Rigid-flexible ZIF-8/dopamine synergistically enhanced paper-based friction material and preparation method thereof

A paper-based friction material, ZIF-8 technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, natural cellulose pulp/paper, paper, etc., can solve problems such as single method and no related research, and achieve Improve interface bonding, improve the ability to resist stress damage, and prevent fiber pull-out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

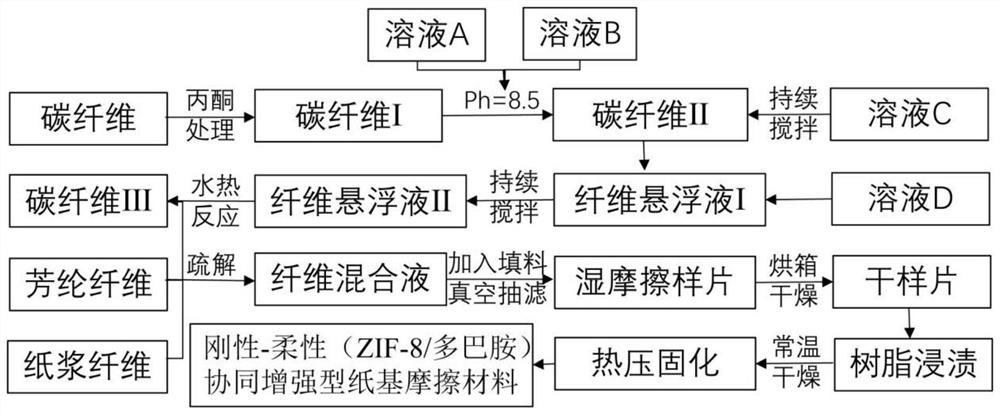

[0048] see figure 1 , a rigid-flexible (ZIF-8 / dopamine) synergistically reinforced paper-based friction material and a preparation method thereof, comprising the following steps:

[0049] Step 1: Take 15g of carbon fiber and soak it in acetone for 12-24 hours to remove the sizing agent and other impurities on the surface of the fiber. After completion, rinse it with deionized water for 3-5 times and dry it in an oven at a temperature of 80-120°C for 12-24 hours. , drying to obtain carbon fiber I with a clean surface;

[0050] Step 2: Dissolve 1.0-1.5 g of tris (Tris buffer) in 0.97-1.45 L of deionized water at room temperature, stir magnetically to obtain solution A, and then dissolve 1.8-2.2 g of dopamine in 0.03 ~0.05L deionized water, conduct ultrasonic dispersion to obtain solution B;

[0051] Step 3: Use hydrochloric acid to adjust the pH of solution A to 8-9. During the continuous magnetic stirring process, the magnetic stirring rotation speed is 1200-1500r, pour solut...

Embodiment 1

[0063] Step 1: Take 15g of carbon fiber and soak it in acetone for 12 hours to remove the sizing agent and other impurities on the surface of the fiber. After the completion, rinse it with deionized water for 3 times and dry it in an oven at 80°C for 12 hours. Dry it to obtain carbon fiber with a clean surface I;

[0064] Step 2: Dissolve 1.0 g of tris (Tris buffer) in 0.97 L of deionized water at room temperature, and perform magnetic stirring to obtain solution A, then dissolve 1.8 g of dopamine in 0.03 L of deionized water, and carry out Ultrasonic dispersion to obtain solution B;

[0065] Step 3: Use hydrochloric acid to adjust the pH of solution A to 8. During the continuous magnetic stirring process, the magnetic stirring rotation speed is 1200r, pour solution B into solution A, and make it fully mixed. Put the carbon fiber I obtained in step 1 into the above mixed solution, stir at room temperature, and dry in an oven after the reaction is completed at a temperature of...

Embodiment 2

[0073] Step 1: Take 15g of carbon fiber and soak it in acetone for 16 hours to remove the sizing agent and other impurities on the surface of the fiber. After the completion, rinse it with deionized water for 3 times, and dry it in an oven at 85°C for 18 hours. Dry to obtain carbon fiber with a clean surface I;

[0074] Step 2: Dissolve 1.2g of tris (Tris buffer) in 0.97L of deionized water at room temperature, and perform magnetic stirring to obtain solution A, then dissolve 1.9g of dopamine in 0.03L of deionized water, and carry out Ultrasonic dispersion to obtain solution B;

[0075] Step 3: Use hydrochloric acid to adjust the pH of solution A to 8.5. During the continuous magnetic stirring process, the magnetic stirring rotation speed is 1300r, pour solution B into solution A, and make it fully mixed. Put the carbon fiber I obtained in step 1 into the above mixed solution, stir at room temperature, and dry in an oven after the reaction is completed at a temperature of 90°...

PUM

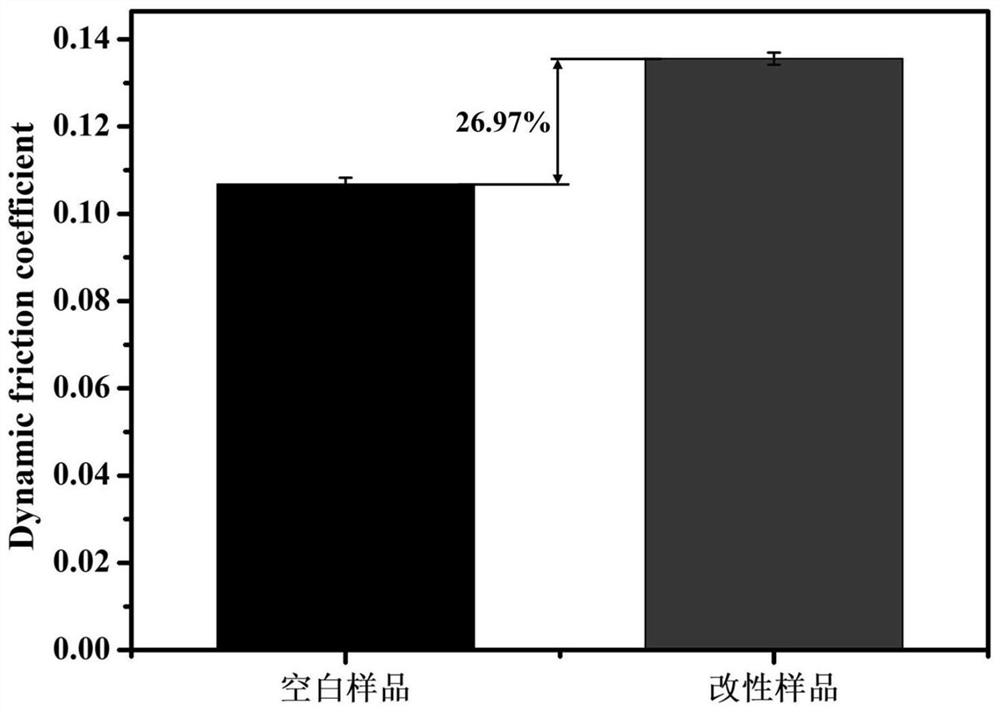

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com