Patents

Literature

32results about How to "High coefficient of kinetic friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricating oil composition

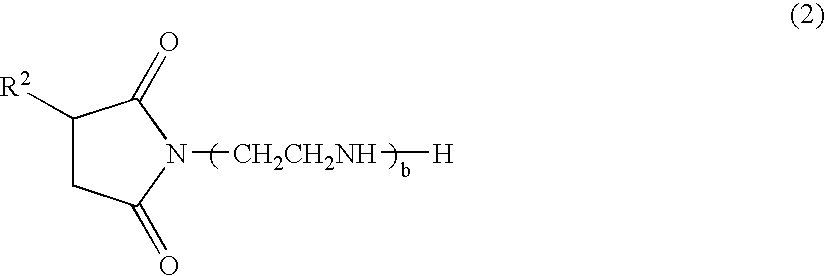

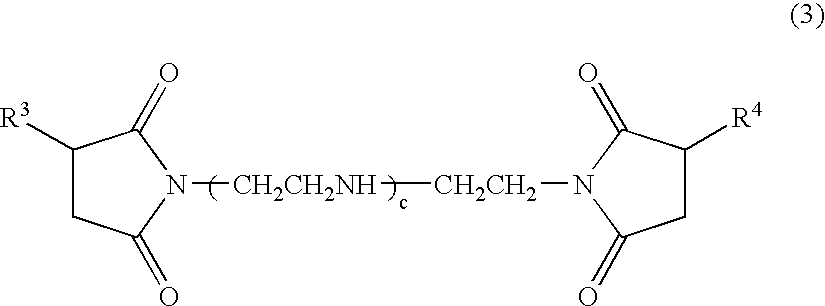

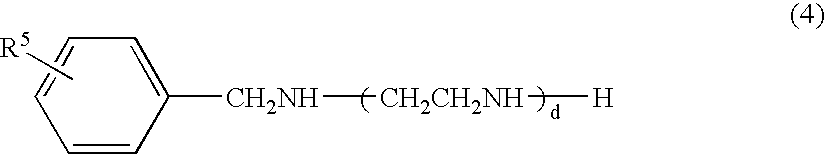

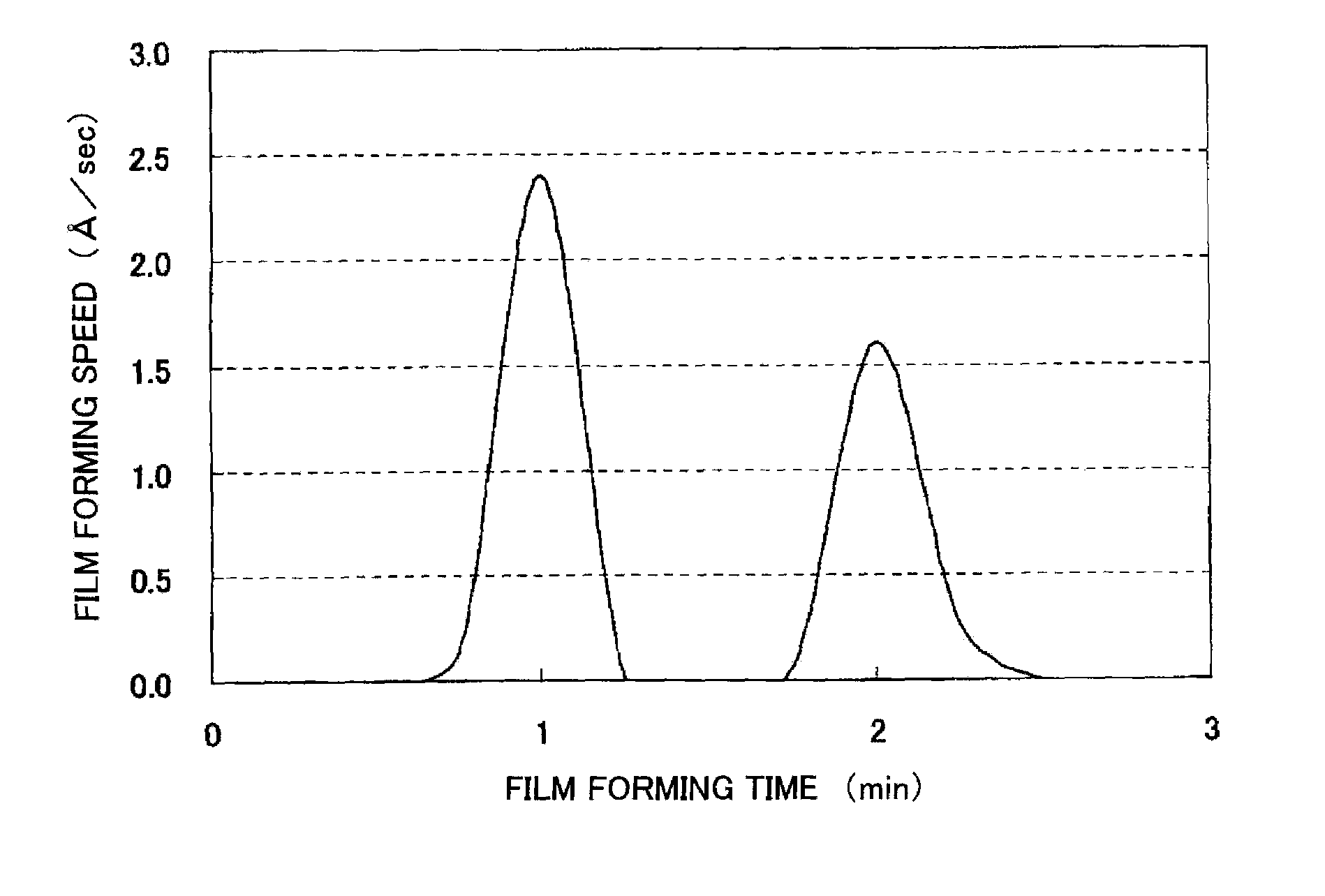

InactiveUS20050026790A1Enhanced dynamic friction coefficientHigh coefficient of kinetic frictionWork treatment devicesLiquid carbonaceous fuelsBase oilMetal

Owner:NIPPON OIL CORP +1

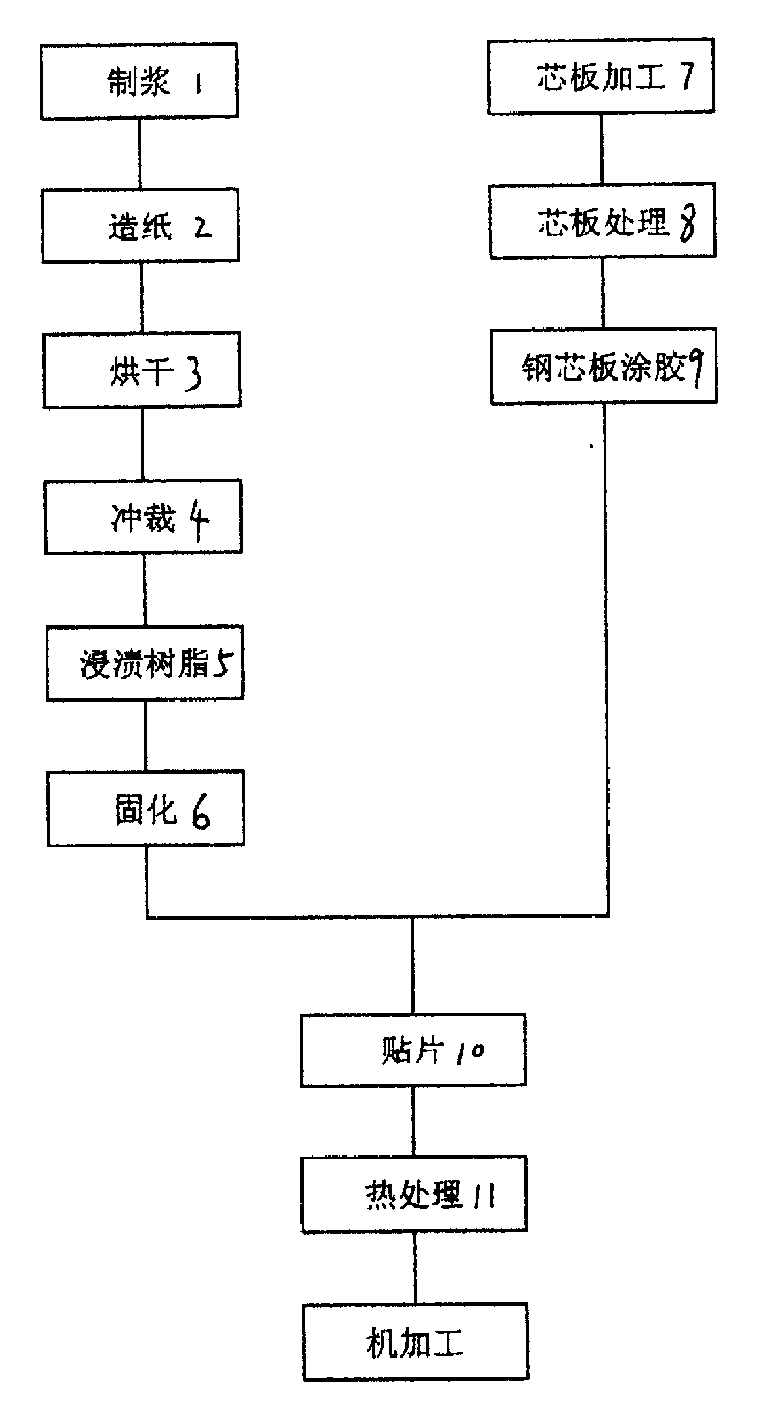

Whisker-modified paper-based friction material and preparation method thereof

ActiveCN103343476AHigh coefficient of kinetic frictionReduce wear rateOther chemical processesPaper/cardboardFiberEvaporation

The invention provides a whisker-modified paper-based friction material and a preparation method thereof. The friction material comprises, by mass, 45 to 55% of a fiber, 5 to 15% of a whisker, 15 to 25% of a modified phenolic resin, 10 to 15% of an inorganic filling material and 1% of a dispersant. The preparation method adopts traditional preparation technology for a paper-based friction material and comprises the following steps: uniformly mixing the fiber, the whisker and the filling material in water for pulping, carrying out papermaking and shaping so as to obtain a prefabricated friction material and drying the prefabricated friction material; and preparing a modified phenolic resin ethanol solution by dissolving the modified phenolic resin in an ethanol solvent, impregnating the prefabricated friction material with the modified phenolic resin ethanol solution and carrying out hot pressing and curing after evaporation of the solvent so as to obtain the whisker-modified paper-based friction material. The whisker-modified paper-based friction material can be used under a wet oil lubrication condition and has the advantages of a high dynamic friction coefficient, a low wear rate and small erosion of couple materials.

Owner:SHAANXI UNIV OF SCI & TECH

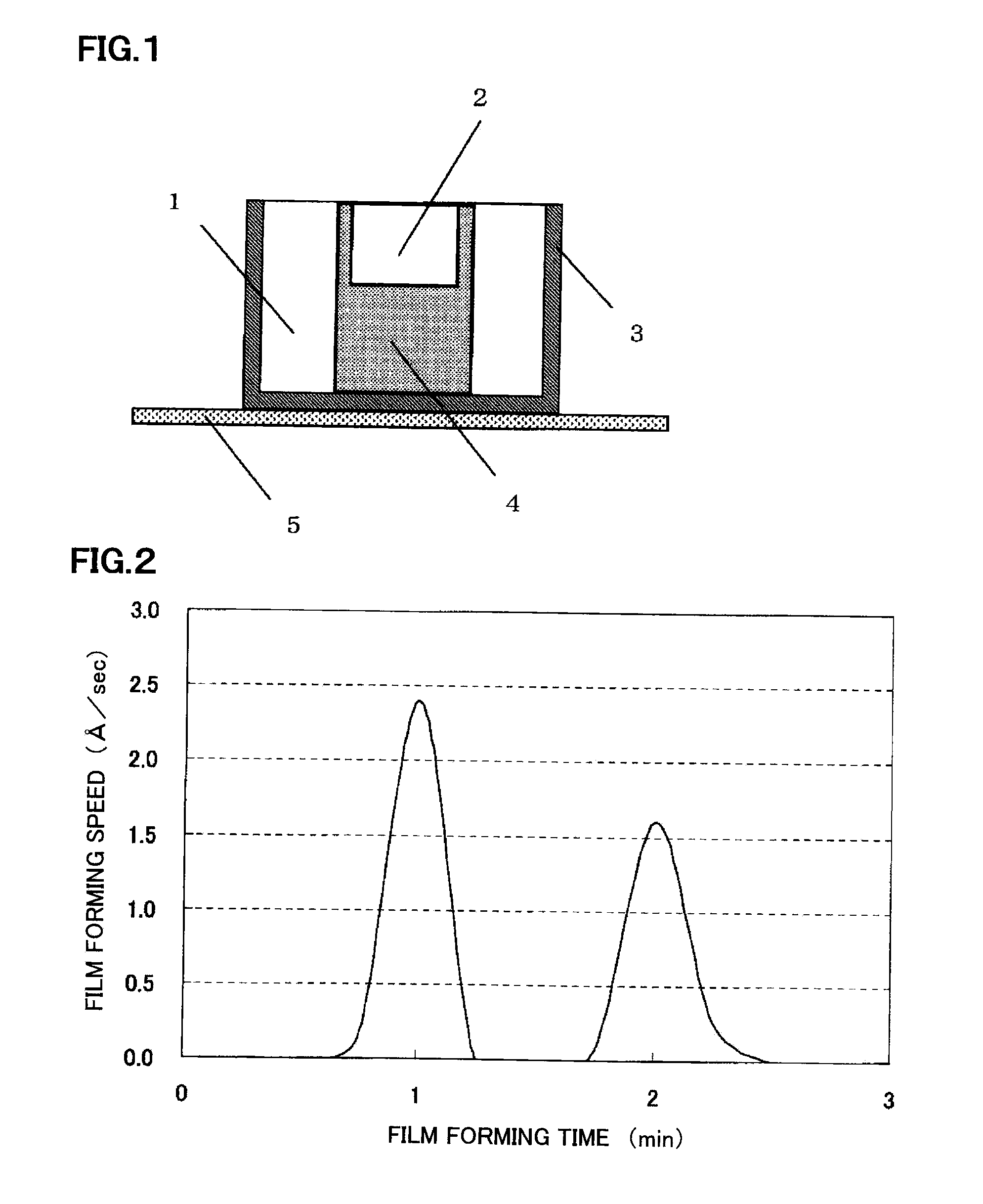

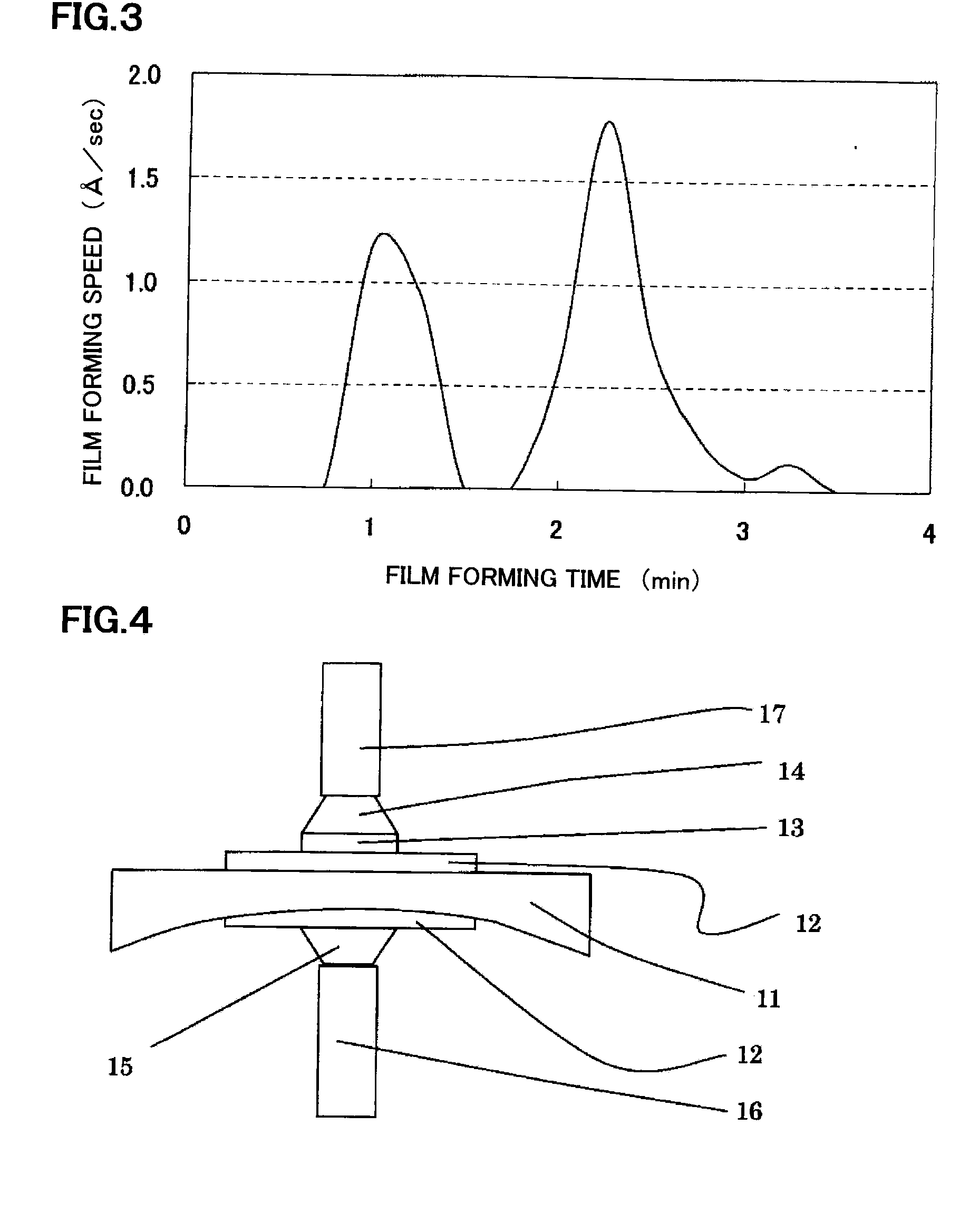

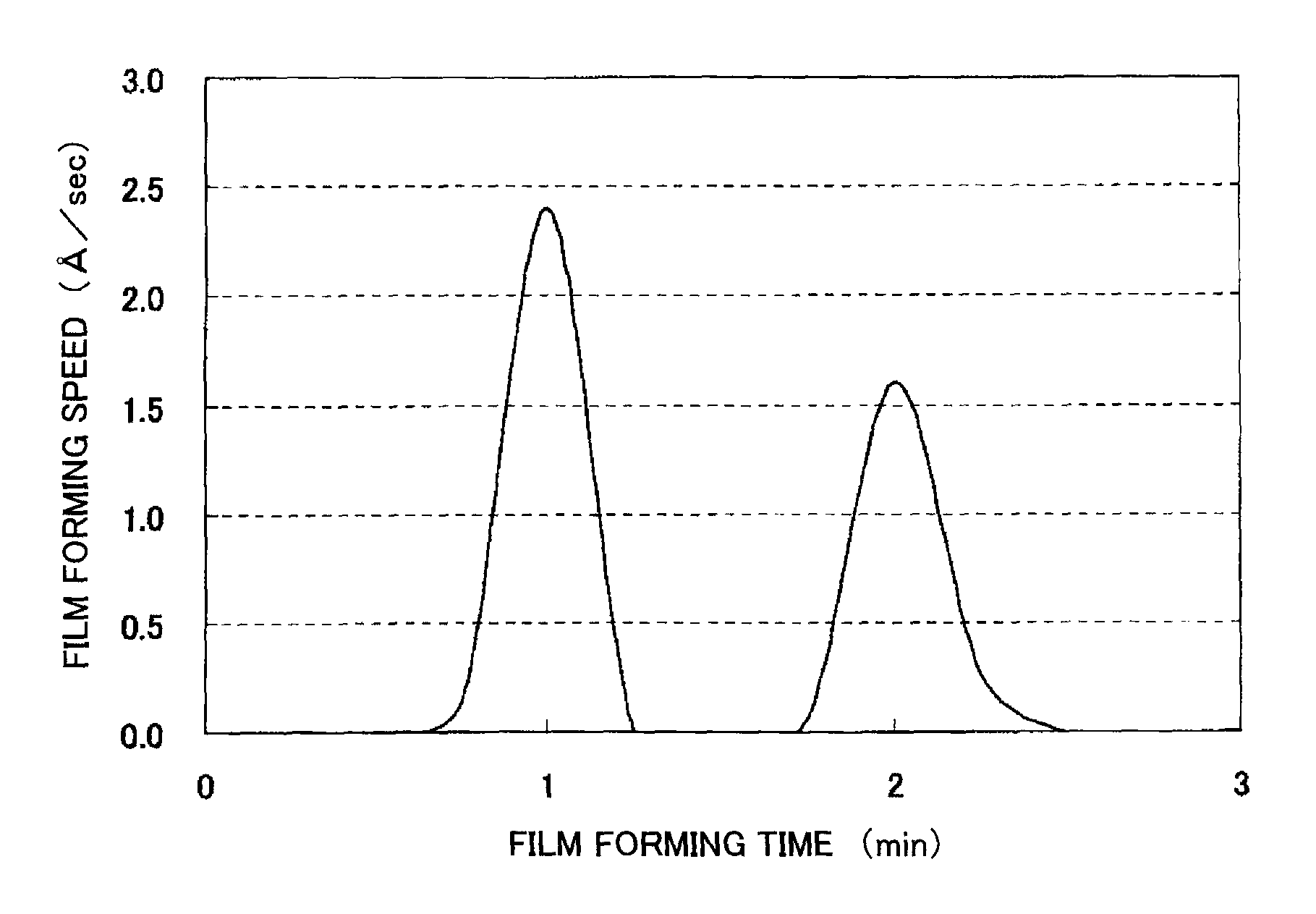

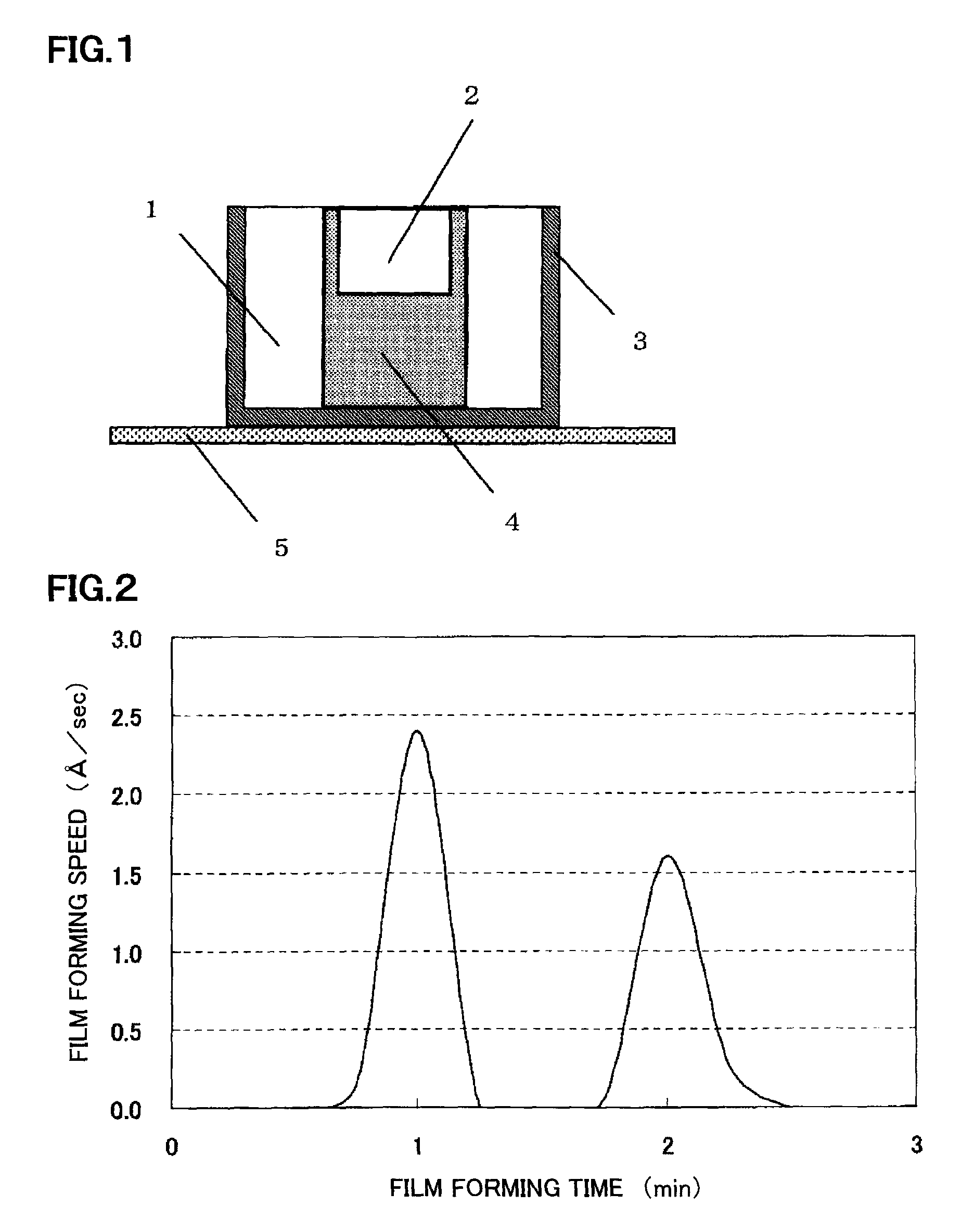

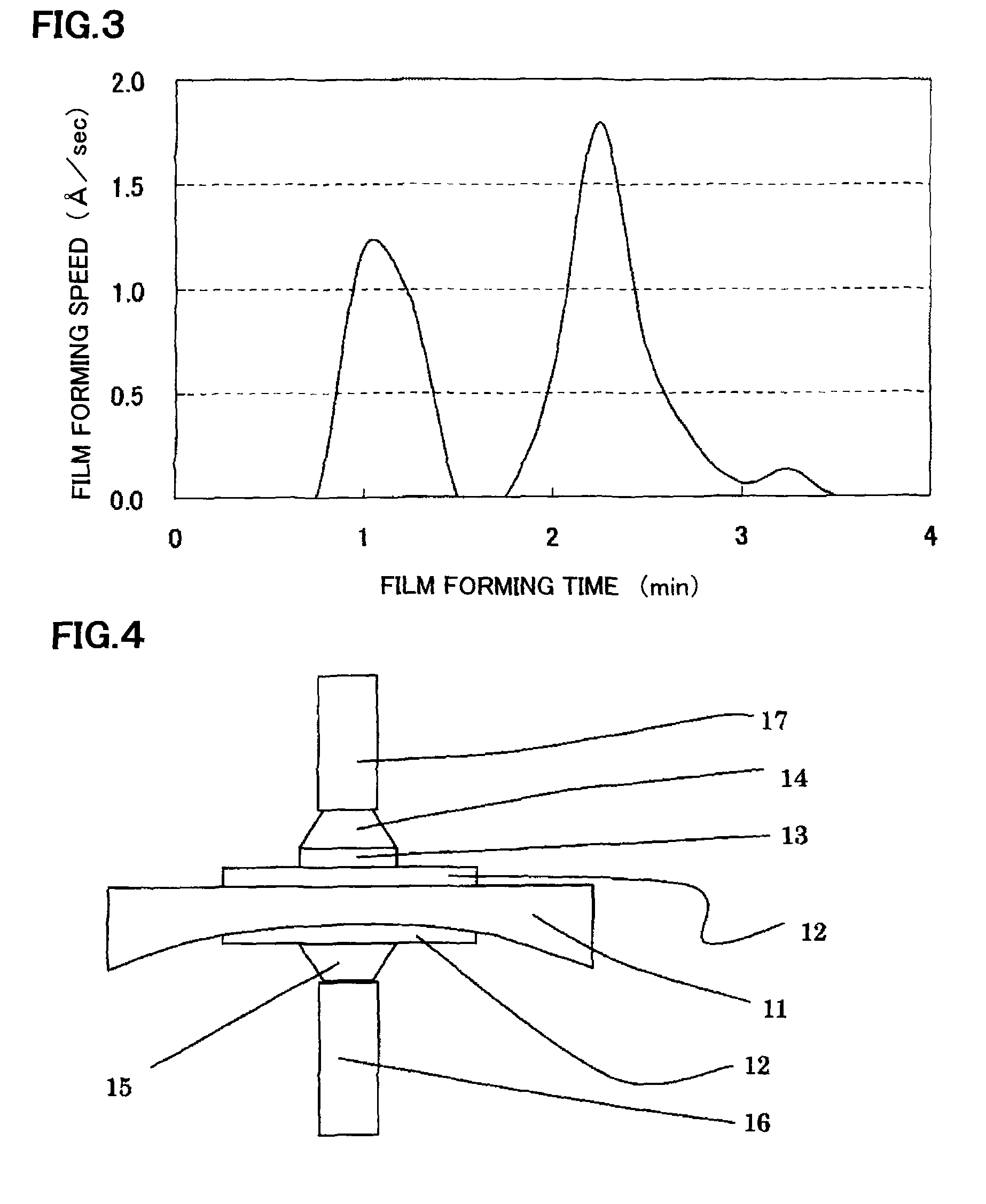

Spectacle lens and method for producing the same

ActiveUS20090257022A1Sufficient processabilityLower coefficient of dynamic frictionSpectales/gogglesSynthetic resin layered productsEyewearLens plate

The disclosure relates to a spectacle lens comprising: a lens base member; a multi-layered anti-reflection film placed on the lens base member, and including a layer mainly made of silicon dioxide as an outermost layer; and a water-and-oil repellent layer provided in contact with the outermost layer of the multi-layered anti-reflection film, and made by using, as raw materials: at least one kind of a first fluorine-substituted alkyl group-containing organosilicon compound and a second fluorine-substituted alkyl group-containing organosilicon compound. The disclosure also relates to methods of producing a spectacle lens that is capable of retaining a sufficient water-and-oil repellency over an extended period, and having sufficient edge processability.

Owner:NIKON ESSILOR

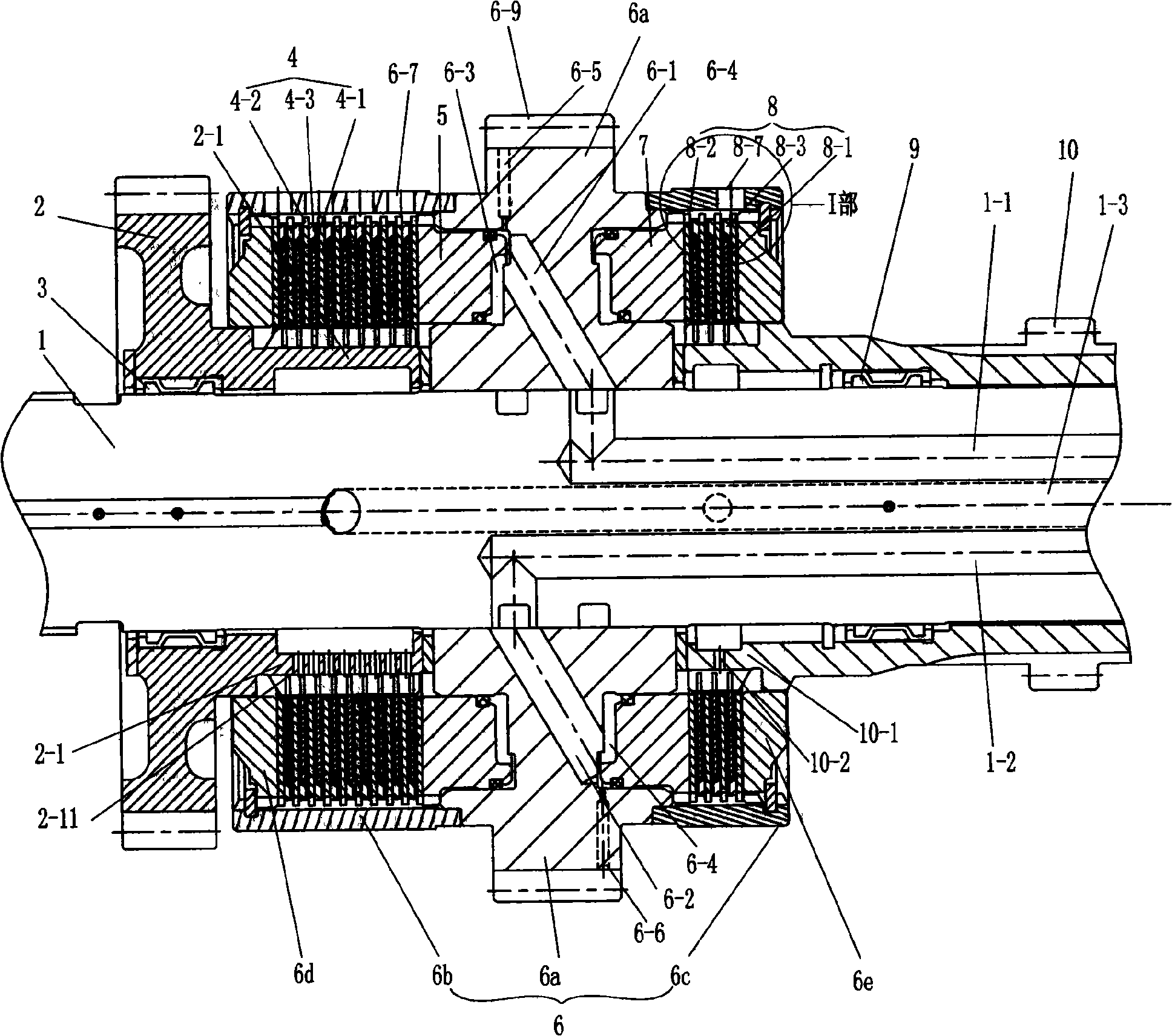

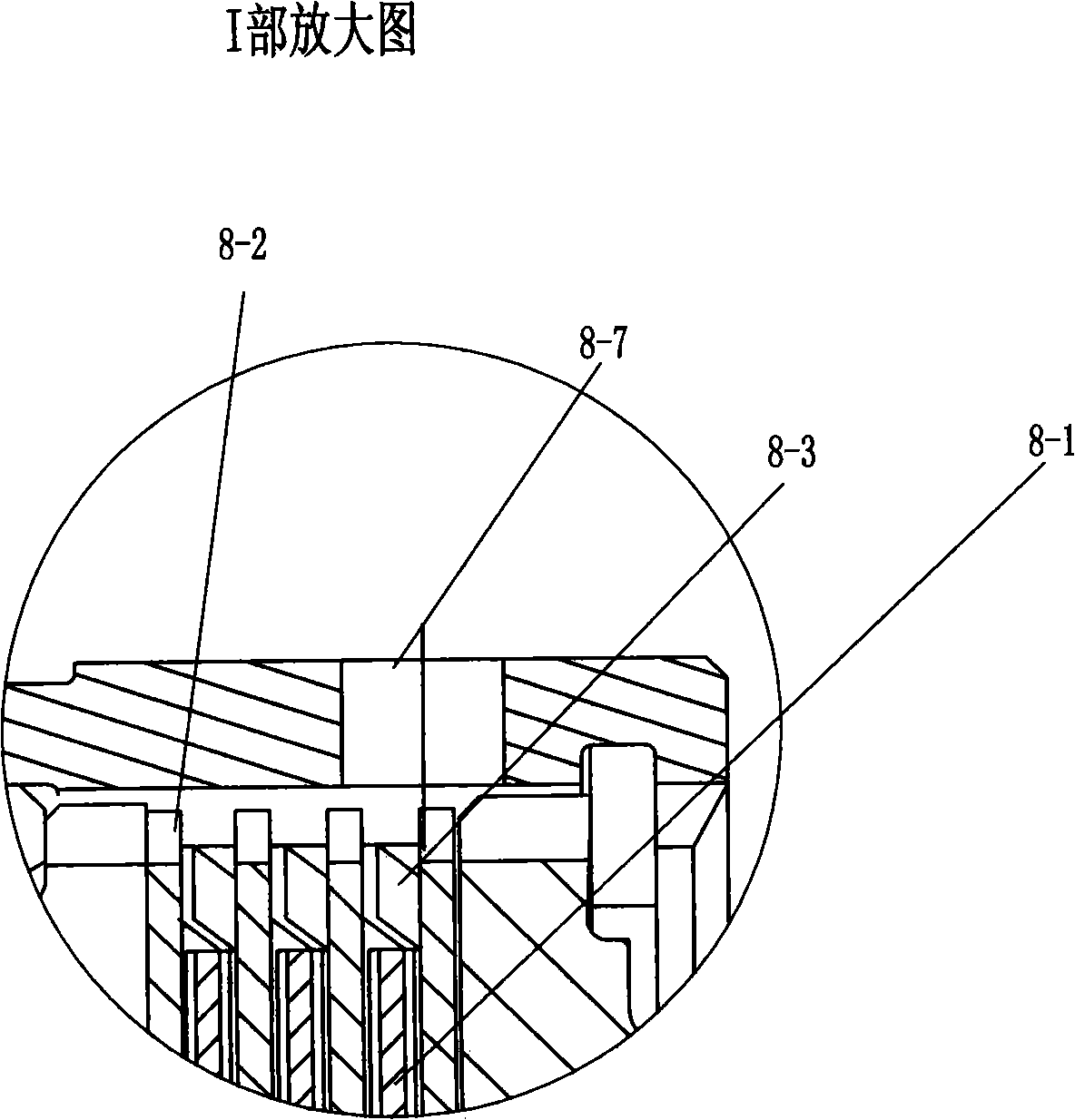

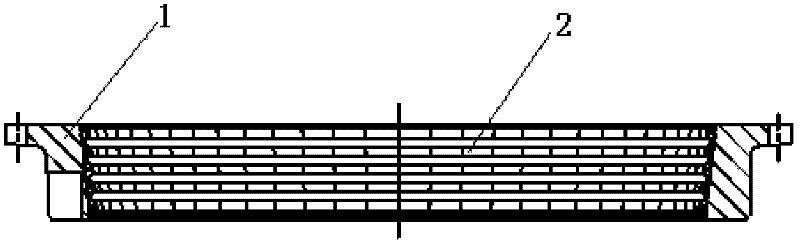

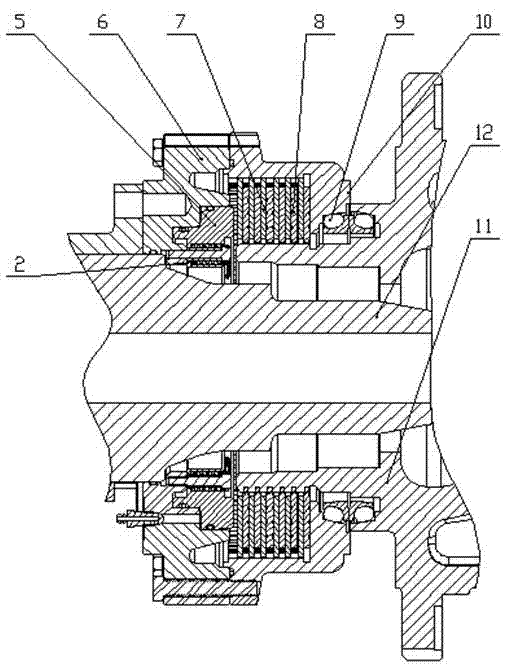

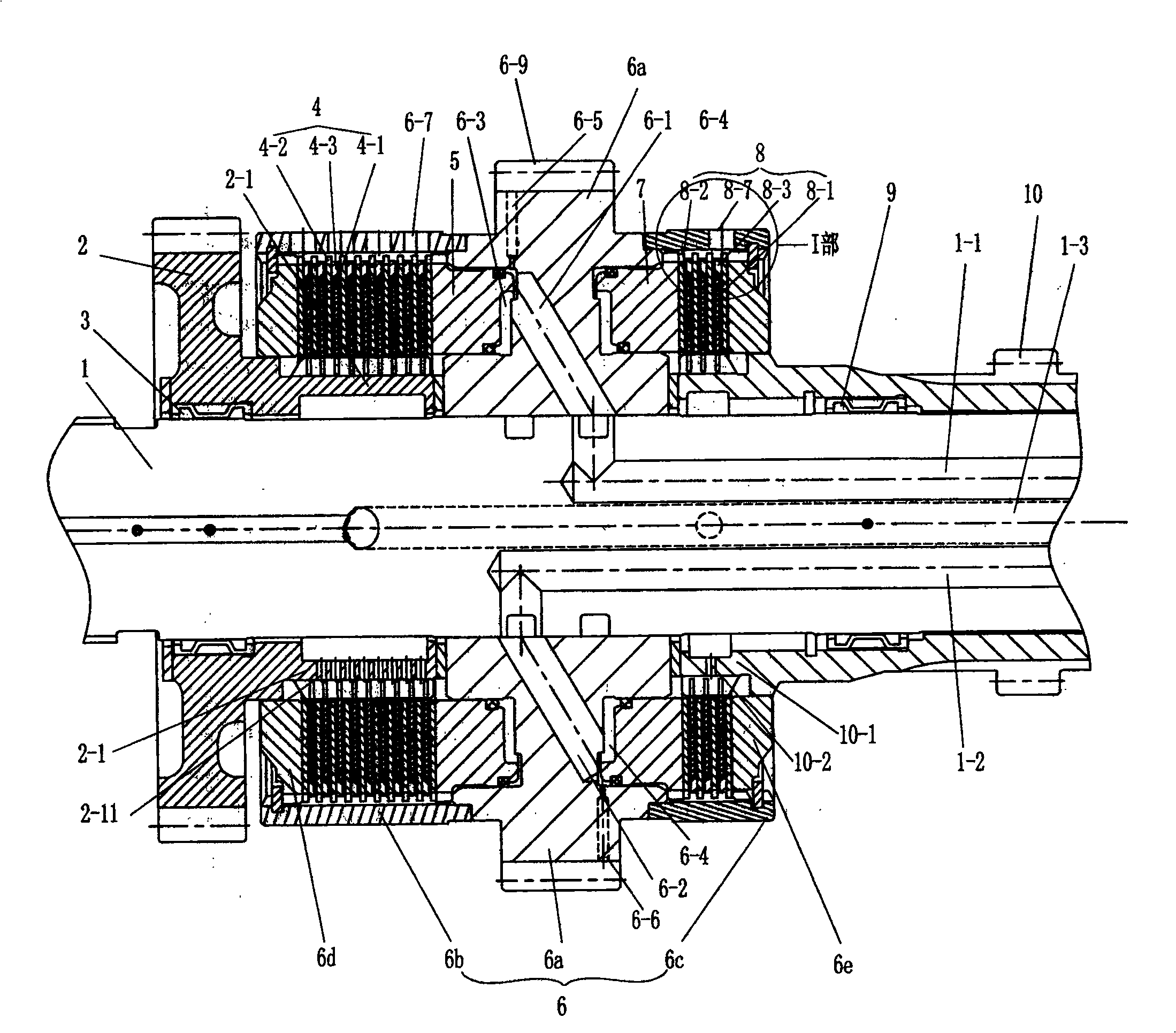

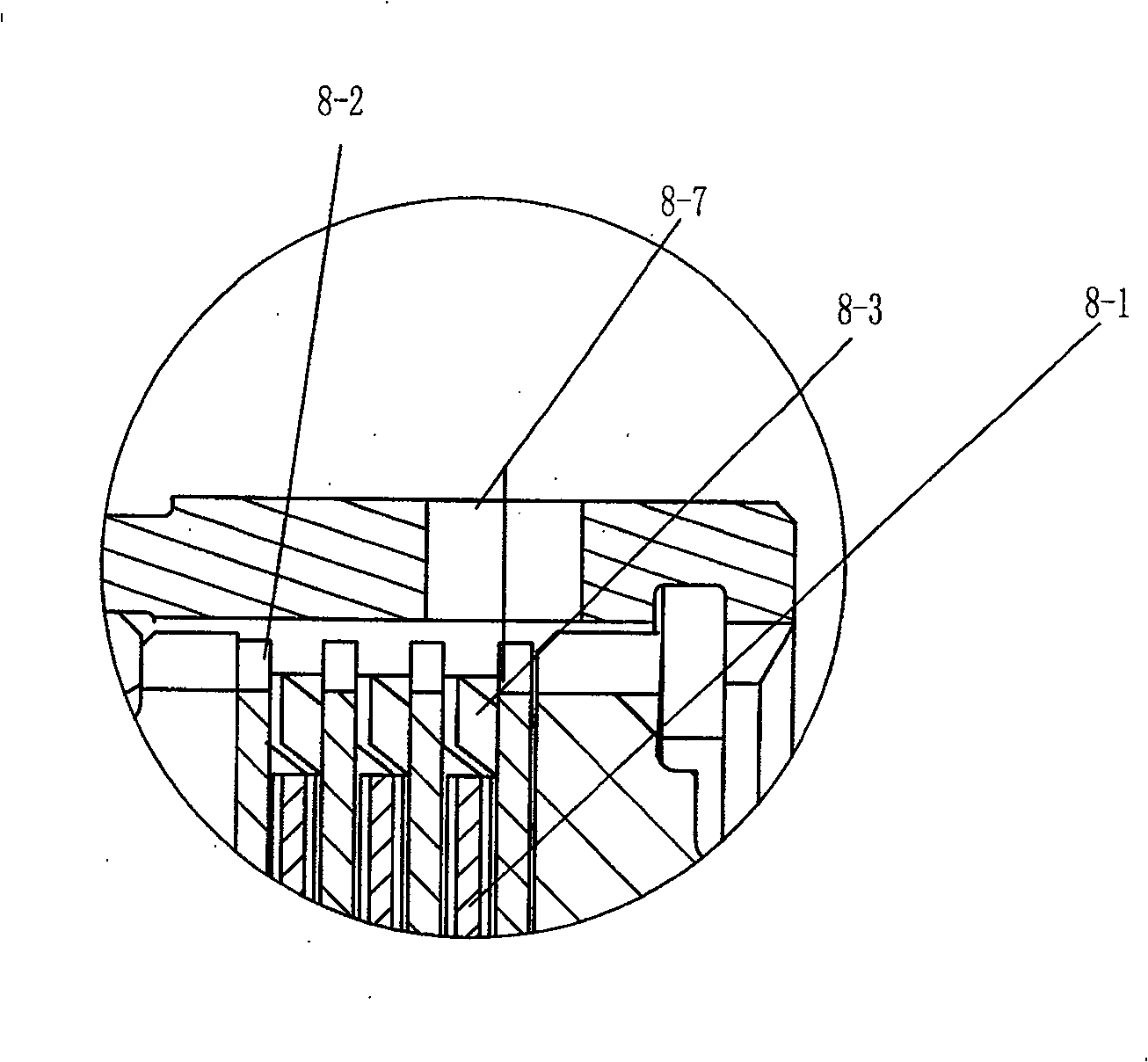

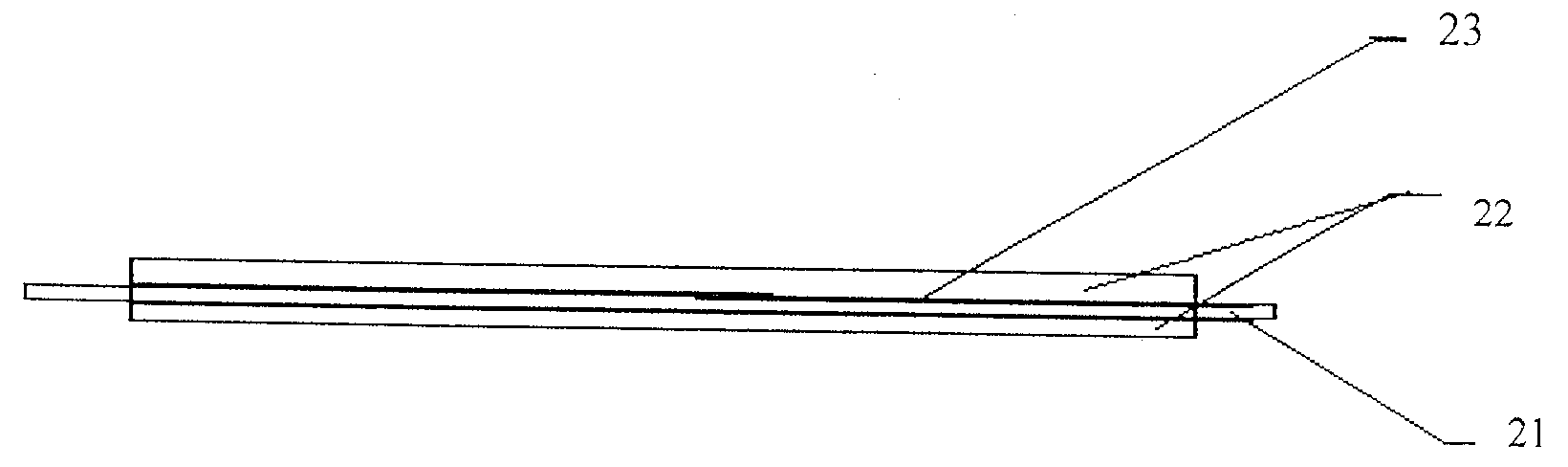

Multi-disc friction type shifting clutch

InactiveCN101270786AImprove carrying capacitySmall structure sizeFluid actuated clutchesInterference fitSheet steel

A multi-disc friction clutch includes a main shaft with a first pressure oil duct and a first piston and a first friction pair, which are arranged side by side. The cylinder body includes the main body of the cylinder body and a first canister body connected with one side of the main body of the cylinder body. The interference fit occurs between the main shaft and the main body of the cylinder body. The circumference of the main body of the cylinder body is provided with a gear ring. The first piston and the first friction pair are arranged in the space enclosed by the main body of the cylinder body and the first canister body. The first friction pair consists of a paper-based friction plate, dual sheet steel and a wave spring, wherein, the paper-based friction plate has a splined connection with the extension section with a first gear and the dual sheet steel has the splined connection with the cylinder body. The invention adopts the paper-based friction plate, the dynamic friction coefficient of which is one time higher than the dynamic friction coefficient of a copper-based plate. The characteristic makes the paper-based plate has a higher bearing capacity than the copper-based plate. When the same torque is transmitted, with the paper-based plate, the structural size of the clutch can be obviously reduced. The invention has the interference connection between the main shaft and the cylinder body in order that enough working torque can be transmitted with less radial structure.

Owner:SINOMACH CHANGLIN CO LTD

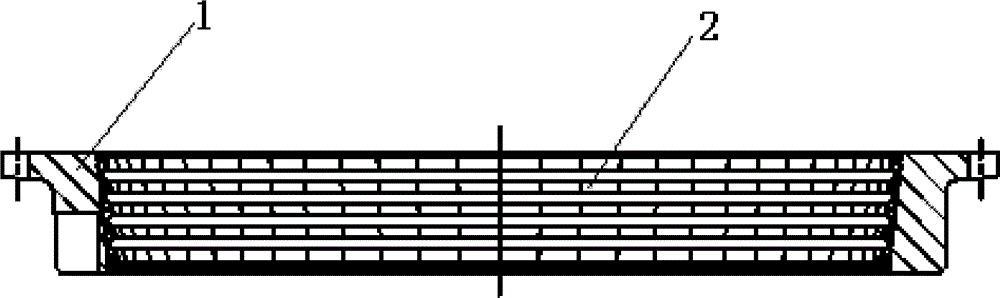

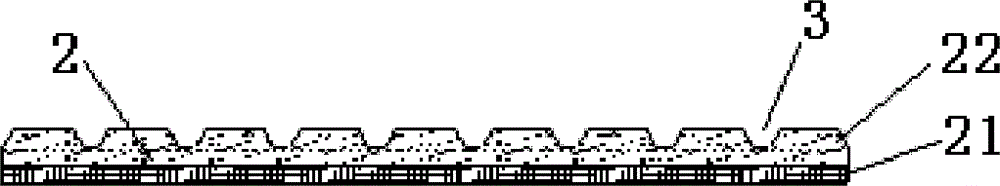

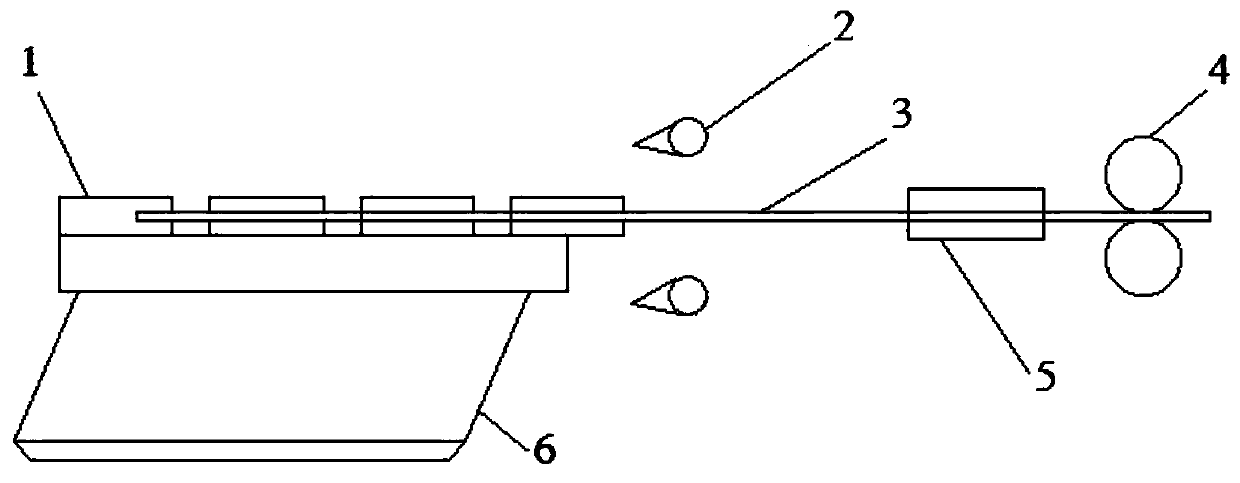

Rubber-resin blended type paper-based friction material

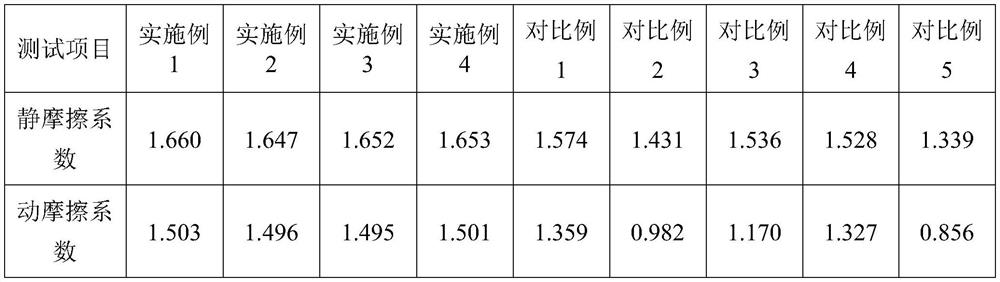

InactiveCN102061145AHigh coefficient of kinetic frictionOther chemical processesPaper/cardboardStatic friction coefficientFrictional coefficient

The invention discloses a rubber-resin blended type paper-based friction material which is used for solving the technical problem that the existing paper-based friction materials have low kinetic frictional coefficients and static frictional coefficients. The technical scheme is that the friction material provided by the invention is prepared from the following components by weight percent: 18-42% of rubber, 6-20% of fiber, 18-40% of modified phenolic resin and 10-20% of filler. By increasing the weight percentage of the rubber component and optimizing with the other components, when the weight percentage of the rubber component is 18-42%, the kinetic frictional coefficient of the paper-based friction material is increased from (1.2-1.3) to (1.6-1.8), and the static frictional coefficient is increased from (0.16-0.17) to (0.18-0.20).

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Synchronous ring for synchronizer and method for manufacturing synchronous ring

ActiveCN102588460AImprove friction and wear performanceImprove reliabilityMechanical actuated clutchesCeramic shaping apparatusEngineeringToughness

The invention discloses a synchronous ring for a synchronizer and a method for manufacturing the synchronous ring. The synchronous ring comprises a synchronous ring base, and a friction plate is arranged in the synchronous ring base and consists of a flexible base layer and a friction layer which are compounded. A combined structure consisting of the flexible base layer and the friction layer replaces an existing machined friction layer structure, a hard friction material without elasticity and toughness is improved to form a bendable adhesive friction material without being machined, and a friction abrasion performance and reliability of the synchronous ring are improved. In addition, an oil drainage groove is directly pressed on the friction layer, process is simplified, and cost is lowered. Besides, the platy friction plate can be cut into various shapes according to actual needs, the process is simple, machining is omitted, materials are saved, and the synchronous ring is applicable to synchronizers.

Owner:SHIYAN TONGCHUANG DRIVE TECH CO LTD

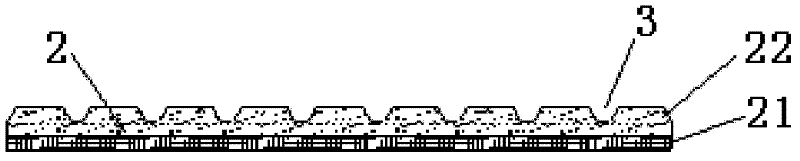

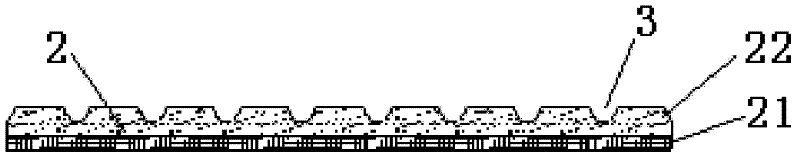

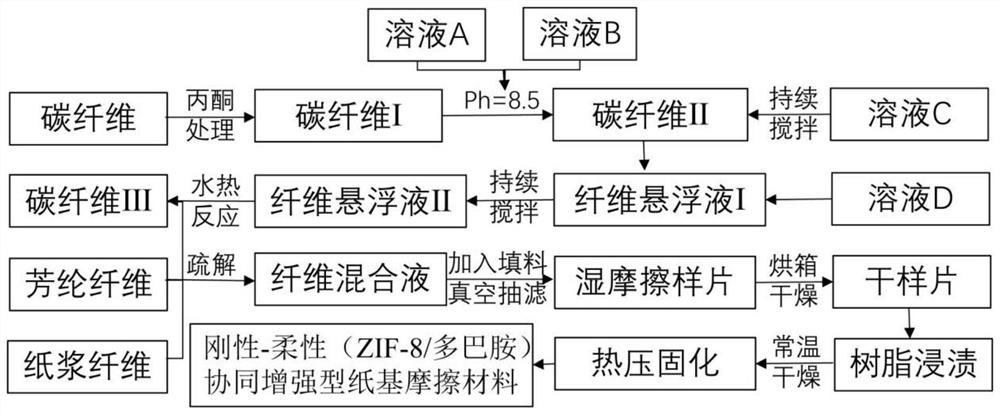

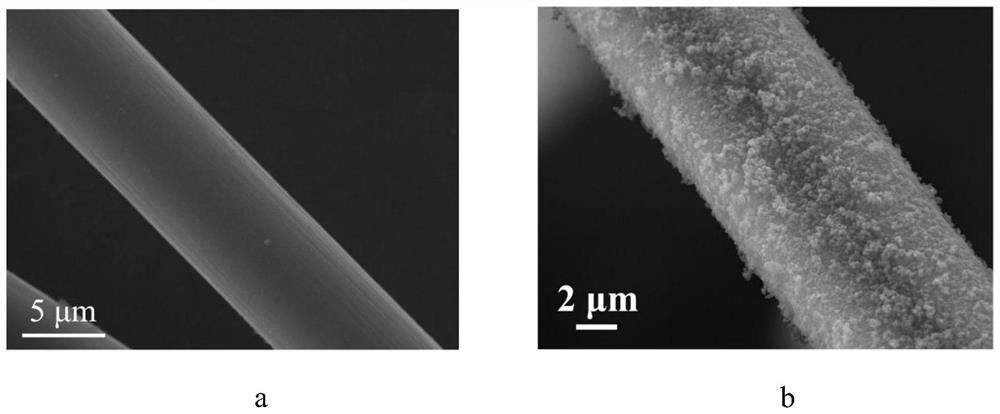

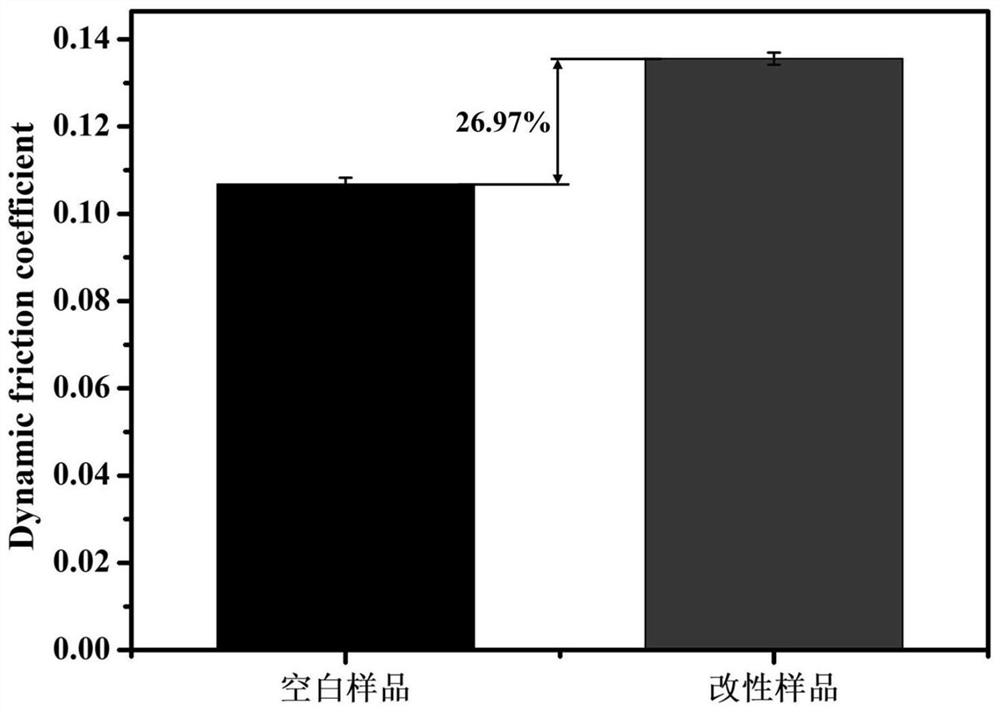

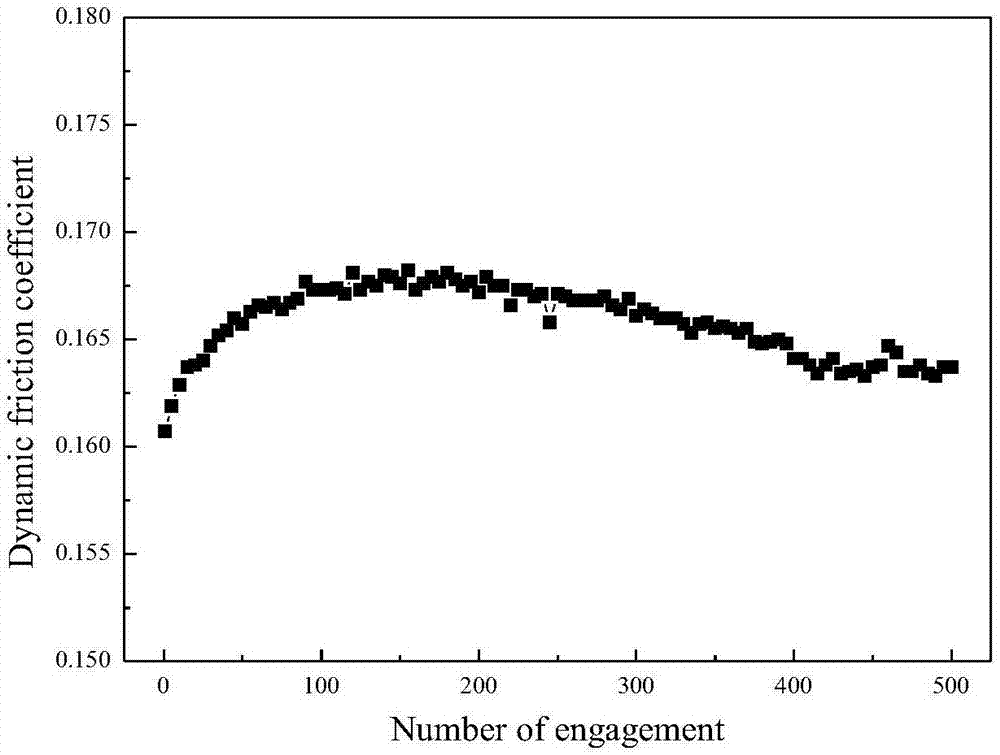

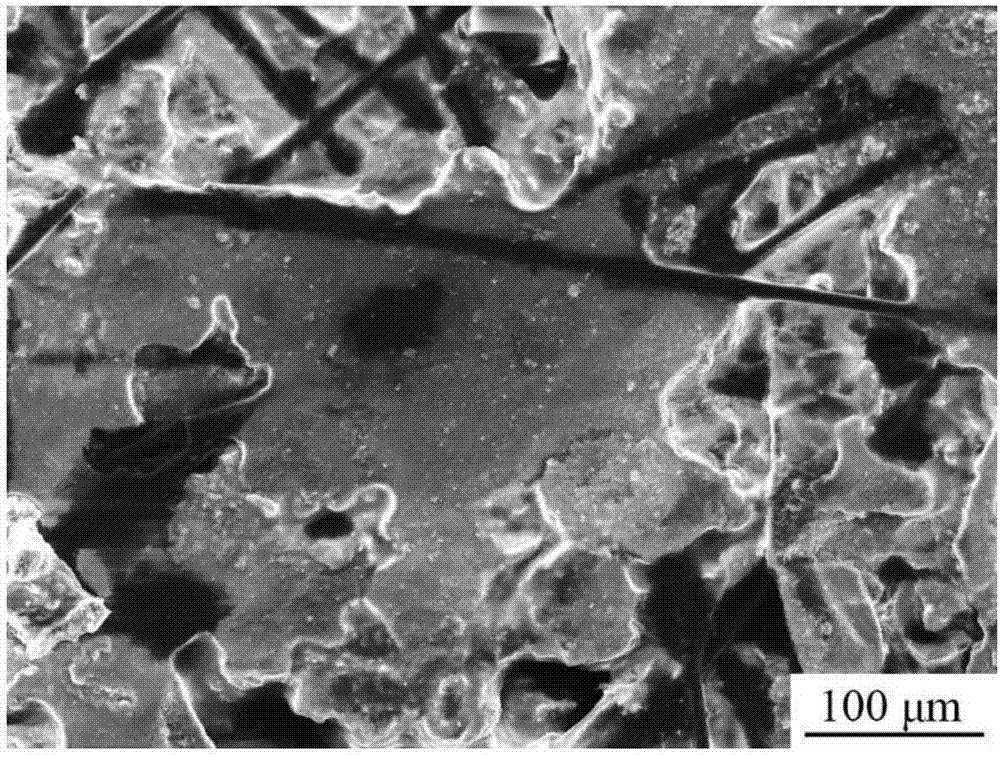

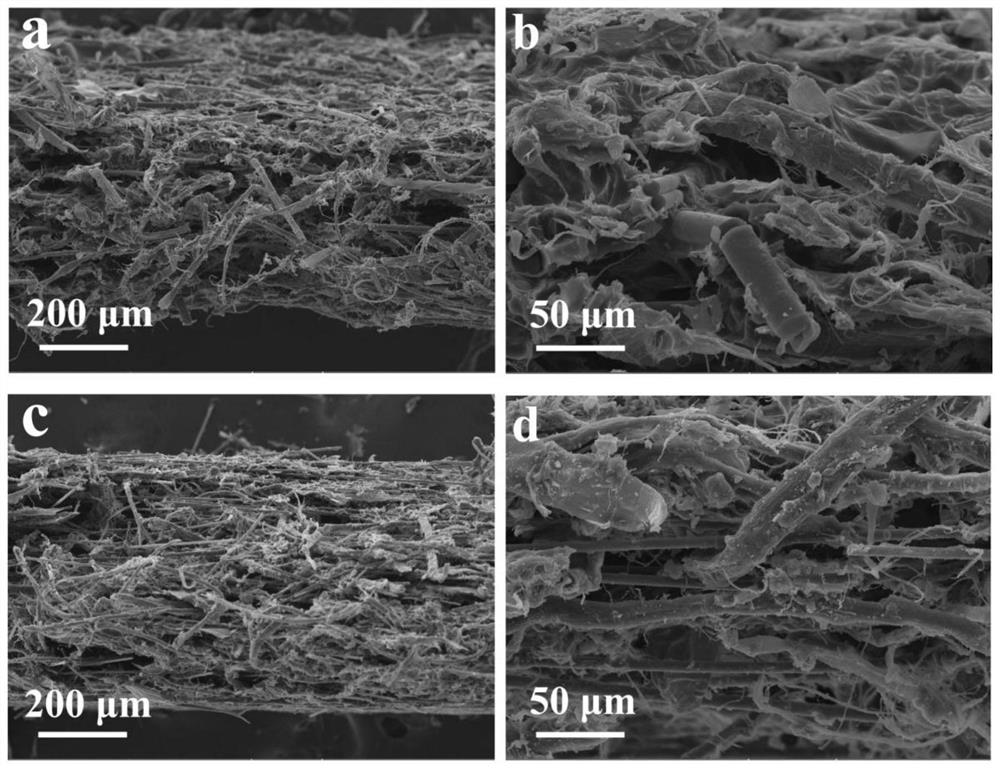

Rigid-flexible ZIF-8/dopamine synergistically enhanced paper-based friction material and preparation method thereof

ActiveCN113445360AImprove performanceEnhanced interface bindingNatural cellulose pulp/paperSpecial paperFiberCarbon fibers

The invention relates to a rigid-flexible ZIF-8 / dopamine synergistically enhanced paper-based friction material and a preparation method thereof. The preparation method comprises the steps that carbon fibers are sequentially placed in tris(hydroxymethyl)aminomethane (Tris buffer solution) and a dopamine solution, and a high-adhesion dopamine flexible film is formed on the surface of the carbon fibers; and then, a compact and uniform nano ZIF-8 crystal rigid layer grows on the surface of the carbon fiber in situ through a green hydrothermal reaction, a rigid-flexible interface enhancement structure is constructed through the modified carbon fiber and a resin matrix, and the ZIF-8 / dopamine synergistic enhancement type paper-based friction material is prepared. The dynamic friction coefficient of the prepared rigidity-flexibility (ZIF-8 / dopamine) synergistically enhanced paper-based friction material is increased from 0.1068 to 0.1356, the increase amplitude is 26.97%, the wear rate is decreased from 3.55*10<-8> cm<3>.J<-1> to 2.45*10<-8> cm<3>.J<-1>, and the decrease amplitude is 30.99%. The synergistic effect of a ZIF-8 / dopamine bi-component enhanced and constructed rigid-flexible interface enhanced structure is fully displayed, and the friction and wear performance of the paper-based friction material can be remarkably improved when the paper-based friction material is applied to the paper-based friction material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Graphene modified paper-based friction material and preparation method

InactiveCN106930138AIncrease frictionImprove wear performancePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperState of artFiber

The invention relates to a graphene modified paper-based friction material and a preparation method. Graphene is introduced into a formula system in a friction performance modifier manner, and components of the paper-based friction material comprise, by weight, 15-35% of reinforced fibers, 10-20% of filling materials, 15-25% of friction performance modifiers, 25-45% of binders, and 1-3% of grapheme. The preparation method comprises the steps of evenly dispersing the reinforced fibers, the friction performance modifiers and the filling materials into water, obtaining a friction material prefab in a papermaking moulding manner and drying the friction material prefab, and obtaining a paper-based friction piece through resin impregnation and hot-pressing solidification. Compared with a traditional preparation method, according to the prepared paper-based friction material, friction performance and abrasion performance of the paper-based friction material can be both promoted, the dynamic friction coefficient is increased from 0.08-0.12 to 0.15-0.17, and the wear rate is reduced from <=6*10<-8>cm<3> / J of the prior art to <=3*10<-8>cm<3> / J.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

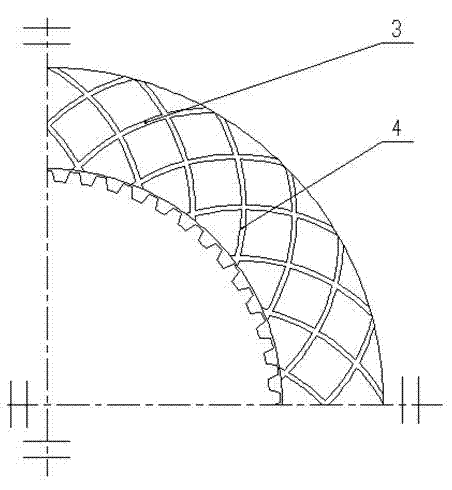

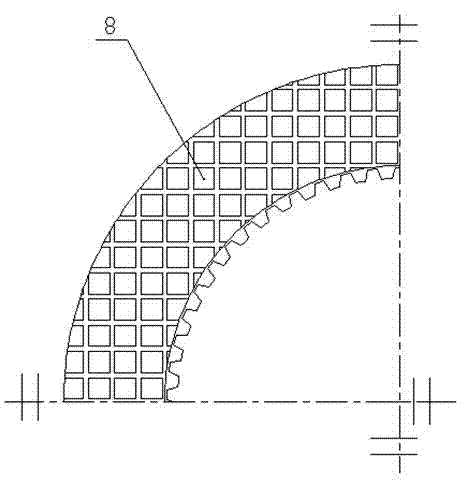

Wet brake for forklift drive axle

InactiveCN102927163AFast dischargeLow utilization rate of cooling effectFluid actuated brakesBraking discsCooling effectExchange time

The invention relates to a wet brake for a forklift drive axle, which comprises a left casing, a right casing, a piston assembly, as well as spacers and frication plates that are arranged in a stagger manner, wherein the piston assembly, as well as the spacers and the frication plates that are arranged in a stagger manner are mounted in a cavity formed by connecting the left casing with the right casing, first arc oil grooves in the clockwise direction and second arc oil grooves in the anti-clockwise direction are uniformly formed in the two side faces of the frication plates respectively, the first arc oil grooves and the second arc oil grooves are staggered with each other to form grids, a floating oil seal is arranged at the end part of the right casing corresponding to a hub, and another matched floating oil seal is mounted at the end part of the corresponding hub when in use. Oil flow channels of the arc oil grooves of the wet brake are longer, vortices are generated at cross points of the grooves, the oil discharging speed is relatively lower, the heat exchange time of the oil with a friction interface is slightly prolonged, and the utilization ratio of the cooling effect of the oil is increased.

Owner:ANHUI HELI CO LTD

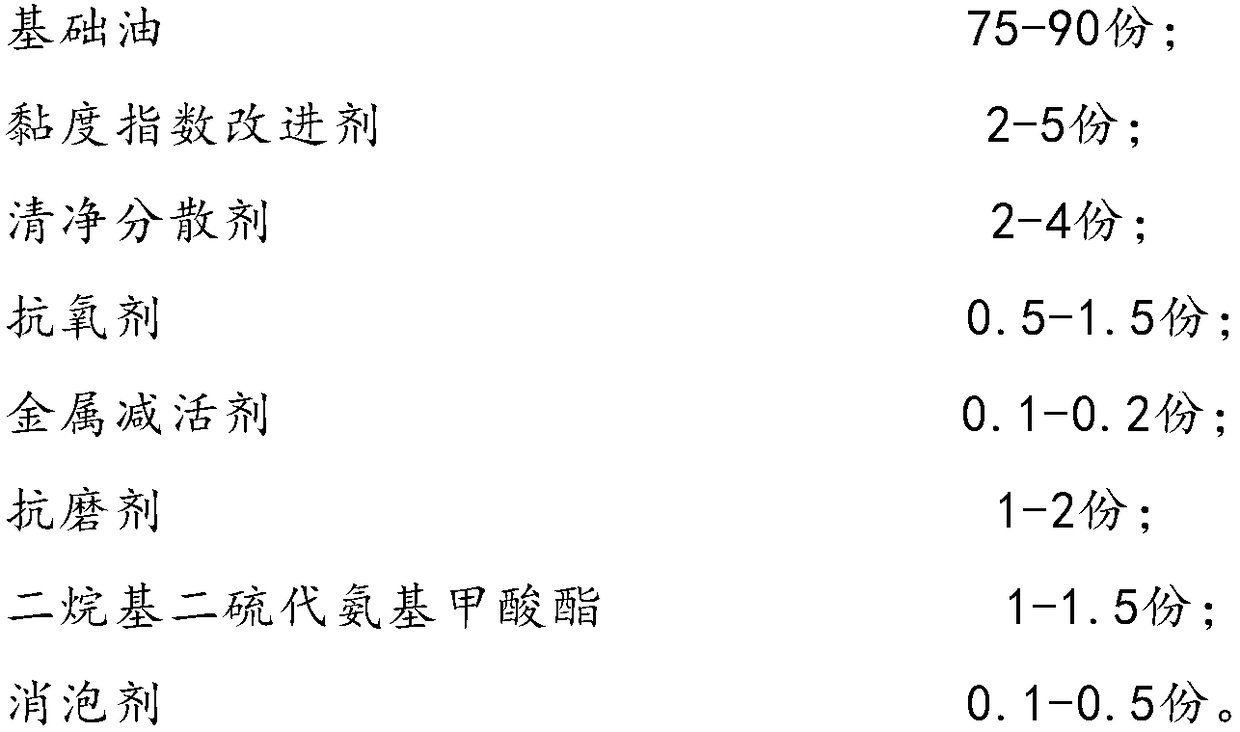

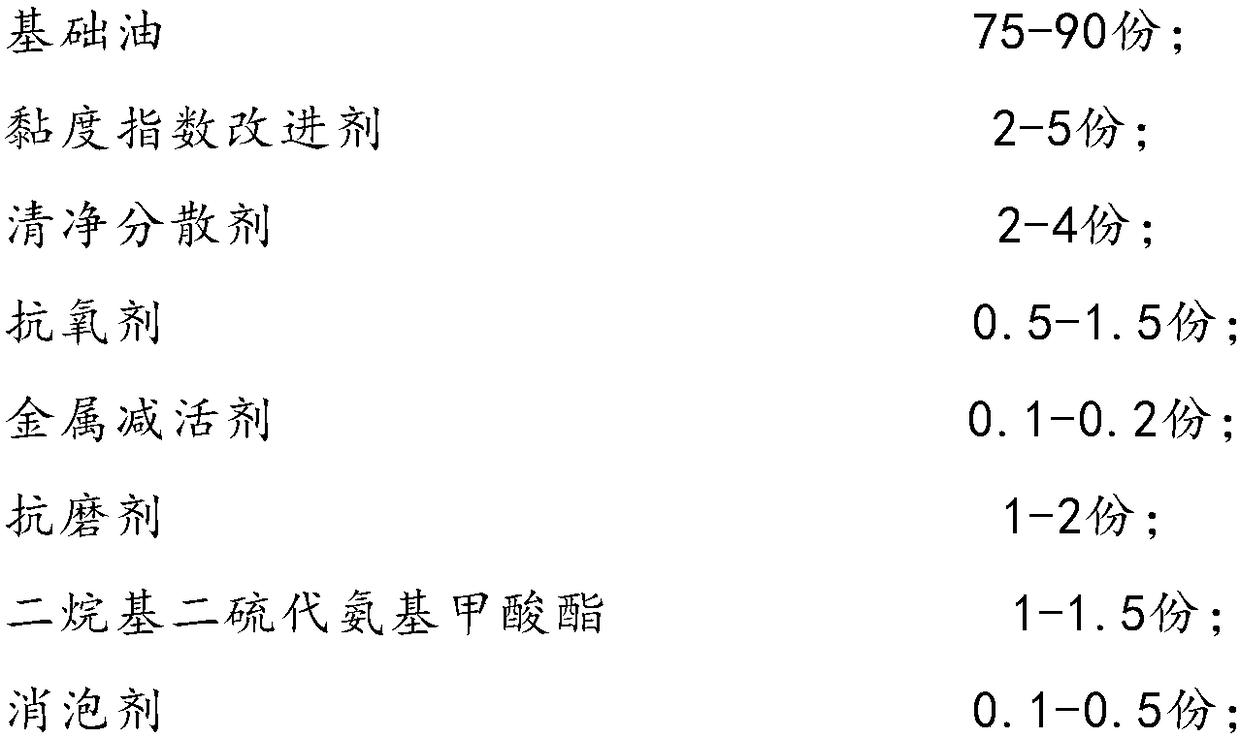

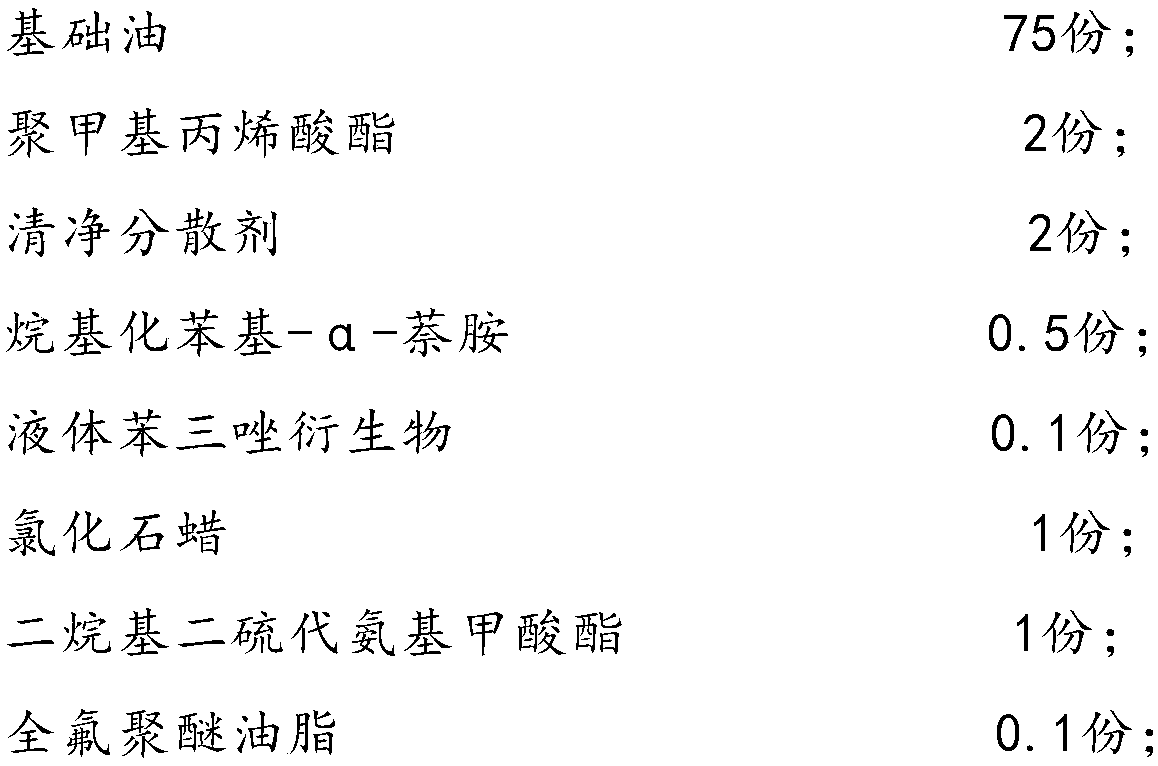

Automatic gearbox oil and preparation method thereof

InactiveCN108728222AGood fluidity at low temperatureAvoid accumulationLubricant compositionAntioxidantOxidation stability

The invention discloses automatic gearbox oil. The automatic gearbox oil comprises the following components in parts by weight: 75-90 parts of base oil, 2-5 parts of a viscosity index improver, 2-4 parts of a detergent dispersant, 0.5-1.5 parts of an antioxidant, 0.1-0.2 part of a metal deactivator, 1-2 parts of an antiwear agent, 1-1.5 parts of dialkyldithiocarbamate, and 0.1-0.5 part of a defoamer. The automatic gearbox oil provided by the invention has excellent lubricating performance, oxidation stability, low-temperature fluidity, high wear resistance and detergent dispersibility, and nofrothing, and the service life is prolonged.

Owner:SHANGHAI DELIAN CHEM

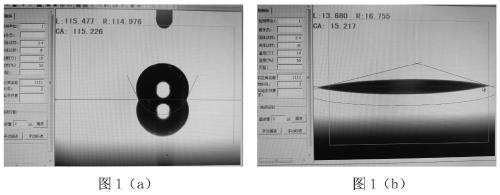

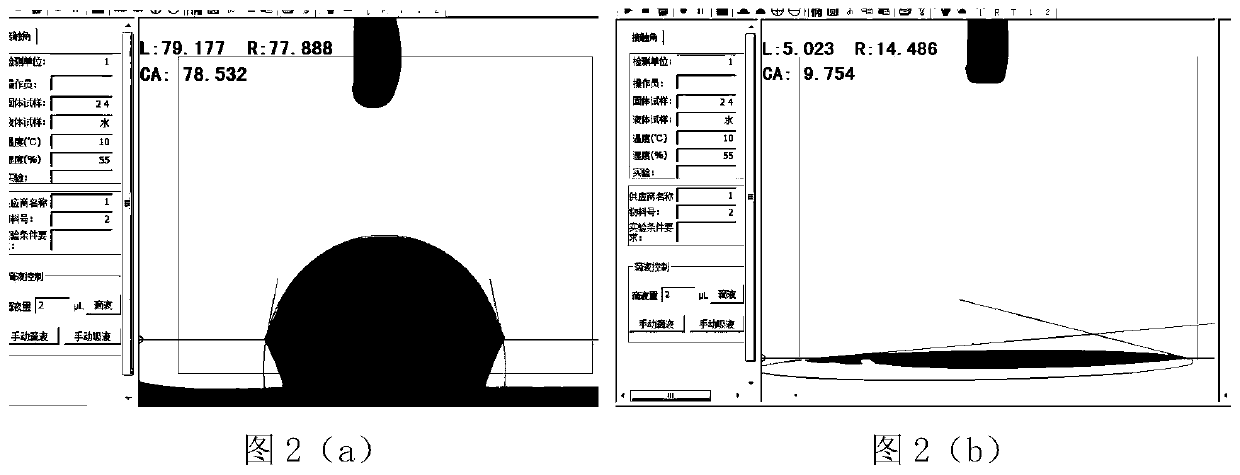

Anti-fingerprint glass coating with high friction coefficient and preparation method thereof

InactiveCN111410435AHigh coefficient of kinetic frictionImprove wear resistanceCoatingsMethyl palmoxirateStain

The invention provides a preparation method of an anti-fingerprint glass coating with a high friction coefficient. The preparation method of the paint used by the coating comprises the following steps: uniformly mixing 20-25 parts by mass of perfluoroalkyl olefin, 8-12 parts by mass of vinylmethoxysilane and 6-8 parts by mass of hexamethyldisiloxane, stirring, heating to 80-100 DEG C, keeping thetemperature constant for 10-12 hours, heating to 110-120 DEG C through silicone oil, and purifying for 4-6 hours to obtain a perfluoropolyether alkylated oligomer with the molecular weight of 3000-4000; and uniformly stirring the following components in parts by mass: 15-25 parts of the obtained perfluoropolyether alkylated oligomer, 25-35 parts of nonafluoro-ethoxy-butane and 45-55 parts of heptafluoro-ethoxy difluoro methyl-propane, so as to obtain the required coating. The glass carrier treated by the coating has the excellent performances of high dynamic friction coefficient, fingerprint resistance, oil stain resistance, scratch resistance and the like. According to the invention, the defect that a common anti-fingerprint coating is used on a 3C rear cover in the 5G era can be effectively overcome, and the preparation method is simple, mild in reaction condition, and free of pollution and harm to human bodies and the environment.

Owner:湖南宏泰新材料有限公司

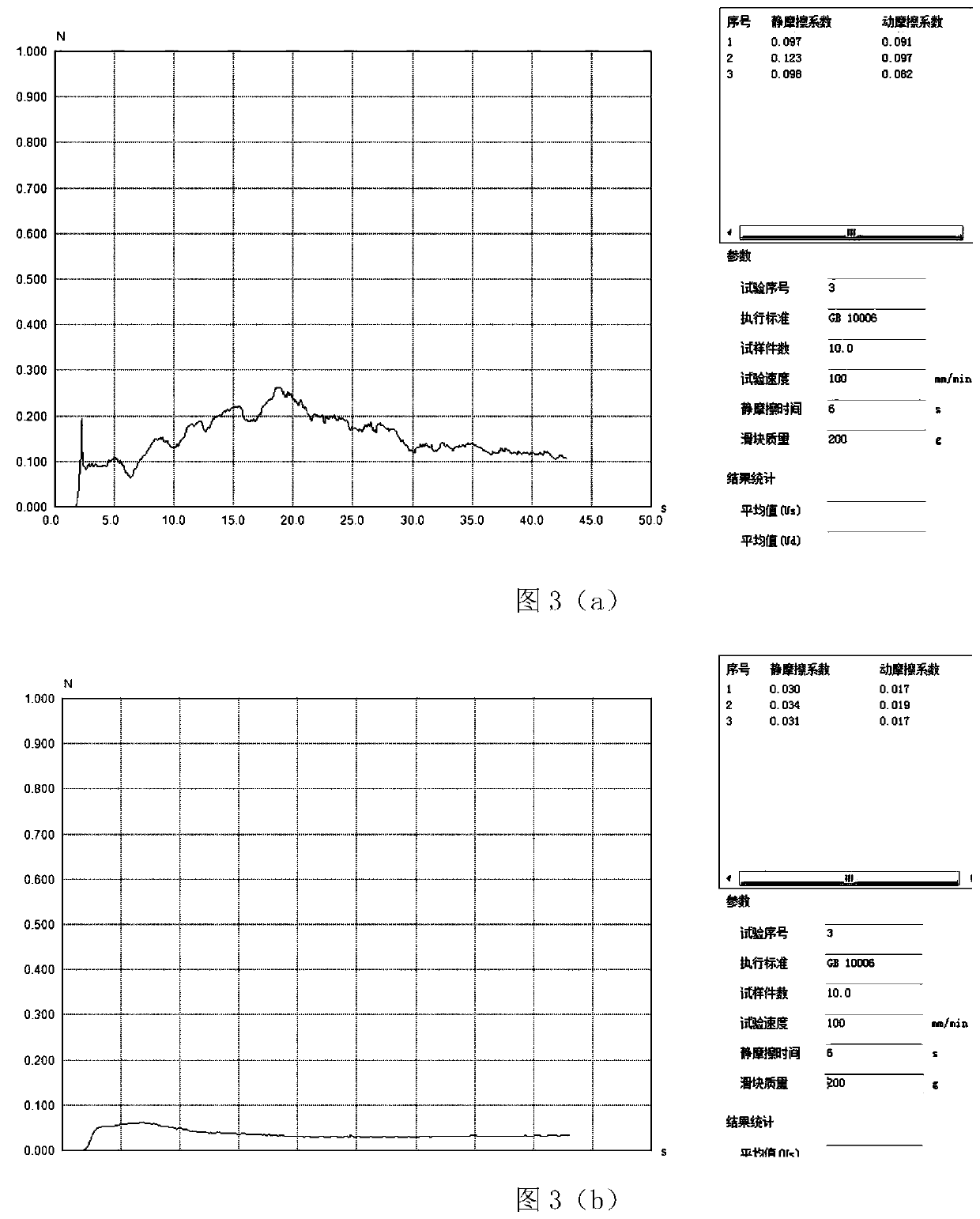

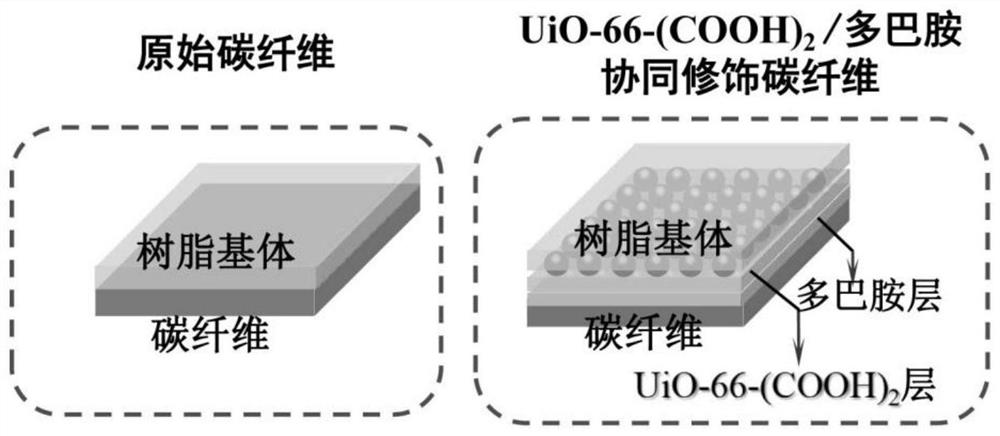

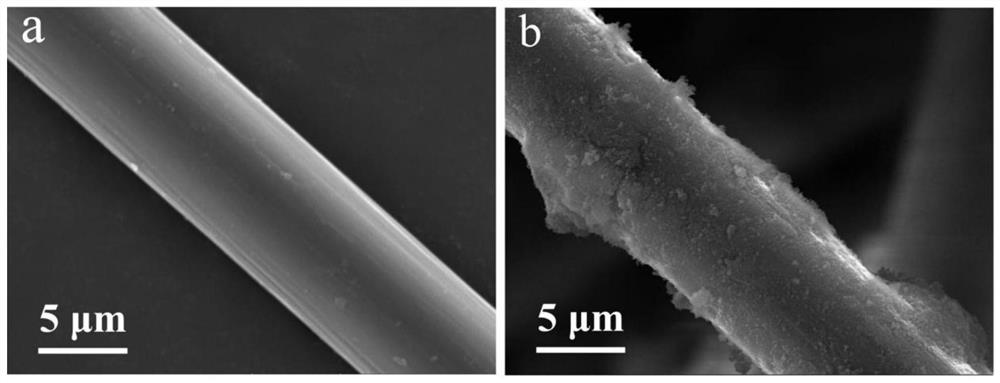

UiO-66-(COOH) 2/dopamine synergistically modified carbon fiber reinforced paper-based friction material and preparation method thereof

ActiveCN114016326AEnhanced interface bindingImprove friction and wear performanceNatural cellulose pulp/paperSpecial paperFiberCarbon fibers

The invention relates to a UiO-66-(COOH) 2 / dopamine synergistically modified carbon fiber reinforced paper-based friction material and a preparation method thereof. The preparation method comprises the steps that carbon fibers with clean surfaces are sequentially placed in trihydroxymethyl aminomethane (Tris buffer solution) and a dopamine solution, and a high-adhesion dopamine flexible film grows and wraps the surfaces of the carbon fibers; then, based on a hydrothermal reaction, a UiO-66-(COOH) 2 crystal layer grows on the surface of the carbon fiber in situ, and after the reaction is completed, the modified carbon fiber is fully washed and dried. An interface structure is constructed and reinforced by adopting the bi-component modified carbon fibers and a resin matrix, and the UiO-66-(COOH) 2 / dopamine synergistically modified carbon fiber reinforced paper-based friction material is prepared. The dynamic friction coefficient of the UiO-66-(COOH) 2 / dopamine synergistically modified carbon fiber reinforced paper-based friction material prepared by the preparation method disclosed by the invention is increased to 0.1353 from 0.1044, and the amplification is 29.60%. The wear rate is reduced from 3.35 * 10 <-8 > cm < 3 >. J <-1 > to 2.65 * 10 <-8 > cm < 3 >. J <-1 >, and the reduction amplitude is 20.89%. The result shows that the UiO-66-(COOH) 2 / dopamine synergistically modifies and reinforces the material interface structure, and the friction and wear performance of the paper-based friction material can be remarkably improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Spectacle lens and method for producing the same

ActiveUS7954944B2Lower coefficient of dynamic frictionHigh coefficient of kinetic frictionSpectales/gogglesSynthetic resin layered productsSilicon dioxideOrganosilicon

The disclosure relates to a spectacle lens comprising: a lens base member; a multi-layered anti-reflection film placed on the lens base member, and including a layer mainly made of silicon dioxide as an outermost layer; and a water-and-oil repellent layer provided in contact with the outermost layer of the multi-layered anti-reflection film, and made by using, as raw materials: at least one kind of a first fluorine-substituted alkyl group-containing organosilicon compound and a second fluorine-substituted alkyl group-containing organosilicon compound. The disclosure also relates to methods of producing a spectacle lens that is capable of retaining a sufficient water-and-oil repellency over an extended period, and having sufficient edge processability.

Owner:NIKON ESSILOR

Ceramic friction material mixture and mixing method thereof

ActiveCN105112016AReduce wear rateImprove quality and performanceOther chemical processesFriction liningSODIUM DODECYL BENZENE SULFONATEGraphite

The invention relates to the technical field of ceramic friction materials, particularly a ceramic friction material mixture and a mixing method thereof. Silicon dioxide, molybdenum disulfide, diesel, manganese carbonate ore, phosphorite, graphite, diatomite, ceramic fibers, carbon fibers, a phenolic resin and sodium dodecyl benzene sulfonate used as raw materials are selected and proportioned to prepare the ceramic friction material. The kinetic friction coefficient of the ceramic friction plate prepared from the ceramic friction material is 0.22-0.23, the static friction coefficient is 0.24-0.25, the kinetic / static friction ratio is 0.88-0.955, and the wear rate is 7.5*10<-6>mm<3>.J<-1>-9*10<-6>mm<3>.J<-1>. By combining the raw material proportioning and adding the manganese carbonate ore and phosphorite, the properties of the ceramic friction material mixture are improved, so that the frictional properties (especially stability, oil conductivity and physical and mechanical properties) of the ceramic friction material are improved.

Owner:贵州领想科技制造有限公司

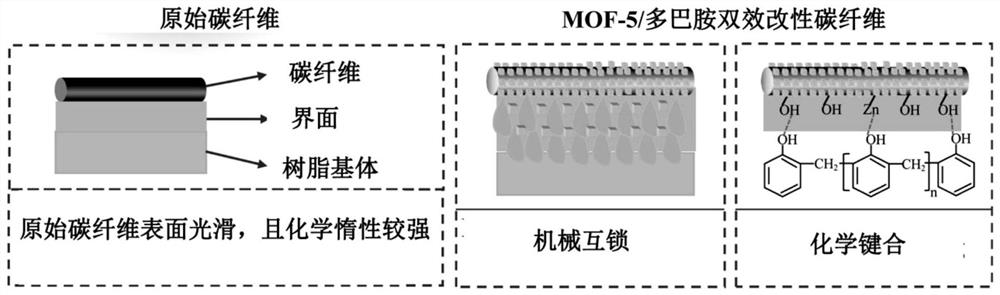

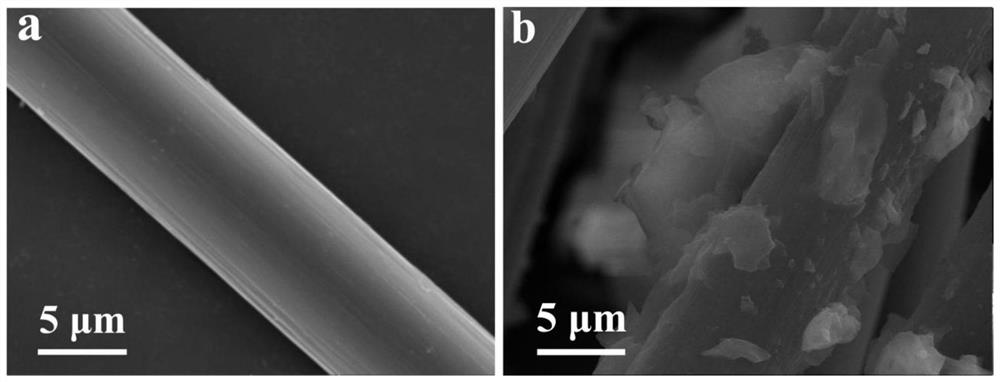

MOF-5/dopamine double-effect enhanced paper-based friction material and preparation method thereof

PendingCN114086424AImprove interface performanceImprove friction and wear performanceNatural cellulose pulp/paperSpecial paperFiberCarbon fibers

The invention relates to an MOF-5 / dopamine double-effect enhanced paper-based friction material and a preparation method thereof. The preparation method comprises the steps that carbon fibers are soaked and cleaned through acetone, and a sizing agent and other impurities on the surfaces of the fibers are removed; carbon fibers with clean surfaces are sequentially put into a trihydroxymethyl aminomethane solution and a dopamine solution, and a high-adhesion dopamine flexible film is formed on the surfaces of the carbon fibers; then, based on a hydrothermal reaction, an MOF-5 crystal layer grows on the surface of the carbon fiber in situ, and after the reaction is completed, the modified carbon fiber is fully washed and dried; the modified carbon fibers and a resin matrix are adopted to construct a double-effect enhanced interface structure, and the MOF-5 / dopamine double-effect enhanced paper-based friction material is prepared. The dynamic friction coefficient of the prepared MOF-5 / dopamine double-effect enhanced paper-based friction material is increased to 0.1279 from 0.1068, and the amplification is 19.76%. The wear rate is reduced from 3.55*10<-8 >cm<3>. J<-1> to 3.00*10<-8>cm<3>. J<-1 >, and the reduction amplitude is 15.49%. The double-effect enhancement effect of MOF-5 / dopamine based on a mechanical interlocking and chemical coupling mechanism is fully displayed, and the friction and wear performance can be remarkably improved when the MOF-5 / dopamine is applied to the paper-based friction material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

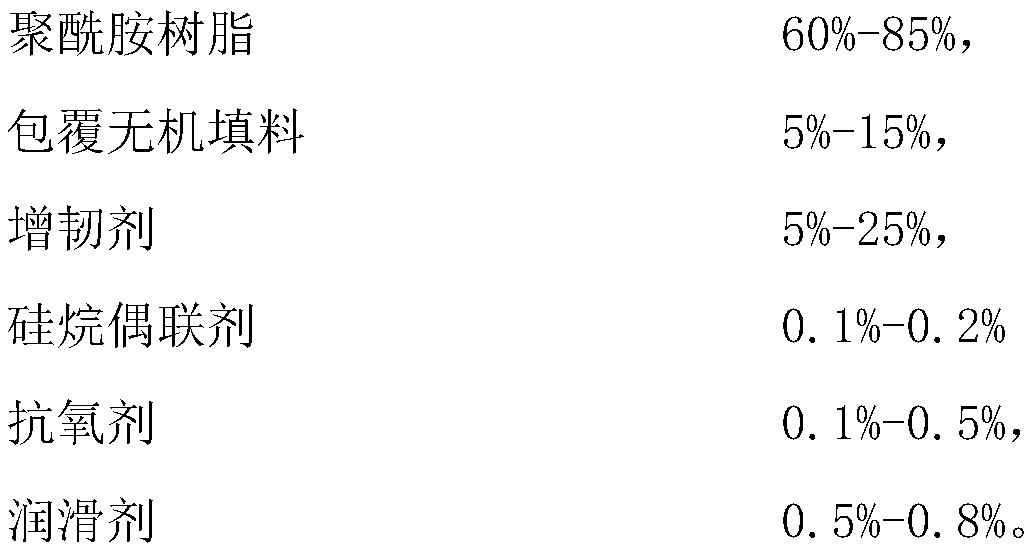

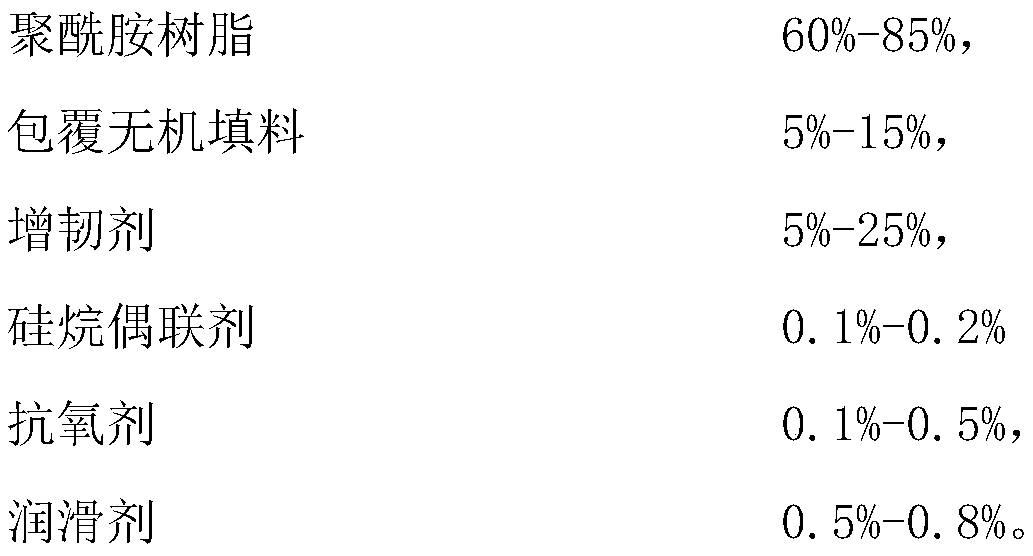

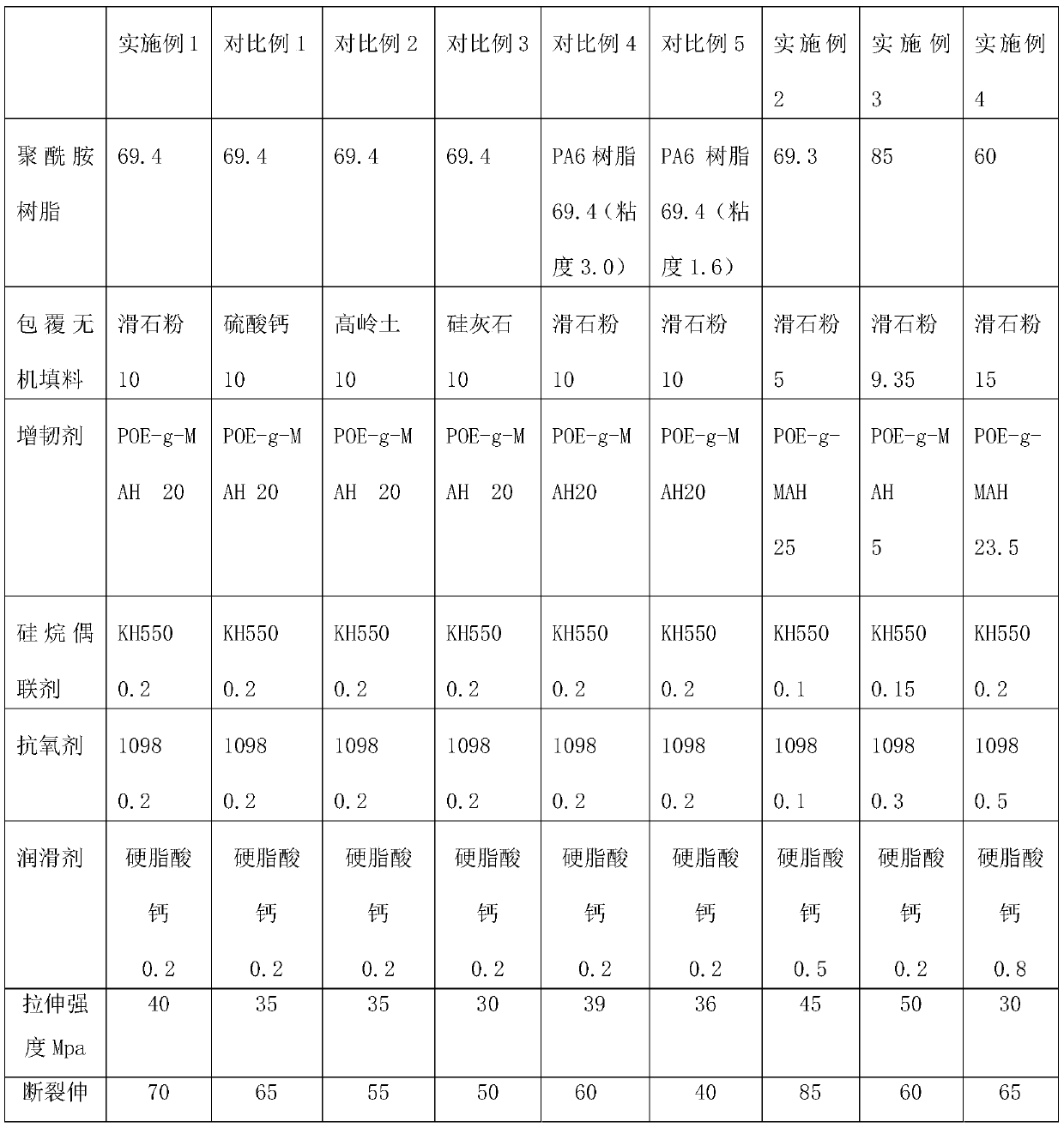

High-friction-coefficient polyamide material and preparing method and application thereof

ActiveCN109943065AHigh coefficient of kinetic frictionImprove wear resistancePolyamideWear resistance

The invention discloses a high-friction-coefficient polyamide material and a preparing method and application thereof. The high-friction-coefficient polyamide material is prepared from, by weight, 60%-85% of polyamide resin, 5%-15% of a coating inorganic filler, 5%-25% of a toughening agent, 0.1%-0.2% of a silane coupling agent, 0.1%-0.5% of an antioxidant and 0.5%-0.8% of a lubricating agent. Thehigh-friction-coefficient polyamide material has the advantages of being good in abrasive resistance, high in dynamic friction coefficient and excellent in mechanical property.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Multi-disc friction type shifting clutch

InactiveCN100535466CImprove carrying capacitySmall structure sizeFluid actuated clutchesInterference fitSheet steel

A multi-disc friction clutch includes a main shaft with a first pressure oil duct and a first piston and a first friction pair, which are arranged side by side. The cylinder body includes the main body of the cylinder body and a first canister body connected with one side of the main body of the cylinder body. The interference fit occurs between the main shaft and the main body of the cylinder body. The circumference of the main body of the cylinder body is provided with a gear ring. The first piston and the first friction pair are arranged in the space enclosed by the main body of the cylinder body and the first canister body. The first friction pair consists of a paper-based friction plate, dual sheet steel and a wave spring, wherein, the paper-based friction plate has a splined connection with the extension section with a first gear and the dual sheet steel has the splined connection with the cylinder body. The invention adopts the paper-based friction plate, the dynamic friction coefficient of which is one time higher than the dynamic friction coefficient of a copper-based plate. The characteristic makes the paper-based plate has a higher bearing capacity than the copper-based plate. When the same torque is transmitted, with the paper-based plate, the structural size of the clutch can be obviously reduced. The invention has the interference connection between the main shaft and the cylinder body in order that enough working torque can be transmitted with less radial structure.

Owner:SINOMACH CHANGLIN CO LTD

Wet-type copper based powder metallurgy friction wafer and manufacturing method

ActiveCN100549451CHigh porosityReduce manufacturing costFriction liningComposite filmRoom temperature

A wet copper-based powder metallurgy friction plate and its manufacturing method. The friction plate is mainly composed of a steel core plate in the middle and a friction layer on at least one side, and a layer of adhesive film is bonded to at least one side of the steel core plate , and a layer of friction layer is compounded on the adhesive film layer; the manufacturing method at least includes friction layer batching, mixing, pressing, sintering, assembling with steel core plate, oil tank processing, and is characterized in that the sintering adopts Pressureless sintering in a continuous sintering furnace. The sintered friction layer is dipped in a vacuum dipping tank at room temperature and dried, and then spliced with the steel core plate. Before splicing, the surface of the steel core plate is coated with glue ; After splicing, it is made by pressurizing and curing on a flat vulcanizing machine; it has the characteristics of high processing efficiency, low cost, increased hardness and strength, and high dimensional accuracy.

Owner:HANGZHOU ADVANCE GEARBOX GRP

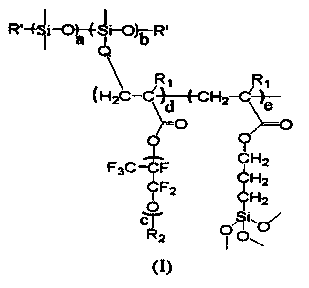

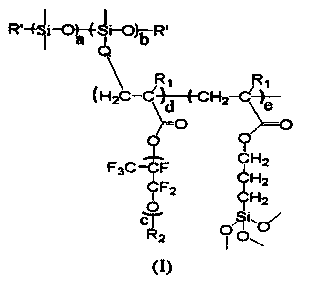

Fluorine-containing organic silicon grafted copolymer as well as preparation method and application thereof

The invention relates to a preparation method and application of a copolymer, and particularly relates to a fluorine-containing organic silicon grafted copolymer. The fluorine-containing organic silicon grafted copolymer is synthesized by polydimethylsiloxane with a sulfydryl and / or acrylate functional group, (methyl) acrylate with a perfluoropolyether functional group, and (methyl) acrylate with an alkyl siloxane functional group. A surface coating prepared by the fluorine-containing organic silicon grafted copolymer has relatively good light transmittance, a relatively low dynamic friction coefficient and relatively excellent pollution resistance. Especially, when the fluorine-containing organic silicon grafted copolymer is applied to a touch screen surface, the pollution resistance and decontamination capacity of the touch screen surface can be improved, the dynamic friction coefficient can be lowered, and good sense of touch and smoothness can be provided.

Owner:JIANGSU NUOFEI NEW MATERIAL TECH

A kind of ceramic friction material mixture and its mixing method

ActiveCN105112016BReduce wear rateImprove friction performanceOther chemical processesFriction liningFiberCarbon fibers

The invention relates to the technical field of ceramic friction materials, particularly a ceramic friction material mixture and a mixing method thereof. Silicon dioxide, molybdenum disulfide, diesel, manganese carbonate ore, phosphorite, graphite, diatomite, ceramic fibers, carbon fibers, a phenolic resin and sodium dodecyl benzene sulfonate used as raw materials are selected and proportioned to prepare the ceramic friction material. The kinetic friction coefficient of the ceramic friction plate prepared from the ceramic friction material is 0.22-0.23, the static friction coefficient is 0.24-0.25, the kinetic / static friction ratio is 0.88-0.955, and the wear rate is 7.5*10<-6>mm<3>.J<-1>-9*10<-6>mm<3>.J<-1>. By combining the raw material proportioning and adding the manganese carbonate ore and phosphorite, the properties of the ceramic friction material mixture are improved, so that the frictional properties (especially stability, oil conductivity and physical and mechanical properties) of the ceramic friction material are improved.

Owner:贵州领想科技制造有限公司

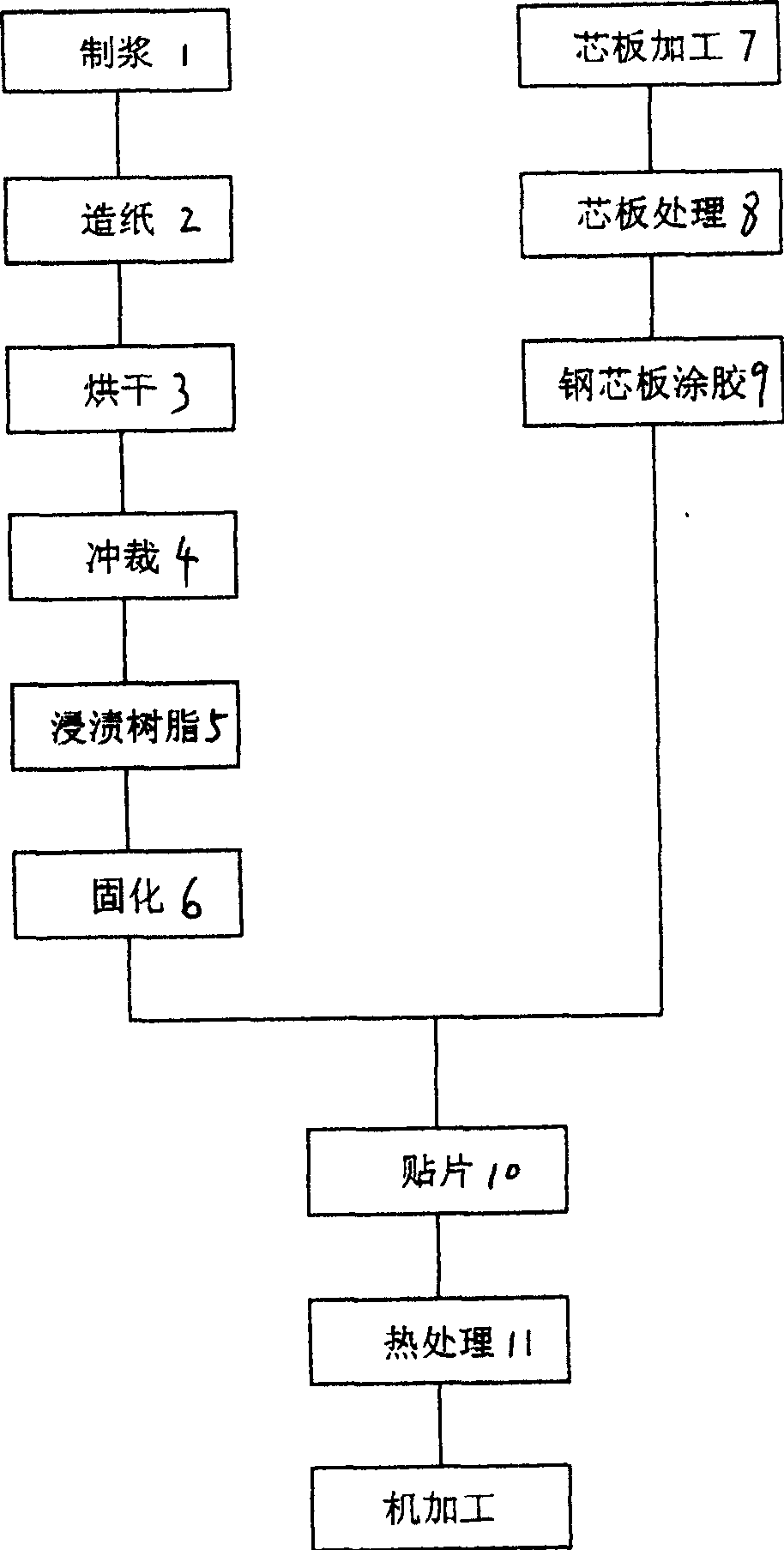

Paper based frictional material and friction plate producing method

InactiveCN1233706CHigh coefficient of kinetic frictionStrong jointLow noiseStatic friction coefficient

A paper-based friction material and a method for making a friction plate. The paper-based friction material uses fibers as a skeleton, resin as a matrix, various oxides and graphite as fillers, organic friction powder and rubber as regulators, and is produced by pulping and papermaking. , drying, impregnated with resin, cured, pasted on the steel core plate, and then heat-treated and machined to make a paper-based friction plate. It has a high coefficient of dynamic friction, close to the coefficient of dynamic and static friction, smooth and soft joints, and does not damage the couple. It has the characteristics of stable braking, low noise, strong torque transmission capacity, no environmental pollution, simple manufacturing process, and low manufacturing cost.

Owner:HANGZHOU ADVANCE GEARBOX GRP

Production process of regenerated anti-static polyester staple fibers

PendingCN112323169AIncrease profitReduce wasteSpinning solution de-aeratingArtificial filament washing/dryingPolyesterFiber

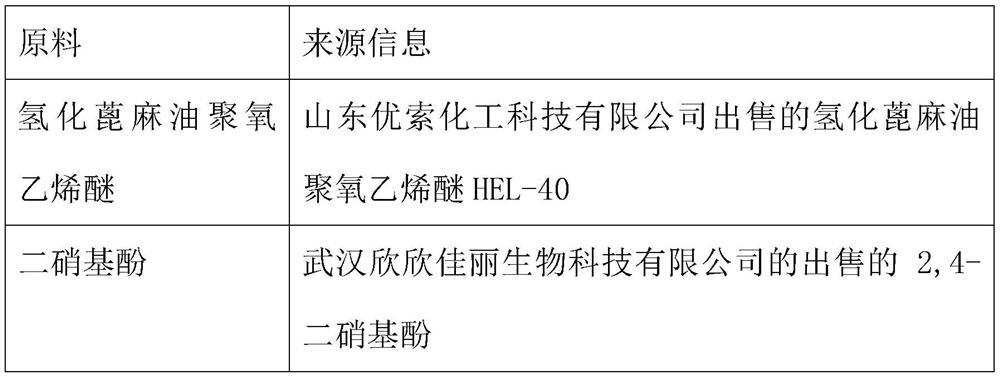

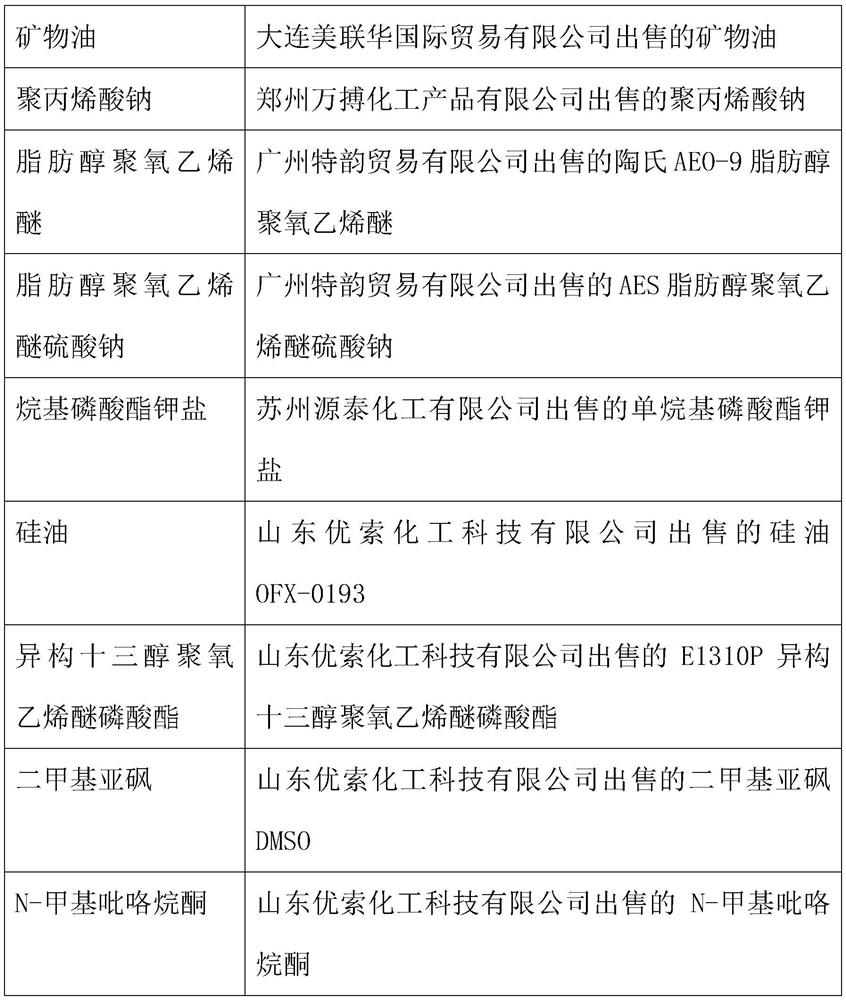

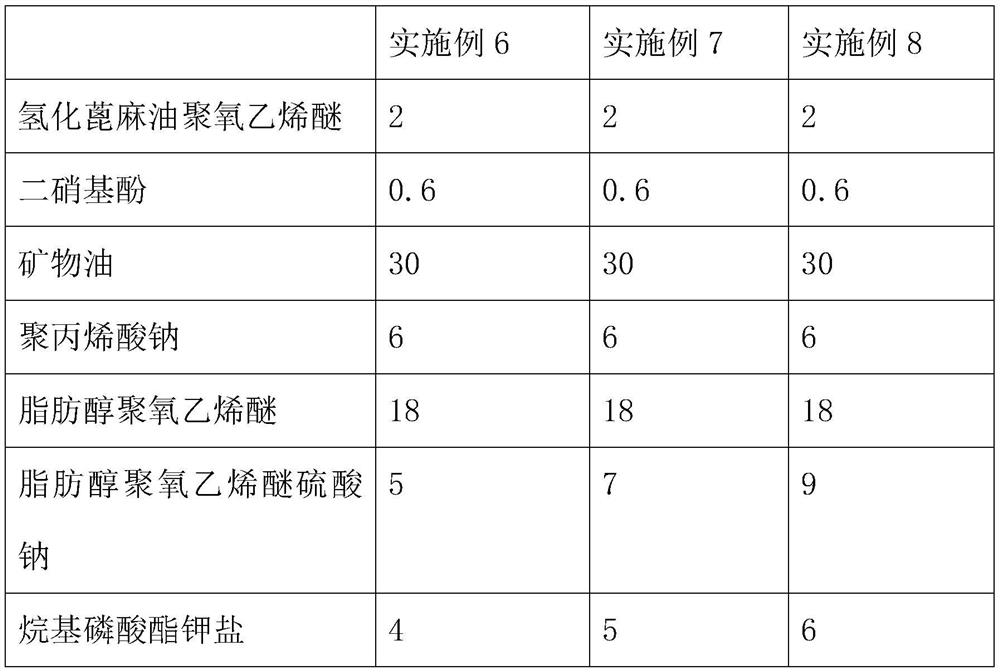

The invention relates to the field of fibers, and particularly discloses a production process of regenerated anti-static polyester staple fibers. The preparation method comprises the following steps:(1) raw materials are dried; (2) melting is conducted, specifically, the dried waste textiles and waste polyester bottle flakes are melted and filtered, then quenching and tempering treatment is conducted, and then secondary filtering treatment is conducted to obtain a filtered melt; (3) spinning is conducted, specifically, the filtered melt is subjected to spinning to form nascent fibers; (4) oiling is conducted, specifically, the nascent fibers are sequentially subjected to cooling, drafting for the first time, and oiling; (5) post-spinning is conducted, specifically, the oiled fibers are subjected to drafting for the second time; (6) shaping is conducted; and the polyester oiling agent in the step (4) is prepared from the components: hydrogenated castor oil polyoxyethylene ether, dinitrophenol, mineral oil, a thickening agent and fatty alcohol-polyoxyethylene ether. The regenerated polyester staple fibers prepared through the method have the advantage of being good in quality underthe good anti-static effect.

Owner:广州市双雄化纤有限公司

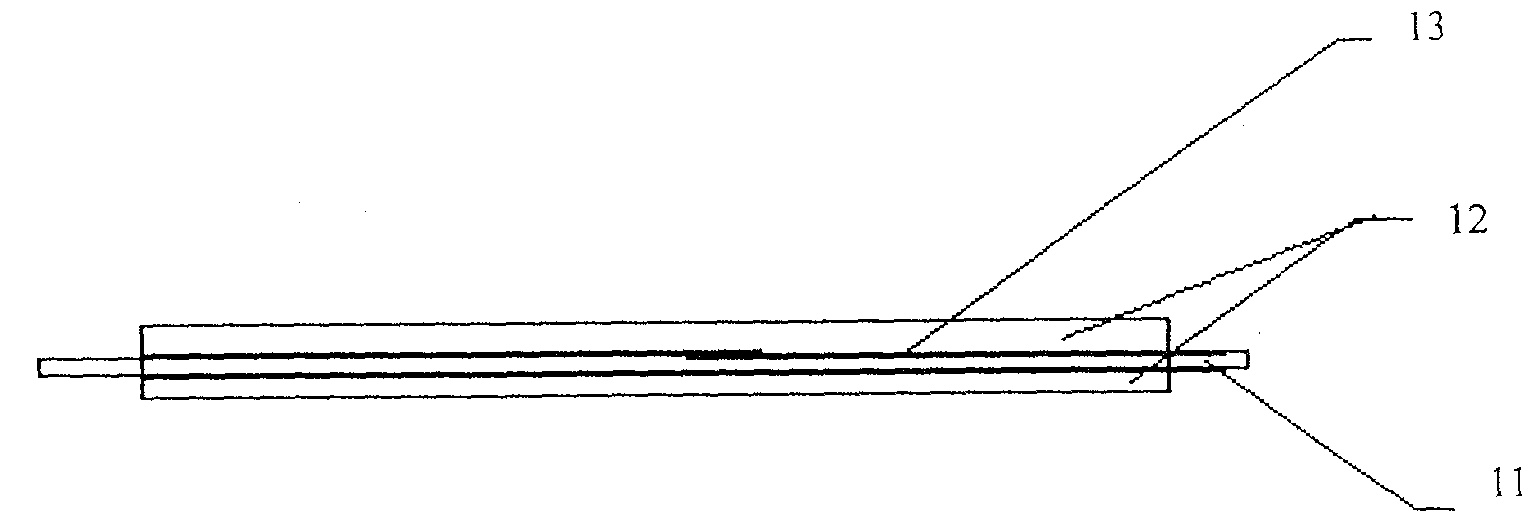

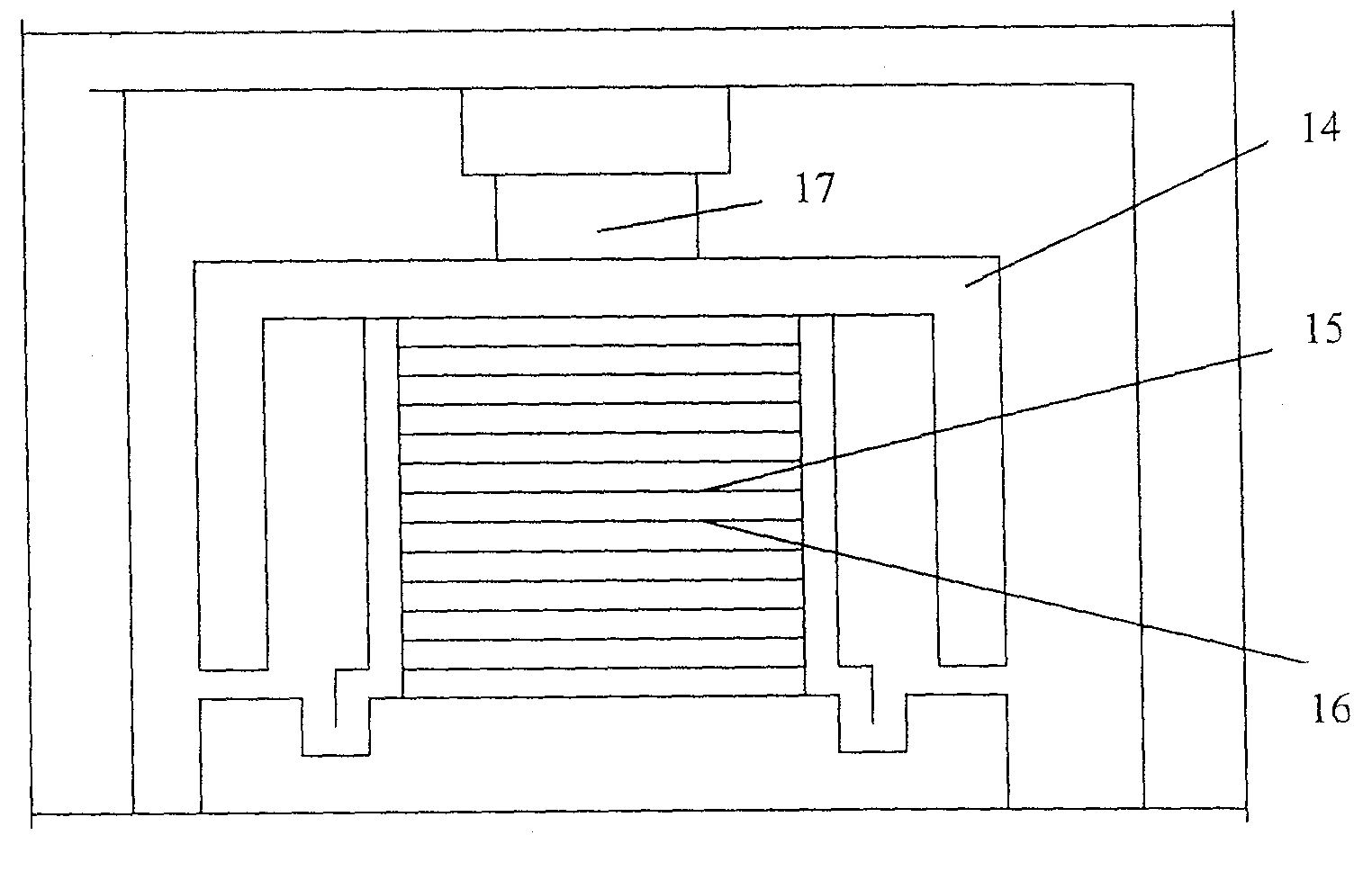

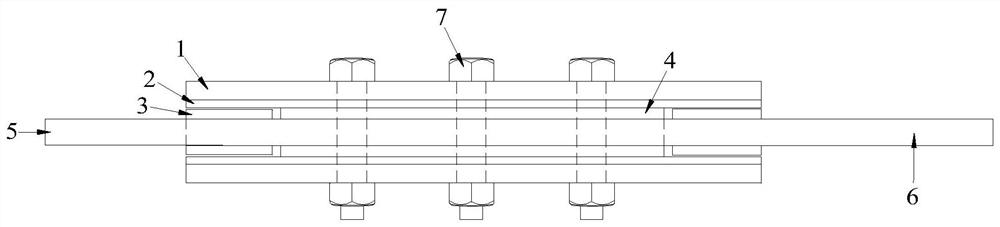

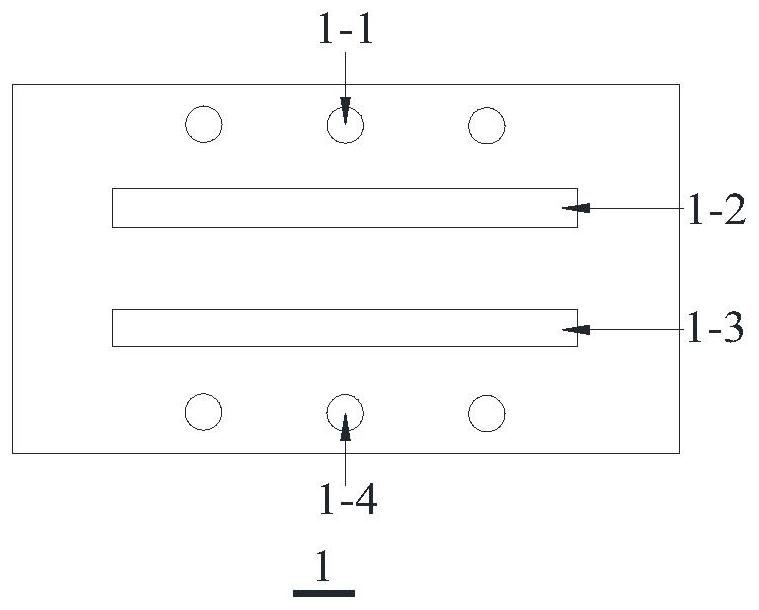

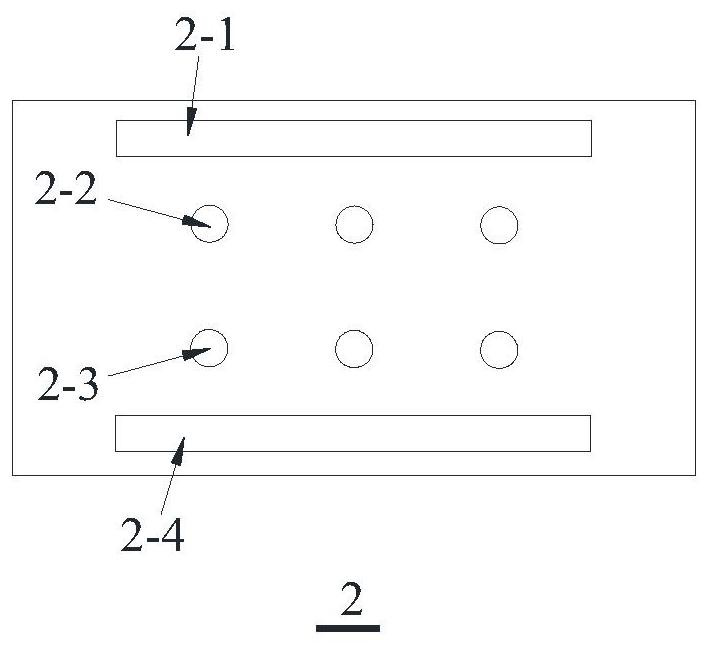

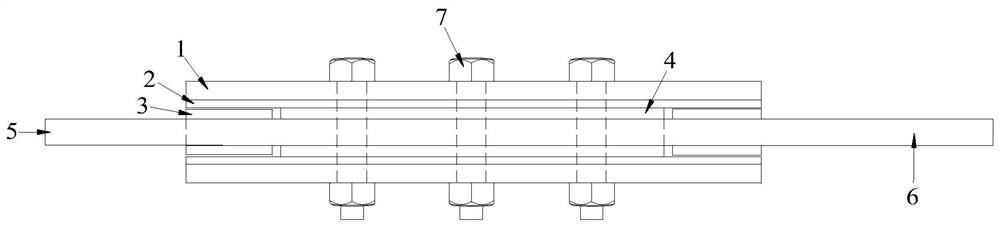

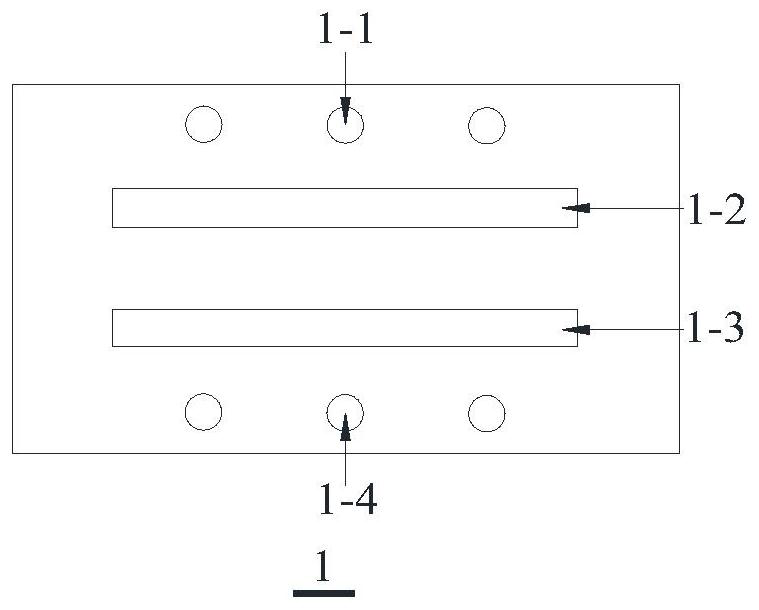

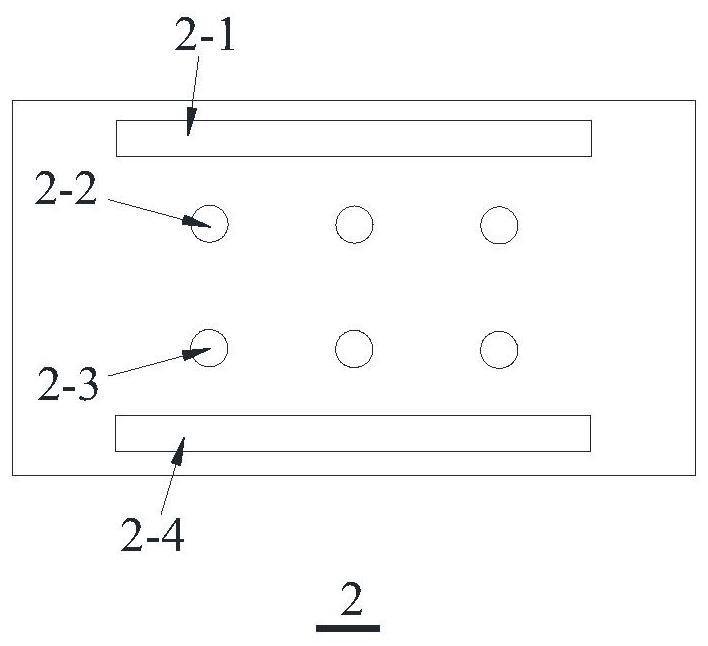

Friction damper with gap for additional stiffness

ActiveCN113107106BEasy to processEasy to assembleProtective buildings/sheltersShock proofingEarthquake resistancePull force

Owner:SICHUAN UNIV

A whisker-modified paper-based friction material and its preparation method

ActiveCN103343476BHigh coefficient of kinetic frictionReduce wear rateOther chemical processesPaper/cardboardFiberEvaporation

Owner:SHAANXI UNIV OF SCI & TECH

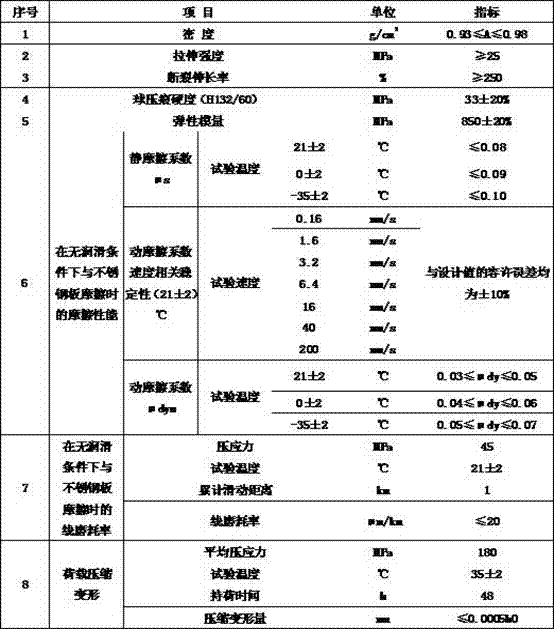

A kind of high friction coefficient wear-resistant composite material and preparation method thereof

The invention belongs to the technical field of wear-resistant materials, and discloses a wear-resistant composite material with a high friction coefficient and a preparation method thereof. The wear-resistant composite material is mainly technically characterized by comprising the following raw materials in parts by weight: 10-30 parts of high-density polyethylene, 30-50 parts of ultra-high molecular weight polyethylene, 10-20 parts of cross-linked rubber powder, 0.1-0.5 part of an antioxidant 1010, 5-20 parts of inorganic powder, and 1-5 parts of carbon black. According to the wear-resistant composite material with the high friction coefficient, provided by the invention, all the components are mixed into pellets by using an internal mixer, then, the compression molding is carried out, and the machinability of the high-density polyethylene, the wear resistance of the ultra-high molecular weight polyethylene, and the high friction coefficient of the cross-linked rubber powder are fully utilized, so that the composite material with a high dynamic friction coefficient, good wear resistance and higher strength is obtained; the wear-resistant composite material with the high friction coefficient is prepared by adopting an internal mixing technology, and leftover materials can be recycled, so that environment friendliness is achieved.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

Gapped friction damper with additional rigidity

ActiveCN113107106AEasy to processEasy to assembleProtective buildings/sheltersShock proofingEarthquake resistancePull force

The invention discloses a gapped friction damper with additional rigidity. The gapped friction damper comprises an outer cover steel plate, a friction plate, an I-shaped plate, rectangular steel sheets, a linear plate, a U-shaped plate and friction high-strength bolts, wherein the outer cover steel plate, the I-shaped plate, the rectangular steel sheets, the linear plate and the U-shaped plate are sequentially stacked from top to bottom and are symmetrically distributed by taking the linear plate and the U-shaped plate as centers. The outer cover steel plate, an outer side rectangular steel sheet and the U-shaped plate are fixed through outer side friction high-strength bolts; the friction plate, an inner side rectangular steel sheet and the linear plate are fixed through inner side friction high-strength bolts; and the I-shaped plate is placed on the upper sides and the lower sides of the linear plate and the U-shaped plate. Compared with a traditional friction damper, the I-shaped plate is pulled in the loading process, the rigidity of a main body structure can be improved while another energy dissipation defense line is provided, and the anti-seismic property of the main body structure is improved.

Owner:SICHUAN UNIV

Anti-slip water-absorbing floor mat and preparation method thereof

ActiveCN114193885AHigh coefficient of static frictionHigh coefficient of kinetic frictionSynthetic resin layered productsFloor coveringsLinear low-density polyethyleneElastomer

The invention relates to the technical field of floor mats, and provides an anti-slip water-absorbing floor mat which comprises a water-absorbing layer and an anti-slip bottom layer which are sequentially arranged from top to bottom, the anti-slip bottom layer is prepared from a component A and a component B. The component A is prepared from, by weight, 90-120 parts of polypropylene and 5-18 parts of filler; the component B comprises the following components in parts by weight: 20-30 parts of polyethylene, 67-85 parts of linear low-density polyethylene, 20-30 parts of a thickening agent, 8-17 parts of a polyolefin elastomer and 3-8 parts of a wear-resistant agent. The invention also provides a preparation method of the anti-slip water-absorbing floor mat. By means of the technical scheme, the problem that in the prior art, a water-absorbing floor mat is poor in skid resistance when used in rainy and snowy days is solved.

Owner:新乐华宝医疗器械有限公司

Synchronous ring for synchronizer and method for manufacturing synchronous ring

ActiveCN102588460BImprove friction and wear performanceImprove reliabilityMechanical actuated clutchesCeramic shaping apparatusToughnessMachining

The invention discloses a synchronous ring for a synchronizer and a method for manufacturing the synchronous ring. The synchronous ring comprises a synchronous ring base, and a friction plate is arranged in the synchronous ring base and consists of a flexible base layer and a friction layer which are compounded. A combined structure consisting of the flexible base layer and the friction layer replaces an existing machined friction layer structure, a hard friction material without elasticity and toughness is improved to form a bendable adhesive friction material without being machined, and a friction abrasion performance and reliability of the synchronous ring are improved. In addition, an oil drainage groove is directly pressed on the friction layer, process is simplified, and cost is lowered. Besides, the platy friction plate can be cut into various shapes according to actual needs, the process is simple, machining is omitted, materials are saved, and the synchronous ring is applicable to synchronizers.

Owner:SHIYAN TONGCHUANG DRIVE TECH CO LTD

A method for controlling the speed of cooling bed input roller table

ActiveCN109454116BReduce wearAccurate control of speed differenceRoll mill control devicesCooling bedsControl systemSteel bar

The invention discloses a control method of the cooling bed entry table speed. The method is implemented specifically according to the following steps that the normal-state advancing coefficient of the speed of each roll table is set according to the linear speed of a rolling mill, and the steel bar splitting advancing coefficient of each roll table is set according to the specification of a steelmaterial; before a flying shear sends a shearing signal, a control system controls the rotating speed of each driving device, and the effect that the speed of each roll table is kept in the normal-state advancing coefficient all the time is guaranteed; after the flying shear sends a shearing signal, before the tail of the steel material is separated from a track, the control system controls the rotating speed of each driving device, and the effect that the speeds of corresponding roll tables is kept in the steel bar splitting advancing constant all the time is guaranteed; and after the tail of the steel material leaves the corresponding roll tables, the control system controls the rotating speed of each driving device, and thus the speeds of the roll tables are restored to the normal-state advancing coefficient. By means of the method, the problem which happens to control over the advancing amount of the cooling bed entry table speed is solved.

Owner:HANZHONG STEEL LTDRP OF SHAANXI STEEL GRP

Anti-slip shrink film and preparation method thereof

ActiveCN102702606BHigh coefficient of kinetic frictionSo as not to damageFlexible coversWrappersLow-density polyethyleneAntistatic agent

Owner:JINWEILONG BRANCH OF GUANGZHOU PLASTICS IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com