Patents

Literature

98results about How to "Lower coefficient of dynamic friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

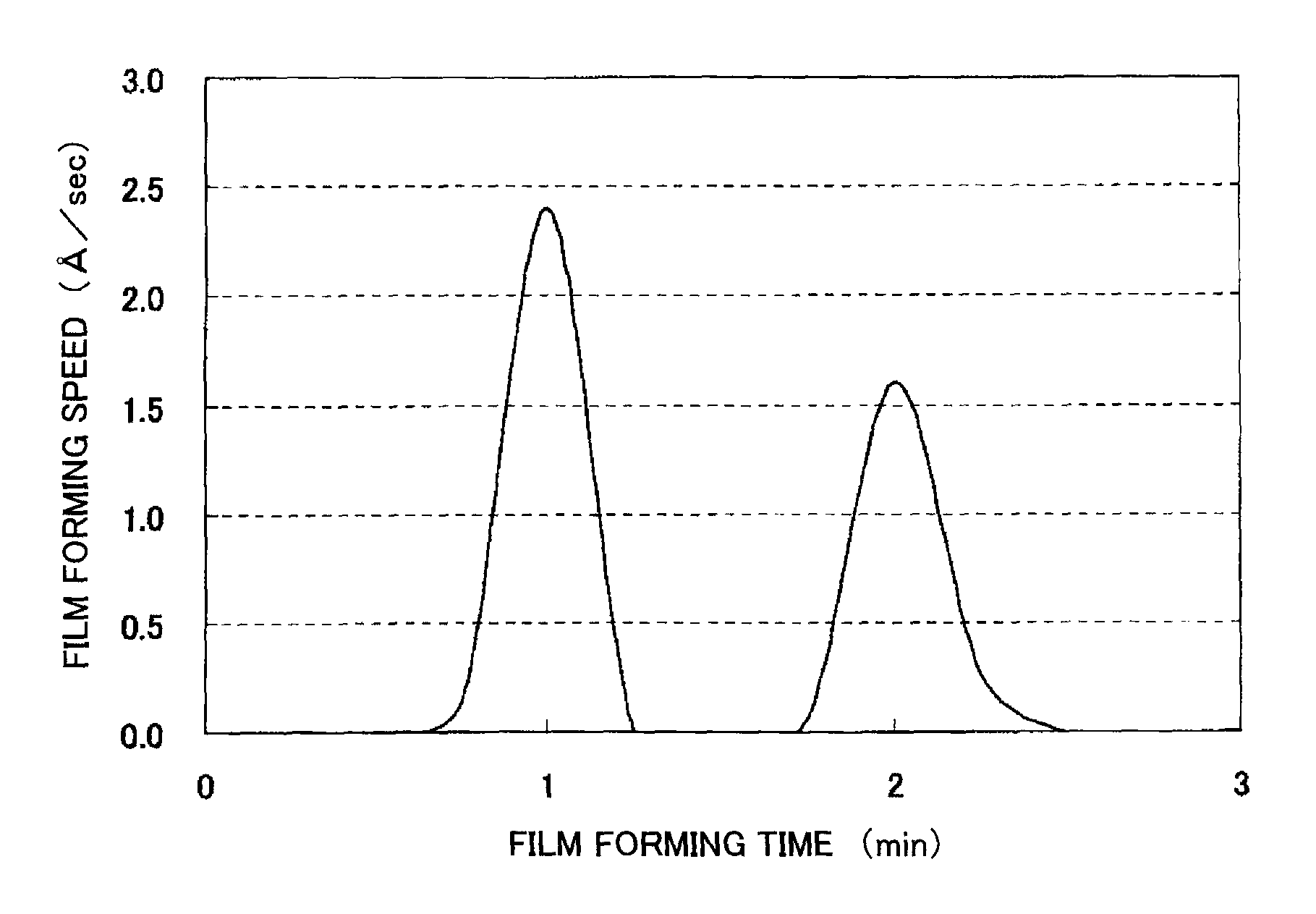

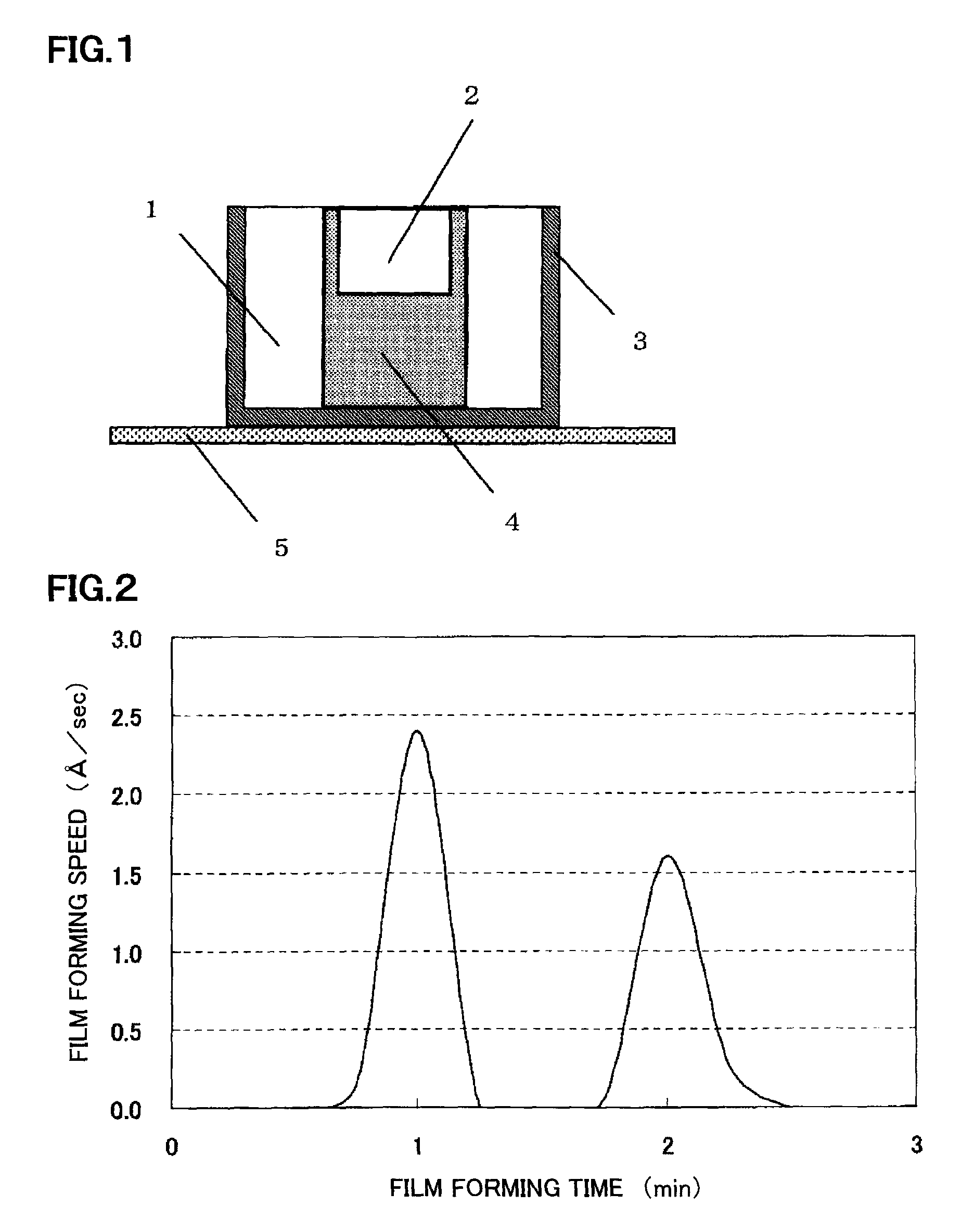

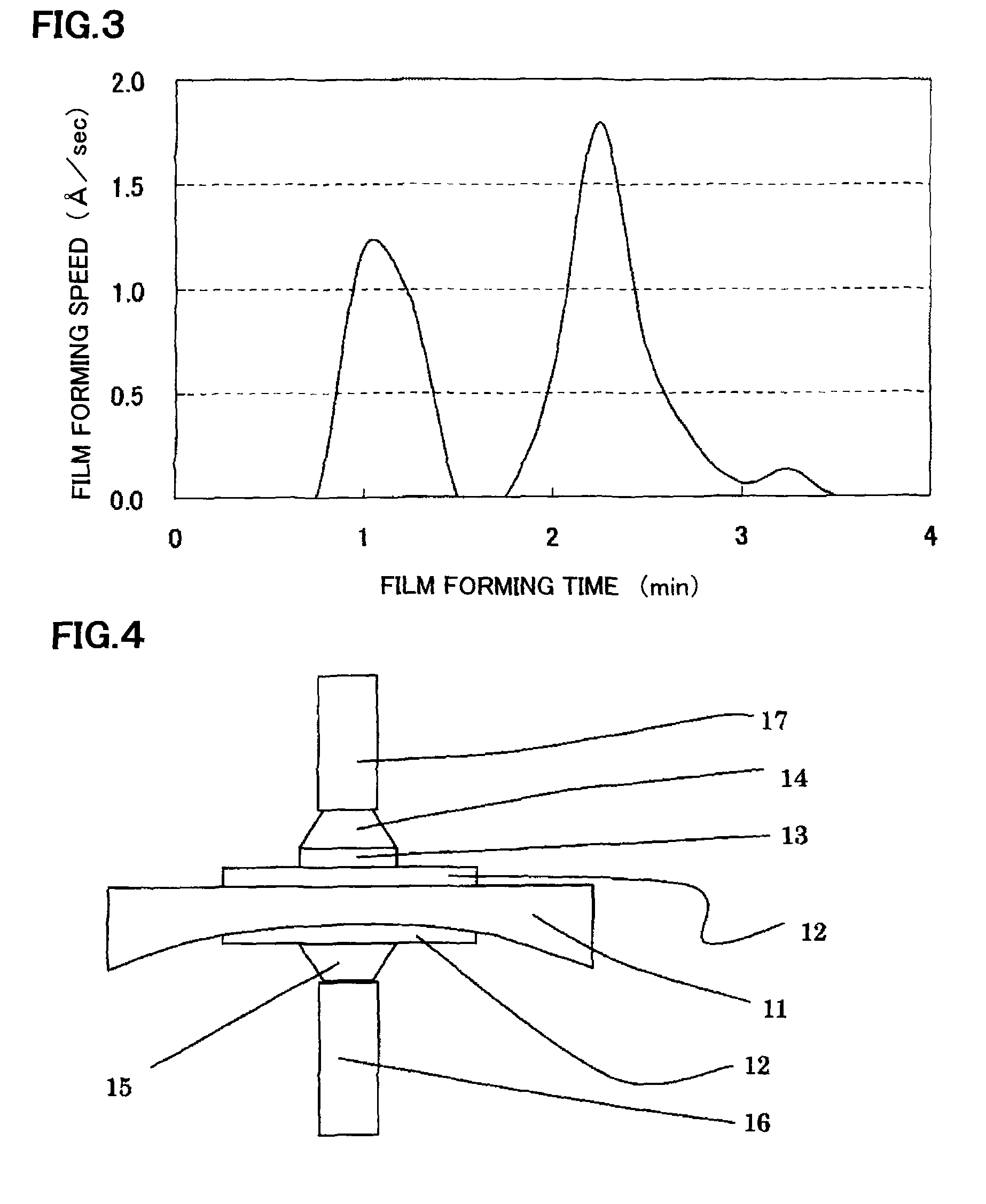

Spectacle lens and method for producing the same

ActiveUS20090257022A1Sufficient processabilityLower coefficient of dynamic frictionSpectales/gogglesSynthetic resin layered productsEyewearLens plate

The disclosure relates to a spectacle lens comprising: a lens base member; a multi-layered anti-reflection film placed on the lens base member, and including a layer mainly made of silicon dioxide as an outermost layer; and a water-and-oil repellent layer provided in contact with the outermost layer of the multi-layered anti-reflection film, and made by using, as raw materials: at least one kind of a first fluorine-substituted alkyl group-containing organosilicon compound and a second fluorine-substituted alkyl group-containing organosilicon compound. The disclosure also relates to methods of producing a spectacle lens that is capable of retaining a sufficient water-and-oil repellency over an extended period, and having sufficient edge processability.

Owner:NIKON ESSILOR

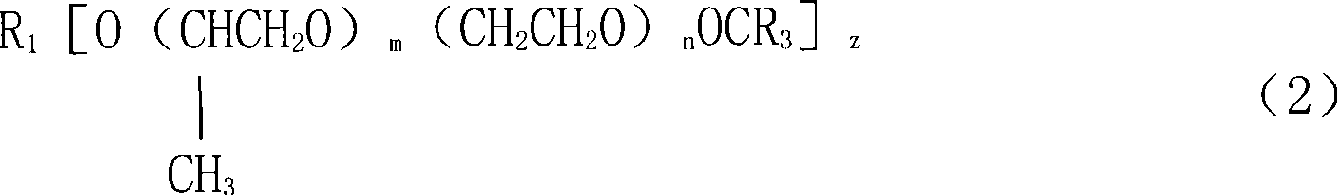

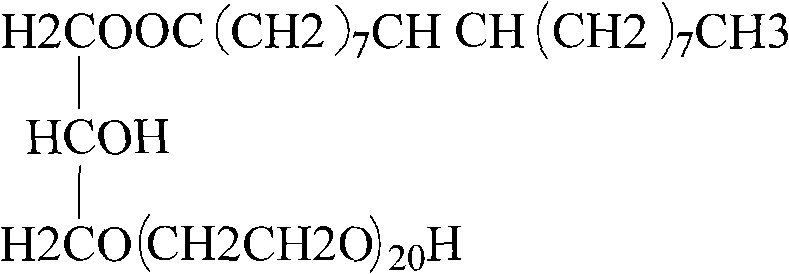

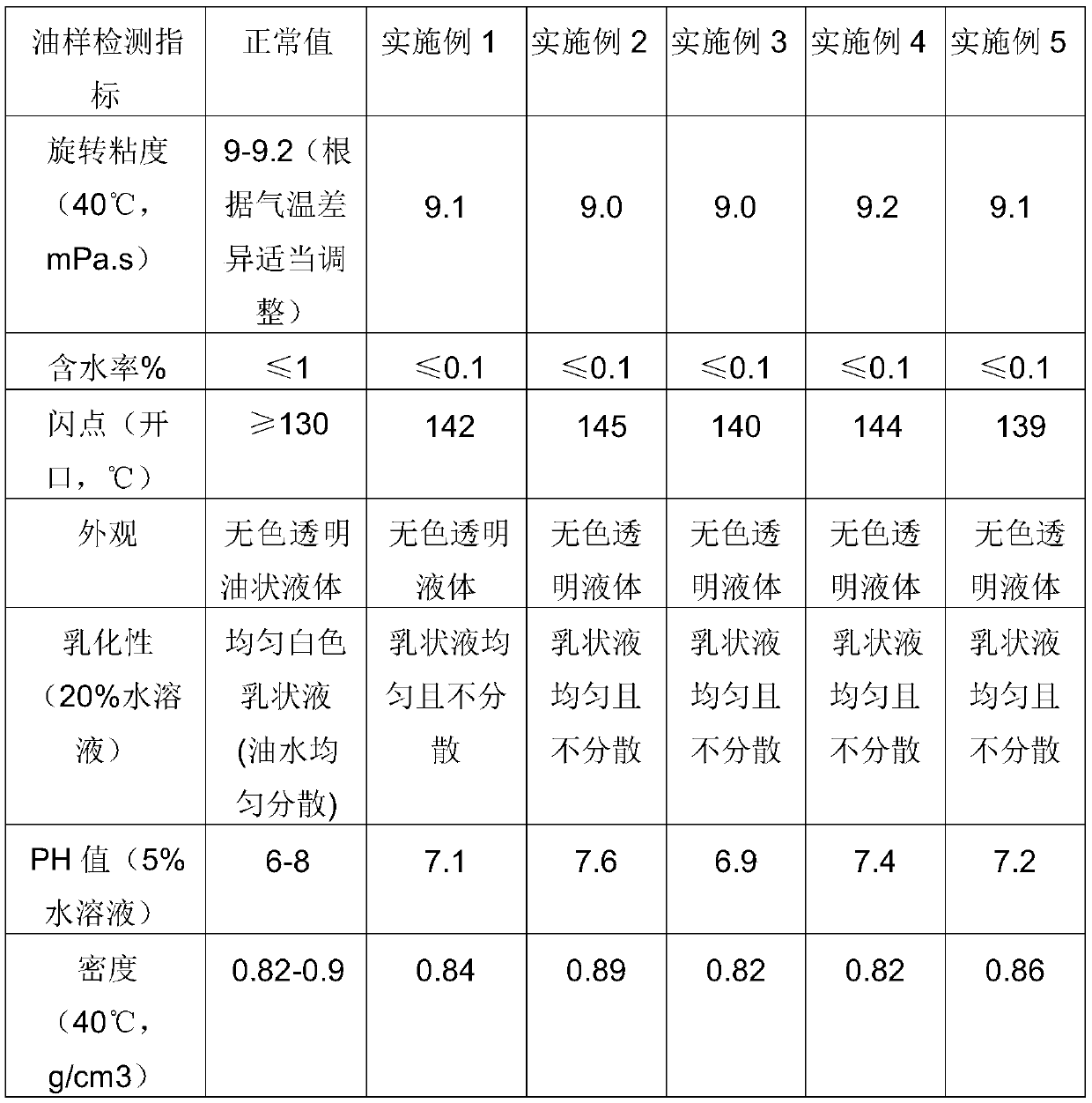

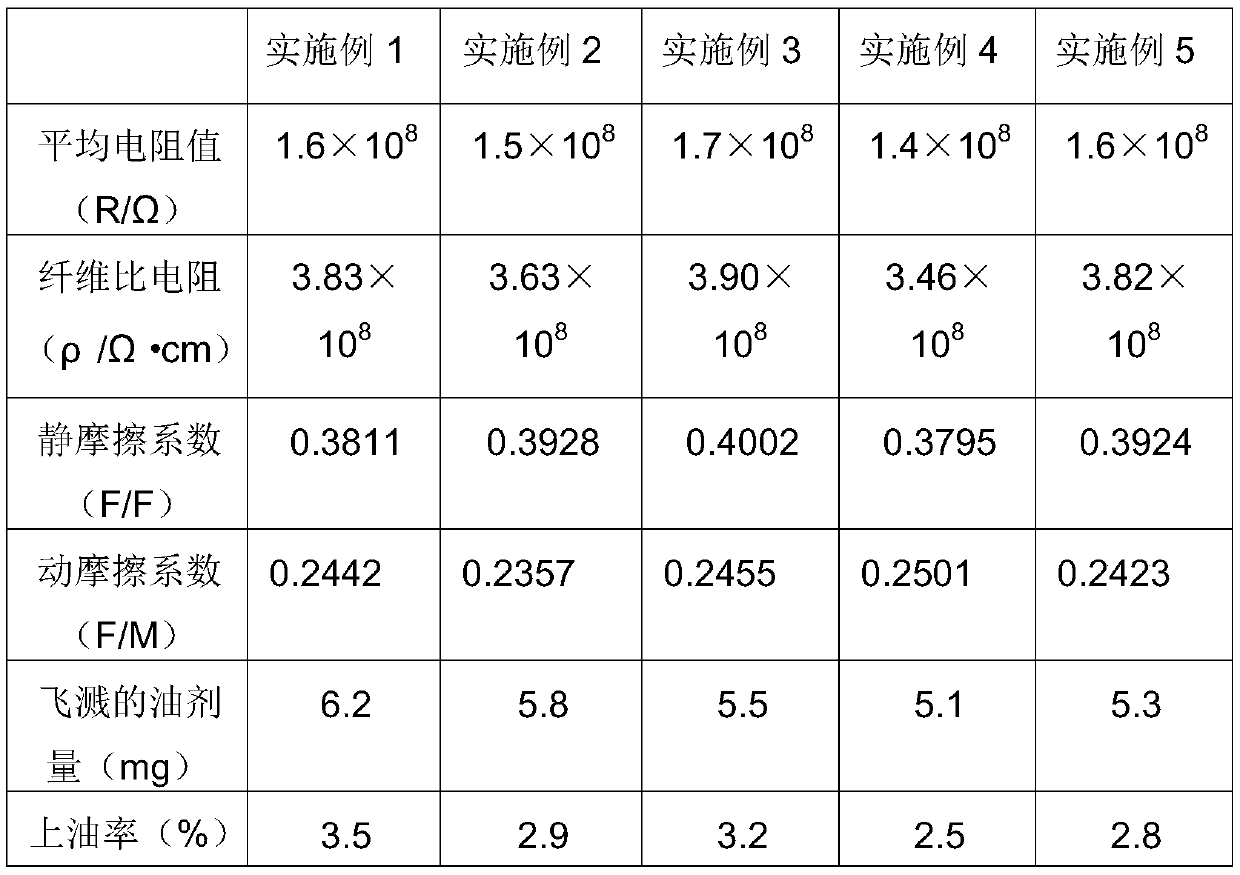

Short-fiber oil agent for aromatic polyamide fiber

The invention discloses a short-fiber oil agent for aromatic polyamide fiber, which is prepared from 3 to 40 weight percent of polyol fatty acid ester, 5 to 70 weight percent of polyoxyethylene polyol fatty acid ester, 5 to 40 weight percent of fatty alcohol ethylene oxide-propylene oxide random copolyether or polyether ester, 1 to 40 weight percent of fatty alcohol polyethenoxy ether organic phosphate salt, 1 to 30 weight percent of fatty alcohol polyethenoxy ether sulfuric acid ester salt and 0.1 to 10 weight percent of polyether modified silicon oil. The oil agent can solve the defects of the poor main performance, i.e. poor electrostatic resistance, poor heat resistance, poor saturation, and the like of the prior oil agent, aims to provide an aramid short-fiber oil agent which has excellent electrostatic resistance, smoothness, softness and dyeing uniformity, enables the aramid short fiber to have excellent post processing performance, and the like.

Owner:CHINA PETROCHEMICAL CORP +1

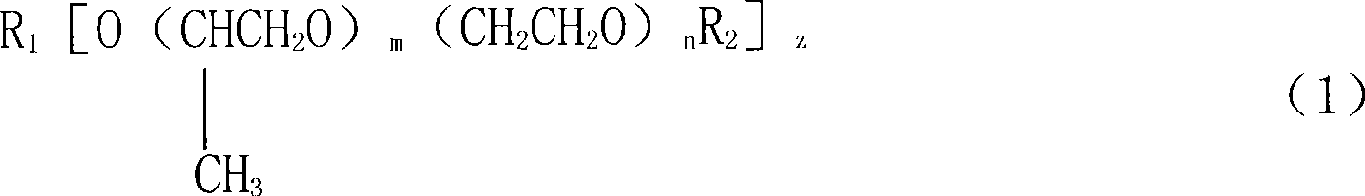

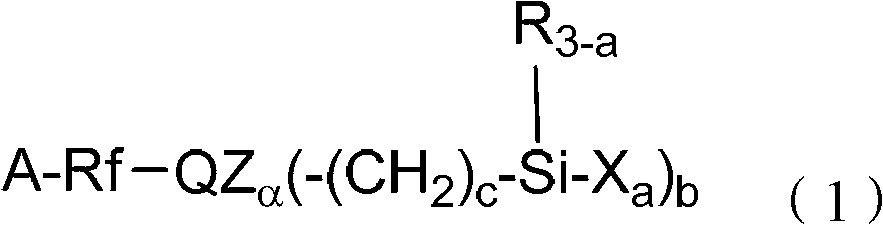

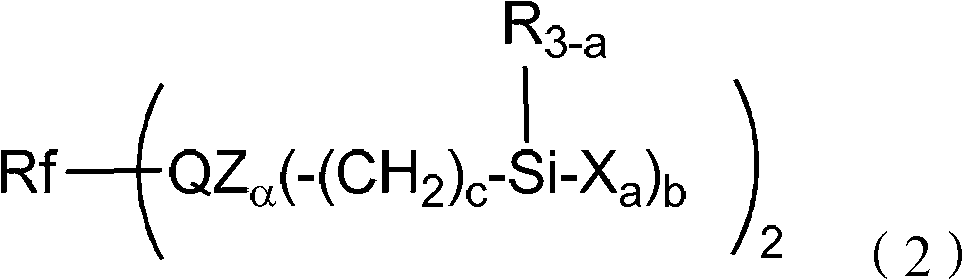

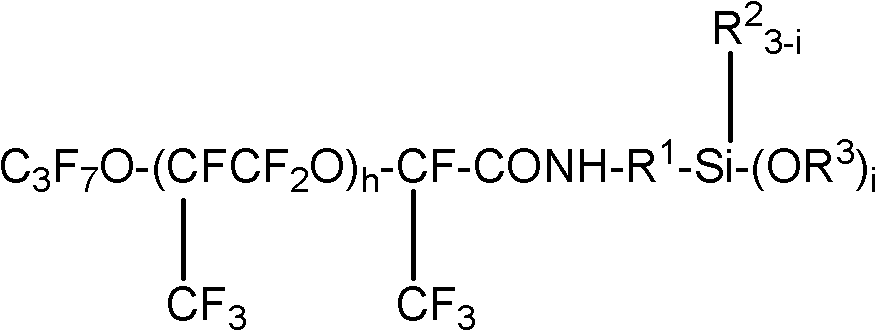

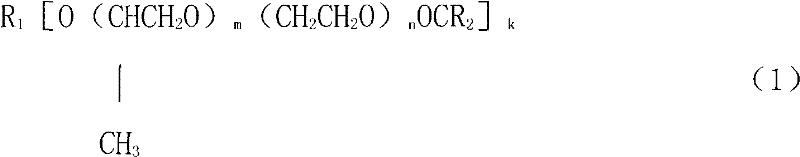

Fluorooxyalkylene group-containing polymer composition, a surface treatment agent comprising the same and an article treated with the agent

ActiveCN102746635ALower coefficient of dynamic frictionImprove wear resistanceAntifouling/underwater paintsAdhesive processes with surface pretreatmentPolymer sciencePolymer composition

A fluorooxyalkylene group-containing polymer composition comprising a liner fluorooxyalkylene group-containing polymer represented by the formula (1) which has a hydrolysable group at a terminal and is hereinafter called one-terminal hydrolyzable polymer, and a liner fluorooxyalkylene group-containing polymer represented by the formula (2) which has hydrolysable groups at both terminals and is hereinafter called "both-terminal hydrolyzable polymer", wherein the amount of the both-terminal hydrolyzable polymer is 0.1 mole % or more but less than 10 mole %, relative to the total mole of the one-terminal hydrolyzable polymer and the both-terminal hydrolyzable polymer.

Owner:SHIN ETSU CHEM IND CO LTD

Method for preparing trivalent chromium compound

InactiveCN101607738AExcellent fingerprint resistanceLower coefficient of dynamic frictionMetallic material coating processesChromium compoundsSteel platesHexavalent chromium

The invention provides a method for preparing a trivalent chromium compound. The method comprises the following steps that a hexavalent chromium compound contacts with a reducing agent and a complexing agent under the existence of water, wherein the reducing agent is a substance capable of reducing hexavalent chromium into trivalent chromium; and the complexing agent is a substance capable of having complexation with trivalent chromium ions. When the trivalent chromium compound prepared by the method is adopted as a film forming agent of a galvanized self-lubricating steel plate, an obtained self-lubricating coating has obviously improved fingerprint resistance, corrosion resistance and adhesive force as well as obviously reduced coefficient of dynamic friction.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Fluoro polymer synergistic coating treatment process for iron and steel material

InactiveCN1616713AGood bindingGood wear resistanceHot-dipping/immersion processesMolten spray coatingNickel coatingHardness

The iron and steel material treating process with synergistic fluoropolymer coating features the first chemical nickel plating of iron and steel material to form the base layer of the synergistic coating, the subsequent pore creating treatment of the nickel coating, the introducing of fluoropolymer to the pores and surface and the heat treatment under vacuum state for the fluoropolymer to fuse with the chemical coating to form the synergistic coating. The said technological process has the advantages of high coating hardness, high wear resistance, the self-lubricating performance and increased wear resistance caused by the fluoropolymer as friction reducing matter, resistance to most harmful matters of the fluoropolymer, and self-lubricating function of the dry coating.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

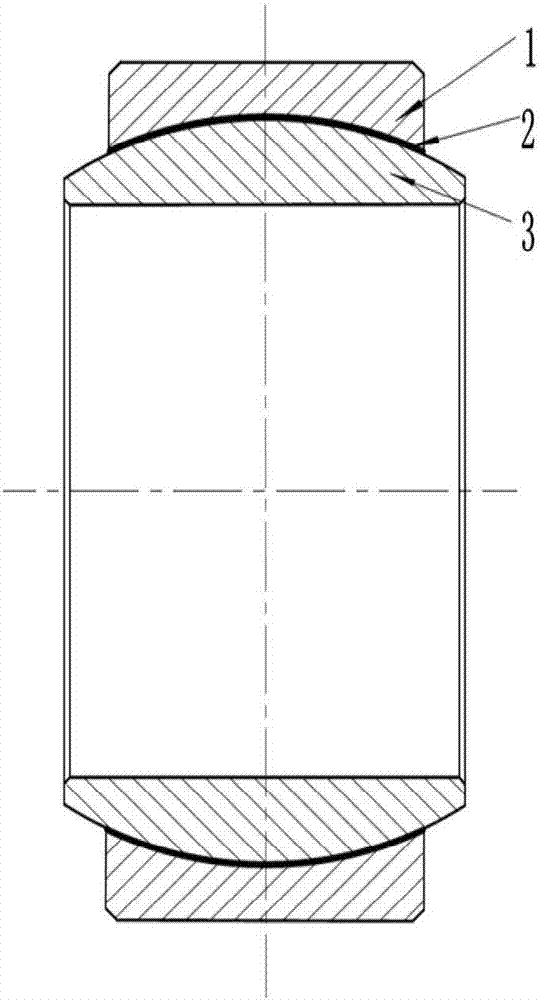

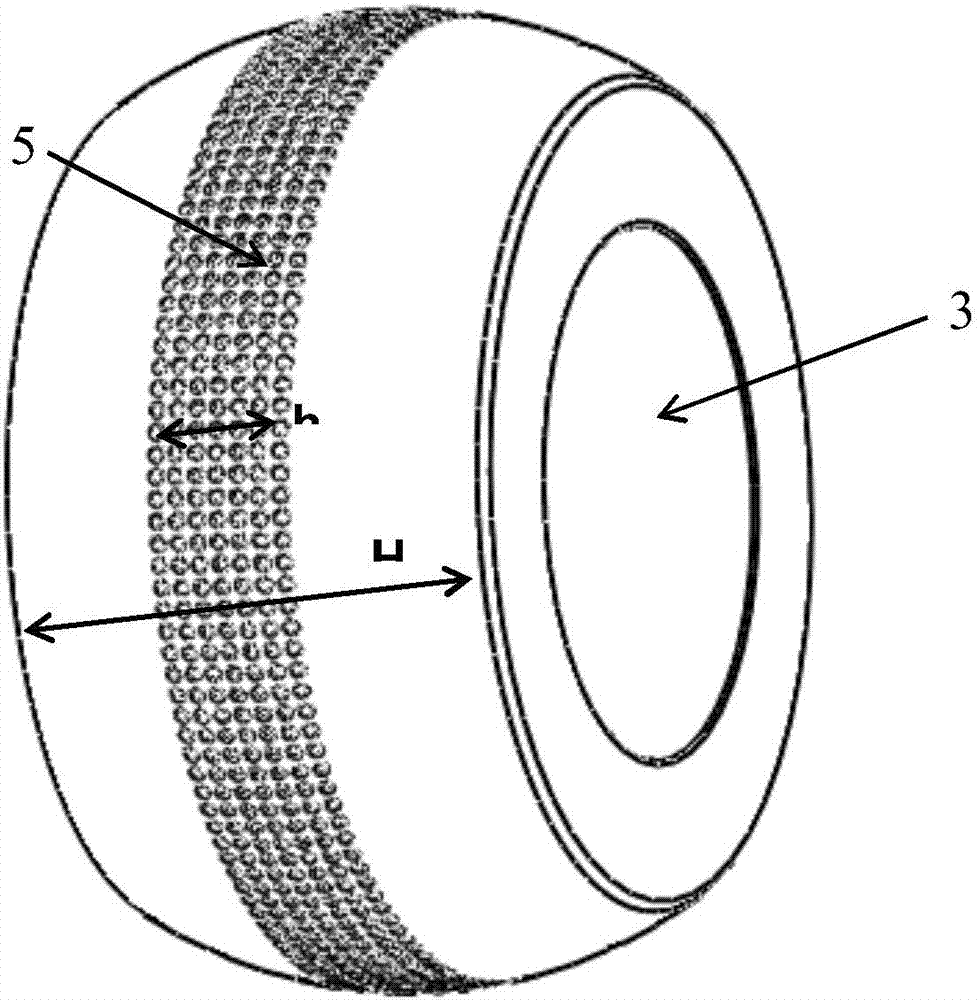

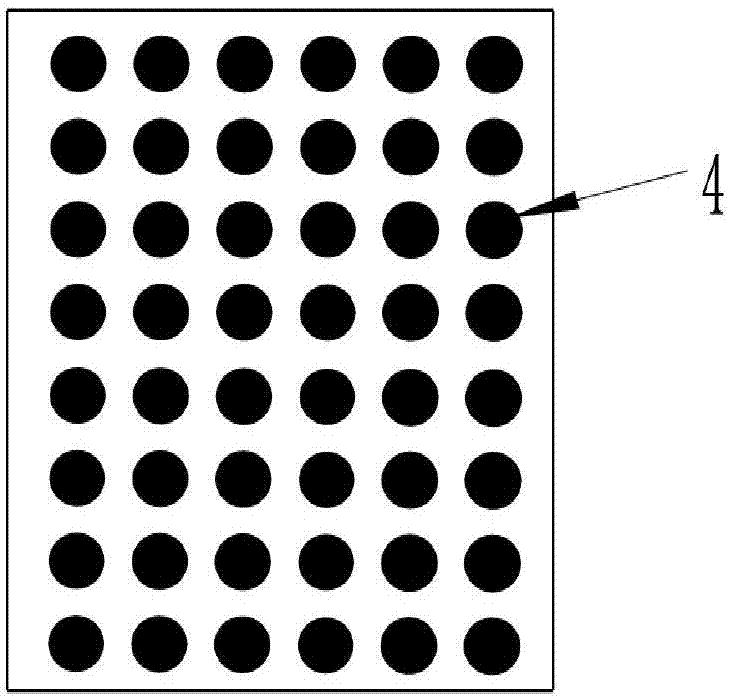

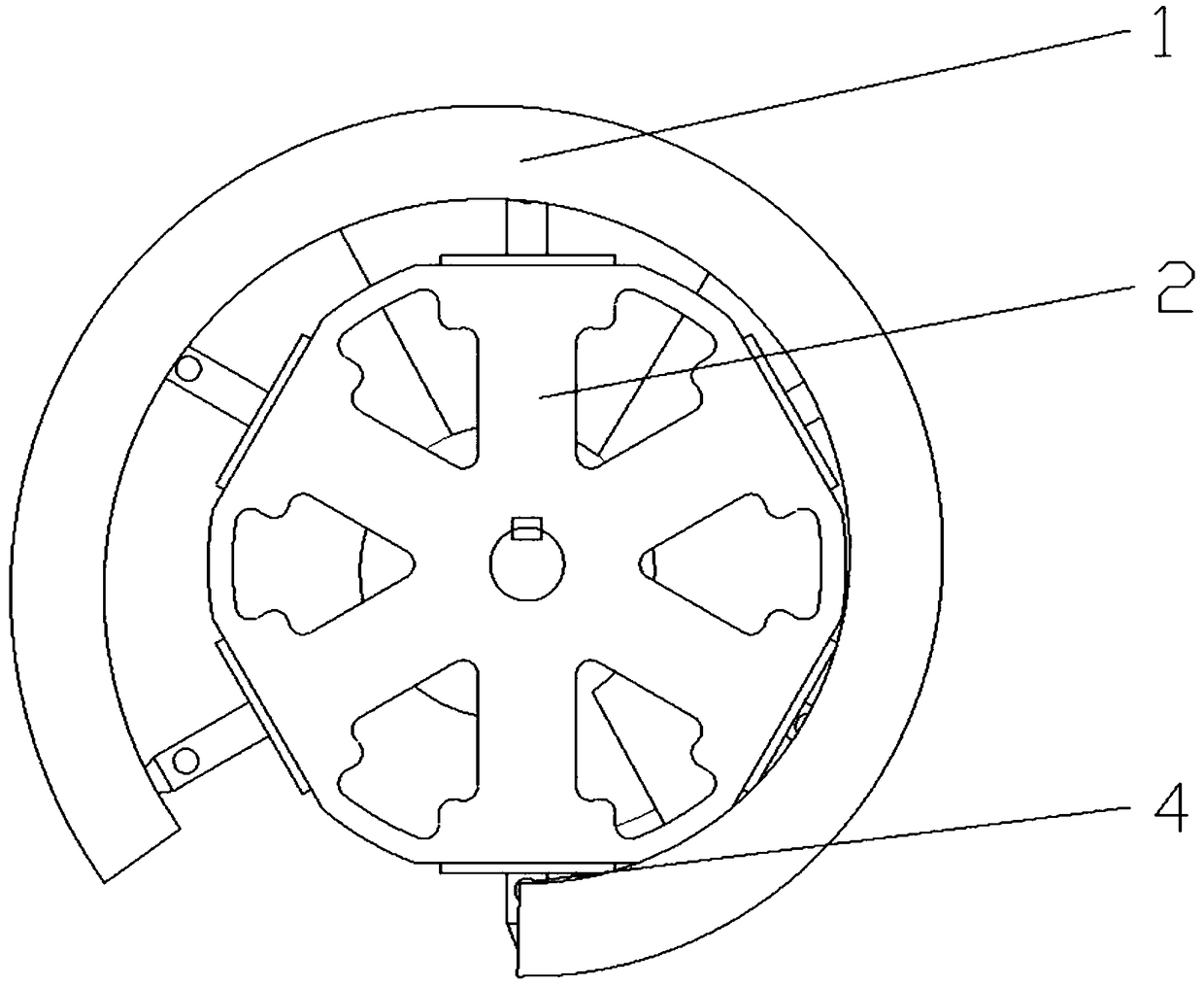

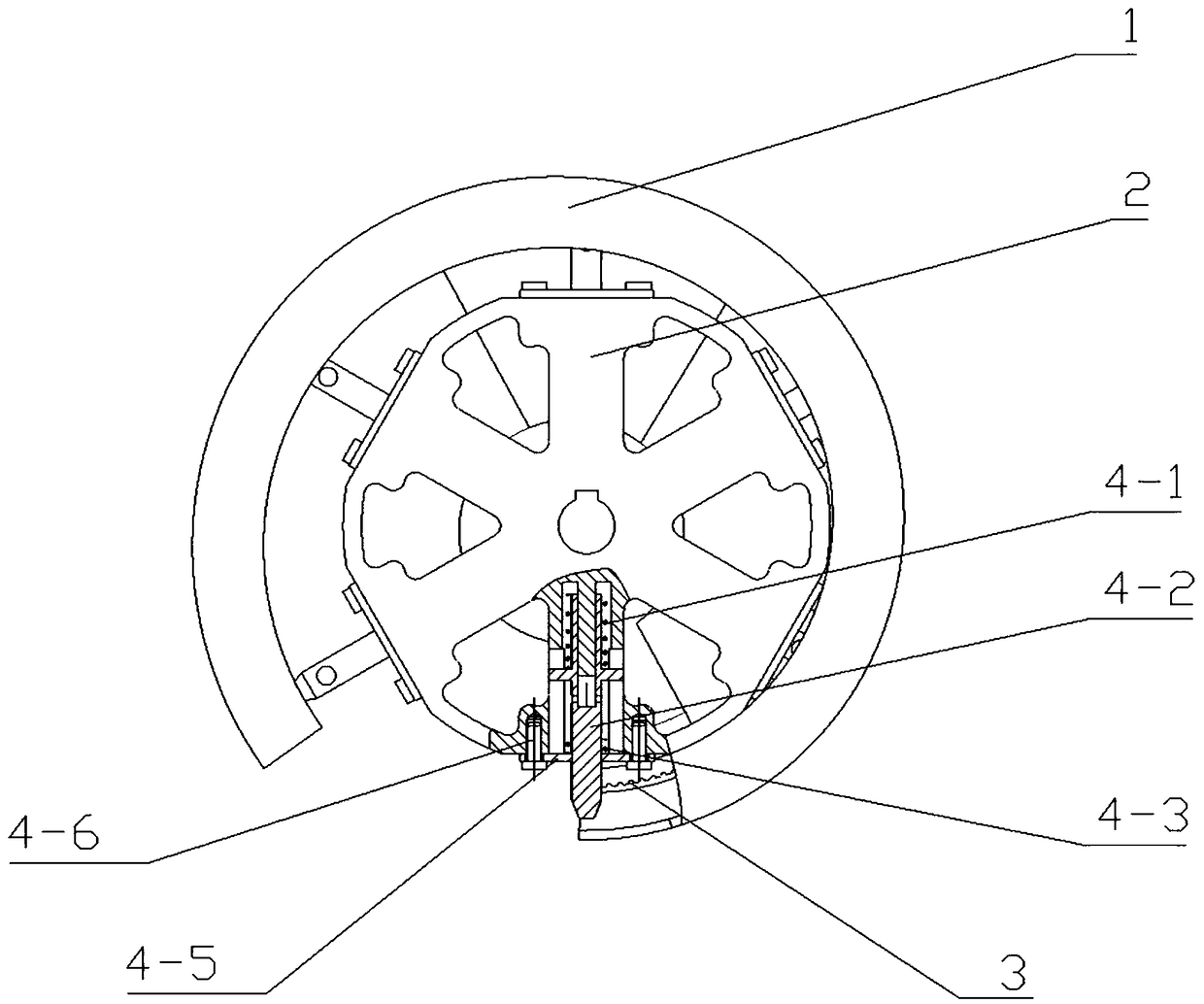

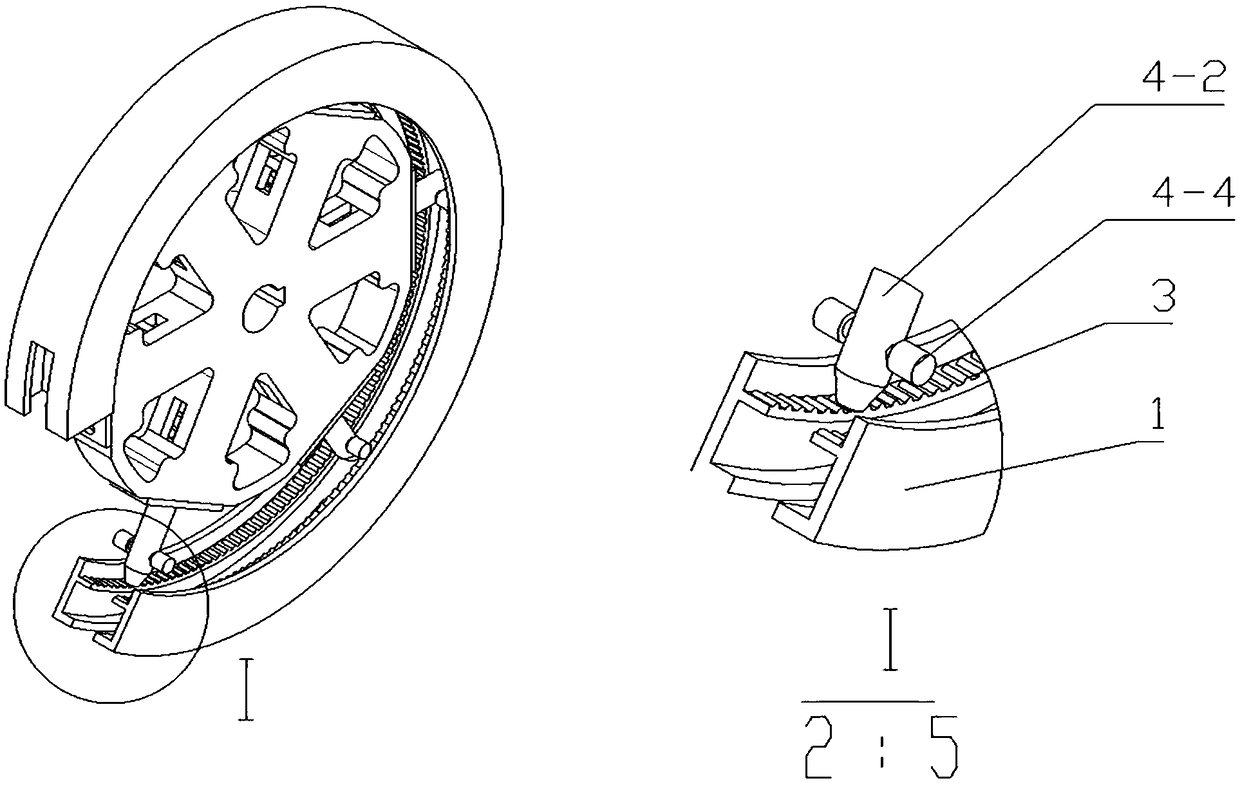

Fabric type surface texture friction pre-filling type self-lubricating knuckle bearing

ActiveCN107387553AExtended service lifePromote generationShaftsBearing componentsStatic friction coefficientEngineering

The invention discloses a fabric type surface texture friction pre-filling type self-lubricating knuckle bearing. The fabric type surface texture friction pre-filling type self-lubricating knuckle bearing comprises an inner ring and an outer ring; a surface texture is machined on the outer sphere face of the bearing inner ring (3) and subjected to self-lubricating material friction pre-filling technology treatment to form a self-lubricating material friction pre-filling surface texture structure; and a layer of fabric self-lubricating material liner is pasted on the surface of the inner sphere face of the bearing outer ring (1). Abrasion to the fabric liner by the edge of the surface texture in the initial stage of friction is avoided to a certain degree, the surface texture is easily full of self-lubricating materials in a friction mode, and the process is simple. The self-lubricating materials pre-filling the textured surface optimize the friction interface material configuration, so that a friction surface transfer membrane is easy to generate, the texture edge cutting effect is weakened to a certain degree, the friction interface has lower static friction coefficient and lower dynamic friction coefficient, and accordingly the service life of the self-lubricating knuckle bearing is greatly prolonged.

Owner:YANSHAN UNIV

Surface microporous SiC ceramic material and preparation method thereof

ActiveCN102030532AIncrease chance of connectionEvenly distributedCeramicwareCarboxymethyl celluloseOxidation resistant

The invention discloses a surface microporous SiC ceramic material, which consists of main raw materials, polycarbosilane and carboxymethyl cellulose, wherein the main raw materials consist of the following components in percentage by weight: 85 to 90 percent of silicon carbide powder and 10 to 15 percent of yttrium aluminum garnet; the polycarbosilane is 5 to 10 percent of the total weight of the main raw materials; and the carboxymethyl cellulose is 2 to 8 percent of the total weight of the main raw materials. Meanwhile, the invention discloses a method for preparing the surface microporous SiC ceramic material, which comprises the following steps of: uniformly mixing the silicon carbide powder, the yttrium aluminum garnet and the polycarbosilane, and adding aqueous solution of the carboxymethyl cellulose and performing ball-milling mixing; drying the obtained size; and molding the obtained powder and performing vacuum sintering at high temperature so as to prepare the surface microporous SiC ceramic material. The surface microporous SiC ceramic material keeps high strength, high hardness, abrasion resistance, corrosion resistance and oxidation resistance, the self-lubricating property of the material is improved, and a cross section can be prevented from being bonded. Therefore, the service life of the material is prolonged.

Owner:ZHEJIANG UNIV

Filament oil agent for poly-p-phenylene telephthalamide

The invention discloses a filament oil agent for poly-p-phenylene telephthalamide, aiming to solve the problems, such as poor heat resistance, smoothness, adaptability and the like of the oil agent in the prior art. The filament oil agent for the poly-p-phenylene telephthalamide, provided by the invention, comprises the following components: (a) 3-60wt% polyol fatty acid ester, (b) 2-40wt% polyoxyethylene polyol fatty acid ester, (c) 5-40wt% fatty alcohol ethylene oxide-propylene oxide polyether fatty acid ester, (d) 1-20wt% polyoxyethylene alkyl phosphonate, (e) 5-30wt% long-chain fatty alcohol and fatty acid ester, (f) 1-20wt% adhesion property improver and (g) 0.1-5wt% polyether modified silicone oil. The oil agent has the advantages of good smoothness, heat resistance, antistatic property, dyeing uniformity and post processing property.

Owner:CHINA PETROLEUM & CHEM CORP +1

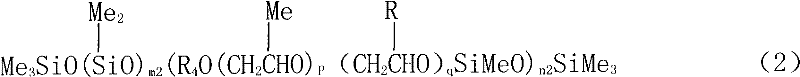

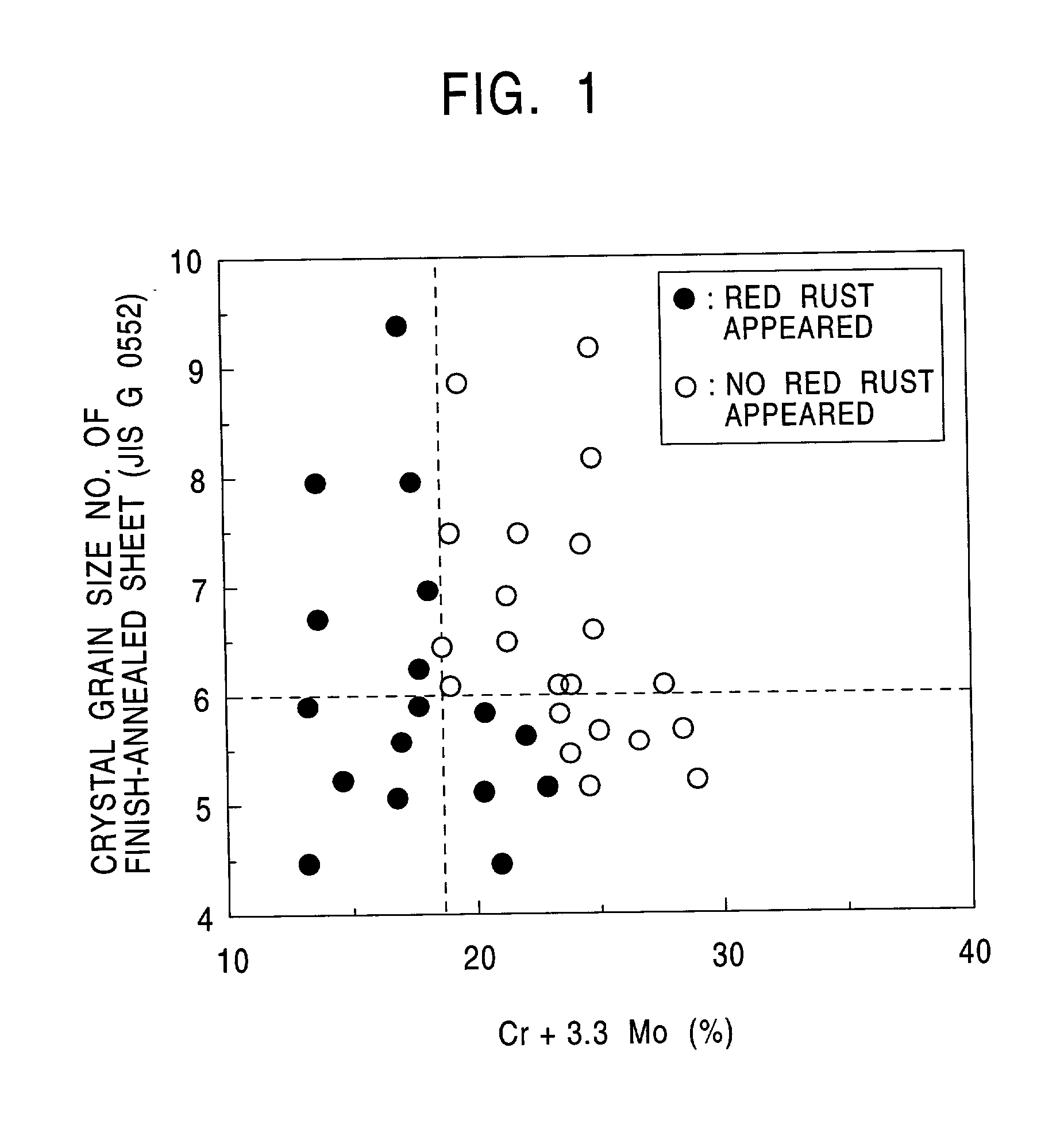

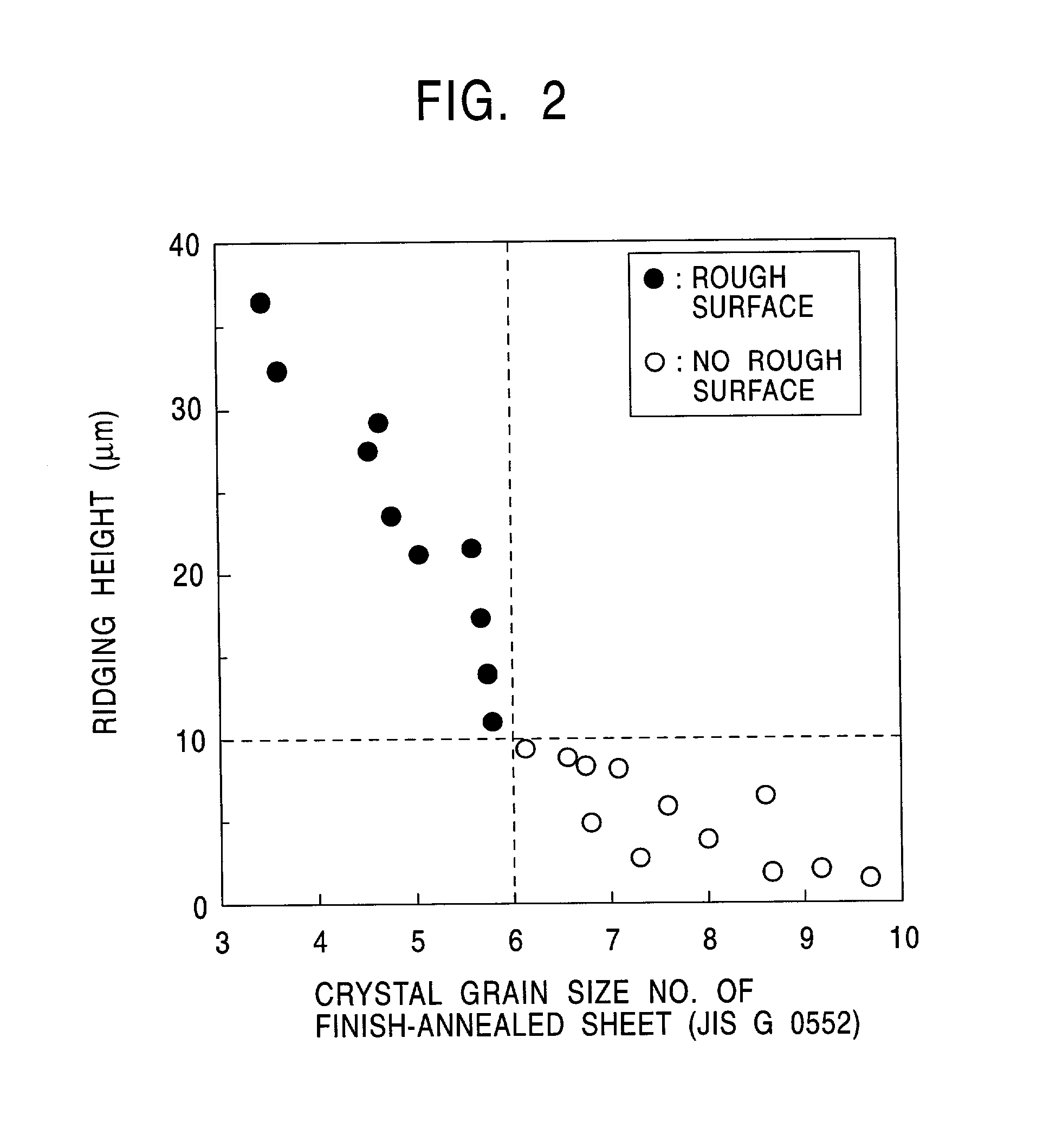

Ferritic stainless steel sheet with excellent workability and method for making the same

InactiveUS20020136661A1Improve deep drawing performanceLower coefficient of dynamic frictionMetallic material coating processesOrganic acidMachinability

A ferritic stainless steel sheet for use in automobile fuel tanks and fuel pipes having smooth surface and resistance to organic acid is provided. The sheet contains, by mass, not more than about 0.1% C, not more than about 1.0 Si, not more than about 1.5% Mn, not more than about 0.06% P, not more than about 0.03% S, about 11% to about 23% Cr, not more than about 2.0% Ni, about 0.5% to about 3.0% Mo, not more than about 1.0% Al, not more than about 0.04% N, at least one of not more than about 0.8% Nb and not more than about 1.0% Ti, and the balance being Fe and unavoidable impurities, satisfying the relationship: 18<=Nb / (C+N)+2Ti / (C+N)<=60, wherein C, N, Nb, and Ti in the relationship represent the C, N, Nb, and Ti contents by mass percent, respectively. A process for making the same is also provided.

Owner:JFE STEEL CORP

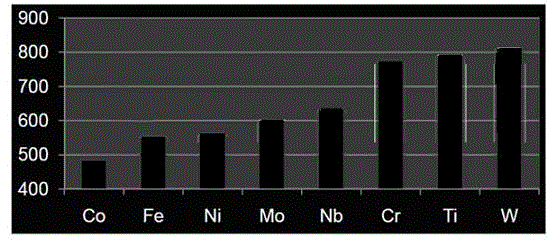

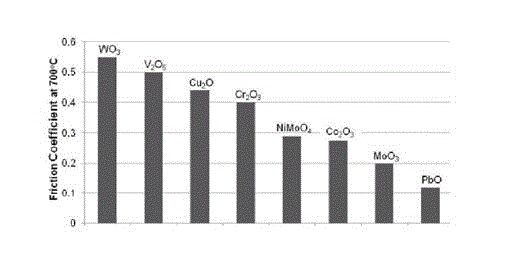

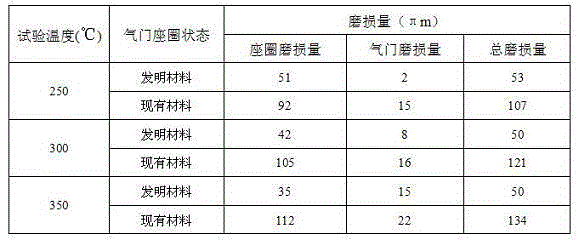

Valve seat ring for alternative fuel engine

ActiveCN104630659ALow initial oxidation temperatureLower coefficient of dynamic frictionTurbinesOther manufacturing equipments/toolsAlternative fuelsWear resistance

The invention relates to a valve seat ring for an alternative fuel engine. The valve seat ring comprises the following chemical components (weight percent): 0.8% -1.2% of C, 0.8% -1.2% of Si, 0. 4% -0.7% of Mn, 0.6% -0.9% of S, 5% -7% of Ni, 4% -6% of Cr, 10% -15% of Mo, 22%-27 % of Co, and the balance of Fe. The valve seat ring is machined by a powder metallurgy method in a vacuum environment, and the production process of two-time pressing and two-time sintering is adopted in the machining process. The valve seat ring has high abrasion resistance, high heat resistance and high corrosion resistance, the good matching of the valve seat ring and a valve is also ensured, and the high-strength valve seat ring material has good machinability, and the excessive machining cost cannot be caused. The content of hard particles reaches about 45%, and the high-strength valve seat ring can meet the requirements of various alternative fuels.

Owner:CHERY AUTOMOBILE CO LTD

Compound wax microemulsion composition, and preparation method and application thereof

ActiveCN109487560AHigh Hydrophilic ContentHigh hardnessGrip property fibresVegetal fibresWater basedYarn

The invention discloses a compound wax microemulsion composition, and a preparation method and an application thereof. The compound wax microemulsion composition comprises the following components inpercent by weight: 8-28wt% of high melting point oxidized polyethlene wax, 4-14wt% of low melting point wax, 1-3wt% of a hyperbranched Gemini surfactant, 0.5-3wt% of a hyperbranched softener, 3-13wt%of an emulsifier, 0.1-1wt% of sodium hydroxide or potassium hydroxide and 50-80wt% of water based on the total weight of the compound wax microemulsion. The compound wax microemulsion can be preparedby a one-step high-temperature emulsification method which is simple in process. The prepared compound wax microemulsion is good in centrifugal stability and diluting stability. By trimming the microemulsion to a textile, the smooth performance of the textile can be improved obviously, the coefficient of kinetic friction of yarns can be reduced, the sewing performance and hydrophilia of a knittedfabric are improved, and yellowing is reduced.

Owner:TAICANG BAONI IND CO LTD

Polyester spandex super-quick-drying knitted fabric and processing method thereof

ActiveCN109056171AAchieve the effect of moisture absorption and quick dryingSoftSolvent-treatmentWeft knittingFiberPolyester

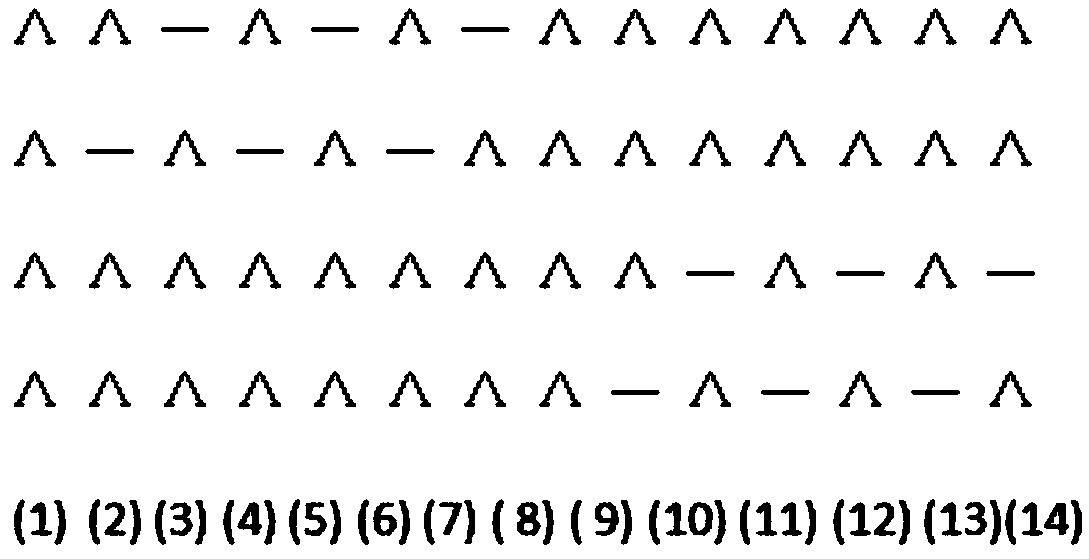

The invention discloses a polyester spandex super-quick-drying knitted fabric and a processing method thereof. The fabric is woven through a special weaving method with complete-extinction super-fine-denier polyester fibers with the filament number of 1.1-1.7 D and spandex fibers as the raw materials, and the close-fitting surface of the fabric is provided with dotted jacquard protrusions capableof guiding moisture in one direction. The processing method includes the steps of conducting weaving through a four-track single-side knitting machine, wherein four needles 1, 2, 3 and 4 are adopted;forming one loop through fourteen paths; conducting post-processing through polyester keratase. By means of the special weaving structure, the close-fitting surface has a small protrusion jacquard effect, the contact area of the close-fitting surface and a human body is reduced, and the movable friction coefficient is reduced; the dotted protrusion jacquard part making contact with skin has a one-way moisture guide function, and the water expanding capacity is improved. The complete-extinction super-fine-denier polyester fibers are selected as the raw material, the surface area of the fibers is increased, subsequent fibers have a certain anti-UV effect, and the knitted fabric has the advantages of being soft in color and luster, good in deep dyeing performance, high in textile drapability,strong in shielding performance and the like.

Owner:SHANGHAI JIALE

Tin-plated copper-alloy material for terminal and method for producing the same

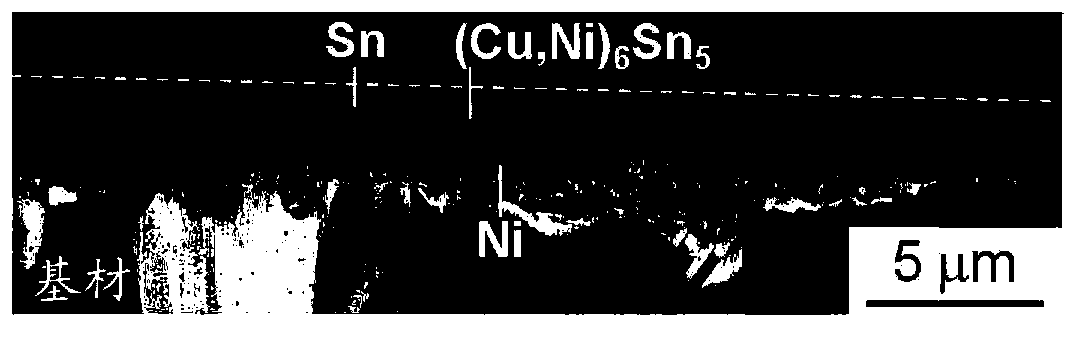

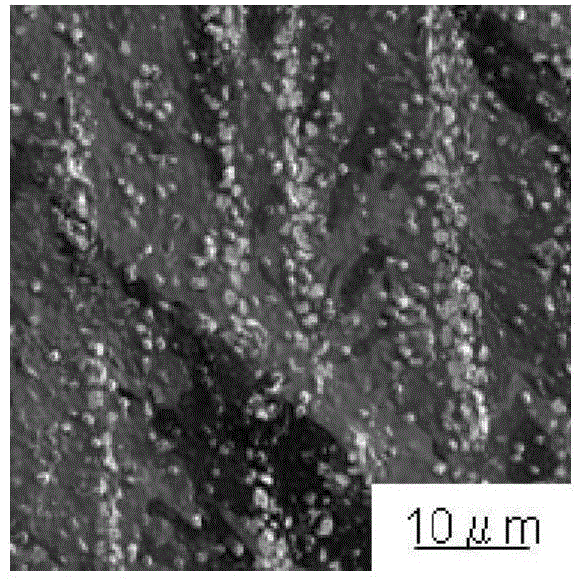

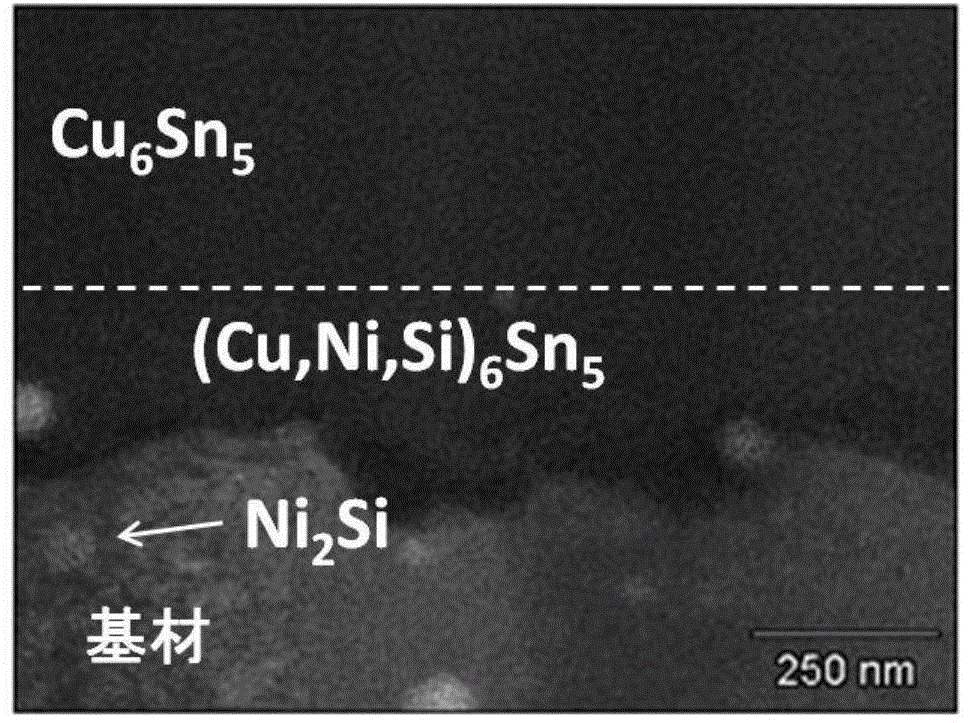

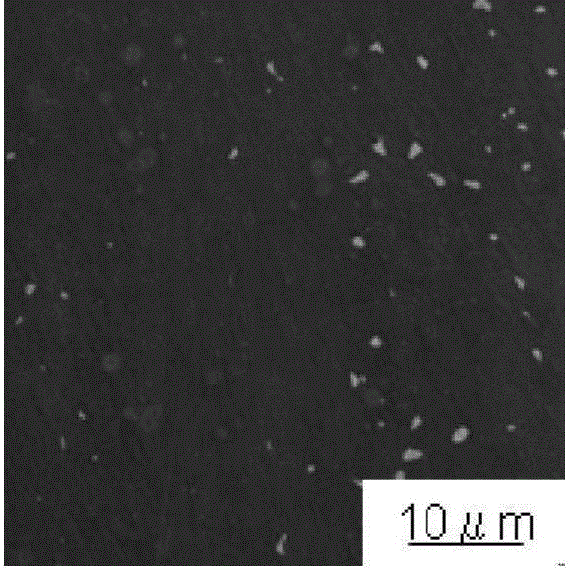

ActiveCN103531933ALower coefficient of dynamic frictionLow pluggabilityConductive materialCoupling contact membersTinningSurface layer

The invention provides a tin-plated copper-alloy material for terminal and a method for producing the same with an excellent insertion / extraction performance and has an object of reducing dynamic friction coefficient to 0.3 or less with an excellent electrical-connection characteristic. A Cusn alloy layer / a NiSn alloy layer / a Ni or Ni alloy layer are formed between a Sn-based surface layer and a substrate made of Cu or Cu alloy; the Cusn alloy layer is a compound-alloy layer containing Cu 6 Sn 5 as a major proportion and a part of Cu in the Cu 6 Sn 5 is displaced by Ni; the Nisn alloy layer is a compound-alloy layer containing Ni 3 Sn 4 as a major proportion and a part of Ni in the Ni 3 Sn 4 is displaced by Cu; an average interval S of point peaks of the Cusn alloy layer is not less than 0.8 [mu]m and not more than 2.0 [mu]m; an average thickness of the Sn-based surface layer is not less than 0.2 [mu]m and not more than 0.6 [mu]m; an exposed-area rate of the CuSn alloy layer exposed at a surface of the Sn-based surface layer is not less than 1% and not more than 40%; an average of equivalent-circle diameter of the exposed portions of the Cusn alloy layer exposed at the surface of the Sn-based surface layer is not less than 0.1 [mu]m and not more than 1.5 [mu]m; and dynamic friction coefficient is not more than 0.3.

Owner:MITSUBISHI MATERIALS CORP

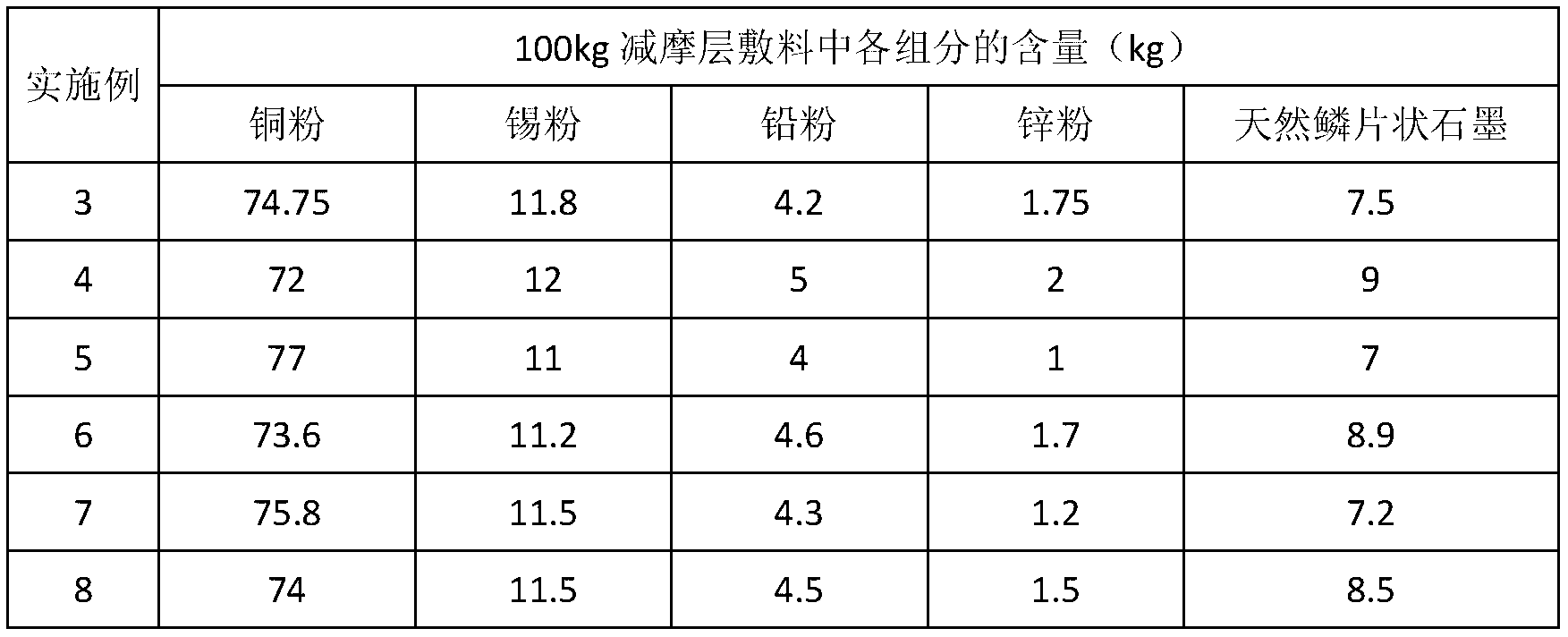

Long-service-life multi-face self-lubricating antifriction plate and manufacture method thereof

The invention relates to a long-service-life multi-face self-lubricating antifriction plate in rubber tire mould manufacture industries and a manufacture method thereof. The antifriction plate comprises a steel base plate and an antifriction layer dressing. The manufacture method comprises applying the antifriction layer coating on the surface of the base plate, placing the base plate in a sintering furnace protected by decomposition ammonia for sintering at the temperature in a range of 800 DEG C to 900 DEG C for 20 minutes to 30 minutes, performing cold rolling and annealing treatment, and sending the base plate into a finishing roller for rolling. A copper alloy coating with the thickness larger than or equal to 0.1mm is coated after the base plate is subjected to planning processing and sand blasting, and the antifriction dressing layer is formed by mixing and preparing, by weight, 72% to 77% of copper powder, 11% to 12% of tin powder, 4% to 5% of lead powder, 1% to 2% of zinc powder and 7% to 9% of natural flaky graphite. The multi-face self-lubricating antifriction plate manufactured through the method has the advantages of being low in frictional coefficient, high in antifriction performance, few in maintenance time, long in service life and the like.

Owner:沈阳思莱德模具有限公司

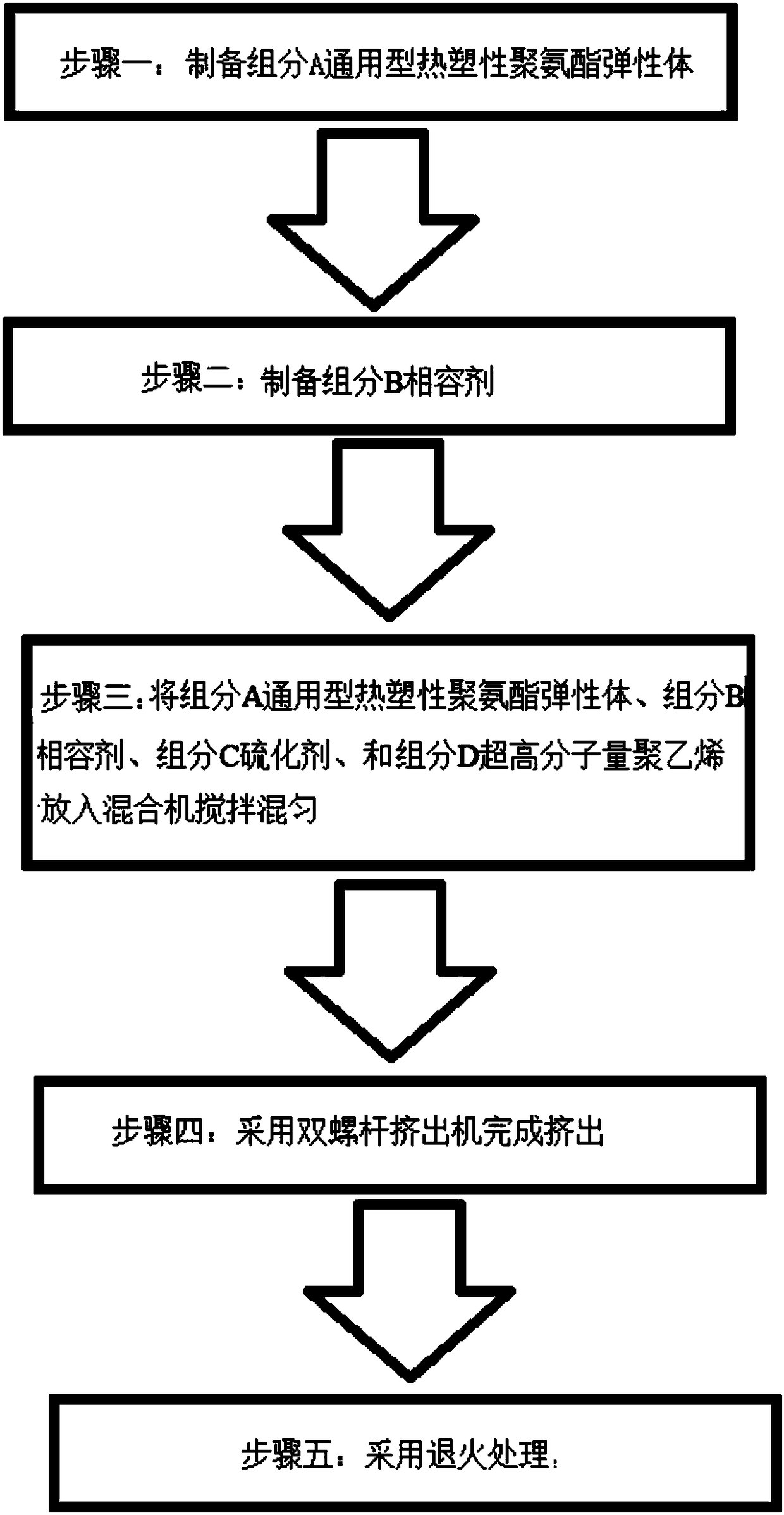

Antifriction modified thermoplastic polyurethane elastomer formula as well as preparation method and application thereof

InactiveCN108250725AReduce coefficient of frictionSolve the problem of different polarity and poor compatibilityPolyurethane elastomerThermoplastic polyurethane

The invention belongs to the field of a polyurethane elastomer and particularly relates to an antifriction modified thermoplastic polyurethane (TPU) elastomer formula as well as a preparation method and application thereof. The formula comprises a component A, a component B, a component C and a component D according to the mass ratio of (95-105):(7-9):(0.04-0.06):(14-16), wherein the component A is a universal type thermoplastic polyurethane elastomer; the component B is a compatilizer; the component C is a vulcanizing agent; and the component D is ultrahigh-molecular-weight polyurethane. Theformual has the following beneficial effects: the ultrahigh-molecular-weight polyurethane with the characteristic of low friction coefficient is used for antifriction and high-temperature-resistant modification of TPU, grafting modification is conducted by adding the compatilizer, the problems that the thermoplastic polyurethane elastomer and the ultrahigh-molecular-weight polyurethane have different polarities and low compatibility are solved, the dynamical friction coefficient of the antifriction modified thermoplastic polyurethane elastomer can be reduced by 43 to 46 percent, the wear ratecan be reduced by 87 to 91 percent and the tensile strength can be increased by 28 to 34 percent.

Owner:山西精专致科技股份有限公司

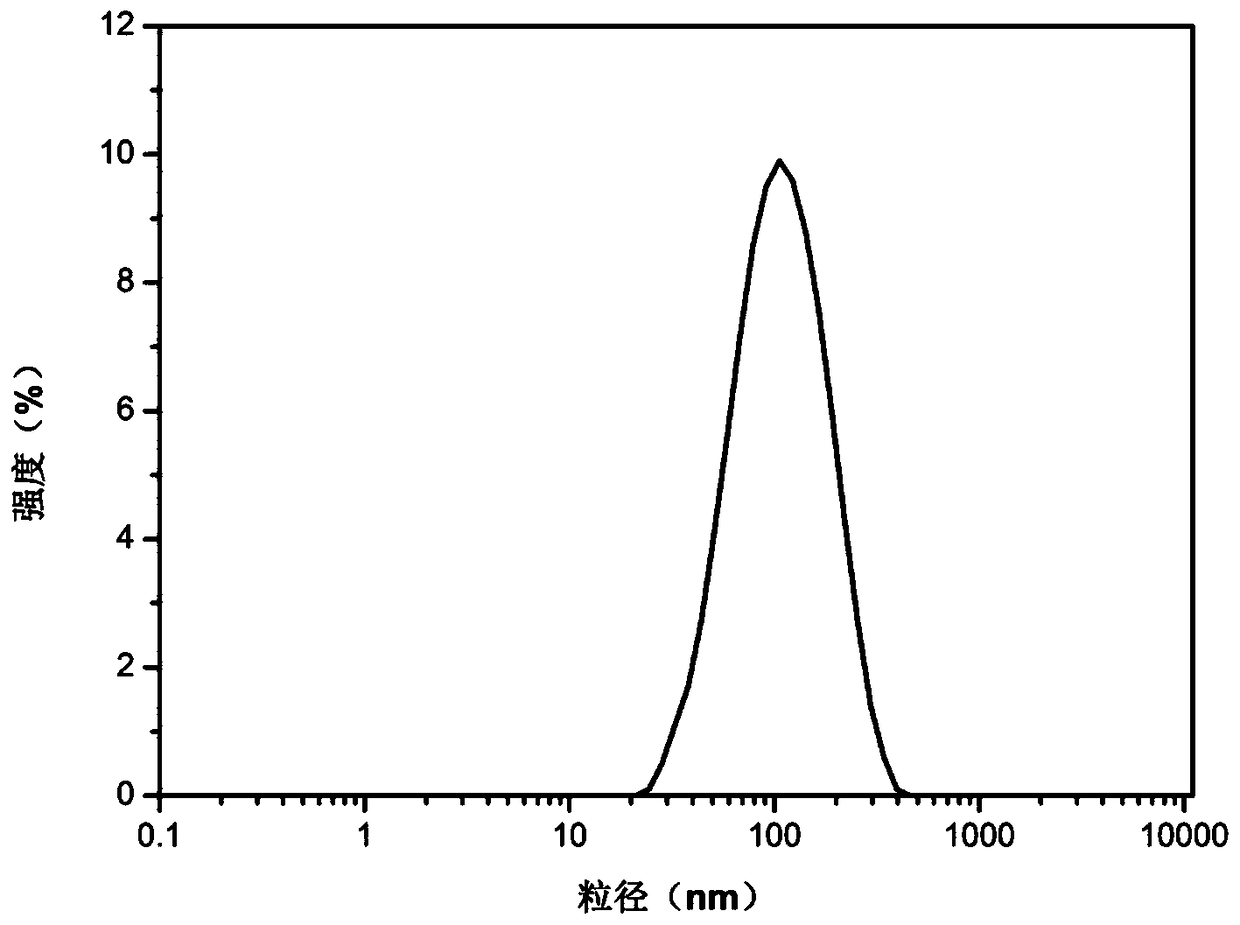

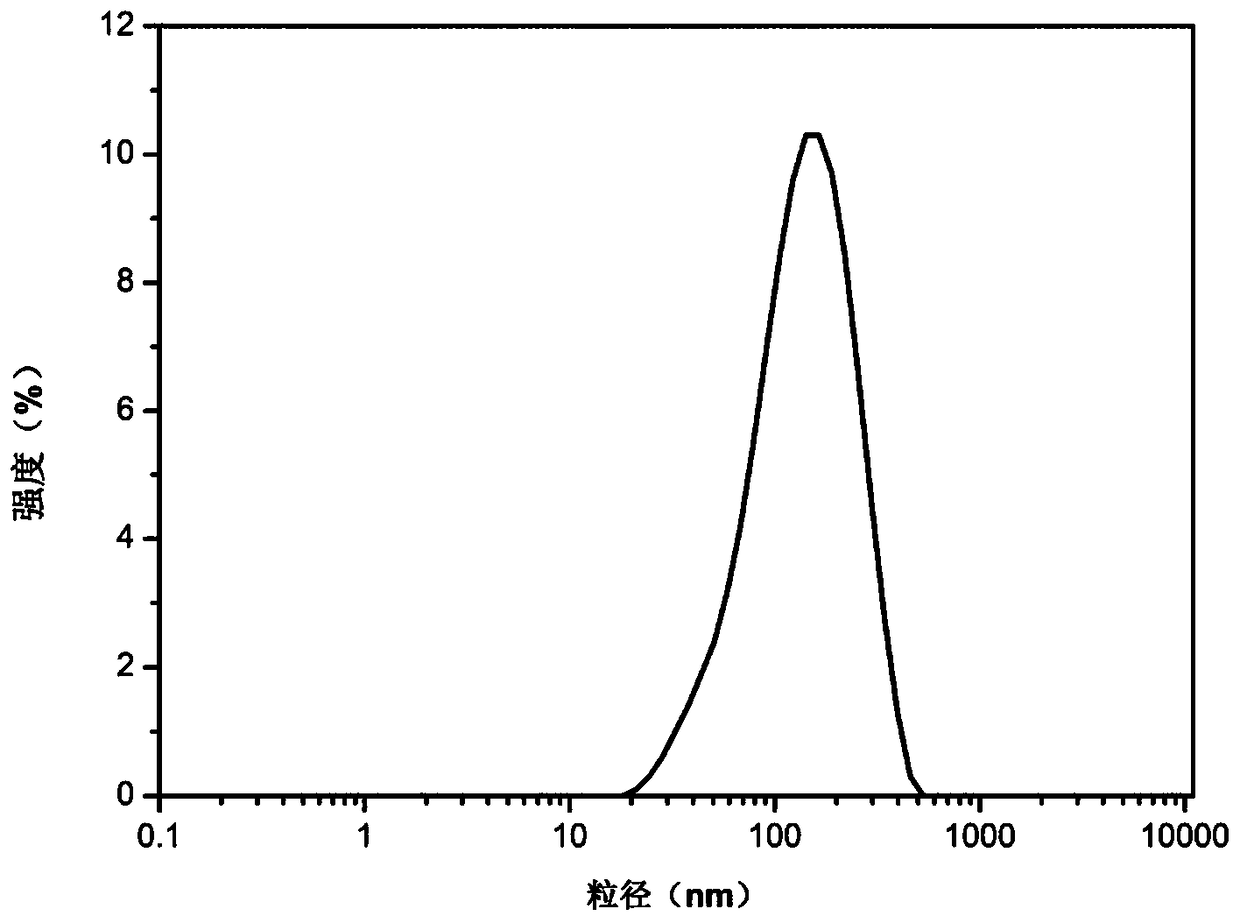

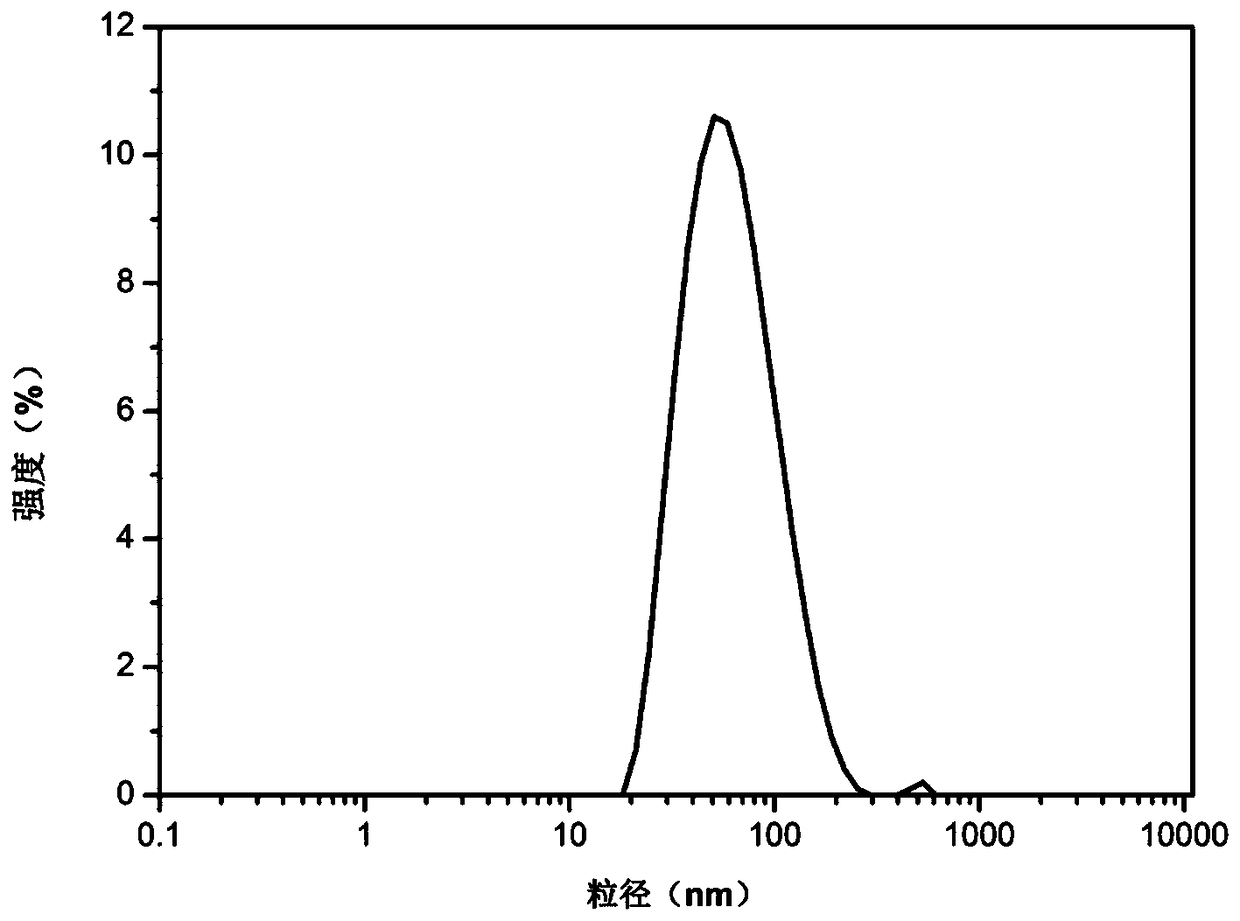

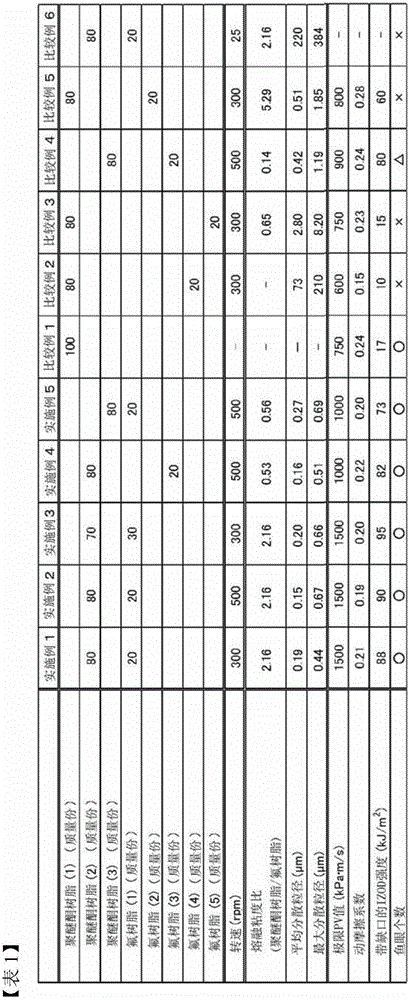

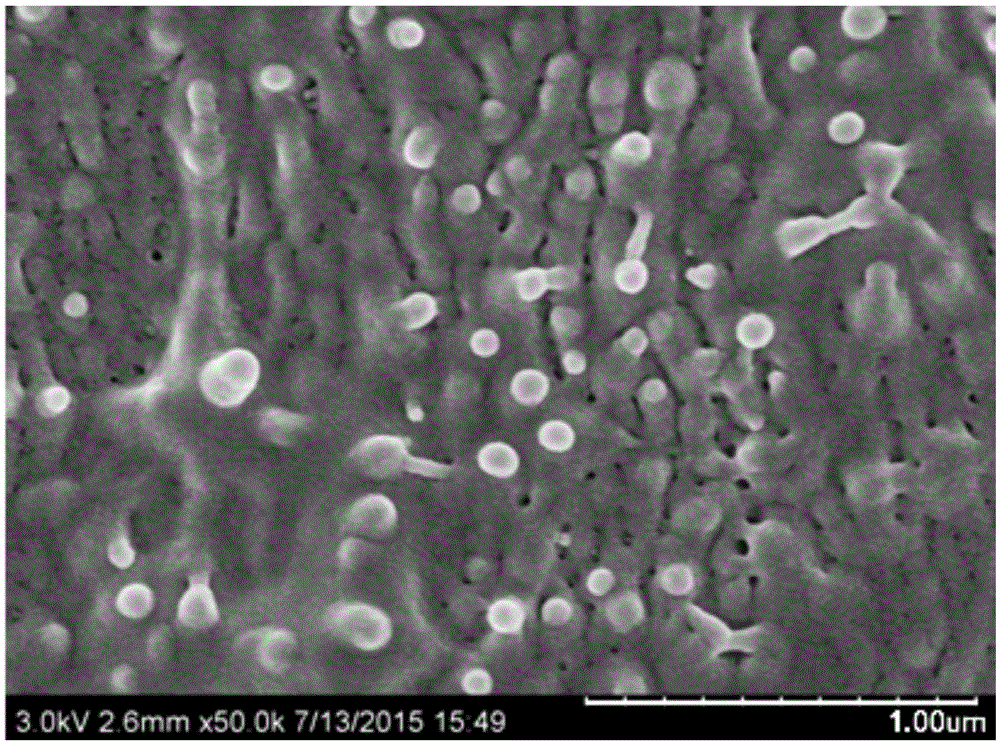

Resin composition and molded article

ActiveCN103958608ALower coefficient of dynamic frictionHigh limit PV characteristicsCarbon numberTetrafluoroethylene

The purpose of the present invention is to provide a resin composition that enables a molded article provided with both a low coefficient of kinetic friction and a high PV limit value to be obtained. The present invention is a resin composition containing an aromatic polyether ketone resin (I) and a fluorine resin (II), and is characterized in that the fluorine resin (II) is a copolymer of tetrafluoroethylene and a perfluoro ethylenically unsaturated compound represented by general formula (1): CF2=CF-Rf1 (1) (In the formula, Rf1 represents -CF3 or -ORf2. Rf2 represents a perfluoroalkyl group with a carbon number of 1 to 5.) The resin composition is further characterized in that: the mass ratio, (I):(II), between the aromatic polyether ketone resin (I) and the fluorine resin (II) is 95:5 to 50:50; the melt viscosity ratio, (I) / (II), between the aromatic polyether ketone resin (I) and the fluorine resin (II) is 0.3 to 5.0; the fluorine resin (II) is dispersed in the form of particulates in the aromatic polyether ketone resin (I); and the average dispersed particle diameter of the fluorine resin (II) is less than 3.0 mum.

Owner:DAIKIN IND LTD

Dip molded article and method for manufacturing dip molded article

ActiveCN106103554ALow tensile strengthLower coefficient of dynamic frictionLiquid surface applicatorsCoatingsNitrile rubberUltimate tensile strength

Provided is a dip molded article obtained by dip molding a composition for dip molding comprising a latex of a carboxy-group-containing nitrile rubber. The dip molded article is characterized in that at least one surface thereof is subjected to a surface treatment, a film thickness is 0.02 to 0.2 mm, a coefficient of dynamic friction of the surface-treated surface is 0.5 or less, and a tensile strength after the surface treatment is 30 MPa or more.

Owner:ZEON CORP

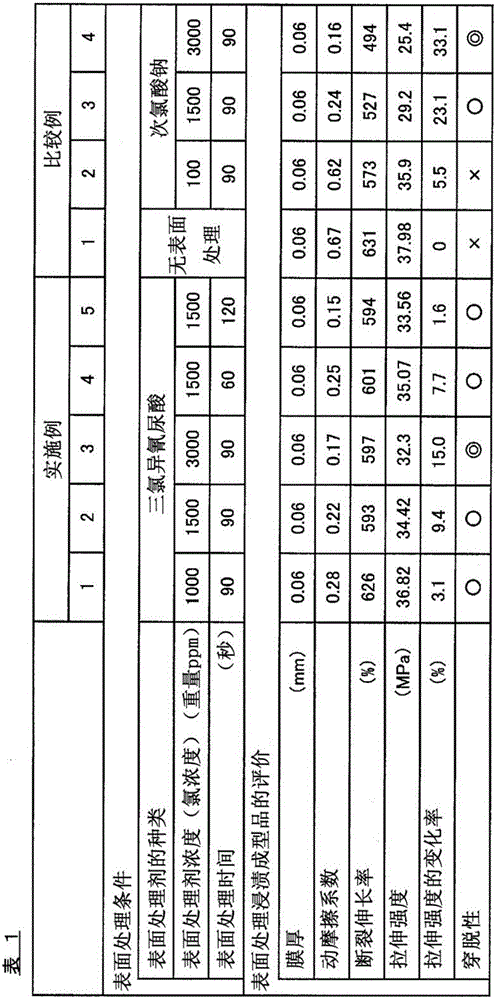

Injectable decellularized scaffold for cartilage repair as well as preparation method and application of injectable decellularized scaffold

ActiveCN112807489ASolve the problem of repairing irregular cartilage damagePromote degradationTissue regenerationProsthesisCartilage cellsAcellular scaffold

The invention discloses an injectable decellularized scaffold for cartilage repair as well as a preparation method and application of the injectable decellularized scaffold, and relates to the technical field of medical materials. According to the method, a double-injection mode is adopted, and the gelated gradient injectable decellularized scaffold is obtained by injecting a pre-gel solution and a viscosity modifier simultaneously. The decellularized scaffold can load MSCs to be implanted into a body, is hydrolyzed under a physiological pH value, and slowly releases a medicine at an injured part, so that the differentiation of the loaded MSCs to cartilage cells is promoted, and the injured cartilage tissue is repaired; Due to the gradient property, original biological characteristics of the cartilage tissue can be better simulated, and a better repairing effect is achieved. According to the decellularized scaffold and the technology, the raw materials are cheap and wide in source, after clinical popularization, the pain of a patient can be remarkably relieved, the operation frequency is reduced, the treatment effect is improved, and remarkable social and economic benefits are achieved.

Owner:GUANGDONG GENERAL HOSPITAL

Tin-plated copper-alloy material for terminal having excellent insertion/extraction performance

InactiveCN104078782ALower coefficient of dynamic frictionLow pluggabilityConductive materialCoupling contact membersTinningSurface layer

To provide tin-plated copper-alloy material for terminal having an excellent insertion / extraction performance by reducing dynamic friction coefficient to 0.3 or less with bringing out an excellent electrical-connection characteristic. Tin-plated copper-alloy terminal material in which an Sn-based surface layer is formed on a surface of a substrate made of Cu alloy, and a Cu-Sn alloy layer is formed between the Sn-based surface layer and the substrate; the Cu-Sn alloy layer contains Cu 6 Sn 5 as a major proportion and has a compound in which a part of Cu in the Cu 6 Sn 5 is substituted by Ni and Si in the vicinity of a boundary face at the substrate side; an arithmetic average roughness Ra of the Cu-Sn alloy layer is 0.3 [mu]m or more in at least one direction and an arithmetic average roughness Ra in all direction is 1.0 [mu]m or less; an oil-sump depth Rvk of the Cu-Sn alloy layer is 0.5 [mu]m or more; and an average thickness of the Sn-based surface layer is 0.4 [mu]m or more and 1.0 [mu]m or less and dynamic friction coefficient is 0.3 or less.

Owner:MITSUBISHI MATERIALS CORP

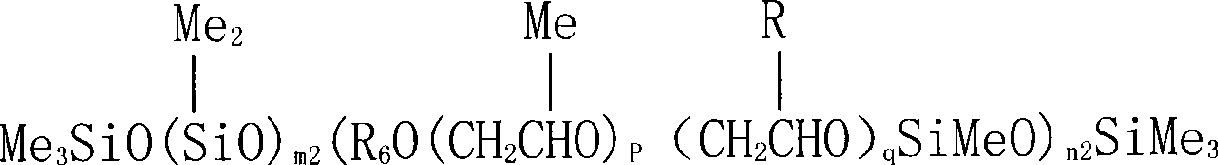

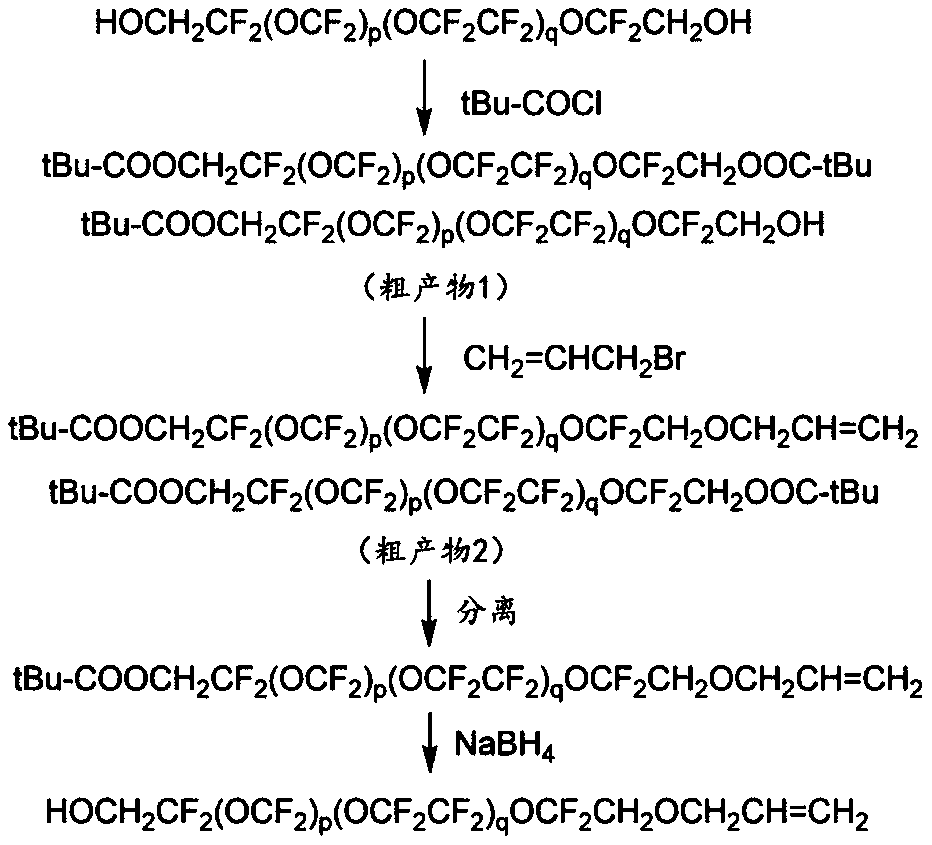

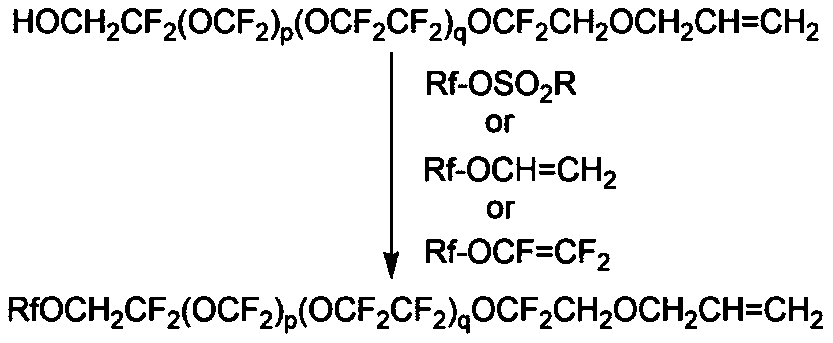

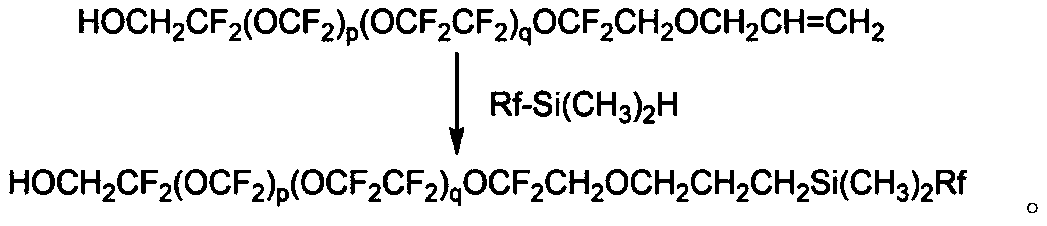

Method for using perfluoroalkyl-containing chain-terminated double-terminal functional group perfluoropolyether for producing single-terminal functional group perfluoropolyether

ActiveCN109970967AImprove smoothnessPoor smoothnessAntifouling/underwater paintsPaints with biocidesPerfluoropolyetherChain structure

The invention relates to a method for using perfluoroalkyl-containing chain-terminated double-terminal functional group perfluoropolyether for producing single-terminal functional group perfluoropolyether. According to the method, through reaction of a perfluoroalkyl-containing compound, allyl bromide and the dihydroxy-terminal perfluoropolyether, perfluoroalkyl-containing chain-terminated perfluoropolyether allyl ether or the hydroxyl-terminated perfluoroalkyl-containing chain-terminated perfluoropolyether is obtained. Compared with the double-terminal functional group perfluoropolyether rawmaterial, the single-terminal functional group perfluoropolyether raw material produced through the method has more excellent smoothness, lubricity and rub resistance. A molecular chain of the single-terminal functional group perfluoropolyether is of a linear-chain structure, and has excellent flexibility, and an unfixed terminal has a very high degree of freedom after being rubbed.

Owner:TIANJIN UNIV OF SCI & TECH

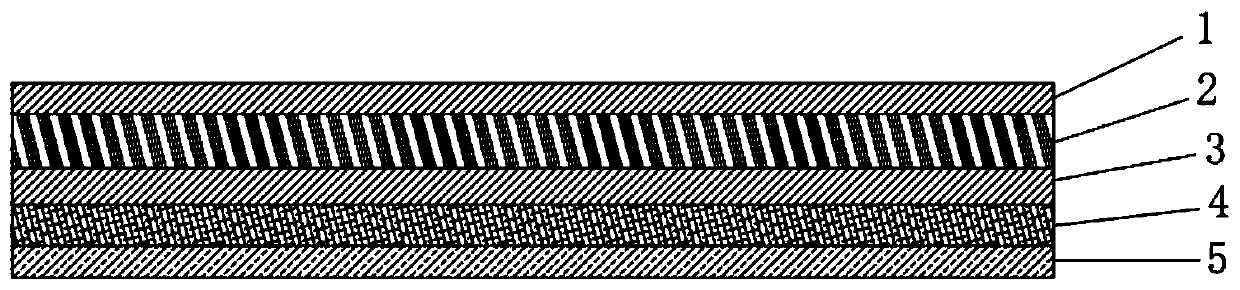

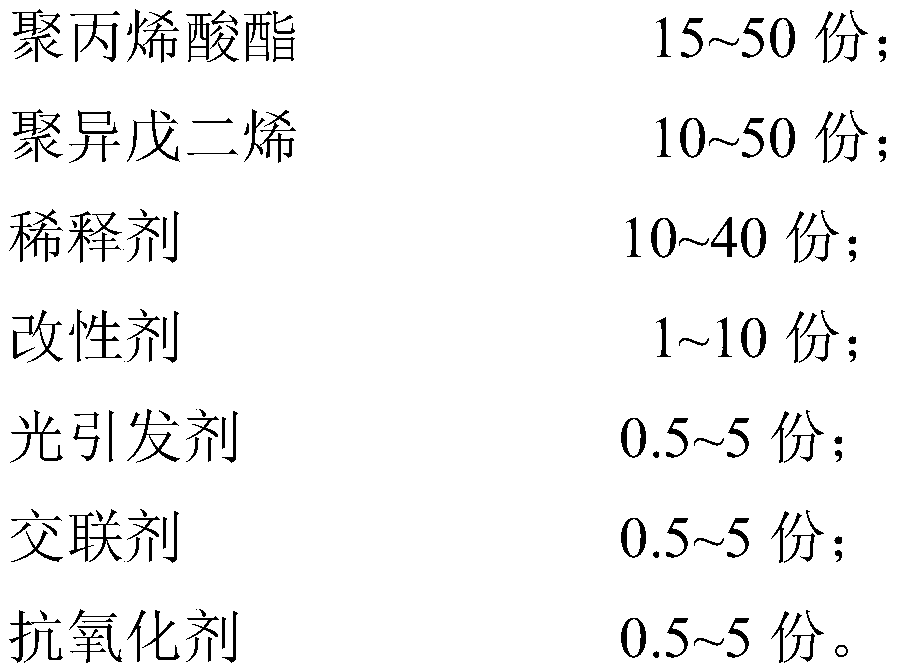

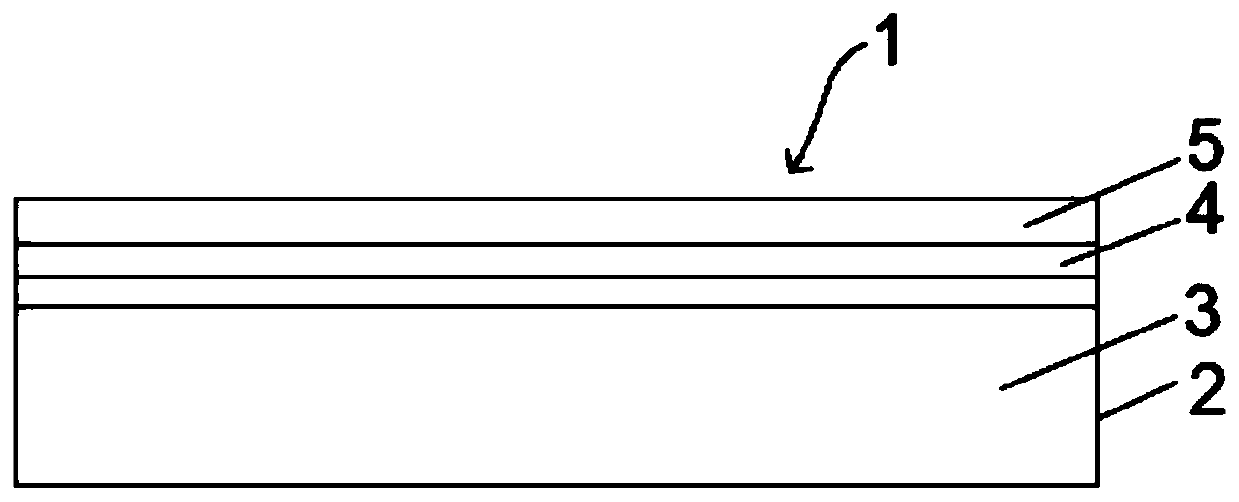

Bendable protective film for folding screen and preparation method thereof

InactiveCN111171742AImprove bending resistanceHigh light transmittanceNon-macromolecular adhesive additivesFilm/foil adhesive primer layersAdhesiveOptical transmittance

The invention discloses a bendable protective film for a folding screen and a preparation method thereof. The protective film comprises a first flexible HC processing layer, a bendable base material layer, a second flexible HC processing layer, an anti-rebound OCA optical adhesive layer and a release isolation layer which are sequentially arranged in a stacked mode. The anti-rebound OCA optical adhesive layer is obtained by coating the surface of the second flexible HC processing layer with an anti-rebound OCA optical adhesive and then curing the anti-rebound OCA optical adhesive. The bendableprotective film for the folding screen is excellent in bending resistance, high in light transmittance, low in haze, excellent in scratch resistance and rebound resistance, excellent in bonding strength, relatively good in fingerprint resistance and oil stain resistance, small in dynamic friction coefficient, smooth in surface and relatively good in hand feeling; the bendable protective film canbe well applied to protection of flexible screens and curved screens which require bending performance and have scratch resistance and wear resistance.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Wet friction material

InactiveUS20100256259A1Improve heat resistanceLower coefficient of dynamic frictionFriction liningActuatorsFiberHeat resistance

The purpose of the present invention is to provide a wet friction material which has a high coefficient of friction, has reduced overall thickness change, and excellent heat resistance (resistance to heat spots).In order to accomplish the purpose, the present invention provides a wet friction material prepared by impregnating a base material comprising a fibrous substance with a thermosetting resin, and then thermally curing it, wherein the aspect ratio of the fibrous substance is 10 or higher, and the fibrous substance is contained in the base material in an amount of 60 to 75 weight % .

Owner:AICA KOGYO CO LTD

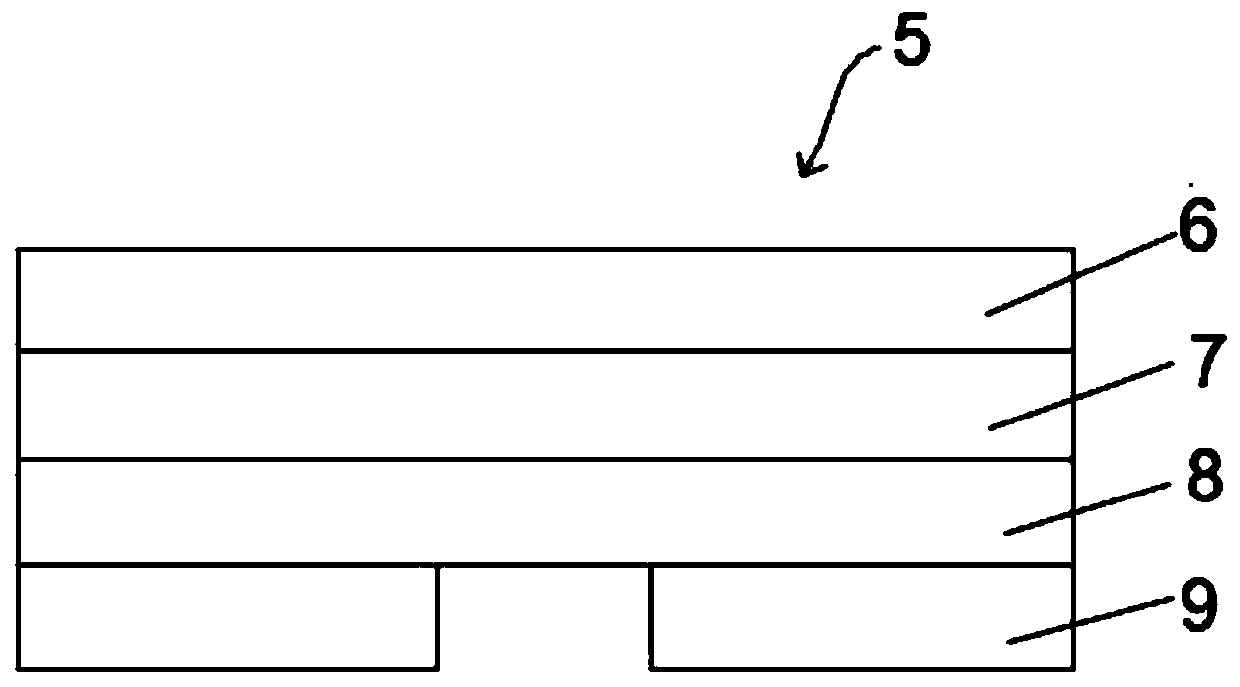

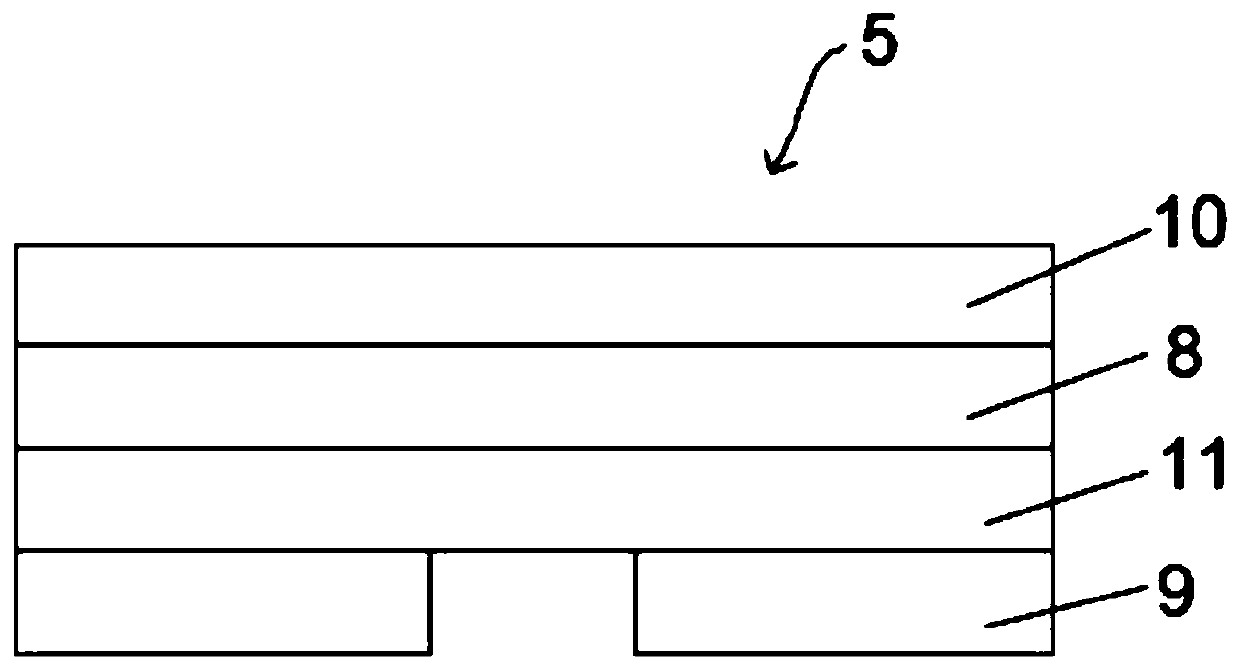

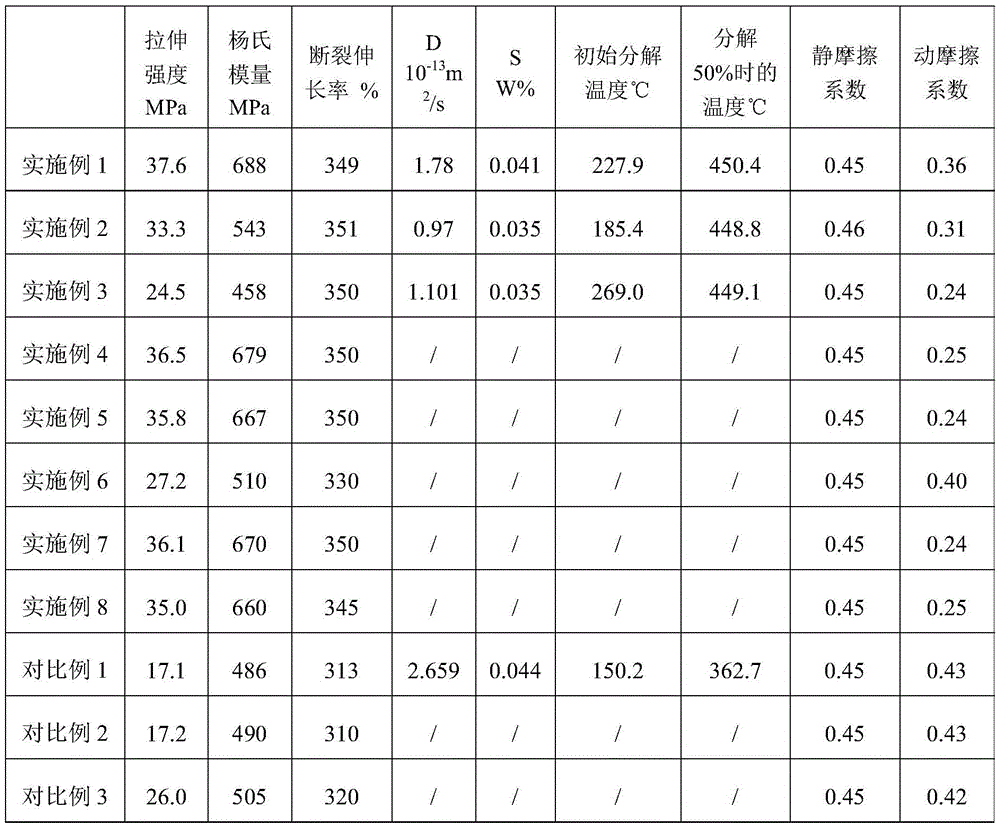

Flexible display screen cover plate

InactiveCN110576664AThe overall thickness is thinReduce thicknessSynthetic resin layered productsElectrical equipmentPolysilazanePolyamide

The invention discloses a flexible display screen cover plate and relates to the field of optical film technology. The flexible display screen cover plate comprises a transparent aromatic polyamide substrate; a polysilazane layer disposed on one side surface of the transparent aromatic polyamide substrate; a polarizing layer disposed on the aromatic polyamide substrate and on the other side, relative to the polysilazane layer, the aromatic polyamide substrate; and a hardened layer arranged on the polarizing layer and on the other side, relative to the transparent aromatic polyamide substrate,of the polarizing layer. According to the invention, the polarizing layer is directly prepared on the transparent aromatic polyamide substrate, so that the overall thickness of the flexible display screen cover plate is reduced, and meanwhile, the overall hardness of the flexible display screen cover plate is greatly improved.

Owner:新纶电子材料(常州)有限公司

Latex special for dry method dustless paper and its preparing method

InactiveCN1554829AHigh molecular weightHigh viscosityWater-repelling agents additionFiberWet strength

The present invention relates to latex specially for dry process dustless paper and its preparation process, and belongs to the field of special chemical. butyl acrylate, methyl acrylate, ethoxyl acrylate, styrene, acrylic acid and butyl methacrylate as monomers, are added with deionized water, emulsifier, NaHCO3 and initiator to produce branch chain connection to form copolymer. The present invention can meet the requirement of producing dustless paper and is favorable to spraying. The present invention has high fiber combining strength of paper, high dry and wet strength, simple production operation and stable product quality.

Owner:李泽潜 +3

Efficient manufacturing technology of DTY elasticity enhancement addition agent composite material

ActiveCN111501338AImprove washabilitySimple processFibre treatmentManufacturing technologyEngineering

The invention discloses an efficient manufacturing technology of a DTY elasticity enhancement addition agent composite material. The efficient manufacturing technology of the DTY elasticity enhancement addition agent composite material comprises the following steps that mineral oil A and mineral oil B are added and mixed in proportion to obtain mixed mineral oil with the viscosity of being 20Pa.s,and then the mixed mineral oil is stirred for 30 minutes under the conditions of normal temperature and normal pressure; a splashing resistant agent, a penetrating agent and a composite material areadded to the stirred mixed mineral oil in sequence, the materials are mixed and stirred, the materials are stirred for 30 minutes under the conditions of normal temperature and normal pressure, and amixed oil agent is obtained; the mixed oil agent is transferred to an intermediate tank and statically placed for 24 hours, and the DTY elasticity enhancement addition agent composite material is obtained; and the DTY elasticity enhancement addition agent composite material is canned, and the canned DTY elasticity enhancement addition agent composite material leaves a factory after the DTY elasticity enhancement addition agent composite material is detected and qualified. The efficient manufacturing technology of the DTY elasticity enhancement addition agent composite material is simple and efficient in technology and reasonable in formula, the manufactured DTY elasticity enhancement addition agent composite material is safe and environmentally friendly and has good smoothness, good antistatic property, good washability and stable storage performance, the splashing problem is solved, the DTY elasticity enhancement addition agent composite material has good usage performance, and the requirement of production can be met.

Owner:江苏悦孚油品有限公司

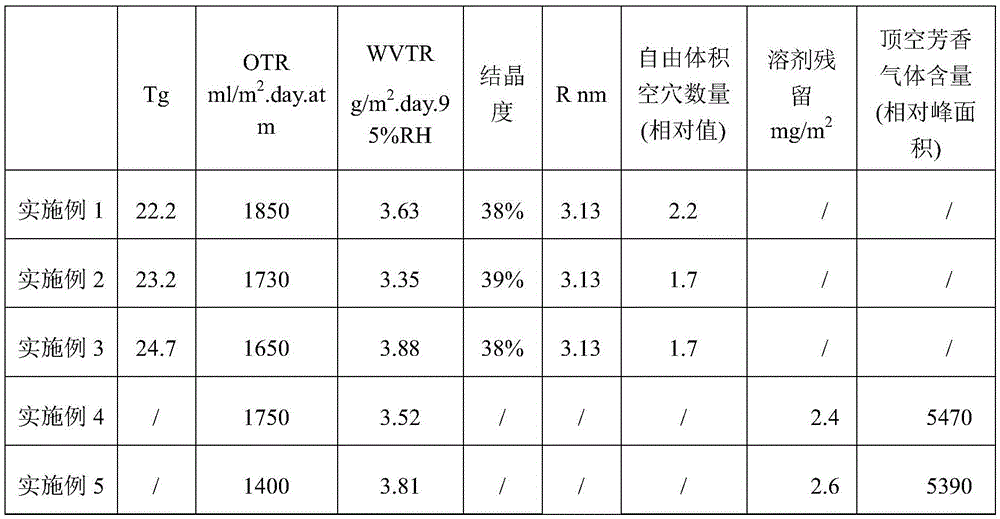

High performance polypropylene film and preparation method thereof

ActiveCN105538855AImprove securityLower coefficient of dynamic frictionSynthetic resin layered productsDomestic containersSolventPolypropylene

The invention provides a high performance polypropylene film and a preparation method thereof. The film comprises a top film, a core film and a lower film. The top film includes 2.0-3.0% of a nano-silica composition and 97.0-98.0% of first polypropylene, the core film includes 0.5-2.0% of a nano-silica composition and 99.5-98.0% of second polypropylene, and the lower film includes 3.5-5.0% of a nano-silica composition and 96.5-95% of third polypropylene, wherein the nano-silica composition includes 50-55% of nano-silica particles and 45-50% a resin modifier. Each layer of the film contains a specific content of nano-silica composition, so that the film has high modulus and elongation at break, low diffusion coefficient and solubility parameter to solvent small molecules, low dynamic friction coefficient, and has good comprehensive properties, thus being suitable for flexible packaging materials.

Owner:GETTEL GRP TONGCHENG PLASTIC IND +1

Rock crushing sampling device for asteroidenvironment

ActiveCN109060401AReduce disturbanceIncrease disturbanceWithdrawing sample devicesGeomorphologySurface layer

The invention belongs to the technical field of spatial exploration, provides a rock crushing sampling device for the asteroid environment, and particularly relates to the rock crushing sampling device for the asteroid environment. The problems that as for a traditional sampling device, when samples on the surface layer and the sub-surface layer of an asteroid are collected, the rock samples are hard to collect, the collected samples are broken, energy consumption is large, the size is large, the mass is large, and the structure is complete are solved. The rock crushing sampling device comprises a worm-shaped cam, a center rotating wheel, a needle bearing and an impacting unit. The rock crushing sampling device is mainly used for rock crushing work.

Owner:HARBIN INST OF TECH

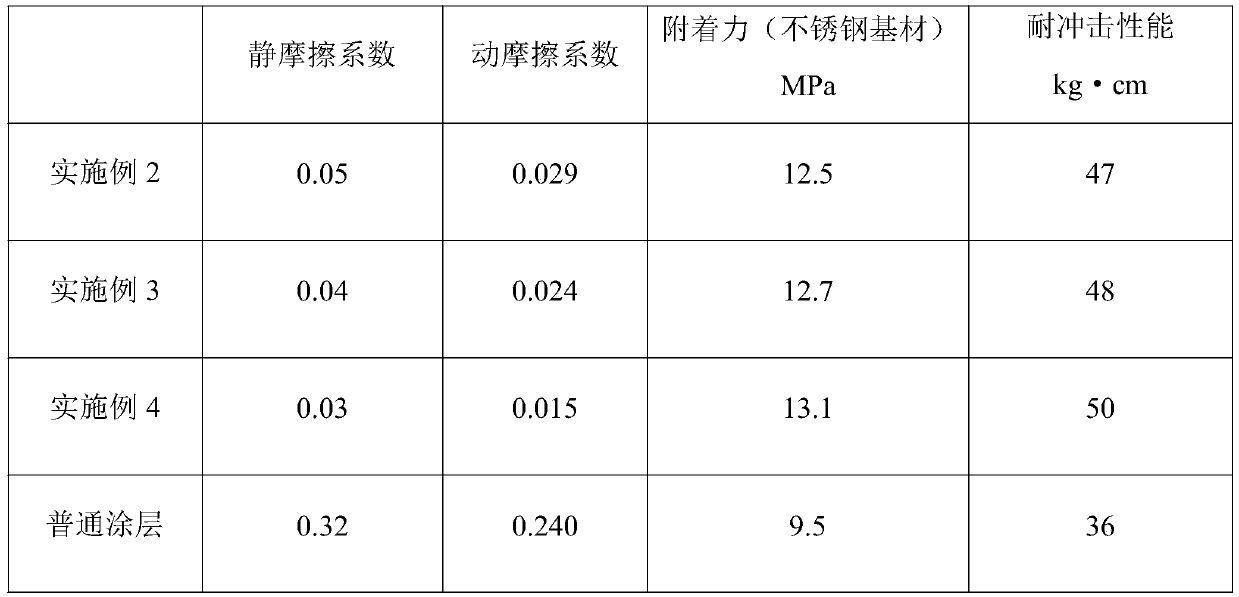

Non-stick coating layer and coating process thereof

InactiveCN111171682AGood lubricityGood non-stickPretreated surfacesSpecial surfacesPolytetrafluoroethyleneFirming agent

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:骋润(嘉兴)新材料科技有限公司

Latex special for dry method dustless paper and its preparing method

InactiveCN1234938CNot easy to break emulsionViscosity smallWater-repelling agents additionFiberWet strength

The present invention relates to latex specially for dry process dustless paper and its preparation process, and belongs to the field of special chemical. butyl acrylate, methyl acrylate, ethoxyl acrylate, styrene, acrylic acid and butyl methacrylate as monomers, are added with deionized water, emulsifier, NaHCO3 and initiator to produce branch chain connection to form copolymer. The present invention can meet the requirement of producing dustless paper and is favorable to spraying. The present invention has high fiber combining strength of paper, high dry and wet strength, simple production operation and stable product quality.

Owner:李泽潜 +3

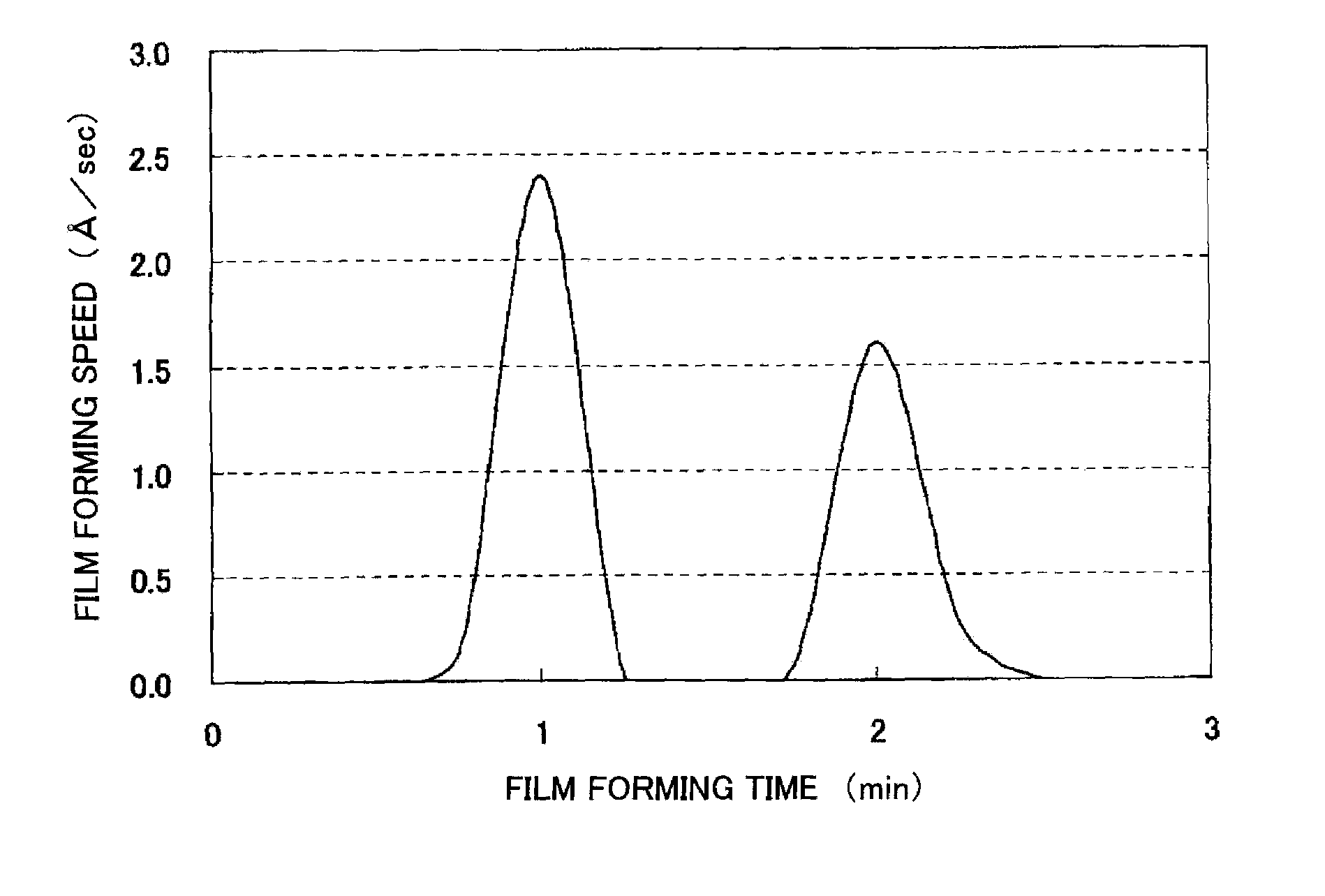

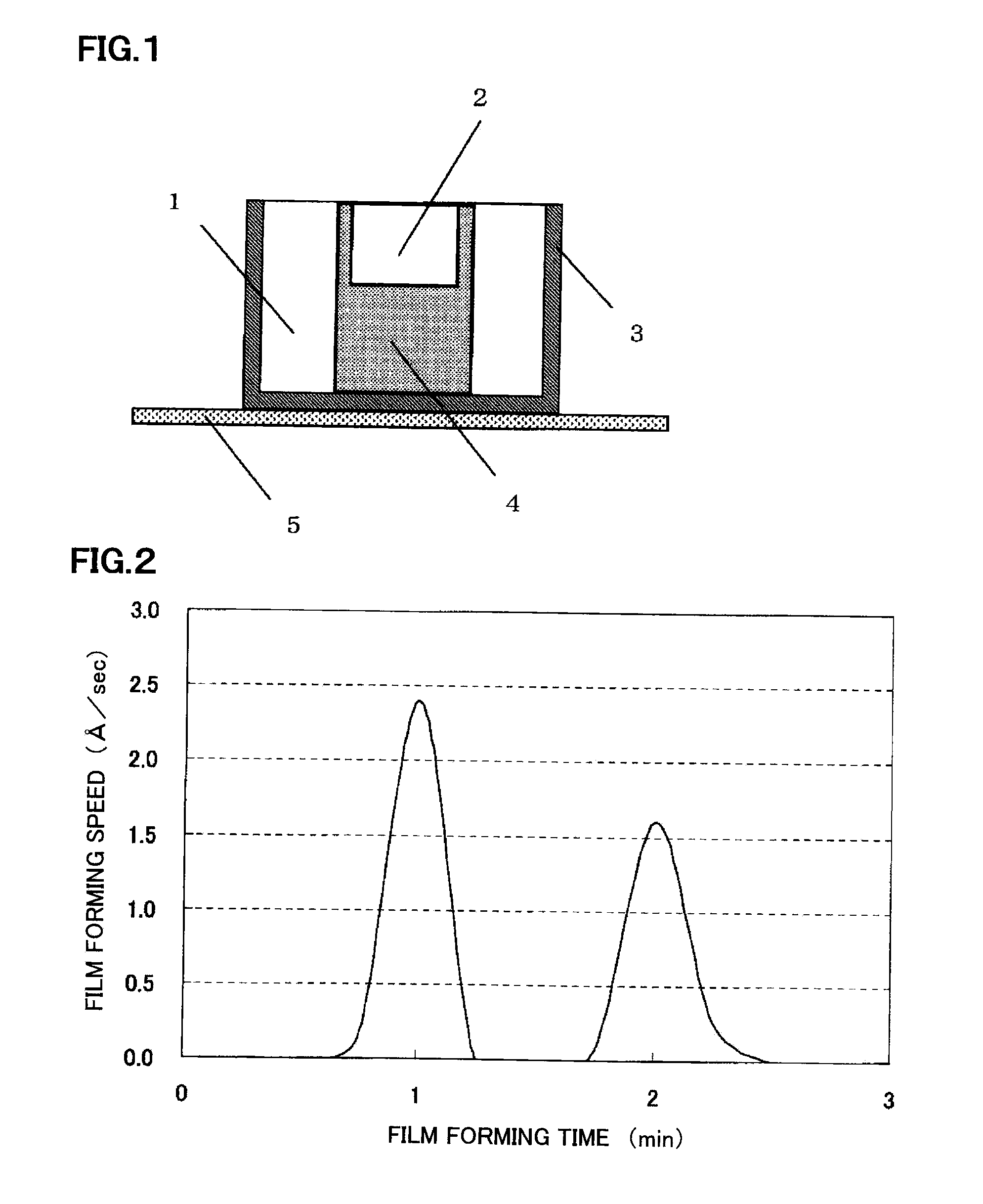

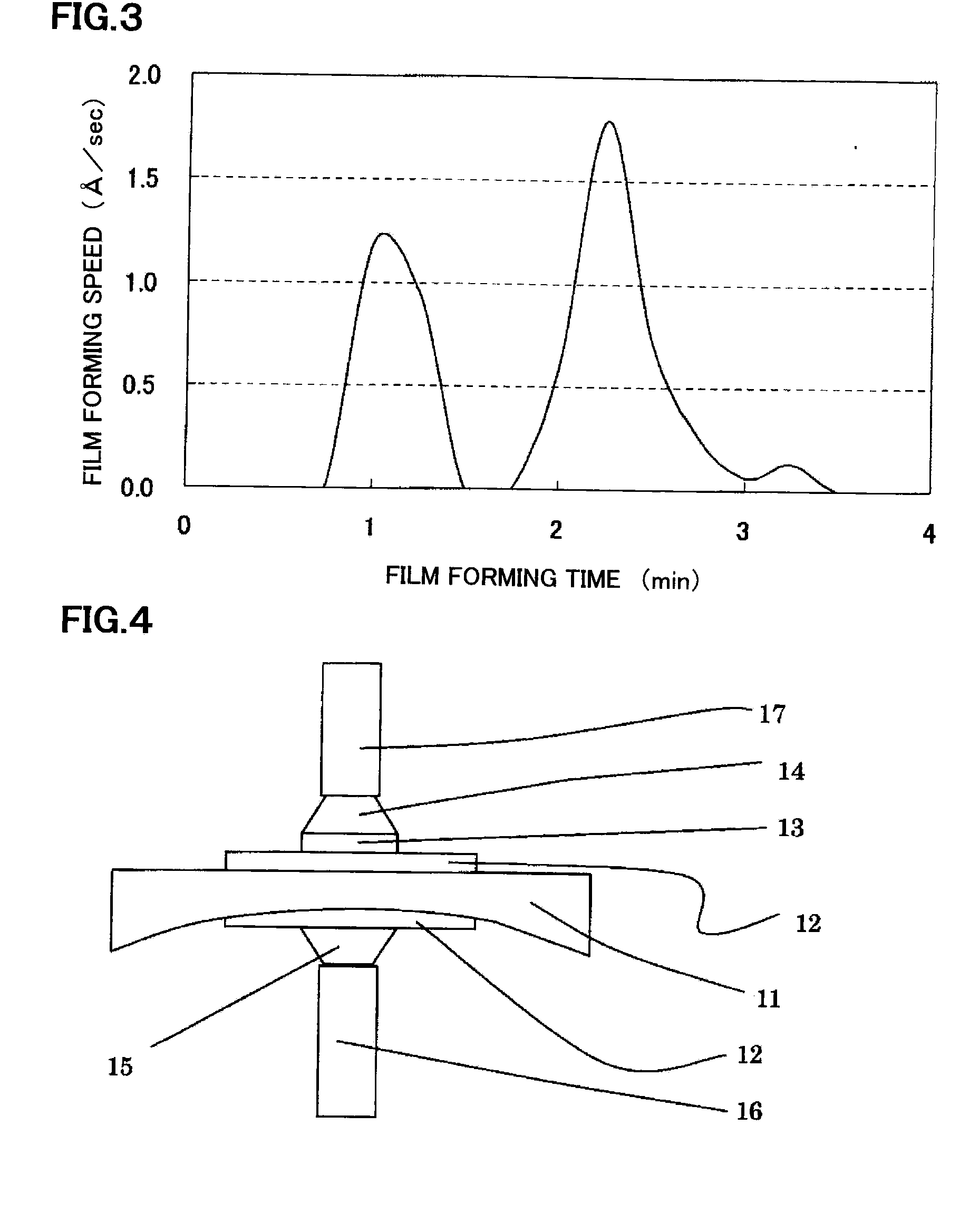

Spectacle lens and method for producing the same

ActiveUS7954944B2Lower coefficient of dynamic frictionHigh coefficient of kinetic frictionSpectales/gogglesSynthetic resin layered productsSilicon dioxideOrganosilicon

The disclosure relates to a spectacle lens comprising: a lens base member; a multi-layered anti-reflection film placed on the lens base member, and including a layer mainly made of silicon dioxide as an outermost layer; and a water-and-oil repellent layer provided in contact with the outermost layer of the multi-layered anti-reflection film, and made by using, as raw materials: at least one kind of a first fluorine-substituted alkyl group-containing organosilicon compound and a second fluorine-substituted alkyl group-containing organosilicon compound. The disclosure also relates to methods of producing a spectacle lens that is capable of retaining a sufficient water-and-oil repellency over an extended period, and having sufficient edge processability.

Owner:NIKON ESSILOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com