Patents

Literature

114results about How to "Stable contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

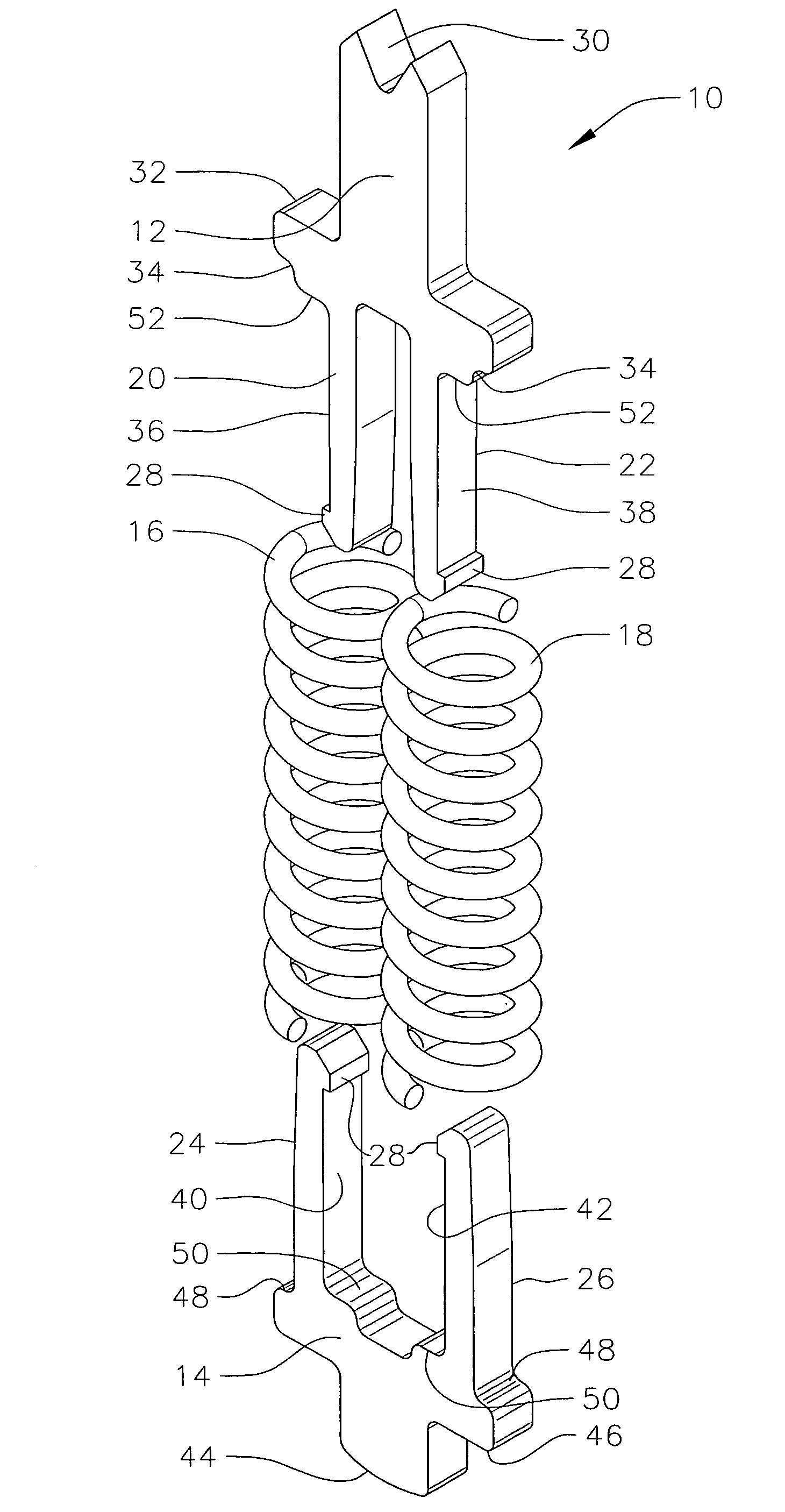

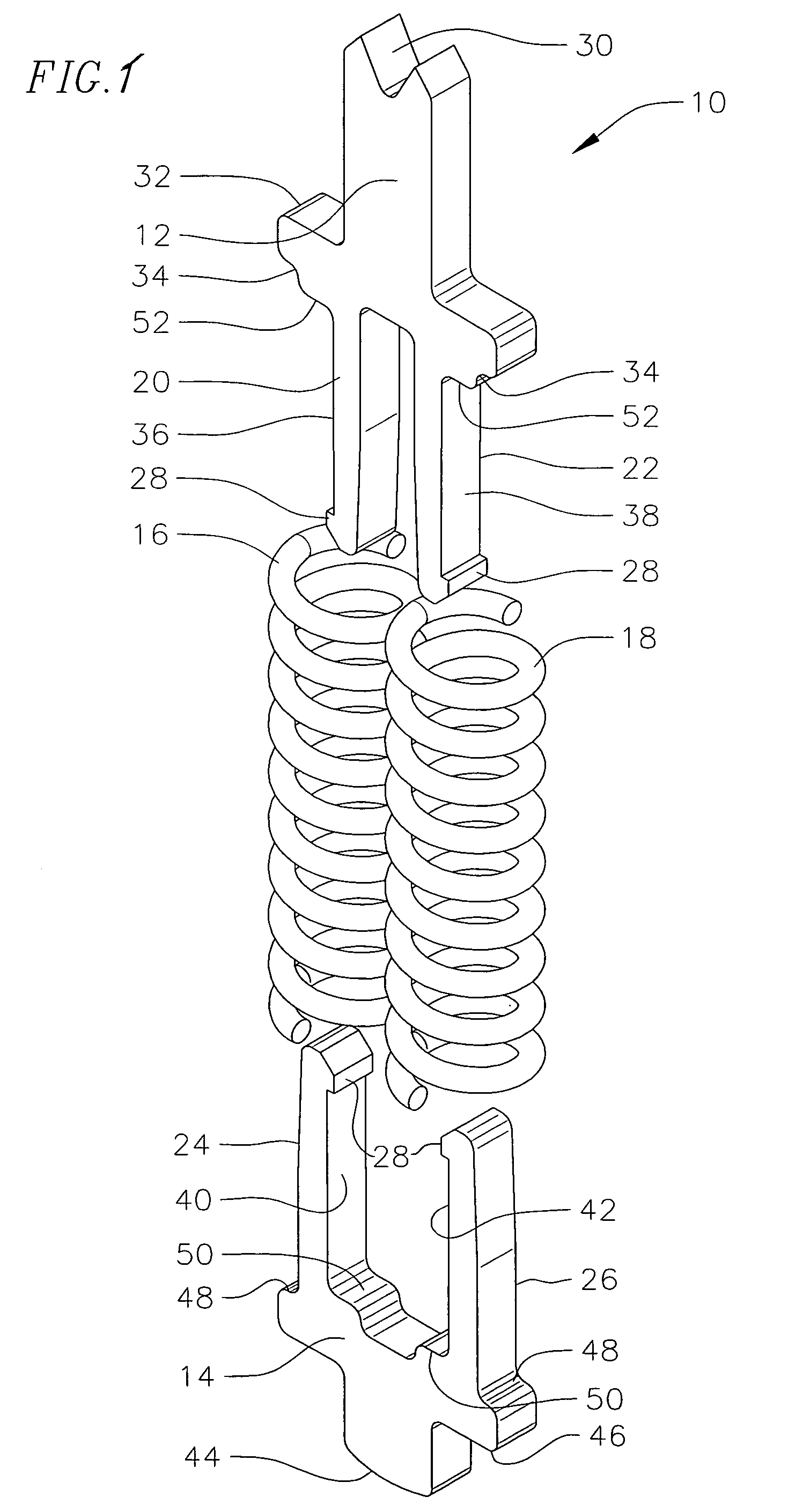

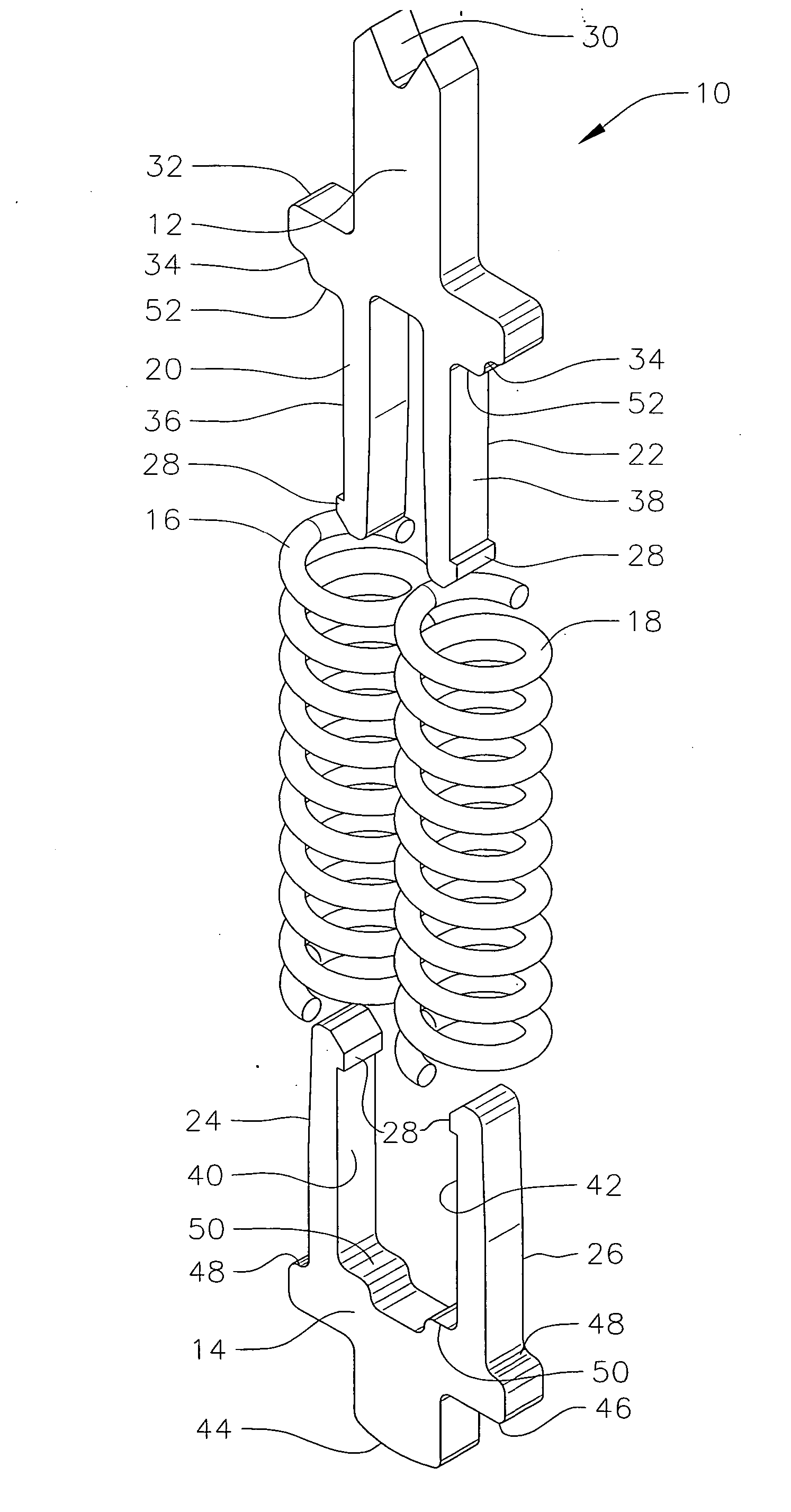

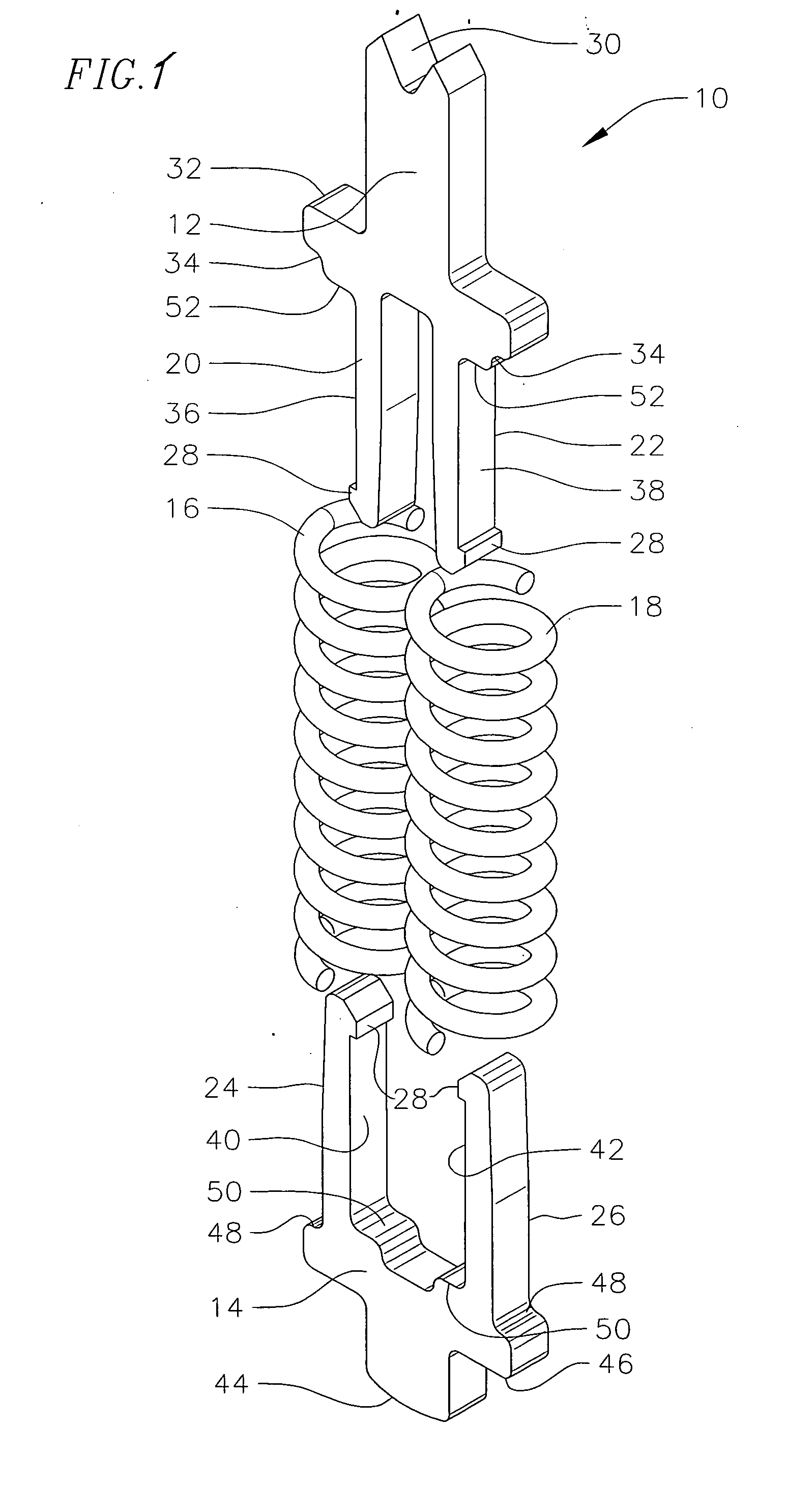

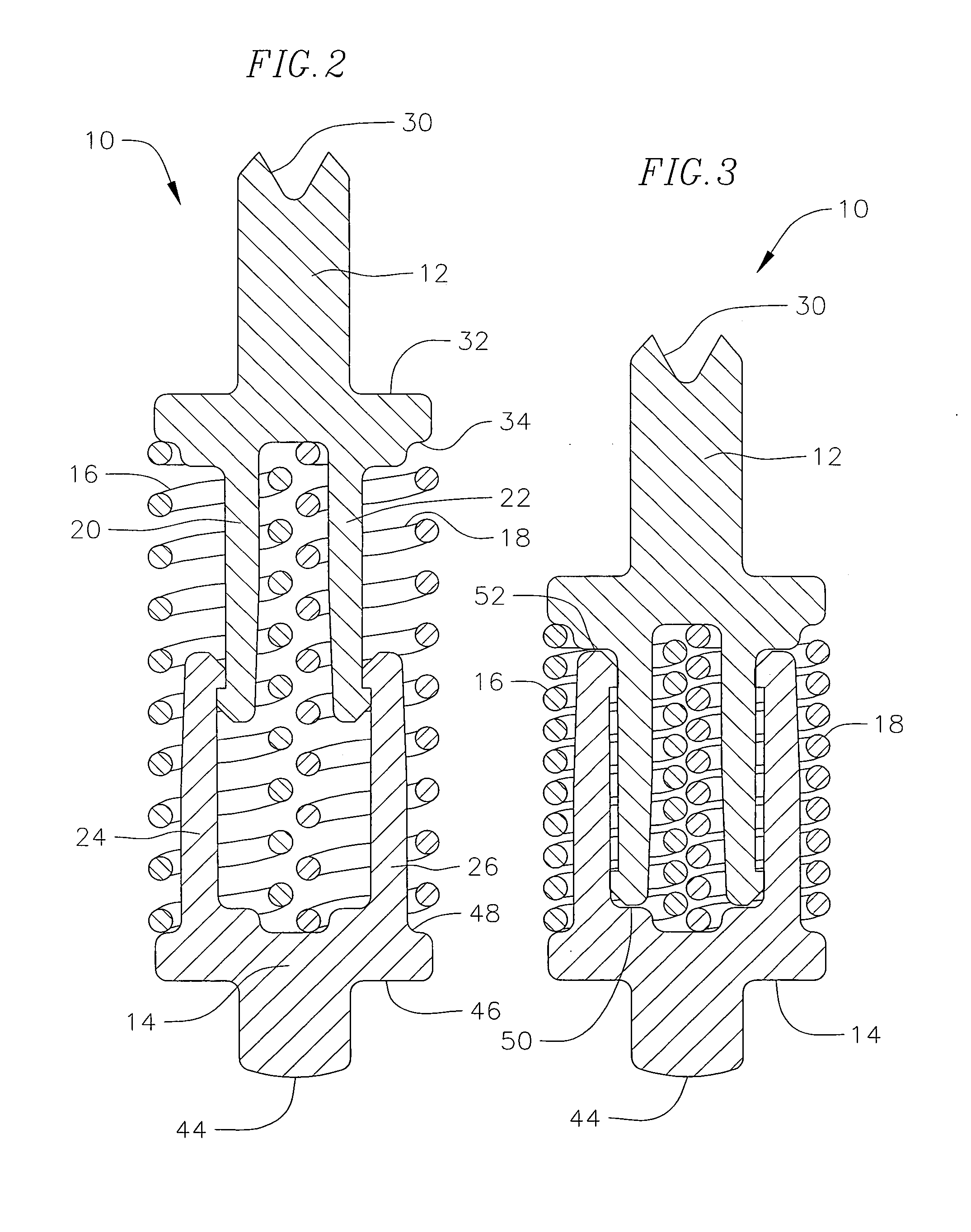

Electrical contact probe with compliant internal interconnect

ActiveUS7256593B2Maximize high-frequency responseMaximize complianceElectrical measurement instrument detailsContactless circuit testingContact forceEngineering

A compliant electrical interconnect having a first component and a second component interlockingly engaged with the first component. Each component has two cantilever arms lockingly engaged and continuously biased against each other. Contact springs are captivated by the cantilever arms providing a contact force for the first and second components.

Owner:XCERRA

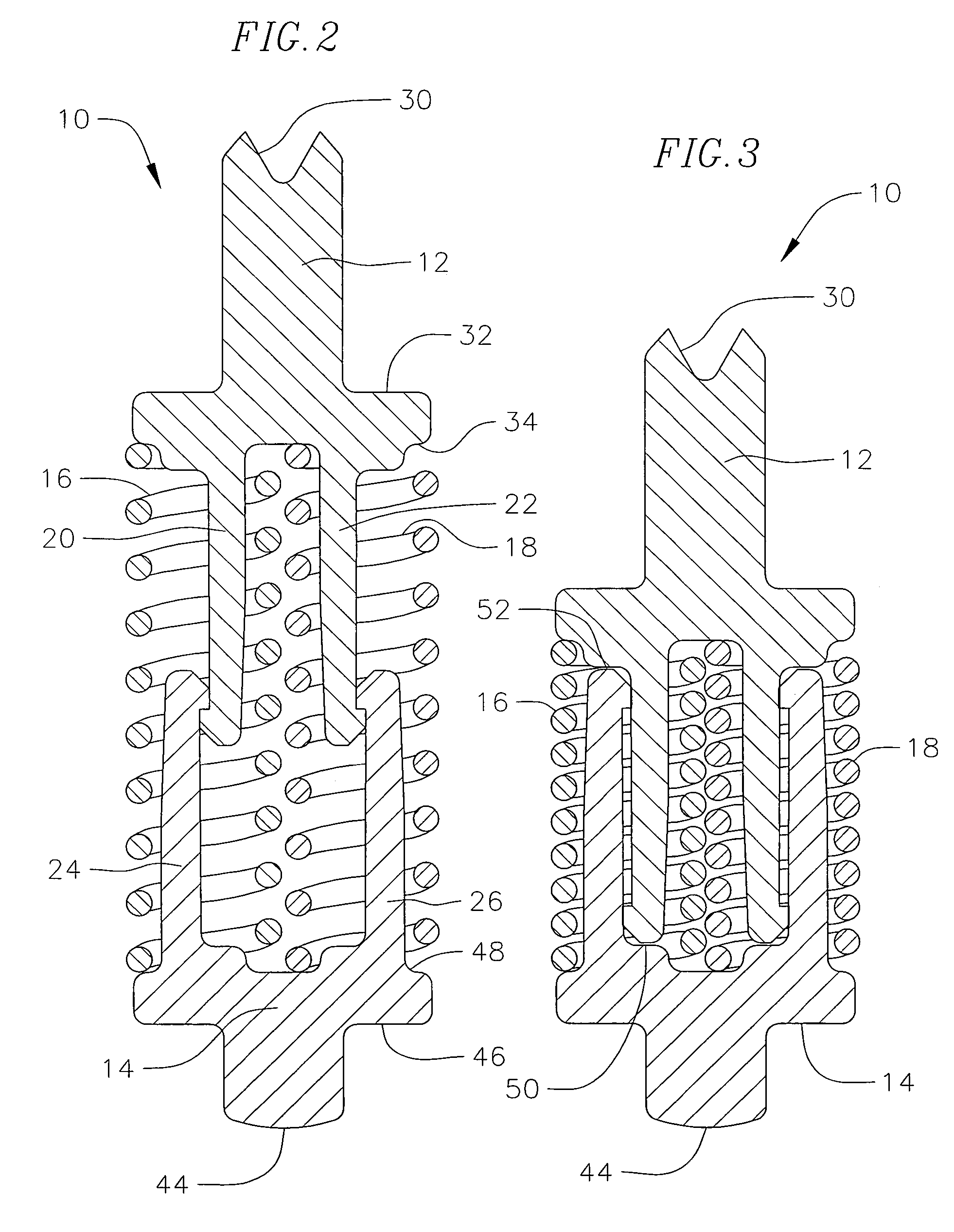

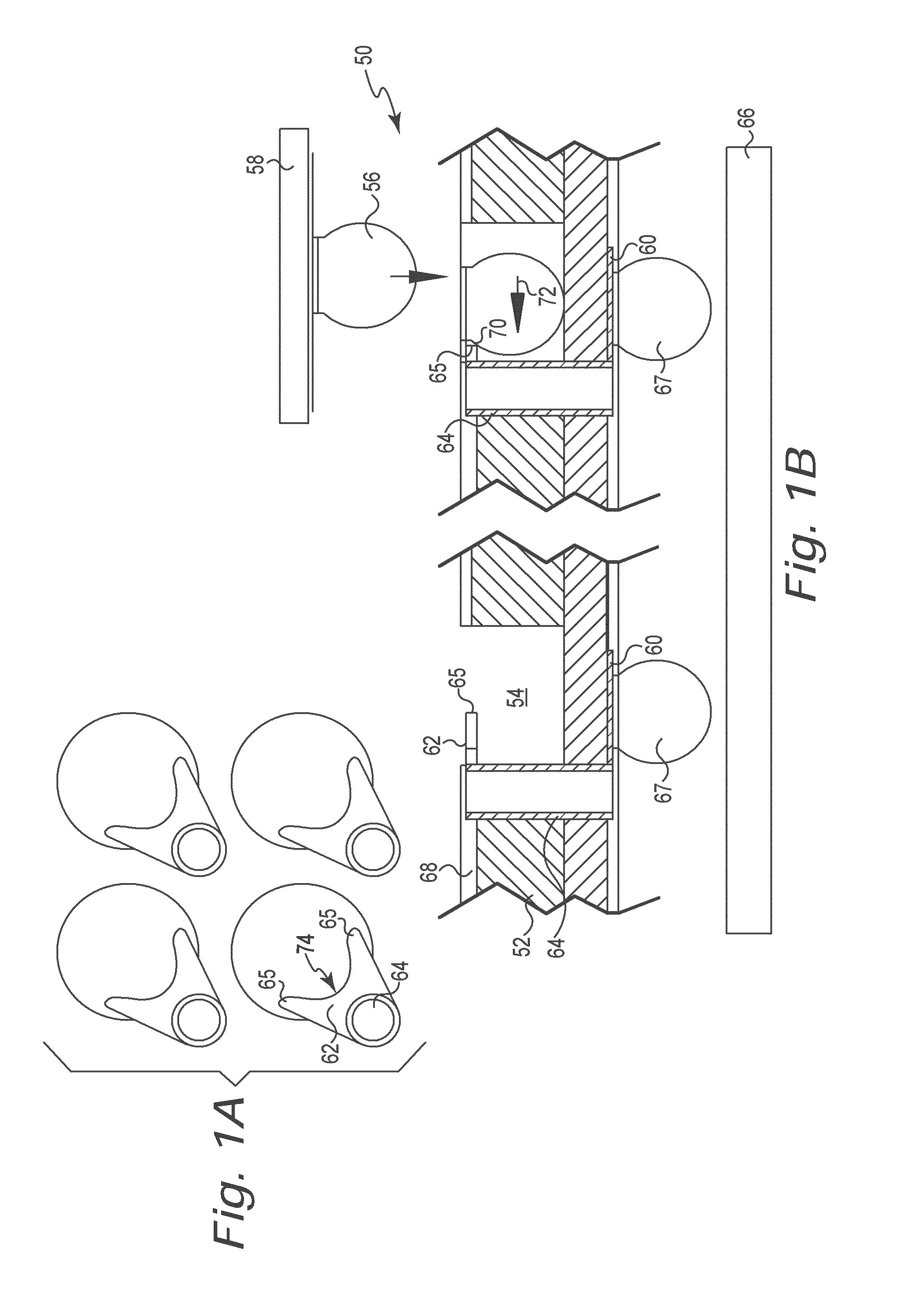

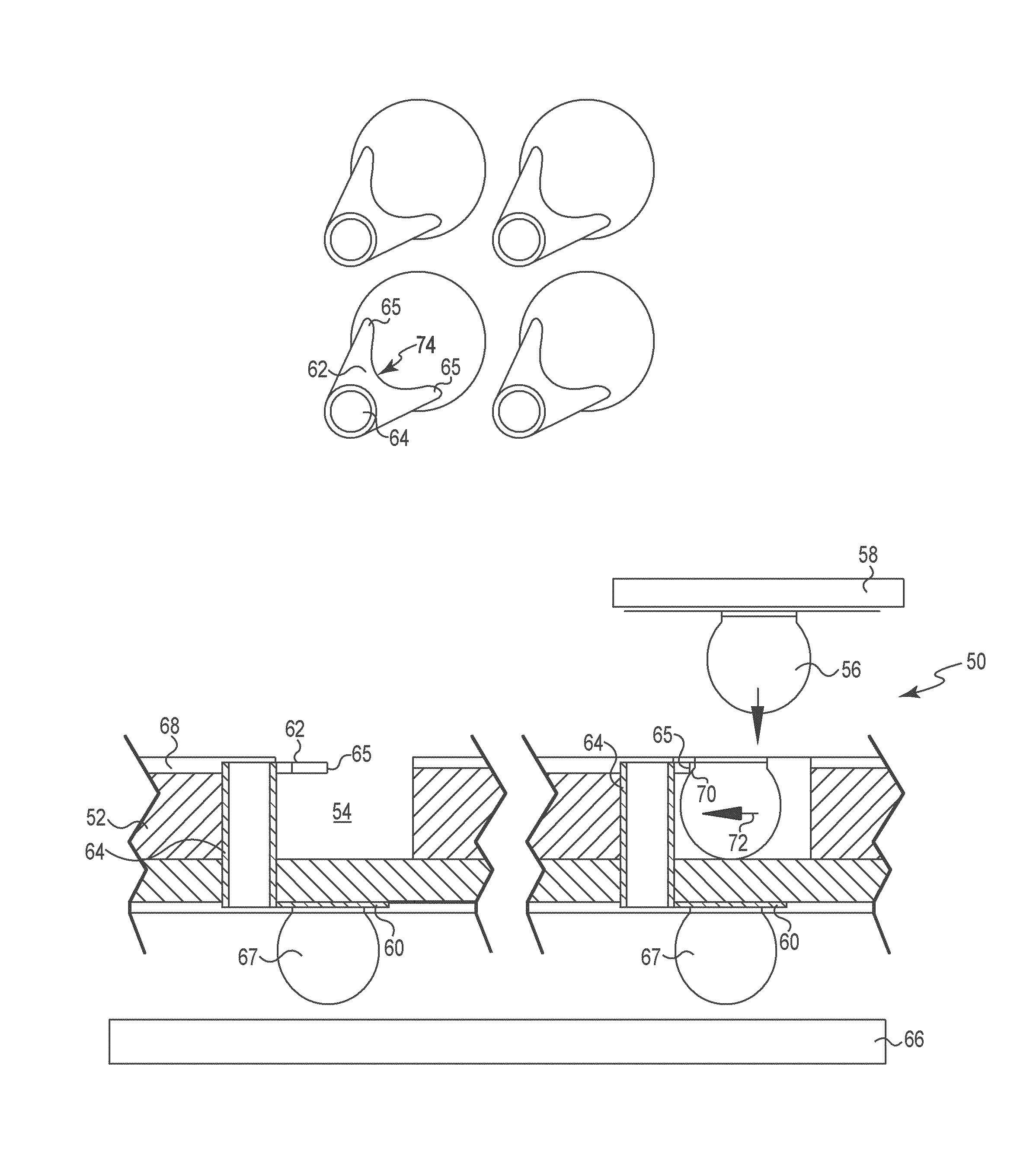

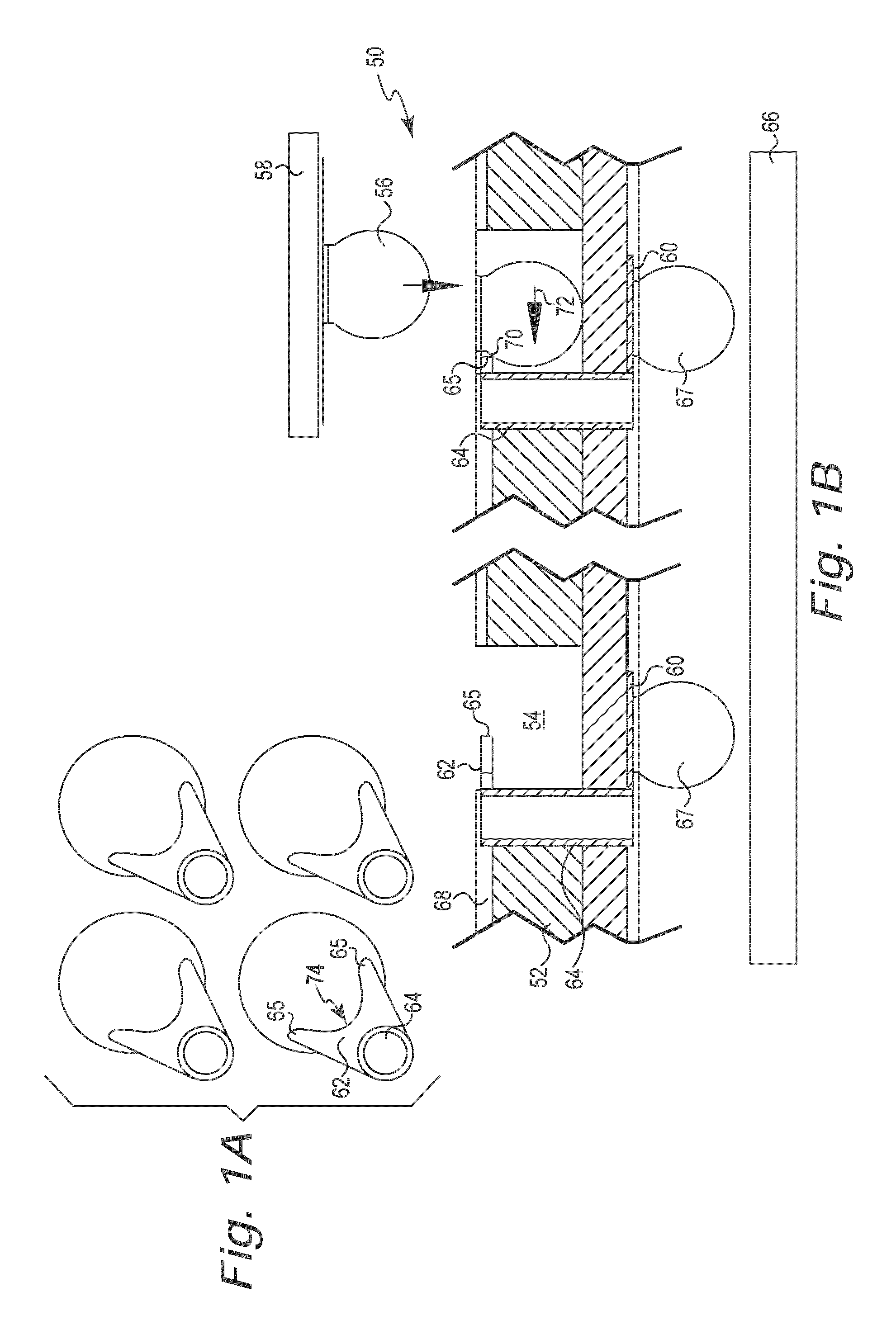

High performance surface mount electrical interconnect with external biased normal force loading

ActiveUS20120244728A1Low enough forceEasy to disassembleCoupling device connectionsContact member manufacturingContact padSurface mounting

A surface mount electrical interconnect adapted to provide an interface between solder balls on a BGA device and a PCB. A socket substrate is provided with a first surface, a second surface, and a plurality of openings sized and configured to receive the solder balls on the BGA device. A plurality of electrically conductive contact tabs are attached to the socket substrate so that contact tips on the contact tabs extend into the openings. The contact tips electrically couple with the BGA device when the solder balls are positioned in the openings. Vias electrically couple the contact tabs to contact pads located proximate the second surface of the socket substrate. Solder balls are bonded to the contact pads to electrically and mechanically couple the electrical interconnect to the PCB.

Owner:HSIO TECH

Electrical contact probe with compliant internal interconnect

ActiveUS20060279301A1Maximize high-frequency responseMaximize complianceElectrical measurement instrument detailsElectrical testingContact forceEngineering

A compliant electrical interconnect having a first component and a second component interlockingly engaged with the first component. Each component has two cantilever arms lockingly engaged and continuously biased against each other. Contact springs are captivated by the cantilever arms providing a contact force for the first and second components.

Owner:XCERRA

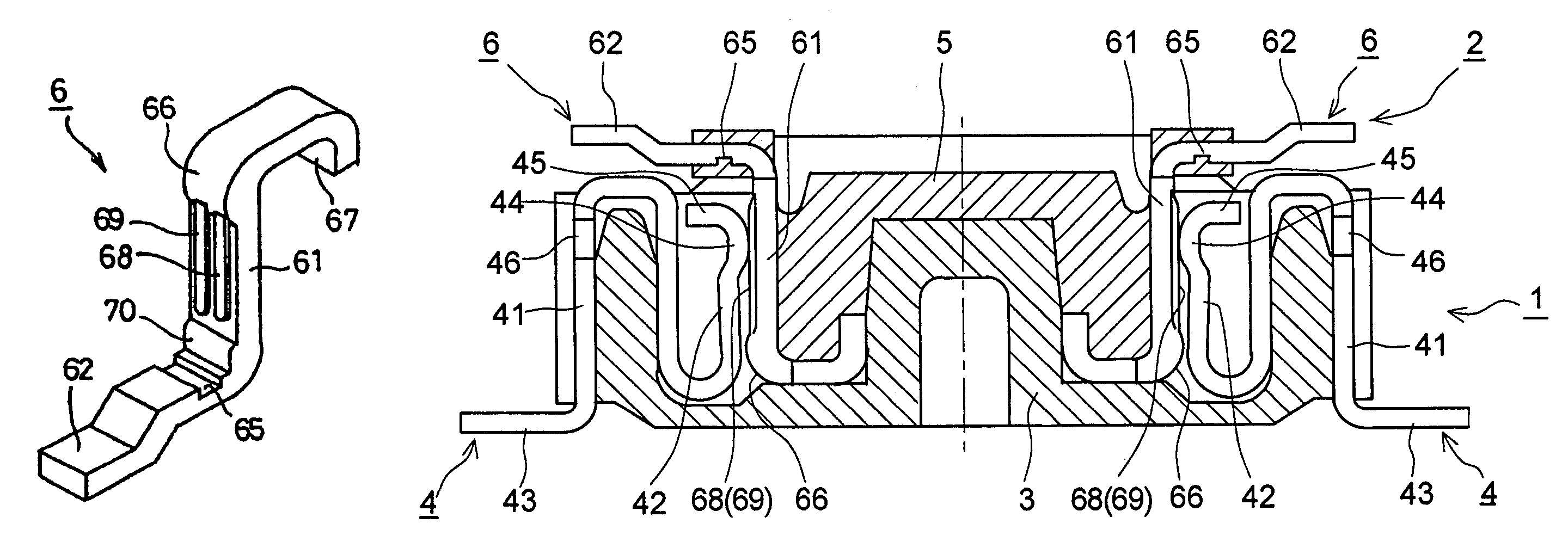

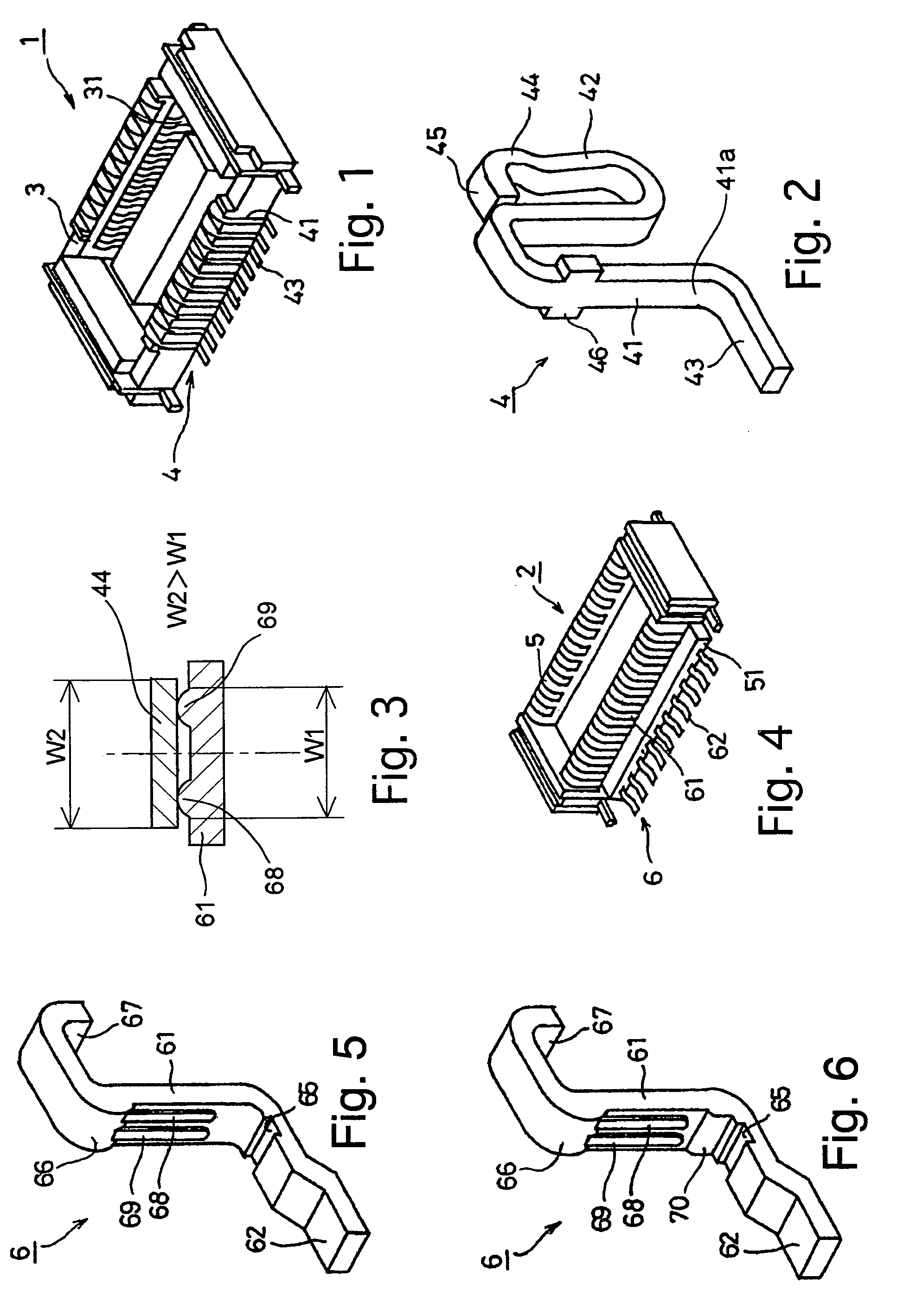

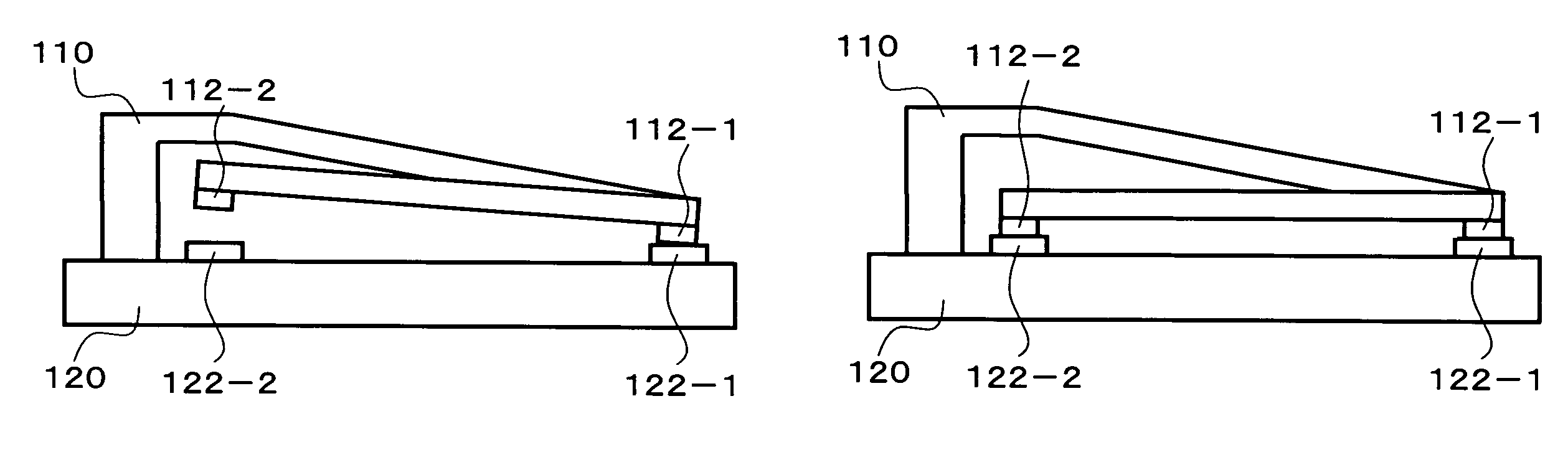

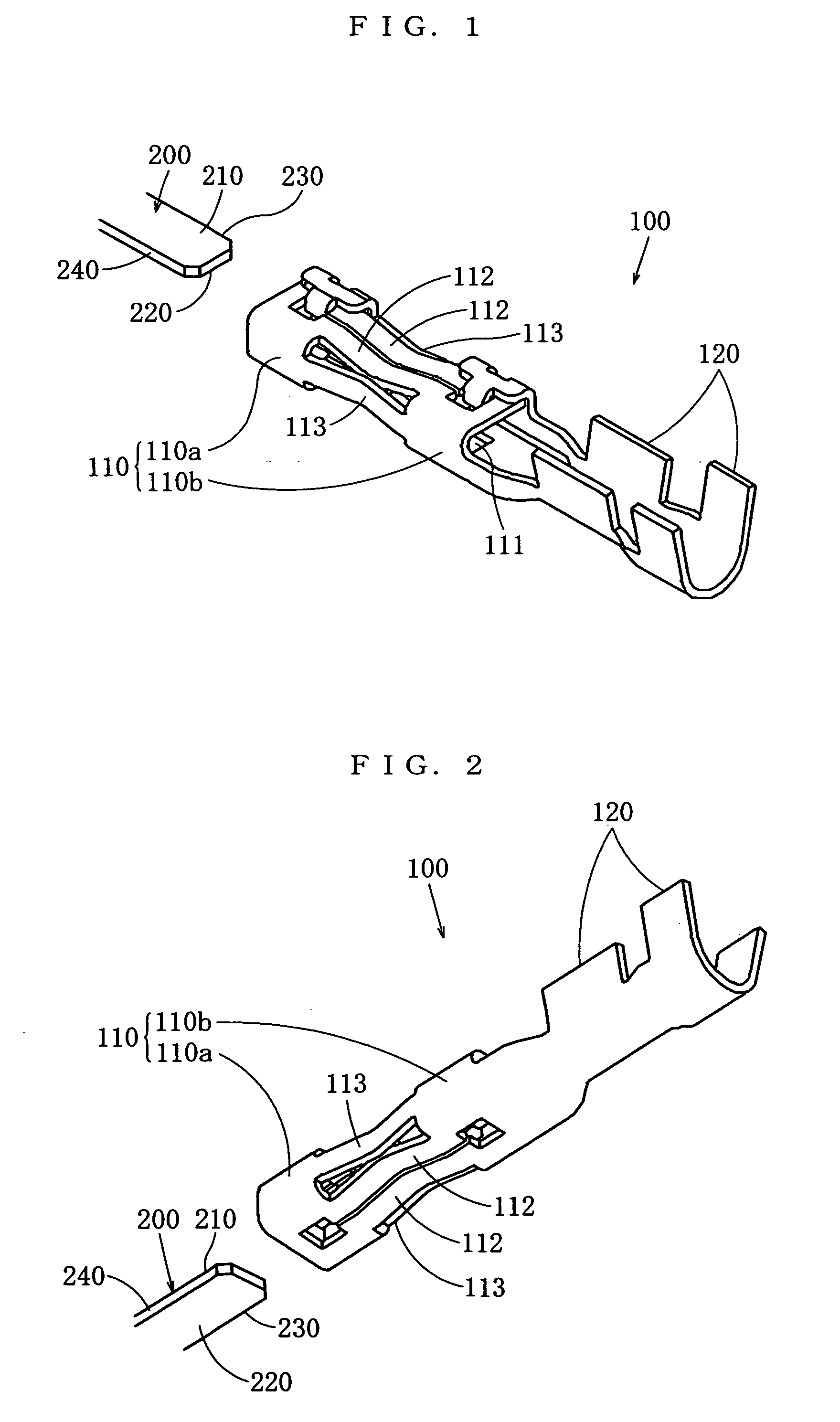

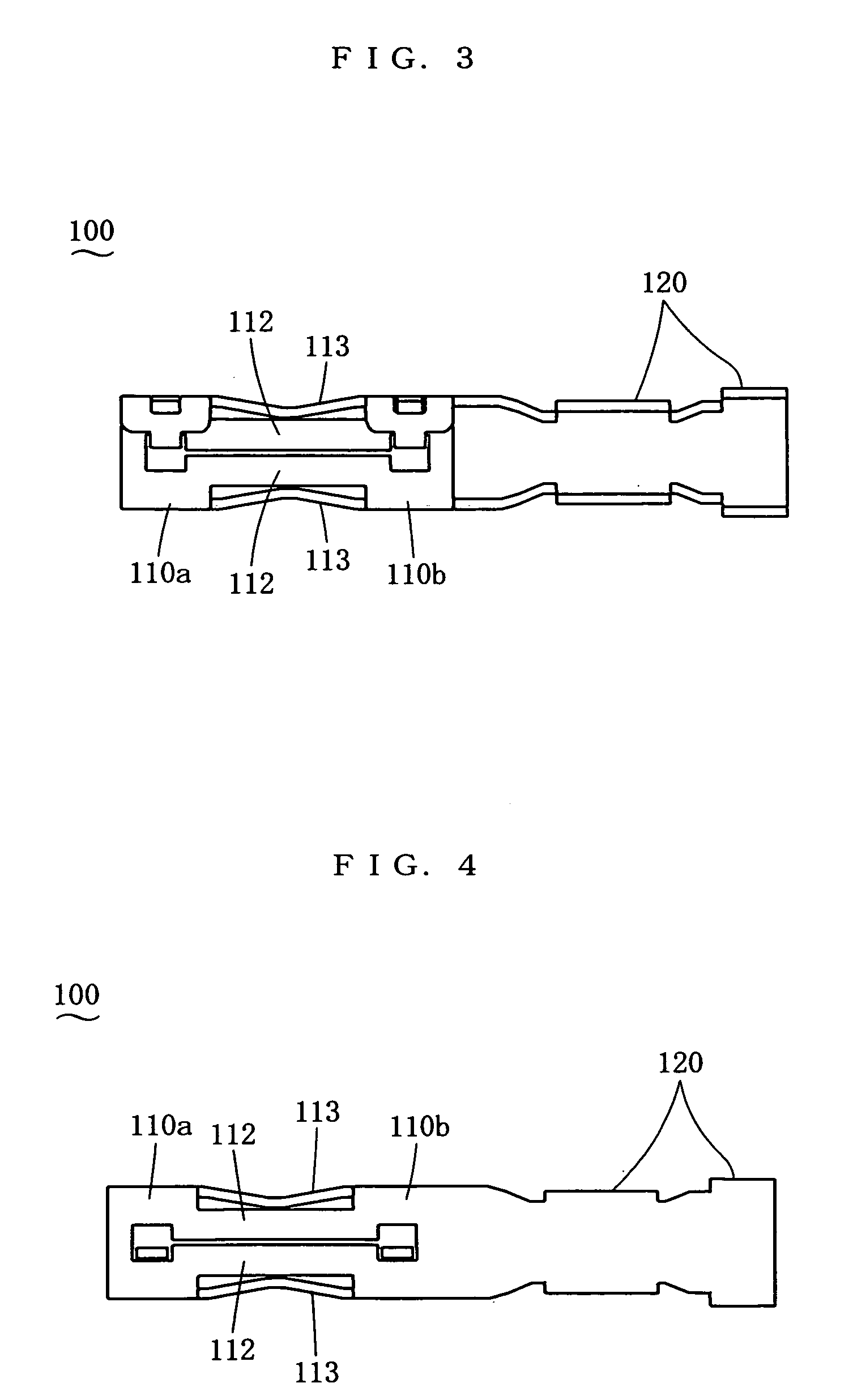

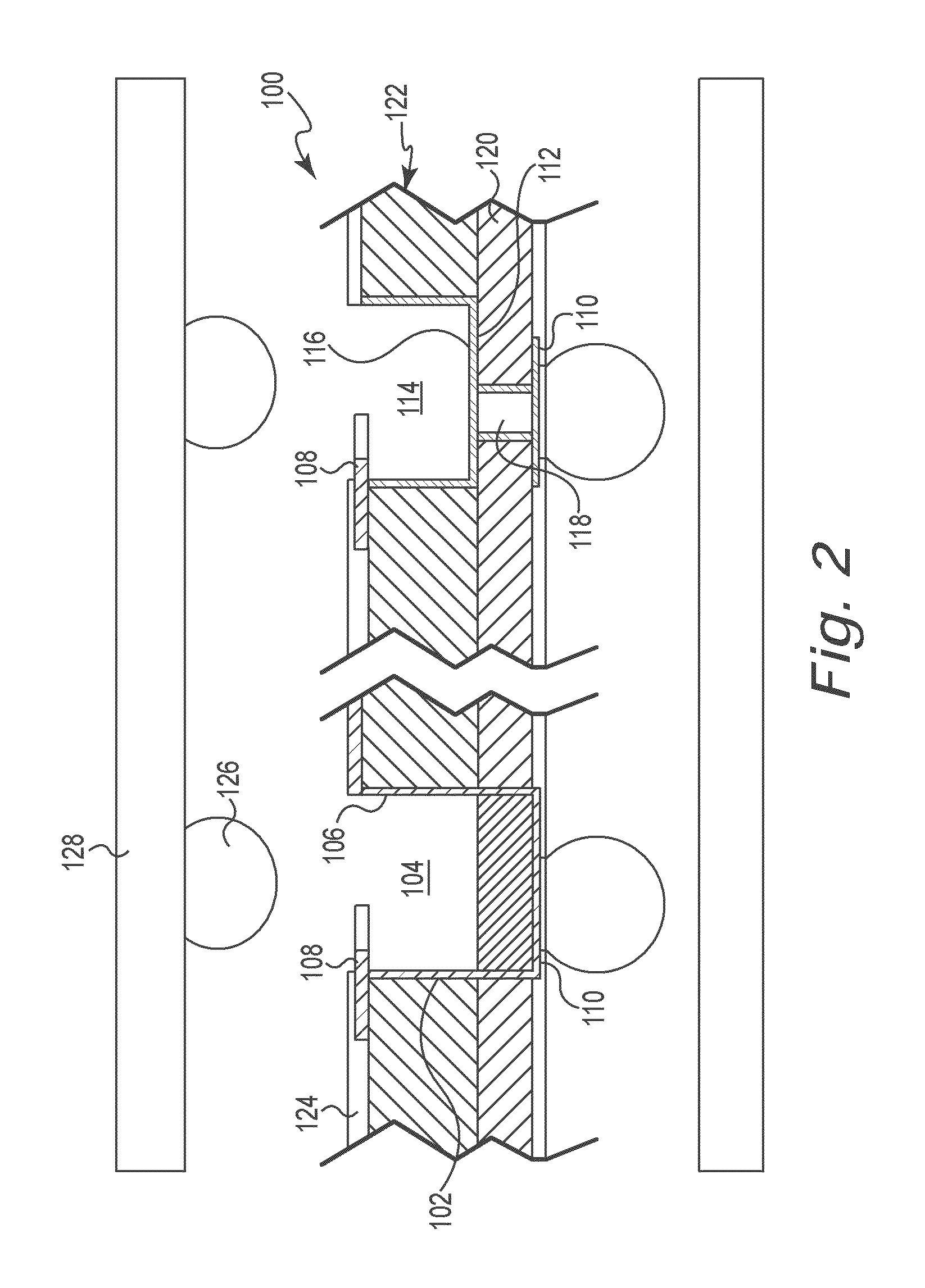

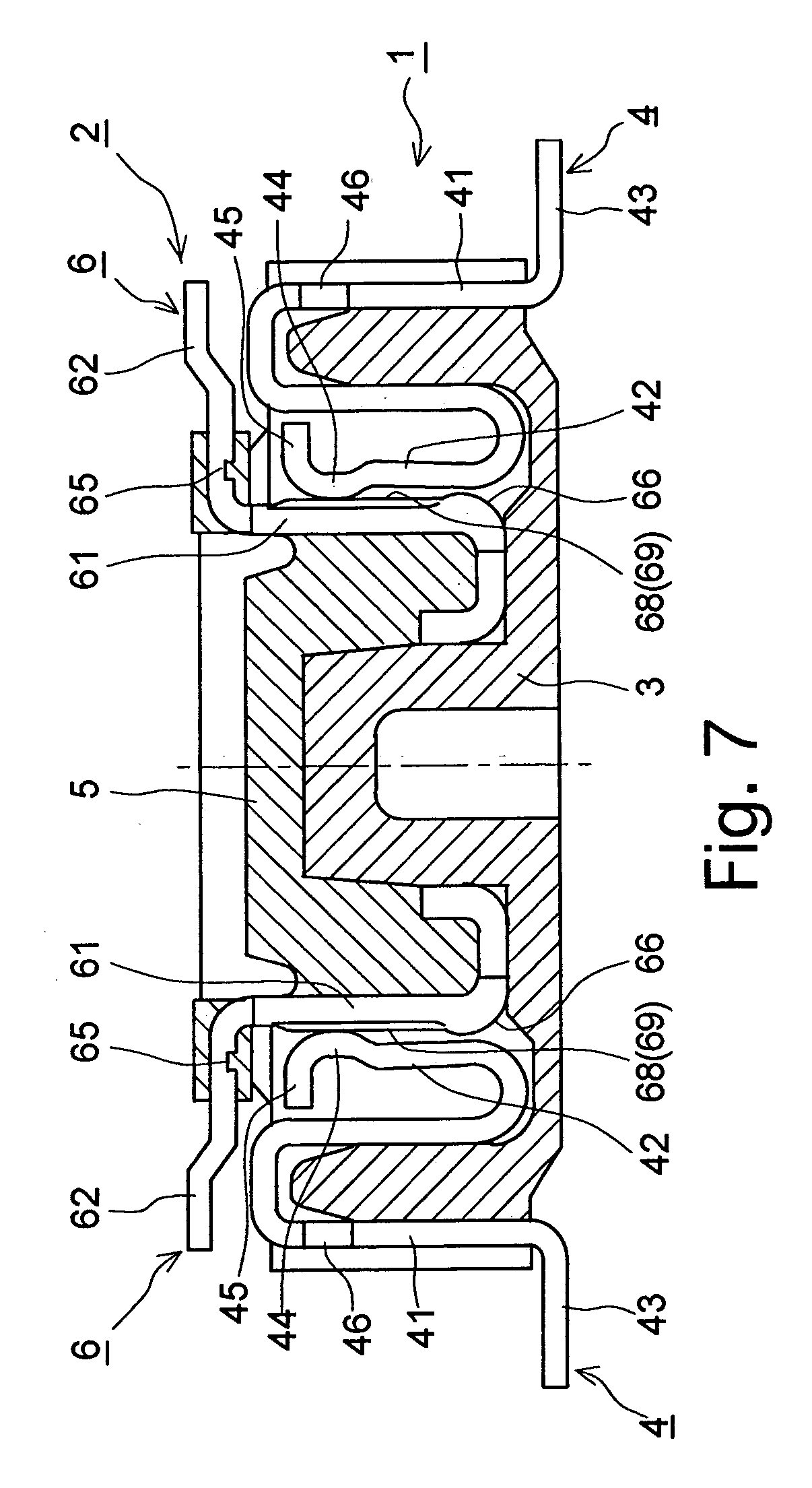

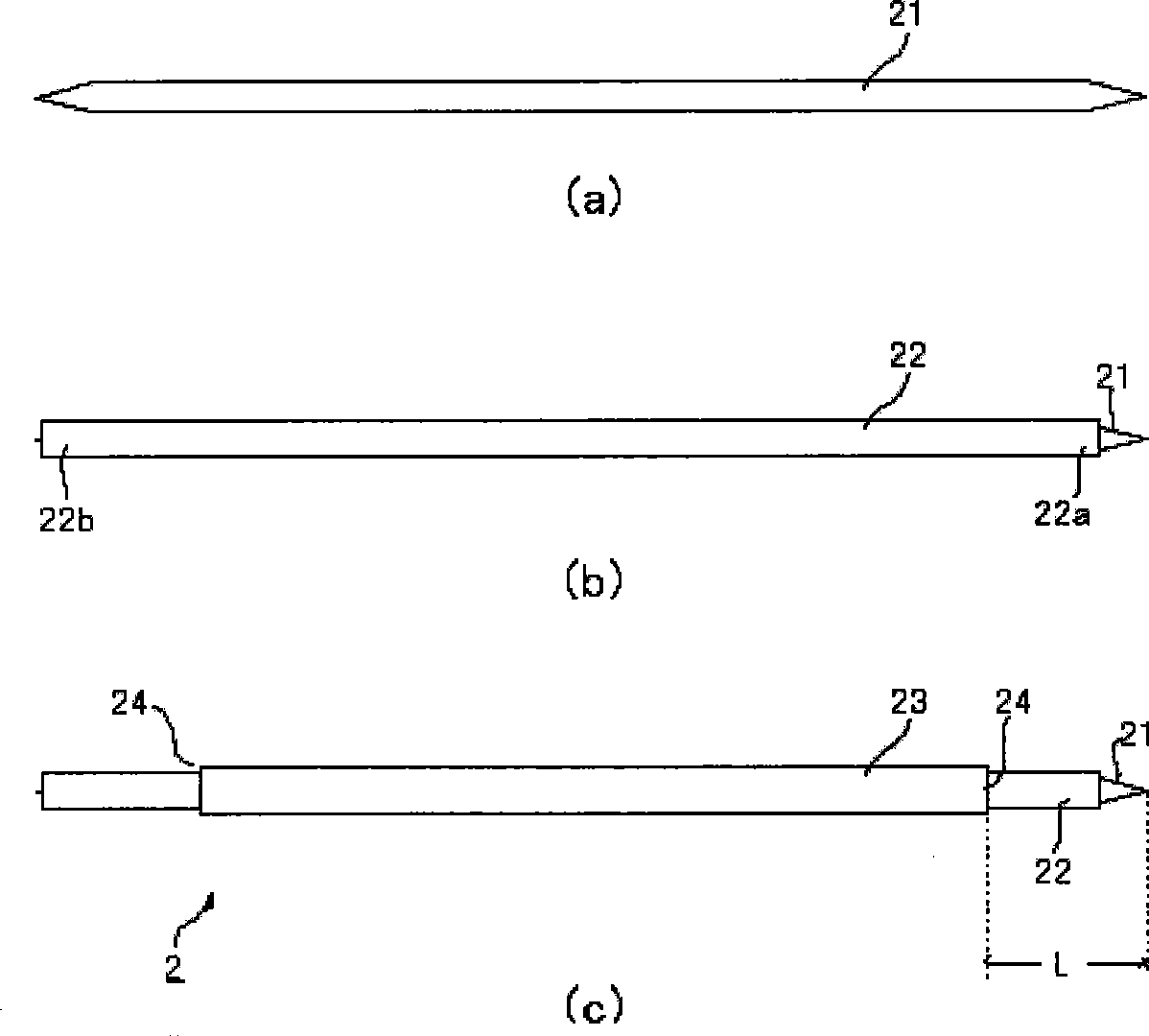

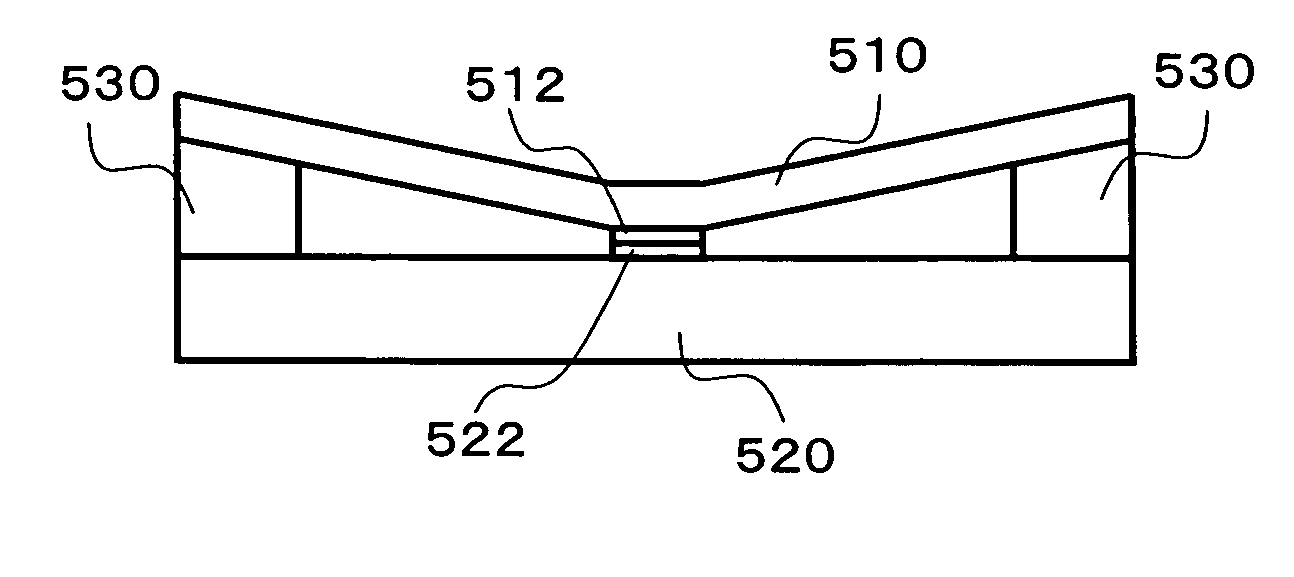

Connector, and portable terminal equipment including the connector

ActiveUS7195495B2Increase distanceEasy to disassembleElectric discharge tubesCoupling contact membersTerminal equipmentMechanical engineering

A connector includes a plug including a plug body made of an insulating material and at least one plug contact supported by the plug body; a receptacle including a receptacle body made of an insulating material and at least one receptacle contact supported by the receptacle body; a contact projecting portion formed on one of the plug contact and the receptacle contact; a contacting portion formed on the other of the plug contact and the receptacle contact; and a first projecting portion and at least one second projecting portion which is formed on the contacting portion, the second projecting portion being formed integral with the first projecting portion to be elongated in an insertion / extraction direction of the plug. A portion of the contact projecting portion is formed as a flat surface having a width greater than a width of the second projecting portion.

Owner:KYOCERA CORP

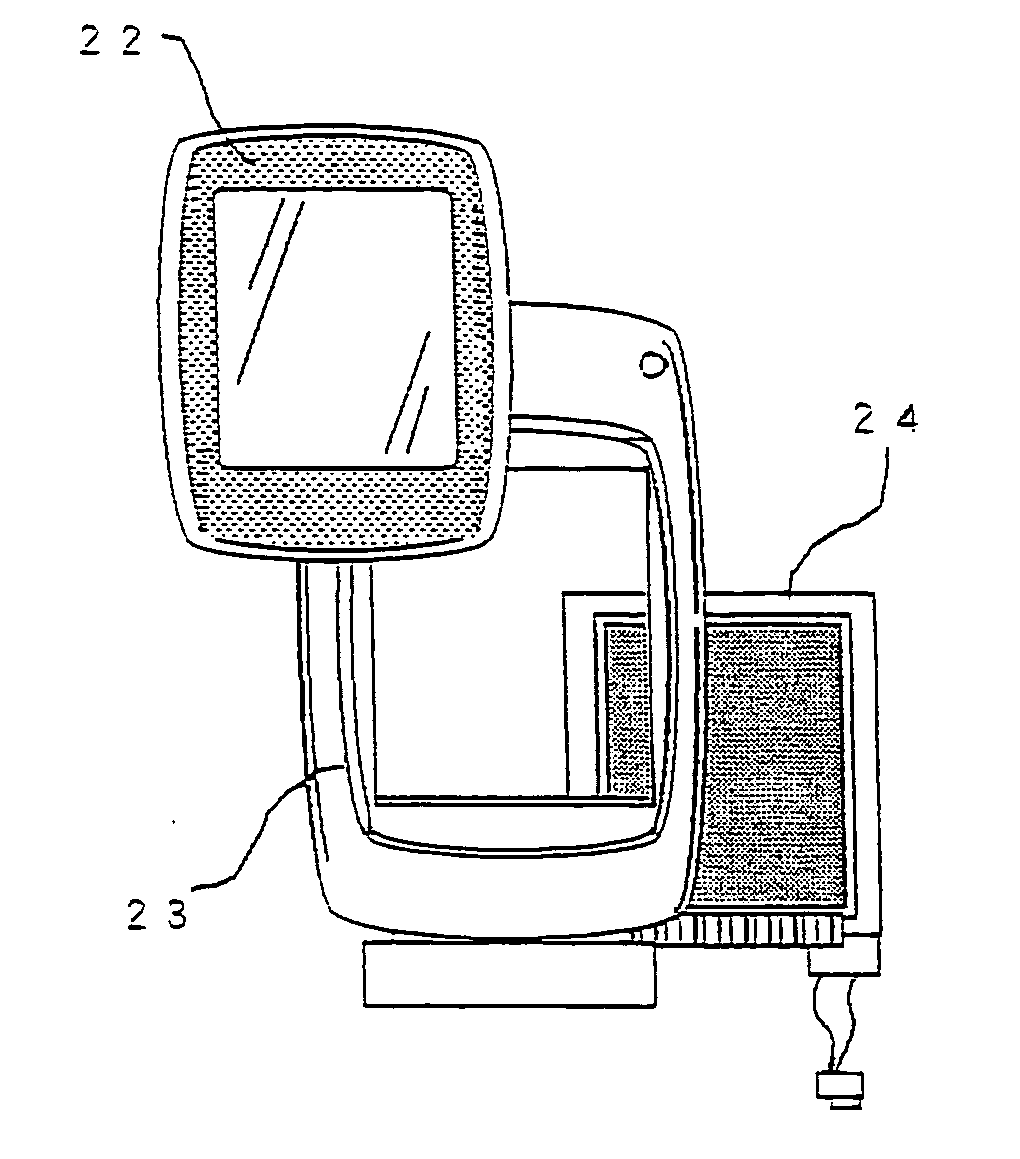

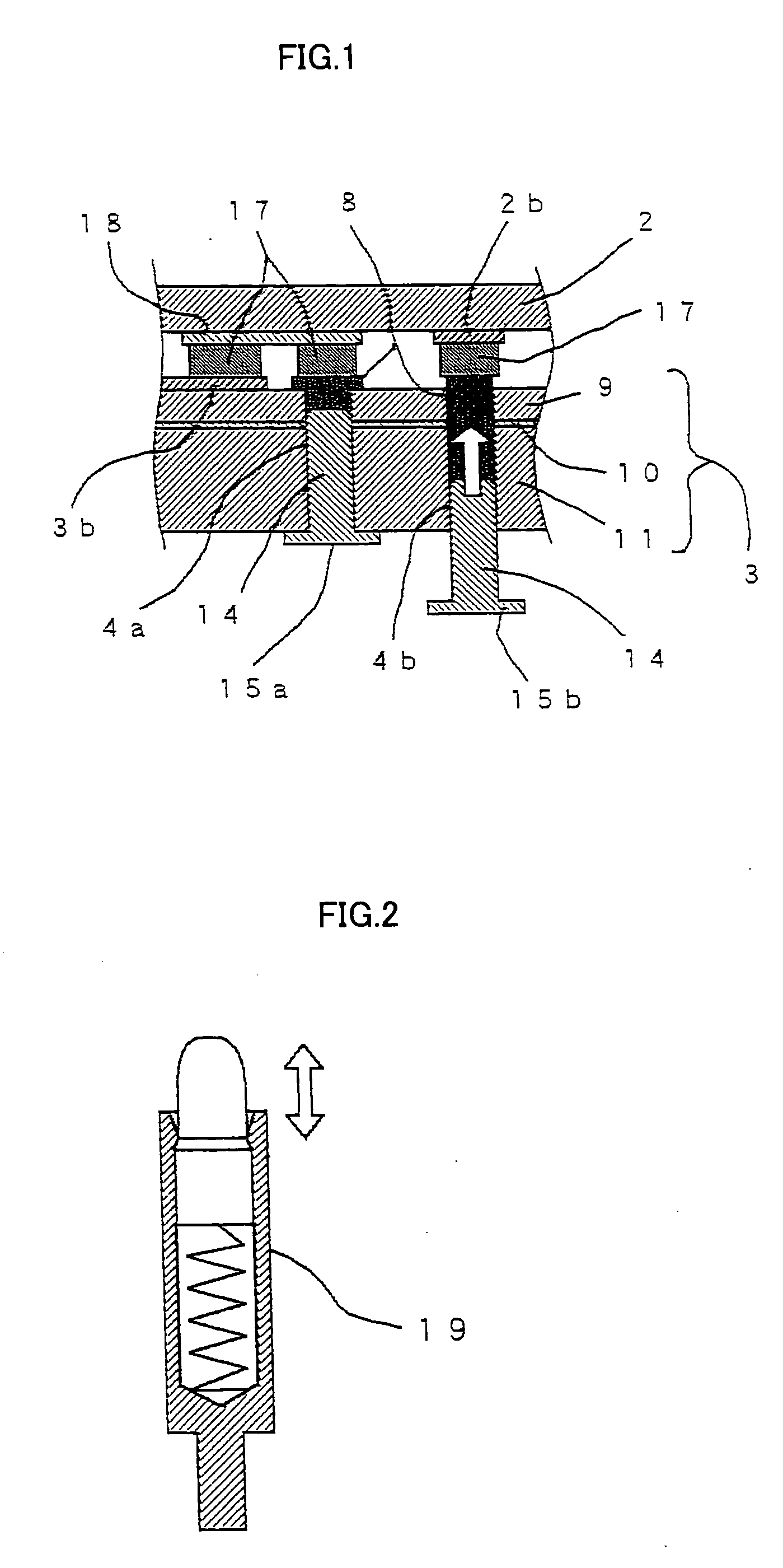

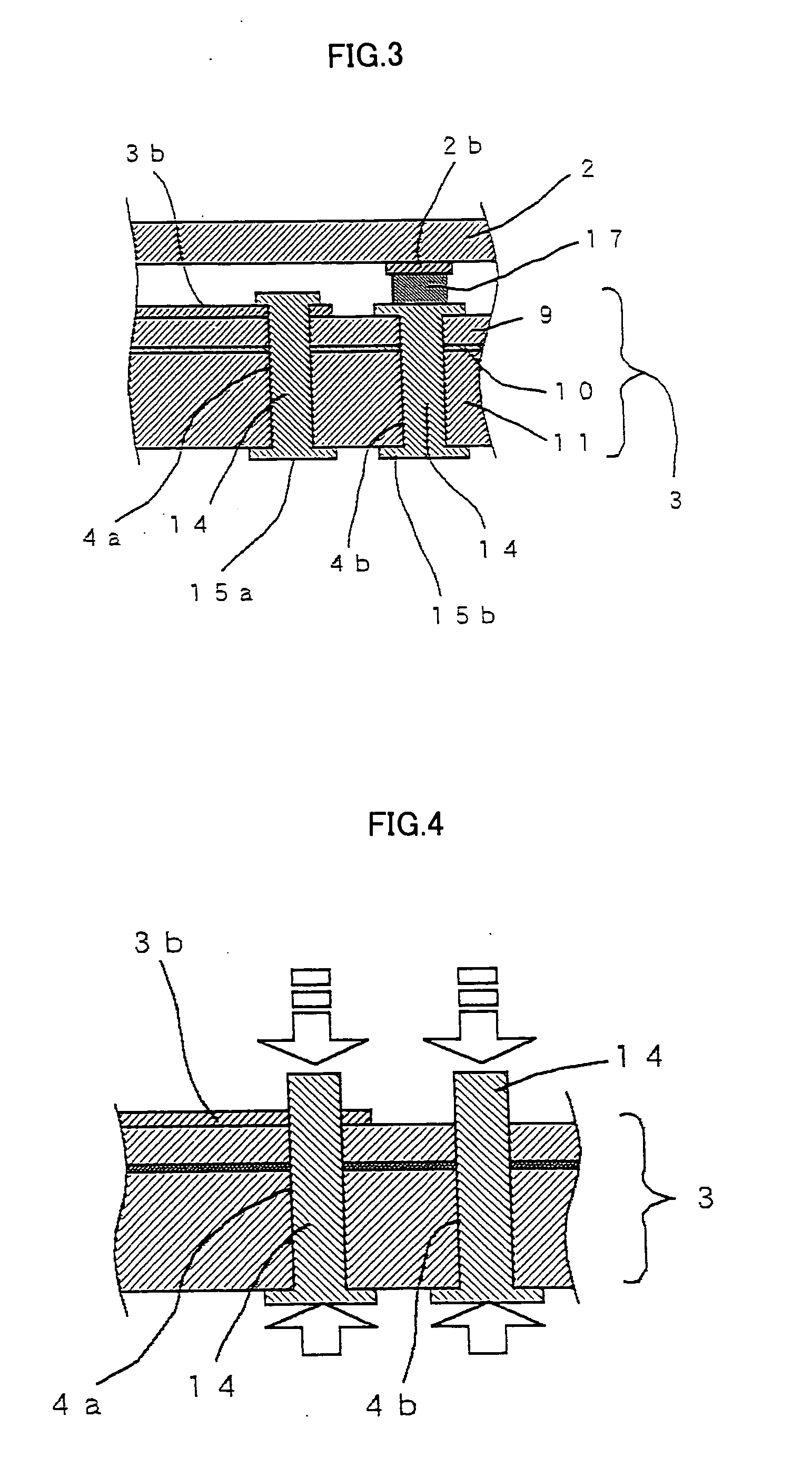

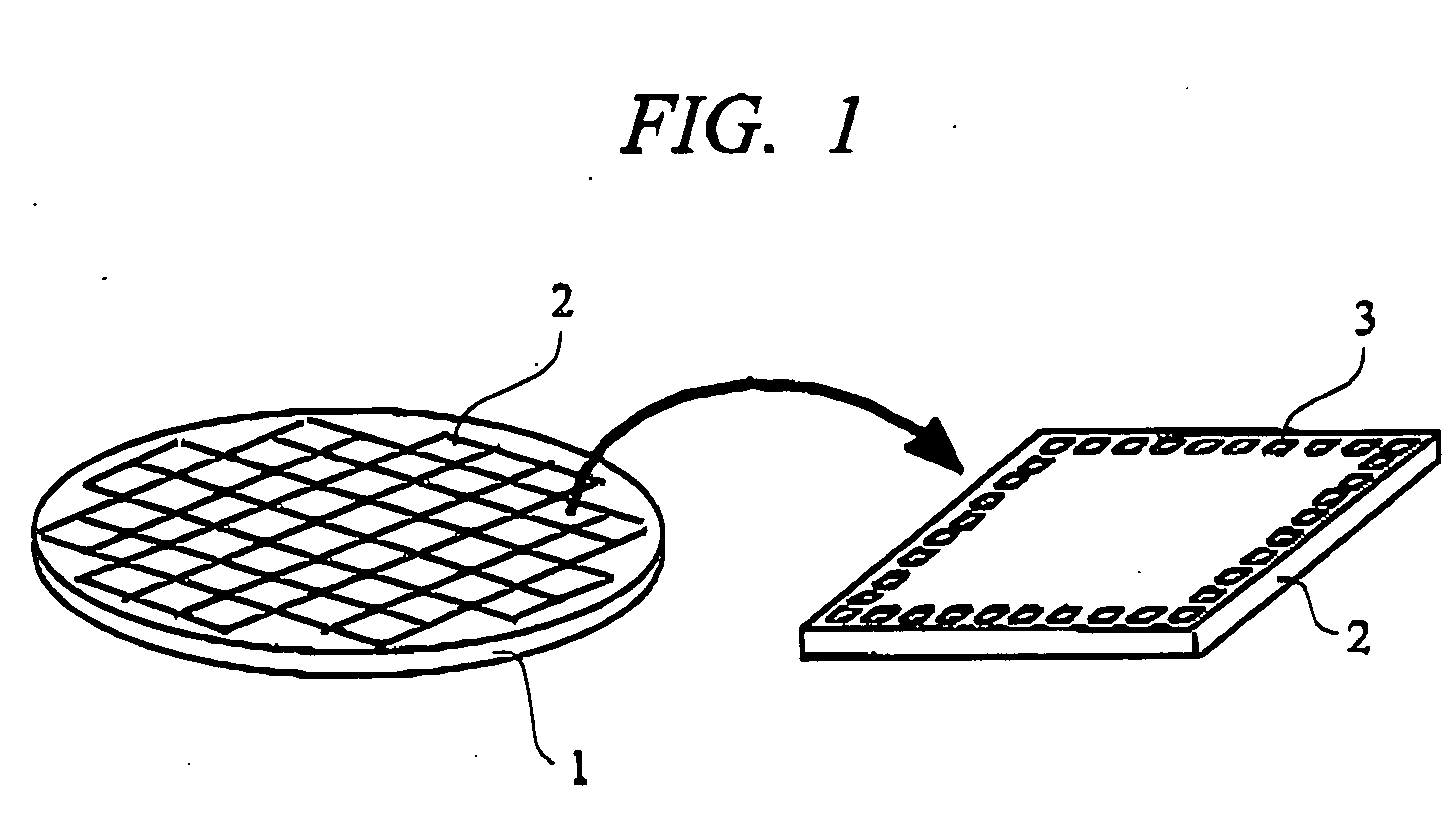

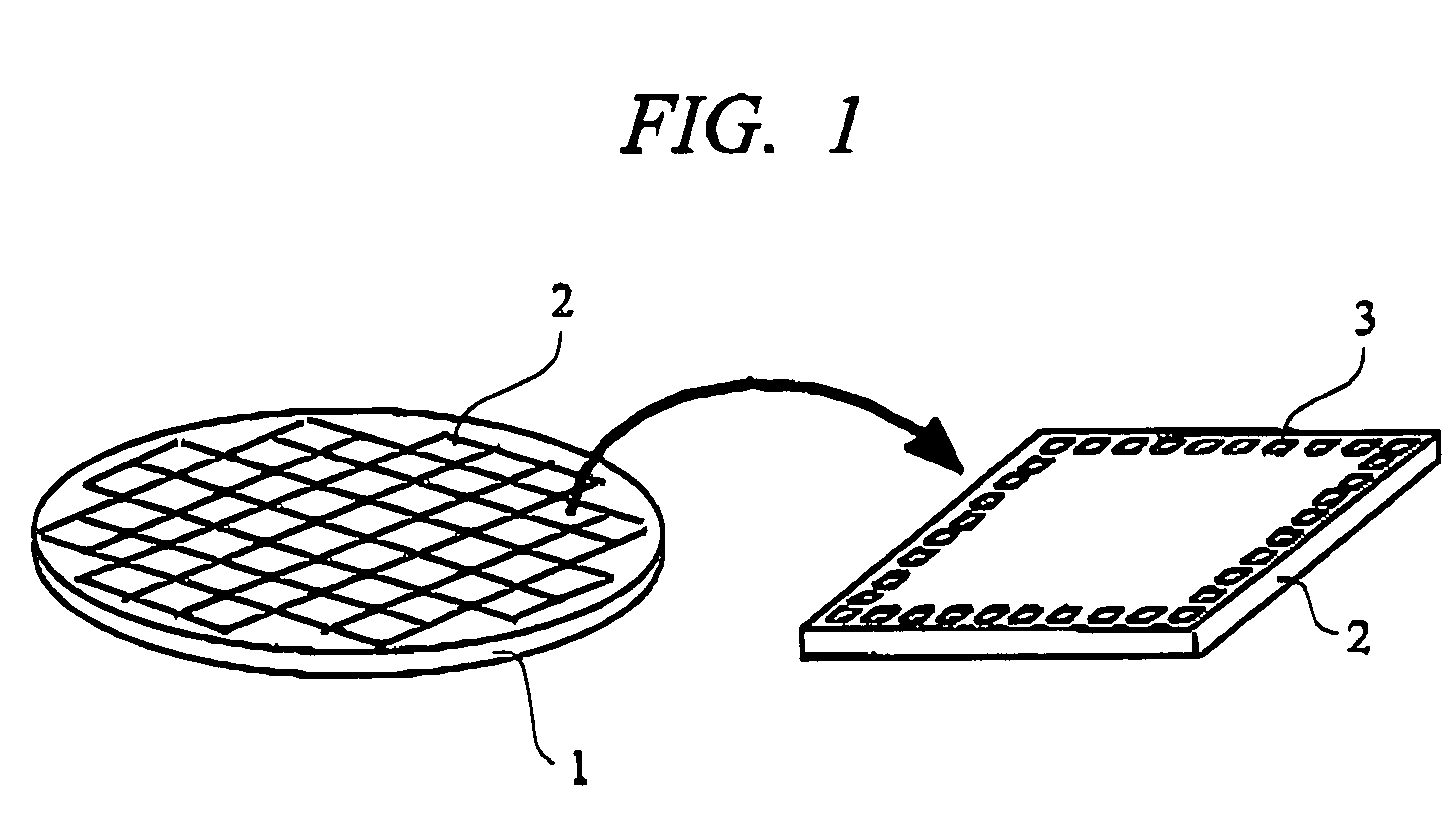

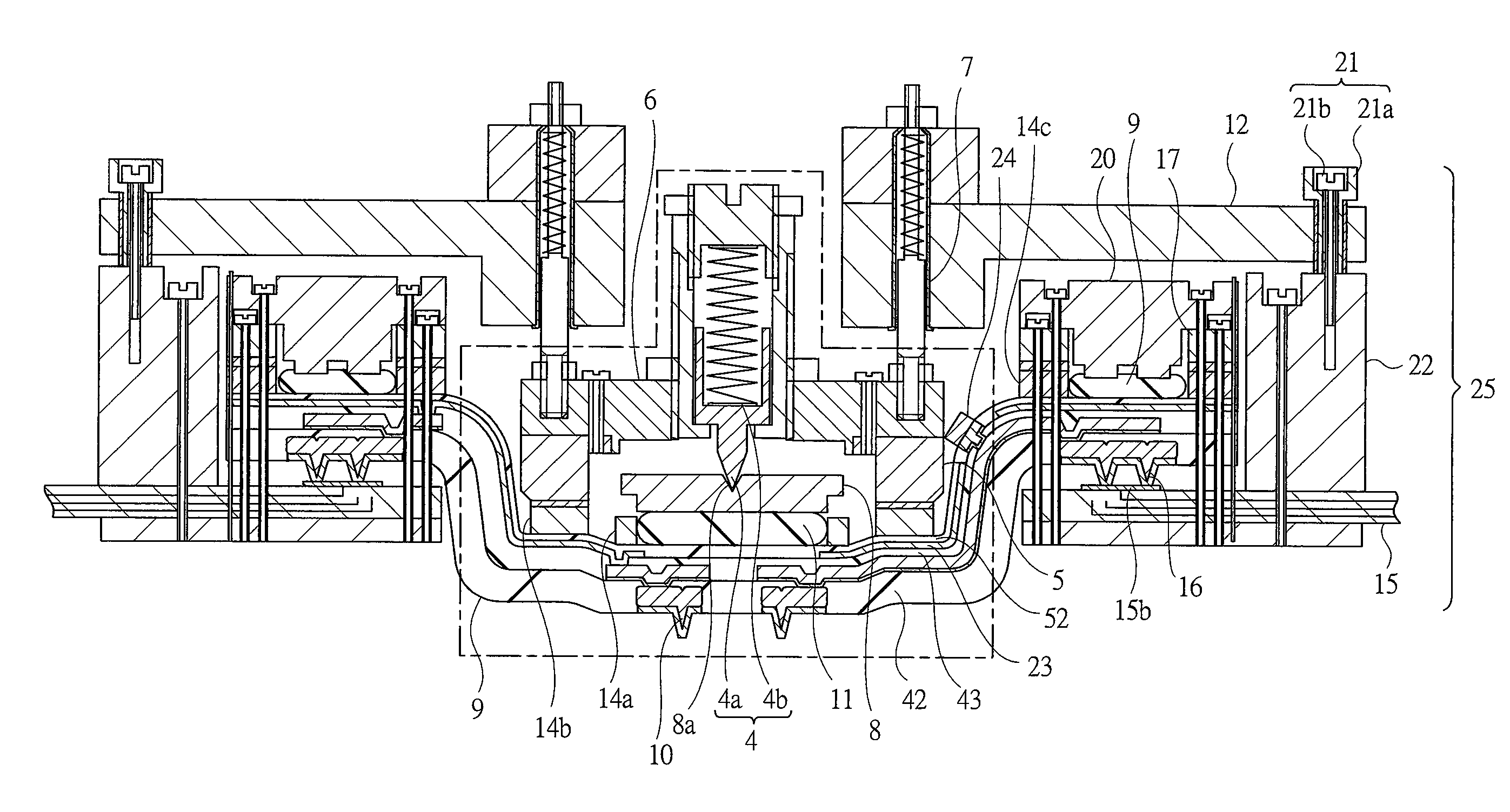

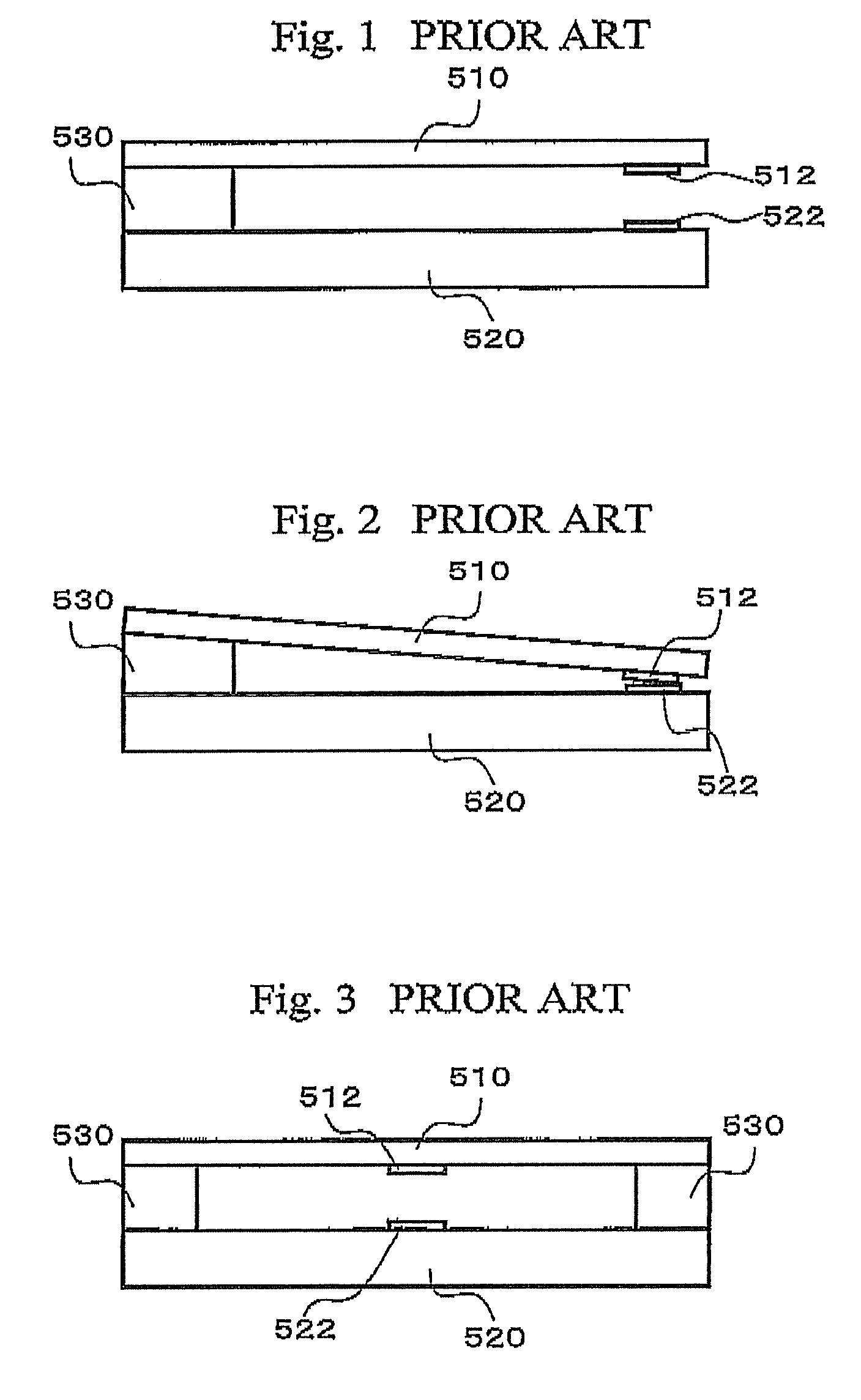

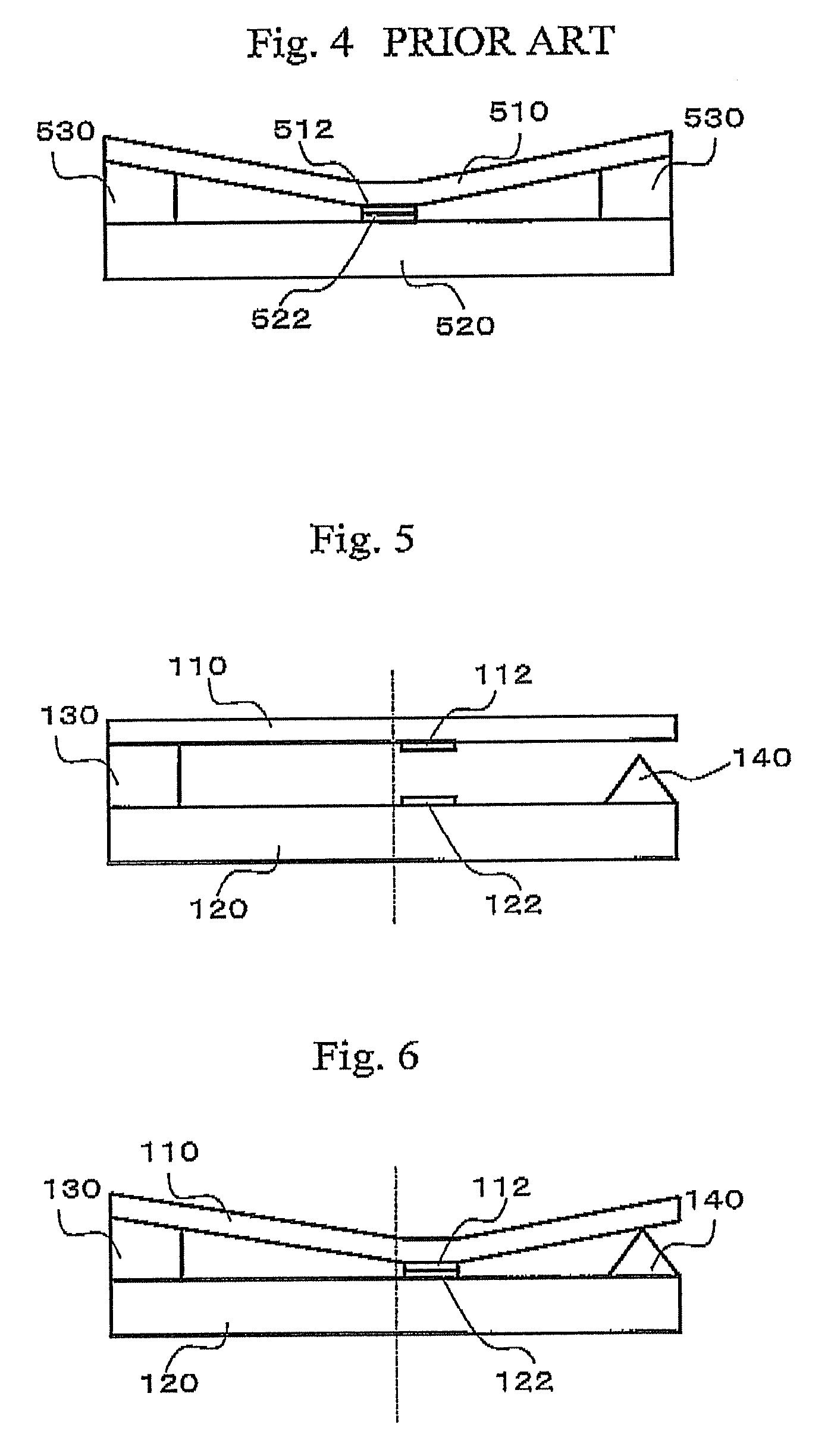

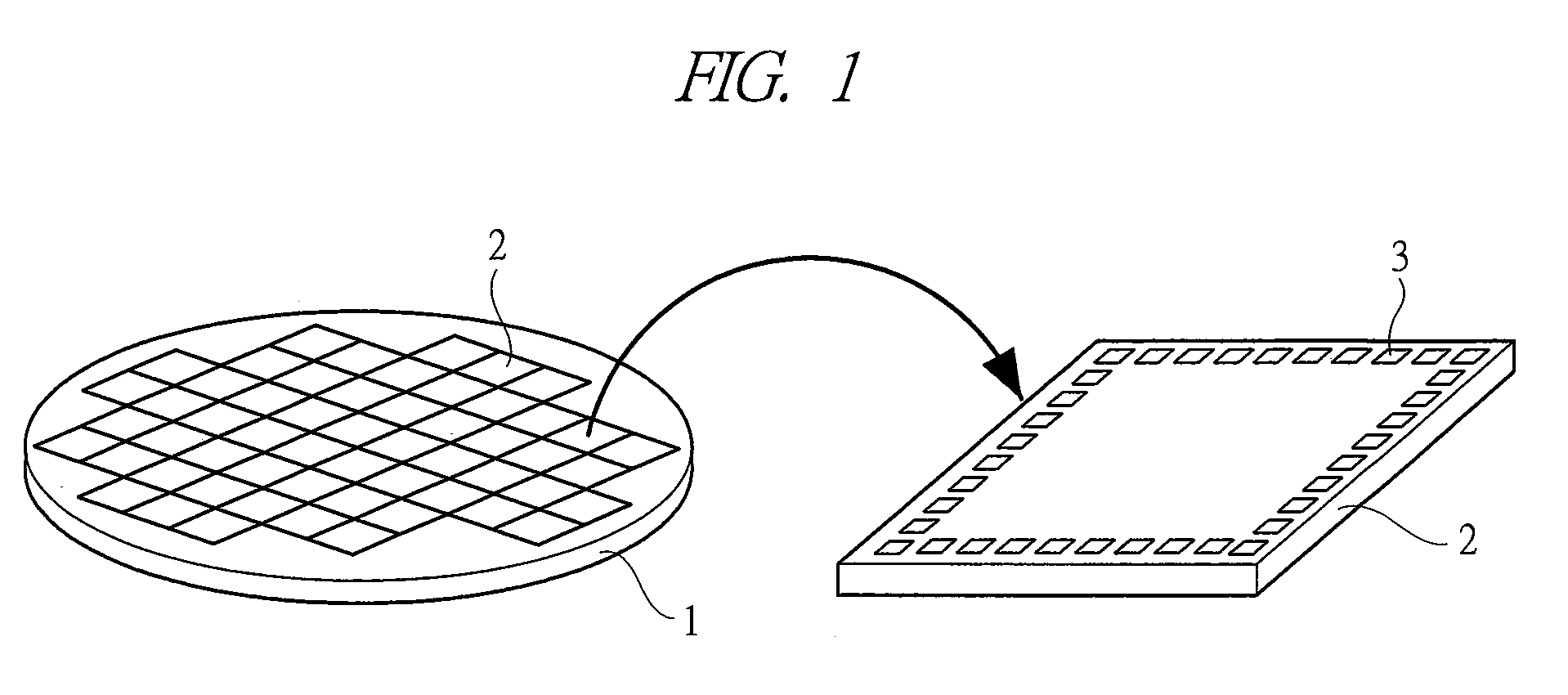

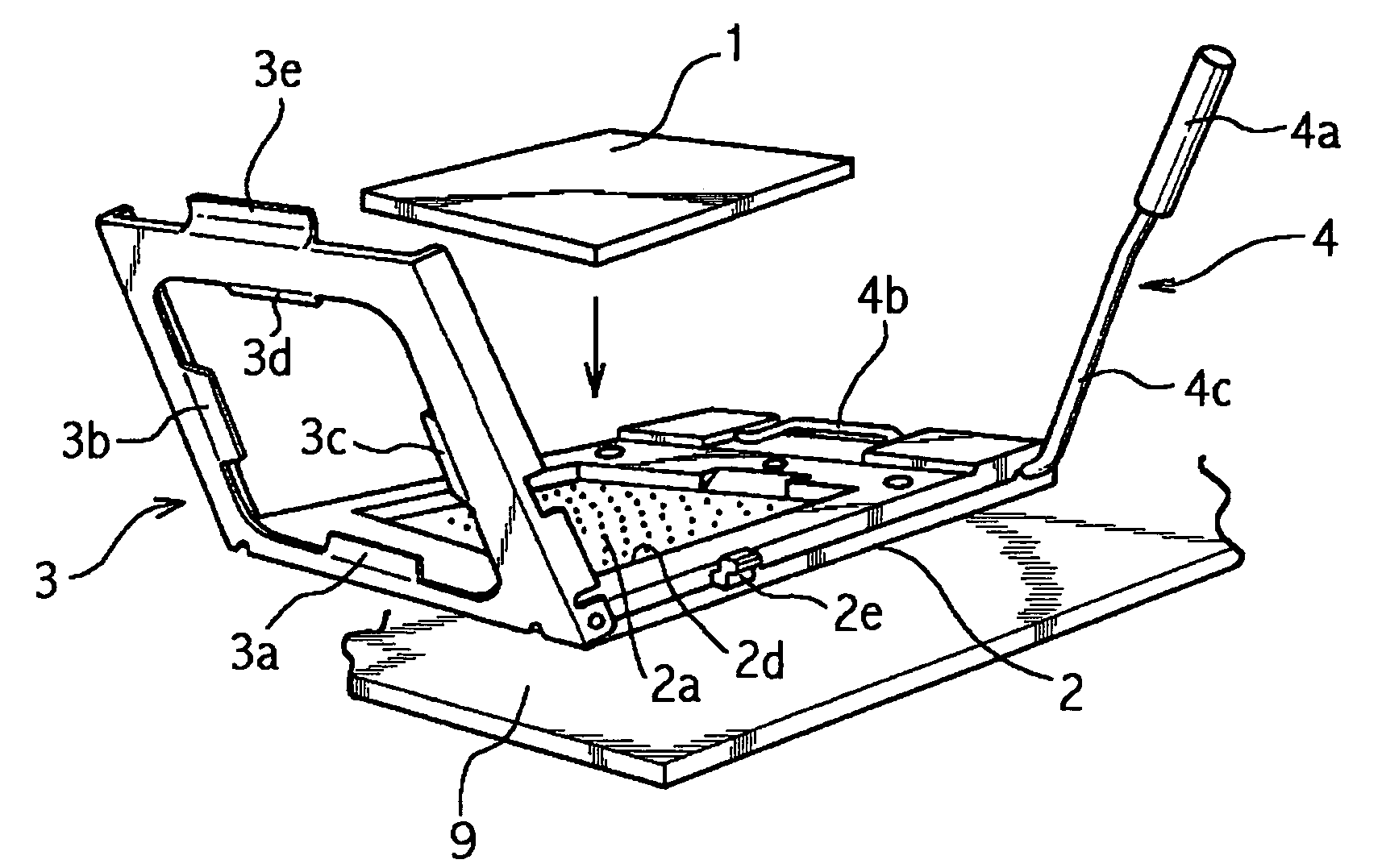

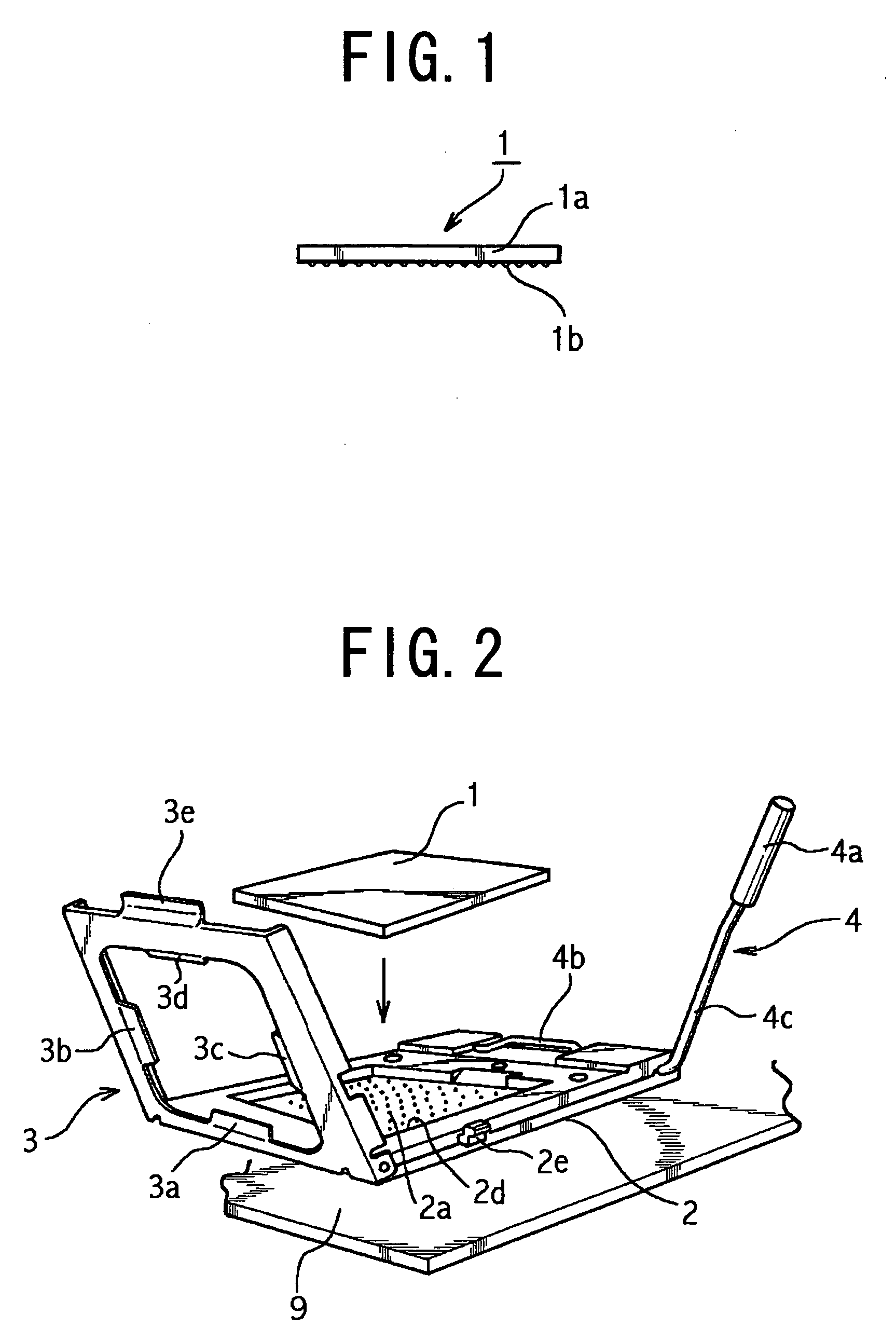

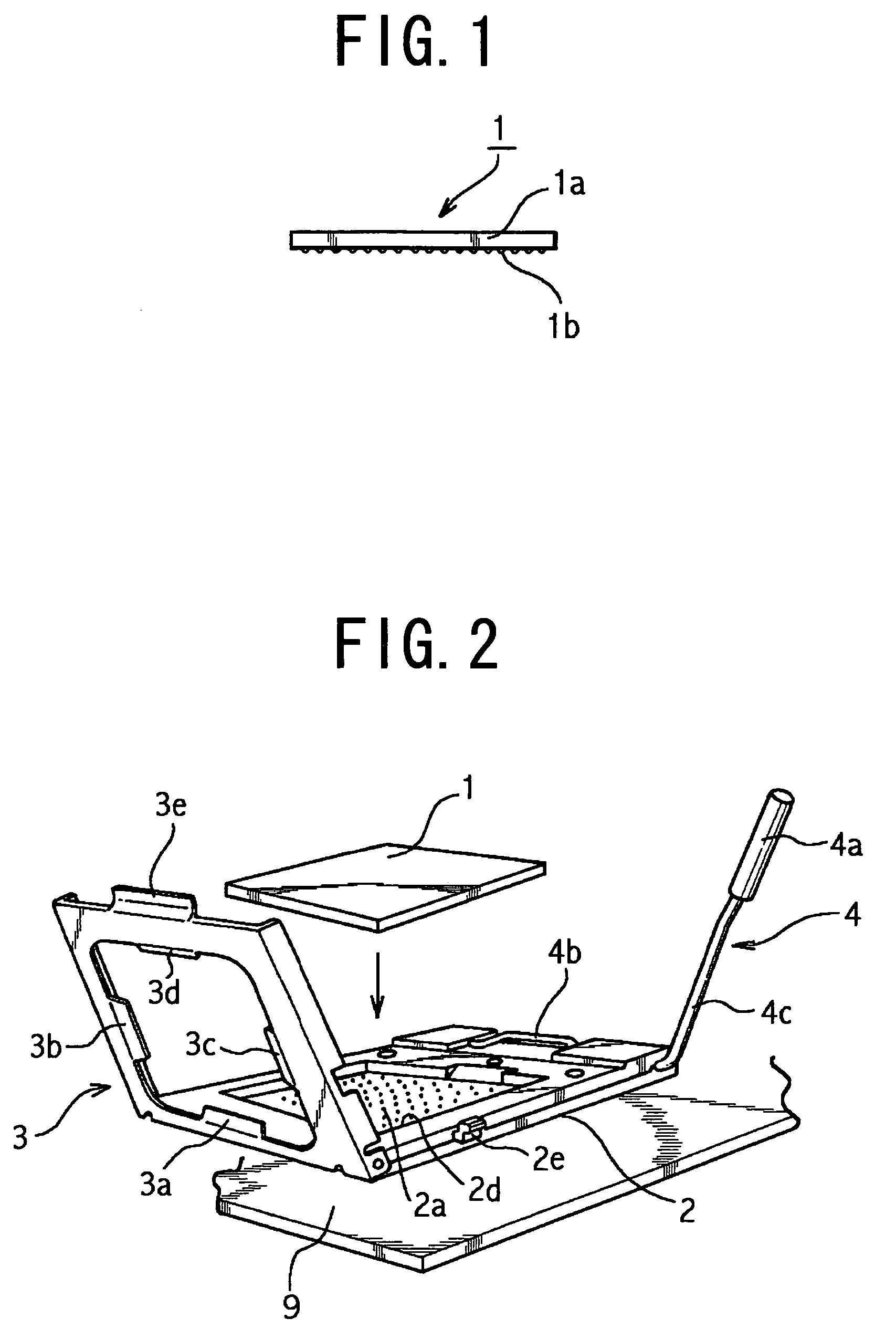

Touch Panel And Protective Panel For Display Window Of Electronic Device Using The Same

InactiveUS20070218957A1Firmly connectedEasy to carryPrinted circuit aspectsSubstation equipmentConductive pasteEngineering

There is provided a touch panel capable of obtaining a stable connection resistance without requiring fitting accuracy at the time of the connection to an external terminal, and a protective panel for a display window of an electronic device using the same. The analog type touch panel includes a touch side substrate 2 and a non-touch side substrate 3 each having resistive films 2a, 3a provided on opposed inner surfaces thereof. Through-holes 4a, 4b, 4c, 4d formed at the periphery of the non-touch side substrate 3. A connecting part 5 for electrically connecting electrodes of the resistive films 2a, 3a to an external terminal, in which a conductive paste is injected into the through-holes and a rivet 14 is inserted into each of the through-holes from the lower surface side so that a head of the rivet 14 forms flat connecting electrodes 15a, 15b for connection to the external terminal on the lower surface of the non-touch side substrate 3.

Owner:NISSHA PRINTING COMPANY

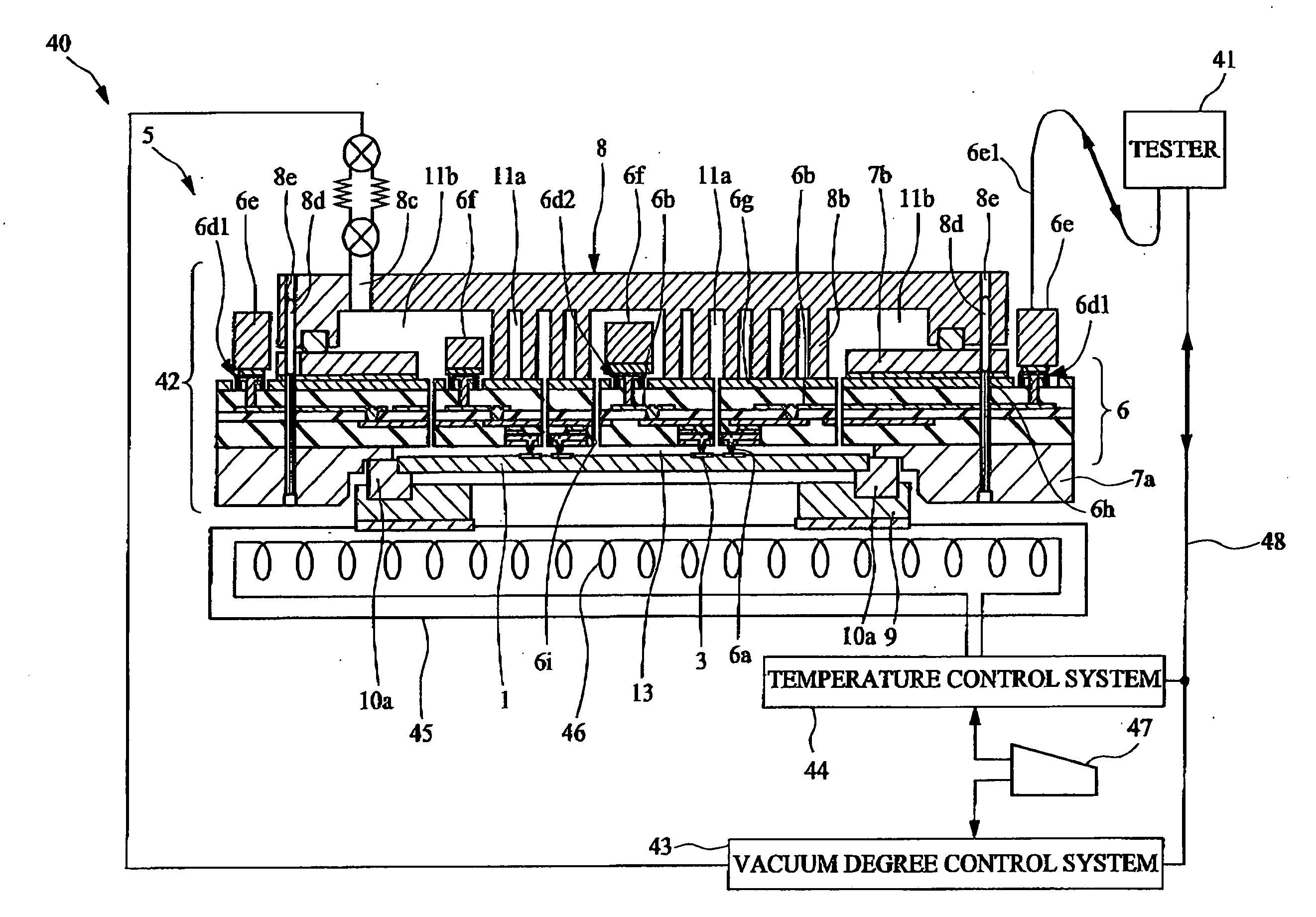

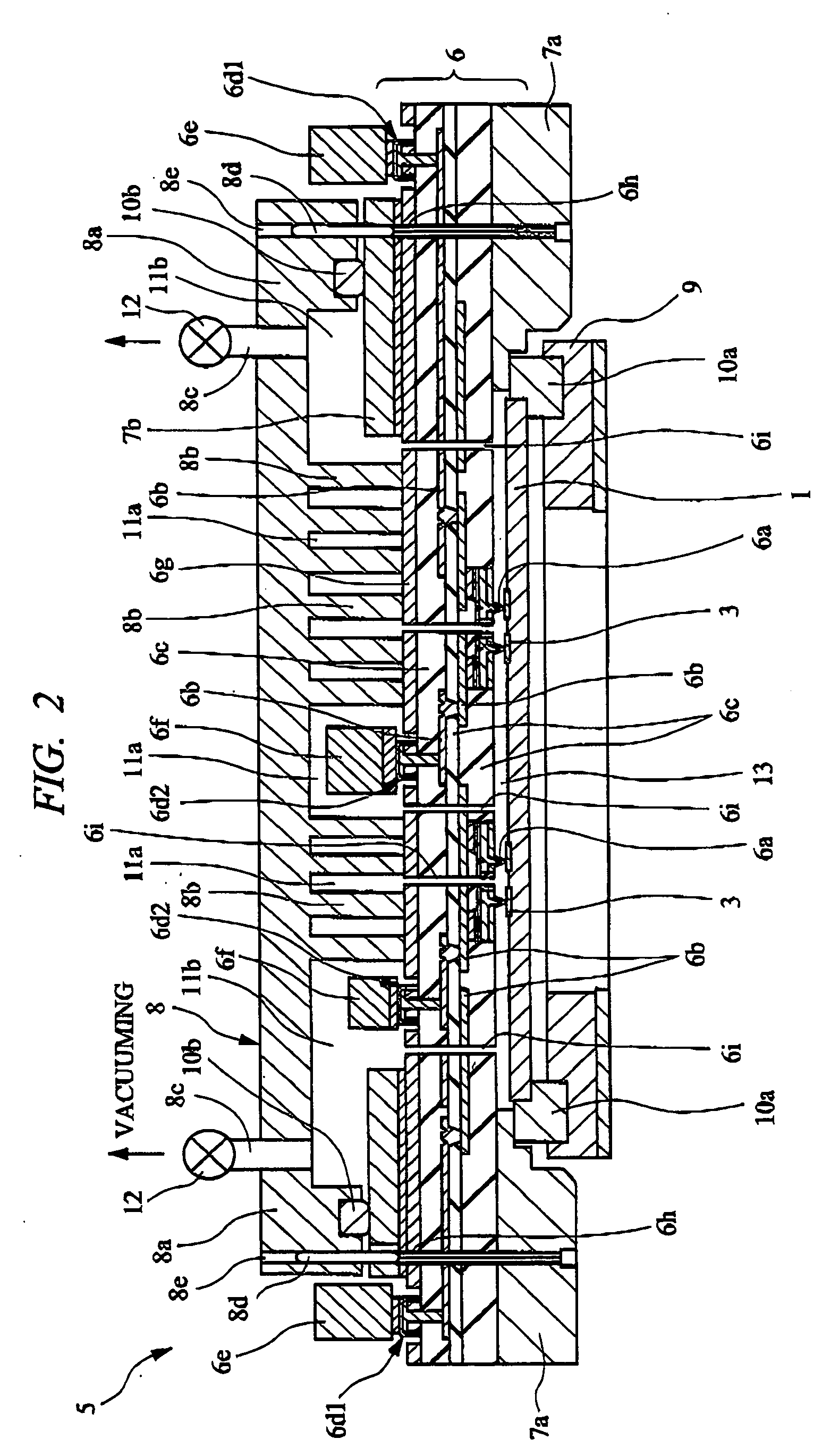

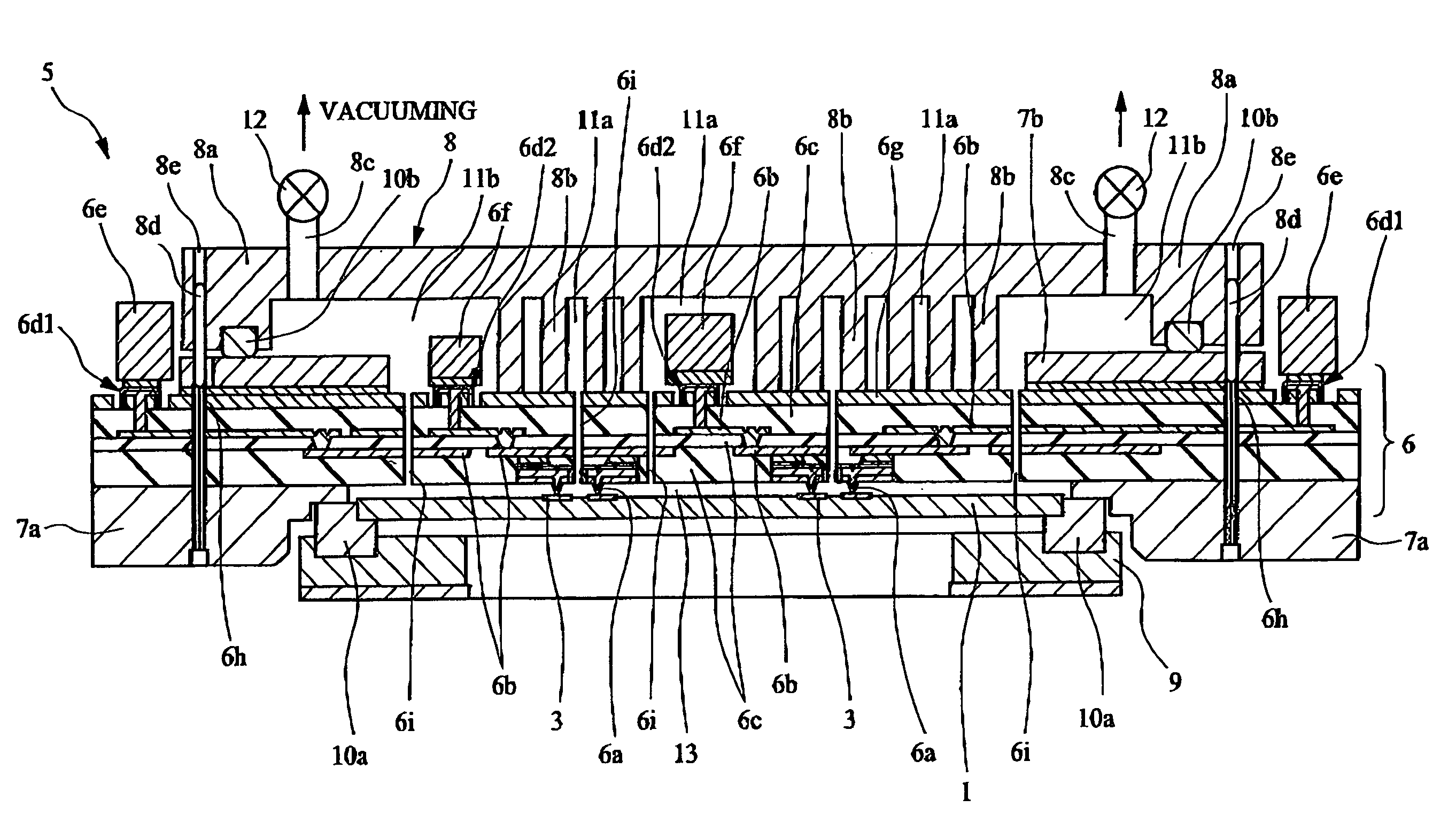

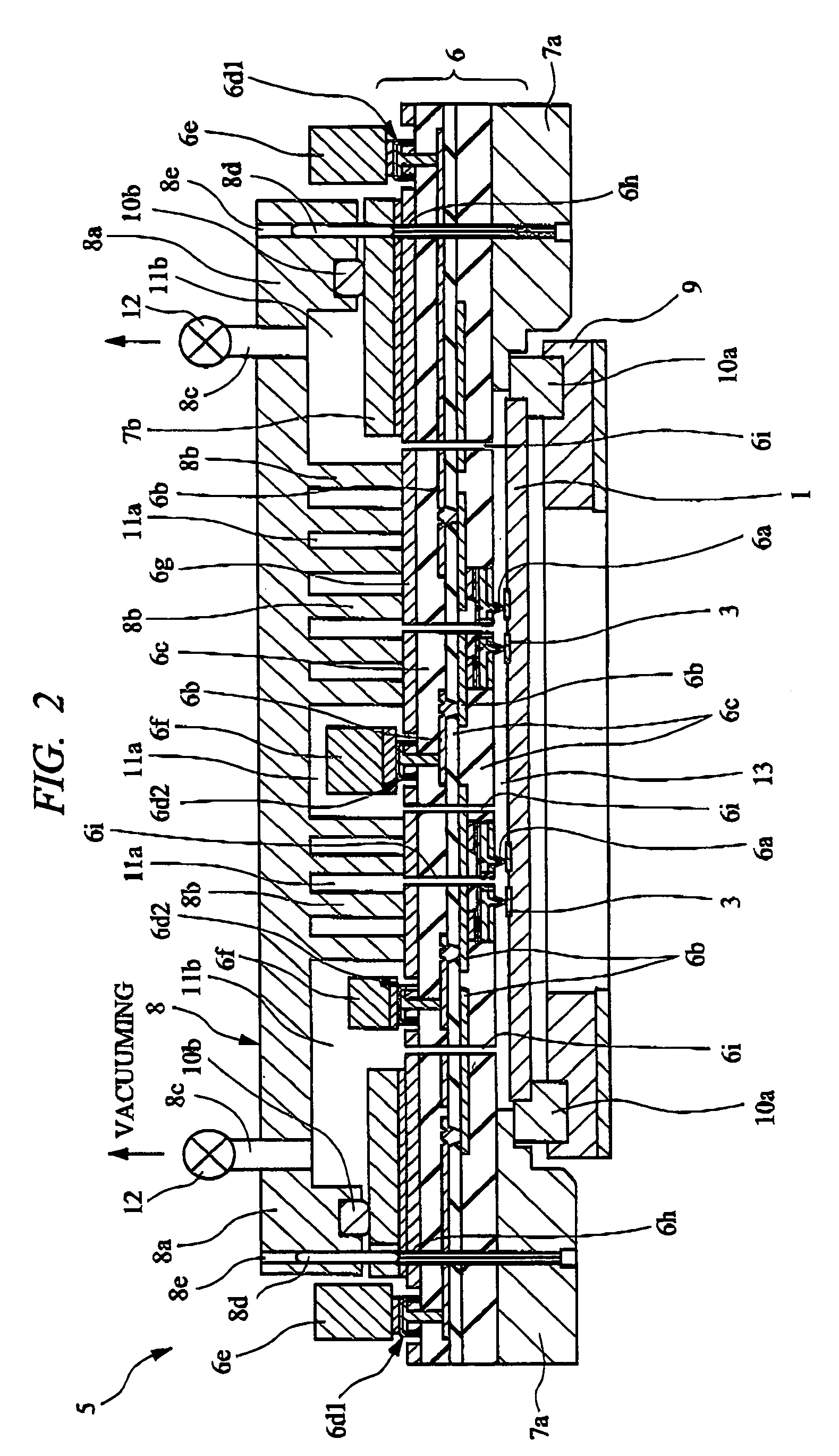

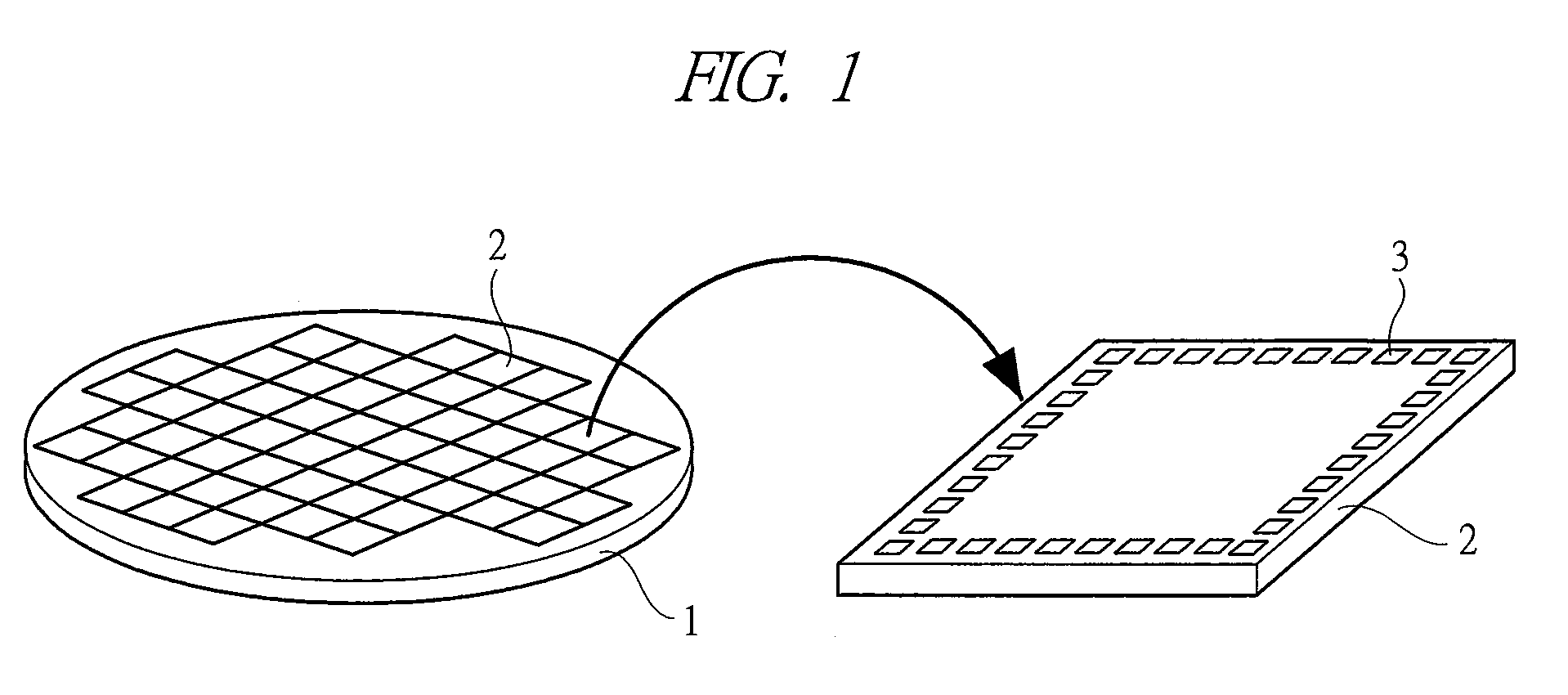

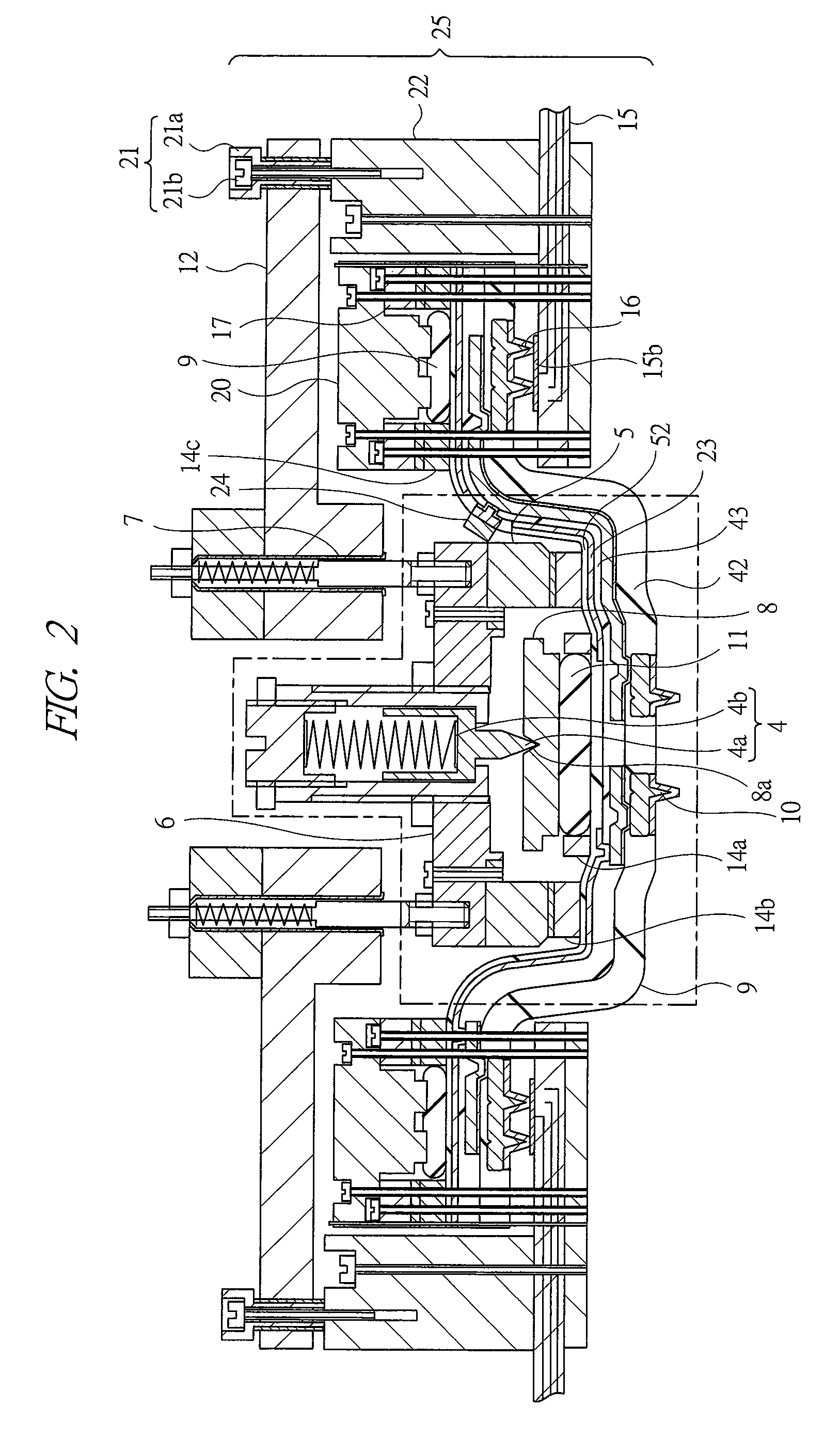

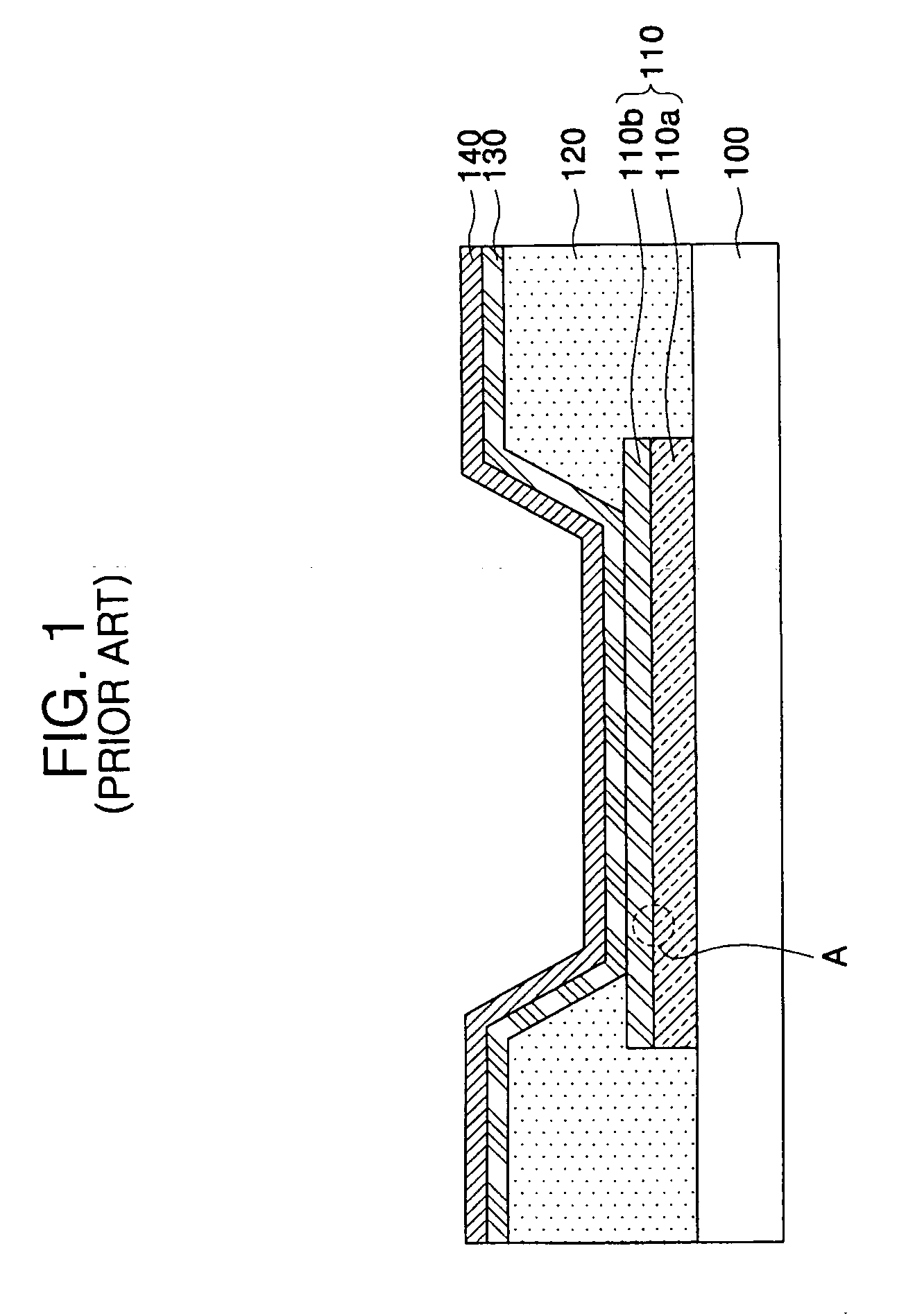

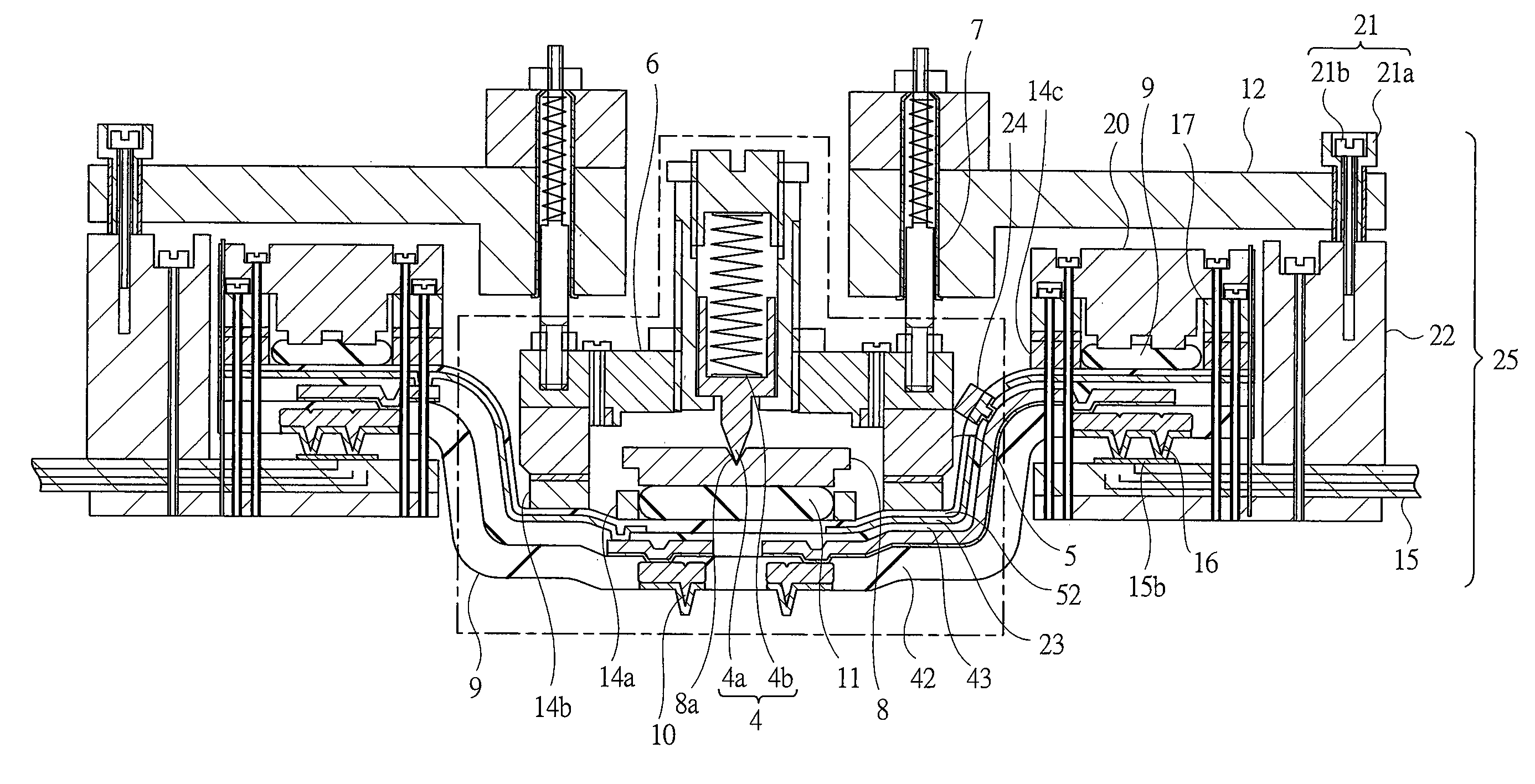

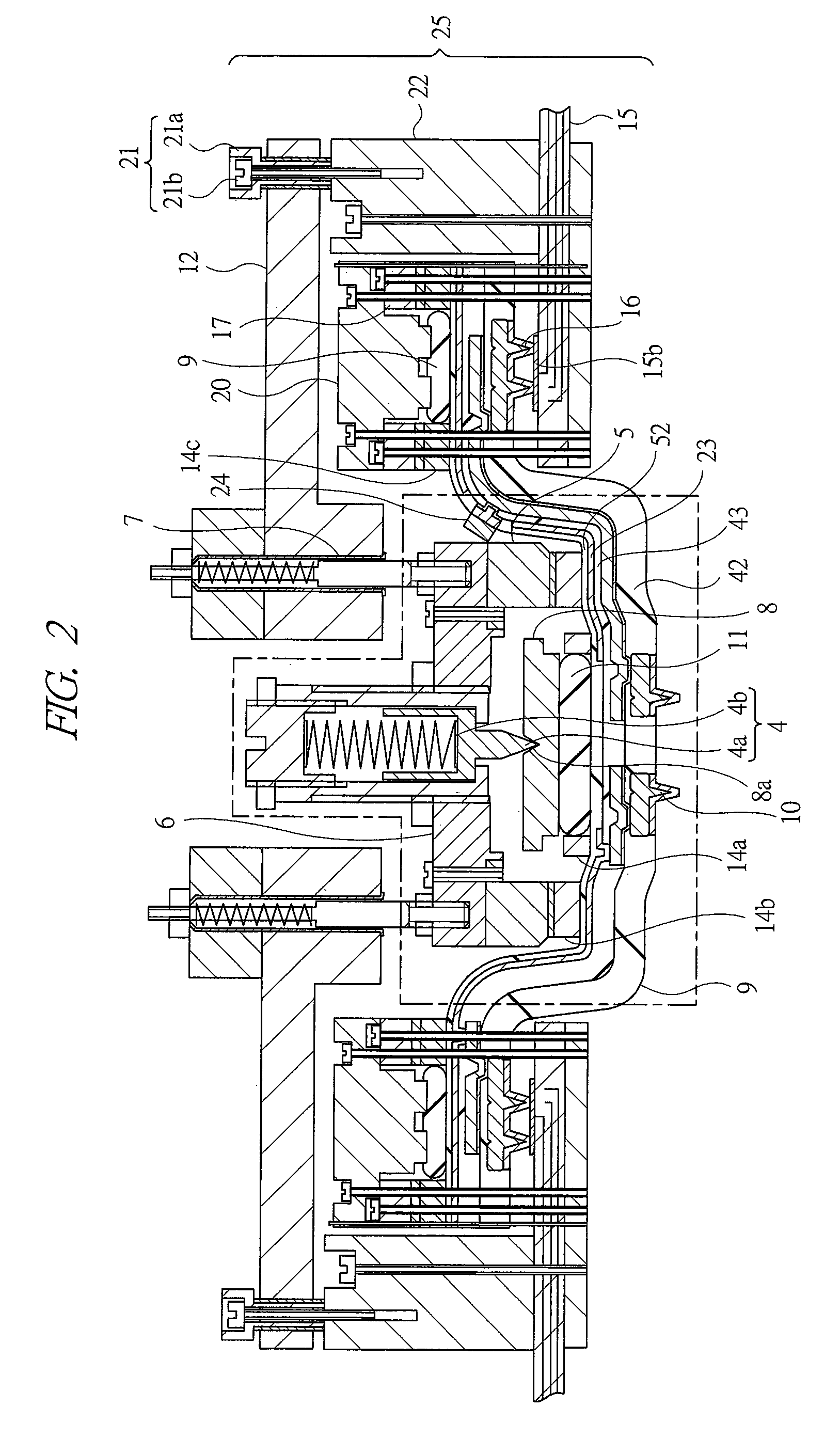

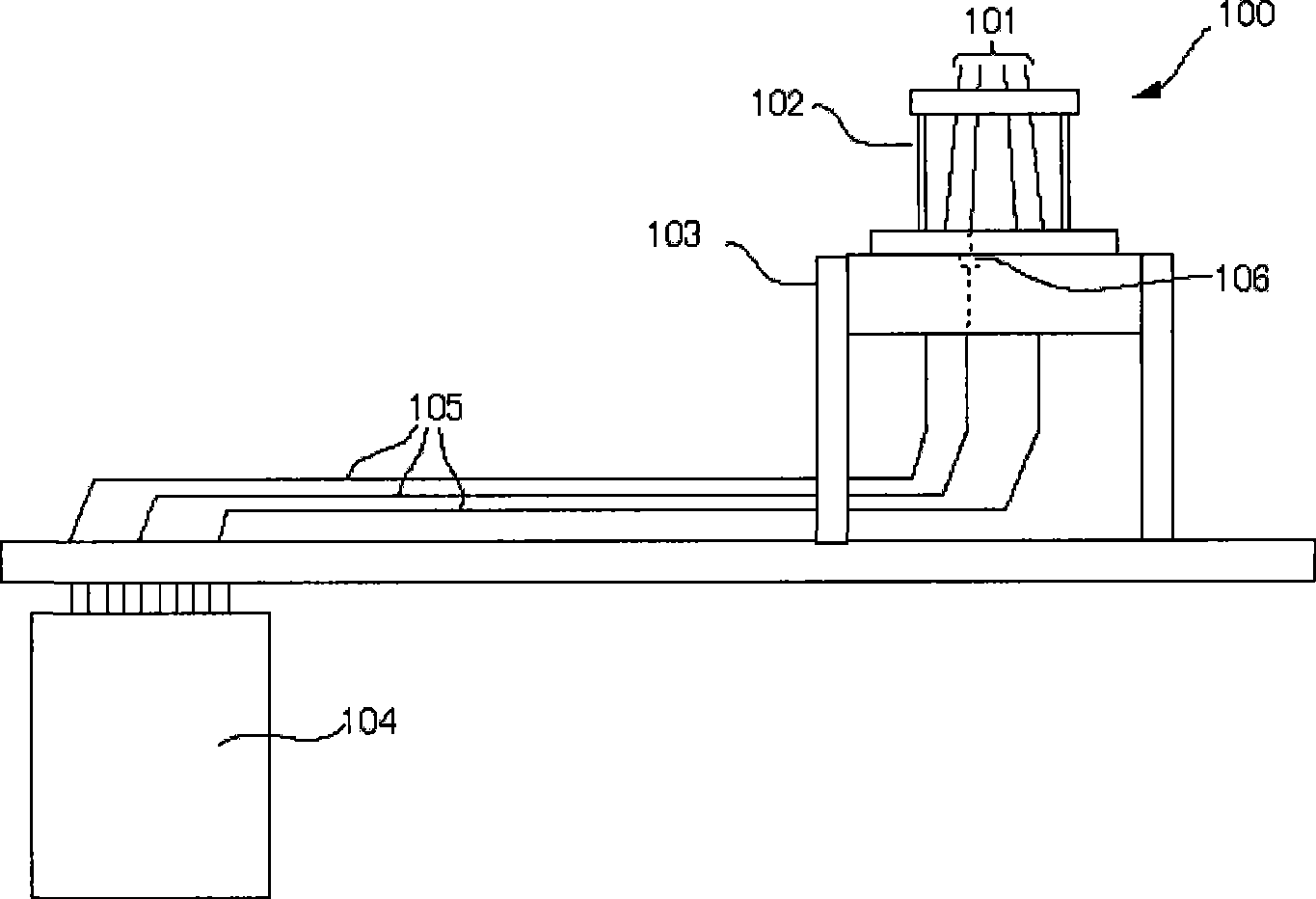

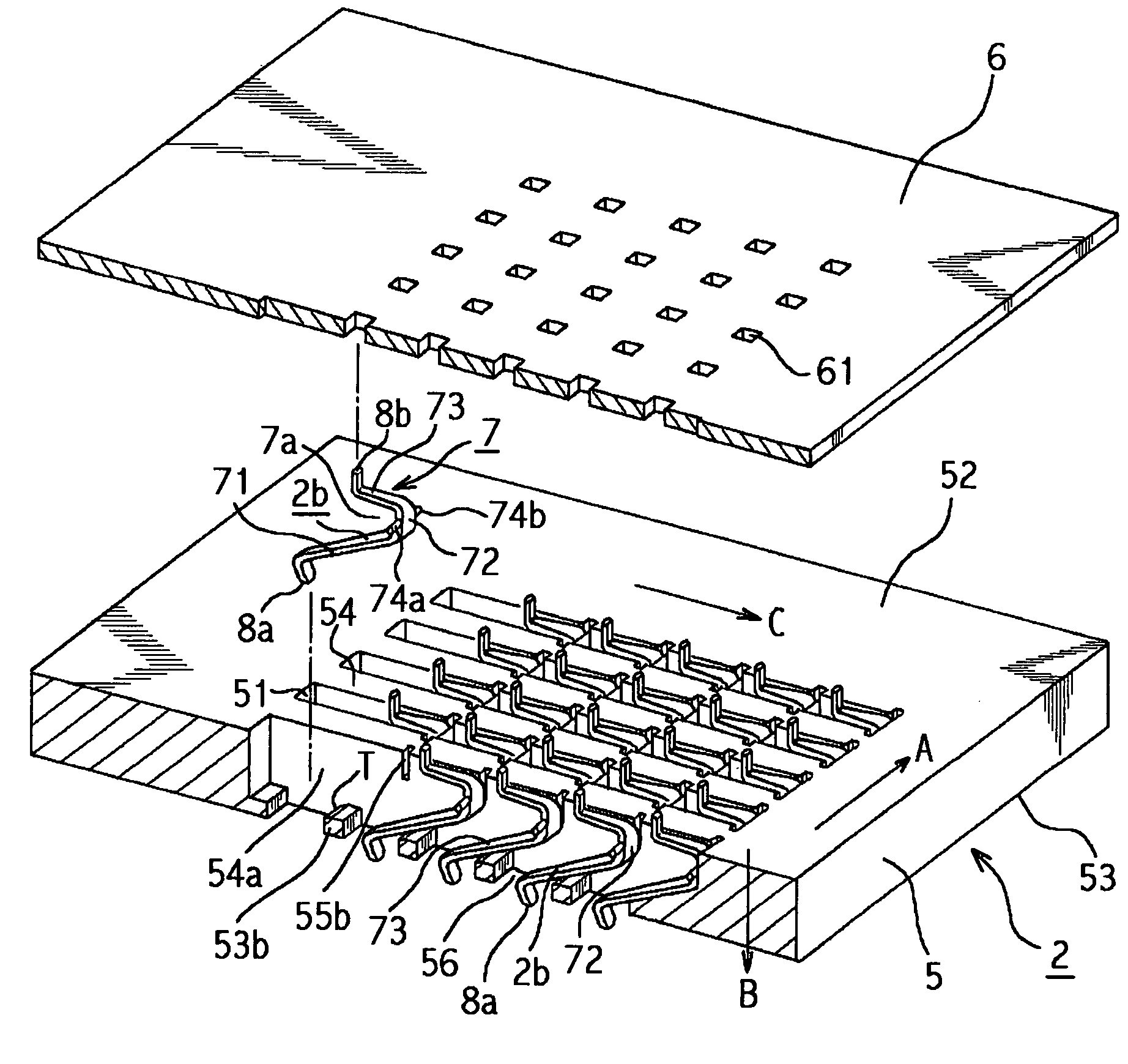

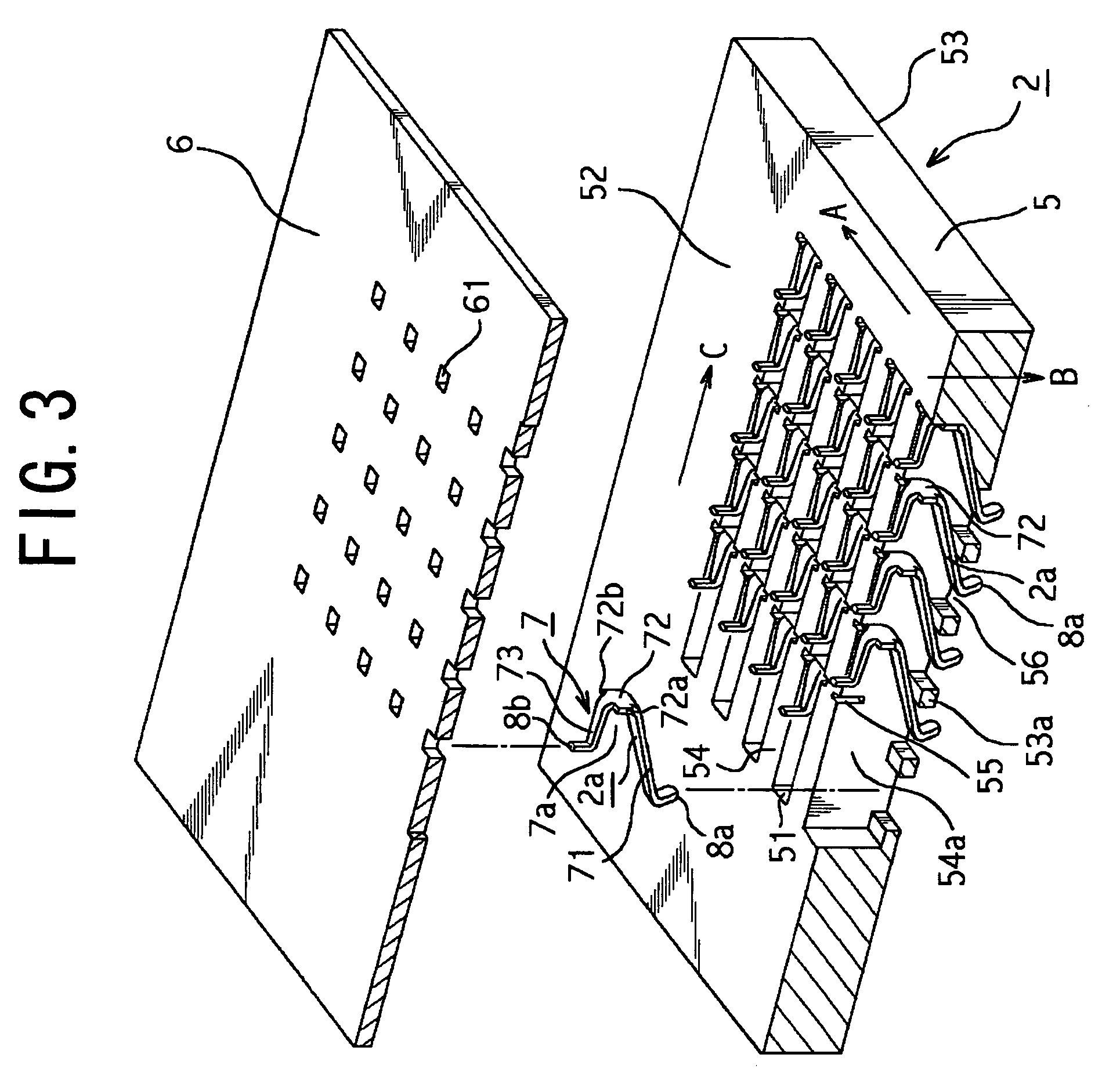

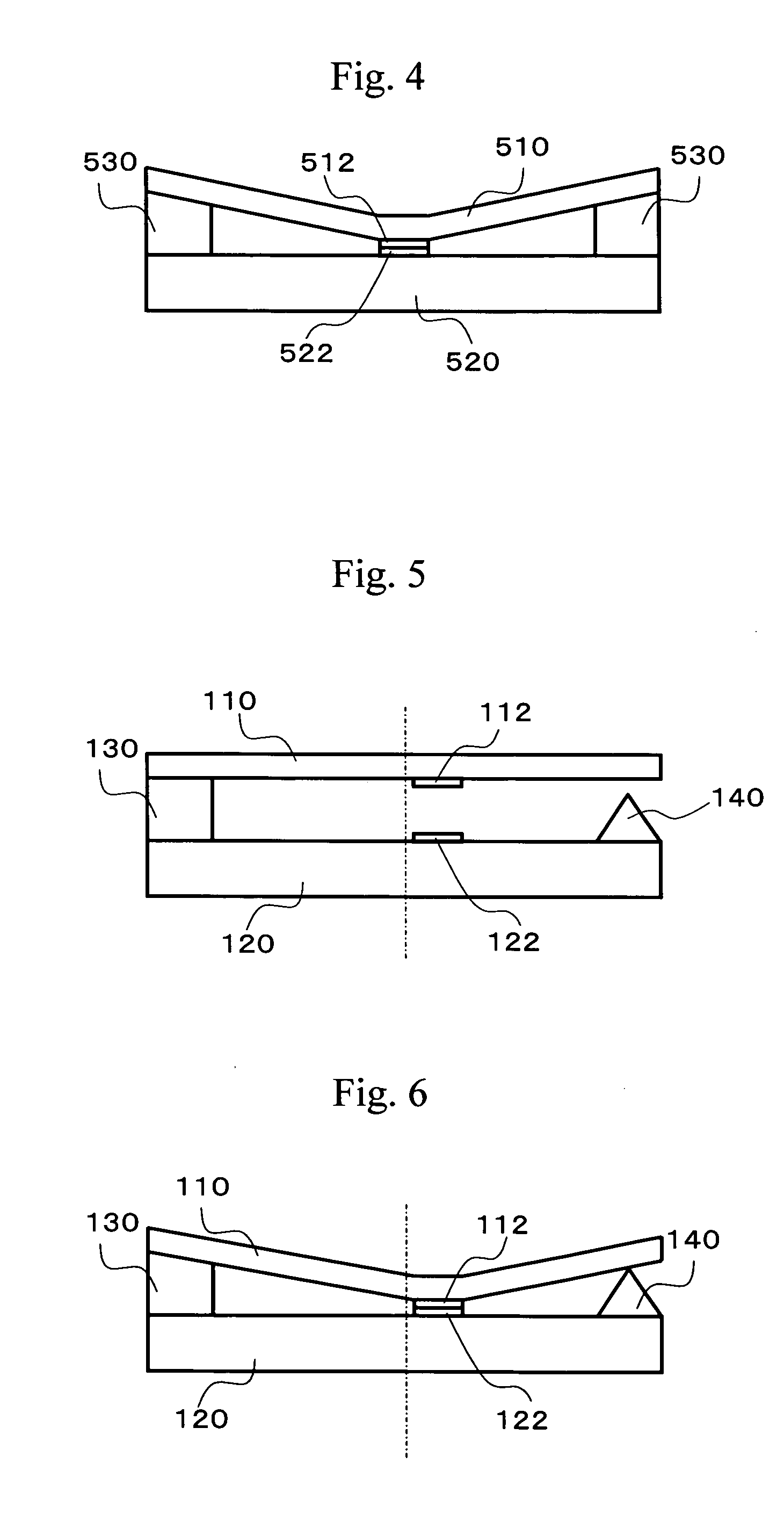

Semiconductor inspection apparatus and manufacturing method of semiconductor device

InactiveUS20060139042A1Ensure positioning accuracyStable contact resistanceElectrical measurement instrument detailsElectrical testingDevice materialSemiconductor chip

When electrical properties of semiconductor chips of a semiconductor wafer are inspected by bringing plural contact terminals disposed on the principal surface of a probe sheet of a probe cassette constituting a semiconductor inspection apparatus into contact with plural electrodes of the plural semiconductor chips on the principal surface of the semiconductor wafer which is disposed so as to face the principal surface of the probe sheet, the air pressure of the space formed between the facing surfaces of the principal surface of the probe sheet and the principal surface of the semiconductor wafer is reduced so as to suck the semiconductor wafer toward the side of the principal surface of the probe sheet and deform mainly the semiconductor wafer, thereby pressing the plural electrodes of the plural semiconductor chips of the semiconductor wafer against the plural facing contact terminals of the principal surface of the probe sheet.

Owner:RENESAS ELECTRONICS CORP

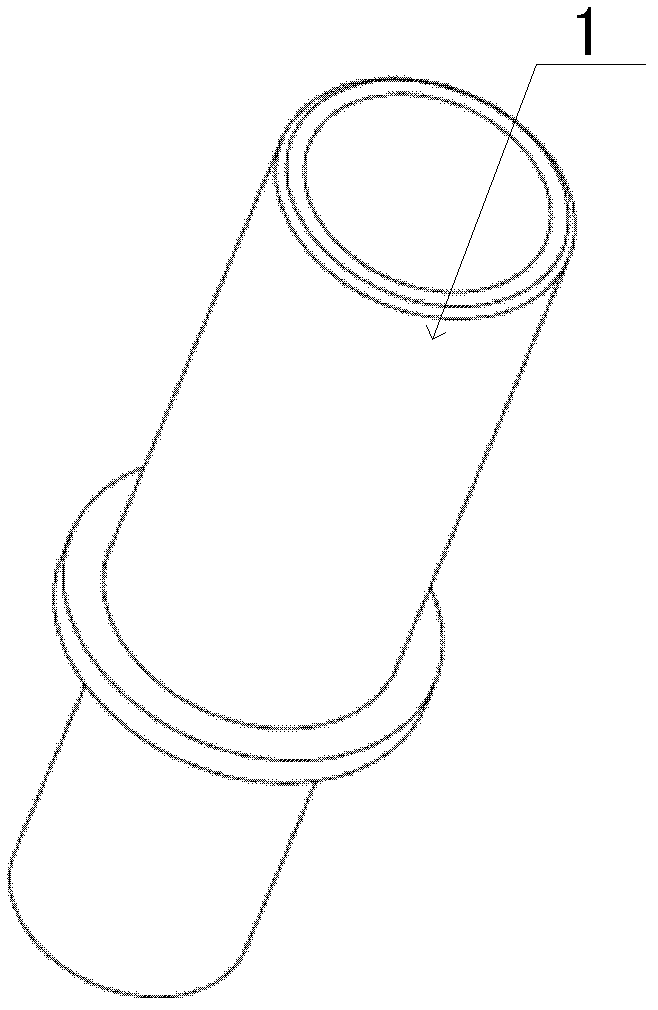

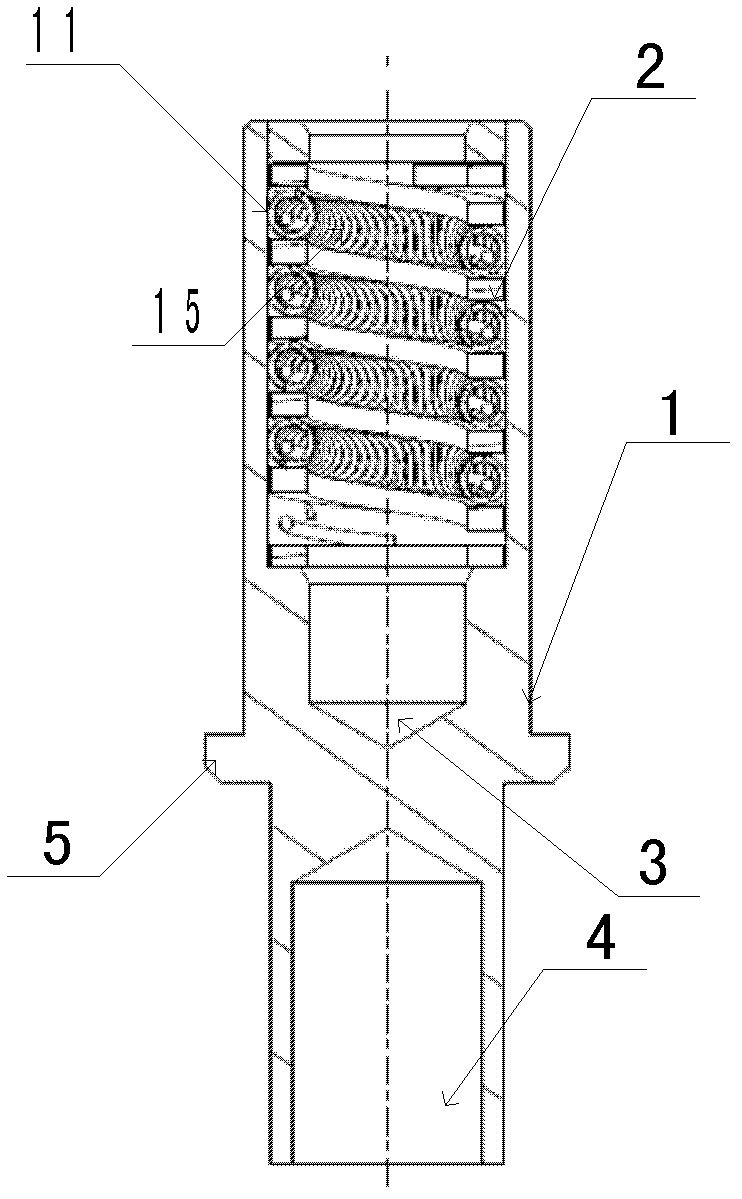

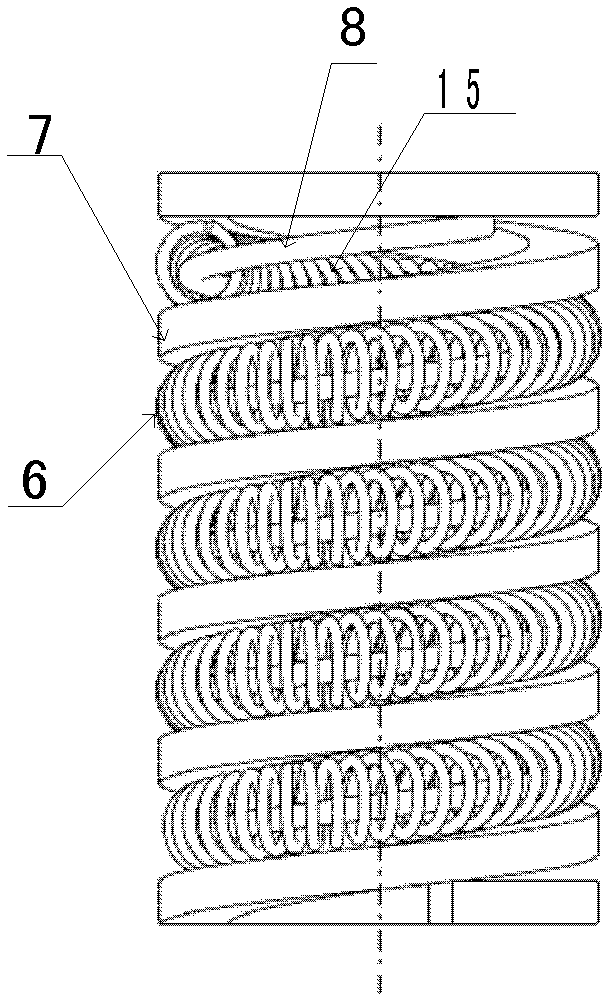

Socket conductor and socket system

InactiveCN102570115BIncrease touch pointsExtended contact pathCoupling device detailsContact impedanceElectrical conductor

The embodiment of the invention discloses a socket conductor and a socket system. The socket conductor comprises a socket body, an inclined oval two-way spiral spring contact finger, a single-line spring and an offset-line spring, wherein the inclined oval two-way spiral spring contact finger is spirally surrounded into a unit ring by a spring wire along an inclined oval track, the unit ring is in two-way spiral wounding along the axial line, the inclined oval two-way spiral spring contact finger is sheathed on the single-line spring and is embedded into a groove of the offset-line spring in an adapting way, the inner circumference of the spring contact finger forms an insertion hole, and the offset-line spring is arranged in a socket body hole. When a plug is inserted into the socket conductor, the inner wall of the inclined oval two-way spiral spring contact finger is extruded by the plug to deform, the inclined oval deformation of the unit ring is gradually generated in the spiral axial direction in the insertion process, the contact points and the contact paths of the plug and the socket conductor are increased, on the basis, the stress deformation degree becomes lenitive, the contact is more reliable, and the contact impedance is more stable.

Owner:深圳市簧中簧电子有限公司

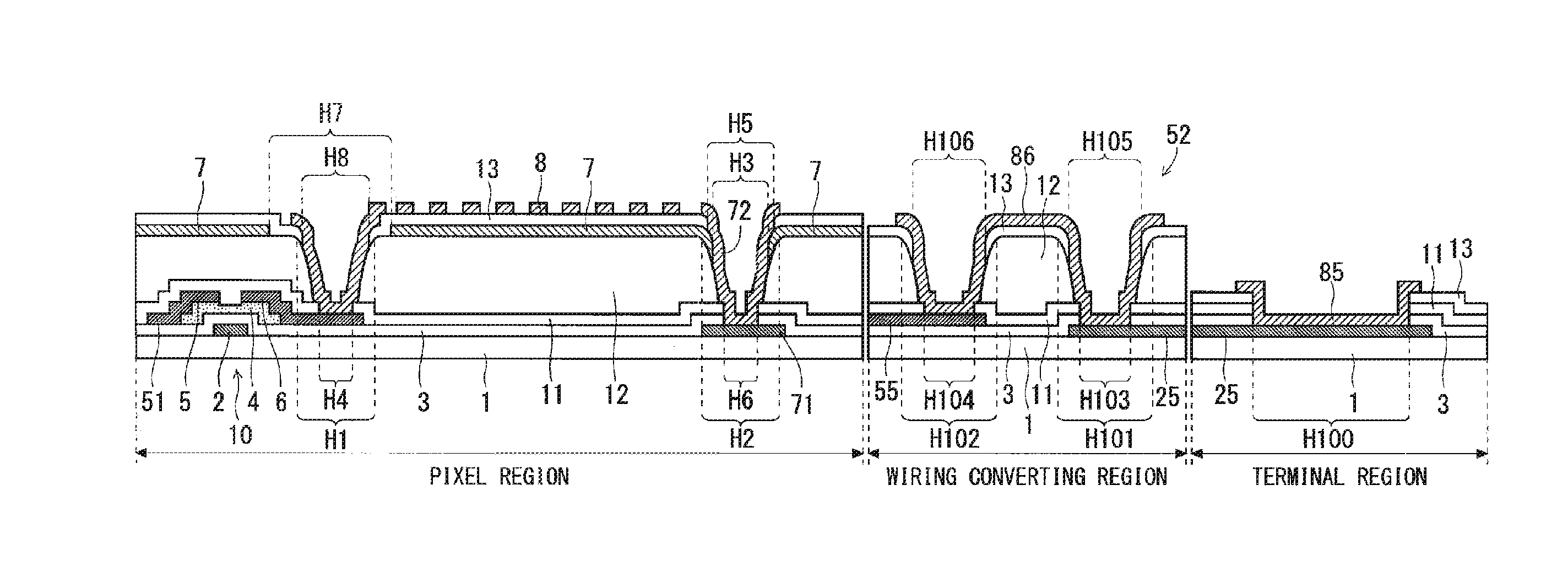

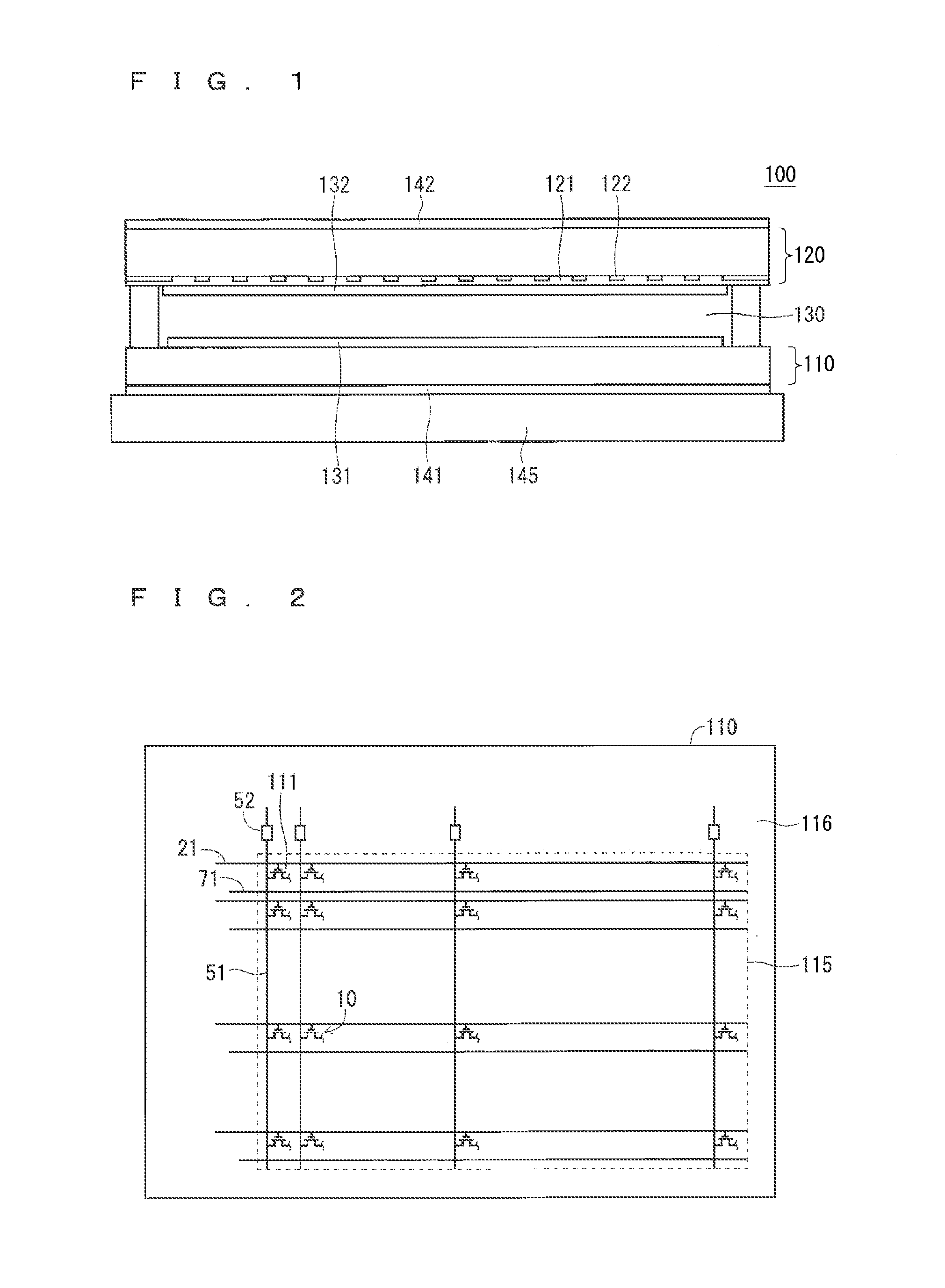

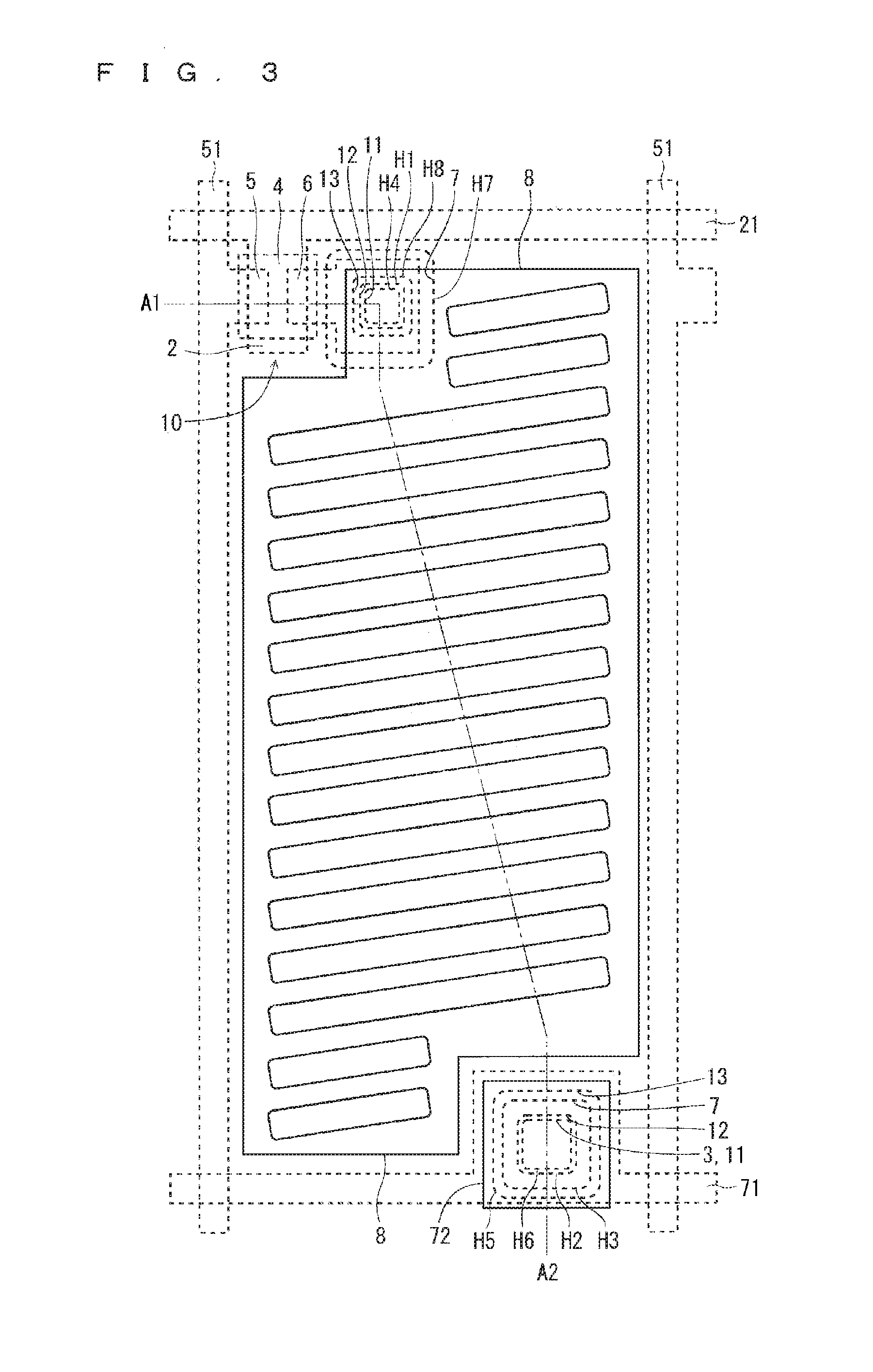

Thin film transistor array substrate

ActiveUS20150076501A1Stable contact resistanceReduce loadSolid-state devicesNon-linear opticsOptoelectronicsTransistor

A pixel electrode of an array substrate is connected with a drain electrode of a TFT via a first aperture formed on a second interlayer insulating film, a second aperture that includes a bottom portion of the first aperture and is formed on a common electrode, a third aperture that includes at least a part of the bottom portion of the first aperture, is included in a second aperture and is formed on a third interlayer insulating film, and a fourth aperture that is formed on the first interlayer insulating film in a region where the third aperture overlaps with the bottom portion of the first aperture.

Owner:TRIVALE TECH

Semiconductor inspection apparatus and manufacturing method of semiconductor device

InactiveUS7227370B2Ensure positioning accuracyStable contact resistanceElectrical measurement instrument detailsIndividual semiconductor device testingSemiconductor chipAtmospheric pressure

Owner:RENESAS ELECTRONICS CORP

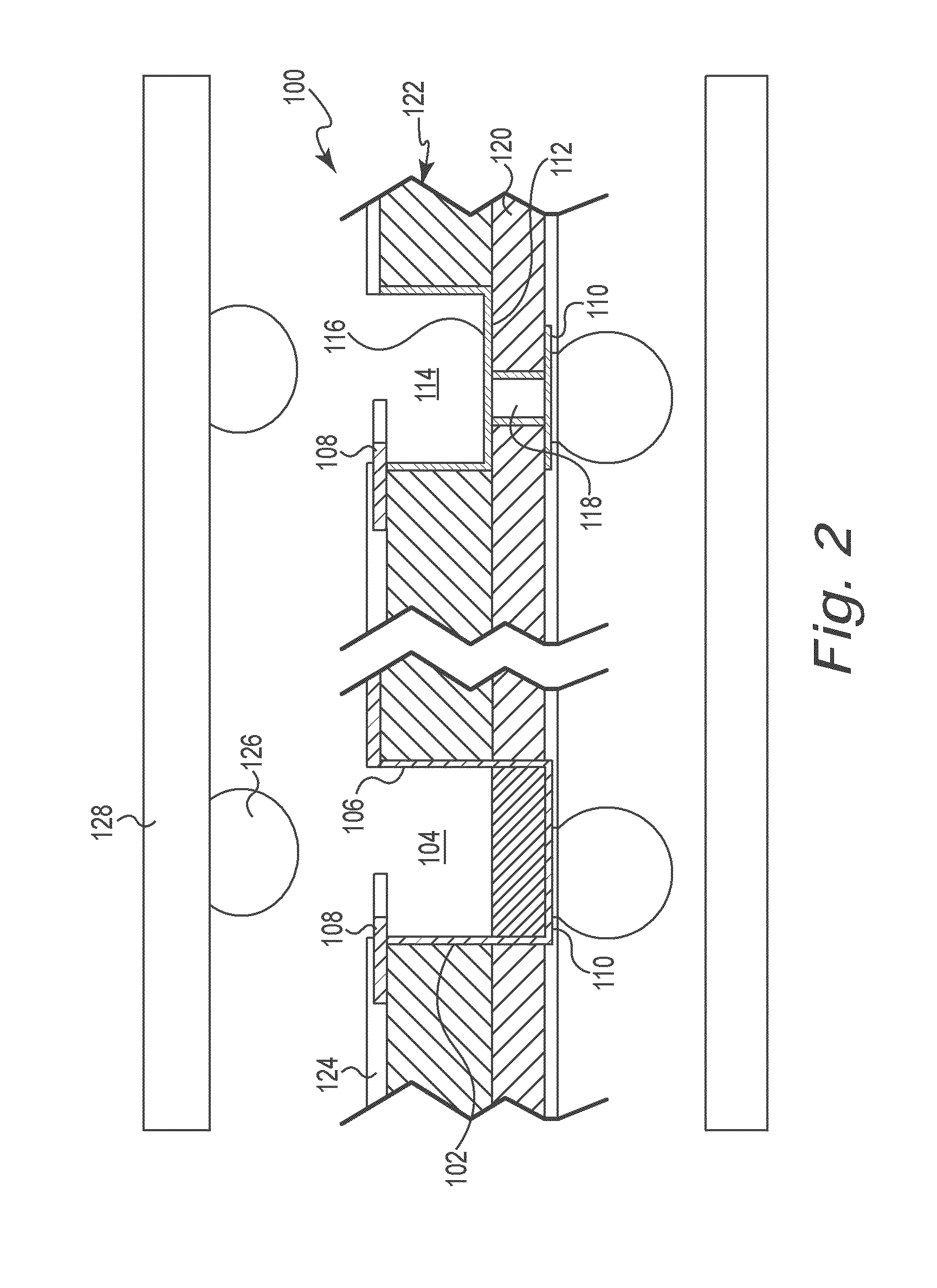

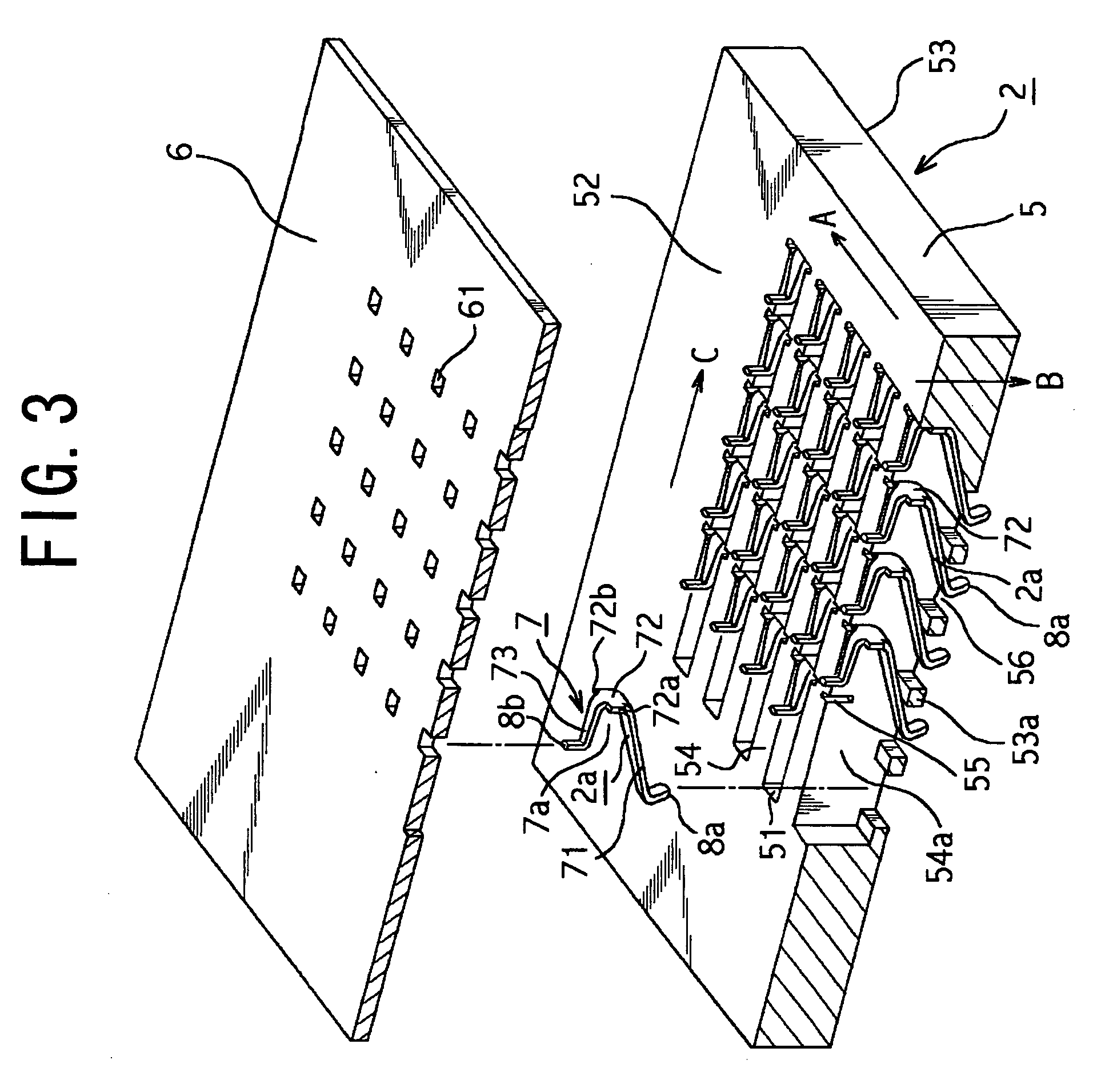

Probe card, semiconductor inspecting apparatus, and manufacturing method of semiconductor device

InactiveUS7956627B2High positionalRoughness of electrode pad faces caused by probingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardMechanical engineering

A frame bonded and fixed to a back face of a probe sheet so as to surround a group of pyramid-shaped or truncated pyramid-shaped contact terminals collectively formed at a central region portion of the probe sheet on a probing side thereof is protruded from a multi-layered wiring board, and pressing force is imparted to the frame and a pressing piece at a central portion by a plurality of guide pins having spring property so as to tilt finely.

Owner:RENESAS ELECTRONICS CORP

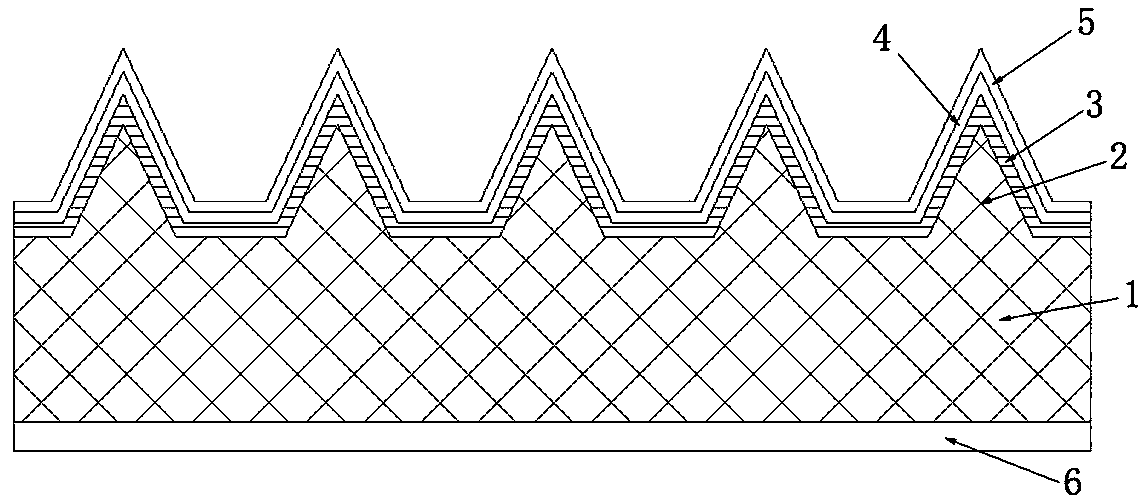

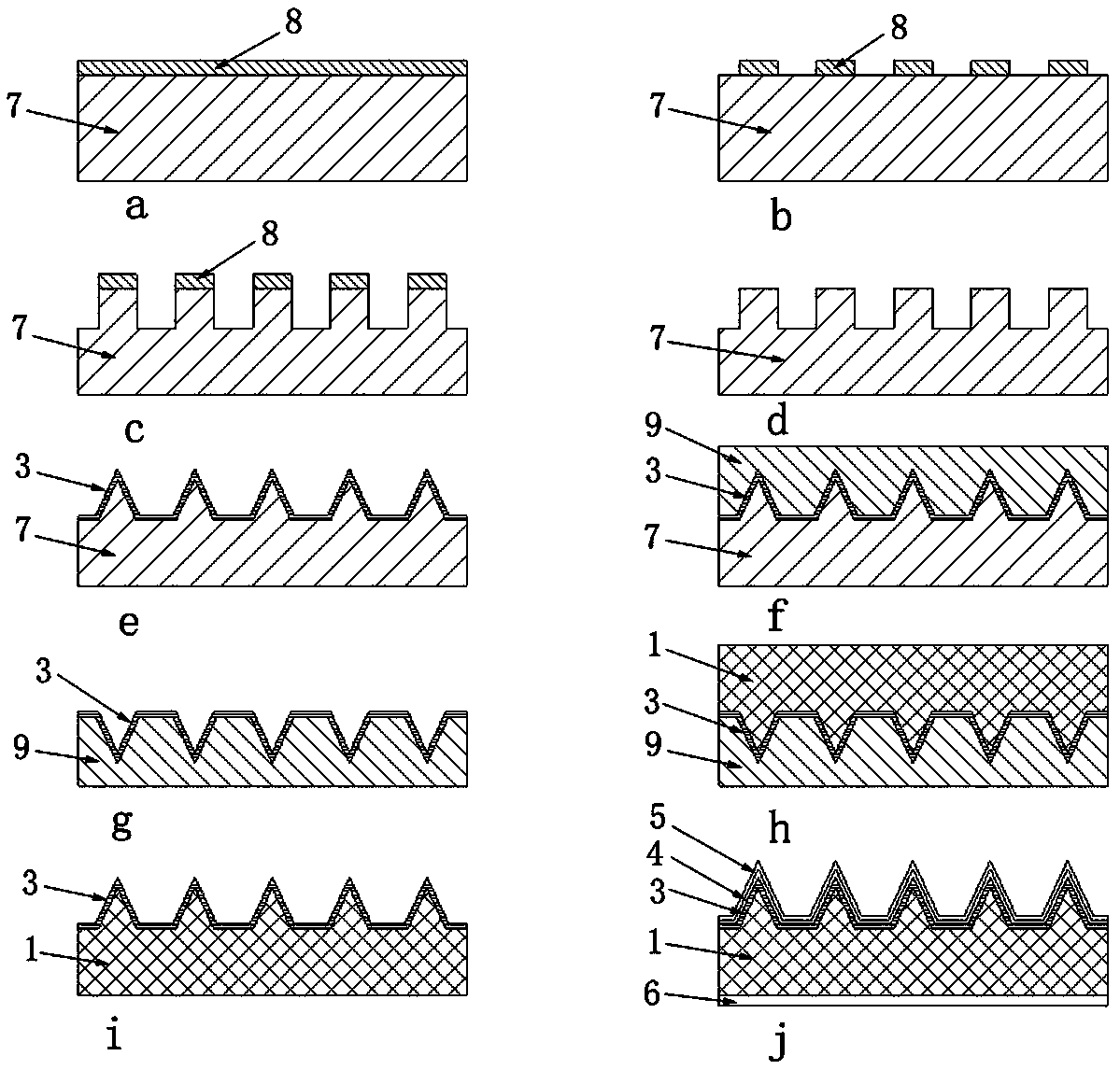

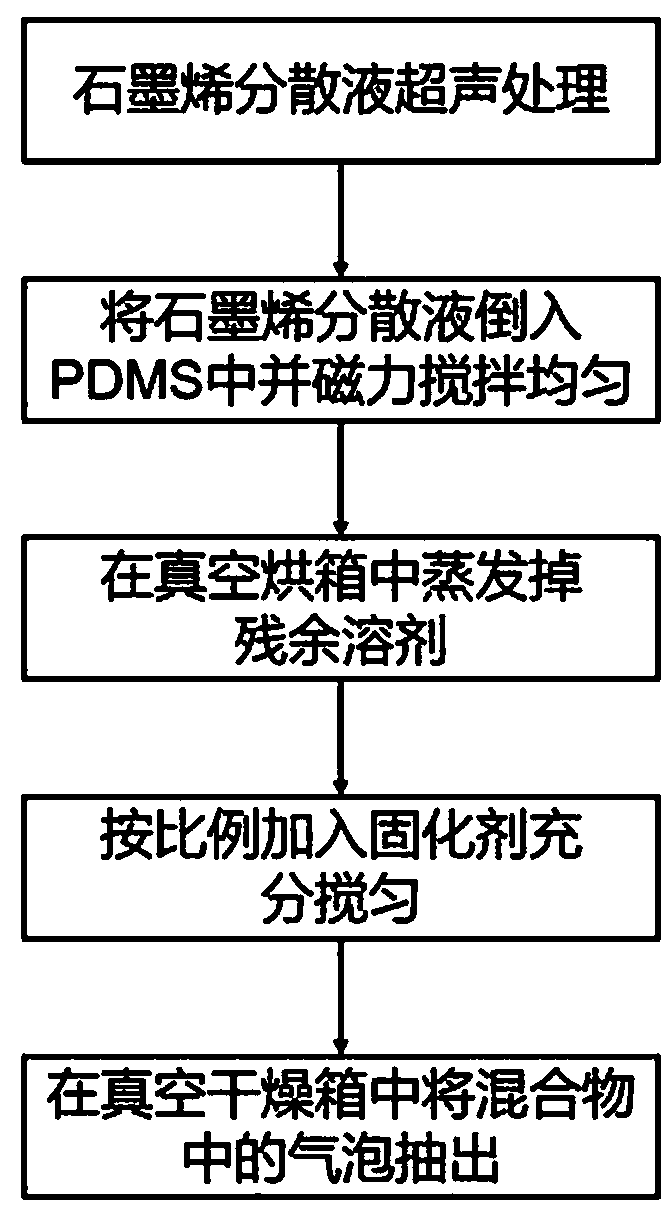

Graphene-PDMS flexible substrate electrocardiogram dry electrode based on tip array structure and preparation method thereof

ActiveCN108975266AReduce contact resistanceImprove stabilityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEcg signalSputtering

The invention relates to a graphene-PDMS flexible substrate electrocardiogram dry electrode based on a tip array structure and a preparation method thereof. a graphene-PDMS flexible substrate is designed on a top surface thereof, a paraxylene film is deposited on tip array structure, metal seed layer is sputtered on paraxylene film, a metal lalyer is sputtered on the metal seed layer. The bottom surface of the graphene-PDMS flexible conductive substrate is coated with a conductive silver paste layer. The process of the invention is simple, the cost is low, and the production of the mould is favorable for batch production. The materials such as conductive silver colloid, PDMS, graphene, paraxylene film and sputtered titanium and gold have good biological compatibility, and can effectively inhibit bacteria and reduce skin irritation. The tip array structure designed by the invention has a larger contact area, and can pass through the stratum corneum by directly contacting with the skin,so that contact impedance of the skin-electrode can be effectively reduced, thus obtaining a stable ECG signal.

Owner:ZHONGBEI UNIV

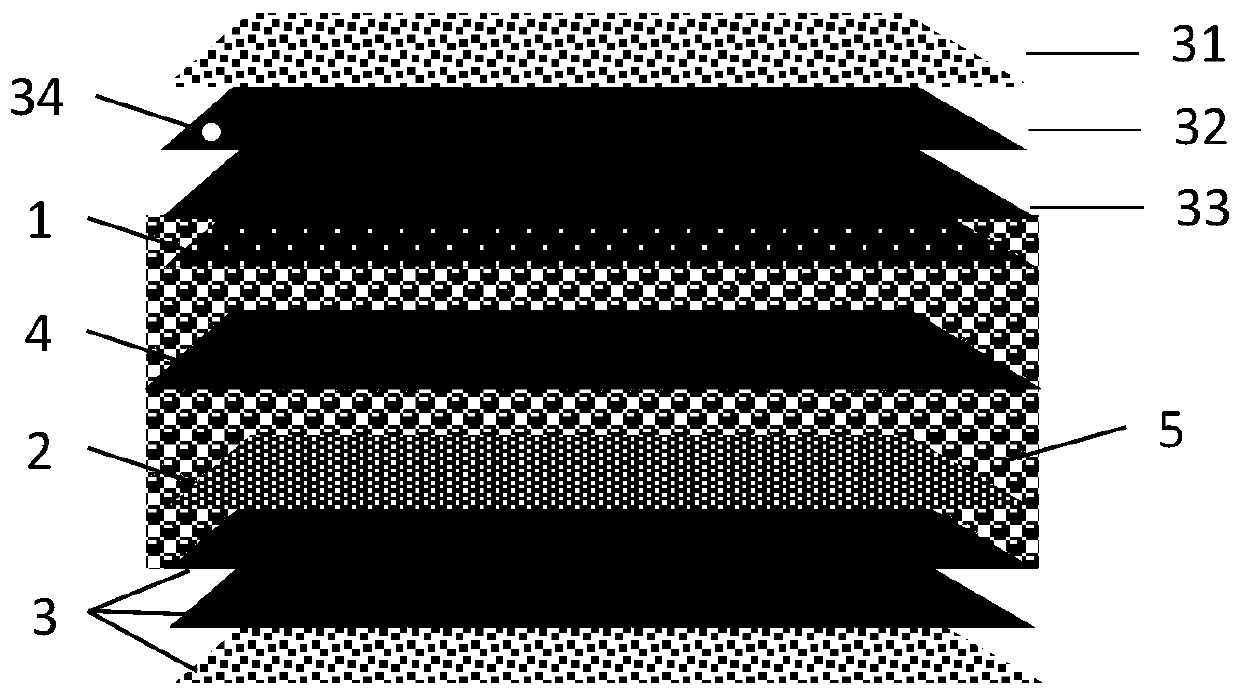

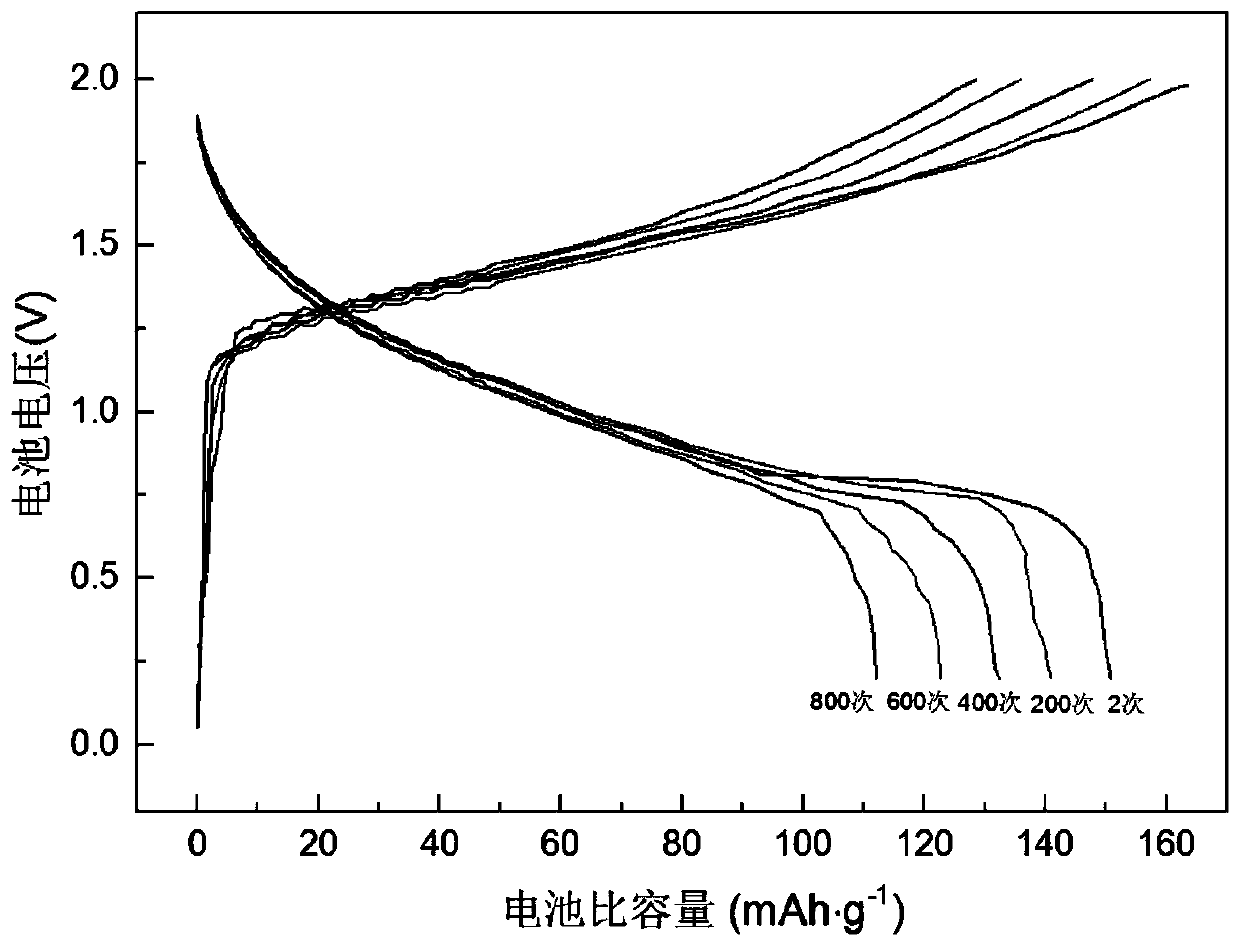

Flexible water system zinc ion battery

ActiveCN110190344AAvoid safety hazardsNot easy to decomposeFinal product manufactureSecondary cellsElectrical batteryDynamic balance

The invention discloses a flexible water system zinc ion battery. The flexible water system zinc ion battery comprises a cathode layer, an anode layer, a current collection layer, a diaphragm and an aqueous electrolyte. The current collection layer comprises a breathable layer and a substrate layer, the substrate layer is provided with at least one opening holes. The perforated structure of the breathable layer and the substrate layer solves the problems of gas generation and electrolyte drying in the battery circulation process, so that the internal and external gaseous water of the battery reaches the states of circulation exchange and dynamic balance, and the circulation performance of the battery is greatly improved; and the assembled flexible water system zinc ion battery has the advantages of light weight, thin thickness, low cost, environmental friendliness, high safety, good rate capability, high power density and the like, and the excellent bending performance and flexibilityof the flexible water system zinc ion battery can meet the bending requirements of different angles, so that the flexible water system zinc ion battery is suitable for large-scale application and industrial production in the field of wearable electronic equipment.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

Switch device

InactiveUS7501920B2Accurate operationDegree of improvementContact mechanismsElectrostatic/electro-adhesion relaysEngineeringElectrical and Electronics engineering

Owner:FUJITSU COMPONENENT LTD

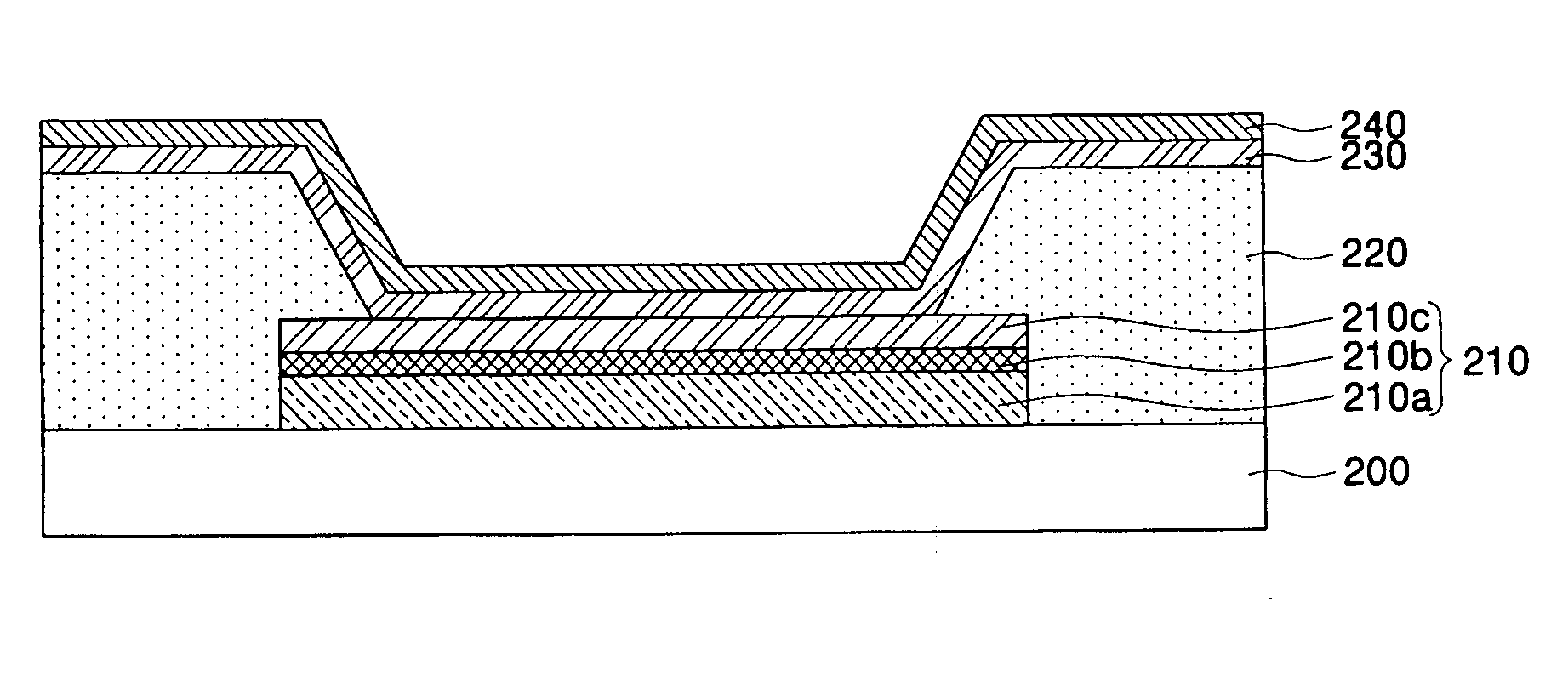

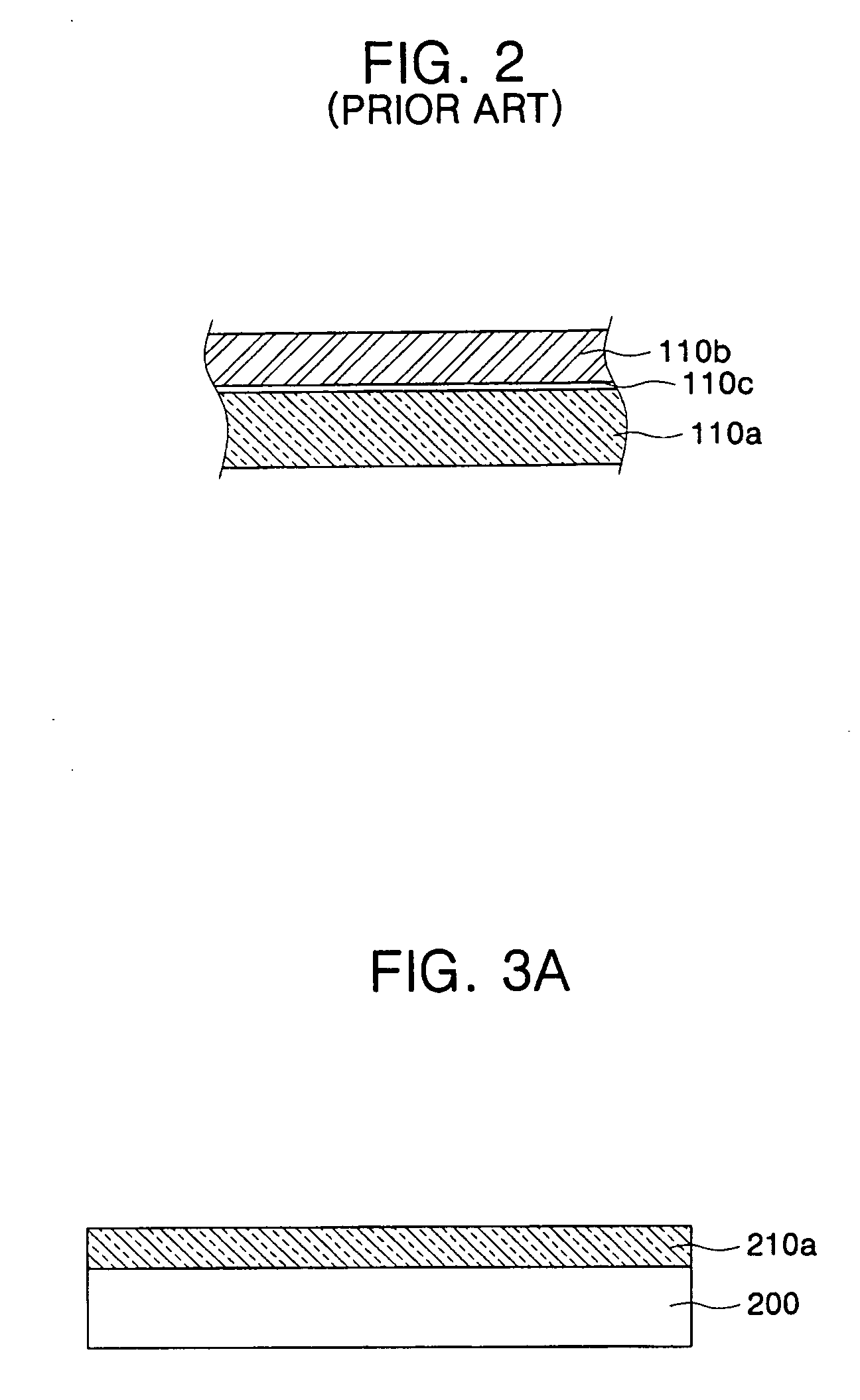

Top-emission organic electroluminescent display and method of fabricating the same

ActiveUS20050224789A1Suppress oxidationQuality improvementElectroluminescent light sourcesSolid-state devicesOrganic electroluminescenceOptoelectronics

A top-emission organic electroluminescent display is disclosed. The top-emission organic electroluminescent display includes a first electrode layer having a reflective layer, a metal-silicide layer and a transparent electrode layer on a substrate; an organic layer including at least one emission layer; and a second electrode layer. The metal-silicide layer is disposed between the reflective layer and the transparent electrode layer to suppress galvanic corrosion caused at an interface of the reflective layer and the transparent electrode layer, and to stabilize a contact resistance between the layers, thereby obtaining uniform brightness in the pixels, and realizing a high quality image.

Owner:SAMSUNG DISPLAY CO LTD

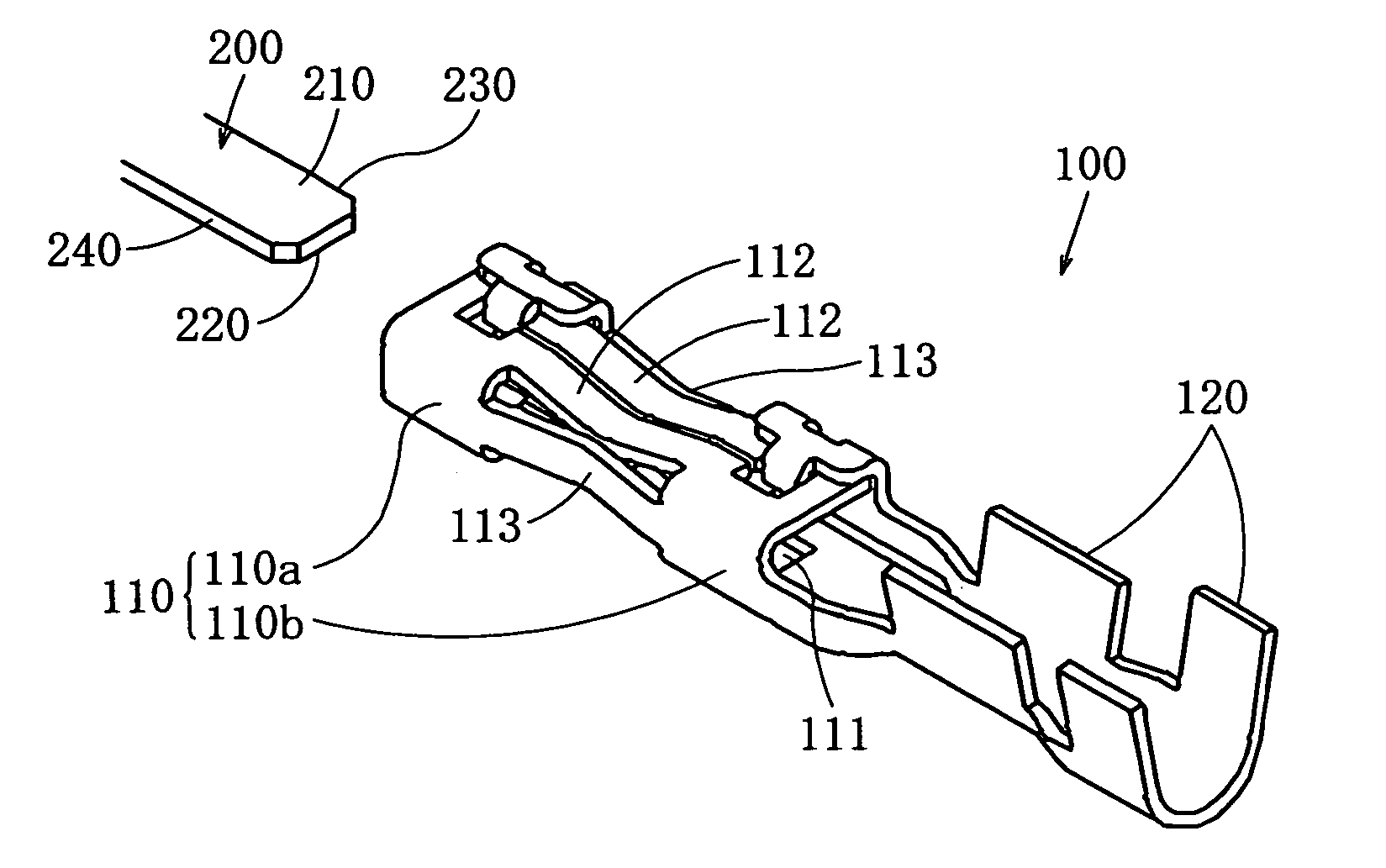

Female terminal for heavy current and female terminal for heavy current with shell

ActiveUS20050118891A1Stable contact resistanceContact resistance can not be sufficientlyCoupling contact membersElectric connection basesContact pressureEngineering

To provide a female terminal for heavy current, which reduces the contact resistance between it and a male terminal, allows stable flow of heavy current at low loss and correctly positions a blade. The body part of the female terminal for heavy current is provided with a first elastic piece, which is provided at least on one side in the height direction of a receiving space in such a way that it can undergo elastic deformation in the height direction and has, on the inner side thereof, a contacting part extending for a certain width, and a second elastic piece, which is provided at least on one side in the width direction of the receiving space in such a way that it can undergo elastic deformation in the width direction and has, on the inner side thereof, a contacting part extending for a certain height. When the blade is inserted into the receiving space, the contacting part of the first elastic piece will contact, with a contact pressure, one end face in the height direction of the blade and the contacting part of the second elastic piece will contact, with a contact pressure, one end face in the width direction of the blade.

Owner:JST MFG CO LTD

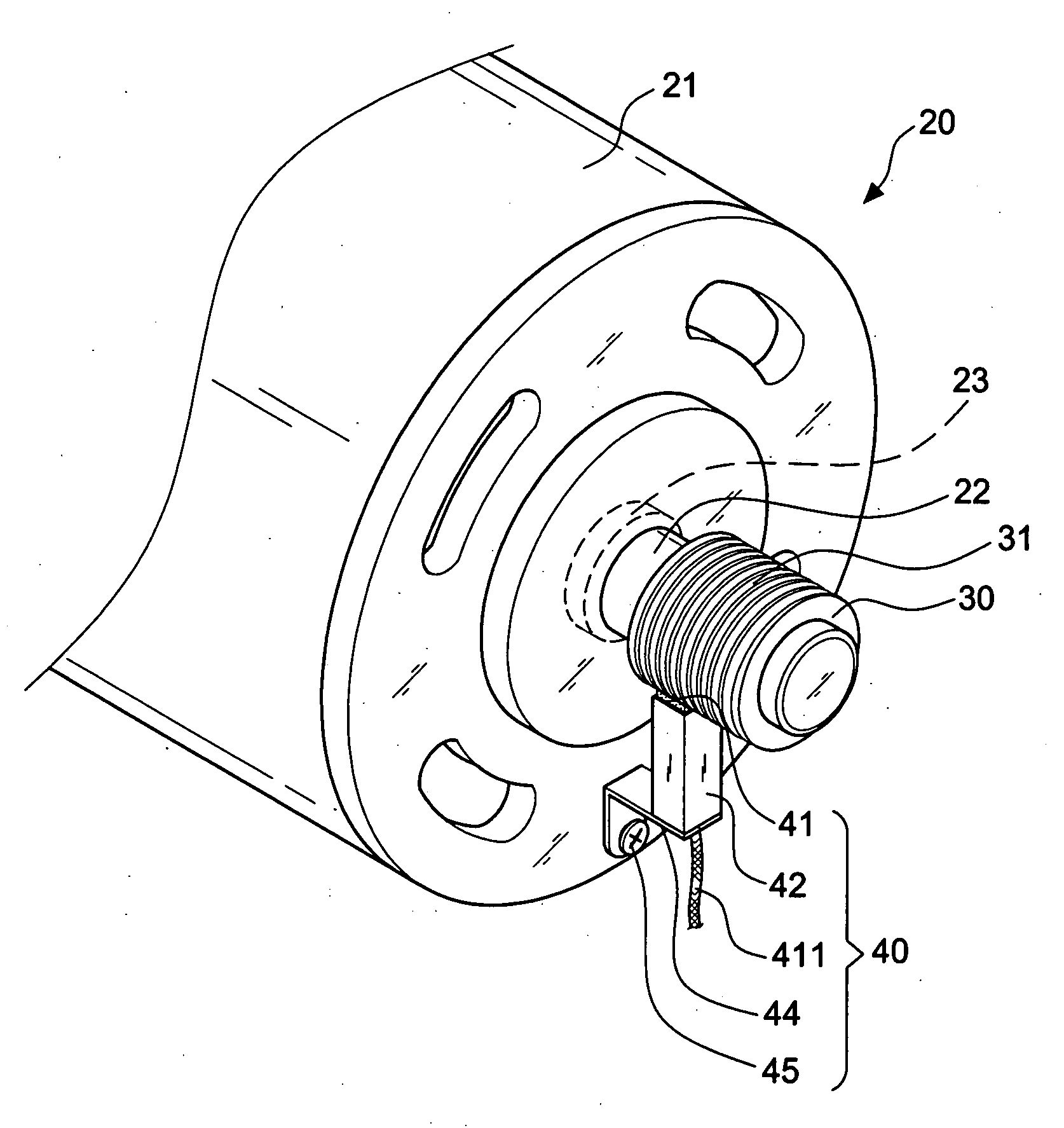

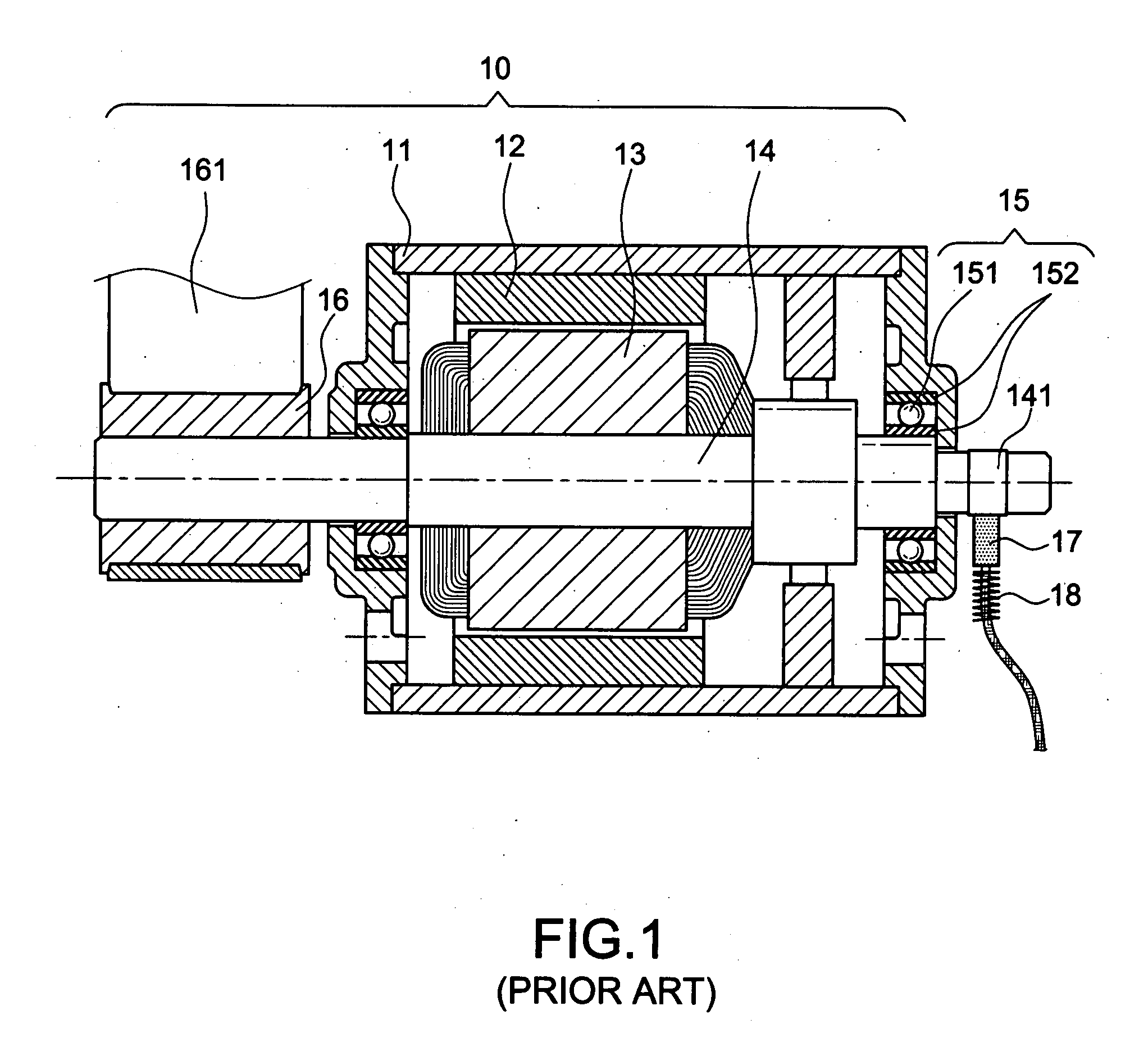

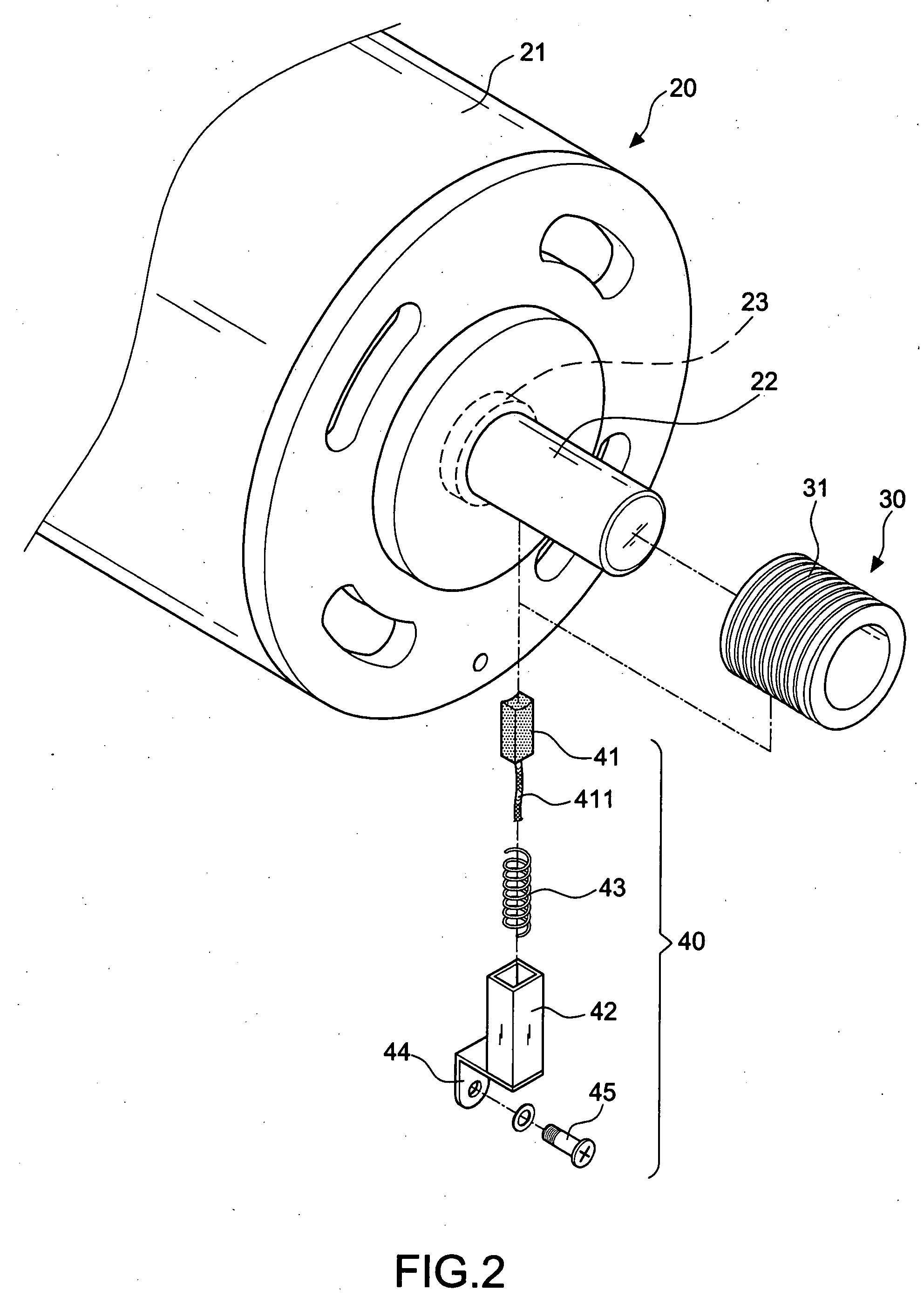

Shaft grounding thread structure of an electric motor

InactiveUS20090015083A1Stable contact resistanceEasy to cleanRotary current collectorAssociation with grounding devicesEngineeringCopper

Thread structure for the shaft grounding of an electric motor having a thin thread formed on the surface of the slip ring or the shaft to replace the conventional face contact with the “linear contact” between the surface of the carbon brush and the thread head. During the rotation, the development of friction heat and the oxidation film will be substantially eliminated. Furthermore, the effect of spiral conveyor belt is created when the thread rotates. This can remove the toner, copper powder, etc. produced by friction acting on the surface of the carbon brush and keep a permanent cleanness of the surface of the carbon brush. In this way, a stable contact resistance between the shaft (or the slip ring) and the carbon brush can be maintained and a long-term test shows that the wear of the carbon brush will be further reduced before improvement.

Owner:CHI HUA FITNESS

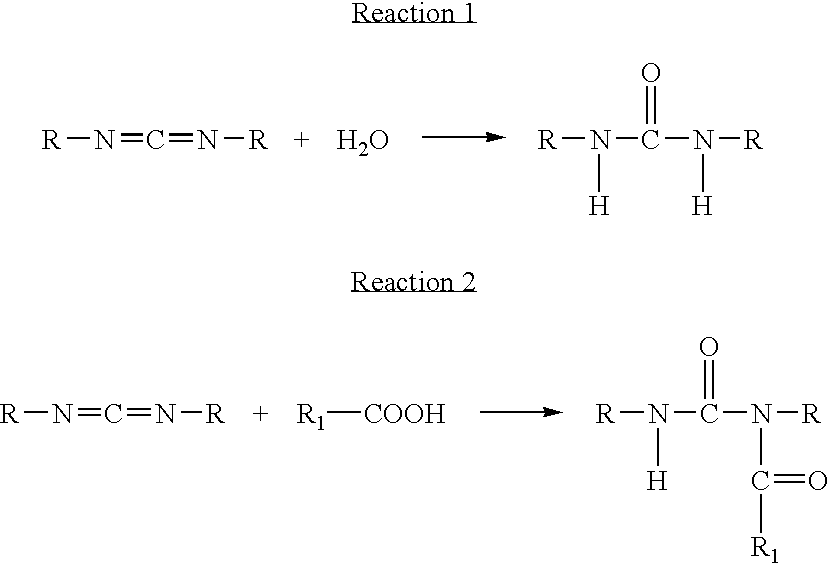

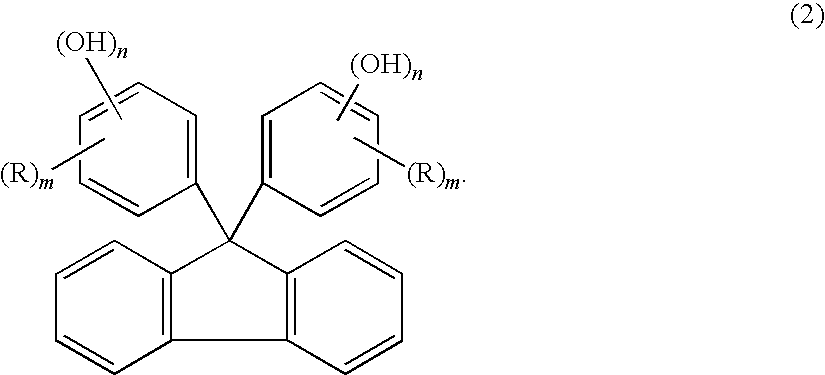

Adhesive film composition for electric and electronic devices and adhesive film using the same

InactiveUS20100159234A1Avoid hydrolysisStable adhesive strengthNon-macromolecular adhesive additivesFilm/foil adhesivesMeth-Electron

An adhesive film composition for electric and electronic devices and an adhesive film produced using the same, the composition including a binder, the binder including an ester linkage-containing resin, a carbodiimide group-containing compound, a (meth)acrylate group-containing compound; and an organic peroxide.

Owner:CHEIL IND INC

Probe card, semiconductor inspecting apparatus, and manufacturing method of semiconductor device

InactiveUS20090042323A1High positionalRoughness of electrode pad faces caused by probingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsProbe cardEngineering

A frame bonded and fixed to a back face of a probe sheet so as to surround a group of pyramid-shaped or truncated pyramid-shaped contact terminals collectively formed at a central region portion of the probe sheet on a probing side thereof is protruded from a multi-layered wiring board, and pressing force is imparted to the frame and a pressing piece at a central portion by a plurality of guide pins having spring property so as to tilt finely.

Owner:RENESAS ELECTRONICS CORP

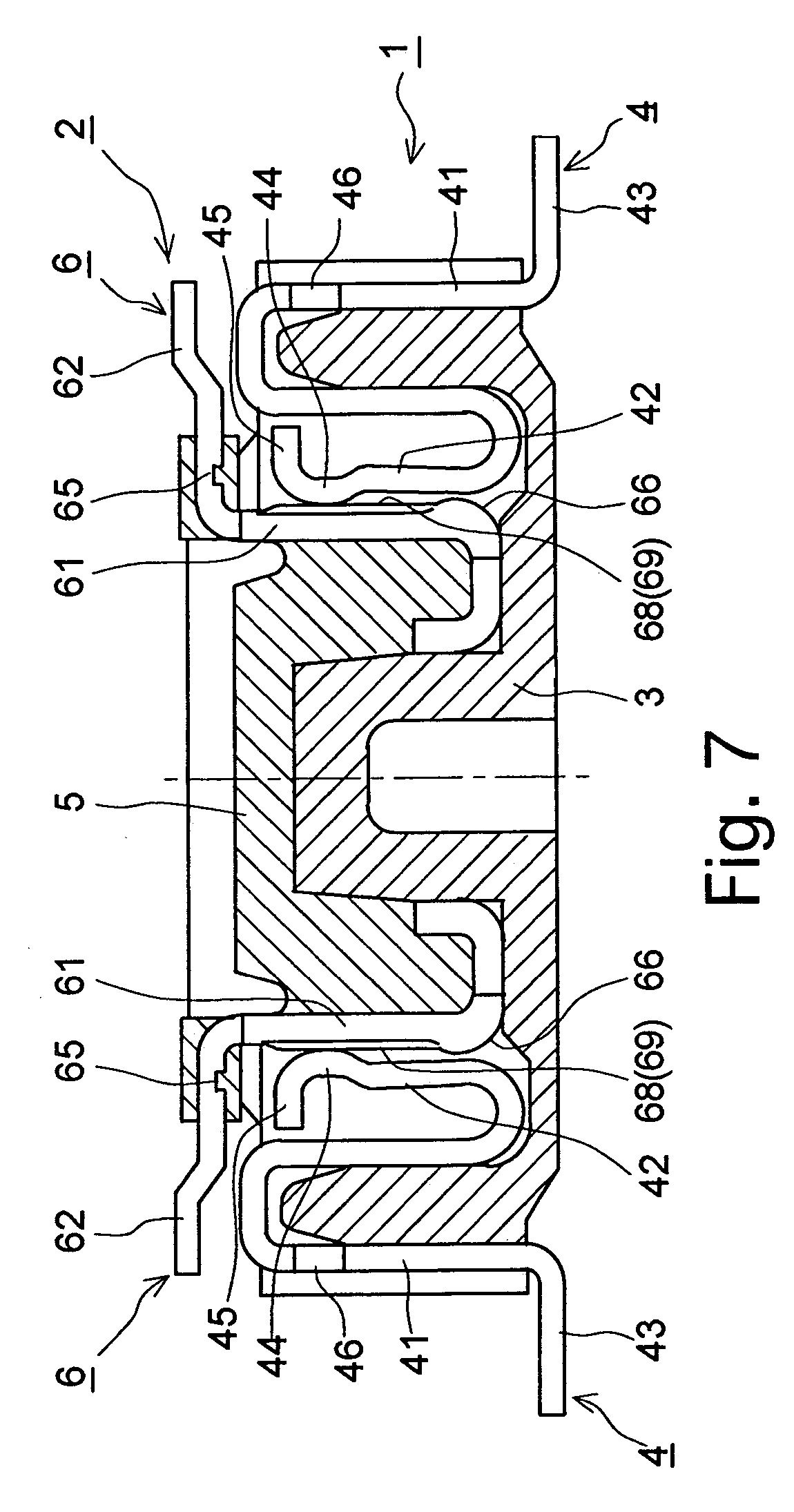

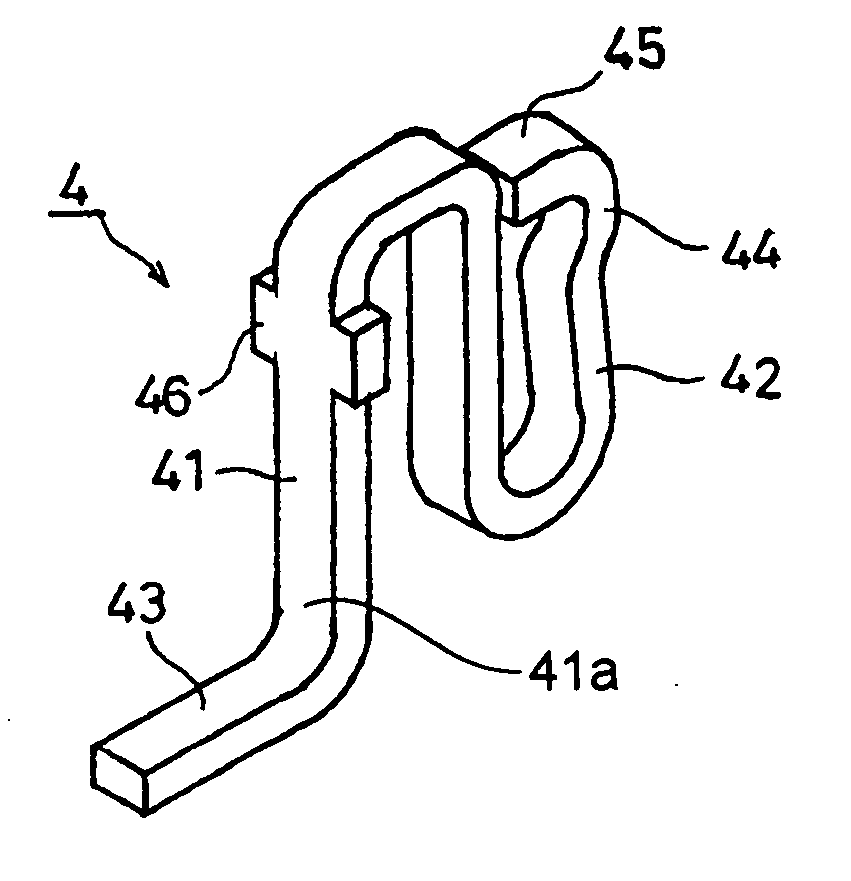

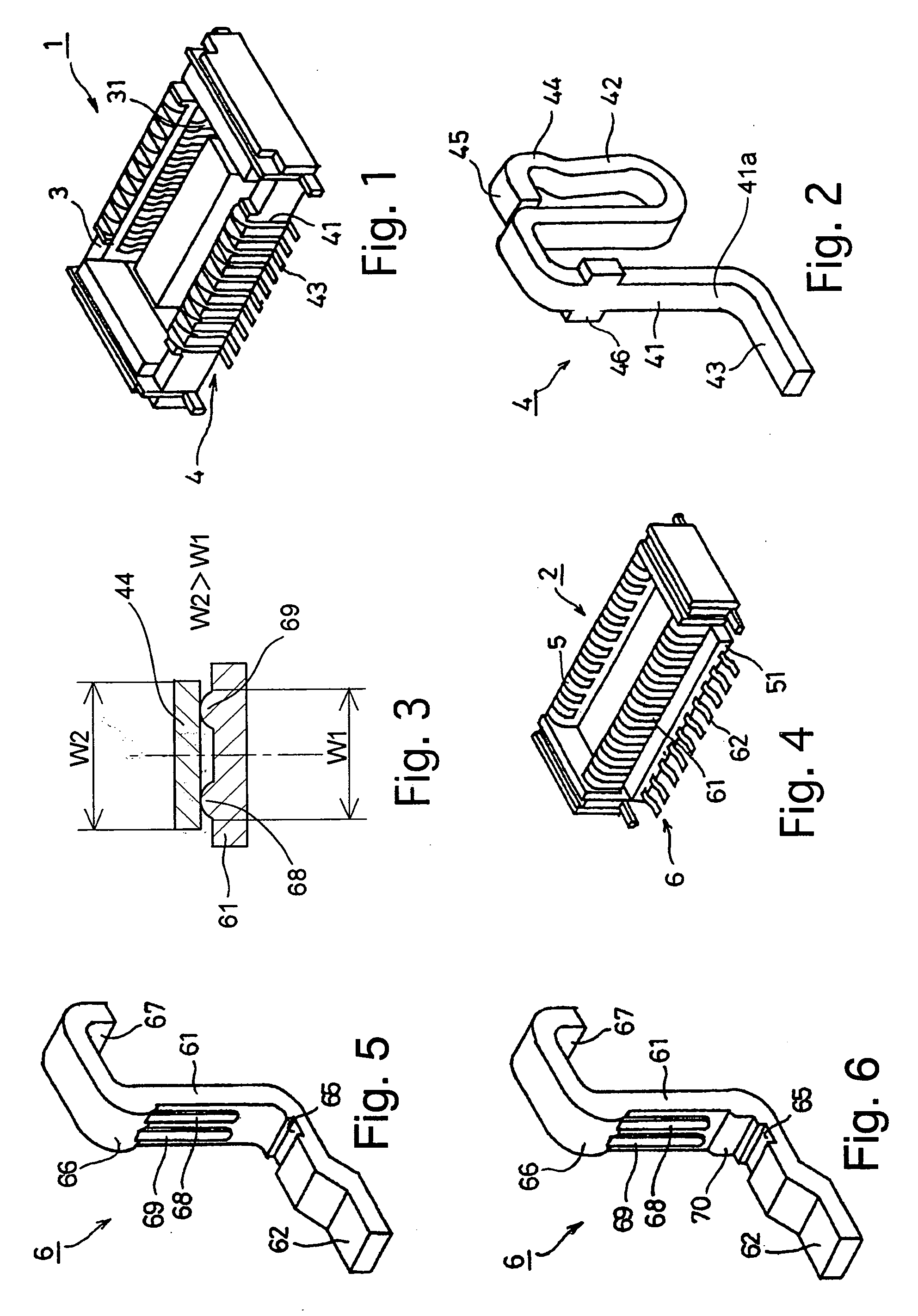

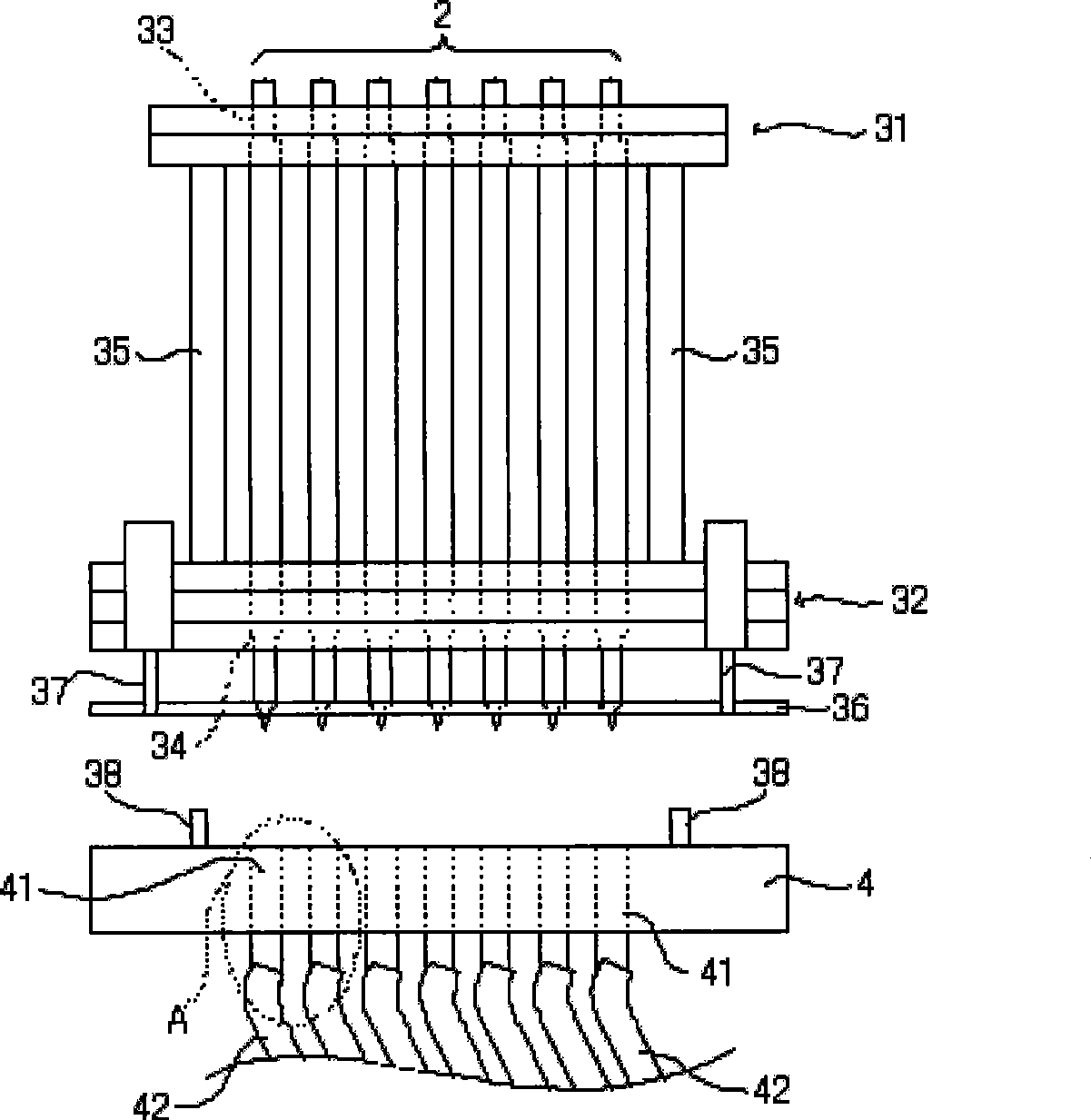

Socket for electronic part

InactiveUS20050020117A1Improve AssemblabilityImprove workabilityEngagement/disengagement of coupling partsElectrically conductive connectionsCouplingEngineering

In a socket for an electronic part, each electrode portion includes a leaf spring portion which is disposed by bending a conductive plate material substantially into a U-shape and facing an opening part in a direction substantially perpendicular to the thickness direction of a socket body, a first contact which is unitarily provided at one free end of the leaf spring portion and which is held in electrical contact with the corresponding electrode terminal of the electronic part, and a second contact which is unitarily provided at the other free end of the leaf spring portion and which is held in electrical contact with the corresponding electrode terminal of a printed circuit board. The leaf spring portion includes a horizontally extending portion which is arranged substantially in parallel with the horizontal surface of the printed circuit board, a coupling portion which is unitarily provided at one end part of the horizontally extending portion in the thickness direction of the socket body, and an obliquely extending portion which is unitarily provided at the end part of the coupling portion so as to oppose to the horizontally extending portion and to obliquely rise up toward the electronic part. Engagement pieces which are held in engagement with engagement grooves provided in partition walls are formed on both the sides of the coupling portion unitarily with this coupling portion.

Owner:TNG CORP LTD

High performance surface mount electrical interconnect with external biased normal force loading

ActiveUS9196980B2Low enough forceEasy to disassembleCoupling device connectionsResistor terminals/electrodesContact padSurface mounting

Owner:RATHBURN JAMES

Connector, and portable terminal equipment including the connector

ActiveUS20060040525A1Stable contact resistanceWide rangeElectric discharge tubesCoupling contact membersTerminal equipmentMechanical engineering

A connector includes a plug including a plug body made of an insulating material and at least one plug contact supported by the plug body; a receptacle including a receptacle body made of an insulating material and at least one receptacle contact supported by the receptacle body; a contact projecting portion formed on one of the plug contact and the receptacle contact; a contacting portion formed on the other of the plug contact and the receptacle contact; and a first projecting portion and at least one second projecting portion which is formed on the contacting portion, the second projecting portion being formed integral with the first projecting portion to be elongated in an insertion / extraction direction of the plug. A portion of the contact projecting portion is formed as a flat surface having a width greater than a width of the second projecting portion.

Owner:KYOCERA CORP

Substrate inspecting jig, and electrode structure of connecting electrode unit in the jig

ActiveCN101443669AReduce contact resistance valueStable contact resistanceElectronic circuit testingElectrical measurement instrument detailsContact groupContact resistance

Provided is a substrate inspecting jig, which can reduce a contact resistance between a contact maker and a connecting electrode unit and which has a stable contact resistance without regard to the number of uses. In order to inspect the electric characteristics of an object substrate, the substrate inspecting jig acquires the electric conductions between a substrate inspecting device body and a plurality of substrate inspection points formed at the wiring pattern of the object substrate. The substrate inspecting jig comprises a group of electrically conductive contacts having two end portions for electric conductions, one of which is forced to contact with one of the substrate inspection points, a contact holder for holding the contact group, and a connecting electrode member including the connecting electrode unit arranged to confront the other end portions of the individual contacts of the contact group and adapted to be connected with the substrate inspecting device body. At least a portion of the side circumference near each of the other end portions is brought, when the other end portions of the contact group and the connecting electrode member are to be connected, into contact with a portion of the confronting connecting electrode unit thereby to establish the electrically conductive state.

Owner:NIDEC-READ CORPORATION

Ultrathin palladium plating and gold plating process for lead wire frame

ActiveCN102817055AAppearance bright and silverCrystal fine and smoothSemiconductor/solid-state device detailsSolid-state devicesElectrolysisThin layer

The present invention discloses an ultrathin palladium plating and gold plating process for a lead wire frame. The process comprises the following steps: carrying out electrolysis degreasing, carrying out an activation treatment on a lead wire frame substrate, carrying out electrodeposition of a nickel plating layer, carrying out an activation treatment on the nickel layer, carrying out electrodeposition of a palladium plating thin layer, and carrying out high-frequency pulse electrodeposition of a gold plating thin layer, wherein a palladium-plated lead wire frame substrate is placed into a gold plating liquid to carry out electrodeposition for 10-20 s, cleaned with gold recovery water, dried and is subjected to gold protection to obtain the finished product. According to the present invention, under the premise of ensurence of passing of the test trial, the ultrathin gold-palladium plating layer is formed, wherein a thickness of the electroplated palladium layer is 0.02-0.1 mum, and is far lower than a thickness of 2-5 mum of the electroplated palladium layer in the existing process, and the electroplated gold layer is 0.003-0.01 mum, and is far lower than a thickness of 0.3-1.2 mum of the electroplated gold layer in the existing process, such that excellent performances of the original palladium plating layer and the original gold plating layer are ensured, gold consumption and palladium consumption are reduced, use of noble metals is substantially reduced, metal utilization rate is effectively improved, and cost is saved.

Owner:ACKOTEC ZHONGSHAN ELECTRONICS PARTS

Socket for electronic part

InactiveUS7083424B2Easy to assembleReduce thicknessEngagement/disengagement of coupling partsElectrically conductive connectionsCouplingEngineering

In a connector board (socket) for an electronic component, each electrode member is a leaf spring formed by bending a conductive plate into a substantially U-shape with an opening facing substantially parallel to a surface of the connector board. A first contact is unitary with one free end of the leaf spring and is held in electrical contact with a corresponding terminal of electronic component, and a second contact is unitary with the other free end of the leaf spring and is held in electrical contact with a corresponding terminal of a printed circuit board. The leaf spring includes a first leg which extends substantially in parallel with a surface of the connector board, a coupling portion which is unitary with the first leg, and a second leg which is unitary with the coupling portion so as to oppose the first leg and which extends obliquely toward a surface of the connector board. Engagement elements are seated within grooves provided in partition walls and are formed unitarily with the coupling portion.

Owner:TNG CORP LTD

Copper/rare-earth oxide/carbon contact and method for producing same

ActiveCN1595569AImprove welding resistanceReduce burning lossContact materialsRare earthOxidation resistant

A copper / rare earth oxide / carbon aontact, whose material composite ratio(mass percentage) is: carbon 0.1-2.0, ytterbium trioxide or samarium trioxide 0.1-15, alloy 0.05-2.0 and copper the other, uses method of powder metallurgy and electroplating sediment to produce and the contact produced has excellent resistance to oxidation and electric arc burnt.

Owner:浙江帕特尼触头有限公司

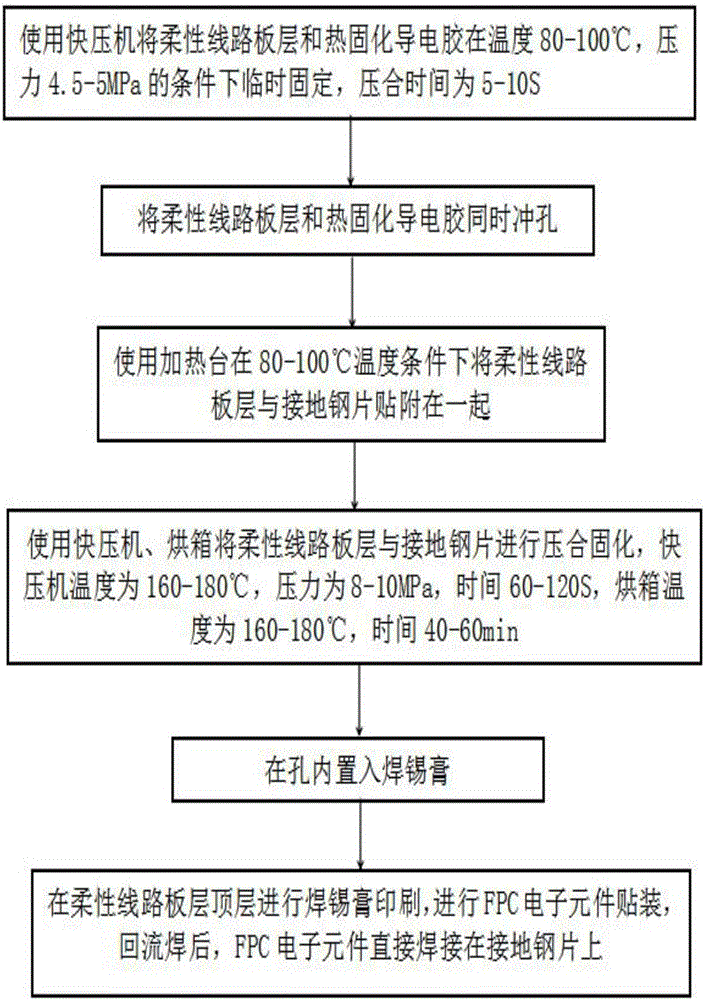

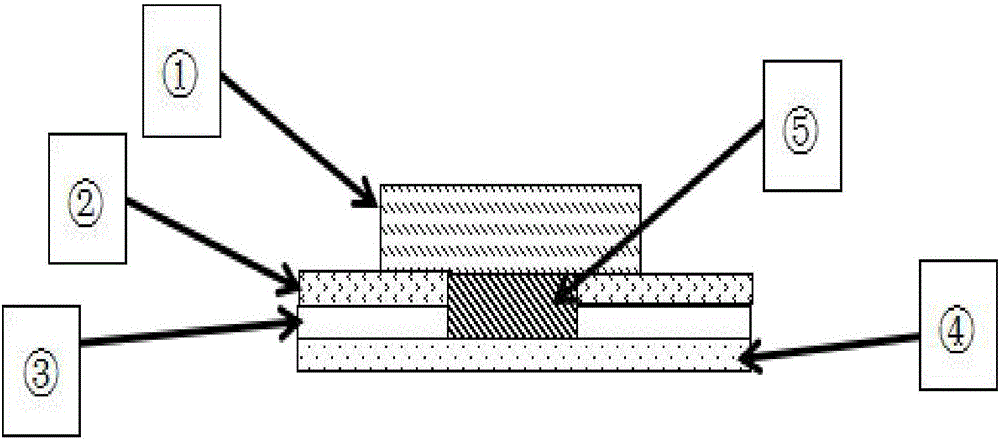

Flexible printed circuit board element and grounding steel sheet connecting device and method

ActiveCN106211564AStable contact resistanceImprove efficiencyPrinted circuit assemblingPrinted circuit groundingSolder pasteContact resistance

The invention relates to a flexible printed circuit board element and grounding steel sheet connecting device and method and belongs to the field of electrified connectors. The method comprises the steps that a flexible printed circuit board layer and thermal-cured conducting resin are temporarily fixed with a rapid compressing machine at the temperature of 80-100 DEG C and the pressure of 4.5-5 MPa, wherein the laminating time is 5-10 S; the flexible printed circuit board layer and the thermal-cured conducting resin are punched at the same time; the flexible printed circuit board layer and the grounding steel sheet are attached together with a heating table at the temperature of 80-100 DEG C; the flexible printed circuit board layer and the grounding steel sheet are laminated and cured with the rapid compressing machine and an oven, wherein the temperature of the rapid compressing machine is 160-180 DEG C, the pressure of the rapid compressing machine is 8-10 MPa, the time of the rapid compressing machine is 60-120 S, the temperature of the oven is 160-180 DEG C, and the time of the oven is 40-60 min; soldering paste is put into holes; FPC electronic elements are attached to the flexible printed circuit board layer and make contact with the soldering paste. The flexible printed circuit board element and grounding steel sheet connecting device and method have the advantages that the contact resistance is effectively reduced and stabilized, the efficiency is improved, and the production cost is reduced.

Owner:DALIAN JIXING ELECTRONICS

Switch device

InactiveUS20060131150A1Accurate operationHigh freedom of movementContact mechanismsElectrostatic/electro-adhesion relaysEngineeringElectrical and Electronics engineering

Owner:FUJITSU COMPONENENT LTD

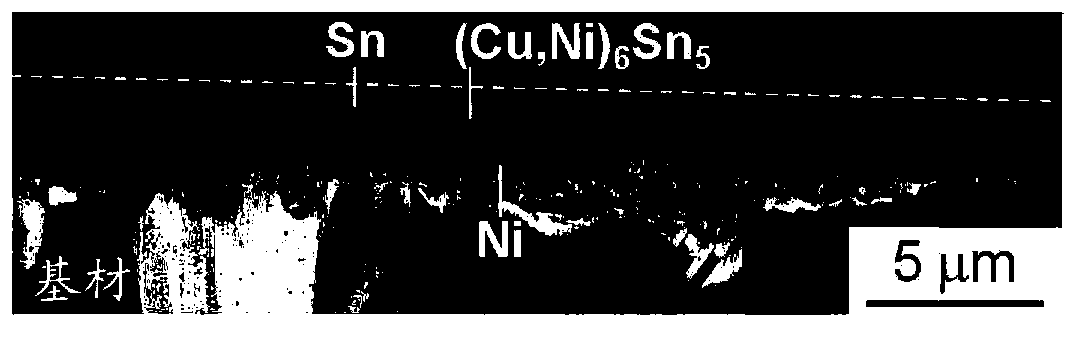

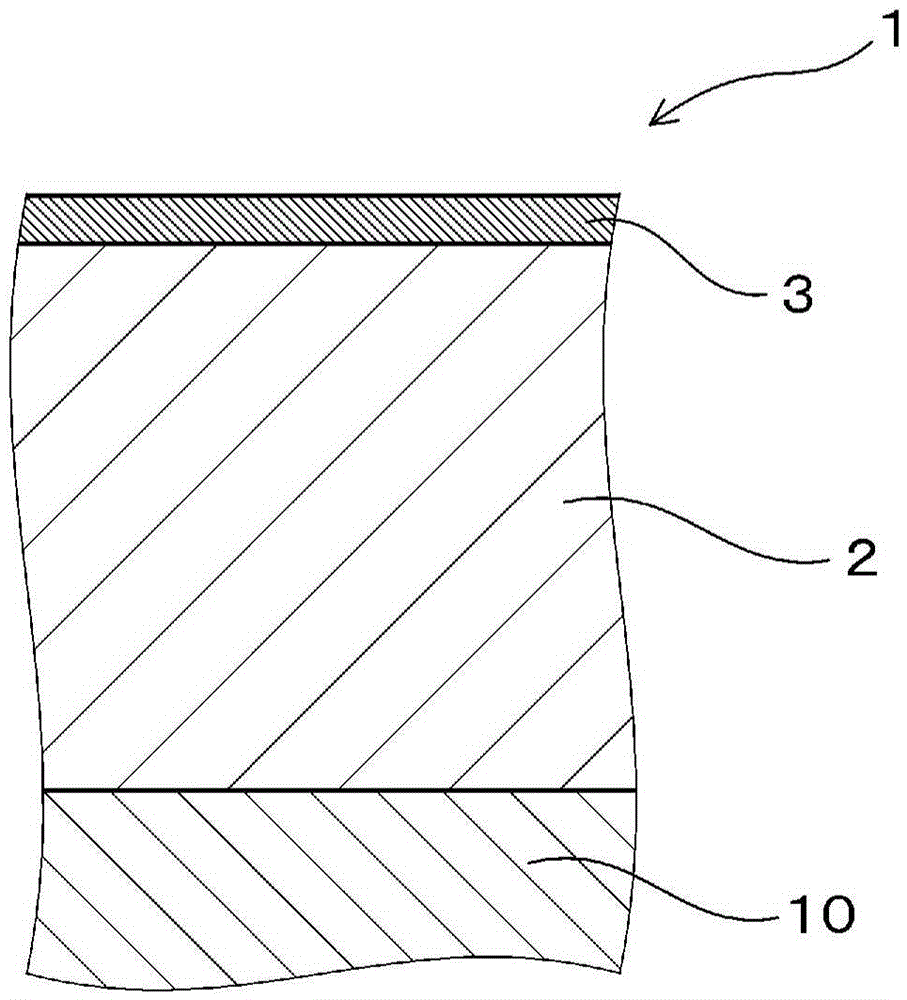

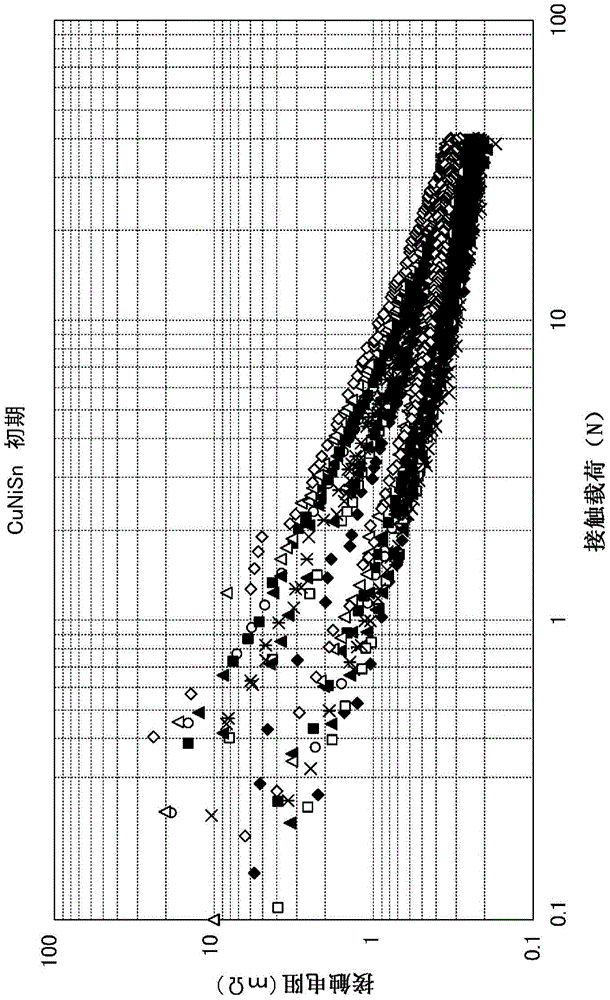

Tin-plated copper-alloy material for terminal and method for producing the same

ActiveCN103531933ALower coefficient of dynamic frictionLow pluggabilityConductive materialCoupling contact membersTinningSurface layer

The invention provides a tin-plated copper-alloy material for terminal and a method for producing the same with an excellent insertion / extraction performance and has an object of reducing dynamic friction coefficient to 0.3 or less with an excellent electrical-connection characteristic. A Cusn alloy layer / a NiSn alloy layer / a Ni or Ni alloy layer are formed between a Sn-based surface layer and a substrate made of Cu or Cu alloy; the Cusn alloy layer is a compound-alloy layer containing Cu 6 Sn 5 as a major proportion and a part of Cu in the Cu 6 Sn 5 is displaced by Ni; the Nisn alloy layer is a compound-alloy layer containing Ni 3 Sn 4 as a major proportion and a part of Ni in the Ni 3 Sn 4 is displaced by Cu; an average interval S of point peaks of the Cusn alloy layer is not less than 0.8 [mu]m and not more than 2.0 [mu]m; an average thickness of the Sn-based surface layer is not less than 0.2 [mu]m and not more than 0.6 [mu]m; an exposed-area rate of the CuSn alloy layer exposed at a surface of the Sn-based surface layer is not less than 1% and not more than 40%; an average of equivalent-circle diameter of the exposed portions of the Cusn alloy layer exposed at the surface of the Sn-based surface layer is not less than 0.1 [mu]m and not more than 1.5 [mu]m; and dynamic friction coefficient is not more than 0.3.

Owner:MITSUBISHI MATERIALS CORP

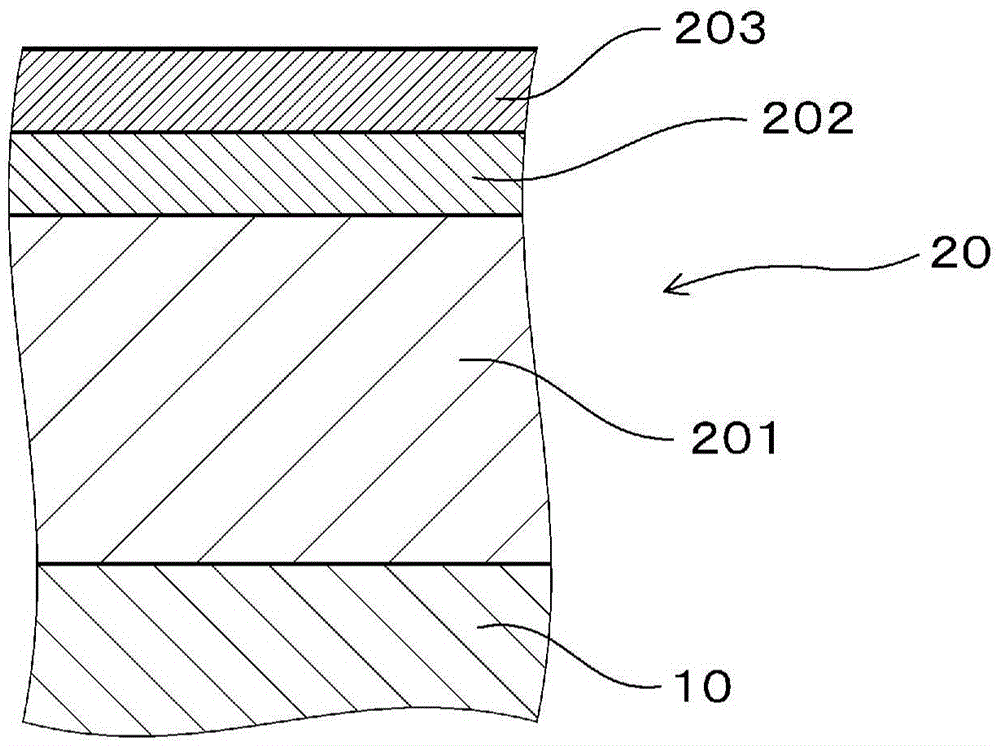

Electric contact material for connector, and method for producing same

ActiveCN105593411AIncreased durabilityEasy to manufactureConductive materialCoupling contact membersChemical compoundMetallic materials

An electric contact material for a connector comprises: a base material (10) made from a metallic material; an alloy layer (2) of a ternary or higher system, which is formed on the base material (10), contains Sn and Cu, and additionally contains at least one metal selected from Zn, Co, Ni and Pd; and an electrically conductive coating film layer (3) which is formed on the surface of the alloy layer (2). The alloy layer (2) contains an intermetallic compound which is produced by substituting a part of Cu in Cu6Sn5 by at least one kind of metal selected from Zn, Co, Ni and Pd. It is preferred that the content of the at least one kind of metal selected from Zn, Co, Ni and Pd in the alloy layer (2) falls within the range from 1 to 50 at.% wherein the total content of the at least one kind of metal and Cu is 100 at.%.

Owner:AUTONETWORKS TECH LTD +2

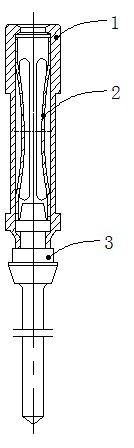

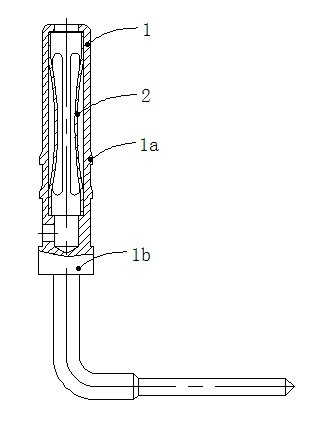

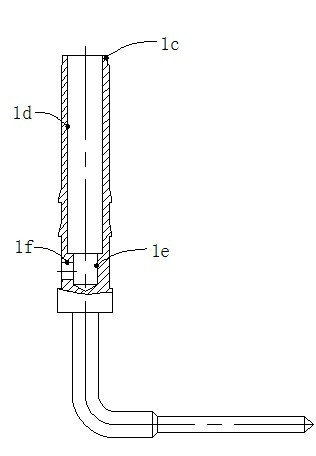

Bent type jack contact for crown spring

InactiveCN102683956ASimple structureImprove processing efficiencyCoupling contact membersInterference fitButt joint

The invention provides a bent type jack contact for a crown spring. The bent type jack contact consists of a bent type jack and a crown spring type contact ring. The tail end of the bent type jack is in a 90-degree bent structure; no inner space for mounting the crown spring type contact ring exists in equipment at a butt-joint end; and the crown spring type contact ring is fixed in the bent type jack through interference fit of an inner hole. The bent type jack contact provided by the invention has the advantages of simple structure, high machining efficiency, high machining precision of the 90-degree bent part, good consistency, reliable signal transmission, simple assembly and good structure stability, and can be used for effectively ensuring the direction of a bending pin. The bent type jack contact is applicable to a bend-plug type circuit connector for a printed board, and has the advantages of smaller contact distance, light plug force requirement and large contact row quantity.

Owner:ZUNYI JINGXING AEROSPACE ELECTRICAL APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com