Multi-disc friction type shifting clutch

A shifting clutch, friction-type technology, applied in the field of multi-plate friction shifting clutches, can solve the problems of large radial and axial dimensions at the joint, small dynamic friction coefficient of copper-based wet friction plates, and heavy clutch weight, etc., to achieve The effect of reducing the structure size and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

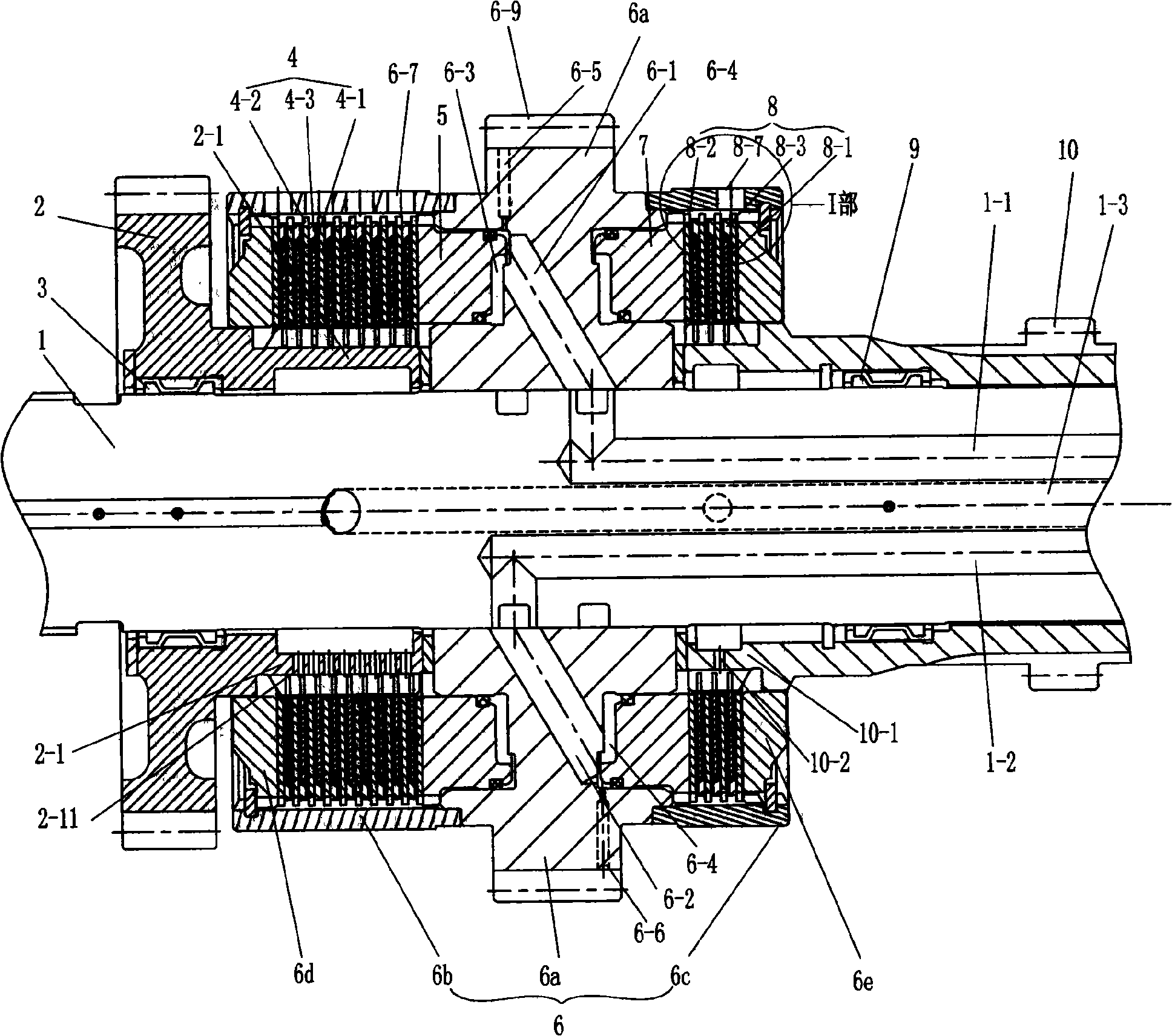

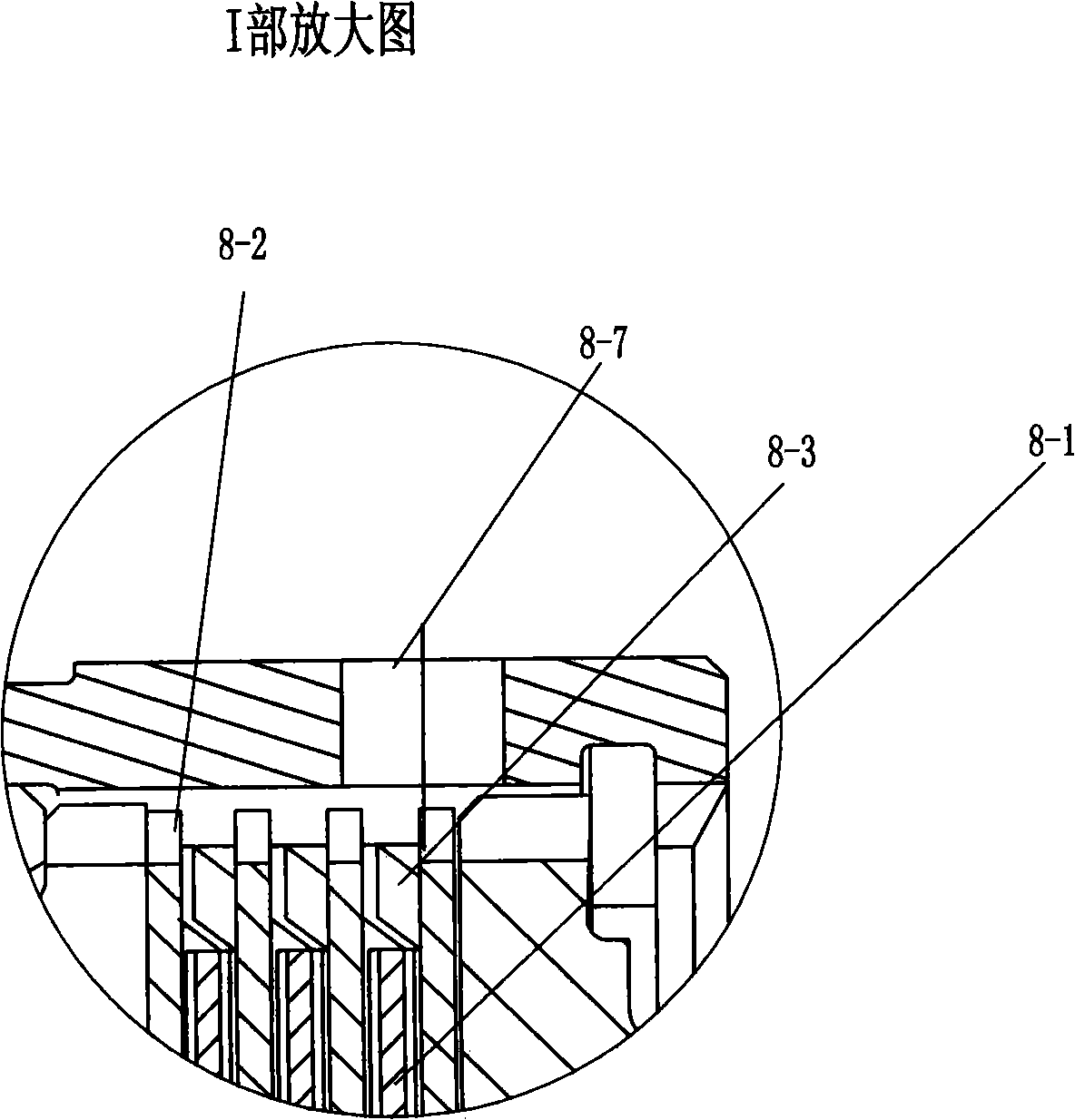

[0021] The embodiment shown in the drawings includes a main shaft 1 with a first pressure oil passage 1-1 and a second pressure oil passage 1-2. One of the two pressure oil passages is the second gear pressure oil passage, and the other pressure oil passage is the fourth gear pressure oil passage. The main shaft 1 is connected with the cylinder body 6 and the first gear 2 and the second gear 10 respectively located on both sides of the cylinder body 6 through interference fit. The first gear 2 is connected to the main shaft 1 through the first bearing 3, and the second gear 10 is connected through The second bearing 9 is connected on the main shaft 1 . The cylinder 6 includes a cylinder main body 6a and a first cylinder 6b and a second cylinder 6c welded to both sides of the cylinder main body 6a. The first cylinder 6b includes an end cap 6d, and the second cylinder 6c includes an end cap 6e. The outer circumference of the cylinder main body 6a is a ring gear 6-9, and the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com