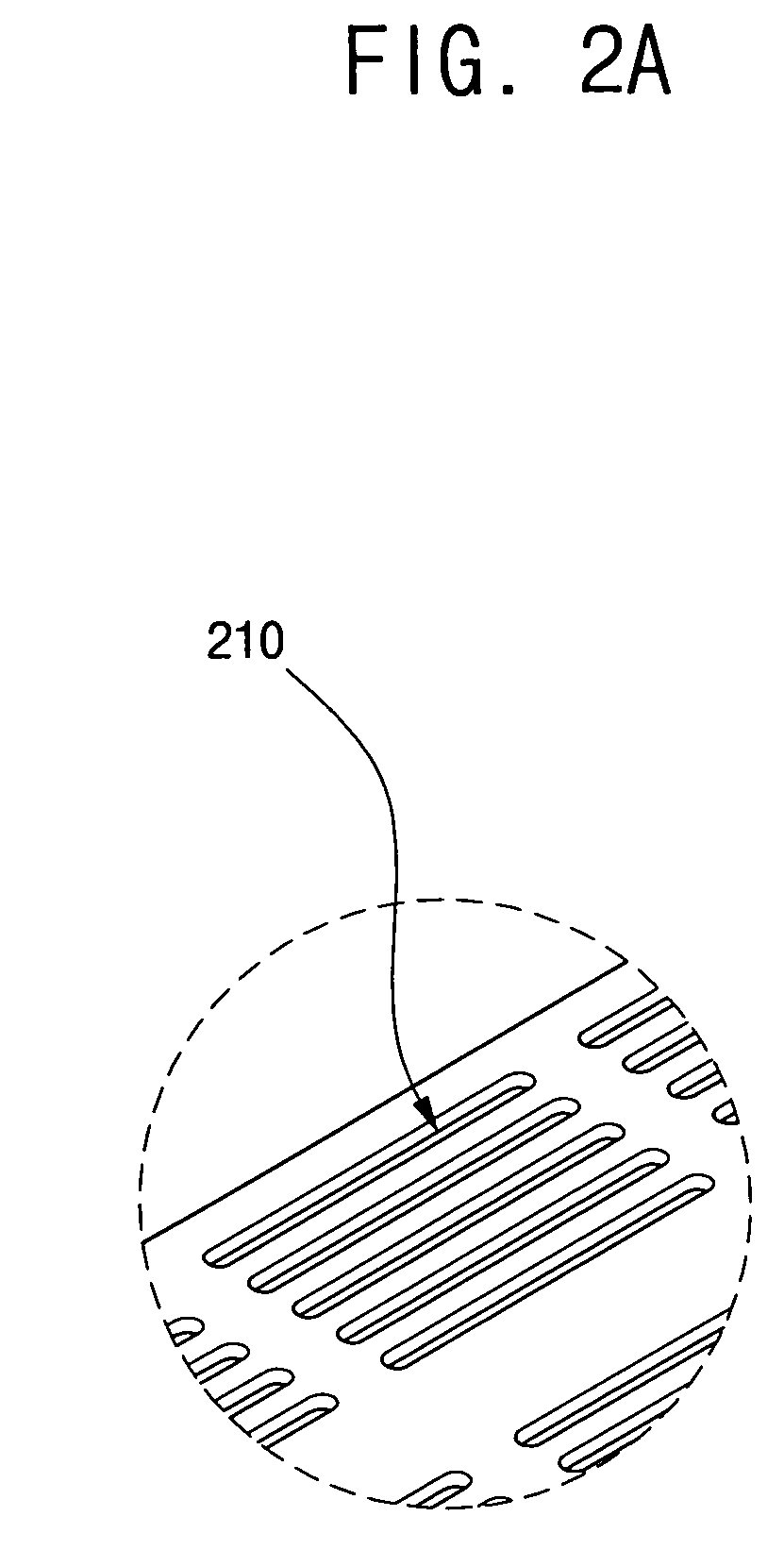

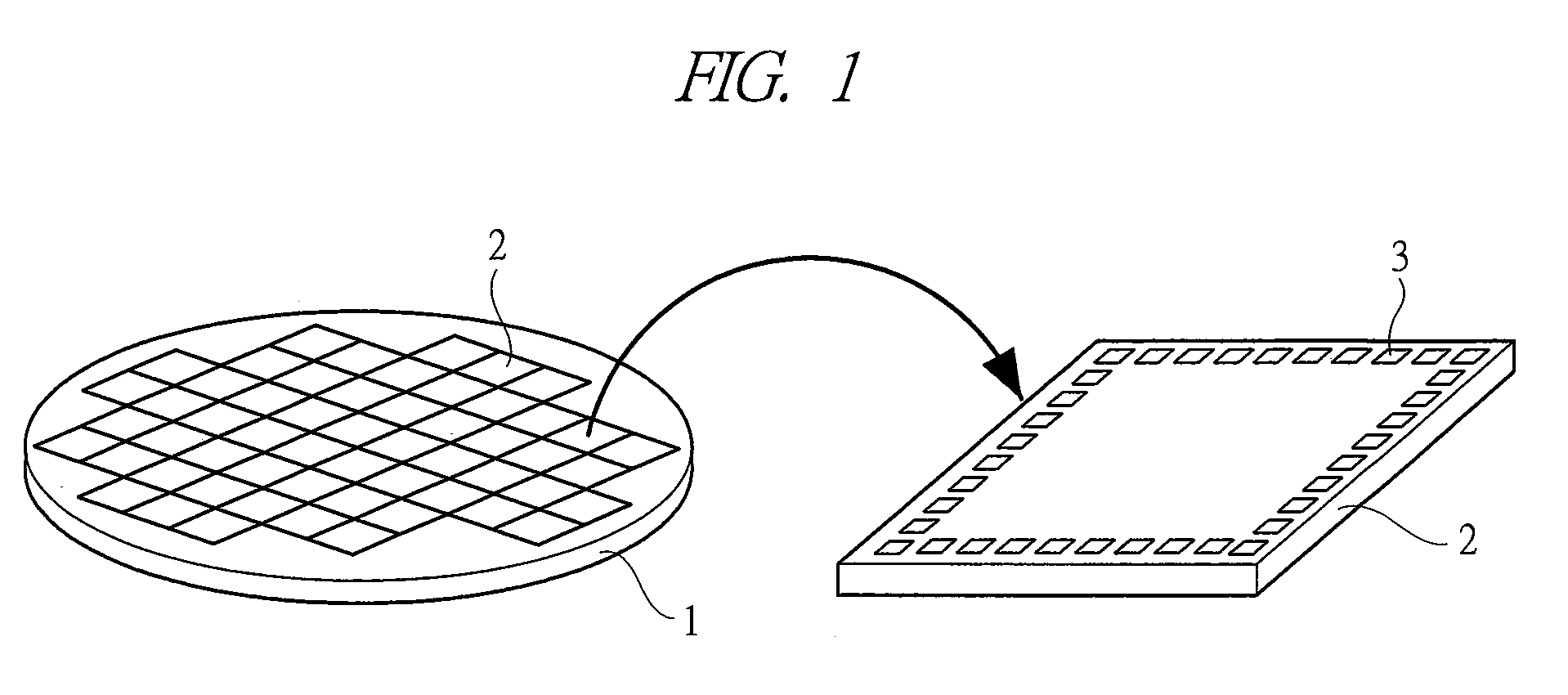

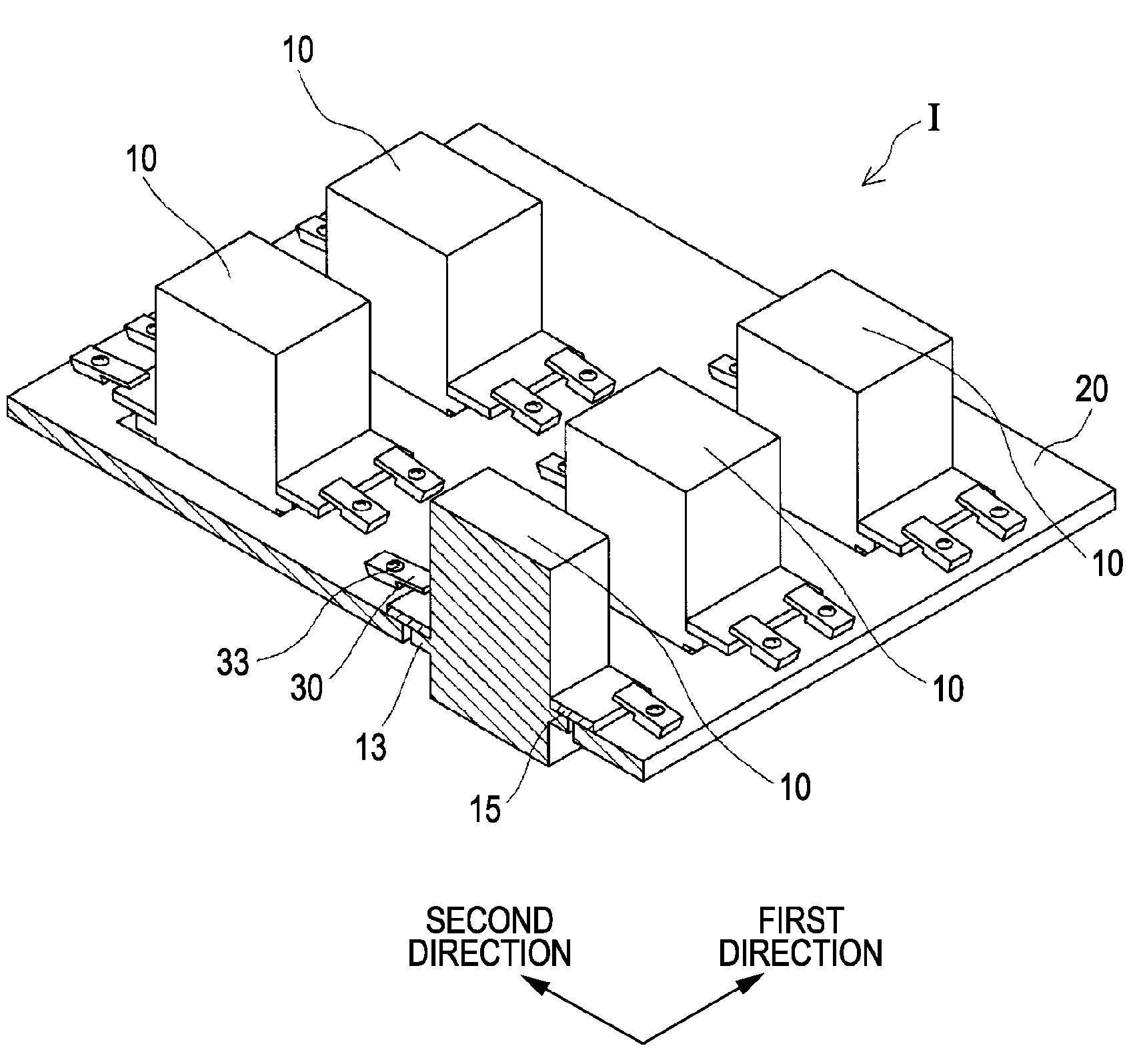

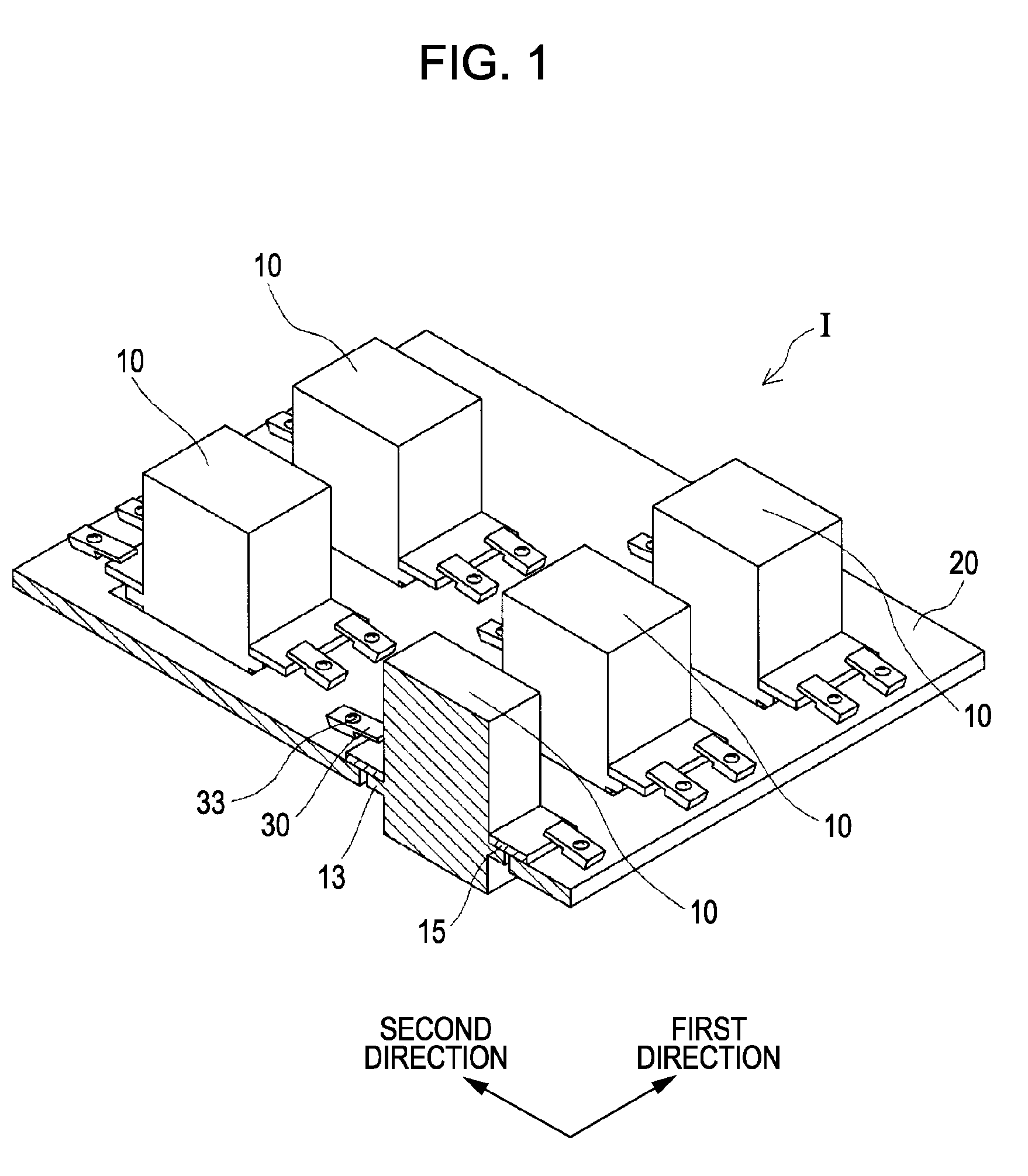

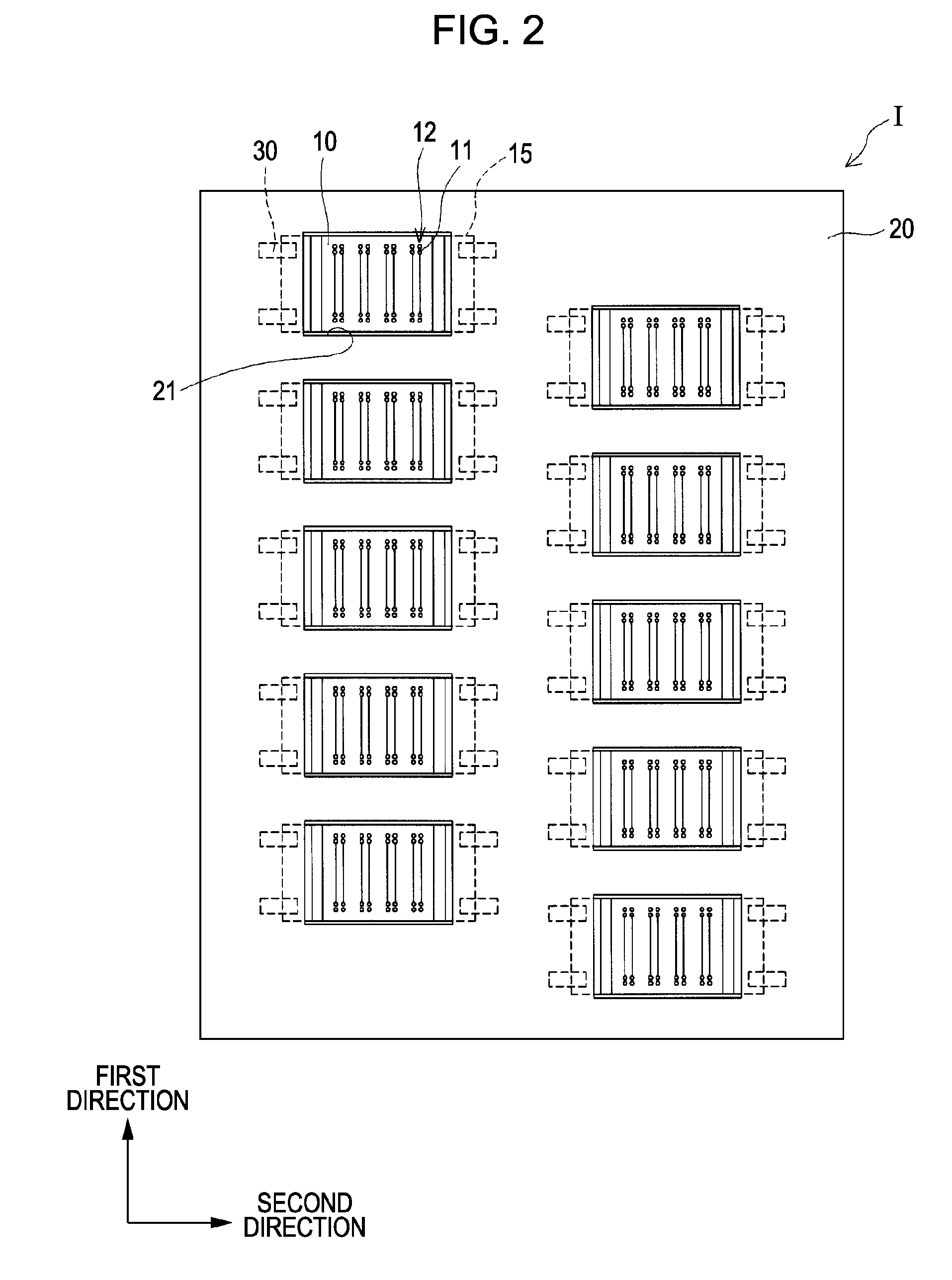

Mask assembly and method of fabricating the same

ActiveUS20090297768A1Easily weldPosition precision be highLiquid surface applicatorsLayered productsEngineeringFailure rate

In a mask assembly and a method of fabricating the same, when the mask assembly is fabricated by tensile welding a pattern mask to a mask frame, a tensile welding portion of the pattern mask welded to the mask frame is structurally changed. Thus, the pattern mask can be easily welded to the mask frame, and patterns of the pattern mask can be precisely aligned, thereby minimizing stain failure rate due to the mask assembly. The mask assembly includes: a mask frame including an opening and a support; and a pattern mask including a pattern portion having a plurality of patterns arranged in a matrix and a plurality of tensile welding portions extending from the pattern portion in a first direction and spaced apart from each other in a second direction perpendicular to the first direction. The method includes: providing a mask frame, a support, and a pattern mask as described above; disposing the pattern mask and the mask frame in a unique manner; combining the pattern mask with the mask frame by welding; measuring an aligned state of the pattern arranged in the first direction of the pattern mask; and welding a tensile welding portion using a secondary welding process according to an aligned state.

Owner:SAMSUNG DISPLAY CO LTD

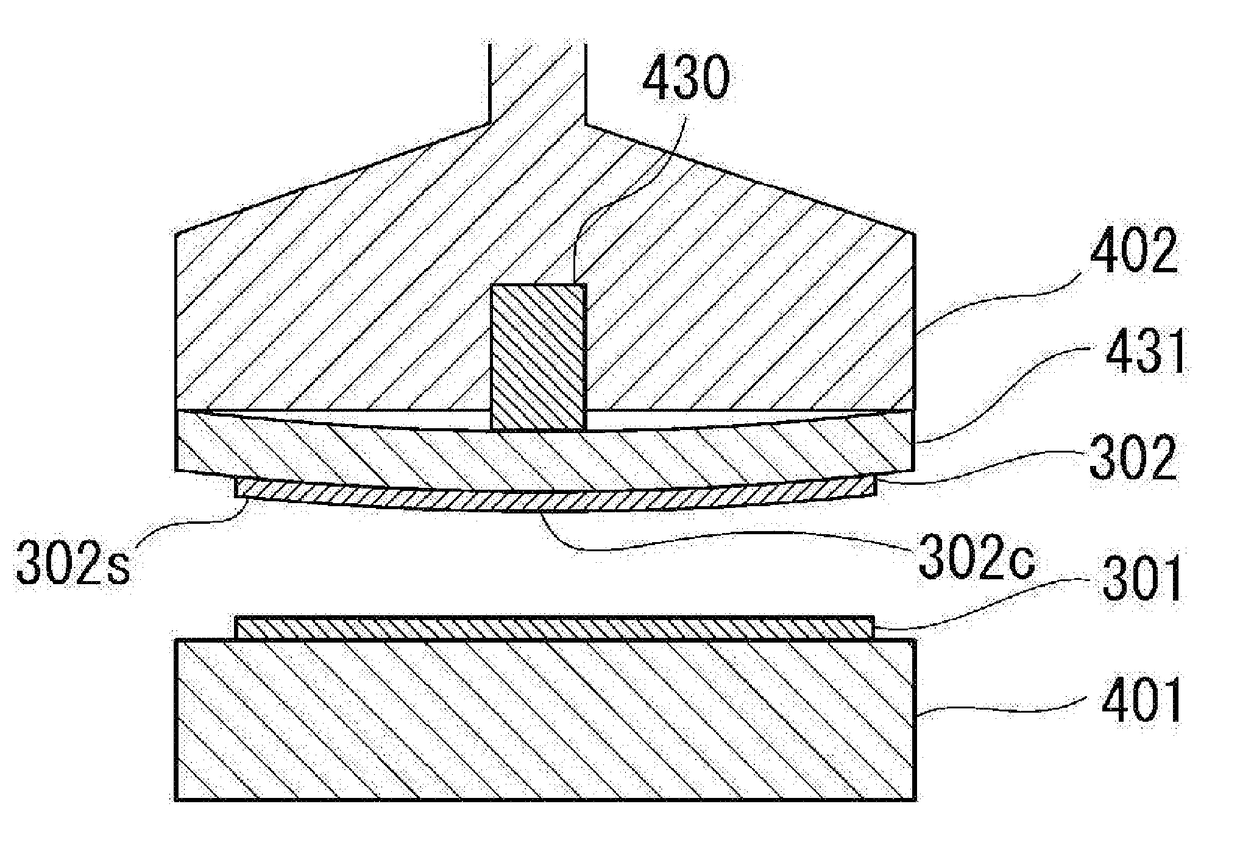

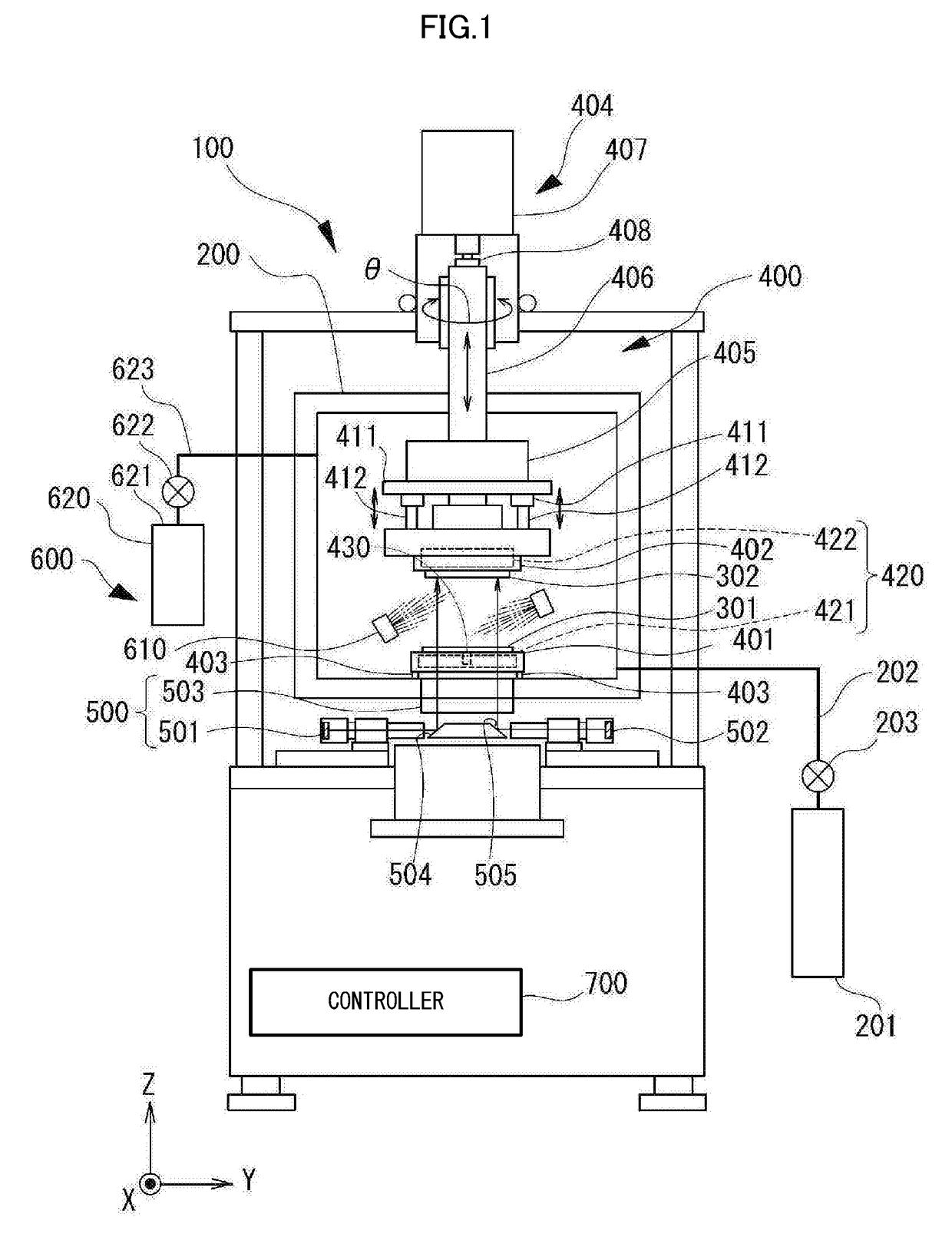

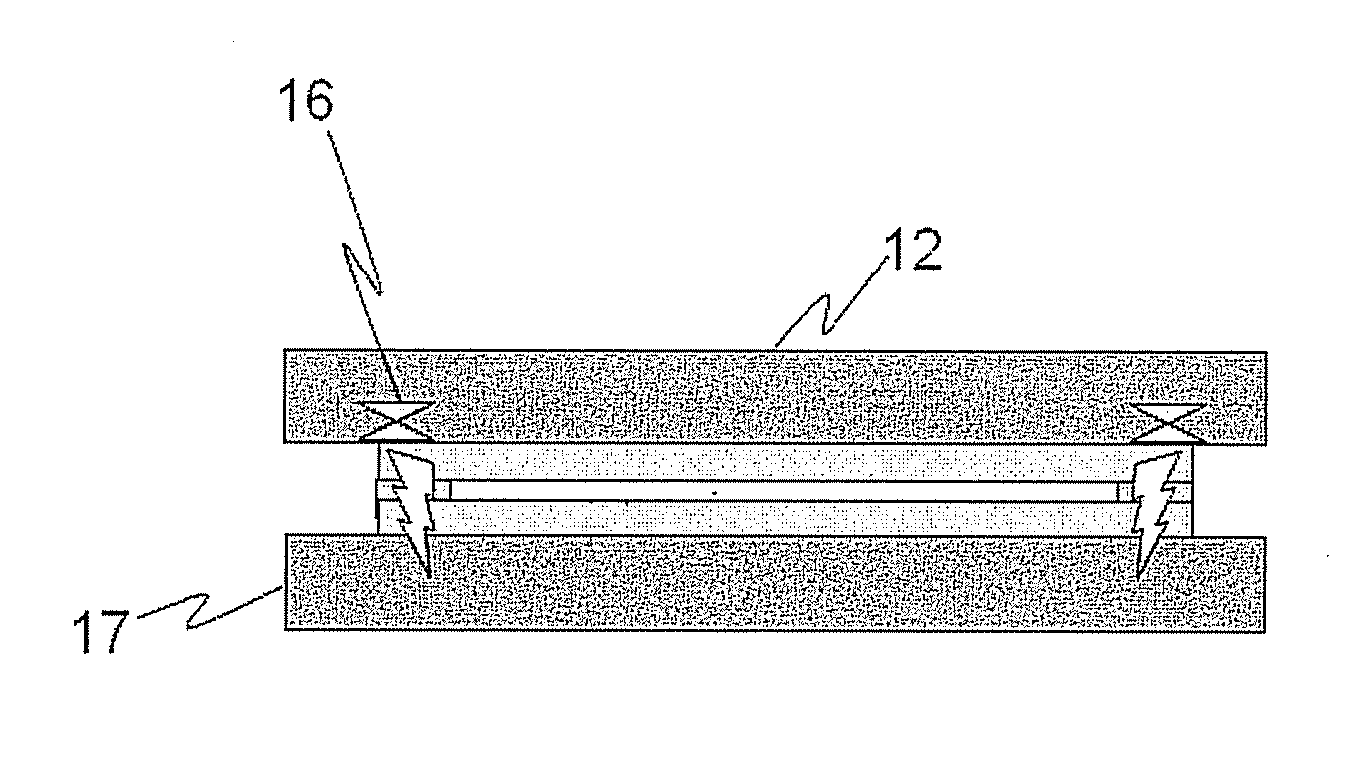

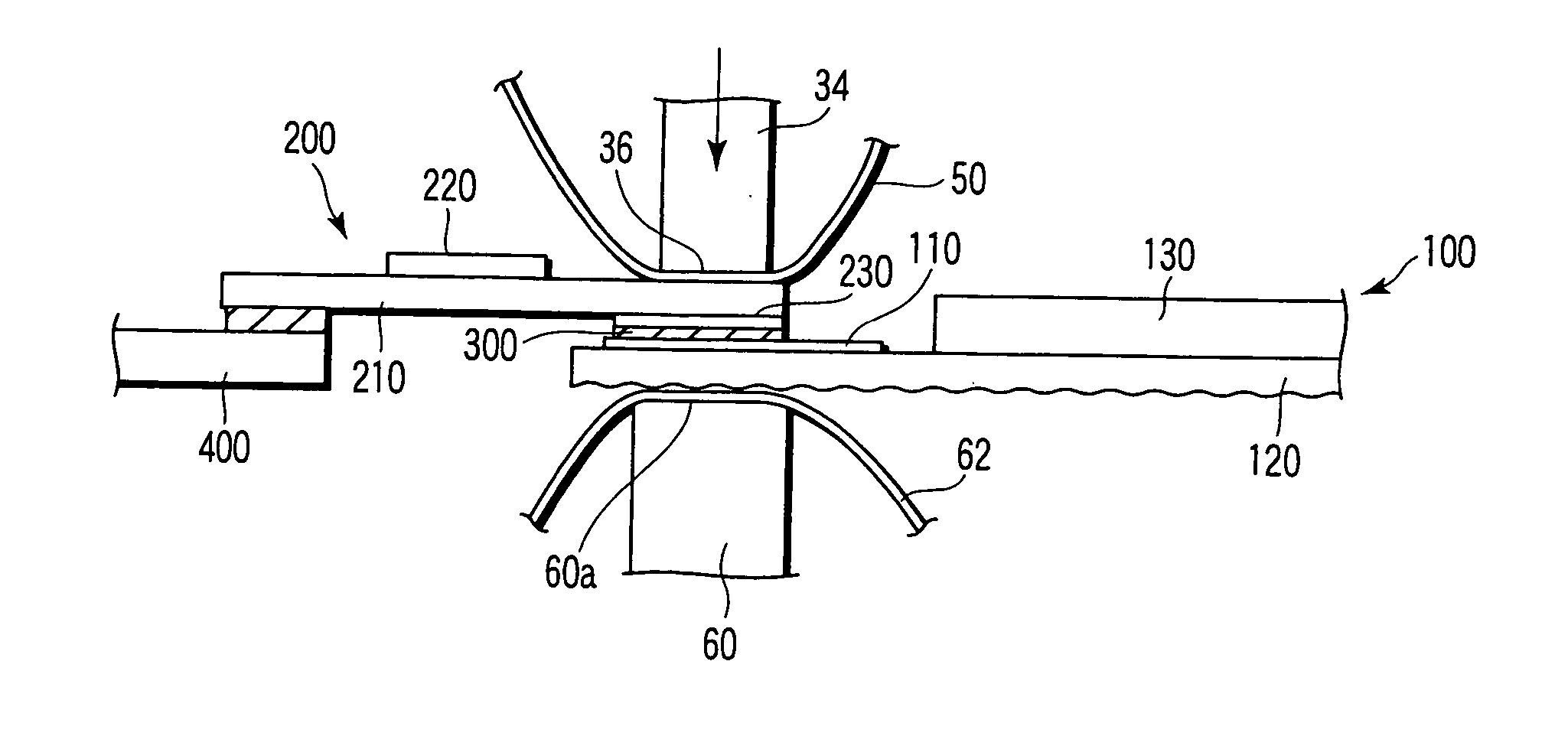

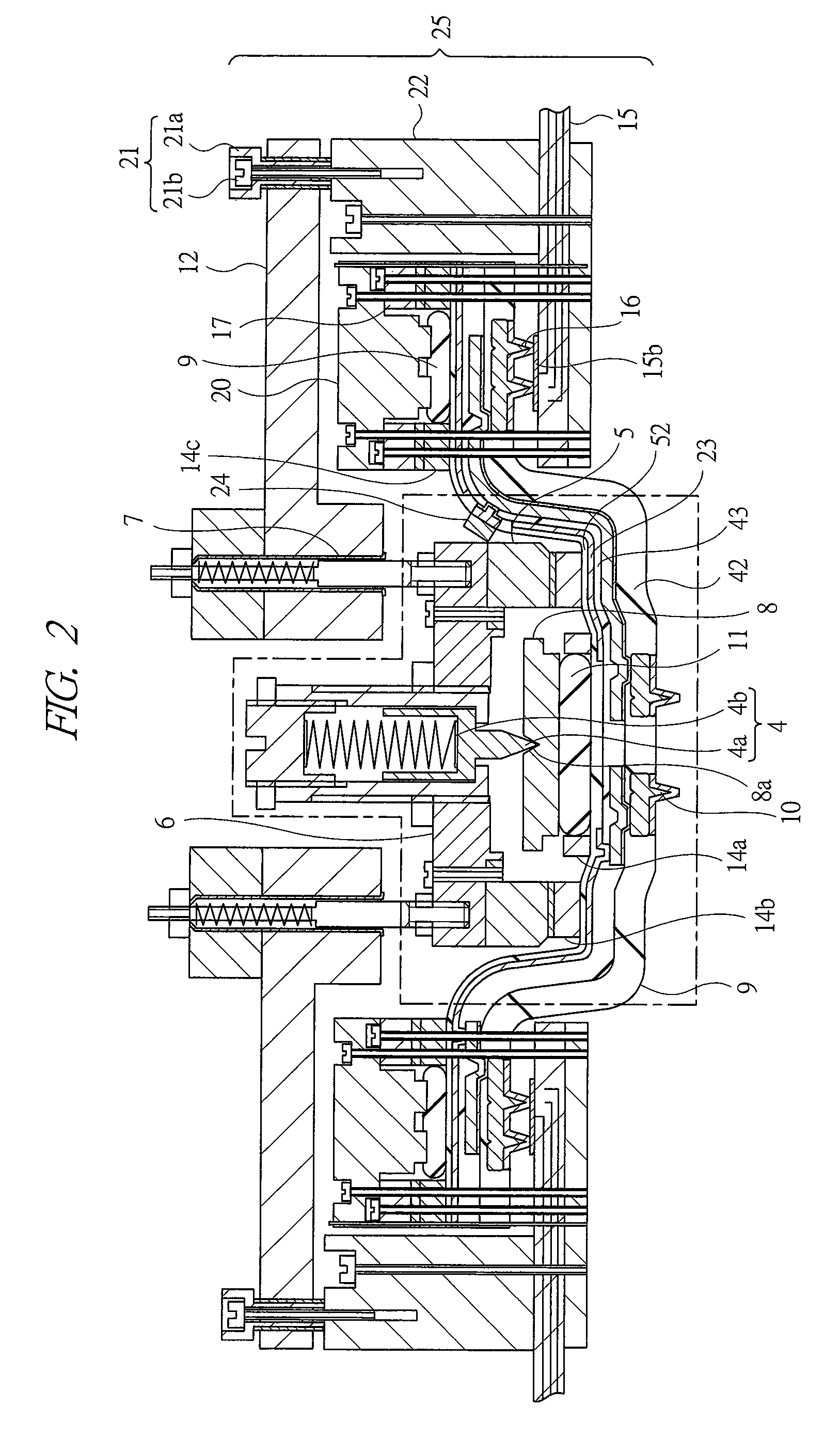

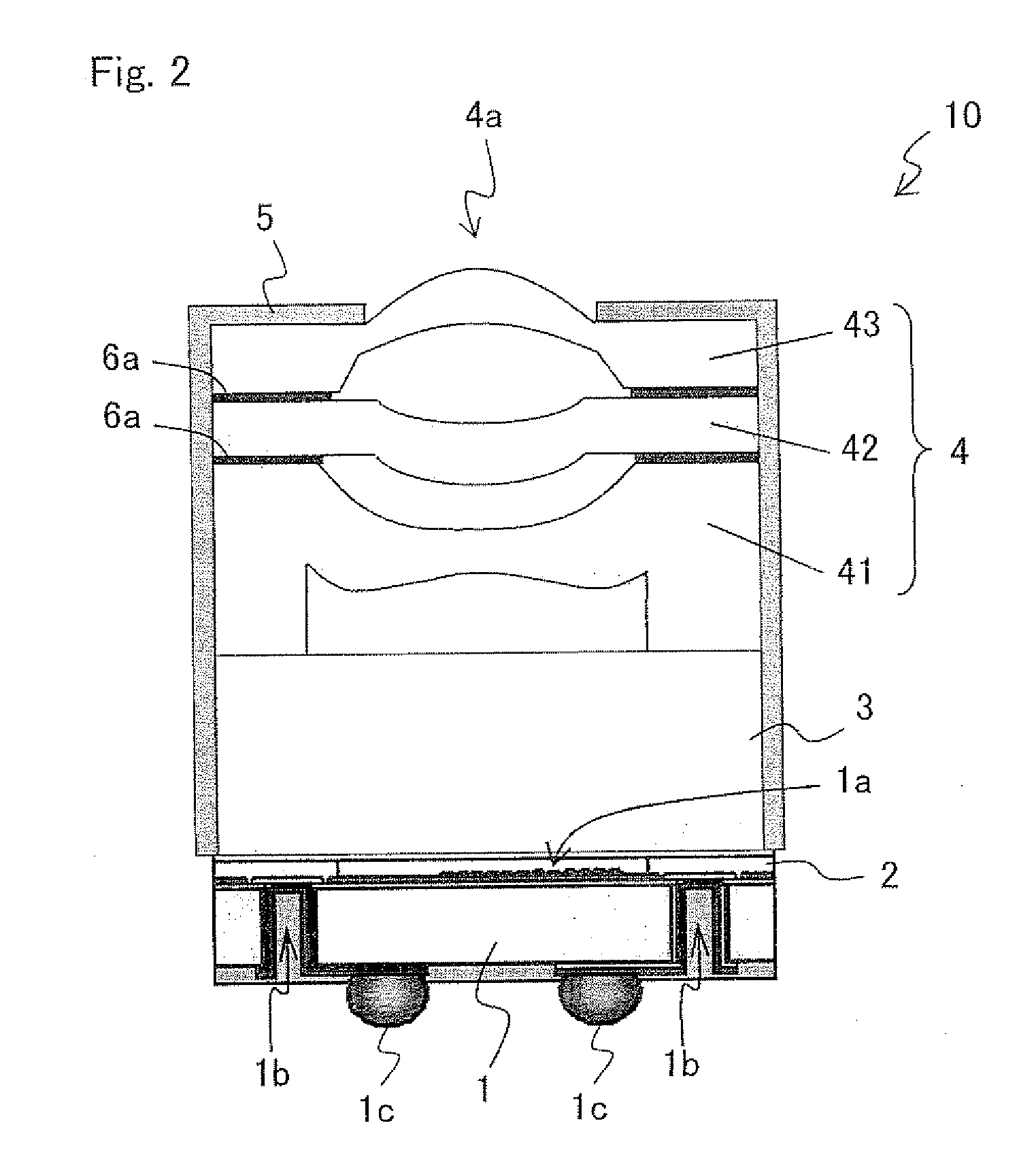

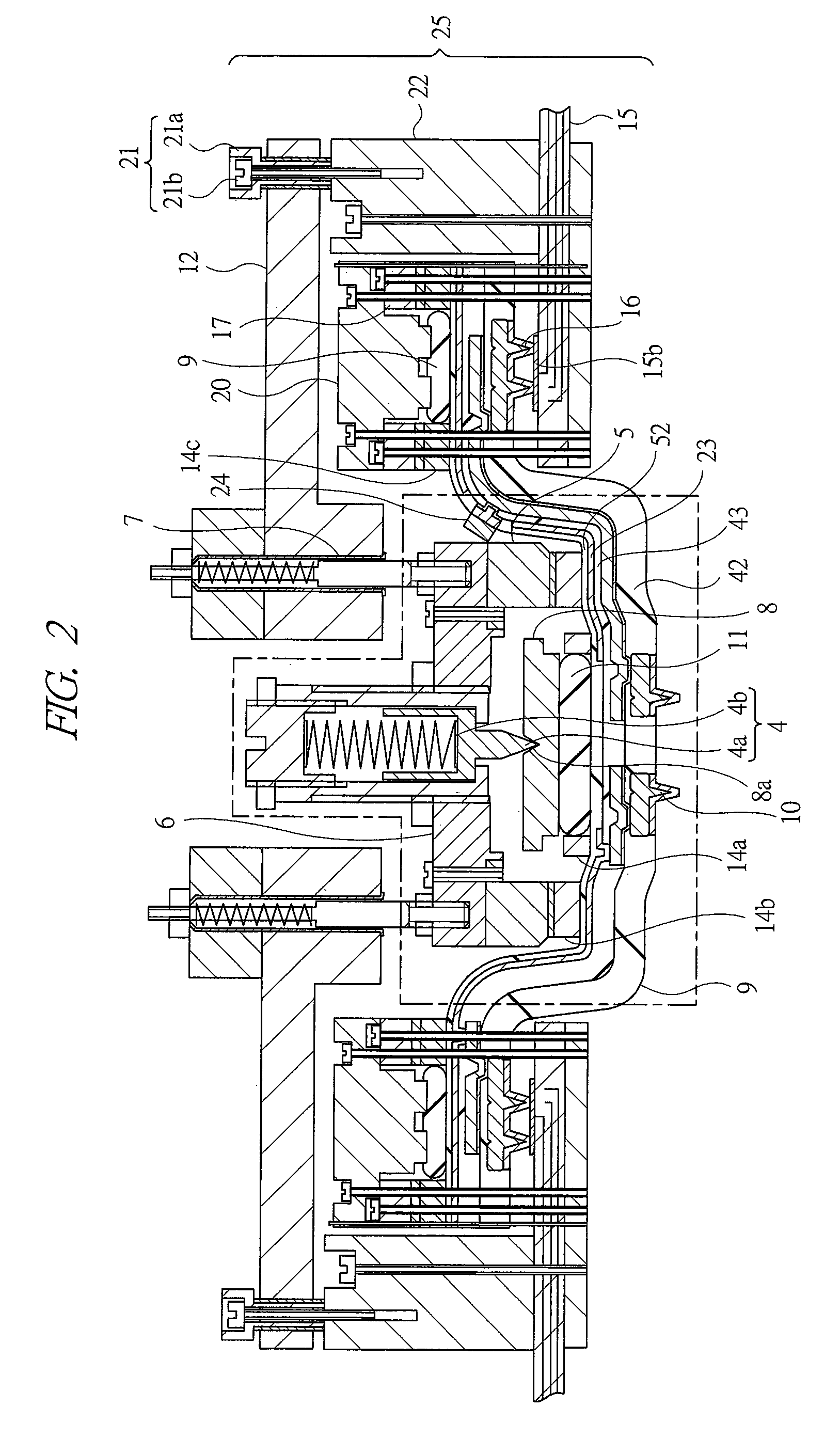

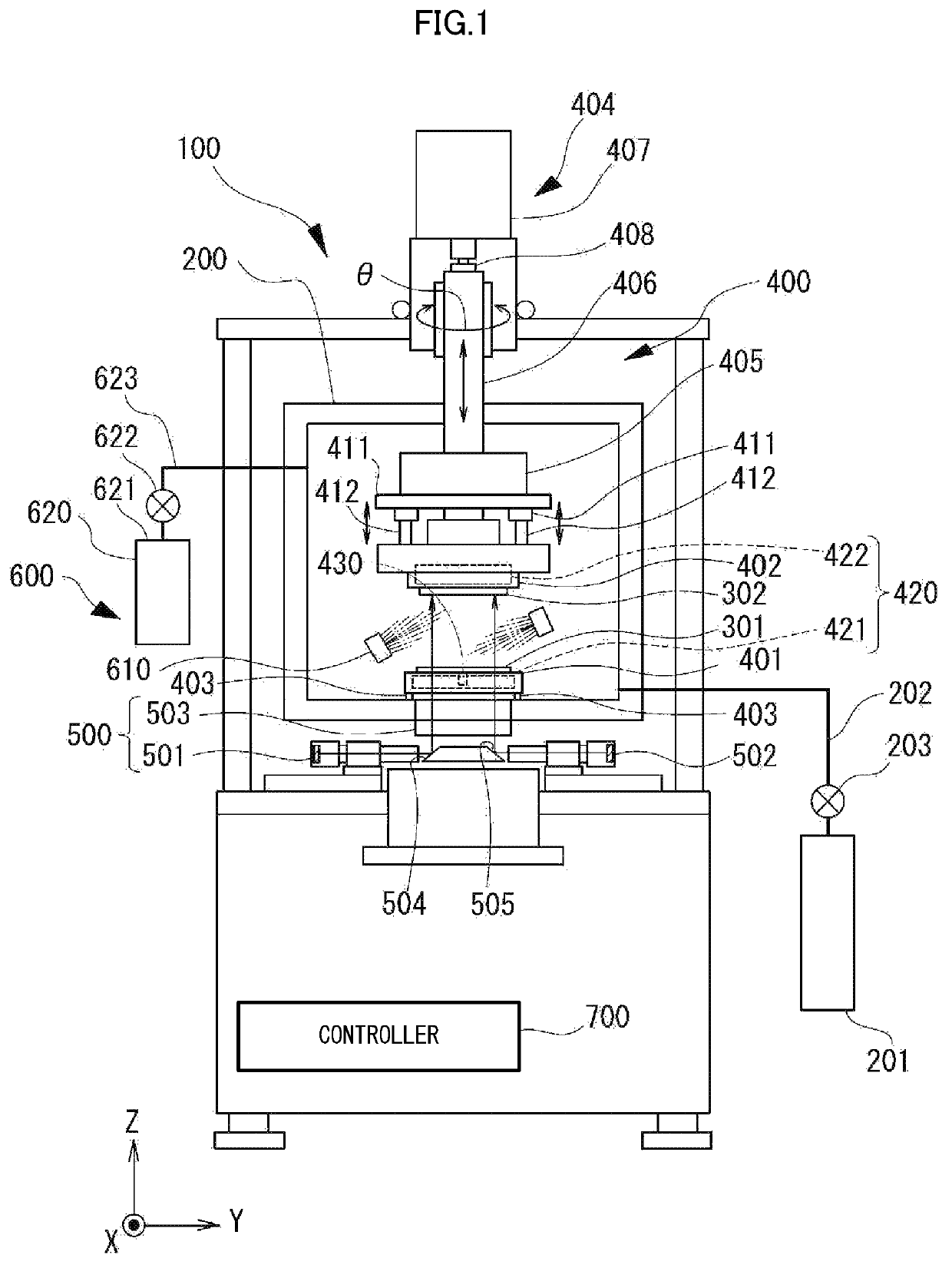

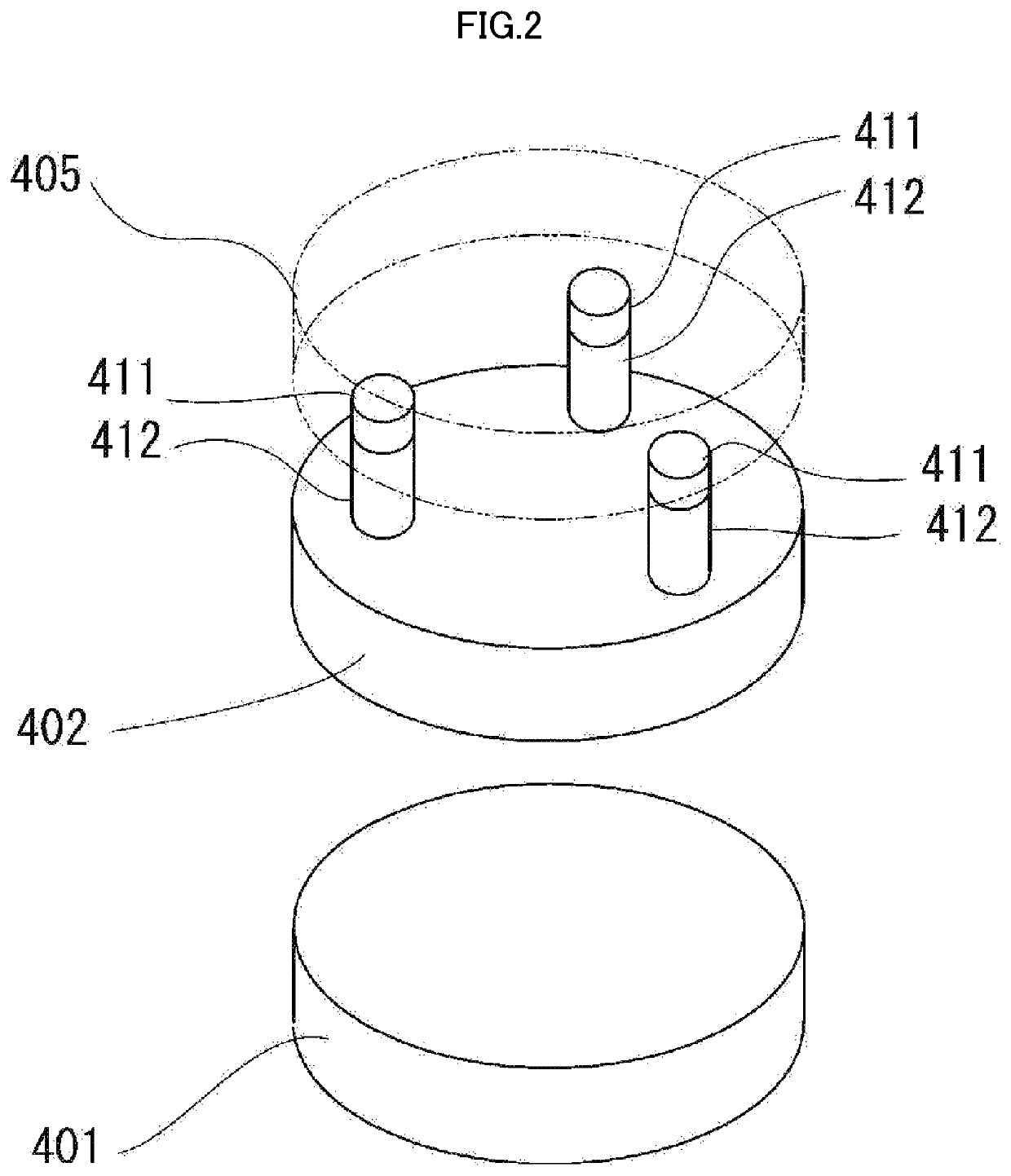

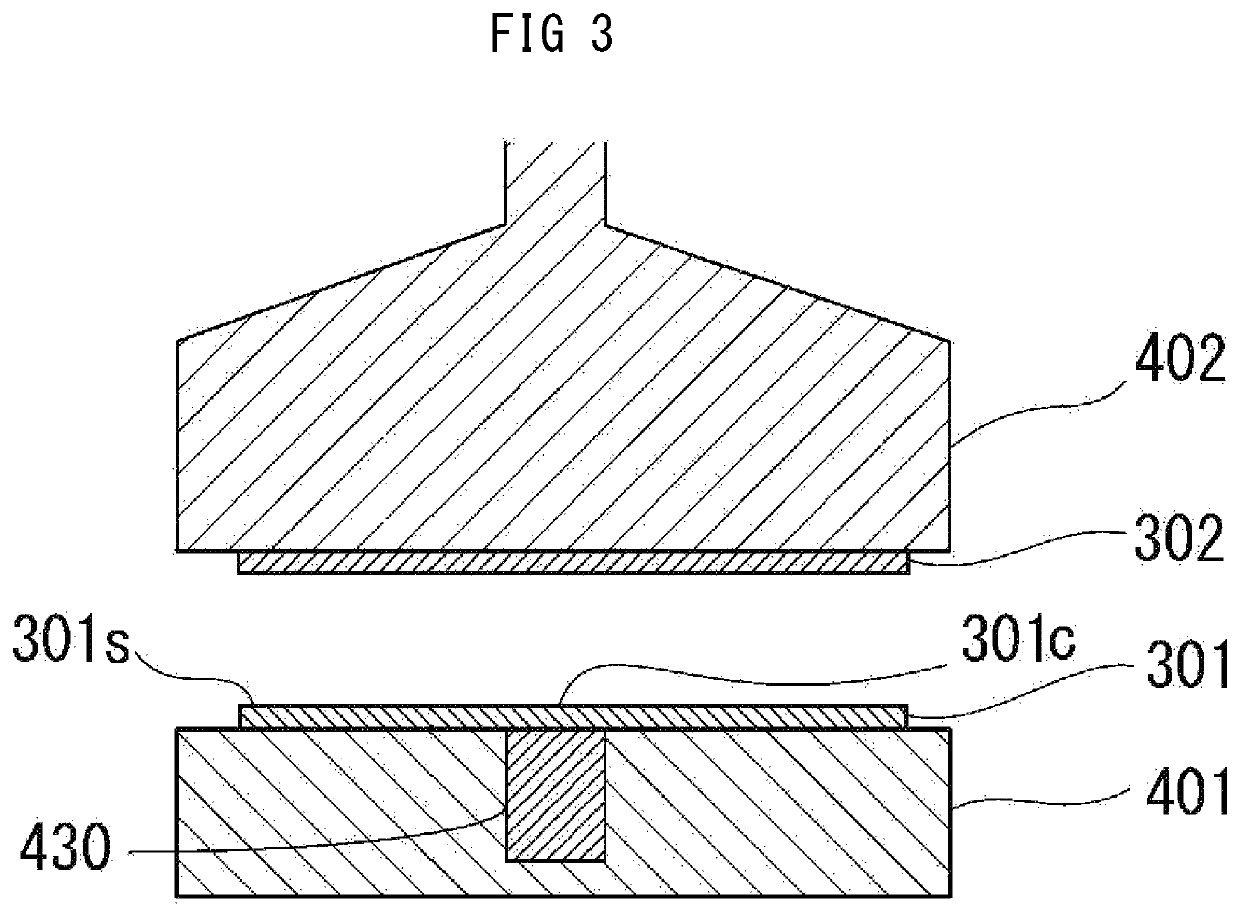

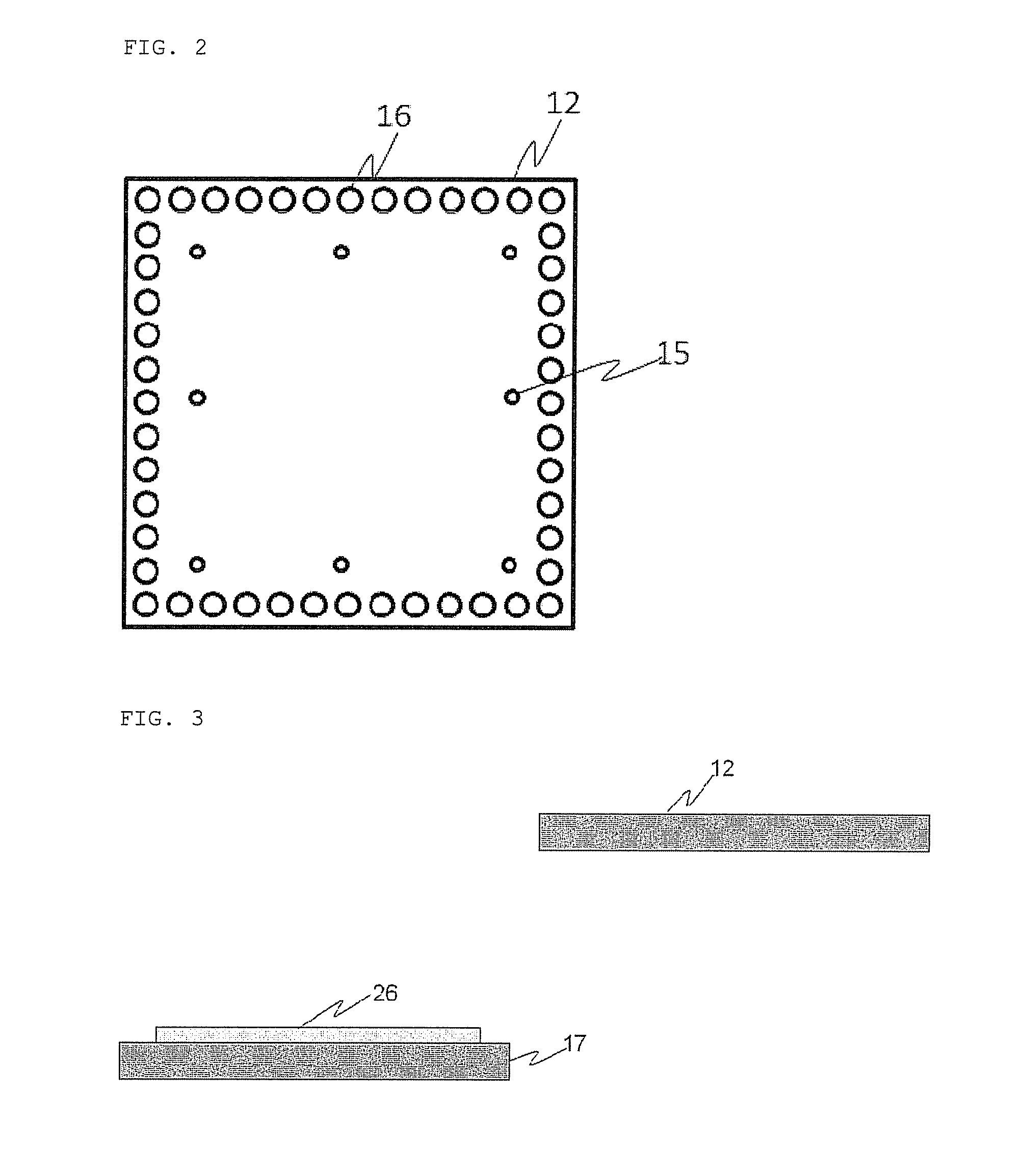

Method for bonding substrates together, and substrate bonding device

ActiveUS20170221856A1Inhibit productionHigh positionalSemiconductor/solid-state device detailsWelding/cutting auxillary devicesHydrophilizationChemistry

A production of voids between substrates is prevented when the substrates are bonded together, and the substrates are bonded together at a high positional precision while suppressing a strain. A method for bonding a first substrate and a second substrate includes a step of performing hydrophilization treatment to cause water or an OH containing substance to adhere to bonding surface of the first substrate and the bonding surface of the second substrate, a step of disposing the first substrate and the second substrate with the respective bonding surfaces facing each other, and bowing the first substrate in such a way that a central portion of the bonding surface protrudes toward the second substrate side relative to an outer circumferential portion of the bonding surface, a step of abutting the bonding surface of the first substrate with the bonding surface of the second substrate at the respective central portions, and a step of abutting the bonding surface of the first substrate with the bonding surface of the second substrate across the entirety of the bonding surfaces, decreasing a distance between the outer circumferential portion of the first substrate and an outer circumferential portion of the second substrate with the respective central portions abutting each other at a pressure that maintains a non-bonded condition.

Owner:BONDTECH

Method of manufacturing translucent rigid substrate laminate

InactiveUS20130081752A1Improve production efficiencyHigh positionalLamination ancillary operationsSynthetic resin layered productsEngineeringSemi transparent

Owner:DENKA CO LTD

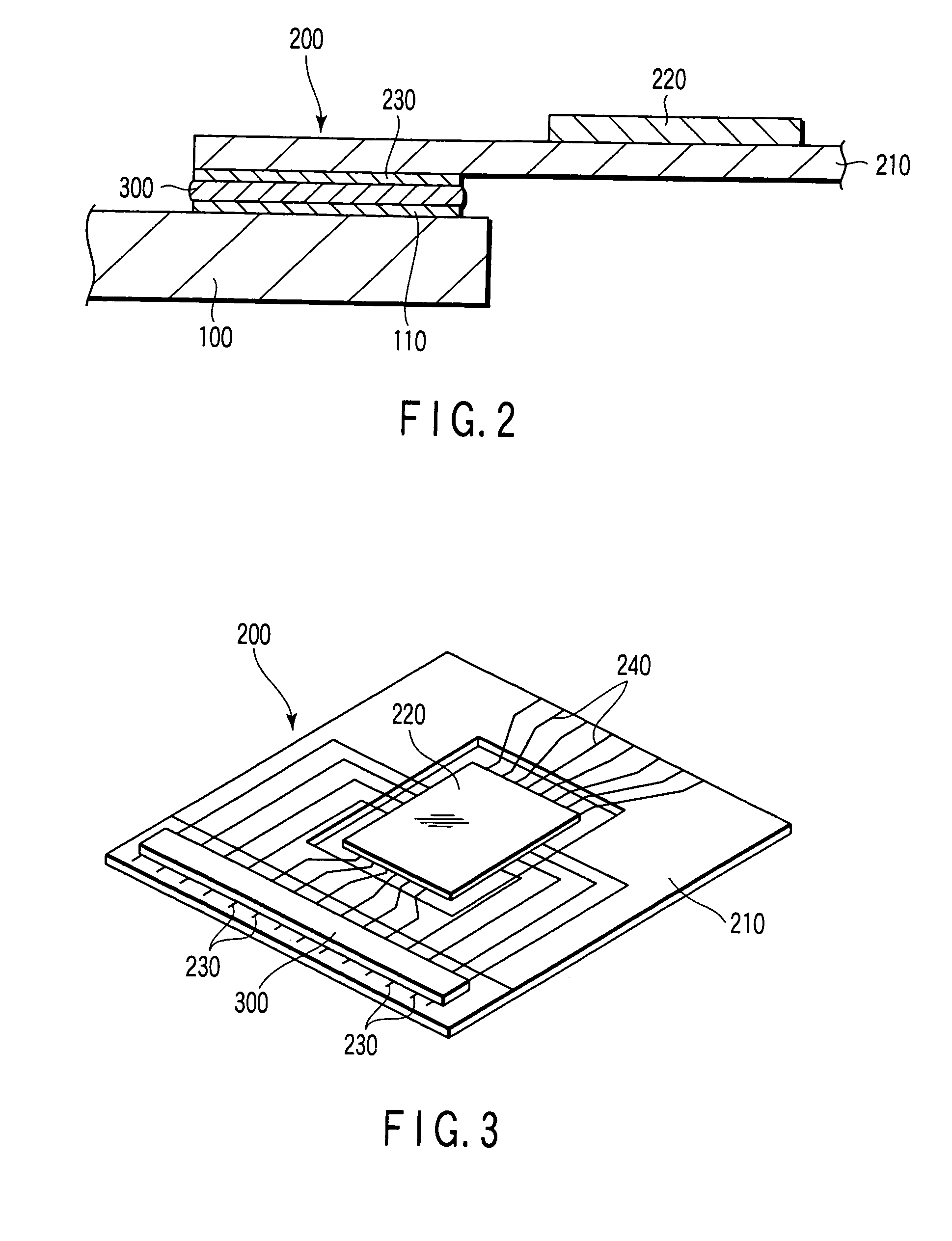

Press-bonding apparatus and press-bonding method

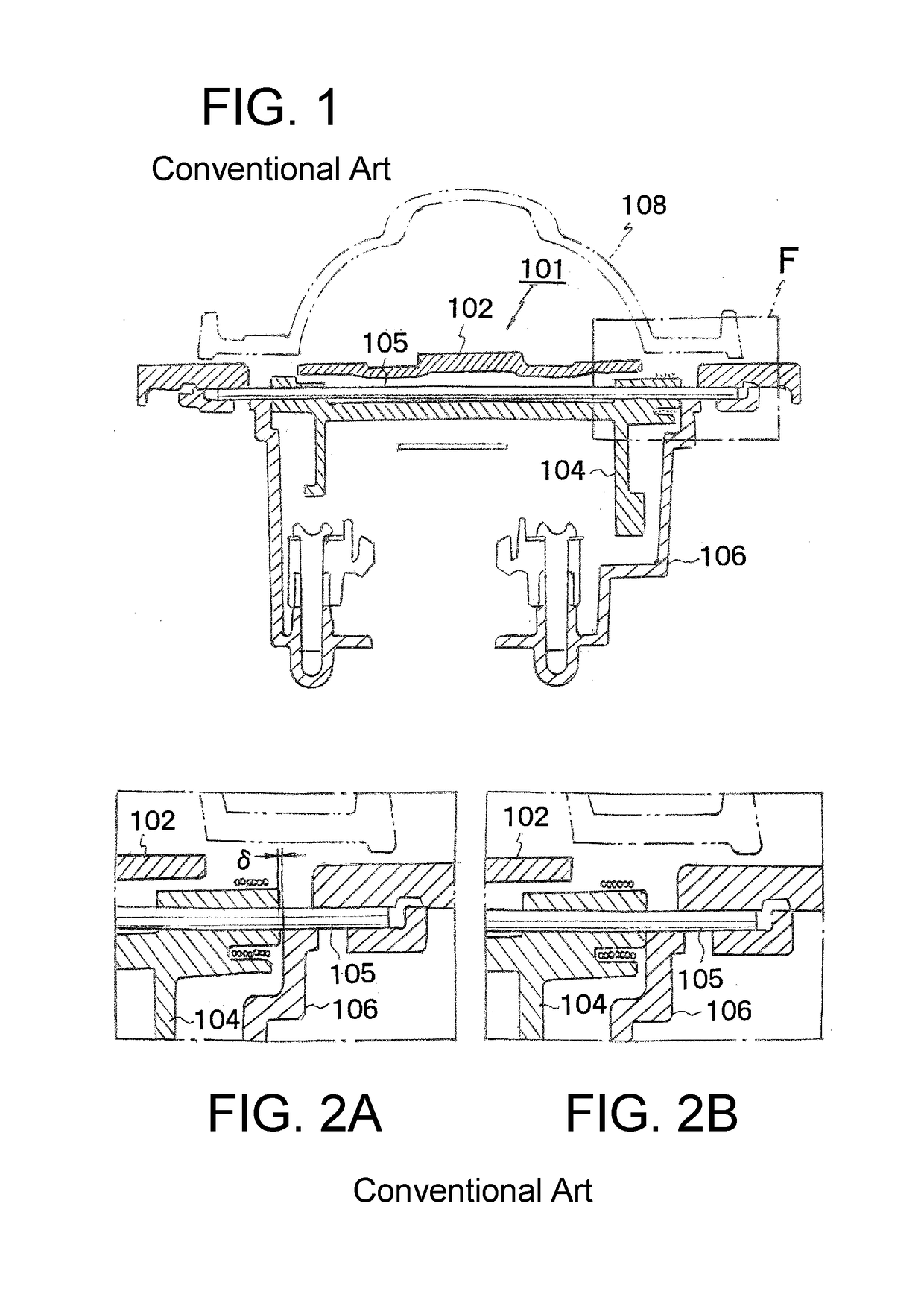

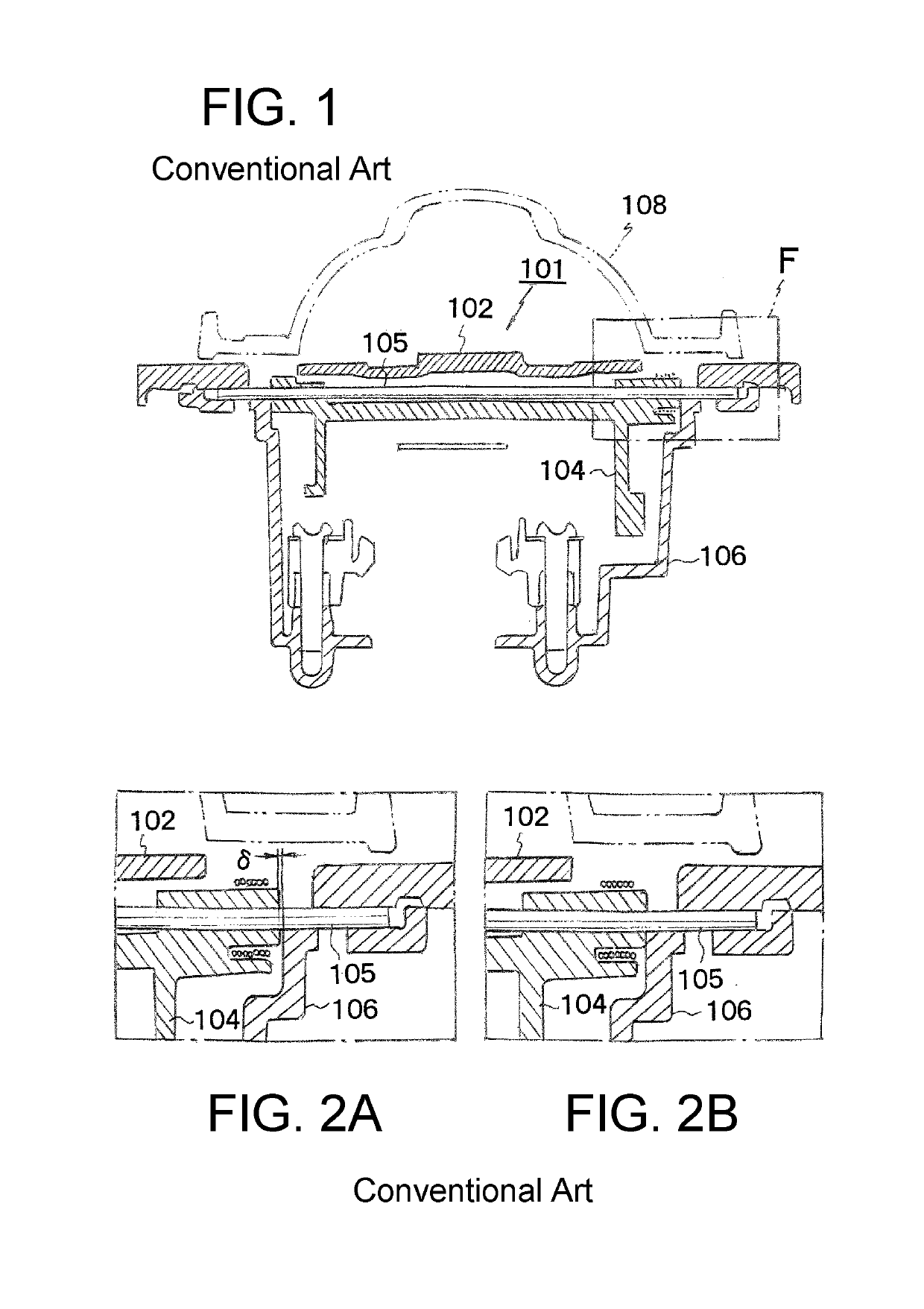

InactiveUS20070084566A1Avoid damageAvoid partialPrinted circuit aspectsPrinted circuit manufactureEngineeringHeat sensitive

A press-bonding apparatus includes a backup member which supports a display panel, a heater tool which presses a wiring board, which is aligned at a predetermined position on the display panel via an adhesive member, toward the display panel between the heater tool and the backup member, and press-bonds the wiring board to the display panel, and a thermal resistor which is interposed between the backup member and the display panel.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH +1

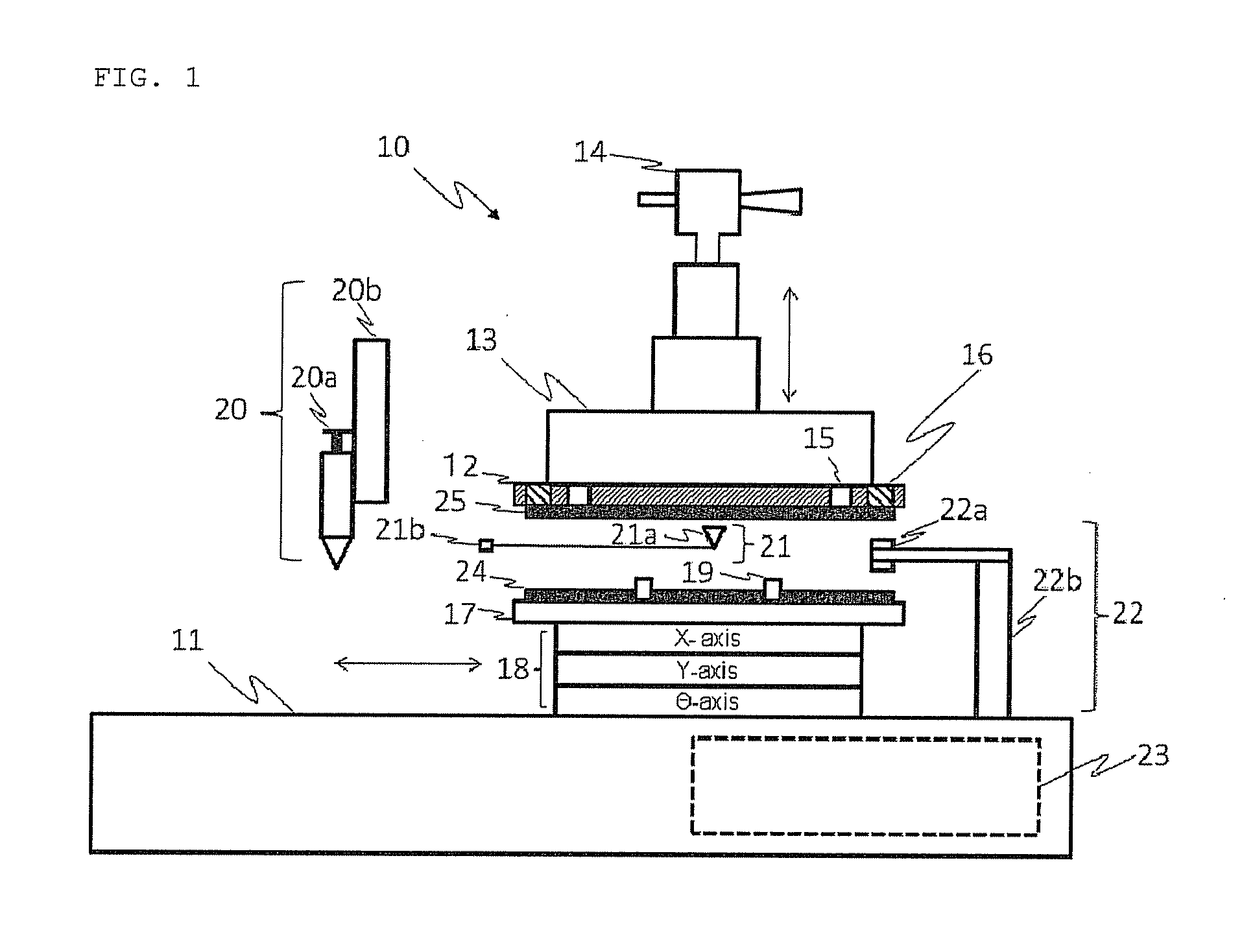

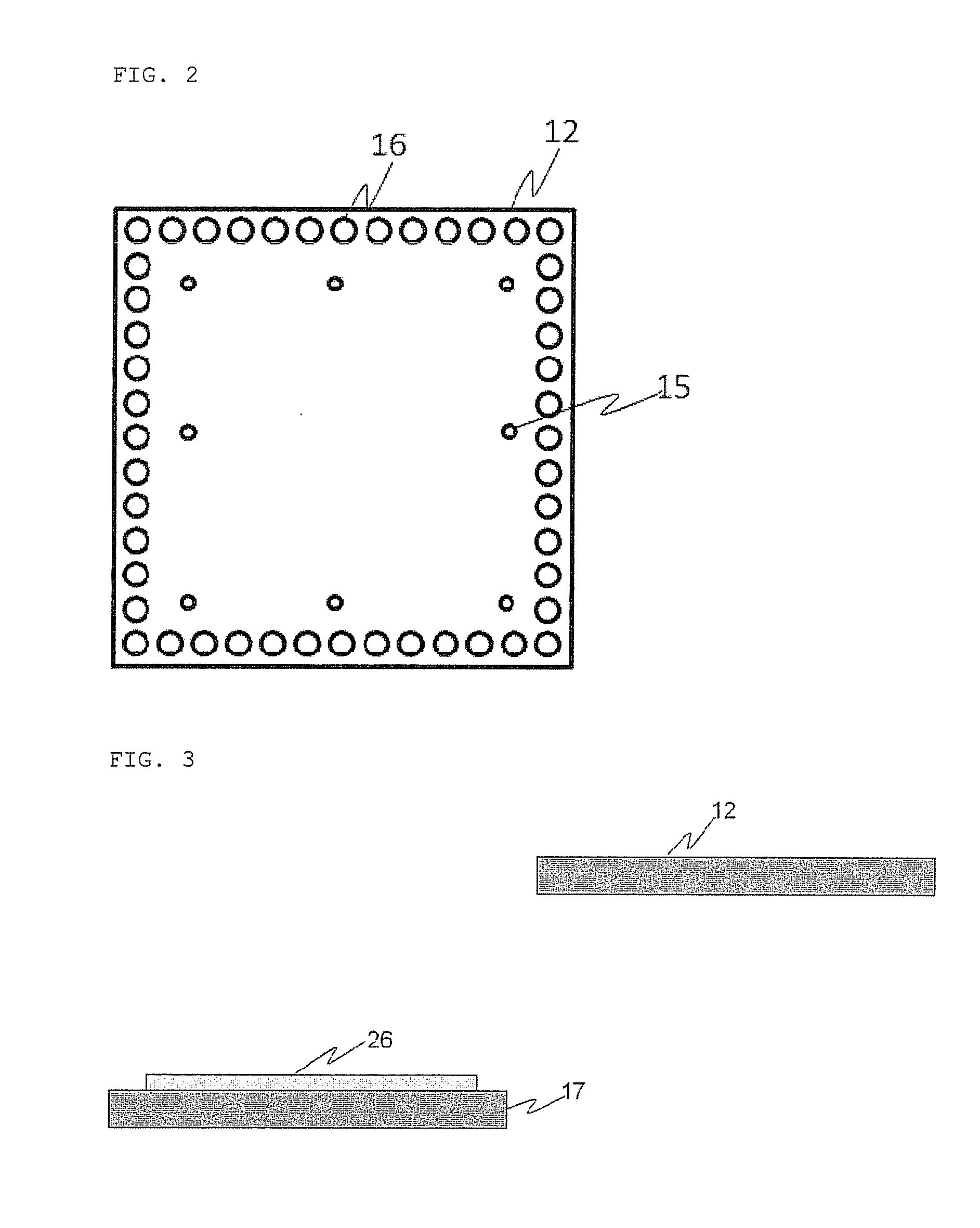

Probe card, semiconductor inspecting apparatus, and manufacturing method of semiconductor device

InactiveUS7956627B2High positionalRoughness of electrode pad faces caused by probingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardMechanical engineering

A frame bonded and fixed to a back face of a probe sheet so as to surround a group of pyramid-shaped or truncated pyramid-shaped contact terminals collectively formed at a central region portion of the probe sheet on a probing side thereof is protruded from a multi-layered wiring board, and pressing force is imparted to the frame and a pressing piece at a central portion by a plurality of guide pins having spring property so as to tilt finely.

Owner:RENESAS ELECTRONICS CORP

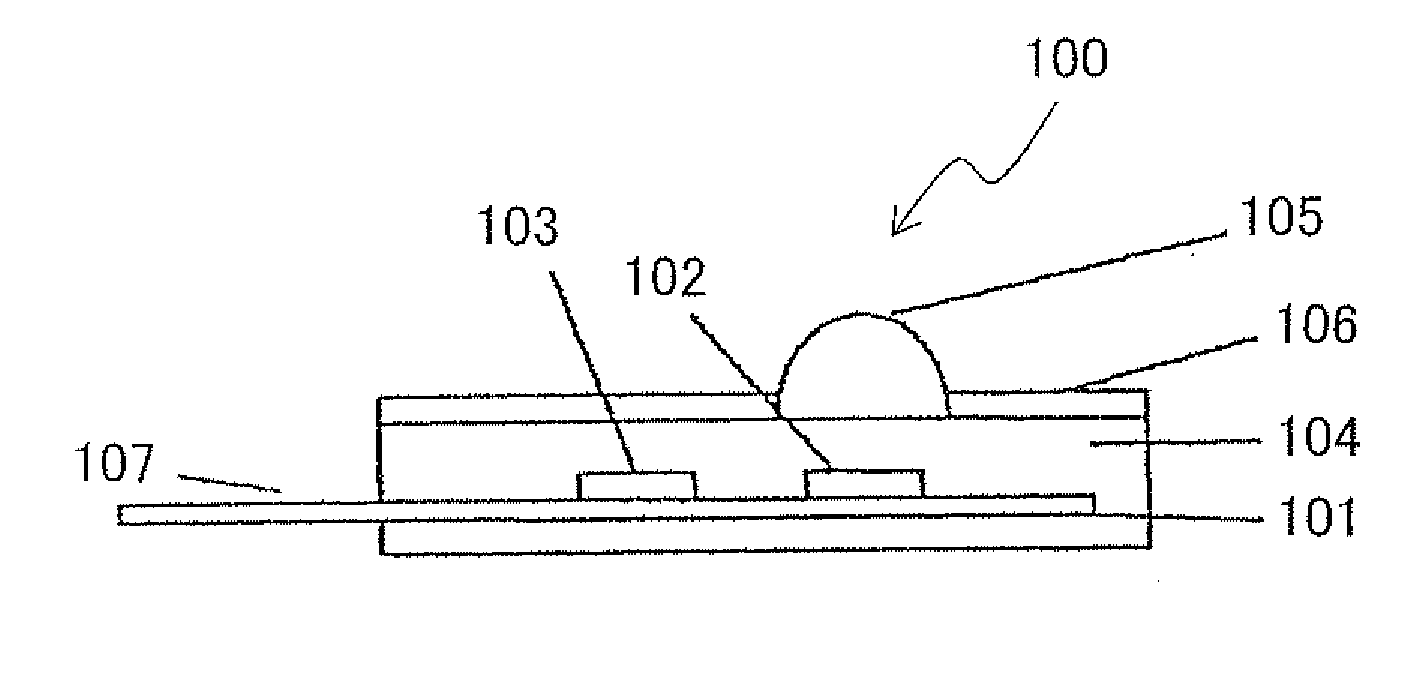

Electronic element wafer module and method for manufacturing same, electronic element module, optical element wafer module and method for manufacturing same, and electronic information device

InactiveUS20100133419A1High positionalHigh positioning accuracyTelevision system detailsVacuum evaporation coatingComputer moduleEngineering

A method for manufacturing an electronic element wafer module is provided, the method comprising: a protective resin film forming step of forming a protective resin film on only light openings of the plurality of wafer-shaped optical elements; a light shielding film forming step of filming a light shielding film on an area except for the light openings or an entire area including the light openings; and an optical aperture forming step of removing the protective resin film, or removing the protective resin film and a light shielding film material on the protective resin film, to form an optical aperture structure by the light shielding film at the light openings.

Owner:SHARP KK

Mask assembly and method of fabricating the same

ActiveUS8151729B2Easy to weldHigh positionalLiquid surface applicatorsLayered productsFailure rateEngineering

Owner:SAMSUNG DISPLAY CO LTD

Probe card, semiconductor inspecting apparatus, and manufacturing method of semiconductor device

InactiveUS20090042323A1High positionalRoughness of electrode pad faces caused by probingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardEngineering

A frame bonded and fixed to a back face of a probe sheet so as to surround a group of pyramid-shaped or truncated pyramid-shaped contact terminals collectively formed at a central region portion of the probe sheet on a probing side thereof is protruded from a multi-layered wiring board, and pressing force is imparted to the frame and a pressing piece at a central portion by a plurality of guide pins having spring property so as to tilt finely.

Owner:RENESAS ELECTRONICS CORP

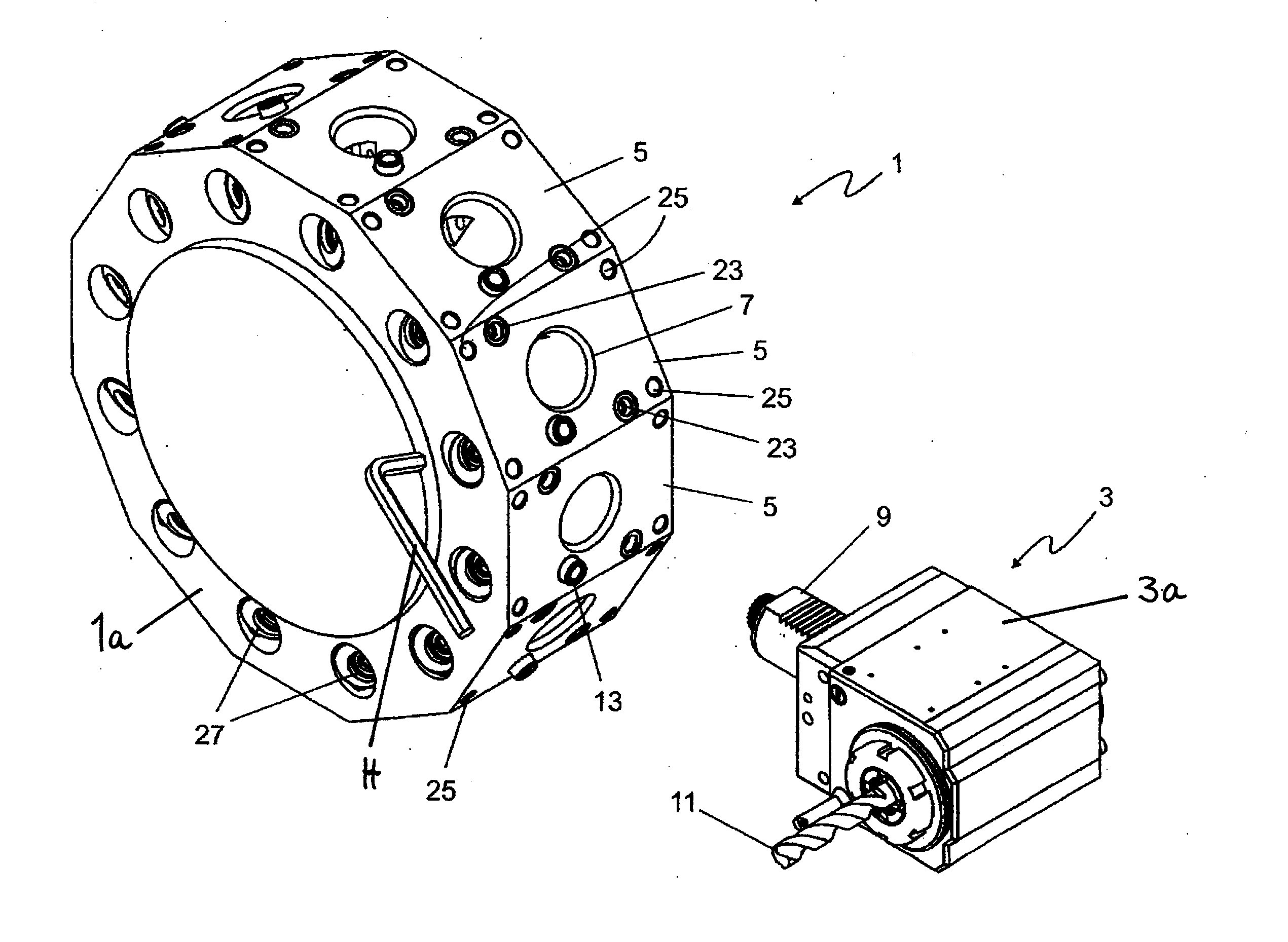

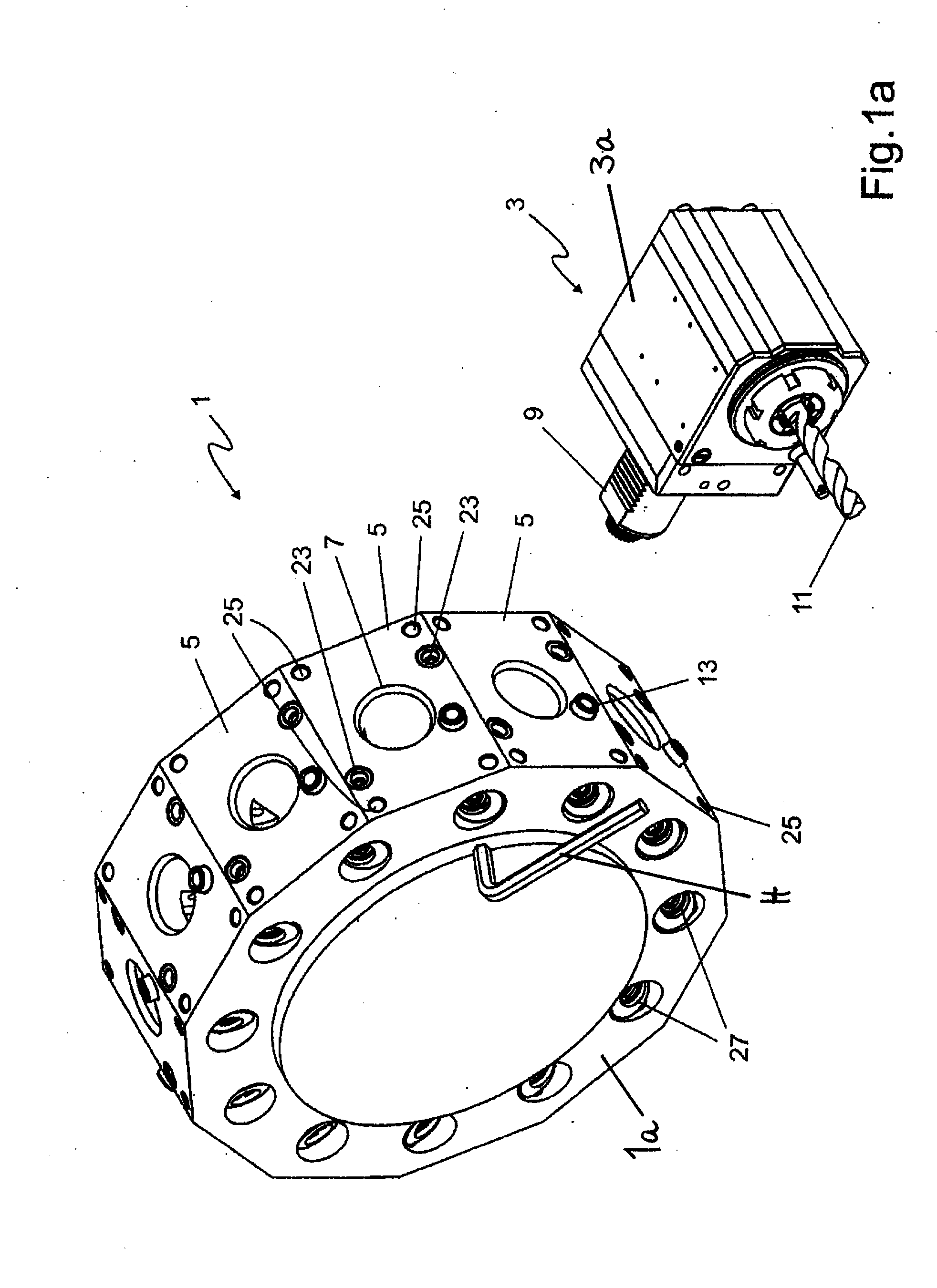

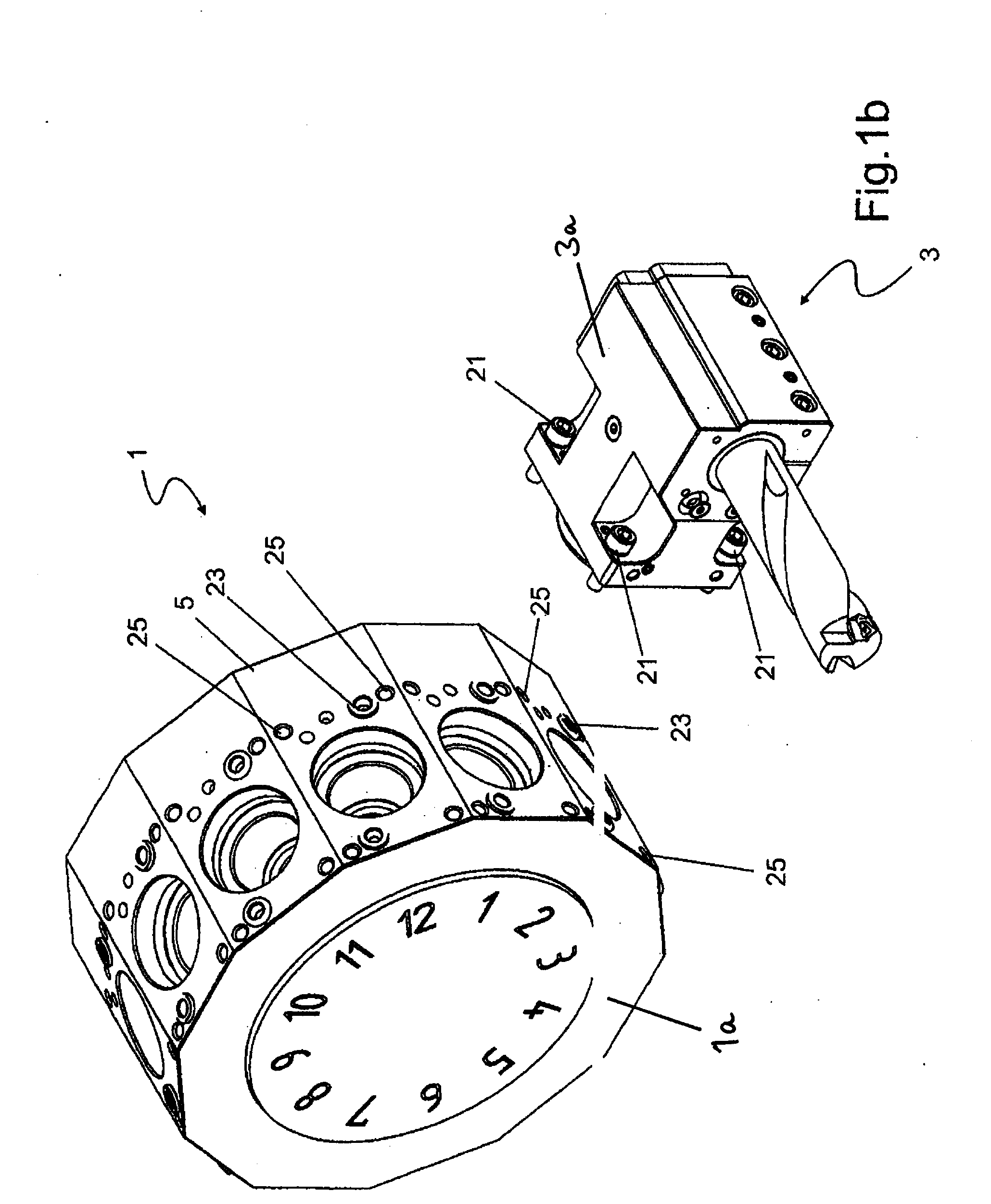

Tool Support with Exchangeable Tool Holders and Tool Holder

InactiveUS20110023276A1Simple configurationHigh positioning accuracyAutomatic/semiautomatic turning machinesTool holdersEngineeringMachine tool

A tool support for a machine tool has a clamping surface. A positioning device for a tool holder is provided that is positioned at the clamping surface. The positioning device has at least one conical element wherein a longitudinal axis of the conical element extends orthogonally to the clamping surface. The conical element is a conical bore or a conical pin. The tool holder is equipped with complementary conical elements so that a positive-locking, precise positioning of the tool holder relative to the receiving bore in the tool support is ensured.

Owner:WTO WERKZEUG EINRICHTUNGEN

Liquid ejecting head and liquid ejecting apparatus

InactiveUS20100026759A1High positionalImprove printing qualityInking apparatusEngineeringLiquid drop

Owner:SEIKO EPSON CORP

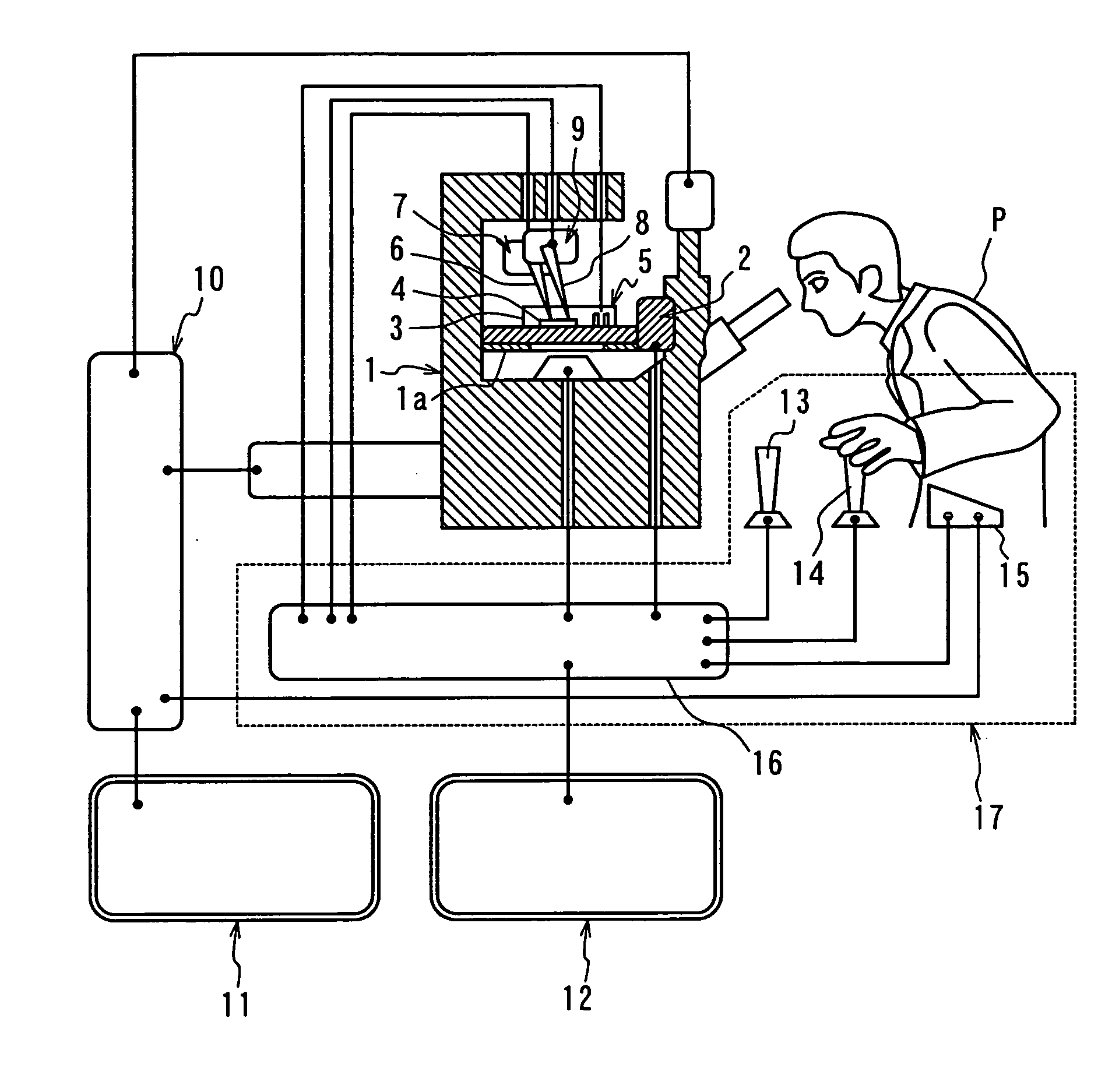

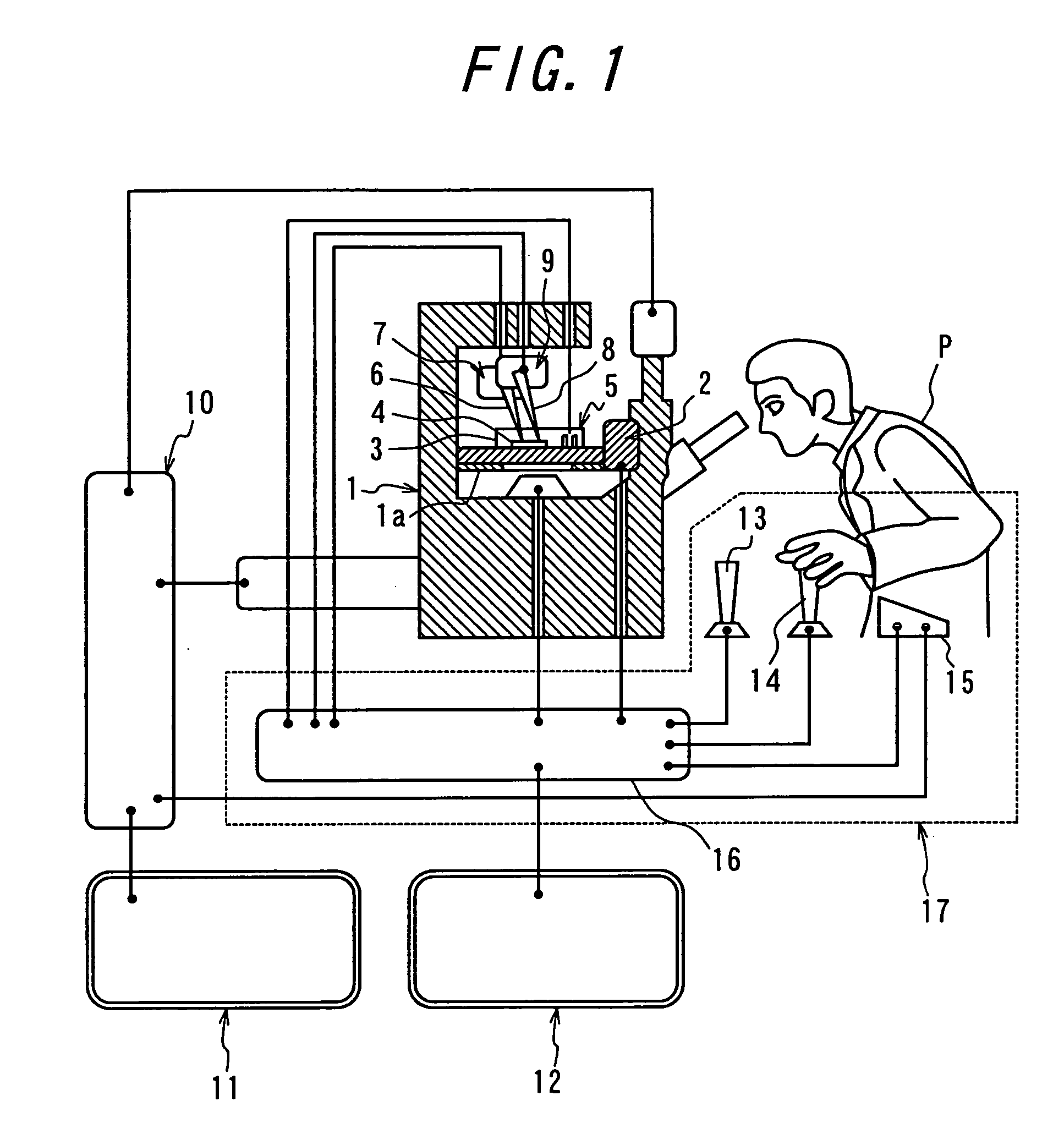

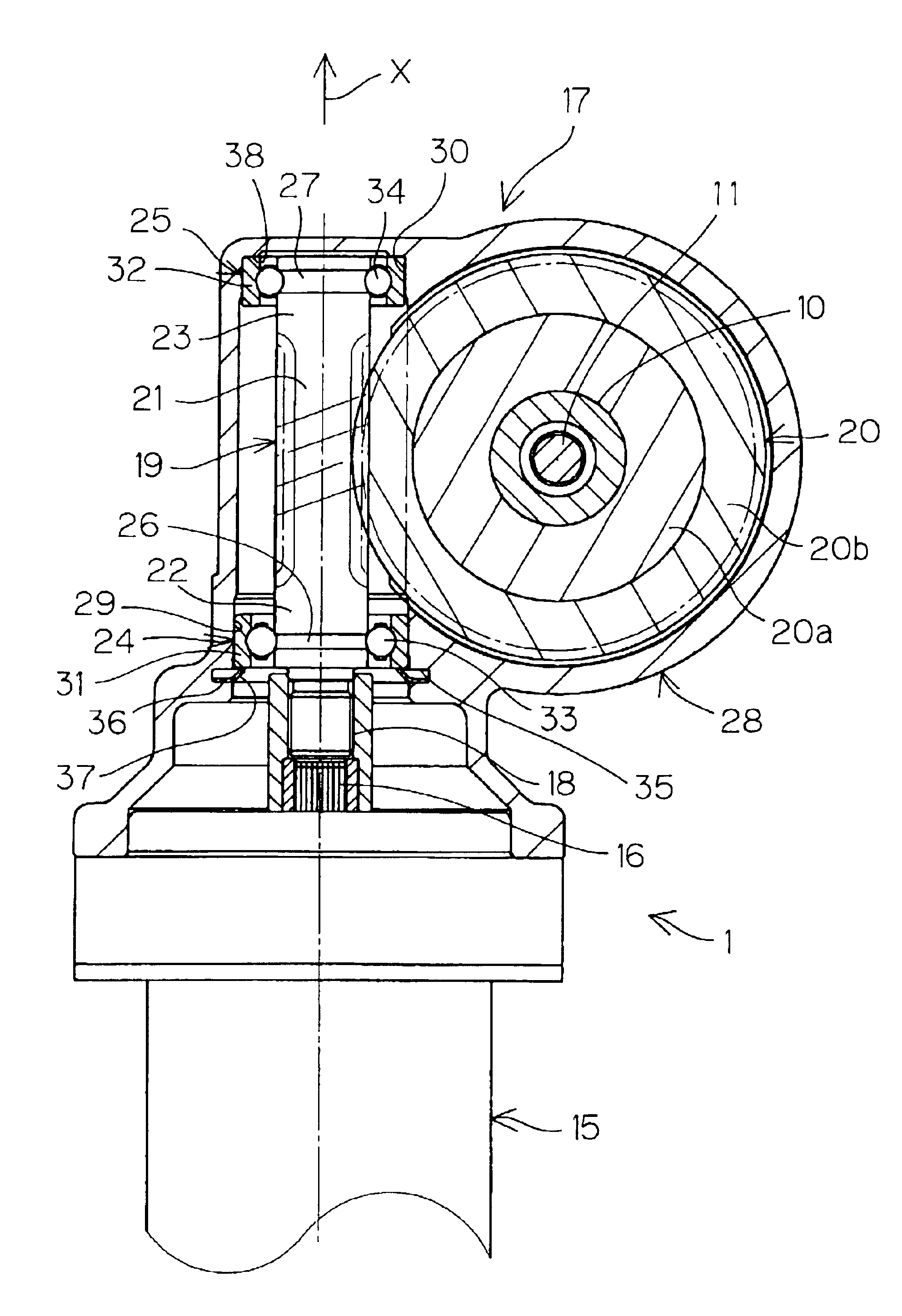

Single cell operation supporting robot

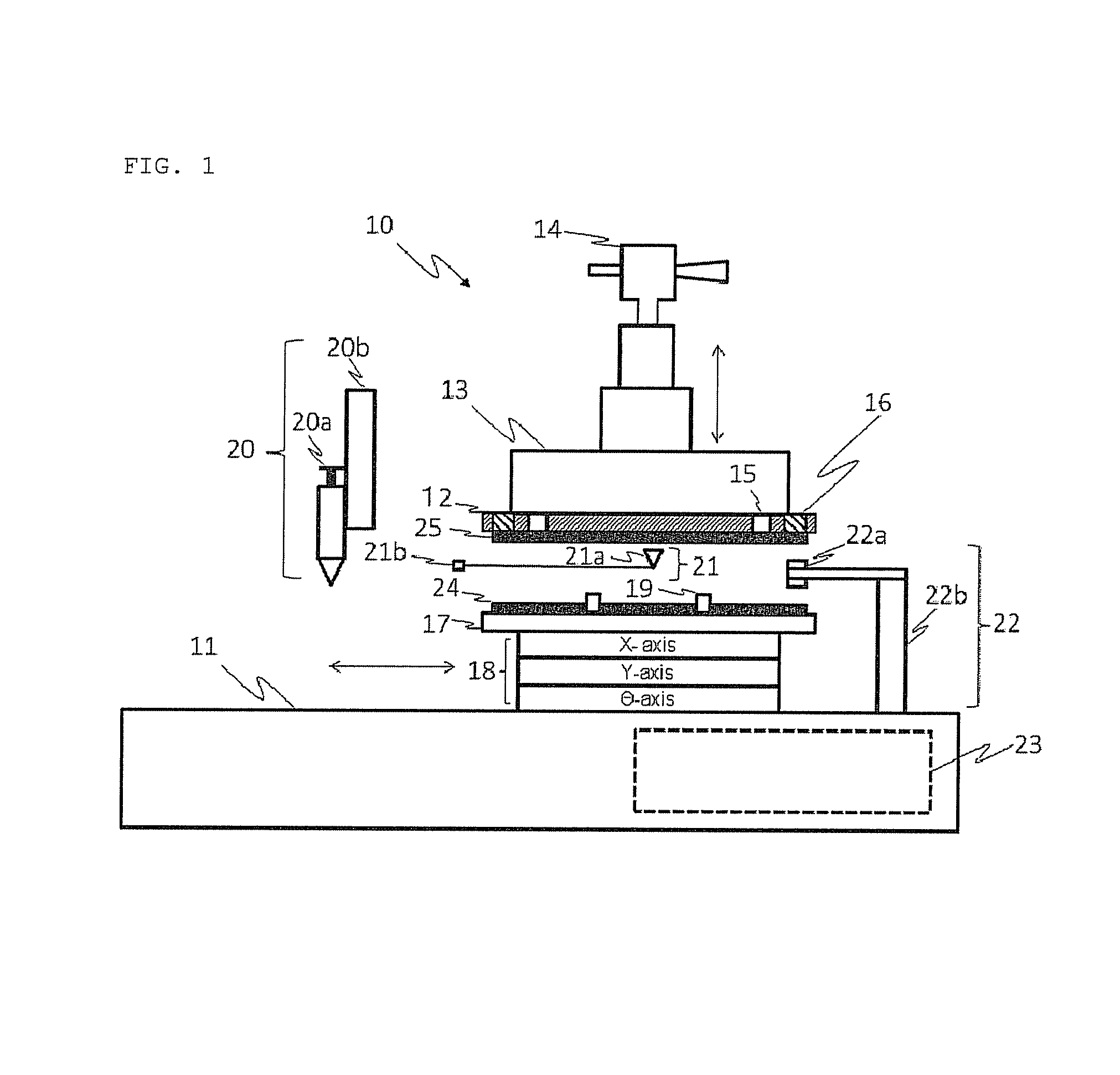

InactiveUS20050254046A1Movement range is thus narrowedNot easy to interfereMicroscopesTissue/virus culture apparatusAutomatic controlMeasurement device

A single-cell operation supporting robot for supporting a single-cell operation work with multi-purposes by carrying out a work which an operator himself / herself carries out difficultly, according to the indication of the operator. The robot is equipped with a microscope 1, multi-micro well 4 for storing cells and a single-cell stimulating device 5 which are respectively provided on the stage 1a of the microscope 1, a sample injection transportation means 7 which transports a glass capillary 6 for injecting a sample into the single-cell relatively to and from the multi-microwell 4 and an automatic stage 2, a cell transportation device 9 which transports a glass capillary 8 for holding the single-cell relatively to and from each well of the multi-microwell 4, the single-cell stimulating device 5 and the glass capillary 6, a microscopic spectral measurement device 10 which is combined with the microscope 1, computers 11 and 12 which automatically control an actuation of at least one among the microscope 1, the sample injection transportation device 7, the cell transportation device 9, the automatic stage 2, the single-cell stimulating device 5 and the microscopic spectral measurement device 10, and a manual operation device 17 which inputs signals to the computers 11 and 12 based on an operation by an operator and actuates the microscope and the like.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

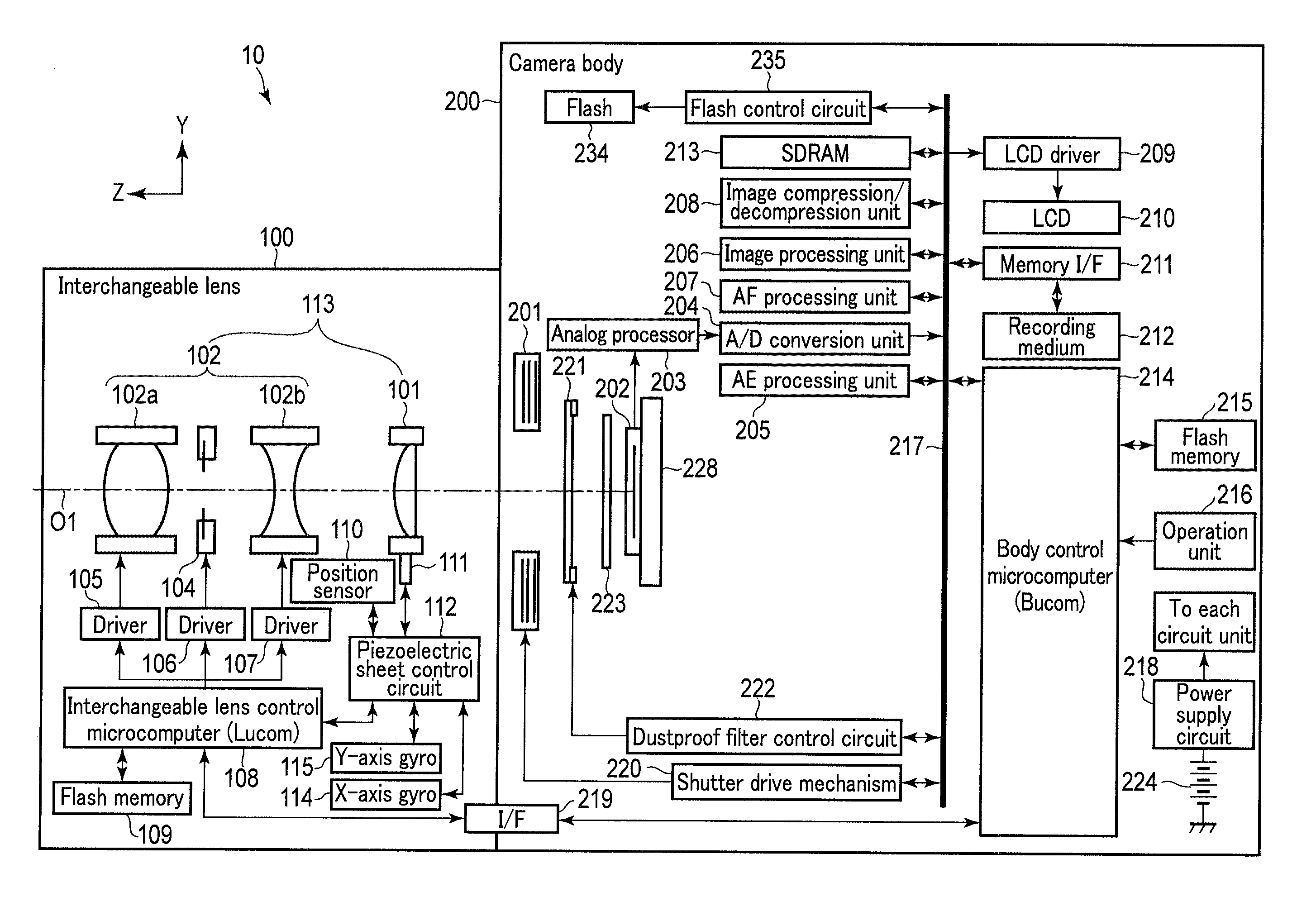

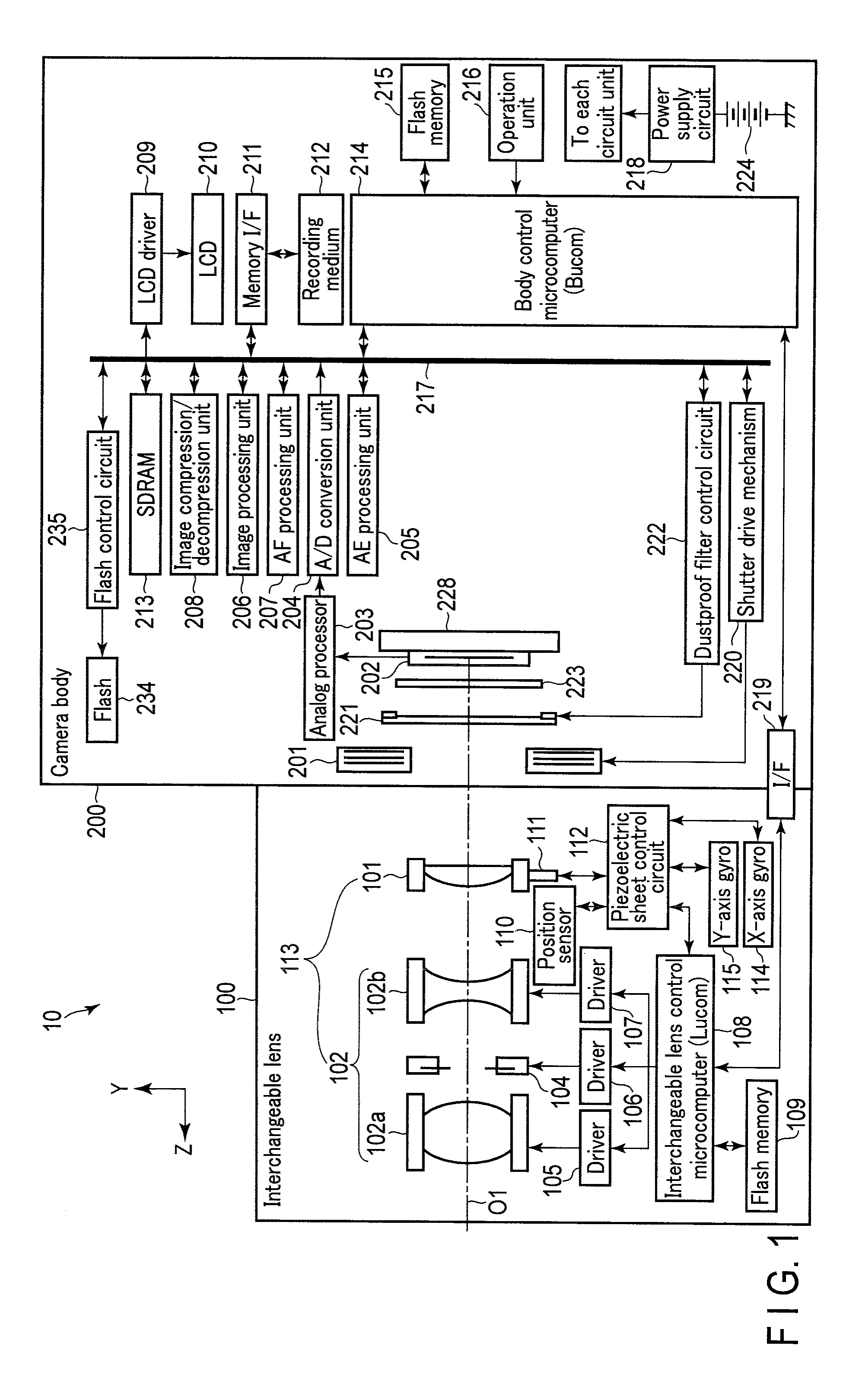

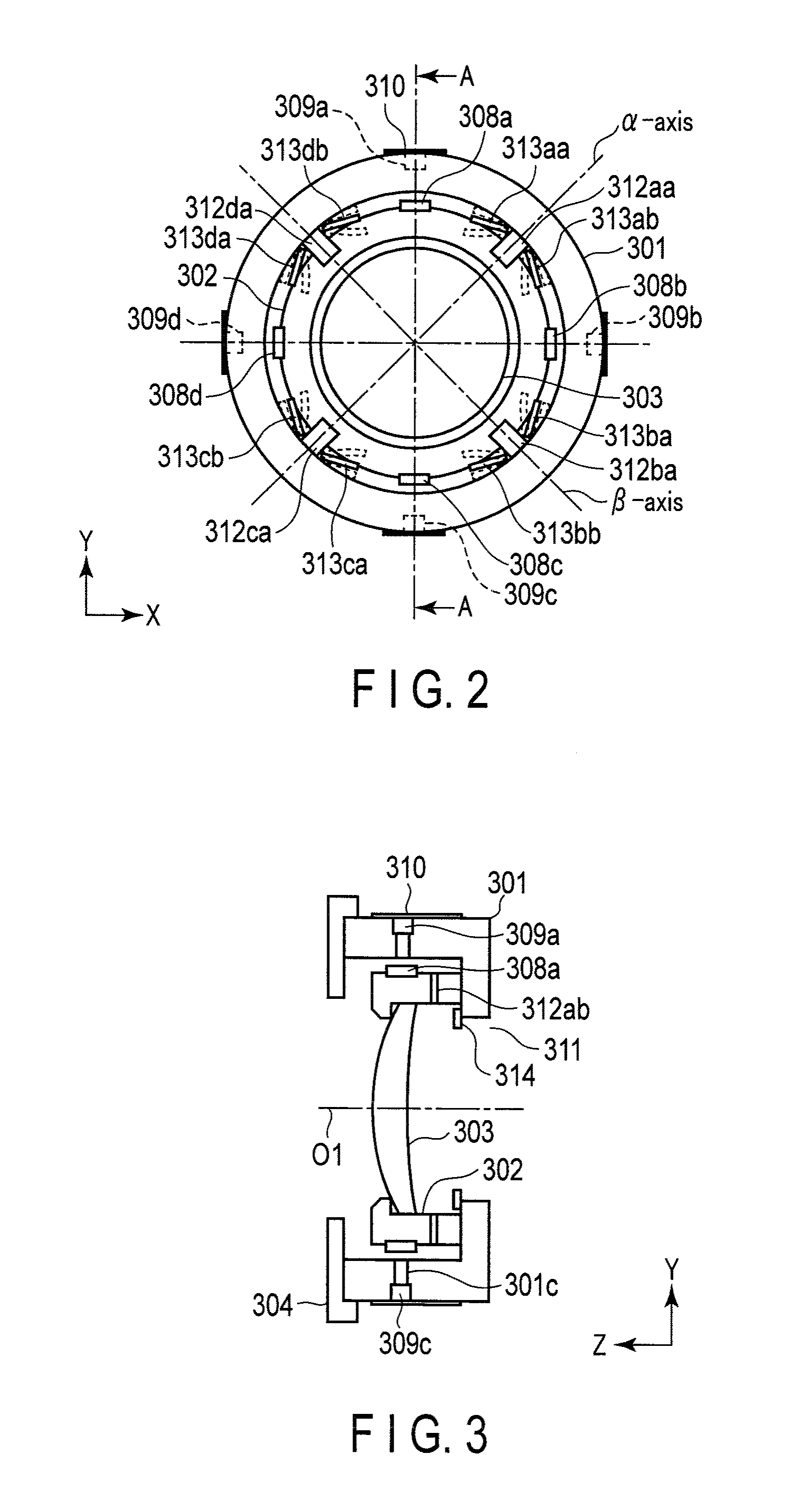

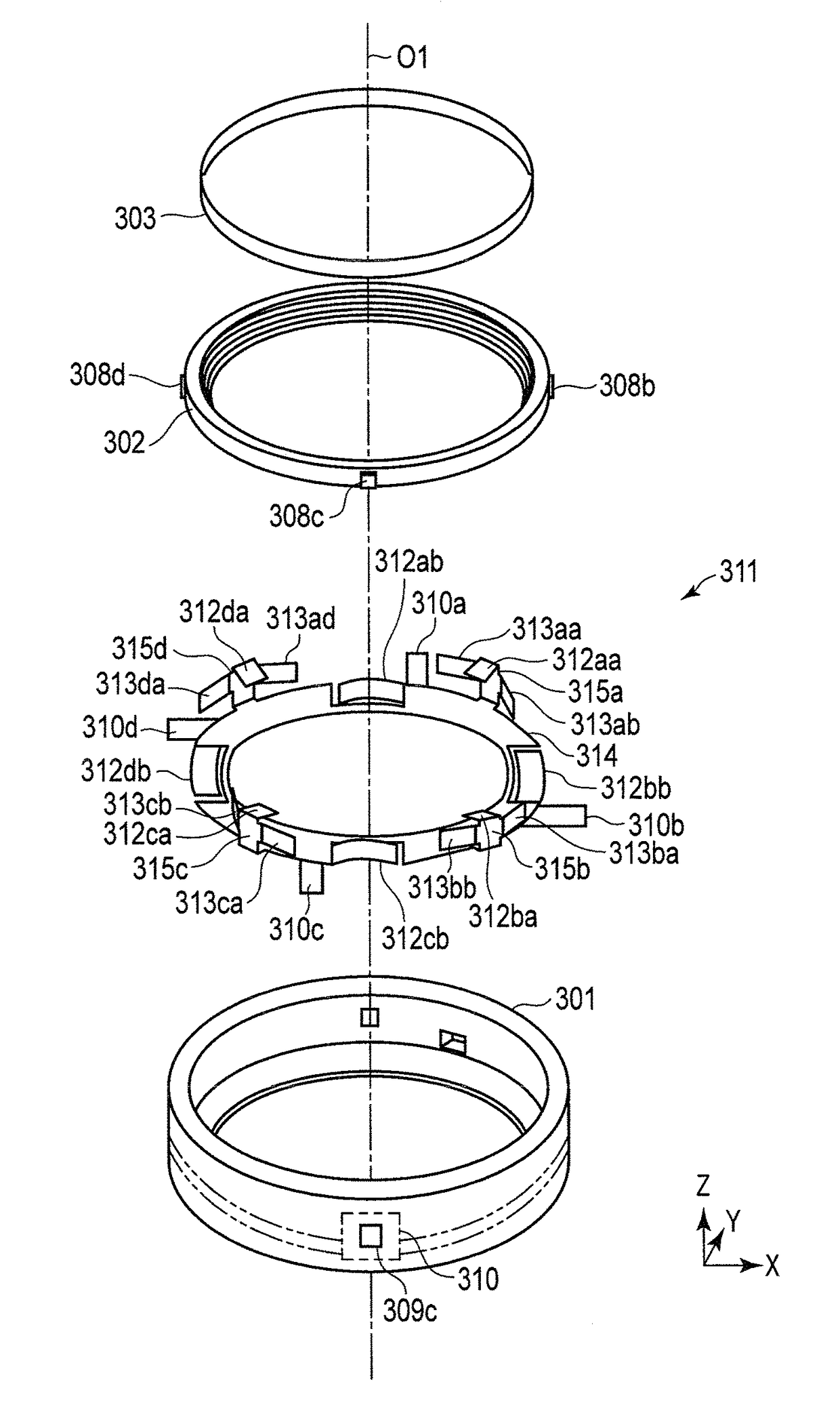

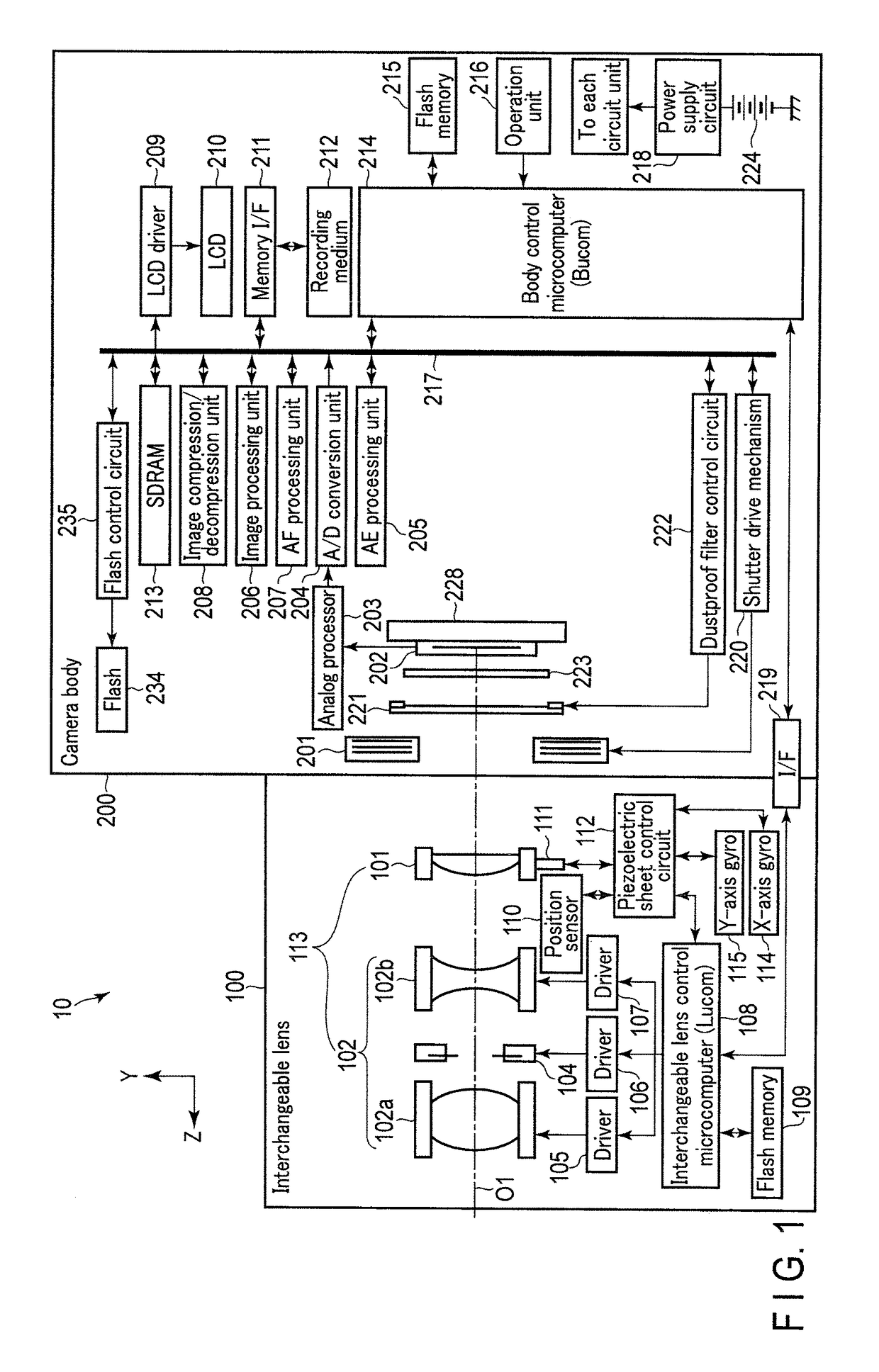

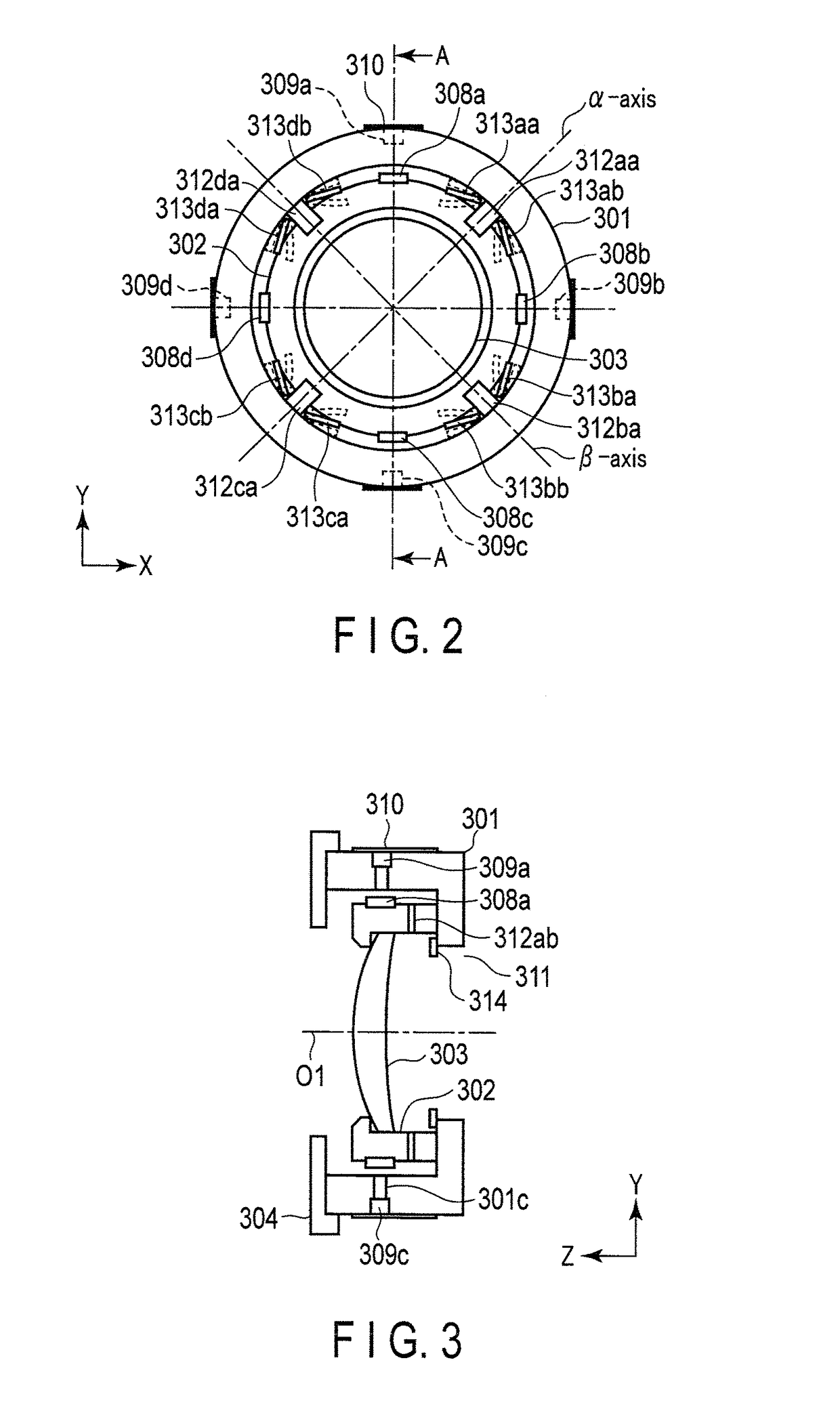

Driver and image instrument

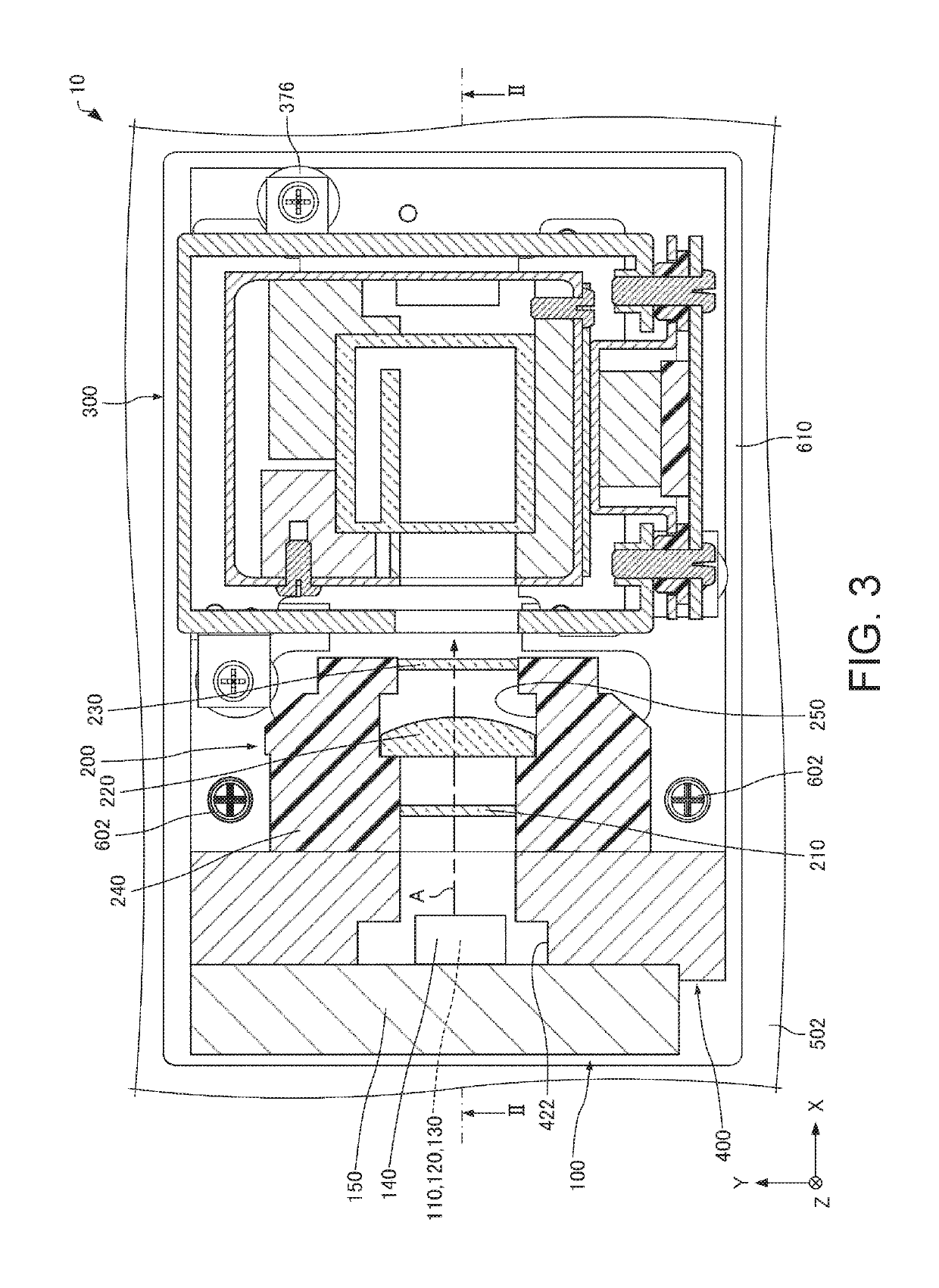

ActiveUS20160205325A1High positionalAccurately utilize a photographing opportunityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesFixed frameEngineering

A driver includes a piezoelectric sheet, a fixing frame, a moving frame, and a control circuit. The piezoelectric sheet includes a first piezoelectric body portion which bends in a first direction, a second piezoelectric body portion which bends in a second direction that intersects at right angles with the first direction, and a connection portion which connects the first and second piezoelectric body portions. The fixing frame is fixed to the connection portion. The moving frame is supported on the first and second piezoelectric body portions. The control circuit applies voltage signals to the first and second piezoelectric body portions to bend the first and second piezoelectric body portions and which moves the moving frame in one of the first direction and the second direction or in a composite direction of the first direction and the second direction.

Owner:OM DIGITAL SOLUTIONS CORP

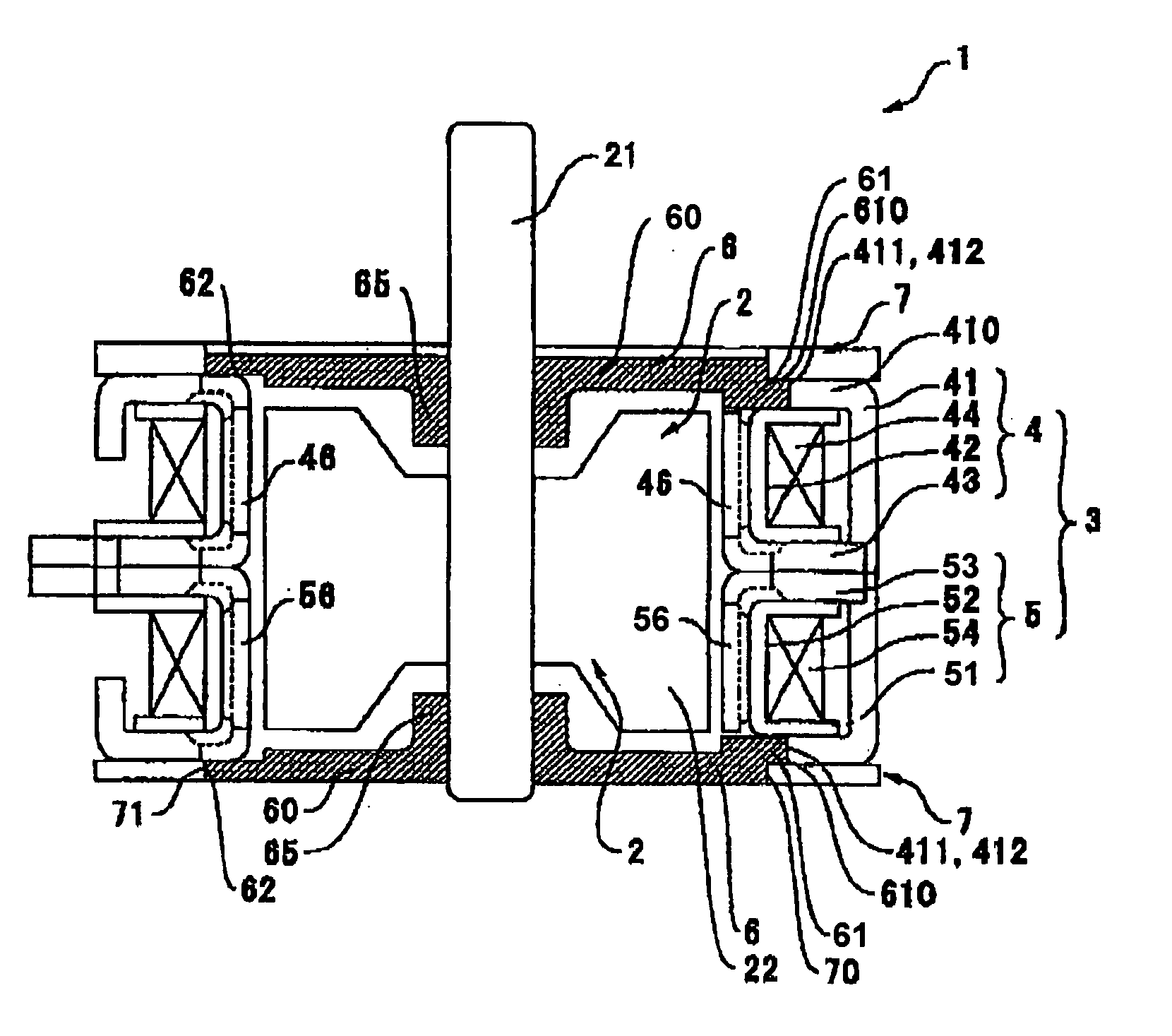

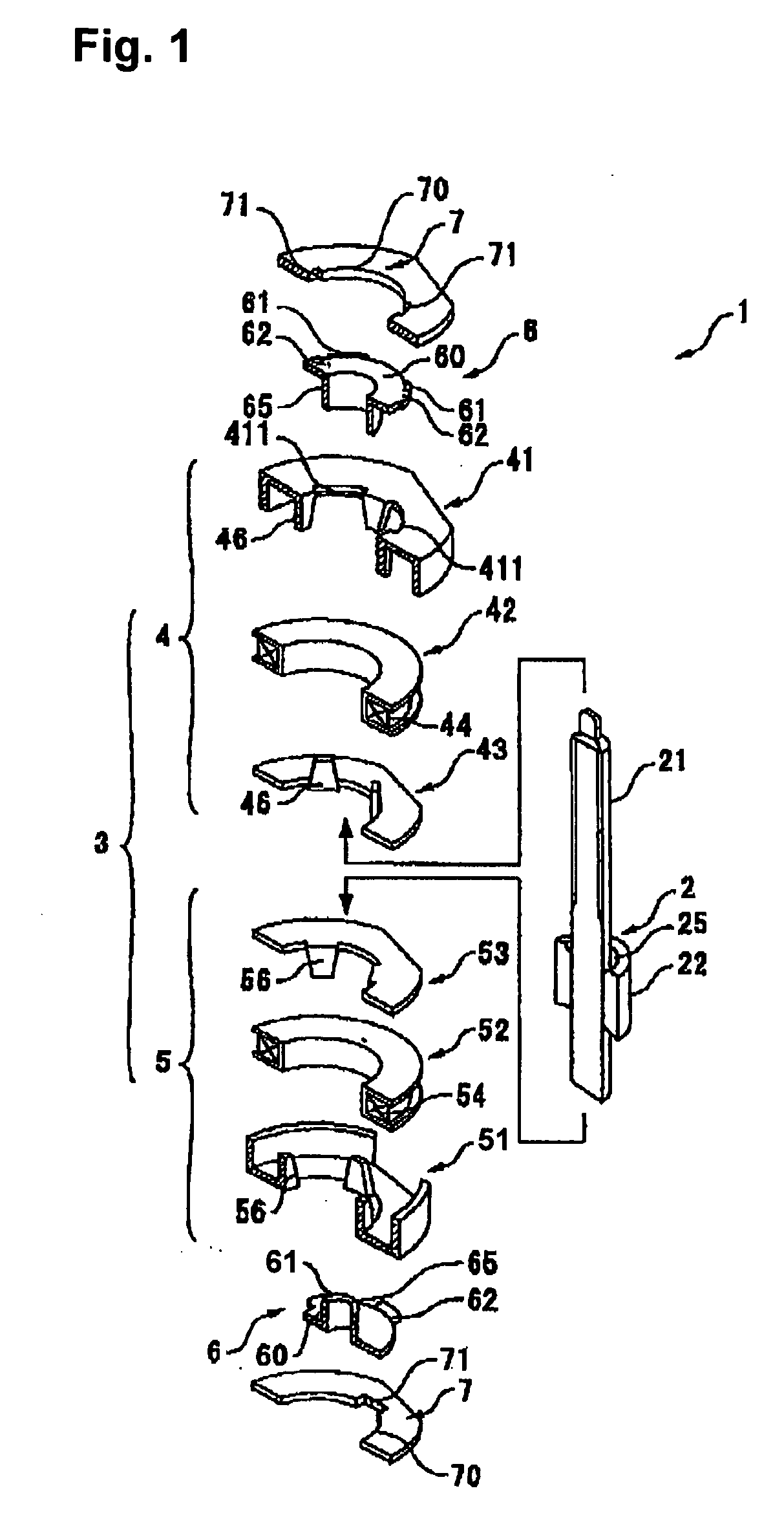

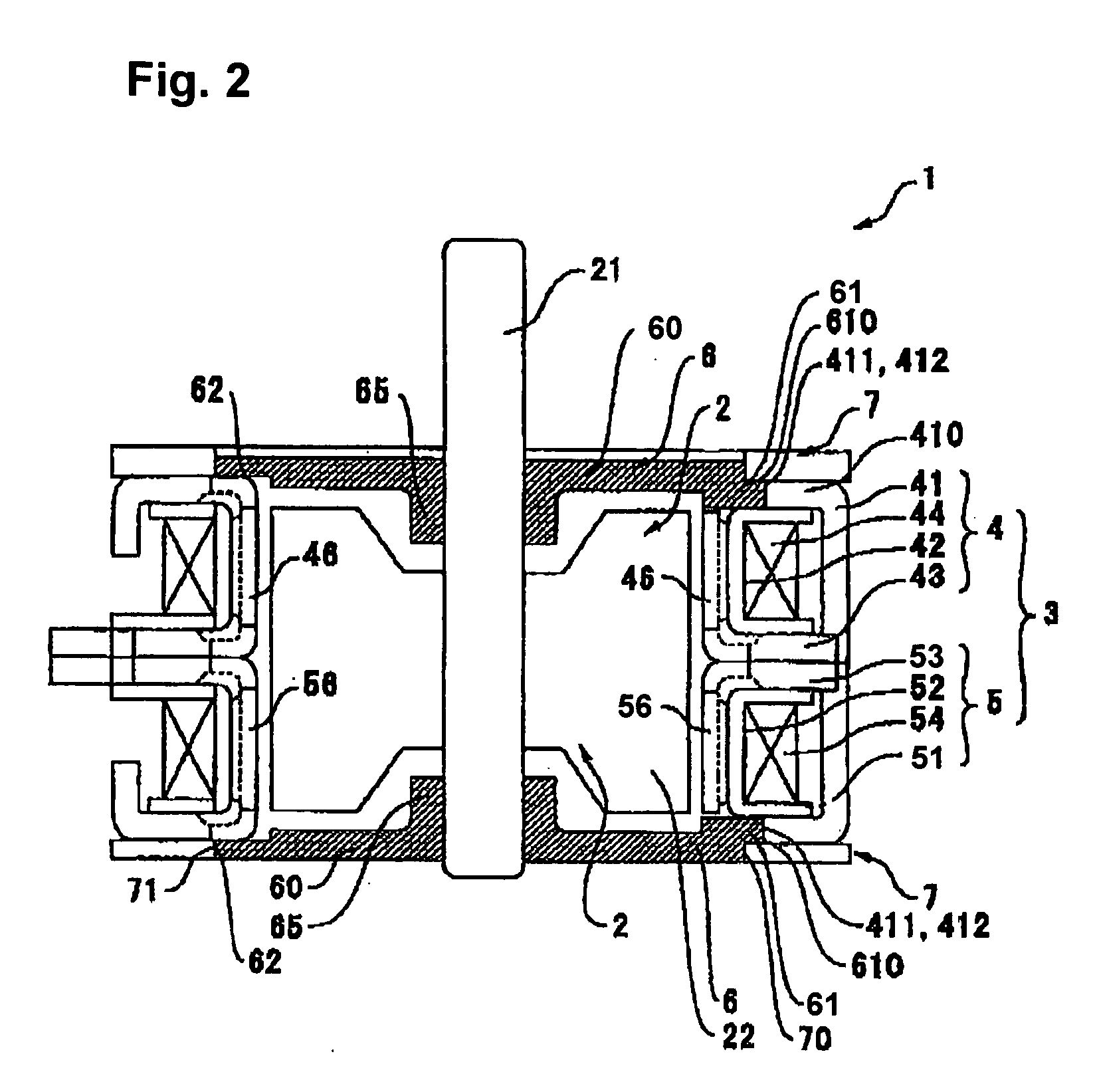

Motor with improved rotary shaft supporting structure

InactiveUS20050225185A1Simple structureWelding is requiredMagnetic circuit stationary partsMaster clocksEngineeringMagnet

A stepping motor includes a rotor with a permanent magnet, a rotary shaft extending from the rotor and a stator placed around the rotor. The stepping motor comprises a stator core placed on one end section in a motor axial line direction of the stator, a bearing plate that includes a bearing for rotatably supporting the rotary shaft and is placed at an end section of the stator adjacent to the stator core, and an end plate fixed to an end surface of the stator core on an outer circumference side of the bearing plate. The stator core includes a plurality of salient poles that bend in the motor axial line direction at an inner circumferential edge of the stator core to oppose the permanent magnet, and concave sections that recede in the radial direction and formed between the bent parts of the salient poles. The end plate is affixed to an end surface of the stator core on an outer circumference side of the bearing plate, wherein the bearing plate has a plurality of engaging sections that hook on the end surface of the stator core and a plurality of convex sections that protrude towards inside of the concave sections of the stator core and hook on an end surface of the end plate.

Owner:SANKYO SEIKI MFG CO LTD

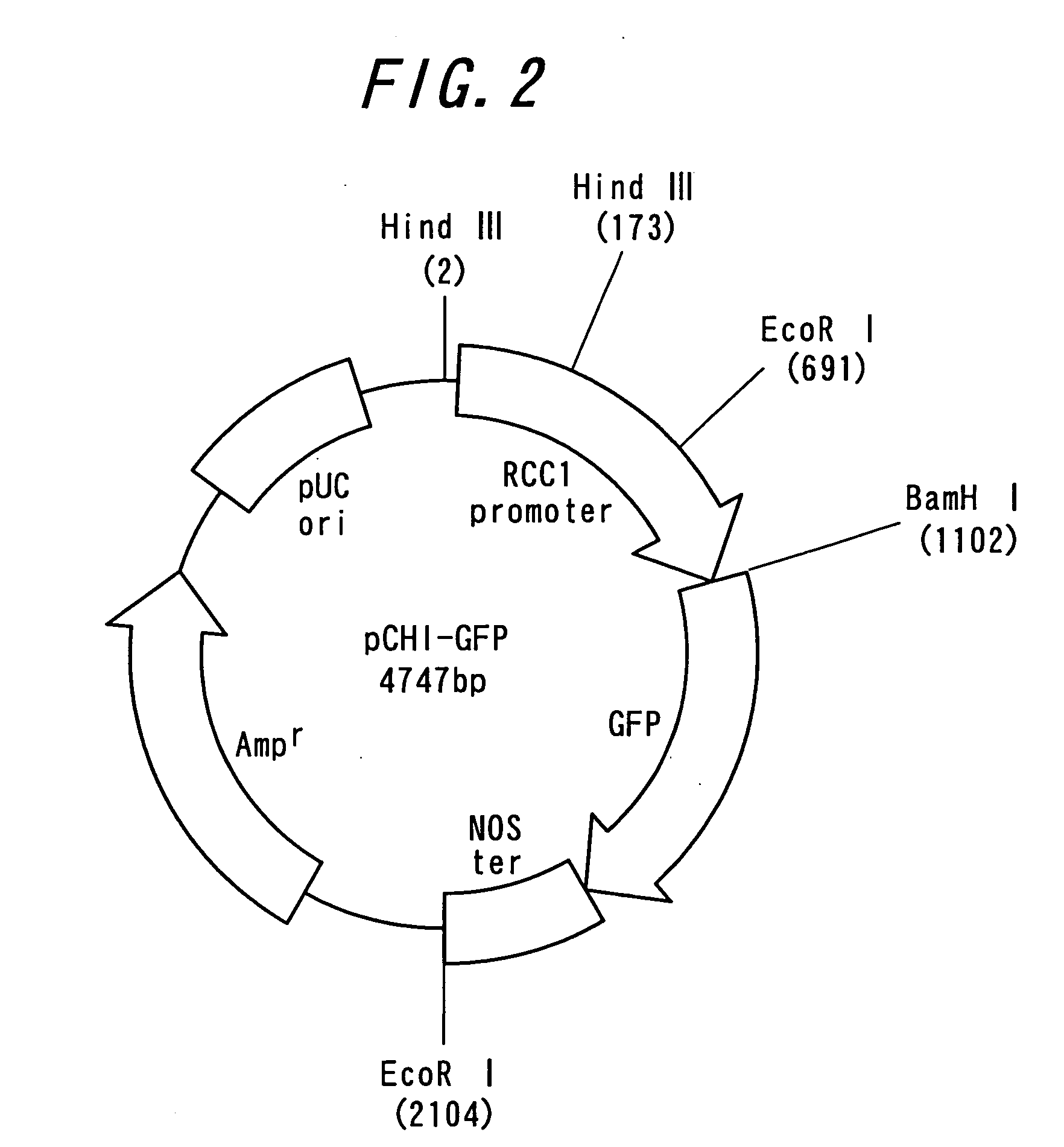

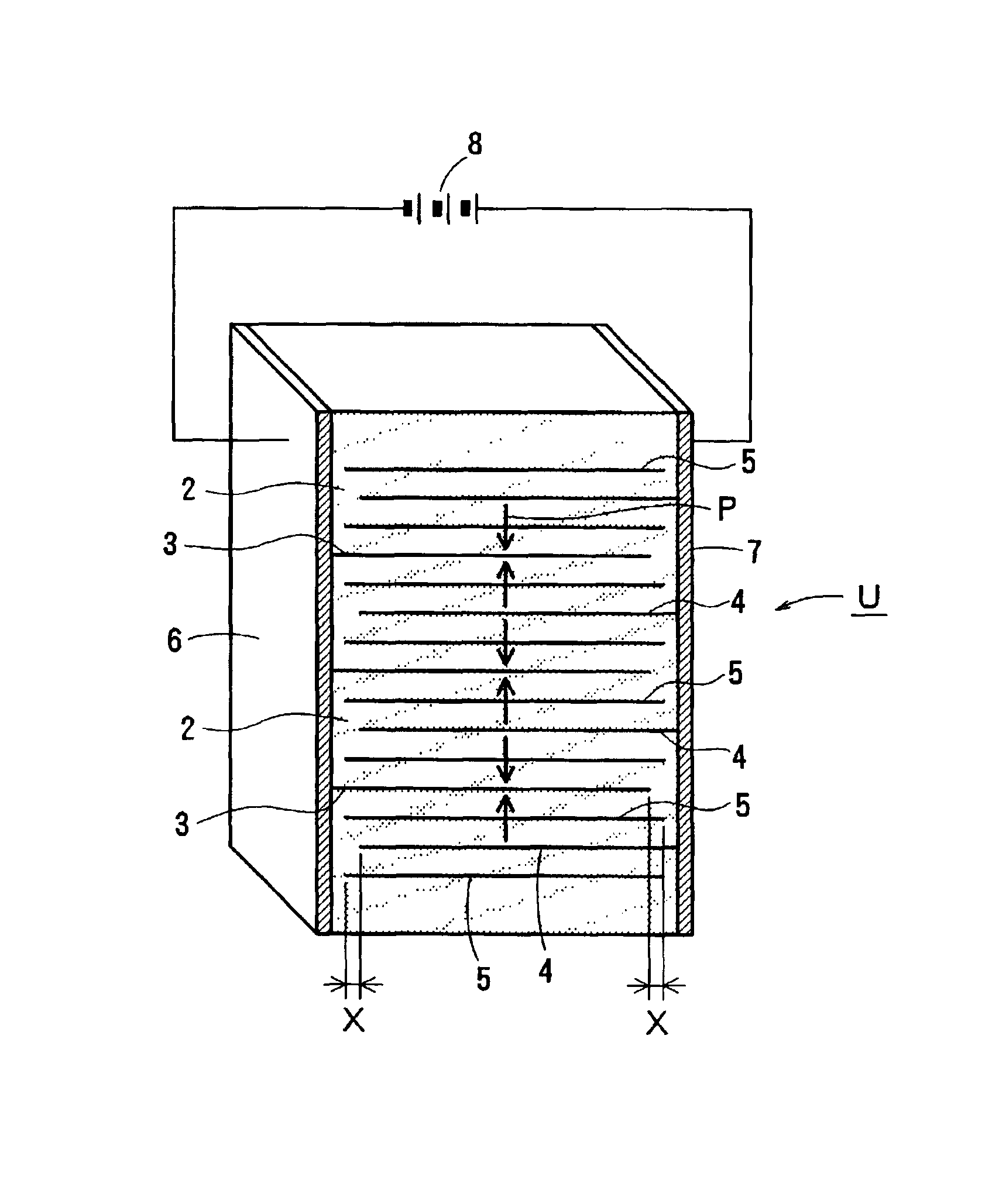

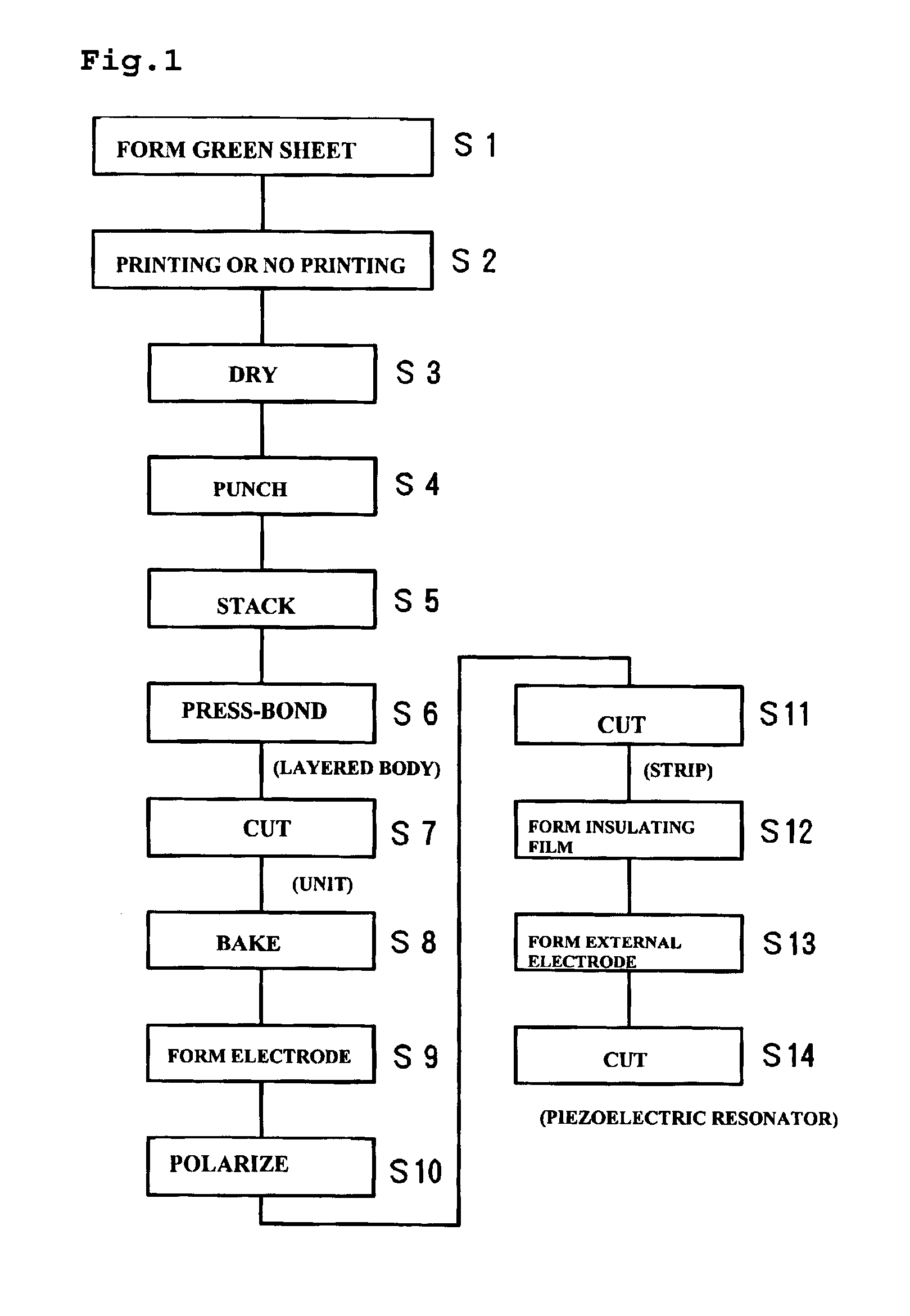

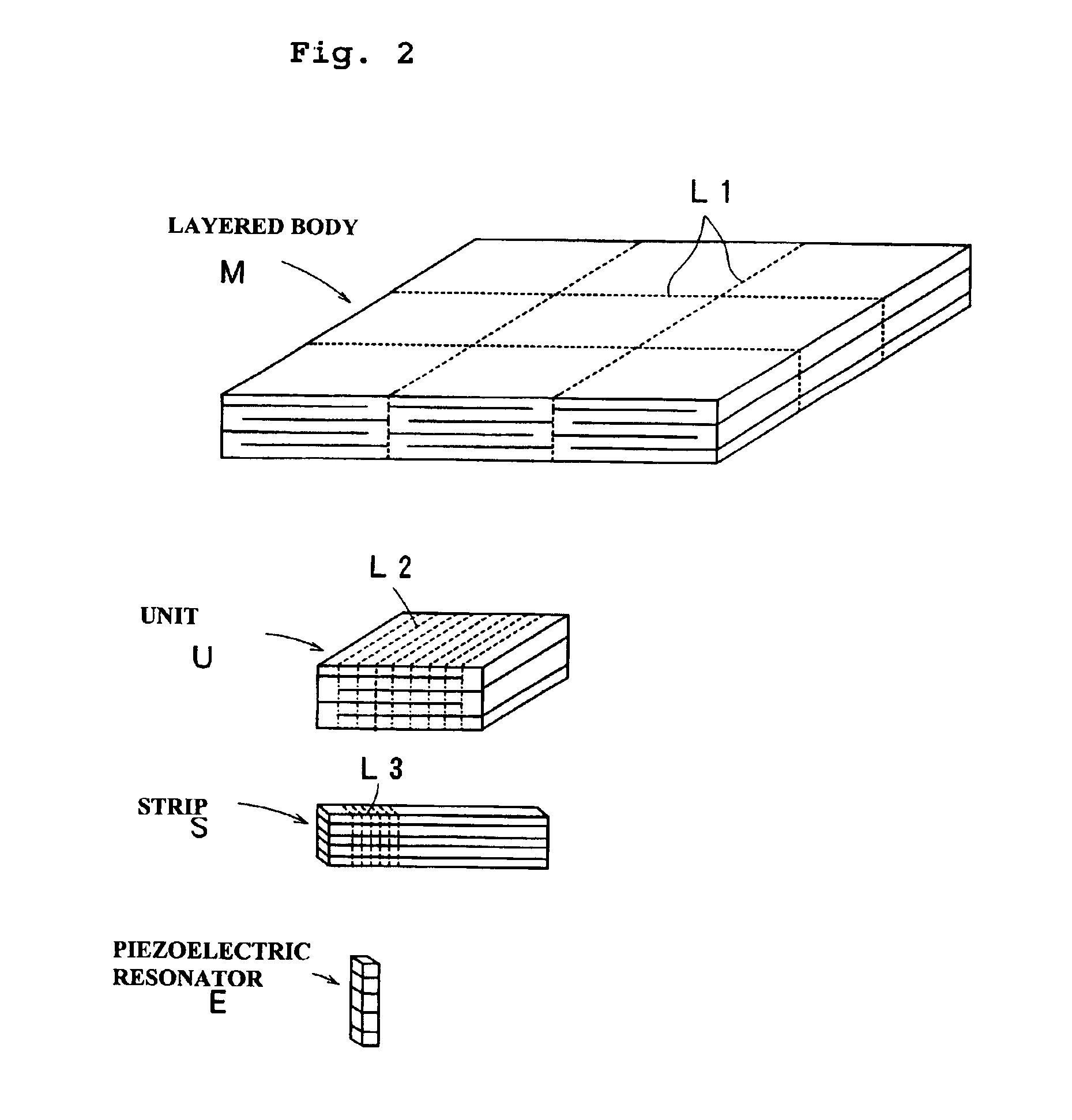

Method of producing multilayer piezoelectric resonator

InactiveUS6912761B2Reduce the differenceInhibited DiffusionPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyPunchingEngineering

A method of producing a piezoeIectric resonator includes the steps of forming first to third internal electrodes by printing an electrically conductive paste onto a green sheet, punching out portions of the green sheet having the first to third internal electrodes formed thereon, so that at least three types of green sheets are punched out with a location of the internal electrode serving as a reference location, in which the first sheet is punched out by shifting a punching location by a first shift amount in a first direction with respect to the reference location, the second sheet is punched out by shifting a punching location by the first shift amount in a direction opposite to the first direction, and the third sheet is punched out at the reference location, forming a layered body by stacking the punched out green sheets, and forming a unit by cutting the layered body.

Owner:MURATA MFG CO LTD

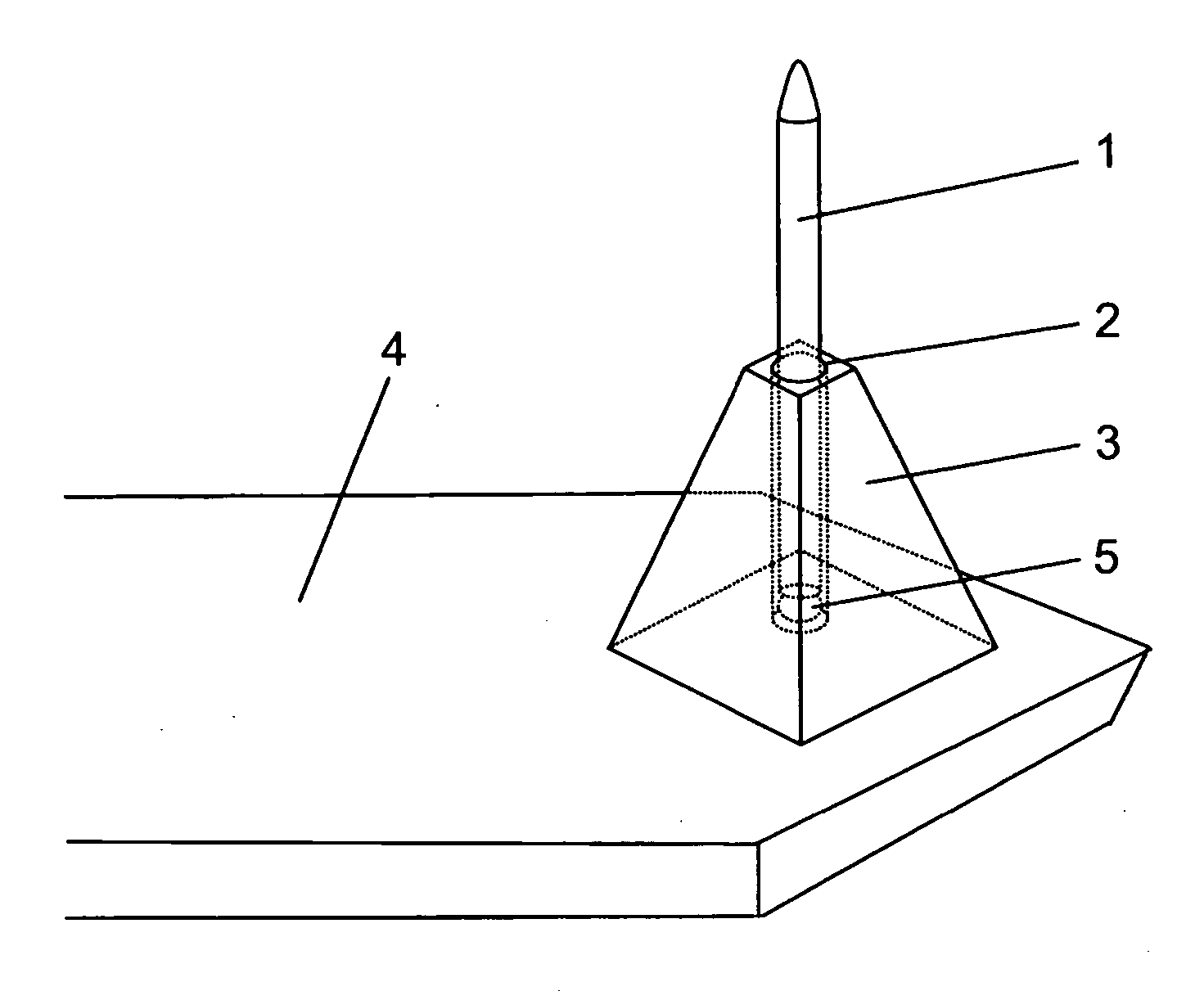

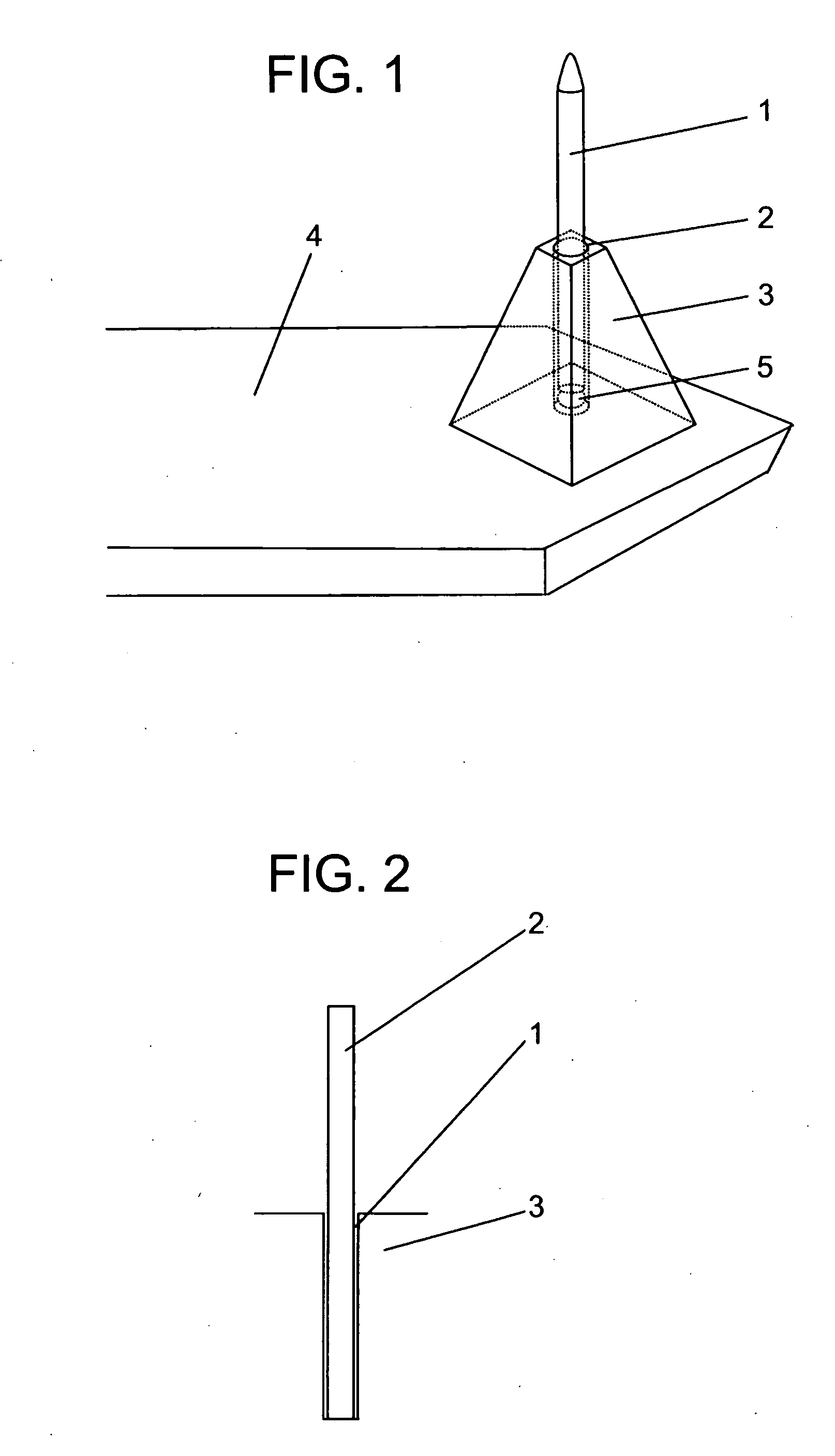

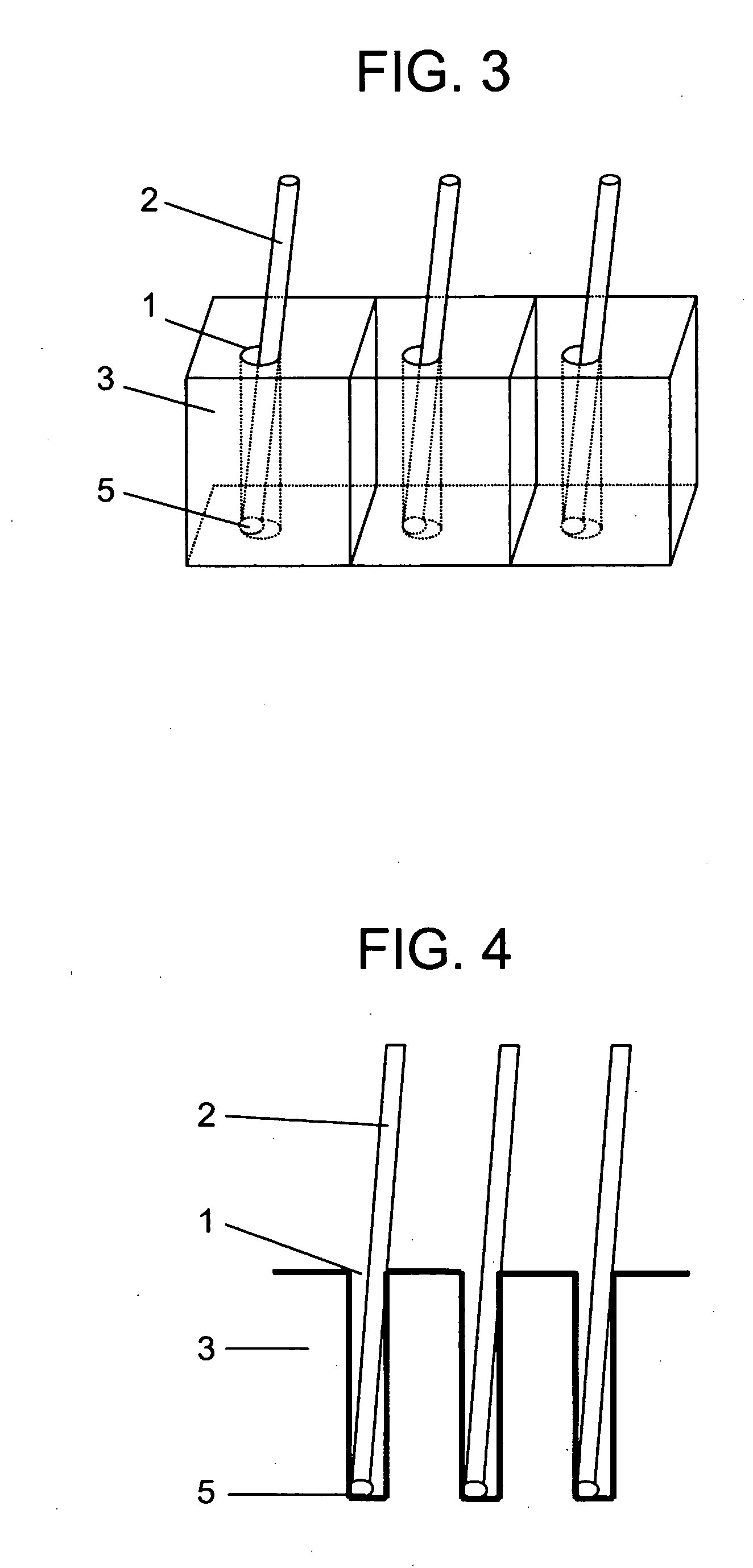

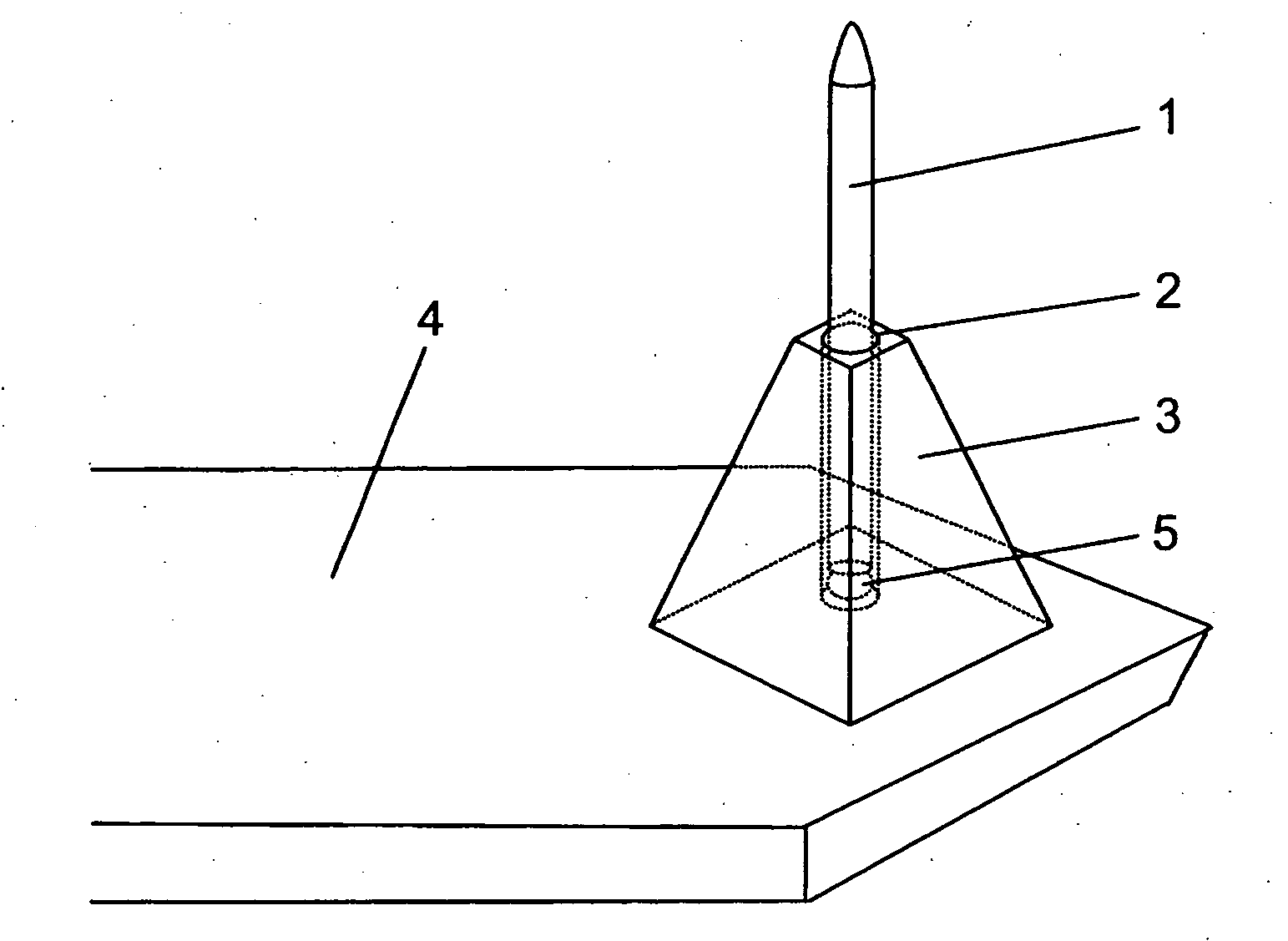

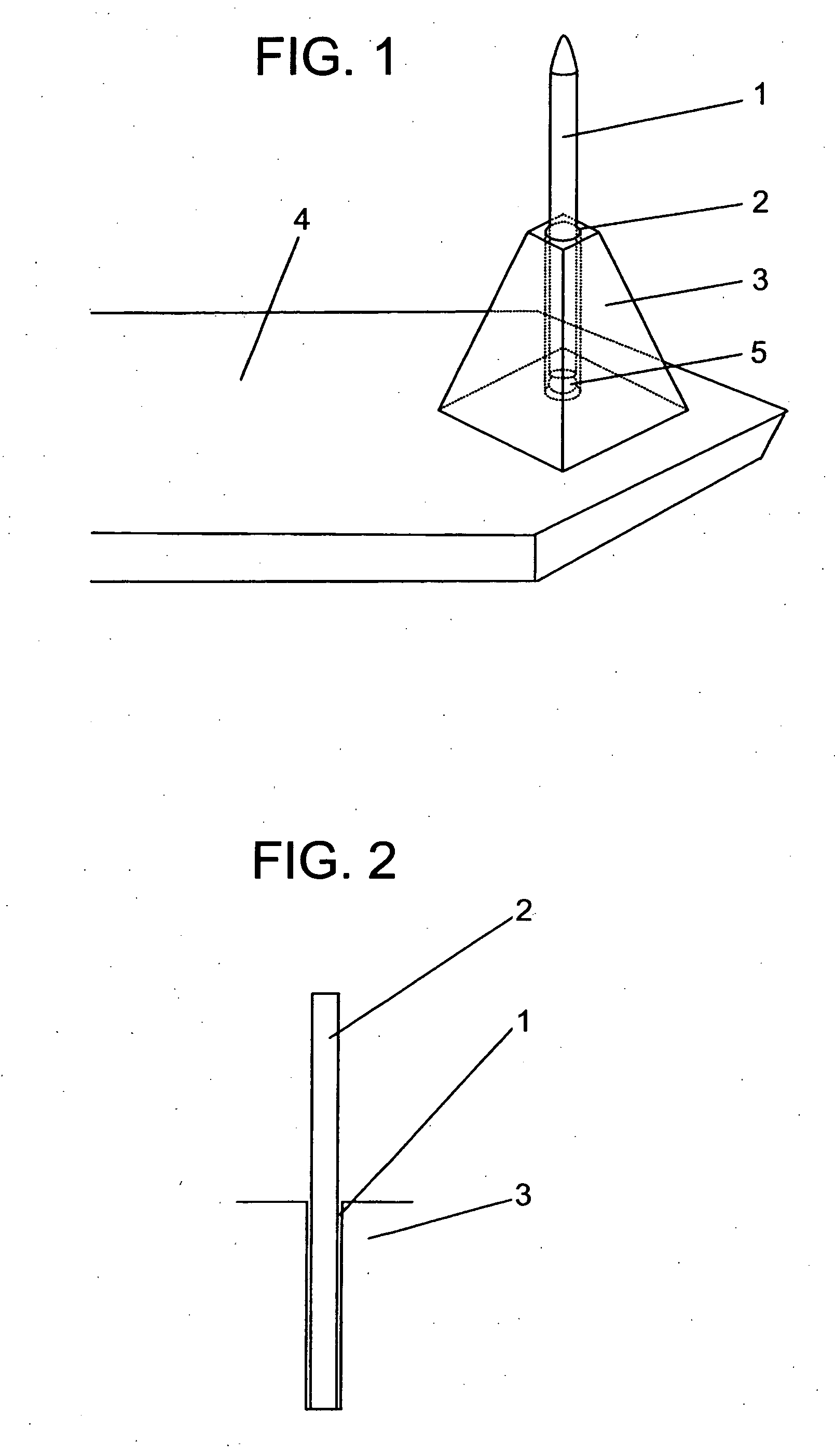

Micro-protruding structure

InactiveUS20050212010A1High positionalSmall sizeFixed microstructural devicesVolume/mass flow by thermal effectsClassical mechanicsDisplay device

A micro-protruding structure which has a high positional precision and an angular (directional) precision, which is made of a linear material having a large aspect ratio, and which is provided for an analyzer, a display device, a machining device, a measuring device and an observation device. The micro-protruding structure is fabricated by growing a linear material of a carbon nano-tube from the bottom of the hole structure perforated by a focused ion beam. This permits a direction from the bottom of the hole structure to the opening to become nearly in alignment with the direction of the linear material that protrudes from the hole structure.

Owner:SII NANOTECHNOLOGY INC

Clamping device and workpiece conveying robot

InactiveUS20140110959A1High positioning accuracyHigh positionalGripping headsSemiconductor/solid-state device manufacturingMechanical engineeringRobot

Owner:SINFONIA TECHNOLOGY CO LTD

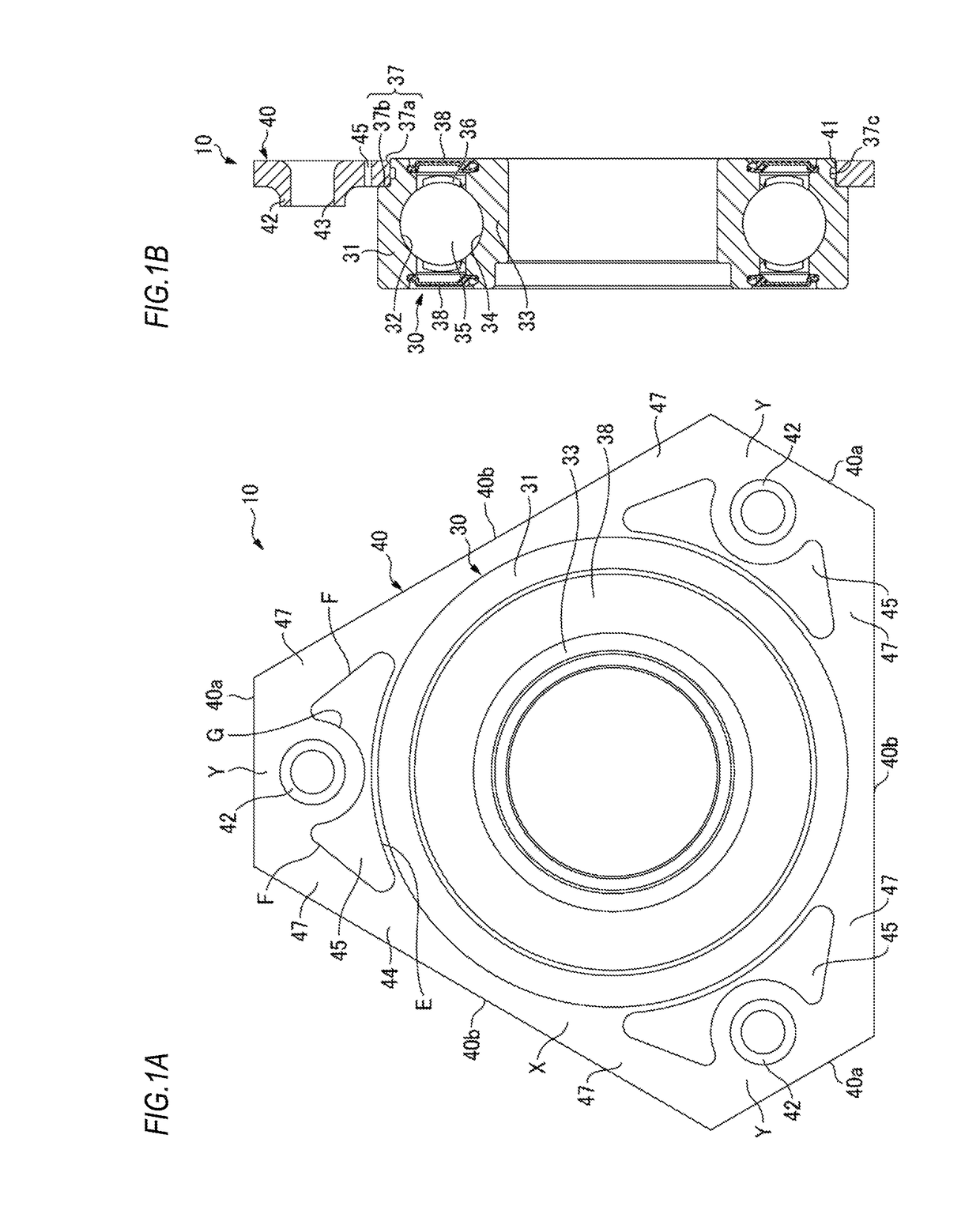

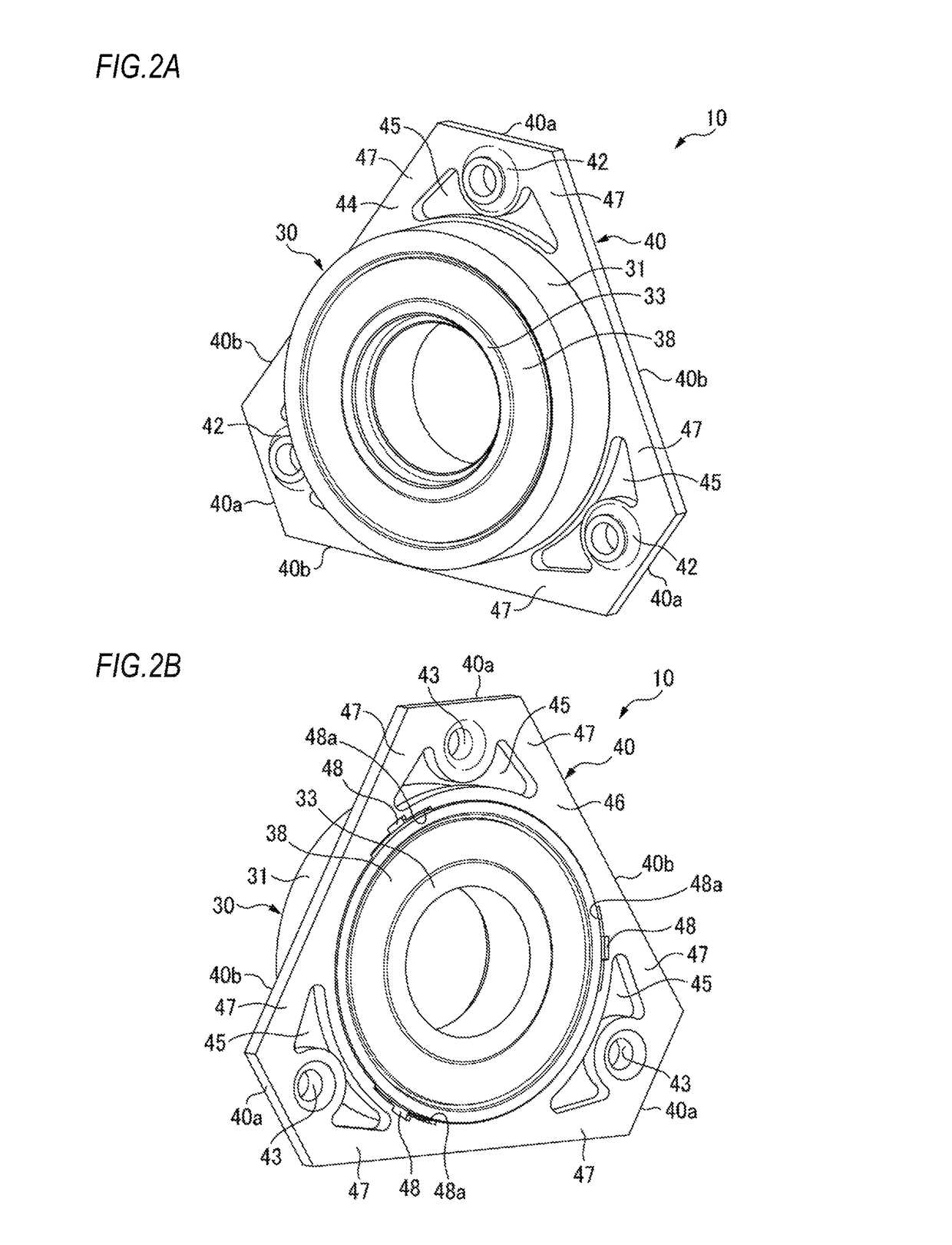

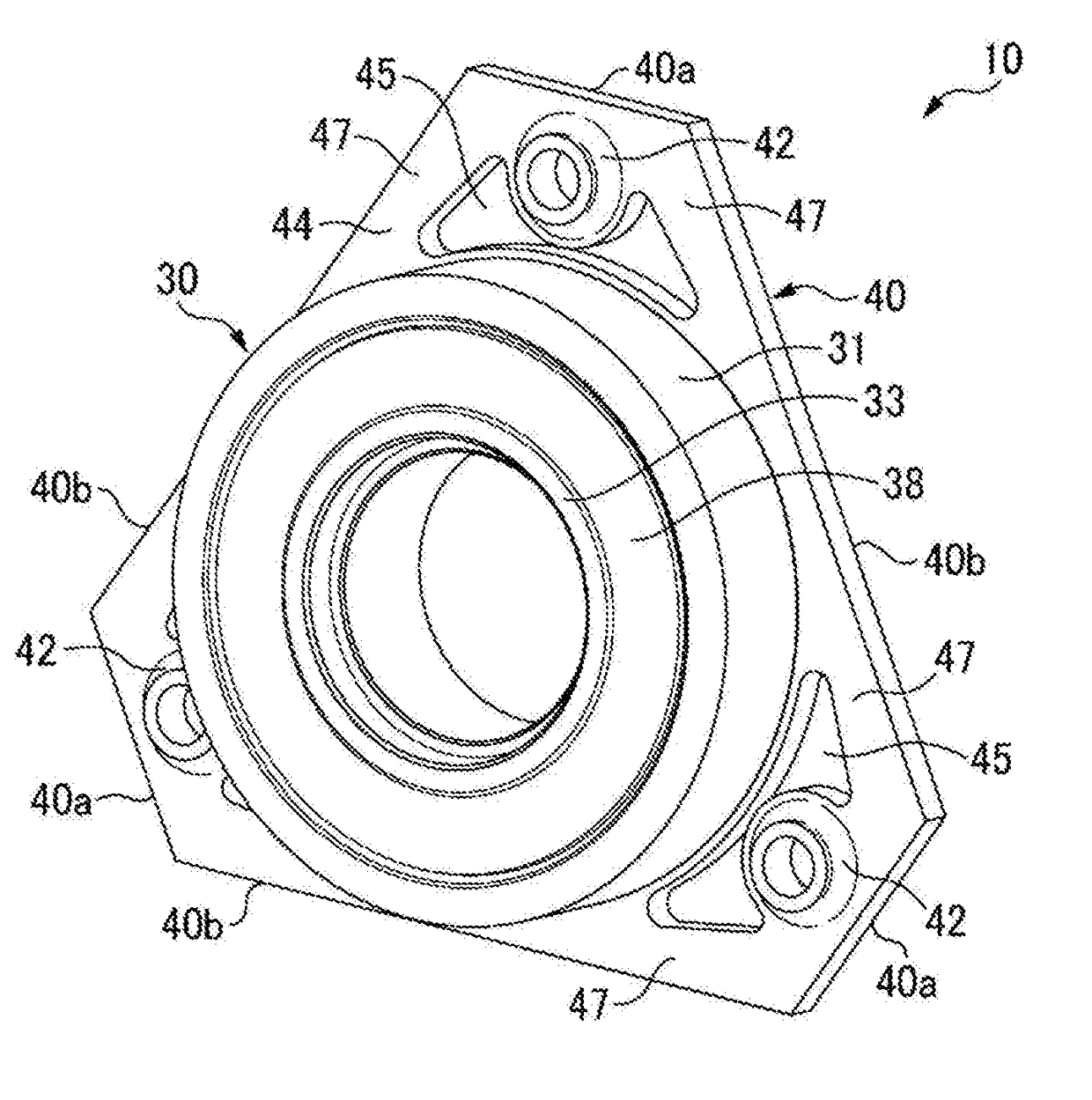

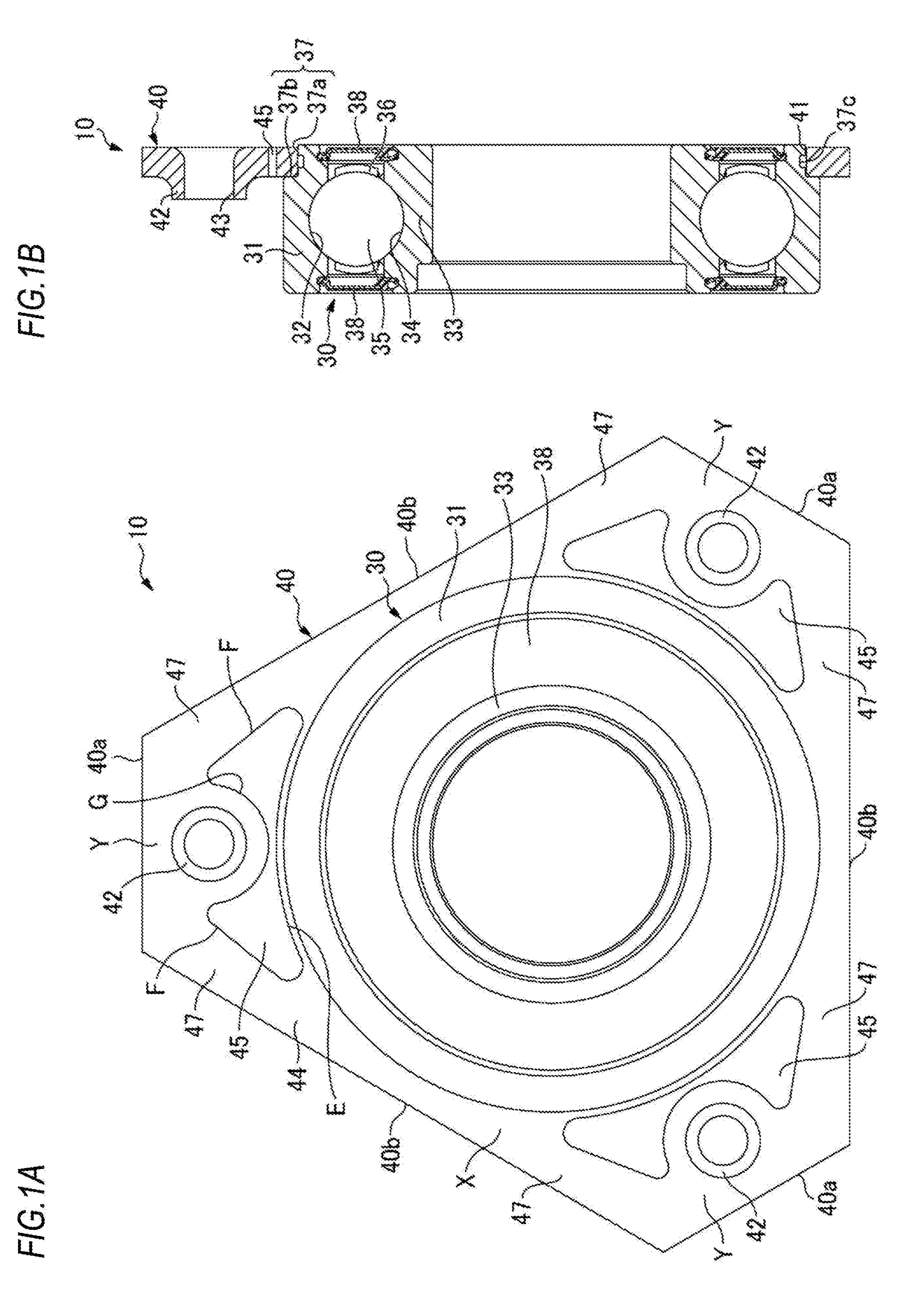

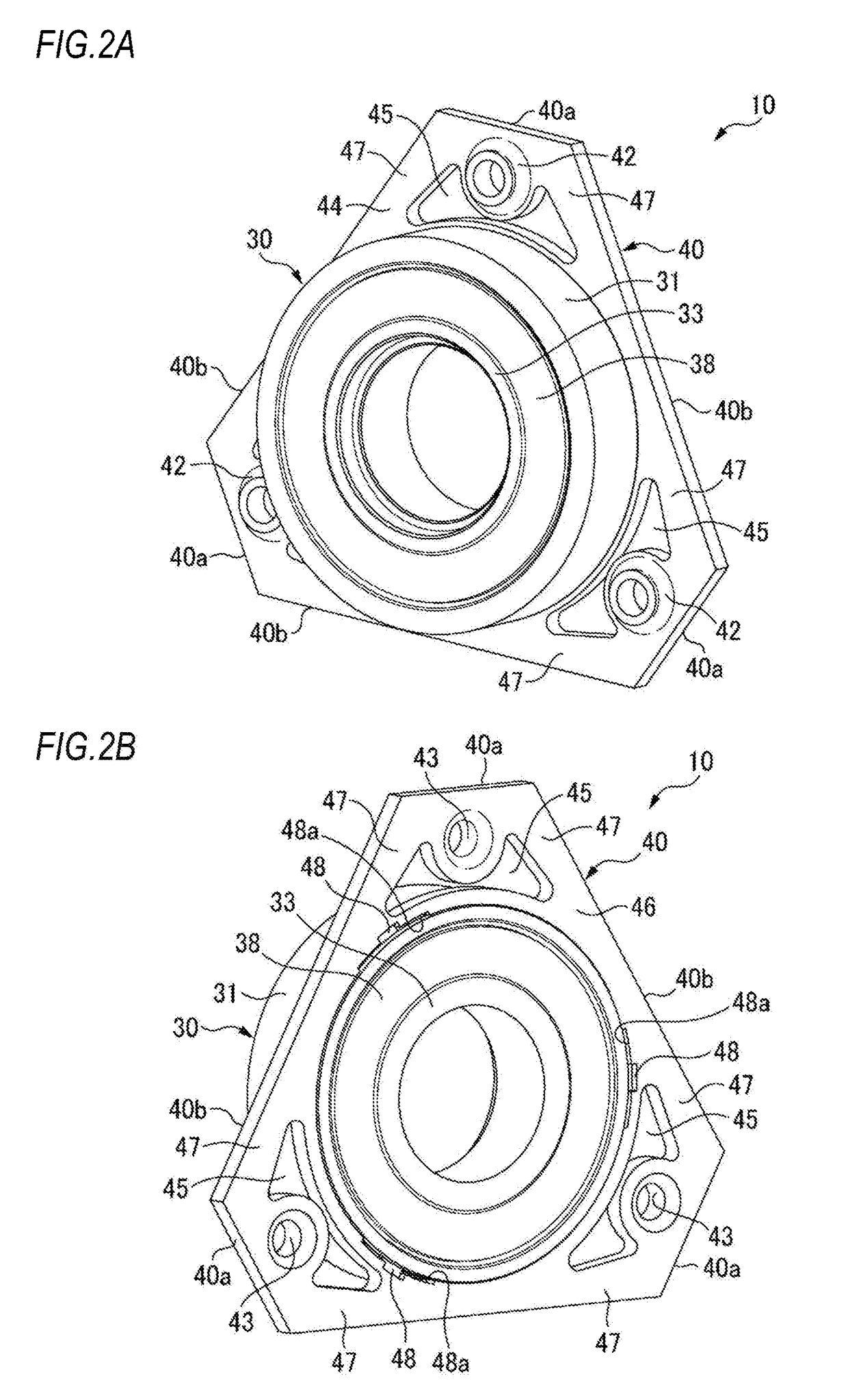

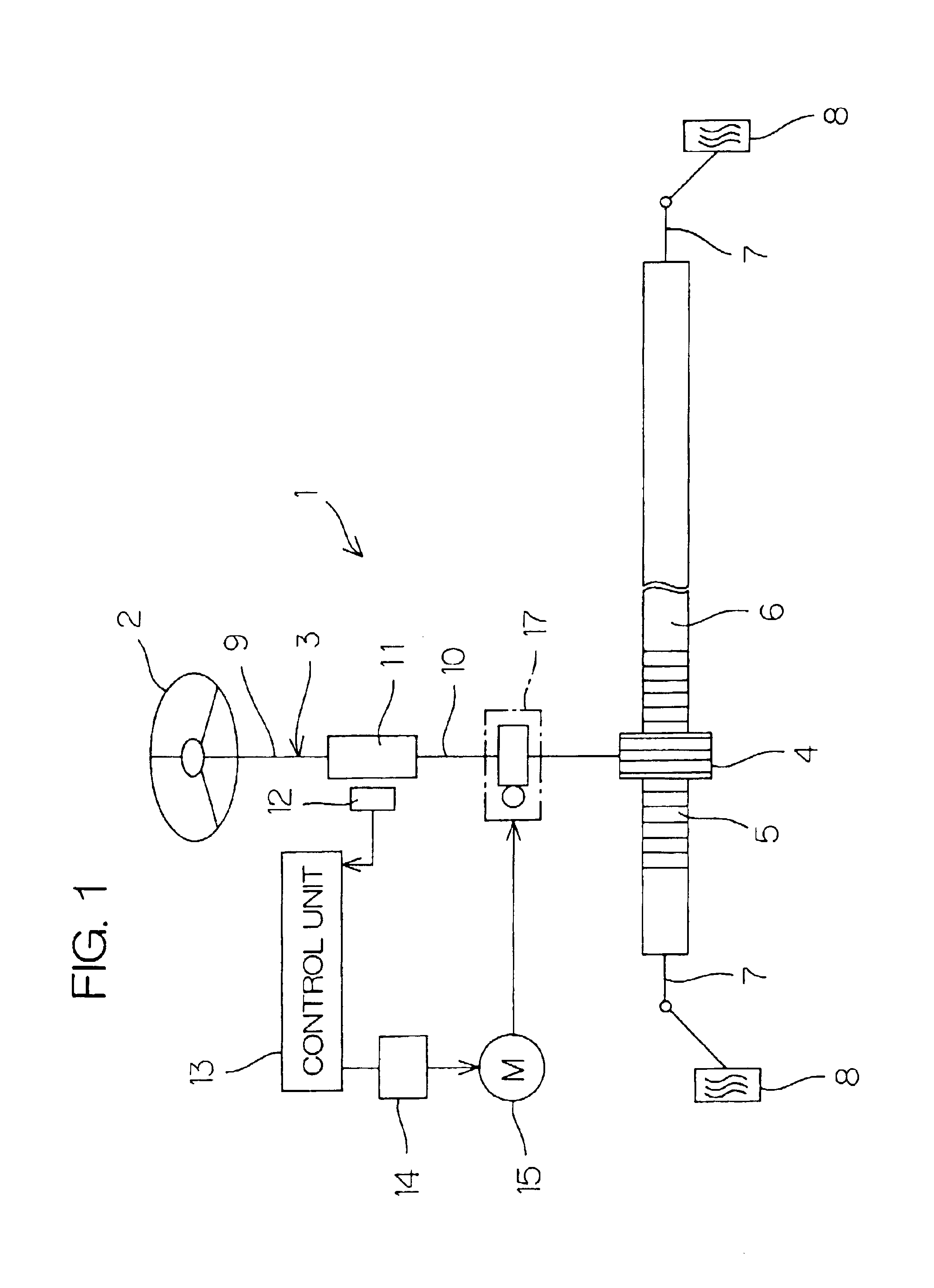

Bearing device and beading device fixing plate

ActiveUS10001174B2Suppress an influence on the roundness of the outer ring racewayEasy maintenanceBearing assemblyBall bearingsMechanical engineering

Owner:NSK LTD

Method for bonding substrates together, and substrate bonding device

ActiveUS10580752B2Inhibit productionHigh positionalControlling laminationSemiconductor/solid-state device detailsHydrophilizationEngineering

A production of voids between substrates is prevented when the substrates are bonded together, and the substrates are bonded together at a high positional precision while suppressing a strain. A method for bonding a first substrate and a second substrate includes a step of performing hydrophilization treatment to cause water or an OH containing substance to adhere to bonding surface of the first substrate and the bonding surface of the second substrate, a step of disposing the first substrate and the second substrate with the respective bonding surfaces facing each other, and bowing the first substrate in such a way that a central portion of the bonding surface protrudes toward the second substrate side relative to an outer circumferential portion of the bonding surface, a step of abutting the bonding surface of the first substrate with the bonding surface of the second substrate at the respective central portions, and a step of abutting the bonding surface of the first substrate with the bonding surface of the second substrate across the entirety of the bonding surfaces, decreasing a distance between the outer circumferential portion of the first substrate and an outer circumferential portion of the second substrate with the respective central portions abutting each other at a pressure that maintains a non-bonded condition.

Owner:BONDTECH

Bearing device and beading device fixing plate

ActiveUS20170204911A1Easy maintenanceHigh positioning accuracyBearing assemblyBall bearingsEngineeringMechanical engineering

Owner:NSK LTD

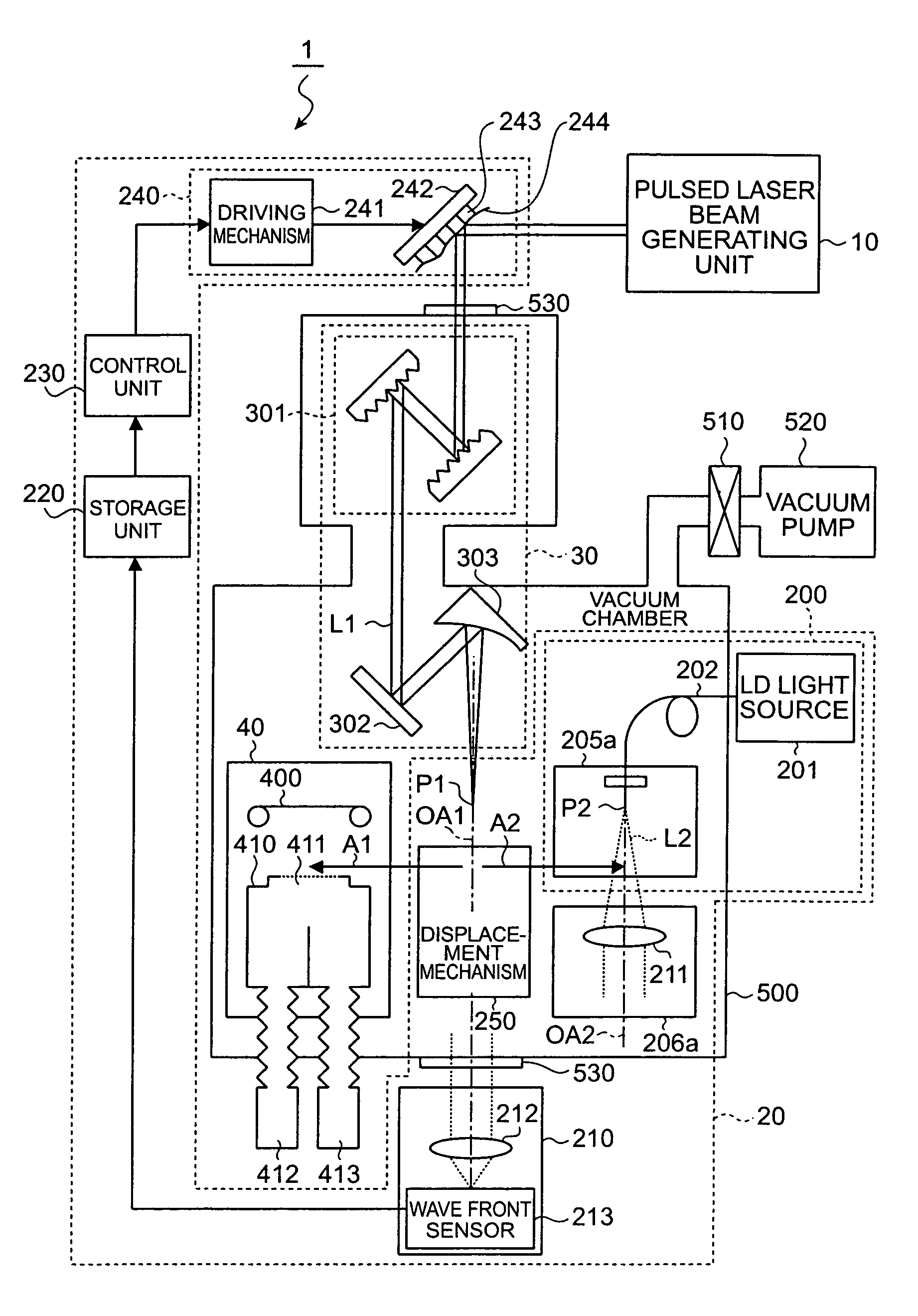

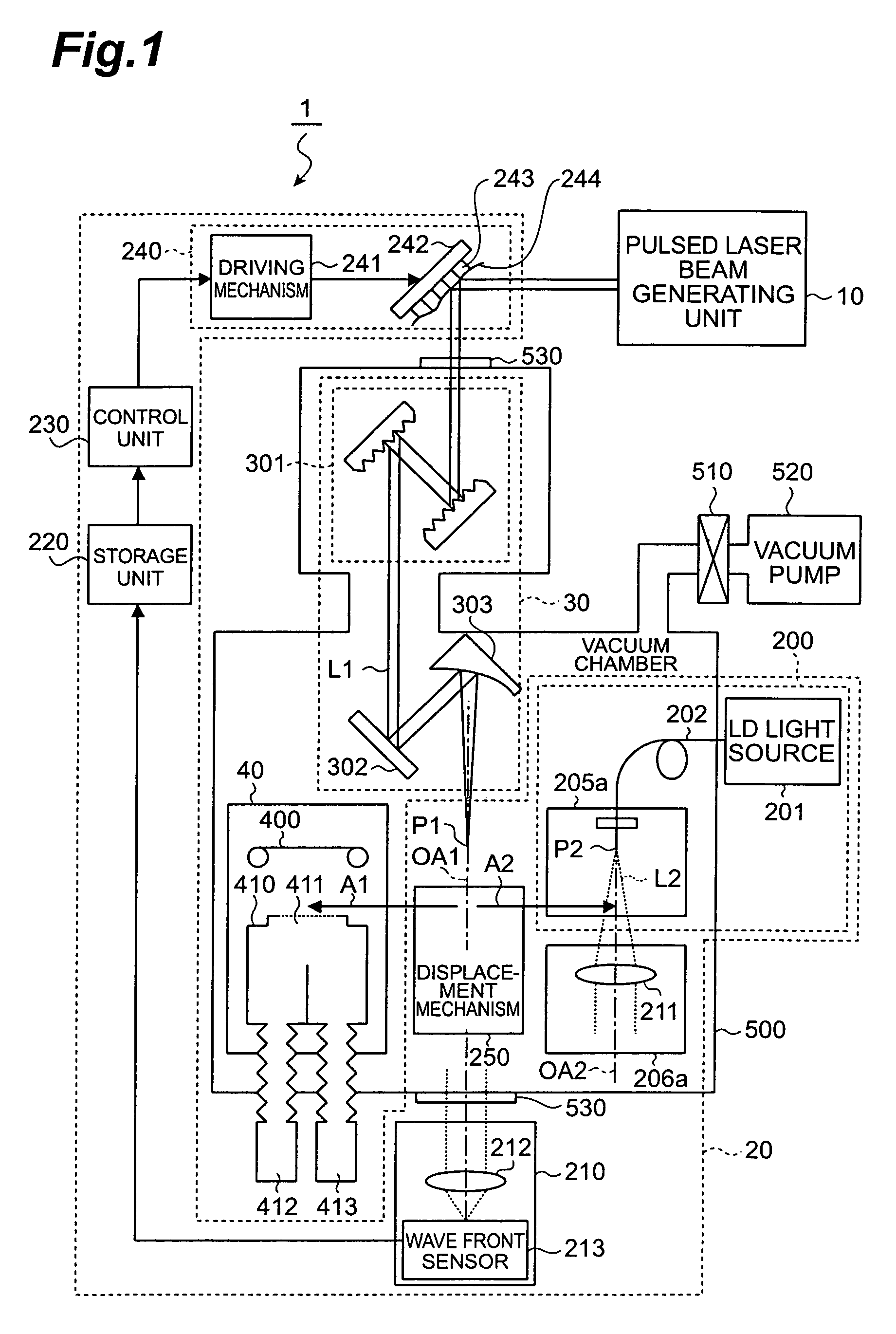

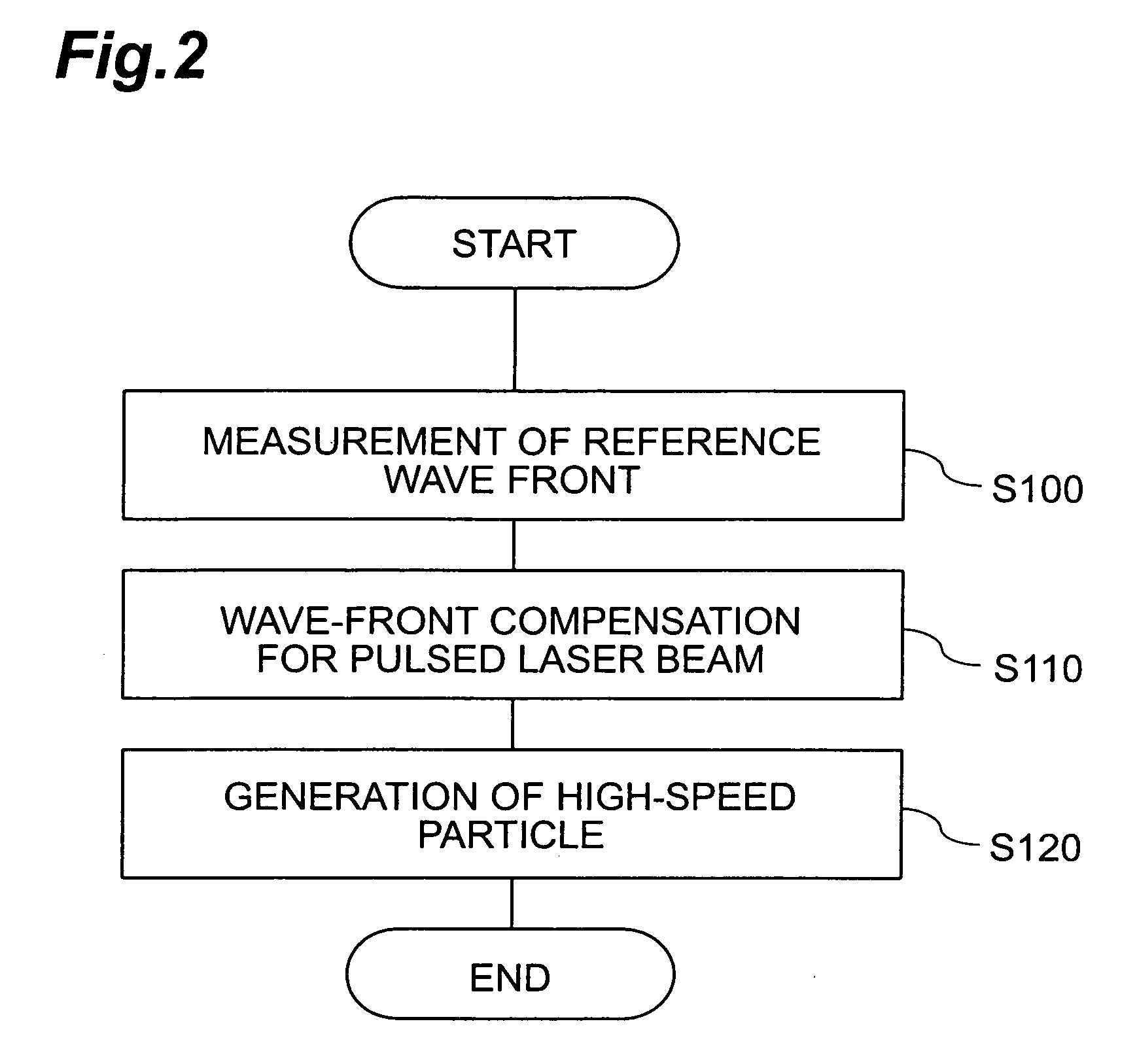

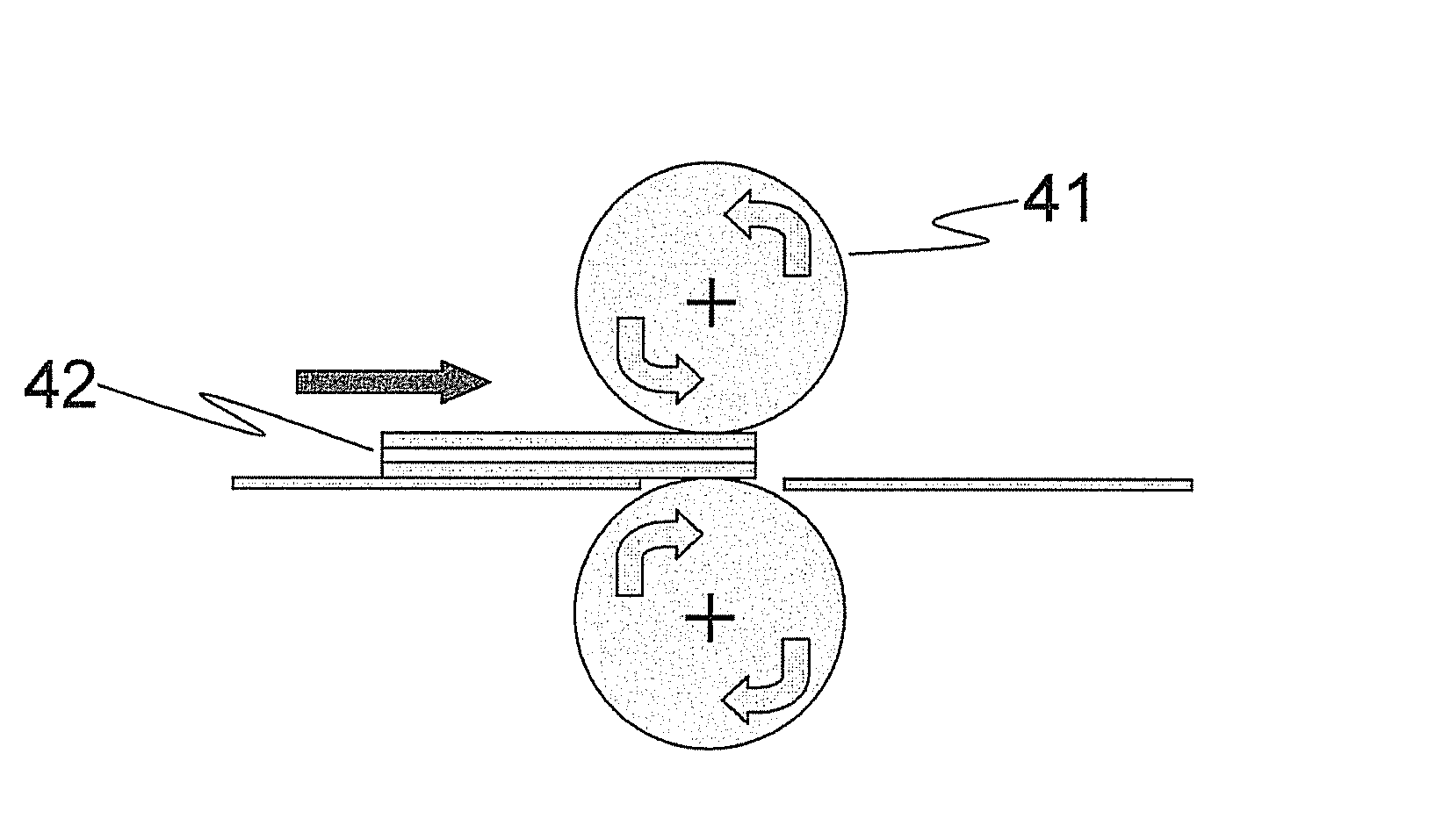

Method for generating high-speed particle and system for generating high-speed particle

InactiveUS7189976B2Generate efficientlyHigh positionalLaser detailsRadiation/particle handlingPulsed laser beamIrradiation

The present invention relates to a high-speed particle generating method and so on for generating high-speed particles from a high-speed particle generating target by condensing a pulsed laser beam to a micro-spot on the surface of a high-speed particle generating target. The high-speed particle generating method is a method that generates high-speed particles by condensing a pulsed laser beam generated from a pulsed laser beam generator through an irradiation optical system at a predetermined condensing point, and irradiating the pulsed laser beam to the high-speed particle generating target that is set at the predetermined condensing point, the method including a first step of preparing a reference data, a second step of measuring the wave front of the pulsed laser beam, and a third step of compensating the wave front of the pulsed laser beam based on the reference data.

Owner:HAMAMATSU PHOTONICS KK

Method of manufacturing translucent rigid substrate laminate

InactiveUS9061485B2Improve production efficiencyHigh positionalLamination ancillary operationsSynthetic resin layered productsEngineering

Owner:DENKA CO LTD

Driver and image instrument

ActiveUS9712748B2High positionalAccurately utilize a photographing opportunityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesFixed frameEngineering

A driver includes a piezoelectric sheet, a fixing frame, a moving frame, and a control circuit. The piezoelectric sheet includes a first piezoelectric body portion which bends in a first direction, a second piezoelectric body portion which bends in a second direction that intersects at right angles with the first direction, and a connection portion which connects the first and second piezoelectric body portions. The fixing frame is fixed to the connection portion. The moving frame is supported on the first and second piezoelectric body portions. The control circuit applies voltage signals to the first and second piezoelectric body portions to bend the first and second piezoelectric body portions and which moves the moving frame in one of the first direction and the second direction or in a composite direction of the first direction and the second direction.

Owner:OM DIGITAL SOLUTIONS CORP

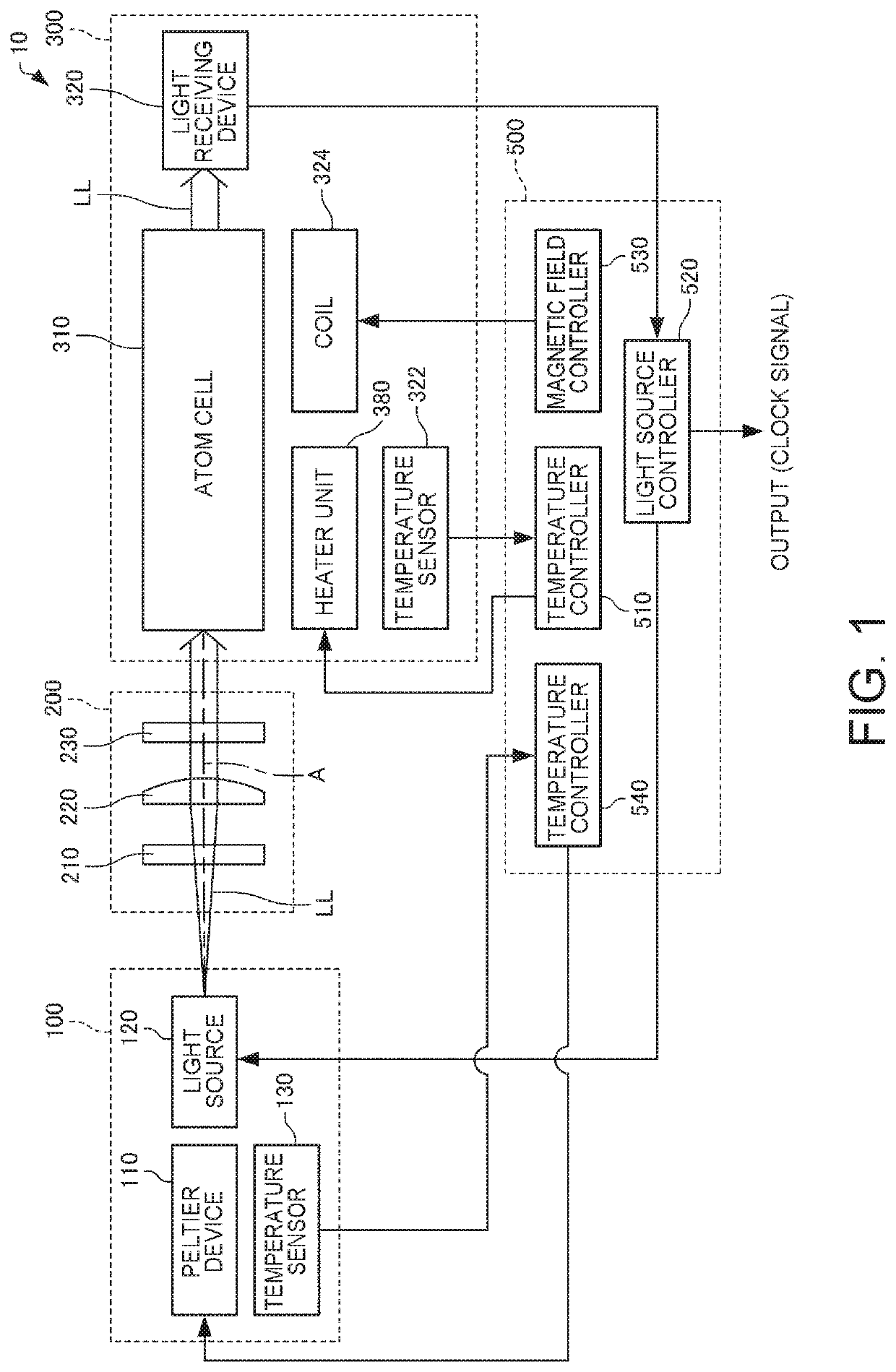

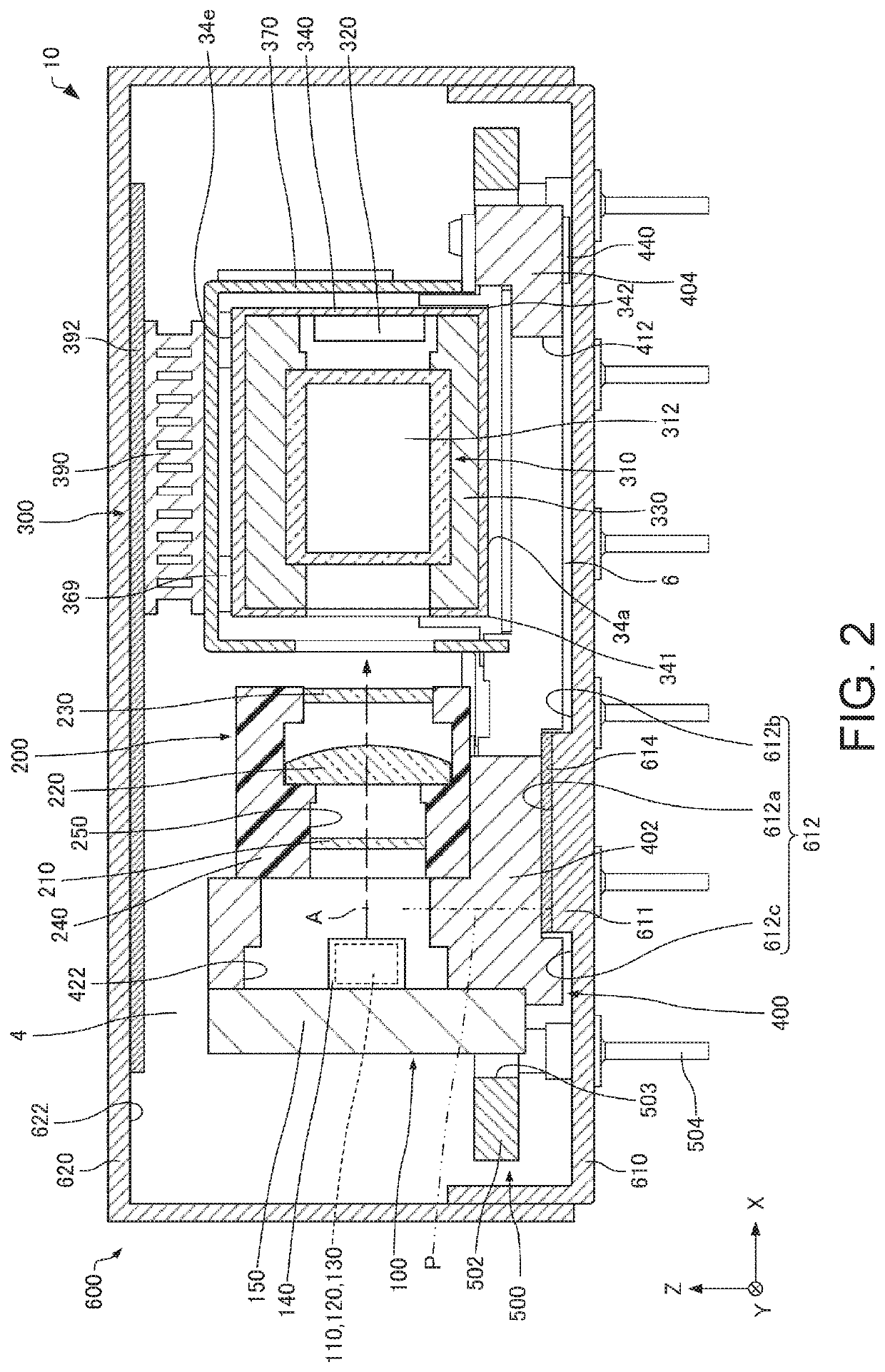

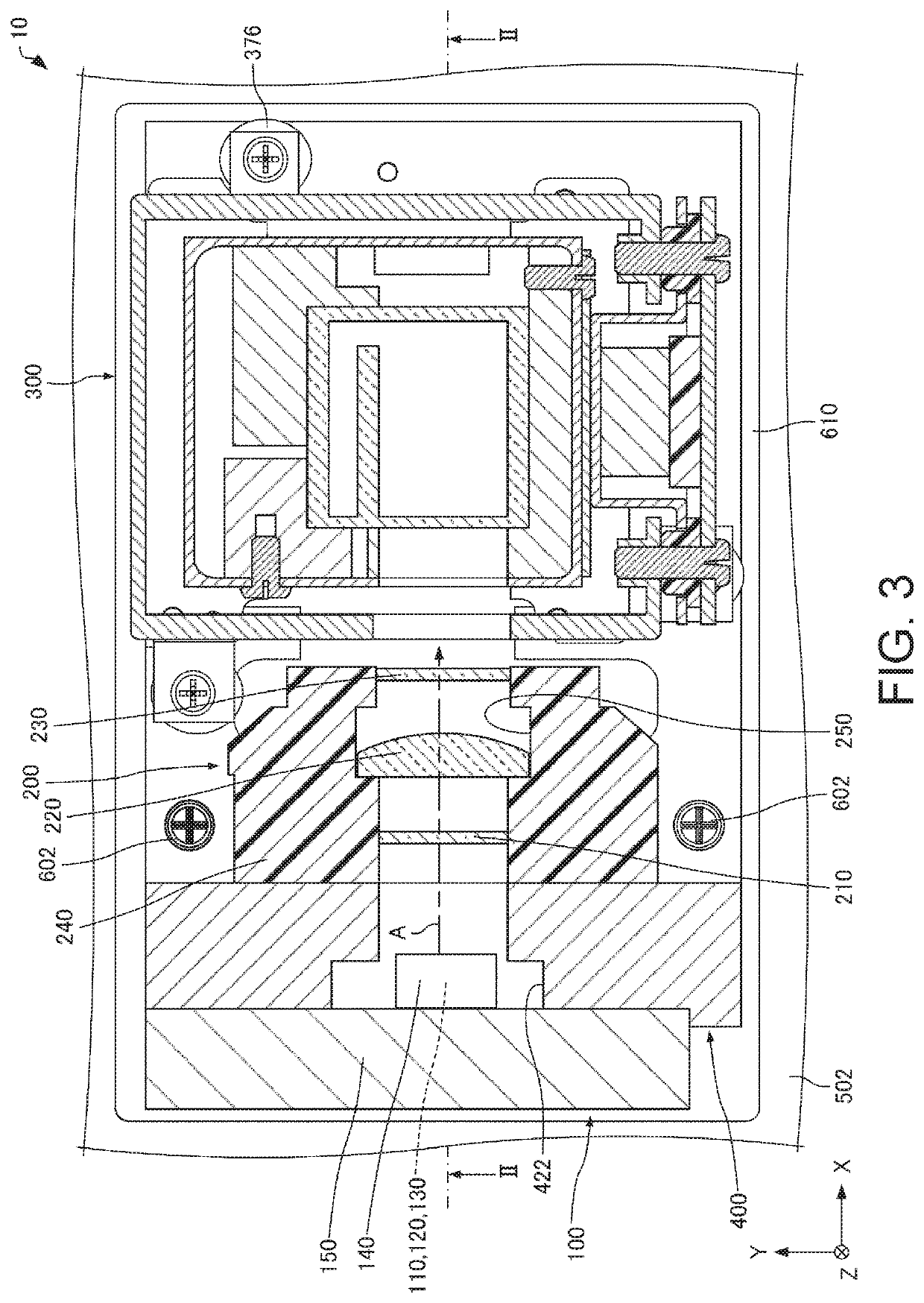

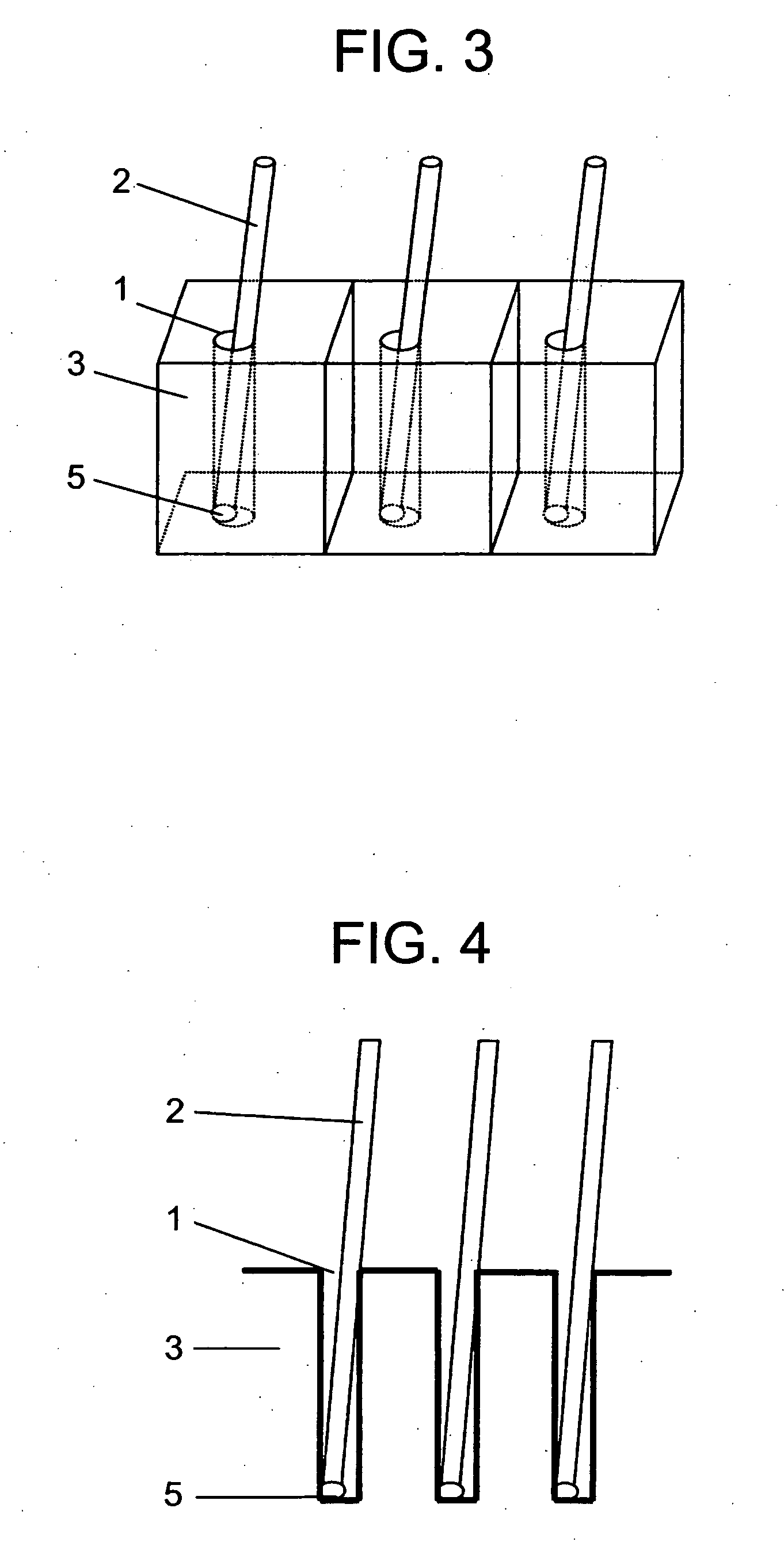

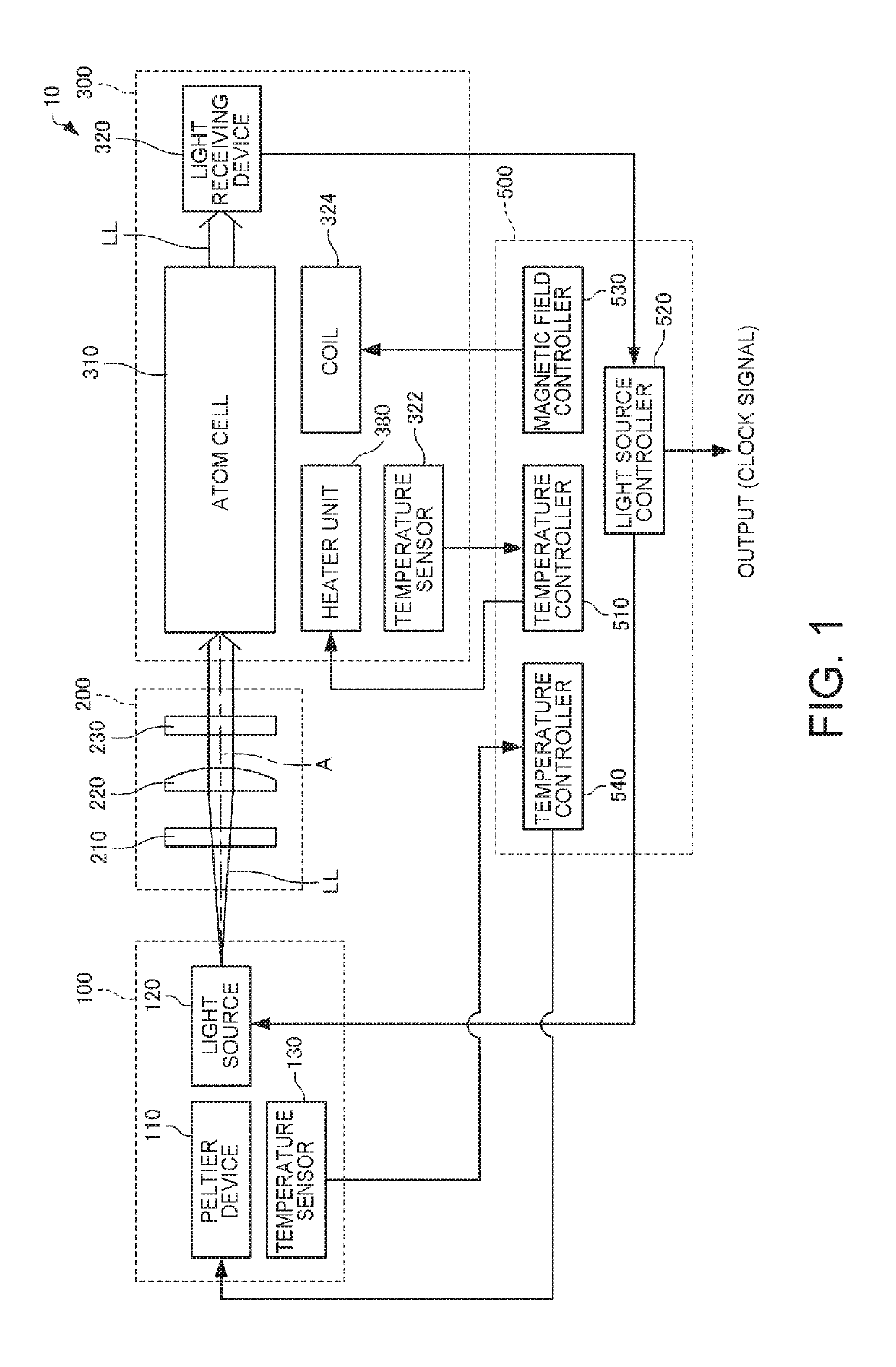

Atomic oscillator

ActiveUS10727850B2Prevent heat transferHigh positioning accuracyPulse automatic controlApparatus using atomic clocksParticle physicsAlkali metal

An atomic oscillator includes an atom cell that accommodates an alkali metal atom therein, a container that houses the atom cell, a substrate on which the container is disposed, and a thermally insulating mount that is fixed to the substrate and positions the container relative to the substrate.

Owner:MICROCHIP TECH INC

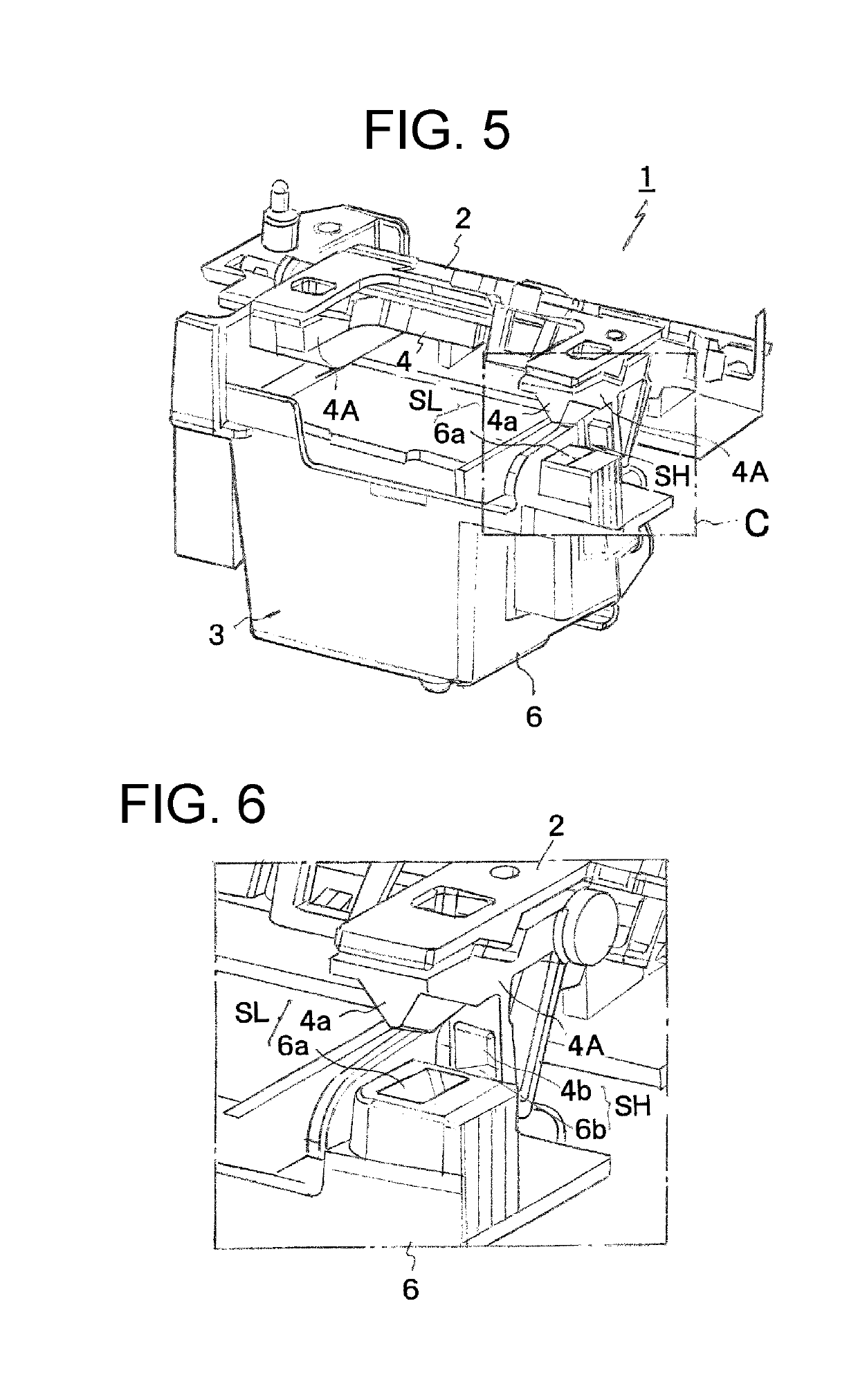

Light amount control mechanism for vehicle headlight

ActiveUS20190063714A1High positionalSuppress mutationVehicle headlampsLighting and heating apparatusEngineeringActuator

A light amount control mechanism for a vehicle headlamp can maintain high positional precision of a movable shade in its rotation axis direction to suppress variation in light distribution while allowing stable rotation of the movable shade. The light amount control mechanism includes a movable shade configured to be rotatably supported by a housing and selectively pivots to a first position or a second position to switch a shielding amount of light emitted from a light source, and an actuator configured to drive the movable shade. The light amount control mechanism for a vehicle headlamp may further include a stopper configured to position and hold the movable shade at the first position and the second position, the stopper being constituted by a V-shaped convex portion formed on any one of the movable shade and the housing and a V-groove-shaped concave portion formed on the other thereof as a pair.

Owner:STANLEY ELECTRIC CO LTD

Light amount control mechanism for vehicle headlight

ActiveUS10436411B2High positionalSuppress mutationVehicle headlampsLighting and heating apparatusEngineeringActuator

A light amount control mechanism for a vehicle headlamp can maintain high positional precision of a movable shade in its rotation axis direction to suppress variation in light distribution while allowing stable rotation of the movable shade. The light amount control mechanism includes a movable shade configured to be rotatably supported by a housing and selectively pivots to a first position or a second position to switch a shielding amount of light emitted from a light source, and an actuator configured to drive the movable shade. The light amount control mechanism for a vehicle headlamp may further include a stopper configured to position and hold the movable shade at the first position and the second position, the stopper being constituted by a V-shaped convex portion formed on any one of the movable shade and the housing and a V-groove-shaped concave portion formed on the other thereof as a pair.

Owner:STANLEY ELECTRIC CO LTD

Worm speed change apparatus and electric power steering apparatus

InactiveUS6925902B2Low production costHigh precisionGearboxesToothed gearingsElectric power steeringEngineering

Owner:KOYO SEIKO CO LTD

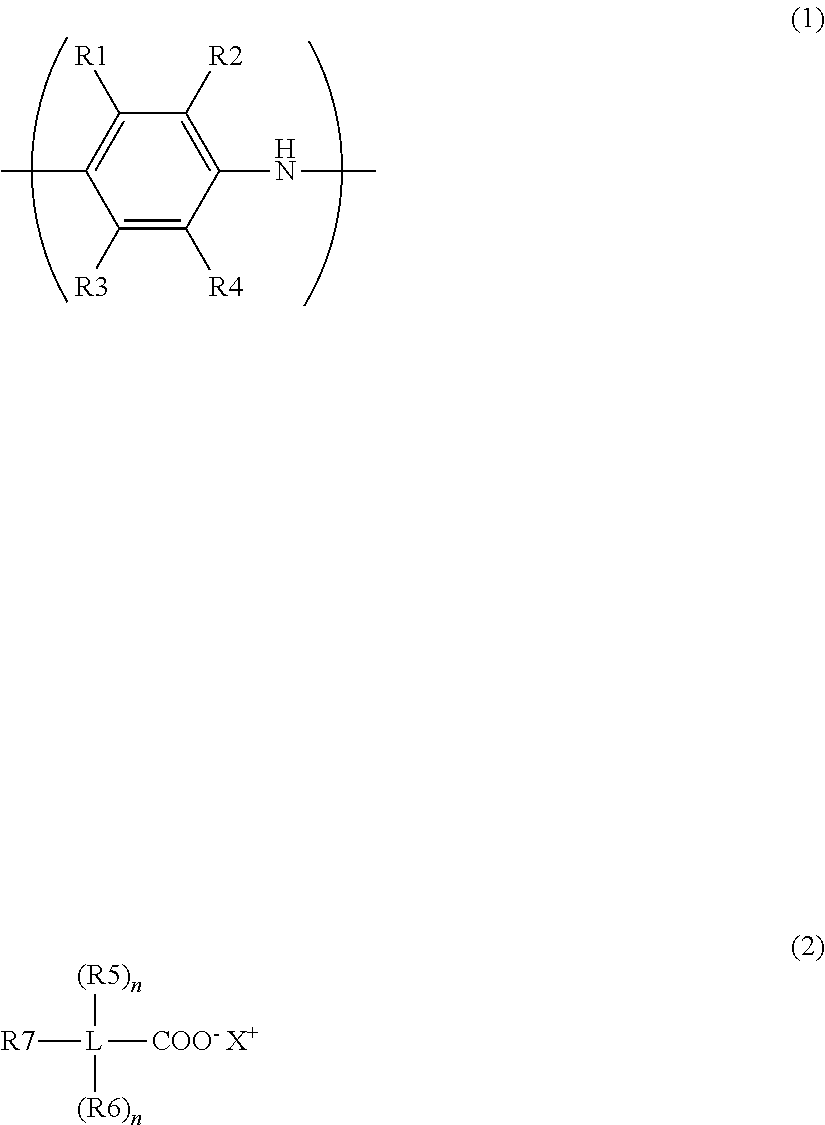

Conductive polymer composition, coated product and patterning process

PendingUS20200292941A1Improve efficiencyPrecise positioningConductive materialInksPolymer scienceConductive polymer

An object of the present invention is to provide a conductive polymer composition which has good filterability and good film formability of a flat film on an electron beam resist and can be suitably used for an antistatic film for electron beam resist writing, showing excellent antistatic property in the electron beam writing process due to the property of low volume resistivity (Ω·cm), and, reducing an effect on lithography by making an effect of an acid diffused from the film minimum, and further having excellent peelability by H2O or an alkaline developer after writing.A conductive polymer composition which comprises (A) a polyaniline-based conductive polymer having at least one kind or more of a repeating unit represented by the following general formula (1), and (B) a carboxylic acid salt represented by the following general formula (2):

Owner:SHIN ETSU CHEM IND CO LTD

Micro-protruding structure

InactiveUS20080272301A1High positionalSmall sizeVolume/mass flow by thermal effectsFixed microstructural devicesMeasurement deviceClassical mechanics

A micro-protruding structure which has a high positional precision and an angular (directional) precision, which is made of a linear material having a large aspect ratio, and which is provided for an analyzer, a display device, a machining device, a measuring device and an observation device. The micro-protruding structure is fabricated by growing a linear material of a carbon nano-tube from the bottom of the hole structure perforated by a focused ion beam. This permits a direction from the bottom of the hole structure to the opening to become nearly in alignment with the direction of the linear material that protrudes from the hole structure.

Owner:SHIGENO MASATSUGU

Atomic oscillator

ActiveUS20190149159A1High positioning accuracyPrevent heat transferApparatus using atomic clocksPulse automatic controlEngineeringAlkali metal

An atomic oscillator includes an atom cell that accommodates an alkali metal atom therein, a container that houses the atom cell, a substrate on which the container is disposed, and a thermally insulating mount that is fixed to the substrate and positions the container relative to the substrate.

Owner:MICROCHIP TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com